Page 1

INSTRUCTION MANUAL

DIGITAL THEODOLITE

DT-200/200L

SERIES

Page 2

Page 3

FOREWORD

Thank you for purchasing the TOPCON Digital Theodolite. For the best performance of the instruments, please carefully read these instructions and

keep them in a convenient location for future reference.

1

Page 4

General Handling Precautions

Before starting work or operation, be sure to check that the instrument is

functi onin g correctly w i th normal perf ormance.

Do not submerge the instrument into water.

The instrument can not be submerged underwater.

The instrument is designed based on the International S tanda rd IP66,

therefore it is protected from the normal rainfall.

Setting the instrument on a tripod

When mounti n g the i ns tru me nt on a tripod , use a wooden tri pod when po ssible. The vibr ations th at may occur when usi ng a metallic tripod can effect the

measuring precision.

Installing the tribrach

If the tribrach is installed incorrectly, the me asuring precisi on could be

effe cted . Occasionall y chec k the adjust ing scr ews on the tribrac h. Make sure

the base fix in g lever is locked and the base f ixin g screws are tightened.

Guarding the instrument against shocks

When transpor ting the instrument, provide some protection to minimize risk

of shocks. Heavy shocks may cause the measurement to be faulty.

Carrying the instrument

Always carry the instrum ent by its handgr ip.

Exposing the instrument to extreme heat.

Do not leave the instrument in extreme heat for longer than necessary.

It could adversely affect its performance.

Sudden changes of temperature

Any sud den chang e of temper atu re to the instrument or pris m may resu lt i n a

reduction of measuring distance range, i.e when taking the instrument out

from a heated vehicle. Let instrument acclimate itself to ambient temperature. When a high degree of precision is required for measurement, provide

shade against direct sunlight for the instrument and tripod.

Battery level check

Confirm bat t ery le vel re maining before opera t ing.

Store with the batteries removed, when operation is halted for more than a

month. Leav i ng the batteries att a che d for ext e nded period of time can res ult

in battery leakage, which may lead to malfunctioning.

2

Page 5

Notice on Transceiver

When using high out put transceiver etc. , make sure it does not come near

the instrument.

Opening the carrying case

When opening the carrying case and taking out the instrument, place the

case ho riz ontally, then open the case.

3

Page 6

Display for Safe Use

In order t o encour age the safe use of pro ducts and prevent any danger to the

operat or and oth er s or dam age to properties, importan t warni ng s are put on

the products and inserted in the instruction manuals.

We suggest that everyone understand the meaning of the following displays

and icons before reading the “Safety Cautions” and text

Display Meaning

WARNING

CAUTION

● Injury refe rs to hurt, burn, electric shock, etc.

● Physical damage refers to extensive damage to buildings or equipment and

furniture.

Ignoring or disregard of this display may lead to the

dang er of deat h o r serious injury.

Ignoring or disregard of this display may lead to personal inj ury or ph ysical damage.

Safety Cautions

WARNING

•There i s a risk of f ire, electric shock or phy sical harm if you attempt

to disasse mb le or repair the instru men t y oursel f .

This is only to be carried out by TOPCON or an authorized deale r,

only!

•La ser beams can be danger ous, and ca n cause ey e inju ry's if used

incorrectly.

Never attempt to repair the instrument yourself.

•Cause eye injury or blindness .

Do not stare into beam.

•Cause eye injury or blindness .

Do not look at the sun through a telescope.

•High temperature may cause fire.

Do not connect the batt ery to an instrument while it is charging.

•Risk of fire or electric shock.

Do not use a wet battery or charger.

•M ay ign ite exp l osi vely.

Never use an instrument near flammable gas, liquid matter, and do

not use in a coal mine.

4

Page 7

•Batt ery can cau se ex pl o sion or inj u ry.

Do not dispose in fire or heat.

•Risk of fire or electric shock.

Do not use any po wer v o ltage except th e one given on manufacturers instructions.

•Batt ery can cause outb reak of fire.

Do not block up the vent of the bat tery.

•The short circuit of a battery can cause a fire.

Do not short circuit battery when storing it.

CAUTION

Use of controls or adjustment or performance of procedures other

than those specified herein may result in hazardous radiation exposure.

Do not connect or disconnect equipment with wet hands , you are at

risk of electric shocks if you do!

Risk of injury by overturn the carrying case.

Do not stand or sit on the carrying cases.

Please note that the t ips of tripod can be hazardous , be a ware of th is

when setting up or carrying the tripod.

Risk of injury by falling down the instrument or case.

Do not use a carrying case with a damaged which belts, grips or

latches.

Do not allow skin or clothing to come into contact with acid from the

batteries, if this does occur then wash off with copious amounts of

water and seek medical advice.

A plumb bob can cause an injury to a person if used incorrectly.

It could be dang erous if the instrument falls over, please ensure you

attach a handle to the instrument securely.

Ensure that y ou mount the Tribrac h correctly, f aili ng to do so may re-

sult in injury if the tribrach were to fall over.

It could be dangerous if the instrument falls over, please check that

you fix the instrument to the tripod correctly.

Risk of injury by falling down a tripod and an instrument.

Alw ays c heck t ha t the sc re ws of tri pod are t ig h t ened.

5

Page 8

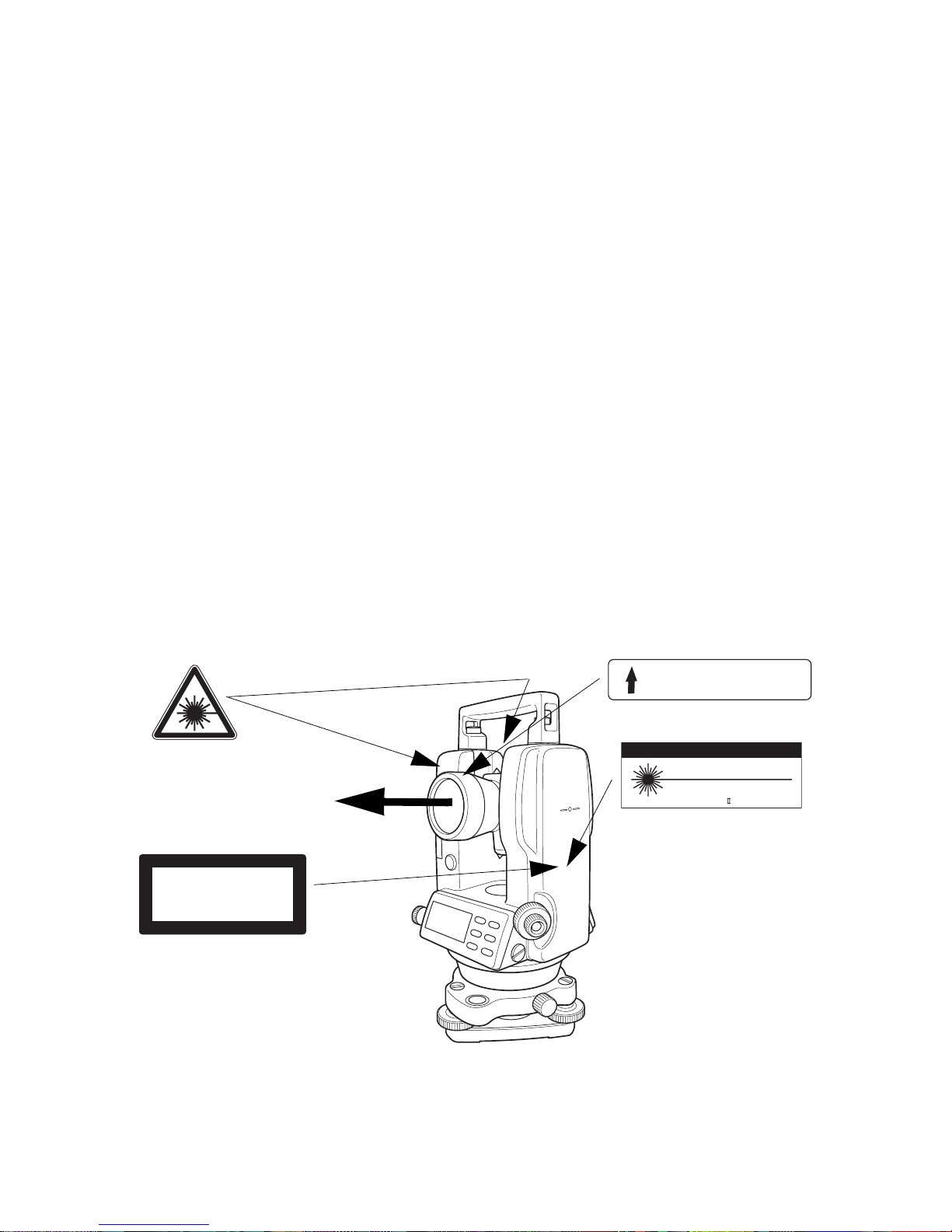

La s er Sa fe ty

E

DT-205L/207L/209L uses the visible laser beam. DT-205L/207L/209L products are ma nufactured and sold in accordance with “Radiation Safety of

Laser Products, Equipment Classification, Requirements and User‘s Guide”

(IEC Publication 60825-1) or “Performance Standards for Light-Emitting

Products” (FDA/BRH 21 CFR 1040) provided on the safety standards for

laser beam.

As per the said standards, DT-205L/207L/209L classified as “Class 2

(CLASS II) Laser Products”.

The laser bea m belongs not v ery dangerous type b ut we requ est y ou to kee p

and underst and “ Sa fety sta nda r d f or users” as menti o ned in the man ual

instruction.

In case of any failure, do not disassemble the instrument. Contact TOPCON

or your TOPCON dealer.

Labels

Find the labels which describes the caution and safety about the laser beam

as follows in DT-205L/ 207 L/209L. We request yo u to repl ace it one an ytim e

the cautio n labels are dama ged or lost and paste a new one at the same

place . You can get the labe ls fr om Topcon or your deale r.

Beam aperture

LASER RADIA TION

DO NOT STARE INTO THE BEAM OF VIEW

DIRECTLY WITH OPTICAL INSTRUMENTS

CLASS 3A @LASER PRODUCT

Depen ding on t he country where the inst rume nt is sold,

either of these labels may be found on the instrument.

AVOID EXPOSUR

LASER LIGHT IS EMITTED

FROM THIS APERTURE

CAUTION

LASER RADIATION

DO NOT STARE INTO BEAM

WAVE LENGTH 633nm

0.6mW MAXIMUM OUTPUT

CLASSII LASER PRODUCTDIODE LASER

6

Page 9

User

1) This product is for professional use only!

The user is required to be a qualified surveyor or have a good knowledge

of surveying, in order to understand the user and safety instructions,

before operating, inspecting or adjusting.

2) Wear the required protectors (safety shoes, helmet, etc.) when operating.

Exceptions from Responsibility

1) The user of this product is expected to follow all operating instructions

and make periodic checks of the product’s performance.

2) The manufacturer, or its representatives, assumes no responsibility for

results of a faulty or intentional usage or misuse including any direct,

indirect, consequential damage, and loss of profits.

3) The manufacturer, or its representatives, assumes no responsibility for

consequential damage, and loss of profits by any disaster, (an earthquake, storms, floods etc.).

A fire, accident, or an act of a third party and/or a usage any other usual

conditions.

4) The manufacturer, or its representatives, assumes no responsibility for

any damage, and loss of profits due to a change of data, loss of data, an

interr uption of b usi ness etc., caused by using the product or an unusable

product.

5) The manufacturer, or its representatives, assumes no responsibility for

any d ama ge, a n d loss of p r ofit s cau sed by u sage except for explained in

the user manual.

6) The manufacturer, or its representatives, assumes no responsibility for

damage caused by wrong movement , o r ac t ion due t o connecti ng wit h

other products .

7

Page 10

Contents

FOREWORD ........................................................................................................1

General Handling Precautions ...................................................................2

Display for Safe Use ..................................................................................4

Safety Cautions .........................................................................................4

Laser Safety ............................................................................................... 6

User ........................................................................................................... 7

Exceptions from Respo nsi bility ................. ................................................. 7

Contents .................................................................................................... 8

Standard Set Composition ......................................................................... 9

1 NOMENCLATURE AND FUNCTIONS .................................................... 10

1.1 Nomenclature.................................................................................... 10

1.2 Display............................................................................................... 14

1.3 Operating keys.............. ........... .......... ................................ ............... 14

2 PREPARATION FOR MEASUREMENT.................................................. 16

2.1 Setting Instrument Up for Measurement ........................................... 16

2.2 Power Switch Key ON....................................................................... 18

2.3 Battery Level Indi cato r....................................................................... 1 9

2.4 Vertical Angle Tilt Correction............................................................. 1 9

2.5 Serial Signal RS-232C Connector..................................................... 19

3 MEASUREMENT...................................................................................... 20

3.1 Measuring Horizontal Angle Right and Vertical Angle....................... 20

3.2 Switching Horizontal Angle Right / Left ............................................. 21

3.3 Measuring fro m the Required Horiz ontal An gle ................................ 2 2

3.4 Vertical Angle % display.................................................................... 2 2

3.5 Repetition Angle Measurement ......................................................... 23

3.6 Stadia Surveying............................................................................... 25

4 HOW TO OPERATE THE LASER....................... .......... .......................... 2 6

5 THE OTHER FUNCTIONS... ........... .................................................... ..... 2 7

5.1 Buzzer Sounding for Horizontal Angle 90° Increments ..................... 27

5.2 Compasses (vertical angle)............................................................... 27

5.3 Auto Cut Off................... ........... .......... ........... .................................... 27

5.4 Setting Minimum Angle Reading....................................................... 27

5.5 Detach / Attach of Tribrach................................................................ 28

6 SELECTING MODE ................................................................................. 29

6.1 Items of the Selecting Mode..... ......................................................... 29

6.2 How to Set the Selecting Modes....................................................... 31

7 HANDLING POWER SOURCE................................................................ 34

7.1 For removing ..................................................................................... 34

7.2 Replace the battery (DB-35).............................................................. 34

7.3 For installing ...................................................................................... 34

8 CHECK AND ADJUSTMENT................................................................... 35

8.1 Checking /Adjusting the Plate Level.................................................. 36

8.2 Checking and Adjusting the Circular Level........................................ 37

8.3 Adjustment of the Vertical Cross-hair................................................ 38

8.4 Collimation of the Inst rument............................................................. 40

8.5 Checking and Adjusting the Optical Plummet Telescope.................. 42

8.6 Adjustment of Vertical Angle 0 Datum............................................... 43

8.7 Adjustment of Laser Beam................................................................ 44

9 STORAGE PRECAUTIONS. ........... ......................................................... 45

10 OPTIONAL ACCESSORIES.................................................................... 4 6

11 ERROR DISPLAY.................................................................................... 47

12 SPECIFICATIONS.................................................................................... 48

8

Page 11

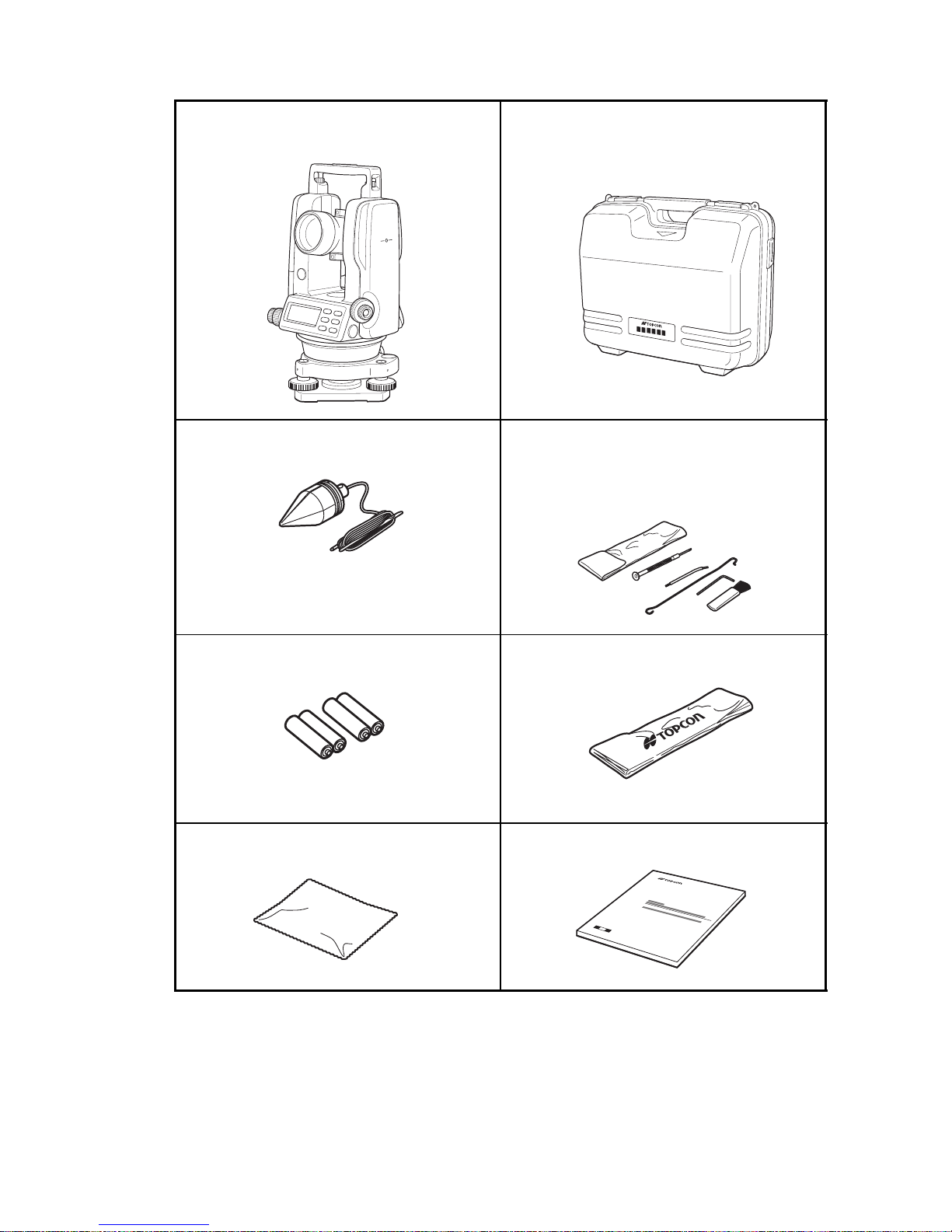

Standard Se t Co mposition

The numerical value in parentheses shows the quantity.

Instrument

(

with lens cap

(1)

Carrying case

)

(1)

Plumb bob set

(1)

Tool kit

Cleaning brush, Screw driver, Rod pins,

Plumb bob hook

(Hexagonal wrench : Only for DT-205/207/209/209P)

(1)

AA batteries (4) Plastic rain cover (1)

Silicon cloth

(1)

Instruction manual (1)

• Make sure that all of the above items ar e with t he ins tru men t when

purchased.

• Guarantee card, Laser use card, Caution sticker are supplied for

certain markets.

9

Page 12

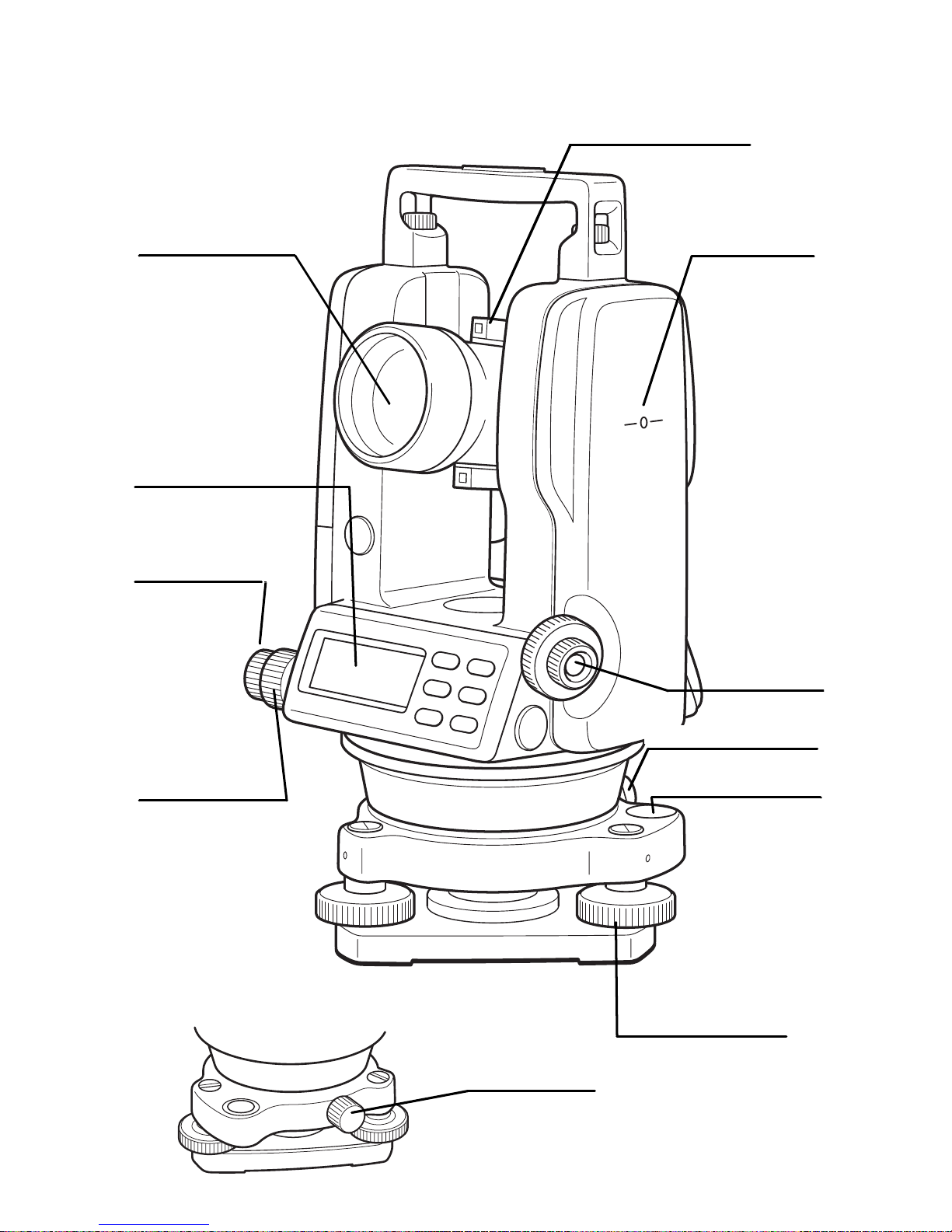

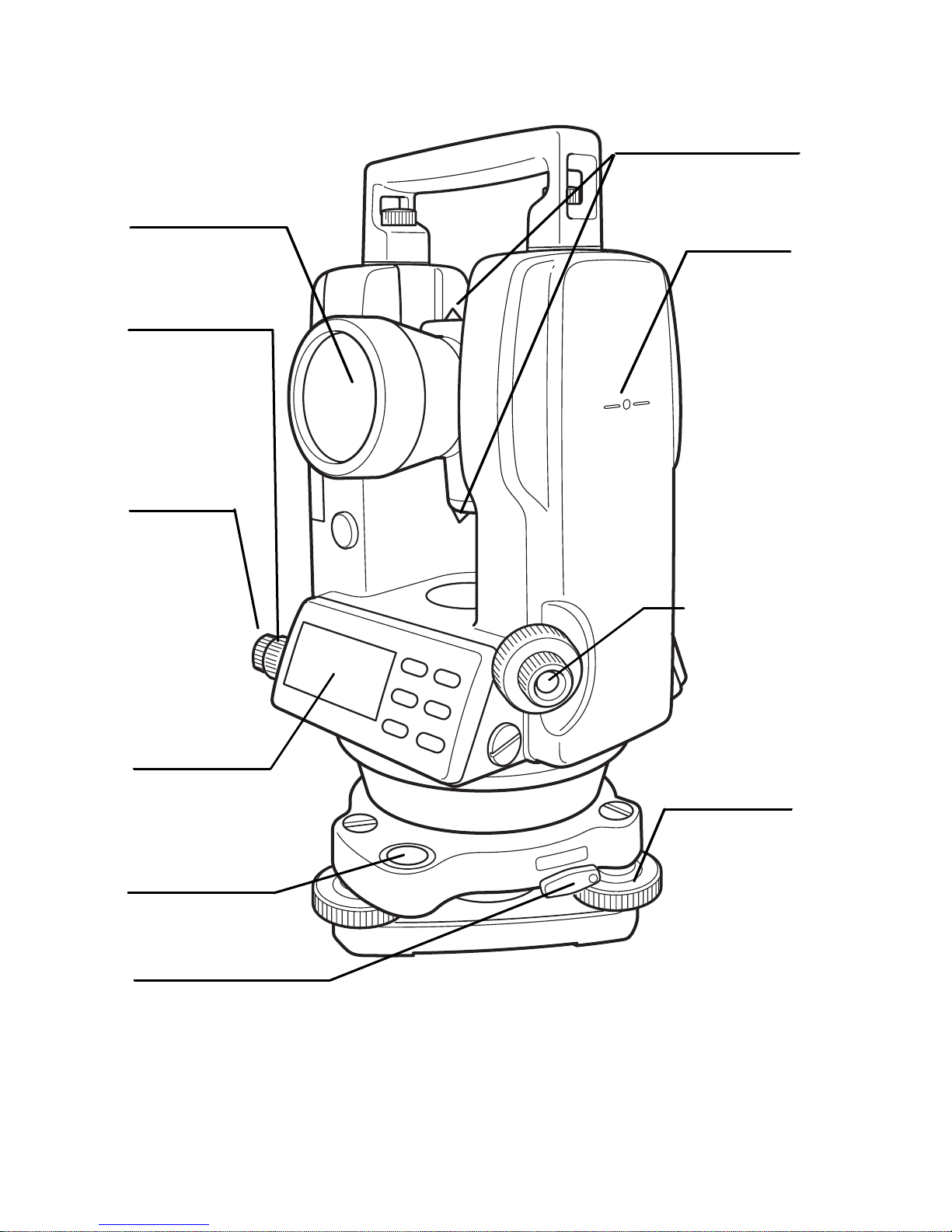

1 NOMENCLATURE AND FUNCTIONS

r

1.1 Nomenclature

DT-205/207/209/209P

Objective lens

Disp la y

window *1)

Horizontal

tangent screw

Sighting collimator

Instrument

height mark

Horizontal

motion clamp

*1) DT-209/209P has one side display only.

Optical

plummet

telescope

Tribrach fixing leve

(2 05 /207 onl y)

Ci rcul ar level

Leveling scr ew

Cent ering scr e w

(209P only)

10

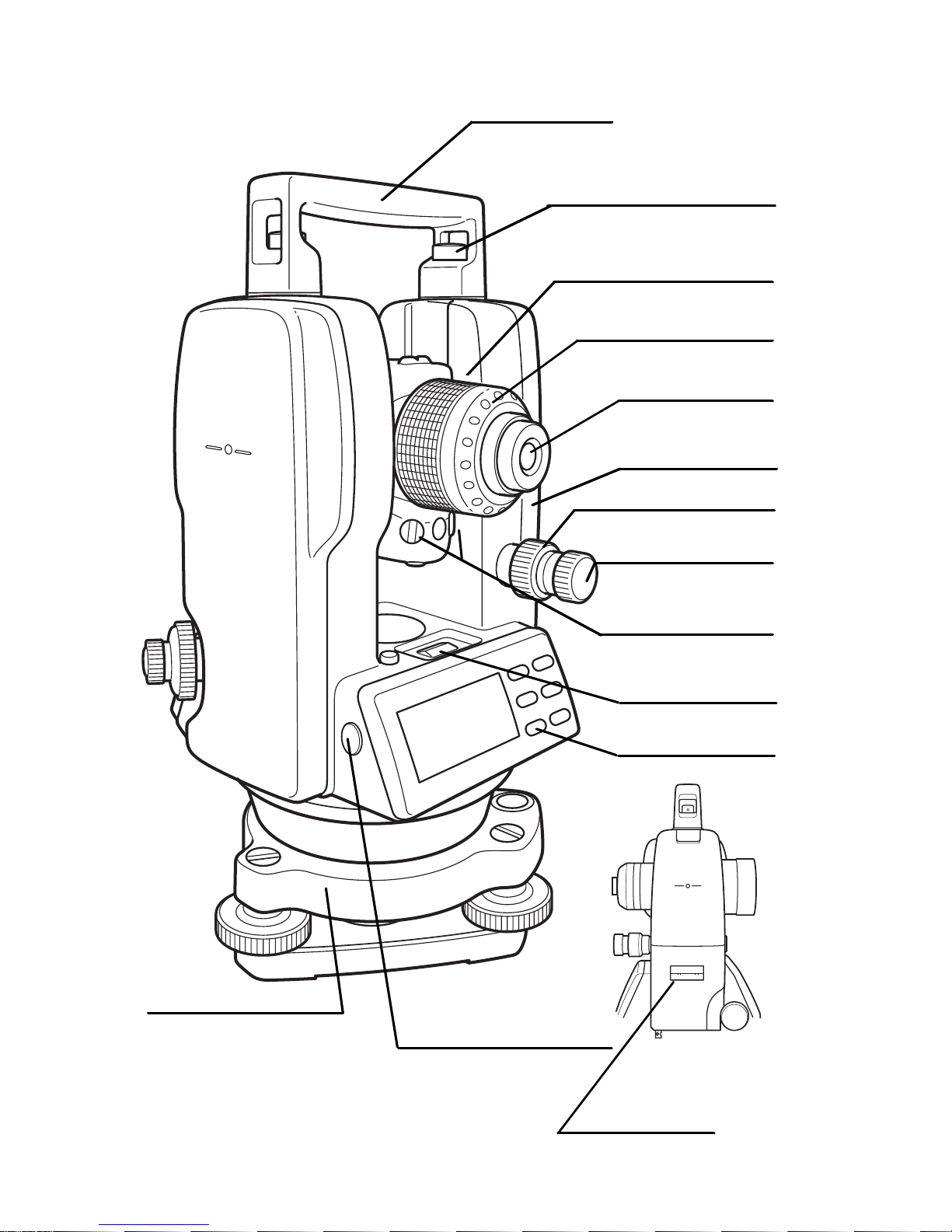

Page 13

l

t

Handle

t

Handle f ixing knob

Telescope

focusing knob

Cross-hair adjustmen

sec tio n cover

Teles cope eyepiece

Battery

Vertical motion

clamp

Base

RS-232C Con n ector

(205 only)

Vertical tangen

screw

Plate leve

Oper ati on keys

Tribrach type

DT-205/207: Detachable

DT-209: Fixing

DT-209P: Centering

Plate level

(207 onl y)

11

Page 14

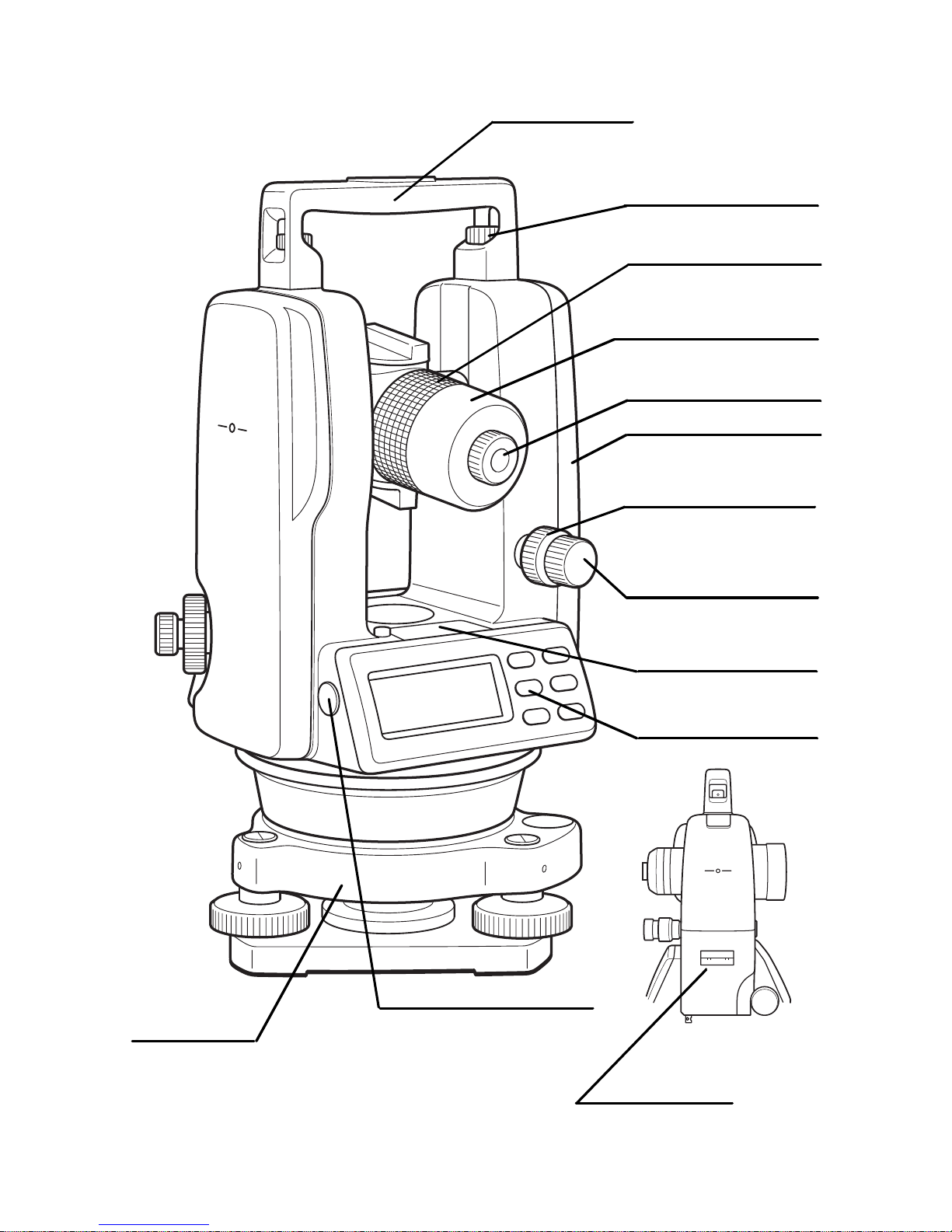

DT-205L/207L/209L

Sighting collimator

Objective lens

Horizontal

motion clam p

Horizontal

tangent screw

Instrument

height mark

Optical

plummet

telescope

Displ ay

window *1)

Circular level

Tribrach fi xing lever

(205L/207L only)

Leveling screw

*1) DT-209L has one side d isp lay only.

12

Page 15

Handle

Handle fixing knob

Telescope

focusing knob

Cross -hai r ad just men t

section cover

Telescope eyepiece

Vertical motion

clamp

Vertical tangent

screw

Battery

Base

Tribrach type

DT-205L/207L: Detachable

DT-209L: Fixing

Laser axis adjusting

screw (with cap)

Plate level

Operation keys

RS-232C Con n ector

(205L only)

Plate le vel

(207L only)

13

Page 16

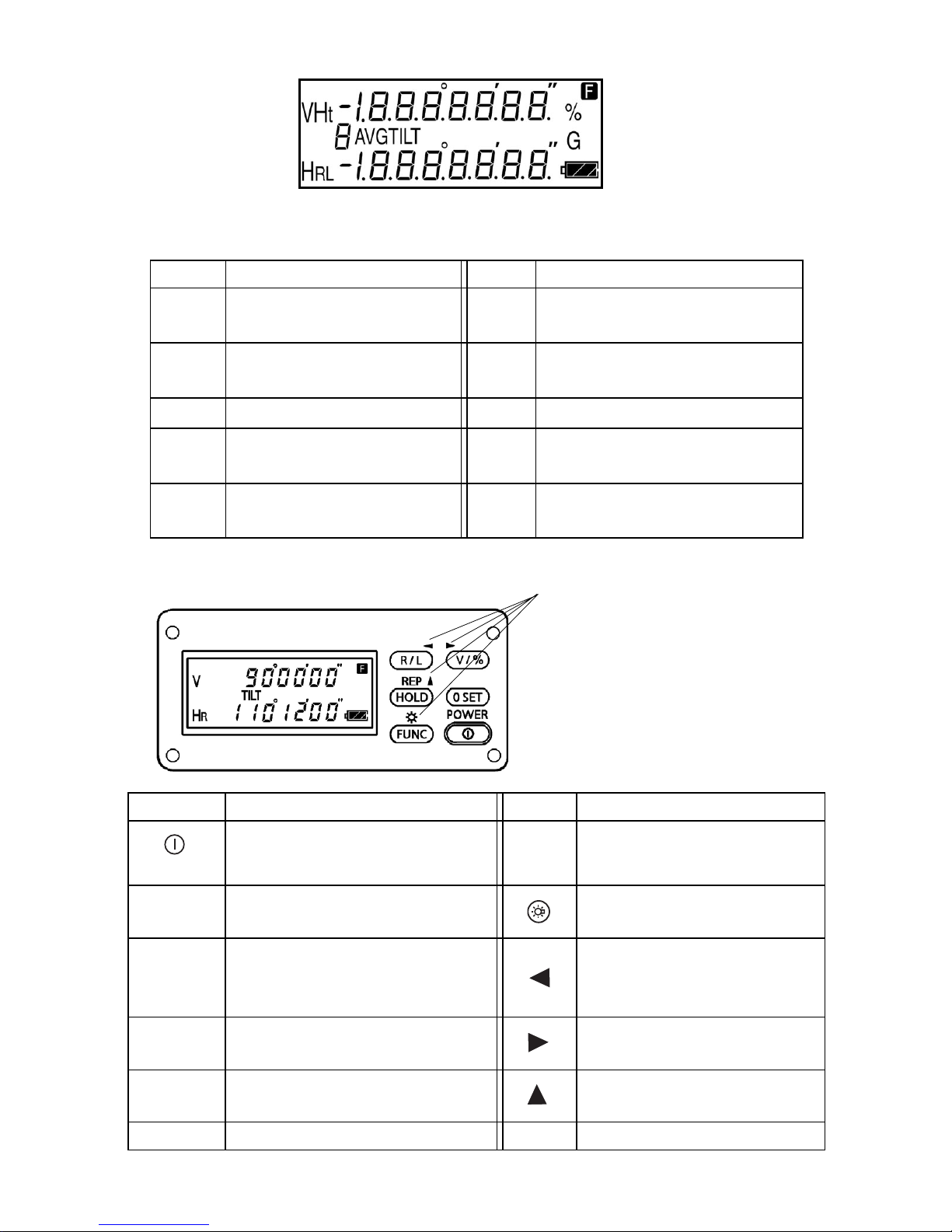

1.2 Display

Display marks

Display Contents Display Contents

V

HR

HL

Ht

Vert i ca l an gl e

Horizontal angle right

Horizontal angle left

Repetition angle measurement

8AVG

The num be r o f repeti tion / Average of an gle

1.3 Operating keys

TILT

F

%

G

Tilt correction mode

(D T-205/20 5L only)

Function key selection

mode

Percent gr ade

Unit disp lay G O N

Function mode

Key Function Key Function (Function mode)

Power switch

R/L

Selection f or horizonta l angle ri ght / le ft meas urem en t

Ver t ic al angle display

V/%

Selection for vertical angle /

percent display

HOLD

0 SET

FUNC

Holdi n g the ho rizo nt al an gl e

Horizont al angle 0° set

Upper function selection

14

REP

Repetiti on angle measurement

Illu mina tion of di sp lay

ON/OFF

Movi ng t h e blin king digi t

to the le ft

Movi ng t h e blin king th e

digit to the right

Increment the blinking

numeral

Page 17

Adjustment mode and Selecting mode

Mode Key

Adjustment mode of vertical angle 0

datum

Selecting mode 1

Selecting mode 2

Turn the power ON while pressing

the [0 S ET] key.

Turn the power ON while pressing

the [R /L] key.

Turn the power ON while pressing

the [V/%] key.

15

Page 18

2 PREPARATION FOR MEASUREMENT

2.1 Setting Instrument Up for Measurement

Setting up the Tripod

First, extend the extension legs to suitable lengths and tighten the screws on

their midsect ions.

Attaching the Instrument on the Tripod Head

Place the inst rumen t caref ully on the tri po d he ad and sl ide the in str ume nt by

loosening the tripod screw. If the plumb bob is positioned right over the center of the point, slightly tighten the tripod screw.

Roughly Leveling the Instrument by Using the Circular Level

1) Turn the leveling screws A and B to move the bubble in the circular level.

The bubble is now located on a line perpendicular to a line running

through the centers of the two leveling screws being adjusted.

2) Turn the leveling screw C to bring the bubble to the center of the circular

level.

Leveling screw C

Leveling screw A

Leveling screw B

16

Page 19

Centering by Using the Plate Level

1) Rotate the instrument horizontally by using the Horizontal motion/clamp

screw and place the plate level par al l el with the line connect ing lev el ing

scre w s A and B, and then bring the b ub b l e to the center of the plate l evel

by turning le velin g screws A and B.

Leveling screw A

Leveling screw B

2) Rotate the instrument 90° (100g) around its vertical axis and turn the

remaining leveling screw or C to center the bubble once more.

Leveling screw C

3) Repe at th e pr ocedures 1 and 2 f or each 90° (100g) r otation of the

instrum ent and che c k whet her t he b ub ble is corre ct ly centere d f or al l four

points.

Centering by Using the Optical Plummet Telescope

Adjust the eyepiece of the optical plummet telescope to your eyesight.

Slide the instrument by loosening the tripod screw, place the point on the

center mark, and then tighten the tripod screw. Sliding the instrument carefully not to rotat e that allows yo u to get the l east dislocation of the bubble

Complet el y Leveling the Instrument

Lev elin g the i nstrument precisely i n a similar w ay to 4. Rotate the instrument

and chec k to see that the bu bbl e is i n the center of the pl a t e l e v e l regar dl es s

of telescope direction, then tighten the tripod screw hard.

17

Page 20

2.2 Power Switch Key ON

1

Confirm the instrument is leveled.

2

Turn the power switch ON.

Every segment turns on for about 1 second.

HR 342°03’41”

3

Press the [V/%] key . The vertical angle is displayed.

Battery Power

Remaining Display

V 11°50’28”

HR 342°03’41”

● Confirm the battery power remaining on the display. Replace with charged

bat tery o r ch ar ge w h en battery le v el is l ow. Ref er to S ec ti on 2.3 “Bat tery L e v el Indicator” .

18

Page 21

2.3 Battery Level Indicator

The battery power indicator shows the level of battery strength.

V 90°10’20”

TILT

HR 123°40’50”

Measurement is po ssibl e.

Battery Power

Remaining Display

Measurement is im possible.

Need to recharge or replace the

battery.

1) The bat tery operati ng time will vary depen di ng on the environ mental

conditions, such as ambient temperature etc. It is recommended for

safety to prepare spare batteries.

2) For general usage of battery, see chapter 7 “HANDLING POWER

SOURCE”

2.4 Vertical Angle Tilt Correction

(DT-205/205L only)

When the tilt sensor is activated, automatic correction of vertical angle for

mislevelment is displayed. To ensure a precise angle measurement, tilt sensors must be turned on. If the "b" display appears the inst ru ment is out of

automatic compensation range and must be leveled manually.

V 90°10’20”

TILT

HR 123°40’50”

In case the instrument is used in an unstable situation, constant indexing of

vertical angle ma y be impossib le . In this cas e , the fun ctio n of tilt corr ecti on

can be stopped.

To stop the function of til t corr ec t ion, refer to Chapt er 6 “SELEC TIN G

MODE”.

2.5 Serial Signal RS-232C Connect or

(DT-205/205L only)

Serial signal c onnecto r is used fo r co nnecting the DT-205/205L with a com puter, whi ch enables the computer to receive measurement data fr om the

DT-205/205L.

Out of the tilt

correc t ion range

19

V b

TILT

HR 123°40’50”

Page 22

3 MEASUREMENT

3.1 Measuring Horizontal Angle Right and Vertical Angle

1

Collimate the first target "A".

V 90°10’20”

HR 120°30’40”

2

Press the [0 SET] key twice to set the horizontal angle of target "A"

°

at 0

00' 00".

V 90°10’20”

HR 0°00’00”

• One time pressing [0 SET] function is available. Refer to "6

SELE CT I NG MODE" .

3

Collimate the second target "B".

The required H/V angle to target B will be displayed.

V 92°10’20”

HR 160°40’20”

20

Page 23

3.2 Switching Horizontal Angle Right / Left

1

Collimate the first target "A".

V 90°10’20”

HR 120°30’40”

2

Press the [R/L] key.

The mode Horizontal angle right (HR) switches to Horizontal angle

left (HL)

V 90°10’20”

H L 239°29’20”

• Every time pressing the [R/L] ke y, HR/HL mode switches.

3

Measu re as HR mode .

Reference : How to Collimate

1

P oi nt the t ele scope tow ar d the li g ht. Turn the diopt er rin g and adju s t

the diopter so that the cross hairs are clearly observed.

(Turn the diopter ring toward you first and then backward to focus.)

2

Aim the target at the peak of the triangle mark of the sighting

colli mator . All ow a ce rtain space be tween the sig hting col li mator an d

yourself for collimating.

3

Focus the target with

the focusing knob.

*If parallax is created

betw een the cross hairs

and the target when

viewing v e rtically or

horizontally while looking

into the telescope,

fo cus i ng is incorrect or

diopter adjustment is

poor.

Eye

Focusing knob

Telescope eyepiece

(Diopter ring)

This adversely affects precision in measurement or survey.

Eliminate the par all a x by care f ull y f ocusi ng and usin g diop t er

adjustment.

21

Page 24

3.3 Measuring from the Required Horizontal Angle

1

Display the r equire d hori zontal angle us ing the horizon tal motion

clamp and horizontal tangent screw.

V 90°10’20”

HR 130°40’20”

2

Press the [HOLD] key.

The displa y of horizontal angle blinks and the horizontal angle will

be held.

V 90°10’20”

HR 130°40’20”

• To return to the ang l e stat us befor e the data is held, press any key

exce pt the [HOLD] key.

3

Collimate the target to set.

4

Press the [HOLD] key. The angle measurement will start from the

held angle.

V 90°10’20”

HR 130°40’20”

3.4 Vertical Angle % display

V 66°23’10”

blinks

1

Press the [V/%] key.

• Every time pressing the [V/%] key, the mode sw itch es .

When th e me asur eme nt i s carr i ed out over t han 45° fro m the

ho rizonta l, the di splay sho ws [ --------].

HR 120°30’40”

V 43.719%

HR 120°30’40”

22

Page 25

3.5 Repetition Angle Measurement

1

Press the [FUNC] key.

F

V 90°10’20”

HR 120°30’40”

2

Press the [REP] key.

Ht 0°00’00”

0

H

3

Collimate the target "A", and press the [0SET] key twice.

Ht 0°00’00”

0

H

4

Collimate the target "B", and press the [HOLD] key.

Ht 45°10’00”

1AVG

H 45°10’00”

5

Recollimate the target "A" and press the [R/L] k ey.

6

Recollimate the target "B", and press th e [HOLD] key.

Total angle

Ht 90°20’00”

2AVG

H 45°10’00”

The number of measurements A verage of angl e

2 measurements

23

Page 26

7

Repeat the procedure 5 and 6 to measure the desired number of

repetition.

Ht 180°40’00”

4AVG

H 45°10’00”

Exampl e: 4 meas urem ents

8

To finish the repet i tion measurement, pr ess the [FU NC] key and

press the [HOLD] key.

• Horizontal angle can be accumulated up to

(2000°00'00" – minimum reading) (horizontal angle right).

In case of 5 second reading, horizontal angle can be

accumulated up to +1999°59'55".

• When the discrepancy value of each measuring is more than

±30", the error code “E04” is displayed. Press the [0S ET] key,

and measure from the beginning.

• Maximum 19 measurements are available.

The 10th or more repetition measurements, the figure of 10th

digit will be omitted.

24

Page 27

3.6 Stadia Surveying

S

This instrument can be used for stadia surveying, Measurement by stadia is

a convenient method for measuring distances with the stadia hairs of the

instrument, in combination wi th a gradua ted rod, such a s a leveling rod o r

stadia rod, which is preferable fo r long distances. The distance from the center of the instrument to the rod is found by sighting through the i nstrument on

the rod and multiplying the stadia interval by 100. The stadia interval is the

distance between the to p stadi a hair r eading and the bott om stadia fai r read ing.

tadia hair s

d

D=100 × d

1

Set the rod on the point to be surveyed.

2

Sight through the telescope of the leveled instrument and determine

the distance or interval, “ d ”, between the top stadia hair reading

and bottom stadia hair reading of the rod.

3

The horizon tal distance “ D ” from the cen ter of the instrument to the

rod is equal to 100 times the stadia inte rv al, “ d ”.

D=100 × d

d

25

Page 28

4 HOW TO OPERATE THE LASER

(DT-205L/207L/209L only)

WARNING

Aiming the instrument into prism or highly reflective surface can result in se rious damage to your eye because the

opt ical axis and laser beam sou rce is in coincidence.

Do not aim the instrument directly into prism or highly re fle cti ve sur face.

Do not look at the laser beam directly.

•Laser beams can be dangerous, and can cause eye injury's

if used incorrectly.

Never attempt to repair the instrument yourself.

1

Co ll i mate a tar get.

2

Press the laser power

switch.

The laser beam will

emit and the green

lam p wil l illumin ate.

Green l am p

DT-205L/207L/209L are so designed as to provide the telescope and

laser beam with simultaneous focussing to give the minimum spot.

ON/OFF

Laser power

switch

26

Page 29

5 THE OTHER FUNCTIONS

5.1 Buzzer Sounding for Horizontal Angle 90° Increments

When the horizontal angle f alls in the range of l ess than ± 1° o f 0°, 90°, 180°

or 270°, the buzzer sounds. Buzzer stops only when the horizontal angle is

adjusted to 0°00’00”, 90° 00 ’ 00” , 180° 00 ’ 00” or 27 0 ° 00’0 0 ”.

To stop the buzzer sounding, refer to "6 SELECTING MODE" .

5.2 Co mpasses (vertical angle)

Ve rtical angl e scale is di splayed as shown below.

To set this function, refer to "6 SELECTING MODE".

°

+90

°

0

-90°

0°

5.3 Auto Cut Off

If no key operation is given for more than 10 or 30 minutes, the power turns

off automatically.

To set this function, refer to "6 SELECTING MODE".

5.4 Setting Minimum Angle Reading

Selec t minimum di splay unit for angle measurement. It is possible t o select it

as shown below.

To set this function, refer to "6 SELECTING MODE".

DT-205/205L 1" / 5" (0.5 mgon / 1 mgon)

DT-207/207L 5" / 10" (1 mgon / 2 mgon)

DT-209/209P/209L 10" / 20" (2 mgon / 5 mgon)

27

Page 30

5.5 Detach / Attach of Tribrach

Only for detachable tribrach type

Securing screw

Alignment piece

Tribrach alignment

groove

Tribrach fi xi ng lever

The inst rumen t is easi ly detac hed or attached to the tribrach, with a tribr ach

locking lever loosened or tightened for this purpose.

● Detachment

1

Loosen the tribrach locking lever, by revolving it 180° or 200g in the

counterclockwise direction (which will point the triangle mark

upwards).

2

Grip the carrying handle firmly with one hand while holding the

tribrach with the other. Then lift the instrument straight upwards and

off.

● Attachment

1

Hold the ins tru me nt by the car rying handle , wit h one hand , and

carefully lower it on top of the tribrach while, at the same time,

coinciding th e a l ignm en t piece w i th the t ribr a ch a l ignment groove on

the instrument and tribrach respect iv ely.

2

When fully seated, revolv e the t ri brach loc king lever 180° or 200 g

clockwise ( which will point the triangle mark downwards again).

● Locking the Tribrach Locking Lever

The tribrach locking lever can be locked, to prevent it be accidentally

removed, especially if the upper instrument section is not being detached

very ofte n. Si mply tighten t he securi ng scr ew on t he locking lever with the

ac cessor y screwdr iver, fo un d in the case .

28

Page 31

6 SELECTING MODE

The following modes are available

6.1 Items of the Selectin g Mode

Selecting mode 1

To set the instrument the selecting mode 1, turn the power ON while pressing the [R/L] key.

Selecting mode 1

[R/L] key + Power on

0 0 0 0 0 0 0

Digit No.1Digit No.7

Selecting mode 1

Digit

No.

1

2

3

4

Items Contents Setting value

Minimum

angle unit

V angle

Z0 / H0

Select the minimum angle

unit.

Select the vertical angle

reading from zen ith o r fr om

(DT-205/205L)

(DT-207/207L)

(DT-209/209P/

209L)

Horizontal 0 Zenith 0

horizontal.

Auto cut off

ON/OFF

Set the function of power

off automatically when no

key operation is continued

10 or 30 minutes.

Auto cut off

time 10 m in.

Set the interval time of

power off automatically.

10 mi n. 30 min.

/ 30 min.

Setting

= 0

5"

10"

20"

value = 1

1"

5"

10"

ON OFF

5

Angle unit

DEG/GON

6

90° buzzer

ON/OFF

7

Angle unit

MIL

Choose degre e (DEG), gon

DEG GON

(GON).

Specify w hether the buzz er

ON OFF

sounds o r not f or e v ery horizontal 90°

Choose angle unit MIL. DEG /GON MIL

29

Page 32

Selecting mode 2

To set the instrument the selecting mode 2, turn the power ON while pressing the [V/%] key.

Selecting mode 2

[V/%] key + Power on

0 0 0 0 0 0 0

Digit No.1Digit No.7

Selecting mode 2

Digit

No.

1

2

3

4

5

6

7

Items Contents Setting

[0 SET] key

pressing

Choose once or t wi ce for pre ssing the [0 SET] key.

once / twice

Compass

ON/OFF

RS-232

Output *1)

H Angle

Memory

Set the function of compass

(Ver tical angle scale).

Set the function of sending the

me asured data .

Horizontal angle set can be retained after the power is turned

off.

Tilt

correction

Set the function of the tilt correction.

ON/OFF *1)

Unused

---

Setting

value = 0

value = 1

Twice Once

OFF ON

OFF ON

OFF ON

OFF ON

--- ---

• Do not cha nge the set ting value (0) of unu sed items.

• *1)DT-205/205L only

30

Page 33

6.2 How to Set the Selecting Modes

● Selecting Mode 1

Sample setting: Auto cut off : OFF, 90

1

Turn the power ON while pressing the [R/L] key.

The instrument will be in the selecting mode 1, and the digit No.1

will blink.

0 0 0 0 0 0 0

2

Let the digit No.3 to be set blink by pressing the [ ] key.

0 0 0 0 0 0 0

° buzzer : OFF

Digit No.1Digi t No.7

Blinking

Blinking

● Pressing t h e [ ] key, bli nking digit moves to the right.

3

Press the [ ] key to set 1 for the digit.

0 0 0 0 1 0 0

● Every time pressing the [ ] key, the blinking digit value 0/1 switches.

4

Let the digit No.6 (90° buzzer) to be set blink by pressing the [ ]

key.

0 0 0 0 1 0 0

Blinking

5

Press the [ ] key to set 1 for the digit.

0 1 0 0 1 0 0

31

Page 34

6

Press the [0 SET] key to set the setting.

S E T

0 1 0 0 1 0 0

7

Turn the po wer off.

32

Page 35

● Selecting mode 2

Sample setting: [0 SET] key pressing : Once, Tilt correction

1

Turn the power ON while pressing the [V/%] key.

The instrument will be in the selecting mode 2, and the digit No.1

( 0set key pressing) will blink

0 0 1 0 0 0 0

2

Press the [ ] key to set 1 for the digit.

0 0 1 0 0 0 1

● Every time pressing the [ ] key, the blinking digit value 0/1 switches.

.

Blinking

: OFF

3

Let the digit No.4 (Tilt correction) to be set blink by pressing the

] key.

[

0 0 1 0 0 0 1

Blinking

● Pressing t h e [ ] key, bli nking digit moves to the right.

4

Press the [ ]key to set 0 for the digit.

0 0 0 0 0 0 1

5

Press the [0 SET] key to set the setting.

6

Turn the po wer off.

S E T

0 0 0 0 0 0 1

33

Page 36

7 HANDLING POWER SOURCE

7.1 For re moving

1

Push the lock le ver downw ar d and pull out t he batt ery.

Lock lever

7.2 Rep la ce the battery (DB-35)

Lid

Hook

1

Push the hook downward and take the lid out.

2

Take out the old batteries and put new batteries as illustratio n shows

in direction of plus and minus sides

3

Insert a convex in a upper hole. Click to close the lid by pressing it.

● Replace all four batteries to new ones at the same time.

● Do not mix the old batteries to the new on es.

Hole

Lid

Convex

7.3 For installing

Place the base of the b attery into the main bod y, push the b at tery tow ard the

instrument side till the battery clicks into position .

34

Page 37

8 CHECK AND ADJUSTMENT

● Pointers on the Adjustment

1

Adjust the eyepiece of the telescope properly prior to any checking

operation which involves sighting through the telescope.

Remember t o f ocus properly, with parallax completely eliminated.

2

Carry out the adjustments in the order of item numbers, as the

adjustm ent s a re dependent one upo n ano t her. Adjust men ts carried

out in the wrong sequence may e ven nu llify previous adjustment.

3

Always conclude adjustments by tightening the adjustment screws

securely (but do not tighten them more than necessary, as you may

strip the threads, twist off the screw or place undue stress on the

parts).

Furthermore, always tighten by revolving in the direction of

tightening tension.

4

The atta chm ent scr e ws mu st also be t ight e ned suffi ciently, upon

comple ti on of adjustment s .

5

Always repeat checking operations after adjustments are made, in

order to confirm results.

● Notes on the Tribrach

1

If any lev elin g screw becomes loose and slack or if collimation is

unstable due to the looseness of leveling screws, adjust by

tightening the adjusting screws (in 2 places) installed over each

leveling screw with a screwdriver

2

If there is an y slack between the l evelin g scr ews an d the base,

loosen the set s crew of t he hol ding ring and t ighten t he holdi ng ring

with adjusting pin, until it is properly adjusted. Re-tighten the set

scre w on completing the adjustment

Adjustment

screw

Adjustment

screw

Leveling

screw

Holding ring Se t screw

35

Page 38

8.1 Checking /Adjusting the Plate Level

Adjus tment is required if the axis of the pl ate level is not perpendicular to the

vertical axis.

●

Check

1

2

ing

Place the pl ate lev el par allel to a l i ne runnin g thr ough the cen t ers of

two leveling screws, say, A and B. Use these two leveling screws

on l y and plac e the bubble i n the cent er of t he plate level.

Rotate the instr ument 180° or 200g arou nd the v ertica l axis and

ch eck bub ble mo vem ent of the plate level. If the bubble has been

displaced, then pr oceed with the f ollo wi ng adjus tme n t.

Plate level

Leveling scr ew A

● Adjustment

1

Adjust the level adjustment capstan screw, with the accessory

adjusting pin and return the bubble towards the cen t er of the p late

level. Correct only one-half of the displacement by this method.

2

Correct the remaining amount of the bubble displacement wi th the

leveling screws.

3

Rotate the instr ument 180° or 200g arou nd the v ertica l axis once

more a nd check bubbl e movem ent. If the bubble is still displaced,

then repeat the adjustme nt.

Level adjustment

capstan screw

Leveling screw B

Half amount of displacement

36

Page 39

8.2 Checking and A djusting the Ci rc ular Level

● Checking

1

Carefully level the instrum ent with the plat e level only. If the bubble

of the circular level is centered properly, adjustment is not required.

Otherwise, proceed with the following adjustment.

● Adjustment

1

Shift t he bubble to the center of the circular level, by adjusting three

capstan adjustment screws on the bottom surface of the circular

level, with the accessory adjust ing pin.

Caps tan adju stment scre ws

Bottom of the base

37

Page 40

8.3 Adjustm ent of the Vertical Cross-hair

Adjustment is required if the vertical cross-hair is not in a place perpendicular to the ho riz ontal axis of t he te l escope ( si nce it mus t be possib le to use

any point on the hair for measuring horizontal angles or running lines).

● Checking

1

Set the instrument up the tripod and carefully level it.

2

Sight the cross-hairs on a well defined Point A at a distance of, at

least, 50 meters (160ft.) and clamp horizontal motion.

3

Next swing the telescope vertically using the ver tical tangent screw,

and check whether the point travels along the length of the vertical

cross-hair.

4

If the point appears to move continuously on the hair, the vertical

cr o ss-hair lies in a plane perpen dic ula r to the h o rizontal axi s ( and

adjustment is not required ).

5

However, if the point appears to be displaced from the vertical

cross-hair, as the telescope is swung vertically, then proceed with

the fol l ow i ng adjustment.

● Adjustment

1

Unscrew the cross-hair adjustment section cover, by revolving it in

the counterclockwise direction, and take it off. This will expose four

ey epiece section att achment screws.

2

Loosen a ll fou r attachment scre w s sli g htl y w it h th e accessory sc re wdrive (while taking note of the number of revolutions).

Then revolve the eyepiece section so that the vertical cross-hair

coincides to Point A’.

Finally, re-tighten the four screws by the amount that they were

loosened.

38

Page 41

3

Ch eck once more and i f the point travels the e nti re lengt h of th e

vertical cross-hair, fur ther adjustment is not required.

Ey epie ce section

attachment screws

Eyepiece

Perform following adjustment after completing the above adjustment .

Section 8.4 “Collimation of the Instrument”, Section 8.6 “Adjustment of Vertical Angle 0 Datum”.

39

Page 42

8.4 Collimatio n of the Instru ment

Eyepiece

Collimation is required to make the line of sight of the telescope perpendicular to the horizontal axis of the instrument, otherwise, it will not be possible to

ext end a st raight line by dir ect me ans.

●

Check

1

2

3

4

ing

Set th e i nstrument up w ith

clear s i ghts of about 50 to

60meters

(160 to 200 ft.) on both

sides of the instrument.

Level the instrument

properly with the plate

level.

Sight Point A at

appro x i ma tel y 50 mete rs

(160 ft.) dist anc e.

Loosen the v ertica l

motion clam p only, and

rotate the telescope 180°

or 200g around the

horizon tal axis , so that the

telescope is pointed in the

opposite dir ecti on.

50

Telescope

50

50

5

Sight Point B, at equal

distance as Point A and

tight en the v ertical motion

clamp.

6

Loosen the horizont al

motion clamp and rotate

the instrument 180 ° or

20 0g around t he ver t ical

axis. Fix a sight on Point

A once more and tighten

the horiz ont al motio n

clamp.

7

Loosen the v ertica l

motion clam p only and

rotate the telescope 180°

or 200g aro und the hori z ontal axis once mo re and fix a sight on

Point C, which should coincide with previous Point B.

8

If Points B and C do not coincide, adjust in the following manner.

50

40

Page 43

Adjustmen

nt

●

1

2

3

t

Unscrew t he cross-hair

adjustment section cover.

Find Point D at a point

between Points C and B,

which should

be equal to 1/4th the

distance between Poi nts

B and C and measured

from Point C. This is

because t he apparent

error between Points B

and C is f our times t he actual err or sin ce

the telescope has been reversed twice during the checking

operation.

Shift the vertical

cross-hair line and

coincide it with

Point D, by revolving

the left and right

capstan adjust m ent

screws with the

hexagonal wrench*

(or adjust ing pin).

Up on completi ng the

adjustm ent , r ep eat

the chec ki ng

opera ti on once mo re .

If Points B and C coincide, further adjustment is not required.

Capstan

adjustment

screw

*DT- 205/207/209/209P : Hexagonal wrench

DT- 205L/207L/209L : Adjusting pin

Capstan

adjustme

screw

Eyepiece

Otherwise, repeat the adjustment.

● First, loosen the capstan adjustment screw on the side to

which the v ertical cross-hai r line must be mov ed. Then tight en

the adjustment screw on the opposite side by an e q ual

amount which wil l leave the tens ion of the adjustment screws

unchanged.

Re volv e in the countercl ockwise direction t o loosen an d in the

clockwise direction to tighten, but revolve as little as possible.

● Perform following adjustment after completing above adjustment . Section 8.6 “Adjustment of Ver t ical Angle 0 Datum”.

41

Page 44

8.5 Checking and Adjusting the Optical Plummet T elescope

Adjustment is required to make the line of sight of the optical plummet telescope coin cide with the ve rtical axis ( otherwise the v ertical axis wil l not be in

the true vertical when the instrument is optically plumbed).

Check

●

1

2

● Adjustment

1

ing

Coincid e the ce nt er ma rk and the poin t . (See Cha pter 2

“PREPARATION FOR MEASUREMENT” .)

Rotate the instr ument 180° or 200g arou nd the v ertica l axis and

check the center mark.

If the point is properly centered in the center mark, adjustment is not

required. Otherwise, adjust in the following manner.

Take off the ad justmen t sect ion cover of the optical plummet

telescope eyepiece. This will expose four capstan adjustment

scre ws which sho uld be adj usted wi th the acces sory adjustin g pin to

shift the center mark to the point. However, correct only one-half of

the displ ace men t in this ma nner.

Capstan

adjustment

screws

2

Use the leveling screws and coincide the point and center mark.

3

Rotate the instr ument 180° or 200g arou nd the v ertica l axis once

more and check the center mark. If it is coincided to the point, then

further adjustment is not required. Otherwise, repeat the

adjustment.

First, loosen the capstan adjustment screw on the side to

Eyepiece

Plum met tel e sco pe

Capstan

adjustment

screws

1/2 of

displacement

which the center mark must be moved. Then tighten the adjustment screw on t he opposite side b y an equal amount which

will leave the tension of the adjustment screws unchan ged.

Re vol v e in th e counter cloc kwi se dir ection to loosen and in the

clockwise direction to tighten, but revolve as little as possible.

42

Page 45

8.6 Adjustm ent of Vertical Angle 0 Datum

If when measuring t he ve rtical angl e of targ et A at tele scope pos iti on normal

(direct) and reverse settings, the amount of normal and reverse measurements combined is other than 360° (ZENITH-0), half of the difference from

360° is the error amount from corrected 0 setting. Carry out adjustment. As

adjustment for vertical angle 0 setting is the criteria for determining instrument coordinate origin, use special care for adjustment.

1

Level the instrument properly with the plate level.

2

While press i ng the [0 SE T]key, turn powe r swi t ch ON.

V STEP-1

3

Collimate target A from the telescope properly in normal setting.

4

Press the [0SET] key.

V STEP-2

5

Collimate target A in reverse telescope setting.

6

Press the [0SET]key.

Measured value is set and carry out normal angle measurement.

SET

7

Turn the po wer switch off.

● Any misoperat ing and error code displa y appears. Repeat the

above procedure from the start.

● Check that the total amount of normal and reverse angular

tra v el is 360°

positions.

collimat ing the target A by normal and re ve rse

43

Page 46

8.7 Ad justm ent of Laser Beam

B

This adjustment must be done after completing following checking and

adjusting. 8.3 “Adjustment of the Vertical Cross-hair”, 8.4 “Collimation of the

Instrument”.

WARNING

● Aiming the instrument int o prism or highly reflecti ve sur f ace can result in serious damage to your eye because the optical axis and laser beam source is in coincidence.

Do not aim t he instrument directly i nto prism or highly re flectiv e surface.

Do not look at the laser beam directly.

In i nterse cti on of the cross-hair does not coincide with the lase r spot , turn the

laser axis adjusting screws to move the laser spot to coincide with intersection of the cross -hair.

1

Remove the caps of the laser axis adjusting screws with coin.

As shown below, the screws are called A and B.

Laser axis adj u sti n g scre w B

Laser axis adjusting screw A

2

Following shows the moving direction of the laser spot by turning the

laser adjusting screws.

Turn screw A

counterclockwise

Turn screw A

clockwise

3

Attach the caps of the laser axis adjusting screws.

Laser spot

Turn screw B

counterclockwise

Laser spot

Turn screw

clockwise

44

Page 47

9 STORAGE PREC AUTIONS

● Whe n re tur ning t h e in stru ment to its ca se, be s ure to ma t c h the wh it e position in g mark s p rovided wit h th e ca se and place the inst ru ment wit h the eyepie ce upwa r d .

● For cleaning the instrument after use, remove dust using a cleaning brush,

then w ipe off wit h a cloth .

● For cleaning the lens surface, use a cleaning brush to remove the dust, then

use a clean lintless cotton cloth. Moisten it with alcohol (or mixture with ether)

to wipe gently in a rotational motion from the center out.

● To remove the dust on the case, never us e thinner o r benzine. Use a clean

clo th mo is tened w ith ne u tral detergent.

● Check e ac h par t of t h e tripod after exte n de d us e. Par t s (s c rew s or cla mps)

may work themselves free.

45

Page 48

10 OPTIONAL ACCE SSORIES

Diagonal Eyepiece, M odel 13

The diagonal eyepiece is used in place of the telescope eyepiece for making

observations up to the zenith.

Instrument eyepiece

Diagonal eyepiece,

model 13

Trough Compass model 5

The trough compass i s simply mounted on top of the carrying ha ndl e.

Ba ck pack

When t ransport i ng the ins tru men t with th i s back pack, it is very convenient

for carry ing the i nstrum ent on the shou lder. This soft case with aluminum

frame is compact and light, yet, is highly shockproof and rainproof.

Aluminum extension leg tripod

Wide frame extension leg tripod (wood)

46

Page 49

11 ERROR DISPLAY

Display Contents Countermeas ure

AnGLE

Error

E04

E70

Displayed when the instrument or the telescope rotated

quickly.

Displayed when the discrepancy value of each measuring

is more than ±30” while repetiti on an g le me as ure men t i s op erated.

When "Adjustment of Vertic al

Angle 0 da t u m " is adju s ted in

wrong procedure.

or

When "Adjustmlent of Vertical

Angle 0 datum " is ca r ried out

to the range out of ±45° from

the horizontal.

In this ca se, i t i s not failure.

However, repair is required when

"AnGLE Error" is displayed frequently.

Press th e [0SET ] ke y, measure

again from the beginning.

Switch off the power, then on again.

Confirm the procedure and adjust

again.

E99

Abnormality in internal memory system while "Adjustment

of Vertical Angle 0 Datum" is

op erated, or hori zontal an g l e

is set zero or hold.

Switch off the power, then on again.

Confirm the procedure and adjust

again.

• If errors still persist after attempting to clear them, contact your dealer or

TOPCON.

47

Page 50

12 SPECIFICATIONS

(DT-2 0 5/207/209/209P)

Item Item

Telescope Length 149mm 149mm 149mm

Objective lens 45mm 45mm 40mm

Magnification 30× 30× 26×

Image Erect Erect Erect

Field of vi ew 1° 30' 1° 30' 1° 30'

Resolving power 2.5" 2.5" 3"

Minimum focus 0.9m 0.9m 0.9m

Stadia ratio 100 100 100

Stadia constant 0 0 0

Electronic Angle Mea-

surement

Display Unit 2 sides 2 sides 1 sides

Illumination Display Yes Yes Yes

Compensator Tilt sensor Automatic

Optical

Plummet

Telescope

Level

Sensitivity

Water protection Standard IP 66 IP 66 IP 66

Power Supply Battery 4 AA

Operating Time

(Al kali ne ma nganes e

dry batteries),

(+20°C [+68°F]Åj

Tribrach Type Detachable Detachable Fixing: DT-209

Method Absolute Absolute Absolute

Detecting Horizontal :

Minimum reading 1"/5"

Accuracy *1) 5" 7" 9"

Diameter circle 71mm 71mm 71mm

Reticle Yes Yes No

Compensating

range

Magnification 3x 3x 3x

Filed of view 3° 3° 3°

Focusing 0.5m~∞ 0.5m~∞ 0.5m~∞

Plate level 40"/2 mm 40"/2 mm 60"/2 mm

Circular level 10'/2mm 10'/2mm 10'/2mm

Theodolite only Approx. 140

Model

DT-205 DT-207

Horizontal :

2 sides

Vertical :

1 side

(0.5mgon/1mgon)

vertical

compensator

± 3' No No

batteries

hours

2 sides

Vertical :

1 side

5"/10"

(1mgon/2mgon)

No No

4 AA

batteries

Approx. 150

hours

DT-209/

209P

Horizontal :

1 sides

Vertical :

1 side

10"/20"

(2mgon/5mgon)

4 AA

batteries

Approx. 170

hours

Centering:

DT-209P

48

Page 51

Item Item

Others Dimension

DxWxH(mm)

Weight (Includ-

ing batteries)

Instrument height 176 mm

Serial signal

RS-232C

connector

*1) Standard deviation based on DIN 18723

(DT-205L/207L/209L)

Model

DT-205 DT-207

149x188x313

(5.87x7.1x12.3 in)

4.1kg

(9.0 lb)

(6.93 in)

Yes No No

149x188x313

(5.87x7.1x12.3 in)

4.1kg

(9.0 lb)

176 mm

(6.93 in)

DT-209/

209P

DT-209:

149x188x305

(5.87x7.1x12.0 in)

DT-209P:

149x188x313

(5.87x7.1x12.3 in)

DT-209:

3.4kg (7.5 lb)

DT-209P:

3.8kg (8.3 lb)

-------

Item Item

Model

DT- 205L DT-207L DT-209L

Telescope Length 152mm 152mm 152mm

Objective lens 45mm 45mm 40mm

Magnification 30× 30× 26×

Image Erect Erect Erect

Field of vi ew 1° 30' 1° 30' 1° 30'

Resolving power 2.5" 2.5" 3"

Minimum focus 1m 1m 1m

Stadia ratio 100 100 100

Stadia constant 0 0 0

Electronic Angle Mea-

surement

Display Unit 2 sides 2 sides 1 sides

Illumination Display Yes Yes Yes

Compensator Tilt sensor Automatic

Method Absolute Absolute Absolute

Detecting Horizontal :

2 sides

Vertical :

1 side

Minimum reading 1"/5"

(0.5mgon/1mgon)

Horizontal :

2 sides

Vertical :

1 side

5"/10"

(1mgon/2mgon)

Accuracy *1) 5" 7" 9"

Diameter circle 71mm 71mm 71mm

Reticle Yes Yes No

No No

vertical

compensator

Compensating

±3' No No

range

Horizontal :

1 sides

Vertical :

1 side

10"/20"

(2mgon/5mgon)

49

Page 52

Item Item

Model

DT- 205L DT-207L DT-209L

Optical

Plummet

Telescope

Level

Sensitivity

Water protection Standard IP 66 IP 66 IP 66

Power Supply Battery 4 AA

Operating Time

(Alkaline manganese

dry batteries),

(+20°C [+68°F]Åj

Tribrach Type Detachable Detachable Fixing

Others Dimension

Laser beam Laser class Class 2

*1) Standard deviation based on DIN 18723

Magnification 3x 3x 3x

Filed of view 3° 3° 3°

Focusing 0.5m~∞ 0.5m~∞ 0.5m~∞

Plate level 40"/2 mm 40"/2 mm 60"/2 mm

Circular level 10'/2mm 10'/2mm 10'/2mm

4 AA

batteries

Theodolite only

Laser only

Theodolite and

laser

DxWxH(mm)

Weight (Includ-

ing batteries)

Instrument height 176 mm

Serial signal

RS-232C

connector

Wave length 633nm 633nm 633nm

Maximum output 0.6mW 0.6mW 0.6mW

Laser beam

range*2)

Approx. 140

Approx. 80

Approx. 45

(hours)

152x188x313

(5.97x7.1x12.3 in)

4.2kg

(9.2 lb)

(6.93 in)

Yes No No

Clas s II

50m 50m 50m

batteries

Approx. 150

Approx. 80

Approx. 45

(hours)

152x188x313

(5.9x7 .1 x1 2.3 in)

4.2kg

(9.2 lb)

176 mm

(6.93 in)

Class 2

Clas s II

4 AA

batteries

Approx. 170

Approx. 80

Approx. 45

(hours)

152x188x305

(5.9x7.1x12.0 in)

3.6kg

(7.9 lb)

---------

Cla ss 2

Cla ss II

Laser beam

Laser class : Class II (Class 2)

Wave leng th : 633nm

Maximum output : 0.6mW

Laser beam range : 50m

Condition Weather : Fine

Laser beam diameter(When focused)

Tel escope

Magnification

30x Beam diameter(m) 0.1x0.2 0.2x0.4 0.5x0.7 0.7x1.1 1.2x1.9

26x Beam diameter(m) 0.1x0.2 0.3x0.4 0.6x0.8 0.8x1.2 1.4x2.0

*2) The laser beam diameters are theoretical values

The visible laser beam diameter will vary with brightness of circumstance.

Time : The daylight hours

*2)

Distance(m) 5 10 20 30 50

50

Page 53

TOPCON POSITIONING SYSTEMS, INC.

5758 West Las Positas Blvd., Pleasanton, CA 94588, U.S.A.

Phone: 925-460-1300 Fax: 925-460-1315 www.topcon.com

TOPCON CALIFORNIA

3380 Industrial Blvd, Suite 105, West Sacramento, CA 95691,

Phone: 916-374-8575 Fax: 916-374-8329

TOPCON MIDWEST

891 Busse Road, Elk Grove Village, IL 60007, U.S.A.

Phone: 847-734-1700 Fax: 847-734-1712

TOPCON EUROPE B.V.

Essebaan 11, 2908 LJ Capelle a/d IJssel, The Netherlands.

Phone: 010-4585077 Fax: 010-4585045 www.topconeurope.com

TOPCON BELGIUM

Preenakker 8, 1785 Merchtem, Belgium

Phone: 052-37.45.48 Fax: 052-37.45.79

TOPCON DEUTSCHLAND G.m.b.H.

Weidkamp 180, 45356 Essen, GERMANY

Phone: 0201-8619-100 Fax: 0201-8619-111 ps@topcon.de

www.topcon.de

TOPCON S.A.R.L.

89, Rue de Paris, 92585 Clichy, Cedex, France.

Phone: 33-1-41069490 Fax: 33-1-47390251 topcon@topcon.fr

U.S.A.

TOPCON ESPAÑA S.A.

HEAD OFFICE

Frederic Mompou 5, ED. Euro 3, 08960, Sant Just Desvern Barcelona, Spain.

Phone: 93-473-4057 Fax: 93-473-3932 www.topconesp.com

MADRID OFFICE

Avenida Burgos, 16E, 1∞28036, Madrid, Spain.

Phone: 91-302-4129 Fax: 91-383-3890

TOPCON SCANDINAVIA A. B.

Neongatan 2 S-43151 Mölndal, SWEDEN

Phone: 031-7109200 Fax: 031-7109249

TOPCON (GREAT

HEAD OFFICE

Topcon House Kennet Side, Bone Lane, Newbury, Berkshire RG14 5PX U.K.

Phone: 44-1635-551120 Fax: 44-1635-551170

survey.sales@topcon.co.uk laser.sales@topcon.co.uk

TOPCON SOUTH ASIA PTE. LTD.

Blk 192 Pandan Loop, Pantech Industrial Complex, #07-01, Singapore 128381

Phone: 62780222 Fax: 62733540 www.topcon.com.sg

TOPCON AUSTRALIA PTY. LTD.

408 Victoria Road, Gladesville, NSW 2111, Australia

Phone: 02-9817-4666 Fax: 02-9817-4654 www.topcon.com.au

TOPCON INSTRUMENTS (THAILAND) CO., LTD.

77/162 Sinn Sathorn Tower, 37th Fl.,

Krungdhonburi Rd., Klongtonsai, Klongsarn, Bangkok 10600 Thailand.

Phone: 662-440-1152~7 Fax: 662-440-1158

TOPCON INSTRUMENTS (MALAYSIA) SDN. BHD.

Excella Business Park Block C, Ground & 1st Floor, Jalan Ampang Putra,

Taman Ampang Hilir, 55100 Kuala Lumpur, MALAYSIA

Phone: 03-42701068 Fax: 03-42704508

TOPCON KOREA CORPORATION

2F Yooseoung Bldg., 1595-3, Seocho-Dong, Seocho-gu, Seoul, 137-876, Korea.

Phone: 82-2-2055-0321 Fax: 82-2-2055-0319 www.topcon.co.kr

TOPCON OPTICAL (H.K.) LIMITED

2/F., Meeco Industrial Bldg., No. 53-55 Au Pui Wan Street, Fo Tan Road,

Shatin, N.T., Hong Kong

Phone: 2690-1328 Fax: 2690-2221 www.topcon.com.hk

TOPCON CORPORATION BEIJING OFFICE

Room No. 962 Poly Plaza Building, 14 Dongzhimen Nandajie,

Dongcheng District, Beijing, 100027, China

Phone: 10-6501-4191~2 Fax: 10-6501-4190

TOPCON CORPORATION BEIRUT OFFICE

P. O. BOX 70-1002 Antelias, BEIRUT-LEBANON.

Phone: 961-4-523525/961-4-523526 Fax: 961-4-521119

TOPCON CORPORATION DUBAI OFFICE

C/O Atlas Medical FZCO., P. O. Box 54304, C-25, Dubai Airport Free Zone,UAE

Phone: 971-4-2995900 Fax: 971-4-2995901

BRITAIN) LTD.

TOPCON CORPORATION

75-1 Hasunuma-cho, Itabashi-ku, Tokyo 174-8580, Japan

Phone: 3-3558-2520 Fax: 3-3960-4214 www.topcon.co.jp

DT-200/200L series 30321 90050 0306(1a)

Loading...

Loading...