Page 1

SURVEYING INSTRUMENTS

INSTRUCTION MANUAL

Direct aiming Station

DS series

DS-101AC

DS-102AC

DS-103AC

DS-105AC

21309 90040

Page 2

HOW TO READ THIS MANUAL

Thank you for selecting the DS-101AC/102AC/103AC/105AC.

• Please read this Operator’s manual carefully, before using this product.

• DS has a function to output data to a connected host computer. Command operations from a host

computer can also be performed. For details, refer to "Communication manual" and ask your local

dealer.

• The specifications and general appearance of the instrument are subject to change without prior

notice and without obligation by TOPCON CORPORATION and may differ from those appearing in

this manual.

• The content of this manual is subject to change without notice.

• Some of the diagrams shown in this manual may be simplified for easier understanding.

• This manual is protected by copyright and all rights are reserved by TOPCON CORPORATION.

• Except as permitted by Copyright law, this manual may not be copied, and no part of this manual

may be reproduced in any form or by any means.

• This manual may not be modified, adapted or otherwise used for the production of derivative works.

Symbols

The following conventions are used in this manual.

G : Indicates precautions and important items which should be read before

operations.

C : Indicates the chapter title to refer to for additional information.

$ : Indicates supplementary explanation.

& : Indicates an explanation for a particular term or operation.

[Softkey] etc. : Indicates softkeys on the display and window dialog buttons.

{Key} etc. : Indicates keys on the operation panel.

<Screen title> etc. : Indicates screen titles.

i

Page 3

Notes regarding manual style

Li-ion

S Li-ion

This is the mark of the Japan Surveying

Instruments Manufacturers Association.

• Except where stated, “DS” means DS-101AC/102AC/103AC/105AC in this manual.

• Face 2 display is available as standard or as a factory option depending on the country of purchase.

• Location of softkeys in screens used in procedures is based on the factory setting. It is possible to

change the allocation of softkeys.

CSoftkey allocation: "19.6 Allocating Key Functions"

• Learn basic operations in "4. PRODUCT OUTLINE" and "5. BASIC OPERATION" before you read

each measurement procedure. For selecting options and inputting figures, see "5.1 Basic Key

Operation".

• Measurement procedures are based on continuous measurement. Some information about

procedures when other measurement options are selected can be found in “Note” (

• KODAK is a registered trademark of Eastman Kodak Company.

• Bluetooth® is a registered trademark of Bluetooth SIG, Inc.

• Windows and Windows CE are registered trademarks of Microsoft Corporation.

• All other company and product names featured in this manual are trademarks or registered

trademarks of each respective organization.

$).

ii

Page 4

CONTENTS

1. PRECAUTIONS FOR SAFE OPERATION............................ 1

2. PRECAUTIONS ..................................................................... 4

3. LASER SAFETY INFORMATION .......................................... 7

4. PRODUCT OUTLINE............................................................. 9

4.1 Parts of the Instrument .................................................................... 9

4.2 Mode Structure .............................................................................. 14

4.3 Bluetooth Wireless Technology ..................................................... 15

5. BASIC OPERATION ............................................................ 17

5.1 Basic Key Operation ...................................................................... 17

5.2 Display Functions .......................................................................... 21

5.3 Inputting Characters using the Input Panel ................................... 25

5.4 Starkey Mode ................................................................................ 26

5.5 Using the Program Selection Screen ............................................ 31

6. USING THE BATTERY........................................................ 32

6.1 Battery Charging ........................................................................... 32

6.2 Installing/Removing the Battery ..................................................... 33

7. SETTING UP THE INSTRUMENT....................................... 35

7.1 Centering ....................................................................................... 35

7.2 Levelling ........................................................................................ 37

8. POWER ON/OFF................................................................. 39

8.1 Resolving Software Issues ............................................................ 40

8.2 Configuring the Touch Panel ......................................................... 40

8.3 Powering ON/OFF from an External Instrument ........................... 41

9. CONNECTING TO EXTERNAL DEVICES .......................... 42

9.1 Wireless Communication using Bluetooth Technology ................. 42

9.2 Communication between the DS and Companion Device ............ 46

9.3 Connection via RS232C Cable ...................................................... 47

9.4 Connecting via USB Cable ............................................................ 48

9.5 Inserting USB Memory .................................................................. 51

10. TARGET SIGHTING ............................................................ 52

10.1 Auto Pointing Settings ................................................................... 53

10.2 Auto-Pointing Function for Target Sighting ................................... 55

10.3 Manually Sighting the Target ......................................................... 56

11. ANGLE MEASUREMENT.................................................... 58

11.1 Measuring the Horizontal Angle between Two Points

iii

Page 5

CONTENTS

(Horizontal Angle 0°) ..................................................................... 58

11.2 Setting the Horizontal Angle to a Required Value

(Horizontal Angle Hold) ................................................................. 59

11.3 Turning the Instrument from the Reference Angle to

a Specified Angle .......................................................................... 60

11.4 Angle measurement and Outputting the Data ............................... 61

12. DISTANCE MEASUREMENT.............................................. 62

12.1 Returned Signal Checking ............................................................. 62

12.2 Using the Guide Light in Distance Measurement .......................... 64

12.3 Distance and Angle Measurement ................................................ 65

12.4 Distance Measurement and Outputting the Data .......................... 66

12.5 REM Measurement ....................................................................... 67

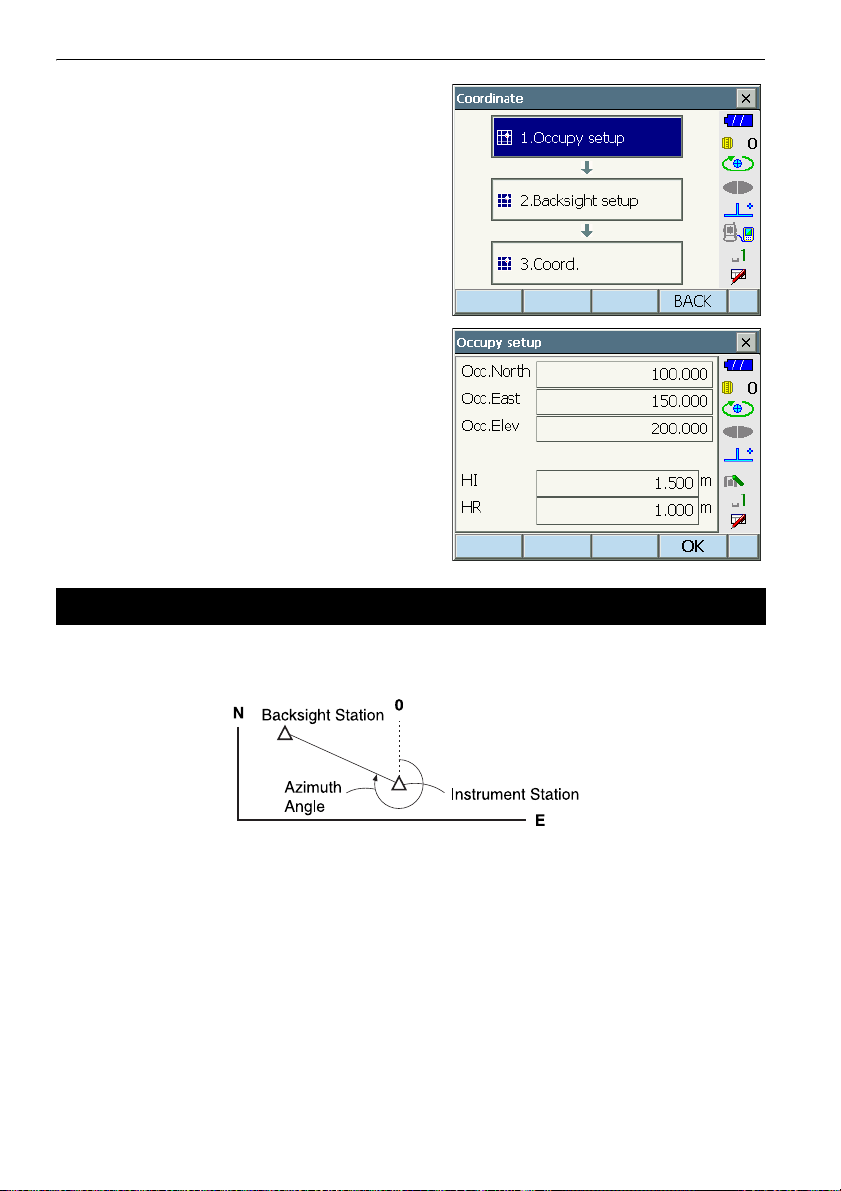

13. COORDINATE MEASUREMENT ........................................ 69

13.1 Entering Instrument Station Data .................................................. 69

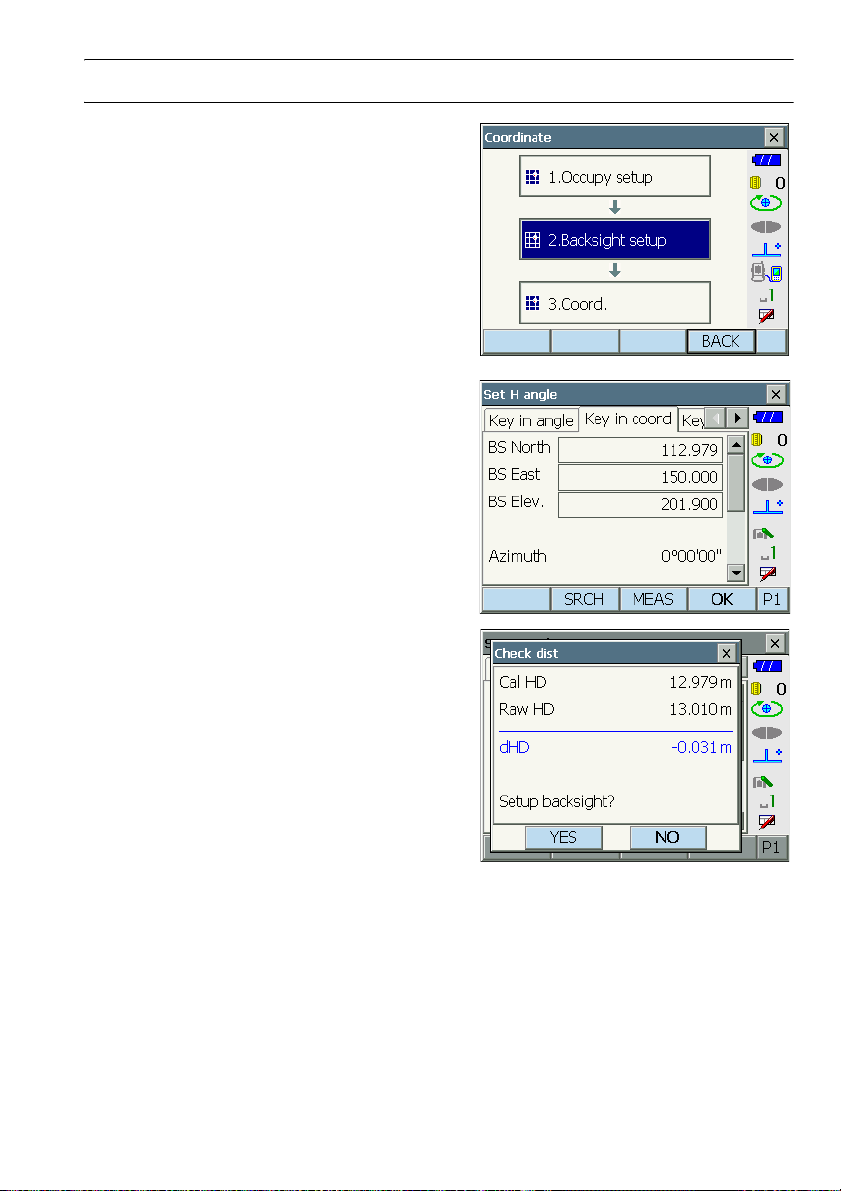

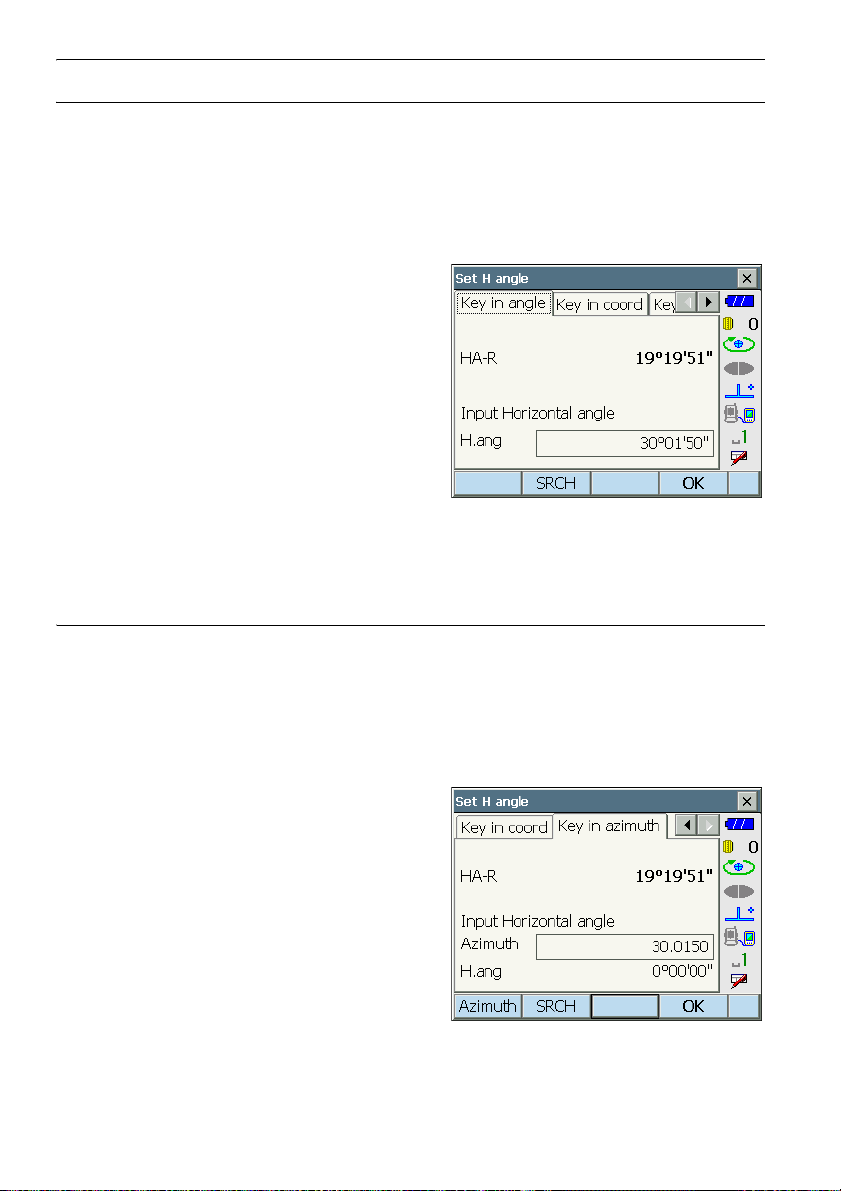

13.2 Azimuth Angle Setting ................................................................... 70

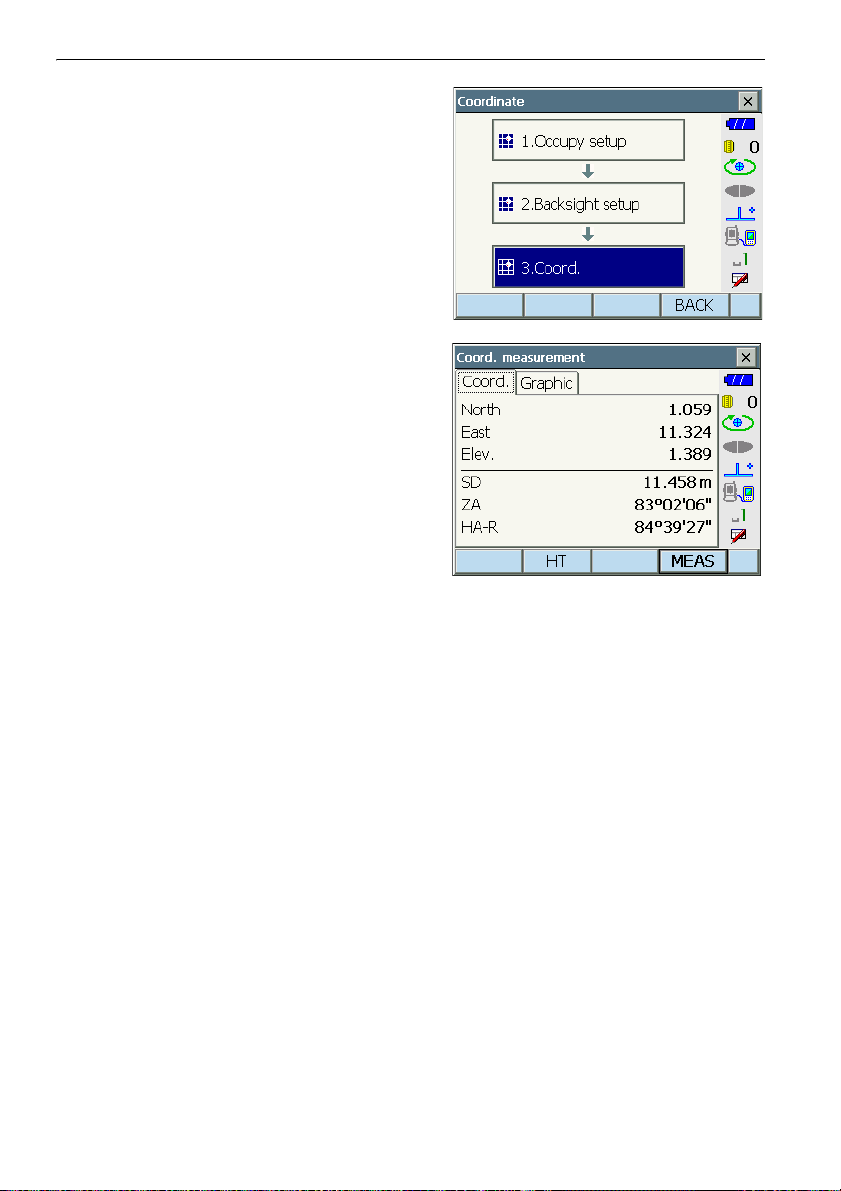

13.3 3-D Coordinate Measurement ....................................................... 73

14. RESECTION MEASUREMENT ........................................... 75

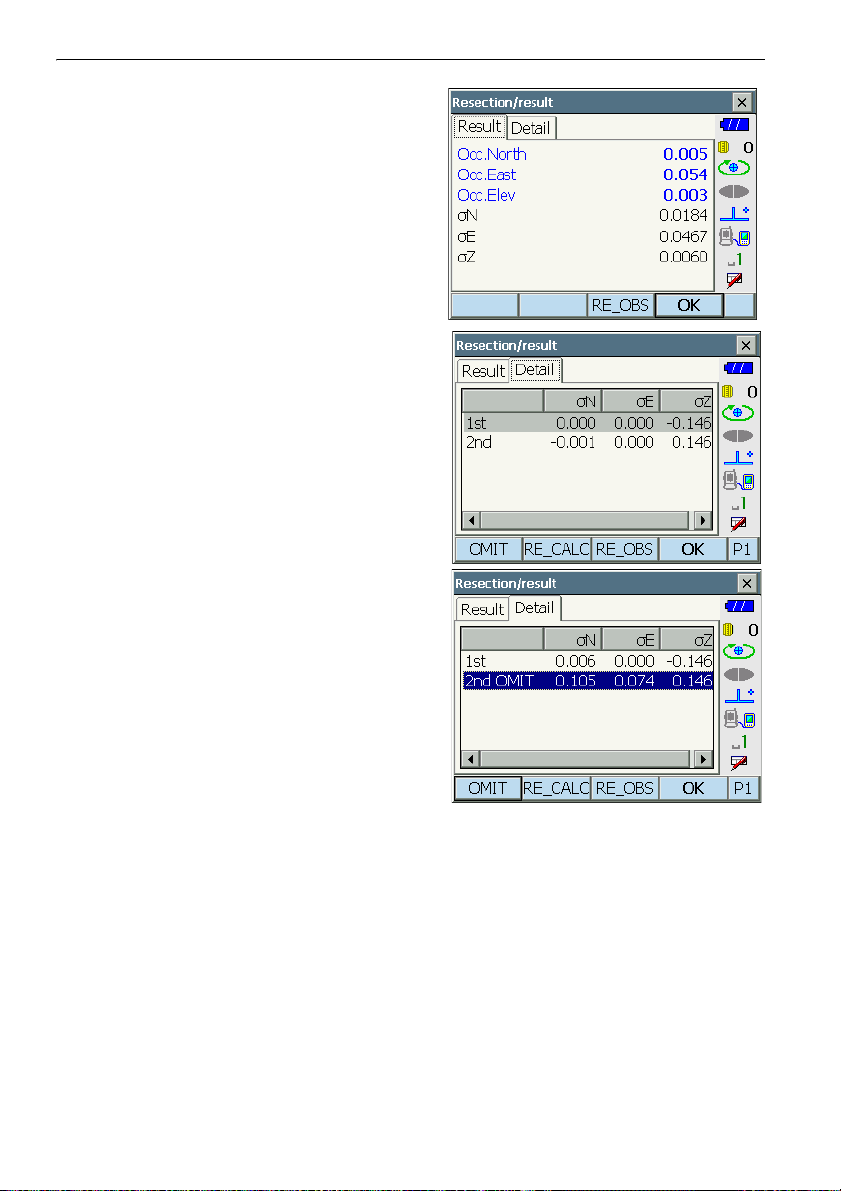

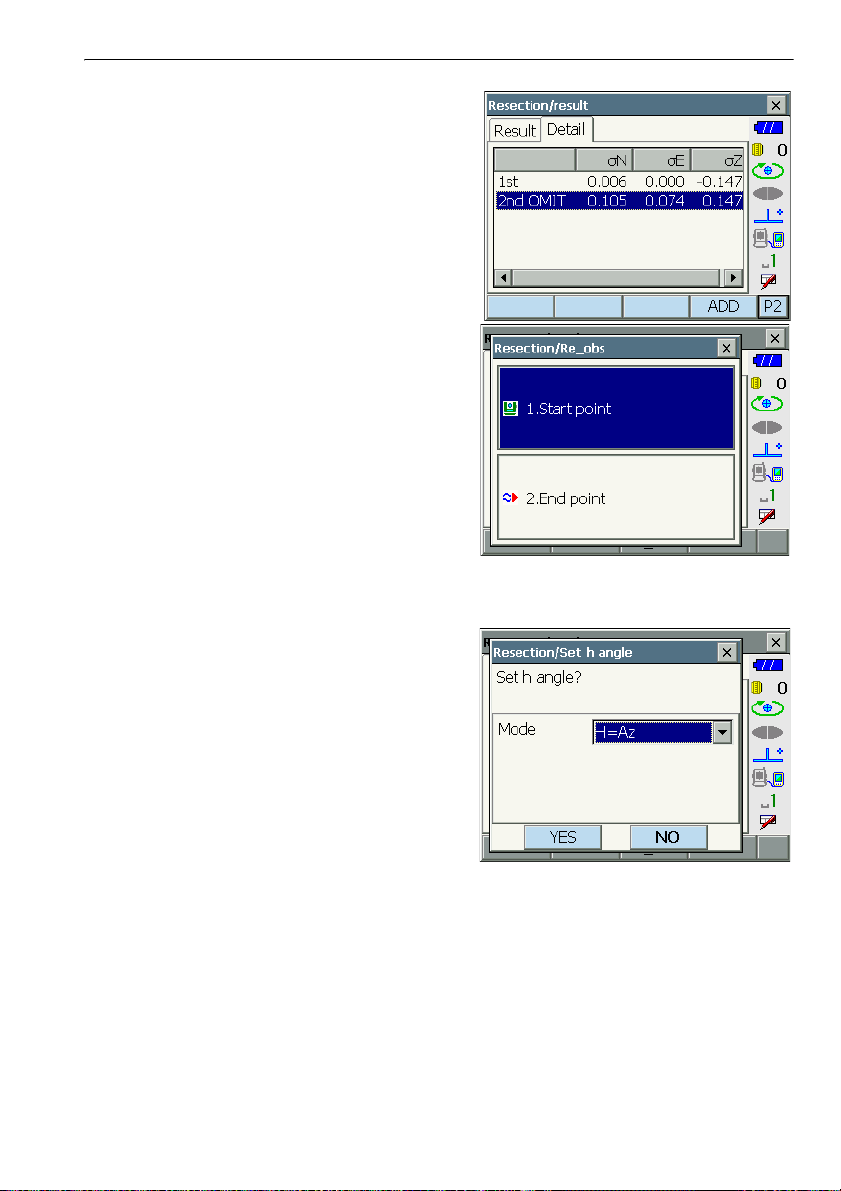

14.1 Coordinate Resection Measurement ............................................. 76

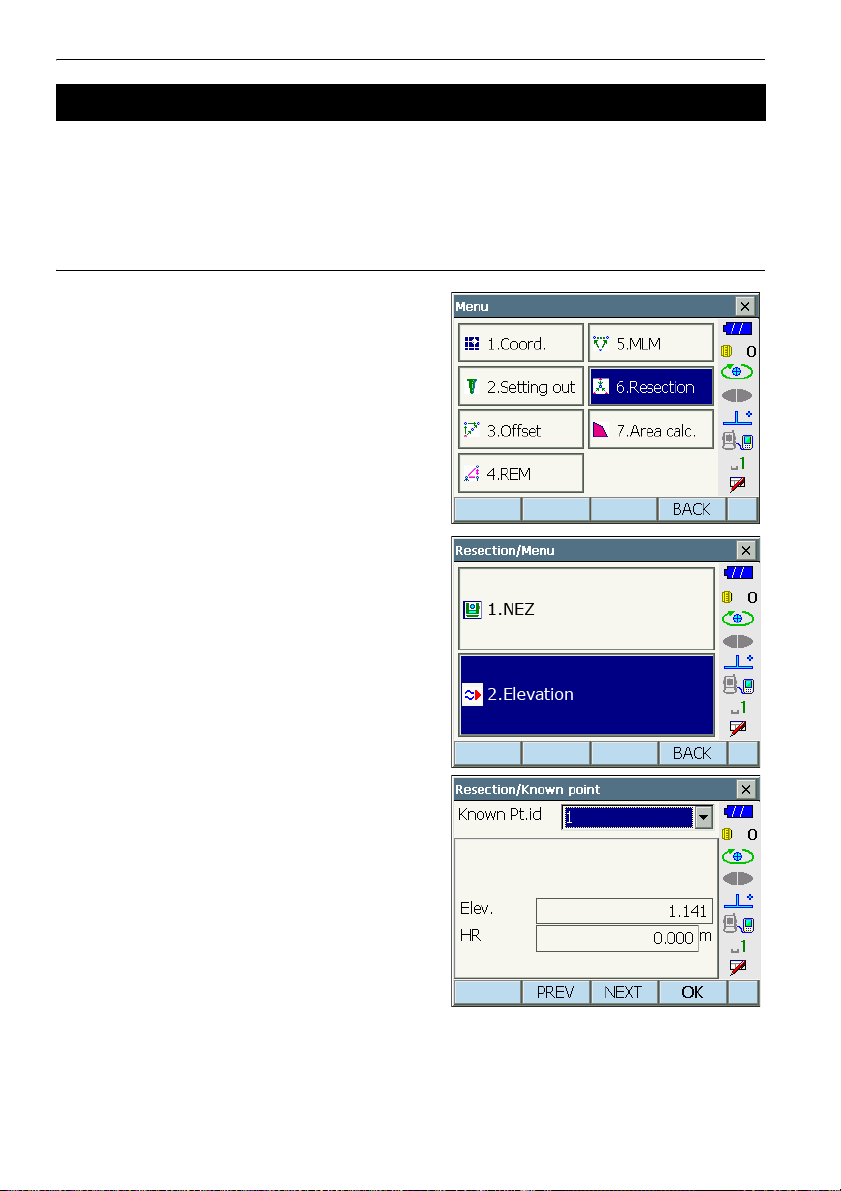

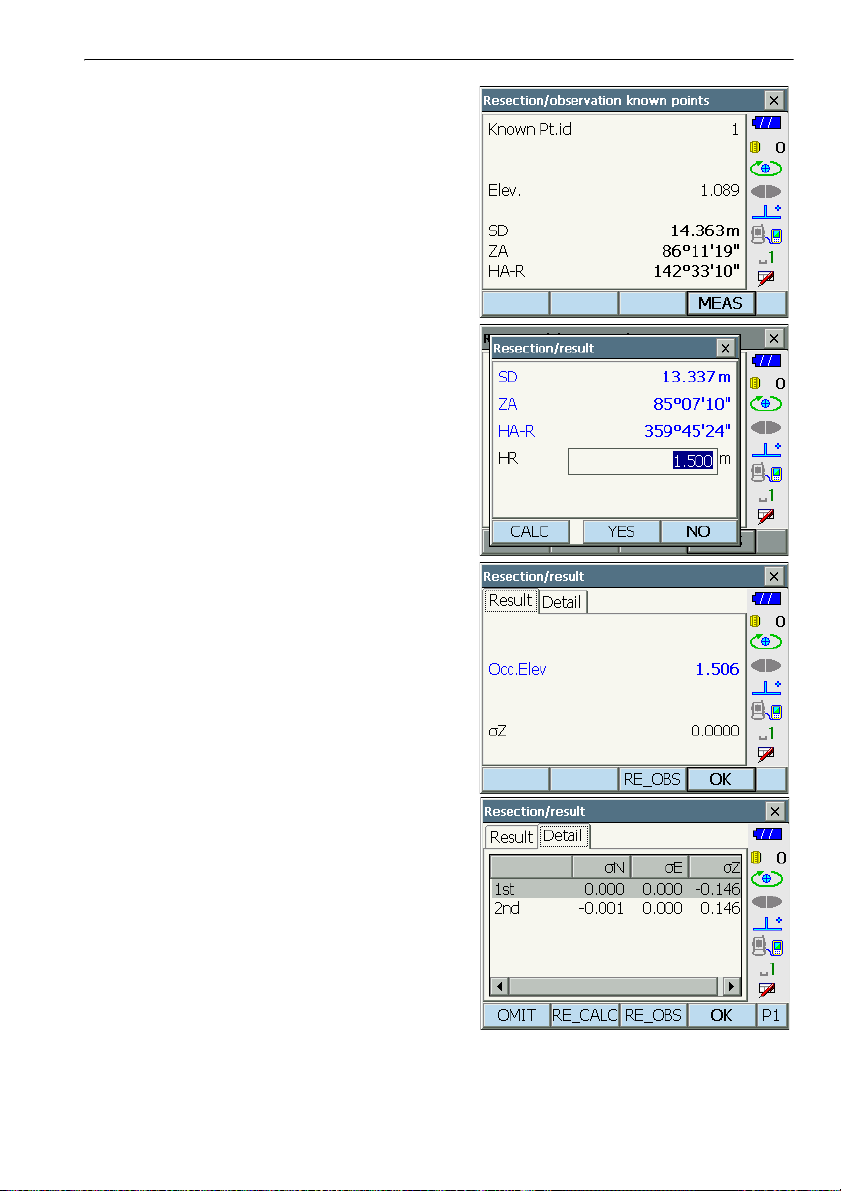

14.2 Height Resection Measurement .................................................... 80

15. SETTING-OUT MEASUREMENT........................................ 85

15.1 Using the Guide Light in Setting-out Measurement ....................... 85

15.2 Distance Setting-out Measurement ............................................... 86

15.3 Coordinates Setting-out Measurement .......................................... 90

15.4 REM Setting-out Measurement ..................................................... 94

16. OFFSET MEASUREMENT.................................................. 96

16.1 Offset Single-distance Measurement ............................................ 96

16.2 Offset Angle Measurement ............................................................ 98

16.3 Offset Two-distance Measurement ............................................. 100

17. MISSING LINE MEASUREMENT ...................................... 103

17.1 Measuring the Distance between 2 or more Points ..................... 103

17.2 Changing the Starting Point ........................................................ 105

18. SURFACE AREA CALCULATION..................................... 107

19. CHANGING THE SETTINGS ............................................ 111

19.1 Observation Conditions ............................................................... 111

19.2 Instrument Configuration ............................................................. 114

19.3 EDM Settings .............................................................................. 116

iv

Page 6

CONTENTS

19.4 Allocating User-defined Tabs ...................................................... 120

19.5 Customizing Screen Controls ...................................................... 123

19.6 Allocating Key Functions ............................................................. 125

19.7 Changing Starkey Mode Icons .................................................... 128

19.8 Units ............................................................................................ 130

19.9 Changing Password .................................................................... 131

19.10 Restoring Default Settings ........................................................... 132

19.11 Date and Time ............................................................................. 132

20. WARNING AND ERROR MESSAGES.............................. 133

21. CHECKS AND ADJUSTMENTS........................................ 136

21.1 Circular Level .............................................................................. 136

21.2 Tilt Sensor ................................................................................... 137

21.3 Collimation ................................................................................... 140

21.4 Reticle ......................................................................................... 141

21.5 Image Sensor Reticle .................................................................. 143

21.6 Optical Plummet .......................................................................... 145

21.7 Additive Distance Constant ......................................................... 146

21.8 Laser Plummet (Option) .............................................................. 147

22. POWER SUPPLY SYSTEM .............................................. 150

23. PRISM SYSTEM................................................................ 151

24. OPPTIONAL ACCESSORIES ........................................... 152

25. SPECIFICATIONS ............................................................. 154

26. EXPLANATIONS .............................................................. 161

26.1 High Accuracy with the 360° Prism ............................................. 161

26.2 Manually Indexing the Vertical Circle by Face Left,

Face Right Measurement ............................................................ 162

27. REGULATIONS ................................................................. 163

28. INDEX ................................................................................ 167

v

Page 7

1. PRECAUTIONS FOR SAFE OPERATION

For the safe use of the product and prevention of injury to operators and other persons as well as

prevention of property damage, items which should be observed are indicated by an exclamation point

within a triangle used with WARNING and CAUTION statements in this operator’s manual.

The definitions of the indications are listed below. Be sure you understand them before reading the

manual’s main text.

Definition of Indication

C

C

J

D

I

General

C

D

G

D

D

E

E

WARNING

CAUTION

This symbol indicates items for which caution (hazard warnings inclusive) is urged.

Specific details are printed in or near the symbol.

This symbol indicates items which are prohibited. Specific details are printed in or near

the symbol.

This symbol indicates items which must always be performed. Specific details are printed

in or near the symbol.

Warning

Do not use the unit in areas exposed to high amounts of dust or ash, in areas where there

is inadequate ventilation, or near combustible materials. An explosion could occur.

Do not perform disassembly or rebuilding. Fire, electric shock, burns, or hazardous

radiation exposure could result.

Never look at the sun through the telescope. Loss of eyesight could result.

Do not look at reflected sunlight from a prism or other reflecting object through the

telescope. Loss of eyesight could result.

Direct viewing of the sun using the telescope during sun observation will cause loss of

eyesight. Use a solar filter (option) for sun observation.

When securing the instrument in the carrying case make sure that all catches, including

the side catches, are closed. Failure to do so could result in the instrument falling out

while being carried, causing injury.

Ignoring this indication and making an operation error could possibly

result in death or serious injury to the operator.

Ignoring this indication and making an operation error could possibly

result in personal injury or property damage.

Caution

C

Do not use the carrying case as a footstool. The case is slippery and unstable so a

D

person could slip and fall off it.

1

Page 8

Do not place the instrument in a case with a damaged catch, belt or handle. The case or

D

instrument could be dropped and cause injury.

Do not touch the instrument or look through the telescope while the motor is in operation.

D

Injury could result.

Do not wield or throw the plumb bob. A person could be injured if struck.

D

Secure handle to main unit with handle locks. Failure to properly secure the handle could

E

result in the unit falling off while being carried, causing injury.

Tighten the adjustment tribrach clamp securely. Failure to properly secure the clamp

E

could result in the tribrach falling off while being carried, causing injury.

Power Supply

Warning

C

Do not short circuit. Heat or ignition could result.

D

Do not place articles such as clothing on the battery charger while charging batteries.

D

Sparks could be induced, leading to fire.

Do not use voltage other than the specified power supply voltage. Fire or electrical shock

D

could result.

Do not use batteries other than those designated. An explosion could occur, or abnormal

D

heat generated, leading to fire.

Do not use damaged power cords, plugs or loose outlets. Fire or electric shock could

D

result.

1. PRECAUTIONS FOR SAFE OPERATION

Do not use power cords other than those designated. Fire could result.

D

Use only the specified battery charger to recharge batteries. Other chargers may be of

E

different voltage rating or polarity, causing sparking which could lead to fire or burns.

Do not use the battery or charger for any other equipment or purpose. Fire or burns

D

caused by ignition could result.

Do not heat or throw batteries or chargers into fire. An explosion could occur, resulting in

H

injury.

To prevent shorting of the battery in storage, apply insulating tape or equivalent to the

E

terminals. Otherwise shorting could occur resulting in fire or burns.

Do not use batteries or the battery charger if wet. Resultant shorting could lead to fire or

D

burns.

Do not connect or disconnect power supply plugs with wet hands. Electric shock could

D

result.

2

Page 9

Caution

C

Do not touch liquid leaking from batteries. Harmful chemicals could cause burns or

F

blisters.

Tripod

Caution

C

When mounting the instrument to the tripod, tighten the centering screw securely. Failure

to tighten the screw properly could result in the instrument falling off the tripod, causing

E

injury.

Tighten securely the leg fixing screws of the tripod on which the instrument is mounted.

E

Failure to tighten the screws could result in the tripod collapsing, causing injury.

Do not carry the tripod with the tripod shoes pointed at other persons. A person could be

D

injured if struck by the tripod shoes.

Keep hands and feet away from the tripod shoes when fixing the tripod in the ground. A

E

hand or foot stab wound could result.

Tighten the leg fixing screws securely before carrying the tripod. Failure to tighten the

E

screws could lead to the tripod legs extending, causing injury.

Bluetooth wireless technology

1. PRECAUTIONS FOR SAFE OPERATION

Warning

C

Do not use within the vicinity of hospitals. Malfunction of medical equipment could

D

result.

Use the instrument at a distance of at least 22 cm from anyone with a cardiac

pacemaker. Otherwise, the pacemaker may be adversely affected by the

E

electromagnetic waves produced and cease to operate as normal.

Do not use onboard aircraft. The aircraft instrumentation may malfunction as a result.

D

Do not use within the vicinity of automatic doors, fire alarms and other devices with

automatic controls as the electromagnetic waves produced may adversely affect

D

operation resulting in an accident.

3

Page 10

2. PRECAUTIONS

Speaker

Telescope

• Aiming the telescope at the sun will cause internal damage to the instrument. Use the solar filter

when observing the sun.

C"24. OPPTIONAL ACCESSORIES"

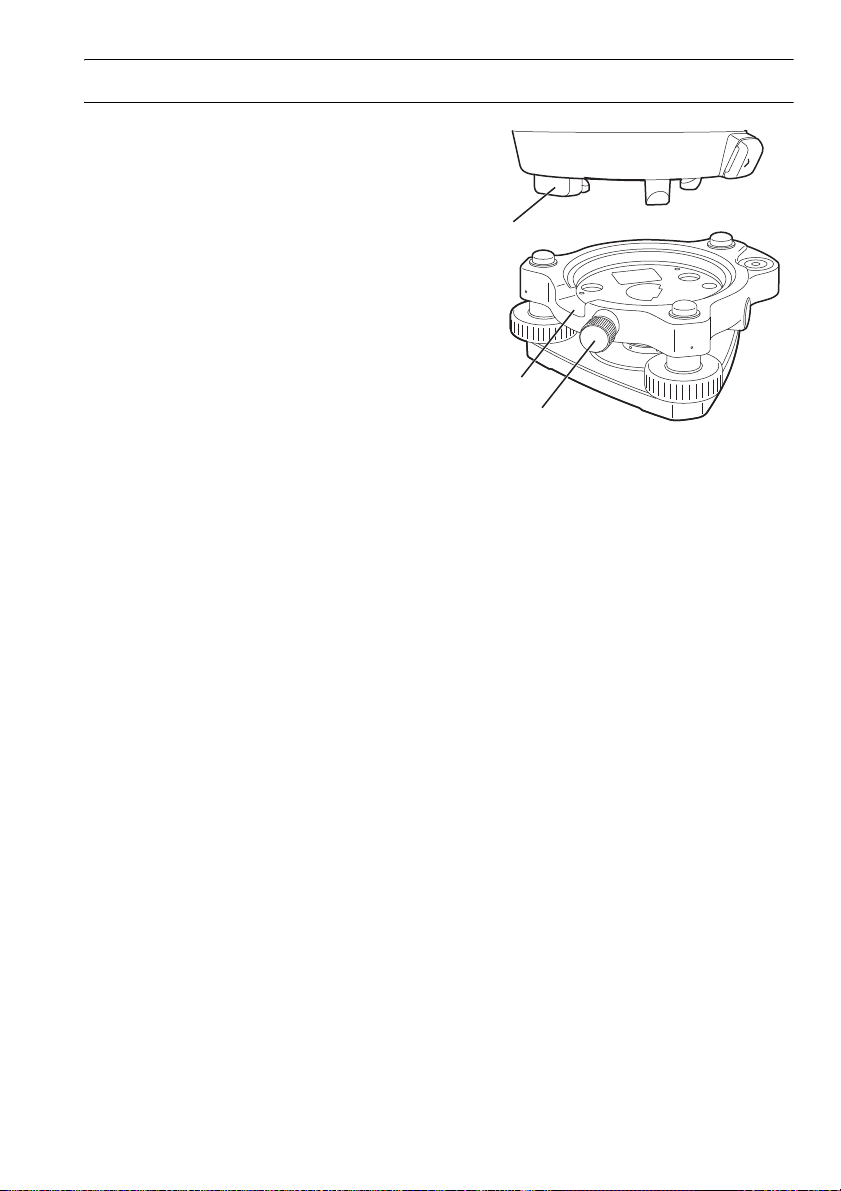

Tribrach Clamp and Handle

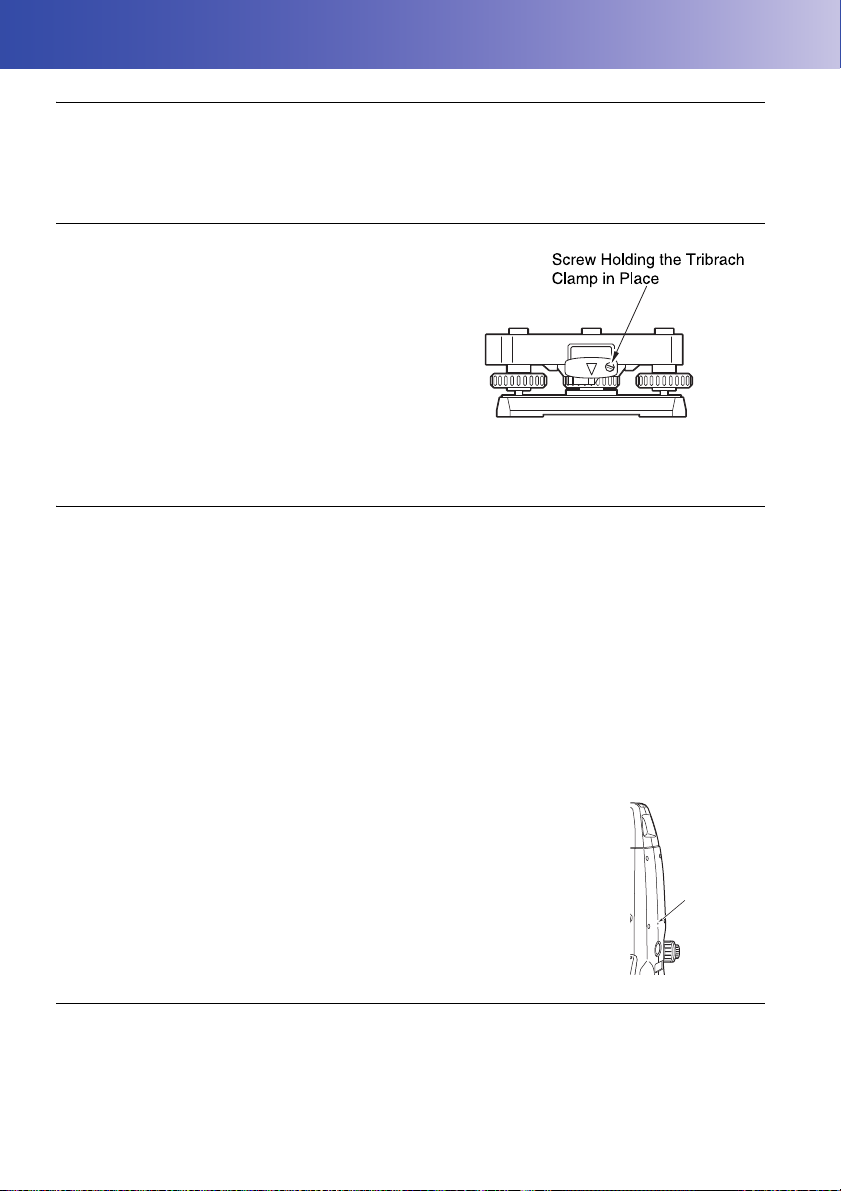

• When the instrument is shipped, the tribrach clamp is held

firmly in place with a locking screw to prevent the

instrument from shifting on the levelling base. Before using

the instrument the first time, loosen this screw with a

screwdriver. And before transporting it, tighten the locking

screw to fasten the tribrach clamp in place so that it will not

shift on the tribrach.

• The handle of the instrument can be removed. When

operating the instrument with the handle attached, always

make sure that the handle is securely fixed to the

instrument body with the handle locks.

Precautions concerning water and dust resistance

The instrument conforms to IP65 specifications for waterproofing and dust resistance when battery

cover, connector cap and the external interface hatch and are closed.

• Be sure to correctly attach the connector caps to protect the instrument from moisture and dust

particles when the connector is not in use.

• Make sure that moisture or dust particles do not come in contact with the terminal or connectors.

Operating the instrument with moisture or dust on the terminal or connectors may cause damage to

the instrument.

• Make sure that the inside of the carrying case and the instrument are dry before closing the case. If

moisture is trapped inside the case, it may cause the instrument to rust.

• If there is a crack or deformation in the rubber packing for the battery cover or external interface

hatch, stop using and replace the packing.

• To retain the waterproof property, it is recommended that you replace the rubber packing once every

two years. To replace the packing, contact your local sales representative.

• Do not press the speaker / luminance sensor / microphone hole using

something with a pointed tip. Doing so will damage an internal waterproof

sheet, resulting in a degraded waterproof property.

The Lithium Battery

• The lithium battery is used to maintain the Calendar & Clock function. It can back up data for

approximately 5 years of normal use and storage (Temperature = 20°, humidity = about 50%), but

its lifetime may be shorter depending on circumstances.

4

Page 11

2. PRECAUTIONS

The Levelling Base

• Always use the levelling base provided. During a traverse observation, it is recommended to use the

same type of levelling base for the target as well for accurate observations.

Backing up data

• Data should be backed up (transferred to an external device etc.) on a regular basis to prevent data

loss.

Other precautions

• Never place the instrument directly on the ground. Sand or dust may cause damage to the screw

holes or the centering screw on the base plate.

• Do not perform vertical rotation of the telescope when using the lens hood, diagonal eyepiece, or

solar filter. Such accessories may strike the instrument causing damage.

• Protect the instrument from heavy shocks or vibration.

• Protect the instrument from rain or drizzle with an umbrella or waterproof cover.

• Never carry the instrument on the tripod to another site.

• Turn the power off before removing the battery.

• Remove the battery before placing the instrument in its case.

• Make sure that the instrument and the protective lining of the carrying case are dry before closing the

case. The case is hermetically sealed and if moisture is trapped inside, the instrument could rust.

• Consult your local dealer before using the instrument under special conditions such as long periods

of continuous use or high levels of humidity. In general, special conditions are treated as being

outside the scope of the product warranty.

Maintenance

• Wipe off moisture completely if the instrument gets wet during survey work.

• Always clean the instrument before returning it to the case. The lens requires special care. First,

dust it off with the lens brush to remove tiny particles. Then, after providing a little condensation by

breathing on the lens, wipe it with the wiping cloth.

• If the display is dirty, carefully wipe it with a soft, dry cloth. To clean other parts of the instrument or

the carrying case, lightly moisten a soft cloth in a mild detergent solution. Wring out excess water

until the cloth is slightly damp, then carefully wipe the surface of the unit. Do not use any alkaline

cleaning solutions, alcohol, or any other organic solvents on the instrument or display.

CFor temporal de-activating the touch panel, see "5.2 Display Functions", "19. CHANGING THE

SETTINGS"

• Store the instrument in a dry room where the temperature remains fairly constant.

• Check the tripod for loose fit and loose screws.

• If any trouble is found on the rotatable portion, screws or optical parts (e.g. lens), contact your local

dealer.

• When the instrument is not used for a long time, check it at least once every 3 months.

C"21. CHECKS AND ADJUSTMENTS"

• Every 4,000 to 5,000 hours operation in total, change grease of driving parts. Contact your local

dealer for the maintenance.

• When removing the instrument from the carrying case, never pull it out by force. The empty carrying

case should be closed to protect it from moisture.

5

Page 12

2. PRECAUTIONS

• Check the instrument for proper adjustment periodically to maintain the instrument accuracy.

Exporting this product

• This product is equipped with the parts/units, and contains software/technology, which are subject

to the EAR (Export Administration Regulations). Depending on countries you wish to export or bring

the product to, a US export license may be required. In such a case, it is your responsibility to obtain

the license. The countries requiring the license as of January 2012 are shown below. Please consult

the Export Administration Regulations as they are subject to change.

North Korea

Iran

Syria

Sudan

Cuba

URL for the EAR of the US: http://www.access.gpo.gov/bis/ear/ear_data.html

Exceptions from responsibility

• The user of this product is expected to follow all operating instructions and make periodic checks

(hardware only) of the product’s performance.

• The manufacturer, or its representatives, assumes no responsibility for results of faulty or intentional

usage or misuse including any direct, indirect, consequential damage, or loss of profits.

• The manufacturer, or its representatives, assumes no responsibility for consequential damage, or

loss of profits due to any natural disaster, (earthquake, storms, floods etc.), fire, accident, or an act

of a third party and/or usage under unusual conditions.

• The manufacturer, or its representatives, assumes no responsibility for any damage (change of

data, loss of data, loss of profits, an interruption of business etc.) caused by use of the product or

an unusable product.

• The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of

profits caused by usage different to that explained in the operator’s manual.

• The manufacturer, or its representatives, assumes no responsibility for damage caused by incorrect

operation, or action resulting from connecting to other products.

6

Page 13

3. LASER SAFETY INFORMATION

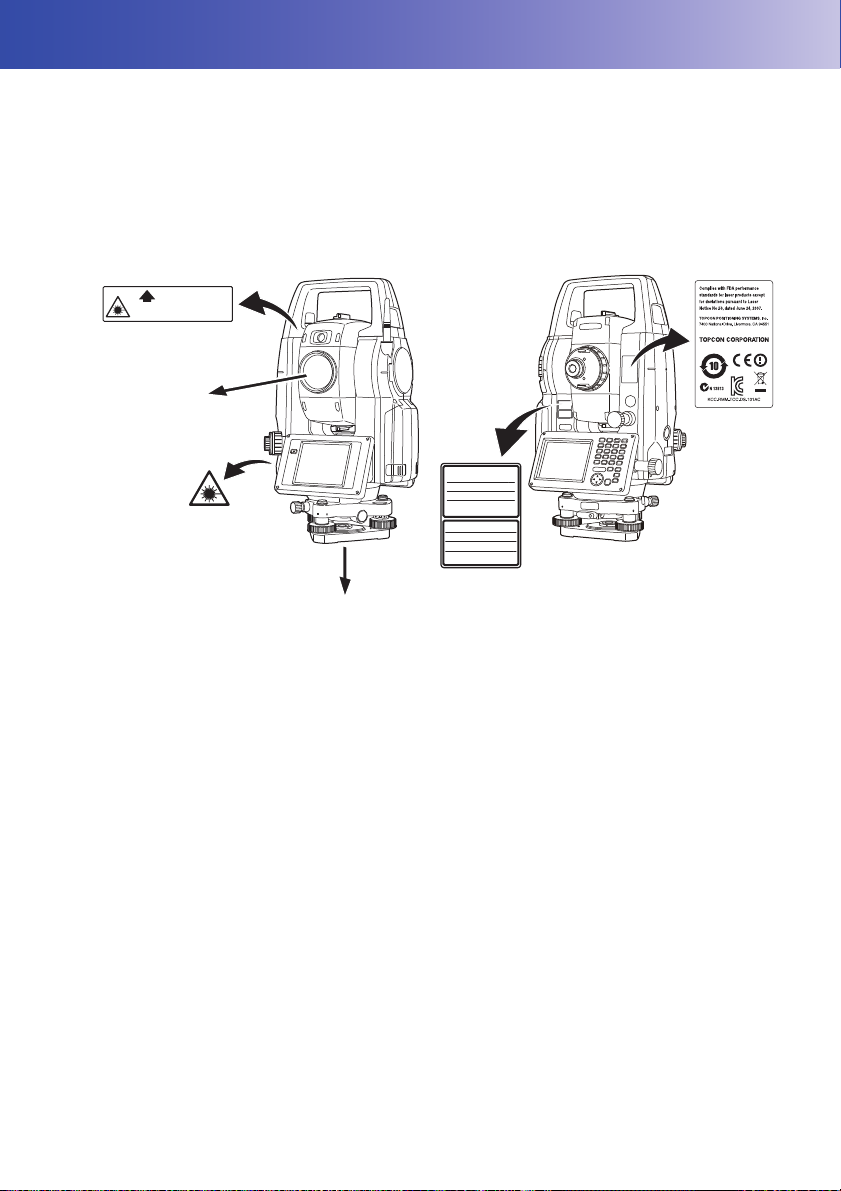

The instrument is classified as the following class of Laser Product according to IEC Standard

Publication 60825-1 Ed.2.0: 2007 and United States Government Code of Federal Regulation FDA

CDRH 21CFR Part 1040.10 and 1040.11 (Complies with FDA performance standards for laser

products except for deviations pursuant to Laser Notice No.50, dated June 24, 2007.)

• EDM device in objective lens: Class 3R Laser Product

(When using prism or reflective sheet as target)Class 1 Laser Product

• Laser plummet (option): Class 2 Laser product

ࠩశߩญ

AVOID EXPOSURE-Laser radiation

is emitted from this aperture.

Laser beam emitted

from here

*

* Laser beam emitted from here

ࠩశ

⋡߳ߩ⋥ធⵍ߫ߊࠍㆱߌࠆߎߣ

/#:O9.&PO

ࠢࠬ4ࠩຠ

,+5%

LASER RADIATION

AVOID DIRECT EYE EXPOSURE

MAX 5mW LD 625-695nm

CLASS3R LASER PRODUCT

IEC 60825-1 Ed. 2.0 : 2007

(only when laser plummet

function is mounted)

G

• EDM device is classified as Class 3R Laser Product when reflectorless measurement is selected.

When the prism or reflective sheet is selected as target, the output is equivalent to the safer class 1.

CWarning

• Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

• Follow the safety instructions on the labels attached to the instrument as well as in this manual to

ensure safe use of this laser product.

• Never point the laser beam at another person. If the laser beam strikes skin or an eye, it could cause

serious injury.

• Do not look directly into the laser beam source or guide light source. Doing so could cause

permanent eye damage.

• Do not stare at the laser beam. Doing so could cause permanent eye damage.

• If an eye injury is caused by exposure to the laser beam, seek immediate medical attention from a

licensed ophthalmologist.

• Never look at the laser beam through a telescope, binoculars or other optical instruments. Doing so

could cause permanent eye damage.

• Sight the target so that the laser beam does not stray from them.

7

Page 14

3. LASER SAFETY INFORMATION

CCaution

• Perform checks at start of work and periodic checks and adjustments with the laser beam emitted

under normal conditions.

• When the instrument is not being used, turn off the power and replace the lens cap.

• When disposing of the instrument, destroy the battery connector so that the laser beam cannot be

emitted.

• Operate the instrument with due caution to avoid injuries that may be caused by the laser beam

unintentionally striking a person in the eye. Avoid setting the instrument at heights at which the path

of the laser beam may strike pedestrians or drivers at head height.

• Never point the laser beam at mirrors, windows or surfaces that are highly reflective. The reflected

laser beam could cause serious injury.

• Only those who have been received training as per the following items shall use this product.

• Read this manual for usage procedures for this product.

• Hazardous protection procedures (read this chapter).

• Requisite protective gear (read this chapter).

• Accident reporting procedures (stipulate procedures beforehand for transporting the injured and

contacting physicians in case there are laser induced injuries).

• Persons working within the range of the laser beam are advised to wear eye protection which

corresponds to the laser wavelength of the instrument being used

• Areas in which the lasers are used should be posted with laser warning notices.

• When using the laser-pointer function, be sure to turn OFF the output laser after distance

measurement is completed. Even if distance measurement is canceled, the laser-pointer function is

still operating and the laser beam continues to be emitted.

8

Page 15

4. PRODUCT OUTLINE

4

4

17

18

1

2

3

7

6

5

9

8

10

11

12

14

13

16

15

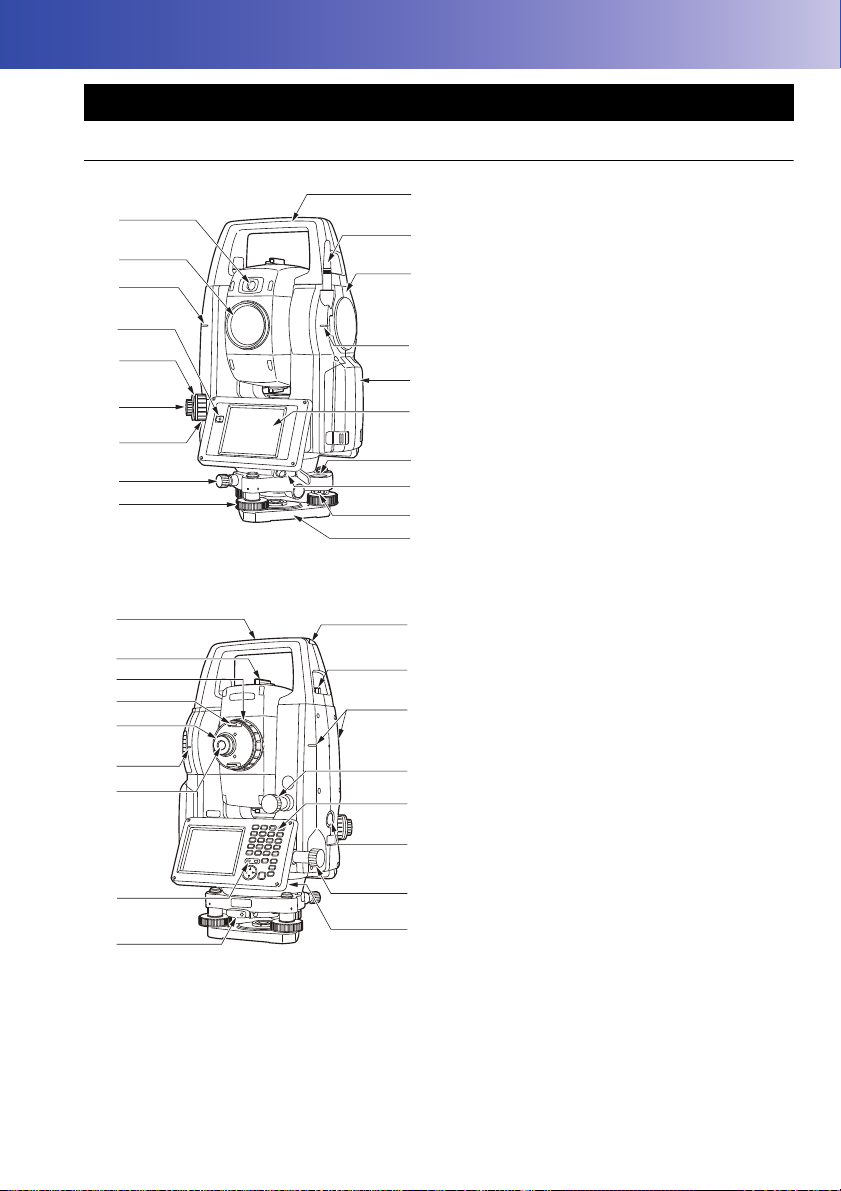

4.1 Parts of the Instrument

Parts and functions of the instrument

Handle

2 Bluetooth antenna

3 External interface hatch

(USB port/reset button)

4 & Instrument height mark

5 Battery cover

6 Display unit

7 Circular level

8 Serial / External power source connector

9 Circular level adjusting screws

10 Base plate

11 Levelling foot screw

12 Levelling base locking screw

13 Optical plummet focussing ring

14 Optical plummet eyepiece

15 Optical plummet reticle cover

16 Luminance sensor

17 Objective lens

(Includes "& Laser-pointer function")

18& Guide light

32

31

30

29

28

4

27

16

26

19 Tubular compass slot

19

20 Handle locking screw

21 & Ver tic al Jog

20

22 Keyboard

C"5.1 Basic Key Operation"

23 & Trigger key

4

24 & Horizontal Jog

25 Stylus (pen)

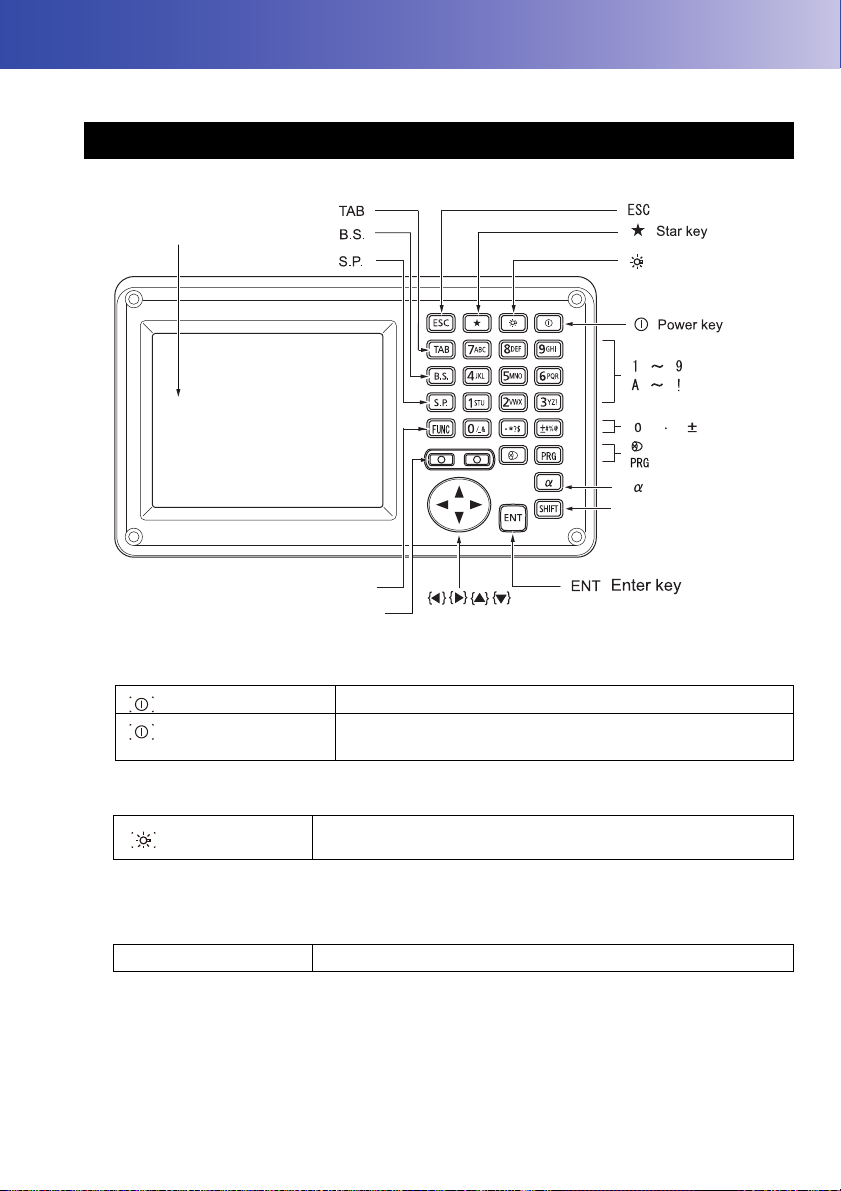

26 Tribrach clamp

21

27 Telescope eyepiece

22

28 Telescope eyepiece screw

29 Telescope knob

23

30 Telescope focussing ring

31&Sighting collimator

32Instrument center mark

24

25

9

Page 16

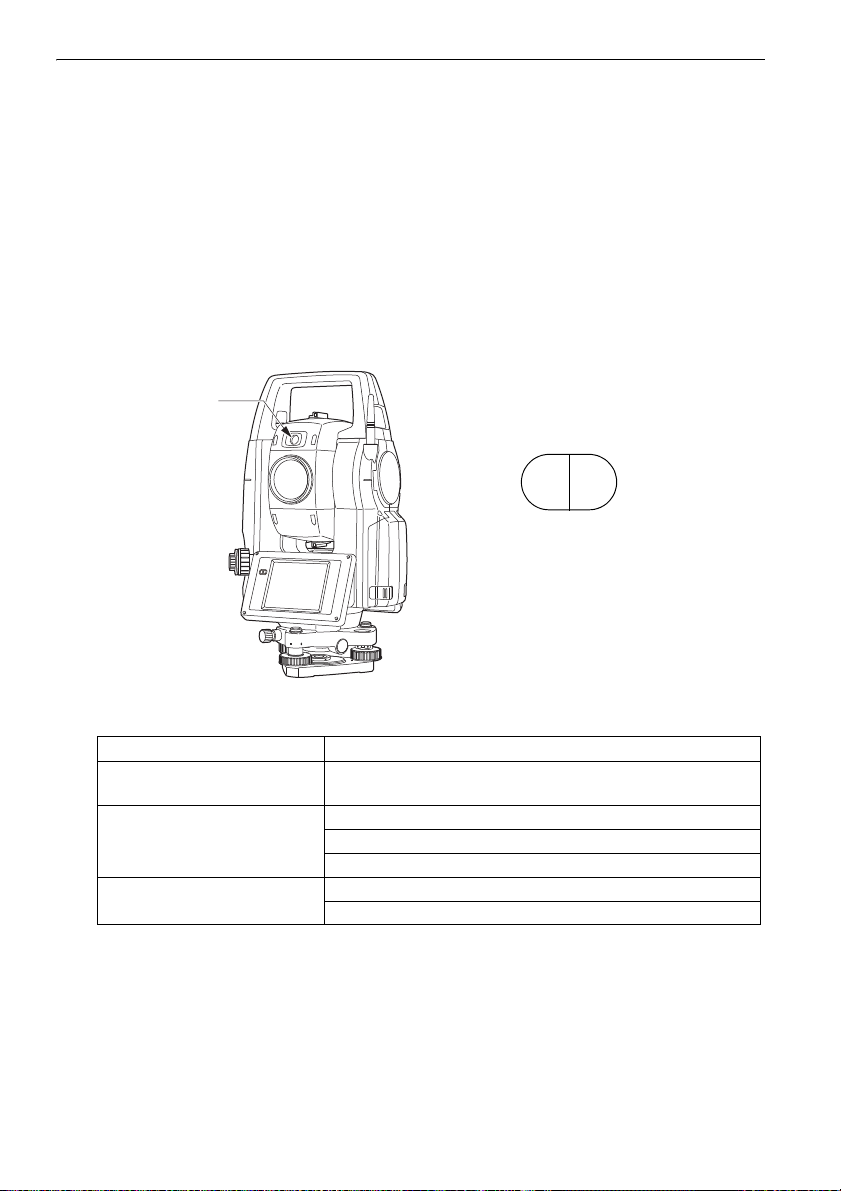

4. PRODUCT OUTLINE

green

red

Guide light

(When seen from the objective lens side

while the instrument is in the Face 1 state)

& Instrument height mark

The height of the instrument is as follows:

• 196mm (from levelling base mounting surface to this mark)

"Instrument height" is input when setting instrument station data and is the height from the

surveying point (where the instrument is mounted) to this mark.

& Laser-pointer function

A target can be sighted with a red laser beam in dark locations without the use of the telescope.

& Guide light

Setting-out measurement etc. can be carried out effectively using the guide light. The guide light

is composed of a light that is divided into green and red sections. A poleman can ascertain the

present position by checking the guide light color.

I Guide light status

Light status Meaning

Slow flashing (Red and green

simultaneously)

Fast flashing (Red and green

simultaneously)

Green and red alternate

flashing

Waiting

Searching in progress

Measuring (continuous measurement)

Returned signal checking in progress

Distance measurement error (no signal, sighting error)

Search error (error screen only)

C"12.2 Using the Guide Light in Distance Measurement", "15.1 Using the Guide Light in

Setting-out Measurement"

10

Page 17

4. PRODUCT OUTLINE

& Vertical and Horizontal Jogs

The instrument and telescope can be rotated manually by hand or, for more precise adjustments,

by turning the vertical and horizontal Jogs.

The faster the Jogs are turned, the faster the instrument and telescope rotate.

C"10.1 Auto Pointing Settings" step 3

& Trigger key

When the Trigger key is pressed the instrument carries out the operation indicated by the softkey

in bold type on the screen. This allows the user to continue operation without having to return to

the display to press softkeys.

& Sighting collimator

Use sighting collimator to aim the instrument in the direction of the measurement point.

Turn the instrument until the apex of the triangle in the sighting collimator is aligned with the

target. A circle surrounds the triangle to make it easier to locate.

Bluetooth antenna

The Bluetooth antenna allows communication via

Bluetooth wireless technology.

G

• Handle the antenna with care. The antenna may be

damaged if struck during operation or while being

stored in the carrying case.

11

Page 18

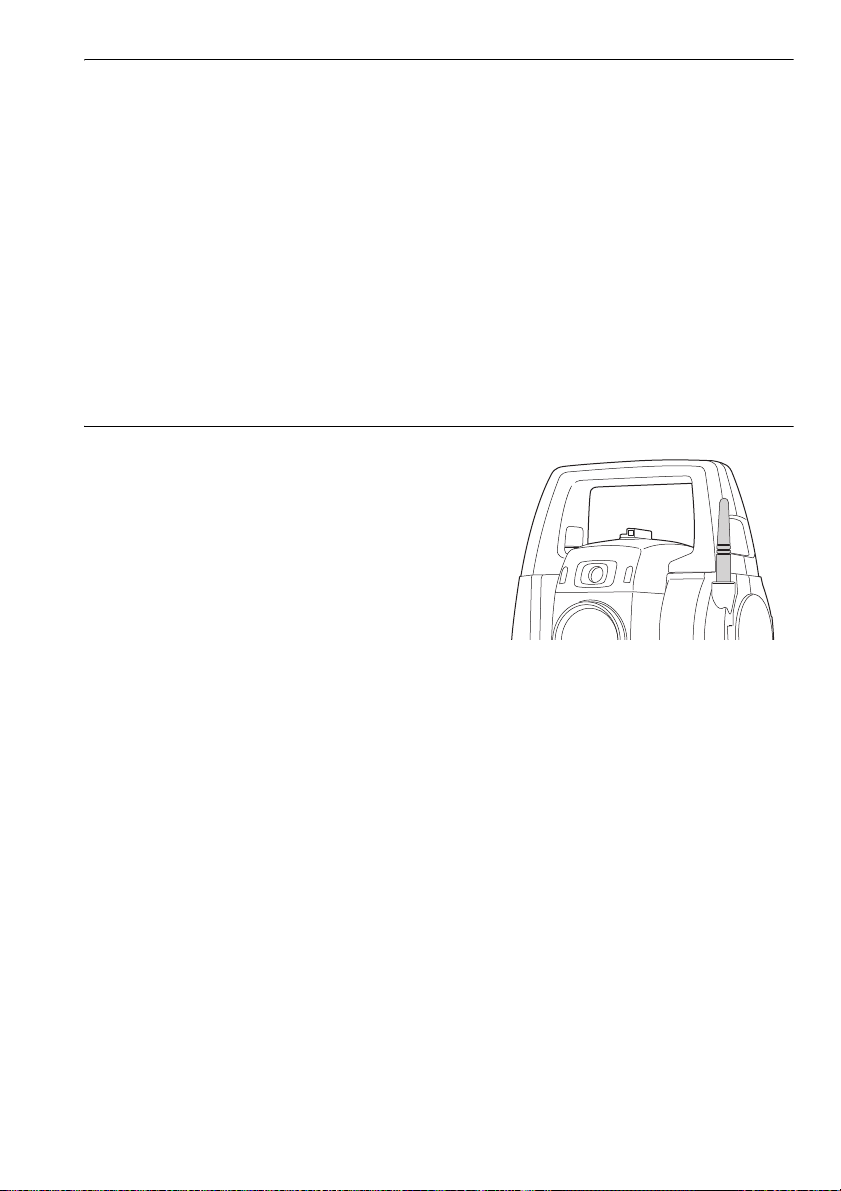

4. PRODUCT OUTLINE

Handle

locking screw

Detaching/attaching the Handle

The carrying handle can be removed from the instrument. To remove it, loosen the handle rocking

screws.

G

• To remove the handle, hold both sides of the handle and lift it straight above. If you hold the handle

by one hand or incline it, the terminal attached on the handle may be damaged.

• Detach the handle if the prism is located at the zenith.

To attache the handle, position the handl as shown, tighthen the 2 handle rocking screws.

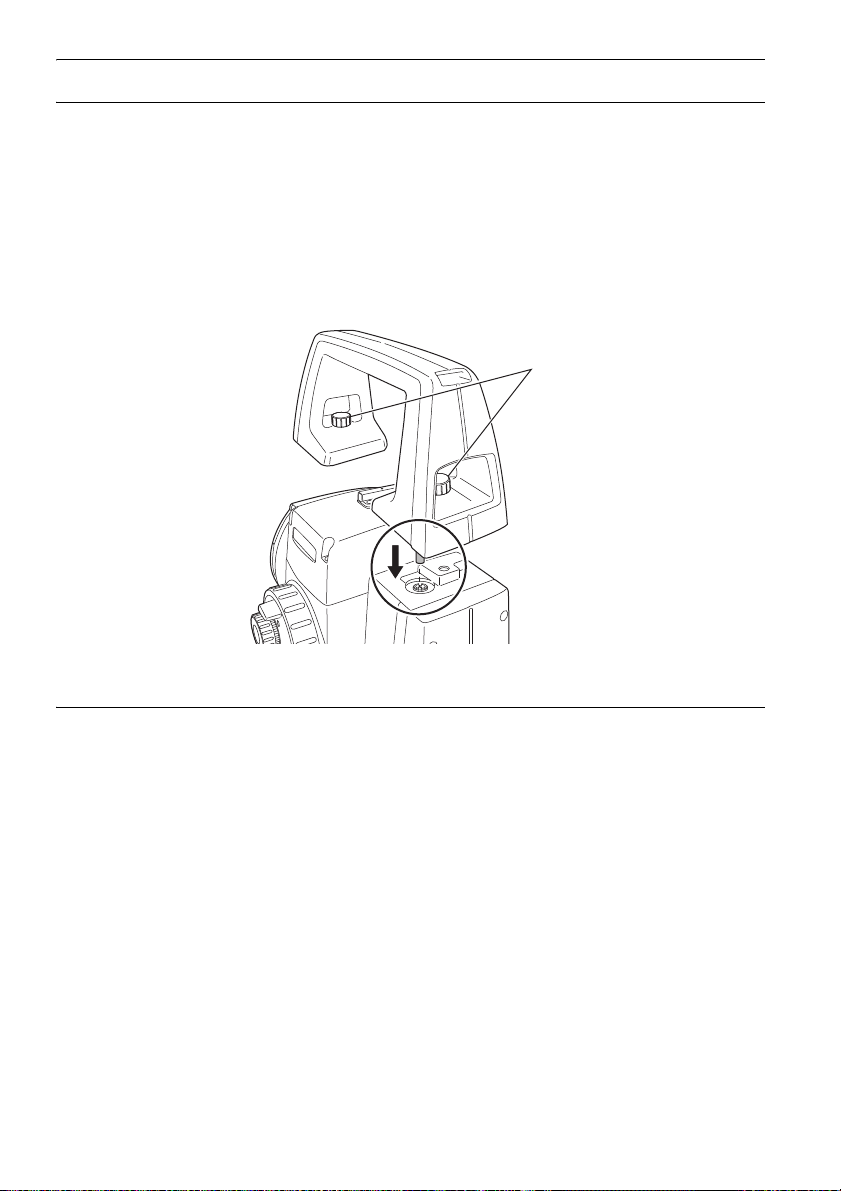

Detaching the instrument from the levelling base

1. Loosen the levelling base locking screw by

turning 2 or 3 rotations in the counterclockwise

direction.

2. Turn the tribrach clamp counterclockwise to

loosen.

3. Lift the instrument to detach.

12

Page 19

Attaching the instrument to the levelling base

(1)

(2)

(3)

1. Check that the levelling base locking screw

has been loosened.

2. Align (1) and (2) and lower the instrument onto

the levelling base.

3. Turn the tribrach clamp (3) clockwise to

tighten.

4. Turn the levelling base locking screw

clockwise to tighten.

$

• Always fully tighten the levelling base locking

screw to reduce adverse effects of motor

operation on accuracy and ensure optimal

results.

4. PRODUCT OUTLINE

13

Page 20

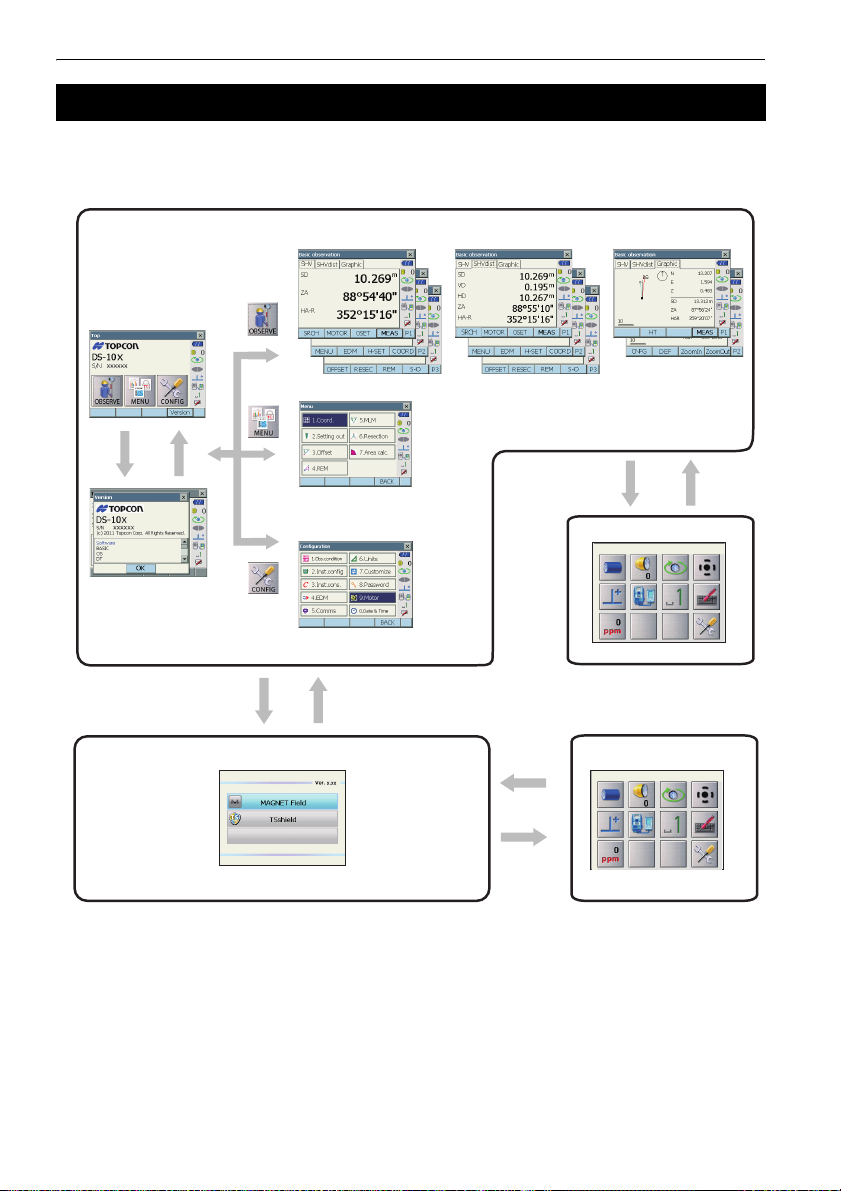

4. PRODUCT OUTLINE

●Program mode

●Starkey mode

Top menu

Observation mode (switching by tab)

Menu mode

Config mode

C“5.2 Display

Functions

”Graphic“ tab”

ÛVersionÝ

=OK?

]ڎ_

●Basic mode

C“5.4 Starkey mode”

]PRG_

]ڎ_

]ESC_

C“19.Changing the settings”

C“13. to 18.”

4.2 Mode Structure

The diagram below describes the different modes of the instrument and key operations for navigating

between them.

G

• Switching between modes is not possible during distance measurement.

• Do not switch between modes by {PRG} or not turn OFF the power just after pressing {PRG} (during

displaying the message "Executing program mode").

14

Page 21

4. PRODUCT OUTLINE

4.3 Bluetooth Wireless Technology

G

• Bluetooth communication is only possible with instruments incorporating the Bluetooth module.

• Use of this technology must be authorized according to telecommunications regulations of the

country where the instrument is being used. Contact your local dealer in advance.

C"27. REGULATIONS"

• TOPCON CORPORATION is not liable for the content of any transmission nor any content related

thereto. When communicating important data, run tests beforehand to ascertain that communication

is operating normally.

• Do not divulge the content of any transmission to any third party.

Radio interference when using Bluetooth technology

Bluetooth communication with the DS uses the 2.4 GHz frequency band. This is the same band used

by the devices described below.

•Industrial, scientific, and medical (ISM) equipment such as microwaves and pacemakers.

• portable premises radio equipment (license required) used in factory production lines etc.

• portable specified low-power radio equipment (license-exempt)

•IEEE802.11b/IEEE802.11g standard wireless LAN devices

The above devices use the same frequency band as Bluetooth communications. As a result, using the

DS within proximity to the above devices may result in interference causing communication failure or

reduction of transmission speed.

Although a radio station license is not required for this instrument, bear in mind the following points

when using Bluetooth technology for communication.

I Regarding portable premises radio equipment and portable specified low-power radio

equipment:

• Before starting transmission, check that operation will not take place within the vicinity of

portable premises radio equipment or specified low-power radio equipment.

• In the case that the instrument causes radio interference with portable premises radio

equipment, terminate the connection immediately and take measures to prevent further

interference (e.g. connect using an interface cable).

• In the case that the instrument causes radio interference with portable specified low-power radio

equipment, contact your local dealer.

I When using the DS in proximity to IEEE802.11b or IEEE802.11g standard wireless LAN

devices, turn off all devices not being used.

• Interference may result, causing transmission speed to slow or even disrupting the connection

completely. Turn off all devices not being used.

I Do not use the DS in proximity to microwaves.

• Microwave ovens can cause significant interference resulting in communication failure. Perform

communication at a distance of 3m or more from microwave ovens.

I Refrain from using the DS in proximity to televisions and radios.

15

Page 22

4. PRODUCT OUTLINE

• Televisions and radios use a different frequency band to Bluetooth communications.

However, even if the DS is used within proximity to the above equipment with no adverse effects

with regard to Bluetooth communication, moving a Bluetooth compatible device (including the

DS) closer to said equipment may result in electronic noise in sound or images, adversely

affecting the performance of televisions and radios.

Precautions regarding transmission

I For best results

• The usable range becomes shorter when obstacles block the line of sight, or devices such as

PDAs or computers are used. Wood, glass and plastic will not impede communication but the

usable range becomes shorter. Moreover, wood, glass and plastic containing metal frames,

plates, foil and other heat shielding elements as well as coatings containing metallic powders

may adversely affect Bluetooth communication and concrete, reinforced concrete, and metal will

render it impossible.

• Use a vinyl or plastic cover to protect the instrument from rain and moisture. Metallic materials

should not be used.

• The direction of the Bluetooth antenna can have adverse effects upon usable range.

I Reduced range due to atmospheric conditions

• The radio waves used by the DS may be absorbed or scattered by rain, fog, and moisture from

the human body with the limit of usable range becoming lower as a result. Similarly, usable range

may also shorten when performing communication in wooded areas. Moreover, as wireless

devices lose signal strength when close to the ground, perform communication at as high a

position as possible.

16

Page 23

5. BASIC OPERATION

SHIFT

Display unit

Luminance sensor / Microphone

Target type

Program mode

Function key

Input mode

SHIFT

Illumination key

FUNC

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

{ }

Learn basic key operations here before you read each measurement procedure.

5.1 Basic Key Operation

I Power ON/OFF

{}

{} (

Press and hold: About 1

second)

I Lighting up the reticle/keys and selecting screen backlight brightness

{}

C Brightness level: "19.2 Instrument Configuration"

I Switching to Starkey mode

{

★ }

C "5.4 Starkey Mode"

Power ON

Power OFF

Switches the reticle illumination and key light On/Off (When Key

light is On, backlight brigthtness goes down)

Switches to Starkey mode / previous screen

17

Page 24

5. BASIC OPERATION

I Switching to Program mode

{PRG} Switches to program mode / basic mode

G

• Do not switch between modes by {PRG} or not turn OFF the power just after pressing {PRG}

(during displaying the message "Executing program mode").

I Switching target type

{}

C"19.3 EDM Settings"

$

• Changes can also be made by tapping the icon on status bar or in Starkey mode.

C"5.2 Display Functions", "5.4 Starkey Mode"

I Switching the Laser-pointer/Guide light ON/OFF

{}

(Press and hold until

a beep sounds

)

$

• Changes can also be made by tapping the icon on status bar or in Starkey mode.

C"5.2 Display Functions", "5.4 Starkey Mode"

Switches between target types

Prism/360° Prism/Sheet/N-prism (reflectorless)

Turn ON/OFF the laser-pointer/guide light

I Switching the page

{FUNC} Toggle between Observation mode screen pages

I Inputting letters/figures

α}

{

{SHIFT} + {1} to {9}

{SHIFT} (Press and hold)

{SHIFT} + {α}

{0} to {9}

{.}

{

±}

Switch between numerals and alphabetic characters

In alphabetic characters mode, switch between lowercase

characters and upper case characters each time

In alphabetic characters mode, switch between lowercase

characters and upper case characters

Display/hide <Input Panel>

Input numeral or symbol printed above the key (during numeric

input mode)

Input alphabetic character in the order they are listed (in

alphabetic input mode)

Input a decimal point (during numeric input mode)

Input code (in alphabetic input mode)

Input a plus or minus sign (during numeric input mode)

Input code (in alphabetic input mode)

18

Page 25

5. BASIC OPERATION

{ESC} Cancel the input data

{TAB} Shift to the next item

{B.S.} Delete a character on the left.

{S.P.}

Input a blank space (increments by 1 when setting the date and

time)

{K}/{L} Move the cursor left/right

O}/{G} Move the cursor up/down

{

{ENT} Select/accept input word/value

CInputting rule and inputting special characters: "5.3 Inputting Characters using the Input

Panel"

I Selecting options

O}/{G} Move the cursor/selection item up/down

{

{K}/{L} Move the cursor/selection item left/right or select other option

{TAB} Shift to the next item

{S.P.} Display other options

{ENT} Select/accept the option

I Selecting tabs

O}/{G} Move tab/cursor in tab up/down

{

{K}/{L} Display next tab at left/right

CTabs: "5.2 Display Functions"

I Others

{ESC} Return to previous screen

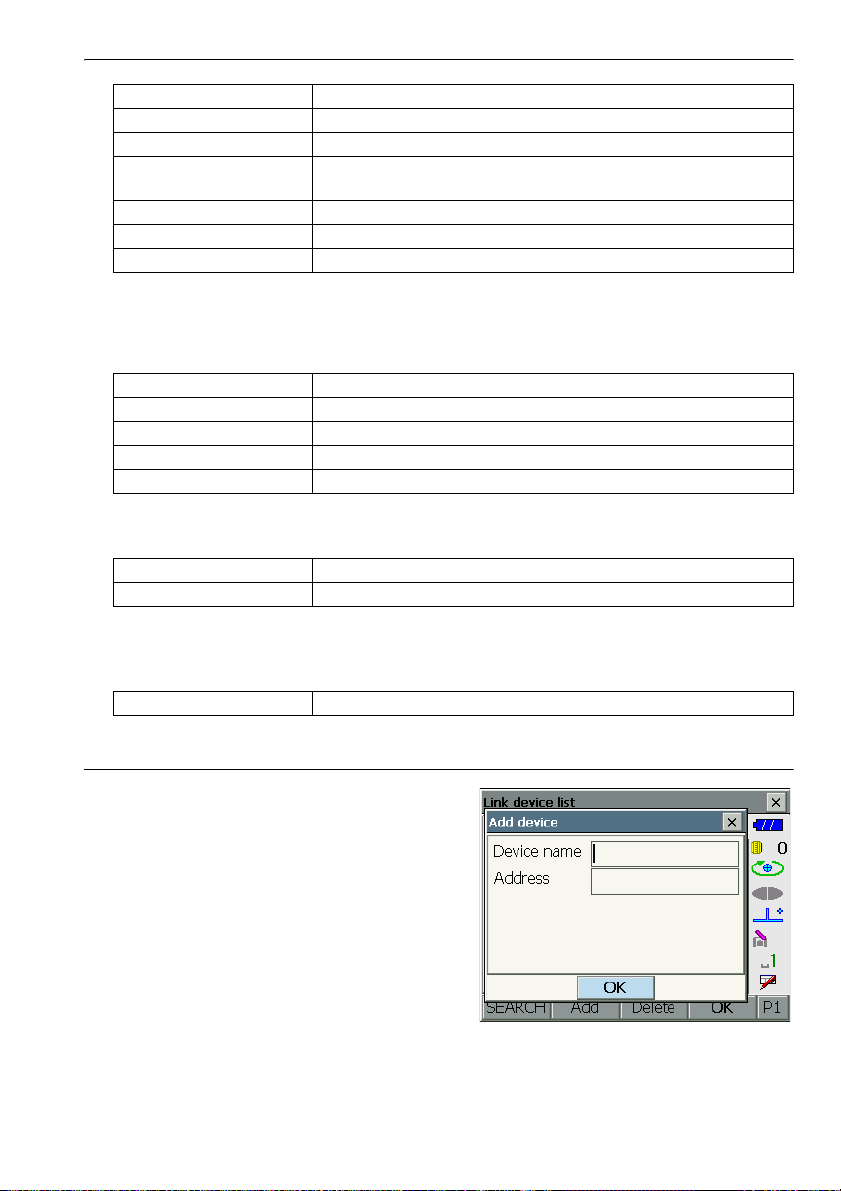

Example: Entering "computer" (lower case) as the name of a new device

1. Tap the input mode icon in the status bar (second

from bottom) until "_a" is displayed.

19

Page 26

2. Press {7} three times.

P1

"c" is displayed.

3. Press {5} three times.

"o" is displayed.

4. Press {L}.

Press {5}. "m" is displayed.

5. BASIC OPERATION

5. Continue to input letters. Press {ENT} to

complete inputting.

20

Page 27

5. BASIC OPERATION

5.2 Display Functions

Screens can be selected/operated using the keys on the keyboard or the touch panel. The touch panel

can be operated using either the stylus pen provided or your fingers.

It is also possible to de-activate the touch panel temporarily.

C "19. CHANGING THE SETTINGS"

G

• Do not scratch the display or use any sharp implement other than the stylus pen to operate the touch

panel.

Using the stylus

The stylus pen can be used to select menus and buttons on the screen and operate the scroll bar.

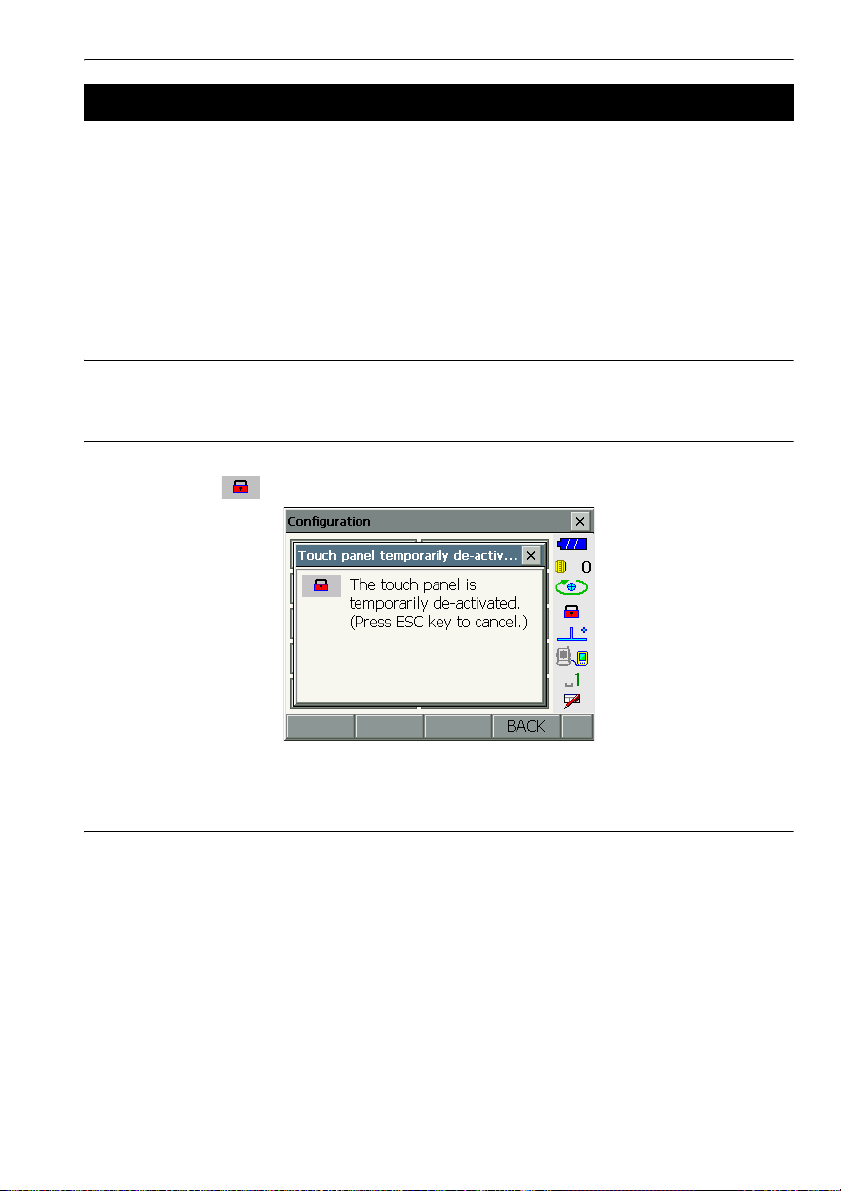

Temporarily de-activating the touch panel

The touch panel can be temporarily de-activated. This is especially useful when cleaning the display.

To de-activate, tap on the status bar. <Touch panel temporarily de-activated> is displayed.

The touch panel cannot be operated while the above message is displayed. Press {ESC} to cancel

the message and re-activate the touch panel.

Displaying and operating screens

• To close a screen, tap the cross in the top right corner, or press {ESC}.

• Tabs, softkey allocations, displayed tab items, and character sizes can all be changed in accordance

with user preferences.

C"19. CHANGING THE SETTINGS"

21

Page 28

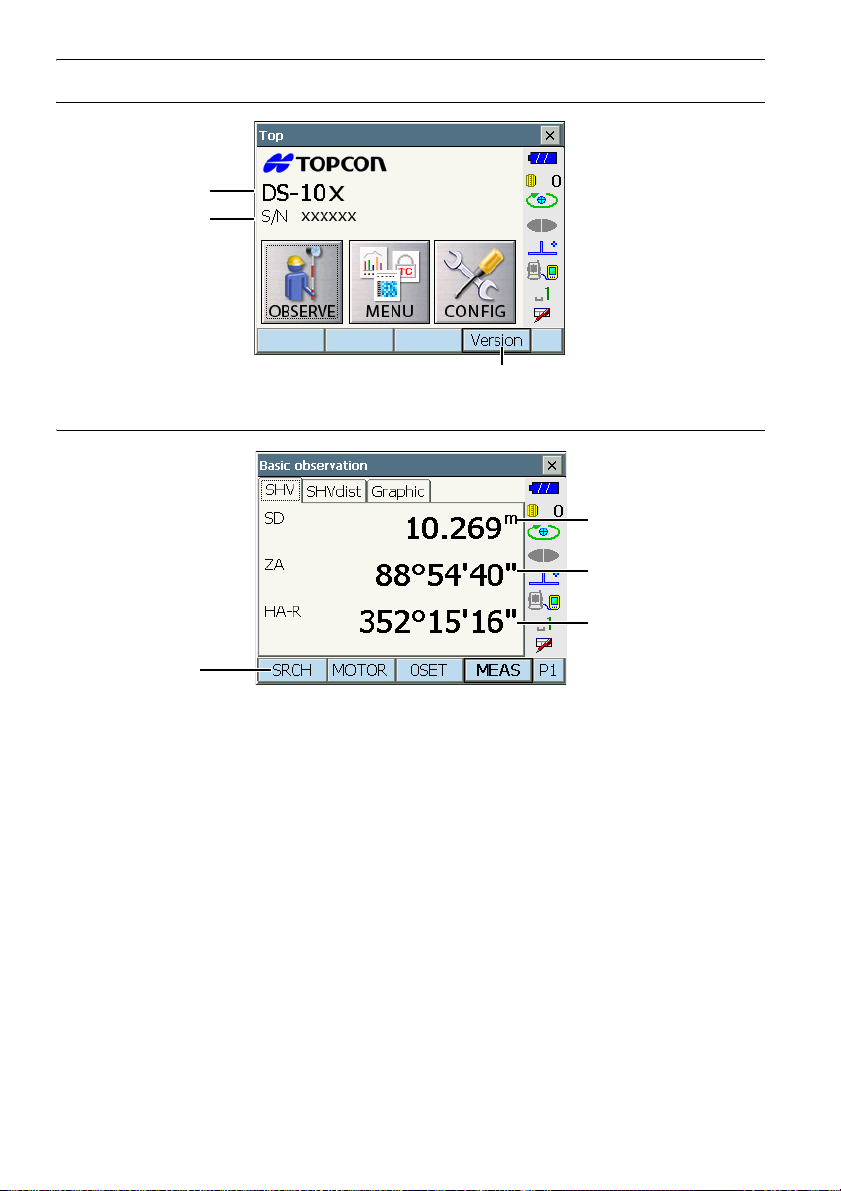

Top menu

Instrument name

Serial Number

Application software version

(1) Distance

(2) Vertical angle

(3) Horizontal angle

Soft key

Observation mode screen

5. BASIC OPERATION

(1) Distance

Horizontal distance and height difference are also displayed in "SHVdist" tab.

Displayed items in "SHV" tab can be changed.

C"19.1 Observation Conditions"

(2) Vertical angle

The Vertical angle display can be switched between Zenith (Z=0°)/Horiz (H=0°)/Horiz (H=±90°)

To switch vertical angle/slope in %, press [ZA/%] when allocated to the Observation mode screen.

The capitalized letter in the softkey indicates the currently selected mode.

CChanging display: "19.1 Observation Conditions", allocating [ZA/%]: "19.6 Allocating Key

Functions"

(3)Horizontal angle

Press [R/L] when allocated to the Observation mode screen to switch the display status. The

capitalized letter in the softkey indicates the currently selected mode.

HA-R: Horizontal angle right

HA-L: Horizontal angle left

CAllocating [R/L]: "19.6 Allocating Key Functions"

22

Page 29

Input screen/configuration screen

Display all options

Scroll down for more

Values can be input/

items

edited

Instrument station

Scale

(units: m)

Arrow indicates north as set backsight

Target point

"Graphic" tab

5. BASIC OPERATION

The "Graphic" tab display can be modified using the softkeys in the second page.

[CNFG] : In <Graphic configuration> the user can specify the orientation of the "graphic" tab

[DEF.] : Returns to the original orientation display.

[ZoomIn] : Zooms in.

[ZoomOut] : Zooms out.

display and which point, target or station, to set at the center of the display.

23

Page 30

5. BASIC OPERATION

Number

Status bar

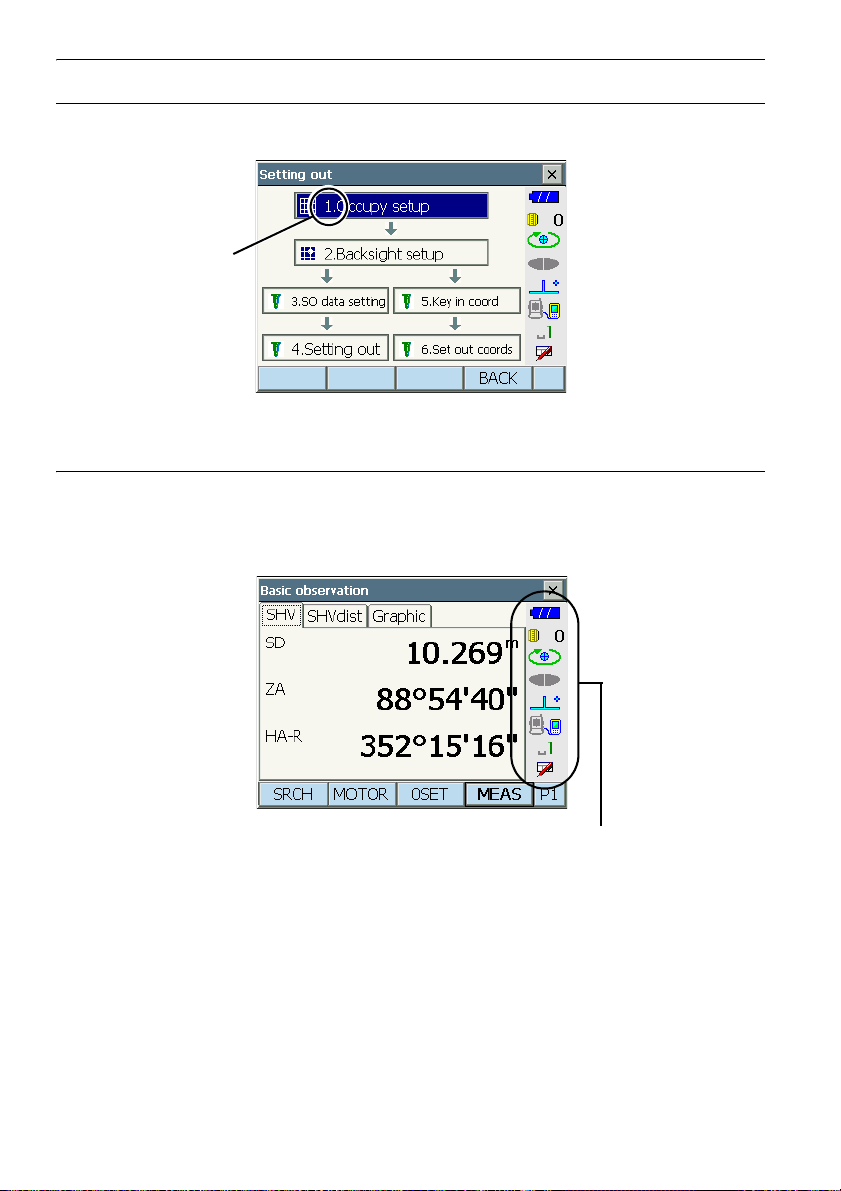

Selecting menus

To select a menu, tap the touch panel or press the relevant number key.

Status bar

Indicates the current status of the instrument.

Tapping icons will switch between the relevant options for that item.

Tapping and holding will display a list of all available options for that item and, in certain cases, a

link to the configuration screen for that item.

Allocation of the icons of the status bar corresponds with that of Starkey mode.

CAbout icons: "5.4 Starkey Mode"

24

Page 31

5.3 Inputting Characters using the Input Panel

5. BASIC OPERATION

To d i s p la y <Input Panel>, tap of status bar/Starkey mode or while pressing

This keyboard can be used to input numeric and alphabetic characters as well as symbols. Tap the

icon again to close.

{SHIFT} press {α}.

$

• When <Input Panel> is covering the icon of the status bar, use the stylus pen to drag the input

panel to another part of the screen so that you can access the icon.

Input panel

Esc : Deletes all input characters

Tab : Moves the cursor to the next text box

CAP : Alternates between upper and lower case alphabetic characters and numbers/

symbols

Shift : Alternates between upper and lower case alphabetic characters and numbers/

Ctl : No function

Del/A : Delete the character to the left/right or deletes the entire text in the active section

←→ : Move the cursor left/right

ENT : Accept input characters

Space : Input a blank space

áü : Accesses further Latin/Germanic characters/symbols. Is canceled after inputting a

symbols. Is canceled after inputting a single character.

single character.

25

Page 32

5. BASIC OPERATION

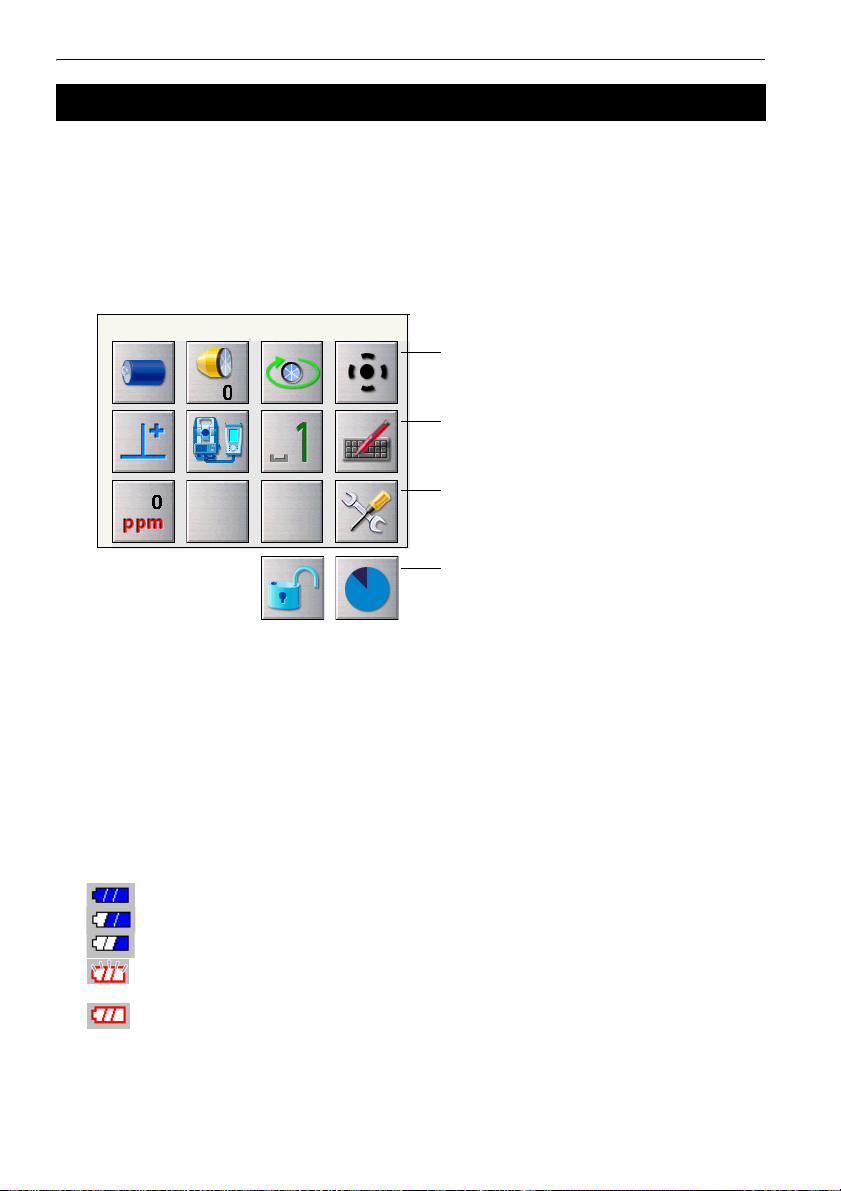

(1) (2) (3) (4)

(5) (6) (7) (8)

(9) (10)

(11) (12)

when instrument was shipped.

11 and 12 are not allocated

5.4 Starkey Mode

Via Starkey mode, you can jump from each basic mode screen to the screen of checking/changing the

various settings directly. Press starkey {

pressed and hold in the same way with status bar.

• 12 icons allocated in Starkey mode and the above 8 icons correspond with that status bar

• Allocation of the icons can be changed.

CChanging allocation of Starkey mode: "19.7 Changing Starkey Mode Icons"

★ } to enter Starkey mode. Each icon can be tapped or

Indicates the current status of the instrument.

Tapping icons will switch between the relevant options for that item. Tapping and holding will display

a list of all available options for that item and, in certain cases, a link to the configuration screen for

that item. (The numbers correspond to above icons).

(1) Battery icon

Remaining battery power indicator (BDC70/external battery BT-73Q, Temperature = 20°C, EDM

on).

The remaining battery power displayed when distance measurement is in progress may differ to

that displayed at other times.

: Level 3 Full power

: Level 2 Plenty of power remains

: Level 1 Half or less power remains

: Level 0 Little power remains Prepare a replacement battery.

(Flashes red and black)

: No power Stop operation and charge the battery.

(Red display in the center of the screen)

C"6.1 Battery Charging"

26

Page 33

5. BASIC OPERATION

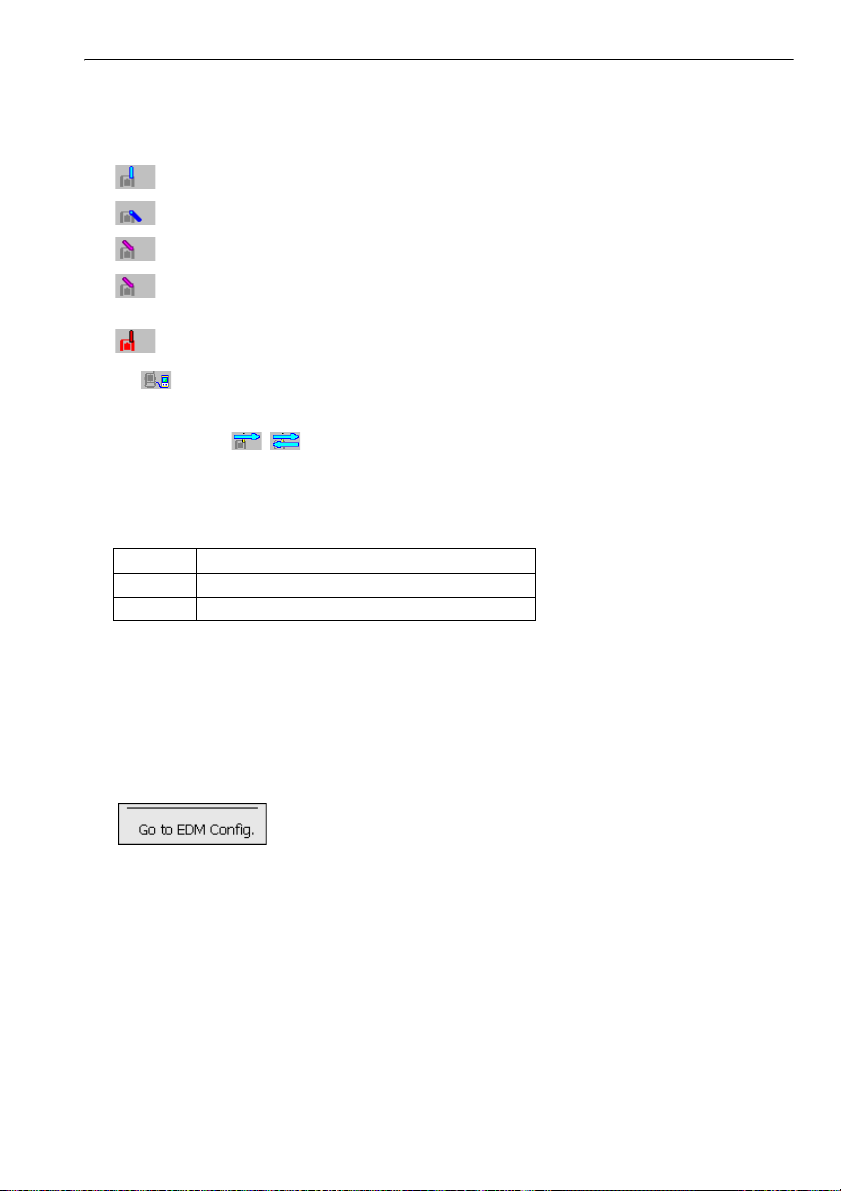

When using external battery

: Level 3 Full power

: Level 2 Plenty of power remains

: Level 1 Half or less power remains

: Level 0 Little power remains. Prepare a replacement battery.

: No power Stop operation and charge the battery.

C"6.1 Battery Charging"

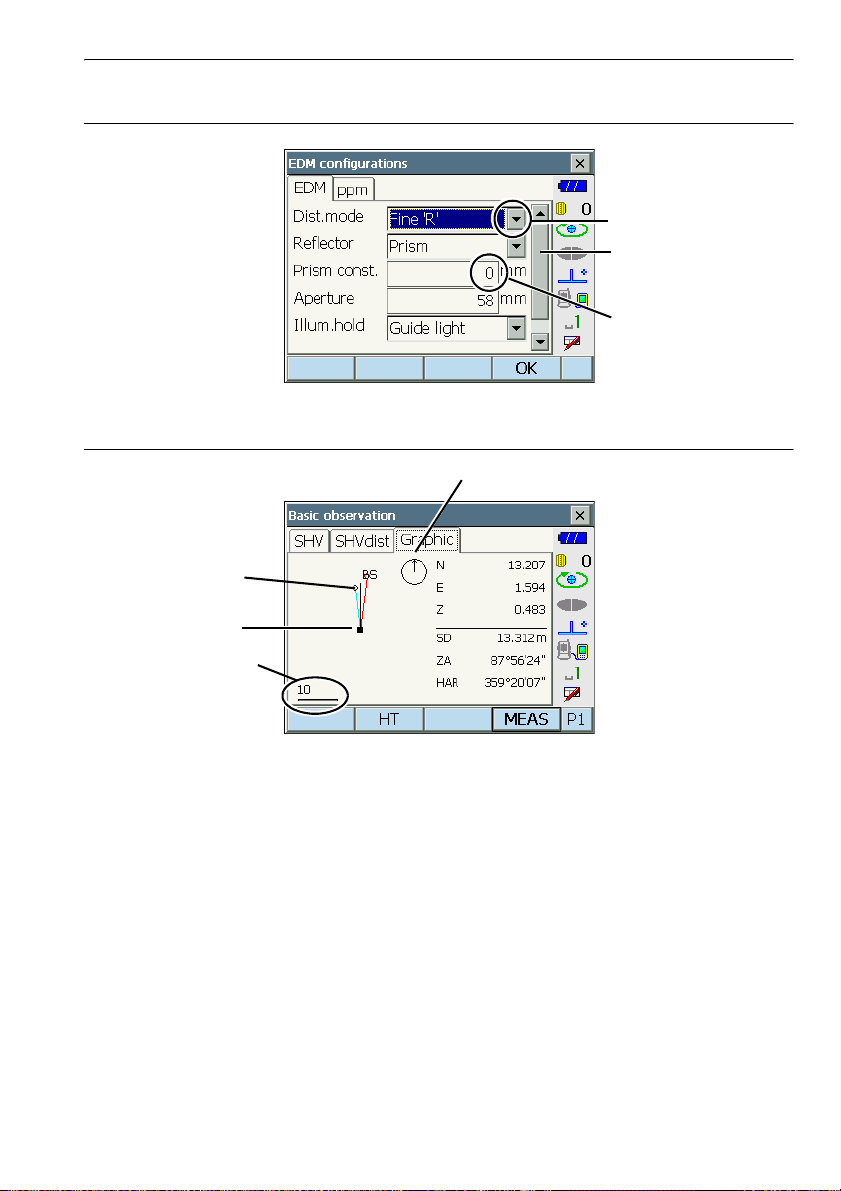

(2) Target type icon

Selection of target type and configuration of prism constant correction value.

: Prism (0mm)

: 360° prism (-7mm)

: Sheet (0mm)

: N-Prism

Target information can be edited/recorded in <Reflector setting>.

C"19.3 EDM Settings PROCEDURE Recording and editing target information"

(3) Motor icon

Configuration of Auto Pointing status. The display may change slightly depending on the target

type selected.

: Auto Pointing ON

: Auto Pointing OFF

: Begin searching

: Rotates the instrument 180°

One of the following icons will be displayed while the motor is in operation to indicate the current

status of the instrument.

: Rotating

: Rotating at fixed velocity

: Searching

$

• Auto Pointing cannot be performed when "Reflectorless" has been selected as the target type.

will be displayed.

• An arrow indicating turn direction will be displayed when the instrument is rotating at a fixed

velocity.

C "11.3 Turning the Instrument from the Reference Angle to a Specified Angle"

27

Page 34

5. BASIC OPERATION

(4) Laser-pointer/guide light icon

Configuration of laser-pointer/guide light status.

C Switching the laser-pointer/guide light ON/OFF: "5.1 Basic Key Operation"

: Guide light ON

: Guide light OFF

: Laser-pointer ON

: Laser-pointer OFF

$

• The laser-pointer will be automatically switched OFF during distance measurement.

(5) Tilt angle compensation icon

The vertical and horizontal angles are automatically compensated for small tilt errors using the

dual-axis tilt sensor. This icon displays the status of this function.

: Horizontal and vertical tilt angles compensated (blue)

: No compensation

: Only vertical tilt angle compensated (green)

$

• is displayed when the instrument is out of level.

(6) Communication status with external devices icon

Selection and configuration of communication status with external devices. This icon is not

displayed in Program mode.

: Connection via RS232C cable

: Connection via Bluetooth wireless technology (DS set as "Master"

device) (blue antenna)

: Connection via Bluetooth wireless technology (DS set as "Slave"

device) (green antenna)

$

• When Bluetooth communication is selected (DS set as "Master" device) a connection can be

initiated/canceled by tapping / .

28

Page 35

5. BASIC OPERATION

Connection status to external devices is displayed as follows.

i) Connection via Bluetooth wireless technology

When DS is set as the "Master" device the antenna icon is blue. When the DS is set as the "Slave"

device the antenna icon is green.

: Connecting

: Canceling connection

: (Antenna is moving) Inquiring about other Bluetooth devices

: (Antenna is stationary) Communication settings in progress/Preparing for

communication (Instrument just powered ON or just switched to "Slave")

: Connection error (icon flashes) (the color depends on the setting)

ii) : Connection via RS232C cable

$

• An arrow (e.g. / ) is displayed to indicate that data transmission is in progress. A red

arrow indicates that data transmission has failed and data needs to be sent again.

(7) Input mode icon

Selection of input mode

_1 Inputting numbers and symbols

_a Inputting lower case alphabetic characters

_A Inputting upper case alphabetic characters

C"5.1 Basic Key Operation I Inputting letters/figures"

(8) Input panel icon

C "5.3 Inputting Characters using the Input Panel"

(9) PPM setting icon

Current atmospheric correction factor setting is displayed.

Configuration of EDM.

(10) Config mode icon

Switch to Config mode.

C"19. CHANGING THE SETTINGS"

29

Page 36

5. BASIC OPERATION

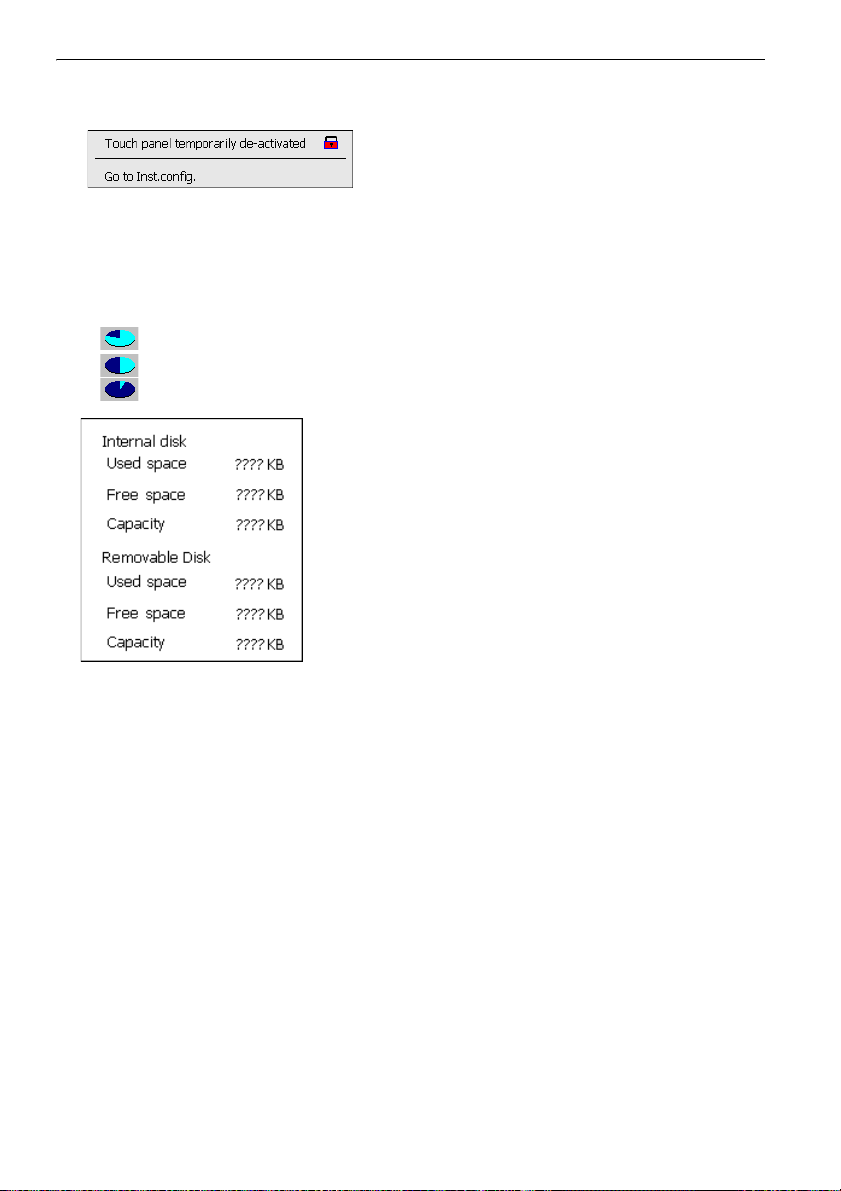

(11) Touch panel icon

C"19.7 Changing Starkey Mode Icons"

:Touch panel temporarily de-activated.

$

• This icon cannot be operated during distance measurement, or during data transmission.

(12) Disk usage icon

Tap and hold disk icon in the status bar to check the detail of the disk usage.

C"19.7 Changing Starkey Mode Icons"

: Less than 20%

: 20 to 50%

: More than 50%

Internal Disk

Used space : Usage space of disk capacity of the instrument

Free space : Free space of disk capacity of the instrument

Capacity : Disk capacity of the instrument

Removable Disk

Used space : Usage space of disk capacity of the external disk connected to the

Free space : Free space of disk capacity of the external disk connected to the

Capacity : Disk capacity of the external disk connected to the instrument

instrument

instrument

G

• "Removable Disk" is displayed only when an external disk is connected to the instrument.

30

Page 37

5. BASIC OPERATION

An icon without an

be selected

Next page

Previous page

5.5 Using the Program Selection Screen

The program selection screen displays a list of all programs installed on the instrument. Each screen

page contains a maximum of 5 program icons. When multiple screen pages exist, navigating between

pages is possible using the arrows that appear at the left/right of the screen.

Navigating between pages

The previous/next screen page can be displayed by pressing {O}/{G}/{L}/{K}, or that appear at the

left/right of the screen.

31

Page 38

6. USING THE BATTERY

Guides

Slot 1

Slot 2

Charging

lamp

Grooves

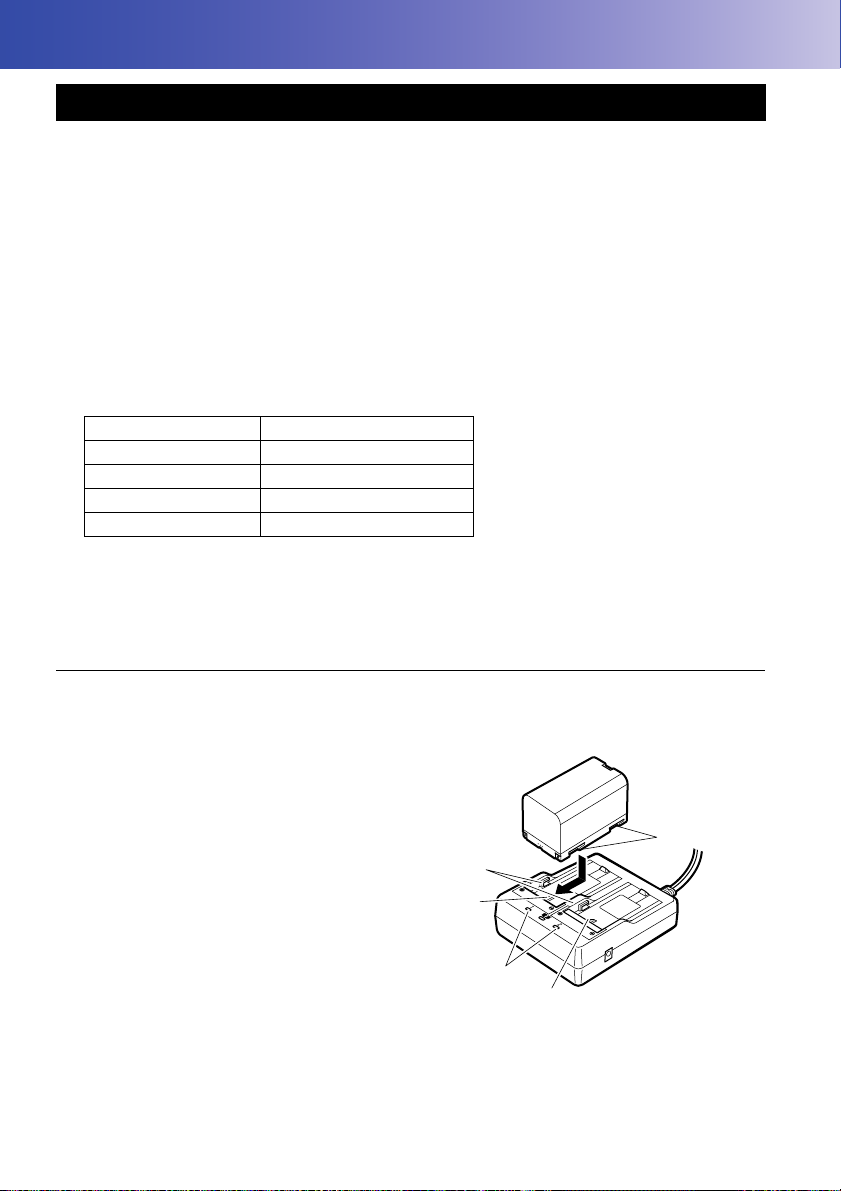

6.1 Battery Charging

The battery was not charged at the factory. Charge the battery fully before using the instrument.

G

• The charger will become rather hot during use. This is normal.

• Do not use to charge batteries other than those specified.

• The charger is for indoor use only. Do not use outdoors.

• Batteries cannot be charged, even when the charging lamp is flashing, when the temperature is

outside the charging temperature range.

• Remove batteries from the charger before putting into storage.

• When not in use, disconnect the power cable plug from the wall outlet.

• Store the battery in a dry room where the temperature is within the following ranges. For long-term

storage, the battery should be charged at least once every six months.

Storage period Temperature range

1 week or less -20 to 50°C

1 week to 1 month -20 to 45°C

1 month to 6 months -20 to 40°C

6 months to 1 year -20 to 35°C

• Batteries generate power using a chemical reaction and as a result have a limited lifetime. Even

when in storage and not used for long periods, battery capacity deteriorates with the passage of

time. This may result in the operating time of the battery shortening despite having been charged

correctly. In this event, a new battery is required.

PROCEDURE

1. Connect the power cable to the charger and

plug the charger into the wall outlet.

2. Mount the battery in the charger by matching

the grooves on the battery with the guides on

the charger.

3. When charging starts, the lamp starts blinking.

4. The lamp lights when charging is finished.

32

Page 39

6. USING THE BATTERY

Battery cover

5. Remove the battery and unplug the charger.

$

• Slots 1 and 2:

The charger starts charging the battery mounted

first. If you place two batteries in the charger, the

battery in slot 1 is charged first, and then the

battery in slot 2. (

• Charging lamp:

The charging lamp is off when the charger is

outside the charging temperature range or when the battery is mounted incorrectly. If the lamp is still

off after the charger falls within its charging temperature range and the battery is mounted again,

contact your local dealer. (

• Charging time per battery (at 25°C):

BDC70:about 5.5 hours

C step 2)

Csteps 2 and 3)

6.2 Installing/Removing the Battery

Mount the charged battery.

C Type of power source: "22. POWER SUPPLY SYSTEM"

G

• Use the attached battery (BDC70).

• Before removing the battery, turn off the power to the instrument. If the battery is removed while the

power is switched on, a warm boot may occur. File and folder data may be lost as a result.

• Do not open the battery cover while the power is on.

• Do not damage the projected sensor inside the battery cover. Also, be careful not to shut the battery

cover on your fingers.

• When installing/removing the battery, make sure that moisture or dust particles do not come in

contact with the inside of the instrument.

• Remove batteries from the surveying instrument or charger before putting into storage.

PROCEDURE Mounting the battery

1. Slide down the catches on the battery cover to

open.

33

Page 40

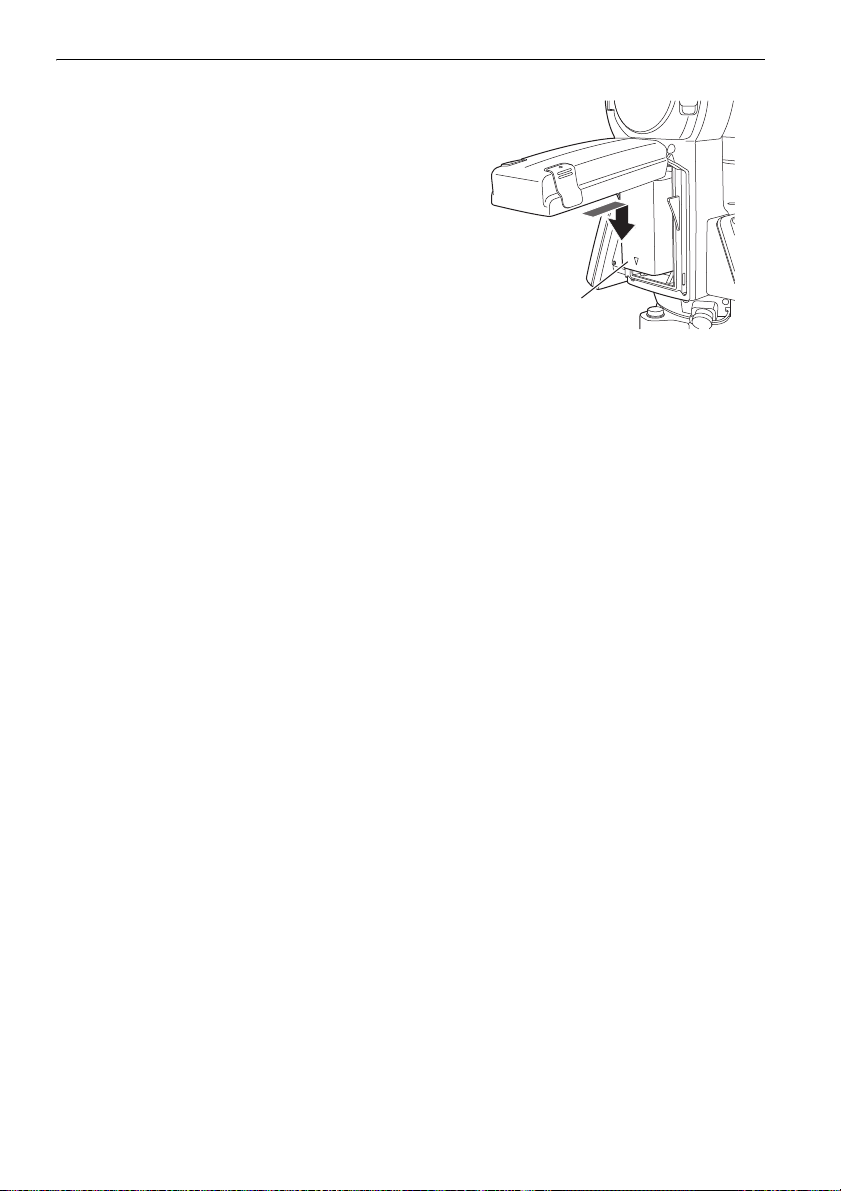

2. Insert the battery in the direction of the arrow

Battery

on the side of the battery.

G

• Do not insert the battery inclined. Doing so

may damage the instrument or battery

terminals.

3. Close the battery cover. A click is heard when

the cover is secure.

6. USING THE BATTERY

34

Page 41

7. SETTING UP THE INSTRUMENT

Centering screw

Focussing on the survey point

Focussing on

the reticle

G

• Mount the battery in the instrument before performing this operation because the instrument will tilt

slightly if the battery is mounted after levelling.

7.1 Centering

PROCEDURE Centering with the optical plummet eyepiece

1. Make sure the legs are spaced at equal

intervals and the head is approximately level.

Set the tripod so that the head is positioned over

the survey point.

Make sure the tripod shoes are firmly fixed in the

ground.

2. Place the instrument on the tripod head.

Supporting it with one hand, tighten the centering

screw on the bottom of the unit to make sure it is

secured to the tripod.

3. Looking through the optical plummet eyepiece,

turn the optical plummet eyepiece to focus on

the reticle.

Turn the optical plummet focussing ring to focus

on the survey point.

35

Page 42

PROCEDURE Centering with the laser plummet (Option)

1. Set up the tripod and affix the instrument on the

tripod head.

C"7.1 Centering"

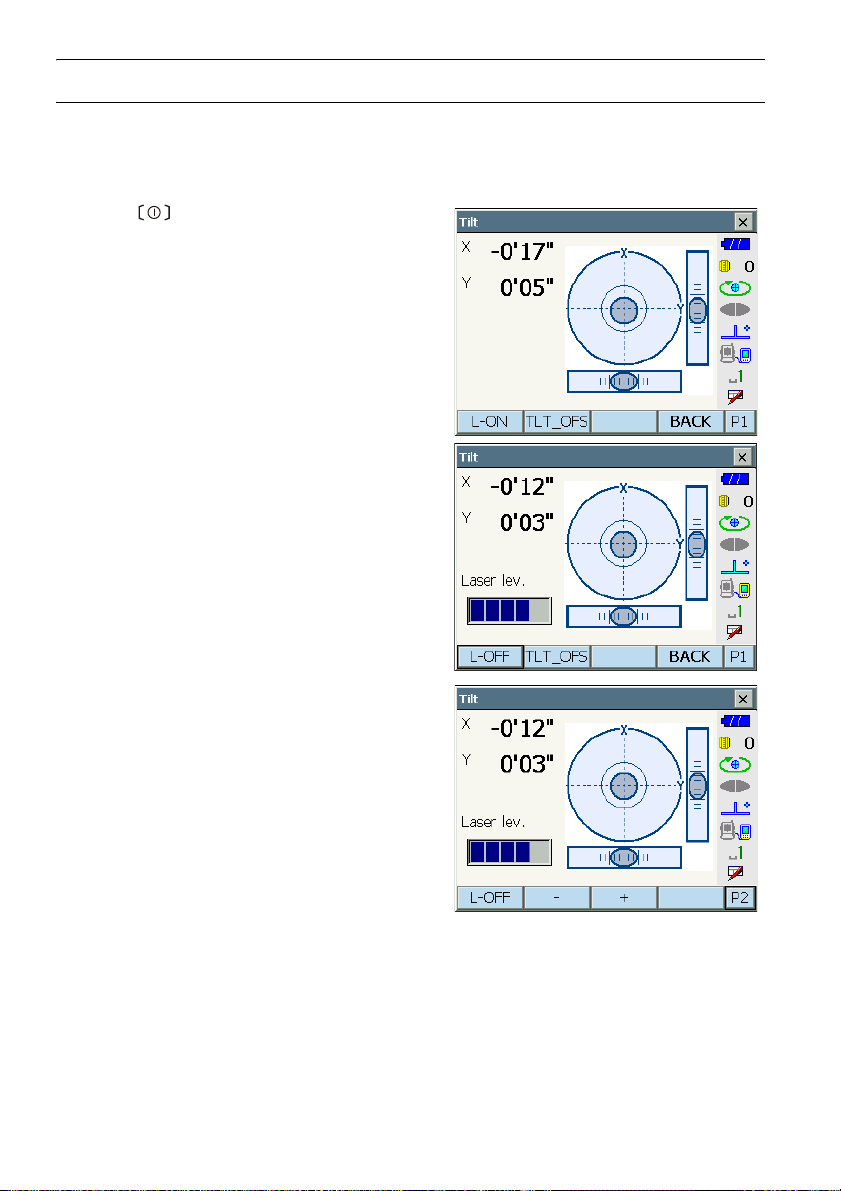

2. Press {} to power on

C"8. POWER ON/OFF"

The electric circular level is displayed on the <Tilt>.

3. Press [L-ON].

The laser plummet beam will be emitted from the

bottom of the instrument.

7. SETTING UP THE INSTRUMENT

4. Use [-]/[+] on the second page to adjust the

brightness of the laser.

5. Adjust the position of the instrument on the tripod

until the laser beam is aligned with the center of the

survey point.

6. Press [L-OFF] to turn the laser plummet off.

Alternatively, press {ESC} to return to another

screen. The laser plummet will switch off

automatically.

36

Page 43

7. SETTING UP THE INSTRUMENT

Tripod legs

adjustment

$

• Visibility of the laser spot may be affected when operating in direct sunlight. In this event, provide

shade for the survey point.

7.2 Levelling

PROCEDURE

1. Adjust the levelling foot screws to center the

survey point in the optical plummet reticle.

2. Center the bubble in the circular level by either

shortening the tripod leg closest to the offcenter

direction of the bubble or by lengthening the tripod

leg farthest from the offcenter direction of the

bubble. Adjust one more tripod leg to center the

bubble.

Turn the levelling foot screws while checking the

circular level until the bubble is centered in the

center circle.

3. Power ON the instrument.

C"8. POWER ON/OFF"

The electric circular level is displayed on the <Tilt>.

“z” indicates the bubble in circular level. The range

of the inside circle is ±1.5' and the range of the

outside circle is ±6'.

4. Center “z” in the circular level.

When the bubble is in the center, proceed to step

7.

37

Page 44

5. Turn the instrument until the telescope is parallel

to a line between levelling foot screws A and B.

6. Set the tilt angle to 0° using foot screws A and B

for the X direction and levelling screw C for the Y

direction.

7. Loosen the centering screw slightly.

Looking through the optical plummet eyepiece, slide

the instrument over the tripod head until the survey

point is exactly centered in the reticle.

Retighten the centering screw securely.

If the instrument is levelled using laser plummet,

emit the laser plummet beam and check it again.

C"7.1 Centering PROCEDURE Centering with

the laser plummet (Option)"

8. Check again to make sure the bubble in the electric

circular level is centered.

If not, repeat the procedure starting from step 6.

7. SETTING UP THE INSTRUMENT

9. Press {ESC} to return to Observation mode.

38

Page 45

8. POWER ON/OFF

G

• When the power cannot be switched ON or the power is soon turned OFF even though the battery

is mounted, there may be almost no battery power remaining. Replace it with a fully charged battery.

C"20. WARNING AND ERROR MESSAGES"

PROCEDURE Power ON

1. Press {}.

When the power is switched on, the Tilt screen is

displayed.

Press {ESC} to go to Observation mode screen.

If "Out of range" is displayed, the instrument tilt

sensor is indicating that the instrument is out of level.

Level the instrument once again using circular level,

then the tilt screen will be displayed.

$

• "Tilt crn." in "Obs. condition" should be set to "No" if the display is unsteady due to vibration or strong

wind.

C "19.1 Observation Conditions"

& Resume function

The Resume function redisplays the screen appearing before the instrument was powered OFF

when the instrument is powered back ON. All parameter settings are also saved. Even if

remaining battery power is completely depleted, this function will remain active for 1 minute,

after which it is canceled. Replace a depleted battery as soon as possible.

PROCEDURE Power OFF

1. Press and hold (about 1sec) {}.

G

• When there is almost no battery power remaining,

the battery icon in the status bar will start to blink.In

this event, stop measurement, switch off the power

and charge the battery or replace with a fully

charged battery.

• To save power, power to the instrument is

automatically cut off if it is not operated for a fixed

period of time. This time period can be set in

"Power off" in <Inst.config.>.

C"19.2 Instrument Configuration"

39

Page 46

8. POWER ON/OFF

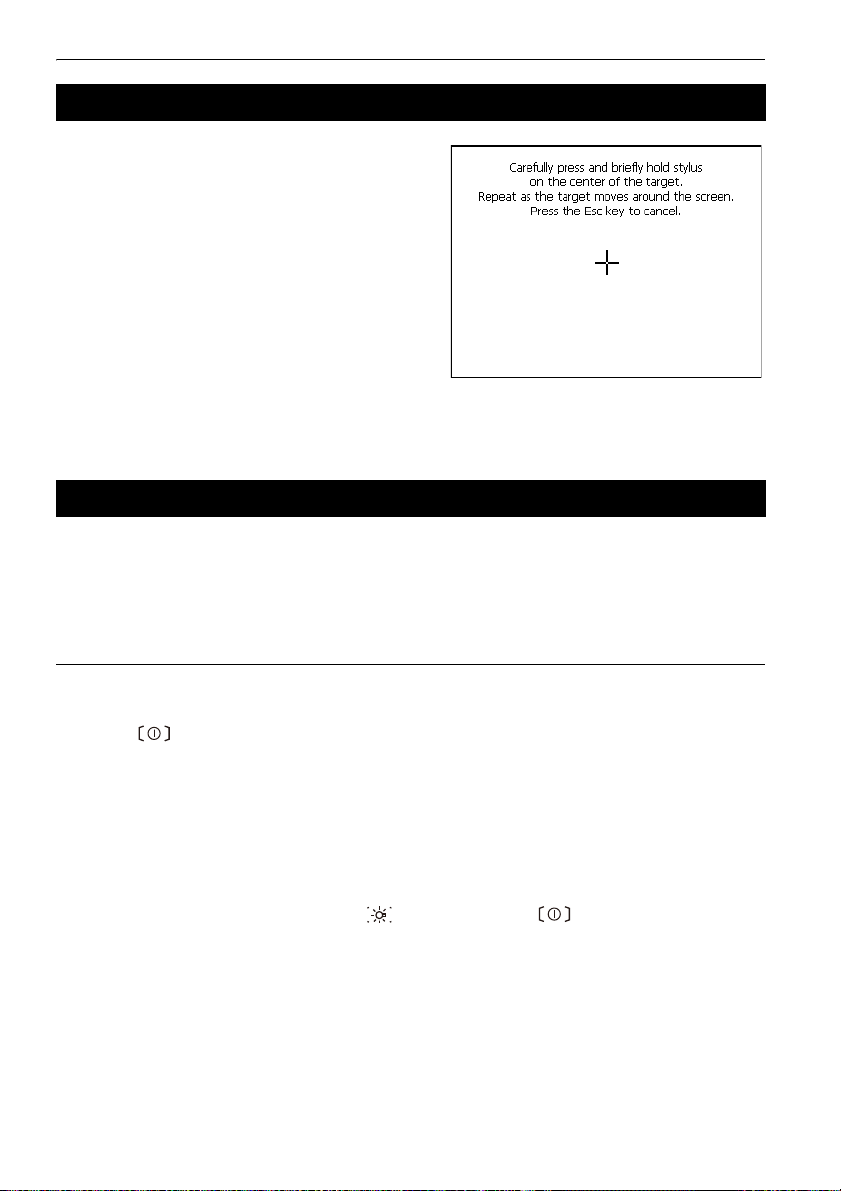

8.1 Configuring the Touch Panel

When using for the first time, or after performing a cold

boot, the screen for configuring the touch panel will be

displayed.

Follow the instructions on the screen. Tap the crosshairs at the center of the display with the stylus pen.

Tap 5 times. Press {ENT} to complete touch panel

configuration. Press {ESC} to retain previous settings.

$

• Touch panel configuration can be performed at any

time during normal operation by pressing [PNL

CAL] in <Inst.config.>.

C"19.2 Instrument Configuration"

8.2 Resolving Software Issues

If you are experiencing problems with the instrument and suspect a fault in the program, you should

try a warm boot. If the problem is not resolved with a warm boot the next step is to perform a cold boot.

A warm boot will not erase surveying data in the instrument but will cancel the resume function.

Whenever possible transmit the data to a personal computer before rebooting.

PROCEDURE

1. Power OFF the instrument.

2. Press {} while pressing {ENT}.

The instrument is reset and powers ON as normal.

& Cold boot

If the problem is not resolved with a warm boot the next step is to perform a cold boot. A cold

boot will not erase surveying data in the instrument but all the parameters will be changed to the

factory settings. If the data in the memory is necessary, BE SURE TO TRANSFER IT TO A

PERSONAL COMPUTER BEFORE PERFORMING A COLD BOOT.

To perform a cold boot, while holding {}, and {S.P.}, press {}.

The instrument is reset and powers ON as normal.

C "19.11 Restoring Default Settings"

40

Page 47

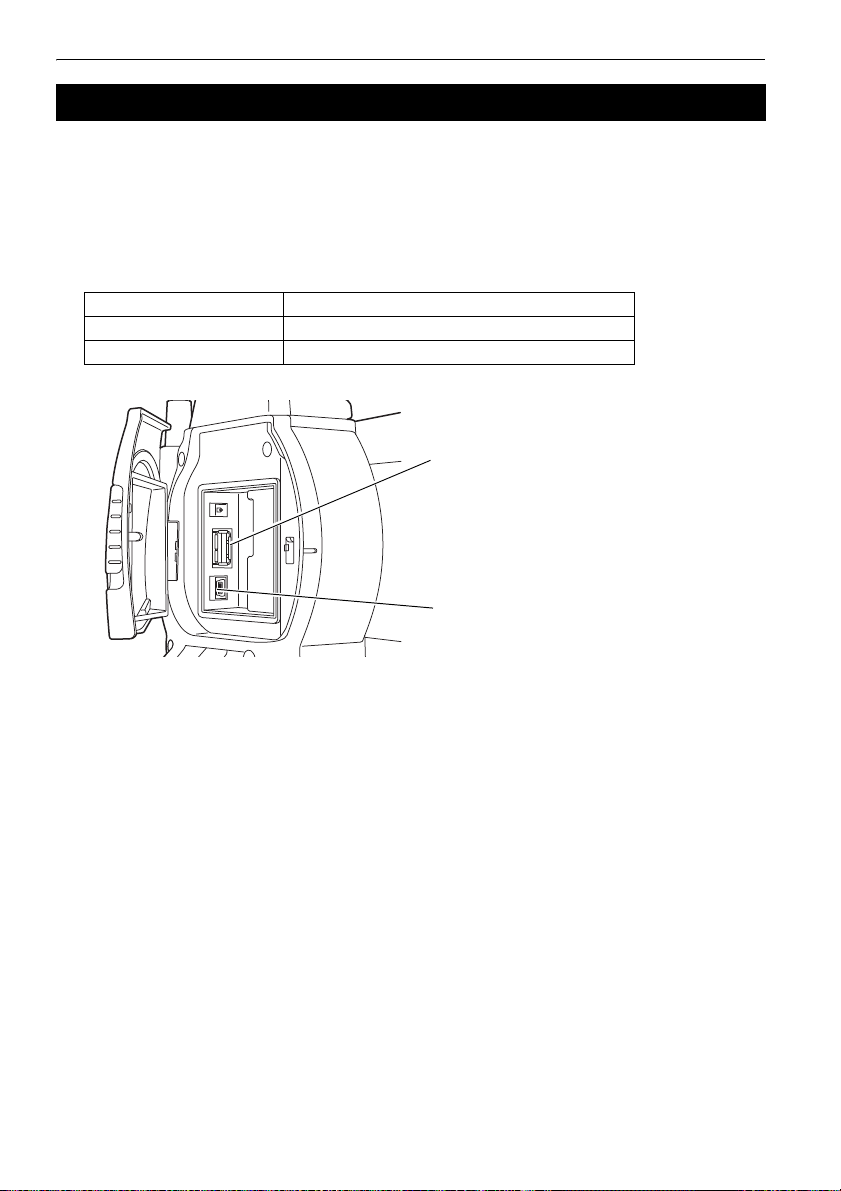

8. POWER ON/OFF

Reset button

& Problems Powering OFF

When the instrument cannot be powered OFF as normal, depress the reset button with the tip

of the stylus pen.

G

• Pressing the Reset button may result in file and folder data being lost.

8.3 Powering ON/OFF from an External Instrument

The instrument can be powered ON/OFF from an external device such as a computer or data collector.

G

• The password must be input after powering ON the instrument from an external device when a

password has been set.

C Remote PWR-On function: "19.2 Instrument Configuration", Setting a password:

"19.9 Changing Password"

41

Page 48

9. CONNECTING TO EXTERNAL DEVICES

The instrument supports Bluetooth wireless technology and RS232C for communication with data

collectors etc. Inputting/outputting data is also possible by inserting a USB memory or by connecting

to a USB device. Read this manual in conjunction with the operator’s manual for the relevant external

device.

G

• When doing Bluetooth communication, read "4.3 Bluetooth Wireless Technology".

9.1 Wireless Communication using Bluetooth Technology

The Bluetooth module incorporated in the instrument can be used for communication with Bluetooth

devices such as data collectors.

& Bluetooth connections

Communication between a pair of Bluetooth devices requires one device to be set as the

"Master" and the other as the "Slave". To initiate connections from the DS side, set the DS as

the "Master" device. To initiate connections from the paired device side, set the DS as the

"Slave" device. The factory setting is "Slave".

PROCEDURE Necessary settings for Bluetooth communication

1. Select "Comms" in Config mode. Set Comms

mode in the "Comms setup" tab to "Bluetooth".

G

• Changing communication settings during

Bluetooth communication will cancel the

connection.

• The status bar icon cannot be tapped in

<Communication Setup>.

Items set and options (*: Factory setting)

(1) Comms mode : RS232C*/Bluetooth

(2) Check sum : yes/No*

(3) Controller : Remote/2 Way/2

Way+Remote*

(4) REC Type : REC-A* (newly measured

data is output)/REC-B

(displayed data is output)

(5) Terminate

(6) MOTOR State : On (with search state

(7) Ack mode

& : ETX*/ETX+CR/ETX+CR+LF

information)/Off*

& :On*/Off

42

Page 49

9. CONNECTING TO EXTERNAL DEVICES

& Te rmi nate

Select the option Off or On for carrige return (CR) and line feed when collecting measurement

data with a computer.

& ACK mode

When communicating to an external device, the protocol for handshaking can omit the [ACK]

coming from the external device so data is not sent again.

On : Standard

Off : Omit the [ACK]

$

• Setting’ (5) and (7) are for an instrument using

GTS commands.

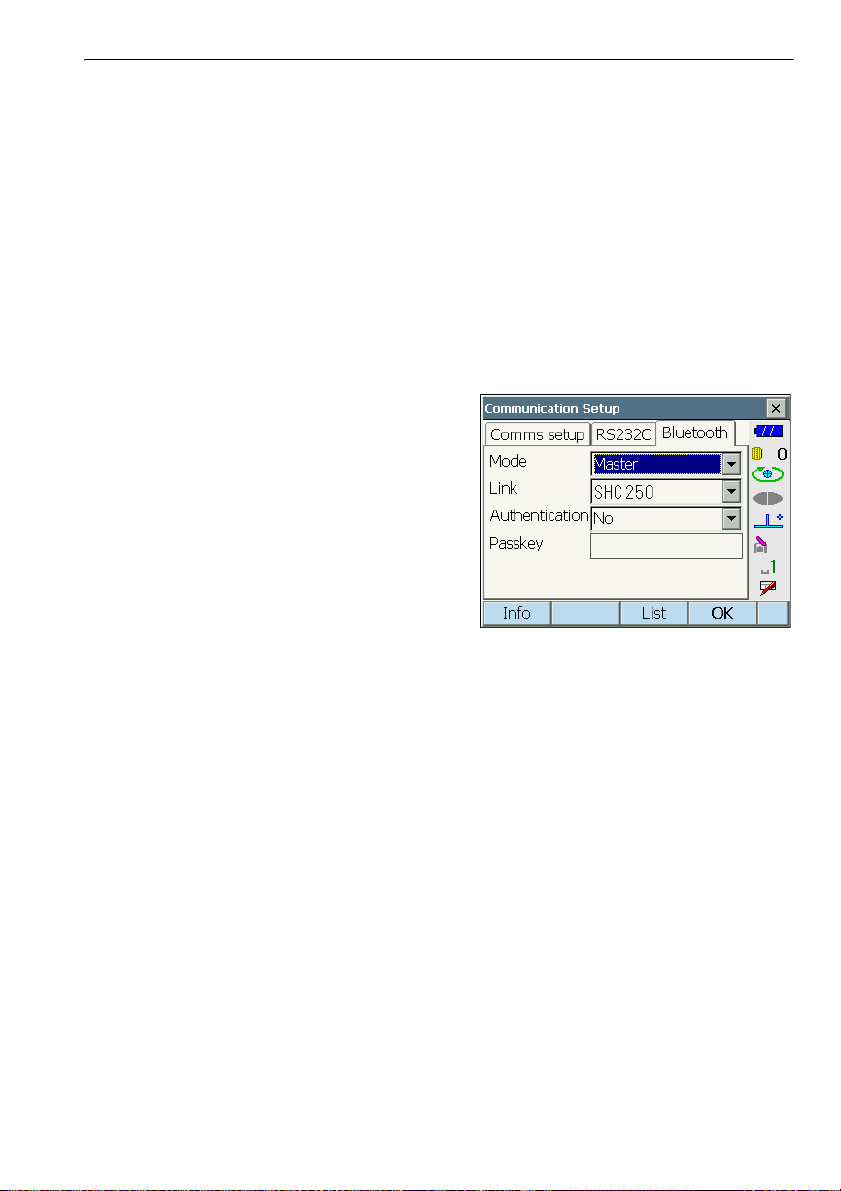

2. Select a mode for the DS in the "Bluetooth" tab.

The factory setting is "Slave".

Register companion devices.

• "Master" cannot be selected when no

companion devices have been registered.

C "Master"/"Slave": "& Bluetooth

connections"

3. Select, in "Link", a companion device from among

the Bluetooth devices already registered in the

instrument.

C Registering devices: "PROCEDURE

Registering Bluetooth companion devices"

• Companion devices cannot be selected when

the DS is set as "Slave".

4. Set "Authentication" to "Yes" or "No".

If "Authentication" is set to "Yes" for the DS the

passkey will also need to be input on the

companion device.

43

Page 50

9. CONNECTING TO EXTERNAL DEVICES

5. When "Authentication" is set to "Yes", input the

same passkey as that for the intended companion

device. Even if "Authentication" is set to "No", a

passkey is requested when authentication is set

on the companion device being used.

• Up to 16 numeral characters can be input. Input

characters will be displayed as asterisks (e.g.

"*****"). The passkey was set to "0123" at the

factory.

6. Press [OK] to finish settings.

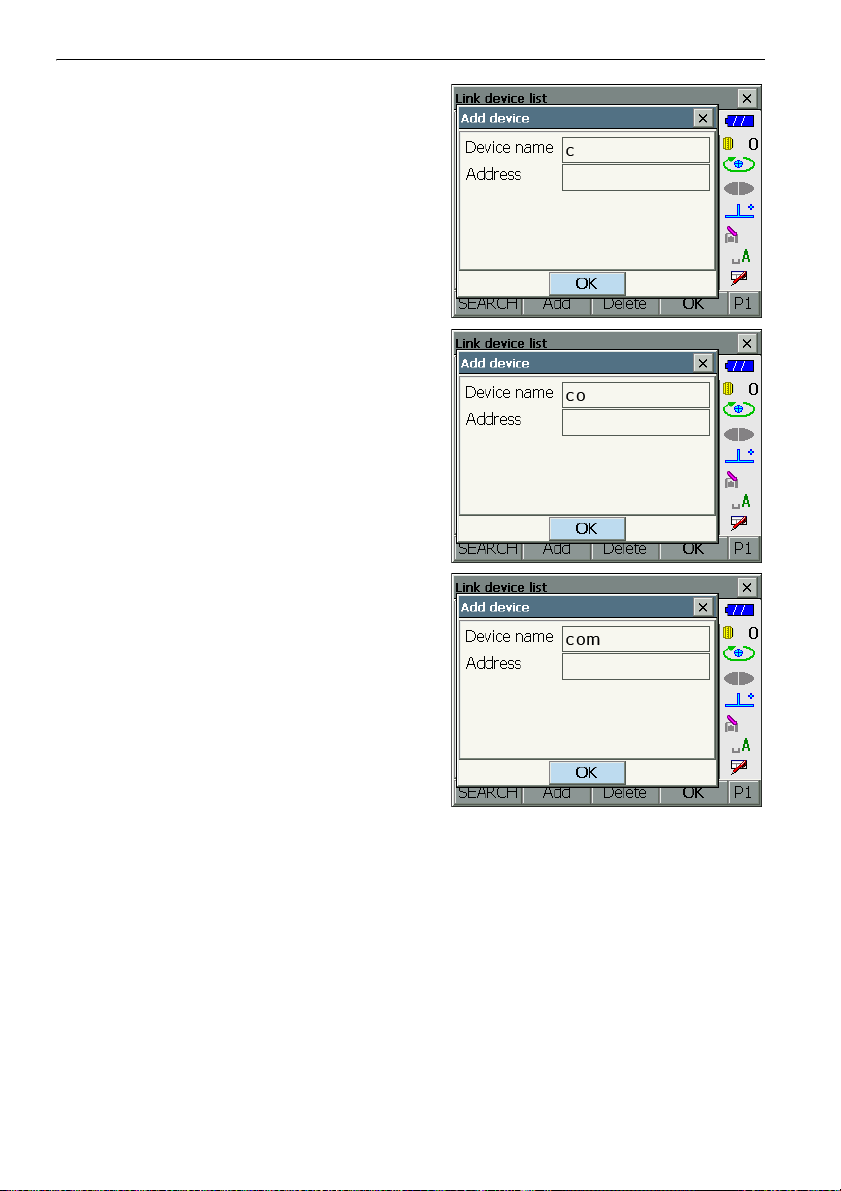

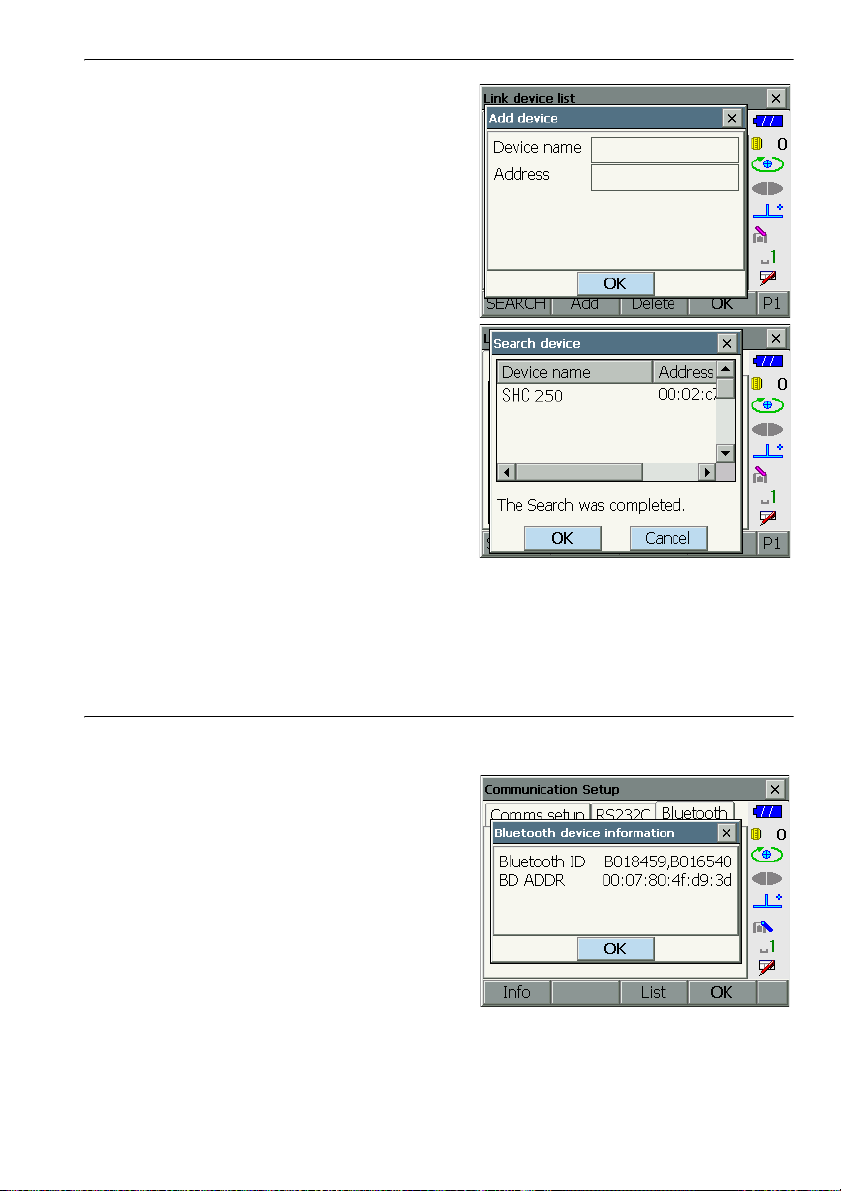

PROCEDURE Registering Bluetooth companion devices

1. Power on the companion device.

2. Select "Bluetooth" in "Comms mode" in the

"Comms setup" tab.

3. Press [LIST] to display a list of all registered

devices.

Register the data collectors to use in "Serial" tab

and devices to use with the Dial-Up Program in

"Dial-up" tab.

$

• Maximum number of devices registered: 6

4. Register your Bluetooth device(s).

44

Page 51

•Press [Add] to display <Add device>. Input the

device name and Bluetooth address and press

[OK]. Both should be 12 characters (numbers 0

to 9 and letters from A to F) in length.

•Press [Search] to search about Bluetooth

devices in the immediate vicinity of the

instrument and display their device name and

address in a list. Select a device from this list and

press [OK] to add to the Link device list in step 3.

•Press [Delete] to delete the selected device

name. Deleted device names cannot be

retrieved.

• Select a device and press [Edit] in the second

page to update the device name and/or device

address.

5. Press [OK] to complete registration and return to

the screen in step 2.

9. CONNECTING TO EXTERNAL DEVICES

PROCEDURE Displaying Bluetooth information for the DS

1. Select "Comms" in Config mode.

2. Press [Info] in the "Bluetooth" tab to display

information for the DS. Register the Bluetooth

address (BD ADDR) displayed here in the paired

device set as "Master".

& Bluetooth device address

This is a number unique to one particular Bluetooth device used to identify devices during

communication. This number consists of 12 characters (numbers 0 to 9 and letters from A to F).

Some devices may be referred to by their Bluetooth device address.

45

Page 52

9. CONNECTING TO EXTERNAL DEVICES

9.2 Communication between the DS and Companion Device

G

• Bluetooth communication causes instrument battery power to be depleted at a rate higher than that

for normal operation.

• Check that the companion device (data collector, computer, or cellular phone etc.) is turned on and

the relevant Bluetooth settings are complete.

• All communication settings will be changed to factory settings when a cold boot is performed.

Comms setup will need to be performed again.

C"9.1 Wireless Communication using Bluetooth Technology"

PROCEDURE Bluetooth communication

1. Complete the necessary DS settings for

Bluetooth communication.

C "9.1 Wireless Communication using

Bluetooth Technology"

2. Start communication

When DS is set as the "Master" device, the

[Connect] softkey is allocated to the fourth page

of Observation mode. When [Connect] is pressed

the DS searches for the device selected in "Link"

and a connection starts. When a connection has

been successfully established is displayed

in the status bar.

The establishing of a connection can also be

initiated by tapping in the status bar.

C Communication status:"5.4 Starkey Mode"

$

• When DS is set as the "Slave" device, the

establishing of a connection can only be

initiated/canceled by the companion device set

as "Master".

3. Press [Cancel] in the fourth page of Observation

mode to terminate the connection.

A connection can also be terminated by tapping

in the status bar.

46

Page 53

9. CONNECTING TO EXTERNAL DEVICES

9.3 Connection via RS232C Cable