Page 1

http://www.topcon.co.jp

Please see the attached address list or the following website for contact addresses.

GLOBAL GATEWAY http://global.topcon.com/

INSTRUCTION MANUAL

DIGITAL LEVEL

DL-500 SERIES

DL-502

DL-503

FC11808-A022-02

Page 2

SURVEYING INSTRUMENTS

DIGITAL LEVEL

DL-502

DL-503

DL-500 SERIES

INSTRUCTION MANUAL

Thank you for selecting the Digital Level DL-502/503.

• Please read this operator's manual carefully before using this

product.

• Verify that all equipment is included. See "20.1 Standard Equipment".

• DL-502/503 has a function to output data saved in DL-502/503 to

a connected computer. Commands operations from a computer

can also be performed. For details, refer to the “Output Formats

and Command Explanations (DL Edition)” manual and ask your

local dealer.

• The specifications and general appearance of the instrument are

subject to change without prior notice and without obligation by

TOPCON Corporation and may differ from those appearing in this

manual.

• The content of this manual is subject to change without notice.

• Some of the diagrams in this manual may be simplified for easier

understanding.

1

Page 3

CONTENTS

Read This First

Introduction

Preliminaries

Surveying

Managing

Recorded Data

1. Precautions for Safe Operation ..........................4

2. Precautions.........................................................7

3. DL Functions ......................................................9

3.1 Parts of the Instrument and Operation .......9

3.2 Display......................................................11

3.3 Operating Keys.........................................15

3.4 Operating Modes ......................................16

4. Installing and Removing the Battery.................18

5. Setting Up the Instrument.................................19

6. Focusing and Sighting ......................................20

7. Basic Operation ................................................22

7.1 Reading the Staff......................................22

7.2 Measuring in Status Mode........................25

7.3 Measuring using Wave-and-Read ............26

8. Setting Up Data Storage...................................29

8.1 JOB Setting ..............................................29

8.2 Record Conditions ....................................31

8.3 Double-run Measurement.........................32

8.4 Flow of Recording Data ............................32

9. Measuring Height Difference ............................36

10. Measuring Elevation .........................................39

11. Setting Out Height Difference, Distance, and

Elevation...........................................................42

11.1 Setting Out Height Difference...................42

11.2 Setting Out Distance.................................44

11.3 Setting Out Elevation................................45

12. Other Measurement Functions .........................48

12.1 Measuring Horizontal Angle .....................48

12.2 Using the Instrument as a Standard

Level .........................................................48

13. Displaying Recorded Data ................................49

13.1 Data Check and Edit.................................49

2

Page 4

Managing

Recorded Data

Other

Procedures

Specifications

Regulations

13.2Number of Recorded Points............................50

14. JOB Delete .......................................................51

15. Sending Recorded Data ...................................53

15.1 Connecting to a Computer or Data

Collector ...................................................53

15.2 Data Output ..............................................54

16. Changing the Settings ......................................56

16.1 Measuring Mode.......................................56

16.2 Fractional / Decimal representation of

Height Unit................................................57

16.3 Communication Parameters .....................58

16.4 Auto Power-Off .........................................58

16.5 Unit of Measurement ................................59

17. Warnings and Error Messages .........................60

18. Charging the Battery.........................................63

19. Checks and Adjustments..................................65

19.1 Adjusting the Circular Level......................65

19.2 Adjusting the Reticle.................................66

20. Equipment and Accessories .............................72

20.1 Standard Equipment.................................72

20.2 Optional Accessory...................................73

20.3 Staffs ........................................................74

21. Specifications ...................................................76

22. Regulations.......................................................80

3

Page 5

1. Precautions for Safe Operation

For the safe use of the product and prevention of injury to operators

and other persons as well as prevention of property damage, items

which should be observed are indicated in this operator's manual by

WARNING and CAUTION indications.

The definitions of the indications are listed below. Be sure you

understand them before reading the manual's main text.

Definitions of Indications

Read This First

Ignoring this indication and making an operation

WARNING

CAUTION

General

Warning

• Do not use voltage other than the specified power supply voltage.

Fire or electrical shock could result.

• Do not use the unit in areas exposed to high amounts of dust or

ash, in areas where there is inadequate ventilation, or near

combustible materials. An explosion could occur.

• Do not perform disassembly or rebuilding. Fire, electric shock or

burns could result.

• Never look at the sun through the telescope. Loss of eyesight could

result.

• Do not look at reflected sunlight from a prism or other reflecting

object through the telescope. Loss of eyesight could result.

Caution

• Do not use the carrying case as a footstool. The case is slippery

and unstable so a person could slip and fall off it.

• Do not place the instrument in a case with a damaged catch, belt or

handle. The case or instrument could be dropped and cause injury.

error could possibly result in death or serious

injury to the operator.

Ignoring this indication and making an operation

error could possibly result in minor injury or

property damage.

4

Page 6

Staff

Warning

• Do not use under thunderous weather conditions. This unit is

conductive and if struck by lightning, death or injury could result.

• Handle with care when using near high voltage cables or

transformers. This unit is conductive and contact could result in

electric shock.

Tripod

Caution

• When mounting the instrument to the tripod, tighten the centering

screw securely. Failure to tighten the screw properly could result in

the instrument falling off the tripod, causing injury.

• Tighten securely the leg fixing screws of the tripod on which the

instrument is mounted. Failure to tighten the screws could result in

the tripod collapsing, causing injury.

• Do not carry the tripod with the tripod shoes pointed at other

persons. A person could be injured if struck by the tripod shoes.

• Keep hands and feet away from the tripod shoes when fixing the

tripod in the ground. A hand or foot stab wound could result.

• Tighten the leg fixing screws securely before carrying the tripod.

Failure to tighten the screws could lead to the tripod legs extending,

causing injury.

Power Supply

Warning

• Use only the specified battery charger to recharge batteries. Other

chargers may be of different voltage rating or polarity, causing

sparking which could lead to fire or burns.

• Do not place articles such as clothing on the battery charger while

charging batteries. Sparks could be induced, leading to fire.

• Do not use damaged power cords, plugs or loose outlets. Fire or

electric shock could result.

• Do not use batteries or the battery charger if wet. Resultant

shorting could lead to fire or burns.

Read This First

5

Page 7

• To prevent shorting of the battery in storage, apply insulating tape

or equivalent to the terminals. Otherwise shorting could occur

resulting in fire or burns.

• Do not heat or throw batteries into fire. An explosion could occur,

resulting in injury.

• Do not connect or disconnect power supply plugs with wet hands.

Electric shock could result.

Caution

• Do not touch liquid leaking from batteries. Harmful chemicals could

Read This First

cause burns or blisters

6

Page 8

2. Precautions

Using the Instrument

• The DL-502/503 is a precision instrument. Avoid severe shocks or

vibration.

• Be careful when removing the instrument from its case.

• Do not place the DL-502/503 directly on the ground.

• When the operator leaves the DL-502/503, the vinyl cover should

be placed on the instrument.

• Never carry the DL-502/503 on the tripod to another site.

• Always turn the instrument off and remove the battery before

storing the instrument in its case.

• When the instrument is placed in the carrying case, see "20.1

Standard Equipment".

• Always wipe off moisture and dirt adhering to the instrument during

survey work. Moisture or dirt on the lens may result in incorrect

readings.

• Consult your local dealer before using the instrument under special

conditions such as long periods of continuous use or high levels of

humidity. In general, special conditions are treated as being outside

the scope of the product warranty.

Maintenance

• Always clean the instrument before returning it to the case. The

lens requires special care. Dust it off with the lens brush first, to

remove tiny particles. Then, after providing a little condensation by

breathing on the lens, wipe it with the supplied cleaning cloth or

lens tissue.

• If the display is dirty, carefully wipe it with a soft, dry cloth. To clean

other parts of the instrument or the carrying case, lightly moisten a

a soft cloth in a mild detergent solution. Wring out excess water

until the cloth is slightly damp, then carefully wipe the surface of the

unit. Do not use any organic solvents or alkaline cleaning solutions.

• Store the instrument and accessories in a dry room where the

temperature remains fairly constant.

• If any trouble is found with the screws or optical parts (e.g. lens),

contact your local dealer.

Read This First

7

Page 9

• Always close the case when empty to protect the interior from

humidity and dust.

• Regular checking and adjustment is recommended to maintain

instrument precision.

Exceptions from responsibility

• The user of this product is expected to follow all operating

instructions and make periodic checks (hardware only) of the

product’s performance.

• The manufacturer, or its representatives, assumes no responsibility

Read This First

for results of faulty or intentional usage or misuse including any

direct, indirect, consequential damage, or loss of profits.

• The manufacturer, or its representatives, assumes no responsibility

for consequential damage, or loss of profits due to any natural

disaster, (earthquake, storms, floods etc.), fire, accident, or an act

of a third party and/or usage under unusual conditions.

• The manufacturer, or its representatives, assumes no responsibility

for any damage (change of data, loss of data, loss of profits, an

interruption of business etc.) caused by use of the product or an

unusable product.

• The manufacturer, or its representatives, assumes no responsibility

for any damage, and loss of profits caused by usage different to

that explained in the operator’s manual.

• The manufacturer, or its representatives, assumes no responsibility

for damage caused by incorrect operation, or action resulting from

connecting to other products.

8

Page 10

3. DL Functions

• Except where stated, screens and illustrations appearing in this

manual are of DL-502/503.

• In principle, screens used in procedures are based on the factory

setting.

Important:

1

2

3

4

5

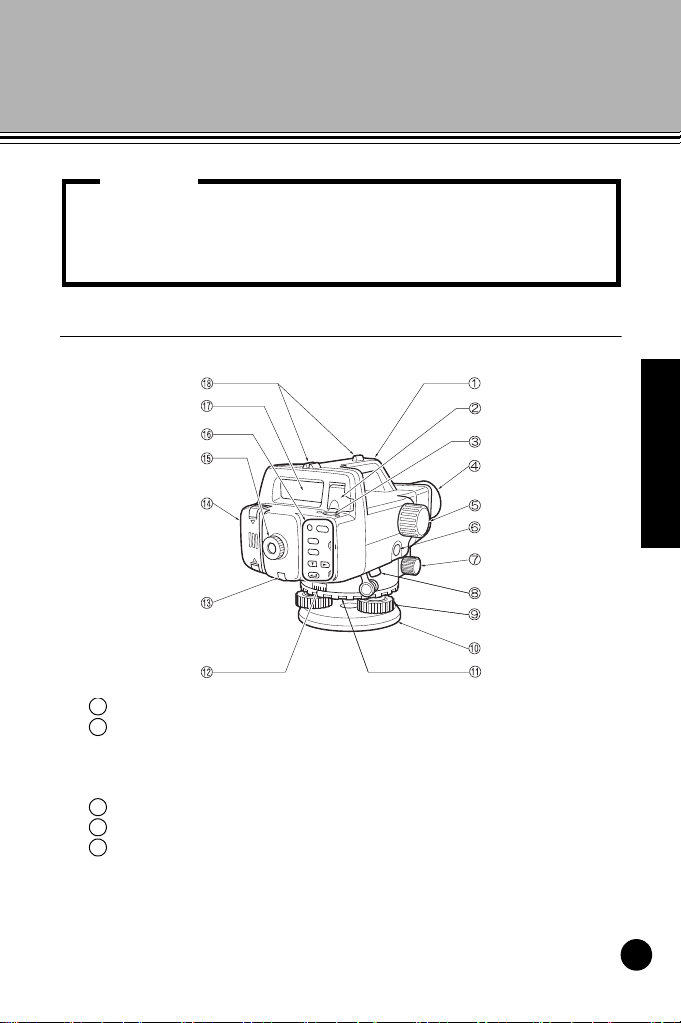

3.1 Parts of the Instrument and Operation

Introduction

Handle

Bubble mirror

When the instrument is placed high up and cannot be viewed

from above, you can use the mirror to check the position of the

bubble in the tube.

Circular level

Objective lens

Focusing knob

Use this knob to focus on the staff.

9

Page 11

Introduction

6

Measure

7

8

9101112131415

161718

Measure key (appears as in this manual)

Starts measurement.

(See "3.3 Operating Keys".)

Horizontal fine motion knobs (both sides)

Use these knobs to finely adjust the instrument's horizontal

position.

Data output connector

You can connect a data collector or computer to this connector.

Leveling foot screw

Base plate

Horizontal circle positioning ring

You can rotate the horizontal scale while the instrument is fixed

in position. Use to align benchmarks with '0', etc.

Horizontal circle

Reticle adjusting screw and screw cover

Use this screw to mechanically adjust the reticle.

Battery cover

Eyepiece

Adjust the reticle focus to suit your eyesight.

Keyboard (See "3.3 Operating Keys".)

Display (See "3.2 Display".)

Gunsight

Use for coarse adjustment of the orientation of the instrument.

10

Page 12

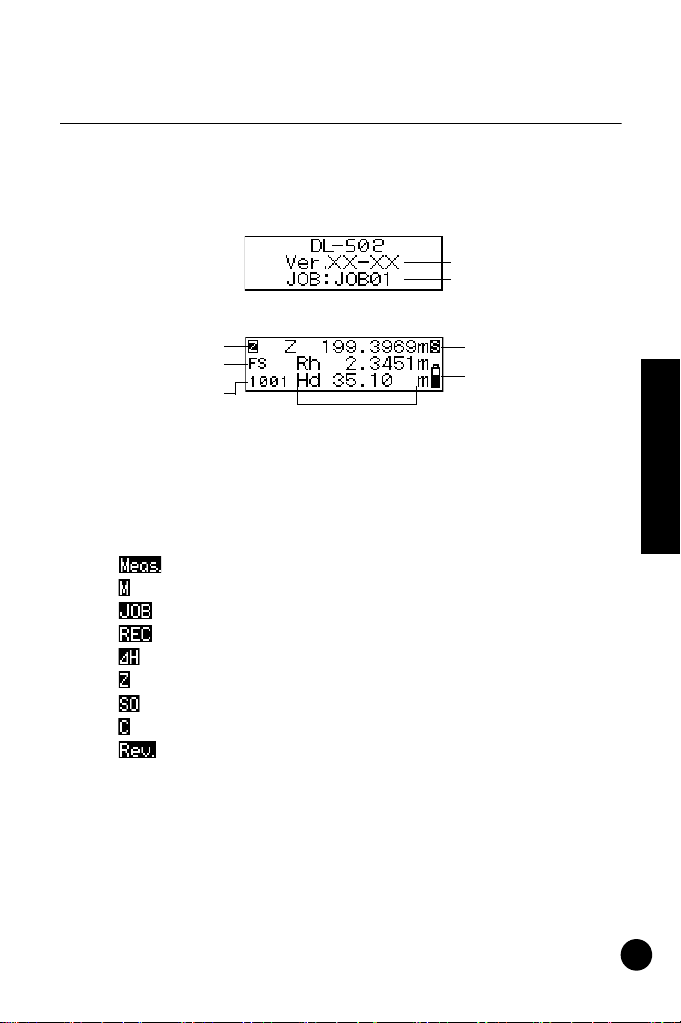

3.2 Display

Version number

Currently selected

JOB

Measurement

Battery level

conditions

indicator

Mode indicator

Attribute•Measure-

Point number

ment step

Measurement values and other data

The display includes the following marks which indicate the

operating status and current mode, and help the operator to

keep track of the measurement procedure.

• Point number display

The next point number to be recorded is displayed.

• Mode display

The displayed mark shows the current mode.

: Status mode or Measurement mode

: Menu mode

: JOB setting mode

: Record setting mode

: Height difference measurement mode

: Elevation measurement mode

: Setting out mode

: Configuration mode

: Data review menu

Introduction

11

Page 13

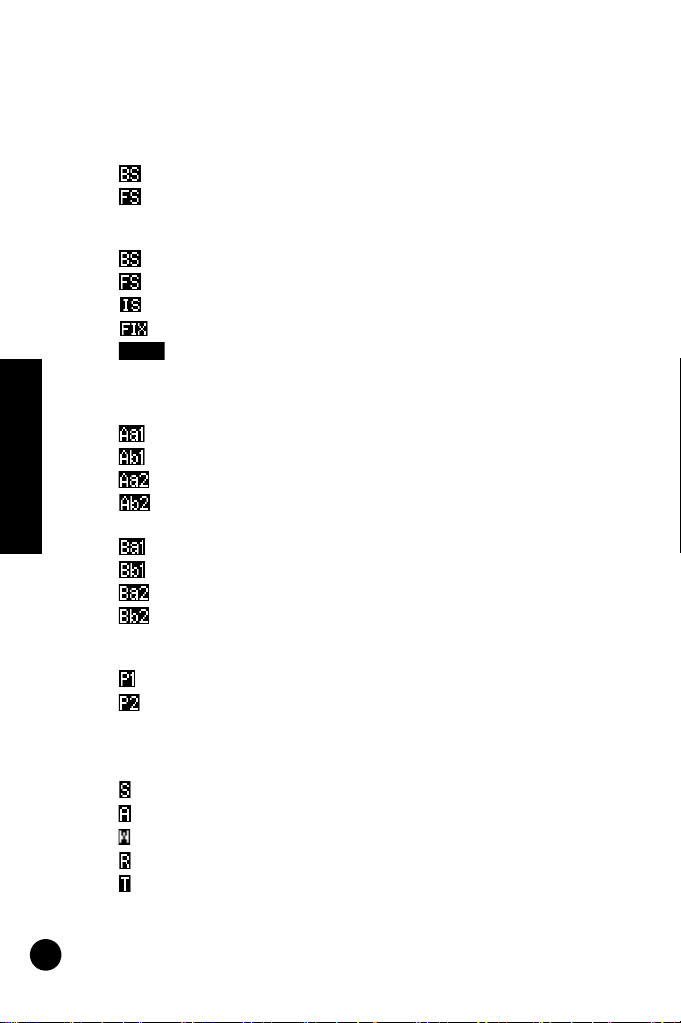

• Attribute•Measurement step display

Displays the backsight and foresight (in Height difference, Setting

out, or Measuring elevation modes).

: Backsight

: Foresight

Displays the attribute of the recorded measurement value (Height

difference measurement mode, Elevation measurement mode).

: Backsight point

: Foresight point

: Intermediate sight

: Fixed point

:Off

Displays the measurement step (when Adjustment is selected in

the Configuration mode).

At position A

: Take a reading on staff a.

: Take a reading on staff b.

Introduction

: Take a reading on staff a with the tripod turned 180°.

: Take a reading on staff b with the tripod turned 180°.

At position B

: Take a reading on staff a.

: Take a reading on staff b.

: Take a reading on staff a with the tripod turned 180°.

: Take a reading on staff b with the tripod turned 180°.

Displays the page number of the active menu (when the Menu

mode or Configuration mode is selected).

:First page

: Second page

• Measuring mode (not displayed on menu screens)

Displays the currently selected measuring mode.

: Single measurement

: Average measurement

: Wave-and-Read measurement

: Repeat measurement

: Tracking measurement

12

Page 14

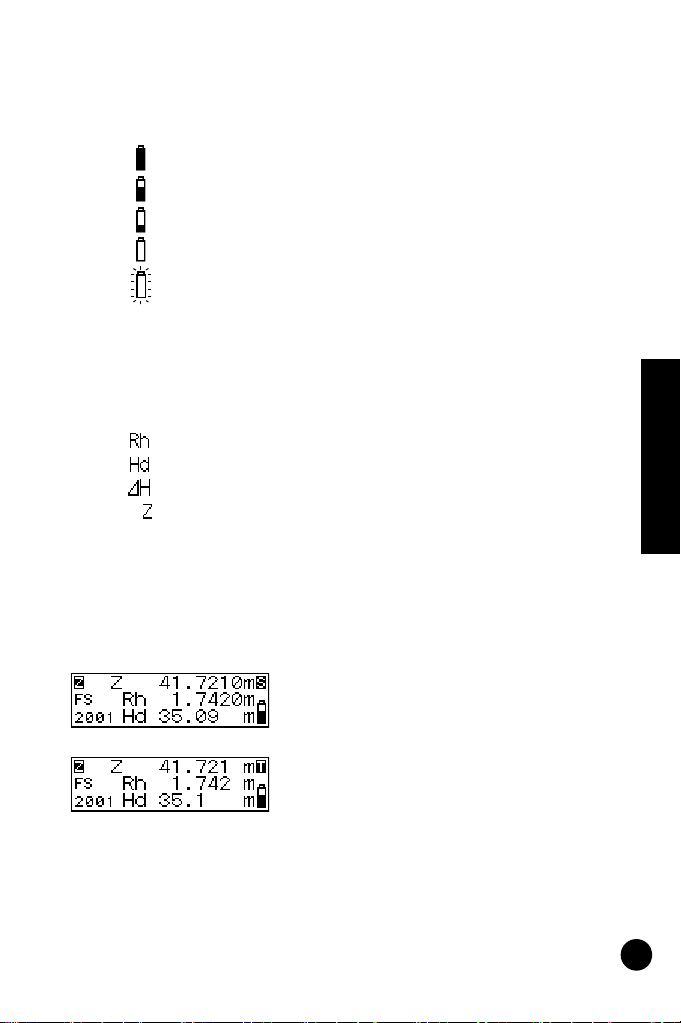

• Battery level (not displayed on menu screens)

Displays the current power level of the battery.

: Level 3: Full power.

: Level 2: Plenty of power remains.

: Level 1: Half or less power remains.

: Level 0: Little power remains. Charge the battery.

: Low: No power remains (A beep tone sounds and the

battery symbol blinks.) Charge the battery. Operation

cannot be performed. After a short time the instrument

automatically powers off.

• Measurements

The following symbols are displayed.

: Staff reading (height)

: Horizontal distance to staff

: Height difference

:Elevation

The fractional/decimal display format for measurement value,

calculation value and input value depends on the settings in

measuring mode and fractional/decimal representation of height

units. (See "16. Changing the Settings".)

• When the fractional/decimal display format is set to "0.0001m" and

the unit of measurement is "m", the display is as follows:

When measuring mode is "Single",

"Average" or "Repeat"

Height: Up to 4 decimals

Distance: Up to 2 decimals

When measuring mode is "Tracking"

Height: Up to 3 decimals

Distance: Up to 1 decimal

Introduction

13

Page 15

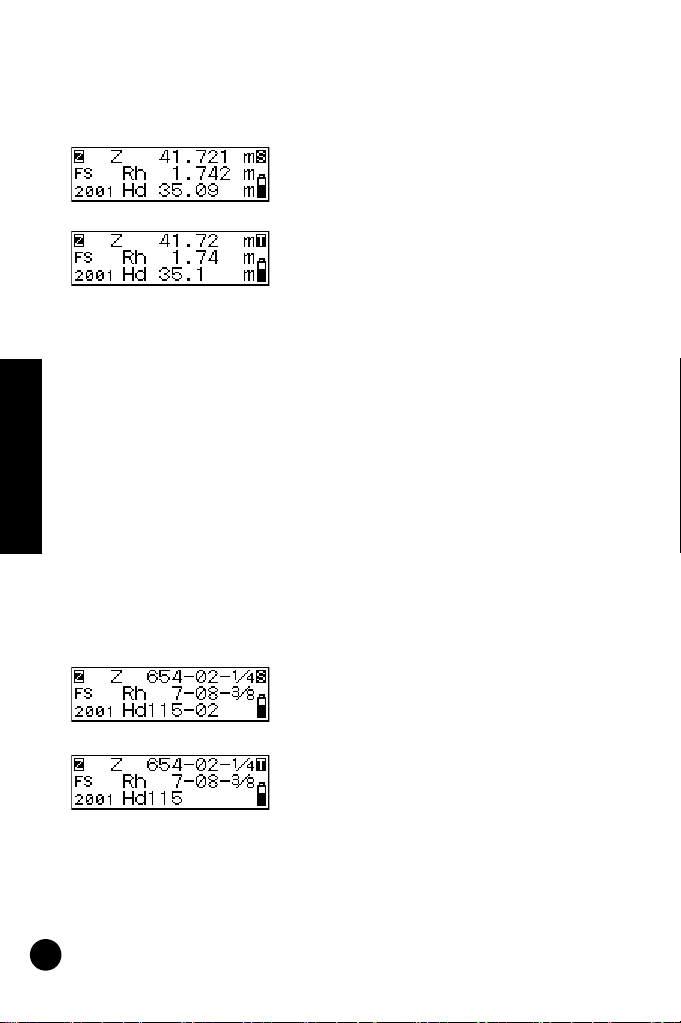

• When the fractional/decimal display format is set to "0.001m" and

the unit of measurement is "m", the display is as follows:

When measuring mode is "Single",

"Average" or "Repeat"

Height: Up to 3 decimals

Distance: Up to 2 decimals

When measuring mode is "Tracking"

Height: Up to 2 decimals

Distance: Up to 1 decimal

• When the fractional/decimal display format is set to "0.001ft" and

the unit of measurement is "ft", data is displayed as follows:

When measuring mode is "Single", "Average" or "Repeat"

Height: Up to 3 decimals

Distance: Up to 1 decimal

When measuring mode is "Tracking"

Height: Up to 2 decimals

Distance: 0 decimal

• When the fractional/decimal display format is set to "0.01ft" and the

unit of measurement is "ft", data is displayed as follows:

Introduction

When measuring mode is "Single", "Average" or "Repeat"

Height: Up to 2 decimals

Distance: Up to 1 decimal

When measuring mode is "Tracking"

Height: Up to 1 decimal

Distance: 0 decimal

• When the fractional/decimal display format is set to "1/8" and the

unit of measurement is "inch", the display is as follows:

When measuring mode is "Single",

"Average" or "Repeat"

Height: **-**-*/

*

Distance: **-**

When measuring mode is "Tracking"

Height: **-**-*/

*

Distance: **

14

Page 16

3.3 Operating Keys

• The fractional/decimal display format for distance measurements

depends on the setting in measuring mode only.

Note:

Measure

Measure

Learn main key operations here.

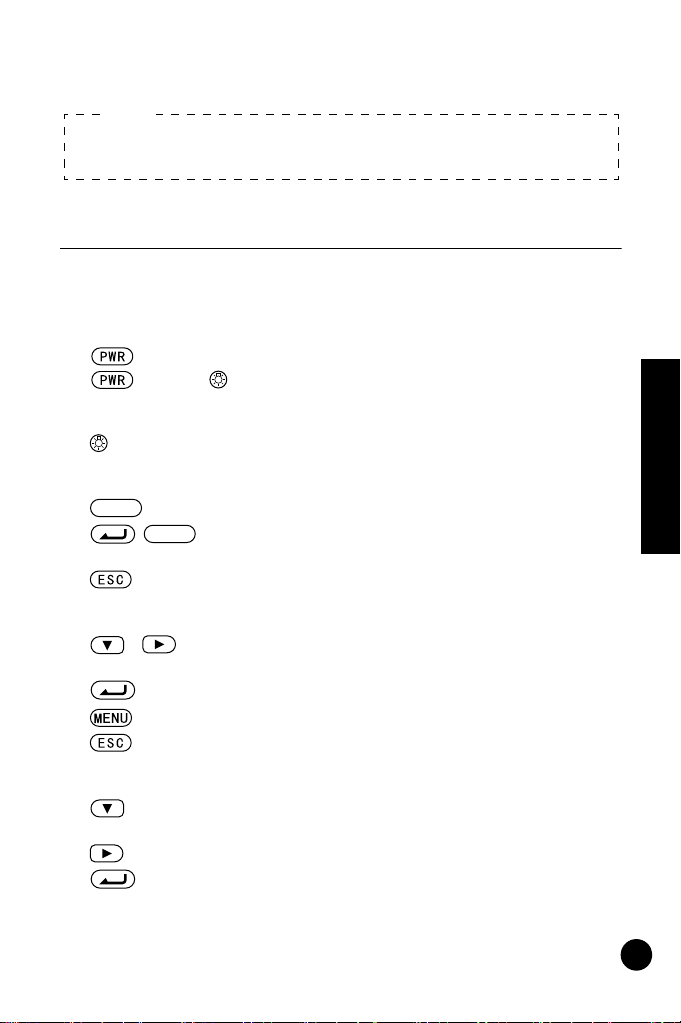

• Power ON/OFF

: Power the instrument ON

(hold) + : Power the instrument OFF

• Light up the display

: Switch the display backlight ON / OFF

• Measurement start / stop

: Start measurement

/ : Stop measurement (in repeat, average or tracking

mode)

: Cancel measurement

• Select / cancel (return to former procedure) menus and options

/ : Scroll to next position (JOB selection, item selection,

etc.)

: Accept the option

: Enter Menu mode

: Return to former procedure or to Status mode

• Value input / cancel

: Advance the numeral

Toggle the +/- sign

: Change the position of the inverted cursor

: Accept the input value

Introduction

15

Page 17

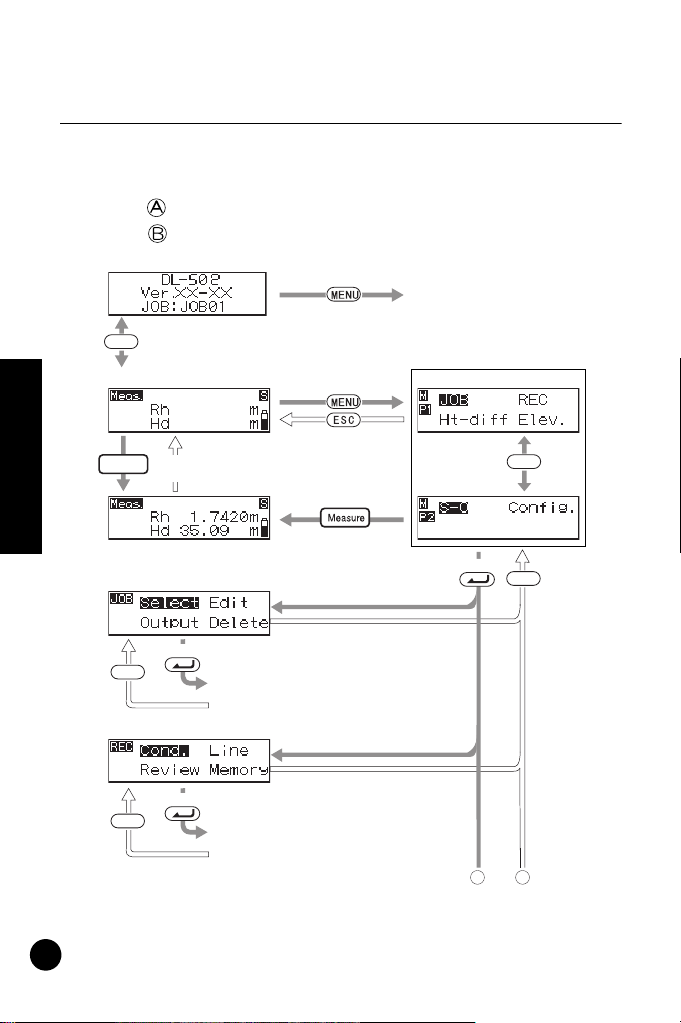

3.4 Operating Modes

The DL has a number of functional modes. This section

shows the screens that can be displayed in each mode.

: Key operation for selecting each menu

: Key operation for returning to previous screen

[Instrument information mode]

ESC

[Status mode]

[Screen showing the number

of points that can be

recorded is displayed]

[Menu mode]

(Page 1)

Introduction

16

[At completion of a

Measure

measurement]

[Measurement mode]

[Job setting mode]

Select

ESC

[Record setting mode]

ESC

[Menu of selected

function is displayed]

Select

[Menu of selected

function is displayed]

(Page 2)

Select

A B

MENU

ESC

Page 18

[Height difference measurement mode]

ESC

Select

[Menu of selected

function is displayed]

Select

[Menu of selected

function is displayed]

[Elevation measurement mode]

[Setting out .....]

[Config. mode]

(Page 1)

(Page 2)

MENU

A B

Introduction

17

Page 19

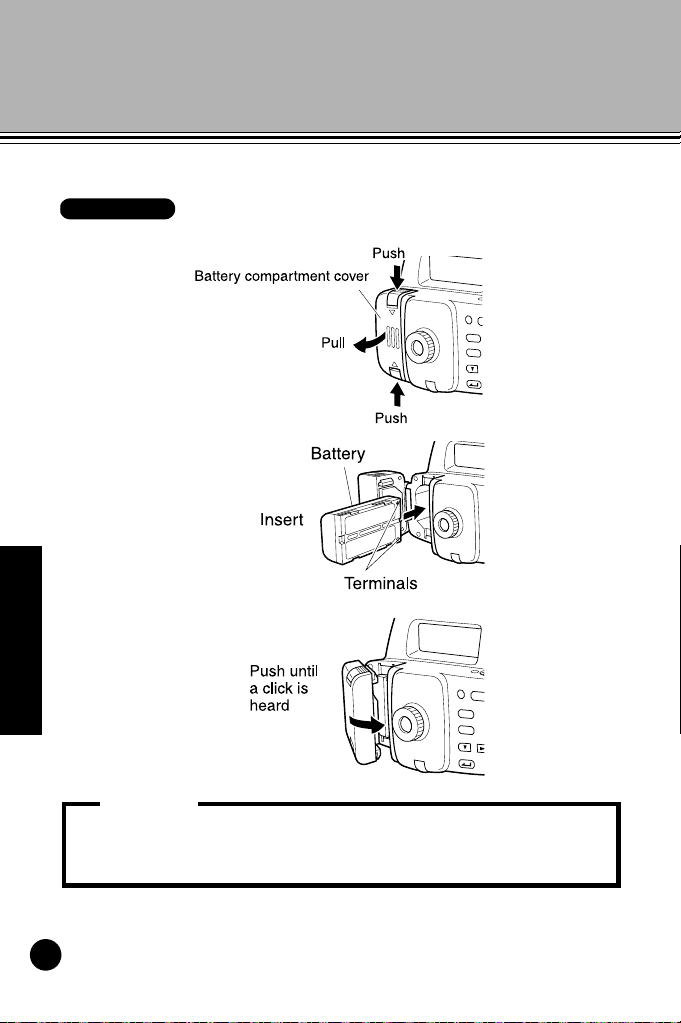

4. Installing and Removing the Battery

Procedure

• Always turn off the power before removing the battery from the

instrument. If the battery is removed when the power is still on,

stored data may be lost.

Important:

Install a fully-charged battery (see "18. Charging the Battery").

1

2

3

Preliminaries

18

Page 20

5. Setting Up the Instrument

Procedure

1 Set up the tripod.

Spread the tripod legs about the same distance apart so that the

tripod head is approximately level. Tread the tripod shoes firmly into

the ground.

2 Mount the instrument on the tripod.

Hold the instrument on the tripod head and tighten the centering

screw.

3 Level the instrument.

Spherical head tripod: Loosen the centering screw and slide the

instrument across the tripod head until the

bubble is centered in the circular level.

Tighten the centering screw.

Flat head tripod: Extend or push in the tripod legs until the

bubble is centered in the circular level.

When the bubble is more or less centered,

turn the leveling foot screws until the

bubble is exactly centered in the circle.

When you turn a screw clockwise, raising

the instrument, the bubble will move toward

the position of that screw.

Preliminaries

19

Page 21

6. Focusing and Sighting

Procedure

• If deviation occurs at step 5, errors will occur when taking

measurements. Always make sure the instrument is correctly

focused.

Important:

• Before using the instrument

Turn the eyepiece to adjust the eyepiece image.

1 Using the gunsight, aim the objective lens toward the staff.

2 Gradually turn the eyepiece outward, stopping just before the

reticle cross-lines become blurred.

3 Turn the horizontal fine motion knobs until the staff is nearly

centered in the field of view, then turn the focusing knob to focus on

the staff.

4 Looking through the telescope, shift your eyes slightly up and down

and to each side.

Preliminaries

5 If the staff and reticle show no deviation, the instrument is ready for

use.

If the staff and reticle deviate, return to step 2.

20

Page 22

• Focusing when taking measurements

Procedure

• If the staff barcodes are out of focus, they will not be readable

and measurements cannot be taken. Make sure they are

correctly focused.

Important:

1 Using the gunsight, aim the objective lens toward the staff.

2 Turn the horizontal fine motion knobs until the staff is nearly

centered in the field of view, then turn the focusing knob to focus on

the staff.

Preliminaries

21

Page 23

7. Basic Operation

• Set up the staff in an area free of obstacles.

Avoid placing the staff next to mirror-like surfaces. The effect of

strong light could make measurement impossible.

• Support the staff so that it is perpendicular, checking the circular

bubble scope on the staff. If the staff is tilting, height and distance

measurements will be incorrect.

• If the surface is catching the light, turn it just enough to stop the

reflection.

• Make sure shadows are not cast on the staff as this could make

measurement impossible.

• When holding the staff during measurement, make sure your

hand does not cover the RAB code.

• If dark locations make measurement difficult, shine a flashlight on

the staff. Stand at a distance so that the beam shines evenly

over the length of the staff.

Important:

7.1 Reading the Staff

Simply focus on the RAB* code for an automatic reading of

the staff. The following explains how to read the RAB code

of the staff.

* : RAB code (Random Bi-directional code) is a coded staff

used with DL-500 line of digital levels.

Surveying

22

(Continued on next page)

Page 24

(Continued from previous page)

• If waterdrops or dirt adhere to the barcode, measurement may be

impossible. Wipe the staff clean with a soft cloth.

• Clean the staff if grit or dirt gets stuck between the sections. If the

staff is dirty, measurements will not be very accurate.

• Avoid scratching or soiling the barcode surface as this could

make measurement impossible. Store and carry the staff inside

its case.

• If the BGS series staff is used for leveling, and the height

difference and temperature difference are much larger than

normal, temperature variations may cause the staff to expand or

contract and cause differences in relative height measurements.

DL-502/503 reads in measurements up to 0.1mm and minor

deviations in the accuracy of the staff will adversely affect

accuracy. To obtain high accuracy measurements, it is important

to perform temperature corrections for the staff. (See the Note

below for details.)

Procedure

• Setting up the staff

1 Connect the staffs correctly by making sure the numbers on the

numeric scale side of the staffs run in unbroken order.

2 Set the foot plate on the ground so that the staff will not sink.

3 Keeping an eye on the circular bubble scope on the staff, set the

staff in the foot plate so that it stands up straight.

4 Turn the barcode scale toward the instrument.

Surveying

23

Page 25

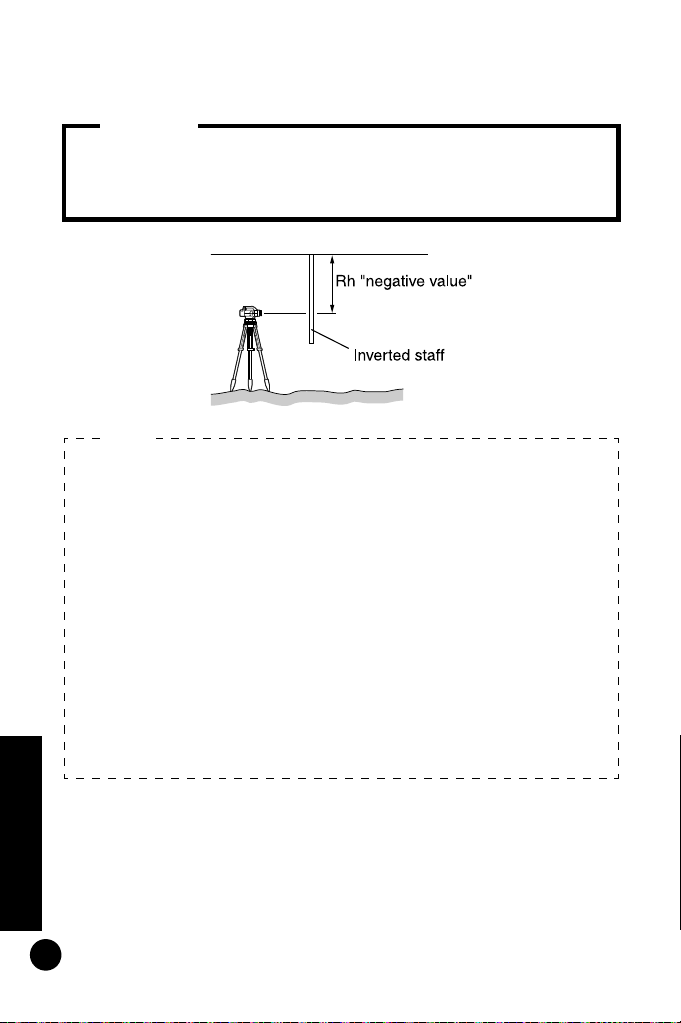

• Measuring the height from a ceiling

• Not possible with Wave-and-Read function. Attempting such

measurement with the Wave-and-Read function will result in an

error.

Important:

Formula for correcting expansion and contraction of the

staff due to temperature changes

C={C0+(T-T0)x }x h

C: Staff correction value

C0: Scale factor

T: Measured temperature during observation (average

temperature during measurement of known site,

intermediate site, new site)

T

0: Reference temperature of 20 C

: Line expansion coefficient

(BGS series : 20x10

-6

1/ C)

h: Height difference

ΔαΔΔ°α°

Δ

Note:

Surveying

24

Page 26

7.2 Measuring in Status Mode

• During measurement, if direct sunlight or strong light enters the

eyepiece and measurement cannot be performed,

"Measurement error" or "Too bright" is displayed (see "17.

Warnings and Error Messages"). Shield the eyepiece from the

light source using your body or cover the eyepiece with your

hand and resume measurement.

• If the DL-502/503 is subjected to shocks or vibration during use,

measurement may be impossible. Resume measurement during

more stable conditions.

Important:

Procedure

Measure

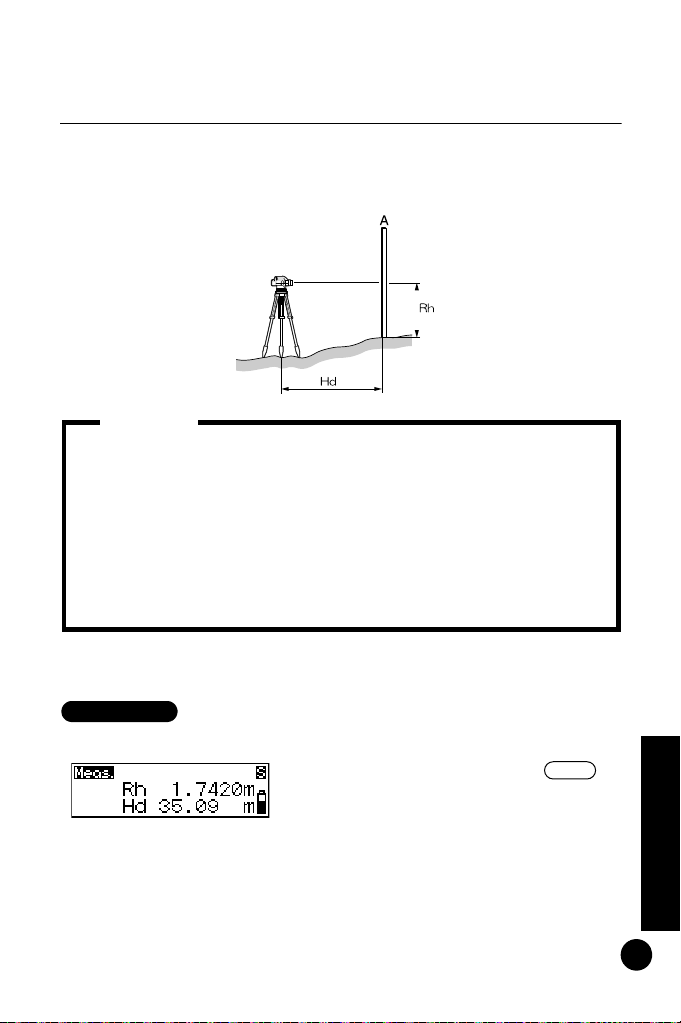

In status mode you can sight point A, take the staff reading

(Rh), and measure the horizontal distance (Hd) to the staff.

The procedure below is for taking single measurements. For

repeat measurements, see the notes.

1 Turn the power switch on.

2 Focus on the staff and press .

Operation starts and the display blinks

while measurements are being taken.

When measurement is completed,

the staff readings (Rh) and horizontal

distance (Hd) are displayed.

Surveying

25

Page 27

7.3 Measuring using Wave-and-Read

• In Repeat, Average, or Tracking mode:

Step 2: Values are renewed at each measurement.

Press or to stop the reading.

Press to cancel the reading.

Measure

Note:

Wave staff

back and forth

The Wave-and-Read function reduces measurement error due to the

staff not being vertical (i.e. tilting). It also allows measurement using a

staff not equipped with a bubble scope.

Wave-and-Read can be used to take the staff reading (Rh), and

measure the horizontal distance (Hd) to the staff.

Surveying

26

Page 28

The forward and backward movement with respect to vertical position

Vertical

OK

No good No good

Procedure

A should be equal and not in excess of 5 to 10°.

1 Turn the power switch on.

2 Set measuring mode to “Waving”.

(see "16.1 Measuring Mode")

3 Focus on the staff.

4 Wave the staff backwards and

forwards (5 to 10°) through the

vertical position. Waving speed

should be equivalent to 3 passings of

the staff through the vertical position

in approximately 3 seconds.

Surveying

27

Page 29

5 Press to start measurement.

Measure

• During measurement, if direct sunlight or strong light enters the

eyepiece and measurement cannot be performed,

"Measurement error" or "Too bright" is displayed (see "17.

Warnings and Error Messages"). Shield the eyepiece from the

light source using your body or cover the eyepiece with your

hand and resume measurement. Conversely, measurement

cannot be performed when light conditions are too dark.

• Measurement cannot be performed when the staff is waved too

fast.

• Measurement cannot be performed when the staff is waved from

side to side (left to right). "Measurement error" is displayed (see

"17. Warnings and Error Messages").

Important:

A beep tone sounds and the display

blinks. Consecutive arrows are

displayed to indicate the progress of

measurement.

When measurement is completed, a

beep tone sounds twice and the staff

readings (Rh) and horizontal distance

(Hd) are displayed.

Surveying

28

Page 30

8. Setting Up Data Storage

• *: Factory setting

• Settings are saved even after the instrument is turned off.

• Up to 2000 points can be registered. If 2000 points have already

been recorded, a beep tone sounds twice and the number of

free points remaining is displayed as "0". Measurement results

are not recorded. Press any button to return to the previous

screen.

• See "15.2 Data Output" and "14. JOB Delete" for how to "Output"

and "Delete" in the JOB setting mode.

• See "13. Displaying Recorded Data" for how to use "Review" and

"Memory" in the Record setting mode.

Notes:

• Between 1 and 12 characters can be set for the JOB name.

• If measurement data has already been saved in the selected

JOB, the unit of measurement (m or ft) cannot be changed. The

same unit of data will be applied in the future to data that is saved

to the same JOB.

• JOB names already used cannot be set.

Notes:

Data can be stored in Height difference measurement mode or

Elevation measurement mode. JOB setting mode and record setting

mode must be set up before data can be recorded.

JOB setting mode Record setting mode

8.1 JOB Setting

Set the JOB containing the measurement data to be recorded.

Select from JOB01* to JOB20.

Surveying

29

Page 31

• JOB Selection

Procedure

• JOB Quick Access

Step 2: When JOB numbers 1 to 10 are displayed, press

to jump to JOB number 11. When JOB numbers 11 to 20

are displayed, press to jump back to JOB number

1.

Note:

Procedure

• Changing the JOB name

1 In the menu mode, select "JOB," and

then select "Select."

The currently selected JOB and

number of data recorded in the JOB

are displayed.

2 Select the JOB you will store the data

to.

3 Press to confirm the selected

JOB.

1 In menu mode, select "JOB" and

then "Edit."

The currently selected JOB name is

displayed and can now be edited.

The characters that can be input are

shown below. Each time is

pressed, the cursor jumps to the first

character of each row shown below.

Surveying

30

Page 32

0123456789

ABCDEFGHIJ

KLMNOPQRST

UVWXYZ.+-

Example: Displaying the word AT

2 Press four times to display "A."

3 Press to move the cursor to the

next character.

4 Press five times to display "T."

5

When the word has been input, press

8.2 Record Conditions

Select the method for recording measurement data.

In the menu mode, select "REC," and then "Cond."

* Manual: When measurement is completed, check and

Auto: Data is automatically recorded for foresight point

Off: Data cannot be recorded.

record the data

measurements (check and record backsight

point measurements manually)

to record the JOB name.

31

Surveying

Page 33

8.3 Double-run Measurement

Note:

When "Return" is selected, "*" is displayed in front of measurement

value Rh.

You can set single-run or double-run measurement data as

additional information. When data is sent, you can

distinguish single-run from double-run measurement data.

In menu mode, select "REC" and then "Line."

* Go: Record sent data

Return: Record returned data

8.4 Flow of Recording Data

The following explains the flow of recording measurement

data. When using the numerical scale side of the staff and

not the RAB code, manually input the measurement data.

A detailed explanation is provided below for items indicated

by a *.

Surveying

32

Page 34

Set the backsight point

number*

Measure the backsight

point

Check and record the

measurement results

Set attributes of foresight

point*

Set the point number of the

foresight point*

Measure (foresight) point

Check and record the

measurement results

Move the instrument point

Measure previous point as

backsight point

Measure next foresight

point

Procedure

The following procedure is an example of measurement in height

difference measurement mode.

• Setting the point number

1 Press when measuring the

backsight point.

The point number can now be set.

Surveying

33

Page 35

2 Set the point number.

Advancing the point number

If the point number is not set, data is recorded using the

automatically set number in the currently selected JOB. Check the

measurement results together with the point number. Point

number is displayed as follows:

• First record after power is switched ON • No data stored in JOB...

0001

• First record after power is switched ON • Data stored in JOB...

point number of last measurement point

• Second or later record after power is switched ON • turning

point...point number of last measurement point

• Second or later record after power is switched ON • No turning

point...point number of last measurement point +1

Notes:

Procedure

3 Press to confirm the point

number.

• Setting attribute (only foresight)

1 Press when measuring the

foresight point.

The attribute can now be set.

2 Set the attribute.

Each time or is pressed: IS

(intermediate sight) Æ FIX (fixed

point) Æ Off Æ FS (foresight) Æ IS

(intermediate sight)

Surveying

34

Page 36

3 Press to confirm the selected

If the attribute is not set, a point other than the backsight point is

recorded as the foresight point.

Note:

Procedure

attribute.

The point number can now be set.

(See "Setting the point number".)

• Inputting measurement data (measure the point using the

numerical scale side of the staff)

1 Focus the DL-502/503 on the

numerical scale side of the staff and

measure the backsight point.

2 Press .

Measurement data can now be input

manually.

3 Input the measurement value found

in step 1.

4 Check the point number and press

"Yes" to record the selected data.

5 Measure the next point.

Surveying

35

Page 37

9. Measuring Height Difference

ΔH

• When moving the instrument to a new position (step 8 below),

press "Yes" to save the turning point before switching off the

power.

Important:

Procedure

You can measure the height difference ΔH

A) and foresight (point B).

The procedure below is for taking single measurements

when "manual" is selected in the Record conditions menu.

1 Set up the instrument midway between

points A and B.

2 In menu mode, select "Ht-diff".

3 Measure the backsight.

4 Select "Yes" to accept the point

number attribute and measurement

value.

The result is saved and the number

of points that can be recorded in

Surveying

available memory is displayed.

between the backsight (point

36

Page 38

5 Measure the foresight.

The instrument calculates the height

difference

Δ

H relative to the back-

sight, and displays the result.

6 Select "Yes" to accept the point

number, attribute and measurement

value.

The result is saved.

7 Press .

A message asks whether you want to

change the instrument position.

8 If moving the instrument, select "Yes".

In step 5, the measured foresight is

recorded as turning point (TP) height

difference.

9 Transfer to the next instrument position

and repeat the measurements from

step 3.

The height difference measured at step

5 is displayed as the height difference

of the backsight (TP).

37

Surveying

Page 39

• Point number input

Step 3: Press to ready the instrument for point

number input.

Step 5: Press twice to ready the instrument for

point number input.

(See "8.4 Flow of Recording Data".)

• Attribute setting

Step 5:

Press to ready the instrument for attribute

setting. (See

"8.4 Flow of Recording Data"

.)

• Go and Return setting

Step 3:

Press to display the Go and Return Setting

Screen. (See

"8.3 Double-run Measurement"

.)

• Reviewing stored data

Steps 3 and 5:

Press to display the contents of the

selected JOB. (See "13.1

Data Check and Edit"

.)

• Manually inputting measurement data

Steps 3 and 5:

Press . Measurement data can now be input

manually. (See

"8.4 Flow of Recording Data"

.)

Notes:

Surveying

38

Page 40

10. Measuring Elevation

• When moving the instrument to a new position (step 9 below),

press "Yes" to save the Turning Point before switching off the

power.

Important:

Procedure

From a known elevation (point A), you can measure the elevation (HA

Δ

H) of a specified ground point (point B).

+

The procedure below is for taking single measurements

when "Manual" is selected in the Record conditions menu.

1 Set up the instrument between points

A and B.

2 In menu mode, select "Elev.".

3 Input the backsight elevation.

4 Measure the backsight.

Surveying

39

Page 41

5 Select "Yes" to accept the point

number and measurement value.

The result is saved and the number

of points that can be recorded in

available memory is displayed.

6 Measure the foresight.

The instrument calculates the foresight

elevation (Z), and displays the result.

7 Select "Yes" to accept the point

number, attribute and measurement

value.

The result is saved.

8 Press .

A message asks whether you want to

change the instrument position.

9 If moving the instrument, select

"Yes".

In step 6, the measured foresight is

recorded as turning point (TP)

elevation.

10 Transfer to the next instrument position

and repeat the measurements from

step 3.

The elevation measured at step 6 is

measured as the elevation of the

backsight (TP).

Surveying

40

Page 42

• Point number input

Step 4: Press to ready the instrument for point

number input.

Step 6: Press twice to ready the instrument for

point number input.

(See "8.4 Flow of Recording Data".)

• Attribute setting

Step 6:

Press to ready the instrument for attribute

setting. (See

"8.4 Flow of Recording Data"

.)

• Go and Return setting

Step 4:

Press to display the Go and Return Setting

Screen. (See

"8.3 Double-run Measurement"

.)

• Storing backsight elevation

Steps 3 and 10: Even after power off, backsight elevation is

stored or turning point is stored as the next

backsight elevation. Since this value is the

same as the value in the setting out elevation

mode, the backsight elevation is stored to

whichever mode is set last. (See "11.3 Setting

Out Elevation".)

• Reviewing stored data

Steps 4 and 6:

Press to display the contents of the

selected JOB. (See "13.1

Data Check and Edit"

.)

• Manually inputting measurement data

Steps 4 and 6: Press . Measurement data can now be

input manually. (See "8.4 Flow of Recording

Data".)

Notes:

Surveying

41

Page 43

11. Setting Out Height Difference, Distance, and Elevation

Procedure

You can locate ground points that correspond to entered numerical

data. The Set-Out menu provides three modes - height difference,

distance, and elevation.

11.1 Setting Out Height Difference

By entering the height difference (ΔH) from a benchmark

(point A), you can find a ground point (point B) at a specified

height difference from the benchmark.

The procedure below is for taking single measurements.

1 Set up the instrument between points

A and B.

2 In menu mode, select "Set-out", then

select "Ht-diff".

Surveying

42

3 Input the height difference value that

you want to stake out.

Page 44

4 Measure the backsight.

• When in this menu and setting-out has already been taken (for

the second or subsequent reading):

Step 4: The previous backsight measurement will be displayed

and the program skips to step 5.

• Storing setting out height difference:

Step 3: Even after power off, the height difference is stored.

Notes:

The instrument takes the backsight

reading and displays the measurement.

5 Select "Yes" to accept the value.

6 Measure the foresight.

The instrument calculates the difference between the measurement and

the input value, and displays the

result.

7 Move the staff by the amount shown

on the screen, then take another

foresight reading.

If "Fill" is displayed, move the staff

upward.

If "Cut" is displayed, move the staff

downward.

When the display shows '0', you have

found the specified ground point.

8 Press or .

Height difference set-out is completed.

Set out the next ground point.

Surveying

43

Page 45

11.2 Setting Out Distance

Procedure

By entering the distance (Hd) from a benchmark (point A),

you can find a ground point (point B) at a specified distance

from the benchmark.

The procedure below is for taking single measurements.

1 Set up the instrument at point A.

2 In menu mode, select "Set-out", then

3 Input the distance that you want to

select "Dist.".

stake out.

Surveying

44

4 Measure the foresight.

The instrument calculates the difference between the measurement and

the input value, and displays the

result.

Page 46

5 Move the staff by the amount shown

• Storing setting out distance

Step 3: Even after power off, distance is stored.

Note:

on the screen, then take another

foresight reading.

If "Out" is displayed, move the staff

backward.

If "In" is displayed, move the staff

forward.

When the display shows '0', you have

found the specified ground point.

6 Press or .

Distance set-out is completed. Set

out the next ground point.

11.3 Setting Out Elevation

By entering the elevation (HA + ΔH) from a known benchmark

(point A), you can find a ground point (point B) at a specified

elevation.

The procedure below is for taking single measurements.

Surveying

45

Page 47

1 Set up the instrument midway

Procedure

between points A and B.

2 In menu mode, select "Set-out", then

select "Elev.".

3 Input the backsight elevation.

4 Measure the backsight.

The instrument takes the backsight

reading and displays the measurement.

5 Select "Yes" to accept the value.

6 Input the elevation that you want to

stake out.

7 Measure the foresight.

The instrument calculates the difference between the measurement and

the input value, and displays the result.

8 Move the staff by the amount shown

on the screen, then take another

foresight reading.

If "Fill" is displayed, move the staff

upward.

If "Cut" is displayed, move the staff

downward.

Surveying

When the display shows '0', you have

found the specified ground point.

46

Page 48

9 Press or .

• When in this menu and setting-out has already been taken (for

the second or subsequent reading):

Step 4: The previous backsight measurement will be displayed

and the program skips to step 5.

• Storing backsight elevation:

Step 3: Even after power off, backsight elevation is stored.

Since this value is the same as the value in the

elevation measurement mode, the backsight elevation

is stored to whichever mode is set last. (See "10.

Measuring Elevation".)

• Storing setting out elevation

Step 6: Even after power off, elevation is stored.

Notes:

Elevation set-out is completed. Set

out the next ground point.

Surveying

47

Page 49

12. Other Measurement Functions

12.1 Measuring Horizontal Angle

You can measure the horizontal angle between point A and

point B by using the horizontal circle.

12.2 Using the Instrument as a Standard Level

By using the numeric scale side of the staff, you can use the

DL-502/503 as a standard level. Simply focus on the staff

and read the scale.

In the Height difference measurement mode and Elevation

measurement mode, the sighted value can be manually

input in the currently selected JOB. (See "8.4 Flow of

Recording Data".)

Surveying

48

Page 50

13. Displaying Recorded Data

• Attributes can be changed in the following order only: BS

(backsight point) Æ FS (foresight point) Æ IS (intermediate sight)

Æ FIX (fixed point) Æ Off Æ DEL (delete). (Example: Data

recorded as IS (intermediate sight) can be changed to FIX (fixed

point), Off or DEL (delete), but not to BS (backsight point) or FS

(foresight point).

• Point number and measurement results cannot be edited.

Important:

Procedure

Data recorded in Height difference measurement mode or Elevation

measurement mode can be edited.

Use the Record Setting Mode to check data and display the number of

recorded points.

13.1 Data Check and Edit

Check the contents saved in the currently selected JOB.

Attributes can be changed.

1 In menu mode, select "REC" and

then select "Review."

The last recorded data in the

currently selected JOB is displayed.

2 Display the data that you want to

review.

Press to display the previously

displayed data.

Managing Recorded Data

49

Page 51

3 Press .

• "DEL" setting and Number of points that can be recorded

If the DEL attribute is selected for recorded data, the data is not

displayed. Setting DEL does not delete data from memory, so the

number of points that can be stored in free memory does not

increase. When a JOB is deleted, all data with the DEL attributes

recorded in other JOBs is also deleted.

• Double-run Measurement

When "Return" is selected, "*" appears in front of measurement

value Rh.

Notes:

• You can reach here also by pressing and then in

status mode.

Note:

The attributes can now be changed.

4 Display the attribute you want to

change.

5 Press to confirm the selected

attribute.

Managing Recorded Data

13.2 Number of Recorded Points

In the menu mode, select "REC," and then "Memory." The

number of points (up to 2000) that can be recorded is

displayed.

50

Page 52

14. JOB Delete

• JOBs that cannot be output (indicated by * next to JOB) cannot

be deleted.

Important:

Procedure

Delete the JOB and the contents of the JOB.

Carry out JOB deletion in the JOB setting mode. (JOBs cannot be

deleted when the battery is LOW.)

1 In menu mode, select "JOB" and

then "Delete."

The currently selected JOB and

number of data recorded in the JOB

are displayed.

2 Display the JOB you want to delete.

3 Press , and then select "Yes."

The selected JOB and contents of

the JOB are deleted.

Managing Recorded Data

51

Page 53

Managing Recorded Data

• JOB Quick Access

Step 2:

When JOB numbers 1 to 10 are displayed, press to

jump to JOB number 11. When JOB numbers 11 to 20 are

displayed, press to jump back to JOB number 1.

• JOB name

Step 3: After the JOB is deleted, the default JOB name set at

the factory is displayed: JOB01 to JOB20.

• Number of points that can be recorded

When a JOB is deleted, data with the DEL attributes recorded in

other JOBs is also deleted, and the value indicating the number

of points that can be stored in free memory increases.

Notes:

52

Page 54

15. Sending Recorded Data

• The DL-502/503 accepts commands only when in status mode or

menu mode. Received commands are not executed in any other

state.

Important:

Recorded data can be sent to a connected computer or data collector.

Commands sent from a computer or the data collector instruct the DL502/503 to carry out measurement, and the measurement results are

output.

15.1 Connecting to a Computer or Data Collector

Managing Recorded Data

Use the dedicated communication cable to connect the

502/503

• Communication cable

If using a data collector, use the cable supplied with the data

collector.

to the data collector or a computer.

Computer Cable Notes

IBM PC/AT or

compatible

Other personal

computers

DOC26 Length: 2m

Pin Numbers and signal levels:

DOC27

F-4

F-24

DOC1 No connector for attachment to

D-sub connector:

a computer.

RS-232C compatible

DOC26: 25 pins (female)

DOC27: 9 pins (female)

DL-

53

Page 55

• Pin assignments of the data output connector

• Data recorded in a JOB that has not been sent is indicated by an

asterisk (*).

Important:

Procedure

Pin No. Signal

1SG (GND)

2 NC (unused)

3SD (TXD)

4 RD (RXD)

5 Power source (output)

6 Reserved (must not be used)

Managing Recorded Data

15.2 Data Output

The contents of a JOB can be output to a computer in CSV

or SDR2X format.

1 Use a cable to connect the

to a computer. ("15.1 Connecting

503

to a Computer or Data Collector")

2 In menu mode, select "JOB" and

then "Output." The currently selected

JOB and recorded point numbers are

displayed.

3 Select the JOB you wish to send.

54

DL-502/

Page 56

4 Select the data output format.

• JOB Quick Access

Step 2: When JOB numbers 01 to 10 are displayed, press

to jump to JOB number 11. When numbers 11 to

20 are displayed, press to jump to JOB number

1.

Step 4: Press to display the communication conditions

setting screen.

• Data output format/command operations

For details, refer to the "Output Format and Command

Explanations (DL Edition)" manual and ask your local dealer.

Note:

Data is output. When data output is

completed, the

JOB setting mode.

DL-502/503

returns to

Managing Recorded Data

55

Page 57

16. Changing the Settings

• Press to toggle between the pages.

• Asterisks (*) indicate factory settings.

• Settings are kept in memory after power-off.

• "19.2 Adjusting the Reticle" for the check and adjustment

procedure.

Notes:

You can change settings such as the measuring mode and the number

of decimals in displayed data.

When you select "Config." in menu mode, the two-page configuration

menu is displayed.

Page 1

• Meas. (measuring mode)

• Display (fractional/decimal

representation of height units)

• Adjust (checks and adjustment)

• RS-232C (communication

parameters)

Other Procedures

16.1 Measuring Mode

Page 2

• Auto-off (auto power-off)

• Unit (unit of measurement)

You can select any of the following measuring modes.

Page 1

* Single: The instrument automatically terminates fine

measurement after taking one reading.

Average: Displays the average value calculated from the

56

number of times fine measurement is repeated.

(Repeat default setting: 5 times, Repeat setting

range: 2 to 9 times.)

Page 58

Waving: For measurement using Wave-and-Read

Measure

Measure

• When is pressed in Set-out mode, the Measurement

conditions setting screen can be displayed.

Note:

function

Repeat: The instrument repeats fine measurements

until the operator presses or .

Page 2

Tracking:

The instrument repeats coarse measurements

until the operator presses or .

16.2 Fractional/Decimal Representation of Height

Units

You can set the fractional/decimal display format for

displaying height values.

The following options are available when using "m" as the unit:

* 0.0001m: Up to 4 decimals (when measuring mode is

0.001m:

The following options are available when using "ft" as the unit:

* 0.001ft: Up to 3 decimals (when measuring mode is

0.01ft:

Only the following option is available when using

"single", "repeat", "average" or "Waving")/Up to

3 decimals (when measuring mode is

"tracking")

Up to 3 decimals ("single", "repeat", "average" or

"

Waving

")/Up to 2 decimals ("tracking").

"single", "repeat" or "average")/Up to 2

decimals (when measuring mode is "tracking").

Up to 2 decimals ("single", "repeat" or "average")/

Up to 1 decimal ("tracking").

"inch" as

the unit:

Other Procedures

57

Page 59

1/8: **-**-*/

The fractional/decimal display format for distance values depends

on the settings only in measuring mode.

(See "3.2 Display".)

Note:

• Outputting start code and end code (CSV format)

Press to display the setting screen for outputting start and

end codes.

Yes: During data output, outputs start code (STX) and end

code (ETX).

* No: Outputs text data only.

Note:

*

16.3 Communication Parameters

You can select the communication parameters for

connecting a data collector or a computer.

The baud rate and parity settings can be selected from the

following.

• Baud rate: *1200 bps / 2400 bps / 4800 bps /

• Parity: *None / Odd / Even

Other Procedures

9600 bps / 19200 bps / 38400 bps

16.4 Auto Power-Off

You can enable or disable the auto power-off function.

* On(30min): The instrument powers off automatically 30

minutes after the last key operation.

Off: The auto power-off function is disabled.

58

Page 60

16.5 Unit of Measurement

• If measurement data has already been saved in the selected

JOB, the unit of measurement cannot be changed.

• "Inch" here means "fraction of an inch", "fraction of an inch" is the

unit used in the United States and expressed like the following

example.

Note:

You can select the display unit to be used.

*m

ft

inch

Other Procedures

59

Page 61

17. Warnings and Error Messages

The table below shows the warnings and error messages displayed by

the DL-502/503 and describes the cause of each warning or error

message.

Error Message Coded Message Meaning

E400

E401

E402

E405

E406

Other Procedures

• System error due to a fault

in the instrument. Contact

your local dealer.

• Calculation error in Waveand-Read measurement.

60

Page 62

Error Message Coded Message Meaning

E410

E411

E412

E413

E414

E415

E416

E417

E418

E419

E420

E421

E422

E423

E424

E425

E426

E427

E428

E429

• An object other than the

staff is being sighted.

• The staff is out of focus.

• The staff is partly unreadable because obscured

by an obstacle or damaged.

• The staff is too close or

too far away.

• A shadow is falling on

part of the staff.

• The staff was incorrectly

sighted.

• Light is coming into the

eyepiece.

Use your hand or body to

shield eyepiece from light

source.

• The staff is set up in the

inverted position for

Wave-and-Read

measurement.

E430

E433

• Too bright.

• The brightness level suddenly altered during the

measurement.

• Something is shining

nearby or at back of the

staff.

• Light is coming into the

eyepiece.

• Use your hand or body to

shield eyepiece from light

source.

E431

• Something obscured the

staff or the brightness

level suddenly altered during the measurement.

Other Procedures

61

Page 63

Error Message Coded Message Meaning

• Coded messages are not displayed on DL-502/503 display.

• No error message displayed when compensation range (±15') is

exceeded.

Note:

E432 • Too dark.

• The brightness level suddenly altered during the

measurement.

E440 • The instrument is subject

to excessive vibrations or

hot conditions are producing shimmer.

• The staff is stationary, or

the waving angle thereof

is insufficient when performing Wave-and-Read

measurement.

E456

E457

• The staff height being

sighted is either less than

0.5m (too low) or greater

than 4m (too high) when

performing Wave-and-

Other Procedures

E458

E459

Read measurement.

• The distance to the staff

is either less than 5m

(too near) or greater than

50m (too far) when performing Wave-and-Read

measurement.

E498 • Measurement results not

obtained within 20 seconds of starting Waveand-Read measurement.

62

Page 64

18. Charging the Battery

• Do not short circuit. Heat or ignition could result.

• Batteries cannot be charged, even when the charging lamp is

flashing, when the temperature is outside the charging

temperature range.

• Do not leave the battery anywhere exposed to high

temperatures. Battery life may be reduced.

• Charge the battery once a month to maintain its quality when not

in use for long periods.

• Do not charge the battery just after charging is completed.

Battery performance may decline.

• Do not use to charge batteries other than those specified.

• If you allow the battery level to get too low, the battery may not be

rechargeable or operating time may decline. Keep the battery

always charged.

• The charger will get rather hot while in use. This is normal.

Important:

Procedure

1 Connect the power cable to the CDC68 charger and plug the

charger into the wall outlet.

2 Mount the battery (BDC46B) in the charger (CDC68) matching the

groove on the battery with the guides on the charger.

When charging starts, the lamp starts blinking.

Other Procedures

63

Page 65

3 Charging takes approximately 2.5 hours.

• Slots 1 and 2

• Step 2: The charger starts charging the battery mounted

first. If you place two batteries in the charger, the

battery in slot 1 is charged first, and then the

battery in slot 2.

• Charging lamp

• Steps 2 and 3: The charging lamp is off when

•The charger is outside the charging temperature

range.

•The battery is mounted incorrectly.

If the lamp is still off after the charger falls within

its charging temperature range and the battery is

mounted again, contact your local dealer.

Notes:

The lamp lights when charging is finished.

4 Remove the battery and unplug the charger.

Other Procedures

64

Page 66

19. Checks and Adjustments

Procedure

Always check and adjust before use to ensure accurate

measurements.

• Make sure the instrument is securely set up and stable before

performing checks and adjustments.

• Do not perform checks and adjustments with “Waving” selected as

measuring mode.

19.1 Adjusting the Circular Level

Check that the bubble remains centered in the circular level.

Adjust if the bubble shifts position.

1

Adjust the leveling foot screws until

the bubble is centered in the circle.

2 Turn the instrument 180°.

The bubble should not shift from the

center. If the bubble does move,

adjust as follows:

3 Compensate for one-half of the shift

by adjusting the leveling foot screws

Other Procedures

65

Page 67

4 Eliminate the remaining shift by

Adjust with the level

adjusting screw

Adjusting screws

Procedure

turning the circular level adjusting

screws with the hexagonal wrench

until the bubble is centered.

5 Turn the instrument 180°.

If the bubble stays in the center,

adjustment is completed. If the

bubble moves, repeat steps 3 and 4.

19.2 Adjusting the Reticle

The reticle cross-lines can be corrected if out of adjustment.

While reading the staff RAB-code, adjust the reticle by

Other Procedures

• Correcting the reference value of the CCD line sensor

correcting the reference value of the CCD line sensor and

then make mechanical adjustments to the instrument.

As described in the following procedure, high accuracy

readings are obtained by turning the tripod and taking repeat

readings of the staff. For less accurate readings, see Notes

for checking the reticle without turning the tripod.

66

1 In menu mode, select "Config", then

in page 1 of the Config. menu, select

"Adjust".

2 Place staffs a and b approximately

30m apart and set the instrument

halfway between the staffs (position

A).

Page 68

Place staffs to within 50cm (20 inch)

of the distances described in the

procedure.

Otherwise, measurement accuracy

may be adversely affected.

3 Press .

4 Measure staff a.

5 Select "Yes" to accept the value.

6 Measure staff b.

7 Select "Yes" to accept the value.

8 Select "Yes".

9 Turn the tripod 180°.

10 Repeat steps 4 through 6, sighting the

two staffs and taking the readings.

11 Select "Yes" to accept the value.

12 Move the instrument to a position

approximately 3m from staff a along

a straight line joining staffs a and b.

The new position is B.

13 Press .

14 Repeat steps 4 through 11, sighting

the two staffs and taking the readings.

If you turned the tripod at step 8, a

diagram of the tripod positions will be

displayed. Turn the tripod again.

Other Procedures

67

Page 69

Other Procedures

15 Check the difference between the

results and decide whether correcting

the reference value of the sensor is

required.

If the difference is 0.3mm or less, no

adjustment is necessary.

If the difference exceeds the 0.3mm

permissible range, adjustment is

necessary.

68

Page 70

If correcting the reference value is not necessary:

16 Select "No".

17 Select "Yes" to exit from the Adjust

menu.

If correcting the reference value is required:

16 Select "Yes".

The instrument calculates and records

the required reticle adjustment from

the measurement results, and then

returns to the menu selection.

17 Repeat steps 1 through 15. Make

sure that the difference between the

results is within 0.3mm.

• Mechanical adjustment

1 Sight the barcode face of staff b from

position B and measure with the

instrument.

2 Sight the scale face of staff b from

position B and take a visual reading.

3 If the difference between the mea-

surements taken at steps 1 and 2 is

2mm or more, adjust the cross-line

as described below.

If the difference is less than 2mm, the

following steps are not necessary.

Other Procedures

69

Page 71

Other Procedures

4 Remove the adjusting screw cover

and insert a hexagonal wrench (M3)

in the adjusting screw.

5 Turn the adjusting screw, then repeat

steps 1 and 2. Adjust so that the

difference between the two measurements is less than 2mm.

If the measurement at step 2 is larger

than the measurement at step 1, lower

the cross-line by slightly loosening the

adjusting screw.

If the measurement at step 2 is

smaller than the measurement at step

1, raise the cross-line by slightly

tightening the adjusting screw.

6 Replace the adjusting screw cover.

70

Page 72

• Saving measurement values during correcting the reference

value of the sensor and power off

• Steps 9, 12 and 14:

"Data keep" screen asks whether or not you

want to save the measurement values during

setting internal constants.

Select "Yes" to save measurement values

and turn power off. When power is turned on

again and page 1 of the Config. menu is

selected, Screen Status at last power off is

displayed.

Select "No" to cancel measurement values

and turn power off.

• Difference calculations:

• Step 15: If the tripod is turned and repeat measurements taken:

Value at position A = {[(1st reading on staff a) + (1st

reading on staff b)] + [(2nd

reading on staff a) – (2nd reading

on staff b)]} / 2

Value at position B = {[(1st reading on staff a) + (1st

reading on staff b)] + [(2nd

reading on staff a) – (2nd reading

on staff b)]} / 2

Difference = absolute value of [(value at position A) –

(value at position B)]

If the tripod is not turned and only one set of

measurements are taken:

Value at position A = [(reading on staff a) – (reading on

staff b)]

Value at position B = [(reading on staff a) – (reading on

staff b)]

Difference = absolute value of [(value at position A) –

(value at position B)]

Notes:

Other Procedures

71

Page 73

20. Equipment and Accessories

1

2

3

456

7

8

9

10

20.1 Standard Equipment

Before using your DL-502/503, first make sure that all the

follow-ing products were supplied.

Other Procedures

72

• Layout Plan

DL-502/503 ....................................................................1

Battery (BDC46B) ..........................................................1

Charger (CDC68)...........................................................1

Power cable (EDC113A/113B/113C)..............................1

Hexagonal wrench M2.5 (for circular level)....................1

Dust cover......................................................................1

Cleaning cloth ................................................................1

Operator's manual .........................................................1

Carrying case.................................................................1

The optional accessory can also be placed in the carrying case.

Diagonal eyepiece (DE23) .............................................1

(2 batteries can be placed here)

Page 74

20.2 Optional Accessory

• Diagonal eyepiece (DE23)

The diagonal eyepiece is useful for taking measurements in

confined spaces.

First remove the standard DL-502/503 eyepiece by turning it

counter-clockwise. Then, screw the diagonal eyepiece in

place of the standard eyepiece.

Other Procedures

73

Page 75

20.3 Staffs

• Staff types

Name Material Length/Front/Reverse Feature

BIS20 Invar 2.0m (6.6ft)

Front: RAB code

BIS30 Invar 3.038m (9.8ft)

Front: RAB code

BGS40 Glass fiber 4.08m (3 sections)

Front: RAB code

Reverse: graduated

BGS50 Glass fiber 5.09m (4 sections)

Front: RAB code

Other Procedures

BGS50G Glass fiber 5.09m (4 sections)

BAS55 Aluminum 5.0m (5 sections)

BRS55 Aluminum 5.0m (5 sections)

Reverse: graduated

Front: RAB code

Reverse: graduated

Front: RAB code

Reverse: graduated

Front: RAB code

Reverse: graduated

on reflective surface

ISO 12858-1:

1999 compatible

ISO 12858-1:

1999 compatible

For high precision

leveling

With handle

With handle

With handle

Unit: feet

Distances can be

measured with Total

Station by using the

reverse side

(reflective sheet).

(Applies only to

instruments that

can measure in

sheet mode.)

74

Page 76

*:RAB code (RAndom Bi-directional code) is a coded staff used with

TOPCON digital levels.

Other Procedures

75

Page 77

21. Specifications

Except where stated, the following specifications apply to all DLs.

Teles cope

Length 260 mm

Objective aperture: DL-502: Ø45mm

Magnification: DL-502: 32x

Image: Erect

Resolving power: DL-502: 3″

Field of view: 1°20′

Minimum focus: 1.5m (5.0 ft)

Stadia ratio: 1:100

Stadia additive constant: 0

Staffs

Invar staff

Specifications

Glass fiber staff

BGS40: 58mm (W) x 28mm (D) x 4080mm (H)

BIS20: 85mm (W) x 40mm (D) x 2000mm (H)

BIS30: 85mm (W) x 40mm (D) x 3038mm (H)

The coefficient of linear expansion: α=1 x 10

BGS50/50G: 58mm (W) x 28mm (D) x 5090mm (H)

DL-503: Ø36mm

DL-503: 28x

DL-503: 3.5″

{3.4in. (W) x 1.6in. (D) x 6.6ft (H)}

4.3kg (9.5lb.) (one staff) 17.1kg (37.7lb.)

(two staffs and case)

{3.4in. (W) x 1.6in. (D) x 10.0ft (H)}

5.5kg (12.2lb.) (a staff) 23.4kg (51.6lb.)

(two staffs and case)

(3 sections)

{2.3in. (W) x 1.1in. (D) x 13.3ft (H)}

2.4kg (5.3lb.) (one staff) 3.0kg (6.6lb.)

(a staff and case)

(4 sections)

{2.3in. (W) x 1.1in. (D) x 16.7ft (H)}

3.0kg (6.6lb.) (one staff) 3.6kg (8.0lb.)

(one staff and case)

-6

/°C

76

Page 78

The coefficient of linear expansion: α=20 x 10

-6

/°C

Aluminum staff

BAS55: 50mm (W) x 27.8mm (D) x 5005mm (H)

(5 sections)

{2.0in. (W) x 1.1in. (D) x 16.4ft (H)}

1.9kg (4.2lb.) (one staff) 2.2kg (4.9lb.)

(one staff and case)

The coefficient of linear expansion : α=24 x 10

-6

/°C

Measurement

Horizontal circle: Diameter: 103mm

Graduation:1° / 1gon

Measuring range:*1

Height 0 to 4m (13.3 ft) (with BGS40 staff)

0 to 5m (16.7 ft) (with BGS50 staff)

DL-502:

0.0375 to 1.9305m (0.124 to 6.333 ft)

(with BIS20 staff)

0.0375 to 2.9725m (0.124 to 9.752 ft)

(with BIS30 staff)

Distance 1.6 to 100m

Minimum display:

Height 0.0001m / 0.001m (0.001 ft/0.01ft)

(selectable)

(single, repeat, average or Wave-and-

Read mode)

0.001m / 0.01m (0.01ft/0.1ft) (tracking

mode)

Distance 0.01m (0.1ft) (single, repeat or average

mode)

0.1m (1 ft) (tracking or Wave-and-Read

mode)

Accuracy:*1 (with staff BGS40/50 or BIS20/30)

Height Standard deviation for 1 km of double-run

DL-502:

Electronic Measurement

0.6mm (0.03in.) (with BIS20/30)

1.0mm (0.04in.) (with BGS40/50/50G)

1.2mm (0.047in.) (with BAS55)

Visual Measurement

1.0mm (0.04in.) (with BGS40/50/50G)

1.5mm (0.06in.) (with BAS55)

Specifications

77

Page 79

DL-503:

Electronic Measurement

Visual Measurement

Distance ±10mm (less than 10m measurement)

Measuring modes: Single / Repeat / Average / Tracking /

Measuring time:*2

Automatic compensator: Magnetic damping and pendulum

Compensation range: ±15′

Wave-and-Read

Recommended brightness level for measurement

Recommended speed for waving of staff

Measuring range

Waving angle:5 to 10

Specifications

Recommended staff*3: BGS series

*1 When measuring outdoors with minimal atmospheric motion,

*2 When measuring to a staff set up outdoors in fine to cloudy

*1, 2 These specifications may change depending on the weather

Height : 0.5 to 4m

Distance: 5 to 50m

the staff set up in natural sunlight and luminosity at the surface

of the staff equal to 20lx.

conditions.

conditions and measurement conditions.

0.8mm (0.03in.) (with BIS20/30)

1.5mm (0.06in.) (with BGS40/50/50G)

1.7mm (0.047in.) (with BAS55)

2.0mm (0.08in.) (with BGS40/50/50G)

2.5mm (0.06in.) (with BAS55)

±(0.1% x D) (10 to 50m measurement)

±(0.2% x D) (more than 50m measurement)

(D: measured distance, unit: m)

Wave-and-Read

Single

/

Average No. of measurements set

Tracking

mechanism

150 lx or more

0.5Hz (3 passings of the staff through the

vertical position in 3 seconds)

(selectable)

Repeat approx. 2.5 sec.

x approx.

approx.

2.5

1 sec.

sec.

° either side of the vertical position