Page 1

INSTRUCTION MANUAL

DIGITAL LEVEL

DL-501

21122 99024

Page 2

Li-ion

S Li-ion

This is the mark of the Japan Surveying

Instruments Manufacturers Association.

Page 3

DL-501

• Thank you for selecting the DL-501 Advanced/Standard.

• Please read this operator’s manual carefully before using this product.

• Verify that all equipment is included.

"23. STANDARD EQUIPMENT"

• DL-501 has a function to output data to a connected host computer. Command

operations from a host computer can also be performed. For details, refer to

"Communication Manual" and ask your local dealer.

• The specifications and general appearance of the instrument are subject to

change without prior notice and without obligation by TOPCON CORPORATION

and may differ from those appearing in this manual.

• The content of this manual is subject to change without notice.

• Some of the diagrams shown in this manual may be simplified for easier

understanding.

Page 4

HOW TO READ THIS MANUAL

Symbols

The following conventions are used in this manual.

Indicates precautions and important items which should be read before

:

operations.

[Softkey] etc. : Indicates softkeys on the display and window dialog buttons.

{Key} etc. : Indicates keys on the operation panel.

<Screen title> etc.: Indicates screen titles.

Notes regarding manual style

• Except where stated, “DL" means DL-501 Advanced and DL-501 Standard in this manual.

• Screens and illustrations appearing in this manual are of DL-501 Advanced.

• Learn basic operations in "3. PRODUCT OUTLINE" and "4. BASIC OPERATION" before you read

each measurement procedure. For selecting options and inputting figures, see "4.1 Basic Key

Operation".

• Bluetooth® is a registered trademark of Bluetooth SIG, Inc.

• All company and product names featured in this manual are trademarks or registered trademarks of

each respective organization.

: Indicates the chapter title to refer to for additional information.

: Indicates supplementary explanation.

: Indicates an explanation for a particular term or operation.

ii

Page 5

CONTENTS

1. PRECAUTIONS FOR SAFE OPERATION ................. 1

2. PRECAUTIONS .......................................................... 4

3. PRODUCT OUTLINE ................................................. 6

3.1 Parts of the Instrument ...................................................... 6

3.2 Mode Structure .................................................................. 8

3.3 Bluetooth Wireless Technology ......................................... 9

4. BASIC OPERATION ................................................. 11

4.1 Basic Key Operation ....................................................... 11

4.2 Display Functions ............................................................ 15

5. USING THE BATTERY ............................................. 17

5.1 Battery Charging ............................................................. 17

5.2 Installing/Removing the Battery ...................................... 18

6. SETTING UP THE INSTRUMENT ........................... 21

6.1 Setting Up ....................................................................... 21

6.2 Leveling ........................................................................... 21

7. POWER ON/OFF .....................................................24

7.1 Resolving Software Issues .............................................. 25

8. FOCUSING AND SIGHTING THE STAFF ................ 26

8.1 Using the DL-501 Advanced ........................................... 26

8.2 Using the DL-501 Standard ............................................. 28

9. CONNECTING TO EXTERNAL DEVICES ............... 29

9.1 Wireless Communication using Bluetooth Technology ... 29

9.2 Establishing a connection between the DL and paired

Bluetooth device .............................................................. 31

9.3 Outputting data using Bluetooth communication ............. 32

9.4 Communication between the DL and Companion Device .. 32

9.5 Connecting via Communication Cable ............................ 33

10. BASIC OPERATION ................................................. 34

10.1 Reading the Staff ............................................................ 34

10.2 Measuring in Measure Mode ........................................... 36

11. SIMPLE MEASUREMENT .......................................37

11.1 Measuring Height Difference ........................................... 37

11.2 Measuring Elevation ........................................................ 40

11.3 Viewing Simple Measurement Data ................................ 42

11.4 Deleting Simple Measurement Data ............................... 43

12. HEIGHT DIFFERENCE MEASUREMENT ............... 45

iii

Page 6

CONTENTS

12.1 Route Setup .................................................................... 45

12.2 Height Difference Measurement ..................................... 49

12.3 Setting-Out Measurement ............................................... 54

13. OTHER MEASUREMENT FUNCTIONS .................. 57

13.1 Measuring Horizontal Angle ............................................ 57

13.2 Using the Instrument as a Standard Level ...................... 57

14. CALCULATION FUNCTIONS ................................... 58

14.1 Double-run Discrepancy .................................................. 58

14.2 Closure Error ................................................................... 60

14.3 Adjusting for Closure ....................................................... 63

14.4 Reobserved Route Merge ............................................... 69

15. SELECTING/DELETING A JOB ............................... 72

15.1 Selecting a JOB .............................................................. 72

15.2 Deleting a JOB ................................................................ 73

15.3 Backing Up a JOB ........................................................... 74

15.4 Restoring a JOB .............................................................. 75

15.5 Deleting Backed Up Data ................................................ 76

16. ROUTE SETTINGS .................................................. 78

16.1 Deleting a Route ............................................................. 78

16.2 Displaying Route Information .......................................... 79

16.3 Deleting IS Points ............................................................ 80

17. MANAGING KNOWN POINT DATA .........................82

17.1 Using the Key Entry Method ........................................... 82

17.2 Reading in from External Media ...................................... 83

17.3 Viewing Known Point Data .............................................. 85

17.4 Deleting Known Point Data ............................................. 87

18. OUTPUTTING DATA ................................................ 89

18.1 Outputting JOB Data ....................................................... 89

18.2 Outputting Route Data .................................................... 92

19. CHANGING THE SETTINGS ................................... 95

19.1 Observation Conditions ................................................... 95

19.2 Instrument Configuration ................................................. 96

19.3 Communication Setup ..................................................... 96

19.4 Units ................................................................................ 97

19.5 Date and Time ................................................................. 97

19.6 Restoring Default Settings .............................................. 98

20. WARNING AND ERROR MESSAGES ....................99

iv

Page 7

CONTENTS

21. CHECKS AND ADJUSTMENTS ............................105

21.1 Circular Level ................................................................ 105

21.2 Tilt Sensor ..................................................................... 106

21.3 Adjusting the Reticle ..................................................... 109

22. POWER SUPPLY SYSTEM ................................... 113

23. STANDARD EQUIPMENT ...................................... 114

23.1 DL-501 Advanced ......................................................... 114

23.2 DL-501 Standard ........................................................... 116

24. OPTIONAL ACCESSORIES .................................. 117

25. SPECIFICATIONS .................................................. 118

26. REGULATIONS ...................................................... 122

v

Page 8

vi

Page 9

1. PRECAUTIONS FOR SAFE OPERATION

For the safe use of the product and prevention of injury to operators and other persons as well as

prevention of property damage, items which should be observed are indicated by an exclamation point

within a triangle used with WARNING and CAUTION statements in this operator’s manual.

The definitions of the indications are listed below. Be sure you understand them before reading the

manual’s main text.

Definition of Indication

General

WARNING

CAUTION

This symbol indicates items for which caution (hazard warnings inclusive) is urged.

Specific details are printed in or near the symbol.

This symbol indicates items which are prohibited. Specific details are printed in or near

the symbol.

This symbol indicates items which must always be performed. Specific details are printed

in or near the symbol.

Warning

Do not use the unit in areas exposed to high amounts of dust or ash, in areas where there

is inadequate ventilation, or near combustible materials. An explosion could occur.

Do not perform disassembly or rebuilding. Fire, electric shock, or burns could result.

Never look at the sun through the telescope. Loss of eyesight could result.

Do not look at reflected sunlight from a prism or other reflecting object through the

telescope. Loss of eyesight could result.

When securing the instrument in the carrying case make sure that all catches, including

the side catches, are closed. Failure to do so could result in the instrument falling out

while being carried, causing injury.

Ignoring this indication and making an operation error could possibly

result in death or serious injury to the operator.

Ignoring this indication and making an operation error could possibly

result in personal injury or property damage.

Caution

Do not use the carrying case as a footstool. The case is slippery and unstable so a

person could slip and fall off it.

Do not place the instrument in a case with a damaged catch, belt or handle. The case or

instrument could be dropped and cause injury.

1

Page 10

1. PRECAUTIONS FOR SAFE OPERATION

Staff

Caution

Do not use under thunderous weather conditions. The staff is conductive and if struck by

lightning, death or injury could result.

Handle with care when using near high voltage cables or transformers. The staff is

conductive and contact could result in electric shock.

Power Supply

Warning

Do not short circuit. Heat or ignition could result.

Do not disassemble, rebuild, mutilate, incinerate, heat or short circuit the battery and

charger. Fire, electric shock, burns or an explosion could result.

Do not use voltage other than the specified power supply voltage. Fire or electrical shock

could result.

Do not use batteries other than those designated. An explosion could occur, or abnormal

heat generated, leading to fire.

Do not use damaged power cords, plugs or loose outlets. Fire or electric shock could

result.

Do not place articles such as clothing on the battery charger while charging batteries.

Sparks could be induced, leading to fire.

Use only the specified battery charger to recharge batteries. Other chargers may be of

different voltage rating or polarity, causing sparking which could lead to fire or burns.

Do not heat or throw batteries into fire. An explosion could occur, resulting in injury.

Do not use the battery, charger or AC (power) cable for any other equipment or purpose.

Fire or burns caused by ignition could result.

To prevent shorting of the battery in storage, apply insulating tape or equivalent to the

terminals. Otherwise shorting could occur resulting in fire or burns.

Do not use batteries or the battery charger if wet. Resultant shorting could lead to fire or

burns.

Do not connect or disconnect power supply plugs with wet hands. Electric shock could

result.

Caution

Do not touch liquid leaking from batteries. Harmful chemicals could cause burns or

blisters.

2

Page 11

Tripod

Caution

When mounting the instrument to the tripod, tighten the centering screw securely. Failure

to tighten the screw properly could result in the instrument falling off the tripod, causing

injury.

Tighten securely the leg fixing screws of the tripod on which the instrument is mounted.

Failure to tighten the screws could result in the tripod collapsing, causing injury.

Do not carry the tripod with the tripod shoes pointed at other persons. A person could be

injured if struck by the tripod shoes.

Keep hands and feet away from the tripod shoes when fixing the tripod in the ground. A

hand or foot stab wound could result.

Tighten the leg fixing screws securely before carrying the tripod. Failure to tighten the

screws could lead to the tripod legs extending, causing injury.

Remote Trigger (DLC1A)

Caution

Do not leave batteries within reach of small children. If swallowed, consult a physician

immediately.

Bluetooth wireless technology

1. PRECAUTIONS FOR SAFE OPERATION

Warning

Do not use within the vicinity of hospitals. Malfunction of medical equipment could

result.

Use the instrument at a distance of at least 22 cm from anyone with a cardiac

pacemaker. Otherwise, the pacemaker may be adversely affected by the

electromagnetic waves produced and cease to operate as normal.

Do not use onboard aircraft. The aircraft instrumentation may malfunction as a result.

Do not use within the vicinity of automatic doors, fire alarms and other devices with

automatic controls as the electromagnetic waves produced may adversely affect

operation resulting in an accident.

3

Page 12

2. PRECAUTIONS

Precautions concerning water and dust resistance

DL conforms to IP54 specifications for waterproofing and dust resistance when the battery cover,

External interface hatch, and Multi Port cap is closed.

• Make sure that moisture or dust particles do not come in contact with the terminal or connectors.

Operating the instrument with moisture or dust on the terminal or connectors may cause damage to

the instrument.

• Be sure to correctly attach the connector cap to protect the DL from moisture and dust particles

when the connector is not in use.

• Make sure that the inside of the carrying case and the instrument are dry before closing the case.

If moisture is trapped inside the case, it may cause the instrument to rust.

The Lithium Battery

The lithium battery is used to maintain the DL Calendar & Clock function. It can back up data for

approximately 5 years of normal use and storage (Temperature = 20°, humidity = about 50%), but its

lifetime may be shorter depending on circumstances. When the voltage of the lithium battery has

decreased, or the battery itself is depleted the date/time may not be displayed correctly and an error

message "The battery for the clock function needs to be replaced." will be displayed.

For details on replacing lithium batteries contact your local dealer.

Backing up data

Data should be backed up (transferred to an external device etc.) on a regular basis to prevent data

loss.

Other precautions

• Never place the instrument directly on the ground. Sand or dust may cause damage to the screw

holes or the centering screw on the base plate.

• Protect the instrument from heavy shocks or vibration.

• Protect the instrument from rain or drizzle with an umbrella or waterproof cover.

• When the operator leaves the instrument attached to the tripod, the vinyl cover should be placed on

the instrument.

• Never carry the instrument on the tripod to another site.

• Turn the power off before removing the battery.

• Remove the battery before placing the DL in its case.

• Make sure that the instrument and the protective lining of the carrying case are dry before closing

the case. The case is hermetically sealed and if moisture is trapped inside, the instrument could

rust.

• Consult your local dealer before using the instrument under special conditions such as long periods

of continuous use or high levels of humidity. In general, special conditions are treated as being

outside the scope of the product warranty.

Maintenance

• Wipe off moisture completely if the instrument gets wet during survey work.

• Always clean the instrument before returning it to the case. The lens requires special care. First,

dust it off with the lens brush to remove tiny particles. Then, after providing a little condensation by

breathing on the lens, wipe it with the wiping cloth.

4

Page 13

2. PRECAUTIONS

• If the display is dirty, carefully wipe it with a soft, dry cloth. To clean other parts of the instrument or

the carrying case, lightly moisten a soft cloth in a mild detergent solution. Wring out excess water

until the cloth is slightly damp, then carefully wipe the surface of the unit. Do not use any alkaline

cleaning solutions, alcohol, or any other organic solvents on the instrument or display.

• Store the instrument in a dry room where the temperature remains fairly constant.

• Check the tripod for loose fit and loose screws.

• If any trouble is found on the rotatable portion, screws or optical parts (e.g. lens), contact your local

dealer.

• When the instrument is not used for a long time, check it at least once every 3 months.

"21. CHECKS AND ADJUSTMENTS"

• When removing the instrument from the carrying case, never pull it out by force. The empty carrying

case should be closed to protect it from moisture.

• Check the instrument for proper adjustment periodically to maintain the instrument accuracy.

Exceptions from responsibility

• The user of this product is expected to follow all operating instructions and make periodic checks

(hardware only) of the product’s performance.

• The manufacturer, or its representatives, assumes no responsibility for results of faulty or intentional

usage or misuse including any direct, indirect, consequential damage, or loss of profits.

• The manufacturer, or its representatives, assumes no responsibility for consequential damage, or

loss of profits due to any natural disaster, (earthquake, storms, floods etc.), fire, accident, or an act

of a third party and/or usage under unusual conditions.

• The manufacturer, or its representatives, assumes no responsibility for any damage (change of

data, loss of data, loss of profits, an interruption of business etc.) caused by use of the product or

an unusable product.

• The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of

profits caused by usage different to that explained in the operator’s manual.

• The manufacturer, or its representatives, assumes no responsibility for damage caused by incorrect

operation, or action resulting from connecting to other products.

5

Page 14

3. PRODUCT OUTLINE

13

12

11

10

9

8

5

4

2

1

6

7

3

22

20

19

17

15

14

18

16

21

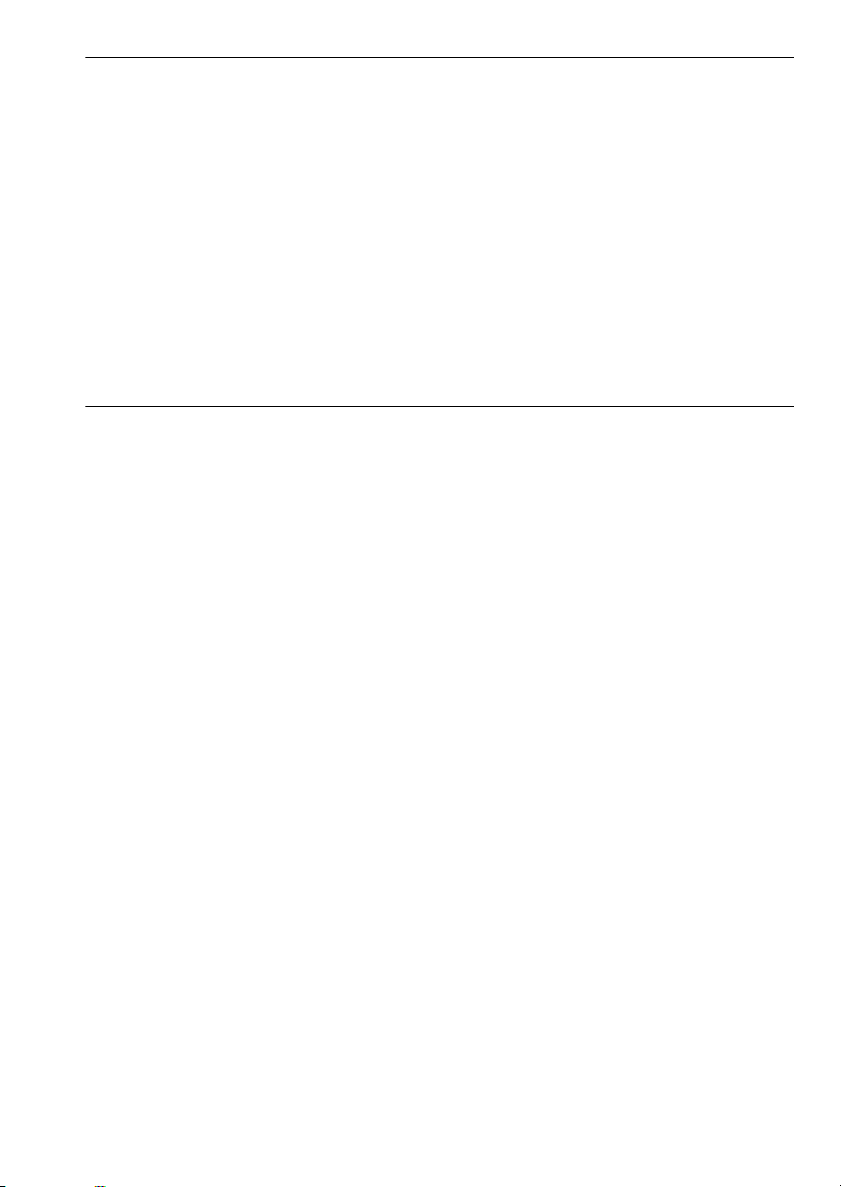

3.1 Parts of the Instrument

Parts of the instrument (DL-501 Advanced)

1Handle

2Focusing knob

3Keyboard

4Measure key

5Leveling foot screw

6Base plate

7Horizontal circle positioning ring

8Horizontal circle

9 Waterproof Multi Port

10Beam detector for Remote trigger

11Eyepiece screw

12 Display

13 View finder

14 View finder eyepiece screw

15 Circular level

16 Bubble mirror

17 Horizontal fine motion knobs (both

sides)

18External interface hatch

SD card slot

" SD card slot"

USB port

19 Battery cover

20Objective lens

21Bluetooth antenna (option)

22 View finder axis alignment screw

6

Page 15

3. PRODUCT OUTLINE

1

Parts of the instrument (DL-501 Standard)

1Simple finder

• All other parts are identical to DL-501 Advanced.

Functions of the instrument

SD card slot

The DL supports SD/SDHC cards (hereafter referred to collectively as "SD card" unless

otherwise stated) for data write only. The SD card slot is located in the external interface hatch.

Inserting an SD card

An SD card should be inserted with the contacts facing downwards.

Removing an SD card

Push an inserted SD card further into the slot and release to eject.

7

Page 16

3. PRODUCT OUTLINE

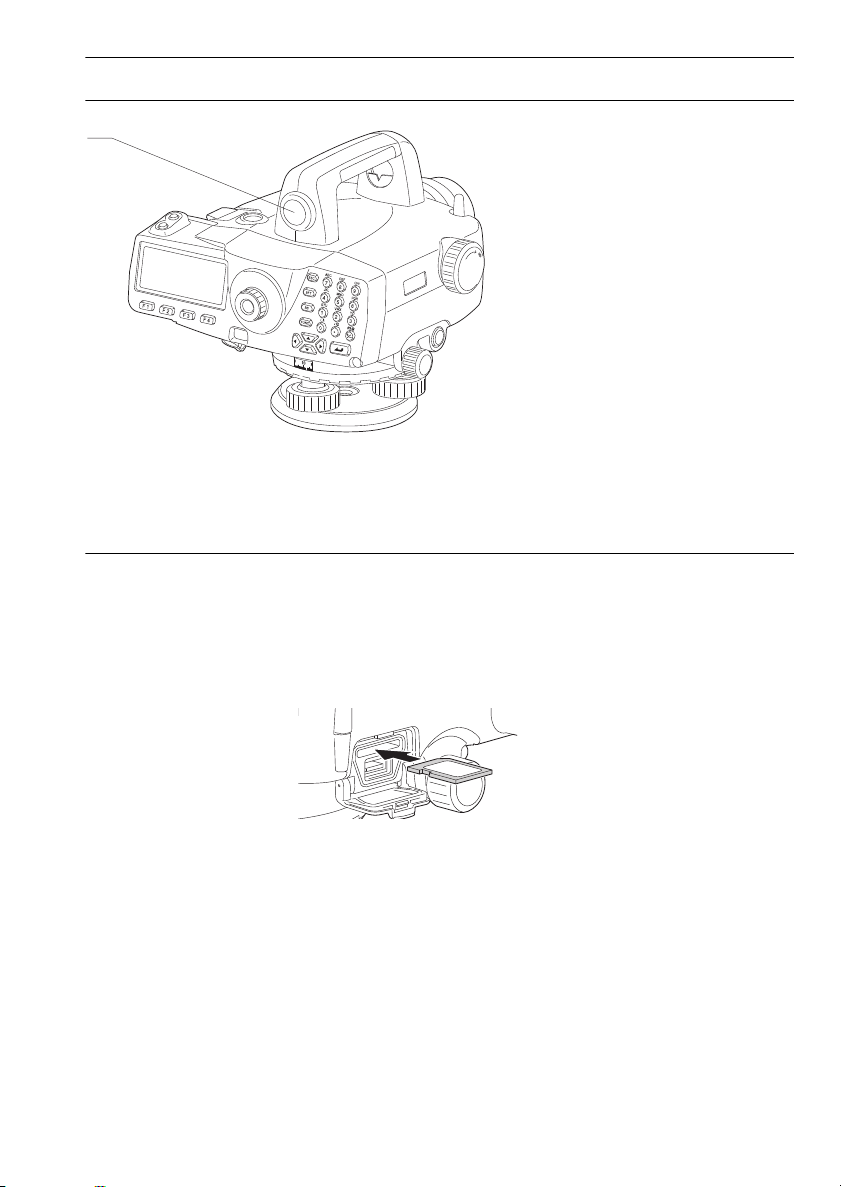

3.2 Mode Structure

The diagram below describes the different modes of the DL and key operations for navigating between

them.

Job: JOB1

Route: ec.remainder

DL-501 Adv

Meas.pt: 9995

S/N 999999

Start info: 997 ( 99)

Appli :Ver.XXXX-XX-XX

Fixed pt: 1997( 98)

Sensor:Ver.XXXX-XX-XX

Feb/03/2012 14:23:34

Status Screen Tilt Screen

{ESC}

{ESC}

[OK]

[TILT]

OK

Rh

Hd S

TILT MENU FOCUS

Meas mode

[MENU]

{ESC}

Menu

1.Meas

2.Management

3.Config

4.Calculation

1.Meas

2.Management

{ESC}

3.Config

4.Calculation

Meas menu

1.Height dif.

2.Check & adjust.

3.Simple measurement

Management menu

1.JOB

2.Route

3.Known point data

4.Simple meas. data

Config menu

Config menu

1.Obs.condition

2.Instr.config

3.Comms setup

4.Tilt offset

5.Unit

Calculation menu

1.Dble-run discrePancy

2.Closure error

3.Reobs.route merge

.

8

Page 17

3. PRODUCT OUTLINE

3.3

• Bluetooth communication is only possible with instruments incorporating the Bluetooth module.

• Use of this technology must be authorized according to telecommunications regulations of the

country where the instrument is being used. Contact your local dealer in advance.

Bluetooth

Wireless Technology

"26. REGULATIONS"

• TOPCON CORPORATION is not liable for the content of any transmission nor any content related

thereto. When communicating important data, run tests beforehand to ascertain that communication

is operating normally.

• Do not divulge the content of any transmission to any third party.

Radio interference when using Bluetooth technology

Bluetooth communication with the DL uses the 2.4 GHz frequency band. This is the same band used

by the devices described below.

•Industrial, scientific, and medical (ISM) equipment such as microwaves and pacemakers.

• portable premises radio equipment (license required) used in factory production lines etc.

• portable specified low-power radio equipment (license-exempt)

•IEEE802.11b/IEEE802.11g standard wireless LAN devices

The above devices use the same frequency band as Bluetooth communications. As a result, using the

DL within proximity to the above devices may result in interference causing communication failure or

reduction of transmission speed.

Although a radio station license is not required for this instrument, bear in mind the following points

when using Bluetooth technology for communication.

Regarding portable premises radio equipment and portable specified low-power radio

equipment:

• Before starting transmission, check that operation will not take place within the vicinity of portable

premises radio equipment or specified low-power radio equipment.

• In the case that the instrument causes radio interference with portable premises radio equipment,

terminate the connection immediately and take measures to prevent further interference (e.g.

connect using an interface cable).

• In the case that the instrument causes radio interference with portable specified low-power radio

equipment, contact your local dealer.

When using the DL in proximity to IEEE802.11b or IEEE802.11g standard wireless LAN

devices, turn off all devices not being used.

• Interference may result, causing transmission speed to slow or even disrupting the connection

completely. Turn off all devices not being used.

Do not use the DL in proximity to microwaves.

• Microwave ovens can cause significant interference resulting in communication failure. Perform

communication at a distance of 3m or more from microwave ovens.

Refrain from using the DL in proximity to televisions and radios.

• Televisions and radios use a different frequency band to Bluetooth communications.

9

Page 18

3. PRODUCT OUTLINE

However, even if the DL is used within proximity to the above equipment with no adverse effects

with regard to Bluetooth communication, moving a Bluetooth compatible device (including the DL)

closer to said equipment may result in electronic noise in sound or images, adversely affecting the

performance of televisions and radios.

Precautions regarding transmission

For best results

• The usable range becomes shorter when obstacles block the line of sight, or devices such as PDAs

or computers are used. Wood, glass and plastic will not impede

range becomes shorter. Moreover, wood, glass and plastic containing metal frames, plates, foil and

other heat shielding elements as well as coatings containing metallic powders may adversely affect

Bluetooth

• Use a vinyl or plastic cover to protect the instrument from rain and moisture. Metallic materials

should not be used.

• The direction of the Bluetooth antenna can have adverse effects upon usable range.

Reduced range due to atmospheric conditions

The radio waves used by the DL may be absorbed or scattered by rain, fog, and moisture from the

human body with the limit of usable range becoming lower as a result. Similarly, usable range may

also shorten when performing communication in wooded areas. Moreover, as wireless devices lose

signal strength when close to the ground, perform communication at as high a position as possible.

communication and concrete, reinforced concrete, and metal will render it impossible.

communication but the usable

10

Page 19

4. BASIC OPERATION

OFF

{0} to {9}

{ }

{ } { } { }

{ }

{ }

{ }

{.} to {+/-}

Display

{FUNC}

{BS}

{SFT}

{ESC}

Softkey selection

Measure key

Learn basic key operations here before you read each measurement procedure.

4.1 Basic Key Operation

Power ON/OFF

{} (Press and hold)

{} while pressing {}

Switching screen/key backlight ON/OFF

{} Switches the screen backlight/key backlight ON/OFF

Power ON

Power OFF

Measurement (Auto Focus)

Automatically focuses on the staff and starts measurement. (DL-

Measure key

501 Advanced)

Starts measurement (DL-501 Standard)

Softkey operation

Softkeys are displayed on the bottom line of the screen.

{F1} to {F4} Select the function matching the softkeys

{FUNC} Toggle between softkey pages

Inputting letters/figures

{SFT} Switch between numeric and alphabetic (upper/lower case)

characters.

{0} to {9} Input numeral or symbol printed above the key (during numeric

input mode)

Input alphabetic character in the order they are listed (in

alphabetic input mode)

{.} Input a decimal point (during numeric input mode)

{+/-} Input a plus or minus sign (during numeric input mode)

{}/{} Right and left cursor/Select other option.

{ESC} Cancel the input data.

11

Page 20

4. BASIC OPERATION

OK

Route id

: ROUTE M

Memo

:

:

A

{BS} Delete a character on the left.

{} Select/accept input word/value.

Selecting options

{

}/{} Move the cursor/selection item up/down

{}/{} Move the cursor/selection item left/right or select other option

{} Select/accept the option

Other operation

{ESC} Return to previous screen

Example :Entering "Route M" in the Route ID field

1. Press {6} three times.

"R" is displayed.

2. Press {5} three times.

"O" is displayed.

3. Press {1} three times.

"U" is displayed.

4. Press {} once.

5. Press {1} twice.

"T" is displayed.

6. Press {8} twice.

"E" is displayed.

7. Press {} twice.

Input a blank space.

8. Press {5} once.

"M" is displayed. Press { } to complete

inputting.

.

12

Page 21

4. BASIC OPERATION

{MEAS}

{ENT}

{ESC}

Beam source

Key panel

Remote operation

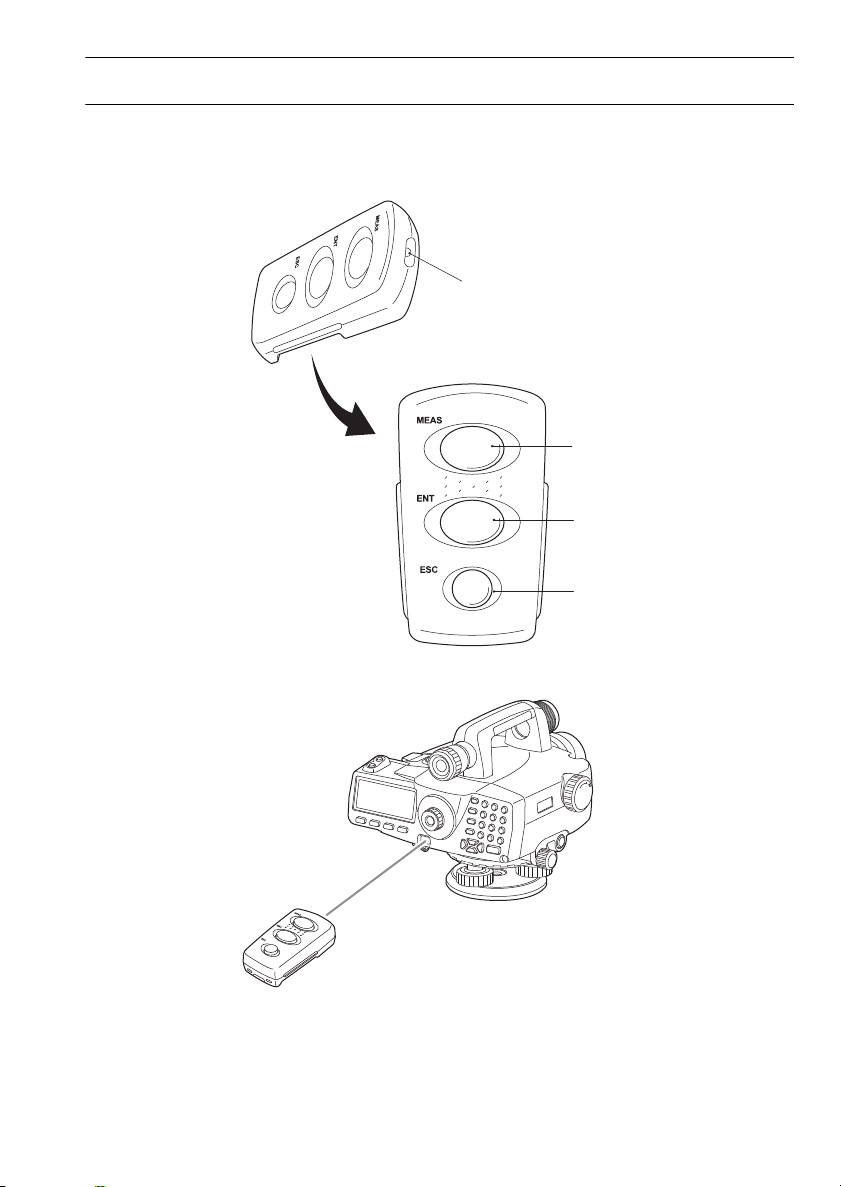

Key operation for Remote trigger (DLC1A)

DLC1A comes as standard with the DL-501 Advanced and is an optional accessory for the DL-501

Standard.

"4.1 Basic Key Operation"

The DL is operated from the Remote trigger by pointing the Remote trigger beam at the DL and

pressing the required operation keys.

• When sunlight shines directly into the Beam detector on the DL, remote operation with the Remote

trigger may not work correctly.

13

Page 22

4. BASIC OPERATION

• If other DLC1A-compatible instruments are turned ON and placed within the operating range of the

Remote trigger, they may be unintentionally operated at the same time.

• Do not place the Remote trigger under heavy objects or in a tight space. A key may be continuously

depressed and deplete battery power.

• Working duration shortens under low temperatures.

{MEAS} Performs same operation as Measure key on the

DL

{ENT} Same operation as {} on DL

{ESC} Same operation as {ESC} on DL

14

Page 23

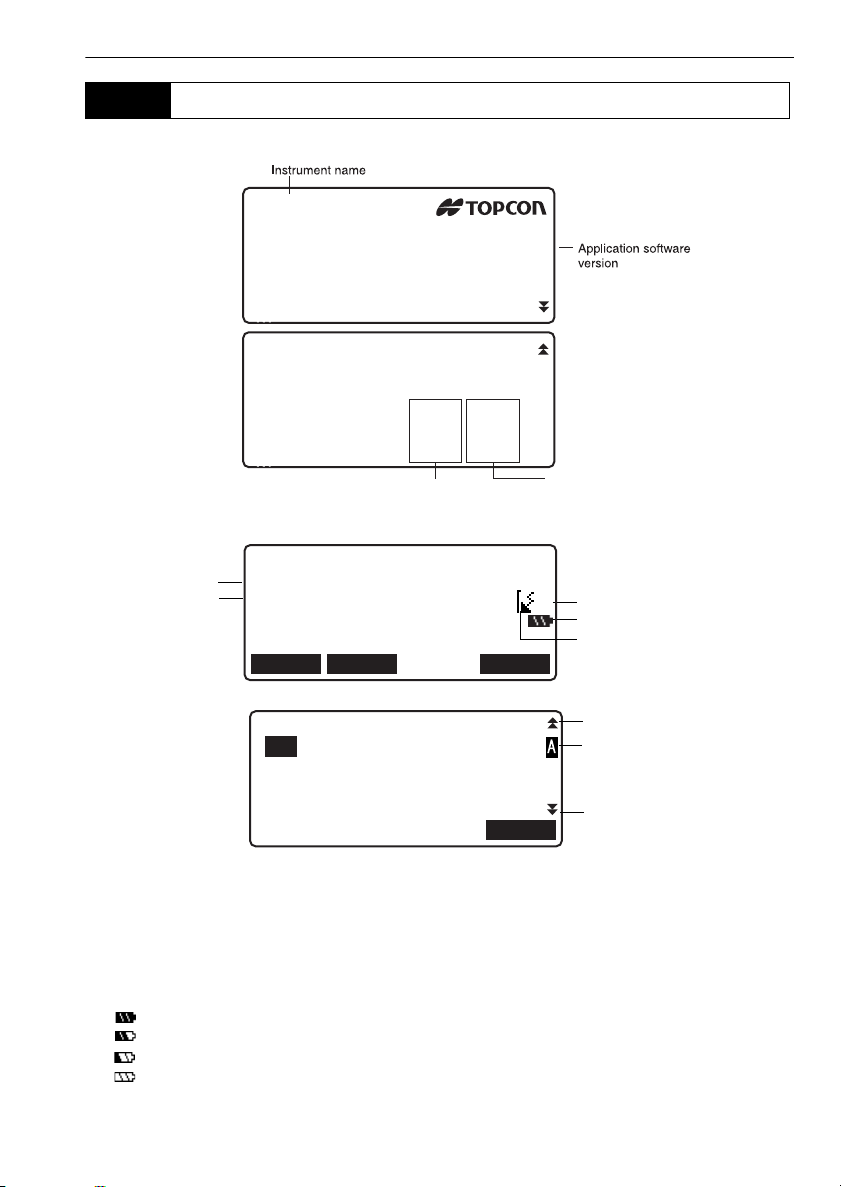

4.2 Display Functions

DL-501 Adv

S/N 999999

Appli :Ver.XXXX-XX-XX

Sensor:Ver.XXXX-XX-XX

Feb/03/2012 14:23:34

Job: XXXX

Route:XXXX

Rec.remainder

Meas.pt: XXXX(XXX)

Start info: XXXX(XXX)

Fixed pt: XXXX(XXX)

Available memory

(current route)

Available memory

(total)

*1

*2

*3

*4

Rh

Hd S

TILT MENU FOCUS

*5

End bench mark id

:B2

End bench mark elev.

: 165.00000m

OK

Previous page

Next page

*6

Status screen

Meas Mode screen

4. BASIC OPERATION

Input screen

*1 Rh: Staff reading (height)

*2 Hd: Horizontal distance to staff

*3 Measurement mode

S: Single

R: Repeat

A: Average

T: Rapid

* 4 Remaining battery power (BDC58/70, Temperature=25°C)

: level 3 Full power.

: level 2 Plenty of power remains.

: level 1 Half or less power remains.

: level 0 Little power remains. Prepare replacement battery where available.

15

Page 24

4. BASIC OPERATION

"Battery low! Please charge battery." (with audio tone) displayed alternately with current screen

: No power remains.

Stop measurement and save data. Then turn the instrument off and charge the battery.

"5.1 Battery Charging"

*5 Bluetooth communication status

: Connection established

(flashing): Waiting

(flashing): Disconnecting

:DL Bluetooth device is OFF

*6 Input mode

A :Inputting capital letters

a :Inputting small letters

1 :Inputting numeric characters

16

Page 25

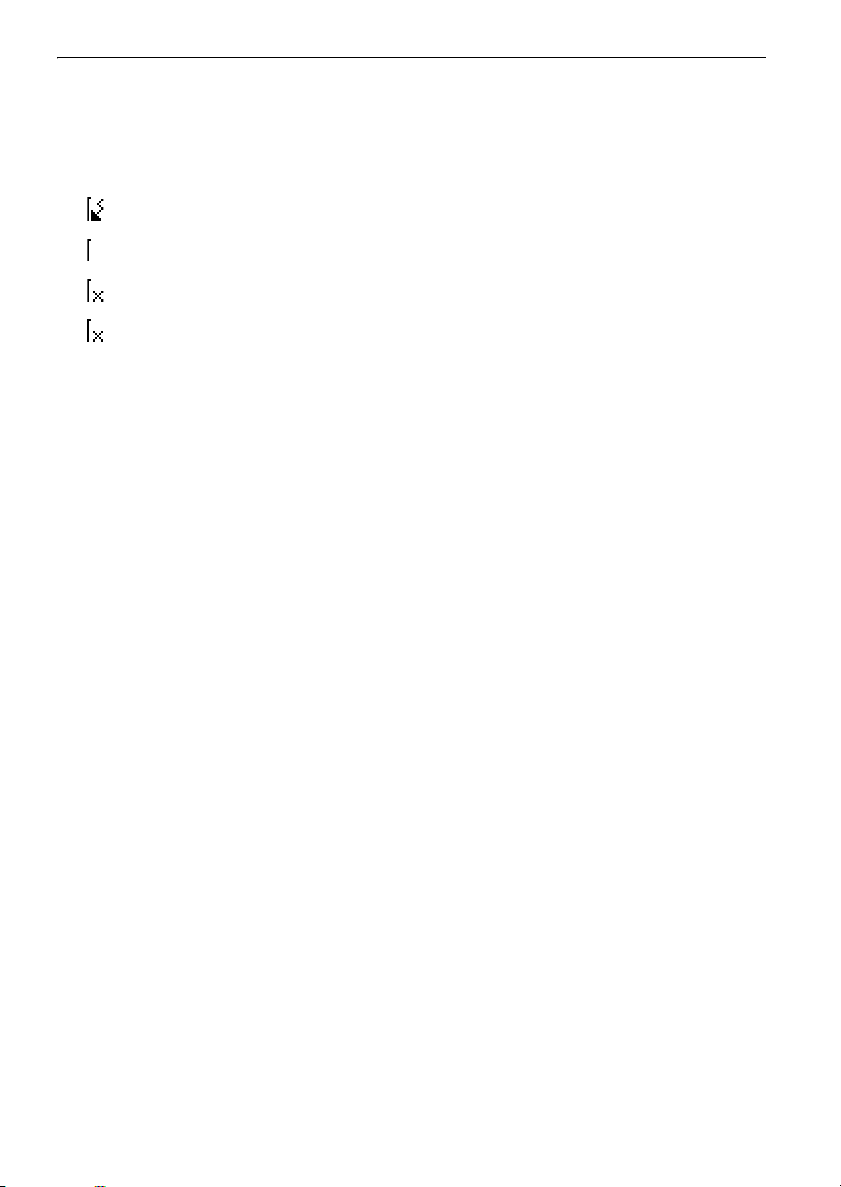

5. USING THE BATTERY

Guides

Slot 1

Slot 2

Charging

lamp

Grooves

Types of power source: "22. POWER SUPPLY SYSTEM"

5.1 Battery Charging

The battery was not charged at the factory. Charge the battery fully before using the DL.

• The charger will become rather hot during use. This is normal.

• Do not use to charge batteries other than those specified.

• The charger is for indoor use only. Do not use outdoors.

• Batteries cannot be charged, even when the charging lamp is flashing, when the temperature is

outside the charging temperature range.

• Remove batteries from the charger before putting into storage.

• When not in use, disconnect the power cable plug from the wall outlet.

PROCEDURE

1. Connect the power cable (EDC113A/113B/

113C) to the charger (CDC68/68A) and plug

the charger into the wall outlet.

2. Mount the battery in the charger by matching

the grooves on the battery with the guides on

the charger.

3. When charging starts, the lamp starts blinking.

4. The lamp lights when charging is finished.

5. Remove the battery and unplug the charger.

17

Page 26

5. USING THE BATTERY

• Slots 1 and 2:

The charger starts charging the battery mounted first. If you place two batteries in the charger, the

battery in slot 1 is charged first, and then the battery in slot 2. ( step 2)

• Charging lamp:

The charging lamp is off when the charger is outside the charging temperature range or when the

battery is mounted incorrectly. If the lamp is still off after the charger falls within its charging

temperature range and the battery is mounted again, contact your local dealer. (steps 2 and 3)

• Charging time per battery (at 25°C):

BDC58: about 4 hours

BDC70: about 5.5 hours

(Charging can take longer than the times stated above when temperatures are either especially

high or low.)

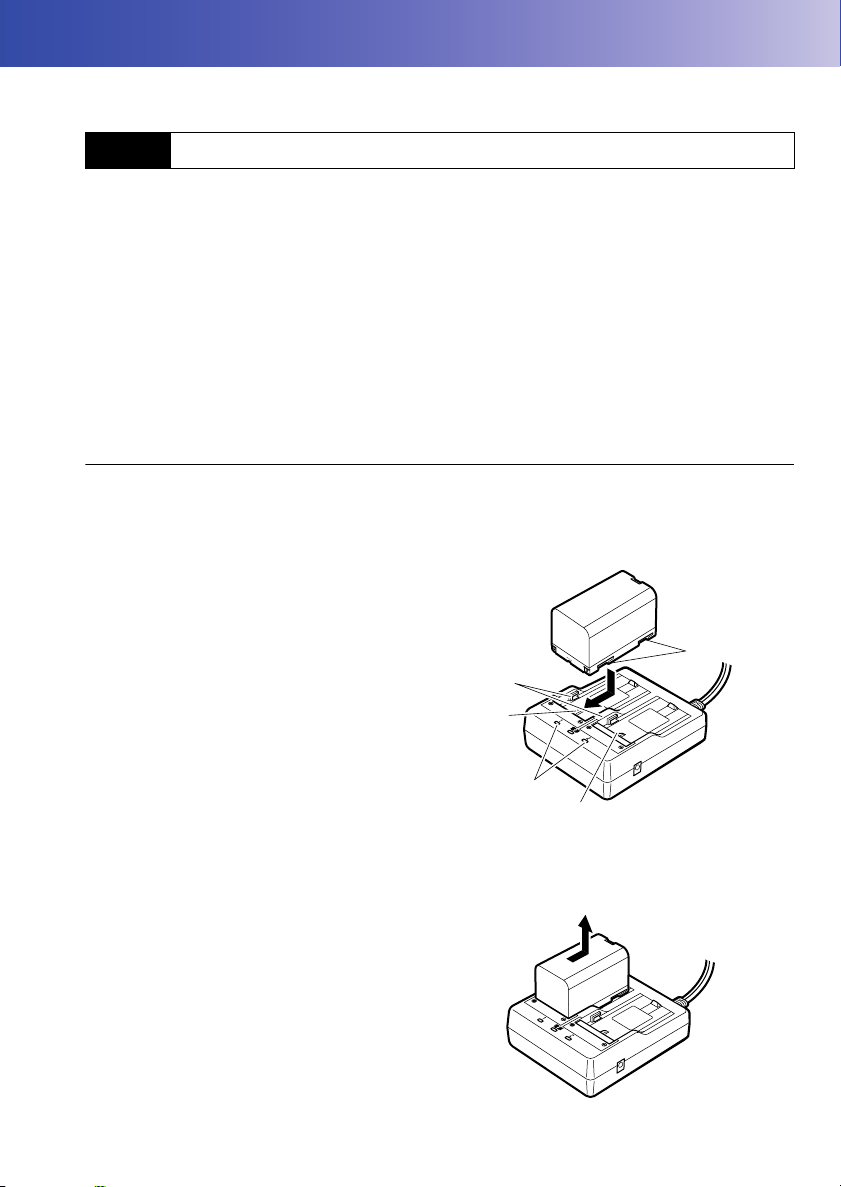

5.2 Installing/Removing the Battery

Mount the charged battery.

BDC46C and battery adapter SB178 are optional accessories.

• Before removing the battery, turn off the power to the instrument.Settings, and file and folder data

may be lost if the battery is removed while the power is switched on.

• When installing/removing the battery, make sure that moisture or dust particles do not come in

contact with the inside of the instrument.

• Remove batteries from the instrument or charger before putting into storage.

• Store the battery in a dry room where the temperature is within the following ranges

Storage period Temperature range

1 week or less -20 to 50°C

1 week to 1 month -20 to 45°C

1 month to 6 months -20 to 40°C

6 months to 1 year -20 to 35°C

For long-term storage, the battery should be charged at least once every six months.

• The BDC58/70 generates power using a chemical reaction and as a result has a limited lifetime.

Even when in storage and not used for long periods, battery capacity deteriorates with the passage

of time. This may result in the operating time of the battery shortening despite having been charged

correctly. In this event, a new battery is required.

18

Page 27

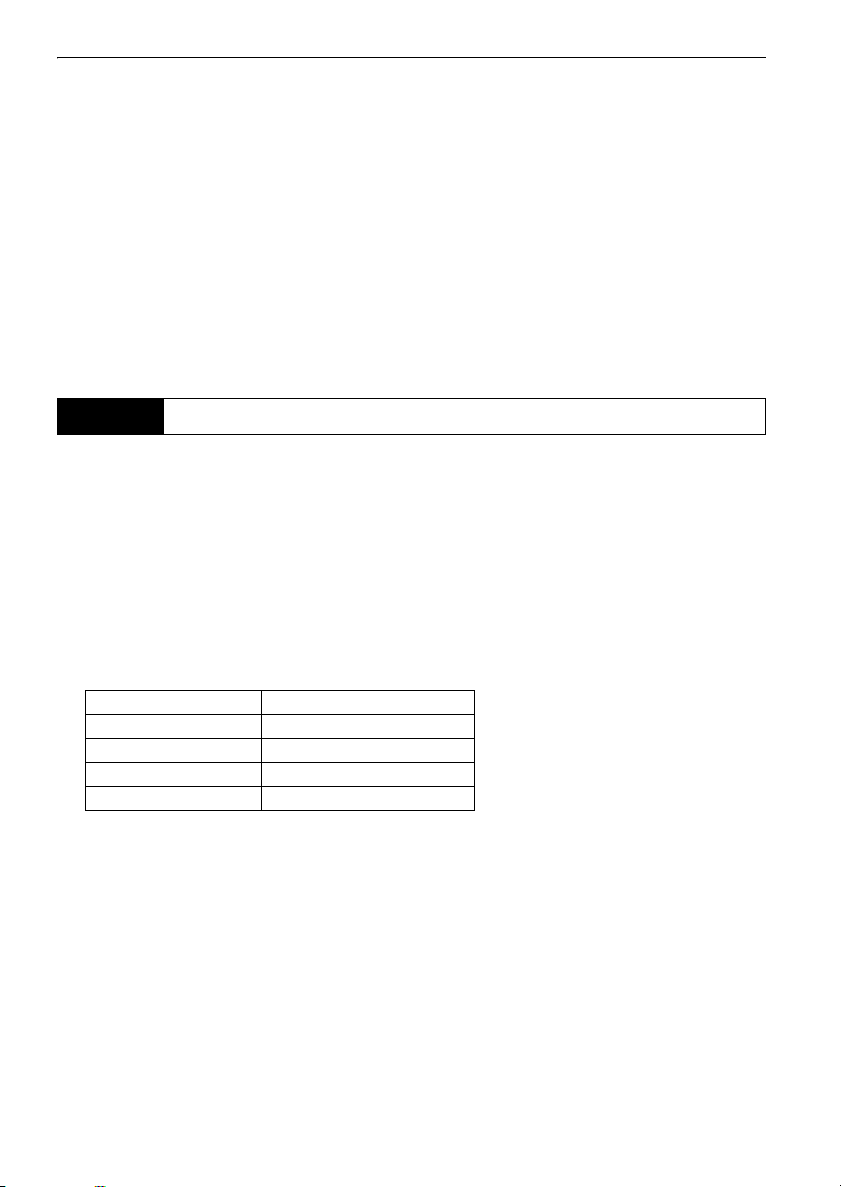

PROCEDURE Mounting the battery

Battery cover

Catch

Battery

Release

lever

1. Push the catch on the battery cover away from

the objective lens.

2. Insert the battery in the direction of the arrow

on the side of the battery.

3. Close the battery cover. A click is heard when

the cover is secure.

PROCEDURE Removing the battery

1. Push the catch on the battery cover away from

the objective lens.

5. USING THE BATTERY

2. Push the release lever down. Grip the battery

and slide out.

• If the release lever is not pushed down

completely when removing the BDC46C, the

battery adapter may jam against the release

lever. In this event, push the lever down fully

and remove, or re-insert the battery into the

instrument and try removing again.

3. Close the battery cover. A click is heard when

the cover is secure.

19

Page 28

5. USING THE BATTERY

Battery notch

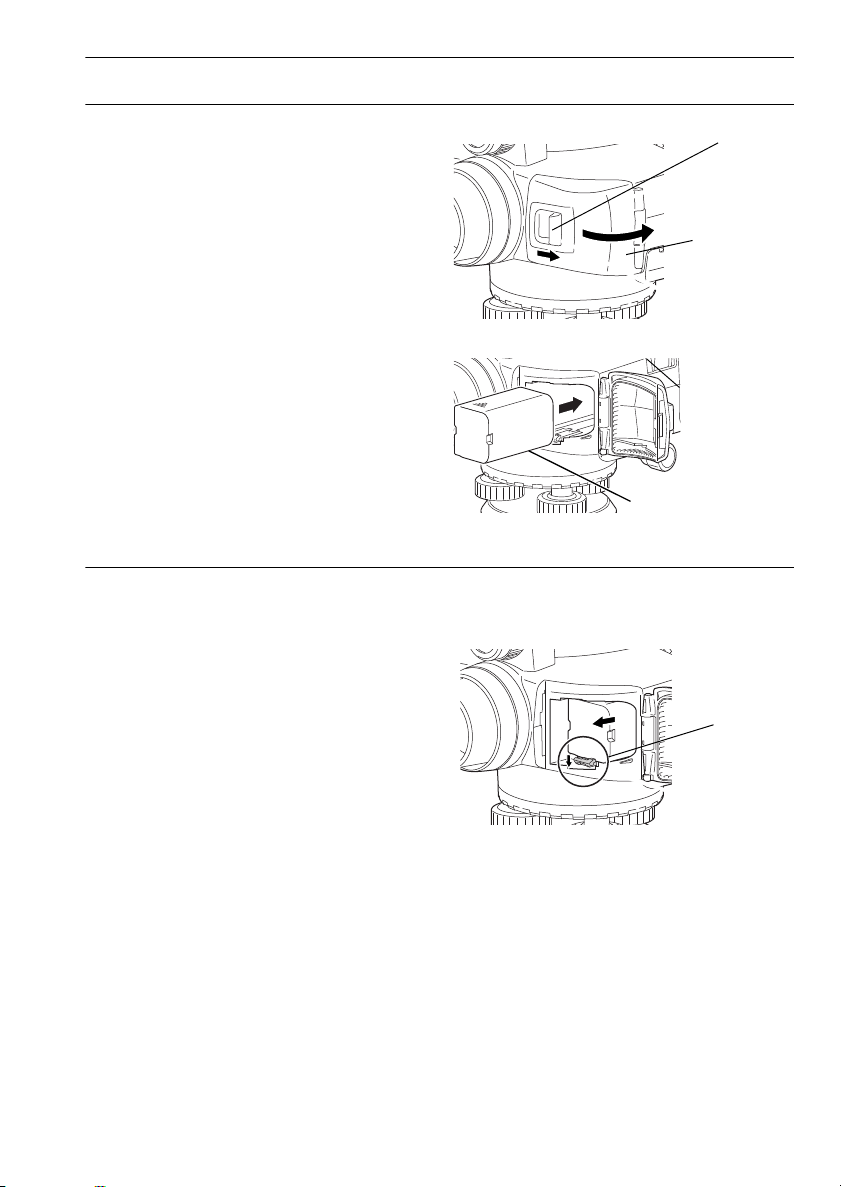

PROCEDURE Using the Battery adapter

Insert the BDC46C into the battery adapter (SB178). The battery can now be mounted in the same

way as the BDC58/70.

1. Align the notch in the BDC46C with the SB178

as shown at right. With the terminals-end of

the battery inserted, push until the battery

adapter is fully extended.

2. Slot the top end of the battery into the battery

adapter. The extendable portion of the battery

adapter will automatically retract and hold the

battery in place.

• To remove, grip both sides of the battery towards

the terminals-end and pull out.

• It is possible to charge the BDC46C without

removing from the battery adapter.

20

Page 29

6. SETTING UP THE INSTRUMENT

Bubble

mirror

• Mount the battery in the instrument before performing this operation because the instrument will tilt

slightly if the battery is mounted after leveling.

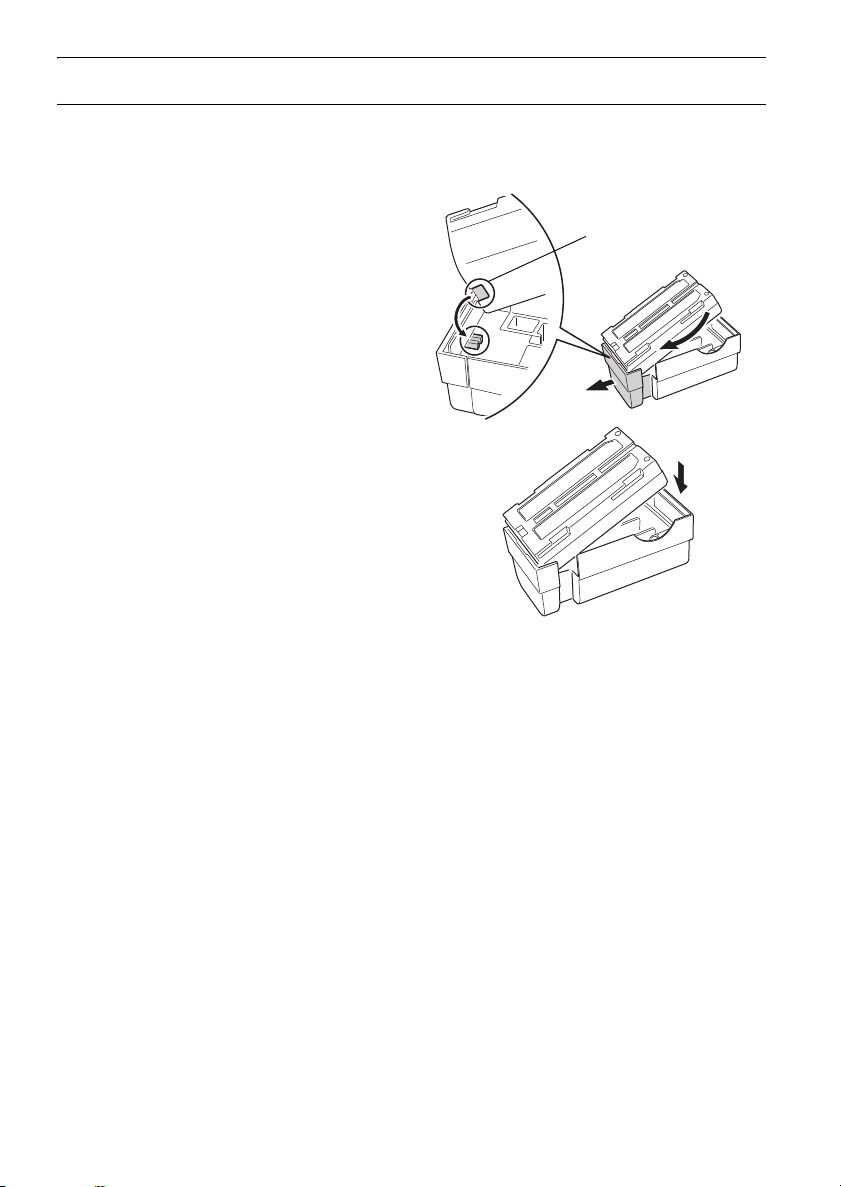

6.1 Setting Up

PROCEDURE

1. Make sure the legs are spaced at equal

intervals and the head is approximately level.

Set the tripod so that the head is positioned over

the survey point.

Make sure the tripod shoes are firmly fixed in the

ground.

2. Place the instrument on the tripod head.

Supporting with one hand, tighten the centering

screw on the bottom of the unit to make sure it is

secured to the tripod.

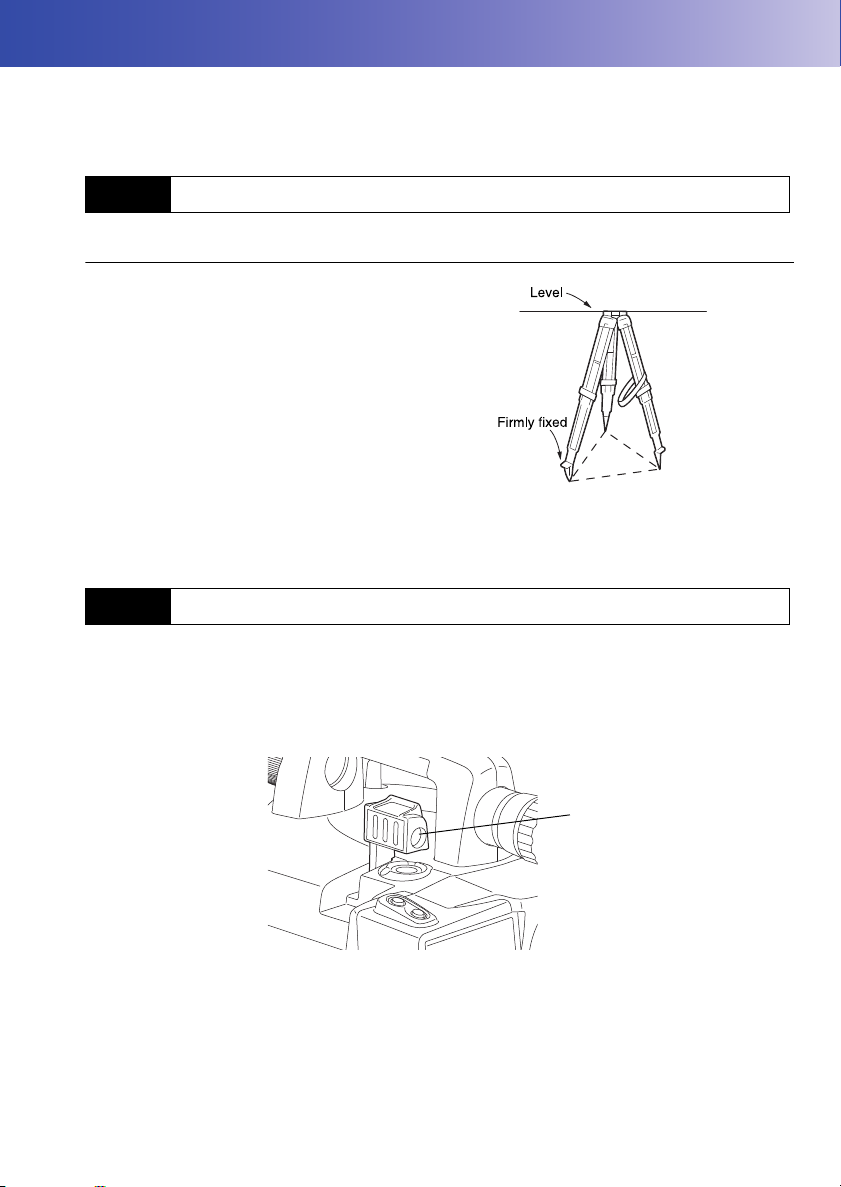

6.2 Leveling

Instrument can also be levelled using the screen.

“ Leveling on the screen”

The mirror can be used to check the position of the bubble in the tube when it cannot be viewed from

above.

21

Page 30

6. SETTING UP THE INSTRUMENT

Spherical head

tripod

Centering

screw

Tripod legs

adjustment

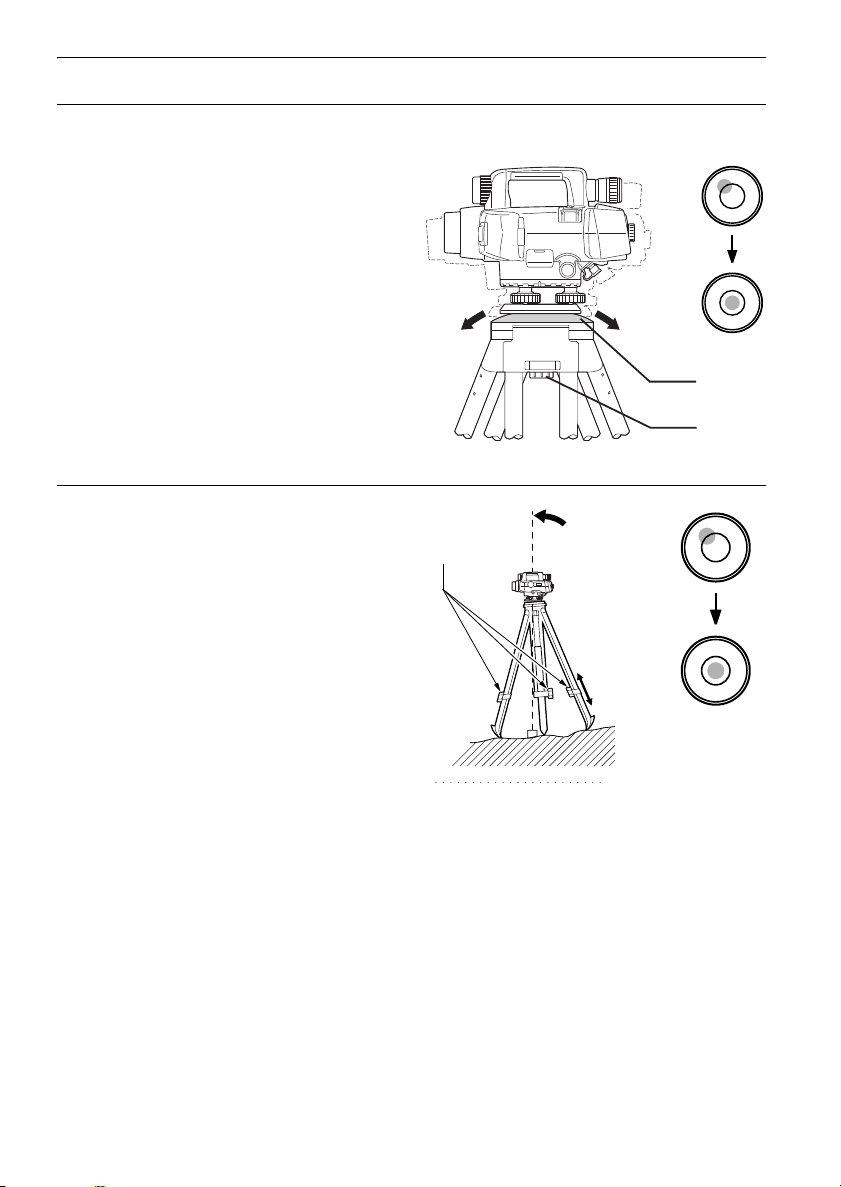

PROCEDURE Leveling with the Spherical head tripod

1. Loosen the centering screw.

2. Slide the instrument across the tripod head until

the bubble is centered in the circular level.

3. Tighten the centering screw.

4. Level the DL using the leveling foot screws.

PROCEDURE Leveling with the Flat head tripod

1. Center the bubble in the circular level by either

shortening the tripod leg closest to the offcenter

direction of the bubble or by lengthening the

tripod leg farthest from the offcenter direction of

the bubble.

2. Adjust one more tripod leg until the bubble is

roughly centered.

3. Turn the leveling foot screws while checking the

circular level until the bubble is exactly centered

in the center circle. When you turn a screw

clockwise, raising the instrument, the bubble will

move towards the position of that screw.

22

Page 31

6. SETTING UP THE INSTRUMENT

OFF

MENU

PROCEDURE Leveling on the screen

1. Turn the instrument on.

"7. POWER ON/OFF"

2. The screen shown at right is displayed.

3. Center “” in the circular level.

"6.2 Leveling PROCEDURE Leveling

with the Spherical head tripod/"6.2 Leveling

PROCEDURE Leveling with the Flat head

tripod"

“” indicates the bubble in circular level. The

range of the inside circle is 12' and the range of

the outside circle is 24’.

•Press [OFF]/[BEEP] to turn the audio tone

OFF/ON.

• Measurement cannot be performed when the Tilt screen is displayed.

• The tilt screen is automatically displayed on startup when "Tilt warn" in "Obs.condition" is set to

"Yes" and the instrument tilt exceeds the allowable range. Set to "No" to skip levelling on startup.

"Tilt warn." setting: "19.2 Instrument Configuration"

•Pressing [MENU] in the screen shown above returns the screen to <Menu> without completing

leveling. However, measurement cannot be performed until the instrument is levelled.

23

Page 32

7. POWER ON/OFF

Rh

Hd S

TILT MENU FOCUS

PROCEDURE Power ON

1. Press {}.

When the power is switched on, a RAM check

is run. The Meas mode screen is displayed.

If the tilt screen is displayed, the instrument tilt

sensor is indicating that the instrument is out of

level. Level the instrument once again and the

Meas mode screen will be displayed.

• The tilt screen is automatically displayed on startup when "Tilt warn" in "Obs.condition" is set to "Yes"

and the instrument tilt exceeds the allowable range. Set to "No" to skip levelling on startup.

• Do not remove the battery while the TOPCON logo is displayed.

• "Tilt warn." in "Obs. condition" should be set to "No" if the display is unsteady due to vibration or

strong wind.

"19.1 Observation Conditions"

Resume function

The Resume function redisplays the screen appearing before the instrument was powered OFF

when the instrument is powered back ON. All parameter settings are also saved. This function

is only activated when the power is turn off while performing height difference measurement or

checks and adjustments. When powering back on the screen is returned to the beginning of the

procedure being performed on power OFF.

PROCEDURE Power OFF

Press {} while pressing {}.

• When there is almost no battery power remaining, "Battery low! Please charge battery." (with

audio tone) is displayed alternately with current screen. In this event, stop measurement, switch

off the power and charge the battery or replace with a fully charged battery. Data and settings

may be lost if the battery is removed while the power is on.

• To save power, power to the DL is automatically cut off if it is not operated for a fixed period of

time. This time period can be set to "30 min." or "No" in "Power off" in "Instr.config".

"19.2 Instrument Configuration"

24

Page 33

7. POWER ON/OFF

7.1 Resolving Software Issues

If you are experiencing problems with the DL and suspect a fault in the software, you should try

resetting. If the problem is not resolved the next step is to initialize data.

"19.6 Restoring Default Settings"

• Be sure to back up stored data to an external memory device or computer in advance.

PROCEDURE Initializing data

1. Power OFF the instrument.

2. Press

{}

{F3} until the TOPCON logo appears.

"Clearing memory..." is displayed and data is

initialized. The instrument then powers on as

normal.

while holding {BS}, {F1}, and

25

Page 34

8.

FOCUSING AND SIGHTING THE STAFF

8.1 Using the DL-501 Advanced

•If the view finder sighting axis is not aligned with the sighting axis of the objective lens, errors will

occur when taking measurements. Always make sure the axes are correctly aligned when using

the view finder.

•The View finder can be used to sight staffs at distances of 7m or more.

•Focussing can also be performed manually by turning the focusing knob while looking through

the eyepiece. If the staff barcodes are out of focus, they will not be readable and measurements

cannot be taken. Make sure they are correctly focused.

•Even when Auto Focus has finished the image in the telescope eyepiece may appear out of

focus depending on the eyesight of the operator.

View finder and Auto Focus function

The view finder is used when aligning the DL telescope with the staff. Simply aligning the two

center circles in the view finder with the center of the staff and pressing the Measure key

automatically focuses the DL on the staff and starts measurement reducing operator workload

and increasing operator efficiency in the field.

PROCEDURE Always perform before using the instrument

1. Look through the telescope at a bright and

featureless background.

2. Looking through the eyepiece, turn the eyepiece

screw clockwise, then counterclockwise little by

little until just before the reticle image becomes

focussed.

Using these procedures, frequent reticle

refocussing is not necessary since your eye is

focussed at infinity.

3. Looking through the telescope, shift your eyes

slightly up and down and to each side. If the

staff and reticle show no deviation, the

instrument is ready for use.

If the staff and reticle deviate, return to step 2.

4. Sight a clear vertical line, such as the wall of a

building, at a distance usually used for

operation.

26

Page 35

8. FOCUSING AND SIGHTING THE STAFF

5. Turn the horizontal fine motion knobs until that

vertical line is centered in the field of view.

6. Looking through the view finder, turn the view

finder eyepiece screw until the 2 circles are

focussed.

7. Use the view finder axis alignment screw to

align the 2 circles in the view finder with the

same vertical line described in step 4.

The sighting axis of the view finder is now

aligned with the sighting axis of the telescope

as seen through the eyepiece.

Eliminating parallax

This is the relative displacement of the target image with respect to the reticle when the

observer’s head is moved slightly before the eyepiece.

Parallax will introduce reading errors and must be removed before observations are taken.

Parallax can be removed by refocussing the reticle.

PROCEDURE Using Auto Focus to focus on the staff

1. Turn the instrument on.

"7. POWER ON/OFF"

2. Aim the objective lens roughly in the direction of

the staff.

3. Use the horizontal fine motion knobs to align the

2 circles in the view finder until the staff is

approximately centered.

4. Press the Measure key. The instrument

automatically focuses on the staff and

measurement starts.

27

Page 36

8. FOCUSING AND SIGHTING THE STAFF

8.2 Using the DL-501 Standard

• If the staff barcodes are out of focus, they will not be readable and measurements cannot be

taken. Makes sure they are correctly focused.

PROCEDURE

1. Look through the telescope at a bright and

featureless background.

2. Looking through the eyepiece, turn the

eyepiece screw clockwise, then

counterclockwise little by little until just before

the reticle image becomes focussed.

Using these procedures, frequent reticle

refocussing is not necessary since your eye is

focussed at infinity.

3. Use the Simple Finder to point the objective

lens at the staff.

4. Turn the horizontal fine motion knobs until the

staff is nearly centered in the field of view, then

turn the focusing knob to focus on the staff.

5. Looking through the telescope, shift your eyes

slightly up and down and to each side. If the

staff and reticle show no deviation, the

instrument is ready for use.

If the staff and reticle deviate, return to step 2.

"8.1 Using the DL-501 Advanced

Eliminating parallax"

•Repeat steps 3 and 4 each time measurement is performed.

28

Page 37

9. CONNECTING TO EXTERNAL DEVICES

Menu

1.Meas

2.Management

3.Config

4.Calculation

Config menu

1.Obs.condition

2.Instr.config

3.Comms setup

4.Tilt offset

5.Unit

INFO

Mode :Bluetooth

Authenticate:No

STX/ETX(CSV):No

The DL can be connected to a data collector to allow remote operation. Read this manual in

conjunction with the operator’s manual for the relevant external device and software thereof.

9.1

The Bluetooth module incorporated in the DL can be used for communication with Bluetooth devices

such as data collectors.

Wireless Communication using Bluetooth Technology

• Connection settings are returned to factory settings when defaults are restored. Perform settings

again after restoring defaults.

Bluetooth connections

Communication between a pair of Bluetooth devices requires one device to be set as the

"Master" and the other as the "Slave". DL is always the "Slave" device. Connections are initiated

from the paired device side

PROCEDURE Necessary settings for Bluetooth communication

1. Select "Config" in <Menu>.

2. Select "Comms setup" in <Config menu>.

3. Select "Bluetooth" in "Mode".

4. Set "Authenticate" to "Yes" or "No".

If "Authenticate" is set to "Yes" for the DL the

passkey will also need to be input on the

companion device.

29

Page 38

9. CONNECTING TO EXTERNAL DEVICES

INFO

Mode :Bluetooth

Authenticate:Yes

Passkey

:****

STX/ETX(CSV):No

AVG out mode:1

INFO

Mode :Bluetooth

Authenticate:No

STX/ETX(CSV):No

Bluetooth ID

: Bxxxxxx,Bxxxxxx

Firmware Ver.x.x.x

BD_ADDR

: 00:AA:BB:CC:DD:FF

OK

5. When "Authenticate" is set to "Yes", input the

same passkey as that for the intended

companion device. Even if "Authenticate" is

set to "No", a passkey is requested when

authentication is set on the companion device

being used.

Up to 16 numeral characters can be input.

Input characters will be displayed as asterisks

(e.g. "*****"). The passkey was set to "0123" at

the factory.

6. Set STX/ETX (CSV) settings

"19.3 Communication Setup STX/

ETX (CSV)"

7. Set average output mode

"19.3 Communication Setup AVG o ut

mode"

PROCEDURE Displaying Bluetooth information for the DL

1. Select "Config" in <Menu>

2. Select "Comms setup" in <Config menu>

3. Select "Bluetooth" in "Mode" and press

[INFO].

The Bluetooth information for the DL is

displayed. The "BD_ADDR" for the DL must be

registered on your Bluetooth device.

30

Page 39

9. CONNECTING TO EXTERNAL DEVICES

Rh

Hd S

P2

Bluetooth Device Address

This is a number unique to one particular Bluetooth device used to identify devices during

communication. This number consists of 12 characters (numbers 0 to 9 and letters from A to F).

Some devices may be referred to by their Bluetooth device address.

9.2

Establishing a connection between the DL and paired

Bluetooth device

When "Mode" is set to "Bluetooth" in "Comms setup" in <Config menu> [ ]/[ ] is

displayed in Meas mode.

PROCEDURE

1. Complete the necessary settings for Bluetooth

communication.

"9.1 Wireless Communication using

Bluetooth Technology"

2. Press [] in the second page of Meas

mode screen.

The Bluetooth module in the DL powers on and

connection starts.

The Bluetooth icon indicates communication

status.

"4.2 Display Functions"

• Softkeys (in Meas mode)

[]:Press to enter waiting status

[]:Press to cancel the connection/exit waiting status

• Audio tones

(While connecting/disconnecting)

Start paging/waiting: short beep

Connection successfully established: long beep

Connection canceled/being canceled: two short beeps

31

Page 40

9. CONNECTING TO EXTERNAL DEVICES

9.3

Setting a data collector as the companion device allows measurement and other operations to be

performed from the data collector side.

Communication between the DL and Companion Device

•

Bluetooth

normal operation.

• Check that the companion device (data collector etc.) is turned on and the relevant Bluetooth

settings are complete.

PROCEDURE

1. Complete the necessary settings for Bluetooth

2. Check communication status.

3. Initiate measurement using the paired

communication causes DL battery power to be depleted at a rate higher than that for

communication.

"9.1 Wireless Communication using

Bluetooth Technology"

"9.2 Establishing a connection between

the DL and paired Bluetooth device"

Bluetooth device (e.g. a data collector). DL will

respond and measurement will start.

Measured values are then displayed in the

Meas mode screen.

9.4

It is possible to set a computer as the companion device and output JOB data and route data via

wireless communication.

Outputting data using Bluetooth communication

PROCEDURE Outputting JOB data to a host computer

1. Complete the necessary settings for Bluetooth

communication.

"9.1 Wireless Communication using

Bluetooth Technology"

2. Check communication status.

"9.2 Establishing a connection between

the DL and paired Bluetooth device"

32

Page 41

9. CONNECTING TO EXTERNAL DEVICES

Job id

JOB1

Format CSV_1

Outputting 98/ 99

Bluetooth

Waiting for

connection...

3. Select "Comms output" in <JOB menu> and

set "Com.locat."

"18.1 Outputting JOB Data PROCEDURE

Outputting JOB data to host computer"

DL starts outputting data.

• If a connection has not yet been established,

the screen at right is displayed. After a

connection has been established, the data is

output.

9.5 Connecting via Communication Cable

PROCEDURE Basic cable settings

1. Connect the DL to the external device using

the cable.

Cables:

"24. OPTIONAL

ACCESSORIES"

2. Select "Comms setup" in <Config menu>.

Set communication conditions.

"19.3 Communication Setup"

33

Page 42

10.BASIC OPERATION

ΔαΔ

Δ

10.1 Reading the Staff

Simply focus on the RAB* code for an automatic reading of the staff. The following explains how to

read the RAB code of the staff.

*RAB code (RAndom Bi-directional code) is a coded staff used with certain digital levels.

• Set up the staff in an area free of obstacles.

• Avoid placing the staff next to mirror-like surfaces. The effect of strong light could make

measurements impossible.

• Support the staff so that it is perpendicular, checking the circular bubble scope on the staff. If the

staff is tilting, height and distance measurements will be incorrect.

• If the surface is catching the light, turn it just enough to stop the reflection.

• Make sure shadows are not cast on the staff as this could make measurement impossible.

• When holding the staff during measurement, make sure your hand does not cover the RAB code.

• If dark locations make measurement difficult, shine a flashlight on the staff. Stand at a distance so

that the beam shines evenly over the length of the staff.

• If waterdrops or dirt adhere to the barcode, measurement may be impossible. Wipe the staff clean

with a soft cloth.

• Clean the staff if grit or dirt gets stuck between the sections. If the staff is dirty, measurements will

not be very accurate.

• Avoid scratching or soiling the barcode surface as this could make measurement impossible. Store

and carry the staff inside its case.

• If the BIS/BGS series staff is used for leveling, and the height difference and temperature difference

are much larger than normal, temperature variations may cause the staff to expand or contract and

cause differences in relative height measurements. DL reads in measurements up to 0.01mm and

minor deviations in the accuracy of the staff will adversely affect accuracy. To obtain high accuracy

measurements, it is important to perform temperature corrections for the staff. See below.

• Formula for correcting expansion and contraction of the staff due to temperature changes.

C={C0+(T-T0)x }x h

C: Staff correction value

C0: Scale factor

T: Measured temperature during observation (average

temperature during measurement of known site,

34

Page 43

intermediate site, new site)

°

α

Δ

Rh "negative value"

Inverted staff

T0: Reference temperature of 20 C

: Line expansion coefficient

h: Height difference

PROCEDURE Setting up the staff

1. Set the foot plate on the ground so that the

staff will not sink.

2. When using a BGS staff, connect the sections

correctly by making sure the numbers on the

numeric scale side of the staffs run in

unbroken order.

3. Keeping an eye on the circular bubble scope

on the staff, set the staff in the foot plate so

that it stands up straight.

4. Turn the barcode scale towards the instrument.

PROCEDURE Measuring the height from a ceiling

10. BASIC OPERATION

35

Page 44

10. BASIC OPERATION

A

Rh

Hd

FOCUS

Rh 1.2345 m

Hd 4.321 m

MENUTILT

S

10.2 Measuring in Measure Mode

In Measure mode you can sight point A, take the staff reading Rh, and measure the horizontal distance

Hd to the staff.

• If direct sunlight or strong light enter the eyepiece during measurement, ambient light is too low, or

the staff is set against a background which is too bright, and measurement cannot be performed, an

error is displayed (

• If the DL or staff is subjected to shocks or vibration during use, measurement may be impossible.

Resume measurement during more stable conditions.

PROCEDURE

"20. WARNING AND ERROR MESSAGES").

1. Turn the instrument on.

"7. POWER ON/OFF"

2. Aim the instrument at the staff and press the

Measure key. Measurement starts. When

measurement is complete, the staff readings

(Rh) and horizontal distance (Hd) are

displayed.

• In Repeat, Average, or Rapid mode, values

are renewed with each measurement. Press

[STOP] or the Measure key to stop reading.

Press {ESC} to cancel the reading.

•Auto focus functionality is not available for the DL-501 Standard. Therefore [FOCUS] is not

displayed in the screen of step 2.

36

Page 45

11.SIMPLE MEASUREMENT

A

B

dH

Menu

1.Meas

2.Management

3.Config

4.Calculation

Meas menu

1.Height dif.

2.Check & adjust.

3.Simple measurement

Simple meas. menu

1.Ht-diff. meas.

2.Elevation meas.

3.View

4.Deletion

FOCUS

BS Go

BS0001

Rh

Hd

PT.ID

CNFGTILT

S

P1

This chapter explains how to measure height difference or elevation without setting a route.

•The maximum number of points per JOB is 2000.

11.1 Measuring Height Difference

This function allows the user to calculate the height difference (

foresight (B).

1. Select "Meas" in <Menu>.

2. Select "Simple measurement" in <Meas

menu>.

3. Select "Ht-diff. meas." in <Simple meas.

menu>.

dH) between backsight (A) and

4. Set up the DL between A and B.

5. Measure backsight.

• [FOCUS]: Press to perform Auto Focus only.

37

Page 46

11. SIMPLE MEASUREMENT

OK

Pt.id

:0000A

Meas.pt type:BS

Line :Go

Decr.

A.F.setting :Yes

Tilt warn :Yes

Meas mode :Single

Ht reso.

Dist reso.

:0.01mm

:0.001m

Auto rec :No

Data input

Rh : 0.00000m

Hd : 0.000 m

OK

1

OK

BS Go

BS0001

Rh 2.45678m

Hd 17.891 m

S

FOCUS

FS Go

FS0001

Rh

Hd

PT.ID

CNFGTILT

S

P1

• [PT.ID]: Press to change the current point ID.

Subsequent point IDs will be assigned

automatically in either ascending or

descending order.

Select [Decr.]/[Incr.] for descending/

ascending order.

• ( ) will be displayed to the right of the

point ID when ascending (descending)

order is selected.

•Point ID settings can be changed mid-route.

•[CNFG]: Press to configure measurement

settings.

• Press [INPUT] on page 2 to manually input

Rh values and Hd values obtained using the

telescope stadia lines.

6. Check point ID, double-run setting, and

measurement results.

Press [OK].

7. Measure foresight.

38

Page 47

8. Check point ID, double-run setting, and

OK

FS Go

FS0001

Rh 2.34567m

Hd 12.345 m

h -1.23456m

S

TURN P

FS Go

FS0001

Rh 2.34567m

Hd 12.345 m

h -1.23456m

S

"Auto rec" set to "No"

"Auto rec" set to "Yes"

FS Go

FS0001

Rh

Hd

TURN PINPUT

S

P2

YES

Operation will continue

from last measurement.

OK?

NO

measurement results.

Press [OK].

Results are recorded and the screen in step 7

is restored.

• When "Auto rec" is set to "Yes", results are

displayed for approx. 1 sec. before the

screen in step 7 is restored.

9. Press [TURN P] on page 2 to set the

previously measured foresight as a turning

point.

10. Move the DL to the next position.

Repeat from step 5 using the foresight

measured in step 7 as the new backsight.

11. SIMPLE MEASUREMENT

• When operation has been canceled after moving

screens during measurement, the following

message will be displayed the next time "Ht-diff.

meas." is selected in <Simple meas. menu>.

Press [YES] to resume measurement from

where you left off last time.

39

Page 48

11. SIMPLE MEASUREMENT

A

B

dH

HA + dH

0m

HA (Elevation

of known point)

Simple meas. menu

1.Ht-diff. meas.

2.Elevation meas.

3.View

4.Deletion

OK

BS

Z : 1.20000m

READ

1

FOCUS

BS Go

BS0001

Rh

Hd

PT.ID

CNFGTILT

S

P1

11.2 Measuring Elevation

This function allows the user to calculate the elevation (HA + dH) of a specified point (B) based on the

elevation of known point (A).

1. Select "Meas" in <Menu>.

2. Select "Simple measurement" in <Meas

menu>.

3. Select "Elevation meas." in <Simple meas.

menu>.

4. Set up the DL between A and B.

5. Input elevation of known point and press [OK].

•When elevation has been selected, press

[READ] to read in the elevation of a known

point.

• "12.3 Setting-Out Measurement

PROCEDURE Reading in recorded

known point data"

6. Measure backsight.

40

Page 49

7. Check point ID, double-run setting, and

OK

BS Go

BS0001

Rh 2.45678m

Hd 17.891 m

S

FOCUS

FS Go

FS0001

Rh

Hd

PT.ID

CNFGTILT

S

P1

OK

FS Go

FS0001

Rh 2.34567m

Hd 12.345 m

Z 1001.23456m

S

TURN P

FS Go

FS0001

Rh 2.34567m

Hd 12.345 m

Z 1001.23456m

S

"Auto rec" set to "No"

"Auto rec" set to "Yes"

FS Go

FS0001

Rh

Hd

TURN PINPUT

S

P2

measurement results.

Press [OK].

8. Measure foresight.

9. Check point ID, double-run setting, and

measurement results.

Press [OK].

Results are recorded and the screen in step 8

is restored.

• When "Auto rec" is set to "Yes", results are

displayed for approx. 1 sec. before the

screen in step 8 is restored.

11. SIMPLE MEASUREMENT

10. Press [TURN P] on page 2 to set the

previously measured foresight as a turning

point.

11. Move the DL to the next position.

Repeat from step 5 using the foresight

measured in step 8 as the new backsight.

41

Page 50

11. SIMPLE MEASUREMENT

YES

Operation will continue

from last measurement.

OK?

NO

Simple meas. menu

1.Ht-diff. meas.

2.Elevation meas.

3.View

4.Deletion

BS0000 BS

FS0001 FS

IS0002 IS

IS0003 IS

FIX0004 FIX

LAST

TOP

...P

SRCH

EDIT

BS Go

BS0000

Rh 2.45678m

Hd 17.891 m

PREV

NEXT

• When operation has been canceled after moving

screens during measurement, the following

message will be displayed the next time

"Elevation meas." is selected in <Simple meas.

menu>. Press [YES] to resume measurement

from where you left off last time.

11.3 Viewing Simple Measurement Data

It is possible to display measurement data obtained using simple measurement.

PROCEDURE

1. Select "Meas" in <Menu>.

2. Select "Simple measurement" in <Meas

menu>.

3. Select "View" in <Simple meas. menu>.

•Data can also be displayed via

<Management menu>

4. Align the cursor with the data to be displayed

and press {}.

Detailed information for the selected point is

displayed.

• [PREV]: Press to display detailed information

for the previous point.

• [NEXT]: Press to display detailed information

for the next point.

• [EDIT]: Press to edit point id and

measurement point type.

42

Page 51

11. SIMPLE MEASUREMENT

Search

Pt.id

:IS0003

OK

Simple meas. menu

1.Ht-diff. meas.

2.Elevation meas.

3.View

4.Deletion

BS0000

FS0001

IS0002

IS0003 DEL

FIX0004 DEL

LAST

TOP

...P

OK

P1

•Press [SRCH] to search for point data by

point id.

5. Press {ESC} to return to <Simple meas. data

menu>

11.4 Deleting Simple Measurement Data

It is possible to delete measurement data obtained using simple measurement.

PROCEDURE Deleting specific simple measurement data

1. Select "Meas" in <Menu>.

2. Select "Simple measurement" in <Meas

menu>.

3. Select "Deletion" in <Simple meas. menu>.

• Data can also be deleted via

<Management menu>

Align the cursor with the data to be deleted and

press {}. "DEL" is displayed to the right of

the point id.

43

Page 52

11. SIMPLE MEASUREMENT

BS0000

FS0001

IS0002

IS0003 DEL

FIX0004 DEL

P2

DETAIL

BS Go

0001

Rh 2.34567m

Hd 12.345 m

Meas. data deletion

Simple meas. data

deletion

Confirm?

NO

YES

Simple meas. data menu

1.View

2.Deletion

3.Initialize

All simple meas. data

will be deleted.

OK?

NO

YES

• Press [DETAIL] in the second page to

display detailed information for the

selected simple meas. data.

•Press {ESC} to return to the point list.

• Backsight data can be deleted only after all

the related foresight data are deleted.

4. Press [OK] in the screen of step 4 to display a

confirmation dialog.

Press [YES] to delete and return to the point

list.

PROCEDURE Deleting all simple measurement data (initialization)

1. Select “Management” in <Menu>.

2. Select “Simple meas. data” in <Management

menu>.

3. Select “Initialize”.

4. Press [YES] to delete all simple measurement

data in the selected JOB.

44

Page 53

12.HEIGHT DIFFERENCE MEASUREMENT

B

A

C

D

E

Menu

1.Meas

2.Management

3.Config

4.Calculation

Height difference measurement allows the user to calculate the relative height between a known point

and a specified point. The instrument is moved from instrument station to instrument station along a

route from the known point to the unknown point taking measurements at each section. The total of

measurements at all sections gives the height difference between the known point and the specified

point. This method is particularly useful when the known and unknown points are far apart, relative

height is great, or there are obstacles preventing sighting.

• Except when special circumstances exist, there should be an even number of sections along a

route.

12.1

The route between bench mark and bench mark must be set before starting measurement. Select an

existing route or create a new route.

• Route setup is performed in <Route menu>.

• It is possible to select a partially completed route and recommence measurement from where you

left off.

• When performing double-run leveling, each run is treated as a separate route.

• It is possible to change the route ID and memo of routes containing measurement data.

• Procedures for reobservation are explained elsewhere in this manual.

"14.4 Reobserved Route Merge"

• The maximum number of routes per JOB is 100.

• The maximum number of fixed points/end points per route is 100 (2000 total in all routes incl. fixed

points/end points)

• The maximum number of start conditions per route is 100 (1000 total in all routes incl. start

conditions)

PROCEDURE Selecting a route

1. Select "Meas" in <Menu>.

Route Setup

45

Page 54

12. HEIGHT DIFFERENCE MEASUREMENT

Meas menu

1.Height dif.

2.Check & adjust.

3.Simple measurement

Height dif. menu

1.Route

2.Measurement

OK

Route setting

:R1

DETAIL

NEWLIST

*R1 20

R2 20

LINE01 15

LINE02 10

LINE03 0

LAST

TOP

...P

[...P]

OK

Route setting

:R2

DETAIL

NEWLIST

2. Select "Height dif." in <Meas menu>.

3. Select "Route" in <Height dif. menu>.

4. The currently selected route is displayed.

Press [LIST]. Align the cursor with the desired

route name and press {}.

• [NEW]: Press to set a new route.

“PROCEDURE Recording a new route”

• [DETAIL]: Press to display route settings.

Route name can also be changed.

“PROCEDURE”

• = Use {

to page.

• [...P] = Use {

point.

•Press [TOP] to move to the first point number

on the first page.

•Press [LAST] to move to the last point

number on the last page.

}/{} to move from page

}/{} to select individual

5. Press [OK] to confirm route settings.

PROCEDURE Recording a new route

1. Select "Meas" in <Menu>.

2. Select "Height dif." in <Meas menu>.

3. Select "Route" in <Height dif. menu>.

46

Page 55

4. Press [NEW].

OK

Route setting

:R1

DETAIL

NEWLIST

OK

Start bench mark id

:B1

Start bench mark elev.

: 150.00000m

READ

1

OK

End bench mark id

:B2

End bench mark elev.

: 165.00000m

READ

1

OK

Line :Go

Order :1

Meas.Proc:BFFB

OK

Ht reso. :0.1mmGo

Dist reso.:0.001m

Rh range : 0.50mm

dH range : 1.00mm

OK

Route id

: Route-001

Memo

:

:

A

OK

Upper dist :40.000 mo

Lower dist: 3.000 m

Upper Rh : 2.80000m

Lower Rh : 0.20000m

1

5. Set the following data items.

(1) Route ID

(2) Memo

(3) Start bench mark ID

(4) Start bench mark elevation

(5) End bench mark ID

(6) End bench mark elevation

(7) Double-run setting

(8) Measurement order

(9) Measurement procedure

(10) Ht resolution

(11) Distance resolution

(12) Rh range

(13) dH range

(14) Upper tolerance (distance)

(15) Lower tolerance (distance)

(16) Upper tolerance (ht)

(17) Lower tolerance (ht)

(18) Distance difference between backsight

and foresight

(19) Total distance difference between

backsight and foresight

12. HEIGHT DIFFERENCE MEASUREMENT

• Press [READ] to read in route data when

setting

Start bench mark ID and End bench

mark ID.

"12.3 Setting-Out Measurement

PROCEDURE Reading in recorded

known point data"

47

Page 56

12. HEIGHT DIFFERENCE MEASUREMENT

OK

BF dist diff.

: 1.000 m

Total dist diff.

: 3.000 m

1

YES

New route setting

is registered.

Confirm?

NO

6. Press [OK] in the screen of step 5 when all

data items have been set.

Press [YES] in the subsequent screen to

confirm route settings.

Conditions such as character input restrictions, input range, and selectable options for the above data

items are as follows.

• Route ID/bench mark ID: up to 16 characters

• Memo: 2 rows of up to 16 characters

• Elevation: -20000.00000 to 20000.00000m

• Double-run setting: Go/Return

• Measurement order: 1/2/3/4/5 (each number is allocated to a commonly used measurement

procedure making selection of a measurement procedure easier. This allocation is saved in the set

route)

• Measurement procedure: BFFB/BBFF/BF/aBFFB/aFBBF/BFBF/aBF("B" means backsight and "F"

means foresight, "a" signifies alternation of measurement procedure at subsequent instrument

station)

• Ht resolution: 0.01/0.1/1mm

• Distance resolution: 0.001/0.01/0.1m

• Ht/Distance range: 0.00 to 99.99mm ("0.00" setting: no restrictions on this data item)

• Upper/Lower tolerance (distance): 0.000 to 200.000m ("0.000" setting: no restrictions on this data

item)

• Upper/Lower tolerance (ht): 0.00000 to 9.99999m ("0.00000" setting: no restrictions on this data

item)

• Distance difference between backsight and foresight/Total distance difference between backsight

and foresight: 0.000 to 200.000m ("0.000" setting: no restrictions on this data item)

• Format: CSV_1/CSV_2

48

Page 57

PROCEDURE Editing route ID

OK

Route setting

:R1

DETAIL

NEWLIST

OK

Route id

: R1

Memo

:

:

A

1. Select "Route" in <Height dif. menu>.

2. Press [LIST]. Align the cursor with the desired

route and press {}.

3. Press [DETAIL].

4. Edit the memo/route ID and press [OK] to

confirm.

• Data items other than memo/route ID for

routes/reobserved routes containing

measurement data cannot be edited.

12. HEIGHT DIFFERENCE MEASUREMENT

12.2

Each section along the set route is measured using the backsight/foresight sequence selected in the

"Meas. Proc." data item in route settings. Fixed points can be established along the route while

measuring.

• Power to the instrument can be turned off while moving between sections. The Resume function

maintains measurement results obtained prior to shutdown.

• When "Rec cond." is set to "Yes", start conditions must be set when starting measurement of a new

route.

Fixed points

When checking the accuracy of measurement results, fixed points common to both the go and

return runs are set. Fixed points are also set when stopping measurement temporarily.

Height Difference Measurement

49

Page 58

12. HEIGHT DIFFERENCE MEASUREMENT

Height dif. menu

1.Route

2.Measurement

Height dif. meas menu

1.Start cond.

2.Meas start

3.View

OK

Feb/17/2009 10:03:28

Temp : 15.0 C

Weather :Fine

Wind :Calm

Wind dir :---

1

OK

Observer

:

Memo

:

:

A

FOCUS

Pre.meas.

Rh 1.2345 m

Hd 34.567 m

OK

CNFGTILT

PROCEDURE Measurement procedure BFFB

1. Select "Meas" in <Menu>.

2. Select "Height dif." in <Meas menu>.

3. Select "Measurement" in <Height dif. menu>.

4. Select "Start cond." in <Meas menu>.

• Select "Meas start" to skip Start cond. input

and proceed to step 7.