Page 1

1

目录

PRECAUTIONS ...........................................................................................................................4

SAFETYGUIDE...........................................................................................................................5

OPERATOR ..................................................................................................................................6

DECLARATIONOFEXCEPTIONALRESPONSIBILITY................................................6

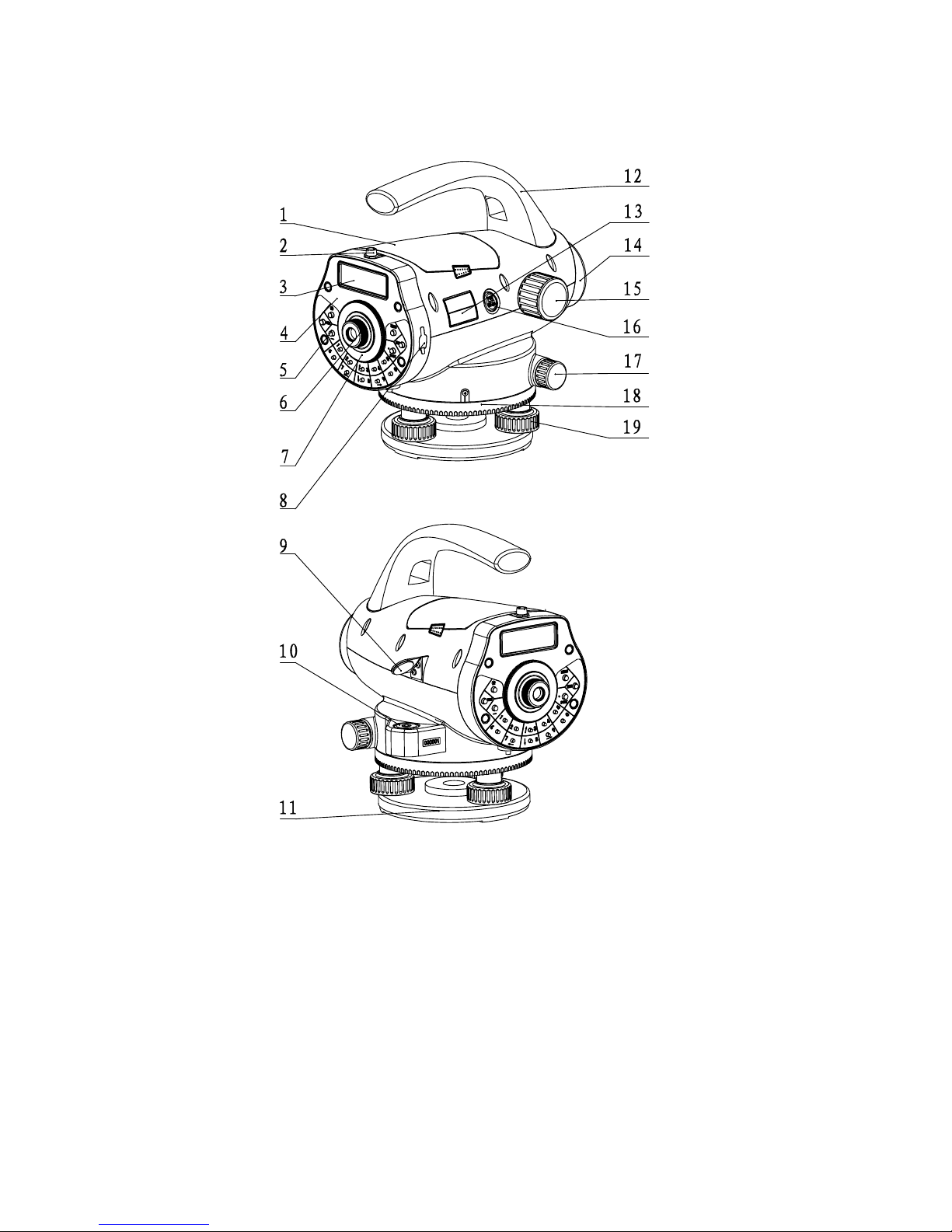

1.NAMEOFEACHCOMPONENT&ITSFUNCTION ...................................................8

1.1 Name of Each Component......................................................................8

1.2 Operation Keys & Functions ................................................................10

1.3 Display.................................................................................................. 11

1.4 Symbols ................................................................................................12

2.PREPARATIONFORMEASUREMENT.......................................................................13

2.1 Mounting the Instrument ......................................................................13

2.2 Power On ..............................................................................................15

2.3 Remaining Battery Display...................................................................15

2.4 Setting the record mode ........................................................................16

2.5 SD Card ................................................................................................18

2.6 Menu.....................................................................................................18

2.7 SET .......................................................................................................19

2.8 Inputting Characters..............................................................................19

2.9 Staff Collimation and Focus .................................................................21

2.10 Surveying Note ...................................................................................22

3.STANDARDMODE ............................................................................................................23

3.1 Measure ................................................................................................23

3.2 S.O G.H( Stake out Ground Point)........................................................26

3.3 S.O H.D(Stake out Height Difference).................................................29

3.4 S.O Dist(Stake out Distance)................................................................31

4.LEVELING............................................................................................................................. 34

4.1 Start Leveling........................................................................................34

4.2 End the Leveling Measurement on the Transition Point.......................66

Page 2

2

4.3 End the Leveling Measurement on the Bench Mark Point...................68

4.4 Continue Leveling ................................................................................70

5.OTHERFUNCTIONS......................................................................................................... 72

5.1 Manually Inputting Data Key—[MANU] ............................................72

5.2 Display the Distance—[DIST]..............................................................74

5.3 Inverse Staff Mode—[-]........................................................................74

5.4 Record Data Search—[SRCH] .............................................................75

6HORIZOTALANGLEMEASUREMENT .......................................................................79

7.FORMARFLASHORSDCARD ..................................................................................... 81

8.DATAMANAGE...................................................................................................................84

8.1 Create Group.........................................................................................86

8.2 Search Job.............................................................................................87

8.3 Copy Job ...............................................................................................88

8.4 Delete Job .............................................................................................90

8.5 Check the Capacity of Flash or SD Crad..............................................91

8.6 File Out .................................................................................................92

9.SET ..........................................................................................................................................94

9.1 Set Menu...............................................................................................94

9.2 Alter the Setting Mode..........................................................................97

10.BATTERYANDCHARGER ........................................................................................... 99

10.ADJUSTMENT ...............................................................................................................100

10.1 Method A ..........................................................................................100

10.2 Method B ..........................................................................................104

11.TRANSPORTATION,STORINGANDCLEANING.............................................. 104

12.SPECIFICATION............................................................................................................ 106

Page 3

3

FOREWORDS

Congratulations on your purchasing the Digital Level DL-201/2007. In order to

operate this instrument correctly, please read this user manual carefully and keep it

well so as to refer to it easily in the future. Before use, please check the standard

features and make sure all the equipments and accessories are available.

In order to facilitate reading, some pictures are simplified.

Page 4

4

PRECAUTIONS

Before using this instrument, please make sure that each function is running well.

●Avoid to make the surface of the digital staff as well as the joints between each

section dirty or damaged, otherwise it will influence on the accuracy of reading and

measurement. This is because the instrument needs to transfer the black & white bar

code to electric signal. That’s why in case the digital staff is dirty, the accuracy would

be descended, or even the instrument is not able to measure.

●Tripod

The digital level should be mounted on wooden tripod. Metal tripod is lighter and

shack easily, which will affect the accuracy. Each leg of the tripod should be fixed well

by screws.

●Tribrach

Please check the adjusting screw on the tribrach frequently, do make sure the central

fixing screw is tightened.

●Packing well to avoid the instrument shaked

The digital level should be handled carefully to avoid shaking and crashing during

transportation. Severe shaking would damage the measurement functions. When

packing the instrument in the case, make sure the instrument is power off and take off

the battery too.

●Carry the instrument carefully

When you need to move the instrument, you must grasp the lifting handle and take it

off from the tripod.

●Avoid to expose the instrument in sun, rain or humid condition

Leaving the instrument in place of high temperature (+50℃) would damage the

instrument. Do not shoot the sun with the objective len; otherwise the spare parts

inside the instrument may be damaged.

●Avoid the great change of temperature

A great change on instrument temperature would descend the measuring range. For

example, when the instrument is moved out from a hot car, please leave the

instrument to adapt to the surrounding temperature before use.

●Battery Inspection

Check the remaining battery before use.

Page 5

5

●Digital Staff

Wear a glove when using a digital staff.

SAFETY GUIDE

Serious injury or even death may occur if the following cautions are ignored.

●In case of explosion, do not place the instrument close to inflammable gas, liquid, or

solid. Do not operate it in coal mine or dusty place.

●Do not disassemble or repair the instrument without authorization in case of

dangers like fire, electric shock or damage to the instrument. Disassembling and

maintenance are only implemented by RUIDE and its authorized service providers.

●Do not use the telescope to sight at the sun or sunlight that are refracted by

reflectors like prisms in case of any hurt to the eyes.

●Do not operate the instrument with the digital staff near high voltage cables or

transformers, in case of electric shock accident.

●Do not use the digital staff when under bad weather (thunder) in case of electric

shock.

●Do not use chargers and batteries produced by a third party in case of fire.

●Do not use a broken power supply, wires, sockets and plugs in case of fire or electric

shock.

●Do not use humid batteries or chargers in case of fire or electric shock.

●Do not place the batteries in fire or high-temperature environment in case of

explosion or damage.

●Do not use the power supply mentioned in the manuals of non-manufacturers in

case of fire or electric shock.

●Do not circuit the batteries in case of fire.

●Do not disassemble or assemble the instrument or operate the plug with wet hands

in case of electric shock.

●Do not cover the charger when it is charging in case of fire.

●Do not touch the liquid leaked from the battery in case of hurt by the harmful

chemicals. And please change the battery.

●Injury to persons or damage to goods may occur if the following cautions are not

Page 6

6

followed by operators.

●Harm: means hurt, burn, electric shock, etc.

●Damage: means serious damage caused to building, instrument or furniture.

●Overturning the instrument case may damage the instrument.

●Do not stand or sit on the case.

●Do not use the instrument case with broken belt, buckle, hinge, or lifting handle, in

case that the instrument is damaged or it hurts the legs if the case falls.

●When mounting or delivering the instrument please be careful with the leg tips of

the tripod.

●When mounting the instrument on the tripod, make sure the central fixing screw is

tightened well to prevent the instrument from falling down.

●When mounting the instrument, make sure the screws of the tripod are tightened

well.

●When moving the tripod, make sure the screws of the tripod are tightened well.

OPERATOR

●This instrument is only operated by technician.

It is required that the operator should be a qualified surveyor. Before operation,

inspection and calibration, operators should be acknowledged the safety guidence.

●Please wear necessary suits for protection (e.g. safety shoes, safety helmet).

●Do not place the instrument directly on the ground. If the operator has to leave the

instrument alone, please cover the instrument with a nylon cover (if available).

DECLARATION OF EXCEPTIONAL RESPONSIBILITY

●Users of this product should read the user manual thoroughly and implement

periodical inspection to the performance of the instrument.

●Manufacturer and its dealers shall not be responsible for any direct or indirect

consequences and profit loss resulted from destructive or intentional improper use.

●Manufacturer and its dealers shall not be responsible for any direct or indirect

consequences and profit loss resulted from natural calamities (e.g. earthquake,

hurricane, flood, etc.), fire, accidents, or fault of a third party.

Page 7

7

●Manufacturer and its dealers shall not be responsible for failure to operate resulted

from the fact that the data is changed or lost, or that operation is interfered.

●Manufacturer and its dealers shall not be responsible for any consequences and

profit loss resulted from extra use without following the user manual.

●Manufacturer and its dealers shall not be responsible for any consequences and

profit loss resulted from improper transportation or connecting with other products.

Page 8

8

1. NAME OF EACH COMPONENT & ITS FUNCTION

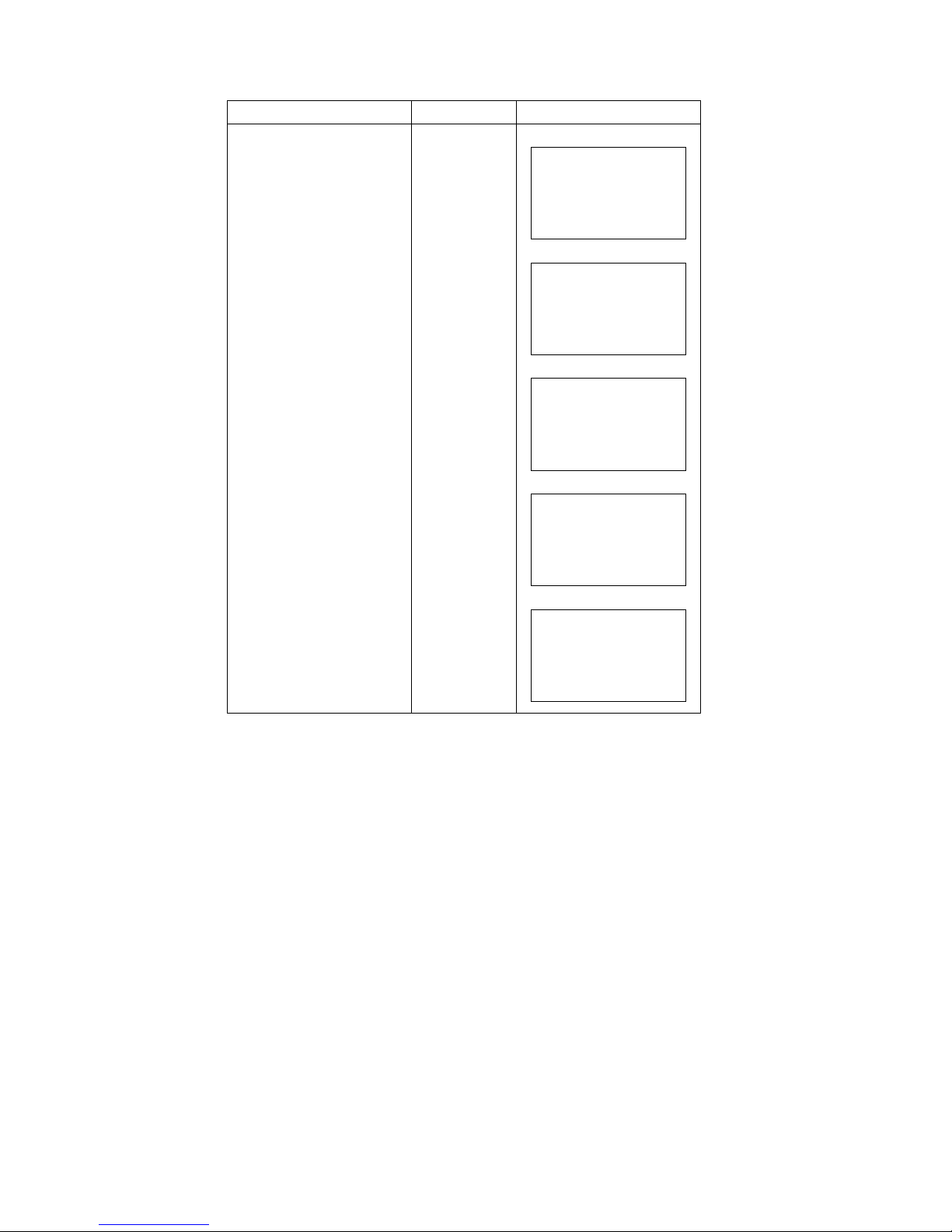

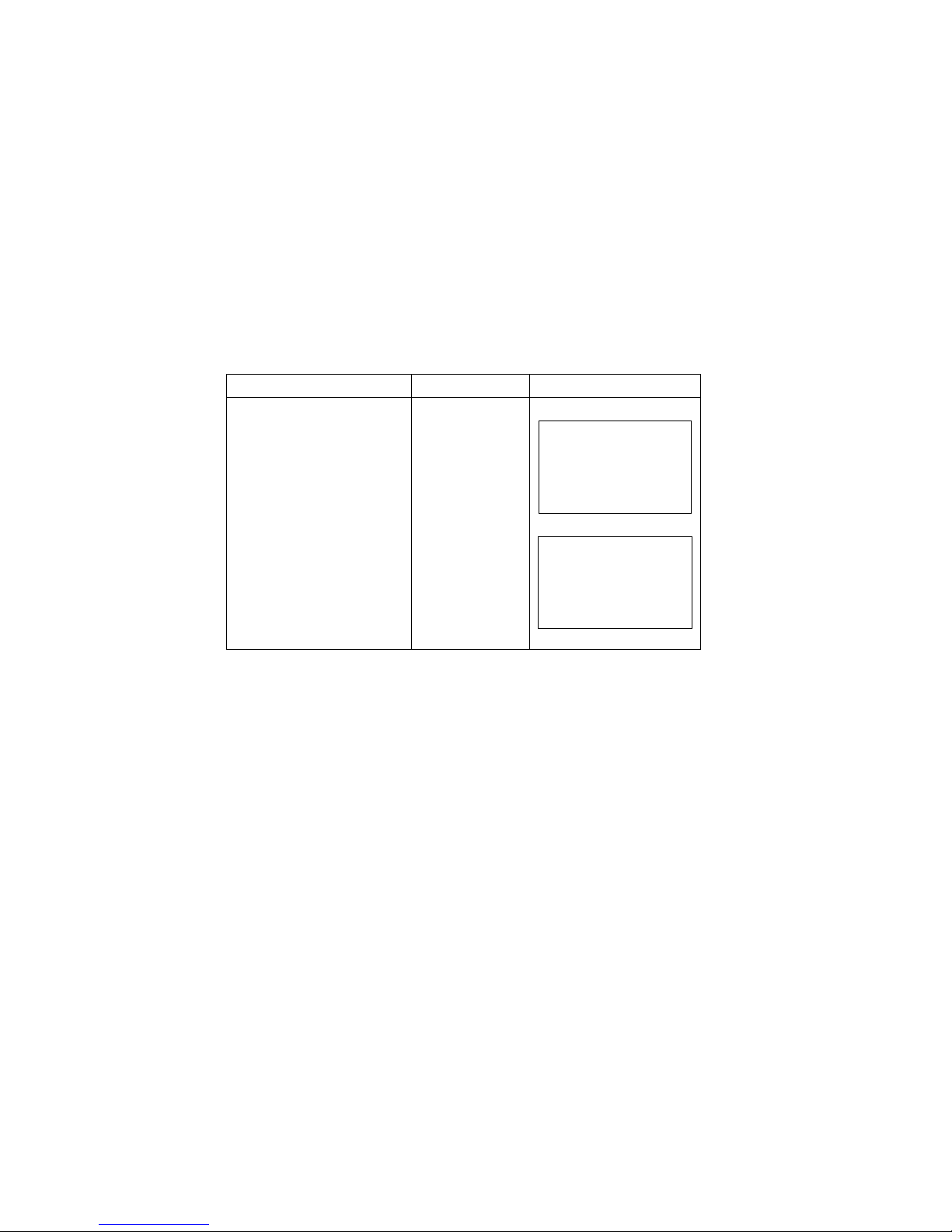

1.1 Name of Each Component

Page 9

9

1 battery

2 rough collimator

3 LCD display

4 keyboard panel

5 keys

6 eyepieces: use for adjusting the definition of the crosshair.

7 protecting cover of eyepieces: by releasing this cover, you can implement the

mechanical adjustment of the reticle in order to correct the optical collimation line

error.

8 data transfer port: connecting with PDA or computer.

9 reflector of circular vial

10 circular vial

11 tribrach

12 lifting handle

13 model label

14 objective lens

15 focusing hand wheel: use for focusing of digital staff.

16 power/measure key: use for instrument power ON/OFF, and measure.

17 horizontal tangent hand wheel

18 horizontal dial: use for setting the horizontal direction value of the collimating

direction to 0 or other required values.

19 leveling screws of the tribrach

Page 10

10

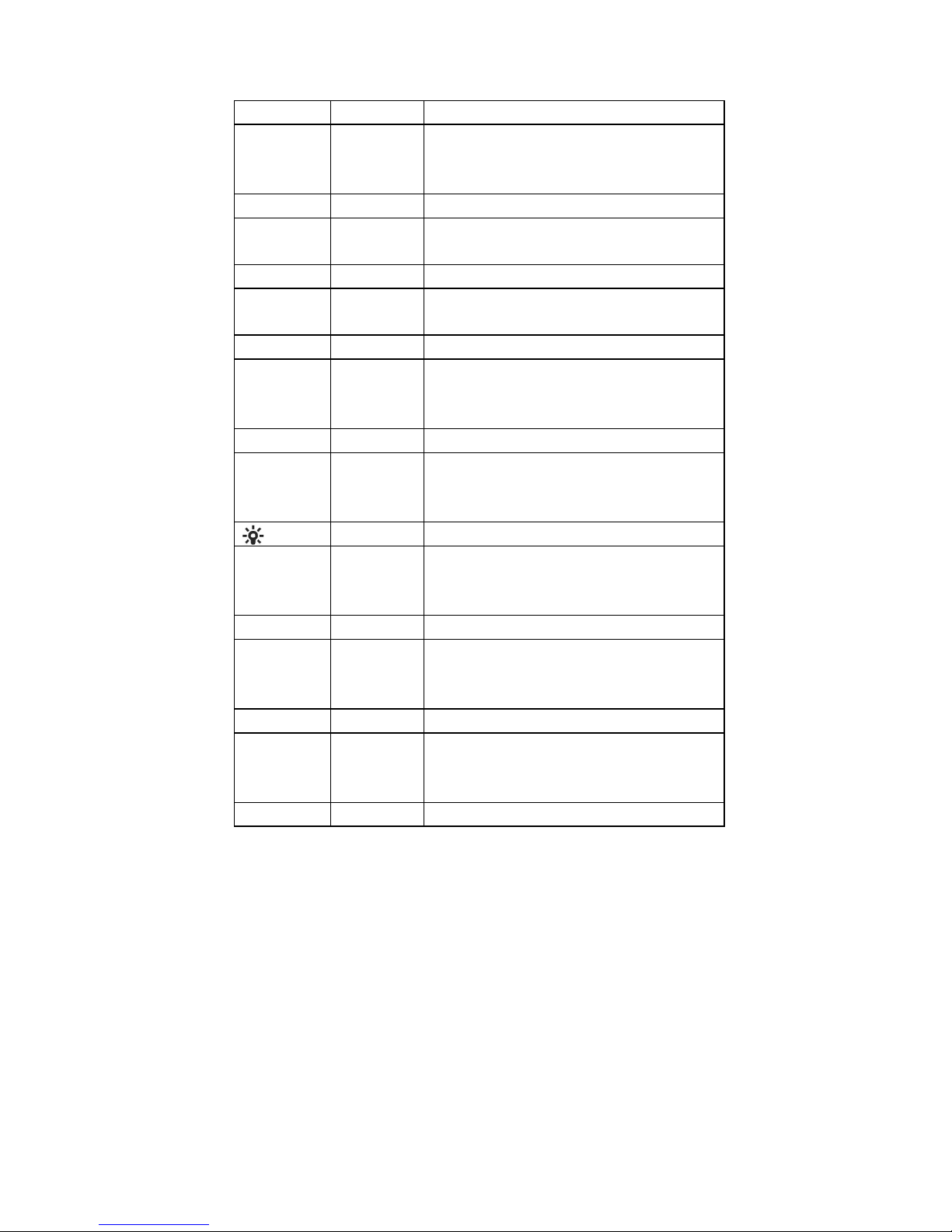

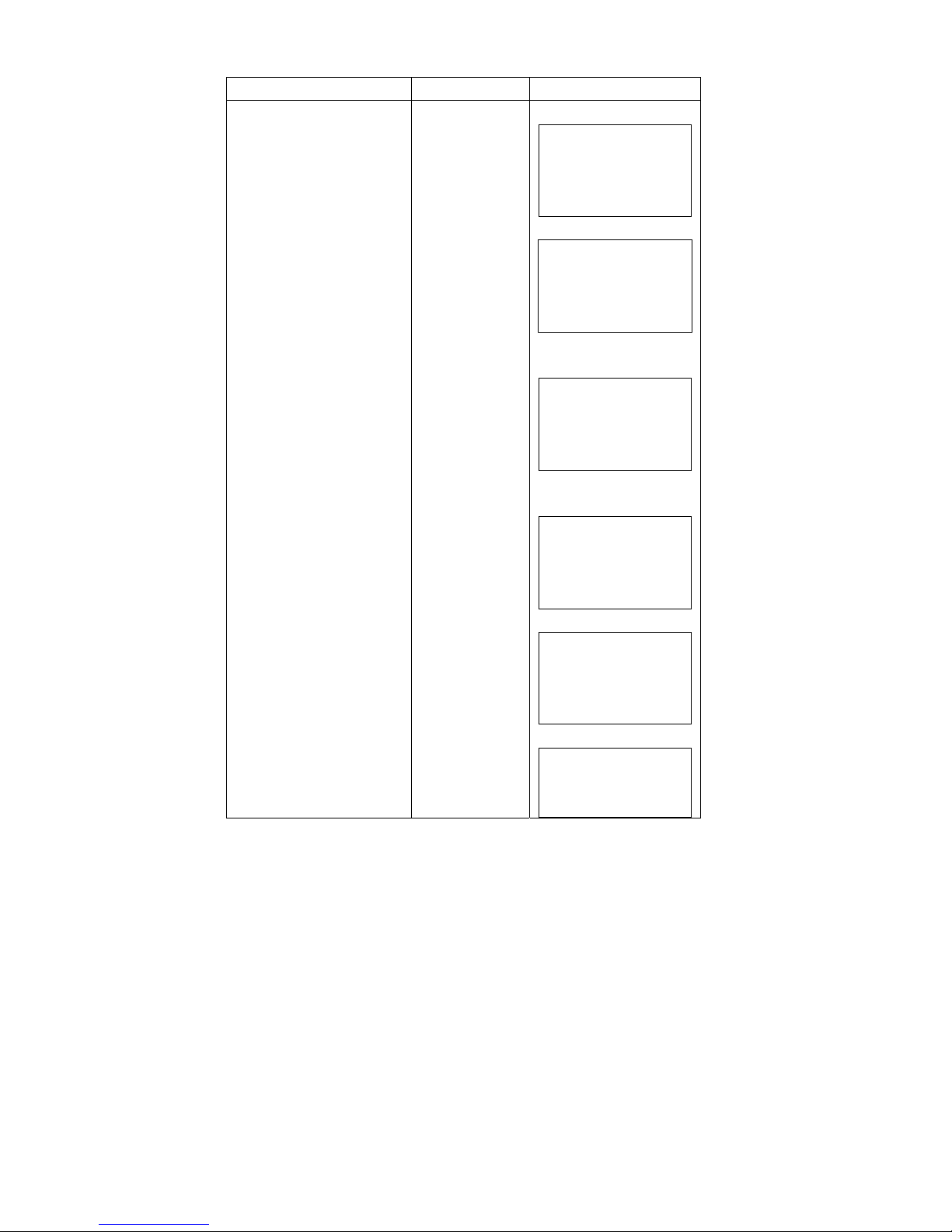

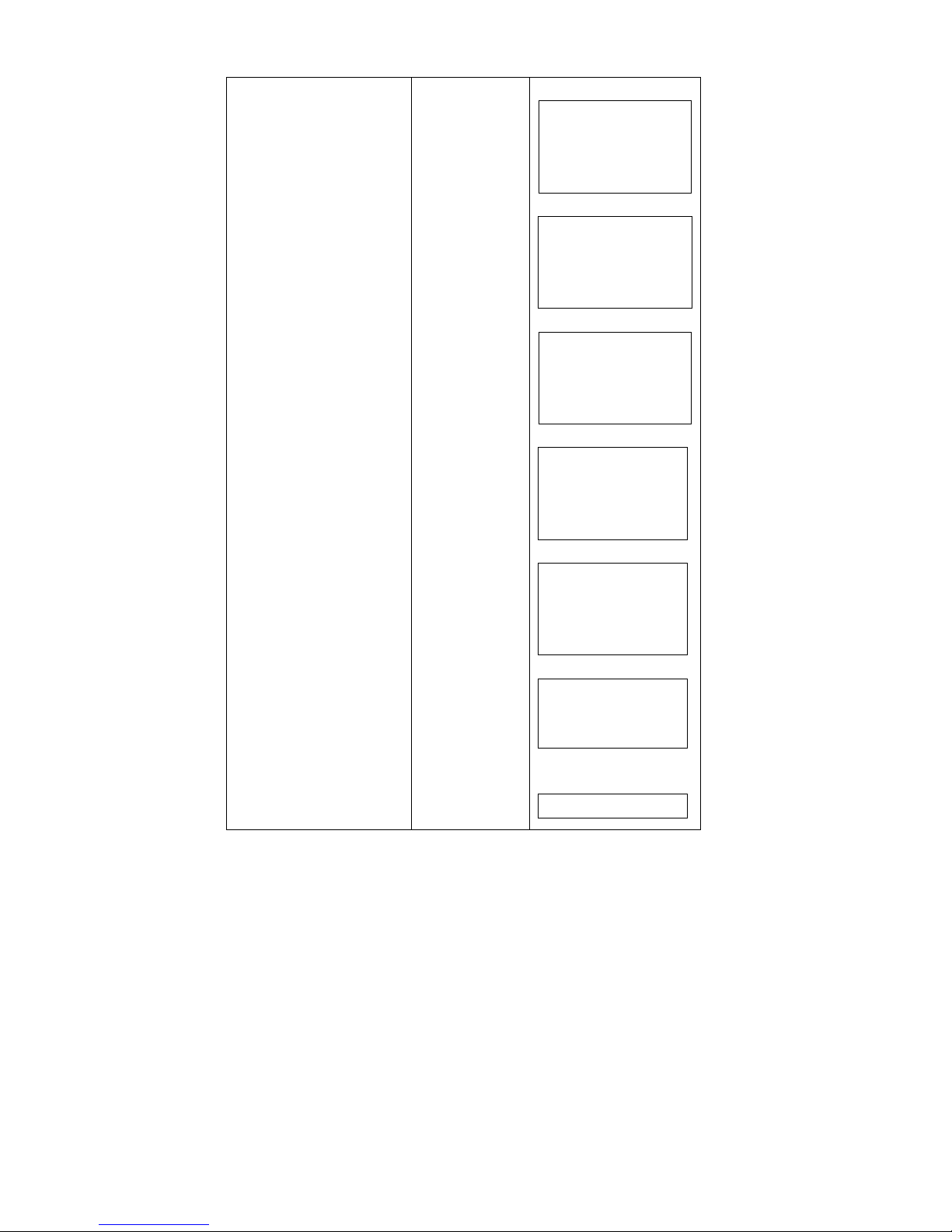

1.2 Operation Keys & Functions

key name function

POW/MEAS

Power

ON/OFF

Measure

Power ON/OFF, and start to measure.

Power ON: press once;

Power OFF: hold on for 2 seconds.

MENU menu Return to the menu list.

DIST distance

measure

In measurement status, press it to start measure

the distance and display the distance.

↑↓

select Turn the page of menu list or data list.

→

←

Number

moving

Turn the left or right page when viewing the data,

or move left or right in inputting status.

ENT enter To conf irm the parameters or inputting data.

ESC ESC To escape from menu or any setting mode. Also

to go backspace to delete a character in

inputting mode.

0~9

number keys Inputting numbers.

-

Mode of

setting

inverse staff

Use for inputting inverse staff. Set the inverse

staff. You should activate this function in

parameter setting first.

illumination Turn ON/OFF the illumination

. decimal

point

Input a decimal point; while inputting symbols or

characters use this key to switch between

alphabets and numerals.

REC Record key To record the measured data

SET Set key

Enter the setting mode to set the measurement

parameter, condition parameter and instrument

parameter.

SRCH Search key Use for searching and displaying the record data.

IN/SO

Intermediate

point/Stake

out key

To measure the intermediate point or to skake

out while carrying out the Leveling

measurement.

MANU Manually To input the data manually when the [MEAS] key

Page 11

11

input key cannot be used to take measurement.

REP

Repeat

measuring

key

To repeat measuring the measured backsight or

foresight point in the leveling measurement

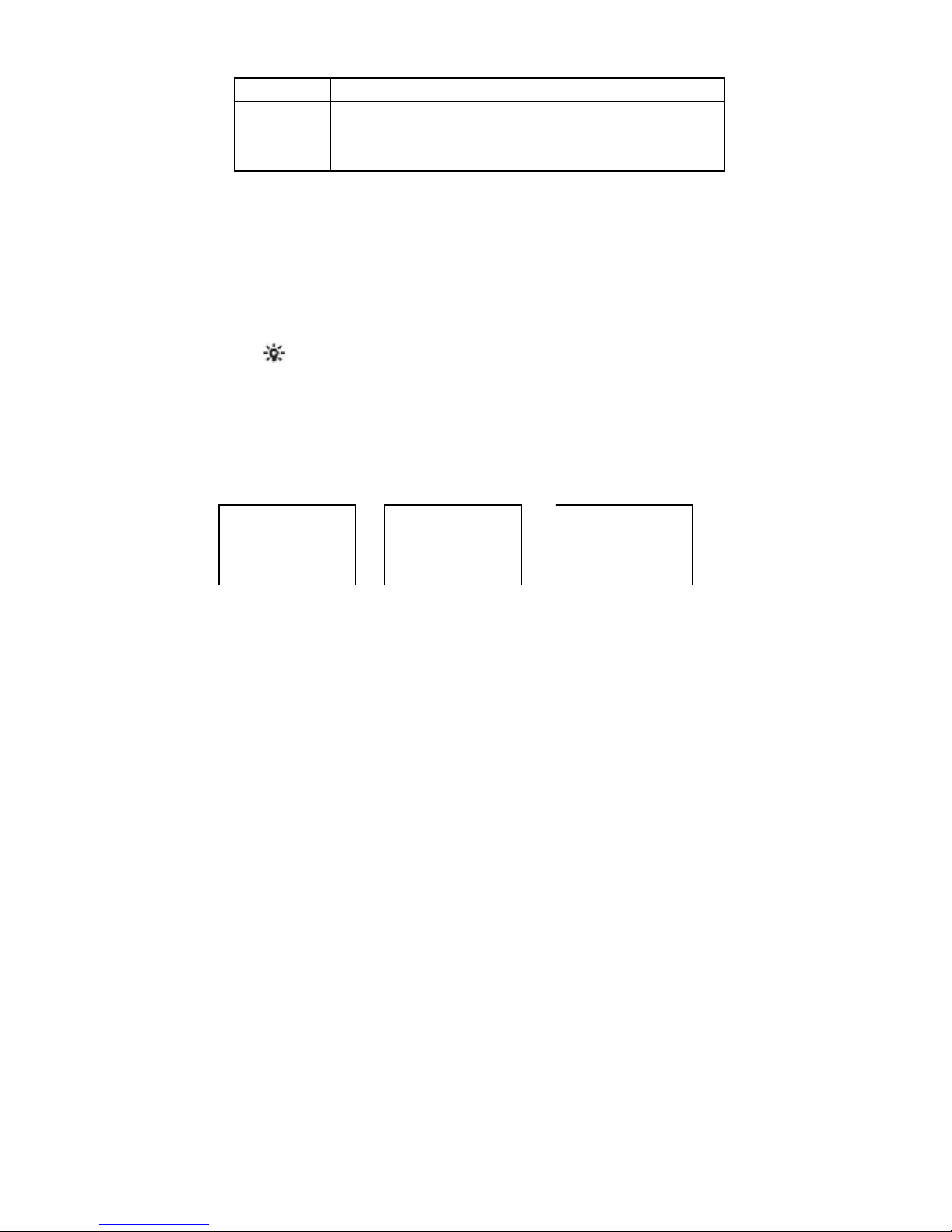

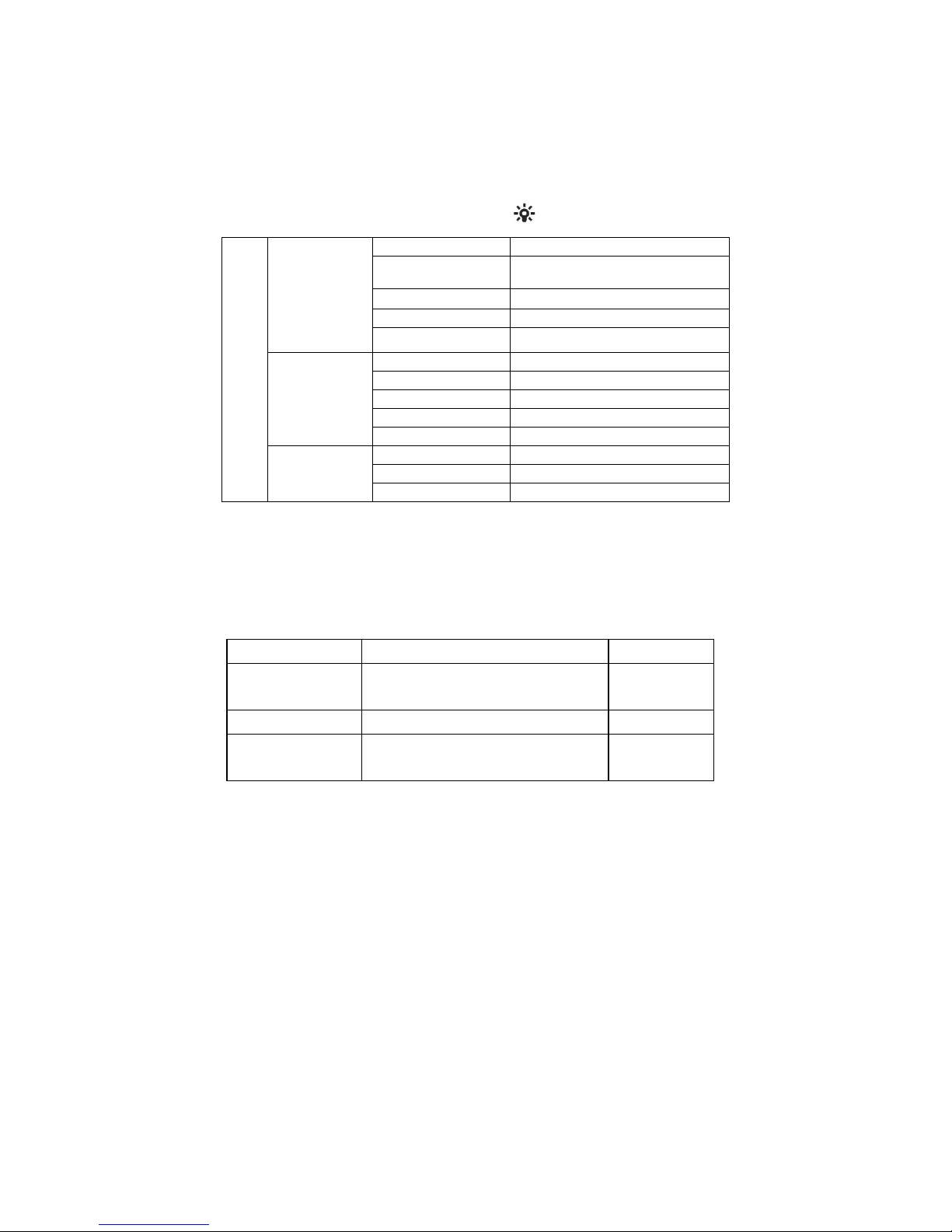

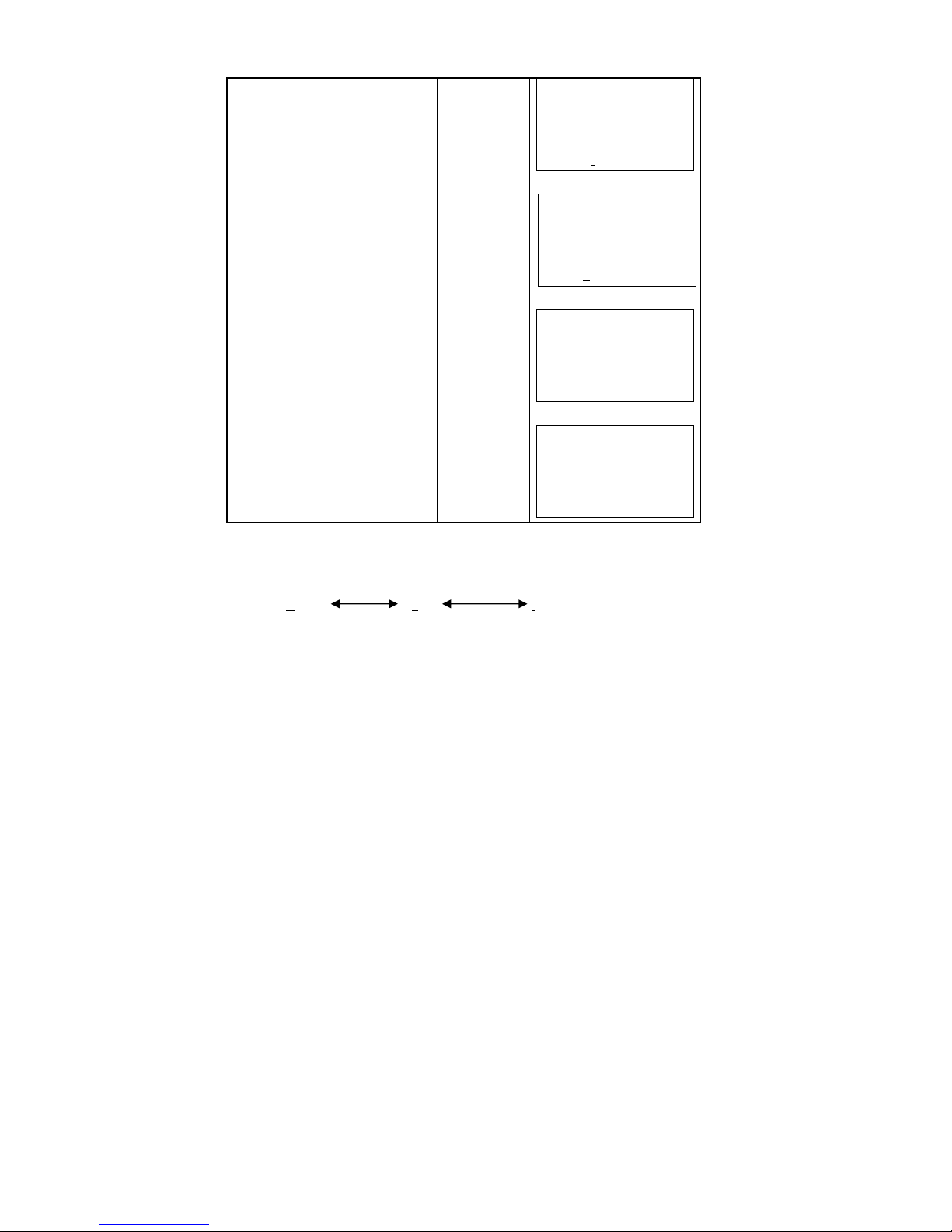

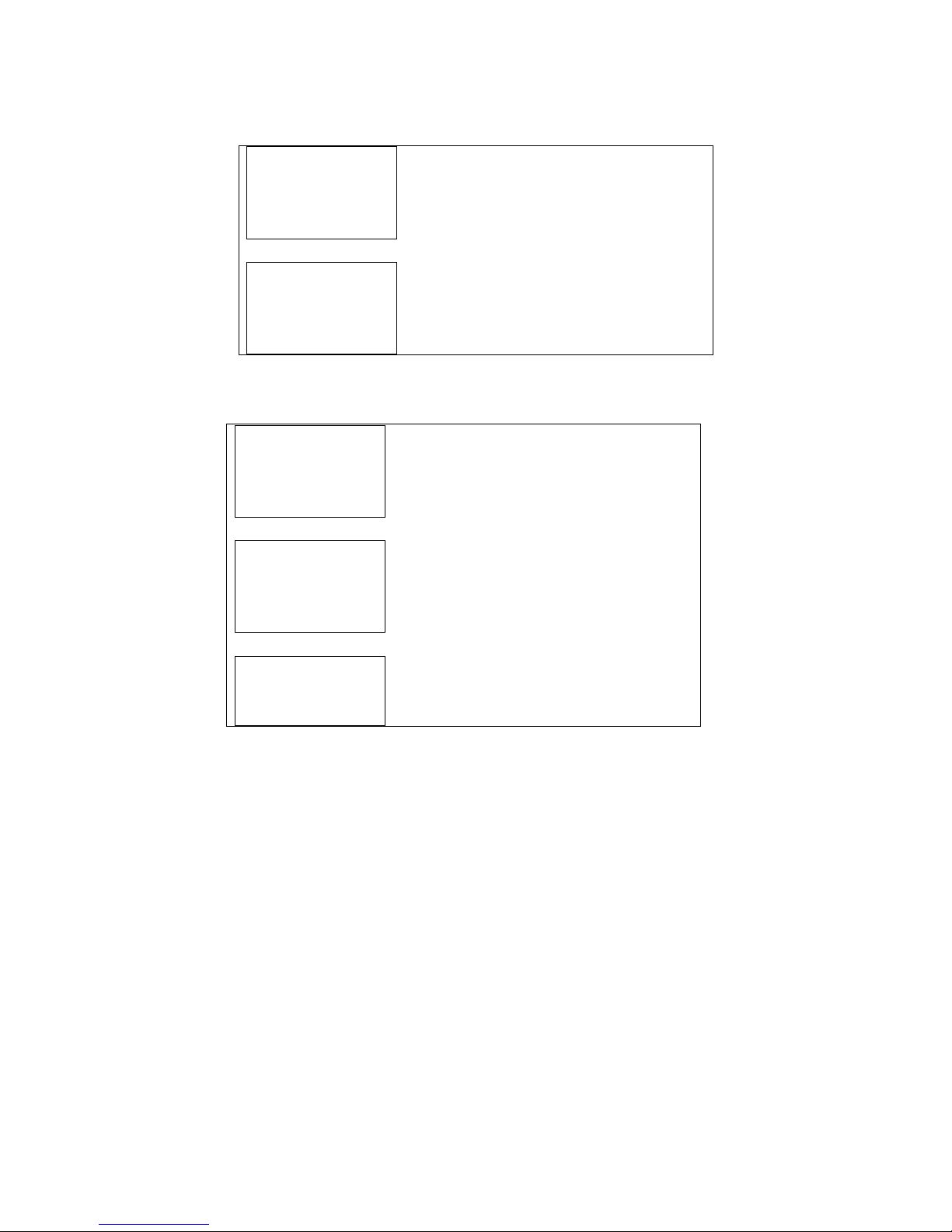

1.3 Display

The display adopts dot matrix LCD, displaying 4 lines, with 20 characters in each.

LCD illumination: ON/OFF.

Press to turn ON or OFF the illumination. It can be set in instrument parameters

too.

Setting Contrast

There’re 9 degrees for the contrast. Please refer to parameter setting to know how to

set the contrast.

Example:

Stardard Mode Leveling Mode Measuring

Menu 1/2

►Standard Mode

Leveling

Adjust

Menu 1/2

Standard Mode

► Leveling

Adjust

Measure

Rod:

Dist:

N:3 >>>>>>>

Page 12

12

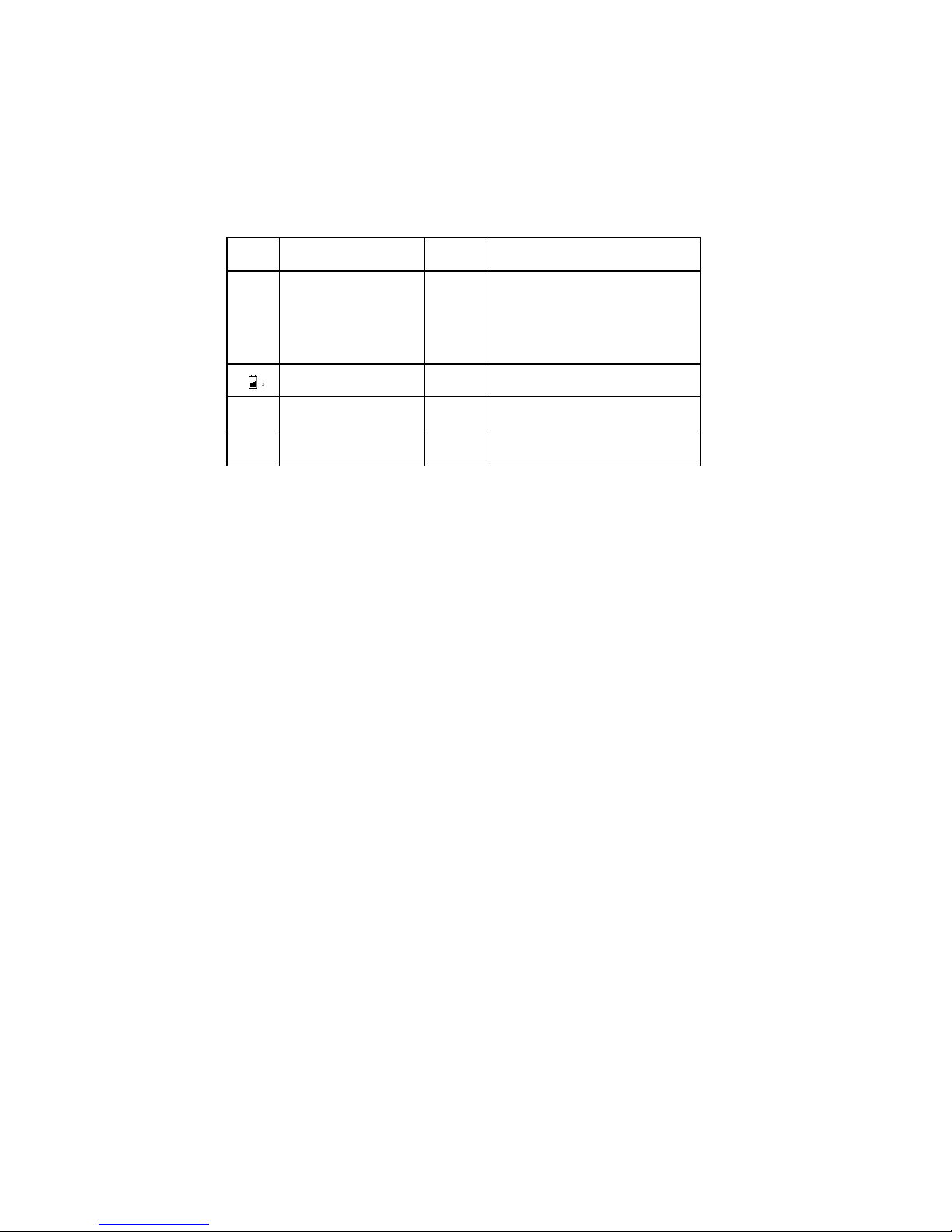

1.4 Symbols

key function key function

p

The current data has

been saved.

a/b

Several pages or menus are

available which can be selected

by [▲] [▼],

b: total pages, a: current page

Battery level Inst Ht Instrument height

BM# Bench Mark CP# Changeover Point

I Staff Inversion

Page 13

13

2. PREPARATION FOR MEASUREMENT

2.1 Mounting the Instrument

Placing the Tripod.

Type E aluminum tripod with flat or dome head tripod is required.

(1) Adjust the three legs of the tripod to a proper length and tighten the fixing screws

at the middle of the leg.

(2) Tighten the hexagonal nut on the head of the tripod in order to make the tripod

legs not too loosen. Place the tripod on a certain point, expand the legs until the

distance between each leg is about 1m. First, f ix a leg, and move the other 2 legs to

make the head of the tripod approximately leveled. If necessary, adjust the length of

the tripod legs.

(3) Trample the legs into the earth or fix it well on the ground.

Mount the Instrument on the Head of the Tripod.

Take out the instrument carefully and place it on the head of the tripod.

(1) Aim the tripod central screw to the center of the tribrach and tighten the screw

until it is fixed at the head of the tripod.

(2) If you need to define an angle or a line through the horizontal dial, you should

center the instrument precisely with a plummet.

(3) Center the circular bubble by adjusting the three leveling screws of the tribrach. If

you are using a dome headed tripod, you should slightly loosen the tripod central

screw and rotate the instrument round the head of the tripod until the circular bubble

is centered, then tighten the screw.

Mounting the Instrument on a Certain Point (centering)

If you need to measure an angle or alignment, please precisely center the instrument

at a certain point with the plummet.

(1) Hang the plummet at the plummet hook of the central screw of the tripod.

(2) Adjust the plummet line to a proper height.

(3) In case the instrument is not centered at the known point, you can move the

instrument to that point without changing the position relationship between the

tripod leg and its head. First, put the tripod on the known point approximately until

Page 14

14

the plummet is about 1cm away from the point. Second, grasp two legs of the tripod

and adjust the tripod by the third leg until the head of tripod is leveled approximately

with a proper height. Expand the legs of the tripod and fix it on the ground.

(4) Finally, observe the plummet and the hook and trample the legs into the ground.

(5) Slightly loosen the central screw of the tripod and move the instrument on the

head until the plummet is centered at the known point. Tighten the tripod central

screw.

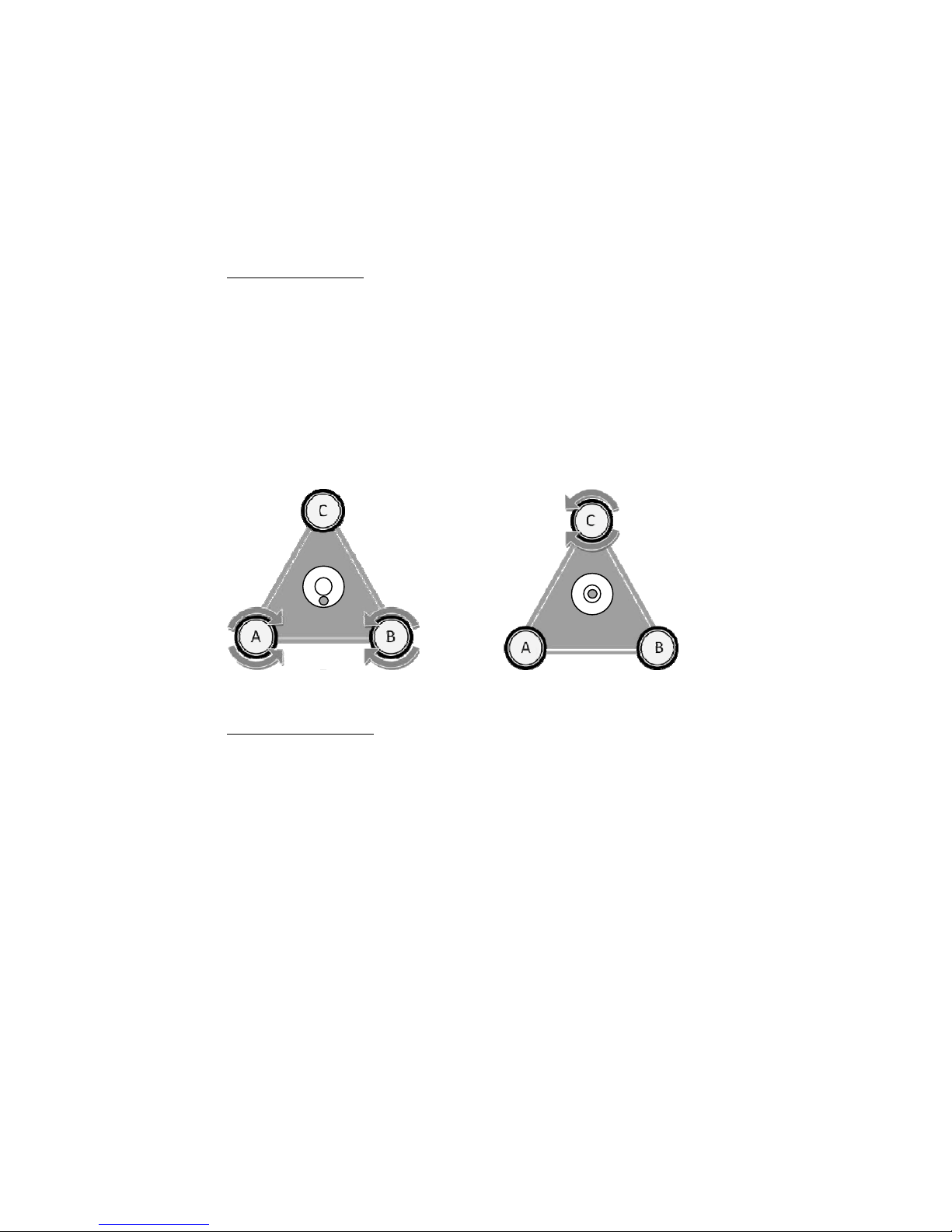

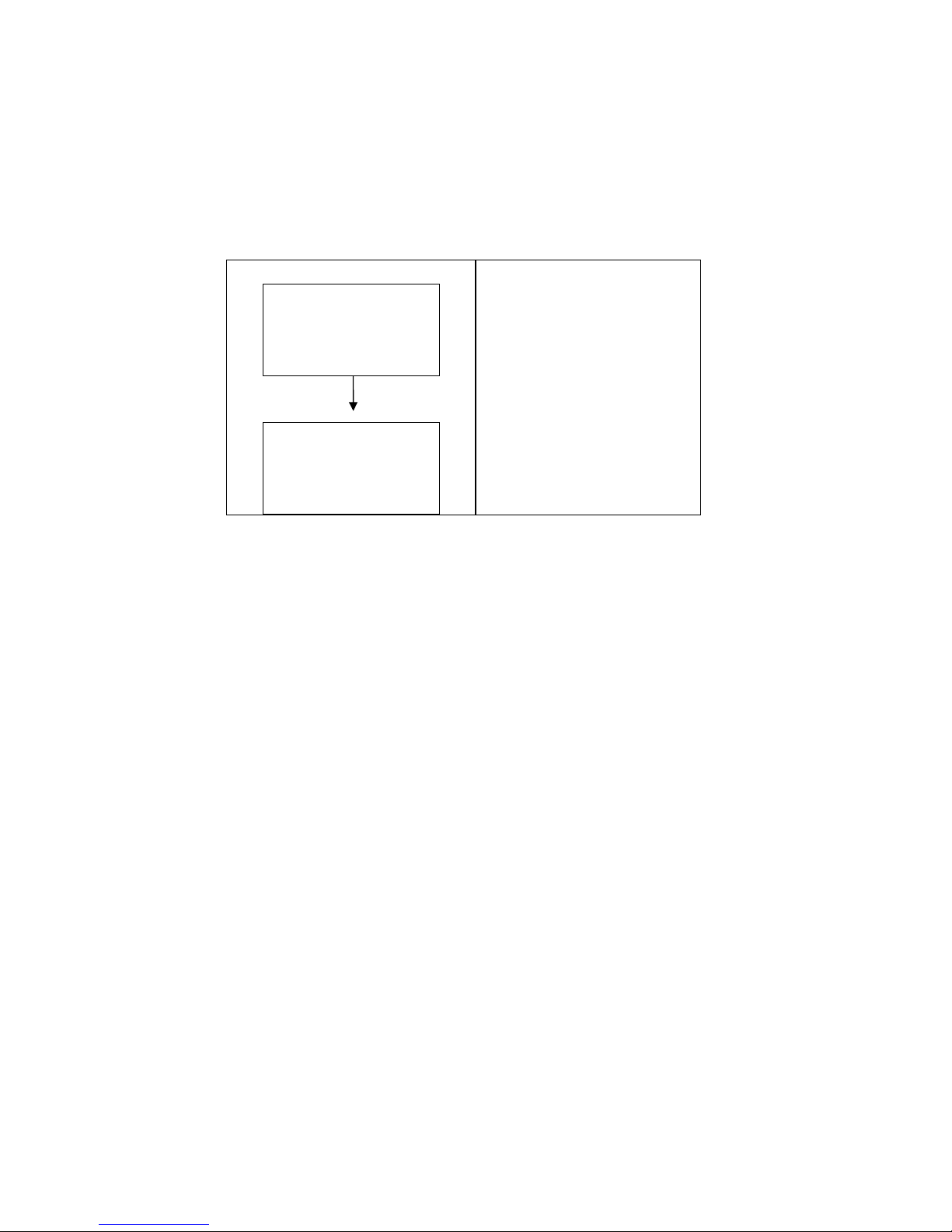

Leveling the Instrument

Center the circular bubble by adjusting the tribrach screw.

First, put the tribrach as the below picture shown. Rotate 2 screws at the same time in

opposite direction until the bubble moves to a position where the line between the

bubble and screw C is perpendicular to the line between screw A and B (refer to

Picture A). Then rotate the screw C to move the bubble to the center of the central

circle. This procedure should be repeated for times until the bubble is centered on any

directions. While leveling, remember the “Left Thumb Principle” which means that the

moving direction of the bubble is the same as that of the left thumb. Do not rotate the

leveling screw without thinking.

Notice: Do not touch the telescope during leveling.

Collimating and Focusing

(1) Sight at the digital staff with the rough collimator.

(2) Rotate the eyepiece slowly until the image of the crosshair becomes clear.

(3) Rotate the focusing hand wheel until the image of digital staff becomes clear.

Rotate the horizontal tangent to move the image of the staff to the center of the

Page 15

15

vertical hair of the crosshair.

(4) Observe through the eyepiece. Move your eye slightly up, down, left and right to

check whether the relative position between the crosshair and the image of the staff is

not changed. If not, please return to step 1.

Notice: Measurement accuracy may be influenced if the crosshair and focusing is not

clear.

2.2 Power On

Press the power key (POW/MEAS).

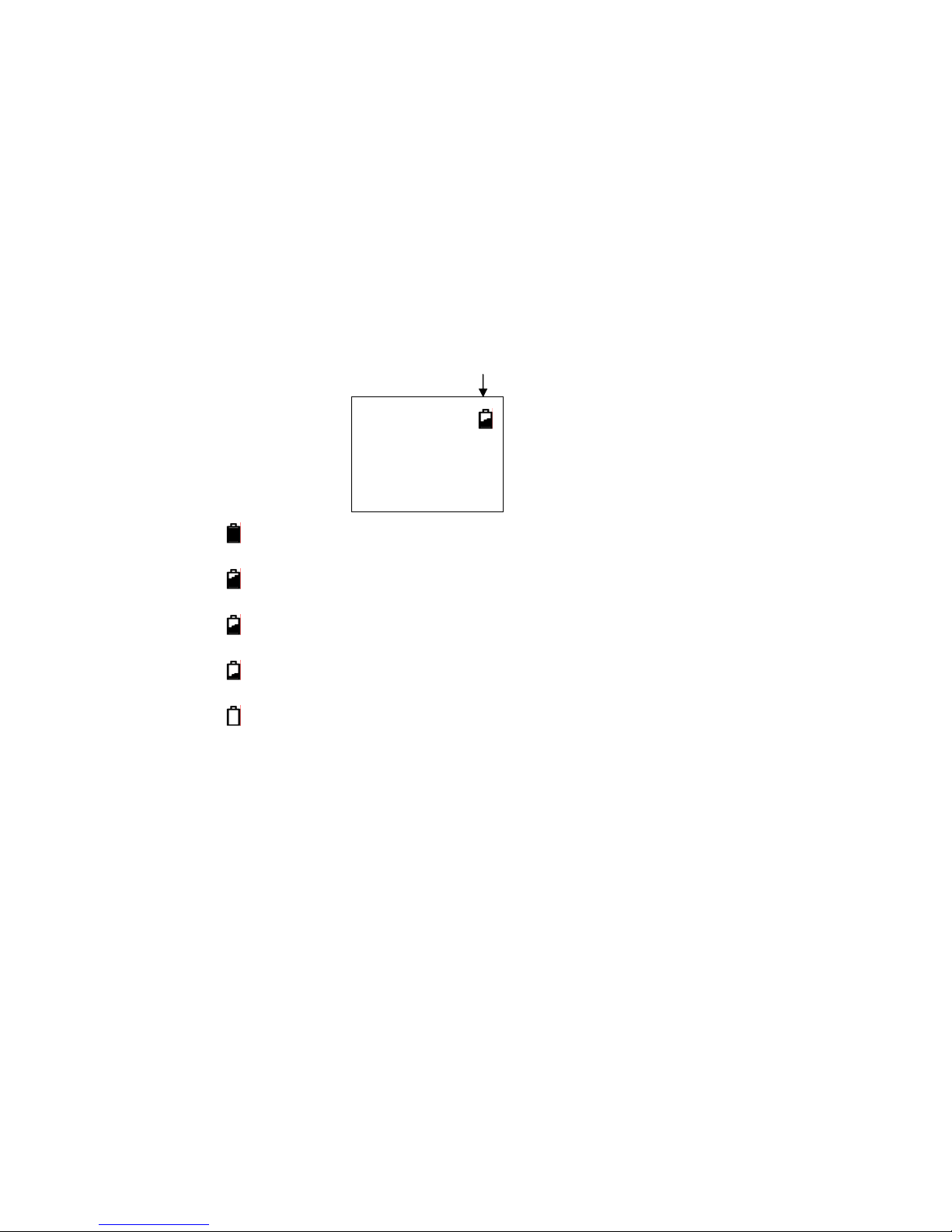

2.3 Remaining Battery Display

The battery symbol indicates the remaining battery.

battery symbol

Menu

►Standard Mode

Leveling

Adjust

Full

Sufficient

Half

Battery low. Please change the battery.

The power will be cut off soon. You need to change the battery.

Page 16

16

2.4 Setting the record mode

In order to save the measurement data in the internal memory of the instrument, the

data saving mode should be set as auto save before leveling measurement. The

default setting is “OFF”.

Flash:

Save the measured data (jobs) into the internal memory

•User can choose “Flash” in “Out Module” of “Condition” Setting if the data needs to

be saved in the flash.

•The maximum storage of memory is about 20,000.

•The maximum number of jobs is 500.

•Folder can not be created in the memory.

SD Card:

The measured data can be saved directly into the SD card.

• User can choose “SD” in “Out Module” of “Condition” Setting if the data needs to be

saved in the SD card.

Communication Port:

Connect DL-201 with external device by cable to receive the real-time measuring data.

User can only use Standard Measurement mode in this condition.

Off:

The measuring data will be displayed without storing and outputting, user can not use

Leveling Measurement mode in this condition.

See next page for the example.

Page 17

17

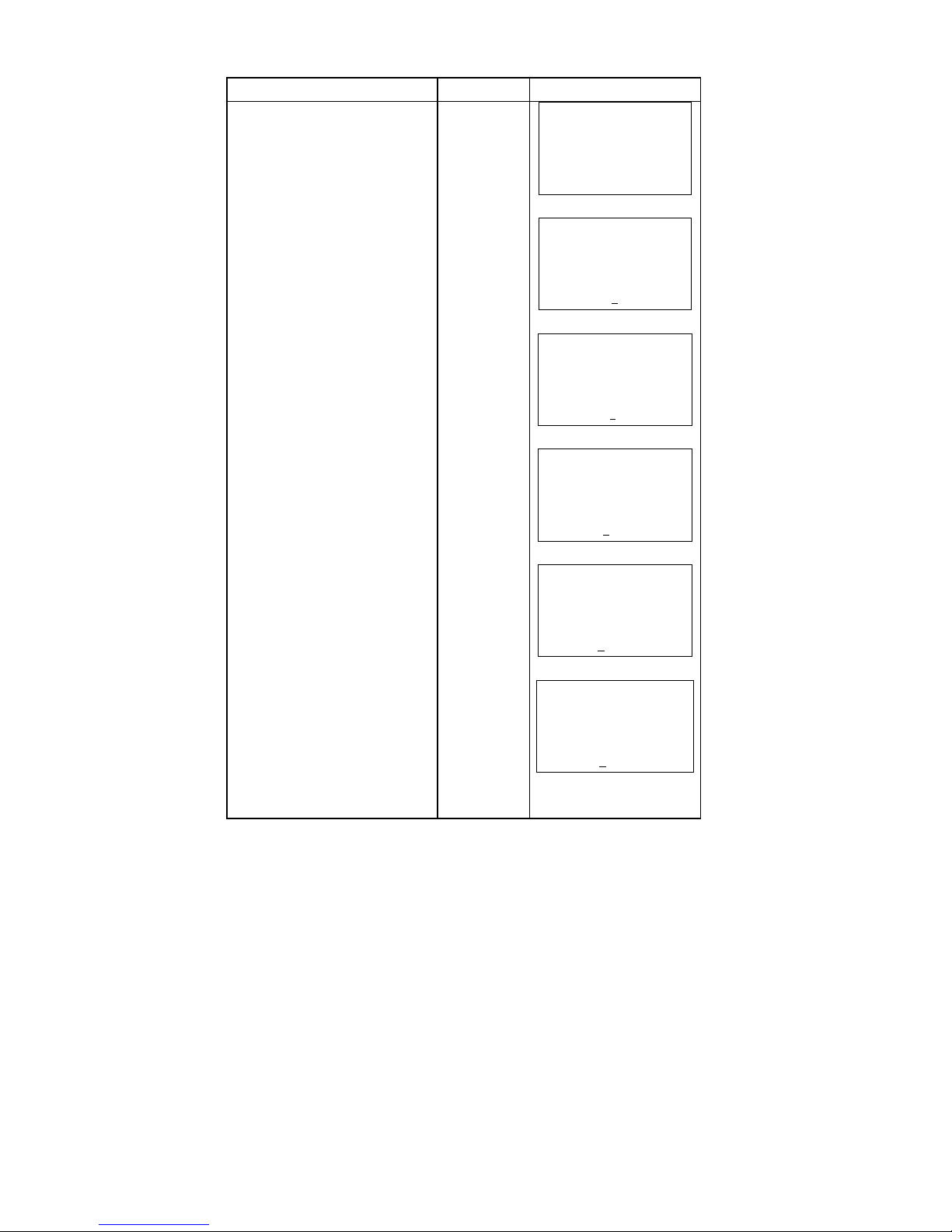

Operating Procedures Operation Display

1. Press [Set] key to enter the

setting mode on Menu screen,

see detail in Chapter 9 “Set”.

2. Press [▲] or [▼] key to enter

the “Out Module” in Condition

setting.

3.Press [ENT] key;

4. Press [▲] or [▼] key to

select.

5.Press [ENT] to confirm.

[SET]

[▲] or [▼]

[ENT]

[▲] or [▼]

[ENT]

Menu 1/2

►Standard Mode

Leveling

Adjust

Setting

Measurement

►Condition

Instrument

Condition 1/2

Point No.

Wait Time

►Out Module

Out Module 1/2

►OFF

Flash

SD

Out Module 1/2

OFF

► Flash

SD

Note: When the output is in “Flash”, the “F” mark will be displayed on the top right side of

the screen; when the output is in SD card, the “S” mark will be displayed; when the output

is by USB, the “U” mark will be displayed; when the output is off, no mark will be displayed.

Page 18

18

2.5 SD Card

User can use SD card for data storage, data copy and data search.

SD card function only can be used while the”Out Module” is set as “SD”

To format the SD card please refer to the Chapter 7 “Format Flash or SD Card”

For SD card management, please refer to the Chapter 8 “Data Manage”

Note: When the system is loading data from the SD card, do not remove the battery

and SD card, otherwise, the saved data will be damaged, even it will influence on the

memory storage; the defective SD card may damage the memory storage.

2.6 Menu

The menu includes following programs, the functions located in different menus which can’t

be always optional at the same time. (You may change the mode for different funcitons)

For example, when the “Out Module” is “Communication port” or “OFF”, the Leveling Mode

and Adjust Mode can not be carried out. If user enters the Leveling mode, the “Start Leveling”

and “Continue Leveling” can not be chosen at the same time.

1

st

Menu 2ndMenu 3rdMenu 4thMenu

Measure

S.O G.H

S.O H.D

Standart

Mode

S.O Dist

Start Levelin

g

BFFB

Continue BBFF

End Levelin

g

BF/BIF

Leveling

Outward

/

Return

Method A

Adjust

Method B

Make Grou

p

Input Pt

Search

Flash/SD Job/PN/BM#

Copy Job

Flash/SD

Delete Job

Flash/SD

Check Capacit

y

Flash/SD

Data

manage

File Out

Flash/SD

Menu

Format

Flash/SD

Page 19

19

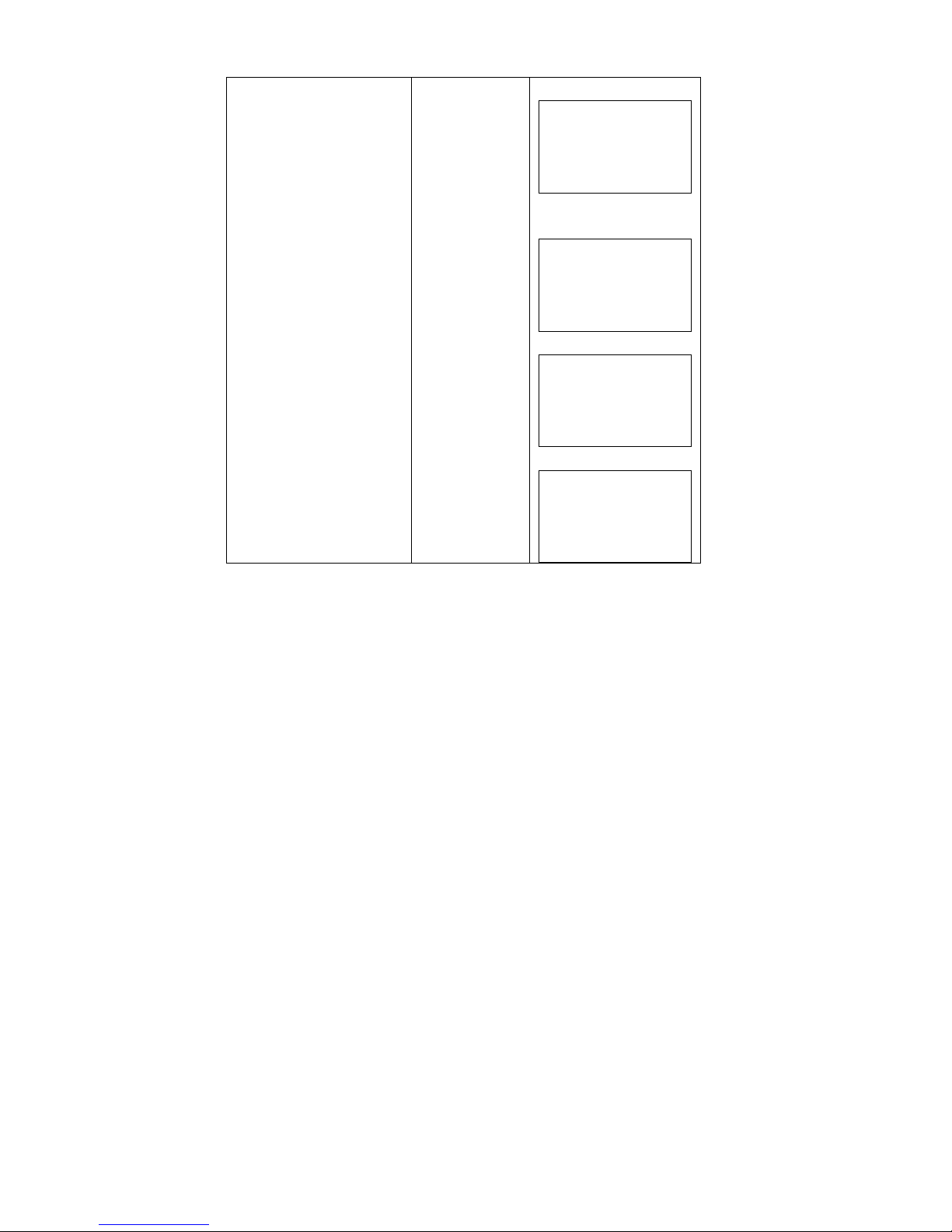

2.7 SET

“Set” key is used for setting the parameters. When carry out the precise measurement, it is

recommended to use the continuous measuring mode which will help improve the accuracy

by the average value; “Auto power off” is available, which means that the power will be cut off

in 5 minutes without any operation; Data will be saved automatically in the Leveing mode while

power off; The backlight can be switched by using the

key.

Measure Mode

Single/N Times/Continuous

Minimum Reading

Srandard 1mm/Precise 0.1mm

Inverse Mode Use / No Use

Unit m(meter) / ft(US.ft

)

Measurement

Diff B-F Dif/TolDil/StafDif

Point No.

Increase/Descend

Wait Time 1~9 Second

Out Module OFF/Flash/SD/Communication

Communication

Standard/User

Condition

Auto Off 5 min

/

Off

Contrast 1~9

Backlight On/Off

SET

Instrument

Instrument Info

2.8 Inputting Characters

When the “Out Module” is on, user can input the alphabets and numerals in the place that

needs to be noted.

Lowercase letters and symbols are only available inputted into the Info, on other

inputting status, only capital letter and number are available.

Program Character Maximum

Group

(SD Card Only)

Only capital letter, number and “-” etc. 8 Characters

Job Only capital letter number and “-” etc. 8 Characters

Info Lowercase and capital letter, number

and all symbols

16 Characters

For example: Input “Tp#7” in Info1

Page 20

20

Operating Procedures Operation Display

1. Press [●] key to enter the

capital letter inputting mode.

2. Press [◄] or [►] key until the

cursor flashes in the let

er “T”.

3. Press [ENT] key to enter “T”

which will be displayed at the

bottom of the line.

4. Press [●] to input the lowercase

lette.

5. Press [◄] or [►] key until the

cursor flashes in the letter “p” and

press[ENT].

[●]

[◄]or[►]

[ENT]

[●]

[◄]or[►]

[ENT]

Measure

Info#1

=>

Measure

Info#1 ?

=>

QRSTUVWXYZABCDEFGHIJ

Measure

Info#1 ?

=>

JKLMNOPQRSTUVWXYZABC

Measure

Info#1 ?

=> T

qrstuvwxyzabcdefghij

Measure

Info#1 ?

=> T

ghijklmnopqrstuvwxy

Measure

Info#1 ?

=> Tp

fghijklmnop

qrstuvwxy

Page 21

21

6. Press [●] to enter the symbol

inputting mode.

7. Press [◄] or [►] key until the

cursor flashes in the letter “#”,

then press [ENT].

8. Press [ESC] key to enter

numeral inputting mode.

9. Press numeric key [7], after

confirming the inputted content,

press [ENT] key.

[●]

[◄] or [►]

[ENT]

[ESC]

[7]

[ENT]

Measure

Info#1?

=> Tp

?@[_]^{|}!

”#$%&’()*

Measure

Info#1?

=> Tp

[_]^{|}!”#$%&’()*+-

Measure

Info#1?

=> Tp#

[_]^{|}!”#$%&’()*+-

Measure

Info#1?

=> Tp#7

● Use [●] key to switch the input mode.

Capital letter Lowercase letter Symbol

A

BCD abcd !”#$

●Available symbols to input are as follow:

!″ #$%& ()*+-./ :;<=>?@[_]^\ {|}

2.9 Staff Collimation and Focus

(1) Focusing

Adjust the eyepiece focusing screw until the crosshair can be seen clearly. Then adjust

the focusing screw until you can see the staff clearly through the objective lens.

A precise focusing can shorten the measuring time and improve the accuracy.

Page 22

22

Measurement of high accuracy requests precise focusing as well as continuous

measures.

(2) Obstacles

Measurement can be implemented if the staff is blocked less than 30%. Even if the

crosshair center is blocked, as long as the field of view is blocked less than 30%,

measurement still can be implemented. However, in this case, the accuracy might be

affected.

(3) Shadow

The surveying accuracy may be influenced if the staff is covered by shadow. In some

cases, it is not possible to measure.

(4) Backlight

If the background of the staff is very bright, it will affect the contrast of the staff, the

digital level might not be able to measure. You can cover something ahead of the

objective len in order to reduce the background light invading to the len. When a

strong light comes into the eyepiece, it might not be able to measure either. You can

also cover the eyepiece in order to block the strong light from coming into the

eyepiece.

When the sun is in a low position (for example, in the morning or at night fall), or if the

sun light comes into the objective lens directly, it is suggested to block the sunlight

with hands.

2.10 Surveying Note

In order to make full use of the functions of instrument, please pay attention to the

following:

(1) Set up the staff in bright place. If possible, prolong the staff completely. If

illumination is employed, it is suggested to illuminate the whole staff, otherwise the

accuracy might be affected.

(2) The shortest distance between instrument and staff is 1.5m.

(3) It will affect the accuracy when staff blocked. If the bar code on the staff is

Page 23

23

blocked by tree branches or leaves, the digital level might display error, or the

accuracy decreased.

(4) If the place where the staff located darker than that of the eyepiece, an error

might occur; you can block the light for the eyepiece with something proper.

(5) Deflection and pitching of the staff may affect the accuracy. During the

measurement, make sure the staff is paralleled to the vertical hair of the reticle. The

staff should be unfolded completely and fixed well. Make sure the joints of the staff

are well and precise. Avoid to measure through the glass window.

(6) After a long storage or transportation, check and calibrate the digital and

optical sight errors. Then adjust the circular vial and keep the optical parts clean.

3. STANDARD MODE

Standard Mode includes Measure, S.O G.H, S.O H.D and S.O Dist.

3.1 Measure

In Measure function, user can measureing the staff reading and distance without

calculating the ground height. When the “Out Module” in “Condition Setting” is set as

“Flash” or “SD”, user needs to input job name and information. All Data will be saved in

the flash or SD card.

For the measuring time, please refer to the “Measure Mode” of “Measurement

Set”

[Example]: “Out Module” is “Flash”, “Measure Mode” is 3 times

Page 24

24

Operating Procedures Operation Display

1. Press [ENT] key.

2. Press [ENT] key.

3. Input the job name and

press [ENT].

※1), 3)

4. Input measuring point

name 12 and press [ENT].

※1), 3)

5. Input the note1-3 and

press [ENT].

※1) ※3)

●If user want to skip the

note 2 and enter to step 6, it

just needs to press [ENT] key.

[ENT]

[ENT]

Input job name

[ENT]

Input measuring

point

[ENT]

Input Info 1

[ENT]

Input Info 2

[ENT]

Menu 1/2

►Standard Mode

Leveling

Adjust

Standard Mode 1/2

►Measure

S.O G.H

S.O H.D

Measure

Job Name?

=>J01

Measure

Meas#

=>12

Measure

Info#1?

=>1

Measure

Info#2?

=>1

Page 25

25

6. Collimate at the staff.

7. Press [MEAS] key.

Measuring for 3 times and

the result will be displayed

for M seconds※4)※5).

● If the Measure Mode is

Continuous, press [ESC], the

last measuring result will be

displayed for M seconds.

8. Press [REC] key to save the

result. ※6).

Input Info 3

[ENT]

[MEAS]

Continuous

[ESC]

[REC]

Measure

Info#3?

=>1

Measure

Press[MEAS] to meas

Meas#:12

Measure

Rod:

Dist:

N:3 >>>>>>>

Measure 1/2

Rod Ave:0.8263m

Dist Ave:18.818m

N:3 δ:0.04mm

※1) The maximum of job name is 8 characters of capital letter or number, and the

maximum of note is 16 characters of lowercase and capital letter, number and

symbols.

※2) The maximum of point name is 8 characters.

※3) When the “record mode” is off, the job name, point name and note can not be

inputted.

●Relationship between measuring number(Mn)and point name(Pn)is as follow:

Mn 11 Pn 1 Mn 12 Pn 1 Mn 13 Pn 1……

Pn 2 Pn 2 Pn 2

Pn 3 Pn 3 Pn 3

Page 26

26

· · ·

· · ·

· · ·

※4) “Wait Time” can be set manually, please refer to “Set”

※5) After measuring, the result will be displayed. Press [▲] or [▼] to switch the page.

※6) After being saved, the point name will increase or descend automatically.

After measuring, press [▲] or [▼] key to switch the pages

Measure 1/2

Rod Ave:0.8263m

Dist Ave:18.818m

N:3 δ:0.04mm

Measure 2/2

Meas#:12

PN:1

Distance display:

N-times: average surveying value

Continuous: last surveying value

N: Surveying time

δ: Standard offset

measured point name

point name

3.2 S.O G.H (Stake out Ground Point)

System can measure the height of corresponding point B by the height value (Ha+H),

which is calculated by the height (Ha) of the known point A. The measurement result

will not be saved.

Please see the example in the next page.

Page 27

27

Operating Procedures Operation Display

1. Press [ENT] key.

2. Press [ENT] key.

[ENT]

[ENT]

Menu 1/2

►Standard Mode

Leveling

Adjust

Standard Mode 1/2

Measure

►S.O G.H

S.O H.D

Page 28

28

3. Input the ground height of

backsight point and press

[ENT].

4. Input the ground height of

stakeout point and press

[ENT].

5. Focus and sight at the

backsight point, then press

[MEAS].

6. The measuring result of

backsight point will be

displayed, then press [ENT]

key.

7. Focus and sight at the

stakeout point, then press

[MEAS].

8. The measuring value and

stakeout value will be

displayed. ↑ indicates that

the staff is too low and it

needs to be moved up.

Input BS G.H

[ENT]

Input SO G.H

[ENT]

[MEAS]

[ENT]

[MEAS]

[▲] or [▼]

S.O G.H

Input BS G.H

=23.000 m

S.O G.H

Input SO G.H

=25.000 m

S.O G.H

Meas BS Pt

Press[MEAS] to meas

S.O G.H F

B Rod: 1.512m

B Dist: 26.78m

N:3 δ:0.4mm

S.O G.H

Meas SO Pt

Press[MEAS] to meas

S.O G.H

S Rod: 1.612m

S.O:↑2.100m

N:3 δ:0.4mm

S.O G.H

Page 29

29

9. Press [▲] or [▼] key to

switch to the page of sight

distance and height of

stakeout point, then press

[ENT].

10. Press [REP] to start a new

stakeout job and start over

backsight point surveying.

Press [ENT] to continue

stakeout measurement.

Press [ESC] to exit.

[ENT]

S Dist: 26.78m

G.H: 22.90m

S.O G.H

REP: New Meas

ENT: Continue

ESC: Exit

3.3 S.O H.D (Stake out Height Difference)

According to the inputted height difference H which calculated from known point A

and point B, system can measure out the corresponding point B, the measurement

result will not be saved.

Operating Procedures Operation Display

Page 30

30

1. Press [ENT] key.

2. Press [ENT] key.

3. Input height difference

value and press [ENT].

4. Focus and sight at the

backsight point, then press

[MEAS].

5. The measuring result of

backsight point will be

displayed, then press [ENT]

key.

6. Focus and sight at the

stakeout point, then press

[MEAS].

[ENT]

[ENT]

Input H.D

[ENT]

[MEAS]

[ENT]

[MEAS]

[▲] or [▼]

Menu 1/2

►Standard Mode

Leveling

Adjust

Standard Mode 1/2

Measure

S.O G.H

►S.O H.D

S.O H.D

Input SO H.D

=-1.000 m

S.O H.D

Meas BS Pt

Press[MEAS] to meas

S.O H.D F

B Rod: 1.512m

B Dist : 26.78m

N:3 δ:0.4mm

S.O H.D

Meas SO Pt

Press[MEAS] to meas

S.O H.D

Page 31

31

7. The measuring value and

stakeout value will be

displayed. ↓ indicates that

the staff is too high and it

needs to be moved down.

8. Press [▲] or [▼] key to

switch to the page of S Dist

(Sight Distance) and H.D

(Height Difference) of

stakeout point, then press

[ENT].

9. Press [REP] to start a new

stakeout job and start over

backsight point surveying.

Press [ENT] to continue

stakeout measurement.

Press [ESC] to exit.

[ENT]

S Rod: 1.612m

H.D:↓0.900m

N:3 δ:0.4mm

S.O H.D

S Dist: 26.78m

H.D: -0.100m

S.O H.D

REP: New Meas

ENT: Continue

ESC: Exit

3.4 S.O Dist(Stake out Distance)

According to the inputted distance Dab from known point A to point B, system can

measure the corresponding point B. The measurement result will not be saved.

Operating Procedures Operation Display

Page 32

32

1. Press [ENT] key.

2. Press [▼] key.

3. Press [ENT] key;

4. Input stakeout distance

and press [ENT];

5. Focus and sight at the

stakeout point, then press

[MEAS].

6. Press [▲] or [▼] to switch

page and display the rod

reading and input value, then

press [ENT].

7. Press [ENT] to continue

stakeout measurement.

Press [ESC] to exit.

[ENT]

[▼]

[ENT]

Input S.O Dist

[ENT]

[MEAS]

[▲] or [▼]

[ENT]

[ENT] or [ESC]

Menu 1/2

►Standard Mode

Leveling

Adjust

Standard Mode 1/2

Measure

S.O G.H

►S.O H.D

Standard Mode 2/2

►S.O Dist

S.O Dist

Input SO Dist

=15.000 m

S.O Dist

Meas SO Pt

Press[MEAS] to meas

S.O Dist

S Dist: 26.78m

Dist: ←11.78m

S.O Dist

S Rod: 1.005m

Page 33

33

Input: 15.00m

S.O Dist

ENT:Continue

ESC:Exit

Page 34

34

4. LEVELING

In Leveling Mode, “Out Module” should be set as “Flash” or “SD”. In this section, we

take “Flash” for example.

If user wants to save leveling measured data directly to SD card, the “Out Module”

should be set as “SD”.

4.1 Start Leveling

In “Start Leveling” function, user should input job name, pointname and height of

benchmark, and then start to do the measuring.

Leveling 1: B1→F1→F2→B2

Leveling 2: B1→B2→F1→F2

Leveling 3: B→F/ B→I→F

Leveling 4:Outward/Return:B1→F1→F 2→B 2/ F 1→B 1→B 2→F 2

After measuring a station, user can switch off the instrument to save power, the

instrument will automatically continue the next station measurement after power on. If

the measurement do not finish while power off, the point needs to be remeasured

after switching on the instrument.

Page 35

35

Operating Procedures Operation Display

1. Press [ENT] key.

2. Press [ENT] key.

3. Input job name and press

[ENT].

4. Press [▲] or [▼] to choose

Leveling Measurement mode

and press [ENT];

5. Press [▲] or [▼] to choose

from Input BS Pt or

Transfer(call up an existed

basepoint height). ※1) Then

press Enter.

6. Input the point name of

benchmark and press [Ent]

[ENT]

[ENT]

Input Job Name

[ENT]

[ENT]

[▲] or [▼]

[ENT]

Input BM#

[ENT]

Leveling F

BM#?

=>B01

Menu 1/2

Standard Mode

► Leveling

Adjust

Leveling

►Start Leveling

Continue Leveling

End Leveling

Leveling

Job Name?

=>J01

Leveling

►B1→F1→F2→B2

B1→B2→F1→F2

B→F/B→I→F

Leveling 1/2 F

Input BS Pt

Tra ns fe r

Page 36

36

7. Input the information and

press [ENT].

(Press [ENT] directly to skip).

8. Input ground height of

backsight point and press

[ENT].

Input Info

[ENT]

[ENT]

F

Input BS G.H

=100 m

F

Info#1

=>1

F

Info:#2

=>1

F

Info:#3?

=>1

※1) The existed point data can be input in the menu→Data Manage→Input Pt.

※2) User can input three groups of notes, each notes has 16 characters of numbers or

symbols

Leveling: Measurement of backsight and foresight data

Leveling measurement 1: B1→F1→F2→B2

Please see the example next page.

Page 37

37

Operating Procedures Operation Display

1. After inputting the ground

height of backsight point,

the screen will display “Bk1

(backsight). If the previous

step is “Start Leveling”,

screen will display

BM#(Benchmark number).

2. Sight at the staff which is

on the backsight point (Bk1).

3. Press [MEAS] key.

Example: If it measures 3

times, after surveying, the

average value will be

displayed for M seconds※1).

4. When it is in continuous

measuring mode, press [ESC]

to display the last measuring

data for M seconds.

5. Then the screen will

display “Fr1” and the

foresight point name will

increase or descend

automatically. Now press

[ESC] can modify the point

name. After that, collimate

the staff in the foresight

Sight at Bk 1

[MEAS]

In continuous

measuring mode

[ESC]

Sight at Fr1

[MEAS]

Level BFFB

B1Rod:0.8259m

B1Dist: 3.914m

N:3 >>>>>>>>>

Level BFFB

Bk1

BM#:B01

Press [MEAS] to meas

Level BFFB F

Bk1

BM#:B01

>>>>>>>>>

Level BFFB 1/2

B1Rod Ave:0.8259m

B1Dist Ave: 3.914m

N:3 δ:0.00mm

Level BFFB

Fr1

PN :P01

Press [MEAS] to meas

Page 38

38

point (Fr1).

6. Press [MEAS].

After measuring, the

average value will be

displayed for M seconds.

7. Sight at the staff in the

foresight point (Fr2) and

press [MEAS].

8. After measuring, the

average value will be

displayed for M seconds.

9. Focus and sight at the staff

in the backsight point (Bk2)

and press [MEAS].

10. If there are more

backsight and foresight

points, user can start from

the step 2 to 9.

Sight at Fr2

[MEAS]

Sight at Bk 2

[MEAS]

Level BFFB 1/2

F1Rod Ave:0.8260m

F1 Dist Ave: 3.914m

N:3 δ:0.02mm

Level BFFB

Fr2

PN :P01

Press [MEAS] to meas

Level BFFB 1/2

F2 Rod Ave:0.8260m

F2 Dist Ave: 3.913m

N:3 δ:0.02mm

Level BFFB

Bk2

BM#:B01

Press [MEAS] to meas

Level BFFB 1/2

B2 Rod Ave:0.8261m

B2 Dist Ave: 3.915m

N:3 δ:0.02mm

※1) User can set the display time in the “Condition Setting”.

After measuring, following data will be displayed.

Press [▲] or [▼] key to turn page.※

Page 39

39

After measuring the backsight point 1(Bk 1), press [▲] or [▼] to display the following

interface:

Level BFFB 1/2

B1 Rod Ave:0.8259m

B1 Dist Ave : 3.914m

N:3 δ:0.00mm

Level BFFB 2/2

BM#:B01

The following items are only displayed on

the N-times measuring mode:

Distance to the Backsight point

N times mode: Average value

Continuous mode: Last measuring value

N: Total measuring times

δ: Standard offset

Backsight point name

After measuring the foresight point 1(Fr 1), press [▲] or [▼] to display the following

interface:

Level BFFB 1/2

F1 Rod Ave:0.8260m

F1 Dist Ave : 3.914m

N:3 δ:0.02mm

Level BFFB 2/2

H.D 1: -0.0001m

Fr GH1:99.9999m

PN :P01

Disance to the foresight point

N times mode: Average value

Continuous mode: Last measuring value

N: Total measuring times

δ: Standard offset

Height Difference from Bk1 to Fr1

Ground height of forsight point

After measuring the foresight point 2(Fr 2), press [▲] or [▼]to display the following

Page 40

40

interface:

Level BFFB 1/2

F2 Rod Ave:0.8260m

F2 Dist Ave : 3.913m

N:3 δ:0.02mm

Level BFFB 2/2

d :0.000m

Σ:7.828m

PN :P01

Disance to the foresight point

N times mode: Average value

Continuous mode: Last measuring value

N: Total measuring times

δ: Standard offset

d:backsight distance sum-foresight distance sum

Σ:backsight distance sum+oresight distance sum

Foresight point name

After measuring the backsight point 2(Bk 2), press [▲] or [▼]to display the following

interface:

Level BFFB 1/3

B2 Rod Ave:0.8260m

B2 Dist Ave :3.915m

N:3 δ:0.02mm

Level BFFB 2/3

E.V Limit: 0.0mm

d: 0.001m

Σ: 7.828m

Level BFFB 3/3

H.D 2:0.0000mm

Fr GH2: 100.0000m

BM#:B01

Distance to the Backsight point

N times mode: Average value

Continuous mode: Last measuring value

δ: Standard offset

E.V:Elevation offset difference=(Bk1-Fr1)-(Bk2-Fr2)

d: backsight distance sum-foresight distance sum

Σ:backsight distance sum+foresight distance sum

Height Difference from Bk2 to Fr2

Ground height of foresight point

Backsight point name

Page 41

41

Leveling measurement 2: B1→B2→F1→F2

Operating Procedures Operation Display

1. After inputting the ground

height of backsight point, the

screen will display “Bk1

(backsight).If the previous step is

“Start Leveling”, screen will

display BM (Bench Mark).

2. Sight at the staff in the

backsight point (Bk1) and Press

[MEAS] key.

3. Focus and sight at the staff in

the backsight point (Bk2) and

press [MEAS].

4. Sight at the staff in the

foresight point [Fr1].

Meanwhile press [ESC] can

change the foresight point name.

Press [MEAS] to measure.

5. Sight at the staff in the

foresight point (Fr2) and press

[MEAS].

6. Move the station and sight at

Sight at Bk 1

[MEAS]

Sight at Bk 2

[MEAS]

Sight at Fr1

[MEAS]

Sight at Fr2

[MEAS]

Level BBFF

Fr1

PN:P01

Press [MEAS] to meas

Level BBFF

Bk1

BM#:B01

Press [MEAS] to meas

Level BBFF

Bk1

BM#:B01

>>>>>>>>>>>

Level BBFF

Bk2

BM#:B01

Press [MEAS] to meas

Level BBFF

Fr2

PN:P01

Press [MEAS] to meas

Page 42

42

the staff in the backsight point

(Bk1), and then press [MEAS].

If there are more backsight and

foresight points, please repeat

step 2 to 5.

Sight at Bk 1

[MEAS]

Level BBFF

Bk1

PN:P01

Press [MEAS] to meas

After measuring, the following data will be displayed.

Press [▲] or [▼] key to turn page※

After measuring the backsight point 1(Bk 1), press [▲] or [▼] to display the

following interface:

Level BBFF 1/2

B1 Rod Ave:0.8259m

B1 Dist Ave : 3.914m

N:3 δ:0.00mm

Level BFFB 2/2

BM#:B01

The following items are only displayed on the

N-times measuring mode:

Distance to the Backsight point

N times mode: Average value

Continuous mode: Last measuring value

N: Total measuring times

δ: Standard offset

Backsight point name

After measuring the backsight point 2(Bk 2), press [▲] or [▼]to display the following

interface:

Page 43

43

Level BBFF 1/2

B2 Rod Ave:0.8260m

B2 Dist Ave:3.915m

N:3 δ:0.02mm

Level BBFF 2/2

BM#:B01

Distance to the Backsight point

N times mode: Average value

Continuous mode: Last measuring value

δ: Standard offset

Backsight point name

After measuring the foresight point 1(Fr 1), press [▲] or [▼] to display the following

interface:

Level BBFF 1/2

F1 Rod Ave:0.8260m

F1 Dist Ave: 3.914m

N:3 δ:0.02mm

Level BBFF 2/2

H.D 1: -0.0001m

Fr GH1:99.9999m

PN :P01

Disance to the foresight point

N times mode: Average value

Continuous mode: Last measuring value

N: Total measuring times

δ: Standard offset

Height difference from Bk1 to Fr1

Ground height of foresight point

After measuring the foresight point 2(Fr 2), press [▲] or [▼] to display the following

interface:

Page 44

44

Level BBFF 1/3

F2 Rod Ave:0.8260m

F2 Dist Ave: 3.913m

N:3 δ:0.02mm

Level BBFF 2/3

E.V Limit:0.0mm

d :0.000m

Σ:7.828m

Level BBFF 3/3

H.D 2: 0.0000m

Fr GH2:100.000m

PN :P01

Disance to the foresight point

N times mode: Average value

Continuous mode: Last measuring value

N: Total measuring times

δ: Standard offset

E.V:Elevation offset difference=(Bk1-Fr1)-(Bk2-Fr2)

d: backsight distance sum-foresight distance sum

Σ:backsight distance sum+oresight distance sum

Foresight point name

Height Difference from Bk2 to Fr2

Ground height of foresight point

Leveling measurement 3: B→F/B→I→F

Operating Procedures Operation Display

1. After inputting the ground

height of backsight point, the

screen will display “Bk1

(backsight).

2. Sight at the staff in the

backsight point (Bk1) and Press

[MEAS] key.

Sight at Bk 1

[MEAS]

Level BIF

Bk1

BM#:B01

Press [MEAS] to meas

Level BIF

Bk1

BM#:B01

>>>>>>>>>>>

Page 45

45

3. Press [IN/SO] ( Intermediate

and Stake out).

4. Chosse “Intermediate” and

press [ENT].

5. Input the point name of

intermediate point and press

[ENT].

6. Input the information and

press [ENT].

7. Focus and collimate the staff in

the intermediate point.

Press [MEAS] to measure.

8. Press [REC] to save data;

press [ENT] if user wants to

continue intermediate point

measurement; press [ESC] to exit.

[IN/SO]

[▲] or [▼]

[ENT]

Point name

[ENT]

Info

[ENT]

[MEAS]

[REC]

[ESC]

Level BIF

Fr1

Pn :P01

Press [MEAS] to meas

Level BIF

►InterMediate

Stake Out

InterMediate

PN ?

=>TP01_

InterMediate

Info#1?

=>

Level BIF

BRod Ave:0.8260m

BDist Ave: 3.913m

N:3 δ:0.02mm

InterMediate

PN :TP01

Press [MEAS] to meas

Page 46

46

9. Sight at the staff in the

foresight point (Fr1) and press

[MEAS].

10. Focus and sight at the staff in

the backsight point (Bk2) and

press [MEAS].

11. Press [IN/SO] to choose

“Intermediate point and Stakeout

measurement”

12. Choose “Stake Out” and press

[ENT].

13. Whether to load the ground

height data, [ENT] for yes,[ESC]

for no.

14. Input the ground height and

press [ENT].

15. Input the point name of

stakeout point and press [ENT].

Sight at Fr1

[MEAS]

Sight at Bk 2

[MEAS]

[IN/SO]

[▲] or [▼]

[ENT]

[ESC]

[ENT]

S.O point

name

[ENT]

Level BIF

Fr1

PN :P01

Press [MEAS] to meas

Level BIF

Bk2

PN :P01

Press [MEAS] to meas

Level BIF

Fr2

PN :P02

Press [MEAS] to meas

Level BIF

InterMediate

► Stake Out

Stake Out

Load Data?

Yes: [ENT] No: [ESC]

InterMediate

Rod Ave:0.9030m

Dist Ave:17.008m

N:3 δ:0.02mm

InterMediate

SaveData [REC]

Continue [ENT]

Exit [ESC]

Page 47

47

16. Input the Info and press [ENT]

17. Sight at the stakeout point

and press [MEAS].

18. Screen will display the S.O

Rod (Stakeout rod value) and S.O

H.D (Direction and Height of the

staff movement).

19. Press [REC] to save data; press

[ENT] if user wants to continue

intermediate point measurement;

press [ESC] to exit.

20. Press [ENT] to continue the

foresight point measurement.

Input note

[ENT]

[MEAS]

[REC]

[ESC]

[ENT]

Stake Out

Input SO G.H

=3.000 m

Stake Out

Set G.H: 3.000m

PN :G01

Stake Out

Info#1

=>_

Stake Out

Set G.H: 3.000m

PN :G01

Press [MEAS] to meas

Stake Out

S.O Rod: 0.9980m

S.O H.D: ↓0.0275m

N:3 δ:0.02mm

Stake Out

SaveData [REC]

Continue [ENT]

Exit [ESC]

Level BIF

Fr1

PN :P02

Press [MEAS] to meas

Page 48

48

After measuring the backsight point 1(Bk 1), press [▲] or [▼] to display the following

interface:

Level BIF 1/2

BRod Ave:0.8260m

BDist Ave:3.915m

N:3 δ:0.02mm

Level BIF 2/2

PN:P05

Distance to the Backsight point

N times mode: Average value

Continuous mode: Last measuring value

δ: Standard measurement

Backsight point name

After measuring the foresight point 1(Fr 1), press [▲] or [▼] to display the following

interface:

Level BIF 1/3

F2Rod Ave:0.8260m

F2Dist Ave: 3.913m

N:3 δ:0.02mm

Level BIF 2/3

Fr GH:100.000m

d :0.000m

Σ:7.828m

Level BIF 3/3

H.D 2: 0.0000m

PN :P01

Disance to the foresight point

N times mode: Average value

Continuous mode: Last measuring value

N: Total measuring times

δ: Standard offset

Ground height of the foresight point

d: backsight distance sum-foresight distance sum

Σ:backsight distance sum+oresight distance sum

Height Difference from Bk2 to Fr2

Foresight point name

After measuring the intermediate point, press [▲] or [▼] to display the following

interface:

Page 49

49

InterMediate 1/2

Rod Ave:0.8260m

Dist Ave:3.915m

N:3 δ:0.02mm

InterMediate 2/2

Int GH:2.008m

PN :TP05

Distance to intermediate point

N times mode: Average value

Continuous mode: Last measuring value

δ: Standard measurement

Ground height of intermediate point

Point name of intermediate point (the point

name will increase or descend only after

being saved.)

After staking out, press [▲] or [▼] to display the following interface:

Stake Out 1/2

S.O Rod: 0.8260m

S.OH.D: ↑ 3.915m

N:3 δ:0.02mm

Stake Out 2/2

Dist: 12.008m

S.O G.H0:2.005m

Measured value of the staff

N times mode: Average value

Continuous mode: Last measuring value

Height difference of staff upward or

downward movement.

δ:Standard measurement

Sight distance of stakeout point

Ground height of stakeout point

Page 50

50

Leveling measurement 4: Outward/Return

B1→F1→F 2→B 2/ F 1→B 1→B 2→F 2

Operating Procedures Operation Display

1. Press [MEAS] to measure the

height of the backsight bench

mark (Bk1) and press [ENT].

2. Press [MEAS] to measure the

height of foresight point (Fr1)

and press [ENT].

3. Press [MEAS] to measure the

height of foresight point (Fr2)

and press [ENT].

4. Press [MEAS] to measure the

height of the backsight bench

mark (Bk2) and press [ENT].

5. Press [ENT] to continue

Leveling measurement.

[MEAS]

[ENT]

[MEAS]

[ENT]

[MEAS]

[ENT]

[MEAS]

[ENT]

[ENT]

Outward BFFB 1

Bk1

BM#:B01

Press [MEAS] to meas

Outward BFFB 1

Fr1

PN:P01

Press [MEAS] to meas

Outward BFFB 1

Fr2

PN:P01

Press [MEAS] to meas

Outward BFFB 1

Bk2

BM#:B01

Press [MEAS] to meas

Outward BFFB 1

ENT: Next Meas

REP: Repeat

MENU:End

Page 51

51

6. Press [MEAS] to measure the

height of foresight point (Fr1)

and press [ENT].

7. Press [MEAS] to measure the

height of backsight point (Bk1)

and press [ENT].

8. Press [MEAS] to measure the

height of backsight point (Bk2)

and press [ENT].

9. Press [MEAS] to measure the

height of foresight point (Fr2)

and press [ENT].

10. Press [ENT] to continue

Leveling measurement.

11. Press [MEAS] to measure

the height of the backsight

bench mark (Bk1) and press

[ENT].

[MEAS]

[ENT]

[MEAS]

[ENT]

[MEAS]

[ENT]

[MEAS]

[ENT]

[ENT]

[MEAS]

[ENT]

Outward FBBF 2

Fr1

PN:P02

Press [MEAS] to meas

Outward FBBF 2

Bk1

PN:P01

Press [MEAS] to meas

Outward FBBF 2

Bk2

PN:P01

Press [MEAS] to meas

Outward FBBF 2

Fr2

PN:P02

Press [MEAS] to meas

Outward BFFB 2

ENT: Next Meas

REP: Repeat

MENU:End

Outward BFFB 3

Bk1

PN:P02

Press [MEAS] to meas

Page 52

52

12. Press [MENU] to end the

Leveling measurement.

13. Press [ENT] to confirm

14. Press [▲] [▼] to choose

“End Outward”.

15. Input PN (point name) and

press [ENT] to confirm.

16. Input the information and

press [ENT] to confirm.

17. Press [▲] [▼] to view the

measurement data.

18. Press [ENT] to continue the

return measurement.

[MENU]

[ENT]

[▲][▼]

[ENT]

Input PN

[ENT]

Input Info

[ENT]

[▲][▼]

[ENT]

Outward FBBF 6

PN ?

=>_

Outward FBBF 6

ENT: Next Meas

REP: Repeat

MENU:End

Outward FBBF 6

Even station,

End meas?

Yes: [ENT] No: [ESC]

Outward FBBF 6

CP Close

►End Outward

Outward FBBF 6

Info#1

=>_

Outward FBBF 6 1/2

h CP 0.558m

hΣCP 1.007m

ΣD CP 52.00m

Page 53

53

19. Press [MEAS] to measure

the height of backsight point

(Bk1) and press [ENT].

20. Press [MEAS] to measure

the height of foresight point

(Fr2) and press [ENT].

21. Press [MENU] to end the

measurement.

22. Press [ENT] to confirm.

23. Press [▲][▼] to choose.

24. Input the point name and

press [ENT] to confirm.

25. Input the note and press

[ENT] to confirm.

[MEAS]

[ENT]

[MEAS]

[ENT]

[MENU]

[ENT]

[▲][▼]

Point name

[ENT]

Info

[ENT]

Return FBBF 6

ENT: Next Meas

REP: Repeat

MENU:End

Return FBBF 6

PN ?

Outward FBBF 6 2/2

ΣD BM 108.05m

G.H BM 5.007m

Return BFFB 1

Bk1

BM#:P06

Press [MEAS] to meas

Return FBBF 2

Fr2

PN :P07

Press [MEAS] to meas

Return FBBF 6

Even station,

End meas

Yes: [ENT] No: [ESC]

Return FBBF 6

CP Close

►End Return

Page 54

54

26. Press [▲][▼] to view the

measurement data.

27. Press [ENT] to exit Return

Leveling measurement.

[▲][▼]

[ENT]

=>

Return FBBF 6 2/2

ΣD BM 110.08m

G.H BM 5.003m

Menu 1/2

Standard Mode

► Leveling

Adjust

Return FBBF 6

Info#1 =>

Return FBBF 6 1/2

h CP 0.558m

hΣCP 0.003m

ΣD CP 52.00m

After measuring, following data will be displayed.

Press [▲] or [▼] key to switch the page

After measuring the backsight point 1(Bk 1), press [▲] or [▼] to display the following

interface:

Level BFFB 1/2

The following items only display on the

N-times measuring mode:

Distance to the Backsight point

Page 55

55

B1Rod Ave:0.8259m

B1Dist Ave: 3.914m

N:3 δ:0.00mm

Level BFFB 2/2

BM#:B01

N times mode: Average value

Continuous mode: Last measuring value

N: Total measuring times

δ: Standard offset

Backsight point name

After measuring the foresight point 1(Fr 1), press [▲] or [▼] to display the following

interface:

Level BFFB 1/2

F1Rod Ave:0.8260m

F1Dist Ave: 3.914m

N:3 δ:0.02mm

Level BFFB 2/2

H.D 1: -0.0001m

Fr GH1:99.9999m

PN :P01

Disance to the foresight point

N times mode: Average value

Continuous mode: Last measuring value

N: Total measuring times

δ: Standard offset

Height difference from Bk1 to Fr1

Ground height of foresight point

After measuring the foresight point 2(Fr 2), press [▲] or [▼] to display the following

interface:

Page 56

56

Level BFFB 1/2

F2Rod Ave:0.8260m

F2Dist Ave: 3.913m

N:3 δ:0.02mm

Level BFFB 2/2

d :0.000m

Σ:7.828m

PN :P01

Disance to the foresight point

N times mode: Average value

Continuous mode: Last measuring value

N: Total measuring times

δ: Standard offset

d: backsight distance sum-foresight distance sum

Σ:backsight distance sum+oresight distance sum

Point name of backsight point

After measuring the backsight point 2(Bk 2), press [▲] or [▼] to display the following

interface:

Level BFFB 1/3

B2Rod Ave:0.8260m

B2Dist Ave:3.915m

N:3 δ:0.02mm

Level BFFB 2/3

E.V Limit:0.0mm

d: 0.001m

Σ: 7.828m

Level BFFB 3/3

H.D 2:0.0000mm

Fr GH2: 100.0000m

BM#:B01

Distance to the Backsight point

N times mode: Average value

Continuous mode: Last measuring value

δ: Standard measurement

E.V: Elevation offset difference =

(Bk1-Fr1)-(Bk2-Fr2)

d: backsight distance sum-foresight distance sum

Σ:backsight distance sum+oresight distance sum

Foresight point name

Height difference from Bk2 to Fr2

Ground height of foresight point

Point name of backsight point

Page 57

57

Introduction to point name of leveling measurement

Point Name Modification

Before measuring the foresight point, the point name can be modified, please refer to

the next chapter “Modify the Point Name”

Available Characters In Point Name

Numeral, capital letters and “-“can be used for point name which is up to 8 characters.

The used point name can be reused.

Auto Decreasing and Increasing of the Point Name

Please refer to the Chapter 9 “Set”.

Auto Increase Stepsize

If the last character of the last inputted point name is numeral, the point name will add

1 automatically.

Auto Numeral Increasing

As if the point name is less than 8 characters, the number will move rightward and add

1 automatically.

Example:Last ABCD-99

Now ABCD-100

As if the point name is 8 chatacters, the number will not move.

Example:Last ABCDE-99

Now ABCDE-00

Auto Decreasing Stepsize

If the last character of the last inputted point name is numeral, the point name will

descend 1 automatically.

When the last character is greater than 1, the numeral character will descend 1.

Example: Last ABC-02

Now ABC-01

Next ABC-00

Page 58

58

When the last character is 0

Next character will be “9” and up to 8 characters.

Example: Last ABC-00

Now ABC-9999

Next ABC-9998

Note: When the point name is only numeral, then it will descend 1. As if the point

name is 1, next one will be “99999999”。

●Modify the Point Name

User can modify the point name before measuring the foresight point 1 (Fr1)

Operating Procedures Operation Display

1. Press [ESC] before foresight

measurement, the point name

will move leftward.

2. Press [ESC] (C) to delete the

character.

3. Input a new poing name ※

1),2)

[For example:2008];

4. Press [ENT].

[ESC]

[ESC]

3 times

2008

[ENT]

Level BFFB

Fr1

PN :P01

Press [MEAS] to meas

Level BFFB

PN ?

=>P01

Level BFFB

PN ?

=>

Level BFFB

PN ?

=>2008

Page 59

59

※1) The inputted alphabets or

numerals can be up to 8

characters

※2) The used point name can

be reused in the same Leveling

measurement.

Level BFFB

Fr1

PN :2008

Press [MEAS] to meas

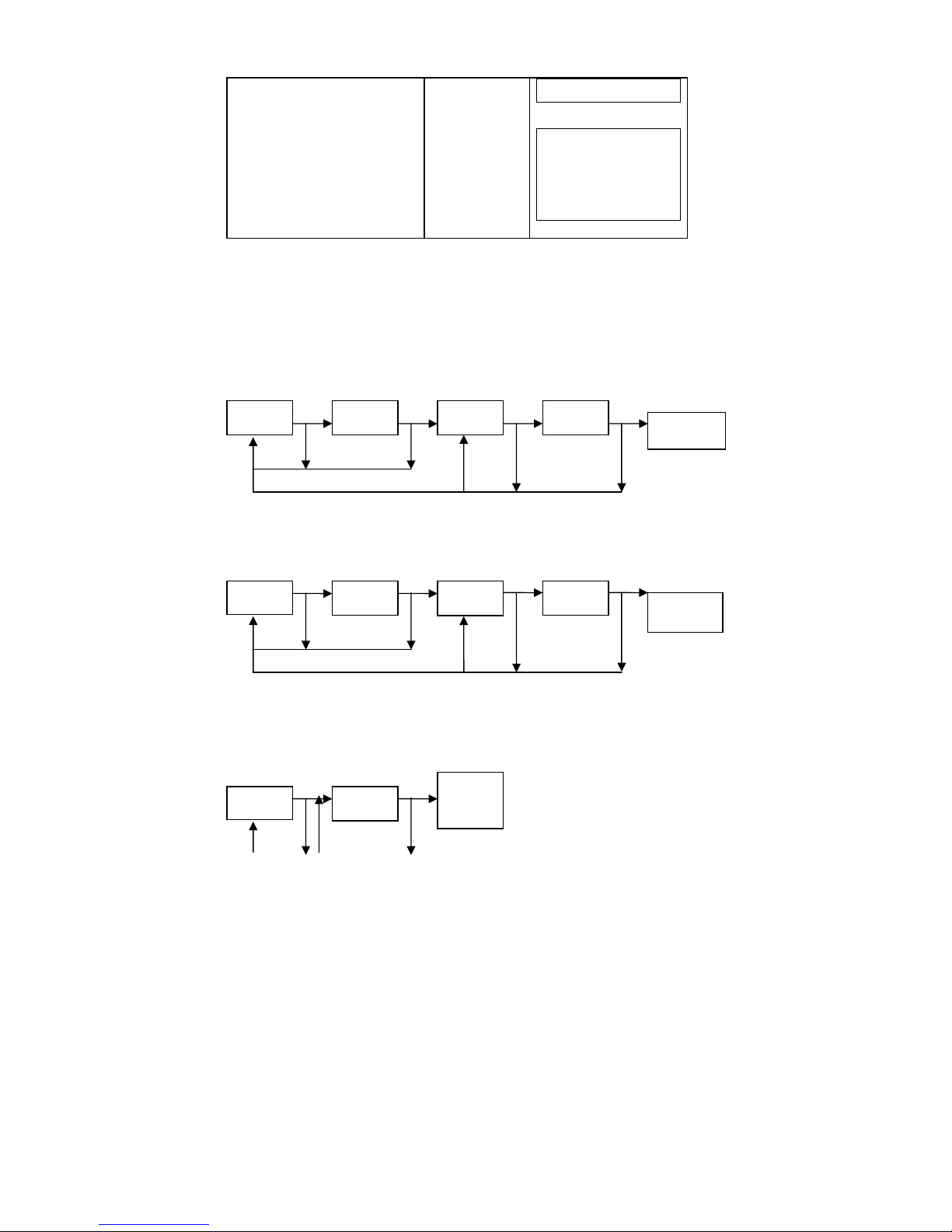

Repeated Measuring key [REP]

[REP] key is used for recollecting the surveying data of backsight or foresight points

when the measurement is incorrect. The saved data before repeating measuring will

not influence on every calculating result.

[Leveling Measurement 1]

[REP] [REP]

[REP] [REP]

●After measuring the Bk1 or Fr1, user can repeat the measurement form Bk1.

●After measuring the Fr2 or Bk2, user can repeat the measurement from Fr2 or Bk1.

[Leveling Measurement 2]

[REP] [REP]

[REP] [REP]

●After measuring the Bk1 or Bk2, user can repeat the measurement form Bk1.

●After measuring the Fr1 or Fr2, user can repeat the measurement from Fr1 or Bk1.

[Leveling Measurement 3]

Bk1 Fr1 Fr2

Next Bk1

Bk2

Bk1 Bk2

Next Bk1

Fr1 Fr2

Bk1

Fr1

Next

Bk1

Page 60

60

[REP] [REP]

[Leveling Measurement 4]

[REP] [REP] [REP] [REP]

●After measuring the Bk1 or Fr1, user can repeat the measurement form Bk1.

●After measuring the Fr2 or Bk2, user can repeat the measurement from Fr2 or Bk1.

[REP] [REP] [REP] [REP]

●After measuring the Bk1 or Fr1, user can repeat the measurement form Bk1.

●After measuring the Fr2 or Bk2, user can repeat the measurement from Fr2 or Bk1.

Example:[ Leveling Measurement 1] After measuring Fr2, user can remeasure from Bk1

Operating Procedures Operation Display

1. When “Bk2” shows on the

screen, press [REP].

2. Press [ENT] to confirm which

measurement needs to be

remeasured.

3. Sight at backsight point and

press [MEAS] to remeasure. After

that, the measured data will

[REP]

[ENT]

[MEAS]

Level BFFB

Bk2

BM#:B01

Press [MEAS] to meas

Level BFFB

Repeat meas FS2 ?

PN :P01

Yes: [ENT] No: [ESC]

Level BFFB

Repeat meas BS1 ?

BM#:B01

Bk 1

Fr 1 Fr 2

Next Fr1

Bk 2

Fr 1

Bk 1 Bk 2

Next Bk1

Fr 2

Page 61

61

Intermediate Measurement [IN/SO]

[IN/SO] key is used for collecting the separated intermediate point and sideshot point

data in Leveling measurement.

Operating Procedures Operation Display

1. After measuring the

backsight point, press [IN/SO].

2. Press [ENT] to set the

instrument to be ready for the

[IN/SO]

[ENT]

Input PN

Level BFFB

Fr1

PN :P01

Press [MEAS] to meas

Level BFFB

► InterMediate

display for N second.

4. Sight at foresight point and

press [MEAS] to remeasure.

5. Sight at Fr2 and press [MEAS]

to remeasure.

6 Sight at Forsight and press

[MEAS]

Sight at

backsight

press

[MEAS]

Sight at

foresight

press

[MEAS]

Sight at

foresight

press

[MEAS]

Yes: [ENT] No: [ESC]

Level BFFB

Bk1

BM#:B01

Press [MEAS] to meas

Level BFFB

Fr1

PN :P01

Press [MEAS] to meas

Level BFFB

Fr2

PN :P01

Press [MEAS] to meas

Page 62

62

intermediate point

measurement.

3. Input the point name and

information of the

intermediate point.

4. Collimate the staff in the

intermediate point and press

[MEAS].

After measurement, the rod

average value will be displayed

for M seconds.

5 Press [ENT], the instrument is

ready for the next intermediate

point measurement; after

being recorded, the point

name will increase

automatically; If user want to

collect more data of

intermediate point, please

repeat the step 4 and 5.

6. Press [ESC] to exit and return

to the Leveling measurement.

[ENT]

Input Info

[ENT]

Collimate

intermediate

press

[MEAS]

[▲] or [▼]

Press

[REC],[ENT] or

[ESC]

Stake Out

InterMediate

PN ?

=>TP01_

InterMediate

Info#1

=>_

InterMediate

PN :TP01

Press [MEAS] to meas

InterMediate 1/2

Rod Ave:2.9378m

Dist Ave:32.455m

N:3 δ:0.02mm

InterMediate 2/2

Int GH:10.0000m

PN:TP01

InterMediate

SaveData [REC]

Page 63

63

Continue [ENT]

Exit [ESC]

StakeOut Key [IN/SO]

In stakeout mode, user can stakeout the point with presetting ground height.

According to the record mode setting, the coordinate data of stakeout point can be saved in

“Memory” or “SD card”.

Operating Procedures Operation Display

1. After the backsight

measurement press [IN/SO]

before taking the foresight

measurement.

2. Press [▲]or[▼] to choose

“Stake Out”

3. Press [ENT], the coordinate

of stakeout point can be

recalled in the flash or SD card,

which can be choose in the

Condition Setting.

[IN/SO]

[ENT]

[ENT]

Level BFFB

Fr1

PN :P01

Press [MEAS] to meas

Level BFFB

InterMediate

► Stake Out

Stake Out

Load Data ?

Yes:[ENT] No:[ESC]

Page 64

64

4. Press [▲] or [▼] to choose

one job and press [ENT].

5. Press [▲] or [▼] to choose

one point and press [ENT].

6. Confirm the chosen point

and press [ENT];

7.Input point name and press

[ENT];

8. Input the information and

press [ENT];

9. Sight at the staff in the

stakeout point and press

[MEAS]. After measuring,

3-times measuring value and

the average value will be

displayed.

10. Press [ENT] to stakeout next

[▲] or [▼]

[ENT]

[▲] or [▼]

[ENT]

[ENT]

Input PN

[ENT]

Input Info

[ENT]

[MEAS]

Select PoiP01

►P01

P02

Select JobP02

►J01

J02

J03

Select PoiP01

PN :P01

G.H:10.0011m

Yes: [ENT] No: [ESC]

Stake Out

Set G.H: 10.0011m

PN :G01_

Stake Out

Info#1

=>_

Stake Out

Set G.H: 10.0011m

PN :G01

Press [MEAS] to meas

Stake Out 1/2

S.O Rod: 0.0020m

S.O H.D:↓1.002m

Page 65

65

point, the point name will

increase automatically; press

[ESC] to exit the Stakeout mode

and go back to the Leveling

measurement.

[REC], [ENT] or

[ESC]

N:3 δ:0.02mm

Stake Out

SaveData: [REC]

Continue: [ENT]

Exit: [ESC]

The presetting coordinate data is not in the “memory” or “SD card”.

[Example 2] Manually input the ground height, point name and other information of

the stakeout point, the measuring time is 3.

Operating Procedures Operation Display

1. After the backsight

measurement press [IN/SO]

before taking the foresight

measurement.

Use [▲] or [▼] to choose

“Stake Out”, then press [ENT].

2. Press [ESC] to cancel

recalling the data from

memory.

3. Input the ground height

and press [ENT].

4. Input the point name and

press [ENT].

[IN/SO]

[▲] or [▼]

[ENT]

[ESC]

Input G.H

[ENT]

Input PN

[ENT]

Level

InterMediate

► Stake Out

Stake Out

Load Data

Yes:[ENT] No:[ESC]

Stake Out

Input SO G.H

=10 m

Stake Out

Set G.H:10.000m

PN :G01

Page 66

66

5. Input the note and press

[ENT];

6. Sight at the staff in the

stakeout point and press

[MEAS]. After measuring,

3-times measuring value and

the average value will be

displayed.

7. Press [ENT] to stakeout

next point, the point name

will increase automatically;

press [ESC] to exit the

Stakeout mode and go back

to the Leveling

measurement.

Input note

[ENT]

Sight at stakeout

point

[MEAS]

Press [REC] or

[ENT],[ESC]

Stake Out

Info#1

=>

Stake Out

Set G.H:10.000m

PN :G01

Press [MEAS] to meas

Stake Out 1/2

S.O Rod:0.0020m

S.O H.D ↑1.002m

N:3 δ:0.02mm

Stake Out

SaveData: [REC]

Continue: [ENT]

Exit: [ESC]

4.2 End the Leveling Measurement on the Transition Point

User can end the leveling measurement job on the transition point

The close job can be restarted. If user wants to continue the leveling measurement job

from a transition control point, please refer to “Continue Leveling”.

Please see the example next page.

Page 67

67

Operating Procedures Operation Display

1. After measuring, when the

screen display “Bk1”, press

[MENU] before next

measurement.

2. Press [▲] or [▼] to choose

“End Leveling”.

3. Select “CP Close” and press

[ENT].

[MENU]

[▲] or [▼]

[ENT]

[ENT]

Level BFFB

Bk1

PN :P01

Press [MEAS] to meas

Leveling

Start Leveling

Continue leveling

►End Leveling

Level BFFB

►CP Close

BM Close

Page 68

68

4. Input the transition control

point (CP) name.

5. Input information 1 and 2.

● Press [ENT] to skip inputting

the information. Up to 16

characters can be inputted.

6. Press [ENT].

7. Press [▲] or [▼] to view the

data

8. Press [ENT] to exit.

Input CP

name

+

[ENT]

Input Info 1

[ENT]

Input Info 2

[ENT]

[▲] or [▼]

[ENT]

Level BFFB

PN ?

=>

Level BFFB

Info#1

=>

Level BFFB

Info#2

=>

Level BFFB 1/2

Δh CP: 0.000m

Δh ΣCP: 0.002m

ΣD CP: 38.950m

Level BFFB 2/2

ΣD ΣCP: 233.676m

G.H.CP : 10.0002m

Menu 1/2

Standard Mode

► Leveling

Adjust

4.3 End the Leveling Measurement on the Bench Mark Point

Page 69

69

Operating Procedures Operation Display

1. After measuring, when the

screen display “Bk1”, press

[MENU] before next

measurement.

2. Press [▲] or [▼] to choose

“End Leveling”.

3. Select “BM Close” and press

[ENT].