PowerDual

iQ 18B

USER MANUAL

2

CONTENTS

1. Introduction...............................................................................................................5

2. Unpacking.................................................................................................................5

3. Connectors/Cabling.................................................................................................5

4. Polarity Checking.....................................................................................................6

5. Amplification & Power Handling...............................................................................6

6. Operation..................................................................................................................6

7. Equalisation..............................................................................................................7

8. Dimensions..............................................................................................................7

9. Positioning................................................................................................................8

10. Flying......................................................................................................................9

10.1. Flying an iQ 18B............................................................................................10

10.2. Flying Double iQ 18B....................................................................................10

10.3. Flying an iQ 18B with iQ 10...........................................................................11

10.4. Flying Double iQ 18B and iQ 10....................................................................12

11. Performance Data................................................................................................13

12. Technical Specifications......................................................................................14

13. iQ 18B Service Parts and Accessories...............................................................16

14. Warranty...............................................................................................................16

3

4

1. Introduction

Thank You for purchasing Tannoy PowerDual™ iQ i8B.

The iQ 18B is a dedicated sub-woofer designed for high definition sound reinforcement

at low frequencies. It comprises an 18” driver in a horn-loaded cabinet, giving increased

efficiency and improved LF output.

For optimal performance, the iQ 18B has been designed to operate in conjunction with

the iQ 10 mid/high horn-loaded cabinet, where the system is controlled by a dedicated

loudspeaker management system TDX2.

The cabinet is constructed from high quality 18mm birch plywood, featuring handles for

easier transportation, convenient M8 flying points and a pole-mount stand socket that

serves as a base for locating the iQ 10 mid/high speakers in the air.

2. Unpacking

Every Tannoy iQ 18B is carefully tested and inspected before packing. After unpacking,

please inspect your iQ 18B for any damage sustained during transit. In the unlikely

event of any damage, would you please notify your dealer immediately and retain your

shipping carton, as your dealer may ask the faulty unit to be returned for inspection.

3. Connectors/Cabling

The iQ 18B is fitted with two 4-pole Speakon™ connectors. Speakon™ has the

following advantages over EP and XLR type connectors: All terminations are solderless,

making life easier at the time of installation or when field servicing is required. Contacts

will accept 6 sq. mm wire with an outside diameter of up to 15 mm and a current rating

of 30 Amps.

The pins of the two Speakon™ sockets, marked input/output on the rear of the speaker,

are paralleled within the enclosure.

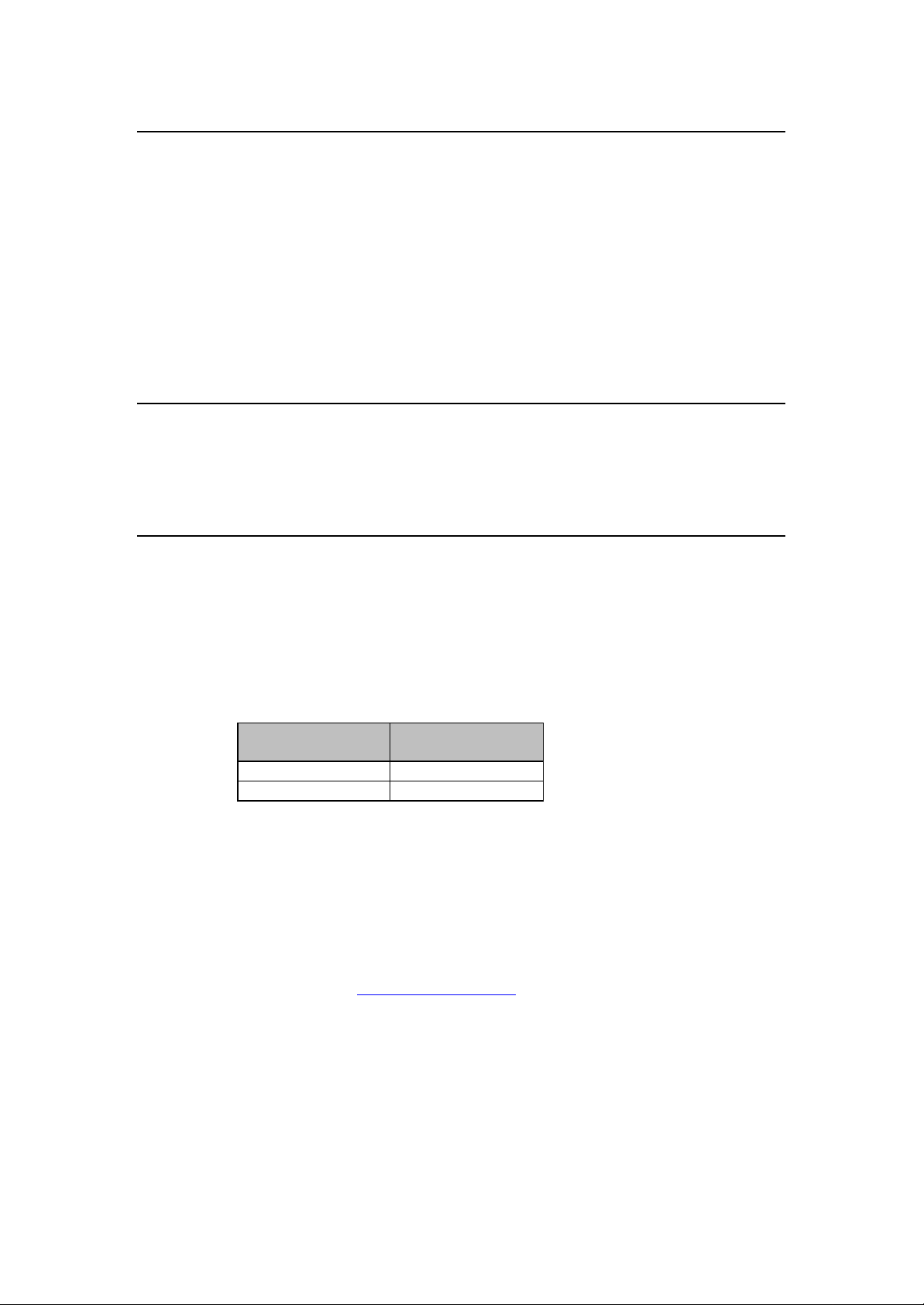

Tannoy has adopted the following wiring standard for iQ 18B: -

SPEAKON™

CONNECTOR

Pin 1+ Positive

Pin 1- Negative

Should you encounter any problems obtaining Speakon™ connectors, please contact

Neutrik or its distributors on the following numbers: -

UK: NEUTRIK MARKETING: 01983 811 441

USA: NEUTRIK USA INC.: 732 901 9488

For a worldwide list of distributors, please contact Neutrik directly on: NEUTRIK AG: +423 237 2424

Or visit their website on http://www.neutrik.com/

Cable choice consists mainly of selecting the correct cross sectional area in relation to

the cable length and the load impedance. A small cross sectional area would increase

the cables series resistance, inducing power loss and response variations (damping

factor).

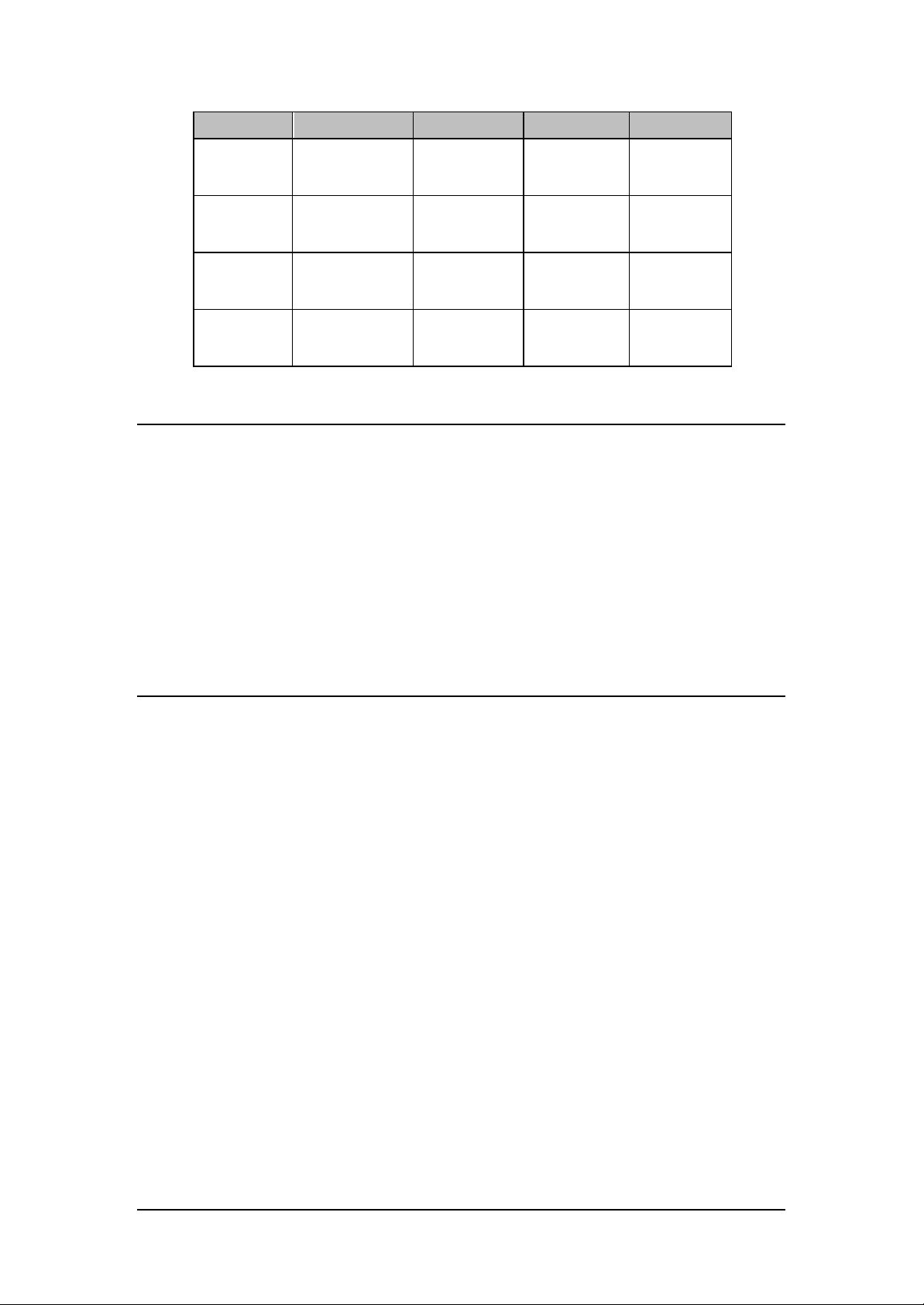

Connectors should be wired with a minimum of 2.5 sq. mm (12 gauge) cable. This will

be perfectly satisfactory under normal conditions. In the case of very long cable runs

the wire size should exceed this, refer to the following table for guidance: -

SIGNAL

5

CABLE RUN

(m)

10 2.5

25 2.5

50 2.5

100 2.5

4. Polarity Checking

It is most important to check the polarity of the wiring. A simple method of doing this is

to use a pulse based polarity checker for LF units. Connect the speaker leg which you

believe to be connected to Pin 1 to the +

ve

the –

terminal of the amplifier. Check the phase as instructed by the polarity checker

manufacturer. If you have wired it correctly, the polarity checker should indicate the LF

unit is wired in phase, indicating the wiring is correct. If however the polarity checker

indicates negative phase, the input connections must be inverted.

C.S.A. OF EACH

CONDUCTOR (mm)

4.0

6.0

4.0

6.0

4.0

6.0

4.0

6.0

CABLE

RESISTANCE ΩΩ

0.14

0.09

0.06

0.35

0.22

0.14

0.69

0.43

0.29

1.38

0.86

0.58

ve

terminal of the amplifier and likewise Pin 2 to

% POWER LOSS

INTO 8ΩΩ LOAD

1.7

1.1

0.73

4.3

2.7

1.8

8.6

5.4

3.6

17.0

11.0

7.2

% POWER LOSS

INTO 4ΩΩ LOAD

3.5

2.2

1.5

8.6

5.4

3.6

17.0

11.0

7.2

35.0

22.0

14.0

If problems are encountered, inspect the cable wiring in the first instance. It should also

be noted that different amplifier manufacturers utilise different pin configurations and

polarity conventions. If you are using amplifiers from more than one manufacturer,

check the polarity at the amplifiers as well as the loudspeakers.

5. Amplification & Power Handling

As with all professional loudspeaker systems, the power handling is a function of voice

coil thermal capacity. Care should be taken to avoid running the amplifier into clip

(clipping is the end result of overdriving any amplifier). Damage to the loudspeaker will

be sustained if the amplifier is driven into clip for any extended period of time.

Headroom of at least 3dB should be allowed. When evaluating an amplifier, it is

important to take into account its behaviour under low impedance load conditions. A

loudspeaker system is highly reactive and with transient signals it can require more

current than the nominal impedance would indicate.

Generally, a higher power amplifier running free of distortion will do less damage to the

loudspeaker than a lower power amplifier continually clipping. It is also worth

remembering that a high powered amplifier running at less than 90% of output power

generally sounds a lot better than a lower power amplifier running at 100%. An amplifier

with insufficient drive capability will not allow the full performance of the loudspeaker to

be realised.

It is important when using different manufacturers amplifiers in a single installation that

they have very closely matched gains, the variation should be less than ±0.5dB. This

precaution is important to the overall system balance when only a single

compressor/limiter or active crossover is being used with multiple cabinets; it is

therefore recommended that the same amplifiers be used throughout.

6. Operation

6

For optimal performance the PowerDual™ iQ 18B has been designed to operate with

PowerDual™ iQ 10 mid/high cabinet, where overall system control is achieved by

utilising the TDX2 system controller. The TDX2 has been factory preset to provide the

recommended cross-over points, delays and overall system balance. Please refer to the

TDX2 manual for operation.

If you intend using an alternative loudspeaker management system (e.g. BSS™, Klark

Teknik™, XTA™ etc) please contact your distributor or visit our website,

www.tannoy.com for the correct parameter settings or refer to the recommended

crossover points in the technical specifications section of this manual.

7. Equalisation

The iQ 18B loudspeaker is designed to need no equalisation or correction to overcome

system limitations. As a result, it will only need equalisation to compensate for difficult

acoustic environments.

Over equalisation can reduce system headroom, and introduce phase distortion

resulting in greater problems than cures. If equalisation is required then it should be

applied gently and smoothly. Violent equalisation will be detrimental to the overall

sound quality.

8. Dimensions

7

9. Positioning

When a bass loudspeaker is used in an environment with boundary surfaces, its

placement affects its frequency response. When such effects are properly understood,

they can be used to great effect in producing the desired sound quality without the aid

of additional amplification.

Consider Figure 8a in the diagram below, here we see a loudspeaker in free field or

anechoic conditions. We measure its sound pressure level at a distance D, and refer to

this as our reference level, or 0 dB SPL.

If we now place a large reflective surface (i.e., a wall, ceiling or floor) next to the

loudspeaker, Figure 8b, the sound that is radiated towards the boundary is reflected.

As a result, the sound pressure level can increase by as much as 3dB (effectively

doubling the available amplifier power). The loudspeaker is radiating its power into half

as much space, this is known as half space loading. For each additional boundary, the

SPL can increase by 3dB. Corner placement or eighth space loading can increase a

bass speakers’ efficiency by up to 9dB.

This effect is not the same at all frequencies. Loudspeakers are only essentially omni

directional at low frequencies (where the wavelength is large compared to the

loudspeaker). At high frequencies sound radiates in a more directional manner. We can

position full range loudspeakers next to a boundary in order to boost the lower

frequencies while the highs remain unchanged.

Coupling, or placing bass cabinets together will also increase bass output.

Figure 8a Figure 8b

Figure 8c Figure 8d

8

10. Flying

Convenient flying points are provided on the iQ 18B which will allow the optional flying

equipment to be used, as shown in Figure 10a. In the addition to flying the iQ 18B by

itself, it can also be flown in conjunction with Tannoy iQ 10 Mid/High unit. They can

also be configured to be flown double. Please refer to the following sections for more

detailed instructions. A pole mount is also provided for flying a mid/high cabinet in the

air. The optional Eyebolt Set can be used when flying an individual iQ 18B.

The following optional flying kit is available:

1) SR18 Rail Kit

2) SR18/10 Rail Kit

3) JK1 Jointing Kit

4) SCB Beam Kit

5) EBS10 Eyebolt Set

The easy to use system combines flexibility with the highest levels of safety. As with

any flying system, safety can only be guaranteed when all precautions have been

implemented correctly.

NOTE: The installation of this product must be carried out in conformity with

local building codes and standards. If necessary, consult your local safety

standards officer before installing any product. Alternatively, check any laws or

bylaws. Tannoy will not be held responsible for any damage caused by the

improper installation of any flying gear or loudspeaker.

Figure 10a

9

10.1. Flying an iQ 18B

To fly the iQ 18B by itself, the following accessories are required: SR18 Side Rail Kit

and SCB Beam Kit.

The flown system is assembled as shown in Figure 10b . The SR18 side rail kit is

screwed to the side of the cabinet using the screws provided (1). The SCB Beam Kits

are then placed above and below the speaker (2). The Lynch Pin is inserted into the

holes of the side rail kit top and bottom (3) and the Pin folded to secure it in place

(Figure 10c ).

Figure 10c

Figure 10b

10

10.2. Flying Double iQ 18B

To fly two iQ 18Bs, the following accessories are required: 2 × SR18 Side Rail Kit, 2 ×

SCB Beam Kit and 1 × JK1 Jointing Kit.

The flown system is assembled as shown in Figure 10d. The SR18 side rail kit is

screwed to the side of each cabinet using the screws provided (1). The JK1 Jointing Kit

is slotted between two SCB Beam Kits for both the top and bottom (2). The combined

SCB Beam Kits are placed above and below the speaker (3). The Lynch Pin is inserted

into the holes of the side rail kit top and bottom (4) and the Pin folded to secure it in

place (Figure 10c , page 10).

Figure 10d

10.3. Flying an iQ 18B with iQ 10

11

To fly the iQ 18B with the iQ 10 Mid/High unit (with optional trapezoidal cabinet), the

following accessories are required: SR18/10 Side Rail Kit and SCB Beam Kit.

The flown system is assembled as shown in Figure 10e. First, the SR18/10 side rail kit

is screwed to the side of both the iQ 18B and iQ 10 cabinets using the screws provided

(1). The SCB Beam Kits are placed above and below the speaker assembly (2). The

Lynch Pin is inserted into the holes of the side rail kit top and bottom (3) and the Pin

folded to secure it in place (Figure 10f ).

Figure 10f

Figure 10e

12

10.4. Flying Double iQ 18B and iQ 10

To fly double combined iQ 18B with the iQ 10 Mid/High unit (with optional trapezoidal

cabinet), the following accessories are required: 2 × SR18/10 Side Rail Kit, 2 × SCB

Beam Kit and JK1 Jointing Kit.

The flown system is assembled as shown in Figure 10g. First, the SR18/10 side rail kit

is screwed to the side of each iQ 18B and iQ 10 cabinet using the screws provided (1).

The JK1 Jointing Kit is slotted between two SCB Beam Kits for botht he top and bottom

(2). The combined SCB Beam Kits are placed above and below the speaker assemblies

(3). The Lynch Pin is inserted into the holes of the side rail kit top and bottom (4) and

the Pin folded to secure it in place (Figure10f, page 12).

Figure 10g

11. Performance Data

13

Anechoic Frequency Response, with TDX2 Controller

Impedance Response, Passive

12. Technical Specifications

14

Frequency Response (+/- 3dB) 39Hz - 230Hz, (-10dB Point) 33Hz

Recommended Amplifier Power 600 - 1200 watt / 8 ohm

Power Handling Average (2) Programme Peak (10ms)

600 watt 1200 watt 2400 watt

Sensitivity (1)

2.83 volt @ 1m (20-180Hz) 104dB (half space)

Maximum SPL (3) Average Peak

@ 1m 132dB 138dB

Impedance Nominal 8.0Ω

Minimum 7.0Ω

Distortion

10% Full Power 2

100 Hz 1.91% 0.59%

250 Hz 0.78% 1.11%

1% Full Power 2nd Harmonic 3rd Harmonic

100 Hz 0.56% 0.47%

250 Hz 0.37% 0.47%

Driver Complement 1 x 18” (458mm) LF Driver

Crossover Point 70Hz-230Hz, 24dB/Octave

Enclosure Trapezoidal folded horn 18mm birch plywood

Finish Textured black/grey paint

Connectors 2 x Speakon™ NL4MP – in/out

Fittings 4 x Recessed Carrying Handles, 8 x M10 flying inserts

2 x Pullback points

Accessories SR18 Flying Kit, SR1810 Flying Kit, SCB

Dimensions 980mm x 680mm x 540mm (38 9/16 x 26 3/4 x 21 1/4")

nd

Harmonic 3rd Harmonic

Beam Kit

Weight 55kg (121.3lbs)

Shipping Dimensions 1040mm (H) × 700mm (W) × 590mm (D)

41” (H) × 27.6” (W) × 23.2” (D)

Shipping Weight 55 kg

121 lb

NOTES: (1) Average over stated bandwidth. Measured at 1m on axis, in an anechoic chamber.

(2) Long term power handling capacity as defined in EIA standard RS - 426A.

(3) Unweighted pink noise input, measured at 1m

Tannoy operates a policy of continuous research and development. The introduction of new materials or manufacturing

methods will always equal or exceed the published specificat ions which Tannoy reserve the right to alter without prior

notice.

Please verify the latest specifications when dealing with critical applications

15

13. iQ 18B Service Parts and Accessories

Part Number Description

7900 0954 Driver Kit Type 4504

7900 0955 Recone Kit Type 4504

8001 2070 SR 18 Side Rail Kit

8001 2080 SR 18/10 Side Rail Kit

8001 2090 JK1 Jointing Kit

8001 2180 SCB Single Cabinet Beam

8001 2190 EBS10 Eyebolt Set

8000 0727 TDX2 Digital loudspeaker management system 60-250V - UK

8000 0728 TDX2 Digital loudspeaker management system 60-250V - EUR

8000 0729 TDX2 Digital loudspeaker management system 60-250V - USA

14. Warranty

No maintenance of the PowerDual™ iQ 18B loudspeaker is necessary.

All Tannoy professional loudspeaker products are covered by a 5-year warranty from the

date of manufacture subject to the absence of misuse, overload or accidental damage.

Claims will not be considered is the serial number has been altered or removed. Work

under warranty should only be carried out by a Tannoy Professional dealer or service

agent. This warranty in no way affects your statutory rights. For further information,

please contact your dealer or distributor in your country. If you cannot locate your

distributor, please contact Customer Services, Tannoy Ltd at the address given below.

Customer Services

Tannoy Ltd.

Coatbridge

ML5 4TF

Scotland

Telephone: 01236 420199 (National)

+44 1236 420199 (International)

Fax: 01236 428230 (National)

+44 1236 428230 (International)

E-Mail: service@tannoy.com

Website: www.tannoy.com

DO NOT SHIP ANY PRODUCT TO TANNOY WITHOUT PREVIOUS AUTHORISATION

Our policy commits us to incorporating improvements to our products through

continuous res earch and development. Please confirm current specifications for critical

applications with your supplier.

EASE Data for Tannoy Professional products available on request.

16

17

Tannoy Limited, Professional Division, Coatbridge, Strathclyde, ML5 4TF, Scotland.

Tel: +44 (0) 1236 420199 Fax +44 (0) 1236 428230

e-mail: prosales@tannoy.com Website: www.tannoy.com

Tannoy / TGI North America Inc. , 335 Gage Avenue, Suite 1, Kitchener, Ontario, Canada N2M 5E1.

Tel: (519) 745-1158 Fax: (519) 745-2364

e-mail: inquiries@tgina.com Website: www.tannoy.com

Tannoy Ne derland b.v., Anthonetta Kuijlstraat 19, 3066 GS Rotterdam.

Tel: (010) 286 0554 Fax: (010) 286 0431

e-mail: info@tannoy.nl Website: www.tannoy.nl

Tannoy is a member of the Group of Companies

ML 6th March 2001

18

19

Loading...

Loading...