FPS SERIES

1000W In 1U

Front End Power Supplies

INSTRUCTION MANUAL

This Manual Cover Models:

FPS1000-12 FPS1000-24

FPS1000-32 FPS1000-48

FPS-S1U 19” Rack Single Output

FPS-T1U 19” Rack Triple Output

DWG NO: IA599-04-02-A

FPS1000 SERIES

INSTRUCTION MANUAL

DWG NO: IA599-04-02 A

TABLE OF CONTENTS

Warranty .................................................................................................................................Pg. 1

FPS1000, FPS-S1U and FPS-T1U rack Safety instructions ................................................. Pg. 2

FPS1000 Power Supply

Chapter 1: FPS1000 Series Specifications ............................................................................ Pg. 4

Chapter 2: FPS1000 Series Outline drawings ........................................................................Pg. 5

Chapter 3: FPS1000 Series Installation instructions ..............................................................Pg. 7

Chapter 4: Functions and features .......................................................................................Pg. 11

Chapter 5: Basic connections for operation .........................................................................Pg. 14

Chapter 6: Parallel and Series operation .............................................................................Pg. 16

2

Chapter 7: I

C BUS Interface option ....................................................................................Pg. 19

Chapter 8: FPS1000 Maintenance ......................................................................................Pg. 23

FPS-S1U rack

Chapter 9: FPS-S1U rack Specifications .............................................................................Pg. 25

Chapter 10: FPS-S1U rack Installation instructions .............................................................Pg. 26

Chapter 11: FPS-S1U and FPS-S1U/P Outline drawings ....................................................Pg. 30

Chapter 12: Basic connections for operation .......................................................................Pg. 32

Chapter 13: Parallel and Series operation ...........................................................................Pg. 34

2

Chapter 14: FPS-S1U I

C BUS Interface option ..................................................................Pg. 37

Chapter 15: FPS-S1U rack Maintenance .............................................................................Pg. 38

FPS-T1U rack

Chapter 16: FPS-T1U rack Specifications ............................................................................Pg. 40

Chapter 17: FPS-T1U rack Installation instructions .............................................................Pg. 41

Chapter 18: FPS-T1U and FPS-T1U/P Outline drawings ....................................................Pg. 45

Chapter 19: Basic connections for operation .......................................................................Pg. 47

Chapter 20: Parallel and Series operation ...........................................................................Pg. 49

2

Chapter 21: FPS-T1U I

C BUS Interface option ..................................................................Pg. 51

Chapter 22: FPS-T1U rack Maintenance .............................................................................Pg. 52

FPS1000 Instruction Manual

WARRANTY

This Densei-Lambda product is warranted against defects in materials and workmanship for a period of

two years from date of shipment.

During the warranty period , Densei-Lambda will, at it's option, either repair or replace products which

prove to be defective.

LIMITATION OF WARRANTY

The warranty shall not apply to defects resulting from improper or inadequate usage or maintenance by

the buyer, buyer supplied products or interfacing. The warranty shall not apply to defects resulting from

unauthorized modifications or from operation exceeding the environmental specifications of the product

or if the Warranty seal has been removed or altered by anyone other than Densei-Lambda authorized

personnel.

Densei-Lambda does not warrant the buyers circuitry or malfunctions of Densei- Lambda products resulting

from the buyer's circuitry. Furthermore, Densei-Lambda does not warrant any damage occurring as a

result of the buyer's circuitry or the buyer's-supplied products.

No other warranty is expressed or implied.

WARRANTY SERVICE

This product must be returned to an authorized Densei-Lambda service facility for repairs or other warranty

service. For products returned to Densei-Lambda for warranty service, the buyer shall prepay shipping

charges to Densei-Lambda and Densei-Lambda shall pay the shipping charges to return the product to

the buyer.

DISCLAIMER

The information contained in this document is subject to change without notice.

Densei-Lambda shall not be liable for errors contained in this document or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material. No part of this document

may be photo-copied, reproduced or translated to another language without prior written consent of DenseiLambda.

1

FPS1000 POWER SUPPLY AND FPS-S1U RACK SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

Operating personnel must not remove the FPS1000, FPS-S1U and the FPS-T1U cover.

No internal adjustment or component replacement is allowed by non Densei-Lambda qualified service personnel. Never

replace components with power cable connected. To avoid injuries,always disconnect power, discharge circuits and remove

external voltage sources before touching components. These products are not authorized for use as critical components

in nuclear control systems, life support systems or equipment for use in hazardous environments without the express written

approval of the managing director of Densei-Lambda.

Restricted Access Area: The equipment should only be installed in a Restricted Access Area.

Access should be available to service personnel only.

WICHTIGE SICHERHEITSHINWEISE

Bedienungspersonal oder Anwender duerfen die Gehaeuseabdeckung des FPS1000, FPS-S1U und desFPS-T1U nicht entfernen.

Ersatzteiltausch - und Aenderungen duerfen nur von autorisiertem Densei-Lambda SERVICE-Personen bzw. Organisationen

durchgefuehrt werden.

Energieversorgungsanschluesse sind immer zu trennen, um Personenverletzungen durch gefaehrliche Energieinhalte und

Spannungen auszuschliessen.

Die Stromkreise sind zu entladen, externe Spannungsquellen sind zu entfernen bevor Bauteile bzw. Komponenten getauscht

werden.

Der direkte Zugriff auf das Racksystem ist nur dem geschulten Service-Personal erlaubt.

SAFETY APPROVALS

Vor Austausch von Bauteilen ist das Netzkabel bzw. die Versorgungsspannung zu trennen.

UL60950-1, UL Recognized, C-UL for canada. IEC/EN60950-1. CE marking, when applied to the FPS1000, FPS-S1U and

the FPS-T1U products, indicates compliance with the Low Voltage Directive (73/23EEC) as modified by the CE Marking

Directive (93/68EEC) in that it complies with EN60950-1.

SAFETY-CLASS OF INSULATION

The FPS1000, FPS-S1U and the FPS-T1U are designed for the following safety parameters: Material group IIIa, Pollution

degree 2, Overvoltage category II, Class I (earthed), indoor use as part of an overall equipment such that the FPS product

is accessible to service personnel only.

GROUNDING

These products are Safety Class I instruments. To minimize shock hazard, the instruments chassis must be connected to

an electrical ground. The instruments must be connected to the AC power supply mains through a three conductor power

cable, with the ground wire firmly connected to an electrical ground (safety ground) at the power outlet.

For instruments designed to be hard-wired to the supply mains, the protective earth terminal must be connected to the

safety electrical ground before any other connection is made.

Any interruption of the protective ground conductor, or disconnection of the protective earth terminal will cause a potential

shock hazard that might cause personal injury.

INPUT RATINGS

Do not use AC supply which exceeds the input voltage and frequency rating of these instruments. The input voltage and

frequency rating is: 100-240V~ , 50/60Hz. For safety reasons, the mains supply voltage flactuations should not exceed +/10% of nominal voltage.

FPS-S1U RACK AC INPUT

CAUTION:

Risk of electrical shock and energy hazard. Disconnecting one power supply disconnects only one power supply

module. To isolate the unit completely, disconnect all power supplies.

ACHTUNG:

Spannungsfuehrende Teile - Gefahr durch elektrischen Schlag order hohe Energieinhalte.

Alle Netzstecker der einzelnen Komponenten bzw. der Einschuebe muessen getrennt werden, damit das System

“spannungsfrei” ist.

2

FPS1000 Instruction Manual

ATTENTION:

Risque de choc et de danger e'lectriques. Le de'branchement d'une seule alimenttation stabilise'e ne de'branche uniquement

qu'un module "Alimentation Stabilise'e".

Pour isoler completement le module en cause, il faut de'brancher toutes les alimentations stabilise'es.

SAFETY SYMBOLS

CAUTION Risk of Electrical Shock.

Instruction manual symbol. The instrument will be marked with this symbol when it is

necessary for the user to refer to the instruction manual.

Indicates hazardous voltage.

Indicates ground terminal.

Protective Ground Conductor Terminal

Denotes hazard. An attention to a procedure is called. Not following the procedure correctly

could result in personal injury. A WARNING sign should not be skipped and all indicated

conditions must be fully understood and met.

Denotes hazard. An attention to a procedure is called. Not following the procedure correctly

could result in damage to the equipment.

ENERGY HAZARD

The FPS1000, FPS-S1U and the FPS-T1U products are capable of providing hazardous energy.

Manufacturers final equipment must provide protection to service personnel against inadvertent contact with these models

output terminals. If set such that hazardous energy can occur then the output terminals or connections therefore must not

be user accessible.

OVERCURRENT PROTECTION:

A readily accessible Listed branch circuit overcurrent protective device rated 20 A must be incorporated in the building wiring.

SERIAL OPERATION

The FPS-T1U product is capable of providing hazardous voltage output in case of the serial connection of two or more FPS1000

units in the rack. Manufacturers final equipment must provide protection to service personnel against inadvertent contact with

these models output terminals. If set such that hazardous voltage can occur then the output terminals or connections therefore

FUSES

There are no user replaceable fuses in the FPS1000, FPS-S1U and the FPS-T1U products. Internal fuses are sized for fault

protection and if a fuse was opened it would indicate that service is required. Fuse replacement should be made by qualified

technical personnel.

FPS-S1U and FPS-T1U racks contains no fuses. FPS1000 fuses rating are described below.

F101: F20A H 250Vac

F102: 6.3A 400Vdc

SICHERHEITSHINWEISE

Vor Anschluss an die Netzversorgung ist die Aufstellanleitung zu beachten!

1. Absicherung: F101: F20A H 250VAC, F102: 6.3A 400VDC

2. Der maximale Ableitstrom der Gesamtanlage darf 3.5mA nicht ueberschreiten.

3. Die Gehaeuseabdeckung darf nur im stromlosen Zustand geoeffnet werden.

ACHTUNG:

Sicherungen duerfen nur durch geschulte Service Personen getauscht werden.

3

CHAPTER 1 FPS1000 SERIES SPECIFICATIONS

FPS1000 SERIES SPECIFICATIONS

1V

Rated output voltage

2V

Output voltage set point

3V

Output voltage range

4A

Maximum Output Current (Refer to Fig.1)

5W

Maximum output power

6

Input voltage / frequency range

7

Maximum input current (at 100/200Vac)

8 ---

Power Factor (Typ)

9 (*2) %

Efficiency (Typ)

10 (*3) A

Inrush current

11 mS

Hold-up time

12 (*5) ---

Maximum line regulation

13 (*6) ---

Max load regulation

14 (*4) mV

Output Ripple and noise pk-pk

15 ---

Temperature stability

16

Temperature coefficient

17 (*7) V

Remote sensing

18 (*9) ---

Parallel operation

19

Series operation

20 ---

Over current protection

21 (*8) V

Over voltage protection

22 ---

Over temperature protection

23 ---

Remote On/Off control

24 ---

DC OK signal

25 ---

Over-Temp. warning

26 ---

AC fail signal

27 ---

Auxiliary power supply

28 ---

Vout voltage trimming

29 ---

Front panel indicators

2

30 ---

I

C Interface

31 ---

Operating temperature-models without IEC inlet

32 ---

Storage temperature

33 ---

Operating humidity

34 ---

Storage humidity

35 ---

Cooling

36 ---

Vibration

37 ---

Shock

38 ---

Conducted emission

39 ---

Radiated emission

40 ---

Applicable safety standards

Withstand voltage

41

42 ---

Insulation resistance

43 mA

Leakage current

44 Kg

Weight (Typ)

45 ---

Size (W*H*D)

models with IEC inlet

(*1) ---

A

PPM/°C

---

---

(*10)

---

FPS1000-12

12

12+/-1%

10.5~13.2

72

864

81/83%

20mS typical at 100Vac input, rated output voltage and less than 80% of rated load.

150

0.05% of rated Vout for 8hrs after 30min warm-up. Constant line, load and temperature.

14.3~15.7

By electrical signal or dry contact. ON: 0~0.6V or short. OFF: 2~15V or open.

Open collector signal. On when Vout>80+/-5% rated output. Max.sink current: 10mA

Possible, via Vout Trim pin in the I/O connector. Refer to Instruction Manual.

0~50°C: 100% load. Derate 2%/°C, 50°C to 60°C, Derate 2.5%/°C, 60°C to 70°C.

Input-Output: 3000Vrms, 1min. Input-Ground: 2000Vrms, 1min. Output-Ground:

More than 100Mohm at 25° C and 70% RH. Output-Ground: 500Vdc

FPS1000-24

24

24+/-1%

21.5~29

40

960

85~265Vac continuous, 47~63Hz, Single phase

12.0/6.0

>0.98 at 115/230V and maximum output power

84/86%

Less than 40A

0.40%

0.80%

200

200

Possible. Refer to Instruction Manual.

Possible. Refer to Instruction Manual.

Possible. Refer to Instruction Manual.

105~125% of maximum output current. Refer to Fig. 1

31~34

Inverter shut down method, automatic reset.

Open collector signal. Refer to Instruction Manual

Open collector signal. Refer to Instruction Manual

11.2~12.5VDC. 0.25A Maximum output current.

AC OK, DC OK, DC FAIL

Optional. Refer to Instruction Manual.

0~50°C: 100% load. Derate 2%/°C, 50°C to 60°C.

-30~85°C

10~90% RH, no condensation.

10~95% RH, no condensation.

By internal Fans. Variable speed control.

Built to meet ETS 300 019

Built to meet ETS 300 019

EN55022B, FCC part 15J-B, VCCI-B

EN55022B, FCC part 15J-B, VCCI-B

UL60950-1, EN60950-1

Less Than 1.1mA at 230Vac

2.0

127x41x290mm. Refer to Outline Drawing.

FPS1000-32

32

32+/-1%

28.8~38.4

31

992

84/86%

250

41.5~45.5

FPS1000-48

48

48+/-1%

43~58

21

1008

85/88%

300

62~66

500Vrms,1min.

Notes:

*1: For cases where conformance to various safety standards (UL, EN etc.) is required,

to be described as 100-240Vac (50/60Hz).

*2: At 100/200Vac, rated load and 25˚C ambient temperature.

*3: Not applicable for the noise filter inrush current less than 0.2mS.

*4: Measured with JEITA RC-9131A 1:1 probe, 20MHz B.W.

*5: From 85~132Vac or 170~265Vac, constant load.

*6: From No-load to Rated load, constant input voltage. Measured at the sensing point in Remote sense.

*7: Remote sensing can compensate up to 1V drop on each load wire.

*8: Inverter shut down method. Reset by AC voltage recycle or by On/Off control.

*9: Derate Maximum output power by 10% for input voltage less than 100V

RMS

.

*10 For FPS 1000-12/P(S), when used not with FPS-S1U or FPS-T1U

racks, an EMI suppressor clamp should be attached to the AC cable,

as close as possible to the AC inlet, to meet class B.

Vout (V)

V2

V1

Model FPS1000 FPS1000 FPS1000

V/I -24 -32 -48

V1 (V)

V2 (V)

I1 (A)

I2 (A)

FPS1000

-12

12

13.2

66

72

24 32 48

29 38.4 58

33 26 17.25

40 31 21

Fig. 1: Rated output current vs output voltage

I2

I1

Iout (A)

4

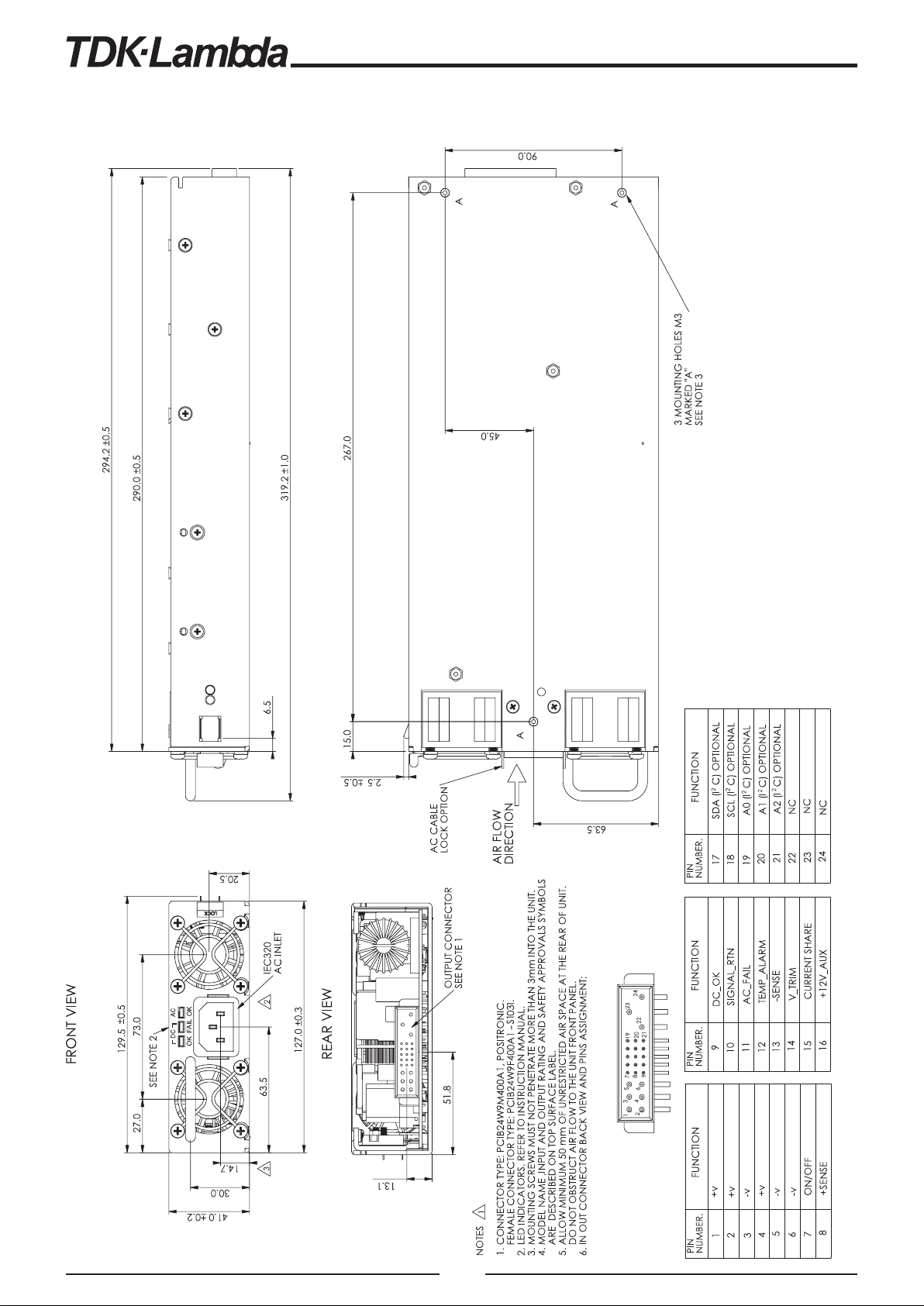

CHAPTER 2 OUTLINE DRAWINGS

1.2 FPS 1000 SERIES OUTLINE DRAWINGS

FPS1000 Instruction Manual

5

2.2 FPS 1000/P SERIES OUTLINE DRAWINGS

6

FPS1000 Instruction Manual

CHAPTER 3 FPS1000 POWER SUPPLY INSTALLATION

3.1 GENERAL

This chapter contains instructions for initial inspection, preparation for use and repackaging forshipment.

NOTE

FPS1000 power supplies series generate magnetic field

which might affect the operation of other instruments.

If your equipment is susceptible to magnetic fields, do

not position it adjacent to the FPS1000 unit.

3.2 PREPARATION FOR USE

In order to be operational the power supply must be connected to an appropriate AC source.

The AC source voltage should be within the power supply specification. Do not apply power before reading

sections 3.6 and 3.7.

Table 3-1 below describes the basic setup procedure. Follow the instructions in Table 3-1 in the sequence

given to prepare the power supply for use.

Step no Item Description Reference

1 Inspection Initial physical inspection of the power supply Section 3.3

2 Installation Installing the power supply. Section 3.4

Ensuring adequate ventilation. Section 3.5

3 AC source AC source requirements Section 3.6

4 Load connection Wire size selection. Local / Remote Section 3.7

sensing. Single or multiple loads.

Table 3-1: Basic setup procedure

3.3 INITIAL INSPECTION

Prior to shipment this power supply was inspected and found free of mechanical or electrical defects.

Upon unpacking of the power supply, inspect for any damage which may have occurred in transit.

The inspection should confirm that there is no exterior damage to the power supply.

Keep all packing material until the inspection has been completed. If damage is detected , file a claim with

carrier immediately and notify the Lambda sales or service facility nearest you.

3.4 FPS1000 MOUNTING

The FPS1000 power supplies series is designed to fit in the FPS-S1U and FPS-T1U, 19" rack, or in an

equivalent rack designed for the FPS1000 power supply.

The FPS1000 is secured to the rack using the spring lock device, located at the FPS1000 front panel.

Refer to the FPS1000 and the FPS-S1U and FPS-T1U outline drawings in Chapter 2, Chapter 11 and

Chapter 18.

When installation using mounting screws is required, the FPS1000 can be secured to the equipment using

the M3 mounting holes at its bottom surface. Refer to the FPS1000 outline drawings.

3.5 LOCATION MOUNTING AND COOLING

This power supply is fan cooled. The air intake is at the front panel and the exhaust is at the rear panel.

Upon installation allow cooling air to reach the front panel ventilation inlets and allow minimum 50mm of

unrestricted air space at the rear of the unit for the air exhaust.

3.6 AC SOURCE REQUIREMENTS

The FPS1000 series can be operated from a nominal 100V to 240V, single phase, 47~63Hz. Refer to the

specifications in chapter 1 for the input voltage range and the current required.

Ensure that under heavy load, the AC voltage supplied to the power supply does not fall below the "low

limit" specifications.

CAUTION

Connection of this power supply to an AC

power source should be made by an

electrician or other qualified personnel.

WARNING

There is a potential shock hazard if the power supply

chassis and cover are not connected to an electrical safety

ground via the safetyground in the AC input connector.

7

3.7 CONNECTING THE LOAD

WARNING

Turn off the AC input power before making or changing any rear panel

connection. Ensure that all connections are securely tightened before

applying power. There is a potential shock hazard when using a power

supply with a rated output greater than 40V.

3.7.1 Load Wiring.

The following considerations should be made to select wiring for connecting the load to the power supply:

* Current carrying capacity of the wire (refer to 3.7.2).

*Insulation rating of the wire should be at least equivalent to the maximum output voltage of the power

supply.

*Maximum wire length and voltage drop (refer to 3.7.2).

*Noise and impedance effects of the load wiring (refer to 3.7.3).

3.7.2 Current Carrying Capacity

Two factors should must be considered while selecting the wire size. 1.Wires should be at least heavy

enough not to overheating while carrying the power supply load current at the rated load, or the current

that would flow in the event the load wires were shorted, whichever is greater.

2.Wire size should be selected to enable voltage drop per lead to be less than 1.0V at the rated current.

Please refer to Tables 3-2 and 3-3 for maximum wire length to limit the voltage drop in American and

European dimensions respectively.

wire size

Resistivity Maximum length in Feet to limit voltage

AWG Ohm/kft drop to 1V or less.

5A 10A 20A 50A 150A

14 2.526 80 40 20 8 2

12 1.589 120 60 30 12 3.4

10 0.9994 200 100 50 20 6

8 0.6285 320 160 80 32 10

6 0.3953 500 250 125 50 16

4 0.2486 800 400 200 80 26

2 0.1564 1200 600 300 125 40

0 0.0983 2000 1000 500 200 68

Table 3-2:Maximum wire length for 1V drop on lead (in feet).

Cross sect. Resistivity

Area

Ohm/km drop to 1V or less.

Maximum length in meters to limit voltage

(mm^2) 5A 10A 20A 50A 150A

2.5 8.21 24.0 12.0 6.0 2.4 0.8

4 5.09 39.2 18.6 9.8 4.0 1.4

6 3.39 59.0 29.4 14.8 5.8 2.0

10 1.95 102.6 51.2 25.6 10.2 3.4

16 1.24 160.0 80.0 40.0 16.0 5.4

25 0.795 250.0 125.0 62.0 25.2 8.4

35 0.565 354.0 177.0 88.0 35.4 11.8

Table 3-3:Maximum wire length for 1V drop on lead (in meters).

For currents not shown in Tables 3-2 and 3-3 , use the formula :

Maximum length=1000/(current*resistivity)

Where current is expressed in ampers and resistivity in ohms/km or ohms/1000ft.

8

FPS1000 Instruction Manual

3.7.3 Noise and Impedance Effects

To minimize the noise pickup or radiation, the load wires and remote sense wires should be twisted-pairs

of the shortest possible length. Shielding of the sense leads may be necessary in high noise environments.

Even if noise is not a concern, the load and remote sense wires should be twisted-pairs to reduce coupling

between them, which might impact the stability of power supply. The sense leads should be separated

from the power leads.

Twisting the load wires reduces the parasitic inductance of the cable which could produce high frequency

voltage spikes at the load and the output of power supply because of current variation in the load itself.

The impedance introduced between the power supply output and the load could make the ripple and noise

at the load worse than the noise at the power supply rear panel output. Additional filtering with bypass

capacitors at the load terminals may be required to bypass the high frequency load current.

3.7.4 Inductive loads

To prevent damage to the power supply from inductive kickback, a diode should be connected across the

output. The diode voltage and current rating should be greater than the power supply maximum output

voltage and current rating. Connect the cathode to the positive output and the anode to the negative

output. Where positive load transients such as back EMF from a motor may occur, connect a surge

suppressor across the output to protect the power supply. The breakdown voltage rating of the suppressor

must be approximately 10% higher than the maximum output voltage of the power supply.

3.7.5 Making the load connections

Hazardous voltages may exist at the outputs and the load connections

when using a power supply with a rated output greater than 40V. To protect

personnel against accidental contact with hazardous voltages, ensure that

the load and it's connections has no accessible live parts.

Ensure that the load wiring insulation rating is greater than or equal to the

maximum output voltage of the power supply.

3.7.6 Front panel controls and indicator

1

2

3

4

Fig. 3-1: FPS1000 front panel

1

2 34

!

WARNING

5

1: Handle

2: DC OK green LED, on when the output

voltage is above 80% +/- 5% of its rated value.

56

3: DC Fail red LED, on when the output voltage

is lower than 80% +/- 5% of its rated value.

4: AC OK green LED, on when the input

voltage is higher than 85Vrms

5: Lock/Unlock lever. Automatically locks the

power supply to the FPS-S1U rack chassis

when the FPS1000 power supply is

inserted. Push the Lock/Unlock lever toward

the power supply cooling fan to withdraw

the FPS1000 from the rack.

6: IEC320 AC inlet

Fig. 3-2: FPS1000/P front panel

9

3.7.7 Input/Output connector information

The FPS1000 series uses male connector PCIB24W9M400A1, Positronic connector. To mate FPS1000

series to the load circuitry, use female connector PCIB24W9F400A1-S1031, Positronic connector.

Refer to Table 3-4 and to the Outline drawing in chapter 2 for the connector pinout description.

Pin No Function Description

1,2,4 +V Positive output voltage. Maximum current capacity: 24A/contact.

3,5,6 -V Negative output voltage. Maximum current capacity: 24A/contact.

7 On/Off control

8

+Sense

Turns the output to On and Off by electrical signal or dry contact between pin 7

and pin 10 (Signal Return). 0~0.6V or Short: On, 2~15V or Open: Off.

The maximum source current is 2.6mA.

Positive sensing. The +Sense signal should be connected to the positive terminal

of the load. The +Sense and -Sense leads should be twisted pair to minimize noise

pick-up effect. The maximum load wires drop compensation is 1V/wire.

9 DC_OK

10 Signal_Return

11 AC_Fail

12

13 -Sense

14 V_Trim

15 CS

16 +12V Auxiliary

17 SDA

18 SCL

19,20,21 A0, A1, A2

22 ACG

23 AC Line

24 AC Neutral

Over

Temperature

Alarm

Open collector signal, referenced to pin 10 (Signal Return). On when Vout≥80%+/5% of its rated value. The maximum sink current is 10mA and the maximum

external voltage is 15V.

Return for the following control and supervisory signals: On/Off, DC_OK,

Over_temperature Alarm, AC_Fail, Auxiliary 12V supply. The Signal return is isolated

from the output terminals.

Open collector signal, referenced to pin 10 (Signal Return). On when the input

voltage is ≥85Vrms. The maximum sink current is 10mA and the maximum external

voltage is15Vdc.

Open collector signal, referenced to pin 10 (Signal Return). On when the internal

temperature is within safe limit, Off approx. 10°C below Thermal shut down. The

maximum sink current is 10mA and the maximum external voltage is 15V.

Negative sensing. The -S signal should be connected to the negative terminal of

the load. The -S and +S leads should be twisted pair to minimize noise pick-up

effect. The maximum load wires drop compensation is 1V/wire.

Connection for output voltage trimming. The voltage can be trimmed within its

range specifications.

Current sharing signal. When units are connected in parallel, the CS pins of the

units should be connected to allow current balance between units.

Auxiliary voltage output, 11.2~12.5V, referenced to pin 10 (Signal Return). The

maximum load current is 0.25A. This output has built in Oring diode and is not

controlled by the On/Off control.

Serial Data used in the I

Serial Clock used in the I

2

I

C interface address lines. Refer to the I2C interface description in Chapter 7.

AC Ground connection, refer to the safety instructions for safety standards requirements.

For "/P" models the AC Ground is connected via the front panel IEC inlet.

AC Line connection, refer to the safety instructions for safety standards requirements.

For "/P" models the AC Line is connected via the front panel IEC inlet.

AC Neutral connection, refer to the safety instructions for safety standards requirements.

For "/P" models the AC Neutral is connected via the front panel IEC inlet.

2

C interface option. Refer to the I2C interface description.

2

C interface option. Refer to the I2C interface description.

Table 3-4: Rear In/Out connector pins function description

3.7.8 REPACKAGING FOR SHIPMENT

The original packaging material is reusable. If the original package is not available, contact the Lambda

Sales or service facility near you for details on obtaining suitable packaging and shipping information.

To ensure safe transportation of the instrument, it is recommended to use the original package.

Please attach a tag to the power supply describing the problem and specifying the owner, model number

and serial number of the power supply.

10

FPS1000 Instruction Manual

CHAPTER 4 FUNCTIONS AND FEATURES

4.1 Input Voltage Range

Input voltage is single phase 85~265Vac (47~63Hz). The power supply can be operated also with a DC input voltage,

120~330VDC but the safety approvals apply to the AC voltage only. Input voltage which is out of the specifications

might cause damage to the unit.

4.2 Output voltage trimming

The output voltage can be adjusted within the specifications via the V_Trim pin at the In/Out connector.

Refer to Fig 4-1 typical connection and calculation of the adjustment resistors:

Note that the Over Voltage Protection may trigger if the output voltage exceeds the maximum voltage specification.

Fig 4-1

+V

+S

8

FPS1000 R1 KΩ

V_trim

14

-S

13 R2 KΩ

-V

FPS1000-12:

R2=0.0324*V

R1(K

Ω)=5(KΩ)-R2(KΩ)

FPS1000-24:

R2=0.0785*V

R1(K

Ω)=20(KΩ)-R2(KΩ)

FPS1000-32:

R2=0.0463*V

R1(K

Ω)=20(KΩ)-R2(KΩΩ)

2

out -1.1298*Vout+9.9342

2

out -5.819*Vout+105.132

2

out -4.5805*Vout+109.49

FPS1000-48:

R2=0.0497*V

R1(K

Ω)=50(KΩ)-R2(KΩ)

2

out-7.2795*Vout+259.04

4.3 Over Voltage Protection (OVP)

The OVP triggers when the output voltage exceeds the maximum rating and reaches the OVP limit. When the OVP

is triggered, the output voltage shuts down. In order to resume operation, the AC input voltage should be removed

for more than 30 sec. The OVP level is factory set and is not adjustable.

4.4 Over Current Protection (OCP)

A constant current limiting with automatic recovery is provided. The OCP operates when the output current exceeds

105%~125% of the rated output current. The output voltage recovers automatically when the overload condition is removed.

Avoid operating the power supply under overload condition for long time as it might cause damage to the power

supply.

4.5 Over Temperature Protection (OTP)

The OTP is activated when the ambient temperature or the power supply internal temperature exceeds a safe temperature.

When the OTP is activated, the power supply output shuts down. The output recovers automatically when the ambient

temperature or the internal temperature cools to a safe limit.

4.6 Auxiliary 12V output

An isolated 11.2V~12.5V output is provided (Referenced to the Signals_Return potential). The maximum output

current from this output is 0.25A. This output has a built-in Oring diode to allow paralleling FPS1000 units. Use this

output for the control and monitoring signals described in this chapter or to operate application circuits.

4.7 Over Temperature Alarm

An open collector output provides an Over Temperature Alarm approx. 10°C below shut down by the OTP. The open

collector output is referenced to the Signals_Return potential and is isolated from the power supply +V and -V

terminals

The maximum sink current is 10mA and the maximum external voltage is 15V.

Refer to Fig 4-2 for typical application.

Fig 4-2

12V aux

16

FPS1000 10KΩ

12

Over temperature alarm

10

Signals return

11

4.8 DC_OK signal

An open collector output provides a low output voltage detection signal. The open collector output is on when the

output voltage is higher than 80%+/-5% of the rated output voltage of the power supply.

The open collector output is referenced to the Signals_Return potential and is isolated from the power supply +V

and -V terminals

The maximum sink current is 10mA and the maximum external voltage is 15V.

Refer to Fig 4-3 for typical application.

16 12V aux

FPS1000 10KΩ

9

DC_OK

10

Signals return

Fig 4-3

4.9 AC_Fail signal

An open collector output provides a low AC input voltage detection signal. The open collector output is on when the

input voltage is 85Vac or higher.

The open collector output is referenced to the Signals_Return potential and is isolated from the power supply +V

and -V terminals

The maximum sink current is 10mA and the maximum external voltage is 15V.

Refer to Fig 4-4 for typical application.

16 12V aux

FPS1000 10KΩ

11

AC_Fail signal

10

Signals return

Fig 4-4

4.10 Remote On/Off control

A Remote On/Off control input is provided. The Remote On/Off input is isolated from the power supply +V and -V

terminals and is referenced to the Signals_Return potential. The Remote On/Off can be operated either by electrical

signal or by dry contact.

(1) Operation by electrical signal:

0~0.6V: Output is On.

2~15V: Output is Off.

The maximum sink current is 2.6mA and the maximum external voltage is 15V.

(2) Operation by dry contact (relay or switch):

Short between On/Off input and Signals Return: Output is On.

Open circuit between On/Off input and Signals Return: Output is Off.

When the Remote On/Off function is not used, connect a short circuit between the On/Off control and the Signals_Return.

Refer to Fig 4-5 for the remote On/Off circuit description:

Fig 4-5

FPS1000 4.7KΩ

16 12V aux

7

On/Off control

10

Signals return

12

I source 2.6mA max, 15Vdc max.

FPS1000 Instruction Manual

4.11 Remote Sensing

The Remote sensing compensates voltage drop on the load wiring. The maximum voltage drop on each wire is 1V,

however, it is recommended to minimize the voltage drop on the load wires to improve the response to load current

changes.

In case that the sensing wires are long, use separate twisted pair wires for the sensing and for the load wires to

minimize noise pick-up.

It is recommended to connect electrolytic capacitors in the following locations:

1) Across the load terminals

2) Between the "+S" terminal and the "+V" terminal of the power supply.

3) Between the "-S" terminal and the "-V" terminal of the power supply.

Refer to Fig 4-6 for typical connection of remote sensing.

8

+S

FPS1000

+V

-V

1,2,4

3,5,6

+

+

LOAD

-

Fig 4-6

-S

+

13

13

CHAPTER 5 BASIC CONNECTIONS FOR OPERATION

5.1 Connecting single load, Local sensing

Local sensing is suitable for applications where load regulation is not critical. Fig 5-1 shows recommended

load and sensing connections for applications with a single load.

FPS1000

SIGNAL

RTN

ON/

OFF

1,2,4

+V

+S

8

13

-S

-V

710

3,5,6

+

LOAD

-

Fig 5-1: single load connection, local sensing

In Local sense applications, the +/- sense have to be connected to the

*

+/-V terminals of the FPS1000 units prior the operating the FPS1000 units

5.2 Connecting Single Load, Remote Sensing

Remote sensing is used in cases where the load regulation is important at the load terminals. Use twisted

or shielded wires to minimize noise pick-up. If shielded wires are used, the shield should be connected

to the ground at one point, either the power supply side or the load. The optimal point for the shield ground

should be determined by experimentation. Refer to the power supply specifications for the maximum

voltage drop allowed at the load wires.

Load line.

Up to 1V drop.

Sense lines

Twisted pairs

+

LOAD

-

Load line.

Up to 1V drop.

FPS1000

SIGNAL

RTN

ON/

OFF

1,2,4

+V

8

+S

13

-S

3,5,6

-V

710

Fig 5-2: Remote sensing, single load.

5.3 Connecting Multiple loads, radial distribution method

In cases of multiple loads connected to one supply, each load should be connected to the power supply's

output terminals using separate pairs of wires. It is recommended that each pair of wires will be as short

as possible and twisted or shielded to minimize noise pick-up and radiation.

The sense wires should be connected to the power supply output terminals or to the load with the most

critical load regulation requirement.

FPS1000

SIGNAL

RTN

ON/

OFF

1,2,4

+V

+S

8

13

-S

-V

710

3,5,6

+

-

+

-

+

LOAD # 1

LOAD # 2

LOAD # 3

-

Fig 5-3: Multiple loads connection , radial distribution

14

FPS1000 Instruction Manual

5.4 Multiple loads connection with distribution terminals

If remotely located output distribution terminals are used, the power supply output terminals should be

connected to the distribution terminals by a pair of twisted or shielded wires. Each load should be separately

connected to the remote distribution terminals (see Fig 5-4). If remote sensing is required, the sensing

wires should be connected to the distribution terminals or at the most critical load.

+V

-V

+

-

+

-

+

LOAD # 1

LOAD # 2

LOAD # 3

FPS1000

SIGNAL

RTN

ON/

OFF

1,2,4

+V

+S

8

13

-S

-V

710

3,5,6

-

Fig 5-4: Multiple loads connection with distribution terminal

5.5 Grounding outputs

Either the positive or negative output terminals can be grounded. To avoid noise problems caused by

common-mode current flowing from the load to ground, it is recommended to ground the output terminal

as close as possible to the power supply's output. Always use two wires to connect the load to the power

supply regardless of how the system is grounded.

15

CHAPTER 6 PARALLEL AND SERIES OPERATION

6.1 Parallel operation

Up to 8 FPS1000 units of the same output voltage rating can be connected in parallel. By connecting the CS signal

between the paralleled units, automatic current balance is achieved, with +/-10% accuracy. Derate the total output

current by 10% when using parallel operation to prevent overload condition.

The built-in Oring diodes on the main output and the 12V Auxiliary output allow N+1 operation.

For input voltages less than 100Vac, maximum output Power derated by 10% of the Power rating.

6.1.1 Parallel operation with Remote sensing

Fig 6-1 shows typical connection of parallel operation with Remote sensing. The CS signal wires should be as short

as possible and with the same length.

ON/

OFF

ON/

OFF

ON/

OFF

+V

+S

-S

-V

71015

+V

+S

-S

-V

71015

+V

+S

-S

-V

71015

+S

+S

-S

-S

+S

-S

+S

+V

LOAD

-V

-S

FPS1000 #1

SIG.

RTN

CS

FPS1000 #2

SIG.

RTN

CS

FPS1000 #N

SIG.

RTN

CS

Fig 6-1: Parallel operation with Remote sensing

6.1.2 Output voltage trimming at parallel operation

The output voltage of the units connected in parallel can be made by a single trimmer or resistive divider as shown

in Fig 6-2.

V TRIM

FPS1000 #1

SIG.

RTN

CS

15

FPS1000 #2

SIG.

RTN

15

FPS1000 #N

SIG.

RTN

15

+S

ON/

OFF

710

V TRIM

+S

ON/

OFFCS

710

V TRIM

+S

ON/

OFFCS

710

-S

V TRIM

+V

-S

-V

-S

Fig 6-2: Output voltage trimming at parallel operation

16

+S

-S

R1

R2

FPS1000-12:

R2=0.0324*V

R1(K

Ω)=5(KΩ)-R2(KΩ)

FPS1000-24:

R2=0.0785*V

R1(K

Ω)=20(KΩ)-R2(KΩ)

FPS1000-32:

R2=0.0463*V

R1(K

Ω)=20(KΩ)-R2(KΩΩ)

FPS1000-48:

R2=0.0497*V

R1(K

Ω)=50(KΩ)-R2(KΩ)

2

out -1.1298*Vout+9.9342

2

out -5.819*Vout+105.132

2

out -4.5805*Vout+109.49

2

out-7.2795*Vout+259.04

FPS1000 Instruction Manual

6.1.3 Signal Return bus at parallel operation

The Signal Return of each paralleled unit can be connected together to form a common Signal Return bus.

By this way, the control and monitoring signals of the paralleled units can be connected to the same control and

monitoring circuitry.

The Signal Return bus can be connected to the -V or -S or +V or -S or float. Fig 6-3 shows typical connection of

the Signal Return at parallel operation.

FPS1000 #1

OVER-TEMP

FPS1000 #2

OVER-TEMP

FPS1000 #N

OVER-TEMP

AC_FAIL

DC_OK

ALARM

SIG.

RETURN

AC_FAIL

DC_OK

ALARM

SIG.

RETURN

AC_FAIL

DC_OK

ALARM

SIG.

RETURN

9, 11, 12

10

9, 11, 12

10

9, 11, 12

10

Fig 6-3: Signal Return connection at parallel operation

CONTROL AND

MONITORING CIRCUITS

FPS1000 #1 SIGNALS

FPS1000 #2 SIGNALS

FPS1000 #N SIGNALS

SIGNALS RETURN

6.1.4 Remote On/Off control at parallel operation

The paralleled units can be turned On or Off via a single On/Off control. Refer to Fig 6-4 for typical application. The

Signal Return function of all the paralleled units should be connected together to create a common Signal Return

bus. The Signal Return bus may be connected to the -V or the +V potential or floated. In any case do not connect

the Signal Return bus to different potentials.

FPS1000 #1

FPS1000 #2

FPS1000 #N

ON/OFF

SIG.

RETURN

ON/OFF

SIG.

RETURN

ON/OFF

7

10

7

10

7

ON OFF

SIG.

RETURN

10

Fig 6-4: Remote On/Off control at parallel operation

17

6.2 Series operation

Two units can be seriesly connected to increase the output voltage or to create a bipolar voltage source. It is

recommended to connect diodes in parallel with each output to prevent reverse voltage in case of failure in one of

the power supplies. Each diode should be rated to at least the power supply rated output voltage and output current.

Refer to Fig 6-5 and 6-6 for typical lseries connection of power supplies.

Series connection for increased output voltage.

FPS1000 #1

SIG.

RTN

FPS1000 #2

SIG.

RTN

+S

+V

-V

ON/

-S

OFF

710

+S

+V

-V

ON/

-S

OFF

710

(*) Diodes are user supplied

(*)

(*)

+S

+V

LOAD

-V

-S

Fig 6-5: Series connection for increased output voltage

Series connection for positive and negative output voltage.

FPS1000 #1

SIG.

RTN

FPS1000 #2

SIG.

RTN

+S

+V

-V

ON/

-S

OFF

710

+S

+V

-V

ON/

-S

OFF

710

(*) Diodes are user supplied

(*)

(*)

+V

COMMON

-V

LOAD

Fig 6-6: Series connection for Bipolar output voltage

CAUTION

Series operation is not applicable for units with I

18

2

C bus option.

FPS1000 Instruction Manual

CHAPTER 7 I2C BUS INTERFACE OPTION

7.1 Introduction

2

C interface option includes facilities to monitor operating parameters of the power supply. The parameters

The I

are then transferred to the host PC if demanded, over a standard I

The following data can be monitored for the individual units connected to the I

1. Status of the unit.

2. Actual output voltage, output current and internal temperature of the unit.

3. Manufacturing related data (model, serial number, manufacturing date etc…).

2

C bus.

2

C bus:

7.1.1 Addressing (A0, A1, A2).

2

Three address lines allow up to eight FPS1000 units to be addressed on a single I

C bus. The address lines are

internally pulled-up to +5V by resistors. Addressing of a unit is achieved by hard-wiring an address line to the

-Sense to set it to "0" or leaving the address line open to set it to "1".

7.1.2 Serial clock

This line is clocked by the processor which controls the I

via a pull-up resistor of 2KΩ. The I

2

C interface is designed to run with a serial clock speed of 100KHz.

2

C bus. It should be connected to +5V (referenced to -Sense)

7.1.3 Serial dataThis line is a bidirectional data line. It should be connected to +5V

(referenced to -Sense) via a pull-up resistor of 2KΩ.

7.2 I2C Interface Specifications

7.2.1 General specifications

1. Clock frequency: 100KHz

2. Address lines: Three (A0, A1, A2). Support 8 power supply modules

7.2.2 Output voltage measurement

1. Measurement accuracy: +/-2% of full scale

2. Measurement resolution: 8 bits

3. Measurement range:

0~60.0V for 48V model / 0~40.0V for 32V model / 0-30.0V for 24V model.

7.2.3 Output current measurement

1. Measurement accuracy: +/-10% of full scale

2. Measurement resolution: 8 bits

3. Measurement range: 0~25.0A for 48V model

/

0~50A for 32V & 24V models

7.2.4 Internal temperature measurement

1. Measurement accuracy: +/-3°C

2. Measurement resolution: 8 bits

3. Measurement range: 0-100°C

7.2.5 EEPROM

1. EEPROM type: AT24C02AN-10S , Atmel, or equivalent

2. EEPROM data:

Model name, Serial no., Revision, Manufacture. Name, Output voltage,

Date, Country of manufacturing, Check-Sum

7.2.6 Status register

1. Register type: PCF8574, Philips, or equivalent.

2. Register content: DC Fail, Over-Temperature Protection (OTP)

Temperature Alarm, Fan Fail, AC Fail

CAUTION

The I2C bus address lines, serial clock and data are

referenced to the -Sense potential. When using series

connection of FPS1000 units, do not connect the I

2

C lines

of the units together.

19

2

7.3 Block diagram of the I

C option

Refer to Fig 7-1 for description of the I

2

C block diagram and for typical application.

A0

A1

A2

REGISTER

A0

A1

A2

ADC

OTP

Temperature Alarm

Fan Fail

AC Input Fail

Output voltage

Output current

Temperature

A0 A0

A1 A1

A2 A2

Output Fail

EEPROM

Fig 7-1: I2C option bloack diagram

Serial CLOCK

Serial DATA

7.4 Operation and functions

7.4.1. Digital status

Digital status functions are provided by a PCF8574, 8-bit Register. It provides a single 8-bit word when read by the

2

C controller. Fault is indicated by "1" and Good level is indicated by "0".

I

Refer to Table 7-1 for the register information.

BIT

FUNCTION MEANING

0 Output Fail

Output voltage is <80% +/- 5% of Vout rated

1 Over Temperature Protection Internal temperature is over 80°C. Supply turns off.

2 Temperature Alarm Internal temperature is over 70°C. Supply is on.

3 Fan Fail Failure of an internal fan.

4

AC Input Fail

AC Input <85Vac

5 Not Used Always "0".

6 Not Used Always "0".

7 Not Used Always "0".

Table 7-1

PCF8574 slave address:

Bit 7 6 5 4 3 2 1 0

Value 0 1 0 0 A2 A1 A0 R/W

7.4.2 EEPROM functions

A 256 bytes EEPROM included in the I

2

C option. The EEPROM type is AT24C02 and it is programmed at the factory

with the data shown in Table 7-2.

ADDRESS BYTES DATA

0 4 Number of fields

4 16 Manufacturer

20 20 Serial number

40 16 Revision

56 16 Country of manufacture

72 16 Model name

88 16 Output voltage

104 16 Date of manufacture

254 2 Checksum

Table 7-2

The slave EEPROM address is:

Bit 7 6 5 4 3 2 1 0

Value 1 0

1

0 A2 A1 A0 R/W

20

FPS1000 Instruction Manual

7.4.3 Analog functions

Analog functions are provided by a single PCF8591, 4-channel 8-bit A/D converter. When this device is read by the

serial buscontroller it provides an 8-bit word with the following information:

Channel 1: Output voltage, channel 2: Output current, channel 3: Internal temperature.

The PCF8591 slave address is:

Bit 7 6 5 4 3 2 1 0

Value 1 0 0 1 A2 A1 A0 R/W

The PCF8591 device initially requires a control byte to be written to the configuration register.

The control byte is as follows:

Bit 7 6 5 4 3 2 1 0

Value 0 A 0 0 0 B C D

When a single channel is to be read, A,B,C and D should be determined as follows:

A/D channel A B C D

Voltage 0 0 0 0

Current 0 0 0 1

Temperature 0 0 1 0

To read all channels with a single control byte, A and B have to be "1", C and D have to be "0". This control byte

sets the device so that on each successive read the data from the next A/D is read.Thus, the first result from a

sequence of reads should not be considered.

Note that on each read, a conversion is started for a particular channel and the result will be read from the previous channel.

7.4.4 A/D Scaling

The A/D readback has to be scaled to obtain a correct value for the voltage, current and the temperature. Note that

the voltage reading is made inside the power supply unit before the "Oring" diode and is typically 0.5V higher than

the actual output voltage.

The following scaling should be employed:

Refer to the following table for the scaling of the A/D channels:

FPS1000-12/S

0~15V

0~80A

0~100°C

FPS1000-32/S

The measurement range is from 0 to the maximum value listed in the range column. The resolution or scale of

reading is linear over the entire range and provides a linear output on the A/D converter.

7.5 Measurements and calculation examples

7.5.1 Output voltage readback

The voltage before the "Oring" diode is measured and can be read from the A/D converter. This voltage is higher

than the voltage at the output terminals by 0.5V typically.

Model: FPS 1000-48/S

1. Output voltage (at the output terminals): 48.0V

2. Voltage before the "Oring" diode: 48.0V+0.5V=48.5V

3. .Hex readback: CE (1100 1110).

4. Convert the hex readback to decimal: 206

5. Calculate measured Vout: Vout=206*0.2344=48.286V

0.0586 V/Bit

0.312 A/Bit

0.391°C/Bit

VALUE = BYTE VALUE x RESOLUTION

FPS1000-24/S

FPS1000-48/S

7.5.2 Output current readback

The output current is sensed by an internal shunt and measured by an A/D converter. Refer to the following examplefor

current readback calculation.

1. Actual output current: 21.0A

2. Hex readback: E0 (1110 0000).

3. Convert the hex readback to decimal: 224

4. Calculate measured Iout: Iout=224*0.0977=21.884A.

21

7.5.3 Internal temperature measurement

The internal ambient temperature is measured to provide information of the safe operation of the power supply. The

internal ambient temperature is usually higher than the power supply air intake temperature due to internal power

dissipation. As the power dissipation varies with the load, the internal ambient temperature increases with the load.

Refer to Fig 7-2 for typical internal temperature rise above the air intake temperature versus the load.

Internal temp.

rise (°C)

15

10

5

0

25 50 75 100 % of rated load

Fig 7-2: Internal temperature rise vs. load

Internal temperature calculation example:

1. Hex readback: 68 (0110 1000).

2. Convert hex readback to decimal: 104

3. Calculate the measured temperature:

o

Temp=104*0.391=40.664

C

7.6 Typical application diagram

A typical application is described in Fig 7-3.

PC

RS232

RS232

CABLE

Fig 7-3: Typical application of I

RS232 TO

2

C

I

CONVERTOR

2

C interface

CLOCK

DATA

GND

RETURN

SCL

SDA

FPS1000

A0 A1 A2

ON/OFF

CONTROL

ON/OFFSIGNAL

+S

+V

-V

-S

ADDRESS

SETTING

+

LOAD

-

22

FPS1000 Instruction Manual

CHAPTER 8 FPS1000 MAINTENANCE

8.1 Introduction

This chapter contains information about maintenance, calibration and troubleshooting of the FPS1000 power supply.

8.2 Units under warranty

Units requiring repairs during the warranty period should be returned to Densei-Lambda authorized service office.

Unauthorized repairs performed by other than the authorized service facilities may void the warranty.

8.3 Periodic maintenance

No routine maintenance of the FPS1000 power supply is required except for periodic cleaning. To clean, disconnect

the unit from the AC supply and allow 30sec. for discharging internal voltage. The FPS1000 should be cleaned using

mild solution of detergent and water. The solution should be applied onto a soft cloth, and not directly to the surface

of the unit. Do not use aromatic hydrocarbons or chlorinated solvents for cleaning. Use low pressure compressed

air to blow dust from the unit.

8.4 Adjustments and Calibration

No internal adjustment or calibration are required. Units that are returned for repair will be calibrated at the service

office.In any case ,opening the cover is not allowed.

8.5 Fan life expectancy

The fan life has limitation depending mainly on the ambient temperature. Please refer to Fig 8-1 for the expected

fan life vs. the ambient temperature. In case that the fan should be replaced, contact your nearest Densei-Lambda

authorized service office.

10

Life expectancy (years)

1

100500

Ambient temperature (°C)

Fig 8-1: Expected fan life vs. ambient temperature

8.6 Before concluding that the unit is at fault:

Before concluding that the unit is at fault, make the following tests:

* Check if the AC voltage is within the specification range.

*Check if the input and output wiring is correct.

*Check if the +S and -S wires are connected to the +Vout and -Vout (refer to sec. 4.11).

*Check if the wires size is sufficient (refer to sec. 3.7.2).

*Check if the output voltage control, V_Trim, is connected properly (refer to sec. 4.2).

*Check if the On/Off control is connected properly (refer to sec. 4.10).

*Check if the load current and power consumption are within the power supply specifications.

*Audible noise can be heard during dynamic load operation.

*Audible noise can be heard when the input voltage waveform is not sinusoidal.

8.7 Parts replacement and repair

As repairs are made only by the manufacturer or by its authorized service offices, no parts replacement information

is given inthis manual. In case of failure, unusual or erratic operation of the unit, contact your nearest Densei-Lambda

sales and service office.

23

FPS-S1U 19” Rack Single Output

24

CHAPTER 9 FPS-S1U RACK SPECIFICATIONS

1

Number of power supply modules (*1)

2

Maximum output power (*2)

3

Input voltage / frequency range (*3)

4

Maximum input current (at 100/200Vac)

5

AC input connector

6

Output terminals

7

Remote sensing (*4)

8

Parallel operation

9

Series operation (*5)

10

Remote On/Off control

11

DC_OK signal

12

AC fail signal

13

Over Temperature alarm signal

14

Vout voltage trimming

15

Auxiliary power supply

16

Operating temperature

Storage temperature

17

Operating humidity

18

Storage humidity

19

Vibration

20

Shock

21

Applicable safety standards

22

Withstand voltage

23

Insulation resistance

24

Weight (Typ)

25

Size (W*H*D)

26

Warranty

27

---

W

---

A

---

---

V

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

Kg

---

Yr

Maximum 3 x FPS1000 modules of the same output voltage rating.

FPS-S1U :IEC inlet for each power supply module . FPS-S1U/P :None

Possible. Up to 3 racks with max 8 FPS 1000 units of the same voltage and current rating.

Possible. Up to 2 racks of the same voltage and current rating

Separate control for each FPS 1000 unit , By electrical signal or dry contact

Separate control for each FPS1000 unit, Open collector signal.

Separate control for each FPS1000 unit ,Open collector signal.

Separate control for each FPS1000 unit ,Open collector signal.

Possible, via separate control for each FPS1000 unit .Refer to Instruction Manual.

11.2~12.5VDC.Maximum output current:0.25A*Number of installed FPS1000 units.

Input-Output: 3000Vrms, 1min. Input-Ground: 2000Vrms, 1min. Output-Ground:

More than 100Mohm at 25°C and 70% RH. Output-Ground: 500Vdc

FPS-S1U Instruction Manual

3000

85~265Vac continuous, 47~63Hz, Single phase

12.0/6.0 for each FPS1000 unit installed

Bus-bars.Refer to outline drawing.

Possible.

ON: 0~0.6V or short. OFF: 2~15V or open.

On when Vout >80% +/-5%. Max.sink current: 10mA

Refer to Instruction Manual

Refer to Instruction Manual

0~50°C: 100% load. Derate 2%/°C, 50°C to 60°C.

-30~85°C

10~90% RH, no condensation.

10~90% RH, no condensation.

Built to meet ETS 300 019

Built to meet ETS 300 019

UL60950-1, EN60950-1

500Vrms, 1min.

3.7

440x44x351mm. Refer to Outline Drawing.

Two Years

Notes:

*1: The Output of all the FPS1000 modules are connected in parallel in the rack.

*2: For input voltage lower than 100Vac, maximum output power derated by 10% of the power rating.

*3: For cases where conformance to to various safety standards (UL, EN etc.) is required, to be described

as 100-240Vac (50/60Hz).

*4: Remote sensing can compensate up to 1V drop on each load wire.

*5: Not apllicable for units with I

2

C bus option.

25

CHAPTER 10 FPS-S1U RACK INSTALLATION

10.1 GENERAL

This chapter contains instructions for initial inspection, preparation for use and repackaging for shipment.

In some sections in this chapter, where the instructions for the FPS-S1U and the FPS1000 are identical,

a reference to a section describing the FPS1000 will be given.

10.2 PREPARATION FOR USE

Table 10-1 below describes the basic setup procedure. Follow the instructions in Table 10-1 in the sequence

given to prepare the FPS-S1U rack for use.

Step no Item Description Reference

1 Inspection Initial physical inspection of the power supply Section 3.3

2 Installation Installing the power supply. Section 10.4

Ensuring adequate ventilation. Section 10.5

3 AC source AC source requirements Section 3.6

4 Load connection Wire size selection. Section 10.7

Table 10-1: Basic setup procedure

10.3 INITIAL INSPECTION

Refer to Sec. 3.3 for details.

10.4 FPS-S1U RACK MOUNTING

The FPS-S1U is designed to be mounted in a 19" rack. Use a support bars or surface to provide adequate

support for the rear of the power supply. Secure the FPS-S1U to its location using the front panel using

M6x12 screws via the mounting holes at its front side (Refer to the outline drawings in Chapter 11).

Do not obstruct the air exhaust at the rear panel of the unit.

10.5 LOCATION MOUNTING AND COOLING

The FPS1000 units installed in the FPS-S1U rack are fan cooled. The air intake is at the front panel and

the exhaust is at the rear panel. Upon installation allow cooling air to reach the front panel and allow

minimum 50mm of unrestricted air space at the rear of the unit for the air exhaust.

10.6 AC SOURCE REQUIREMENTS

Refer to Sect 3.6 for details.

10.7 CONNECTING THE LOAD

WARNING

Turn off the AC input power before making or changing any rear panel connection.

Ensure that all connections are securely tightened before applying power. There is a

potential shock hazard when using a power supply with a rated output greater than 40V.

10.7.1 Load Wiring

.Refer to Sec. 3.7.1, 3.7.2 and 3.7.3 for details.

10.7.2 Inductive loads

To prevent damage to the power supply from inductive kickback, a diode should be connected across the

output. The diode voltage and current rating should be greater than the power supply maximum output

voltage and total current rating. Connect the cathode to the positive output and the anode to the negative

output. Where positive load transients such as back EMF from a motor may occur, connect a surge

suppressor across the output to protect the power supply. The breakdown voltage rating of the suppressor

must be approximately 10% higher than the maximum output voltage of the power supply.

26

10.7.3 Making the load connections

FPS-S1U Instruction Manual

!

WARNING

Hazardous voltages may exist at the outputs and the load connections

when using a power supply with a rated output greater than 40V. To

protect personnel against accidental contact with hazardous voltages,

ensure that the load and it's connections has no accessible live parts.

Ensure that the load wiring insulation rating is greater than or equal to

the maximum output voltage of the power supply.

The load wires should be properly terminated with terminals securely attached. DO NOT use unterminated

wires for load connection at the FPS-S1U.

10.7.4 Rear panel description

1

Fig. 10-1: FPS-S1U Rear panel

2 5 1

3

4

1. Mounting brackets. Use M6x12 screws to fix the FPS-S1U to the rack.

2: DB25 connector for control and monitoring signals.

3: Output voltage terminals. Use M6x16 screws and M6 lug to connect the load wire. The recommended

tightening torque is 42~56Kgf.cm.

4. DIP switch for I

2

C option address setting. Refer to Chapter 14 for details.

5. IEC320 AC inlets, shown for FPS-S1U rack. For FPS-S1U/P, there are no IEC320 inlets on the rack.

10.7.5 Control and monitoring signals connector

Pin No Function

1 V_TRIM_B Connection for output voltage trimming of FPS1000 unit "B". The voltage can be

TEMP_ALARM_B2

DC_OK_B3

TEMP_ALARM_A4

ON/OFF_A5

Description

trimmed within its range specifications.

Open collector signal, referenced to pin 11 (Signal Return). On when the internal temperature

of FPS1000 unit "B" is within safe limit, Off approx. 10°C below Thermal shut down. The

maximum sink current is 10mA and the maximum external voltage is 15V.

Open collector signal, referenced to pin 11 (Signal Return). On when the output voltage

of FPS1000 unit "B" is higher than ≥ 80%+/-5%. The maximum sink current: 10mA

and the maximum external voltage is 15V.

Open collector signal, referenced to pin 11 (Signal Return). On when the internal temperature

of FPS1000 unit "A" is within safe limit, Off approx. 10°C below Thermal shut down. The

maximum sink current is 10mA and the maximum external voltage is 15V.

Turns the output of FPS1000 unit "A" to On and Off by electrical signal or dry contact

between pin 5 and pin 11 (Signal Return). 0~0.6V or Short: On, 2~15V or Open:

Off. The maximum source current is 2.6mA.

DC_OK_A6

V_TRIM_A7

+12V_AUX8

Open collector signal, referenced to pin 11 (Signal Return). On when the output

voltage of FPS1000 unit "A" is higher than V

current: 10mA and the maximum external voltage is 15V.

Connection for output voltage trimming of FPS1000 unit "A". The voltage can be

trimmed within its range specifications.

Auxiliary voltage output, 11.2~12.5V, referenced to pin 11 (Signal Return). The

maximum load current is 0.25A. This output has built in Oring diode and is not controlled

by the On/Off control.

out ≥ 80%+/-5%. The maximum sink

27

10.7.5 Control and monitoring signals connector

CS9

V_TRIM_C10

SIGNAL_RETURN11

DC_OK_C12

+SENSE13

AC_FAIL_B14

ON/OFF_B15

AC_FAIL_A16

17 NC

18 NC

19 NC

SCL (I2C)20

SDA (I2C)21

-SENSE22

TEMP_ALARM_C23

AC_FAIL_C24

ON/OFF_C25

Current sharing signal. When FPS-S1U racks are connected in parallel, the CS pins

of the units should be connected to allow current balance between units.

Connection for output voltage trimming of FPS1000 unit "C". The voltage can be

trimmed within its range specifications.

Return for the following control and supervisory signals: On/Off, DC_OK,

Over_temperature Alarm, AC_Fail, Auxiliary 12V supply. The Signal return is isolated

from the output terminals.

Open collector signal, referenced to pin 11 (Signal Return). On when the output voltage

of FPS1000 unit "C” is higher than ≥ 80%+/-5%. The maximum sink current: 10mA

and the maximum external voltage is 15V.

Positive sensing. The +Sense signal should be connected to the positive terminal of

the load. The +Sense and -Sense leads should be twisted pair to minimize noise pickup effect. The maximum load wires drop compensation is 1V/wire.

Open collector signal, referenced to pin 11 (Signal Return). On when the input voltage

of FPS1000 unit "B" is ≥85Vrms. The maximum sink current is 10mA, and the maximum

external voltage is 15Vdc.

Turns the output of FPS1000 unit "B" to On and Off by electrical signal or dry contact

between pin 15 and pin 11 (Signal Return). 0~0.6V or Short: On, 2~15V or Open:

Off. The maximum source current is 2.6mA.

Open collector signal, referenced to pin 11 (Signal Return). On when the input voltage

of FPS1000 unit "A" is ≥85Vrms. The maximum sink current is 10mA, and the maximum

external voltage is 15Vdc.

Not connected

Not connected

Not connected

Serial Clock used in the I

2

C interface option. Refer to the I2C interface description in

the Chapter 7 in this Instruction Manual.

2

Serial Data used in the I

C interface option. Refer to the I2C interface description in

the Chapter 7 in this Instruction Manual.

Negative sensing. The -Sense signal should be connected to the negative terminal

of the load. The -Sense and +Sense leads should be twisted pair to minimize noise

pick-up effect. The maximum load wires drop compensation is 1V/wire.

Open collector signal, referenced to pin 11 (Signal Return). On when the internal temperature

of FPS1000 unit "C" is within safe limit, Off approx 10°C below Thermal shut down. The

maximum sink current is 10mA and the maximum external voltage is 15V.

Open collector signal, referenced to pin 11 (Signal Return). On when the input voltage

of FPS1000 unit "C" is ≥85Vrms. The maximum sink current is 10mA, and the maximum

external voltage is 15Vdc.

Turns the output of FPS1000 unit "C" to On and Off by electrical signal or dry contact

between pin 25 and pin 11 (Signal Return). 0~0.6V or Short: On, 2~15V or Open: Off.

The maximum source current is 2.6mA.

28

FPS-S1U Instruction Manual

10.7.6 Modules location

Up to three FPS1000 modules of the same output voltage rating can be plugged into an FPS-S1U rack.

Refer to Fig 10-2 for the modules location.

PS MODULE “A”

PS MODULE “B”

Air flow direction

Front side

see note 1

PS MODULE “C”

Fig 10-2: FPS1000 modules location

Note 1: Forced air cooling allow minimum 50mm of unrestricted air space at the rear of the unit. Do not

obsruct air flow to the unit front panel.

10.7.7 Blank panels

Each FPS-S1U rack is supplied with two blank panels in the package. Use the blank panels to close the

front panel opening in places where FPS1000 power supplies are not installed. Use M3x6 screws to fix

the blank panel to the chassis. Refer to the outline drawings in chapter 11 for details.

10.7.8 Repackaging for shipment

Refer to Sec. 3.7.8 for details.

29

CHAPTER 11 FPS-S1U AND FPS-S1U/P OUTLINE DRAWINGS

11.1 FPS-S1U Outline Drawing

30

11.2 FPS-S1U/P Outline Drawing

FPS-S1U Instruction Manual

31

CHAPTER 12 BASIC CONNECTIONS FOR OPERATION FPS-S1U RACK

12.1 Connecting single load, Local sensing

Local sensing is suitable for applications where load regulation is not critical. Fig 12-1 shows recommended

load and sensing connections for applications with a single load.

FPS-S1U

SIGNAL

RTN

ON/

OFF

A

ON/

OFF

B

ON/

OFF

C

+V

+S

13

22

-S

-V

2515511

+V

LOAD

-V

Fig 12-1: single load connection, local sensing

In Local sense applications, the +/- sense have to be connected to the

*

+/-V terminals of the FPS-S1U prior to operating the FPS1000 units plugged in.

12.2 Connecting Single Load, Remote Sensing

Remote sensing is used in cases where the load regulation is important at the load terminals. Use twisted

or shielded wires to minimize noise pick-up. If shielded wires are used, the shield should be connected

to the ground at one point, either the power supply side or the load. The optimal point for the shield ground

should be determined by experimentation. Refer to the power supply specifications for the maximum

voltage drop allowed at the load wires.

Load line. Up to 1V drop.

+V

LOAD

-V

FPS-S1U

SIGNAL

RET

ON/

OFF

A

511

ON/

OFF

B

ON/

OFF

C

15 25

+V

+S

13

22

-S

-V

Sense lines

Twisted pairs

*

Load line.

Up to 1V drop.

Fig 12-2: Remote sensing, single load.

12.3 Multiple loads connection

If remotely located output distribution terminals are used, the power supply output terminals should be

connected to the distribution terminals by a pair of twisted or shielded wires. Each load should be separately

connected to the remote distribution terminals (see Fig 12-3). If remote sensing is required, the sensing

wires should be connected to the distribution terminals or at the most critical load.

+V

+

-

+

-

+

LOAD # 1

LOAD # 2

LOAD # 3

FPS-S1U

SIGNAL

RET

ON/

OFF

A

511

ON/

OFF

B

15 25

ON/

OFF

C

+V

+S

13

22

-S

-V

-V

-

Fig 12-3: Multiple loads connection with distribution terminal

32

FPS-S1U Instruction Manual

12.4 On/Off control

Fig 12-4 shows typical connection for individual On/Off control of each installed FPS1000 unit. The On/Off

control signal is applied to the DB25 connector located at the rear panel (refer to sec. 10.7.5).

When it is desired to control all the installed units simultaneously, it is possible to connect the On/Off control

as shown in Fig 12-5.

FPS-S1U

ON/OFF_A

ON/OFF_B

ON/OFF_C

SIGNAL_RET

15

25

11

5

ON/

OFF

UNIT

‘C’

ON/

OFF

UNIT

‘B’

ON/

OFF

UNIT

‘A’

FPS-S1U

ON/OFF_A

ON/OFF_B

ON/OFF_C

SIGNAL_RET

15

25

11

5

ON/

OFF

Fig 12-4: Individual On/Off control Fig 12-5: Single On/Off control

12.5 Output voltage trimming

Refer to Fig 12-6 for output voltage trimming typical application.

+V

FPS-S1U

V_TRIM_A

V_TRIM_B

V_TRIM_C

+S

13

7

1

10

22

-S

-V

Fig 12-6: Output voltage trimming

R1

R2

FPS-S1U with FPS1000-12 installed:

R2=0.0324*V

R1(K

Ω)=5(KΩ)-R2(KΩ)

FPS-S1U with FPS1000-24 installed:

R2=0.0785*V

R1(K

Ω)=20(KΩ)-R2(KΩ)

FPS-S1U with FPS1000-32 installed:

R2=0.0463*V

R1(K

Ω)=20(KΩ)-R2(KΩΩ)

FPS-S1U with FPS1000-48 installed:

R2=0.0497*V

R1(K

Ω)=50(KΩ)-R2(KΩ)

2

out -1.1298*Vout+9.9342

2

out -5.819*Vout+105.132

2

out -4.5805*Vout+109.49

2

out-7.2795*Vout+259.04

12.6 Supervisory signals

Supervisory signals are accessible at the J1-DB25 female connector on the rear panel of the rack.

Fig 12-7 shows a typical connection for FPS1000 unit "A" inside the rack.

Units "B" and "C" connections - Reffer to sec 10.7.5.

FPS-S1U

FPS-1000

Module A

FPS-1000 Module B

FPS-1000 Module C

Note: AC_FAIL, DC_OK and TEMP.ALARM are open collector signals.

12V AUX

AC_FAIL_A

DC_OK_A

TEMP.ALARM_A

SIGNAL RET

(J1)

8

16

6

4

11

10K

10K 10K

Application

Monitoring

and Control

circuts

Fig 12-7: Supervisory signals

12.7 Grounding outputs

Either the positive or negative output terminals can be grounded. To avoid noise problems caused by

common-mode current flowing from the load to ground, it is recommended to ground the output terminal

as close as possible to the power supply's output. Always use two wires to connect the load to the power

supply regardless of how the system is grounded.

33

CHAPTER 13 PARALLEL AND SERIES OPERATION

13.1 Parallel operation

Up to 3 FPS-S1U racks with up to 8 FPS1000 installed units of the same output voltage rating can be connected

in parallel. The built-in Oring diodes on the main output and on the +12V auxiliary voltage in each FPS1000 unit