Page 1

www.ti.com

Table of Contents

User’s Guide

Safety Manual for TMS320F28004x

Vanjari, Ashish

ABSTRACT

This document is a safety manual for the Texas Instruments TMS320F28004x safety critical microcontroller

product family. The product family utilizes a common safety architecture that is implemented in multiple

application-focused products.

Table of Contents

1 Introduction.............................................................................................................................................................................3

2 TMS320F28004x Product Safety Capability and Constraints............................................................................................. 5

3 TI Development Process for Management of Systematic Faults....................................................................................... 5

3.1 TI New-Product Development Process.............................................................................................................................. 5

3.2 TI Functional Safety Development Process....................................................................................................................... 6

4 TMS320F28004x Product Overview...................................................................................................................................... 8

4.1 C2000 Architecture and Product Overview........................................................................................................................ 8

4.2 Functional Safety Concept................................................................................................................................................. 9

4.3 C2000 Safety Diagnostics Libraries................................................................................................................................. 19

4.4 TMS320F28004x MCU Safety Implementation................................................................................................................23

5 Brief Description of Safety Elements..................................................................................................................................26

5.1 TMS320F28004x MCU Infrastructure Components.........................................................................................................26

5.2 Processing Elements....................................................................................................................................................... 29

5.3 Memory (Flash, SRAM and ROM)................................................................................................................................... 30

5.4 On-Chip Communication Including Bus-Arbitration..........................................................................................................32

5.5 Digital I/O......................................................................................................................................................................... 35

5.6 Analogue I/O.................................................................................................................................................................... 37

5.7 Data Transmission........................................................................................................................................................... 39

6 Brief Description of Diagnostics......................................................................................................................................... 42

6.1 TMS320F28004x MCU Infrastructure Components.........................................................................................................42

6.2 Processing Elements....................................................................................................................................................... 47

6.3 Memory (Flash, SRAM and ROM)................................................................................................................................... 50

6.4 On-Chip Communication Including Bus-Arbitration..........................................................................................................53

6.5 Digital I/O......................................................................................................................................................................... 54

6.6 Analogue I/O.................................................................................................................................................................... 62

6.7 Data Transmission........................................................................................................................................................... 66

7 References............................................................................................................................................................................ 71

A Safety Architecture Configurations....................................................................................................................................72

B Distributed Developments...................................................................................................................................................75

B.1 How the Functional Safety Lifecycle Applies to Functional Safety-Compliant Products..................................................75

B.2 Activities Performed by Texas Instruments......................................................................................................................75

B.3 Information Provided........................................................................................................................................................76

C Terms and Definitions..........................................................................................................................................................77

D Summary of Safety Features and Diagnostics..................................................................................................................79

E Glossary.............................................................................................................................................................................. 104

Revision History.................................................................................................................................................................... 104

List of Figures

Figure 3-1. TI New-Product Development Process..................................................................................................................... 6

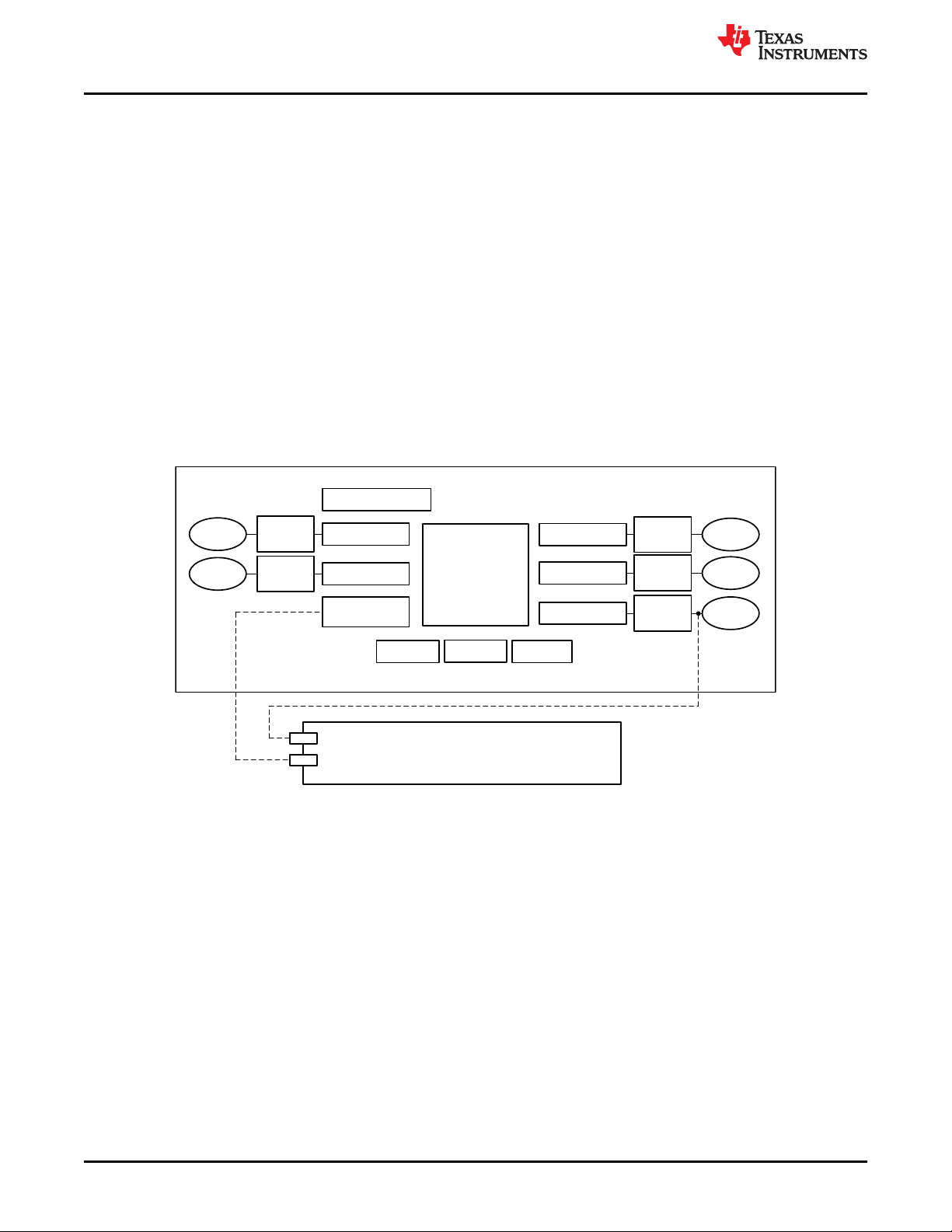

Figure 4-1. Functional Block Diagram of TMS320F28004x MCU................................................................................................8

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Safety Manual for TMS320F28004x 1

Page 2

Trademarks

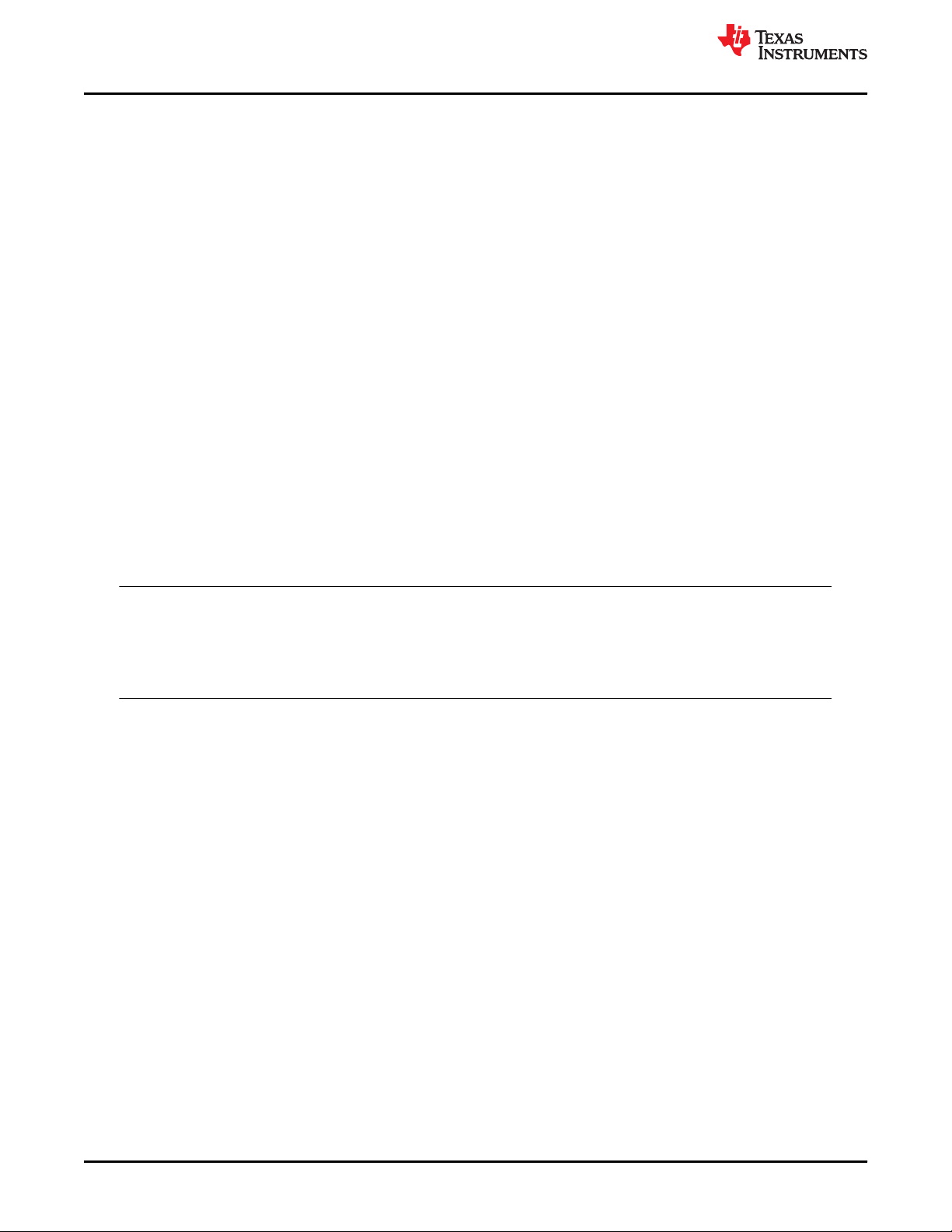

Figure 4-2. Definition of the TMS320F28004x MCU Used in a Compliant Item.......................................................................... 9

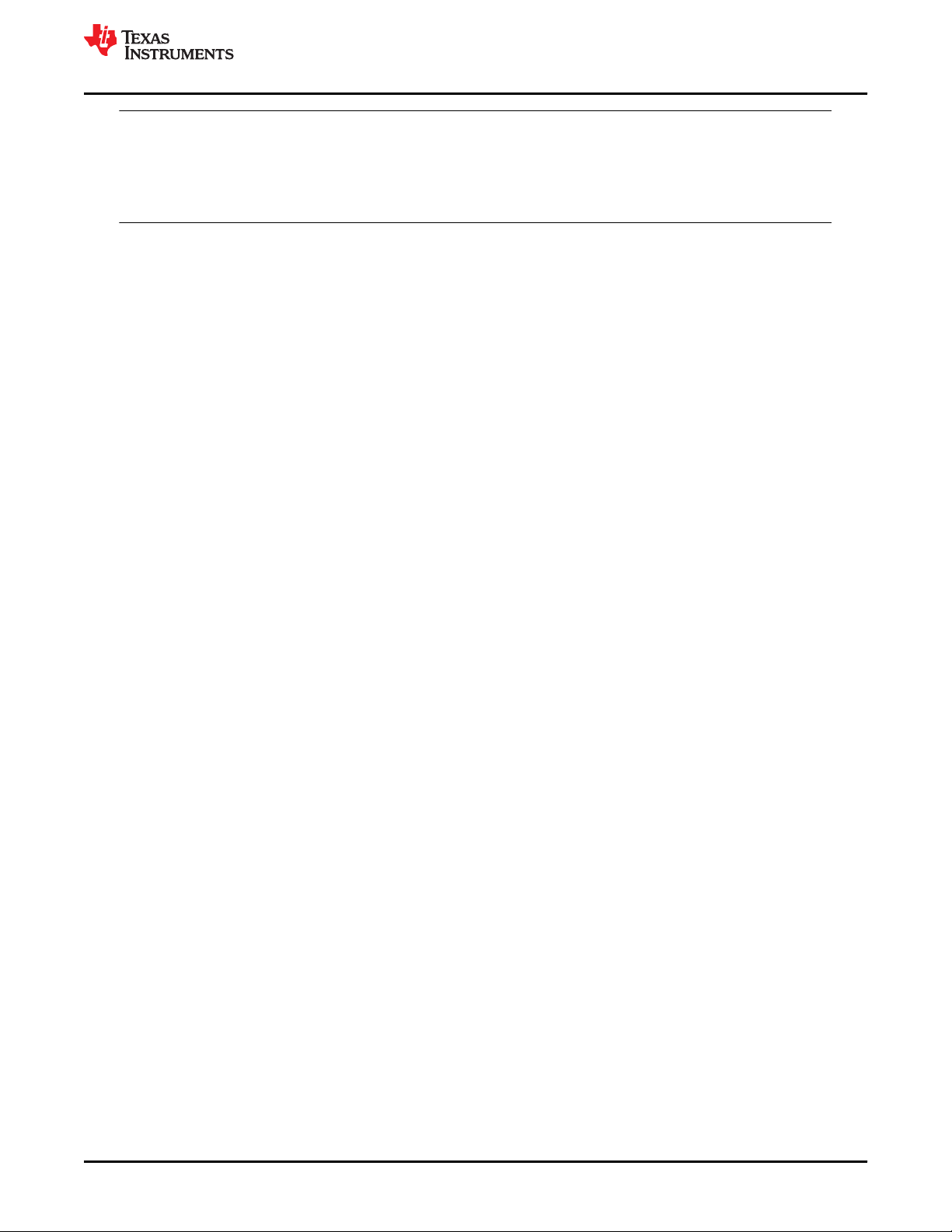

Figure 4-3. E-GAS System Overview From Standard............................................................................................................... 10

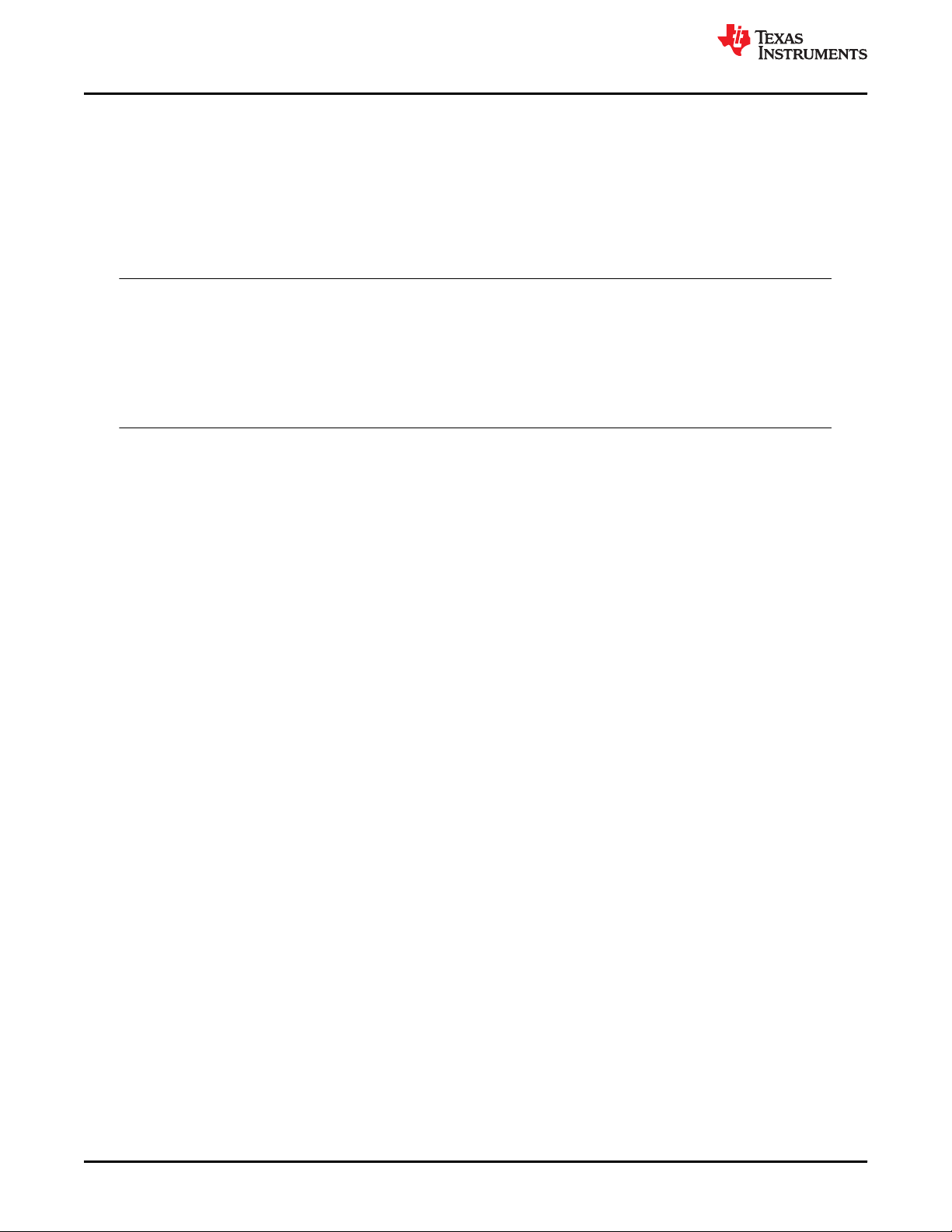

Figure 4-4. VDA E-Gas Monitoring Concept Applied to F28004x MCU.....................................................................................11

Figure 4-5. TMS320F28004x MCU With Safety Features......................................................................................................... 12

Figure 4-6. Relationship Between FDTI, Fault Reaction Time and FTTI...................................................................................13

Figure 4-7. Illustration of FTTI................................................................................................................................................... 13

Figure 4-8. TMS320F28004x MCU Safe State Definition..........................................................................................................14

Figure 4-9. TMS320F28004x MCU Device Operating States....................................................................................................15

Figure 4-10. TMS320F28004x MCU CPU Start-Up Sequence................................................................................................. 16

Figure 4-11. Fault Response Severity........................................................................................................................................16

Figure 4-12. TI Software Development Lifecycle - Quality Level...............................................................................................22

Figure 4-13. Safety Concept Implementation Option 1..............................................................................................................24

Figure 4-14. Safety Concept Implementation Option 2..............................................................................................................25

Figure 5-1. Generic Hardware of a System............................................................................................................................... 26

Figure 6-1. CLA Liveness Check............................................................................................................................................... 47

Figure 6-2. Stack Overflow Monitoring...................................................................................................................................... 49

Figure 6-3. CLAPROMCRC Functional Diagram.......................................................................................................................52

Figure 6-4. ePWM Fault Detection Using X-BAR...................................................................................................................... 55

Figure 6-5. Monitoring of ePWM by ADC.................................................................................................................................. 58

Figure 6-6. HRCAP Calibration..................................................................................................................................................61

Figure 6-7. QMA Module Block Diagram................................................................................................................................... 62

Figure 6-8. DAC to ADC Loopback............................................................................................................................................63

Figure 6-9. Testing PGA Using ADC and DAC.......................................................................................................................... 64

Figure 6-10. ADC Open-Shorts Detection Circuit...................................................................................................................... 65

Figure C-1. ISO 26262 Illustration of Item, System, Component, Hardware Part and Software Unit........................................77

www.ti.com

List of Tables

Table 1-1. Products Supported by This Safety Manual................................................................................................................3

Table 3-1. Functional Safety Activities Overlaid on Top of TI's Standard Development Process................................................ 7

Table 4-1. DC and SCC Targeted for F28004x Diagnostic Libraries......................................................................................... 19

Table 4-2. Tools Required for Integration of the F28004x STL.................................................................................................. 19

Table 4-3. API Mapping............................................................................................................................................................. 21

Table 4-4. MD5 Signatures for C28x-STL..................................................................................................................................22

Table 4-5. MD5 Signatures for CLA-STL................................................................................................................................... 23

Table 6-1. ADC Open-Shorts Detection Circuit Truth Table.......................................................................................................65

Table A-1. Safety Architecture Configurations........................................................................................................................... 72

Table B-1. Activities Performed by Texas Instruments versus Performed by the Customer......................................................75

Table B-2. Product Functional Safety Documentation............................................................................................................... 76

Table D-1. Summary Table Legend........................................................................................................................................... 79

Table D-2. Summary of Safety Features and Diagnostic...........................................................................................................80

Table E-1. Glossary................................................................................................................................................................. 104

Trademarks

C2000™ is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

2 Safety Manual for TMS320F28004x SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 3

www.ti.com Introduction

1 Introduction

WARNING

The TMS320F28004x is being offered as a Functional Safety Compliant Safety Element out of

Context (SEooC) product. This implies that TMS320F28004x was developed in compliance with TI's

ISO-9001/IATF-16949 compliant hardware product development process. Subsequently, this product

was independently assessed to meet a systematic capability compliance of ASIL D (according to

ISO-26262:2018) and SIL 3 (according to IEC-61508:2010), see the Texas Instrument's functional

safety hardware development process. As such, this safety manual is intended to be informative only

to help explain how to use the features of TMS320F28004x device to assist the system designer in

achieving a given ASIL or SIL level. System designers are responsible for evaluating this device in

the context of their system and determining the system-level ASIL or SIL coverage achieved therein.

The products supported by this document have been assessed to be meet a systematic capability compliance of

ASIL D (according to ISO 26262) and SIL 3 (according to IEC 61508). For more information, see the Texas

Instrument's functional safety hardware development process.

This Functional Safety Manual is part of the Functional Safety-Compliant design package to aid customers who

are designing systems in compliance with ISO26262 or IEC61508 functional safety standards.

This document is a safety manual for the Texas Instruments TMS320F28004x safety critical microcontroller

product family. The product family utilizes a common safety architecture that is implemented in multiple

application focused products.

Product configurations supported by this safety manual include silicon revision B of the following products listed

in Table 1-1. The device revision can be determined by the REVID field of the device identification registers

outlined in the product data sheet.

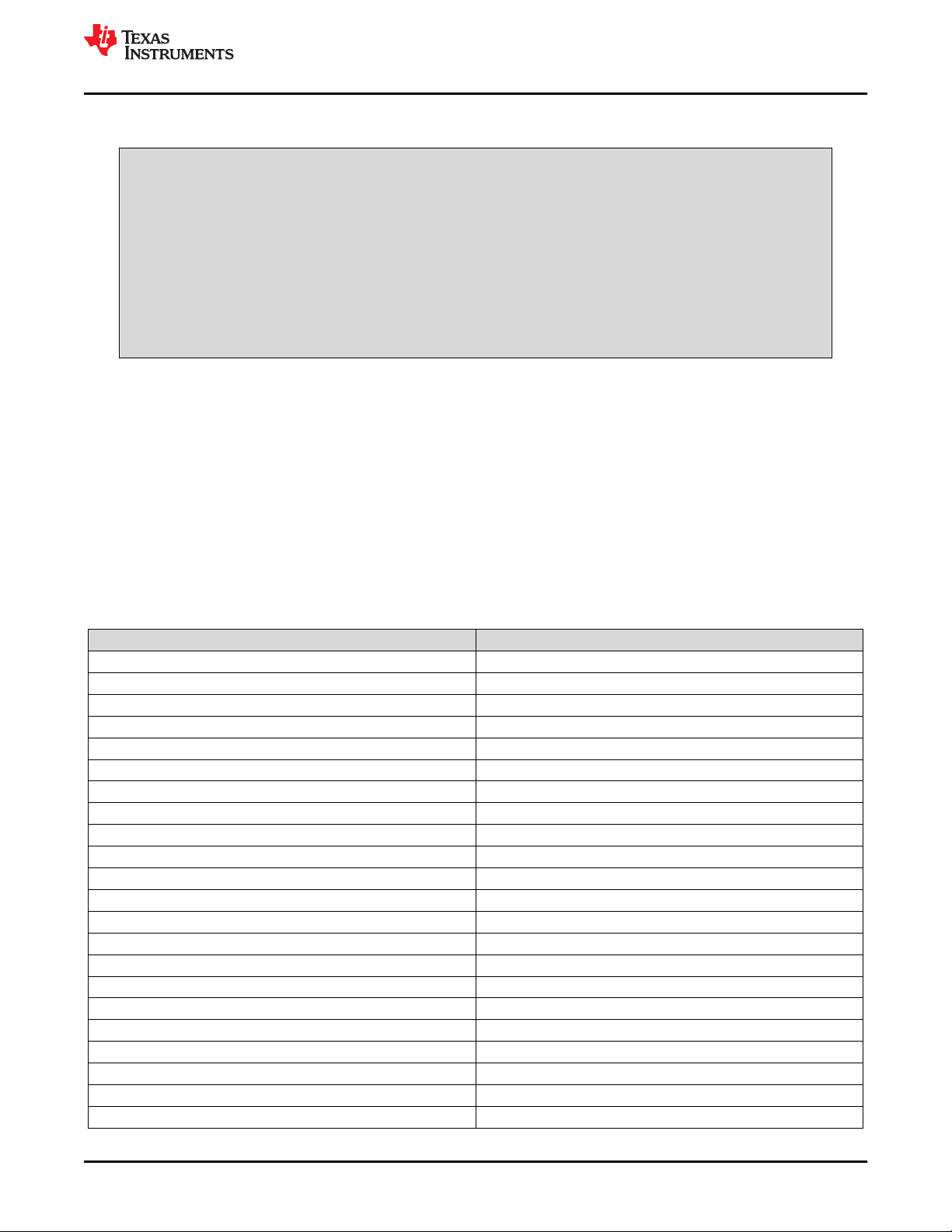

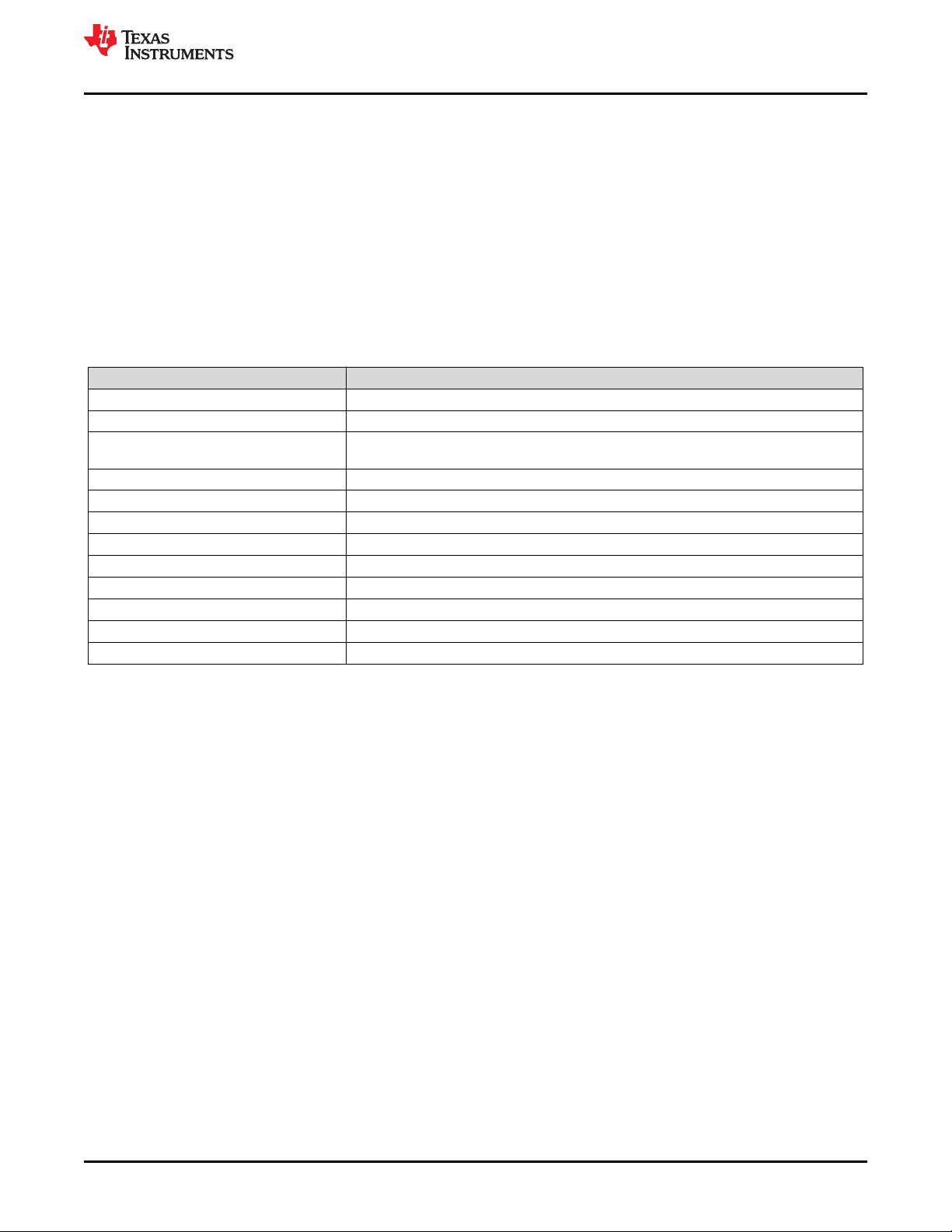

Table 1-1. Products Supported by This Safety Manual

Orderable Devices Supported Safety Integrity Level

F280048CPMQR ASIL B

F280048PMQR ASIL B

F280049CPMS ASIL B

F280049CPZQR ASIL B

F280049CPZS ASIL B

F280049PMS ASIL B

F280049PMSR ASIL B

F280049PZQ ASIL B

F280049PZQR ASIL B

F280049PZS ASIL B

F280049PZSR ASIL B

F280040CPMQR QM

F280040PMQR QM

F280041CPMS QM

F280041CPZQR QM

F280041CPZS QM

F280041CRSHSR QM

F280041PMS QM

F280041PMSR QM

F280041PZQR QM

F280041PZS QM

F280041PZSR QM

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Safety Manual for TMS320F28004x 3

Page 4

Introduction

www.ti.com

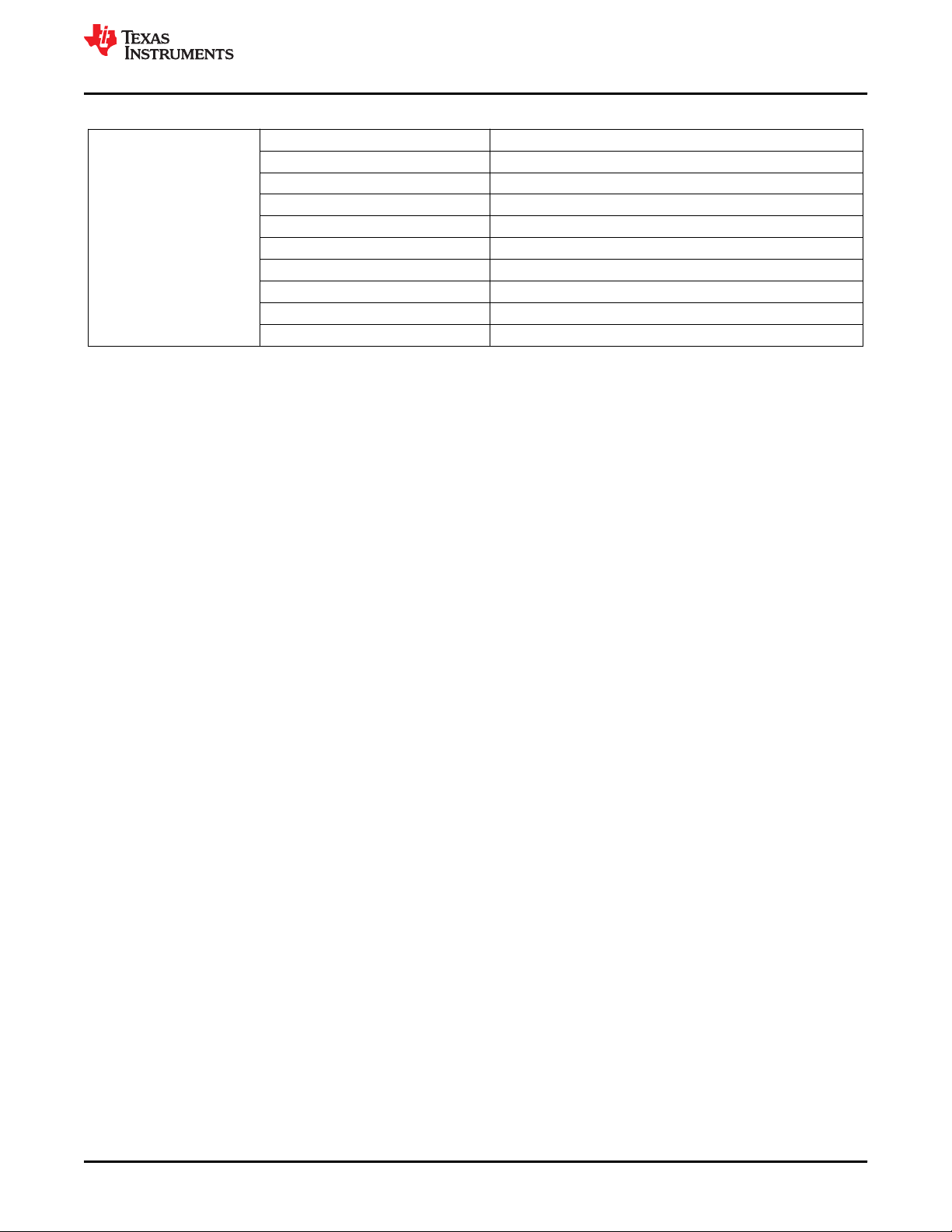

Table 1-1. Products Supported by This Safety Manual (continued)

Orderable Devices Supported Safety Integrity Level

F280041RSHSR QM

F280045PMS QM

F280045PMSR QM

F280045PZS QM

F280045PZSR QM

F280045RSHSR QM

F280049CRSHSR QM

F280049CRSHS QM

F280049RSHSR QM

This Functional Safety Manual provides information needed by system developers to assist in the creation of a

safety critical system using a supported TMS320F28004x MCU. This document contains:

• An overview of the component architecture

• An overview of the development process used to decrease the probability of systematic failures

• An overview of the functional safety architecture for management of random failures

• The details of architecture partitions and implemented functional safety mechanisms

The following information is documented in the Detailed Safety Analysis Report (SAR) for TMS320F28004x

C2000™ Safety Critical Microcontrollers, which is only available under Functional Safety NDA and is not

repeated in this document:

• Failure rates (FIT) of the component

• Fault model used to estimate device failure rates to enable calculation of customized failure rates

• Functional safety metrics of the hardware component for targeted standards (viz. IEC 61508:2010 and ISO

26262:2018)

• Quantitative functional safety analysis (also known as FMEDA, Failure Modes, Effects, and Diagnostics

Analysis) with detail of the different parts of the component, allowing for customized application of functional

safety mechanisms

• Assumptions used in the calculation of functional safety metrics

It is expected that the user of this document should have a general familiarity with the TMS320F28004x product

families. More information can be found at www.ti.com/C2000.

This document is intended to be used in conjunction with the pertinent data sheets, technical reference manuals,

and other documentation for the products being supplied.

For information which is beyond the scope of the listed deliverables, please contact your TI sales representative

or www.ti.com.

4 Safety Manual for TMS320F28004x SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 5

www.ti.com

TMS320F28004x Product Safety Capability and Constraints

2 TMS320F28004x Product Safety Capability and Constraints

This section summarizes the TMS320F28004x product safety capability. Each TMS320F28004x product:

• Is offered as a functional Safety Element Out Of Context (SEooC)

• Was assessed to have met the relevant systematic capability compliance requirements of IEC 61508:2010

and ISO 26262:2018 and

– Achieves systematic integrity of SIL 3 and ASIL D

• In addition, the device can meet hardware architectural metrics up to ASIL B by implementing proper safety

concept (for example, Reciprocal Comparison by Software).

• Contains multiple features to support Freedom From Interference (FFI) for mixed-criticality of safety

requirements assigned to the different sub-elements

• The TMS320F28004x MCUs are Type B devices, as defined in IEC 61508-2:2010

• This device claims no hardware fault tolerance, (for example, no claims of HFT > 0), as defined in IEC

61508:2010

• For safety components developed according to many safety standards, it is expected that the component

functional safety manual will provide a list of product safety constraints. For a simple component or more

complex components developed for a single application, this is a reasonable response. However, the

TMS320F28004x MCU product family is both a complex design and is not developed targeting a single,

specific application. Therefore, a single set of product safety constraints cannot govern all viable uses of the

product

Note

The functional safety assessment of this component is not yet complete.

3 TI Development Process for Management of Systematic Faults

For functional safety development, it is necessary to manage both systematic and random faults. Texas

Instruments follows a new-product development process for all of its components which helps to decrease the

probability of systematic failures. This new-product development process is described in Section 3.1.

Components being designed for functional safety applications will additionally follow the requirements of TI's

functional safety development process, which is described in Section 3.2.

3.1 TI New-Product Development Process

Texas Instruments has been developing components for automotive and industrial markets since 1996.

Automotive markets have strong requirements regarding quality management and product reliability. The TI newproduct development process features many elements necessary to manage systematic faults. Additionally, the

documentation and reports for these components can be used to assist with compliance to a wide range of

standards for customer’s end applications including automotive and industrial systems (e.g ISO 26262-4:2018,

IEC 61508-2:2010).

This component was developed using TI’s new product development process which has been certified as

compliant to ISO 9001 / IATF 16949 as assessed by Bureau Veritas (BV).

The standard development process breaks development into phases:

• Assess

• Plan

• Create

• Validate

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Safety Manual for TMS320F28004x 5

Page 6

Copyright © 2018, Texas Instruments Incorporated

Assess

Review

Plan

Review

Create

Review

Validate

Review

& Release

To Market

Periodic

Post-Release

Reviews

Phase 1:

Assess

Phase 2:

Plan

Phase 3:

Create

Phase 4:

Validate

Sustain

Identify New

Product

Opportunities

Develop Project

Plan

IC Design &

Layout

Develop Product

Specification

IC Design

Verification

Manage Project Execution and Risks

Develop Test and Validation HW/SW

Develop Datasheet and other

Documentation

Product Support

Product

Monitoring

IC Valdiation

IC Qualification

TI Development Process for Management of Systematic Faults

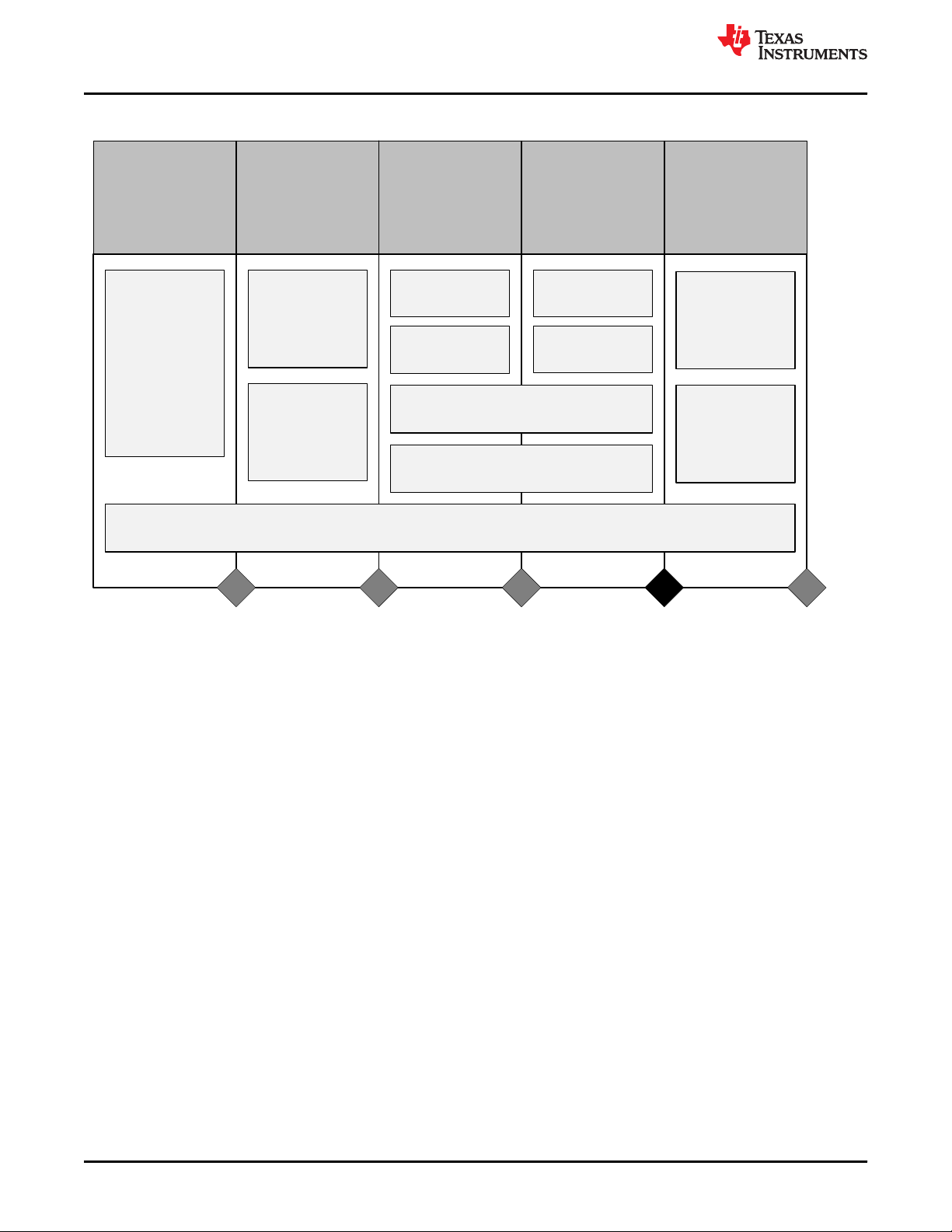

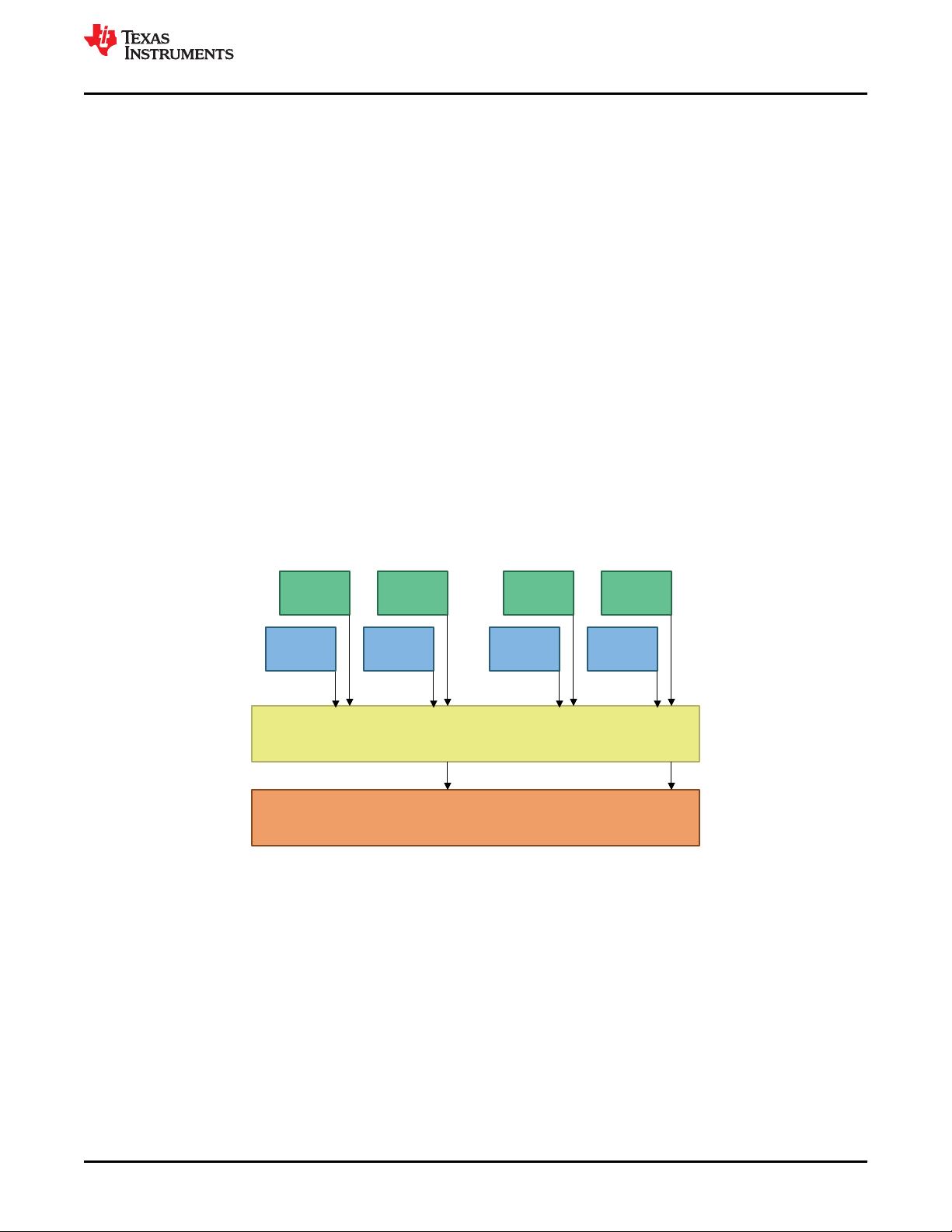

Figure 3-1 shows the standard process.

www.ti.com

3.2 TI Functional Safety Development Process

The TI functional safety development flow derives from ISO 26262:2018 and IEC 61508:2010 a set of

requirements and methodologies to be applied to semiconductor development. This flow is combined with TI's

standard new product development process to develop Functional Safety-Compliant components. The details of

this functional safety development flow are described in the TI internal specification - Functional Safety

Hardware.

Key elements of the TI functional safety-development flow are as follows:

• Assumptions on system level design, functional safety concept, and requirements based on TI's experience

• Qualitative and quantitative functional safety analysis techniques including analyses of silicon failure modes

• Base FIT rate estimation based on multiple industry standards and TI manufacturing data

• Documentation of functional safety work products during the component development

• Integration of lessons learned through multiple functional safety component developments, functional safety

6 Safety Manual for TMS320F28004x SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

with components in functional safety applications

and application of functional safety mechanisms

standard working groups, and the expertise of TI customers

Figure 3-1. TI New-Product Development Process

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 7

www.ti.com TI Development Process for Management of Systematic Faults

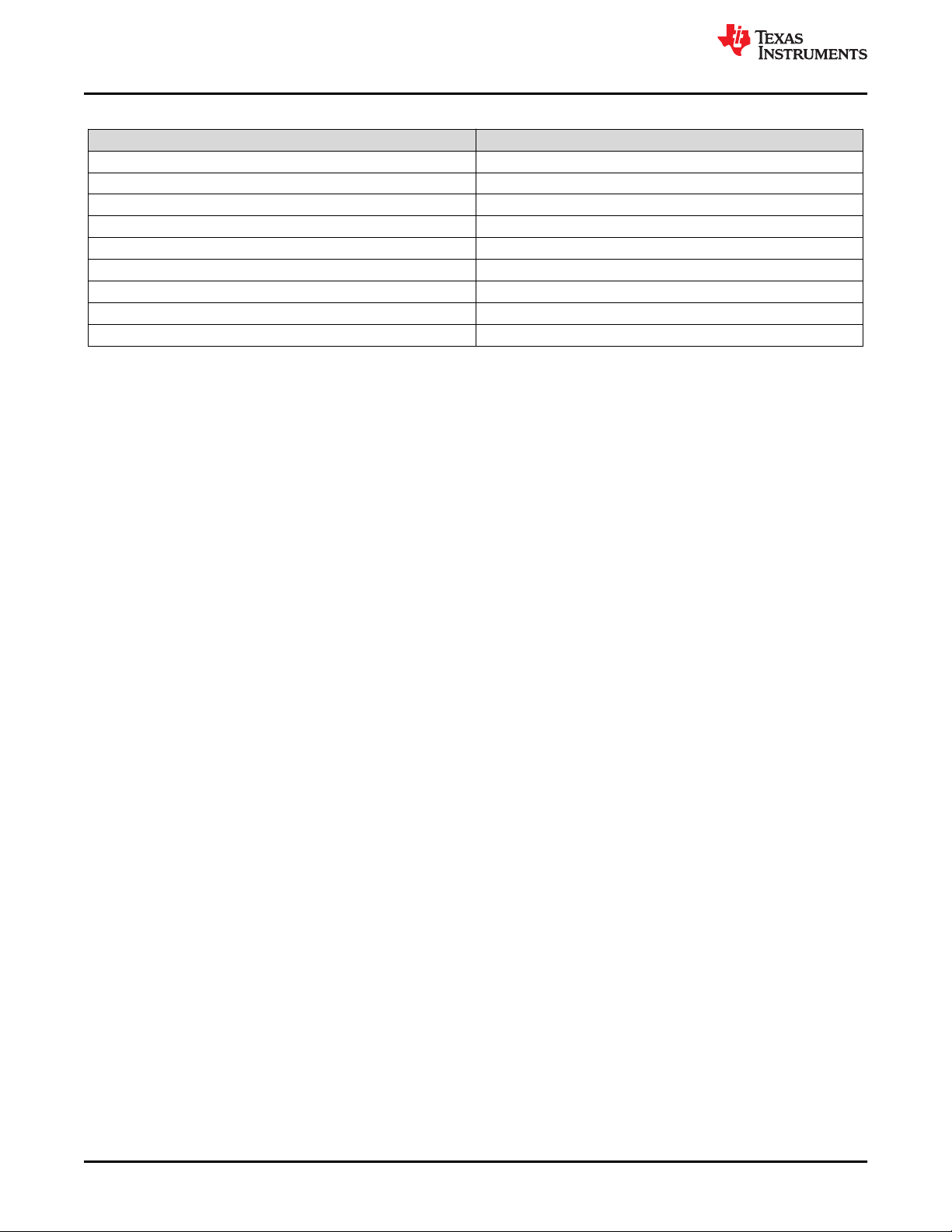

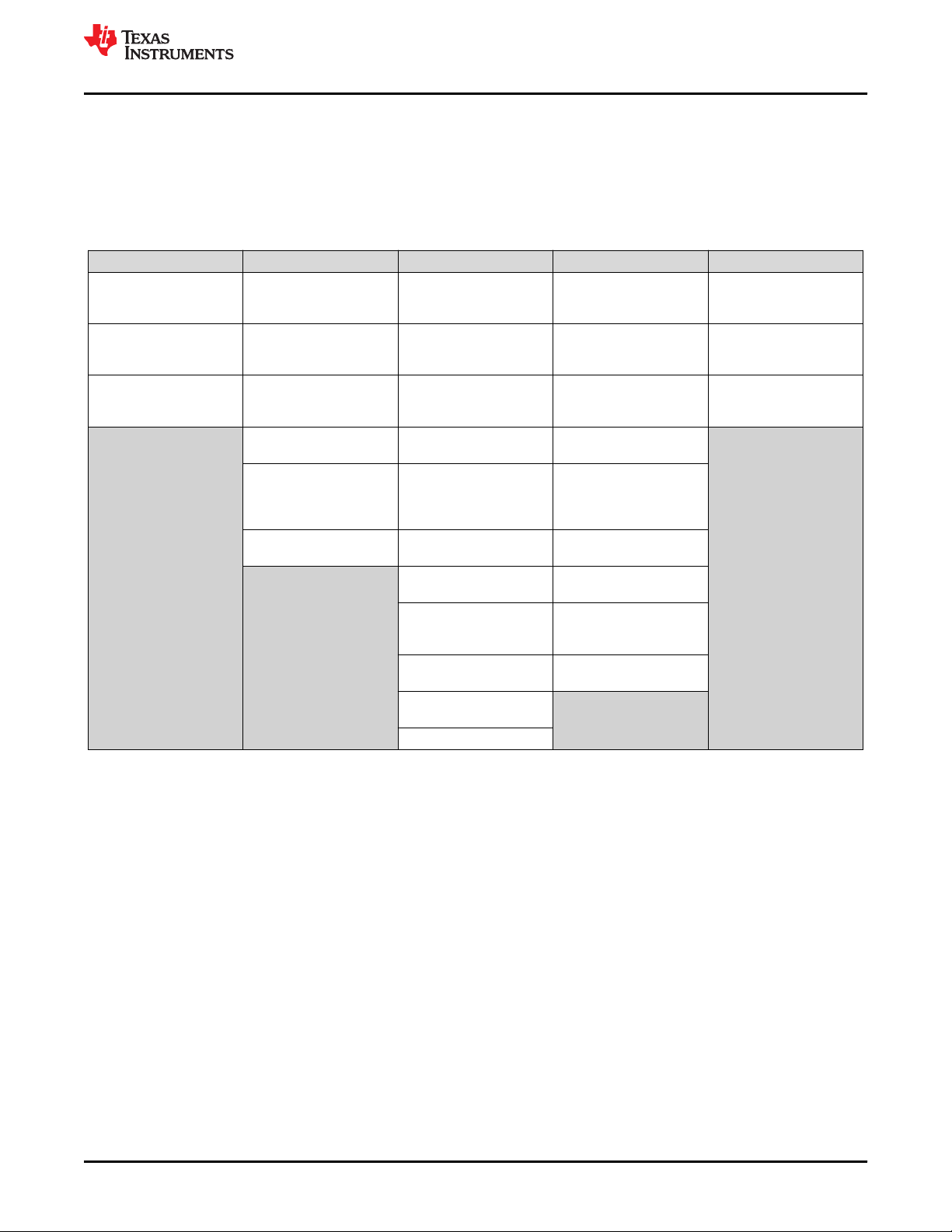

Table 3-1 lists these functional safety development activities that are overlaid atop the standard development

flow in Figure 3-1.

For more information about which functional safety lifecycle activities TI performs, see Appendix B.

The customer facing work products derived from this Functional Safety-Compliant process are applicable to

many other functional safety standards beyond ISO 26262:2018 and IEC 61508:2010.

Table 3-1. Functional Safety Activities Overlaid on Top of TI's Standard Development Process

Assess Plan Create Validate Sustain and End-of-Life

Determine if functional

safety process execution

is required

Nominate a functional

safety manager

End of Phase Audit

Define component target

SIL/ASIL capability

Generate functional safety

plan

Verify the functional safety

plan

Initiate functional safety

case

Analyze target

applications to generate

system level functional

safety assumptions

End of Phase Audit

Develop component level

functional safety

requirements

Include functional safety

requirements in design

specification

Verify the design

specification

Start functional safety

design

Perform qualitative

analysis of design (i.e.

failure mode analysis)

Verify the qualitative

analysis

Verify the functional safety

design

Perform quantitative

analysis of design (i.e.

FMEDA)

Verify the quantitative

analysis

Iterate functional safety

design as necessary

End of Phase Audit

Validate functional safety

design in silicon

Characterize the functional

safety design

Qualify the functional

safety design (per AEC-

Q100)

Finalize functional safety

case

Perform assessment of

project

Release functional safety

manual

Release functional safety

analysis report

Release functional safety

report

End of Phase Audit

Document any reported

issues (as needed)

Perform incident reporting

of sustaining operations

(as needed)

Update work products (as

needed)

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Safety Manual for TMS320F28004x 7

Page 8

Global Shared RAM - Parity

32KW (64KB)

C28x

TMU+FPU+VCU-I

M0 - 1KW (2KB)

M1 - 1KW (2KB)

Boot - 32KW (64KB)

Flash - ECC

C28x RAM - ECC

PIE

CPU Timer0

CPU Timer1

CPU Timer2

10 MHz INTOSC1, INTOSC2

10–20 MHz Crystal Oscillator

NMI Watchdog

Missing Clock Detect

PLL

CLA

(Type 2)

CLA MSG RAM - Parity

DMA

(6 Channels)

3x 12-Bit ADC

8x ePWM

(16 Hi-Res Channels)

7x eCAP

2x eQEP

(CW/CCW Support)

4x SD Filters

1x I2C

7x CMPSS

2x Buffered DAC

7x PGA

1x PMBUS

2x SPI

Windowed Watchdog

LS0–LS7

8x (2KW [4KB])

GS0–GS3

4x (8KW

[16KB])

2x SCI

2x CAN

C28x ROM

DCSM OTP

GPIO

Secure - 64KW (128KB)

Secure

Memories

Flash BANK0 - 16 Sectors

64KW (128KB)

Flash BANK1 - 16 Sectors

64KW (128KB)

CLA to CPU - 128W

CPU to CLA - 128W

1x LIN

CLA ROM

Local Shared RAM - Parity

16KW (32KB)

Data Bridge Data Bridge Data Bridge Data Bridge Data Bridge Data Bridge

Result

Configuration

Program

48KW (96KB)

Data

4KW (8KB)

Copyright © 2017, Texas Instruments Incorporated

Configuration

Data

TMS320F28004x Product Overview

www.ti.com

4 TMS320F28004x Product Overview

p

4.1 C2000 Architecture and Product Overview

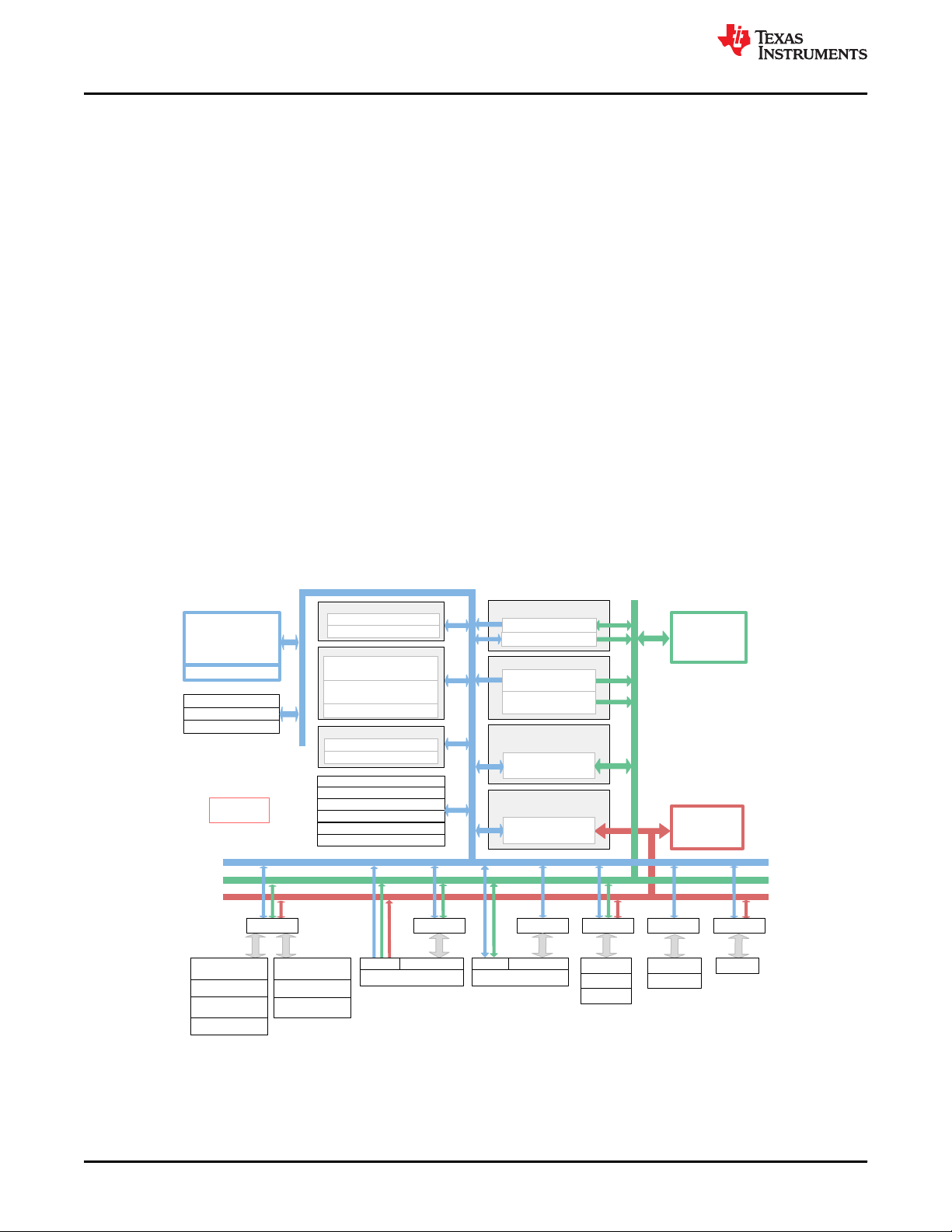

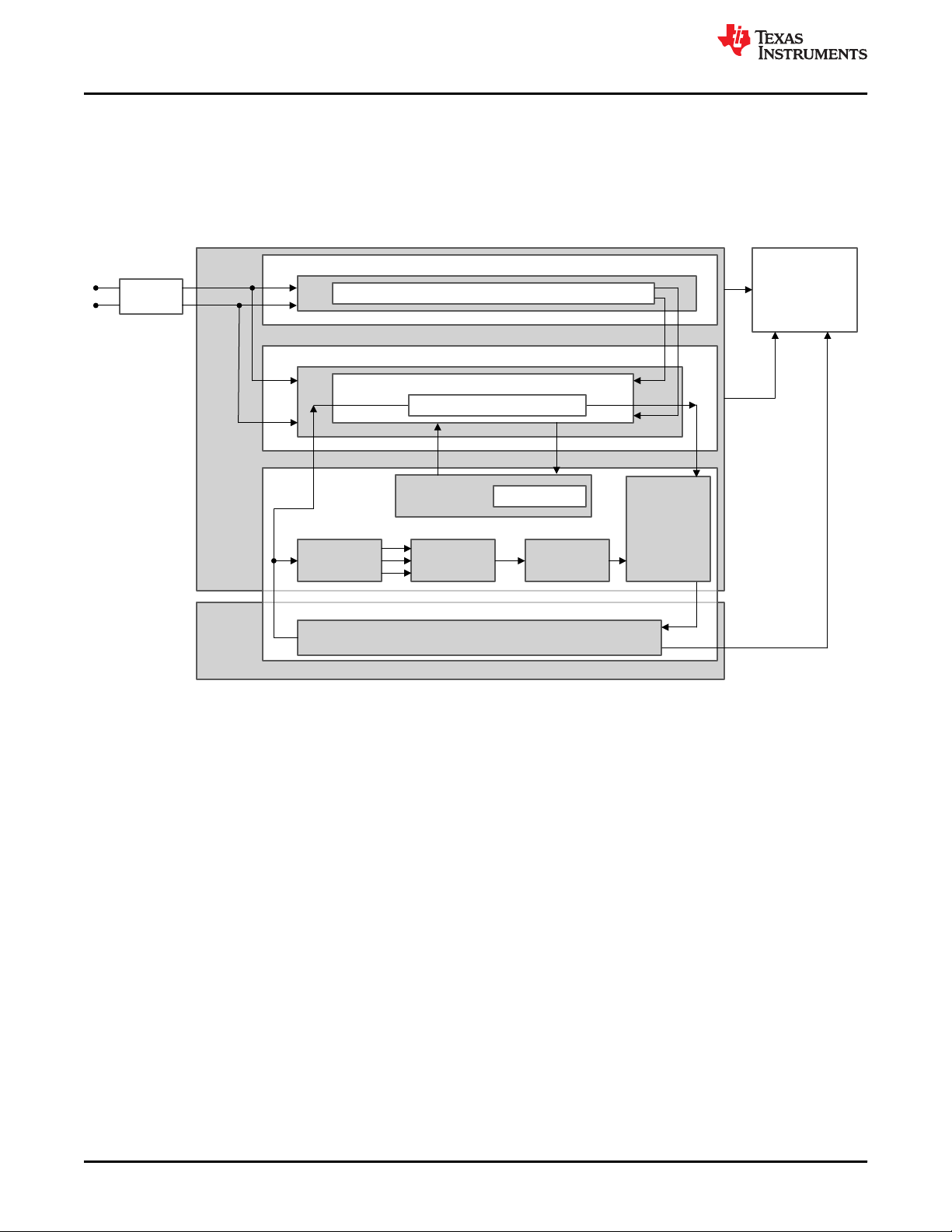

The TMS320F28004x devices are powerful 32-bit floating-point microcontroller unit (MCU) designed for

advanced closed-loop control applications in automotive and industrial applications.

4.1.1 TMS320F28004x MCU

TMS320F28004x supports C28x and CLA as processing elements that boosts system performance for closed

loop control applications. This is a powerful 32-bit floating-point microcontroller unit (MCU) that lets system

integrator to access crucial control peripherals, differentiated analog, and nonvolatile memory on a single device.

The C28x CPU is further boosted by the Trigonometric Math Unit (TMU) accelerator that enables fast execution

of algorithms with trigonometric operations common in transforms and torque loop calculations. The Viterbi,

Complex Math and CRC Unit (VCU) accelerator reduces the time for complex math operations common in

encoded applications. Users may refer to Accelerators: Enhancing the Capabilities of the C2000™ MCU Family

to see how the accelerators can be employed to increase the performance of the MCU in many real-time

applications.

The CLA is an independent 32-bit floating-point accelerator that runs at the same frequency as the main C28x

CPU, responding to peripheral triggers with minimum event latency and executing code concurrently with the

main CPU.

The TMS320F28004x supports up to 256KB (128KW) of on-chip flash memory with error correction code (ECC)

and up to 100KB (50KW) of SRAM with parity or ECC.

Figure 4-1. Functional Block Diagram of TMS320F28004x MCU

8 Safety Manual for TMS320F28004x SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 9

Sensor

Processing

Element

Actuator

S

Remote

Controller

MCU

A

Remote

Controller

S

Remote

Controller

A

Remote

Controller

Sensor

Actuator

Processing Element

www.ti.com

TMS320F28004x Product Overview

High performance analog and control peripherals are also integrated to further enable system consolidation.

Three independent 12-bit ADCs provide precise and efficient management of multiple analog signals, which

ultimately boosts system throughput. The new sigma-delta filter module (SDFM) works in conjunction with the

sigma-delta modulator to enable isolated current shunt measurements. The Comparator Subsystem (CMPSS)

with windowed comparators allows for protection of power stages when current limit conditions are exceeded or

not met. Other analog and control peripherals include the Digital-to-Analog Converter (DAC), Enhanced Pulse

Width Modulation (ePWM), Enhanced Capture (eCAP), Enhanced Quadrature Encoder Pulse (eQEP) and

Programmable Gain Amplifier (PGA). The Programmable Gain Amplifier (PGA) is used to amplify an input

voltage for the purpose of increasing the effective resolution of the downstream ADC and CMPSS modules.

Peripherals such as Controller Area Network (CAN) modules (ISO11898-1/CAN 2.0B-compliant), Inter-Integrated

Communication (I2C) Bus, Local Interconnect Network (LIN), Serial Communications Interface (SCI), Serial

Peripheral Interface (SPI), Power Management Bus (PMBus) Interface, and Fast Serial Interface (FSI) extend

connectivity of TMS320F28004x MCU. The Fast Serial Interface (FSI) module is a serial communication

peripheral capable of reliable high-speed communication across isolation devices.

The device configurations supported by this safety manual for TMS320F28004x MCUs is outlined in the

TMS320F28004x Microcontrollers Data Sheet. Not all variants are available in all packages or all temperature

grades. To confirm availability, contact your local Texas Instruments sales and marketing.

4.2 Functional Safety Concept

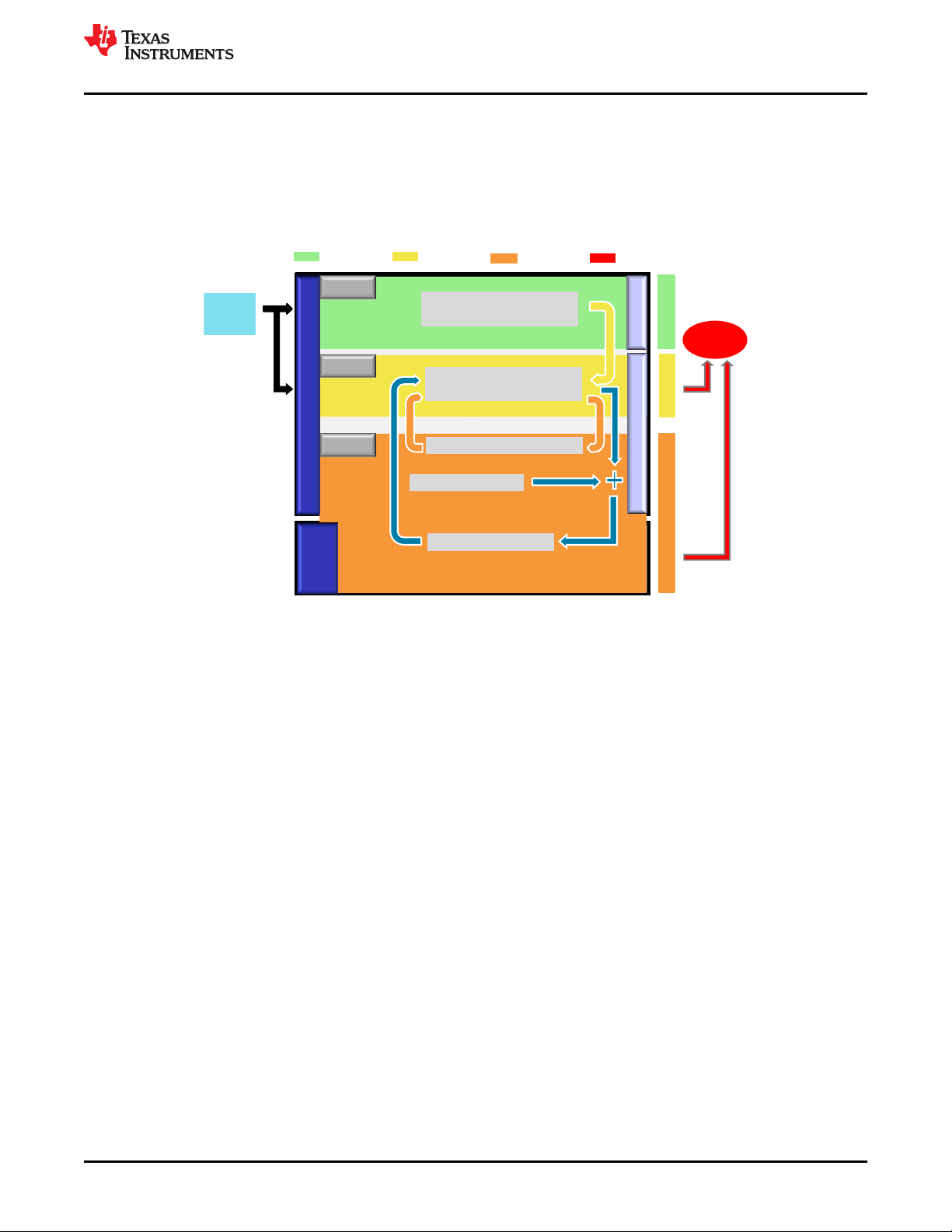

To stay as general as possible, the functional safety concept assumes the MCU playing the role of a processing

unit (or part of it) and connected to remote controller(s) by means of a communication bus as shown in Figure

4-2. The communication bus is directly or indirectly connected to sensor(s) and actuator(s).

IEC 61508-1:2010 defines a compliant item as any item (for example an element) on which a claim is being

made with respect to the clauses of IEC 61508:2010 series. A system including TMS320F28004x microcontroller

as indicated by Figure 4-2 can be used in a compliant item according to IEC 61508:2010.

Figure 4-2. Definition of the TMS320F28004x MCU Used in a Compliant Item

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Safety Manual for TMS320F28004x 9

Page 10

Level 1

ECU Functions

Level 2

Function Monitoring

Level 3

Fault Reaction

Memory Test

Level 2

Quest Spec.

Test Data

Function Spec

Instruction Test

Response

Contribution

Linking

Monitor Modules

Function

Controller

Monitoring

Controller

Input

Signals

Power

Determining Output

Stages/

Safety-Relevant

Bus Communication

Enable

Enable

Program Flow Check

Question Answer

TMS320F28004x Product Overview

www.ti.com

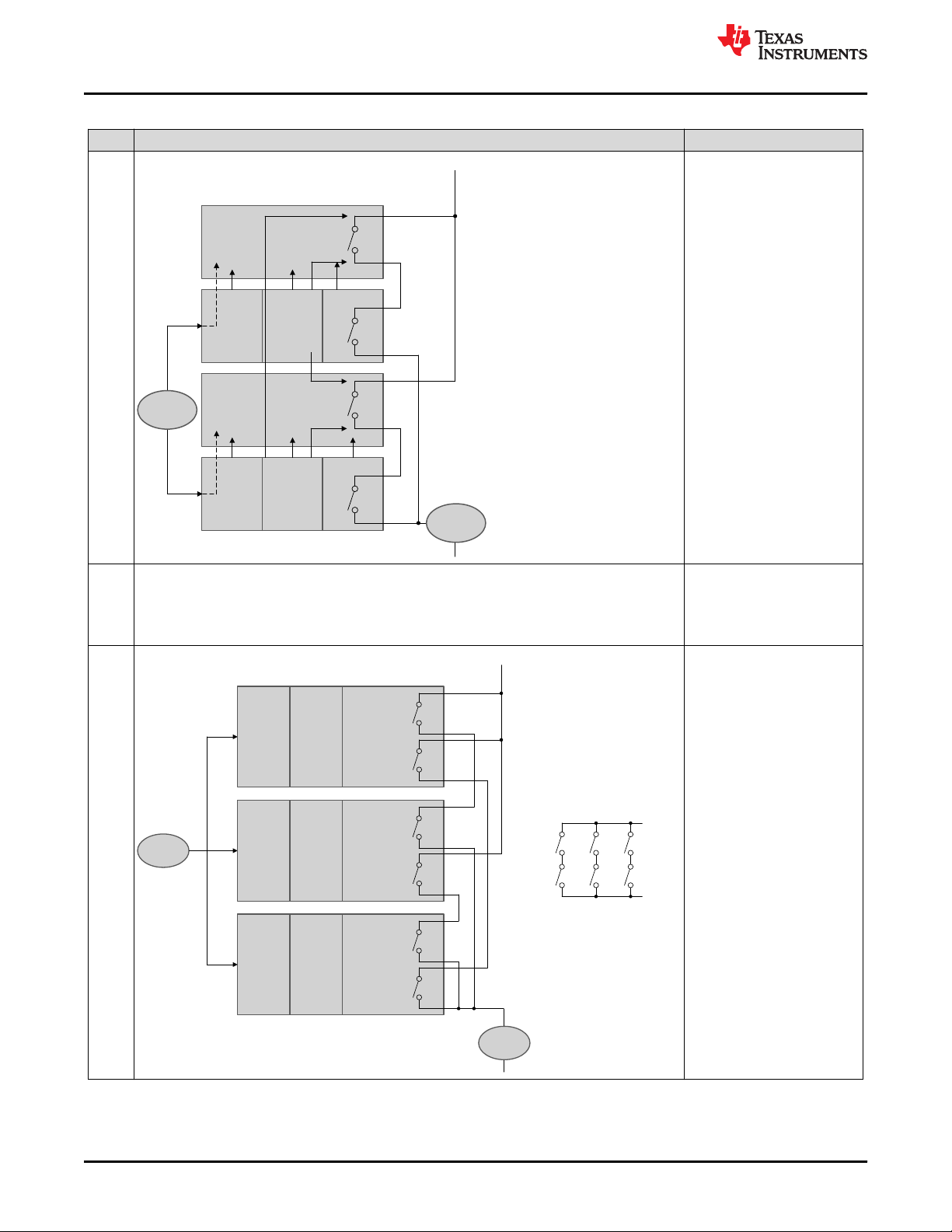

4.2.1 VDA E-GAS Monitoring Concept With TMS320F28004x MCU

The standardized E-GAS monitoring concept [6] for engine management systems generated by the German

VDA working group “E-Gas-Arbeitskreis” is an example of a well-trusted safety-architecture that may be used for

applications other than engine management systems provided it fits the purpose of the new application in terms

of diagnosis feasibility, environment constraints, time constraints, robustness, and so forth [7]. For more

information, see Figure 4-3.

Figure 4-3. E-GAS System Overview From Standard

10 Safety Manual for TMS320F28004x SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 11

Monitor

Safe

State

Level 1

Primary

Input

Signals

Main Function

Level 2

Monitoring Function

Program Flow

Level 3

Verify Sequence

CLA

Device Self-Test

Q&A Monitor

Diagnostics

Real-Time Control

Fault-Response

External

Monitor

Safety Related

Fault Detection

Monitoring Sequence

Monitor

cross-check

28X

C2000

Q & A

Q & A

28X

C2000

www.ti.com

TMS320F28004x Product Overview

The MCU device family supports heterogeneous asymmetric architecture and their functional safety features

lend themselves to an E-GAS concept implementation at system level as indicated in Figure 4-4. In the first level

(Level 1), the functions required for the system mission are computed. Second level (Level 2) checks the correct

formation in first level based on selected set of parameters. Third level (Level 3) implements an additional

external monitoring element, for the correct carrying out of the mission in the first level and/or monitoring in the

second level. The exact functional safety implementation and the modules used for realizing Level 1 and Level 2

and the external monitoring device for realizing Level 3 are left to the system designer.

Figure 4-4. VDA E-Gas Monitoring Concept Applied to F28004x MCU

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Safety Manual for TMS320F28004x 11

Page 12

TMS320F28004x Product Overview

www.ti.com

Due to the inherent versatility of the device architecture, several software voting based functional safety

configurations are possible. Some of the functional safety configurations possible with TMS320F28004x for

improving diagnostic coverage are explained in Table A-1. While implementing these configurations, system

integrator needs to consider the potential common mode failures and address them in an appropriate manner.

This may suitably be modified to adapt to TMS320F28004x requirements based on the availability of processing

units. (As stated earlier, the device claims no hardware fault tolerance, (for example, no claims of HFT > 0), as

defined in IEC 61508:2010).

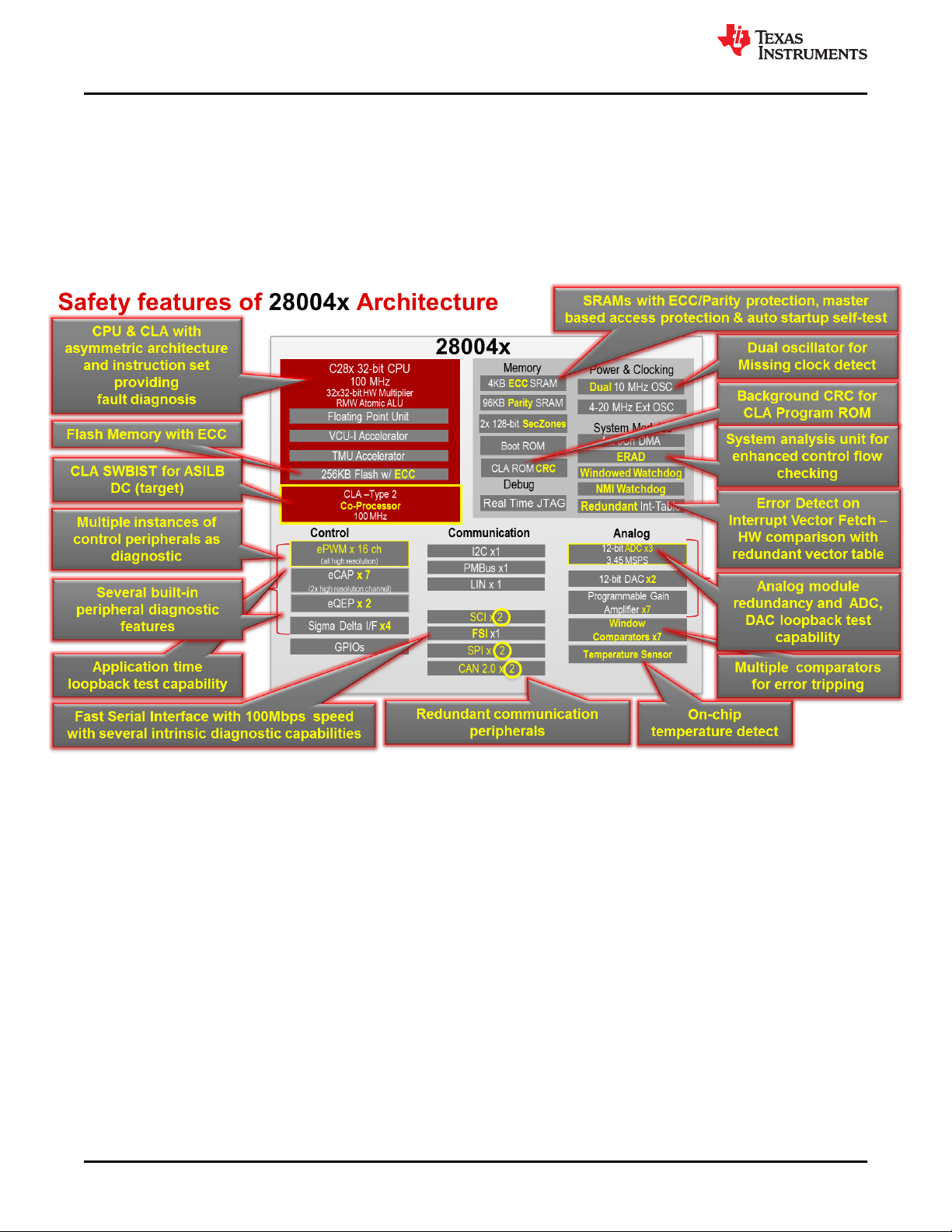

The major safety features of TMS320F28004x are shown in Figure 4-5.

Figure 4-5. TMS320F28004x MCU With Safety Features

12 Safety Manual for TMS320F28004x SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 13

Fault

Normal Operation Unsafe State

Safe State

Fault Detection

Hazard

Avoided

T <= FDTI

Fault Reaction

Time

FTTI

Check OK

Check OK

Check NOT OK

Level2/Level3

function

Level1

function

Cross check Period (Tcc)

FTTI Budget for the MCU

Delay for MCU to

enter safe state,

Td

Tcc + Td < FTTI

www.ti.com

TMS320F28004x Product Overview

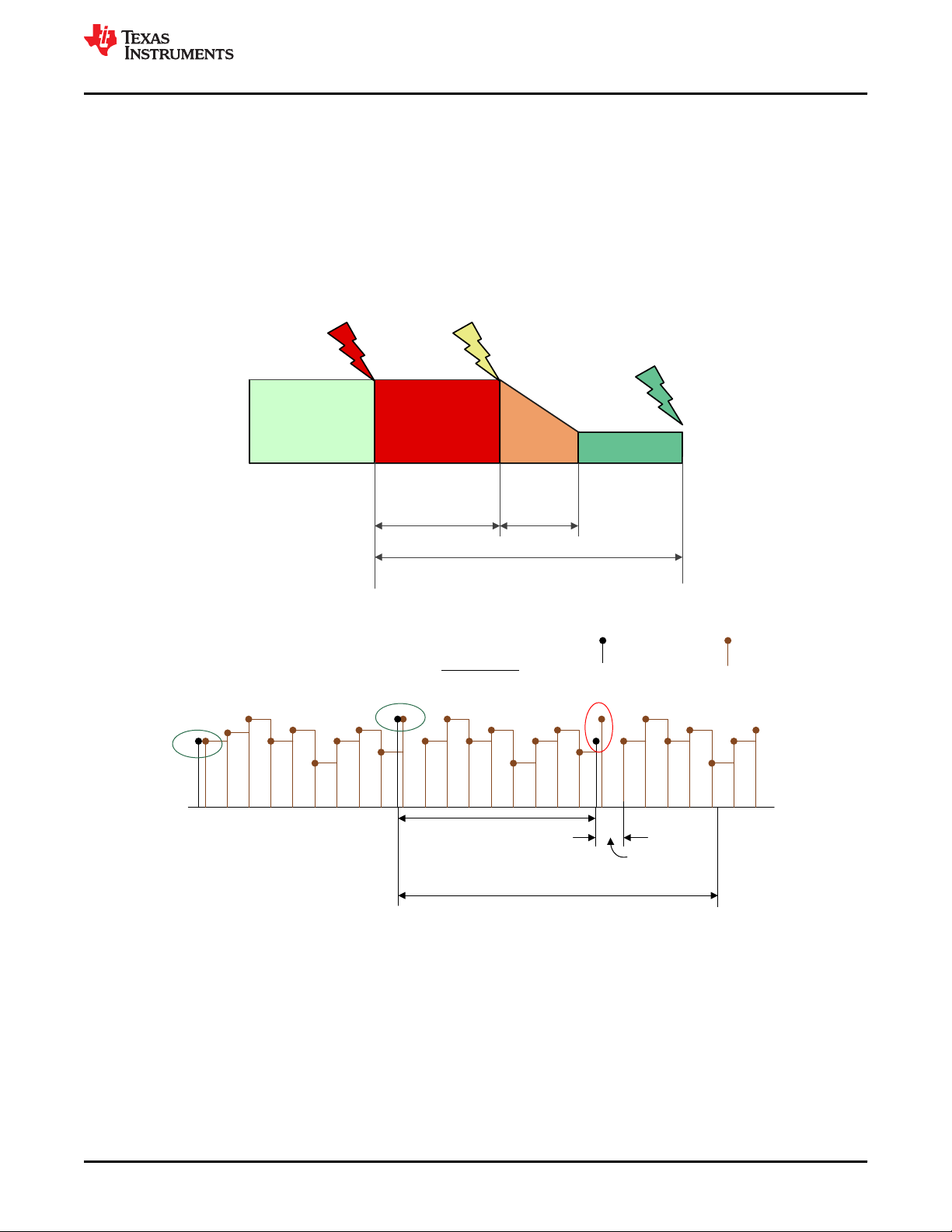

4.2.2 Fault Tolerant Time Interval (FTTI)

Various functional safety mechanisms in the devices are either always-on (see CPU Handling of Illegal

Operation, Illegal Results and Instruction Trapping, and so forth) or executed periodically (see VCU CRC Check

of Static Memory Contents, and so forth) by the application software. The maximum time that a safety

mechanism will take to detect a fault is termed as Fault Diagnostic Test Time Interval (FDTI). Once the fault is

detected, depending on the fault reaction of the associated fault (for example, external system reaction to

ERRORSTS pin assertion), the system will enter in the safe-state. The time-span in which a fault or faults can be

present in a system before a hazardous event occurs is called Fault Tolerant Time Interval (FTTI) as defined in

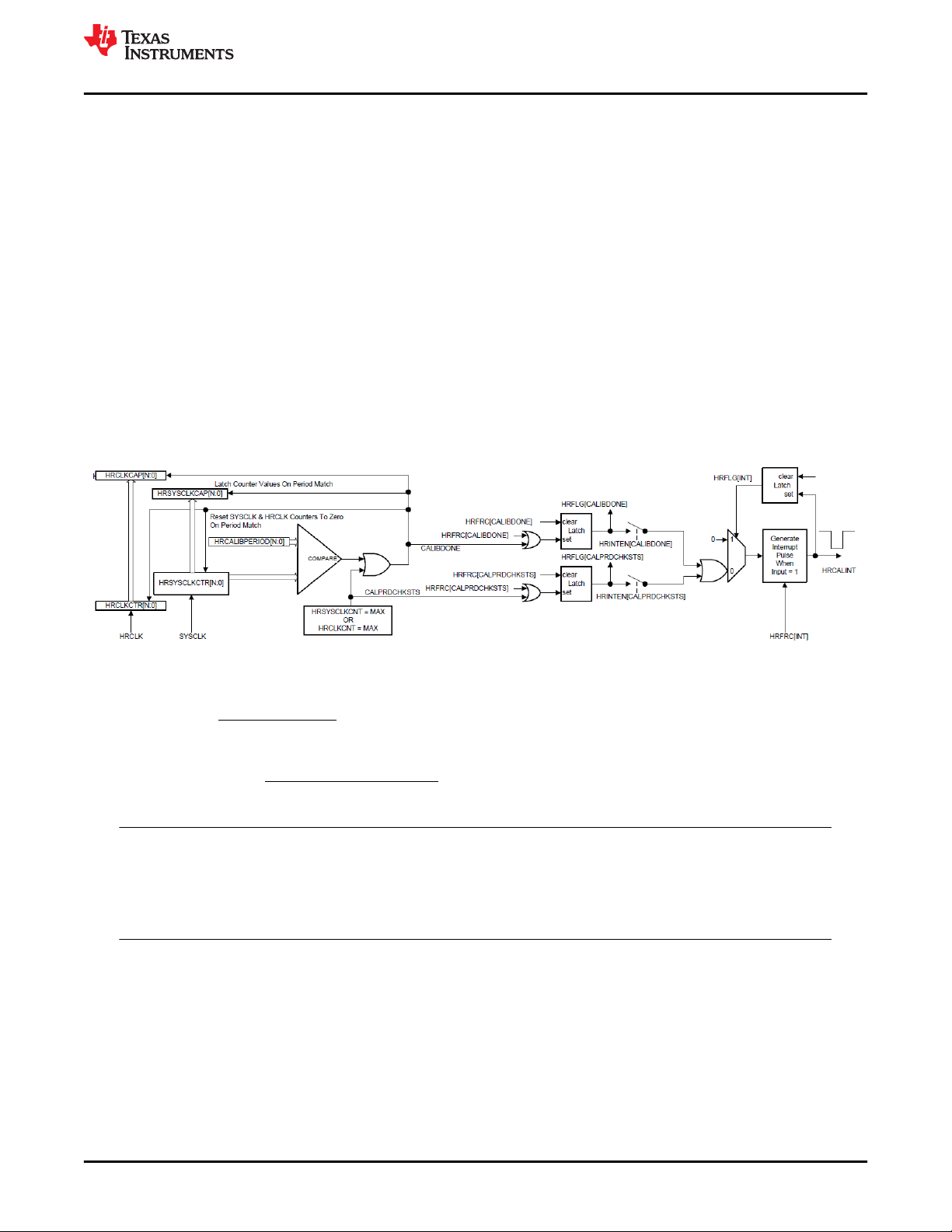

ISO 26262. This is similar to Process Safety Time (PST) defined in IEC 61508. Figure 4-6 illustrates the

relationship between FDTI, Fault Reaction Time and FTTI.

The frequency and extent of each of the Level 2 and Level 3 checks in E-GAS monitoring concept should be

consistent with the Fault Tolerant Time Interval (FTTI). Figure 4-7 illustrates the frequency of the required

checks. The checks should be such that single point faults of the microcontroller should be detected and

responded to, such that the TMS320F28004x MCU enters a safe state within the FTTI budget. The

microcontroller on detection of a fault enters into one of the safe states as illustrated in Figure 4-8. An example

of a diagnostic for single point faults is ECC/Parity for memories.

Figure 4-6. Relationship Between FDTI, Fault Reaction Time and FTTI

Figure 4-7. Illustration of FTTI

Copyright © 2020 Texas Instruments Incorporated

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Safety Manual for TMS320F28004x 13

Page 14

+ -

TMS320F28004x

XRSn

Input

Output

ERRORSTS

3.Reset state: MCU is

kept in reset

+ -

TMS320F28004x

XRSn

Input

Output

ERRORSTS

2.Safe state: Power supply cut-off or

not in proper operating range.

+ -

TMS320F28004x

XRSn

Input

Output

Tristated

ERRORSTS

5.Safe state: MCU

Output is tristated

+ -

TMS320F28004x

XRSn

Input

Output

ERRORSTS

4. Safe state: ERRORSTS

pin is asserted

+ -

TMS320F28004x

XRSn

Input

Output

ERRORSTS

1.Proper Operational State

TMS320F28004x Product Overview

www.ti.com

The proposed functional safety concept, subsequent functional safety features and configurations explained in

this document are for reference purpose only. The system and equipment designer or manufacturer is

responsible to ensure that the end systems (and any Texas Instruments hardware or software components

incorporated in the systems) meet all applicable safety, regulatory and system-level performance requirements.

4.2.3 TMS320F28004x MCU Safe State

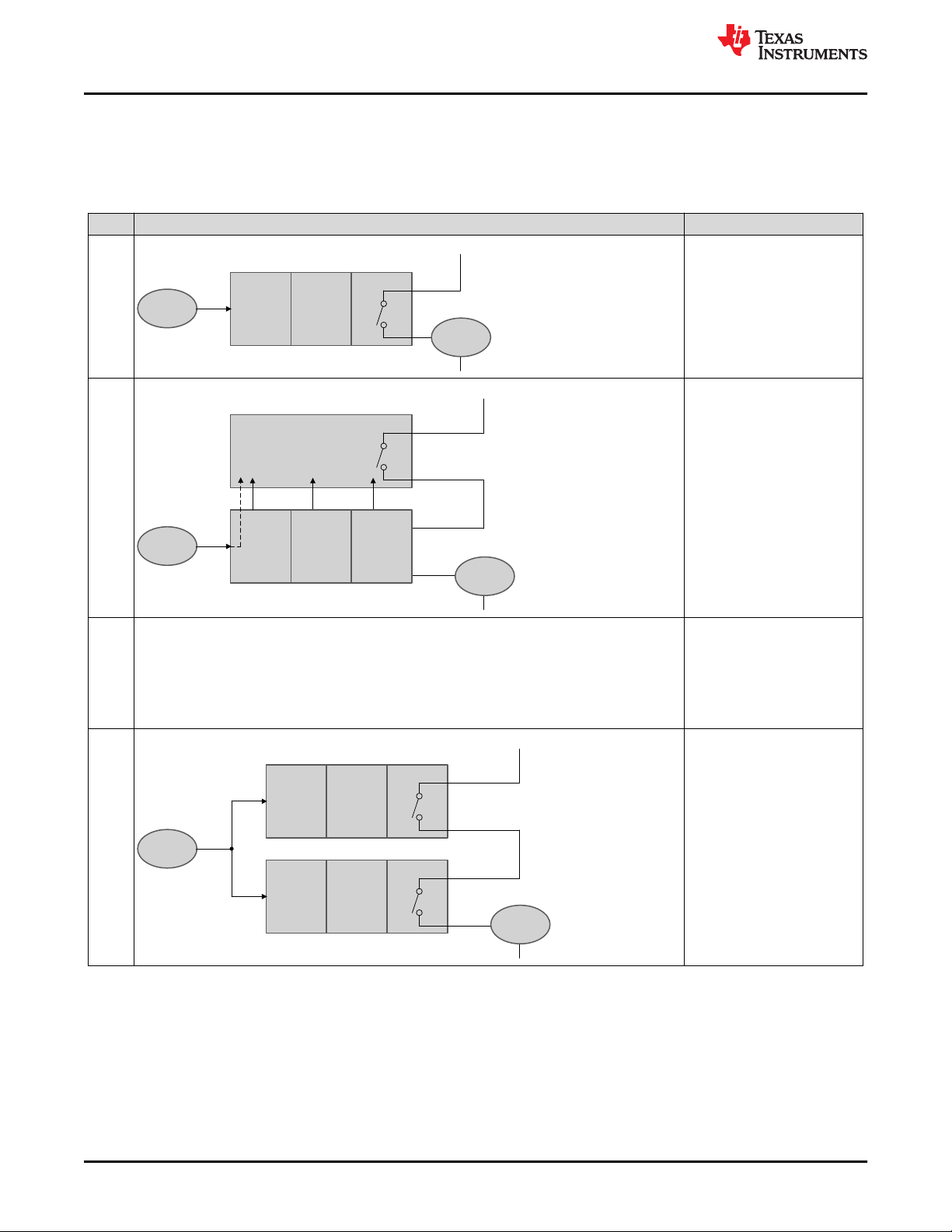

Referring to Figure 4-8, the safe state of the TMS320F28004x MCU is defined as the one in which:

• TMS320F28004x MCU Reset is asserted

• Power supply to TMS320F28004x MCU is disabled using an external supervisor as a result of Level 3 check

failure. In general, a power supply failure is not considered in detail in this analysis as it is assumed that the

system level functionality exists to manage this condition.

• External system is informed using one of C2000 MCU’s IO pins as a result of Level 2 check failure (for

example, ERRORSTS pin is asserted).

• Output of the TMS320F28004x MCU driving the actuator is forced to inactive mode as a result of Level 2

check failure (for example, GPIO pins corresponding to the mission function is tri-stated).

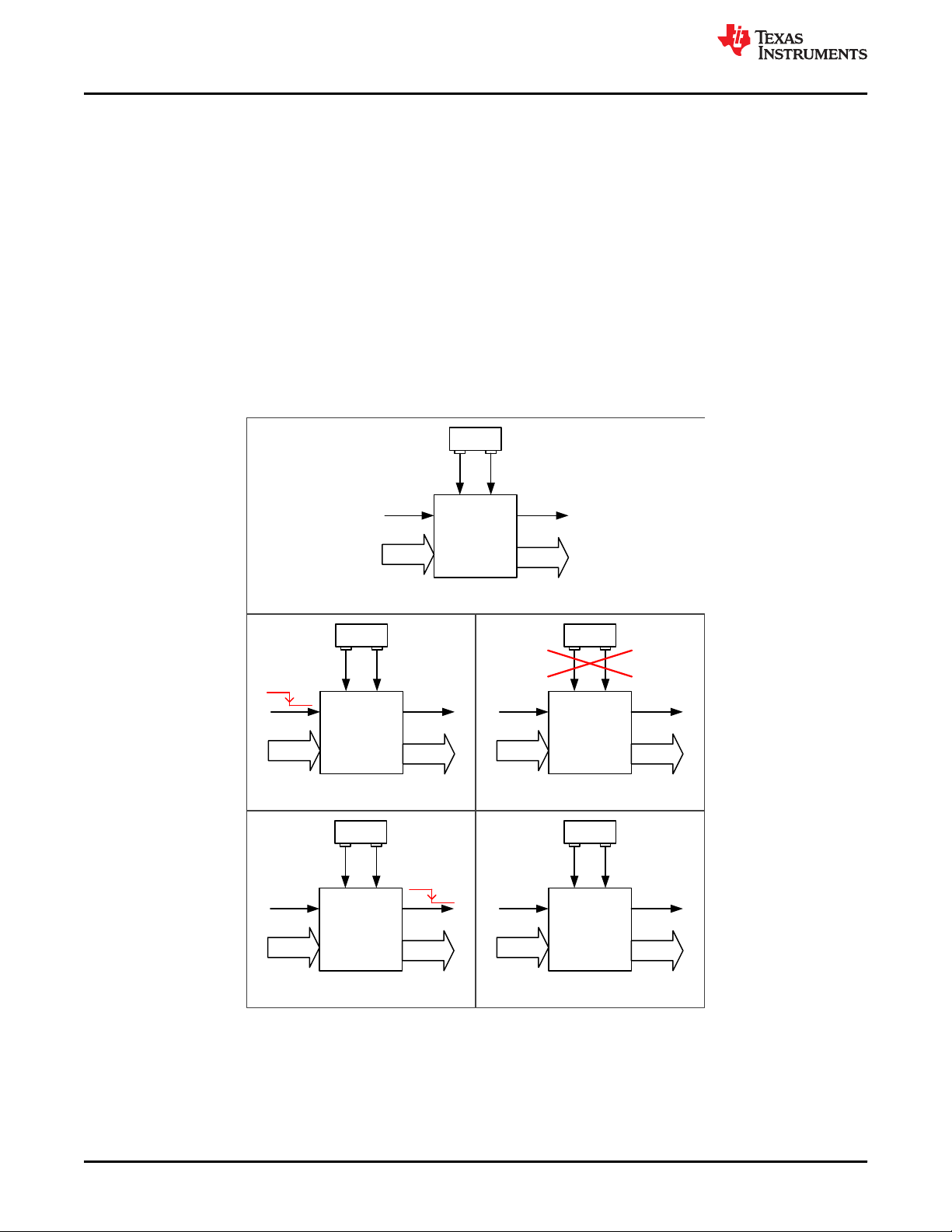

Figure 4-8. TMS320F28004x MCU Safe State Definition

14 Safety Manual for TMS320F28004x SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 15

Powered

Off

Reset

State

Cold Boot

Warm

Boot

Pre-

Operational

Operational

Power removed

Power applied

Chip Pin Reset

released

Defined Safe State

conditions

CPU1 Reset

released

Device boot phaseCPUSS operation

Safe State

XRSn = 0

www.ti.com

TMS320F28004x Product Overview

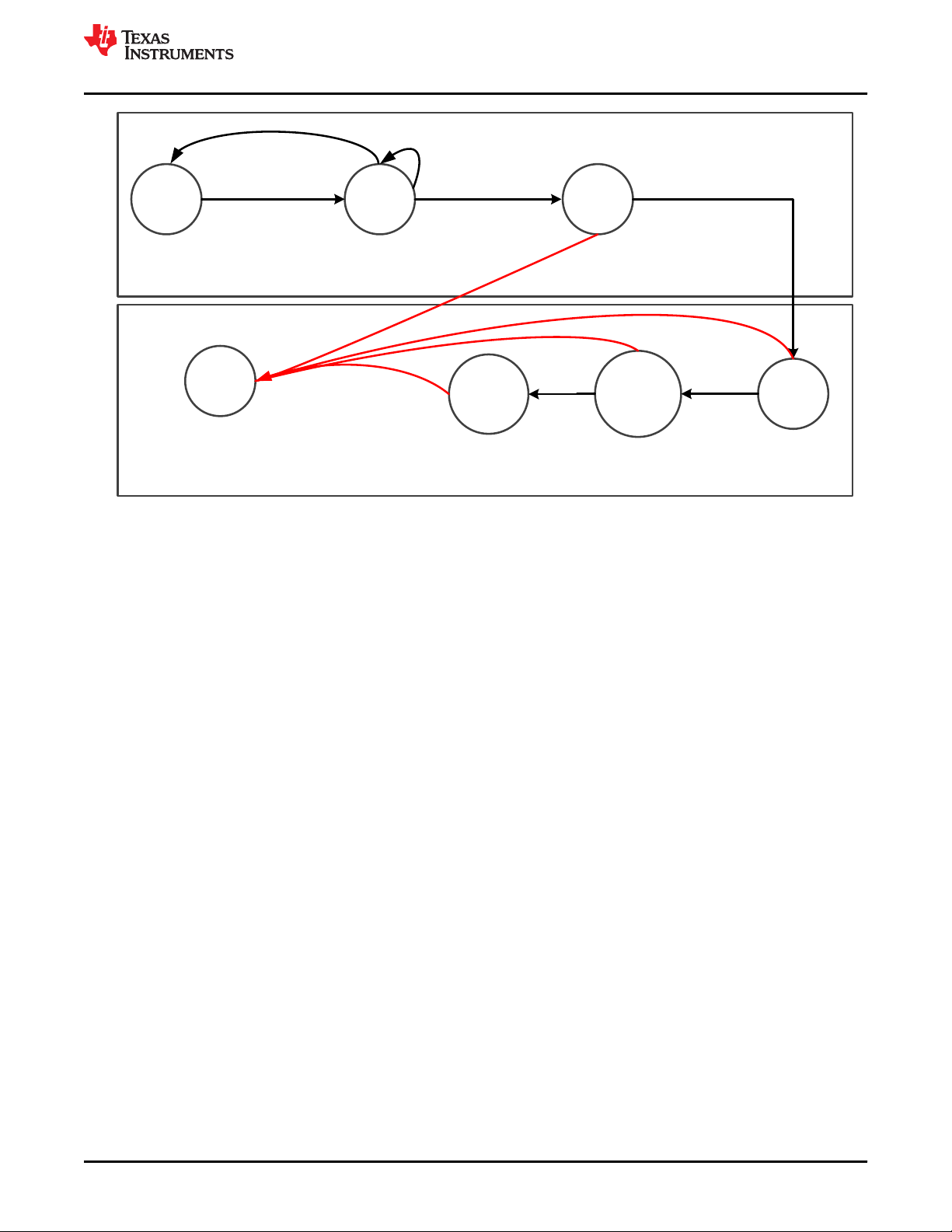

Figure 4-9. TMS320F28004x MCU Device Operating States

4.2.4 Operating States

The C2000 MCU products have a common architectural definition of operating states. These operating states

should be observed by the system developer in their software and system level design concepts. The operating

states state machine is shown in Figure 4-9. The operating states can be classified into device boot phase and

CPU Subsystem (CPUSS) operation phase.

The various states of the device operating states state machine are:

• Powered Off - This is the initial operating state of TMS320F28004x MCU. No power is applied to either core

or I/O power supply and the device is non-functional. An external supervisor can perform this action (powerdown the TMS320F28004x MCU) in any of the TMS320F28004x MCU states as response to a system level

fault condition or a fault condition indicated by the TMS320F28004x MCU.

• Reset State – In this state, the device reset is asserted either using the external pins or using any of the

internal sources.

• Safe State – In the Safe state, the device is either not performing any functional operations or an internal fault

condition is indicated using the device I/O pins.

• Cold Boot - In the cold boot state, key analog elements, digital control logic, and debug logic are initialized.

The CPU remains powered but in reset. When the cold boot process is completed, the reset of the CPU is

internally released, leading to the warm boot stage.

• Warm Boot - The CPU begins execution from Boot ROM during the warm boot stage.

• Pre-operational - Transfer of control from boot code to customer code takes place during this phase.

Application specific configurations (for example, clock frequency, peripheral enable, pinmux, and so forth) are

performed in this phase. Boot time self-test/proof-test required to ensure proper device operation is

performed during this phase. For details, see ROM8-Power-Up Pre-Operational Security.

• Operational – This marks the system exiting the pre-operational state and entering the functional state. The

device is capable of supporting safety critical functionality during operational mode.

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Safety Manual for TMS320F28004x 15

Page 16

Cold Boot

Power

Applied

Efuse autoload

(cold boot phase)

Boot ROM

execution and

security

initialization

(Warm boot phase)

Reset

Released

Customer

Code Starts

Operational Phase

Pre Operational Phase

Warm Boot

TI boot code execution. Can be characterized

based on device configuration Customer code Self-test code

Pre operational checks by CPU1

(Verify RAM, Flash, Watchdog,

CPU, %RRW520«..)

XRSn

Internal

Reset

Boot ROM

Customer pre-operational checks

ERROR_STS

(active-low)

Efuse Autoload

Customer application code

Security Init

Analog (DAC,

ADC, OSC) Init

Bootmode SelPwr Mgmt init

Boot exception

init

x Device Powerdown

x Assertion of XRSn pin

x Assertion of CPU Reset

x NMI and assertion of ERRORSTS pin

x CPU Interrupt

TMS320F28004x Product Overview

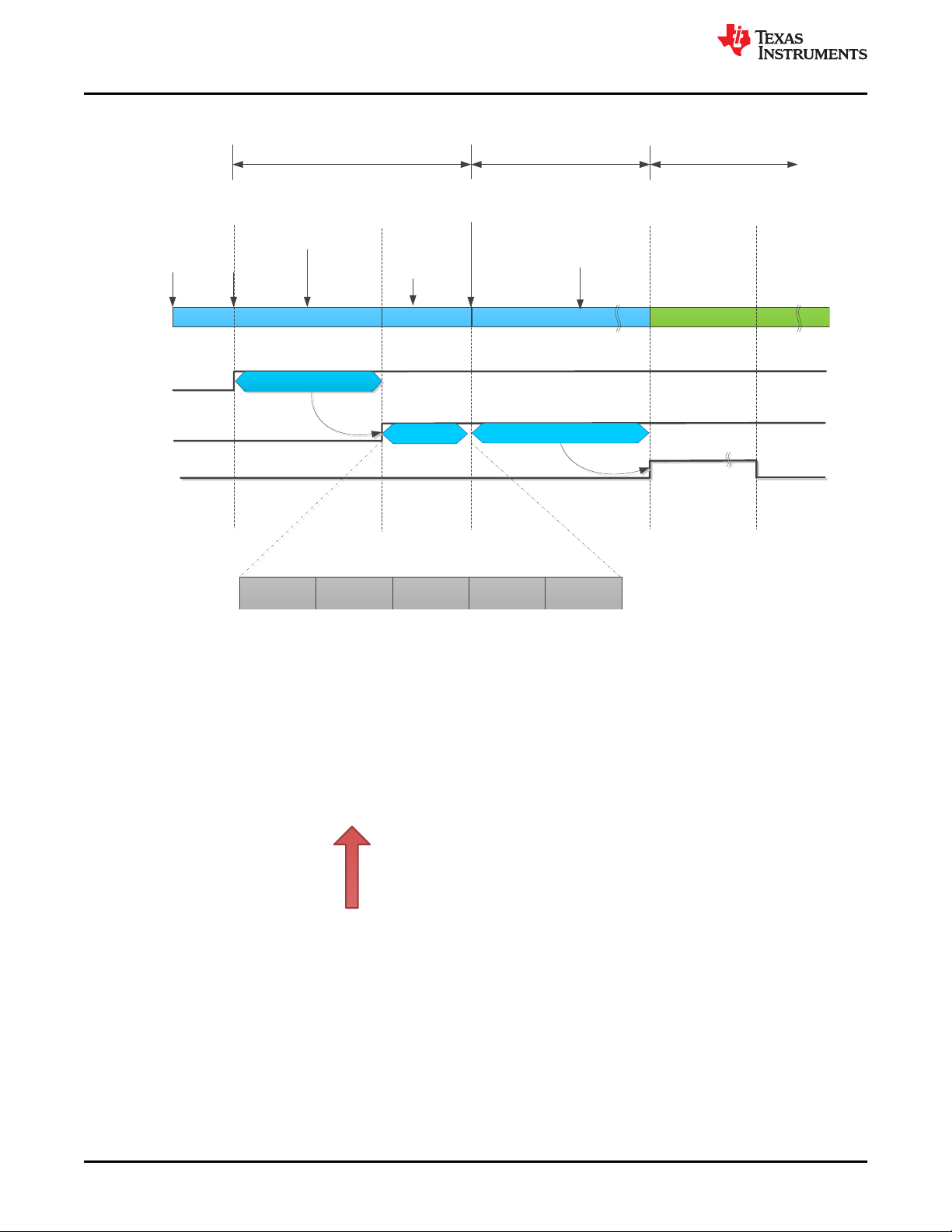

The device start-up timeline for both the CPUs are shown in Figure 4-10.

www.ti.com

Figure 4-10. TMS320F28004x MCU CPU Start-Up Sequence

4.2.5 Management of Faults

The TMS320F28004x MCU product architecture provides different levels of fault indication from internal safety

mechanisms using CPU Interrupt, Non Maskable Interrupt (NMI), assertion of ERRORSTS pin, assertion of CPU

input reset and assertion of warm reset (XRSn). The fault response is the action that is taken by the

TMS320F28004x MCU or system when a fault is indicated. Multiple potential fault responses are possible during

a fault indication. The system integrator is responsible to determine which fault response should be taken to

ensure consistency with the system safety concept. The fault indication ordered in terms of severity (device

power down being the most severe) is shown in Figure 4-11.

Figure 4-11. Fault Response Severity

• Device Powerdown: This is the highest priority fault response where the external component (see Section

4.4.1) detects malfunctioning of the device or other system components and powers down the

TMS320F28004x MCU. From this state, it is possible to re-enter cold boot to attempt recovery.

• Assertion of XRSn: The XRSn reset could be generated from an internal or external monitor that detects a

critical fault having potential to violate safety goal. Internal sources generate this fault response when the

TMS320F28004x MCU is not able to handle the internal fault condition by itself (for example, CPU1 (master

CPU) is not able to handle NMI by itself). From this state, it is possible to re-enter cold boot and attempt

recovery.

16 Safety Manual for TMS320F28004x SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 17

www.ti.com

TMS320F28004x Product Overview

• Assertion of CPU Reset: CPU Reset changes the state of the CPU from pre-operational or operational state

to warm boot phase. The CPU Reset is generated from an internal monitor that detects any security

violations. Security violations may be the effect of a fault condition.

• Non Maskable Interrupt (NMI) and assertion of ERRORSTS pin: C28x CPU supports a Non Maskable

Interrupt (NMI), which has a higher priority than all other interrupts. The TMS320F28004x MCU is equipped

with a NMIWD module responsible for generating NMI to the C28x CPU. ERRORSTS pin will also be

asserted along with NMI. Depending on the system level requirements, the fault can be handled either

internal to the TMS320F28004x MCU using software or at the system level using the ERRORSTS pin

information.

• CPU Interrupt: CPU interrupt allows events external to the CPU to generate a program sequence context

transfer to an interrupt handler where software has an opportunity to manage the fault. The peripheral

interrupt expansion (PIE) block multiplexes multiple interrupt sources into a smaller set of CPU interrupt

inputs.

4.2.6 Suggestions for Improving Freedom From Interference

The following techniques and safety measures shall be used as applicable for improving independence of

function when using the TMS320F28004x MCU:

1. Hold peripherals clocks disabled if the available peripherals are unused (CLK14-Peripheral Clock Gating

(PCLKCR)).

2. Hold peripherals in reset if the available peripherals are unused (RST9-Peripheral Soft Reset (SOFTPRES)).

3. When possible, separate critical I/O functions by using non adjacent I/O pins/balls.

4. Partition the memory as per the application requirements to respective processing units and configure the

Access Protection Mechanism for Memories, for each memory instance such that only the permitted masters

have access to memory.

5. The Dual Code Security Module (DCSM) can be used for functional safety where functions with different

safety integrity levels can be executed from different security zones (zone1, zone2, and unsecured zone),

acting as firewalls and thus mitigating the risk due to interference from one secure zone to another. For more

information, see Achieving Coexistence of Safety Functions for EV/HEV Using C2000™ MCUs

6. TMS320F28004x supports SYS10-Peripheral access protection - Type 0. After programming peripheral

access protection registers, each master can exclusively control the peripheral to safeguard usage by

particular application against errant writes or corruption by other masters in the system. This is enabled using

the dedicated access control bits per peripheral which allow or protect against the access from given master.

Each peripheral has two bit qualifier per master to decode the access allowed. For more details, see the

PERIPH_AC_REGS Registers in TMS320F28004x Technical Reference Manual.

7. ADC11-Disabling Unused Sources of SOC Inputs to ADC can help avoid interference from unused

peripherals to disturb functionality of ADC.

8. DMA9-Disabling of Unused DMA Trigger Sources will help minimize interference caused by unintentional

DMA transfers.

9. CLA11-Disabling of Unused CLA Trigger Sources will mitigate risk of interference caused due to the trigger

events.

10.To avoid interference from spurious activity on MCU’s debug port, JTAG1-Hardware Disable of JTAG Port can

be used.

11. Safety applications running on the CPU can be interfered by unintentional faulty interrupt events to PIE

module. PIE7-Maintaining Interrupt Handler for Unused Interrupts and PIE8-Online Monitoring of Interrupts

and Events will detect such interfering failures.

12.MCU resources in supporting CPU execution such as memory, interrupt controller, and so forth could be

impacted by resources from lower safety integrity safety functions coexisting on same MCU. Safety

mechanisms such as SRAM11-Access Protection Mechanism for Memories, SRAM16–Information

Redundancy Techniques, SRAM17-CPU Handling of Illegal Operation, Illegal Results and Instruction

Trapping will be able to detect such interference.

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Safety Manual for TMS320F28004x 17

Page 18

TMS320F28004x Product Overview

www.ti.com

13.Critical configuration registers could be victim of interference from bus masters on MCU which implements

lower safety integrity functions. These can be protected by SYS1-Multi-Bit Enable Keys for Control Registers,

SYS2-Lock Mechanism for Control Registers, SYS8-EALLOW and MEALLOW Protection for Critical

Registers.

4.2.7 Suggestions for Addressing Common Cause Failures

System Integrator needs to execute a common cause failure analysis to consider possible dependent/common

cause failures on the sub-elements of the TMS320F28004x MCU, including pin level connections.

1. Consider a relevant list of dependent failure initiators, such as the lists found in ISO 26262-11:2018. Analysis

of dependent failures should include common cause failures among functional redundant parts and also

between functions and the respective safety mechanisms.

2. Verify that the dependent failure analysis considers the impact of the software tasks running on the

TMS320F28004x MCU, including hardware and software interactions.

3. Verify that the dependent failure analysis considers the impact of the pin or ball level interactions on the

TMS320F28004x MCU package, including aspects related to the selected I/O multiplexing.

The following should be considered for addressing the common cause failures when using the TMS320F28004x

MCU:

1. Redundant functions and safety mechanism can be impacted by common power failure. A common cause

failure on power source can be detected by PWR1-External Voltage Supervisor, PWR2-External Watchdog.

2. In general, a clock source which is common to redundant functions should be monitored and any failures on

the same can be detected by safety mechanisms such as CLK1-Missing Clock Detect (MCD), CLK2-Clock

Integrity Check Using CPU Timer, CLK5-External Clock Monitoring via XCLKOUT and CLK8-Periodic

Software Read Back of Static Configuration Registers. Specifically, to avoid common clock failure affecting

Internal Watchdog (WD) and CPU, it is recommended to use either INTOSC2 or X1/X2 as clock source to

PLL.

3. Failure of common reset signal to redundant functions can be detected by RST1-External Monitoring of Warm

Reset (XRSn), RST2-Reset Cause Information.

4. Common cause failure on Interconnect logic could impact both redundant functions and also functional safety

mechanism in same way. In addition to other safety mechanisms, INC1-Software Test of Function Including

Error Tests can be implemented to detect faults on interconnect logic.

5. Common cause failure could impact two functions used in a redundant way. In case the of communication

peripherals, module specific Information Redundancy Techniques Including End-to-End Safing can be

implemented to detect common cause failures, for example, CAN2-Information Redundancy Techniques

Including End-to-End Safing, SPI2-Information Redundancy Techniques Including End-to-End Safing, SCI3Information Redundancy Techniques Including End-to-End Safing, I2C3-Information Redundancy Techniques

Including End-to-End Safing.

6. Use different voltage references and SOC trigger sources for ADC (see Section 6.5.8).

7. Use ePWM modules from different sync groups for implementing Hardware Redundancy.

8. Use GPIO pins from different groups when implementing Hardware Redundancy for GPIO pins.

9. It is recommended that two PGA modules used in redundant way to not share same ground pin. Refer to

device specific datasheet for details on which PGA's share common ground.

18 Safety Manual for TMS320F28004x SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 19

www.ti.com TMS320F28004x Product Overview

4.3 C2000 Safety Diagnostics Libraries

The diagnostics libraries designed for the F28004x family of devices comprise of three libraries, namely, the

CLA_STL, C28x_STL and SDL. These libraries are designed to help TI customers, using the F28004x, develop

functionally safe systems that can comply with a wide range of standards for end products in the automotive

(ISO 26262), industrial (IEC 61508) and appliance (IEC 60730) markets. The CLA_STL and the C28x_STL

implements the CLA2 - Software Test of CLA and CPU3 - Software Test of CPU safety mechanisms and the SDL

provides examples for several safety mechanisms provided in the safety manual.

Table 4-1. DC and SCC Targeted for F28004x Diagnostic Libraries

Library

CLA_STL ≥ 90% ASIL D/SIL 3

C28x_STL ≥ 60% ASIL D/SIL 3

SDL Examples Only N/A

Permanent fault Diagnostic

Coverage

The CLA_STL and C28x_STL were independently assessed and found to be suitable for being integrated into

safety related systems up to ASIL D and SIL 3 according to ISO 26262:2018 and IEC 61508:2010 respectively.

The CLA_STL represents a safety mechanism with the capability to detect permanent faults of the Control Law

Accelerator (CLA) with a 90% Diagnostic Coverage. The C28x_STL represents a safety mechanism with the

capability to detect permanent faults of the C28x CPU with a 60% Diagnostic Coverage.

Systematic Capability

Compliance Description

This STL implements CLA2 -

Software Test of CLA

This STL implements CPU3 -

Software Test of CPU

The SDL provides examples of

several safety mechanisms

described in the safety manual

The SDL is generally called a Software Diagnostic Library and is an integral part of the overall safety related

collateral provided by TI. It comprises general example implementations of several safety mechanisms. The SDL

examples are developed using a Baseline Quality software development flow and are not required to be

compliant with any particular standard. As such, the SDL is not certified by TÜV SÜD. Users are expected to

study and adapt the provided examples into their safety related applications and are responsible to for their own

product level third party certifications.

In order to assist customers with getting their own product level certifications, TI has developed an F28004x

Compliance Support Package (CSP). The CSP provides documentation, source code, static analysis results,

MISRA C compliance results, unit test reports, dynamic analysis results, functional tests and integration

examples. The STL (C28x_STL and CLA_STL) libraries and the corresponding source code released in the CSP

demonstrate the product of a software development flow that is compliant with ISO 26262 ASIL D systematic

capability.

WARNING

In order to maintain the diagnostic coverage, the source code of C28x_STL and CLA_STL listed in

Table 4-4 and Table 4-5 must be used as delivered by TI and must not be modified when integrating

the libraries into the customer application. Any modification will certainly result in a compromise of

the safety goal for the final product, resulting in an unsafe operating environment for the end user.

Table 4-2 shows the tools used to develop the F28004x libraries.

Table 4-2. Tools Required for Integration of the F28004x STL

SW/HW/Tool Version Dependency

Code Composer Studio 9.2.0.00013 Integrated Development Environment

CGT 20.2.1.LTS Code Generation Tool Chain (Compiler,

C2000Ware V3.01.00.00 F28004x Header Files

TMDSCNCD280049C Rev. A F280049 controlCARD Information Guide

Assembler, Linker)

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Safety Manual for TMS320F28004x 19

Page 20

TMS320F28004x Product Overview

www.ti.com

The system integrator must consult the C28x_STL and CLA_STL user guides for all the details related to

installation and development.

The STLs were tested on the F28004x controlCARD.

4.3.1 Assumptions of Use - F28004x Self-Test Libraries

This section provides the high level details related to what a system integrator must consider during the process

of defining and building their F28004x based safety architecture.

The software support for the various safety mechanisms in the F28004x can be divided into the following three

categories:

• C28x Self-Test Library

• SDL – Software Diagnostic Library

• CLA Self-Test Library

A safe product built on the F28004x device hierarchically deploys each of the software solutions provided by TI.

The first in the hierarchy is the C28x_STL which detect permanent faults inside the CPU by implementing the

CPU3 - Software Test of CPU safety mechanism. The second in the hierarchy is the SDL which provides a

series of examples of safety mechanisms that are designed to detect permanent faults inside several key

elements within the F28004x device. Lastly, the CLA_STL which implements the CLA2 - Software Test of CLA

safety mechanism, can be deployed to detect permanent faults inside the CLA.

The CLA_STL makes use of, and depends on both the C28x CPU and the CLA to test the CLA. Therefore it is

important to run the C28x_STL first to make sure that the CPU is functioning properly and is capable of

performing the required safety operations. The SDL supports safety mechanisms such as: CLK2 - Clock Integrity

Check Using CPU Timer, CLK10 - Software Test of Watchdog (WD) Operation, CLK12 - Software Test of

Missing Clock Detect Functionality, SRAM14 - Software Test of Parity Logic, SRAM13 - Software Test of ECC

Logic, SRAM3 - Software Test of SRAM and several other key processing elements. The system integrator must

study all the safety mechanisms supported by the SDL and determine their applicability into the safety system

being designed. The safety system must be evaluated with respect to the startup and runtime constraints and

whether the software diagnostic tests can be run during POST, PEST or a combination of both.

The successful completion of the software diagnostics, selected by the system integrator, can be used as the

qualifier to run the test vectors supported by the CLA_STL.

4.3.2 Operational Details - F28004x Self-Test Libraries

The C28x_STL, SDL and the CLA_STL are co-hosted onto an F28004x target in order to enable the

comprehension of safety in the host application. Therefore, it is important for a system integrator to fully

comprehend all aspects of the associated system constraints imposed by the integration of the STLs to

comprehend safety.

4.3.2.1 Operational Details – C28x Self-Test Library

The C28x_STL implements the CPU3 - Software Test of CPU. This library achieves a diagnostic coverage of

60% and certified by TÜV SÜD to meet LFM for ISO26262:2018 ASIL B. The C28x_STL runs directly on the

CPU and effectively tests a subset of CPU Registers, CPU instructions, CPU flags, the FPU, TMU and VCUCRC functionality. The Viterbi and Complex Math instructions in VCU are not covered by C28x_STL and should

not be used for safety related software.

In order to run these tests, the C28x_STL occupies program memory storage space, and dedicated execution

RAM space. All the C28x_STL tests are destructive in nature, and do not have a method to restore the system

back to the original a sate. Since the C28x_STL tests and reports on the health of the CPU itself and the system

state cannot be meaningfully saved and restored, it must be integrated into the startup portion of the application.

System integrator should enable the watchdog to ensure the application is protected against runaway code.

The system integrator must consult the C28x_STL user guides and understand all aspects of integrating the

library into the host application.

20 Safety Manual for TMS320F28004x SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 21

www.ti.com

TMS320F28004x Product Overview

4.3.2.2 Operational Details – CLA Self-Test Library

The CLA_STL, implements the CLA2 - Software Test of CLA. Similar to the C28x_STL the CLA_STL’s startup

tests are also destructive in nature and should be run during startup operations. The CLA_STL’s run time tests

comprise the bulk of the tests designed to run in conjunction with the host application. The CLA host application

must allocate the time and space for the run time tests. To achieve 90% permanent DC, the CPU must run both

the CLA_STL POST and PEST tests.

The system integrator must consult the CLA_STL user guides and understand all aspects of integrating the

library into the host application.

4.3.2.3 Operational Details – SDL

Table 4-3 is a mapping of SDL software modules and APIs to safety features and diagnostic.

Table 4-3. API Mapping

API Name Unique Identifier

STL_CAN_RAM CAN4, CAN15

STL_CPU_REG None, added for IEC 60730

STL_CRC

STL_March SRAM3

STL_OSC_CT CLK2

STL_OSC_HR OTTO1, CLK3

STL_PIE_RAM PIE6

sdl_ex_flash_ecc_test FLASH6

sdl_ex_mcd_test CLK12

sdl_ex_ram_access_protect SRAM10

sdl_ex_ram_ecc_parity_test SRAM13, SRAM14

sdl_ex_watchdog CLK10

Generic CRC calculation that could be used for any memory or for adding CRC to

communications - probably applies to several mechanisms

4.3.3 C2000 Safety STL Software Development Flow

The C28x-STL and CLA-STL are developed using the TUV-SUD Certified TI internal software development

process specification which targets software development flows for baseline quality, automotive quality and/or

functional safety quality. (for functional safety, specifically the target is systematic capability compliance with the

IEC 61508 and ISO 26262 standards). TUV-SUD certificate for TI's SW development process is available here.

The software development process specification describes the contents of the required deliverables during each

of the four phases, namely, Assess, Plan, Create and Validate. By adhering to this specification and complying

with the underlying processes, including methods and techniques (IEC 61508-3, ISO 26262-6), which are

comprehended in the work-products, it is ensured that a TI SW/FW development achieves a systematic

capability of ASIL D (ISO 26262-6) and SIL 3 (IEC 61508-3).

• Figure 4-12 depicts TI's (TUV-SUD certified) Software Development Life Cycle with respect to the various

quality levels supported by the process.

• Detailed supporting procedures are documented to ensure functional safety throughout the project life cycle.

Additional tools and techniques respecting the safety integrity levels of the targeted standards are applied at

each development phase.

• Functional safety audits and assessments are planned and conducted as per defined procedure. Qualified

personnel with adequate independence as required by the targeted standards and safety levels do these

audits and assessments.

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Safety Manual for TMS320F28004x 21

Page 22

TMS320F28004x Product Overview www.ti.com

Figure 4-12. TI Software Development Lifecycle - Quality Level

4.3.4 Software Delivery Form (SDF) for STLs

The source code delivered with both C28x_STL and the CLA_STL must be validated with the reference MD5

information provided in Table 4-4 and Table 4-5 respectively. This is strongly recommended as a precautionary

step to ensure that the source code is exactly the same as what was certified by TÜV SÜD.

Table 4-4. MD5 Signatures for C28x-STL

c28x_stl.c 84a196c75d5ffabebf7c9041cd3ab4ca

c28x_stl.h 8c87c78bffddb4f8a803278d16b6e8a9

c28x_stl_s.asm 615df2a99ad9fced513cdca3e45aaa04

c28x_stl_tg00.asm d244f2f993ae616c4d417a93d01d3b3f

c28x_stl_tg01.asm d232dfb25921b336bf9b20a630d8d890

c28x_stl_tg02.asm 37077dbb7f7b0225d7a74a389a2f2710

MD5 Signature

c28x_stl_tg03.asm 56f2c5bdb0872bfe1d4e175165a14688

c28x_stl_tg04.asm aa2954de7fa798adf2e1de0fca768cb0

c28x_stl_tg05.asm 38eddd1531564c2c988701a735821c99

c28x_stl_tg06.asm 866f9ebce8c5b38e15567caa10656752

c28x_stl_tg07.asm 1514d04858e81aa27eea9039ec072a9c

c28x_stl_tg08.asm 44faeb49184284bbe6a76e7fbecccddb

c28x_stl_tg09.asm fa4940544caa8228d20658babca23825

22 Safety Manual for TMS320F28004x SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 23

www.ti.com

TMS320F28004x Product Overview

Table 4-5. MD5 Signatures for CLA-STL

stl_cla_pest.c 41ec9de76bf24afc76fbd48b5b1ee197

stl_cla_post.c 8af146b665c6a5c7f76d87e8f7754181

stl_cla_registers_1.c f5d6c238e71a41e4fdf9554d51cd8bad

stl_cla_registers_2.c 4b055558d5bb49bc52fc7d2453cafadb

MD5 Signature

stl_cla_registers_3.c a2ebbc79d3f1d8a5ab347dd47443b324

stl_cla_s.asm 01c9c8f5839cf821846e97d7441a234e

stl_cla_utils.c aceeae34b58a96a403ec65bde3ec0888

stl_claswbist_s.asm 3eeb54030a2a08efef2a0a06039a5d65

stl_cla.h 3acb93691a464c7ae39020a77023d35d

stl_cla_internal.h 05b82e678c762b3250e9c5e0a4f11d74

4.4 TMS320F28004x MCU Safety Implementation

4.4.1 Assumed Safety Requirements

The following assumed safety requirements need to be implemented using external components by the Level 3

checker (VDA E-gas concept).

• External voltage monitor to supervise the power supply provided to the TMS320F28004x MCU

• External Watchdog timer that can be used for diagnostic purposes

• Components required for taking the system to safe state as per the TMS320F28004x MCU safe state defined

in Section 4.2.3.

4.4.2 Example Safety Concept Implementation Options on TMS320F28004x MCU

TMS320F28004x class of devices supports a pair of diverse processing units (C28x and CLA) with

heterogeneous asymmetric architectures, instruction sets and software tools. Either of the processing units can

be used to execute the intended function (the main real-time control function). The safety functions, which

ensure that each safety goal can be met, can be implemented by one of the processing units, utilizing the other

processing unit for diagnostic of random hardware failure by running Reciprocal Comparison by Software in

separate processing units providing high diagnostic coverage for the processing units (ISO 26262-5:2018, Table

D.4 and IEC 61508-2:2010, Table A.4). Safety mechanisms such as CPU Handling of Illegal Operation, Illegal

Results and Instruction Trapping, CLA Handling of Illegal Operation and Illegal Results, Internal Watchdog (WD)

and so forth, can also be utilized. Software Test of CLA and Software Test of CPU can be used to implement

latent fault coverage of the diagnostic function. Heterogeneous CPU cores minimize possibility of common mode

failures while implementing this reciprocal comparison, thereby improving confidence in its Diagnostic Coverage.

For common cause failures such as clock, power and reset, an external watchdog should be used. Here are

some definitions:

• Intended Function: Control application implemented on TMS320F28004x (PFC, DCDC, traction-inverter etc.)

• Safety Function: Achieves risk reduction and implemented for safety goals identified from HARA

– Example: prevent over-current, over/under voltage, over temperature, forward/reverse torque etc.)

– Shall meet >= 90% SPFM for both permanent and transient faults

• Diagnostic Function: Ensures safety-function will operate correctly when required

– Shall meet >= 60% LFM for ISO 26262:2018 (ASIL B compliance targeted) systems

The following are the safety concept options which can be implemented on TMS320F28004x.

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Safety Manual for TMS320F28004x 23

Page 24

`

Power

Electronics

Ref

+

C28x

PFC+Safety

Actuation

Sensing

CLA

DC-DC

Actuation

Ref

+

Sensing

±

±

+

Power

Electronics

+

C2000 Microcontroller

TMS320F28004x Product Overview

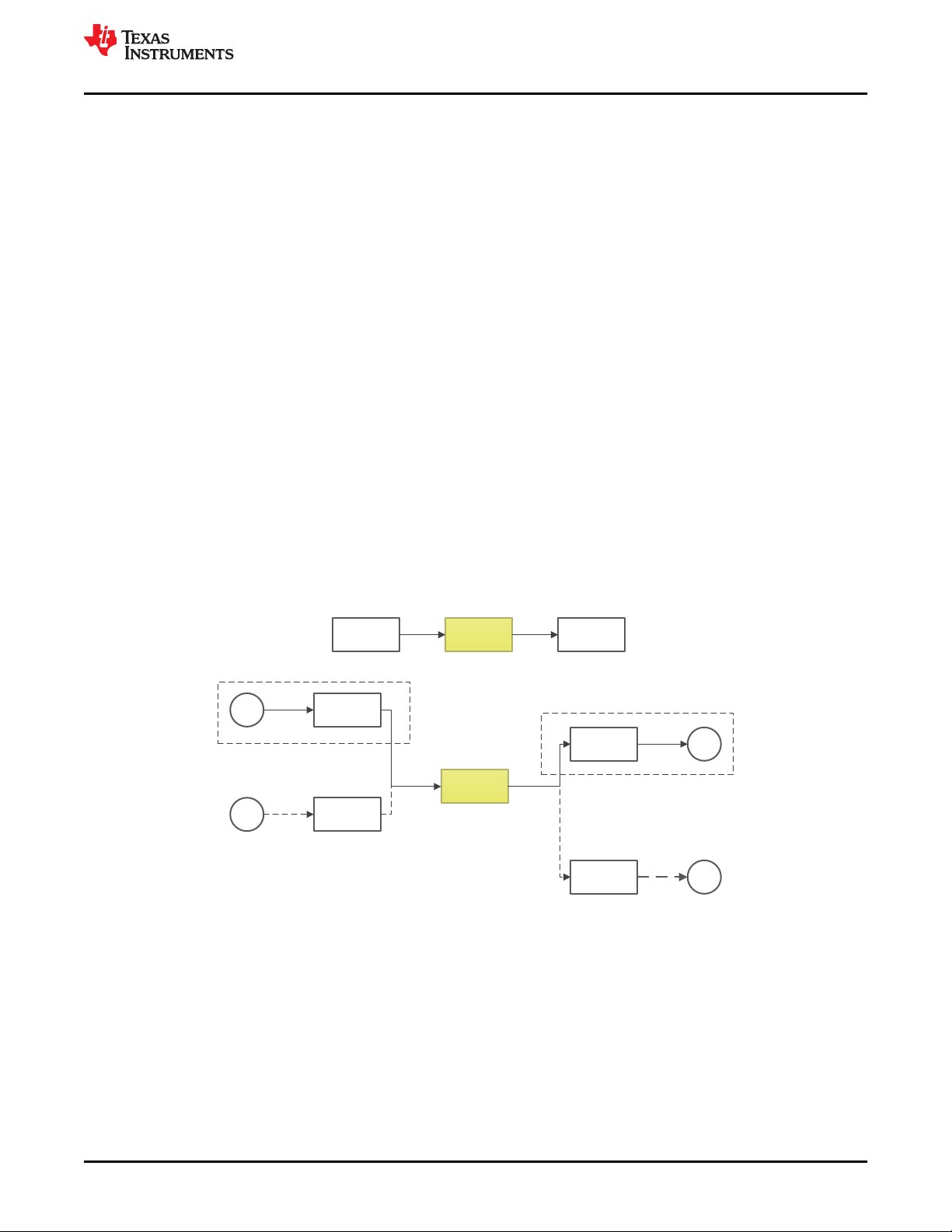

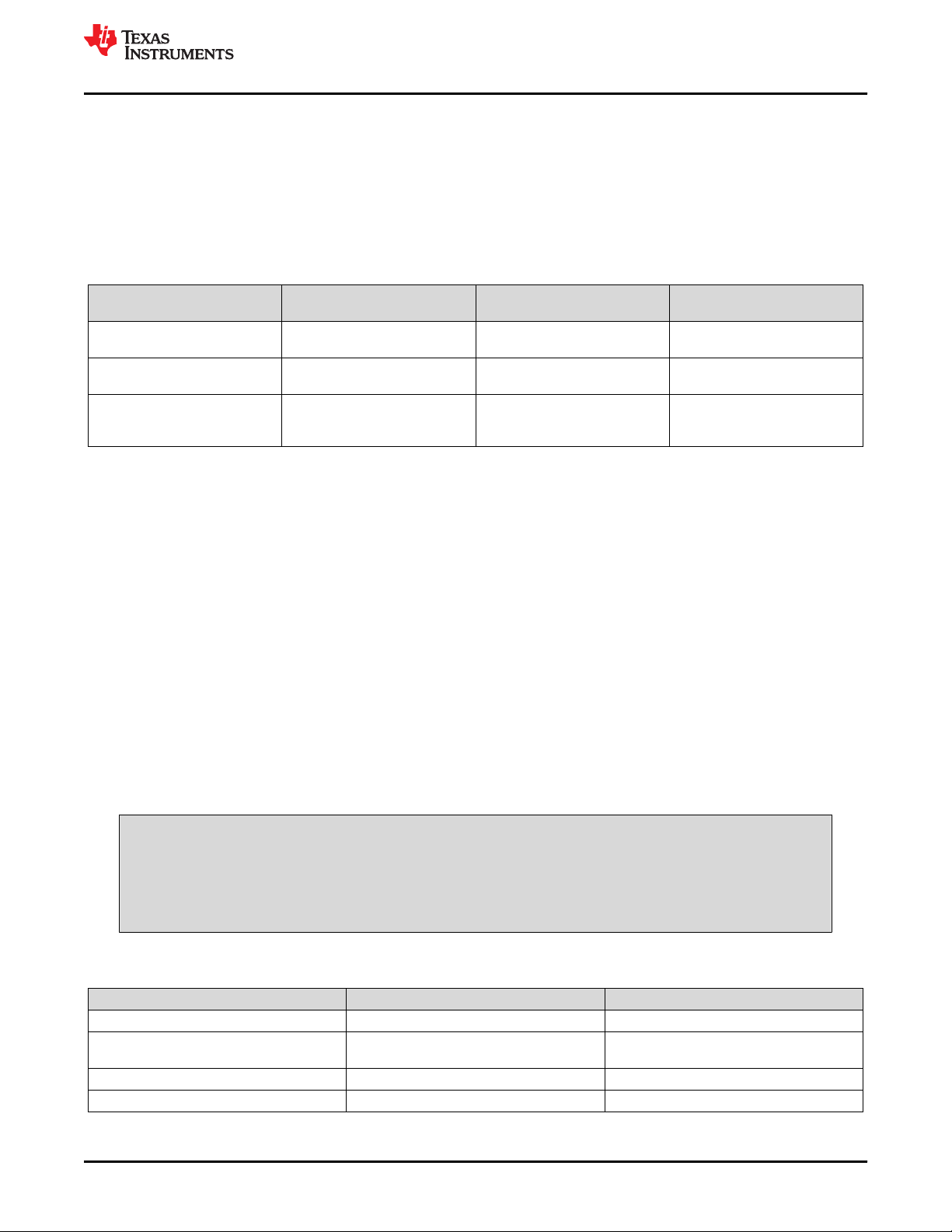

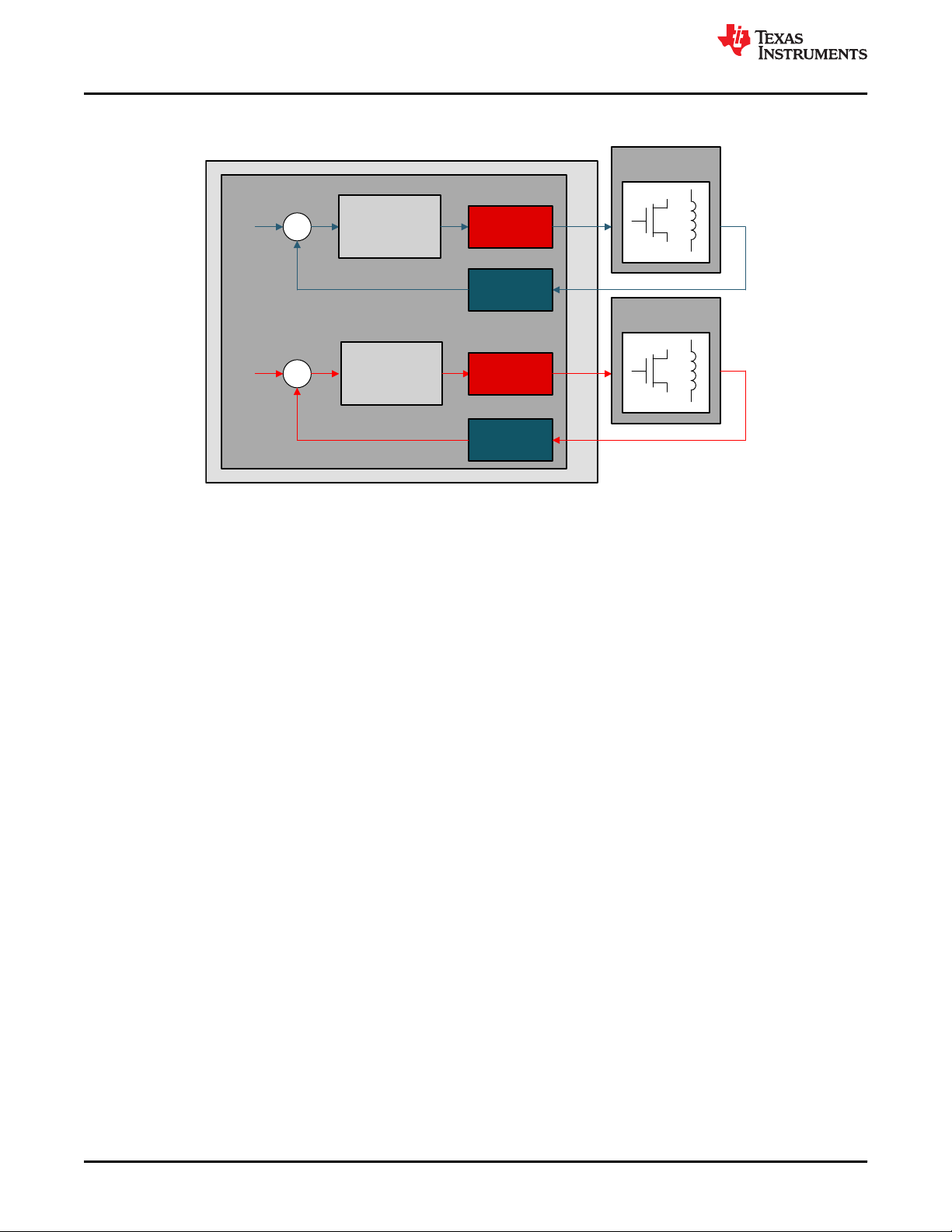

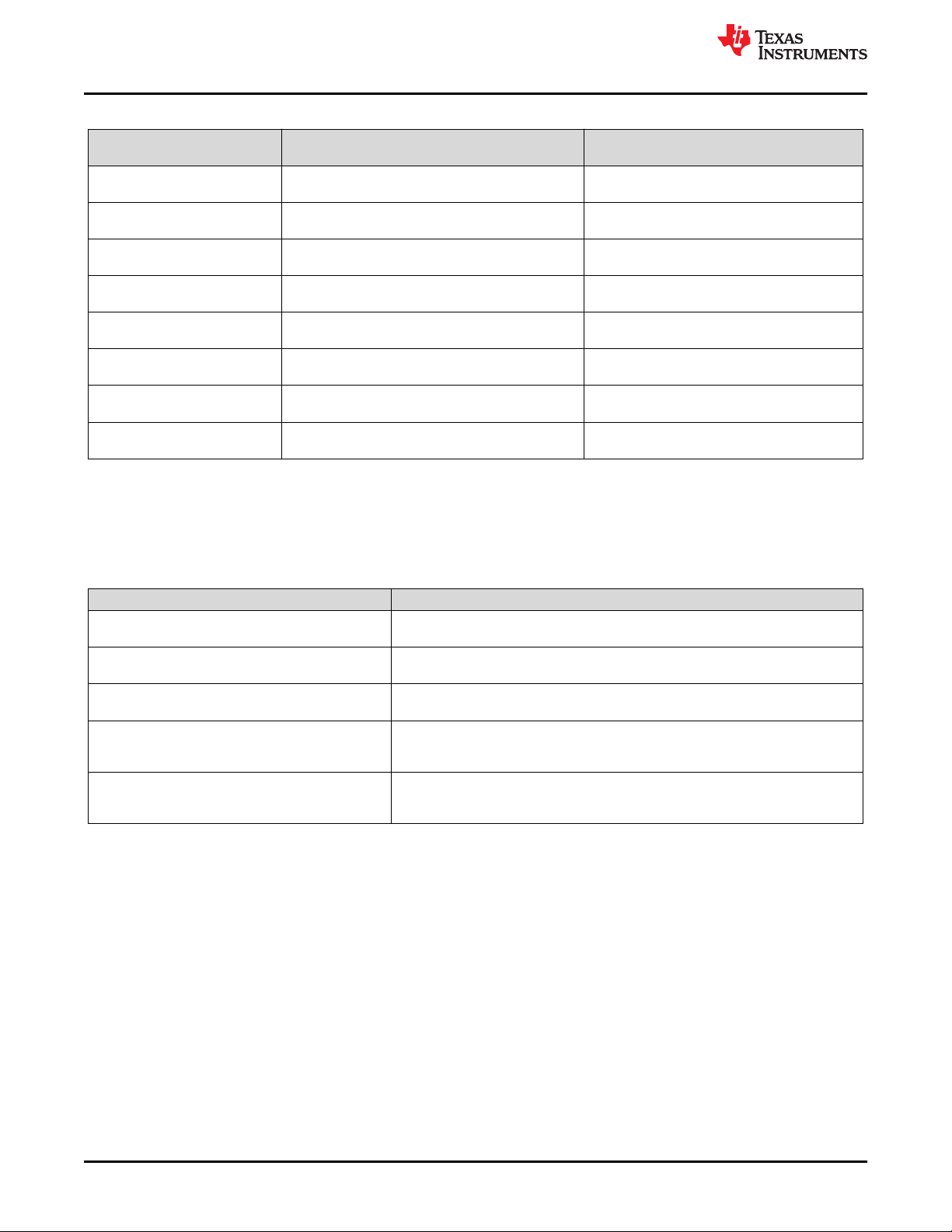

4.4.2.1 Safety Concept Implementation: Option 1

Figure 4-13. Safety Concept Implementation Option 1

www.ti.com

• Intended Function: can be implemented on both C28x and CLA.

• Safety Function: Implement on C28x or CLA.

– SPFM can be met by Reciprocal Comparison by Software

• Diagnostic Function: Implement on the other processing unit.

– LFM can be met by Software Test of CLA or Software Test of CPU

24 Safety Manual for TMS320F28004x SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 25

`

Power

Electronics

Ref

+

C28x

PFC

Actuation

Sensing

CLA

DC-DC

Actuation

Ref

+

Sensing

±

±

+

Power

Electronics

+

PPB

ADC

+

±

CMP

TRIP-PWM

ERRORSTS

C2000 Microcontroller

DAC

www.ti.com

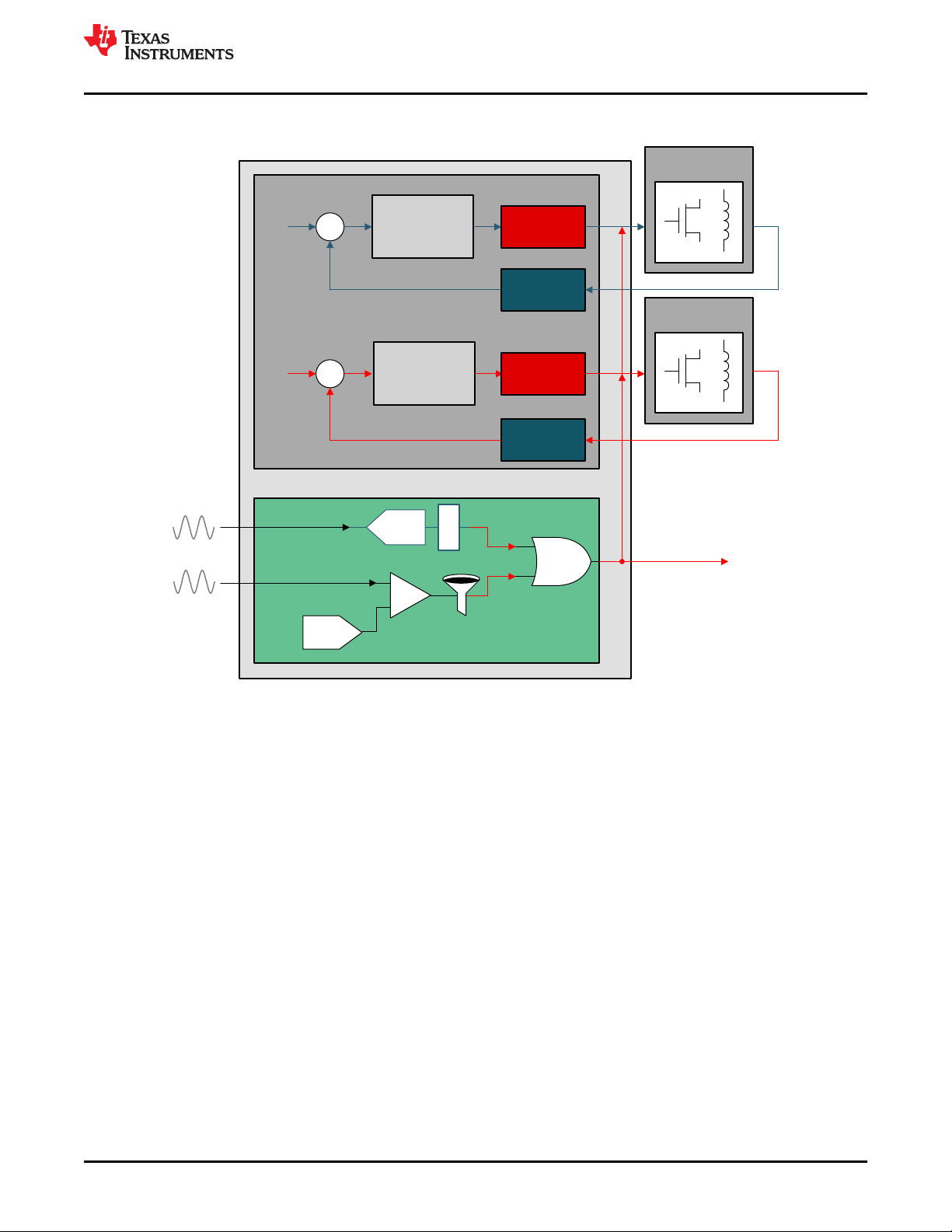

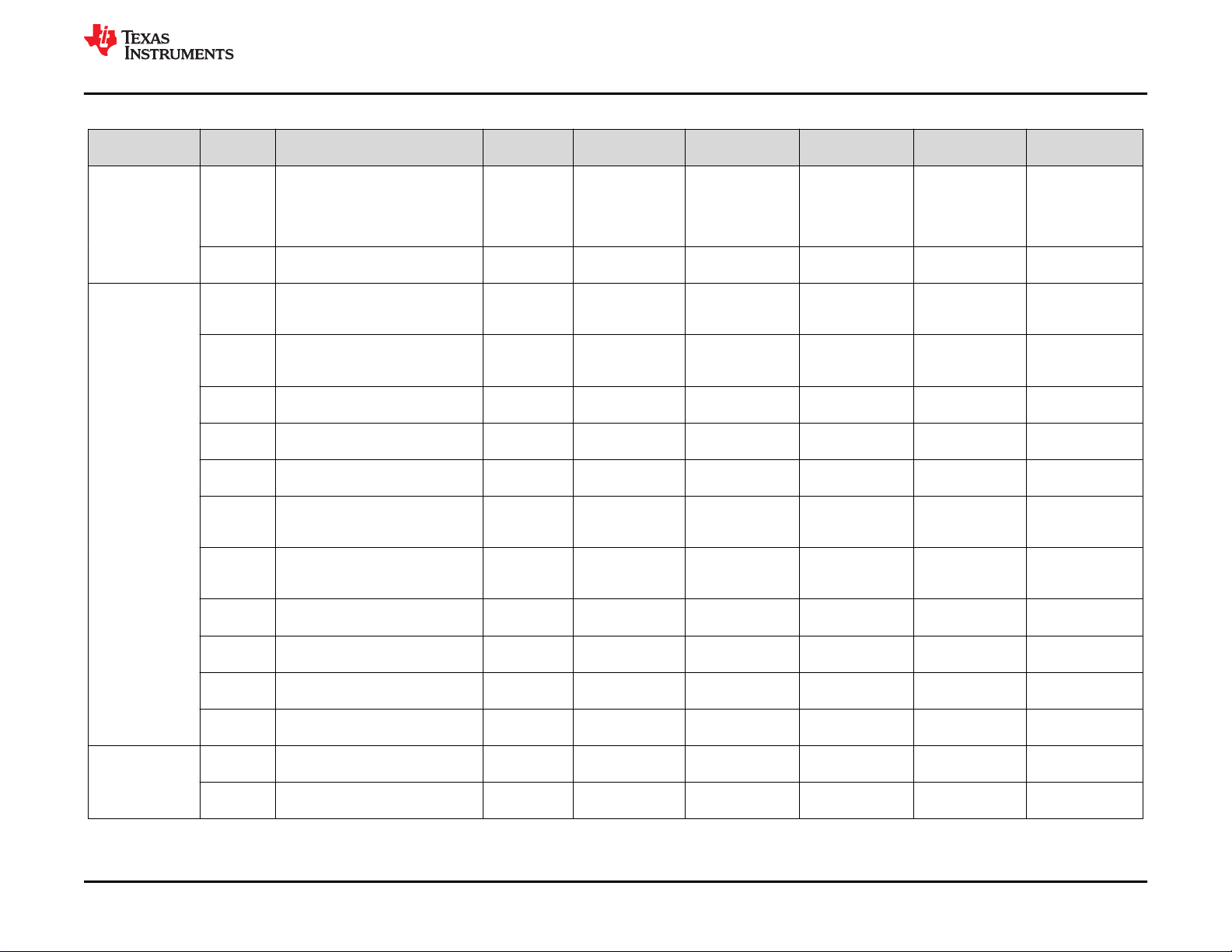

4.4.2.2 Safety Concept Implementation: Option 2

TMS320F28004x Product Overview

Figure 4-14. Safety Concept Implementation Option 2

• Intended Function: can be implemented on both C28x and CLA.

• Safety Function: Implement using hardware modules such as ADC-PPB, CMPSS, SDFM secondary filter,

CLB, and so forth.

– SPFM of the safety goal can be met by hardware redundancy between the modules used in implementing

safety function, Periodic Software Read Back of Static Configuration Registers and so forth.

• Diagnostic Function: Implement with hardware modules such as ADC-PPB, CMPSS, SDFM secondary filter,

CLB, and so forth

– LFM can be met by Software Test of Function Including Error Tests and so forth.

SPRUID8C – AUGUST 2019 – REVISED SEPTEMBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Safety Manual for TMS320F28004x 25

Page 26

D.2 E/E System

D.5 Digital I

D.7 Power Supply

D.5 Digital I

D.6 Bus

interface

D.4

Processing Unit

RAM

D.5 Digital 0

D.5 Analogue 0

D.3 Relay

ROM

D.8 Clock

D.2 E/E System

D.3

Harnesses

D.10

Actuator

D.3

Harnesses

D.10

Actuator

D.3

Harnesses

D.10

Actuator

D.3

Harnesses

D.9

Sensor

D.3

Harnesses

D.9

Sensor

Brief Description of Safety Elements

www.ti.com

5 Brief Description of Safety Elements

This section contains a brief description of the elements on the TMS320F28004x MCU device family, organized

based on the classification of parts of generic hardware of a system as indicated in Figure 5-1. For a full

functional description of any of these modules, see the device-specific technical reference manual. The brief

description of the hardware part is followed by the list of primary safety mechanisms that can be employed to

provide diagnostic coverage to the hardware part. Some safety standards have the requirement to provide

diagnostic coverage for the primary diagnostic measures (for example, Latent Fault Metric requirement from ISO

26262:2018). These measures are called as test of diagnostics. Primary diagnostics of type “Software” and

“Hardware/Software” involves execution of the software on the processing units and also use many of the MCU

parts like Interconnect, Memory (Flash, SRAM and ROM) and TMS320F28004x MCU infrastructure components

(Clock, Power, Reset and JTAG). In order to ensure integrity of the implemented primary diagnostics and their

associated diagnostic coverage values, measures to protect execution of primary diagnostics on respective

processing units needs to be implemented. Appropriate combination of test of diagnostics is recommended to be

implemented for parts of the MCU contributing the successful operation of the processing units. For diagnostics

for these parts, see the respective sections in this safety manual.

In case, separate test of diagnostic measures exist for a primary diagnostic measure, they are mentioned along

with the respective hardware part.

Figure 5-1. Generic Hardware of a System

5.1 TMS320F28004x MCU Infrastructure Components

5.1.1 Power Supply

The C2000 MCU device family requires an external device to supply the necessary voltage and current for

proper operation. Separate voltage rails are available for core (1.2 V), Analog (3.3 V), Flash (3.3 V) and I/O logic