Page 1

CHIP FORM

查询TL1454供应商

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

D

Two Complete PWM Control Circuits

D

Outputs Drive MOSFETs Directly

D

Oscillator Frequency...50 kHz to 2 MHz

D

3.6-V to 20-V Supply-Voltage Range

D

Low Supply Current...3.5 mA Typ

D

Adjustable Dead-Time Control, 0% to 100%

D

1.25-V Reference

description

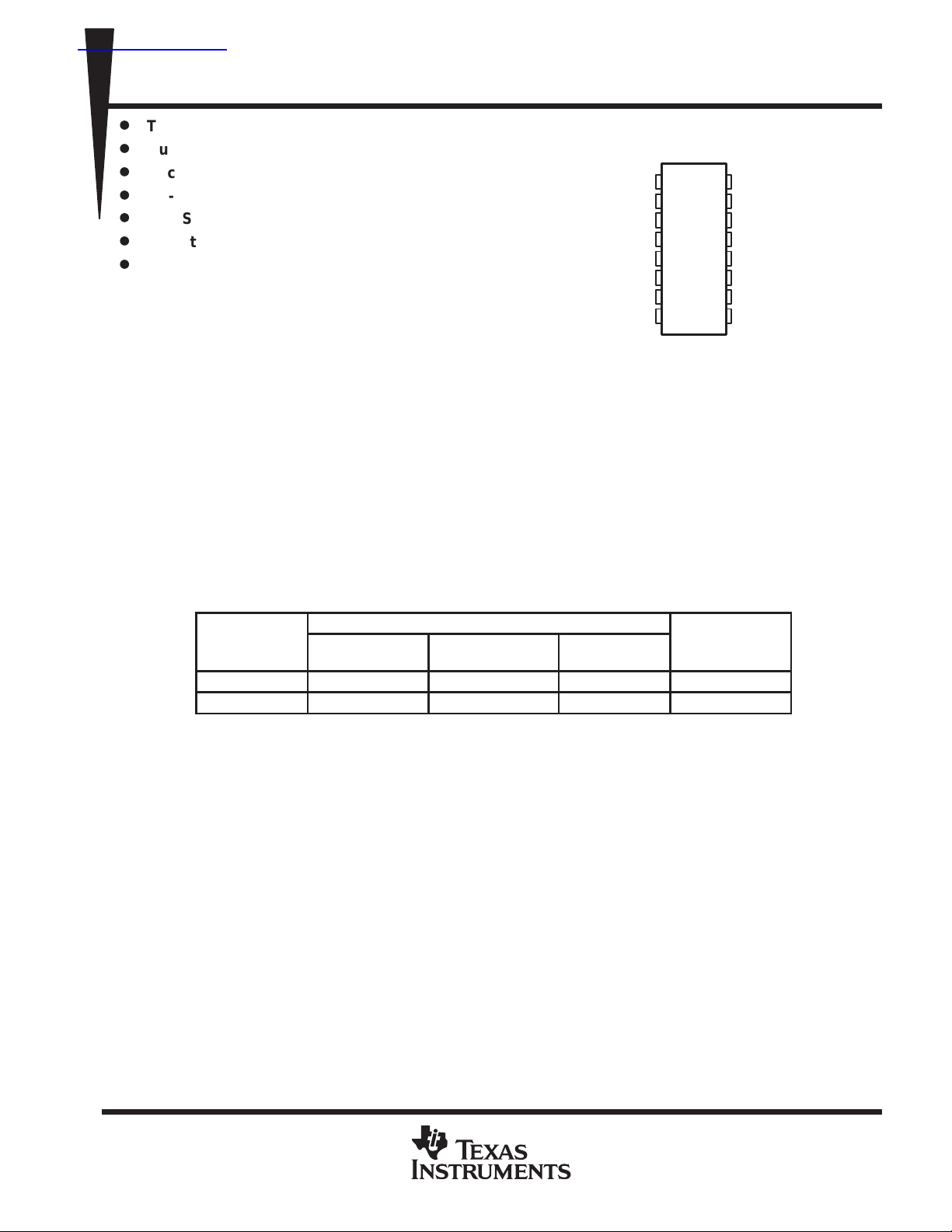

D, N OR PW PACKAGE

(TOP VIEW)

CT

1

RT

2

DTC1

IN1+

IN1–

COMP1

GND

OUT1

3

4

5

6

7

8

16

15

14

13

12

11

10

9

REF

SCP

DTC2

IN2+

IN2–

COMP2

V

CC

OUT2

The TL1454 is a dual-channel pulse-width-modulation (PWM) control circuit, primarily intended for

low-power, dc/dc converters. Applications include

LCD displays, backlight inverters, notebook computers, and other products requiring small, high-frequency , dc/dc converters. Each PWM channel has its own

error amplifier, PWM comparator, dead-time control comparator, and MOSFET driver. The voltage reference,

oscillator, undervoltage lockout, and short-circuit protection are common to both channels.

Channel 1 is configured to drive n-channel MOSFETs in step-up or flyback converters, and channel 2 is

configured to drive p-channel MOSFETs in step-down or inverting converters. The operating frequency is set

with an external resistor and an external capacitor, and dead time is continuously adjustable from 0 to 100%

duty cycle with a resistive divider network. Soft start can be implemented by adding a capacitor to the dead-time

control (DTC) network. The error-amplifier common-mode input range includes ground, which allows the

TL1454 to be used in ground-sensing battery chargers as well as voltage converters.

AVAILABLE OPTIONS

PACKAGED DEVICES

T

A

–20°C to 85°C TL1454CD TL1454CN TL1454CPWLE TL1454Y

–40°C to 85°C TL1454ID TL1454IN — —

†

The D package is available taped and reeled. Add the suffix R to the device name (e.g., TL1454CDR). The

PW package is available only left-end taped and reeled (indicated by the LE suffix on the device type; e.g.,

TL1454CPWLE).

SMALL OUTLINE

(D)

PLASTIC DIP

(N)

†

TSSOP

(PW)

(Y)

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Copyright 1997, Texas Instruments Incorporated

1

Page 2

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

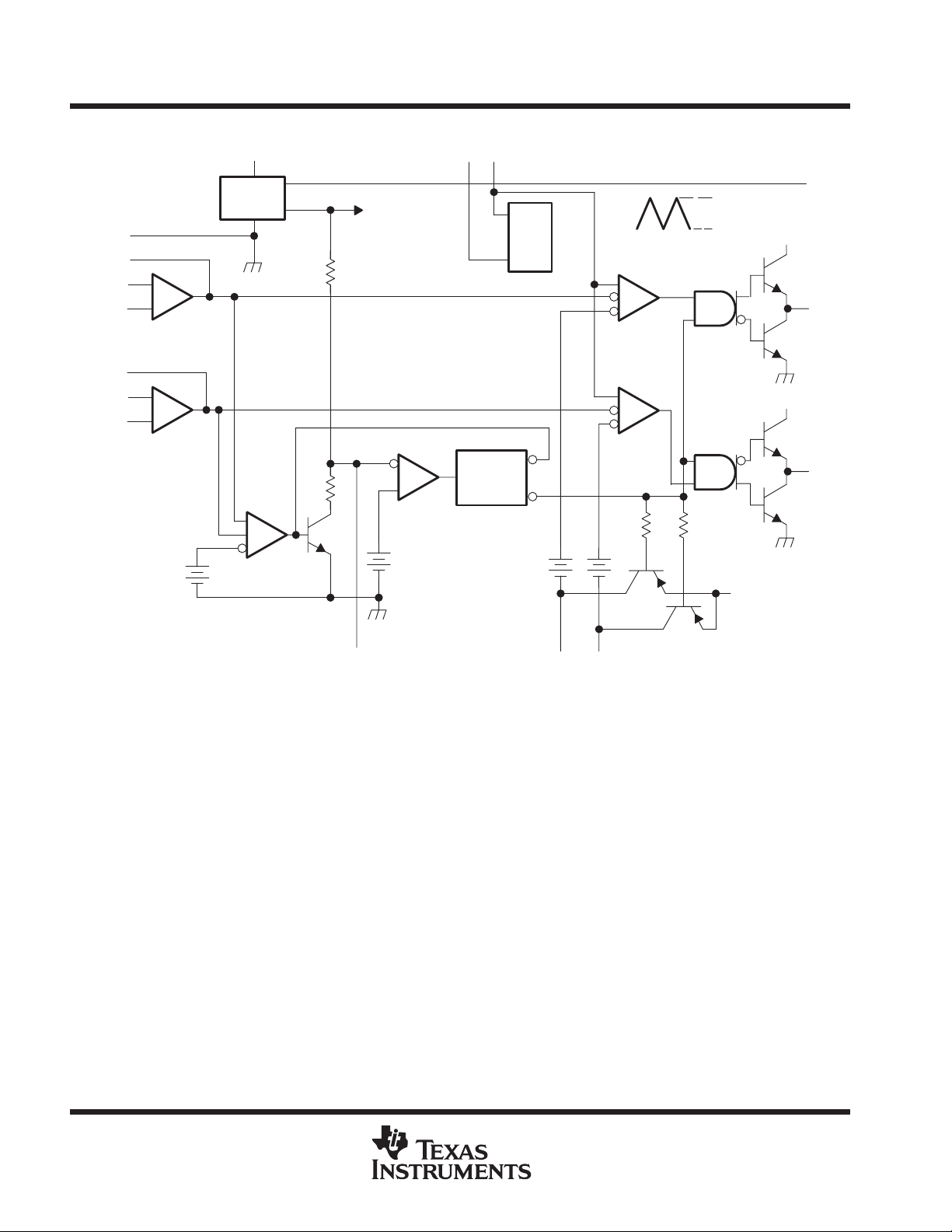

functional block diagram

GND

COMP1

IN1+

IN1–

COMP2

IN2+

IN2–

7

6

4

+

5

_

Error

Amplifier 1

11

13

+

12

_

Error

Amplifier 2

V

CC

10

Voltage

REF

1.25 V

2.5 V

To Internal

Circuitry

SCP

Comparator 2

CTRT

21

UVLO

and

SCP Latch

OSC

PWM

Comparator 1

PWM

Comparator 2

1.8 V

1.2 V

16

REF

V

CC

8

OUT1

V

CC

9

OUT2

1 V

SCP

Comparator 1

SCP

15

1 V

0.65 V

DTC1 DTC2

0.65 V

1.25 V

143

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 3

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

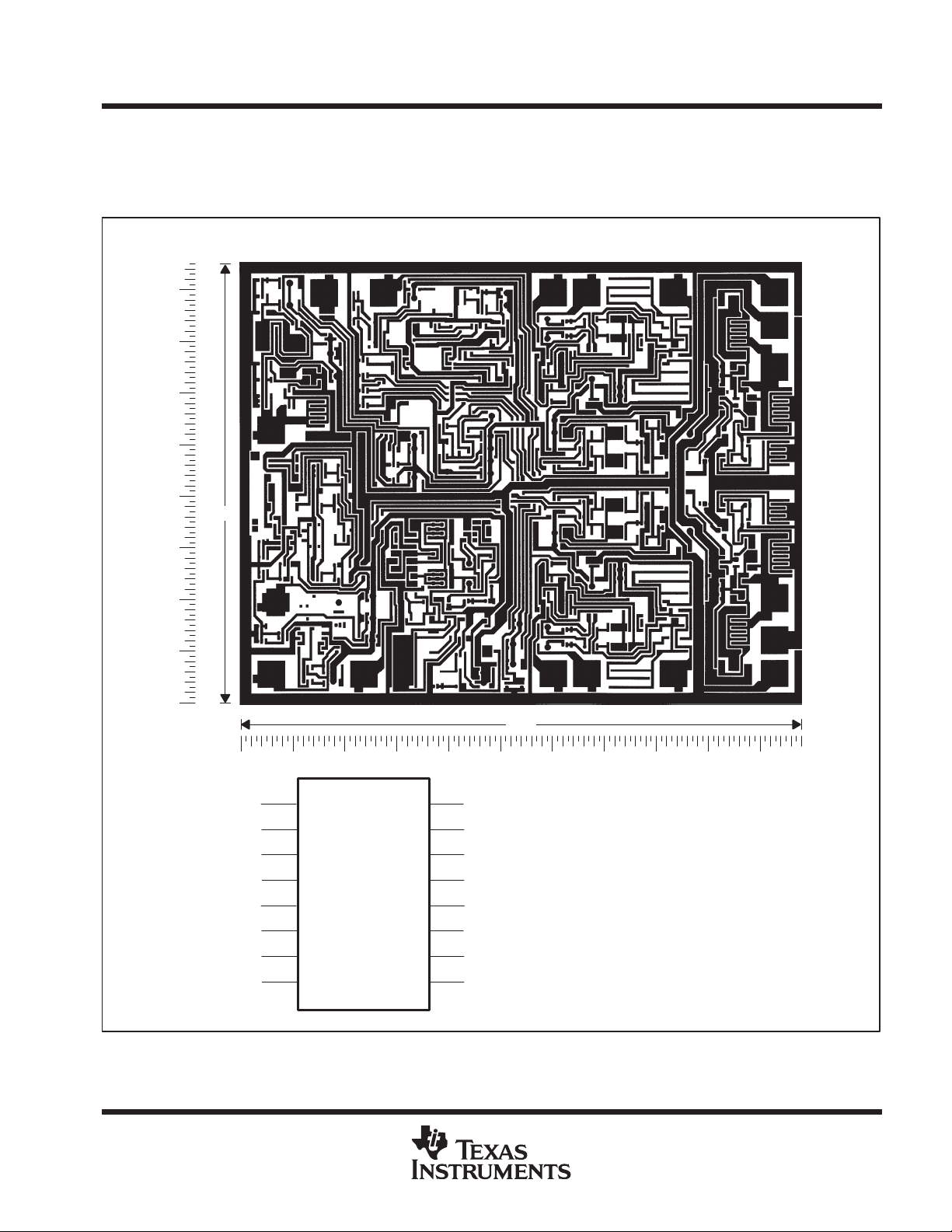

TL1454Y chip information

This chip, when properly assembled, displays characteristics similar to the TL1454C. Thermal compression or

ultrasonic bonding may be used on the doped aluminum bonding pads. The chips may be mounted with

conductive epoxy or a gold-silicon preform.

BONDING PAD ASSIGNMENTS

(16)

86

(1)

(2) (3)

(12)(13)(14)(15)

(4) (5) (6) (7)

108

(10)(11)

(9)

(8)

CT

RT

DTC1

IN1+

IN1–

COMP1

GND

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(16)

REF

(15)

SCP

(14)

DTC2

(13)

TL1454Y

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

IN2+

(12)

IN2–

(11)

COMP2

(10)

V

CC

(9)

OUT2OUT1

• HOUSTON, TEXAS 77251–1443

CHIP THICKNESS: 15 TYPICAL

BONDING PADS: 4 × 4 MINIMUM

TJmax = 150°C

TOLERANCES ARE ±10%.

ALL DIMENSIONS ARE IN MILS.

3

Page 4

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

theory of operation

reference voltage

A linear regulator operating from V

generates a 2.5-V supply for the internal circuits and the 1.25-V reference,

CC

which can source a maximum of 1 mA for external loads. A small ceramic capacitor (0.047 µF to 0.1 µF) between

REF and ground is recommended to minimize noise pickup.

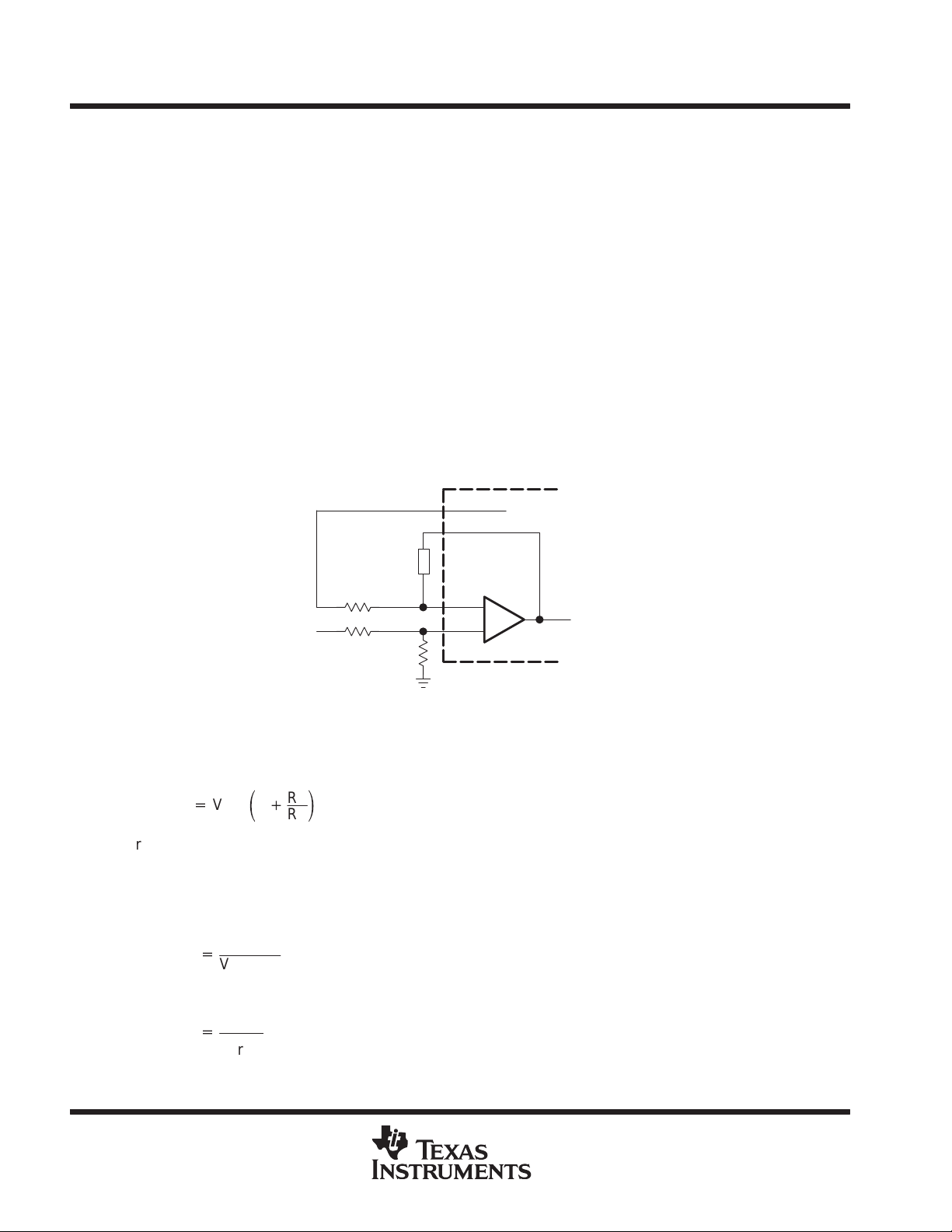

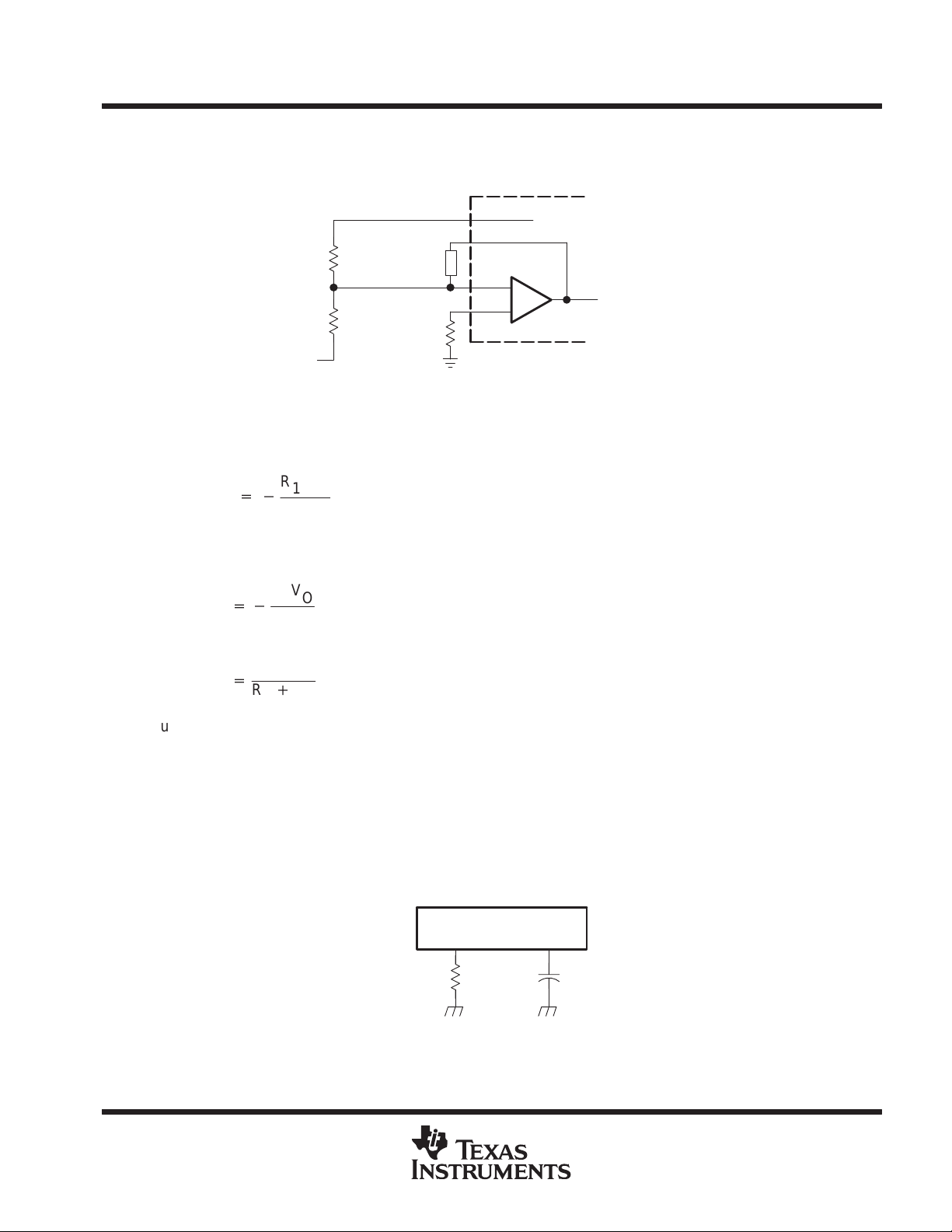

error amplifier

The error amplifier generates the error signal used by the PWM to adjust the power-switch duty cycle for the

desired converter output voltage. The signal is generated by comparing a sample of the output voltage to the

voltage reference and amplifying the difference. An external resistive divider connected between the converter

output and ground, as shown in Figure 1, is generally required to obtain the output voltage sample.

The amplifier output is brought out on COMP to allow the frequency response of the amplifier to be shaped with

an external RC network to stabilize the feedback loop of the converter. DC loading on the COMP output is limited

to 45 µA (the maximum amplifier source current capability).

Figure 1 illustrates the sense-divider network and error-amplifier connections for converters with positive output

voltages. The divider network is connected to the noninverting amplifier input because the PWM has a phase

inversion; the duty cycle decreases as the error-amplifier output increases.

_

+

TL1454

To PWM

Converter

Output

Compensation

V

O

Network

R3

R1

REF

COMP

IN–

IN+

R2

Figure 1. Sense Divider/Error Amplifier

Configuration for Converters with Positive Outputs

The output voltage is given by:

R1

where V

VO+

= 1.25 V.

ref

ǒ

V

1

ref

)

R2

Ǔ

The dc source resistance of the error-amplifier inputs should be 10 kΩ or less and approximately matched to

minimize output voltage errors caused by the input-bias current. A simple procedure for determining appropriate

values for the resistors is to choose a convenient value for R3 (10 kΩ or less) and calculate R1 and R2 using:

R3V

VO–V

R3V

V

ref

O

ref

O

R1+

R2+

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 5

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

error amplifier

R1 and R2 should be tight-tolerance (±1% or better) devices with low and/or matched temperature coefficients

to minimize output voltage errors. A device with a ±5% tolerance is suitable for R3.

REF

COMP

ref

Compensation

Network

R3

IN–

IN+

_

+

To PWM

R2

R1

Converter

Output

V

O

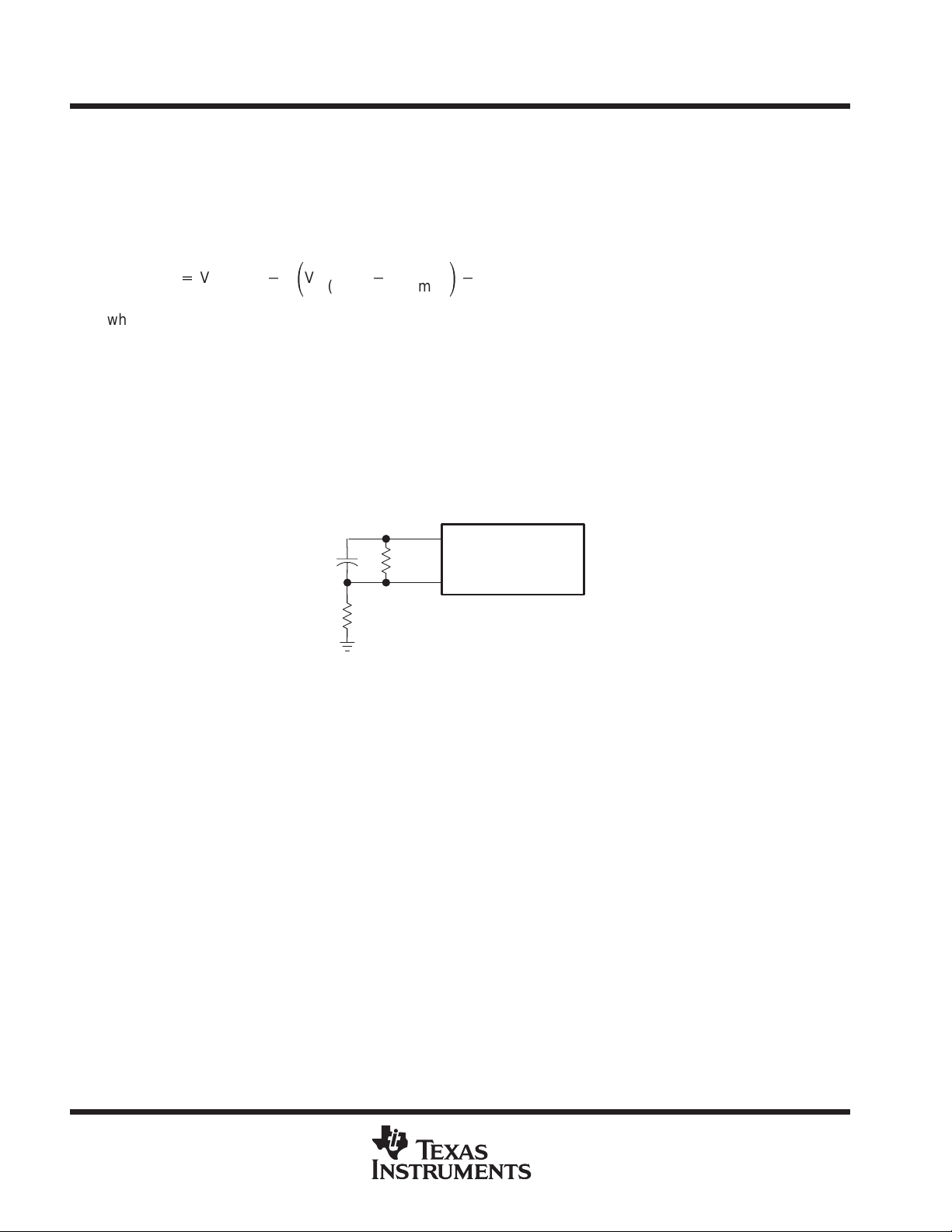

Figure 2. Sense Divider/Error Amplifier Configuration for Converters with Negative Outputs

Figure 2 shows the divider network and error-amplifier configuration for negative output voltages. In general,

the comments for positive output voltages also apply for negative outputs. The output voltage is given by:

R1V

VO+*

R

2

The design procedure for choosing the resistor value is to select a convenient value for R2 (instead of R3 in

the procedure for positive outputs) and calculate R1 and R3 using:

R2V

R1+*

R3+

R1)

V

R1R

ref

O

2

R

2

V alues in the 10-kΩ to 20-kΩ range work well for R2. R3 can be omitted and the noninverting amplifier connected

to ground in applications where the output voltage tolerance is not critical.

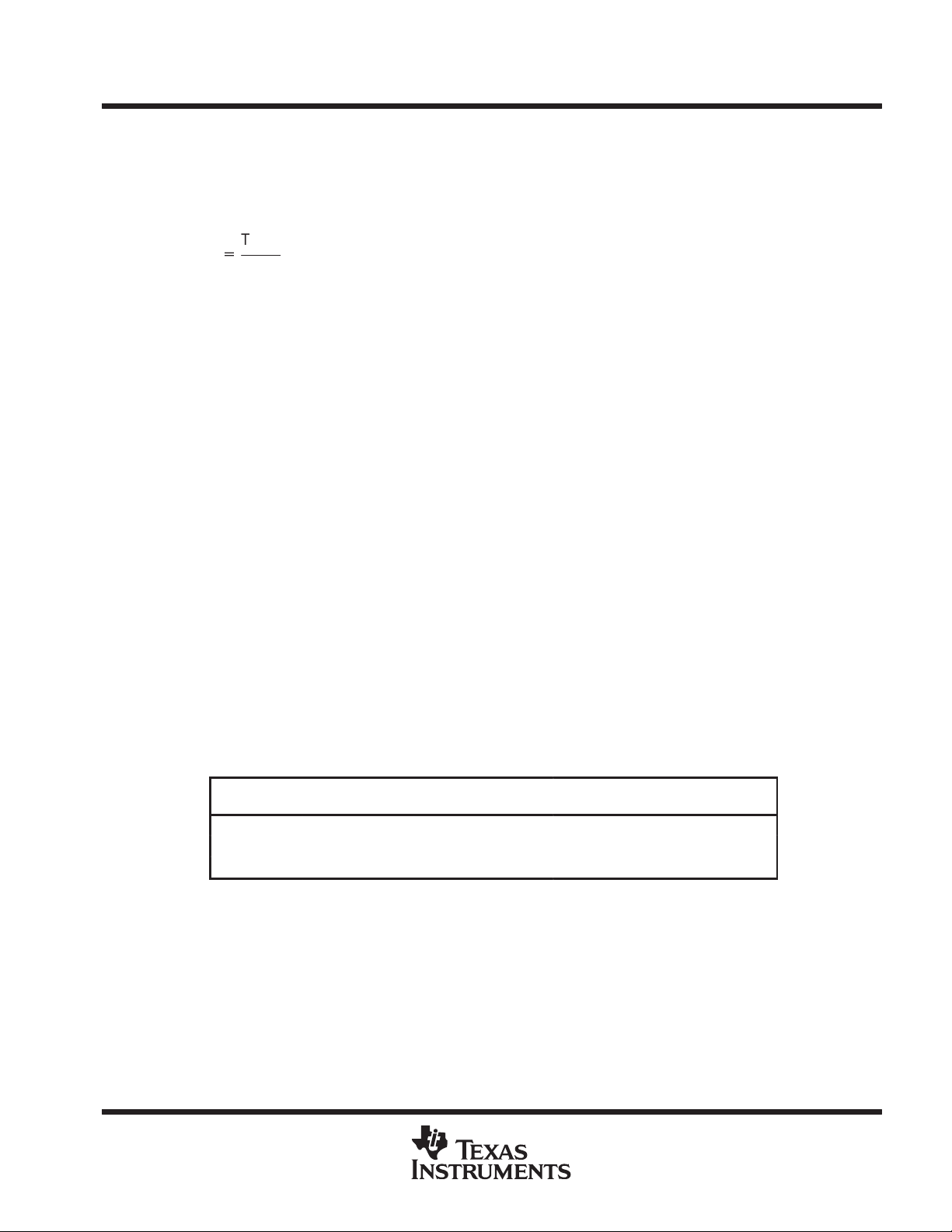

oscillator

The oscillator frequency can be set between 50 kHz and 2 MHz with a resistor connected between RT and GND

and a capacitor between CT and GND (see Figure 3). Figure 6 is used to determine R

and CT for the desired

T

operating frequency. Both components should be tight-tolerance, temperature-stable devices to minimize

frequency deviation. A 1% metal-film resistor is recommended for R

capacitor is recommended for C

.

T

TL1454

RT CT

21

R

T

C

T

, and a 10%, or better, NPO ceramic

T

Figure 3. Oscillator Timing

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

5

Page 6

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

dead-time control (DTC) and soft start

The two PWM channels have independent dead-time control inputs so that the maximum power-switch duty

cycles can be limited to less then 100%. The dead-time is set with a voltage applied to DTC; the voltage is

typically obtained from a resistive divider connected between the reference and ground as shown in Figure 4.

Soft start is implemented by adding a capacitor between REF and DTC.

The voltage, V

VDT+

where V

O(max)

, required to limit the duty cycle to a maximum value is given by:

DT

V

O(max)

and V

ǒ

V

*

D

O(max)

are obtained from Figure 9, and D is the maximum duty cycle.

O(min)

*

V

O(min)

Ǔ

*

0.65

Predicting the regulator startup or rise time is complicated because it depends on many variables, including:

input voltage, output voltage, filter values, converter topology , and operating frequency. In general, the output

will be in regulation within two time constants of the soft-start circuit. A five-to-ten millisecond time constant

usually works well for low-power converters.

The DTC input can be grounded in applications where achieving a 100% duty cycle is desirable, such as a buck

converter with a very low input-to-output differential voltage. However, grounding DTC prevents the

implementation of soft start, and the output voltage overshoot at power-on is likely to be very large. A better

arrangement is to omit R

cycle can reach 100% and still allows the designer to implement soft start using C

(see Figure 4) and choose R

DT1

16

R

DT2

R

DT1

C

SS

REF

DTC

= 47 kΩ. This configuration ensures that the duty

DT2

TL1454

SS

.

Figure 4. Dead-Time Control and Soft Start

PWM comparator

Each of the PWM comparators has dual inverting inputs. One inverting input is connected to the output of the

error amplifier; the other inverting input is connected to the DTC terminal. Under normal operating conditions,

when either the error-amplifier output or the dead-time control voltage is higher than that for the PWM triangle

wave, the output stage is set inactive (OUT1 low and OUT2 high), turning the external power stage off.

undervoltage-lockout (UVLO) protection

The undervoltage-lockout circuit turns the output circuit off and resets the SCP latch whenever the supply

voltage drops too low (to approximately 2.9 V) for proper operation. A hysteresis voltage of 200 mV eliminates

false triggering on noise and chattering.

short-circuit protection (SCP)

The TL1454 SCP function prevents damage to the power switches when the converter output is shorted to

ground. In normal operation, SCP comparator 1 clamps SCP to approximately 185 mV. When one of the

converter outputs is shorted, the error amplifier output (COMP) will be driven below 1 V to maximize duty cycle

and force the converter output back up. When the error amplifier output drops below 1 V, SCP comparator 1

releases SCP, and capacitor, C

error-amplifier output rises above 1 V before C

normal operation resumes. If C

, which is connected between SCP and GND, begins charging. If the

SCP

reaches 1 V , SCP comparator 2 turns on and sets the SCP latch, which turns

SCP

is charged to 1 V , SCP comparator 1 discharges C

SCP

off the output drives and resets the soft-start circuit. The latch remains set until the supply voltage is lowered

to 2 V or less, or C

is discharged externally.

SCP

SCP

and

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 7

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

short-circuit protection (SCP) (continued)

The SCP time-out period must be greater than the converter start-up time or the converter will not start. Because

high-value capacitor tolerances tend to be ±20% or more and IC resistor tolerances are loose as well, it is best

to choose an SCP time-out period 10-to-15 times greater than the converter startup time. The value of C

may be determined using Figure 6, or it can be calculated using:

T

SCP

+

C

SCP

80.3

SCP

where C

is in µF and T

SCP

is the time-out period in ms.

SCP

output stage

The output stage of the TL1454 is a totem-pole output with a maximum source/sink current rating of 40 mA and

a voltage rating of 20 V . The output is controlled by a complementary output AND gate and is turned on (sourcing

current for OUT1, sinking current for OUT2) when all the following conditions are met: 1) the oscillator triangle

wave voltage is higher than both the DTC voltage and the error-amplifier output voltage, 2) the

undervoltage-lockout circuit is inactive, and 3) the short-circuit protection circuit is inactive.

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

Supply voltage, V

Error amplifier input voltage: IN1+, IN1–, IN2+, IN2– 23 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output voltage: OUT1, OUT2 20 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous output current: OUT1, OUT2 ±200 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Peak output current: OUT1, OUT2 1 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

Storage temperature range, T

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: All voltage values are with respect to network GND.

(see Note 1) 23 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC

: C suffix –20°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

I suffix –40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

†

DISSIPATION RATING TABLE

PACKAGE

D 950 mW 7.6 mW/°C 608 mW 494 mW

N 1250 mW 10.0 mW/°C 800 mW 650 mW

PW 500 mW 4.0 mW/°C 320 mW 260 mW

TA ≤ 25°C

POWER RATING

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

DERATING FACTOR

ABOVE TA = 25°C

• HOUSTON, TEXAS 77251–1443

TA = 70°C

POWER RATING

POWER RATING

TA = 85°C

7

Page 8

TL1454, TL1454Y

Operating free-air temperature, T

°C

PARAMETER

TEST CONDITIONS

UNIT

V

Output voltage, REF

V

Output voltage change with temperature

mV

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

No pullup

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

recommended operating conditions

MIN MAX UNIT

Supply voltage, V

Error amplifier common-mode input voltage –0.2 1.45 V

Output voltage, V

Output current, I

COMP source current –45 µA

COMP sink current 100 µA

Reference output current 1 mA

COMP dc load resistance 100 kΩ

Timing capacitor , C

Timing resistor , R

Oscillator frequency 50 2000 kHz

p

CC

O

O

T

T

p

A

TL1454C –20 85

TL1454I –40 85

electrical characteristics over recommended operating free-air temperature range, VCC = 6 V,

= 500 kHz (unless otherwise noted)

f

osc

3.6 20 V

20 V

±40 mA

10 4000 pF

5.1 100 kΩ

°

reference

IO = 1 mA, TA = 25°C 1.23 1.25 1.28

IO = 1 mA 1.2 1.31

TA = T

TA = 25°C to 85°C, IO = 1 mA –12.5 –2.5 12.5

= 0 V 30 mA

ref

to 25°C, IO = 1 mA –12.5 –1.25 12.5

A(min)

I

ref

OS

p

Input regulation VOC = 3.6 V to 20 V, IO = 1 mA 2 6 mV

Output regulation IO = 0.1 mA to 1 mA 1 7.5 mV

p

Short-circuit output current V

p

undervoltage lockout (UVLO)

V

IT+

V

IT–

V

hys

Positive-going threshold voltage 2.9 V

Negative-going threshold voltage

Hysteresis, V

IT+

– V

IT–

TA = 25°C

short-circuit protection (SCP)

V

IT

†

V

stby

V

I(latched)

V

IT(COMP)

†

This symbol is not presently listed within EIA/JEDEC standards for semiconductor symbology.

Input threshold voltage TA = 25°C 0.95 1 1.05 V

Standby voltage

Latched-mode input voltage

Comparator threshold voltage COMP1, COMP2 1 V

Input source current TA = 25°C, V

p

p

O(SCP)

TL1454

MIN TYP MAX

TL1454

MIN TYP MAX

2.7 V

100 200 mV

TL1454

MIN TYP MAX

140 185 230 mV

60 120 mV

= 0 –5 –15 –20 µA

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 9

PARAMETER

TEST CONDITIONS

UNIT

Frequency change with temperature

kH

PARAMETER

TEST CONDITIONS

UNIT

VITInput threshold voltage

V

PARAMETER

TEST CONDITIONS

UNIT

V

PARAMETER

TEST CONDITIONS

UNIT

VOHHigh-level output voltage

V

VOLLow-level output voltage

V

C

2000 pF

T

25°C

ns

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

electrical characteristics over recommended operating free-air temperature range, VCC = 6 V,

= 500 kHz (unless otherwise noted) (continued)

f

osc

oscillator

TL1454

MIN TYP MAX

f

osc

dead-time control (DTC)

V

I(latched)

I

IB

Frequency CT = 120 pF, RT = 10 kΩ 500 kHz

Standard deviation of frequency 50 kHz

Frequency change with voltage VCC = 3.6 V to 20 V, TA = 25°C 5 kHz

p

Maximum ramp voltage 1.8 V

Minimum ramp voltage 1.1 V

p

Latched-mode input voltage 1.2 V

Common-mode input bias current DTC1, IN1+ ≈ 1.2 V 4 µA

Latched-mode (source) current TA = 25°C –100 µA

TA = T

TA = 25°C to 85°C –10 ±20

Duty cycle = 0% 1 1.1 1.2

Duty cycle = 100% 0.4 0.5 0.6

to 25°C –2 ±20

A(min)

MIN TYP MAX

TL1454

z

error-amplifier

TL1454

MIN TYP MAX

V

IO

I

IO

I

IB

V

ICR

A

V

CMRR Common-mode rejection ratio 60 80 dB

V

OM(max)

V

OM(min)

I

O+

I

O–

Input offset voltage 6 mV

Input offset current

Input bias current –160 –500 nA

Input voltage range VCC = 3.6 V to 20 V –0.2 to 1.40 V

Open-loop voltage gain RFB = 200 kΩ 70 80 dB

Unity-gain bandwidth 3 MHz

Positive output voltage swing 2.3 2.43

Negative output voltage swing 0.63 0.8

Output sink current VID = –0.1 V, VO = 1.20 V 0.1 0.5 mA

Output source current VID = 0.1 V, VO = 1.80 V –45 –70 µA

VO = 1.25 V, VIC = 1.25 V

100 nA

output

TL1454

MIN TYP MAX

p

p

t

rv

t

fv

Output voltage rise time

Output voltage fall time

IO = –8 mA VCC–2 4.5

IO = –40 mA VCC–2 4.4

IO = 8 mA 0.1 0.4

IO = 40 mA 1.8 2.5

p

=

L

,

°

=

A

220

220

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

9

Page 10

TL1454, TL1454Y

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

Output voltage change with temperature

mV

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

No pullup

PARAMETER

TEST CONDITIONS

UNIT

Frequency change with temperature

kH

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

electrical characteristics over recommended operating free-air temperature range, VCC = 6 V,

= 500 kHz (unless otherwise noted) (continued)

f

osc

supply current

TL1454

MIN TYP MAX

I

CC(stby)

I

CC(average)

Standby supply current

Average supply current

RT open, CT = 1.5 V, No load,

VO (COMP1, COMP2) = 1.25 V,

RT = 10 kΩ,

50% duty cycle,

CT = 120 pF,

Outputs open

3.1 6 mA

3.5 7 mA

electrical characteristics, VCC = 6 V, f

= 500 kHz, TA = 25°C (unless otherwise noted)

osc

reference

V

I

ref

OS

Output voltage, REF IO = 1 mA, 1.25 V

Input regulation VOC = 3.6 V to 20 V, IO = 1 mA 2 mV

Output regulation IO = 0.1 mA to 1 mA 1 mV

p

Short-circuit output current V

p

IO = 1 mA –1.25

IO = 1 mA –2.5

= 0 V 30 mA

ref

undervoltage lockout (UVLO)

V

IT+

V

IT–

V

hys

Positive-going threshold voltage 2.9 V

Negative-going threshold voltage 2.7 V

Hysteresis, V

IT+

– V

IT–

short-circuit protection (SCP)

V

IT

†

V

stby

V

I(latched)

V

IT(COMP)

†

This symbol is not presently listed within EIA/JEDEC standards for semiconductor symbology.

Input threshold voltage 1 V

Standby voltage

Latched-mode input voltage

Comparator threshold voltage COMP1, COMP2 1 V

Input source current V

p

p

= 0 –15 µA

O(SCP)

TL1454Y

MIN TYP MAX

TL1454Y

MIN TYP MAX

200 mV

TL1454Y

MIN TYP MAX

185 mV

60 mV

oscillator

f

osc

10

Frequency CT = 120 pF, RT = 10 kΩ 500 kHz

Standard deviation of frequency 50 kHz

Frequency change with voltage VCC = 3.6 V to 20 V 5 kHz

Maximum ramp voltage 1.8 V

Minimum ramp voltage 1.1 V

p

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

TL1454Y

MIN TYP MAX

–2

–10

z

Page 11

PARAMETER

TEST CONDITIONS

UNIT

VITInput threshold voltage

V

PARAMETER

TEST CONDITIONS

UNIT

V

PARAMETER

TEST CONDITIONS

UNIT

VOHHigh-level output voltage

V

VOLLow-level output voltage

V

C

2000 pF

ns

PARAMETER

TEST CONDITIONS

UNIT

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

electrical characteristics, VCC = 6 V , f

= 500 kHz, TA = 25°C (unless otherwise noted) (continued)

osc

dead-time control (DTC)

TL1454Y

MIN TYP MAX

Duty cycle = 0% 1.1

Duty cycle = 100% 0.5

V

I(latched)

p

Latched-mode input voltage 1.2 V

Latched-mode (source) current –100 µA

error-amplifier

TL1454Y

MIN TYP MAX

I

IB

A

V

CMRR Common-mode rejection ratio 80 dB

V

OM(max)

V

OM(min)

I

O+

I

O–

Input bias current VO = 1.25 V, VIC = 1.25 V –160 nA

Open-loop voltage gain RFB = 200 kΩ 80 dB

Unity-gain bandwidth 3 MHz

Positive output voltage swing 2.43

Negative output voltage swing 0.63

Output sink current VID = –0.1 V, VO = 1.20 V 0.5 mA

Output source current VID = 0.1 V, VO = 1.80 V –70 µA

output

TL1454Y

MIN TYP MAX

p

p

t

rv

t

fv

Output voltage rise time

Output voltage fall time

IO = –8 mA 4.5

IO = –40 mA 4.4

IO = 8 mA 0.1

IO = 40 mA 1.8

p

=

L

220

220

supply current

I

CC(stby)

I

CC(average)

Standby supply current

Average supply current

RT open, CT = 1.5 V, No load,

VO (COMP1, COMP2) = 1.25 V,

RT = 10 kΩ,

50% duty cycle,

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

CT = 120 pF,

Outputs open

TL1454Y

MIN TYP MAX

3.1 mA

3.5 mA

11

Page 12

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

PARAMETER MEASUREMENT INFORMATION

Oscillator

COMP

DTC

SCP Reference

OUT1

OUT2

SCP Comparator

Output

SCP

V

CC

2.9-V Typical

Lockout threshold

1.8 V

1.2 V

1 V

H

Dead-Time 100%

L

H

Dead-Time 100%

L

H

L

2.5 V

1 V

0 V

(tpe)

0 V

Figure 5. Timing Diagram

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 13

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

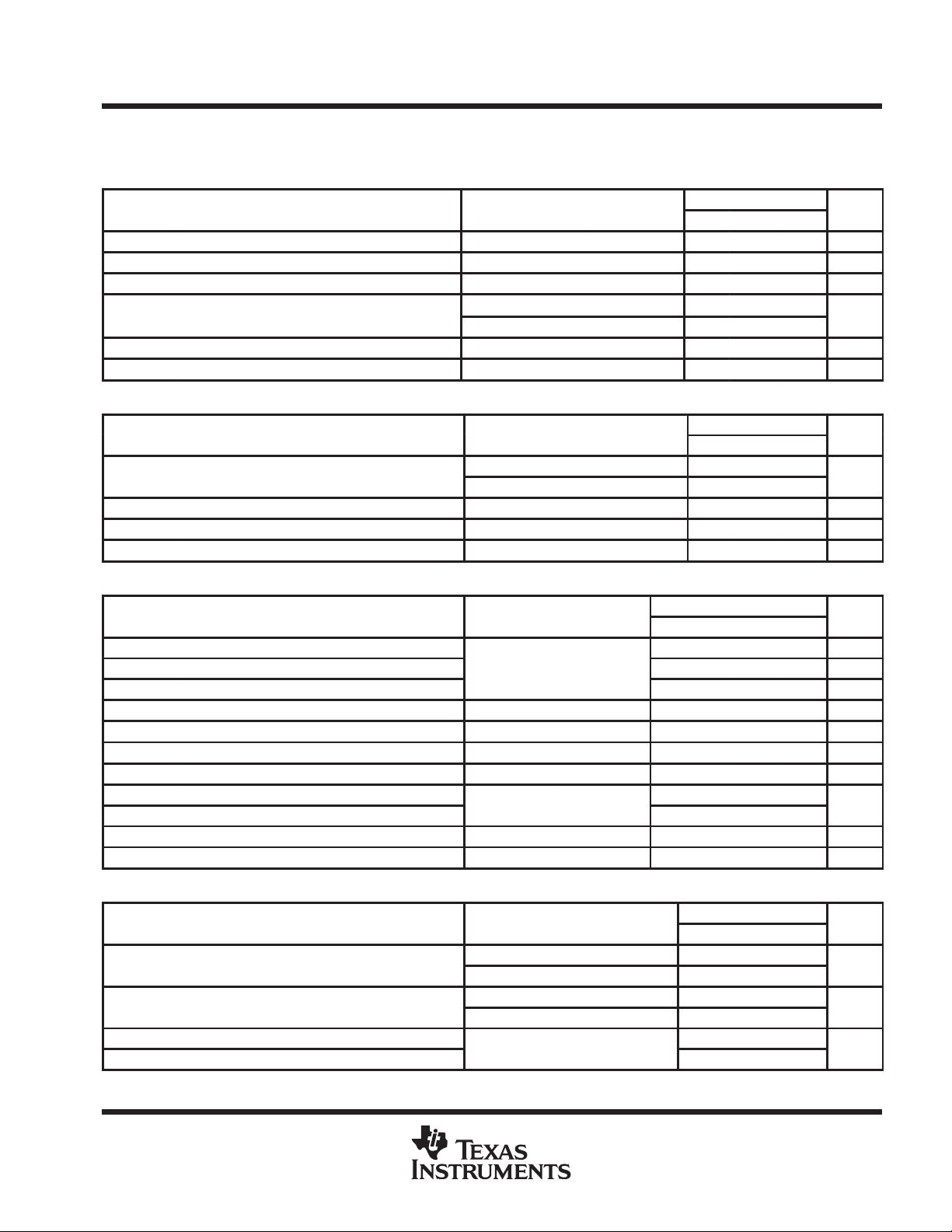

TYPICAL CHARACTERISTICS

OSCILLATOR FREQUENCY

vs

TIMING RESISTANCE

10 M

100 k

f – Oscillator Frequency – Hz

VCC = 6 V

TA = 25°C

1 M

CT = 300 pF

CT = 1000 pF

10 k

1 k

1 k 10 k 100 k

CT = 3900 pF

RT – Timing Resistance – Ω

CT = 10 pF

CT = 120 pF

Figure 6

OSCILLATOR PERIOD

2

10

VCC = 6 V

RT = 5.1 kΩ

TA = 25°C

sµ

1

10

0

10

t – Oscillation Period –

–1

10

0

10

TIMING CAPACITANCE

1

10

CT – Timing Capacitance – pF

vs

2

10

Figure 7

10

3

10

4

10

5

OSCILLATOR FREQUENCY

vs

FREE-AIR TEMPERATURE

530

VCC = 6 V

RT = 10 kΩ

CT = 120 pF

520

510

500

– Oscillator Frequency – kHz

490

osc

f

480

–50 0 50 100

TA – Free-Air Temperature – ° C

Figure 8

PWM TRIANGLE WAVEFORM AMPLITUDE

2

1.9

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1

0.9

0.8

VCC = 6 V

0.7

PWM Triangle W aveform Amplitude – V

0.6

0.5

10

RT = 5.1 kΩ

TA = 25°C

0

vs

TIMING CAPACITANCE

V

O(max)

V

O(min)

1

10

Timing Capacitance – pF

10

2

Figure 9

10

3

10

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

13

Page 14

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

TYPICAL CHARACTERISTICS

1.4

1.2

1

0.8

0.6

DTC Input Threshold Voltage – V

0.4

–50

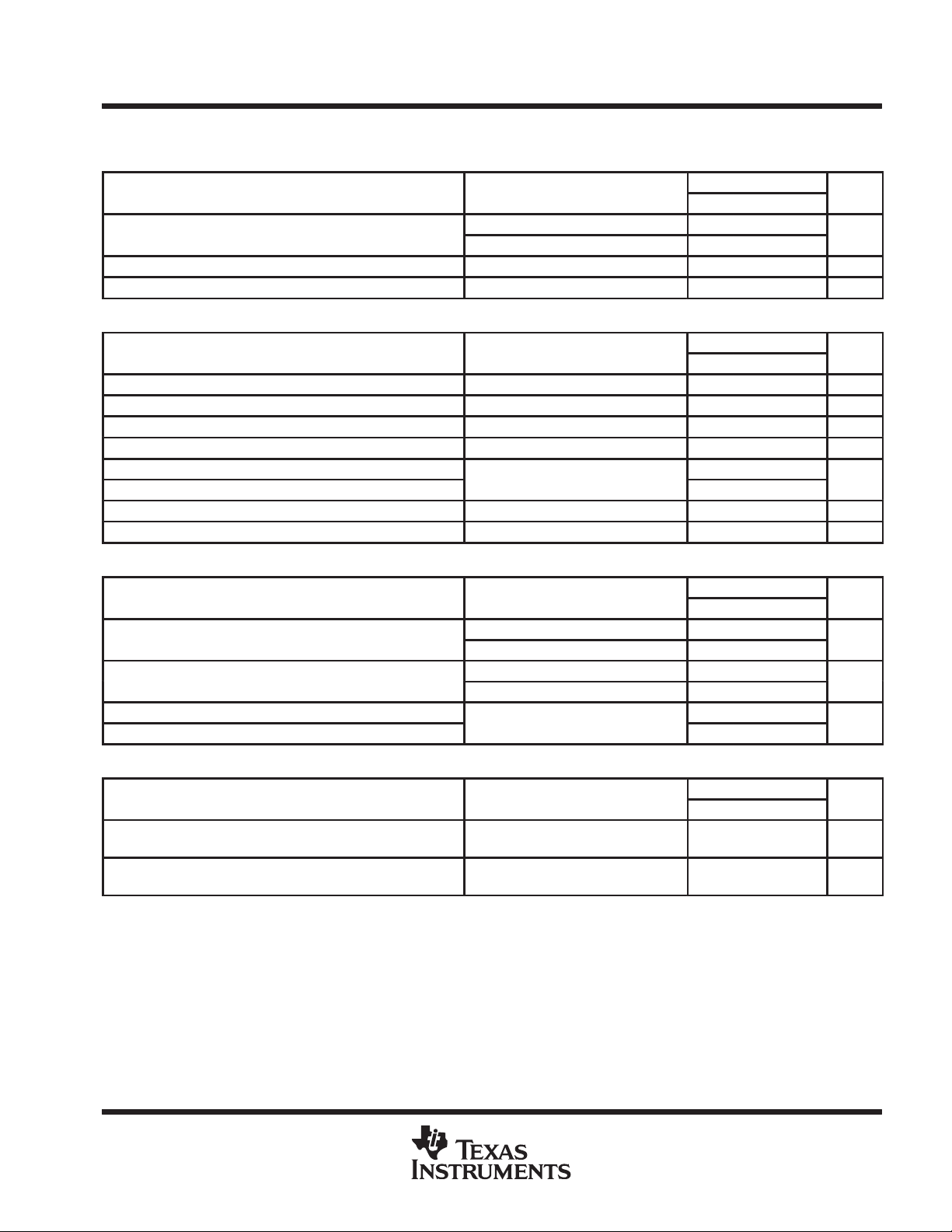

DTC INPUT THRESHOLD VOLTAGE

vs

FREE-AIR TEMPERATURE

VCC = 6 V

RT = 5.1 kΩ

CT = 1000 pF

VIT (0% Duty Cycle)

VIT (100% Duty Cycle)

0 50 100

TA – Free-Air Temperature – ° C

Figure 10

SCP TIME-OUT PERIOD

SCP CAPACITANCE

2

VCC = 6 V

TA = 25°C

1.5

1

0.5

– SCP Time-Out Period – s

SCP

t

0

0 5 10 15

SCP Capacitance – µF

vs

20 25

Figure 11

1.04

1.02

1

0.98

– SCP Threshold Voltage – V

IT

0.96

V

0.94

–50

SCP THRESHOLD VOLTAGE

vs

FREE-AIR TEMPERATURE

VCC = 6 V

0 50 100

TA – Free-Air Temperature – ° C

Figure 12

3.5

3

2.5

2

– SCP Latch Reset Voltage – V

1.5

I(reset)

V

1

SCP LATCH RESET VOLTAGE

vs

FREE-AIR TEMPERATURE

VCC = 6 V

–25 0 25 50 75 100–50

TA – Free-Air Temperature – ° C

Figure 13

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 15

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

TYPICAL CHARACTERISTICS

3.5

3

2.5

2

– UVLO Threshold Voltage – V

IT(L)

V

1.5

IT(H)

V

1

–50

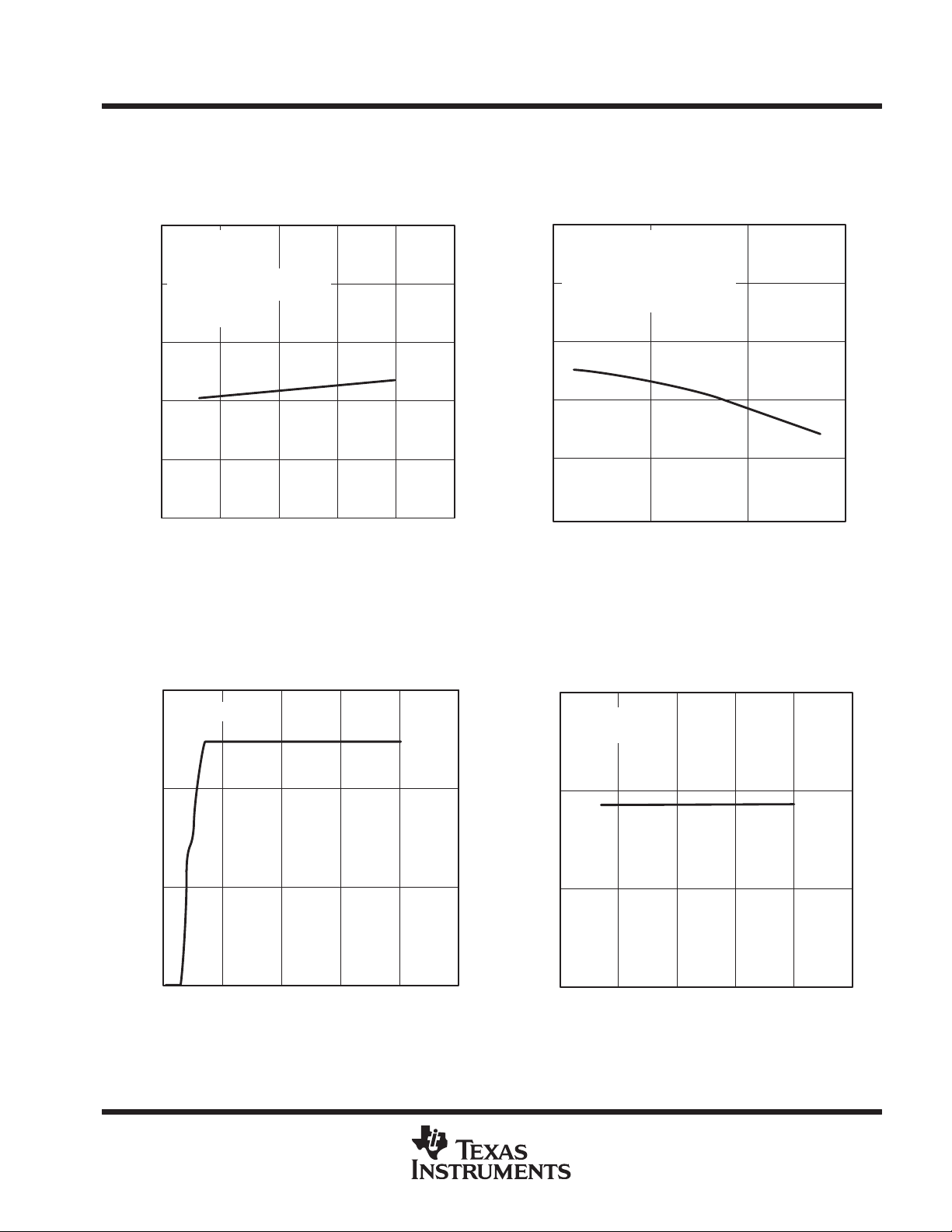

UVLO THRESHOLD VOLTAGE

vs

FREE-AIR TEMPERATURE

V

IT(H)

V

IL(L)

–25 0 25 50 75 100

TA – Free-Air Temperature – ° C

Figure 14

120

100

80

60

Duty Cycle – %

40

20

0

0

DUTY CYCLE

DTC INPUT VOLTAGE

0.25

V

I(DTC)

0.5

– DTC Input Voltage – V

Figure 15

vs

0.75

VCC = 6 V

CT = 120 pF

RT = 10 kΩ

TA = 25°C

1.25

1

1.5

ERROR-AMPLIFIER MAXIMUM OUTPUT VOLTAGE

vs

SOURCE CURRENT

2.5

2

1.5

1

0.5

– Error-Amplifier Maximum Output Voltage – V

0

OM +

V

04080

Source Current – µA

VCC = 6 V

VID = 0.1 V

TA = 25°C

Figure 16 Figure 17

120

ERROR-AMPLIFIER MINIMUM OUTPUT VOLTAGE

vs

SINK CURRENT

2.5

VCC = 6 V

VID = 0.1 V

2

1.5

1

0.5

– Error-Amplifier Minimum Output Voltage – V

0

OM –

0 0.5 1 1.5

V

Sink Current – mA

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

15

Page 16

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

TYPICAL CHARACTERISTICS

ERROR AMPLIFIER MAXIMUM

PEAK-TO-PEAK OUTPUT VOLTAGE SWING

vs

FREQUENCY

2.5

VCC = 6 V

TA = 25°C

2

1.5

1

Output Voltage Swing – V

0.5

– Error Amplifier Maximum Peak-to-Peak

O(PP)

V

0

1 k 10 k 100 k 1M 10 M 100 M

f – Frequency – Hz

Figure 18

ERROR-AMPLIFIER MINIMUM OUTPUT

0.8

VCC = 6 V

No Load

Amplifier 1

0.7

0.6

0.5

0.4

– Error-Ampplifier Minimum Output Voltage Swing – V

0.3

OM+

V

VOLTAGE SWING

vs

FREE-AIR TEMPERATURE

–25 0 25 50 75 100–50

TA – Free-Air Temperature – ° C

Figure 19

ERROR AMPLIFIER OPEN-LOOP GAIN AND PHASE SHIFT

vs

FREQUENCY

80

VCC = 6 V

TA = 25°C

60

40

Phase Shift

20

0

Error Amplifier Open-Loop Gain – dB

–20

100 1 k 10 k 100 k 1M 10 M

Gain

f – Frequency – Hz

–0°

–36°

–72°

–108°

–144°

–180°

Figure 20

Phase Shift

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 17

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

TYPICAL CHARACTERISTICS

ERROR-AMPLIFIER POSITIVE OUTPUT

VOLTAGE SWING

vs

FREE-AIR TEMPERATURE

2.5

VCC = 6 V

No Load

Amplifier 1

2.45

2.4

6

5

4

3

– High-Level Output Voltage – V

2

OH

V

– Error-Ampplifier Positive Output Voltage Swing – V

OM+

V

2.35

–25 0 25 50 75 100–50

HIGH-LEVEL OUTPUT VOLTAGE

vs

OUTPUT CURRENT

VCC = 6 V

TA = 25°C

T

– Free-Air Temperature – ° C

Figure 21

5.5

4.5

– High-Level Output Voltage – V

3.5

OH

V

HIGH-LEVEL OUTPUT VOLTAGE

vs

FREE-AIR TEMPERATURE

VCC = 6 V

5

IO = 8 mA

IO = 40 mA

4

1

020406080

I

– Output Current – mA

O

Figure 22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

3

–25 0 25 50 75 100–50

TA – Free-Air Temperature – ° C

Figure 23

17

Page 18

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

TYPICAL CHARACTERISTICS

LOW-LEVEL OUTPUT VOLTAGE

vs

LOW-LEVEL OUTPUT CURRENT

6

VCC = 6 V

TA = 25°C

5

4

3

– Low-Level Output Voltage – V

2

OL

V

1

020406080

I

– Low-Level Output Current – mA

OL

Figure 24

250

VCC = 6 V

IO = 8 mA

200

150

100

– Low-Level Output Voltage – mV

50

OL

V

0

LOW-LEVEL OUTPUT VOLTAGE

vs

FREE-AIR TEMPERATURE

–25 0 25 50 75 100–50

TA – Free-Air Temperature – ° C

Figure 25

3

2.5

2

1.5

– Low-Level Output Voltage – V

1

OL

V

0.5

LOW-LEVEL OUTPUT VOLTAGE

vs

FREE-AIR TEMPERATURE

VCC = 6 V

IO = 40 mA

–25 0 25 50 75 100–50

TA – Free-Air Temperature – ° C

Figure 26

AVERAGE SUPPLY CURRENT

vs

FREE-AIR TEMPERATURE

6

VCC = 6 V

RT = 10 kΩ

CT = 1.5 V

5

COMP1, COMP2 = 1.25 V

No Load

4

3

– Average Supply Current – mA

2

CC(a)

I

1

–50 –25 0 25 50 75

TA – Free-Air Temperature – ° C

Figure 27

100

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 19

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

TYPICAL CHARACTERISTICS

STANDBY SUPPLY CURRENT

vs

SUPPLY VOLTAGE

6

VCC = 6 V

RT = Open

CT = 1.5 V

5

COMP1, COMP2 = 1.25 V

No Load

TA = 25°C

4

3

– Standby Supply Current – mA

2

CC(stby)

I

1

0 5 10 15 20 25

VCC – Supply Voltage – V

Figure 28

STANDBY SUPPLY CURRENT

FREE-AIR TEMPERATURE

6

VCC = 6 V

CT = 1.5 V

RT = Open

5

COMP1, COMP2 = 1.25 V

No Load

4

3

– Standby Supply Current – mA

2

CC(stby)

I

1

– 50 0 50

TA – Free-Air Temperature – ° C

Figure 29

vs

100

REFERENCE VOLTAGE

vs

SUPPLY VOLTAGE

1.5

TA = 25°C

1

0.5

– Reference Voltage – V

ref

V

0

0 5 10 15 20 25

VCC – Supply Voltage – V

Figure 30

REFERENCE VOLTAGE

vs

SUPPLY VOLTAGE

1.26

IO = 1mA

TA = 25°C

1.25

1.24

– Reference Voltage – V

ref

V

1.23

0 5 10 15 20 25

VCC – Supply Voltage – V

Figure 31

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

19

Page 20

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

TYPICAL CHARACTERISTICS

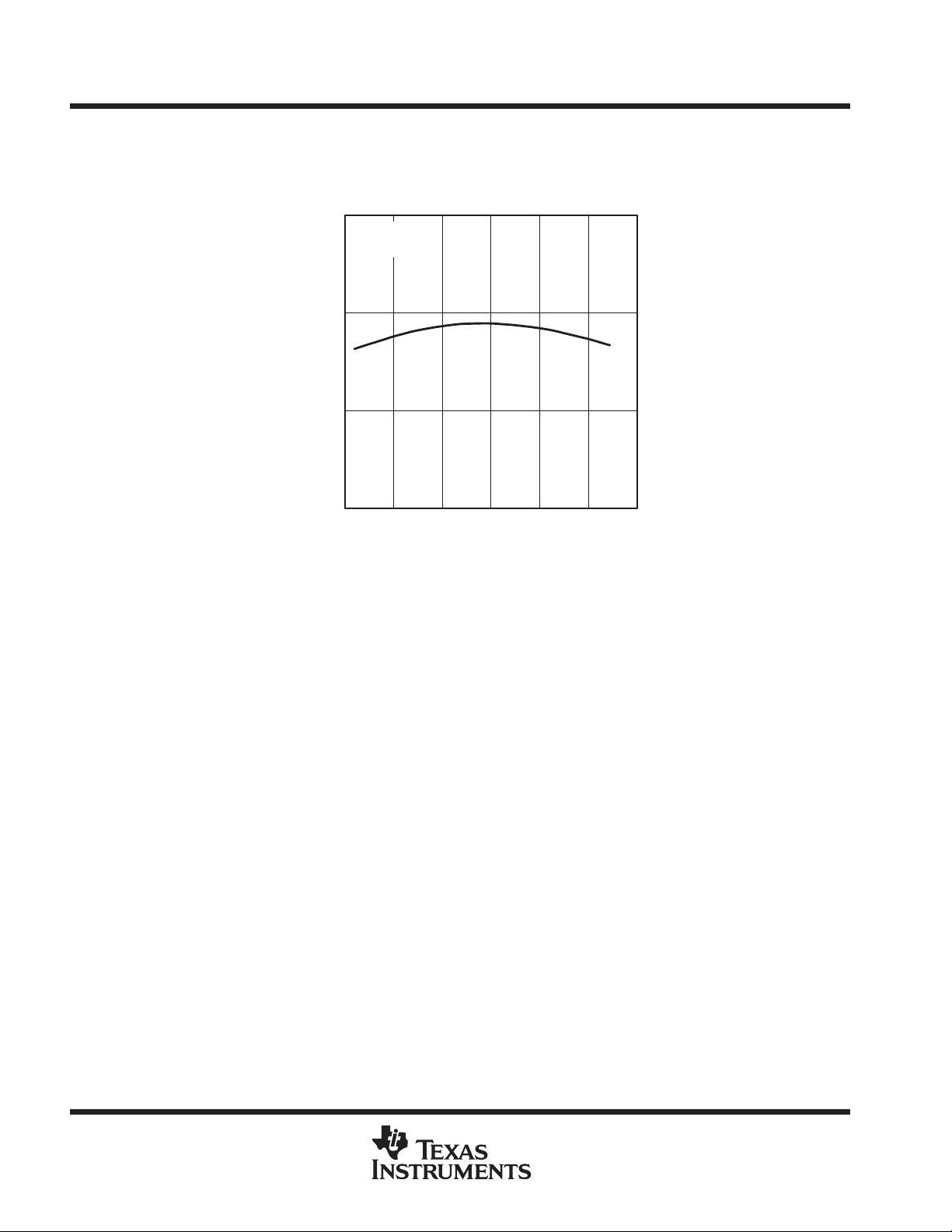

REFERENCE VOLTAGE

vs

FREE-AIR TEMPERATURE

1.26

VCC = 6 V

IO = –1 mA

1.25

– Reference Voltage – V

1.24

ref

V

1.23

–50

–25 0 25 50 75 100

TA – Free-Air Temperature – ° C

Figure 32

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

Page 21

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

MECHANICAL DATA

D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PIN SHOWN

14

1

0.069 (1,75) MAX

0.050 (1,27)

A

0.020 (0,51)

0.014 (0,35)

0.010 (0,25)

0.004 (0,10)

8

7

0.010 (0,25)

0.157 (4,00)

0.150 (3,81)

M

0.244 (6,20)

0.228 (5,80)

Seating Plane

0.004 (0,10)

PINS **

DIM

A MAX

A MIN

0.008 (0,20) NOM

Gage Plane

0°–8°

8

0.197

(5,00)

0.189

(4,80)

14

0.344

(8,75)

0.337

(8,55)

0.010 (0,25)

0.044 (1,12)

0.016 (0,40)

4040047/B 10/94

16

0.394

(10,00)

0.386

(9,80)

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0.006 (0,15).

D. Four center pins are connected to die mount pad

E. Falls within JEDEC MS-012

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

21

Page 22

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

MECHANICAL DATA

N (R-PDIP-T**) PLASTIC DUAL-IN-LINE P ACKAGE

16 PIN SHOWN

A

16

9

PINS **

DIM

14

16

18

20

1

0.035 (0,89) MAX

0.021 (0,53)

0.015 (0,38)

0.070 (1,78) MAX

0.020 (0,51) MIN

0.100 (2,54)

0.010 (0,25)

A MAX

0.260 (6,60)

0.240 (6,10)

8

0.200 (5,08) MAX

0.125 (3,18) MIN

M

0.010 (0,25) NOM

A MIN

Seating Plane

0.775

(19,69)

0.745

(18,92)

0.775

(19,69)

0.745

(18,92)

0.920

(23.37)

0.850

(21.59)

0.975

(24,77)

0.940

(23,88)

0.310 (7,87)

0.290 (7,37)

0°–15°

NOTES: A. All linear dimensions are in inches (millimeters).

22

B. This drawing is subject to change without notice.

C. Falls within JEDEC MS-001 (20-pin package is shorter than MS-001)

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

14 Pin Only

4040049/C 7/95

• HOUSTON, TEXAS 77251–1443

Page 23

TL1454, TL1454Y

DUAL-CHANNEL PULSE-WIDTH-MODULATION (PWM)

CONTROL CIRCUIT

SLVS086B – APRIL 1995 – REVISED NOVEMBER 1997

MECHANICAL DATA

PW (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PIN SHOWN

0,65

14

1

1,20 MAX

A

7

0,10 MIN

0,32

0,17

8

6,70

4,70

4,30

6,10

M

0,13

Seating Plane

0,10

0,15 NOM

Gage Plane

0,25

0°–8°

0,70

0,40

PINS **

DIM

A MAX

A MIN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

8

3,30

2,90

14

5,30

4,90

16

5,30

20

6,80

6,404,90

24

8,10

7,70

28

10,00

9,60

4040064/B 10/94

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

POST OFFICE BOX 1443

• HOUSTON, TEXAS 77251–1443

23

Page 24

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...