Low-Noise, Low-Distortion, Wideband Application Circuit

NONINVERTING SMALL SIGNAL

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments

查询THS3201供应商

www.ti.com

!

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

FEATURES

D Unity Gain Bandwidth: 1.8 GHz

D High Slew Rate: 10500 V/µs

D Distortion at 100 MHz: (G = 10 V/V,

RL = 100 Ω, 2-VPP envelope)

− IMD3: −80 dBc

− OIP3: 41 dBm

D Noise Figure : 11 dB (G = 10 V/V,

RG = 28 Ω, RF = 255 Ω)

D Input Referred Noise (f > 10 MHz)

− Voltage Noise: 1.65 nV/√Hz

− Noninverting Current Noise: 13.4 pA/√Hz

− Inverting Current Noise: 20 pA/√Hz

D Output Current: +115/−100 mA

D Power Supply Voltage Range: ±3.3 V to ±7.5 V

APPLICATIONS

D Arbitrary Waveform Driver

D High-Resolution, High-Sampling Rate ADC

Drivers

D High-Resolution, High-Sampling Rate DAC

Output Buffers

D If Amplification for Wireless Communications

Applciations

D Broadcast Video and HDTV Line Drivers

DESCRIPTION

The THS3201 is a wide-band, high-speed

current-feedback amplifier, designed to operate over a

wide supply range of ±3.3 V to ±7.5 V for todays high

performance applications.

The wide supply range combined with distortion as low as

−74 dBc at 10 MHz, plus an extremely high slew rate of

10500 V/µs makes the THS3201 ideally suited for arbitrary

waveform driver applications. The distortion performance

also enables driving high-resolution and high-sampling

rate ADCs. Moreover, the gain of +2 bandwidth of 850

MHz, combined with a 0.1 dB flatness of 380 MHz makes

the THS3201 ideal for broadcast video and HDTV

applications. The THS3201 also offers excellent

performance for IF amplification in wireless

communications systems by having IMD

−80 dBc, OIP

of 41 dBm, and a noise figure of 1 1 dB, all at

3

100 MHz with a gain +10 V/V, while driving a 2-V

envelope into a 100-Ω load.

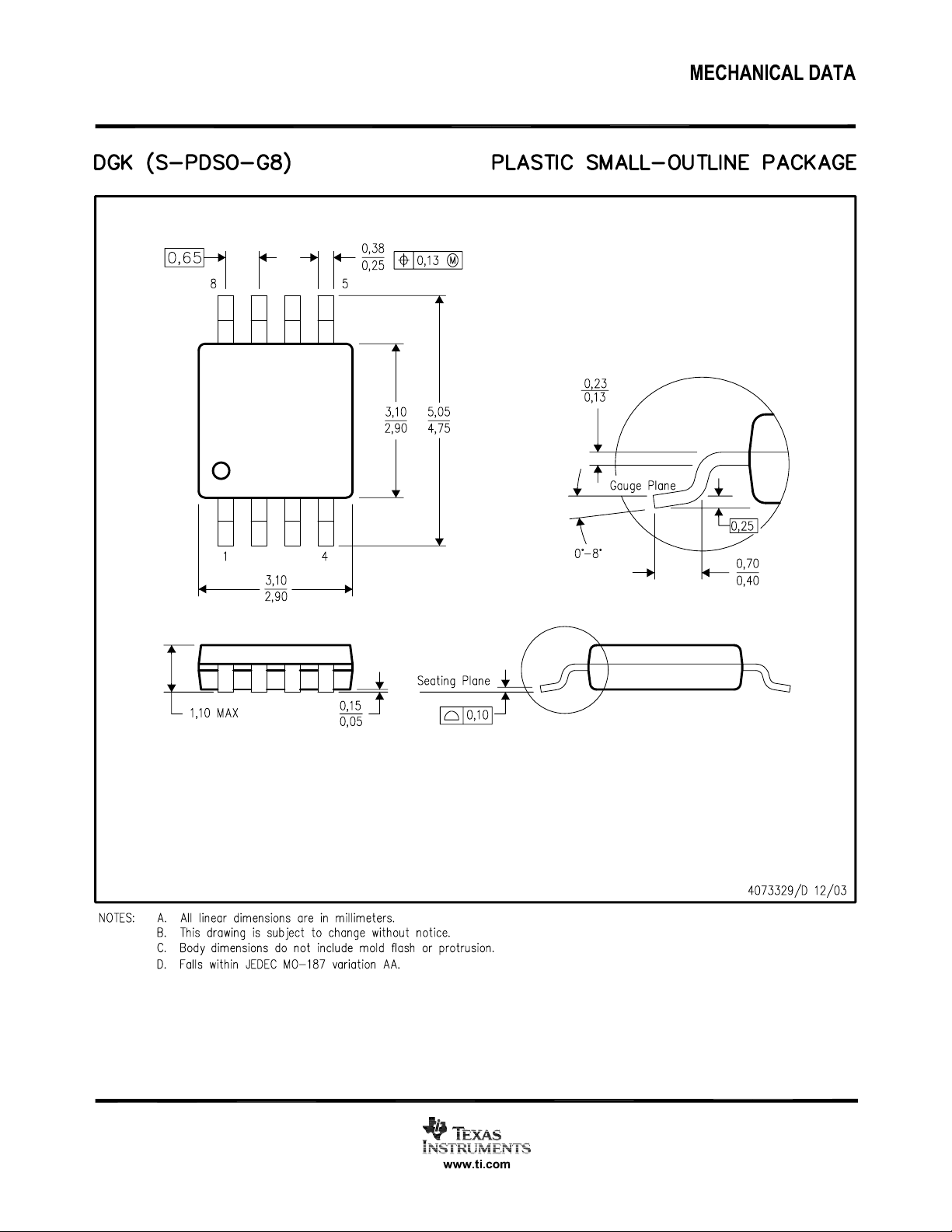

The THS3201 is offered in a 5-pin SOT−23, 8-pin SOIC,

and an 8-pin MSOP with PowerPAD packages.

RELATED DEVICES AND DESCRIPTIONS

THS3202 ±7.5-V 2-GHz Dual Low Distortion CFB Amplifier

THS3001 ±15-V 420-MHz Low Distortion CFB Amplifier

THS3061/2 ±15-V 300-MHz Low Distortion CFB Amplifier

THS3122 ±15-V Dual CFB Amplifier With 350 mA Drive

THS4271 ±7.5-V 1.4-GHz Low Distortion VFB Amplifier

performance of

3

PP

FREQUENCY RESPONSE

50 Ω Source

50 Ω

V

I

NOTE:Power supply decoupling capacitors not shown

semiconductor products and disclaimers thereto appears at the end of this data sheet.

PowerPAD is a trademark of Texas Instruments Incorporated.

"#$%&'()"%# "* +,&&-#) (* %$ .,/0"+()"%# 1()- &%1,+)*

+%#$%&' )% *.-+"$"+()"%#* .-& )2- )-&'* %$ -3(* #*)&,'-#)* *)(#1(&1 4(&&(#)5

&%1,+)"%# .&%+-**"#6 1%-* #%) #-+-**(&"05 "#+0,1- )-*)"#6 %$ (00 .(&('-)-&*

49.9 Ω

768 Ω

+7.5 V

+

THS3201

_

−7.5 V

768 Ω

49.9 Ω

50 Ω

8

7

6

5

4

3

Gain = 2.

2

Noninverting Gain − dB

Copyright 2003 − 2004, Texas Instruments Incorporated

RL = 100 Ω,

VO = 0.2 VPP.

1

VS = ±7.5 V

0

100 k 1 M 10 M 100 M 1 G 10 G

RF = 768 Ω

f − Frequency − Hz

ESD ratings:

PACKAGE

(1)

PACKAGE

JC

(°C/W)

JA

(°C/W)

Supply voltage

V

OUTLINE

−40°C to 85°C

BEO

BEN

BGP

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

www.ti.com

ABSOLUTE MAXIMUM RATINGS

over operat i n g f ree-air temperature range unless otherwise noted

UNIT

Supply voltage, V

Input voltage, V

Output current, IO

Differential input voltage, V

Continuous power dissipation See Dissipation Rating Table

Maximum junction temperature, T

Maximum junction temperature, continuous

operation, long term reliability T

Operating free-air temperature range, T

Storage temperature range, T

Lead temperature

1,6 mm (1/16 inch) from case for 10 seconds

S

I

(2)

ID

(3)

J

(4)

J

A

stg

HBM 3000 V

ESD ratings:

CDM 1500 V

MM 100 V

(1)

Stresses above these ratings may cause permanent damage.

Exposure to absolute maximum conditions for extended periods

may degrade device reliability. These are stress ratings only, and

functional operation of the device at these or any other conditions

beyond those specified is not implied.

(2)

The THS3201 may incorporate a PowerPAD on the underside

of the chip. This acts as a heat sink and must be connected to a

thermally dissipative plane for proper power dissipation. Failure

to do so may result in exceeding the maximum junction

temperature which could permanently damage the device. See TI

technical briefs SLMA002 and SLMA004 for more information

about utilizing the PowerPAD thermally enhanced package.

(3)

The absolute maximum temperature under any condition is

limited by the constraints of the silicon process.

(4)

The maximum junction temperature for continuous operation is

limited by package constraints. Operation above this temperature

may result in reduced reliability and/or lifetime of the device.

16.5 V

±V

S

175 mA

±3 V

150°C

125°C

−40°C to 85°C

−65°C to 150°C

300°C

(1)

This integrated circuit can be damaged by ESD. Texas

Instruments recommends that all integrated circuits be

handled with appropriate precautions. Failure to observe

proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to

complete device failure. Precision integrated circuits may be more

susceptible t o damage because very small parametric changes could

cause the device not to meet its published specifications.

PACKAGE DISSIPATION RATINGS

θ

JCθJA

POWER RATING

(TJ = 125°C)

TA ≤ 25°C TA = 85°C

DBV (5) 55 255.4 391 mW 156 mW

D (8) 38.3 97.5 1.02 W 410 mW

DGN (8) 4.7 58.4 1.71 W 685 mW

DGK (8 pin) 54.2 260 385 mW 154 mW

(1)

This data was taken using the JEDEC standard High-K test PCB.

(2)

Power rating is determined with a junction temperature of 125°C.

This is the point where distortion starts to substantially increase.

Thermal management of the final PCB should strive to keep the

junction temperature at or below 125°C for best performance and

long term reliability.

(2)

RECOMMENDED OPERATING CONDITIONS

MIN MAX UNIT

Dual supply ±3.3 ±7.5

Single supply 6.6 15

Operating free-air temperature, T

A

−40 85 °C

PACKAGE/ORDERING INFORMATION

PIN ASSIGNMENTS

NOTE:If a PowerPAD is used, it is electrically isolated from the active circuitry.

2

PACKAGED DEVICES

TEMPERATURE

PLASTIC SMALL

OUTLINE

(1)

(D)

(DBV) SYM (DGN) SYM (DGK) SYM

SOT-23

(2)

THS3201D THS3201DBVT

THS3201DR THS3201DBVR

(1)

Available in tape and reel. The R suffix standard quantity is 2500 (e.g. THS3201DGNR).

(2)

Available in tape and reel. The R suffix standard quantity is 3000. The T suf fix standard quantity is 250 (e.g. THS3201DBVT).

SOT−23TOP VIEW

1

5

V

OUT

V

S−

IN+

2

3

V

S+

4

IN−

PLASTIC MSOP

THS3201DGN

THS3201DGNR

TOP VIEW

POWERPAD

NC

V

IN−

V

IN+

V

S−

(1)

PLASTIC MSOP

THS3201DGK

THS3201DGKR

1

2

3

4

NC

8

7

V

6

5

S+

V

OUT−

NC

NC = No Internal Connection

(1)

D, DGN, DGK

www.ti.com

PARAMETER

TEST CONDITIONS

Small-signal bandwidth, −3 dB

Small-signal bandwidth, −3 dB

Typ

(VO = 200 mVPP)

MHz

Slew rate (25% to 75% level)

V/µs

Typ

ns

Typ

2nd harmonic

dBc

Typ

3rd harmonic

dBc

Typ

c

f = 200 kHz,

Differential gain

G = +2, R

= 150 Ω,

G = +2, RL = 150 Ω

Differential phase

RF = 768

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

ELECTRICAL CHARACTERISTICS

VS = ±7.5 V: Rf = 768 Ω, RL = 100 Ω, and G = +2 unless otherwise noted

THS3201

TYP OVER TEMPERATURE

25°C 25°C

AC PERFORMANCE

G = +1, RF= 1.2 kΩ 1.8 GHz

G = +2, RF = 768 Ω 850

(VO = 200 mVPP)

Bandwidth for 0.1 dB flatness

Large-signal bandwidth G = +2, VO = 2 V

Rise and fall time G = +2, VO = 4-V step, RF = 768 Ω 0.6 ns Typ

Settling time to 0.1% G = −2, VO = 2-V step 20

0.01% G = −2, VO = 2-V step 60

Harmonic distortion G = +5, f = 10 MHz, VO = 2 V

Third-order intermodulation

distortion (IMD3)

Third-order output intercept

point (OIP3)

Noise figure

Input voltage noise f > 10 MHz 1.65 nV/√Hz Typ

Input current noise (noninverting) f > 10 MHz 13.4 pA/√Hz Typ

Input current noise (inverting) f > 10 MHz 20 pA/√Hz Typ

G = +5, RF = 619 Ω 565

G = +10, RF = 487 Ω 520

G = +2, VO = 200 mV

RF = 768 Ω

G = +1, VO = 5-V step 6200

G = +2, VO = 10-V step 10500

RL = 100 Ω −75

RL = 500 Ω −77

RL = 100 Ω −91

RL = 500 Ω −93

G = +10, fc = 100 MHz,

∆

V

O(envelope)

G = +10, fc = 100 MHz,

RF = 255 Ω, RG = 28

RF = 768 Ω

pp,

= 715 Ω 880 MHz Typ

pp, RF

pp

= 2 V

pp 41 dBm Typ

NTSC 0.008% Typ

,

PAL 0.004% Typ

NTSC 0.007° Typ

PAL 0.011° Typ

380 MHz Typ

−80 dBc Typ

11 dB Typ

0°C to

70°C

−40°C

to 85°C

UNITS

MHz

MIN/TYP/

MAX

DC PERFORMANCE

Open-loop transimpedance gain VO = ±1 V, RL = 1 kΩ 300 200 140 120 kΩ Min

Input offset voltage VCM = 0 V ±0.7 ±3 ±3.8 ±4 mV Max

Average offset voltage drift VCM = 0 V ±10 ±13 µV/°C Typ

Input bias current (inverting) VCM = 0 V ±13 ±60 ±80 ±85 µA Max

Average bias current drift (−) VCM = 0 V ±300 ±400 nA/°C Typ

Input bias current (noninverting) VCM = 0 V ±14 ±35 ±45 ±50 µA Max

Average bias current drift (+) VCM = 0 V ±300 ±400 nA/°C Typ

3

PARAMETER

TEST CONDITIONS

Input resistance

Voltage output swing

V

Min

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

www.ti.com

ELECTRICAL CHARACTERISTICS

VS = ±7.5 V: Rf = 768 Ω, RL = 100 Ω, and G = +2 unless otherwise noted

THS3201

TYP OVER TEMPERATURE

25°C 25°C

INPUT

Common-mode input range ±5.1 ±5 ±5 ±5 V Min

Common-mode rejection ratio VCM = ±3.75 V 71 60 58 58 dB Min

Inverting input impedance, Z

Input capacitance Noninverting 1 pF Typ

OUTPUT

Current output, sourcing RL = 20 Ω 115 105 100 100 mA Min

Current output, sinking RL = 20 Ω 100 85 80 80 mA Min

Closed-loop output impedance G = +1, f = 1 MHz 0.01 Ω Typ

in

Open loop 16 Ω Typ

Noninverting 780 kΩ Typ

Inverting 11 Ω Typ

RL = 1 kΩ ±6 ±5.9 ±5.8 ±5.8

RL = 100 Ω ±5.8 ±5.7 ±5.5 ±5.5

0°C to

70°C

−40°C

to 85°C

UNITS

MIN/TYP/

MAX

POWER SUPPLY

Minimum operating voltage Absolute minimum ±3.3 ±3.3 ±3.3 V Min

Maximum operating voltage Absolute maximum ±8.25 ±8.25 ±8.25 V Max

Maximum quiescent current 14 18 21 21 mA Max

Power supply rejection (+PSRR) VS+ = 7 V to 8 V 69 63 60 60 dB Min

Power supply rejection (−PSRR) VS− = −7 V to –8 V 65 58 55 55 dB Min

4

www.ti.com

PARAMETER

TEST CONDITIONS

Small-signal bandwidth, −3dB

Small-signal bandwidth, −3dB

Typ

(VO = 200 mVPP)

MHz

Slew rate (25% to 75% level)

V/µs

Typ

2nd harmonic

dBc

Typ

3rd harmonic

dBc

Typ

c

f = 200 kHz,

Differential gain

G = +2, R

= 150 Ω,

G = +2, RL = 150 Ω,

Differential phase

RF= 768

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

ELECTRICAL CHARACTERISTICS

VS = ±5 V: Rf = 715 Ω, RL = 100 Ω, and G = +2 unless otherwise noted

THS3201

TYP OVER TEMPERATURE

25°C 25°C

AC PERFORMANCE

G = +1, RF= 1.2 kΩ 1.3 GHz

G = +2, RF = 715 Ω 725

(VO = 200 mVPP)

Bandwidth for 0.1 dB flatness

Large-signal bandwidth G = +2, VO = 2 Vpp, RF= 715 Ω 900 MHz Typ

Rise and fall time

Settling time to 0.1% G = −2, VO = 2-V step 20 ns Typ

0.01% G = −2, VO = 2-V step 60 ns Typ

Harmonic distortion G = +5, f = 10 MHz, VO = 2 V

Third-order intermodulation

distortion (IMD3)

Third-order output intercept

point (OIP3)

Noise figure

Input voltage noise f > 10 MHz 1.65 nV/√Hz Typ

Input current noise (noninverting) f > 10 MHz 13.4 pA/√Hz Typ

Input current noise (inverting) f > 10 MHz 20 pA/√Hz Typ

G = +5, RF = 576 Ω 540

G = +10, RF = 464 Ω 480

G = +2, VO = 200 mV

RF= 715 Ω

G = +1, VO = 5-V step 5200

G = +2, VO = 5-V step 5200

G = +2, VO = 4-V step,

RF= 715 Ω

RL = 100 Ω −68

RL = 500 Ω −70

RL = 100 Ω −72

RL = 500 kΩ −74

G = +10, fc = 100 MHz,

∆

V

O(envelope)

G = +10, fc = 100 MHz,

RF = 255 Ω, RG = 28

RF= 768 Ω

pp,

pp

= 2 V

pp 33.5 dBm Typ

NTSC 0.006% Typ

PAL 0.004% Typ

NTSC 0.03° Typ

PAL 0.04° Typ

170 MHz Typ

0.7 ns Typ

−65 dBc Typ

11 dB Typ

0°C to

70°C

−40°C

to 85°C

UNITS

MHz

MIN/TYP/

MAX

DC PERFORMANCE

Open-loop transimpedance gain VO = +1 V , RL = 1 kΩ 300 200 140 120 kΩ Min

Input offset voltage VCM =0 V ±0.7 ±3 ±3.8 ±4 mV Max

Average offset voltage drift VCM = 0 V ±10 ±13 µV/°C Typ

Input bias current (inverting) VCM = 0 V ±13 ±60 ±80 ±85 µA Max

Average bias current drift (−) VCM = 0 V ±300 ±400 nA/°C Typ

Input bias current (noninverting) VCM = 0 V ±14 ±35 ±45 ±50 µA Max

Average bias current drift (+) VCM = 0 V ±300 ±400 nA/°C Typ

5

PARAMETER

TEST CONDITIONS

Input resistance

Voltage output swing

V

Min

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

www.ti.com

ELECTRICAL CHARACTERISTICS continued

VS = ±5 V: Rf = 715 Ω, RL = 100 Ω, and G = +2 unless otherwise noted

THS3201

TYP OVER TEMPERATURE

25°C 25°C

INPUT

Common-mode input range ±2.6 ±2.5 ±2.5 ±2.5 V Min

Common-mode rejection ratio VCM = ±2.5 V 71 60 58 58 dB Min

Inverting input impedance, Z

Input capacitance Noninverting 1 pF Typ

OUTPUT

Current output, sourcing RL = 20 Ω 115 105 100 100 mA Min

Current output, sinking RL = 20 Ω 100 85 80 80 mA Min

Closed-loop output impedance G = +1, f = 1 MHz 0.01 Ω Typ

in

Open loop 17.5 Ω Typ

Noninverting 780 kΩ Typ

Inverting 11 Ω Typ

RL = 1 kΩ ±3.65 ±3.5 ±3.45 ±3.4

RL = 100 Ω ±3.45 ±3.33 ±3.25 ±3.2

0°C to

70°C

−40°C

to 85°C

UNITS

MIN/TYP/

MAX

POWER SUPPLY

Minimum operating voltage Absolute minimum ±3.3 ±3.3 ±3.3 V Min

Maximum operating voltage Absolute maximum ±8.25 ±8.25 ±8.25 V Max

Maximum quiescent current 14 16.8 19 20 mA Max

Power supply rejection (+PSRR) VS+ = 4.5 V to 5.5 V 69 63 60 60 dB Min

Power supply rejection (−PSRR) VS− = −4.5 V to –5.5 V 65 58 55 55 dB Min

6

www.ti.com

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

TYPICAL CHARACTERISTICS

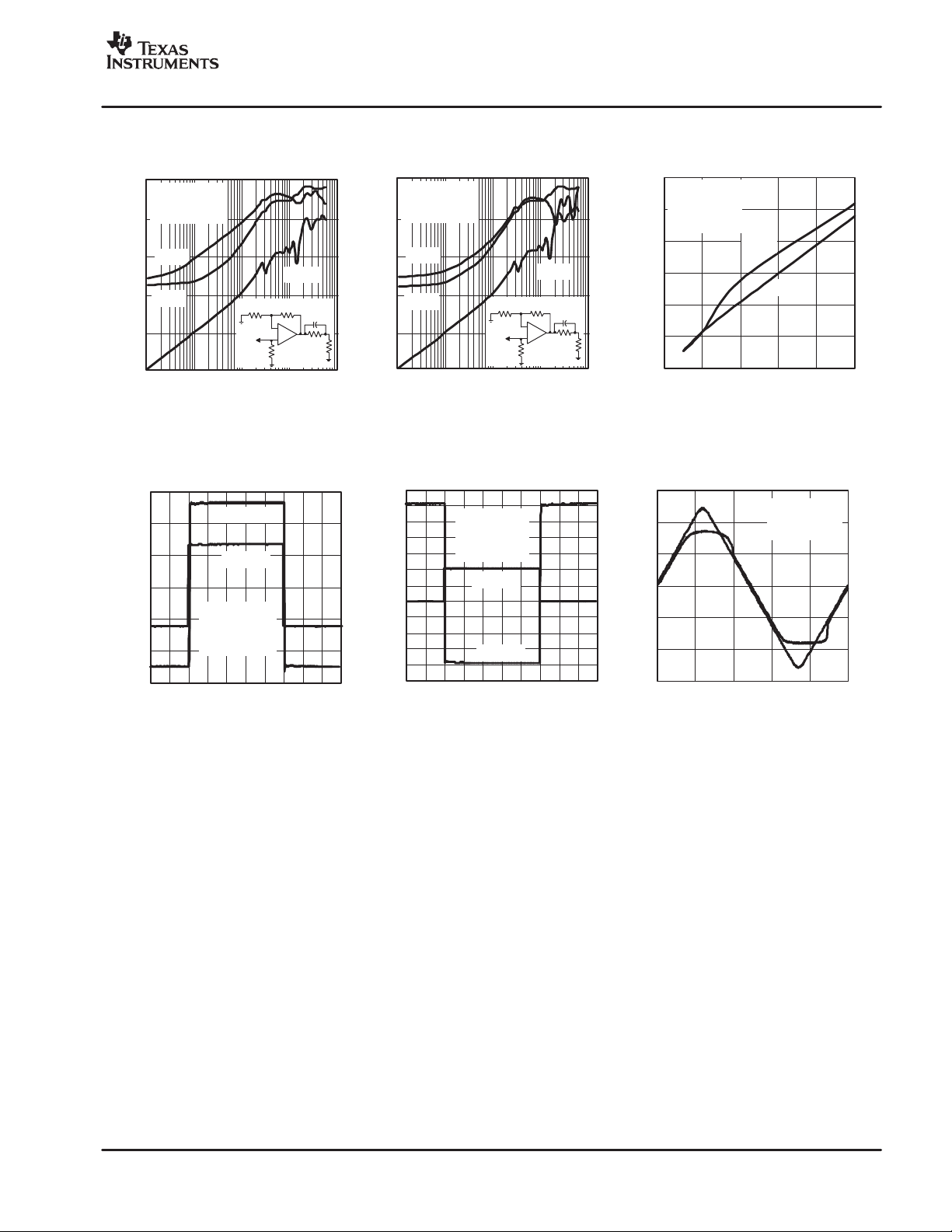

Table of Graphs (V

Noninverting small signal frequency response 1, 2

Inverting small signal frequency response 3

Noninverting large signal frequency response 4

Inverting large signal frequency response 5

0.1 dB gain flatness frequency response 6

Capacitive load frequency response 7

Recommended switching resistance vs Capacitive Load 8

2nd harmonic distortion vs Frequency 9

3rd harmonic distortion vs Frequency 10

Harmonic distortion vs Output voltage swing 11, 12

Third-order intermodulation distortion (IMD3) vs Frequency 13

Third-order output intercept point (OIP3) vs Frequency 14

S − Parameter vs Frequency 15, 16

Input voltage and current noise vs Frequency 17

Noise figure vs Frequency 18

Transimpedance vs Frequency 19

Input offset voltage vs Case Temperature 20

Input bias and offset current vs Case Temperature 21

Slew rate vs Output voltage step 22, 23

Settling time 24, 25

Quiescent current vs Supply voltage 26

Output voltage vs Load resistance 27

Rejection ratio vs Frequency 28

Noninverting small signal transient response 29

Inverting large signal transient response 30

Overdrive recovery time 31

Differential gain vs Number of loads 32

Differential phase vs Number of loads 33

Closed-loop output impedance vs Frequency 34

= ±7.5 V)

S

FIGURE

Table of Graphs (VS = ±5 V)

FIGURE

Noninverting small signal frequency response 35

Inverting small signal frequency response 36

2nd harmonic distortion vs Frequency 38

3rd harmonic distortion vs Frequency 39

Harmonic distortion vs Output voltage swing 40, 41

Third-order intermodulation distortion (IMD3) vs Frequency 42

Third-order output intercept point (OIP3) vs Frequency 43

S − Parameter vs Frequency 44, 45

Slew rate vs Output voltage step 46

Noninverting small signal transient response 47

Inverting large signal transient response 48

Overdrive recovery time 49

37

7

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

www.ti.com

VS = ±7.5 V Graphs

NONINVERTING SMALL SIGNAL

FREQUENCY RESPONSE

8

7

6

5

4

3

Gain = 2.

2

Noninverting Gain − dB

RL = 100 Ω,

VO = 0.2 VPP.

1

VS = ±7.5 V

0

100 k 1 M 10 M 100 M 1 G 10 G

RF = 619 Ω

RF = 768 Ω

RF = 1 kΩ

f − Frequency − Hz

Figure 1

INVERTING LARGE SIGNAL

FREQUENCY RESPONSE

16

14

12

10

Inverting Gain − dB

G =−5, RF = 576 Ω

8

G = 2, RF = 715 Ω

6

4

RL = 100 Ω,

VO = 2 VPP.

2

VS = ±7.5 V

0

100 k 1 M 10 M 100 M 1 G

f − Frequency − Hz

Figure 4

NONINVERTING SMALL SIGNAL

FREQUENCY RESPONSE

24

22

20

18

16

14

12

10

8

6

Noninverting Gain − dB

4

2

0

−2

−4

100 k 1 M 10 M 100 M 1 G 10 G

G = 10, RF = 487 Ω

G = 5, RF = 619 Ω

RL = 100 Ω,

VO = 0.2 VPP.

VS = ±7.5 V

G = 2, RF = 768 Ω

G =1, RF = 1.2 kΩ

f − Frequency − Hz

Figure 2

INVERTING LARGE SIGNAL

FREQUENCY RESPONSE

16

14

12

10

8

6

4

Inverting Gain − dB

2

0

−2

−4

G =−5, RF = 549 Ω

RL = 100 Ω,

VO = 2 VPP.

VS = ±7.5 V

G = −1, RF = 576 Ω

100 k 1 M 10 M 100 M 1 G

f − Frequency − Hz

Figure 5

INVERTING SMALL SIGNAL

FREQUENCY RESPONSE

24

22

20

18

16

14

12

10

8

6

4

Noninverting Gain − dB

2

0

−2

−4

100 k 1 M 10 M 100 M 1 G 10 G

G = −10, RF = 499 Ω

G = −5, RF = 549 Ω

RL = 100 Ω,

VO = 0.2 VPP.

VS = ±7.5 V

G = −2, RF = 576 Ω

G = −1, RF = 619 Ω

f − Frequency − Hz

Figure 3

0.1 dB GAIN FLATNESS

FREQUENCY RESPONSE

6.4

Gain = 2,

6.3

RF = 768 Ω,

RL = 100 Ω,

6.2

VO = 0.2 VPP,

VS = ±7.5 V

6.1

6

5.9

Noninverting Gain − dB

5.8

5.7

5.6

100 k 10 M 100 M 1 G 10 G

1 M

f − Frequency − Hz

Figure 6

Gain − dB

8

CAPACITIVE LOAD

FREQUENCY RESPONSE

16

R

= 30 Ω, CL = 22 pF

14

12

10

−2

(ISO)

R

= 20 Ω,

(ISO)

CL = 50 pF

Gain = 5

RF = 619 Ω

8

RL = 100 Ω

VS = ±7.5 V

6

4

R

= 15 Ω,

(ISO)

CL = 100 pF

2

R

= 20 Ω,

(ISO)

0

CL = 47 pF

0 100 200 300 400 500

f − Frequency − MHz

Figure 7

RECOMMENDED R

vs

60

50

Ω

−

40

ISO

R

30

20

Recommended

10

0

CAPACTIVE LOAD

Gain = 5,

RF = 619 Ω

RL = 100 Ω,

VS = ±7.5 V

R

_

ISO

+

10 100

C

L

CL − Capacitive Load − pF

Figure 8

ISO

2nd HARMONIC DISTORTION

vs

FREQUENCY

−40

VO = 2 VPP,

RL = 100 Ω,

−50

VS = ±7.5 V

G = 1, RF = 1.2 kΩ

−60

−70

−80

−90

2nd Harmonic Distortion − dBc

−100

1 10 100

f − Frequency − MHz

G = 5, RF = 619 Ω

G = 2, RF = 768 Ω

Figure 9

www.ti.com

G

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

3rd HARMONIC DISTORTION

vs

−40

−50

−60

−70

−80

−90

3rd Harmonic Distortion − dBc

−100

1

FREQUENCY

VO = 2 VPP,

RL = 100 Ω,

VS = ±7.5 V

G = 1, RF = 1.2 kΩ

G = 2, RF = 768 Ω

f − Frequency − MHz

G = 5, RF = 619 Ω

10 100

Figure 10

THIRD-ORDER INTERMODULATION

DISTORTION

vs

−60

−65

−70

−75

−80

−85

−90

−95

−100

Third-Order Intermodulation Distortion − dBc

10 100 200

FREQUENCY

RL = 100 Ω

VO = 2VPP Envelope

VS = ±7.5 V

200 kHz Tone Spacing

G = 2, RF = 768 Ω

G = 5, RF = 619 Ω

f − Frequency − MHz

G = 10, RF = 487 Ω

Figure 13

HARMONIC DISTORTION

vs

OUTPUT VOLTAGE SWING

−60

Gain = 5

RF = 619 Ω

−65

f = 8 MHz

−70

VS = ±7.5 V

HD2, RL = 100 Ω

−75

−80

−85

−90

Harmonic Distortion − dBc

−95

−100

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

VO − Output Voltage Swing − ± V

HD2, RL = 499 Ω

HD3, RL = 100 Ω

HD3, RL = 499 Ω

Figure 11

THIRD-ORDER OUTPUT

INTERCEPT POINT

vs

FREQUENCY

60

55

50

45

40

G = 5, RF = 619 Ω

35

Third-Order Output Intersept Point − dBm

VO = 2 VPP Envelope

RL = 100 Ω

VS = ±7.5 V

200 kHz Tone Spacing

G = 10, RF = 487 Ω

G = 2, RF = 768 Ω

20 40 60 80 1000

f − Frequency − MHz

Figure 14

HARMONIC DISTORTION

vs

OUTPUT VOLTAGE SWING

−50

−55

−60

−65

−70

−75

−80

−85

Harmonic Distortion − dBc

−90

−95

−100

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

HD2

RL = 100 Ω

RL = 499 Ω

VO − Output Voltage Swing − ± V

HD2, RL = 499 Ω

HD3,

HD3, RL = 100 Ω

Gain = 5, RF = 619 Ω

f = 32 MHz, VS = ±7.5 V

Figure 12

S − PARAMETER

vs

FREQUENCY

0

VS = ±7.5 V

Gain = +10

C = 0 pF

−20

S22

−40

−60

S−Parameter − dB

−80

−100

1 M 10 M 100 M 10

f − Frequency − Hz

R

G

50 Ω

Source

S11

Figure 15

R

−

+

50 Ω

1 G

S12

F

C

50 Ω

50 Ω

S − PARAMETER

vs

FREQUENCY

0

VS = ±7.5 V

Gain = +10

C = 3.3 pF

−20

S22

−40

−60

S11

S−Parameter − dB

−80

−100

1 M 10 M 100 M 10 G

f − Frequency − Hz

R

50 Ω

Source

R

G

−

+

50 Ω

1 G

Figure 16

INPUT VOLTAGE

AND CURRENT NOISE

vs

50

45

pA Hz

40

S12

F

C

50 Ω

50 Ω

35

30

25

20

15

Input Current Noise Density −

−

10

n

I

100 k 1 M 10 M 100 M

FREQUENCY

VS = ±7.5 V and ±5 V

TA = 25°C

V

n

Inverting

Noise Current

Noninverting

Current Noise

f − Frequency − Hz

Hz

4

nV/

3.5

3

2.5

1.5

0.5

Voltage Noise Density −

−

n

0

V

Figure 17

9

OS

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

www.ti.com

NOISE FIGURE

vs

14

13

12

11

10

9

Noise Figure − dB

8

7

6

0 50 100 150 200 250 300 350 400

FREQUENCY

Gain = +10

RG = 28 Ω

RF = 255 Ω

VS = ±7.5 V & ±5 V

f − Frequency − MHz

Figure 18

INPUT BIAS AND OFFSET CURRENT

vs

CASE TEMPERATURE

17

VS = ±7.5 V

16

Aµ

15

14

13

12

− Input Bias Currents −

IB

I

11

10

−40−30−20−10 0 10 20 30 40 50 60 70 80 90

TC − Case Temperature − °C

IIB−

IIB+

I

OS

Figure 21

120

100

80

60

40

Transimpedance Gain −dBΩ

20

0

100 k 10 M 1 G100 M1 M

7

6

5

4

3

2

1

0

8000

7000

Aµ

sµ

6000

V/

5000

4000

3000

SR − Slew Rate −

2000

− Input Offset Currents −

1000

I

0

TRANSIMPEDANCE

vs

FREQUENCY

VS = ±5 and ±7.5V

_

10 Ω

+

V

+

_

Gain W +

f − Frequency − Hz

O

I

IB

Figure 19

SLEW RATE

vs

OUTPUT VOLTAGE

Gain = 1

RL = 100 Ω

RF = 1.2 kΩ

VS = ±7.5 V

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

VO − Output Voltage − V

Rise

Fall

PP

Figure 22

INPUT OFFSET VOLTAGE

vs

CASE TEMPERATURE

3

2.5

2

1.5

1

− Input Offset Voltage − mV

0.5

OS

V

0

VS = ±7.5 V

VS = ±5 V

−40−30−20−10 0 10 20 30 40 50 60 70 80 90

TC − Case Temperature − °C

Figure 20

SLEW RATE

vs

OUTPUT VOLTAGE

11000

Gain = 2

10000

RL = 100 Ω

9000

sµ

V/

SR − Slew Rate −

RF = 768 Ω

VS = ±7.5 V

8000

7000

6000

5000

4000

3000

2000

1000

0

012345678910

VO − Output Voltage − V

Rise

Fall

Figure 23

PP

10

QUIESCENT CURRENT

vs

1.5

1

0.5

0

−0.5

− Output Voltage − V

O

V

−1

−1.5

SETTLING TIME

Rising Edge

Gain = −2

RL = 100 Ω

RF = 576 Ω

f= 1 MHz

VS = ±7.5 V

Falling Edge

0246810

t − Time − ns

3

2.5

2

1.5

1

0.5

0

−0.5

−1

− Output Voltage − V

O

−1.5

V

−2

−2.5

−3

Figure 24

SETTLING TIME

Rising Edge

Gain = −2

RL = 100 Ω

RF = 576 Ω

f= 1 MHz

VS = ±7.5 V

Falling Edge

0 2.5 7.5 12.5

510

t − Time − ns

Figure 25

20

18

16

14

12

10

8

6

Quiescent Current − mA

4

2

0

SUPPLY VOL TAGE

TA = 85°C

TA = 25°C

TA = −40°C

2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5

VS − Supply Voltage − ±V

Figure 26

www.ti.com

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

OUTPUT VOLTAGE

vs

LOAD RESISTANCE

7

6

5

4

3

2

1

0

−1

−2

− Output Voltage − V

−3

O

V

−4

−5

−6

−7

10 100 1000

RL − Load Resistance − Ω

VS = ±7.5 V

TA = −40 to 85°C

Figure 27

INVERTING LARGE-SIGNAL

TRANSIENT RESPONSE

6

5

4

3

2

1

0

−1

−2

− Output Voltage − V

O

−3

V

−4

−5

−6

Gain = −5

RL = 100 Ω

RF = 549 Ω

VS = ±7.5 V

Input

Output

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

t − Time − µs

Figure 30

REJECTION RATIO

vs

FREQUENCY

80

70

60

50

40

PSRR+

30

Rejection Ratios − dB

20

10

0

100 k 1 M 10 M 100 M

CMRR

f − Frequency − Hz

VS = ±7.5 V

Figure 28

OVERDRIVE RECOVERY TIME

10

8

6

4

2

0

−2

− Output Voltage − V

−4

O

V

−6

−8

−10

0 0.2 0.4 0.6 0.8 1

t − Time − µs

G = 2,

RF = 768 Ω,

VS = ±7.5 V

Figure 31

5

4

3

2

1

0

−1

− Input Voltage − VV

−2

I

−3

−4

−5

NONINVERTING SMALL-SIGNAL

TRANSIENT RESPONSE

0.3

0.2

0.1

0

− Output Voltage − V

−0.1

O

V

−0.2

−0.3

Output

Input

Gain = 2

RL = 100 Ω

RF = 715 Ω

VS = ±7.5 V

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

t − Time − µs

Figure 29

DIFFERENTIAL GAIN

vs

0.030

0.025

0.020

0.015

0.010

Differential Gain − %

0.005

NUMBER OF LOADS

Gain = 2

RF = 768 Ω

VS = ±7.5 V

40 IRE − NTSC and Pal

Worst Case ±100 IRE Ramp

0

012345678

Number of Loads − 150 Ω

Figure 32

PAL

NTSC

DIFFERENTIAL PHASE

vs

0.040

0.035

0.030

°

0.025

0.020

0.015

Differential Phase −

0.010

0.005

NUMBER OF LOADS

Gain = 2

RF = 768 kΩ

VS = ±7.5 V

40 IRE − NTSC and Pal

Worst Case ±100 IRE Ramp

PAL

NTSC

0

012345678

Number of Loads − 150 Ω

Figure 33

CLOSED-LOOP OUTPUT IMPEDANCE

vs

Gain = 2

RF = 715 Ω

RL = 100 Ω

VS = ±7.5 V

f − Frequency − Hz

FREQUENCY

1000

Ω

100

10

1

0.1

0.01

Closed-Loop Output Impedance −

0.001

100 k 1 M 10 M 1 M 1 G

Figure 34

11

THIRD-ORDER INTERMODULATION

0

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

www.ti.com

VS = ±5 V Graphs

NONINVERTING SMALL SIGNAL

FREQUENCY RESPONSE

24

22

20

18

16

14

12

10

8

6

Noninverting Gain − dB

4

2

0

−2

−4

100 k 1 M 10 M 100 M 1 G 10 G

G = 10, RF = 464 Ω

G = 5, RF = 576 Ω

RL = 100 Ω,

VO = 0.2 VPP.

VS = ±5 V

G = 2, RF = 715 Ω

G =1, RF = 1.2 kΩ

f − Frequency − Hz

Figure 35

2nd HARMONIC DISTORTION

vs

−40

−50

−60

−70

−80

−90

2nd Harmonic Distortion − dBc

−100

1 10 100

FREQUENCY

VO = 2 VPP,

RL = 100 Ω,

VS = ±5 V

G = 1, RF = 1.2 kΩ

G = 2, RF = 715 Ω

f − Frequency − MHz

G = 5, RF = 576 Ω

Figure 38

INVERTING SMALL SIGNAL

FREQUENCY RESPONSE

24

22

20

18

16

14

12

10

8

6

Inverting Gain − dB

4

2

0

−2

−4

100 k 1 M 10 M 100 M 1 G 10 G

G = −10, RF = 499 Ω

G = −5, RF = 549 Ω

RL = 100 Ω,

VO = 0.2 VPP.

VS = ±5 V

G = −2, RF = 576 Ω

G =−1, RF = 576 Ω

f − Frequency − Hz

Figure 36

3rd HARMONIC DISTORTION

vs

−40

−50

−60

−70

−80

−90

3rd Harmonic Distortion − dBc

−100

1 10 100

FREQUENCY

VO = 2 VPP,

RL = 100 Ω,

VS = ±5 V

G = 1, RF = 1.2 kΩ

G = 5, RF = 576 Ω

f − Frequency − MHz

G = 2, RF = 715 Ω

Figure 39

0.1 dB GAIN FLATNESS

FREQUENCY RESPONSE

6.4

Gain = 2,

RF = 715 Ω,

6.3

RL = 100 Ω,

6.2

VO = 0.2 VPP,

VS = ±5 V

6.1

6

5.9

5.8

Noninverting Gain − dB

5.7

5.6

100 k 1 M 10 M 100 M 1 G 10 G

f − Frequency − Hz

Figure 37

HARMONIC DISTORTION

vs

OUTPUT VOLTAGE SWING

−50

−55

−60

−65

−70

−75

−80

−85

Harmonic Distortion − dBc

−90

−95

−100

0

HD2, RL = 499 Ω

HD2, RL = 100 Ω

HD3, RL = 499 Ω

HD3, RL = 100 Ω

Gain = 5

RF = 576 Ω

f = 8 MHz

VS = ±5 V

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

VO − Output Voltage Swing − ± V

Figure 40

HARMONIC DISTORTION

vs

OUTPUT VOLTAGE SWING

−40

−45

−50

−55

−60

−65

−70

−75

−80

−85

Harmonic Distortion − dBc

−90

−95

−100

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

HD2, RL = 499 Ω

HD2, RL = 100 Ω

HD3, RL = 100 Ω

HD3, RL = 499 Ω

VO − Output Voltage Swing − ± V

Figure 41

12

Gain = 5

RF = 576 Ω

f = 32 MHz

VS = ±5 V

DISTORTION

vs

−40

−45

−50

−55

−60

−65

−70

−75

−80

−85

−90

Third-Order Intermodulation Distortion − dBc

10 100 200

FREQUENCY

RL = 100 Ω

VO = 2VPP Envelope

VS = ±5 V

200 kHz Tone Spacing

G = 2, RF = 715 Ω

G = 10, RF = 464 Ω

f − Frequency − MHz

G = 5, RF = 576 Ω

Figure 42

THIRD-ORDER OUTPUT

INTERCEPT POINT

vs

55

VO = 2 VPP Envelope

RL = 100 Ω

VS = ±5 V

50

200 kHz Tone Spacing

45

40

35

30

Third-Order Output Intersept Point − dBm

0

FREQUENCY

G = 10, RF = 464 Ω

G = 2, RF = 715 Ω

G = 5, RF = 576 Ω

20 40 60 80 10

f − Frequency − MHz

Figure 43

www.ti.com

S−Parameter − dB

I

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

S − PARAMETER

vs

FREQUENCY

0

VS = ±5 V

Gain = +10

C = 0 pF

−20

S22

−40

−60

S11

S−Parameter − dB

−80

−100

1 M 10 M 100 M 10 G

f − Frequency − Hz

R

G

50 Ω

Source

R

−

+

50 Ω

1 G

Figure 44

NONINVERTING SMALL-SIGNAL

TRANSIENT RESPONSE

0.3

0.2

0.1

0

−0.1

− Output Voltage − V

O

V

−0.2

−0.3

Output

Input

Gain = 2

RL = 100 Ω

RF = 715 Ω

VS = ±5 V

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

t − Time − µs

S − PARAMETER

vs

0

FREQUENCY

VS = ±5 V

Gain = +10

−20

C = 3.3 pF

−40

S22

S12

−60

F

C

50 Ω

50 Ω

S11

−80

50 Ω

−100

1 M 10 M 100 M 10 G

Source

f − Frequency − Hz

S12

R

R

F

G

−

+

50 Ω

1 G

C

50 Ω

50 Ω

6000

Gain = 2

RL = 100 Ω

5000

RF = 715 Ω

sµ

VS = ±5 V

4000

V/

3000

2000

SR − Slew Rate −

1000

0

012345

Figure 45

SLEW RATE

vs

OUTPUT VOLTAGE

Rise

Fall

VO − Output Voltage − V

Figure 46

PP

INVERTING LARGE-SIGNAL

TRANSIENT RESPONSE

3

2.5

2

1.5

1

0.5

0

−0.5

−1

− Output Voltage − V

O

−1.5

V

−2

−2.5

−3

Gain = −5

RL = 100 Ω

RF = 549 Ω

VS = ±5 V

Input

Output

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

t − Time −µs

OVERDRIVE RECOVERY TIME

6

G = 2,

4

2

0

−2

− Output Voltage − V

O

V

−4

−6

0 0.2 0.4 0.6 0.8 1

t − Time − µs

RF = 715 Ω,

VS = ±5 V

3

2

1

0

−1

− Input Voltage − VV

−2

−3

Figure 47

Figure 48

Figure 49

13

1

2

5

10

−1

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

APPLICATION INFORMATION

WIDEBAND, NONINVERTING OPERATION

www.ti.com

Table 1. Recommended Resistor Values for

Optimum Frequency Response

The THS3201 is a unity gain stable 1.8-GHz

current-feedback operational amplifiers, designed to

operate from a ±3.3-V to ±7.5-V power supply.

Figure 50 shows the THS3201 in a noninverting gain of

2V/V configuration typically used to generate the

performance curves. Most of the curves were

characterized using signal sources with 50-Ω source

impedance, and with measurement equipment presenting

a 50-Ω load impedance. The 49.9-Ω shunt resistor at the

V

terminal in Figure 50 matches the source impedance of

I

the test generator.

7.5 V

+V

S

+

50 Ω Source

V

I

49.9 Ω

768 Ω

R

G

+

THS3201

_

−7.5 V

100 pF

R

F

768 Ω

100 pF

−V

S

0.1 µF 6.8 µF

49.9 Ω

50 Ω

0.1 µF 6.8 µF

+

THS3201 RF for AC When R

Gain

(V/V)

−2 ±7.5 and ±5 287 576

−5 ±7.5 and ±5 110 549

−10 ±7.5 and ±5 49.9 499

Supply Voltage

(V)

±7.5 — 1.2 k

±5 — 1.2 k

±7.5 768 768

±5 715 715

±7.5 154.9 619

±5 143 576

±7.5 54.9 487

±5 51.1 464

±7.5 619 619

±5 576 576

= 100 Ω

load

RG (Ω) RF (Ω)

WIDEBAND, INVERTING GAIN OPERATION

Figure 51 shows the THS3201 is a typical inverting gain

configuration where the input and output impedances and

signal gain from Figure 50 are retained in an inverting

circuit configuration.

7.5 V

+V

S

+

100 pF

0.1 µF 6.8 µF

Figure 50. Wideband, Noninverting Gain

Configuration

Unlike voltage-feedback amplifiers, current-feedback

amplifiers are highly dependent on the feedback resistor

R

for maximum performance and stability . Table 1 shows

F

the optimal gain setting resistors R

and RG at different

F

gains to give maximum bandwidth with minimal peaking in

the frequency response. Higher bandwidths can be

achieved, at the expense of added peaking in the

frequency response, by using even lower values for R

Conversely, increasing R

decreases the bandwidth, but

F

stability is improved.

14

+

THS3201

_

50 Ω Source

V

I

.

F

R

287 Ω

R

M

60.4 Ω

G

−7.5 V

R

F

576 Ω

100 pF

−V

S

49.9 Ω

50 Ω

0.1 µF 6.8 µF

+

Figure 51. Wideband, Inverting Gain

Configuration

www.ti.com

)

)

768

768

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

SINGLE SUPPLY OPERATION

The THS3201 has the capability to operate from a single

supply voltage ranging from 6.6V to 15V. When operating

from a single power supply, care must be taken to ensure

the input signal and amplifier is biased appropriately to

allow for the maximum output voltage swing. The circuits

shown in Figure 52 demonstrate methods to configure an

amplifier in a manner conducive for single supply

operation

+V

S

50 Ω Source

V

I

50 Ω Source

V

I

60.4 Ω

+V

2

+

49.9 Ω

S

2

S

2

R

G

768 Ω

THS3201

_

768 Ω

576 Ω

V

S

_

THS3201

+

R

F

R

F

R

T

+V

S

2

+V

R

G

287 Ω

R

T

+V

S

49.9 Ω

50 Ω

49.9 Ω

50 Ω

Ω

THS3201

V

I

75 Ω

±7.5 V

−

+

±7.5 V

Ω

75-Ω Transmission Line

75 Ω

n Lines

75 Ω

75 Ω

75 Ω

V

O(1

V

O(n

Figure 53. Video Distribution Amplifier

Application

ADC DRIVER APPLICATION

The THS3201 can be used as a high-performance ADC

driver in applications like radio receiver IF stages, and test

and measurement devices. All high-performance ADCs

have differential inputs. The THS3201 can be used in

conjunction with a transformer as a drive amplifier in these

applications. Figure 54 and Figure 55 show two different

approaches.

In Figure 54, a transformer is used after the amplifier to

convert the signal to differential. The advantage of this

approach is fewer components are required. R

are required for impedance matching the transformer.

OUT

and R

T

Figure 52. DC-Coupled Single Supply Operation

VIDEO AND HDTV DRIVERS

The exceptional bandwidth and slew rate of the THS3201

matches the demands for professional video and HDTV.

Most commercial HDTV standards requires a video

passband of 30-MHz. To ensure high signal quality with

minimal degradation of performance, a 0.1-dB gain

flatness should be at least 7x the passband frequency to

minimize group delay variations—requiring 210-MHz

0.1-dB frequency flatness from the amplifier. High slew

rates ensures there is minimal distortion of the video

signal. Component video and RGB video signals require

fast transition times and fast settling times to keep a high

signal quality. The THS8135, for example, is a 240 MSPS

video DAC and has a transition time approaching 4-ns.

The THS3201 is a perfect candidate for interfacing the

output of such high-performance video components.

V

S+

0.1 µF

THS3201

0.1 µF

R

F

R

1:n

OUT

V

S−

24.9 Ω

R

T

24.9 Ω

47pF

47pF

ADC

CM

0.1 µF

R

G

V

IN

Figure 54. Differential ADC Driver Circuit 1

In Figure 55, a transformer is used before two amplifiers to

convert the signal to differential. The two amplifiers then

amplify the differential signal. The advantage to this

approach is each amplifier is required to drive half the

voltage as before. R

is used to impedance match the

T

transformer.

15

V

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

V

S+

0.1 µF

R

G

1:n

V

IN

R

T

R

G

THS3201

THS3201

R

F

R

F

24.9 Ω

47pF

24.9 Ω

47pF

ADC

CM

www.ti.com

Placing this pole at about 10x the highest frequency of

interest insures it has no impact on the signal. Since the

resistor is typically a small value, it is very bad practice to

place the pole at (or very near) frequencies of interest. At

the pole frequency, the amplifiers sees a load with a

magnitude of:

2ǸxR

If R is only 10 Ω, the amplifier is very heavily loaded above

the pole frequency, and generates excessive distortion.

0.1 µF

0.1 µF

V

S−

Figure 55. Differential ADC Driver Circuit 2

It is almost universally recommended to use a resistor and

capacitor between the op amp’s output and the ADC’s

input as shown in both Figures.

This resistor-capacitor (RC) combination has multiple

functions:

D The capacitor is a local charge reservoir for ADC

D The resistor isolates the amplifier from the ADC

D In conjunction, they form a low-pass noise filter

During the sampling phase, current is required to charge

the ADC’s input sampling capacitors. By placing external

capacitors directly at the input pins, most of the current is

drawn from them. They are seen as a very low impedance

source. They can be thought of as serving much the same

purpose as a power supply bypass capacitor; to supply

transient current, with the amplifier then providing the bulk

charge.

Typically, a low-value capacitor in the range of 10 pF to

100 pF provides the required transient charge reservoir.

The capacitance and the switching action of the ADC is

one of the worst loading scenarios that a high-speed

amplifier encounters. The resistor provides a simple

means of isolating the associated phase shift from the

feedback network and maintaining the phase margin of the

amplifier.

DAC DRIVER APPLICATION

The THS3201 can be used as a high-performance DAC

output driver in applications like radio transmitter stages,

and arbitrary waveform generators. All high-performance

DACs have differential current outputs. Two THS3201s

can be used as a differential drive amplifier in these

applications as shown in Figure 56.

R

on the DAC output is used to convert the output

PU

current to voltage. The 24.9-Ω resistor and 47-pF capacitor

between each DAC output and the op amp input is used

to reduce the images generated at multiples of the

sampling rate. The values shown form a pole a 136 MHz.

R

sets the output impedance of each amplifier.

OUT

S+

0.1 µF

DAC

IOUT1

IOUT2

AV

DD

R

PU

24.9 Ω

24.9 Ω

R

PU

AV

DD

47pF

47pF

R

G

0.1 µF

R

G

THS3201

R

0.1 µF

THS3201

F

V

S−

R

F

R

OUT

V

OUT1

R

OUT

V

OUT2

Typically , a low value resistor in the range of 10 Ω to 100 Ω

provides the required isolation. Together, the R and C form

a real pole in the s-plane located at the

frequency:

f

16

1

+

P

2pRC

Figure 56. Differential DAC Driver Circuit

www.ti.com

−50

F

y

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

POWER SUPPLY

The performance of the THS3201 is dependent upon the

power supply. Slew rate, bandwidth, and distortion are

graphed against the power supply to highlight this

dependence. As the power supply is increased from ±5 V

to ±7.5 V, the slew rate increases, the bandwidth

increases, and the distortion improves.

11000

10000

9000

8000

µs

7000

6000

5000

4000

Slew Rate − V/

3000

2000

1000

0

01234 5678

Figure 57. Slew Rate vs Output Voltage Step

−45

−50

−55

−60

−65

−70

−75

−80

−85

2nd Harmonic Distortion − dBc

−90

−95

1

Rise

VS = ± 7.5 V

RF = 768 Ω

Rise

VS = ± 5 V

RF = 715 Ω

Fall

VS = ± 5 V

RF = 715 Ω

VO − Output Voltage Step − V

VS = ± 5 V

RF = 715 Ω

VS = ± 7.5 V

RF = 768 Ω

Gain = +2

RL = 100 Ω

VO = 2 V

10 100

f − Frequency − MHz

Fall

VS = ± 7.5 V

RF = 768 Ω

Gain = +2

RL = 100 Ω

PP

PP

910

Gain = +2

−55

RL = 100 Ω

VO = 2 V

−60

−65

−70

−75

−80

−85

−90

3 rd Harmonic Distortion − dBc

−95

−100

1

PP

VS = ± 5 V

RF = 715 Ω

f − Frequency − MHz

VS = ± 7.5 V

RF = 768 Ω

10 100

igure 59. 3rd Harmonic Distortion vs Frequenc

7

6

5

4

VS = ± 5 V

3

RF = 715 Ω

2

Noninverting Gain − dB

Gain = +2

1

RL = 100 Ω

VO = 2 V

0

10 100 1 k 10 k

PP

f − Frequency − Hz

VS = ± 7.5 V

RF = 768 Ω

Figure 60. Noninverting Small Signal

Frequency Response

Figure 58. 2nd Harmonic Distortion vs Frequency

17

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

www.ti.com

PRINTED-CIRCUIT BOARD LAYOUT

TECHNIQUES FOR OPTIMAL

PERFORMANCE

Achieving optimum performance with high frequency

amplifier-like devices in the THS3201 requires careful

attention to board layout parasitic and external component

types.

Recommendations that optimize performance include:

D Minimize parasitic capacitance to any ac ground for all

of the signal I/O pins. Parasitic capacitance on the

output and input pins can cause instability. To reduce

unwanted capacitance, a window around the signal

I/O pins should be opened in all of the ground and

power planes around those pins. Otherwise, ground

and power planes should be unbroken elsewhere on

the board.

D Minimize the distance (< 0.25”) from the power supply

pins to high frequency 0.1-µF and 100 pF decoupling

capacitors. At the device pins, the ground and power

plane layout should not be in close proximity to the

signal I/O pins. Avoid narrow power and ground traces

to minimize inductance between the pins and the

decoupling capacitors. The power supply connections

should always be decoupled with these capacitors.

Larger (6.8 µF or more) tantalum decoupling

capacitors, effective at lower frequency, should also

be used on the main supply pins. These may be

placed somewhat farther from the device and may be

shared among several devices in the same area of the

PC board. The primary goal is to minimize the

impedance seen in the differential-current return

paths. For d r i v i n g dif ferential loads with the THS3201,

adding a capacitor between the power supply pins

improves 2nd order harmonic distortion performance.

This also minimizes the current loop formed by the

differential drive.

D Careful selection and placement of external

components preserve the high frequency

performance of the THS3201. Resistors should be a

very low reactance type. Surface-mount resistors

work best and allow a tighter overall layout. Again,

keep their leads and PC board trace length as short as

possible. Never use wirebound type resistors in a high

frequency application. Since the output pin and

inverting input pins are the most sensitive to parasitic

capacitance, always position the feedback and series

output resistors, if any, as close as possible to the

inverting input pins and output pins. Other network

components, such as input termination resistors,

should be placed close to the gain-setting resistors.

Even with a low parasitic capacitance shunting the

external resistors, excessively high resistor values

can create significant time constants that can degrade

performance. Good axial metal-film or surface-mount

resistors have approximately 0.2 pF in shunt with the

resistor. For resistor values > 2.0 kΩ, this parasitic

capacitance can add a pole and/or a zero that can

effect circuit operation. Keep resistor values as low as

possible, consistent with load driving considerations.

D Connections to other wideband devices on the board

may be made with short direct traces or through

onboard transmission lines. For short connections,

consider the trace and the input to the next device as

a lumped capacitive load. Relatively wide traces

(50 mils to 100 mils) should be used, preferably with

ground and power planes opened up around them.

Estimate the total capacitive load and determine if

isolation resistors on the outputs are necessary. Low

parasitic capacitive loads (< 4 pF) may not need an R

since the THS3201 is nominally compensated to

operate with a 2-pF parasitic load. Higher parasitic

capacitive loads without an RS are allowed as the

signal gain increases (increasing the unloaded phase

margin). If a l o n g t r a c e i s r e q u i r e d , a n d t h e 6 - d B s i g n a l

loss intrinsic to a doubly-terminated transmission line

is acceptable, implement a matched impedance

transmission line using microstrip or stripline

techniques (consult an ECL design handbook for

microstrip and stripline layout techniques).

A 50-Ω environment is not necessary onboard, and in

fact, a higher impedance environment improves

distortion as shown in the distortion versus load plots.

With a characteristic board trace impedance based o n

board material and trace dimensions, a matching

series resistor into the trace from the output of the

THS3201 is used as well as a terminating shunt

resistor at the input of the destination device.

Remember also that the terminating impedance is t h e

parallel combination of the shunt resistor and the input

impedance of the destination device: this total

effective impedance should be set to match the trace

impedance. If the 6-dB attenuation of a doubly

terminated transmission line is unacceptable, a long

trace can be series-terminated at the source end only.

Treat the trace as a capacitive load in this case. This

does not preserve signal integrity as well as a

doubly-terminated line. If the input impedance of the

destination device is low, there is some signal

attenuation due to the voltage divider formed by the

series output into the terminating impedance.

D Socketing a high speed part like the THS3201 is not

recommended. The additional lead length and

pin-to-pin capacitance introduced by the socket can

create an extremely troublesome parasitic network

which can make it almost impossible to achieve a

smooth, stable frequency response. Best results are

obtained by soldering the THS3201 parts directly onto

the board.

S

18

www.ti.com

4

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

PowerPAD DESIGN CONSIDERATIONS

The THS3201 is available in a thermally-enhanced

PowerPAD family of packages. These packages are

constructed using a downset leadframe upon which the die

is mounted [see Figure 61(a) and Figure 61(b)]. This

arrangement results in the lead frame being exposed as a

thermal pad on the underside of the package [see

Figure 61(c)]. Because this thermal pad has direct thermal

contact with the die, excellent thermal performance can be

achieved by providing a good thermal path away from the

thermal pad.

The PowerPAD package allows for both assembly and

thermal management in one manufacturing operation.

During the surface-mount solder operation (when the

leads are being soldered), the thermal pad can also be

soldered to a copper area underneath the package.

Through the use of thermal paths within this copper area,

heat can be conducted away from the package into either

a ground plane or other heat dissipating device.

The PowerPAD package represents a breakthrough in

combining the small area and ease of assembly of surface

mount with the, heretofore, awkward mechanical methods

of heatsinking.

DIE

Side View (a)

DIE

End View (b)

Thermal

Pad

Bottom View (c)

Although there are many ways to properly heatsink the

PowerPAD package, the following steps illustrate the

recommended approach.

0.205

0.060

Pin 1

0.030

0.075 0.025

0.010

vias

0.013

0.035

Top View

0.017

0.09

0.040

Figure 62. DGN PowerPAD PCB Etch and Via

Pattern

Figure 61. Views of Thermally Enhanced Package

19

T

T

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

www.ti.com

PowerPAD PCB LAYOUT CONSIDERATIONS

1. Prepare the PCB with a top side etch pattern as shown

in Figure 62. There should be etch for the leads as well

as etch for the thermal pad.

2. Place five holes in the area of the thermal pad. These

holes should be 10 mils in diameter. Keep them small

so that solder wicking through the holes is not a

problem during reflow.

3. Additional vias may be placed anywhere along the

thermal plane outside of the thermal pad area. This

helps dissipate the heat generated by the THS3201

IC. These additional vias may be larger than the 10-mil

diameter vias directly under the thermal pad. They can

be larger because they are not in the thermal pad area

to be soldered so that wicking is not a problem.

4. Connect all holes to the internal ground plane.

5. When connecting these holes to the ground plane, do

not use the typical web or spoke via connection

methodology. Web connections have a high thermal

resistance connection that is useful for slowing the

heat transfer during soldering operations. This makes

the soldering of vias that have plane connections

easier. In this application, however, low thermal

resistance is desired for the most efficient heat

transfer. Therefore, the holes under the THS3201

PowerPAD package should make their connection to

the internal ground plane with a complete connection

around the entire circumference of the plated-through

hole.

6. The top-side solder mask should leave the terminals

of the package and the thermal pad area with its five

holes exposed. The bottom-side solder mask should

cover the five holes of the thermal pad area. This

prevents solder from being pulled away from the

thermal pad area during the reflow process.

7. Apply solder paste to the exposed thermal pad area

and all of the IC terminals.

8. With these preparatory steps in place, the IC is simply

placed in position and run through the solder reflow

operation as any standard surface-mount

component. This results in a part that is properly

installed.

POWER DISSIPATION AND THERMAL

CONSIDERATIONS

To maintain maximum output capabilities, the THS3201

does not incorporate automatic thermal shutoff protection.

The designer must take care to ensure that the design

does not violate the absolute maximum junction

temperature of the device. Failure may result if the

absolute maximum junction temperature of 150°C is

exceeded. For best performance, design for a maximum

junction temperature of 125°C. Between 125°C and

150°C, damage does not occur, but the performance of the

amplifier begins to degrade.

The thermal characteristics of the device are dictated by

the package and the PC board. Maximum power

dissipation for a given package can be calculated using the

following formula.

*

+

max

P

Dmax

where:

P

is the maximum power dissipation in the

Dmax

amplifier (W).

T

is the absolute maximum junction

max

temperature (°C).

TA is the ambient temperature (°C).

θ

= θJC + θ

JA

θ

is the thermal coefficient from the silicon

JC

CA

junctions to the case (°C/W).

θ

is the thermal coefficient from the case to

CA

ambient air (°C/W).

A

q

JA

20

www.ti.com

PD

d

F

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

For systems where heat dissipation is more critical, the

THS3201 i s o f fered in an 8-pin MSOP with PowerPAD and

the THS3201 is available in the SOIC−8 PowerPAD

package offering even better thermal performance. The

thermal coefficient for the PowerPAD packages are

substantially improved over the traditional SOIC.

Maximum power dissipation levels are depicted in the

graph for the available packages. The data for the

PowerP AD packages assume a board layout that follows

the PowerPAD layout guidelines referenced above and

detailed in the PowerPAD application note number

SLMA002. The following graph also illustrates the effect of

not soldering the PowerPAD to a PCB. The thermal

impedance increases substantially which may cause

serious heat and performance issues. Be sure to always

solder the PowerPAD to the PCB for optimum

performance.

4.0

3.5

3.0

2.5

2.0

1.5

1.0

− Maximum Power Dissipation − W

0.5

D

P

Results are With No Air Flow and PCB Size = 3”x3”

θJA = 158°C/W

0.0

−40 −20 0 20 40 60 80 100

TA − Free-Air Temperature − °C

θJA = 58.4°C/W

θJA = 58.4°C/W for 8-Pin MSOP w/PowerPad (DGN)

θJA = 98°C/W for 8-Pin SOIC High Test PCB (D)

θJA = 158°C/W for 8-Pin MSOP w/PowerPad w/o Solder

TJ = 125°C

θJA = 98°C/W

quantify because the signal pattern is inconsistent, but an

estimate of the RMS power dissipation can provide

visibility into a possible problem.

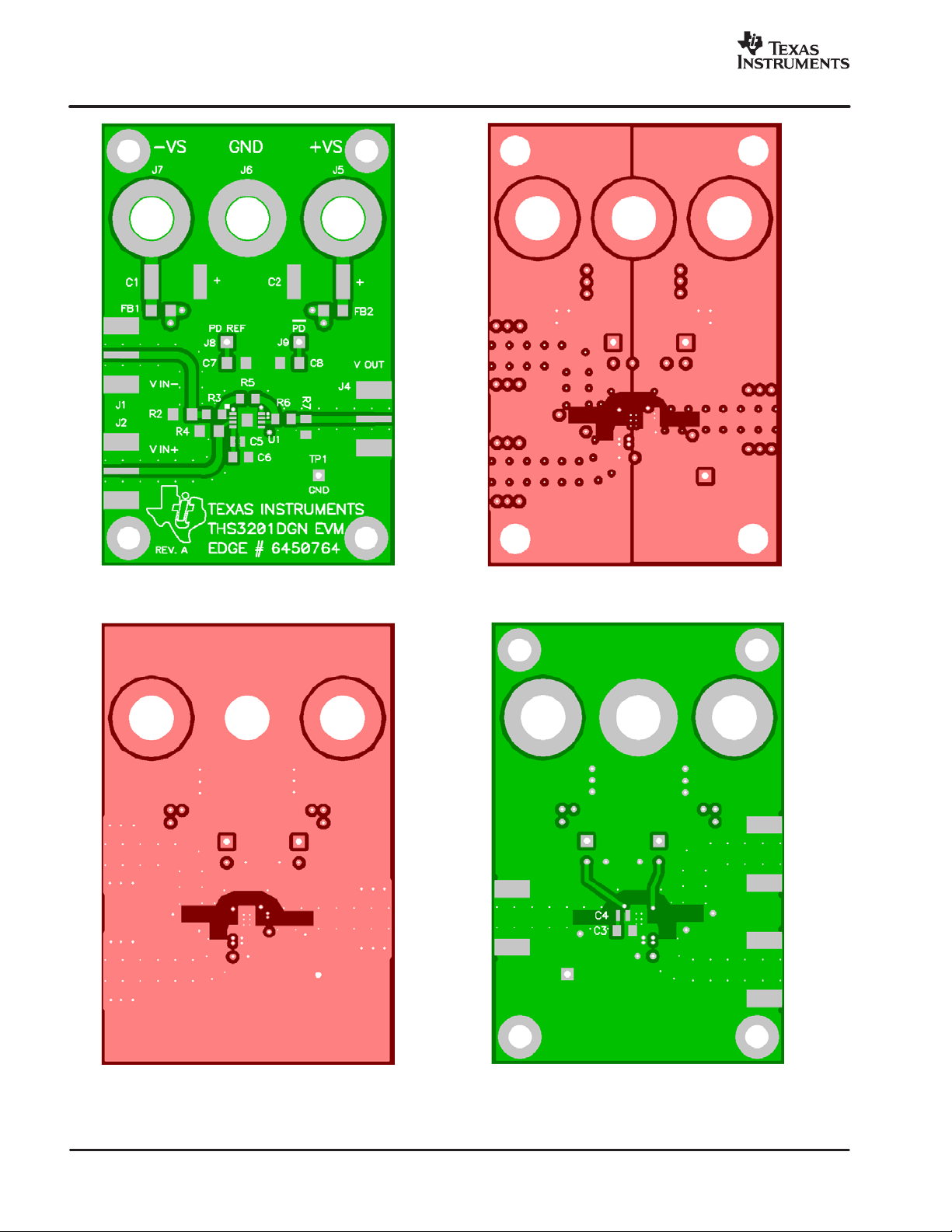

DESIGN TOOLS

Evaluation Fixture, Spice Models, and

Applications Support

Texas Instruments is committed to providing its customers

with the highest quality of applications support. To support

this goal an evaluation board has been developed for the

THS3201 operational amplifier. The board is easy to use,

allowing for straightforward evaluation of the device. The

evaluation board can be ordered through the Texas

Instruments web site, www.ti.com, or through your local

Texas Instruments sales representative. The schematic

diagram, board layers, and bill of materials of the

evaluation boards are provided below.

J9*

R6

C8*

R7

Not Populate

J4

Vout

Vs+

J1

Vin

−

0 Ω

J2

Vin+

49.9 Ω

*Does Not Apply to the THS3201

R3

768 Ω

R2

R4

2

3

7418

_

+

Vs−

R5

768 Ω

U1

C7*

J6

GND

PD

6

49.9 Ω

J8*

Ref

TP1

Figure 63. Maximum Power Dissipation vs

Ambient Temperature

When determining whether or not the device satisfies the

maximum power dissipation requirement, it is important to

not only consider quiescent power dissipation, but also

dynamic power dissipation. Often times, this is difficult to

C1

VS−

+

J7

22 µF

FB1

C6 C5

0.1 µF

VS−

100 pF

VS+

C4

100 pF 0.1 µF

C3

FB2

J5

VS+

Figure 64. THS3201 EVM Circuit Configuration

+

C2

22 µ

21

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

www.ti.com

Figure 65. THS3201 EVM Board Layout (Top

Layer)

Figure 67. THS3201 EVM Board Layout (Third

Layer, Power)

Figure 66. THS3201 EVM Board Layout (Second

Layer, Ground)

22

Figure 68. THS3201 EVM Board Layout (Bottom

Layer)

www.ti.com

SLOS416A − JUNE 2003 − REVISED JANUARY 2004

Table 2. Bill of Materials

THS3201DGN E V M

Item Description

1 Bead, ferrite, 3 A, 80 Ω 1206 FB1, FB2 2 (Steward) HI1206N800R−00

2 Cap, 22 µF , tanatalum, 25V, 10% D C1, C2 2 (AVX) TAJD226K025R

3 Cap, 100 pF, ceramic, 5%, 150V AQ12 C4, C5 2 (AVX) AQ12EM101JAJME

4 Cap, 0.1 µF, ceramic, X7R, 50V 0805 C3, C6 2 (A VX) 08055C104KAT2A

6 Open 0805 R7 1

7 Resistor, 49.9 Ω, 1/8W, 1% 0805 R6 1 (Phycomp) 9C08052A49R9FKHFT

9 Resistor, 768 Ω, 1/8W, 1% 0805 R3, R5 2 (Phycomp) 9C08052A7680FKHFT

10 Open 1206 C7, C8 2

11 Resistor, 0 Ω, 1/4W, 1% 1206 R2 1 (KOA) RK73Z2BLTD

12 Resistor, 49.9 Ω, 1/4W, 1% 1206 R4 1 (Phycomp) 9C12063A49R9FKRFT

13 Test point, black TP1 1 (Keystone) 5001

14 Open J8, J9 2

15 Jack, Banana Recptance, 0.25” dia. hole J5, J6, J7 3 (HH Smith) 101

16 Connector, edge, SMA PCB jack J1, J2, J4 3 (Johnson) 142−0701−801

17 Standoff, 4−40 hex, 0.625” length 4 (Keystone) 1804

18 Screw, Phillips, 4−40, .250” 4 SHR−0440−016−SN

19 IC, THS3201 U1 1 (TI) THS3201DGN

20 Board, printed circuit 1 (TI) Edge # 6447972 Rev.A

NOTE:The components shown in the BOM were used in test by TI.

SMD

Size

Ref Des

PCB

Quantity

Manufacturer’s Part Numb e r

Computer simulation of circuit performance using SPICE

is often useful when analyzing the performance of analog

circuits and systems. This is particularly true for video and

RF-amplifier circuits where parasitic capacitance and

inductance ca n h a v e a major ef fect o n circuit performance.

A SPICE model for the THS3201 is available through

either the Texas Instruments web site (www.ti.com) or as

one model on a disk from the Texas Instruments Product

Information Center (1–800–548–6132). The PIC is also

available for design assistance and detailed product

information at this number. These models do a good job of

predicting small-signal ac and transient performance

under a wide variety of operating conditions. They are not

intended to model the distortion characteristics of the

amplifier, nor do they attempt to distinguish between the

package types in their small-signal ac performance.

Detailed information about what is and is not modeled is

contained in the model file itself.

ADDITIONAL REFERENCE MATERIAL

PowerPAD Made Easy, application brief (SLMA004)

PowerPAD Thermally Enhanced Package, technical brief

(SLMA002)

Voltage Feedback vs. Current Feedback amplifiers,

(SLVA051)

Current Feedback Analysis and Compensation

(SLOA021)

Current Feedback Amplifiers: Review, Stability, and

Application (SBOA081)

Effect of parasitic capacitance in op amp circuits

(SLOA013)

23

PACKAGE OPTION ADDENDUM

www.ti.com

11-Feb-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

THS3201D ACTIVE SOIC D 8 75 Pb-Free

THS3201DBVR ACTIVE SOT-23 DBV 5 3000 Green (RoHS &

no Sb/Br)

THS3201DBVT ACTIVE SOT-23 DBV 5 250 Green (RoHS &

no Sb/Br)

THS3201DGK ACTIVE MSOP DGK 8 100 Green (RoHS &

no Sb/Br)

THS3201DGKR ACTIVE MSOP DGK 8 2500 Green (RoHS &

no Sb/Br)

THS3201DGN ACTIVE MSOP-

Power

DGN 8 80 Green (RoHS &

no Sb/Br)

PAD

THS3201DGNR ACTIVE MSOP-

Power

DGN 8 2500 Green (RoHS &

no Sb/Br)

PAD

THS3201DR ACTIVE SOIC D 8 2500 Pb-Free

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(RoHS)

(RoHS)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-2-260C-1YEAR/

Level-1-220C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-2-260C-1YEAR/

Level-1-220C-UNLIM

(3)

(2)

Eco Plan - May not be currently available - please check http://www.ti.com/productcontent for the latest availability information and additional

product content details.

None: Not yet available Lead (Pb-Free).

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean "Pb-Free" and in addition, uses package materials that do not contain halogens,

including bromine (Br) or antimony (Sb) above 0.1% of total product weight.

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDECindustry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...