Page 1

LM3464

Application Note 2071 LM3464A 4 Channel LED Driver Evaluation Board

Literature Number: SNVA449C

Page 2

LM3464A 4 Channel LED Driver Evaluation Board AN-2071

LM3464A 4 Channel LED

Driver Evaluation Board

Introduction

This evaluation board demonstrates the high power efficiency

and outstanding output current accuracy of the LM3464A typical application circuit. With four LED strings connected, the

total output power is about 50W. The schematic, bill of material and PCB layout drawing of the LM3464A evaluation board

are provided in this document. This evaluation board can be

adapted to different types of power supply with changes of a

few components. The PCB of this evaluation board is pin to

pin compatible to both LM3464 and LM3464A with 80V and

95V maximum input voltage respectively. The information being presented in this document are also applicable to both the

LM3464 and LM3464A.

The LM3464A is a 4 channel linear LED driver which combined the advantages of high power efficiency of switching

regulators and low current ripple of linear current regulators.

With the incorporation of the proprietary Dynamic Headroom

Control (DHC) technology, the LM3464A optimizes system

efficiency automatically while providing outstanding output

stability and accuracy. Each LED current regulators of this

board consists of an external MOSFET and a control circuit

inside the LM3464A to provide the best flexibility to fulfill the

needs of different applications. The LM3464A includes a builtin Low Drop-Out (LDO) voltage regulator which accepts an

input voltage up to 95V (LM3464A) to provide power and voltage references to internal circuits, allowing the LM3464A to

adapt to difference source voltages easily. The integrated

thermal foldback control circuit protects the LED Strings from

damages due to over-temperature. This eventually secures

the lifetime of the entire lighting system. The LM3464A includes a fault handling mechanism which latches off output

channels upon open or short circuit of the LED strings, preventing substantial damages due to failures of the LEDs. The

number of output channel can be expanded by cascading

several LM3464A evaluation boards to achieve high luminous

output.

National Semiconductor

Application Note 2071

SH Wong

June 3, 2011

Standard Settings of the Evaluation Board

• Vin range 12V to 95V (LM3464A)

• 48V LED turn ON voltage

• 350mA LED current per channel

• 2kHz thermal foldback dimming frequency

Because the LM3464A evaluation board is designed to turn

on the LED strings at 48V rail voltage, applying excessive input voltage to this board will increase power dissipation on the

MOSFETs and could eventually damage the circuit. In order

to avoid permanent damages, it is not recommended not to

apply higher than 60V input voltage to this evaluation board.

This board is generally designed to drive 4 LED strings at

350mA which each sting contains 12 serial LEDs. For driving

LED strings of different configuration, the value of a few components should be adjusted following the descriptions in this

document.

Highlight Features

• Dynamic Headroom Control (DHC)

• Thermal foldback control

• High speed PWM dimming

• Minimum brightness limit for thermal foldback control

• Cascade operation for output channel expansion

• Vin Under-Voltage-Lockout

• Fault protection and indication

• Programmable startup voltage

• Thermal Shutdown

© 2011 National Semiconductor Corporation 301271 www.national.com

Page 3

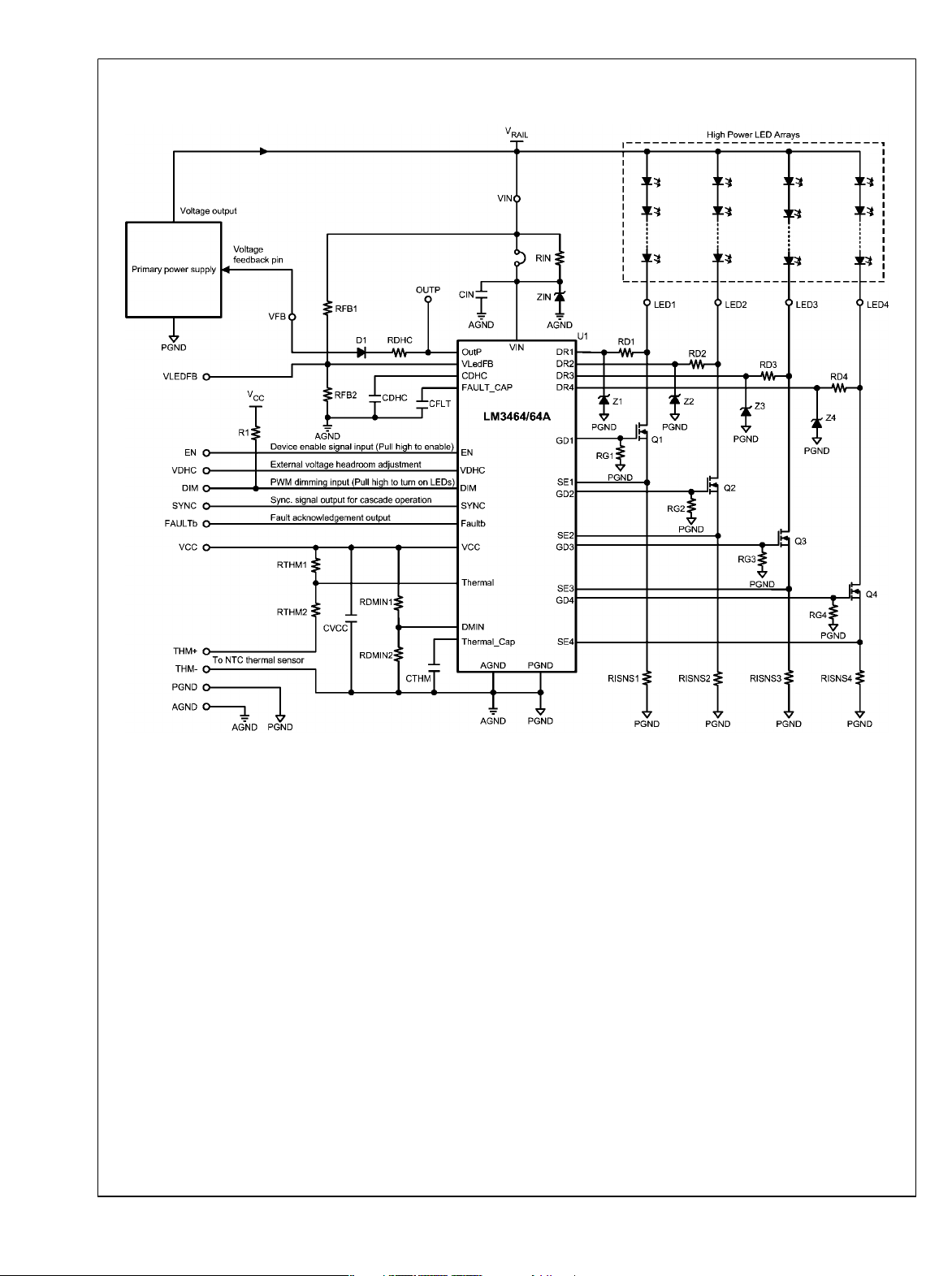

Evaluation Board Schematic

AN-2071

FIGURE 1. LM3464A Evaluation Board Schematic

www.national.com 2

30127101

Page 4

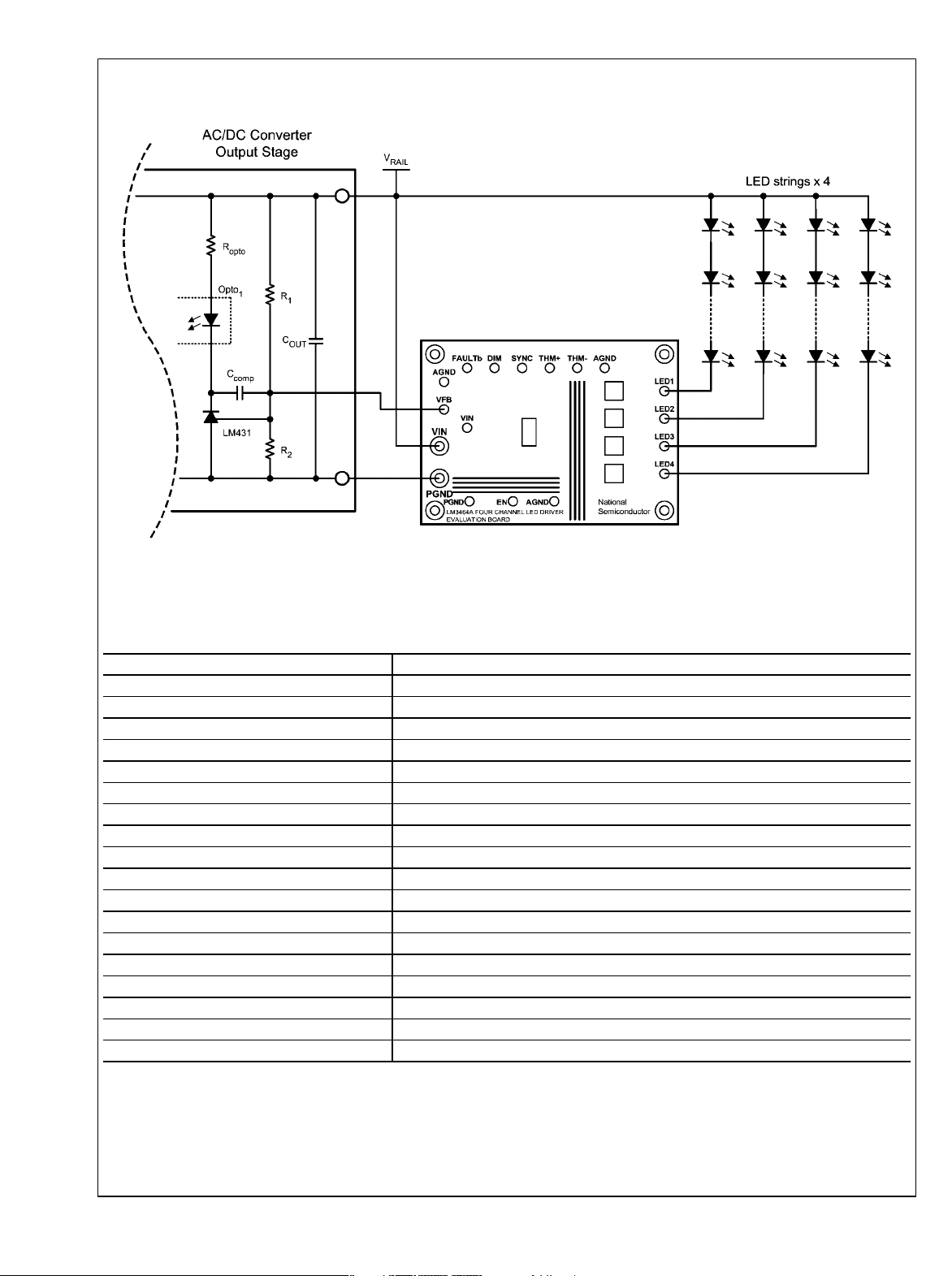

Bill of Materials

Designation Description Package Manufacturer Part # Vendor

U1 LED Driver IC, LM3464A eTSSOP-28 eTSSOP-28 LM3464AMH NSC

D1 Schottky Diode 40V 1.1A DO219AB DO219AB SL04-GS08 Vishay

Q1,Q2,Q3,Q4

CIN Cap MLCC 100V 2.2uF X7R 1210 1210 GRM32ER72A225KA35L Murata

CVCC Cap MLCC 10V 1uF X5R 0603 0603 GRM185R61A105KE36D Murata

CDHC Cap MLCC 50V 0.22uF X5R 0603 0603 GCM188R71H224KA64D Murata

CFLT Cap MLCC 50V 2.2nF X7R 0603 0603 GRM188R71H222KA01D Murata

CTHM Cap MLCC 50V 68nF X7R 0603 0603 GRM188R71H683KA01D Murata

R1 Chip Resistor 8.06Kohm 1% 0603 0603 CRCW06038K06FKEA Vishay

RTHM1 Chip Resistor 4.87Kohm 1% 0603 0603 CRCW06034K87FKEA Vishay

RTHM2 Chip Resistor 232ohm 1% 0603 0603 CRCW0603232RFKEA Vishay

RDMIN1 Chip Resistor 15.4Kohm 1% 0603 0603 CRCW060315K4FKEA Vishay

RDMIN2 Chip Resistor 1.05Kohm 1% 0603 0603 CRCW06031K05FKEA Vishay

RDHC Chip Resistor 2.67Kohm 1% 0603 0603 CRCW06032K67FKEA Vishay

RFB1 Chip Resistor 48.7Kohm 1% 0603 0603 CRCW060348K7FKEA Vishay

RFB2 Chip Resistor 2.67Kohm 1% 0603 0603 CRCW06032K67FKEA Vishay

RISNS1, RISNS2,

RISNS3, RISNS4

RIN, RD1, RD2, RD3,

RD4

VIN,PGND Banana Jack 5.3(mm) Dia 5.3 (mm) Dia. 575-8 Keystone

FAULTb,DIM, SYNC,

THM+, THM-,

AGND, VFB, VIN,

PGND, EN

LED1, LED2, LED3,

LED4

PCB LM3464EVAL PCB 82.5 X 60 (mm) 82.5 x 60 (mm) N/A NSC

RG1, R2, RG3, RG4 No Connection 0603

ZIN, Z1, Z2, Z3, Z4 No Connection SMA

MOSFET N-CH 150V 29A D-PAK D-PAK FDD2572 Fairchild

MOSFET N-CH 150V 50A TO252–3 TO252–3 IPD200N15N3 Infineon

Chip Resistor 1.13ohm 1% 0603 0603 CRCW06031R13FKEA Vishay

Chip Resistor 0ohm 1% 0603 0603 CRCW06030000Z0EA Vishay

Turret 2.35(mm) Dia 2.35 (mm) Dia. 1502-2 Keystone

Turret 2.35(mm) Dia 2.35 (mm) Dia. 1502-2 Keystone

Turret 2.35(mm) Dia 2.35 (mm) Dia. 1502-2 Keystone

AN-2071

3 www.national.com

Page 5

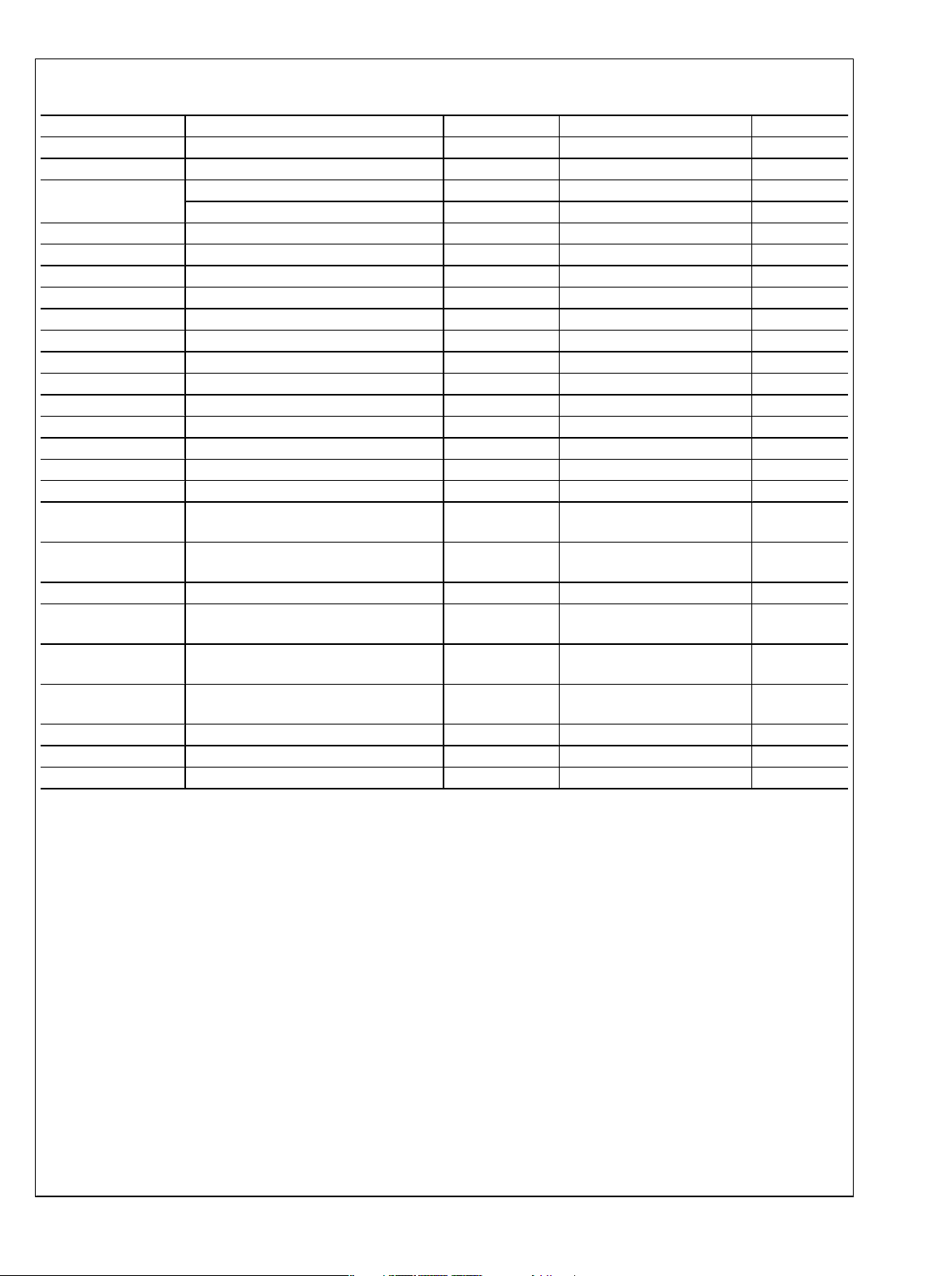

Connectors and Test Pins

AN-2071

30127102

FIGURE 2. Typical Connection Diagram

Evaluation Board Quick Setup Procedures

Terminal Designation Description

VIN Power supply positive (+ve) connection

PGND Power supply negative (-ve) connection

AGND LM3464A analog signal ground

LED1 Output Channel 1 (Connect to cathode of LED string 1)

LED2 Output Channel 2 (Connect to cathode of LED string 2)

LED3 Output Channel 3 (Connect to cathode of LED string 3)

LED4 Output Channel 4 (Connect to cathode of LED string 4)

EN LM3464A enable pin (pull down to disable)

VFB Connect to voltage feedback node of primary power supply for DHC

FAULTb Acknowledgement signal for arising of ‘FAULT’

DIM PWM dimming signal input (TTL signal compatible)

SYNC Synchronization signal for cascade operation

THM+ Connect to NTC thermal sensor for thermal foldback control

THM- Connect to NTC thermal sensor for thermal foldback control

VLEDFB Connected to LM3464A VLedFB pin

OUTP Connected to LM3464A OutP pin

VCC LM3464A internal voltage regulator output

VDHC Connected to LM3464A VDHC pin

www.national.com 4

Page 6

AN-2071

Structure of the System

A LM3464A LED lighting system is basically consist of three

main parts, the LM3464A evaluation board, an AC/DC power

supply and an LED array containing four LED strings. In general, the LM3464A evaluation board can be regarded as four

independent current sources that the dropout voltages on the

current sources are being monitored by an internal circuit that

generates the DHC signal. The LM3464A evaluation board is

designed to drive 4 LED strings of 12 LEDs in series. With

350mA driving current for every LED string, the default total

output power of the LM3464A evaluation board is around

60W. In order to ensure proper operation, the AC/DC power

supply and LED array should be selected following the steps

presented in this document.

Selection of AC/DC Power Supply

The LM3464A evaluation board can be powered by an AC/

DC power supply through the banana-plug type connectors

on the board as shown in figure 2. Assuming the nominal forward voltage of one LED is 3.5V, the total forward voltage of

a LED string containing 12 LED is about 42V. In order to reserve extra voltage headroom to compensate the variations

of the LED forward voltages due to changes of operation temperature, the LED turn ON voltage of this evaluation board is

set to 48V. As this evaluation board is designed to deliver

350mA for each output channel, which is about 60W output

power at 48V rail voltage, the AC/DC power supply must be

able to supply no less than 60W continuous output power at

48V. Therefore, a 60W AC/DC power supply with 48V output

voltage is needed.

In order to facilitate Dynamic Headroom Control (DHC), the

output voltage of the AC/DC power supply is adjusted by the

LM3464A. The LM3464A adjusts the output voltage of the AC/

DC power supply by sinking current from the output voltage

feedback node of the AC/DC converter through a resistor

RDHC into the OutP pin according to the dropout voltage of

the linear current regulators. The OutP pin of the LM3464A is

a open drain pin that can only sink current from the voltage

feedback node of the AC/DC power supply, thus the

LM3464A evaluation board is only able to increase the output

voltage of the AC/DC power supply to acquire wider voltage

headroom.

Since the output voltage of the AC/DC converter will be increased by the LM3464A to allow dynamic head room control

(DHC), the nominal output voltage of the AC/DC power supply

must be reduced prior to connecting to the LM3464A evaluation board to reserve voltage headroom for DHC to take

place. This is achieved by modifying the resistance of the

output voltage sensing resistors of the AC/DC power supply.

To adapt the AC/DC power supply to the LM3464A evaluation

board, the nominal output voltage of the AC/DC power supply

is recommended to be reduced from 48V to 36V. Usually, the

nominal output voltage of the AC/DC power supply can be

reduced by changing the resistance of the resistor divider for

output voltage feedback. Figure 2 shows the voltage feedback circuit using LM431 which has been widely used in

typical AC/DC power supplies as an example.

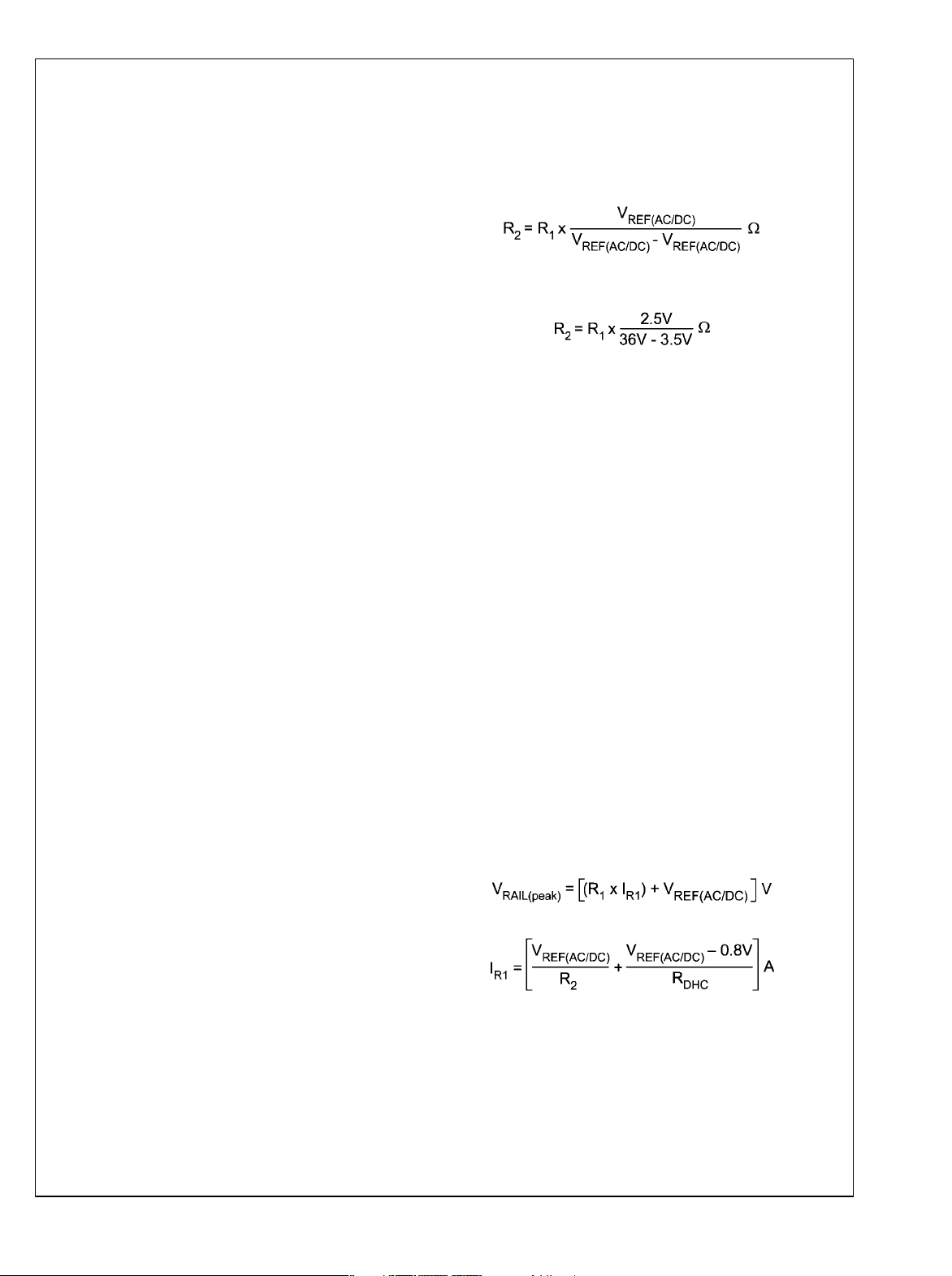

To reduce the output voltage of the AC/DC power supply from

48V to 36V, the resistance of R2 is increased without changing

the value of R1. The output voltage and value of R2 are related

by the following equations:

(1)

For V

And V

REF(AC/DC)

RAIL(nom)

= 2.5V

= 36V:

(2)

In the above equations, V

of the AC/DC converter for output voltage feedback. V

is the objective rail voltage level being adjusted to. In this

(nom)

example, reducing of the rail voltage is achieved by increasing

REF(AC/DC)

is the reference voltage

RAIL

the value of R2. With the rail voltage is reduced to 36V, the

LED strings are unable to be driven at 350mA due to insufficient voltage headroom until the DHC loop functions. In order

to ensure the LED strings an regulated driving current at the

time that the LED stings being turned on, the LM3464A increases the output voltage of the AC/DC power supply

(V

) from 36V to 48V (V

RAIL

LED strings. The level of V

of the resistors, RFB1 and RFB2. Figure 3 shows the changes

of V

upon the AC/DC power supply is powered until the

RAIL

system enters steady state operation.

DHC_READY

DHC_READY

) prior to turning on the

is defined by the value

As the output voltage of the AC/DC power supply is depending on the current being sunk from the output voltage feedback node of the AC/DC power supply, the output voltage

could increase to exceed the rated output voltage of the AC/

DC power supply and damage the system if the resistance of

the RDHC is too low and the OutP pin of the LM3464A is accidentally shortened to GND (V

value of the RDHC must be selected appropriately following

the equations below. In the equations, V

imum voltage that V

to GND. R1 and R2 are the resistors of the output voltage

can reach if the OutP pin is shortened

RAIL

= 0V). To avoid this, the

OutP

RAIL(peak)

is the max-

feedback resistor divider of the AC/DC power supply. When

designing the values of the RDHC, it is essential to ensure

that the V

of the AC/DC power supply, otherwise the AC/DC power sup-

RAIL(peak)

does not exceed the rated output voltage

ply could be damaged.

(3)

where

(4)

5 www.national.com

Page 7

AN-2071

FIGURE 3. Changes of Rail Voltage Upon Power Up

Setting of V

When V

pin of the LM3464A equals 2.5V. As the voltage at the

RAIL

DHC_READY

reaches V

DHC_READY

, the voltage at the VLedFB

VLedFB pin reaches 2.5V, the LM3464A performs a test for

no long than 400uS to identify and exclude the idle (no LED

connected) or failed (shorten / open circuit of LED string) output channels from the DHC loop. When a LED string is open

circuit, the voltage drop on the current sensing resistors

(V

— V

SE1

maintains below 30mV longer than the fault detection time

) is below 30mV. If the voltage of the SEx pin

SE4

defined by CFLT, an 'open fault' is recognized. When a LED

string is short circuit, causing the drain voltage of an external

MOSFET 8.4V higher than the drain voltage of any other

channel and maintains longer than the fault detection time

defined by CFLT, an short fault is recognized. Either a short

or open fault will cause the Faultb pin to pull low. When a LED

string experiences an open or short circuit, the corresponding

output channel will be disabled and excluded from the DHC

loop to sustain normal operation of the remaining LED strings.

The LM3464A will maintain the failed channels in disable

state until the EN pin is pulled low or the entire system is repowered. When the test is completed, the LM3464A enables

the output channels and provides constant current to the LED

strings.

The level of V

RFB2 on the evaluation board and can be adjusted to any

DHC_READY

is defined by the values of RFB1 and

level below 80V / 95V (LM3464/LM3464A) as desired. By default, the V

no more than 20V higher than the forward voltages of any LED

DHC_READY

is set at 48V. The V

DHC_READY

must set

30127103

string connected to the system under possible temperatures,

otherwise a ‘short fault’ may arise and results in immediate

output channel latch-off to protect the MOSFETs from overheat. The V

(5):

DHC_READY

is can be adjusted following equation

(5)

Adjusting Voltage Headroom

The voltage headroom of the LM3464A evaluation board can

be altered by adjusting the voltage at the VDHC pin (V

in the range of 0.8V to 2V. For the applications with high rail

voltage ripple, the voltage headroom should be increased to

secure accurate output current regulation. By default, the VDHC pin is biased internally to 0.9V as shown in figure 4.

VDHC

)

www.national.com 6

Page 8

30127104

FIGURE 4. Adjusting the VDHC Pin Voltage

To adjust V

tor divider (RA and RB) can be added across the VDHC test

pad and VCC or AGND terminals on the board. The values of

of RA and RB should be below 100kΩ and 16kΩ respectively

to ensure the accuracy of the headroom voltage under steady

state. The V

where

on the evaluation board, an additional resis-

VDHC

is governed by the following equation:

VDHC

(6)

Connecting the LED Strings

The LM3464A evaluation board is designed to drive 4 common anode LEDs strings of 12 serial LEDs per string. The

board includes four turret connectors, LED1, LED2, LED3 and

LED4 for cathode connections of the LED strings. The anode

of the LED strings should connect to the positive power output

terminal of the AC/DC power supply. By default, the output

current for each output channel is set at 350mA. The output

currents of the LM3464A evaluation board can be programmed individually by changing the value of the resistors

RISNS1, RISNS2, RISNS3 and RISNS4 accordingly. The

LED driving current is governed by the following equation:

(8)

Adjusting Frequency Response of the LM3464A Circuit

The frequency response of the LM3464A evaluation board

can be adjusted by changing the value of the capacitor,

C

. Higher capacitance of C

DHC

response of the LM3464A driver stage. In order to ensure

stable system operation, it is recommended to set the dominant pole of the LM3464A one decade lower than the dominant pole of the AC/DC converter. The default value of the

C

on the evaluation board is 0.22uF. For applications with

DHC

slow response AC/DC power supply (e.g. converters with active PFC), the value of CDHC should be increased to make

the frequency response of the board slower than the response

of the AC/DC power supply. The cut-off frequency of the

LM3464A driver stage is governed by the following equation:

results in slower frequency

DHC

AN-2071

(7)

(9)

7 www.national.com

Page 9

Thermal Foldback Control

The LM3464A evaluation board features an interface that en-

AN-2071

ables thermal foldback control by connecting a NTC thermal

sensor to the THM+ and THM- terminals. With the NTC sensor attached to the chassis of the LEDs, the integrated thermal foldback control circuit reduces the average LED current

and effectively reduces the LED temperature to prevent thermal breakdown of the LEDs. The thermal foldback control

circuit reduces the LED currents by means of PWM dimming

which the dimming frequency is set by the capacitor, CTHM

following the equation shows below:

(10)

The default value of the CTHM on the LM3464A evaluation

board is 68nF, which set the thermal foldback dimming frequency at 258Hz.

Thermal foldback control is activated when the voltage at the

Thermal pin, V

in figure 5. Thermal foldback control begins when V

below 3.25V. The LED current will be reduced to zero as

V

falls below 0.4V. The average LED current varies ac-

Thermal

cording to the Thermal pin voltage following the equation:

is in between 3.25V and 0.4V as shown

Thermal

Thermal

is

(11)

FIGURE 5. Changes of Average LED Current with Thermal Foldback Control

When the voltage at the DMIN pin is below 0.4V, the minimum

on time for thermal foldback control is restricted by the value

of C

. As the voltage of the Thermal pin is set below 0.4V,

THM

the on time for all output channels equals the discharge time

of the C

following the equation:

THM

(12)

30127113

Thus the minimum dimming duty cycle for thermal foldback is

calculated approximately equal to 0.5%:

(13)

www.national.com 8

Page 10

Design Example

AN-2071

FIGURE 6. Attaching NTC Thermistor to the LEDs

A NTC thermistor is connected to the THM+ and THM- terminals of the LM3464A evaluation board as shown in figure

6 to activate the thermal foldback control function.

Assuming that thermal foldback control is required to begin at

70°C LED chassis temperature and reduce 55% average LED

current (45% dimming duty cycle) when the chassis temperature reaches 125°C. Using the NTC thermister NXFT15WB473FA1B from MURATA, which has 4.704kΩ resistance at

70°C (R

V

at 125°C (45% dimming duty cycle):

Thermal

) and 1.436kΩ at 125°C (R

NTC(70°C)

NTC(125°C)

).

(14)

(15)

(16)

In the above equation, V

pin and D

back control. When thermal foldback begins:

is the dimming duty cycle under thermal fold-

THMFB

is the voltage at the Thermal

Thermal

(17)

(18)

(19)

When the temperature goes up to 125°C

30127114

(20)

By combining the equations (17) and (18), the values of

RTHM1 and RTHM2 can be obtained:

(21)

The default values of RTHM1 and RTHM2 on the LM3464A

evaluation board are 4.87kΩ and 232Ω respectively.

Minimum Dimming Duty Cycle for Thermal Foldback Control

The minimum dimming duty cycle for thermal foldback control

(D

THMFB_MIN

pin of the LM3464A. The minimum dimming duty cycle limit

overrides the minimum dimming level defined by RTHM1,

RTHM2 and the NTC thermistor. This function is especially

useful for the applications that require to maintain certain

brightness level under high operation temperature. The level

) can be limited by setting the voltage at the DMIN

9 www.national.com

Page 11

of minimum duty cycle limit is governed by the following equation:

AN-2071

PWM Dimming

PWM dimming control can be realized by applying PWM dimming signal to the DIM terminal of the board directly. When

the DIM pin is pulled to logic high, all output channles are

enabled. When the DIM pin is pulled to logic low (GND), all

(22)

output channels are turned OFF. In cascade operation, the

DIM signal should only be applied to the MASTER unit. The

LM3464A on the MASTER unit propagates the PWM dimming

signal on its DIM pin to the slave units one by one through the

SYNC pin. PWM dimming control is allowed when thermal

foldback control is activated. When PWM dimming and thermal foldback controls are required simultaneously, the PWM

dimming frequency should be set at least ten times below the

thermal foldback dimming frequency. The thermal foldback

dimming signal reduces the LED currents according to the

voltage at the Thermal pin when the signal at the DIM pin is

being pulled ‘high’ as shown in figure 7.

30127115

FIGURE 7. Thermal Foldback + PWM Dimming Control

www.national.com 10

Page 12

Cascade Operation

AN-2071

FIGURE 8. Cascading LM3464A Evaluation Boards for Output Channel Expansion

11 www.national.com

30127162

Page 13

The total output power of the LED lighting system can be expanded by cascading the LM3464A evaluation boards. In

cascade operation, the system involves one master unit and

AN-2071

multiple slave units. Both master and slave units are

LM3464A evaluation boards with minor modifications to program the LM3464A into master or slave modes. The connection diagram for cascade operation is shown in figure 8. The

master unit is responsible to provide functions as listed in below:

1. Detect rail voltage upon system startup

2. Command slave units to turn on LEDs as its VLedFB voltage reaches 2.5V

3. Provide dimming signal to slave units according to the

PWM dimming signal received at its DIM pin

4. Provide dimming signal to slave units according to the voltage of its Thermal pin

By default, the LM3464A evaluation board is set to master

mode. To set the board to slave mode, the following changes

to the board are required:

• Remove resistors RFB1 and RFB2

• Connect VLEDFB to VCC

When connecting the master and slaves, the following connections are required:

• Connect the VIN terminal of master and slave units together

and then to the POSITIVE output of the AC/DC power supply

• Connect the PGND terminal of master and slave units together and then to the NEGATIVE output of the AC/DC power

supply

• Connect the SYNC terminal of the master unit to DIM terminal of the next slave unit in the chain.

• Connect the VFB terminal of master and slave units together

and then to the voltage feedback node of the AC/DC power

supply.

If more than one slave unit is required, the SYNC pin of the

first slave unit should connect to the DIM pin of the next slave

unit to allow propagation of the control signal along the system

chain.

Connection To Led Arrays

When LEDs are connected to the LM3464A driver stage

through long cables, the parasitic components of the cable

harness and external MOSFETs may resonant and eventually lead to unstable system operation. In applications that the

cables between the LM3464A driver circuit and LED light engine are longer than 1 meter, a 4.7kΩ resistor should be

added across the GDx pins to GND as shown in Figure 12.

30127164

FIGURE 9. Additional Resistor Across GDx and SEx for

Cable Harness Over 1m Long

www.national.com 12

Page 14

AN-2071

FIGURE 10. Additional Voltage Clamping Circuits for V

Applications With High Rail Voltage

Since the LM3464A is rated to 95V supply voltage, applying

a voltage to any pin of the device exceeding the absolute rated

voltage could damage the device permanently. For the applications that the rail voltage could increase to exceed 95V,

external voltage clamping circuit must be added to the Vin and

DRx pins to avoid system breakdown. Figure 13 shows a typical application circuit with 150V peak rail voltage.

In figure 13, Z1, Z2, Z3, Z4 and ZIN are zener diodes for limiting

voltages at the DRx and VIN pins of the LM3464A. The reverse voltage of the selected zener diodes must not exceed

the rated voltage of the corresponding pin. For the LM3464A

30127165

RAIL(peak)

> 80V/95V (LM3464A)

evaluation board, the reverse voltage of the additional zener

diodes must not exceed 95V. The resistors R

R

, R

DR3

difference across the DRx pins and V

Calculating the Values of Zx and R

and RIN are resistors for absorbing the voltage

DR4

RAIL

DRx

.

:

DR1

, R

DR2

,

Since the current being passed through the zener diodes are

derived by the resistance of R

be calculated properly according to the reverse current of the

, the value of the R

DRx

DRx

must

zener diode and input current of the DRx pins of the LM3464A

avoid unnecessary power dissipations. For instant, a 500mW/

75V zener diode CMHZ5267B (Central Semiconductor) is

used to clamp the DRx pins at 75V. Because the reverse cur-

13 www.national.com

Page 15

rent of the CMHZ5267B is 1.7mA at 75V zener voltage, the

maximum allowable reverse current is 6.67mA at 500mW

power dissipation.

AN-2071

Given that the input current of the DRx pins of the LM3464A

at 100V is 63uA maximum, if the DRx pin voltage is below

100V, the current flowing into the DRx pin (I

63uA. In the following calculations, I

to reserve operation margin to compensate the characteris-

is assumed to 63uA

DRx

tics variations of the components.

Because V

pins, the maximum resistance of R

RAIL(peak)

lowing this equation:

is the possible highest voltage at the DRx

can be calculated fol-

DRx

Where VZ and IZ are the reverse voltage and current of the

zener diode Zx respectively.

For V

RAIL(peak)

= 150V, the maximum value of R

) is below

DRx

is:

DRx

Thus, a standard 42.2kΩ resistor with 0.25W power rating

(1206 package) and 1% tolerance can be used.

Calculating the Values of ZIN and RIN:

Assume the VIN pin of the LM3464A is about to be clamped

to 75V, a 1.5W/75V zener diode CMZ5946B from Central

Semiconductor is used to ensure adequate conduction current for ZIN. Because the reverse current of the CMZ5946B is

5mA at 75V, the allowable current flows through ZIN is in between 5mA to 20mA. Similar to the requirements of selecting

the Zx and R

is clamped to 75V by a voltage clamping circuit consists of

, the voltage at the VIN pin of the LM3464A

DRx

ZIN and RIN. Also since the maximum operating and shutdown current (VEN < 2.1V) are 3mA and 700uA respectively,

to ensure the voltage of the VIN pin is clamped close to 75V

even when the LM3464A is disabled, the value of RIN should

be calculated following the equations below:

Maximum value of RIN:

And the minimum value of R

Thus, the value of R

DRx

is:

DRx

must be selected in the range:

To minimize power dissipation on the zener diodes, a standard 42.2kΩ resistor can be used for the R

power dissipation on the R

is then equals to:

DRx

. The maximum

DRx

Minimum value of RIN:

So the value of RIN must be in the range:

To minimize power dissipations on both the ZIN and RIN, a

standard 9.31kΩ resistor can be selected for the RIN. Then

the maximum power dissipation on RIN is:

Thus, a standard 9.38kΩ resistor with 2512 package (1W)

and 1% tolerance can be used.

www.national.com 14

Page 16

AN-2071

Typical Performance and Waveforms All curves taken at V

= 48V with configuration in typical

IN

application for driving twelve power LEDs with four output channels active and output current per channel = 350mA. TA = 25°C,

unless otherwise specified.

Output Current Variation

30127120

VCC Variation (%)

Efficiency (%)

30127121

DHC in Cascade Operation

V

of Master Unit

SYNC

30127122

30127124

30127123

V

at System Startup

SYNC

30127125

15 www.national.com

Page 17

Evaluation Board Layout

AN-2071

30127126

FIGURE 11. Top Layer and Top Overlay

30127127

FIGURE 12. Bottom Layer and Bottom Overlay

www.national.com 16

Page 18

Notes

AN-2071

17 www.national.com

Page 19

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

www.national.com

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH® Tools www.national.com/webench

Audio www.national.com/audio App Notes www.national.com/appnotes

Clock and Timing www.national.com/timing Reference Designs www.national.com/refdesigns

Data Converters www.national.com/adc Samples www.national.com/samples

Interface www.national.com/interface Eval Boards www.national.com/evalboards

LVDS www.national.com/lvds Packaging www.national.com/packaging

Power Management www.national.com/power Green Compliance www.national.com/quality/green

Switching Regulators www.national.com/switchers Distributors www.national.com/contacts

LDOs www.national.com/ldo Quality and Reliability www.national.com/quality

LED Lighting www.national.com/led Feedback/Support www.national.com/feedback

Voltage References www.national.com/vref Design Made Easy www.national.com/easy

PowerWise® Solutions www.national.com/powerwise Applications & Markets www.national.com/solutions

Serial Digital Interface (SDI) www.national.com/sdi Mil/Aero www.national.com/milaero

Temperature Sensors www.national.com/tempsensors SolarMagic™ www.national.com/solarmagic

PLL/VCO www.national.com/wireless PowerWise® Design

University

www.national.com/training

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2011 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Technical

Support Center

Email: support@nsc.com

AN-2071 LM3464A 4 Channel LED Driver Evaluation Board

www.national.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

Page 20

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Audio www.ti.com/audio Communications and Telecom www.ti.com/communications

Amplifiers amplifier.ti.com Computers and Peripherals www.ti.com/computers

Data Converters dataconverter.ti.com Consumer Electronics www.ti.com/consumer-apps

DLP® Products www.dlp.com Energy and Lighting www.ti.com/energy

DSP dsp.ti.com Industrial www.ti.com/industrial

Clocks and Timers www.ti.com/clocks Medical www.ti.com/medical

Interface interface.ti.com Security www.ti.com/security

Logic logic.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Power Mgmt power.ti.com Transportation and Automotive www.ti.com/automotive

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Mobile Processors www.ti.com/omap

Wireless Connectivity www.ti.com/wirelessconnectivity

TI E2E Community Home Page e2e.ti.com

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2011, Texas Instruments Incorporated

Loading...

Loading...