-

MINI

FLEXIBLE

DISK

DRIVE

INSTRUCTION

MANUAL

TEAC

FD-55(L)

MINI FLEXIBLE DISK

INSTRUCTION

MANUAL

DRIVE

P/N

10131159-0CA

-

1.

-

TABLE

OF

CONTENTS

2-1

INSTRUcrIONS

2-1-1

2-1-2

2-1-3

2-1-4

2-1-5

2-1-6

2-2

INSTRUcrIONS

2-

2-1

2-2-2

2-2-2-1

2-2-2-2

2-2-2-3

2-2-3

2-2-3-1

2-2-3-2

Disk

Disk

Write

FDD

Installation

Precautions

Precautions

Connector

Setting

...•...............................................•.........

Handling

Protect

Handling

Signal

Power

Frame

Terminators

Straps

Title

FOR

HANDLING

...........

..........................................

~

........

......................................

and

Ejection

for

Transportation

FOR INSTALLATION

for

Installation

and

Cable

connector

connector

grounding

of

Straps

and

..........................................................

Connection

and

aria

................................................

and

interface

of

Disk

... ~ ...............•..................

cable

cable

Terminator

........•..•.......................•...

drivers

...................................

..................••.................

........................•..........

.........................•.•.........

...........•................•...•

"

..............................

~

.............

............•...................

.............•...........•....

Page

201

201

205

209

.

210

.

211

213

214

214

216

217

221

223

225

226

229

2-2-3-3

2-2-3-4

2-2-3-5

2-2-4

2-2-5

2 - 3

2-4

2-4-1

2-4-2

2-4-3

2-

5 WRITE/READ

2-5-1

2-5-2

Turn-on

Rotating

Operating

Inductive

Front

CONTROL P ROCEDURE

POWER

SUPPLY

Power

Internal

Current

Single

Double

conditions

conditions

conditions

Noise

Bezel

On

Density

Densi

......................................................

............•..........................................

and

Current

Consumption

METHOD

ty

of

front

of

of

in

Installed

................•..............•..................

Off

........•........•.................•..•..........

Consumption

Timing

....................................•.............

.........•.................................•.......

.......•.....•.....•..............•................

spindle

head

Environment

of

Chart

bezel

motor

load

the

.................................

indicator

........•........•.........

solenoid

FDD

...........•.........

•........................

.........•................

....................

237

240

242

244

248

2

50

255

255

257

261

264

265

267

-

ii

-

2-1.

INSTRUCTIONS FOR

The

to

TEAC

as

FDD)

FD-55(L)

does

HANDLING

series

not

require

mini

flexible

specially

disk

delicate

drive

(hereinafter

handling

as

long

referred

as

it

is

2-1-1.

handled

The

same

Read

or

through

system

Disk

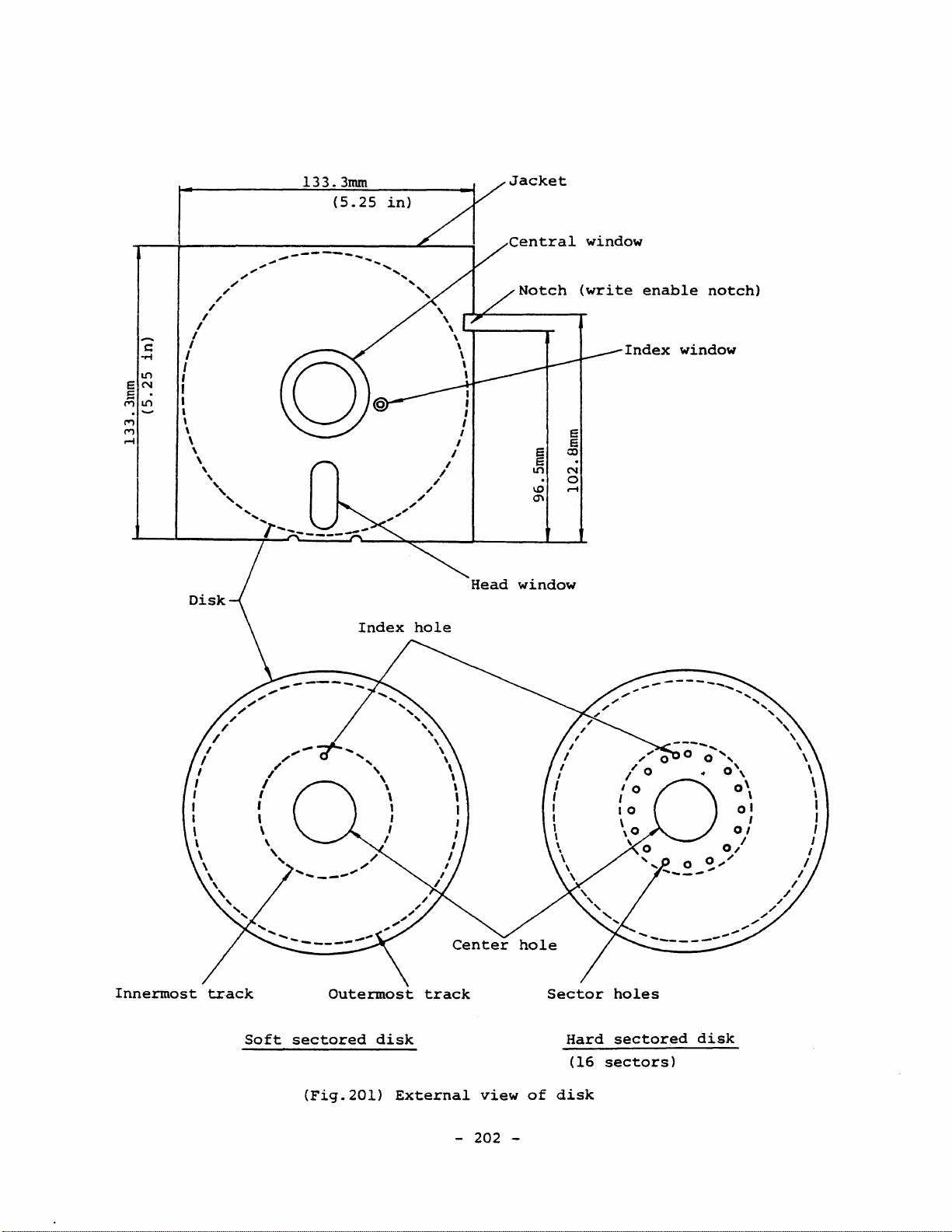

Two

(hereinafter

One

by

means

records

The

disk

Fig.20l

that

according

care

design

types

is

hard

an

FD-55

is

used

shows

the

as

other

and

referred

so

are

commercially

referred

sectored

of

sector

identification

may

be

only

the

hard

sectored

to

that

used

for

external

the

similar

to

method,

holes.

with

some

following

to

this

the

FDD

available

as

disk)

The

pattern

either

specific

view

disk

has

mini

Instruction

can

which

other

of

the

instructions.

flexible

show

for

the

5.25

according

detects

is

soft

on

the

initial

type

of

applications.

the

disks.

same

number

disk

Manual

expected

to

each

sectored

disks.

drives

inch

the

sector

position

The

of

is

before

performance.

(mini)

sectoring

photo-electrically

method

Generally,

only

difference

sector

required.

your

operation

flexible

of a track.

which

of

each

hard

holes

sector.

sectored

as

disks

is

the

number

The

of

disk

polyethylene

in a vinyl

-the

disk

driving

with

the

(index

In

high

window).

order

quality

sectors,

itself

chloride

surface.

window

disk

to

maintain

on

film

(central

(head

disks.

on a concentric

which

with

The

coated

jacket

jacket

data

with

window),

window),

high

data

-

are

magnetic

liner

has

oval

and

index/sector

reliability,

201

circle

recorded

surfaces.

to

open

areaSi

window

-

together

is

retain

for

it

made

The

dust

disk

magnetic

hole

is

recommended

with

of

an

80~

disk

without

positioning

head

detection

index

thick

is

protected

damage

window

to

hole.

and

disk

contact

use

to

133.3mm

(5.25

in)

.-

Central

Notch

I

,

I

I

I

I

I

I

/

/

/

/

"

-,'

'"

Head

window

window

(write

e

e

co

N

o

.....

enable

Index

notch)

window

Innermost

track

I

I

,

,

\

Soft

,,-

/

"

/

Outermost

sectored

(Fig.201)

disk

External

track

Sector

Hard

view

of

disk

-

202

-

(16

holes

sectored

sectors)

disk

There

are

many

types

in

the

commercially

available

soft

sectored

disks

(1)

(2)

which

appropriate

Oata

recording

Single

Da

not

Expected

A

double

All

the

density

Number

Single

1

can

be

are

classified

one

density

density

(FM

use a single

data

reliability

density

models

of

recordings.

of

used

sided

sides

(only

used).

according

for

your

method)

density

disk

can

FD-55A~F

side

0

to

application.

or

Double

disk

will

be

are

can

not

used

be

for

used

used)

the

be

for

following

density

a

double

obtained

a

single

for

both

or

(MFM

double

factors.

method)

density

and

density

single

sided

recording.

error

and

Select

may

occur.

recording.

double

(both

sides

the

0

most

and

Use a double

is

degraded.

A

double

(3)

Track

48tpi

It

density

reliability

Though

cause

used

for a double

sided

density

or

96tpi.

is

recommended

of

such

practical

sided

an

might

an

FOO.

disk

sided

disk

can

to

use a disk

If

be

degraded

application

problem,

for a double

FDO, data

be

used

a

48tpi

disk

rarely.

of

using

it

is

not

-

203

for

of

the

thoughtful

-

sided

reliability

a

single

same

is

used

a

96tpi

FDD.

sided

track

for

disk

to

If

of

density

a

96tpi

for

use

a

the

FDO.

a

in

single

side

as

FOO, the

48tpi

that

sided

1

might

the

FOD

way.

disk

track

data

does

be

not

(4)

Track

Same

35

tracks

numbers

of

commercially

from

track

available

00

to

34.

48tpi

And

single

35

track

sided

disks

FOOs

are

can

used

access

by

only

same

(5)

people

The

operation

40

tracks).

are

not

Almost

40

tracks.

High

density

For

the

use

an

Generally,

Da

not

degraded.

in a few

However,

guaranteed

all

the

disk

high

density

exclusive

disks

use

an

application.

of

the

when a 35

disks

HO

written

HO

disk

FO-55A

the

data

commercially

FDD

(FO-55G)

disko

Da

by

with

FO-55A ~ F.

is

guaranteed

reliability

track

available

which

not

use

an

FD-55A ~ F

disk

is

is

disks

The

for

of

used.

are

put

for

cannot

da

track

five

00

tracks

guaranteed

to

practical

FO-55A ~ F.

be

read

ta

reliability

through

from

for

by

use

an

may

39

<total

35

to

up

to

recently,

FD-55G.

be

39

-

204

-

2-1-2.

Disk

Handling

Disk

precautions.

(1)

Oe

(2)

Oe

the

(3)

Oe

the

For

area

Opening

not

not

normal

not

disk).

manual

Disk

areas

is

aprecision

tear,

install

touch

in

Fig.202.

(Jacket)

fold,

a

read

the

Fingerprints

handling

of

jac

or

damaged

or

write

opening

ket

recording

distort

disk

media.

the

in

operation

areas

left

of

the

I

I

I

I

~.,

I

I

~

I I : I

I

L..

__________

•

of

on

disk,

'--::~',

I,

1I

':~,,'

r,

~

jacket

the

but

the

the

it

\\

I I

,"""

I

.J\-

Be

FDD,

also

jacket

disk

is

recommended

I

I

____

I

I

I

I

I

I

I

I

--'

.'"'

sure

or

disk.

damaged

it

(magnetic

will

to

observe

may

cause

Label

Write

Envelope

disk

damage

errors.

to

the

not

coating

hold

area

enable

only

the

the

following

disturbs

FDD.

area

label

notch

of

(4)

Return

whenever

outside

(5)

For a long

the

Far

a

(Fig.202)

the

of

envelope

a

short

container.

it

disk

is

the

term

in

term

Protective

to

its

removed

protective

storage,

an

upright

storage,

Da

not

envelope

from

lean

envelope

the

envelope

keep

position.

a

few

the

-

for

FDD.

the

disks

disks

205

the

such

disk

-

and

label

protection

The

disk

as

on a desk

in a protective

may

be

and

do

not

should

piled

place

area

of

of

even

horizontally

any

the

the

window

not

be

for a while.

container

heavy

disk

area

left

with

without

objects

(6)

such

Keep

as

and

books

use

on

the

the

disk

disk,.

away

which

from

will

dust.

cause

Also

distortion

do

not

install

of

the

a

disk.

dusty

(7)

(S)

(9)

(10)

disk

Generally,

into

cause

Da

Oe

such

surface.

as a feIt

stuck

the

D6

the

Index

data

not

not

as a lead

on

information.

not

eraser

label

the

errors

clip

write

Use a soft

tip

it

the

ruh

out

may

FOO.

the

on

pencil

pen.

is

disk.

the

get

shold

Such

and

jacket.

the

index

desirable

It

information

into

be

dust,

may

shorten

The

label

or a ball

writing

is

recommended

the

applied

clipped

object

not

jacket.

on

if

of

point

to

on

the

carried

the

portion

the

pen

which

write

the

label

to

life

of

jacket

which

will

on a label

to

stick

label

area

the

magnetic

the

disk

will

with

be

with a hard

may

not

damage

which

the

label

an

shown

and

distorted.

damage

is

after

eraser.

in

Fig.202.

head,

the

tipped

the

the

already

Rubbish

may

FDO.

object

disk

disk

writing

such

from

(lI)

(12)

(13)

{14}

Da

not

Keep

motors,

ambient

Da

not

it

damages

Da

not

the

disk

electric

Disks

apply

the

smear

expose

should

more

disks

etc.

stray

the

the

away

apparatus

be

than

away

These

magnetic

disk

magnetic

the

disk

from

heater

such

operated

from

may

with

two

magnetic

degrade

field

coating

to

sunlight,

or

as

within

labels

should

a

solvent

stove.

TV

set.

-

on

the

fields

the

recorded

not

of

the

micro-waves,

Also

the

following

206

-

such

disk.

same

•

such

exceed

as

do

area

.

as

by

data

not

on

50

Oersted.

thinner,

or

put

conditions:

magnets,

the

disk.

freon,

infrared

the

disk

transformers,

The

or

alcohol,

ray.

on

Keep

the

Ambient

temperature:

10°C ~ Sl.soe

(50°F ~ 125°F)

Relative

Wet

The

operating

required

FDD

Generally

limit

good

performance

Also a sudden

within

(15)

Disks

Ambient

humidity:

bulb

above

temperature:

temperature

condition,

against

assembled

upper

of

the

contact

the

should

temperature:

20\ ~ 80\

the

in

a

host

limit

jacket

material

between

characteristics.

change

specified

be

stored

29°C

applies

(84°F),

to

approximately

operating

system

of

the

temperature

because

the

disk

in

environmental

and

range.

within

the

4°C ~ sl.soe

Max.

the

jacket

15°C

limit

into

taking

consideration.

the

the

magnetic

conditions

following

(40°F ~ 125°F)

surface.

of

temperature

the

is

determined

jacket

conditions:

temperature

deformation

head

which

should

In

the

margin

by

adeformation

may

be

avoided

actual

is

rise

disturbs

degrade

in

the

even

Relative

(16)

For

recommended

outer

stray

Disks

Ambient

Relative

Temperature

(17)

Disks

exceeding

Such

humidity:

transportation,

that

surface

magnetic

should

be

temperature:

humidity:

gradient:

which

have

the

disks

should

8% ~ 80%

a

sufficient

of

the

fields

transported

8% ~ 90%

been

operating

be

disks

should

space

final

will

container,

be

negligible.

within

-40°C ~ sl.soe

20oe/hour

stored

or

conditions

subjected

to a conditioning

be

in

the

exists

so

the

following

(-40°F

transported

may

exhibit

protective

between

that

~

125°F)

at

the

risk

of

conditions:

temperature

degradeed

period

container.

recorded

damage

and

perfQrmance.

of

not

disk

due

humidity

less

to

It

is

and

than

-

207

-

(18)

24

When

hours

you

within

install

the

the

operating

disk

to

environment

the

FDO,

be

prior

careful

to

to

use.

handle

it

slowly.

Rough

may

installation

cause

incorrect

will

accelerates

installation.

the

degration

of

the

disk

and

it

-

208

-

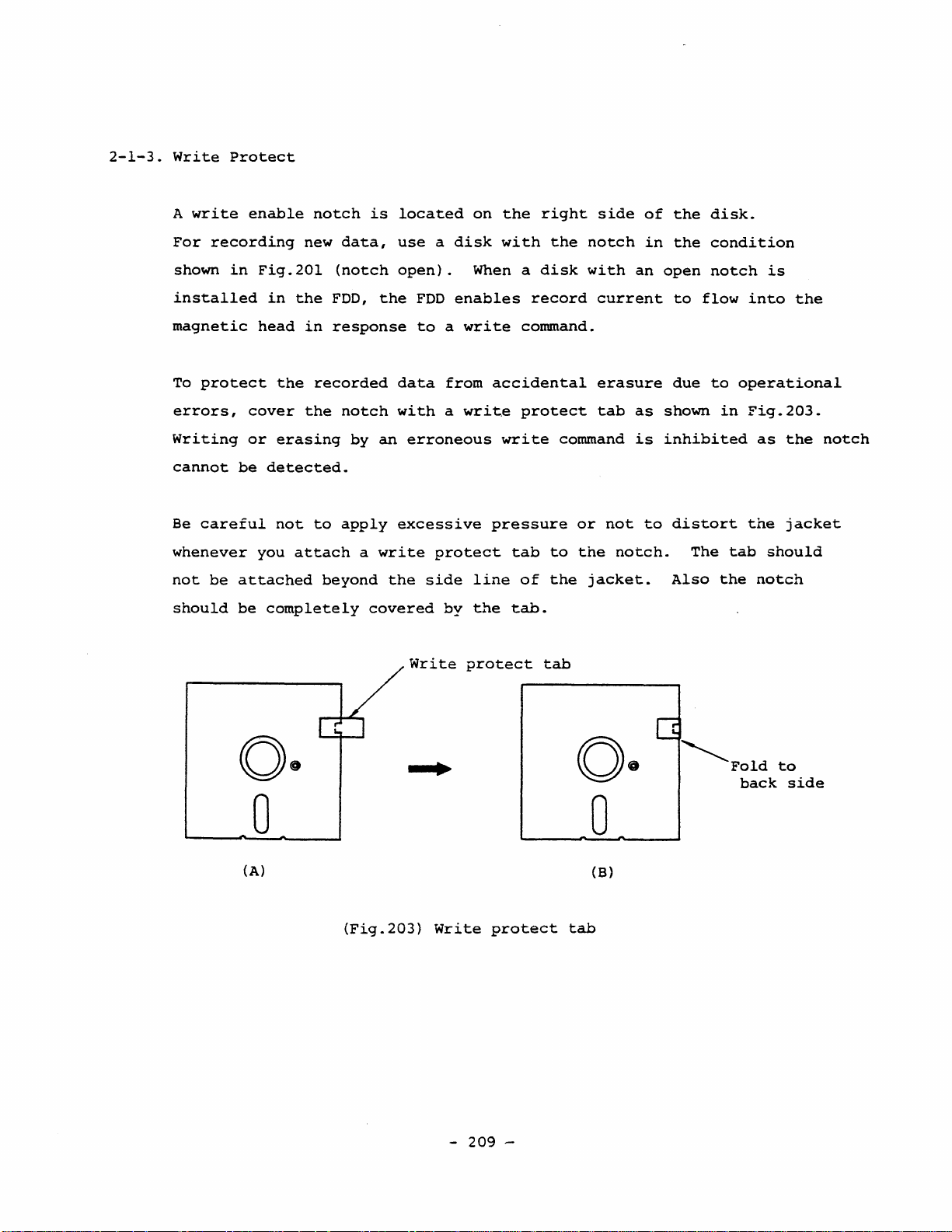

2-1-3.

Write

A

write

For

Proteet

enable

reeording

noteh

new

data,

is

loeated

use a disk

on

the

with

right

the

side

noteh

of

in

the

the

disko

eondition

shown

installed

magnetie

To

proteet

errors,

Writing

eannot

Be

eareful

whenever

not

be

should

in

Fig.201

in

head

eover

or

be

deteeted.

you

attaehed

be

comp1ete1y

the

in

the

reeorded

the

erasing

not

to

attaeh

(noteh

FOO,

response

noteh

by

apply

a

beyond

open).

the

FOO

to a write

data

with a write

an

erroneous

exeessive

write

the

side

eovered

Write

When a

enables

from

proteet

line

by

the

proteet

disk

reeord

eommand.

aeeidenta1

proteet

write

pressure

tab

to

of

the

tabe

tab

with

eurrent

erasure

tab

eommand

or

not

the

jaeket.

an

as

is

to

noteh.

open

inhibited

to

due

shown

distort

The

Also

noteh

f10w

to

is

into

operational

in

Fig.203.

as

the

tab

should

the

noteh

the

the

jaeket

noteh

(A)

(Fig.203)

Write

-

209

protect

-

o·

o

(B)

tab

Q

~FOld

baek

to

side

2-1-4.

(1)

FOO

Handling

The

FOO

Inserting

should

and

be

handled

ejecting

according

procedure

to

the

of a disk

following

should

instructions.

be

performed

according

Insert

(2)

A

sudden

relative

within

at

the

environmental

(3)

Keep

(4)

Remove

time.

(5) Keep

by

transformer,

a

the

new

and

the

the

to

item

disk

correctly

change

humidity

specified

operating

condition.

use

the

disk

FOO

away

2-1-5.

in

environmental

should

range.

condition

FOO

away

from

the

from

stray

magnet,

and

be

from

FOO

CRT

carefully.

conditions

avoided

Sufficient

if

there

dust

when

it

magnetic

display,

as

and

will

etc.

such

far

as

possible

hours

was a

of

sudden

damp.

not

be

or

electromagnetic

as

temperature

even

storage

change

operated

or

if

it

is

required

in

the

for a long

fields

such

is

as

(6)

(7)

(8)

If

such

data

errors

Refer

Da

FDD

For

to

to

,not

except

transportation,

the

apart

item

touch

FDD.

or

the

for

or

equipment

degrades

2-2

for

variable

trained

data

installation

resistors

technicians

refer

to

is

not

reliability.

item

-

2-1-6

210

sufficiently

Refer

of

the

FOD.

or

screw

concerning

not

-

shielded,

to

adjusting

FD-55.

to

apply

it~

2-2-4.

parts

excessive

it

may

in

impact

cause

the

2-1-5.

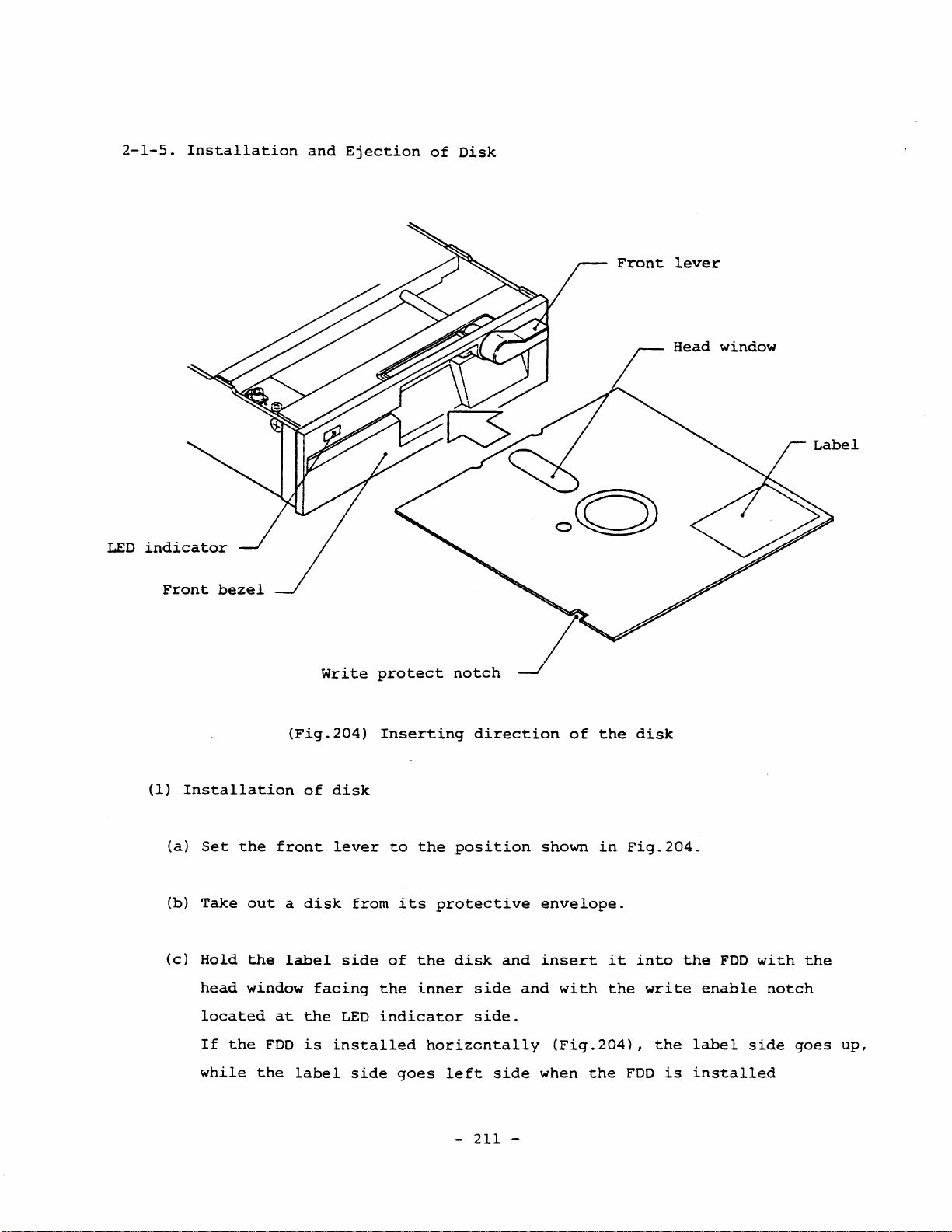

Installation

and

Ejeetion

of

Disk

LED

indieator

Front

bezel

Write

proteet

noteh

Front

lever

Head

window

(1)

Installation

(a)

(b)

(e)

Set

the

Take

Hold

head

loeated

If

the

while

(Fig.204)

of

front

out a disk

the

label

window

FDD

the

at

faeing

the

is

label

Inserting

disk

lever

from

side

the

LED

indieator

installed

side

to

its

of

goes

the

the

inner

direetion

position

proteetive

disk

side

side.

horizcntally

left

side

-

211

and

and

-

of

shown

envelope.

insert

with

(Fig.204)

when

the

the

in

it

the

disk

Fig.204.

into

write

,

the

FDD

is

the

FDD

enable

label

installed

with

noteh

side

the

goes

up,

(d)

(d

l

vertically

Insert

)

For

the

the

models

with

disk

front

fully

with

lever

and

disk

up.

straightly

eject

option,

into

a

the

light

FDD

with

depressing

enough

force

care.

is

required

before

When

sure

(e)

Take

turning

aution:Never

(2)

Ejection

(a)

Turn

lever.

It

for

the

it

is

to

insert

off

your

90°

elose

fingers.

be

damaged.

of

the

front

is

recommended

the.

bottom.

inserted

in

If

disk

full

it

fully.

fingers

the

~~e

the

lever

to

insertion

to

the

from

clockwise

front

disk

90°

lever

is

in

pineh

of

the

bottom,

the

disk,

a

click

and

direction.

with

clamped

depressing

with

eounterelockwise

the

lever

with

disk

close

bent

from

sound

two

the

can

the

the

eonäition,

direction

fingers

point

be

front

disk

to

not

lcm,approx.

heard.

lever

with

the

open

to

by

your

disk

the

apply

Be

may

(b)

(~)

(e)

excessive

Hold

For

the

Put

from

the

the

the

lever

the

impact.

rear

FDD.

models

is

disk

side

with

open.

back

of

into

the

disk

eject

the

disk

with

option,

protective

-

212

-

your

disk

envelope

fingers

pops

lightly

out

(See

and

from

Fig.202l.

the

draw

FDD

out

when

2-1-6.

(I)

Precautions

The

following

of

the

FOO

In

order

to

for

and

protect

Transportation

precautions

the

system

the

should

in

which

magnetic

be

the

head

referred

FOO

assembly

to

for

is

assembled.

from

transportation

vibration

and

impact

during

FOO.

a

disk,

(a)

The

After

and

(b)

When

projection

sheet

(2) Be

(3)

careful

Since

transportation.

to

package

transportation,

The

protection

is

installed

insertion

closing

fix

the

lever.

ejecting

of

for

another

not

to

the

FOD

is

several

sheet,.

to

of

the

the

front

the

protection

the

sheet

transportation.

expose

small

To

protect

FODs

be

sure

which

all

the

protection

lever,

with

the

FDD

and

light,

the

in

one

to

attach

is

FOOs

sheet

pull

sheet,

your

to

it

FOD

box.

the

made

at

of

the

is

up

the

open

finger.

excessive

might

from

such

protection

thick

shipment

done

like

projection

the

lever

Store

moisture.

fall

or

abuse,

sheet

paper

from

a

disk

of

depressing

the

removed

be

thrown

it

is

to

the

shaped

the

like

factory.

installation.

the

sheet

the

protection

down

recommended

during

(4)

When

should

transportation.

to

absorb

the

be

FOD

enough

impact

is

shipped

strong

Also

so

that

assembled

to

withstand

the

packaging

the

FOD

will

- 213 -

in a system,

vibration

of

the

system

not

suffer

the

and

system

impact

should

from

cabinet

during

be

constructed

excessive

impact.

2-2.

INSTRUCTIONS

FOR

INSTALLATION

2-2-1.

(1)

(2)

Refer

your

system

Precautions

Keep

For

the

excessive

It

is

(natural

heat.

When a

th~

adhered

to

the

following

so

the

FDD

example,

operation

dust.

recommended

air

fan

is

air.

to

If

the

that

for

away

install

ability

cooling

attached

the

FDD.

items

theFDD

Installation

from

dust.

the

of

to

operate

should

in

FDD

is

for

can

FDD

the

the

blown

installing

exhibit

away

FDD.

the

not

system

strongly,

from

Such

FDD

be

obstructed)

and

the

expected

the

floor,

care

in a weIl

cabinet,

a

large

assembling

performance.

without

will

protect

ventilated

to

dissipate

install

quantity

it

of

the

disturbing

the

FDD

situation

the

to

draw

of

dust

FDD

into

from

radiated

out

may

be

(3)

(4)

(5)

(6)

(7)

Da

not

magnetic

up

such

position.

00

not

stove.

Da

not

Da

not

The

screws

surface

place

noise

noises

See

expose

place

place

more

the

the

the

for

FDD

source.

which

item

the

FDD

FDD

installing

than

2-2-4.

FOD

Smm.

near

may

to

in

in

a

strong

The

magnetic

cause

sunlight.

an

environment

a

situation

the

errors.

FDD

magnetic

head

Keep

with

subject

should

Be

the

not

noise

and

careful

FDD

corrosive

to

protrudc

read

strong

source

amplifier

about

away

or a electro-

the

from

heater

air.

vibration.

from

the

will

pick

installing

or

FDD

-

214

-

(8)

Da

not

apply

excessive

force

when

installing

the

FDD

in a system

cabinet.

of

(9)

For

(lO)

For

FDD

The

at

(11)

After

it

Protruding

seek

(12)

Fundamental1y,

indicator

the

magnetic

the

connection

the

setting

PCBA,

setting

shipment.

checking

is

bent

operation,

Frame

refer

and

of

head.

of

to

to

match

Confirm

that

extraordinary,

cable

the

the

may

which

front

the

of

the

item

your

the

be

FOD

FDD

the

straps

2-2-3.

these

head

caught

cause

shou1d

lever

may

be

cables,

(short

system

settings

attach

misalignment

cable

by

be

up

might

the

installed

(magnetic

distorted

refer

bars)

be

before

of

the

FDD

other

which

to

item

and

different

operation.

FDD

to

the

parts

of

the

horizontal1y

head

2-2-2.

the

does

system

or

increases

head

up),

causes

terminator

from

not

protrude

cabinet.

or

seek

with

or

vertica11y

misalignment

on

the

the

setting

nor

load

at

errors.

the

that

head

with

the

left

FDD

should

for a 96tpi

Da

not

orientation

of a disk).

between

head.

As

to

tion

angle

consideration

install

the

the

of

the

against

side

not

FOO

or

These

magnetic

other

right

down

and

the

form a greater

against

the

FDD

the

front

orientation

orientations

side

the

horizontal

is

required.

the

with

head

down

front

horizontal

the

bezel

and

with

angle

magnetic

up

of

the

than

plane

lever

than

in

vertical

the

FDD

disk

explained

the

indicator

than

up.

plane

or

In

30°

head

may

may

above

explained

either

for a 48tpi

with

the

down

orientatiop

disturb

cause

up

in

(such

or

above),

misalignment

forming a greater

orientation,

FOO

and

front

horizontal

the

(top

stable

as

the

separate

bezel

the

15°

up.

loading

contact

of

orienta-

the

- 215 -

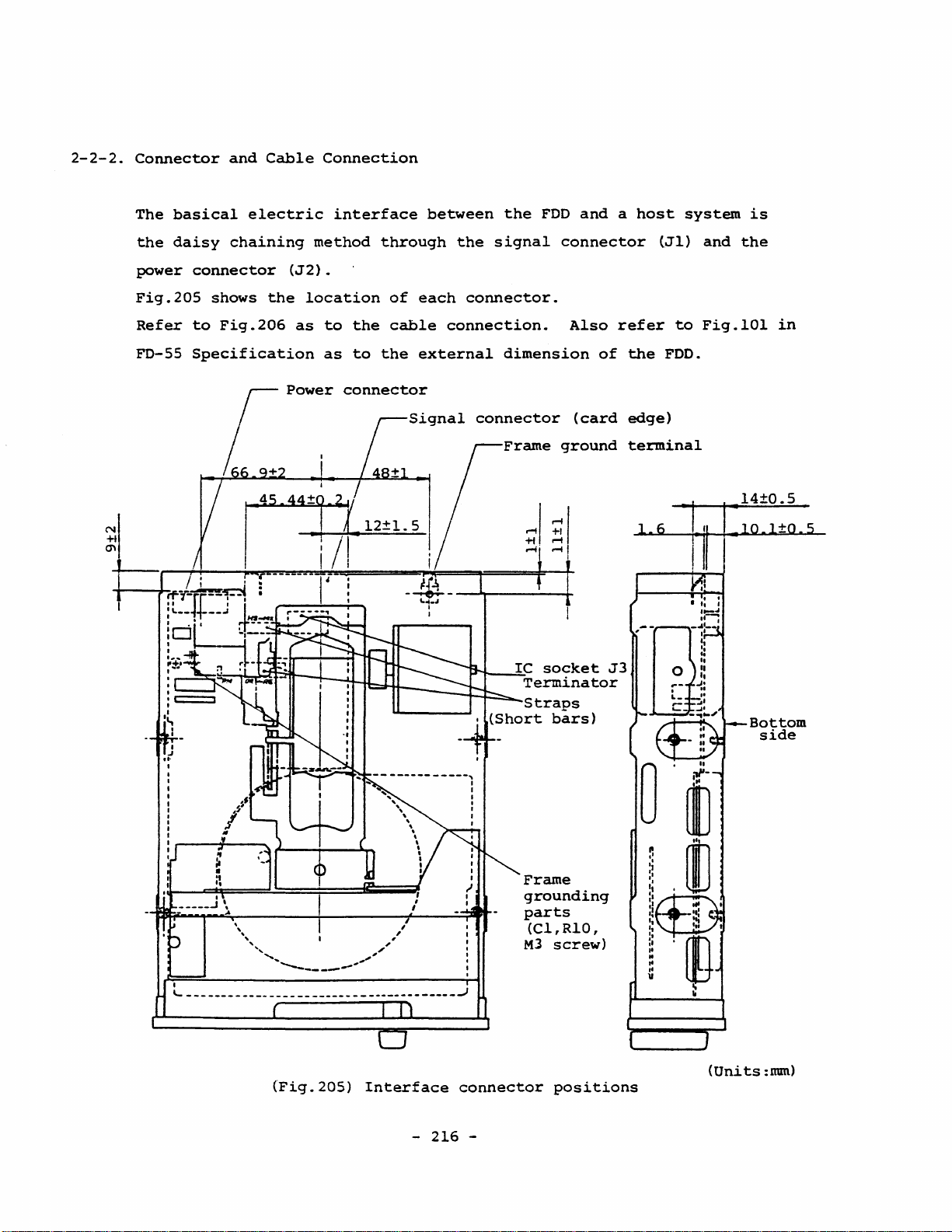

2-2-2.

Connector

The

basical

the

daisy

and

Cable

electric

chaining

Connection

interface

method

through

between

the

the

signal

FDD

and a host

connector

(Jl)

system

and

is

the

N

+1

'"

power

Fig.205

Refer

FD-55

connector

to

Specification

iT/-~~

:t

__

~+

!c:jH"

I

.....

.

....

,....

(J2).

shows

Fig.206

the

45

location

as

Power

q

44+

l

1

r

------·1

__

..:

J

~I::~·

,.

-

=1'

of

each

to

the

cable

as

to

the

external

connector

~r'

12±1.5

;-

~~--.

connector.

connection.

dimension

connector

Frame

~

__

~IC

Terminator

.

Straps

(Short

Also

(card

ground

socket

bars)

refer

of

J3

to

the

FDD.

edge)

terminal

Fig.lOl

.l4±O.5

in

Bottom

side

I

....

Frame

grounding

parts

(Cl,RlO,

M3

screw)

-

--

----

-

--

--

----

--

-----

---

-------

-

-----..}

(Fig.20S)

Interface

-

connector

216

-

(Units

positions

:mm)

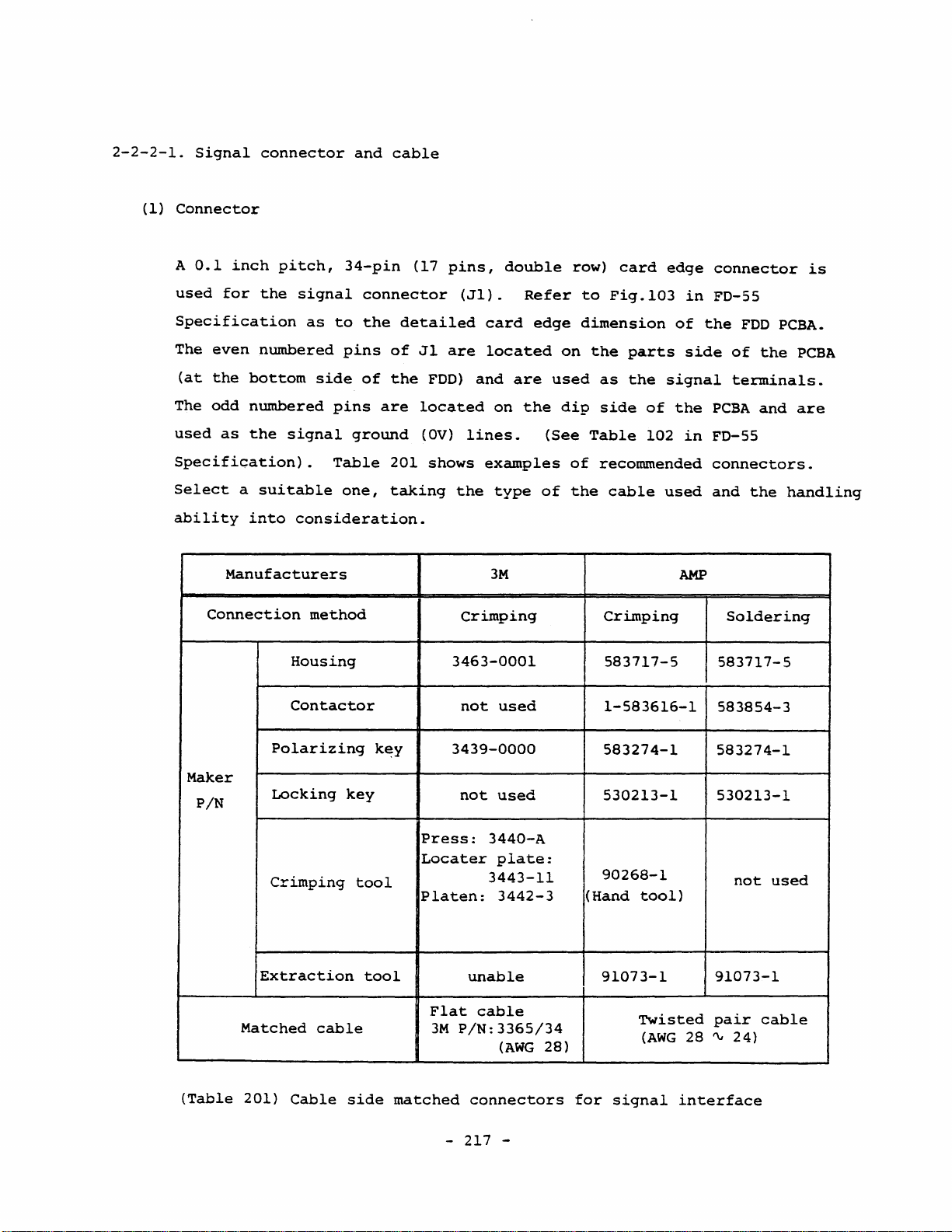

2-2-2-1.

(I)

Signal

Connector

A

0.1

inch

connector

pitch,

and

34-pin

cable

(17

pins,

double

row)

card

edge

connector

is

used

for

the

Specification

The

(at

The

used

even

the

odd

bottom

numbered

as

the

numbered

Specification).

Se1ect

ability

a

suitab1e

into

Manufacturers

Connection

signal

as

connector

to

the

pins

side

of

pins

signal

ground

Table

one,

consideration.

method

Housing

Contactor

detailed

of

the

are

201

taking

(Jl).

Jl

are

FOD)

10cated

(OV)

shows

the

Crimping

3463-0001

not

card

10cated

and

on

lines.

examples

type

3M

used

Refer

are

the

edge

used

(See

of

to

Fig.103

dimension

on

the

as

dip

side

Table

of

recommended

the

cab1e

Crimping

583717-5

1-583616-1

parts

the

of

102

in

of

side

signal

the

in

used

AMP

FO-55

the

FDO

of

the

terminals.

PCBA

and

FD-55

connectors.

and

the

Soldering

583717-5

583854-3

PCBA.

PCBA

are

handling

Maker

P/N

(Table

Po1arizing

Locking

Crimping

Extraction

Matched

201)

Cable

key

cab1e

too1

too1

side

k~y

matched

3439-0000

not

Press:

Locater

P1aten:

F1at

3M

P/N:3365/34

-

used

3440-A

plate:

3443-11

3442-3

unab1e

cab1e

(AWG

connectors

217

-

28)

583274-1

530213-1

90268-1

(Hand

91073-1

for

too1)

Twisted

(AWG

signal

583274-1

530213-1

91073-1

pair

28

'"

interface

not

2 4 )

used

cab1e

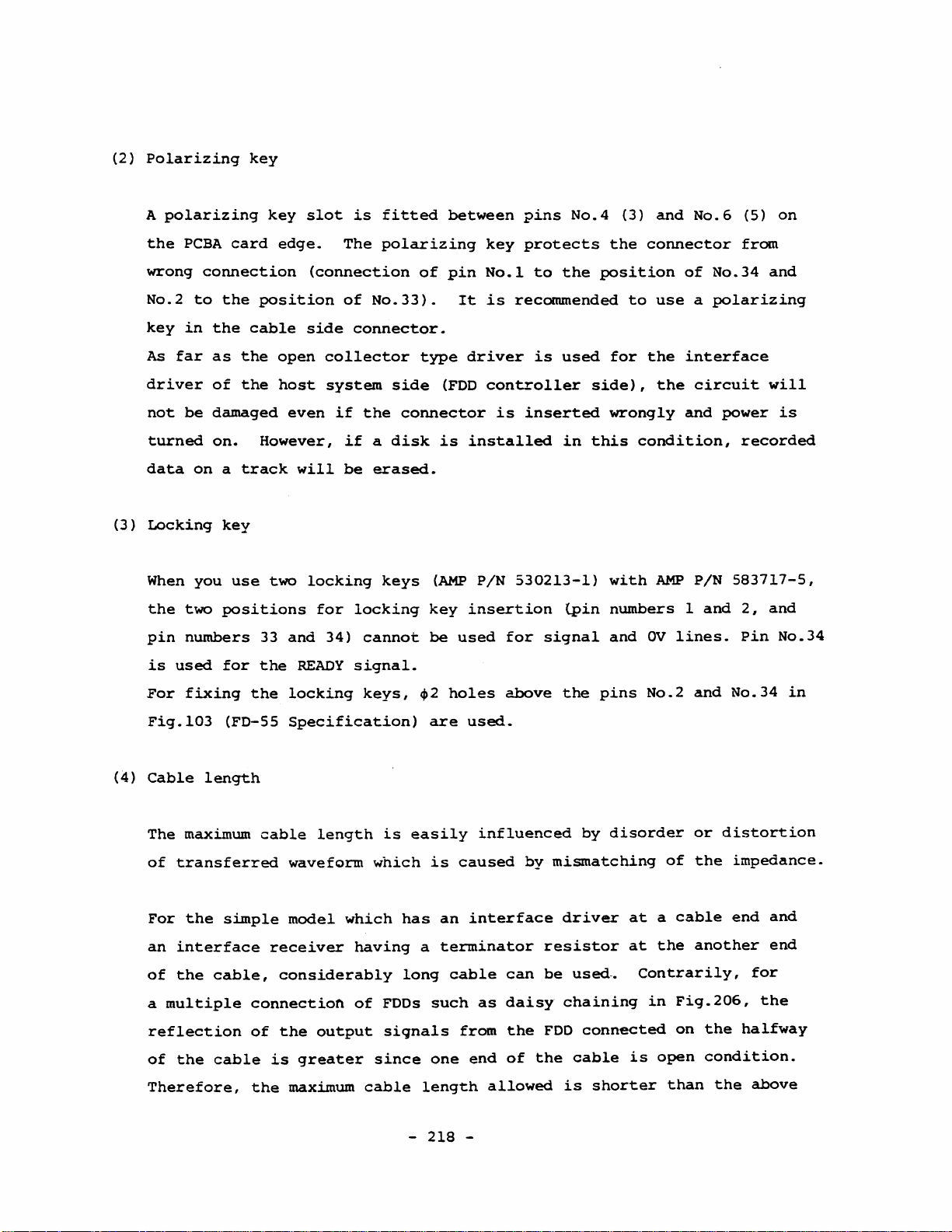

(2)

Polarizing

A

the

polarizing

PCBA

card

key

key

slot

edge.

is

The

fitted

between

polarizing

key

pins

No.4

protects

(3)

the

and

No.6

connector

eS)

fram

on

(3)

wrong

No.2

key

As

to

in

far

driver

not

be

turned

data

on a track

Locking

When

pin

For

the

i5

you

two

numbers

used

fixing

Fig.103

connection

the

position

the

cable

as

the

open

of

the

damaged

on.

However,

key

use

two

positions

33

for

the

the

(FD-SS

(connection

of

side

connector.

collector

host

even

system

if

the

if a disk

will

be

locking

for

locking

and

34)

cannot

READY

locking

signal.

keys,

Specification)

of

No.33).

type

side

connector

erased.

keys

~2

pin

(FDD

is

(AMP

key

be

holes

are

No.l

It

is

driver

controller

is

installed

P/N

insertion

used

for

above

used.

to

the

position

recommended

is

used

for

side),

inserted

530213-1)

signal

in

(pin

the

wrongly

this

with

numbers

and

pins

of

No.34

to

use a polarizing

the

interface

the

circuit

and

power

condition,

AMP

P/N

land

OV

lines.

No.2

and

and

will

is

recorded

583717-5,

2,

and

Pin

No.34

No.34

in

(4)

Cable

The maximum

of

For

an

of

a

multiple

reflection

of

Therefore,

length

transferred

the

simple

interface

the

cable,

the

cable

cable

length

waveform

model

receiver

considerably

connection

of

the

output

is

greater

the

maximum

is

which

which

easily

is

has

caused

an

interface

influenced

having a terminator

10ng

cable

of

FDDs

siqnals

since

cable

such

fram

one

length

as

end

allowed

- 218 -

by

can

daisy

the

of

the

by

disorder

mismatching

driver

resistor

be

used..

chaining

FDD

connected

cable

is

shorter

or

of

the

at a cable

at

the

another

Contrarily,

in

Fig.206,

on

the

is

open

condition.

than

distortion

impedance.

end

and

end

for

the

halfway

the

above

explained

simple

model.

In

the

case

of

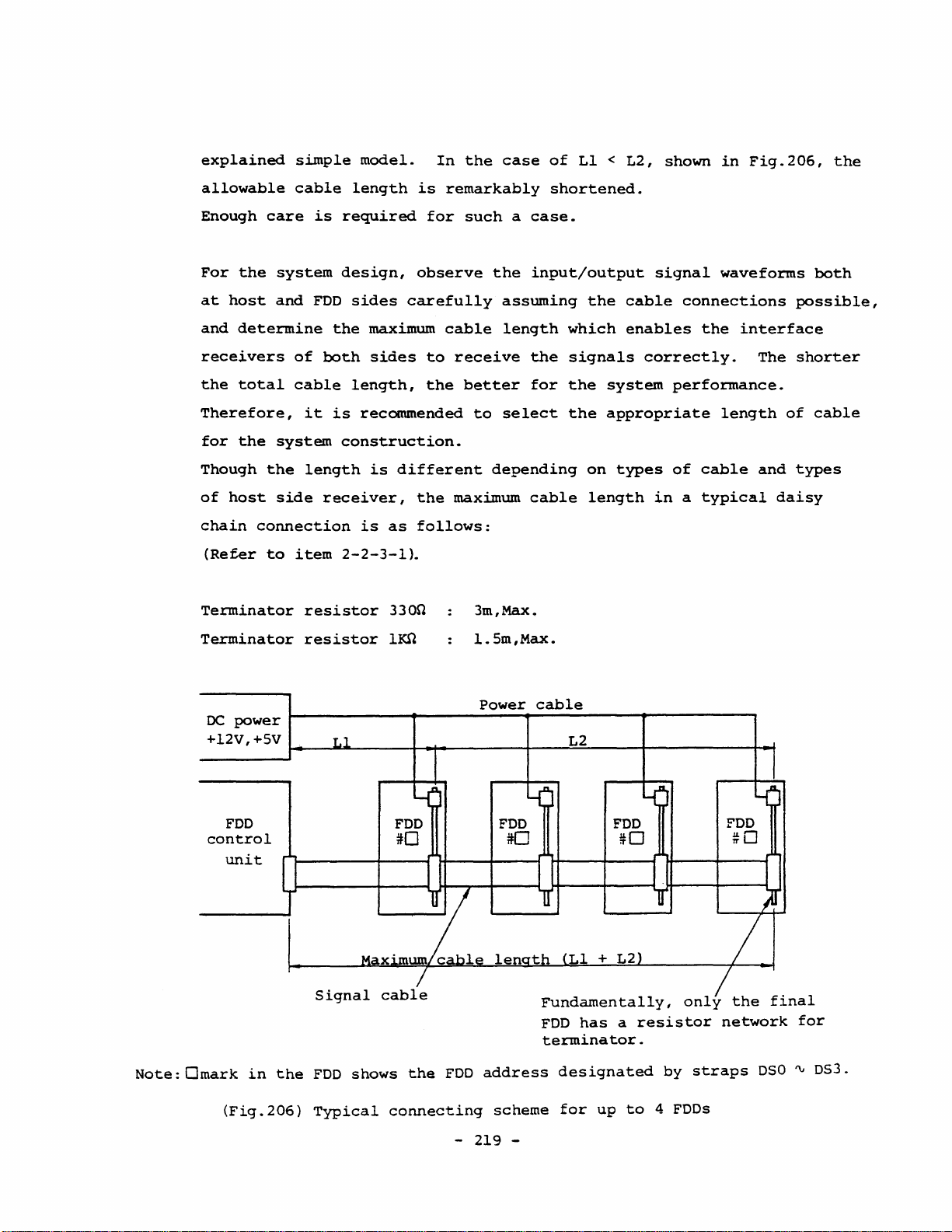

LI < L2,

shown

in

Fig.206,

the

allowable

Enough

For

at

and

receivers

the

Therefore,

for

Though

of

chain

(Refer

Terminator

Terminator

care

the

system

host

host

and

determine

total

the

system

the

side

connection

to

cable

is

FDD

of

both

cable

it

length

receiver,

item

resistor

resistor

length

required

design,

sides

the

length,

is

construction.

2-2-3-1).

carefully

maximum

sides

recommended

is

different

is

as

3300

lKn

is

remarkably

for

such a case.

observe

cable

to

receive

the

better

the

maximum

follows:

the

input/output

assuming

length

the

for

to

select

depending

cable

3m,Max.

1.5m,Max.

shortened.

the

which

signals

the

system

the

appropriate

on

types

length

signal

cable

enables

connections

correctly.

performance.

of

in a typical

waveforms

the

interface

length

cable

The

and

daisy

both

possible,

shorter

of

cable

types

oe

+12V,+5V L2

control

Note:Omark

power

FDD

unit

in

the

(Fig.206)

Power

~--~~------~~---------+----~~----~----------~~

Signal

FDD

Typical

cable

shows

connecting

the

FDD

address

- 219 -

cable

scheme

Fundamentally,

FDD

has a resistor

terminator.

designated

for

up

to 4 FDDs

by

only

straps

the

final

network

DSO ~ OS3.

for

(5)

Connecting

Be

sure

to

and

disconnecting

turn

the

power

off

the

first.

connector

When

you

plug-in

the

connector,

check

the

excessive

by

pulling

1

and

34)

orientation

force.

the

cable,

of

the

cable

If

of

you

since

are

the

connector

use a flat

the

outermost

easily

cable,

broken

and

by

plug-in

never

lines

excessive

straightly

disconnect

(corresponds

force).

without

the

to

connector

pin

Nos.

-

220

-

2-2-2-2.

(1)

Power

Connector

A

nylon

connector

housing,

and

'4-pin

cable

connector

is

used

as

the

power

connector

(J2).

Table

This

202

connector

construction.

Be

sure

to

connector.

Connection

Maker

P/N

shows

an

prevents

turn

the

Manufacturer

Housing

Contactor

Crimping

Extraction

examp1e

power

method

wrong

tool

tool

of

recommended

connection

off

before

or

connecting

1-480424-0

170148-1

60617-1

90123-2

1-305183-2

connector

because

AMP

Crimping

for

of

the

or

disconnecting

60619-1

90124-2

1-305183-2

the

cable

housing

side.

the

(2)

(Table

Cable

Determine

at

J2

connector

and

(2)

cab1e

and

Matched

202)

the

in

FD-55

the

cable

Cable

thickness

will

Specification,

maximum

side

be

matched

and

in

power

AWG

connector

the

1ength

the

specified

taking

consumption

-

221

24

-

""

18

of

tolerance

the

of

for

the

volcage

the

AWG

power

cable

FDD

20

""

interface

so

range

drop

into

14

that

the

in

item

through

consideration.

voltage

1-4

the

(1)

Use

(see

the

Table

correct

202).

contactor

and

crimping

tool

to

suit

the

cable

thickness

- 222 -

2-2-2-3.

Frame

As

described

to

the

grounding

in

frame

of

item

the

1-10

FOO

of

FO-55

through

Specification,

Cl

(O.OlpF,

500V)

oe

and

OV

RIO

is

connected

(lOOKO)

in

parallel

at

Fig.205.

connectors

the

M3

screw

oe OV-Frame

acceptance

system).

applications

methods

Another

(1)

When

(2) When

(For

However,

in

frame

the

the

example,

shipping.

Cl

and

are

located,

for

connection

inspection

from

item

(A)

grounding

FOO

FOD

RIO

are

frame

purpos~

this

items

~

is

assembled

is

installed

installed

Refer

mounted

and

they

grounding

by

O.Ol~F//

connection

(1)

to

(C)

is

is

required:

on

to

Fig.109

on

the

are

connected

(see

100Kn

for

FOO

is

(3).

Secure

required.

in a system

or

placed

the

vibration

in

FO-55

PCBA

on

Fig.205).

is

sufficient

unit

only

insufficient

connection

cabinet.

on a metallic

tester,

Specification

which

to

the

interface

frame

for

(not

assembled

for

plate

placed

the

by

and

through

shipping

in

the

following

one

of

the

during

on a metallic

or

tests.

plane

(3)

Ouring

Another

(A)

Connect

cabinet

Specification).

to

(B)

Utilizing

side

in

electro-static

frame

the

with

oe

OV

of

the

thermostatic

grounding

FOO

frame

the

installation

It

of

the

power

the

frame

FOO,

connect

oven)

noise

method:

securely

is

required

supply

ground

the

- 223 -

test.

to

taps

for

unit

terminal

frame

the

(refer

the

by

an

(faston

ground

metallic

to

system

appropriate

securely

cabinet

Fig.10l

cabinet

terminal)

(system

in

tQ

methode

at

to

OC

FO-55

be

the

OV

of

connected

rear

the

(C)

power

AWG

14).

Connect

to

oe

supply

the

OV

through

unit

test

through

plane

a

low

a

low

or

test

impedance

impedance

equipment

cable.

cable

used

Otherwise,

for

(thicker

testing

insert

than

the

a

FDD

thick

If

any

(Cl,

If

it

off

one

If

oe

from

the

result,

insulation

vibration

of

RIO,

is

unavoidable

Cl

and

and

execute

OV

electro-magnetic

static

expected

the

M3

screw)

RIO

and

the

electricity

tester).

above

plate

with

one

frame

reliability

between

methods

in

the

to

remove

a

cutting

of

either

are

inductive

generated

the

FDD

is

executed,

FDD

may

these

plier

(A)

completely

noises

by

will

still

or

not

and

parts

or

(B)

the

the

the

be

replace

method.

open,

and

moving

be

obtained.

test

frame

mounted.

for

system

.

the

the

there

parts

plane

grounäing

M3

FDD

is

(unsuitable

construction,

screw

is

easily

no

way

in

the

parts

with

suffered

to

discharge

FDD.

a

plastic

And

for

cut

in

-

2~4

-

2-2-3.

Setting

The

FDD

of

Straps

is

equipped

and

with

Terminator

16

straps

and a terminator

resistor

network.

Users

Be

set

1-11

The

double

Refer

(4 FDDs,Max.)

sure

for

and

short

can

to

your

row

to

select

check

1-12

bars

pins

Fig.206

an

that

system

in

FD-55

and

and

as

appropriate

the

be

fore

Specification.

the

terminator

IC

socket

to

the

setting

short

bars

operation

J3

connection

resistor

on

the

for

and

the

according

network

bot

tom

of

several

their

terminator

to

side

FDDs

systems.

this

are

PCBA.

are

item

mounted

by

daisy

correctly

or

items

on

the

chaining

- 225 -

2-2-3-1.

(I)

Terminators

FDD

side

and

terminator

interface

drivers

Terminators

at

shipment

Terminator

separated

to

the

ion).

a

14-pin

Input

signals

Other

bottom

All

resistor

DRIVE

DRIVE

DRIVE

DRIVE

input

fo~

(refer

resistor

from

terminators

side

the

terminators

SELECT

SELECT

SELECT 2

SELECT 3

signals

the

network

0

1

input

to

for

PCBA

1-

1

item

the

of

interface

1-8-1

DRIVE SELECT 0 ~ 3

for

the

the

FOD

except

and

mounted

Strap~

DSO

OSI

OS2

OS3

Terminator

h3 L

\!.4

~~

signals

(3)

in

other

(refer

for

the

on

FDO

RAI

.--:::

__

j;

________

FD-SS

input

the

--,

__

-J

are

equipped

Specification}.

input

signals

to

Fig.102

DRIVE SELECT

IC

socket

-

PCBA

Rl3

Fixed

terminator

+SV

GI

~2

L-~--~-to

resistor

.....

+

~~to

network

SV

internai

to

signals

and

in

FO-SS

are

J3.

internal

circuit

all

the

is

is

soldered

Specificat-

packaged

(soldered)

circuit

(7-circuits)

FDDs

as

FO-55{L)

Table

each

The

1Kn

generation.

203

type

feature

type

series

shows

of

of

is

the

(Fig.207)

has

two

the

details

termination.

3300

type

relatively

Terminator

types

of

is a relatively

low

-

connection

of

termination

resistor

current

226

-

in

FOD

(3300

values

longer

consumption

and

cable

type

LQW

and

and

level

length

low

lKO

current

and

noise

type).

that

for

of

Items

3300

termination

type

FD-55(L)

lKSl

type

termination

Resistor

value

DRIVE

line

(LOW

Other

signal

(LOW

Interface

SELECT

current

level)

input

level)

driver

Notes:

current

1.

Resistor

2.

TTL

DRIVE

Other

Terminator

Internal

Total

Terminator

Internal

Type

Sink

74LS38

the

interface

SELECT

input

current(il+i2)

current

values

or

(Table

(Rl3)

signal(RAl)

current(il)

circuit

current(i3)

circuit

capability

and

7438

driver.

203)

Details

current(i2)1

current(i4>

input

are

used

signal

in

of

FDD

I

,

I

'!'TL

48mA(0.4V}

line

an

FDD

termination

3300

3300

l4.8mA

1.6mA 1.6mA

l6.4mA

l4.8mA

0.4mA

7438

current

of

lKn

I

are

type

types

TTL

l2mA(0.4V}

24mA(0.5V}

typical

termination

4700

11m

10.4mA

l2mA

4.9mA

0.4mA

74LS38

7438

values.

or

as

(2)

Installation

For a multiple

network

resistor

However,

in

sink

FDDs.

network

multiple

Also

halfway

It

is

host

and

only

on

networks

if

the

current

For

such a case

and

additional

resistor

when

and

the

distances

may

have

recommended

FDD

sides

removal

connection

the

final

on

the

interface

capability,

networks

resistor

to

observe

actually

of

of

FDD

other

driver

that

FDDs

are

between

network

terminators

FDDs

resistor

an

are

the

for

- 227 -

in

as

shown

FDDs

FDD

rather

using a pair

of

the

already

externally

each

instead

inp~t/output

the

design

daisy

networks

FDD

chaining,

in

Fig.206,

host

connected

favorable.

are

cf

of

of

side

may

systemed

rather

the

final

signal

the

leave

and

tweezers.

has

sufficient

be

left

has

in

short,

waveforms

system.

the

remove

on

resistor

daisy

an

FDD.

terminator

the

margin

multiple

chaining,

FDD

in

of

the

the

(3)

Host

Use

side

the

terminator

same

resistor

value

as

the

host

side

terminator.

Or

use a smaller

(4)

(5)

resistor

side

driver.

If

the

FOO

the

minimum

FOO

side

Refer

Host

to

side

Required

satisry

For

DRIVER SELECT

Driver

capability

value

side

driver

table

driver

current

the

within

driver

for

TTL

203

sink

following

signaliine:

>

the

is

74LS38.

and

item

capability

expression

Terminator

allowable

TTL

7438,

(2).

current(il)

sink

l20n

(IoL)

~efer

current

is

for

to

the

minimum,

the

host

Fig.2071.

+

internal

capability

side

circuit

of

while

driver

the

FOO

430n

is

should

current{i2)

For

other

Driver

LOW

level

than

as

even

O.4V.

TTL

though

WRITE

received

input

capability

output

74LS38

DATA

and

with

For

cannot

it

a

signal

>

voltage

example,

has

24mA

IN

USE/HEAD

Shumitt

lines:

[Terminator

mountedJ

FOD

connected]

(VoL)

for

be

used

capability.

LOAD

TTL

which

current(i3}

+

[Internal

of

the

FOD

since

signals,

-

228

the

host

with

only

Especially,

LOW

level

-

circuit

side

330n

l2mA

since

x

No.

driver

terminator,

is

guaranteed

care

these

threshold

of

resistor

current(i4)

shall

is

required

signals

is

networks

x

No.of

be

less

such a driver

for

VoL ~ O.4V

are

O.5V(Min.)

for

the

2-2-3-2.

On

Straps

the

bottom

side

PCBA

of

the

FOO,

16

straps

are

mounted.

They

are

divided

PM

block.

into

three

HS

OSO

DSI

HM

DS2

DS3

MX

pin

Cl

(]

0

(]

(]

0

Cl

blocks

Cl

(]

(]

(]

(]

0

(]

that

are

HS ~ MX

~

PM

Cl

Cl

UR

Cl

(]

(]

Cl

(]

[]

0

MI,

IU

HL

SM

UO

Ul

RE

Cl

(]

(]

Cl

Cl

(]

(]

block,

UR ~ RE

block,

and

of

Specification

the

SpecificatiQn.

short

at

(1)

Installation

Installation

the

Insertion

the

to

the

short

shipping

power.

strap.

most

bars,

(Fig.208)

of a short

Straps

at

shipping.

appropriate

bars

referring

Since

it

is

stage.

and

removal

and

removal

bar

are

many

desired

Straps

onto

set

condition

to

combinations

to

of

short

of

short

The

this

reset

-

and

the

to

229

their

post

the

setting

for

item

it

bars

bars

-

locations

pin

condition

can

the

system

or

to

are

by

users

must

is

defined

in

be

easily

items

possib1e

to

be

done

as

the

item·1-11-4

changed

construction.

1-11,

avoid

after

for

1-12

setting

the

turning

on-state

of

FD-55

by

user

Reset

in

the

confusion

off

(a)

Installation

Install

in

the

on-state,

of

(b) Removal

To

short

nipped

Be

(2)

Ordering

If

more

or

if

parallel)

short

the

post

protect

bars

up

careful

of

short

short

a

short

bar

it

from

are

with

not

short

bars

bar

in

Fig.208.

insertion.

is

recommended

pins.

unwanted

very

fingers,

to

damage

bars

bars

than

as

securely

securely

spare

pull

the

parts

to

There

However,

to

removal

inserted.

up

the

parts

standard

are

short

is

no

for

insert

due

slowly

around

installation

required,

the

two

restriction

the

easy

the

metal

to

vibration

If

it

with a small

it.

order

pins

visual

bar

is

at

lleft

for

at

and

not

round

shipping

with

and

the

approach

checking

the

upper

impact,

removed

nose

the

following

right

the

when

are

of

of

the

side

pliers.

required,

(3)

parts

Short

HS

(a)

number.

bar

~

MX

strap

MX

strap

The

on-state

to

the

condition

The

off-state

are

daisy

DRIVE

to

SELECT

set

TEAC

Maker

block

system.

independent

chained

the

MX

P/N

P/N

of

this

All

of

input

strap

:

13121149

: Honda

strap

the

this

or

when

signal

off

Tsushin

is

input/output

of

the

strap

is

input/output

for

of

any

used

DRIVE

used

only

daisy

Kogyo

when

only

signals

SELECT

when

signals

one

FOD

chained

Co.,

Ltd.

one

are

signal.

multiple

connected.

FDD

DIC-S252

FDO

is

valid

FODs

are

in

(4 FODs, Max.)

enabled

It

in a multiple

connected

this

by

the

is

necessary

-

230

-

connection.

(b)

This

strap

indicator

DSO

'V

These

multiple

When

as

Any

The

FDDs

for

the

an

of

OS

are

each

Refer

straps

the

front

and

DS3

straps

straps

control

MX

on-state

the

strap

set

input

to

items

(or

the

bezel

has

no

the

rotating

designate

by

strap

four

must

is

OS

strap

addresses

be

to a single

signal

2-2-3-3

DRIVE SELECT

indicator,

relation

daisy

off,

set

and

to

condition

the

drive

cahin

the

enables

0

to

address,

cause

through

spindle

the

number

connection.

same

all

through

different

function

2-2-3-5

signals)

turn~on

of

condition

the

(addressl

number

the

3

of

input/output

can

be

number

they

start

errors

for

and

the

motor,

or

spindle

the

designated.

for

operation

and

the

relation

operating

head

of

the

front

motor.

of

the

FDD

DRIVE SELECT

signals.

each

FDD.

simultaneously

data

errors.

between

conditions

load

solenoid.

in

signal

If

bezel

the

multiple

these

of

(c)

HS

and

These

i)

For

Only

HS

When

executed

while

the

Never

ON

inherent

RH

straps

straps

the

when

and

the

determine

model

the

HM

SM

by

the

head

SM

and

set

both

and

DRIVE SELECT

functions

straps

and

the

the

the

with

SM

head

strap

become

the

HS

DRIVE SELECT

loading

HM

straps

the

HS

and

signals

of.

these

head

load

in

the

effective.

straps

will

are

RH

load

solenoid:

UR

are

signal

be

executed

on.

straps

will

two

signals.

condition.

'V

RE

on,

the

selected

on

be

wired

strap

by

at

block

head

by

the

the

ORed

loading

DSO

MOTOR

same

which

is

'V

time.

on-state,

will

DS3

straps,

ON

signal

The

disturbs

be

when

MOTOR

the

-

231

-

ii)

For

HS

the

and

model

HM

straps

without

have

head

no

load

meaning

solenoid

for

CSS

(CSS

model):

(Contact

Start/Stop)

models.

(4)

{al

Even

influence

these

UR ~ RE

IU

and

Straps

(signal

i)

For

When

as

DRIVE SELECT

indicator

though

straps

strap

HL

straps

to

select

connector

the

the

the

IN

to

block

model

IU

USE

and

one

the

should

the

with

strap

signal.

signal,

to

of

other

pin

control

these

functions.

be

set

function

number

head

is

on-state,

The

is

straps

to

of

is

4)

load

solenoid:

IN

provided

the

rotation

is

set

However,

off-state.

the

IN

the

signal

USE

function,

to

to

on-state,

USE/HEAD

of

turn.

on

of

the

it

as a general

LOAD

pin

independent

the

spindle

input

number 4 functions

front

bezel

motor

will

of

have

rule,

signal

the

by

no

setting

the

ML

strap

the

operating

motor.

If

HL

strap

the

HEAD

loading

is

off,

of

the

HEAO

DSO ~ DS3

It

is

possible

same

time.

functions

Also

both

both

functions

LOAD

will

the

straps.

of

straps

in

item

conditions

is

on-state,

signal.

be

executed

head

LOAD

In

loading

signal

to

set

such a case,

the

IN

may

of

the

(d).

USE

be

of

the

If

by

will.

and

both

and

set

signal

-

Refer

the

the

the

the

of

the

the

to

232

to

items

front

signal

MX

be

the

off

will

-

of

strap

HEAD

DRIVE SELECT

signal

HEAD

LOAD

executed

IU

and

LOAD.

at

be

invalid.

bezel

pin

is

of

the

2-2-3-3

indicator

number 4 functions

on

signal,

by

the

pin

same

and

2-2-3-4

and

at

this

time,

while

the

ANDed

signal

HL

number 4 has

straps

time.

selected

In

spindle

as

the

the

MX

condition

by

on

at

the

two

such a case

for

head

strap

ii)

CSS

For

no

model:

the

means.

CSS

model

Even

without

though

the

head

on-state

load

solenoid,

of

the

HL

the

strap

HL

strap

has

has

no

(b)

previous

SM

strap

Strap

i)

For

When

determined.

For

SM

not

strap

influence

rule.

Only

to

the

used

the

must

be

the

enable