Taylor H63 Installation Manual

Shake Freezer

Model H63

Operating Instructions

048887 --M 5/09/02

Complete this page for quick reference when service is required:

Taylor Distributor:

Address:

Phone:

Service:

Parts:

Date of Installation:

Information found on the data label:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: A

Minimum Wire Ampacity: A

E May, 2002 Taylor

All rights reserved.

048887--M

Taylor

The word T aylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Table of Contents

Section 1 To the Installer 1............................................

Water Connections (Water Cooled Units Only) 1............................

Air Cooled Units 1.......................................................

Electrical Connections 1.................................................

Section 2 To the Operator 2...........................................

Compressor Warranty Disclaimer 2.......................................

Section 3 Safety 3....................................................

Section 4 Operator Parts Identification 4...............................

Accessories 6..........................................................

Section 5 Important: To the Operator 7.................................

Symbol Definitions 7....................................................

Power Switch 8.........................................................

Liquid Crystal Display 8..................................................

Consistency Control 8...................................................

Product Ready Light 8...................................................

Reset Mechanism 8.....................................................

Operating Screen Descriptions 8..........................................

Operator Menu 11.......................................................

Section 6 Operating Procedures 15.....................................

Assembly 15............................................................

Sanitizing 19............................................................

Priming 20..............................................................

Daily Closing Procedures 21..............................................

Daily Opening Procedures 22..............................................

Manual Brush Cleaning 23................................................

Draining Product From The Freezing Cylinder 23............................

Rinsing 24..............................................................

Hopper Cleaning 24......................................................

Disassembly 24..........................................................

Brush Cleaning 25.......................................................

Model H63 Table of Contents

Table of Contents -- Page 2

Section 7 Important: Operator Checklist 26..............................

During Cleaning and Sanitizing 26.........................................

Troubleshooting Bacterial Count 26........................................

Regular Maintenance Checks 26...........................................

Winter Storage 27........................................................

Section 8 Troubleshooting Guide 28....................................

Section 9 Parts Replacement Schedule 33...............................

Section 10 Parts List 34.................................................

Wiring Diagrams 41......................................................

Note: Contin u ing research results in steady improvements; therefore, information

in this manual is subject to change without notice.

Table of Contents Model H63

Section 1 To the Installer

This machine is designed for indoor use only.

DO NOT install the machine in an area where

a water jet could be used to clean or rinse the machine.

Failure to follow this instruction may result in serious

electrical shock.

Water Connections

(Water Cooled Units Only)

An adequate cold water supply must be provided with

a hand shut-off valve. On the underside rear of the

base pan, two 3/8” I.P.S. water connections for inlet

and outlet have been provided for easy hook-up. 1/2”

inside diameter water lines should be connected to the

machine. (Flexible lines are recommended, if local

codes permit.) Depending on local water conditions, it

may be advisable to install a water strainer to prevent

foreign substances from clogging the automatic water

valve. There will be only one water “in” and one water

“out” connection. DO NOT install a hand shut-off valve

on the water “out” line! Water should always flow in this

order: first, through the automatic water valve; second,

through the condenser; and third, through the outlet

fitting to an opentrapdrain.

Code (NEC), ANSI/NFPA 70--1987. The purpose of

the NEC code is the practical safeguarding of persons

and property from hazards arising from the use of

electricity. This code contains provisions considered

necessary for safety. Compliance therewith and

proper maintenance will result in an installation

essentially free from hazard!

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

Stationary appliances which are not equipped with a

power cord and a plug or other device to disconnect

the appliance from the power source must have an

all--pole disconnecting device with a contact gap of at

least 3 mm installed in the external installation.

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECTRICAL SHOCK!

Air Cooled Units

Air cooled units require a minimum of 6” (152 mm) of

clearance around all sides of the freezer and 7-1/2”

(191 mm) on the bottom to allow for adequate air flow

across the condenser. Failure to allow adequate

clearance can reduce the refrigeration capacity of the

freezer and possibly cause permanent damage to the

compressor.

Electrical Connections

Each freezer requires one power supply. Check the

data label on the freezer for fuse, circuit ampacity and

electrical specifications. Refer to the wiring diagram

provided inside of the control box, for proper power

connections.

In the United States, this equipment is intended to be

installed in accordance with the National Electrical

Beater rotation must be clockwise as viewed looking

into the freezing cylinder.

NOTE: The following procedures should

be performed by a trained service technician.

To correct rotation on a three-phase unit, interchange

any two incoming power supply lines at freezer main

terminal block only.

To correct rotation on a single-phase unit, change the

leads inside the beater motor. (Follow the diagram

printedonthemotor.)

Electrical connections are made directly to the

terminal block provided in the main control box

mounted on the right hand side of the freezer.

050831

Model H63 To the Installer

1

Section 2 To the Operator

The Model H63 shake freezer has been carefully

engineered and manufactured to give you dependable

operation. This unit, when properly operated and

cared for, will produce a consistent, quality product.

Like all mechanical products, it will require cleaning

and maintenance. A minimum amount of care is

necessary if the operating procedures outlined in this

manual are followed closely .

This Operator’s Manual should be read before

operating or performing any maintenance on your

equipment.

Your Taylor freezer will NOT eventually compensate

for and correct any errors during the set-up or filling

operations. Thus, the initial assembly and priming

procedures are of extreme importance. It is strongly

recommended that personnel responsible for the

equipment’s operation, both assembly and

disassembly, go through these procedures together in

order to be properly trained and to make sure that no

confusion exists.

In the event you should require technical assistance,

please contact your local authorized Taylor Distributor.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other similar

legislation in effect after August 13, 2005. Therefore,

it must be collected separately after its use is

completed, and cannot be disposed as unsorted

municipal waste.

The user is responsible for returning the product to the

appropriate collection facility, as specified by your local

code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or local

distributor.

Compressor Warranty Disclaimer

The refrigeration compressor(s) on this machine are

warranted for the term indicated on the warranty card

accompanying this machine. However, due to the

Montreal Protocol and the U.S. Clean Air Act

Amendments of 1990, many new refrigerants are

being tested and developed, thus seeking their way

into the service industry. Some of these new

refrigerants are being advertised as drop-in

replacements for numerous applications. It should be

noted that, in the event of ordinary service to this

machine’s refrigeration system, only the refrigerant

specified on the affixed data label should be used.

The unauthorized use of alternate refrigerants will void

your compressor warranty. It will be the owner’s

responsibility to make this fact known to any technician

he employs.

It should also be noted that Taylor does not warrant the

refrigerant used in its equipment. For example, if the

refrigerant is lost during the course of ordinary service

to this machine, Taylor has no obligation to either

supply or provide its replacement either at billable or

unbillable terms. T aylor does have the obligation to

recommend a suitable replacement if the original

refrigerant is banned, obsoleted, or no longer available

during the five year warranty of the compressor.

Taylor will continue to monitor the industry and test

new alternates as they are being developed. Should a

new alternate prove, through our testing, that it would

be accepted as a drop-in replacement, then the above

disclaimer would become null and void. To find out the

current status of an alternate refrigerant as it relates to

your compressor warranty, call the local Taylor

Distributor or the Taylor Factory. Be prepared to

provide the Model/Serial Number of the unit in

question.

070122

2

Model H63To the Operator

Section 3 Safety

We at Taylor are concerned about the safety of the

operator when he or she comes in contact with the

freezer and its parts. Taylor has gone to extreme

efforts to design and manufacture built-in safety

features to protect both you and the service technician.

As an example, warning labels have been attached to

the freezer to further point out safety precautions to the

operator.

IMPORTANT -- Failure to adhere to the following

safety precautions may result in severe personal

injury. Failure to comply with these warnings may

damage the machine and its components.

Component damage will result in part

replacement expense and service repair expense.

To Operate Safely:

S DO NOT allow untrained personnel to

operate this machine.

S DO NOT operate the freezer unless all

service panels and access doors are

restrained with screws.

S DO NOT remove the door, beater, scraper

blades, drive shaft, or torque rotor shaft

unless the power switch is in the OFF

position.

S DO NOT put objects or fingers in the door

spout or the spinner housing.

Failure to follow these instructions may result in

contaminated product or severe personal injury to

fingers or hands from hazardous moving parts.

USE EXTREME CAUTION when removing

the beater assembly. The scraper blades are very

sharp and may cause injury.

DO NOT operate the freezer without reading

this operator’s manual. Failure to follow this instruction

may result in equipment damage, poor freezer

performance, health hazards, or personal injury.

S DO NOT operate the freezer unless it is

properly grounded.

S DO NOT attempt any repairs unless the

main power supply to the freezer has been

disconnected.

S DO NOT operate the freezer with larger

fuses than specified on the freezer data

label.

Failure to follow these instructions may result in

electrocution or damage to the machine. Contact your

local authorized Taylor Distributor for service.

DO NOT use a water jet to clean or rinse the

freezer. Failure to follow this instruction may result in

serious electrical shock.

DO NOT draw product or attempt to

disassemble the unit during the HEAT cycle. The

product is hot and under extreme pressure.

This freezer must be placed on a level

surface. Failure to comply may result in personal injury

or equipment damage.

DO NOT obstruct air intake and discharge openings:

6” (152 mm) minimum air clearance on all sides and

7--1/2” (191 mm) minimum on bottom. Failure to follow

this instruction may cause poor freezer performance

and damage to the machine.

This freezer is designed to operate indoors, under

normal ambient temperatures of 70_-- 7 5 _F

(21_-- 2 4 _C). The freezer has successfully performed

in high ambient temperatures of 104_ F(40_C) at

reduced capacities.

NOISE LEVEL: Airborne noise emission does not

exceed 78 dB(A) when measured at a distance of 1.0

meter from the surface of the machine and at a height

of 1.6 meters from the floor.

070122

Model H63 Safety

3

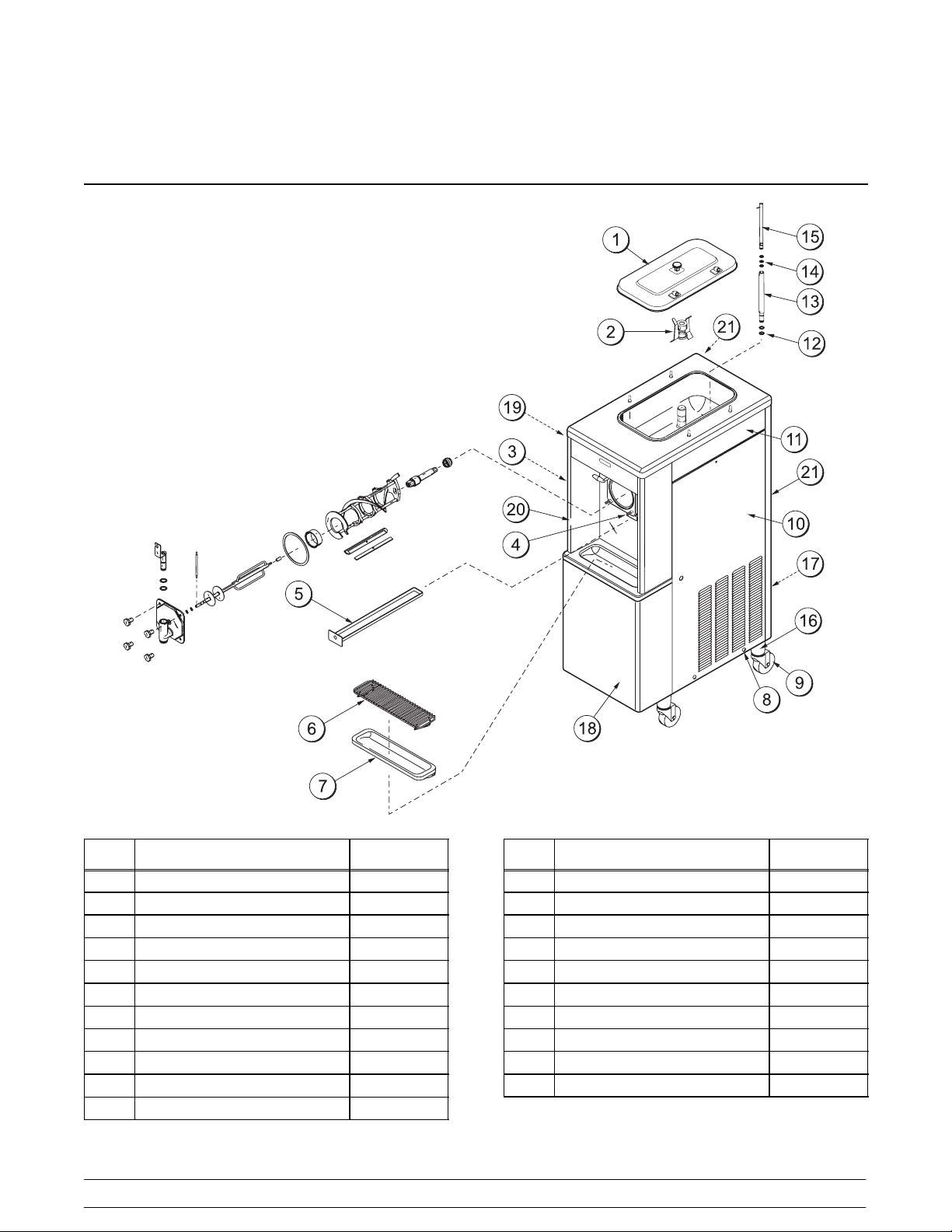

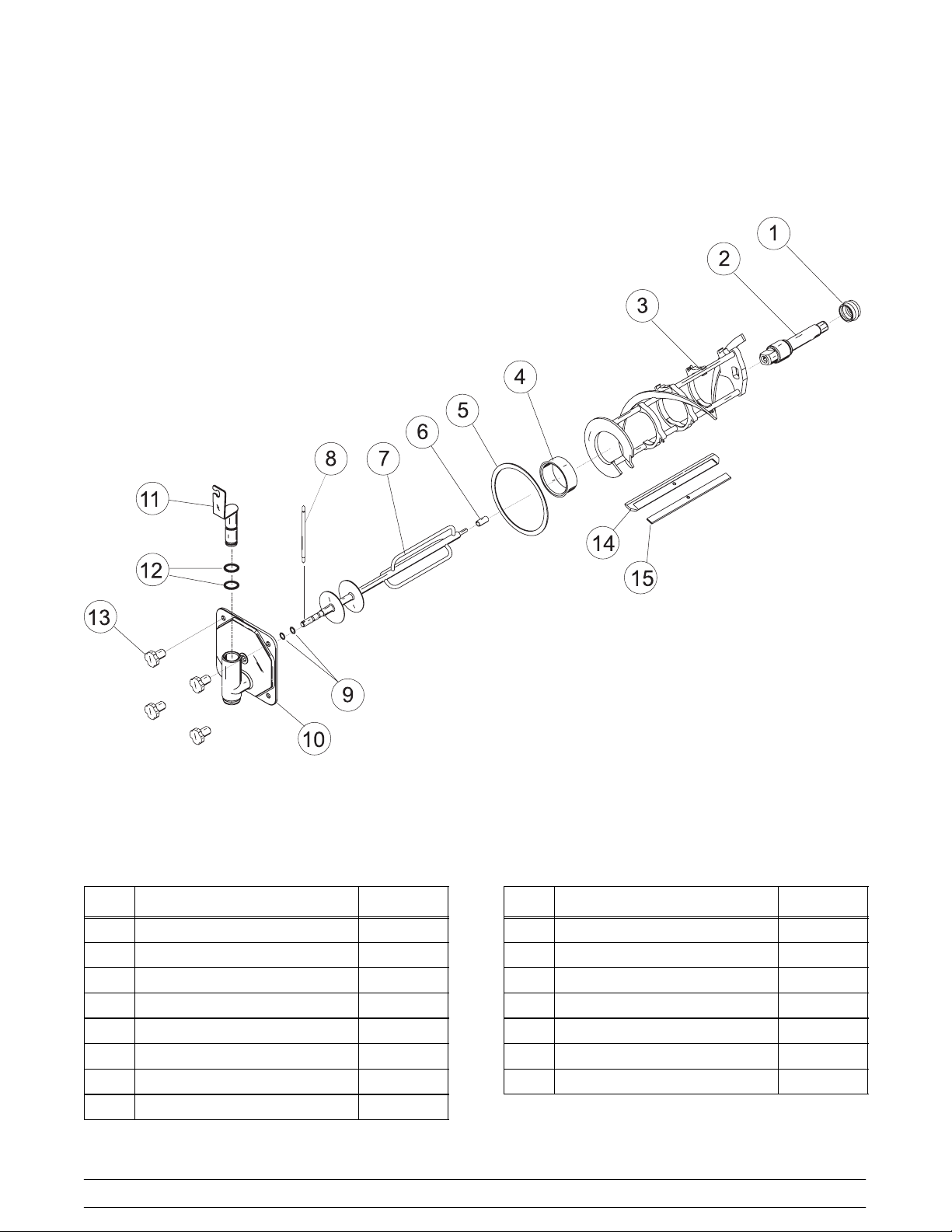

Section 4 Operator Parts Identification

H63

ITEM DESCRIPTION PART NO.

1 COVER A. --HOPPER INS. 053809

2 AGITATOR A. *HT*20 QT X44797

3 PANEL A.- -SIDE LEFT X48285

4 STUD-- NOSE CONE 011390

5 PAN-- DRIP 19-- 1/2 LONG 035034

6 SHIELD--SPLASH--WIRE 046177

7 TRAY-- DRIP 14.8 046275

8 SCREW-- 1/4--20X5/8 005542

9 CASTER-- SWV 5/8 STEM 018794

10 PANEL A.-- SIDE RIGHT X48286

11 PANEL-- SIDE UPPER 042317

ITEM DESCRIPTION PART NO.

12 O--RING--.643 OD X .077W 018572

13 TUBE A.-- FEED --OUTER-- HT X34641

14 O--RING--.291 ID X .080W 018550

15 TUBE A.-- FEED --SC-- INNER X32824-- 5

16 ADAPTOR A.--CASTER X18915

17 PANEL-- REAR W/LOUVERS 026980--SP

18 PANEL-- SERVICE 048380

19 LOUVER--SIDE 013631

20 PANEL A. --FRONT X48371

21 TRIM --REAR CORNER 046668

4

Model H63Operator Parts Identification

H63 Door and Beater Assemblies

ITEM DESCRIPTION PART NO.

1 SEAL-- DRIVE SHAFT 032560

2 SHAFT-- BEATER 035527

3 BEATER A. --7QT--1 PIN X46233

4 BEARING--FRONT 013116

5 GASKET-- DOOR 5.177ID 016672

6 BEARING--GUIDE 014496

7 TORQUE A. X17381

8 ARM-- TORQUE 014500

Model H63 Operator Parts Identification

ITEM DESCRIPTION PART NO.

9 O--RING-- .291 ID X .080W 018550

10 DOOR A.--1 SPOUT-- METAL X17373

11 VALVE A. --DRAW X56119

12 O--RING--1--1/16 OD X .139W 013029

13 NUT--STUD *GENERAL USAGE* 021508

14 BLADE--SCRAPER-- PLASTIC 046237

15 CLIP --SCRAPER BLADE*8.75” 046238

5

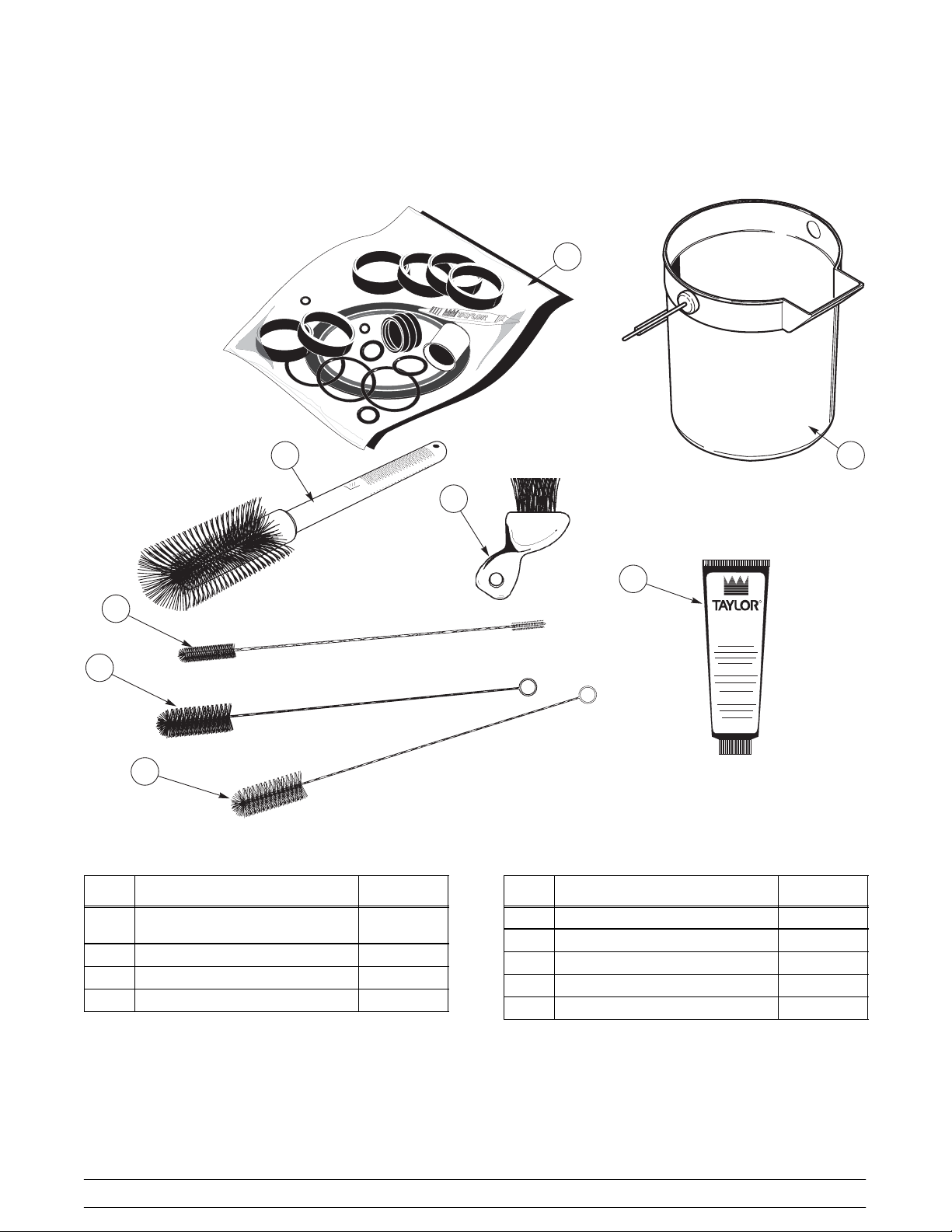

Accessories

0

4

8

2

6

0

3

0

4

8

2

6

0

1

4

5

6

ITEM DESCRIPTION PART NO.

8

2

7

R

B

U

E

L

H

P

ITEM DESCRIPTION PART NO.

1 BRUSH-MIX PUMP BODY -

3” X 7” WHITE

2 BRUSH-END-DOOR-SPOUT 039719

3 KIT A.-TUNE UP X48404

4 BRUSH-DOUBLE ENDED 013072

023316

5 BRUSH-REAR BRG 1IN.D X 2IN 013071

6 BRUSH-DRAW VALVE 014753

7 LUBRICANT-TAYLOR HI PERF 048232

8 PAIL-MIX 10 QT. 013163

* SANITIZER·KAY-5·125·PKTS 041082

*NOT SHOWN

6

Model H63Operator Parts Identification

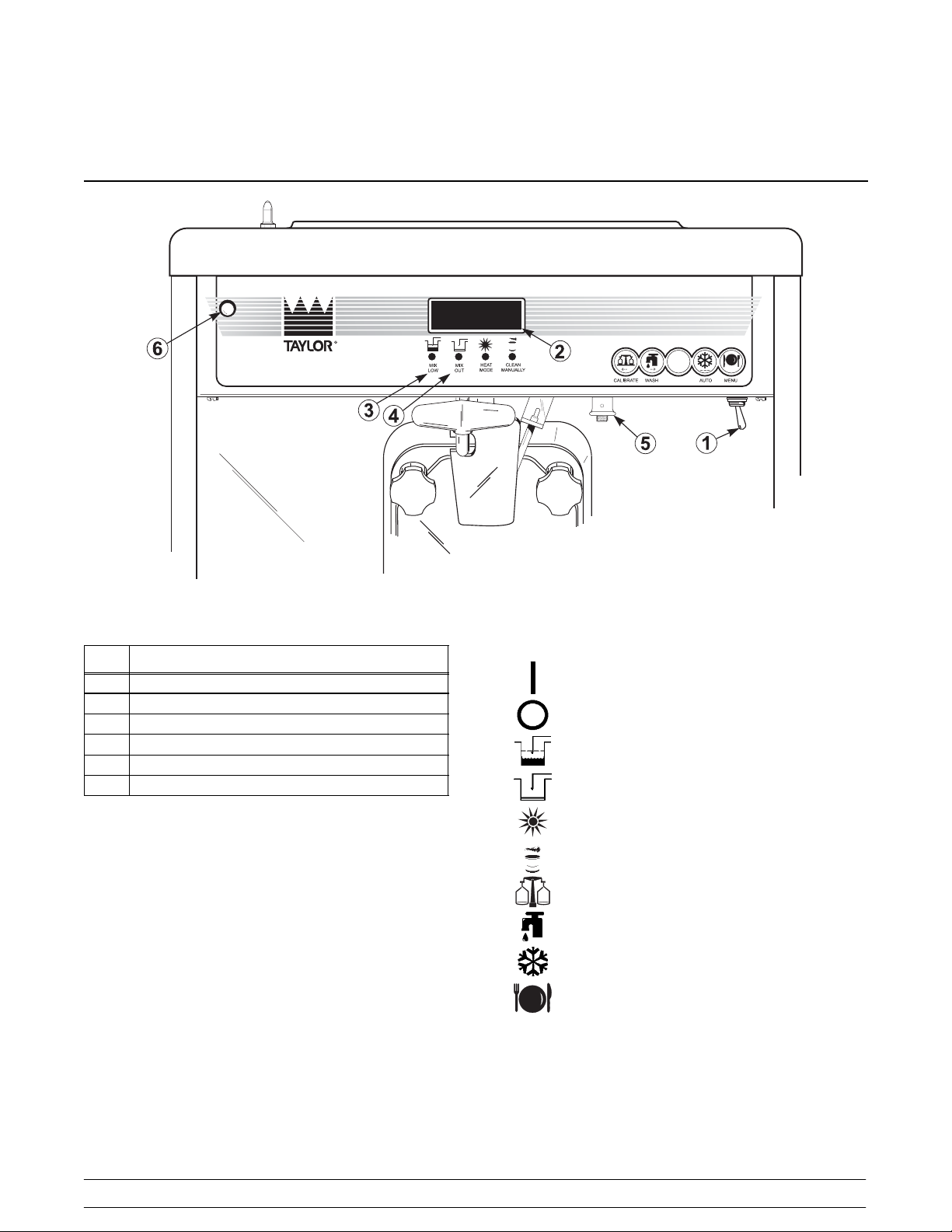

Section 5 Important: To the Operator

H63

Item Description

1 Power Switch (Toggle)

2 Liquid Crystal Display

3 LCD Indicator -- MIX LOW (PCB A.--LED)

4 LCD Indicator -- MIX OUT (PCB A.--LED)

5 Consistency Control (Switch--Torque)

6 Light--Indicator--Product Ready

Symbol Definitions

To better communicate in the International arena, the

words on many of our operator switches and buttons

have symbols to indicate their functions. Your Taylor

equipment is designed with these International

symbols.

The following chart identifies the symbol definitions

used on the operator switches.

=ON

=OFF

=MIXLOW

= MIX OUT

=HEATMODE

= CLEAN MANUALLY

=CALIBRATE

= WASH

=AUTO

=MENU

Model H63 Important: To the Operator

7

Power Switch

Product Ready Light

When placed in the ON position, the power switch

allows control panel operation. The power switch is

located on the left side of the control channel.

Liquid Crystal Display

The Liquid Crystal Display (LCD) is located on the front

control panel. The LCD is used to show the current

mode of operation, and whether or not there is

sufficient mix.

LCD Indicator -- MIX LOW

The “MIX LOW” indicator flashes to indicate that there

is a low supply of mix. The mix hopper should be filled

as soon as possible.

LCD Indicator -- MIX OUT

The MIX OUT light will illuminate, indicating that the

mix hopper has an insufficient supply of mix to operate

the freezer. The MIX OUT indicator will flash. At this

time, the freezer will go into the STANDBY mode of

operation. To return the freezer to the AUTO mode, fill

the hopper with mix and press the AUTO key . The

freezer will automatically begin operation.

Consistency Control

The viscosity (thickness) of the shake is controlled by

a sensing device called the consistency control. The

consistency control knob is located to the lower right

of the control channel. To achieve a thicker shake, turn

the knob clockwise and counterclockwise to achieve a

thinner shake consistency.

Allow the refrigeration system to cycle on and off 2 or

3 times before an accurate consistency can be

evaluated.

The Product Ready Indicator Light illuminates when

the product is ready to serve.

Reset Mechanism

The reset button is located under the right side panel.

The reset mechanism protects the beater motor from

an overload condition. If an overload occurs, the reset

mechanism will trip. To properly reset the freezer,

press the reset button firmly and clear the tone per

instructions in “Clearing Fault Tones” on page 12.

If the reset mechanism trips again, contact your

authorized Taylor Distributor to resolve the problem.

Warning: Do not use metal objects to

press the reset button. Failure to comply may

result in severe personal injury or death.

Operating Screen Descriptions

When the machine is powered the system will initialize.

The screen will display “INITIALIZING”. There will be

four types of data the system will check: LANGUAGE,

SYSTEM DATA, CONFIG DATA, and LOCKOUT

DATA. During the INITIALIZING... LANGUAGE

screen, the alarm will be on. If the system data,

configuration data, or lockout history data has become

corrupt, the following screen will alert the operator that

the system settings may have been changed.

NVRAM FAULT

RESET TO DEFAULTS

PRESS SEL KEY

8

Model H63Important: To the Operator

Once the system has initialized the SAFETY

TIMEOUT screen is displayed and the alarm is turned

on.

MODE: OFF

MIX: OK

HOPPER TEMP: 40.0F

BRUSH CLEAN ON: MM/DD

SAFETY TIMEOUT

ANY KEY ABORTS

This screen will be displayed, with the alarm on, for 60

seconds or until any key is pressed.

After the safety timeout has been completed, and the

power switch is OFF, one of the following screens is

displayed.

The first screen is displayed if the machine is not in a

brush clean state.

POWER SWITCH OF F

MIX: OUT TIME: 4:30

HOPPER: 62.1

BARREL: 67.7

If any of the requirements for a brush clean have not

been met, the time displayed will remain at 5:00

minutes. When all the requirements for a brush

cleaning are met, and the five minutes expire, the

screen will change to the second screen, which is the

standard power switch OFF screen.

The next display indicates the freezer is operating in

two different modes. The following information is

given:

The machine is operating in the WASH and PUMP

modes and the mix level in the hopper is low. The

temperature of the mix hopper is 40_F(4.4_C), and the

machine needs to be brush cleaned on October 31st.

MODE: WSH -PMP

MIX: LOW

HOPPER TEMP: 40.0 F

BRUSH CLEAN ON: 10/31

The following displays pertain to the HEAT cycle:

While in the heating phase, you will see this display. It

shows the present temperature of the hopper.

MODE: HEAT

PHASE: HEAT

HOPPER: 140.0 F

BRUSH CLEAN ON: MM/DD

The mix temperature must be raised above 151_F

(66.1_C) within 90 minutes or the freezer will be locked

in STANDBY, and the cycle failure display will appear.

POWER SWITCH OF F

-- = -- = -- = -- = -- = -UNIT CLEANED

In the example, the hopper temperature is 140_F

(60_C). The phase shows that the machine is in the

heat phase of the heat treatment cycle.

When the heating phase is complete, the freezer goes

into the holding phase of the cycle. The holding phase

will hold the temperature above 151_F (66.1_C) for a

When the power switch is set in the ON position, the

minimum of 30 minutes.

system mode of operation screen is displayed. In this

example, the machine is ON, but no mode of operation

has been selected. The second line of the display

In this example, the hopper temperature is 151_F

(66.1_C).

indicates whether there is a sufficient supply of mix in

the hopper or if there is a LOW or OUT mix condition.

The third line of the display shows the temperature of

the mix hopper. After pressing the AUTO key, the last

line of the display shows the month and date (MM =

month, DD = day) that the machine needs to be

MODE: HEAT

PHASE: HOLD

HOPPER: 151.0 F

BRUSH CLEAN ON: MM/DD

disassembled and brush cleaned.

Model H63 Important: To the Operator

9

The final phase of the heat treatment cycle is the

cooling phase. Now the freezer must cool the mix

below 41_F(5_C). If the product fails to cool in two

hours, the freezer will lock out.

This example illustrates that the temperature is being

lowered, but has not yet reached the set point.

MODE: HEAT

PHASE: COOL

HOPPER TEMP: 55.0 F

BRUSH CLEAN ON: MM/DD

The entire heat treatment cycle must be completed in

four hours.

When the entire heat cycle has been completed, the

normal display will appear, showing the machine in the

STANDBY mode. The machine may now be placed in

the AUTO mode or left in the STANDBY mode.

MODE: STANDBY

MIX: OK

HOPPER: 41.0 F

BRUSH CLEAN ON: MM/DD

The next display is the screen which will appear after

the failure message. Tocomply with health codes, heat

treatment system freezers must complete a heat

treatment cycle daily, and must also be brush cleaned

every 14 days. Brush cleaning is the normal

disassembly and cleaning procedures. Failure to

follow these guidelines will cause the control to lock the

freezer out of the AUTO mode. Press the WASH key.

NO AUTO OPERATION

ALLOWED UNTIL

BRUSH CLEANING

PRESS WASH KEY

The next display is the screen which will appear after

the brush cleaning message and illustrates that the

control is in the OFF mode and the machine needs to

be disassembled and brush cleaned.

Hard Lock: There are two causes for a hard lock:

1. Fourteen days have elapsed since the last

brush cleaning. The following screen will be

displayed.

14 DAY TIMEOUT

CLEANING REQ’D

FREEZER LOCKED

PRESS SEL KEY

2. There has been a thermistor failure (freezing

cylinder, hopper, or glycol) during the heat

treatment process.

SYSTEM FAULT

SERVICE REQ’D

FREEZER LOCKED

PRESS SEL KEY

All four LED’s on the front of the freezer will light. Press

the MENU/SEL key.

MODE: OFF

MIX: OK

HOPPER TEMP: 41.0 F

FREEZER LOCKED

Once the unit is unlocked, only the MIX OUT and MIX

LOW LED’s will light.

Soft Lock: If a heat treatment cycle has not been

initiated within the last 24 hours, all four LED’s on the

front of the machine will light and a message will

appear on the LCD. Line 3 of the LCD will indicate the

reason the message appears.

NO HEAT TREAT START

BECAUSE

VARIABLE MESSAGE

PRESS SEL KEY

10

Model H63Important: To the Operator

Following are the variable messages which will appear

on line 3:

1. POWER SWITCH OFF: Power switch was in

the OFF position.

2. MIX OUT PRESENT: There was mix out

condition present.

3. AUTO OR STANDBY OFF: The unit was not in

the AUTO or STANDBY mode.

NO AUTO OPERATION

ALLOWED. PRESS

AUTO FOR HEAT CYCLE

WASH TO BRUSH CLEAN

If the WASH key is pressed, the next display will

appear and the freezer will have to be disassembled

and brush cleaned.

4. NO HEAT CYCLE TRIED: A heat treatment

cycle was not attempted in the last 24 hours.

(AUTO HEAT TIME was advanced, or a power

loss was experienced at the time the cycle was

to occur, or a heat cycle failure not due to a

thermistor failure.)

If the following screen appears, a soft lock has

occurred during the heat treatment cycle.

HEAT TREAT CYCLE

FAILURE

FREEZER LOCKED

PRESS SEL KEY

If the temperature of the product has not fallen below

41_F(5_C) by the endof the COOL cycle, thefollowing

screen will appear.

PRODUCT OVER TEMP

FREEZER LOCKED

PRESS SEL KEY

Press the MENU/SEL key to advance to the next

display.

MODE: OFF

MIX: OK

HOPPER TEMP: 41.0F

FREEZER LOCKED

Once the freezer is unlocked by starting a heat

treatment cycle, only the heat cycle LED will light. If the

freezer is unlocked by brush cleaning, the mix low and

mix out LED’s will light.

Operator Menu

The OPERATOR MENU is used to enter the operator

function displays. To access the OPERATOR MENU,

simply press the MENU/SEL key. The cursor will flash

over the letter “A” indicating that this is screen “A”. To

select a different screen, use the arrow keys and move

the cursor to the desired screen selection and press

the MENU/SEL key.

OPERATOR MENU

BCDEFGHIJK

A

EXIT FROM MENU

<--- ---> SEL

When one of these messages appears, automatic

freezer operation cannot take place until the freezer is

disassembled and brush cleaned or has completed a

heat treatment cycle.

Screen “B” is FAULT DESCRIPTION. The fault

description will indicate if there is a fault with the

freezer and the side of the freezer where the fault

occurred.

The next display will instruct the operator to start a heat

treatment cycle manually (by pressing the AUTO key),

or to disassemble and brush clean the freezer. If the

FAULT DESCRIPTION

VARIABLE MESSAGE

AUTO key is pressed, the freezer will automatically

start the heat treatment cycle and only the heat cycle

CLR SEL

LED will light.

Model H63 Important: To the Operator

11

Loading...

Loading...