Page 1

Rockton, Illinois 61072

800-255-0626

Phone 815-624-8333 Fax 815-624-8000

www.taylor-company.com

e-mail: info@taylor-company.com

International Office

Taylor Company S.r.l.

Roma, Italy

Tel: +39-06-420-12002 Fax: +39-06-420-12034

e-mail: romeoff@taylor-company.com

H60

Item No. _______________________________

H60

Offer four separate shake flavors: chocolate, strawberry,

vanilla (unflavored shake mix) and an optional flavor.

Heat Treatment System

Provides a daily heating and cooling cycle to safely maintain dairy

products up to two weeks before a complete disassembly and

cleaning is required.

Freezing Cylinder

One, 7 quart (6.6 liter).

Mix Hopper

One, 20 quart (18.9 liter). Refrigerated to maintain mix below 41ºF

(5ºC).

Indicator Lights

Mix Low light alerts the operator to add mix. When the Mix Out

light flashes, the unit automatically goes into Standby mode to

prevent damage.

Electronic Controls

Viscosity is continually measured to serve consistent quality shakes.

The LCD (Liquid Crystal Display) readout will identify temperatures

in the hopper or freezing cylinder at any point of operation. History

of temperatures and times during the last 13 heat cycles may be

viewed.

Standby

During long no-use periods, the standby feature maintains safe

product temperatures in the mix hopper and freezing cylinder.

Shake Syrup System

Shake flavors are selected from touch pads. Self-contained air

compressor delivers shake syrup from three, 1 gallon (3.8 liter)

syrup tanks located in the lower front compartment. Use only single

strength syrup, free from pulp and seeds.

Automatic Dispensing

Press the desired flavor and raise the draw handle. Frozen shake

mix and syrup automatically blends to dispense the chosen flavor.

After the shake is drawn, press the Rinse touch pad to eliminate

flavor carryover. Rinse water connection under side of base is 3/8”

FPT.

Features

Shake Freezer

Four Flavor

Page 2

H60

H60Shake Freezer

Electrical

One dedicated electrical connection is required. See the Electrical chart for

the proper electrical requirements. Manufactured to be permanently

connected. Consult your local Taylor distributor for cord & receptacle

specifications as local codes allow.

Beater Motor

One, 1.0 HP

Refrigeration System

One, 11,000 BTU/hr. R404A.

(BTUs may vary depending on compressor used.)

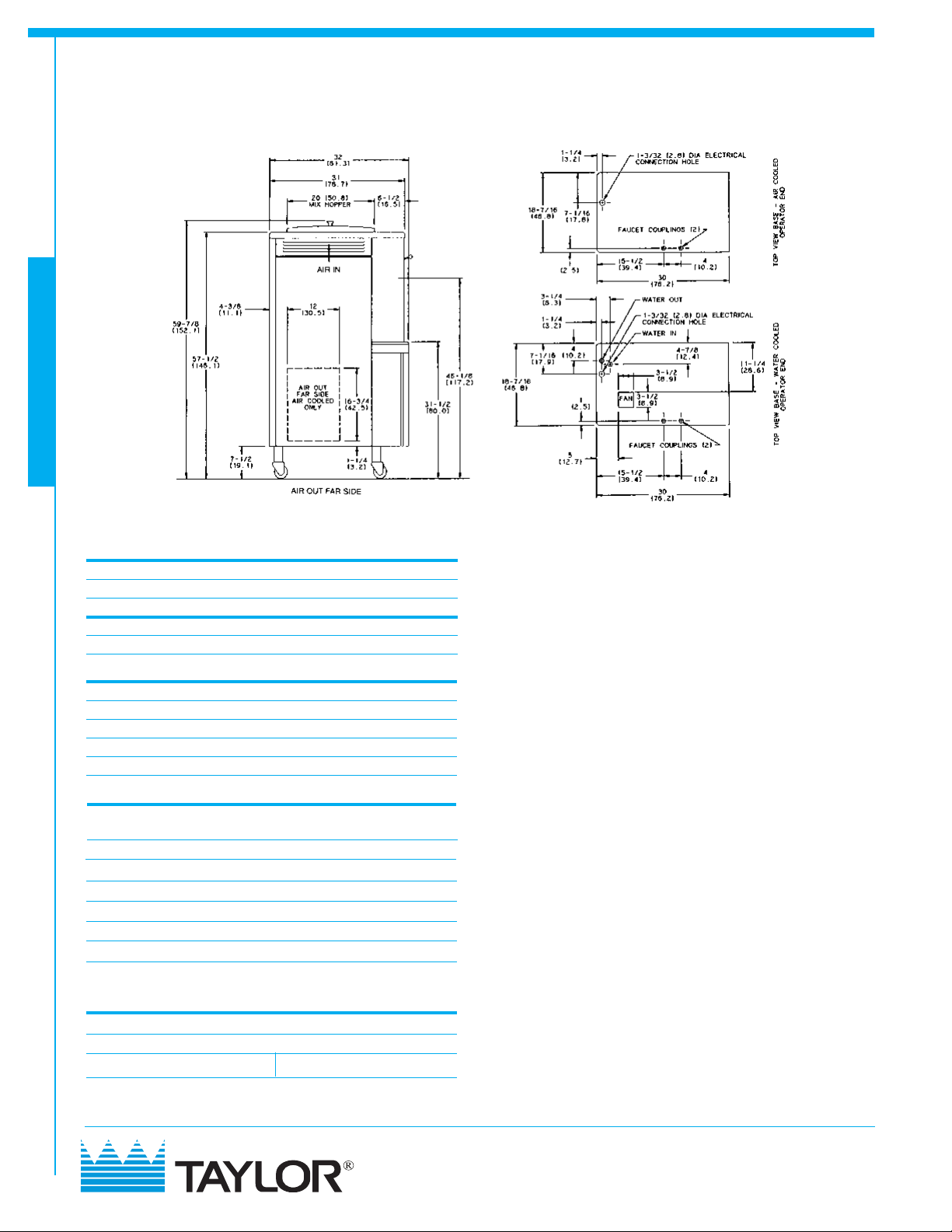

Air Cooled

Minimum Clearance: 6” (152 mm) on all sides. Minimum air clearances must

be met to assure adequate air flow for optimum performance.

Water Cooled

Water inlet and drain connections under side of base 3/8” FPT.

Printed in U.S.A.

Weights lbs. kgs.

Net 544 246.7

Crated 557 252.7

cu. ft. cu. m.

Volume 35.4 1.0

Dimensions in. cm.

Width 18-7/16 468

Depth 32 813

Height 59-7/8 1521

Floor Clearance 7-1/2 191

*Mounted on standard casters

Bidding Specs

Electrical: Volt ___________________ Hz__________ ph _________

Neutral: Yes No Cooling: Air Water NA

Options:_________________________________________________

_________________________________________________________

Faucet

Hopper Locks

Options

Specifications

046433-ADV

3/05

Continuing research results in steady improvements; therefore, these

specifications are subject to change without notice.

Taylor Company,

A Division of Carrier Commercial Refrigeration, Inc.

Rockton, Illinois 61072

815-624-8333 800-255-0626 Fax 815-624-8000

www.taylor-company.com

Electrical Maximum Minimum Poles (P)

Fuse Size Circuit Ampacity Wires (W)

208-230/60/1 Air 30 22 2P 3W

208-230/60/1 Water 30 22 2P 3W

208-230/60/3 Air 25 17 3P 4W

208-230/60/3 Water 25 17 3P 4W

220-240/50/1 Air 30 20 2P 3W

380-415/50/3N~ Air 15 15 4P 5W

This unit may be manufactured in other electrical characteristics. Refer to the

local Taylor Distributor for availability.

(For exact electrical information, always refer to the data label of the unit.)

Loading...

Loading...