Page 1

OPERATING INSTRUCTION AND MAINTENANCE

MANUALE D’USO E MANUTENZIONE

Serie-Series

CH02 05

Page 2

IMPORTANT

We recommend that you read this manual fully and carefully before using your

appliance.

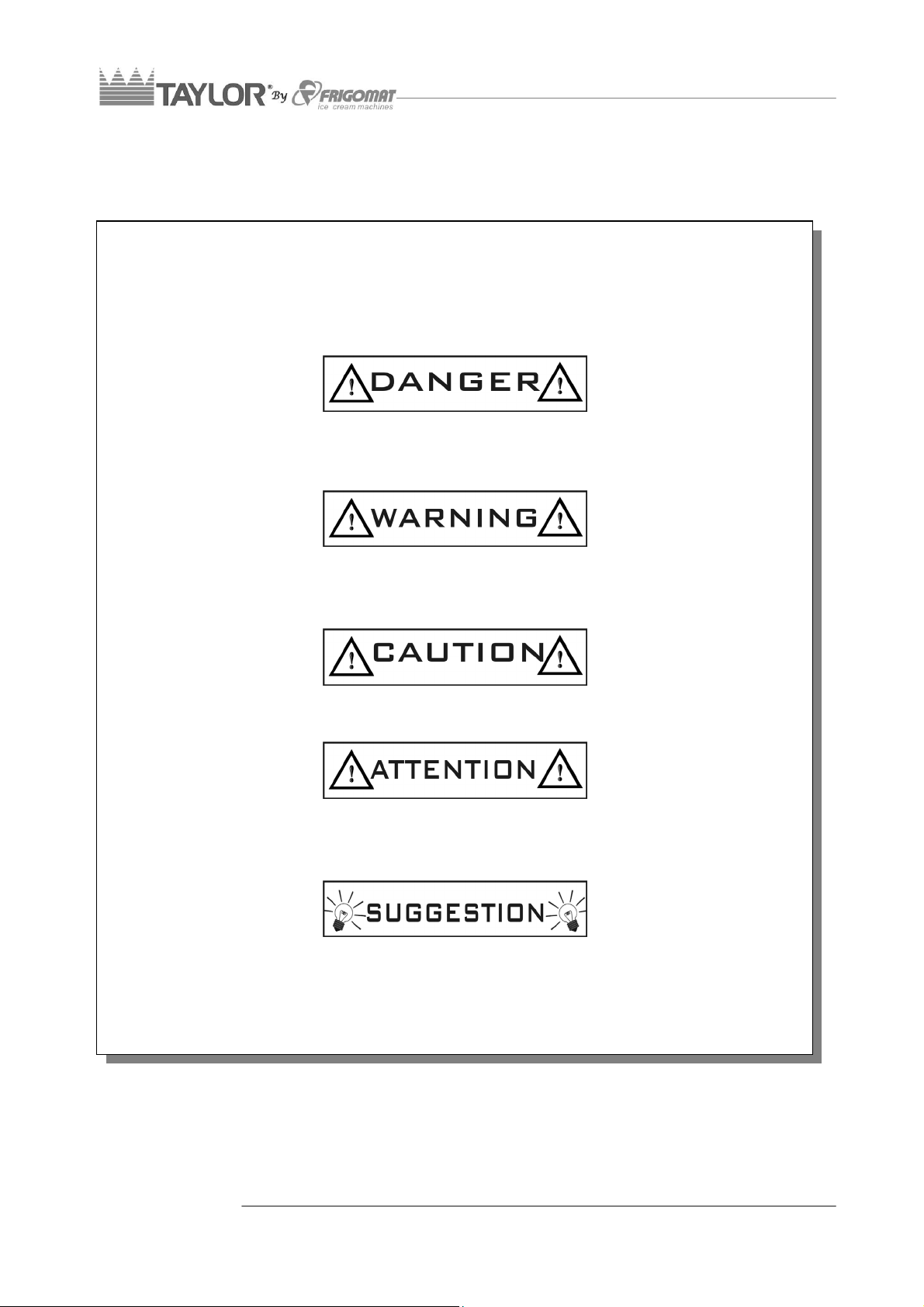

It is in your interest to pay special attention to the warnings marked as follows:

Failure to comply with this signal causes very serious risks for health, death, and

medium and long term permanent damage.

Failure to comply with this signal can cause very serious risks for heath, death, and

medium and long term permanent damage.

Failure to comply with this signal can cause injuries or damage to the machine.

Comply with these warnings for your machine to work properly and/or to be serviced

correctly.

The machine can perform at best only through compliance with these warnings.

FRGMTMEB2916000

1 - ENGLISH

Page 3

We congratulate you for having chosen to purchase a TAYLOR machine.

This manual, supplied together with the machine, must be considered an integral and

essential part and must be delivered to the final user. Before carrying out any operations,

we recommend studying these instructions carefully. Only by reading them carefully can

you obtain the maximum performance from your machine. The following pages carry all of

the indications required to perform installation, operation, adjustments and routine

maintenance correctly. TAYLOR reserves the right to carry out the modifications it deems

necessary to improve its product or the technical manual without prior warning, inserting

the variations in the subsequent editions.

Total or partial reproduction, adaptation or translations of this manual without prior written

consent by TAYLOR is prohibited.

The machine is covered by warranty according to the terms illustrated in the "WARRANTY

CARD" supplied. It must be duly filled in and returned to:

FRIGOMAT s.r.l., via 1° Maggio, 28 26862 GUARDAMIGLIO (LODI) – ITALY

Please write the serial number of your machine in the field below.

Serial number

Dealer's stamp

ENGLISH - 2

Page 4

INDEX

1. TRANSPORTATION, HANDLING AND STORAGE …………………… 4

2. MARKING AND GRAPHIC SIGNS …………………………………………… 5

3. GENERAL SAFETY STANDARDS …………………………………… 7

4. INSTALLATION …………………………………………………… 8

4.1 Use ……………………………………………. 8

4.2 Working limits ……………………………………………. 8

4.3 Noise …………………………………………………… 8

4.4 Supplied with machine …………………………………………… 8

4.5 Activation …………………………………………………… 9

5. SAFETY DEVICES ……………….………………………………….. 10

6. OPERATION …………………………………………………… 11

6.3.1 Automatic cycle 85° …………………………………… 15

6.3.2 Semi-automatic …………………………………… 16

6.3.3 Automatic cycle 65° ………………………………….. 18

6.5 Extraction of boiling mixtures ………….……………….………. 19

7. MAINTENANCE ………………………………………….……..... 20

7.1 Routine maintenance ………………………………………….……….. 20

7.2 Extraordinary maintenance ………………………………..…………. 24

8. INSTRUCTIONS FOR IDENTIFYING FAULTS ………………….……….. 26

8.1 Alarm management ………………………………..…………. 26

8.2 Troubleshooting …………………………………………………… 27

9. APPENDICES ............................................................. A1

9.4 Spare parts ...………………………………..... A4

1.1 Preliminary inspection and storage…………………………..…….. 4

1.2 Dimensions and weights of packaged machines …………… 4

1.3 Indications for decommissioning ………………………….. 4

6.1 Machine …………………………………………………… 11

6.2 Control panel …………………………………………………… 12

6.3 Thermal processing of mixtures …………………………… 14

9.1 Technical data ……………..…………………………….. A1

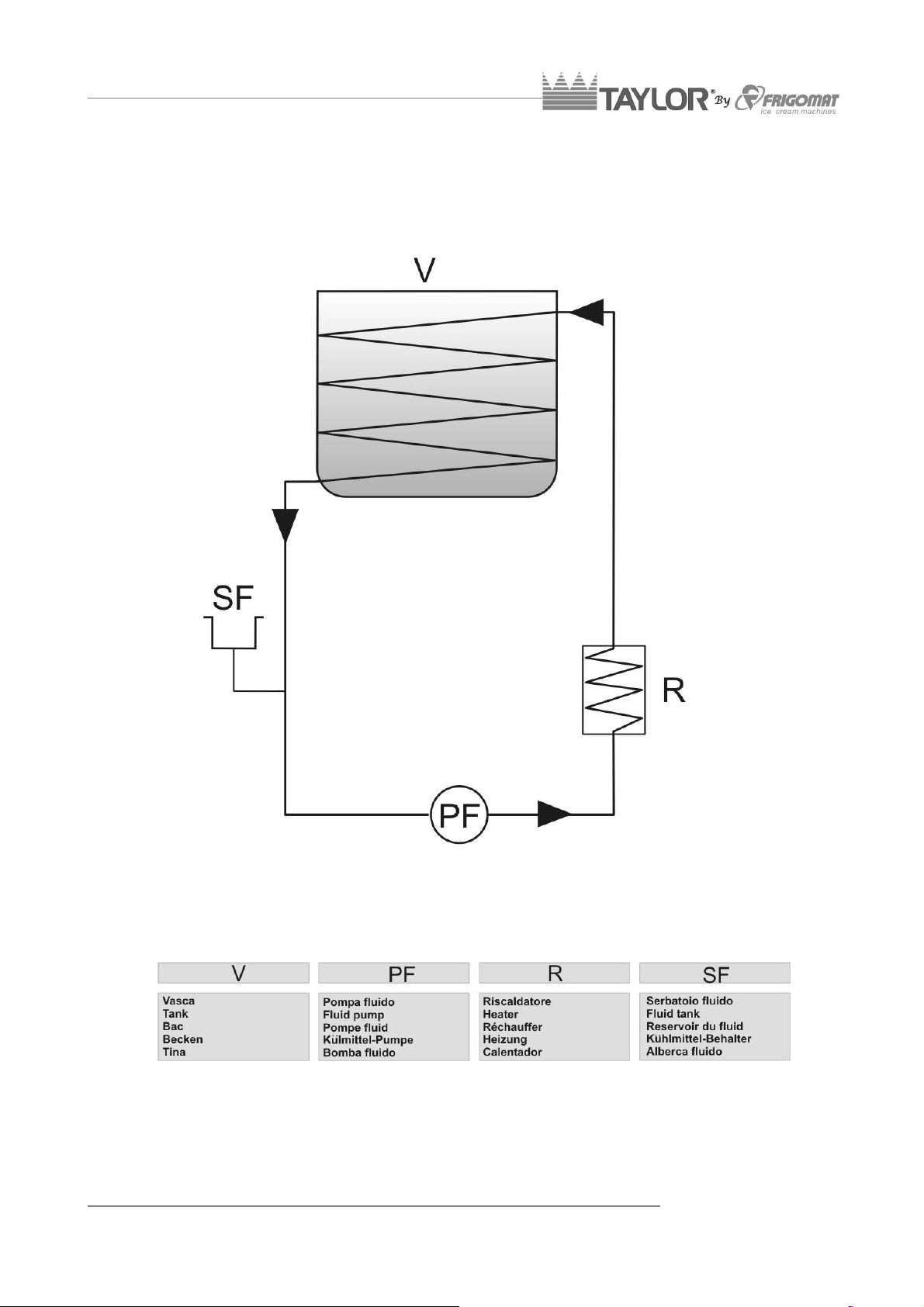

9.2 Heating circuit layout ………………………… .…………………….… A2

9.3 Electrical system ……………………………………………. A3

3 - ENGLISH

Page 5

1. TRANSPORTATION, HANDLING AND STORAGE.

1.1 PRELIMINARY INSPECTION AND STORAGE

The machine is transported at the risk and peril of the customer. If you notice any damage

to the packaging, immediately inform the carrier.

Inform the carrier immediately after opening the package if the machine is damaged even

if a few days after delivery.

It is always preferable to accept goods SUBJECT TO CLEARANCE.

The appliance must be handled with care; it can be damaged by falls and blows even

without exterior damages.

Storage temperature must be between 0° and + 50°C, and humidity between 30 and 95%

with no dew.

Once the appliance has been unpacked, the packaging must be kept in a dry place out of

the reach of children. If stored properly, it can be reused if the machine is moved.

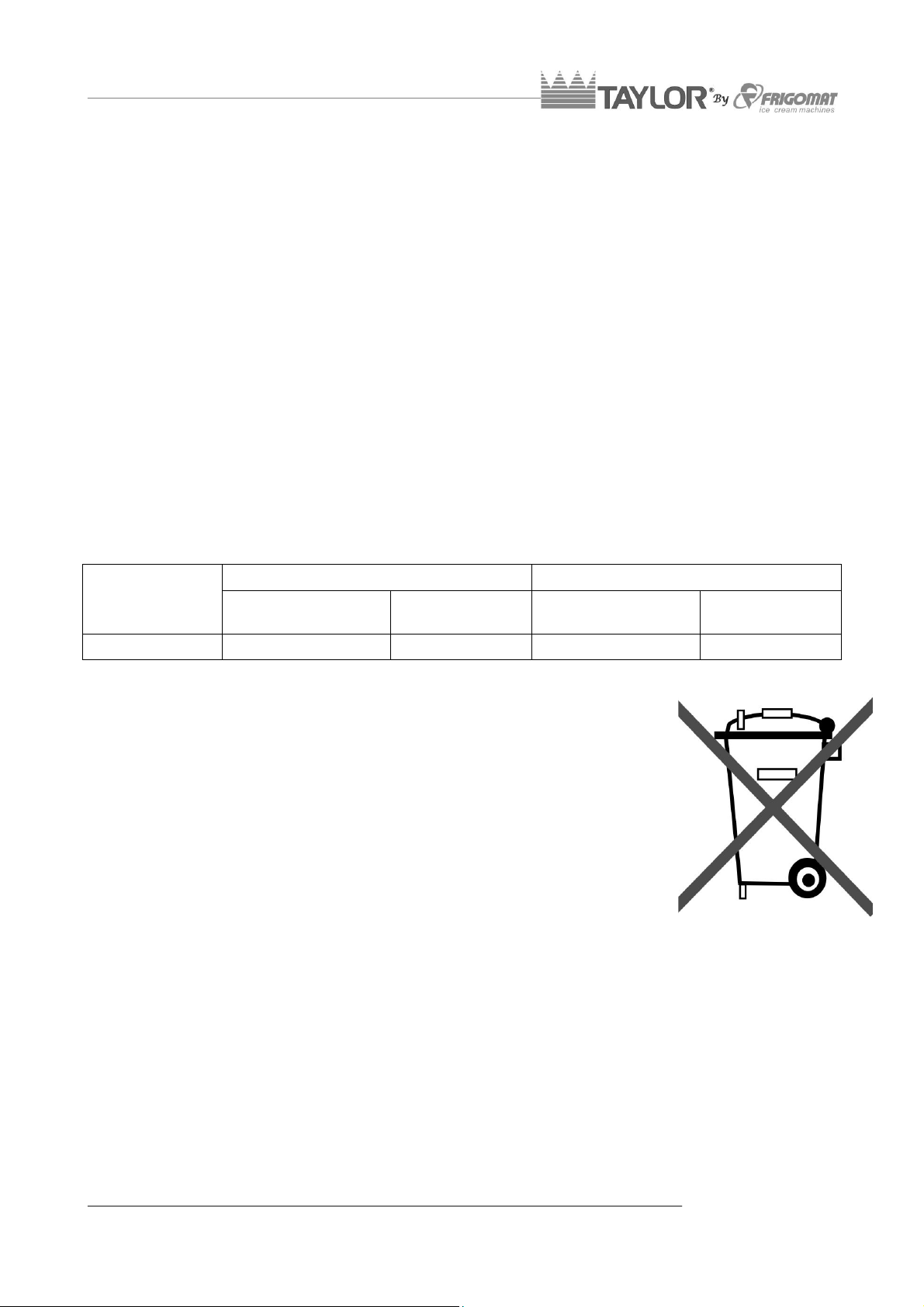

1.2 DIMENSIONS AND WEIGHTS OF PACKAGED MACHINES

CRATE BOX PALLET

MODEL

CH02

1.3 INDICATIONS FOR DECOMMISSIONING

The machine contains electrical and/or electronic materials and can

contain fluids and/or oil. If it must be decommissioned or disposed of,

comply with the Standards in force in the Country where it is used.

Even packaging materials (crates or boxes) must be divided by type

and disposed of in compliance with Standards in force in the Country

where it is used when the machine is decommissioned.

MEASUREMENTS

(CM)

WEIGHT N-G

(KG)

MEASUREMENTS

(CM)

WEIGHT N-G

60.5X50.5X53 35-42 - -

(KG)

ENGLISH - 4

Page 6

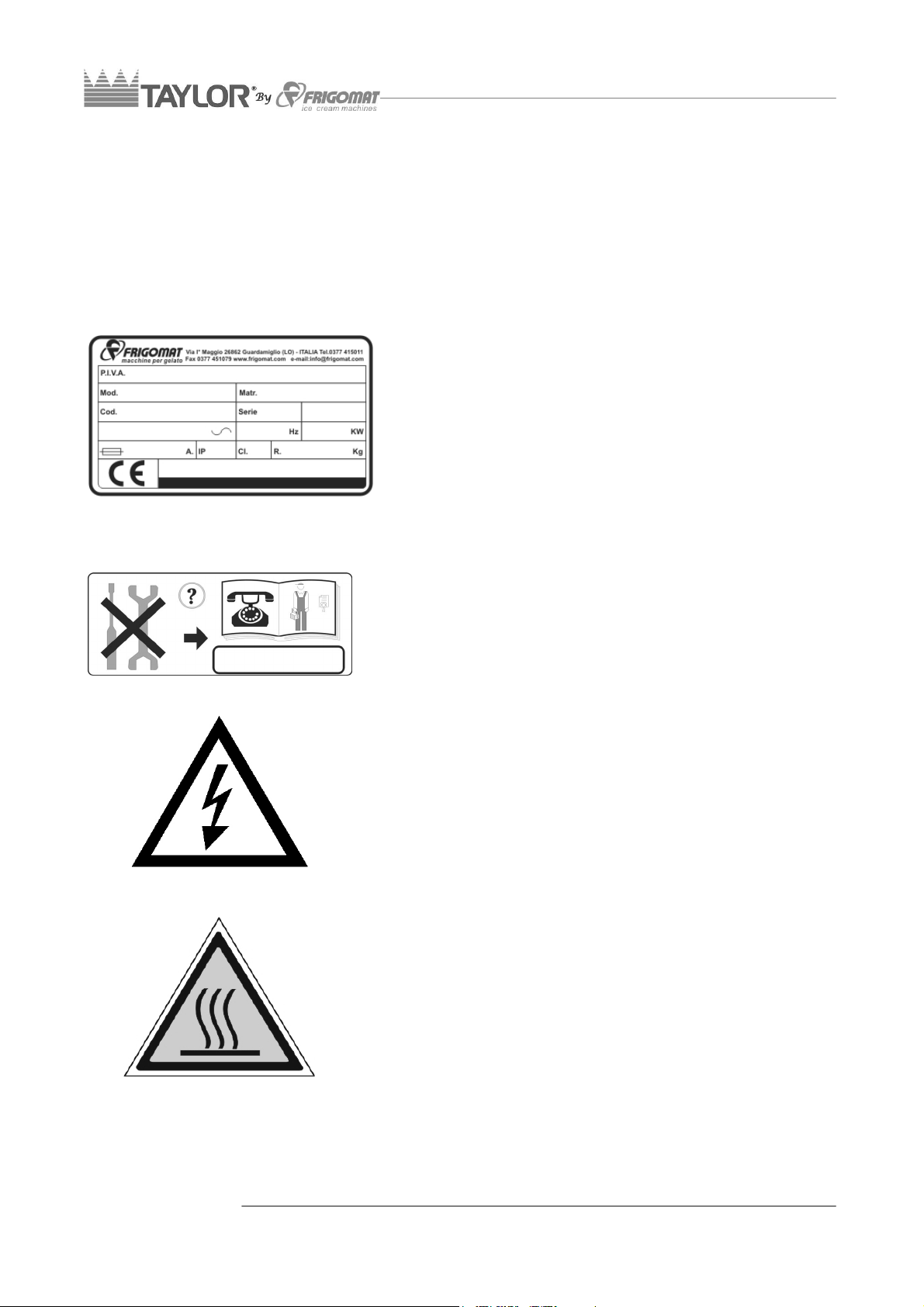

2. MARKING AND GRAPHIC SIGNS

The machine is provided with an identification plate and several pictograms. They must be

known along with the manual to guarantee safe use.

Machine data plate

The adhesive plate applied on the rear enables to

identify the model. It includes the following indications:

Name and address of the manufacturer; machine

model and version; serial number; nominal electrical

features; type and weight of gas used; year of

manufacture.

Attention!

Maintenance reserved for qualified personnel. This

plate applied on the rear panel prohibits extraordinary

maintenance and/or repairs to anyone but authorised

personnel, whose address is indicated in the space

provided.

Attention!

High voltage inside; electrocution hazard.

This plate is applied on the cover of the electrical box

and warns the operator that it must not be removed

for any reason whatsoever, thus avoiding the danger

of electrocution which could be fatal. In this case also,

maintenance of internal components is reserved for

qualified personnel.

Attention!

Burns hazard.

This plate is applied on the top of the machine and

warns the operator that the cover must be opened

with great care since he could be assailed by steam.

5 - ENGLISH

Page 7

Attention!

Crushing hazard.

This plate is applied on the top panel at the right of the

vessel cover. It indicates that one must pay attention,

both during cleaning and charging, since it can fall

and injure the operator if hit.

All CHEF LCD cream cookers are equipped with an

advanced limb-shearing-prevention safety system

capable of stopping moving parts if the lid is opened.

Nonetheless, all cleaning and maintenance must be

performed with the machine at "STOP" and the

master switch disconnected.

Indication

Level of glycol.

The following label is attached on the tank wall of the

exchange fluid inside the machine and indicates the

optimal level of glycol.

ENGLISH - 6

Page 8

3. GENERAL SAFETY STANDARDS

Strictly comply with the general Safety and Accident-prevention Standards listed hereafter:

- Use of the machine is reserved for personnel in good health, responsible and

appropriately trained regarding allowed use and risks present.

- Use of the machine is reserved for operators who have read, understood and taken

in all that is included in this manual.

- It is forbidden to remove or tamper with the safety systems installed on the

machine.

- While the appliance is operating, it is mandatory to check that dangerous situations

for persons do not occur. Should these conditions transpire, stop the appliance

immediately.

- When you have finished working with the machine, it is mandatory to cut power by

acting on the master switch.

- When unusual noise or anomalous functioning is perceived, it is mandatory to

immediately stop operations in progress and to search for the cause of these

irregularities. If in doubt, avoid improper operations by contacting the

manufacturer's after-sales service.

- Any tampering or modification of the machine automatically entails the immediate

termination of the warranty and relieves the manufacturer of all and any liability for

direct or indirect damage caused.

- It is mandatory to check that the place where the machine is installed is ventilated

and correctly illuminated. The surface where the appliance is installed must be

solid, flat and levelled.

- During loading, unloading and handling operations, it is mandatory to use

equipment with a capacity adequate for the mass (weight) of the machine, using

hoisting devices and accessories with features and state of use suitable for the

purpose.

- Use only TAYLOR original spare parts when performing maintenance. The

manufacturer will not be held liable for damage caused by use of non-original spare

parts. Use of non-original spare parts entails automatic termination of the warranty.

- It is mandatory to position the machine far away from equipment which emits

electromagnetic radiation which could cause the circuit boards to malfunction.

- If fire-prevention equipment is necessary use types which are compatible with the

presence of voltage on board.

- It is forbidden to wear long and loose apparel, ties, jewellery, scarves or similar

clothing which could get caught in the moving parts of the machine.

- Hair must be tied back and shirt-sleeves tight.

7 - ENGLISH

Page 9

4. INSTALLATION

4.1 USE

Appliance suitable for the thermal processing bakery products and mixtures for ice cream,

according to use allowed by Law.

4.2 WORKING LIMITS

Do not use the machine with inconstant power supplies or +/- 10% beyond the value

indicated on the plate or with the power cable damaged;

Do not use the machine in explosive atmospheres;

Do not wash the machine with high-pressure water jets or with harmful substances;

Do not expose the machine to excessive heat or humidity;

Do not use unbalanced mixtures and/or amounts which do not comply with the

specifications carried on the packs.

Use not expressly indicated in this manual is to be considered improper and therefore

must be strictly avoided.

The manufacturer will not be held liable for direct or indirect harm to persons or animals or

damage to objects caused by improper use of the machine.

4.3 NOISE

SOUND EMISSION LEVEL EXPRESSED IN DECIBELS (measurement method A)

As foreseen by Machinery Directive 89/392 EN 23741 Standard

(A-weighted equivalent continuous sound pressure level)

MODEL LEVEL (A) MODEL LEVEL (A)

CH02

< = 68 dB (A)

4.4 SUPPLIED WITH MACHINE

-

- Spatula

- Brush

- Gasket extractor

- O-ring kit

- Lubricant

- Use and maintenance manual

- Declaration of conformity

- Warranty certificate

ENGLISH - 8

Page 10

4.5 ACTIVATION (INTENDED FOR QUALIFIED PERSONNEL)

TAYLOR declines all and any liability for damage caused by failure to comply with the

following indications. This lack of compliance causes the warranty to terminate.

Connection of the machine to the water mains must be performed in compliance with

national regulations of the Country where the machine is installed.

To commission the machine, bring it to the place of use, checking what is requested for its

installation:

• Make sure the appliance is positioned on a solid, stable, flat and levelled surface.

• If required, adjust the rear feet.

• Leave at least 10 cm between the machine and the walls or other obstacles.

• Check the exact correspondence between the voltage and power of the mains

compared to the values carried on the data plate applied on the rear panel;

• Connect the machine to the electrical power supply system. Install an omnipolar master

switch upstream the appliance with minimum contact opening of 3 mm of adequate

power, with a fuse and circuit breaker protective system. Use an approved interlocking

plug to allow only the open circuit to connect and disconnect.

• The cable must be well laid, without being rolled-up or overlapped. It must not be

exposed to blows or tampering. It must not be in the vicinity of liquids or water and heat

sources. It must not be damaged in any way. If so, before connecting the machine to

the mains, have it replaced by qualified personnel with another section and type 3G1.5

H05VV-F

• For safety purposes, make sure the earthing system to which the machine plug is

connected is compliant with standards and perfectly efficient.

• If needed, carry out an equipotential bonding, using the screw

placed on the rear of the machine below the frame and

marked with the symbol shown to the left.

• Operating temperature should be between 15° and 35°C.

• Humidity should be between 30 and 60%.

9 - ENGLISH

Page 11

5. SAFETY DEVICES

Motor overheating safety device: Implemented by means of self-resetting thermal

protectors (clixon) to protect the operation machine motors from overloads. Once the

normal work temperature is restored, reset occurs automatically.

Heat elements safety device: implemented by means of safety thermostat; it protects the

heat element from overheating, by signalling the relative alarm message on the display,

emitting an intermittent acoustic signal and allowing restore directly from the push button

control panel.

Protection against short circuit of auxiliary utilities: Implemented by fuses which

intervene on the logic unit or auxiliary power supply in the event of short-circuits.

SELV safety circuit: the push button control panel is powered at low voltage by means of

an approved dual-insulation safety transformer, protected against short circuits by fuses.

ENGLISH - 10

Page 12

6. OPERATION

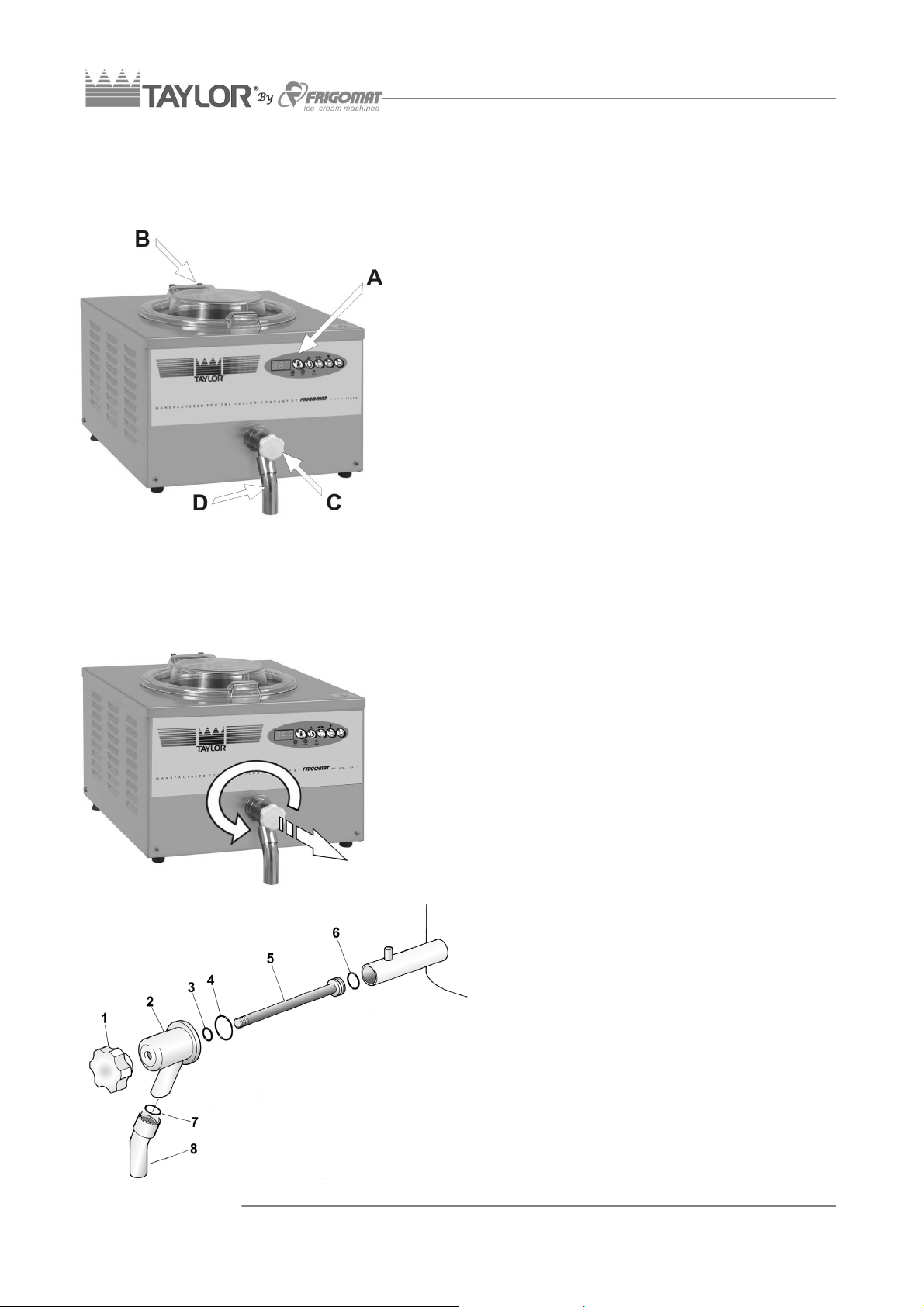

6.1 MACHINE

REMOVING THE DISPENSER TAP

A. Push button control panel

Enables to select the work programs.

B. Tank lid

Closes the tank during the processing phases. It can

be easily removed for cleaning.

C. Tap knob

Allows to adjust the extracting flow of the product from

the tank.

D. Dispenser tap

Used when extracting the product and emptying water

during the tank cleaning procedure.

• Release the dispenser tap by turning it

anticlockwise of 90° and then pull it as

indicated in the figure

• Remove the drain pipe pos 8 and remove and

grease the OR gasket pos. 7, using the

provided tool 7

• Loosen the hand wheel pos. 1 and remove the

piston pos 5, and then verify and lubricate the

gaskets pos. 3-4-6

• Once the unit has been re-assembled, block it

again.

11 - ENGLISH

Page 13

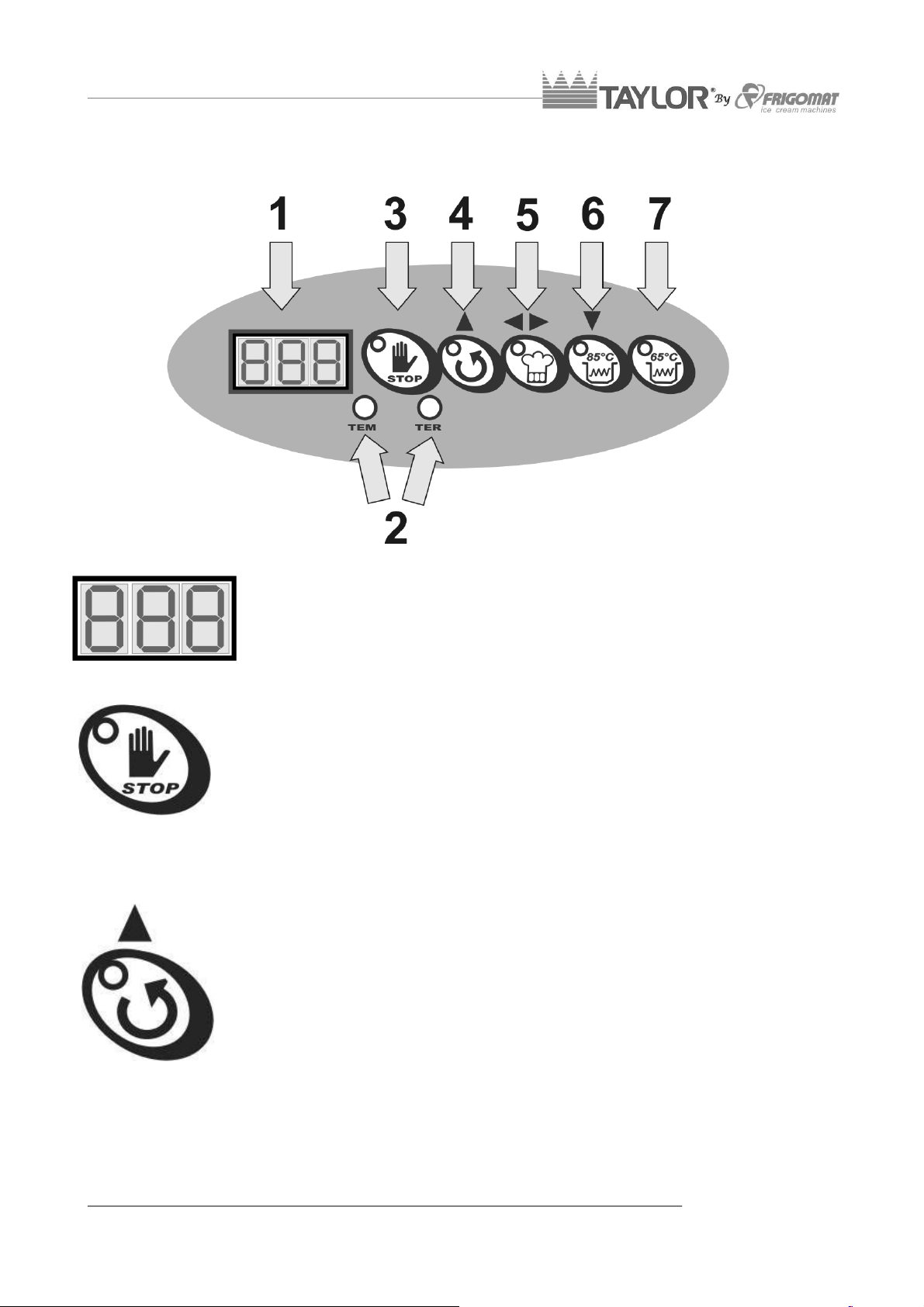

6.2 CONTROL PANEL

3. DISPLAY

Displays the information relative to work programs and allowed

adjustments.

4. STOP

In whatever operating phase the machine is in, pressing the STOP

key stops the machine and cancels the function in progress.

3. MIXING/UP (▲)

This button has 2 functions:

1. With the machine at STOP, by pressing the STIRRING key, the

2. With the machine in programming, by pressing the UP (▲) key it is

beater motor starts up and the LED turns on.

With the machine in SEMI-AUTOMATIC, AUTOMATIC 85°, and

AUTOMATIC 65° mode, by pressing the STIRRING key, the

ongoing operation interrupts, the machine changes to mixing only

and the LED turns on.

possible to increase the value of the selected parameter.

ENGLISH - 12

Page 14

4. SEMI-AUTOMATIC/CONFIRM (◄►)

This button has 4 functions:

1. Whatever the function in progress, the pressing the SEMI-AUTOMATIC

key, access is gained to the programming of the semi-automatic thermal

processing cycle, were it possible to program the maximum temperature

of the product in tank and time for which said temperature will be kept

constant.

2. With the machine in programming, by pressing the CONFIRM (◄►) key

it is possible to confirm the value of the selected parameter.

3. With the machine in SEMI-AUTOMATIC mode, by keeping the SEMIAUTOMATIC key pressed for at least 3”, the instantaneous temperature

of the bain-marie fluid is temporarily shown on display.

4. With the machine in SEMI-AUTOMATIC mode, by keeping the SEMIAUTOMATIC key pressed for at least 10”, access is gained to the

control mode of the bain-marie fluid programming (only for qualified

personnel).

5. AUTOMATIC 85°/ DOWN (▼)

This button has 4 functions:

1. Whatever the function in progress is, by pressing the AUTOMATIC 85°

key, the key LED switches on and starts the automatic heating cycle at

85°C.

2. During programming, by pressing the DOWN (▼) key it is possible to

reduce the value of the selected parameter.

3. With the machine in AUTOMATIC 85° mode, by keeping the

AUTOMATIC 85° key pressed for at least 3”, the instantaneous

temperature of the bain-marie fluid is temporarily shown on display.

4. With the machine in AUTOMATIC 85° mode, by keeping the

AUTOMATIC 85° key pressed for at least 10”, access is gained to the

control mode of the bain-marie fluid programming (only for qualified

personnel).

6. AUTOMATIC 65°

This button has 4 functions:

1. Whatever the function in progress is, by pressing the AUTOMATIC 65°

key, the key LED switches on and the automatic heating cycle at 65

starts with subsequent maintenance for 30'.

2. With the machine in AUTOMATIC 65° mode, by keeping the

AUTOMATIC 65° key pressed for at least 3”, the instantaneous

temperature of the bain-marie fluid is temporarily shown on display.

3. With the machine in AUTOMATIC 65° mode, by keeping the

AUTOMATIC 65° key pressed for at least 10”, access is gained to the

control mode of the bain-marie fluid programming (only for qualified

personnel).

7.LED TER - TEM

The LED switches on to signal any system anomalies.

13 - ENGLISH

Page 15

6.3 THERMAL PROCESSING OF MIXTURES

After having installed the machine in compliance with the instructions of chapter 3 and

having accurately washed and sanitised it, according to the instructions contained in

chapter 7, proceed as follows to start thermal processing:

- Make sure the master switch is closed and that

the machine is powered correctly.

- Make sure the dispenser tap is closed and that the

tank beater is assembled correctly.

- Lift the cover and pour the ingredients in the tank,

strictly observing the minimum and maximum

amounts admitted per cycle and carried on the

following table:

MODEL

CH02

Failure to comply with the minimum and maximum

load values can entail machine malfunctioning and

even breakage.

- Lower the lid and select the wanted work cycle,

referring to the instructions in the successive

paragraphs.

MIN

(LITRES)

3 8

MAX

(LITRES)

ENGLISH - 14

Page 16

6.3.1 AUTOMATIC CYCLE 85°C

Fig.1

Fig.2

Fig.3

Fig.4

- Press the AUTOMATIC 85° key to start the

automatic heating cycle at 85°C. The key LED such

as on and the instantaneous temperature of the

product in tank during the entire processing cycle is

shown on display (fig.1-2).

- When a few minutes have elapsed and temperature

of 85°C is reached, the display flashes and the

buzzer sounds intermittently to inform the operator

that the boiling mixture can be removed (fig.3). If

this is not possible right away, the beater will keep

on mixing and the electrical heat element will hold

the mixture at the correct temperature, thus starting

the PRESERVATION phase without limits of time.

- During the preservation phase, the temperature of

the product in tank flashes on the display.

- It is possible to go to the product extraction phase

at any time (fig.3).

At any moment, it is possible to verify the

instantaneous temperature value of the bain-marie

fluid by keeping the AUTOMATIC 85° key pressed

for at least 3" (fig.4). This value will be displayed for

about 10".

15 - ENGLISH

Page 17

6.3.2 SEMI-AUTOMATIC CYCLE

Fig.1

Fig.2

Fig.3

Fig.4

Fig.5

- Press the SEMI-AUTOMATIC key to select

the semi-automatic thermal treatment cycle

with temperature and stand-by time control

(Fig. 1).

- The LEDs of the UP (▲), Confirm (◄►) and

DOWN (▼) keys start flashing and the

numbers relative to the set of temperature to

be configured, between 30 and 90, appear

on the display: press the “UP (▲)” and

“DOWN (▼)” keys to increase or decrease

this value (Fig. 2). Once the wanted value is

reached, press the CONFIRM (◄►) key to

save the programming made (Fig. 3).

- After programming of the temperature set to

be reached, select the time during which this

temperature is kept constant.

- The LEDs of the UP (▲), Confirm (◄►) and

DOWN (▼) keys start flashing and the

numbers relative to the set of time to be

configured, between 0' and 10' hours, appear

on the display: press the “UP (▲)” and

“DOWN (▼)” keys to increase or decrease

this value (Fig. 4).

- Once the wanted value is reached, press the

CONFIRM (◄►) key to save the

programming made and start the processing

cycle (Fig. 5).

By selecting heating temperatures between

65° and 85°C, the machine automatically

calculates the stand-by time required to

guarantee absolute product hygiene.

This time value can be modified at any time,

but it is strongly advised against as products

with excessively high bacterial loads may be

obtained.

- Once the programmed temperature is

reached and any standby time has passed,

the display flashes and the buzzer sounds

intermittently, to inform the operator that the

mixture can be extracted (fig.6). If this is not

ENGLISH - 16

Page 18

Fig.6

Fig.7

possible right away, the beater will keep on

mixing and the electrical heat element will

hold the mixture at the correct temperature,

thus starting the PRESERVATION phase

without limits of time.

- During the preservation phase, in addition to

any programs downtime time, the

temperature of the product in tank flashes on

the display (fig.6).

- It is possible to go to the product extraction

phase at any time.

At any moment, the instantaneous

temperature value of the bain-marie fluid can

be verified, by keeping the SEMIAUTOMATIC (fig.7) key pressed for at least

3". This value will be displayed for about 10".

17 - ENGLISH

Page 19

6.3.3 AUTOMATIC CYCLE 65°

Fig.1

Fig.2

Fig.3

Fig.4

- Press the AUTOMATIC 65° key to start the

automatic heating cycle at 65° and subsequent

maintenance for 30'. The key LED such as on and

the instantaneous temperature of the product in

tank during the entire processing cycle is shown on

display (fig.1-2).

- Once the temperature of 65° is reached and 30'

standby time has passed, the display flashes and

the buzzer sounds intermittently, to inform the

operator that the mixture can be extracted (fig.3). If

this is not possible right away, the beater will keep

on mixing and the electrical heat element will hold

the mixture at the correct temperature, thus starting

the PRESERVATION phase without limits of time.

- During the preservation phase, the temperature of

the product in tank flashes on the display.

- It is possible to go to the product extraction phase

at any time (fig.3).

At any moment, it is possible to verify the

instantaneous temperature value of the bain-marie

fluid by keeping the AUTOMATIC 65° key pressed

for at least 3" (fig.4). This value will be displayed for

about 10".

ENGLISH - 18

Page 20

6.5 EXTRACTION OF BOILING MIXTURES

- Ensure the amount of product to be

transferred is compatible with the useful

capacity of the container of destination.

- Make sure the heater tap is in vertical position

to allow the product to flow directly into the

container you wish to use.

- Regardless of the function in progress, press

the STIRRING key on the control panel of the

heater (fig.1).

To quickly and completely remove the

product from inside the vessel, the beater

must always be operating.

- To begin the transfer, pull the knob slowly

and carefully.

Pay the utmost attention during transfer of

boiling mixtures; handle the tap piston with

extreme care, use suitable containers and

take all possible precautions to reduce the

risk of injuries, even serious, due to contact

with boiling product.

F

- When the entire product has been transferred

inside the container and the heater vessel is

empty, push the piston to the closed position.

- Press “STOP” on the heater control panel

(fig.3).

19 - ENGLISH

Page 21

7. MAINTENANCE

7.1 ROUTINE MAINTENANCE (INTENDED FOR USER)

The fats present in the ice cream mixtures are ideal fields for the proliferation of bacterial

loads and mould. To eliminate this serious problem, all the parts which come into contact

with the product must be thoroughly washed and sanitized by careful procedures and

using suitable sanitizing products. The stainless and plastic materials used on our

machines, in fact, comply with the strictest international provisions and their special shape

facilitates their washing. However this is not enough to prevent the formation of mould and

bacteria caused by insufficient or incorrect cleaning.

TAYLOR recommends thoroughly washing and sanitizing the parts in direct contact with

the product after each work shift and in compliance with hygienic standards in force in the

Country where the machine is installed.

To correctly clean your machine, refer to the following operations:

PREWASHING

• Pour the maximum admitted load of warm

(approximately 50°C) drinking water into the tank.

• Press the MIXING key to start the beater motor. Let it

run for about 3’. Open the dispenser tap and drain all

the wash water. Repeat the procedure until the water

coming out is clear and clean.

• Pour the maximum load admitted of

cleanser/sanitizer into the tank.

• Press the STIRRING button to start the beater motor.

Let it run for about 15’. Open the dispenser tap and

drain the sanitizer.

•

We suggest using the following sanitising

solution:

Ecolab P3 Topax-san

(4% dilution = 200 ml).

ENGLISH - 20

Page 22

Pour the maximum admitted load of cold drinking

water into the tub to rinse the surfaces which were

just treated with the sanitizer.

• Drain the rinse water and turn the machine off.

• When pre-washing is over, all the removable parts in

contact with the product must be disassembled and

sanitized in a separate tub.

SANITIZING REMOVABLE PARTS

PREPARATION OF WASHING TUB

• Wash your hands well and/or wear disposable

gloves.

• Fill a clean tub with a sufficient amount of drinking

water at approximately 50°C and the sanitizer.

REMOVING AND CLEANING COVER

• Pull the hinge pin off and remove the cover, holding it with both hands.

Emerge the previously disassembled components into the tub with the sanitizer and

brush the surfaces with care. Pay special attention to the surfaces in direct contact with

the product.

We suggest using the following sanitising

solution:

Ecolab P3 Topax-san

(4% dilution = 200 ml every 5 litres of water).

• Prepare the supplied brush and the OR disassembly

device and immerse them in the solution.

21 - ENGLISH

Page 23

REMOVING AND CLEANING BEATER

• Pull the beater upwards to pull it out of the tub.

• Emerge the previously disassembled component into

the tub with the sanitizer and brush the surfaces with

care. Pay special attention to the inner duct of the

beater shaft.

REMOVING AND CLEANING THE TAP

• Rotate the tap block anticlockwise and of 90° until

releasing it.

• Pull the block tap until removing it from the machine.

• Remove the drain pipe pos 8 and remove the OR

gasket pos. 7, using the provided tool 7

• Loosen the hand wheel pos. 1 and remove the piston

pos 5.

• Emerge the previously disassembled components

into the tub with the sanitizer and brush the surfaces

with care. Pay special attention to the inner duct of

the tap, to the holes and seats of the OR.

All the disassembled parts must remain soaking in the Ecolab P3 Topax-san sanitizer

(4% dilution) for at least 15’ before they are rinsed with plenty of cold drinking water.

SANITIZING FIXED PARTS

While the removable parts soak in the sanitizer

inside the tub, proceed sanitizing the fixed parts of

the machine:

SANITIZING THE TUB

• Immerse a disposable paper cloth in the sanitising

liquid.

• Pass the cloth over all the surfaces of the tub and

fixed transmission shaft.

• Pass the cloth over the outer edge of the tub until

reaching the surfaces of the cover and front panel.

ENGLISH - 22

Page 24

• Use the brush previously emerged in the sanitizer to thoroughly clean the drain duct

which connects the tank to the tap.

• Never use any type of solvents and/or thinners to preserve the plastic parts and

gaskets during washing.

• Chemical sanitizing products must be used in compliance with standards in force and

with the utmost caution.

• During sanitizing operations, do not touch parts with tissues, sponges, rags or any

other non-sterile material.

RINSING AND DRYING

• Wash your hands well and/or wear disposable latex

gloves.

• Remove from the sanitising tank all the components

which were previously disassembled, brushed and

immersed.

• Rinse them with plenty of cold drinking water, making

sure to remove all possible leftover sanitising solution.

• Place the rinsed components on a clean table and let

them dry in the air.

DO NOT use rags, sponges or anything else to dry the

components. Make sure no dust or other impurities

come into contact with the sanitized surfaces while

they are drying.

• Also carefully rinse the fixed parts of the machine

which were treated with the sanitizing solution

(cylinder, drive shaft, etc.)

• When all the components are dry, put them back onto

the machine, making sure the gaskets are in good

conditions.

23 - ENGLISH

Page 25

7.3 EXTRAORDINARY MAINTENANCE (INTENDED FOR QUALIFIED PERSONNEL)

g.2

g

These operations are reserved exclusively for authorised qualified personnel. TAYLOR

S.r.l. will not be held liable for damage to objects or harm to persons which occur due to

failure to comply with the above.

HEATER MEB² BOARD PROGRAMMING

Refer to the following instructions to program the circuit board:

Fig.1

1. Ensure the lid is assembled in machine and in

closing position.

2. Power the machine.

3. With the machine at STOP, press the “STOP” and

“MIXING” keys simultaneously and release them

only after the password identification screen

appears (fig.1).

Fi

4. Press the “MIXING(▲)”, “AUTOMATIC 85° (▼)”

and “SEMI-AUTOMATIC (◄►)” keys to enter the

password and then confirm it (fig.2). If you do not

know the password, contact the TAYLOR

assistance service.

5. When the password has been accepted, the screen

accesses the list of programming steps directly. The

Fi

.3

first programming step P01 is selected

automatically

6. If you do not wish to change the value of the

selected step, press “MIXING (▲)” to directly

access the following step (Fig. 3).

7. If, instead, you wish to change the selected step,

press ““SEMI-AUTOMATIC (◄►)” to access the

Fig.4

parameters relative to the same step, and

subsequently press “MIXING (▲)” or “AUTOMATIC

85° (▼)” to increase or decrease the value.

Subsequently, press the “SEMI-AUTOMATIC

(◄►)” key to confirm the data (fig.4).

8. To exit programming and save the changes press

Fig.5

the "STOP" key (fig.5).

ENGLISH - 24

Page 26

“MEB²” BOARD PROGRAMMING TABLE (**)

P DESCRIPTION MIN MAX CH02 STEP

P1 Model Selection 1 2 2

P2 Tank probe correction (TEV) -10° +10° * 0,5°C

P3

P4

P5

P6

P7

P8

P9 Lim. control hysteresis TEF 1° 10° 1° 1°C

P10 Temperature indication on display 0 1 1

compensation when TEV>40°C

TEF Control Lim. in AUTOMATIC

Probe correction

fluid (TEF)

Tank overtemperature

TEF Control Lim. in SEMI-

AUTOMATIC

85° and 65°

Not active

Not active

-10° +10° * 0,5°C

-10° +10° * 0,5°C

30° 130° 98° 1°C

30° 130° 98° 1°C

1= TWIN

2= CH02

0=°F

1=°C

9.

(*) These parameters vary for each unit and variant.

(**) The parameters may vary depending on the software version or customisation. It is

always possible to refer to the test inspection board supplied with the machine.

25 - ENGLISH

Page 27

8. TROUBLESHOOTING INSTRUCTIONS

8.1 MANAGEMENT OF HEATER ALARMS

MESSAGE DESCRIPTION REMEDIES

Wait a few minutes and then

press STOP to restore machine

operation.

If the alarm continues, contact

the technician.

TER

A circuit breaker or the transformer fuse

has intervened.

The buzzer emits an intermittent acoustic

signal.

DIS

TEv Int

TEv cor

TEf Int

TEf cor

Communication between the board and

the display interrupted.

The tank probe is interrupted.

The buzzer emits an intermittent acoustic

signal.

The tank probe is in short-circuit.

The buzzer emits an intermittent acoustic

signal.

The fluid probe is interrupted.

The buzzer emits an intermittent acoustic

signal.

The fluid probe is in short-circuit.

The buzzer emits an intermittent acoustic

signal.

Contact the technician.

Contact the technician to check

and replace the faulty probe.

Contact the technician to check

and replace the faulty probe.

Contact the technician to check

and replace the faulty probe.

Contact the technician to check

and replace the faulty probe.

ENGLISH - 26

Page 28

8.2 HEATER TROUBLESHOOTING

PROBLEM PROBABLE CAUSES REMEDIES

Master switch open. Close the switch.

The machine does not start

(STOP button off).

Electrical anomaly. Contact the technician.

Fuses blown. Contact the technician.

After the extraction there is

still too much product in the

vessel

The machine works regularly

but the heating times are

long.

During functioning the

machine becomes noisy and

the beater stops.

The machine becomes noisy

during operation.

The machine does not heat

within normal time and a loss

of blue fluid is detected

under the machine.

Adjust the rear feet so that the

Insufficient rear feet adjustment.

Product insufficient.

Open lid.

Faulty resistance or fluid pump. Contact the technician.

The belt slips.

Transmission shaft without

lubrication.

Loss of glycol from the system. Contact the technician.

product contained in the vessel

comes out.

Work with at least 1/2 the

maximum amount of product

allowed.

Make sure that the lid is

assembled and closed properly.

Contact the technician to check

the belts tension and possibly

replace it.

Remove the mixer and pull the

transmission shaft upwards.

Verify and lubricate with food

grease.

27 - ENGLISH

Page 29

9 APPENDICI / APPENDICES / ANNEXES / ANHANG / APENDICES

9.1 Dati tecnici / Machine specifications / Caractéristiques techniques / Technische

Daten / Datos Tecnicos

Modello

Model

Modell

Modale

Modelo

Alimentazione

Current

Stromart

Tension

Tensiòn

Potenza

Power

Nennleistung

Puissance

Potencia

Altezza

Height

Höle

Hauteur

Altura

Larghezz

a

Width

Breite

Largeur

Anchura

Profondità

Dept

Tiefe

Profondeur

Profundidad

Peso

Weight

Gewicht

Poids

Peso

CH02

(kw) (cm) (cm) (cm) (kg)

220/50-60/1 2,2 33 43 49+7 35

1 - APPENDICI

Page 30

9.2 Schema circuito frigorifero / Refrigerant circuit diagram

APPENDICI - 2

Page 31

9.3 IMPIANTO ELETTRICO / ELECTRIC SYSTEM / GROUPE ELECTRIQUE /

ELEKTRISCHE ANLAGE / INSTALACION ELECTRICA

3 - APPENDICI

Page 32

9.4 RICAMBI / SPARE PARTS / PIECES DETACHEES / ERSATZTEILE / REPUESTOS

Per la richiesta delle parti di ricambio, si raccomanda di indicare sempre il numero di codice

relativo e la denominazione riportata sulla legenda di ciascuna tavola. Si raccomanda inoltre di

comunicare sempre il modello ed il numero di matricola della macchina, nonché le caratteristiche

della stessa (voltaggio, frequenza e fasi), facilitando in tal modo l’identificazione del particolare.

Per ordinare la componentistica di ricambio del compressore indicare sempre anche il modello

specificato sulla targhetta del motore. In caso di sostituzione di pezzi, richiedere solo ricambi

ORIGINALI TAYLOR ad un concessionario o ad un Rivenditore Autorizzato. TAYLOR declina ogni

responsabilità per danni a persone e/o cose derivanti dall’utilizzo di ricambi non originali.

For spare parts ordering, always mention the corresponding code number and the name reported

on each table caption. It is also recommended to always mention the machine model and the serial

number as well as the technical data (voltage, frequency and phases), to make the identification of

the component easier. To order spare parts for the compressor, always mention the model

specified on the motor nameplate. In case it is necessary to replace a component, always ask a

distributor or an authorized retailer for ORIGINAL spare parts. TAYLOR declines any liability for

damages to people and/or things due to employment of non-original spare parts.

En cas de demande de pièces détachées, l’on recommande vivement d’indiquer le numéro de

code correspondant et la description figurant sur la légende de chaque tableau. L’on recommande

aussi de communiquer le modèle et le numéro d’immatriculation de la machine, ainsi que ses

caractéristiques (voltage, fréquence et phases), afin de faciliter l’identification de la pièce. Pour

commander les composants de rechange du compresseur, il faut également indiquer le modèle qui

est spécifié sur la plaque d’identification du moteur. En cas de remplacement de pièces, demander

uniquement des pièces détachées ORIGINALES TAYLOR en vous adressant à un

concessionnaire ou à un Revendeur Autorisé. TAYLOR décline toute responsabilité en cas de

dommages aux personnes ou aux choses qui dériveraient de l’utilisation de pièces détachées non

originales.

Für die Anfrage von Ersatzteilen raten wir Ihnen, immer die Kodenummer und die entsprechende

Benennung einer jeden Tafel mitzuteilen. Wir raten weiterhin, immer das Modell und die

Seriennummer der Maschine mitzuteilen als auch die Maschineneigenschaften (Voltleistung,

Frequenz und Phasen), um die Erkennung von Besonderheiten zu vereinfachen. Um Ersatzteile

des Kompressors zu bestellen, muß man auch das direkte Modell angeben, welches auf dem

Motorschild verzeichnet ist. Im Austauschfall von Teilen nur Originalteilen der Firma Firgomat beim

Konzessionär oder autorisiertem Wiederverkäufer anfragen. Die Firma TAYLOR ist von jeglichem

Schadensersatz an Personen u/o Gegenständen entbunden, die auf den Einsatz von nicht

originalen Ersatzteilen zurückzuführen sind.

Para la petición de las partes de recambio, se recomienda indicar siempre el número de código

relativo y la denominación indicada en la leyenda de cada tabla. Además, se recomienda

comunicar siempre el modelo y el número de matrícula de la máquina, así como las características

de la misma (voltaje, frecuencia y fases), facilitando de esta manera la identificación de la parte.

Para pedir los componentes de recambio del compresor indicar siempre también el modelo

especificado en al placa del motor. En caso de sustitución de piezas, pedir sólo recambios

ORIGINALES TAYLOR a un concesionario o a un Revendedor Autorizado. TAYLOR declina

cualquier responsabilidad por daños a personas y/o cosas derivados del uso de recambios no

originales.

APPENDICI - 4

Page 33

CH02 s05 Tav.1

5 - APPENDICI

Page 34

CH02 s05 Tav.1

P. COD. DESCRIZIONE DESCRIPTION DESCRIPTION BESCHREIBUNG DESCRIPTION

1

2

-

3

4

5

6

7

8

9

10

11

12

13

14

A06.185

E15.40826

E13.38654

E15.40831

M02.38287

P14.37043

F03.325

A02.38240

P06.077

F01.160

C03.189

L19.37042

B15.037

B15.038

B09.215

Gruppo isolamento Insulation unit Groupe isolant Isolationsgruppe Grupo aislamiento

Scheda pulsantiera

Cavo scheda

pulsantiera

Scheda comando Control card Carte de commande Bedienungskarte Tarjeta de mando

Etichetta anteriore Front label Etiquette antérieure Frontkleber Etiqueta anterior

Piedino Foot Pied Fuss Pie

Protezione fondo Bottom guard Protection du fond Bodenschutz Protección Fondo

Carenatura anteriore Front panel Panneau Frontal Vordere Blechtafel Panel anterior

Piedino Foot Pied Fuss Pie

Telaio Frame Châssis Gestell Armazón

Pannello posteriore Back panel Panneau postérieur Hinteres Blech Panel posterior

Perno cerniera Hinge Pin Goujon pour fermoir Scharnierstift Perno para bisagra

Cerniera fissa Fixed hinge Fermoir fixe Festes Scharnier Bisagra fija

Cerniera mobile Moving hinge Fermoir mobile

Vite cerniera Hinge screw Vis pour fermoir Scharnierschraube Tornillo para bisagra

Pushbutton panel

card

Wiring pushbutton

panel card

Carte du tableau de

commande

Cable carte du

tableau de

Tastenkarte

Tastenkarte-Kabel

Bewegliches

Scharnier

Tarjeta caja

pulsadores

Cablo tarjeta caja

pulsadores

Bisagra móvil

15

P16.37041

Coperchio Cover Couvercle deckel Tapa

APPENDICI - 6

Page 35

CH02 s05 Tav.2

7 - APPENDICI

Page 36

CH02 s05 Tav.2

P. COD. DESCRIZIONE DESCRIPTION DESCRIPTION BESCHREIBUNG DESCRIPTION

1

2

A02.164

A06.199

Termostato di

sicurezza

Corpo riscaldatore Heater body Corp du réchauffeur Heizergehaeuse Cuerpo Calentador

Safety thermostat

Thermostat de

sécurité

Sicheruheits-

Thermostat

Termostato

3

4

5

6

7

8

9

10

11

12

13

14

15

16

D08.046

P10.128

A06.198

C06.072

P03.194

P26.37681

T10.090

B13.015

R07.022

P10.137

B01.394

D04.215

E05.38215

P10.105

Resistenza Resistance Résistance Wiederstand Resistencia

Guarnizione

OR 6225

Riscaldatore

completo

Serbatoio fluido Fluid Tank Réservoir de fluid Flussigkeitsbehaelter Depósito fluido

Tappo per sebatoio Fluid tank plug Bouchon du résérvoir

Indicatore liquido Liquid sight glass Témoin pour liquide

Tubo sfiato Drain pipe

Fascetta 16-27/9 Clamp 16-27/9 Bague 16-27/9 Klemme 16-27/9 Abrazadera 16-27/9

Portagomma Hose connector Terminal de douche Schlauchansnschluß Portagoma

OR 120 OR 120 OR 120 OR 120 OR 120

Motopompa Pump mtor Moteur pompe Motorpumpe Motor Bomba

Condensatore

avviamento

Sonda temperatura Temperature probe Sonde température Temperatursonde Sonda temperatura

OR 123 OR 123 OR 123 OR 123 OR 123

OR 6225 OR 6225 OR 6225 OR 6225

Heater assy Réchauffeur complet Heizer kompl. Calentador completo

Start condenser

Tuyau

d’échappement

Condensateru de

demarrage

Verschluss

Flussigkeitsbehaelter

Flüssigkeitskontrolla

mpe

Überlaufrohr Tubo de desfogue

Startkondensator Condensador

Tapón depósito fluido

Testigo líquido

17

T10.093

Tubo gomma (nero)

15X25,5

Rubber tube (black)

15X25,5

Tuyau de coutchouc

(noir) 15X25,5

Gummirohr (schwarz)

15X25,5

Tubo goma (nero)

15X25,5

APPENDICI - 8

Page 37

CH02 s05 Tav.3

9 - APPENDICI

Page 38

CH02 s05 Tav.3

P. COD. DESCRIZIONE DESCRIPTION DESCRIPTION BESCHREIBUNG DESCRIPTION

1

2

B06.401

P10.077

Canotto agitatore Beater holding tube

Guarnizione OR 119 OR 119 OR 119 OR 119 OR 119

Tuyau porte-

mélangeur

Ruehrwerksroerchen Barra porta Agitador

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

B10.265

B06.400

A11.38270

B06.402

V14.072

B14.036

L06.38173

L21.38174

V13.069

B10.264

P02.36780

B02.158

E01.37826

A04.37828

A05.045

A05.046

E06.37827

Boccola Bush Douille Buchse Anillo

Albero agitatore Beater shaft Arbre mélangeur Ruerwerkswelle Eje Agitador

Bronzina Bushing Douille en bronze Bronzenbuchse Casquillo

Centrante Pipe guide Centreur Zentralrohr Centrador

Seeger Seeger Seeger Seeger Seeger

Cuscinetto Bearing Galet Rolle Cojinete

Puleggia condotta

Completa di boccola

Distanziale Shim Rondelle Scheibe Distanciador

Dado EMB 14 Nut Ecrou Mutetr Tuerca

Fondello inferiore Bottom Fond Boden Fondo

Cinghia Belt Courroie Riemen Correa

Puleggia conduttrice Guide pulley Poulie de condite Geführte Rolle Polea conductora

Motore mescolatore Mixer motor Moteur mélangeur Rühmotor Motor mezclador

Supporto copriventola Fan cover support

Ventola Fan Ventilateur

Copriventola Fan cover

Condensatore marcia Running condenser Condensateur allure Betriebskondensator Condensador

Guided pulley Poulie conduite Geführte Rolle Polea conducta

Support Couverture

du ventilateur

Couverture du

ventilateur

Fluegelraddecke

-halter

Flügelrad

Fluegelraddeckel Cobertura ventilador

Soporte Cobertura

ventilador

Aventador

APPENDICI - 10

Page 39

CH02 s05 Tav.4

11 - APPENDICI

Page 40

CH02 s05 Tav.4

P. COD. DESCRIZIONE DESCRIPTION DESCRIPTION BESCHREIBUNG DESCRIPTION

1

2

3

4

5

6

7

8

P02.176

B12.174

P10.110

P10.045

B12.168

P10.077

P10.136

B12.170

Pomello fissaggio Handle Poignée Griff Pomo

Corpo rubinetto Cock body Corp du Robinet Abgabehangehaeuse Cuerpo Grifo

Guarnizione OR 112 OR 112 OR 112 OR 112 OR 112

Guarnizione OR 3100 OR 3100 OR 3100 OR 3100 OR 3100

Pistone Piston Piston Kolben Piston

Guarnizione OR 119 OR 119 OR 119 OR 119 OR 119

Guarnizione OR 3087 OR 3087 OR 3087 OR 3087 OR 3087

Tubo di scarico Drain Pipe Tube d’écoulement Abflussrohor Tubo de descargo

APPENDICI - 12

Page 41

NOTE / NOTES / NOTES / BEMERKUNG / NOTA

Page 42

Page 43

FRIGOMAT s.r.l., via 1° Maggio 26862 GUARDAMIGLIO (LO) – ITALIA

tel. 0377.415011 – Fax. 0377.451079

www.frigomat.com

info@frigomat.com

MARZO 2013

Loading...

Loading...