Page 1

OPERATING INSTRUCTIONS

AND MAINTENANCE

Series-Série-Serie

C124 04

C125 03

Page 2

1 - ENGLISH

Page 3

ENGLISH - 2

IMPORTANT

We recommend to carefully and fully read the present manual before using your

TAYLOR machine.

In your own interest, pay particular attention to the following warnings:

The non-observance of this warning can jeopardize the user’s health and the

correct operation of the machine.

A careful observance of these warnings can lead to a top performance of the

machine.

The machine is covered by guarantee according to the conditions reported in the

“GUARANTEE CARD “ enclosed to the machine, which shall be duly filled up and sent

back to:

FRIGOMAT s.r.l., via 1° Maggio 26862 GUARDAMIGLIO (LODI) – ITALIA

In the following field, please write your machine serial number in capital letters

Serial number

Distributor’s stamp

Page 4

3 - ENGLISH

INDEX

1. TRANSPORT, HANDLING AND STORAGE………………………………… 4

1.1 Preliminary Inspection ………………………………………… 4

1.2 Machine unpacking ………………………………………… 4

1.3 Packing dimensions ………………………………………… 4

2. MARKING AND GRAPHICS ………………………………………… 5

3. INSTALLATION ………………………………………… 6

3.1 Field of use ………………………………………… 6

3.2 Limits of use ………………………………………… 6

3.3 Machine outfit ………………………………………… 6

3.4 Commissioning ………………………………………… 6

4. OPERATIONS ………………………………………… 7

4.1 Controls ………………………………………… 7

4.2 Ice cream and granita production………………………………….… 9

4.3 Coffee-granita production ………………………………………… 10

4.4 Conservation of ice cream ………………………………………… 11

5. MAINTENANCE ………………………………………... 12

5.1 Routine maintenance ………………………………………… 12

6. TROUBLE-SHOOTING ………………………………………… 14

7. APPENDIXES ………………………………………… A1

7.1 Technical data ………………………………………… A1

7.2 Refrigerant circuit diagram ………………………………………… A2

7.3 Wiring diagram ………………………………………… A3

7.4 Spare parts ………………………………………… A4

Congratulations on purchasing a machine TAYLOR.

The present manual, enclosed to the machine, is integrant and essential part of the

machine and shall be delivered to the final user. Before performing any kind of operation, it

is recommended to carefully study the reported instructions, as only a careful reading

allows you getting the highest performance from your machine. The following pages report

all information necessary to correctly install, commission, adjust and service your machine.

TAYLOR reserves the right to carry out all changes necessary to improve its product or

manual without prior notice and to insert them in the subsequent issues.

Page 5

ENGLISH - 4

1 TRANSPORT, HANDLING AND STORAGE.

MODEL

CASE

SIZES (CM)

WEIGHT N- L (KG)

C124

56,5 X 52,5X h. 48,5

45-63

C125

595 X 590 X h. 465

55-73

1.1 PRELIMINARY INSPECTION

The machine travels at the customer’s risk. In case packing is damaged, immediately

inform the carrier.

Immediately inform the carrier also in case of damage to the machine, even if you open

the packing a few days after the delivery.

It is always advisable to accept the goods SUBJECT TO INSPECTION.

The equipment shall be assembled with great care: falls and shocks can damage it without

showing external damages.

1.2 MACHINE UNPACKING

For a correct machine unpacking, carefully follow the instructions hereunder reported:

in case of packing carton on wooden frame:

Remove the strap fixing the carton to the bottom and take the packing off from the top.

In case of wood case:

Remove the case upper side and the side walls by means of a nail drawer, pay

attention not to disperse the nails and the wood splinters;

Remove the plastic bag and put it in a safe place;

Lift the machine and hook it up

The packing shall be stored in a dry place, out of the children’s reach. It can be used

again, if correctly preserved, for a possible transfer of the machine.

The storing temperature shall range between +5°C and +55 °C.

Humidity shall range between 30 and 95%.

Packing elements such as plastic bags, nails, expanded polystyrene, cartons, etc. must be

left out of the children’s reach.

1.3 PACKING DIMENSIONS

Page 6

5 - ENGLISH

2. MARKINGS AND GRAPHICS

Never touch the machine with hands and tools during production or maintenance and

cleaning operations, without making sure that the machine is in STOP position, the master

switch is off and/or the multipolar plug disconnected.

TAYLOR declines any liability for accidents deriving from an improper use of the machine

due to the non-compliance with the above-mentioned recommendations.

The machine is provided with a plate and some pictograms, which together with the

present manual allow using the machine in safer conditions.

Machine data plate

The adhesive label located on the back of the

machine allows identifying the model and reports the

following indications:

Manufacturer’s name and address; Machine model

and version; Serial number; Rated electrical

characteristics; Type and weight of employed Freon;

Manufacturing year.

Warning!

Maintenance allowed to qualified personnel only.

The following plate placed on the machine back

panel forbids extraordinary maintenance operations

and/or repairs delegating them to authorized people

only, whose address is indicated in the provided

space.

Warning!

High voltage inside, danger of fulguration.

The following plate is placed on the electric box

cover and warns the operator that in no case the

cover must be removed avoiding this way the risk of

lethal fulguration. Also in this case, maintenance

operations on internal components must be

performed by authorized personnel only.

Page 7

ENGLISH - 6

3. INSTALLATION

3.1 FIELD OF USE

The batch freezers SERIES G are espressly designed and engineered for ice-cream batch

freezing cycles and for the production of granita.

3.2 LIMITS OF USE

Never use the machine with variable supply voltage and/or more than +/- 10% of the value

showed in the nameplate or when the feeder is damaged;

Do not use the machine for purposes different from the ones indicated in the present

manual;

Do not use the machine in explosive environment;

Do not wash the machine with high-pressure jets of water or poisonous substances;

Do not expose the machine to excessive heat or humidity;

Do not use completely unbalanced mixtures and/or quantities not in compliance with the

specifications reported on the packing.

3.3 MACHINE OUTFIT

- Cleaning rod

- Stiff paddle

- Manual of use and maintenance

3.4 COMMISSIONING

Bring the machine to the place of employment and check that everything is all right as far

as installation concerns:

Place the machine far from walls or other obstacles at least 10 cm and 30 on the lateral

left panel

Make sure that the supply voltage and power comply with the values reported on the

rating plate placed on the back panel;

Connect the machine to the mains; upstream the machine, arrange an omnipolar

master switch with minimum contact opening equal to 3 mm and adequate power,

interlocked with fuses to allow plugging and unplugging at open circuit.

Connect the feeder to a type-approved plug: the feeder shall be well stretched, to avoid

rolling and overlapping. It shall not be exposed to possible shocks or tampering

attempts and far from liquids, water and heat sources. It shall not be damaged,

otherwise make it be replaced by qualified personnel with another section and type

3G1,5H05VV-F before connecting the machine to the mains.

Arrange the connection of the yellow-green wire to a good earth connection.

The ideal temperature shall range between 15°C and 25°C.

The ideal humidity shall range between 30 and 60%.

- Declaration of conformity

- Certificate of guarantee

Page 8

7 - ENGLISH

4. OPERATION

4.1 CONTROLS

1. Cover

It hermetically seals the cylinder

during the working cycles it

avoids that the mix gets in

contact with powders and It can

be easily removed for cleaning

purpose.

2. Cover Pin

Maintains the cover in correct

position.

3. Security Device

It acts when the cover is lifted

and puts the machine in STOP.

By lowing the cover the machines

starts automatically.

4. Protection Condenser Grip

It avoids that the user can touch

even accidentally the condenser.

Leave at least 30 cm distance

between the grid and any other

object or obstacles.

5. Draning plug

6.Agitator

It agitates the mix permitting the

freezing of the product and the

correct volume increase by

incorporating air.

7.Scraper

Realized in atoxic material, it

scrapes the cylinder wall

guaranteeing always a perfect

product.

Page 9

ENGLISH - 8

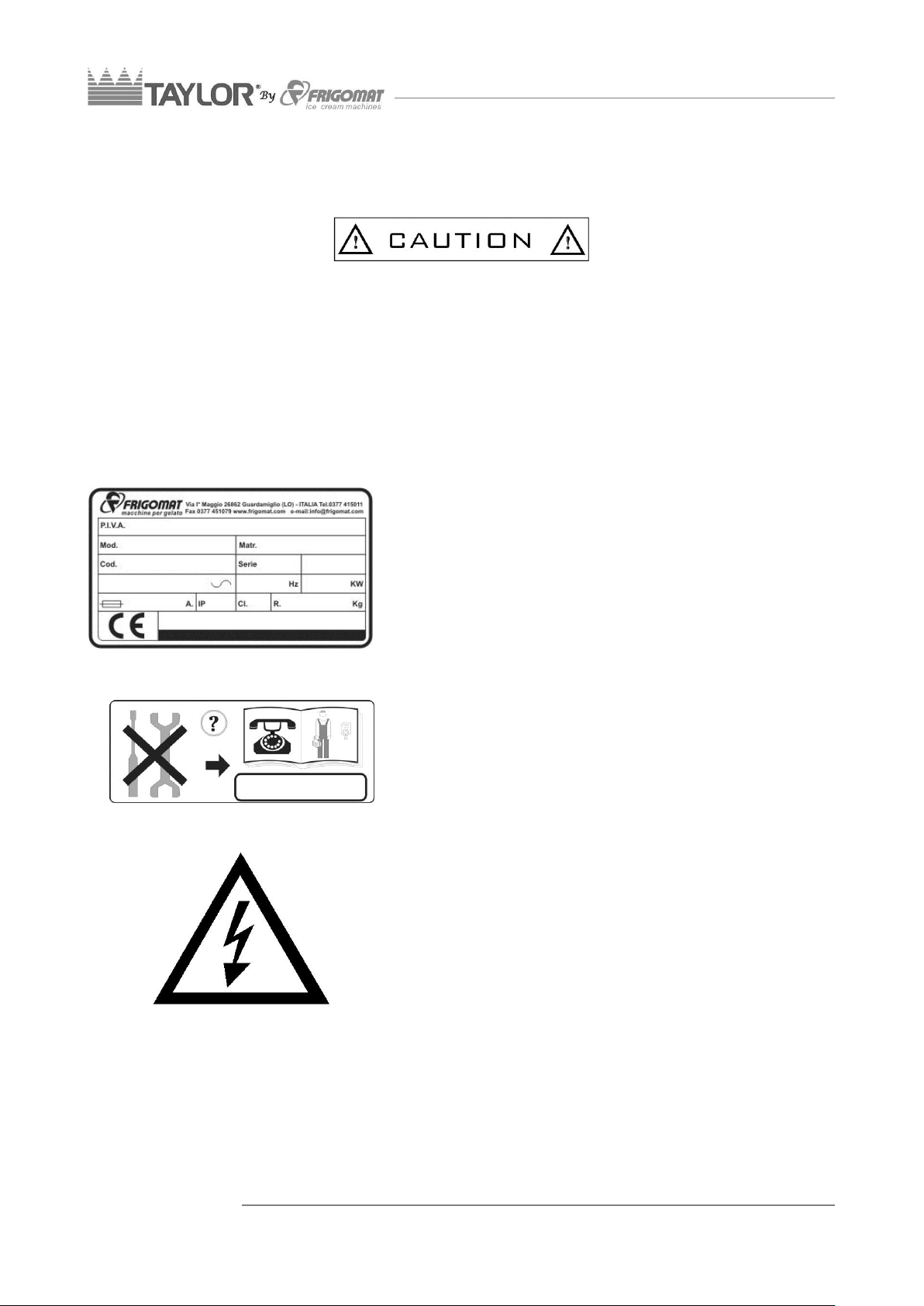

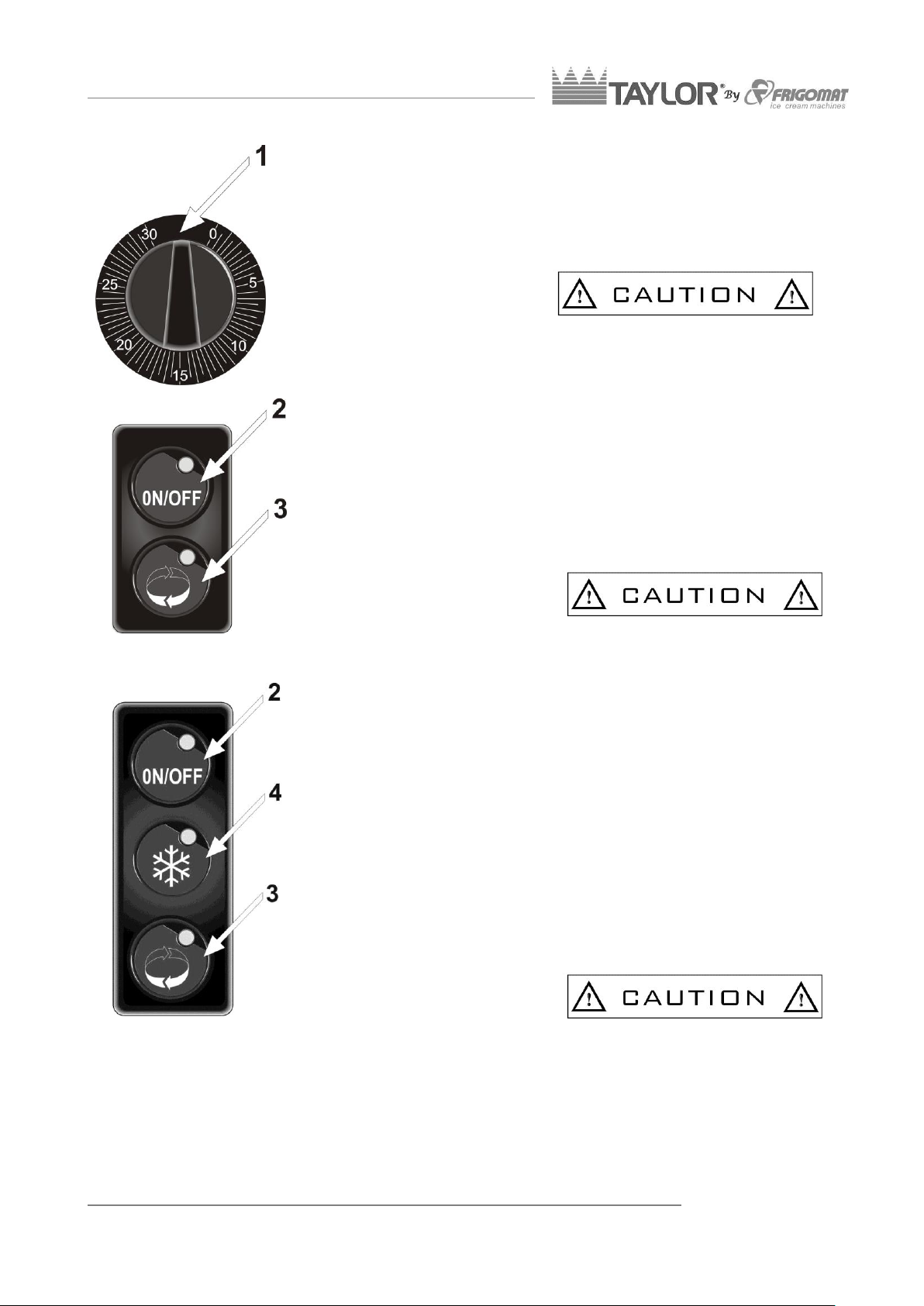

1. FREEZING TIMER

With the freezing timer it is possible to set the

production timeand consequently changing the

consistency and the look of the product.

Turning the timer you activate the compressor and you

start the production.

In order to activate the compressor and starting the

production it is necessary to change over the machine

in ON and check that the led is green

2. Pushbutton ON-OFF

With grey led, pressing the pushbutton ON-OFF, you

change over the machine in ON, the led becames

green and the continuous agitatation is automatically

activated.With green led, pressing the pushbutton ONOFF, you change over the machine in OFF, the led

becames grey and you desactived both the agitation

and the compressor.

The machine has shearing prevention system which

desactive the agitation when the cover is not

assembled or when it is not lowered. For re-activating

the agitation, verify that the cover is correctly

assembled and that it is lowered.

3. Pushbutton “cyclic agitation” for granita

With grey led, pressing pushbutton “cyclic agitation”

you change over the machine in “cyclic agitation ON”,

the led becames green and you activate the function of

agitation for the production of granita without air

incorporation.

With green led, pressing pushbutton “cyclic agitation”

you change over the machine in “cyclic agitation OFF”,

the led becames grey and you go back to the function

of continuous agitation.

In order to activated the function “cyclic agitation” it is

necessary to change over the machine in ON and

check that the led of both pushbuttons are green.

4. BUTTON “ICE CREAM CONSERVATION (for

model G10 only).

Page 10

9 - ENGLISH

MODELL

MIN (LITRES)

MAX (LITRES)

C124 1 1,5

C125 1 2,2

4.2 ICE-CREAM PRODUCTION

fter the machine has been installed according to

the instructions reported in chapter 3 and

carefully cleaned and sanitized according to the

instructions reported in chapter 6, proceed as

follows to start up the ice-cream production:

- Check that the master switch is closed.

- Lift the cover and pour the mixture into the

cylinder. Observe the suggested minimum

and maximum quantities per cycle according

to the following table:

The non-observance of the minimum and

maximum batch values can cause the

malfunction of the machine and, sometimes,

serious damages.

- Lower the cover and press the pushbutton

ON-OFF for starting the machine and the

agitation; verify that the led of the

pushbutton is green.

- Turn the freezing-timer on the required time.

This operation activates the compressor and

starts the production.

Remember always to set the freezing time

otherwise the freezing cycle can not start.

- Once passed the presetted freezing period

fixed by the timer the compressor stops and

the agitation keeps in function; if the

consistency is not the required one, it is

possible to set on the timer a new timevalue which guarantees an higher

consistency.

Page 11

ENGLISH - 10

It is possible to increase or decrease the

remaingin freezing period acting on the timer in

whatever moment.

- Once optained the required consistency,

stop the machine by pressing the ON-OFF

pushbutton and check that the led is grey.

Lift the cover and proceed with the

extraction of the product using the showel in

outfit.

4.3 Production of coffee-granita

The coffee-granita is a delightful speciality

which requires for its preparation a cyclic

agitation which maintains its classic dark colour.

For this reason the machine is equipped with a

special program which permits the production of

granita with a minimum air incorporation.

For selecting the program ”cyclic agitation”

proceed as follows:

- Pour into the machine the required mix as

already previously explained

- Press the pushbutton ON-OFF and verify

that the led is green

- Press the pushbutton “cyclic agitation” and

verify that the led is green. In this function

the agitator will stop for at about 57 sec. and

and works for at about 3 sec.

- Regulate the freezing timer as explained

previously in order to start the production.

- Once finished the production, desactivated

the program “cyclic agitation” by pressing

the respective pushbutton and check that

the led is grey.

- Switch off the machine and extract the

product from the cyclinder.

Page 12

11 - ENGLISH

4.4. CONSERVATION OF ICE CREAM (for

model G10 only)

The function of “ice cream conservation”

maintains the product for a long period of time at

correct temperature and consistency directly in

the freezing tank.

Thanks to this function you may decide to

distribute the ice cream according to needed

quantity and time periods .

Further more, you may add in whenever moment

fresh product to compensate the distributed

quantity.

In order to select the program “ice cream

conservation” proceed as following:

- pour the mix in the freezing tank and start the

freezing cycle as per cap. 4.2.

- in whenever moment press button

CONSERVATION (4) and check that green led is

on. Once finished the preset freezing cycle, the

machine will automatically changeover to

conservation

- During the conservation period, the beater motor

and compressor will cyclic be on in automatic

way.

- During the freezing cycle, if you lift the cover, for security reasons, the production cycle

will be interrupted and the led (5) will be on. To restart the freezing cycle, close the cover

and check that the led is off.

- During the conservation cycle, if you lift the cover, for security reasons, the beater and

compressor will stop. If the led (5) will be off, this means that the product is at correct

distribution temperature; if the led is on, this means that the product may not be at correct

temperature for the distribution of the product and therefore you have to close the cover

to bring the machine in ideal conditions.

- During the conservation cycle it is possible to increase low product quantity with fresh

mix without acting on the freezer timer. On the contrary, if the poured quantity is too

much, it may be necessary to act on the timer in order to start e new short freezing cycle.

Page 13

ENGLISH - 12

5. MAINTENANCE

5.1 ROUTINE MAINTENANCE (ADDRESSED TO THE USER)

During production, cleaning and maintenance operations, never touch the machine with

hands or tools without making sure that the machine has been disconnected from mains.

In case of troubles, make sure that they are not caused by a lack of servicing. On the

contrary, ask for the intervention of a TAYLOR customer service. In case it is necessary to

replace a piece, always ask a distributor or an authorized retailer for ORIGINAL spare

parts.

It is advisable to make the machine be checked by a Customer Service every 6/8 months.

6.1.1 CLEANING AND SANITIZATION

Bacteria and moulds easily proliferate due to the presence of fats in cream, that is why it is

necessary to carefully wash and clean all parts in contact with the product, such as the

cylinder, the agitator and the door.

Rustless materials and/or made of plastic for

food industry used for our machines, in

conformity with the most severe international

standards, make washing operations easier,

however they cannot prevent mould

proliferation, etc. caused by insufficient

cleaning.

TAYLOR recommends cleaning the tank and

the parts in contact with the product after the

employment and in any case in compliance with

the sanitary standards in force in the country of

installation. To thoroughly clean your batch

freezer, proceed as follows:

1. Switch off the machine by pressing the

pushbutton ON-OFF and verify that the led

is grey. To set to zero the freezing timer and

verify that the led of the pushbutton “cyclic

agitation” is grey.

2. Withdraw the cover pin and remove the

cover.

3. Descrew the knob and withdraw the agitator

upwards; remove the scraper.

4. Immerge the components into a cleaning

solution and wash carefully. Use the

cleaning rod in the outfit for the cleaning of

the agitator shaft.

5. Use a sponge for removing from the cylinder

the left product.

Page 14

13 - AENGLIS

6. Pour in the cylinder a little quantity of

cleaning solution. Wash carefully.

7. Use a sponge for removing from the cylinder

Rinse carefully using clear warm water. If

required repeat the operation.

8. Sanitize carefully the cylinder and all

components previously disassembled and

cleaned. Let them dry in the open air.

- To preserve plastic components and

gaskets, never use solvents and/or diluents

during washing.

- Sanitizing chemicals shall be used

according to laws in force and with the

utmost caution.

- After any sanitizing operation, it is

indispensable not to touch the sterilized

parts either with hands or with towels,

sponges or other.

- Avoid making the agitator run empty, as the

machine can be damaged.

Page 15

ENGLISH - 14

6. TROUBLE-SHOOTING

TROUBLE

POSSIBLE CAUSES

REMEDIES

the machien does not start

(pushbutton ON-OFF is activated

with green led)

master switch oper

turn the switch off

cover lifted up or not assembled

lower the cover and /or verify if it is

correctly assembled

select “cyclic agitation”

verify that the led of the

pushbutton “cyclic agitation” is

grey

incorrect power supply

verify supply

Electrical trouble.

Send a technician

Since the first phases of the batch

freezing cycle, the compressor

works intermittently

condensator dirty or fan broken

clean condensator with a brush

and verify the fuctionning of the fan

motor

The freezing period is too long and

the ice-cream is wet.

insufficient condensating

check that between the lateral left

panel and the wall or other

obstacles there is at least 30 cm

space

high ambient temperature

verify that the ambient temperature

is not higher than 25°C

too high mix temperature

The max. production of the

machine is reached using liquid

mix at 4 °C. Using mix at higher

temperature, the freezing time

becames longer, which is normal

and is not a trouble.

Worn out agitator scraper

verify and replace if required

trouble in the freezing system

send a technician

the product is too soft

insufficient freezing time

select on the timer a longer time-

period

the product is too hard

excessive freezing time

select on the timer a shorter time-

period

durino the batch freezing the

machine is noisy

presence of ice on the cylinder wall

the ice cream is ready to be

extracted

verify that the mix quantity is not

less than the required minimum

one.

the belt slip

send a technician

driving shaft bearing worn out

send a technician

Page 16

1 - APPENDICI

Modello / Model

C124

C125

Dimensioni (mm)

Size (mm)

Larghezza 431,5

Profondità 467,5

Altezza 321,5

Width 480

Depth 490

Height 340

Peso netto (kg)

Net Weight (kg)

46,8

55

Tensione di alimentazione

Supply Voltage

230/50/1

230/50/1

Potenza installata (kw) (*)

Installed Power (kw) (*)

0,7

1

Condensazione

Cooling

Aria

Air

Aria

Air

Gas

R 404 – 0,450 kg

R404- 0,425 kg

Capacità (lt)

Capacity (lt)

1,5

2,2

Produzione (kg/h)

Production (kg/h)

5

10

7 APPENDICI / APPENDICES

7.1 Dati tecnici / Machine Specification

INDICATIONS FOR DECOMMISSIONING

The machine contains electrical and/or

electronic materials and can contain fluids

and/or oil. If it needs to be decommissioned

or disposed of, comply with the standards in

force in the Country where it is used.

Even packaging materials (crates or boxes)

must be divided by type and disposed of in

compliance with standards in force in the

Country where it is used when the machine

is decommissioned.

Page 17

APPENDICI - 2

C124

C125

Page 18

3 - APPENDICI

7.2 Refrigerant circuit diagram

Page 19

APPENDICI - 4

7.3 Electric System C124

Page 20

5 - APPENDICI

7.3 Electric System C125

Page 21

6 - APPENDICI

7.4 SPARE PARTS

For spare parts ordering, always mention the corresponding code number and the name

reported on each table caption. It is also recommended to always mention the machine

model and the serial number as well as the technical data (voltage, frequency and

phases), to make the identification of the component easier. To order spare parts for the

compressor, always mention the model specified on the motor nameplate. In case it is

necessary to replace a component, always ask a distributor or an authorized retailer for

ORIGINAL spare parts. FRIGOMAT declines any liability for damages to people and/or

things due to employment of non-original spare parts.

Page 22

7 - APPENDICI

C124/s04 Tav.1/3

Page 23

8 - APPENDICI

C124/s03 Tav.1/3

P.

COD.

DESCRIZIONE

DESCRIPTION

1

L20.42381

Perno portello

Cover pin

2

P14.37569

Pomolo coperchio

Cover knob

3

E07.37566

Magnete

Magnet

4

P18.37729

Pattino raschiante

Scraper

5

E07.37565

Sensore

Switch

6

D04.104

Timer

FreezingTimer

7

E07.37511

Gruppo pulsanti

Pushbuttons

8

M02.37806

Etichetta anteriore

Lower label

9

A02.38557

Carenatura anteriore

Front panel

10

A02.37510

Pannello posteriore

Back panel

11

Z56.42733

Evaporatore completo

Complete evaporator

12

Z70.427324

Agitatore

Agitator

13

L18.37559

Pomolo agitatore

Knob agitator

14

P16.40151

Coperchio

Cover

15

B15.037

Cerniera fissa

Fixed hinge

16

P19.37838

Tappo scarico

Tank drain plug

17

P10.062

OR 2037

OR 2037

18

P10.045

OR 3100

OR 3100

19

P11.42015

Boccola

Bushing

Page 24

9 - APPENDICI

C125/s03 Tav.1/3

Page 25

10 - APPENDICI

C125/s03 Tav.1/3

P.

COD.

DESCRIZIONE

DESCRIPTION

1

L20.42381

Perno portello

Cover pin

2

P14.37569

Pomolo coperchio

Cover knob

3

E07.37566

Magnete

Magnet

4

P18.37729

Pattino raschiante

Scraper

5

E07.37565

Sensore

Switch

6

B15.037

Cerniera fissa

Fixed hinge

7

D04.104

Timer

FreezingTimer

8

M02.37806

Gruppo pulsanti

Pushbuttons

9

M02.38304

Etichetta anteriore

Lower label

10

P19.37838

Tappo scarico

Tank drain plug

11

P10.062

OR 2037

OR 2037

12

A02.37979

Carenatura anteriore

Front panel

13

A02.37597

Pannello posteriore

Back panel

14

Z56.37590

Evaporatore completo

Complete evaporator

15

Z70.40654

Agitatore

Agitator

16

L18.37559

Pomolo agitatore

Knob agitator

17

P16.40151

Coperchio

Cover

18

P10.045

OR 3100

OR 3100

19

P11.40724

Boccola

Bushing

Page 26

11 - APPENDICI

C124/s04 Tav.2/3

Page 27

12 - APPENDICI

C124/s03 Tav2/3

P.

COD.

DESCRIZIONE

DESCRIPTION

1

A03.116

Condensatore aria

Air condenser

2

B03.37488

Ventola

Fan

3

B03.37489

Staffa

Fan support

4

A01.37480

Telaio

Frame

5

P06.104

Piedino

Foot

6

D06.143

Pressacavo

Cable grip

7

A02.37514

Griglia

Grate

8

A01.218

Compressore 230/50/1

Compressor 230/50/1

9

D04.231

Condensatore avviamento

Start condenser

10

E01.37487

Motore ventilatore

Fan motor

11

E06.37700

Klixon

Klixon

12

E06.37699

Relè

Relay

13

B04.37490

Filtro

Filter

Page 28

13 - APPENDICI

C125/s03 Tav.2/3

Page 29

14 - APPENDICI

C125/s03 Tav2/3

P.

COD.

DESCRIZIONE

DESCRIPTION

1

A03.096

Condensatore aria

Air condenser

2

B03.37587

Ventola

Fan

3

B03.37092

Staffa

Fan support

4

A01.37584

Telaio

Frame

5

P06.104

Piedino

Foot

6

D06.143

Pressacavo

Cable grip

7

A02.37514

Griglia

Grate

8

E06.41895

Klixon 220/50/1 (A01.234)

Klixon 220/50/1 (A01.234)

8

E06.38621

Klixon 115/60/1 (B01.38104)

Klixon 115/60/1 (B01.38104)

9

E06.41894

Relè 220/50/1 (A01.234)

Relay 220/50/1 (A01.234)

9

E06.37582

Relè 208-240/60/1

(B01.36744)

Relay208-240/60/1

(B01.36744)

10

B04.37841

Raccogli liquido

Fluid collector

11

B04.37589

Filtro

Filter

12

A01.234

Compressore 230/50/1

Compressor

12

B01.36744

Compressore

Compressor

12

B01.38104

Compressore 115/60/1

Compressor 115/60/1

13

E06.41896

Condensatore avv. 220/50/1

(A01.234)

Start condenser 220/50/1

(A01.234)

13

E06.37580

Condensatore avv.

208-240/60/1

(B01.36744)

Start condenser

208-240/60/1

(B01.36744)

14

E01.37586

Motore ventilatore 230/50-60/1

Fan motor 230/50-60/1

14

E01.38105

Motore ventilatore 115/50-60/1

Fan motor

15

A04.37982

Staffa termostato

Brachet thermostat

16

B11.37981

Termostato

Thermostat

17

E06.37581

Condensatore di marcia

208-240/60/1

(B01.36744)

Running condenser

208-240/60/1

(B01.36744)

18

E06.38107

Relè + condensatore 115/60/1

(B01.38104)

Relay + condenser 115/60/1

(B01. 38104)

Page 30

15 - APPENDICI

C124/s04 Tav.3/3

Page 31

16 - APPENDICI

C124/s04 Tav.3/3

P.

COD.

DESCRIZIONE

DESCRIPTION

1

E01.37491

Motore agitatore 230/50/1

Beater motor 230/50/1

E01.37962

Motore agitatore 115/60/1

Beater motor 115/60/1

2

D04.216

Condensatore marcia (E01.37491)

Running condenser (E01.37491)

E06.38622

Condensatore marcia (E01.37962)

Running condenser (E01.37962)

3

L06.37492

Puleggia conduttrice

Guide pulley

4

V02.050

Vite 10X50

Screw 10X50

5

A11.37495

Cuscinetto

Bearing

6

V13.006

Dado

Nut

7

B65.37494

Tendicinghia

Belt tightener

8

L06.37493

Puleggia condotta

Guided pulley

9

B60.42725

Albero trasmissione

Driving shaft

10

P10.37496

Cinghia

Belt

11

A01.37481

Piastra motore

Support plate

12

D03.105

Relè SLCD 220 v.

(RS)

Relay SLCD 220 v.

(RS)

E08.38339

Relè SLCD 115/60/1

Relay SLCD 115/60/1

13

E01.37599

Ciclico

Ciclic

E01.38337

Ciclico 115/60/1

Ciclic 115/60/1

14

E08.37600

Relè FINDER 230/50/1 (R)

Relay FINDER 230/50/1 (R)

E08.38338

Relè FINDER 115/60/1 (R)

Relay FINDER 115/60/1 (R)

15

V14.072

Anello elastico

Seeger

16

B14.036

Cuscinetto

Bearing

17

P10.014

OR 2137

OR 2137

18

L21.41558

Distanziale

Tube

19

V14.073

Anello elastico

Seeger

20

P02.42007

OR 0250

OR 0250

21

L21.42723

Supporto

Support

22

L21.37518

Ghiera di fissaggio

Fixing nut

23

A21.41900

Rasamento

Shim

24

P21.41899

Trappola termica

Insulating support

25

L21.41891

Canotto

Transmission tube

26

L1.42251

Fermo boccola

Stop bushing

27

A11.42009

Boccola

Bushing

28

P10.067

OR 2087

OR 2087

29

L21.41892

Sede boccola

Seat bushing

30

P10.072

OR 3072

OR 3072

Page 32

17 - APPENDICI

C125/s03 Tav.3/3

Page 33

18 - APPENDICI

C125/s03 Tav.3/3

P.

COD.

DESCRIZIONE

DESCRIPTION

1

E01.37491

Motore agitatore 230/50/1

Beater motor 230/50/1

E01.37962

Motore agitatore 115/60/1

Beater motor 115/60/1

2

D04.216

Condensatore marcia (E01.37491)

Running condenser (E01.37491)

E06.38622

Condensatore marcia (E01.37962)

Running condenser (E01.37962)

3

L06.37492

Puleggia conduttrice

Guide pulley

4

V02.050

Vite 10X50

Screw 10X50

5

A11.37495

Cuscinetto

Bearing

6

V13.006

Dado

Nut

7

B65.37494

Tendicinghia

Belt tightener

8

L06.37493

Puleggia condotta

Guided pulley

9

B60.42722

Albero trasmissione

Driving shaft

10

P10.37496

Cinghia

Belt

11

A01.37481

Piastra motore

Support plate

12

D03.105

Relè SLCD 220 v.

Relay SLCD 220 v.

E08.38339

Relè SLCD 115/60/1

Relay SLCD 115/60/1

13

E01.37599

Ciclico

Ciclic

E01.38337

Ciclico 115/60/1

Ciclic 115/60/1

14

E08.37600

Relè FINDER 230/50/1 (R)

Relay FINDER 230/50/1 (R)

E08.38338

Relè FINDER 115/60/1 (R)

Relay FINDER 115/60/1 (R)

15

V14.072

Anello elastico

Seeger

16

B14.036

Cuscinetto

Bearing

17

P10.014

OR 2137

OR 2137

18

L21.41558

Distanziale

Tube

19

V14.073

Anello elastico

Seeger

20

P02.42007

OR 0250

OR 0250

21

L21.42723

Supporto

Support

22

L21.37518

Ghiera di fissaggio

Fixing nut

23

A21.41900

Rasamento

Shim

24

P21.41899

Trappola termica

Insulating support

25

L21.41891

Canotto

Transmission tube

26

L1.42251

Fermo boccola

Stop bushing

27

A11.42009

Boccola

Bushing

28

P10.067

OR 2087

OR 2087

29

L21.41892

Sede boccola

Seat bushing

30

P10.072

OR 3072

OR 3072

Page 34

NOTE / NOTES / NOTES / BEMERKUNG / NOTA

Page 35

Page 36

FRIGOMAT s.r.l., via 1° Maggio 26862 GUARDAMIGLIO (LO) – ITALIA

tel. 0377.415011 – Fax. 0377.451079

www.frigomat.com

info@frigomat.com

2018

cod. M04.37847

Loading...

Loading...