Page 1

D50564.01

MARCH 2009

CODEC SOFTWARE: V7.2

CONTROL SOFTWARE: V2.2

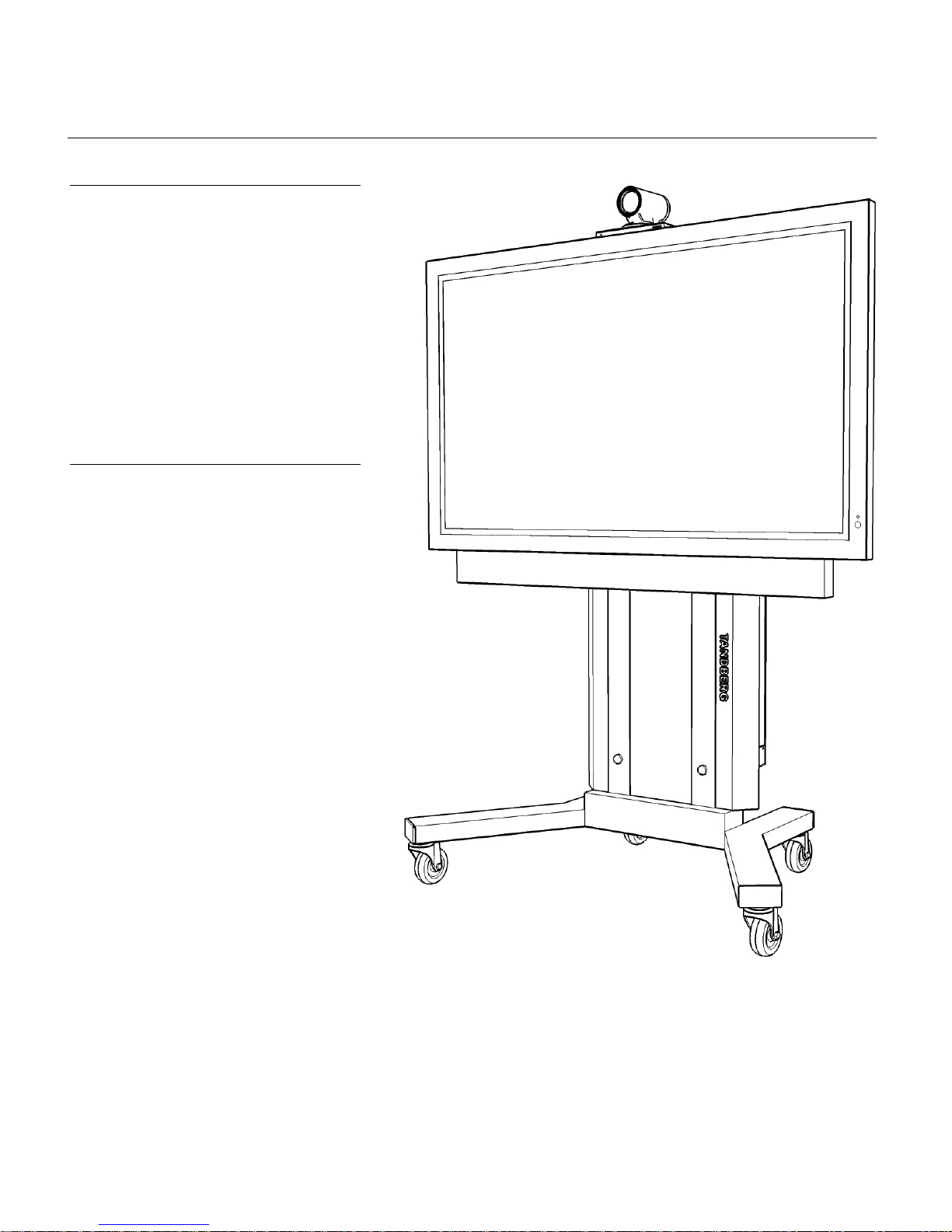

TANDBERG Scholar MXP

Assembly, Setup & User Guide

This document is not to be reproduced in whole or in part

without the permission in writing from TANDBERG.

Page 2

Trademarks & Copyright

Environmental Issues

All rights reserved. This document contains information

that is proprietary to TANDBERG. No part of this

publication may be reproduced, stored in a retrieval

system, or transmitted, in any form, or by any means,

electronically, mechanically, by photocopying, or

otherwise, without the prior written permission of

TANDBERG. Nationally and internationally recognized

trademarks and trade names are the property of their

respective holders and are hereby acknowledged.

Portions of this software are © 1996-2007 RADVISION

Ltd. All intellectual property rights in such portions of the

Software and documentation are owned by RADVISION

and are protected by United States copyright laws, other

applicable copyright laws and international treaty

provisions. RADVISION and its suppliers retain all rights

not expressly granted.

Contains iType™ from Agfa Monotype Corporation.

Disclaimer

The information in this document is furnished for

informational purposes only, is subject to change

without prior notice, and should not be construed as a

commitment by TANDBERG.

The information in this document is believed to be

accurate and reliable; however TANDBERG assumes no

responsibility or liability for any errors or inaccuracies

that may appear in this document, nor for any

infringements of patents or other rights of third parties

resulting from its use. No license is granted under any

patents or patent rights of TANDBERG.

Thank you for buying a product, which contributes to a

reduction in pollution, and thereby helps save the

environment. Our products reduce the need for travel and

transport and thereby reduce pollution. Our products have

either none or few consumable parts (chemicals, toner,

gas, paper). Our products are low energy consuming

products.

Battery handling

Batteries for the Remote Control are Long Life and Alkaline

batteries saving the environment; please follow guidelines

on the packing material for handling and disposal of the

batteries.

Waste handling

No need to send material back to TANDBERG as there are

no consumables to take care of. Please contact your local

dealer for information on recycling the product by sending

the main parts of the product for disassembly at local

electronic waste stations, marking recyclable parts so the

waste station can disassemble and re-use these parts.

Production of Products

Our factories employ the most efficient environmental

methods for reducing waste and pollution and ensuring the

products are recyclable.

Portions of this document written by the Solutions Group

of TANDBERG, U.S.A. and the Technical Support

Department of TANDBERG, Norway. We are committed

to maintaining a high level of quality in all our

documentation. Towards this effort, we welcome your

comments and suggestions regarding the content and

structure of this document. Please fax or mail your

comments and suggestions to the attention of:

TANDBERG Solutions Group

1860 Michael Faraday Drive, Suite 100

Reston, Virginia 20190

Tel: 703-709-4281, Fax: 703-709-4231

Page 3

OPERATOR SAFETY SUMMARY

For your protection, please read these safety instructions completely before operating the equipment and keep this

manual for future reference. The information in this summary is intended for operators. Carefully observe all warnings,

precautions and instructions both on the apparatus and in the operating instructions.

Warnings

• Water and moisture - Do not operate the

equipment under or near water - for example near

a bathtub, kitchen sink, or laundry tub, in a wet

basement, or near a swimming pool or in areas

with high humidity.

• Cleaning - Unplug the apparatus from the wall

outlet before cleaning or polishing. Do not use

liquid cleaners or aerosol cleaners. Use a lint-free

cloth lightly moistened with water for cleaning the

exterior of the apparatus.

• Ventilation - Do not block any of the ventilation

openings of the apparatus. Install in accordance

with the installation instructions. Never cover the

slots and openings with a cloth or other material.

Never install the apparatus near heat sources such

as radiators, heat registers, stoves, or other

apparatus (including amplifiers) that produce heat.

• Grounding or Polarization - Do not defeat the safety

purpose of the polarized or grounding-type plug. A

polarized plug has two blades with one wider than

the other. A grounding type plug has two blades

and a third grounding prong. The wide blade or

third prong is provided for your safety. If the

provided plug does not fit into your outlet, consult

an electrician.

• Power-Cord Protection - Route the power cord so as

to avoid it being walked on or pinched by items

placed upon or against it, paying particular

attention to the plugs, receptacles, and the point

where the cord exits from the apparatus.

• Accessories - Use only with a cart, stand, tripod,

bracket, or table specified by the manufacturer, or

sold with the apparatus. When a cart is used, use

caution when moving the cart/apparatus

combination to avoid injury from tip-over.

• Lightning - Unplug this apparatus during lightning

storms or when unused for long periods of time.

• ISDN cables - CAUTION - To reduce the risk of fire,

use only No. 26 AWG or larger telecommunication

line cord.

• Servicing - Do not attempt to service the apparatus

yourself as opening or removing covers may expose

you to dangerous voltages or other hazards, and

will void the warranty. Refer all servicing to

qualified service personnel.

• Damaged Equipment - Unplug the apparatus from

the outlet and refer servicing to qualified personnel

under the following conditions:

When the power cord or plug is damaged or frayed

If liquid has been spilled or objects have fallen into

the apparatus

If the apparatus has been exposed to rain or

moisture

If the apparatus has been subjected to excessive

shock by being dropped, or the cabinet has been

damaged

• Attachments - Only use attachments as

recommended by the manufacturer.

If the apparatus fails to operate in accordance with

the operating instructions

Page 4

TABLE OF CONTENTS

TRADEMARKS & COPYRIGHT ........................... 2

ENVIRONMENTAL ISSUES................................. 2

OPERATOR SAFETY SUMMARY......................... 3

TABLE OF CONTENTS........................................ 4

AT A GLANCE ..................................................... 5

TANDBERG SINGLE PLASMA CART ASSEMBLY

FOR SCHOLAR MXP........................................... 6

CONTROL WIRING DIAGRAM .......................... 15

AUDIO WIRING DIAGRAM................................ 16

VIDEO WIRING DIAGRAM ................................ 17

SYSTEM OVERVIEW......................................... 18

CONTROL INTERFACES................................... 18

AUDIO AND VIDEO SOURCES.......................... 18

TANDBERG SCHOLAR MXP SETUP GUIDE......20

SYSTEM CONFIGURATION | CODEC & TOUCH

PANEL ..............................................................20

CODEC CONFIGURATION..............................20

TOUCHPANEL CONFIGURATION...................22

TOUCH PANEL OPERATION..............................25

MAIN PAGE ...................................................25

MAKING A CALL ...............................................27

DIRECTORY DIAL ..........................................27

MANUAL DIAL ...............................................28

WHEN IN A CALL..............................................28

MAIN SOURCES............................................28

PRESENTATION ............................................29

FAR END CONTROL ......................................29

MULTISITE ....................................................30

DISCONNECTING A CALL..............................30

APPENDIX.........................................................31

INTEGRATING TANDBERG PRECISION HD

CAMERAS WITH THE OPTIONAL TANDBERG

VIDEO SWITCH..............................................31

OTHER COMPONENTS .................................... 19

Page 4 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

SERVICING .......................................................32

Page 5

AT A GLANCE

The TANDBERG Scholar MXP and videoconferencing solution is designed to be modular. The Scholar Electronics Rack

houses the TANBERG Applications Module MXP and the 6000 MXP codec, which are connected by an umbilical cable,

providing flexibility that allows this system to be setup in various locations with various equipment.

System Components

A full integration of the

TANDBERG Scholar MXP

system can include the

following:

such as DOC CAM and/or DVD Player)

Dual Display “Student” Carts

w/ Scholar Equipment Rack

(optional 2nd display)

Precision HD Camera

Touch Panel

Podium

(houses optional peripherals

Audio Science Microphone

(mounted on ceiling / optional)

Single Display “Instructor” Cart w/ PHD Camera

(optional)

The core components for the TANDBERG Scholar MXP system are:

• Scholar MXP Equipment Rack – TANDBERG 6000 MXP Codec, 1U shelf w/ power supplies, 1U Power Outlet

(The TANDBERG Video Switcher option will include a 1U Interface Panel in the rack.)

• 10” color touch panel with integrated 35’ cable containing power and control

• PHD Camera

• Table microphone

• Associated connection cables

Unpacking

To avoid damage to the system during transport the system is carefully packed and, in some cases, delivered as separate

components. Carefully unpack the components, cables, and accessories to prepare for installation and setup.

NOTE: Be sure to save the packaging in the event you need to transport the system to another location.

Page 5 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 6

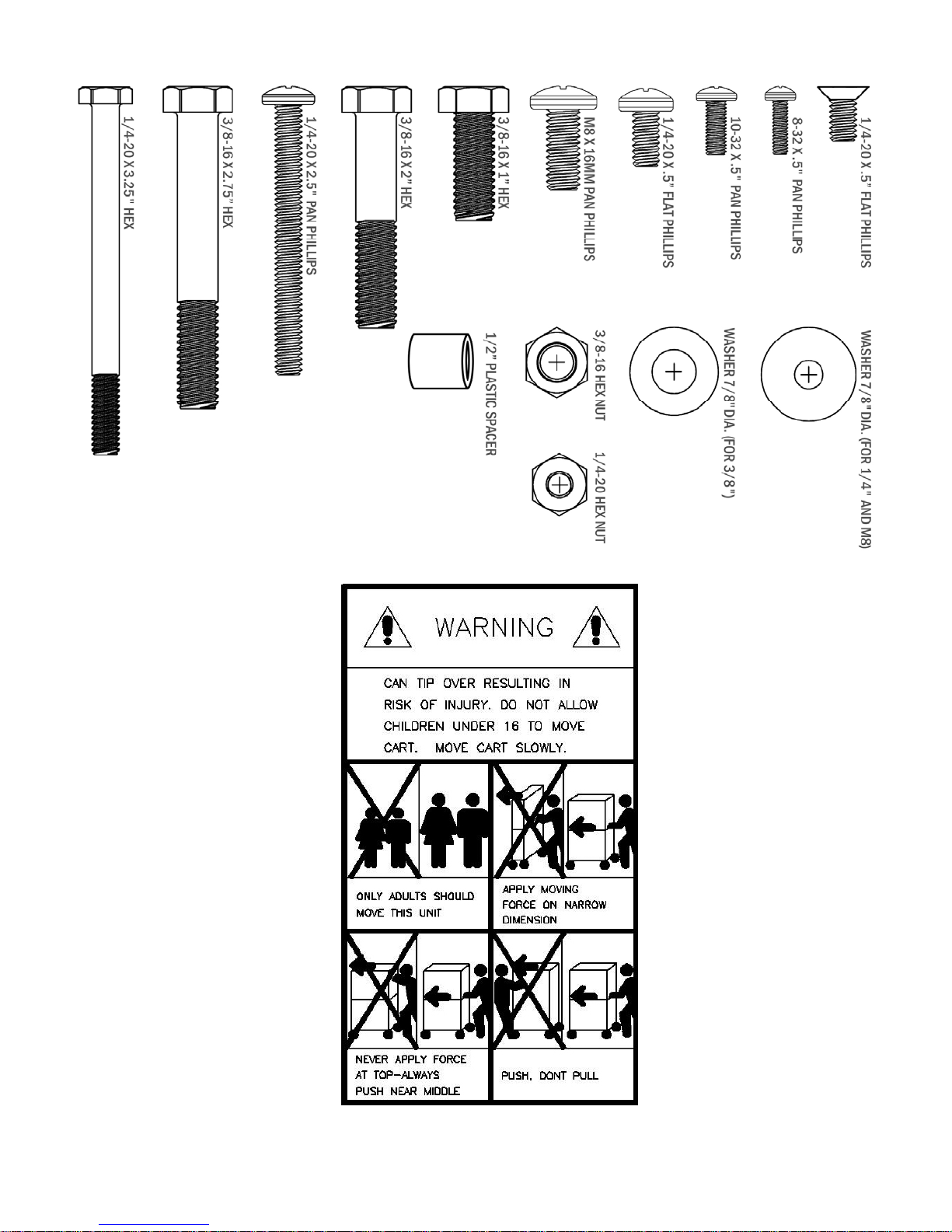

TANDBERG Single Plasma Cart Assembly for Scholar MXP

PARTS LIST

A. cart base with wheels

B. vertical support posts (2)

C. horizontal “U” channels (2)

D. handles (2)

E. beauty panel

F. speaker bar

G. display brackets (2)

H. TANDBERG Precision HD Camera

I. speaker bracket A (2)

J. speaker bracket B (2)

K. camera bracket

L. camera shelf

M. codec brackets (2)

N. J-hook

O. TANDBERG codec

P. display

Q. hardware for assembly

ASSEMBLY HARDWARE KIT

QTY DESCRIPTION

11 3/8-16 x 1" hex-head bolt grade 5

verticals to base, handles to horizontals & J-hook

29 washer for 3/8" bolt, 7/8" outside diameter

washers for all 3/8" and M8 bolts

4 3/8-16 x 2.75" hex-head bolt grade 5

horizontals to verticals

4 3/8-16 x 2" hex-head bolt grade 5

display mounting brackets to horizontals

6 M8 x 16 pan-head Phillips screw

display mounting brackets to plasma

2 1/4-20 x 3.25" hex-head bolt grade 5

mounting speaker bracket to verticals

10 1/4-20 hex-nut grade 5

mounting speaker bracket, beauty panel

4 washer for 1/4" screw, 7/8" outside diameter

mounting speaker bracket, beauty panel

12 washer for 1/4" screw, 7/8" outside diameter

mounting speaker bracket

2 nylon spacer for 1/4" screw, 1/2" long, 1/2" OD.

mounting speaker bracket

4 10-32 x .5” pan-head Phillips screw

codec brackets

4 1/4-20 screw, 2.5 pan-head Phillips

beauty panel

4 hinged screw cap for 1/4-20 screw

beauty panel

4 8-32 x 1/2” screw, pan-head Phillips

for Edge codec VESA bracket

1 vinyl-coated steel J-Hook (80lb. load)

attach to lower horizontal bar for cable management

5 3/8”-16 hex nut, grade 2

for handles, J-hook

4 ¼”-20 x ½” screw, Phillips

to attach User Control Module brackets

4 10-32 x 1/2" screw, pan Phillips

camera shelf to camera bracket / bracket to horizontal

4 #10 x .438OD washer

camera shelf to camera bracket / bracket to horizontal

1 1/4-20 x 1/2" screw, flat Phillips

camera shelf to HD camera

1 1” diameter adhesive back felt pad

camera shelf

Page 6 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 7

TANDBERG SCHOLAR MXP DISPLAY CART OVERVIEW

TANDBERG PRECISION HD CAMERA

CAMERA SHELF

CAMERA BRACKET

SPEAKER BRACKET (B) – 2X

HORIZONTAL “U” CHANNEL – 2X

DISPLAY

SPEAKER BAR

DISPLAY MOUNTING

BRACKET – 2X

DISPLAY BRACKET

ADAPTER – 4X

SPEAKER BRACKET (A) – 2X

VERTICAL SUPPORT POST – 2X

CART HANDLE – 2X

J-HOOK

CAPS – 4X

VESA MOUNT

BRACKET – 100MM

(OPTION)

CART BASE

COVER PANEL

WHEELS -- 4X

SCHOLAR MXP

EQUIPMENT RACK

Page 7 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 8

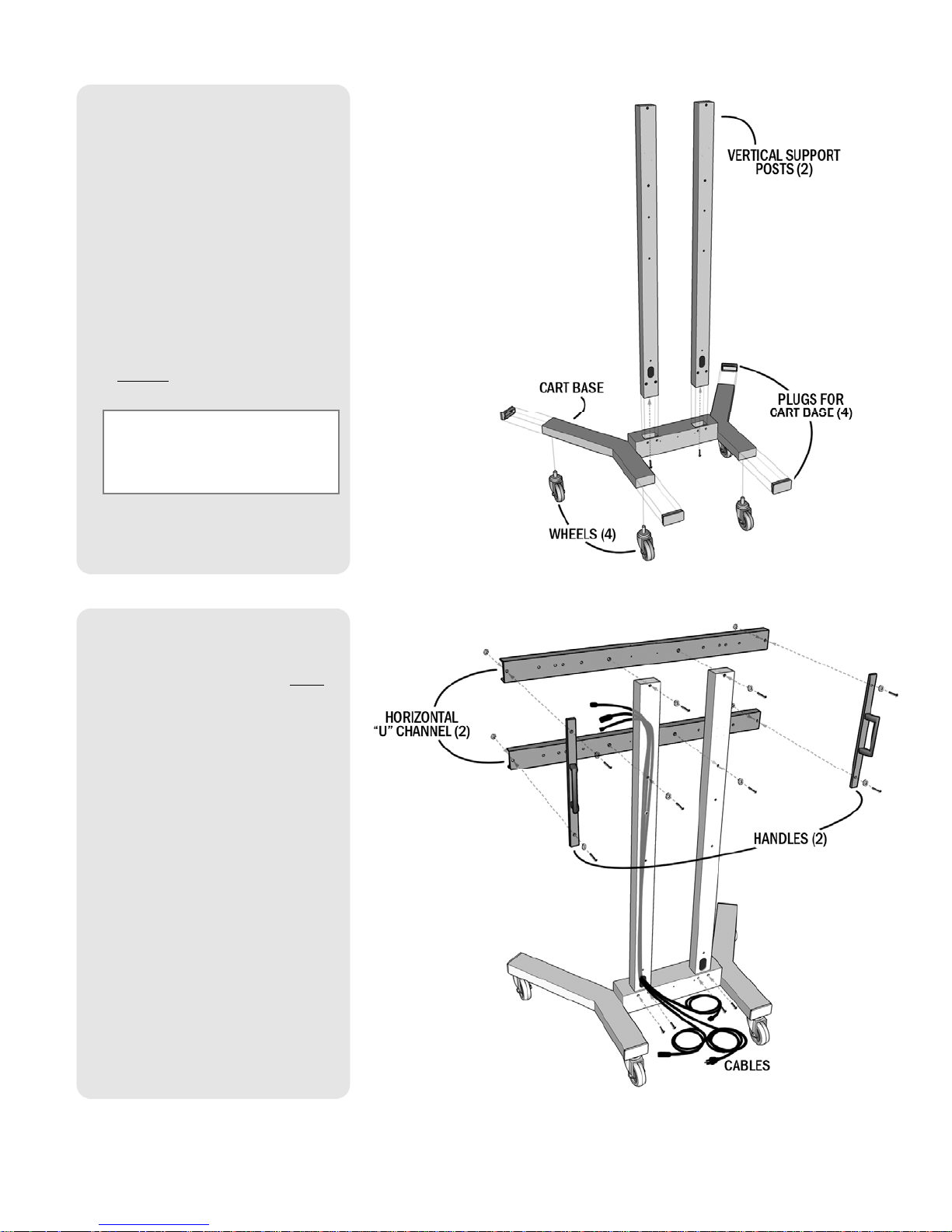

TOOLS REQUIRED: 7/16 wrench or ratchet set

9/16 wrench or ratchet set

#2 Phillips screwdriver

Page 8 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 9

1. If needed, attach 4” WHEELS

(4) to the CART BASE using

supplied WHEELS and NUTS,

and if necessary, insert PLUGS

(4) into the open ends of the

CART BASE.

2. Position the VERTICAL

SUPPORT POSTS (2) into the

CART BASE as shown.

3. Use 3/8”–16 x 1” HEX BOLTS

& WASHERS (2) to secure the

VERTICAL POSTS to the

bottom of the cart.

NOTE: Ensure that the

WHEELS are set in the LOCK

position before proceeding.

4. Use 3/8”–16 x 1” HEX BOLTS

& WASHERS (4) to secure the

VERTICAL POSTS at the

back

of the cart.

5. Mount the HORIZONTAL “U”

CHANNELS (2) to the UPRIGHT

SUPPORT POSTS using 3/8”–

16 x 2¾“ HEX BOLTS and

WASHERS (4).

6. Fasten the cart’s HANDLES (2)

to the HORIZONTAL “U”

CHANNELS using 3/8”–16 x

1” HEX BOLTS, WASHERS, and

NUTS (4).

IT IS RECOMMENDED THAT

THE NECESSARY CABLES FOR

THE SYSTEM ARE RUN

THROUGH EITHER OR BOTH

VERTICAL POSTS AT THIS

TIME.

Refer to the WIRING DIAGRAM for

necessary cables to run per

system/room requirements.

Page 9 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 10

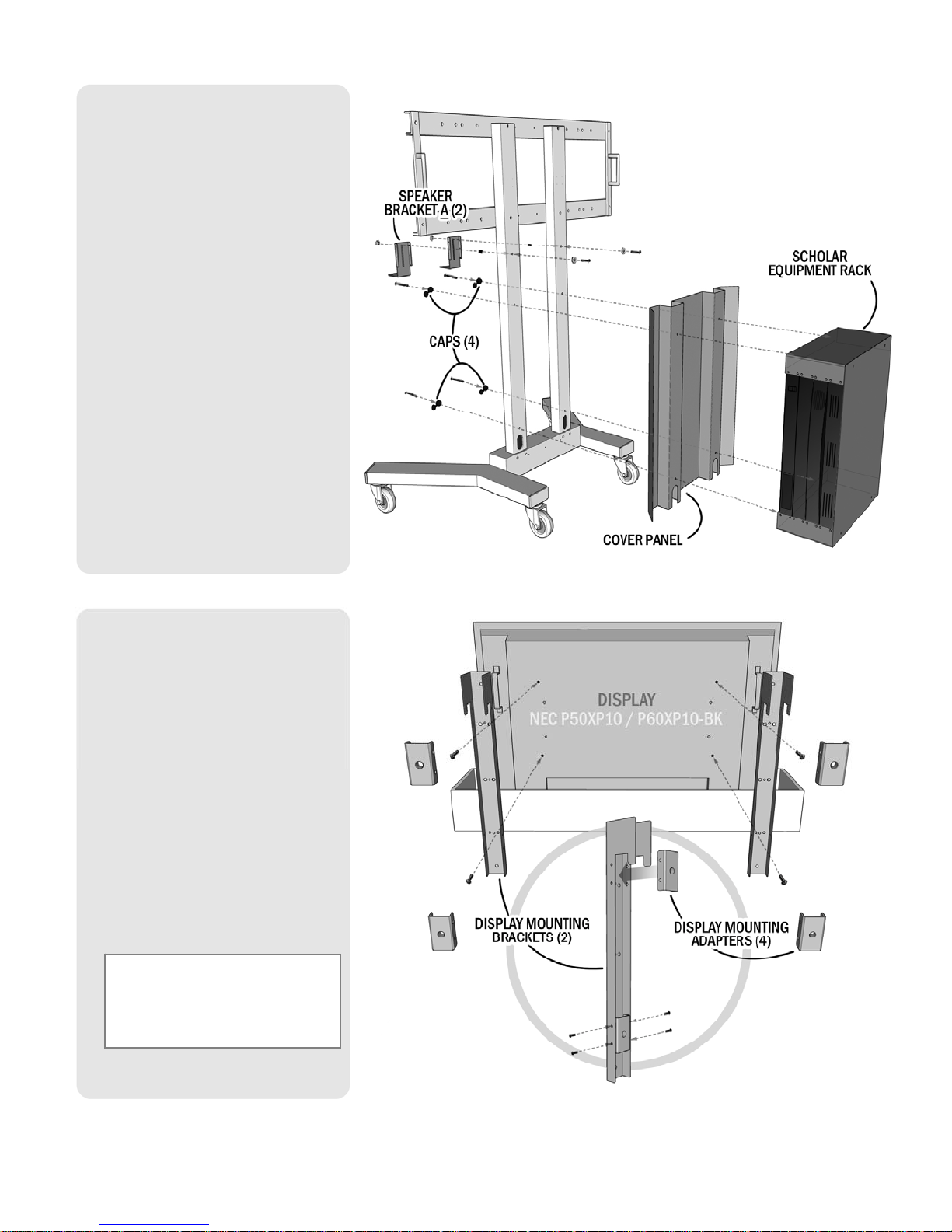

7. Insert the ¼“–20 x 2.5”

BOLTS (4) into the CAPS (4)

mounting the COVER PANEL

and the SCHOLAR EQUIPMENT

RACK to the VERTICAL POSTS.

8. Place the .5” SPACERS (2)

behind SPEAKER BRACKETS-A

(2) and mount them to each of

the POSTS using ¼”–20 x

3¼” BOLT & NUTS and ¼”

WASHERS (8).

DO NOT TIGHTEN SPEAKER

BRACKETS AT THIS TIME.

9. Remove the top cover for each

of the DISPLAY BOXES. Leave

the DISPLAY in the bottom

packaging for the next step.

10. Attach

*

the DISPLAY

MOUNTING BRACKETS (2) to

the rear of the DISPLAYS using

M8 x 16 BOLTS (4).

* When attaching the BRACKET to the

NEC displays you will need to remove

the DISPLAY MOUNTING ADAPTERS

(4) to access the appropriate

mounting holes for your particular

display. Replace the ADAPTERS when

BRACKETS are mounted.

NOTE: Use the INSIDE HOLES on

the DISPLAY MOUNTING

BRACKETS as shown to attach to

the DISPLAY.

Page 10 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 11

MOUNTING POSITIONS FOR DISPLAYS

NEC P50XP10 (50”) / NEC P60XP10-BK (60”) / LG 50PM1M (50”)

LARGE HOLE =

MOUNTING

POINTS ON

HORIZONTAL

U-CHANNEL

SMALL HOLE =

MOUNTING

POINTS ON

DISPLAY

LARGE HOLE =

MOUNTING

POINTS ON

HORIZONTAL

U-CHANNEL

Page 11 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

SMALL HOLE =

MOUNTING

POINTS ON

DISPLAY

Page 12

MOUNTING POSITIONS FOR DISPLAYS

PIONEER PDP-507CMX (50”) / PIONEER PDP-607CMX (60”)

LARGE HOLE =

MOUNTING

POINTS ON

HORIZONTAL

U-CHANNEL

SMALL HOLE =

MOUNTING

POINTS ON

DISPLAY

LARGE HOLE =

MOUNTING

POINTS ON

HORIZONTAL

U-CHANNEL

Page 12 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

SMALL HOLE =

MOUNTING

POINTS ON

DISPLAY

Page 13

11. Lift* and hook the DISPLAY to

the top HORIZONTAL “U”

CHANNEL to mount onto the

CART.

* THIS REQUIRES THE SUPPORT

OF AT LEAST ANOTHER

PERSON TO LIFT AND MOUNT

THE HEAVY DISPLAY!

12. Use the 3/8”–16 x 2” BOLTS

(4) to secure the DISPLAY to

the FRAME.

13. Mount the J-HOOK with a

3/8”–16 x 1” BOLT, NUT, and

WASHER into

any spare hole

located on the HORIZONTAL

“U” CHANNEL.

14. Attach ADHESIVE-BACKED

FOAM to the

top-front of

SPEAKER BAR as shown and

trim any excess foam.

15. Attach SPEAKER BRACKETS-B

(2) to the SPEAKER BAR using

the EXISITING SCREWS (4).

16. Attach the SPEAKER CABLE to

the SPEAKER BAR.

17. Mount the SPEAKER BAR and

BRACKET-B to SPEAKER

BRACKET-A on the FRAME

using ¼”–20 NUTS and ¼”

WASHERS (4) with the existing

studs on BRACKET-A.

18. Adjust the SPEAKER BAR to

align with the DISPLAY’S front

and bottom and securely

tighten the screws.

Page 13 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 14

y

19. Use the ¼”–20 x ½” SCREW

to secure the HD CAMERA to

the CAMERA SHELF*.

* Affix the FELT PAD to the center-front

area on the bottom of the CAMERA

SHELF to protect from scratching the

top of the DISPLAY.

20. Align the CAMERA BRACKET

with the bracket holes along

the top “U” CHANNEL and

secure the bracket using 1032 x .5” SCREWS (2).

21. Slide the CAMERA SHELF into

the CAMERA BRACKET and

secure the two parts together

with 10-32 x .5” SCREWS (2).

22. An OPTIONAL 100mm VESA

MOUNT BRACKET (2) can be

installed for mounting a VESA

compatible PC or other

peripheral device.

23. Use the WIRING DIAGRAM on

the following page to connect

the appropriate cables and

devices.

24.

Return the BACK PANEL to the

COLLABORATOR EQUIPMENT

RACK.

25.

The system assembly is

complete.

Please refer to the following

sections to complete system

setup and understand how to

operate the TANDBERG

Collaborator.

Please refer to the TANDBERG

CODEC MANUAL to set up and

configure the system’s codec

per the network requirements

our environment.

for

Page 14 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 15

CONTROL WIRING DIAGRAM

Page 15 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 16

AUDIO WIRING DIAGRAM

Page 16 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 17

VIDEO WIRING DIAGRAM

Page 17 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 18

SYSTEM OVERVIEW

The TANDBERG Scholar MXP videoconferencing system is comprised of the following: components for CONTROL,

components for AUDIO and VIDEO, and ancillary components that can be added to provide a richer videoconferencing and

presentation experience.

Control Interfaces

The TANDBERG videoconferencing system is easily controlled through the touch panel interface. The touch panel controls

all presentation and videoconferencing needs via the SCHOLAR MXP and the codec.

TOUCH PANEL

The 10” touch panel is incorporated to enable a user to configure and manage the presentation from a podium or desktop.

The touch panel incorporates single screen operation and a video window that displays current local and remote site

transmissions. The touch panel interface is intuitively designed to maximize presentation effectiveness.

WEB BROWSER

A separate web-based user interface for technician/diagnostic control is available. The embedded web interface loaded with

the controller requires an IP connection for web-based control.

TANDBERG SCHOLAR MXP CONTROL MODULE

The controller in the SCHOLAR MXP modules directs the codec, and enables control of multiple devices, such as room

cameras, VCR’s, DVD players, document cameras.

TANDBERG 6000 MXP CODEC

The Codec is the heart of the system. The main task for the Codec is the compression of outgoing video, audio and data, the

transmission of this information to the far end and the decompression of the incoming information -- hence the name Codec;

compression and decompression.

Audio and Video Sources

MAIN CAMERA & AUX CAMERA

The Main Camera is generally mounted on top of the primary display. The Main Camera is a high quality color camera

with a fast pan/tilt/zoom action. The Main Camera is controlled by the touch panel control, or the system’s infrared

remote control. You can pre-store up to 10 camera positions using Camera Presets (5 for the Main camera and 5 for

the Aux).

MICROPHONES

You may connect up to three microphones to your TANDBERG system. There are several microphone solutions that

can be integrated with your system:

AudioScience

Microphone

(optional)

TANDBERG's award-winning AudioScience microphone is a transparent, ceiling-mounted,

wide-coverage, boundary microphone, which can eliminate the need for table

microphones. It is designed to pick up the audio from all conference participants seated

within in its pick-up area, defined by hemisphere of approximately 14-foot (4.25m) radius

extended in front of, and to the sides of the microphone. Using the Automatic Gain Control

(AGC) on the codec maintains the audio signal level at a fixed value by attenuating strong

signals and amplifying weak signals.

Table

Microphones

Page 18 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

The optional high-quality table microphones are designed to lie on a table during a

videoconference. The ideal location for the microphone is on a flat surface at least 6.5 ft

(2m) from the front of the system. The microphone cable should always point towards the

system. The system will automatically equalize sound levels. Loud and soft voices are

picked up and transmitted to the far end at approximately the same level.

Page 19

SPEAKER BAR

Audio is heard through the SPEAKER BAR. It is connected to the display. The Scholar MXP Module supplies the audio

to the display.

DOCUMENT CAMERA

A composite video source is available for integrating an optional document

camera. Document cameras can be used to show a wide variety of media, such

as whitepapers, film negatives, or standard overhead projector transparencies.

Source selection, zoom, focus and lighting can all be controlled from the button

panel of the document camera.

If the document camera is one of the supported controllable devices and

configured, the document camera functions can be controlled from the touch

panel when that input is selected.

DVD/VCR PLAYER & RECORDER

Standard composite video VCR’s or DVD players can be added for playback and

recording. Using codec features such as audio “ducking” (lowering the VCR

output while the presenter is talking) allows seamless presentations and

participant interaction.

When configured, the device controls will be available on the touch panel. You

may also use the front panel controls or the supplied remote control specific to

these devices.

When recording is desired, select the “Record Control” button to bring up the

video source to record. You may choose to record the far or near end video as

the source being recorded. “Start Record” will begin the recording. Pressing stop

on the lower controls will stop the recording.

See the peripheral wiring diagram for the Scholar MXP to ensure proper connections for recording.

PC/LAPTOP COMPUTER

A user supplied PC or laptop can be connected to the system to enhance presentation. You can connect the

PC/laptop to the DVI input on the codec, or to a high-resolution document camera.

Other Components

ADDITIONAL MONITORS

An additional monitor can be added for viewing the far or local video. Typically

used to view the far side in a teaching environment, the monitor will also show

the local image when giving a local presentation.

On/Off controls of certain displays is available. Current some Epson, LG, and

pioneer devices can be turned on/off via RS-232 control to extend monitor life

and avoid screen burn in.

REMOTE CONTROL

The handheld TANDBERG Remote Control is used to control most functions of

the system. The system also emulates the remote control via the touch panel.

The reach of the remote control signal is 20 meters. For users sitting in an open plan office, this can cause problems.

Use the little, white switch placed under the batteries to change the reach of the signal from 20 meters to 2 meters.

This will prevent you from unintentionally controlling your neighbor's video system, when you control your own system.

Detailed instructions on how to use the TANDBERG Remote Control can be found in the codec manual.

Page 19 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 20

TANDBERG Scholar MXP Setup Guide

Once the TANDBERG Scholar MXP cart has been assembled and all components and connections have been

made to the system, the system can be powered on:

1. Plug the system’s power cord into a power outlet.

2. Make sure the switch on the power distribution unit on the Scholar MXP Equipment Rack is turned ON.

3. Ensure that the Net/Video port on the touch panel is connected to the Scholar MXP Equipment Rack.

Once the system is powered-up, the touch panel will become active and run through a 15 second boot cycle.

The system is ready when the WELCOME SCREEN is displayed on the touch panel.

NOTE: Before proceeding with your system, be sure to provide basic setup and configuration for the

CODEC and TOUCHPANEL by following the procedures outlined below (SYSTEM

CONFIGURATION | CODEC & TOUCH PANEL).

System Configuration | Codec & Touch Panel

The system must be configured for each installation. Network, audio, and other codec configuration settings are made

using the TANDBERG Remote Control.

CODEC CONFIGURATION

NOTE: While the touch panel is the primary source for presentation operation, the

remote is required for codec setup and menu navigation. Video switching controlled by

the remote control will not always function properly. It is recommended that you use the

touch panel to control video switching.

You can access the remote control emulator on the touch panel by entering the SYSTEM

SETUP page and selecting System Setup > IR FUNCTION. Make sure you select the FAR

END SOURCE in the video window while in this screen to view the codec’s menu. This is

done by touching FAR in the window.

You may use either the physical remote control or the touch panel emulation of the remote control – both function

identically.

1. Press TOUCH TO START on the WELCOME PAGE after the system has run through its boot cycle.

2. Press the

point the remote in the direction of the camera as the IR sensor is located on the front of the camera.)

3. Navigate through the menu system using the

Menu.

NOTE: If an external IMUX or non-standard network is being used it may be necessary to configure any associated external

equipment.

NOTE: Refer the ‘TANDBERG 6000 MXP User Manual’ for detailed codec menu navigation and configuration.

Page 20 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

OK button on the remote control to display the ‘Main Menu’ on your main display monitor. (Be sure to

ARROW KEYS and OK. Press Cancel [ X ] to return to the previous

Page 21

General Codec Configuration:

1. Open the General Settings menu

a. Press OK on the remote to open the ‘Main Menu’ (if it is not already open).

b. Select ‘Control Panel’ and then select ‘Administrator Settings’.

c. Select ‘General’ to open the ‘General Settings’ menu.

2.

Language

Press OK in the Language field and select the language you want to use from the list. There are 13 languages to

choose from. The touch panel will only display English.

NOTE: This changes the language used on the menus of the codec only and not the touch panel!

3. System Name

Enter a name in the ‘System Name’ field using the number keys on the remote control, as you would do with a

mobile or cellular phone.

4.

Dual Monitor

If you are using two monitors, set Dual Monitor to On.

If you are using one

5. Auto Answer, Max Call Length, Global Phone Book Settings and Permissions

Leave Auto Answer, Max Call Length, Access code and Permissions unchanged if no special needs are required.

monitor, set Dual Monitor to Off.

6. Screen Settings

When using wide screen (16:9) monitors, set TV Monitor Format to Wide (16:9). TANDBERG also recommends

setting Picture Layout to Picture outside Picture when using 16:9 monitors. Picture outside Picture provides a

display layout optimized for wide screen monitors. The display layout may be changed at any time using the Layout

button on the remote control.

7. Software Options

To activate MultiSite and bandwidth, you must enter a new option key in the Software Options menu (see

paperwork accompanying your system). For more information on these options, contact your TANDBERG

representative.

8. Save changes

Remember to save any changes you make in a menu by selecting the Save button on the Menu line and pressing

OK.

Network configuration:

1. Open the Network menu

Open the ‘Administrator Settings’ menu and choose ‘Network’.

2. ISDN configuration

Set ‘Current Network’ to the network you want to use. Specify the settings for the selected network in the relevant

menu.

3. LAN configuration

In the ‘Administrator Settings’ menu, choose ‘Network and LAN Settings’. Specify the necessary LAN settings

according to the instructions from your LAN administrator.

4. Save changes

Remember to save any changes you make in a menu by selecting the Save button on the Menu line and pressing

OK.

Monitor volume:

1. Adjust monitor volume

Use the monitor remote control to adjust the volume of the monitors. This volume will be the default volume for all

calls.

Page 21 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 22

TOUCHPANEL CONFIGURATION

System Setup

There are a number of setup options and

configurations that can be utilized to customize

and configure your system. Press the SETUP

button to enter the utilities and setup page.

IR FUNCTION Presents a page for remote control emulation.

CONFIGURE

SOURCES

PASSWORD

PROTECTION

DISPLAY

CONFIGURATION

SYSTEM

INFORMATION

EXIT Exits setup page and returns to the MAIN page.

DISPLAY POWER Powers down the display monitor(s) and puts the system/codec to sleep

Configure the peripheral devices that appear on the touch panel.

Setup password protection for access to dialing, system, and setup pages.

Configure display types to control.

General system information.

Page 22 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 23

IR FUNCTIONS

Pressing this will present the TANDBERG Remote Control on the touch panel. Much of the remote’s functions are

emulated on this page to control the codec.

CONFIGURE SOURCES

Pressing CONFIGURE SOURCES provides source options

that can be defined to appear in the source list that shows

on the left side of the MAIN PAGE.

AUXILLARY CAMERA

Highlight this to enable the INSTRUCTOR CAM (AUX)

button to appear on the Main Page. This option should

be selected when a second camera is present.

PC/VGA INPUT

This option will show the PC source button on the Main

Page.

DOCUMENT CAMERA

Selecting this option will show a submenu to specify

which document camera that is connected to the

system is to be controlled from the touch panel. The

DOC CAM button will appear on the Main Page when

selected.

VCR/DVD

Selecting this source will show the VCR/DVD button on the Main Page. When this is selected, a submenu will appear to

specify which video playback device is connected to the system that is to be controlled from the touch panel.

PASSWORD PROTECTION

This selection provides three options to set and enable

passwords for the system: DIALING, SETUP, and SYSTEM

passwords can be set.

Press an option at the top of the page to toggle between

ENABLED (green) and DISABLED (red). The corresponding

password(s) can be set in the lower window using the

KEYPAD. The passwords are 4-digit number combinations.

When a password is set an enabled for:

DIALING

a password challenge will appear when the MAKE A

CALL button is pressed on the Main Page.

SETUP

a password challenge will appear when the SETUP

button is pressed on the Main Page.

SYSTEM

a password challenge will appear when the TOUCH TO START button is pressed (upon waking up the system or when

the system has been rebooted).

NOTE: the system’s default master password is 4263. This password can override any of the three password challenges on

the touchpanel.

Page 23 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 24

DISPLAY CONFIGURATION

This selection allows for the setup of the specific display

monitors that can be power managed by the system.

SYSTEM INFORMATION

Pressing this will display general system information.

This information can be helpful when troubleshooting

with TANDBERG Technical Support.

Page 24 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 25

USING THE SYSTEM

Touch Panel Operation

Upon start-up the interactive touch panel will display the INTRODUCTORY SPLASH

PAGE.

MAIN PAGE

The MAIN PAGE is the launching pad from which you will begin your presentation.

The following image describes what the user will initially see after start

VIDEO DISPLAY WINDOW

-up.

CALL CONTROL

MAIN SOURCE

SELECTION

LAYOUT OPTIONS

SOURCE CONTROLS

VOLUME CONTROL / MUTE

VIDEO DISPLAY WINDOW

This window will either display the currently selected video source or the received video from the far end. The

Local Video (Student Cam) is the default video source. When in a call, touching NEAR or FAR in the upper corners

of the video window will toggle between the two video sources.

LAYOUTS

Touching the LAYOUT button will toggle through the different display layouts that are available dependent on the

presentation scenario and how many call are connected.

Page 25 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 26

SOURCE CONTROLS

This area presents the control options for the currently selected source.

MAIN SOURCE SELECTION

This area provides available sources to select from during presentation.

STUDENT

CAM

INSTRUCTOR

CAM

PC

DOC CAM

DVD/VCR

Local view. The camera controls appear in the SOURCE

CONTROL area.

When a second camera is connected and configured, this

source and its controls will appear in the SOURCE CONTROL

area.

Presents the content that is presented using a computer

(PC/MAC/other) that is connected to the system. No controls are

available.

Presents the content that is presented using the document

camera configured for the system. The DOC CAM controls

specific for the device that is configured will appear in the

SOURCE CONTROL area.

Presents the content that is presented through a VCR, DVD

player, or other A/V source connected to the system. The

controls specific to the VCR/DVD unit that is configured will

appear in the SOURCE CONTROL area. Any other A/V source will

not be controllable.

CALL CONTROL

This area provides the necessary options for presentation, as well as call control. Different functions will be

available when applicable.

MAKE A CALL

DISCONNECT

PRESENTATION

ADD SITE

SETUP

Access to the Directory and Manual Dial page.

Ends a call.

When in a call, the PRESENTATION button shows the

presentation source options to be viewed by the participants.

Touching ADD SITE will enable additional calls/sites to be

placed when already in a call. The system can accommodate a

total of 5 video sites (including you, the host) and an additional

3 audio/phone connections.

Access to the SYSTEM SETUP pages.

AUDIO

VOLUME

INDICATOR

MIC MUTE Mutes the local system microphone.

Page 26 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Control the volume level for the system.

Page 27

Making a Call

Placing a videoconference call is a simple process:

1. Touch MAKE CALL to view dialing options.

2. Manually dial a number or select a directory entry to dial.

3. Press CONNECT to place the call.

DIRECTORY DIAL

When DIRECTORY DIAL is selected, a list of local, user-defined entries are presented.

1. Select the directory entry to call.

2. Press CONNECT.

Additional calls may be added by touching ADD CALL from the MAIN PAGE to begin a MultiSite session.

accommodate a total of 5 video sites (including you, the host) and an additional 3 audio/phone connections.

DIRECTORY SETUP

Touch DIRECTORY SETUP to ADD, EDIT, or DELETE directory

entries.

ADD

Touch ADD to enter the name and call requirements for the

new directory entry. Press SAVE ENTRY to include this entry

to the local directory.

EDIT

Touch the directory entry to be modified and touch EDIT

ENTRY. Modify as needed and press SAVE ENTRY.

DELETE

Touch the directory entry to be removed and touch DELETE

ENTRY. A confirmation page will appear to verify directory

entry removal.

The system can

NOTE: The directory entries are stored locally on the touch panel. While the Scholar MXP does not support the retrieval

of Global or Corporate Global Directories, the local touch panel directory can be synchronized with the codec’s directory

by touching RETREIVE CODEC DIRECTORY on the DIRECTORY SETUP page.

Page 27 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 28

MANUAL DIAL

When placing a call that is not in the directory, touch the MANUAL DIAL button to enter the required call information.

1.

Enter the NUMBER or ADDRESS you wish to dial. You may enter any combination of alphanumeric* characters.

2.

Enter any call options necessary:

3.

Press CONNECT to dial the number.

When In a Call

When a call has been placed and connected, the system will display the MAIN PAGE. You can choose to:

use the MAIN SOURCES to show

your content/presentation

disconnect your call by touching

enhance your presentation with

add additional sites for a MultiSite

MAIN SOURCES

Selecting a MAIN SOURCE will display the content on the system’s display:

STUDENT

CAM

INSTRUCTOR

CAM

Local view. The camera controls appear in the SOURCE

CONTROL area.

When a second camera is connected and configured, this

source and its controls will appear in the SOURCE CONTROL

area.

DISCONNECT

dual streams (H.239) by touching

PRESENTATION

videoconference call by touching

ADD SITES. (requires MultiSite

option to be installed).

PC

DOC CAM

DVD/VCR

Page 28 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Presents the content that is presented using a computer

(PC/MAC/other) that is connected to the system. No controls are

available.

Presents the content that is presented using the document

camera configured for the system. The DOC CAM controls

specific for the device that is configured will appear in the

SOURCE CONTROL area.

Presents the content that is presented through a VCR, DVD

player, or other A/V source connected to the system. The

controls specific to the VCR/DVD unit that is configured will

appear in the SOURCE CONTROL area. Any other A/V source will

not be controllable.

Page 29

PRESENTATION

Utilizing the PRESENTATION tool can be an effective way to present content other than through the MAIN

CAMERA. You are now able to present contents of a connected PC/laptop computer, a document

camera, or a video clip from a VCR or DVD player with a second stream, while the main camera can be

utilized to maintain “eye-contact” with the

1. While in a videoconference call, press PRESENTATION. If the button is not present, you are not able to initiate a

Presentation session at this time

2. The Presentation page will appear. You will see source selections for the MAIN video display, as well as the

source selections for the PRESENTATION display.

audience.

3. Select the desired PRESENTATION source you wish to present. The far-end site will be able to see your selected

source.

4. Press PRESENTATION again to discontinue sending a presentation source. This will not disconnect your call.

FAR END CONTROL

It is possible to get some control of the far end system. This allows for

control of the conference partner’s camera, video sources and

presets. Enabling Far End Control in the codec’s ‘Control Panel’ will

allow the system to do Far End camera control and camera presets

on the far end camera. See Far End Control in the TANDBERG 6000

MXP Manual for more details.

You can initiate Far End Control using your touch panel only if the Far

End has been properly configured.

Press the FAR END button to view the FAR END CONTROLS (purple). If the Far End is not configured to do, the touch panel

will display “Far End Control Not Possible.” (You may ask the Far End participant to enable Far End Control via their

codec’s Control Panel.)

Page 29 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 30

MULTISITE

The optional MultiSite capability enables several sites to participate in the same conference. You can have a maximum of

5 video- and 3 telephone-participants including yourself (the host). The participants are tiled up on the screen and are on

display simultaneously in a Split Screen. During an MCU conference, the status line will provide information about the

conference.

A MultiSite conference can be established in different ways. The MultiSite Services vary depending on how you make the

call. Refer to the TANDBERG 6000 MXP User Manual for more about MultiSite and MCU Services.

1. While in a call, press ADD SITE and select a directory entry or enter a number manually.

2. Press CONNECT.

Repeat steps 1 and 2 if you would like to connect additional sites. You can add a site at any time by entering the CALL

CONTROL page.

3. Operate the conference as normal.

DISCONNECTING A CALL

Pressing the red DISCONNECT button during a call will prompt you to confirm the termination of that call before the

connection is terminated.

When in a MultiSite call, pressing the DISCONNECT button will allow you to choose to disconnect individual sites, or to

disconnect the entire MultiSite session.

Page 30 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 31

•

APPENDIX

Integrating TANDBERG Precision HD Cameras with the

optional TANDBERG Video Switch

Up to two TANDBERG PHD Cameras can be integrated into this system (SCHOLAR MXP), using the TANDBERG Video Switch

(TVS), to provide high-definition video. The TVS enables the system to switch between the HD camera signals.

These cameras correspond to MAIN and AUX.

CAMERA OPTIONS

SOURCE INPUT CAMERA DETECTED USES TVS INPUT CONTROL CONNECTION CABLE

Camera #1 Precision HD DVI-D #1 Via TVS “Data 1 HD” 115420 (6’) C6000

Camera #2 Precision HD DVI-D #2 Direct via Display 2 breakout Use adapter T278-0008

Camera #1 Ctrl

To Codec Dataport 2

DVI Cabling: The DVI connections

to the TVS are Digital only (DVID)

• Power: Each camera and the TVS

will require a 12VDC power

supply.

Auxiliary #1, DVI 3 or RGB 6

Camera #1

Camera #2, DVI 2 or RGB 5

• TRC4 Remote Control: This

remote can be used but the

direct video input switch buttons

will not function correctly with

the TAM MXP.

TANDBERG recommends rack mounting the TVS within 6’ (1.5m) of the codec. If you have the TANDBERG student cart,

there is 1U blank panel above the codec, or on the 1U shelf. The power distribution bars behind the PC connection should

have adequate outlets available.

The TVS OUTPUT connects to the codec digital input on DATAPORT #2 replacing the existing Precision camera which now

connects to CAMERA 1.

CAMERA 1 (MAIN/STUDENT) connects to DVI-D 1 and control to DATA 1 HD

CAMERA 2 (AUX/INSTRUCTOR) connects to DVI-D 2 for the Precision HD Camera.

DISTANCE CONSIDERATIONS

If using the Precision HD camera as an instructor camera (looking at one specific person), it should be no further than 30’

(9m) from the subject due to the zoom capabilities of the camera.

CONNECTION DIAGRAM WITH TANDBERG VIDEO SWITCH

The schematic on the following page will show how the TVS is to be integrated with the TANDBERG Precision HD cameras.

Please note that the connections are different from the non-HD connection diagram (D5034602).

Page 31 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Page 32

SERVICING

Do not attempt to service the TANDBERG system yourself, otherwise the warranty will be voided. Opening or

removing covers may expose you to dangerous voltage or other hazards. Refer all servicing t o qualified service

personnel.

Damage Requiring Service

Unplug the apparatus from the outlet and refer servicing to qualified personnel under the following conditions:

When the power cord or plug is damaged or frayed.

If liquid has been spilled or an object has fallen into the apparatus.

If the apparatus has been exposed to rain or moisture.

If the apparatus has been subject to excessive shock by being dropped.

If the apparatus does not operate normally when following the operating instructions.

NOTE: TANDBERG will provide on request circuit diagrams and component parts list of the system.

For servicing, please call one of the following service centers:

USA

TANDBERG Inc.

1860 Michael Faraday Drive

Suite 100

Reston, Virginia, USA 20190

Tel: 703-709-4281

Toll free: 800 889 7440

Fax: 703-709-4231

Video: 703 437 6991

Canada

TANDBERG Canada Inc.

6505 TransCanada Highway

Montreal, Quebec

H4T 1S3

Tel: 514 748 5224

Fax: 514 748 1002

Video: 514 748 7790

Page 32 of 32 TANDBERG SCHOLAR ASSEMBLY, SETUP AND USER GUIDE | D50564.01

Loading...

Loading...