Sony XR-C5120RA Service manual

XR-C5120RA

SERVICE MANUAL

SPECIFICATIONS

Cassette player section

Tape track 4-track 2-channel stereo

Wow and flutter 0.08 % (WRMS)

Frequency response 30 – 18,000 Hz

Signal-to-noise ratio

Cassette type

TYPE II, IV 61 dB

TYPE I 58 dB

Tuner section

FM

Tuning range 87.5 – 108.0 MHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz

Usable sensitivity 9 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 65 dB (stereo),

Harmonic distortion at 1 kHz

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

MW/LW

Tuning range MW: 531 – 1,602 kHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity MW: 30 µV

68 dB (mono)

0.7 % (stereo),

0.4 % (mono)

LW: 153 – 281 kHz

LW: 50 µV

AEP Model

Model Name Using Similar Mechanism XR-C5100R

Tape Transport Mechanism Type MG-25G-136

Power amplifier section

Outputs Speaker outputs

Speaker impedance 4 – 8 ohms

Maximum power output 40 W × 4 (at 4 ohms)

General

Outputs Audio output

Tone controls Bass ±8 dB at 100 Hz

Power requirements 12 V DC car battery

Dimensions Approx. 188 × 58 × 181 mm

Mounting dimensions Approx. 182 × 53 × 164 mm

Mass Approx. 1.2 kg

Supplied accessories

Design and specifications are subject to change

without notice.

(sure seal connectors)

Power aerial relay control

lead

Power amplifier control

lead

Telephone ATT control

lead

Treble ±8 dB at 10 kHz

(negative earth)

(w/h/d)

(w/h/d)

Parts for installation and

connections (1 set)

Front panel case (1)

UK Model

MICROFILM

FM/MW/LW CASSETTE CAR STEREO

TABLE OF CONTENTS

1. GENERAL

Location of controls ........................................................ 3

Resetting the unit ............................................................ 3

Detaching the front panel................................................ 3

Setting the clock.............................................................. 3

2. DISASSEMBLY ......................................................... 4

3. ASSEMBLY OF MECHANISM DECK........... 5

4. MECHANICAL ADJUSTMENTS ....................... 8

5. ELECTRICAL ADJUSTMENTS......................... 8

6. DIAGRAMS

6-1. Block Diagram – TUNER Section – .............................. 12

6-2. Block Diagram – TAPE/MAIN Section – ...................... 13

6-3. Block Diagram – DISPLAY/

KEY CONTROL/BUS CONTROL/

POWER SUPPLY Section – ........................................... 14

6-4. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 15

6-5. Printed Wiring Board

– MAIN Board (Component Side) – .............................. 16

6-6. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 17

6-7. Schematic Diagram – MAIN Board (1/2) – ................... 18

6-8. Schematic Diagram – MAIN Board (2/2) – ................... 19

6-9. Printed Wiring Board – KEY Board –........................... 20

6-10. Schematic Diagram – KEY Board – ............................. 21

6-11. IC Pin Function Description ........................................... 24

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

7. EXPLODED VIEWS................................................ 28

8. ELECTRICAL PARTS LIST ............................... 31

2

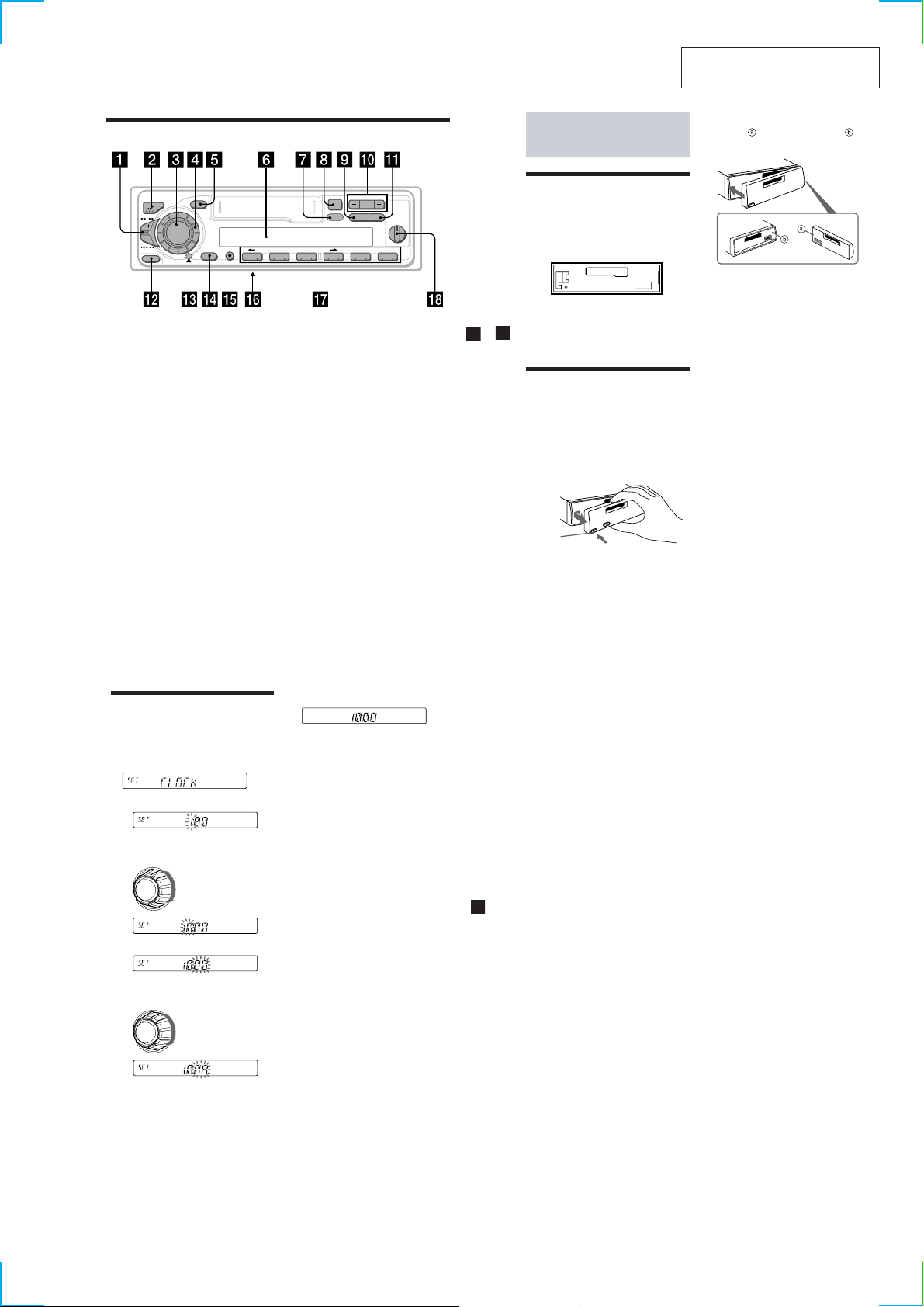

Location of controls

SECTION 1

GENERAL

Getting Started

This section is extracted from

instruction manual.

Attaching the front panel

Attach part of the front panel to part of

the unit as illustrated and push the left side

into position until it clicks.

SOURCE

SOUND

OFF

SHIFT SET UP

MODE

SEEK / AMS

RELEASE

Refer to the pages listed for details.

1 SEEK/AMS (seek/Automatic Music

Sensor/manual search) control

6, 8, 10, 13, 19

2 MODE (o)button

During tape playback:

Playback direction change 6

During radio reception:

BAND select 7, 8

During CD or MD playback:

CD/MD unit select 18

3 SOURCE (TAPE/TUNER/CD/MD) button

6, 7, 8, 11, 18

4 Dial (volume/bass/treble/left-right/rear-

front control) 5, 16

5 SOUND button 16

6 Display window

7 DSPL (display mode change) button

6, 8, 9, 18

8 Z (eject) button 6

9 PTY button

RDS Programme 13

+

PRESET

–

DISC

Z

PLAY MODE

0… PRESET/DISC button

During radio reception:

Preset stations select 8

During CD/MD playback:

Disc change 19

qa` AF/TA button

9, 10, 11, 12

qs“ RELEASE (front panel release) button

4, 21

qd Reset button (located on the front side

of the unit behind the front panel) 4

qf OFF button 4, 6

qg SHIFT button

PLAY MODE 7, 8, 10, 12, 19

SET UP 5, 13, 16, 18

qh POWER SELECT switch

(located on the bottom of the unit)

See “POWER SELECT switch” in the

Installation/Connections manual.

qj Number buttons 8, 10, 12

qk D-BASS control 17

D-BASS

AF/TAPTYDSPL

1

2

OFF

3

564321

Resetting the unit

Before operating the unit for the first time or

after replacing the car battery, you must reset

the unit.

Remove the front panel and press the reset

button with a pointed object, such as a

ballpoint pen.

Reset button

Note

Pressing the reset button will erase the clock

setting and some memorized functions.

Detaching the front panel

You can detach the front panel of this unit to

protect the unit from being stolen.

1

Press (OFF).

2

Press (RELEASE), then slide the front

panel a little to the left, and pull it off

towards you.

(RELEASE)

Notes

• Be sure not to drop the panel when detaching it

from the unit.

• If you detach the panel while the unit is still

turned on, the power will turn off automatically

to prevent the speakers from being damaged.

• When carrying the front panel with you, use the

supplied front panel case.

(OFF)

Notes

• Be sure not to attach the front panel upside

down.

• Do not press the front panel too hard against the

unit when attaching it.

• Do not press too hard or put excessive pressure

on the display window of the front panel.

• Do not expose the front panel to direct sunlight

or heat sources such as hot air ducts, and do not

leave it in a humid place. Never leave it on the

dashboard of a car parked in direct sunlight or

where there may be a considerable rise in

temperature.

Caution alarm

If you turn the ignition key switch to the OFF

position without removing the front panel, the

caution alarm will beep for a few seconds

(only when the POWER SELECT switch on the

bottom of the unit is set to the A position).

If you connect an optional power amplifier and

do not use the built-in amplifier, the beep

sound will be deactivated.

Setting the clock

The clock uses a 24-hour digital indication.

Example: To set the clock to 10:08

1

Press (SHIFT), then press (2) (SET UP)

repeatedly until “CLOCK” appears.

1 Press (4) (t).

The hour indication flashes.

2 Set the hour.

to go backward

to go forward

3 Press (4) (t).

The minute indication flashes.

4 Set the minute.

to go backward

to go forward

2

Press (SHIFT).

The clock starts.

3

Press (SHIFT).

After the clock setting is complete, the

display returns to normal playback mode.

Note

If the POWER SELECT switch on the bottom of the

unit is set to the B position, turn the power on

first, then set the clock.

3

4

5

3

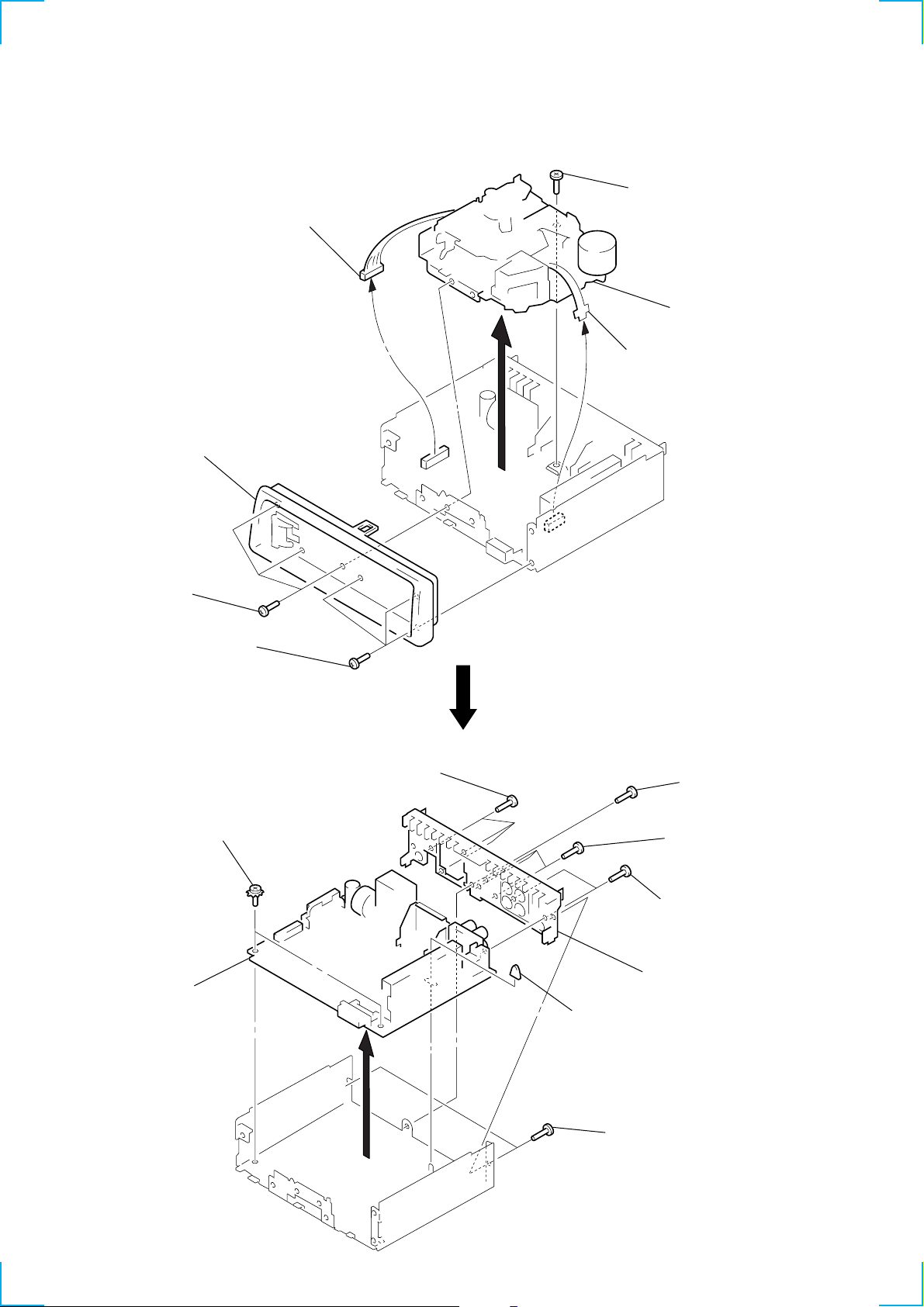

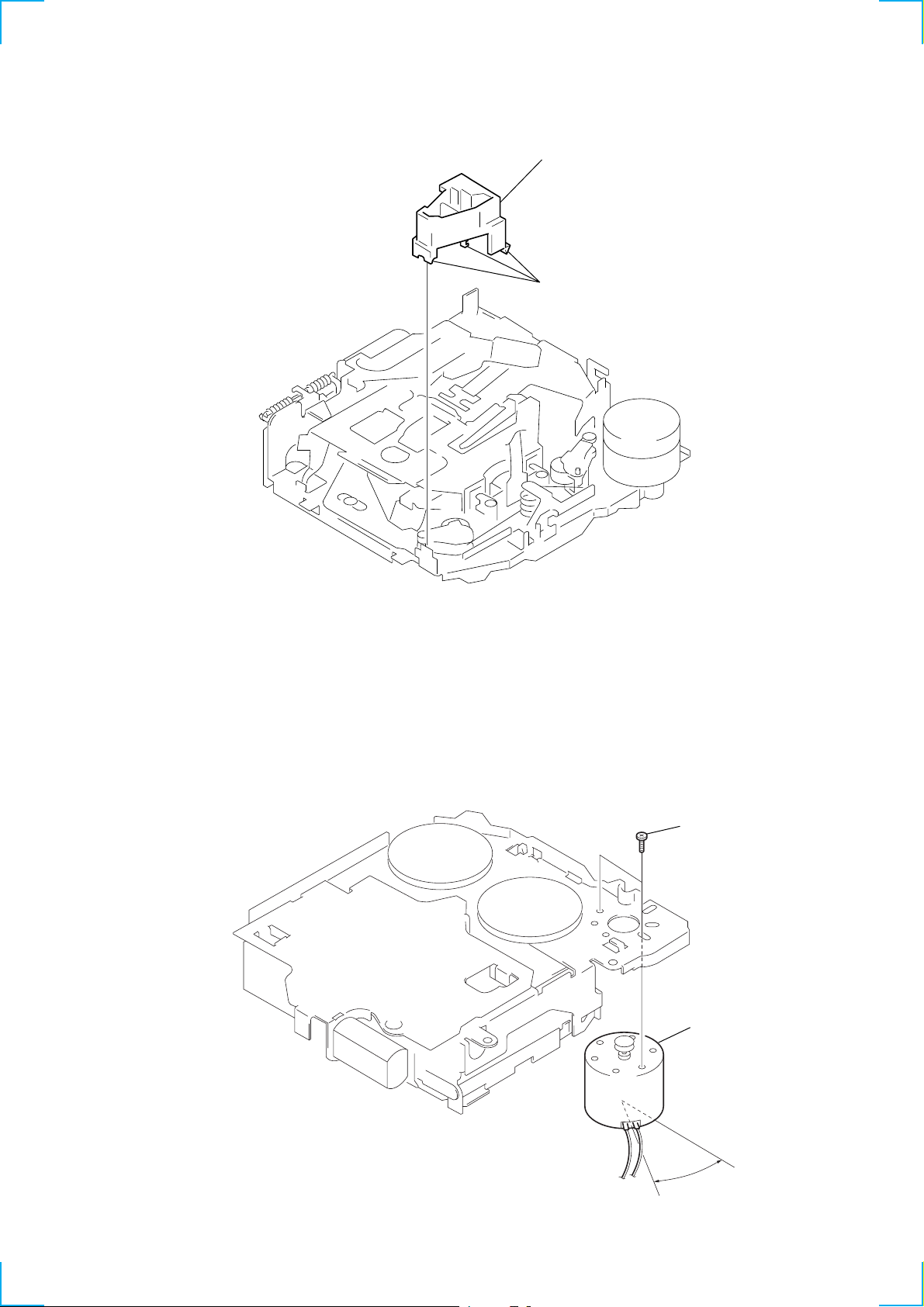

SECTION 2

k

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

SUB PANEL, MECHANISM DECK (MG-25G-136)

3

connector

(CN302)

2

sub panel

5

screw

(PTT2.6

6

4

flexible flat cable

(CN301)

×

6)

mechanism dec

(MG-25G-136)

1

three screws

(PTT2.6

×

8)

1

three screws

(PTT2.6

×

MAIN BOARD, HEAT SINK

3

two ground point

screws

4

main board

8)

5

three screws

(PTT2.6

×

8)

2

rubber cap (25)

5

7

heat sink

1

screw

(PTT2.6

6

three screws

(PTT2.6

two screws

(PTT2.6

×

8)

×

12)

×

8)

1

two screws

(PTT2.6

×

8)

4

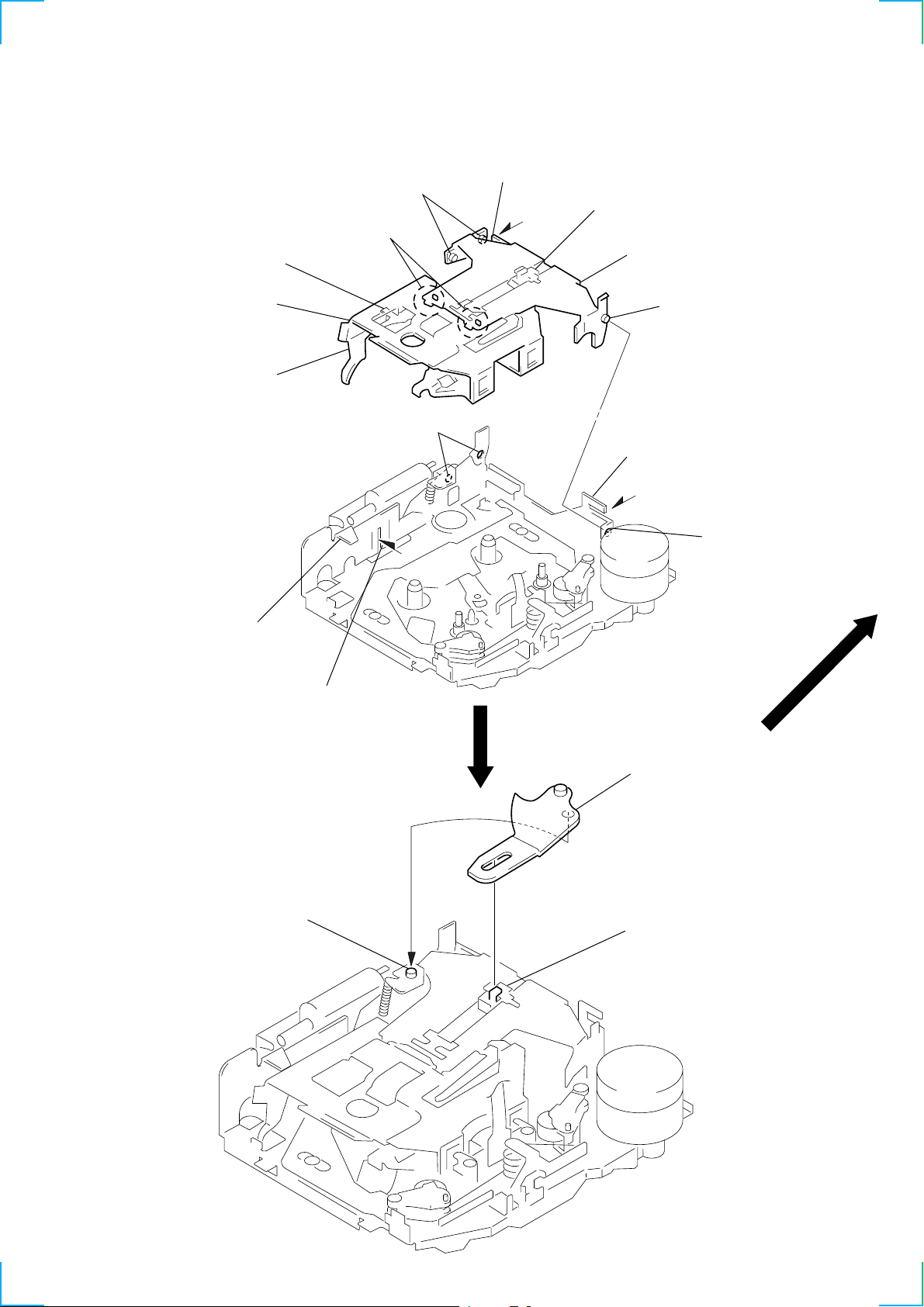

SECTION 3

2

Move the arm (suction) in the arrow

direction and fit on projection.

1

Fit the arm (suction) on the shaft.

projection

ASSEMBLY OF MECHANISM DECK

Note: Follow the assembly procedure in the numerical order given.

HOUSING

5

Fit projection on C part.

2

Install the hanger onto

two claws of the housing.

4

Fit claw on B part.

3

Put the housing

under

A

part.

housing

C

part

7

Holder the hanger by bending the claw.

1

Install the catch to the hanger.

hanger

6

Fit projection on D part.

8

Hold the hanger by

bending the claw.

ARM (SUCTION)

A

part

B

part

D

part

5

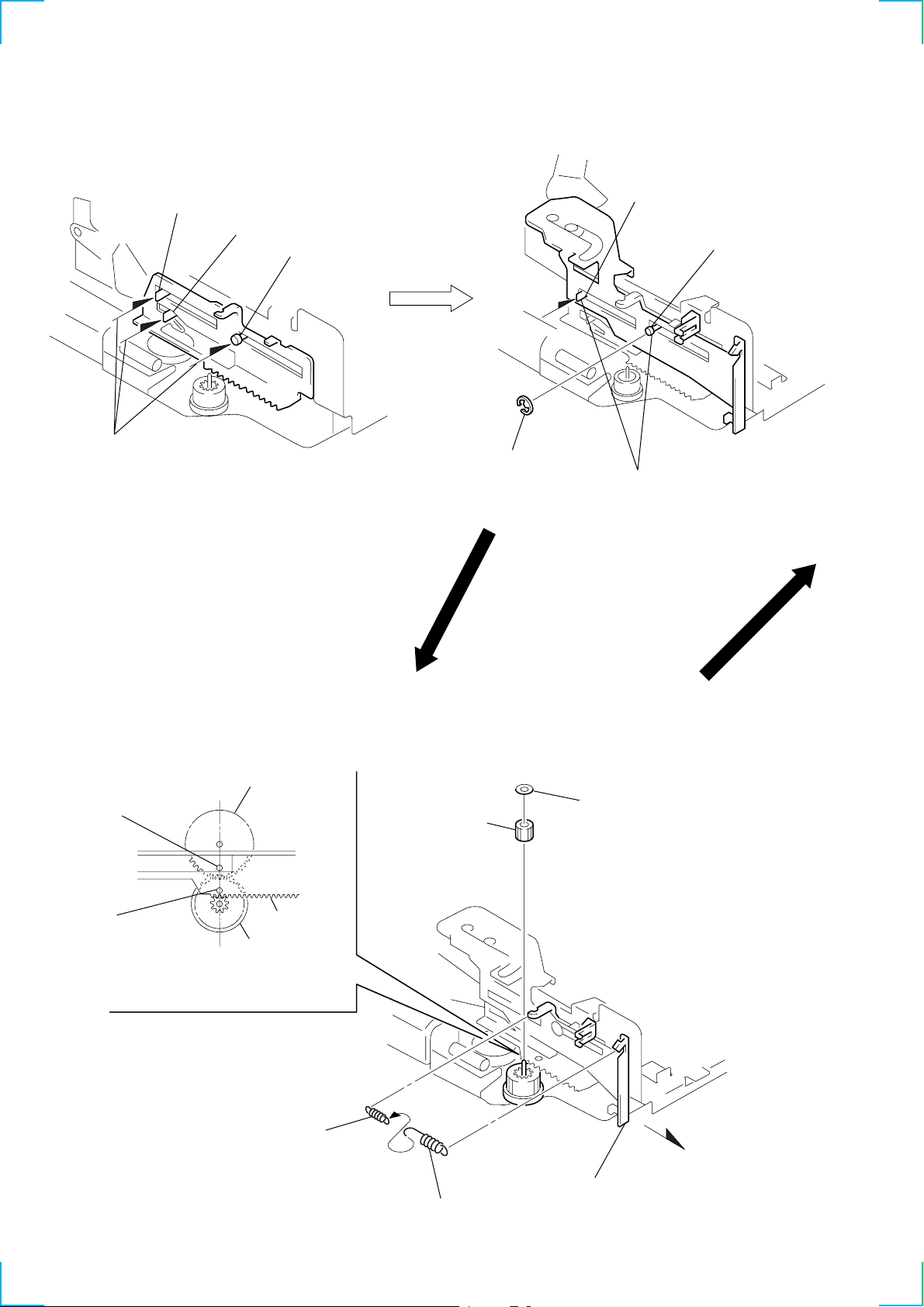

LEVER (LDG-A) / (LDG-B)

)

shaft

A

shaft

1

Fit the lever (LDG-A) on

shafts A – C and install it.

B

shaft

C

3

type-E stop ring 2.0

shaft

A

Fit the lever (LDG-B) on

2

shafts

install it.

A

and B and

shaft

B

GEAR (LDG-FT)

hole

hole

4

gear (LDG-D)

lever (LDG-A)

gear (LDG-FB)

Align hole in the gear (LDG-D)

with hole the lever (LDG-A).

2

tension spring (LD-2)

5

gear (LDG-FT)

1

6

polyethylene washer

3

Move the lever (LDG-B

2

tension spring (LD-1)

6

in the arrow direction.

GUIDE (C)

2

guide (C)

1

three claws

MOUNTING POSITION OF CAPSTAN/REEL MOTOR (M901)

two precision screws

×

2)

(P2

capstan/reel motor

(M901)

30˚

7

SECTION 4

r

MECHANICAL ADJUSTMENTS

SECTION 5

ELECTRICAL ADJUSTMENTS

1. Clean the following parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belt capstan

idler

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the power supply

voltage unless otherwise noted.

• Tor que Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C

Forward

Back Tension (0.01 – 0.06 oz•inch)

Reverse CQ-102RC

Reverse

Back Tension (0.01 – 0.06 oz•inch)

FF, REW CQ-201B

CQ-102C

CQ-102RC

30 – 65 g•cm

(0.42 – 0.90 oz•inch)

0.5 – 4.5g•cm

30 – 65 g•cm

(0.42 – 0.90 oz•inch)

0.5 – 4.5g•cm

60 – 200 g•cm

(0.83 – 2.78 oz•inch)

• Tape T ension Measurement

Mode Tension Meter Meter Reading

Forward CQ-403A

Reverse CQ-403R

more than 90 g

(more than 3.18 oz)

more than 90 g

(more than 3.18 oz)

TEST MODE

This set have the test mode function. In the test mode, FM Auto

Scan/Stop Level and AM (MW) Auto Scan/Stop Level adjustments

can be performed easier than it in ordinary procedure.

<Set the Test Mode>

1. Set the “power select” switch (S501) is “A (ON)” position.

2. Turn ON the regulated power supply. (All LEDs on the set

lights up, and the clock is displayed.)

Note: Press the [OFF] button, if the clock is not displayed.

3. Push the preset [4] button.

4. Push the preset [5] button.

5. Press the preset [1] button for more than two seconds.

6. Then the display indicates all lights, the test mode is set.

<Release the Test mode>

1. Push the [OFF] button.

2. Return the “power select” switch (S501) to initially set position.

See the adjustment location from on page 11 for the

adjustment.

TAPE DECK SECTION

0 dB=0.775 V

Tape Speed Adjustment

Setting:

speed checker

or

test tape

WS-48A

(3 kHz, 0 dB)

frequency counte

10 k

Ω

set

AUDIO OUT jack (CNJ151)

+–

Procedure:

1. Put the set into the FWD PB mode.

2. Adjust adjustment resistor for inside capstan motor so that the

reading on the speed checker or frequency counter becomes in

specification.

Specification: Constant speed

Speed checker Frequency counter

–1.5 to +2.5% 2,955 to 3,075 Hz

Adjustment Location: See page 11.

8

TUNER SECTION

0 dB=1 µV

Cautions during repair

When the tuner unit is defective, replace it by a new one because its internal block is difficult to repair.

Note:

Adjust the tuner section in the sequence shown below.

1. FM Auto Scan/Stop Level Adjustment

2. FM Stereo Separation Adjustment

3. FM RDS S Meter Adjustment

4. MW Auto Scan/Stop Level Adjustment

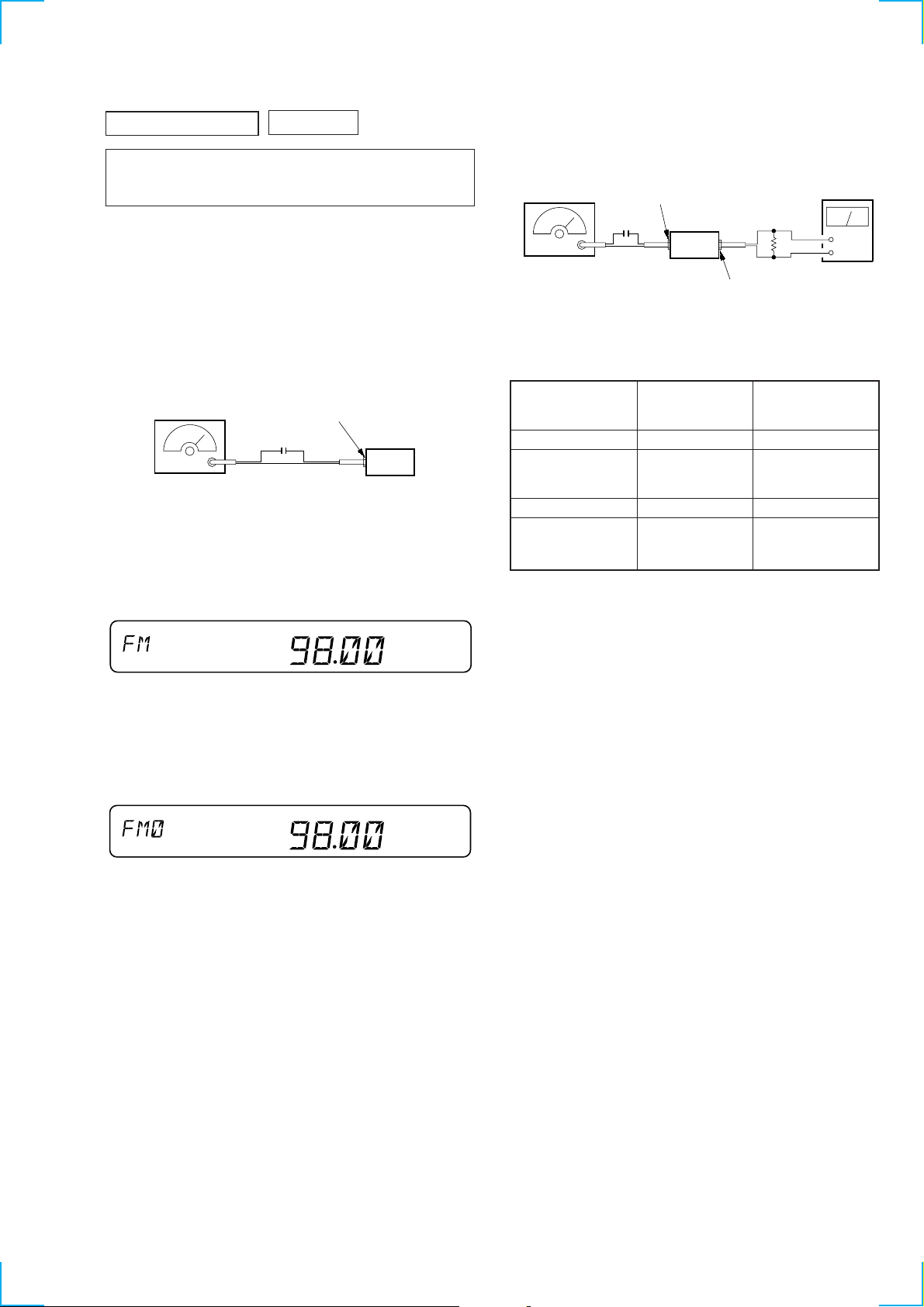

FM Auto Scan/Stop Level Adjustment

Setting:

[SOURCE] button: FM

FM RF signal

generator

Carrier frequency : 98.0 MHz

Output level : 22 dB (12.6

Mode : mono

Modulation : 1 kHz, 22.5 kHz deviation (30%)

Procedure:

1. Set to the test mode. (See page 8)

2. Push the [SOURCE] button and set to FM.

antenna jack (J1)

0.01 µF

Display

set

µ

V)

FM Stereo Separation Adjustment

Setting:

[SOURCE] button: FM

FM RF signal

generator

Carrier frequency : 98.0 MHz

Output level : 70 dB (3.2 mV)

Mode : stereo

Modulation : main: 1 kHz, 20 kHz deviation (26.7%)

antenna jack (J1)

0.01 µF

set

sub: 1 kHz, 20 kHz deviation (26.7%)

: 19 kHz pilot: 7.5 kHz deviation (10%)

10 k

AUDIO OUT jack (CNJ151)

Procedure:

FM Stereo

signal generator

output channel

L-CH L-CH A

R-CH L-CH Adjust RV4 on TU1

R-CH R-CH C

L-CH R-CH Adjust RV4 on TU1

Level meter Level meter

connection reading (dB)

for minimum reading.

for minimum reading.

L-CH Stereo separation: A-B

R-CH Stereo separation: C-D

The separations of both channels should be equal.

level meter

Ω

B

D

+

–

SHUF

3. Adjust with the v olume RV2 on TU1 so that the “FM” indication turns to “FM0” indication on the display window.

But, in case of already indicated “FM0”, turn the RV2 so that

put out light “0” indication and adjustment.

Display

SHUF

Adjustment Location: See page 11.

Specification: Separation more than 30 dB

Adjustment Location: See page 11.

9

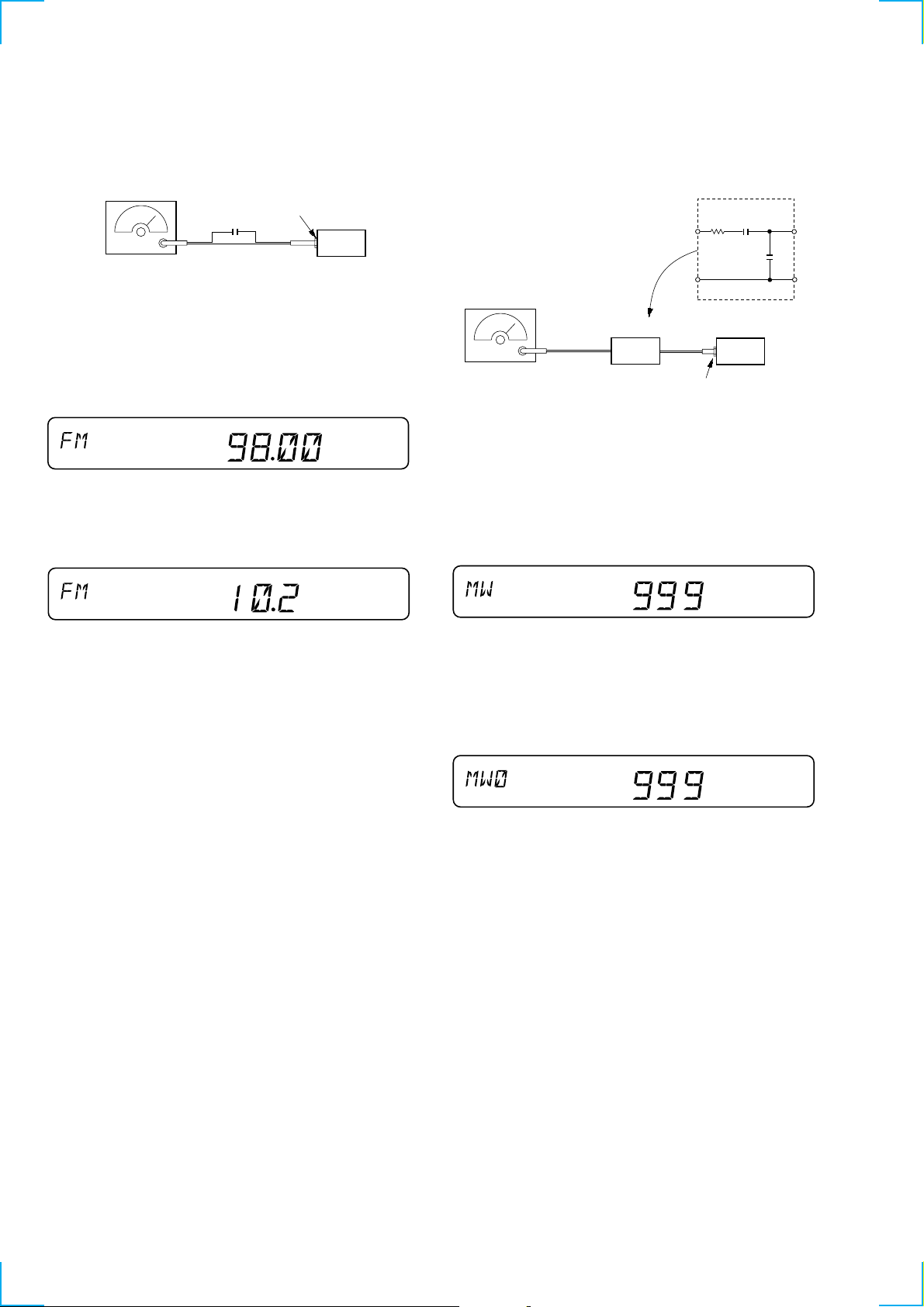

FM RDS S Meter Adjustment

(

)

Setting:

[SOURCE] button: FM

FM RF signal

generator

Carrier frequency : 98.00 MHz

Output level : 35 dB (56.2

Mode : mono

Modulation : no modulation

Procedure:

1. Set to the test mode. (See page 8)

2. Push the [SOURCE] button and set to FM.

3. Push the [6] button.

4. Adjust RV1 so that the display indication is “10.2”.

0.01 µF

Display

antenna jack (J1)

set

µ

V)

SHUF

MW Auto Scan/Stop Level Adjustment

Make this adjustment after “FM Auto Scan/Stop Level Adjustment”.

Setting:

[SOURCE] button: MW

30

Ω

15 pF

65 pF

AM RF signal

generator

AM dummy antenna

(50 Ω)

Carrier frequency : 999 kHz

30% amplitude

modulation by

1 kHz signal

Output level : 33 dB

44.7 µV

Procedure:

1. Set to the test mode. (See page 8)

2. Push the

[SOURCE] button and set to FM.

3. Push the [MODE] button and set to MW.

set

antenna jack (J1)

Display

Specification: Display indication: 10.0 to 10.4

Adjustment Location: See page 11.

SHUF

Display

TP SHUF

4. Adjust with the volume RV1 on TU1 so that the “MW” indication turns to “MW0” indication on the display window.

But, in case of already indicated “MW0”, turn the R V1 so that

put out light “0” indication and adjustment.

Display

TP SHUF

Adjustment Location: See page 11.

10

Adjustment Location:

t

– SET UPPER VIEW –

Tape Speed Adjustment

TU1

RV1 MW Auto Scan/Stop Level Adjustmen

RV2 FM Auto Scan/Stop Level Adjustment

RV4 FM Stereo Separation Adjustment

RV1 FM RDS S Meter Adjustment

1111

Loading...

Loading...