Sony STR-DH130 Service Manual

STR-DH130

SERVICE MANUAL

Ver. 1.0 2012.01

Specifi cations

AUDIO POWER

SPECIFICATIONS

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

(US model only)

With 8 ohm loads, both channels driven, from

20 – 20,000 Hz; rated 90 watts per channel

minimum RMS power, with no more than 0.09%

total harmonic distortion from 250 milliwatts to

rated output.

Amplifi er section

US, Canadian and AEP models

Minimum RMS Output Power (8 ohms, 20 Hz –

20 kHz, THD 0.09%)

90 W + 90 W

Stereo Mode Output Power (8 ohms, 1 kHz,

THD 1%)

100 W + 100 W

1)

Measured under the following conditions:

Area Power requirements

US, Canadian 120 V AC, 60 Hz

AEP 230 V AC, 50 Hz

Frequency response

Analog 10 Hz – 70 kHz

+0.5/–2 dB (with BASS =

0 dB, TREBLE = 0 dB)

Input

Analog (PORTABLE IN)

Sensitivity: 1 V/

50 kilohms

S/N

Inputs

Analog (Except PORTABLE IN)

Sensitivity: 500 mV/

50 kilohms

S/N

Outputs

Analog (AUDIO OUT)

Voltage: 500 mV/

10 kilohms

1)

2)

: 96 dB (A, 500 mV3))

2)

: 96 dB (A, 500 mV3))

Tone

Gain levels ±10 dB, 1 dB step

2)

INPUT SHORT (with BASS = 0 dB, TREBLE =

0 dB).

3)

Weighted network, input level.

FM tuner section

Tuning range 87.5 MHz – 108.0 MHz

Antenna (aerial) FM wire antenna (aerial)

Antenna (aerial) terminals

75 ohms, unbalanced

AM tuner section

Tuning range

Area Tuning scale

US, Canadian 530 kHz – 531 kHz –

AEP

Antenna (aerial) Loop antenna (aerial)

General

Power requirements

Area Power requirements

US, Canadian 120 V AC, 60 Hz

AEP 230 V AC, 50/60 Hz

Power consumption 200 W

Power consumption (during standby mode)

0.3 W

Dimensions (w/h/d) (Approx.)

430 mm × 132.5 mm ×

279 mm (17 in × 5 1/4 in ×

11 in) including projecting

parts and controls

Mass (Approx.) 6.4 kg (14 lb 2 oz)

10 kHz step 9 kHz step

1,710 kHz 1,710 kHz

– 531 kHz –

1,602 kHz

US Model

Canadian Model

AEP Model

Supplied accessories

s Operating Instructions

s Quick Setup Guide

s FM wire antenna (aerial) (1)

s AM loop antenna (aerial) (1)

s Remote control (RM-AAU130) (1)

s R6 (size AA) batteries (2)

Design and specifi cations are subject to

change without notice.

Halogenated fl ame retardants are not used in

the certain printed wiring boards.

9-890-596-01

2012A08-1

2012.01

©

FM STEREO / FM-AM RECEIVER

Sony Corporation

Published by Sony EMCS (Malaysia) PG Tec

STR-DH130

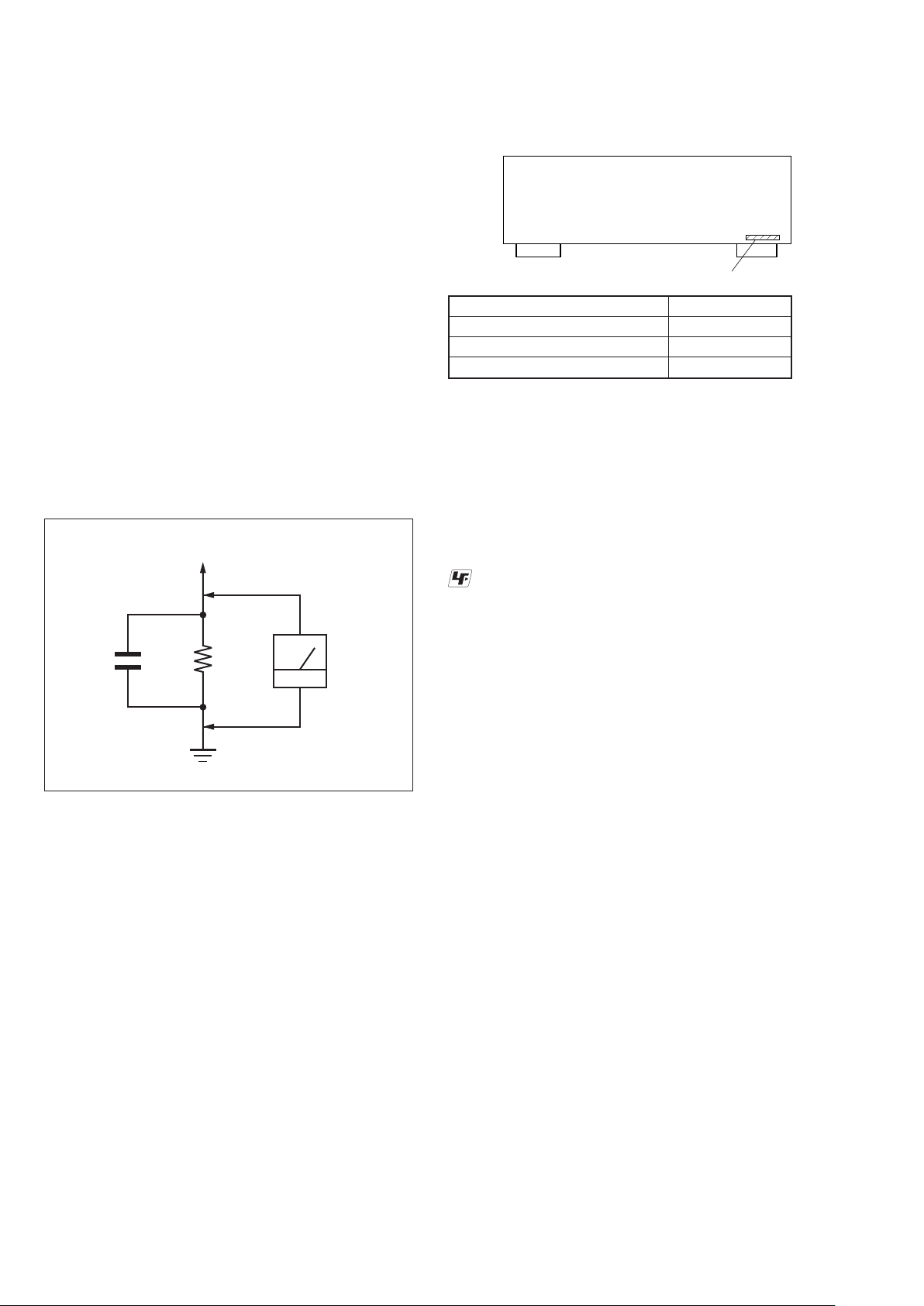

SAFETY CHECK-OUT (US MODEL)

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

MODEL IDENTIFICATION

–BACK PANEL–

Part No.

Model Part No.

US

AEP

Canadian 4-408-213-2

4-408-213-0[]

4-408-213-1[]

[]

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

AC

1.5 kΩ0.15 μF

Earth Ground

voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY-RELATED COMPONET WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS QUE

PAR DES PIÈCES SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

TABLE OF CONTENTS

1. DISASSEMBLY

1-1. Case ..................................................................................... 4

1-2. Back Panel Section ............................................................. 5

1-3. Front Panel Section ............................................................. 5

1-4. MAIN Board Section .......................................................... 6

2. TEST MODE ...................................................................... 7

3. FM TUNER CHECK ........................................................ 9

4. DIAGRAMS

4-1. Block Diagram – Main Section – ......................................11

4-2. Block Diagram – Display and Power Section – ............... 12

4-3. Printed Wiring Board – Main Board – .............................. 14

4-4. Schematic Diagram – Main Board 1/3 – .......................... 15

4-5. Schematic Diagram – Main Board 2/3 – .......................... 16

4-6. Schematic Diagram – Main Board 3/3 – .......................... 17

4-7. Printed Wiring Board – Display and

Power Key Board – ........................................................... 18

4-8. Schematic Diagram – Display and

Power Key Board – ........................................................... 19

4-9. Printed Wiring Board – Headphone, Thermal and

Tuner1 Board – ................................................................. 20

4-10. Schematic Diagram – Headphone, Thermal and

Tuner1 Board – ................................................................. 20

STR-DH130

5. EXPLODED VIEWS

5-1. Case Section ...................................................................... 26

5-2. Front Panel Section ............................................................ 27

5-3. Back Panel Section ............................................................ 28

5-4. Chassis Section .................................................................. 29

6. ELECTRICAL PARTS LIST ....................................... 30

3

STR-DH130

SECTION 1

DISASSEMBLY

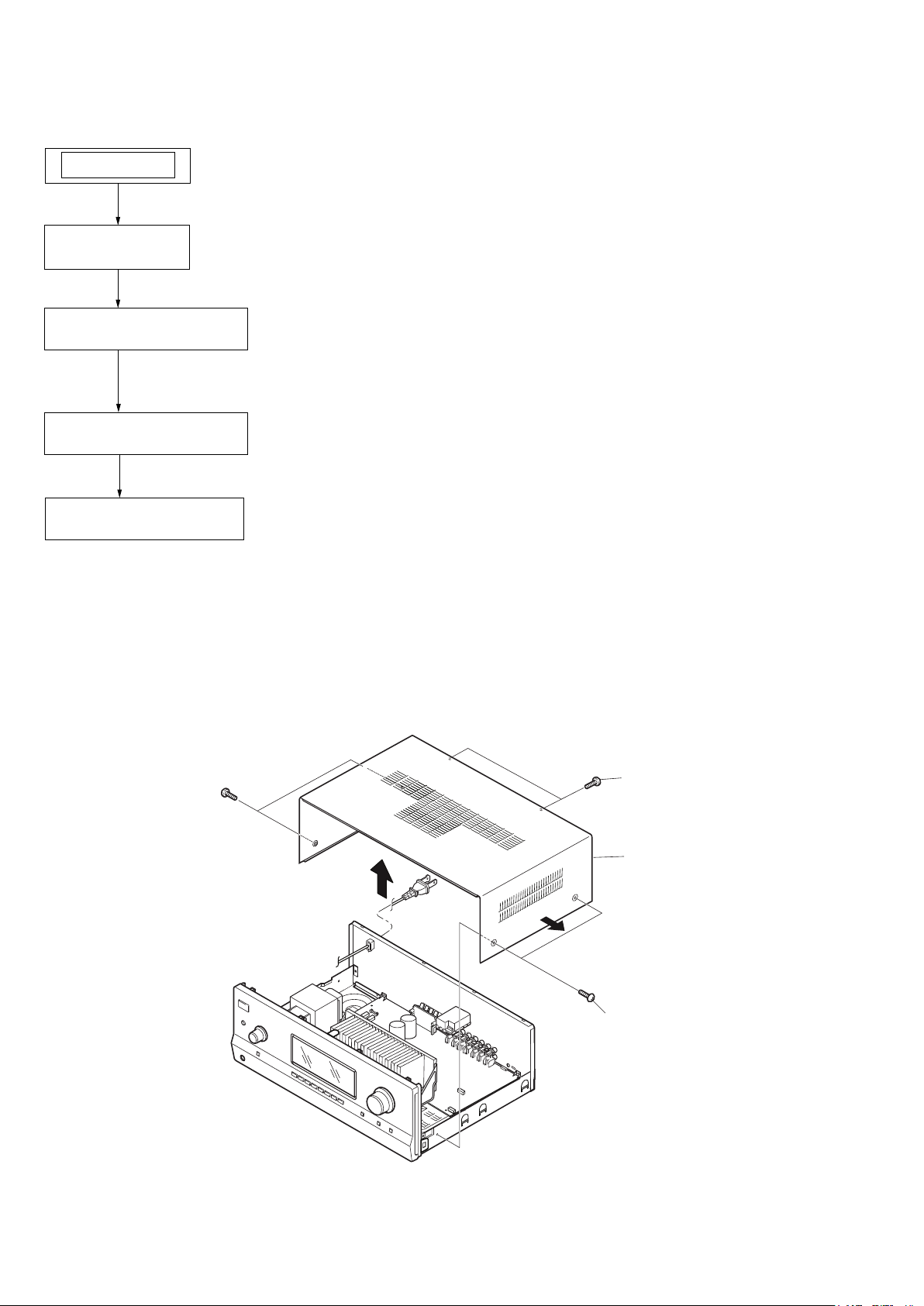

Note: This set can be disassemble according to the following sequence.

SET

1-1. CASE

(Page 4)

1-2. BACK PANEL SECTION

(Page 5)

1-3. FRONT PANEL SECTION

(Page 5)

1-4. MAIN BOARD SECTION

(Page 6)

Note: Follow the disassembly procedure in the numerical order given.

1-1. CASE

1 two

screws

(+BVST 4x8)

3 two

screws

(+BVTP 3x8)

4 case

2 two

screws

(+BVST 4x8)

4

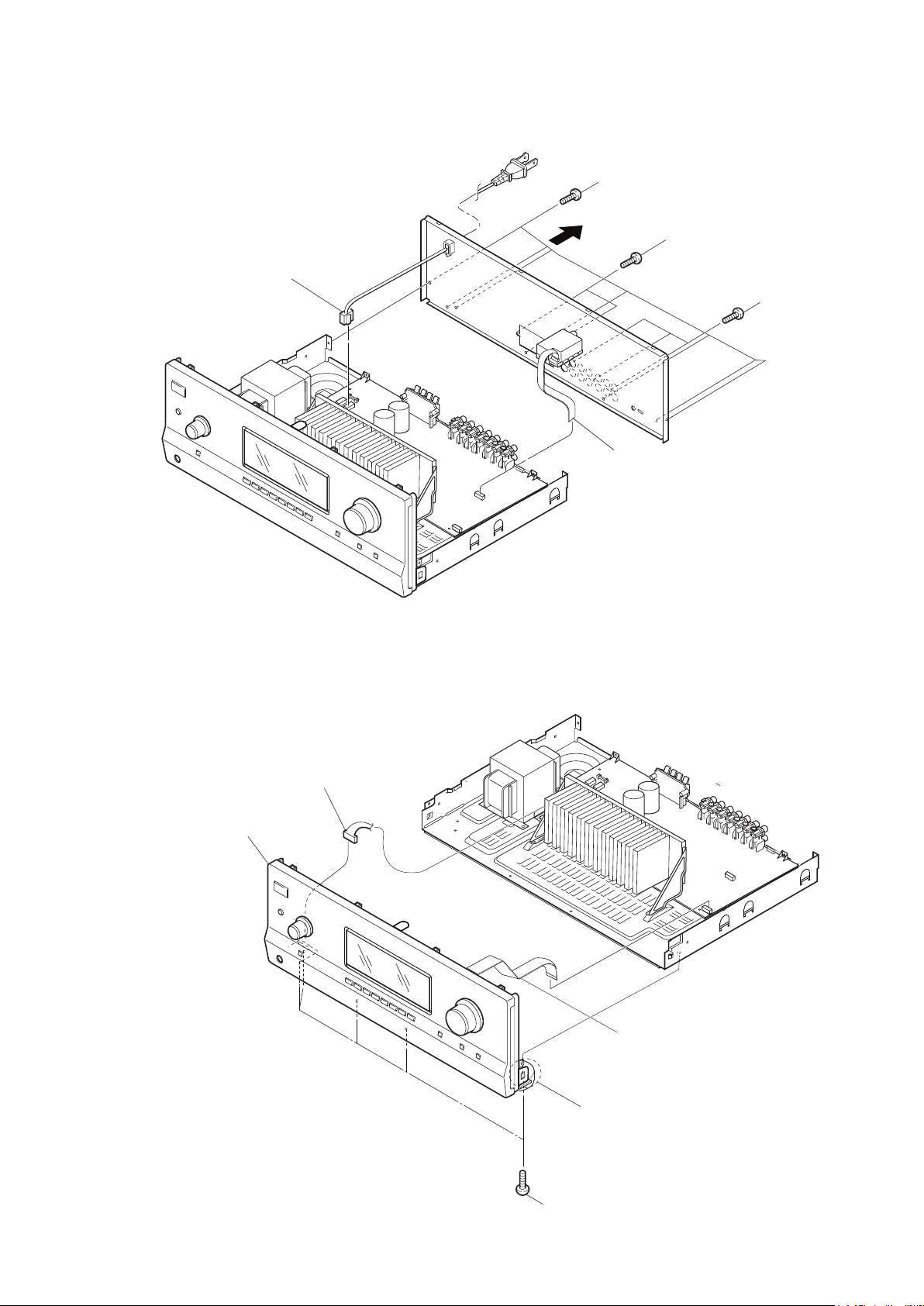

1-2. BACK PANEL SECTION

STR-DH130

1 CNP901 (3P)

5 seven

(+BVTP 3x8)

screws

4 two

screws

(+BVTP 3x8)

2 wire (flat type) (9 core)

(CNS402)

3 three

(+BVTP 3x8)

screws

1-3. FRONT PANEL SECTION

1 CNP790 (4P)

5 front panel section

2 wire (flat type) (15 core)

(CNS600)

4 claw

3 five

screws

(+BVTP 3x8)

5

STR-DH130

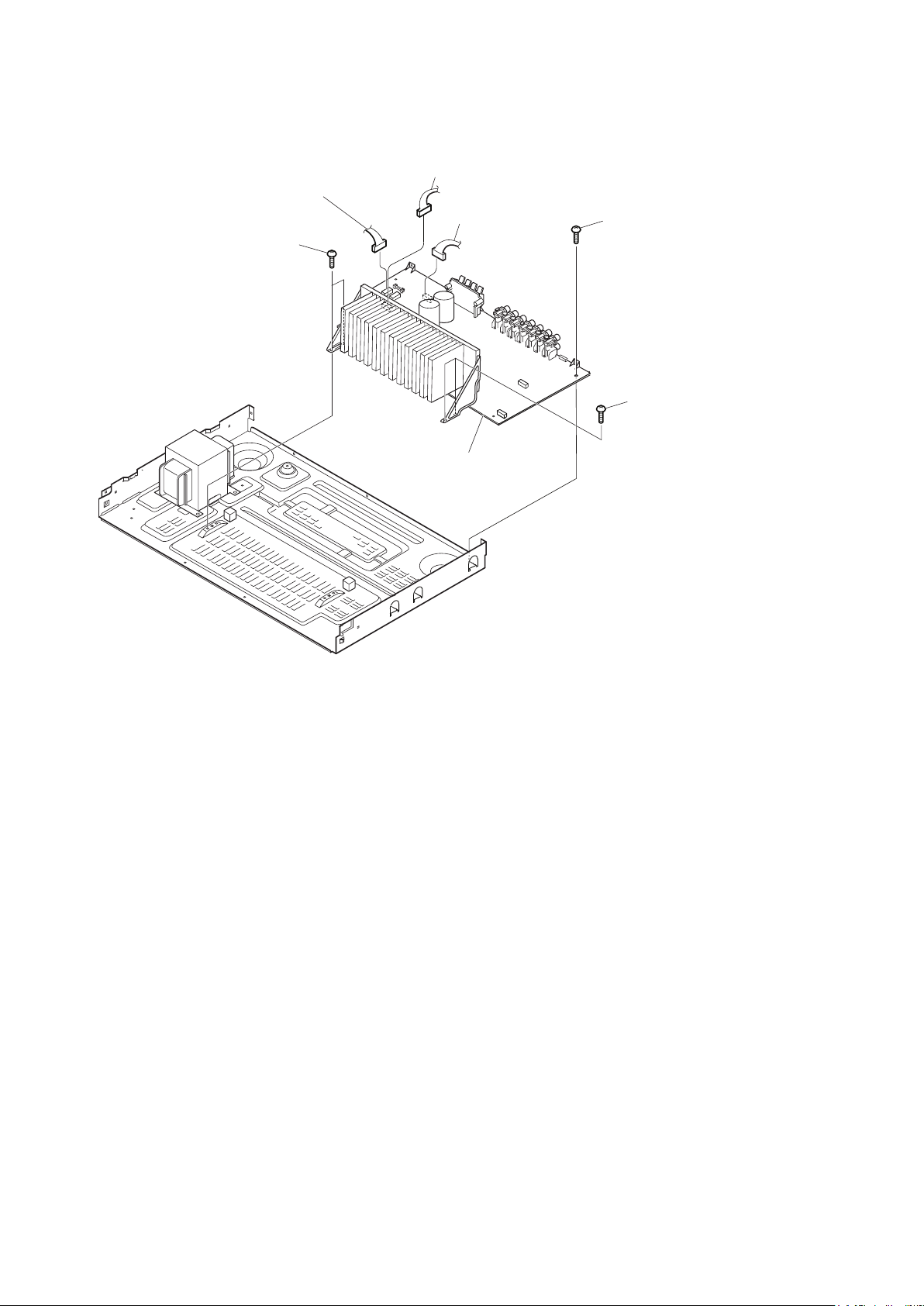

1-4. MAIN BOARD SECTION

2 CNP911 (5P)

1 CNP902 (2P)

5 two

screws

(+BVTP 3x8)

3 CNP930 (5P)

7 MAIN board section

4 one

screws

(+BVTP 3x8)

6 two

screws

(+BVTP 3x8)

6

SECTION 2

TEST MODE

STR-DH130

[AM CHANNEL STEP 9 kHz/10 kHz SELECTION MODE]

(US, Canadian model only)

* Either the 9 kHz step or 10 kHz step can be selected for the AM

channel step.

* Procedure:

1. While pressing the [TUNING MODE] button, press the

[

] button to turn on the main power.

?/1

2. The message “9K STEP” or “10K STEP” appears for a

moment

and the channel step is changed.

[SOFTWARE VERSION DISPLAY MODE]

* The software version is displayed.

* Procedure:

1. While pressing the [SPEAKERS (OFF/A/B/A+B)] and the

[MUTING] buttons simultaneously, press the [

] button to

?/1

turn on the main power.

2. The destination and the software version are displayed.

Destination D1 D2 D3 VERSION

UNKNOWN U N K

U2 U 2 1. 0 5 A

CA2 C A 2 2. 0 5 A

CEL C E L 3. 0 5 A

[KEY CHECK MODE]

* Button check

* Procedure:

1. While pressing the [SPEAKERS (OFF/A/B/A+B)] and the

[DIMMER] buttons simultaneously, press the [

] button to

?/1

turn on the main power.

2. The message “REST 13” appears.

3. Every press of any button other than the [

] counts down

?/1

the buttons. The buttons which are already counted once are

not counted again. When all buttons are pressed “REST 00”

appears.

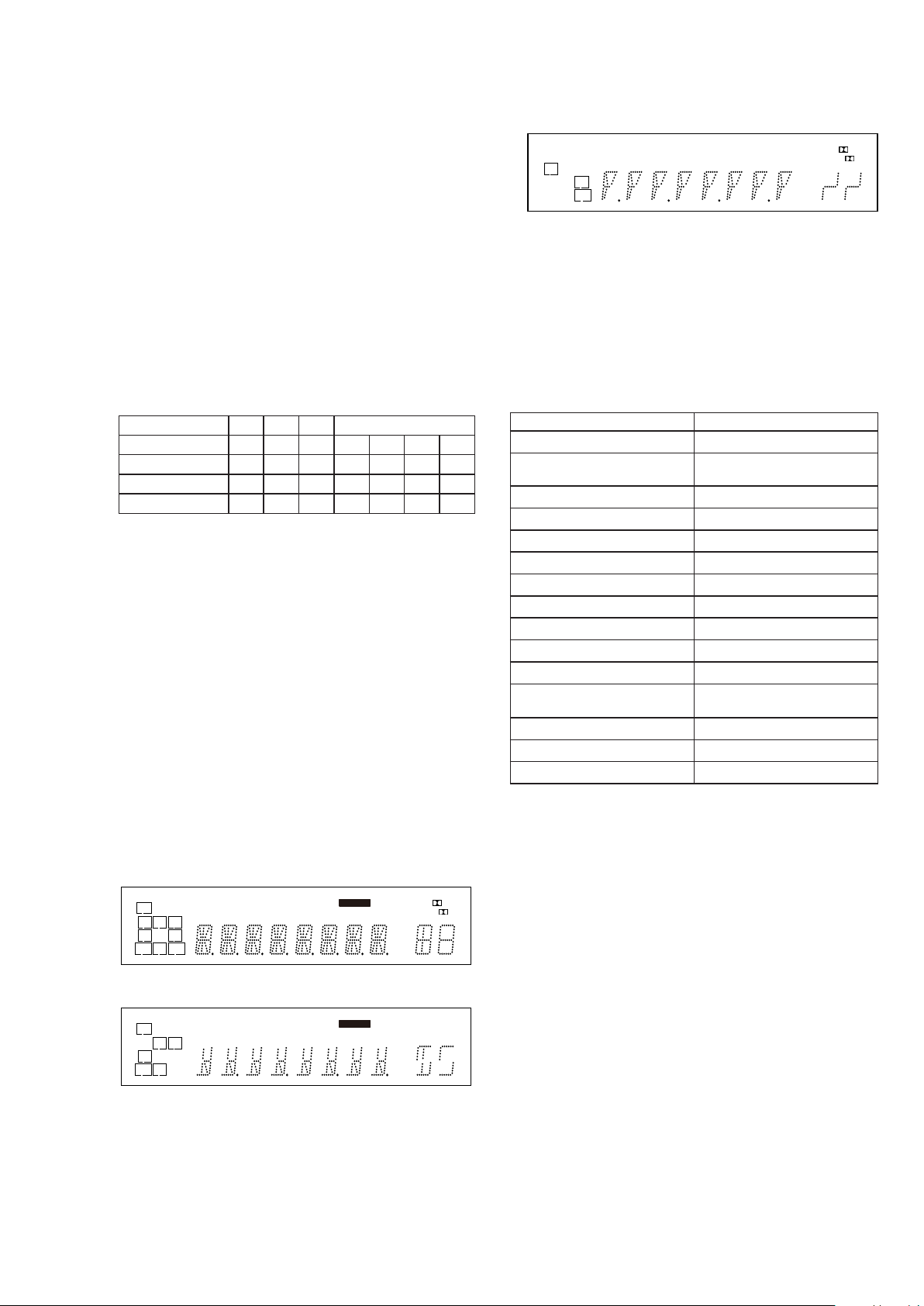

[VACUUM FLUORESCENT DISPLAY TEST MODE]

* All fl uorescent segments are tested. When this test is activated,

all segments light on at the same time, then each segment lights

on one after another.

* Procedure:

While pressing the [SPEAKER (OFF/A/B/A+B)] and the

[DISPLAY] buttons simultaneously, press the [

] button to

?/1

turn on the main power.

1. ALL segments light on.

SW

LFE

LR

C

SL SR

S

SBL SB SBR

SP

SP B

HDMI

A

OPT

S-AIR

96/24

DTS

-ES

CAT

NEO:6COAX

SAT

MEMORY

D.RANGE

RDS

MONO

ZONE 2

SLEEP

dB

k

m

MHz

II

xPL

EXST

D

Hz

ft.

2. Turn the [INPUT SELECTOR] control, confi rm display.

LFE

LR

S

SP B

S-AIR

-ES

MEMORY

NEO:6COAX

SAT

ZONE 2

k

MHz

xPL

EXST

ft.

3. Turn the [INPUT SELECTOR] control, confi rm display.

SW

C

SL SR

SBL SB SBR

SP

HDMI

A

OPT

96/24

DTS

CAT

D.RANGE

RDS

MONO

SLEEP

dB

m

II

D

Hz

4. Turn the [INPUT SELECTOR] control, all segments light off.

[HISTORY MODE]

* The state that the set is used is memorized.

* Procedure:

1. While pressing the [TREBLE +] and [SPEAKERS (OFF/A/

B/A+B)] buttons, press the [

] button to turn on the power

?/1

and “HISTORY” is displayed.

2. Each time the []/[] buttons on the remote commander is

pressed, the item is switched in order as follows.

Item Display

History HISTORY

Count how many time of

protector happen

COUNT xx

Total single power on time xxxxxHxx01

Input function FUNCTION

HP ON/OFF HP xxx

Volume VOL xxx

Bass BASS xxx

Treble TREB xxx

Balance F xxx

Total power on time xxxxxHxx02

Muting MUTE xxx

Power on counter

(Rebox Test Mode)

REBXxxxx

Protector Type PROTxxxx

VACS step VACS xx

Return to history HISTORY

[PROTECTOR AUTO OFF]

* To disable auto off after protector occur

* Procedure:

1. While pressing the [TREBLE -] and [SPEAKERS (OFF/A/B/

A+B)] buttons, press the [

] button to turn on the main

?/1

power.

2. “PROT OFF” appears and switch off the set.

[SHIPMENT MODE]

* All preset contents are reset to the default setting.

* Procedure:

1. While pressing the [TUNING MODE] and the [MUTING]

buttons simultaneously, press the [

] button to turn on the

?/1

main power.

2. “CLEARING” and “CLEARED” appear and switch off the

set.

7

STR-DH130

[DESTINATION WRITE MODE]

* Write the set destination when the destination is “UNKNOWN”.

This mode can be performed once only.

* Procedure:

1. Press the [

2. Press the [FM MODE] and [DISPLAY] buttons

simultaneously.

3. “DEST XXX” appears and turns [INPUT SELECTOR] to

select the required destination.

4. Press [MEMORY/ENTER] button to save the destination.

5. “CLEARING” and “CLEARED” appear and the set will

switch on.

6. Perform [SOFTWARE VERSION DISPLAY MODE] to

confi rm the written destination.

] button to turn on the main power.

?/1

Selection Destination

DEST U2 U.S.A

DEST CEL Europe

DEST CA2 CANADA

8

SECTION 3

FM TUNER CHECK

STR-DH130

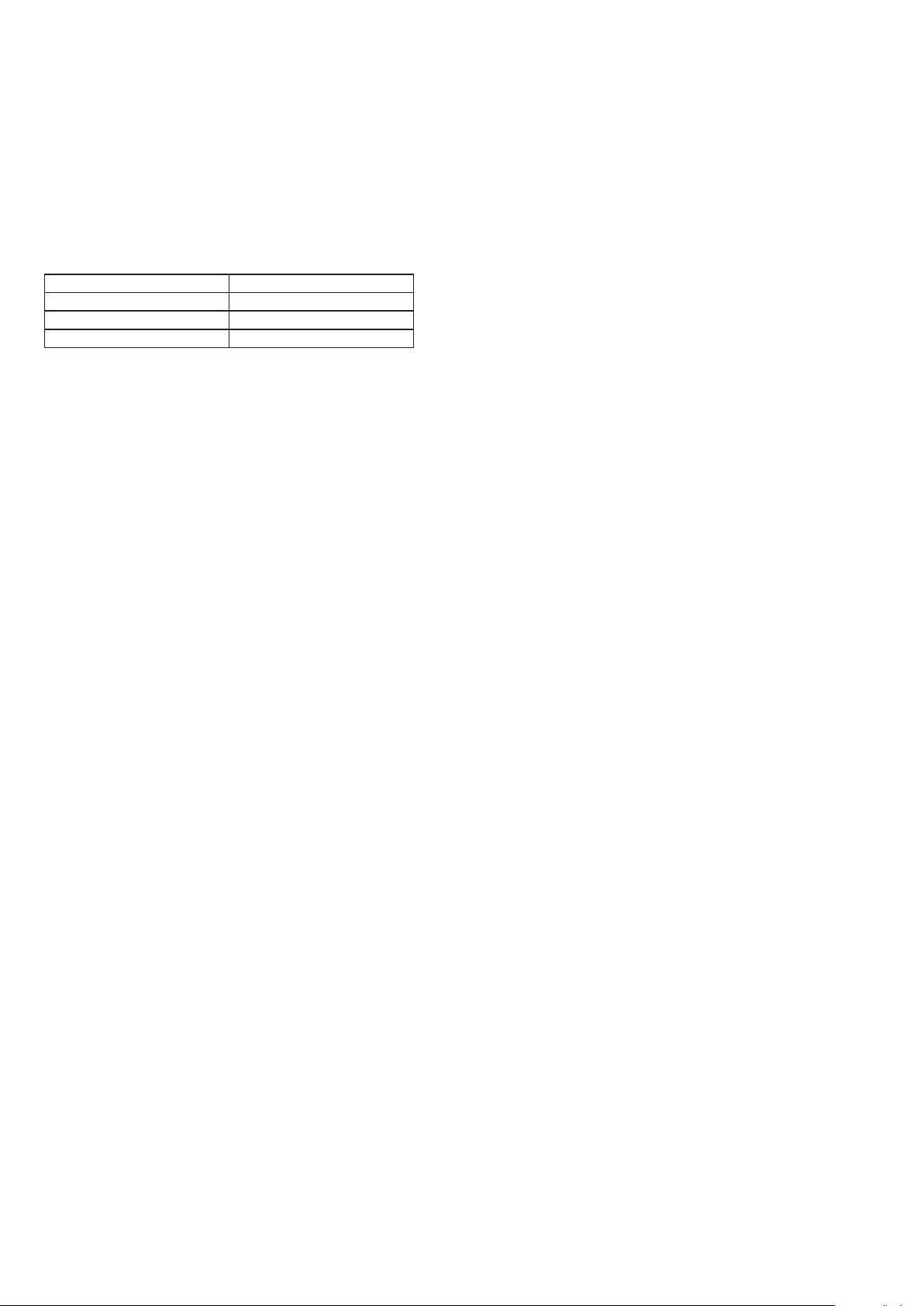

FM AUTO STOP CHECK

set

Procedure:

1. Turn on the set.

2. Input the following signal from Signal Generator to FM

antenna input directly.

* Carrier Frequency: A=87.5 MHz, B=98 MHz, C=108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note:

Please use 75 ohm “coaxial cable” to connect SG and the set. You

cannot use video cable for checking.

Please use SG whose output impedance is 75 ohm.

3. Set to FM tuner function and scan the input FM signal with

automatic scanning.

4. Confi rm that input Frequency of A, B and C are detected and

automatic scanning stops.

generator

OUT (75 Ω)

The stop of automatic scanning means “The station signal is received in good condition.”

9

STR-DH130

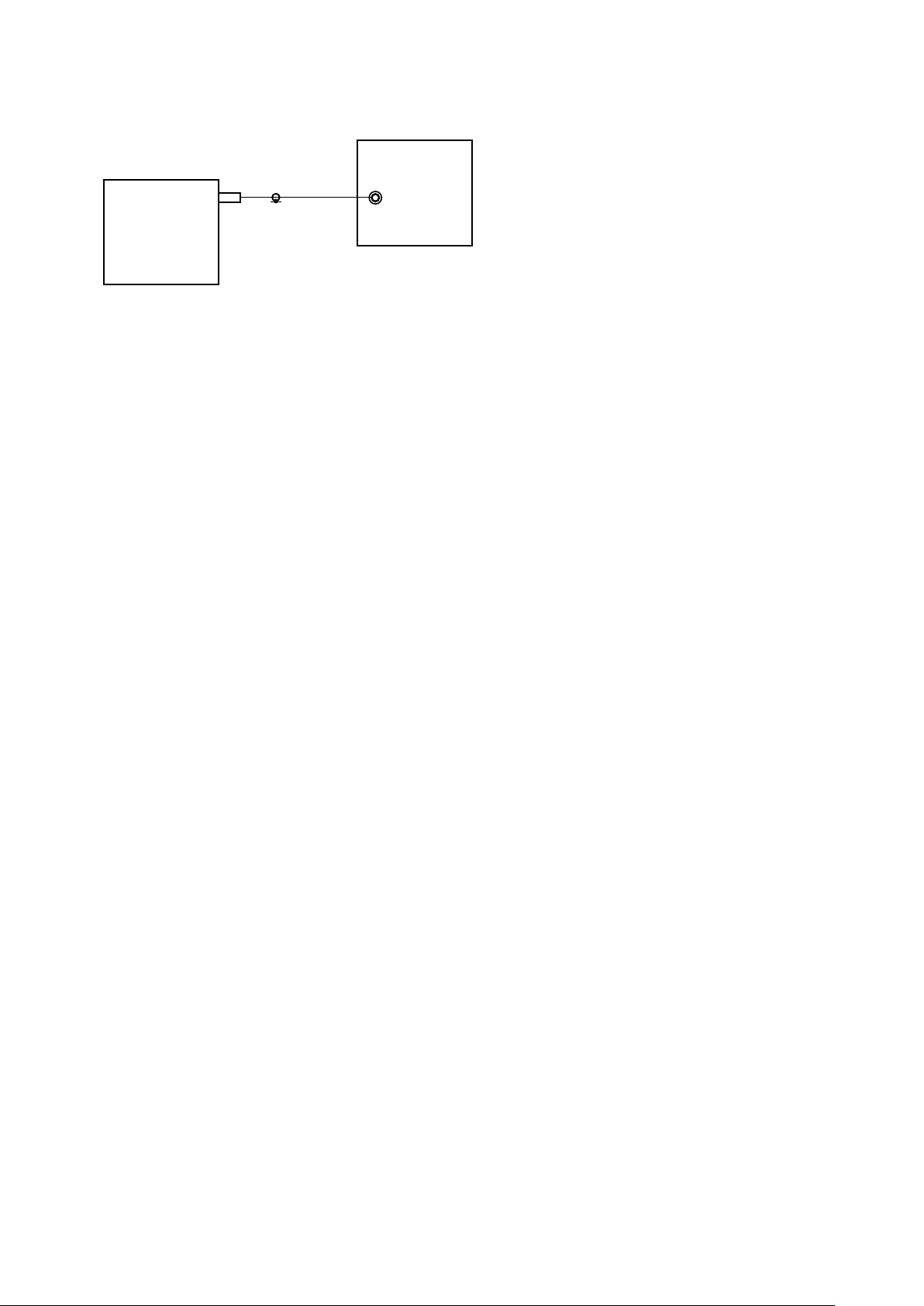

• Circuit Boards Location

SECTION 4

DIAGRAMS

THERMAL board

(for US and Canadian model only)

POWER KEY board

HEADPHONE board

DISPLAY board

TUNER1 board

MAIN board

10

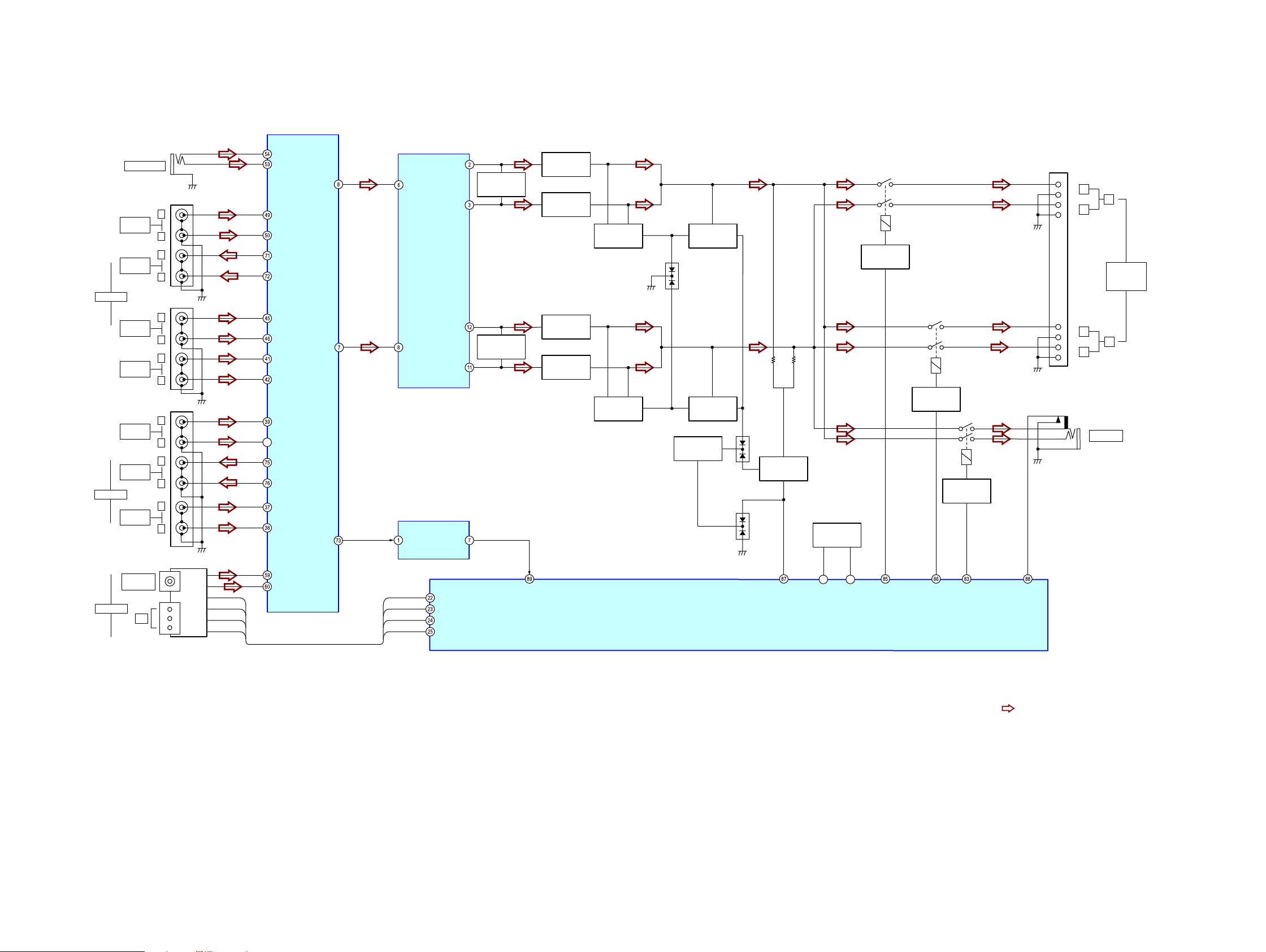

4-1. BLOCK DIAGRAM — MAIN SECTION —

J404

PORTABLE IN

J401

AUDIO

OUT

AUDIO

IN

SAT

AUDIO

OUT

AUDIO

IN

L

R

L

R

J402

L

R

L

R

J403

L

R

L

R

L

R

MD/TAPE

VIDEO

SA-CD/CD

AUDIO IN

AUDIO IN

BD-DVD

AUDIO IN

INR9

INL9

INL7

INR7

RECL1

RECR1

INL5

INR5

INL3

INR3

INL2

INR2

40

RECL3

RECR3

INL1

INR1

INPUT SELECTOR

IC400

OUTPUT L

OUTPUT R

REC L2

POWER AMP

IC700

IN1

IN2

SOUND DETECTOR

IC603

IN

+V OUT1

-V OUT1

+V OUT2

-V OUT2

OUT

LIMITER

Q701, Q702

LIMITER

Q751, Q752

BOOSTER

Q703

BOOSTER

Q704

BOOSTER

Q753

BOOSTER

Q754

OVERLAND

DETECTOR

Q711

OVERLAND

DETECTOR

Q761

D705

PROTECTOR

OVERLAND

DETECTOR

OVERLAND

DETECTOR

Q325

Q712

Q762

D326

D325

PROTECTOR

Q323, Q324

US, CND only

THERMAL

CIRCUIT

RELAY

DRIVE

Q350

RY350

RELAY

DRIVE

Q355

RY355

RELA

DRIVE

Q360

Y

RY360

J790

TB401

STR-DH130

+

L

-

+

-

+

-

+

-

R

L

R

A

B

PHONES

SPEAKER

INPEDANCE

USE 8-16:

ANTENNA

FM 75:

COAXIAL

AM

TUNER

AUDIO L

AUDIO R

RDS

INL 12

CK

DA

CE

CK

RDS

DA

CE

INR 12

CK

RDS

DA

CE

TUNER_SCL

TUNER_RDS

TUNER_SDA

TUNER_CE

SOUND DETECT

SYSTEM CONTROLLER

IC702 (1/2)

PROTECT

91

TEMP_SENSOR2

90

TEMP_SENSOR1

Y

SP_A_R

HP_RY

SP_B_RY

HP_DETECT

SLJnDl SDWK

: AUDIO

AEEUHYLDWLon

CND CDnDGLDn PoGHl

STR-DH130

11 11

Loading...

Loading...