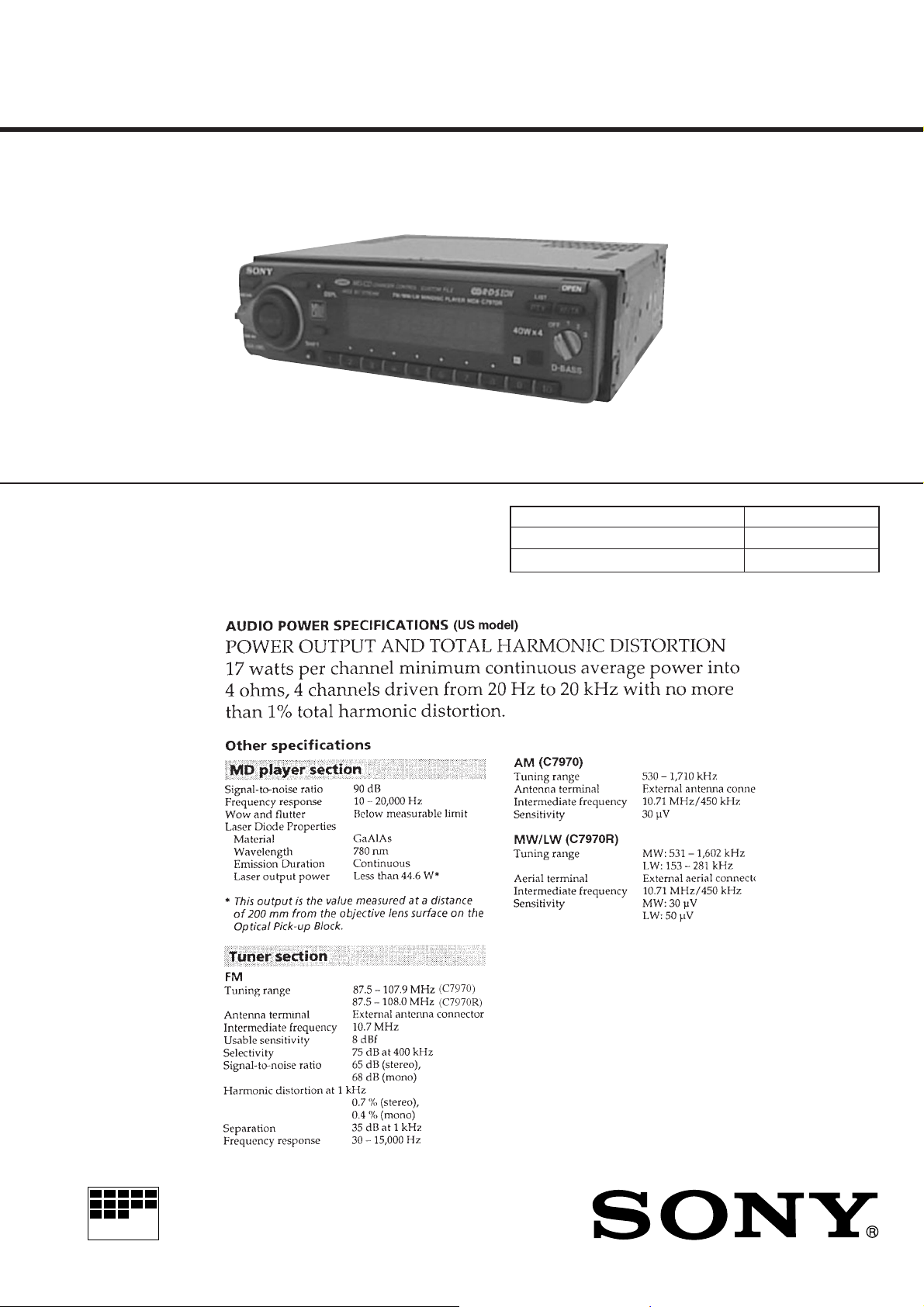

Sony MDXC-7970, MDXC-7970-R Service manual

MDX-C7970/C7970R

SERVICE MANUAL

For RM-X4S (Remote Commander),

please refer to RM-X4S Service Manual

(9-925-698-∏) previously issued.

Photo: MDX-C7970R

SPECIFICATIONS

US Model

Canadian Model

E Model

MDX-C7970

AEP Model

UK Model

MDX-C7970R

Model Name Using Similar Mechanism MDX-C7900/C7900R

Base Mechanism Type MG-164N-138

Optical Pick-Up Name KMS-241B/J1NP

MICROFILM

– Continued on next page –

FM/AM(MW/LW) MINIDISC PLAYER

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right avove when

checking it for adustment. It is feared that you will lose your sight.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

(KMS-241B/J1NP)

The laser diode in the optical pick-up block may suffer electrostatic break-down easily. When handling it, perform soldering

bridge to the laser-tap on the flexible board. Also perform m easures

against electrostatic break-down suff iciently before the operation.

The flexible board is easily damaged and should be handled with

care.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMA TIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

laser-tap

OPTICAL PICK-UP FLEXIBLE BOARD

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

– 2 –

TABLE OF CONTENTS

1. GENERAL

Location of Controls ....................................................... 4

Resetting the Unit ........................................................... 5

Detaching the Front Panel............................................... 5

Preparing the Rotary Commander .................................. 5

Setting the Clock............................................................. 5

Using the Rotary Commander ........................................ 5

Adjusting the Sound Characterisitics ............................. 5

Attenuating the Sound .................................................... 5

Changing the Sound and Display Settings ..................... 6

Boosting the Bass Sound ................................................ 6

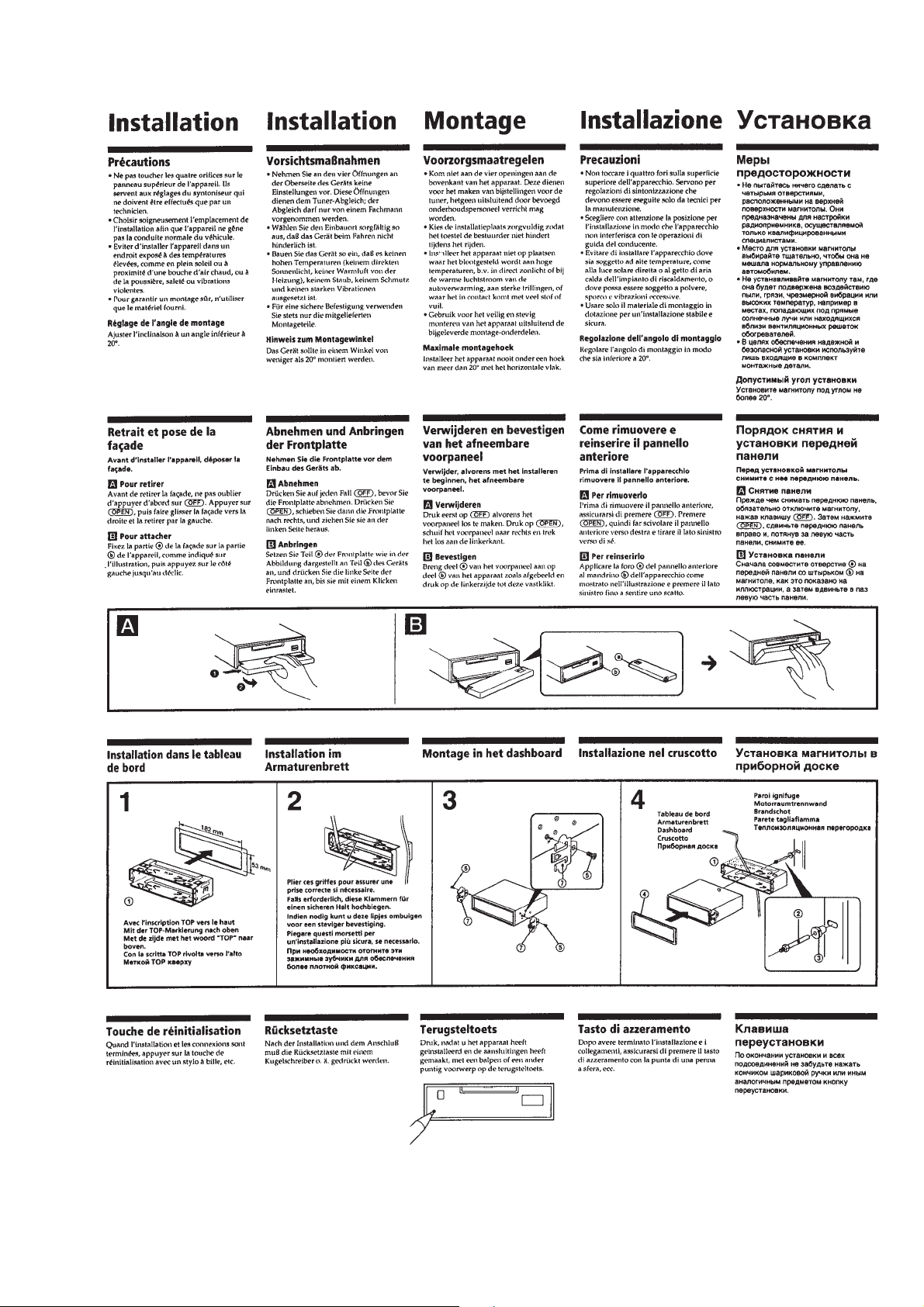

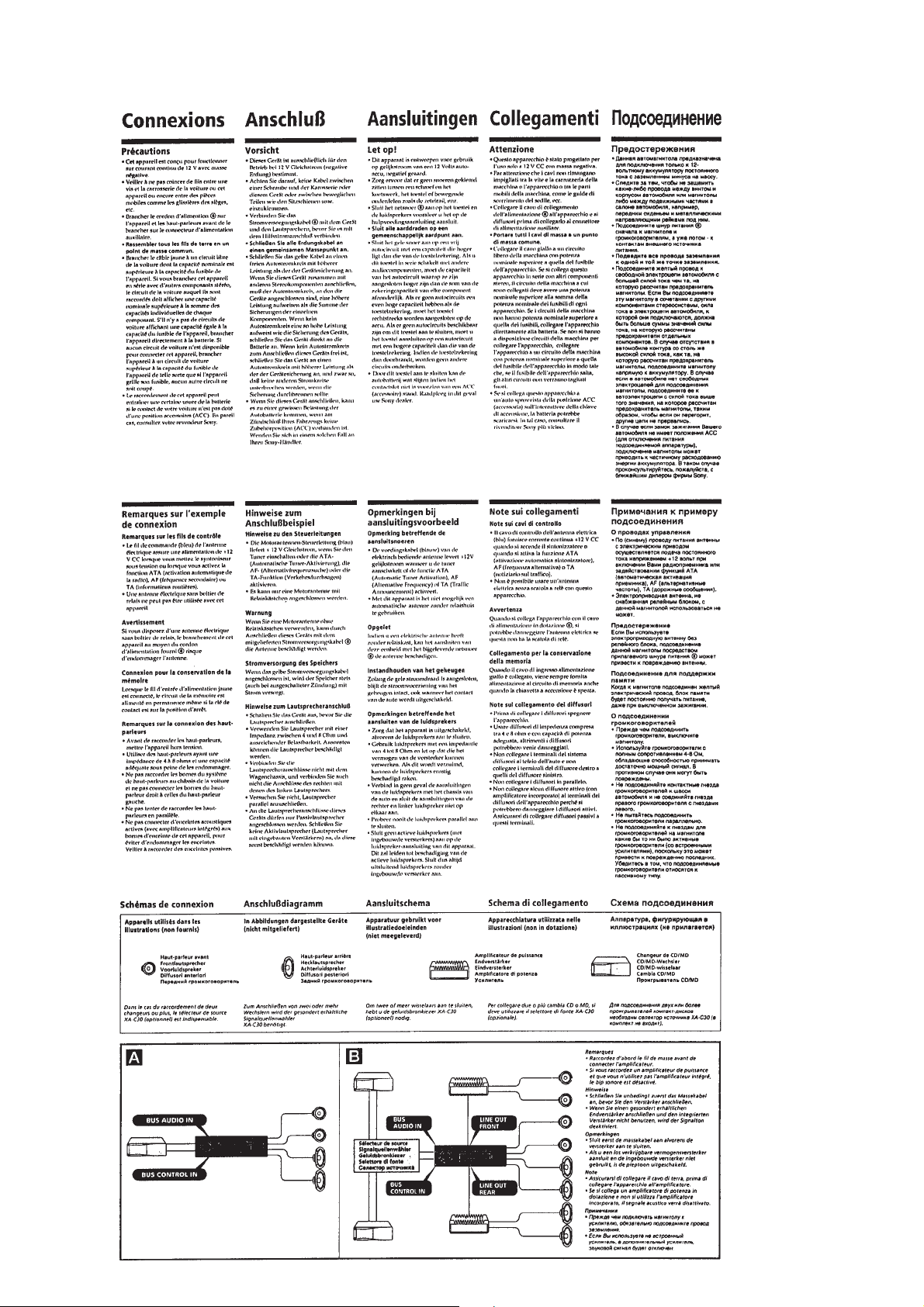

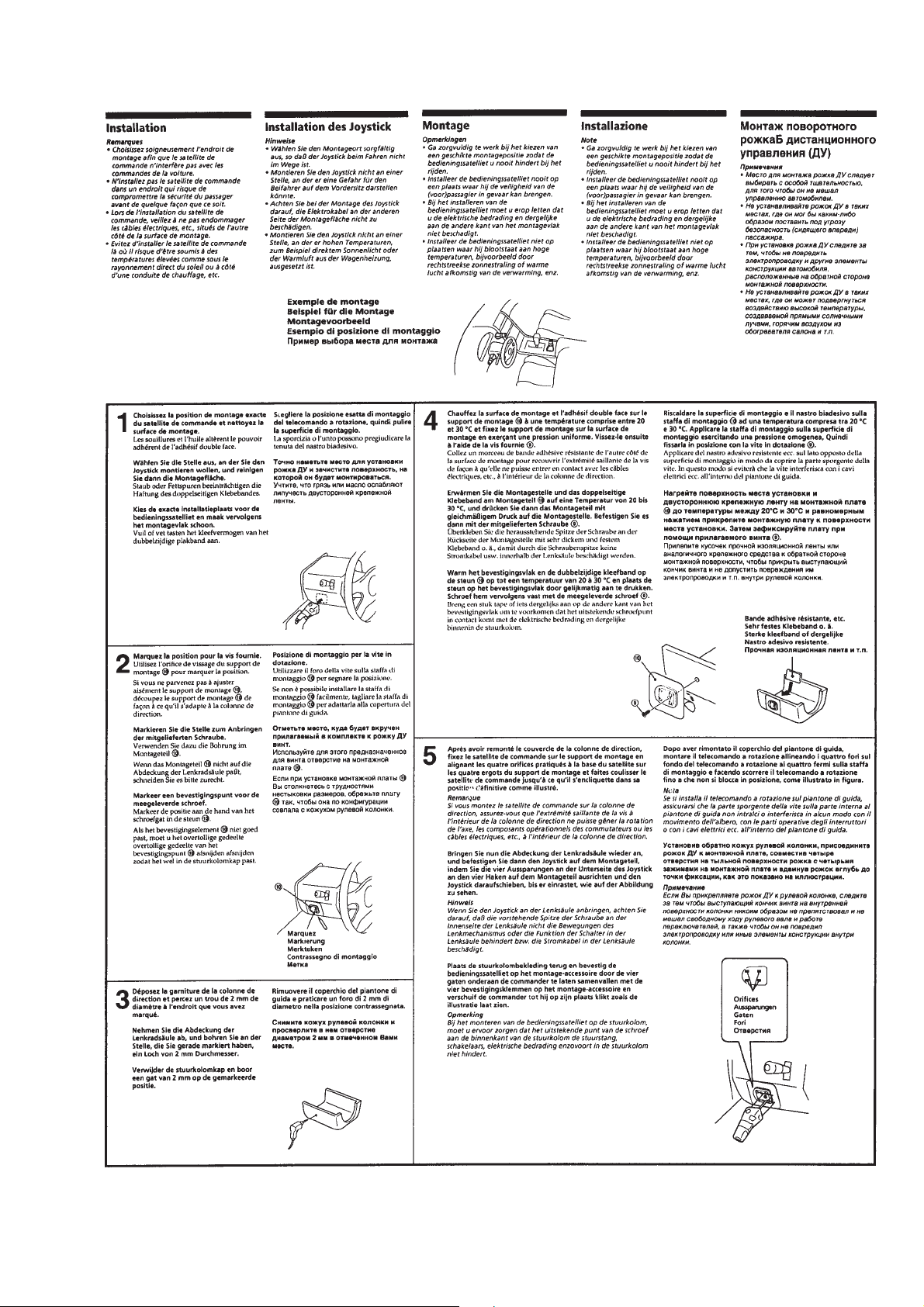

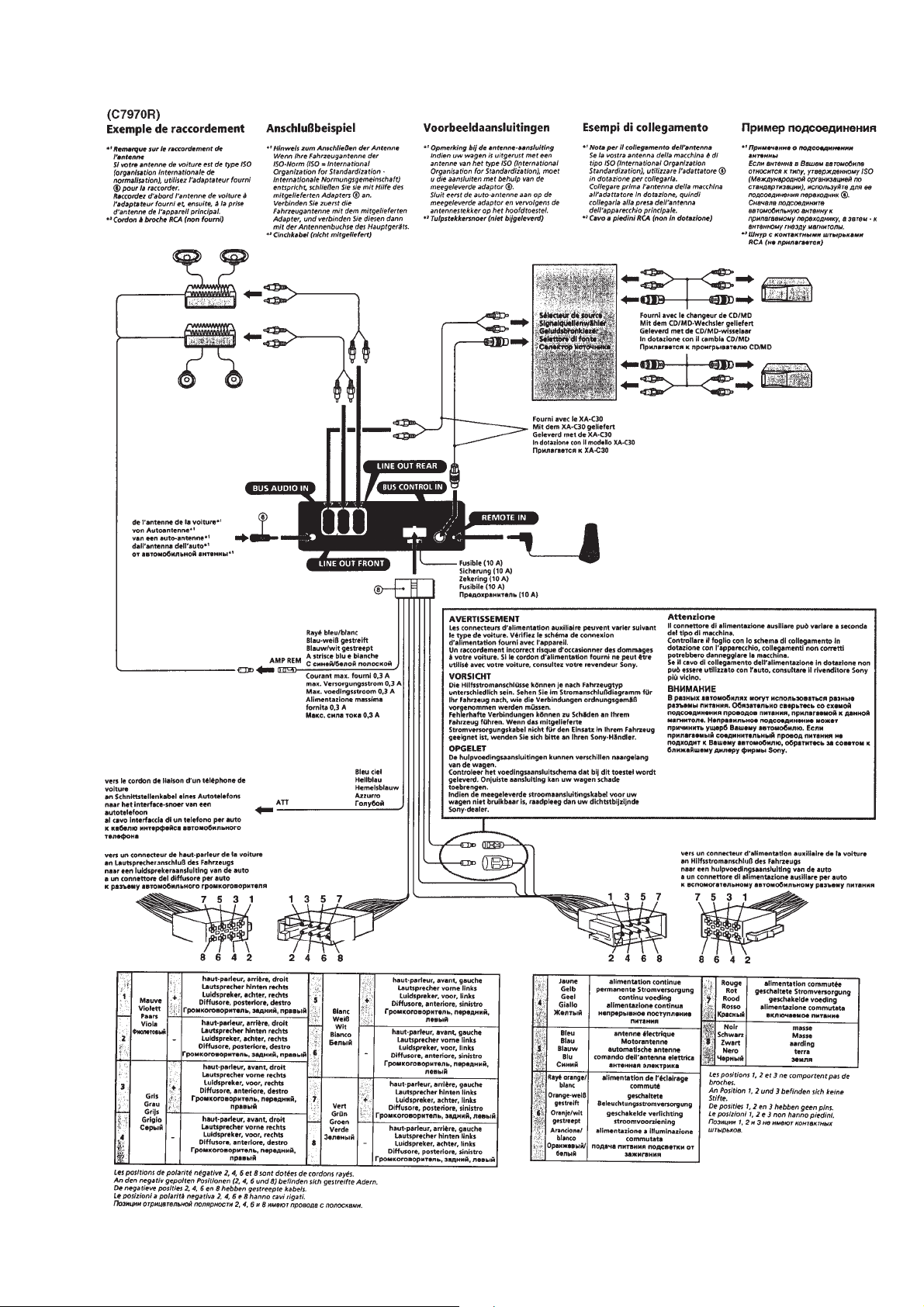

Installation....................................................................... 7

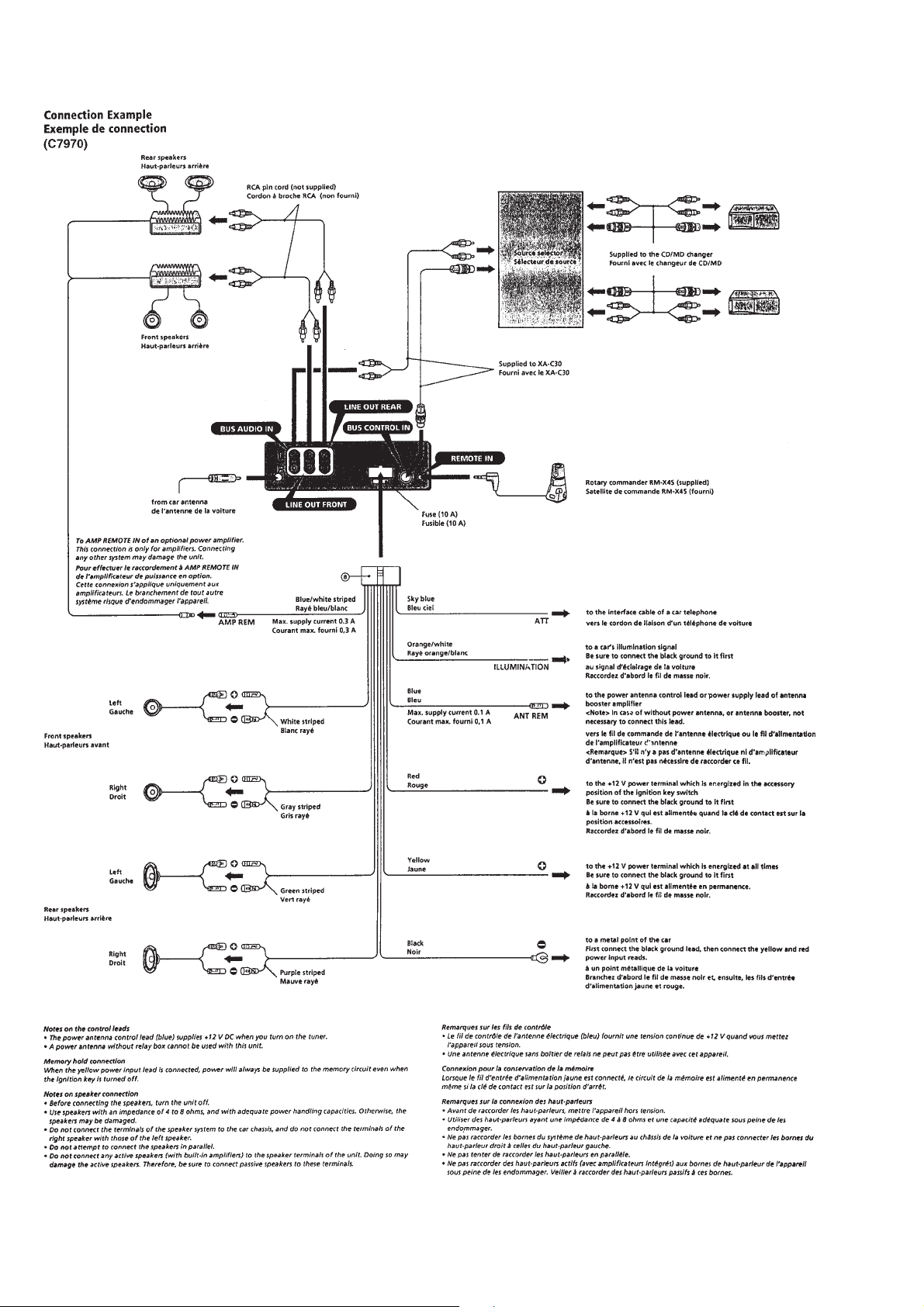

Connections..................................................................... 8

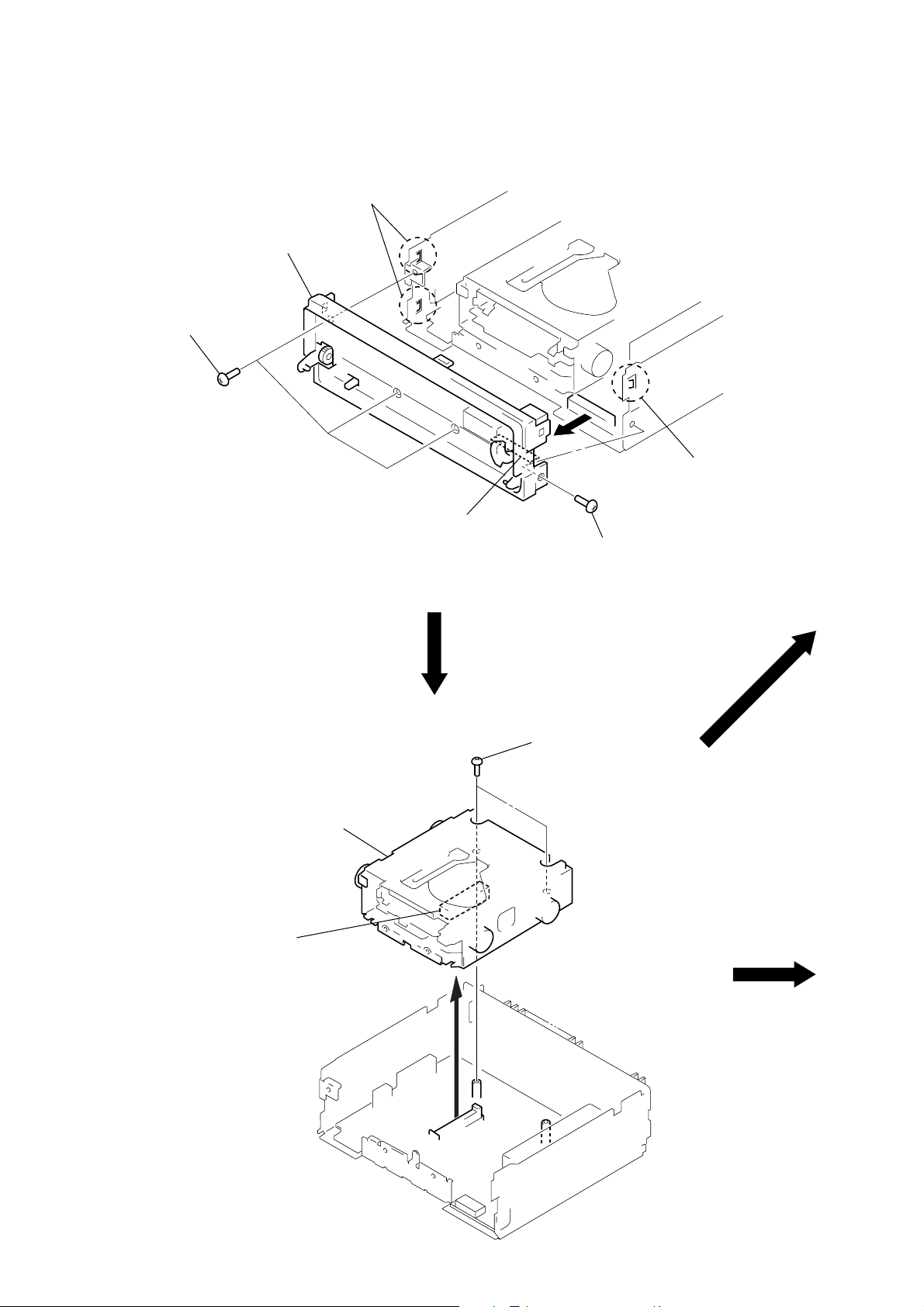

2. DISASSEMBLY ......................................................... 12

3. ELECTRICAL ADJUSTMENTS

Test Mode........................................................................ 18

MD Section ..................................................................... 18

Tuner Section .................................................................. 18

4. DIAGRAMS

4-1. Block Diagram – SERVO Section – ............................... 23

4-2. Block Diagram – TUNER Section – .............................. 25

4-3. Block Diagram – MAIN Section – ................................. 27

4-4. Block Diagram

– DISPLAY/KEY CONTROL Section –........................ 29

4-5. Block Diagram

– BUS CONTROL/POWER SUPPLY Section – ........... 31

4-6. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 33

4-7. Printed Wiring Boards – SERVO Section – ................... 35

4-8. Schematic Diagram – SERVO Board (1/3) – ................. 37

4-9. Schematic Diagram – SERVO Board (2/3) – ................. 39

4-10. Schematic Diagram – SERVO Boar d (3/3) – ................. 41

4-11. Printed Wiring Board

– MAIN Board (Component Side) – .............................. 43

4-12. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 45

4-13. Schematic Diagram – MAIN Board (1/4) – ................... 47

4-14. Schematic Diagram – MAIN Board (2/4) – ................... 49

4-15. Schematic Diagram – MAIN Board (3/4) – ................... 51

4-16. Schematic Diagram – MAIN Board (4/4) – ................... 53

4-17. Printed Wiring Board – DISPLAY Board – ................... 55

4-18. Schematic Diagram – DISPLAY Board – ...................... 57

4-19. Printed Wiring Board – SUB Board – ............................ 59

4-20. Schematic Diagram – SUB Board – ............................... 61

4-21. IC Pin Function Description ........................................... 69

5. EXPLODED VIEWS ................................................ 79

6. ELECTRICAL PARTS LIST ............................... 83

– 3 –

SECTION 1

GENERAL

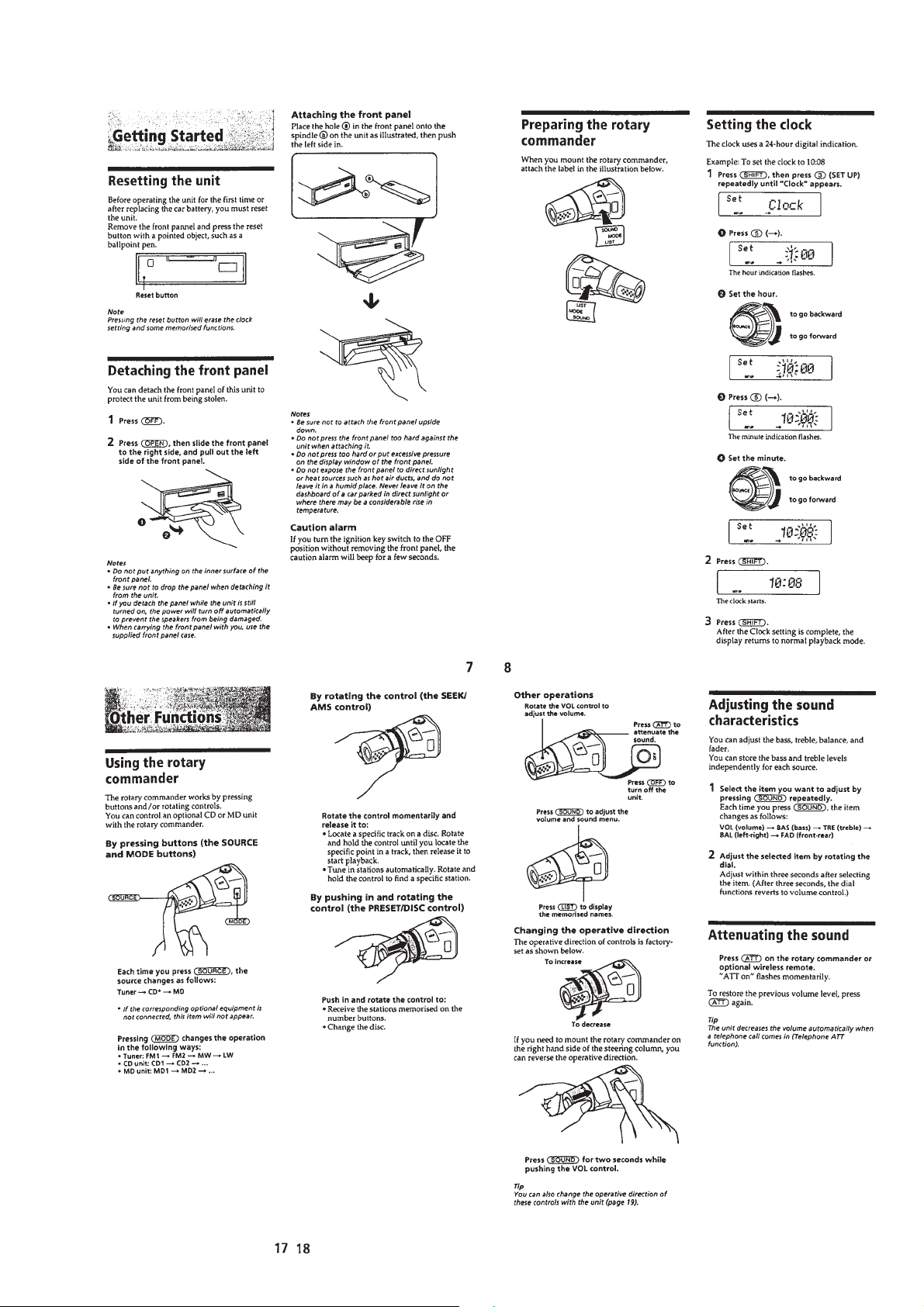

This section is extracted from

instruction manual.

– 4 –

– 5 –

– 6 –

– 7 –

– 8 –

– 9 –

– 10 –

– 11 –

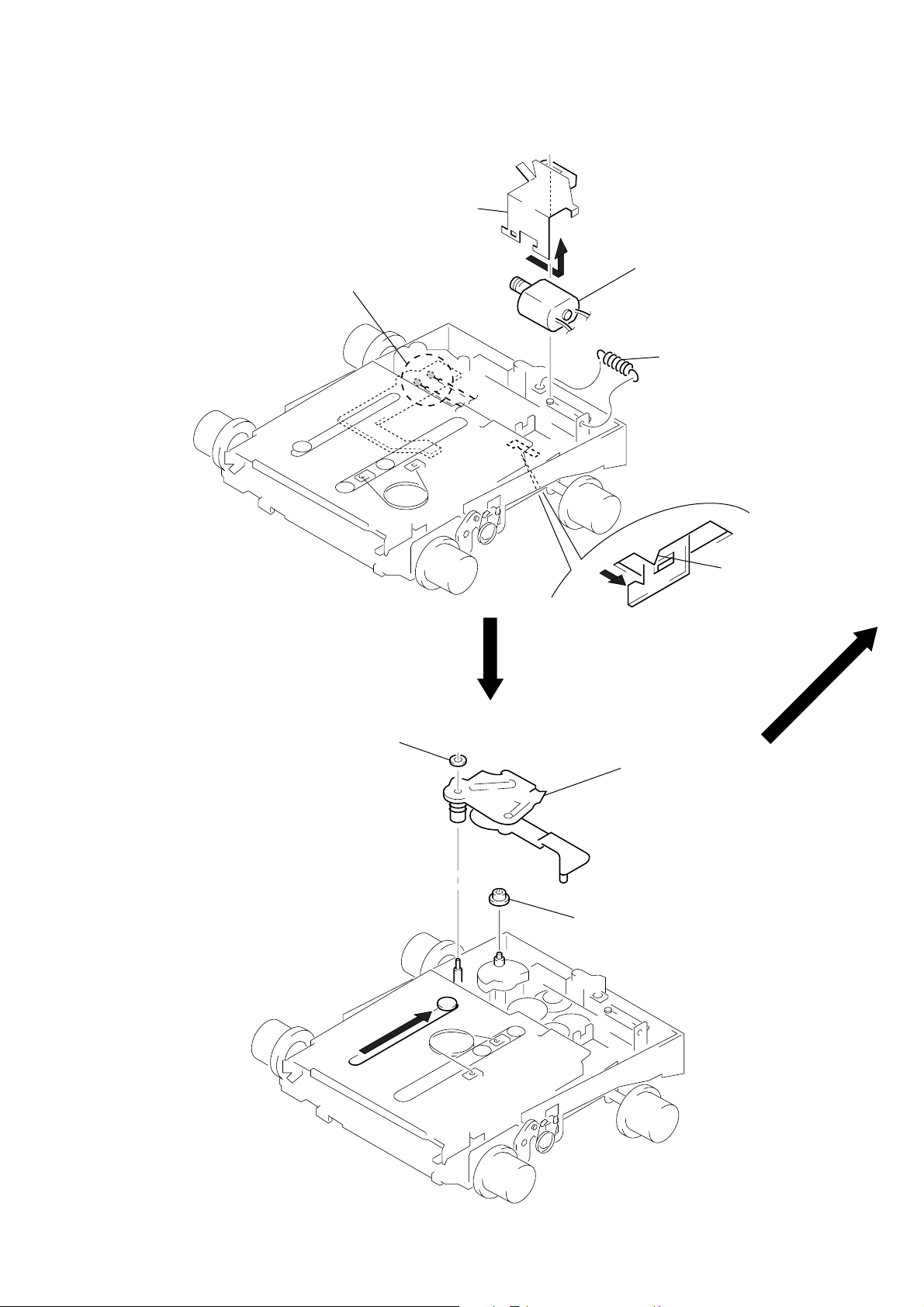

SECTION 2

w

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

SUB PANEL ASS’Y

2

two claws

4

sub panel ass’y

1

three screws

(PTT2.6 × 6)

2

cla

MECHANISM DECK (MG-164N-138)

3

mechanism deck

(MG-164N-138)

2

connector

(CN200)

3

connector

(CN901)

1

two screws

(PTT2.6

1

screw

(PTT2.6 × 6)

×

4)

– 12 –

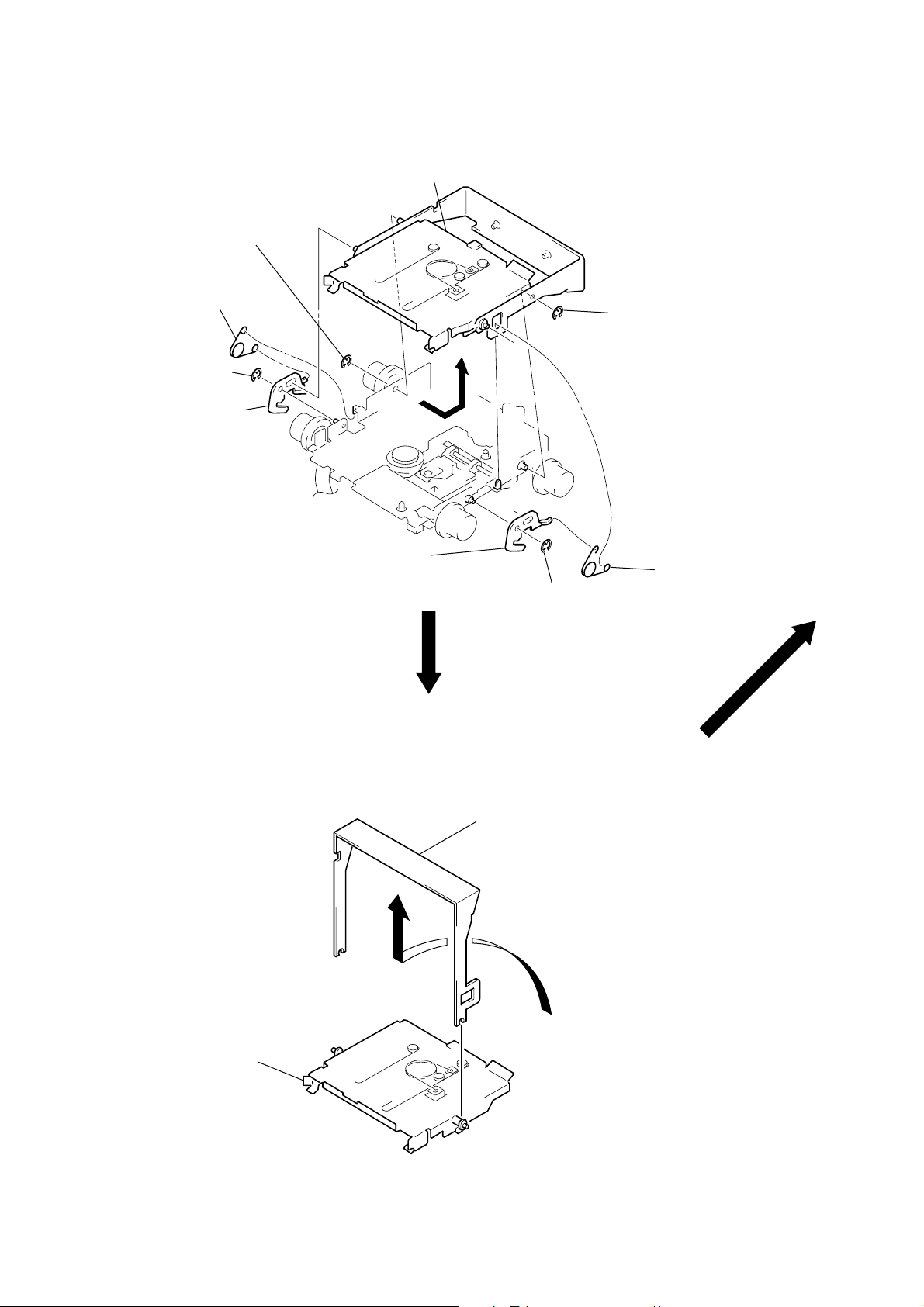

MAIN BOARD, HEAT SINK

d

2

three screws

(PTT2.6 × 6) (ground point)

3

main board

4

insulating sheet

5

eight screws

(PTT2.6 × 10)

6

heat sink

1

two screws

(PTT2.6 × 10)

SERVO BOARD

1

2

two screws

(BVTT2

×

4)

sensor flexible board

(CN102)

2

two screws

(BVTT2

×

4)

3

servo board

1

flexible boar

(CN103)

– 13 –

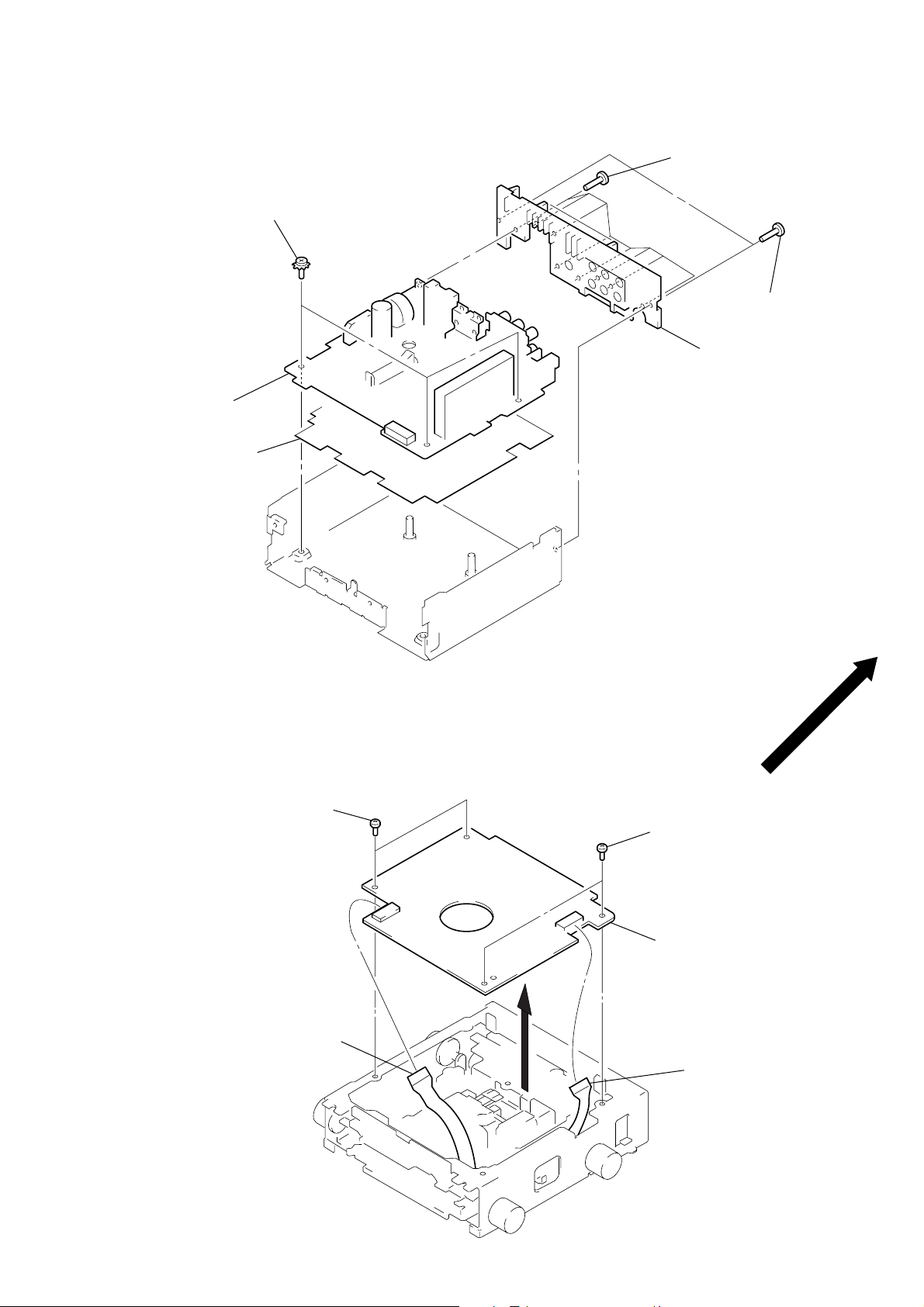

MD COVER ASS’Y

)

3

MD cover ass’y

shaft (MD cover guide)

cassette holder

1

four screws

(B2

×

3)

FLOAT BLOCK

float block

A

2

Pushing the Cassette Holder toward the direction A with a

screwdriver, etc., disengage the Shaft (MD Cover Guide) from

the slot in the MD Cover Ass’y.

Note:Take care not to scratch the Optiocal Pick-up when pushing

the Cassette Holder with a screwdriver. etc.

3

Pushing an arrow A part, raise the float block

up ward at the front to release a lock.

1

A

tension spring (FL2)

lever (lock R)

lever (lock L)

2

two tension springs (FLOAT F)

– 14 –

1

tension spring (FL2

LO MOTOR ASS’Y (LOADING) (M903)

4

Remove the bracket (LO)

in the direction of the arrow

A

.

LEVER (LE) ASS’Y

1

Remove solders of motor. (M903)

A

5

LO motor ass’y (loading)

(M903)

2

tension spring (rack)

3

claw

2

stopper washer

1

3

roller (GLE)

2

lever (LE) ass’y

– 15 –

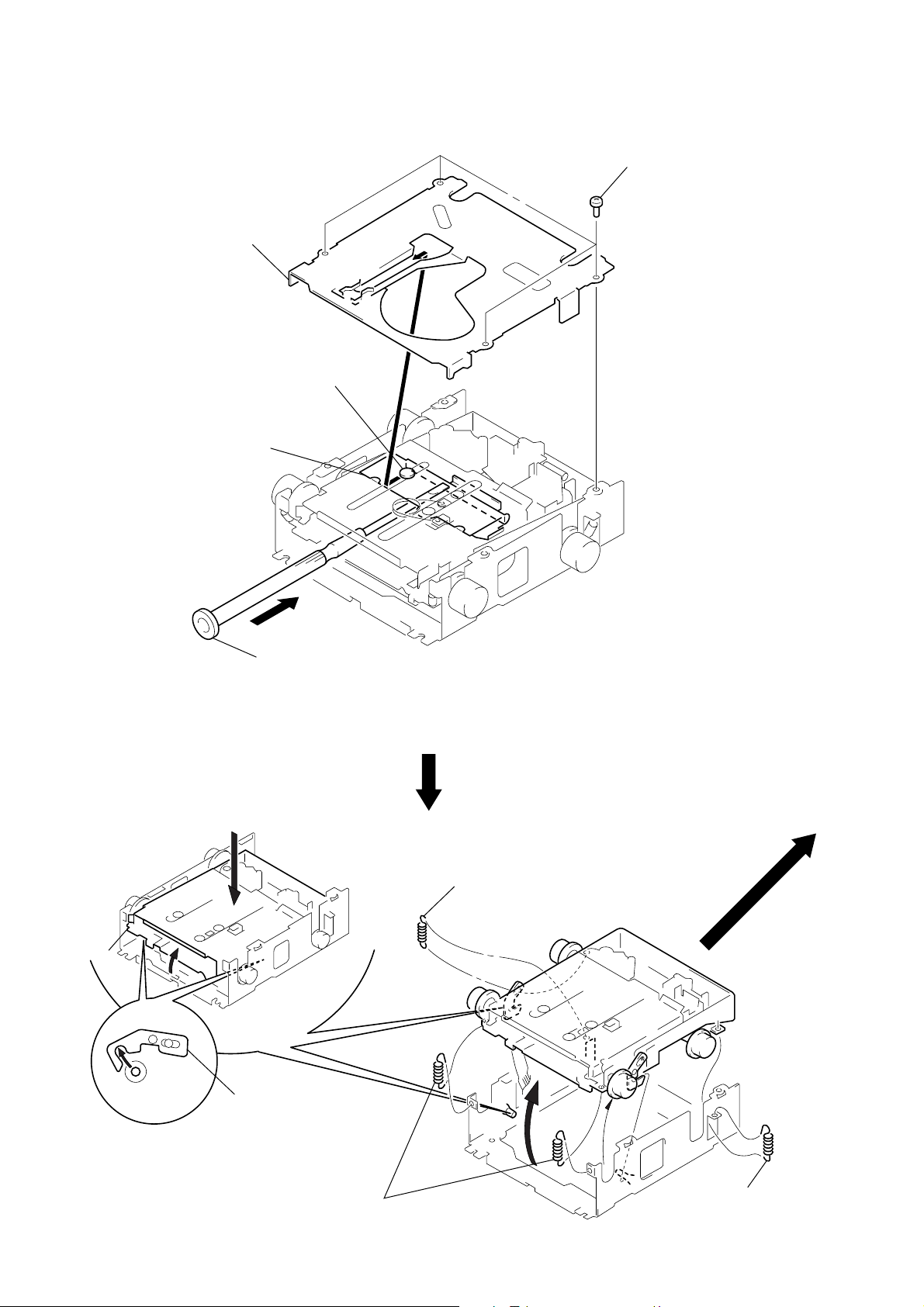

HOLDER ASS’Y

2

type-E stop ring 1.5

3

2

type-E stopring 1.5

1

spring (CHKG)

lever (lock R)

3

lever (lock L)

4

Remove the holder ass’y in the

direction of the arrow.

2

2

type-E stop ring 1.5

type-E stop ring 1.5

1

spring (CHKG)

CHUCKING ARM ASS’Y

holder ass’y

1

Remove the chucking arm ass’y

in the direction of the arrow.

– 16 –

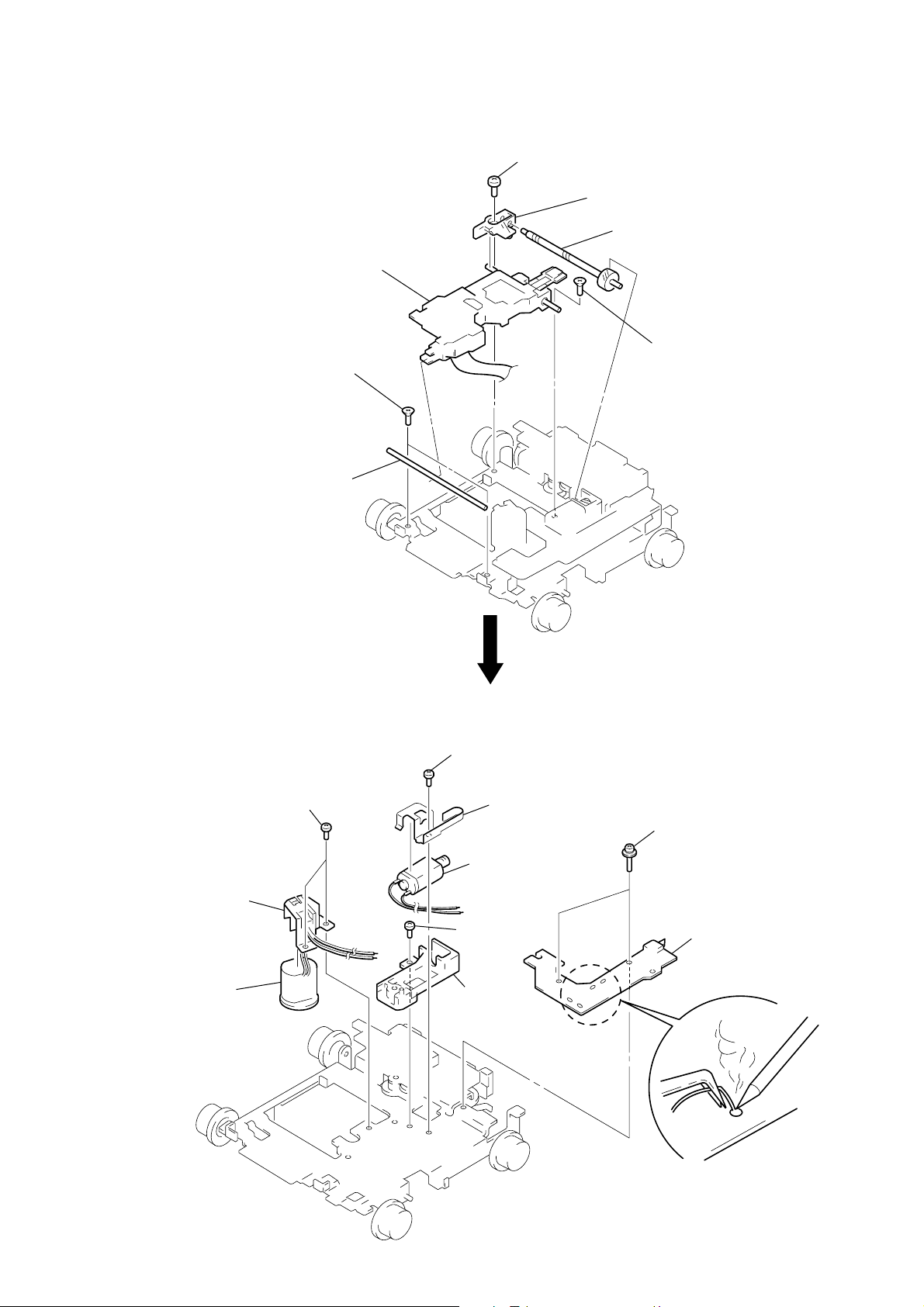

OPTICAL PICK-UP (KMS-241B/J1NP)

y

4

screw

(P1.7 × 1.8)

5

bracket (SL)

9

two screws

(P1.7 × 1.8)

!º

retainer (SP)

!¡

SP motor ass’y

(spindle) (M901)

7

screw

(B2 × 3)

2

two screws

(2 × 8)

3

sensor board

1

Remove solders of motors.

(M901, M902)

8

base (SL)

6

SL motor ass’y

(sled) (M902)

7

optical pick-up

(KMS-241B/J1NP)

1

two screws

(K2 × 3)

2

shaft (SL2)

4

screw

(B2 × 3)

6

bearing (SL)

5

feed screw ass’

3

screw

(K2 × 3)

SL MOTOR ASS’Y (SLED) (M902), SP MOTOR ASS’Y (SPINDLE) (M901)

– 17 –

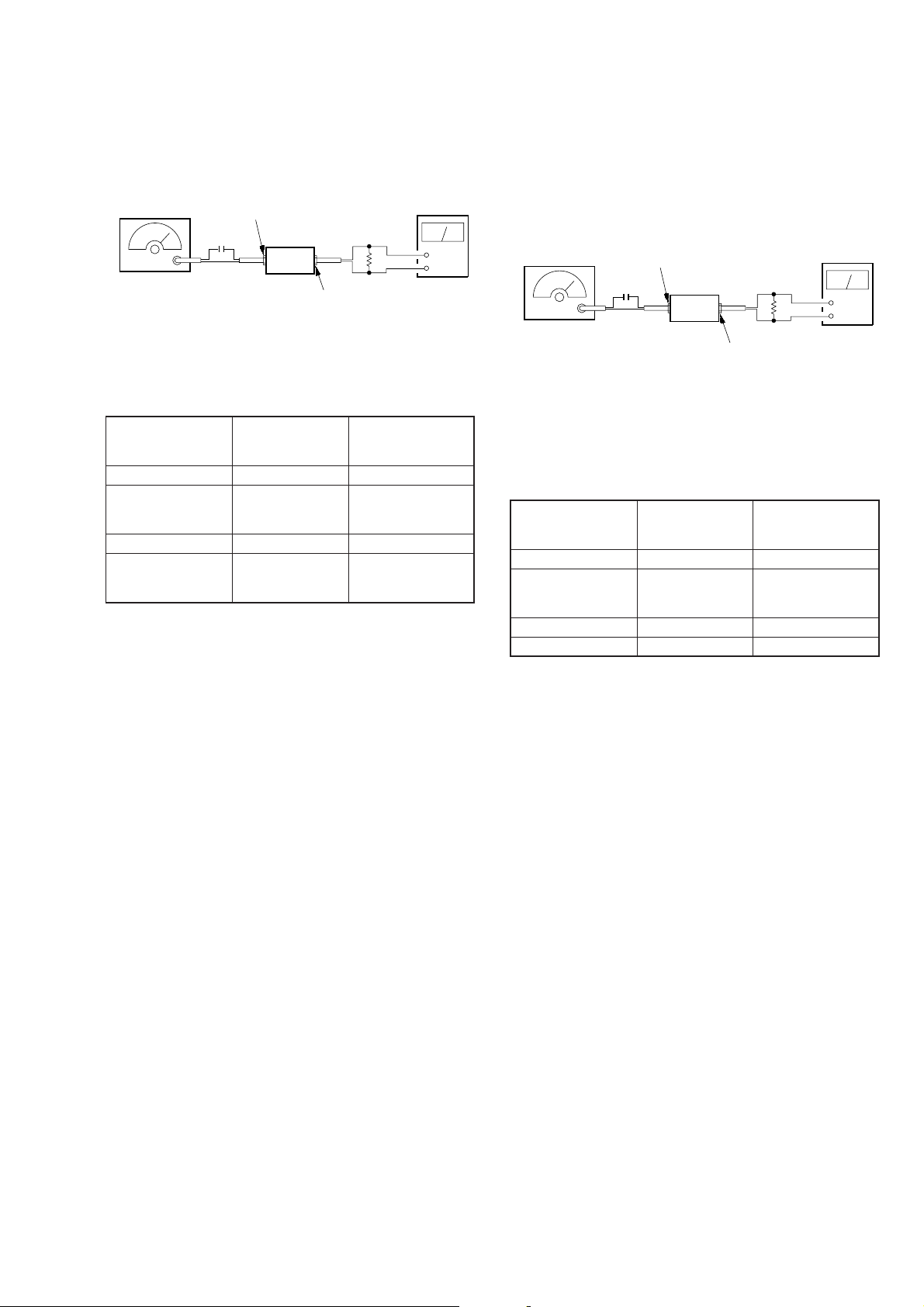

SECTION 3

ELECTRICAL ADJUSTMENTS

TEST MODE

This set have the test mode function. In the test mode, FM Auto

Scan/Stop Level and AM (MW) Auto Scan/Stop Lev el adjustments

can be performed easier than it in ordinary procedure.

<Set the Test Mode>

1. Turn ON the regulated po wer supply . ( The clock is displayed)

Note: Press the [OFF] button, if the clock is not displayed.

2. Push the preset [4] button.

3. Push the preset [5] button.

4. Press the preset [1] button for more than two seconds.

5. Then the display indicates all lights, the test mode is set.

<Release the Test mode>

1. Push the [OFF] button.

See the adjustment location from on page 22 for the adjustment.

MD SECTION

MD section adjustments are done automatically in this set.

TUNER SECTION

0 dB=1 µV

Cautions during repair

When the tuner unit is defective, replace it by a new one because its internal block is difficult to repair.

Note: Adjust the tuner section in the sequence shown below.

1. FM Auto Scan/Stop Level Adjustment

2. FM Stereo Separation Adjustment (MDX-C7970)

3. FM Stereo Separation Adjustment (Wide) (MDX-C7970R)

4. FM Stereo Separation Adjustment (Narrow) (MDX-C7970R)

5. FM RDS S-Meter Adjustment (MDX-C7970R)

6. AM (MW) Auto Scan/Stop Level Adjustment

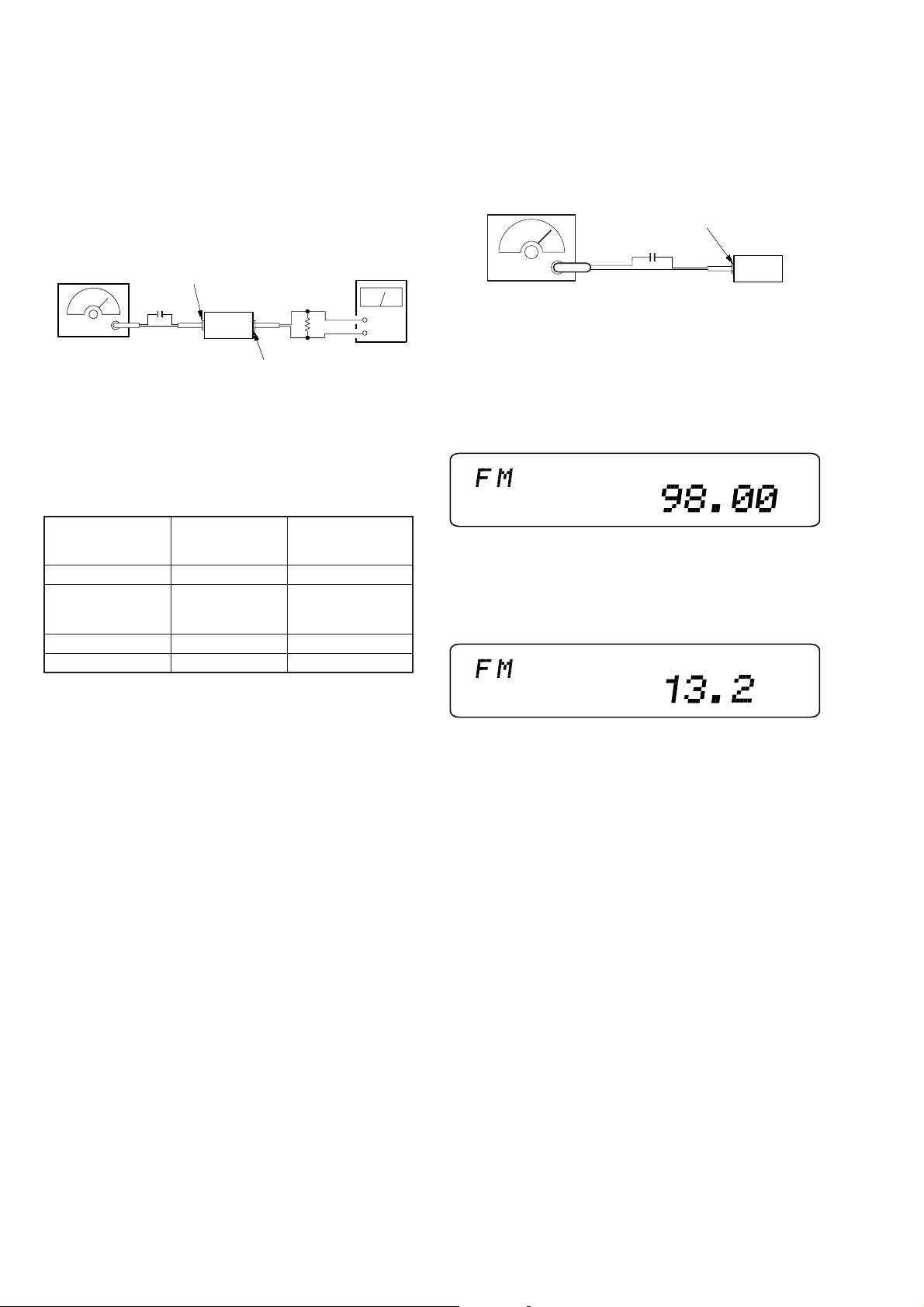

FM Auto Scan/Stop Level Adjustment

Setting:

[SOURCE] button : FM

FREQUENCY SELECT switch: FM 200 k (E model)

FM RF signal

generator

Carrier frequency: 97.9 MHz (MDX-C7970)

Output level : 22 dB (12.6

Mode : mono

Modulation : 1 kHz, 22.5 kHz deviation (30%)

98.0 MHz (MDX-C7970R)

antenna jack (CN1)

µ

F

0.01

µ

V)

set

Procedure:

1. Set to the test mode.

2. Push the

[SOURCE] button and set to FM.

Display

SHUF

*1

3. Adjust the volume RV2 on TU1 by turning clockwise untill

“0” is shown next to “FM” on the display window, If “0” is

already shown or the volume RV2 has been turned too far,

turn it back counterclockwise untill “0” is disappeared once,

then try this adjustment.

Display

SHUF

*1

*1: MDX-C7970R indicates “98.00”.

Adjustment Location: See page 22.

– 18 –

FM Stereo Separation Adjustment (MDX-C7970)

Setting:

[SOURCE] button : FM

FREQUENCY SELECT switch: FM 200 k (E model)

FM RF signal

generator

Carrier frequency : 97.9 MHz

Output level : 70 dB (3.2 mV)

Mode : stereo

Modulation : main: 1 kHz, 33.75 kHz deviation (45%)

antenna jack (J1)

0.01 µF

set

sub : 1 kHz, 33.75 kHz deviation (45%)

: 19 kHz pilot: 7.5 kHz deviation (10%)

10 k

LINE OUT jack (CNP300)

Procedure:

FM Stereo

signal generator

output channel

L-CH L-CH A

R-CH L-CH Adjust RV4 on TU1

R-CH R-CH C

L-CH R-CH Adjust RV4 on TU1

Level meter Level meter

connection reading (dB)

for minimum reading.

for minimum reading.

L-CH Stereo separation: A-B

R-CH Stereo separation: C-D

The separations of both channels should be equal.

Specification: Separation more than 30 dB

Adjustment Location: See page 22.

level meter

Ω

B

D

FM Stereo Separation Adjustment (Wide) (MDX-C7970R)

Setting:

[SOURCE] button : FM

[SHIFT] button : ON (light up SET UP and PLAY MODE)

Preset [4] (PLAY MODE) →

[5] (→) buttons : WIDE mode

+

–

FM RF signal

generator

Carrier frequency : 98.00 MHz

Output level : 70 dB (3.2 mV)

Mode : stereo

Modulation : main: 1 kHz, 33.75 kHz deviation (45%)

antenna jack (J1)

0.01 µF

Ω)

(75

sub : 1 kHz, 33.75 kHz deviation (45%)

: 19 kHz pilot: 7.5 kHz deviation (10%)

set

10 k

LINE OUT jack (CNP300)

Procedure:

1. Adjust the volume RV3 on FM/AM tuner unit (TU1) for the

best separation.

FM Stereo

signal generator

output channel

L-CH L-CH A

L-CH R-CH Adjust RV3 on TU1

R-CH R-CH C

R-CH L-CH D

Level meter Level meter

connection reading (dB)

for minimum reading.

L-CH Stereo separation: A-B

R-CH Stereo separation: C-D

The separations of both channels should be equal.

Specification: Separation more than 24 dB

Ω

level meter

+

–

B

Adjustment Location: See page 22.

– 19 –

FM Stereo Separation Adjustment (Narrow)

(MDX-C7970R)

Setting:

[SOURCE] button : FM

[SHIFT] button : ON (light up SET UP and PLAY MODE)

Preset [4] (PLAY MODE) →

[5] (→) buttons : NARROW mode

FM RF signal

generator

antenna jack (J1)

0.01 µF

(75

Ω)

10 k

set

Ω

level meter

FM RDS S-Meter Adjustment (MDX-C7970R)

Setting:

[SOURCE] button : FM

FM RF signal

generator

Carrier frequency : 98.00 MHz

+

–

Output level : 35 dB (56.2

Mode : mono

Modulation : no modulation

antenna jack (J1)

µ

F

0.01

µ

V)

set

Carrier frequency : 98.00MHz

Output level : 70 dB (3.2 mV)

Mode : stereo

Modulation : main: 1 kHz, 20 kHz deviation (26.7%)

sub : 1 kHz, 20 kHz deviation (26.7%)

: 19 kHz pilot: 7.5 kHz deviation (10%)

LINE OUT jack (CNP300)

Procedure:

1. Adjust the volume RV4 on FM/AM tuner unit (TU1) for the

best separation.

FM Stereo

signal generator

output channel

L-CH L-CH A

L-CH R-CH Adjust RV4 on TU1

R-CH R-CH C

R-CH L-CH D

Level meter Level meter

connection reading (dB)

B

for minimum reading.

L-CH Stereo separation: A-B

R-CH Stereo separation: C-D

The separations of both channels should be equal.

Specification: Separation more than 18 dB

Adjustment Location: See page 22.

Procedure:

1. Set to the test mode. (See page 18)

2. Push the

[SOURCE] button and set to FM.

Display

SHUF

3. Push the preset

[10] button .

4. Adjust RV1 on MAIN board so that the display indication is

“13.2”.

Display

SHUF

Specification: Display indication: 13.0 to 13.4

Adjustment Location: See page 22.

– 20 –

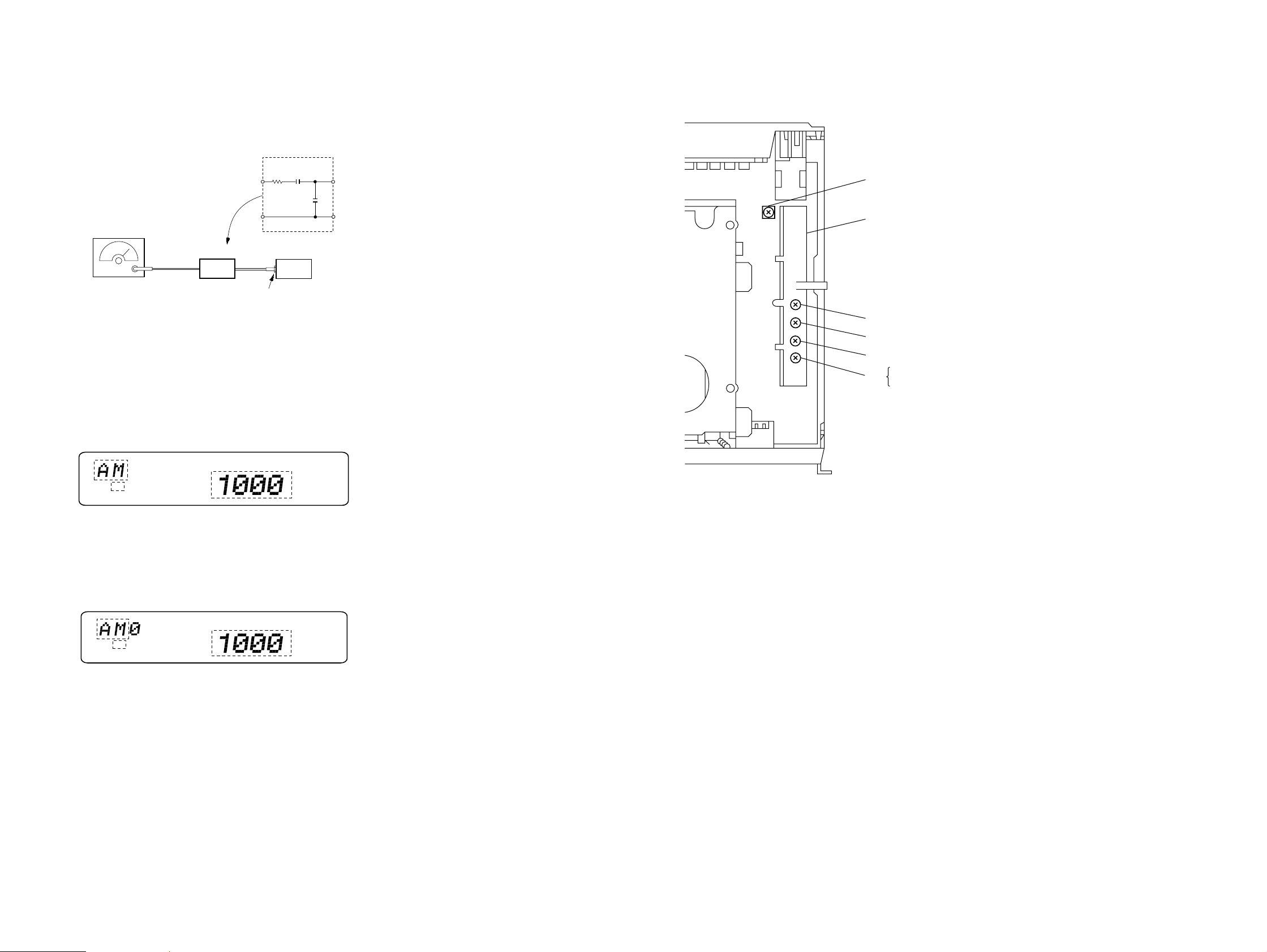

MW Auto Scan/Stop Level Adjustment

(

)

Setting:

[SOURCE] n [MODE] button : AM (MDX-C7970)

MW (MDX-C7970R)

FREQUENCY SELECT switch : AM 10 k (E model)

30

AM RF signal

generator

AM dummy antenna

(50 Ω)

antenna jack (J1)

Carrier frequency : 1000 kHz (MDX-C7970)

30% amplitude

modulation by

1 kHz signal

Output level : 33 dB

Procedure:

1. Set to the test mode. (See page 18)

2. Push the

3. Push the

[SOURCE] button and set to FM.

[MODE] button and set to AM or MW.

999 kHz (MDX-C7970R)

44.7 µV

Ω

15 pF

65 pF

set

Adjustment Location:

– SET UPPER VIEW –

RV1 RDS S-Meter Adjustment (MDX-C7970R)

TU1

RV1 AM (MW) Auto Scan/Stop Level Adjustment

RV2 FM Auto Scan/Stop Level Adjustment

RV3 FM Stereo Separation Adjustment (Wide) (MDX-C7970R)

FM Stereo Separation Adjustment (MDX-C7970)

RV4

FM Stereo Separation Adjustment (Narrow) (MDX-C7970R)

Display

*2

TP

*4

SHUF

*3

4. Adjust with the volume RV1 on TU1 so that the “ AM” or “MW”

indication turns to “AM0” or “MW0” indication on the display window.

But, in case of alredy indicated “AM0” or “MW0”, turn the

RV1 so that put out light “0” indication and adjustment.

Display

*2

TP

*4

SHUF

*3

*2: MDX-C7970R indicates “MW”.

*3: MDX-C7970R indicates “999”.

*4: Only MDX-C7970R indicates.

Adjustment Location: See page 22.

– 21 – – 22 –

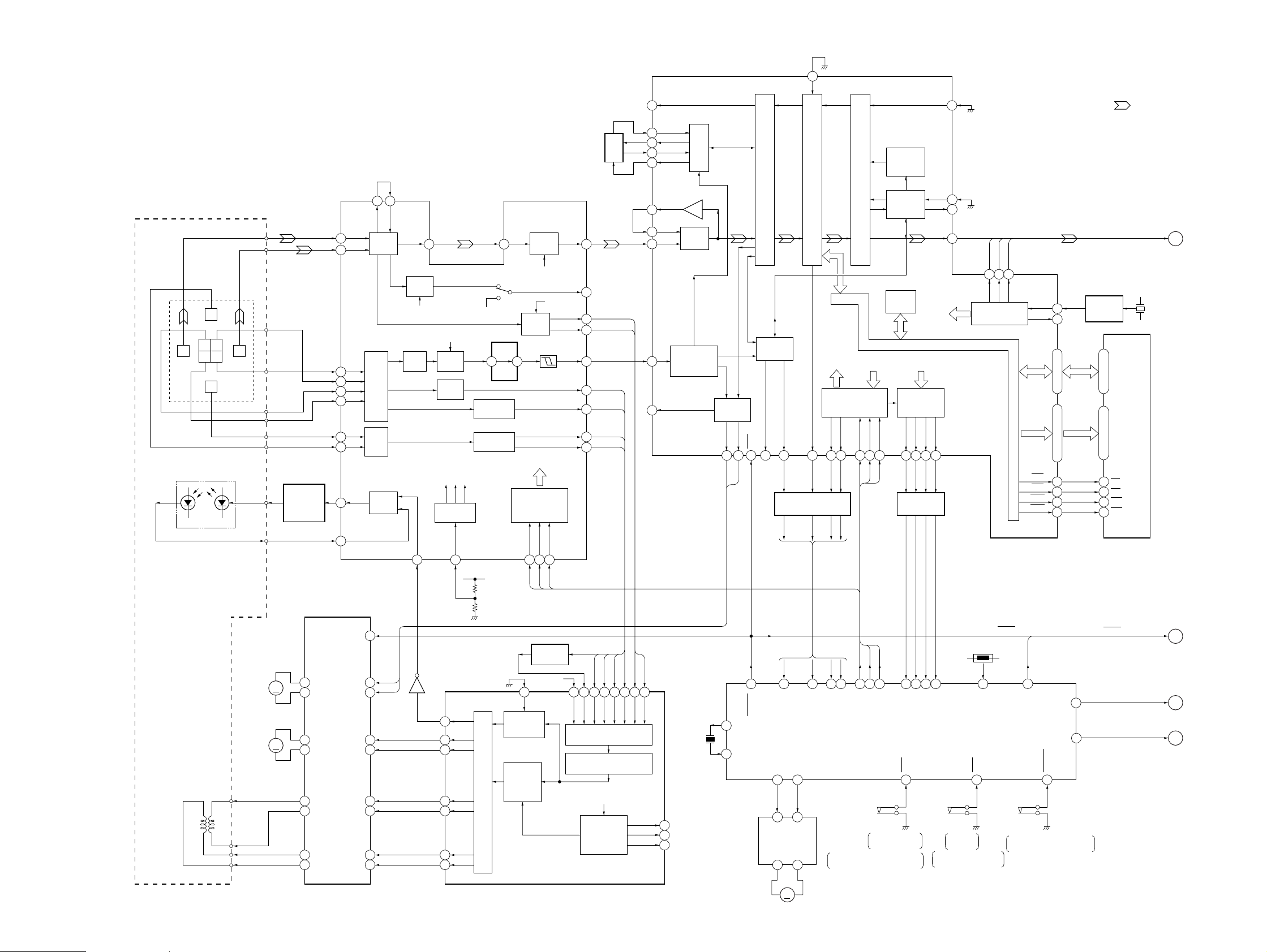

MDX-C7970/C7970R

4-1. BLOCK DIAGRAM – SERVO Section –

SECTION 4

DIAGRAMS

100

EFMO

15

TX

IC301 (1/2)

ADDT

• SIGNAL PATH

23

: MD PLAY

FILI

59

PCO

58

61

FILTER

60

RF AMP,

FOCUS/TRACKING ERROR AMP

48 47

MORFI

MORFO

IC303

I

1

RF AMP

J

2

A

4

B

5

I-V

C

AMP

6

D

7

E

8

I-V

F

AMP

9

APC

PD

IN4R

IN4F

IN2F

IN2R

IN1F

IN1R

IN3F

IN3R

LD/PD

16PSB

3

4

29

30

19

18

14

15

11

10

AMP

SPFD

SPRD

RFO

AT

AMP

B.P.F.

46

3T

APCREF

12

IC306

WBL

B.P.F.

ABCD

AMP

WBL3TEQ

V-I

CONVERTER

F0CNT

20

APCREF

83

SFDR

92

SRDR

91

FFDR

88

FRDR

89

TFDR

86

TRDR

85

TEMP

ADFM

29 30

FOCUS

ERROR AMP

TRACKING

ERROR AMP

+3.3V

PWM GENERATOR

40

I

J

F

C B

I J

D A

E

DETECTOR

LASER DIODE

OPTICAL PICK-UP

(KMS-241B/J1NP)

2-AXIS

DEVICE

(FOCUS)

(TRACKING)

05

LDPD

ILCC

PD

M901

(SPINDLE)

M902

(SLED)

FCS+

FCS–

TRK+

TRK–

B

A

C

D

E

F

AUTOMATIC

POWER

CONTROL

Q302

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

OUT4F

6

M

8

OUT4R

OUT2F

27

M

25

OUT2R

OUT1F

21

23

OUT1R

OUT3F

12

10

OUT3R

IC302

AGCI

RF AGC

& EQ

EQ

WBL

PEAK &

BOTTOM

ADIN

COMMAND

SERIAL/

PARALLEL

CONVERTER,

DECODER

XLAT

SCLK

SWDT

1716 18

PEAK HOLD

Q301

+3.3V

13

RECP

AUTOMATIC

POWER

CONTROL

DIGITAL

SERVO

SIGNAL

PROCESS

DIGITAL SERVO

SIGNAL PROCESSOR

IC301 (2/2)

RF

AUX

PEAK

BOTM

ADFG

ABCD

FE

TE

SE

ABCD

AUX1

38

33

37

36

32

35

34

26

28

7465647566 63

FE

TE

AUX2

ABCD

ANALOG MUX

A/D CONVERTER

FROM CPU

INTERFACE

AUTO

SEQUENCER

73 62

SE

PEAK

XLRF

CKRF

DTRF

51

52

55

78

79

BOTM

CLTV

FILO

ASYO

ASYI

COMPA-

RFI

RATOR

ADIP

ADFG

DEMODULATOR/

DECODER

F0CNT

X501

10MHz

80

81

82

PLL

EFM/ACIRC

ENCODER/DECODER

SUBCODE

PROCESSOR

SPINDLE

SERVO

SPFD

SPRD

DQSY11SQSY14XINT

XRST

94 93

10

12

59 62 55 54 52 45 51 64 26 27 28 29

MD-RST

31

EXTAL

XTAL

32

7 6

LOADING

MOTOR DRIVE

IC305

M903

(LOADING)

5 4

RIN FIN

OUT1 OUT2

1 7

SHOCK PROOF

MEMORY CONTROLLER

51331

LEVEL SHIFT

IC502

61242

SQSY

CC-XINT

EJECT

LOAD

M

ATRAC

CPU

INTERFACE

SENS

SRDT

SWDT

9 8 5 6 7

SWDT

SENS

MD-SI

MD-SO

MD MECHANISM CONTROLLER

ON:When the disc loading start

and the disc eject completion.

SAMPLING

RATE

CONVERTER

DIGITAL

AUDIO

ENCODER/DECODER

INTERFACE

D-RAM

INTERNAL BUS

MONITOR

CONTROL

SCLK

XLAT

MNT0

MNT1

1 2 3 4

135

13

LEVEL SHIFT

IC503

246

12

FOK

SHOCK

SCLK

XLAT

MNT0

MD-LAT

MD-CKO

IC501 (1/2)

C-SW

63

LOADING START/

EJECT END

DIN

DOUT

DADT

MNT2

MNT3

XBUSY

SLOCK

MNT1

MNT2

MNT3

ON:When completion of

DIGITAL SIGNAL PROCESSOR,

EFM/ACIRC ENCODER/DECODER,

SHOCK PROOF MEMORY CONTROLLER,

ATRAC ENCODER/DECODER, 2M BIT D-RAM

21

22

24

LOADING

END

the disc loading.

IC301 (1/2)

BCK

LRCK

FS256

2526 27

XBCK

LRCK

FS256

CLOCK

GENERATOR

RESET

TH501

39

TEMP

E-SW

11 56

OSCI

OSCO

XOE

XWE

XRAS

XCAS

EMPHASIS

66

DEEMP

(LIMIT)

ON:When the optical pick-up is

inner position.

A-MUTE

16

17

D0 – D3A00 – A09

47, 46, 48, 49

32 – 29, 34 – 38, 43

41 22

45 3

44 4

42 23

LOCK

21

67

LIMIT-IN

DADT, BCK, LRCK, FS256

512FS OSC

IC304

D0 – D3

1, 2, 24, 25

A0 – A9

9 – 12, 14 – 18, 5

OE

WE

RAS

CAS

D-RAM

IC307

RESET, EMPHASIS

LOCK

MD-ATT

(Page 27)

A

X301

22.5792MHz

(Page 27)

B

C

(Page 27)

D

(Page 27)

– 23 – – 24 –

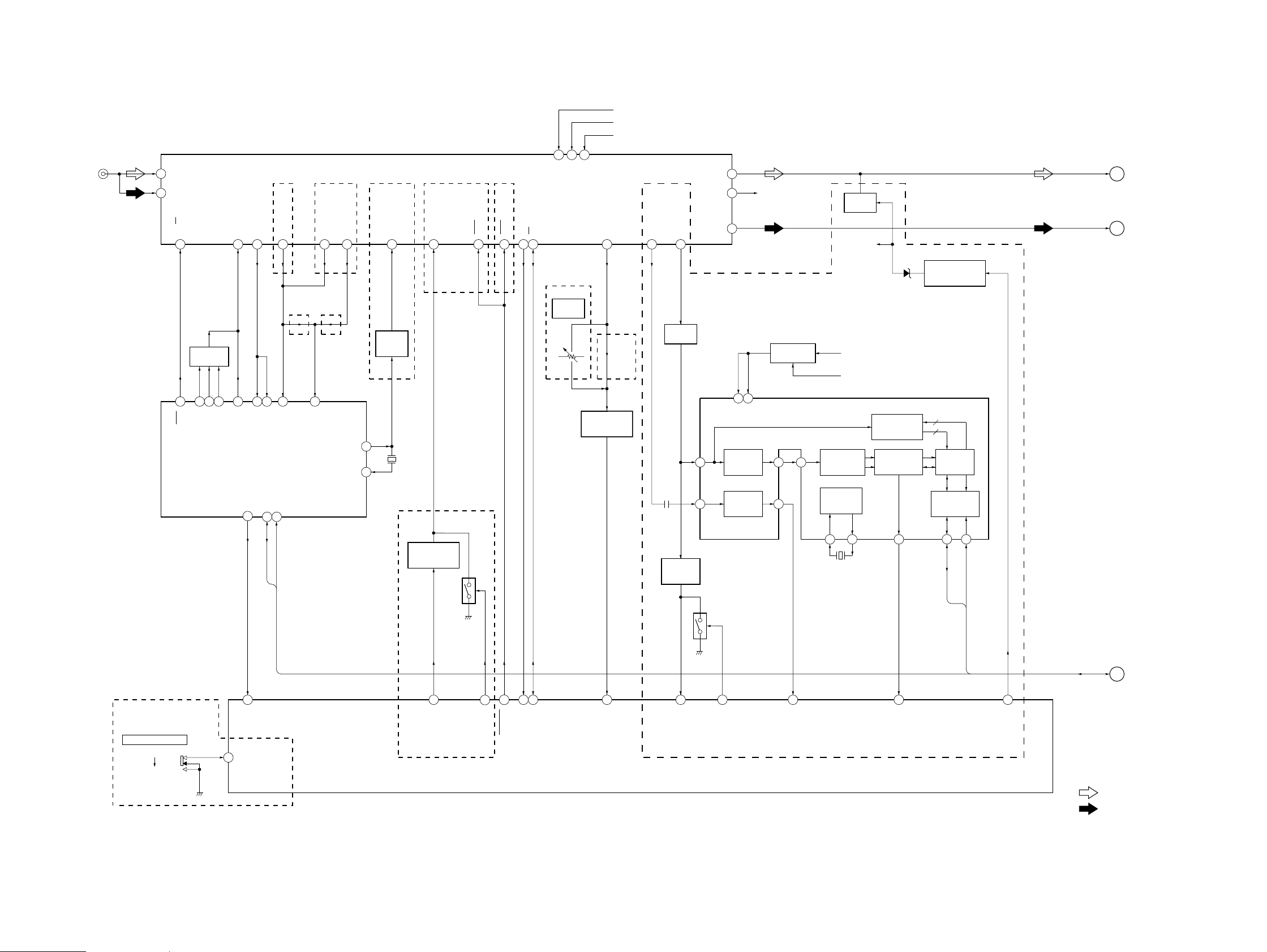

4-2. BLOCK DIAGRAM – TUNER Section –

FM/AM TUNER UNIT

2

1

FM-ANT

AM-ANT

LO/DX

4

TU1

FILTER

VCO

VT

5

FM/AM-IF

6

21

(C7970)

J1

(FM/AM ANTENNA)

(C7970R)

FM-IF

21

(C7970R)

11

AM-IF

13

AM OSC

BUFFER

Q4

AM OSC

WIDE/NARROW

24

MDX-C7970/C7970R

FM B+

AM B+

TUNER B+

9

10

8

(C7970)(C7970R)(C7970)(C7970)

ST/MONO

SD

SEEK

SEEK

20

11

13

22

(C7970R)

FM +B

RV1

FM RDS

S-METER

+B

AM +B

19

(C7970R)

S-METER15S-METER (RDS)

(C7970)

23

BUFFER

Q50

FM-DET

FM-LCH

FM-RCH

AM-DET

18

16

R-CH

12

B+ SWITCH

Q51

MUTING

Q101

R-CH

BACKUP +5V

FM B+

D5

MUTING

CONTROL SWITCH

Q103

FM

AM

E

F

(Page 27)

(Page 27)

(C7970: E model)

S701

FREQUENCY SELECT

MW 10K/FM 200K

MW 9K/FM 50K

05

5 283

2

1

SEEK

LP HC

LP FM

LP AM

100

24

25

FM IN

AM IN

LP OUT

FM/AM PLL

IC100

SSTOP

SDA

16

13 12

DATA

69

SSTOP

BAND (9K-10K)

15

SCL

CLOCK

IF FM

14

IF AM

OSCOUT

OSCIN

10

9

FM/AM SIGNAL

METER BUFFER

Q1

X1

10.25MHz

WIDE/NARROW

SWITCH

Q7

Q8

WIDE/

NARROW

SWITCH

68

NARROW

(C7970R) (C7970R)

66

82

WIDE

SEEKOUT

83

81

SD-IN

ST-MONO

MASTER CONTROLLER

IC700 (1/4)

53

S-METER (VSM)

BAND-PASS

FILTER

IC101

51

QUALITY

16

20

BAND-PASS

MPX

LVIN

Q5

NOISE DET

DISCHARGE

SWITCH

35

NS-MASK

14

7

VDDA

57 kHz

FILTER

MULTI

PATH

DETECTOR

VDDD

OUT

SC

18

MPTH

RDS DECODER

2

52

IC102

CIN

19

MPDH (MTP)

CLOCKED

COMPARATOR

OSCILLATOR

& CLOCK

OSCI

OSCO

4

5

X2

4.332MHz

SIGNAL

QUALITY

DECODER

RDS/RDBS

DEMODULATOR

& DECODER

DAVN

8

67

DAVN

5

4

INTERFACE

REGISTER

IIC BUS

SLAVE

TRANSCEIVER

SDA

SCL

9

10

DATA

CLOCK

62

TU-ATT

DATA, CLOCK

• SIGNAL PATH

(Page 27)

G

: FM

: AM (MW/LW)

– 25 –

– 26 –

Loading...

Loading...