Page 1

MDX-C5960R/C5970/C5970R

SERVICE MANUAL

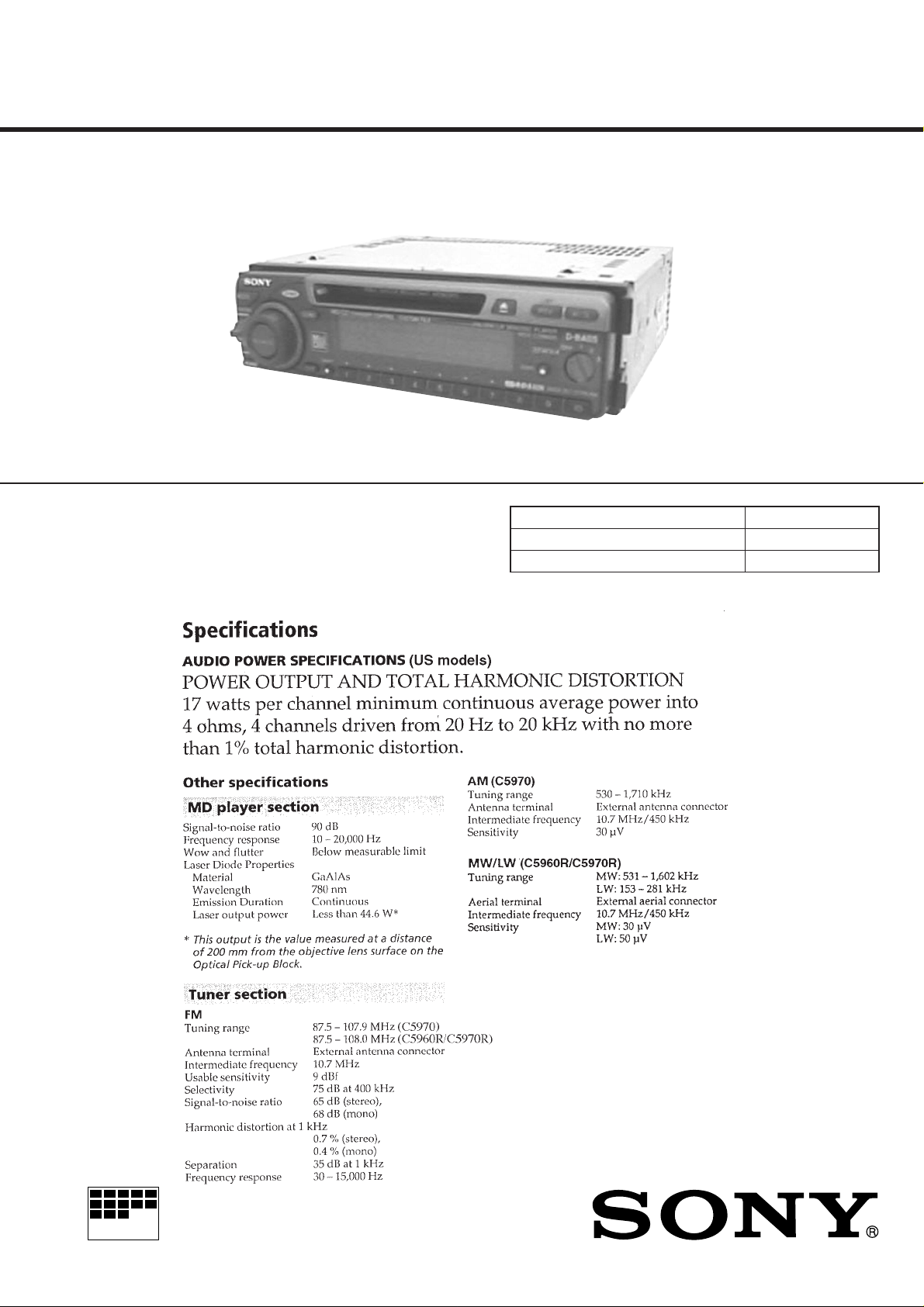

Photo: MDX-C5960R

SPECIFICATIONS

German Model

MDX-C5960R

US Model

Canadian Model

E Model

MDX-C5970

AEP Model

UK Model

MDX-C5970R

Model Name Using Similar Mechanism MDX-C7900/C7900R

Base Mechanism Type MG-164N-138

Optical Pick-Up Name KMS-241B/J1NP

MICROFILM

– Continued on next page –

FM/AM (MW/LW) MINIDISC PLAYER

Page 2

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right avove when

checking it for adustment. It is feared that you will lose your sight.

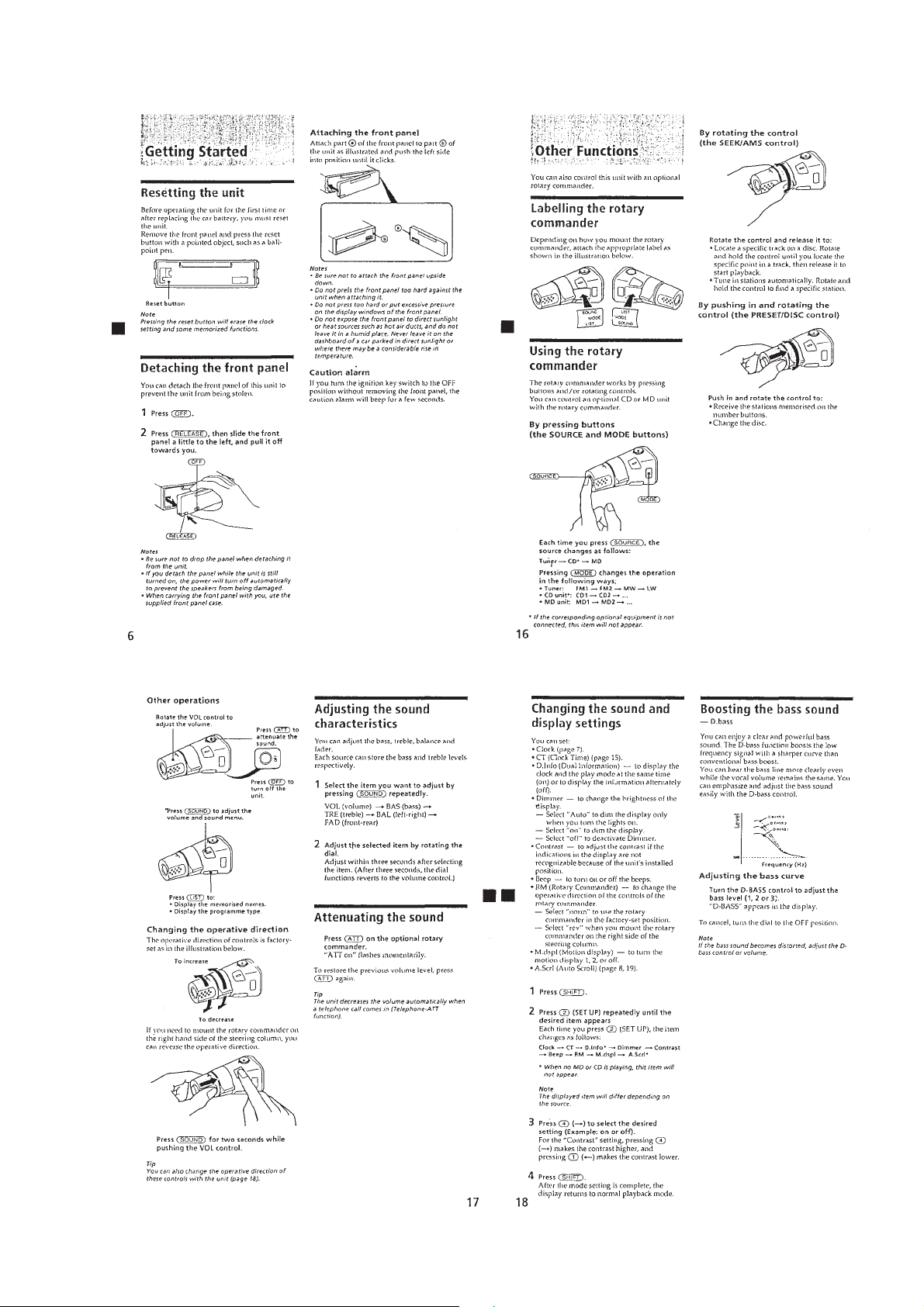

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

(KMS-241B/J1NP).

The laser diode in the optical pick-up block may suffer electrostatic break-down easily. When handling it, perform soldering

bridge to the laser-tap on the flexible board. Also perform m easures

against electrostatic break-down suff iciently before the operation.

The flexible board is easily damaged and should be handled with

care.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

laser-tap

OPTICAL PICK-UP FLEXIBLE BOARD

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

– 2 –

Page 3

TABLE OF CONTENTS

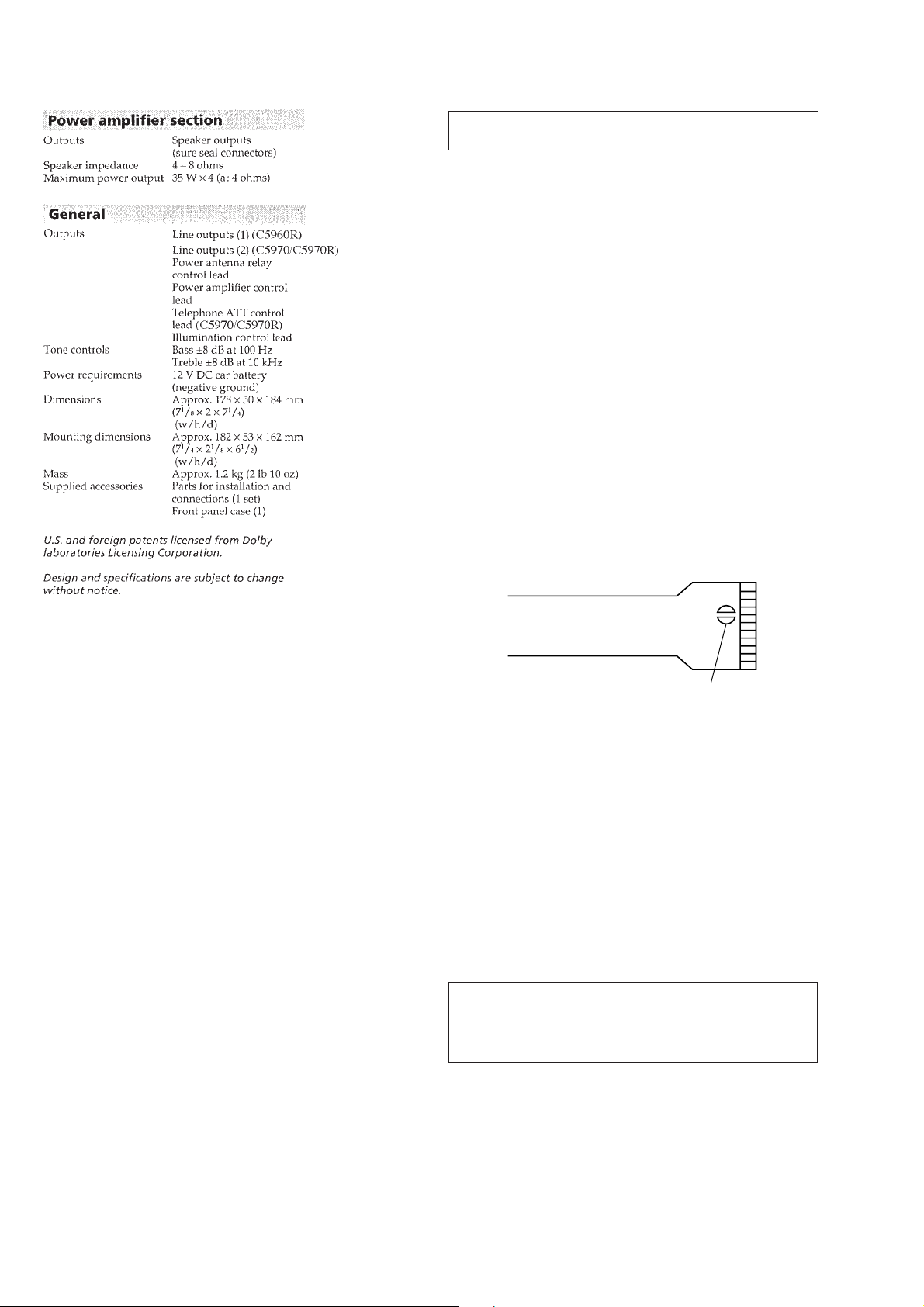

1. GENERAL

Location of controls ........................................................ 4

Resetting the unit ............................................................ 5

Detaching the front panel................................................ 5

Labelling the rotary commander..................................... 5

Using the rotary commander .......................................... 5

Adjusting the sound characterisitics............................... 5

Attenuating the sound ..................................................... 5

Changing the sound and display settings ....................... 5

Boosting the bass sound.................................................. 5

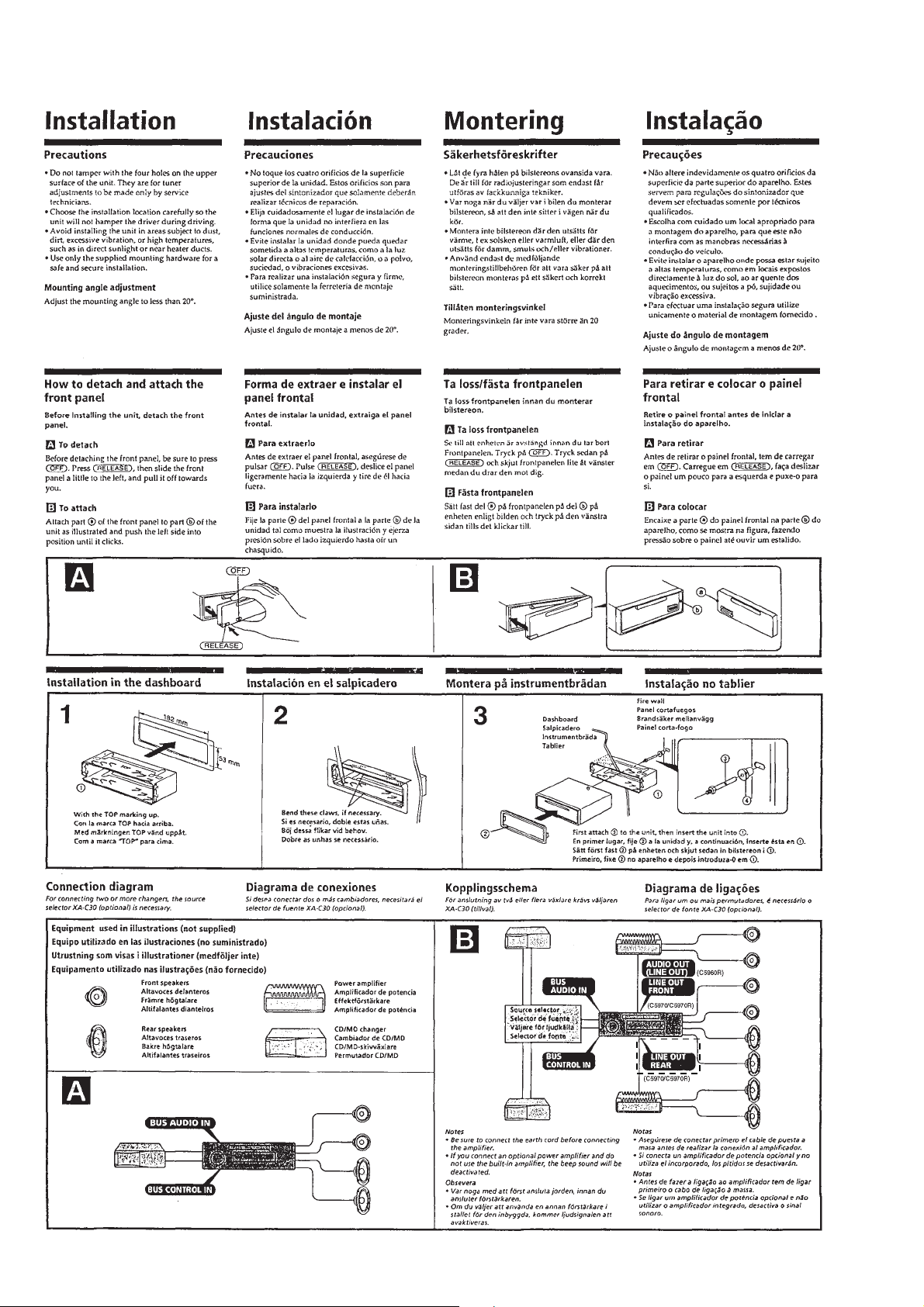

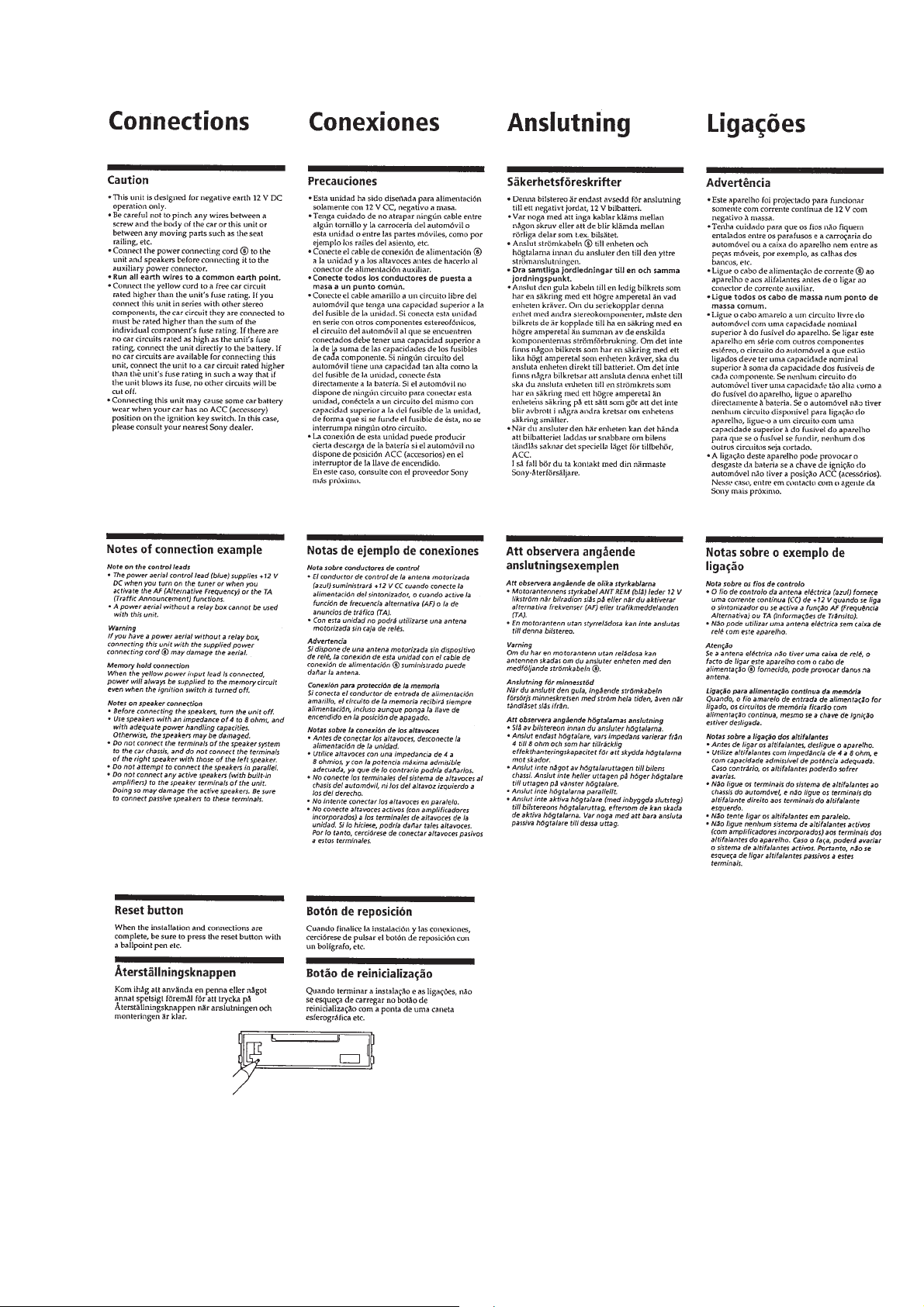

Installation....................................................................... 6

Connections..................................................................... 7

2. DISASSEMBLY ......................................................... 10

3. ELECTRICAL ADJUSTMENTS......................... 16

Test Mode........................................................................ 16

MD Section ..................................................................... 16

Tuner Section .................................................................. 16

4. DIAGRAMS

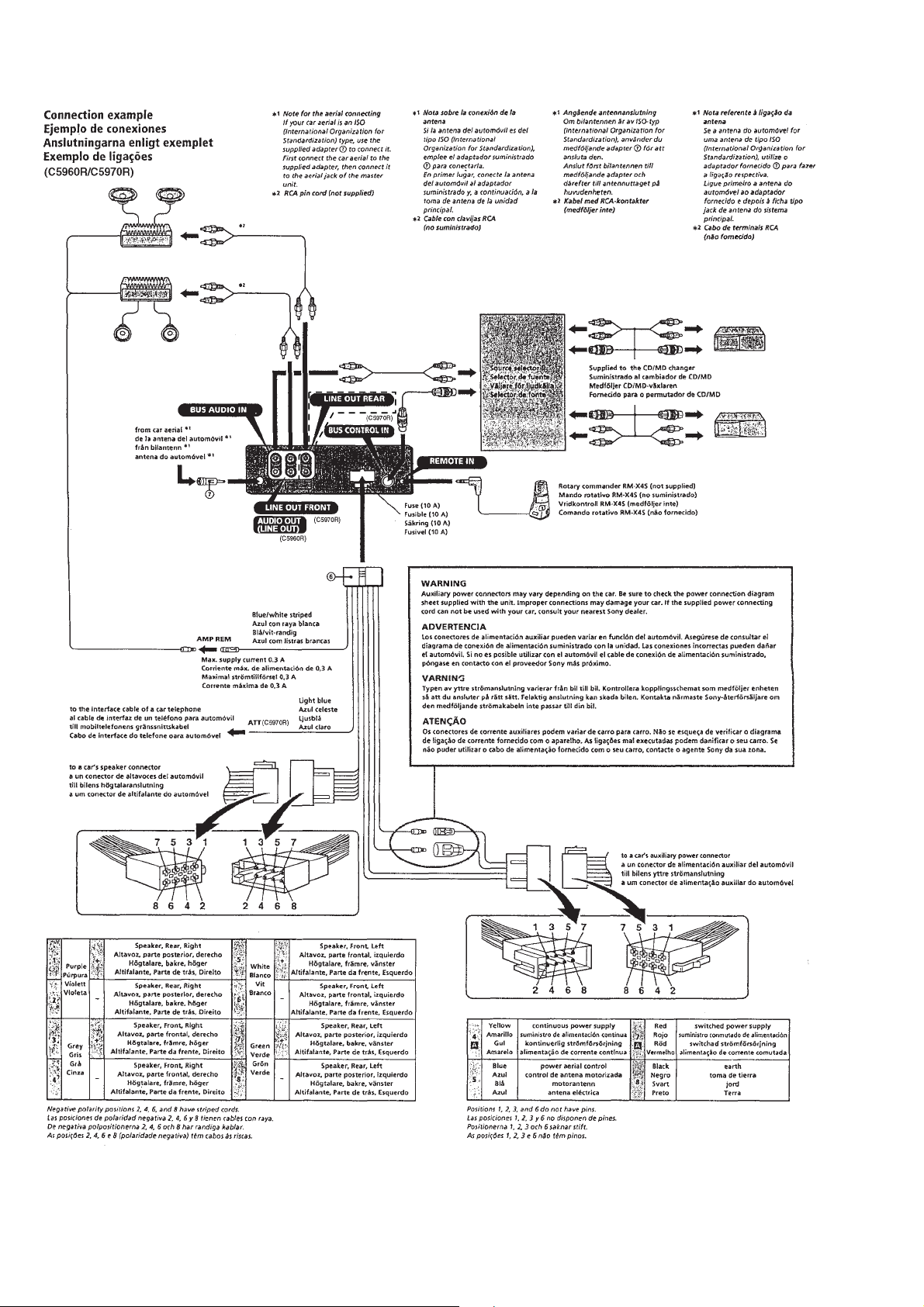

4-1. Block Diagram – SERVO Section – ............................... 19

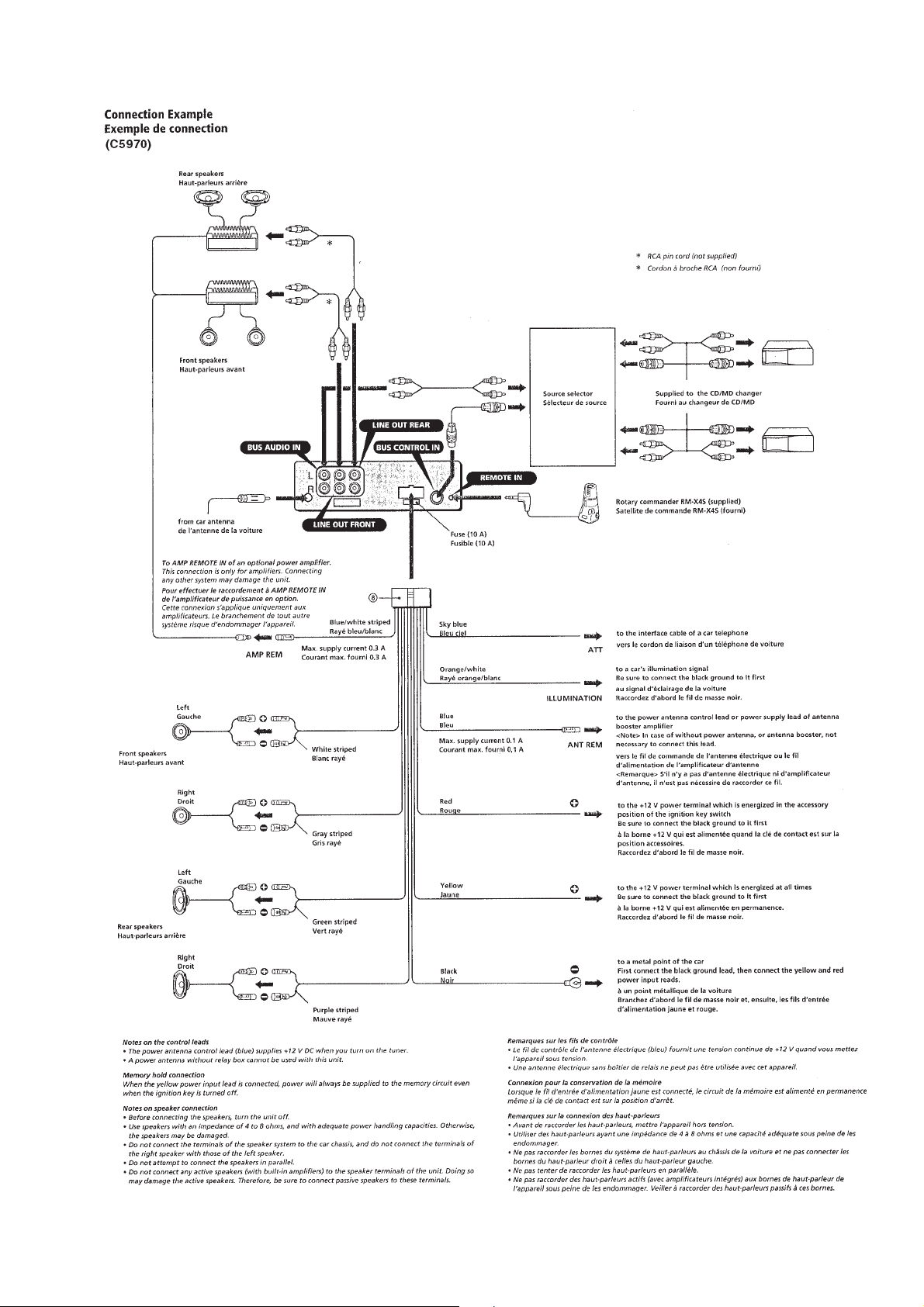

4-2. Block Diagram – TUNER Section – .............................. 21

4-3. Block Diagram – MAIN Section – ................................. 23

4-4. Block Diagram

– DISPLAY/KEY CONTROL Section –........................ 25

4-5. Block Diagram – BUS CONTROL/

POWER SUPPLY Section – ........................................... 27

4-6. Notes for Printed Wiring Boards and

Schematic Diagrams ....................................................... 29

4-7. Printed Wiring Board – SERVO Board – ....................... 31

4-8. Schematic Diagram – SERVO Board (1/3) – ................. 33

4-9. Schematic Diagram – SERVO Board (2/3) – ................. 35

4-10. Schematic Diagram – SERVO Board (3/3) – ................. 37

4-11. Printed Wiring Board

– MAIN Board (Component Side) – .............................. 39

4-12. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 41

4-13. Schematic Diagram – MAIN Board (1/4) – ................... 43

4-14. Schematic Diagram – MAIN Board (2/4) – ................... 45

4-15. Schematic Diagram – MAIN Board (3/4) – ................... 47

4-16. Schematic Diagram – MAIN Board (4/4) – ................... 49

4-17. Printed Wiring Board – KEY Board –............................ 51

4-18. Schematic Diagram – KEY Board – .............................. 53

4-19. IC Pin Function Description ........................................... 62

5. EXPLODED VIEWS................................................ 72

6. ELECTRICAL PARTS LIST ............................... 76

– 3 –

Page 4

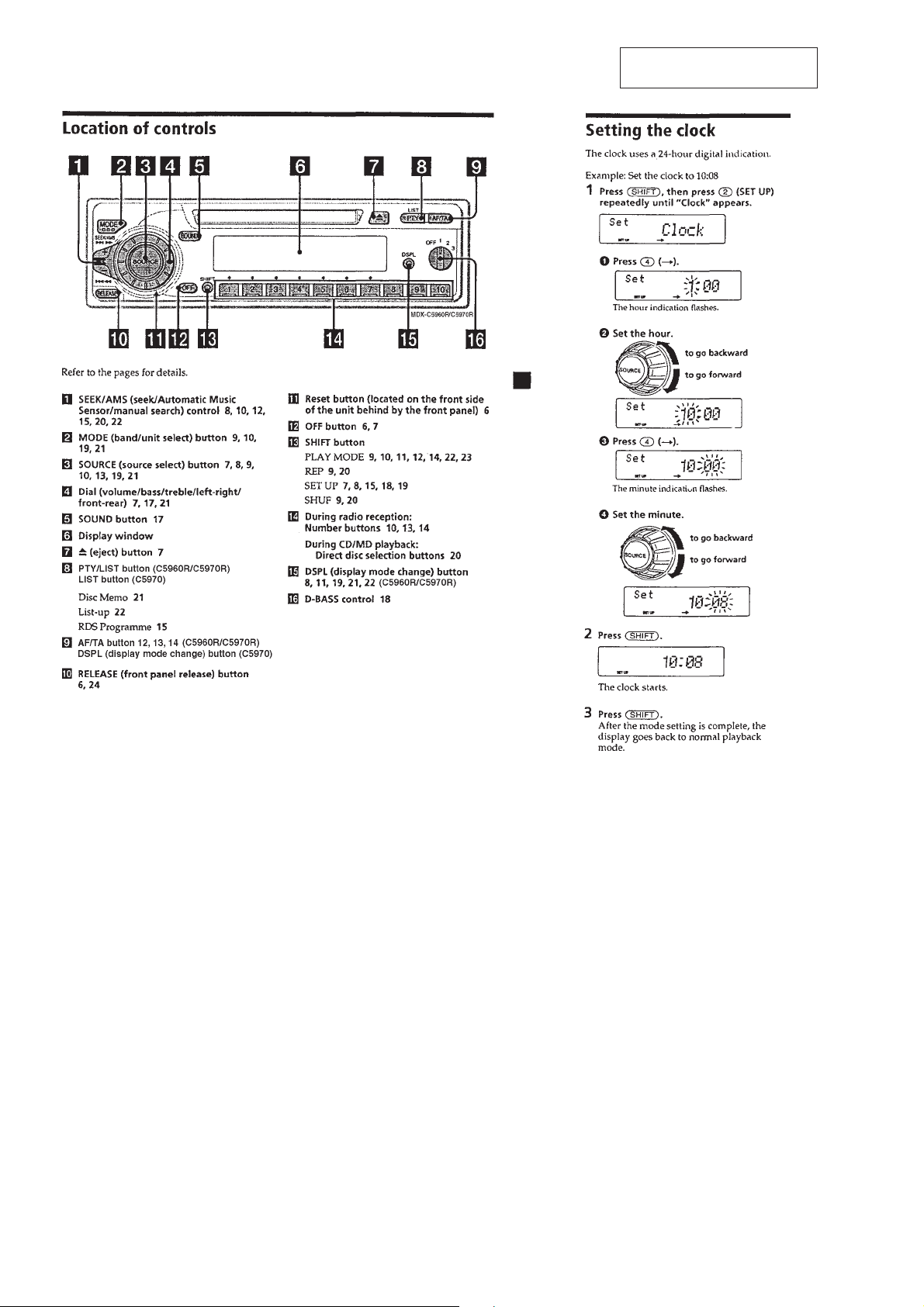

SECTION 1

GENERAL

This section is extracted from

instruction manual.

– 4 –

Page 5

– 5 –

Page 6

– 6 –

Page 7

– 7 –

Page 8

– 8 –

Page 9

– 9 –

Page 10

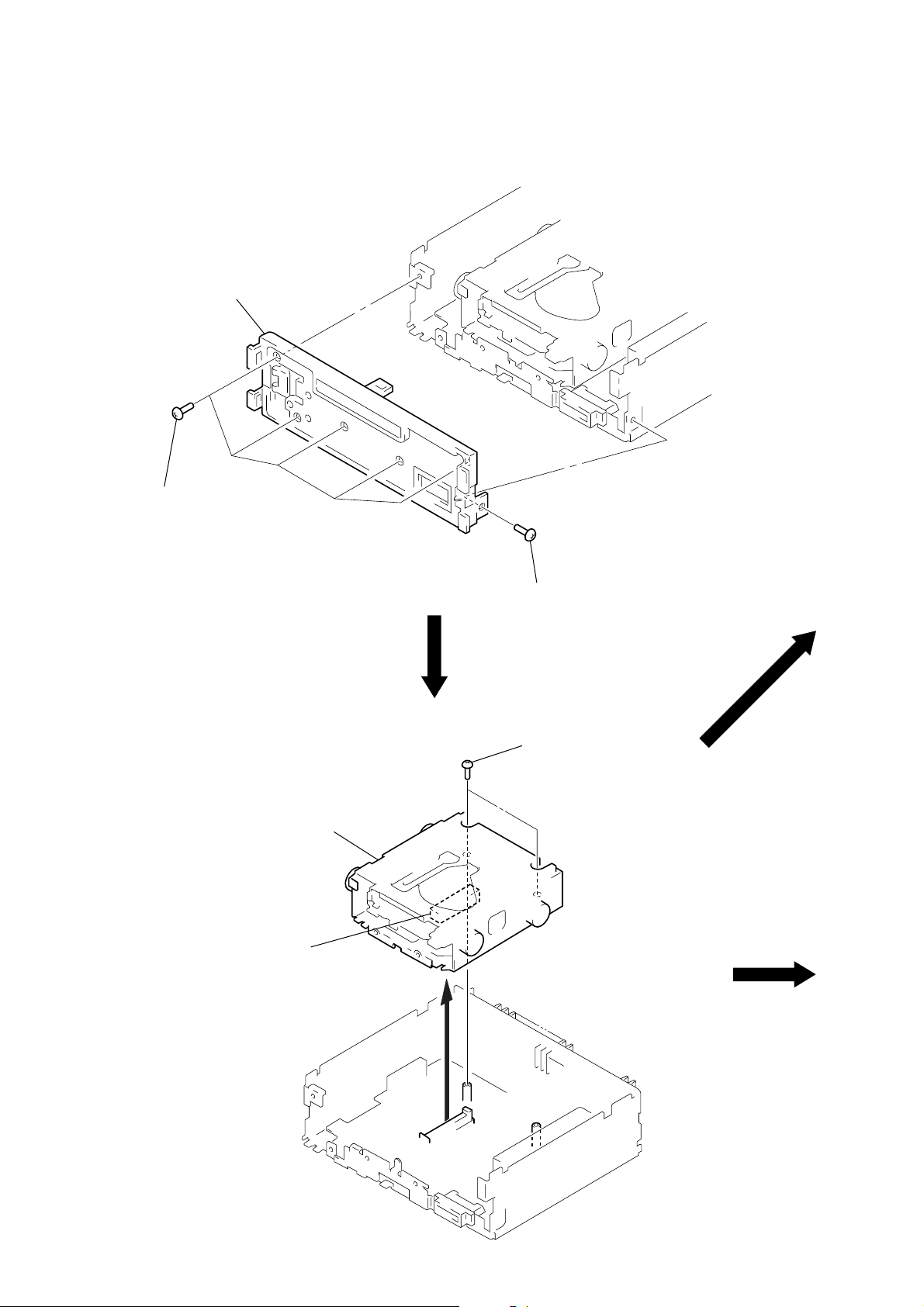

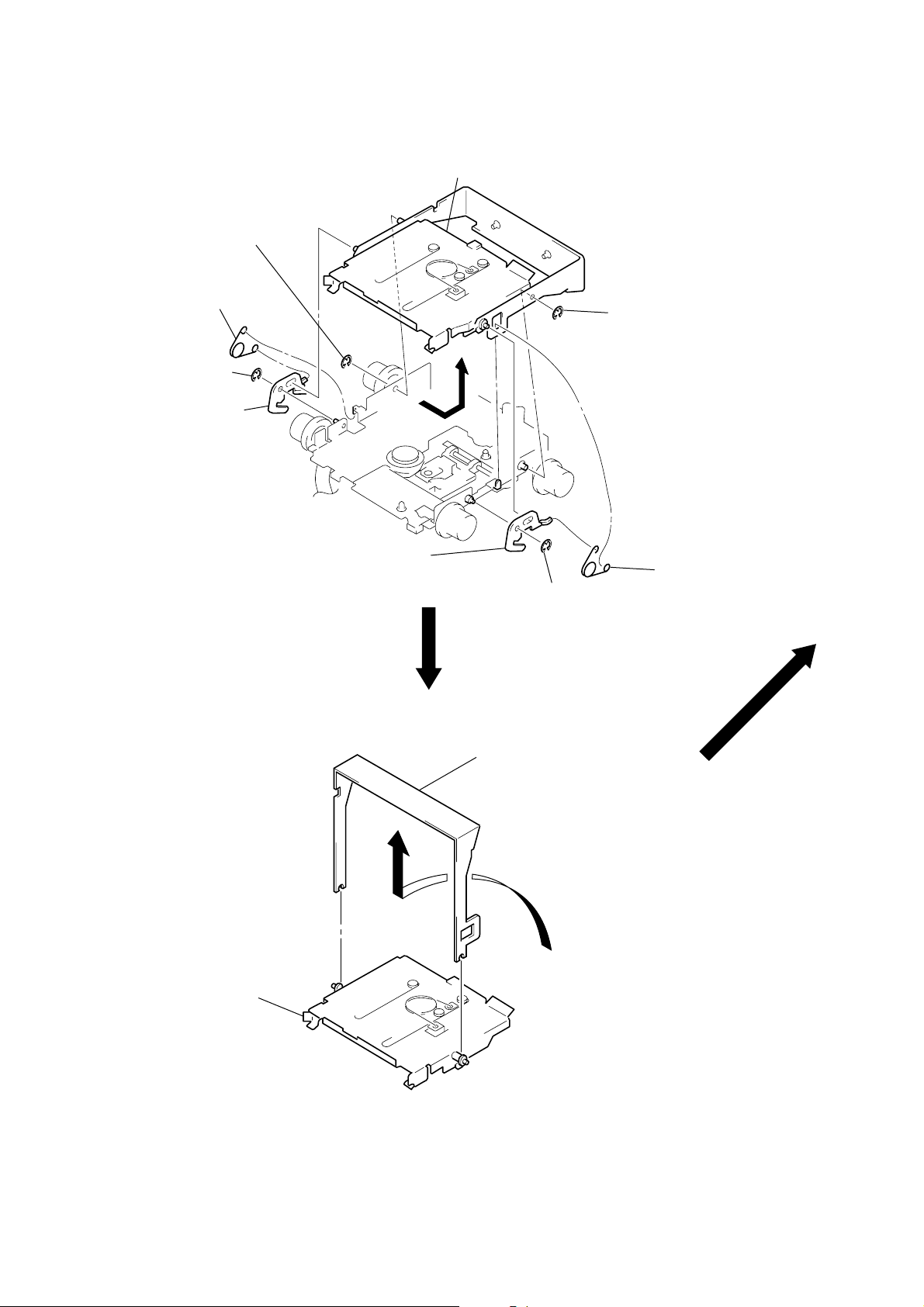

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

SUB PANEL

2

sub panel

1

five screws

(PTT2.6

×

6)

MECHANISM DECK (MG-164N-138)

3

mechanism deck

(MG-164N-138)

2

connector

(CN200)

1

screw

(PTT2.6

1

two screws

(PTT2.6

×

6)

×

4)

– 10 –

Page 11

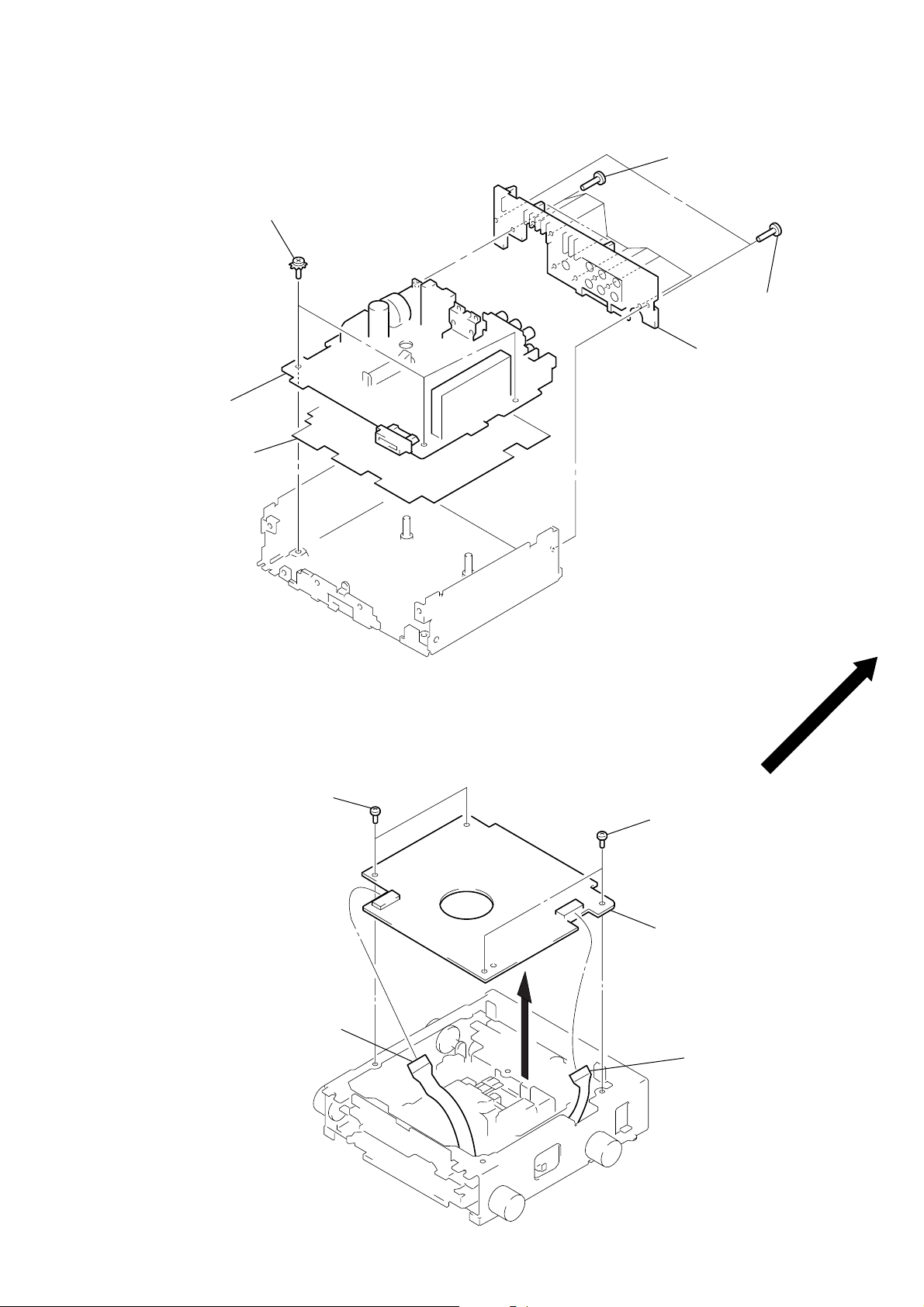

MAIN BOARD, HEAT SINK

d

2

three screws

(PTT2.6

3

main board

4

insulating sheet

×

6) (ground point)

5

eight screws

(PTT2.6

6

×

10)

1

two screws

(PTT2.6

heat sink

×

10)

SERVO BOARD

1

2

two screws

(BVTT2

×

4)

sensor flexible board

(CN102)

2

two screws

(BVTT2

×

4)

3

servo board

1

flexible boar

(CN103)

– 11 –

Page 12

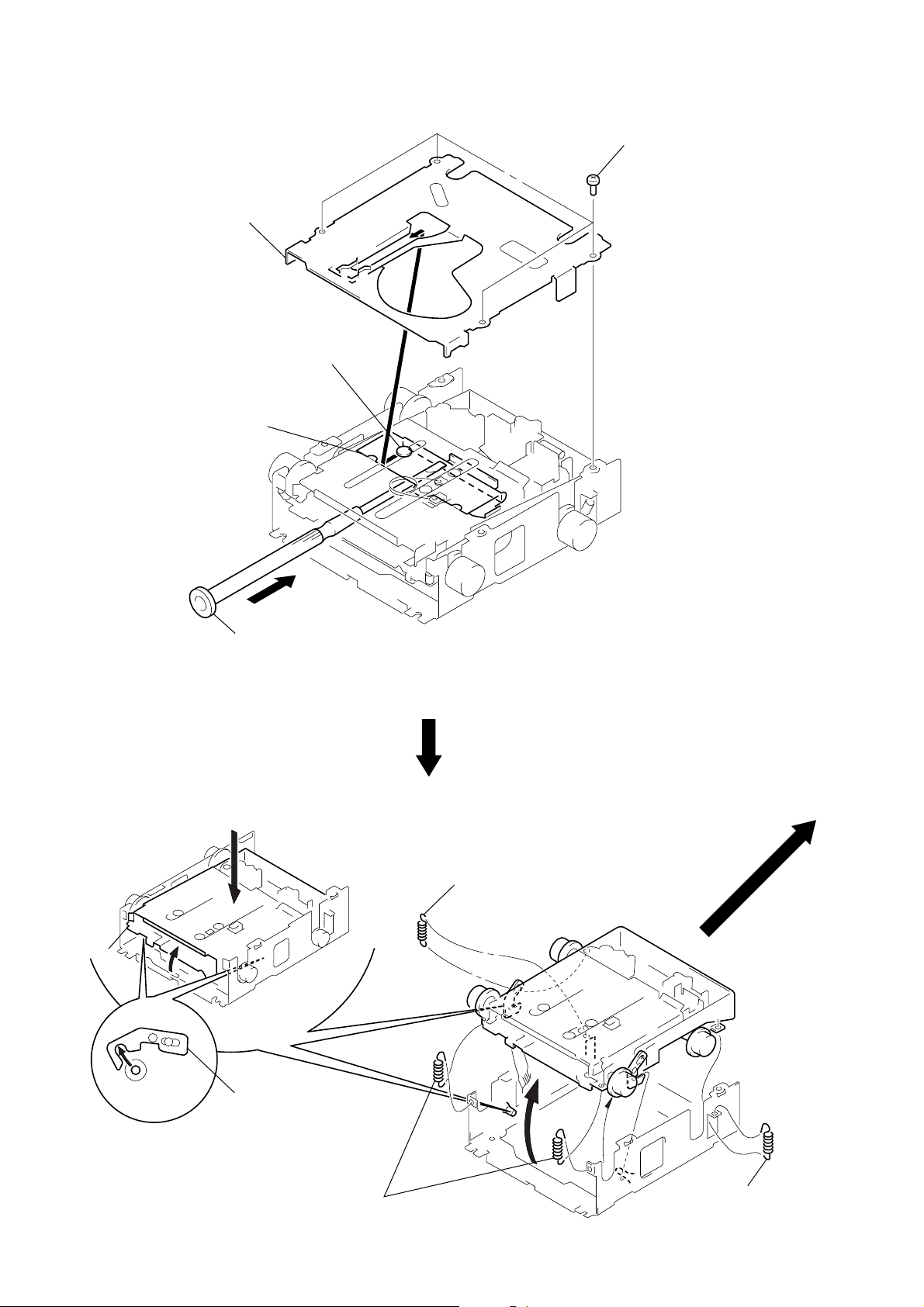

)

MD COVER ASS’Y

3

MD cover ass’y

shaft (MD cover guide)

cassette holder

1

four screws

(B2 × 3)

FLOAT BLOCK

float block

A

2

Pushing the Cassette Holder toward the direction A with a

screwdriver, etc., disengage the Shaft (MD Cover Guide) from

the slot in the MD Cover Assy.

Note:Take care not to scratch the optiocal Pick-up when pushing

the Cassette Holder with a screwdriver. etc.

3

Pushing an arrow A part, raise the float block

up ward at the front to release a lock.

1

A

tension spring (FL2)

lever (lock R)

lever (lock L)

2

two tension springs (FLOAT F)

– 12 –

1

tension spring (FL2

Page 13

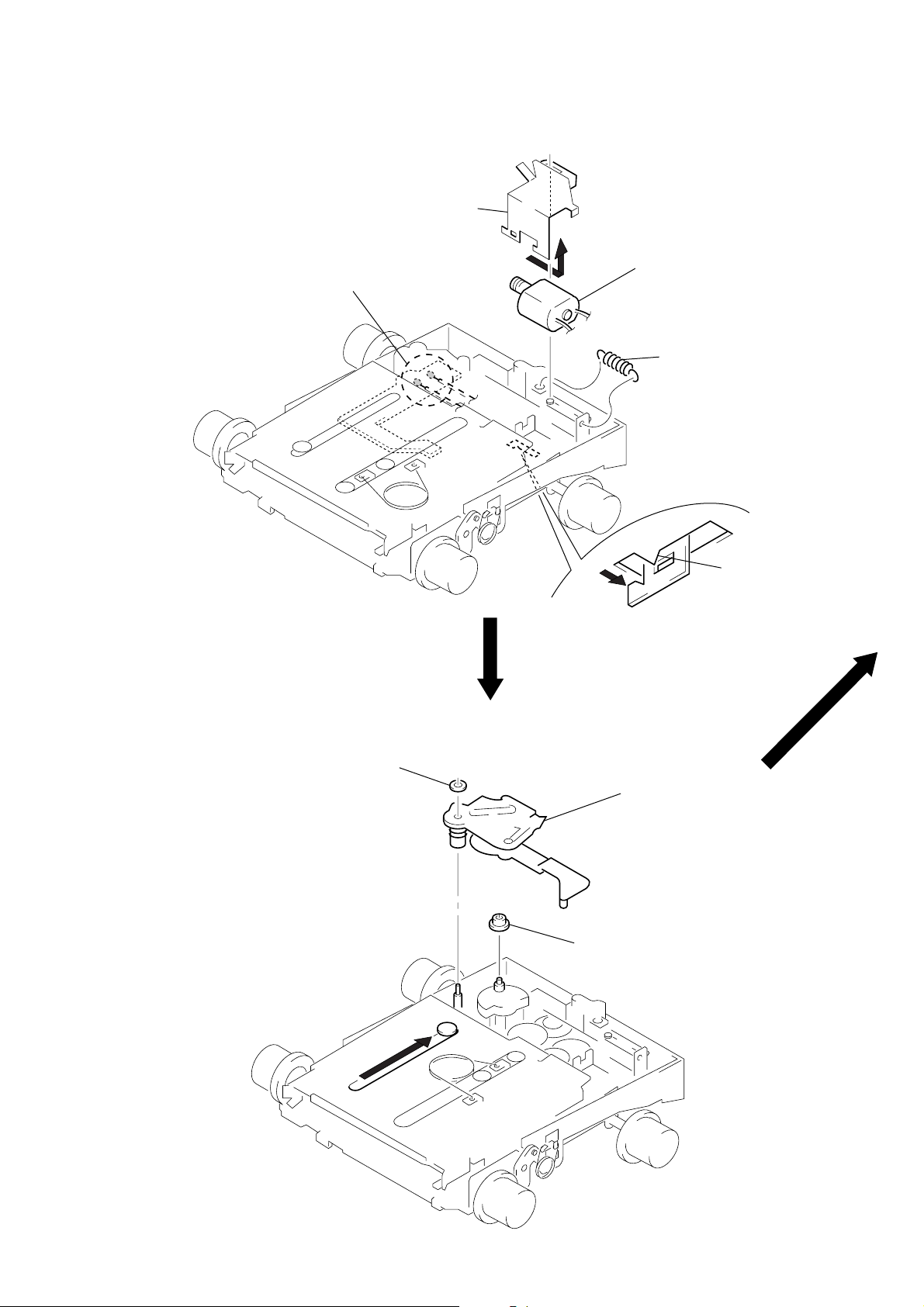

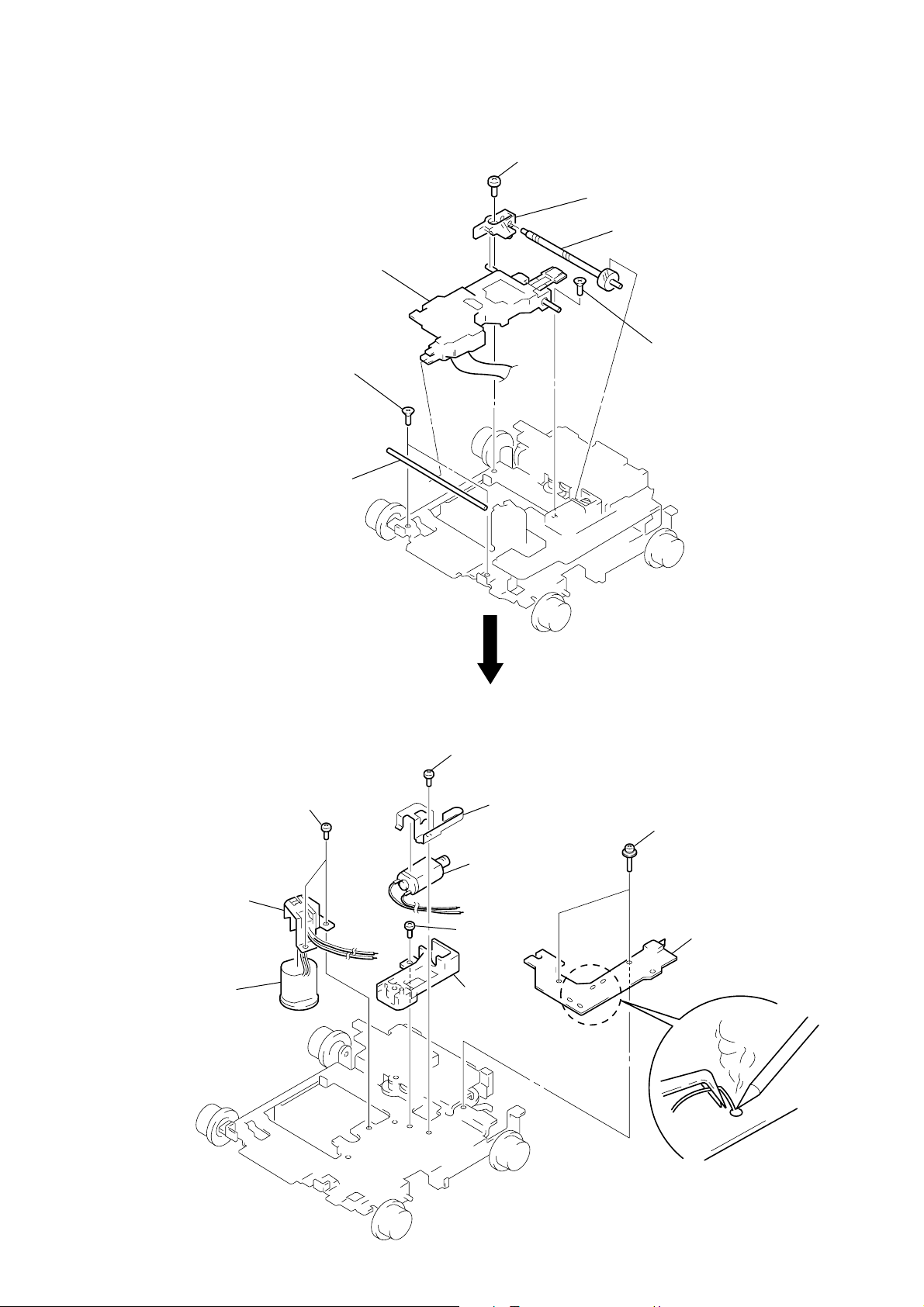

LO MOTOR ASS’Y (LOADING) (M903)

4

Remove the bracket (LO)

in the direction of the arrow

A

.

1

Remove solders of motor (M903)

A

5

LO motor ass’y (loading)

(M903)

2

tension spring (rack)

3

claw

LEVER (LE) ASS’Y

2

stopper washer

1

3

roller (GLE)

2

lever (LE) ass’y

– 13 –

Page 14

HOLDER ASS’Y

2

type-E stopring 1.5

3

2

type-E stopring 1.5

1

spring (CHKG)

lever (lock R)

3

lever (lock L)

4

Remove the holder ass’y in the

direction of the arrow.

2

2

type-E stopring 1.5

1

type-E stopring 1.5

spring (CHKG)

CHUCKING ARM ASS’Y

holder ass’y

1

Remove the chucking arm ass’y

in the direction of the arrow.

– 14 –

Page 15

OPTICAL PICK-UP (KMS-241B/J1NP)

y

4

screw

(P1.7 × 1.8)

5

bracket (SL)

9

two screws

(P1.7 × 1.8)

!º

retainer (SP)

!¡

SP motor ass’y

(spindle) (M901)

7

screw

(B2 × 3)

2

two screws

(2 × 8)

3

sensor board

1

Remove solders of motors

(M901, M902)

8

base (SL)

6

SL motor ass’y

(sled) (M902)

7

optical pick-up

(KMS-241B/J1NP)

1

two screws

(K2 × 3)

2

shaft (SL2)

4

screw

(B2 × 3)

6

bearing (SL)

5

feed screw ass’

3

screw

(K2 × 3)

SL MOTOR ASS’Y (SLED) (M902), SP MOTOR ASS’Y (SPINDLE) (M901)

– 15 –

Page 16

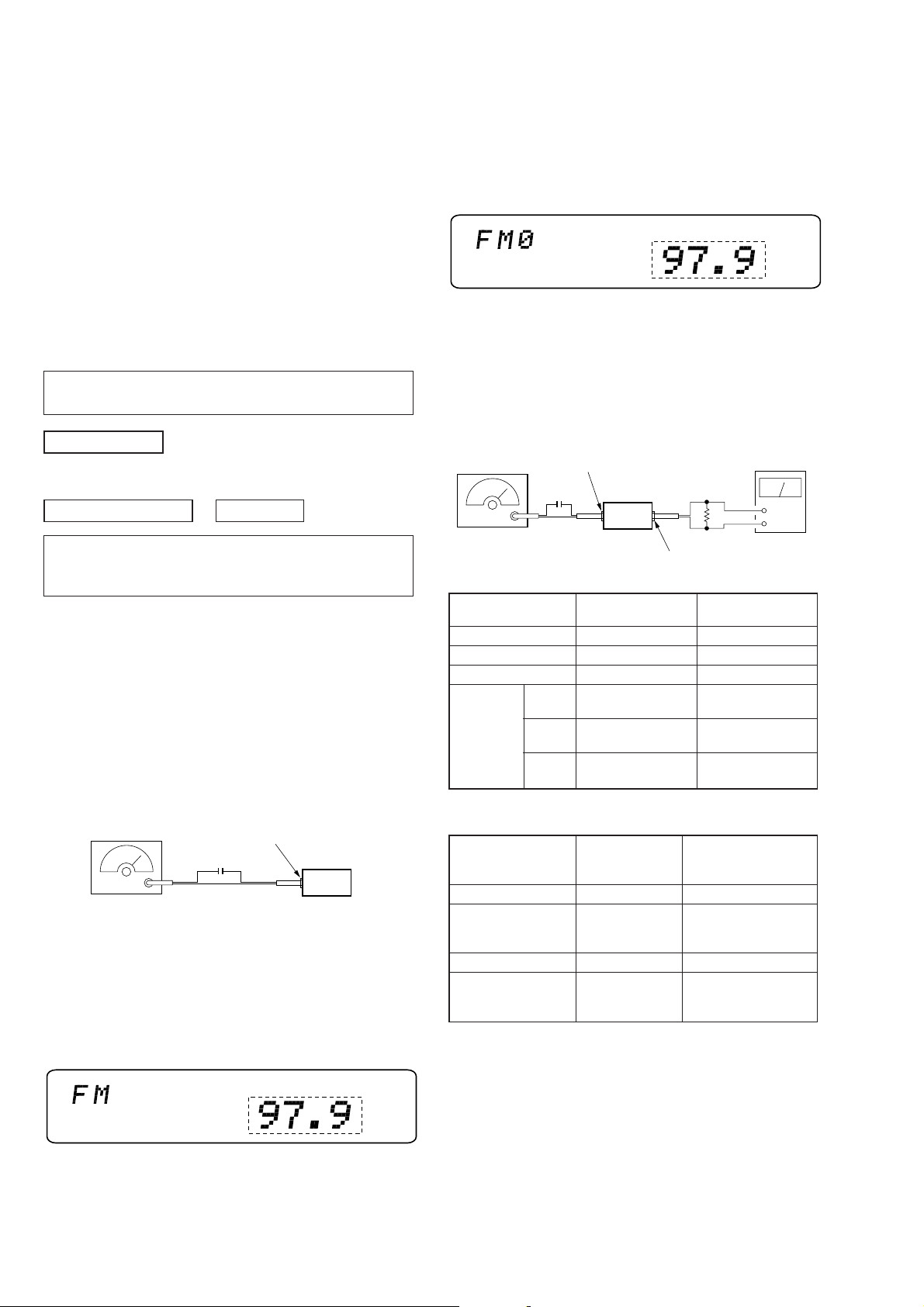

SECTION 3

ELECTRICAL ADJUSTMENTS

TEST MODE

This set have the test mode function. In the test mode, FM Auto

Scan/Stop Level and AM (MW) Auto Scan/Stop Lev el adjustments

can be performed easier than it in ordinary procedure.

<Set the Test Mode>

1. Turn ON the regulated po wer supply. (The clock is displayed)

Note: Press the [OFF] button, if the clock is not displayed.

2. Push the preset [4] button.

3. Push the preset [5] button.

4. Press the preset [1] button for more than two seconds.

5. Then the display indicates all lights, the test mode is set.

<Release the Test mode>

1. Push the [OFF] button.

See the adjustment location from on page 18 for the adjustment.

MD SECTION

MD section adjustments are done automatically in this set.

TUNER SECTION

Cautions during repair

When the tuner unit is defective, replace it by a new one because its internal block is difficult to repair.

Note:

Adjust the tuner section in the sequence shown below.

1. FM Auto Scan/Stop Level Adjustment.

2. FM Stereo Separation Adjustmnet.

3. AM (MW) Auto Scan/Stop Level Adjustment.

4. RDS S-Meter Adjustment. (MDX-C5960R/5970R)

FM Auto Scan/Stop Level Adjustment

Setting:

[SOURCE] button: FM

FREQUENCY SELECT switch: FM 200 k (E model)

0 dB=1 µV

3. Adjust with the volume R V2 on TU1 so that the “FM” indication turns to “FM0” indication on the display window.

But, in case of already indicated “FM0”, turn the RV2 so that

put out light “0” indication and adjustment.

Display

SHUF

*1

*1: MDX-C5960R/C5970R indicate “98.00”.

Adjustment Location: See page 18.

FM Stereo Separation Adjustment

Setting:

[SOURCE] button: FM

FREQUENCY SELECT switch: FM 200 k (E model)

FM RF signal

generator

Carrier frequency 97.9 MHz 98.0 MHz

Output level 60 dB (1 mV) 70 dB (3.2 mV)

Mode stereo stereo

Modulation sub

antenna jack (J1)

0.01 µF

set

LINE OUT jack (CNP300)

MDX-C5970

main

19 kHz 7.5 kHz 7.5 kHz

pilot deviation (10%) deviation (10%)

1 kHz, 33.75 kHz 1 kHz, 16.25 kHz

deviation (45%) deviation (21.7%)

1 kHz, 33.75 kHz 1 kHz, 16.25 kHz

deviation (45%) deviation (21.7%)

10 k

level meter

Ω

+

–

MDX-C5960R/

C5970R

FM RF signal

generator

Carrier frequency: 97.9 MHz (MDX-C5970)

Output level : 22 dB (12.6

Mode : mono

Modulation : 1 kHz, 22.5 kHz deviation (30%)

98.0 MHz (MDX-C5960R/C5970R)

antenna jack (J1)

0.01 µF

µ

V)

Procedure:

1. Set to the test mode.

2. Push the [SOURCE] button and set to FM.

Display

SHUF

*1

set

Procedure:

FM Stereo

signal generator

output channel

L-CH L-CH A

R-CH L-CH Adjust RV4 on TU1

R-CH R-CH C

L-CH R-CH Adjust RV4 on TU1

Level meter Level meter

connection reading (dB)

for minimum reading.

for minimum reading.

L-CH Stereo separation: A-B

R-CH Stereo separation: C-D

The separations of both channels should be equal.

Specification: Separation more than 30 dB

Adjustment Location: See page 18.

B

D

– 16 –

Page 17

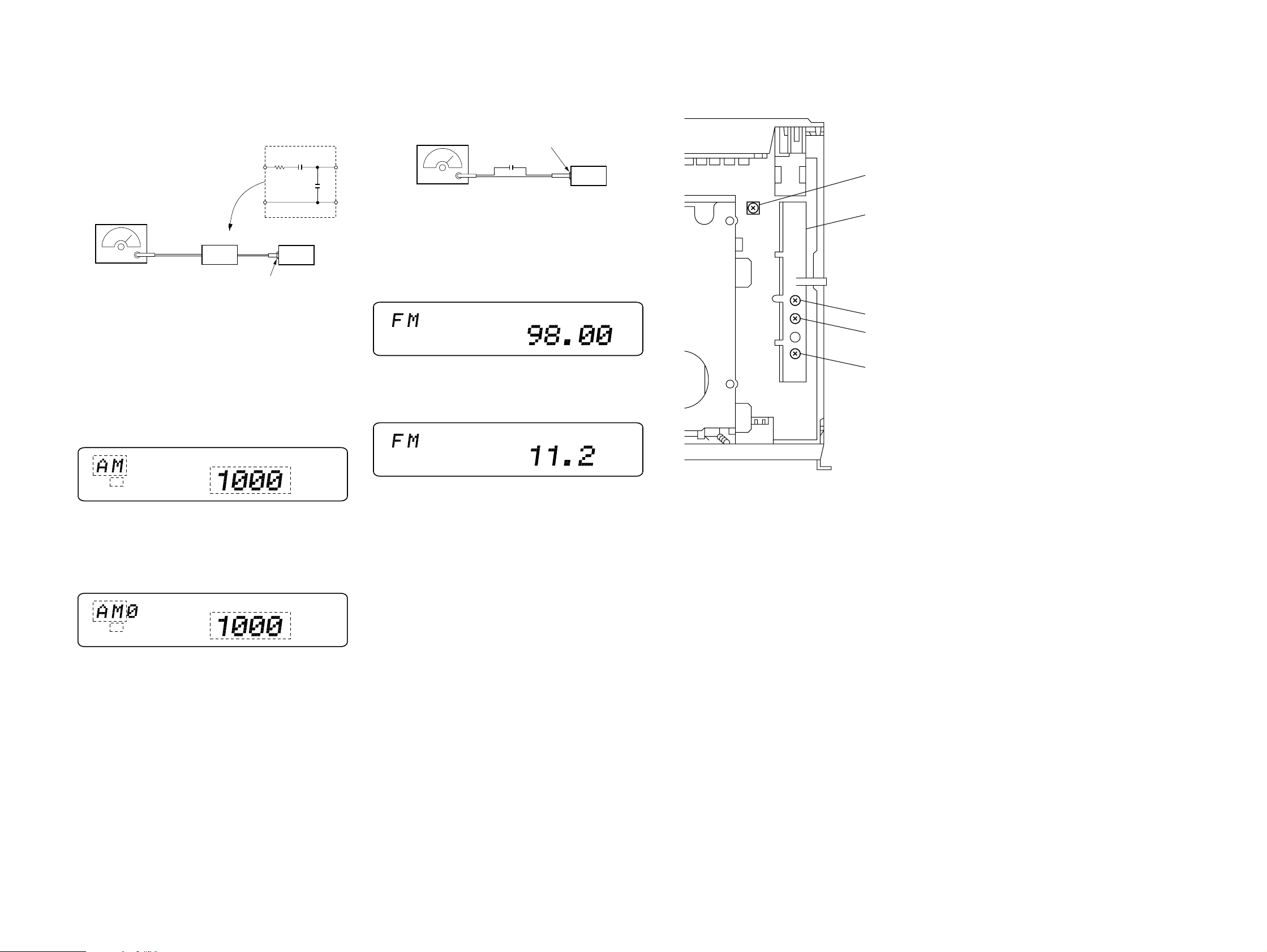

AM (MW) Auto Scan/Stop Level Adjustment

t

Setting:

[MODE] button (MDX-C5970): AM

[MODE] button (MDX-C5960R/C5970R): MW

FREQUENCY SELECT switch: AM 10 k (E model)

15 pF

30

Ω

65 pF

AM RF signal

generator

AM dummy antenna

(50 Ω)

antenna jack (J1)

Carrier frequency: 1000 kHz (MDX-C5970)

30% amplitude

modulation by

1 kHz signal

Output level : 33 dB (44.7

999 kHz (MDX-C5960R/5970R)

µ

V)

set

Procedure:

1. Set to the test mode. (See page 16)

2. Push the [SOURCE] button and set to FM.

3. Push the [MODE] button and set to AM (MDX-C5970) or MW

(MDX-C5960R/C5970R).

RDS S-Meter Adjustment (MDX-C5960R/C5970R)

Setting:

[SOURCE] button: FM

FM RF signal

generator

Carrier frequency: 98.0 MHz

Output level : 35 dB (56.2

Mode : mono

Modulation : no modulation

antenna jack (J1)

0.01 µF

µ

set

V)

Procedure:

1. Set to the test mode. (See page 16)

2. Push the [SOURCE] button and set to FM.

Display

SHUF

3. Push the preset [10] button.

4. Adjust RV1 on MAIN board so that the display indication is

“11.2”.

Display

Adjustment Location:

– SET UPPER VIEW –

RV1 RDS S-Meter Adjustment

(MDX-C5960R/C5970R)

TU1

RV1 AM (MW) Auto Scan/Stop Level Adjustmen

RV2 FM Auto Scan/Stop Level Adjustment

RV4 FM Sereo Separation Adjustment

Display

*2

*3

TP

*4

SHUF

4. Adjust with the volume RV1 on TU1 so that the “ AM” or “MW”

indication turns to “AM0” or “MW0” indication on the display window.

But, in case of already indicated “AM0” or “MW0”, turn the

RV1 so that put out light “0” indication and adjustment.

Display

*2

*3

TP

*4

SHUF

*2: MDX-C5960R/C5970R indicate “MW”.

*3: MDX-C5960R/C5970R indicate “999”.

*4: Only MDX-C5960R/C5970R indicate.

Adjustment Location: See page 18.

SHUF

Specification: Display indication : 10.8 to 11.6

Adjustment Location: See page 18.

– 17 – – 18 –

Page 18

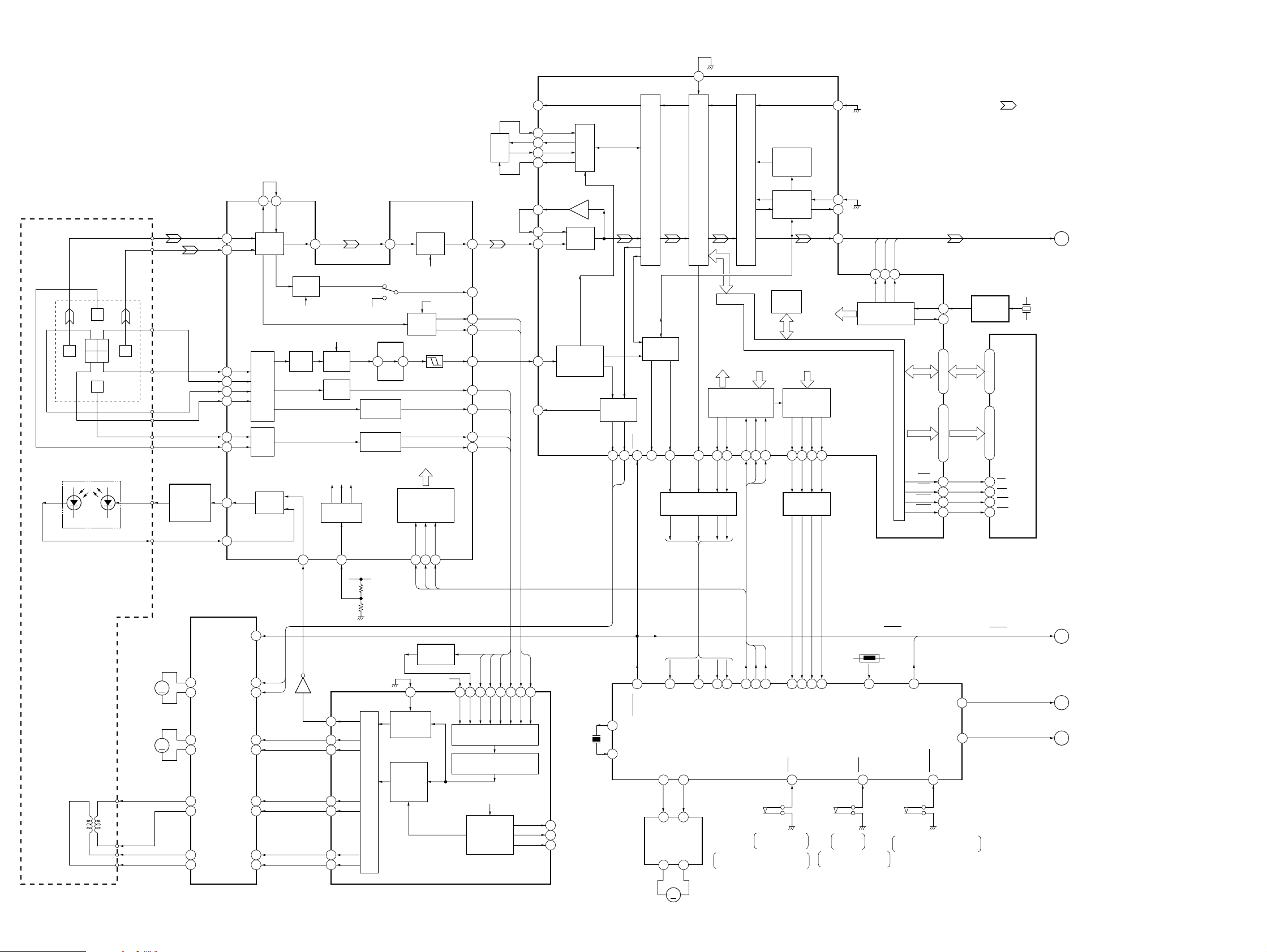

MDX-C5960R/C5970/C5970R

4-1. BLOCK DIAGRAM – SERVO Section –

SECTION 4

DIAGRAMS

100

EFMO

15

TX

IC301 (1/2)

ADDT

• SIGNAL PATH

23

: MD PLAY

FILI

59

PCO

58

61

FILTER

60

RF AMP,

FOCUS/TRACKING ERROR AMP

48 47

MORFI

MORFO

IC303

I

1

RF AMP

J

2

A

4

B

5

I-V

C

AMP

6

D

7

E

8

I-V

F

AMP

9

APC

PD

IN4R

IN4F

IN2F

IN2R

IN1F

IN1R

IN3F

IN3R

LD/PD

16PSB

3

4

29

30

19

18

14

15

11

10

AMP

SPFD

SPRD

RFO

B.P.F.

AT

AMP

12

46

3T

APCREF

IC306

WBL

B.P.F.

ABCD

AMP

WBL3TEQ

V-I

CONVERTER

F0CNT

20

APCREF

83

SFDR

92

SRDR

91

FFDR

88

FRDR

89

TFDR

86

TRDR

85

TEMP

ADFM

29 30

FOCUS

ERROR AMP

TRACKING

ERROR AMP

+3.3V

PWM GENERATOR

40

I

J

F

C B

I J

D A

E

DETECTOR

LASER DIODE

OPTICAL PICK-UP

(KMS-241B/J1NP)

2-AXIS

DEVICE

(FOCUS)

(TRACKING)

05

LDPD

ILCC

PD

M901

(SPINDLE)

M902

(SLED)

FCS+

FCS–

TRK+

TRK–

B

A

C

D

E

F

AUTOMATIC

POWER

CONTROL

Q302

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

OUT4F

6

M

8

OUT4R

OUT2F

27

M

25

OUT2R

OUT1F

21

23

OUT1R

OUT3F

12

10

OUT3R

IC302

AGCI

RF AGC

& EQ

EQ

PEAK &

BOTTOM

ADIN

COMMAND

SERIAL/

PARALLEL

CONVERTER,

DECODER

SCLK

SWDT

1716 18

PEAK HOLD

Q301

+3.3V

13

RECP

AUTOMATIC

POWER

CONTROL

DIGITAL

SERVO

SIGNAL

PROCESS

DIGITAL SERVO

SIGNAL PROCESSOR

IC301 (2/2)

WBL

XLAT

RF

AUX

PEAK

BOTM

ADFG

ABCD

FE

TE

SE

ABCD

AUX1

38

33

37

36

32

35

34

26

28

7465647566 63

FE

TE

AUX2

ABCD

ANALOG MUX

A/D CONVERTER

FROM CPU

INTERFACE

AUTO

SEQUENCER

73 62

SE

PEAK

XLRF

CKRF

DTRF

51

52

55

78

79

BOTM

CLTV

FILO

ASYO

ASYI

COMPA-

RFI

RATOR

ADFG

DEMODULATOR/

DECODER

F0CNT

10MHz

80

81

82

ADIP

X501

PLL

EFM/ACIRC

ENCODER/DECODER

SUBCODE

PROCESSOR

SPINDLE

SERVO

SPFD

SPRD

DQSY11SQSY14XINT

XRST

94 93

10

12

59 62 55 54 52 45 51 64 26 27 28 29

MD-RST

31

EXTAL

XTAL

32

7 6

LOADING

MOTOR DRIVE

IC305

M903

(LOADING)

5 4

RIN FIN

OUT1 OUT2

1 7

SHOCK PROOF

MEMORY CONTROLLER

51331

LEVEL SHIFT

IC502

61242

SQSY

CC-XINT

EJECT

LOAD

M

ATRAC

CPU

INTERFACE

SENS

SRDT

SWDT

9 8 5 6 7

SWDT

SENS

MD-SI

MD-SO

MD MECHANISM CONTROLLER

ON:When the disc loading start

and the disc eject completion.

SAMPLING

RATE

CONVERTER

DIGITAL

AUDIO

ENCODER/DECODER

INTERFACE

D-RAM

INTERNAL BUS

MONITOR

CONTROL

SCLK

XLAT

MNT0

1 2 3 4

13

LEVEL SHIFT

IC503

12

FOK

SCLK

XLAT

MNT0

MD-LAT

MD-CKO

IC501 (1/2)

C-SW

63

LOADING START/

EJECT END

DIN

DOUT

DADT

MNT1

MNT2

MNT3

135

246

SHOCK

XBUSY

SLOCK

MNT1

MNT2

MNT3

ON:When completion of

DIGITAL SIGNAL PROCESSOR,

EFM/ACIRC ENCODER/DECODER,

SHOCK PROOF MEMORY CONTROLLER,

ATRAC ENCODER/DECODER, 2M BIT D-RAM

21

22

24

LOADING

END

the disc loading.

IC301 (1/2)

BCK

LRCK

FS256

2526 27

XBCK

LRCK

FS256

CLOCK

GENERATOR

RESET

TH501

39

TEMP

E-SW

11 56

OSCI

OSCO

XOE

XWE

XRAS

XCAS

EMPHASIS

66

DEEMP

(LIMIT)

ON:When the optical pick-up is

inner position.

A-MUTE

16

17

D0 – D3A00 – A09

47, 46, 48, 49

32 – 29, 34 – 38, 43

41 22

45 3

44 4

42 23

LOCK

21

67

LIMIT-IN

DADT, BCK, LRCK, FS256

512FS OSC

IC304

D0 – D3

1, 2, 24, 25

A0 – A9

9 – 12, 14 – 18, 5

OE

WE

RAS

CAS

D-RAM

IC307

RESET, EMPHASIS

LOCK

MD-ATT

(Page 23)

A

X301

22.5792MHz

(Page 23)

B

C

(Page 23)

D

(Page 23)

– 19 – – 20 –

Page 19

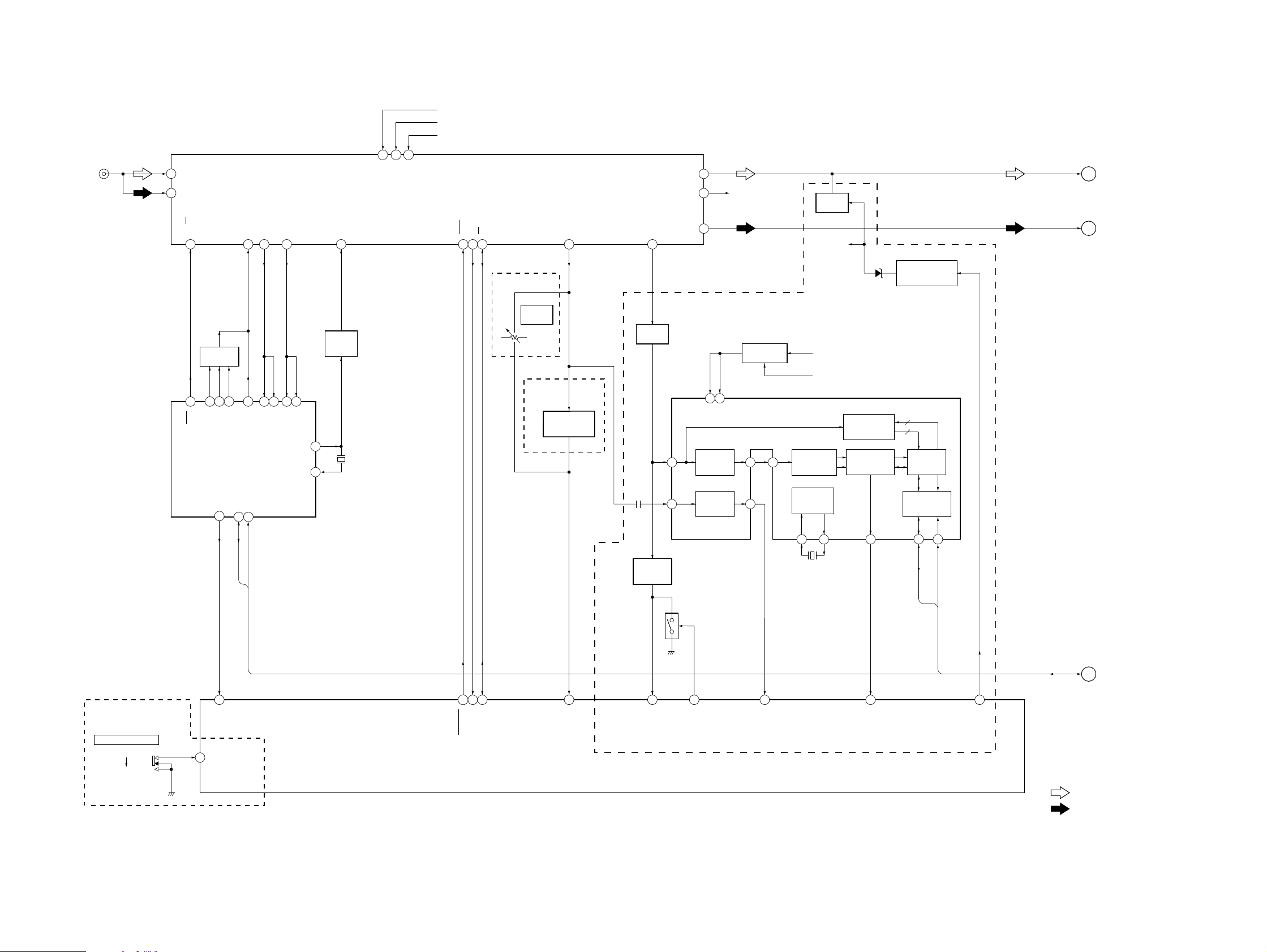

4-2. BLOCK DIAGRAM – TUNER Section –

FM/AM TUNER UNIT

2

1

FM-ANT

AM-ANT

TU1

LO/DX

4

FILTER

5 283

2

1

SEEK

LP HC

LP FM

SSTOP

16

LP AM

FM/AM PLL

IC100

SDA

13 12

VT

5

LP OUT

SCL

24

6

VCO

25

FM IN

21

15

AM IN

OSCOUT

FM/AM-IF

14

IF FM

IF AM

OSCIN

J1

(FM/AM ANTENNA)

10

9

AM OSC

13

AM OSC

BUFFER

Q4

X1

10.25MHz

8

FM +B

10

AM +B

MDX-C5960R/C5970/C5970R

FM B+

AM B+

TUNER B+

9

AM

FM

E

F

(Page 23)

(Page 23)

+B

ST/MONO

SD

SEEK

20

11

22

(C5960R/C5970R)

RV1

FM RDS

S-METER

(C5970)

S-METER

19

FM/AM SIGNAL

METER BUFFER

Q1

FM-DET

23

(C5960R/C5970R)

BUFFER

Q50

FM-LCH

FM-RCH

AM-DET

16

20

MPX

LVIN

18

16

12

14

7

VDDA

57 kHz

BAND-PASS

FILTER

MULTI

PATH

DETECTOR

VDDD

R-CH

OUT

B+ SWITCH

SC

18

MPTH

2

Q51

RDS DECODER

IC102

CIN

19

MUTING

Q101

BACKUP +5V

FM B+

CLOCKED

COMPARATOR

OSCILLATOR

& CLOCK

OSCI

OSCO

4

5

R-CH

DEMODULATOR

D5

SIGNAL

QUALITY

DECODER

RDS/RDBS

& DECODER

DAVN

8

MUTING

CONTROL SWITCH

Q103

5

4

INTERFACE

REGISTER

IIC BUS

SLAVE

TRANSCEIVER

SDA

SCL

9

10

(C5970: E model)

S701

FREQUENCY SELECT

MW 10K/FM 200K

MW 9K/FM 50K

05

100

BAND (9K-10K)

69

SSTOP

DATA

CLOCK

83

82

SEEKOUT

81

SD-IN

ST-MONO

MASTER CONTROLLER

IC700 (1/4)

53

S-METER (VSM)

BAND-PASS

FILTER

IC101

51

QUALITY

Q5

NOISE DET

DISCHARGE

SWITCH

35

NS-MASK

52

MPDH (MTP)

X2

4.332MHz

67

DAVN

DATA

CLOCK

62

TU-ATT

DATA, CLOCK

• SIGNAL PATH

(Page 23)

G

: FM

: AM (MW/LW)

– 21 –

– 22 –

Page 20

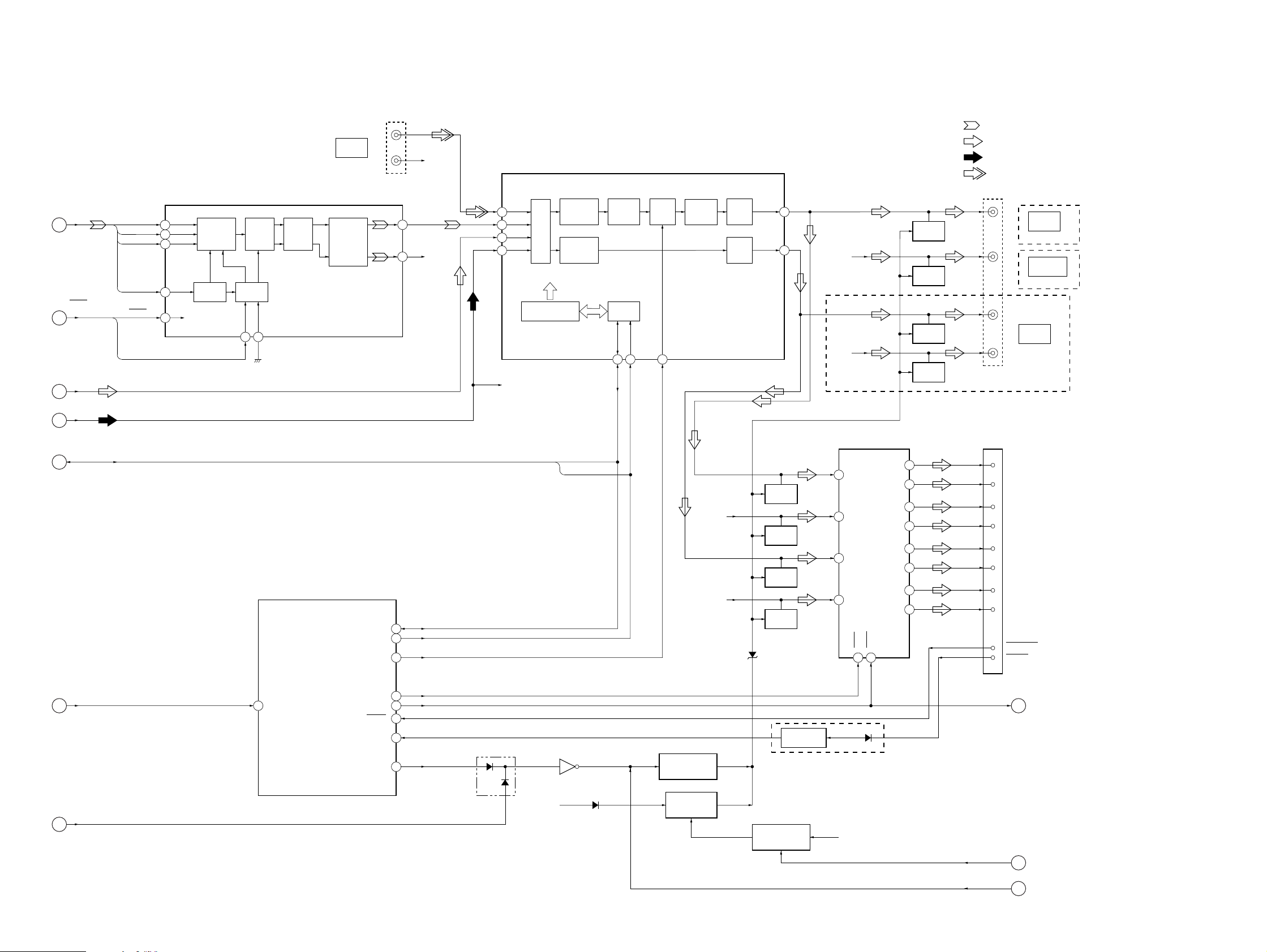

MDX-C5960R/C5970/C5970R

4-3. BLOCK DIAGRAM – MAIN Section –

CNP300 (1/2)

BUS

AUDIO IN

• SIGNAL PATH

: MD PLAY

(L)

INPUT SELECT,

(R)

R-CH

ELECTRICAL VOLUME

IC300

: FM

: AM (MW/LW)

: BUS AUDIO IN

(Page 20)

(Page 20)

(Page 22)

(Page 22)

(Page 22)

A

B

E

F

G

DADT,

BCK,

LRCK,

FS256

RESET,

EMPHASIS

FM

AM

DATA, CLOCK

DADT

BCK

LRCK

FS256

RESET

EMPHASIS

CNP300 (2/2)

(L)

(R)

(L)

(R)

CNP500 (1/2)

(POWER CONNECTOR)

1

FRONT L (+)

9

FRONT L (–)

4

FRONT R (+)

12

FRONT R (–)

2

REAR L (+)

10

REAR L (–)

3

REAR R (+)

11

REAR R (–)

15

TEST MODE

TEL-ATT

13

FRONT

LINE OUT

(C5970/C5970R)

AUDIO OUT

(LINE OUT)

(C5960R)

REAR

LINE OUT

DATA

CLOCK

VOLUME

CONTROL

CIRCUIT

IIC BUS

SCL

SDA

SOFT

MUTE

2625 24

INPUT

SELECTOR

CIRCUIT

LOUDNESS

CONTROL

CIRCUIT

LOUDNESS

CONTROL

CIRCUIT

PDL

11

12

28

1

SE2L

SE1L

SE3L

R-CH

DIGITAL CONTROL

D/A

IC101

VOUTL

VOUTR

SDA

SCL

AF ATT

12

9

R-CH

70

71

61

DATA

5

BCK

6

LRCK

4

XTI

1

RSTB

15

INPUT

INTERFACE

CLK

CONTROL

DIGITAL

FILTER

MODE

CONTROL

DM1

17 16

DM0

NOISE

SHAPER

MASTER CONTROLLER

CONVERTER

DIGITAL FILTER,

D/A CONVERTER

IC700 (2/4)

MUTE

TONE

CONTROL

CIRCUIT

R-CH

R-CH

FADER

FADER

OUT FL

OUT RL

D701

22

20

MUTING

Q302

MUTING

Q403

MUTING

Q303

MUTING

Q402

R-CH

(C5970/C5970R)

R-CH

POWER AMP

IC500

12

FL-IN

14

FR-IN

11

RL-IN

15

RR-IN

MUTE

22

4

ST-BY

FL+

FL–

FR+

FR–

RL+

RL–

RR+

RR–

5

3

21

23

9

7

17

19

MUTING

Q301

MUTING

Q401

MUTING

Q300

MUTING

Q400

(Page 20)

(Page 20)

LOCK

C

MD-ATT

D

05

LOCK IN

58

AMP ON

TESTIN

TEL-ATT

AU ATT

55AMP ATT

56

32

80

D700

60

COM +8V

Q702 (1/2)

D703

MUTING

CONTROL SWITCH

Q702 (2/2)

BATTERY OFF

MUTE DRIVER

Q704

LEVEL SHIFT

Q500

(C5970/C5970R)

MUTING

CONTROL SWITCH

Q703

D511

BATT B+

AMP ON

STB

MUTE

H

I

J

(Page 27)

(Page 28)

(Page 27)

– 23 – – 24 –

Page 21

4-4. BLOCK DIAGRAM – DISPLAY/KEY CONTROL Section –

EN801

VOLUME/BASS/TREBLE/

(LSW804: MDX-C5960R/C5970R only)

BALANCE/FADER CONTROL

MDX-C5960R/C5970/C5970R

J900

REMOTE IN

D900

49 72

RC-IN0

X1

93

X700

3.68MHz

RC-IN1

92

X0

LSW801 – 804,

LSW806 – 821

46

47

KEY-IN0

X1A

73

X701

32.768kHz

KEY-IN1

X0A

74

D912

ROTARY

ENCODER

EN801

VOL–

VOL+

106

107

RE-IN0

RE-IN1

LSW805

D-BASS

50

D-BASS IN

79

KEYACK

LCD SO13LCD CKO14LCD CE

104

KEY ACTIVE

SWITCH

Q905

37

AD-ON

BACKUP +5V

MASTER CONTROLLER

IC700 (3/4)

CNP801

FRONT PANEL SIDE

CN900

MAIN BODY SIDE

D813 – 817,

LSW802, 808, 811

1

1

12

NOSE-SW

BUZZER

DRIVE

Q701

15

BEEP

BZ1

(BUZZER)

LCDANG

40

LSW801, 804, 806,

LSW807, 809, 810,

(LSW804: MDX-C5960R/C5970R only)

R845

OSC

21

OSC OUT

05

20

OSC IN

SEG1 – SEG39, SEG48 – SEG73

32, 26 – 31, 33 – 38, 56 – 65,

75 – 90, 39 – 55, 66 – 74

LCD801

LIQUID CRYSTAL DISPLAY

18

17

19

CLK

STB

DATA

COM0 – COM7

100 – 93

KEY IN1 – KEY IN4

LIQUID CRYSTAL DISPLAY DRIVER

22 – 25

IC801

LSW812 – 821

PL801, 802

(LCD BACK LIGHT)

REGULATOR

Q806

REGULATOR

Q805, 807

3

DIMMER

4

POWER ON

LCD +10V

11 – 6

VLC0 – VLC5

CONTRAST

SWITCHING

Q901

LCD +10V

– 25 –

– 26 –

Page 22

MDX-C5960R/C5970/C5970R

4-5. BLOCK DIAGRAM – BUS CONTROL/POWER SUPPLY Section –

CNJ600

BUS CONTROL IN

(FOR SONY BUS)

RESET

DATA

CLK

BUS ON

BATT

2

5

4

6

7

BUS ON SWITCH

Q600

BACKUP +5V

RESET SIGNAL

GENERATOR

IC801

SONY BUS INTERFACE

IC600

RST

DATA

CLK

BUS ON

OUT

BATT

RESET

SWITCH

BUS ON

SWITCH

BATTERY

SWITCH

2

6

4

1

3

RST

DATA IN

DATA OUT

CLK IN

BUS

ON IN

BU IN

BACKUP +5V

RAM RESET

IC802

D916

S900

RESET

13

9

8

11

12

10

D702

MASTER CONTROLLER

IC700 (4/4)

102

RAMBU

RESET

90

86

HSTX

29

SYSRST

UNI SO

21

20

UNI SI

22

UNI CKIO

36

BUS-ON

BU-IN

76

PW-ON

FM-ON

TU-ON

STB

D804

+5V

(TUNER CIRCUIT B+)

TUNER B+

109

110

111

+5V

REGULATOR

Q6

D3

(AUDIO CIRCUIT B+)

FM B+

(FM CIRCUIT B+)

AM B+

(AM CIRCUIT B+)

COM +8V

BACKUP +5V

D802

11

10

6

8

9

5

AMP+B

ANT+B

FM8V

AM8V

COM8V

BU+B

REGULATOR

IC800

STB

4

VCC

MODE1

23

MODE2

D803

BATT B+

POWER AMP

(IC500) B+

7

(Page 24)

I

CNP500 (2/2)

(POWER CONNECTOR)

6

ANT REM

AMP REM

5

(Page 24)

(Page 24)

BATT B+

J

H

TH600

MUTE

AMP ON

D604

D603

BATTERY

DETECT

Q601

D606

D607

LEVEL SHIFT

Q603

LAMP ON (ILL ON)

ACC IN

ILL IN

MD MECHANISM CONTROLLER

IC501 (2/2)

60

BU-IN

BUS-ON

61

30

49

48

50

46

RESET

UNISI

UNICKIO

UNISO

LINKOFF

MDMON

LCD +10V

LCD DRIVER (IC801)/

ILLUMINATION LED B+

108

64

57

65MD-ON

10

REGULATOR

CONTROL SWITCH

Q906

REGULATOR

CONTROL SWITCH

Q255

LOAD +12V

LOADING MOTOR

DRIVER (IC305) B+

+3.3V

VCC

+3.3V

REGULATOR

IC401, Q401

ACCESSORY CHECK

Q900

B+ SWITCH

Q402, 403

DRIVER +5V

MOTOR/COIL DRIVER

(IC303) B+

CONVERTER

DC/DC

IC250

+10V

REGULATOR

Q903, 904

D913

D500

+12V

REGULATOR

Q254

B+ SWITCH

Q250, 251

F1

16

BATT

7

ACC

14

ILL IN

05

– 27 –

– 28 –

Page 23

4-6. NOTES FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

MDX-C5960R/C5970/C5970R

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

r

•

•

: Through hole.

¢

: internal component.

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern f ace side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

: internal component.

4

W or less unless otherwise

• C : panel designation.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

• U : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 14.4V and fed with regulated dc po w er supply

from ACC and BATT cords.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : FM

f : AM (MW/LW)

L : BUS AUDIO IN

E : MD PLAY

• Abbreviation

CND : Canadian model.

G : German model.

– 29 –

Page 24

MDX-C5960R/C5970/C5970R

4-7. PRINTED WIRING BOARD – SERVO Board –

(Page 41)

• Semiconductor

Location

Ref. No. Location

D401 E-6

D501 E-4

IC301 B-5

IC302 C-2

IC303 B-3

IC304 C-5

IC305 F-6

IC306 B-4

IC307 B-8

IC401 E-6

IC501 F-3

IC502 D-5

IC503 D-4

Q301 A-4

Q302 C-1

Q401 D-6

Q402 E-7

Q403 E-7

– 31 – – 32 –

Page 25

4-8. SCHEMATIC DIAGRAM – SERVO Board (1/3) –

• See page 55 for Waveforms. • See page 58 for IC Block Diagrams.

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque ! sont

critiques pour la sécurité. Ne les remplacer que

par une piéce portant le numéro spécifié.

• Voltages and waveforms are dc with respect

to ground under no-signal conditions.

no mark : MD PLAY

: Impossible to measure

∗

MDX-C5960R/C5970/C5970R

(Page 35)

– 33 – – 34 –

Page 26

MDX-C5960R/C5970/C5970R

4-9. SCHEMATIC DIAGRAM – SERVO Board (2/3) – • See page 55 for Waveforms. • See page 57 for IC Block Diagrams.

(Page 34)

(Page 37)

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : MD PLAY

: Impossible to measure

∗

– 35 – – 36 –

Page 27

4-10. SCHEMATIC DIAGRAM – SERVO Board (3/3) – • See page 55 for Waveforms.

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : MD PLAY

: Impossible to measure

∗

MDX-C5960R/C5970/C5970R

(Page 36)

(Page 43)

– 37 –

– 38 –

Page 28

MDX-C5960R/C5970/C5970R

4-11. PRINTED WIRING BOARD – MAIN Board (Component Side) –

• Semiconductor Location

(Component Side)

Ref. No. Location

D1 C-11

D3 F-11

D5 H-11

D6 F-9

D7 F-9

D8 G-13

D200 I-5

D202 F-4

D301 B-12

D500 B-5

D501 C-5

D503 C-6

D504 B-6

D505 B-6

D506 B-6

D507 B-8

D508 B-8

D509 B-9

D510 B-9

D511 B-5

D520 B-6

D521 A-9

D522 B-4

D600 B-2

D601 B-2

D602 B-3

D603 E-3

D604 C-3

D606 E-3

D607 B-13

D700 H-5

D701 H-4

D702 J-6

D703 F-4

D800 B-3

D801 B-3

D802 H-3

D803 D-3

D804 E-4

D900 C-1

D901 J-5

D902 K-12

D903 K-12

D904 K-12

D905 K-12

D907 K-12

D908 K-11

D909 K-11

D910 K-11

D911 K-11

Ref. No. Location

D912 J-10

D913 C-6

D914 K-11

D915 K-4

D916 K-4

IC100 E-11

IC101 E-9

IC102 I-12

IC250 I-5

IC300 F-8

IC600 B-4

IC700 I-8

IC801 J-2

IC802 J-2

Q1 C-11

Q4 D-11

Q5 F-9

Q6 C-10

Q50 H-13

Q51 I-14

Q101 H-11

Q102 G-11

Q103 H-11

Q250 I-5

Q251 H-6

Q254 E-5

Q255 F-4

Q300 B-10

Q301 B-11

Q302 C-7

Q303 C-6

Q400 B-10

Q401 B-11

Q402 C-8

Q403 C-8

Q500 B-5

Q600 D-3

Q601 D-4

Q603 B-4

Q701 F-3

Q702 G-5

Q703 G-5

Q704 G-4

Q900 D-6

Q901 J-6

Q905 J-9

Q906 J-5

– 39 – – 40 –

Page 29

4-12. PRINTED WIRING BOARD – MAIN Board (Conductor Side) –

MDX-C5960R/C5970/C5970R

• Semiconductor

Location

(Conductor Side)

Ref. No. Location

D502 C-3

IC500 A-7

IC800 E-1

Q903 H-2

Q904 H-3

(Page 52)

– 41 –

(Page 31)

– 42 –

Page 30

MDX-C5960R/C5970/C5970R

4-13. SCHEMATIC DIAGRAM – MAIN Board (1/4) – • See page 55 for Waveforms. • See page 60 for IC Block Diagrams.

(Page 38)

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : FM

( ) : AM (MW)

[]: LW

〈〈 〉〉 : MD PLAY

(Page 45)

(Page 48)

– 43 – – 44 –

(Page 49)

Page 31

4-14. SCHEMATIC DIAGRAM – MAIN Board (2/4) –

MDX-C5960R/C5970/C5970R

(Page

44)

(Page 49)

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

no mark : FM

– 45 – – 46 –

Page 32

MDX-C5960R/C5970/C5970R

4-15. SCHEMATIC DIAGRAM – MAIN Board (3/4) – • See page 55 for Waveforms. • See page 60 for IC Block Diagrams.

(Page 44)

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : FM

( ) : AM (MW)

[]: LW

– 47 – – 48 –

(Page 49)

Page 33

4-16. SCHEMATIC DIAGRAM – MAIN Board (4/4) – • See page 61 for IC Block Diagrams.

(Page

44)

MDX-C5960R/C5970/C5970R

(Page 45)

(Page 48)

(Page 53)

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

no mark : FM

( ) : AM (MW)

[]: LW

〈〈 〉〉 : MD PLAY

– 49 – – 50 –

Page 34

MDX-C5960R/C5970/C5970R

4-17. PRINTED WIRING BOARD – KEY Board –

• Semiconductor

Location

(Component Side)

Ref. No. Location

D811 C-3

D812 B-3

D813 A-4

D814 A-2

D815 B-1

D816 C-2

D817 A-11

IC801 B-8

Q806 C-4

Q807 B-1

• Semiconductor

Location

(Conductor Side)

Ref. No. Location

D802 B-12

D803 B-12

D804 B-12

D806 B-5

D807 B-6

D808 A-12

D819 B-2

Q805 B-2

(Page 41)

– 51 – – 52 –

Page 35

4-18. SCHEMATIC DIAGRAM – KEY Board – • See page 56 for Waveforms.

(Page 50)

MDX-C5960R/C5970/C5970R

– 53 – – 54 –

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : FM

Page 36

• Wavef orms

– SERVO Board –

– MAIN Board –

– KEY Board –

1 IC302 @§ (TE) (MD PLAY Mode)

2 IC302 #¢ (FE) (MD PLAY Mode)

3 IC302 #• (RF) (MD PLAY Mode)

Approx.

0.5 Vp-p

Approx.

0.3 Vp-p

6 IC501 #¡ (EXTAL) (MD PLAY Mode)

2.7 Vp-p

0.1 µs

7 IC304 3 (IN) (MD PLAY Mode)

3.5 Vp-p

44 ns

1 IC100 9 (OSC IN) (FM/AM (MW) Mode)

2.7 Vp-p

94 ns

2 IC102 5 (OSC1) (FM Mode)

2.8 Vp-p

224 ns

3 IC250 2 SWE (MD PLAY Mode)

6 IC700 (£ (X1)

271 ns

5.8 Vp-p

1 IC801 @º (OSC IN)

2.8 Vp-p

3.5 µs

1.2 Vp-p

4 IC301 @∞ (LRCK) (MD PLAY Mode)

3.5 Vp-p

23 µs

5 IC301 @§ (XBCK) (MD PLAY Mode)

4.5 Vp-p

14.2 Vp-p

24 µs

4 IC250 3 TC (MD PLAY Mode)

1.1 Vp-p

12 µs

5 IC700 &¢ (XOA)

2.1 Vp-p

356 µs

30 µs

– 55 – – 56 –

Page 37

• IC Block Diagrams

– SERVO Board –

IC101 PCM1718E/2K

XTI

DGND

VDD

LRCIN

DIN

BCKIN

ZERO

D/C_R

VOUTR

AGND

1

2

3

4

5

6

7

8

9

10

INPUT

INTERFACE

DIGITAL

FILTER

NOISE SHAPER

5 LEVEL

DAC

LOWPASS

FILTER

CMOS

AMP

CONTROL

IC301 CXD2652AR

EFMO

DVSS

TEST3

TEST2

99 98 97 96 95 94 93

SUBCODE

CLOCK

MNT0

MNT1

MNT2

MNT3

SWDT

SCLK

XLAT

SRDT

SENS

XRST

SQSY

DQSY

RECP

XINT

OSCI

OSCO

XTSL

DVSS

DIN

DOUT

100

1

2

MONITOR

CONTROL

3

4

5

6

CPU I/F

7

8

9

10

11

PROCESSOR

12

13

14

15

TX

16

17

GENERATOR

18

19

NC

20

21

22

CLK

TEST1

EACH

BLOCK

EACH

BLOCK

MODE

CONTROL

5 LEVEL

DAC

LOWPASS

FILTER

CMOS

AMP

FGIN

SPINDLE

SERVO

ADIP

DECODER

EACH

BLOCK

SPFD

SPRD

DIGITAL

AUDIO

XTO

20

CLKO

19

MUTE

18

DM1

17

DM0

16

RSTB

15

FORMAT

14

D/C_L

13

VOUTL

12

VCC

11

SFDR91SRDR90FS489FRDR88FFDR87DVDD86TFDR85TRDR84LDDR83APCREF82DTRF81CKRF80XLRF79F0CNT78ADFG77APC76DCHG

92

PWM

SHOCK RESISTANT

MEMORY CONTROLLER

SAMPLING

I/F

RATE

CONVERTER

GENERATOR

SERVO

DSP

CONVERTER

AUTO

A/D

SEQUENCER

ANALOG

DECODER

ENCODER/

EFM/ACIRC

COMP

MUX

PLL

75

AUX2

74

TE

73

SE

72

AVSS

71

ADRB

70

ADRT

69

AVDD

68

ADIO

67

VC

66

AUX1

65

FE

64

ABCD

63

BOTM

62

PEAK

61

CLTV

60

FILO

59

FILI

58

PCO

57

PDO

56

AVSS

55

RFI

54

BIAS

53

AVDD

52

ASYI

51

ASYO

ADDT

DADT

LRCK

23

24

25

28

26

27

XBCK

DVDD

FS256

ATRAC

ENCODER/DECODER

ADDRESS/DATA BUS A00 - A11, D0 - D3

40

39

A1138A0837A0736A0635A0534A0433A1032A0031A0130A0229A03

41

DVSS

XOE

42

43

XCAS

A09

44

XRAS

XWE

50

49D348D247D046D145

MVCI

– 57 –

Page 38

IC302 CXA2523R

MORFO47MORFI46RFO45OPN

48

–

+

RFA1

+

–

AA

BB

CC

DD

EE

FF

–

–

–

–

–

–

–

GRVA

1

2

1

2

RFA2

CFST

+

–

+

–

FBAL

HLPT

GRV

1I

2J

CVB

3VC

4A

IVR

5B

IVR

6C

IVR

7D

IVR

8E

IVR

9F

IVR

GSW IV

+

–

+

–

+

–

+

–

+

–

+

–

+

–

OPO43ADDC42COMPP41COMPO40AGCI39RF AGC38RF37PEAK

44

EE'

USROP

+

+

+

+

+

+

–

–

–

–

+

+

–1

–2

–2

–1

FF'

+

–

BPF3T

PTGR

ABCDA

FEA

BPF22

WBL

ATA

WBL

–

+

–

+

EFB TESW

RF AGC EQ

USRC

PEAK

BOTTOM

WBL

ADIP

PTGR

PEAK3T

P-P

AGC

WBL

3T

EQ

3T

3T WBL

PBH

DET

–1

–2

–1

–2

TEMP

DET

EQ

BPFC

SEA

TEA

VI CONV

TG

TG

36

BOTM

35

ABCD

34

FE

33

AUX

32 ADFG

31 ADAGC

30 ADIN

29 ADFM

28 SE

27 CSLED

26 TE

25 WBLADJ

15

AUXSW

TEMPR

COMMAND

SCRI - PARA

DECODE

17

16

SCLK

SWDT

BGR

VREF

24

23

22

21

20

19

18

XLAT

XSTBY

F0CNT

VREF

EQADJ

3TADJ

VCC

10PD

11APC

12APCREF

+

–

+

–

14

13

GND

TEMPI

– 58 –

Page 39

IC303 BH6511FS-E2

CAPA–

CAPA+

IN2R

IN2F

VM2

OUT2F

PGND2

OUT2R

VM12

OUT1R

PGND1

OUT1F

VM1

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17

IN4F

AMP

AMP

VM4

INTERFACE

CHARGE

PUMP.

OSC

INTERFACE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

VG

GND

IN4R

OUT4F

PGND4

AMP

OUT4R

VM34

AMP

OUT3R

PGND3

AMP

AMPAMPAMP

OUT3F

INTERFACE

PREDRIVEPREDRIVE

PREDRIVEPREDRIVE

INTERFACE

VM3

IC305 BA6287F

1

OUT1

VM

2

8

GND

7

OUT2

IN1F

IN3F

IN1R

IN3R

V

PSB

DD

V

DD

PSB

DRIVER DRIVER

TSD

3

VCC

FIN

POWER

SAVE

4

CONTROL LOGIC

IC307 MN41V4400TT-08S

1

D1

2

D2

XWE

3

4

XRAS

NC

5

NC

6

7

NC

A9

8

A0

9

10

A1

A2

11

12

A3

A0–A9

A0–A9

ADDRESS BUFFER

CLOCK OSC

COLUMN DECODER

SENSE REFRESH AMP

INPUT/OUTPUT CONTROL SWITCH

MEMORY CELL

(4194204 BIT)

ROW DECODER

6

VREF

5

RIN

GND

26

D4

25

24

D3

XCAS

23

XOE

22

BUFFER

(4) INPUT

BUFFER

(4) OUTPUT

21

NC

20

NC

NC

19

A8

18

A7

17

16

A6

15

A5

1413

A4VDD

– 59 –

Page 40

– MAIN Board –

IC100 TDA7427AD

LP OUT

11 BIT

PROGRAMMABLE

COUNTER

SWITCH

OUT

INLOCK

CHARGE

PUMP

DETECTOR

PARATOR

+

–

SWITCH

LP1/LP2

3 41 2 7

VREF

LP HC

LP FM

LP AM

PROGRAMMABLE

PHASE

COM-

SWITCH

SWM/DIR

5 BIT

COUNTER

PRE

COUNTER

SWITCH

SWM/DIR

16 BIT

PROGRAMMABLE

COUNTER

LOGIC

PORT

EXTENSION

5 6 11 129

DOUT3

DOUT4

TEST

8

DOUT5

DOUT6

FM/AM

SWITCH

TIMER

14 BIT

PROGRAMMABLE

COUNTER

REFERENCE

OSCILLATOR

10

OSCIN

OSCOUT

VDD2

AM IN

GND-AM

NC

NC

FM IN

POWER ON RESET

11 – 21 BIT

PROGRAMMABLE

GND-SIG

SUPPLY &

CONTROL

COUNTER

VDD1

ADDR

IIC BUS

INTERFACE

SCL

DOUT1/INLOCK

HFREF

SSTOP

DOUT2

FM/AM

SWITCH

13 14

SDA

IF FM

1516171819202122232425262728

IF AM

IC102 SAA6588T-118 (MDX-C5960R/C5970R)

6

VSSD

VREF

17

SIGNAL QUALITY

CLOCK

DATA

87

DAVN

VDDD

MPX

DECODER

445

INTERFACE

REGISTER

VSSA

15

POWER SUPPLY

& RESET

LVIN

20

MULTI

PATH

DETECTOR

2

1

MRO

MPTH

CIN

19

CLOCKED

COMPARATOR

RDS/RDBS

DEMODULATOR

TEST

CONTROL

3

TCON

SCOUT

18

BAND-PASS FILTER

OSCILLATOR

& CLOCK

4 5

OSCO

57kHz

8th ORDER

RDS/RDBS

DECODER

OSCI

VDDA

14

CLOCK

DATA

IIC BUS SLAVE

TRANSCEIVER

9 10

1316

SDA

AFIN

SCL

PAUSE

DETECTOR

IC250 NJM2360AM (TE2)

MAD

PSWN

11

12

Q2

1CS

Q1

2ES

3CT

4GND

VREF

1.25V

QS

R

+

–

CT OSC

COMP

Ipk

8CD

7SI

6V+

5 INVIN

– 60 –

Page 41

IC300 TDA7462D013TR

SE3L

SE3R

MUTE

SDA

SCL

PAUSE

OUT FL

OUT FR

OUT RL

OUT RR

SUBOUT+

SUBOUT–

VDD

GND

CREF

SE1L

SE1R

MD+

MD–

CDL+

CDL–

CDR–

CDR+

PDR

PDGND

PDL

SE2L

SE2R

INPUT

GAIN &

AUTO

ZERO

PAUSE

DETECT

INPUT MULTIPLEXER &

MIXING STAGE

REAR SIDE

SELECTOR

FRONT SIDE

SELECTOR

LOUDNESS

CONTROL

CIRCUIT

INPUT

GAIN

BEEP

LOUDNESS

CONTROL

CIRCUIT

SOFT

MUTE

VOLUME

CONTROL

CIRCUIT

COMPANDER

TREBLE/

BASS

CONTROL

CIRCUIT

SUBWOOFER

OUT

FADER

SUBWOOFER

LP

IIC

BUS

DIGITAL CONTROL CIRCUIT

POWER

SUPPLY

FRONT

FADER

FRONT

FADER

REAR

FADER

REAR

FADER

VOICE BANDPASS

HP LP

SDA

SCL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

IC600 BA8270F-E2

BUS ON

SWITCH

RESET

SWITCH

BATTERY

SWITCH

BUS ON

1

2

RST

BATT

3

4

CLK

5

VREF

6

DATA

GND

7 8

14

13

12

11

10

9

VCC

RST

BUS ON

CLK IN

BU IN

DATA IN

DATA OUT

IC800 BA3918-V3

1

NC

2 3

MODE2

4

STB

MODE1

–

+

– 61 –

REGULATOR

OVER VOLTAGE

PROTECT

5 6 7 8 9 10 1211

VDD

AMP

VCC

ANT

COM

–

+

AM

–

+

–

+

FM

GND

Page 42

4-19. IC PIN FUNCTION DESCRIPTION

• SERVO BOARD IC301 CXD2652AR

(DIGITAL SIGNAL PROCESSOR, DIGITAL SERVO PROCESSOR, EFM/ACIRC ENCODER/DECODER,

SHOCK PROOF MEMORY CONTROLLER, ATRAC ENCODER/DECODER, 2M BIT D-RAM)

Pin No. Pin Name I/O Function

1 MNT0 O

2 MNT1 O

3 MNT2 O

4 MNT3 O

5 SWDT I

6 SCLK I

7 XLAT I

8 SRDT O (3)

9 SENS O (3)

10 XRST I Reset signal input from the MD mechanism controller (IC501) “L”: reset

11

SQSY O

Focus OK signal output to the MD mechanism controller (IC501)

“H” is output when focus is on (“L”: NG)

Track jump detection signal output to the MD mechanism controller (IC501)

Busy monitor signal output to the MD mechanism controller (IC501)

Spindle servo lock status monitor signal output to the MD mechanism controller (IC501)

Writing serial data signal input from the MD mechanism controller (IC501)

Serial data transfer clock signal input from the MD mechanism controller (IC501)

Serial data latch pulse signal input from the MD mechanism controller (IC501)

Reading serial data signal output to the MD mechanism controller (IC501)

Internal status (SENSE) output to the MD mechanism controller (IC501)

Subcode Q sync (SCOR) output to the MD mechanism controller (IC501)

“L” is output every 13.3 msec Almost all, “H” is output

12

13 RECP I

14 XINT O Interrupt status output to the MD mechanism controller (IC501)

15 TX I

16 OSCI I System clock signal (512Fs=22.5792 MHz) input from the oscillator circuit

17 OSCO O System clock signal (512Fs=22.5792 MHz) output terminal Not used (open)

18 XTSL I

19 RVDD — Power supply terminal (+3.3V) (digital system)

20 RVSS — Ground terminal (digital system)

21

22

23

24

25

26

27 FS256 O

28 DVDD — Power supply terminal (+3.3V) (digital system)

29 to 32

33

34 to 38

39

40 DVSS — Ground terminal (digital system)

41 XOE O Output enable signal output to the D-RAM (IC307) “L” active

42 XCAS O Column address strobe signal output to the D-RAM (IC307) “L” active

43 A09 O Address signal output to the D-RAM (IC307)

44 XRAS O Row address strobe signal output to the D-RAM (IC307) “L” active

45 XWE O Write enable signal output to the D-RAM (IC307) “L” active

DQSY O

DIN I Digital audio signal input terminal when recording mode Not used (fixed at “L”)

DOUT O Digital audio signal output terminal when playback mode Not used (open)

ADDT I Recording data input terminal Not used (fixed at “L”)

DADT O Playback data output to the PCM1718E (IC101)

LRCK O L/R sampling clock signal (44.1 kHz) output to the PCM1718E (IC101)

XBCK O Bit clock signal (2.8224 MHz) output to the PCM1718E (IC101)

A03 to A00 O Address signal output to the D-RAM (IC307)

A10 O

A04 to A08 O Address signal output to the D-RAM (IC307)

A11 O

Digital In U-bit CD format subcode Q sync (SCOR) output terminal

“L” is output every 13.3 msec Almost all, “H” is output Not used (open)

Laser power selection signal input terminal

“L”: playback mode, “H”: recording mode (fixed at “L” in this set)

Recording data output enable signal input terminal

Writing data transmission timing input (Also serves as the magnetic head on/off output)

Not used (fixed at “L”)

Input terminal for the system clock frequency setting

“L”: 45.1584 MHz, “H”: 22.5792 MHz (fixed at “H” in this set)

Clock signal (11.2896 MHz) output to the PCM1718E (IC101)

Address signal output to the external D-RAM Not used (open)

Address signal output to the external D-RAM Not used (open)

– 62 –

Page 43

Pin No. Pin Name I/O Function

46 D1 I/O

47 D0 I/O

48 D2 I/O

Two-way data bus with the D-RAM (IC307)

49 D3 I/O

50 MVCI I Digital in PLL oscillation input from the external VCO Not used (fixed at “L”)

51 ASYO O Playback EFM full-swing output terminal

52 ASYI I (A) Playback EFM asymmetry comparator voltage input terminal

53 AVDD — Power supply terminal (+3.3V) (analog system)

54 BIAS I (A) Playback EFM asymmetry circuit constant current input terminal

55 RFI I (A) Playback EFM RF signal input from the CXA2523R (IC302)

56 AVSS — Ground terminal (analog system)

57 PDO O (3) Phase comparison output for clock playback analog PLL of the playback EFM Not used (open)

58 PCO O (3) Phase comparison output for master clock of the recording/playback EFM master PLL

59 FILI I (A) Filter input for master clock of the recording/playback master PLL

60 FILO O (A) Filter output for master clock of the recording/playback master PLL

61 CLTV I (A) Internal VCO control voltage input of the recording/playback master PLL

62 PEAK I (A) Light amount signal (RF/ABCD) peak hold input from the CXA2523R (IC302)

63 BOTM I (A) Light amount signal (RF/ABCD) bottom hold input from the CXA2523R (IC302)

64 ABCD I (A) Light amount signal (ABCD) input from the CXA2523R (IC302)

65 FE I (A) Focus error signal input from the CXA2523R (IC302)

66 AUX1 I (A) Auxiliary signal (I

3 signal/temperature signal) input terminal Not used (fixed at “H”)

67 VC I (A) Middle point voltage (+1.65V) input from the CXA2523R (IC302)

68 ADIO O (A) Monitor output of the A/D converter input signal Not used (open)

69 AVDD — Power supply terminal (+3.3V) (analog system)

70 ADRT I (A) A/D converter operational range upper limit voltage input terminal (fixed at “H” in this set)

71 ADRB I (A) A/D converter operational range lower limit voltage input terminal (fixed at “L” in this set)

72 AVSS — Ground terminal (analog system)

73 SE I (A) Sled error signal input from the CXA2523R (IC302)

74 TE I (A) Tracking error signal input from the CXA2523R (IC302)

75 AUX2 I (A) Auxiliary signal input terminal Light amount signal input from the CXA2523R (IC302)

76 DCHG I (A) Connected to the +3.3V power supply

77 APC I (A) Error signal input for the laser automatic power control Not used (fixed at “L”)

78 ADFG I ADIP duplex FM signal (22.05 kHz ± 1 kHz) input from the CXA2523R (IC302)

79 F0CNT O Filter f0 control signal output terminal Not used (open)

80 XLRF O Serial data latch pulse signal output terminal Not used (open)

81 CKRF O Serial data transfer clock signal output terminal Not used (open)

82 DTRF O Writing serial data output terminal Not used (open)

83 APCREF O

Control signal output to the reference voltage generator circuit for the laser automatic power

control

84 LDDR O PWM signal output for the laser automatic power control Not used (open)

85 TRDR O Tracking servo drive PWM signal (–) output to the BH6511FS (IC303)

86 TFDR O Tracking servo drive PWM signal (+) output to the BH6511FS (IC303)

87 DVDD — Power supply terminal (+3.3V) (digital system)

88 FFDR O Focus servo drive PWM signal (+) output to the BH6511FS (IC303)

89 FRDR O Focus servo drive PWM signal (–) output to the BH6511FS (IC303)

90 FS4 O Clock signal (176.4 kHz) output terminal (X’tal system) Not used (open)

91 SRDR O Sled servo drive PWM signal (–) output to the BH6511FS (IC303)

– 63 –

Page 44

Pin No. Pin Name I/O Function

92 SFDR O Sled servo drive PWM signal (+) output to the BH6511FS (IC303)

93 SPRD O Spindle servo drive PWM signal (–) output to the BH6511FS (IC303)

94 SPFD O Spindle servo drive PWM signal (+) output to the BH6511FS (IC303)

95

96

97

98

99 DVSS — Ground terminal (digital system)

100 EFMO O EFM signal output terminal when recording mode Not used (open)

* I (A) for analog input, O (3) for 3-state output, and O (A) for analog output in the column I/O.

FGIN I Not used (fixed at “L”)

TEST1 I

TEST2 I Input terminal for the test (fixed at “L”)

TEST3 I

– 64 –

Page 45

• SERVO BOARD IC302 CXA2523R (RF AMP, FOCUS/TRACKING ERROR AMP)

Pin No. Pin Name I/O Function

1II

2JI

3VCO

4 to 9 A to F I

10 PD I

11 APC O

12 APCREF I

13 GND —

14 TEMPI I

15

TEMPR O

16 SWDT I

17 SCLK I

18 XLAT I

19 XSTBY I

20 F0CNT I

21 VREF O

22 EQADJ I

23 3TADJ I

24 VCC —

25 WBLADJ I

26 TE O

27 CSLED I

28 SE O

29 ADFM O

30 ADIN I

31 ADAGC I

32 ADFG O

33 AUX O

34 FE O

35 ABCD O

36 BOTM O

37 PEAK O

38 RF O

39 RFAGC I

40 AGCI I

41 COMPO O

42 COMPP I

43 ADDC I

44 OPO O

45 OPN I

46 RFO O

47 MORFI I

48 MORFO O

I-V converted RF signal I input from the optical pick-up block detector

I-V converted RF signal J input from the optical pick-up block detector

Middle point voltage (+1.65V) generation output terminal

Signal input from the optical pick-up detector

Light amount monitor input from the optical pick-up block laser diode

Laser amplifier output terminal to the automatic power control circuit

Reference voltage input terminal for setting laser power

Ground terminal

Connected to the temperature sensor Not used (open)

Output terminal for a temperature sensor reference voltage Not used (open)

Writing serial data input from the MD mechanism controller (IC501)

Serial data transfer clock signal input from the MD mechanism controller (IC501)

Serial data latch pulse signal input from the MD mechanism controller (IC501)

Standby signal input terminal “L”: standby (fixed at “H” in this set)

Center frequency control voltage input terminal of internal circuit (BPF22, BPF3T, EQ) input

terminal

Reference voltage output terminal Not used (open)

Center frequency setting terminal for the internal circuit (EQ)

Center frequency setting terminal for the internal circuit (BPF3T)

Power supply terminal (+3.3V)

Center frequency setting terminal for the internal circuit (BPF22)

Tracking error signal output to the CXD2652AR (IC301)

Connected to the external capacitor for low-pass filter of the sled error signal

Sled error signal output to the CXD2652AR (IC301)

FM signal output of the ADIP

Receives a ADIP FM signal in AC coupling

Connected to the external capacitor for ADIP AGC

ADIP duplex signal (22.05 kHz ± 1 kHz) output to the CXD2652AR (IC301)

3

Auxiliary signal (I

signal/temperature signal) output terminal Not used (open)

Focus error signal output to the CXD2652AR (IC301)

Light amount signal (ABCD) output to the CXD2652AR (IC301)

Light amount signal (RF/ABCD) bottom hold output to the CXD2652AR (IC301)

Light amount signal (RF/ABCD) peak hold output to the CXD2652AR (IC301)

Playback EFM RF signal output to the CXD2652AR (IC301)

Connected to the external capacitor for RF auto gain control circuit

Receives a RF signal in AC coupling

User comparator output terminal Not used (open)

User comparator input terminal Not used (fixed at “L”)

Connected to the external capacitor for cutting the low band of the ADIP amplifier

User operational amplifier output terminal Not used (open)

User operational amplifier inversion input terminal Not used (fixed at “L”)

RF signal output terminal

Receives a MO RF signal in AC coupling

MO RF signal output terminal

– 65 –

Page 46

• SERVO BOARD IC501 CXP84340-201Q (MD MECHANISM CONTROLLER)

Pin No. Pin Name I/O Function

1 to 5 TIN3 to TIN7 I/O

6 LOAD

7 EJECT O

8, 9 NCO O

10 MDMON O

Input of the 4×8 matrix test keys (“L” is always output, except in test mode) Not used (open)

O Loading motor control signal output to the motor driver (IC305) “H” active *1

Loading motor control signal output to the motor driver (IC305) “H” active *1

Not used (open)

Power supply on/off control signal output of the MD mechanism deck section main power supply

and loading motor drive (IC305) power supply “H”: power on

11 E-SW I

12 AG-OK O

13 ADJ-OK O

14 to 17 NCO O

18 DFCTSEL I

19 DPLLSEL I

20 EMPHSEL I

21 LOCK O

22 NCO O

23 2M/4M I

24, 25 NCO O

26

27 MNT1 I

28 MNT2 I

29 MNT3 I

30 RESET I

31 EXTAL

32 XTAL

33 VSS

34 TX

35 TEX

36 AVSS

37 AVREF

38 INIT

39 TEMP

40 ACNT

41 DO-SEL

42 EE-CS

43 EE-CKO

44 EE-SIO I/O

45 MD-SO O

46 LINKOFF O

MNT0

Inputs the disc loading completion detect switch detection signal

“L”: When completed of the disc loading operation

Output of aging status in test mode “L”: under aging, “H”: aging completed Not used (open)

Output of status when aging completed in test mode “L”: aging NG, “H”: aging OK

Not used (open)

Not used (open)

Select whether defect function is used for the CXD2652AR (IC301)

“L”: used this function , “H”: not used this function (fixed at “H” in this set)

Select whether digital PLL function is used for the CXD2652AR (IC301)

“L”: used this function , “H”: not used this function (fixed at “H” in this set)

Select whether emphasis signal output from pin or unilink data

“L”: outputs from both pin and unilink data, “H”: output from pin only (fixed at “H” in this set)

Mini-disc lock detection signal output to the master controller (IC700) “H”: lock

Not used (open)

Select whether D-RAM capacitance 2M bit or 4M bit “L”: 4M bit (external D-RAM) , “H”: 2M

bit (internal D-RAM of CXD2652AR) (fixed at “L” in this set)

Not used (open)

Focus OK signal input from the CXD2652AR (IC301)

I

“H” is input when focus is on (“L”: NG)

Track jump detection signal input from the CXD2652AR (IC301)

Busy monitor signal input from the CXD2652AR (IC301)

Spindle servo lock status monitor signal input from the CXD2652AR (IC301)

System reset signal input from the master controller (IC700), reset signal generator (IC801) and

reset switch (S900) “L”: reset For several hundreds msec. after the power supply rises, “L” is

input, then it changes to “H”

O Main system clock output terminal (10 MHz)

I Main system clock input terminal (10 MHz)

— Ground terminal

O Sub system clock output terminal (32.768 kHz) Not used (open)

I Sub system clock input terminal (32.768 kHz) Not used (fixed at “L”)

— Ground terminal (for A/D converter)

I Reference voltage input terminal (+5V) (for A/D converter)

I Initial reset signal input terminal (A/D input) (fixed at “H”)

I Temperature sensor (TH501) input terminal (A/D input)

Select the number of load/eject aging times (A/D input)

I

0H – 54H (30 times), 55H – OA9H (20 times), OAAH – OFFH (10 times)

I Select the digital output bits (A/D input)

O Chip select signal output to the external EEPROM device Not used (open)

O Serial data transfer clock signal output to the external EEPROM device Not used (open)

Two way data bus with the external EEPROM device Not used (open)

Writing serial data signal output to the CXD2652AR (IC301) and CXA2523R (IC302)

Unilink on/off control signal output for the SONY bus “L”: link on, “H”: link off

– 66 –

Page 47

Pin No. Pin Name I/O Function

n

47 UNIREQ O

48 UNICKIO I/O

49 UNISI I

50 UNISO O

51 MD-CKO O

52 MD-SI I

53 NCO O

54 SENS I

55 CC-XINT

56 LIMIT-IN

57 EJT-KEY I

58 ERROR-PWM O

59 MD-RST O

Data request signal output terminal (for SONY bus) “H”: request on Not used (open)

Serial clock signal input from the master controller (IC700) or serial clock signal output to the

SONY bus interface (IC600) and master controller (IC700) (for SONY bus)

Serial data input from the SONY bus interface (IC600)

Serial data output to the SONY bus interface (IC600)

Serial data transfer clock signal output to the CXD2652AR (IC301) and CXA2523R (IC302)

Reading serial data signal input from the CXD2652AR (IC301)

Not used (open)

Internal status (SENSE) input from the CXD2652AR (IC301)

I Interrupt status input from the CXD2652AR (IC301)

Detection input from the sled limit-in detect switch

I

The optical pick-up is inner position when “L”

Eject request signal input terminal “L”: eject on Not used (fixed at “H”)

PWM error monitor output terminal (C1and ATER is output when test mode) Not used (open)

Reset signal output to the PCM1718E (IC101), CXD2652AR (IC301) and BH6511FS (IC303)

“L”: reset

60 BU-IN I

61 BUS-ON I

62 SQSY

63 C-SW I

64 MD-LAT O

65 MD-ON O

66 DEEMP O

67 A-MUTE O

68 NCO O

69 TSTCKO O

70 TSTSO O

71 TSTMOD I

72 VCC —

73 NIL I

74 to 77

78 to 80 TIN0 to TIN2 I/O

TOUT0 to TOUT3

O

Battery detect signal input from the SONY bus interface (IC600) and battery check circuit

“H”: battery on

SONY bus on/off control signal input from the master controller (IC700) “L”: bus on

Subcode Q sync (SCOR) input from the CXD2652AR (IC301)

I

“L” is input every 13.3 msec Almost all, “H” is input

Inputs the disc loading start or disc eject completion detect switch detection signal

“L”: When start or eject completed of the disc loading operation

Serial data latch pulse signal output to the CXD2652AR (IC301) and CXA2523R (IC302)

Power supply on/off control signal output of the MD mechanism deck section main power supply

“H”: power on

Emphasis on/off control signal output to the PCM1718E (IC101) “H”: emphasis on

Audio muting on/off control signal output terminal

Not used (open)

Output of clock signal for the test mode display Not used (open)

Output of data for the test mode display Not used (open)

Setting terminal for the test mode “L”: test mode, “H”: normal mode

Power supply terminal (+5V)

Not used (fixed at “H”)

Output of the 4×8 matrix test keys Not used (open)

Input of the 4×8 matrix test keys (“L” is always output, except in test mode) Not used (open)

*1 Loading motor (M903) control

Operatio

Terminal

LOAD (pin 6)

EJECT (pin 7)

IN OUT BRAKE STOP

“H” “L” “H” “L”

“L” “H” “H” “L”

– 67 –

Page 48

MAIN BOARD IC700 (MASTER CONTROLLER)

•

MB90574PFV-G-188-BND (MDX-C5960R/C5970R) MB90574PFV-G-187-BND (MDX-C5970)

Pin No. Pin Name I/O Function

1 to 7 NC O

8 VCC —

9 PLL SI I

10 PLL SO O

11 PLL CKO O

12 NOSE-SW I

13 LCD SO

14 LCD CKO

15

16 DBMOD2 O

17 DOOR-SW I

18, 19 NC O

20 UNI SI

21 UNI SO

22 UNI CKIO

23 NC O

24

25 PACK-IND

26 VOL SO

27 VOL CKO

28 DSTSEL0 I

29 SYSRST O

30 DSTSEL1 I

31 DBMOD1 O

32 TESTIN

33

34 C —

35 NS-MASK O

36 BUS- ON

37 AD-ON

38 DVCC —

39 DVSS —

40 LCDANG

41 VOL CE

42 AVCC

BEEP O Beep sound drive signal output terminal

SIRCS

VSS

Not used (open)

Power supply terminal (+5V)

PLL serial data input terminal Not used (open)

PLL serial data output terminal Not used (open)

PLL serial data transfer clock signal output terminal Not used (open)

Front panel block remove/attach detection signal input terminal

“L”: front panel is attached

O Serial data output to the liquid crystal display driver (IC801)

O Serial data transfer clock signal output to the liquid crystal display driver (IC801)

D-BASS mode control signal output terminal Not used (open)

Front panel open/close detection signal input “L” is input when the front panel is closed

Not used (open)

Not used (open)

I Serial data input from the SONY bus interface (IC600)

O Serial data output to the SONY bus interface (IC600)

Serial clock signal output to the MD mechanism controller (IC501) and SONY bus interface

I/O

(IC600) or serial clock signal input from the MD mechanism controller (IC501) (for SONY bus)

Not used (open)

I

Sircs remote control signal input terminal Not used (fixed at “L”)

LED drive signal output of the MD disc slot illumination and 6 indicator “H”: LED on

O

“H” is output to turn on LED when front panel is opened Not used (open)

O Serial data output for the electrical volume Not used (open)

O Serial data transfer clock signal output for the electrical volume Not used (open)

Destination setting terminal

(Except German models: fixed at “H”, German model: fixed at “L”)

System reset signal output to the MD mechanism controller (IC501) and SONY bus interface

(IC600) “L”: reset

Destination setting terminal

(US, Canadian models: fixed at “H”, E model: fixed at “L”)

D-BASS mode control signal output terminal Not used (open)

I Setting terminal for the test mode “L”: test mode, Normally: fixed at “H”

—

Ground terminal

Connected to coupling capacitor for the power supply

Discharge control signal output for the noise detection circuit “H”: discharge

Used for the MDX-C5960R/C5970R only (MDX-C5970: Not used (open))

Bus on/off control signal output to the MD mechanism controller (IC501) and SONY bus

O

interface (IC600) “L”: bus on

A/D converter power control signal output terminal

O

When the KEYACK (pin &ª) that controls reference voltage power for key A/D conversion input

is active, “L” is output from this terminal to enable the input

Power supply terminal (+5V) (for D/A converter)

Ground terminal (for D/A converter)

View field angle control signal is output when front panel is fully opened

O

“H”: front panel is fully opened

O Chip enable signal output for the electrical volume Not used (open)

— Power supply terminal (+5V) (for A/D converter)

– 68 –

Page 49

Pin No. Pin Name I/O Function

43 AVRH

44 AVRL

45 AVSS

46 KEY-IN0

47 KEY-IN1

48 KEY-IN2

49 RC-IN0

50 D-BASS IN

51 QUALITY

52 MPDH (MTP)

53

54 VCC —

55 AMP ATT

56 AMP ON

57 ILL IN

58 LOCK IN

59 EMPH ON

60 AU ATT

61 AF ATT

62 TU-ATT O

63 VSS —

64 ACC IN

65 AF-SEEK O

S-METER

(VSM)

I Reference voltage (+5V) input terminal (for A/D converter)

I Reference voltage (0V) input terminal (for A/D converter)

— Ground terminal (for A/D converter)

Key input terminal (A/D input) (LSW801 to LSW804, LSW806 to LSW810)

I

OFF, SOURCE, SEEK/AMS + ) + = 0 – , DSPL, SOUND, MODE, SHIFT, 1, 2

keys input (LSW804 DSPL: MDX-C5960R/C5970R only)

Key input terminal (A/D input) (LSW811 to LSW821)

6, AF/TA (MDX-C5960R/C5970R) DSPL (MDX-C5970), LIST PTY (MDX-C5960R/

I

C5970R) LIST (MDX-C5970), 10 to 3 keys input

I Key input terminal (A/D input) Not used (open)

I Rotary remote commander key input terminal (A/D input)

I D-BASS switch (LSW805) input terminal (A/D input)

Noise level detection signal input at SEEK mode (A/D input)

I

Used for the MDX-C5960R/C5970R only (MDX-C5970: Not used (open))

Multi-path detection signal input from the RDS decoder (IC102) (A/D input)

I

Used for the MDX-C5960R/C5970R only (MDX-C5970: Not used (open))

FM and AM signal meter voltage detection input from the FM/AM tuner unit (TU1)

I

(A/D input)

Power supply terminal (+5V)

Power amp muting on/off control signal output to the power amplifier (IC500)

O

“L”: muting on

Standby on/off control signal output to the power amplifier (IC500)

O

“L”: standby mode, “H”: amp on

Auto dimmer control illumination line detection signal input terminal

I

“L” is input at dimmer detection

I Mini-disc lock detection signal input from the MD mechanism controller (IC501) “H”: lock

O Emphasis control signal output terminal Not used (open)

O Audio line muting on/off control signal output terminal “H”: muting on

O Preamp muting on/off control signal output to the electrical volume (IC300) “H”: muting on

Muting on/off control signal output of the FM tuner signal “H”: muting on