Sony MDSW-1 Service manual

MICROFILM

MDS-W1

SERVICE MANUAL

SPECIFICATIONS

AEP Model

Model Name Using Similar Mechanism MDS-JE520

MD Mechanism Type MDM-5B

Optical Pick-up Type KMS-260A/J1N

— Continued on next page —

MINIDISC DECK

– 1 –

SELF-DIAGNOSIS FUNCTION

The self-diagnosis function consists of error codes for customers which are displayed automatically when errors occur, and error codes which

show the error history in the test mode during servicing. For details on how to view error codes for the customer, refer to the following box

in the instruction manual. For details on how to check error codes during servicing, refer to the following “Procedure for using the SelfDiagnosis Function (Error History Display Mode)”.

Procedure for using the Self-Diagnosis Function (Error History Display Mode).

Note: Perform the self-diagnosis function in the “error history display mode” in the test mode. The following describes the least required

procedure. Be careful not to enter other modes by mistake. If you set other modes accidentally, press the MENU/NO button to exit

the mode.

As this unit uses two mechanism Deck A and Deck B, it carries out self-diagnosis for eac h deck. For buttons or knobs not specified as

(Deck A) or (Deck B) in the procedure, use that of the corresponding deck.

1. With the power ON, press the 0 (Deck B) button while pressing the OUTPUT and CLEAR (Deck A) buttons together.

2. Rotate the AMS knob and when “(Service)” is displayed, press the YES button.

3. Rotate the AMS knob and display “ERR DP MODE”.

4. Pressing the YES button sets the error history mode and displays “total rec”.

5. Select the contents to be displayed or executed using the AMS knob.

6. Pressing the AMS knob will display or execute the contents selected.

7. Pressing the AMS knob another time returns to step 4.

8. Pressing the MENU/NO button displays “ERROR DP MODE” and exits the error history mode.

9. To exit the test mode, press the MD SYNC button. The unit sets into the STANDBY state, and the test mode ends.

– 2 –

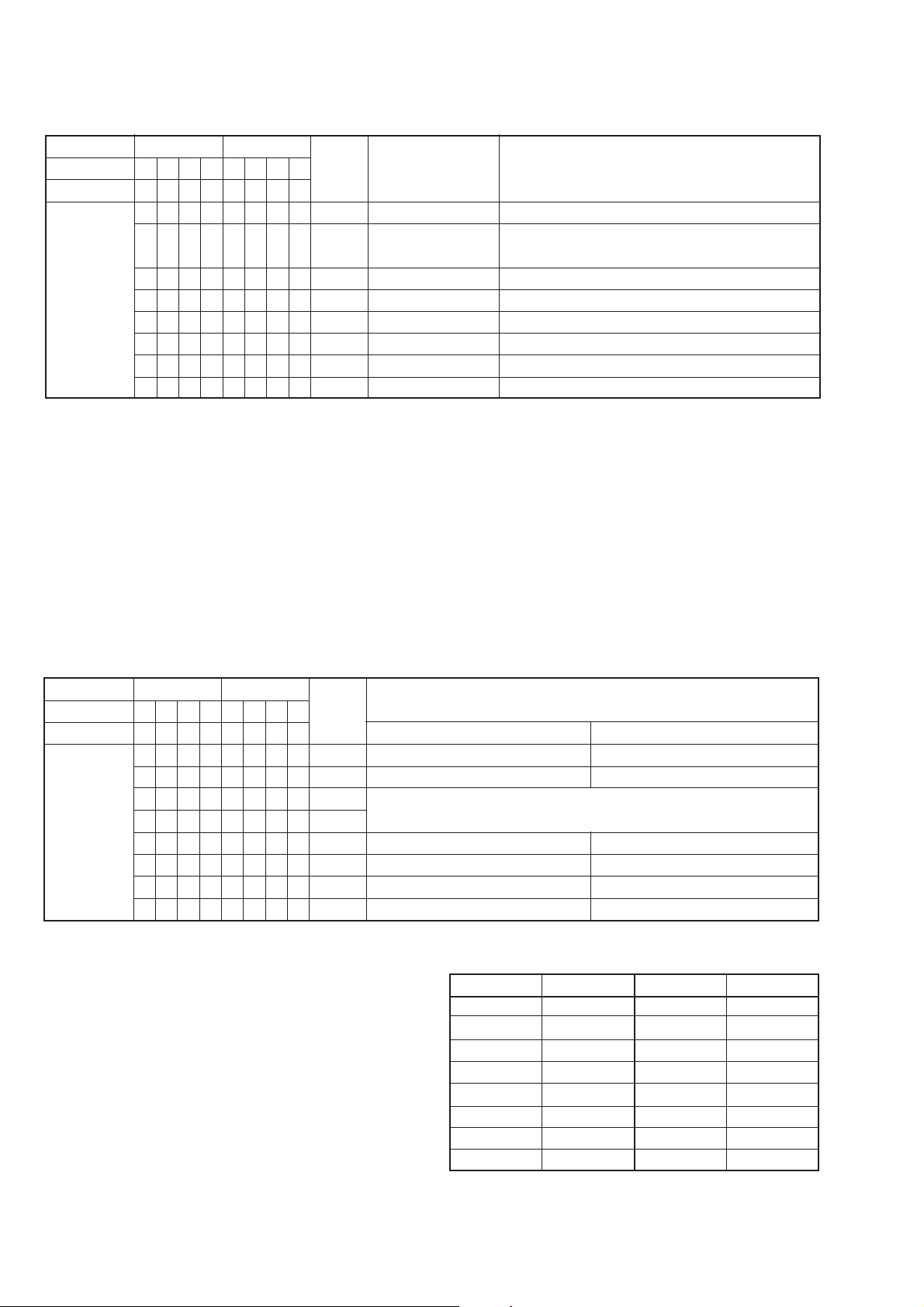

ITEMS OF ERROR HISTORY MODE ITEMS AND CONTENTS

Selecting the Test Mode

Display

total rec

total play

retry err

total err

err history

er refresh

Details of History

Displays the recording time.

Displayed as “rππππππh”.

The displayed time is the total time the laser is set to the high power state.

This is about 1/4 of the actual recording time.

The time is displayed in decimal digits from 0h to 65535h.

Displays the play time.

Displayed as “pππππππh”. The time displayed is the total actual play time. Pauses are not counted.

The time is displayed in decimal digits from 0h to 65535h.

Displays the total number of retries during recording and number of retry errors during play.

Displayed as “rππ pππ”.

“r” indicates the retries during recording while “p” indicates the retry errors during play.

The number of retries and retry errors are displayed in hexadecimal digits from 00 to FF.

Displays the total number of errors.

Displayed as “total ππ”.

The number of errors is displayed in hexadecimal digits from 00 to FF.

Displays the 10 latest errors.

Displayed as “0π E@@”.

π indicates the history number. The smaller the number, the more recent is the error. (00 is the latest).

@@ indicates the error code.

Refer to the following table for the details. The error history can be switched by rotating the AMS knob.

Mode which erases the “retry err”, “total err”, and “err history” histories.

When returning the unit to the customer after completing repairs, perform this to erase the past error history,

After pressing the AMS button and “er refresh?” is displayed, press the YES button to erase the history.

“Complete!” will be displayed momentarily.

Be sure to check the following when this mode has been executed.

• The data has been erased.

• The mechanism operates normally when recording and play are performed.

tm refresh

Table of Error Codes

Error Code

E00

E01

E02

E03

E04

No error

Disc error. PTOC cannot be read

(DISC ejected)

Disc error. UTOC error

(DISC not ejected)

Loading error

Address cannot be read (Servo has deviated)

Mode which erases the “total rec” and “total play” histories.

These histories serve as approximate indications of when to replace the optical pickup.

If the optical pickup has been replaced, perform this operation and erase the history.

After pressing the AMS button and “tm refresh?” is displayed, press the YES button to erase the history.

“Complete!” will be displayed momentarily.

Be sure to check the following when this mode has been executed.

• The data has been erased.

• The mechanism operates normally when recording and play are performed.

Details of Error

Error Code

E05

E06

E07

E08

E09

E0A

Details of Error

FOK has deviated

Cannot focus (Servo has deviated)

Recording retry

Recording retry error

Playback retry error

(Access error)

Play retry error (C2 error)

– 3 –

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the equipment manufacturer.

Discard used batteries according to manufacture’s instructions.

ADVARSEL!

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilakting skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av

apparatfabrikanten.

Brukte batterier katterier kasseres i henhold til fabrikantens

VARNIG

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som rekommender as

av apparattillverkaren.

Kassera använt batteri enligt gällande föreakrifter.

VAROITUS

Parist voi räjähtää, jos se on virheellisesti asennettu.

V aihda paristo ainoastaan laitev almistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

The following

caution label is

located inside of

the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 4 –

TABLE OF CONTENTS

1. SERVICING NOTE .......................................................... 6

2. GENERAL ........................................................................ 11

3. DISASSEMBLY

3-1. Front Panel ......................................................................... 35

3-2. Slider (Cam) ........................................................................ 35

3-3. Base Unit (MBU-5B) and BD Board .................................. 36

3-4. SW Board and Loading Motor (M103) ..............................36

4. TEST MODE ..................................................................... 37

5. ELECTRICAL ADJUSTMENTS ............................... 41

6. DIAGRAMS

6-1. Circuit Boards Location ...................................................... 50

6-2. Block Diagrams

• BD Section .......................................................................51

• Input/Output Section ........................................................53

• Control Section ................................................................ 55

• Power Section .................................................................. 58

6-3. Printed Wiring Board – BD Section –................................. 61

6-4. Schematic Diagram – BD (1/2) Section – ...........................63

6-5. Schematic Diagram – BD (2/2) Section – ...........................65

6-6. Schematic Diagram – Jack (1/2) Section – ......................... 67

6-7. Schematic Diagram – Jack (2/2) Section – ......................... 69

6-8. Printed Wiring Board – Jack Section – ............................... 71

6-9. Printed Wiring Board – Main Section –..............................73

6-10. Schematic Diagram – Main (1/5) Section – ......................77

6-11. Schematic Diagram – Main (2/5) Section – ......................79

6-12. Schematic Diagram – Main (3/5) Section – ......................81

6-13. Schematic Diagram – Main (4/5) Section – ......................83

6-14. Schematic Diagram – Main (5/5) Section – ......................85

6-15. Schematic Diagram – BD Switch Section – ..................... 87

6-16. Printed Wiring Board – BD Switch Section –................... 87

6-17. Printed Wiring Board – Panel Section –............................ 89

6-18. Schematic Diagram – Panel Section – .............................. 91

6-19. Printed Wiring Board – Power Section – .......................... 93

6-20. Schematic Diagram – Power Section – .............................95

6-21. Printed Wiring Board – Trans Section – ........................... 97

6-22. Schematic Diagram – Trans Section – .............................. 99

6-23. IC Block Diagrams .........................................................101

6-24. IC Pin Functions .............................................................105

7. EXPLODED VIEWS

7-1. Case Section ...................................................................... 115

7-2. Front Panel Section ........................................................... 116

7-3. Chassis Section ................................................................. 117

7-4. Mechanism Deck Section (MDM-5B) .............................. 118

7-5. Base Unit Section (MBU-5B) ........................................... 119

8. ELECTRICAL PARTS LIST ...................................... 120

– 5 –

SECTION 1

3

r

SERVICING NOTE

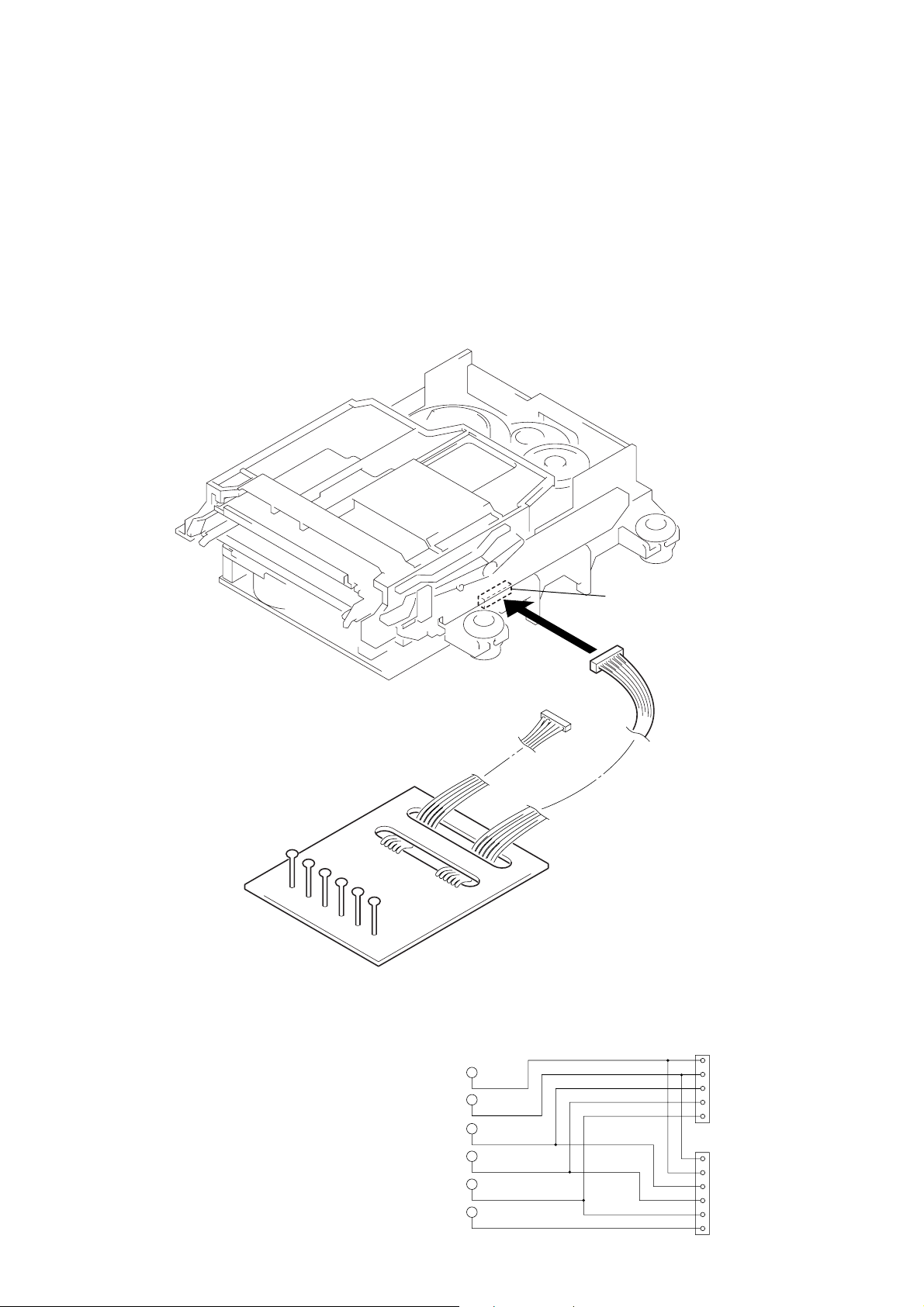

JIG FOR CHECKING BD BOARD WAVEFORM

The special jig (J-2501-149-A) is useful for checking the waveform of the BD board. The names of terminals and the checking items to be

performed are shown as follows.

GND : Ground

I+3V : For measuring IOP (Check the deterioration of the optical pick-up laser)

IOP : For measuring IOP (Check the deterioration of the optical pick-up laser)

TEO : TRK error signal (Traverse adjustment)

VC : Reference level for checking the signal

RF : RF signal (Check jitter)

Mechanism deck

RF

VC

TEO

IOP

I+3V

CN110

6P connecto

5P Connector

GND

1

RF

VC

TEO

IOP

I+3V

GND

RF

VC

For

TEO

MDM-

IOP

I-3V

5

1

VC

RF

For

TEO

MDM-5

IOP

I+3V

6

GND

– 6 –

IOP DATA RECORDING AND DISPLAY WHEN PICKUP AND NON-V OLA TILE MEMOR Y (IC171 OF BD BOARD)

ARE REPLACED

The IOP value labeled on the pick-up can be recorded in the non-volatile memory . By recording the value, it will eliminate the need to look

at the value on the label of the optical pick-up. When replacing the pick-up or non-volatile memory (IC171 of BD board), record the IOP

value on the pick-up according to the following procedure.

For buttons or knobs not specified as (Deck A) or (Deck B) in the procedure, use that of the corresponding deck.

Record Precedure:

1. With the power ON, press the 0 (Deck B) button while pressing the OUTPUT and CLEAR (Deck A) buttons together.

2. Rotate the AMS knob to display “(Service)”, and press the YES button.

3. Rotate the AMS knob to display “lop.Write” (S: 28), and press the YES button.

4. The display becomes “Ref=@@@.@” (@ is an arbitrary number) and the numbers which can be changed will blink.

5. Input the IOP value written on the optical pick-up.

To select the number : Rotate the AMS knob.

To select the digit :Press the AMS knob.

6. When the YES button is pressed, the display becomes “Measu=@@@.@” (@ is an arbitrary number).

7. As the adjustment results are recorded for the 6 value. Leave it as it is and press the YES button.

8. The value will be recorded in the non-volatile memory and the display will become “Iop Write”.

9. Press the MD SYNC button to complete.

Display Precedure:

1. With the power ON, press the 0 (Deck B) button while pressing the OUTPUT and CLEAR (Deck A) buttons together.

2. Rotate the AMS knob to display “(Service)”, and press the YES button.

3. Rotate the AMS knob to display “lop.Read” (S: 27).

4. “@@.@/##.#” is displayed and the recorded contents are displayed.

@@.@ : indicates the Iop value labeled on the pick-up.

##.# : indicates the Iop value after adjustment

5. To end, press the AMS button or MENU/NO button to display “Iop Read”. Then press the MD SYNC button.

– 7 –

CHECKS PRIOR TO PARTS REPLACEMENT AND ADJUSTMENTS

Before performing repairs, perform the following checks to determine the faulty locations up to a certain extent.

Details of the procedures are described in “5 Electrical Adjustments”.

Laser power check

(5-6-2 : See page 44)

Traverse check

(5-6-3 : See page 44)

Focus bias check

(5-6-4 : See page 45)

C PLAY check

(5-6-5 : See page 45)

Self-recording/playback

check

(REC/PLAY)

(5-6-6 : See page 45)

TEMP check

(Temperature

compensation

offset check)

(5-6-1 : See page 44)

Criteria for Determination

(Unsatisfactory if specified value is not satisfied)

• 0.9 mW power

Specified value : 0.84 to 0.92 mW

• 7.0 mW power

Specified value : 6.8 to 7.2 mW

lop (at 7mW)

• Labeled on the optical pickup

Iop value ± 10mA

• Traverse waveform

Specified value : Below 10% offset

• Error rate check

Specified value : For points a, b, and c

C1 error : Below 220

AD error : Below 2

• Error rate check

Specified value:

a.When using test disc (MDW-74/AU-1)

C1 error : Below 80

AD error : Below 2

b.When using check disc (TDYS-1)

C1 error : Below 50

• CPLAY error rate check

Specified value:

C1 error : Below 80

AD error : Below 2

• Unsatisfactory if displayed as T=@@ (##) (NG”

NG

(@@, ## are both arbitrary numbers)

Measure if unsatisfactory:

• Clean the optical pick-up

• Adjust again

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

If always unsatisfactory:

• Replace the overwrite head

• Check for disconnection of the circuits around the

overwrite head

If occasionally unsatisfactory:

• Check if the overwrite head is distorted

• Check the mechanism around the sled

• Check for disconnection of the circuits around D101

(BD board)

• Check the signals around IC101, IC121, CN102,

CN103 (BD board)

Note:

The criteria for determination above is intended merely to determine if satisfactory or not, and does not serve as the specifie d value for

adjustments.

When performing adjustments, use the specified values for adjustments.

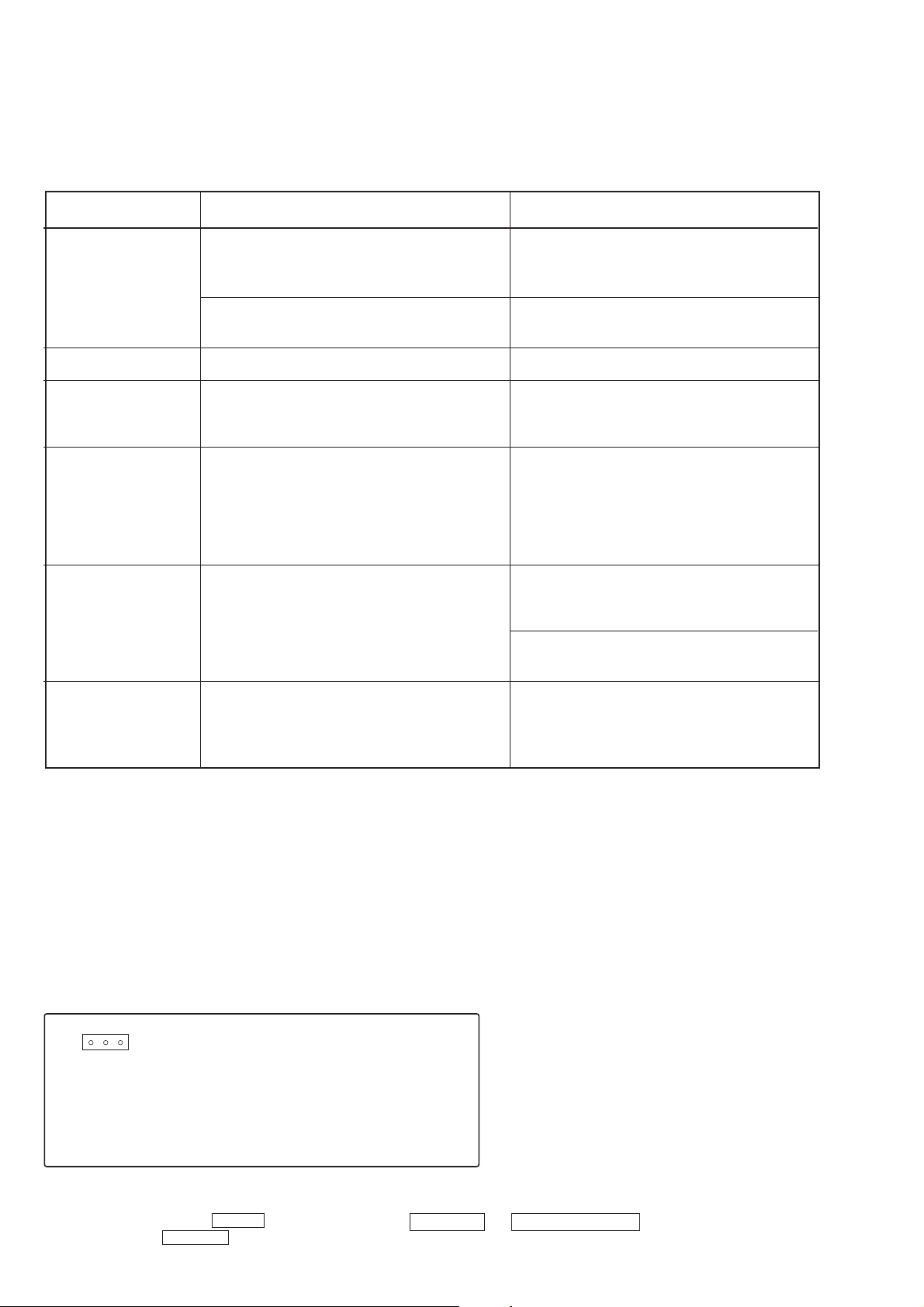

FORCED RESET

The system microprocessor can be reset in the following procedure.

Use these procedure when the unit cannot be operated normally due to the overrunning of the microprocessor, etc.

Procedure :

Disconnect the power plug from the outlet, short-circuit Pins 1 and 2 of CN302 of the MAIN board and discharge the backup battery.

[MAIN BOARD] (Component Side)

3

21

CN302

Complete lighting of fluorescent display tube

The fluorescent display tube can be lit completely by the following method:

With the power ON, press the TIMER button while pressing the p (Deck A) and MENU/NO (Deck A) buttons.

To turn off, press the DISPLAY button.

– 8 –

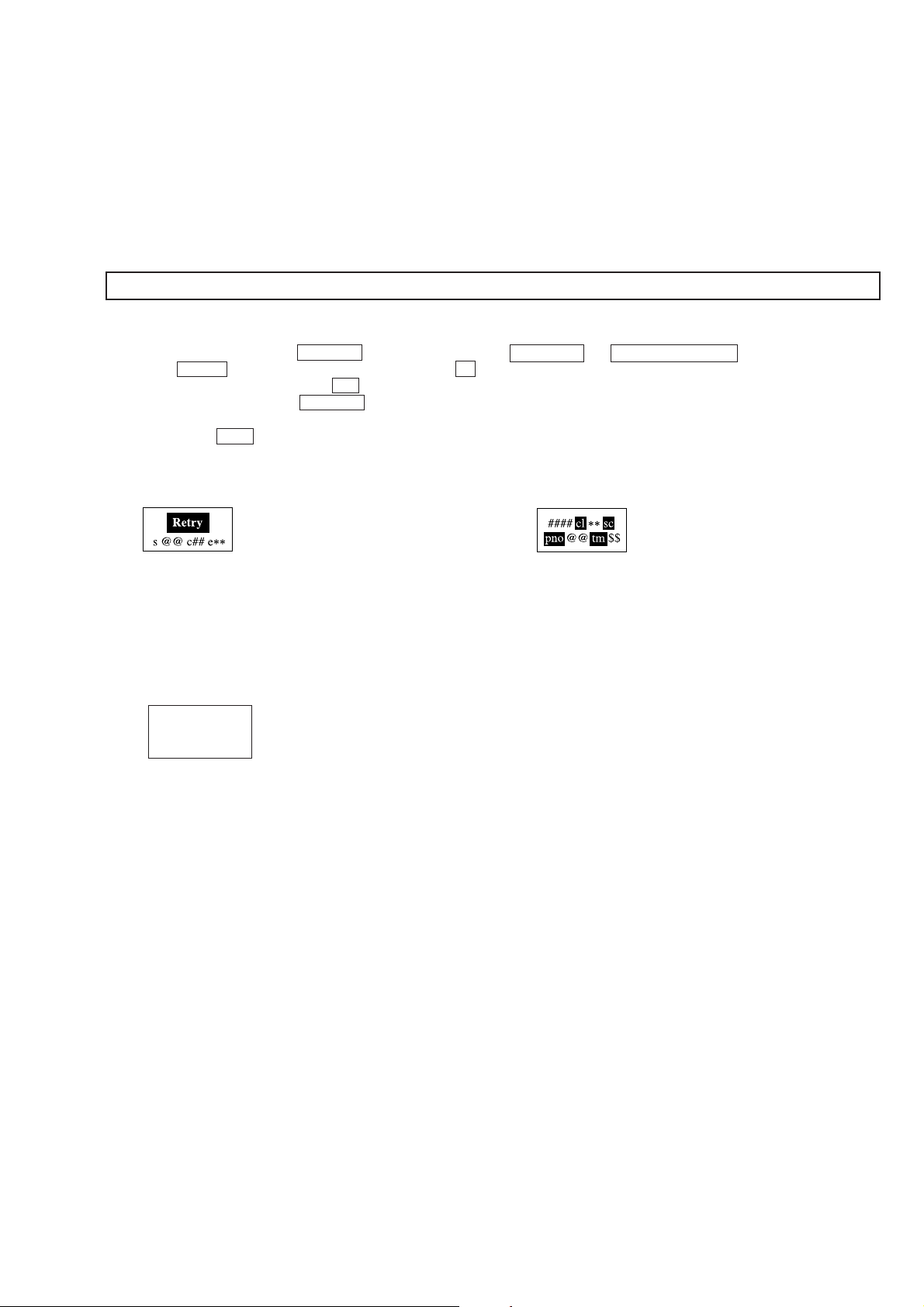

RETRY CAUSE DISPLAY MODE

• In this test mode, the causes for retry of the unit during recording can be displayed on the fluorescent indicator tube. During playback, the

“track mode” for obtaining track information will be set.

This is useful for locating the faulty part of the unit.

• The following will be displayed :

During recording and stop : Retry cause, number of retries, and number of retry errors.

During playback : Information such as type of disc played, part played, copyright.

These are displayed in hexadecimal.

For buttons or knobs not specified as (Deck A) or (Deck B) in the procedure, use that of the corresponding deck.

Precedure:

1. Load recordable discs (the contents will be erased) in both decks.

2. With the STOP state, press the DISPLAY button while pressing the p (Deck A) and MENU/NO (Deck A) buttons together.

3. Press the r REC button to start recording. Then press the P button and start recording.

4. To check the “track mode”, press the · button to start play.

5. To exit the test mode, press the DISPLAY button on the STOP state.

If the test mode cannot be exited, refer to “Forced Reset” on page 8.

Note: Rotating the AMS knob during STOP will display as shown in Fig. 3. This is however not used in servicing.

Fig. 1 Reading the Test Mode Display

(During recording and stop)

Fluorescent display tube display

@@ : Cause of retry

## : Number of retries

** : Number of retry errors

Fig. 3. (This display is not used in servicing.)

@@/@@/@@

maker : @@

model : @@

Fluorescent display tube display

@@ : Any number

Fig. 2 Reading the Test Mode Display

(During playback)

Fluorescent display tube display

@@ : Parts No. (name of area named on TOC)

## : Cluster

** : Sector

$$ : Track mode (Track information such as copyright

information of each part)

} Address (Physical address on disc)

– 9 –

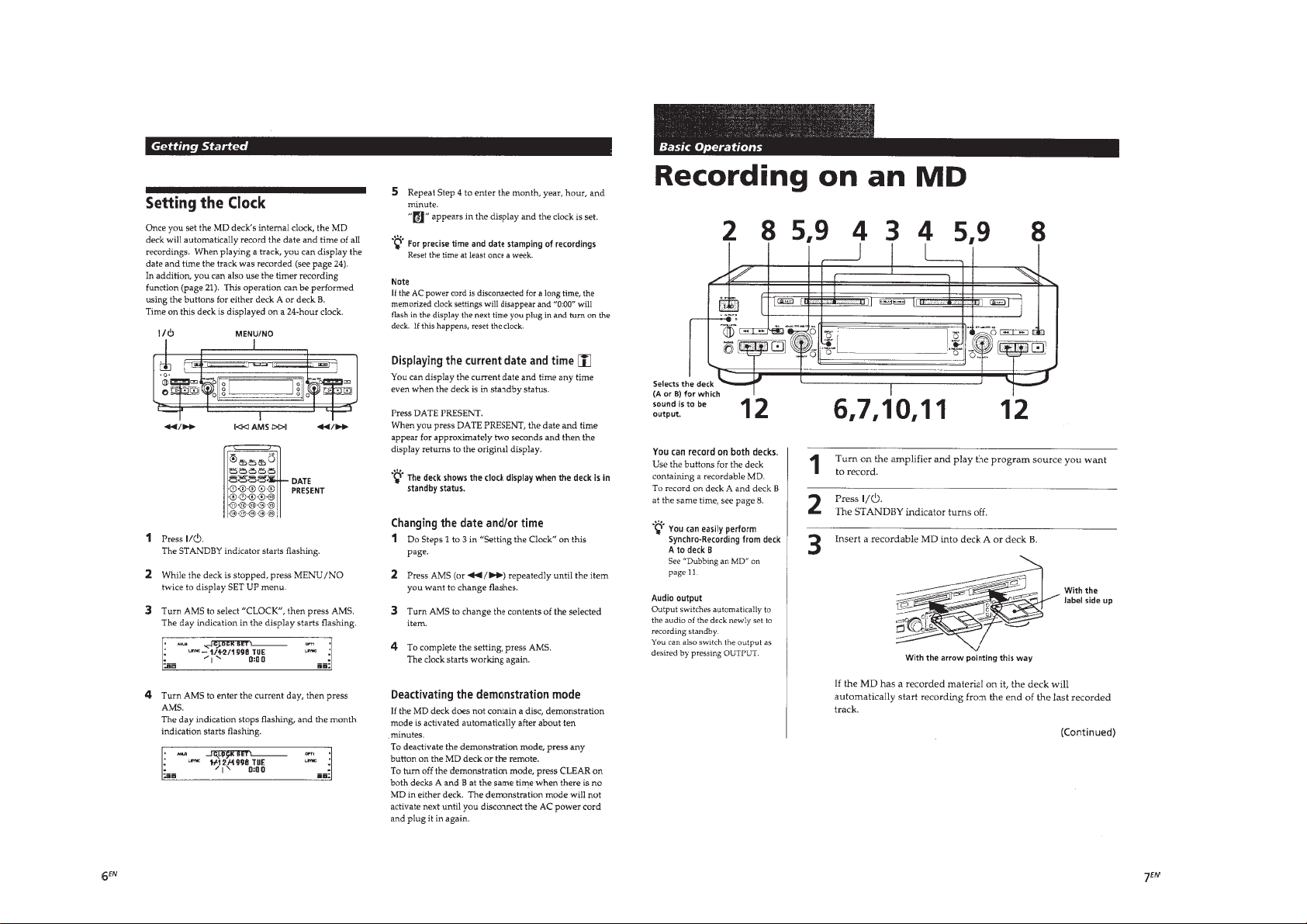

Reading the Retry Cause Display

Higher Bits

Hexadecimal

Bit

Binary

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example

When 42 is displayed:

Higher bit : 4 = 0100 n b6

Lower bit : 2 = 0010 n b1

In this case, the retry cause is combined of “CLV unlock” and “ader5”.

When A2 is displayed:

Higher bit : A = 1010 n b7+b5

Lower bit : 2 = 0010 n b2

The retry cause in this case is combined of “access fault”, “IVR rec error”, and “ader5”.

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Lower Bits

Hexa-

decimal

01

02

04

08

10

20

40

80

Cause of Retry Occurring conditions

shock

ader5

Discontinuous address

DIN unlock

FCS incorrect

IVR rec error

CLV unlock

Access fault

When track jump (shock) is detected

When ADER was counted more than five times

continuously

When ADIP address is not continuous

When DIN unlock is detected

When not in focus

When ABCD signal level exceeds the specified range

When CLV is unlocked

When access operation is not performed normally

Reading the Track Mode Display

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

Reading the Display:

Convert the hexadecimal display into binary display. If more than

two causes, they will be added.

Example

When 84 is displayed:

Higher bit : 8 = 1000 n b7

Lower bit : 4 = 0100 n b2

In this case, as b2 and b7 are 1 and others are 0, it can be

determined that the retry cause is combined of “emphasis OFF”,

“monaural”, “original”, “copyright e xists”, and “write allowed”.

Example

When 07 is displayed:

Higher bit : 0 = 1000 n All 0

Lower bit : 7 = 0111 n b0+b1+b2

In this case, as b0, b1, and b2 are 1 and others are 0, it can be

determined that the retry cause is combined of “emphasis ON”,

“stereo”, “original”, “copyright exists”, and “write prohibited”.

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

01

02

04

08

10

20

40

80

Emphasis OFF

Monaural

This is 2-bit display. Normally 01.

01:Normal audio. Others:Invalid

Audio (Normal)

Original

Copyright

Write prohibited

– 10 –

Details

When 0 When 1

Emphasis ON

Stereo

Invalid

Digital copy

No copyright

Write allowed

Hexadecimal n Binary Conversion Table

Hexadecimal Binary Hexadecimal Binary

0

1

2

3

4

5

6

7

0000

0001

0010

0011

0100

0101

0110

0111

8

9

A

B

C

D

E

F

1000

1001

1010

1011

1100

1101

1110

1111

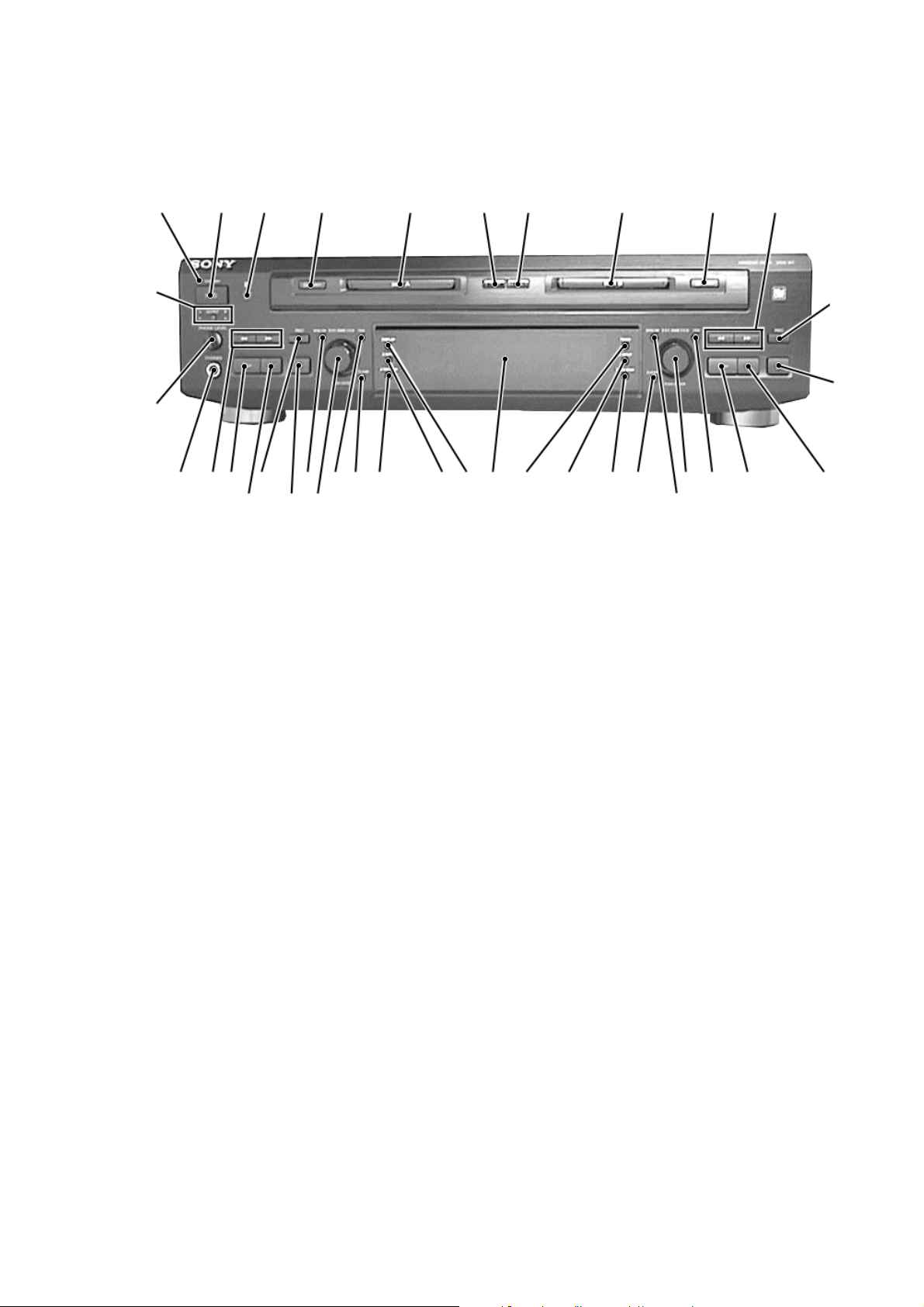

Front Panel

SECTION 2

GENERAL

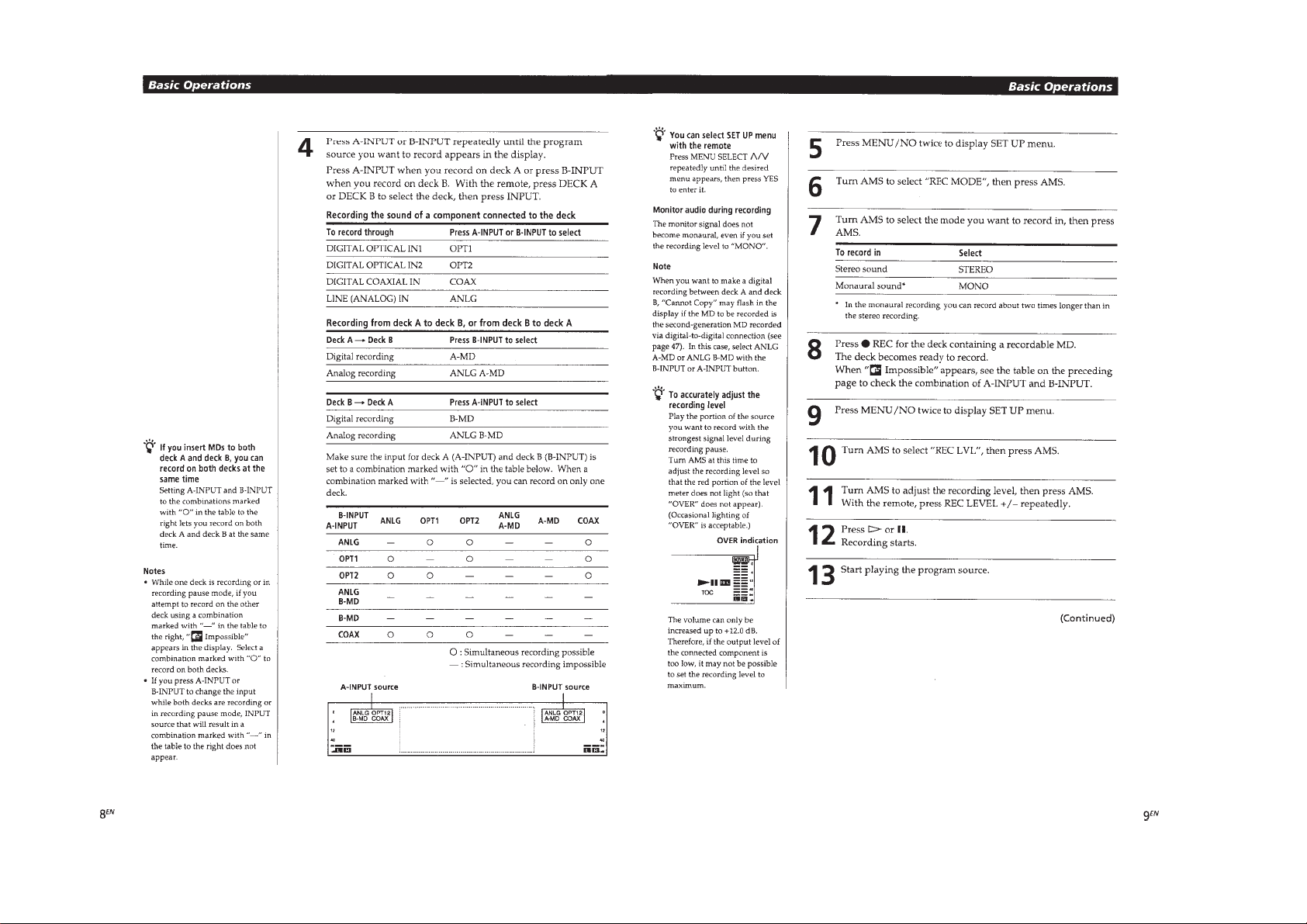

2 4 6 7 8 9 10 11

35

1

37

323330343536

2931

Location of Parts and Controls

1920 14

1617242526 2122232728

15

18

12

13

1 OUTPUT button and A. B indicator

2 STANDBY indicator

3 1/u (Power) button

4 Remote sensor

5 § EJECT (Deck A) button

6 DISK compartment (Deck A)

7 RELAY button and indicator

8 MD SYNC button and indicator

9 DISK compartment (Deck B)

10 § EJECT (Deck B) button

11 0, ) (Deck B) button

12 r REC (Deck B) button

13 p (STOP) (Deck B) button

14 P (P AUSE) (Deck B) button

15 · (PLAY) (Deck B) button

16 YES (Deck B) button

17 ≠ AMS ± (PUSH ENTER) (Deck B) knob

18 MENU/NO (Deck B) button

19 CLEAR (Deck B) button

* AMS is the abbreviation for Automatic Music Sensor.

20 B TIME/CHAR button

21 B INPUT button

22 TIMER button

23 Display window

24 DISPLAY button

25 A INPUT button

26 A TIME/CHAR button

27 CLEAR (Deck A) button

28 YES (Deck A) button

29 ≠ AMS ± (PUSH ENTER) (Deck A) knob

30 MENU/NO (Deck A) button

31 p (STOP) (Deck A) button

32 r REC (Deck A) button

33 P (P AUSE) (Deck A) button

34 · (PLAY) (Deck A) button

35 0, ) (Deck A) button

36 PHONES jack

37 PHONE LEVEL knob

– 11 –

– 12 –

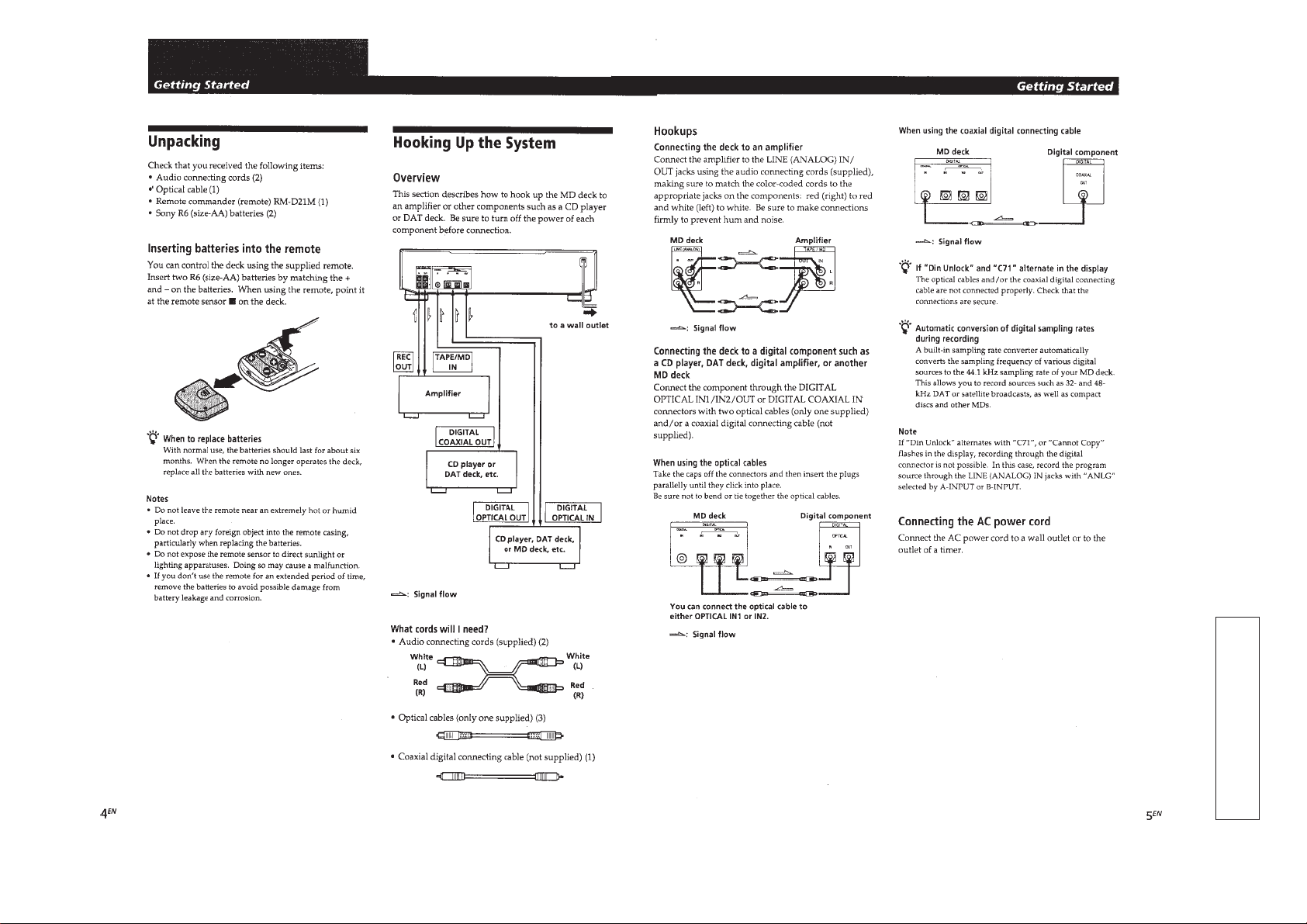

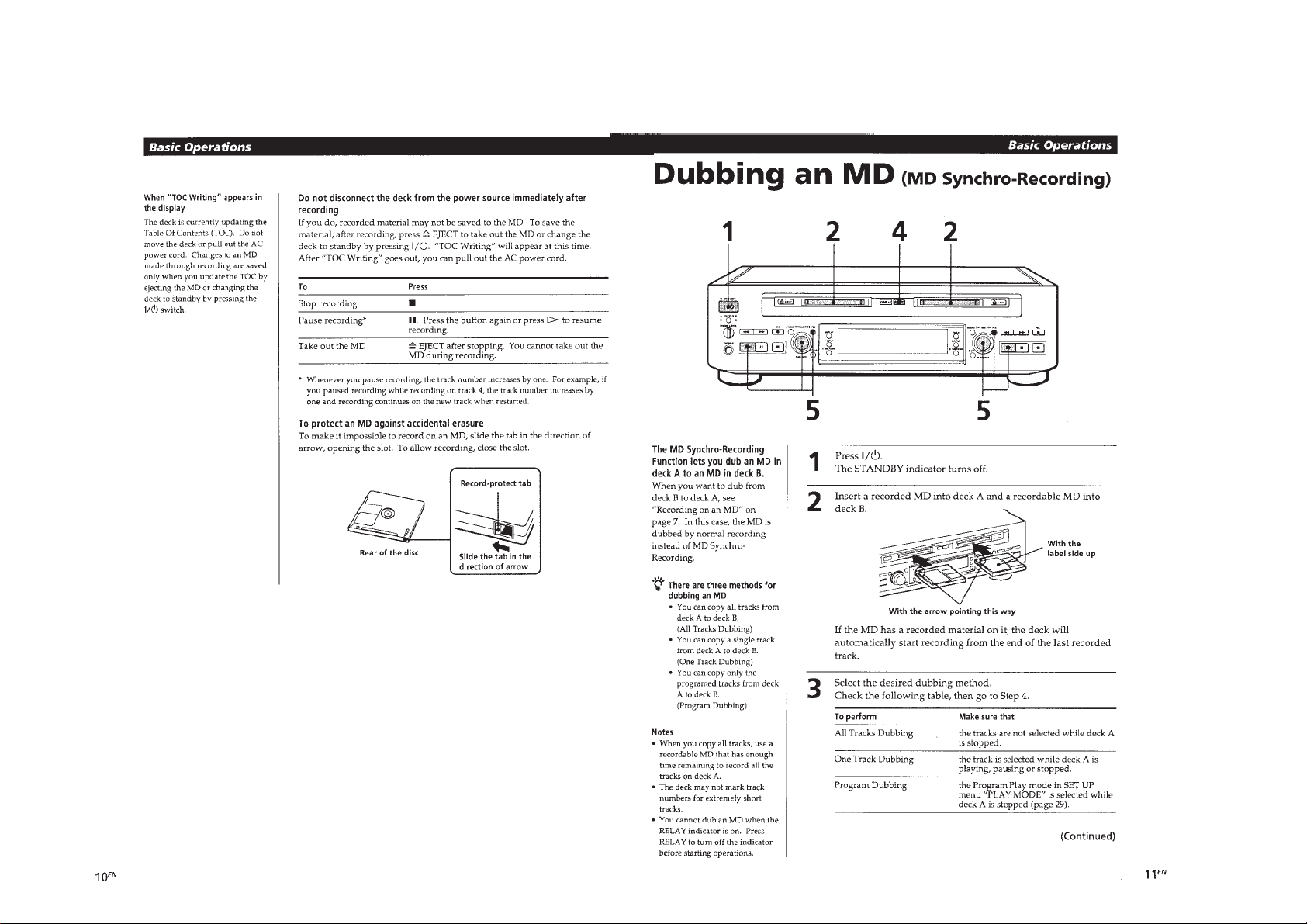

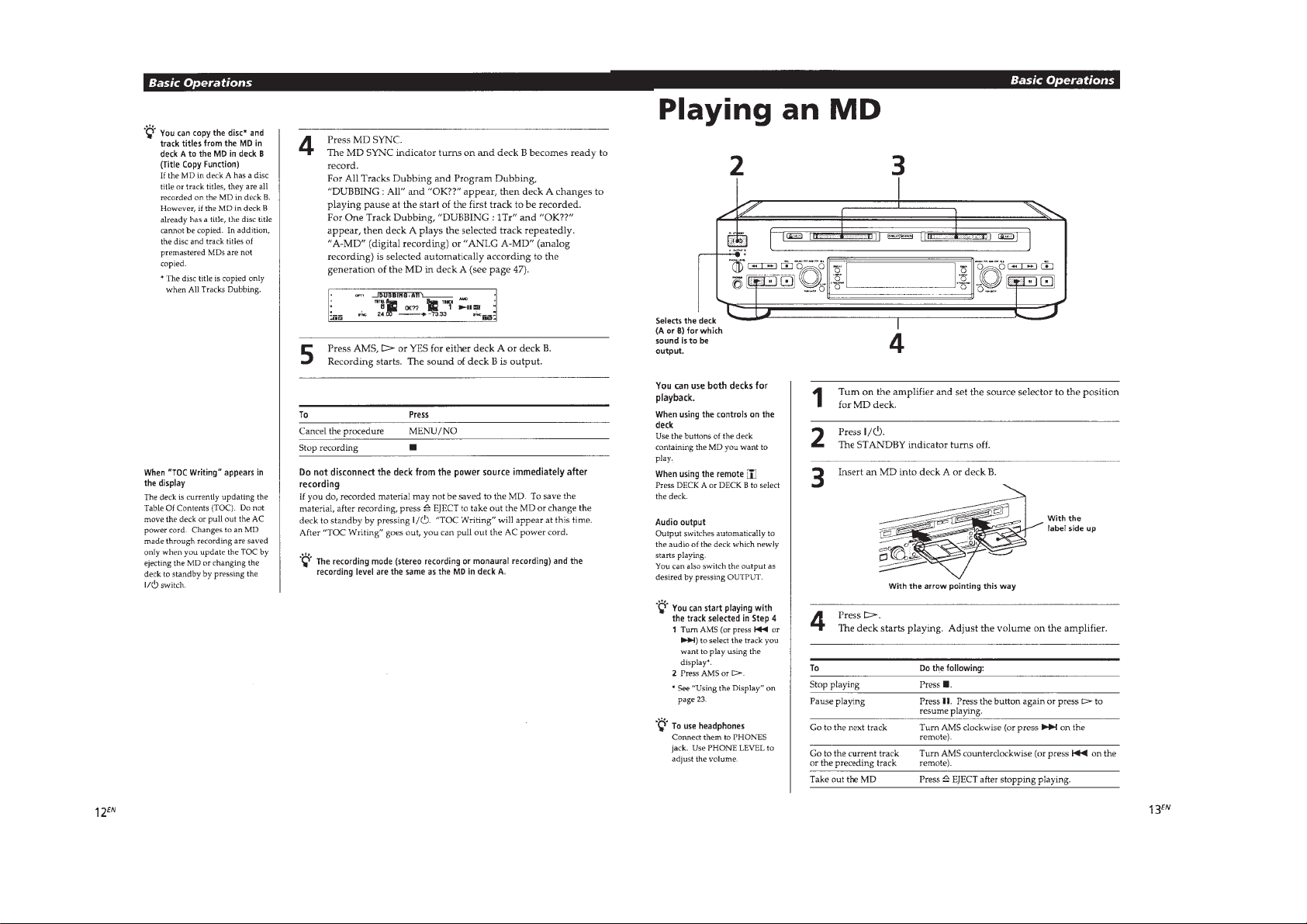

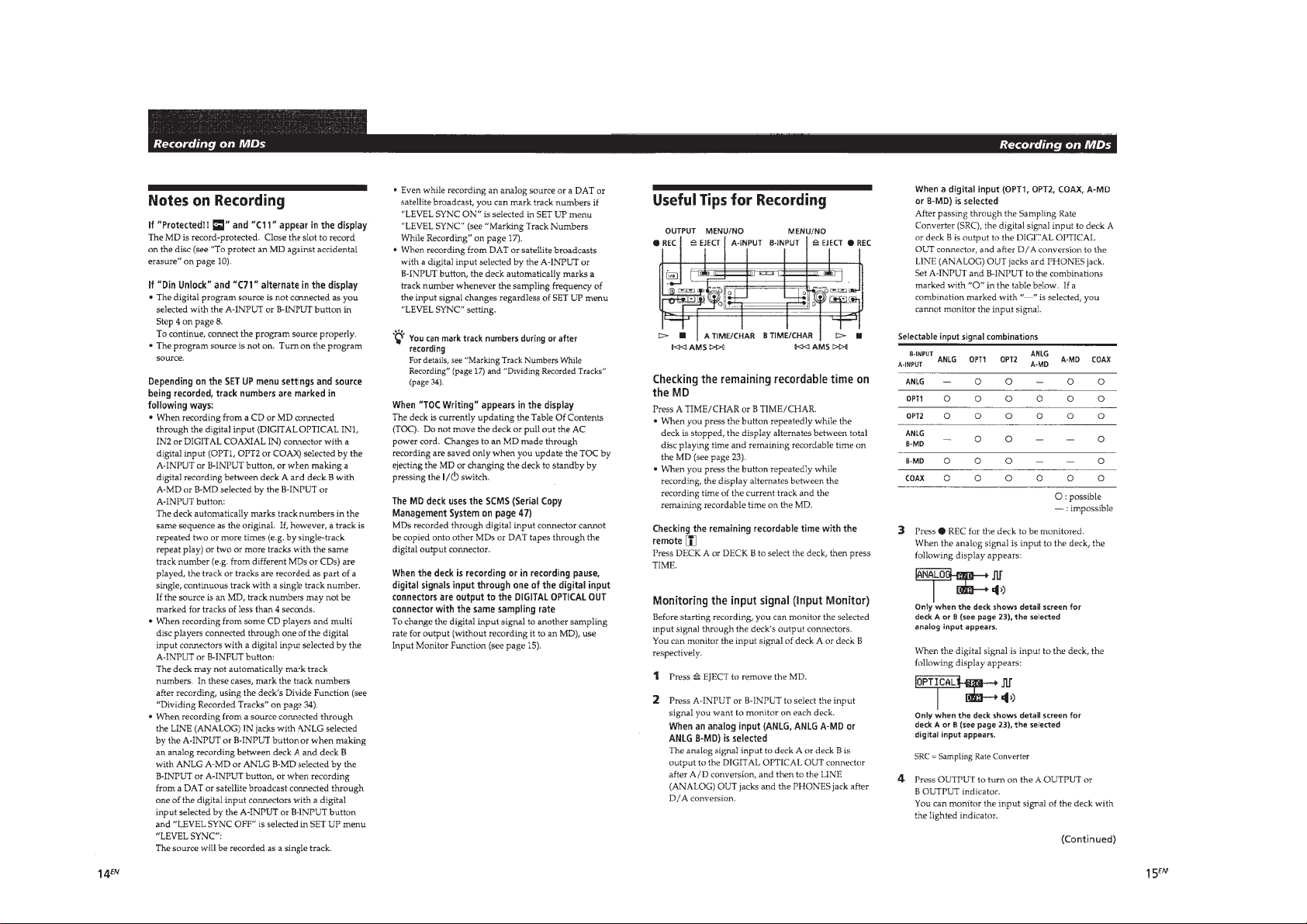

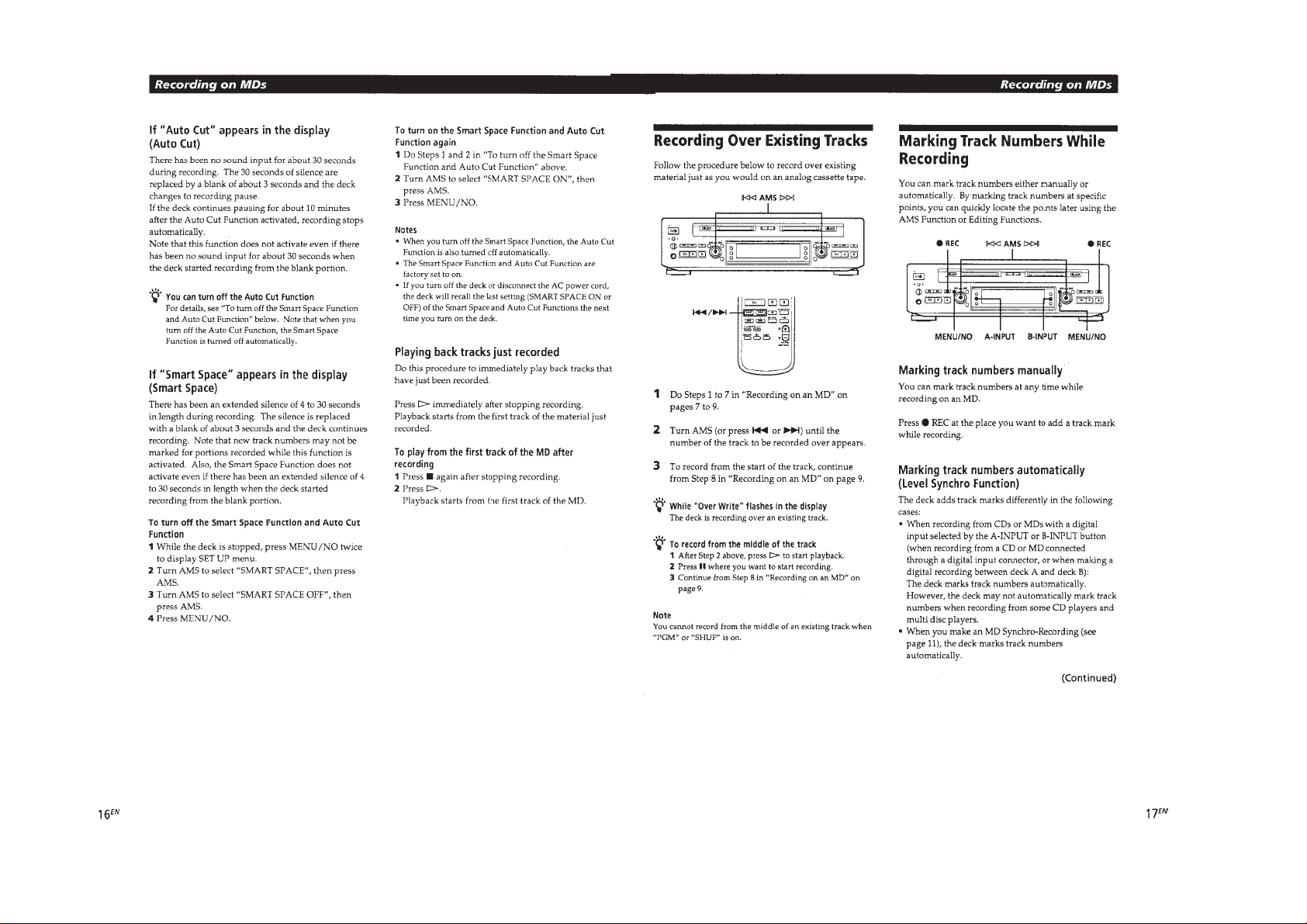

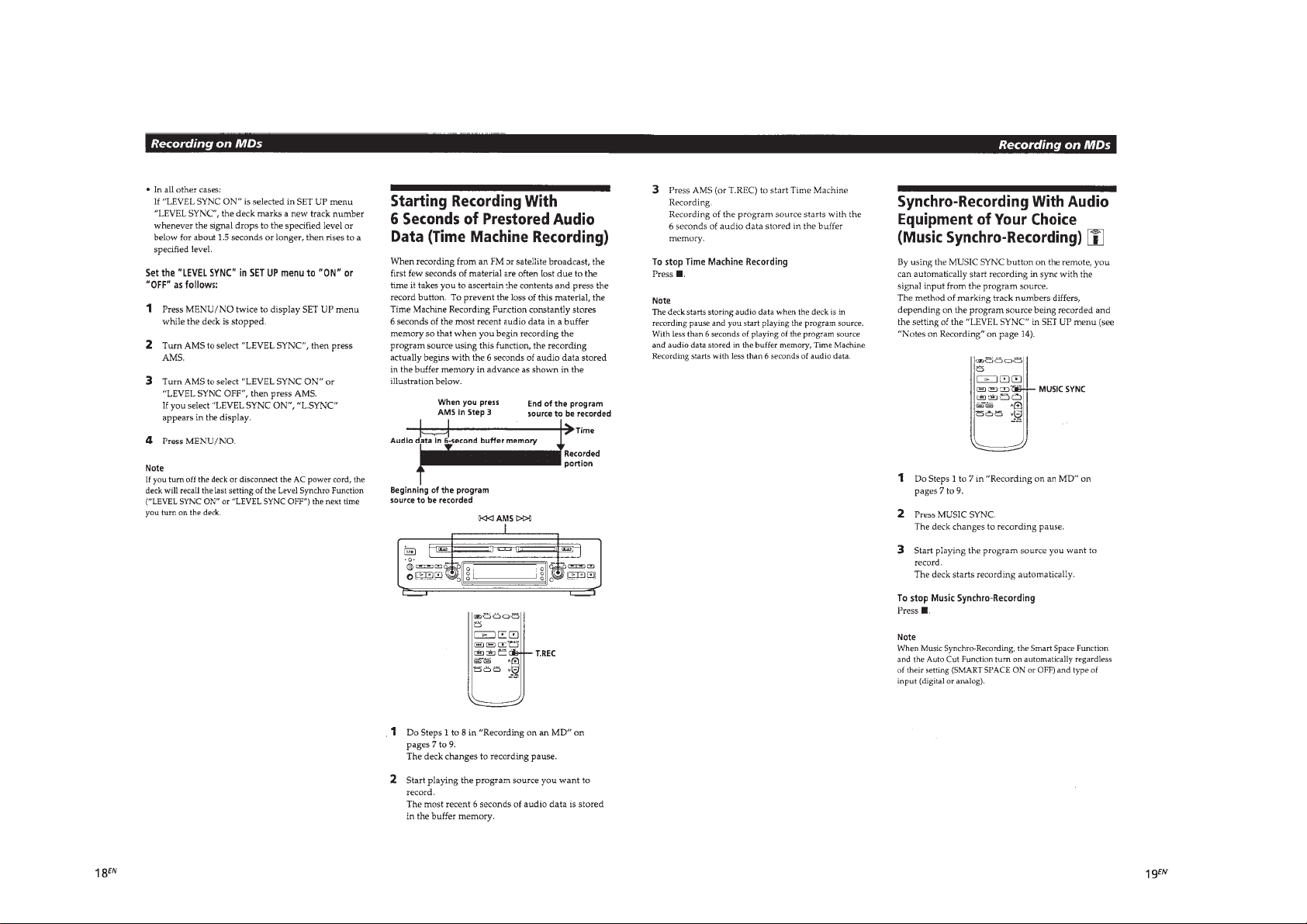

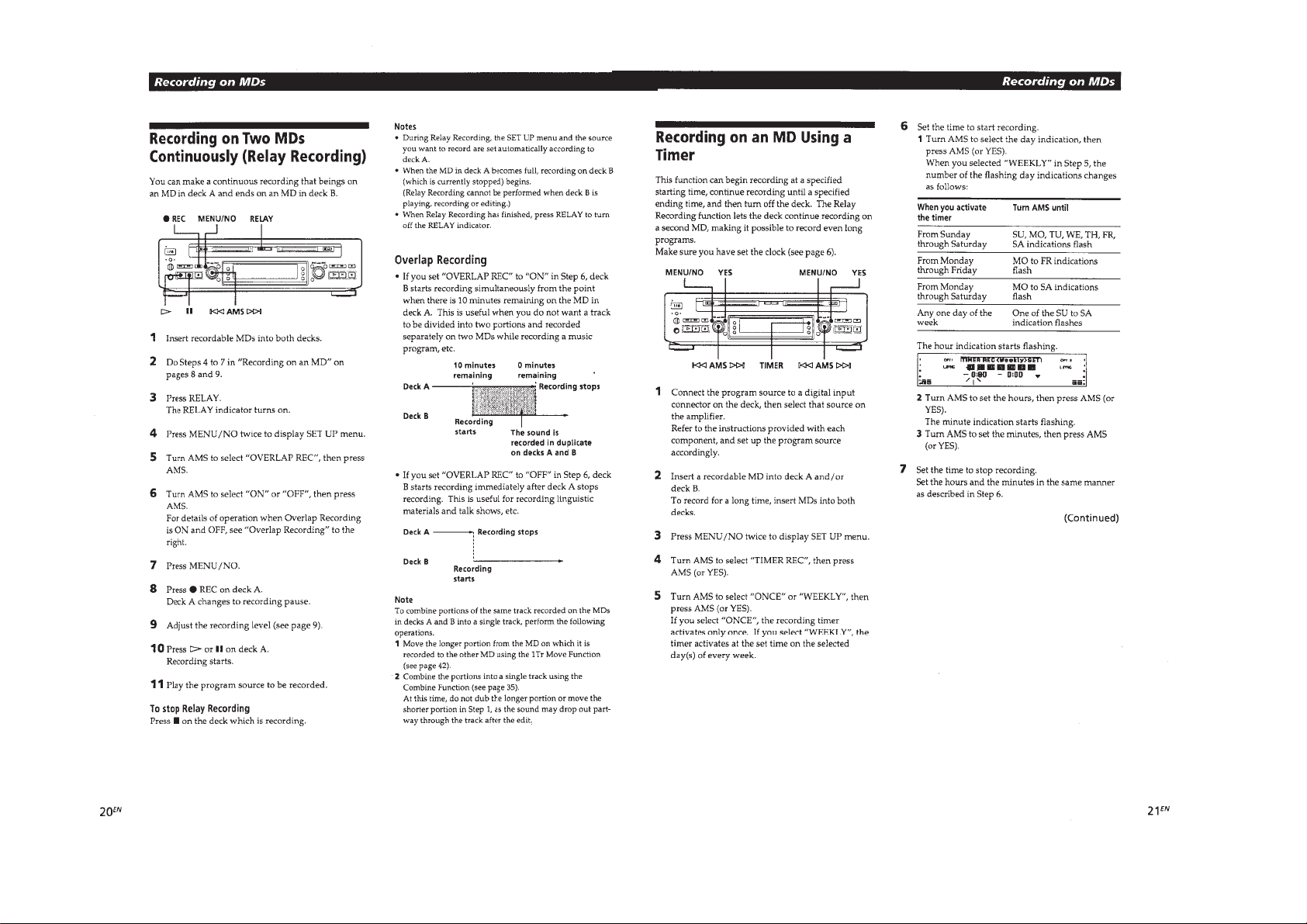

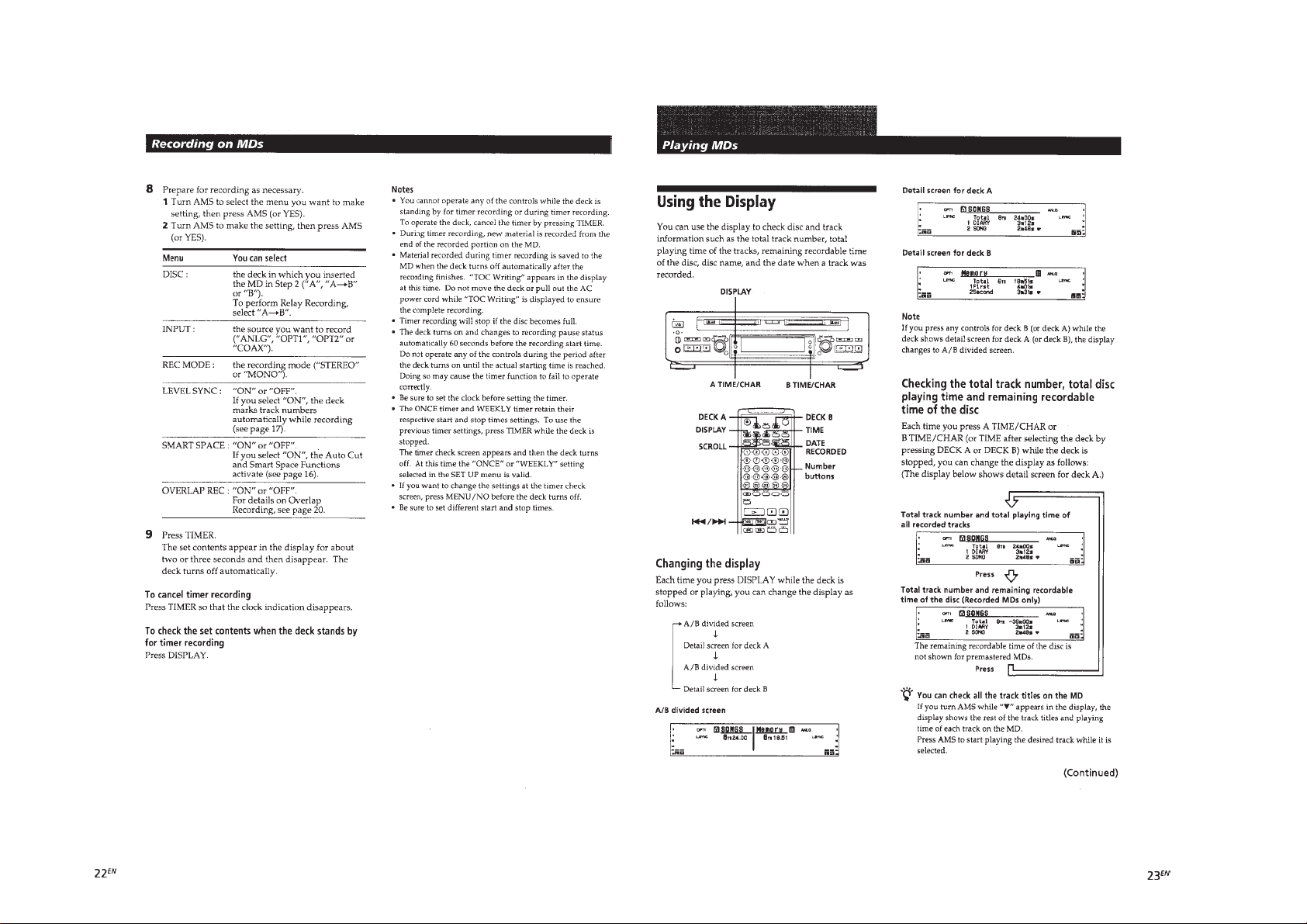

This section is extracted from

instruction manual.

– 13 –

– 14 –

– 15 –

– 16 –

– 17 –

– 18 –

– 19 –

– 20 –

– 21 –

– 22 –

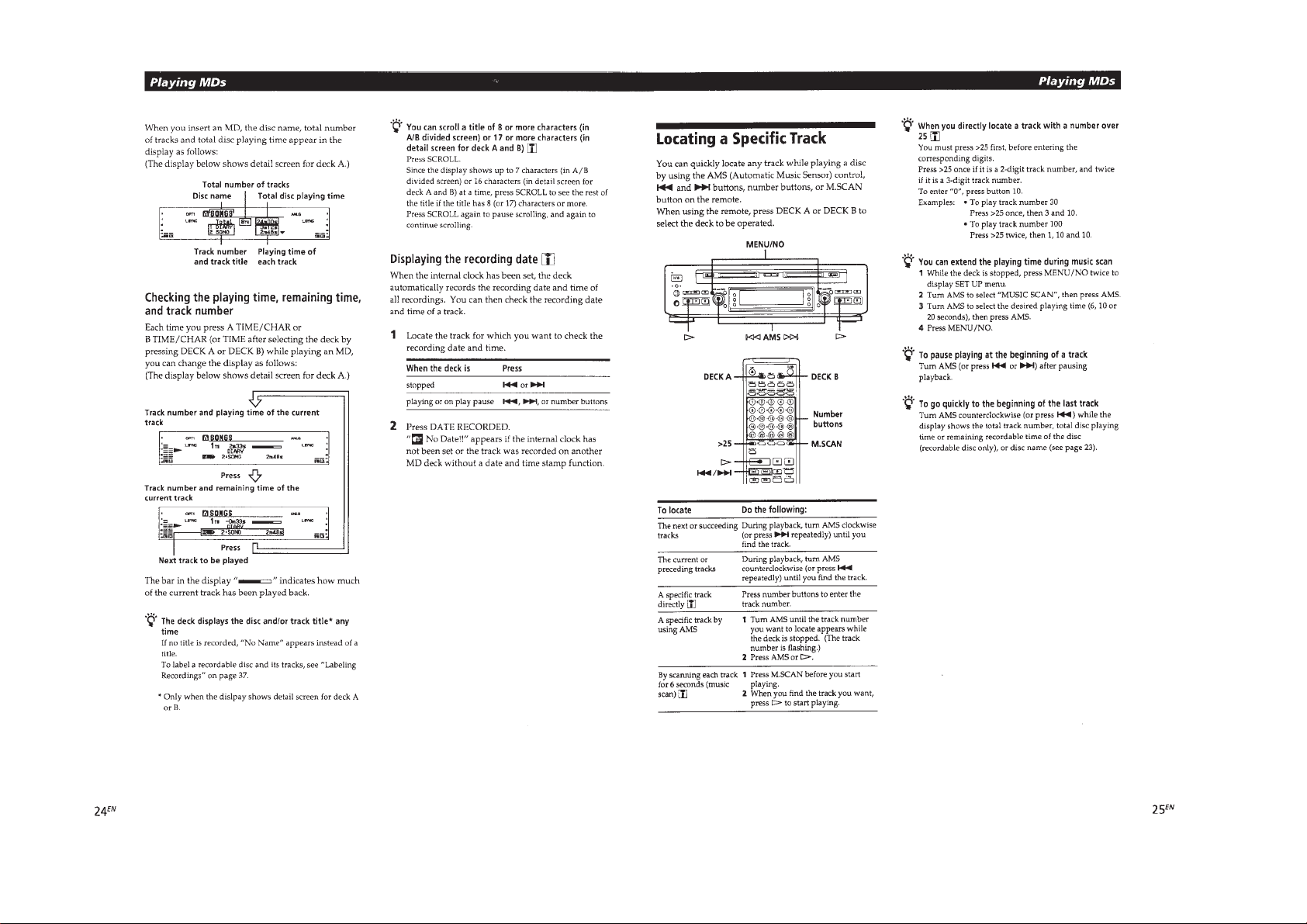

– 24 –

– 25 –

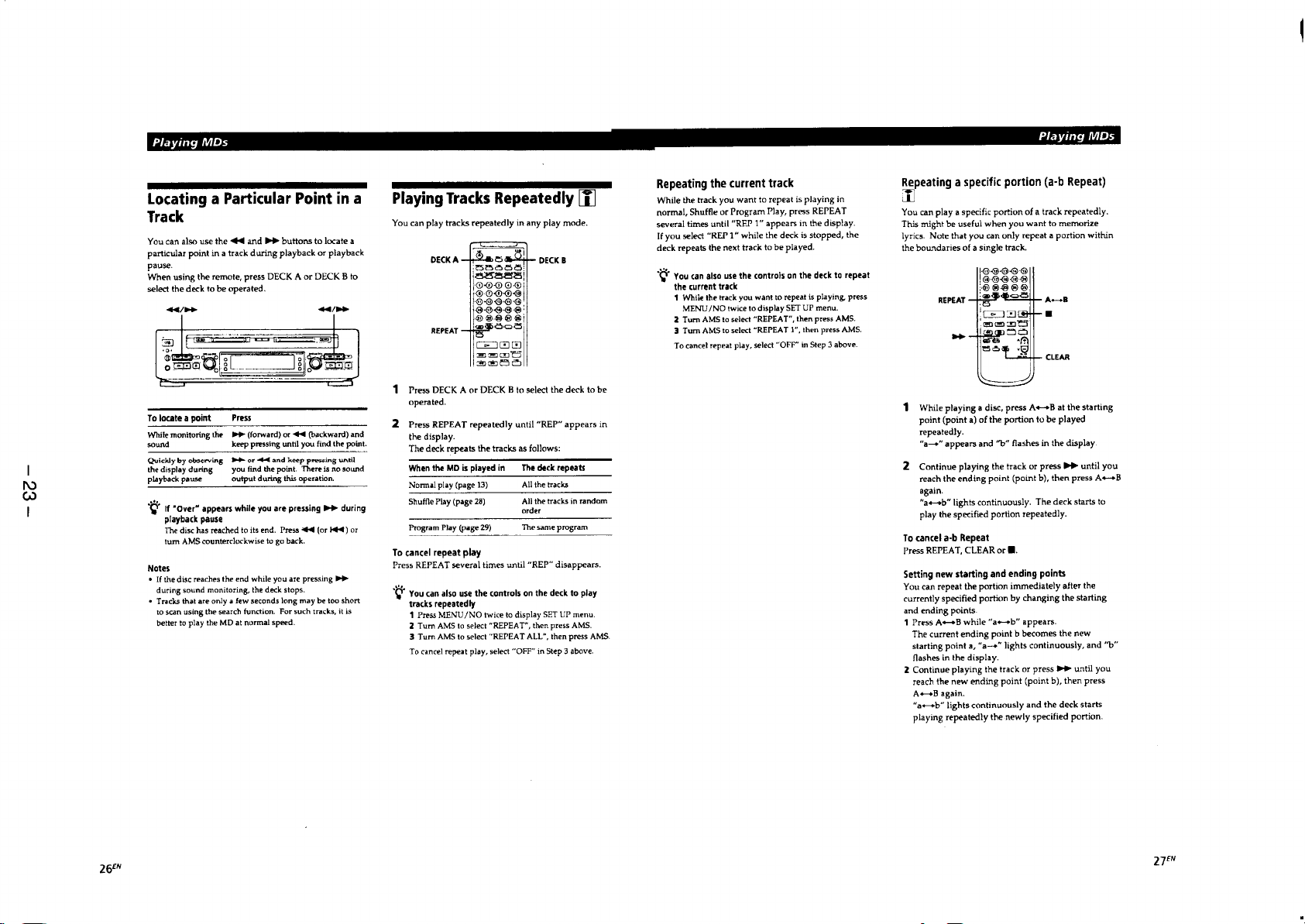

– 26 –

– 27 –

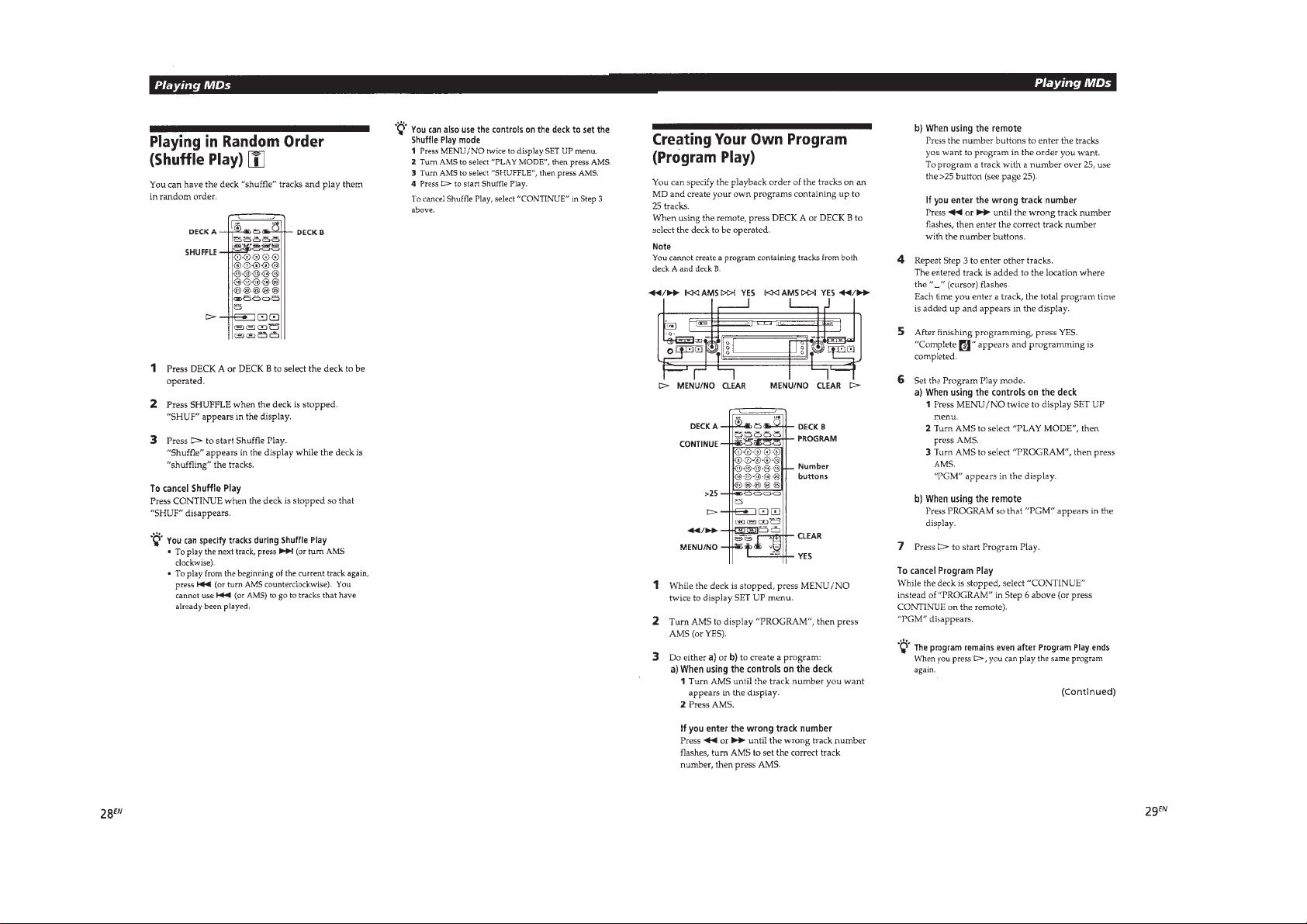

– 28 –

– 29 –

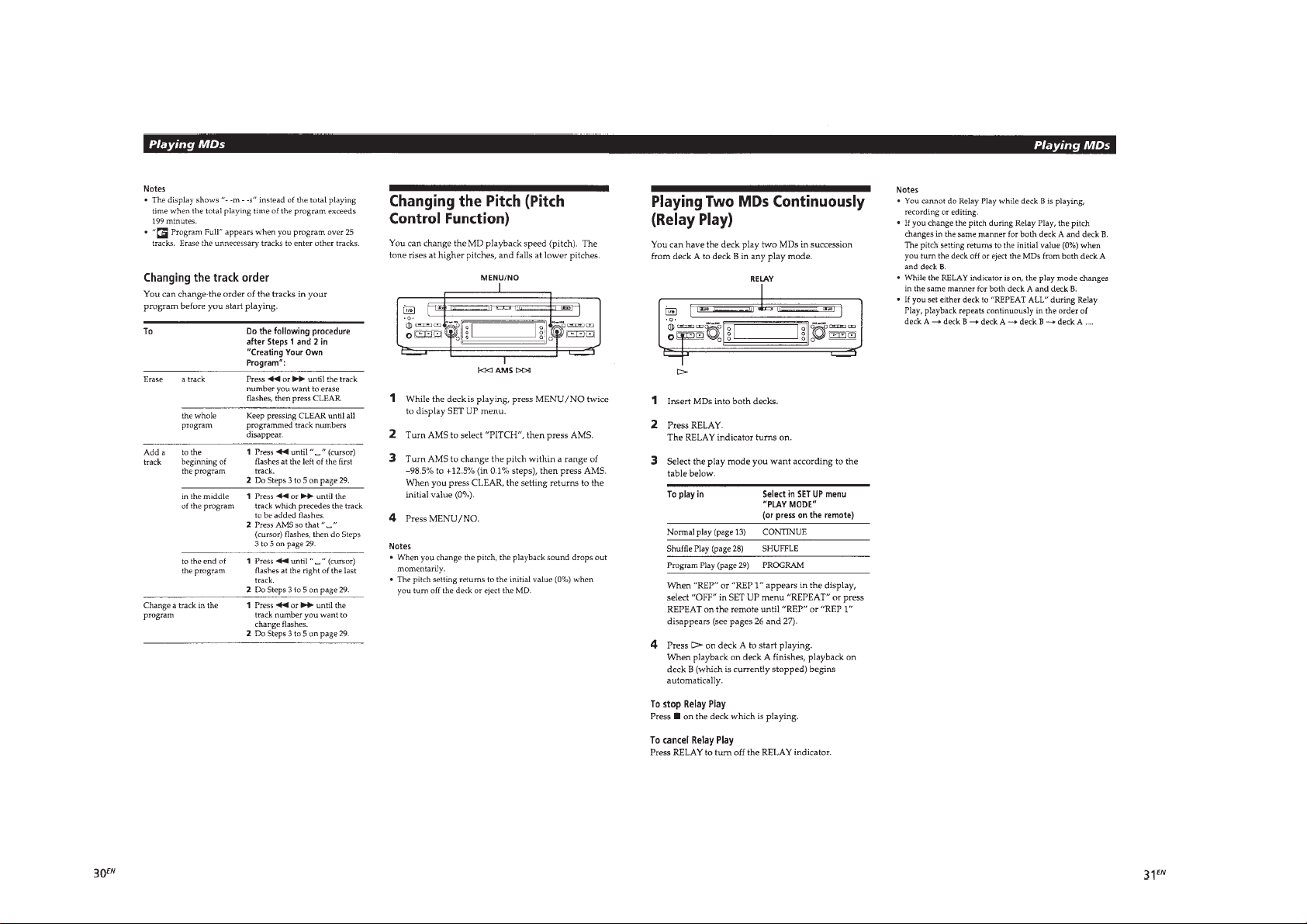

– 30 –

Loading...

Loading...