Sony MDS-SP55,CMT-SP55MD,CMT-SP55TC Service Manual

1

MDS-SP55

SPECIFICATIONS

SERVICE MANUAL

MINIDISC DECK

Model Name Using Similar Mechanism MDS-JE330

MD Mechanism Type MDM-5A

Optical Pick-up Type KMS-260B/S1NP

AEP Model

UK Model

E Model

System MiniDisc digital audio system

Laser Semiconductor laser (λ=780 nm)

Emission duration: continuous

Laser output Max. 44.6 µW*

*This output is the value

measured at a distance of 200 mm

from the objective lens surface on

the Optical Pick-up Block with

7 mm aperture.

Sampling frequency 44.1 kHz

Frequency response 20 Hz – 20 kHz

Inputs

DIGITAL OPTICAL CD IN: Optical

DIGITAL OPTICAL AUX IN: Optical

Output

DIGITAL OPTICAL OUT: Optical

General

Dimensions (w/h/d) incl. projecting parts and controls

Approx. 202 × 101 × 298 mm

Mass Approx. 1.7 kg

Supplied accessories System cable (1)

Digital cable (1)

Design and specifications are subject to change

without notice.

MDS-SP55 is the MD section in CMT -SP55MD ,

and MDS-SP55 is sold in the option as a

minidisk deck of CMT-SP55TC.

Ver 1.1 2001. 06

9-929-537-12

2001F0200-1

© 2001.6

Sony Corporation

Home Audio Company

Shinagawa Tec Service Manual Production Group

2

SELF-DIAGNOSIS FUNCTION

The self-diagnosis function consists of error codes for customers which are displayed automatically when errors occur, and error codes which

show the error history in the test mode during servicing. For details on how to view error codes for the customer, refer to the following box

in the instruction manual. For details on how to check error codes during servicing, refer to the following “Procedure for using the SelfDiagnosis Function (Error History Display Mode)”.

Procedure for using the Self-Diagnosis Function (Error History Display Mode).

Note: Perform the self-diagnosis function in the “error history display mode” in the test mode. The following describes the least required

procedure. Be careful not to enter other modes by mistake. If you set other modes accidentally, press the MENU/NO button (MD)

to exit the mode.

1. When the power OFF (STANDBY), press the ?/1 button (TA) while pressing the s button (MD) and ENTER/YES button (MD)

together.

2. Press the MENU/NO button, and when “Check” is displayed.

3. Rotate the l L knob (MD) and when “[Service]” is displayed, press the ENTER/YES button (MD).

4. Rotate the l L knob (MD) and display “ERR DP MODE”.

5. Pressing the ENTER/YES button (MD) sets the error history mode and displays “total rec”.

6. Select the contents to be displayed or executed using the l L knob (MD).

7. Pressing the CD SYNC REC button (MD) and to execute the contents selected.

8. Pressing the CD SYNC REC button (MD) another time returns to step 5.

9. Pressing the MENU/NO button (MD) displays “ERROR DP MODE” and exits the error history mode.

10.To exit the test mode, press the ?/1 button (TA). The unit sets into the STANDBY state, the disc is ejected, and the test mode ends.

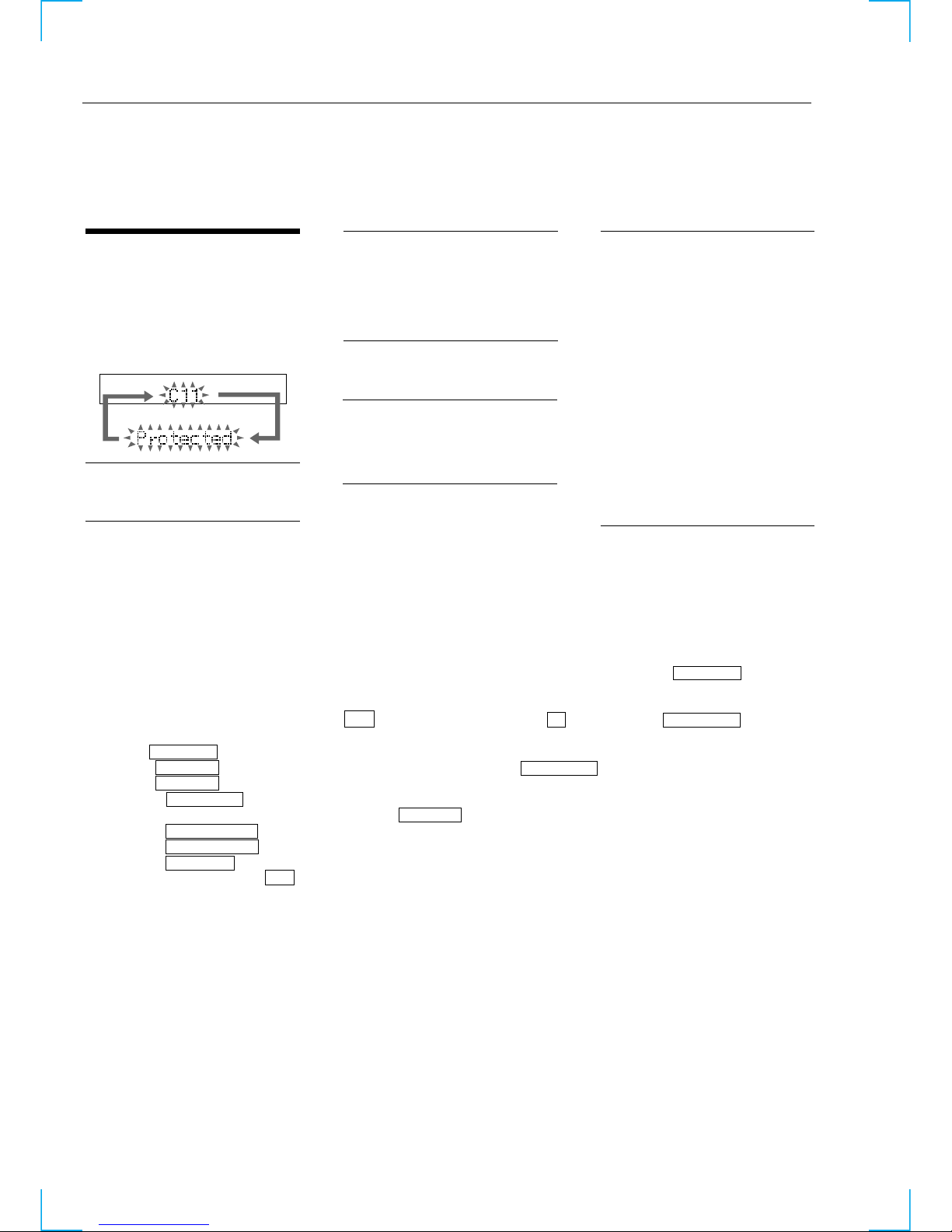

Self-diagnosis Display

This system has a Self-diagnosis display function

to let you know if there is a system malfunction.

The display shows a code made up of three letters

and a message alternately to show you the

problem. To solve the problem refer to the

following list. If any problem persists, consult

your nearest Sony dealer.

C11/Protected

The MD is protected against erasure.

cRemove the MD and slide the tab to close the

slot (See page 11).

C12/Cannot Copy

You tried to record a CD or MD with a format

that the system does not support, such as a CDROM.

cRemove the disc and turn off the system once,

then turn it on a

g

ain.

C13/REC Error

Recording could not be performed properly.

cMove the system to a stable place, and start

recording over from the beginning.

The MD is dirty or scratched, or the MD does

not meet the standards.

cReplace the MD and start recording over from

the beginning.

C13/Read Error

The MD deck cannot read the disc information

properly.

cRemove the MD once, then insert it again.

C14/Toc Error

The MD deck cannot read the disc information

properly.

cReplace the MD.

cErase all the recorded contents of the MD

using the All Erase function (See page 32).

C41/Cannot Copy

The sound source is a copy of a commercially

available music software, or you tried to record

a CD-R (Recordable CD).

cThe Serial Copy Management System

prevents making a digital copy .

You cannot record a CD-R (see page 43).

C71/Check OPT-IN

This appears momentarily because of the signal

of the digital broadcast during recording.

cThere is no affect on the recorded contents.

No component is connected to the DIGITAL

OPTICAL IN jack, or a digital component is

not connected properly.

cConnect a digital component to the DIGITAL

OPTICAL IN jack properly using a digital

connecting cable (an optical cable) (not

supplied (See page 39).

The connected digital component is not turned

on.

cSee the operating instructions supplied with

the connected component and confirm

whether the component is turned on.

The digital connecting cable (an optical cable)

connected to the DIGITAL OPTICAL IN jack

is pulled out, or the connected digital

component is turned off during digital

recording.

cConnect the cable, or turn on the digital

component.

3

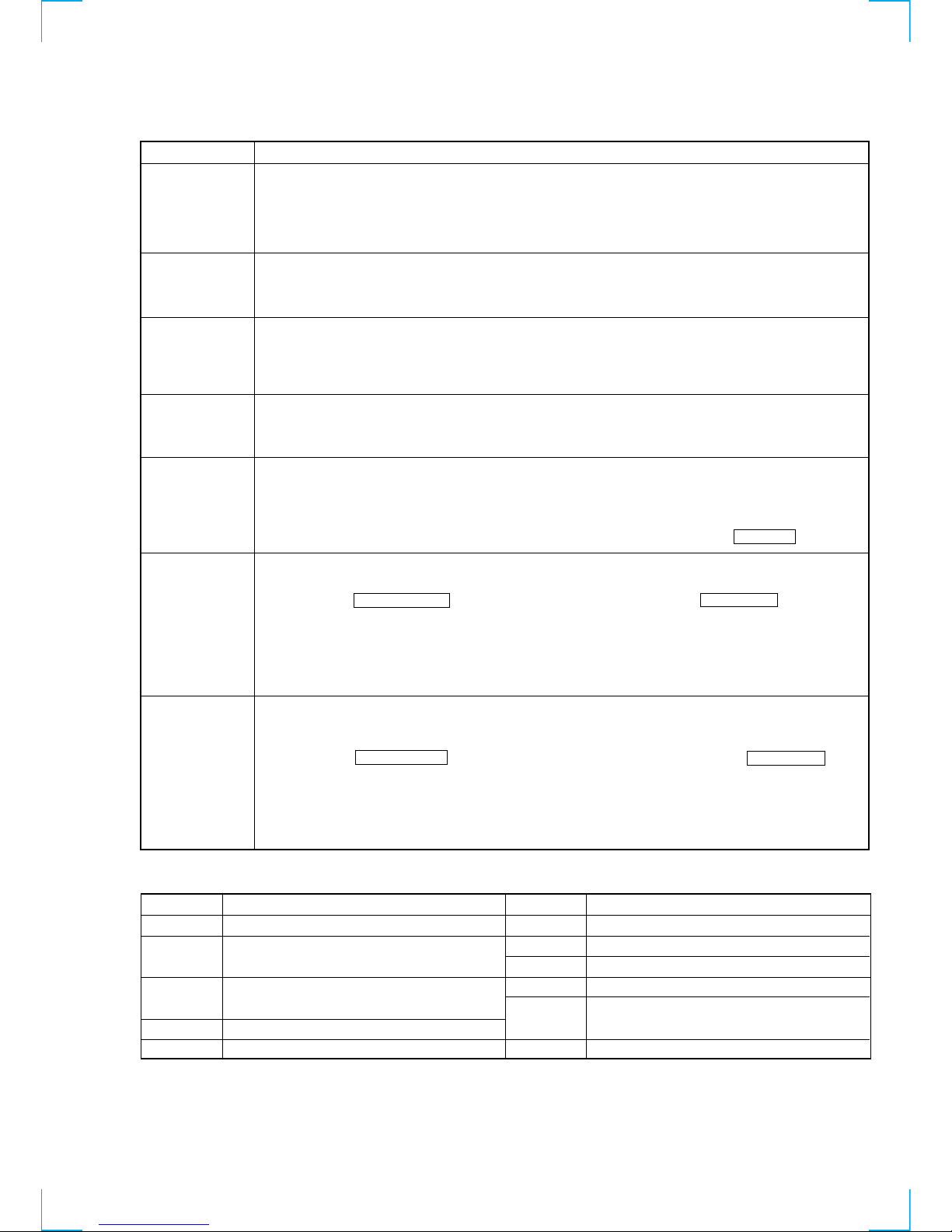

Displays the recording time.

Displayed as “rssssssh”.

The displayed time is the total time the laser is set to the high power state.

This is about 1/4 of the actual recording time.

The time is displayed in decimal digits from 0h to 65535h.

Displays the play time.

Displayed as “pssssssh”. The time displayed is the total actual play time. Pauses are not counted.

The time is displayed in decimal digits from 0h to 65535h.

Displays the total number of retries during recording and number of retry errors during play.

Displayed as “rss pss”.

“r” indicates the retries during recording while “p” indicates the retry errors during play.

The number of retries and retry errors are displayed in hexadecimal digits from 00 to FF.

Displays the total number of errors.

Displayed as “total ss”.

The number of errors is displayed in hexadecimal digits from 00 to FF.

Displays the 10 latest errors.

Displayed as “0s E@@”.

s indicates the history number. The smaller the number, the more recent is the error. (00 is the latest).

@@ indicates the error code.

Refer to the following table for the details. The error history can be switched by rotating the l L knob (MD).

Mode which erases the “retry err”, “total err”, and “err history” histories.

When returning the unit to the customer after completing repairs, perform this to erase the past error history,

After pressing the CD SYNC REC button (MD) when “er refresh” appears, press ENTER/YES button (MD) to

erase the history.

“Complete!!” will be displayed momentarily.

Be sure to check the following when this mode has been executed.

• The data has been erased.

• The mechanism operates normally when recording and play are performed.

Mode which erases the “total rec” and “total play” histories.

These histories serve as approximate indications of when to replace the optical pick-up.

If the optical pick-up has been replaced, perform this operation and erase the history.

After pressing the CD SYNC REC button (MD) when “tm refresh?” is displayed, press the ENTER/YES button

(MD) to erase the history.

“Complete!” will be displayed momentarily.

Be sure to check the following when this mode has been executed.

• The data has been erased.

• The mechanism operates normally when recording and play are performed.

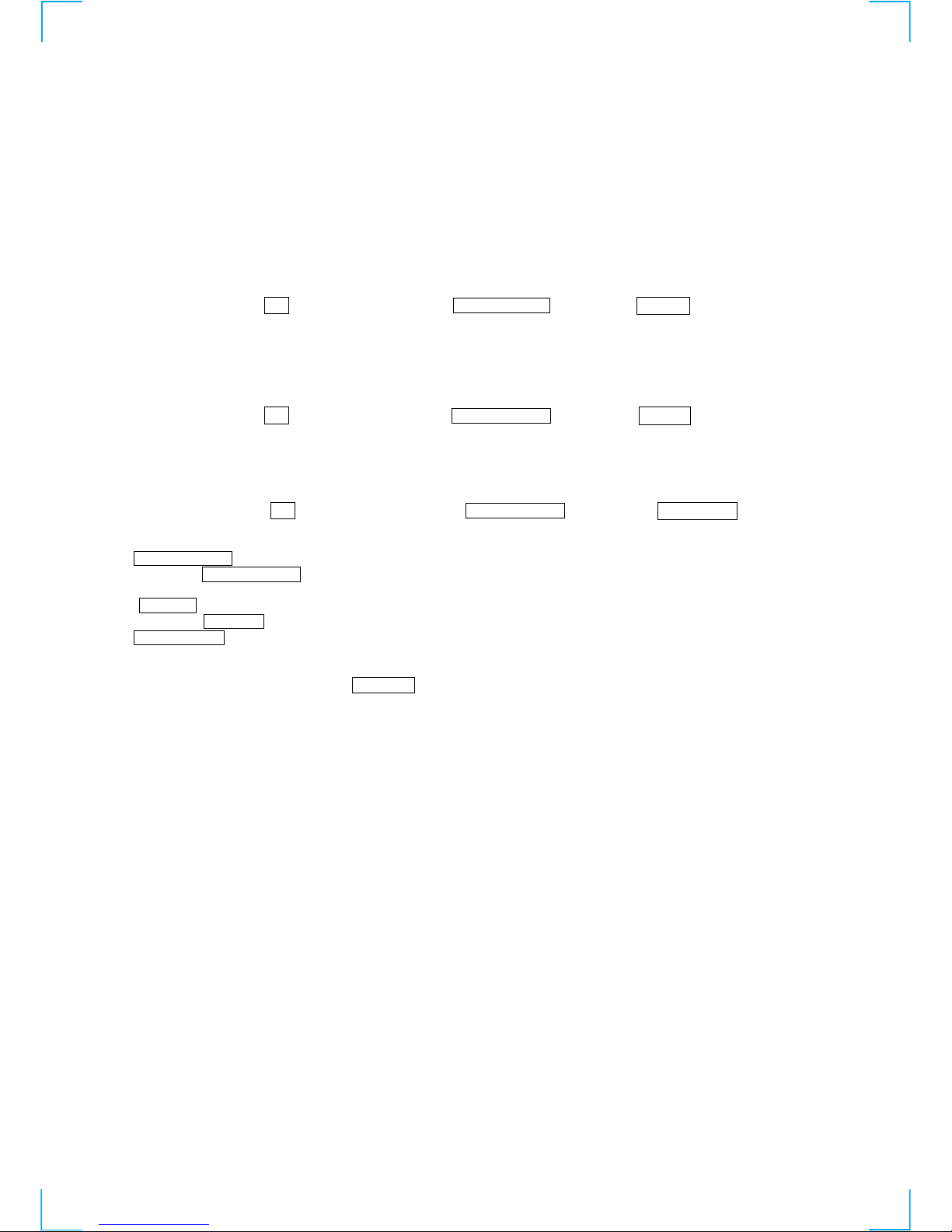

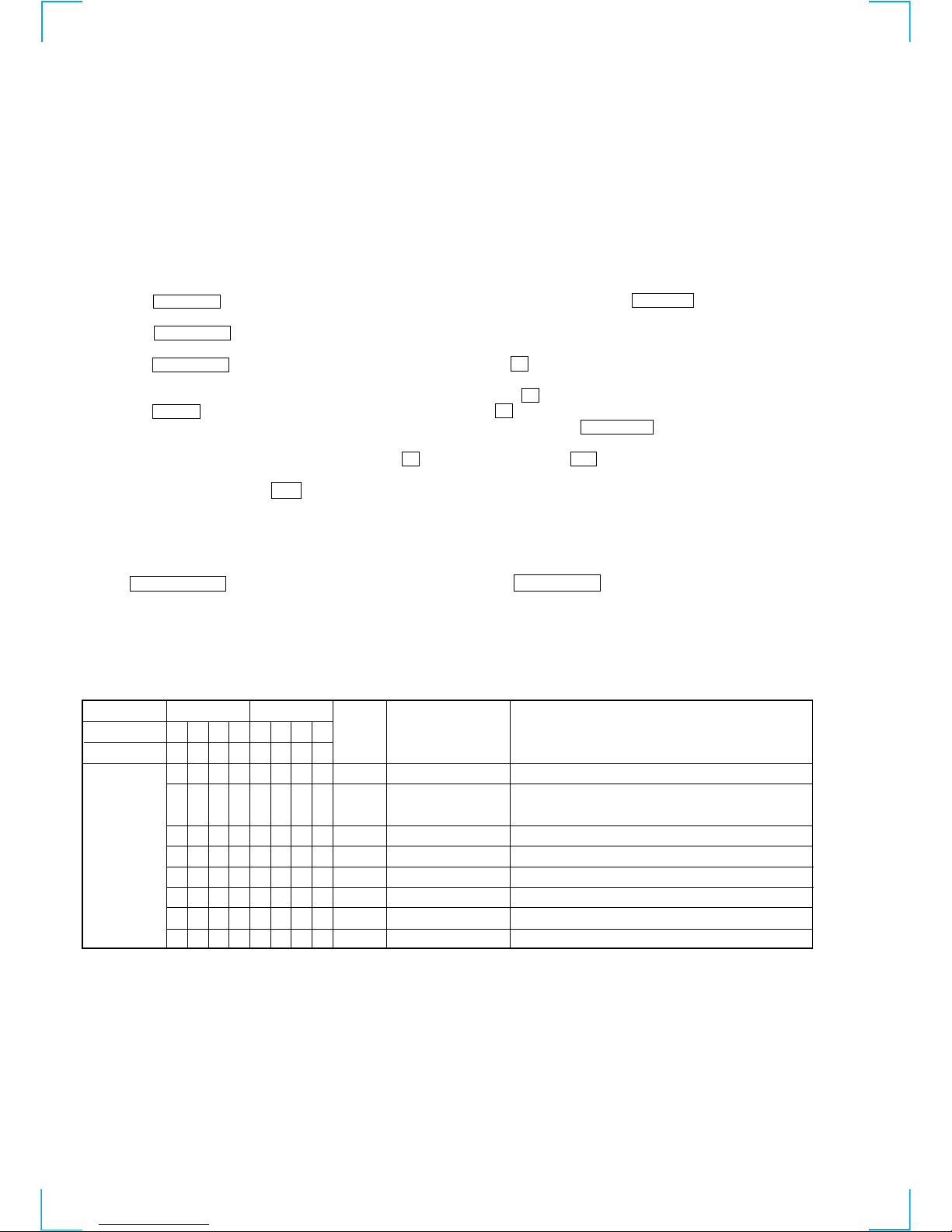

ITEMS OF ERROR HISTORY MODE ITEMS AND CONTENTS

Selecting the Test Mode

Display

total rec

total play

retry err

total err

err history

er refresh

tm refresh?

Details of History

No error

Read error. PTOC cannot be read

(DISC ejected)

TOC error. UTOC error

(DISC not ejected)

Loading error

Address cannot be read (Servo has deviated)

Table of Error Codes

Error Code

E00

E01

E02

E03

E04

E05

E06

E07

E08

E09

E0A

FOK has deviated

Cannot focus (Servo has deviated)

Recording retry

Recording retry error

Playback retry error

(Access error)

Play retry error (C2 error)

Details of Error

Error Code

Details of Error

4

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

This caution

label is located

inside the unit.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the equipment manufacturer.

Discard used batteries according to manufacture’s instructions.

ADVARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilakting skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av

apparatfabrikanten.

Brukte batterier katterier kasseres i henhold til fabrikantens

VARNIG

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som rekommenderas

av apparattillverkaren.

Kassera använt batteri enligt gällande föreakrifter.

VAROITUS

Parist voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

5

TABLE OF CONTENTS

1. SERVICING NOTE .......................................................... 6

2. GENERAL ........................................................................ 13

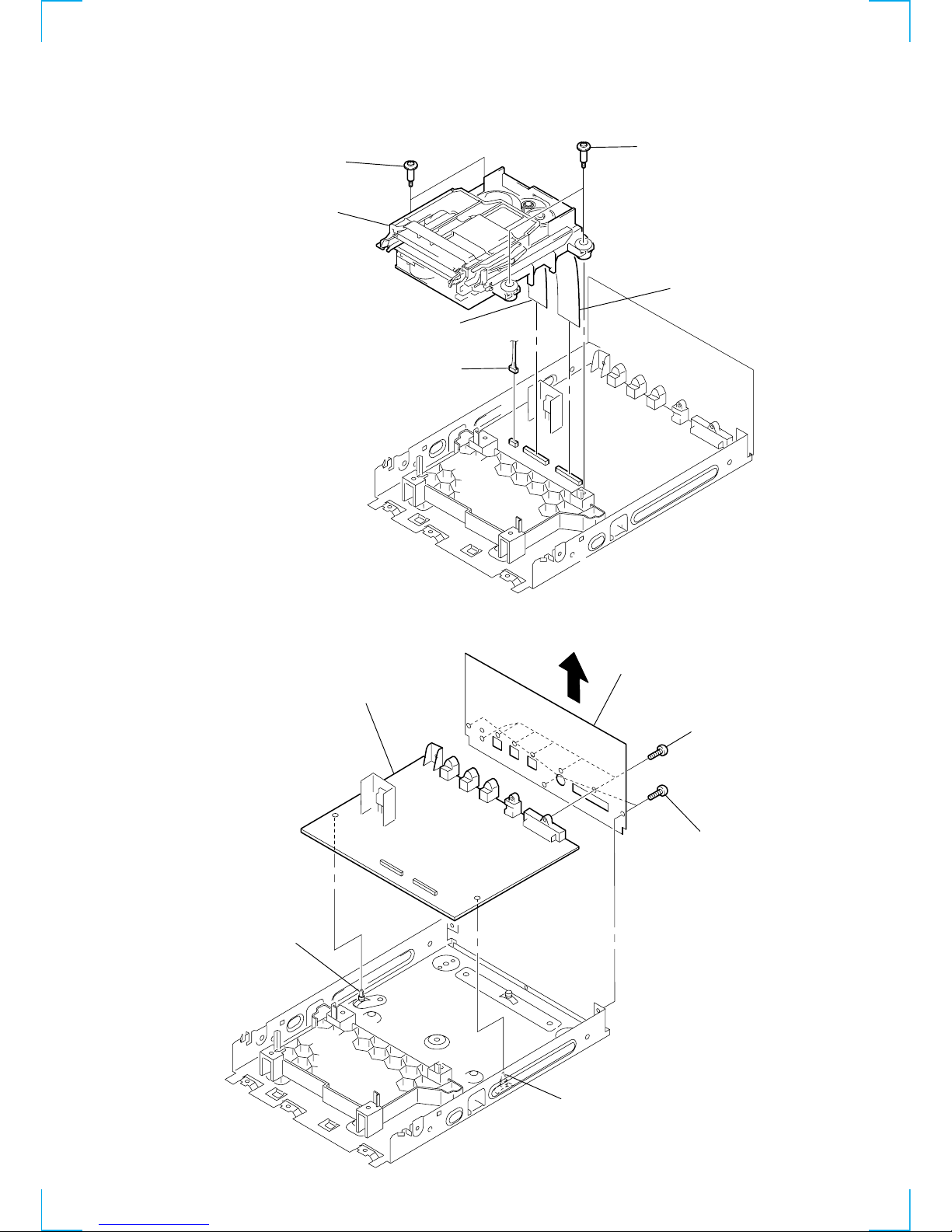

3. DISASSEMBLY

3-1. Case ..................................................................................... 14

3-2. Front Panel Assy ................................................................. 14

3-3. MD Mechanism Deck (MDM-5A) ..................................... 15

3-4. Main Board ......................................................................... 15

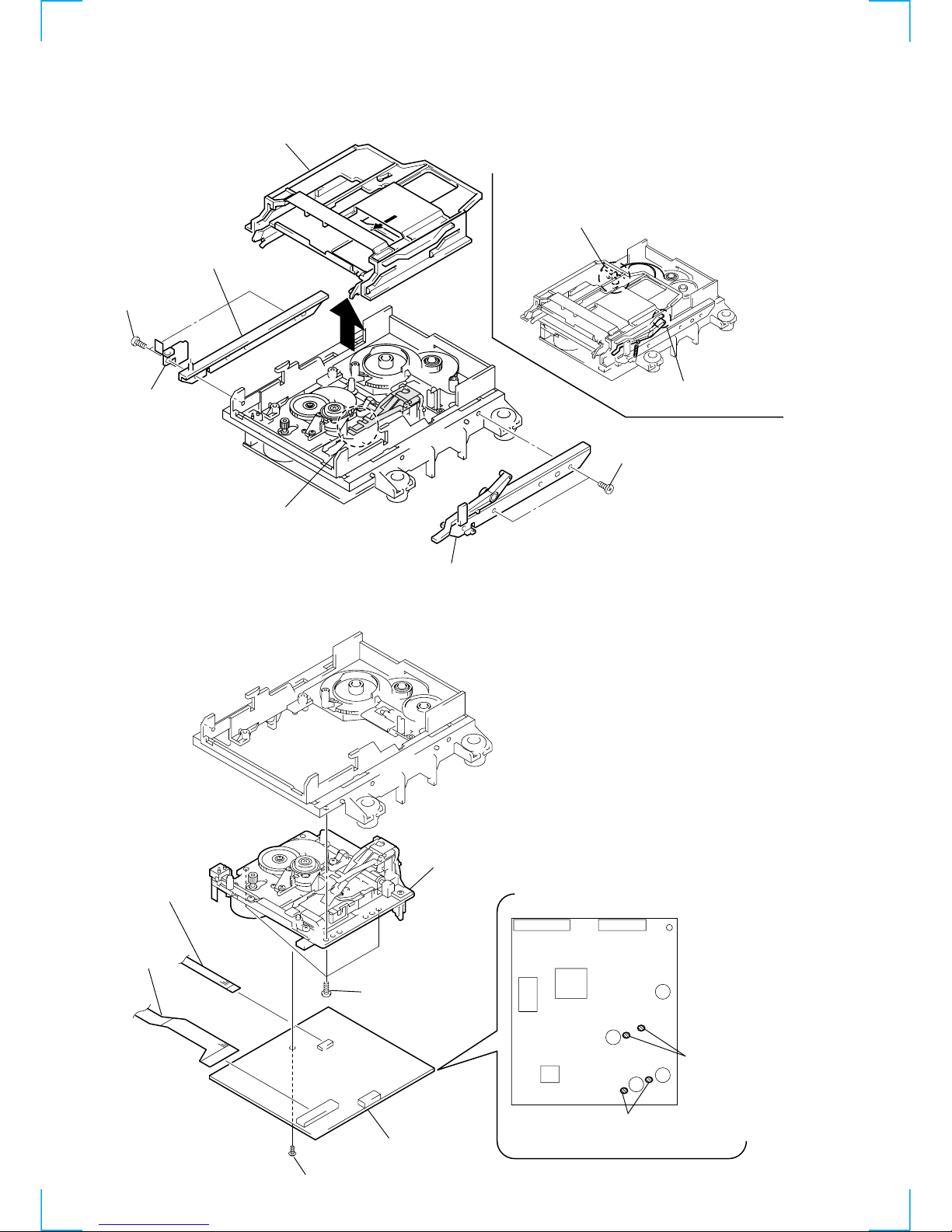

3-5. Slider (Cam) ........................................................................ 16

3-6. BD Board ............................................................................ 16

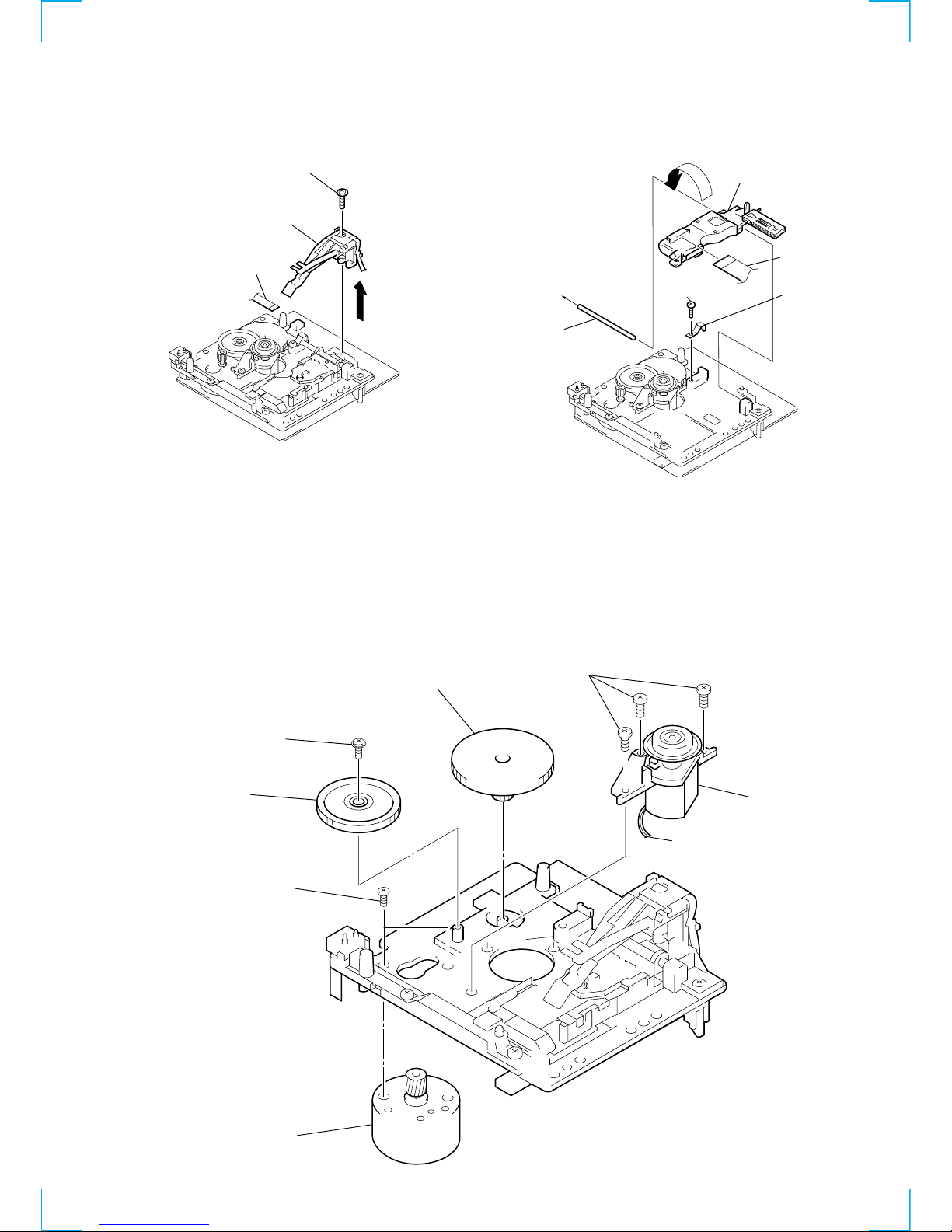

3-7. Over Write Head ................................................................. 17

3-8. Optical Pick-up (KMS-260A/J1N) ..................................... 17

3-9. Spindle Motor, Sled Motor ................................................. 17

4. TEST MODE ..................................................................... 18

5. ELECTRICAL ADJUSTMENTS ............................... 22

6. DIAGRAMS

6-1. Block Diagrams

• BD Section ....................................................................... 32

• Main Section .................................................................... 33

6-2. Printed Wiring Board – BD Section – ................................. 34

6-3. Schematic Diagram – BD (1/2) Section – ........................... 35

6-4. Schematic Diagram – BD (2/2) Section – ........................... 36

6-5. Schematic Diagram – Main (1/2) Section – ........................ 37

6-6. Schematic Diagram – Main (2/2) Section – ........................ 38

6-7. Printed Wiring Board – Main Section – .............................. 39

6-8. Printed Wiring Board – Panel Section – ............................. 40

6-9. Schematic Diagram – Panel Section – ................................ 41

6-10. Schematic Diagram – BD Switch Section – .................... 42

6-11. Printed Wiring Board – BD Switch Section – .................. 42

6-12. IC Block Diagrams ........................................................... 42

6-13. IC Pin Functions ............................................................... 45

7. EXPLODED VIEWS

7-1. Case and Front Panel Section ............................................. 50

7-2. Mechanism Deck Section (MDM-5A) ................................ 51

7-3. Base Unit Section (MBU-5A) ............................................. 52

8. ELECTRICAL PARTS LIST ........................................ 53

MODEL IDENTIFICATION

— BACK PANEL —

• Abbreviation

AED : North European model

MY : Malaysia model

SP : Singapore model

HK : Hong kong model

KR : Korea model

MODEL

AEP, UK, AED models

HK, MY, SP models

KR model

PARTS No.

4-229-665-0s

4-229-665-2s

4-229-665-3s

Parts No.

6

SECTION 1

SERVICING NOTE

This unit cannot be repaired by itself.

When repairing, connect the whole system except for the speaker.

CD Text Display

• This unit displays CD text.

Text is displayed for the first 50 track only and will not be displayed from the 51st track onwards. Do not suspect a fault in this case.

In some cases, some special characters will not be displayed and may be replaced by other characters. Do not suspect a fault in this case.

Cold Reset

• The cold reset clears all data including preset data stored in the RAM to initial conditions. Execute this mode when returning the set to the

customer.

Procedure :

1. When the power ON, press the ?/1 button (TA) while pressing the TUNING MODE button (ST) and ML buttons (CD) together.

2. “COLD RESET” is displayed on the fluorescent indicator tube and reset is executed.

Hot Reset

• This mode reset the preset data kept in the memory. The hot reset mode functions same as if the power cord is plugged in and out.

Procedure :

1. When the power ON, press the ?/1 button (TA) while pressing the TUNING MODE button (ST) and lm buttons (CD) together.

2. Turn off the unit and reset is executed.

GC Test Mode

Procedure :

1. When the power ON, press the ?/1 button (TA) while pressing the TUNING MODE button (ST) and PLAY MODE buttons (CD)

together.

2. LCD are all turned on.

3. Press TUNING MODE button (ST) to enter the model destination indecation mode. “SP55 CE2” or “SP55 ASIA2” appears.

4. Every pressing of TUNING MODE button (ST) changes the display in the following order.

MC Version t CD Version t ST Version t TC Version t TA Version t TM Version t model destination display.

5. Press DISPLAY button (ST) and the date appears as “ 00615a ”

Every pressing of DISPLAY button (ST) changes the display in the Version display and model destination display.

6. Press TUNER/BAND button (ST) to enter the key check mode.

7. In the key check mode, the fluorescent indicator tube displays “Key 0 Vol 0”. Each time a button is pressed, “Key” value increases.

However, once a button is pressed, it is no longer taken into account.

“Vol” Value increases like “1, 2, 3 ...” if rotating VOLUME knob (TA) in the clockwise direction, or decreases like “0, 9, 8 ...” if rotating

in the counterclockwise diretion.

8. To exit from this mode, disconnect the power cord.

7

JIG FOR CHECKING BD BOARD WAVEFORM

The special jig (J-2501-149-A) is useful for checking the waveform of the BD board. The names of terminals and the checking items to be

performed are shown as follows.

GND : Ground

I+3V : For measuring IOP (Check the deterioration of the optical pick-up laser)

IOP : For measuring IOP (Check the deterioration of the optical pick-up laser)

TEO : TRK error signal (Traverse adjustment)

VC : Reference level for checking the signal

RF : RF signal (Check jitter)

RF

VC

TEO

For

MDM-3

For

MDM-5

A

IOP

I-3V

VC

RF

TEO

IOP

I+3V

GND

VC

RF

TEO

IOP

I+3V

GND

1

5

1

6

CN110

RF

5P connector

6P connecto

r

VC

TEO

IOP

I+3V

GND

Mechanism deck

8

IOP DATA RECORDING AND DISPLAY WHEN OPTICAL PICK-UP AND NON-VOLATILE MEMORY (IC171 OF

BD BOARD) ARE REPLACED

The IOP value labeled on the optical pick-up can be recorded in the non-volatile memory. By recording the value, it will eliminate the need

to look at the value on the label of the optical pick-up. When replacing the optical pick-up or non-volatile memory (IC171 of BD board),

record the IOP value on the optical pick-up according to the following procedure.

Record Precedure:

1. When the power OFF (STANDBY), press the ?/1 button (TA) while pressing the s button (MD) and ENTER/YES button (MD)

together.

2. Press the MENU/NO button (MD), and when “Check” is displayed.

3. Rotate the l L knob (MD) to display “MD [Service]”, and press the ENTER/YES button (MD).

4. Rotate the l L knob (MD) to display “MD lop Write”, and press the ENTER/YES button (MD).

5. The display becomes “MD Ref=@@@.@” (@ is an arbitrary number) and the numbers which can be changed will blink.

6. Input the IOP value written on the optical pick-up.

To select the number : Press the MENU/NO button (MD), and when “Check” is displayed.

To select the digit : Press the CD SYNC REC button (MD).

7. When the ENTER/YES button (MD) is pressed, the display becomes “MD Measu=@@@.@” (@ is an arbitrary number).

8. As the adjustment results are recorded for the 6 value. Leave it as it is and press the ENTER/YES button (MD).

9. “MD Complete!” will be displayed momentarily. The value will be recorded in the non-volatile memory and the display will become

“MD Iop Write”.

10. Press the ?/1 button (TA) to complete.

Display Precedure:

1. When the power OFF (STANDBY), press the ?/1 button (TA) while pressing the s button (MD) and ENTER/YES button (MD)

together.

2. Press the MENU/NO button (MD), and when “Check” is displayed.

3. Rotate the l L knob (MD) to display “MD [Service]”, and press the ENTER/YES button (MD).

4. Rotate the l L knob (MD) to display “MD lop Read”.

5. “MD @@.@/##.#” is displayed and the recorded contents are displayed.

@@.@ : indicates the Iop value labeled on the pick-up.

##.# : indicates the Iop value after adjustment

6. To end, press the MENU/NO button (MD) to display “MD Iop Read”. Then press the ?/1 button (TA).

9

• 0.9 mW power

Specified value : 0.84 to 0.92 mW

• 7.0 mW power

Specified value : 6.8 to 7.2 mW

lop (at 7mW)

• Labeled on the optical pick-up

Iop value ± 10mA

• Traverse waveform

Specified value : Below 10% offset

• Error rate check

Specified value : For points a, b, and c

C1 error : Below 220

AD error : Below 2

• Error rate check

Specified value:

a.When using test disc (MDW-74/GA-1)

C1 error : Below 80

AD error : Below 2

b.When using check disc (TDYS-1)

C1 error : Below 50

• CPLAY error rate check

Specified value:

C1 error : Below 80

AD error : Below 2

• Unsatisfactory if displayed as T=@@ (##) [NG]

NG

(@@, ## are both arbitrary numbers)

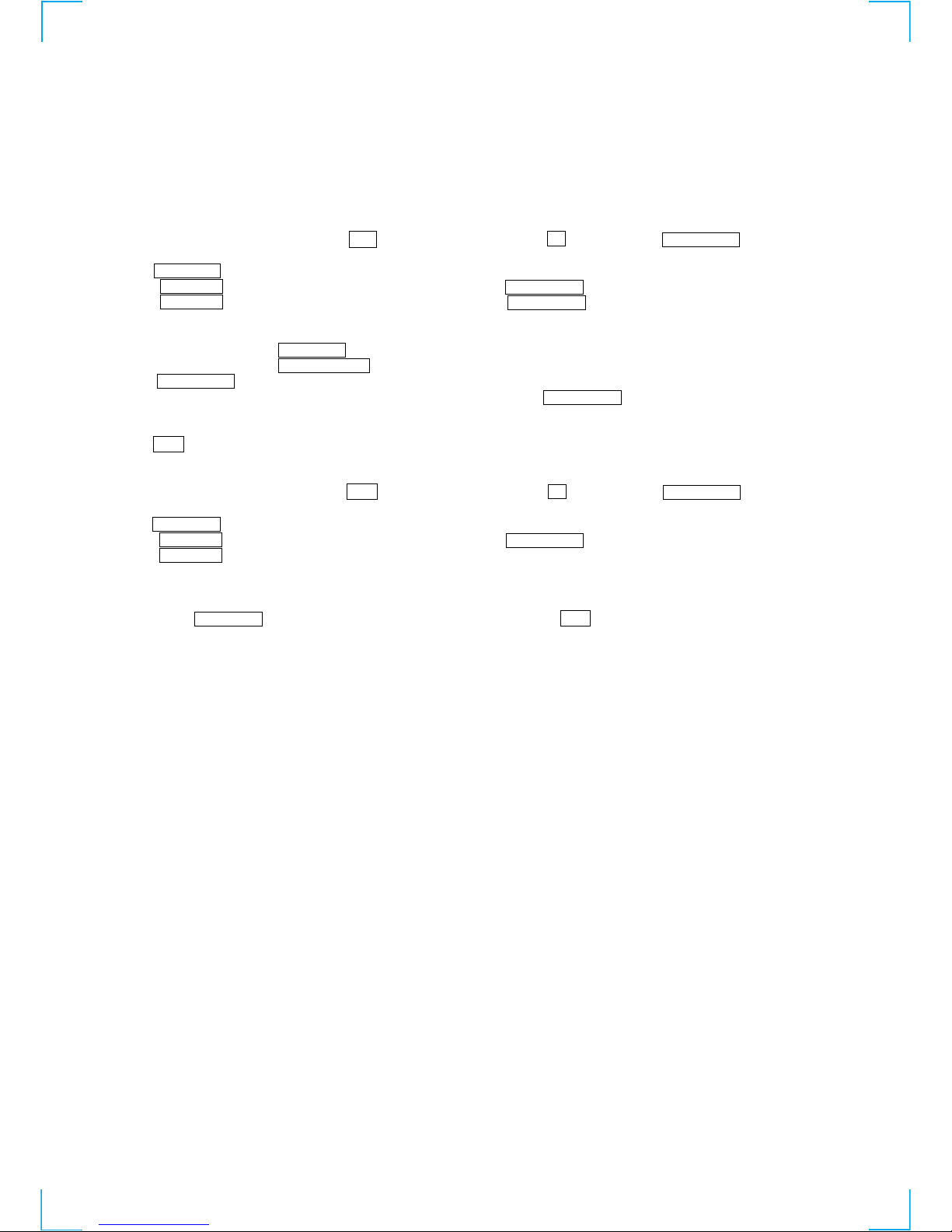

CHECKS PRIOR TO PARTS REPLACEMENT AND ADJUSTMENTS

Before performing repairs, perform the following checks to determine the faulty locations up to a certain extent.

Details of the procedures are described in “5 Electrical Adjustments”.

Laser power check

(5-6-2 : See page 24)

Traverse check

(5-6-3 : See page 24)

Focus bias check

(5-6-4 : See page 25)

C PLAY check

(5-6-5 : See page 25)

Self-recording/playback

check

(REC/PLAY)

(5-6-6 : See page 25)

TEMP check

(Temperature

compensation

offset check)

(5-6-1 : See page 24)

Criteria for Determination

(Unsatisfactory if specified value is not satisfied)

• Clean the optical pick-up

• Adjust again

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

If always unsatisfactory:

• Replace the overwrite head

• Check for disconnection of the circuits around the

overwrite head

If occasionally unsatisfactory:

• Check if the overwrite head is distorted

• Check the mechanism around the sled

• Check for disconnection of the circuits around D101

(BD board)

• Check the signals around IC101, IC121, CN102,

CN103 (BD board)

Measure if unsatisfactory:

Note:

The criteria for determination above is intended merely to determine if satisfactory or not, and does not serve as the specified value for

adjustments.

When performing adjustments, use the specified values for adjustments.

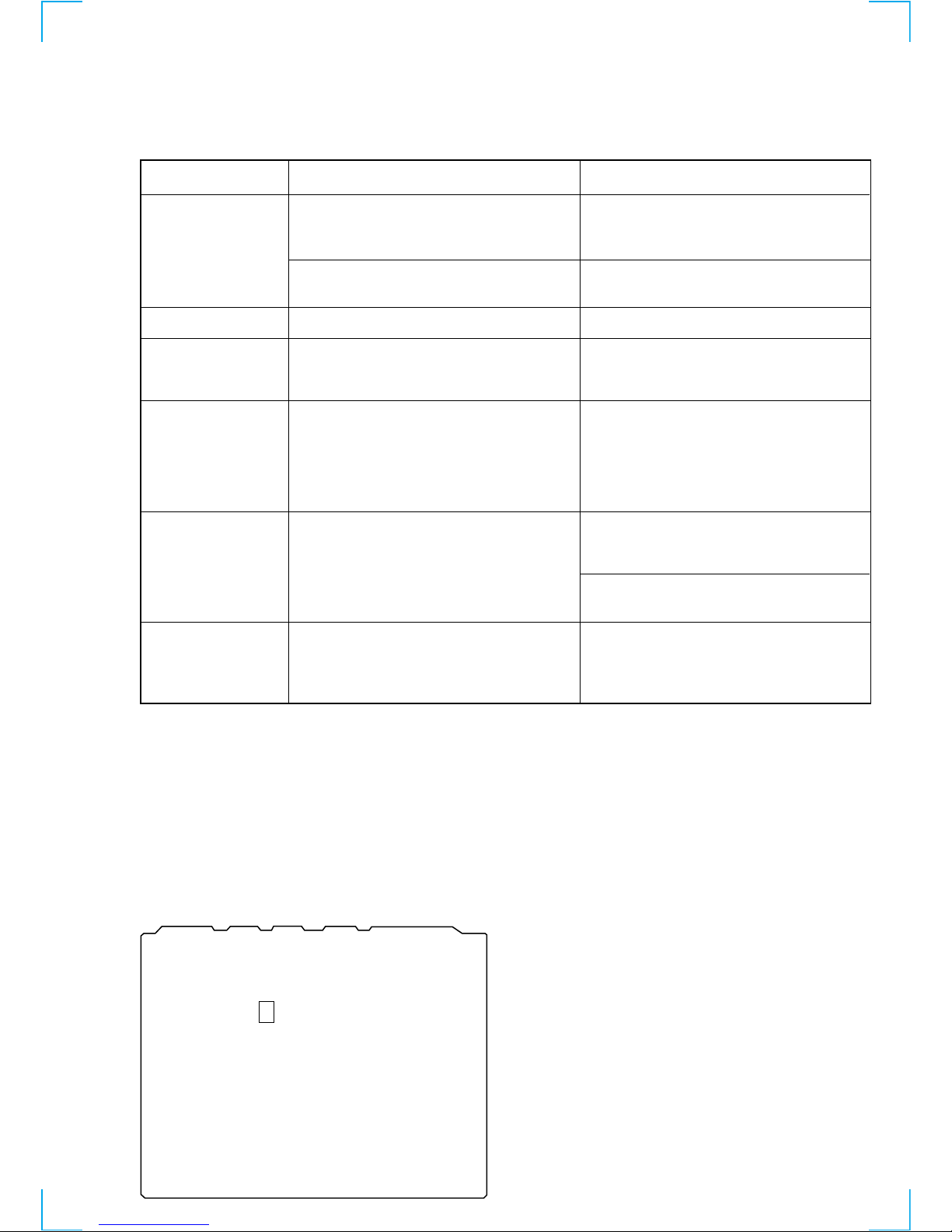

FORCED RESET

The system microprocessor can be reset in the following procedure.

Use these procedure when the unit cannot be operated normally due to the overrunning of the microprocessor, etc.

Procedure :

Remove the short-pin attached to CN821, and power off or del AC cable, and then attach it again. Remove the AC code, and wait for about

five seconds, and turn on the power again, and put the short-pin.

[MAIN BOARD] (Component Side)

CN821

10

RETRY CAUSE DISPLAY MODE

• In this test mode, the causes for retry of the unit during recording can be displayed on the fluorescent indicator tube. During playback, the

“track mode” for obtaining track information will be set.

This is useful for locating the faulty part of the unit.

• The following will be displayed :

During recording and stop : Retry cause, number of retries, and number of retry errors.

During playback : Information such as type of disc played, part played, copyright.

These are displayed in hexadecimal.

Procedure:

1. Load a recordable disc whose contents can be erased, into the unit.

2. Press the MENU/NO button (MD). When “Edit/Menu” is displayed on the LCD display, Rotate the l L knob (MD) to display

“All Erase??”.

3. Press the ENTER/YES button (MD).

4. “All Erase??” is displayed on the LCD display.

5. Press the ENTER/YES button (MD) to display “Complete!!”, and press the s button (MD) immediately. Wait for about 10 seconds

while pressing the button.

6. When the “MD Blank disk” displayed on the LCD display goes off, release the s button (MD).

7. Press the z REC button (MD) to enter recording standby. Then press the S button (MD) and start recording. In about 2 seconds, the

record mode retry cause is displayed. (Fig.1) If recording cannot be performed, rotate the FUNCTION konb (TA) and set a different

section.

8. To check the “track mode”, stop recording by pressing s button (MD) and press the H button (MD) to start play and the track

information in the play mode appears.

9. To exit the test mode, press the ?/1 button (TA), and turn OFF the power. When “STNDBY” disappears, disconnect the power plug

from the outlet. If the test mode cannot be exited, refer to “Forced Reset”on page 9.

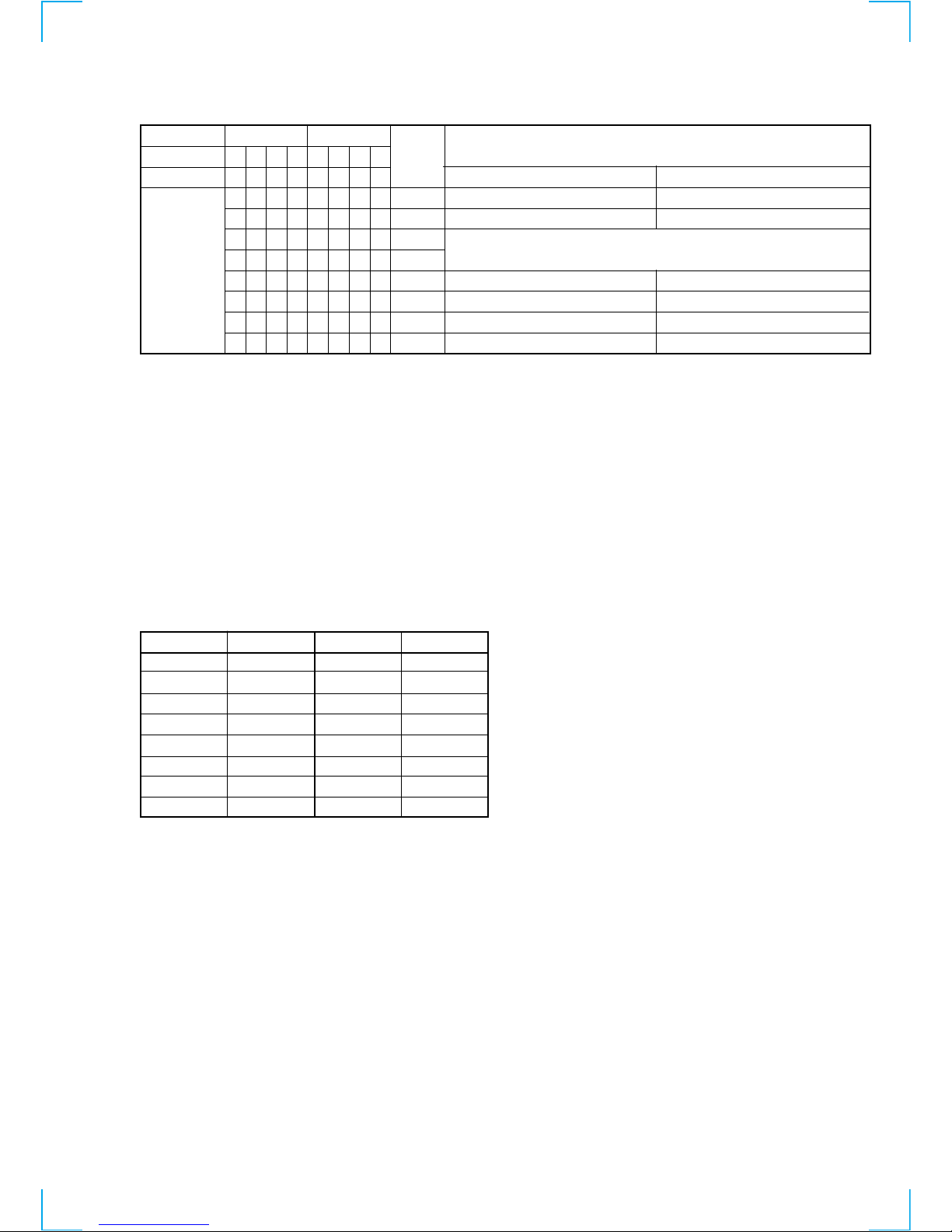

} Address (Physical address on disc)

Hexadecimal

Bit

Binary

Higher Bits Lower Bits

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

When track jump (shock) is detected

When ADER was counted more than five times

continuously

When ADIP address is not continuous

When DIN unlock is detected

When not in focus

When ABCD signal level exceeds the specified range

When CLV is unlocked

When access operation is not performed normally

Hexa-

decimal

shock

ader5

Discontinuous address

DIN unlock

FCS incorrect

IVR rec error

CLV unlock

Access fault

Cause of Retry Occurring conditions

01

02

04

08

10

20

40

80

Fig. 1 Reading the Test Mode Display

(During recording and stop)

RTs@@c##c**

Fluorescent display tube display

@@ : Cause of retry

## : Number of retries

** : Number of retry errors

Fig. 2 Reading the Test Mode Display

(During playback)

@@####**$$

Fluorescent display tube display

@@ : Parts No. (name of area named on TOC)

## : Cluster

** : Sector

$$ : Track mode (Track information such as copyright

information of each part)

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example

When 42 is displayed:

Higher bit : 4 = 0100 t b6

Lower bit : 2 = 0010 t b1

In this case, the retry cause is combined of “CLV unlock” and “ader5”.

When A2 is displayed:

Higher bit : A = 1010 t b7+b5

Lower bit : 2 = 0010 t b1

The retry cause in this case is combined of “Access fault”, “IVR rec error”, and “ader5”.

Reading the Retry Cause Display

11

Hexadecimal

Bit

Binary

Higher Bits Lower Bits

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

Details

01

02

04

08

10

20

40

80

Emphasis OFF

Monaural

This is 2-bit display. Normally 01.

01:Normal audio. Others:Invalid

Audio (Normal)

Original

Copyright

Write prohibited

When 0 When 1

Emphasis ON

Stereo

Invalid

Digital copy

No copyright

Write allowed

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example When 84 is displayed:

Higher bit : 8 = 1000 t b7

Lower bit : 4 = 0100 t b2

In this case, as b2 and b7 are 1 and others are 0, it can be determined that the retry cause is combined of “Emphasis OFF”, “Monaural”,

“Original”, “Copyright exists”, and “Write allowed”.

Example When 07 is displayed:

Higher bit : 0 = 1000 t All 0

Lower bit : 7 = 0111 t b0+b1+b2

In this case, as b0, b1, and b2 are 1 and others are 0, it can be determined that the retry cause is combined of “Emphasis ON”, “Stereo”,

“Original”, “Copyright exists”, and “Write prohibited”.

Hexadecimal t Binary Conversion Table

Hexadecimal Binary Hexadecimal Binary

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

Reading the Track Mode Display

12

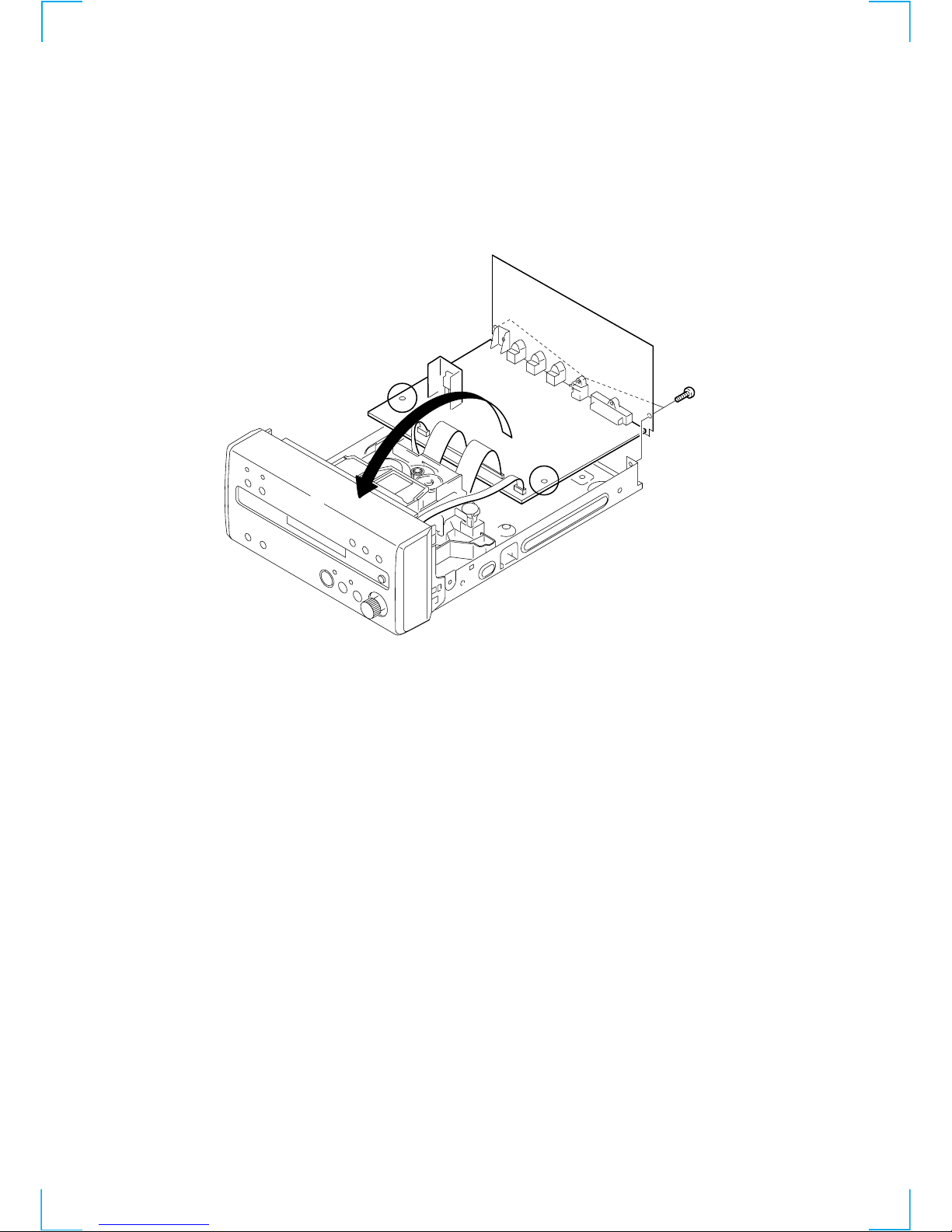

SERVICING POSITION

1. Remove the four screws securing the upper case, and remove the upper case.

2. Remove the three screws A securing the rear panel.

3. Remove the two craws B securing the MAIN board.

4. Remove the MAIN board with the rear panel.

A

B

B

13

SECTION 2

GENERAL

1 CD SYNC REC button

2 CD SYNC REC indicator

3 z REC button

4 z REC indicator

5 MENU/NO button

6 ENTER/YES button

7 CLEAR button

8 A button

9 l L knob

q; s button

qa S indicator

qs S button

qd H insdicator

qf H button

qg M button

qh m button

1 42 5 6 7

8

90qsqf qaqgqh

3

qd

14

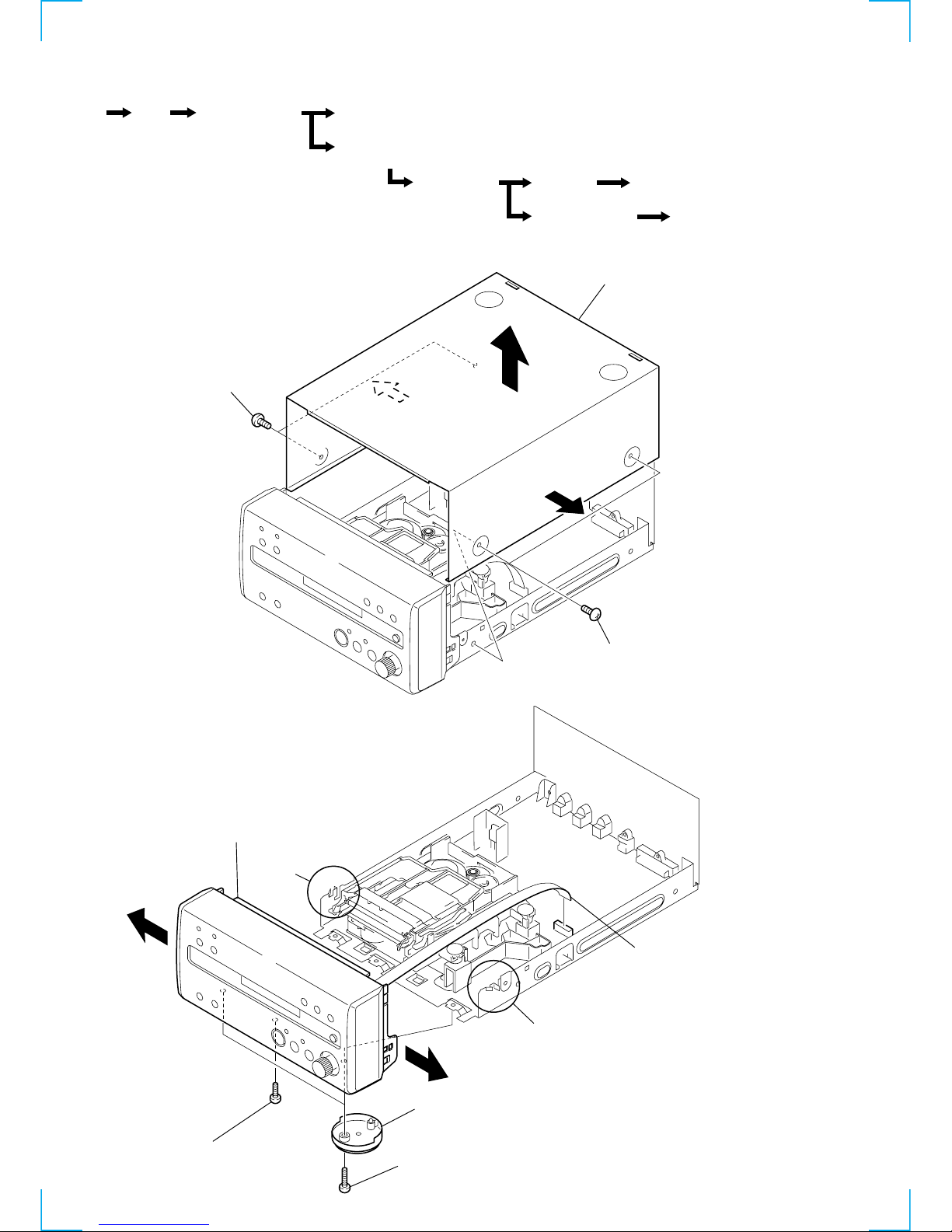

3-1. CASE

3-2. FRONT PANEL ASSY

Note: Follow the disassembly procedure in the numerical order given.

SECTION 3

DISASSEMBLY

1 two screws

(case 3 TP2)

4 case

1 two screws

(case 3 TP2)

2

2

3

1 flat type wire (11 core

)

(CN791)

4 screw (BVTP 3x12)

5 front panel assy

2 two screws

(BVTP 3x12)

3 two foot assy's

claws

claws

Set Case Front Panel Assy

MD Mechanism Deck (MDM-5A)

(Page 15)

Slider (Cam)

(Page 16)

BD Board

(page 16)

Spindle Motor, Sled Motor

(page 17)

Optical pick-up

(page 17)

Over Write Head

(Page17)

Main Board

(Page 15)

15

3-3. MD MECHANISM DECK

(MDM-5A)

3-4. MAIN BOARD

1 flat type wire (23 core)

(CN702)

2 flat type wire (21 core)

(CN501)

5 MD mechanism deck

3 connector

(CN701)

4 two screws

(BVTPWH M3)4 two screws

(BVTPWH M3)

2 three screw

s

(BVTP 3x8)

4 claw

4 claw

3 panel back

1 six screws

(BVTP 3x8)

5 main board

16

3-5. SLIDER (CAM)

• Note for installation of Slider (CAM)

Set the shaft of Cam gear to

be at the position in the figure.

Set the shaft of Lever (O/C) to

be at the position in the figure.

6 slider (cam)

2 bracket (guide L)

5 bracket (guide R)

4 two screws

(BTP 2.6x6)

1 two screws

(BTP 2.6x6)

3 leaf spring

A

When attaching the slider (cam),

this part of the over write head should

be inside arrow A.

2 base unit (MBU-5A)

1 three screws

(BTP 2.6x6)

5 screw

(M 1.7x4)

8 BD (MD) board

6 flexible board

7 flexible board

CN104

CN101

CN110

spindle motor

3 Remove the two solders.

Read wire's color

Red : +

Black :

-

4 Remove the two solders.

sled motor

-

+

3-6. BD BOARD

17

3-7. OVER WRITE HEAD

1 flexible board

2 screw (P 1.7x6)

3 over write head

(HR901)

1 screw (B 2x8)

3 main shaft

2 leaf spring

(SHAFT)

4 flexible board

5 optical pick-up (for MD

)

A

5 spindle motor

(M901)

7 sled motor

(M902)

4 three screws

(B 2x5)

6 two screws

(P 1.7x2.5)

1 screw (M1.7)

3 gear (SL-B)

2 gear (SL-A)

The BD (MD) board is soldered

at two parts.

(See page 16.)

3-8. OPTICAL PICK-UP

(KMS-260B/S1NP)

3-9. SPINDLE MOTOR, SLED MOTOR

Note:

Turn the optical pick-up

inside out, and pull out

the flexible board.

18

SECTION 4

TEST MODE

4-1. PRECAUTIONS FOR USE OF TEST MODE

• As loading related operations will be performed regardless of the test mode operations being performed, be sure to check that the disc is

stopped before setting and removing it.

Even if the A button (MD) is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc will not

stop rotating.

Therefore, it will be ejected while rotating.

Be sure to press the A button (MD) after pressing the MENU/NO button (MD) and the rotation of disc is stopped.

4-1-1. Recording laser emission mode and operating buttons

• Continuous recording mode (MD CREC MODE)

• Laser power check mode (MD LDPWR CHECK)

• Laser power adjustment mode (MD LDPWR ADJUST)

• Traverse (MO) check (MD EF MO CHECK)

• Traverse (MO) adjustment (MD EF MO ADJUST)

• When pressing the z REC button (MD).

4-2. SETTING THE TEST MODE

The following are two methods of entering the test mode.

1. Rotate the FUNCTION knob (TA), and set the function to “MD” before hand. When the power OFF (STANDBY), press the ?/1 button

(TA) while pressing the s button (MD) and ENTER/YES button (MD) together.

2. Press the MENU/NO button (MD), and when “MD Check” is displayed.

3. When the test mode is set, “MD [Check]” will be displayed. Rotate the l L knob (MD) switches between the following four

groups; ···Tt MD Check Tt MD Adjust Tt MD Service Tt MD Develop Tt ···.

4-3. EXITING THE TEST MODE

Press the ?/1 button (TA). The disc is ejected when loaded, and “Standby” display blinks, and the STANDBY state is set.

4-4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the l L knob (MD), ENTER/YES button (MD), and MENU/NO button (MD).

The functions of these buttons are as follows.

Function name

l L knob (MD)

ENTER/YES button (MD)

MENU/NO button (MD)

Function

Changes parameters and modes

Proceeds onto the next step. Finalizes input.

Returns to previous step. Stops operations.

Loading...

Loading...