Sony KV-42DRC700 Service Manual

TRINITRON

®

COLOR TELEVISION

SERVICE MANUAL

DX-1A

CHASSIS

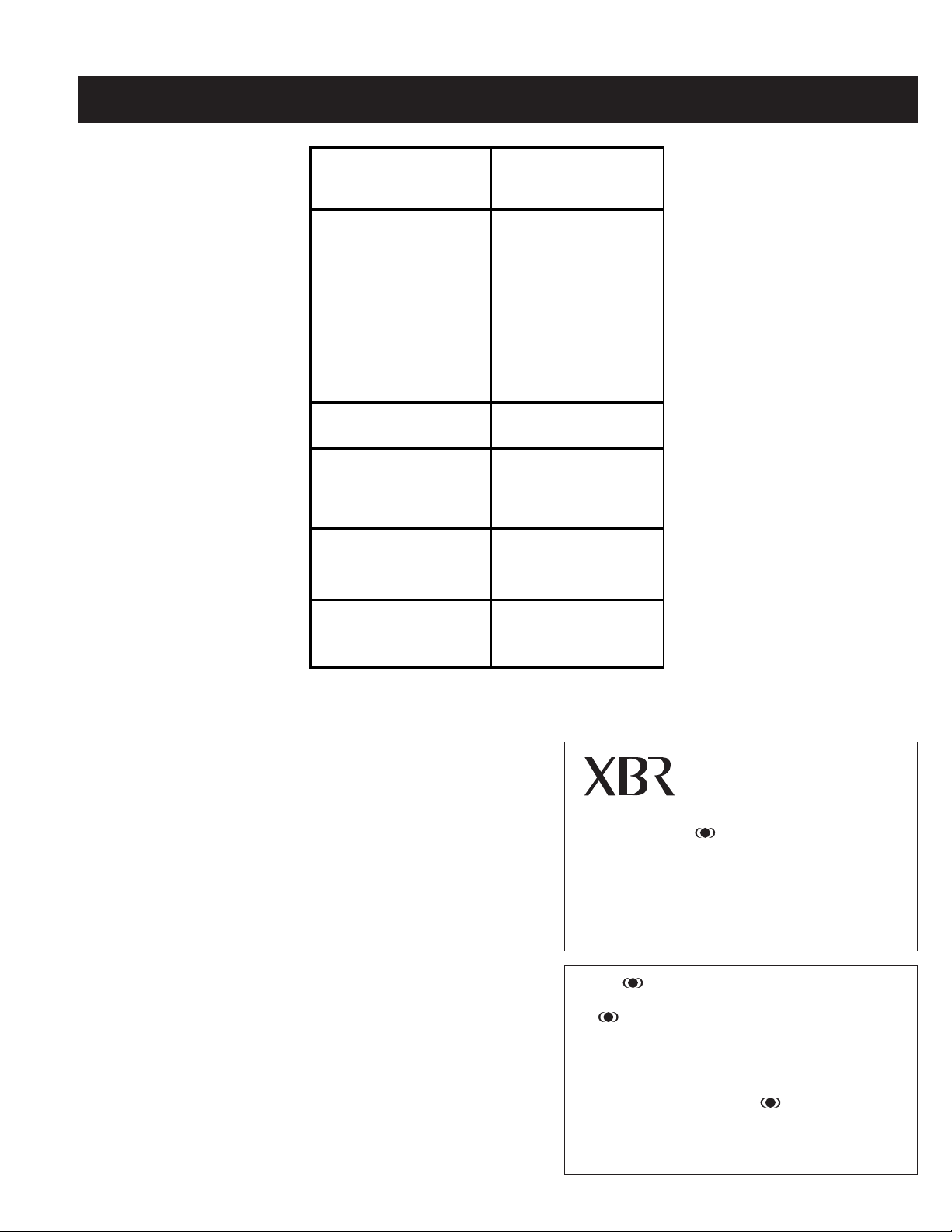

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-42DRC700

RM-Y184 E SCC-S48F-A

Self Diagnosis

Supported model

9-965-920-01

KV-42DRC700

RM-Y184

— 3 —

KV-42DRC700

TABLE OF CONTENTS

Specifi cations ................................................................................. 4

Warnings and Cautions .................................................................. 5

Safety Check-Out ........................................................................... 6

Self-Diagnostic Function................................................................. 7

1. Disassembly

1-1. Rear Cover Removal.............................................................. 9

1-2. Chassis Assembly Removal................................................... 9

1-3. Service Position ..................................................................... 9

1-4. Picture Tube Removal .......................................................... 10

Anode Cap Removal Procedure................................................... 10

2. Set-Up Adjustments

2-1. Beam Landing ...................................................................... 11

2-2. V-PIN and V-CEN Adjustment .............................................. 12

2-3. Convergence ........................................................................ 12

2-3.1. Vertical and Horizontal Static Convergence ............. 12

2-3.2. Operation of BMC (Hexapole) Magnet..................... 12

2-3.3. TLH Plate Adjustment .............................................. 12

2-3.4. Screen Corner Convergence ................................... 13

2-3.5. Dynamic Convergence Adjustments ........................ 13

2-4. Focus Adjustment................................................................. 13

2-5. Screen (G2).......................................................................... 13

2-6. Picture Quality Adjustments ................................................. 14

2-6.1. Video Input - Two Picture Sub Contrast

Adjustment ............................................................... 14

2-6.2. Video Input - Sub Hue/Sub Color Adjustment.......... 14

2-6.3. RF Input - Two Picture Sub Contrast Adjustment ..... 15

2-6.4. RF Input - Sub Hue/Sub Color Adjustment .............. 15

2-7. White Balance (CRT) and Sub Bright Adjustment ............... 16

2-8. Raster Center Adjustment .................................................... 16

2-9. Picture Distortion Adjustments............................................. 16

2-9.1. NTSC (DRC) Full Mode Adjustment ........................ 16

2-9.2. 1080i HD Mode Adjustment ..................................... 17

2-9.3. Vertical Compressed Mode Check and

Confi rmation............................................................. 17

SECTION TITLE PAGE

3. Safety Related Adjustments

3-1.

X

RV8001, RV8002 Confi rmation Method and

HV Service Adjustments ...................................................... 18

3-2. B+ Max Confi rmation ........................................................... 18

3-3. HV Service Flowchart .......................................................... 18

4. Circuit Adjustments

4-1. Setting the Service Adjustment Mode.................................. 19

4-1.1. Resetting the Data ................................................... 19

4-2. Memory Write Confi rmation Method .................................... 19

4-3. Remote Adjustment Buttons and Indicators ......................... 19

4-4. Service Data Lists ................................................................ 20

5. Diagrams

5-1. Circuit Boards Location ........................................................ 48

5-2. Printed Wiring Board and Schematic Diagram Information.. 48

5-3. Block Diagram and Schematics

Block Diagram...................................................................... 49

A Board ................................................................................ 54

B Board ................................................................................ 61

BC Board.............................................................................. 75

C Board ................................................................................ 78

D Board ................................................................................ 81

DH Board ............................................................................. 88

HA Board.............................................................................. 90

HB Board.............................................................................. 92

S Board ................................................................................ 93

U Board ................................................................................ 94

W Board ............................................................................... 96

5-4. Semiconductors ................................................................... 98

6. Exploded Views

6-1. Chassis ............................................................................... 100

6-2. Picture Tube ........................................................................ 101

7. Electrical Parts List ....................................................................... 102

SECTION TITLE PAGE

— 4 —

KV-42DRC700

TruSurround is a trademark of

SRS Labs, Inc. SRS and the SRS

symbol are registered trademarks

of SRS Labs, Inc. in the United

States and in select foreign coun-

tries. SRS and TruSurround are

incorporated under license from SRS Labs, Inc. and are protected

under United States Patent Nos. 4,748,669 and 4,841,572 with

numerous additional issued and pending foreign patents. Pur-

chase of this product does not convey the right to sell recordings

made with the TruSurround technology.

Television system

American TV standard, NTSC

Channel coverage

VHF: 2-13/ UHF: 14-69/ CATV: 1-125

Picture tube

FD Trinitron

®

tube

Visible screen size

40-inch picture measured diagonally

Actual screen size

42-inch measured diagonally

Antenna

75 ohm external terminal for VHF/UHF

Supplied Accessories

Remote Commander RM-Y184

Two Size AA (R6) Batteries

Optional Accessories

Connecting cables: VMC-10/30HG, VMC-810S/820/830HGS, VMC-810S/820S,

RKG69HG, RKC-515HG

TV Stand: SV-40XBR7

SPECIFICATIONS

SRS (SOUND RETRIEVAL SYSTEM)

The SRS (SOUND RETRIEVAL SYSTEM) is manufactured by

Sony Corporation under license from SRS Labs, Inc. It is covered

by U.S. Patent No. 4,748,669. Other U.S. and foreign patents

pending.

The word ‘SRS’ and the SRS symbol are registered trade-

marks of SRS Labs, Inc. BBE and BBE symbol are trademarks of

BBE Sound, Inc. and are licensed by BBE Sound, Inc. under U.S.

Patent No. 4,638,258 and 4,482,866.

Design and specifi cations are subject to change without notice.

1)

1 Vp-p 75 ohms unbalanced, sync negative

2)

Y: 1 Vp-p 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

3)

More than 408 mVrms at the maximum volume setting (variable)

More than 408 mVrms (fi x)

4)

500

m

Vrms (100% modulation), Impedance: 47 kilohms

5)

Y: 1.0 Vp-p, 75 ohms, sync negative;

PB: 0.7 Vp-p, 75 ohms

PR: Vp-p, 75 ohms

TruSurround

™

by SRS

®

KV-42DRC700

Power requirements 120V, 60 Hz

Number of inputs/outputs

Video

1)

4

S Video

2)

3

Audio

3)

6

Audio Out

4)

1

Y,P

B

, P

R

5)

2

Monitor Out 1

Control-S (in/out) YES

Speaker output(W)

7.5W x 2

15W Subwoofer

Power Consumption(W)

In use(Max) 245W

In standby 2W

Dimensions(W/H/D)

(mm)

1093 x 836 x 665 mm

(in)

43

1

/

8

x 33 x 26

1

/8

in

Mass

(kg) 138 kg

(lbs) 304 lbs.

— 5 —

KV-42DRC700

WARNINGS AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield, or carbon painted on the CRT,

after removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the AC power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and

!

mark on the schematic diagrams, exploded views, and in the parts list are critical for

safe operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

ATTENTION!!

Apres avoir deconnecte le cap de l’anode, court-circuiter l’anode du tube cathodique et celui de l’anode du cap au chassis metallique

de l’appareil, ou la couche de carbone peinte sur le tube cathodique ou au blindage du tube cathodique.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout

dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque

!

sur les schemas de principe, les vues explosees et les listes de

pieces sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont

le numero de piece est indique dans le present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont

l’importance est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de

chaque remplacement de composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

— 6 —

KV-42DRC700

To Exposed Metal

Parts on Set

0.15 F

1.5 K Ω

AC

Voltmeter

(0.75 V)

Earth Ground

Trouble Light

AC Outlet Box

Ohmmeter

Cold Water Pipe

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if sets

always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage

as described below.

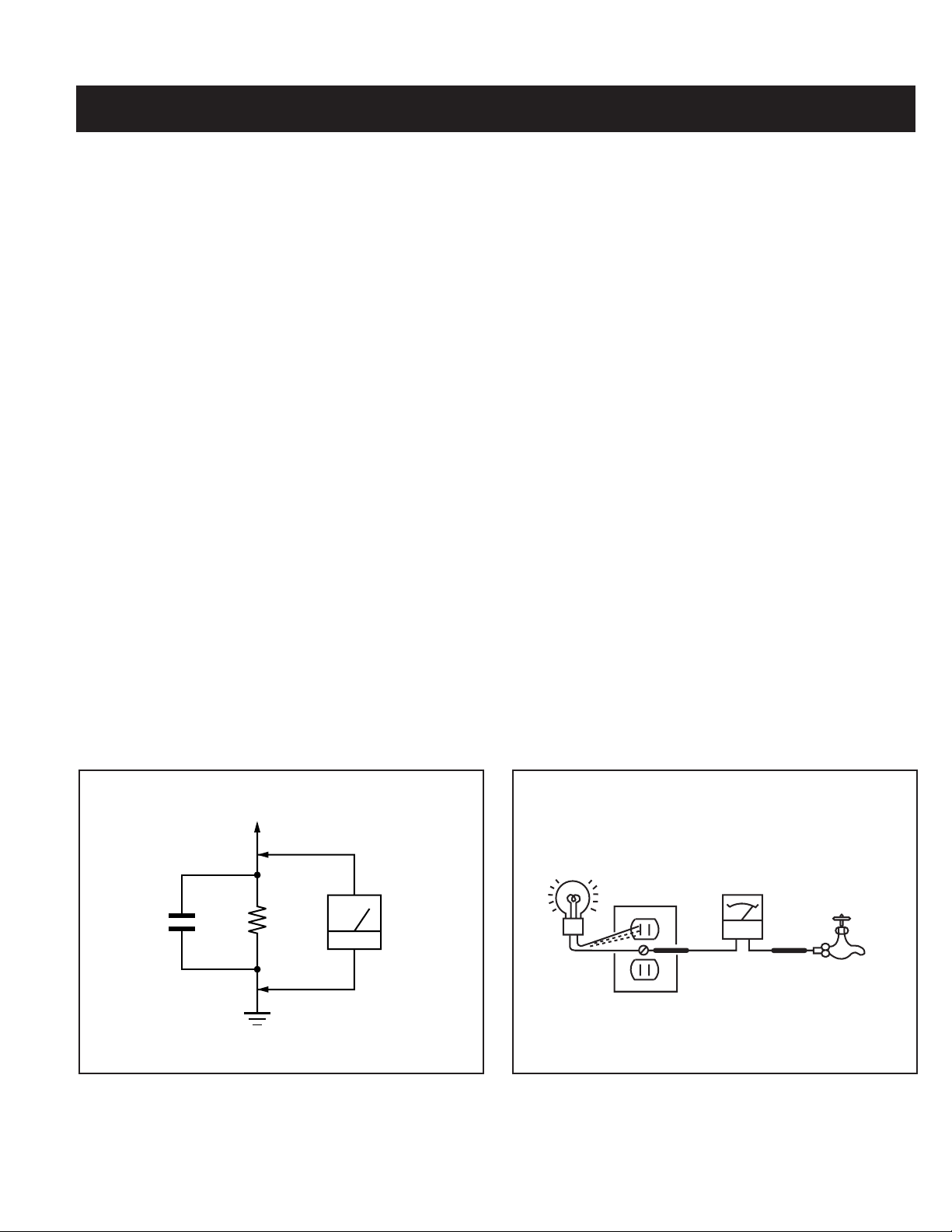

Leakage Test

The AC leakage from any exposed metal part to earth ground and from

all exposed metal parts to any exposed metal part having a return to

chassis, must not exceed 0.5 mA (500 microamperes). Leakage current

can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75 V,

so analog meters must have an accurate low voltage scale. The

Simpson’s 250 and Sanwa SH-63TRD are examples of passive

VOMs that are suitable. Nearly all battery-operated digital multimeters

that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining

screw on most AC outlet boxes is also at earth ground. If the retaining

screw is to be used as your earth ground, verify that it is at ground

by measuring the resistance between it and a cold-water pipe with an

ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt trouble-

light (not a neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot side on the

line; the lamp should light at normal brilliance if the screw is at ground

potential (see Figure B).

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

— 7 —

KV-42DRC700

SELF-DIAGNOSTIC FUNCTION

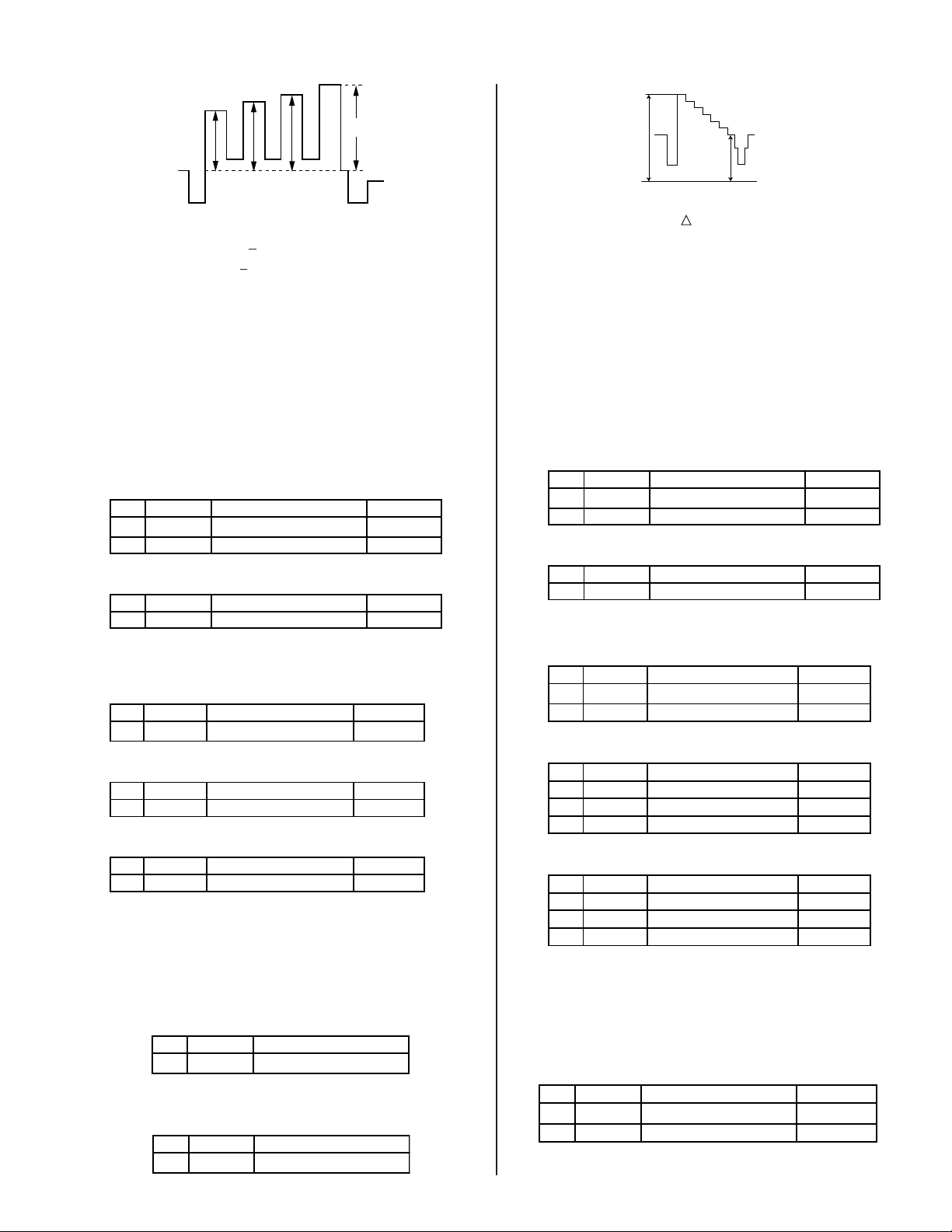

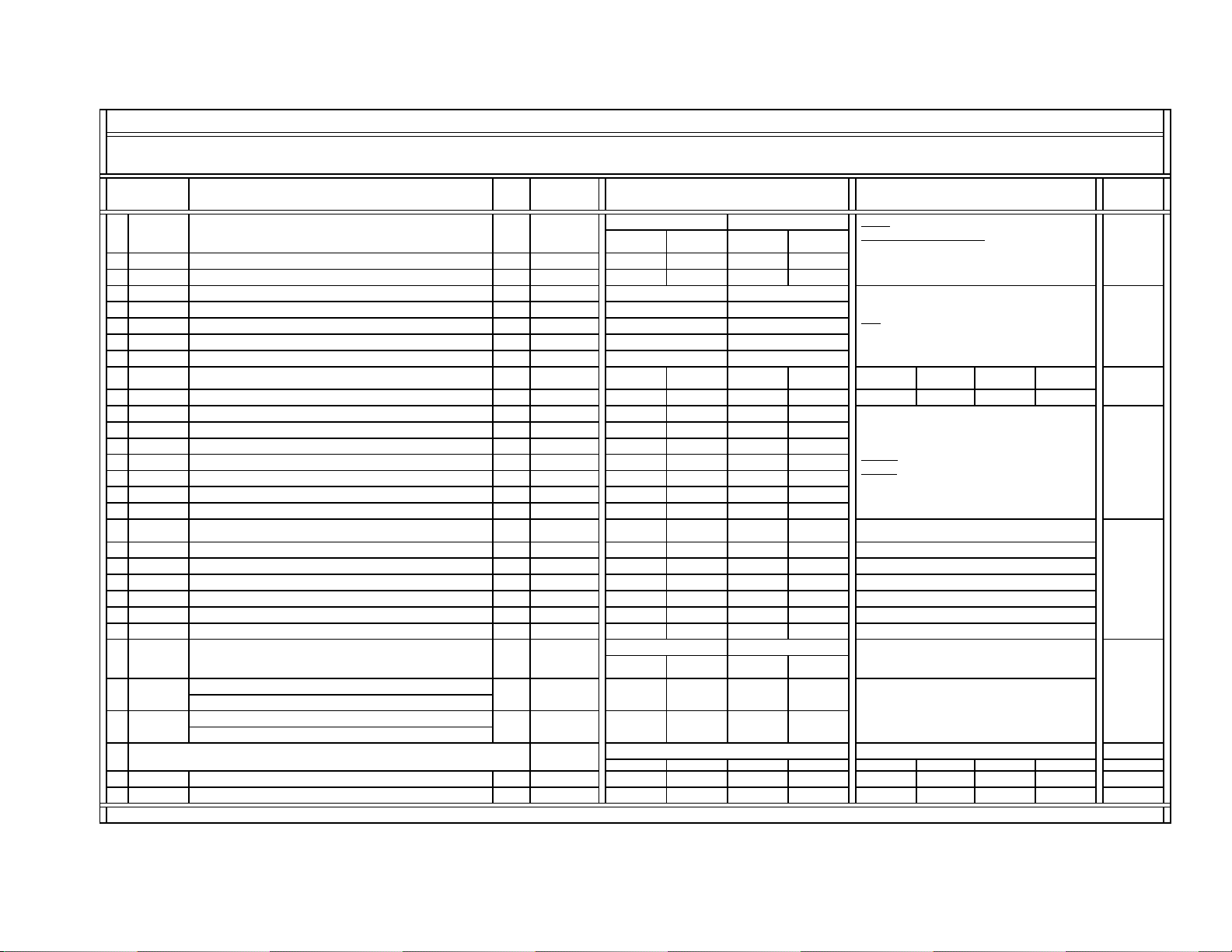

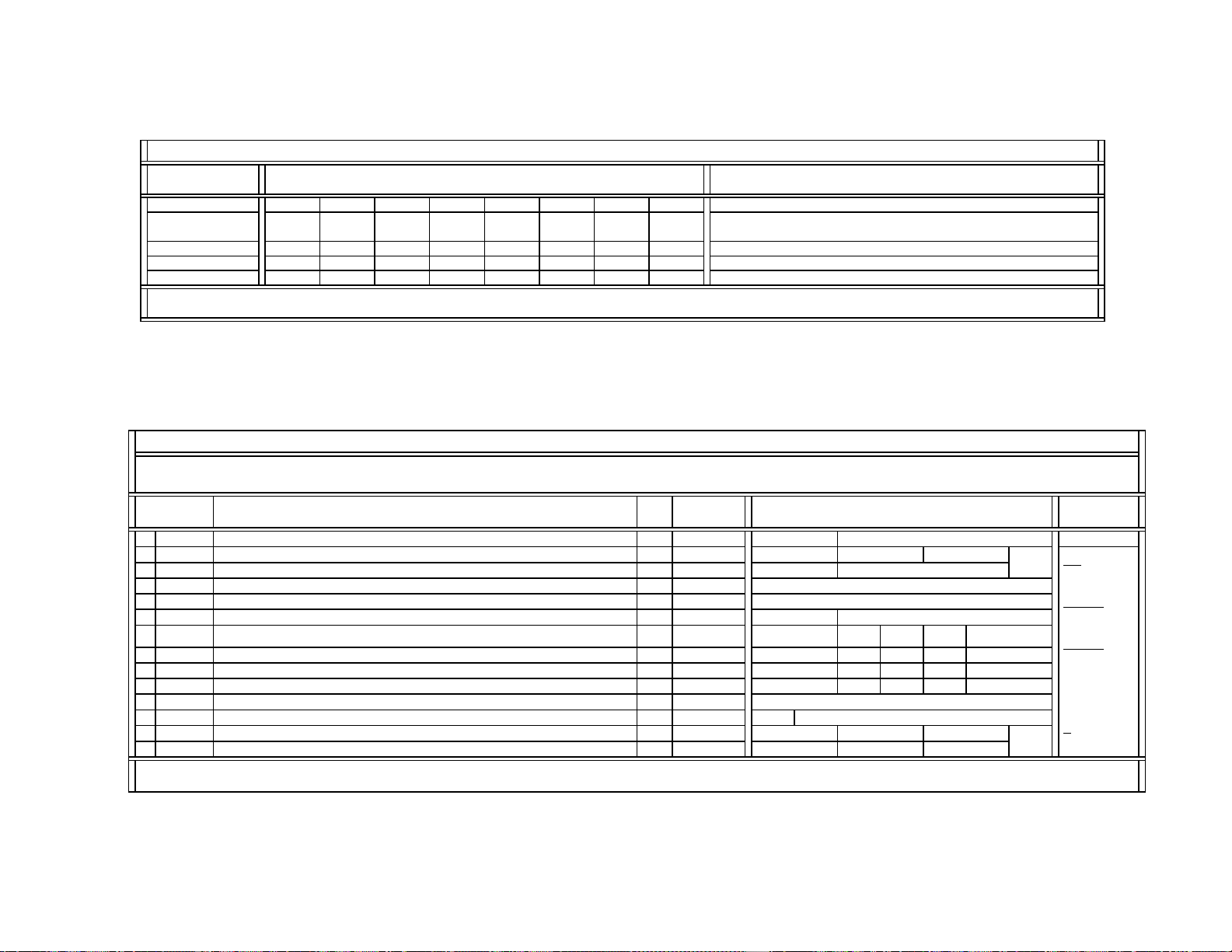

Display of STANDBY/STEREO LED Flash Count

Diagnostic items Flash count

Lamp OFF 3 sec.

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

STANDBY/STEREO LED

+B Overcurrent (OCP) 2 times

+B Overvoltage (OVP) 3 times

Vert. Deflection Stopped 4 times

White Balance Failure 5 times

Low B OCP/OVP 6 times

Horiz. Deflection Stopped 7 times

Stopping the STANDBY/STEREO LED Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/STEREO LAMP from fl ashing.

Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confi rmed, it is possible to bring up

past occurrences of failure on the screen for confi rmation.

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/STEREO LED will automatically begin to fl ash. The number

of times the LED fl ashes translates to a probable source of the problem. A defi nition of the STANDBY/STEREO LED fl ash indicators is listed in the

instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review

the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

Diagnostic Test Indicators

When an error occurs, the STANDBY/STEREO LED will fl ash a set number of times to indicate the possible cause of the problem. If there is more

than one error, the LED will identify the fi rst of the problem areas.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

No. of times STANDBY/

Diagnostic Item STEREO lamp fl ashes Display Result Probable Cause Location Detected Symptoms

Power does not turn on Does not light • Power cord is not plugged in. • Power does not come on.

• Fuse is burned out F6001 (A Board). • No power is supplied to the TV.

• AC power supply is faulty.

+B Overcurrent (OCP) 2 times 2:0 or 2:1 • H.OUT (Q5030) is shorted (D Board). • Power does not come on.

(See Note 1) • +B PWM (Q5003) is shorted (D Board). • Load on power line is shorted.

• IC9001, IC9002, IC9003 is shorted (C Board).

+B Overvoltage (OVP) 3 times 3:0 or 3:1 • IC6505 is faulty (D Board). • Has entered standby mode.

Vertical Defl ection Stopped 4 times 4:0 or 4:1 • ± 15V is not supplied (D Board). • Has entered standby state after

• IC5004 is faulty (D Board). horizontal raster.

• Vertical defl ection pulse is stopped.

• Power line is shorted or power

supply is stopped.

White Balance Failure 5 times 5:0 or 5:1 • Video OUT (IC9001-IC9003) is faulty (C Board). • No raster is generated.

(not balanced) • CRT drive (IC201) is faulty (A Board). • CRT Cathode current detection

• G2 is improperly adjusted (See Note 2). reference pulse output is small.

LOW B OCP/OVP 6 times 6:0 or 6:1 • +5 line is overloaded (A, B Boards). • No picture.

(overcurrent/overvoltage) • +5 line is shorted (A, B Boards).

(See Note 3) • IC6007 is faulty (A Board).

Horizontal Defl ection Stopped 7 times 7:0 or 7:1 • No picture.

Note 1: If a +B Overcurrent is detected, stoppage of the Vertical Defl ection is detected simultaneously. The symptom that is diagnosed fi rst by the microcontroller is displayed on screen.

Note 2: Refer to Screen (G2) Adjustment in Section 2-5. of this manual.

Note 3: If STANDBY/STEREO LED fl ashes six (6) times, unplug the unit and wait 10 seconds before performing the adjustment.

Self Diagnosis

Supported model

* One fl ash count is not used for self-

diagnostic.

— 8 —

KV-42DRC700

SELF DIAGNOSIS

2: +B OCP N/A

3: +B OVP N/A

4: V STOP 0

5: AKB 1

6: LOWB 0

7: H-STOP 0

101: WDT 24

Handling of Self-Diagnostic Screen Display

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs. When you

have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the repairs.

Clearing the Result Display

To clear the result display to “0”, press buttons on the Remote Commander sequentially when the diagnostic screen is displayed, as shown below:

Channel

8

ENTER

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn off the power switch on the Remote Commander or the main unit.

Self-Diagnostic Circuit

+B Overcurrent (OCP)

Occurs when an overcurrent

(more than 6A) on the +B

(135V) line is detected by

R6598/R6591. It will cause

Q6520 to turn on and force the

AC relay to turn off through

Q6532 and Q6530.

+B Overvoltage (OVP)

Occurs when 1) overvoltage

(more than +140V) on the

+B (135V) line is detected by

IC6505, or 2) an overvoltage

(more than 7.5 V) on the unreg

7V line is detected by D6014.

The AC relay will turn off

through Q6532 and Q6530.

Vertical Defl ection Stopped

Occurs when an absence of

the vertical defl ection pulse

is detected by IC201. Power

supply will shut down when

waveform interval exceeds 2

seconds.

White Balance Failure

If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will be detected by IC201. TV will stay on, but there

will be no picture.

*(Refers to the RGB levels of the AKB detection Ref pulse that detects 1K).

Low B OCP/OVP Error

Occurs when set 5V is out.

Horizontal Defl ection Stopped

Occurs when either: 1) a +B overcurrent is detected (IC5007), or 2) overheating is detected (Thermistor TH5002).

Numeral “0” means that no fault

was detected.

Numeral “1” means a fault was detected

one time only.

To Bring Up Screen Test

In standby mode, press buttons on the Remote Commander sequentially,

in rapid succession, as shown below:

DISPLAY

Channel

5

Sound volume

-

Power ON.

AKB

VPROT

HPROT

SCL

SDA

IC701

MAIN UCOM

STBY LED

HA

STR

STBY-LED

OCP

OVP

LOW B ERR

AC RLY

CLKO

DATO

29

30

69

43

45

44

48

Q6532

Q6530

D6537

D6501

Q6527

RY6501

SET ON

200V OCP

+B OCP

OVP

D8027

D8003

0

0

I

UNREG 7V

D6014

D6018

SET 5V

26

25

58

35

34

CRT

VDY -

R5125

R5104 R5105

IC5007

214

Q5018

I5V

2

1

3

OVP

Q6522

STBY 5V

Q6524

Q6521

IC6505

+B OVP

+B

Q6520

IC6007

IC201

Y/C JUNGLE

D

A

A

A

D

— 9 —

KV-42DRC700

1-1. REAR COVER REMOVAL

1-2. CHASSIS ASSEMBLY REMOVAL 1-3. SERVICE POSITION

SECTION 1: DISASSEMBLY

2

1

1

1

CAUTION! - Heat sink on IC5004 is -15V. Care must be

taken not to allow heat sink to touch any other components.

2

Gently pull the chassis assembly away from the bezel.

1

Pull up and rotate both the A and D Boards in order to

service the unit.

Remove 22 (+BVTP 4x16) screws from areas

indicated with a circle or line.

Chassis

Assembly

— 10 —

KV-42DRC700

1

Discharge the anode of the CRT and remove the

anode cap.

2

Unplug all interconnecting leads from the defl ection

yoke, neck assembly, degaussing coils and CRT

grounding strap.

3

Remove the Speaker Assemblies.

4

Remove the C Board from the CRT.

5

Remove the chassis assembly.

6

Loosen the neck assembly fi xing screw and remove.

7

Loosen the defl ection yoke fi xing screw and remove.

8

Place the set with the CRT face down on a cushion

and remove the degaussing coil holders.

9

Remove the degaussing coils.

10

Remove the CRT grounding strap and spring tension

devices.

11

Unscrew the four CRT fi xing screws [located on each

CRT corner] and remove the CRT [Take care not to

handle the CRT by the neck].

1-4. PICTURE TUBE REMOVAL

WARNING: BEFORE REMOVING THE ANODE CAP

High voltage remains in the CRT even after the power is disconnected. To avoid electric shock,

discharge CRT before attempting to remove the anode cap. Short between anode and CRT

coated earth ground strap.

Coated

Earth

Ground

Strap

ANODE CAP REMOVAL PROCEDURE

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electric shock, discharge CRT before attempting to remove

the anode cap. Short between anode and coated earth ground strap of CRT.

NOTE: After removing the anode cap, short circuit the anode of the picture tube and the anode cap to either the metal chassis, CRT shield, or

carbon painted on the CRT.

REMOVAL PROCEDURES

HOW TO HANDLE AN ANODE CAP

1. Do not use sharp objects which may cause damage to the surface of the

anode cap.

2. To avoid damaging the anode cap, do not squeeze the rubber covering too hard.

A material fi tting called a shatter-hook terminal is built into the rubber.

3. Do not force turn the foot of the rubber cover. This may cause the shatter-hook

terminal to protrude and damage the rubber.

2

1

3

4

5

6

7

8

9

10

11

a

b

Anode Button

c

Turn up one side of the rubber cap in

the direction indicated by arrow

a

.

Use your thumb to pull the rubber

cap fi rmly in the direction indicated

by arrow

b

.

When one side of the rubber cap separates from

the anode button, the anode cap can be removed

by turning the rubber cap and pulling it in the

direction of arrow

c

.

— 11 —

KV-42DRC700

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

These adjustments should be performed with rated power supply

voltage unless otherwise noted.

The controls and switch should be set as follows unless otherwise

noted:

VIDEO MODE: STANDARD (RESET)

SECTION 2: SET-UP ADJUSTMENTS

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)

5. White Balance

Test Equipment Required:

1. Color Bar Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

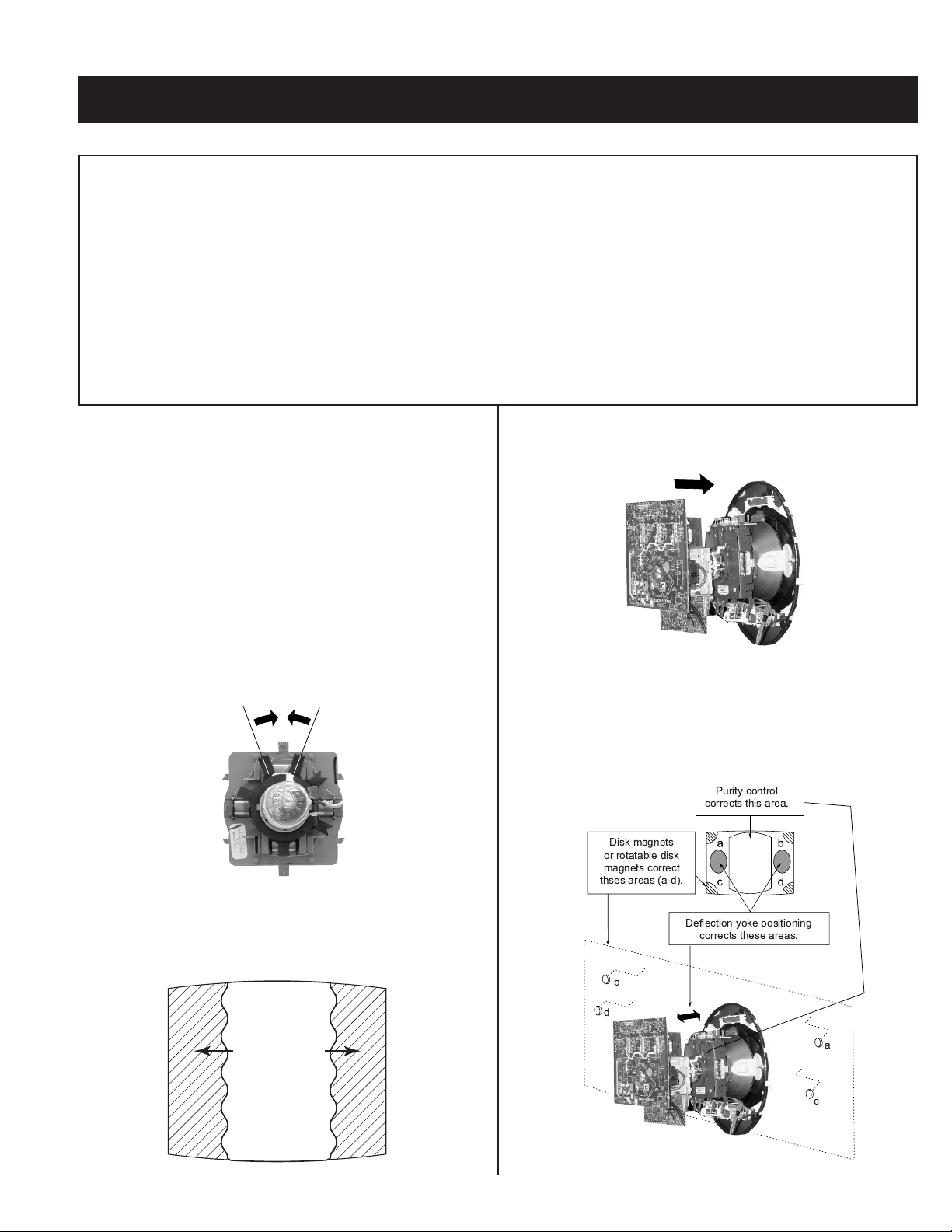

2-1. BEAM LANDING

Preparation:

• Input a white pattern signal.

• Face the picture tube in an East or West direction to reduce the

infl uence of geomagnetism.

NOTE: Do not use the hand degausser; it magnetizes the CRT .

1. Input white pattern from pattern generator. Set the PICTURE control

to maximum, and the BRIGHTNESS control to standard.

2. Perform Focus, G2 and White Balance adjustments.

3. Loosen the defl ection yoke mounting screw, and set the purity control

to the center as shown below:

Purity Control

4. Input a green pattern from the pattern generator.

5. Move the defl ection yoke backwards, and adjust with the purity control

so that green is in the center and red and blue are even on both

sides.

Blue Red

Green

6. Move the defl ection yoke forward, and adjust so that the entire screen

becomes green.

7. Switch over the raster signal to red and blue and confi rm the

condition.

8. When the position of the defl ection yoke is determined, tighten it with

the defl ection yoke mounting screw.

9. If landing at the corner is not right, adjust it by using the disk magnets.

Purity control

corrects this area.

Deflection yoke positioning

corrects these areas.

Disk magnets

or rotatable disk

magnets correct

thses areas (a-d).

b

d

a

c

— 12 —

KV-42DRC700

2-2. V-PIN AND V-CEN ADJUSTMENT

Preparation:

• Input a cross hatch pattern signal.

• Face the picture tube in a North/South direction and correct rotation.

• Set Video Mode to: Standard (Reset)

1. Adjust service mode CXA2150D-1 04 V-CEN so that the top pin and

bottom pin are symmetrical from top to bottom.

2. Adjust service mode CXA2150D-1 05 V-PIN so that the top pin and

bottom pin are symmetrical from top to bottom.

3. Lines should be straight from left to right. Check landing for side

effect.

2-3. CONVERGENGE

Preparation:

• Set the CONTRAST and BRIGHTNESS control to 50%.

• Input HD dot pattern.

2-3.1. VERTICAL AND HORIZONTAL STATIC

CONVERGENCE

1. Disconnect the dynamic convergence before adjusting static

convergence (CN5510), except for minor touch-up.

2. Adjust H.STAT convergence, RV9001, to converge red, green, and

blue dots in the center of the screen.

3. Adjust V. STAT magnet to converge red, green and blue dots in the

center of the screen.

R

G

B

Center dot

RV9001

V. S TAT

V.STAT magnet

R G B

4. Tilt the V.STAT magnet and adjust static convergence to open or close

the V.STAT magnet.

B

G

R

B

G

R

1

2-3.2. OPERATION OF BMC (HEXAPOLE)

MAGNET

The respective dot positions result from moving each magnet interact.

Perform the following adjustments while tracking.

1. Use the V.STAT tabs to adjust the red, green and blue dots so that

they line up at the center of the screen (move the dots in a horizontal

direction).

HMC Correction HMC Correction

RGB

A=B

AB

R

GB

A

>

B

AB

RGB

A=B

AB

R

GB

A

<

B

AB

VMC Correction

R

G

B

C

<

D

C

D

R

G

B

C=D

VMC Correction

R

G

B

C

<

D

C

D

R

G

B

C=D

2-3.3. TLH PLATE ADJUSTMENT

Preparation:

• Input a cross hatch pattern signal.

• Adjust PICTURE QUALITY to Standard, PICTURE and

BRIGHTNESS to 50%, and OTHER to Standard.

• Adjust unbalanced horizontal convergence of red and blue dots by

adjusting the TLH Plate on the defl ection yoke.

TLH Plate

RV9002

RV9001

W Board

C Board

TLV

XCV

TLH+

TLH-

RB

(B)(R)

BR

(R)(B)

1. Adjust XCV core to balance X axis.

2. Adjust the vertical red and blue convergence with V.TILT (TLV VR).

Note: Perform adjustments while tracking Item 1.

— 13 —

KV-42DRC700

2-3.4. SCREEN-CORNER CONVERGENCE

Preparation:

• Input a cross hatch pattern signal.

1. Affi x a permalloy assembly corresponding to the misconverged areas.

d

c

a

b

a-d: screen-corner

misconvergence

a

b

cd

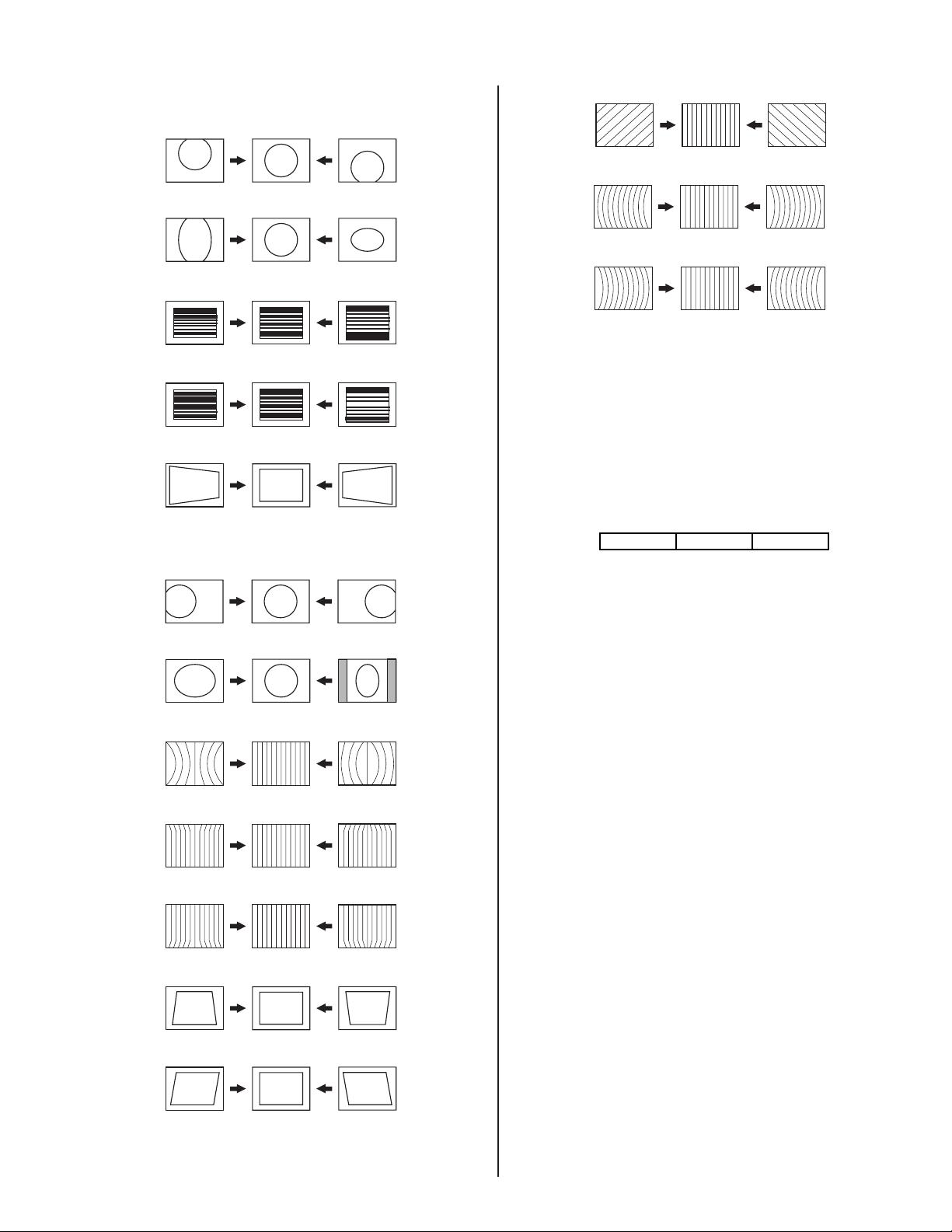

2-3.5. DYNAMIC CONVERGENCE

ADJUSTMENTS

Set dynamic convergence using the following service mode adjustment

data.

NO.

Register

Function Data Length Initial Data

1 YBWU VCA9 0-63 31

2 YBWL VCA10 0-63 31

3 RSAP DC-AMP1 0-63 31

4 RUBW VCA5 0-63 31

5 RLBW VCA6 0-63 31

6 LSAP DC-AMP2 0-63 31

7 LUBW VCA10 0-63 31

8 LLBW VCA2 0-63 31

CXA8070AP

1. YBWU (Upper Y-BOW)

BR BR

2. YBWL (Bottom BOW)

BR BR

3. RSAP (Right AMP)

RB

4. RUBW (Right Side Upper C-BOW)

BR

5. RLBW (Right Side Bottom C-BOW)

RB

6. LSAP (Left AMP)

BR

7. LUBW (Left Side Upper C-BOW)

BR

8. LLBW (Left Side Bottom C-BOW)

BR

2-4. FOCUS ADJUSTMENT

1. Input a dot signal.

2. Set Video Mode to STANDARD.

3. Adjust focus VR counter-clockwise to confi rm that the dot’s shape is

centered.

4. Input a HP monoscope signal.

5. Confi rm center focus with focus VR.

FOCUS

DOT SHAPE:

2-5. SCREEN (G2)

1. Input a monoscope pattern (NTSC).

2. Set to service mode and adjust as follows:

CXA2150P-2

NO.

Disp.

Item Avg.

0 ALBK ALL_BLK 0

3. Adjust RV9002 on the C Board so that the voltage on red, green and

blue cathodes is 175 ± 2 VDC.

4. Adjust the hotizontal line at the top of the screen so it is cut off.

Note: Never set ALBK to 1 when external power supply is connected

to cathode.

— 14 —

KV-42DRC700

2-6. PICTURE QUALITY ADJUSTMENTS

Preparation:

• Set PRO MODE (Picture: MAX, GAMMA: 0).

• Dynamic-color: Off (=Trinitron: MID).

• Set the Service Mode to the following:

NO. Name Control Function Avg. Data

06 UDCL Dynamic Color: OFF 0

08 UGRAM GRAMMA 5

15 DCTR DC-TRAN 2

16 DPIC DYNAMIC PIC: OFF 1

C2150P-4

1. Input signal (480i):

• Color Bar Video 75 IRE (White) 75% modulation 7.5% Set-up.

• Color Bar RF 75 IRE (White) 75% modulation 7.5% Set-up.

2-6.1. VIDEO INPUT - TWO PICTURE SUB

CONTRAST ADJUSTMENT

Preparation:

• Input a Color Bar signal to VIDEO 1 (75 IRE 75%).

• Set picture mode: P&P (PRO MODE).

1. Set to Service Mode and adjust as follows:

NO. Name Control Function Avg. Data

00 UPIC PICTURE 63

02 UCOL COLOR 0

NO. Name Control Function Avg. Data

01 RGBS R ON 4

2150P-4

2150P-2

INITIAL DATA (IMPORTANT)

NO. Name Control Function Avg. Data

23 SCON SUB-CONT 8

NO. Name Control Function Avg. Data

00 YLEV Y-OUT 23

NO. Name Control Function Avg. Data

00 YLEV Y-OUT 23

2150P-4

2103-1

2103-2

2. Connect oscilloscope to Pin 1 of CN9001 (R.DRV) on the C Board.

3. Adjust MAIN (left) side contrast according to Service Mode for SCON.

NO. Name Control Function

02 SCON SUB-CONT

2103-1

4. Adjust SUB (right) side contrast according to Service Mode for SCON.

NO. Name Control Function

02 SCON SUB-CONT

2103-2

white

black

GND

VR2

VR1

VR1-VR2 = VR = 2.08 ± 0.05 Vp-p

5. Write data from Steps 3 and 4 above, into memory.

2-6.2. VIDEO INPUT - SUB HUE/SUB COLOR

ADJUSTMENT

Preparation:

• Input a Color Bar signal to VIDEO 1 (75 IRE 75%).

• Set picture mode: P&P (PRO MODE).

1. Set to Service Mode and adjust as follows:

NO. Name Control Function Avg. Data

00 UPIC PICTURE 63

02 UCOL COLOR 31

NO. Name Control Function Avg. Data

01 RGBS R ON 7

2150P-4

2150P-2

2. Connect an oscilloscope to Pin 5 of CN9001 (B. DRV) on the C Board.

3. Adjust MAIN (left) side color according to Service Mode for SCOL.

4. Adjust MAIN (left) side color according to Service Mode for SHUE.

NO. Name Control Function

03 SCOL SUB-COL

04 SHUE SUB-HUE

2103-1

5. Adjust SUB (right) side color according to Service Mode for SCOL.

6. Adjust SUB (right) side color according to Service Mode for SHUE.

NO. Name Control Function

03 SCOL SUB-COL

04 SHUE SUB-HUE

2103-2

— 15 —

KV-42DRC700

VB4

VB3VB2VB1

COLOR: VB1 < VB4 (=VB1 + 0~90 mV)

HUE: VB2 < VB3 (=VB2 + 0~90 mV)

(HUE: Adjust data -2 STEP)

7. Write data into memory.

2-6.3. RF INPUT - TWO PICTURE SUB

CONTRAST ADJUSTMENT

Preparation:

• Input a Color Bar signal to RF (75 IRE 75%).

• Set picture mode: P&P (PRO MODE).

1. Set to Service Mode and adjust as follows:

NO. Name Control Function Avg. Data

00 UPIC PICTURE 63

02 UCOL COLOR 0

NO. Name Control Function Avg. Data

01 RGBS R ON 4

2150P-4

2150P-2

INITIAL DATA (IMPORTANT)

NO. Name Control Function Avg. Data

23 SCON SUB-CONT 8

NO. Name Control Function Avg. Data

00 YLEV Y-OUT 23

NO. Name Control Function Avg. Data

00 YLEV Y-OUT 23

2150P-4

2103-1

2103-2

Note: Use the same average data as 2-6.1., Items 3 - 4 after the

adjustment.

2. Connect an oscilloscope to Pin 1 of CN9001 (R. DRV) on the C

Board.

3. Adjust MAIN (left) side contrast according to service mode for SCON.

NO. Name Control Function

02 SCON SUB-CONT

2103-1

4. Adjust SUB (right) side contrast according to Service Mode for SCON.

NO. Name Control Function

02 SCON SUB-CONT

2103-2

white

black

GND

VR2

VR1

VR1-VR2 = VR = 2.08 ± 0.05 Vp-p

5. Write data from Steps 3 - 4 above, into memory.

2-6.4. RF INPUT - SUB HUE/SUB COLOR

ADJUSTMENT

Preparation:

• Input a Color Bar signal to RF (75 IRE 75%).

• Set picture mode: P&P (PRO MODE).

1. Set to Service Mode and adjust as follows:

NO. Name Control Function Avg. Data

00 UPIC PICTURE 63

02 UCOL COLOR 31

NO. Name Control Function Avg. Data

01 RGBS R ON 7

2150P-4

2150P-4

INITIAL DATA (IMPORTANT)

NO. Name

Control Function

Avg. Data

24 CLOF OFFSET for UCOL 8

25 HUOF OFFSET for UHUE 4

NO. Name

Control Function

Avg. Data

01 CLEV CB & CR-OUT 20

20 CBOF CB-OFFSET 31

21 CROF CR-OFFSET 31

NO. Name

Control Function

Avg. Data

01 CLEV CB & CR-OUT 19

20 CBOF CB-OFFSET 31

21 CROF CR-OFFSET 31

2150P-4

2103-1

2103-2

Note: Use the same average data as 2-6.2., Items 3-6 after the

adjustment.

2. Connect an oscilloscope to pin 5 of CN9001 (B. DRV) on the C Board.

3. Adjust MAIN (left) side color according to Service Mode for SCOL.

4. Adjust MAIN (left) side color according to Service Mode for SHUE.

NO. Name Control Function

Avg. Data

03 SCOL SUB COLOR Adjust

04 SHUE

SUB HUE

Fix: 8

2103

-

1

5. Adjust SUB (right) side color according to Service Mode for SCOL.

— 16 —

KV-42DRC700

6. Adjust SUB (right) side color according to Service Mode for SHUE.

NO. Name Control Function Avg. Data

03 SCOL SUB COLOR Adjust

04 SHUE SUB HUE

Fix: 5

2103-2

VB4

VB3VB2VB1

COLOR: VB1 < VB4 (=VB1 + 0~90 mV)

HUE: VB2 < VB3 (=VB2 + 0~90 mV)

(HUE: Adjust data -2 STEP)

7. Write data into memory.

2-7. WHITE BALANCE (CRT) AND SUB

BRIGHT ADJUSTMENT

Preparation

• Input an all white 480I (15.734 KHz) signal into the VIDEO 1 input

terminal to perform the White Balance (highlight, cut-off) adjustments.

The parameters to adjust are in the CXA2150P in Service Mode.

1. Set the following:

Picture: Full Mode

Pro Mode

Color: Center

2. Adjust White Balance in the Service Mode and set the following data:

NO. Name Control Function Avg. Data

05 RDRV R-DRIVE Fix: 46

06 GDRV G-DRIVE Adjust

07 BDRV B-DRIVE Adjust

08 RCUT R-CUT OFF Fix: 41

09 GCUT G-CUT OFF Adjust

10 BCUT B-CUT OFF Adjust

21

5

0P

-

1

3. Adjust Sub Brightness: Input an all black signal (to IRE 7.5% set up)

480i (15.75 KHz) signal into the VIDEO 1 input terminal. Adjust the

following parameter of CXA2150P-1:

4. Check Initial Data (Important).

NO. Name Control Function Avg. Data

04 SBRT SUB-BRIGHT 20

CXA2150P-1

NO. Name Control Function Avg. Data

00 SBOT SUB-BRT OFFSET 7

12 SBOF SUB-BRT OFFSE

T

63

2150P-1

5. Repeat Steps 2-4.

2-8. RASTER CENTER ADJUSTMENT

Preparation:

• Input a monoscope signal.

• Set to NTSC (DRC) mode.

1. Set to Service Mode and adjust as follows:

NO.

Name Control Function Avg. Data

06 AGNG AGING 1, AGING 2 2

NO.

Name Control Function Avg. Data

02 HSIZ Horiz Size Adjust

NO.

Name Control Function Avg. Data

00 HBLK Blanking Enable 0

CXA2150P-2

CXA2150D-2

CXA2150D-3

2. Reduce HSIZ to see sides of raster.

3. Adjust H-Center with CXA2150D-2 00.

4. Adjust to the best screen position with H-CENT and write data.

5. Restore aging, HSIZ and HBLK to original condition.

2-9. PICTURE DISTORTION ADJUSTMENTS

2-9.1. NTSC (DRC) FULL MODE

ADJUSTMENT

1. Face the picture tube in an east-west direction.

2. Complete V-PIN and V-CEN adjsuments fi rst (A2150-D1 05 V-PIN,

A2150-D1 04 V-CEN).

3. Input a monoscope and crosshatch signal. Adjust the picture

distortion with the following service parameters to balance the best

condition for these two signals.

A2150-D1 00 VPOS

A2150-D1 01 VSIZ

A2150-D1 02 VLIN

A2150-D1 03 VSCO

A2150-D1 04 VCEN

A2150-D1 05 VPIN

A2150-D1 07 HTPZ

A2150-D2 01 HPOS

A2150-D2 02 HSIZ

A2150-D2 03 SLIN

A2150-D2 04 MPIN

A2150-D2 06 UCP

A2150-D2 07 LCP

A2150-D2 13 PPHA

A2150-D2 14 VANG

A2150-D2 15 LANG

A2150-D2 16 VBOW

A2150-D2 17 LBOW

Note: Make sure that the picture size is within specs. Vertical size is

11.7 ± 0.1 sq. and horizontal size is 15.6 ± 0.1 sq.

4. Write data into memory and then set the screen to 1080i mode.

— 17 —

KV-42DRC700

CXA2150D-1

0. VPOS (V-POSITION)

1. VSIZ (V-SIZE)

2. VLIN (V-LINE)

3. VSCO (VS-COR)

7. HTPZ (H-TRAPEZOID)

CXA2150D-2

1. HPOS (H-POSITION)

2. HSIZ (H-SIZE)

5. PIN (PIN AMP)

6. UCP (UP COR PIN COR)

7. LCP (LOW CO PIN COR)

13. PPHA (PIN PHASE)

14. VANG (AFC-ANGLE)

15. LANG (L-ANGLE)

16. VBOW (AFC-BOW)

17. LBOW (L-BOW)

2-9.2. 1080i HD MODE ADJUSTMENT

1. Input a 1080i cross-hatch signal and an HD monoscope signal that

contains overscan markers.

2. Adjust the raster position per Section 2-8., only if this procedure was

not performed for full mode.

3. Adjust the geometry similar to Full DRC mode. Vertical size is 11.7

± 0.1 sq. and horizontal size is 15.6 ± 0.1 sq., if monoscope signal is

available. Otherwise, set the Vertical size to 91.0 ± 0.6% scan and

Horizontal size as 91.0 ± 0.6% scan.

4. Use the following register to adjust the horizontal parameter:

A

2150-D2 01 HPOS

Note: If necessary, touch up the geometry using the data register

listed above for Full mode.

5. Write the data into memory.

2-9.3. VERTICAL COMPRESSED MODE

CHECK AND CONFIRMATION

1. Input a monoscope and crosshatch signal.

2. Check vertical compressed mode.

— 18 —

KV-42DRC700

SECTION 3: SAFETY RELATED ADJUSTMENTS

3-2. B+ MAX CONFIRMATION

Standard............................................................................ 135.3 ± 1 VDC

Check Condition:

AC input voltage: 120 (± 2) VAC at Board Adjustment Process

130 (± 2) VAC at QC

120 (± 2) VAC at Overall Adjustment (after aging)

Note: If using a stabilized power supply, make sure that the distortion

factor is 3% or less.

Setting Mode:........................................................................... Full mode

Signal Input:................................................ Cross-hatch of NTSC at QC

Initial Setting:........................................................ Reset condition at QC

Confi rm Point:.......................................Across C6544 for B+ of D Board

3-1. X RV8001, RV8002 CONFIRMATION METHOD AND HV SERVICE ADJUSTMENTS

3-3. HV SERVICE FLOWCHART

Is T8001

Changed?

Is D-Board

Replaced?

Replace RV8001, RV8002 with the same value:

HV project adjust and inspection

1. Turn RV8001 fully counter-clockwise.

2. Turn set on with black video signal then adjust RV8002 slowly to obtain

35.5kV.

3. Turn RV8001 clockwise slowly until hold down operation initially activates.

4. Adjust RV8002 clockwise, then turn the set on. Change video to white field then

slowly turn RV8002 counter-clockwise to get 34.8 ± 0.2kV. Confirm set does

NOT TURN OFF at this condition. If yes, then repeat from step 1 again.

5. Finally, set back RV8002 to 31.50kv + 0.2kv at video cut off (black video).

Start

No

Ye s

Change any

or

marked parts

Ye s

No

Ye s

No

Start from

the beginning.

Ye s

Is +B, Vd and

hold down

confirmed?

Finish for

hold-down

check.

Confirm +B, Vd and check hold-down on the D Board video with no signal (standard

reset mode) as follows:

1. Confirm +B across C6544 to make sure that it is 135.3 ± 1 Vdc.

2. Confirm Vd at Pin 2 CN5506 or at TP-Vd for 4.3V

<

Vd

<

4.65 Vdc.

3. Apply 5.5 ± 0.5 Vdc at Pin 2 of CN5506, then confirm that set holds down.

If all adjustments are complete, then seal and secure RV8001, RV8002 with

epoxy to prevent any possible misadjustment by non-trained technical

service.

— 19 —

KV-42DRC700

4-1. SETTING THE SERVICE ADJUSTMENT

MODE

1. Standby mode (Power off).

2. Press the following buttons on the Remote Commander within one

second of each other:

DISPLAY

Channel

5

Sound Volume

+

Power

SERVICE ADJUSTMENT MODE VIEW

2150P-1 0 +7 SERVICE

SBOT TV

Device Item Data Item

Register

Item

F/A FLAG:

CBA FLAG:

WSL: 0

READING THE MEMORY

1. Enter into Service Mode.

2. Press

0

on the Remote Commander.

3. Press

ENTER

to read memory.

ADJUSTING THE PICTURE

1. Enter into Service Mode

2. Press

2

or

5

on the remote to select the device item.

3. Press

1

or

4

on the remote to select an item.

4. Press

3

or

6

on the remote to change the data.

5. Press

MUTING

then

ENTER

to write into memory.

4-1.1. RESETTING THE DATA

Note: Be careful when using the remote! It will clear and re-initialize

ALL NVM data including defl ection adjustment data if not reset

properly as follows:

RESETTING THE DEFLECTION NVM DATA

1. Enter into Service Mode.

2. Press

7

, then

MENU

, and then press

ENTER

on the remote.

RESETTING THE SYSTEM NVM DATA

1. Enter into Service Mode.

2. Press

7

, then

9

, and then press

ENTER

on the remote.

RESETTING THE SYSTEM NVM DATA

1. Enter into Service Mode.

2. Press

8

and then press

ENTER

on the remote.

4-2. MEMORY WRITE CONFIRMATION

METHOD

1. After adjustment, pull out the plug from the AC outlet, then replace the

plug in the AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confi rm they were adjusted.

4-3. REMOTE ADJUSTMENT BUTTONS AND

INDICATORS

SECTION 4: CIRCUIT ADJUSTMENTS

ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER

Use the Remote Commander (RM-Y184) to perform the circuit adjustments in this section.

Test Equipment Required: 1. Pattern generator 2. Frequency counter 3. Digital multimeter 4. Audio oscillator

RM-Y184

WRITE

INTO MEMORY

ITEM UP

ITEM DOWN

TEST

RESET

DEVICE UP

DATA UP

DATA DOWN

DEVICE DOWN

EXECUTE

READ

MEMOR

Y

— 20 —

KV-42DRC700

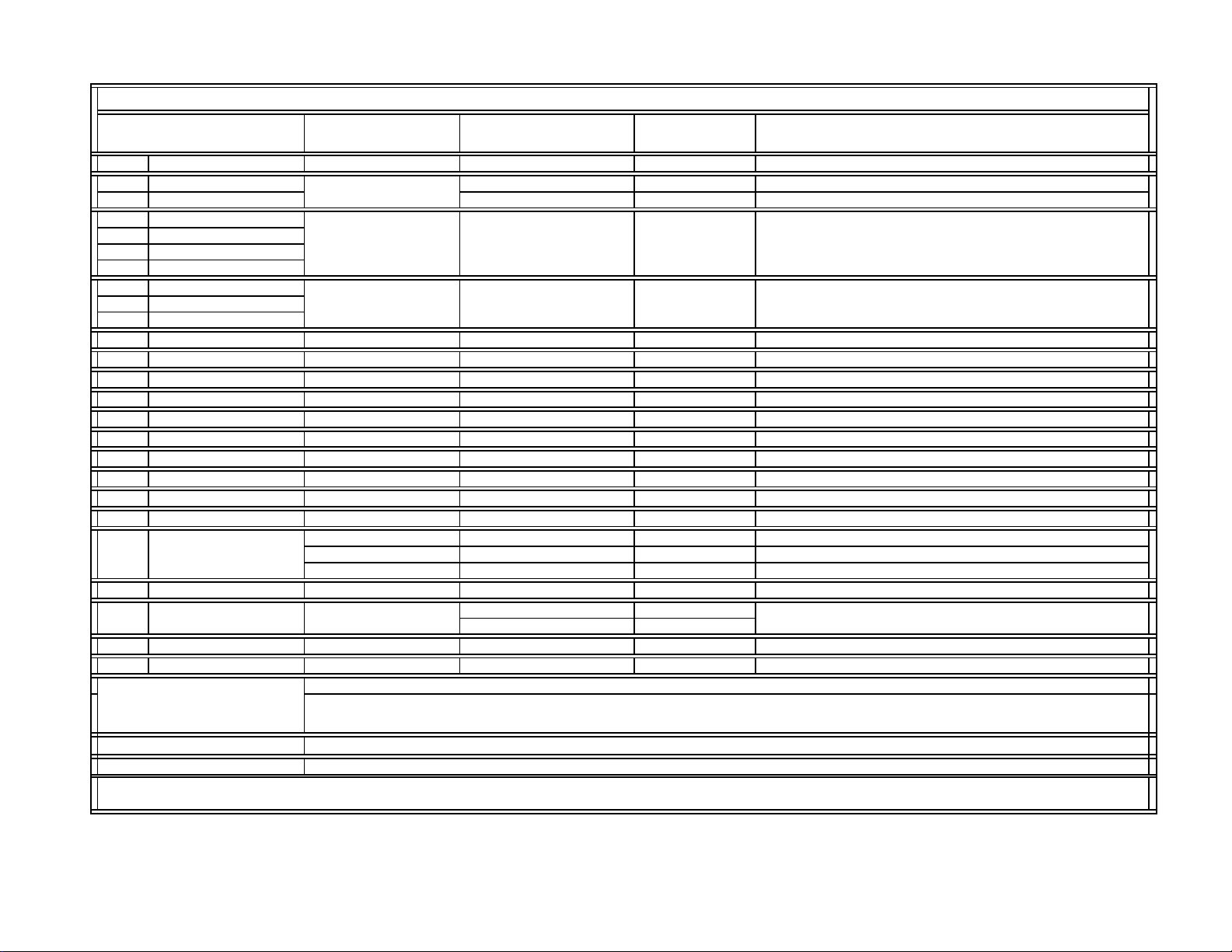

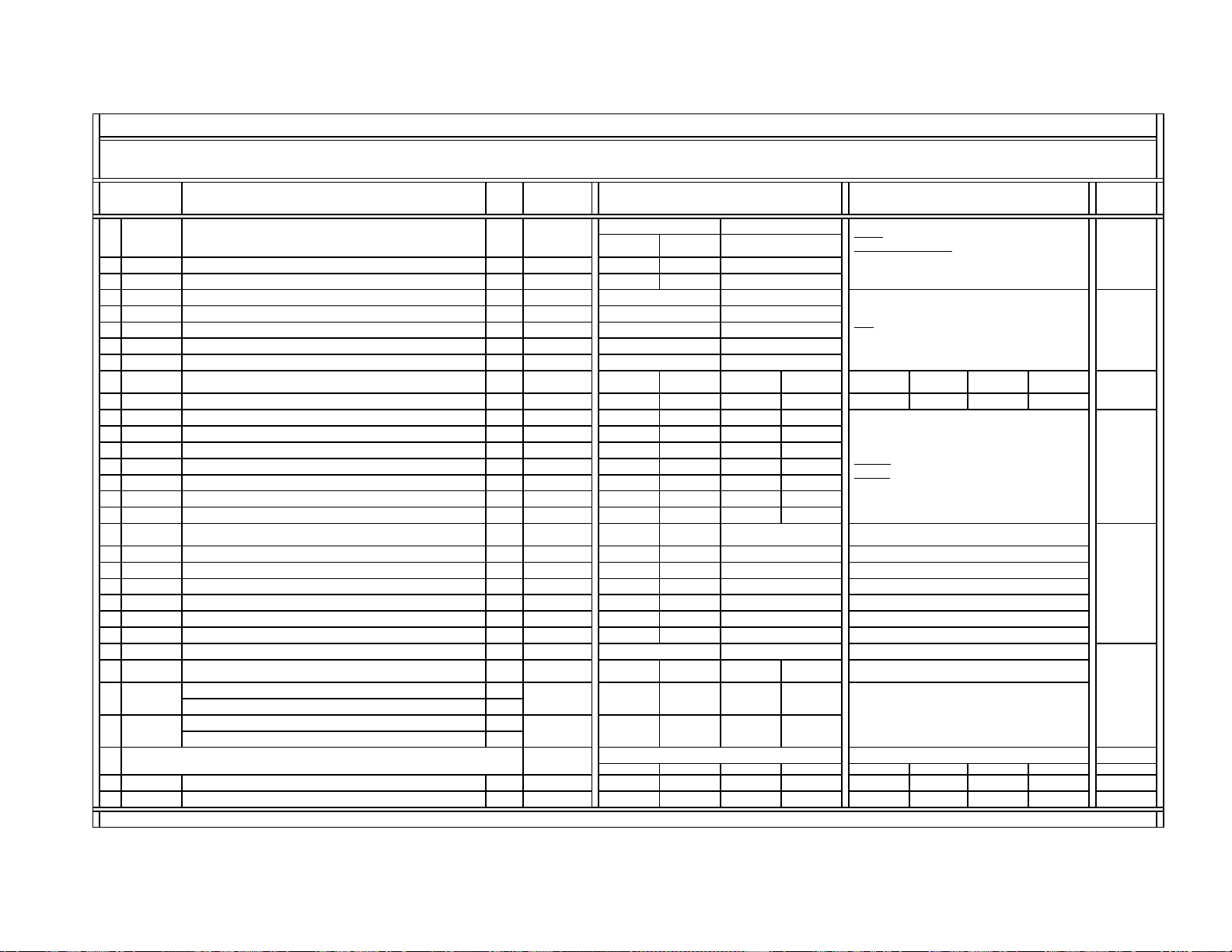

4-4. SERVICE DATA LISTS

Device Name

Device Reference

Number

Slave Address Comment

# 1 3D-COMB µPD64082 IC3501 / BC-board B8h (W) & B9h (R) W&R: Write & Read

# 2-1 CXA2103-1 (Main) IC3048 (Main) / B-board 9Ah

# 2-2 CXA2103-2 (Sub) IC3110 (Sub) / B-board 9Eh

# 3-1 CXA2150P-1

# 3-2 CXA2150P-2

# 3-3 CXA2150P-3

# 3-4 CXA2150P-4

# 4-1 CXA2150D-1

# 4-2 CXA2150D-2

# 4-3 CXA2150D-3

# 5 CXA2151 CXA2151Q IC3001 / B-board 84h

# 6 D-CON

V

CXA8070P IC5513 / D-board DEh

# 7 CXA2026 CXA2026AS IC5511 / D-board 8Eh

# 8 AP

BH3868FS

IC7001 / A-board 82h

# 9 TRUS NJM2180M IC4101 / S-board 2Eh

Controlled through CXA1315M ( IC4103 / S-board / 48h )

# 10 MID1 CXD9509AQ IC3408 / B-board 2Eh

Controlled through MID-XA Micro ( IC3090 / B-board / 64h )

# 11 MID2 CXD9509AQ IC3408 / B-board 2Eh

Controlled through MID-XA Micro ( IC3090 / B-board / 64h )

# 12 MID3 CXD9509AQ IC3408 / B-board 2Eh

Controlled through MID-XA Micro ( IC3090 / B-board / 64h )

# 13 MID5 CXD9509AQ IC3408 / B-board 2Eh

Controlled through MID-XA Micro ( IC3090 / B-board / 64h )

# 14

OSD

M306V2ME-153FP IC701 / A-board 60h DX1A-2001 S

y

stem Micro

{

V1.0

}

µPD64082 IC3501 / BC-board B8h (W) & B9h (R)

CXA2103Q IC3048 (Main) / B-board 9Ah

CXA2150Q IC201 / A-board 86h

# 16 ID1 CXD2085M IC3603 / B-board 40h

IC3602 (Main) / B-board

68h (Main)

IC3601 (Sub) / B-board

6Ch (Sub)

# 18

OP

M306V2ME-153FP IC701 / A-board 60h DX1A-2001 S

y

stem Micro

{

V1.0

}

# 19

ID

M306V2ME-153FP IC701 / A-board 60h DX1A-2001 S

y

stem Micro

{

V1.0

}

86hCXA2150Q

IC201 / A-board

IC201 / A-board

CXP85840A-039Q

SNNR

CXA2103Q

CXA2150Q 86h

DX1A-2001* Service List ------ Contents & Notes

Category Number & Name

# 15

# 17

CCD&VCHIP

CCD&Vchip Micro (V2.14)

DX1A-2001 CCD&Vchip Micro

s

MB94918RPF-G-137-BND (MASK), Software Version 12/08/00, IC3090/B-board (Slave Address: 64h)

CXP85840A-039Q (MASK), Software Version 2.14, IC3602/B-board (Main/Slave Address: 68h) & IC3601/B-board (Sub/Slave Address:

Note:

* This service list is used for DX1A-2001 ONLY. Some service data is the same in DX1A-2001 & 2000, as noted in the data sheets.

DX1A-2001 System Micro &

Notes for Services

DX1A-2001 MID-XA Micro

M306V2ME-153FP (MASK), Software Version 1.0, IC701/A-board (Slave Adress: 60h)

The system micro name, software&patch versions, and the status of NVM devices are displayed only when in the service catergory

(#19): ID.

— 21 —

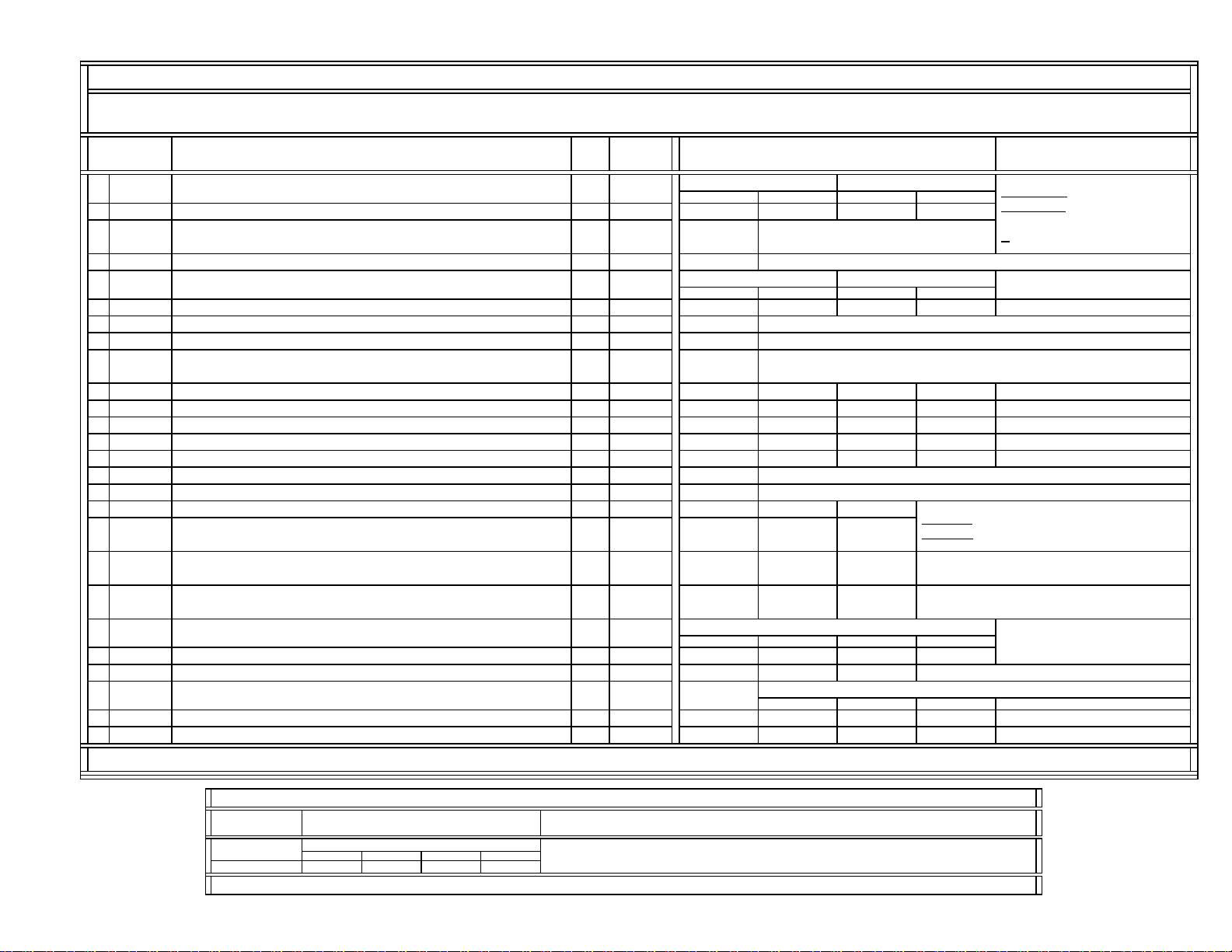

KV-42DRC700

SERVICE DATA LISTS

Control Register

Function & Link

Data

Type

Data

Range

Comment

Standard

Non-standard

Standard Non-standard

0

NRMD

O

p

eration mode settin

g

0~30133

1

YAPS

Y-output correction

(

V-a

p

erture com

p

ensation & Y-

p

eakin

g

filterin

g)

C 0~3 3

2

CLKS

S

y

stem clock settin

g

C 0~3 1

Standard

Non-standard

Standard Non-standard

3

NSDS

Selection for standard/non-standard si

g

nal

p

rocessin

g

0~30000

4

MSS

Selection for inter-frame/inter-line

p

rocessin

g

C 0~3 0

5

KILS

Killer

p

rocessin

g

selection C 0~3 1

6

CDL

C-signal phase with respect to the Y-signal

(

Fine ad

j

ustment at 70 ns/ste

p)

C 0~7 3

NRMD Setting-based Control Table for DYCO, DYGA, DCCO, DCGA NRMD = 0 NRMD = 1 NRMD = 2 NRMD = 3

7

DYCO

DY detection corin

g

level

(

Y motion detection corin

g)

0~15 2222

8

DYG

A

DY detection

g

ain

(

Y motion detection

g

ain

)

0~15 10 10 10 10

9

DCCO

DC detection corin

g

level

(

C motion detection corin

g)

0~15 5555

10

DCG

A

DC detection

g

ain

(

C motion detection

g

ain

)

0~15 5555

11

Y

NRL

Frame recersive YNR nonlinear filter limit level C 0~3 1

12

CNRL

Frame recersive CNR nonlinear filter limit level C 0~3 1

UHF/VHF Video1~4 Video5&6

13

VTRH

Hysteresis for Hsync non-standard signal detection

(

out-of-Hs

y

nc intra-field

)

0~3 1 1 1

14

VTRR

Sensitivity for Hsync non-standard signal detection

(

out-of-Hs

y

nc intra-field

)

0~3 1 1 1

15

LDSR

Sensitivity for frame non-standard signal detection

(

out-of-Hs

y

nc inter-frame

)

0~3 2 2 2

VM = Off VM = Low VM = Mid VM = High

16

VAPG

V-a

p

erture com

p

ensation

g

ain 0~70234

17

VAPI

V-a

p

erture com

p

ensation conver

g

ence

p

oint 0~31 4 4 4

SNNR = 0 SNNR = 1 SNNR = 2 SNNR = 3

18

Y

PFT

Y

p

eakin

g

filter

(

BPF

)

center fre

q

uenc

y

0~30000 0

19

Y

PFG

Y

p

eakin

g

filter

(

BPF

)

g

ain 0~15 7012 3

Note: The same 3D-COMB service data is used for DX1A-2001&2000.

SVideoUHF/VHF & CVideo

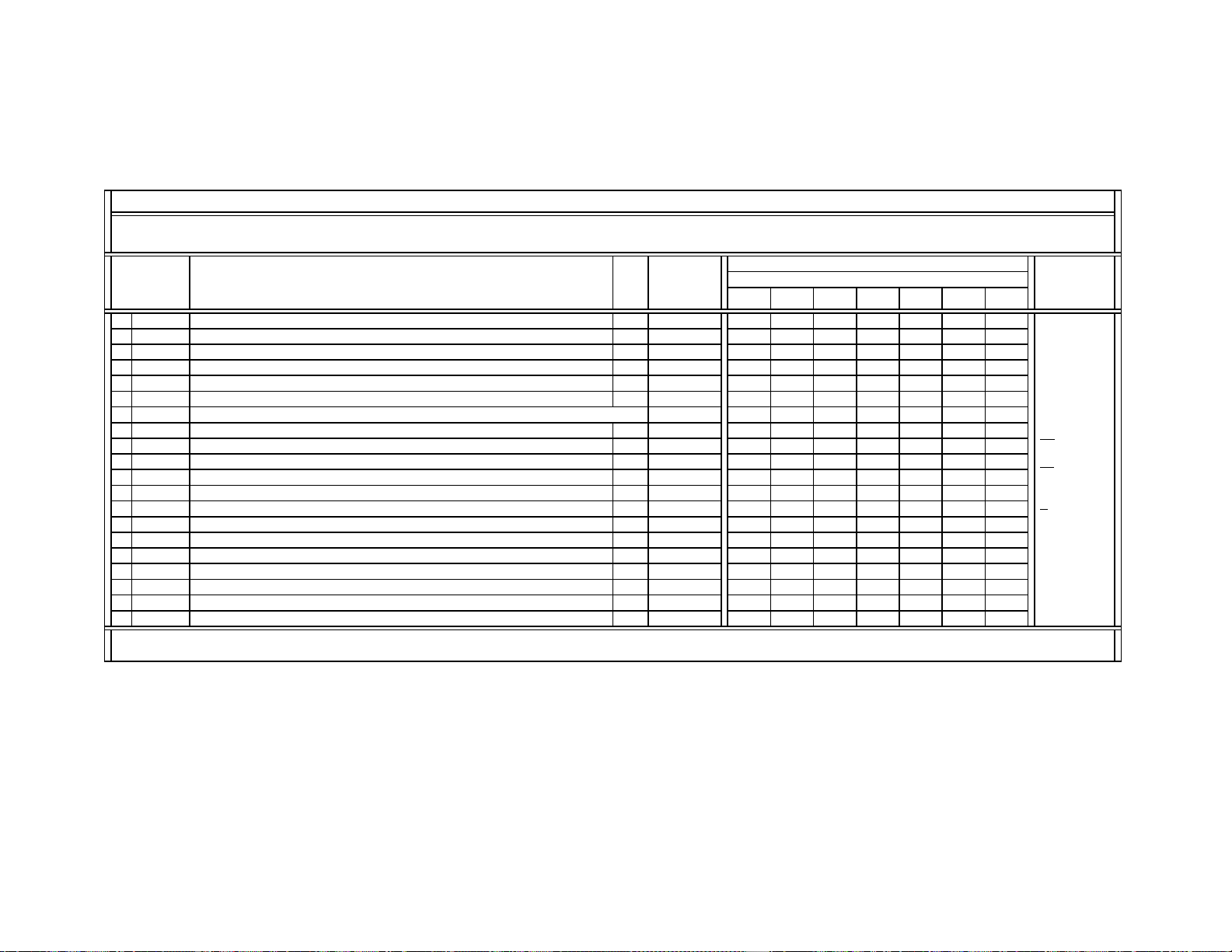

DX1A-2001&2000 SERVICE LIST (#1): 3D-COMB / mPD64082 (Part-1/4)

VAPG1 Data Based on MENU/VM Setting

Device Name: mPD64082GF { 3D-Comb Filter / NEC } / IC3501 (BC-board) / P/N: 8-759-594-44 (SB#: V7372)

Slave Address: B8h (Write Address) / B9h (Read Address)

CVideo (CV): CVideo1~4 inputs

SVideo (SV)

: SVideo1~3 inputs

C

: Common data

Video1~4

: CVideo1~4 & SVideo1~3 inputs

Video5&6

: YPbPr-480i/480p/1080i inputs

Data Initial/Average Setting

(32V&36V CRTs)

Register

No & Name

SVideoUHF/VHF & CVideo

This setting continues to

the next page.

SNNR Setting-based Control Table for YPFT & YHFG

SNNR Setting (-Offset)

8

VM&SNNR Setting-based Control Table for VAPG & VAPI

VAPG= VAPG1 - VAPG2

Register

No & Name

SNNR = 0 SNNR = 1 SNNR = 2 SNNR = 3

#16 VAPG

(

cont.

)

0000

Data Initial/Average Setting

(32V&36V CRTs)

Comment

DX1A-2001&2000 SERVICE LIST (#1): 3D-COMB / mPD64082 (Part-2/4)

Note: The same 3D-COMB service data is used for DX1A-2001&2000.

VAPG2 Data Based on SNNR/Offset-setting

— 22 —

KV-42DRC700

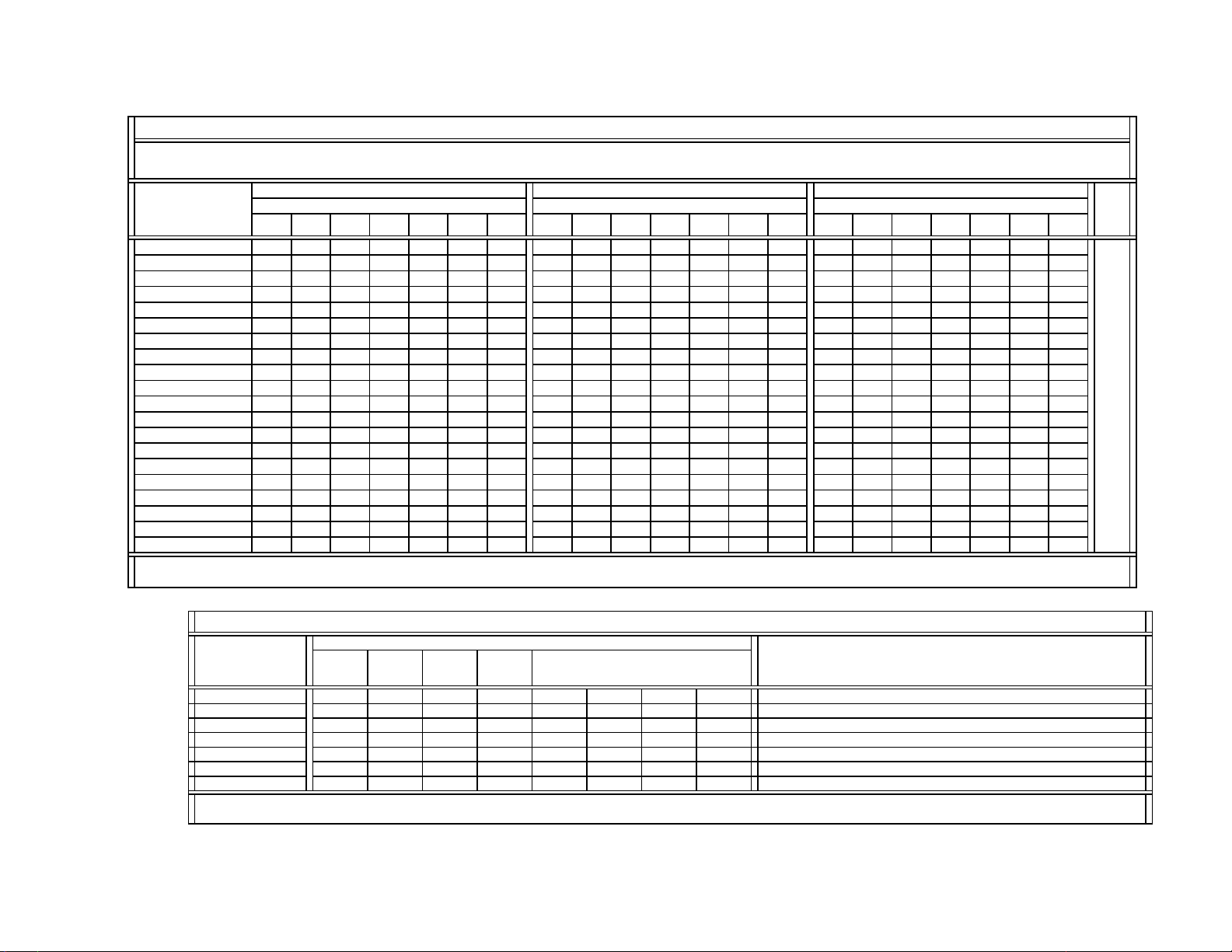

SERVICE DATA LISTS

Control Register

Function & Link

Data

Type

Data

Range

Comment

SNNR Setting-based Control Table for YHCO & YHCG SNNR = 0 SNNR = 1 SNNR = 2 SNNR = 3

(Not SNNR Offset Dat

a

20

YHCO

Y output high frequency component coring 0~3 1 1 1 1

21

YHCG

Y output high frequency component coring gain 0, 1 0 0 0 0

22

HSSL

Hsync slice level C 0~15 12

23

VSSL

Vsync slice level C 0~15 8

24

ADCL

ADC clock delay C 0~3 3

NRMD Setting-based Control Table for D2GA NRMD = 0 NRMD = 1 NRMD = 2 NRMD = 3

25

D2GA

Moving detection gain 0~7 4 4 4 4

26

KILR

Killer detection reference C 0~15 3

27

OP1

Option1:

Selection of comb filter & recursive noise reduction t

yp

es

C 0, 1 1

UHF/VHF CVideo1 SVideo1

28

NR1

Noise reduction on/off 0, 1 0 0 1

29

NR2

SNNR control on/off C 0, 1 0

30

WSL

Noise level detection data 0~255

31

HPLL H-PLL filter

(

Must be set to 1 when MN si

g

nal is input.

)

C

0, 1 1

32

BPLL

Burst PLL filter

C

0, 1 1

33

FSCF

Burst extraction gain

C

0, 1 0

34

PLLF

PLL loop gain

C

0, 1 1

UHF/VHF Video1~4 Video5&6

35

CC3N

Selection of a line-comb filter C separation filter characteristic 0, 1 0 0 0

36

HDP

Fine adjustment of the system H-phase C 0~7 5

37

BGPS

Internal burst gate start position

{Gate Start Position from Hsync center = 0.25 x BGPS +

2

(

ms

)}

C 0~15 4

38

BGPW

Internal burst gate width

{

Gate Width = 0.25 x BGPW + 0.5

(

ms

)}

C 0~15 10

39

TEST

Test bit {0: Normal mode, 1: Test mode (forbidden settin

g

C 0, 1 0

40

WSC

Amount of noise detection coring C 0~3 1

Video5&6

41

LIND

DRC-M line-doubling setting for non-standard signals

Micro

0~63 2

42

PFGO

(YPFG offset at GR on) --- Not used for DX1A --- 0~7 3

Register

No. & Name

Data Initial/Average Setting

(32V&36V CRTs)

C: Common data

1 Byte Data from Read Register WSL

This setting is used for non-standard

signals

such as Play Station signals.

Note: The same 3D-COMB service data is used for DX1A-2001&2000.

(Not used for DX1A)

UHF/VHF & Video1~4

0

YHCO&YHCG

settings are sent

directl

y

to 3D-Comb

DX1A-2001&2000 SERVICE LIST (#1): 3D-COMB / mPD64082 (Part-3/4)

This setting continues to

the next page.

Video1~4

: CVideo1~4 & SVideo1~3

inputs

Video5&6

: YPbPr-480i/480p/1080i

Register

No & Name

CVideo2 SVideo2 CVideo3 SVideo3

#28 NR1

(

cont.

)

0101

Comment

DX1A-2001&2000 SERVICE LIST (#1): 3D-COMB / mPD64082 (Part-4/4)

Note: The same 3D-COMB service data is used for DX1A-2001&2000.

Data Initial/Average Setting

(32V&36V CRTs)

— 23 —

KV-42DRC700

SERVICE DATA LISTS

Control Register

Function & Link

Data

Type

Data

Range

Note

P&P-Left

(M)-DRC

P&P-Left

(M)-1080i

P&P-Left

(M)-DRC

P&P-Left

(M)-480i

0

Y

LEV

Y-Out

g

ain 0~63 23 27* 35 31*

1

CLEV

Cb&Cr-Out

g

ains 0~63 20 55* 37 31*

2

SCON

Sub contrast

Adj.

0~15

3

SCOL

Sub color

Adj.

0~15

4

SHUE

Sub hue Ad

j

. 0~15

5

Y

DL

Y

Y/C dela

y

time 0~3

SNNR Data-related Settings UHF/VHF CVideo SVideo

Y

PbPr

480i

SNNR=0

(

-offset

)

SNNR=1

(

-offset

)

SNNR=2

(-offset)

SNNR=3

(

-offset

)

6

SHAP

Shar

p

ness 0~15 6444 0123

7

SHF0

Shar

p

ness f0 selector 0~3 0000

8

PREO

Shar

p

ness

p

re/over-shoot ratio 0~3 3000

9

BPF0

Chroma band filter f0 settin

g

0~3 3000

10

BPFQ

Chroma band filter Q settin

g

0~3 0333

11

BPSW

Chroma band filter on/off 0, 1 1000

12

TRAP

Y bolck chroma tra

p

filter on/off 0, 1 0000

13

LPF

YPbPr-Out

p

ut LPF on/off 0, 1 0000

UHF/VHF Video

Y

PbPr

480i

14

AFCG AFC Loo

p

Gain

(

PLL between Hs

y

nc & HVCO

)

0, 1 1 0 0

15

CDMD

V countdown s

y

stem mode selector 0~3 3 3 3

16

SSMD

H&Vs

y

nc slide level settin

g

0~3 0 0 0

17

HMSK

Maskin

g

of macrovision si

g

nal on/off 0, 1 1 1 1

18

HALI

H automatic ad

j

ustment on/off 0, 1 0 0 0

19

PPH

A

H TIM

p

hase ad

j

ustment for video 0~15 7 7 7

P&P-Left

(M)-DRC

P&P-Left

(M)-1080i

P&P-Left

(M)-DRC

P&P-Left

(M)-480i

Cb-Offset1 of Cb IN (Pin34)

Cb-Offset2 of EXT Cb (Pin38)

Cr-Offset1 of Cr IN (Pin35)

Cr-Offset2 of EXT Cr (Pin39)

Single

UBLK = 0 UBLK = 1 UBLK = 2 UBLK = 3 UBLK = 4 UBLK = 5 UBLK = 6 UBLK = 7 UBLK = 0~7

22

ATPD

Auto-

p

edestal Inflection Point 0~3 0

123

1232 0

23

DCTR

DC Transmission Ratio 0~3 0

111

2223 0

Adj.: Adjusted data

[Adj.-2steps]: The adjusted data - 2 steps

CVideo

: CVideo1~4 Inputs

SVideo

: SVideo1~3 Inputs

*: Settings not used

(31): The center setting = 31

UHF/VHF

7 [7]

31*31 31* 31

CXA2150P-4/#13 UBLK Setting-related Controls for ATPD & DCTR

31*

7 [7]

Data Initial/Average Setting

(32V&36V CRTs)

Video: CVideo1~4 & SVideo1~3 Inputs

P&P-Left (M)-1080i&480i

: If P&P-Left is

1080i/480p signal, the signal from the main

chroma decoder is sent to MID/VDO input.

*: Settings not used

31*0~(31)~63

YPbPr-480i

UHF/VHF & Video

8 [Adj.-2steps]

UHF/VHF & Video

0

Video

7 [7]

7 [7]

7 [Adj.-2steps]

0

P&P & Favorite

CBOF

3131

CROF

0~(31)~63

YPbPr-480i

P&P & Favorite

Note: The same CXA2103 service data (Main&Sub) is used for DX1A-2001&2000.

20

21

Register

No & Name

Data Initial Setting & [Average Data]

(32V&36V CRTs)

DX1A-2001&2000 SERVICE LIST (#2-1):

CXA2103-1 {Main}

Device Name: CXA2103Q { NTSC-YCT (Chroma Decoder) / SONY } / IC3048 (B-board) / P/N: 8-752-089-50 (SBorSD#: NA)

Slave Address: 9Ah { Main }

— 24 —

KV-42DRC700

SERVICE DATA LISTS

Control Register

Function & Link

Data

Type

Data

Range

Note

P&P-Right

(S)

P&P-Right

(S)-DRC

0

Y

LEV

Y-Out

g

ain 0~63 23 28

1

CLEV

Cb&Cr-Out

g

ains 0~63 18 24

2

SCON

Sub contrast

Adj.

0~15

3

SCOL

Sub color

Adj.

0~15

4

SHUE

Sub hue Ad

j

. 0~15

5

Y

DL

Y

Y/C dela

y

time 0~3

SNNR Data-related Settings UHF/VHF CVideo SVideo

SNNR=0

(

-offset

)

SNNR=1

(

-offset

)

SNNR=2

(-offset)

SNNR=3

(

-offset

)

6

SHAP

Shar

p

ness 0~15 6 4 4 0 1

2

3

7

SHF0

Shar

p

ness f0 selector 0~3 0 0 0

8

PREO

Shar

p

ness

p

re/over-shoot ratio 0~3 3 0 0

9

BPF0

Chroma band filter f0 settin

g

0~3 0 0 0

10

BPFQ

Chroma band filter Q settin

g

0~3 0 0 0

11

BPSW

Chroma band filter on/off 0, 1 0 0 0

12

TRAP

Y bolck chroma tra

p

filter on/off 0, 1 0 0 0

13

LPF

YPbPr-Out

p

ut LPF on/off 0, 1 0 0 0

UHF/VHF Video

14

AFCG AFC Loo

p

Gain

0, 1 1 0

15

CDMD

V countdown s

y

stem mode selector 0~3 3 3

16

SSMD

H&Vs

y

nc slide level settin

g

0~3 0 0

17

HMSK

Maskin

g

of macrovision si

g

nal on/off 0, 1 1 1

18

HALI

H automatic ad

j

ustment on/off 0, 1 0 0

19

PPH

A

H TIM

p

hase ad

j

ustment for video 0~15 7 7

P&P-Right

(S)

P&P-Right

(S)-DRC

P&P-Right

(S)

P&P-Right

(S)-DRC

Cb-Offset1 of Cb IN

(

Pin34

)

Cb-Offset2 of EXT Cb

(

Pin38

)

Cr-Offset1 of Cr IN

(

Pin35

)

Cr-Offset2 of EXT Cr

(

Pin39

)

Single

UBLK = 0 UBLK = 1 UBLK = 2 UBLK = 3 UBLK = 4 UBLK = 5 UBLK = 6 UBLK = 7 UBLK = 0~7

22

ATPD

Auto-

p

edestal Inflection Point 0~3 0

123

12

3

20

23

DCTR

DC Transmission Ratio 0~3 0

111

22

2

30

Note: The same CXA2103 service data (Main&Sub) is used for DX1A-2001&2000.

00

7 [7] 7 [7]

UHF/VHF Video

7 [7]

Data Initial/Average Setting

(32V&36V CRTs)

Device Name: CXA2103Q { NTSC-YCT (Chroma Decoder) / SONY } / IC3110 (B-board) / P/N: 8-752-089-50 (SBorSD#: NA)

Slave Address: 9Eh { Sub }

Register

No & Name

DX1A-2001&2000 SERVICE LIST (#2-2):

CXA2103-2 {Sub}

7 [7]

31* 31*

UHF/VHF & CVideo

31*310~(31)~63

31 31

21

CROF

0~(31)~63

YPbPr-480i

31*

CBOF

UHF/VHF & Video

Data Initial Setting & [Average Data]

(32V&36V CRTs)

P&P & Favorite P&P & Favorite

20

5 [Adj.-2steps] 7 [Adj.-2steps]

Adj.: Adjusted data

[Adj.-2steps]: The adjusted data - 2 steps

*: Settings not used

(31): The center setting = 31

CVideo

: CVideo1~4 Inputs

SVideo

: SVideo1~3 Inputs

31

Video

: CVideo1~4 & SVideo1~3 Inputs

P&P-Right (S)-DRC

: If P&P-Left is 1080i/

480p signal, the signal from the sub chroma

decoder is switched to DRC path.

CXA2150P-4/#13 UBLK Setting-related Controls for ATPD & DCTR

— 25 —

KV-42DRC700

SERVICE DATA LISTS

Control Register

Function & Link

Data

Type

Data

Range

Comment

UHF

V

HF

CV SV

YPbPr

480i

YPbPr

480

p

YPbPr

1080i

P&P

0 SBOT Offset for SBRT 0~

(

7

)

~157777777

1 YOF Y_OFFSET: DC-offset for Y si

g

nal 0~

(

7

)

~150000000

2 CBOF CB_OFFSET: DC-offset for Cb si

g

nal

0~(31)~63

31 31 31 33 30 31 13

3 CROF CR_OFFSET: DC-offset for Cr si

g

nal

0~(31)~63

31 31 31 42 36 31 23

4 SBRT SUB_BRIGHT: Sub Bri

g

h

t

0~63

5 RDRV R_DRIVE: R out

p

ut drive C

0~63

6 GDRV G_DRIVE: G out

p

ut drive Ad

j

.

0~63

7 BDRV B_DRIVE: B out

p

ut drive Ad

j

.

0~63

8 RCUT R_CUTOFF: R out

p

ut cutof

f

C

0~63

9 GCUT G_CUTOFF: G out

p

ut cutof

f

Ad

j

.

0~63

10 BCUT B_CUTOFF: B out

p

ut cutof

f

Ad

j

.

0~63

Pro

11 WBSW

WB_SW: White balance offset on/off

(

Related to UTMP settin

g

s

)

0, 1

0

12 SBOF Offset for SBRT 0~

(

63

)

~127 63

13 RDOF Offset for RDRV 0~

(

63

)

~127 63

14 GDOF Offset for GDRV 0~

(

63

)

~127 63

15 BDOF Offset for BDRV 0~

(

63

)

~127 63

16 RCOF Offset for RCUT 0~

(

63

)

~127 63

17 GCOF Offset for GCUT 0~

(

63

)

~127 63

18 BCOF Offset for BCUT 0~

(

63

)

~127 63

Data Initial Settings & [Average Data]

(32V&36V CRTs)

Register

No & Name

1

(Warm)

63

MovieVivid

0

(Cool)

46

36 [36]

Device Name: CXA2150AQ { CRT Driver / SONY } / IC201 (A-board) / P/N: 8-752-093-35 (SBorSD#: NA)

Slave Address: 86h

DX1A-2001&2000 SERVICE LIST (#3-1):

CXA2150P-1 {Picture Controls: P1}

20 [20]

63

63**

63

33 [33]

66**

63

0

(Neutral)

63

Standard

63

63**

66**

41

63 60

63

63

63

11 [11]

22 [22]

73**

75**

Note:

The same CXA2150 service data is used for DX1A-2001&2000.

63

CV:

CVideo1~4

SV

:

SVideo1~3

( ): Settings at

center

Adj.

:

Adjusted data

C

:

Common data

Initial Setting

= [Avg. Data]

63

63

60

**: The color

temperature

offset data

— 26 —

KV-42DRC700

SERVICE DATA LISTS

Control Register

Function & Link

Data

Type

Data

Range

Comment

0 ALBK

PIC_ON: RGB output including AKB reference pulse on/of

f

(

Settin

g

= 0 for

p

ower on reset

)

--- G2 ad

j

ustment re

g

ister settin

g

C 0, 1 1

1 RGBS

R_ON/G_ON/B_ON: R/G/B outputs on/of

f

(

AKB reference

p

usle can not be turned on/off.

)

(

0

,

1/0

,

1/0

,

1

)

C 0~7 7

2 BLKB

BLK_BTM: RGB output bottom limit level (Black Limit)

(

AKB reference

p

usle DC-volta

g

e

)

C 0~3 3

3 LIML PLIMIT_LEV: Threshold level for excessivel

y

hi

g

h in

p

uts

(

White Limi

t

C 0~3 0

4 PABL P_ABL: DC-level in RGB out

p

ut detection for PEAK ABL C

0~15

15

5 SABL S_ABL: S_ABL

g

ain C 0~3 0

6 AGNG

AGING_W/AGING_B: AGING_W/AGING_B modes on/of

f

(

Set luminance to 80/01IRE flat-field si

g

nal.

)

C

0~3

(

0

,

1/0

,

1

)

0

7 AKBO AKBOFF: Automatic/Manual-Cutoff settin

g

C 0, 1 0

YPbPr

480i

YPbPr

480

p

YPbPr

1080i

P&P

8 SYPH SYNC_PHASE: Hs

y

nc dela

y

with res

p

ect to Video

(

100%: H-

p

eriod

)

0~3 0000

9 CLPH CLP_PHASE: Internal clam

p

p

ulse

p

hase

(

100%: H-

p

eriod

)

0~3 3333

10 CLG

A

CLP_GATE: Switch for the

g

ated internal clam

p

p

ulse with Hs

y

nc in

p

u

t

0, 1 0000

11 JAXS JAXIS: Color axis switch 0, 1

12 BLKO BLKO: Blankin

g

switch 0, 1

0

3

Video1~4:

CVideo1~4 &

SVideo1~3

Note:

The same CXA2150 service data is used for DX1A-2001&2000.

U/VHF &

Video1~4

C:

Common data

0

Data Initial/Average Settings

(32V&36V CRTs)

0

Register

No & Name

DX1A-2001&2000 SERVICE LIST (#3-2):

CXA2150P-2 {Picture Controls: P2}

Device Name: CXA2150AQ { CRT Driver / SONY } / IC201 (A-board) / P/N: 8-752-093-35 (SBorSD#: NA)

Slave Address: 86h

0

— 27 —

KV-42DRC700

SERVICE DATA LISTS

UHF

V

HF

CV SV

YPbPr

480i

YPbPr

480p

YPbPr

1080i

P&P

0 SYSM SYSTEM: Si

g

nal bandwidth settin

g

0~3 1111122

1 UVML VM_LEV: VM_OUT level

C

0~3 3

2 VMMO S

y

stem Micro

p

in#40 0, 1 0000000

3 VMCR VM_COR: VM_OUT corin

g

level 0~3 3333333

4 VMLM VM_LMT: VM_OUT limit level 0~3 3333333

5 VMF0 VM_F0: VM_f0 0~3 2222222

6

V

MDL VM_DLY: VM_OUT

p

hase

(

defined b

y

p

hase difference from R_OUT

)

0~3 3333313

7 SHOF Offset for USHP = SHOF x 4 0~3 2223302

8 SHF0 SHP_F0: Shar

p

ness circuit f0 0, 1 1111101

9 PROV PRE/OVER: Y si

g

nal

p

re/over-shoot ratio 0~3 3331303

10 F1LV SHP_F1: Shar

p

ness for hi

g

her f0

(

4.2/5.6 MHz

@

NORMAL mode

)

0~3 0333333

11 CDSP SHP_CD: Shar

p

ness in

p

art of hi

g

h color saturation 0~3 3333333

12 LTLV LTI_LEV: Luminance transient im

p

rovement

(

LTI

)

0~3 3333333

13 LTMD LTI_MODE: LTI mode settin

g

0~3 0000001

14 CTLV CTI_LEV: Chrominance transient im

p

rovement

(

CTI

)

0~3 0000020

15 CTMD CTI_MODE: CTI mode settin

g

0~3 0000000

16 UBOF Offset for UBRT

(

Picture clarit

y

ad

j

ustment

)

0~

(

7

)

~15 11 11 11 11 11 14 11

17 UCOF Offset for UCOL = UCOF x 2

(

Picture clarit

y

ad

j

ustment

)

0~3 3333303

18 UHOF Offset for UHUE

(

Picture clarit

y

ad

j

ustment

)

0~3 2222222

19 MIDE MID enhancement settin

g

0~15 333711------

Comment

Picture Mode: Vivid

Data Initial/Average Settings (32V&36V CRTs)

Device Name: CXA2150AQ { CRT Driver / SONY } / IC201 (A-board) / P/N: 8-752-093-35 (SBorSD#: NA)

Slave Address: 86h

Data

Range

Control Register

Function & Link

These settings

continue to

the next page.

CV

:

CVideo1~4

SV

:

SVideo1~3

C

:

Common data

( ): Settings at

center

Data

Type

Note:

The same CXA2150 service data are used for DX1A-2001&2000.

Register

No & Name

DX1A-2001&2000 SERVICE LIST (#3-3):

CXA2150P-3 {Picture Controls: P3} (Part-1/3)

— 28 —

KV-42DRC700

SERVICE DATA LISTS

UHF

VHF

CV SV

YPbPr

480i

YPbPr

480p

YPbPr

1080i

P&P

UHF

V

HF

CV SV

YPbPr

480i

YPbPr

480p

YPbPr

1080i

P&P

UHF

VHF

CV SV

YPbPr

480i

YPbPr

480p

YPbPr

1080i

P&P

#0 SYSM

(

cont.

)

1111122 1111122 1111122

#1 UVML

(

cont.

)

300

#2 VMMO

(

cont.

)

0000000 0000000 0000000

#3 VMCR

(

cont.

)

3333333 3333333 3333333

#4 VMLM

(

cont.

)

3333333 3333333 3333333

#5 VMF0

(

cont.

)

2222222 2222222 2222222

#6 VMDL

(

cont.

)

1333313 1111113 1111113

#7 SHOF

(

cont.

)

0333302 0333303 0111101

#8 SHF0

(

cont.

)

0111101 0000001 0000001

#9 PROV

(

cont.

)

3331303 3331303 3331303

#10 F1LV

(

cont.

)

0333333 0000003 0000003

#11 CDSP

(

cont.

)

3333333 0000000 0000000

#12 LTLV

(

cont.

)

2222223 0000000 0000000

#13 LTMD

(

cont.

)

1111111 1111001 1111001

#14 CTLV

(

cont.

)

0000020 0000000 0000000

#15 CTMD

(

cont.

)

0000000 0000000 0000000

#16 UBOF

(

cont.

)

7777777 7777777 7777777

#17 UCOF

(

cont.

)

3333303 0000000 0000000

#18 UHOF

(

cont.

)

2222222 0000000 0000000

#19 MIDE

(

cont.

)

222610------ 11159------ 00048------

See

next

page

Picture Mode: Standard

Data Initial/Average Settings (32V&36V CRTs) Data Initial/Average Settings (32V&36V CRTs)

DX1A-2001&2000 SERVICE LIST (#3-3): CXA2150P-3 {Picture Controls: P3} (Part-2/3)

Note

Note:

The same CXA2150 service data are used for DX1A-2001&2000.

Data Initial/Average Settings

(32V&36V CRTs)

Register

No & Name

Picture Mode: Movie Picture Mode: Pro

#1 UVML

(

cont.

)

0000

#3 VMCR

(

cont.

)

0 + 1 + 2 + 3

#10 F1LV

(

cont.

)

0 - 1 - 2 - 3

#11 CDSP

(

cont.

)

0000

#12 LTLV

(

cont.

)

0000

#14 CTLV

(

cont.

)

0000

#19 MIDE

(

cont.

)

0000

Register

No & Name

Note:

The same CXA2150 service data are used for DX1A-2001&2000.

Data Initial/Average Settings

(32V&36V CRTs)

Comment

SNNR=0

(Offset)

SNNR=1

(Offset)

SNNR=2

(Offset)

SNNR=3

(Offset)

DX1A-2001&2000 SERVICE LIST (#3-3): CXA2150P-3 {Picture Controls: P3} (Part-3/3)

— 29 —

KV-42DRC700

SERVICE DATA LISTS

Control Register

Function & Link

Data

Type

Data

Range

Comment

Pro

0 UPIC PICTURE: Picture

0~63

31

1 UBRT BRIGHT: Bri

g

htness

0~63

31

2 UCOL COLOR: Colo

r

0~63

31

3 UHUE HUE: Hue

0~63

31

SNNR Setting-related Controls for USHP

4 USHP SHARPNESS: Sharpness 0~63 31

5 UTMP Color Tem

p

erature

(

0: Warm, 1: Neutral, 2: Cool

)

0~2 1

6 UDCL DCOL: D

y

namic color settin

g

0~3 2

YPbPr

480i