Page 1

SERVICE MANUAL

MODEL COMMANDER DEST. CHASSIS NO.

RE-3W

CHASSIS

KP-44PS2 RM-903 AEP SCC-P38E-A

KP-44PS2U RM-903 UK SCC-P64A-A

KP-51PS2 RM-903 AEP SCC-P38D-A

TV

D

O

I

E

V

1

2

3

4

5

6

7

8

9

0

PROGR

MENU

RM

S

RM-903

903

KP-44PS2/44PS2U

KP-51PS2

∗ Please file according to model size. ...

44

51

PROJECTION TV

Page 2

KP-44PS2/44PS2U/51PS2

RM-903

SPECIFICATIONS

TV system

B/G/H, D/K, I, L

Colour system

PAL, SECAM

NTSC 3.58, 4.43 (only Video In)

Channel coverage

VHF: E2-E12

UHF: E21-E69

CATV: S1-S20

HYPER: S21-S41

D/K: R1-R12, R21-R69

I: UHF B21-B69

L: F2-F10, B-Q, F21-F69

Projected picture size

KP-44PS2/44PS2U:

44 inches (approx. 112 measured diagonally).

KP-51PS2:

51 inches (approx. 130 measured diagonally).

Rear Terminals

C

• Centre speaker input terminals (2

terminals)

• (L, R) audio outputs (phono jacks)

• i1/ 21-pin Euro connector (CENELEC

standard)

including audio/video input, RGB

input,

TV audio/video output.

• i2/r 2 21-pin Euro connector (CENELEC

(SMARTLINK)

• i3/r 3 21-pin Euro connector (CENELEC

Front Terminals

r 4 S video input - 4 pin DIN

t 4 video input - phono jack

4 audio inputs - phono jacks

Headphones jack - minijack stereo

standard) including audio/video

input, S video input,

selectable audio/video output and

Smartlink interface.

standard)

including audio/video input, S video

input,

audio/video output (monitor out).

Sound output

2 x 30 W (music power)

2 x 15 W (RMS)

Centre SP input

30 W (RMS) (using as the centre speaker)

Power consumption

225 W

Standby Power consumption

< 0.7 W

Dimensions (w x h x d)

KP-44PS2/44PS2U: Approx. 1100 x 1161 x 543 mm

KP-51PS2: Approx. 1256 x 1264 x 633 mm

Weight

KP-44PS2/44PS2U: Approx. 87 kg

KP-51PS2: Approx. 97 kg

Accessories supplied

1 Remote Control (RM-903)

2 Batteries (IEC designated)

Other features

DRC 100 Hz picture

Digital Comb filter (High resolution)

TELETEXT, Fastext, TOPtext (2000 page TEXT memory)

NexTView

NICAM

Sleep Timer

Smartlink

Digital Noise detection

Graphic Equaliser

Personal ID

Auto Format

Design and specifications are subject to change without notice.

CAUTION

SHORT CIRCUIT THE ANODE OF HTE PICTURE TUBE

AND THE ANODE CAP TO THE METAL CHASSIS, CRT

SHIELD, OR CARBON PAINTED ON THE CRT, AFTER

REMOVING THE ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

! ON THE SCHEMATIC DIAGRAMS, EXPLODED

VIEWS AND IN THE PARTS LIST ARE CRITICAL TO

SAFE OPERATION. REPLACE THESE COMPONENTS

WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –– 2 –

Page 3

TABLE OF CONTENTS

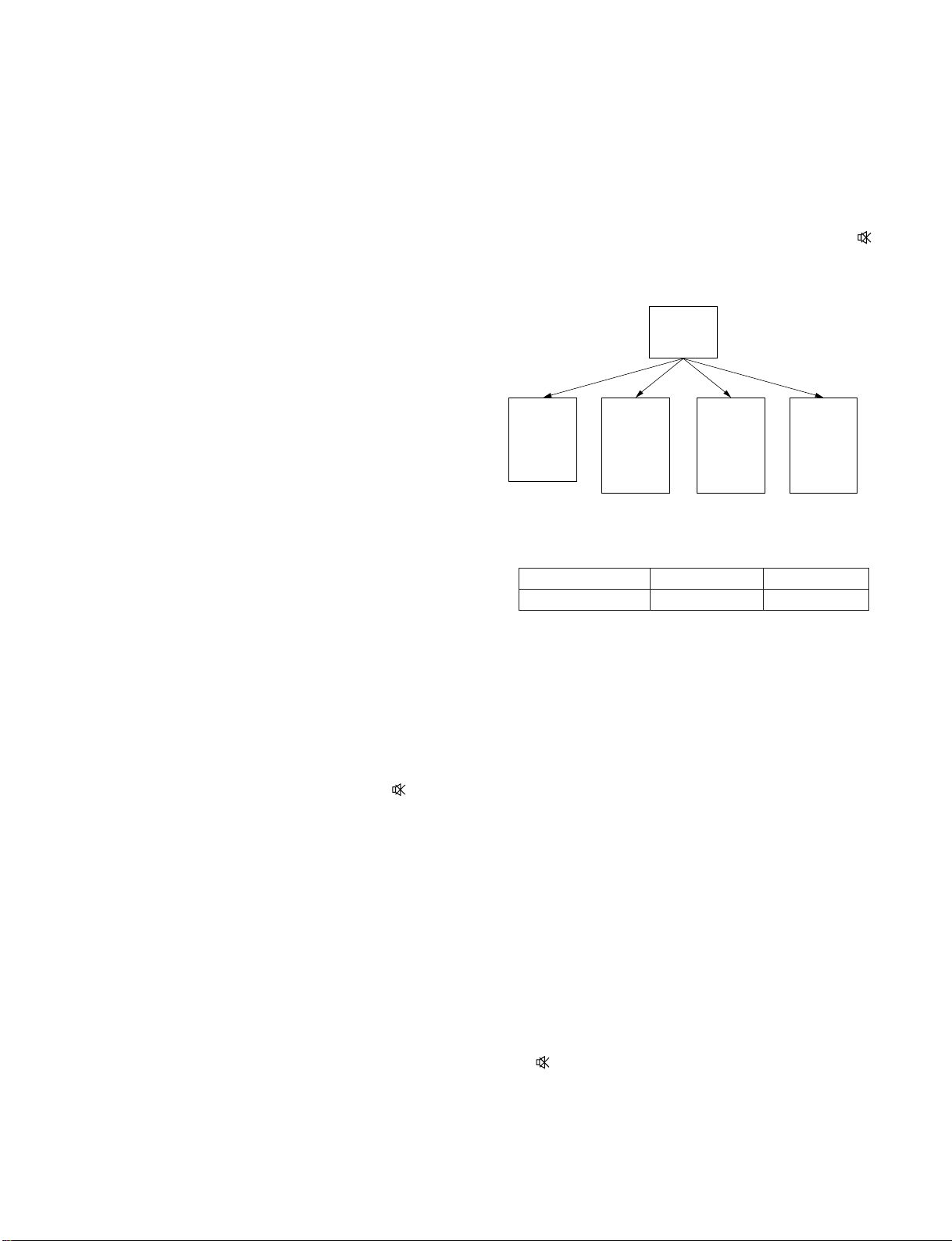

1. SELF DIAGNOSIS FUNCTION

1-1. RE-3W Self Diagnostic Software ...................... 4

1-2. Error Detection Monitor..................................... 5

1-2-1. Error Monitor Menu....................................... 5

1-2-2. Error Reader Display ..................................... 6

2. GENERAL ................................................................. 7

3. DISASSEMBLY

3-1. Rear Board Removal ......................................... 21

3-2. Main Bracket Block Removal ........................... 21

3-3. Service Position ................................................. 21

3-4. Control Panel Block Removal .......................... 22

3-5. Resistor Assembly (Focus Pack) Removal ....... 22

3-6. HB, HA and Control Panel Block Removal ...... 23

3-7. Beznet Block Removal ...................................... 23

3-8. Chassis Block Removal...................................... 24

3-9. Terminal Board Removal ................................... 25

3-10. AP and D Boards Removal ................................ 25

3-11. G Board Removal ............................................... 26

3-12. J, B3, E, M and S Boards Removal ................... 26

3-13. A Board Removal ............................................... 27

3-14. High-Voltage Cable Removal and Installation.. 27

3-15. Picture Tube Removal ........................................ 27

4. SET-UP ADJUSTMENTS

4-1. Screen Voltage Adjustment

(Rough Alignment) ........................................... 28

4-2. Screen (G2) Adjustment .................................... 28

4-3. Focus Rough Adjustment .................................. 28

4-4. Deflection Yoke Tilt Adjustment ...................... 28

4-5. 2-Pole Magnet Adjustment ................................ 29

4-6. 4-Pole Magnet Adjustment ................................ 29

4-7. Green, Red and Blue Focus Adjustment............ 29

4-7-1. Green, Red and Blue Lens Focus

Adjustment .................................................... 29

4-7-2. Green, Red and Blue Electrical Focus

Adjustment .................................................... 29

5. SAFETY RELATED ADJUSTMENT

5-1. HV Hold-Down Adjustment ............................. 30

6. ELECTRICAL ADJUSTMENTS

6-1. Adjustments with Commander .......................... 31

6-1-1. How to Select Each Mode ............................. 31

6-1-2. How to Enter TT Mode .................................. 31

6-1-3. How to Enter Service Menu .......................... 31

6-1-4. Screen Display for Service Menu .................. 32

6-1-5. Service List (Projector Engine) ..................... 37

6-2. Registration Adjustment .................................... 39

KP-44PS2/44PS2U/51PS2

RM-903

Section Title PageSection Title Page

6-2-1. Setup for Adjustment ..................................... 39

6-2-2. Main Deflection Adjustment ......................... 39

6-2-3. Operation Method for

Projector Engine Mode .................................. 40

6-2-4. Projector Engine Adjustment

(Sub Deflection Adjustment)......................... 41

6-3. Auto Convergence Offset................................... 44

6-4. Picture Center Adjustment ................................. 44

6-5. White Balance Adjustment ................................ 44

6-6. Sub Bright Adjustment....................................... 45

6-7. Sub Color Adjustment........................................ 45

6-8. Auto Convergence Error Code List ................... 46

6-9. Test-Test Mode................................................... 47

7. DIAGRAMS

7-1. Block Diagrams .................................................. 49

7-2. Frame Schematic Diagram................................. 75

7-3. Circuit Boards Location ..................................... 78

7-4. Schematic Diagrams and Printed Wiring

Boards ................................................................. 79

(1) Schematic Diagram of J (1/2) Board ................. 80

(2) Schematic Diagram of J (2/2) Board ................ 83

(3) Schematic Diagram of A Board ........................ 91

(4) Schematic Diagram of B3 (1/5) Board .............. 94

(5) Schematic Diagram of B3 (2/5) Board .............. 97

(6) Schematic Diagram of B3 (3/5) Board .............. 100

(7) Schematic Diagram of B3 (4/5) Board .............. 103

(8) Schematic Diagram of B3 (5/5) Board .............. 107

(9) Schematic Diagram of HA and HB Boards ....... 109

(10) Schematic Diagram of E Board ......................... 113

(11) Schematic Diagram of AP Board....................... 117

(12) Schematic Diagram of D Board ......................... 120

(13) Schematic Diagrams of CR, CG, CB, ZR, ZG

and ZB Boards.................................................... 129

(14) Schematic Diagram of M Board ........................ 132

(15) Schematic Diagram of S Board.......................... 135

(16) Schematic Diagram of G Board ......................... 138

7-5. Semiconductors ................................................. 143

7-6. IC Block Diagrams............................................. 146

8. EXPLODED VIEWS

8-1. Screen and Cover Block (KP-44) ..................... 149

8-2. Control Panel and Cabinet Block (KP-44) ....... 150

8-3. Screen and Cover Block (KP-51) ...................... 151

8-4. Control Panel and Cabinet Block (KP-51) ........ 152

8-5. Main Bracket Block ........................................... 153

8-6. Picture Tube Block............................................. 154

9. ELECTRICAL PARTS LIST ............................ 155

– 3 –– 3 –– 3 –

Page 4

KP-44PS2/44PS2U/51PS2

RM-903

SECTION 1

SELF DIAGNOSIS FUNCTION

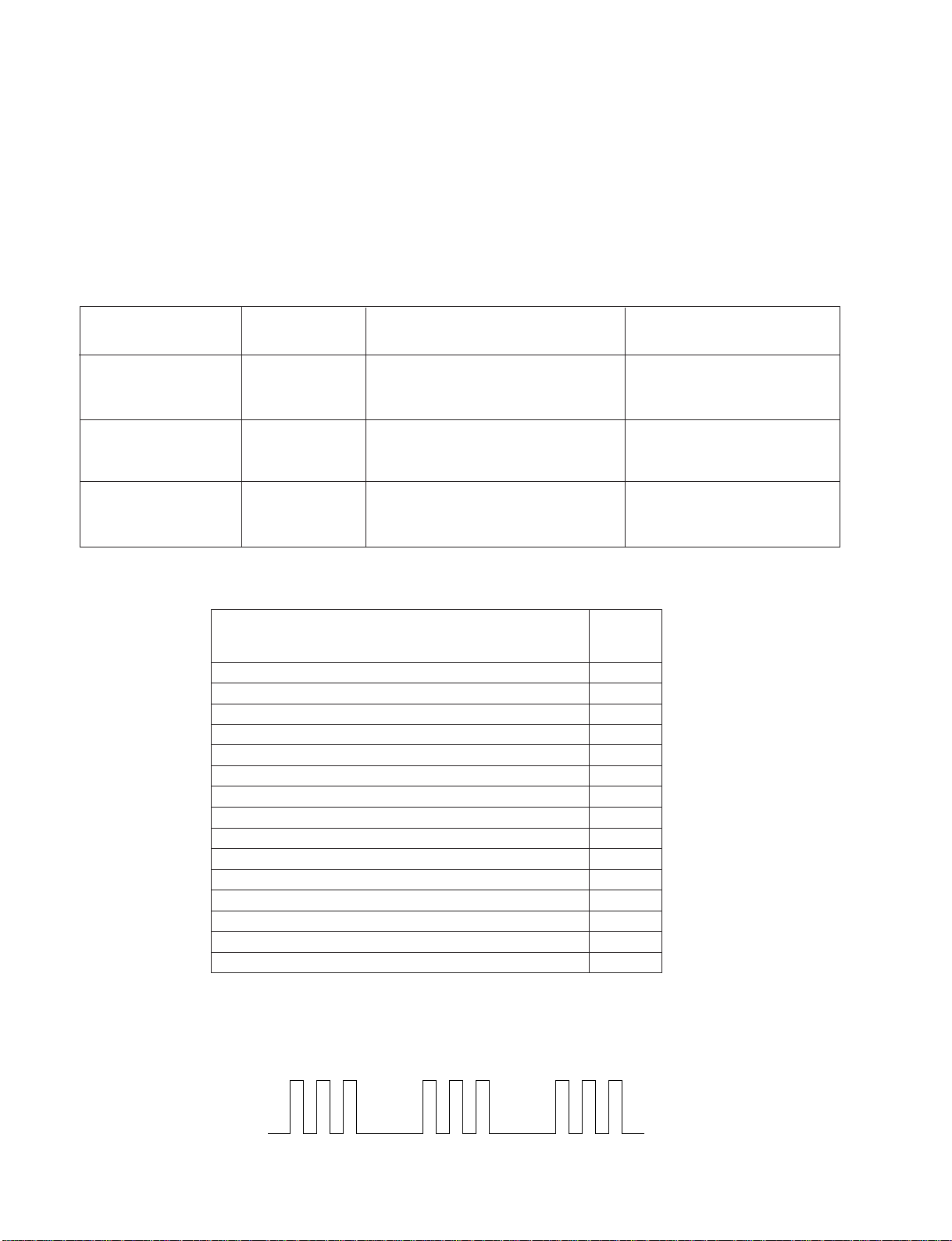

1-1. RE-3W SELF DIAGNOSTIC SOFTWARE

The identification of errors within the RE-3W chassis is triggered in one of two ways : - 1: Busy or 2: Device failure to respond to IIC.

In the event of one of these situations arising the software will first try to release the bus if busy (Failure to do so will report with a

continuous flashing LED) and then communicate with each device in turn to establish if a device is faulty. If a device is found to be

faulty the relevant device number will be displayed through the LED (Series of flashes which must be counted) See table 1., non fatal

errors are reported using this method.

Diagnostic Item

Description

Power does not turn on Does not light

+B Overcurrent (OCP) 2 times Linearity FET (Q5105) is shorted (D Board)

Vertical Deflection stopped 4 times –15 V is not supplied R5341 open (D Board)

No. of times Standby

LED Flashes

Probable cause Location

Power cord is not plugged in

Fuse is open circuit

H. OUT (Q5104) is shorted (D Board)

IC6004 Power IC is shorted (G Board)

+15 V is not supplied R5340 open (D Board)

IC5302 is shorted (D Board)

ERROR ERROR

COUNT

No error 00

Not allowed (may be confused with Sircs response flash) 01

Over Current Protection 02

Over Voltage Protection 03

Vertical Protection 04

Not used 05

Horizontal Protection 06

Speaker Protection 07

General IIC Line 0 error 08

MEGATEXT (IC9502) 09

NVM (IC9108) 10

Main colour decoder (IC8301) 11

Backend (IC4301) 14

Multi sound processor (IC4702) 15

External RAM (IC9107) 17

Detected Symptoms

Power does not come on

No power is supplied to the TV

AC power supply is faulty

Power does not come on

Load on power line has shorted

Vertical deflection pulse has stopped

Power line has shorted

LED

Flash Timing Example : e.g. error number 3

ON

OFF OFF

ON ONStandby LED

– 4 –

Page 5

KP-44PS2/44PS2U/51PS2

1-2. ERROR DETECTION MONITOR

Device acknowledge is used to check IIC errors. Device acknowledge is checked by sending an IIC start sequence during CRT power

on. Each device is checked three times, if there is no acknowledge after each attempt, it will be regarded as an error.

There are three steps to check for errors.

1. IIC line 0

If all devices except the NVM have errors, IIC line 0 error is displayed.

2. Board check

If all devices mounted on one board have errors, board error is displayed.

3. Each device check

if IIC line error and board error are not detected then the device with an error is displayed.

The detected errors can be displayed as follows:

1. Error Monitor Menu

2. Error Reader

RM-903

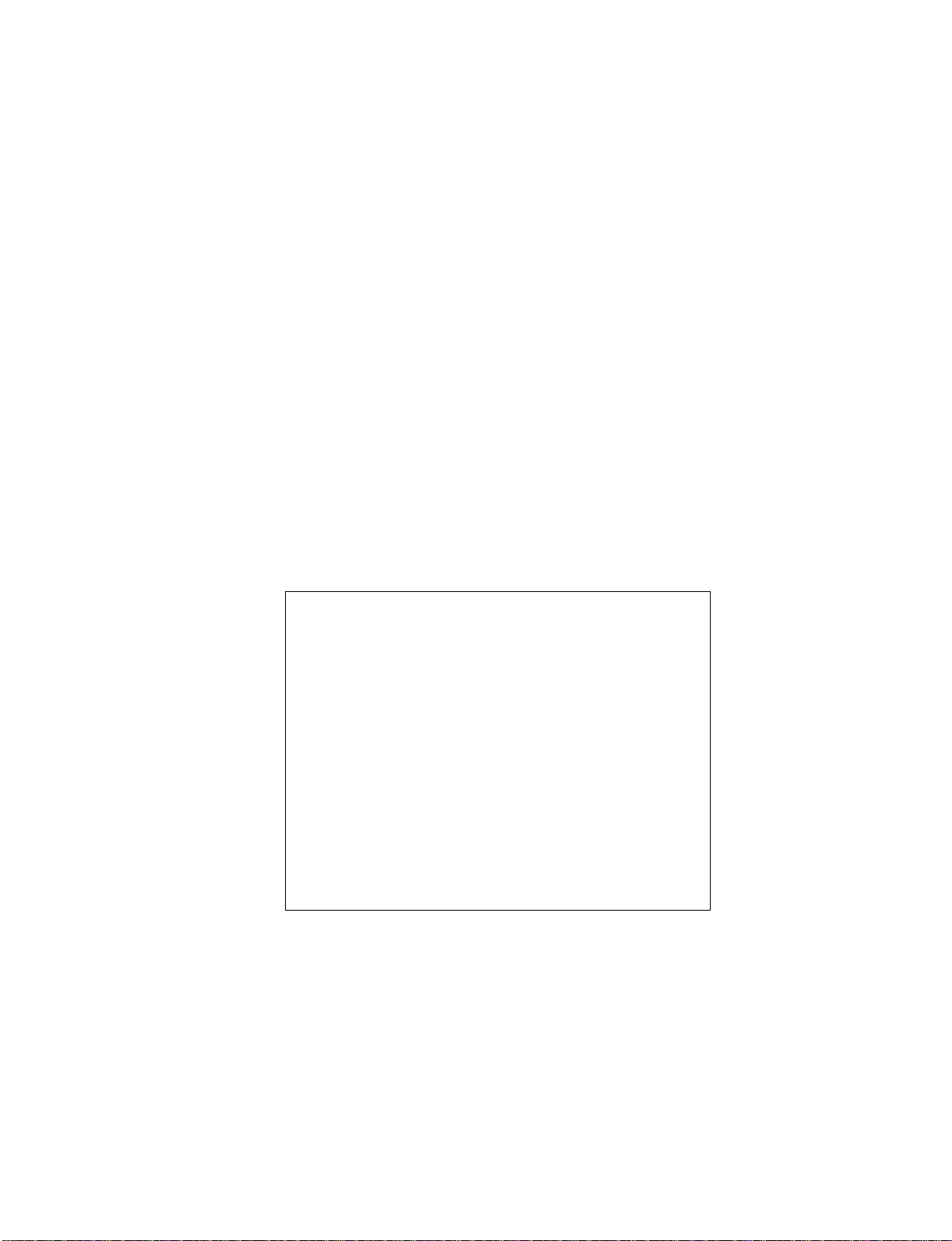

1-2-1. Error Monitor Menu

The error monitor menu is displayed by selecting TT33. The following menu will be displayed:

Error Monitor

Ignore Errors OFF

1

Operating Time :

Stored Errors :

1. A-Board

2. B3-B CXA2100 MID

3. J-B CXA2123 Main Col Dec

4. Error Code Not Valid

5. Error Code Not Valid

Current Error :

Start Error Sequence

000021 h 40 min

ON ON

– 5 –

Page 6

KP-44PS2/44PS2U/51PS2

RM-903

1-2-2. Error Reader Display

The error reader display is connected to the service connector to read actual error codes. The part number for the error reader display

is S-188-900-10.

Once an error has been detected it will then be displayed on the two digit error reader. The errors displayed refer to the following table:

Send Data to Error Reader

Error Code Data High Data Low Error Type Function

00 00h – f0h no device

Gen. IIC Error

00 01h f0h 01h IIC 0 line

00 02h f0h 02h IIC 1 line not used

Board Error

01 00h f1h 00h A Board

04 00h f4h 00h B3 Board

06 00h f6h 00h E Board

07 00h f7h 00h J/S Board

08 00h f8h 00h M Board

Device Error

A Board

01 01h f1h 01h CXA1875 Port Expander

01 02h f1h 02h TU1301 Main Tuner

01 03h f1h 03h TU1302 Sub Tuner

B3 Board

04 01h f4h 01h CXD9509 MID

E Board

06 01h f6h 01h CXA2100 Backend

J Board

04 04h f4h 04h TDA9178 Picture Booster

07 01h f7h 01h CXA2057 Auto Wide

07 03h f7h 03h CXA2123 Sub Colour

07 04h f7h 04h CXA2123 Main Colour

07 0Ah f7h 0Ah CXA2149 AV SW

S Board

07 05h f7h 05h CXA1875 Sub Sound

07 08h f7h 08h MSP3410D Sound Proc

M Board

08 01h f8h 01h ST24C32 NVM

– 6 –

Page 7

KP-44PS2/44PS2U/51PS2

RM-903

SECTION 4

SET-UP ADJUSTMENTS

4-1. SCREEN VOLTAGE ADJUSTMENT

(ROUGH ALIGNMENT)

1. Receive the Monoscope signal.

2. Set 50% BRIGHTNESS and minimum PICTURE.

3. Turn the red VR on the focus pack all the way to the left and

then gradually turn it to the right until the point where you

can see the retrace line.

4. Next gradually turn it to the left to the position where the

retrace line disappears.

RG

RG

B

SCREEN

B

FOCUS

Focus Pack

Fig. 4-1

4-2. SCREEN (G2) ADJUSTMENT

1. Turn on the power of the set.

2. Select VIDEO1 mode without signals.

3. Supply DC 175 ±0.5 V from external power supply to

TP7103 (KR), TP7203 (KG) or TP7303 (KB) of CR board,

CG board and CB board.

3. Adjust red, green and blue screen voltage to until retrace

line disappears with screen VR on the focus pack.

5. Rotate the green lens and align to obtain the best lens focus

at the center area.

6. Rotate the green focus VR on the focus pack and align to

obtain the best electrical focus in the top right corner.

7. Perform the same alignment for red and blue lenses and electric focus.

8. Fix lens screw.

A

Minimize both A and B.

Lens

Fig. 4-3

B

Fig. 4-4

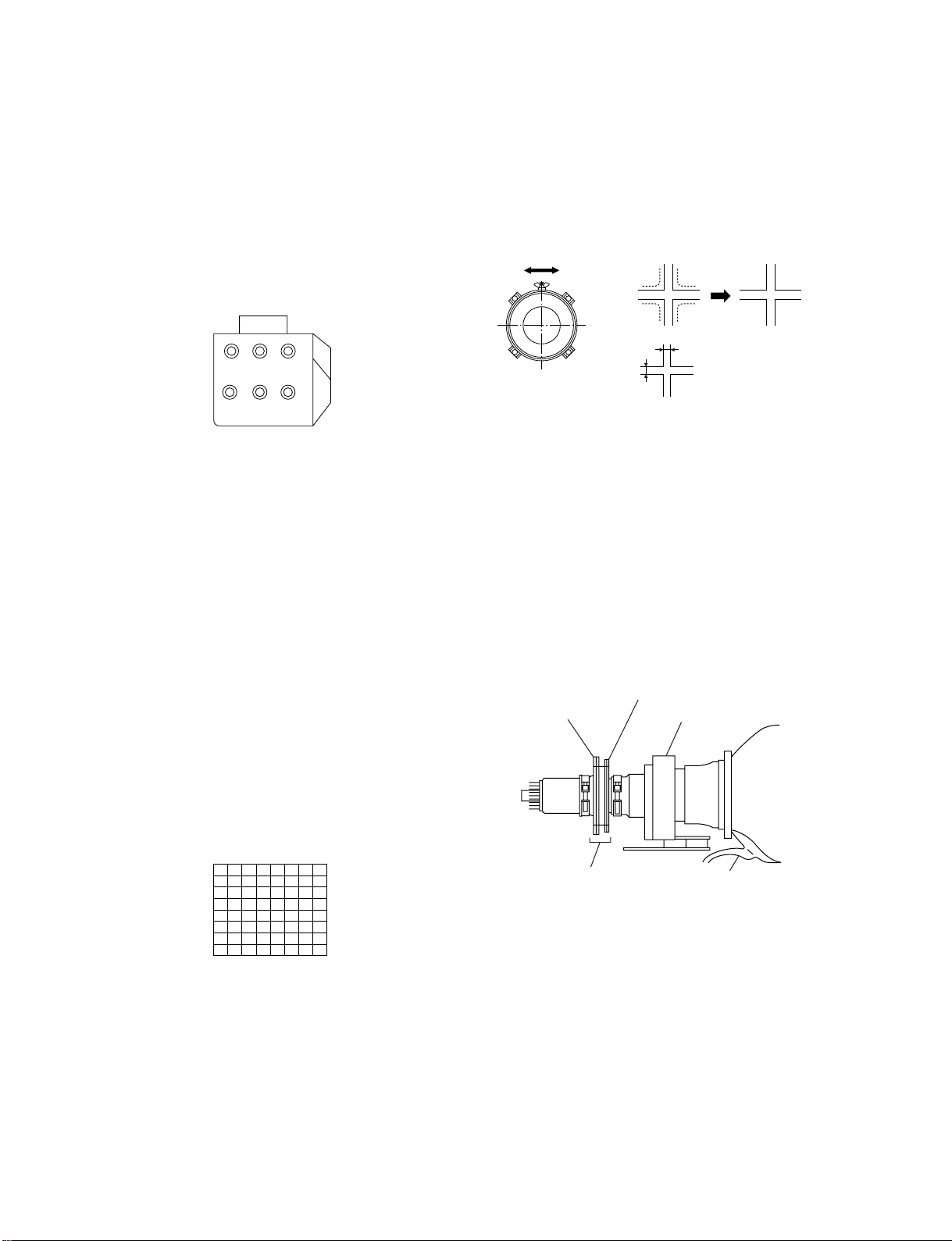

4-4. DEFLECTION YOKE TILT ADJUSTMENT

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the green

color.

3. Loosen the deflection yoke setscrew and align the tilt of the

Deflection yoke so that the bars at the center of the

monoscope pattern are horizontal.

4. After aligning the deflection yoke, fasten it securely to the

funnel-shaped portion (neck) of the CRT.

5. The tilt of the deflection yoke for red and blue is aligned the

same as was done for green.

4-3. FOCUS ROUGH ADJUSTMENT

1. Loose the lens screw.

2. Enter the TT mode. (Refer to SECTION 6.)

3. Place the caps on the red and blue lens so that only the green

color is shown.

4. Press “MENU” twice on the commander and select “Device

Register Setting” b “Projector Engine”, press “6” three

times on the Commander to display the test signal (crosshatch) on the screen.

Test signal

Fig. 4-2

4-pole magnet

2-pole magnet

Neck Assy

Make sure deflection yoke is

touching CRT closely.

Fig. 4-5

Deflection yoke

Anode cap

– 28 –

Page 8

KP-44PS2/44PS2U/51PS2

RM-903

4-5. 2-POLE MAGNET ADJUSTMENT

1. Receive the Dot signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Turn the green focus VR on the focus pack to the right and

set to over focus to enlarge the spot.

4. Now align the 2-Pole Magnet so that the enlarged spot is in

the center of the just focus spot.

(center of the dot doesn't move)

5. Align the green focus VR and set for just (precise) focus.

6. Perform the same alignment for red and blue.

Use the center dot

Fig. 4-6

4-6. 4-POLE MAGNET ADJUSTMENT

1. Receive the Dot signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Turn the green focus VR on the focus pack to the left and set

to under focus to enlarge the spot.

4. Now align the 4-Pole Magnet so that the enlarged spot becomes a perfect circle.

5. Perform the same alignment for red and blue.

4-7. GREEN, RED AND BLUE FOCUS

ADJUSTMENT

4-7-1. Green, Red and Blue Lens Focus Adjustment

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Rotate the green lens and adjust to obtain the best lens focus

at the center area.

4. Fix lens screw.

5. Repeat above process for red and blue.

4-7-2. Green, Red and Blue Electrical Focus

Adjustment

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Rotate the green focus VR on the focus pack and adjust to

obtain the best electrical focus at the center area.

4. Repeat above process for red and blue.

Use the center dot

Fig. 4-7

OKNG NG

Adjust Point

Fig. 4-8

– 29 –

Page 9

KP-44PS2/44PS2U/51PS2

RM-903

SECTION 5

SAFETY RELATED ADJUSTMENT

When replacing the following components marked with ] on

the schematic diagram, always check hold-down voltage and

if necessary re-adjust.

Part Replaced ([)

R9901

Part Replaced (])

D Board C5123, C5127, C5130, C5143, D5115,

D5204, Q5104, R5136, R5138, R5140,

R9901, T5102, T5104, T5103 (FBT)

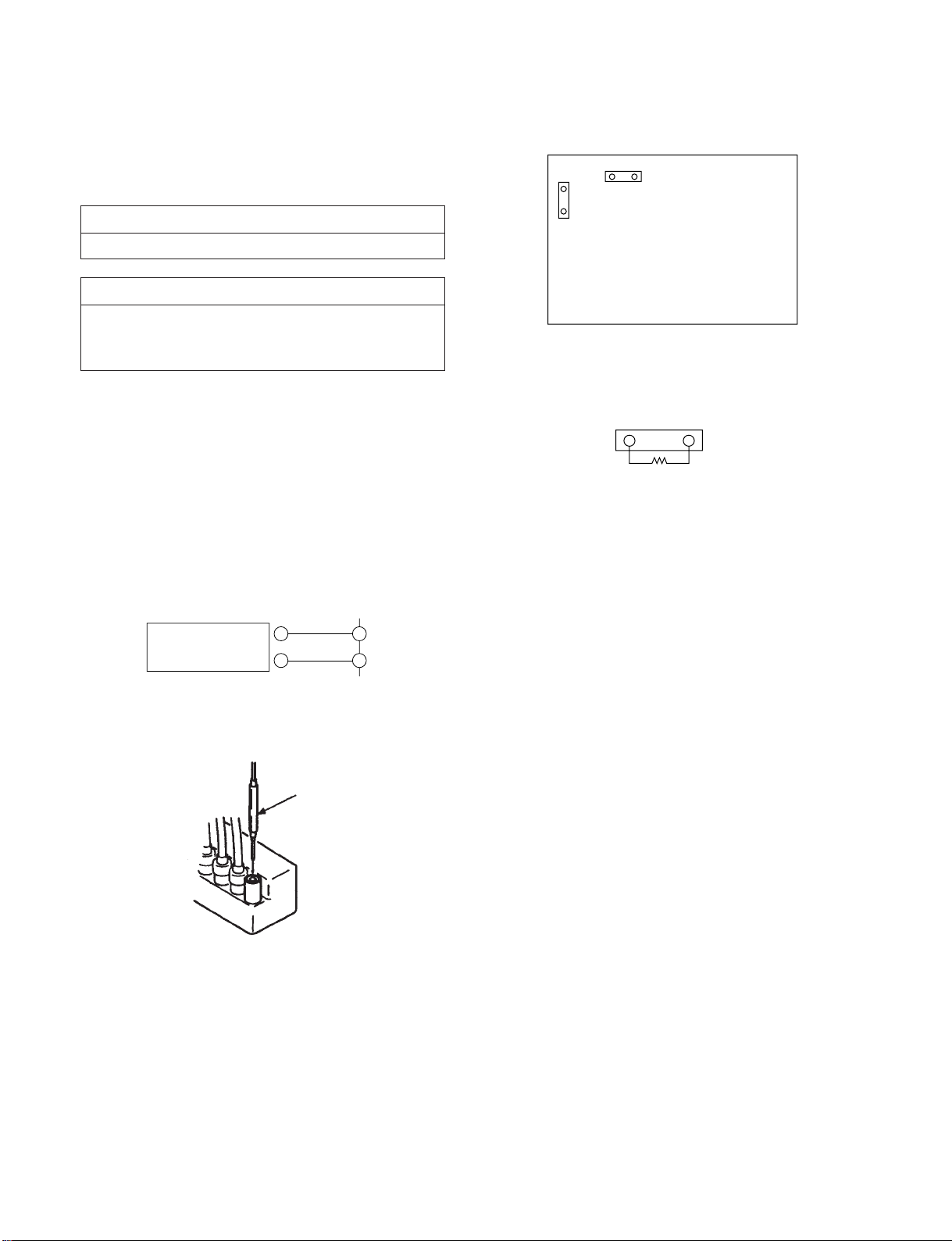

5-1. HV HOLD-DOWN ADJUSTMENT

1. Connect HV static voltmeter to HV Block.

2. Mount a resistor (R9901 : 43 k , 1/4 W, METAL

FILM) at CN5003.

3. Remove CN5002 and connect External Power Supply to

CN5002 1 pin (+135 V) and 2 pin (GND).

4. Turn on the set.

Power

Supply

+

–

Fig. 5-1

Remove the cap off

from the unused

terminal and connect a

HV static voltmeter

there.

1

CN5002

2

D BOARD

CN5002

– CONDUCTOR SIDE –

CN5003

Fig. 5-3

CN5003

R9901

Fig. 5-4

5. Receive the Dot signal and set PICTURE/BRIGHTNESS

to minimum.

6. Slowly up the supply voltage from 0 V to 135 V until

hold-down circuit works (picture disappear).

7. Read the HV static voltmeter of peak HV voltage.

Spec : 33.7 ~ 35.3 kV

8. If Hold-down voltage is less than 33.7 kV then replace

R9901 of 43 k with that of 39 k , and check if the

voltage is within the spec.

9. If hold-down voltage is over than 35.3 kV then replace

R9901 of 43 k with that of 47 k , and check if the voltage is within the spec.

Fig. 5-2

– 30 –

Page 10

SECTION 6

Enter the

“TT MODE”

5

(DIGIT 5) (VOLUME +) (TV MODE)ON SCREEN

DISPLAY

(

)

ELECTRICAL ADJUSTMENTS

KP-44PS2/44PS2U/51PS2

RM-903

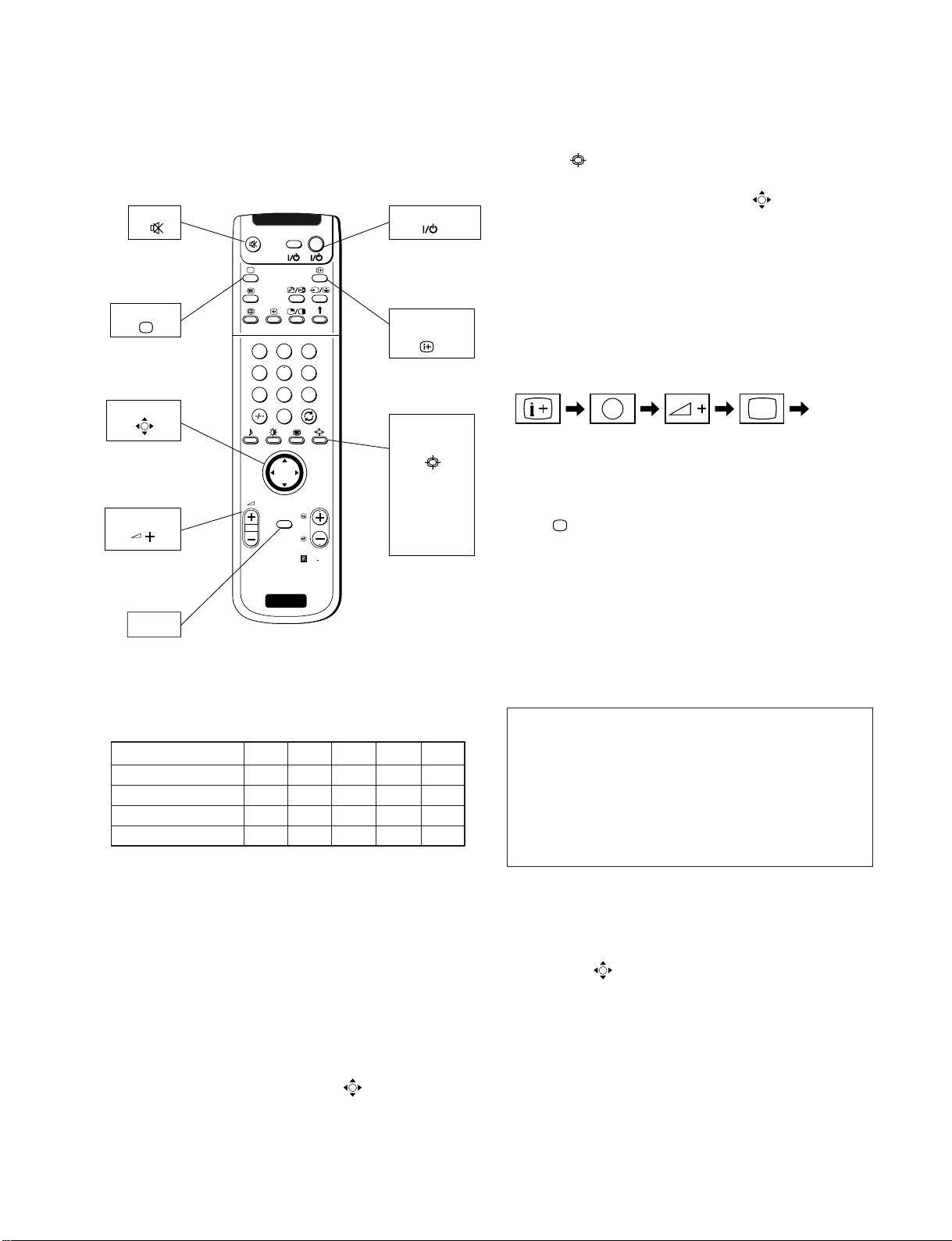

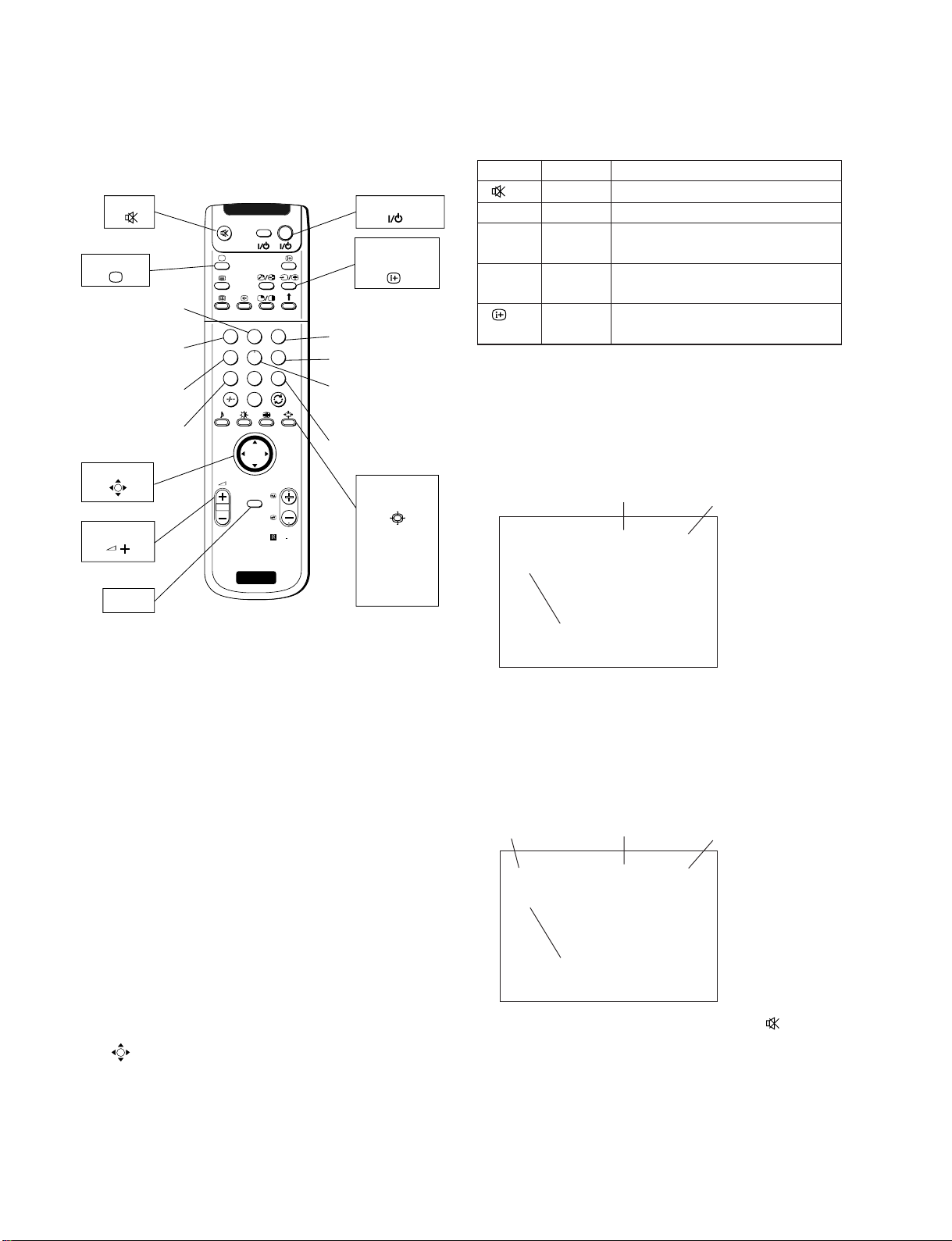

6-1. ADJUSTMENTS WITH COMMANDER

Service adjustment to this model can performed with the supplied remote commander RM-903.

MUTE

TV MODE

JOYSTICK

VOLUME +

MENU

1

4

7

2

5

8

0

OK

MENU

SONY

TV

VIDE O TV

3

6

9

PROGR

RM

903

RM-903

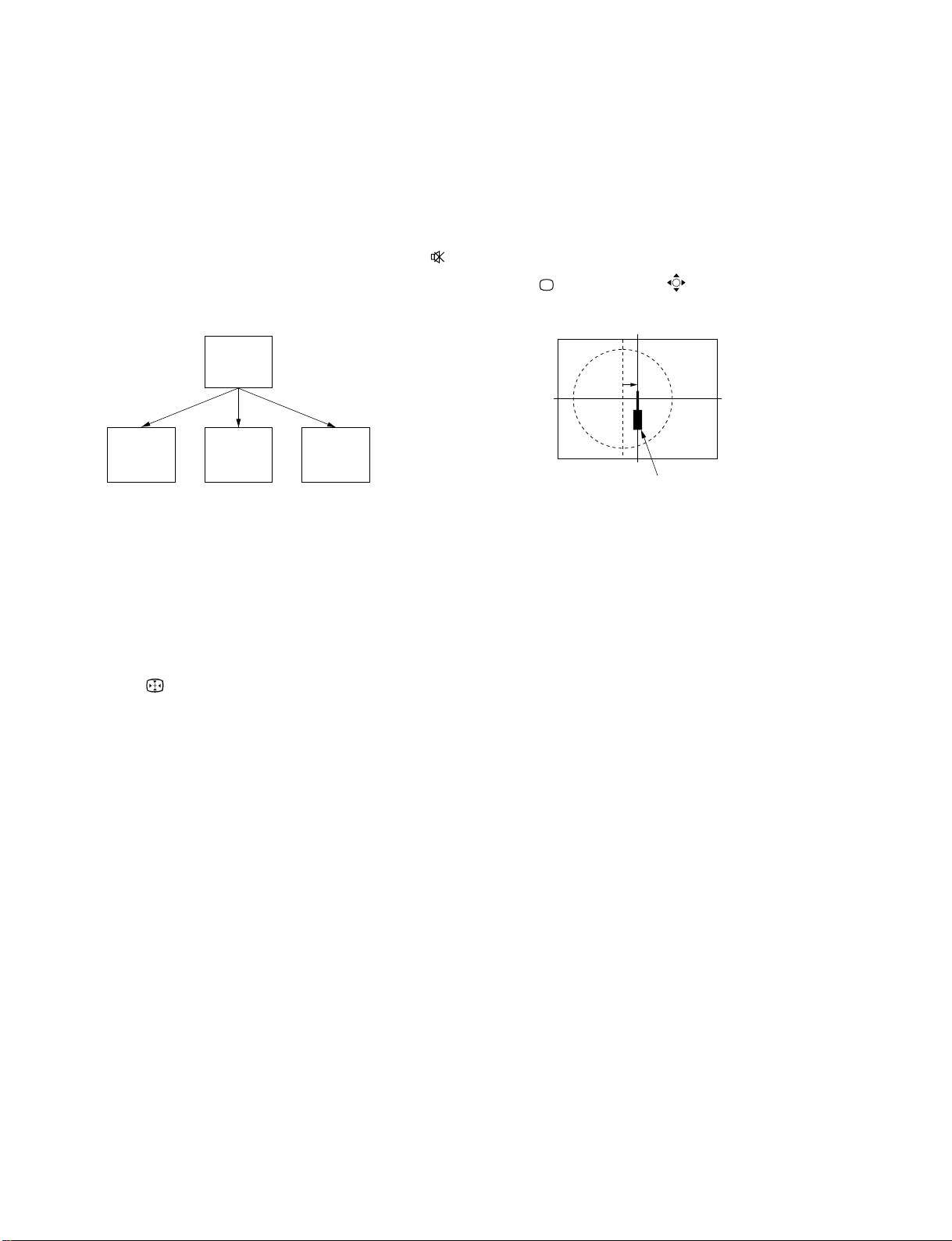

6-1-1. How to Select Each Mode

The adjustment requires the following modes:

TV STANDBY

ON SCREEN

DISPLAY

SCREEN

FORMAT

Wide

Zoom

14 : 9

4 : 3

Smart

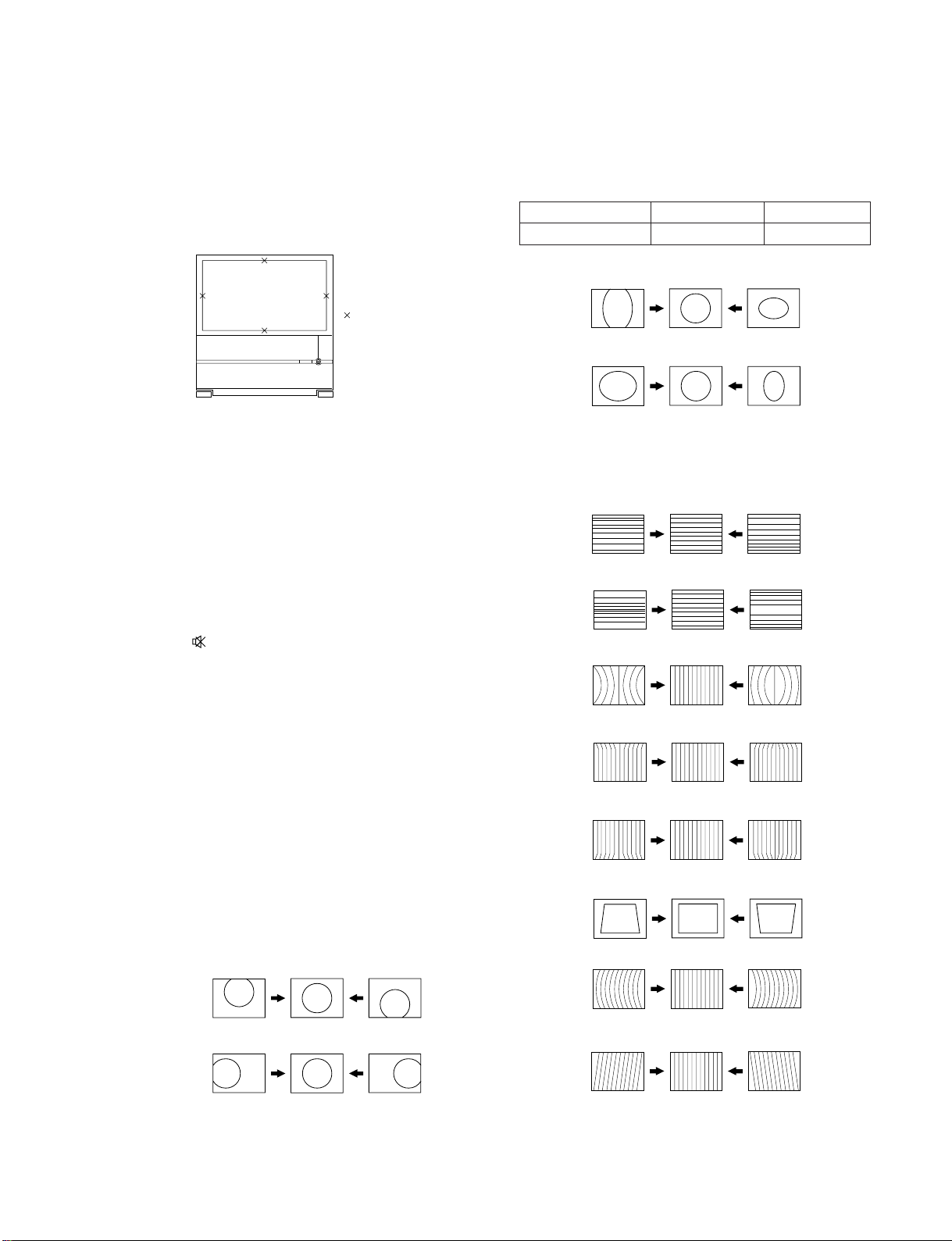

3. Selection of Screen Format

1) Press “ (BLUE)” button on the commander.

2) Press v or V key on the joystick to select “Wide”, “Zoom”,

“14 : 9”, “4 : 3” or “Smart”, and press “ (OK)” button. At

this time, normal screen comes back. (In the TT mode, the

menu is switched to the Service menu.)

6-1-2.How to Enter TT Mode

1. Turn on the main power switch to place this set in standby

mode. (LED will light in red.)

2. Press the buttons on commander as follows, and the TT

mode will be selected.

“TT - -” will appear in the top right corner of the screen.

Other status information will also be displayed.

3. If “ (TV MODE)” button or “-” + “-” button is

pressed, the set exits from the TT mode and returns to normal TV mode.

6-1-3.How to Enter Service Menu

1. Enter the TT mode.

2. Press “MENU” button on the commander once, and normal

menu screen will appear, or press it once more, and the following service menu screen will appear.

Service AE5(A)

Wide Zoom 14 : 9 4 : 3 Smart

DRC 100 (PAL) aaa× a

DRC 50 (PAL) aaa× a

DRC 100 (NTSC) aaa× a

DRC 50 (NTSC) aaa× a

1. Selection of Mode Between PAL and NTSC

PAL mode : Enter PAL signal.

NTSC mode: Enter NTSC signal. (VIDEO input only)

2. Selection of Digital Mode

1) Press “MENU” button on the commander, and the menu

screen will appear.

2) Press B key on the joystick to enter the “Picture Adjustment” menu.

3) Press v or V key on the joystick to select “Digital Mode”,

and press B key.

4) Press v or V key on the joystick to select“Normal”,

“DRC50” or “DRC100”, and press “

5) Press “MENU” button to return to normal screen.

(In the TT mode, the menu is switched to the Service menu)

(OK)”.

Initialising

Reset Devices

Monitoring

Device Register Setting

Special Adjustment

Select : v V Next menu : B

3. Following the screen, press v or V key on the joystick to

select the desired item, and press B key to enter the selected

item.

4. Press v or V key on the joystick to change data of each item,

and press “

(OK)” button to write changed data.

(Except Projector Engine mode)

5. To return from each item, press b key on the joystick. Or, to

return to the TT mode, press the “MENU” button.

(Except Projector Engine mode)

– 31 –

Page 11

KP-44PS2/44PS2U/51PS2

RM-903

6-1-4. Screen Display for Service Menu

If each item of service menu is selected, the following screen is

displayed.

• Initialising

Initialising

Model Setting

Destination Setting

Basic Setting

Feature Setting

Select : v V Next menu : B

• Initialising b Model Setting

Model Setting

1 KV-29FX60

2 KV-29FC60

3 KV-29FS60

4 KV-28FX60

5 KV-32FX60

6 KV-32FS60

7 KV-28FC60

8 KV-32FC60

9 KV-28FC60Z

10 KV-32FC60Z

11 KV-28FS70

12 KV-32FS70

13 KV-36FS70

14 KP-48PS1

15 KP-53PS1

16 KP-61PS1

17 KP-44PS2

18 KP-51PS2

19 KF-50SX100

Select : v V Last menu : b Set Model : B

• Initialising b Basic Setting

Basic Setting

No Descr. Min Max Data

1 Sys. B/G OFF ON ON

2 Sys. D/K OFF ON ON

3 Sys. L OFF ON ON

4 Sys. I (UK) OFF ON ON

5 Sys. I (IRL) OFF ON ON

6 TXT Nat. Option 1 4 3

7 Simple PAT OFF ON OFF

8 16 : 9 CRT OFF ON ON

9 Sub-Woofer OFF ON OFF

10 Auto Stand-By OFF ON ON

11 Comb-Filter OFF ON ON

12 Auto YC det OFF ON ON

13 Auto Comb det OFF ON ON

14 AV2 Available OFF ON ON

15 AV3 Available OFF ON ON

16 AV4 Available OFF ON ON

17 AV3 Front & Rear OFF ON OFF

18 SECAM Tape OFF ON ON

19 AV1 Sound Mute OFF ON OFF

Select : v V Last menu : b Enter Item : B

• Initialising b Feature Setting

Feature Setting

No Descr. Min Max Data

1 PAP OFF ON ON

2 PAT OFF ON ON

3 INDEX OFF ON ON

4 EPG OFF ON ON

5 Full EPG OFF ON ON

6 PictBoostBypass OFF ON OFF

Select : v V Last menu : b Enter Item : B

• Initialising b Destination Setting

Destination Setting

Multi

A

B

D

E

K

R

U

Select : v V Last menu : b Set Dest. : B

• Reset Devices

Reset Devices

Backend

Deflection

Ext. Deflection

Dynamic Convergence

Colour Decoder 1

Colour Decoder 2

Audio/Video Switch

MID-X

External PLL MID-X

Panorama Chip

Autowide

Sound

Picture Booster

Select : v V Last menu : b Reset Dev. : B

– 32 –

Page 12

KP-44PS2/44PS2U/51PS2

RM-903

• Monitoring

Monitoring

Device Status Monitor

Error Monitor

Production Monitor

NVM Monitor

Format Monitor

CNI Monitor

Select : v V Next menu : B

• Device Register Setting

Device Register Setting

Backend

Deflection

Ext. Deflection

Dynamic Convergence

Colour Decoder 1

Colour Decoder 2

Audio/Video Switch

MID-X

External PLL MID-X

Panorama Chip

Autowide

Sound

Projector Engine

Picture Booster

Select : v V Next menu : B

• Device Register Setting b Backend

Backend

No Descr. Def. Min Max Data

1 D-Col OFF OFF ON OFF

2 Contrast 44 0 63 31

3 Limit-Lvl 3 0 3 3

4 Hue 32 0 63 32

5 Colour 31 0 63 26

6 CTI-Level 2 0 3 2

7 Brightness 31 0 63 31

8 Gamma 3 0 3 3

9 Sharpness 31 0 63 16

10 R-Drive 31 0 63 27

11 G-Drive 31 0 63 31

12 B-Drive 31 0 63 25

13 Sub Bright 31 0 63 31

14 VM-Level 2 0 3 2

15 R-Cutoff 31 0 63 31

16 Pre/Over 2 0 3 2

17 G-Cutoff 31 0 63 31

18 DPIC-Level 1 0 3 1

19 B-Cutoff 31 0 63 31

20 DC-Tran. 0 0 3 0

21 Sub-Cont. 10 0 15 10

22 LRGB2-Lvl 8 0 15 8

23 P-Abl 15 0 15 15

24 Sharp. F0 ON OFF ON ON

25 CB-Offset1 7 0 15 7

26 CR-Offset1 7 0 15 7

27 CB-Offset2 7 0 15 7

28 CR-Offset2 7 0 15 7

29 Sub Colour 0 –8 8 –1

Select : v V Last menu : b Enter Item : B

– 33 –

Page 13

KP-44PS2/44PS2U/51PS2

RM-903

• Device Register Setting b Deflection

Deflection

No Descr. Def. Min Max Data

1 V-Size 31 0 63 34

2 V-Position 31 0 63 36

3 V-Comp 1 0 3 1

4 V-Linear 7 0 15 7

5 S-Corr 7 0 15 7

6 H-Size 31 0 63 51

7 Ew-Dc OFF OFF ON OFF

8 Pin-Amp 31 0 63 31

9 Up-CPin 31 0 63 31

10 M-Pin 2 0 3 2

11 Lo-CPin 31 0 63 31

12 Trapezium 7 0 15 7

13 H-Position 31 0 63 47

14 AFC-Bow 7 0 15 7

15 AFC-Angle 7 0 15 7

16 Up-Vlin 0 0 15 0

17 Lo-Vlin 0 0 15 0

18 MPIP PAmp –5 –10 10 –5

19 MPIP UCPin 0 –10 10 0

20 MPIP LCPin 0 –10 10 0

21 MPIP Trap 0 –10 10 0

22 EPG PAmp –3 –10 10 –3

23 EPG UCPin 0 –10 10 0

24 EPG LCPin 1 –10 10 1

25 EPG Trap 0 –10 10 0

Select : v V Last menu : b Enter Item : B

• Device Register Setting b Dynamic Convergence

Dynamic Convergence

No Descr. Def. Min Max Data

1 Range 63 0 63 63

2 H stat 33 0 63 33

3 H amp l 37 0 63 37

4 H amp r 36 0 63 36

5 Up Y 31 0 63 31

6 Low Y 33 0 63 33

7 Y up l 30 0 63 30

8 Y up r 30 0 63 30

9 Y low l 31 0 63 31

10 Y low r 30 0 63 30

11 Mbow up l 31 0 63 31

12 Mbow up r 32 0 63 32

13 Mbow low l 32 0 63 32

14 Mbow low r 32 0 63 32

15 V stat 32 0 63 32

16 TCorPCtrl OFF OFF ON OFF

17 TopCorPin 31 0 63 31

18 BCorPCtrl OFF OFF ON OFF

19 BotCorPin 31 0 63 31

Select : v V Last menu : b Enter Item : B

• Device Register Setting b Colour Decoder 1

Colour Decoder 1

• Device Register Setting b EXT. Deflection

EXT. Deflection

No Descr. Def. Min Max Data

1 Linearity 127 0 255 127

2 H Centre 31 0 63 31

3 H Trap 31 0 63 31

4 Rotation 0 0 255 0

5 FocusPhase 127 0 255 127

Select : v V Last menu : b Enter Item : B

No Descr. Def. Min Max Data

1 TINT 31 0 63 31

2 SUB COLOUR 7 0 15 7

3 SUB CONTR 7 0 15 7

4 SHARP GAIN 8 0 15 8

5 Y-OUT LEV. 50 0 63 40

6 C-OUT LEV. 50 0 63 45

7 Y-DL 8 0 10 3

8 Cr OFF. 1 7 0 15 7

9 Cb OFF. 1 7 0 15 7

10 Cr OFF. 2 7 0 15 7

11 Cb OFF. 2 7 0 15 7

12 V CD FREQ 3 0 7 3

13 V CD MODE 1 0 3 1

14 MVM OFF OFF ON OFF

15 S R-Y ADJ 7 0 15 7

16 S B-Y ADJ 2 0 15 5

17 BELL/HPF 2 0 3 2

18 BELL F0 OFF OFF ON OFF

19 S GP 0 0 3 0

Select : v V Last menu : b Enter Item : B

– 34 –

Page 14

KP-44PS2/44PS2U/51PS2

RM-903

• Device Register Setting b Colour Decoder 2

Colour Decoder 2

No Descr. Def. Min Max Data

1 TINT 31 0 63 31

2 SUB COLOUR 7 0 15 7

3 SUB CONTR 7 0 15 7

4 SHARP GAIN 8 0 15 8

5 Y-OUT LEV. 50 0 63 31

6 C-OUT LEV. 50 0 63 45

7 Y-DL 8 0 10 3

8 Cr OFF. 1 7 0 15 7

9 Cb OFF. 1 7 0 15 7

10 Cr OFF. 2 7 0 15 7

11 Cb OFF. 2 7 0 15 7

12 V CD FREQ 3 0 7 3

13 V CD MODE 1 0 3 1

14 MVM OFF OFF ON OFF

15 S R-Y ADJ 7 0 15 7

16 S B-Y ADJ 2 0 15 5

17 BELL/HPF 2 0 3 2

18 BELL F0 OFF OFF ON OFF

19 S GP 0 0 3 0

Select : v V Last menu : b Enter Item : B

• Device Register Setting b MID-X

• Device Register Setting b External PLL MID-X

External PLL MID-X

No Descr. Def. Min Max Data

1 VCO7-0PAL 184 0 255 184

2 VCO7-0NTSC 172 0 255 172

3 VCO11-8 6 0 15 6

4 DIV1, 2, 4, 8 2 0 3 2

5 Fine Delay 0 0 63 0

6 Coar. Delay 0 0 3 0

7 Ch. Pump 0 0 3 0

8 PD Pol. ON OFF ON ON

9 DSync Wdth 3 0 3 3

10 Dsync Del OFF OFF ON OFF

11 Sync Pol ON OFF ON ON

12 DSync Pol ON OFF ON ON

13 Clk En ON OFF ON ON

14 NClk En OFF OFF ON OFF

15 Clk/2 En OFF OFF ON OFF

16 NClk/2 En OFF OFF ON OFF

17 DSync En ON OFF ON ON

18 Unlock En OFF OFF ON OFF

19 VCO Bypass ON OFF ON ON

20 Synth Pwr ON OFF ON ON

21 Rdout Pwr OFF OFF ON OFF

22 DIVOUT En ON OFF ON ON

23 DSync Byp OFF OFF ON OFF

24 DSync Hold OFF OFF ON OFF

Select : v V Last menu : b Enter Item : B

MID-X

No Descr. Def. Min Max Data

1 M H POS 0 –31 31 0

2 S H POS 0 –8 8 0

3 D YS SEL 1 0 3 1

4 D YS DELAY 7 0 7 7

5 D SYNC MOD ON OFF ON ON

6 Text Sharp OFF OFF ON OFF

Select : v V Last menu : b Enter Item : B

• Device Register Setting b Panorama Chip

Panorama Chip

No Descr. Def. Min Max Data

1 ROM speed 25 0 255 25

2 Prog. No. 0 0 11 3

3 HSize Offs 3 0 15 3

4 IMODE 0 0 255 0

5 Disable OFF OFF ON OFF

6 Send AUX OFF OFF ON OFF

7 AUX0 67 0 255 67

8 AUX1 0 0 255 0

9 AUX2 68 0 255 68

10 AUX3 0 0 255 0

11 AUX4 12 0 255 12

12 AUX5 81 0 255 81

13 AUX6 7 0 255 7

14 AUX7 0 0 255 0

15 AUX8 65 0 255 65

16 AUX9 244 0 255 244

17 AUX10 32 0 255 32

18 AUX11 209 0 255 209

19 AUX12 7 0 255 7

20 AUX13 0 0 255 0

Select : v V Last menu : b Enter Item : B

– 35 –

Page 15

KP-44PS2/44PS2U/51PS2

RM-903

• Device Register Setting b Autowide

Autowide

No Descr. Def. Min Max Data

1 Upara ON OFF ON ON

2 Upthin OFF OFF ON OFF

3 Enjtoz OFF OFF ON OFF

4 X149J ON OFF ON ON

5 Syncslc OFF OFF ON OFF

6Tm 1 0 3 1

7 Uprlvl OFF OFF ON OFF

8 Ofslvl OFF OFF ON OFF

9 Alpf 3 0 3 3

10 eddec2 3 0 3 3

11 Lnstblz ON OFF ON ON

12 Lnhys OFF OFF ON OFF

13 Drkpri ON OFF ON ON

Select : v V Last menu : b Enter Item : B

• Device Register Setting b Sound

Sound

No Descr. Def. Min Max Data

1 Carr.-Mute ON OFF ON ON

2 SCART1 Vol 79 0 127 79

3 SCART2 Vol 79 0 127 79

4 SCART-Pr. 27 0 127 27

5 I2S1-Pr. 16 0 127 16

6 I2S2-Pr. 16 0 127 16

7 FM Pr. 27 0 127 27

8 BG Nic. Pr. 53 0 127 53

9 L Nic. Pr. 59 0 127 59

10 DK Nic.Pr. 53 0 127 53

11 I Nic. Pr. 97 0 127 97

12 Irl NicPr. 97 0 127 97

13 SubW. Vol. 0 –127 0 0

14 Bass Offs 0 –3 3 0

15 TrebleOffs 2 –3 3 2

16 Loudn. Offs 0 0 9 0

17 HP-VolOffs –2 –5 5 –2

18 M-S Limit 30 –128 127 30

19 M-B Limit –30 –128 127 –30

20 S-M Limit 12 –128 127 12

21 S-B Limit –20 –128 127 –20

22 B-M Limit –12 –128 127 –12

23 B-S Limit 20 –128 127 20

24 Err. Max 40 0 255 40

25 Err. Min 18 0 255 18

26 Vol.Offset –3 –6 0 –3

• Device Register Setting b Picture Booster

Picture Booster

No Descr. Def. Min Max Data

1 DEM OFF OFF ON OFF

Select : v V Last menu : b Enter Item : B

• Special Adjustment

Special Adjustment

No Descr. Min Max Data

1 RGB Level 0 7 0

2 RGB Gain 0 31 6

3 RGB PAT Level 0 7 0

4 RGB PAT Gain 0 31 12

5 Extra FW 0 255 255

6 EPG ChkS Check OFF ON ON

7 Slicer High OFF ON ON

8 FCW Wide OFF ON OFF

9 Mpeg NR OFF ON OFF

10 Notch Filter OFF ON OFF

11 NLD step –7 0 –1

12 PKD step –15 0 –5

13 CRD step 0 15 5

14 SHP step –7 0 –5

15 COL step –7 0 –1

16 NTSC AutoYc AV2 OFF ON ON

17 NTSC AutoYc AV3 OFF ON ON

18 RGB Disable OFF ON OFF

19 Telop C/M OFF ON ON

20 Intern GD OFF ON OFF

21 AV2 YC mix out OFF ON OFF

22 Line 318 TXT OFF ON OFF

Select : v V Last menu : bEnter Item : B

Select : v V Last menu : b Enter Item : B

– 36 –

Page 16

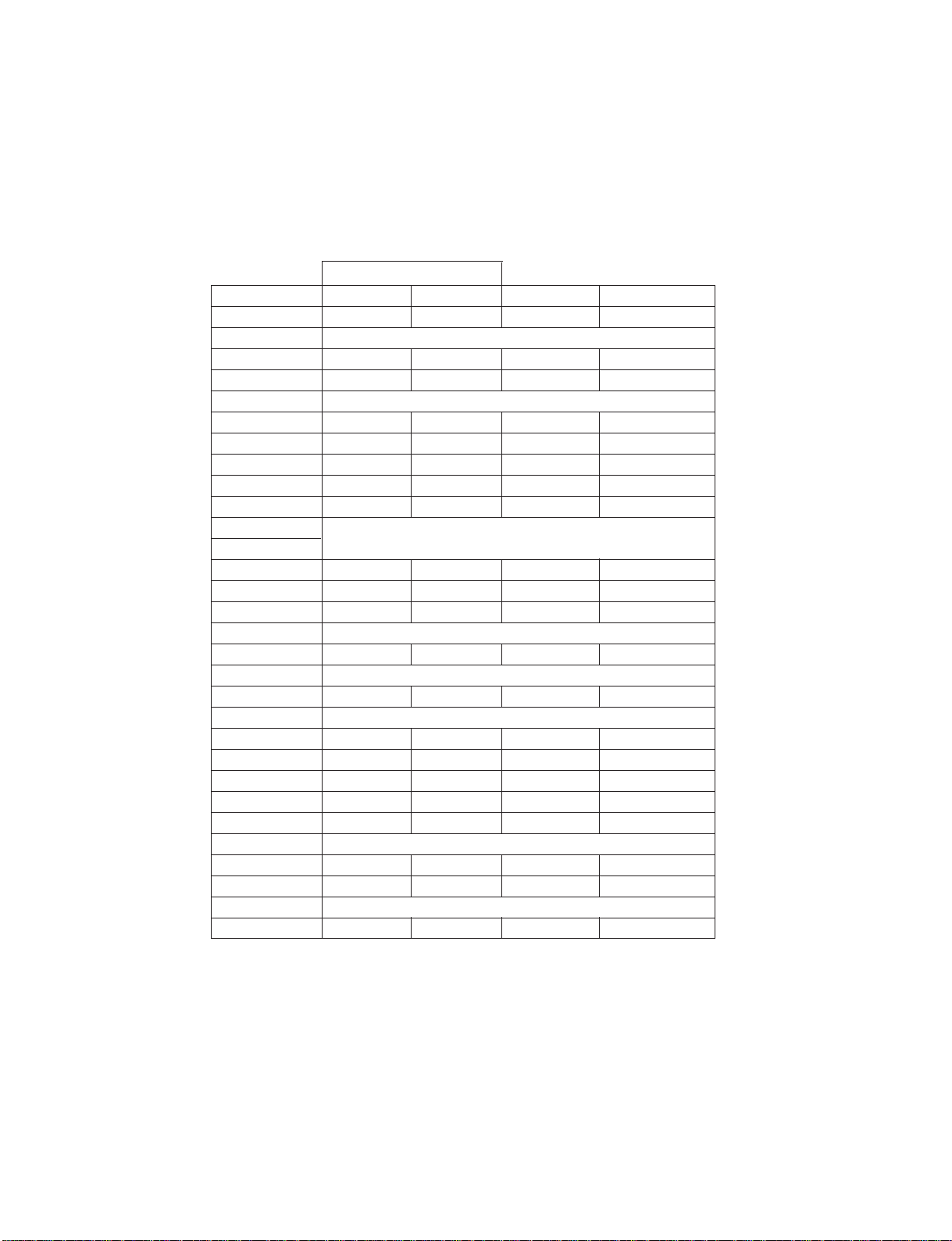

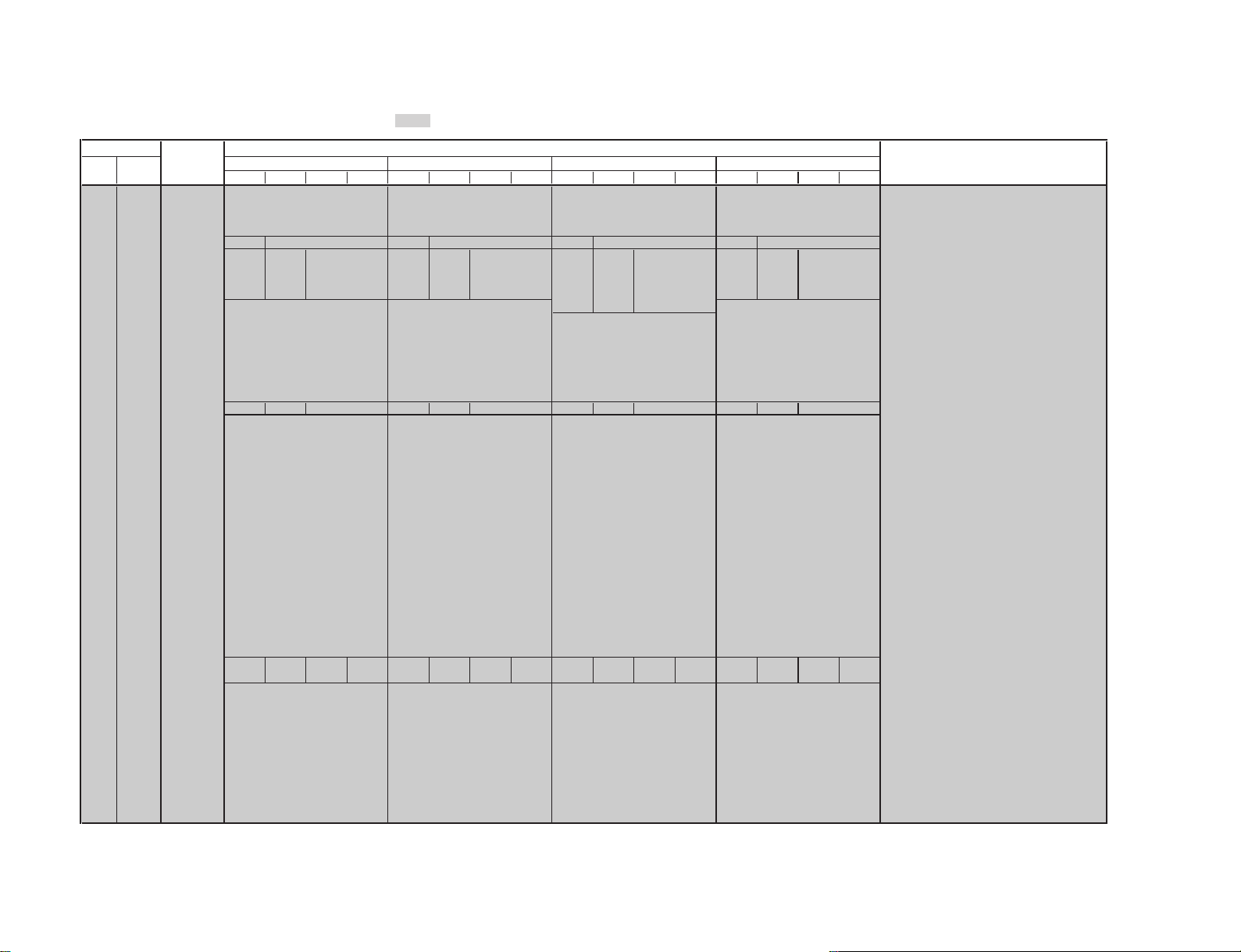

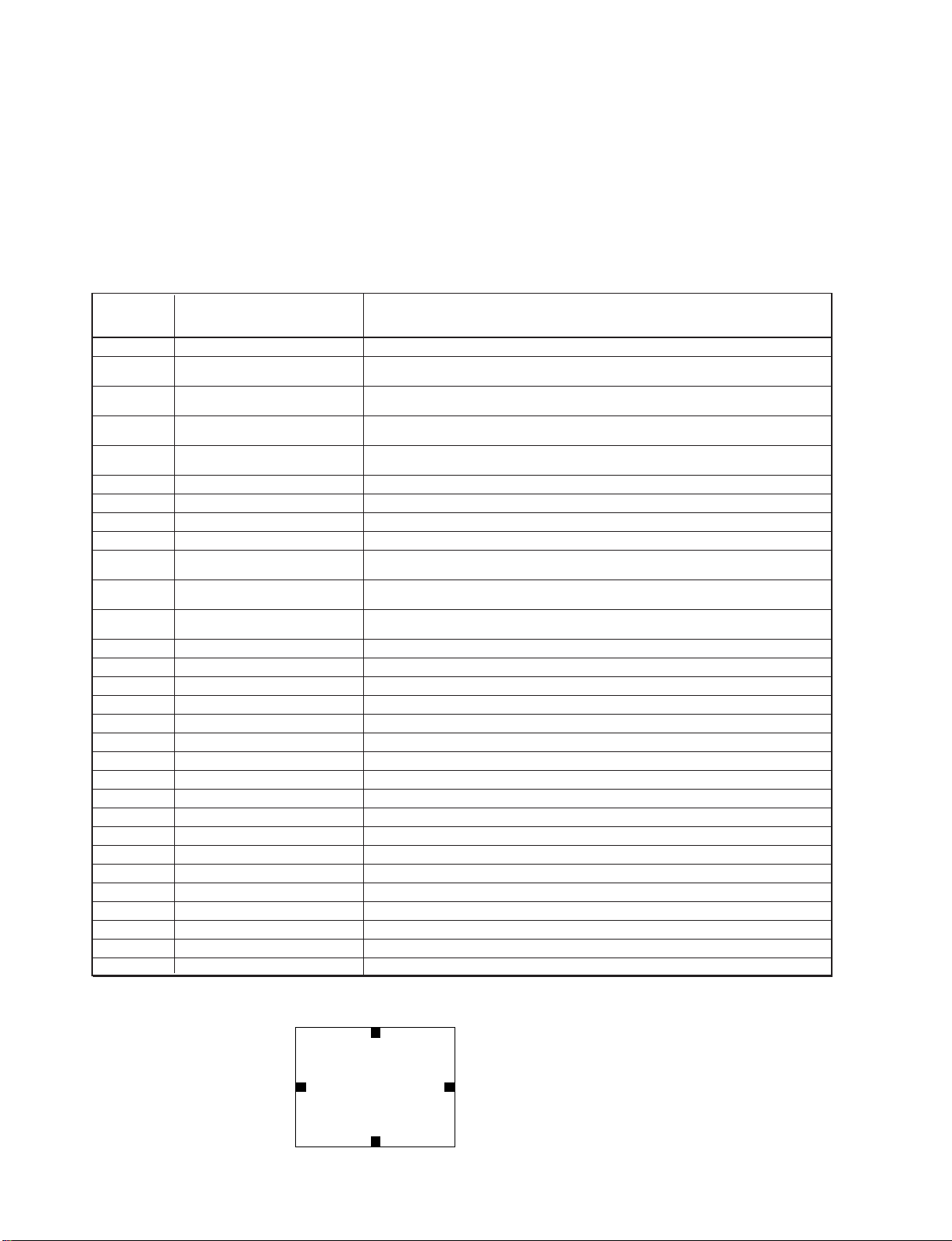

6-1-5. Service List (Projector Engine)

Item

No. Name

00 FDIS Switch of display for fine adjustment data

01 COPY Service copy adjustment

02 ALCP Service all copy adjustment

03 OSDH OSD horizontal position of PJED service menu

04 OSDV 32 75 24 62 OSD vertical position of PJED service menu

05 FVSL 00 14 00 14 00 14 00 14 Start position of fine adjustment

06 FVSP 05 17 15 39 05 16 14 29 Start line of fine adjustment

07 V1DL 01 77 01 148 01 52 01 135 Value of V1 delay

08 V1CU 750 985 375 491 897 1183 449 592 Value of V1 count up

09 V1OH 30 03 Value of V1 offset higher data

10 V1OL Value of V1 offset lower data

11 OEVP Odd/Even select position

12 COHP Horizontal phase for rough adjustment

13 34CS Start center clamp position of H3 and H4 pulse

14 34CW Width center clamp position of H3 and H4 pulse

15 FIHP Horizontal phase for fine adjustment

16 TPHP Horizontal phase for test pattern

17 TPVP 26 58 53 117 20 49 47 103 Vertical phase for test pattern

18 DFHP Horizontal phase for dynamic focus

19 DFHG Value of horizontal parabola wave for dynamic focus

20 DFVG Value of vertical parabola wave for dynamic focus

– 37 –

21 DFDC Value of center for dynamic focus

22 DFV1 Value of V1 saw wave for dynamic focus

23 SDHP Compensation of horizontal phase for shading

24 SDH1 Value of horizontal saw wave for dynamic focus

25 RVCS Start position of RED vertical clamp

26 RVCW Width of RED vertical clamp

27 GVCS Start position of GREEN vertical clamp

28 GVCW Width of GREEN vertical clamp

29 BVCS Start position of BLUE vertical clamp

30 BVCW Width of BLUE vertical clamp

31 RHCS Start position of RED horizontal clamp

32 RHCW Width of RED horizontal clamp

33 GHCS Start position of GREEN horizontal clamp

34 GHCW Width of GREEN horizontal clamp

35 BHCS Start position of BLUE horizontal clamp

36 BHCW Width of BLUE horizontal clamp

37 BDVU 23 18 27 21 23 18 27 21 23 18 27 21 23 18 27 21 Vertical position for border line 1

38 BDVL 905 686 1061 811 905 686 1061 811 905 686 1061 811 905 686 1061 811 Vertical position for border line 2

39 BDHL Horizontal position for border line 1

40 BDHR Horizontal position for border line 2

41 HBLD Horizontal phase for output of H.Blank out

42 HBLW Width for output of H.Blank out

43 PWM2 PWM2 output width setting of Regi. IC

44 COGV GREEN vertical center offset data for Auto Regi.

45 CORV RED vertical center offset data for Auto Regi.

46 COBV BLUE vertical center offset data for Auto Regi.

47 COGH GREEN horizontal center offset data for Auto Regi.

48 CORH RED horizontal center offset data for Auto Regi.

49 COBH BLUE horizontal center offset data for Auto Regi.

Data Range

Wide Zoom 14 : 9 Smart Wide Zoom 14 : 9 Smart Wide Zoom 14 : 9 Smart Wide Zoom 14 : 9 Smart

00, 01

00, 01

00, 01

01 ~ 255

01 ~ 255

00 ~ 15

00 ~ 255

00 ~ 255

00 ~ 4095

00 ~ 255

00 ~ 255

00 ~ 4095

00 ~ 4095

00 ~ 31

00 ~ 31

00 ~ 4095

00 ~ 4095

00 ~ 255

00 ~ 4095

—128 ~ 127

—128 ~ 127

—128 ~ 127

—128 ~ 127

00 ~ 4095

—128 ~ 127

00 ~ 31

00 ~ 31

00 ~ 31

00 ~ 31

00 ~ 31

00 ~ 31

00 ~ 31

00 ~ 31

00 ~ 31

00 ~ 31

00 ~ 31

00 ~ 31

00 ~ 2047

00 ~ 2047

00 ~ 2047

00 ~ 2047

00 ~ 4095

00 ~ 4095

00 ~ 4095

—128 ~ 127

—128 ~ 127

—128 ~ 127

—128 ~ 127

—128 ~ 127

—128 ~ 127

: Fixed data. xxxx : Cannot change.

Standard Data

DRC 100 (PAL) DRC 50 (PAL) DRC100 (NTSC) DRC 50 (NTSC)

00

00

00

26

40

00

1056

4095

14

00

1110

67

100

—90

—40

127

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

159

1253

00

00

00

00

00

00

00

00

00

00

00

00

26

37

00

1056

4095

14

00

1110

67

100

—90

—40

127

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

159

1253

00

00

00

00

00

00

00

00

00

00

00

00

26

01

1056

4095

14

00

1110

67

100

—90

—40

127

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

159

1253

00

00

00

00

00

00

00

00

00

00

00

00

26

994211652

239648

20

31

01

1056

4095

14

00

1110

67

100

—90

—40

127

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

159

1253

00

00

00

00

00

00

00

00

00

Name/Description

15151515

35172309

59

5011001440880

71339346

KP-44PS2/44PS2U/51PS2

RM-903

Page 17

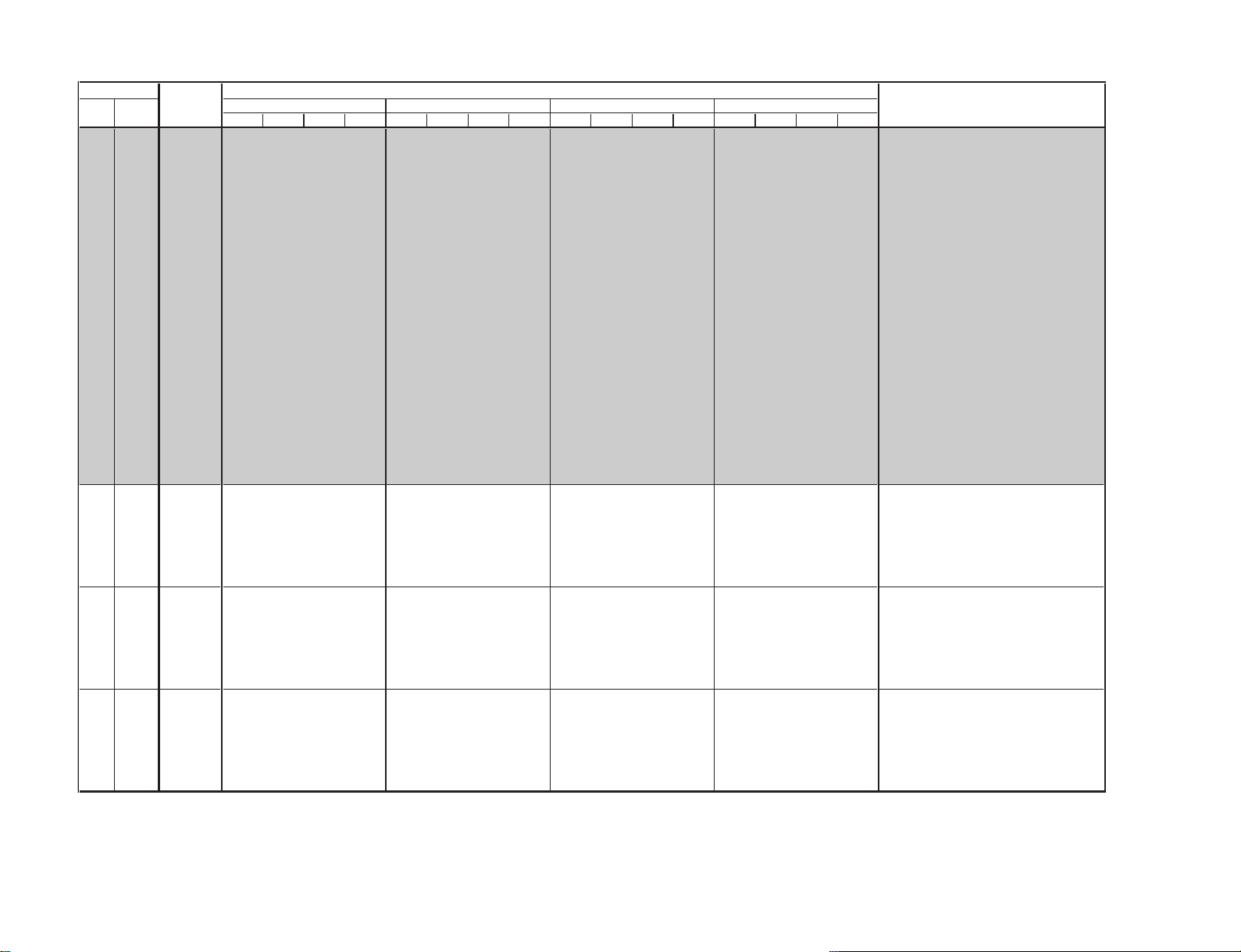

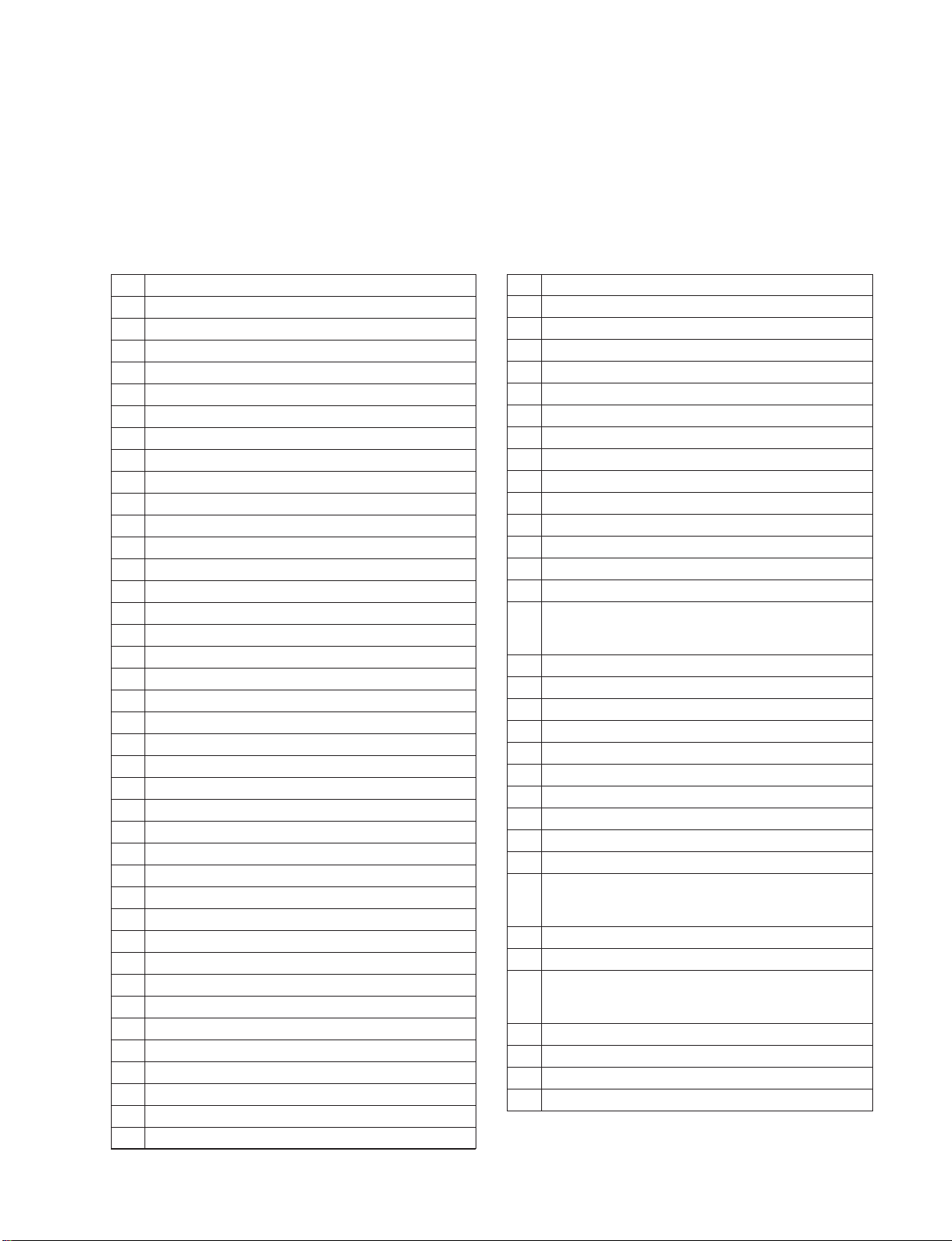

KP-44PS2/44PS2U/51PS2

Item

No. Name

50 SOGV GREEN vertical skew offset data for Auto Regi.

51 SORV RED vertical skew offset data for Auto Regi.

52 SOBV BLUE vertical skew offset data for Auto Regi.

53 SOGH GREEN horizontal skew offset data for Auto Regi.

54 SORH RED horizontal skew offset data for Auto Regi.

55 SOBH BLUE horizontal skew offset data for Auto Regi.

56 ZOGH GREEN horizontal size offset data for Auto Regi.

57 ZORH RED horizontal size offset data for Auto Regi.

58 ZOBH BLUE horizontal size offset data for Auto Regi.

59 LOGH GREEN horizontal linearity offset data for Auto Regi.

60 LORH RED horizontal linearity offset data for Auto Regi.

61 LOBH BLUE horizontal linearity offset data for Auto Regi.

62 ERR Auto Regi. Error code

63 ADTM A/D data input timing of Auto Regi.

64 VUP Auto Regi. Pattern upper vertical position

65 VUPM Auto Regi. Pattern upper middle vertical position

66 VMID Auto Regi. Pattern middle vertical position

67 VLOM Auto Regi. Pattern lower middle vertical position

68 VLOW Auto Regi. Pattern lower vertical position

69 HLE Auto Regi. Pattern left horizontal position

70 HLEM Auto Regi. Pattern left middle horizontal position

71 HMID Auto Regi. Pattern middle horizontal position

72 HRIM Auto Regi. Pattern right middle horizontal position

– 38 –

73 HRIV Auto Regi. Pattern right horizontal position

74 SFTF Switch of shift fast 00 : Normal 01 : Quick

75 ACTL Account time counter lower byte

76 ACTH Account time counter higher byte

77 SLSW Auto Regi. Adjustment item select

GRN

BLU

RED

Data Range

–128 ~ 127

–128 ~ 127

–128 ~ 127

–128 ~ 127

–128 ~ 127

–128 ~ 127

–128 ~ 127

–128 ~ 127

–128 ~ 127

–128 ~ 127

–128 ~ 127

–128 ~ 127

00 ~ 255

00 ~ 127

00 ~ 2047

00 ~ 2047

00 ~ 2047

00 ~ 2047

00 ~ 2047

00 ~ 4095

00 ~ 4095

00 ~ 4095

00 ~ 4095

00 ~ 4095

00, 01

00 ~ 255

00 ~ 255

00 ~ 03

–512 ~ 511

CENT GREEN Horizontal/Vertical center

–512 ~ 511

SKEW GREEN Horizontal/Vertical skew

–512 ~ 511

SIZE GREEN Horizontal/Vertical size

–512 ~ 511

LIN GREEN Horizontal/Vertical linearity

–512 ~ 511

KEY GREEN Vertical keystone

–512 ~ 511

PIN GREEN Horizontal/Vertical pincushion

–512 ~ 511

MLIN GREEN Horizontal mid linearity

–512 ~ 511

MSIZ GREEN Horizontal mid size

–512 ~ 511

CENT BLUE Horizontal/Vertical center

–512 ~ 511

SKEW BLUE Horizontal/Vertical skew

–512 ~ 511

SIZE BLUE Horizontal/Vertical size

–512 ~ 511

LIN BLUE Horizontal/Vertical linearity

–512 ~ 511

KEY BLUE Vertical keystone

–512 ~ 511

PIN BLUE Horizontal/Vertical pincushion

–512 ~ 511

MLIN BLUE Horizontal mid linearity

–512 ~ 511

MSIZ BLUE Horizontal mid size

–512 ~ 511

CENT RED Horizontal/Vertical center

–512 ~ 511

SKEW RED Horizontal/Vertical skew

–512 ~ 511

SIZE RED Horizontal/Vertical size

–512 ~ 511

LIN RED Horizontal/Vertical linearity

–512 ~ 511

KEY RED Vertical keystone

–512 ~ 511

PIN RED Horizontal/Vertical pincushion

–512 ~ 511

MLIN RED Horizontal mid linearity

–512 ~ 511

MSIZ RED Horizontal mid size

DRC 100 (PAL) DRC 50 (PAL) DRC100 (NTSC) DRC 50 (NTSC)

Wide Zoom 14 : 9 Smart Wide Zoom 14 : 9 Smart Wide Zoom 14 : 9 Smart Wide Zoom 14 : 9 Smart

00

00

00

00

00

00

00

00

00

00

00

00

00

80

31

00

290

00

560

135

00

640

00

1170

00

00

00

00

000/000

000/000

000/–200

000/000

xxxx/000

000/250

000/xxxx

000/xxxx

000/000

000/000

000/–200

000/000

xxxx/000

000/250

000/xxxx

000/xxxx

000/000

000/000

000/–200

000/000

xxxx/000

000/250

000/xxxx

000/xxxx

00

00

00

00

00

00

00

00

00

00

00

00

00

80

31

00

290

00

560

135

00

640

00

1170

00

00

00

00

000/000

000/000

000/–200

000/000

xxxx/000

000/250

000/xxxx

000/xxxx

000/000

000/000

000/–200

000/000

xxxx/000

000/250

000/xxxx

000/xxxx

000/000

000/000

000/–200

000/000

xxxx/000

000/250

000/xxxx

000/xxxx

Standard Data

00

00

00

00

00

00

00

00

00

00

00

00

00

120

45

00

475

00

930

135

00

645

00

1170

00

00

00

00

000/000

000/000

000/–200

000/000

xxxx/000

000/250

000/xxxx

000/xxxx

000/000

000/000

000/–200

000/000

xxxx/000

000/250

000/xxxx

000/xxxx

000/000

000/000

000/–200

000/000

xxxx/000

000/250

000/xxxx

000/xxxx

00

00

00

00

00

00

00

00

00

00

00

00

00

120

45

00

475

00

930

135

00

645

00

1170

00

00

00

00

000/000

000/000

000/–200

000/000

xxxx/000

000/250

000/xxxx

000/xxxx

000/000

000/000

000/–200

000/000

xxxx/000

000/250

000/xxxx

000/xxxx

000/000

000/000

000/–200

000/000

xxxx/000

000/250

000/xxxx

000/xxxx

Name/Description

RM-903

Page 18

KP-44PS2/44PS2U/51PS2

RM-903

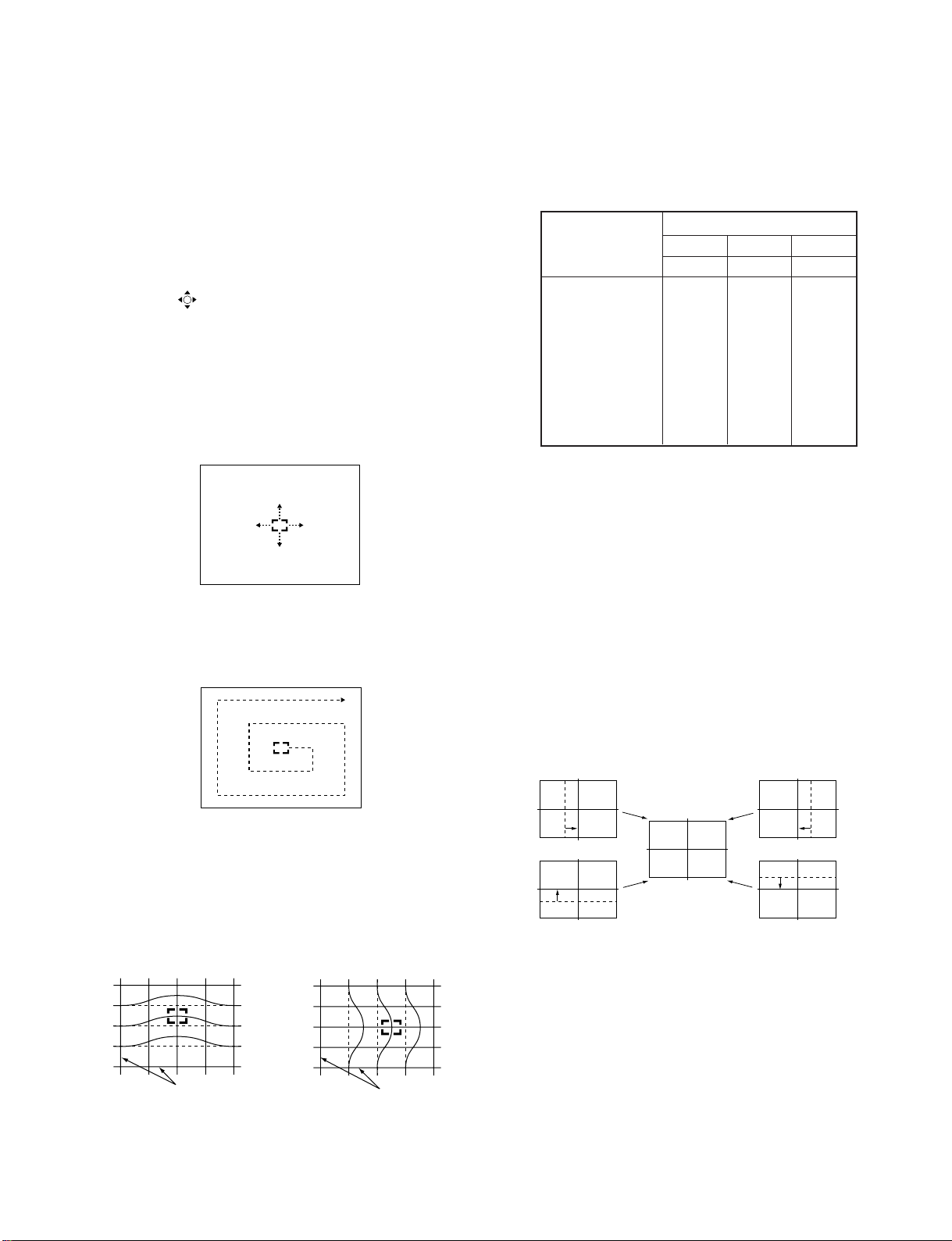

6-2. REGISTRATION ADJUSTMENT

6-2-1.Setup for Adjustment

1. Marking

1) At the 4 insides of the screen, locate the middle. Use a tape

measure to identify the middle.

: middle

2. Data Setting

1) Set DRC100 (PAL-Wide) mode.

2) Enter the Service menu, and select “Device Register Setting” b “Projector Engine”.

3) Press “7” + “-” (READ) buttons on the commander to read

the data from NVM. Then all the default data are restored.

Note : When you replaced printed circuit boards or devices or

CRTs, and when correction is drastically necessary, press

“5” + “-” (PJE INITIAL) buttons to initialize the data

in the Projector Engine mode.

Press “ (MUTE)” + “-” buttons on the commander to

write the data.

5. Adjust “1 V-Size” and “6 H-Size” so that the picture size is

within the specification.

SPEC Overscan Spec. = 7.5%

Input Signal H SIZE V SIZE

PAL SPCB 16.7 ± 0.1 sq. 12.5 ± 0.1 sq.

1 V -Size

6 H-Size

6. Adjust the following items so as to attain the optimum

picture.

4 V -Linear

5 S-Corr

8 Pin Amp

6-2-2. Main Deflection Adjustment

The data values are same in all modes, and therefore the adjustment for the DRC100 (PAL-Wide) mode only is performed here.

1. Place the caps on the red and blue lenses so that only the

green color is displayed.

2. Enter the PAL SPCB signal to set the DRC100 (PAL) mode.

3. Set the screen format to “Wide”.

4. Enter the Service menu, and select “Device Register Setting” b “Deflection”.

5. Adjust “2 V-Position” and “13 H-Position” so that the picture is displayed in the center of screen.

2 V -P osition

13 H-Position

9 Up-CPin

11 Lo-CPin

12 T r apezium

14 AFC-Bow

15 AFC-Angle

– 39 –

Page 19

KP-44PS2/44PS2U/51PS2

RM-903

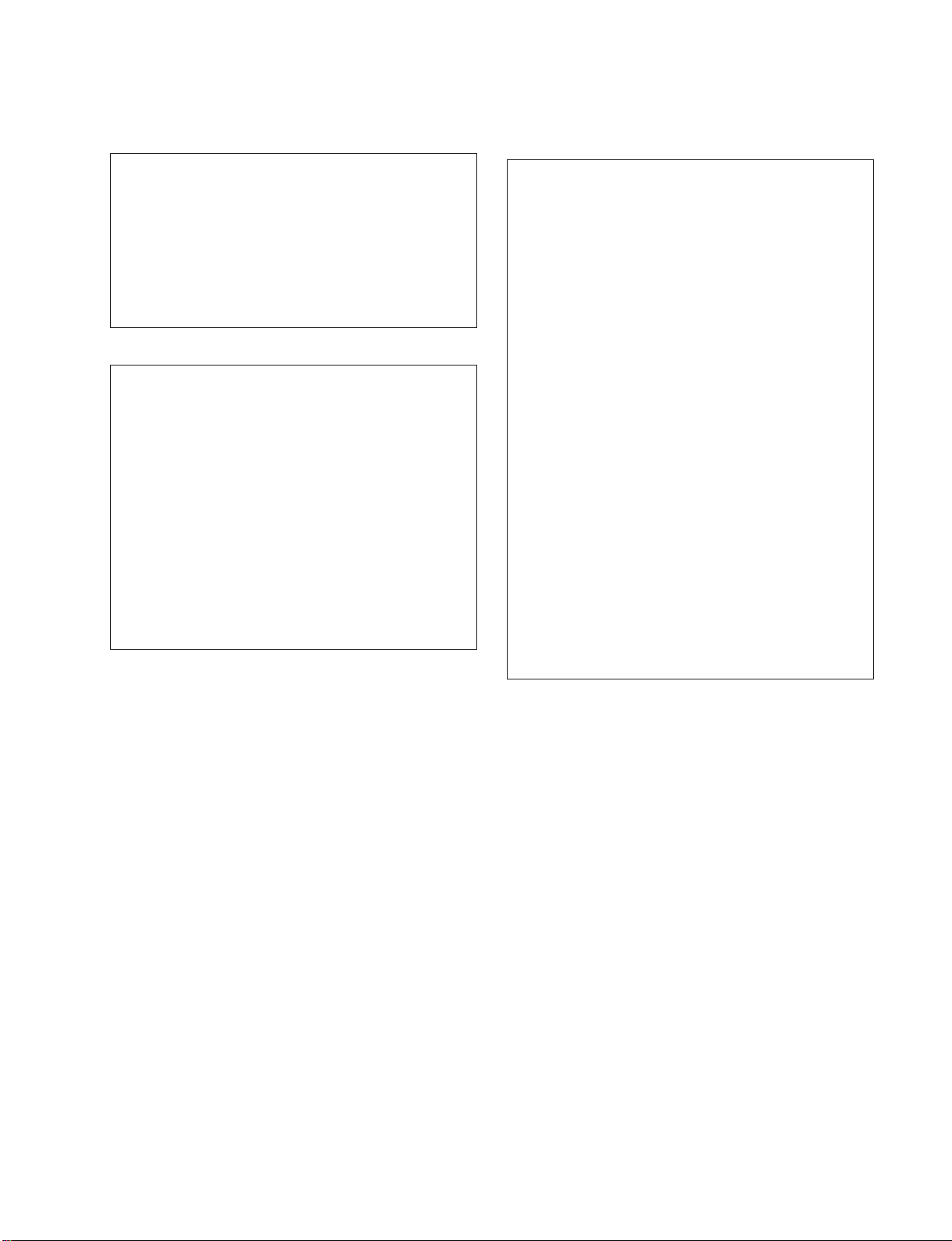

6-2-3. Operation Method for Projector Engine

Mode

MUTE

Write data to NVM

TV MODE

Copy data to all

mode

Adjustment item

up

Adjustment item

down

Read data from

NVM

JOYSTICK

VOLUME +

MENU

1

4

7

2

5

8

0

OK

MENU

SONY

TV

VIDE O TV

3

6

9

RM

PROGR

903

TV STANDBY

ON SCREEN

DISPLAY

Copy PAL data

to NTSC

Color change

Internal test signal

Initialize data

(Not stored)

Mode select

(Fine or Rough)

SCREEN

FORMAT

Wide

Zoom

14 : 9

4 : 3

Smart

RM-903

1. Functions of Keys on Commander

• 1 : Changes adjustment item. (item No. moves up)

: Marker moves clockwise from center to out-

side. (in fine adjustment mode)

• 4 : Changes adjustment item.

(item No. moves down)

: Marker moves counterclockwise from outside

to center. (in fine adjustment mode)

• v V b B : Changes data value. (up or down)

: Marker moves up, down, or to the left or right.

(in fine adjustment mode)

• 3 : Changes adjustment color.

(except item No. 00~77) GRN c BLU c RED

• 6 : Displays or changes internal test signals.

: crosshatch + external signal c dot + external

signal c crosshatch only c dot only c off

• 9 : Switches adjustment mode.

rough adjustment mode c fine adjustment

mode

•

(OK) : Switches marker moving method.

(in fine adjustment mode)

joystick (v, V, b, B) keys c 1 and 4 buttons

Commander Function

Buttons Mode Description

+ - WRITE Writes data to NVM.

7 + - READ Reads data from NVM.

5 + - PJE Service data initialization. Not stored.

2 + - PJE Copies and writes data of DRC1250

INITIAL

COPY

+ - PJE Copies data of PAL mode to NTSC mode.

WRT5060

(Be sure not to use usually)

(50Hz) mode to all other modes.

2. Operation Method for Rough Adjustment

1) Enter the Service menu, and select “Device Register Setting” b “Projector Engine”.

2) Press “1” or “4” button on the commander to select the

item, and press v, V, b, B key on the joystick to change the

data.

Item No.

PJE 00 00

FDIS |

Adjustment Item

Data

v, B : Data up

V, b : Data down

3) Select “GRN CENT” . When BLU or RED is displayed,

press “3” button on the commander to change the adjustment color in the order of GRN c BLU c RED.

4) In the GRN, BLU, or RED mode, v, V keys on the joystick

can change the data in vertical direction, or b, B keys in

horizontal direction.

Color

GRN 000 000

CENT

Data (H)

Data (V)

b : Data (H) up

B : Data (H) down

Adjustment Item

v : Data (V) up

V : Data (V) down

5) Before returning to the Service menu, press “

(MUTE)”

+“-” buttons on the commander to write the data.

(Omission of this operation causes the set data to be returned

to the data before adjustment)

6) Press “MENU” button on the commander to return to the

Service menu.

– 40 –

Page 20

KP-44PS2/44PS2U/51PS2

RM-903

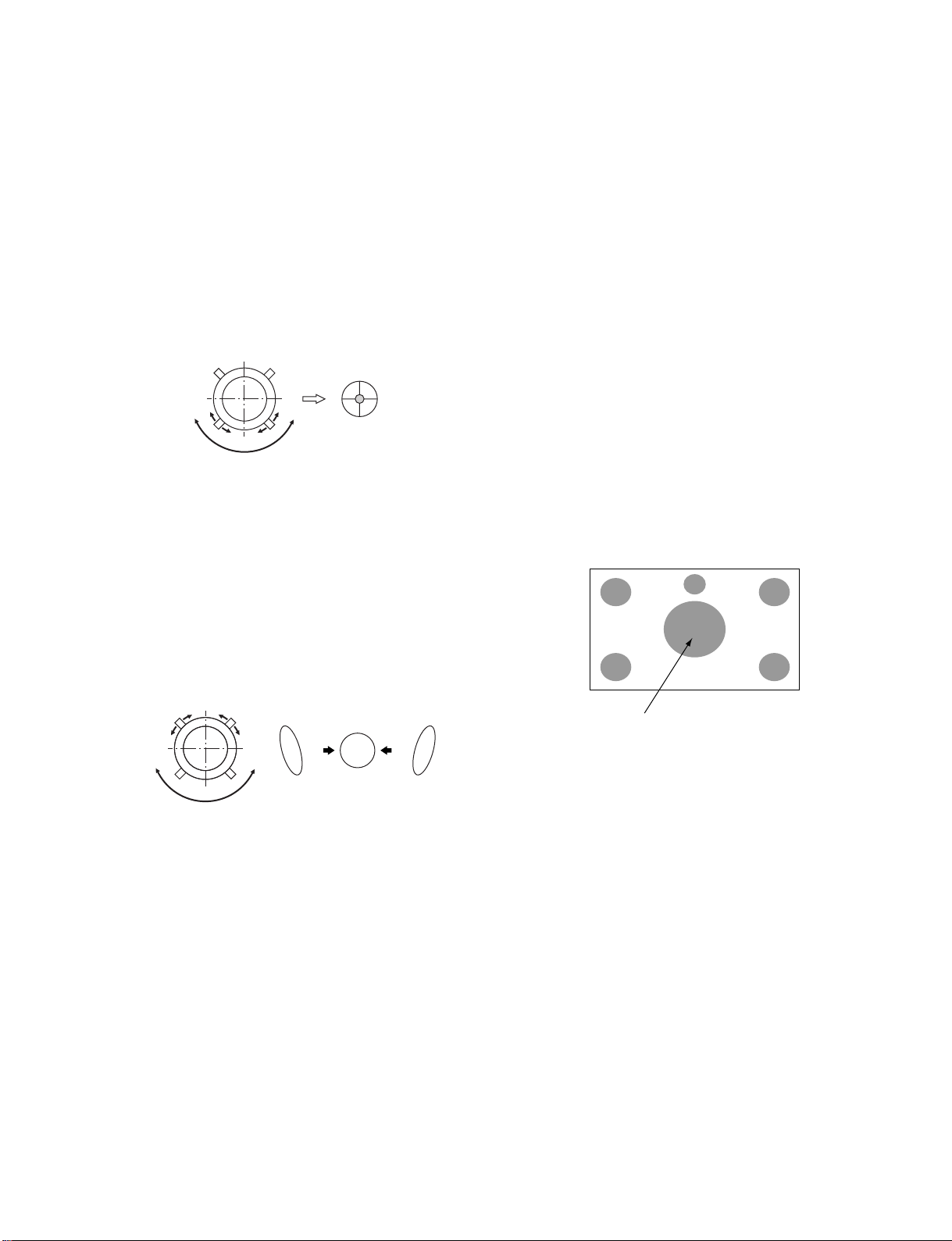

3. Operation Method for Fine Adjustment

(in GRN, BLU, or RED Mode)

1) Select the Projector Engine mode.

2) Select FDIS so that the data at each position can be displayed

in the fine adjustment mode, and set the data to “01”.

3) Press “9” button on the commander, and the fine adjustment mode will be active where a green marker appears in

the center of screen (in the case of GRN mode).

4) Press “

switched between green (GRN mode) and white alternately.

5) Use “1” or “4” button on the commander, or the joystick

to move the marker to the position to be adjusted, where fine

adjustment can be made.

• When marker color is white.

(in this case, fine adjustment is disabled)

• When marker color is green. (GRN mode)

(OK)” button, and the marker color will be

Operating the joystick can move the marker

up, down, or to the left or right freely.

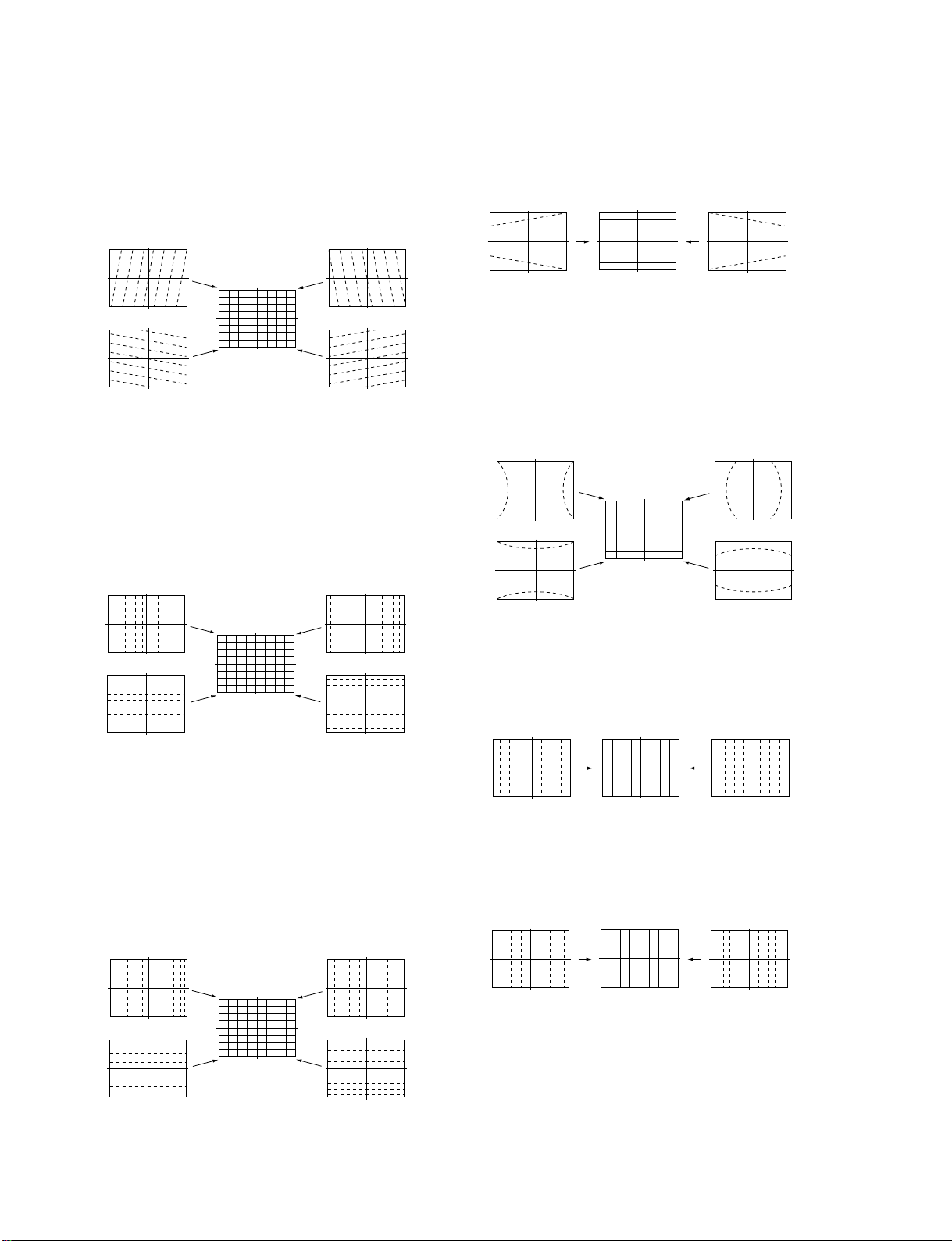

6-2-4.Projector Engine Adjustment

(Sub Deflection Adjustment)

Adjustment a : Yes – : No

Adjustment Type

Adjustment Item GRN RED BLU

H / V H / V H / V

CENT a / aa / aa / a

SKEW a / aa / aa / a

SIZE a / aa / aa / a

LIN a / aa / aa / a

KEY – / a – / a – / a

PIN a / aa / aa / a

MLIN a / – a / – a / –

MSIZ a / – a / – a / –

<Adjustment for DRC100 (PAL-Wide) Mode>

1. Green Adjustment

1) Place the caps on the red and blue lenses so that only the

green color is displayed.

2) Enter the PAL SPCB signal to set the DRC100 (PAL) mode.

3) Set the screen format to “Wide”.

4) Select the Projector Engine mode.

5) Press “6” button on the commander to display internal test

signal (crosshatch).

6) Select “GRN CENT”, and adjust so that the picture coincide

in the center of screen.

1 : moves the marker clockwise from center to outside.

4 : moves the marker counterclockwise from outside to center.

• Fine adjustment can be made on the basis of marker

position using v, V, b, B keys on the joystick.

Movement when v key

on joystick is pressed.

CROSSHATCH

Movement when B key

on joystick is pressed.

CROSSHATCH

6) Press “9” button on the commander to return to the rough

adjustment mode.

• GRN CENT (horizontally/vertically)

Push the joystick

to B

Push the joystick

to v

Push the joystick

to b

Push the joystick

to V

– 41 –

Page 21

KP-44PS2/44PS2U/51PS2

RM-903

7) Select “GRN SKEW”, and correct the tilt of horizontal lines

and vertical lines.

• GRN SKEW (horizontally/vertically)

Push the joystick

to B

Push the joystick

to v

Push the joystick

to b

Push the joystick

to V

8) Select “GRN SIZE”, and adjust so that each distance from

center to left end and to right end is equal. Adjust so that

each distance from center to top and to bottom is equal.

• GRN SIZE (horizontally/vertically)

Push the joystick

to B

Push the joystick

to b

10) Select “GRN KEY”, and adjust so that upper and lower hori-

zontal lines on the screen become parallel.

• GRN KEY (vertically)

Push the joystick

to v

Push the joystick

to V

11) Select “GRN PIN”, and adjust so that right and left vertical

lines on the screen become straight. Adjust so that upper and

lower horizontal lines on the screen become straight.

• GRN PIN (horizontally/vertically)

Push the joystick

to B

Push the joystick

to b

Push the joystick

to v

Push the joystick

to V

9) Select “GRN LIN”, and adjust so that each space at the right

end and at the left end of screen is equal. Adjust so that each

space at the top and at the bottom of screen is equal.

• GRN LIN (horizontally/vertically)

Push the joystick

to B

Push the joystick

to v

Push the joystick

to b

Push the joystick

to V

Push the joystick

to v

Push the joystick

to V

12) Select “GRN MLIN”, and correct the sizes of the horizontal

line at the center of the screen are symmetrical left and right.

• GRN MLIN (horizontally)

Push the joystick

to B

Push the joystick

to b

13) Select “GRN MSIZ”, and correct the space intervals for the

horizontal section of the screen are equal.

• GRN MSIZ (horizontally)

Push the joystick

to B

Push the joystick

to b

14) Press “9” button on the commander to enter the fine adjustment mode.

15) Make fine adjustment so that horizontal lines and vertical

lines become straight.

16) Press “9” button on the commander to return to the rough

adjustment mode.

– 42 –

Page 22

KP-44PS2/44PS2U/51PS2

DRC100

(PAL)

Zoom

14 : 9

Smart

DRC50

(PAL)

Wide

Zoom

14 : 9

Smart

DRC100

(PAL)

Wide

DRC100

(NTSC)

Wide

Zoom

14 : 9

Smart

DRC50

(NTSC)

Wide

Zoom

14 : 9

Smart

Copy Registration Data.

RM-903

2. Blue Adjustment

1) Place a cap on the red lens so that green and blue colors are

displayed.

2) Press “3” button on the commander to select BLU mode.

3) Adjust the following items so that blue lines overlap with

green lines.

• BLU CENT (horizontally/vertically)

• BLU SKEW (horizontally/vertically)

• BLU SIZE (horizontally/vertically)

• BLU LIN (horizontally/vertically)

• BLU KEY (vertically)

• BLU PIN (horizontally/vertically)

• BLU MLIN (horizontally)

• BLU MSIZ (horizontally)

4) Press “9” button on the commander to enter the fine adjustment mode.

5) Make fine adjustment so that horizontal lines and vertical

lines overlap with green lines.

6) Press “9” button on the commander to return to the rough

adjustment mode.

3. Red Adjustment

1) Place a cap on the blue lens so that green and red colors are

displayed.

2) Press “3” button on the commander to select RED mode.

3) Hereinafter, use same manner as that of blue adjustment to

adjust so that the red lines overlap with green lines.

4. Registration Data Writing

1) After each adjustment of green, blue, and red for the

DRC100 (PAL-Wide) mode finished, press “ (MUTE)”+

“-” buttons on the commander to write registration data to

the NVM.

<Copy of All Registration Data>

1. Make sure that the adjustment for DRC100 (PAL-Wide)

mode finished and the data have already been written.

2. Select the Projector Engine mode.

3. Select ALCP and set the data to “01”, and press “

(MUTE)”+“-” buttons on the commander.

4. The data of DRC100 (PAL-Wide) mode are copied to all

other modes.

<Adjustment for DRC100 (PAL-Smart) Mode>

SPEC Overscan Spec. = 7.5%

Input Signal H SIZE V SIZE

PAL SPCB 17.0 ± 0.1 sq. 11.2 ± 0.1 sq.

1. Place the caps on the red and blue lenses so that only the

green color is displayed.

2. Enter the PAL SPCB signal to set the DRC100 (PAL) mode.

3. Set the screen format to “Smart”.

4. Select the Projector Engine mode.

5. Press “6” button on the commander to display internal test

signal (crosshatch).

6. Hereinafter, use same manner as that of adjustment for

DRC100 (PAL-Wide) mode to perform the green adjustments.

9. Press “9” button on the commander to enter the fine adjustment mode.

10. Make a fine adjustment so that horizontal lines and vertical

lines become straight.

11. Press “9” button on the commander to return to the rough

adjustment mode.

12. Hereinafter, use same manner as that of adjustment for

DRC100 (PAL-Wide) mode to perform the blue and red adjustments.

13. After each adjustment of green, blue, and red

for the DRC100 (PAL-Smart) mode finished, press

“

(MUTE)”+“-” buttons on the commander to write reg-

istration data to the NVM.

– 43 –

Page 23

KP-44PS2/44PS2U/51PS2

RM-903

<Copy of Smart Mode Registration Data>

1. Make sure that the adjustment for DRC100 (PAL-Smart)

mode finished and the data have already been written.

2. Set the screen format to “Smart”.

3. Select the Projector Engine mode.

4. Select COPY and set the data to “01”, and press “

(MUTE)”+“-” buttons on the commander.

5. The data of DRC100 (PAL-Smart) mode are copied to all

other Smart modes.

DRC100

(PAL)

Smart

Copy Registration Data.

DRC50

(PAL)

Smart

DRC100

(NTSC)

Smart

DRC50

(NTSC)

Smart

6-3. AUTO CONVERGENCE OFFSET

This adjustment must be performed after the registration adjustment was made or after readjustment was made by any reason.

1. Darken the periphery of this set.

2. Enter the PAL SPCB signal to set the DRC100 (PAL) mode.

3. Set the screen format to “Wide”.

4. Select the Projector Engine mode.

5. Press “

panel of the set.

(The offset value is now automatically stored)

6. Select “62 ERR” of Projector Engine mode.

Confirm ERR is “00”. If ERR is not “00”, recheck. (Refer to

6-8.)

7. Exit the TT mode.

8. Enter the NTSC monoscope signal, and perform the same

steps in the DRC50 (NTSC-Wide) mode respectively.

(AUTO CONVERGENCE)” button on the front

6-4. PICTURE CENTER ADJUSTMENT

1. Enter the SPCB signal.

2. Select the TT mode, and press “3”+“2” buttons on the

commander.

TT32 : Horizontal center adjustment for MID-X input

3. Pressing b or B key on the joystick, move the picture in

horizontal direction to center the picture on the OSD mark.

4. Press “

mander to return to normal TV mode.

6-5. WHITE BALANCE ADJUSTMENT

1. Enter the monoscope signal.

2. Press “MENU” button on the commander to enter the Picture

Adjustment menu.

3. Set the Picture Mode to “Personal”, and the Digital Mode to

“DRC100”, and the screen format to “Wide”.

4. Enter the Service menu, and select “Device Register Setting” b “Backend”.

5. Adjust “13 Sub Bright” so that 10 IRE section barely grows.

6. Enter all-white pattern signal.

7. Fix “17 G-Cutoff” to “31”, and adjust “15 R-Cutoff” and “19

B-Cutoff” so as to attain the optimum white balance.

Condition: All-White Pattern 20 IRE

8. Adjust “13 Sub Bright” so that 100 IRE section barely

grows.

9. Adjust “10 R-Drive” and “12 B-Drive” so as to attain the

optimum white balance.

10. Repeatedly adjust the white balance for the minimum and

maximum picture setting.

(TV MODE)” or “ (OK)” button on the com-

Adjust picture center to

the position of this OSD mark.

– 44 –

Page 24

KP-44PS2/44PS2U/51PS2

RM-903

6-6. SUB BRIGHT ADJUSTMENT

1. Enter the monoscope signal.

2. Press “MENU” button on the commander to enter the Picture

Adjustment menu.

3. Set respective items as follows:

• Picture Mode c Personal

• AI (Artificial Intelligence) c OFF

• Contrast c Minimum

• Brightness c 50%

4. Enter the Service menu, and select “Device Register Setting” b “Backend”.

5. Adjust “13 Sub Bright” so that the border between 0 IRE and

10 IRE becomes distinct.

6-7. SUB COLOR ADJUSTMENT

1. Enter the color bar signal.

2. Connect the oscilloscope probe to the CN4500 pin 5 on the E

board.

3. Enter the Service menu, and set respective items as follows.

However, record current set values so that they can be restored later.

1) Select “Device Register Setting” b “Backend”.

• 1 D-Col c OFF

• 2 Contrast c 31

• 5 Color c 31

• 18 DPIC-Level c 0

• 20 DC-Tran. c 0

2) Select “Initializing” b “Feature Setting”.

• 6 PictBoostBypass c ON

4. Select “Device Register Setting” b “Backend”.

5. Measure waveform, and adjust “29 Sub Color” so that the

height of “a”, “b” and “c” is same as shown in figure.

6. Return the data set in step 3 to original values.

Same level

abc

– 45 –

Page 25

KP-44PS2/44PS2U/51PS2

RM-903

6-8. AUTO CONVERGENCE ERROR CODE LIST

If an error code is displayed after the set has been fully adjusted, correctly, plese check the following items : position, tilt and sizing. If

either of these adjustments are off, even slightli, the auto registration pattern will not hit the four sensors properly. This occurs when the

internal generator patterns is being flashed on the screen for the sensor to read. Therefore, auto registration (called auto convergence)

cannot operate properly causing an error code to be displayed. In order for this function to operate properly, correct position, tilt and

size must be adjusted properly.

ERROR CODE LIST

ERROR

CODE

00 No Error

10 Sensor 0 low output Check sensor 0, connection/wiring, circuit, and pattern position

11 Sensor 1 low output Check sensor 1, connection/wiring, circuit, and pattern position

12 Sensor 2 low output Check sensor 2, connection/wiring, circuit, and pattern position

13 Sensor 3 low output Check sensor 3, connection/wiring, circuit, and pattern position

20 Sensor 0 high output Check sensor 0 and circuit.

21 Sensor 1 high output Check sensor 1 and circuit.

22 Sensor 2 high output Check sensor 2 and circuit.

23 Sensor 3 high output Check sensor 3 and circuit.

30 V CENT or SKEW adjustment Check “66 VMID” data and check registration condition.

31 H CENT or SKEW adjustment Check “71 HMID” data and check registration condition.

32 H LIN or SIZE adjustment Check “71 HMID” data and check registration condition.

40 V CENT regi data overflow Check “66 VMID” data and confirm V CENT data (all mode) is not near 511.

41 H CENT regi data overflow Check “71 HMID” data and confirm H CENT data (all mode) is not near 511.

42 V SKEW regi data overflow Check “66 VMID” data and confirm V SKEW data (all mode) is not near 511.

43 H SKEW regi data overflow Check “71 HMID” data and confirm H SKEW data (all mode) is not near 511.

44 H LIN regi data overflow Check “71 HMID” data and confirm H CENT data (all mode) is not near 511.

45 H SIZE regi data overflow Check “71 HMID” data and confirm H CENT data (all mode) is not near 511.

50 V CENT regi data overdrow Check “66 VMID” data and confirm V CENT data (all mode) is not near –512.

51 H CENT regi data overdrow Check “71 HMID” data and confirm H CENT data (all mode) is not near –512.

52 V SKEW regi data overdrow Check “66 VMID” data and confirm V SKEW data (all mode) is not near –512.

53 H SKEW regi data overdrow Check “71 HMID” data and confirm H SKEW data (all mode) is not near –512.

54 H LIN regi data overdrow Check “71 HMID” data and confirm H CENT data (all mode) is not near –512.

55 H SIZE regi data overdrow Check “71 HMID” data and confirm H CENT data (all mode) is not near –512.

60 H or V CENT offset overflow Check “71 HMID” data and check “66 VMID” data.

61 H or V SKEW offset overflow Check SKEW adjustment.

62 H SiZE or LIN offset overflow Check “71 HMID” data, check “66 VMID” data and check SIZE and LIN adjustment.

70 H or V CENT offset overdrow Check “71 HMID” data and check “66 VMID” data.

71 H or V SKEW offset overdrow Check SKEW adjustment.

72 H SIZE or LIN offset overdrow Check “71 HMID” data, check “66 VMID” data and check SIZE and LIN adjustment.

DESCRIPTION REMEDY

(Is pattern over sensor ?) Adjust “64 VUP” if necessary.

(Is pattern over sensor ?) Adjust “69 HLE” if necessary.

(Is pattern over sensor ?) Adjust “73 HRIV” if necessary.

(Is pattern over sensor ?) Adjust “68 VLOW” if necessary.

loop overflow

loop overflow

loop overflow

[SENSOR POSITION]

0 : UPPER SENSOR

1 : LEFT SENSOR

2 : RIGHT SENSOR

3 : LOWER SENSOR

0

12

SCREEN

3

– 46 –

Page 26

KP-44PS2/44PS2U/51PS2

6-9. TEST-TEST MODE

Is available by pressing “OSD”, “5”, “Volume minus”, “TV” button in the standby mode, OSD “TT--” appears. The functions described below are available by pressing the two numbers. To release the Test-Test mode, Press “-” twice or switch the TV set into

standby mode. Pressing the two PROGR (+ and –) buttons during Power ON will also switch into “TT” mode.

In “TT” mode, it is possible to remove the Menu from the screen by pressing the Speaker OFF button once. Pressing the Speaker OFF

button a second time will cause the menu to reappear. The Function is kept even when the menu is not displayed !!.

RM-903

00 Switch back to normal mode - “TT” mode off

01 Set picture maximum

02 Set picture minimum

03 Set speaker/headphone Volume to 30%

04 Set speaker/headphone Volume to 50%

05 Set speaker/headphone Volume to 65%

06 Set speaker/headphone Volume to 80%

07 Ageing Mode

08 Shipping Condition

09 Enter PJ Engine service mode

10 No function

11 Sub picture adjustment

12 Sub colour adjustment

13 Displayed software version and TV set configuration

14 Production Info Display

15 Picture Rotation

16 Picture level 50%

17 Audio mute on

18 No function

19 Sub brightness adjustment

20 No function

21 Destination A includes text settings, display TV status

22 Destination L includes text settings, display TV status

23 Destination E includes text settings, display TV status

24 Destination U includes text settings, display TV status

25 Destination D includes text settings, display TV status

26 Destination B includes text settings, display TV status

27 Destination K includes text settings, display TV status

28 Destination R includes text settings, display TV status

30 No function

31 Geometry adjustment 1

32 Geometry adjustment 2

33 Error monitor

34 No function

35 CRT 4:3 <–> 16:9 ; Display TV status

36 Line 23 detection switch

37 Velocity Modulation (VM) test

38 No function

39 No function

40 No function

41 Screen mode check

42 Reinitialize geometry

43 No function

44 Screen mode DRC100

45 Screen mode DRC50

46 Reserved for dealer commander

47 Reinitialize NVM with program 99

48 Set NVM as non virgin

49 Set NVM as virgin

50 No function

51 Set Dolby volume to 90%

52 Dolby on left speaker only

53 Dolby on right speaker only

54 Dolby on left centre only

55 Dolby surround speaker only

56

ı No function

59

60 No function

61 Service mode

62 Production mode

65 Reset error codes

68 Ignore errors on

69 Ignore errors off

70 No function

71 No function

72 No function

73 Clear programs

74

ı No function

79

80 No function

82 PAP H adjustment left image

83

ı No function

86

87 Personal ID reset with program 99

88 Parental Lock off

89 No function

90 No function

– 47 –

Page 27

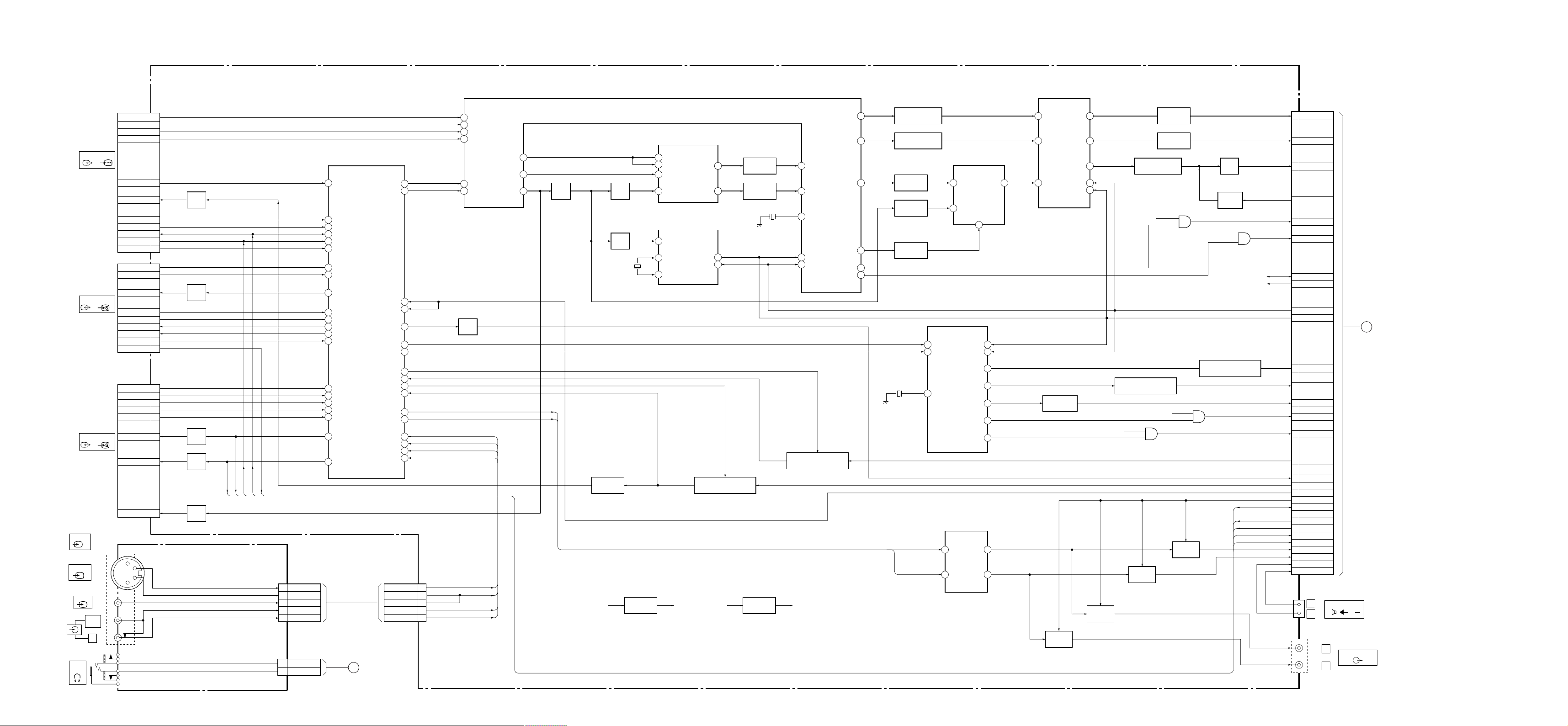

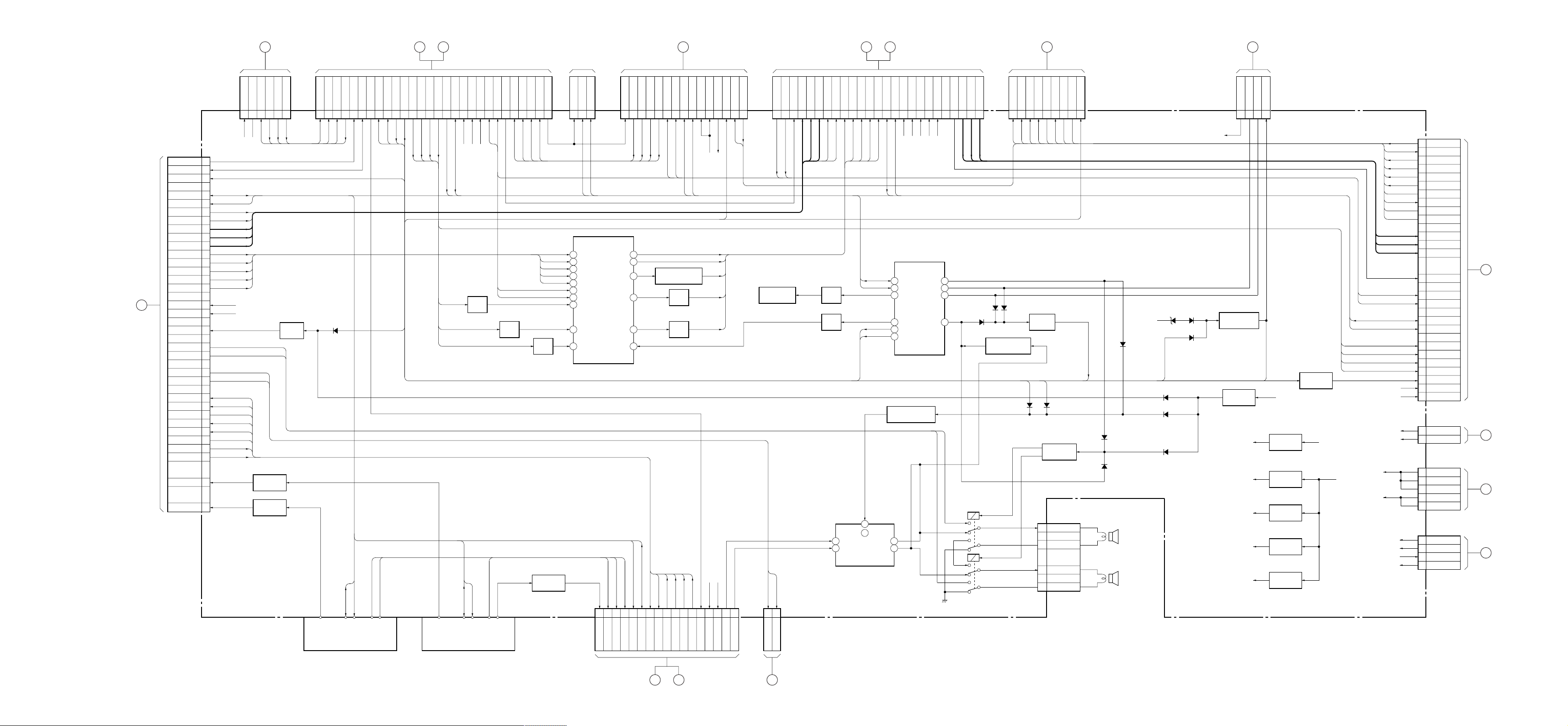

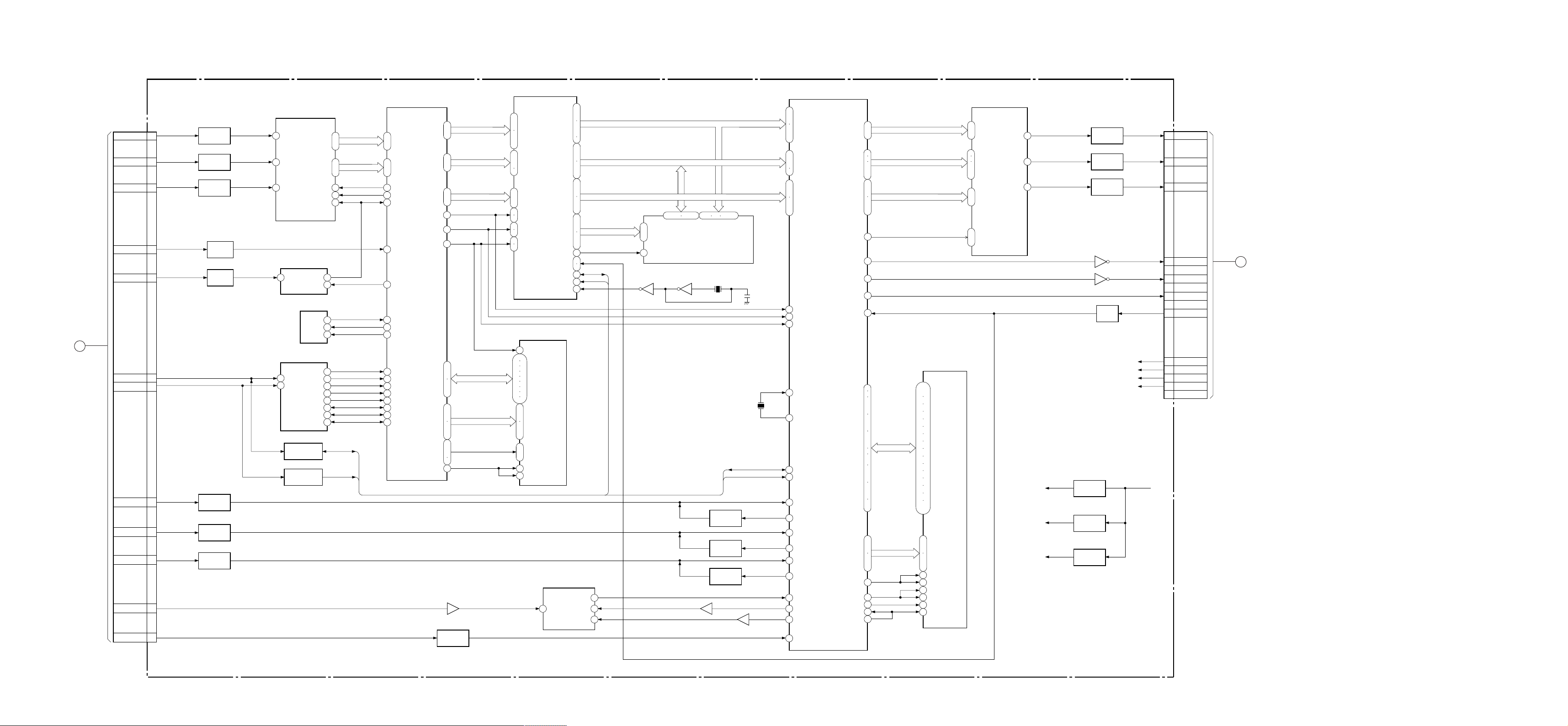

SECTION 7

7-1. BLOCK DIAGRAMS

J

CN8900

AV4

4

S VIDEO

s

VIDEO

(MONO)

J3502

HEAD

PHONE

AV1

1/

AV2

2/ 2

AV3

3/ 3

L

R

BLUE IN

GREEN IN

RED IN

BLANKING

VIDEO IN

VIDEO OUT

RIGHT IN

LEFT IN

RIGHT OUT

LEFT OUT

VIDEO/Y IN

VIDEO OUT

RIGHT IN

LEFT IN

RIGHT OUT

LEFT OUT

AV LINK

VIDEO/Y IN

RIGHT IN

LEFT IN

RIGHT OUT

LEFT OUT

VIDEO OUT

J3501

MODE

CN8901

C IN

MODE

CN8902

C IN

MODE 8

7

11

15

16

20

19

2

6

1

3

8

15

20

19

2

6

1

3

8

10

15

20

2

6

1

3

19

HB

(AV INPUT,HP OUT)

DIAGRAMS

(AV SELECT SW,VIDEO PROCESS)

IC8451

AV SIGNAL SELECT SW

MAIN

Y OUT

MAIN

C OUT

SUBTU-L

SUBTU-R

VIDEO OUT

SUB Y OUT

SUB C OUT

SUB TV

HP LOUT3

HP ROUT3

AV3-R

AV3-L

AV3-V

AV3-C

Q8811

BUFF

Q8452

BUFF

Q8904

BUFF

Q8903

BUFF

Q8901

BUFF

MAIN L

MAIN R

L-TV

AV LINK

R-TV

CN3501

3

1

5

7

9

CN3502

HP R OUT1

HP L OUT4

– 49 –

60

AV1-V

AV1-R

36

AV1-L

29

32

RTV

25

LTV

18

MODE1

AV2-C

52

AV2-V

58

AV2-OUT

9

35

AV2-R

28

AV2-L

40

AV2-R OUT

41

AV2-L OUT

MODE2

19

AV4-C

49

AV4-V

54

AV4-R

33

AV4-L

26

MODE3

20

MAIN ROUT

38

MAIN LOUT

39

C

Y

V

L

R

I

TO A BOARD

CN1301

11

13

30

37

43

45

47

LD1

8

62

LD0

5

64

TV

23

24

34

27

56

51

CN8903

C

Y

V

L

R

IC8301

MAIN COLOR DECODER

23

25

B1

26

G1

27

R1

15

YS3

COMB

45

SYS

SFC

46

CVBS

1

/Y1

48

C1

Q8451

BUFF

Y/V

3

1

5

7

9

C

Y/V

OUT

CVBS

3

OUT

HP L OUT

HP R OUT

R

L

C

L

R

Q8902

BUFF

Q8501

BUFF

Q8700

BUFF

X8700

14.3MHz

Q8814,8815

AMP

IC8304

+5V REG

+6.5V +DIG5V

IO

IC8500

DIGITAL COMB FILTER

23

PNR

LUMINANCE

NTPL1

26

CLOCK IN

37

A/D IN

2

6

A/D IN

XO

25

XI

26

AUTO WIDE

OUT

CHROMA

OUT

IC8700

SCL

SDA

Q8809,8810,8812,8813

AMP,BUFF,DL SW

+6.5V +ANA5V

15

16

9

7

Q8502,8503

BUFF

Q8302,8504

BUFF

X8301

16.2MHz

IC8305

+5V REG

IO

5

7

38

13

14

Q8801,8804,8805,8807

AMP,BUFF,DL SW

COMB Y

COMB C/

FORCED S

Xtal

SCL

SDA

Cr OUT

22

Cb OUT

Y OUT

21 3 7

SCP

10

HS

9

VS

4

Q8620,8621,8623

AMP,BUFF

Q8612,8614,8615

AMP,BUFF

Q8602,8607

BUFF

Q8639,8640

BUFF

Q8636-8638

INV

IC8401

SUB COLOR

DECODER

X8401

16.2MHz

HP R OUT

HP L OUT

48

38

1

CVBS/Y1

C1

Xtal

7

RIN(+) ROUT

LIN(+)

YIN

CVIN

1

IC8452

HP AMP

IC8602

NOISE DET

Y OUT

SW

2

13

SCL

SDA

14

V OUT

23

U OUT

22

Y OUT

21

HS

9

VS

4

1

36

LOUT

– 50 –

IC8601

PICTURE BOOSTER

9

-VIN

-V OUT

8

-UIN

-U OUT

Y OUT

6

YIN

Q8628-8631

AMP,BUFF

Q8906

MUTE SW

SDA

SCL

16

17

19

14

11

+ANA 5V

Q8905

MUTE SW

Q8604,8609

AMP,BUFF

Q8601,8603

AMP,BUFF

Q8605,8610,8611

AMP,BUFF

IC8302(1/2)

+ANA 5V

7

6

5

Q8309

MUTE SW

+ANA 5V

Q8626,8627,8633,8634

AMP,BUFF

2

1

IC8303(2/2)

SYNC BUFF

Q8311

MUTE SW

Q8606

BUFF

Q8616

TRAP SW

3

+ANA 5V

Q8624,8625,8632,8635

6

3

5

2

1

IC8302(1/2)

AMP,BUFF

IC8303(1/2)

SYNC BUFF

AV LINK

R-TV

L-TV

MAIN R

MAIN L

7

+9V

+6.5V

CN8101

V MAIN IN

A24

A25

U MAIN IN

Y MAIN IN

B25

B3

HP MAIN IN

A22

A23

VP MAIN IN

A16

A17

A6

B6

V SUB IN

A20

U SUB IN

B20

B21

Y SUB IN

A19

HP SUB IN

B19

VP SUB IN

CVBS2 OUT

A2

A12

CVBS1 OUT