Page 1

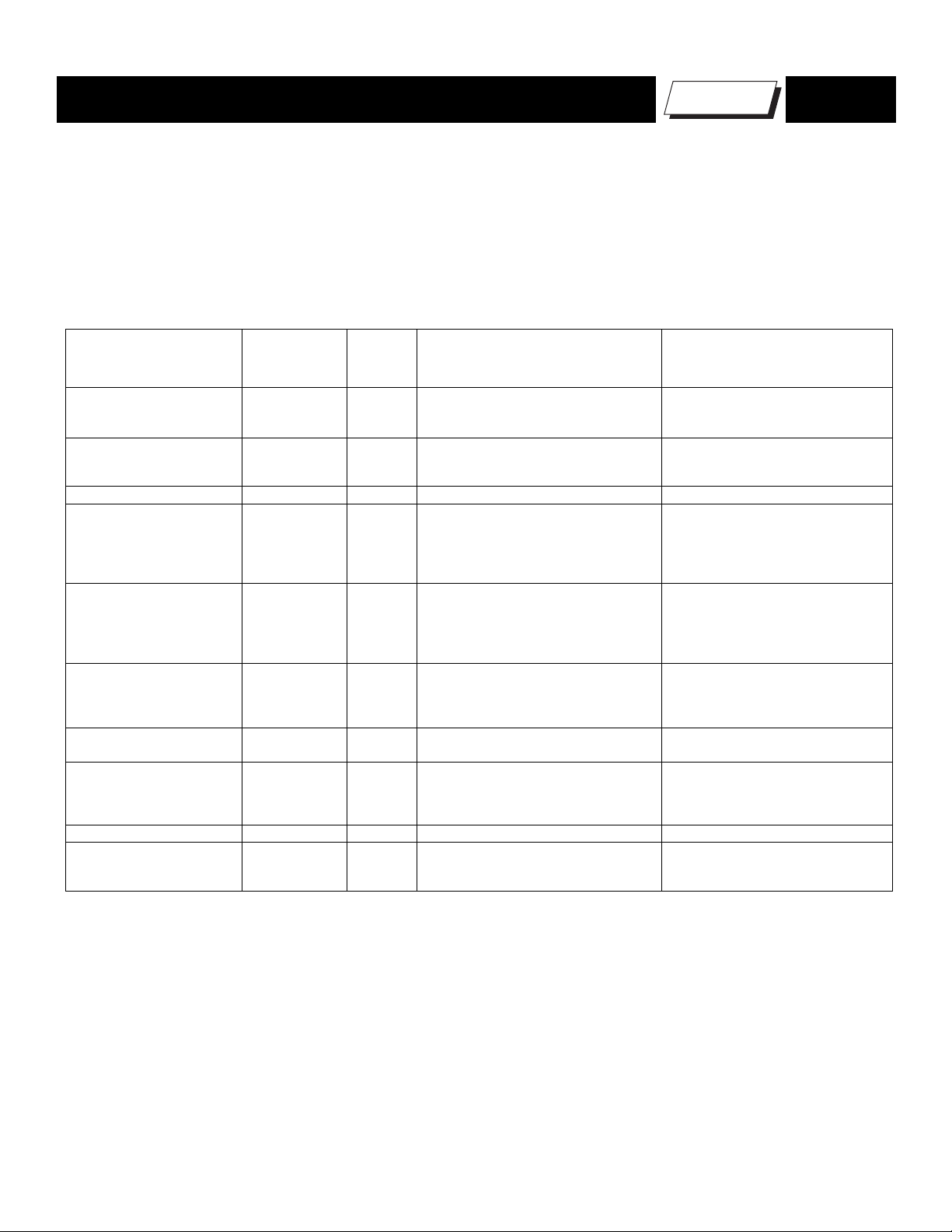

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KP-46WT520

KP-51WS520

KP-57WS520

RM-Y916 US/CND/MX SCC-M37B-A

RM-Y916 US/CND/MX SCC-M37C-A

RM-Y916 US/CND/MX SCC-M37A-A

AX-1X

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 7/2004

REVISION DATE REVISION TYPE SUBJECT

7/2004 No revisions or updates are applicable at this time.

COLOR REAR VIDEO PROJECTION

9-965-968-01

Page 2

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KP-46WT520

KP-51WS520

KP-57WS520

RM-Y916 US/CND/MX SCC-M37B-A

RM-Y916 US/CND/MX SCC-M37C-A

RM-Y916 US/CND/MX SCC-M37A-A

AX-1X

CHASSIS

9-965-968-01

KP-51WS520 RM-Y916

COLOR REAR VIDEO PROJECTION

Page 3

KP-46WT520/51WS520/57WS520

TABLE OF CONTENTS

SECTION TITLE PAGE SECTION TITLE PAGE

Specifi cations ................................................................................. 4

Warnings and Cautions .................................................................. 5

Safety Check-Out ........................................................................... 6

Self-Diagnostic Function................................................................. 7

SECTION 1: DISASSEMBLY............................................................... 10

1-1. Rear Board Removal............................................................ 10

1-2. Chassis Assembly Removal ................................................. 10

1-3. Service Position ....................................................................11

1-4. Terminal Board and P Board Removal..................................11

1-5. BM Board Board Removal ................................................... 12

1-6. A Board, D Board, and G Board Removal............................ 12

1-7. High-Voltage Cable Installation and Removal...................... 13

1-8. Picture Tube Removal .......................................................... 13

1-9. Speaker Grille, HA1 Board, and HB2 Board Removal

(KP-46WT520 Only)............................................................. 14

1-10. Speaker Grille, HA1 Board, and HB1 Board Removal

(KP-51WS520/57WS520 Only)............................................ 14

1-11. Beznet Assembly Removal .................................................. 15

1-11-1. Screen Tape Method................................................ 15

1-12. SR Board Removal .............................................................. 16

Wire Dressing....................................................................... 17

SECTION 2: SET-UP ADJUSTMENTS................................................ 31

2-1. Screen Voltage Adjustment (G2) (Coarse Adjustment)........ 31

2-2. Screen (G2) Adjustment (Fine Adjustment).......................... 31

2-3. Defl ection Yoke Tilt Adjustment............................................ 31

2-4. Focus Lens Adjustment ........................................................ 32

2-5. Focus VR Adjustment........................................................... 32

2-6. Centering Magnet Adjustment .............................................. 33

2-7. 2-Pole Magnet Adjustment .................................................. 33

2-8. 4-Pole Magnet Adjustment ................................................... 33

2-9. Defocus Adjustment (Blue)................................................... 33

2-10. Electrical Adjustments by Remote Commander................... 34

2-10-1. Method of Entering the Service Adjustment Mode .. 34

2-10-2. Memory Write Confi rmation Method ........................ 34

2-10-3. Adjusting Buttons and Indicator ............................... 34

2-11. Adjustable Service Data Lists .............................................. 35

2-11-1. ID Map Table............................................................ 49

2-12. Registration Adjustment (PJE Mode Only)........................... 50

2-12-1. Setup for Adjustment ............................................... 50

2-12-2. Main Defl ection Adjustment..................................... 50

2-12-3. Operation Method for Projector Engine Mode ......... 51

2-13. PJE Adjustment (Sub Defl ection Adjustment) ...................... 52

2-13-1. Adjustment for NTSC Full Mode .............................. 53

2-13-2. Copying All Registration Data to Other Modes ........ 55

2-14. Auto Registration Offsets ..................................................... 55

2-15. Auto Registration Error Codes ............................................. 56

2-16. Auto Registration Diagnostics .............................................. 57

SECTION 3: SAFETY-RELATED ADJUSTMENTS............................. 58

D BOARD ..................................................................................... 58

3-1. HV Regulation Circuit Check and Adjustment...................... 58

3-2. HV Hold Down Circuit Operation Check .............................. 58

G BOARD ..................................................................................... 59

3-3. +B Max Voltage Confi rmation .............................................. 59

3-4. +B OVP Confi rmation........................................................... 59

SECTION 4: CIRCUIT ADJUSTMENTS.............................................. 60

4-1. P & P Sub Contrast Adjustment (Video) (SCON)................. 60

4-2. P & P Sub Contrast Adjustment (RF) (SCON) ..................... 60

4-3. P & P Sub-Hue and Sub-Color Adjustment Video

(SHUE, SCOL) ..................................................................... 60

4-4. P & P Sub-Hue and Sub-Color Adjustment

(RF) (SHUE, SCOL)............................................................. 60

4-5. Blue Offset Adjustment......................................................... 61

SECTION 5: DIAGRAMS..................................................................... 62

5-1. Circuit Boards Location ........................................................ 62

5-2. Printed Wiring Boards and

Schematic Diagrams Information ......................................... 62

5-3. Block Diagrams .................................................................... 64

Signal Flow Block Diagram .................................................. 64

Power Block Diagram........................................................... 65

Audio Signal Path Block Diagram ........................................ 66

Video Path Block Diagram ................................................... 67

SYNC/OSD Path Block Diagram.......................................... 68

5-4. Schematics and Supporting Information ............................. 69

CR Board Schematic Diagram ............................................ 69

CB Board Schematic Diagram ............................................ 70

CG Board Schematic Diagram ............................................ 71

VM Board Schematic Diagram ............................................ 74

A Board Schematic Diagram (1 of 6).................................... 75

A Board Schematic Diagram (2 of 6).................................... 76

A Board Schematic Diagram (3 of 6).................................... 77

A Board Schematic Diagram (4 of 6).................................... 78

A Board Schematic Diagram (5 of 6).................................... 79

A Board Schematic Diagram (6 of 6).................................... 80

D Board Schematic Diagram (1 of 2) ................................... 85

D Board Schematic Diagram (2 of 2) ................................... 86

BM Board Schematic Diagram (1 of 3) ................................ 90

BM Board Schematic Diagram (2 of 3) ................................ 91

BM Board Schematic Diagram (3 of 3) ................................ 92

G Board Schematic Diagram ............................................... 94

HA1 Board Schematic Diagram .......................................... 97

P Board Schematic Diagram................................................ 98

SR Board Schematic Diagram ............................................ 99

HB1 Board Schematic Diagram

(KP-51WS520/57WS520 Only) .............................. 99

HB2 Board Schematic Diagram

(KP-46WT520 Only) ................................................ 99

5-5. Semiconductors ................................................................. 101

SECTION 6: EXPLODED VIEWS...................................................... 102

6-1. Cover (KP-46WT520 Only) ................................................ 102

6-2. Cover (KP-51WS520/57WS520 Only) ............................... 103

6-3. Chassis .............................................................................. 104

6-4. Picture Tube ....................................................................... 105

SECTION 7: ELECTRICAL PARTS LIST......................................... 106

KP-46WT520/51WS520/57WS520

3

Page 4

SPECIFICATIONS

KP-46WT520

KP-51WS520

KP-57WS520

KP-46WT520/51WS520/57WS520

Power Requirements

120V AC, 60Hz

Power Consumption (W)

In Use (Max)

In Standby

Inputs/Outputs

235W

Under 1 W

HDMI IN

Video

1080i, 720p, 480p, 480i

Audio

Two channel linear PCM 32, 44.1, and 48 kHz, 16, 20, and 24 bit

Video (IN)

4 total (1 on front panel)

1Vp-p, 75ohms unbalanced, sync negative

S Video (IN)

3 total (1 on front panel)

Y: 1Vp-p, 75ohms unbalanced, sync negative

C: 0.286Vp-p (Burst signal), 75ohms

Speaker Output (W)

Audio (IN)

7 total (1 on front panel)

500 mVrms (100% modulation)

Impedance:47 kilohm

Component Video Input

2 ( Y,PB,P

Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative;

PB: 0.7 Vp-p, 75 ohms;

PR: 0.7 Vp-p, 75 ohms

Control S (IN/OUT)

1 total

Variable/Fixed Audio (OUT)

More than 408 m Vrms at the maximum volume setting

(Variable)

More than 408 m Vrms (Fixed) Impedance (output):2 kilohms

KP-46WT520

KP-51WS520

20W x 2

R)

KP-57WS520

Dimensions (W x H x D)

mm

in

1086 x 1017 x 609 mm 1194 x 1280 x 666 mm 1326 x 1377 x 692 mm

42

Mass kg

61.3 kg 77.2 kg 88 kg

135 lbs 170 lbs 194 lbs

lbs

Projection System

3 picture tubes, 3 lenses, horizontal in-line system

Picture Tube

7-inch high-brightness monochrome tubes (6.3 raster size),

with optical coupling and liquid cooling system.

Projection Lenses

High performance, large diameter hybrid lens F1.1

Antenna

75 ohm external terminal for VHF/UHF

Television System

NTSC, American TV Standard

Channel Coverage

VHF: 2-13/UHF: 14-69/CATV: 1-125

3/4

x 40 x 24 in 47 x 50

1/2

1/4

x 26

in 52

1/4

x 54

1/4

x 27

1/4

in

Screen Size (measured diagonally)

46 inches (KP-46WT520)

51 inches (KP-51WS520)

57 inches (KP-57WS520)

Supplied Accessories

Remote Control RM-Y916

Batteries (2) size AA (R6)

Optional Accessories

A/V Cable (VMC-810/820/830 HG)

Audio Cable (RKC-515HG)

Component Video Cable (VMC-10/30 HG)

Control S Cable (RK-G69HG)

TV Stand SU-46WT11 (For KP-46WT520 Only)

Design and specifi cations are subject to change without notice.

KP-46WT520/51WS520/57WS520

4

Page 5

KP-46WT520/51WS520/57WS520

WARNINGS AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield, or carbon painted on the CRT, after

removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the ac power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe

operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

ATTENTION!!

Apres avoir deconnecte le cap de l’anode, court-circuiter l’anode du tube cathodique et celui de l’anode du cap au chassis metallique

de l’appareil, ou la couche de carbone peinte sur le tube cathodique ou au blindage du tube cathodique.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout

dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de pieces

sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont le numero

de piece est indique dans le present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont l’importance

est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de chaque

remplacement de composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

KP-46WT520/51WS520/57WS520

5

Page 6

SAFETY CHECK-OUT

e

KP-46WT520/51WS520/57WS520

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if

sets always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

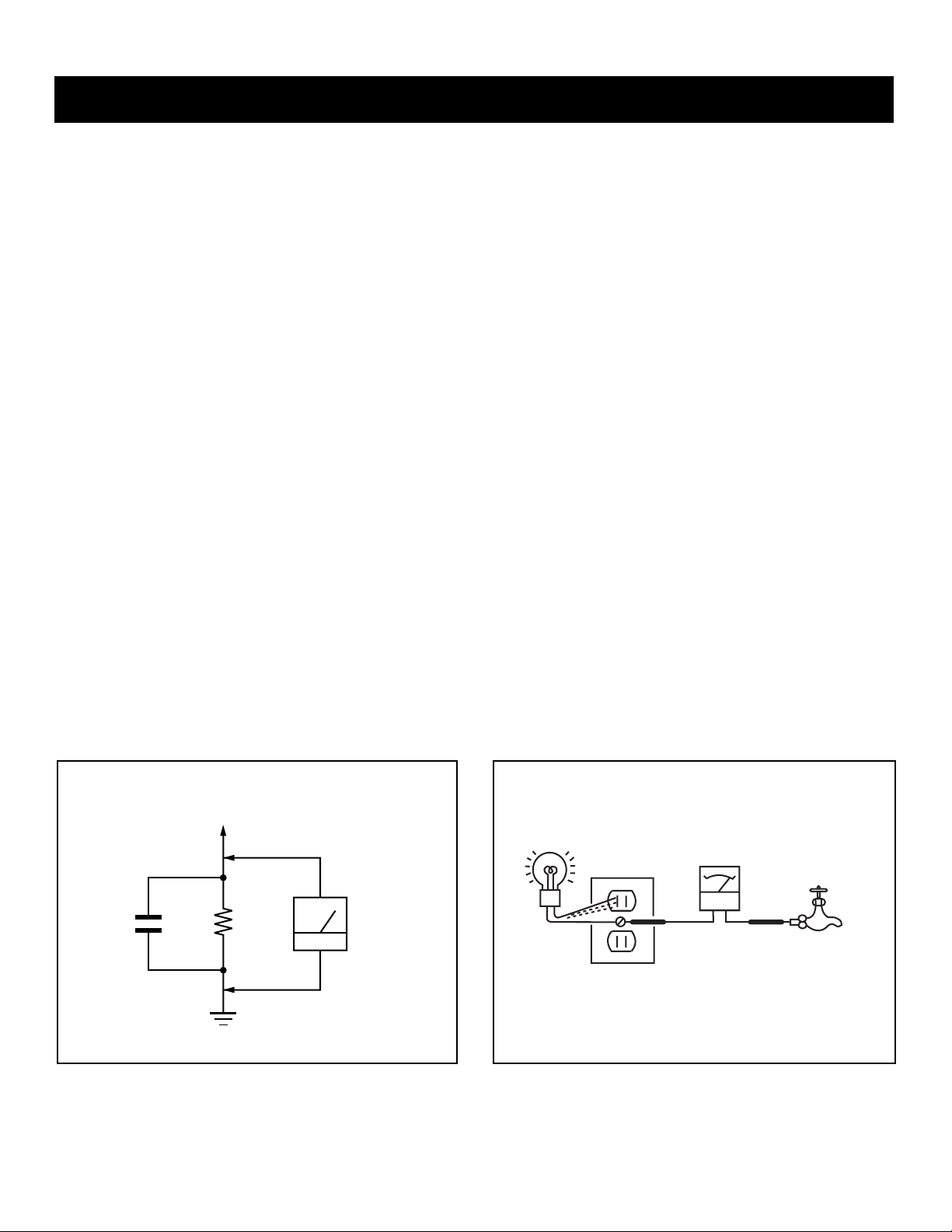

Leakage Test

The AC leakage from any exposed metal part to earth ground and from

all exposed metal parts to any exposed metal part having a return to

chassis, must not exceed 0.5 mA (500 microamperes). Leakage current

can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliammeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75 V,

so analog meters must have an accurate low voltage scale. The

Simpson’s 250 and Sanwa SH-63TRD are examples of passive

VOMs that are suitable. Nearly all battery-operated digital multimeters

that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining

screw on most AC outlet boxes is also at earth ground. If the retaining

screw is to be used as your earth ground, verify that it is at ground by

measuring the resistance between it and a cold-water pipe with an

ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt troublelight (not a neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot side on the

line; the lamp should light at normal brilliance if the screw is at ground

potential (see Figure B).

To Exposed Metal

Parts on Set

.15 µF

kΩ

1.5

Earth Ground

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

KP-46WT520/51WS520/57WS520

AC V oltmeter

(0.75 V)

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pip

6

Page 7

KP-46WT520/51WS520/57WS520

SELF-DIAGNOSTIC FUNCTION

Self Diagnosis

Supported model

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER LED will automatically begin to fl ash. The number

of times the LED fl ashes translates to a probable source of the problem. A defi nition of the STANDBY/TIMER LED fl ash indicators is listed in the

instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review

the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

Diagnostic Test Indicators

When an error occurs, the STANDBY/TIMER LED will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the LED will identify the fi rst of the problem areas.

Results for all of the following diagnostic items are displayed on screen. If the screen displays a “0”, no error has occurred.

No. of times

Diagnostic Item

Power does not turn on Does not light _______

+B Overcurrent (OCP)* 2 times 2:0 or 2:1

+B Overvoltage (OVP) 3 times 3:0 or 3:1

Vertical Deflection Stopped 4 times 4:0 or 4:1

White Balance Failure

(not balanced)

LOW +B OCP/OVP

(overcurrent/overvoltage)***

Horizontal Deflection

Stopped

Audio Protection 8 times 8:0 or 8:1

Zero Crossing Detector 9 times 9:0 or 9:1

HV Protection 10 times 10:0 or

STANDBY /

TIMER lamp

flashes

5 times 5:0 or 5:1

6 times 6:0 or 6:1

7 times 7:0 or 7:1

Display

Result

10:1

Probable Cause Location Detected Symptoms

• Power cord is not plugged in.

• Fuse is burned out (F6000). (G Board)

• H.OUT (Q5001) is shorted. (D Board)

• +B PWM (Q5201) is shorted.

(D Board)

• IC6503 is faulty. (D Board) • Has entered standby mode.

• 15V is not supplied. (D Board)

• IC5101 is faulty. (D Board)

• Video OUT (IC9101, IC9201, IC9301)

is faulty. (CR, CG, CB Board)

• CRT drive (IC452) is faulty.

(A Board)

• G2 is improperly adjusted.**

• +5 line is overloaded.

(A and BM Boards)

• +5 line is shorted. (A and BM Boards)

• IC303 is faulty. (A Board)

• Q5006 is broken (D Board)

• IC452 is faulty (A Board)

• + or - 22V audio supply is not

present—Check PS600 &PS601

• Audio AMP is damaged IC601 on

A Board

• D6116 or D6301 is open (G Board) • No picture

• Q8014 or Q8013 have shorted replace

along with R8051 on D Board

• IC8005 is damaged (D Board)

• Power does not come on.

• No power is supplied to the TV.

• AC Power supply is faulty.

• Power does not come on.

• Load on power line shorted.

• Has entered standby mode after

Horizontal raster.

• Vertical deflection pulse is stopped.

• Power line is shorted or power

supply is stopped.

• No raster is generated.

• CRT cathode current detection

reference pulse output is small.

• No picture

• No picture

• No picture

• No picture

* If a +B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously. The symptom that is diagnosed first by the

microcontroller is displayed on the screen.

** Refer to Screen (G2) Adjustment (Fine Adjustments) in Section 2 of this manual.

*** If STANDBY/STEREO LED flashes six (6) times, unplug the unit and wait 10 seconds before performing the adjustment.

KP-46WT520/51WS520/57WS520

7

Page 8

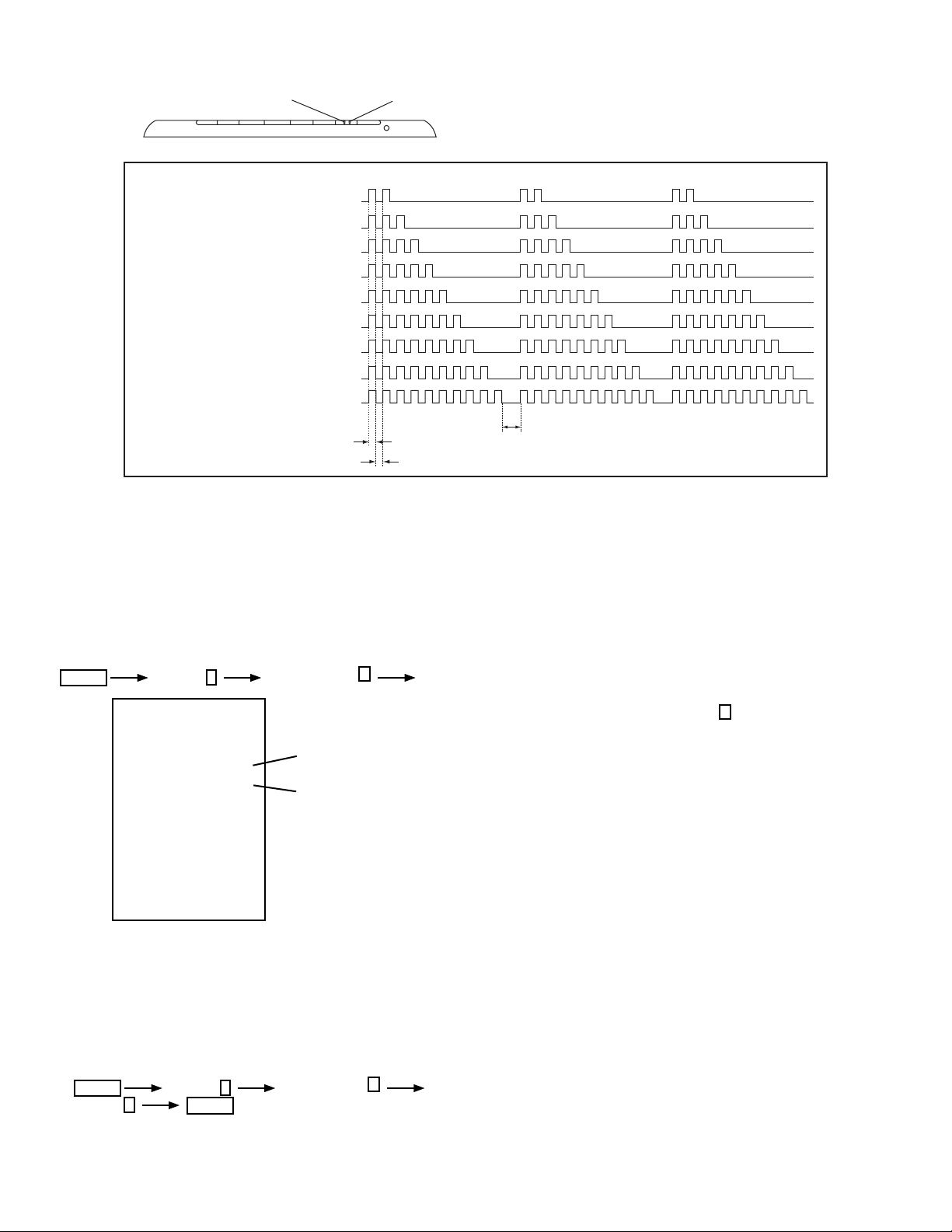

Display of Standby/Timer LED Flash Count

TIMER Indicator

Diagnostic items Flash count

+B Overcurrent 2 times

Low +B Overvoltage 3 times

Vert. Deflection Stopped 4 times

White Balance Failure 5 times

Low +B OCP/OVP 6 times

Horiz. Deflection Stopped 7 times

Audio Protection 8 times

Zero Crossing Detector 9 times

HV Protection 10 times

KP-46WT520/51WS520/57WS520

STAND BY Indicator

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

Lamp OFF 3 sec.

Release of TIMER STAND BY indicator blinking

The TIMER/STANDBY indicator blinking display is released by turning OFF the power switch on the TV main unit or removing the plug from the power.

Self-Diagnosis Screen Displays

In cases of malfunctions where it is not possible to determine the symptom such as when the power goes off occasionally or when the screen

disappears occasionally, there is a screen display on whether the malfunction occurred or not in the past (and whether the detection circuit operated or

not) in order to allow confi rmation.

Screen Display Method

Quickly press the remote command button in the following order from the standby state.

*Note that this differs from entering the service mode (sound volume

Display

Channel

5

SELF DIAGNOSIS

Sound Volume*

_

Power ON

)

+

2: +B OCP 0

3: +B OVP 0

4: VSTOP 0

5: AKB 1

6: LOWB 0

7: H-STOP 0

Numeral “0”

means that no fault was detected.

Numeral “1”

means a fault was detected one

time only.

8: AUDIO 0

9: ZCD 0

10: HV PROT 0

101: WDT 24

Self-Diagnosis Screen Display

The results display is not automatically cleared. In case of repairs and after repairs, check the self-diagnosis screen and be sure to return the results

display to “ 0 ”.

If the results display is not returned to “ 0 ” it will not be possible to judge a new malfunction after completing repairs.

Method of Clearing Results Display

1. Power off (Set to the stand by mode.)

2.

Display

3. Channel

8

Channel

ENTER

Sound Volume

5

(Test reset = Factory preset condition)

+

Power ON (Service Mode)

Method of Ending Self Diagnosis Screen

When ending the self-diagnosis screen completely, turn the power switch OFF on the remote commander or the main unit.

KP-46WT520/51WS520/57WS520

8

Page 9

KP-46WT520/51WS520/57WS520

Self-Diagnosis Function Operation

+B overcurrent (OCP)

Occurs when excessive current fl ows through R6812. The increase in voltage across Q6803 causes it to turn on which sends a high signal to the

micro.

+B overvoltage (OVP)

IC6801 detects +B OVP condition and turns on Q6802. This sends a high signal to the micro and also shuts down the AC relay.

V-STOP

Occurs when an absence of the vertical defl ection pulse is detected by pin 56 of IC452 (A Board). Power supply will shut down when waveform interval

exceeds 2 seconds.

White Balance Failure

If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will be detected by IC452 (A Board). TV will stay on, but

there will be no picture.

*(Refers to the RGB levels of the AKB detection Ref pulse that detects 1K).

Low B OCP/OVP

Occurs when set 5V is out.

Also check for : + 135V line shorted

+ 135V line is going over 145V

Horizontal Defl ection Stopped

Occurs when either:

1) a +B overcurrent is detected (Q6803), or

2) IC452 (A Board) is damaged.

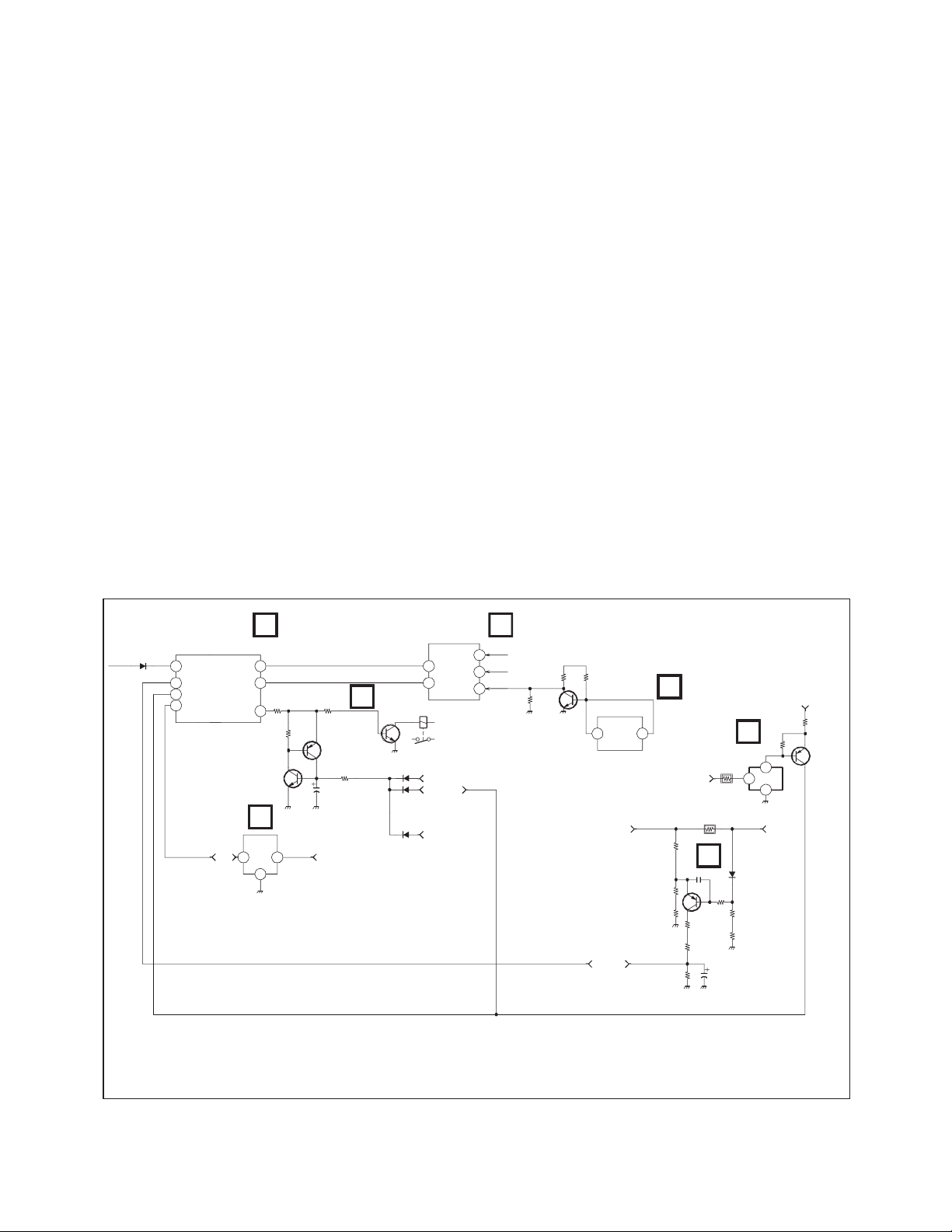

Self-Diagnosis Block Diagram

IC702

STBY-LED

MAIN MICRO

STR

48

STBY-LED

44

OCP

OVP

45

43

LOW B ERR

CLKO

DATO

AC RLY

5V

A

28

31

69

Q452

G

Q6102

Q451

A

IC303

12

3

IC452

Y/C JUNGLE

SCL

53

52

SDA

RY6000

P_SW(-)

21

34

D6803

1K-PROT2

+B OCP

D452

D6505

+BVOP

D453

A

AKB

VPROT

HPROT

CRT

58

VDY-

56

57

R5104 R5105

R5125

Q5018

2

BM

IC5007

14

IC6801

+B

+B +B

R6812

5V

D

2

1

3

Q6802

D

D6805

R6803

+B OCP

KP-46WT520/51WS520/57WS520

9

Page 10

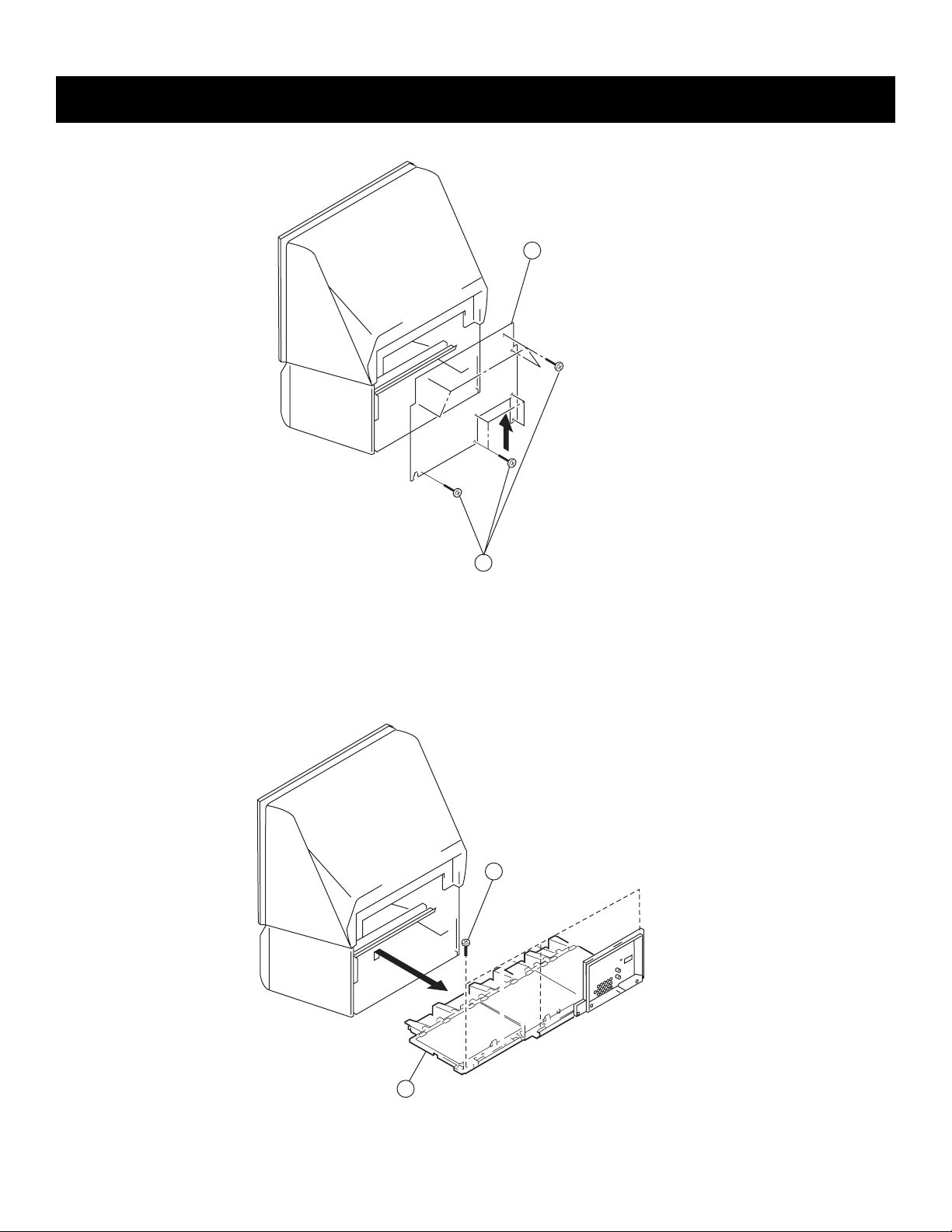

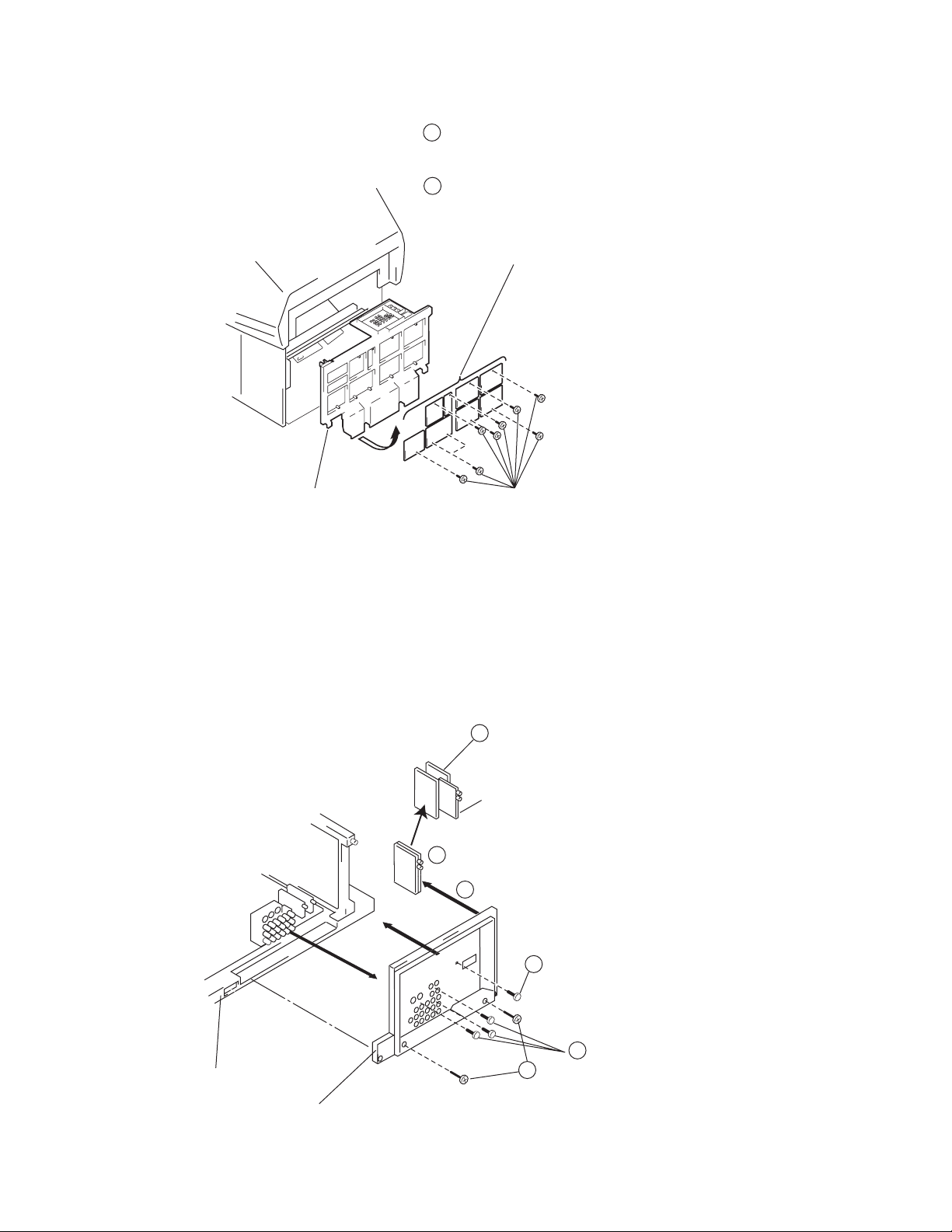

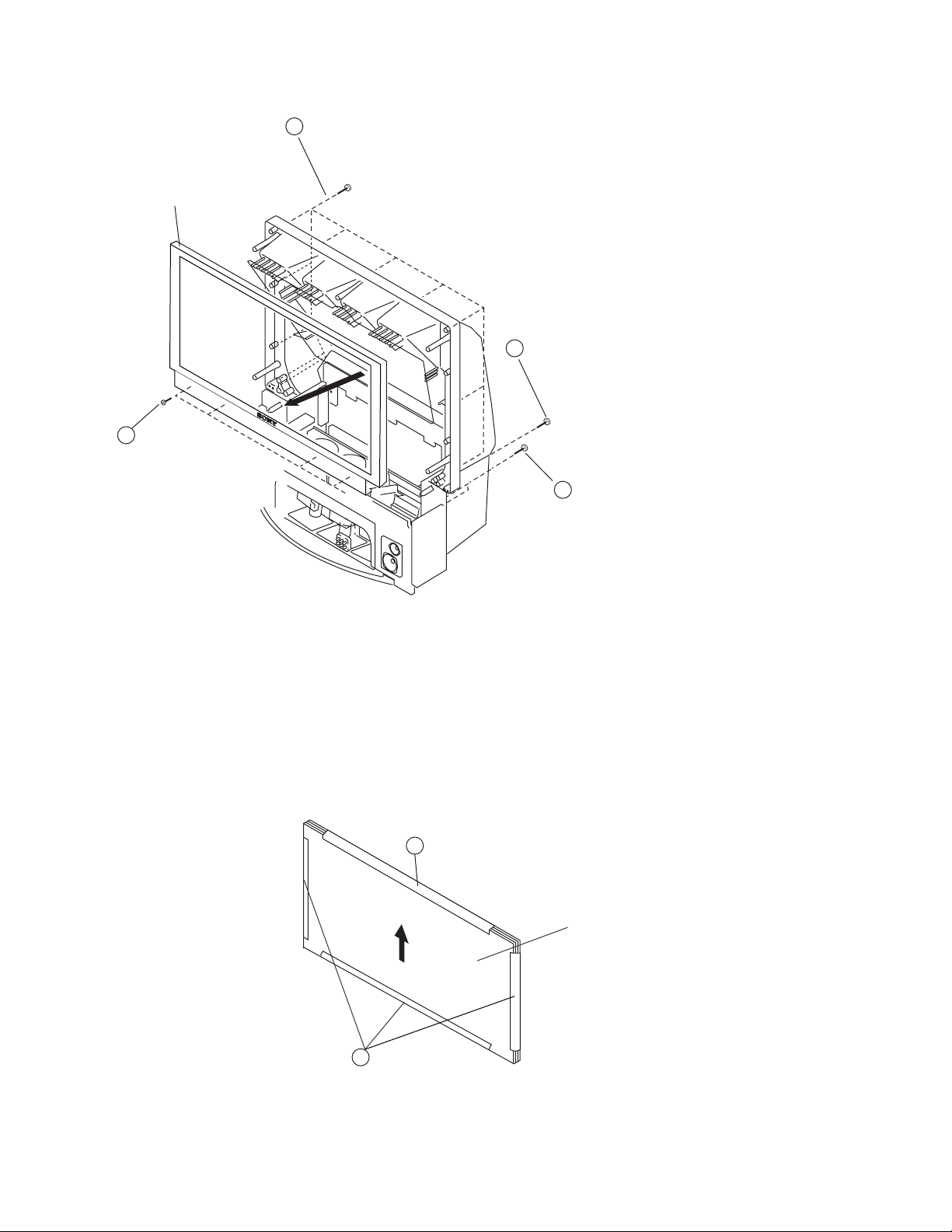

1-1. REAR BOARD REMOVAL

r

SECTION 1: DISASSEMBLY

Rear board

2

KP-46WT520/51WS520/57WS520

1-2. CHASSIS ASSEMBLY REMOVAL

1

10 Screws (KP-46WT520 Only)

13 Screws (KP-51WS520 Only)

12 Screws (KP-57WS520 Only)

Dome Washer Hex Tap 4 x 20

1

Three screws Dome Washe

(Hex Tap 4 x 20)

KP-46WT520/51WS520/57WS520

Chassis assy

2

10

Page 11

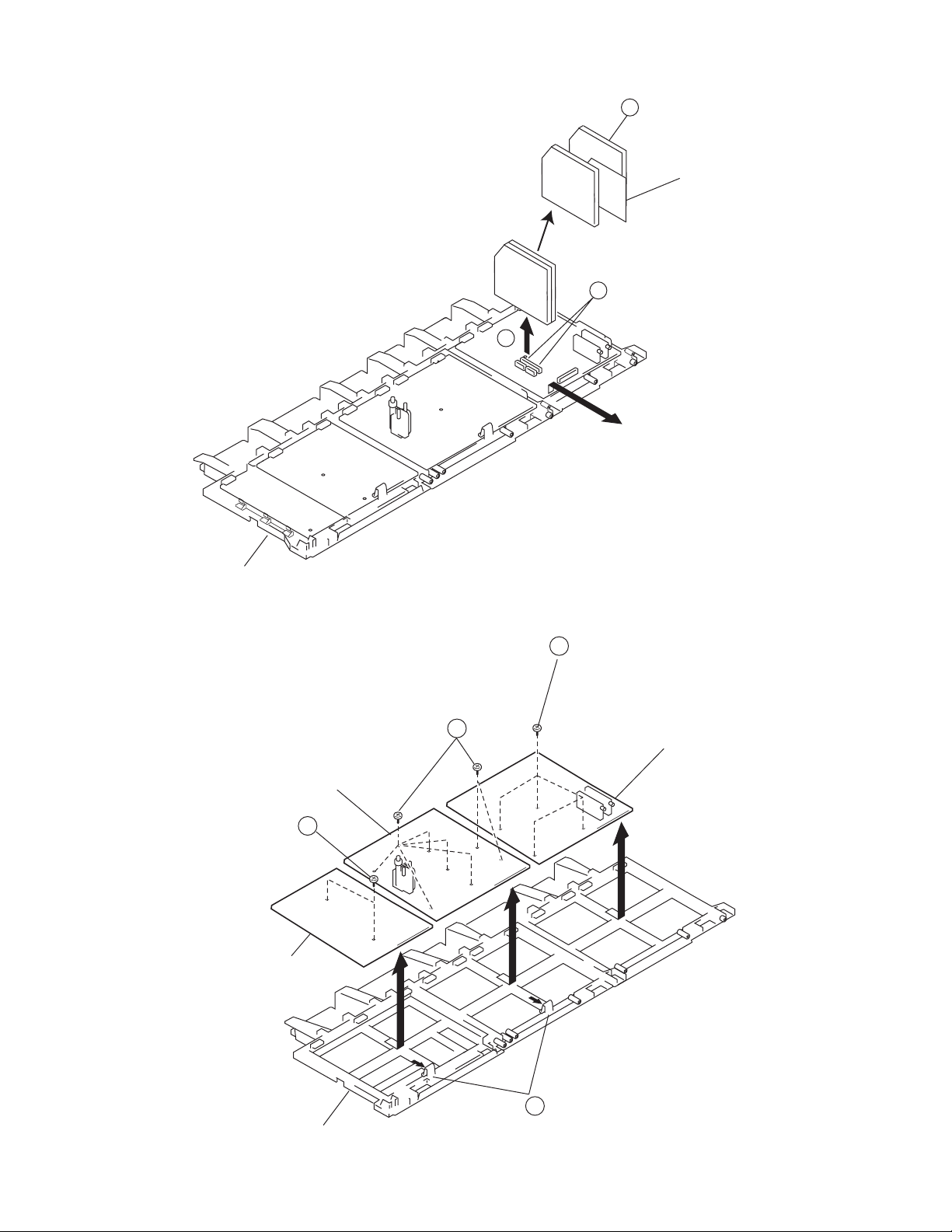

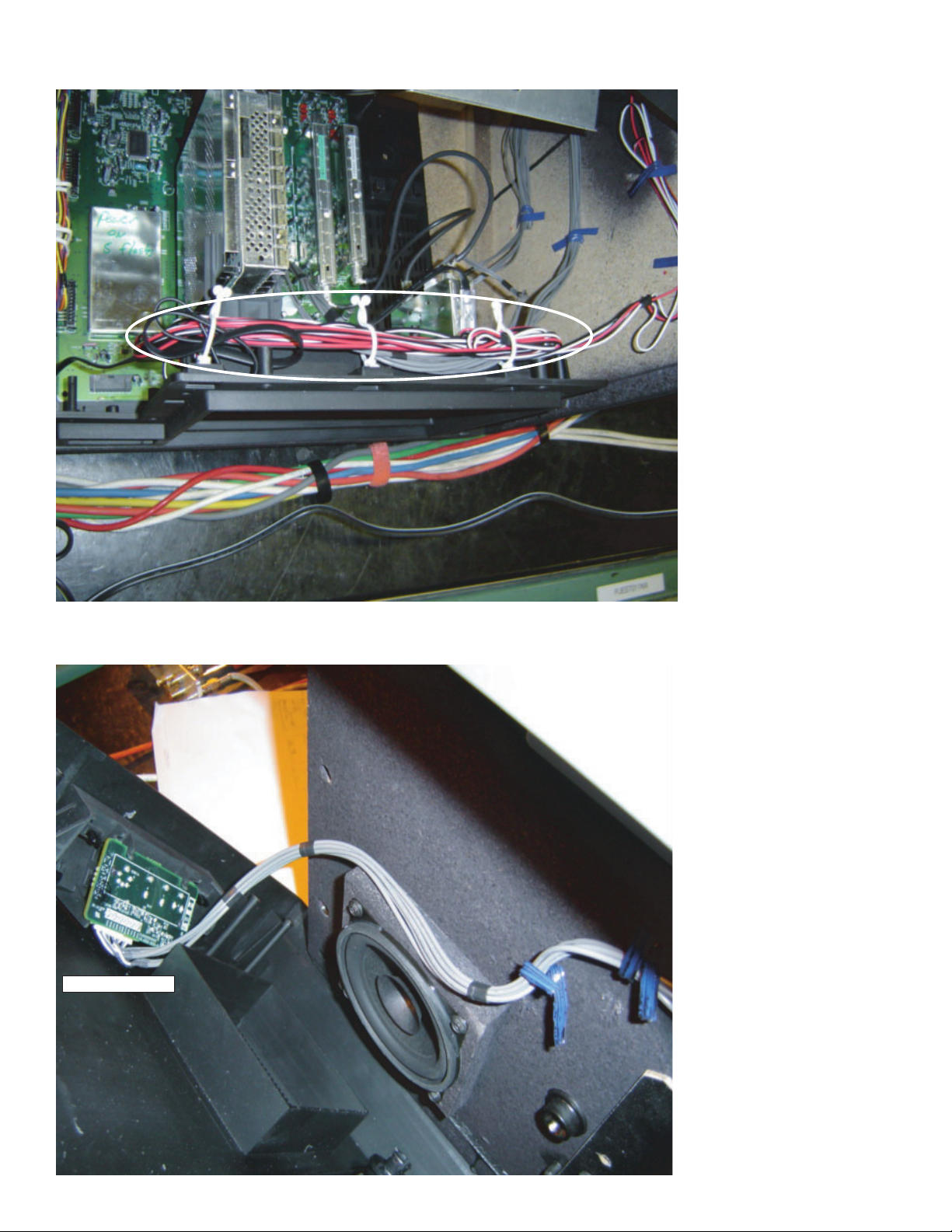

1-3. SERVICE POSITION

Free wiring from purse locks.

1

NOTE: Observe wire dress

and return to original condition.

2

Covers

Remove covers from chassis assembly

with pliers when checking printed circuit boards.

After checking, turn the covers over

and re-secure them with the screws.

KP-46WT520/51WS520/57WS520

Chassis assembly

1-4. TERMINAL BOARD AND P BOARD REMOVAL

6

P board

Disconnect Ground Wire and Cable

4

Two screws

5

+BVTT 3 X 8

Screws

(+BVTP 3x12)

Four screws

+BVTT 3x8

Main bracket

Terminal board

KP-46WT520/51WS520/57WS520

3

One screw

(M3 X 8) P, SW(+)

2

Six screws

1

Two screws

Dome Washer Hex Tap 4 x 20

(+BVTP 3x12)

11

Page 12

1-5. BM BOARD BOARD REMOVAL

KP-46WT520/51WS520/57WS520

Pry apart shield

3

to remove BM board

BM board

Pull gently back on clips

1

to release

2

Main bracket

1-6. A BOARD, D BOARD, AND G BOARD REMOVAL

D board

Two screws

(+BVTP 3x12)

G board

Seven screws

(+BVTP 3x12)

3

2

Four screws

1

(+BVTP 3x12)

A board

KP-46WT520/51WS520/57WS520

Main bracket

4

Claws

12

Page 13

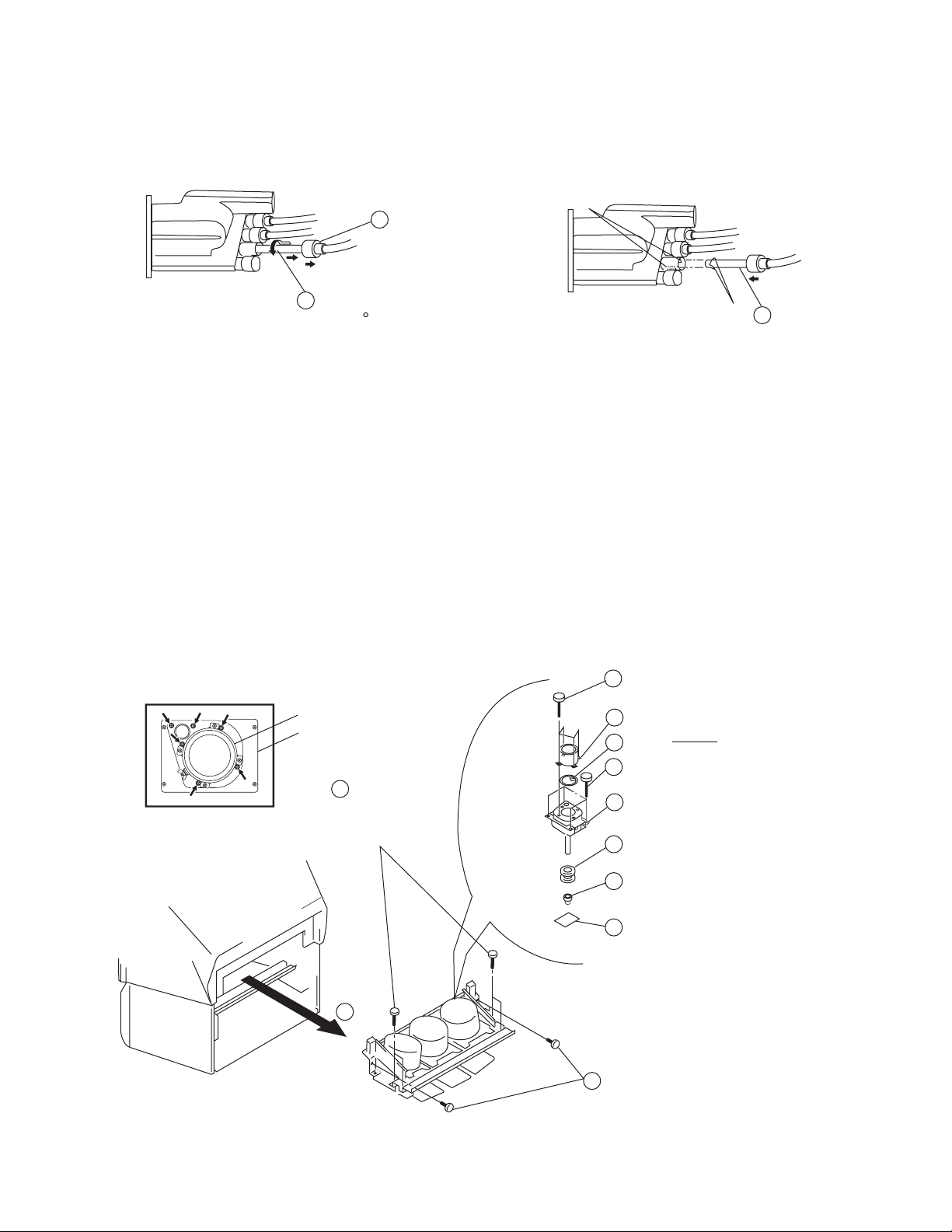

e

1-7. HIGH-VOLTAGE CABLE INSTALLATION AND REMOVAL

KP-46WT520/51WS520/57WS520

(1) Removal

2

HV cable

turn 90

1

Rubber cap

(2) Installation

Gutter

Hook

HV cabl

1

1-8. PICTURE TUBE REMOVAL

CAUTION: Removing the arrow-marked screws is strictly prohibited. If removed, it may cause liquid to spill.

Four screws

4

Lens

Picture tube

2

Four screws

(2 per side)

Dome Washer

Hex Tap 4x20

3

Dome Washer Hex Tap 4x20

Lens

5

Shade

6

10

Four screws

(+BVTP 4x12)

11

Picture tube

Deflection yoke

9

Neck assy

8

CR board

7

(2 screws for Red Shade

1 screw for Green Shade)

(+BVTP 4x12)

KP-46WT520/51WS520/57WS520

1

Four screws (2 per side)

Dome Washer Hex Tap 4x20

13

Page 14

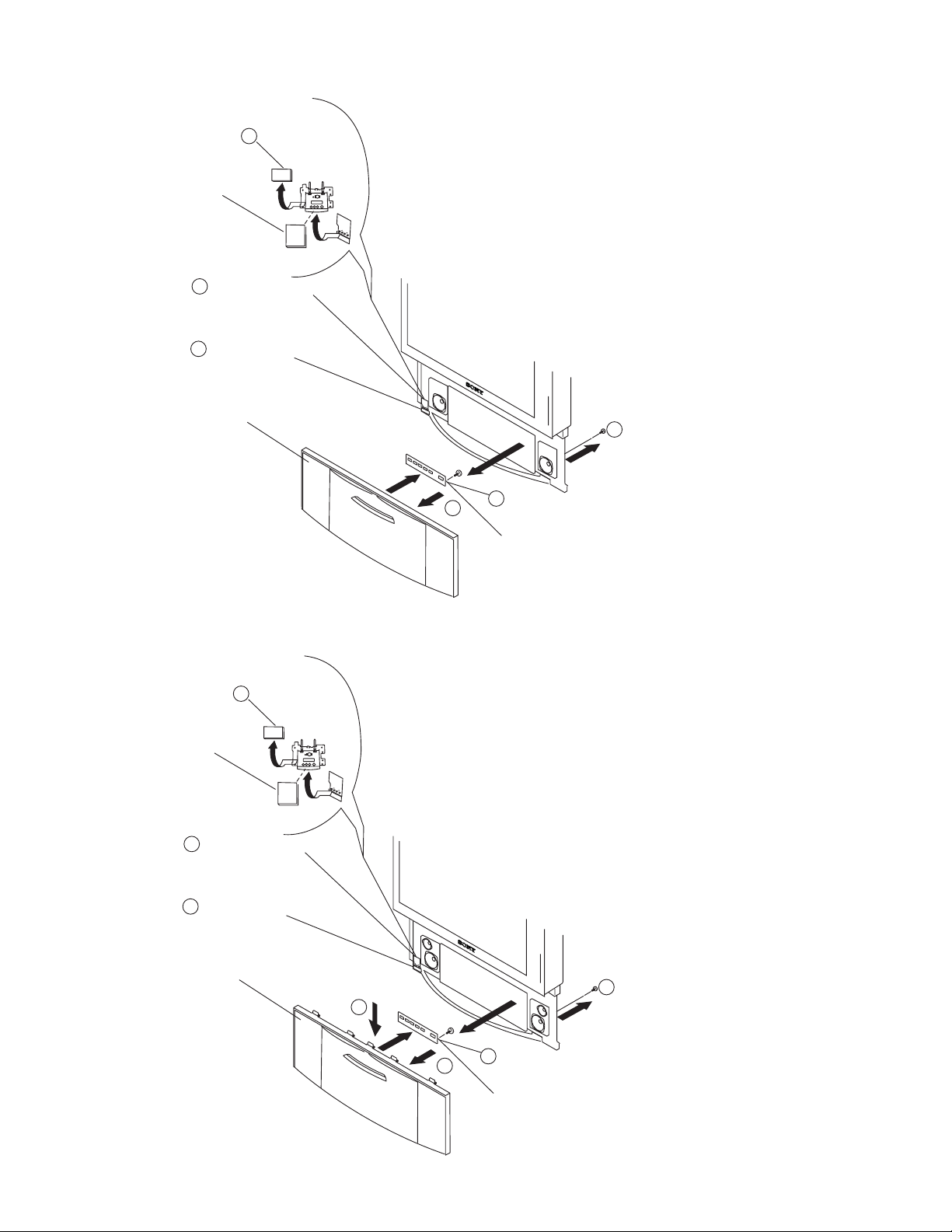

A

A

1-9. SPEAKER GRILLE, HA1 BOARD, AND HB2 BOARD REMOVAL

(KP-46WT520 ONLY)

KP-46WT520/51WS520/57WS520

HB2 board

Two screws

Input Terminal Plate

The Speaker Grille Assy

Note:

fter removing the screws

pull firmly out (from the bottom)

to release it.

(+BVTP 3x12)

5

4

6

Input Terminal Bracket

Four screws

Dome Washer

Hex Tap 4 x 20

Input Terminal Cover

Two screws

(+BVTP 3x12)

1

Four screws

(2 per side)

3

2

Four screws

(+BVTP 3x12)

HA1 board

Dome Washer Hex Tap 4x20

1-10.SPEAKER GRILLE, HA1 BOARD, AND HB1 BOARD REMOVAL

(KP-51WS520/57WS520 ONLY)

HB1 board

Two screws

Input Terminal Plate

The Speaker Grille Assy

Note:

The Speaker Grille Assy

is securely attached.

fter removing the screws

pull firmly out (from the bottom)

then down to release it.

(+BVTP 3x12)

5

4

6

Input Terminal Bracket

Four screws

Dome Washer

Hex Tap 4 x 20

Input Terminal Cover

Two screws

(+BVTP 3x12)

1

Six screws Dome Washer Hex Tap 4x20

2

3

2

Four screws

(+BVTP 3x12)

HA1 board

-3 per side (KP-51WS520/57WS520 Only)

KP-46WT520/51WS520/57WS520

14

Page 15

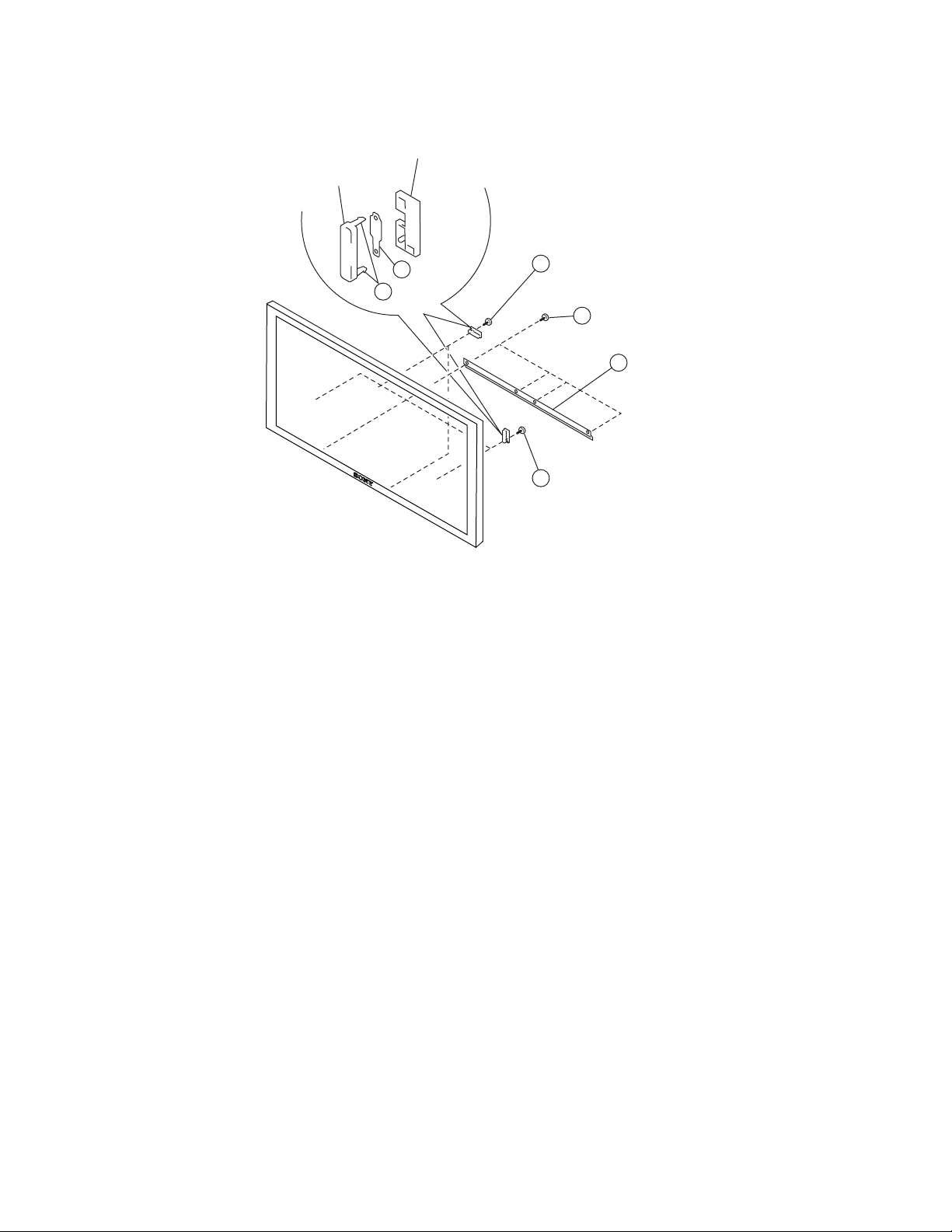

1-11. BEZNET ASSEMBLY REMOVAL

Eight screws (KP-46WT520 Only)

3

Nine screws (KP-51WS520/57WS520 Only)

Dome Washer Hex Tap 4x20

Beznet assy

4

Four screws

Dome Washer

Hex Tap 4x20

KP-46WT520/51WS520/57WS520

Four screws Dome Washer Hex Tap 4x20

2

-2 per side

1

Six screws

-3 per side (KP-46WT520 Only)

Four screws Dome Washer Hex Tap 4x20

-2 per side (KP-51WS520/57WS520 Only)

Dome Washer Hex Tap 4x20

1-11-1. SCREEN TAPE METHOD

The following demonstrates the taping method when replacing the Contrast Screen or Diffusion Plates.

For Part Numbers refer to the Miscellaneous section in the back of the manual.

Tape, Acetate (P2412) 25x30M

1

To p

2

Tape, Acetate (P2412HD) 25MMx30M

Contrast Screen

KP-46WT520/51WS520/57WS520

15

Page 16

1-12.SR BOARD REMOVAL

The Screen Holder does not need

to be removed in order to remove

the SR boards.

Sensor

bracket (B)

Sensor

bracket (A)

6

SR board

5

Claws

One screw

3

(+BVTP 4x12)

1

One screw

4

(+BVTP 4x12)

Four screws

(+BVTP 4x12)

L screen

2

holder

KP-46WT520/51WS520/57WS520

KP-46WT520/51WS520/57WS520

16

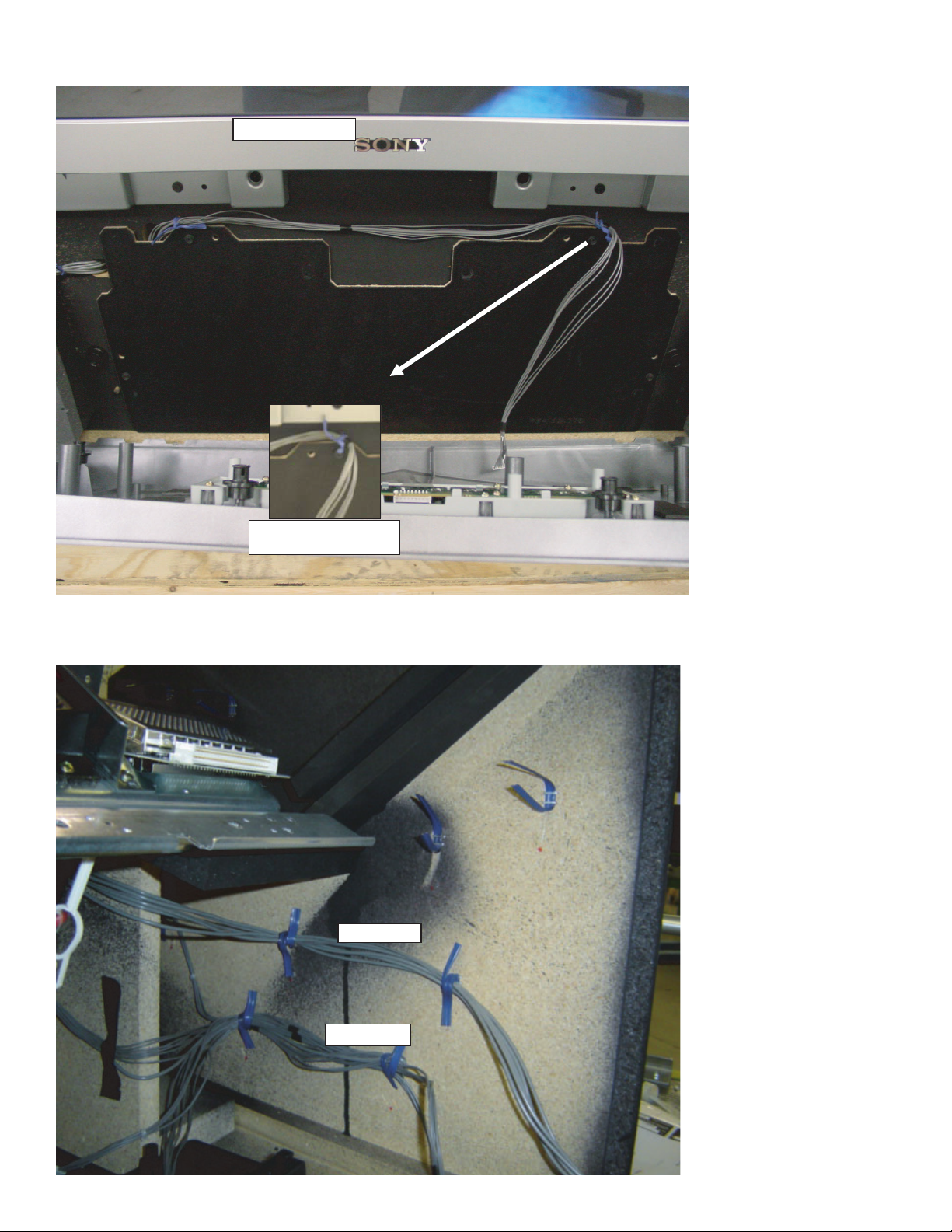

Page 17

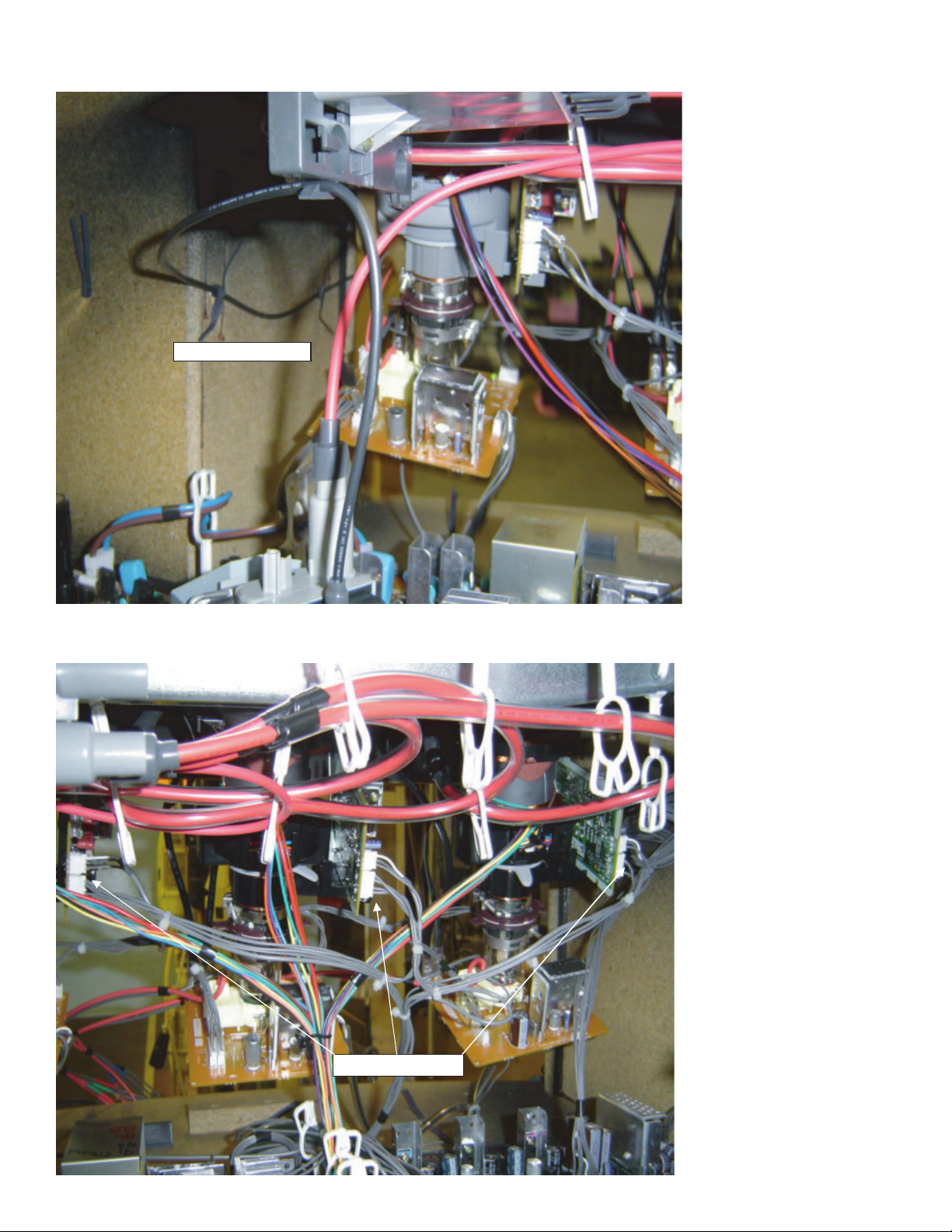

46 Cabinet

KP-46WT520/51WS520/57WS520

WIRE DRESSING

46" HB

KP-46WT520/51WS520/57WS520

17

Page 18

46 Cabinet

KP-46WT520/51WS520/57WS520

46" HA Wire

46 Cabinet

2nd Tape Position

46" HB

KP-46WT520/51WS520/57WS520

46" HA

18

Page 19

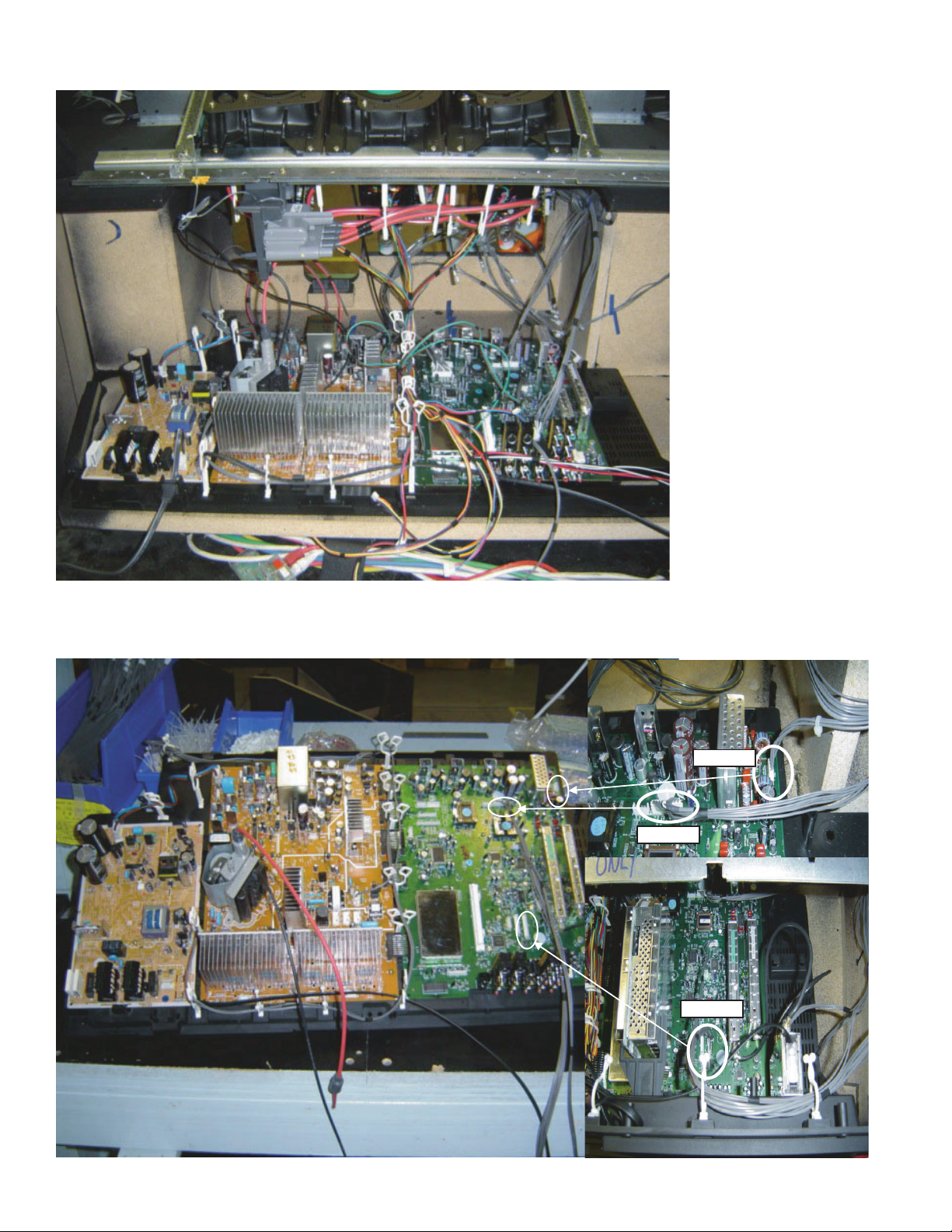

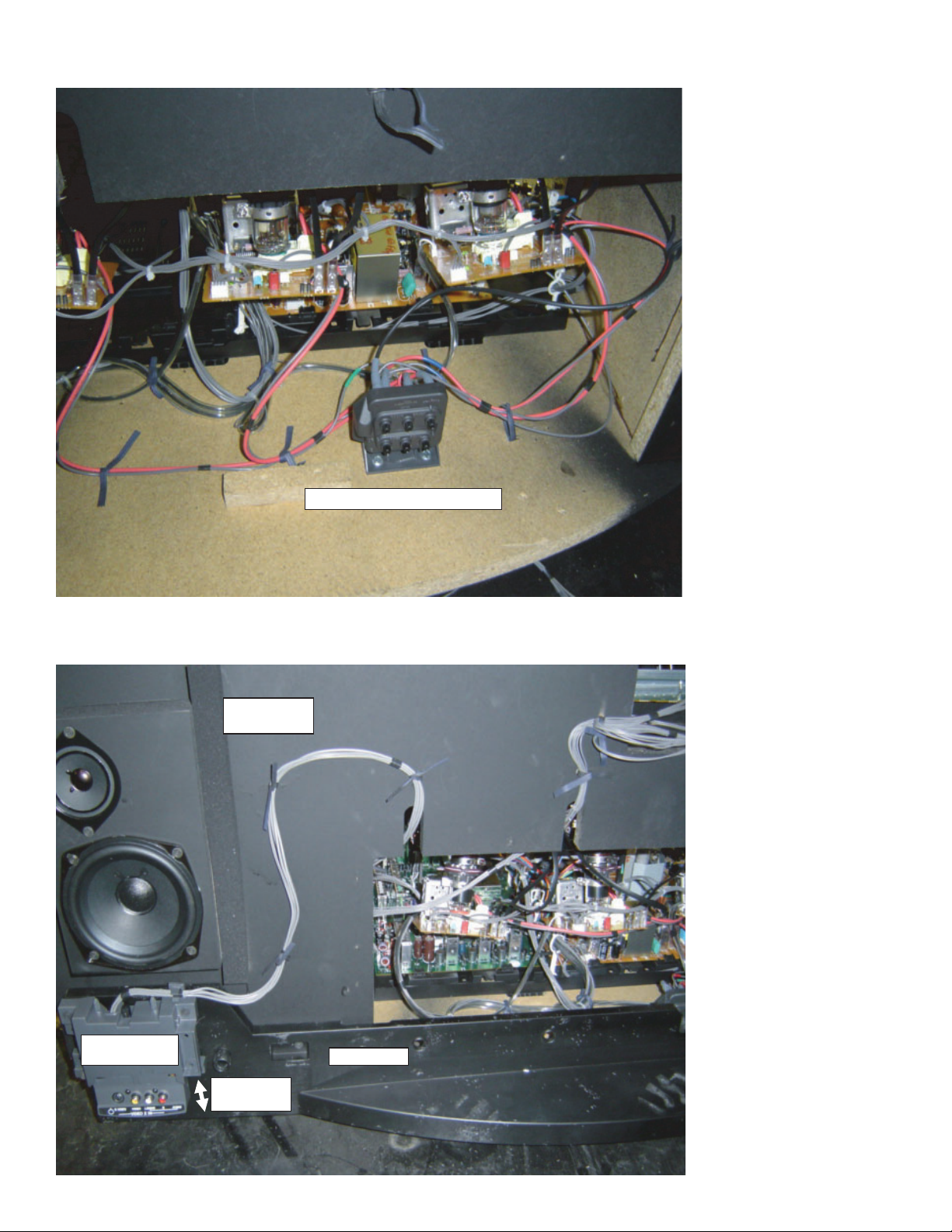

51 & 57 Cabinet

KP-46WT520/51WS520/57WS520

51" & 57" HB

51 & 57 Cabinet

51" & 57" HB

51" & 57" HA

KP-46WT520/51WS520/57WS520

19

Page 20

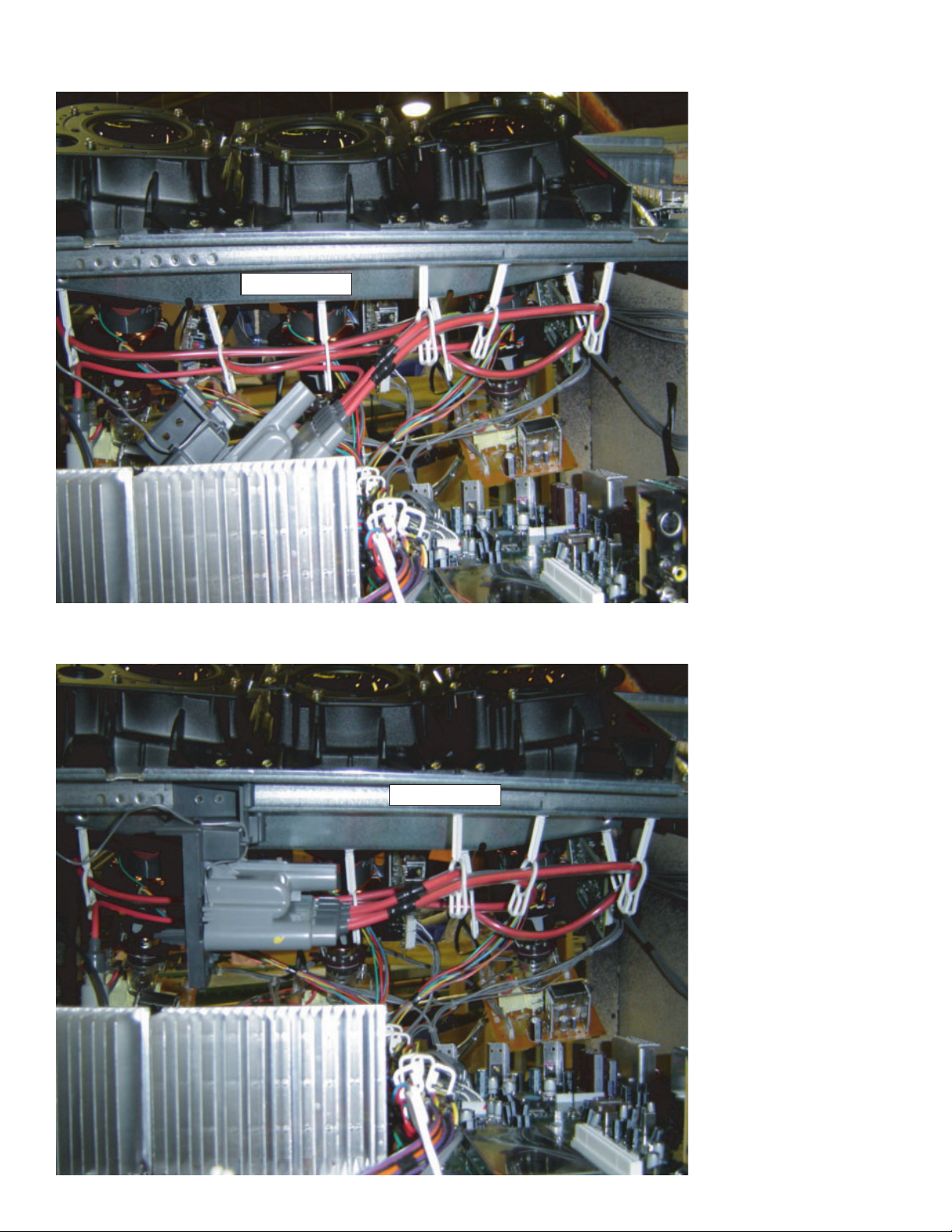

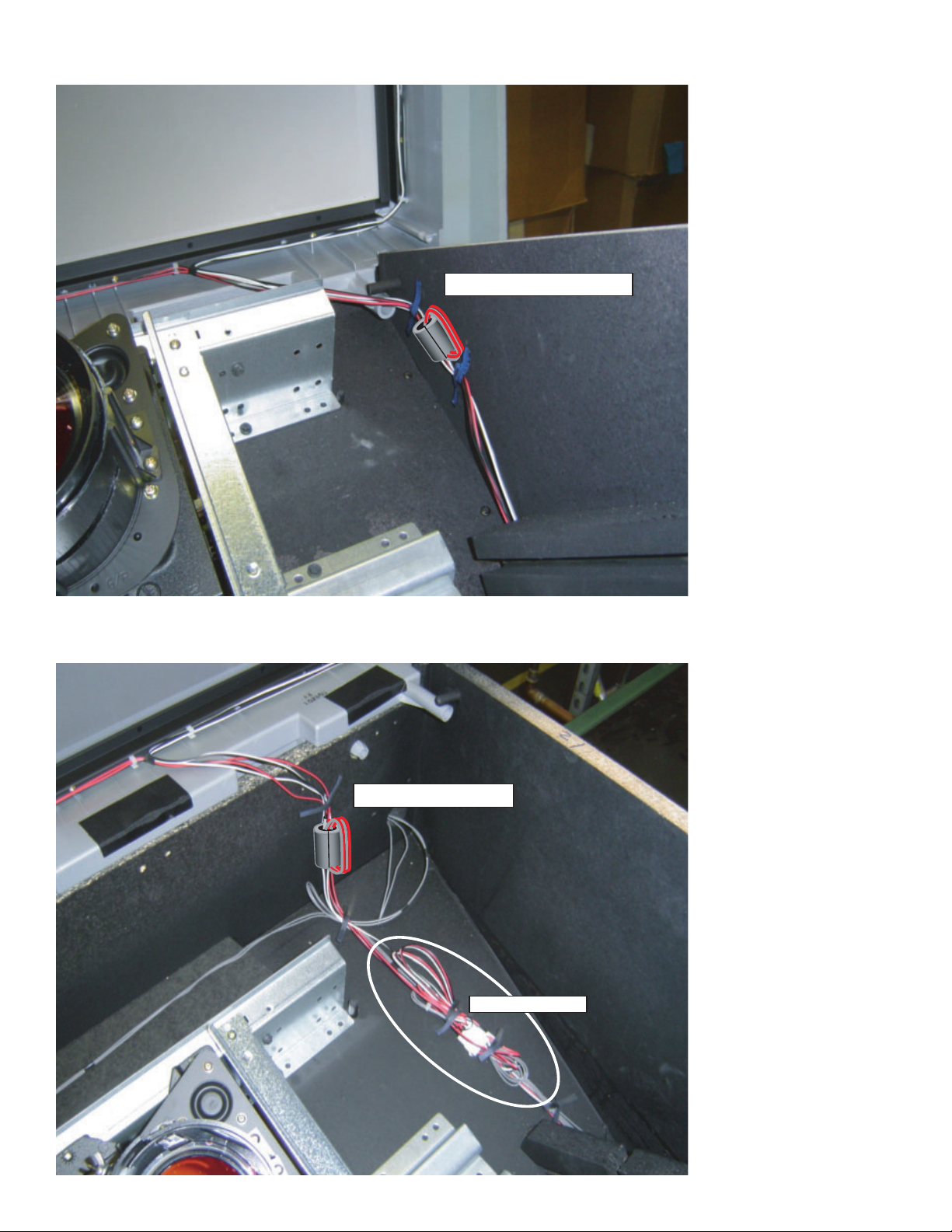

HV Wire

KP-46WT520/51WS520/57WS520

HV wire

HV Wire

HV wire

KP-46WT520/51WS520/57WS520

20

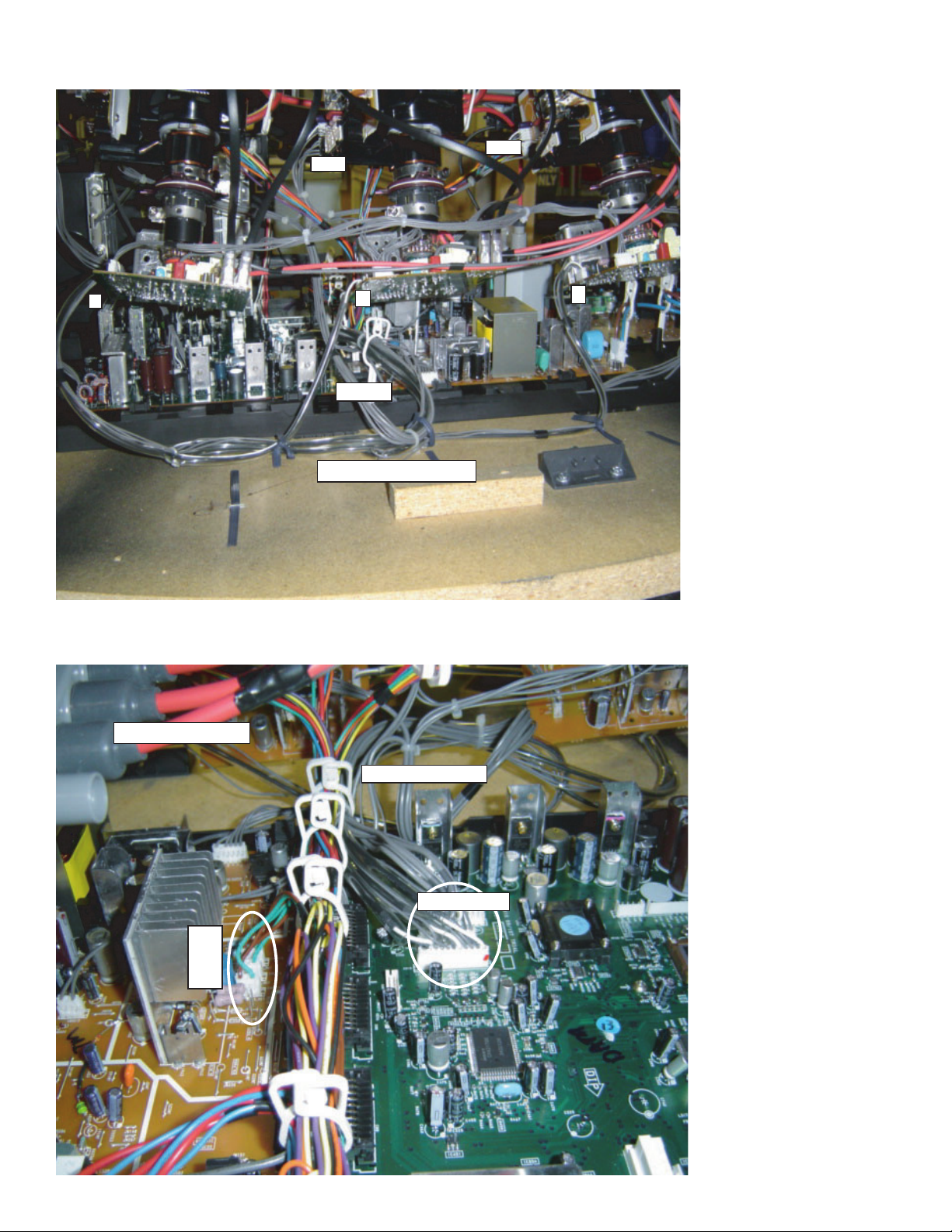

Page 21

HV/MV Wire

KP-46WT520/51WS520/57WS520

HV/MV wire

VM Connect

VM wire

KP-46WT520/51WS520/57WS520

21

Page 22

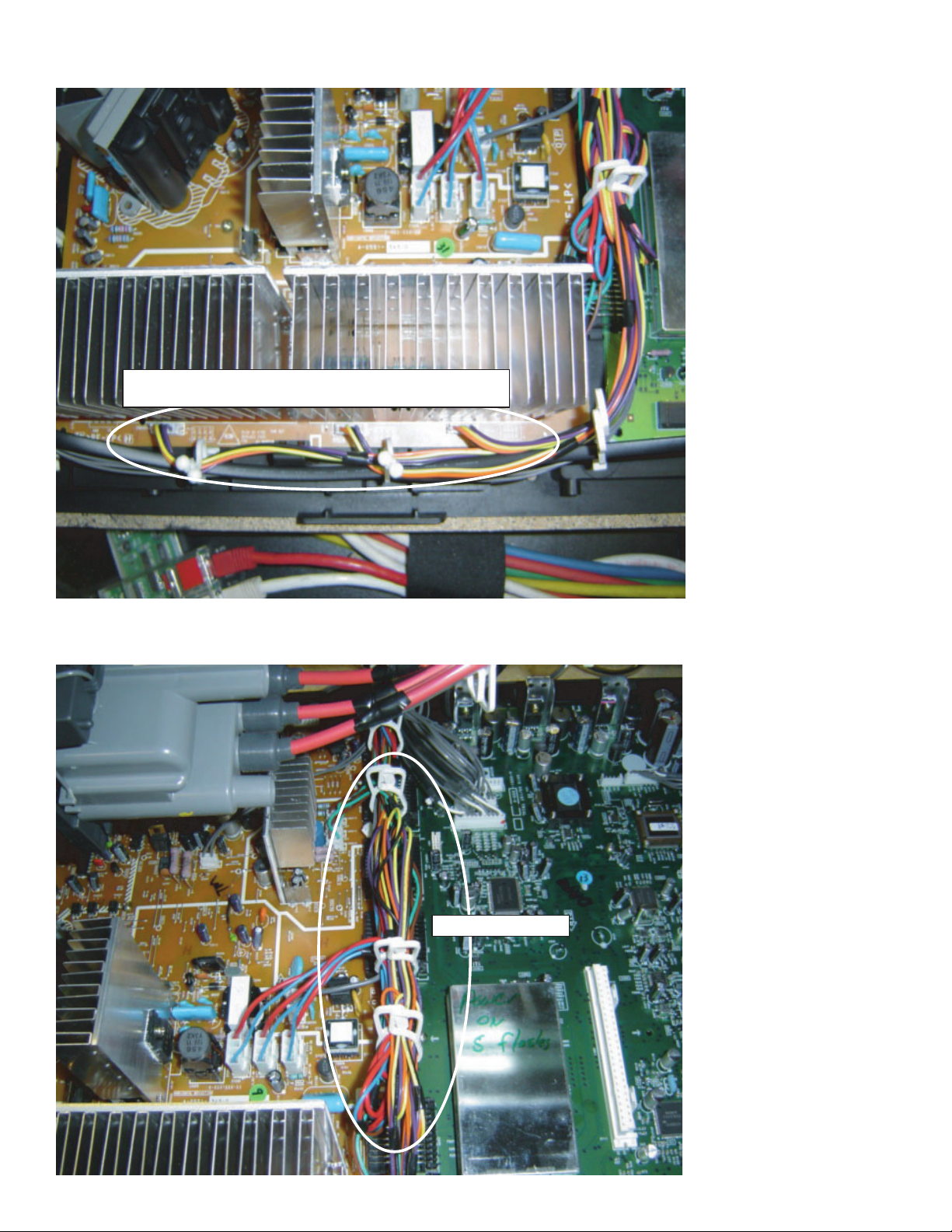

PWB Block Docking

KP-46WT520/51WS520/57WS520

PWB Block Docking

HA Connect

SP Connect

HB Connect

KP-46WT520/51WS520/57WS520

22

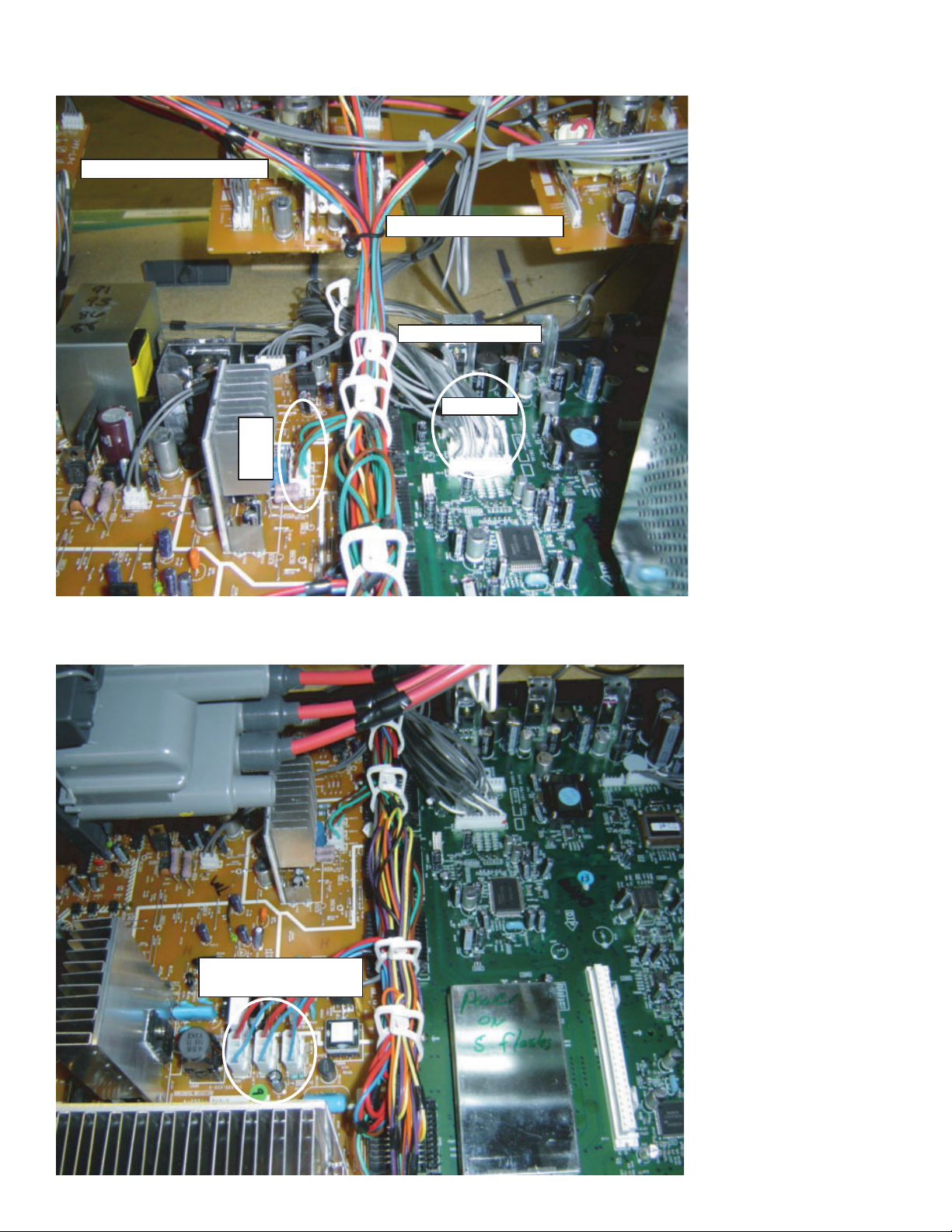

Page 23

C, FP Connect

B

KP-46WT520/51WS520/57WS520

B-

G-

R

46 DY

G

VM

RGB signal wire

46" DY wire

V

DY-B

DY-G

DY-R

KP-46WT520/51WS520/57WS520

Into the 1st purselock

VM,RGB C/N

23

Page 24

51 & 57 DY

51" & 57"DY wire dressing

V

DY-R

DY-G

DY-B

KP-46WT520/51WS520/57WS520

Into the free purselock (8dia)

Into the 2nd purselock

VM,RGB C/N

DY

H

DY-B DY-G DY-R

KP-46WT520/51WS520/57WS520

24

Page 25

DY

Sub

DY-B DY-G

KP-46WT520/51WS520/57WS520

DY

Excess wire

KP-46WT520/51WS520/57WS520

25

Page 26

Terminal Bracket Assy

KP-46WT520/51WS520/57WS520

ANT SW

5v C/N

Sub TU PP

HB C/N

Main TU PP

ANT SW GND

KP-46WT520/51WS520/57WS520

26

Page 27

F.P

KP-46WT520/51WS520/57WS520

51 & 57 V2 Block Assy

51" & 57"

V2 BLK

51" & 57" F.P Wire Dressing

2nd-Assy V2

BLK

Test

Up(lock)/Dow

KP-46WT520/51WS520/57WS520

1st-Assy

27

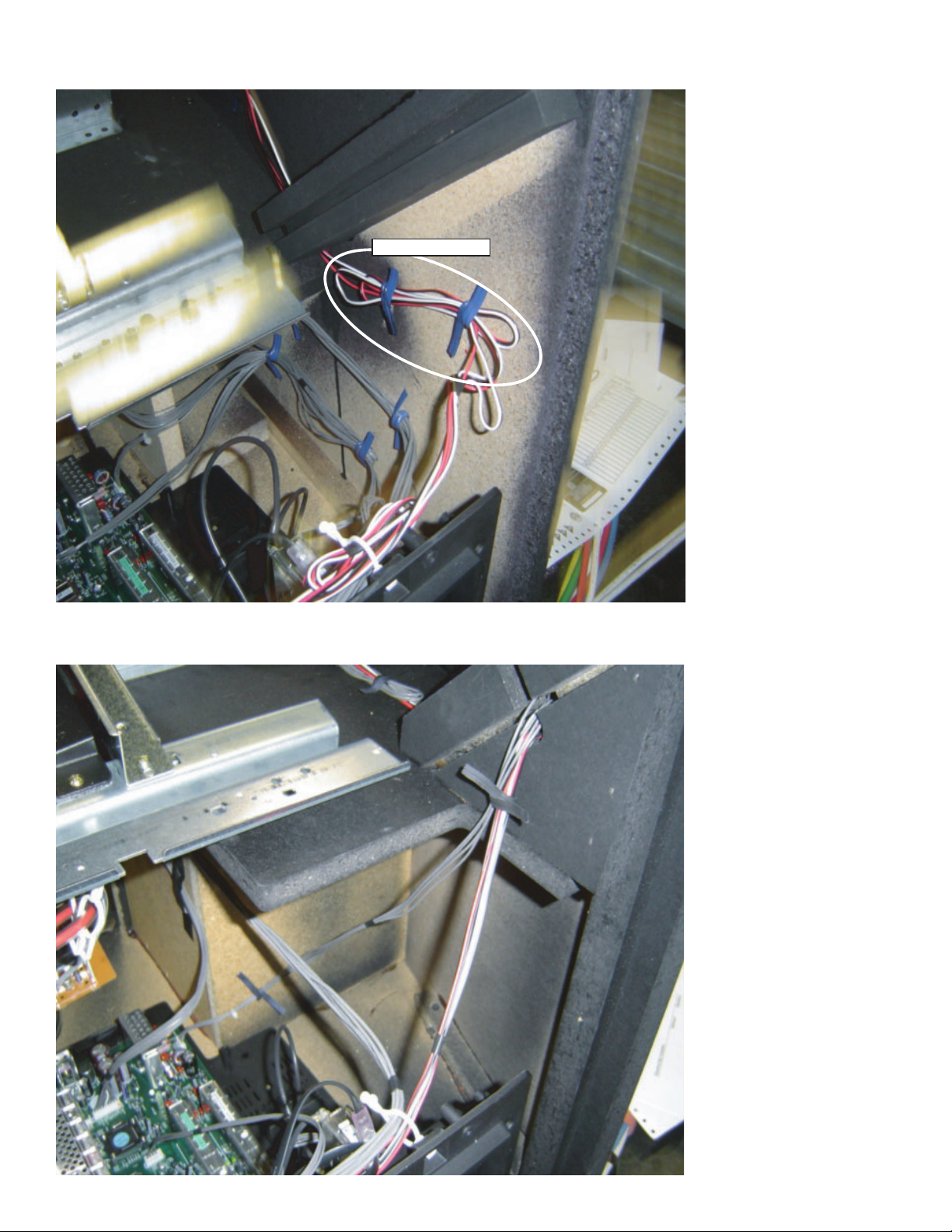

Page 28

AR Sensor

KP-46WT520/51WS520/57WS520

46" & 51"AR Sensor Wire

AR Sensor

57" AR Sensor Wire

Excess Wire

KP-46WT520/51WS520/57WS520

28

Page 29

AR Sensor

KP-46WT520/51WS520/57WS520

Excess Wire

AR Sensor

KP-46WT520/51WS520/57WS520

29

Page 30

AR Sensor

KP-46WT520/51WS520/57WS520

46 V2 Assy

HB Wire Connection

KP-46WT520/51WS520/57WS520

30

Page 31

SECTION 2: SET-UP ADJUSTMENTS

KP-46WT520/51WS520/57WS520

2-1. SCREEN VOLTAGE ADJUSTMENT (G2)

(COARSE ADJUSTMENT)

1. Receive the Monoscope signal.

2. Set BRIGHTNESS to 50% and PICTURE to minimum.

3. Turn the red VR on the focus block all the way to the left and then

gradually turn it to the right until the retrace line is barely visible.

4. Gradually turn the control to the left until the retrace line disappears.

R G B

SCREEN

R G B

FOCUS

FOCUS Block

2-2. SCREEN (G2) ADJUSTMENT (FINE

ADJUSTMENT)

If the jig described below is available, it is recommended that the G2

Fine Mode Adjustment be performed to set the screen controls to their

optimal condition. If desired, you can build the jig illustrated below,

using 3-watt resistors. Please note that if the proper voltage is not

obtained with the listed resistor’s values, then increase or decrease one

of the values in the resistor network to obtain the correct voltage.

2-3. DEFLECTION YOKE TILT ADJUSTMENT

1. Connect the color bar generator monoscope pattern to Video 1 input.

2. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off

the CRTs individually without using lens caps).

3. Loosen the CRT’s defl ection yoke set screw and align the tilt of the

defl ection yoke so that the horizontal bars at the center of the

cross-hatch pattern are parallel to the top and bottom edges of the

screen.

4. After aligning the defl ection yoke fasten it securely to the

funnel-shaped portion (neck) of the CRT.

5. Cover the green and blue CRT lenses with lens caps to allow only

green to show (or use the method shown in the note below for turning

off the CRTs individually without using lens caps), then repeat steps 3

and 4 for the red CRT.

Cover the green and red CRT lenses with lens caps to allow only

green to show (or use the method shown in the note below for turning

off the CRTs individually without using lens caps), then repeat steps 3

and 4 for the blue CRT.

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode MCP-RON, GON, BON.

4-pole magnet

2-pole magnet

Deflection yoke

1. Select VIDEO-1 mode no signal applied (the screen must be black).

2. Connect the G2 JIG.

3. SW on JIG.

4. Connect an oscilloscope to the TP9101(KR), TP9201(KG) and

TP9301(KB) of CR board, CG board, and CB board.

5. Adjust red, green, and blue screen voltage to 177.5+/-0.5V with

screen VR on the focus block.

K

G2 JIG

TO CG BOARD

TP9202

(210V)

GND

3.3k 5.6k 5.6k 6.8k

177.5V +/- 0.5V

SW

GND

All resistors are 3W type

pedestal level

Centering magnet

Anode cap

KP-46WT520/51WS520/57WS520

31

Page 32

KP-46WT520/51WS520/57WS520

R G B

SCREEN

R G B

FOCUS

2-4. FOCUS LENS ADJUSTMENT

In this adjustment, use the remote commander while in service mode.

For details on the usage of the service mode and the remote commander,

please refer to section

2-10. ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER.

1. Loosen the lens screw.

2. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

3. Turn the green lens to adjust to the optimum focus point with the

crosshatch signal.

4. Tighten the lens screw.

5. Cover the green and blue CRT lenses with the lens caps to allow only

red to show (or use the method shown in the note below for turning off

the CRTs individually without using lens caps).

6. Turn the red lens to adjust to the optimum focus point with the

crosshatch signal.

7. Tighten the lens screw.

8. Cover the green and red CRT lenses with the lens caps to allow only

blue to show (or use the method shown in the note below for turning

off the CRTs individually without using lens caps).

9. Turn the blue lens to adjust to the optimum focus point with the

crosshatch signal.

10. Tighten the lens screw.

11. After adjusting the items:

2-5. FOCUS VR ADJUSTMENT,

2-7. 2-POLE MAGNET ADJUSTMENT,

2-8. 4-POLE MAGNET ADJUSTMENT,

reconfi rm the optimum focus point and adjust again if necessary.

2-5. FOCUS VR ADJUSTMENT

1. Set generator to crosshatch.

2. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

3. Turn the green focus VR on the focus block to adjust to the optimum

focus point with the crosshatch signal.

4. Cover the green and blue picture lenses with lens caps to allow only

red to show (or use the method shown in the note below for turning off

the CRTs individually without using lens caps).

5. Turn the red focus VR on the focus block to adjust to the optimum

focus point with the crosshatch signal.

6. Cover the green and red picture lenses with lens caps to allow only

blue to show (or use the method shown in the note below for turning

off the CRTs individually without using lens caps).

7. Turn the blue focus VR on the focus block to adjust to the optimum

focus point with the crosshatch signal.

8. After adjusting the items:

2-4. FOCUS LENS ADJUSTMENT,

2-7. 2-POLE MAGNET ADJUSTMENT,

2-8. 4-POLE MAGNET ADJUSTMENT,

reconfi rm the optimum focus point and adjust again if necessary.

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode MCP-RON, GON, BON.

* In PJE mode, every time 6 is pressed, the test signal changes to:

“crosshatch+video signal” → “crosshatch+borderline (black)” →

”crosshatch (black)” → “dots (black)” → “all white” → off

Test Signal

Scanning line visible.

A

Minimize both A and B.

Lens

B

Center of crosshatch

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode MCP-RON, GON, BON.

FOCUS Block

KP-46WT520/51WS520/57WS520

32

Page 33

KP-46WT520/51WS520/57WS520

2-6. CENTERING MAGNET ADJUSTMENT

1. Set the mode to PRO.

2. Receive the monoscope signal.

3. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

4. Adjust the green CRT’s centering magnet to put the center of the

monoscope signal to the center of the screen.

5. Repeat steps 1 through 4 for the red CRT except now you will cover

the green and blue CRT lenses with lens caps to allow only red to

show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps) and you will adjust the red

centering magnet.

6. Repeat steps 1 through 4 for the blue CRT except now you will cover

the red and green CRT lenses with lens caps to allow only blue to

show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps) and you will adjust the blue

centering magnet.

7. After 2-Pole and 4-Pole adjustment, entering magnet adjustment

needs to be confi rmed. If centering magnet is re-adjusted, then 2-Pole

magnet will need to be confi rmed.

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode MCP-RON, GON, BON.

2-8. 4-POLE MAGNET ADJUSTMENT

1. Set the mode to VIVID and WIDE mode = Zoom, VM:Off.

2. Receive the 100IRE 1080i Dot signal.

3. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

4. Turn the (green) focus VR on the focus block to the right (clockwise)

and set it to under-focus to reduce the spot.

5. Adjust the 4-pole magnet so that the small spot in the center of the

screen becomes round for green and red.

6. Adjust the blue spot for:

a. KP-46WT520/51WS520 to a round shape X:Y=1:1

b. KP-57WS520 to an oval shape X:Y=1.2:1

7. Repeat steps 1 through 6 for the red CRT except now you will cover

the green and blue CRT lenses with lens caps to allow only red to

show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps) and you will adjust the red

focus control on the focus block.

8. Repeat steps 1 through 6 for the blue CRT except now you will cover

the red and green CRT lenses with lens caps to allow only blue to

show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps) and you will adjust the blue

focus control on the focus block.

2-7. 2-POLE MAGNET ADJUSTMENT

1. Set the mode to PRO and picture to MAX.

2. Receive the 100IRE 1080i Dot signal.

3. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

4. Turn the focus VR on the focus block to the left (counter clockwise)

and set it to overfocus to enlarge the spot.

5. Adjust the CRT’s 2-pole magnet so that the small bright spot is in the

center.

6. Align the focus VR on the focus block and set it for the best focus.

7. Repeat steps 1 through 6 for the red CRT covering the green and

blue CRT lenses with lens caps to allow only red to show (or use the

method shown in the note below for turning off the CRTs individually

without using lens caps) and you will adjust the red focus control on

the focus block.

8. Repeat steps 1 through 6 for the blue CRT covering the red and green

CRT lenses with lens caps to allow only blue to show (or use the

method shown in the note below for turning off the CRTs individually

without using lens caps) and you will adjust the blue focus control on

the focus block.

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode MCP-RON, GON, BON.

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode MCP-RON, GON, BON.

Use the center dot

x

y

x : y = 1:1 (Green, Red)

2-9. DEFOCUS ADJUSTMENT (BLUE)

Note: Adjust the blue dot to be slightly larger than red and green dots.

This adjustment provides a more pleasing picture to the customer.

1. Set the mode to PRO, PICTURE : Max, COLOR TEMP : Cool.

2. Receive the 100IRE 1080i Dot signal.

3. Cover the red and green CRT lenses with lens caps to allow only blue

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

4. Turn the blue focus VR on the focus block to the right (clockwise) until

blue spot is in focus.

5. Change mode to VIVID to confi rm Flare level is minimal using cross

hatch signal.

6. Set the generator to an all white signal and check uniformity.

KP-46WT520/51WS520/57WS520

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode MCP-RON, GON, BON.

Adjust Point

33

Page 34

KP-46WT520/51WS520/57WS520

2-10.ELECTRICAL ADJUSTMENTS BY

7. If you want to go back to the most recently saved value, press “0” then

REMOTE COMMANDER

8. Press “MUTING” then “ENTER” to write the new adjustment data into

All of the circuit adjustments can be made by using the remote

commander (RM-Y916).

Note: The following test equipment is required:

1. Pattern Generator (with component outputs)

2. Frequency counter

3. Digital multimeter

4. Audio oscillator

2-10-1. METHOD OF ENTERING THE SERVICE

ADJUSTMENT MODE

SERVICE MODE PROCEDURE

1. TV must be in Standby mode. (Power off)

2. Press “DISPLAY”, “5”, “VOL +”, then “POWER” on the remote

commander.

(Press each button within 1 second of pressing the previous button.)

SERVICE MODE ADJUSTMENT

Item NO.

Category

Adjustment Item

3D-COMB

NRMD

F / A FLAG : XXXXXXXX

CBA FLAG : XXXXXXXX

0 0

WSL : XXX

3. The screen displays the item being adjusted within that category.

4. Press 1 or 4 on the remote commander to select the adjustment item

5. Press 3 or 6 on the remote commander to change the data

6. Press 2 or 5 on the remote commander to select the adjustment

category

Every time you press 2 (Category up), service mode changes in the

order shown below:

Data

SERVICE

TV

9. Turn power off when you want to exit the service mode.

Note:: Press “8” then “ENTER” on the remote commander to restore the

1. After adjustment, turn the power off with the remote commander.

2. Turn the power ON and set to service mode.

3. Cycle through the adjusted items again and confi rm that the

Note: When the PJE mode (which displays an internally generated

signal) is activated, several buttons on the remote commander will have

different functions than the ones listed below. Therefore, when in the PJE

mode, refer to section 2-12-3 for button functions.

“ENTER” to read the memory.

memory.

factory settings for user controls and channel memories (this will also

turn set off and then on to exit the service mode).

2-10-2. MEMORY WRITE CONFIRMATION

METHOD

adjustments were saved.

2-10-3. ADJUSTING BUTTONS AND

INDICATOR

WIDE MODE

MUTING

PICTURE

Category up

Adjustment

item up

Adjustment

item down

Test Reset

DISPLAY

POWER

TV/VIDEO

Data up

Data down

Category

down

ENTER

VERSION

USER

LUMA

COLR

CLTY

MIDE

CCPM

COMB

YCTS

MCP

DEF1

DEF2

DEF3

DEF4

DEF5

MID1

MID2

MID3

VSW

CRNR

RNR

BNR

SNNR

AWID

DDEV

PJED FDIS

PJED V1CM

PJED OTVS

PJED AIVP

PJED A1SV

KP-46WT520/51WS520/57WS520

PJED PV3P

PJED SFTF

PJED ROGH

PJED VUP

PJED DFHG

PJED CENT

AP

MSMO

OSDP

ASEL

VSEL

DRCV

PFID

PFOP

OP

ATSC

ID

ANT

VOLUME

RM-Y916

34

Page 35

2-11. ADJUSTABLE SERVICE DATA LISTS

Only the Adjustable registers are shown in this data list.

A complete set of the service data, Fixed and Adjustable, can be downloaded at:

KP-46WT520/51WS520/57WS520

http://www-ec.sdp.sel.sony.com/padics/Model_Data_List.htm

Only Sony authorized Service Technician can access this site. To request a complete list of the service data in PDF format please contact

Nita Wardlaw at Nita.Wardlaw@am.sony.com.

SERVICE DATA (dec)

CATEGORY # CONDITION

OP 5 OSDH OSD Horizontal Position (common) 21 21 21 0 255

6 OSDF OSD Favorite Positi on (common) 28 28 28 0 63

CCPM 1 YLEV Y Level RF - 60HZ 205 205 205 0 255

2 CLEV C Level RF - 60HZ 110 110 110 0 255

3 SHUE Sub Hue RF - 60HZ 7 7 7 0 15

YCTS 2 SCON Sub Contrast RF 9 9 9 0 15

(CXA2103) OTHER 6 6 6 0 15

3 SCOL Sub Color RF 6 6 6 0 15

4 SHUE Sub Hue RF 3 3 3 0 15

MCP 9 CBOF Cb Offset DRC - RF/BS/CV/YC 31 31 31 0 63

10 CROF Cr Offset DRC - RF/BS/CV/YC 30 30 30 0 63

DEF1 0 VPOS Vertical Position COMMON 25 25 25 0 63

1 VSIZ Vertical Size COMMON 31 31 31 0 63

DEF2 2 HSIZ Horizontal Size WIDEZOOM 24 24 24 0 63

3 SLIN S Linearity WIDEZOOM 7 7 7 0 15

COLR 2 RDRV Red Drive Gain COMMON 38 38 38 0 63

4 BDRV Bl ue Drive Gain COMMON 23 23 23 0 63

5 RCUT Red cut-off COMMON 23 23 23 0 63

7 BCUT Blue cut-off COMMON 27 27 27 0 63

8 SBRT Sub Bright COMMON 23 23 23 0 63

DESCRIPTIONITEM

DESCRIPTIONITEMCATEGORY #

CONDITION

CV - 60HZ 190 190 190 0 255

CV - 60HZ 103 103 103 0 255

CV - 60HZ 7 7 7 0 15

OTHER 555 0 15

OTHER 555 0 15

OTHER 242424 0 63

OTHER 777 0 15

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

SERVICE DATA (dec)

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

MIN

MIN

MAX

MAX

KP-46WT520/51WS520/57WS520

35

Page 36

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

CATEGORY # DESCRIPTIONITEM

PJE 93 R0GH Ratio Offset S0 G H (common) 0 0 0 -128 127

94 R0RH Ratio Offset S0 R H (common) 0 0 0 -128 127

95 R0BH Ratio Offset S0 B H (common) 0 0 0 -128 127

96 R1GH Ratio Offset S1 G H (common) 0 0 0 -128 127

97 R1RH Ratio Offset S1 R H (common) 0 0 0 -128 127

98 R1BH Ratio Offset S1 B H (common) 0 0 0 -128 127

99 R2GH Ratio Offset S2 G H (common) 0 0 0 -128 127

100 R2RH Ratio Offset S2 R H (common) 0 0 0 -128 127

101 R2BH Rati o Offset S2 B H (common) 0 0 0 -128 127

102 R3GH Ratio Offset S3 G H (common) 0 0 0 -128 127

103 R3RH Ratio Offset S3 R H (common) 0 0 0 -128 127

104 R3BH Rati o Offset S3 B H (common) 0 0 0 -128 127

105 R1GV Ratio Offset S1 G V (common) 0 0 0 -128 127

106 R1RV Ratio Offset S1 R V (common) 0 0 0 -128 127

107 R1BV Ratio Offset S1 B V (common) 0 0 0 -128 127

108 R2GV Ratio Offset S2 G V (common) 0 0 0 -128 127

109 R2RV Ratio Offset S2 R V (common) 0 0 0 -128 127

110 R2BV Ratio Offset S2 B V (common) 0 0 0 -128 127

111 PTRH Pattern Offset Top R H (common) 0 0 0 -128 127

112 PTBH Pattern Offset Top B H (common) 0 0 0 -128 127

113 PLRH Pattern Offset Left R H (common) 0 0 0 -128 127

114 PLBH Pattern Offset Left B H (common) 0 0 0 -128 127

115 PLRV Pattern Offset Left R V (common) 0 0 0 -128 127

116 PLBV Pattern Offset Left B V (common) 0 0 0 -128 127

117 PRRH Pattern Offset Right R H (common) 0 0 0 -128 127

118 PRBH Pattern Offset Right B H (common) 0 0 0 -128 127

119 PRGV Pattern Offset Right G V (common) 0 0 0 -128 127

120 PRRV Pattern Offset Right R V (common) 0 0 0 -128 127

121 PRBV Pattern Offset Right B V (common) 0 0 0 -128 127

122 PBGH Pattern Offset Bottom G H (common) 0 0 0 -128 127

123 PBRH Pattern Offset Bottom R H (common) 0 0 0 -128 127

124 PBBH Pattern Offset Bottom B H (common) 0 0 0 -128 127

125 ERR Auto Regi Error Code (common) 0 0 0 0 255

130 VUP

131 VMID

132 VLOW

133 HLE

134 HMID

135 HRIT

Auto Regi V Upper Pattern Position

Auto Regi V Middle Pattern Position (common) 495 495

Auto Regi V Lower Pattern Position (common) 947 947

Auto Regi H Left Pattern Position (common) 181 181

Auto Regi H Middle Pattern Position (common) 853 853

CONDITION

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

MIN

0

50(common) 50

50

495

947

181

853

1522

2047

0 2047

0 2047

0 2047

0 2047

0 2047Auto Regi H Right Pattern Position (common) 1522 1522

MAX

KP-46WT520/51WS520/57WS520

36

Page 37

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

PJE 141 CENT

CONDITIONCATEGORY # DESCRIPTIONITEM

Zoom 40 40 40 -512 511

1080i WideZoom -512 511

R V Cent Ful l / Normal -512 511

Zoom -512 51120 20 20

WideZoom -512 51120 20 20

1080i Zoom -512 51120 20 20

1080i WideZoom -512 51120 20 20

G H Cent -512 511Full / Normal 40

Zoom

51WS520 (U/C)

57WS520 (U/C)

40 40

40Full / NormalR H Cent

40 40 40

20 20 20

40 40

40 40 40

40 40 40

46WT520 (U/C)

MIN

-512 511

-512 511WideZoom 40 40 40

-512 511401080i Full / Normal 40 40

-512 5111080i Zoom 40 40 40

-512 5111080i Full / Normal 20 20 20

-512 511

511WideZoom

-512

MAX

1080i Zoom -51240 40 40

1080i WideZoom

G V Cent Full / Normal

Zoom 20 20

WideZoom

1080i Zoom

1080i WideZoom 20 20 20

40 40 40

20 20 20

20 20 20

20 20 20

20

-512 5111080i Full / Normal 40 40 40

511

-512 511

-512

511

-512 511

-512

511

-512 5111080i Full 20 20 20

-512

511

511

-512

KP-46WT520/51WS520/57WS520

37

Page 38

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

PJE 141

142 SIZE

B H Cent

B V Cent

R H Size

CONDITIONCATEGORY # DESCRIPTIONITEM

Full / Normal

WideZoom

1080i WideZoom 40 40 40

Full / Normal 20 20 20

Zoom 20 20

WideZoom

1080i Zoom

1080i WideZoom

Full / Normal

WideZoom -120 -120 -120

51WS520 (U/C)

57WS520 (U/C)

40 40

40 40

40 40 40

20 20 20

20 20 20

20 20

-120 -120 -120

40

40 -512Zoom

20

20

46WT520 (U/C)

MIN

511

-512

511

-512

511

-512 5111080i Full / Normal 40 40 40

511

-5121080i Zoom 40 40 40

511

-512

511

-512

511

-512

-512 511

-512 5111080i Full / Normal 20 20 20

-512

511

-512

511

-512 511

-512 511Zoom -120 -120 -120

-512 511

MAX

-512 511-1201080i Full / Normal -120 -120

1080i Zoom

1080i WideZoom -512

R V Size Full / Normal -512

Zoom -512 511-80 -80 -80

WideZoom -512 511-80 -80 -80

1080i Zoom -512 511-80 -80 -80

1080i WideZoom -512 511-80 -80 -80

-120 -120

-120 -120

-80 -80

-120

-120

-80

-512 5111080i Full / Normal -80 -80 -80

511-512

511

511

KP-46WT520/51WS520/57WS520

38

Page 39

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

PJE 142 SIZE

CONDITIONCATEGORY # DESCRIPTIONITEM

G H Size Full / Normal -512 511-120 -120 -120

Zoom -512 511-120 -120 -120

WideZoom -512 511-120 -120 -120

1080i Zoom -512 511-120 -120 -120

1080i WideZoom -512 511-120 -120 -120

G V Size Full / Normal -512 511-80 -80 -80

Zoom -512 511-80 -80 -80

WideZoom -512 511-80 -80 -80

1080i Zoom -512 511-80 -80 -80

1080i WideZoom -512 511-80 -80 -80

B H Size Full / Normal -512 511-120 -120 -120

Zoom -512 511-120 -120 -120

WideZoom -512 511-120 -120 -120

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

MIN

MAX

-512 5111080i Full / Normal -120 -120 -120

-512 5111080i Full / Normal -80 -80 -80

1080i Zoom -512 511-120 -120 -120

1080i WideZoom -512 511-120 -120 -120

B V Size Ful l / Normal -512 511-80 -80 -80

Zoom -512 511-80 -80 -80

WideZoom -512 511-80 -80 -80

1080i Zoom -512 511-80 -80 -80

1080i WideZoom -512 511-80 -80 -80

-512 5111080i Full / Normal -120 -120 -120

-512 5111080i Full / Normal -80 -80 -80

KP-46WT520/51WS520/57WS520

39

Page 40

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

PJE 143 LIN

CONDITIONCATEGORY # DESCRIPTIONITEM

R H Lin Full / Normal -512 511300 300 300

Zoom -512 511300 300 300

WideZoom -512 511300 300 300

1080i Zoom -512 511300 300 300

1080i WideZoom -512 511300 300 300

R V Lin Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

G H Lin Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

MIN

MAX

-512 5111080i Full / Normal 300 300 300

-512 5111080i Full / Normal 0 0 0

1080i Zoom -512 511000

1080i WideZoom -512 511000

G V Lin Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

-512 5111080i Full / Normal 0 0 0

-512 5111080i Full / Normal 0 0 0

KP-46WT520/51WS520/57WS520

40

Page 41

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

PJE 143 LIN

144 SKEW

CONDITIONCATEGORY # DESCRIPTIONITEM

B H Lin Full / Normal -512 511-300 -300 -300

Zoom -512 511-300 -300 -300

WideZoom -512 511-300 -300 -300

1080i Zoom -512 511-300 -300 -300

1080i WideZoom -512 511-300 -300 -300

B V Lin Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

R H Skew Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

MIN

MAX

-512 5111080i Full / Normal -300 -300 -300

-512 5111080i Full / Normal 0 0 0

1080i Zoom -512 511000

1080i WideZoom -512 511000

R V Skew Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

-512 5111080i Full 0 0 0

-512 5111080i Full / Normal 0 0 0

KP-46WT520/51WS520/57WS520

41

Page 42

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

PJE 144 SKEW

CONDITIONCATEGORY # DESCRIPTIONITEM

G H Skew Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

G V Skew Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

B H Skew Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

MIN

MAX

-512 5111080i Full / Normal 0 0 0

-512 5111080i Full / Normal 0 0 0

1080i Zoom -512 511000

1080i WideZoom -512 511000

B V Skew Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

-512 5111080i Full / Normal 0 0 0

-512 5111080i Full / Normal 0 0 0

KP-46WT520/51WS520/57WS520

42

Page 43

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

PJE 145 BOW

CONDITIONCATEGORY # DESCRIPTIONITEM

R H Bow Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

R V Bow Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

G H Bow Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

MIN

MAX

-512 5111080i Full / Normal 0 0 0

-512 5111080i Full / Normal 0 0 0

1080i Zoom -512 511000

1080i WideZoom -512 511000

G V Bow Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

-512 5111080i Full / Normal 0 0 0

-512 5111080i Full / Normal 0 0 0

KP-46WT520/51WS520/57WS520

43

Page 44

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

PJE 145 BOW

146 KEY

CONDITIONCATEGORY # DESCRIPTIONITEM

B H Bow Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

B V Bow Ful l / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

R H Key Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

MIN

MAX

-512 5111080i Full / Normal 0 0 0

-512 5111080i Full / Normal 0 0 0

1080i Zoom -512 511000

1080i WideZoom -512 511000

R V Key Full / Normal -512 511130 130 130

Zoom -512 511130 130 130

WideZoom -512 511130 130 130

1080i Zoom -512 511130 130 130

1080i WideZoom -512 511130 130 130

-512 5111080i Full / Normal 0 0 0

-512 5111080i Full / Normal 130 130 130

KP-46WT520/51WS520/57WS520

44

Page 45

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

PJE 146 KEY

CONDITIONCATEGORY # DESCRIPTIONITEM

G H Key Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

G V Key Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

B H Key Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

MIN

MAX

-512 5111080i Full / Normal 0 0 0

-512 5111080i Full / Normal 0 0 0

1080i Zoom -512 511000

1080i WideZoom -512 511000

B V Key Full / Normal -512 511-130 -130 -130

Zoom -512 511-130 -130 -130

WideZoom -512 511-130 -130 -130

1080i Zoom -512 511-130 -130 -130

1080i WideZoom -512 511-130 -130 -130

-512 5111080i Full / Normal 0 0 0

-512 5111080i Full / Normal -130 -130 -130

KP-46WT520/51WS520/57WS520

45

Page 46

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

PJE 147 PIN

CONDITIONCATEGORY # DESCRIPTIONITEM

R H Pin Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

R V Pin Full / Normal -512 511380 380 380

Zoom -512 511380 380 380

WideZoom -512 511380 380 380

1080i Zoom -512 511380 380 380

1080i WideZoom -512 511380 380 380

G H Pin Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

MIN

MAX

-512 5111080i Full / Normal 0 0 0

-512 5111080i Full / Normal 380 380 380

1080i Zoom -512 511000

1080i WideZoom -512 511000

G V Pin Full / Normal -512 511430 430 430

Zoom -512 511430 430 430

WideZoom -512 511430 430 430

1080i Zoom -512 511430 430 430

1080i WideZoom -512 511430 430 430

-512 5111080i Full / Normal 0 0 0

-512 5111080i Full / Normal 430 430 430

KP-46WT520/51WS520/57WS520

46

Page 47

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

PJE 147 PIN

148 MLIN

CONDITIONCATEGORY # DESCRIPTIONITEM

B H Pin Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

1080i Zoom -512 511000

1080i WideZoom -512 511000

B V Pin Full / Normal -512 511380 380 380

Zoom -512 511380 380 380

WideZoom -512 511380 380 380

1080i Zoom -512 511380 380 380

1080i WideZoom -512 511380 380 380

R H Middle Lin Full / Normal -512 511000

Zoom -512 511000

WideZoom -512 511000

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

MIN

MAX

-512 5111080i Full / Normal 0 0 0

-512 5111080i Full / Normal 380 380 380

G H Middle Lin

-512 5111080i Full / Normal 0 0 0

1080i Zoom -512 511000

1080i WideZoom -512 511000

Full / Normal 0 0 0 511

000Zoom -512 511

WideZoom -512000

1080i Zoom 0 0

1080i WideZoom 0 0

0

0

-512

511

-512 5111080i Full / Normal 0 0 0

-512 511

-512 511

KP-46WT520/51WS520/57WS520

47

Page 48

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

PJE 148 MLIN

149 MSIZ

CONDITIONCATEGORY # DESCRIPTIONITEM

B H Middle Lin 511

R H Middle Size Full / Normal 0 0

Full / Normal 0 0 0

Zoom -512 511

WideZoom -512 511

1080i Zoom 0 0

1080i WideZoom 0 0 0 -512 511

Zoom 0 0

WideZoom 0 0 0 -512 511

1080i Zoom 0 0

1080i WideZoom -512 511

Zoom 0 0 0

WideZoom

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

000

000

0 -512

0 -512 511

0

000

00

000

0

MIN

-512

-512 5111080i Full / Normal 0 0 0

511

-512 5110

-512 5111080i Full / Normal 0 0 0

-512 511

511G H Middle Size Full / Normal

-512

-512 511

-512 511

MAX

1080i Full / Normal 0 0

1080i Zoom

1080i WideZoom -512 511

B H Middle Size Full / Normal 0 0

Zoom / V.Comp 0 0

WideZoom -512 511000

1080i Full -512 511000

000

000

0

-512 511

-512 511

0 -512 511

-512 5110

-512 5111080i Full 0 0 0

-512 5111080i V.Comp 0 0 0

KP-46WT520/51WS520/57WS520

48

Page 49

2-11-1. ID MAP TABLE

KP-46WT520/51WS520/57WS520

SERVICE DATA (dec)

ID 0 ID0 ID Byte 0 (common) 89 89 89 0 255

DESCRIPTIONITEMCATEGORY #

1 ID1 ID Byte 1 (common) 255 255 255 0 255

2 ID2 ID Byte 2 (common) 239 239 239 0 255

3 ID3 ID Byte 3 (common) 106 106 106 0 255

4 ID4 ID Byte 4 (common) 75 75 75 0 255

5 ID5 ID Byte 5 (common) 243 243 243 0 255

6 ID6 ID Byte 6 (common) 190 190 190 0 255

7 ID7 ID Byte 7 (common) 155 155 155 0 255

CONDITION

51WS520 (U/C)

57WS520 (U/C)

46WT520 (U/C)

MIN

MAX

KP-46WT520/51WS520/57WS520

49

Page 50

KP-46WT520/51WS520/57WS520

2-12.REGISTRATION ADJUSTMENT

(PJE MODE ONLY)

*ADJUSTING FLOW

START

Turn on the power and wait for 10 minutes.

Set to the NTSC Full mode

Check the deflection yokes, the centering magnets,

2 pole/4 pole magnets

Set to the service mode.

MAIN DEFLECTION ADJUSTMENT (Green)

Green coarse adjustment

Green fine adjustment

2-12-1. SETUP FOR ADJUSTMENT

MARKING

• At the 4 sides of the screen, locate the middle. Use a tape measure to

identify the middle.

: middle

DATA SETTING

1. Set NTSC Full mode.

2. Enter the service mode, and select “PJE”.

NOTE: When you replace printed circuit boards or devices or CRTs, and

when correction is drastically necessary, press the “7” + ENTER on the

remote commander to initialize the data in the Projector Engine mode.

Press the MUTING + ENTER on the remote commander to write the data.

2-12-2. MAIN DEFLECTION ADJUSTMENT

***

Change the

wide screen

mode

Yes

***

Red coarse adjustment

Red fine adjustment

Blue coarse adjustment

Blue fine adjustment

Another wide screen mode?

No

Memorize the FLASH FOCUS offset data

(Run flash focus in PJE Service Mode)

End

COPY

When the NTSC Full mode adjustment has finished,

copy its data to NTSC Zoom, HD Full, and HD Zoom

modes the first time only and be sure to adjust in the order given.

When the NTSC Wide Zoom mode adjustment has finished,

copy its data to HD Wide Zoom mode.

This will serve as a starting point for adjusting these other modes.

See section 2-13-2. Copying All Registration Data To Other Modes

for more information.

SUB

DEFLECTION

ADJUSTMENT

NOTE: Before this adjustment, refer to section 2-11 SERVICE DATA

LISTS for PJE item #141-149 input data.

1. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

2. Enter the monoscope signal and set to NTSC Full mode.

3. Enter the service mode, and select “DEF1”.

4. Adjust “0 VPOS” and “1 VSIZ” so that the picture is displayed in the

center of the screen.

0 VPOS

1 V-Size

5. Select “DEF2” and adjust “2 H-Size” so that the picture size is within

the specifi cation.

SPEC Overscan Spec. = 9%

Input Signal H SIZE V SIZE

Monoscope 15.6 ± 0.2 sq. 11.5 ± 0.2 sq.

2 H-Size

KP-46WT520/51WS520/57WS520

6. Copy the data of the NTSC Full mode to the other wide screen mode

and, if necessary, adjust in the other mode.

50

Page 51

2-12-3. OPERATION METHOD FOR

PROJECTOR ENGINE MODE

DISPLAY

MUTING

Category up

Adjustment

item up

Adjustment

item down

Category

down

Initialize data

(Not stored)

Test Reset

MENU

POWER

Color Select GRN

to BLU to RED

Test signal select

crosshatch + video

signal dots + video signal

crosshatch + black dots

and black off

Mode Select

(Course Adjustment

Fine Adjustment)

ENTER

KP-46WT520/51WS520/57WS520

Press Switches marker moving method.

Joystick (In Fine Adjustment mode)

Pressing down on the joystick in Fine Adjustment mode switches

between selecting and un-selecting a point.

When a point is selected, the cursor changes to that color to indicate

the point is selected and can be adjusted. If a point is not selected the

cursor is white.

Joystick

Commander Function

2. OPERATION METHOD FOR COARSE ADJUSTMENT

1. Enter the service mode and select “PJE”.

2. Press the “1” or “4” button on the remote commander to select the

5 6 3 4

Buttons Mode Description

0 + ENTER READ Reads data to NVM.

MUTING+ENTER WRITE Writes data from NVM.

7 + ENTER PJE Service data initialization.

item, and then use the joystick to change the data.

keys Æ 1 and 4 buttons

INITIAL

Not stored.

(Be sure not to use usually)

RM-Y916

1. FUNCTION OF KEYS ON COMMANDER

1

Changes adjustment item. (Item # moves up)

Marker moves clockwise from center to outside.

(In Fine Adjustment mode)

4

Changes adjustment item. (Item # moves down)

Marker moves counter clockwise from outside to center.

(In Fine Adjustment mode)

2

Changes adjustment category.

(Category # moves up)

5

Changes adjustment category.

(Category # moves down)

Joystick Changes data value. (Up or down)

Marker moves clockwise from center

(up, down, right, and then left) to outside.

(In Fine Adjustment mode)

3

Changes adjustment color.

GRN ÆBLU ÆRED

6

Displays or changes internal test signals.

crosshatch + external signal Æ

crosshatch + borderline Æ

crosshatch only Æ

dot only Æ off

9

Switches adjustment mode.

Coarse adjustment model Æ

Fine adjustment point mode Æ

Fine adjustment row mode Æ

Fine adjustment column mode

Item No.

PJE 00 6000

FDIS

Adjustment Item

3. Select “GRN CENT”. When BLU or RED is displayed, press the “3”

button on the remote commander to change the adjustment color in

the order of GRN ÆBLU ÆRED.

4. In the GRN, BLU, or RED mode, move the joystick 5 or 6to

change the data in vertical direction, or 3 or 4 to change the data

in a horizontal direction.

Color

GRN 000 000 60

CENT

5. Before returning to the service mode, press the “MUTING” +

“ENTER” buttons on the remote commander to write the data.

(You must complete step 5 to write the data. If you omit step 5 the

set data is returned to the data prior to the adjustment.)

Data (H)

Adjustment Item

Data

Data (V)

Joystick

direction:Data up

54

direction:Data down

63

: Data (H) up

3

: Data (H) down

4

: Data (V) up

5

: Data (V) down

6

KP-46WT520/51WS520/57WS520

51

Page 52

KP-46WT520/51WS520/57WS520

3. OPERATION METHOD FOR FINE ADJUSTMENT

1. Enter the service mode and select “PJE”.

2. Select FDIS and set the data to “01” so that the data at each

position can be displayed in fi ne adjustment mode.

3. Press the “9” button on the remote commander and fi ne adjustment

mode will be active where a green marker appears in the center of

the screen. (In the case of GRN mode)

4. Press down on the joystick, and the marker color will be alternately

switched between green (GRN mode) and white.

5. Press the “1” or “4” button on the remote commander or use the

joystick to move the marker to the position to be adjusted, where

fi ne adjustment can be made.

* When the marker color is white:

(in this case, fi ne adjustment is disabled)

Use the joystick to move the marker up, down, left, or right.

* When the marker color is green:

(GRN mode)

2-13.PJE ADJUSTMENT (SUB DEFLECTION

ADJUSTMENT)

Adjustment type

Adjustment item G R B

H/V* H/V* H/V*

CENT O/O O/O O/O

SKEW O/O O/O O/O

SIZE O/O O/O O/O

LIN O/O O/O O/O

BOW O/O O/O O/O

KEY O/O O/O O/O

PIN O/O O/O O/O

MLIN O/- O/- O/MSIZ O/- O/- O/

* H = Horizontal V = Vertical O = Yes = No

Note: If the value is over the limit value, adjust these in the fi ne

adjustment.

Coarse Data Limit Value:

CENT H -135 TO + 205

CENT V -150 TO + 190

SKEW -75 TO + 75

SIZE H -75 MAX

BLUE H LIN -425 MIN

RED H LIN +425 MAX

FINE DATA LIMIT ± 107

Except the extreme left & right outside columns which have no limit

1

: Moves the marker clockwise from the center to the outside.

4

: Moves the marker counter clockwise from the outside to the

center.

* Fine adjustment can be made on the basis of a marker position

using the joystick to move

Move joystick 5 direction

CROSSHATCH

6. Press the “9” button on the remote commander to return to the

coarse adjustment mode.

5 6 3 or4.

Move joystick

4

direction

CROSSHATCH

KP-46WT520/51WS520/57WS520

52

Page 53

KP-46WT520/51WS520/57WS520

2-13-1. ADJUSTMENT FOR NTSC FULL MODE

GRN SIZE (Horizontally/Vertically)

• The adjustment should be done in the numerical order given.

1) GREEN ADJUSTMENT