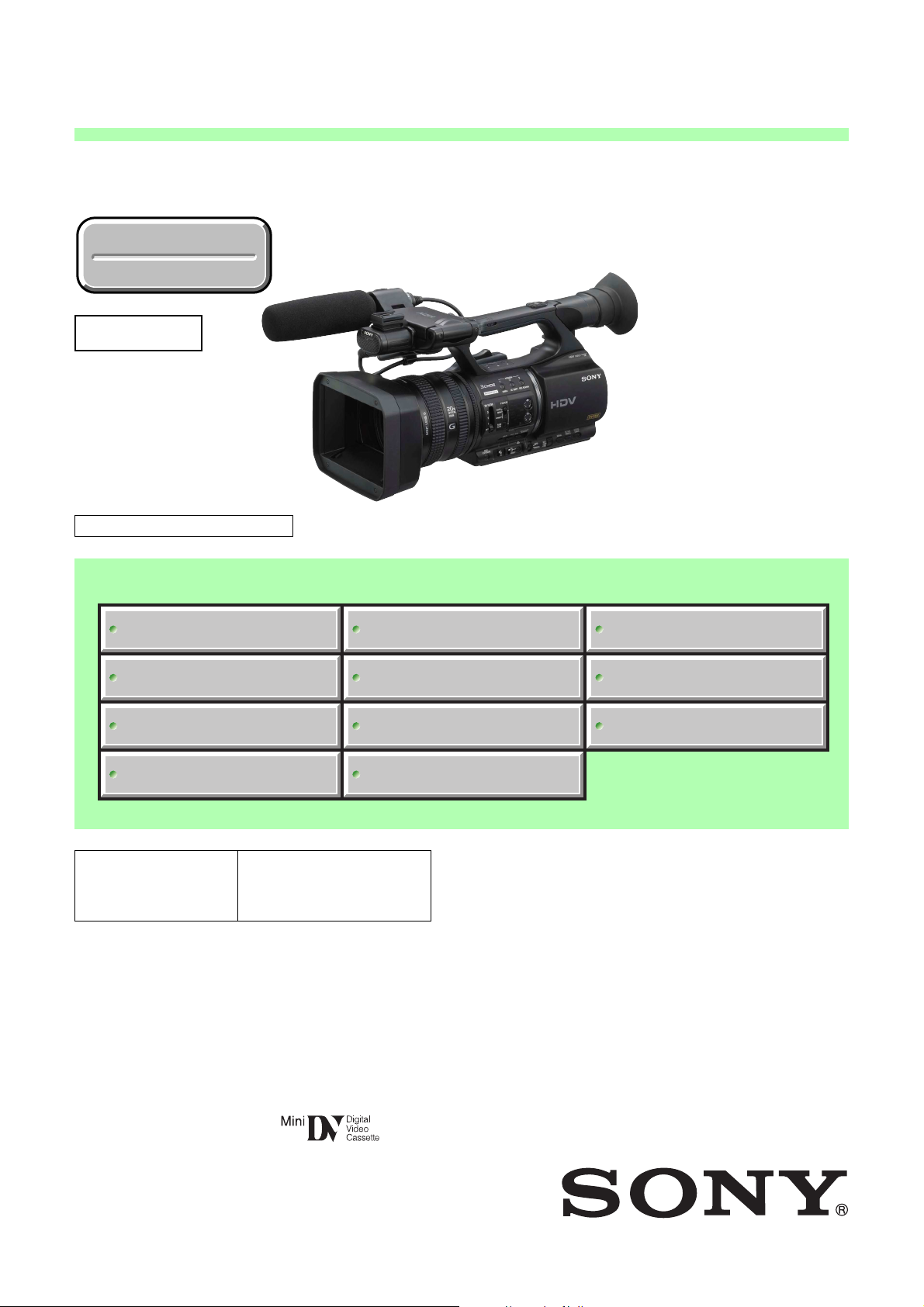

Sony HVR-Z5C, HVR-Z5E, HVR-Z5J, HVR-Z5N, HVR-Z5P Service Manual

...

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

RMT-831

US Model

SERVICE MANUAL

Ver. 1.2 2009.04

Revision History

Revision History

Revised-1

Replace the previously issued

SERVICE MANUAL 9-852-623-12

with this Manual.

Canadian Model

AEP Model

E Model

Chinese Model

Japanese Model

N MECHANISM (MDX-N221)

Link

Link

SPECIFICATIONS

MODEL INFORMATION TABLE

SERVICE NOTE

DISASSEMBLY

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

Photo: HVR-Z5J

BLOCK DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

PRINTED WIRING BOARDS

REPAIR PARTS LIST

ADJUSTMENTS

INSTRUCTION MANUAL

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

DIGITAL HD VIDEO CAMERA RECORDER

2009D0800-1

Sony EMCS Co.

Published by Kohda TEC9-852-623-13

© 2009.04

These specifications are extracted from instruction manual of

HVR-Z5C/Z5E/Z5P.

SPECIFICATIONS

ENGLISH JAPANESE

ENGLISH JAPANESE

System

Video recording system (HDV)

2 rotary heads, Helical scanning system

Video recording system (DVCAM (DV))

2 rotary heads, Helical scanning system

Still image recording system

Exif Ver. 2.2*

Audio recording system (HDV)

Rotary heads, MPEG-1 Audio Layer-2,

Quantization: 16 bits

Fs48kHz (stereo)

transfer rate: 384 kbps

Audio recording system (DVCAM (DV))

Rotary heads, PCM system

Quantization: 12 bits

Fs32kHz (channel 1/2 stereo),

Quantization: 16 bits

Fs48kHz (channel 1/2 stereo)

Video signal

PAL color, CCIR standards

1080/50i specification

Usable cassette

Mini DV cassette with the mark

printed or Mini DVCAM cassette with

the mark printed

Tape speed (HDV)

Approx. 18.831 mm/s

Tape speed (DVCAM)

Approx. 28.221 mm/s

Tape speed (DV SP)

Approx. 18.831 mm/s

Recording/playback time (HDV)

63 min (using a PHDVM-63DM

cassette)

Recording/playback time (DVCAM)

41 min (using a PHDVM-63DM

cassette)

Recording/playback time (DV SP)

63 min (using a PHDVM-63DM

cassette)

Fast forward/rewind time

Approx. 2 min 40 s (using a PHDVM63DM cassette and rechargeable

battery pack)

Approx. 1 min 45 s (using a PHDVM63DM cassette and AC Adaptor/

Charger)

Viewfinder

Electric viewfinder (color, black and

white)

Picture

1.1 cm (0.45 type, aspect

ratio 16:9)

Total dot number

1 226 880 (approx. 852

480)

Image device

6.0 mm (1/3 type) 3CMOS sensor

Recording Pixels (HDV/DV16:9 still

recording):

Max. 1.20 Mega (1 440

Gross: Approx. 1 120 000 pixels

Effective (movie, 16:9):

Approx. 1 037 000 pixels

Effective (movie, 4:3):

Approx. 778 000 pixels

Effective (still, 16:9):

Approx. 1 037 000 pixels

Effective (still, 4:3):

Approx. 778 000 pixels

Lens

G Lens

× (Optical), Approx. 30 × (Digital,

20

when [D.EXTENDER] is set to [ON])

Focal length

f=4.1 - 82.0 mm (3/16 - 3 1/4 in.)

When converted to a 35 mm still

camera

29.5 - 590 mm (1 3/16 - 23 1/4 in.)

(16:9),

36.1 - 722 mm (1 7/16 - 28 1/2 in.)

(4:3)

F1.6 - 3.4

Filter diameter: 72 mm (2 7/8 in.)

× 3[RGB] ×

× 810) pixels**

Color temperature

[AUTO]

(one push) A/B

[INDOOR] (3 200K)

[OUTDOOR] (5 800K±7 offset levels)

[MANU WB TEMP] (2 300K 15 000K in 100K steps)

Minimum illumination

1.5 lx (lux) (Fixed Shutter Speed 1/25,

auto gain, auto iris) (F 1.6)

’

is a file format for still images,

* Exif

established by the JEITA (Japan

Electronics and Information Technology

Industries Association). Files in this

format can have additional information

such as your camcorder

information at the time of recording.

** The unique pixel array of Sony

ClearVid CMOS sensor and image

processing system (new Enhanced

Imaging Processor) allows for still

image resolution equivalent to the sizes

described.

Output connectors

A/V Remote Connector

10-pin connector

When A/V connecting cable is

connected

Video signal: 1 Vp-p, 75

Luminance signal: 1 Vp-p, 75

Chrominance signal: 0.3 Vp-p (burst

Ω (ohms)

signal), 75

When component A/V cable is

connected

Y: 1 Vp-p, 75

+/- 350 mV, 75

Audio signal: -10 dBu (at load

impedance 47 k

impedance with less than 2.2 k

(kilohms)

(0 dBu=0.775 Vrms)

HDMI OUT jack

TypeA (19-pin)

i

(headphones) jack

Stereo-minijack (

Input/Output connectors

LANC jack

Stereo mini-minijack (

INPUT1/INPUT2 jack

XLR 3-pin, female,

-48 dBu: 3k

+4 dBu: 10k

(0 dBu=0.775 Vrms)

HDV/DV jack

i.LINK interface (IEEE 1394, 4-pin

connector S100)

LCD screen

Picture

8.0 cm (3.2 type, aspect ratio 16:9)

Total dot number

921 600 (1 920

General

Power requirements

DC 7.2 V (battery pack)

DC 8.4 V (AC Adaptor/Charger)

Average power consumption*

During camera recording using the

microphone ECM-XM1 and viewfinder

with normal brightness:

HDV recording 6.9 W

DVCAM (DV) recording 6.7 W

During camera recording using the

microphone ECM-XM1 and LCD with

normal brightness:

HDV recording 7.1 W

DVCAM (DV) recording 6.9 W

Operating temperature

0 ˚C to 40 ˚C (32 ˚F to 104 ˚F)

Storage temperature

-20 ˚C to +60 ˚C (-4 ˚F to +140 ˚F)

Ω (ohms), PB/PR, CB/CR:

Ω (kilohms)

Ω (kilohms)

’

s setting

Ω (ohms)

Ω (ohms)

Ω (ohms)

Ω (kilohms)), Output

∅ 3.5 mm)

× 480)

Ω

∅ 2.5 mm)

Dimensions (approx.)

× 188 × 451 mm

169

× 7 1/2 × 17 7/8 in.)

(6 3/4

(w/h/d)

including the projecting parts

× 188 × 451 mm

169

× 7 1/2 × 17 7/8 in.)

(6 3/4

(w/h/d)

including the projecting parts with the

battery pack (NP-F570)

Mass (approx.)

2.2 kg (5 lb 1 oz) including the lens

hood with lens cover

2.5 kg (5 lb 6 oz) including the battery

pack (NP-F570), cassette (PHDVM63DM), lens hood with lens cover and

microphone (ECM-XM1)

’

s

* When the HVR-MRC1 is used, the average

power consumption increases about 2.5 W.

AC Adaptor/Charger AC-VQ1050

Power requirements

AC 100 V - 240 V, 50 Hz/60 Hz

Power consumption

22 W

Output voltage

DC 8.4 V*

Operating temperature

0 ˚C to 40 ˚C (32 ˚F to 104 ˚F)

Storage temperature

-20 ˚C to +60 ˚C (-4 ˚F to +140 ˚F)

Dimensions (approx.)

× 53 × 135 mm

123

× 2 1/8 × 5 3/8 in.) (w/h/d)

(4 7/8

excluding the projecting parts

Mass (approx.)

390 g (13.8 oz) excluding the power

cord (mains lead)

* See the label on the AC Adaptor/Charger for

other specifications.

Rechargeable battery pack NP-F570

Maximum output voltage

DC 8.4 V

Output voltage

DC 7.2 V

Maximum charge voltage

DC 8.4 V

Maximum charge current

3.0 A

Capacity

15.8 Wh (2 200 mAh)

Type

Li-ion

Design and specifications are subject to change

without notice.

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

— 2 —

These specifications are extracted from instruction manual of

HVR-Z5N/Z5U.

SPECIFICATIONS

ENGLISH JAPANESE

ENGLISH JAPANESE

System

Video recording system (HDV)

2 rotary heads, Helical scanning system

Video recording system (DVCAM (DV))

2 rotary heads, Helical scanning system

Still image recording system

Exif Ver. 2.2*

Audio recording system (HDV)

Rotary heads, MPEG-1 Audio Layer-2,

Quantization: 16 bits

Fs48kHz (stereo)

transfer rate: 384 kbps

Audio recording system (DVCAM (DV))

Rotary heads, PCM system

Quantization: 12 bits

Fs32kHz (channel 1/2 stereo),

Quantization: 16 bits

Fs48kHz (channel 1/2 stereo)

Video signal

NTSC color, EIA standards

1080/60i specification

Usable cassette

Mini DV cassette with the mark

printed or Mini DVCAM cassette with

the mark printed

Tape speed (HDV)

Approx. 18.812 mm/s

Tape speed (DVCAM)

Approx. 28.193 mm/s

Tape speed (DV SP)

Approx. 18.812 mm/s

Recording/playback time (HDV)

63 min (using a PHDVM-63DM

cassette)

Recording/playback time (DVCAM)

41 min (using a PHDVM-63DM

cassette)

Recording/playback time (DV SP)

63 min (using a PHDVM-63DM

cassette)

Fast forward/rewind time

Approx. 2 min 40 s (using a PHDVM63DM cassette and rechargeable

battery pack)

Approx. 1 min 45 s (using a PHDVM63DM cassette and AC Adaptor/

Charger)

Viewfinder

Electric viewfinder (color, black and

white)

Picture

1.1 cm (0.45 type, aspect

ratio 16:9)

Total dot number

1 226 880 (approx. 852

480)

Image device

6.0 mm (1/3 type) 3CMOS sensor

Recording Pixels (HDV/DV16:9 still

recording):

Max. 1.20 Mega (1 440

Gross: Approx. 1 120 000 pixels

Effective (movie, 16:9):

Approx. 1 037 000 pixels

Effective (movie, 4:3):

Approx. 778 000 pixels

Effective (still, 16:9):

Approx. 1 037 000 pixels

Effective (still, 4:3):

Approx. 778 000 pixels

Lens

G Lens

× (Optical), Approx. 30 × (Digital,

20

when [D.EXTENDER] is set to [ON])

Focal length

f=4.1 - 82.0 mm (3/16 - 3 1/4 in.)

When converted to a 35 mm still

camera

29.5 - 590 mm (1 3/16 - 23 1/4 in.)

(16:9),

36.1 - 722 mm (1 7/16 - 28 1/2 in.)

(4:3)

F1.6 - 3.4

Filter diameter: 72 mm (2 7/8 in.)

× 3[RGB] ×

× 810) pixels**

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

Color temperature

[AUTO]

(one push) A/B

[INDOOR] (3 200K)

[OUTDOOR] (5 800K±7 offset levels)

[MANU WB TEMP] (2 300K 15 000K in 100K steps)

Minimum illumination

1.5 lx (lux) (Fixed Shutter Speed 1/30,

auto gain, auto iris) (F 1.6)

’

is a file format for still images,

* Exif

established by the JEITA (Japan

Electronics and Information Technology

Industries Association). Files in this

format can have additional information

such as your camcorder

information at the time of recording.

** The unique pixel array of Sony’s

ClearVid CMOS sensor and image

processing system (new Enhanced

Imaging Processor) allows for still

image resolution equivalent to the sizes

described.

Output connectors

A/V Remote Connector

10-pin connector

When A/V connecting cable is

connected

Video signal: 1 Vp-p, 75

Luminance signal: 1 Vp-p, 75

Chrominance signal: 0.286 Vp-p (burst

Ω (ohms)

signal), 75

When component A/V cable is

connected

Y: 1 Vp-p, 75

+/- 350 mV, 75

Audio signal: -10 dBu (at load

impedance 47 k

impedance with less than 2.2 k

(kilohms)

(0 dBu=0.775 Vrms)

HDMI OUT jack

TypeA (19-pin)

i

(headphones) jack

Stereo-minijack (

Input/Output connectors

LANC jack

Stereo mini-minijack (

INPUT1/INPUT2 jack

XLR 3-pin, female,

-48 dBu: 3k

+4 dBu: 10k

(0 dBu=0.775 Vrms)

HDV/DV jack

i.LINK interface (IEEE 1394, 4-pin

connector S100)

LCD screen

Picture

8.0 cm (3.2 type, aspect ratio 16:9)

Total dot number

921 600 (1 920

General

Power requirements

DC 7.2 V (battery pack)

DC 8.4 V (AC Adaptor/Charger)

Average power consumption*

During camera recording using the

microphone ECM-XM1 and viewfinder

with normal brightness:

HDV recording 7.1 W

DVCAM (DV) recording 6.8 W

During camera recording using the

microphone ECM-XM1 and LCD with

normal brightness:

HDV recording 7.3 W

DVCAM (DV) recording 7.0 W

Operating temperature

0 ˚C to 40 ˚C (32 ˚F to 104 ˚F)

Storage temperature

-20 ˚C to +60 ˚C (-4 ˚F to +140 ˚F)

Ω (ohms), P

Ω (kilohms)

Ω (kilohms)

’

s setting

Ω (ohms)

Ω (ohms)

B/PR

Ω (ohms)

Ω (kilohms)), Output

∅ 3.5 mm)

× 480)

, CB/CR:

Ω

∅ 2.5 mm)

— 3 —

Dimensions (approx.)

HVR-Z5U:

169

× 188 × 451 mm

× 7 1/2 × 17 7/8 in.)

(6 3/4

(w/h/d)

including the projecting parts

× 188 × 451 mm

169

× 7 1/2 × 17 7/8 in.)

(6 3/4

(w/h/d)

including the projecting parts with the

battery pack (NP-F770)

HVR-Z5N:

× 188 × 451 mm

169

× 7 1/2 × 17 7/8 in.)

(6 3/4

(w/h/d)

including the projecting parts

× 188 × 451 mm

169

× 7 1/2 × 17 7/8 in.)

(6 3/4

(w/h/d)

including the projecting parts with the

battery pack (NP-F570)

Mass (approx.)

HVR-Z5U:

2.2 kg (5 lb 1 oz) including the lens

hood with lens cover

2.6 kg (5 lb 10 oz) including the battery

pack (NP-F770), cassette (PHDVM-

63DM), lens hood with lens cover and

microphone (ECM-XM1)

HVR-Z5N:

2.2 kg (5 lb 1 oz) including the lens

hood with lens cover

2.5 kg (5 lb 6 oz) including the battery

pack (NP-F570), cassette (PHDVM-

63DM), lens hood with lens cover and

microphone (ECM-XM1)

* When the HVR-MRC1 is used, the average

power consumption increases about 2.5 W.

AC Adaptor/Charger AC-VQ1050

Power requirements

AC 100 V - 240 V, 50 Hz/60 Hz

Power consumption

22 W

Output voltage

DC 8.4 V*

Operating temperature

0 ˚C to 40 ˚C (32 ˚F to 104 ˚F)

Storage temperature

-20 ˚C to +60 ˚C (-4 ˚F to +140 ˚F)

Dimensions (approx.)

× 53 × 135 mm

123

× 2 1/8 × 5 3/8 in.) (w/h/d)

(4 7/8

excluding the projecting parts

Mass (approx.)

390 g (13.8 oz) excluding the power

cord (mains lead)

* See the label on the AC Adaptor/Charger for

other specifications.

Rechargeable battery pack NP-F770

(supplied with HVR-Z5U)

Maximum output voltage

DC 8.4 V

Output voltage

DC 7.2 V

Maximum charge voltage

DC 8.4 V

Maximum charge current

3.0 A

Capacity

31.7 Wh (4 400 mAh)

Type

Li-ion

Rechargeable battery pack NP-F570

(supplied with HVR-Z5N)

Maximum output voltage

DC 8.4 V

Output voltage

DC 7.2 V

Maximum charge voltage

DC 8.4 V

Maximum charge current

3.0 A

Capacity

15.8 Wh (2 200 mAh)

Type

Li-ion

Design and specifications are subject to change

without notice.

概略仕様

表記の記録サイズを実現しています。

ENGLISH JAPANESE

ENGLISH JAPANESE

システム

録画方式(HDV) 回転2ヘッドヘリカルスキャン

録画方式(DVCAM(DV)) 回転2ヘッドヘリカルスキャン

静止画記録方式 Exif Ver.2.2*

録音方式(HDV) 回転ヘッド

MPEG-1 Audio Layer2

16ビット Fs48kHz(ステレオ)

転送レート384kbps

録音方式(DVCAM(DV)) 回転ヘッド、PCMシステム

12ビット Fs32kHz

(チャンネル1/2 ステレオ)

16ビット Fs48kHz(チャンネル1/2 ステレオ)

映像信号 NTSCカラー、EIA標準方式

1080/60i方式

使用可能カセット マークのついたミニDVカセットまたは

マークのついたミニDVCAMカセット

テープ速度(HDV)約18.812mm/秒

テープ速度(DVCAM)約28.193mm/秒

テープ速度(DV SP)約18.812mm/秒

録画/再生時間(HDV) 63分(PHDVM-63DM使用時)

録画/再生時間(DVCAM)41分(PHDVM-63DM使用時)

録画/再生時間(DV SP) 63分(PHDVM-63DM使用時)

早送り、巻き戻し時間 バッテリー使用時:

約2分40秒(PHDVM-63DM使用時)

ACアダプター/チャージャー使用時:

約1分45秒(PHDVM-63DM使用時)

ファインダー 電子ファインダー:カラー、モノクロ

画面サイズ:1.1cm(0.45型、アスペクト比16:9)

総合ドット数:1 226 880ドット

(852×3[RGB]×480相当)

撮像素子 6.0mm(1/3型)3CMOSセンサー

総画素数:約112万画素

静止画記録画素数:最大120万画

素相当**(1 440×810)(HDV/

DV 16:9記録時)

動画時有効画素数(16:9モード):

約104万画素

動画時有効画素数(4:3モード):

約78万画素

静止画時有効画素数(16:9モード):

約104万画素

静止画時有効画素数(4:3モード):

約78万画素

ズームレンズ Gレンズ

20倍(光学)、約30倍(デジタル、

デジタルエクステンダー[ON]時)

f=4.1〜82.0mm

35mmカメラ換算

29.5〜590mm(16:9モード)

(4:3モードでは36.1〜722mm)

F1.6〜3.4

フィルター径72mm

色温度切り換え オート

ワンプッシュ(A、B)

[屋内](3 200K)

[屋外](5 800K±7段階)

色温度指定(2 300〜15 000K、100K刻み)

最低被写体照度 1.5lx(ルクス)(シャッタース

ピード固定(1/30)、オートゲイン

コントロール、アイリスオート)

(F1.6)

*(社)電子情報技術産業協会(JEITA)にて制定

された、撮影情報などの付帯情報を追加する

ことができる静止画用のファイルフォーマット。

**ソニー独自のクリアビッドCMOSセンサー

の画素配列と画像処理システム新エンハンスド

イメージングプロセッサーにより、静止画は

出力端子

A/Vリモート端子 10ピン特殊コネクター

A/V接続ケーブル挿入時

映像:1 Vp-p、75Ω

Y出力 1Vp-p、75Ω

C出力 0.286Vp-p(バースト)、

75Ω

コンポーネントA/Vケーブル挿入時

Y:1Vp-p、75Ω

P

音声:-10dBu(47kΩ負荷時)、

出力インピーダンス2.2 kΩ以下

(0dBu=0.775Vrms)

HDMI OUT端子 タイプA(19ピン)

i(ヘッドホン)端子 ステレオミニジャック(φ3.5mm)

B/PR

. CB/C

R

:±350mV、75Ω

入/出力端子

LANC端子 ステレオミニミニジャック(φ2.5mm)

INPUT1/INPUT2端子 XLR3ピン、凹

-48dBu: 3kΩ

+4dBu: 10kΩ

(0dBu=0.775Vrms)

HDV/DV端子 i.LINK(IEEE1394 4ピンコネ

クター S100)

液晶画面

画面サイズ 8.0cm(3.2型、アスペクト比16:9)

総ドット数 921 600ドット

横1 920×縦480

電源部、その他

電源電圧 DC7.2V(バッテリーパック使用時)

DC8.4V(ACアダプター/チャージャー使用時)

消費電力* マイク(ECM-XM1)、ファインダー使用時、

明るさ標準:

HDV記録時7.1W

DVCAM(DV)記録時6.8W

マイク(ECM-XM1)、

液晶画面使用時、明るさ標準:

HDV記録時7.3W

DVCAM(DV)記録時7.0W

動作温度 0℃〜40℃

保存温度 −20℃〜+60℃

外形寸法 169×188×451mm

(突起部含む)

(幅×高さ×奥行き)

本体質量 約2.2kg(レンズフード含む)

撮影時総質量 約2.6kg(バッテリーパック(NP-F770)、

テープ(PHDVM-63DM)、レンズカバー付きフード、

マイク(ECM-XM1)含む。)

*HVR-MRC1使用時は消費電力が約2.5W増加します。

本機の仕様および外観は、改良のため予告なく

変更することがありますが、ご了承ください。

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

— 4 —

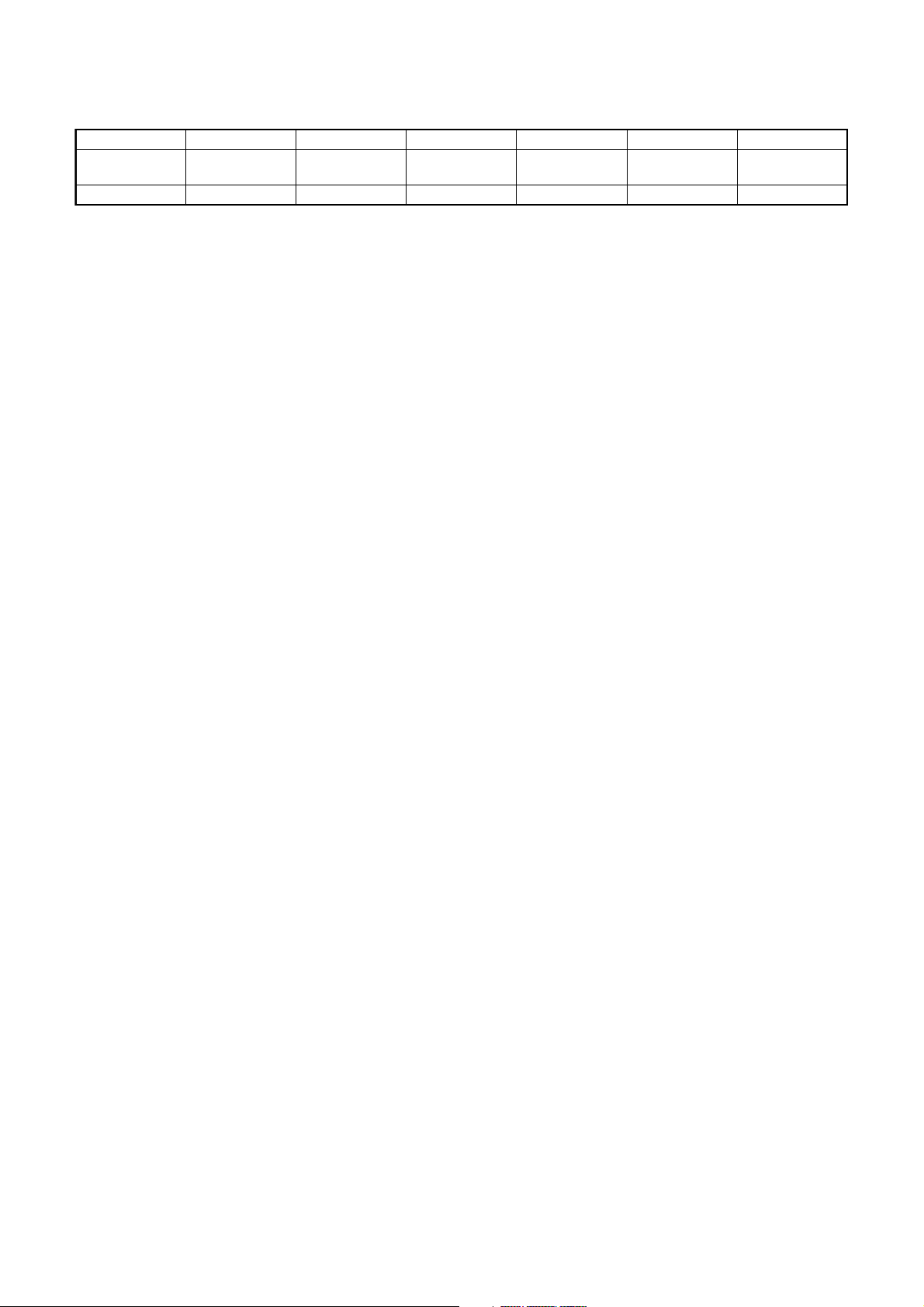

Model information table

Model HVR-Z5E

HVR-Z5C

HVR-Z5J

HVR-Z5N

HVR-Z5P

HVR-Z5U

Destination AEP

CH

PA L

• Abbreviation

CH : Chinese model

CND : Canadian model

J : Japanese model

J

PA LColor system

NTSC

E

NTSC

E

PA L

US, CND

NTSC

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

— 5 —

ENGLISH JAPANESE

ENGLISH JAPANESE

Danger of explosion if battery is incorrectly replaced.

CAUTION

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQ UE 0 SUR LES

DIAGRAMMES SCHÉMA TIQ UES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less pr one to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

— 6 —

ENGLISH JAPANESE

ENGLISH JAPANESE

電池の交換は,正しく行わないと破裂する恐れがあり

注意

ます。電池を交換する場合には必ず同じ型名の電池

又は同等品と交換してください。

サービス,点検時には次のことにご注意下さい。

1. 注意事項をお守りください。

サービスのとき特に注意を要する個所については,

キャビネット,シャーシ,部品などにラベルや捺印で

注意事項を表示しています。これらの注意書き及び取

扱説明書等の注意事項を必ずお守り下さい。

2. 指定部品のご使用を

セットの部品は難燃性や耐電圧など安全上の特性を

持ったものとなっています。従って交換部品は,使用

されていたものと同じ特性の部品を使用して下さい。

特に回路図,部品表に0印で指定されている安全上重要

な部品は必ず指定のものをご使用下さい。

3. 部品の取付けや配線の引きまわしはもとどおりに

安全上,チューブやテープなどの絶縁材料を使用した

り,プリント基板から浮かして取付けた部品がありま

す。また内部配線は引きまわしやクランパによって発

熱部品や高圧部品に接近しないよう配慮されています

ので,これらは必ずもとどおりにして下さい。

4. サービス後は安全点検を

サービスのために取外したネジ,部品,配線がもとど

おりになっているか,またサービスした個所の周辺を

劣化させてしまったところがないかなどを点検し,安

全性が確保されていることを確認して下さい。

5. チップ部品交換時の注意

• 取外した部品は再使用しないで下さい。

• タンタルコンデンサのマイナス側は熱に弱いため交

換時は注意して下さい。

6. フレキシブルプリント基板の取扱いについて

• コテ先温度を270℃前後にして行なって下さい。

• 同一パターンに何度もコテ先を当てないで下さい。

(3回以内)

• パターンに力が加わらないよう注意して下さい。

7. 無鉛半田について

無鉛半田を使用している基板には,無鉛(Lead Free)を

意味するレッドフリーマークがプリントされています。

(注意:基板サイズによっては,無鉛半田を使用して

いてもレッドフリーマークがプリントされて

いないものがあります)

:レッドフリーマーク

無鉛半田には,以下の特性があります。

• 融点が従来の半田よりも約40℃高い。

従来の半田こてをそのまま使用することは可能です

が,少し長めにこてを当てる必要があります。

温度調節機能のついた半田こてを使用する場合,約

350℃に設定して下さい。

注意:半田こてを長く当てすぎると,基板のパター

ン(銅箔)がはがれてしまうことがあります

ので,注意して下さい。

• 粘性が強い

従来の半田よりも粘性が強いため,IC端子などが半田

ブリッジしないように注意して下さい。

• 従来の半田と混ぜて使用可能

無鉛半田には無鉛半田を追加するのが最適ですが,

従来の半田を追加しても構いません。

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

— 7 —

ENGLISH JAPANESE

1. SERVICE NOTE

ENGLISH JAPANESE

1-1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power supply (8.4V), the power is shut off so

that the unit cannot operate.

These following method is available to prevent this.

Method:

Use the AC adaptor/charger (AC-VQ1050) and connecting cord (DK-415).

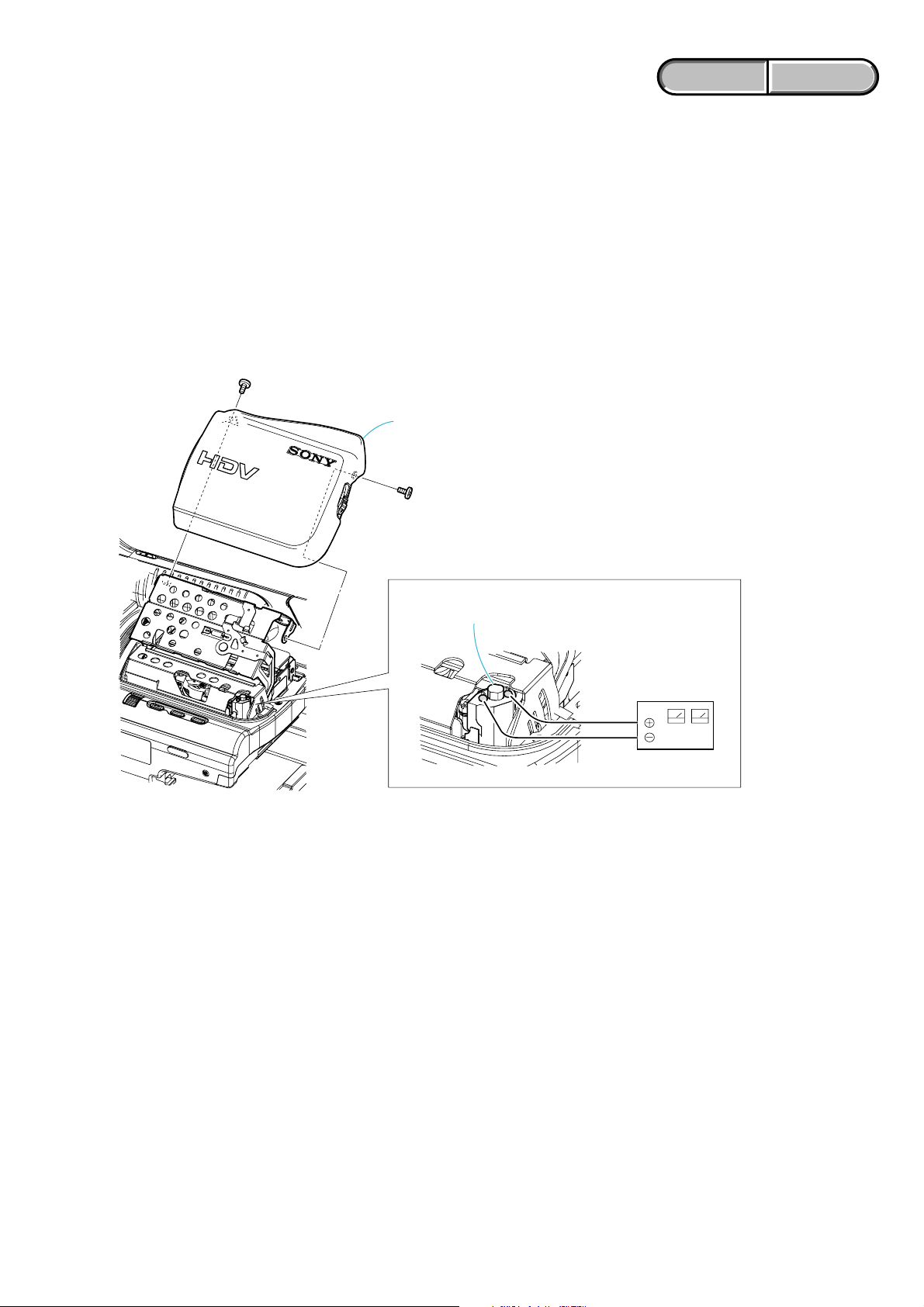

1-2. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Remove the Power supply.

2 Remove two screws and the CS lid (93000) assy.

3 Supply +4.5V from the DC power supply to the loading motor and unload.

CS lid (93000) assy

Loading motor

DC power supply

(+ 4.5 Vdc)

1-3. SETTING THE “FORCED POWER ON” MODE

It is possible to turn on power by adjustment remote commander (RM-95 or NEW LANC JIG).

Operate the VTR function using the adjustment remote commander.

1-3-1. Setting the “Forced Camera Power ON” Mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: A, address: 10, set data: 01 and press the “PAUSE (Write) ” button of the adjustment remote commander.

1-3-2. Setting the “Forced VTR Power ON” Mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: A, address: 10, set data: 02 and press the “PAUSE (Write) ” button of the adjustment remote commander.

1-3-3. Exiting the “Forced Power ON” Mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: A, address: 10, set data: 00 and press the “PAUSE (Write) ” button of the adjustment remote commander.

3) Select page: 0, address: 01, and set data: 00.

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

1-1

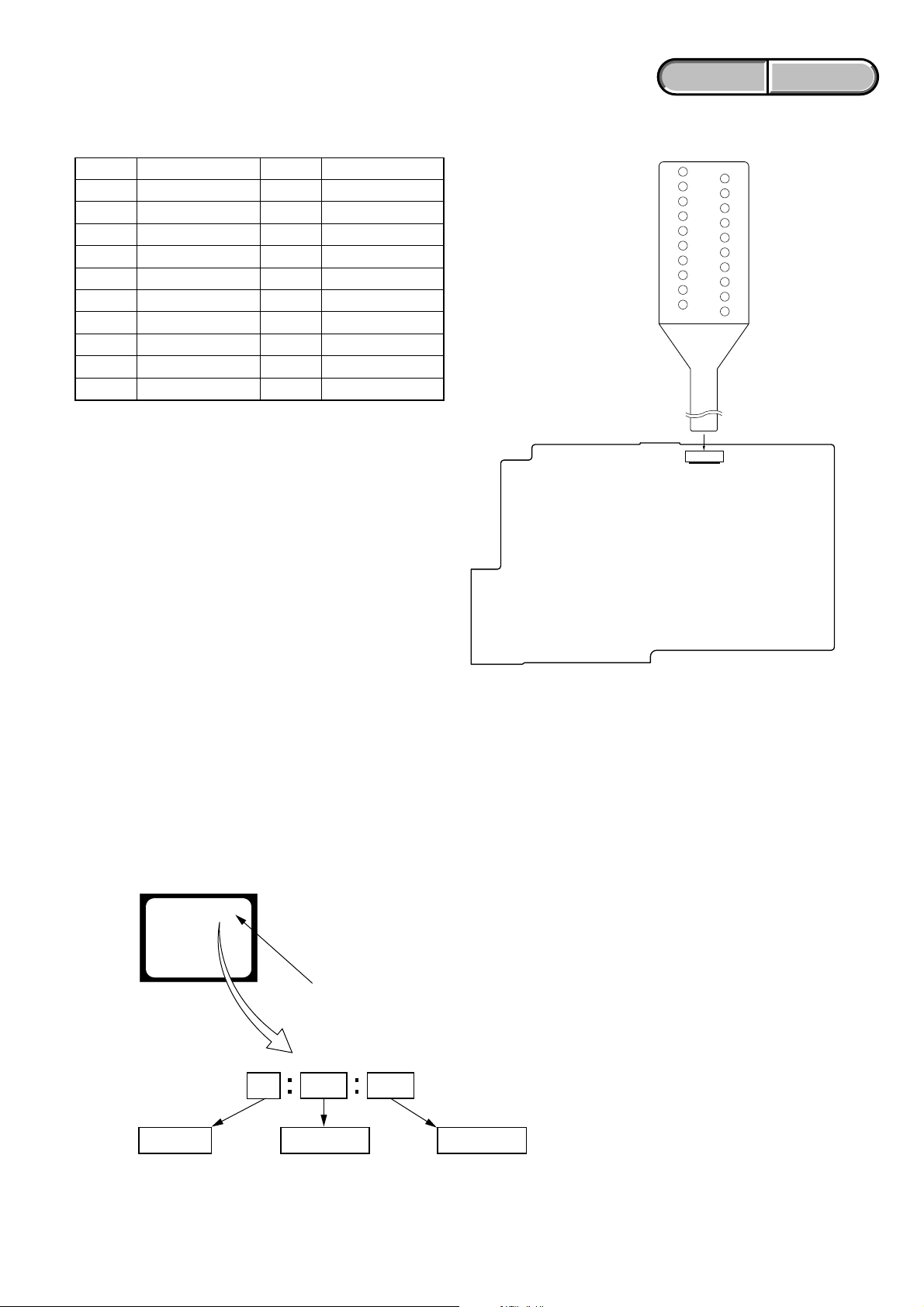

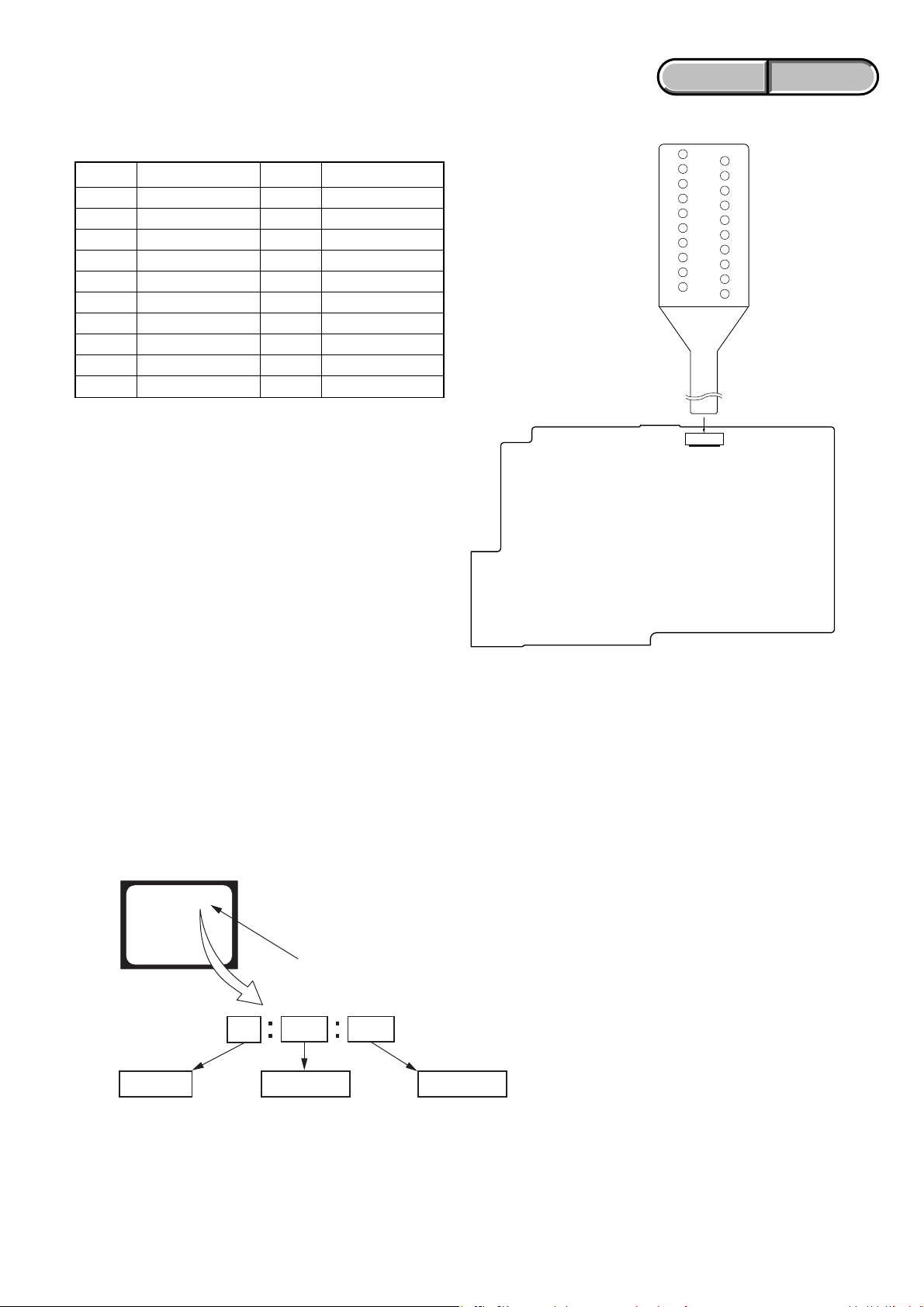

1-4. USING SERVICE JIG

Connect the CPC-13 jig (J-6082-443-A) to the CN1004 on the VC-543 board.

Pin No. Signal Name Pin No. Signal Name

1 (20) REG_GND 11 (10) EEP_SO_C

2 (19) RF_MON 12 (9) EEP_SO_S

3 (18) REG_GND 13 (8) EEP_SCK_C

4 (17) SWP 14 (7) EEP_SCK_S

5 (16) FRRV 15 (6) D_2.8V

6 (15) REG_GND 16 (5) MD2_C

7 (14) GND 17 (4) MD2

8 (13) GND 18 (3) XCS_MC_FLASH_C

9 (12) EEP_SI_C 19 (2) XCS_MC_FLASH

10 (11) EEP_SI_S 20 (1) XSYS_RST

Note: The pin number in ( ) is test terminal number of

CN1004 on the VC-543 board.

VC-543 BOARD (SIDE B)

ENGLISH JAPANESE

ENGLISH JAPANESE

CPC-13

(J-6082-443-A)

1

10

1

20

CN1004

20

11

20

1

1-5. SELF-DIAGNOSIS FUNCTION

1-5-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder or LCD

screen what to do.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder or LCD screen

C : 3 1 : 1 1

Blinks at 3.2Hz

1 1

Refer to “1-5-3. Self-diagnosis Code Table”.

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

3 1C

Block

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

1-5-2. Self-diagnosis Display

When problems occur while the unit is operating, the counter of the

viewfinder or LCD screen shows a 4-digit display consisting of an

alphabet and numbers, which blinks at 3.2 Hz. This 5-character

display indicates the “repaired by:”, “block” in which the problem

occurred, and “detailed code” of the problem.

Detailed Code

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

1-2

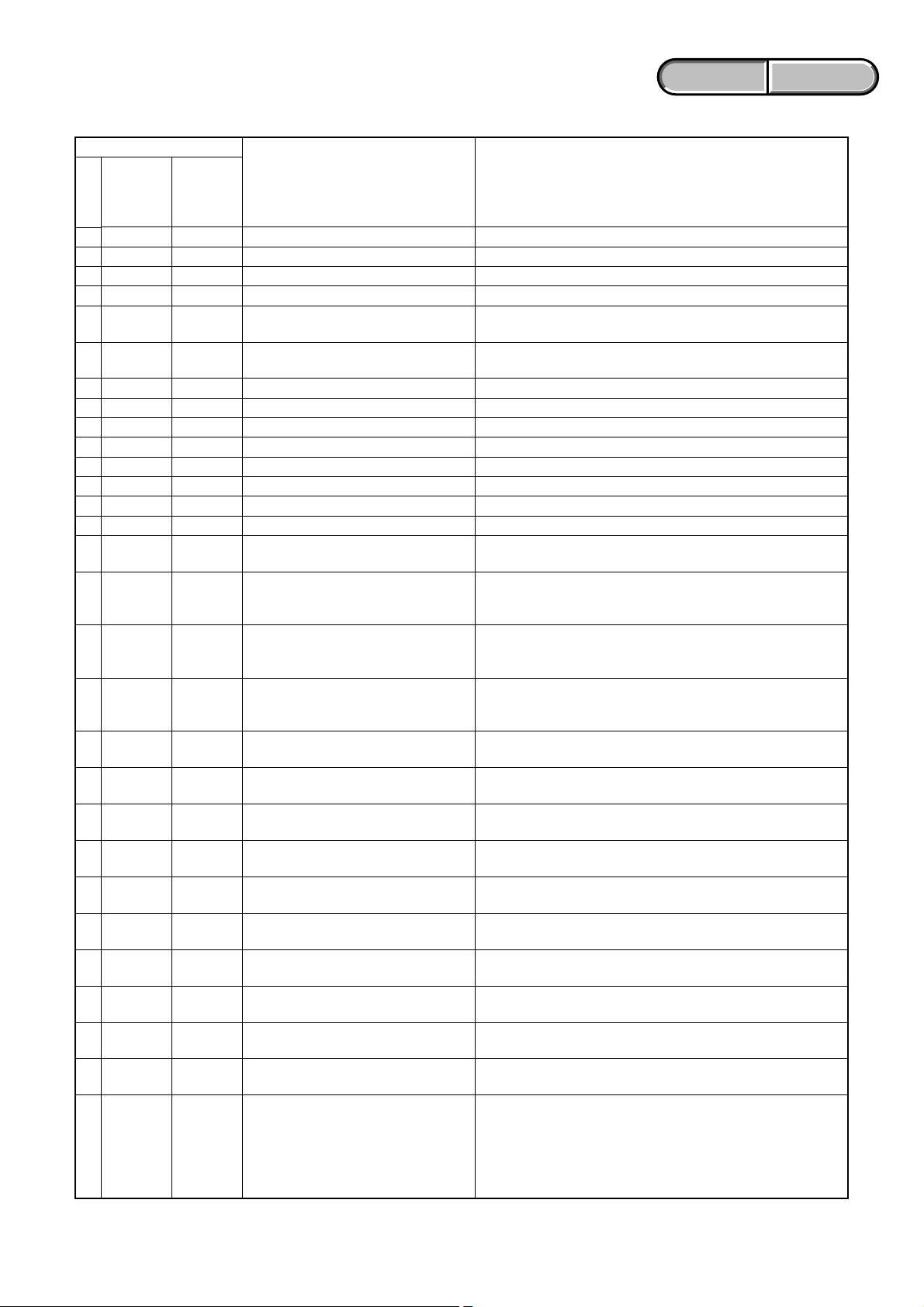

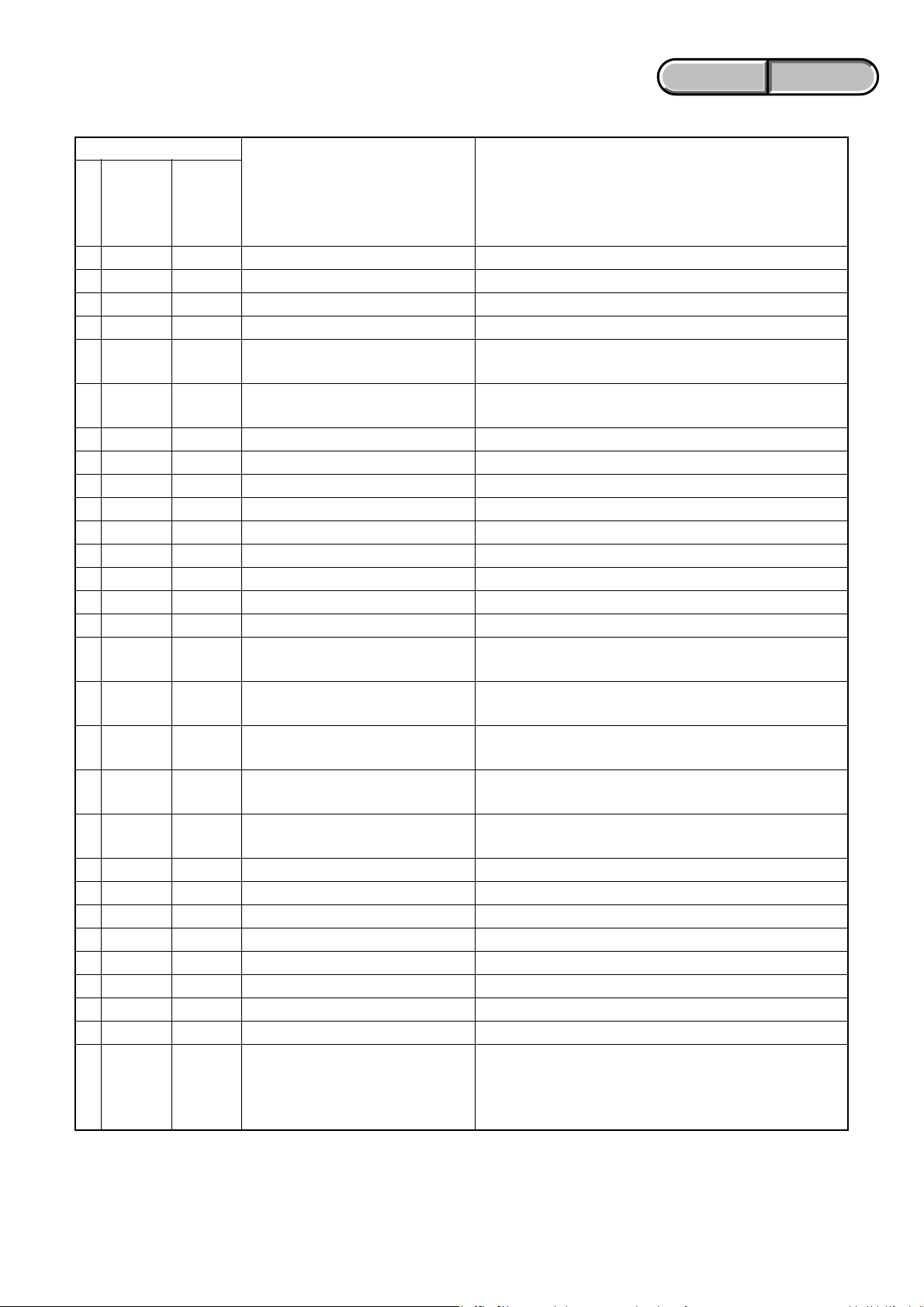

1-5-3. Self-diagnosis Code Table

Self-diagnosis Code

ENGLISH JAPANESE

ENGLISH JAPANESE

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

Block

Function

04

06

21

22

31

31

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

32

Detailed

Code

00

00

00

00

10

11

20

21

22

23

24

30

40

42

72

97

98

99

10

11

20

21

22

23

24

30

40

42

60

Symptom/State

Non-standard battery is used.

The battery is too hot.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

S reel

side tape slacking when unloading

T reel fault.

S reel fault.

T reel and S reel FG short fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

Retry fault when catching one’s finger

in cassette compartment.

Vector fault (Judgement with the set

state that is impossible actually for fault

of sensors.)

Vector fault (Judgement with the set

state that is impossible actually for fault

of sensors.)

Vector fault (Judgement with the set

state that is impossible actually for fault

of sensors.)

LOAD direction loading motor timeout.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

S reel side tape slacking when

unloading.

T reel fault.

S reel fault.

T reel and S reel FG short fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum

operations.

Difficult to adjust focus

(Cannot initialize focus.)

Correction

Use the InfoLITHIUM battery.

Replace the battery or remove it and put it in cool place.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

If it does not recover, inspect the focus MR sensor of lens drive

block (Pin q;, qs of CN5002 on the VC-543 board).

If not faulty, inspect the focus motor drive circuit

(IC6001 on the VC-543 board).

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

1-3

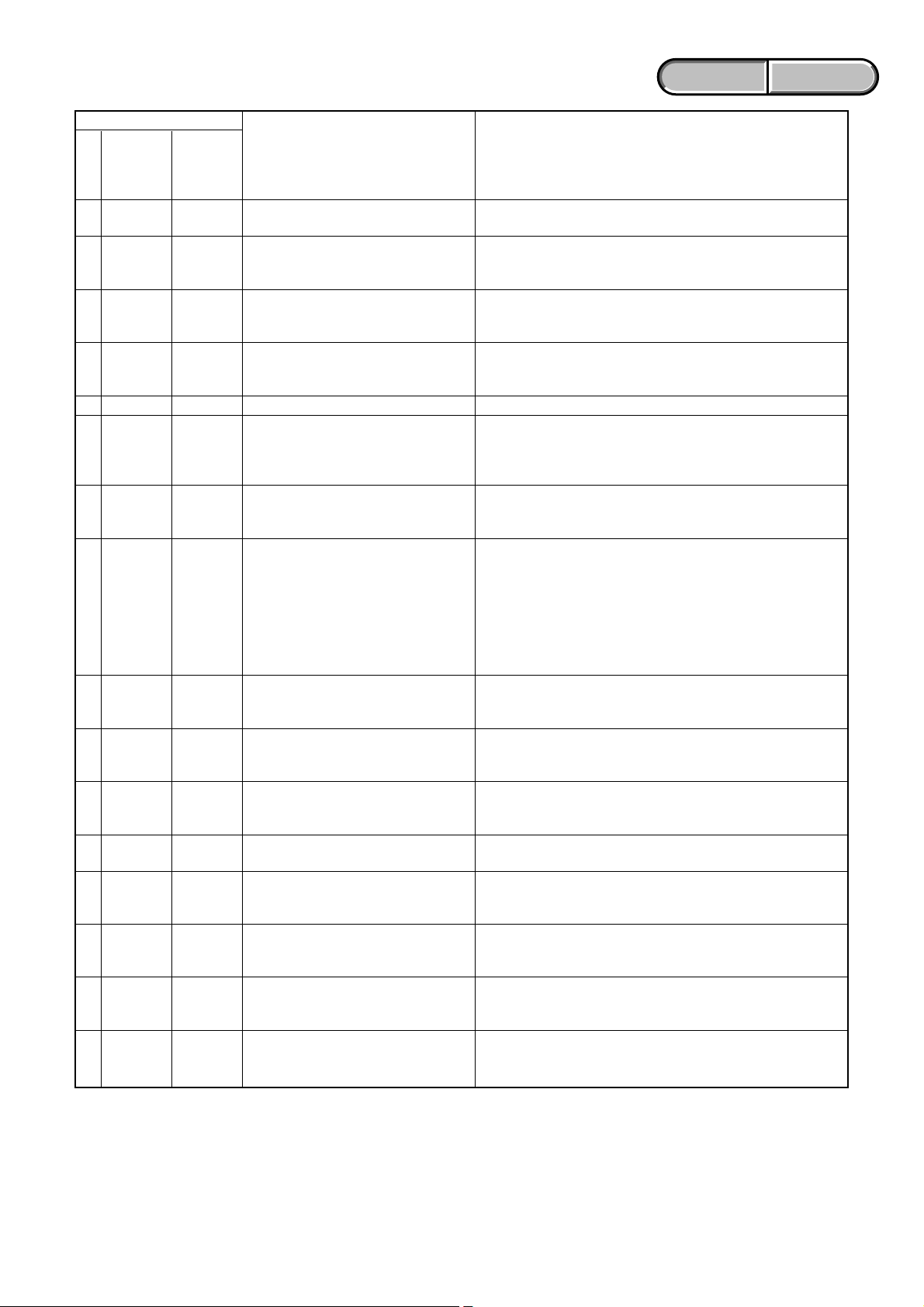

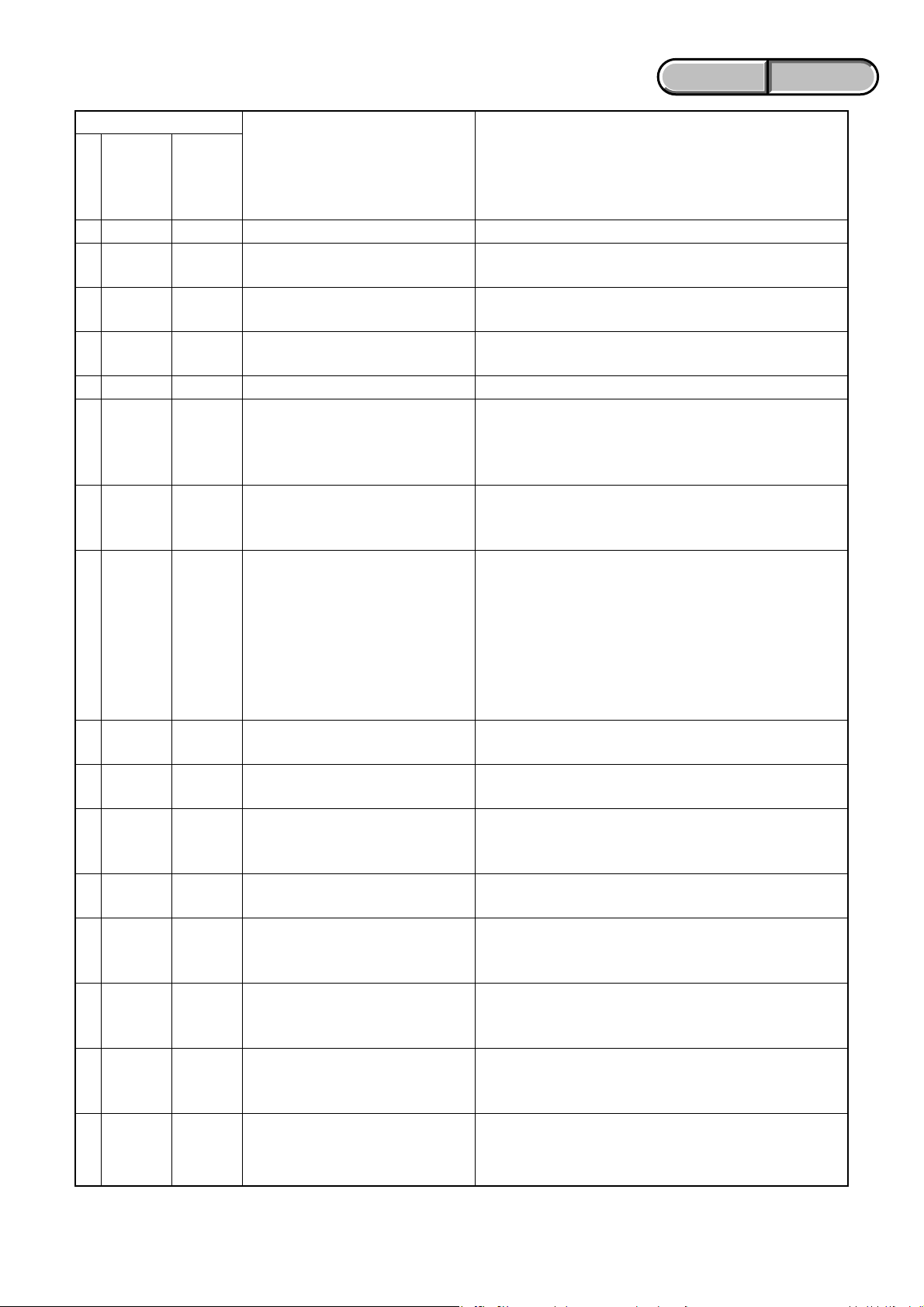

Self-diagnosis Code

ENGLISH JAPANESE

ENGLISH JAPANESE

Repaired by:

C

C

C

C

E

E

E

E

E

E

E

E

E

E

E

E

Block

Function

32

32

32

32

20

61

61

61

62

62

62

62

62

62

62

62

Detailed

Code

72

97

98

99

00

10

11

30

00

01

02

03

10

11

12

20

Symptom/State

Retry fault when catching one’s finger

in cassette compartment.

Vector fault (Judgement with the set

state that is impossible actually for fault

of sensors.)

Vector fault (Judgement with the set

state that is impossible actually for fault

of sensors.)

Vector fault (Judgement with the set

state that is impossible actually for fault

of sensors.)

EEPROM data are rewritten.

Zoom operations fault

(Cannot initialize zoom lens.)

Focus lens initializing failure and zoom

lens initializing failure occur simultaneously.

Reset position detect error when

stepper iris is initialized.

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular velocity sensor output

stopped.)

Abnormality of IC for steadyshot.

IC for steadyshot and micro controller

communication abnormality among.

Shift lens initializing failure

Shift lens overheating (Pitch)

Shift lens overheating (Yaw)

Abnormality of lens thermister

Correction

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Make EEPROM data correct value.

Inspect the zoom MR sensor of lens drive block (Pin es, ef of

CN5002 on the VC-543 board) when zooming is performed when

the zoom switch is operated and the zoom motor drive circuit

(IC6001 on the VC-543 board) when zooming is not performed.

Check both C: 32: 60 and E: 61: 10 of the self-diagnosis code.

Turn on the power and set to T (telephoto) end by rotating the

ZOOM manual ring. While observing the iris blades in the lens,

turn on the power again and check the iris blades in the lens

work properly. Inspect the iris drive motor of lens drive block

(Pin qh to ql of CN5002 on the VC-543 board), when the iris

does not operate. Inspect the iris reset sensor of lens drive block

(Pin qd to qg of CN5002 on the VC-543 board), when the iris

operate.

Inspect pitch angular velocity sensor (SE8501 on the GY-014

board) peripheral circuits.

Inspect yaw angular velocity sensor (SE8502 on the GY-014

board) peripheral circuits.

Inspect the steadyshot circuit (IC7001 on the VC-543 board). If

it does not recover, replace the VC-543 board. (Note) If an error

occurs again, replace the lens block.

Inspect the steadyshot circuit (IC7001 on the VC-543 board).

Inspect the EEPROM (IC4202 on the VC-543 board). If it does

not recover, replace the VC-543 board. (Note) If an error occurs

again, replace the lens block.

Inspect the IC7001 and peripheral circuits on the VC-543 board.

If it does not recover, replace the VC-543 board. (Note) If an

error occurs again, replace the lens block.

Inspect the IC7001 and peripheral circuits on the VC-543 board.

If it does not recover, replace the VC-543 board. (Note) If an

error occurs again, replace the lens block.

Inspect the IC7001 and peripheral circuits on the VC-543 board.

If it does not recover, replace the VC-543 board. (Note) If an

error occurs again, replace the lens block.

Note: When replacing the VC-543 board, remove the EEPROM (IC4202) from the VC-543 board that is going to be repaired. Install the removed EEPROM

(IC4202) to the replaced VC-543 board.

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

1-4

ENGLISH JAPANESE

1. SERVICE NOTE

ENGLISH JAPANESE

1-1. 修理時の電源供給について

本機では,安定化電源(8.4Vdc)からバッテリ端子に電源を供給した場合,約10秒後にシャットオフし,動作しなくなります。

これを避けるため,下記の方法を用いてください。

方法:

ACアダプタ/チャージャ(AC-VQ1050)と接続コード(DK-415)を使用する。

1-2. イジェクトしない時のカセット取出し方法(強制イジェクト)

1 電源を外す。

2 ねじ2本とCS蓋(93000)組立を外す。

3 安定化電源より+4.5Vをローディングモータに加え,アンローディングさせる。

CS蓋(93000)組立

ローディングモータ

安定化電源(+4.5Vdc)

1-3. 強制電源ONモードの設定

調整リモコン(RM-95またはNEWLANCJIG)を使用して,電源を入れることが出来ます。

VTR操作は調整リモコンで行えます。

1-3-1. 強制カメラ電源ONモードの設定

1) ページ:0,アドレス:01にデータ:01をセット。

2) ページ:A,アドレス:10にデータ:01をセットしPAUSE(Write)ボタンを押す。

1-3-2. 強制VTR電源ONモードの設定

1) ページ:0,アドレス:01にデータ:01をセット。

2) ページ:A,アドレス:10にデータ:02をセットしPAUSE(Write)ボタンを押す。

1-3-3. 強制電源ONモードの解除

1) ページ:0,アドレス:01にデータ:01をセット。

2) ページ:A,アドレス:10にデータ:00をセットしPAUSE(Write)ボタンを押す。

3) ページ:0,アドレス:01にデータ:00をセット。

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

1-5

ENGLISH JAPANESE

ENGLISH JAPANESE

1-4. 使用サービス治具

CPC-13治具(J-6082-443-A)をVC-543基板CN1004に接続します。

端子番号 信号名称 端子番号 信号名称

1(20) REGGND 11(10) EEPSOC

2(19) RFMON 12(9) EEPSOS

3(18) REGGND 13(8) EEPSCKC

4(17) SWP 14(7) EEPSCKS

5(16) FRRV 15(6) D2.8V

6(15) REGGND 16(5) MD2C

7(14) GND 17(4) MD2

8(13) GND 18(3) XCSMCFLASHC

9(12) EEPSIC 19(2) XCSMCFLASH

10(11) EEPSIS 20(1) XSYSRST

注意:()内の端子番号は,VC-543基板CN1004のテスト

端子番号です。

VC-543基板(B面側)

CPC-13

(J-6082-443-A)

1

10

20

1

1

20

CN1004

20

11

1-5. 自己診断機能

1-5-1. 自己診断機能について

本機の動作に不具合が生じたとき,自己診断機能が働き,

ビューファインダまたはLCD画面に,どう処置したらよい

か判断できる表示を行います。自己診断機能については取扱

説明書にも掲載されています。

ǻȍÀǽljnjțǨƳƔƤ.%&Ҹศ

C : 3 1 : 1 1

*\ஊร

1 1

ޙǛÀDZ

ÚࠧێǛÀDZÛ

LJߐ

Ѱࡐൌ

% «ſּƊƳࠧƜѰ

* «ಲ౪ஃƜѰ

' «ǝÀǻǡǐțǠdzNJ

ƜѰ

3 1C

ǾȕǫǗൌ

ѰඝඟƣϷŹƠƽƿൌ

gggǮÀǿLJదǁପƎ

gggஏڿLJదǁପƎ

1-5-2. 自己診断表示

本機の動作に不具合が生じたとき,ビューファインダまたは

LCD画面のカウンタ表示部分がアルファベットと数字の4桁

表示になり,3.2Hzで点滅します。この5文字の表示によっ

て対応者分類および不具合の生じたブロックの分類,不具合

の詳細コードを示します。

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

1-6

1-5-3. 自己診断コード表

自己診断コード

対

応

者

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

ブロック

機能

04

06

21

22

31

31

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

32

詳細

コード

00

00

00

00

10

11

20

21

22

23

24

30

40

42

72

97

98

99

10

11

20

21

22

23

24

30

40

42

60

症状/状態

標準でないバッテリを使用している

バッテリが高温になっている

結露している

ビデオヘッドが汚れている

LOAD方向,ローディング所定時間

内終了せず

UNLOAD方向,ローディング所定時

間内終了せず

UNLOAD時,Tリール側テープ弛み

UNLOAD時,Sリール側テープ弛み

Tリール異常

Sリール異常

TリールおよびSリールFGショート異常

キャプスタン起動時FG異常

ドラム起動時FG異常

ドラム定常時FG異常

カセコン指はさみリトライ異常

ベクタ異常(センサ類の異常で現実

に有り得ないセット状態と判断)

ベクタ異常(センサ類の異常で現実

に有り得ないセット状態と判断)

ベクタ異常(センサ類の異常で現実

に有り得ないセット状態と判断)

LOAD方向,ローディング所定時間

内終了せず

UNLOAD方向,ローディング所定時

間内終了せず

UNLOAD時,Tリール側テープ弛み

UNLOAD時,Sリール側テープ弛み

Tリール異常

Sリール異常

TリールおよびSリールFGショート異常

キャプスタン起動時FG異常

ドラム起動時FG異常

ドラム定常時FG異常

フォーカスが合いにくい

(フォーカスの初期化ができない)

ENGLISH JAPANESE

ENGLISH JAPANESE

対応/方法

インフォリチウムバッテリを使用する。

バッテリを交換するか、バッテリを涼しいところに置く。

カセットを取り出して,約1時間してからもう一度入れ直す。

別売のクリーニングカセットできれいにする。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

テープを入れ直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

復帰しない場合,レンズドライブブロックのフォーカスMRセンサ

(VC-543基板CN5002q;,qsピン)を点検。問題がなければフォーカ

スモータドライブ回路(VC-543基板IC6001)を点検。

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

1-7

自己診断コード

対

ブロック

応

機能

者

C

32

C

32

C

32

C

32

E

20

E

61

詳細

コード

72

97

98

99

00

10

症状/状態

カセコン指はさみリトライ異常

ベクタ異常(センサ類の異常で現実

に有り得ないセット状態と判断)

ベクタ異常(センサ類の異常で現実

に有り得ないセット状態と判断)

ベクタ異常(センサ類の異常で現実

に有り得ないセット状態と判断)

EEPROMが書き換えられている

ズーム動作の異常(ズームレンズの

初期化ができない)

ENGLISH JAPANESE

ENGLISH JAPANESE

対応/方法

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

バッテリまたは電源ケーブルを外して付け直し,再度操作し直す。

EEPROMのデータを元の値に戻す。

ズームレバーを操作した時,ズーム動作をすればレンズドラ

イブブロックのズームMRセンサ(VC-543基板CN5002es,ef

ピン)を点検。ズーム動作をしなければズームモータドライ

ブ回路(VC-543基板IC6001)を点検。

E

E

E

E

E

E

E

E

E

E

61

61

62

62

62

62

62

62

62

62

11

30

00

01

02

03

10

11

12

20

(PITCH角速度センサ出力張り付き)

(YAW角速度センサ出力張り付き)

フォーカスレンズ初期化異常,ズー

ムレンズ初期化異常の同時発生

ステッパアイリス初期化時リセット

位置検出エラー

手振れ補正が効きにくい

手振れ補正が効きにくい

手振れ補正用ICの異常

手振れ補正用ICとマイクロコント

ローラとの通信異常

シフトレンズ初期化異常

シフトレンズオーバーヒート

(PITCH)

シフトレンズオーバーヒート

(YAW)

レンズサーミスタの異常

自己診断コードC:32:60とE:61:10の両方を点検。

電源投入後,ズームマニュアルリングを回してT(telephoto)

端にする。レンズ内のアイリス羽に注目しながら電源を再

投入し

,レンズ内の羽が動作しているか確認する

動作しない場合は,レンズドライブブロックのアイリス

モータドライブ(VC-543基板CN5002qh〜qlピン)を点検。

アイリスが動作する場合は,レンズドライブブロックのア

イリスリセットセンサ( VC-543基板CN5002qd〜qgピン)

を点検。

PITCH角速度センサ(GY-014基板SE8501)周辺回路を点検。

YAW角速度センサ(GY-014基板SE8502)周辺回路を点検。

手振れ補正回路(VC-543基板IC7001)を点検。復帰 しない場

合,VC-543基板を交換する。(注意)エラーが再度発生する場

合は,レンズブロックを交換する。

手振れ補正回路(VC-543基板IC7001)を点検。

EEPROM(VC-543基板IC4202)を点検。復帰しない場合,VC-

543基板を交換する。(注意)エラーが再度発生する場合は,レ

ンズブロックを交換する。

VC-543基板のIC7001および周辺回路を点検。復帰しない場

合,VC-543基板を交換する。(注意)エラーが再度発生する場

合は,レンズブロックを交換する。

VC-543基板のIC7001および周辺回路を点検。復帰しない場

合,VC-543基板を交換する。(注意)エラーが再度発生する場

合は,レンズブロックを交換する。

VC-543基板のIC7001および周辺回路を点検。復帰しない場

合,VC-543基板を交換する。(注意)エラーが再度発生する場

合は,レンズブロックを交換する。

。アイリスが

注意: VC-543基板を交換する場合は,修理するVC-543基板からEEPROM(IC4202)を取り外す。取り外したEEPROM

(IC4202)は取り替えたVC-543基板に取り付ける。

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

1-8E

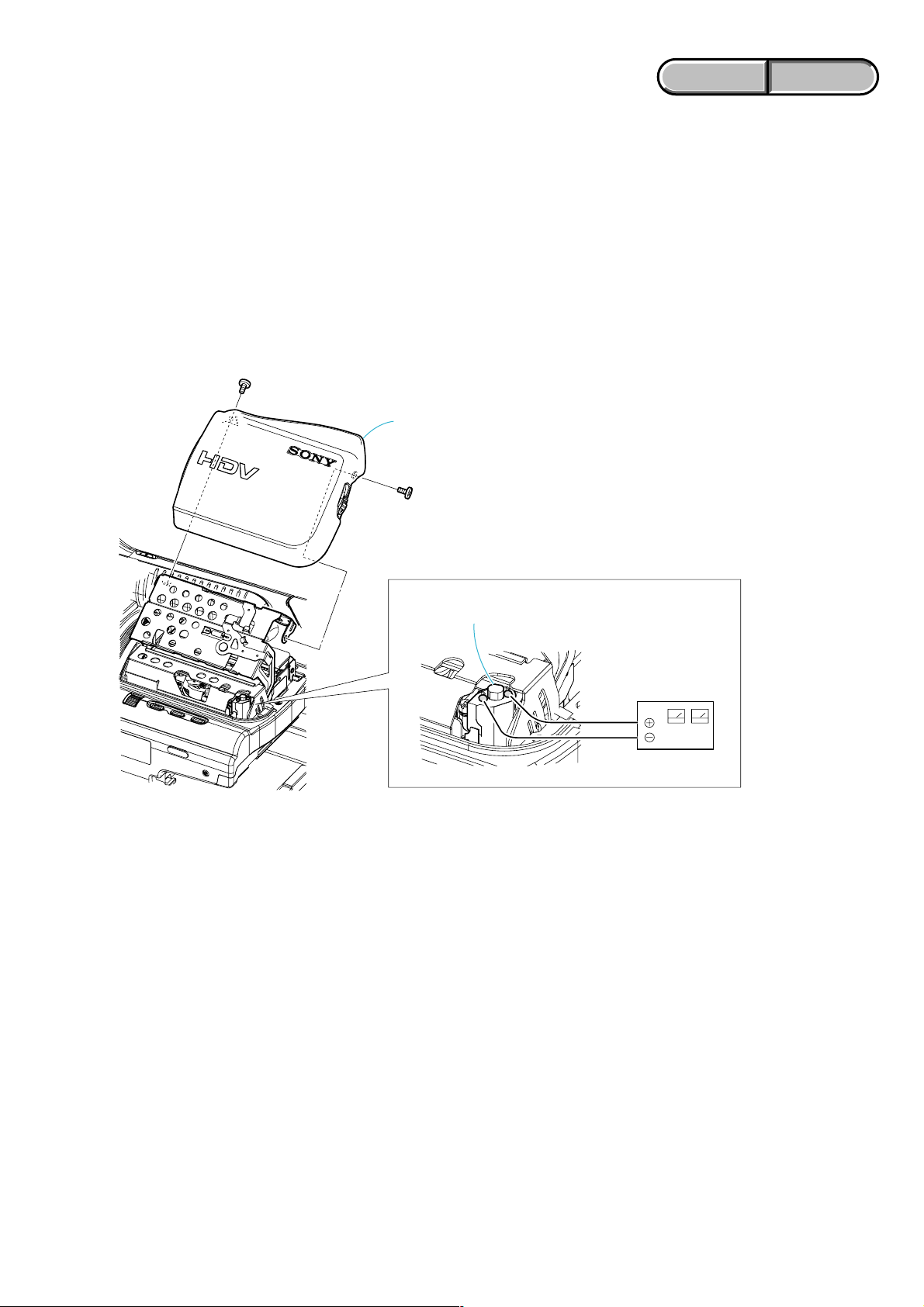

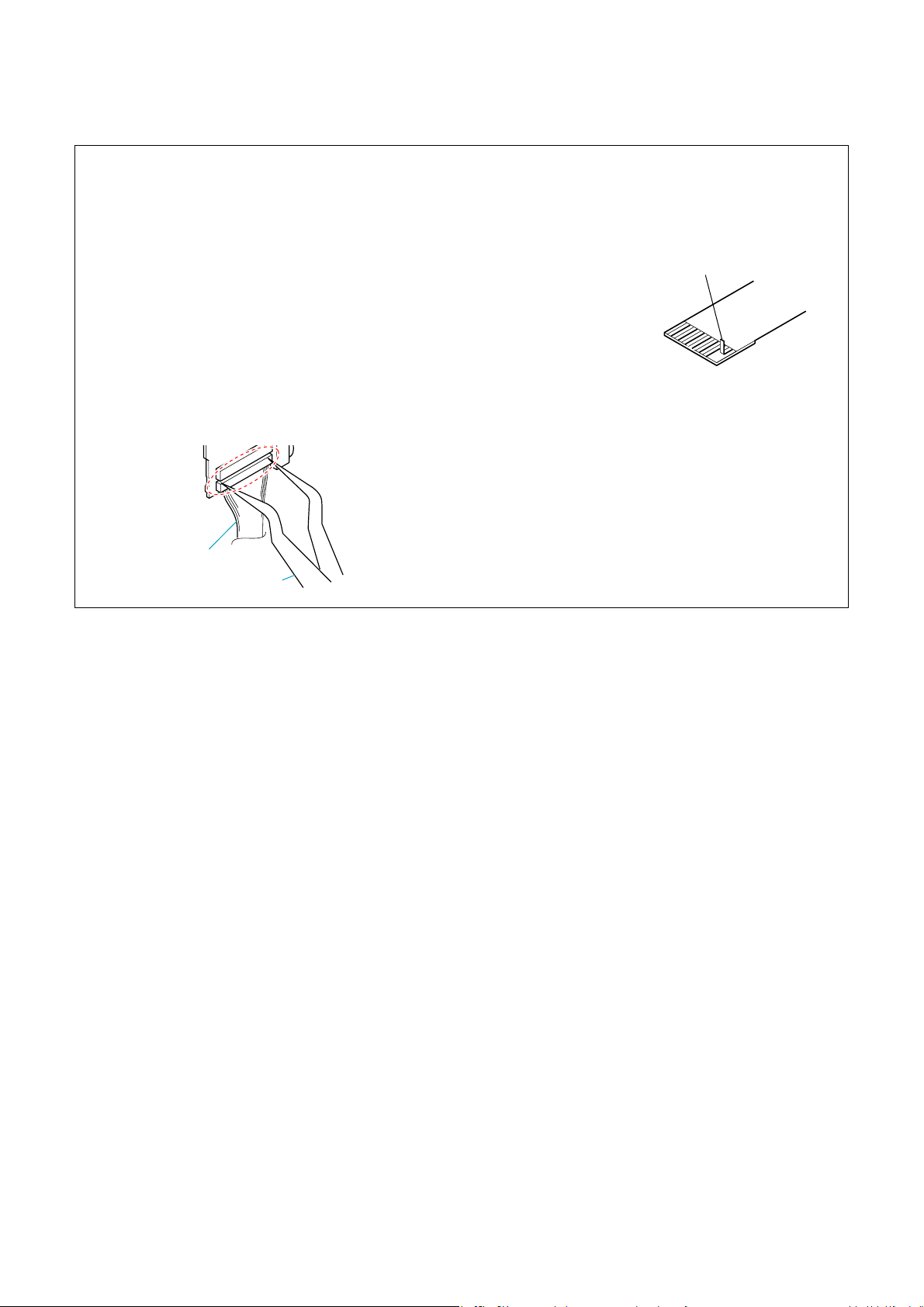

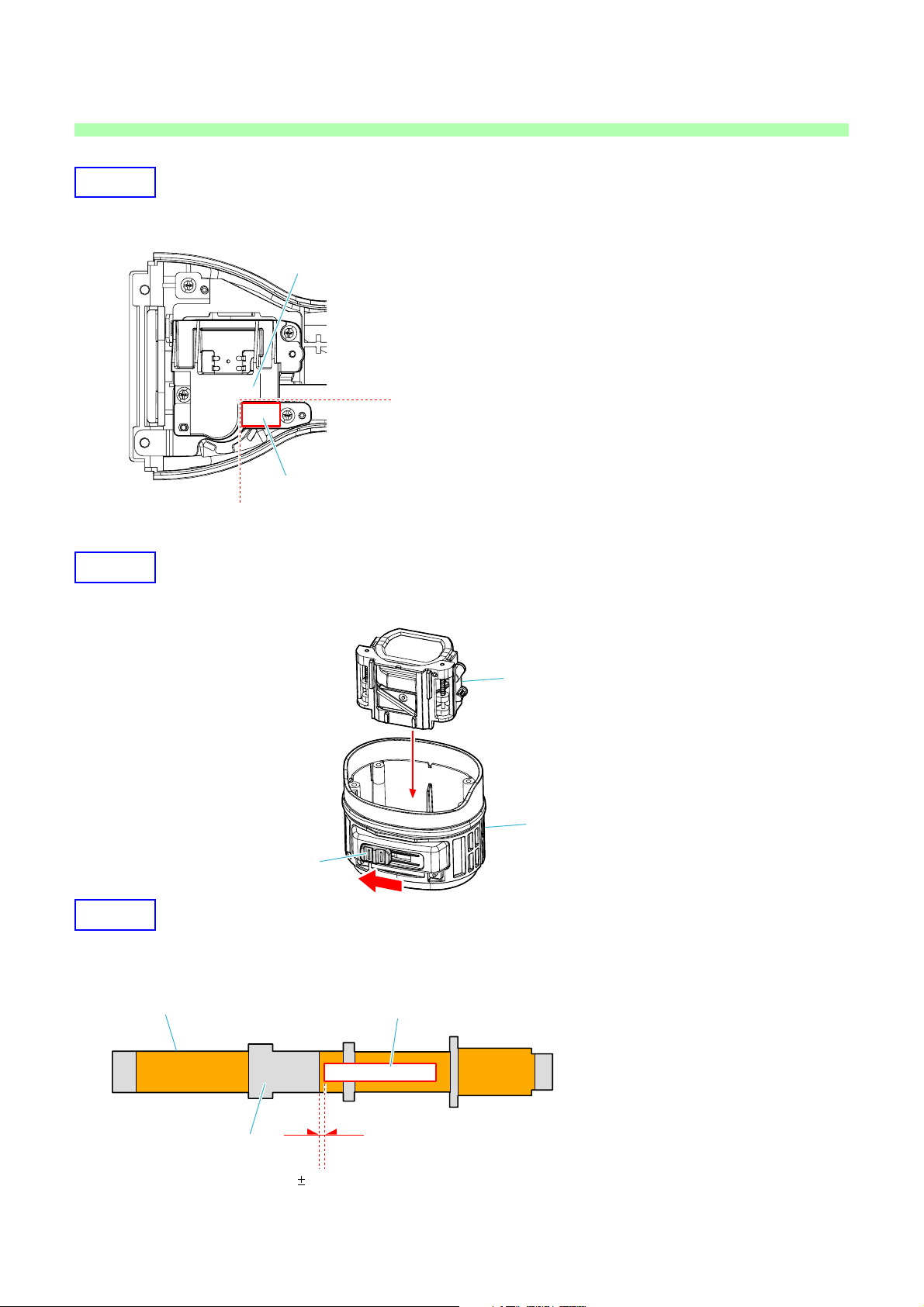

2. DISASSEMBLY

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

NOTE FOR REPAIR

• Make sure that the flat cable and flexible board are not cracked of bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

• When remove a connector, don’t pull at wire of connector. It is possible that a wire is snapped.

• When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

NOTE FOR DISCONNECTING THE HARNESS (COAXIAL CABLE)

When disconnecting the harness (COAXIAL CABLE), do not

pull the harness part but pull off the connector body with tweezers

etc.

Harness

(coaxial cable)

Tweezers etc.

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

2-1

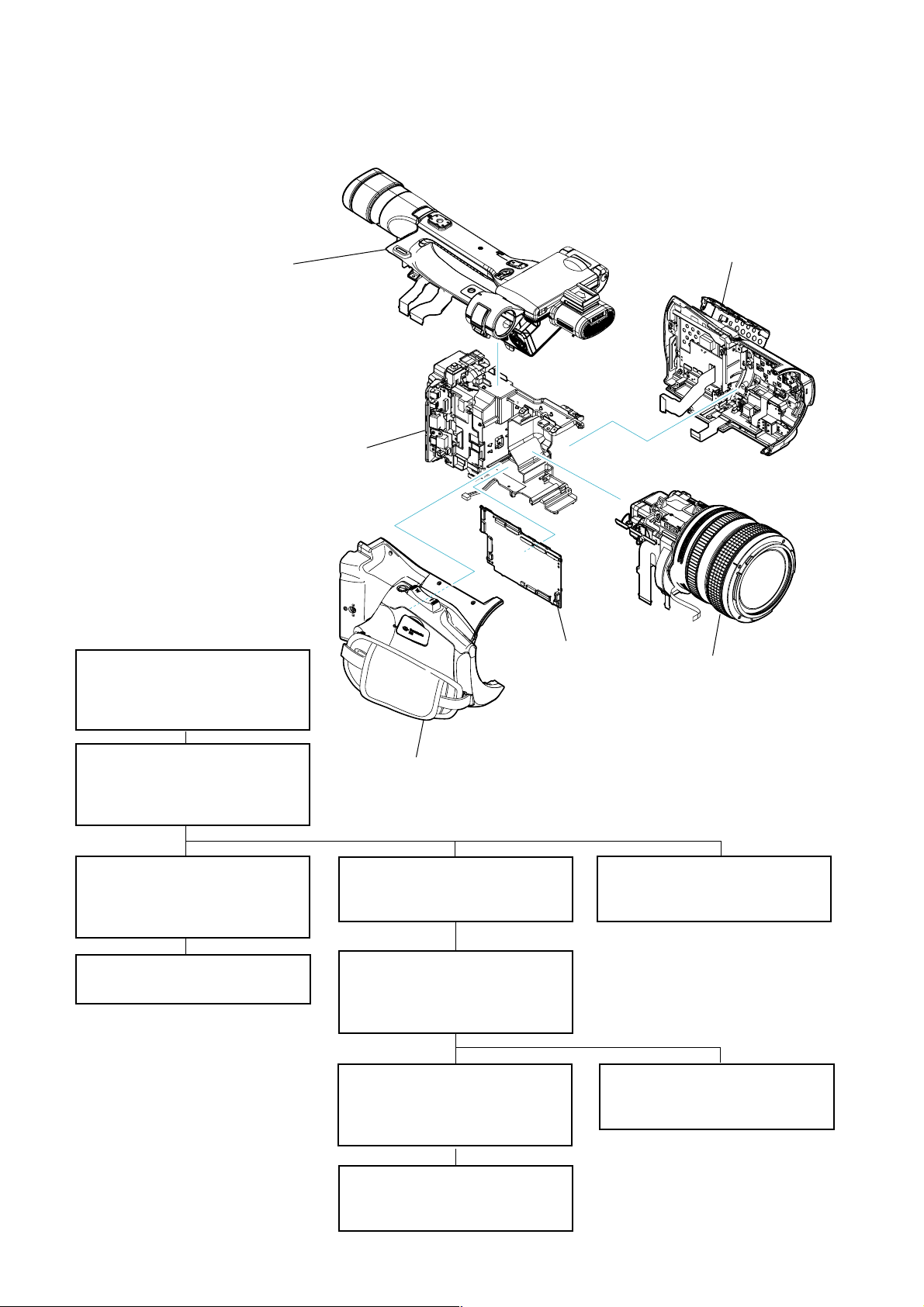

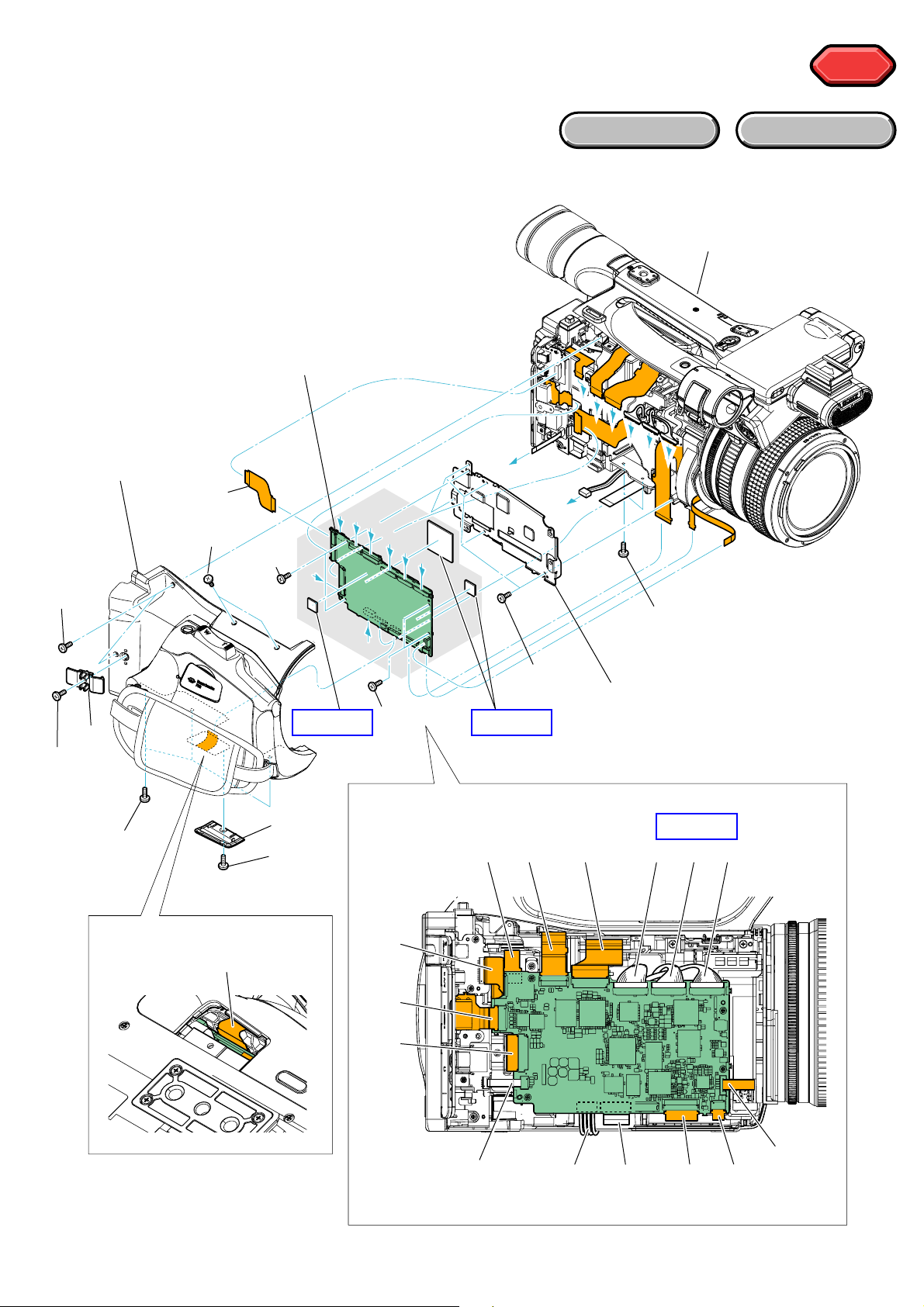

2-1. IDENTIFYING PARTS

Handle Section

⋅ AS-060 Board

⋅ FP-966 Flexible Board

⋅ FP-967 Flexible Board

⋅ GP-025 Board

⋅ HT-002 Board

⋅ KY-105 Board

⋅ MA-454 Board

⋅ PD-372 Board

⋅ PI-029 Board

⋅ VF-178 Board

⋅ XL-010 Board

BT Panel Section

⋅ FP-965 Flexible Board

⋅ HP-153 Board

⋅ JK-376 Board

Cabinet (R) Section

⋅ CK-204 Board

⋅ FP-969 Flexible Board

⋅ MD-141 Board

⋅ Mechanism Deck

MD-141

VC-543

- DISASSEMBLY FLOW -

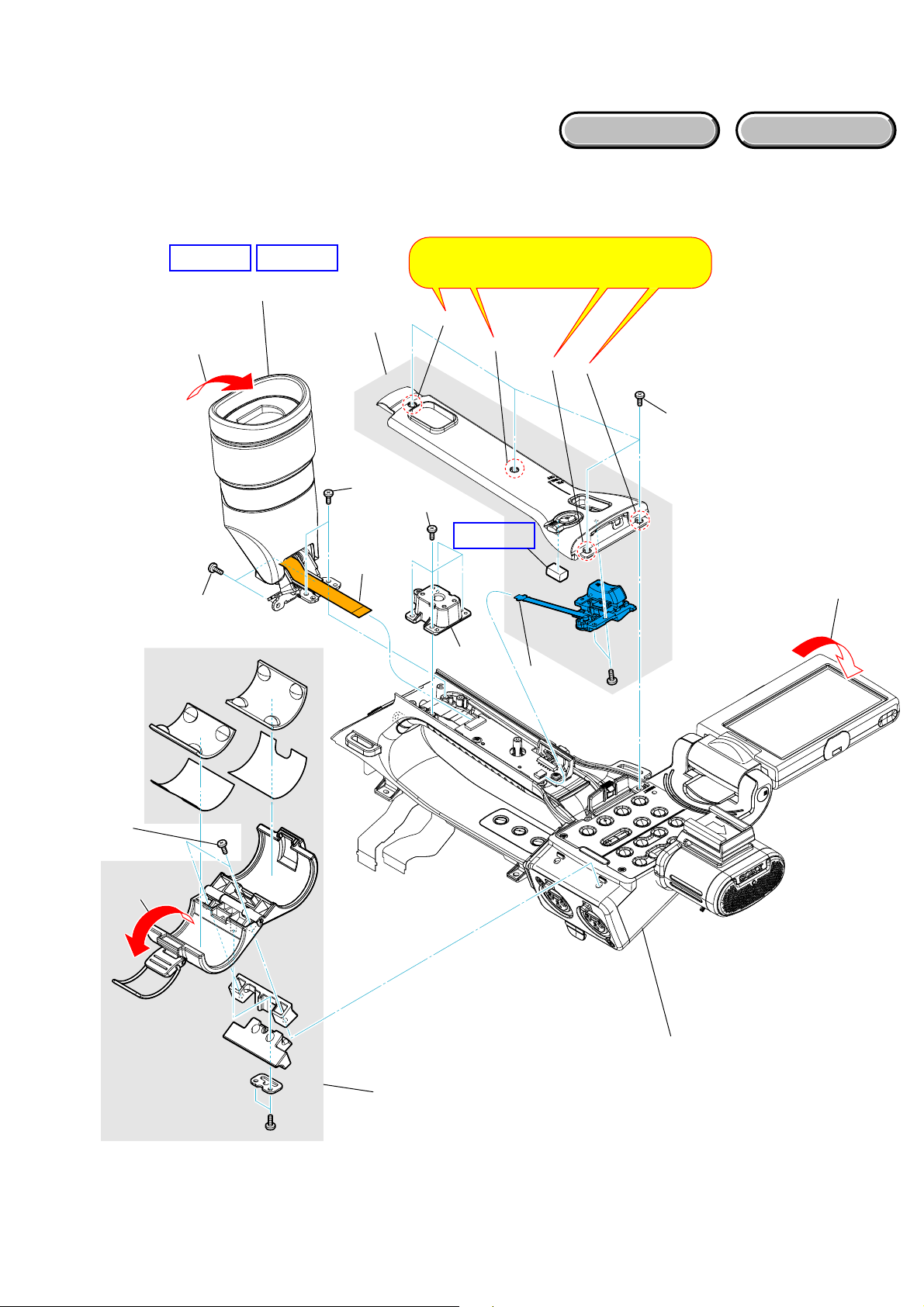

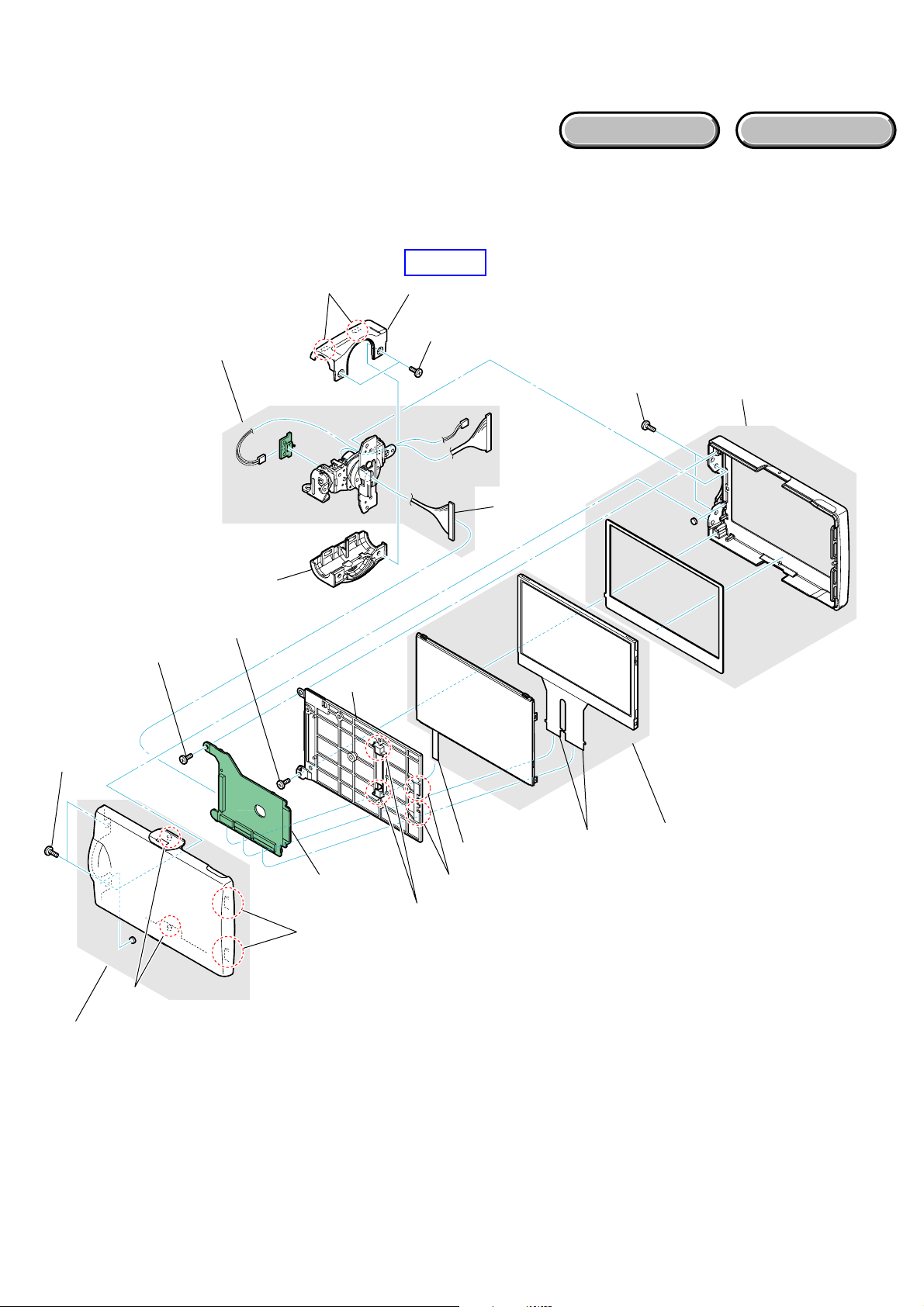

2-2-1. OVERALL SECTION-1

⋅ Cabinet (L) Section

⋅ VC-543 Board

⋅ Main Frame

2-2-2. OVERALL SECTION-2

⋅ Cabinet (R) Section

⋅ Handle Section-1

⋅ Lens Section

2-2-3. CABINET (R) SECTION

⋅ MD Section

⋅ CK-204 Board

⋅ AL Lid (93000)

2-2-4. MD SECTION

⋅ Mechanism Deck

Cabinet (L) Section

⋅ MS-405 Board

2-2-5. HANDLE SECTION-1

⋅ EVF Section

⋅ Microphone Holder Assy

2-2-6. HANDLE SECTION-2

⋅ Control Panel Block

⋅ PI-029 Board

⋅ LCD Section

2-2-7. HANDLE SECTION-3

⋅ GP-025 Board

⋅ XL-010 Board

⋅ Handle Section-4

VC-543 Board

Lens Section

⋅ GY-014 Board

⋅ Prism Device

(CM-097/104 Board)

2-2-10. CABINET (L) SECTION

⋅ Cabinet (L) Block

⋅ Cabinet (G) Block

2-2-9. LCD SECTION

⋅ Hinge Block

⋅ LCD

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

2-2-8. HANDLE SECTION-4

⋅ AS-060 Board

⋅ Microphone Section

2-2

HELP

EXPLODED VIEW

B

A

C

G

D

E

F

H

VC-543

HELP

2-2. DISASSEMBLY

2-2-1. OVERALL SECTION-1

Follow the disassembly in the numerical order given.

1 Cabinet (L) Section (1-1 to 1-8)

2 VC-543 Board (2-1 to 2-18)

3 Main Frame (3-1 to 3-2)

2 VC-543 Board

1 Cabinet (L)

Section

(See Page 2-12)

2-18E

1-8E

(#49)

1-7

(#49)

1-6

1-5

(#49)

2-16

(#50)

G

A

B

C

D

E

G

HELP02 HELP02

VC-543

H

F

2-17

(#50)

H

3-2E

(#49)

A

A

A

B

B

C

C

D

D

E

E

F

3-1

(#49)

3 Main Frame

HARDWARE LIST

Overall Section-2

(See Page 2-4)

1-4

(#49)

1-3 (Disconnect the

flexible board)

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

1-2

1-1

(#49)

Disconnect the flexible boards

and harnesses.

2-11

2-12

2-13

2-14

2-15

2-3

2-92-10

VC-543

VC-543

2-1

2-2

HELP01

2-7

2-6 2-8

2-3 2-4

2-5

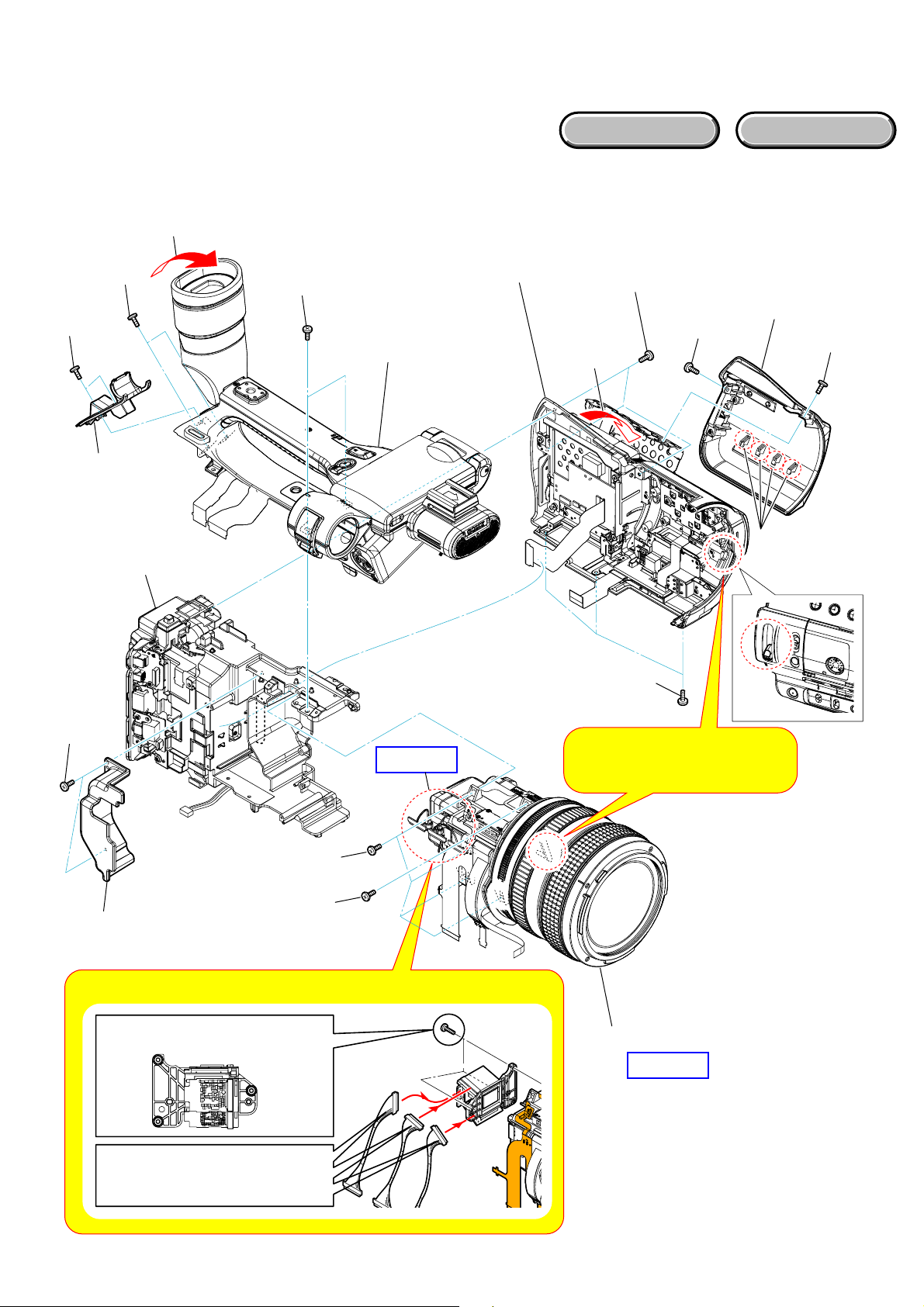

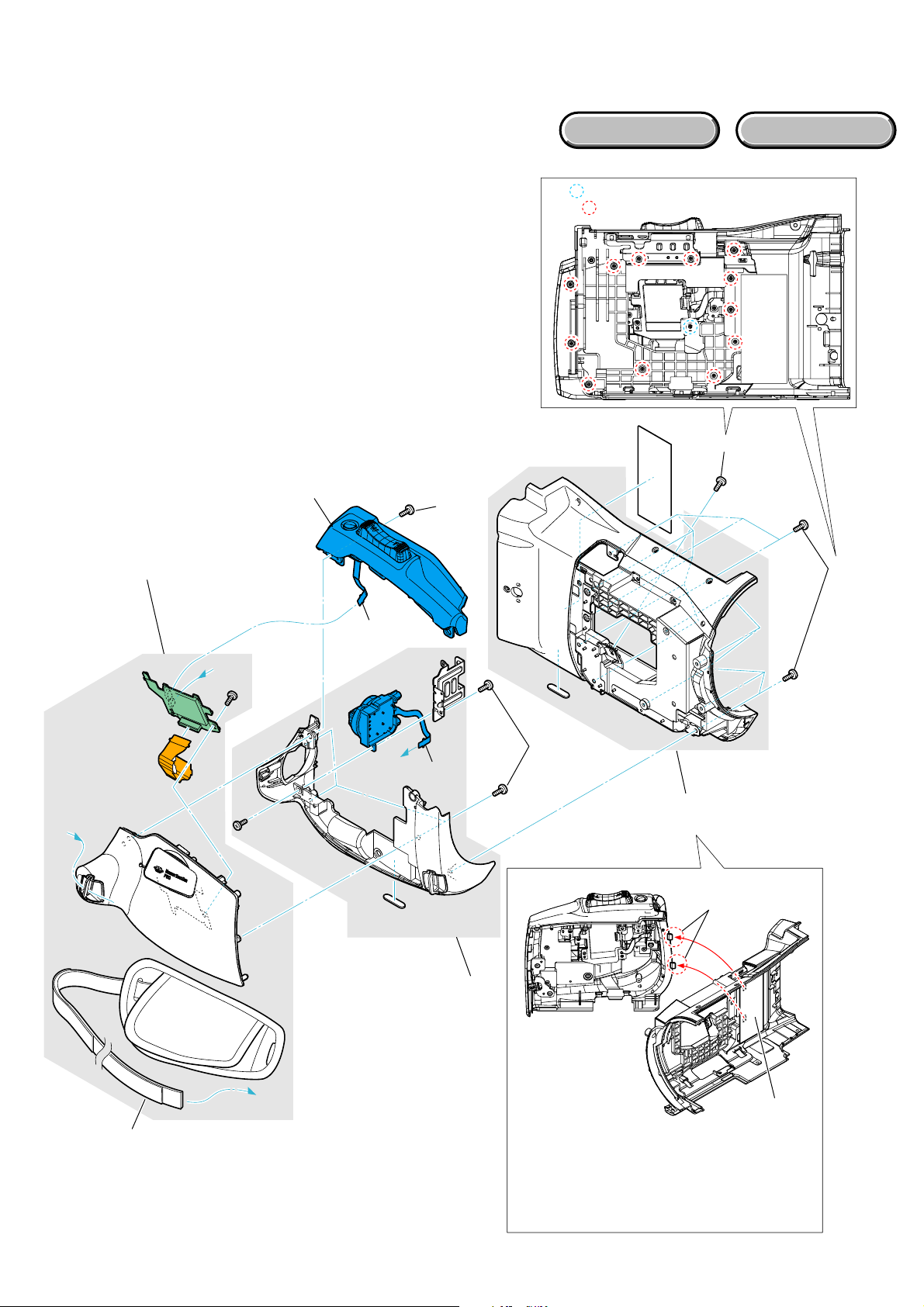

2-2-2. OVERALL SECTION-2

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 Cabinet (R) Section (1-1 to 1-8)

2 Handle Section-1 (2-1 to 2-5)

3 Lens Section (3-1 to 3-3)

2-1

(Open)

2-4

(#119)

2-5E

(#119)

2-2

(#49)

2-3

BT Panel Section

1 Cabinet (R)

Section

(See Page 2-5)

2 Handle Section-1

(See Page 2-7)

1-2

(Open)

MD-141

1-7

(#49)

1-3

(#49)

HARDWARE LIST

1-6

1-5

(Claws)

1-4

(#49)

3-1

(#49)

3-2

Note: Prism Device cautions

Tighten screws in the following order.

1

2

3-3E (#119)

1-1

(#154)

3

HELP03

1-8E

(#49)

Note:

On installation of the lens block,

adjust the position of the

ND filter switch.

3 Lens Section

HELP04

Be sure not to insert the harnesses

forcefully.

(Standard: Insertion; 15N, Pull out; 10N)

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

2-4

EXPLODED VIEW

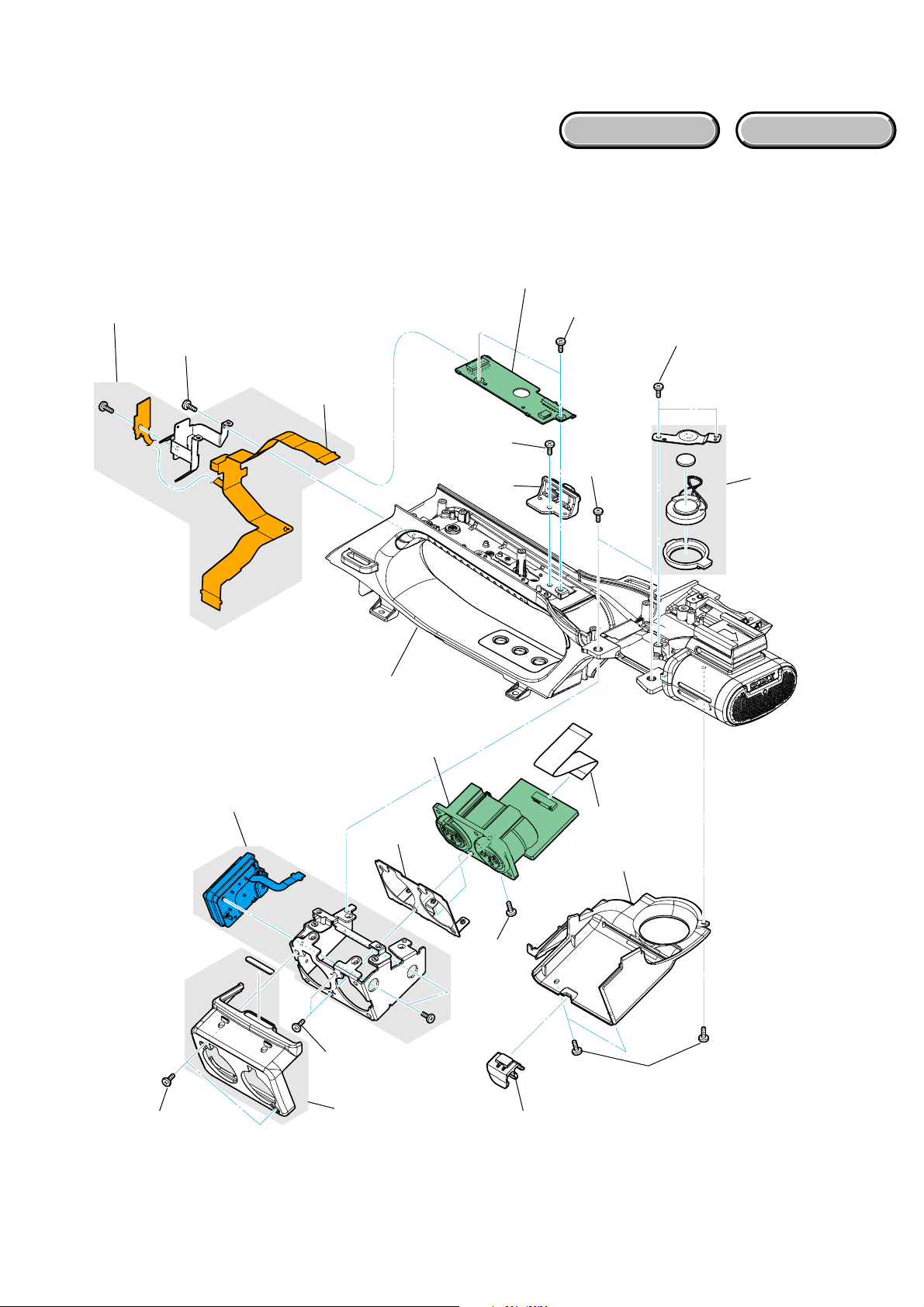

2-2-3. CABINET (R) SECTION

Follow the disassembly in the numerical order given.

1 MD Section (1-1 to 1-2)

2 CK-204 Board (2-1 to 2-9)

3 AL Lid (93000) (3-1 to 3-7)

1 MD Section

(See Page 2-6)

1-2E

(#53)

MD-141

HARDWARE LIST

3 AL Lid (93000)

3-7E

2-4

(#53)

2-1

2-7

(#50)

2-9E

3-1

(#121)

2-5

(#53)

3-2

(#53)

CK-204

A

2-8

A

1-1

2-2

3-4

(#53)

2-6

(#53)

3-5

3-6

3-3

2-3

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

2 CK-204 Board

2-5

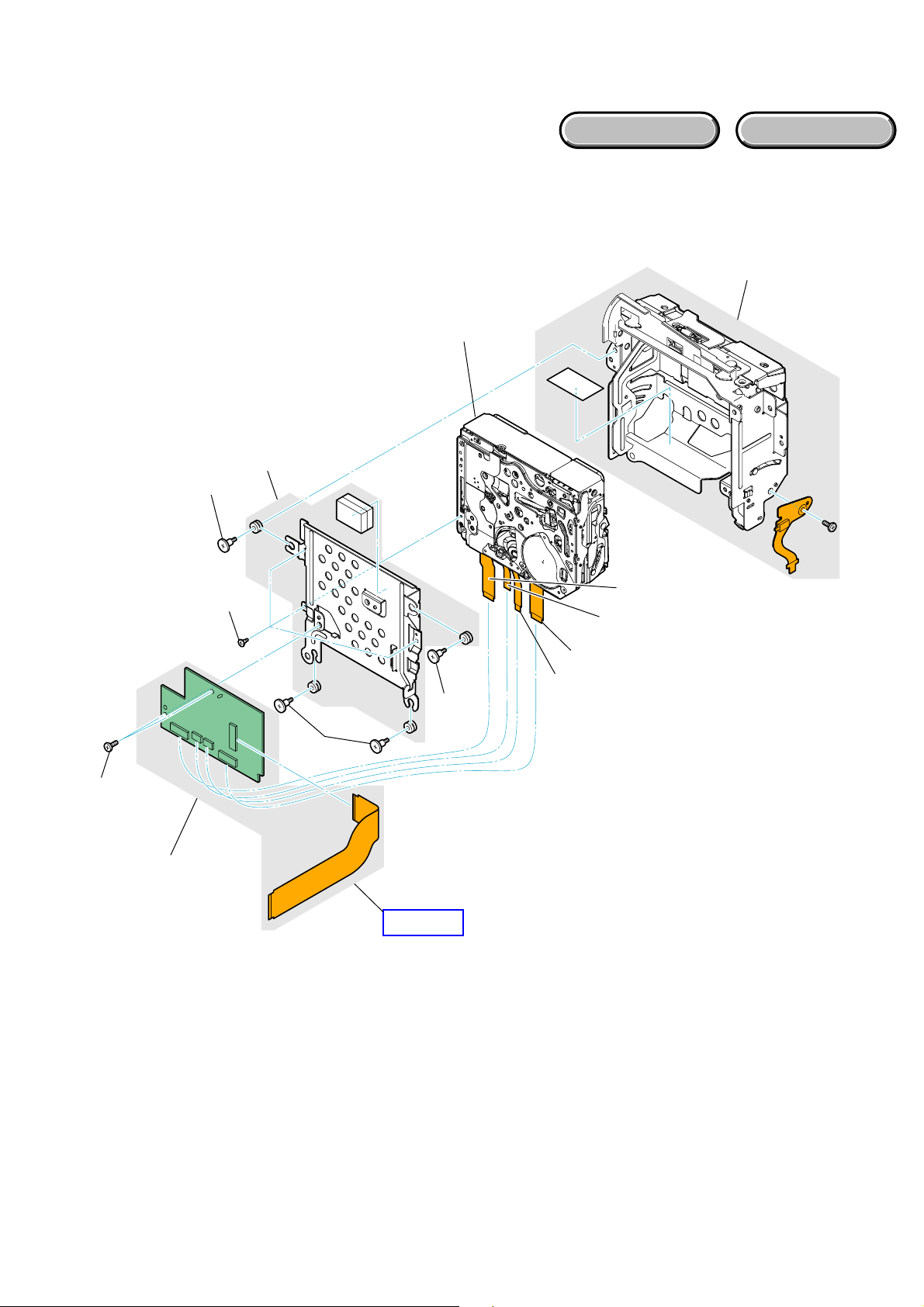

2-2-4. MD SECTION

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 Mechanism Deck (1-1 to 1-12)

1 Mechanism Deck

HARDWARE LIST

1-12E

1-4

(#50)

MD-141

1-9

1-1

(#153)

1-10

(#15)

1-11

1-8

1-7

1-6

1-5

1-3

(#153)

1-2

(#153)

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

HELP05

2-6

EXPLODED VIEW

2-2-5. HANDLE SECTION-1

Follow the disassembly in the numerical order given.

1 EVF Section (1-1 to 1-10)

2 Microphone Holder Assy (2-1 to 2-2)

HELP07 HELP08

1 EVF Section

Secure (UPPER) CABINET (93000) ASSY

Note:

tightening screws in the order A to D.

HARDWARE LIST

1-9

(Open)

1-10E

(#49)

1-4

1-8

(#49)

1-7

1-5

(#49)

D

HELP06

1-6

C

1-3

A

B

1-2 (#49)

1-1 (Open)

2-2E

(#119)

2-1

(Open)

Handle Section-2

(See Page 2-8)

2 Microphone Holder Assy

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

2-7

EXPLODED VIEW

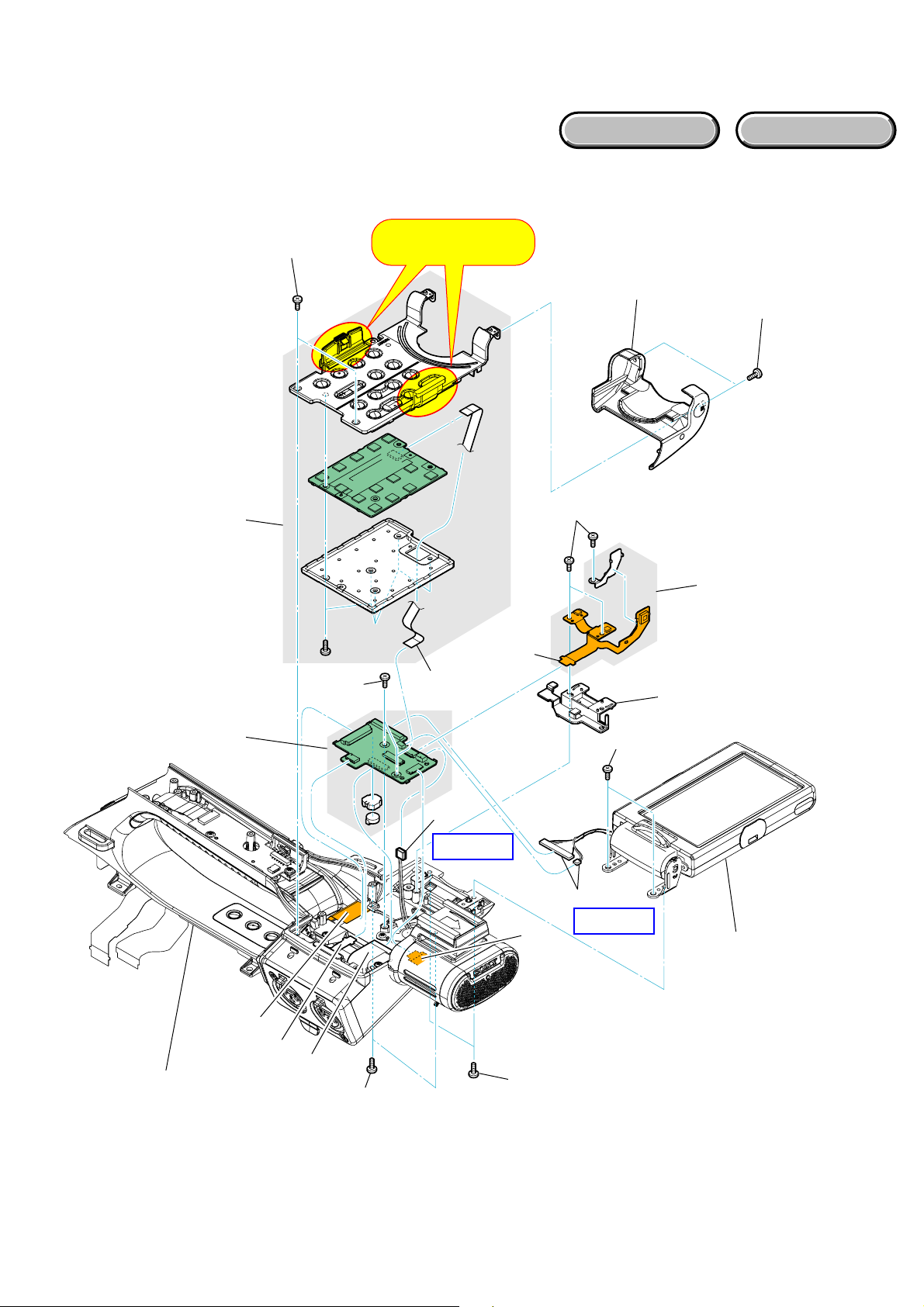

2-2-6. HANDLE SECTION-2

Follow the disassembly in the numerical order given.

1 Control Panel Block (1-1 to 1-5)

2 PI-029 Board (2-1 to 2-11)

3 LCD Section (3-1 to 3-2)

1-4 (#49)

Note:

KY-105

HARDWARE LIST

Be sure not to

touch these parts.

1-2

1-1 (#49)

1 Control Panel

Block

2 PI-029 Board

2-9

(#50)

PI-029

1-5E

2-2

HELP09

2-1

2-3

2-6 (#50)

2-7

2-8

3-2E (#119)

2-11E

HELP09

3 LCD Section

(See Page 2-11)

Handle Section-3

(See Page 2-9)

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

2-5

2-4

2-10

3-1 (#49)

1-3

(#53)

2-8

EXPLODED VIEW

2-2-7. HANDLE SECTION-3

Follow the disassembly in the numerical order given.

1 GP-025 Board (1-1 to 1-2)

2 XL-010 Board (2-1 to 2-11)

3 Handle Section-4 (3-1 to 3-6)

HARDWARE LIST

1 GP-025 Board

3-6E

3-5 (#49)

3 Handle Section-4

(See Page 2-10)

1-2E

3-3 (#49)

2 XL-010 Board

GP-025

3-4

1-1 (#50)

2-6

(#49)

3-1 (#49)

3-2

2-1

(#119)

2-8

2-7

(#119)

2-2

2-11E

2-10

2-5

2-9

(#50)

2-4

(#49)

2-3

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

2-9

EXPLODED VIEW

2-2-8. HANDLE SECTION-4

Follow the disassembly in the numerical order given.

1 AS-060 Board (1-1 to 1-4)

2 Microphone Section (2-1 to 2-7)

HARDWARE LIST

2-7E

2-1

2-5 (#49)

2-2 (#49)

2-3

2-4

HELP11

2 Microphone Section

1-2

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

AS-060

1-3

(#50)

1 AS-060 Baord

HELP10

2-6 (#49)

1-1

1-4E (#53)

2-10

EXPLODED VIEW

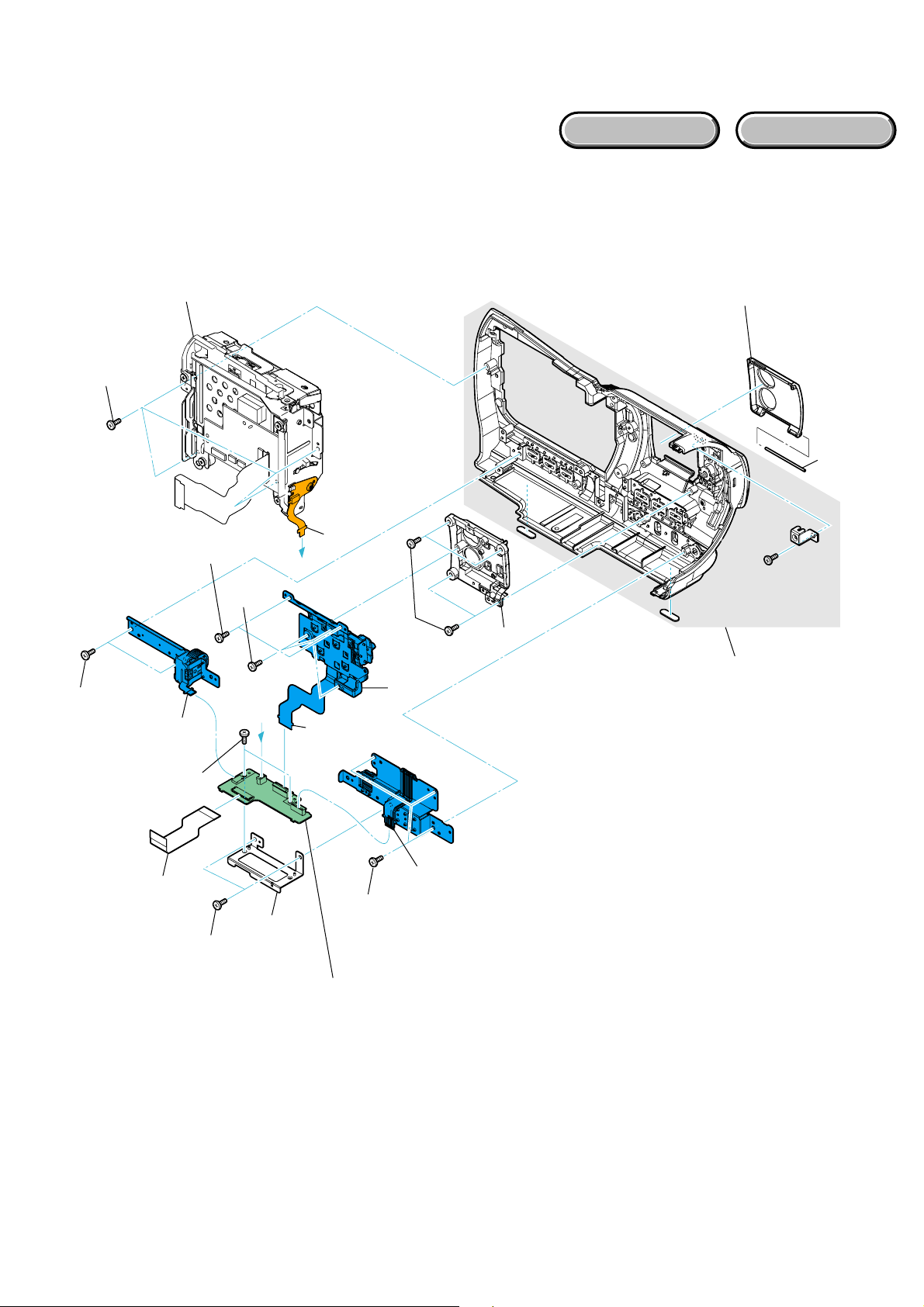

2-2-9. LCD SECTION

Follow the disassembly in the numerical order given.

1 Hinge Block (1-1 to 1-10)

2 LCD (2-1 to 2-9)

1-2 (Claws)

1 Hinge Block

HELP12

1-3

1-1 (#49)

1-10E

1-9

(#49)

HARDWARE LIST

2-9E

1-5

(#49)

1-8

2-3 (#50)

1-6

(Dowels)

1-4

2-6 (#50)

PD-372

2-5

1-7

(Claws)

2-8

2-2

2-7 (Claws)

2-4 (Claws)

2-1

2 LCD

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

2-11

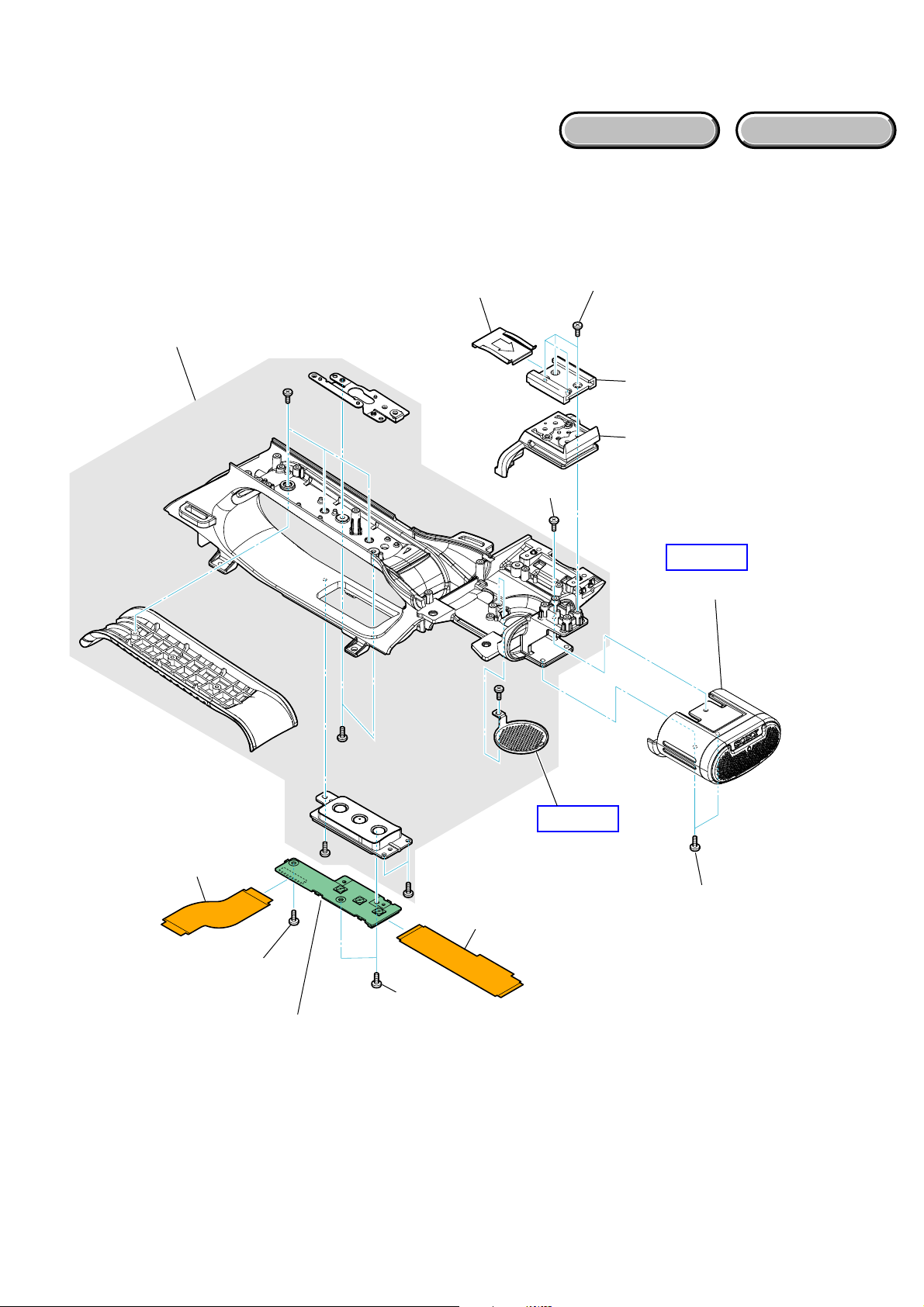

EXPLODED VIEW

Ver. 1.1 2008.12

2-2-10. CABINET (L) SECTION

Follow the disassembly in the numerical order given.

1 Cabinet (L) Block (1-1 to 1-3)

2 Cabinet (G) Block (2-1 to 2-7)

2-4

HARDWARE LIST

place: 1-1 (#49)One

places: 1-2 (#53)Twelve

1-1 (#49)

2-3

(#53)

2 Cabinet (G) Block

A

B

2-1

A

2-2

1-2

(#53)

2-5

(#53)

1 Cabinet (L) Block

1-3E

(Claws)

2-6

2-7E

(Remove the Grip Belt)

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

B

Cabinet (L)

Insulating

Sheet

The Fuse Replacement Caution Label is

put on the Cabinet (L) Insulating Sheet

put on the Cabinet (L (93000)) Assy.

2-12E

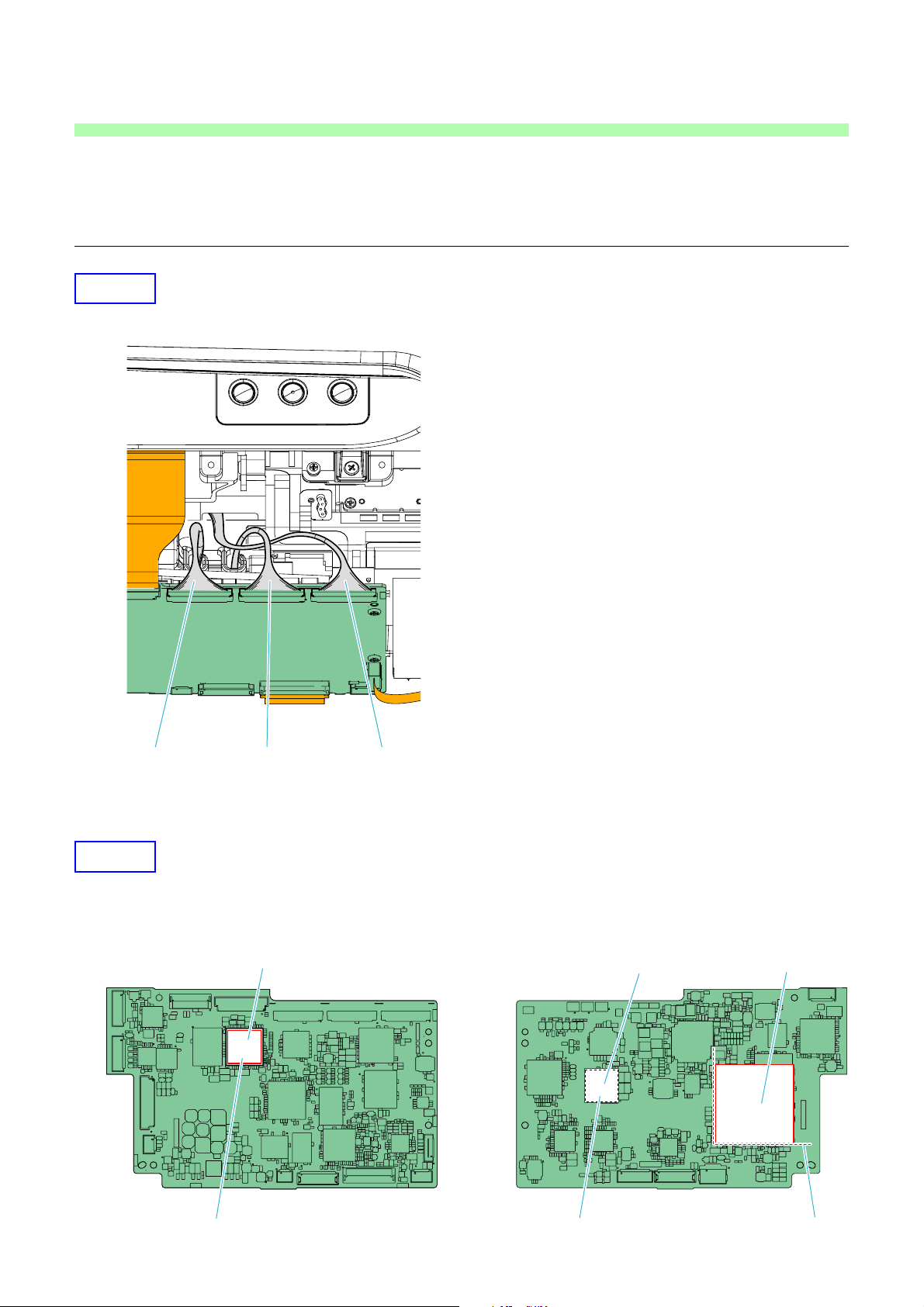

HELP

VC-543

VC-543

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

HELP01

How to arrange Harness (Coaxial Cable).

VC-543

Harness

(Coaxial Cable)

(R)

Harness

(Coaxial Cable)

(G)

HELP02

Sticking standard of Sheets (to VC-543 Board).

a. VC-543 Board (Side A) b. VC-543 Board (Side B)

Electrostatic Sheet (VC)

Harness

(Coaxial Cable)

(B)

VC Radiation

Sheet (1212)

Lens Radiation

Sheet (2828)

VC-543

Be careful not to bring it out of IC.

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

VC-543

Attach covering the IC.

Sticking standard

HELP

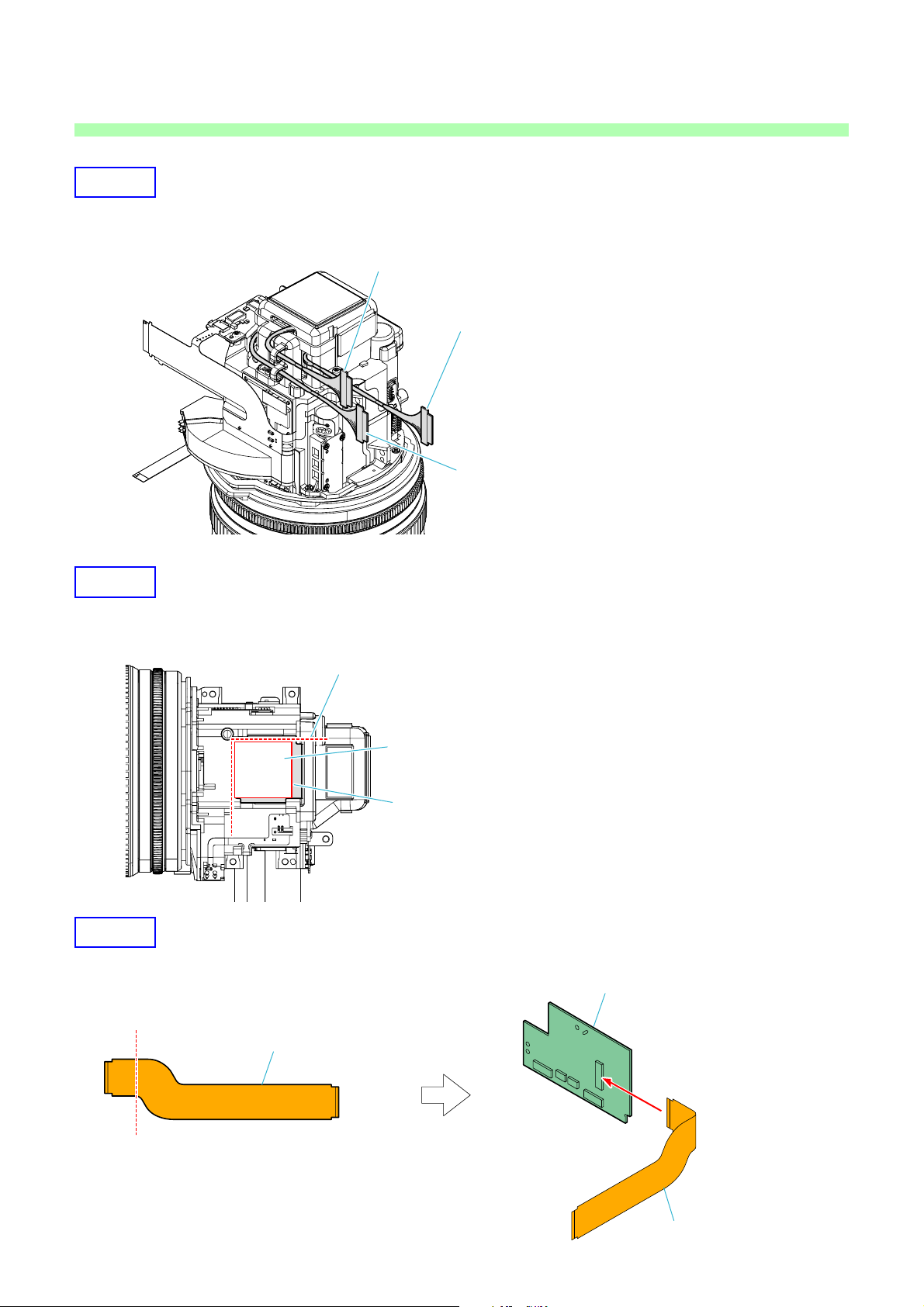

HELP03

How to arrange Harnesses (Coaxial Cable).

Harness (Coaxial Cable) (R)

Harness (Coaxial Cable) (B)

Harness (Coaxial Cable) (G)

HELP04

Sticking standard of the Lens Radiation Sheet (2828).

Sticking standard

Lens Radiation

Sheet (2828)

HELP05

How to fold the FP-983 Flexible Board.

Valley fold

FP-983 Flexible Board

Lens Heat Sink

MD-141 Board

MD-141

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

FP-983 Flexible Board

HELP

HELP06

Sticking standard of the Cushion (Mic)

Control Switch Block

(GZ92000)

Sticking standard

Cushion (Mic)

HELP07

Confirm the Diopter Adjustment Lever is on the left side when installing

the VF Lens Assy.

Diopter Adjustment Lever

HELP08

Sticking standard of the Tape (VF)

FP-974 Flexible Board

VF Lens Assy

Eye Cup (93000) Assy

Tape (VF)

Reinforcing Part

HVR-Z5C/Z5E/Z5J/Z5N/Z5P/Z5U

1.0mm

HELP

Loading...

Loading...