Page 1

HCD-U1BT

SERVICE MANUAL

Ver. 1.3 2006.12

HCD-U1BT is the Amplifier, BLUETOOTH, CD

player, USB and Tuner section in CMT-U1BT.

US and foreign patents licensed from

Dolby Laboratories.

Amplifier section

AUDIO POWER SPECIFICATIONS

(USA model only)

POWER OUTPUT AND TOTAL HARMONIC

DISTORTION:

With 6 ohm loads, both channels driven, from

120 – 10,000 Hz: rated 25 watts per channel

minimum RMS power, with no more than 10%

total harmonic distortion from 250 milliwatts to

rated output.

North American model:

DIN power output (rated): 20 + 20 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

25 + 25 watts (6 ohms at 1 kHz, 10% THD)

European model:

DIN power output (rated): 20 + 20 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

25 + 25 watts (6 ohms at 1 kHz, 10% THD)

Music power output (reference):

25 + 25 watts (6 ohms at 1 kHz, 10% THD)

Korean model:

DIN power output (rated): 20 + 20 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

25 + 25 watts (6 ohms at 1 kHz, 10% THD)

Inputs:

AUDIO IN (stereo mini jack): voltage 620 mV,

impedance 47 kilohms

(USB) port: Type A, maximum current

500 mA

Outputs:

i (PHONES (stereo mini jack)): accepts

headphones of 8 ohms or more

SPEAKER: accepts impedance of 6 ohms

BLUETOOTH section

Communication system:

BLUETOOTH Standard version 2.0

Output:

BLUETOOTH Standard Power Class 2

Maximum communication range:

Line of sight approx. 10 m

Frequency band:

2.4 GHz band (2.4000 GHz – 2.4835 GHz)

Modulation method:

FHSS

Compatible BLUETOOTH profiles2):

A2DP (Advanced Audio Distribution Profile)

AVRCP (Audio Video Remote Control Profile)

Audio format:

SBC (Sub Band Codec)

1) The actual range will vary depending on factors such

as obstacles between devices, magnetic fields around

a microwave oven, static electricity, reception

sensitivity, antenna’s performance, operating system,

software application, etc.

2) BLUETOOTH standard profiles indicate the purpose

of BLUETOOTH communication between devices.

CD

Section

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism HCD-U1

Base Unit Name BU-F4BD83S-WOD

Optical Pick-up Name KSM-215CFP/C2NP

USB section

Supported bit rate

MP3 (MPEG 1 Audio Layer-3):

32 – 320 kbps, VBR

ATRAC: 48 – 352 kbps (ATRAC3 plus),

66/105/132 kbps (ATRAC3)

WMA: 48 – 192 kbps, VBR

AAC: 48 – 320 kbps

Sampling frequencies

MP3 (MPEG 1 Audio Layer-3):

1)

32/44.1/48 kHz

ATRAC: 44.1 kHz

WMA: 44.1 kHz

AAC: 44.1 kHz

CD player section

System: Compact disc and digital audio system

Laser Diode Properties

Emission duration: continuous

Laser Output*: Less than 44.6µW

*This output is the value measurement at a

distance

of 200mm from the objective lens surface on the

Optical Pick-up Block with 7mm aperture.

Frequency response: 20 Hz – 20 kHz

— Continued on next page —

9-887-353-04

2006L16-1

© 2006.12

COMPACT DISC RECEIVER

Sony Corporation

Personal Audio Division

Published by Sony Techno Create Corporation

Page 2

HCD-U1BT

r

Ver. 1.3

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section:

Tuning range

Pan-American models:

87.5 – 108.0 MHz (100 kHz step)

Other models:

87.5 – 108.0 MHz (50 kHz step)

Antenna: FM lead antenna

Antenna terminals: 75 ohms unbalanced

Intermediate frequency: 10.7 MHz

AM tuner section:

Tuning range

Pan-American models:

530 – 1,710 kHz (with the tuning interval

set at 10 kHz)

531 – 1,710 kHz (with the tuning interval

set at 9 kHz)

European model:

531 – 1,602 kHz (with the tuning interval

set at 9 kHz)

Korean model:

530 – 1,710 kHz (with the tuning interval

set at 10 kHz)

531 – 1,602 kHz (with the tuning interval

set at 9 kHz)

Antenna: AM loop antenna, external antenna

terminal

Intermediate frequency: 450 kHz

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

General

Power requirements

North American model:

120 V AC, 60 Hz

European model:

220 – 240 V AC, 50/60 Hz

Korean model:

220 – 240 V AC, 60 Hz

Power consumption: 35 watts

Dimensions (w/h/d) (excl. speakers):

Approx. 160 × 241 × 218 mm

Mass (excl. speakers) 3.2 kg

Design and specifications are subject to change

without notice.

AC

0.15 µF

1.5 k

Ω

Earth Ground

voltmete

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PA RT NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

À LA SÉCURITÉ!

2

Page 3

TABLE OF CONTENTS

HCD-U1BT

Ver. 1.1

1. SERVICING NOTES ................................................ 4

2. GENERAL ................................................................... 6

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 9

3-2. Back Cover ...................................................................... 10

3-3. Top Panel Assy ................................................................ 10

3-4. Front Panel Assy.............................................................. 11

3-5. PANEL Board, ANT Board............................................. 12

3-6. BT Board ......................................................................... 12

3-7. SMASTER Board............................................................ 13

3-8. SW POWER Board ......................................................... 14

3-9. Tuner (FM/AM) ............................................................... 15

3-10. REG Board ...................................................................... 15

3-11. MAIN Board .................................................................... 16

3-12. CD Mechanism Deck (CDM80BT-F4BD83S-WOD)..... 16

3-13. USB Board, HP Board ..................................................... 17

3-14. SP Board .......................................................................... 18

3-15. Chassis (Top) ................................................................... 18

3-16. Lever (Loading R/L)........................................................ 19

3-17. Disc Stop Lever, Disc Sensor Lever................................ 20

3-18. DRIVER Board ............................................................... 20

3-19. BD83S Board, Optical Pick-up (KSM-215CFP) ............ 21

3-20. Holder (BU215T) Assy ................................................... 22

3-21. Lever (BU Lock) ............................................................. 22

3-22. Close Lever ...................................................................... 23

3-23. Lever (DIR), Gear (IDL-B) ............................................. 23

3-24. Gear (IDL-C) ................................................................... 24

4. TEST MODE ............................................................... 25

5. ELECTRICAL ADJUSTMENTS .......................... 26

6. DIAGRAMS

6-1. Block Diagram — BD/DRIVER Section — .................. 28

6-2. Block Diagram — FRONT Section — .......................... 29

6-3. Block Diagram — AUDIO Section — ........................... 30

6-4. Block Diagram — AMP Section —............................... 31

6-5. Block Diagram — POWER Section —.......................... 32

6-6. Printed Wiring Board — BD83S Section — .................. 33

6-7. Schematic Diagram — BD83S Section —..................... 34

6-8. Printed Wiring Board — DRIVER Section — ............... 35

6-9. Schematic Diagram — DRIVER Section — ................. 35

6-10. Printed Wiring Board — MAIN Section — ................... 36

6-11. Schematic Diagram — MAIN Section (1/2) — ............. 37

6-12. Schematic Diagram — MAIN Section (2/2) — ............. 38

6-13. Printed Wiring Board — SMASTER Section — ........... 39

6-14. Schematic Diagram — SMASTER Section — .............. 40

6-15. Printed Wiring Board — PANEL Section — ................. 41

6-16. Schematic Diagram — PANEL Section — .................... 42

6-17. Printed Wiring Board — USB Section — ...................... 43

6-18. Schematic Diagram — USB Section —......................... 44

6-19. Printed Wiring Boards — HP, SP, REG Section — ....... 45

6-20. Schematic Diagram — HP, SP Section — ..................... 46

6-21. Printed Wiring Board — SW POWER Section — ......... 47

6-22. Schematic Diagram — SW POWER Section — ........... 48

6-23. Printed Wiring Boards — BT, ANT Section — ............. 49

6-24. Schematic Diagram — BT, ANT Section — ................. 50

7. EXPLODED VIEWS

7-1. Overall Section................................................................ 66

7-2. Front Panel Section ......................................................... 67

7-3. AMP Section ................................................................... 68

7-4. MAIN Section ................................................................. 69

7-5. CD Mechanism Deck Section-1

(CDM80BT-F4BD83S-WOD) ........................................ 70

7-6. CD Mechanism Deck Section-2

(CDM80BT-F4BD83S-WOD) ........................................ 71

7-7. CD Mechanism Deck Section-3

(CDM80BT-F4BD83S-WOD) ........................................ 72

7-8. Base Unit Section (BU-F4BD83S-WOD)....................... 73

8. ELECTRICAL PARTS LIST .................................. 74

3

Page 4

HCD-U1BT

Ver. 1.3

SECTION 1

SERVICING NOTES

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

* Replacement of USB board IC8 and BT board IC905

used in this set requires a special tool.

• The voltage and wav eform of CSP (chip size package) cannot

be measured, because its lead layout is different from that of

conventional IC.

• Lead layouts

surface

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

This appliance is classified as a

CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT

MARKING is located on the rear

exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

ANTITHEFT LOCK MODE

This mode is used to unable to take sample disc out of disc table in

the shop.

Procedure:

1. Press the @/1 button to turn the power on.

2. Press the CD

3. Press two buttons of x CANCEL and Z for 5 seconds.

4. The message “CD LOCKED” is displayed on the fluorescent

indicator tube and the disc slot is locked. (Even if pressing

the Z button, the message “CD LOCKED” is displayed on

the fluorescent indicator tube and the disc table is locked.)

5. To release from this mode, press two buttons of x CANCEL and

Z for 5 seconds.

6. The message “CD UNLOCKED” is displayed on the fluorescent indicator tube and the disc table is unlocked.

u

button to select “CD”.

Lead layout of

conventional IC

CSP (chip size package)

Note on USB board replacement

New part of EEP ROM (IC6) on the USB board cannot be used. Therefore,

if the mounted USB board (X-2149-040-1) is replaced, exchange new

EEP ROM (IC6) with that used before the replacement.

4

MODEL IDENTIFICATION

– Rear Panel –

Model Part No.

AEP, UK models 2-683-402-0[]

US model 2-683-403-0[]

CND model 2-687-180-0[]

KR model 2-892-323-0[]

Parts No.

•Abbreviation

CND : Canadian model

KR : Korean model

Page 5

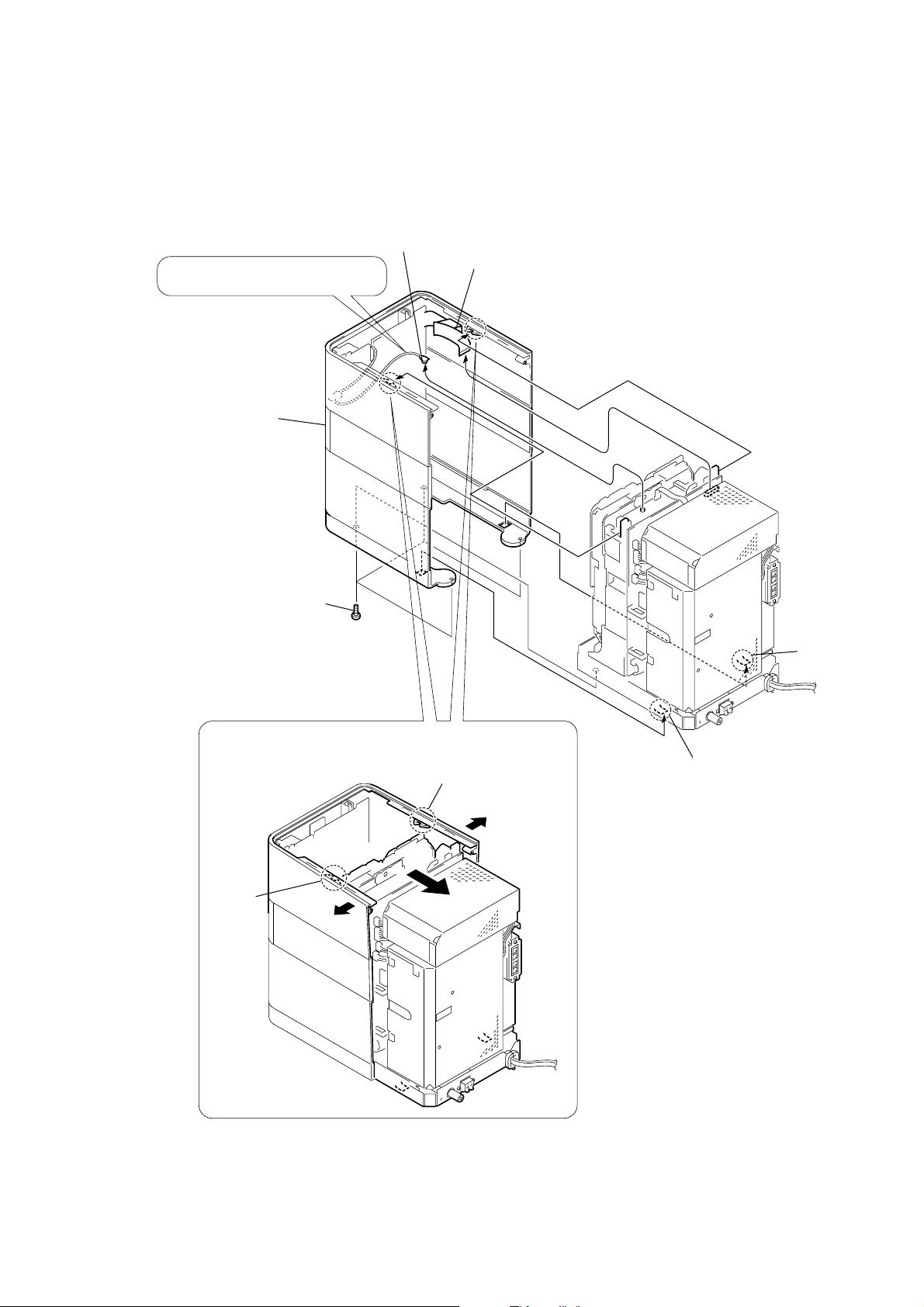

• SERVICE POSITIONS OF THE MAIN BOARD AND THE CD MECHANISM DECK

Be sure to place the mechanism deck on a work

stand or on a spacer so that the movable block

does not receive any physical stress.

movable block

HCD-U1BT

MAIN board

work stand or

on a spacer

• PRECAUTION WHEN REMOVING THE FRONT PANEL ASSY

Be careful not to cut the coaxial cable.

front panel assy

CD mechanism deck

(CDM80BT-F4BD83S-WOD)

BT board

5

Page 6

HCD-U1BT

SECTION 2

GENERAL

This section is extracted

from instruction manual.

6

Page 7

HCD-U1BT

7

Page 8

HCD-U1BT

Ver. 1.3

8

Page 9

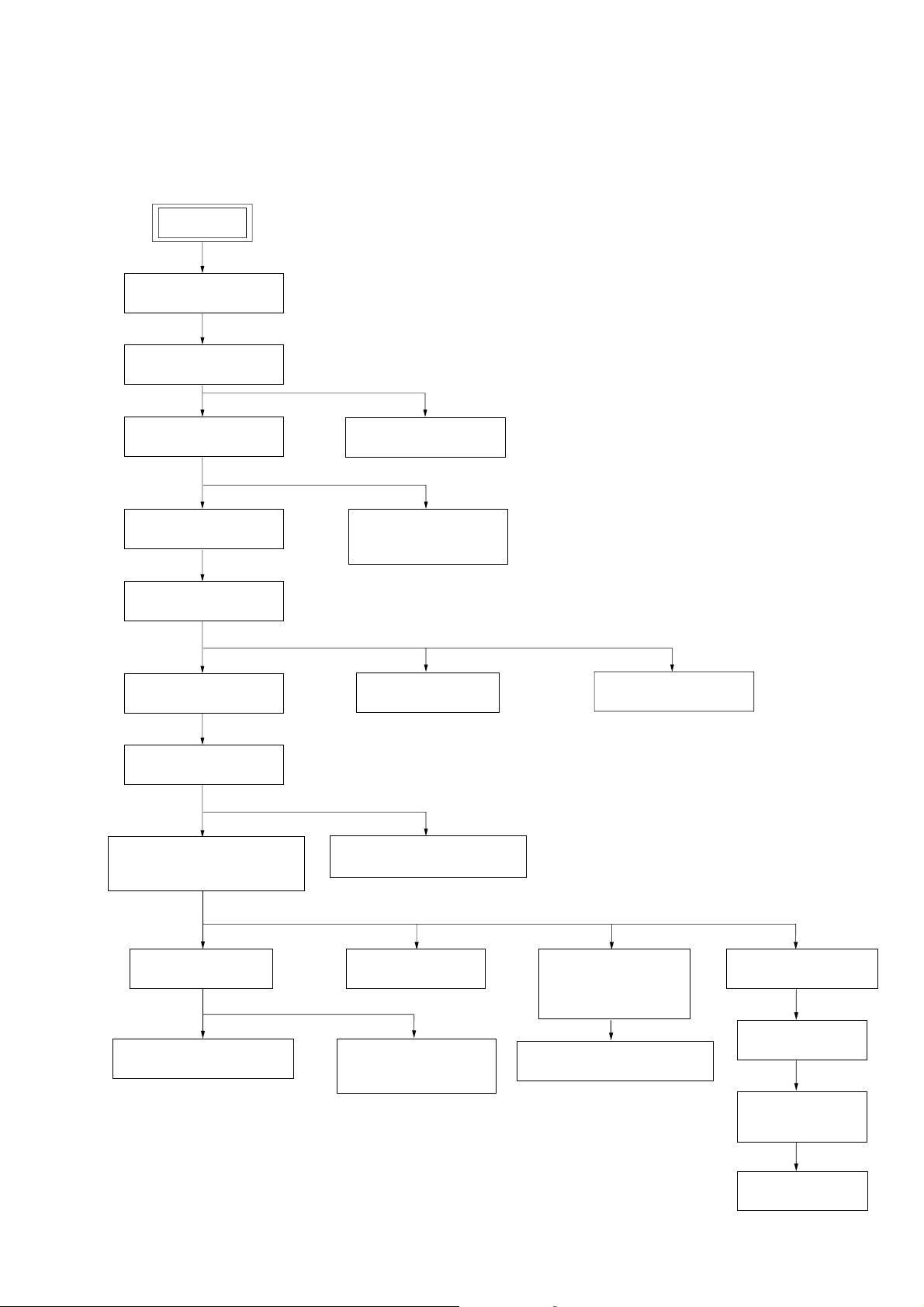

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. BACK COVER

(Page 10)

3-3. TOP PANEL ASSY

(Page 10)

HCD-U1BT

SECTION 3

DISASSEMBLY

3-4. FRONT PANEL ASSY

(Page 11)

3-7. SMASTER BOARD

(Page 13)

3-8. SW POWER BOARD

(Page 14)

3-10. REG BOARD

(Page 15)

3-11. MAIN BOARD

(Page 16)

3-12. CD MECHANISM DECK

(CDM80BT-F4BD83S-WOD)

(Page 16)

3-6. BT BOARD

(Page 12)

3-5. PANEL BOARD,

ANT BOARD

(Page 12)

3-9. TUNER (FM/AM)

(Page 15)

3-13. USB BOARD, HP BOARD

(Page 17)

3-14. SP BOARD

(Page 18)

3-15. CHASSIS (TOP)

(Page 18)

3-16. LEVER (LOADING R/L)

(Page 19)

3-18. DRIVER BOARD

(Page 20)

3-17. DISC STOP LEVER,

DISC SENSOR LEVER

(Page 20)

3-19. BD83S BOARD,

OPTICAL PICK-UP

(KSM-215CFP)

(Page 21)

3-20. HOLDER (BU215T) ASSY

(Page 22)

3-21. LEVER (BU LOCK)

(Page 22)

3-22. CLOSE LEVER

(Page 23)

3-23. LEVER (DIR),

GEAR (IDL-B)

(Page 23)

3-24. GEAR (IDL-C)

(Page 24)

9

Page 10

HCD-U1BT

Note: Follow the disassembly procedure in the numerical order given.

3-2. BACK COVER

1

two screws

(+BVTP 3

×

8

)

3-3. TOP PANEL ASSY

2

two claws

2

three screws

(+BVTP 3

3

top panel assy

3

back cover

×

8

)

1

two claws

10

Page 11

q;

front panel assy

Be careful not to cut the coaxial cable.

9

2

flexible flat cable

15core (CN103)

1

connector

(coaxial cable)

5

claw

4

claw

3

four screws

(+BVTP 3

×

8

)

6

Stretch the front panel assy in the direcution

of the arrows

A

and B.

A

B

7

claw

8

claw

3-4. FRONT PANEL ASSY

HCD-U1BT

11

Page 12

HCD-U1BT

3-5. PANEL BOARD, ANT BOARD

front panel

qf

button

(folder)

qd

(folder A)

base

qs

base

(folder B)

8

button

(DSGX)

qa

button

(enter)

5

button (vol)

6

ANT board

7

connector

(coaxial cable)

lead pin

When installing the PANEL board,

route the coaxial cable as shown

in the figure.

lead pin

coaxial cable

PANEL board

(B side)

4

PANEL board

1

seven screws

(+BVTP 2.6

×

8

)

3-6. BT BOARD

9

button (function)

1

connector

(coaxial cable)

3

two screws

(+BVTP 3

×

q;

8)

base (enter)

3

Remove the

coaxial cable

from the lead pin.

4

BT board

2

flexible flat cable

11core (CN901)

2

seven screws

(+BVTP 2.6

×

8

)

12

Page 13

3-7. SMASTER BOARD

)

1

two screws

(+BVTP 3

HCD-U1BT

3

shield plate (D)

2

two screws

(+BVTP 3

×

8

)

×

8

qs

radiation sheet

qd

SMASTER board

qa

(SMASTER)

q;

two screws

(+BVTP 3

heat sink

×

8

)

8

flexible flat cable

19core (CN700)

9

four screws

(+BVTP 3

×

8

)

7

connector

2P (CN705)

6

connector

4P (CN704)

5

connector

2P (CN703)

4

connector

2P (CN702)

13

Page 14

HCD-U1BT

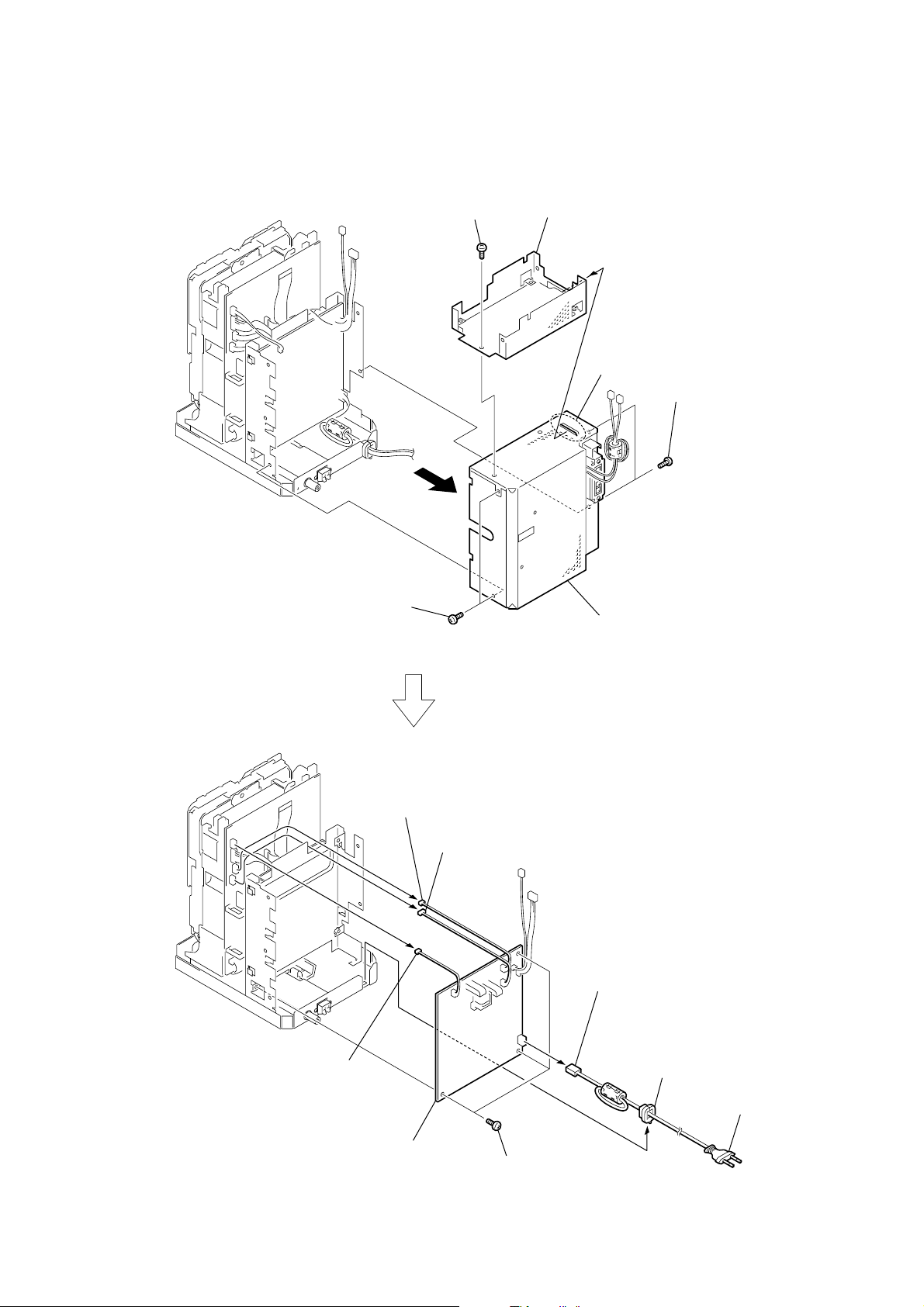

3-8. SW POWER BOARD

1

screw

(+BVTP 3

×

8

)

3

shield plate (C)

2

claw

4

two screws

(+BVTP 3

×

8

)

5

two screws

(+BVTP 3

×

8

)

q;

connector

3P (CN105)

qa

connector

2P (CN104)

6

shield plate (B)

8

connector

2P (CN1)

14

qs

connector

3P (CN102)

qf

SW POWER board

qd

three screws

(+BVTP 3

7

Remove the

cord bushing.

9

power cord

×

8

)

Page 15

3-9. TUNER (FM/AM)

3

tuner (FM/AM)

HCD-U1BT

3-10. REG BOARD

1

connector

8P (CN116)

1

flexible flat cable

11core

2

two screws

(+BVTP 3

×

8

7

)

REG board

6

shield plate (A)

5

two screws

(+BVTP 3

×

8

)

2

two screws

(+BVTT 3

3

two screws

(+BVTT 3

4

two claws

×

6

)

×

6

)

15

Page 16

HCD-U1BT

)

Ver. 1.1

3-11. MAIN BOARD

1

flexible flat cable

11core (CN110)

2

flexible flat cable

23core (CN108)

3

flexible flat cable

9core (CN114)

q;

MAIN board

9

three screws

(+BVTP 3

6

flexible flat cable

11core (CN115)

7

flexible flat cable

19core (CN109)

×

8

)

4

flexible flat cable

15core (CN113)

5

connector

7P (CN701)

3-12. CD MECHANISM DECK (CDM80BT-F4BD83S-WOD)

4

CD MECHANISM DECK

(CDM80BT-F4BD83S-WOD)

3

flexible flat cable

23core (CN102)

8

screw

(+BVTP 3

×

8

)

16

2

tape

1

four screws

(+BVTP 3

×

10

Page 17

3-13. USB BOARD, HP BOARD

1

two screws

(+BVTP 3

HCD-U1BT

4

bracket (CD)

2

two screws

(+BVTP 3

×

8)

3

×

8)

coating clip

9

screw

(+BVTP 3

qs

HP board

×

8)

qa

tape

q;

two dowels

5

screw

(+BVTP 3

8

USB board

×

8)

6

four claws

7

flexible flat cable

15core (CN1)

17

Page 18

HCD-U1BT

3-14. SP BOARD

1

two screws

(+BVTP 3

×

8

)

4

SP board

3

bracket (SP)

2

two screws

(+BVTP 3

×

8

)

3-15. CHASSIS (TOP)

3

two screws

(+P 2 × 10)

5

chassis (top)

4

three screws

(+BVTP 2.6 × 8)

1

screw

(+BVTP 2.6 × 8)

2

lever (CL UP2)

18

Page 19

3-16. LEVER (LOADING R/L)

HCD-U1BT

6

lever (loading R)

4

torsion spring (loading RV) torsion spring (loading LV)

5

two hooks

1

2

two hooks

3

lever (loading L)

PRECAUTION DURING LEVER (LOADING R / L) INSTALLATION

Align the horizontal position.

lever (loading L)

Install the

both levers so that they move symmetrically.

lever (loading R)

19

Page 20

HCD-U1BT

3-17. DISC STOP LEVER, DISC SENSOR LEVER

1

gear (cap)

2

gear (IDL-L)

PRECAUTION DURING DISC STOP LEVER INSTALLATION

5

two hooks

6

disc stop lever

3-18. DRIVER BOARD

3

Remove soldering

from the two points.

3

two claws

4

disc sensor lever

hole

hole

Install the disc stop lever so that the both holes

are aligned.

2

two screws

(+BVTP 2.6

×

8)

5

DRIVER board

chassis (top)

disc stop lever

20

4

motor assy (loading)

1

belt (MOT)

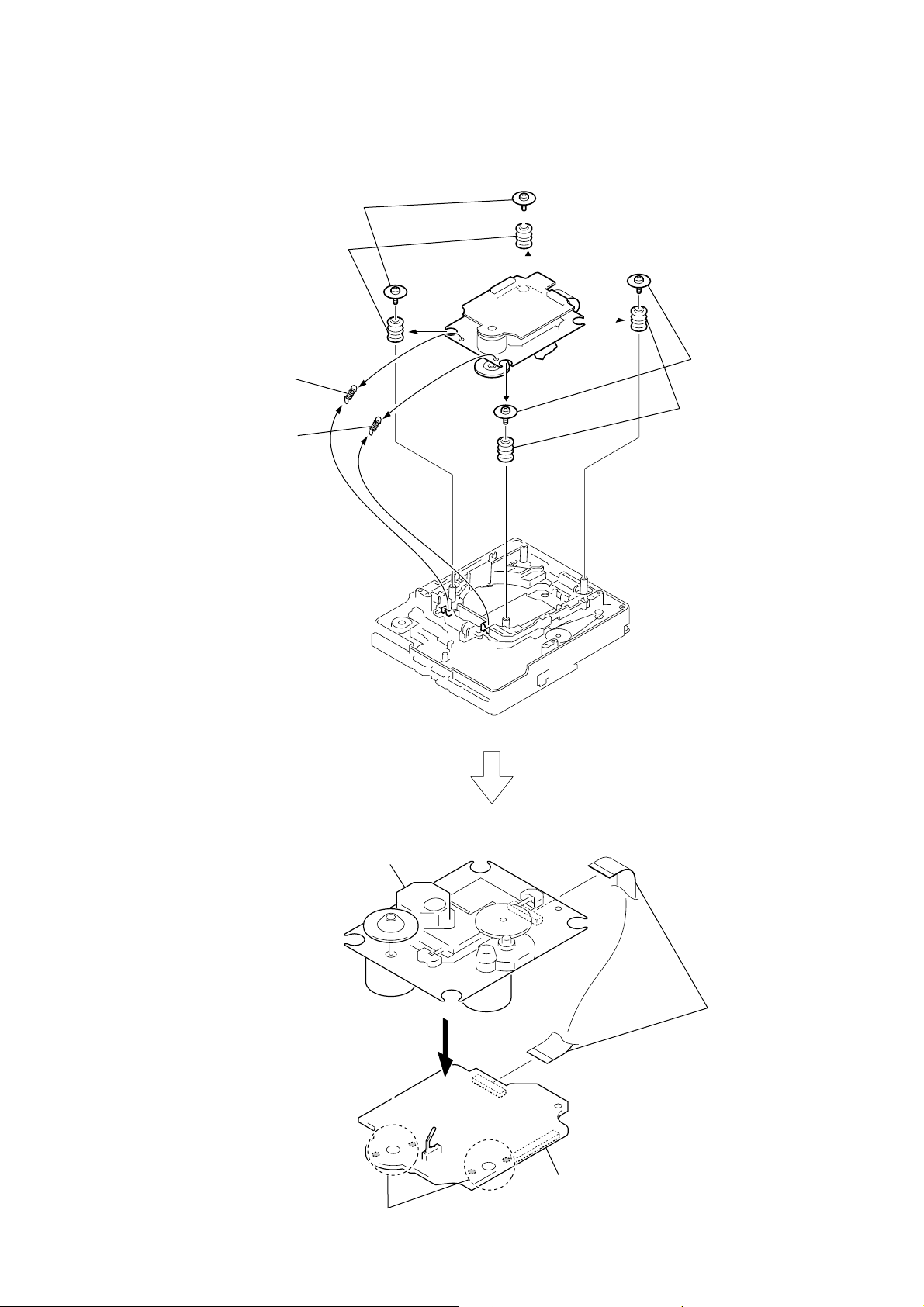

Page 21

8

Remove soldering from

the four points.

7

wire (flat type)

16core (CN301)

q;

BD83S board

9

optical pick-up

(KSM-215CFP)

3

two floating

screws

(+PTPWHM 2.6)

4

two floating

screws

(+PTPWHM 2.6)

6

two vibration proof rubbers

5

two vibration proof rubbers

1

tension coil spring (G-1)

2

tension coil spring (G-2)

3-19. BD83S BOARD, OPTICAL PICK-UP (KSM-215CFP)

HCD-U1BT

21

Page 22

HCD-U1BT

3-20. HOLDER (BU215T) ASSY

6

holder (BU215T) assy

4

floating screw

(+PTPWHM 2.6)

3

coil spring (holder down B)

2

lever (CL UP2)

1

screw

(+BVTP 2.6

3-21. LEVER (BU LOCK)

lever (BU lock)

6

1

gear (cap)

2

gear (BU lock)

3

floating screw

(+PTPWHM 2.6)

5

floating screw

(+PTPWHM 2.6)

×

8)

5

three hooks

4

22

Page 23

3-22. CLOSE LEVER

3

5

claw

close lever

1

washer (3-1-0.4)

2

4

shaft disc stop

HCD-U1BT

close lever spring

3-23. LEVER (DIR), GEAR (IDL-B)

1

tension coil

spring (DIR)

6

Loosen the screw.

2

claw

9

lever (DIR)

3

gear pulley

4

gear (cap)

5

gear (IDL-A)

q;

gear (IDL-B)

8

stopper

7

Hold the release lever

and change the direction.

23

Page 24

HCD-U1BT

3-24. GEAR (IDL-C)

1

3

gear (IDL-D)

2

two claws

gear (IDL-F)

7

gear (IDL-C)

4

three hooks

5

lever (gear loading) assy

6

claw

24

Page 25

SECTION 4

TEST MODE

HCD-U1BT

COLD RESET

The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning the

set to the customer.

Procedure:

1. Press two buttons of [DSGX] and @/1 simultaneously.

2. The fluorescent indicator tube becomes blank momentarily,

then becomes standby states.

COMMON TEST MODE

This mode is used to check operations of Amplifier.

Procedure:

1. Press the @/1 button to turn the power on.

2. Press two buttons of [DSGX] and [VOLUME +] for 5 seconds.

3. When the COMMON test mode is activated, the function

enters “AUDIO IN”, “c PLAY/SLEEP” blink on the fluorescent indicator tube.

4. Press the [ENTER] button, next mode is displayed on the

fluorescent indicator tube.

TONE MAX

TONE MIN

TONE FLAT

5. Press the [VOLUME +] button, “VOLUME MAX” is displayed

on the fluorescent indicator tube.

6. Press the [VOLUME --] button, “VOLUME MIN” is displayed

on the fluorescent indicator tube.

7. To release this mode, press the @/1 button.

PANEL TEST MODE

This mode is used to check the fluorescent indicator tube, LED,

model, destination, software version and button.

Procedure:

1. Press the @/1 button to turn the power on.

2. Press three buttons of [SEARCH], Z and @/1 simultaneously.

3. Fluorescent indicator tube and each LED is all turned on.

4. When the [DSGX] button is pressed, the screen is switched to

the version number and destination display as shown below.

Whenever the [DSGX] button is pressed, the display mode

advances in the order shown below.

MC t GC t USB t BT t CD t CDD t CDMA

TM T TA T ST T BDB T BDA T CDMB

Display example

U1

MC 0.15

CEL

060421

5. When the [ENTER] button is pressed, the machine enters the

key test mode.

6. When all keys are pressed, “KEY17” is displayed.

7. When the [SEARCH] button, the Z button and the @/1 buttons

are pressed simultaneously, the machine can e xit the test mode.

U1 CEL

Destination

Model name

MC 0.15

Version

Type

060421

Released date

CD SHIP MODE

This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the @/1 button to turn the power on.

2. Press the CD u button to select “CD”.

3. Press two buttons of [ENTER] and Z simultaneously.

4. After the “CD Please wait”, “ST ANDBY” display blinks, “CD

LOCK” is displayed on the fluorescent indicator tube, and the

ship mode is set.

5. To release this mode, press the @/1 button.

CD SHIP MODE & MEMORY CLEAR

This mode is used to perform CD ship mode and cold reset

simultaneously.

Procedure:

1. Press the @/1 button to turn the power on.

2. Press the CD u button to select “CD”.

3. Press three buttons of [DSGX], Z and @/1 simultaneously.

4. After the “STANDBY” display blinks, “CD LOCK” is

displayed on the fluorescent indicator tube, and the ship mode

is set.

5. To release this mode, press the @/1 button.

ANTITHEFT LOCK MODE

This mode is used to unable to take sample disc out of disc table in

the shop.

Procedure:

1. Press the @/1 button to turn the power on.

2. Press the CD

u

button to select “CD”.

3. Press two buttons of x CANCEL and Z for 5 seconds.

4. The message “CD LOCKED” is displayed on the fluorescent

indicator tube and the disc slot is locked. (Even if pressing

the Z button, the message “CD LOCKED” is displayed on

the fluorescent indicator tube and the disc table is locked)

5. To release from this mode, press two buttons of x CANCEL and

Z for 5 seconds.

6. The message “CD UNLOCKED” is displayed on the fluorescent indicator tube and the disc table is unlocked.

CD POWER MANAGE

This mode is used to changed over CD power on/of f for decreasing

of reception noise in the tuner mode.

Procedure:

1. Press the @/1 button to turn the power on.

2. Press the CD u button to select “CD”.

3. Press the @/1 button again to turn the power off.

4. Press two buttons of x CANCEL and @/1 simultaneously.

5. The message “CD/CD POWER ON” is displayed on the

fluorescent indicator tube momentarily.

6. Press two buttons of x CANCEL and @/1 simultaneously.

7. The message “CD/CD POWER OFF” is displayed on the

fluorescent indicator tube momentarily.

25

Page 26

HCD-U1BT

SECTION 5

ELECTRICAL ADJUSTMENTS

CD SECTION

Note:

1. CD Block is basically constructed to operate without adjustment.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10 MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

5. Check the focus bias check when optical pick-up block is replaced.

FOCUS BIAS CHECK

oscilloscope

(DC range)

BD83S board

TP (RFACI)

TP (VC)

Procedure :

1. Connect oscilloscope to TP (RFACI) and TP (VC) on the

BD83S board.

2. Press the ?/1 button to turn the power ON, and press

the Z (CD) button to open the CD disc tray.

3. Set disc (YEDS-18) on the tray and press the CD u button

to playback.

4. Confirm that oscilloscope waveform is as sho wn in the f igure

below. (eye pattern)

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

+

–

Checking Location:

– BD83S Board (SIDE B) –

TP

(VC)

IC201

TP

(RFACI)

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level:

0.9

±

0.4 Vp-p

26

Page 27

SECTION 6

DIAGRAMS

HCD-U1BT

Ver. 1.3

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except f or electrolytics and

tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• 2 : nonflammable resistor.

• C : panel designation.

Note:

The components identified by mark 0 or dotted line with mark 0 are

critical for safety.

Replace only with part

number specified.

• A : B+ Line.

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage v ariations ma y be noted due to normal production

tolerances.

•Waveforms are taken with a oscilloscope.

Voltage v ariations ma y be noted due to normal production

tolerances.

– BT Board –

No mark: BLUETOOTH

– Other Board –

No mark: CD PLAY

: Impossible to measure

*

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

J : CD

d : TUNER

f : USB

N : BLUETOOTH

Replacement of IC8 on USB board and IC905 on BT board

*

requires a special tool.

• The voltage and waveform of CSP (chip size package) cannot be measured, because its lead layout is different from

that of conventional IC.

•Abbreviation

CND : Canadian model

KR : Korean model

4

W or less unless otherwise

Note:

Les composants identifiés

par une marque 0 sont critiques pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• f : internal component.

• : Pattern from the side which enables seeing.

Caution:

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Replacement of IC8 on USB board and IC905 on BT board

*

requires a special tool.

• Lead Layouts

CSP (Chip Size Package)Lead layout of conventional IC

• Indication of transistor.

C

Q

B

E

B

These are omitted.

Q

CE

These are omitted.

surface

• Circuit Boards Location

PANEL board

ANT board

HP board

BD83S board

MAIN board

BT board

SP board

SMASTER board

SW POWER board

REG board

USB board

HCD-U1BT

DRIVER board

2727

Page 28

HCD-U1BT

6-1. BLOCK DIAGRAM — BD/DRIVER SECTION —

OPTICAL PICK-UP

BLOCK

(KSM-215CFP/C2NP)

DETECTOR

VCC

VC

A

B

C

D

E

F

LD

GND

PD

VR

FOCUS

COIL

TRACKING

COIL

SP+

M401

M402

M

SP

SL+

M

SL

(SPINDLE)

(SLED)

SYSTEM CONTROLLER

IC107

(1/5)

CD MECHANISM DECK

BLOCK

+1.7V

+3.3V

57

58

59

60

50

51

Q321

AUTOMATIC

POWER

CONTROL

X201

16.9344MHz

IC402

SL/SP MOTOR

DRIVER

FOCUS/TRUCKING

COIL DRIVER

F+

F

T+

T

12

11

13

14

16

15

18

17

CH2OUTF

CH1FIN

CH2OUTR

CH1RIN

CH1OUTR

CH2FIN

CH1OUTF

CH2RIN

CH4OUTF

CH3FIN

CH4OUTR

CH3RIN

CH3OUTR

OPIN+

CH3OUTF

MUTE

+3.3V

S201

(LIMIT)

4

5

6

7

23

22

2

20

66

108

109

67

39

43

44

45

46

41

42

38

IC201

RF AMP,DSP,MP3

A

B

C

D

E

F

LD

XTAO

XTAI

PD

SSTP

TFDR

TRDR

FFDR

FRDR

SFDR

SRDR

MDP

AOUT1

AOUT2

DATA2

REQ-MP3

ACK-MP3

XTACN

XRST

XLAT

DATA

CLOCK

SENS

SCOR

112

117

12

90CLK2

13XLAT-MP3

14

10IREQ-MP3

15

16

89

11

20

26

CDM

CD-L

CD-R

DATA-MP3

CLK-MP3

XLAT-MP3

REQ-MP3

IREQ-MP3

ACK-MP3

7

8

A

XTACN

XRST

XLAT

DATA

CLOCK

SENS

SCOR

AUDIO

SECTION

(Page 30)

5

MP3 DATA OUT

7

MP3 CLK

54

MP3 XLAT

50

MP3 REQ

49

MP3 IREQ

53

MP3 ACK

48

CD XTACN

56

CD XRST

51

CD XLT

45

CD DATA

55

CD CLK

52

CD SENS

19

CD SCOR

LOAD OUT

CDM

LOAD IN

CDM SW1

(OPEN)

CDM SW2

(CLOSE)

79

80

81

82

7

9

IC701

LOADING MOTOR DRIVER

FIN

ROUT

OUT1

OUT2

4

2

S701

(LOADING OUT)

S702

(CHUCKING)

• Signal Path

+

M

–

M701

(LOADING)

HCD-U1BT

M-MUTE

: CD

47

CD DRIVER MUTE

2828

Page 29

6-2. BLOCK DIAGRAM — FRONT SECTION —

HCD-U1BT

(FLUORESCENT INDICATOR TUBE)

FL301

BK

35

34

LAT

33

CLK

32

SI

IC303

REMOTE CONTROL

RECEIVER

3

S507

S509-S516

38

VFD_BK

36

VFD_LAT

VFD_CLK

37

VFD_DATA

35

KEY2

94

IC302(1/2)

PANEL CONTROLLER

XOUT

XIN

RESET

I2C CLK

13

X301

15

5MHz

IC107(2/5)

SYSTEM CONTROLLER

12

29

3

29

GC_RESET

2

C CLK

I

S500-S506,

S508

D501-D505

D507-D513

D500 STANDBY

Q502-Q506

Q508-Q513

LED DRIVE

Q500

LED DRIVE

2

I2C DATA

KEY1

95

LED_USB

LED_USB_FUNC

LED_CD_FUNC

LED_TU_FUNC

LED_AUDIO_IN_FUNC

LED_PLAY

LED_PAUSE

3 20 21 22 23 24 25 26 28

30

LED_DISC

LED_USB_ILLUMM

I

C DATA

30

POWER KEY

74

SIRCS

4

LED STANDBY

91

HCD-U1BT

2929

Page 30

HCD-U1BT

6-3. BLOCK DIAGRAM — AUDIO SECTION —

J620

AUDIO IN

AUDIO CONTROLLER

A2

6

A1

5

IC110

OUT1

OUT2

L-CH

17

R-CH

16

L-CH

OUT2

R-CH

AMP SECTION

C

(Page 31)

AM ANT

BT ANT

FM

CN2

V BUS

D–

D+

GND

BD/DRIVER

SECTION

(Page 28)

5

A

FM/AM

TUNER

IC1

V_BUS SWITCH

OUT

EN

1

3

FLG

CD-L

CD-R

BT-L

TU-L

USB-L

USB-R

IC902

BT AMP

A0UT_N_L

9

AOUT_P_L

SD0

AOUT_P_R

A0UT_N_R

10

8

7

USB PROCESSOR

IC8

UART_RTS

39

RTS

IC905

BT RECIEVER

UART_CTS

UART_RXD

403841

CTS

DATA-OUT

177

176

115

116

119

113

UART_TXD

DATA-IN

INT4

PG2

UDM

UDP

AVSUS12

DVSUS33

RESET

46

RESET

193 192

SIO

ANT IN

DVDD5

IN

4

-

2

AMP

3

+

+

5

AMP

6

-

nSCS0

195 202

1

L

7

R

AOUT L

217

AOUT R

218

TEX

126

X002

127

225

226

48MHz

X001

22.5MHz

PE5

191

nSCK0

TX

EXTAL

XTAL

nRST

101

TU-R

BT-R

IC112

AUDIO SELECTOR

X2

15

X1

14

X0

12

Y0

1

Y1

5

Y2

2

BA

9 10

Q119

SWITCH

Q121

SWITCH

X

13

Y

3

CD-L

CD-R

B1

7

B2

8

Q112

MUTE

C1

9

Q113

C2

10

SI14SC

13

LINE

MUTE-2

Q114

LINE

MUTE-1

12V

Q111

MUTE

IC109

HP AMP

AMP

5

L

AMP

3

R

L-CH

7

R-CH

1

HP MUTE-3

Q108

J621

12V

LINE_MUTE

HP_MUTE

Q110

HP MUTE-1

Q109

HP MUTE-2

Q107

HP MUTE-4

HP_DET

HCD-U1BT

1

100

USB_DO

BT_RESET

90

USB_DI

BT_CTS

34

NOR FLASH ROM

BT_DATA_OUT

35 38

BT_RTS

36

IC6

IC7

SRAM

BT_DATA_IN

42

USB_CS

75

2

USB_RDEN

USB RST

USB_CLK

Q3

43

USB_RESET

IC107 (3/5)

SYSTEM CONTROLLER

XC_OUT

XC_IN

10

11

X101

32.768KHz

X_OUT

13 15

X102

5MHz

X_IN

57

12

Q116

SWITCH

SEL_A

RESET

58

SEL_B

27

DET

AUDIO IN

• Signal Path

60

59

65

61 28

: CD

: TUNER

AMP_DATA

AMP_CLOCK

LINE_MUTE

HP_MUTE

: USB

HP_DET

: AUDIO

: BLUETOOTH

20

AC_CUT

IC108

1

OUT RESET

3030

Page 31

6-4. BLOCK DIAGRAM — AMP SECTION —

HCD-U1BT

AUDIO SECTION

(Page 30)

C

L-CH

X702

49.152MHz

A/D CONVERTER

IC701

LIN

1

15

CLOCK SHIFT

CLOCK BUFFER

S-MASTER SOFT MUTE

DOUT

BCK

SCKI

LRCK

IC703

IC709

SYSTEM CONTROLLER

IC107 (4/5)

S-MASTER DATA

S-MASTER SHIFT

S-MASTER LATCH

S-MASTER PG MUTE

S-MASTER NSP MUTE

S-MASTER INIT

S-MASTER RST

S-MASTER SD

STREAM PROCESSOR

IC705

12

11

10

70

72

78

66

67

76

77

31

30

29

36

48

21

22

23

20

19

18

27

DATA

BCK

LRCK

XFSIIN

XFSOIN

SCDT

SCSHIFT

SCLATCH

PGMUTE

SOFTMUTE

NSPMUTE

INIT

OUTL1

OUTL2

OUTR1

OUTR2

11

9

6

4

DIGITAL POWER AMP

IC707

PWM_A

4

PWM_B

6

PWM_C

14

PWM_D

16

/RST_AB

15

5

OUT_A

OUT_B

OUT_C

OUT_D

/SD

/RST_CD

3

J601

33

30

25

22

L.P.F.

L.P.F.

L.P.F.

L.P.F.

PROTECT

DETECT

Q701

OVER LOAD

DETECT

Q702, 703

+

L

–

SPEAKER

+

R

–

OVER LOAD

DETECT

Q752, 753

R-ch is omitted due to same as L-ch.

Signal path

68

69

: AUDIO

HCD-U1BT

3131

Page 32

HCD-U1BT

Ver. 1.3

6-5. BLOCK DIAGRAM — POWER SECTION —

Q321

SWITCH

+3.3VA

+3.3V

D

+1.8V

+1.8V

+3.3V

ER3.3

VEV

+2.8V

+3.3V

+1.2V

+1.2V

+3.3V

+5V

Q5

+2.8V REG-2

Q6

+2.8V REG-1

IC903

+3.3V REG

VIN

5

VOUT

1

CE

3

IC2

+1.2V REG

VDD

VOUT

IC4

+1.2V REG

VOUT

IC3

+3.3V REG

VOUT

CE

Q1

IOPWR

Q2

IOPWR

V

3

SWITCH

CE

VDD

VIN

SWITCH

Q8,Q10

1

3

4

Q4

5

51

5

SWITCH2

SWITCH1

DD5

DV

+50V

DVDD5

Q123

DVDD5

SWITCH-2

Q122

DVDD5

SWITCH-1

Q9

SWITCH

AVDD5

Q307

SWITCH

RECT

/FILTER

Q310

SWITCH

+12V

+11V

D109

+9V

51

+4V

45

D111

D104

D103

+18V

Q115

LINE FILTER

IC203

+1.8V REG

VIN

VOUT

IC704

+1.8V REG

VIN

VOUT

Q308

Q309

AMP

OUT2 -IN2 +IN2

AMP/PROTECTOR

D108

D105

D302

5

65

7

IC306

OUT1

+IN1

3

1

Q303

SWITCH

VOUT VIN

31

USB CORE POWER

P_MONITOR

IC105

4V REG

31

VOUT

IO_POWER

DRIVE

IC106

+12V REG

Q202

DD5V

SWITCH

VIN

D303

Q319

Q302

SWITCH

+3.3V

M+7V

MULTI VIBRATOR

12

2Q

1Q

4

V

+5

Q117

POWER

RELAY

Q103

+9V REG

Q104

9V SW

D106

Q105

PROTECTOR

IC702

+3.3V REG

VOUT VIN

45

IC304

67

15 14

IC302(2/2)

PANEL CONTROLLER

35

9

2A

VFD_DATA

1A

36

VFD_LAT

1

VFD_

4

POWER

IC103

DD5V REG

VOUT VIN

21

Q102

DD5V

SWITCH

Q201

15W

PROTECTOR

IC101

+5V REG

VOUT VIN

3

IC104

+7V REG

VOUT VIN

31

T603

ST-BY

TRANSFORMER

ST-BY

4V

D31

D32

PHOTO COUPLER

IC650

VOLTAGE

DETECT

PH602

PHOTO COUPLER

T31

MAIN

TRANSFORMER

PH11

POWER ON

Q651,652

PROTECTOR

FL18V

Q251

6W PROTECTOR

D652

L101

1

F101

PVDD

+18V

GVDD

+12V

+11V

IC12

3

+12V REG

1

PROTECTOR

+18V

D33

Q650

+11V

+18V

D604

COUPLER

Q12

CONVERTER OUT

Q11

CONVERTER OUT

D14

PH601

PHOTO

16

15

12

9

D603

V SENSE

SWITCH

V SENSE

VG(H)

VS

VG(L)

OCP

5

Q601

IC601

ST-BY

CONVERTER

DRAIN

VCC

FB

2

4

1

IC11

MAIN CONVERTER

CONTROLLER

F/B

VC1

28

D1

TH1

18

VD

D2

US,CND

D3

TH2

LPF

AEP,UK,KR

AC IN

HCD-U1BT

89

I/O POWER

BT_POWER

95

44

USB

P_MONITOR

IC107(5/5)

SYSTEM CONTROLLER

85

USB

CORE

POWER

86

POWER

RELAY

3232

Page 33

6-6. PRINTED WIRING BOARD — BD83S SECTION —

HCD-U1BT

Ver. 1.1

• See page 27 for Circuit Boards Location. :Uses unleaded solder.

C

D

E

F

G

1

2 3 4 5 6 7 8 9 10 11 12

A

BD83S BOARD (SIDE A) BD83S BOARD (SIDE B)

B

R401

R401

C201

R201

C202

C101

C102

C108

C110

R207

C424

R202

C401

C203

C227

4

5

IC203

3

1

C406

R423

X201

C226

R421

C268

1-868-067-

C275

R271

C266

C204

C215

C267

C277

C276

12

(12)

R276

R203

C272

C271

C219

R260

C223

C210

C104

C321

C220

C105

Q321

R256

C109

C232

C206

C107

C274

E

R323

C322

C257

R322

C205

R321

R324

C207

C323

C251

TP(VC)

C254

C252

C253

R252

R255

R254

C224

R253

R102

R101

C208

C256

R451

R452

R104

R105

R107

R109

R108

C103

IC201

TP(RFACI)

C258

C230

CN301

OPTICAL PICK-UP

BLOCK

KSM-215CFP

R257

C451

R103

C260

R110

R250

M

R265

C264

R258

(SPINDLE MOTOR)

R277

R275

R278

C221

C261

R268

C265

R266

C273

M401

R267

C218

C217

C214

C303

R291

C213

C222

R292

R270

C304

C301

C291

S201

(LIMIT)

C292

IC402

R280

C113

C404

C112 R112

C111

1-868-067-

C405

R113

R111

M402

(SLED MOTOR)

M

CN102

12

(12)

MAIN BOARD

A

SUPPLEMENT-1

CN108

SUFFIX-12

Page 36

SUFFIX-13

Page 3

HCD-U1BT

• Semiconductor

Location

Ref. No.

IC201 E-8

IC203 G-3

IC402 C-10

Q321 F-5

Location

3333

Page 34

HCD-U1BT

Ver. 1.1

6-7. SCHEMATIC DIAGRAM — BD83S SECTION —

• See page 51 for Waveforms. • See page 52 for IC Block Diagrams. • See page 58 for IC Pin Function Description.

A

MAIN

BOARD

(2/2)

CN108

SUFFIX-12

Page 38

SUFFIX-13

SUPPLEMENT-1

Page 5

DATA

CLK-MP3

M-MUTE

DVDD(3.3V)

D-OUT

D-GND

L-CH

A-GND

R-CH

AVDD(3.3V)

XTACN

XRST

IREQ-MP3

CLK

DATA-MP3

XLAT-MP3

REQ-MP3

ACK-MP3

XLAT

SENS

SCOR

M-GND

M+7V

BD83S BOARD

CN102

23P

C210

0.1

p

01

0p

.0

7

0

4

0

0

4

3

6

26

2

27

R

C

C

.1

.7k

0

4

5

5

6

6

2

2

R

C

R266

k

1k

0

1

8

R267

26

4.7k

C221

0.1

3

1

A

S

CLK2

0.1

C222

0.1

C213

C214

0.1

C223

0.1

C266C267

10p5p

R270

1k

R271

1M

C276

1

R291

100

C291

470p

C277

1

C292

470p

R292

100

C219

0.1

C220

1

0.1

C401

220

10V

IC203

+1.8V REGULATOR

100

100

100

100

100

100

100

100

100

16.9344MHz

C218

0.1

C201

100

10V

R207 C226

01

2p

2p

2

2

5

3

10

10

C

C

X201

C202

0.1

C217

0.1

IC203

BH18LB1WG-TR

24

351

C227

C203

C204

100

0.1

10V

p

p

p

20

20

20

2

2

2

R401

9

0

107

10

104

C

C

C

C268 C215

C275

10p 0.1

5p

100

R113

100

R112

R111

100

R201

0

2p

2p

2

2

2

3

11

11

C

C

R203

R202

0

R110

R103

R105

R104

R109

R108

R107

R102

R101

p

p

p

20

22p

22p

2

220

220

111

C

1

0

10

102

11

108

C

C

C

C

SVSS

SVDD

JTAGTCK

JTAGTDI

JTAGTDO

JTAGTMS

TRST

VSS

VDD

IOVDD2

DOUT

TEST

TES1

IOVSS2

PLLVDD

PLLVSS

XVSS

XTAO

XTAI

XVDD

AVDD1

AOUT1

VREFL

AVSS1

AVSS2

VREFR

AOUT2

AVDD2

IOVDD0

0

S

S

V

2

IO

34

R276 C271

47k 0.1

R275

100

100

R277

D

T

P

T

S

D

S

A

V

V

E

-M

D

T

B

T

S

S

I

I

D

D

K

C

R

L

I

K

M

K

M

K

C

C

C

C

C

R

P

B

P

B

L

R

I

3

IL

F

IREQ-MP3

L

V

O

O

T

S

T

C

IL

C

L

S

P

F

V

C

V

V

A

RF AMP,DSP,MP3

IC201

CXD3014A-201R

3

3

3

P

P

P

2

-M

-M

-M

K

A

T

T

K

Q

O

A

E

A

L

C

L

C

R

A

X

D

S

O

D

S

C

D

V

P

V

S

S

N

T

C

S

S

A

S

R

T

V

X

X

0

10

8

7

2

R

TP

(RFACI)

1

.47

.0

0

0

0

1

6

6

2

2

C

C

M

1

0

5

2

R

k

0

2

2

8

R257

25

100k

R

I

S

O

Y

Y

IA

S

S

B

A

A

S

T

D

S

A

V

D

L

S

V

X

C272

0.1

R256

C230

100p

C257

C274

p

0

2

2

8

25

C

I

4

3

O

C

FC

S

D

C

A

R

S

D

A

F

F

V

V

R

A

R

A

K

F

D

K

S

C

G

D

C

N

F

V

P

U

E

S

X

X

W

S

R280

0

C208

0.1

22k

0.1

0.1

CN301

16P

VC

R321

C303

C323

R324

100

100k

10V

1

C256

0.1

TP

(VC)

4

S

O

D

D

M

IN

L

P

O

P

FS

2

C

G

D

N

C

U

_

E

D

D

S

G

FD

S

V

_

E

R

D

A

C

C

P

A

B

A

VC

FEO

FEI

TEO

TEI

F

E

AVSS0

AVDD0

IOVDD1

FRDR

FFDR

TRDR

TFDR

SRDR

SFDR

IOVSS1

SSTP

MDP

LOCK

VSS

VDD

VSS

FOK

DFCT

T

R

S

MIRR

U

D

S

O

V

O

C

D

SVDD

S

C

S

V

R255

1k

R254

TP4

R253

1k

R252

TP3

0.1

C206

C224

0.1

100 10V

C207

4700p

C254

10k

470p

C253

4700p

C252

10k

470p

C251

C205

C232

0.1

0.1

FRDR

FFDR

TRDR

TFDR

C404

0.1

FOCUS/TRACKING

C405

0.1

COIL DRIVER,

SLED/SPINDLE

MOTOR DRIVER

IC402

BA5947FM-E2

TP1

(APC)

F

F

R

T

T

UT

U

P

OU

1

2

1O

H

H

H

C

C

C

F

F

T

T

TR

U

U

OU

O

O

3

4

4

H

H

H

C

C

C

-

+

-

P

P

L

S

S

S

2.2

C322

1

R322

2.2

R323

0

C321

1000p

R451

22k

7

k

10

0.04

1

52

4

45

R

C

C424

0.1

C

R

D

F4

T

C

N

V

U

G

CN

W

2O

O

H

P

C

TR

CC

U

V

O

TE

D

W

3

U

N

O

H

P

M

C

G

+

L

S

AUTOMATIC

TP2

(SPI)

R423

10k

Q321

2SA2119K

POWER

CONTROL

10

R

R

R

D

D

D

F

R

R

F

F

T

IN

IN

FIN

R

R

2

2

1

H

H

CH

C

C

IN

IN

FIN

R

4

3

H

H3

H

C

C

C

C301

C304

1

0.1

R

D

F

T

R421

0

-

+

W

IN

FIN

-S

1

PIN

OP

O

IN

CH

A

G

A

C

T

AP

U

VC

F

C

E

O

4

P

R

RE

H

P

V

O

C

C406

0.1

No mark:CD PLAY

VCC

E

D

A

B

C

F

GND

LD

VR

PD

F+

T+

T-

F-

SP+

SP-

SL+

SL-

S201

(LIMIT)

OPTICAL

PICK-UP

BLOCK

(KSM-215CFP)

M401

(SPINDLE)

(SLED)

M402

HCD-U1BT

3434

Page 35

6-8. PRINTED WIRING BOARD — DRIVER SECTION — 6-9. SCHEMATIC DIAGRAM — DRIVER SECTION —

• See page 27 for Circuit Boards Location.

:Uses unleaded solder.

1 2 3 4 5 6

HCD-U1BT

Ver. 1.1

• See page 53 for IC Block Diagram.

A

B

C

D

DRIVER BOARD

IC701

DRIVER BOARD

S702

(CHUCKING)

LOADING MOTOR DRIVER

IC701

VREF

OUT2

RNF

BA6956AN

OUT1

RIN

FIN

GND

VCC

VM

LOADING

OUT

S701

LOADING

OUT

M

M701

(LOADING)

R702

100

7

7

1.1

1.1

C705

R701

D701

MTZJ-4.7C

R702

19

D701

R701

C711

CN701

MAIN

BOARD

B

NO708

SUFFIX-12

Page 36

1-688-337-

12

(12)

SUFFIX-13

SUPPLEMENT-1

Page 3

M701

(LOADING)

MTR-

MTR+

680

C705

0.01

C711

10

50V

S702S701

(CHUCKING)

SW2 (CHUCK SW)

SW1 (OUT SW)

FIN (POS)

RIN (NEG)

No mark:CD PLAY

CN701

M+7V

MGND

7P

B

MAIN

BOARD

(1/2)

NO708

SUFFIX-12

Page 37

SUFFIX-13

SUPPLEMENT-1

Page 4

HCD-U1BT

3535

Page 36

HCD-U1BT

R102

R276

R275

Q122

Q123

R267

R259

R301

R211

C170

R104

6-10. PRINTED WIRING BOARD — MAIN SECTION —

12

MAIN BOARD

A

JW218

R200

R274

R277

CN114

R278

R228

C230

E

R279

C215

C214

JW226

R285

R243

R227

C229

C213

R203

E

R251

R239

C231

C152

C265

C265

R202

R230

R294

C268

JW217

C255

C232

C216

R201

R218

C155

R247

C217

Q108

R219

C212

R204

CN110

IC112

JR108

JR107

R217

R226

IC110

C261

E

Q109

E

Q110

C182

R252

R248

IC109

C175

R292

R268

R264

JW221

R245

R229

JW222

R216

R205

C220

JW189

JW190

C166

S

C266

C224

R238

R282

R258

C251

Q202

R253

R221

C156

R293

R236

C223

C254

R388

C169

C153

C256

JW213

E

R231

R242

R224

B

C

D

I

HP BOARD

CN620

(Page 45)

H

USB BOARD

CN1

(Page 43)

JW220

C267

JW219

R281

R280

C227

JW223

JW224

JW225

Q107

CN113

R272

R270

E

7

1

IC106

3

NO708

C117

B

DRIVER BOARD

CN701

(Page 35)

JW227

EP201

• See page 27 for Circuit Boards Location. :Uses unleaded solder.

34567

BD83S BOARD

A

TUNER

JW209

JW211

R250

C188

R249

R225

Q111

1

R261

Q121

Q119

JW199

JR109

R297

Q112

R260

JW214

JW236

JW200

C222

C264

R298

Q115

E

E

E

C250

E

E

E

JW176

JW216

C262

C252

Q114

C165

JW237

JW215

JW202

JW203

C260

Q113

R240

C154

C154

R235

JW193

JW192

JW191

R237

R296

C113

C228

C228

JW205

R262

E

R346

R302

JW212

R241

R386R295

JW172

JW173

R263

C221

R357

R112

R111

R222

R223

R109

Q102

JW204

JW194

JW188

JW187

JW186

C112

C103

C103

C206

JW185

JW184

JW177

JW174

L102

IC103

5

R104

R104

JW160

R113

JW210

JW207

JW206

R356

C170

C170

R214

C171

C171

24

R213

JW198

JW197

D102

1

JW208

JW183

C205

C137

JW170

JW151

C135

D108

JW182

C115

C134

D109

JW150

C136

JR105

JW181

C109

JW169

22

2

JW180

JW156

23

CN108

1

C150

C149

JW179

C106

JW167

JW166

JW168

JW171

JW127

JW228

JW149

JW146

JW148

R382

R190

R129

R127

R125

JW165

R189

JW128

E

R399

Q251

R124

JW129

R118

R191

R132

JW175

R188

JW133

R395

CN102

(Page 33)

JW163

JW164

R182

R144

R140

R123

R134

R137

R147

JW159

R138

R163

R135

R117

JW157

R287

JW229

JW142

D252

JW178

L101

JW161

JW162

R181

R173

C125

R099

R176

IC107

JW158

R126

R102

R102

C151

JW154

R142

R121

R122

JR104

R290

JW141

JW143

FH102 FH101

R220

JW145

R215

R114

D253

R271

R207

R393

JW195

K

K

CN109

R398R396

D251

R193

R179

R394

JW196

A

L103

F101

12

CN104

D105

R119

R192

R301

R301

FB201

R171

R139

JW153

R136

JW152

R133

R194

R148

X102

X102

R143

JW147

R149

R158

R141

IC108

JW105

1

CN105

R167

R169

R198

C123

JR103

R150

C157

JW126

Q116

D107

C127 C129

C126

5

3

R165

C118

C119

R128

R120

R289

R291

R155

R156

34

1

JR102

R180

R206

R196

R288

X101

C120

JW140

R152

R195

R197

R157

R161

R159

C128

JW139

8

R187

R130

R269

R185

R286

R199

JW121

C124

JW125

JW138

R186

R178

R162

JW124

JW137

D106

Q105

R154

JW144

Q104

R146

2

4

R172

R166

JW120

R164

JW123

C121

CN116

for Write

1

C184

C183

CN107

3

R183

R168

JW117

JW116

JW115

JW114

R174

JR101

R175

JW113

R184

JW122

JW103

K

A

K

A

D103 D104

K

JW136

JW135

R151

R145

E

JW132

R254

E

R244

R234

R233

R232

JW102

R255

1

R108

C162

10

2

JW134

R106

R211

R211

E

JW131

3

CN102

R170

JW119

JW118

E

Q122

Q122

JW130

C172

C172

D201

R256

R267

R267

Q117

JW112

R299

R101

11

CN115

CN115

1

Q123

Q123

JW104

JW107

E

1

CN103

JW108

JW109

JW110

JW111

K

A

E

R259

R259

JW155

JW106

R100

Q201

1-870-569-

K

D111

R276

R276

R275

R275

R266

R266

R265

R265

F

PANEL BOARD

CN301

(Page 41)

O

BT BOARD

CN901

(Page 49)

2

1

2

1

8

• Semiconductor

Location

Ref. No.

D102 E-3

D103 D-6

D104 D-6

D105 D-5

D106 E-6

D107 C-6

D108 B-4

D109 B-4

D111 C-7

D201 E-7

D251 E-5

D252 D-5

D253 C-5

IC103 E-3

IC106 E-2

IC107 B-5

IC108 C-6

IC109 E-2

IC110 C-2

IC112 B-2

Q102 E-3

Q104 E-6

Q105 E-6

Q107 D-1

Q108 D-1

Q109 D-2

Q110 D-2

Q111 D-2

Q112 D-2

Q113 D-2

Q114 D-2

Q115 D-2

Q116 C-6

Q117 D-7

Q119 B-2

Q121 B-2

Q122 C-7

Q123 C-7

Q201 E-7

Q202 E-2

Q251 F-4

Location

F

HCD-U1BT

(CHASSIS)

SMASTER BOARD

CN700

(Page 39)

G

SW POWER BOARD

CN34

(Page 47)

3636

D

C

SW POWER BOARD

CN32

(Page 47)

N

REG BOARD

NO709

(Page 45)

SW POWER BOARD

E

CN604

(Page 47)

Page 37

HCD-U1BT

6-11. SCHEMATIC DIAGRAM — MAIN SECTION (1/2) —

CN103

15P

42

• See page 51 for Waveforms. • See page 53 for IC Block Diagram. • See page 61 for IC Pin Function Description.

R142

R144

10k

10k

0.1

C125

100

100

R124

R125

R132

10k

R135

10k

R138

10k

10k

R163

R106

47k

R108

47k

89

R117

100

100

90

R121

R122

100

R102

4.7K

R126

10k

100

R134

R127

R129

R123

147

R182

R181

R

R137

R140

100

TP106

R188

R189

R190

R191

R118

C_SOFT_TES

M

IC107

M30624MGP

-A57FPU0

T

100

100

100

100

100

100

100

100

100

100

100

100

00

00

100

1

R173

100

100

1

100

171

R176

R169

R099

R

R119

100

R167

100

R165

R120

100

R196

100

10k

R198

R195

100

100

R128

R130

100

R269

100

10k

R197

38

100

R286

0.3

0.4

36

100

R288

35

R289

100

100

34

R291

2SA1235F

UDZW-TE17-8.2B

R101

4.7k

Q201

R154

10k

D106

R152

220

2SC3052F

C121

0.01

R151

Q105

470

2SC3052F

1.0

1.0

1.0

1.0

1.0

244

234

R232

R

R233

R

D201

1SS355WTE

R254

R146

100

Q103

R145

100

CN116

8P

NO709

8P

C102

470

10V

2SB1565EF

C132

470

10V

IC101

KIA7805API

C107

0.1

IC104

TA7807S

R256R299

1k470

R255

10k

Q104

C101

R393

10k

R193

100

R114

0

100

100

100

100

100

TP105

1.GND

47k

100

0

10k

155

R

R158

47k

C113

470

16V

R164

R162

R161

157

R

100

159

R

C126

0.1

R302

4.7k

100

100

100

100

100

100

R271

C151

0.01

1k

D253

1SS355WTE

D103

MC2836

0

R382

CN104

2P

FB201

F-BEAD

48

CN102

3P

48

Q251

2SA1235F

R215

2.2

R220

2.2

D251

1SS355WTE

R395

10k

R398

10k

10k

R396

R301

R290

10k

470k

R399

10k

D111

MC2836

R287

D252

UDZW-TE17-8.2B

100

R192

R194

R394

10k

D104

MC2836

0

141

R133

R179

R136

R139

R

TP103

Q116

2SC3052F

C117

0.1

0

220k

8.PGM

TP104

22p

C118

R148

C119

10p

C120

0.1

R150

Hz

32.768K

X101

IC106

KIA7812API

C123

X102

5MHz

R149

10k

1SS355WTE

0.1

6.3V

1000

124

C

R156

47k

D107

10k

R143

10p

C157

100

100

72

R1

R170

PQ1CG2032FZ

180

R

R206

R166

0k

4.7k

4.7k

10k

10k

1

178

R199

R174

R

TP102

C127

0.1

IC103

TP108

TP107

185

R

R183

R184

0.1

C128

R111

2.2k

R112

22k

R109

4.7k

168

R

100

R175

C184C183

100p100p

DVDD5

CN107

4P

20

R187

100

R186

100

10k

R207

R211

10k

10 50V

C162

10k

IC108

PST3629NR

C129

Q117

2SC3052F

0.1

C172

10k

R100

0.1

38

R292

1k

Q202

RTF025N03TL

10

50V

IC105

TA7804LS

C114

470

10V

C108

0.1

C116

0.1

HCD-U1BT

C170

0.1

C106

0.022

220

25V

C104

C103

0.022

R104

2.2

CN105

3P

FH101 FH102

F101

T2.5AL/250V

48

L101

C109

4700 1 6V

EP201

EARTH TERMINAL

04N

21DQ

D102

L102

47uH

C171

C112

0.1

0.1

R346

10k

C115

2200

16V

R113

2.2k

Q102

2SC3052F

R263

10k

R262

10k

NO708

7P

DRIVER

35

3737

Page 38

HCD-U1BT

6-12. SCHEMATIC DIAGRAM — MAIN SECTION (2/2) —

R280

47k

CN109

19P

0

L103

40

TP113

OVF

1 50V

1 50V

1 50V

C262

C252

C261

C251

1 50V

C254

1 50V

1 50V

R279

47k

C222

220

10V

C264

R229

10k

• See page 53 for IC Block Diagrams.

R281

47k

R278

47k

C221

220 10V

C220

0.1

C223

0.1

R226

470k

C232

C216

R219

470k

C213

0.0022

C212

0.0022

IC110

BD3870FS-E2

Q119

RT1N141C

R217

0

R216

0

C260

1 50V

C250

1 50V

0.1

C217

0.047

R228

0.1

4.7k

0.047

C231

0.1

C215

C230

0.047

0.1

C214

R227

4.7k

0.047

C229

AVDD5

R223 R222

22k 22k

R214

10k

C205

1

50V

CN115

11P

FFCS

R266

4.7K

R265

4.7K

DVDD5

R357R356

47k47k

220

R213

10k

C206

1

50V

220

R241

R235

R275

47K

R260

4.7k

R276

47K

R261

R264

22k

22k

R268

4.7k

5.07

R259

10k

Q123

KTA1271Y

SWITCH-2

R274

R272

22k

R270

10k

C267

1

50V

BT OUT(R)

BT OUT(L)

0

5.07

R267

5.07

470

0

Q122

RT1N141C

SWITCH-1

22k

R277