Sony HCDS-880 Service manual

HCD-S550/S880

SERVICE MANUAL

Ver 1.6 2004.03

Photo: HCD-S550

HCD-S550/S880 is the amplifier, DVD/CD

player and tuner section in DAV-S550/S880.

SPECIFICATIONS

Amplifier section

S550:

Stereo mode 80 W + 80 W (4 ohms at 1 kHz, THD 10 %)

Surround mode Front: 80 W + 80 W

Center*: 80 W

Rear*: 80 W + 80 W (4 ohms at 1 kHz, THD 10 %)

Subwoofer*: 100 W (3 ohms at 100 Hz, THD 10 %)

S880:

Stereo mode 100 W + 100 W (3 ohms at 1 kHz, THD 10 %)

Surround mode Front: 100 W + 100 W

Center*: 100 W

Rear*: 100 W + 100 W (3 ohms at 1 kHz, THD 10 %)

Subwoofer*: 100 W (3 ohms at 100 Hz, THD 10 %)

* Depending on the sound field settings and the source, there may be no sound output.

AEP Model

UK Model

E Model

Australian Model

Chinese Model

Model Name Using Similar Mechanism NEW

Mechanism Type CDM72B-DVBU12

Base Unit Name DVBU12

Optical Traverse Unit Name DBU-1

Inputs (Analog) VIDEO 1, 2:

Sensitivity: 150 mV

Impedance: 50 kilohms

Inputs (Digital) VIDEO 2 (optical):

Sensitivity: –

Outputs (Analog) VIDEO 1 (AUDIO OUT):

Voltage: 2 V

Impedance: 1 kilohms

PHONES:

Accepts low- and high-impedance headphones

9-874-135-07 Sony Corporation

2004C05-1 Home Audio Company

© 2004.03 Published by Sony Engineering Corporation

– Continued on next page –

SACD/DVD RECEIVER

HCD-S550/S880

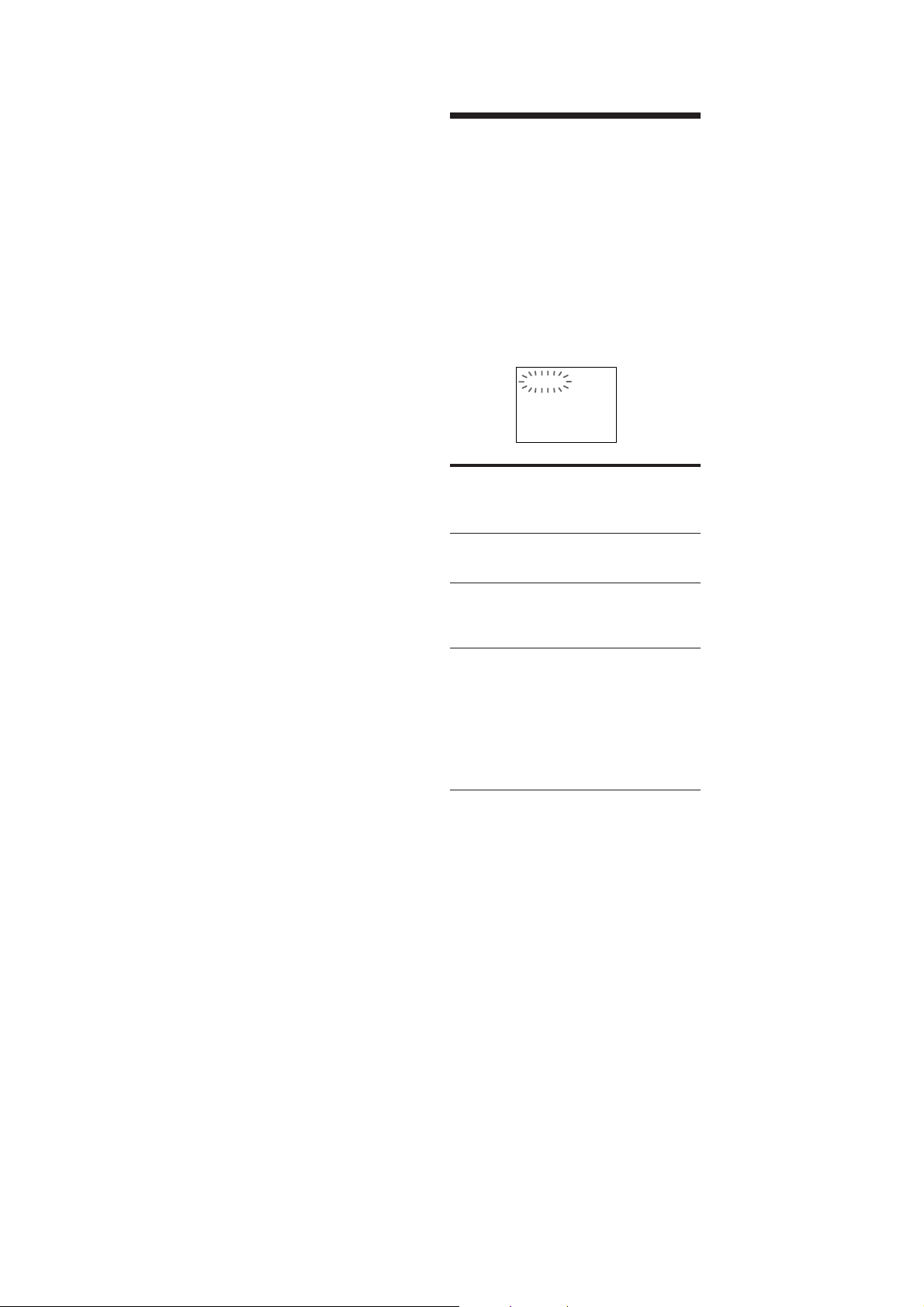

Self-diagnosis Function

(When letters/numbers appear in the

display)

When the self-diagnosis function is

activated to prevent the system from

malfunctioning. In this case a five-character

service number (e.g., C 13 00) with a

combination of a letter and digits appears on

the screen and the front panel display. Refer

to the following table.

First three

characters of

the service

number

C 13

C 31

E XX

(xx is a number)

Cause and/or Corrective

Action

The disc is dirty.

, Clean the disc with a soft

cloth.

The disc is not inserted

correctly.

, Re-insert the disc

correctly.

To prevent a malfunction, the

system has performed the selfdiagnosis function.

, Contact your nearest Sony

dealer or local authorized

Sony service facility and

give the 5-character

service number.

Example: E 61 10

C:13:00

Super Audio CD/DVD system

Laser Semiconductor laser

Signal format system NTSC or NTSC/PAL

Frequency response (at 2 CH STEREO mode)

Signal-to-noise ratio More than 80 dB (VIDEO 1 (A UDIO)

Harmonic distortion Less than 0.03 %

FM tuner section

System PLL quartz-locked digital synthesizer

Tuning range 87.5 – 108.0 MHz (50 kHz step)

Antenna FM wire antenna

Antenna terminals 75 ohms, unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

System PLL quartz-locked digital synthesizer

Tuning range

European, Middle Eastern, and Philipinne models:

Other models: 531 – 1,602 kHz (with the interval set at 9 kHz)

Antenna Loop antenna

Intermediate frequency

(Super Audio CD/DVD: λ = 650 nm)

(CD: λ = 780 nm)

Emission duration: continuous

DVD (PCM): 2 Hz to 22 kHz (±1.0 dB)

CD: 2 Hz to 20 kHz (±1.0 dB)

connectors only)

system

system

531 – 1,602 kHz (with the interval set at 9 kHz)

530 – 1,710 kHz (with the interval set at 10 kHz)

450 KHz

SELF DIAGNOSIS FUNCTION

Video section

Inputs Video: 1 Vp-p 75 ohms

Outputs Video: 1 Vp-p 75 ohms

General

Power requirements

European model: 230 V AC, 50/60 Hz

Australian and Asian models: 220 – 240 V AC, 50/60 Hz

Mexican model: 120 V AC, 60 Hz

Chinese model: 220 V AC, 50/60 Hz

Taiwan model: 110 – 120 V AC, 50/60 Hz

Other models: 110 – 240 V/220 – 240 V AC, 50/60 Hz

Power consumption

S550:

S880:

Dimensions (approx.) 355 × 60 × 323 mm (14 × 2

Mass (approx.) 3.8 kg (8 lb 7 oz)

Operating temperature 5˚C to 35˚C (41˚F to 95˚F)

Operating humidity 5 % to 90 %

Design and specifications are subject to change without notice

S video:

Y: 1 Vp-p 75 ohms

C: 0.286 Vp-p 75 ohms

COMPONENT:

Y: 1 Vp-p 75 ohms

P

B/CB, PR/CR: 0.7 Vp-p 75 ohms

.

120 W (120 V AC) 120 W (230 V AC)

1 W (120 V AC) 2 W (230 V AC)

135 W (120 V AC) 135 W (230 V AC)

1 W (120 V AC) 2 W (230 V AC)

(w/h/d) incl. projecting parts

(at the Power Saving Mode)

(at the Power Saving Mode)

2

3

/8 × 12 3/4 inches)

Note: Refer to the “5. TEST MODE” (page 20) for another self-diagnosis

function.

HCD-S550/S880

1.5 k

Ω

0.15 µF

AC

voltmeter

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This appliance is classified as a

CLASS 1 LASER product. The label

is located on the bottom exterior.

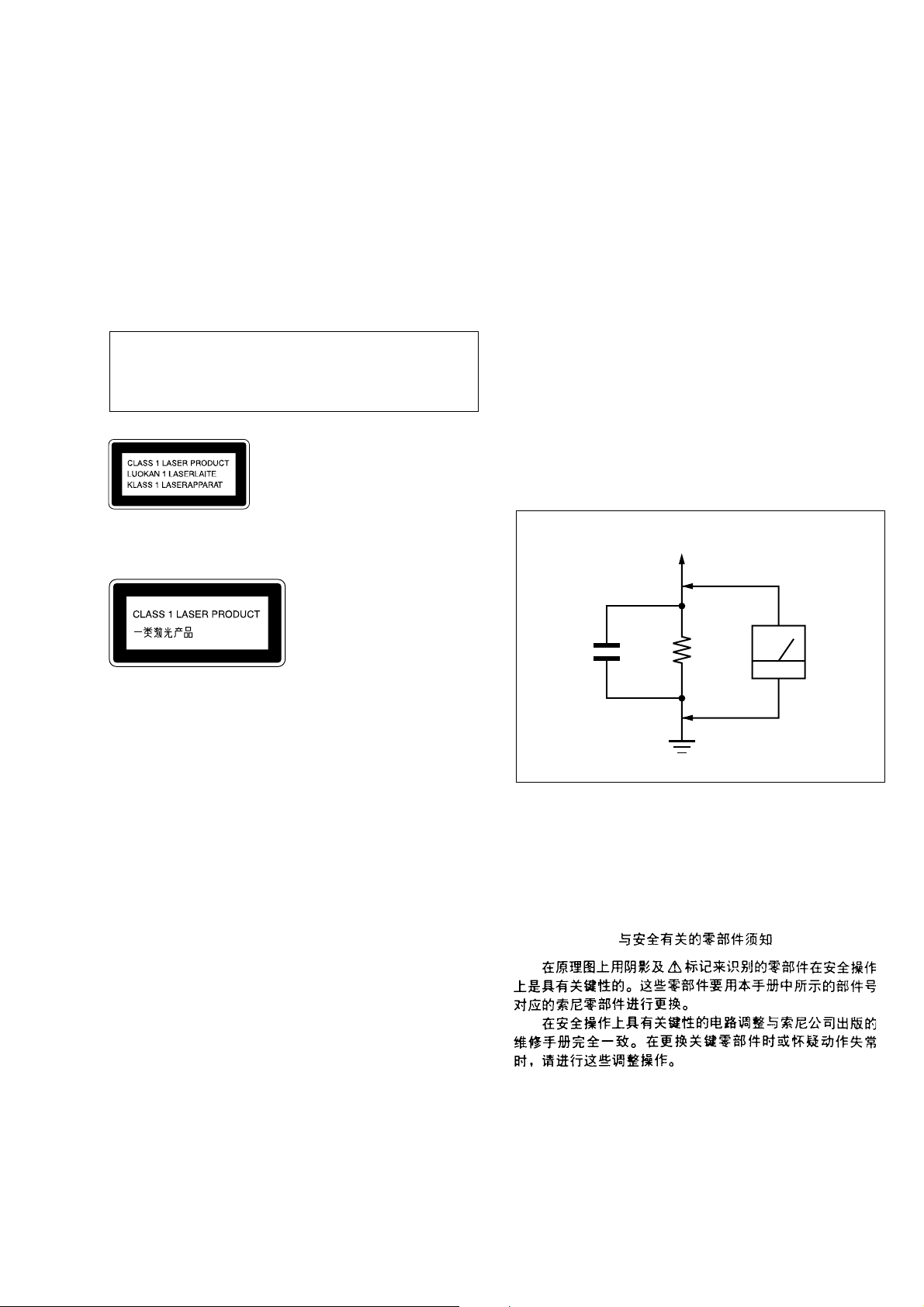

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the man ufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a V OM

or battery-operated A C voltmeter . The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2 V A C range are suitable. (See Fig. A)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Fig. A. Using an AC voltmeter to check AC leakage.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

3

HCD-S550/S880

Ver 1.4

TABLE OF CONTENTS

SELF DIAGNOSIS FUNCTION.................................... 2

1. SERVICING NOTES ............................................... 5

2. GENERAL

Location of Controls ...................................................... 6

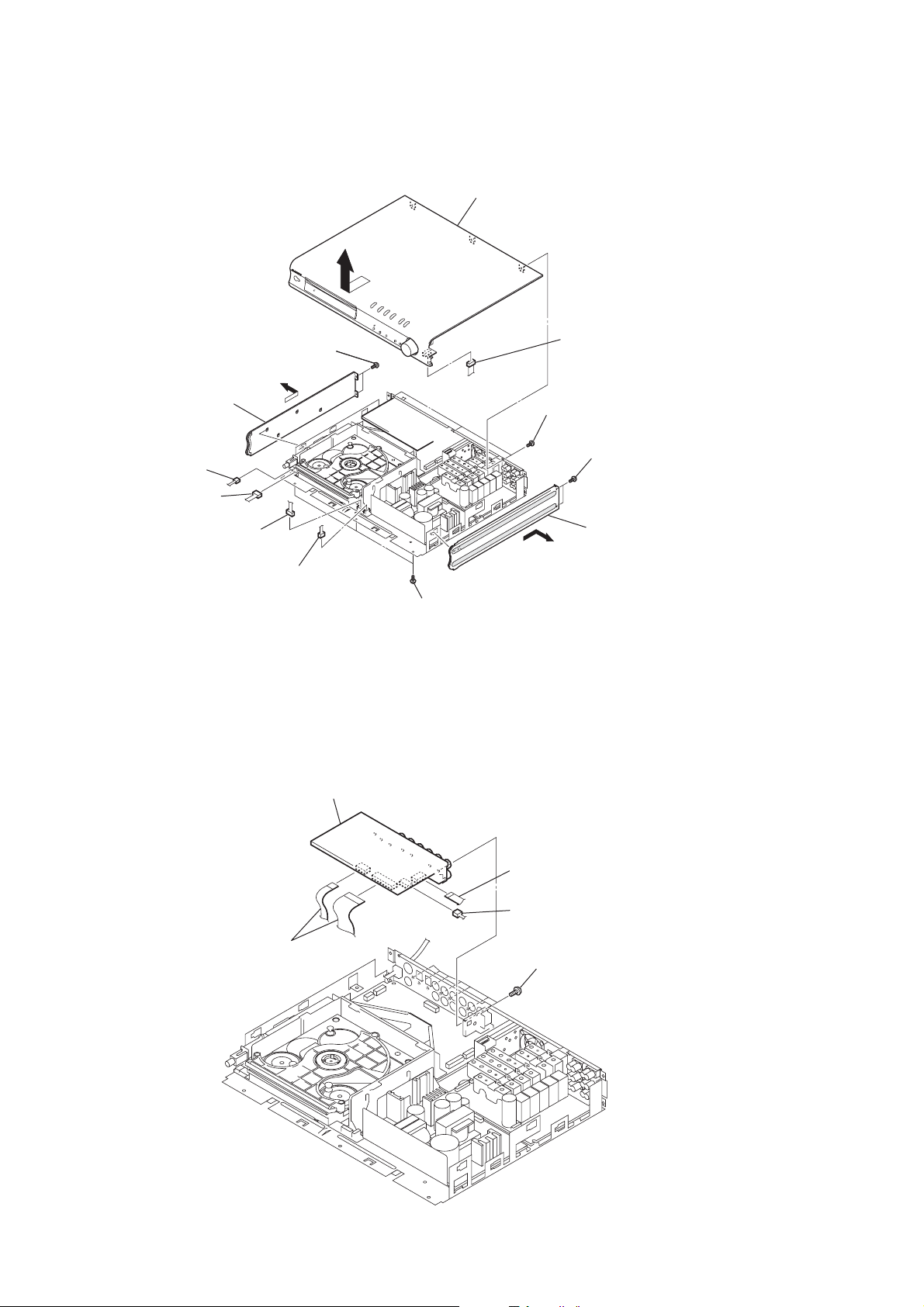

3. DISASSEMBLY

3-1. Disassembly Flow .......................................................... 9

3-2. Front Panel Section, Side Panel (L)/(R) ........................ 10

3-3. I/O Board......................................................................... 10

3-4. SEL Board ....................................................................... 11

3-5. DVD Board...................................................................... 11

3-6. Mechanism Deck Section (CDM72B-DVBU12).......... 12

3-7. POWER SW Board, DDCON Board............................. 12

3-8. Power Board ................................................................... 13

3-9. AMP Board .................................................................... 13

3-10. Optical Pick-up (DVBU12) ........................................... 14

3-11. RELAY Board ................................................................ 14

3-12. Holder (AT) Assy, Retainer (Chassis) Block................. 15

3-13. Belt (L2) ......................................................................... 15

3-14. Pulley (RTR) Assy ......................................................... 16

3-15. Belt (CK) ........................................................................ 16

3-16. Pulley (SPT) Assy .......................................................... 17

3-17. Belt (CK), Motor (CK) Assy (M751) ............................ 17

4. ASSEMBLY

4-1. How to Install Pulley (SPT) Assy .................................. 18

4-2. How to Install Pulley (RTR) Assy ................................. 18

4-3. How to Install Rotary Encoder (Mode) (S741)............. 19

5. TEST MODE............................................................. 20

6. ELECTRICAL ADJUSTMENT........................... 27

7. DIAGRAMS

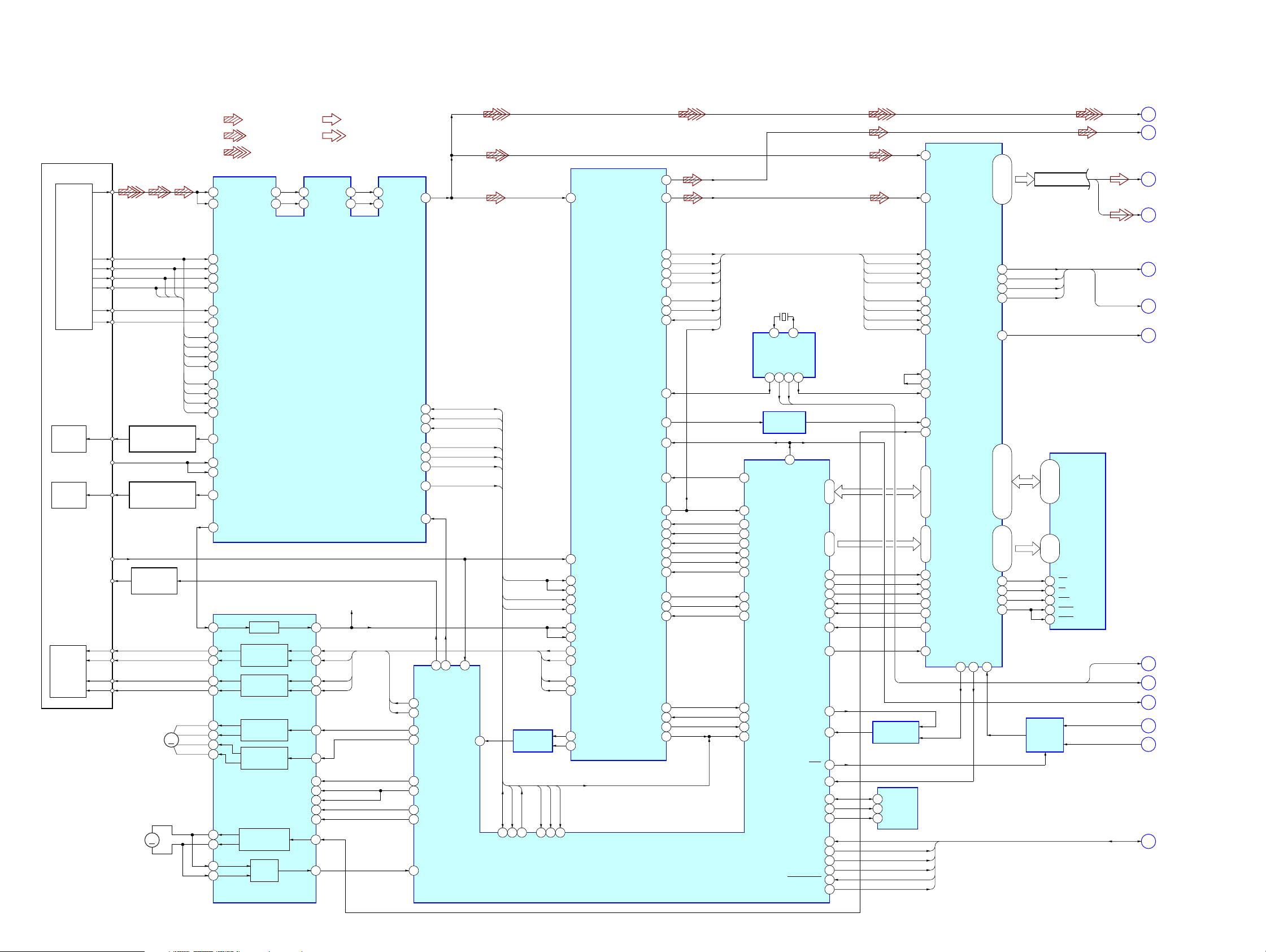

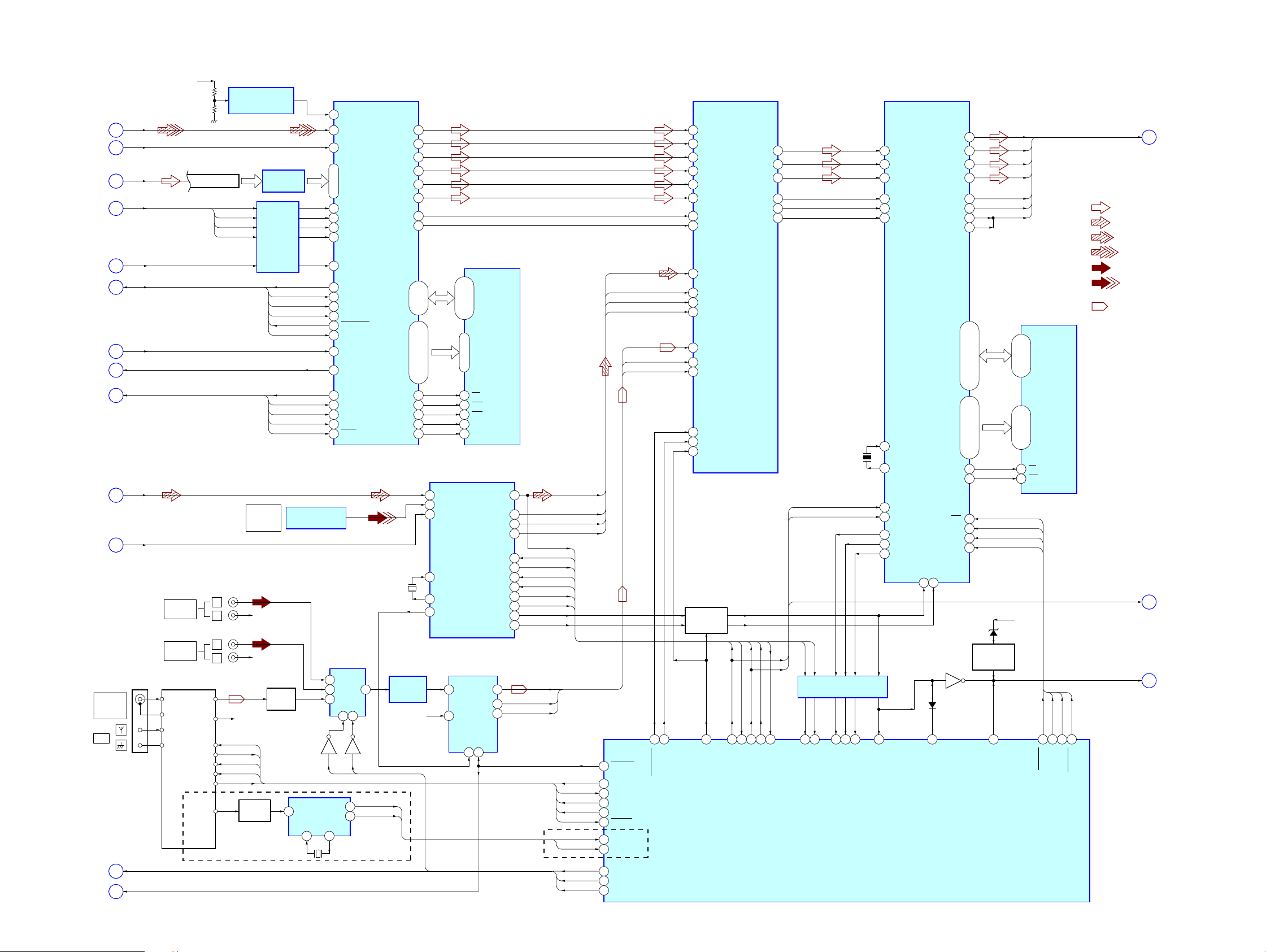

7-1. Block Diagram – RF SERVO Section – ....................... 28

7-2. Block Diagram – AUDIO (DSP) Section – .................. 29

7-3. Block Diagram – AUDIO OUT, PANEL Section – ..... 30

7-4. Block Diagram – VIDEO Section – ............................. 31

7-5. Block Diagram – MECHANISM DECK,

POWER SUPPLY Section – .......................................... 32

7-6. Note for Printed Wiring Boards and

Schematic Diagrams ...................................................... 33

7-7. Printed Wiring Boards – RF Section – ......................... 34

7-8. Schematic Diagram – RF Section –.............................. 35

7-9. Printed Wiring Boards

– MECHANISM DECK Section – ................................ 36

7-10. Schematic Diagram

– MECHANISM DECK Section – ................................ 37

7-11. Printed Wiring Board

– DVD Board (Component Side) – ............................... 38

7-12. Printed Wiring Board

– DVD Board (Conductor Side) – ................................. 39

7-13. Schematic Diagram – DVD Board (1/10) – ................. 40

7-14. Schematic Diagram – DVD Board (2/10) – ................. 41

7-15. Schematic Diagram – DVD Board (3/10) – ................. 42

7-16. Schematic Diagram – DVD Board (4/10) – ................. 43

7-17. Schematic Diagram – DVD Board (5/10) – ................. 44

7-18. Schematic Diagram – DVD Board (6/10) – ................. 45

7-19. Schematic Diagram – DVD Board (7/10) – ................. 46

7-20. Schematic Diagram – DVD Board (8/10) – ................. 47

7-21. Schematic Diagram – DVD Board (9/10) – ................. 48

7-22. Schematic Diagram – DVD Board (10/10) – ............... 49

7-23. Printed Wiring Board – AMP Section (1/2) – .............. 50

7-24. Printed Wiring Boards – AMP Section (2/2) –............. 51

7-25. Schematic Diagram – AMP Section (1/2) – ................. 52

7-26. Schematic Diagram – AMP Section (2/2) – ................. 53

7-27. Printed Wiring Board – I/O Section (1/2) – .................. 54

7-28. Printed Wiring Boards – I/O Section (2/2) – ................ 55

7-29. Schematic Diagram – I/O Section (1/2) – .................... 56

7-30. Schematic Diagram – I/O Section (2/2) – .................... 57

7-31. Printed Wiring Boards

– DC-DC CONVERTER Section – ............................... 58

7-32. Schematic Diagram

– DC-DC CONVERTER Section – ............................... 59

7-33. Printed Wiring Boards – CONTROL Section – ........... 60

7-34. Schematic Diagram – CONTROL Section –................ 61

7-35. Printed Wiring Board – FL Board – ............................. 62

7-36. Schematic Diagram – FL Board – ................................ 63

7-37. Printed Wiring Board – POWER Section (1/2) –......... 64

7-38. Printed Wiring Boards – POWER Section (2/2) – ....... 65

7-39. Schematic Diagram – POWER Section – .................... 66

7-40. IC Pin Function Description .......................................... 84

8. EXPLODED VIEWS

8-1. General Section ............................................................. 102

8-2. Front Panel Section-1.................................................... 103

8-3. Front Panel Section-2.................................................... 104

8-4. Chassis Section-1 .......................................................... 105

8-5. Chassis Section-2 .......................................................... 106

8-6. Chassis Section-3 .......................................................... 107

8-7. Chassis Section-4 .......................................................... 108

8-8. Mechanism Deck Section-1 (CDM72B-DVBU12)...... 109

8-9. Mechanism Deck Section-2 (CDM72A-DVBU12) ..... 110

8-10. Mechanism Deck Section-3 (CDM72A-DVBU12) ..... 111

8-11. Mechanism Deck Section-4 (CDM72A-DVBU12) ..... 112

8-12. Mechanism Deck Section-5 (CDM72A-DVBU12) ..... 113

8-13. Mechanism Deck Section-6 (CDM72A-DVBU12) ..... 114

8-14. Mechanism Deck Section-7 (CDM72A-DVBU12) ..... 115

8-15. Optical Pick-up Section (DVBU12) ............................. 116

9. ELECTRICAL PARTS LIST ............................. 117

4

SECTION 1

)

SER VICING NOTES

HCD-S550/S880

Ver 1.6

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

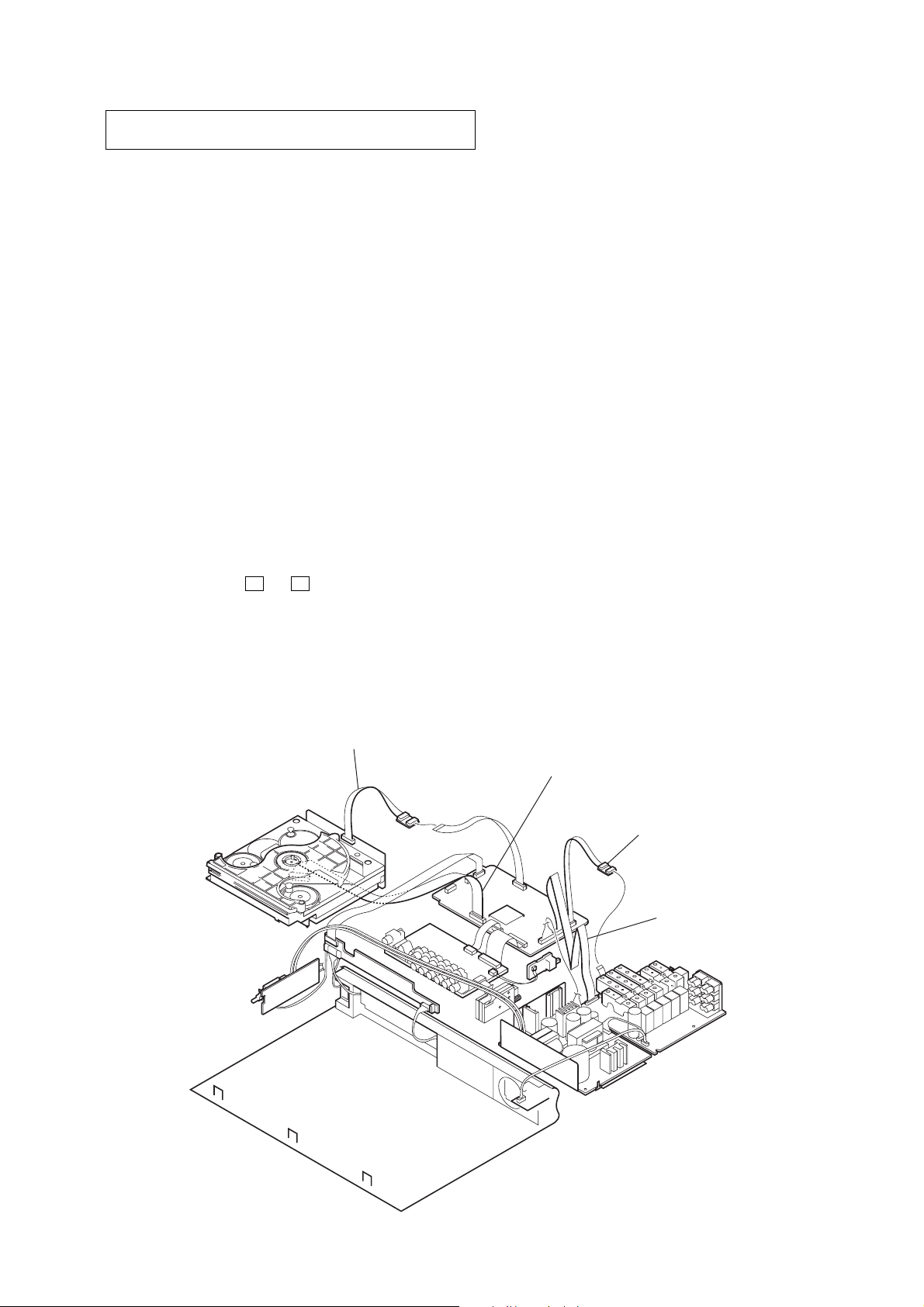

JIG ON REPAIRING

When repairing this set, etc., connect the extension cable as the

figure shown below.

RELEASING THE DISC SLOT LOCK

The disc slot lock function for the antitheft of an demonstration

disc in the store is equipped.

CHECKING OF OPERATIONS WITH REMOTE COMMANDERS OF DIFFERENT MODELS

Some of the signal of remote commander vary between generation of player.

Between DAV-S400/S500/S800/C450/C700/C900 and DAV-S550/

S880/C770/C900, remote commander signal codes of “FUNCTION”, “BAND”, “ST/MONO” and “MEMORY” are different.

Take notice of the above when you check the operation with remote commanders of different models.

NOTE OF REPLACING THE DVD BOARD

When replacing the DVD board, since the adjustment value is not

set up correctly, “Drive Auto Adjustment” can’t be performed.

In this case, initialize Memory in the following procedures.

Procedure:

1. Set the test mode. (See page 20)

2. Press the [2] key of the remote commander , and set the “DRIVE

MANUAL OPERATION”. (See page 22)

3. Press the [6] key of the remote commander, and set the “2-6,

Memory Check”. (See page 24)

4. Press the [CLEAR] key of the remote commander, and initialize Memory.

Releasing Procedure:

1. Press two buttons of A and x simultaneously for three seconds.

2. The message “UNLOCKED” is displayed and the slot is unlocked.

Note: When “LOCKED” is displayed, the slot lock is not released by

turning power on/off with the [POWER] button.

extension cable (with relay board)

(RELAY board-DVD board)

(Part No. J-2501-091-A)

extension cable

(RF board-DVD board)

(Part No. J-2501-217-A)

extension cable

(DVD board-AMP board)

(Part No. J-8000-024-A)

extension cable

(DVD board-AMP board

(Part No. J-2501-198-A)

5

HCD-S550/S880

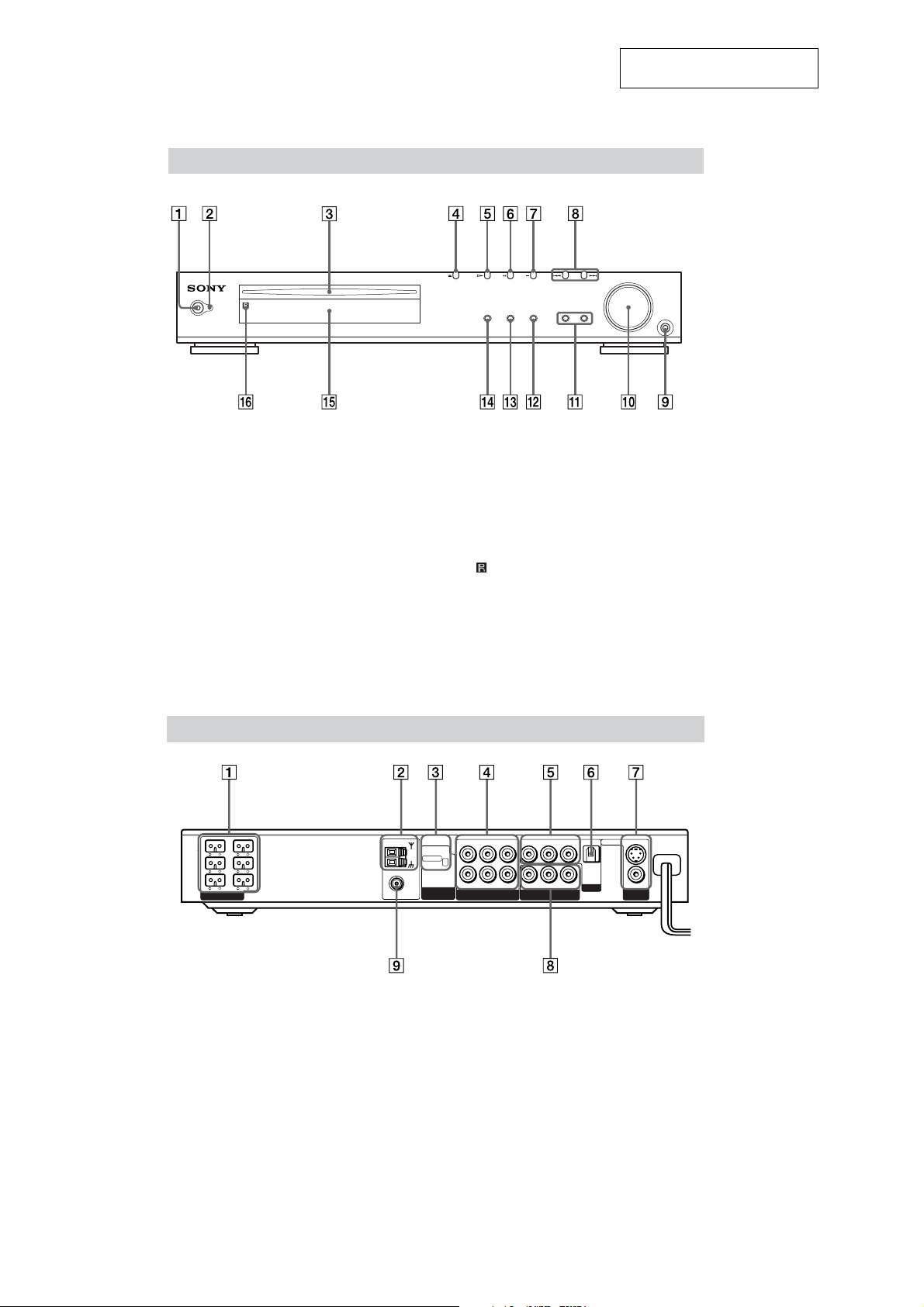

LOCATION OF CONTROLS

Front Panel

SECTION 2

GENERAL

This section is extracted from

instruction manual.

STANDBY

1 POWER switc

2 STANDBY indicator

3 Disc slot

4 A (Eject)

5 H (play)

6 X (pause)

7 x (stop)

8 ./> PREV/NEXT, PRESET –/+

Rear Panel

FUNCTION BAND DISPLAY SOUND FIELD

9 PHONES jack

q; VOLUME control

qa SOUND FIELD –/+

qs DISPLAY

qd BAND

qf FUNCTION

qg Front panel display

(remote sensor)

qh

PHONES

R

OPTICAL

DIGITAL

IN

VIDEO 2

S VIDEO (DVD ONLY)

VIDEO

MONITOR

OUT

FRONT

REAR

L

L

IMPEDANCE

USE

WOOFER 3Ω

EXCEPT

WOOFER 3Ω

FRONT

R

CENTER WOOFER

REAR

R

SPEAKER

1 SPEAKER jacks

2 AM antenna

3 COMPONENT VIDEO OUT/SCAN

SELECT switch

4 VIDEO 1 jacks

AM

COAXIAL

FM

75Ω

AUDIO OUT

VIDEO OUT VIDEO IN

SCAN SELECT

SELECTABLE

INTERLACE

COMPONENT

VIDEO OUT

LR LR

LR

AUDIO IN VIDEO IN

VIDEO 1

AUDIO IN

YPB/CBPR/C

COMPONENT VIDEO OUT

6 DIGITAL IN (OPTICAL) jack

7 MONITOR OUT (VIDEO/S VIDEO)

jacks

8 COMPONENT VIDEO OUT jacks

9 FM 75Ω COAXIAL antenna jack

5 VIDEO 2 jacks

6

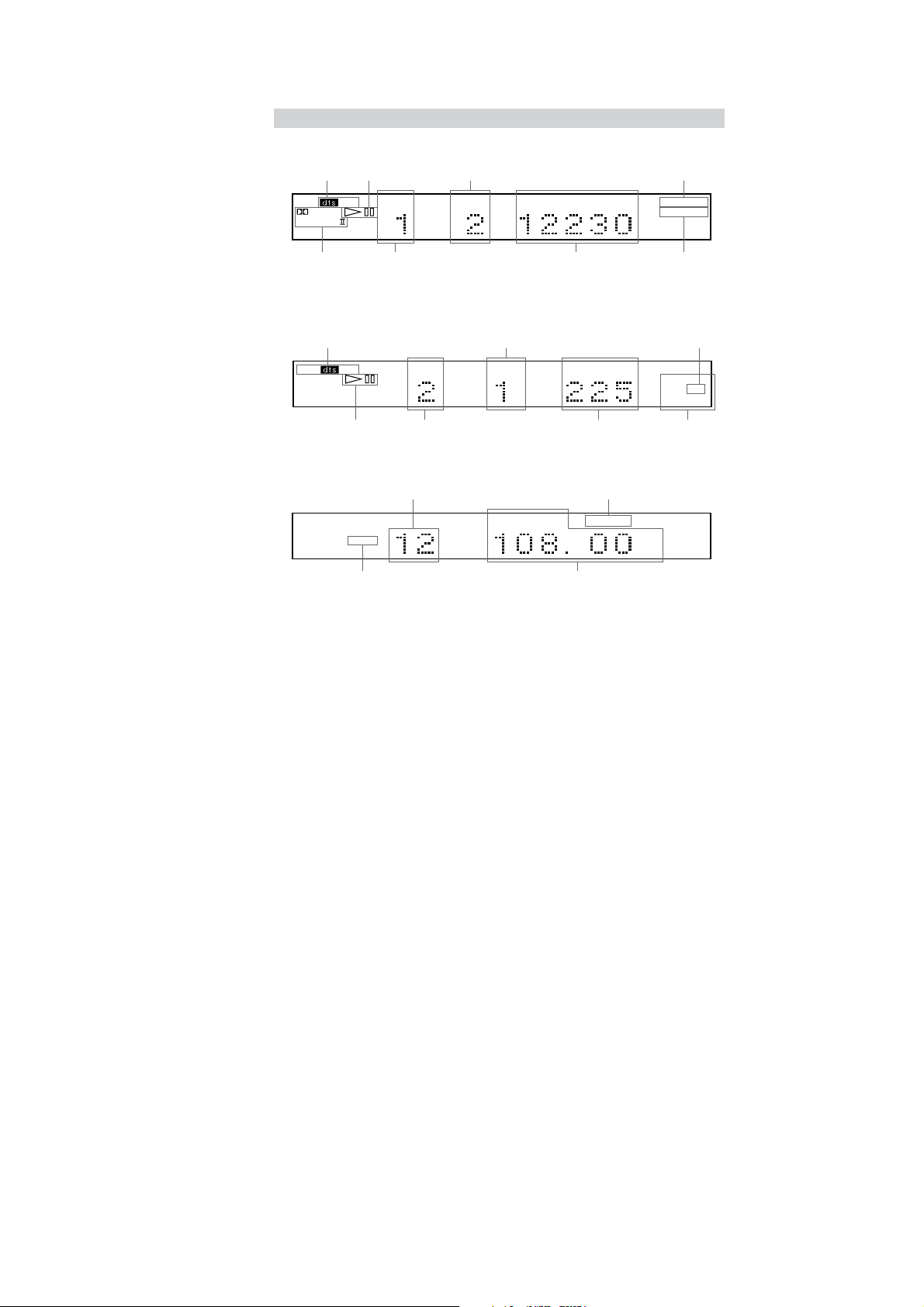

Front Panel Display

When playing back a DVD

Current sound

Playing status

Current chapter number

Lights up when you can

change the angle

HCD-S550/S880

TITLE CHAPTER H M S

PCM

DIGITAL

PRO LOGIC

Current surround

format

Current title

number

Playing time Current repeat mode

When playing back a Super Audio CD, CD, VIDEO CD, or MP3

Current index number

(The index indicator does not appear

Current sound

SACD

Playing status

PCM

Current track number Current play mode

during Super Audio CD or MP3

playback.)

TRACK INDEX M S

Playing time

When listening to the radio

Preset number Monaural/Stereo effect

TUNED MONO ST

FM AM

Current band

Current station

ANGLE

REPEAT 1

Lights up during

PBC playback

(VIDEO CD only)

REPEAT 1

PROG PBC

SHUFFLE

MHz

7

HCD-S550/S880

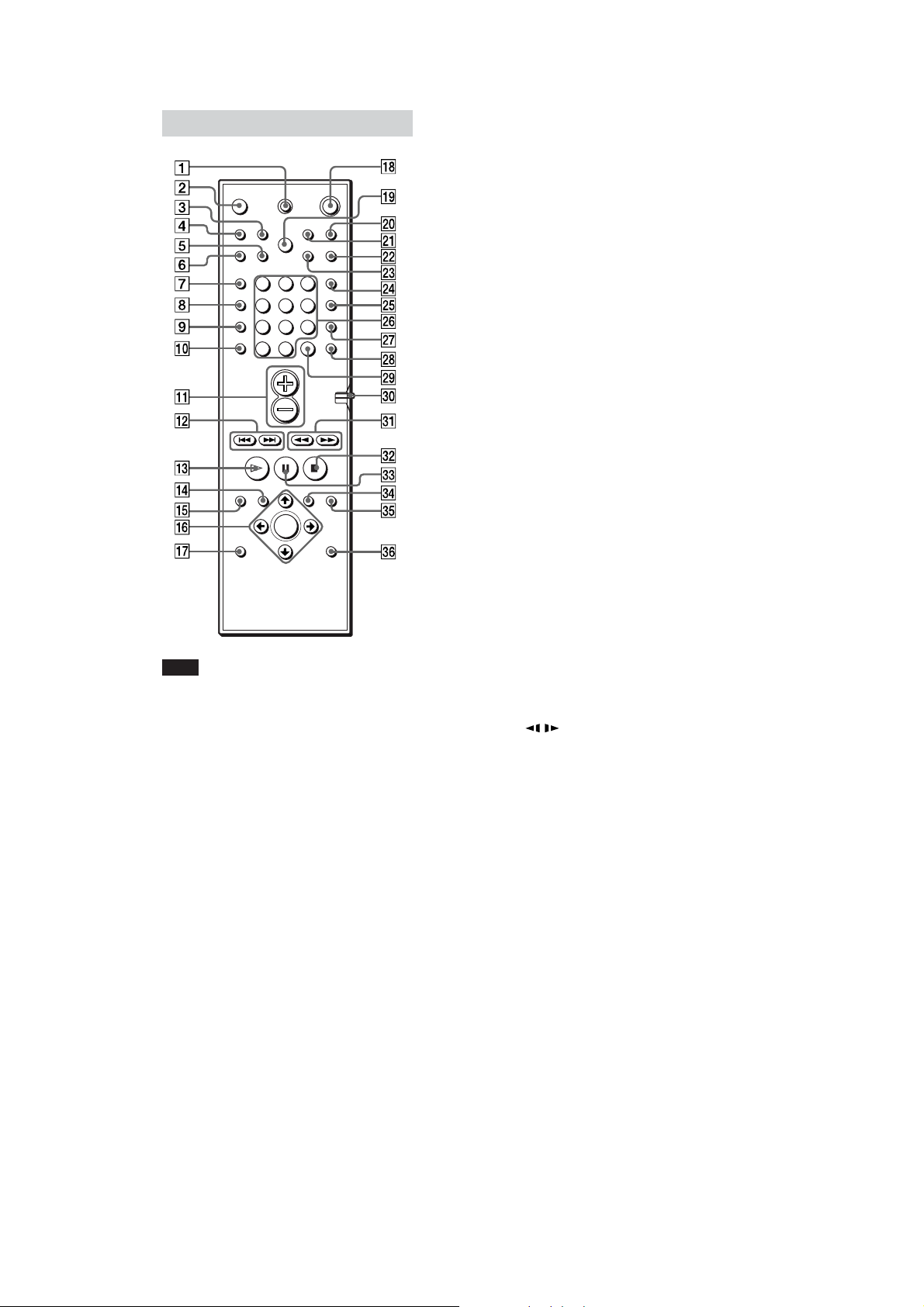

Remote

123

456

7

89

>

10

10/0

1 TV [/1 (on/standby)

2 Z (EJECT)

3 NAME

4 STEREO/MONO

5 MEMORY

6 CLEAR

7 PLAY MODE

8 AUDIO

9 ANGLE

q; SUBTITLE

qa VOL +/–

qs ./> PREV/NEXT, TV CH –/+,

PRESET –/+

qd H PLAY/SELECT

qf DVD TOP MENU

qg DVD DISPLAY

qh C/X/x/c/ENTER

qj DVD SETUP

qk 1 (standby)

ql DIMMER

w; TV/VIDEO

wa REPEAT

ws MUTING

wd TIME

wf FUNCTION

Note

This remote control glows in the dark. However,

before glowing, the remote must be exposed to light

for awhile.

wg BAND

wh Number buttons

wj SOUND FIELD

wk DISPLAY

wl ENTER

e; COMMAND MODE DVD TV switch

ea m/M/

/ SLOW, TUNING –/+

es x STOP

ed X PAUSE

ef DVD MENU

eg O RETURN

eh AMP MENU

8

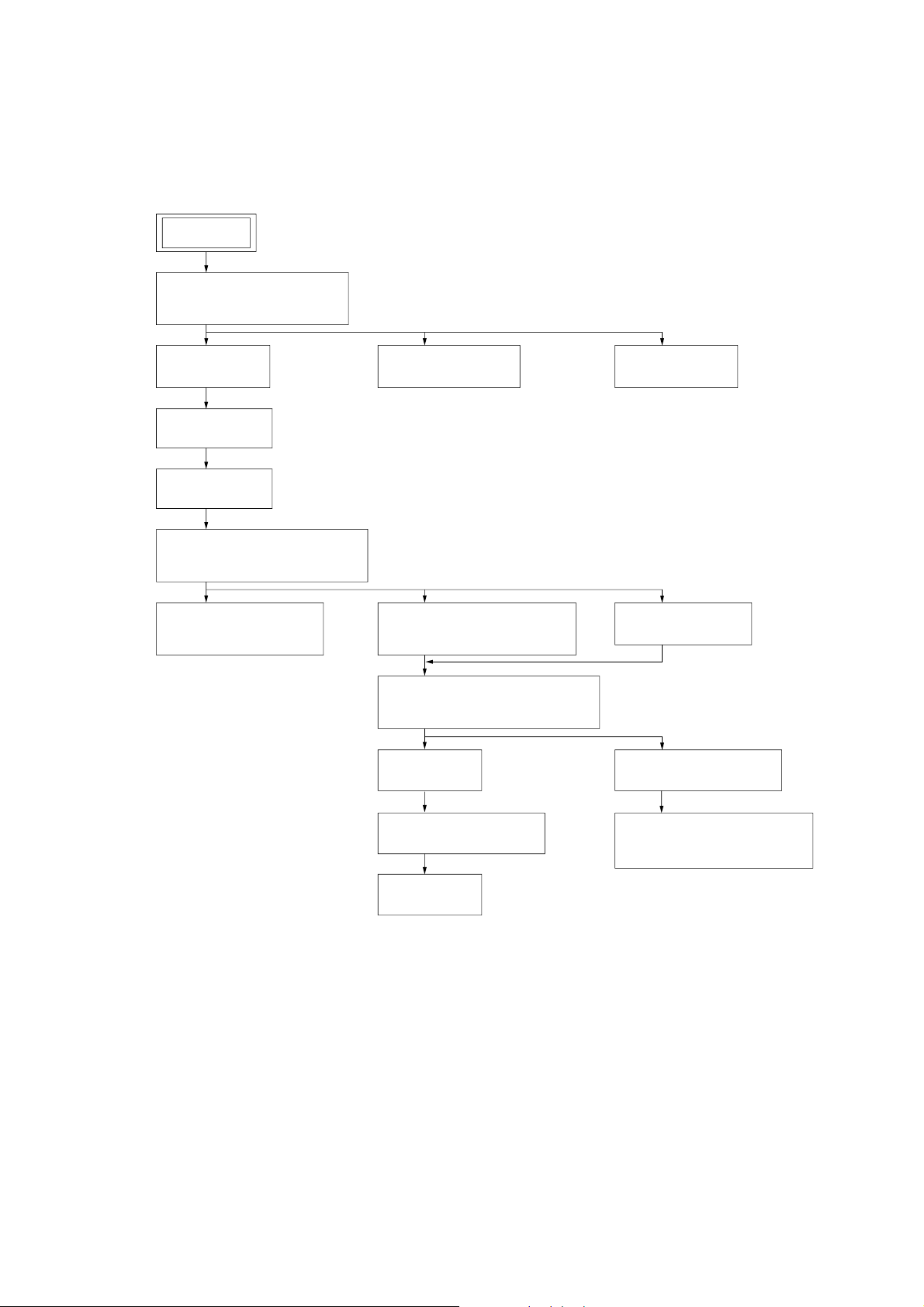

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. FRONT PANELSECTION,

SIDE PANEL (L)/(R)

(Page 10)

HCD-S550/S880

SECTION 3

DISASSEMBLY

3-3. I/O BOARD

(Page 10)

3-4. SEL BOARD

(Page 11)

3-5. DVD BOARD

(Page 11)

3-6. MECHANISM DECK

SECTION (CDM72B-DVBU12)

(Page 12)

3-7. POWER SW BOARD,

DDCON BOARD

(Page 12)

3-8. POWER BOARD

(Page 13)

3-10. OPTICAL PICK-UP BLOCK

(DVBU12)

(Page 14)

3-12. HOLDER (AT) ASSY.

RETAINER (CHASSIS) BLOCK

(Page 15)

3-13. BELT (L2)

(Page 15)

3-9. AMP BOARD

(Page 13)

3-11. RELAY BOARD

(Page 14)

3-16. PULLEY (SPT) ASSY

(Page 17)

3-14. PULLEY (RTR) ASSY

(Page 16)

3-15. BELT (CK)

(Page 16)

3-17. BELT (CK),

MOTOR (CK) ASSY (M751)

(Page 17)

9

HCD-S550/S880

)

Note: Follow the disassembly procedure in the numerical order given.

3-2. FRONT PANEL SECTION, SIDE PANEL (L)/(R)

3

0

two screws

0

two screws

×

8)

×

8)

qa

side panel (L)

8

connector

(CN803)

(BVTP3

(BVTP3

9

front panel section

1

4

connector (CN900)

three screws

×

(BVTP3

8)

qs

two screws

(BVTP3

×

8)

7

3-3. I/O BOARD

2

connector

(CN802)

6

connector

(CN804)

5

connector

(CN805)

two flexible flat cables

(CN202, 203)

5

I/O board

2

three screws

(BVTP3

×

8)

1

flexible flat cable

(CN201)

2

connector (CN205

4

qd

side panel (R)

seven screws

(BVTP3

×

8)

10

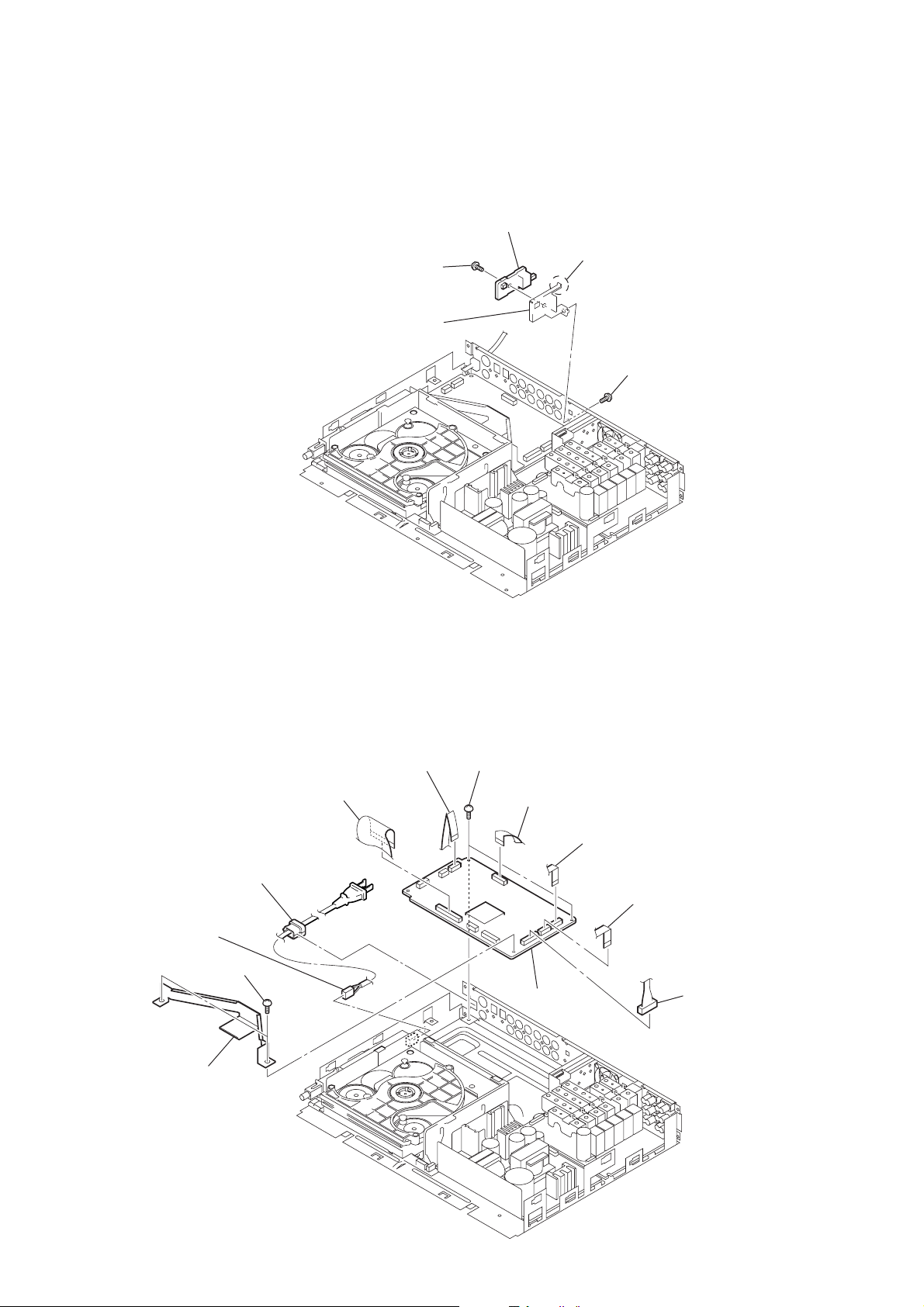

3-4. SEL BOARD

r

3

screw

(DIA. 2.6

4

retainer

×

5

8)

SEL board

2

claw

1

screw

(DIA. 2.6

HCD-S550/S880

×

8)

3-5. DVD BOARD

8

power cord block

9

connector

(CN900)

9

two screws

(BVTP3

×

8)

0

retainer

5

flexible board

(CN401)

1

flexible flat cable

(CN005)

qa

two screws (BVTP3

2

flexible flat cable

(CN006)

qs

DVD board

×

8)

3

flexible flat cable

(CN001)

4

flexible flat cable

(CN004)

6

connecto

(CN008)

11

HCD-S550/S880

)

3-6. MECHANISM DECK SECTION (CDM72B-DVBU12)

1

flexible flat cable

(CN701)

3

mechanism deck

(CDM72B-DVBU12)

2

four screws

×

(BVTP3

8)

3-7. POWER SW BOARD, DDCON BOARD

6

four screws

(P2

×

5

power button section

8

flexible flat cable

(CN814)

9

connector

(CN807)

4

connector

(CN901)

0

two screws

(BVTP3

6)

×

7

power SW board

8)

2

four screws

(BVTP3

3

×

8)

1

connector (CN902

12

qa

DDCON board

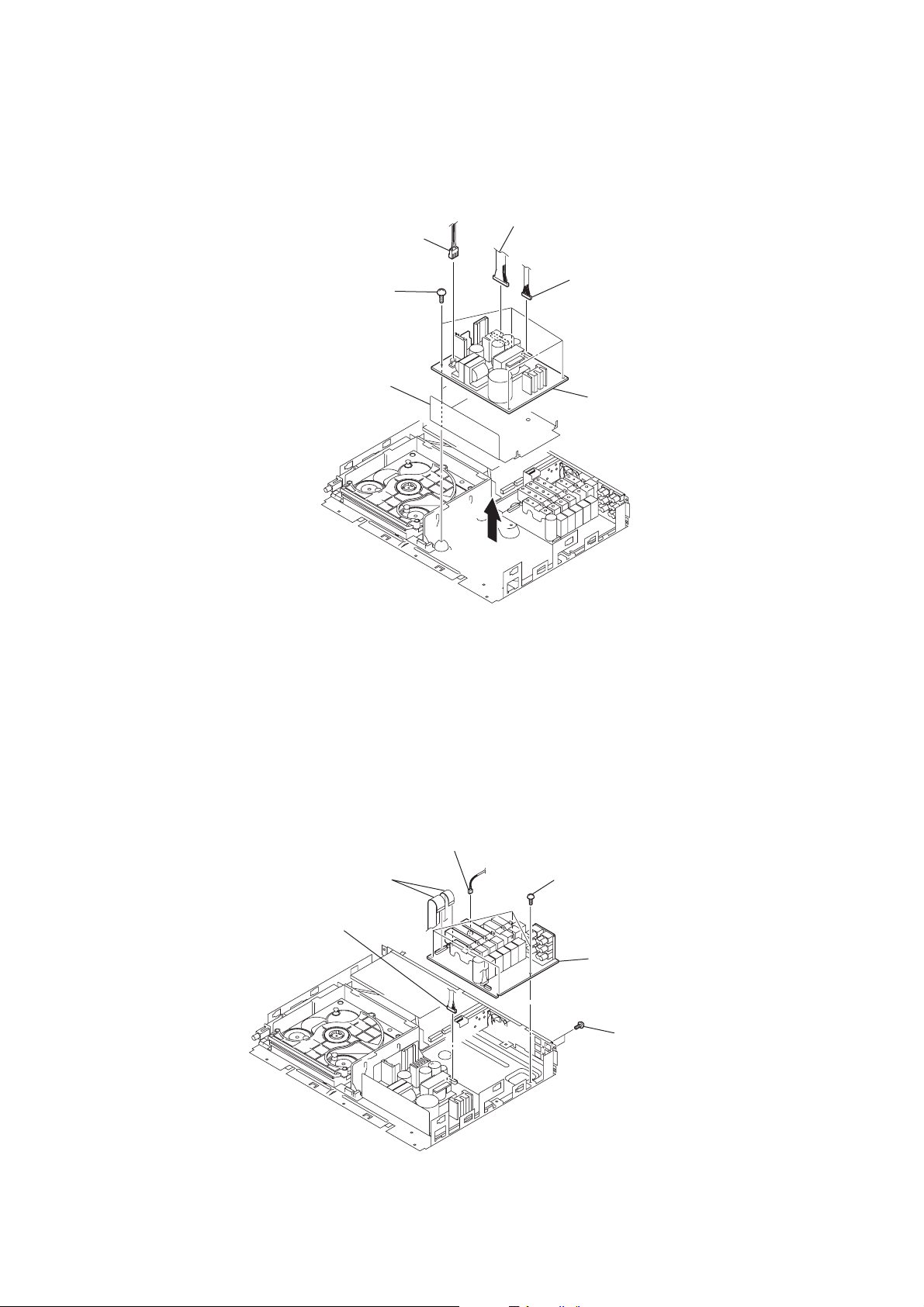

3-8. POWER BOARD

d

4

four screws

(BVTP3

6

power sheet

3

connector

(CN902)

×

8)

2

connector

(CN903)

1

connector

(CN904)

7

HCD-S550/S880

power boar

3-9. AMP BOARD

1

two wires (flat type)

(CN301, 305)

3

connector

(CN904)

2

connector

(CN302)

5

4

four screws

(BVTP3

6

×

8)

AMP board

5

two screws

×

(BVTP3

8)

13

HCD-S550/S880

k

3-10. OPTICAL PICK-UP BLOCK (DVBU12)

3-11. RELAY BOARD

1

screw

(PTPWHM2.6)

9

8

connecter

(CN706)

relay board

7

connector

(CN702)

2

optical pick-up bloc

(DVBU12)

5

4

two screws

(BTP2.6

×

6)

14

3

connector

(CN741)

S880

1

three screws

(BTP2.6

× 6

6

two connector

(CN703, 707)

2

retainer

)

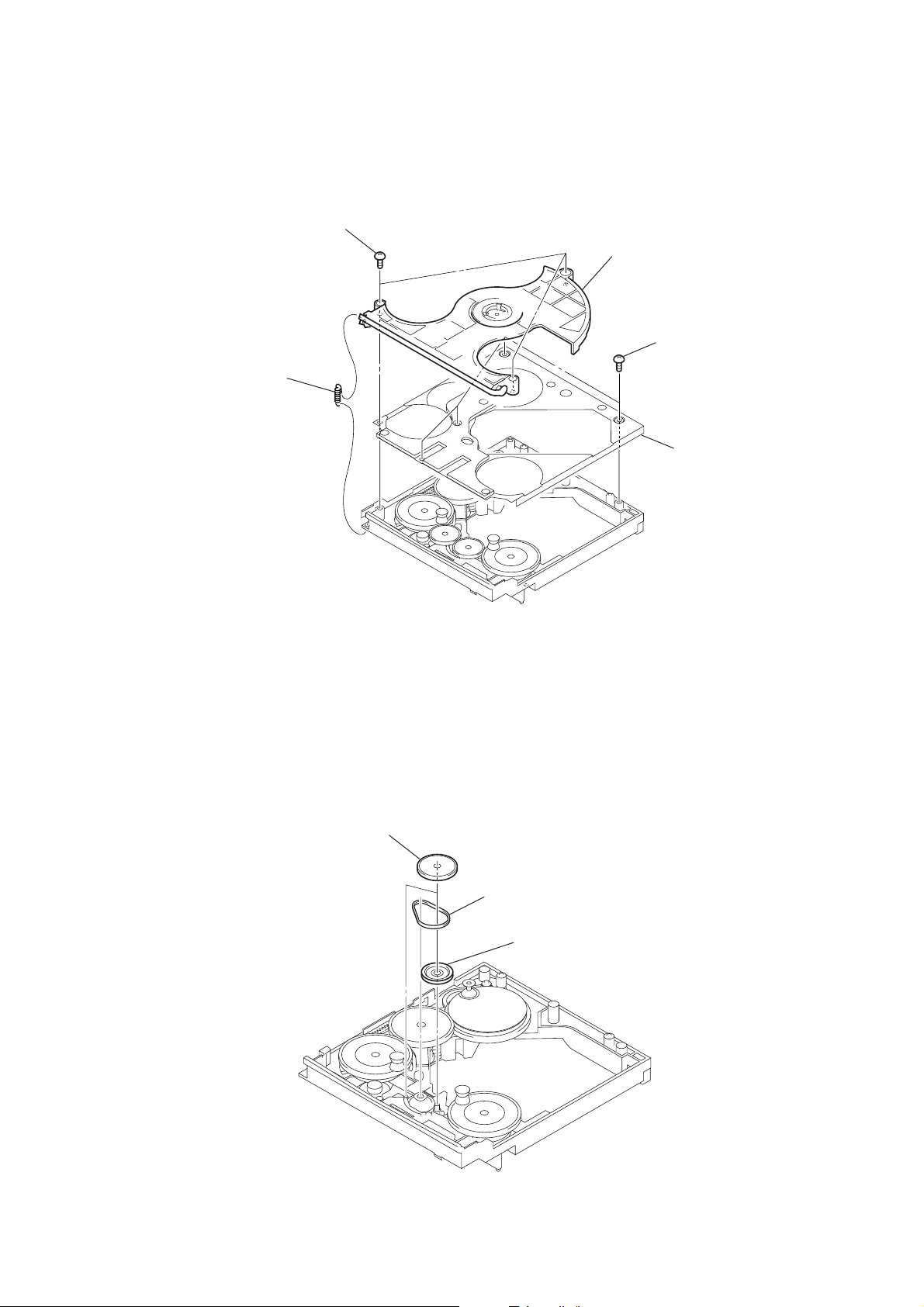

3-12. HOLDER (AT) ASSY, RETAINER (CHASSIS) BLOCK

k

2

three screws

(BTP2.6

×

8)

1

tension spring

(S5)

3

holder (AT) assy

4

HCD-S550/S880

four screws

(BTP2.6

×

6)

5

retainer (chassis) bloc

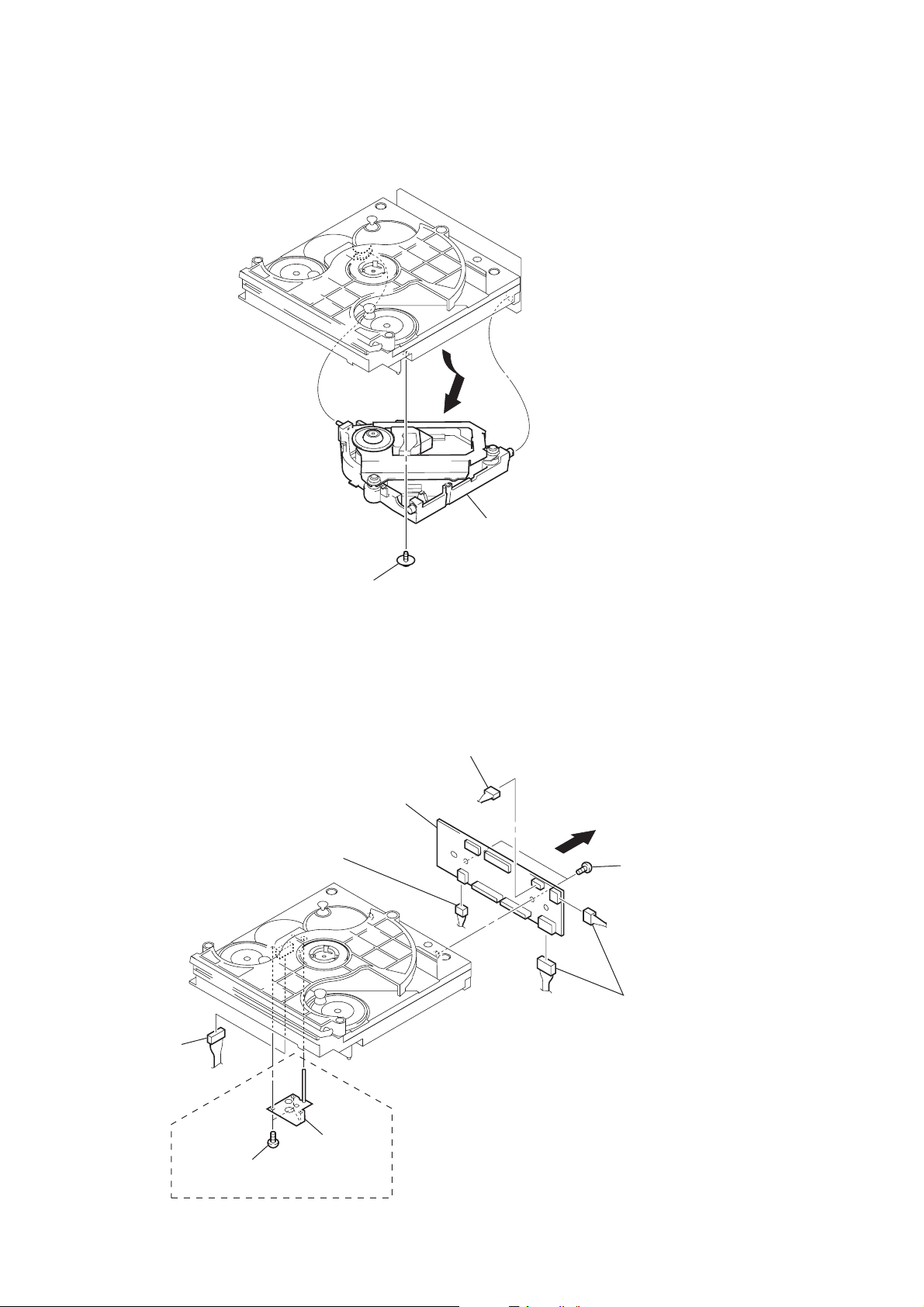

3-13. BELT (L2)

1

two gears

(S1)

2

belt (L2)

3

pulley (LDG)

15

HCD-S550/S880

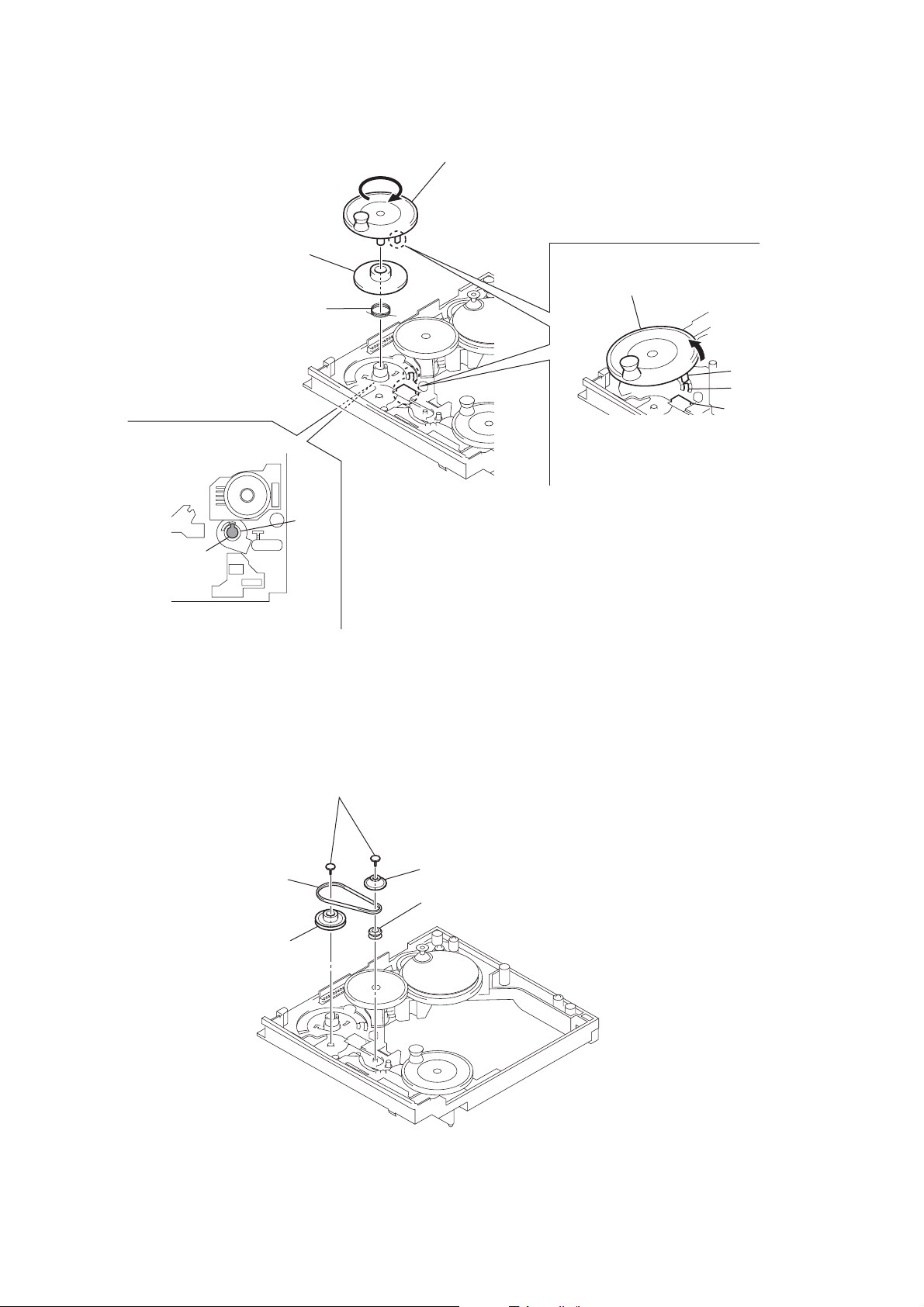

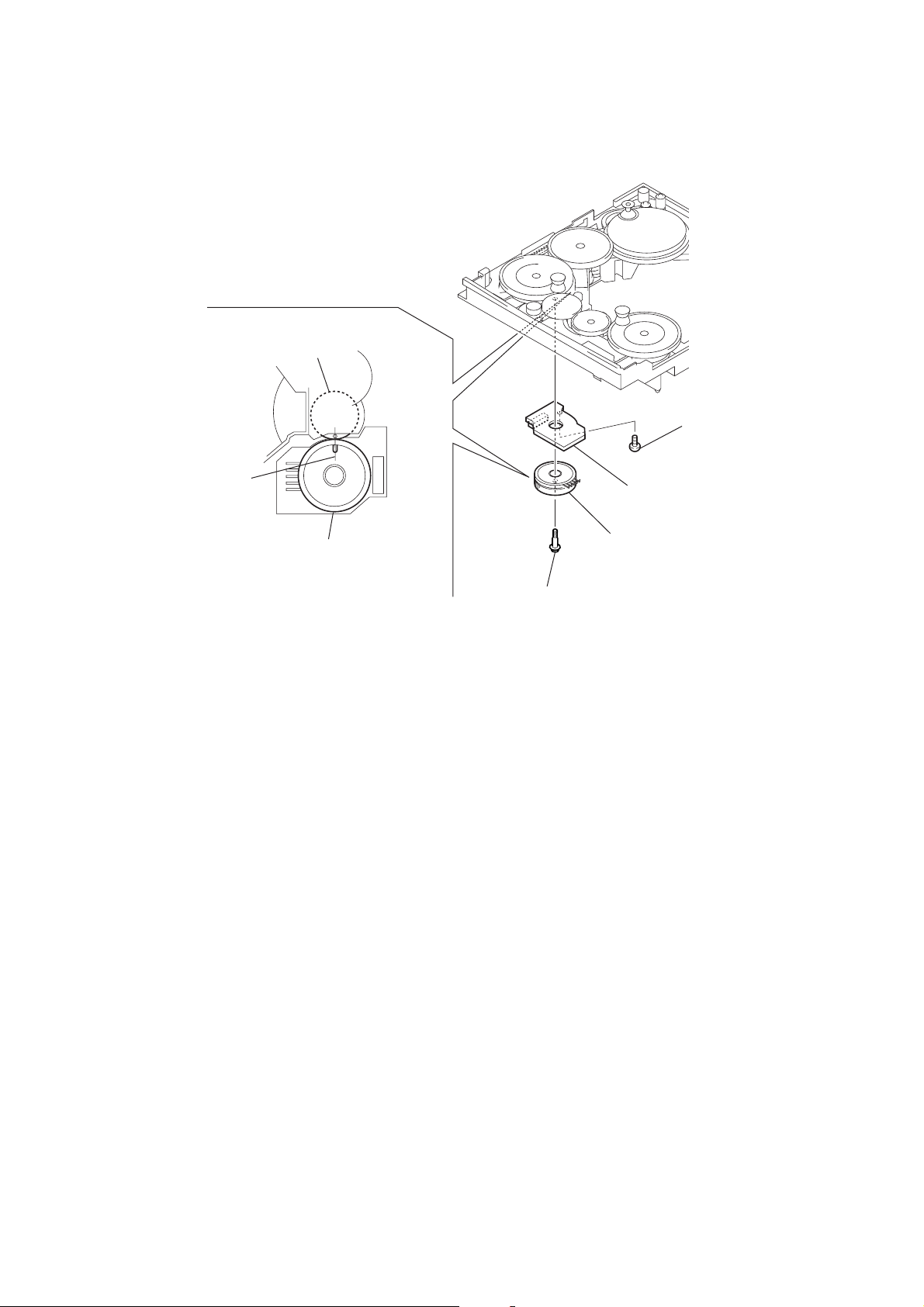

3-14. PULLEY (RTR) ASSY

2

3

gear (L4)

torsion spring

(L)

A

1

Rotate the pulley (RTR) assy in the direction of arrow

to disengage the shaft of the pulley (RTR) assy from

the hole of the chassis (refer to fig. 1), and remove it.

pulley (RTR) assy

B

Tilting the pulley (RTR) assy in the direction

of arrow B, move it over the claw and

the connector of the chassis.

A

boss

claw

connector

shaft

(pulley (RTR) assy)

3-15. BELT (CK)

front

– bottom view –

fig. 1

3

belt (CK)

5

pulley (LCG)

hole

1

two bushings

(CDM72)

2

gear (L5)

4

pulley (L5)

16

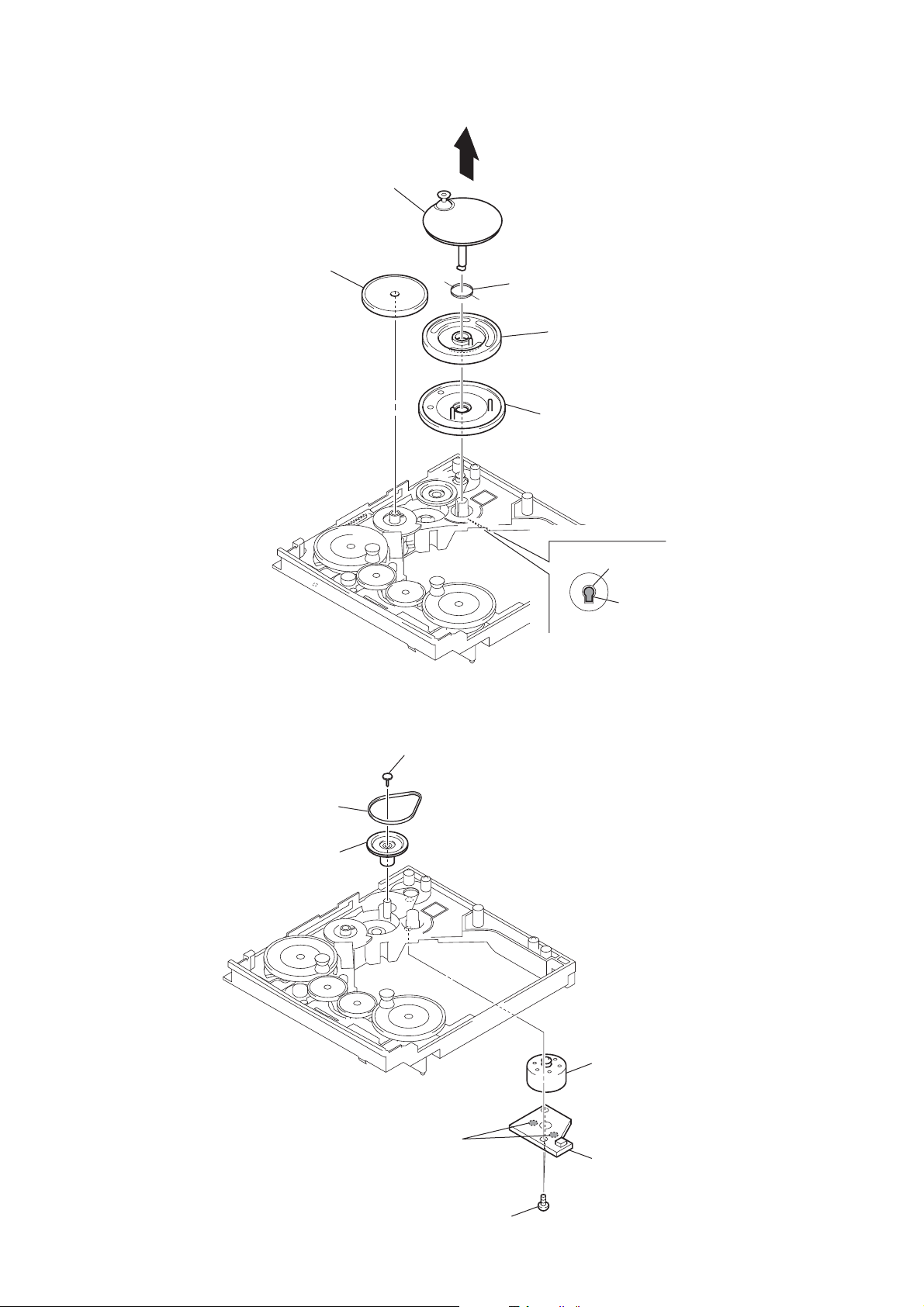

3-16. PULLEY (SPT) ASSY

y

2

pulley (SPT) assy

3

gear (S2)

4

torsion spring (S)

5

gear (SPT)

6

gear (KT)

HCD-S550/S880

3-17. BELT (CK), MOTOR (CK) ASSY (M751)

1

busing (CDM72)

2

belt (CK)

3

pulley (CKG)

hole

shaft

(pulley (SPT) assy

1

Rotate the pulley (SPT) assy to fit position

of the shaft to the hole of the chassis.

4

two solders

5

two screws

(BTP2.6

7

motor (CK) ass

(M751)

6

CK motor board

×

6)

17

HCD-S550/C880

SECTION 4

ASSEMBLY

• This set can be assembled in the order shown below.

4-1. HOW TO INSTALL PULLEY (SPT) ASSY

4

gear (S2)

gear (S2)

5

pulley (SPT) assy

3

torsion spring (S) (Note)

2

gear (SPT)

gear (SPT)

Note: installation of torsion spring (S)

gear (KT)

gear (SPT)

4-2. HOW TO INSTALL PULLEY (RTR) ASSY

torsion spring (S)

1

gear (KT)

18

gear (S2)

pulley (RTR) assy

pulley

(RTR) assy

gear (S2)

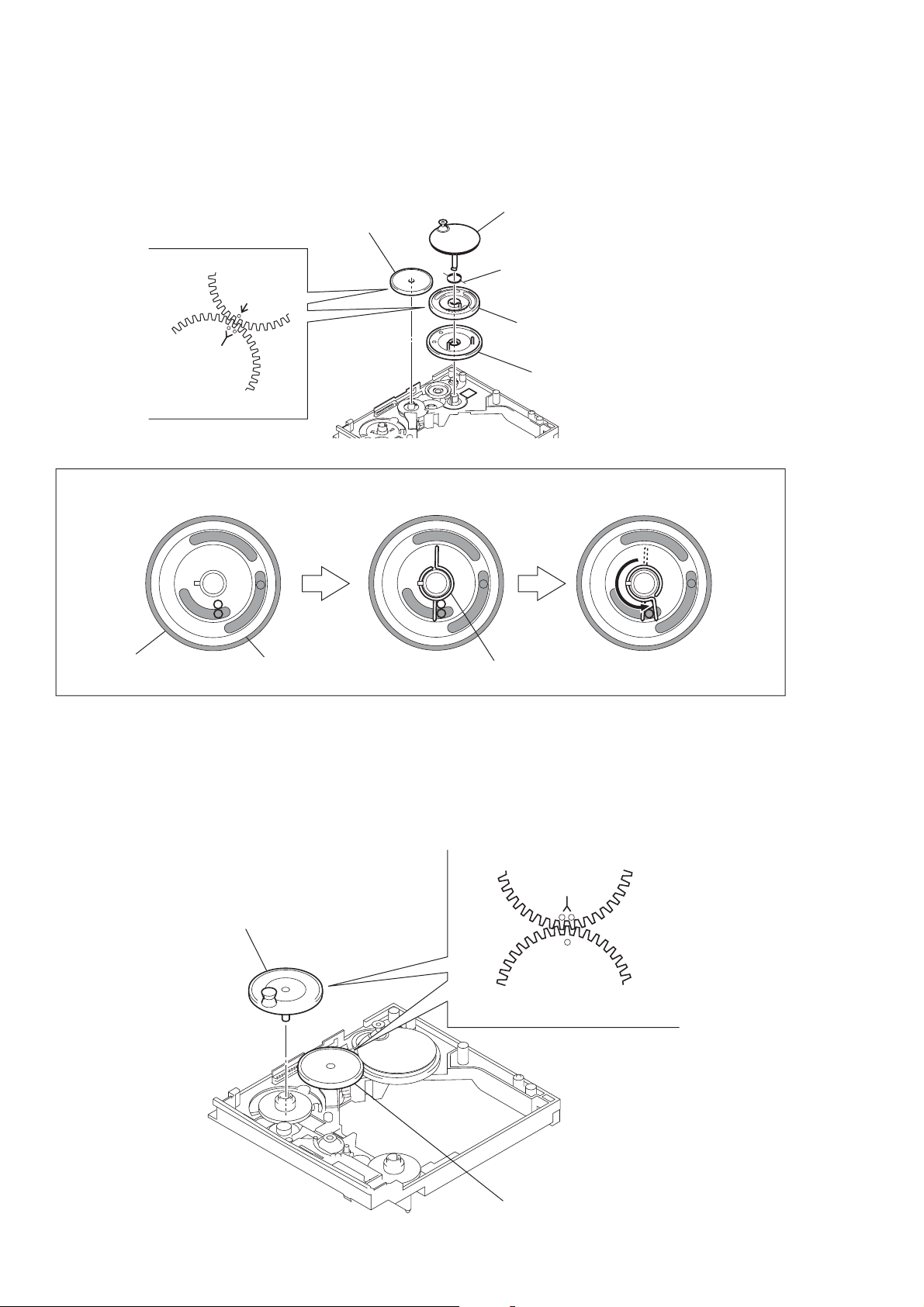

4-3. HOW TO INSTALL ROTARY ENCODER (MODE) (S741)

cam (CDM72)

2

screw

(BTP2.6 × 6)

HCD-S550/S880

linearly

rotary encoder (mode)

(S741)

-bottom view-

4

screw

(PWH,2 × 6)

1

encoder board

3

rotary encoder (mode)

(S741)

19

HCD-S550/S880

Ver 1.4

SECTION 5

TEST MODE

[GENERAL DESCRIPTION]

The T est Mode allows you to make dia gnosis and adjustment easily

using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

[TEST DISC LIST]

Use the following test disc on test mode.

TDV-520CSO (DVD-SL): PART No. J-2501-236-A

LIV-P01 (CD): PART No. 4-999-032-01

TDV-540C (DVD-DL): PART No. J-2501-235-A

Note: Do not use exiting test disc for DVD.

[STARTING TEST MODE]

1. Press the [POWER] button to turn the power on, and set the

function to DVD.

2. While pressing the x and [DISPLAY] button, turn the

[VOLUME] knob clockwise to enter the test mode.

3. It displays “TEST MODE” on the fluorescent indicator tube,

and displays the Test Mode Menu on the monitor screen as

follows. (At the bottom of the menu screen, the model name

and revision number are displayed)

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Mecha Error History

6. Version Information

7. Video Level Adjustment

Exit: POWER Key

Model :DAV-Sxxx

Revision :x.xx

4. To execute each function, select the desired menu and press its

number on the remote commander (RM-SS880J).

5. To release from test mode, press the

the power off.

[POWER] button and tur n

[OPERATING TEST MODE]

0. SYSCON DIAGNOSIS

The same contents as board detail check by serial interface can be

checked from the remote commander operation.

On the Test Mode Menu screen, press [10/0] key on the remote

commander, and the following Check Menu will be displayed.

### Syscon Diagnosis ###

Check Menu

0. Quit

1. All

2. Version

3. EEPROM

4. SPIO

5. SD Bus

6. Video

7. Audio

0-1. All (All items continuous check)

This menu checks all diagnostic items continuously. Normally, all

items are checked successively one after another automatically

unless an error is found, but at a certain item that requires judgment

through a visual check to the result, the following screen is displayed

for the key entry.

• Example display

### Syscon Diagnosis ###

Diag All Check

No.2 Version

2-3. ROM Check Sum

Check Sum = 2320

Press NEXT Key to Continue

Press PREV Key to Repeat

For the ROM Check, the check sum calculated by the Syscon is

output, and therefore you must compare it with the specified value

for confirmation.

Following the message, press the [NEXT ] button to go to the

next item, or press the [ PREV] button to repeat the same

operation again.

To quit the diagnosis and return to Check Menu screen, press the

.

>

[RETURN] key on the remote commander to display Check Menu.

• Error occurred

If an error occurred, the diagnosis is suspended and error is displayed.

Press the

diagnosis, or press the [ PREV] button to repeat the same check

where an error occurred, or press the [NEXT ] button to continue

the check from the item next to faulty item.

General Description of Checking Method

Selecting 2 and subsequent items calls the submenu screen of each

item. And selecting 2 and subsequent items executes respective

menus and outputs the results.

For the contents of each submenu, see “Check Items List” as below .

Check Items List:

[RETURN] key on the remote commander to quit the

.

>

0-2. Version

0-2-1. All

0-2-2. Revision

0-2-3. ROM Check Sum

0-2-4. Model Type

0-2-5. Region

0-3. EEPROM Check

0-3-1. Sampling Check

0-3-2. Detail Check

0-4. GP I/O Check

0-5. SD Bus Check

0-6. Video Check

0-7. Audio Check

0-0. Quit

Quit the Syscon Diagnosis and return to the Test Mode Menu.

20

0-2. Version

0-2-2. Revision

The revision number of ROM (IC204) that the program for

the DVD system processor (IC206) is stored.

(4 digits hexadecimal number)

HCD-S550/S880

0-2-3. ROM Check Sum

The revision number of ROM (IC204) that the program for

the DVD system processor (IC206) is stored.

0-2-4. Model Type

Model name is displayed. (DAV-S550 or DAV-S880)

0-2-5. Region

Model destination code is displayed. (2 digits number)

0-3. EEPROM Check

0-3-1. Sampling Check

EEPROM check at every 64 words.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-3-2. Detail Check

EEPROM check at every 1 word.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-4. GP I/O Check

Pull up/down setting check of the DVD system processor (IC206)

pin 150, 151 and 154 (for clock setting port).

0-5. SD Bus Check

SD bus data check between DVD decoder (IC701) and D-RAM

(IC706).

0-6. Video Check

Output the color bars for video level adjustment.

0-7. Audio Check

Output the test signal (1kHz sine wave) for 5.1 CH test.

1. DRIVE AUTO ADJUSTMENT

On the Test Mode Men u screen, press the [1] key on the remote

commander, and the Adjustment Menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL

1. DVD-SL

2. CD

3. DVD-DL

by pressing the [RETURN] button on the remote commander.

Note: During adjustment of each disc, the measurement for disc type judg-

ment is made. As automatic adjustment does not judge the disc

type unlike conventional models, take care not to insert wrong type

discs. Also, do not give a shock during adjustment.

1-1. DVD-SL (single layer)

Press the [1] key on the remote commander and insert a DVD single

layer disc following the message. Then the adjustment will be made

through the steps below, then adjusted values will be written to the

EEPROM.

DVD Single Layer Disc Adjustment Steps:

1. Sled tilt reset

2. Disc check memory SL

3. Wait 300 msec

4. Set disc type SL

5. LD on

6. Spindle start

7. Wait 1 sec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. Wait 1 sec

14. Sled on

15. Check CLV on

16. Auto LFO adjust

17. Auto focus offset adjust

18. Auto tilt position adjust

19. Auto focus gain adjust

20. Auto focus offset adjust

21. EQ boost adjust

22. Auto loop filter offset adjust

23. Auto track gain adjust

Search Check

24. 32 track jump forward

25. 32 track jump reverse

26. 500 track jump forward

27. 500 track jump reverse

28. All servo stop

29. EEP copy loop filter offset

1-2. CD

Press the

following the message. Then the adjustment will be made through

the steps below , then adjusted values will be written to the EEPR OM.

[2] key on the remote commander and insert a CD disc

Exit: RETURN

Normally, [10/0] is selected to adjust DVD (single layer), CD and

DVD (dual layer) in this order . But, individual items can be adjusted

for the case where adjustment is suspended due to an error. In this

mode, the adjustment can be made easily through the operation

following the message displayed on the screen.

The disc used for adjustment must be the one specified for

adjustment.

1-0. ALL

Press the [10/0] key on the remote commander, and the servo set

data in EEPROM will be initialized. Then, 1. DVD-SL disc, 2. CD

disc and 3. DVD-DL disc are adjusted in this order.

Each time one disc was adjusted, it is ejected. Replace it with the

specified disc following the message. Y ou can finish the adjustment

CD Adjustment Steps

1. Sled tilt rest

2. Disc check memory CD

3. Wait 500 msec

4. Set disc type CD

5. LD on

6. Spindle start

7. Wait 500 msec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. (TC display start)

14. Wait 1 sec

15. Jitter display start

16. Sled ON

17. Check CLV on

21

HCD-S550/S880

18. Auto loop filter offset adjust

19. Auto focus offset adjust

20. Auto focus gain adjust

21. Auto focus offset adjust

22. EQ boost adjust

23. Auto LFO Adjust

24. Auto track gain adjust

Search Check

25. 32Tj forward

26. 32Tj reverse

27. 500Tj forward

28. 500Tj reverse

29. All servo stop

1-3. DVD-DL (dual layer)

Press the [3] key on the remote commander and insert a DVD dual

layer disc following the message. Then the adjustment will be made

through the steps below, then adjusted values will be written to the

EEPROM.

DVD Dual Layer Disc Adjustment Steps:

1. Sled tilt reset

2. Disc check memory DL

3. Wait 500 msec

4. Set disc type DL

5. LD on

6. Spindle start

7. Wait 1 sec

Layer 1 Adjust

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. Wait 500 msec

14. Sled on

15. Check CLV lock

16. Auto loop filter offset adjust, Auto focus adjust

17. Auto focus gain adjust

18. Auto focus offset adjust

19. EQ boost adjust

20. Auto loop filter offset adjust

21. Auto Track Gain Adjust

Search Check

22. 32 track jump forward

23. 32 track jump reverse

24. 500 track jump forward

25. 500 track jump reverse

Layer 0 Adjust

26. Focus jump (L1 t L0)

27. Auto track offset adjust L0

28. CLVA on

29. Wait 500 msec

30. Tracking on

31. Wait 500 msec

32. Sled on

33. Check CLV lock

34. Auto focus filter offset adjust

35. Auto Focus Adjust

36. Auto focus gain adjust

37. Auto focus offset adjust

38. EQ boost adjust

39. Auto Loop Filter Offset

40. Auto track gain adjust

Search Check

41. 32 track jump forward

42. 32 track jump reverse

43. 500 track jump forward

44. 500 track jump reverse

Layer Jump Check

45. Layer jump (L0 ? L1)

46. Layer jump (L1 ? L0)

47. All servo stop

2. DRIVE MANUAL OPERATION

Note: This mode is used for design, and not used in service fundamen-

tally.

On the Test Mode Menu screen, press the [2] key on the remote

commander, and the Operation Menu will be displayed. For the

manual operation, each servo on/off control and adjustment can be

executed manually.

## Drive Manual Operation ##

Operation Menu

1. Disc Type

2. Servo Control

3. Track/Layer Jump

4. Non EEPROM Write Adjust

5. EEPROM Write Adjust

6. Memory Check

7. Disc Check Memory

8. Error Rate Display

9. SACD Water Mark

Exit: RETURN

In using the manual operation menu, take care of the following

points. These commands do not provide protection, thus requiring

correct operation. The sector address or time code field is displayed

when a disc is loaded.

Note:

1. Set correctly the disc type to be used on the Disc Type screen.

2. In case of an alarm, immediately press the x button to stop the

servo operation, and press the [POWER] button to turn the power

off.

Basic operation:

(controllable from front panel or remote commander)

[POWER] :Power OFF (release the Test Mode)

x : Servo stop

A : Stop and eject/Loading

[RETURN] : Return to Operation Menu or Test

Mode Menu

[ PREV], [NEXT ] :Transition between sub modes of menu

>.

[1] to [9], [10/0] : Selection of menu items

Cursor o/

O

: Increase/Decrease in manually

adjusted value

22

HCD-S550/S880

2-1. Disc Type

Disc Type

Disc Type Select

1. Disc Type Auto Check

2. Set Disc Type DVD

3. Set Disc Type CD

4. Set Disc Type Hybrid

Exit: RETURN

2-1-1. Disc Type Auto Check

1) Press the [1] ke y on the remote commander to display the Disc

Type Auto Check screen.

2) Insert a disc and press the [ENTER] key on the remote

commander.

3) It judges the type of inserted disc automatically and displays

the disc type and so on as below.

Disc Type Auto Check

Disc Type xx

Layer xx

Mirr Time xx

Mirr Count xx

FZC Count xx

PI Reference xx

PI Peak xx

2-1-3. Disc Type CD

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: CD disc (normal speed, 12 cm)

[2]: CD disc (double speed, 12 cm)

[3]: CD disc (normal speed, 8 cm)

[4]: CD disc (double speed, 8 cm)

[5]: CD-RW disc (normal speed, 12 cm)

[6]: CD-RW disc (double speed, 12 cm)

[7]: CD-RW disc (normal speed, 8 cm)

[8]: CD-RW disc (double speed, 8 cm)

2-1-4. Disc Type Hybrid

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: SACD Hybrid disc (SACD layer, 12 cm)

[2]: SACD Hybrid disc (CD layer, normal speed, 12 cm)

[3]: SACD Hybrid disc (CD layer, double speed, 12 cm)

[4]: SACD Hybrid disc (SACD layer, 8 cm)

[5]: SACD Hybrid disc (CD layer, normal speed, 8 cm)

[6]: SACD Hybrid disc (CD layer, double speed, 8 cm)

2-2. Servo Control

Note: Be sure to perform the disc type setup before performing this item.

Servo Control

1.LD off R.Sled FWD

2.Focus off L.Sled REV

3.SPDL off U.Sled Reset

4.CLVA off D.Sled Limit

5.Trk. off

6.Sled off

7.Fcs.Srch off

8.Fcs.OppL off

ENTER.Execute

Exit: RETURN

Disc Type : CD, DVD or Hybrid (SACD)

Layer : SINGLE, DUAL or HYBRID

Mirr Time : Mirror time of between disc surface and record

surface when disc type judgment. (hexadecimal

number)

Mirr Count : The number of times which mirror counts between

disc surface and record surface when disc type

judging.

FZC Count : The number of times which focus zero cross points

of each layer when lens down.

PI Reference : The average of PI reference voltage. (hexadecimal

number)

PI Peak : PI peak level voltage. It performs only when disc

type judgment is successful. (hexadecimal number)

2-1-2. Disc Type DVD

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: DVD single layer disc (12 cm)

[2]: DVD dual layer disc (0 layer, 12 cm)

[3]: DVD dual layer disc (1 layer, 12 cm)

[4]: DVD-RW disc (12 cm)

[5]: DVD single layer disc (8 cm)

[6]: DVD dual layer disc (0 layer, 8 cm)

[7]: DVD dual layer disc (1 layer, 8 cm)

[8]: DVD-RW disc (8 cm)

0.All Servo Off

Exit: RETURN

On this screen, the servo on/off control necessary for replay is

executed. Normally, turn on each servo from 1 sequentially and

when CLVA is turned on, the usual trace mode becomes active. In

the trace mode, DVD sector address or CD time code is displayed.

This is not displayed where the spindle is not locked.

The spindle could run overriding the control if the spindle system is

faulty or RF is not present. In such a case, do not operate CLVA.

[1] LD :Turn on/off the laser.

[2] Focus : Search the focus and turn on the focus.

[3] SPDL :Turn on/off the spindle.

[4] CLVA : Turn on/off normal servo of spindle servo.

[5] Trk. : Turn on/off the tracking servo.

[6] Sled : Turn on/off the sled servo.

[7] FCS. Srch : Turn on/off the focus search.

[8] FCS. OppL : Turn on/off the focus search to another

(opposite) layer of designated layer in Disc

Type setting. (dual layer disc only)

[10/0] : All servo off.

[R] Sled FWD (right cursor) : Move the sled forward.

[L] Sled REV (left cursor) : Move the sled reverse.

[U] Sled FWD (up cursor) : Reset the sled.

[D] Sled REV (down cursor):Limit in the sled.

23

HCD-S550/S880

2-3. Track/Layer Jump

Track/Layer Jump

1. 1Tj FWD R.Lj L0>L1

2. 1Tj REV L.Lj L1>L0

3.500Tj Fine FWD U.Fj L0>L1

4.500Tj Fine REV D.Fj L1>L0

5.10kTj Dirc FWD

6.10kTj Dirc REV

7.20kTj Dirc FWD

8.20kTj Dirc REV

0. All Servo Off

Exit: RETURN

On this screen, track jump, etc. can be performed. Only for the DVD

dual layer disc, the focus jump and layer jump are displayed in the

right field

[1] 1Tj FWD : 1 track jump forward.

[2] 1Tj REV : 1 track jump reverse.

[3] 500Tj FWD: 500 track jump (fine search)forward.

[4] 500Tj REV : 500 track jump (fine search) reverse.

[5] 10kTj FWD: 10k track jump (direct search) forward.

[6] 10kTj REV : 10k track jump (direct search) reverse.

[7] 20kTj FWD: 20k track jump (direct search) forward.

[8] 20kTj REV : 20k track jump (direct search) reverse.

[10/0] : All servo off.

2-4. Non EEPROM Write Adjust

2-5. EEPROM Write Adjust

EEPROM Write Adjust

1. Focus Offset

2. Focus Gain

3. Trk. Offset Coarse

4. ——————

5. Trk. Gain

6. EQ Boost

0.All Servo Off

Exit: RETURN

On this screen, each item can be adjusted automatically. Select the

desired number

selected item is adjusted automatically.

[1] to [10/0] from the remote commander, and

[1] Focus Offset: Adjusts focus offset.

[2] Focus Gain : Adjusts focus gain.

[3] TRK. Offset : Adjusts tracking offset of the RF amp

(IC001) side.

[5] TRK. Gain : Adjusts track gain.

[6] EQ Boost : Adjusts amount of boost of equalizer.

[10/0] : All servo off.

2-6. Memory Check

Display images are shown as follows, and all two screens are able

to switch by theOkey (UP) or okey (DW).

Non EEPROM Write Adjust

1. Focus Offset

2. Focus Gain

3. Trk. Offset Coarse

4. Trk. Offset Fine

5. Trk. Gain

6. EQ Boost

0.All Servo Off

Exit: RETURN

On this screen, each item can be adjusted manually. Select the desired

number

setting for the selected item will be displayed, then increase or

decrease numeric value with theOkey or okey. This value is

stored in the EEPROM. If CLV has been applied, the jitter is

displayed for reference for the adjustment.

[1] to [10/0] from the remote commander, and current

[1] Focus Offset: Adjusts focus offset.

[2] Focus Gain : Adjusts focus gain.

[3] TRK. Offset : Adjusts tracking offset of the RF amp

(IC001) side.

[4] TRK. Offset : Adjusts tracking offset of the DSP (IC401)

side.

[5] TRK. Gain : Adjusts track gain.

[6] EQ Boost : Adjusts amount of boost of equalizer.

[10/0] : All servo off.

EEPROM Data 1/2 CD SL L0 L1

Focus Gain xx xx xx xx

Trk. Gain xx xx xx xx

Focus Offset xx xx xx xx

Trk. Offset xx xx xx xx

EQ. Boost xx xx xx xx

PI Level xx xx -- -Fcs. Balance -- xx -- -Jitter xx xx xx xx

Mirror Time xx xx xx -FE Level -- xx -- -Traverse Lv1. -- xx -- -Next:DW Default:CLR Exit:RET

EEPROM Data 2/2 CDRW DVDRW

Focus Gain xx xx

Trk. Gain xx xx

Focus Offset xx xx

Trk. Offset xx xx

EQ. Boost xx xx

Next:UP Default:CLR Exit:RET

On this screen, current servo adjusted data stored in the EEPROM

are displayed. The adjusted data are initialized by pressing the

[CLEAR] key, but be careful that they are not recoverable after

initialization.

Before clearing the adjusted data, make a note of the set data. This

screen will also appear if [0]-All is selected in the Drive Auto

Adjustment. In this case, default setting cannot be made.

24

HCD-S550/S880

2-7. Disc Check Memory

Disc Check Memory

1. SL Disc check

2. SL Disc check

3. SL Disc check

Exit: RETURN

On this screen, measure the mirror time of chucked disc, and write

to the EEPROM.

2-8. Error Rate Display

Error Rate Display

UC CR ADD

PI1 Err Now xx xxxx xxxxxxxx

Max xx xxxx xxxxxxxx

Avg xx xxxx xxxxxxxx

PI2 Err Now xx xxxx xxxxxxxx

Max xx xxxx xxxxxxxx

Avg xx xxxx xxxxxxxx

PO Err Now xx xxxx xxxxxxxx

Max xx xxxx xxxxxxxx

Avg xx xxxx xxxxxxxx

Exit: RETURN

On this screen, measure and display the error rate.

3. MECHA AGING

On the T est Mode Menu screen, selecting [3] executes the aging of

the mechanism deck.

### Aging Test MENU ###

Operation Menu

1. Open/Close Test

Exit: RETURN

1) On the Aging Test MENU screen, press the [1] key on the

remote commander to display the Open/Close Test screen.

2) Insert discs and press the [ENTER] key on the remote

commander.

3) Is starts the aging.

During aging, the disc number, operating status and repeat cyc le

are displayed. Aging can be aborted at any time by pressing

the x key. After the operation is stopped, press the x key or

[RETURN] key aging to return to the Aging Test MENU.

4. EMERGENCY HISTORY

On the Test Mode Menu screen, selecting [4] displays the

information such as servo emergency history.

The history information from last 1 up to 10 can be scrolled with

theOkey orokey. Also, specific information can be displayed

by directly entering that number with ten keys.

UC : Incorrect value

CR : Correct value

Add: Address

2-9. SACD Water Mark Check

SACD Water Mark Check

PSP AMP

PSN

Start: ENTER Exit: RETURN

On this screen, measure the PSP AMP v alue and PSN value of SACD

water mark.

### EMG. History ###

Laser Hours CD xxxxhxxm

DVD xxxxhxxm

a. bb xx xx xx xx xx xx xx

xx xx xx xx xx xx xx xx

a. bb xx xx xx xx xx xx xx

xx xx xx xx xx xx xx xx

Select:1-9 Scroll:UP/DOWN

(1.Latest EMG.) Exit: RETURN

xxxxhxxm: T he laser on total hours. Data below minutes are

omitted.

a. : Error number.

bb : Error code.

xx : Not used.

• Clearing History Information

Clearing laser hours:

Press the

Then both CD and DVD data are cleared.

Clearing emergency history:

Press the [DVD TOP MENU] and [CLEAR] keys in this order.

Initializing set up data:

Press [DVD MENU] and [CLEAR] keys in this order.

The data have been initialized when “Set Up Initialized”

message is displayed. The EMG. History screen will be restored

soon.

[DVD DISPLAY] and [CLEAR] keys in this order.

25

HCD-S550/S880

• Code list of Emergency History

10: Communication to RF AMP (IC001) failed.

11: Each servo for focus, tracking, and spindle is unlocked.

12: Check sum error of EEPROM (IC203).

14: Communication to servo DSP (IC401) failed, or servo DSP

decoder (IC801) is faulty.

15: Communication to DVD decoder (IC701) failed, or DVD

decoder (IC801) is faulty.

16: Communication to DSD decoder (IC801) failed, or DSD

decoder (IC801) is faulty.

20: Initialization of sled servo failed. It is not placed in the ini-

tial position.

23: Sled servo operation error.

24: Made a request to move the sled servo to wrong position.

30: Tracking balance adjustment error.

31: Tracking gain adjustment error.

33: Focus bias adjustment error.

34: Focus gain adjustment error.

35: Equalizer adjustment error.

40: Focus servo does not operate.

41: With a DVD dual layer disc, focus jump failed.

50: CLV (spindle) servo does not operate.

51: Spindle does not stop.

60: Made a request to seek nonexistent address.

61: Seek error of retry more than regulated times.

70: Control data could not be read.

80: Disc reading failed.

5. MECHA ERROR HISTORY

On the T est Mode Menu screen, selecting [5] displays the information

of mechanism deck error history.

The history information from last 1 up to 8 can be scrolled with

theOkey orokey. Also, specific information can be displayed

by directly entering that number with ten keys.

aa: Initialization is completed or not.

FF : Complete.

other number: Not complete.

bb:Operating status of mechanism deck at an error occurred.

(lod sq jcp)

00 : Initializing.

10 to 15 : Open operating.

16 to 19 : Kicking cause open failed.

1A to 1F : Open operating.

20 to 27 : Complete the open operation.

28 : No disc and complete the open operation.

29 to 2F : Complete the open operation.

30 to 3F : Close requesting.

40 to 4F : Open requesting.

50 to 5F : Close operating.

60 to 6F : Complete the chucking operation.

80 to 8F : Complete the release operation.

(BU is home position)

90 to 9F : BU down operating.

A0 to AF : Opening/closing the shutter. Or stationary state in

open/close the shutter is enablement.

B0 to BF : BU up requesting.

C0 to CF : BU down requesting.

D0 to DF: BU upping.

E0 to EF : No disc checking in disc loading.

cc: Operating status of mechanism deck at an error occurred.

(lod oq jcp)

00 : Complete the operation.

10 to 1F : Open operating.

20 to 2F : Close operating.

30 to 3F : Release operating.

60 to 6F : Chucking operating.

70 to 7F : Kicking operating.

80 to 8F : Returning the BU to home position. (after kicking)

### Mecha Error History ###

1. aa bb cc xx xx xx xx xx

2. aa bb cc xx xx xx xx xx

3. aa bb cc xx xx xx xx xx

4. aa bb cc xx xx xx xx xx

5. aa bb cc xx xx xx xx xx

6. aa bb cc xx xx xx xx xx

7. aa bb cc xx xx xx xx xx

8. aa bb cc xx xx xx xx xx

Scroll:UP/DOWN

(1.Latest Err.) Exit: RETURN

26

SECTION 6

ELECTRICAL ADJUSTMENT

HCD-S550/S880

Ver 1.4

6. VERSION INFORMATION

On the Test Mode Menu scr een, selecting [6] displays the ROM

version and region code.

The parenthesized hexadecimal number in version field is checksum

value of ROM.

## Version Information ##

IF con. Ver.x. xx

SYScon. Ver.x. xx (xxxx)

Model DAV-Sxxx

Region 0x

Front End Ver.x.xx

Exit: RETURN

IF con. : The version of system controller (IC901).

SYScon. : The version of DVD system processor (IC206).

Front End: The version of mechanism controller (IC301).

7. VIDEO LEVEL ADJUSTMENT

AUTO SERVO ADJUSTMENT

After parts related to the servo circuit (RF amplifier (IC001), DSP

(IC401), motor driver (IC501), EEPROM (IC302) so on) are

replaced, re-adjusting the servo circuit is necessary. Select “ALL”

at “1. DRIVE AUTO ADJUSTMENT” (Refer to page 21 in TEST

MODE) and adjust DVD-SL (single layer), CD and DVD-DL (dual

layer).

On the Test Mode Menu scr een, selecting [7] displays color bars

for video level adjustment. During display of color bars, OSD

disappears but the menu screen will be restored if pressing the

[RETURN] key.

2727

HCD-S550/S880

SECTION 7

DIAGRAMS

7-1. BLOCK DIAGRAM – RF SERVO Section –

• SIGNAL PATH

: CD PLAY

: DVD PLAY

: SACD PLAY

RF

1

63

DVDRFP

RFSIN

ATOP

ATON

62

61

: AUDIO

: VIDEO

117

RFIN

64

FNP

AIP

59

AIN

60

FNN

535254

DIP

55

DIN

RFAC

57

50

RFAC

DOUT

PCMD

32, 30, 27, 24

HDB0 – HDB7

66

160

MDAT

44, 41, 39, 35,

AV DATA BUS

WARFI

CDDOUT

SD0 – SD7

(for AUDIO SYSTEM)

SD0 – SD7

(for VIDEO SYSTEM)

A

B

C

D

(Page 29)

(Page 29)

(Page 29)

(Page 31)

DETECTOR

OPTICAL PICK-UP

BLOCK

(TDP022W)

LASER

CD LD

DIODE

(FOR CD)

LASER

DVD LD

DIODE

(FOR DVD)

INLIM

FCS+

FCS–

2AXIS

DEVICE

FOCUS/

COIL

TRK+

TRK–

TRACKING

A

B

C

D

F

E

PD

SW

AUTOMATIC POWER

CONTROL (FOR CD)

AUTOMATIC POWER

CONTROL (FOR DVD)

LASER DIODE

M1

(SPINDLE)

SELECT

Q301

M2

(SLED)

MM

D

Q002

Q001

CBA

MM

A2

3

B2

4

C2

5

D2

6

18

CD E

17

CD F

B

12

A

A

11

B

D

10

C

C

9

D

B

16

CD A

A

15

CD B

D

14

CD C

C

13

CD D

22

CDLD

24

CDPD

DVDPD

23

DVDLD

21

V125

36

FOCUS/TRACKING COIL DRIVER,

SPINDLE, SLED MOTOR DRIVER

36 48

37 1

34 3

35 4

32

31

30

29

27

28

47

46

IC501

BUFFER

FOCUS COIL

DRIVE

TRACKING COIL

DRIVE

SLED MOTOR

DRIVE

SLED MOTOR

DRIVE

SPINDLE MOTOR

DRIVE

BUFFER

CD/DVD/SACD RF AMP,

FOCUS/TRACKING ERROR AMP

POWER SAVE

MUTE12

MUTE34

MUTE5

TSD-M

IC001

4042

7

10

39

19

20

21

22

13

45

(1.65V)

FF

FR

TF

TR

AVC

SDATA

SCLK

SDEN

MIRR

LDON

FF

FR

TE

FE

7

8

44

43

97

60

63

73

62

47

46

48

39

40

42MNTR

27

26

76 31

LDSEL

FCS JMP 1

FCS JMP 2

SLED B

SLED A

DSAVE

MUTE 2D

SP ON

TSD

FG

28

LD ON

SLED

DATA_RF

CLK_RF

SDEN

MIRR

INLIM

61

TE

FE

PI

TE

FE

PI

CLK_RF

DATA_RF

82

83

SDATA RF

AMP

IC402 (1/2)

SDEN

2

SDEN

SDCLK RF

BCLK

LRCK

C2PO

WDCK

WFCK

SBSO

DIGITAL SIGNAL PROCESSOR,

DIGITAL SERVO PROCESSOR

SSTP

26

41

TE

40

SE

FE

39

43

RFDC

VC

38

CE

42

FF

33

FFDR

FR

34

FRDR

TF

31

TFDR

TR

32

TRDR

SFDR

29

SRDR

30

MIRR

PI

FE

TE

67PI66

65

FE

TE

MECHANISM

CONTROLLER

IC301 (1/2)

EXCK

IC401

XTAI

MDP

XRST

MD2

SCOR

DATA

CLOK

XLAT

SENS

SQSO

SQCK

LOCK

GFS

MUTE

COUT

SCLK

FOK

MIRR

LRCK

65

C2PO

14

GSCOR

17

WFCK

10

SBSO

79

EXCK

80

SCOR

CLOCK

GENERATOR

IC303

10 3

71

25

2

63

15

4

6

5

7

76

77

24

13

3

19

8

22

20

3

26

49

50

27

9

52

54

75

71

59

30

72

74

29

DOCTR/

ISBTEST

SCOR

DATA CD

CLOK CD

LAT CD

SENS CD

SQSO

SQCK

LOCK CD

GFS CD

MUTE CD

COUT CD

SCLK CD

FOK CD

MIRR

IC703 (2/2)

7 8

XTI

SO2

MO1

13 9

27M

BUFFER

X302

27MHz

XTO

SO3

SO1

768FS

98

XDRST

XRD

XWR

XCS DVD

INT0 DVD

INT1 DVD

GFS DVD

XRST DVD

JIT OFFSET

SACD/DVD

EEP RDY

EEP SI

EEP CLK

EEP CS

SDIN DSD

SDOUT DSD

SCK DSD

XMSLAT

READY DSD

MUTE DSD

JIT

14-21

D0 – D7

89-96

A0 – A7

85

84

12

22

23

58

25

45

64

77

6

5

100

99

47

46

24

51

48

53

BCLK

67

BCLK

LRCK

C2PO

GSCOR

WFCK

SBSO

EXCK

SCOR

COMPARATOR

IC703 (1/2)

5

SDA

6

SCL

7

WP

MSDATO

MSDATI

MSCK

XMSLAT

SHRRDY

SHRMUT

158

BCK

163

LRCK

155

C2PO

146

GSCOR

151

WFCK

148

SBIN

147

EXCK

150

SCOR

DVD DECODER

167

XTA1

169

XTA2

170

XTAL

137

MDIN2

135

SPO

D0 – D7

172-176, 1, 2, 4

A0 – A7

5, 7, 9-14

17

XRD

18

XWR

19

XCS

20

XINT0

21

XINT1

107

GFS

164

XRST

EEPROM

IC302

IC701

AEP0

109

XDCK

XSAK

HDB8

XSHD

MNT2

MDB0 – MDB9,

MDBA – MDBF

MA0 – MA9

WE

XMOE

XRAS

XCAS

XSRQ

MNT1

53

92

48

46

26

49

93

66-69, 71, 73-75, 96, 97,

79, 80, 82-87,

76

94

78

95

XDCK

XSAC

SDEF

XSHD

2-5, 7-10,

99, 101, 102, 104-106

89, 91

21-24,

17

33

18

34

35

SACD/DVD

SELECT

IC814

41-44, 46-49

27-32

WE

OE

RAS

UCAS

LCAS

XMSLAT, SHRRDY, SHRMUT

XDCK, XSAC, SDEF, XSHD

(for AUDIO SYSTEM)

XDCK, XSAC,, SDEFF

(for VIDEO SYSTEM)

WCK

I/O0 – I/O15A0 – A9

16Mbit

D-RAM

IC706

768FS

27M

XRST_DSD

XSRQ

XSRQ-ZIVA

MSDATO, MSDATI, MSCK,

E

F

G

H

J

K

L

M

I

(Page 29)

(Page 31)

(Page 29)

(Page 29)

(Page 31)

(Page 29)

(Page 29)

(Page 31)

(Page 29)

2828

7-2. BLOCK DIAGRAM – AUDIO (DSP) Section –

D5V

REFERENCE VOLTAGE

GENERATOR

(Page 28)

(Page 28)

(Page 28)

(Page 28)

(Page 28)

(Page 28)

(Page 28)

(Page 28)

(Page 31)

(Page 28)

(Page 31)

(Page 31)

(Page 30)

WARFI

A

WCK

G

SD0 – SD7

C

SDEF, XSHD,

XDCK, XSAK

E

768FS

H

MSDATO, MSDATI, MSCK,

XMSLAT, SHRRDY, SHRMUT

M

XRST_DSD

J

XSRQ

K

TDOSA, TDISA,

TCK, TMS, TRST

N

CDDOUT

B

SPDIF

O

COAXIAL

FM

75Ω

AM

AV0 – AV2

P

RSTAD

S

AV DATA BUS

J205 (1/4)

VIDEO 1

AUDIO IN

J206 (1/3)

VIDEO 2

AUDIO IN

FM/AM TUNER PACK

FM ANT

L-CH

GND

R-CH

AM ANT

GND

DI

DO

CK

CE

TUNED

FM-DET

(AEP, UK, Russian)

L

R

L

R

XDCK

XSAK

SDEF

XSHD

R-CH

TUDI

TUDO

TUCLK

TCE

TUN

DET AMP

IC402 (2/2)

LEVEL SHIFT

LEVEL SHIFT

OPTICAL

DIGITAL IN

VIDEO 2

R-CH

R-CH

Q201

IC812

IC813

MSDATO

MSDATI

MSCK

XMSLAT

SHRRDY

SHRMUT

TDOSA

TDISA

TCK

TMS

TRST

OPTICAL RECEIVER

AMP

Q221

4

X201

4.332MHz

IC204

Q205

MUX

XI XO

13 14

127

126

123

169 – 176

166

167

168

165

11

6

4

3

2

7

10

9

164

29

27

26

30

31

AUDIO INPUT

SELECTOR

IC202

2

Y2

1

Y0

5

Y1

10 9

AV2

RDATA

RCLK

WAVRB

WARFI

WCK

SD0 – SD7

SDCK

XSAK

SDEF

XSHD

DSD DECODER

MCKI

MSDATO

MSDATI

MSCK

XMSLAT

MSREADY

SMUTE

XRST

XSRQ

TDO

TDI

TCK

TMS

TRST

Y

AB

Q206

AV0

2

16

RDS DECODER

IC801

12.288MHz

3

RDSD

RDSC

IC201

PHREFO

EXCKO1

X600

DSAL

DSAR

DSAC

DSALFE

DSALS

DSARS

DQ0 – DQ7A0 – A11

XWE

XRAS

XCAS

DCKE

DCLK

LOW-PASS

FILTER

IC603

64

66

69

71

74

76

62

13

134-131

139-136,

162-159, 157-154,

152, 151, 149, 148

143

145

144

142

141

5

DIN2

4

DIN1

3

DIN0

22

XIN

21

XOUT

20

XMCK

R-CH

9, 11, 12

2, 3, 5, 6, 8,

A0 – A11

19-24, 27-32

15

WE

17

RAS

16

CAS

34

CKE

35

CLK

DIGITAL AUDIO

INTERFACE

IC606

A/D CONVERTER

IC602

1

DOUT

LIN

BCK

LRCK

5

RIN

SYSCLK

16 6

DQ0 – DQ7

16Mbit

SD-RAM

IC808

16

DATA

13

CKOUT

14

BCK

15

LRCK

36

DI

35

DO

38

CL

37

CE

17

XSTATE

48

XMODE

34

ERROR

24

AUDIO

15

14

13

RSTB

(AEP, UK, Russian)

EXID2

BCK2

LRCK2

PLOCK

DIGDI

DIGCLK

CSDIR

XST

RSTDIR

DO

EXIMCK

EXILRCK

TUDI

TUDO

TUCLK

TCE

TUN

RDSD

RDSC

AV0

AV1

AV2

EXID1

EXIBCK

33

52

54

55

53

51

88

94

95

96

48

EXID1

EXIMCK

EXIBCK

EXILRCK

AD-RST

TUN-DI

TUN-DO

TUN-CLK

TUN-CE

TUNED

RDS-DATA

RDS-CLK

AV-SEL0

AV-SEL1

AV-SEL2

EXID2

BCK2

LRCK2

98

65

DFIL RST2

DF-SYNC

63

DSIFL

64

DSIFR

65

DSICT

66

DSISW

67

DSISL

68

DSISR

62

DSBCKF

52

MCK

58

EXID1

59

EXIMCK

55

EXIBCK

56

EXILRCK

57

EXID2

29

BCK2

28

LRCK2

79

INIT

78

SYNC

SELEXT

77

ENABLE

SWITCH

Q908 – 910

97

DF-SW

F2FLREX1

F2CSWEX2

F2LRCK

DIGITAL AUDIO

PROCESSOR

IC612

DO

DIGDI

7

25DI8

DIG-DI

F2SLR

CKOUT

F2BCK

CSDIR

DIGCLK

20

DIG-CLK

47

46

45

49

43

44

RSTDIR

24

DIR-CE

DIR-XMODE

X601

13.5MHz

DIGDI

DIGCLK

XST

PLOCK

LEVEL SHIFT

IC900

22

18

6

DSP-DO

DIR-XST

DIR-ZERO

SYSTEM CONTROLLER

IC901 (1/3)

15

17

DSP-HACN

DSP-GP9

18

SDI1

30

SDI2

114

SDI3

22

KFSIO

17

BCKI1

15

LRCKI1

SIGNAL PROCESSOR

9

MCLK1

12

MCLK2

33

HDIN

34

HCLK

35

HDOUT

32

HACN

68

GP9

19

DIR-ERR

SCKOUT

DIGITAL AUDIO

IC607

EXLOCK69GP8

59

D903

23

DIR-AD

SDO4

SDO1

SDO2

SDO3

BCKO

LRCKO

GP10

CS0

WE0

PM

HCS

BST

XRST

Q903

26

23

24

25

14

20

19

67

D0 – D15A0 – A15

44

45

113

36

56

D4

D1

D2

D3

SCK

BCKO

LRCKO

98, 80-77, 75-72

108, 107, 105-102, 99

112, 110, 109,

97-92, 82-85, 66-64

41

17

POWER ON

MUTING

Q490, 492

28

DAMP-MUTEN

RSTDSP

12V

D490

2

D0 – D15

7-10, 13-16,

29-32, 35-38

S-RAM

IC604

A0 – A15

5-1, 44-42,

27-24, 21-18

OE

WE

PM

HCS

BST

PM

13 14 16 12

BST

HCS

DSP-CS

DSP-PM

D1 – D4, SCK,

BCKO, LRCKO

• R-ch is omitted due

to same as L-ch.

• SIGNAL PATH

DIGDI, DIGCLK

NSMUTE

RSTDSP

DSP-BST

DSP-RST

HCD-S550/S880

(Page 30)

Q

: AUDIO

: CD PLAY

: DVD PLAY

: SACD PLAY

: AUX IN

: OPTICAL

DIGITAL IN

: TUNER

(Page 30)

T

(Page 30)

R

2929

HCD-S550/S880

7-3. BLOCK DIAGRAM – AUDIO OUT, PANEL Section –

D/A CONVERTER

3

SDTI

1

MCLK

2

BICK

4

LRCK

8

CDTI

7

CCLK

IC802

DAT

CLK

CS

RST

OSC0

OSC1

VOLUME

S201

SCAN SELECT

INTERLACE

SELECTABLE

IC608

AOUTL+

AOUTL–

AOUTR+

AOUTR–

PDN

65

63

62

61

60

58

59

C818, R840

KEY0, KEY2

KEY INPUT

DETECT

IC903, 904

WAKE UP

DETECT

Q907

SIRCS DETECT

Q906

ROTARY

ENCODER

S800

12

11

10

9

CSN

OSC

I2CDATA

I2CCLK

I2HLP

(Page 29)

(Page 29)

(Page 29)

(Page 29)

(Page 32)

(Page 31)

(Page 31)

• SIGNAL PATH

: AUDIO

DIGDI, DIGCLK

T

RSTAD

S

D1 – D4, SCK,

BCKO, LRCKO

Q

NSMUTE

R

DISC IN

X

I2CDATA,

I2CCLK, I2HLP

W

ZIVARESET

V

FLUORESCENT

INDICATOR TUBE

FL801

D4

SCK

BCKO

LRCKO

DIGDI

DIGCLK

S801 – 806,

S821 – 825

DISC LOADING

DETECT

Q913

REMOTE CONTROL

FL DRIVER

5 – 39

S1 – S35

40 – 51

G1 – G12

4

AD1

3

AD2

RECEIVER

IC801

LOW-PASS

FILTER

IC610

60

57

61

56

82 – 84

93

92

85

86

49

3

5

100

4

MUTING

Q207, 208

SYSTEM CONTROLLER

FL-DATA

FL-CLK

FL-CS

FL-MUTE

KEY0 – KEY2

WAKE

SIRCS

EN-A

EN-B

PROG SW

I2C-DATA

I2C-CLK

I2HLP

CQ-RST

IC901 (2/3)

MUTING CONTROL

Q900

HPSW

HP-MUTE

AU-MUTE

DAS-CS

DAMP-DATA

DAMP-CLK

CS1

CS2

CS3

DAMP-RST

DAMP-MUTING

DIP-RST

DIP-OCP

X1

X2

L

R

J205 (2/4)

VIDEO 1

AUDIO OUT

64

46

47

32

39

38

1

2

29

30

31

26

27

43

44

X901

20MHz

AU-MUTE

DAS-CS

HP-SW

HP-MUTE

AU-MUTE

DAS-CS

SCDT

SHIFT

LATCH1

LATCH2

LATCH3

INIT

PGMUTE

D1

SCK

BCKO

LRCKO

SCDT

SHIFT

LATCH1

INIT

PGMUTE

D2

SCK

BCKO

LRCKO

SCDT

SHIFT

LATCH2

INIT

PGMUTE

D3

SCK

BCKO

LRCKO

SCDT

SHIFT

LATCH3

INIT

PGMUTE

STREAM PROCESSOR

IC305

43

DATA

64

XFSIIN

44

BCK

45

LRCK

38

SCDT

37

SCSHIFT

36

SCLATCH

41

INIT

40

PGMUTE

39

NSPMUTE

STREAM PROCESSOR

IC308

43

DATA

64

XFSIIN

44

BCK

45

LRCK

38

SCDT

37

SCSHIFT

36

SCLATCH

41

INIT

40

PGMUTE

39

NSPMUTE

STREAM PROCESSOR

IC310

43

DATA

64

XFSIIN

44

BCK

45

LRCK

38

SCDT

37

SCSHIFT

36

SCLATCH

41

INIT

40

PGMUTE

39

NSPMUTE

OUTL1–

OUTL2–

OUTR1–

OUTR2–

OUTL1+

OUTL2+

OUTR1+

OUTR2+

XFSOIN

FSOCKO

FSOI

XFSOUT

XFSOIN

OUTR1+

OUTR2+

OUTL1+

OUTL2+

FSOI

XFSOUT

XFSOIN

OUTL1+

OUTL2+

OUTR1+

OUTR2+

FSOI

OVER LOAD

DETECT

Q109, 110

OVER LOAD

DETECT

Q103, 104

OVER LOAD

DETECT

Q105, 106

OVER LOAD

DETECT

Q111, 112

OVER LOAD

DETECT

Q107, 108

OVER LOAD

DETECT

Q101, 102

HP-SW

32V

J401

SPEAKER

FAN

Y

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(Page 32)

J900

PHONES

FRONT

L

FRONT

R

CENTER

WOOFER

REAR

L

REAR

R

21

18

7

4

24

15

10

1

28

73

74

77

28

10

1

24

15

74

77

28

24

15

10

1

74

BUFFER

49.152MHz

IC300

X300

HADPHONE

AMP

IC401

HP-MUTE

CONTROL

POWER AMP

IC301

6

INA

16

INB

ENA

ENB

7 17 8 18

POWER AMP

IC304

6

INA

16

INB

ENA

ENB

7 17 8 18

POWER AMP

IC307

6

INA

16

INB

ENA

ENB

7 17 8 18

POWER AMP

IC306

6

INA

16

INB

ENA

ENB

7 17 8 18

POWER AMP

IC309

6

INA

16

INB

ENA

ENB

7 17 8 18

POWER AMP

IC311

6

INA

16

INB

ENA

ENB

7 17 8 18

PROTECT DETECT

Q113, 114

MUTING

Q902

D181 D192

OUTA

19

OUTB

DIAGA

DIAGB

OUTA

19

OUTB

DIAGA

DIAGB

OUTA

19

OUTB

DIAGA

DIAGB

OUTA

19

OUTB

DIAGA

DIAGB

OUTA

19

OUTB

DIAGA

DIAGB

OUTA

19

OUTB

DIAGA

DIAGB

MUTING

Q900, 901

POWER ON

MUTING

9

D105

9

D102

9

D103

9

D106

9

D104

9

D101

Q192

3030

Loading...

Loading...