Sony DSLR-A580 Service manual

DSLR-A560/A560L/A560Y/A580/A580L/

SERVICE MANUAL

A580Y/A580J

LEVEL 2

983452131.pdf

Revision History

Ver. Date History Contents

1.0 2010.09 Official Release — —

S.M. Rev.

issued

Ver. 1.0 2010.09

Photo: DSLR-A580

SERVICE NOTE (Check the following note before the service.)

– ENGLISH –

1-1. METHOD OF REPLACING THE FOCUS PLATE

1-2. PRECAUTION ON REPLACING THE AM-025 BOARD

1-3. METHOD FOR CHECKING THE AS SLIDER UNIT (863)

1-4. METHOD FOR ADJUSTING THE TEBURE REVISE

1-5. METHOD FOR REPLACING THE AS SLIDER B ASSY

1-6. METHOD FOR REPLACING THE AS HOLDER ACTUATOR ASSY

US Model

AEP Model

UK Model

E Model

Australian Model

Chinese Model

Korea Model

[About the service of this model]

DSLR-A560L/A580L is a commodity that packed the Interchangeable Lens Digital Camera (DSLR-A560/A580) and Zoom Lens Kit (DT 18-55mm

F3.5-5.6 SAM).

DSLR-A560Y/A580Y is a commodity that packed the Interchangeable Lens Digital Camera (DSLR-A560/A580) and W Zoom Lens Kit (DT 18-55mm

F3.5-5.6 SAM/DT 55-200mm F4-5.6 SAM).

DSLR-A580J is a commodity that packed the Interchangeable Lens Digital Camera (DSLR-A580) and Zoom Lens Kit (DT 18-250mm F3.5-6.3).

Refer to each following service manual of the Zoom lens kit, when you repair.

• Zoom Lens Kit

SAL1855 (DT 3.5-5.6/18-55 SAM) (DT 18-55mm F3.5-5.6 SAM) Service Manual (9-852-691-1[])

SAL55200-2 (DT 4-5.6/55-200 SAM) (DT 55-200mm F4-5.6 SAM) Service Manual (9-852-692-1[])

SAL18250 (3.5-6.3/18-250) (DT 18-250mm F3.5-6.3) Service Manual (9-852-228-1[])

INTERCHANGEABLE LENS DIGITAL CAMERA/ZOOM LENS KIT

The components identified

by mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number

specified.

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

9-834-521-31

Sony Corporation

2010I29-1

© 2010.09

Published by Sony Techno Create Corporation

Camera

[System]

Camera Type

Lens A-mount lens

[Image sensor]

Image format

Total pixel number of image sensor

Effective pixel number of camera

[SteadyShot]

System Image sensor-shift

Effect Approx. 2.5 EV to 4 EV in

[Anti-Dust]

System Charge protection coating

[Auto focus system]

System TTL phase-detection

Metering points

Sensitivity Range

AF illuminator

[Live View]

Type Pentamirror tilt mechanism

Image format

Frame coverage

Interchangeable Lens

Digital Camera

DSLR-A580

23.5mm×15.6mm (APSC format) “Exmor” CMOS

image sensor

DSLR-A560

23.4 mm×15.6 mm (APSC format) “Exmor” CMOS

image sensor

DSLR-A580

Approx. 16 700 000 pixels

DSLR-A560

Approx. 14 600 000 pixels

DSLR-A580

Approx. 16 200 000 pixels

DSLR-A560

Approx. 14 200 000 pixels

mechanism

shutter speed (depending

on shooting conditions and

th

e attached lens)

on Low-Pass Filter and

image sensor-shift

mechanism

system (Contrast AF

method is selectable in

focus check Live View

mode)

15 points (3 points cross

type) (11 points in

viewfinder mode)

–1 EV to 18 EV (at ISO

100 equivalent)

Approx. 1 m to 5 m

(3.3 feet to 16.4 feet)

Exclusive image sensor for

Live View

Approx. 90%

SPECIFICATIONS

[Viewfinder]

Type Fixed eye-level penta-

Frame coverage

Magnification

Eye Point Approximately 19 mm

Dioptor Adjustment

[Focus check Live View]

Image format

Frame coverage

[LCD monitor]

LCD panel 7.5 cm (3.0 type) TFT

Total number of dots

[Exposure control]

Metering Cell

Metering method

Metering Range

ISO sensitivity (Recommended

Exposure compensation

Dach-mirror

Approx. 95%

0.80 × with 50 mm lens at

infinity, –1 m

from the eyepiece, 15 mm

from the eyepiece frame at

–1 m

–2.5 m

Image sensor for shooting

Approx. 100%

drive

921 600 (640 × 3 (RGB) ×

480) dots

Live View

Exclusive image sensor for

Live View

Viewfinder

40-segment honeycombpattern SPC

Focus check Live View

“Exmor” CMOS sensor

Live View/Focus check

Live View

1200-zone evaluative

metering

Viewfinder

TTL shutter-open metering

Live View

1 EV to 17 EV on all

metering modes, at ISO

100 equivalent with F1.4

lens)

Viewfinder

2 EV to 20 EV (4 EV to

20 EV on spot metering

mode) (ISO 100 equivalent

with F1.4 lens)

Focus check Live View

DSLR-A580

–2 EV

metering modes (ISO 100

equivalent with F1.4 lens

DSLR-A560

–2 EV to 16 EV on all

metering modes (ISO 100

equivalent with F1.4 lens)

exposure index)

AUTO, ISO 100 to 12800

±2.0 EV (1/3 EV step)

–1

–1

–1

to +1.0 m

to 17 EV on all

(diopter)

–1

[Shutter]

Type Electronically-controlled

Speed range 1/4000 second to 30

Flash sync speed

vertical-traverse, focalplane type

seconds, bulb, (1/3 EV

step)

1/160 second

[Built-In-Flash]

Flash guide number

Recycling time

Flash coverage

Flash compensation

GN 12 (in meters at ISO

100)

Approx. 4 seconds

Covering 18 mm lens

(focal length that the lens

indicates)

±2.0 EV (1/3 EV step)

[Recording format]

File format JPEG (DCF Ver. 2.0, Exif

Movie (AVCHD format)

Movie (MP4 format)

Ver. 2.3, MPF Baseline)

compliant, DPOF

compatible

AVCHD Ver. 1.0

compliant

Video: MPEG-4 AVC/

H.264

Audio: Dolby Digital 2ch,

equipped with Dolby

Digital Stereo Creator

• Manufactured under

rom Dolby

license f

Laboratories.

Video: MPEG-4 AVC/

H.264

Audio: MPEG-4 AAC-LC

2ch

[Recording media]

“Memory Stick PRO Duo”

media, SD card

[Input/output terminals]

USB miniB

HDMI HDMI type C minijack

MIC Terminal

REMOTE Terminal

Ø 3.5 mm Stereo minijack

[Power, general]

Used battery pack

Rechargeable battery pack

NP-FM500H

[Others]

Exif Print Compatible

PRINT Image Matching III

Compatible

Dimensions Approx. 137 mm ×

Mass Approx. 679 g (1 lb 7.9 oz)

Operating temperature

USB communication

104 mm × 84 mm

(5 1/2 inches × 4 1/8 inches

× 3 3/8 inches) (W/H/D,

excluding protrusions)

(with battery and “Memory

Stick PRO Duo” media)

Approx. 599 g (1 lb 5.1 oz)

(body only)

0°C to 40°C (32°F to

104°F)

Hi-Speed USB (USB 2.0

compliant)

BC-VM10 Battery charger

Input rating 100 V - 240 V AC, 50/60

Output rating

Operating temperature range

Storage temperature range

Maximum dimensions

Mass Approx. 90 g (3.2 oz)

Hz, 9 W

8.4 V DC, 0.75 A

0°C to 40°C (32°F to

104°F)

–20°C to +60°C (–4°F to

+140°F)

Approx. 70mm × 25 mm ×

95 mm (2 7/8 inches ×

1 inches × 3 3/4 inches)

(W/H/D)

Rechargeable battery pack

NP-FM500H

Used battery

Maximum voltage

Nominal voltage

Maximum charge voltage

Maximum charge current

Capacity

Typical 1

Minimum 11.5

Maximum dimensions

Mass Approx. 78 g (2.8 oz)

Design and specifications are subject

to change without notice.

Lithium-ion battery

DC 8.4 V

DC 7.2 V

DC 8.4 V

2.0 A

1.8 Wh (1 650 mAh)

Wh (1 600 mAh)

Approx. 38.2 mm ×

20.5 mm × 55.6 mm

(1 9/16 inches × 13/16

inches × 2 1/4 inches)

(W/H/D)

Model information table

Model DSLR-A560 DSLR-A560L DSLR-A560Y

Destination US, AEP, UK, E US, AEP, UK, E, CH AEP, UK, E

Imager sensor 14M 14M 14M

Lens

×

DT 18-55mm F3.5-5.6 SAM

Model DSLR-A580 DSLR-A580L DSLR-A580Y DSLR-A580J

Destination

US, AEP, UK, E, AUS, CH,

KR

US, AEP, UK, E, CH, KR AEP, UK, E, AUS, KR CH

Imager sensor 16M 16M 16M 16M

Lens

• Abbreviation

AUS : Australian model

CH : Chinese model

KR : Korea model

×

DT 18-55mm F3.5-5.6 SAM

DT 18-55mm F3.5-5.6 SAM/

DT 55-200mm F4-5.6 SAM

DT 18-55mm F3.5-5.6 SAM/

DT 55-200mm F4-5.6 SAM

DT 18-250mm F3.5-6.3

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

– 2 –

CHEMICALS

Some chemicals used for servicing are highly volatile.

Their evaporation caused by improper management affects your health

and environment, and wastes resources.

Manage the chemicals carefully as follows.

• Store chemicals sealed in a specific place to prevent from exposure

to high temperature or direct sunlight.

• Avoid dividing chemicals into excessive numbers of small containers

to reduce natural evaporation.

• Keep containers sealed to avoid natural evaporation when chemicals

are not in use.

• Avoid using chemicals as much as possible. When using chemicals,

divide only required amount to a small plate from the container and

use up it.

PLASTIC PARTS

Be careful to the following points for plastic parts used in this unit.

• Use a piece of cleaning paper or cleaning cloth for cleaning plastic

parts. Avoid using chemicals.

Even if you have to use chemicals to clean heavy dirt, don’t use paint

thinner, ketone, nor alcohol.

• Insert the specific screws vertically to the part when installing a

plastic part.

Be careful not to tighten screws too much.

Danger of explosion if battery is incorrectly replaced.

Caution

Replace only with the same or equivalent type.

Dispose of used batteries according to the instructions.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS LIST

ARE CRITICAL TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY

SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched”

or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C during

repairing.

• Do not touch the soldering iron on the same conductor of the circuit

board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

UNLEADED SOLDER

This unit uses unleaded solder.

Boards requiring use of unleaded solder are printed with the lead free

mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with the

lead free mark due to their particular size.)

: LEAD FREE MARK

Be careful to the following points to solder or unsolder.

• Set the soldering iron tip temperature to 350 °C approximately.

If cannot control temperature, solder/unsolder at high temperature

for a short time.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

Unleaded solder is more viscous (sticky, less prone to

flow) than ordinary solder so use caution not to let solder

bridges occur such as on IC pins, etc.

• Be sure to control soldering iron tips used for unleaded solder and

those for leaded solder so they are managed separately. Mixing unleaded solder and leaded solder will cause detachment phenomenon.

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

– 3 –

1. SERVICE NOTE

1-1. METHOD OF REPLACING THE FOCUS PLATE 1-3. METHOD FOR CHECKING THE AS SLIDER UNIT (863)

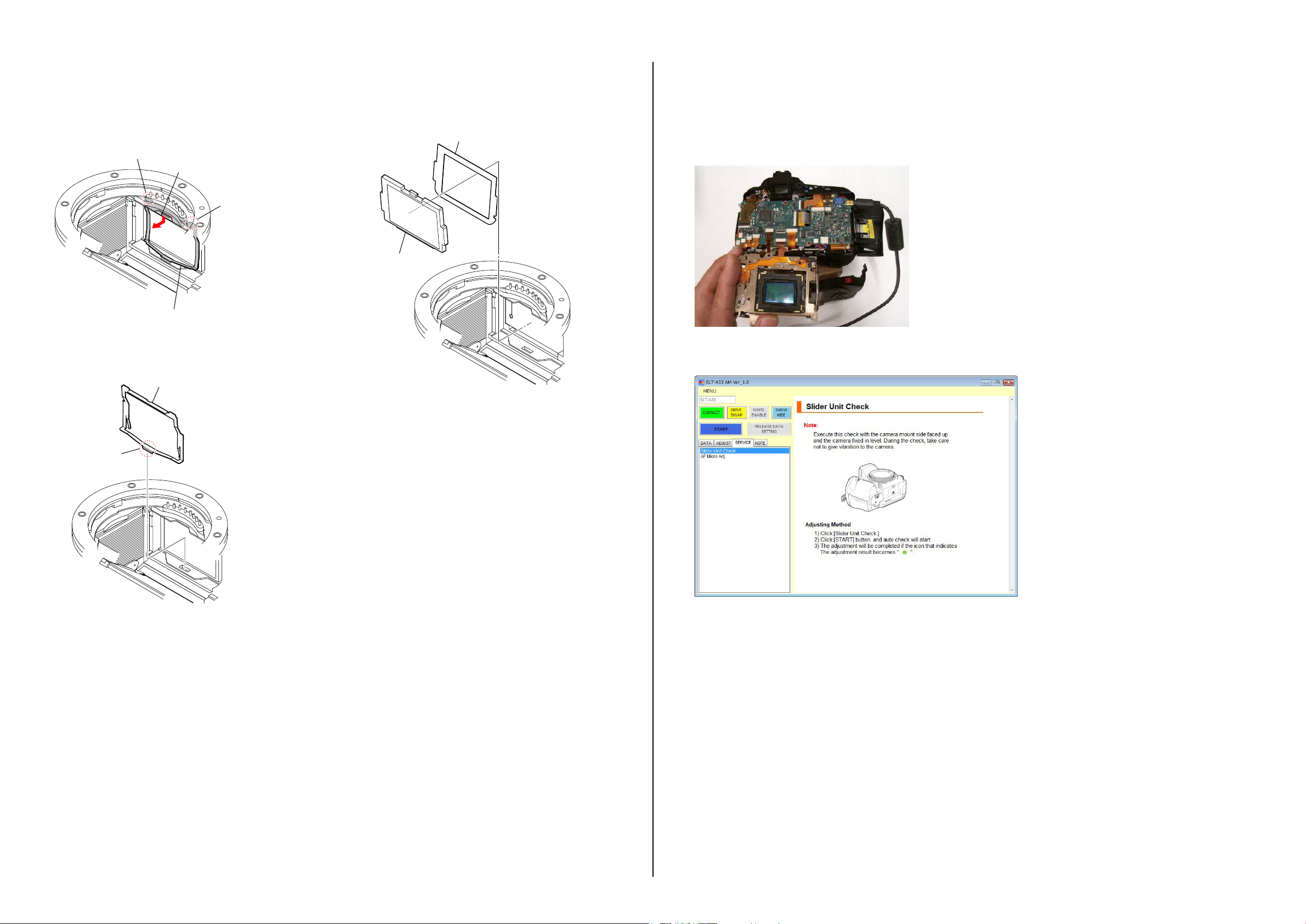

1 Remove two claws pushing part A below,

and remove the VM FS Retainer in the direction

of arrow.

Claw

A

Claw

VM FS Retainer

2 Remove the VM FS Retainer.

VM FS Retainer

3 Remove the Focus Plate and the VB Spacer.

VB Spacer

Focus Plate

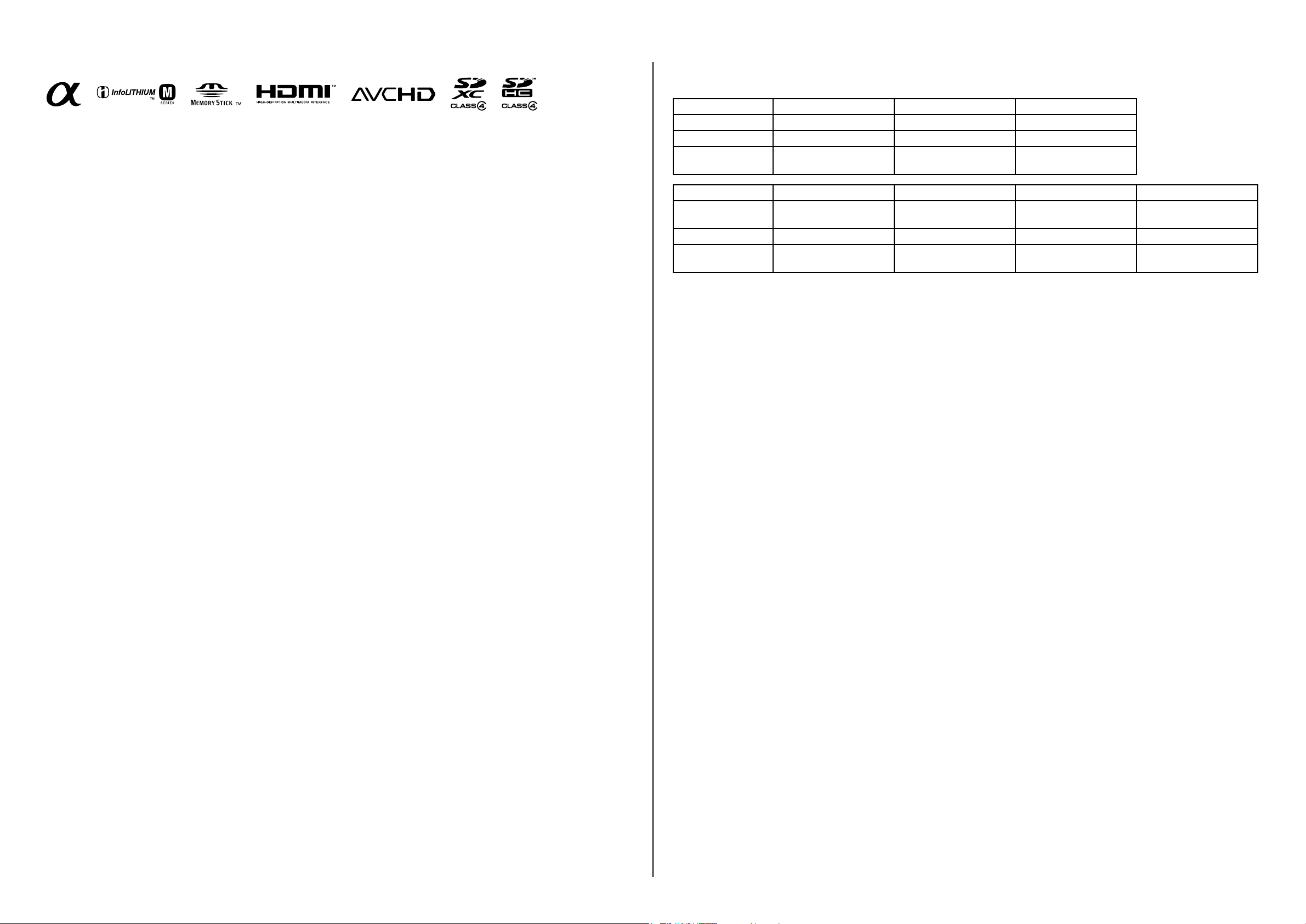

Make sure to confirm below before replacing the AS Slider B Assy or the AS Holder Actuator Assy.

(1) Remove the CV Rear Cover Assy (865), and temporally mount the AS Slider Unit (863).

(2) Set the AS Slider Unit (863) upwards as shown in figure, and put it on a stable place.

(3) Select “Slider Unit Check” of the adjustment software, and then confirm the movement to the directions of Pitch and Yaw, and if an error occurs,

replace it with the component part corresponding to the movement.

Claw

1-2. PRECAUTION ON REPLACING THE AM-025 BOARD

Destination Data

When you replace to the repairing board, the written destination data of repairing board also might be changed to original setting.

USB Serial No.

The set is shipped with a unique ID (USB Serial No.) written in it.

This ID has not been written in a new board for service, and therefore it must be entered after the board replacement.

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

1-1

1-4. METHOD FOR ADJUSTING THE TEBURE REVISE

y

1-5. METHOD FOR REPLACING THE AS SLIDER B ASSY

Make sure to confirm below after replacing the AS Slider B Assy or the AS Holder Actuator Assy.

(1) Remove the CV Rear Cover Assy (865), temporally mount the AS Slider Unit (863) mounted with the Imager Sensor, and then set up the camera

body and hold the AS Slider Unit (863) as shown in figure.

(2) Select “Slider Unit Check” of the adjustment software, and then confirm if the result is OK.

(3) Select “Tebure Revise Adj.” of the adjustment software, and then confirm if the result is OK.

(4) Mount the AS Slider Unit (863) to the camera.

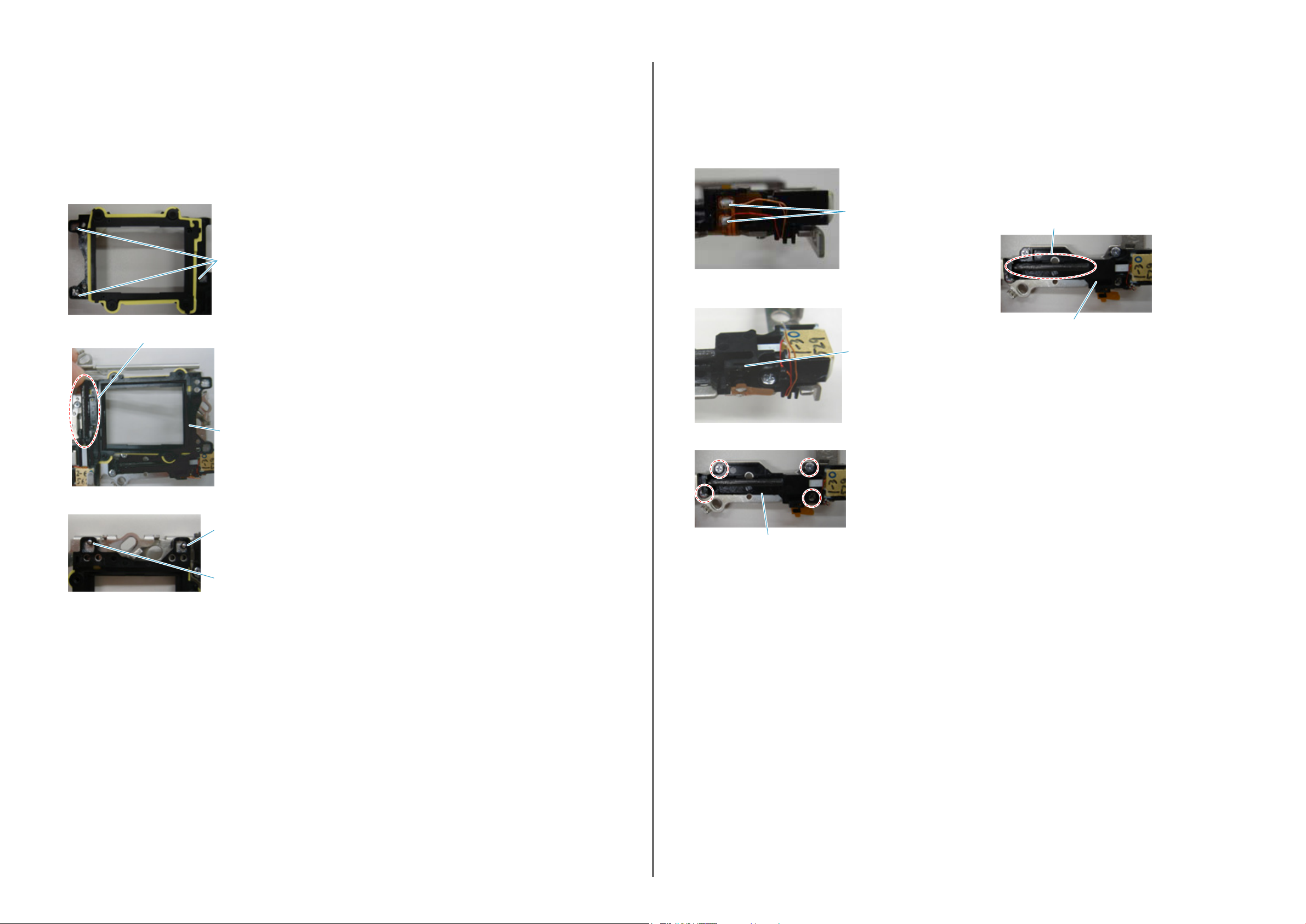

Removal Procedure

(1) Remove the spring.

Spring

(2) Remove the solder on the enamel wires at two places.

Solder

Solder

(3) Remove the flexible board from the AS Slider B Assy.

Flexible Board

(7) Remove two Cap SPs (for Pitch and Yaw).

Cap SP

(8) Remove two Caps (for Pitch and Yaw).

Cap

(9) Remove the AS Slider A Assy.

It can be done easily if A is removed beforehand.

A

(4) Remove two screws.

(10) Remove the AS Slider B Assy.

It can be done easily if B is removed beforehand.

AS Slider A Assy

B

(5) Remove the AS Unit Holder Ball.

AS Unit Holder Ball

(6) Remove two Ball Bearings.

(11) Remove three Ball Bearings.

AS Slider B Ass

Ball Bearing

Ball Bearing

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

1-2

Ball Bearing

1-6. METHOD FOR REPLACING THE AS HOLDER ACTUATOR ASSY

G-15 andGG-116

Assembly Procedure

Note: Make sure to perform the assembly procedures after assembling the AS Holder Actuator Assy.

The assembly procedure is the reverse of the removal procedure.

Apply grease to the portions indicated below.

* Refer to “SUBSIDIARY MATERIALS” on page 2-2 for the part number of grease.

* After applying grease, attach the Ball Bearings.

Ball Bearing

G G-15

G G-15 and G G-116

AS Slider B Assy

Removal Procedure

Note: Make sure to perform the removal procedures after removing the

AS Slider B Assy.

(1) Remove the solder on the enamel wires at two places.

Solder

(2) Remove the flexible board from the hook on the AS Holder Actuator

Assy.

Hook

(3) Remove four screws to remove the AS Holder Actuator Assy.

Assembly Procedure

Note: Make sure to perform the assembly procedures before assembling

the AS Slider B Assy.

The assembly procedure is the reverse of the removal procedure.

Apply grease to the portions indicated below.

* Refer to “SUBSIDIARY MATERIALS” on page 2-2 for the part

number of grease.

G

AS Holder Actuator Assy

* After applying grease, attach the Ball Bearings.

Ball Bearing

G G-15

Ball Bearing

G G-15

AS Holder Actuator Assy

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

1-3E

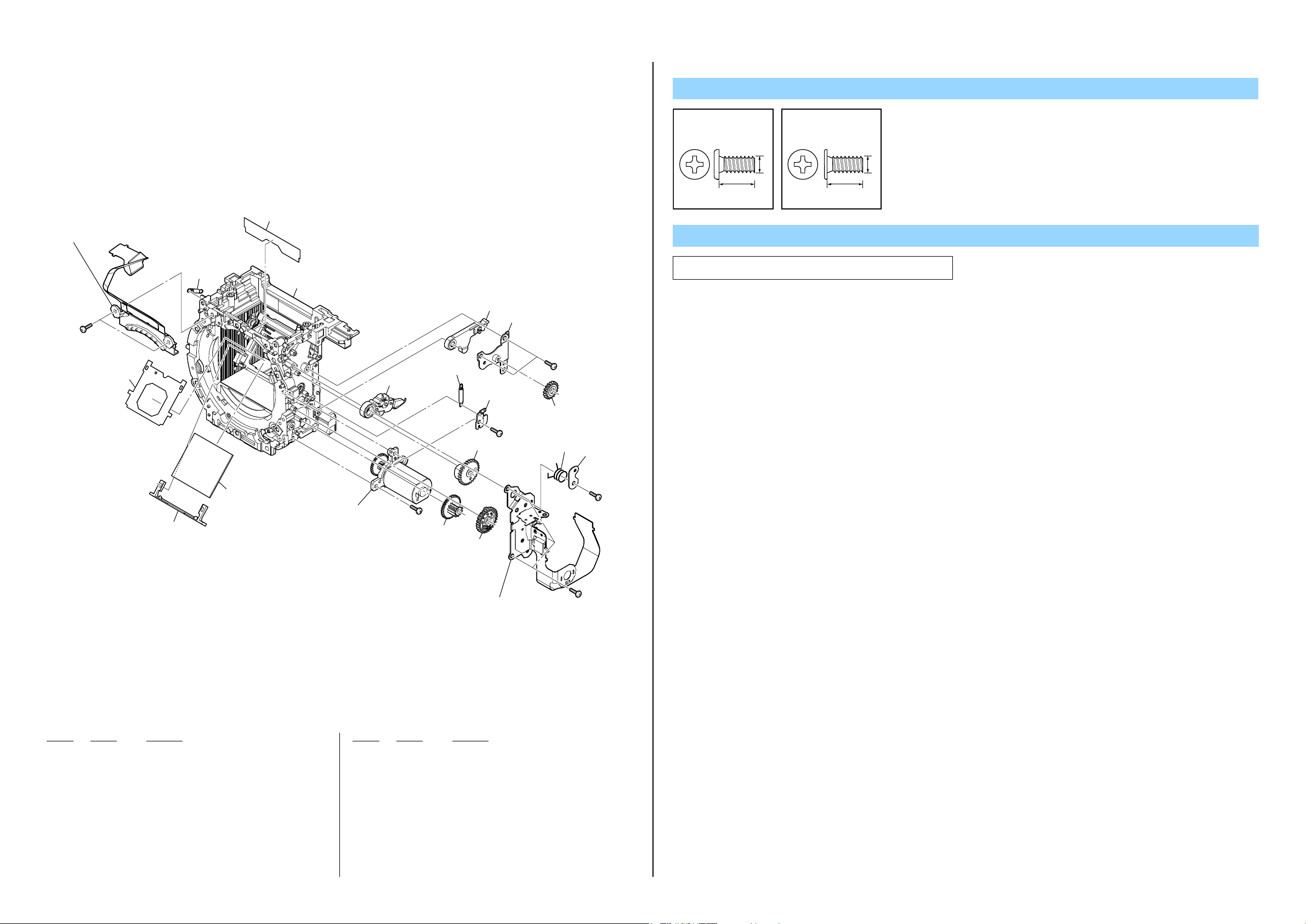

2. REPAIR PARTS LIST

IDENTIFYING PARTS

Follow the disassembly in the given numerical order.

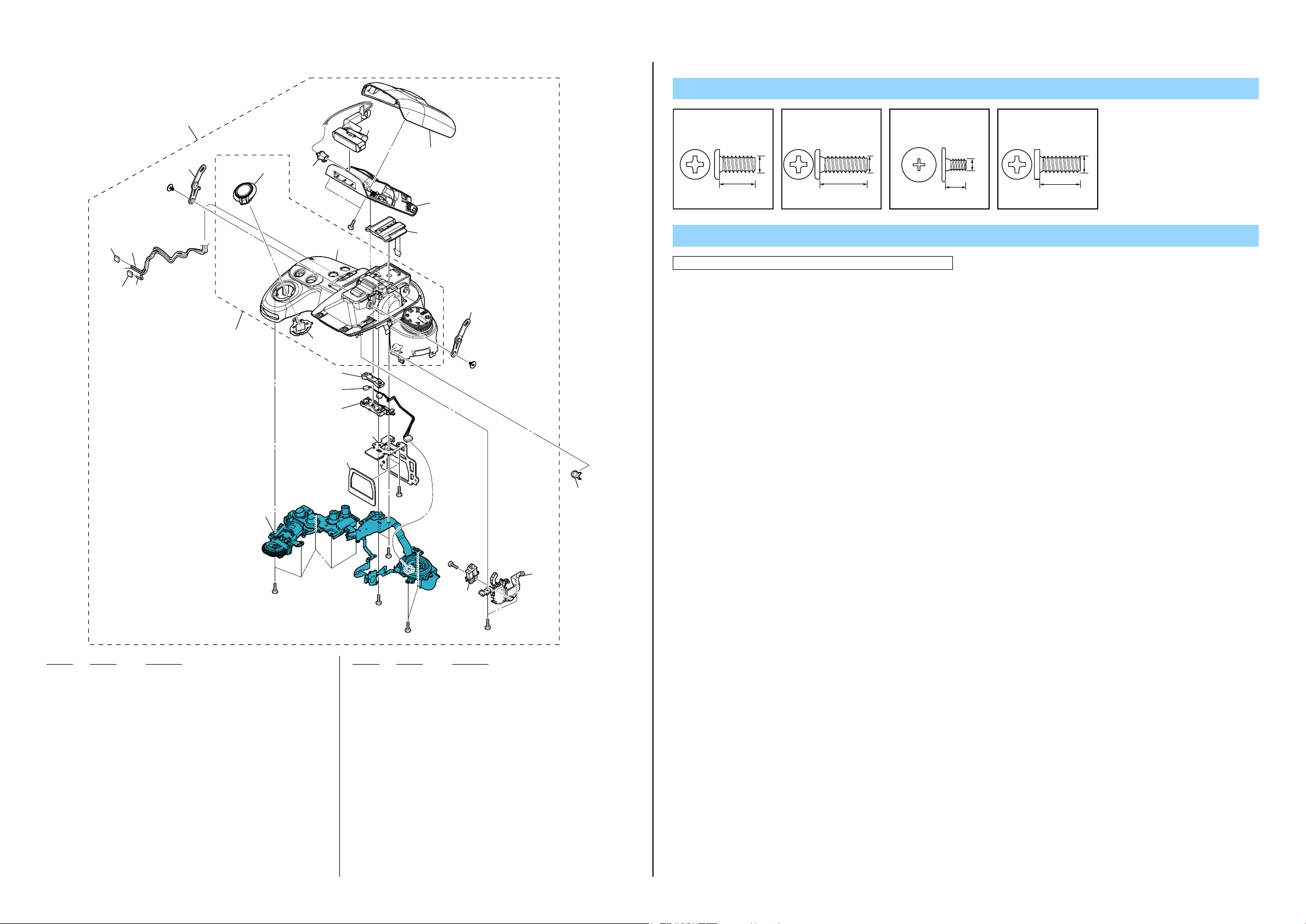

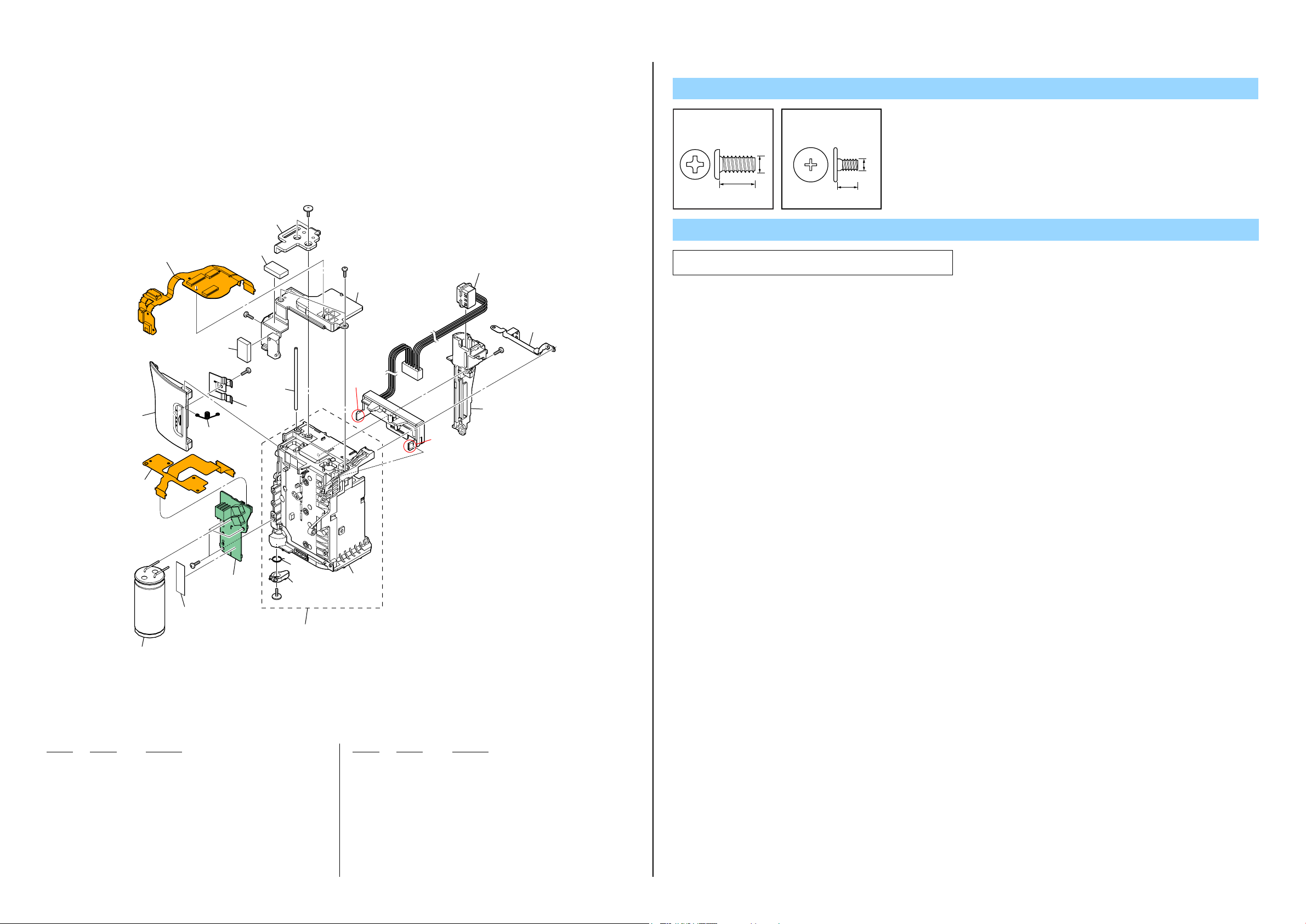

7�Top Cover Section

[Disassembly]

[Exploded View]

qh�Mirror Box Section (Penta Unit)

[Disassembly]

[Exploded View]

qf�Battery Holder Section

[Disassembly]

[Exploded View]

• ST-218 Board

• GYJ-003 Flexible Board

• STG-001 Flexible Board

6�

BD Eye Piece Assy

• EYE-010 Flexible Board

qa�Anti Shake Unit Section

[Disassembly]

[Exploded View]

• Imager Section

• IM Imager Unit

• ISL-001 Flexible Board

• ISP-001 Flexible Board

• Anti Shake Unit Section

2�

Rear Cover Section

[Disassembly]

[Exploded View]

•

Rear Cover Section

•

LCD Section

• PD-390 Board

• LCD-014 Flexible Board

• SHD-001 Flexible Board

8�AM-025 Board

• MM-084 Board

(ENGLISH)

NOTE:

• -XX,-Xmeanstandardizedparts,sotheymayhavesomedifferencesfromtheoriginalone.

• Itemsmarked“*”arenotstockedsincetheyareseldomrequiredforroutineservice.Somedelay

shouldbeanticipatedwhenorderingtheseitems.

• Themechanicalpartswithnoreferencenumberintheexplodedviewsarenotsupplied.

• Duetostandardization,replacementsinthepartslistmaybedifferentfromthepartsspecified

inthediagramsorthecomponentsusedontheset.

• Abbreviation

AUS : Australian model

CH : Chinese model

KR : Korea model

View Position

Left View

Front View

Whenindicatingpartsbyreferencenumber,

pleaseincludetheboardname.

The components identified by mark 0 or

dottedlinewithmark0arecriticalforsafety.

Replaceonlywithpartnumberspecified.

• Color Indication of Appearance Parts

Example:

(SILVER) : Cabinet’s Color

(Silver) : Parts Color

Top View

Back View

Right View

Bottom View

3�

CV Grip Cover Assy

4�

CV Front Cover Assy (865)

qj�Mirror Box Section

[Disassembly]

[Exploded View]

• Sub Unit-1

• Sub Unit-2

qg�

ALX-8650 (AF Module)

0�

BD Bottom Frame

qs�Shutter Unit (AFE-3032)

qd�BD RT Ho

• SMR-001 Flexible

9�BD Main Frame

lder Assy

1�

Board

CV Side Cover L Assy

Link

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

ACCESSORIES

ACCESSORIES ASSEMBLYDISCHARGING OF THE CHARGING CAPACITOR

2-1

NOTE FOR REPAIR

• Makesurethattheflatcableandflexibleboardarenotcrackedor

bentattheterminal.

Donotinsertthecableinsufficientlynorcrookedly.

• When remove a connector,donotpullatwire of connector.It is

possiblethatawireissnapped.

• Wheninstallingaconnector,donotpressdownatwireofconnector.

Itispossiblethatawireissnapped.

• Donotapplyexcessiveloadtothegildedflexibleboard.

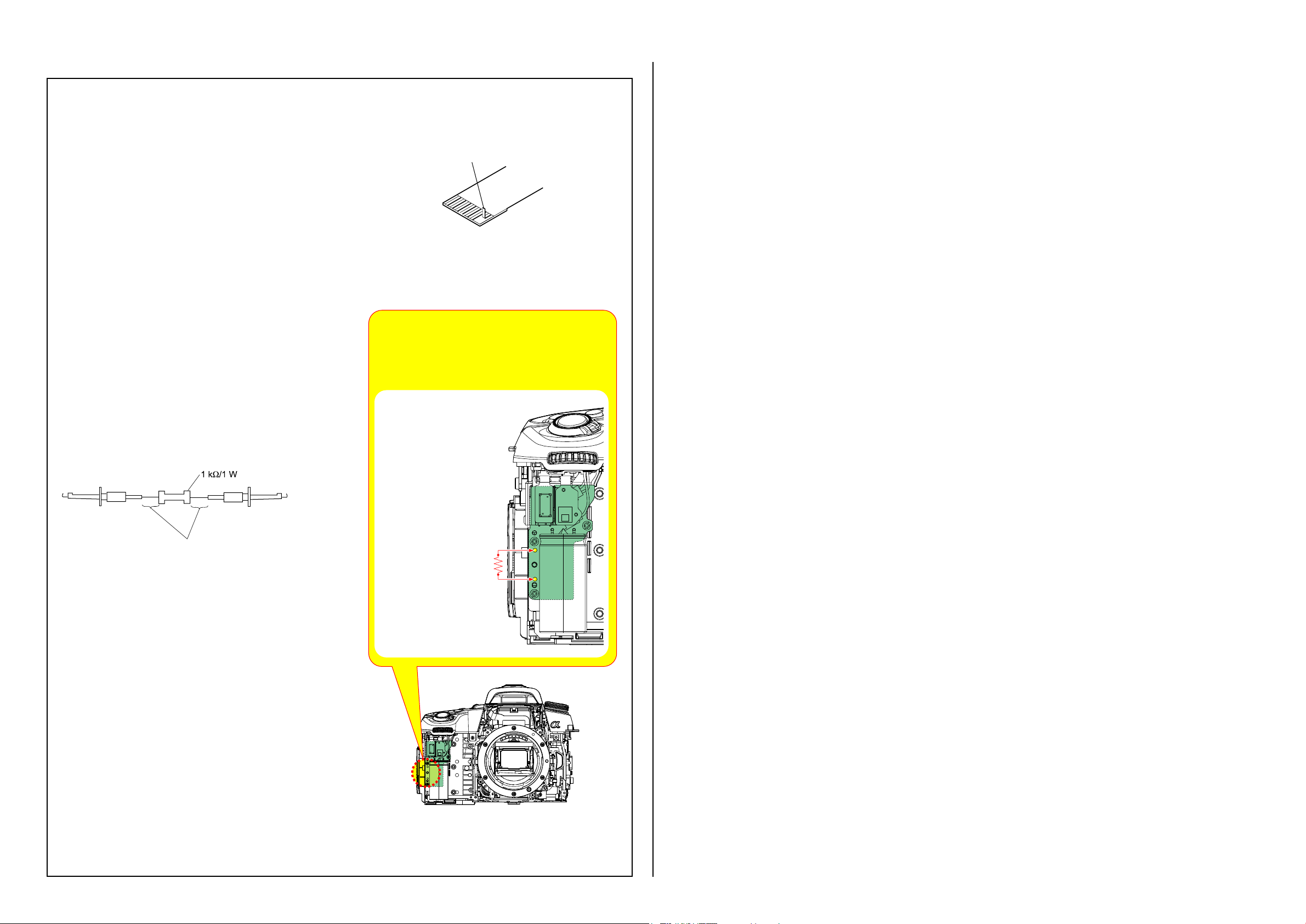

DISCHARGING OF THE CHARGING CAPACITOR

The charging capacitor is charged up to the maximum 330 V

potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the unit is simply turned off. Therefore, the remaining

voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig, a small clip is attached to each end of

a resistor of 1 kΩ /1 W (1-215-869-11).

Wrap insulating tape fully around the leads of the resistor to

prevent electrical shock.

Cut and remove the part of gilt

which comes off at the point.

(Be careful that some

pieces of gilt may be left inside)

Note:Note: High-voltage cautionsHigh-voltage cautions

Discharging the Capacitor

Short-circuit between the two points with the short jig about

Short-circuit between the two points with the short jig about

10 seconds.

10 seconds.

To avoid the spark with the metal plate,wrap the short jig

To avoid the spark with the metal plate,wrap the short jig

with the insulation tape.

with the insulation tape.

Wrap insulating tape.

SUBSIDIARY MATERIALS

B: Adhesive bond

B-50 (J-6082-615-A)

G: Grease

G-15 (J-6082-619-A)

G-85 (J-6082-626-A)

G-116 (J-6082-628-A)

R:1 kΩ/1 W

(Part code: 1-215-869-11)

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

2-2

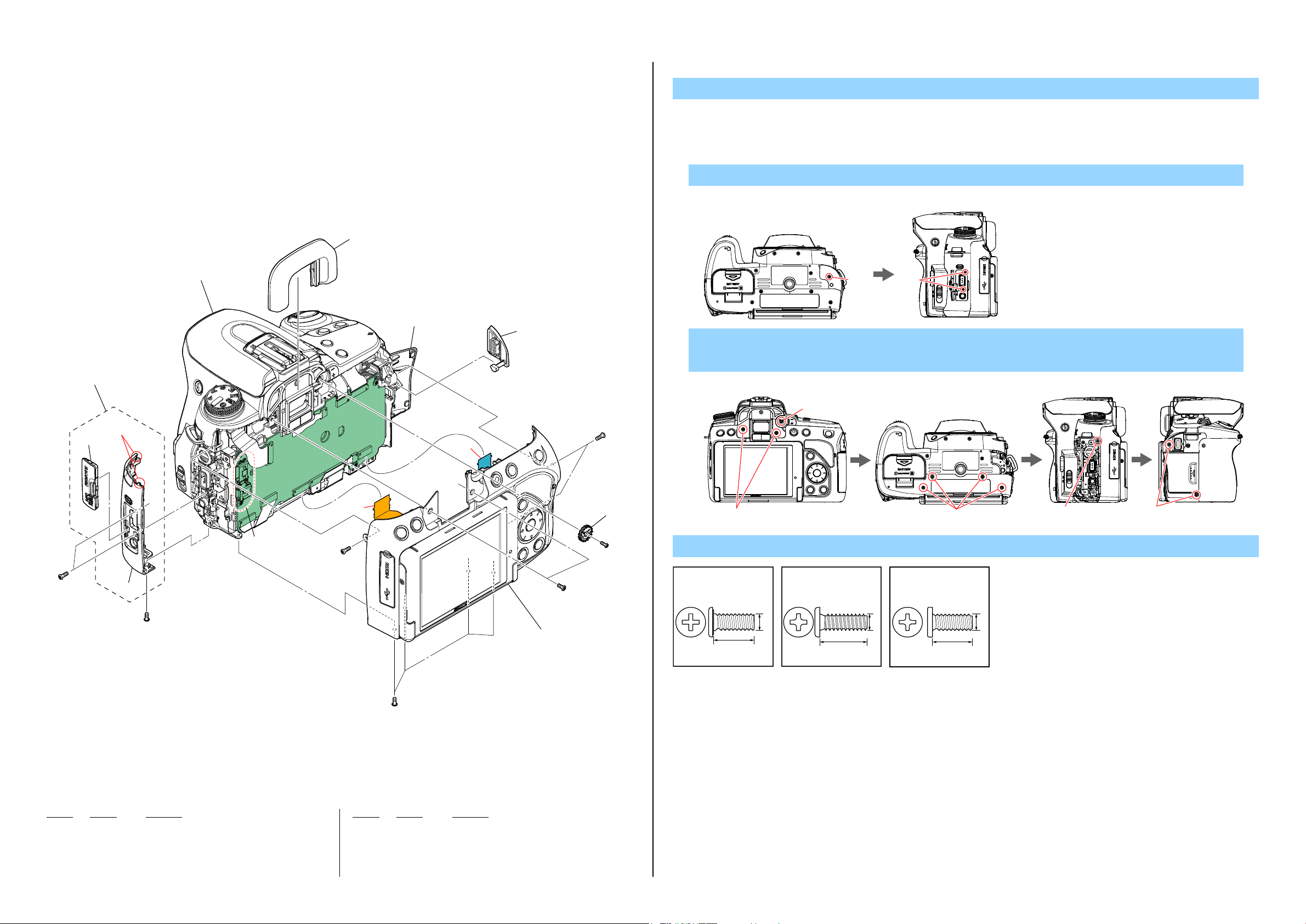

2-1. EXPLODED VIEWS

DISASSEMBLY

2-1-1. OVERALL SECTION

ns:notsupplied

Front Cover Section

(See Page 2-6)

1 1

1(Claw)

2 1

3

2-1

2-4

u-2

4

2-3

#12

1. Remove to numerical order (1 to 2) in the left figure.

2. The meaning of the sign in left figure is as follows. Be careful when it removes.

u-X: Flexible Board, Flat Cable, Harness

1 #2 X 1 → CV Remote Lid open (1) → #12 X 2

Bottom View

#2

Right View

#12

2 CV Eye Hood Assy (857) (2-1) → #112 X 1 → CV Diopter Adjust Dial (857) (2-2) →

#2 X 6 → #12 X 2 → CV DC Jack Lid open (2-3) → #12 X 1 → CV Media Lid open (2-4) →

Jack X 2 (2-5)

Back View Bottom View Right View Left View

#112

#12

ns

#2

2-5

AM-025

#12

u-2

#2

#2

2�Rear Cover Section

(See page 2-4)

2-2

#112

5

#2#2

#12 #12

Screw

#2: M1.7 X 4.0

(Black)

2-635-562-31

4.0

#12: M1.7 X 5.0 (Tapping)

(Black)

3-080-204-21

1.7

5.0

1.7

#112: M1.4 X 5.0

(Black)

2-178-410-11

1.4

5.0

Ref. No. Part No. Description Ref. No. Part No. Description

1 X-2549-446-1 CV SIDE COVER L ASSY

2 4-256-523-01 CV REMOTE LID

3 X-2514-442-1 CV EYE HOOD ASSY (857)

4 4-154-697-01 CV DC JACK LID

* 5 4-154-680-01 CV DIOPTER ADJUST DIAL (857)

#2 2-635-562-31 SCREW (M1.7)

#12 3-080-204-21 SCREW, TAPPING, P2

#112 2-178-410-11 TITE (UB TITE) 1.4

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

2-3

2-1-2. REAR COVER SECTION

ns:notsupplied

Screw

#8: M1.7 X 3.5 (Tapping)

(Silver)

3-078-890-01

#109: M1.7 X 3.0

(Black)

2-515-483-21

#140: M1.7 X 2.0

(Black)

2-635-562-01

#8

51

52

53

ns

54

55

57

58

56

#140

ns

60

Claw

59

65

LCD Section

(See page 2-5)

Claw

#109

61

#140

3.5

1.7

3.0

1.7

1.7

2.0

62

DSLR-A580/A580L/

A580Y/A580J

64

63

Ref. No. Part No. Description Ref. No. Part No. Description

51 1-489-274-11 SWITCH BLOCK, CONTROL (RS86500)

* 52 4-256-528-01 CV FUSE REPLACEMENT LABEL

53 X-2549-449-1 CV REAR COVER ASSY (865)

* 54 4-154-802-01 CV REAR RUBBER TAPE

* 55 4-154-801-01 CV REAR RUBBER

* 56 4-261-877-02 CV REAR CAUTION LABEL (865)

* 57 4-154-808-01 CV HINGE RIGHT COVER

58 X-2514-453-2 CV LCD FLEXIBLE COVER ASSY

* 59 4-154-817-01 CV FPC TAPE 857

60 4-154-720-01 BD CAPACITOR FIXED TAPE

* 61 4-154-809-01 CV HINGE LEFT COVER

* 62 4-258-191-01 EM REAR SHIELD SHEET

* 63 4-264-620-01 COVER, EM REAR SHIELD

* 64 4-156-877-01 CV FPC COVER SHEET

65 4-266-234-01 CV SILENCING CUSHION

#8 3-078-890-01 SCREW, TAPPING

#109 2-515-483-21 SCREW (M1.7), NEW TRU-STAR, P2

#140 2-635-562-01 SCREW (M1.7)

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

(DSLR-A580/A580L/A580Y/A580J)

2-4

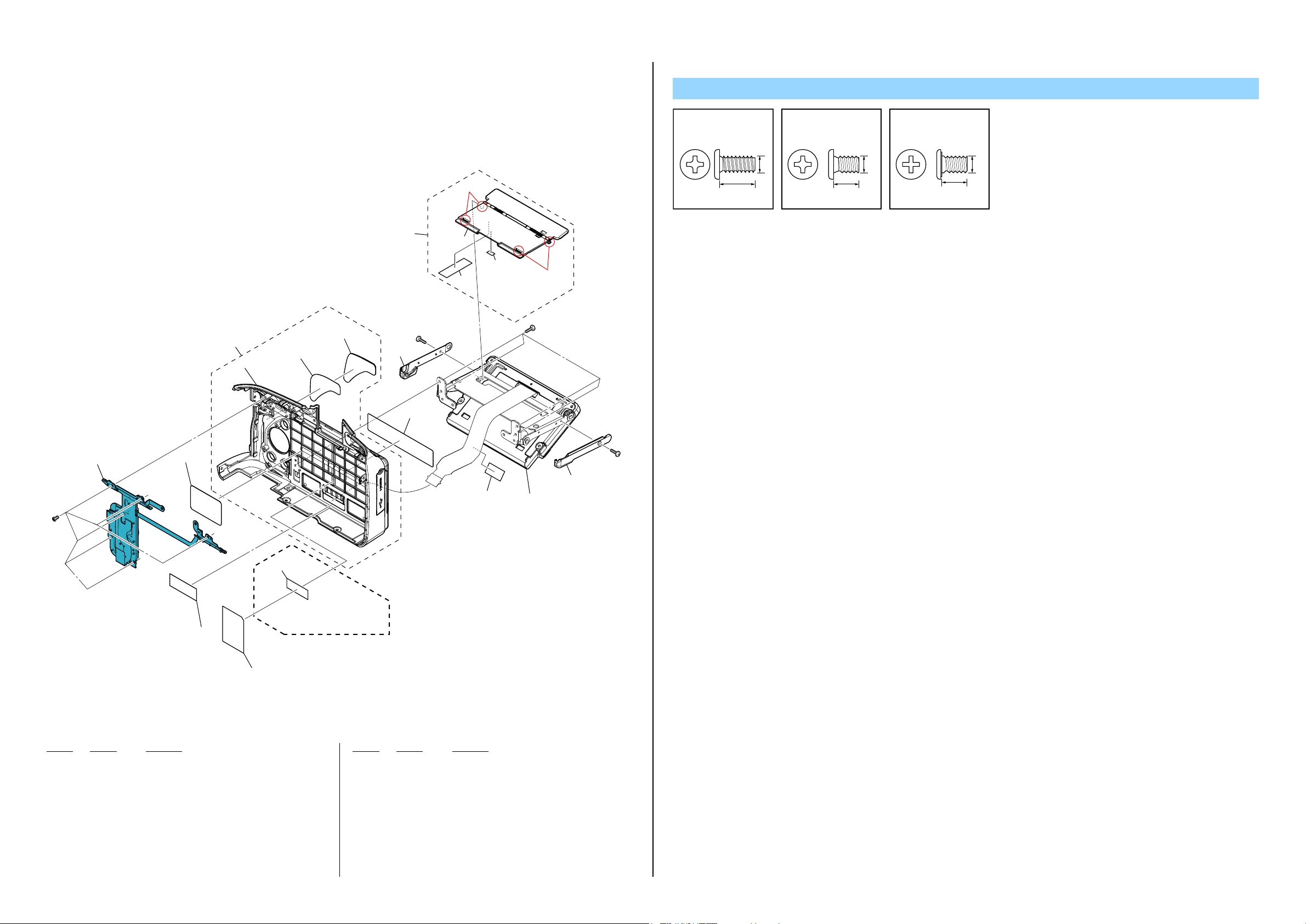

2-1-3. LCD SECTION

112

113

Screw

#12: M1.7 X 5.0 (Tapping)

(Black)

3-080-204-21

5.0

1.7

#12

101

Claw

102

Claw

Claw

106

105

103

107

Claw

104

PD-390

108

111

LCD901

109

110

Ref. No. Part No. Description Ref. No. Part No. Description

101 X-2514-440-1 LCD HINGE ASSY

* 102 4-155-014-01 CV LCD LOWER COVER 858

103 1-880-443-11 LCD-014 FLEXIBLE BOARD

* 104 4-154-811-01 CV FPC INSULATING SHEET

105 A-1735-912-A SHD-001 FLEXIBLE BOARD, COMPLETE

* 106 4-154-817-01 CV FPC TAPE 857

* 107 4-154-816-01 CV SENSOR WINDOW

108 A-1792-091-A PD-390 BOARD, COMPLETE

109 4-154-810-01 CV RELAY PC BOARD FIXED TAPE

110 X-2514-459-1 CV UNIT CASE ASSY 858

111 4-155-013-01 CV LCD CUSHION 858

112 4-155-012-01 CV LCD WINDOW 858

* 113 4-155-015-01 CV LCD UPPER COVER 858

LCD901 8-753-324-36 ACX396BLN-1

#12 3-080-204-21 SCREW, TAPPING, P2

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

2-5

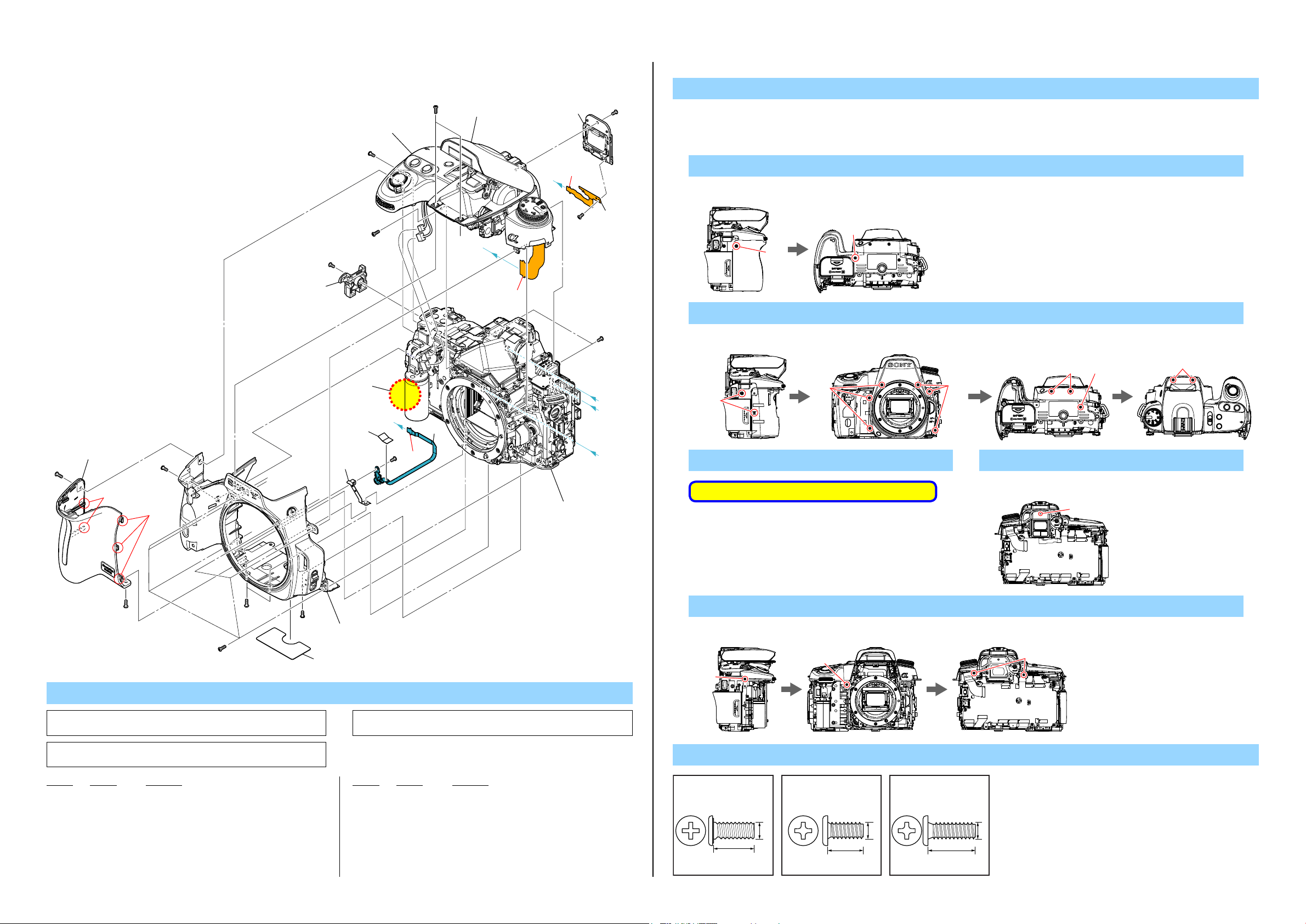

2-1-4. FRONT COVER SECTION

7�Top Cover Section

(See page 2-7)

(Note1, 2)

#2

#12

#12

#12

4-2

BB

6�153

u-6

C

#8

DISASSEMBLY

#2

1. Remove to numerical order (3 to 7) in the left figure.

2. The meaning of the sign in left figure is as follows. Be careful when it removes.

u-X: Flexible Board, Flat Cable, Harness

3 #12 X 2

Left View Bottom View

154

#12

#12

3�151

#12

3(Claw)

#12

3(Claw)

152

4-1

157

5

156

A

#8

u-4

155

u-7

Main Board Section

(See page 2-8)

#12

C

B

A

4 #12 X 1 → CV Eyelet Cover G (4-1) → #12 X 9 → #2 X 1 → POP up the Strobe (4-2) → #12 X 2

Left View Front View Bottom View Top View

#12

#12

#12

5

DISCHARGING OF THE CHARGING CAPACITOR

#12 #2

#12

6 #2 X 1

Back View

#2

#12

#12

#2

4�158

(Note3)

159

#12

Note

Note1: Refer to “Assembly-8: Top C ov er Bl oc kAssy” when y ou

assemble.

Note3: Refer to “Assembly-12:Assemble the CV FRONT COVER

ASSY”whenyouassemble.

Ref. No. Part No. Description Ref. No. Part No. Description

151 X-2549-447-1 CV GRIP COVER ASSY

* 152 4-154-696-21 CV EYELET COVER G

153 X-2514-445-1 BD EYE PIECE ASSY (857)

154 A-1735-726-A EYE-010 FLEXIBLE BOARD, COMPLETE

155 1-489-275-11 SWITCH BLOCK, CONTROL (PRV8650)

156 3-076-631-01 CV PRV FLEXIBLE FIXED TAPE

* 157 4-256-482-01 EM PREVIEW SHEET METAL

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

Note2: Referto “Assembly-9: Flash Unit (FL85700)Harness” when

youassemble.

158 X-2549-441-1 CV FRONT COVER ASSY (865) (Note3)

159 4-154-357-01 CV BOTTOM LABEL A (KR, CH)

159 4-256-505-01 CV BOTTOM LABEL B (EXCEPT KR, CH)

#2 2-635-562-31 SCREW (M1.7)

#8 3-078-890-01 SCREW, TAPPING

#12 3-080-204-21 SCREW, TAPPING, P2

2-6

7 #2 X 1 → #12 X 3

Left View Front View Back View

#2

Screw

#2: M1.7 X 4.0

(Black)

2-635-562-31

4.0

#8: M1.7 X 3.5 (Tapping)

(Silver)

3-078-890-01

1.7

#12

3.5

#12: M1.7 X 5.0 (Tapping)

(Black)

3-080-204-21

1.7

#12

1.7

5.0

2-1-5. TOP COVER SECTION

ns:notsupplied

201 (Note)

214

Screw

#8: M1.7 X 3.5 (Tapping)

(Silver)

3-078-890-01

#12: M1.7 X 5.0 (Tapping)

(Black)

3-080-204-21

#91: M1.7 X 3.0 (Tapping)

(Silver)

2-695-434-11

#172: M1.4 X 4.0 (Tapping)

(Black)

2-178-410-01

211

White

210

Pink

Black

#91

212

207

209

213

208

206

MIC901

205

#12

ns

203

204

215

216

CN901

217

#91

1.7

3.5

1.7

5.0

Note

Note: Referto“Assembly-7:TopCoverBlock”whenyouassemble.

3.5

1.7

1.4

4.0

#12

202

#12

#8

#8

Ref. No. Part No. Description Ref. No. Part No. Description

201 A-1792-106-A TOP COVER BLOCK ASSY (865)

(DSLR-A560/A560L/A560Y) (Note)

201 A-1792-107-A TOP COVER BLOCK ASSY (866)

(DSLR-A580/A580L/A580Y/A580J) (Note)

202 1-489-259-11 SWITCH BLOCK, CONTROL (TK86500)

203 4-256-481-01 BD EYE PIECE DUST CUSHION (865)

* 204 4-256-477-01 BD EYE PIECE FRAME

* 205 4-256-479-01 CV MICROPHONE HOLDER BASE

* 206 4-256-478-01 CV MICROPHONE HOLDER

207 X-2549-443-1 CV TOP COVER ASSY (865)

(DSLR-A560/A560L/A560Y)

207 X-2549-444-1 CV TOP COVER ASSY (866)

(DSLR-A580/A580L/A580Y/A580J)

208 4-190-771-01 CT POWER LEVER CLICK PLATE

209 X-2549-350-1 CT RELEASE BUTTON (M) ASSY

* 210 1-569-617-11 HOUSING, CONNECTOR 2P (White)

211 1-820-649-11 HOUSING, CONNECTOR 2P (Red)

* 212 X-2514-438-1 ST STROBE GUIDE ARM ASSY (R)

* 213 4-154-743-01 ST STROBE HINGE COLLAR

0 214 1-487-407-11 FLASH UNIT (FL85700)

215 4-256-480-01 ST STROBE COVER

216 X-2549-442-1 ST STROBE BASE COVER ASSY

* 217 X-2514-439-1 ST STROBE GUIDE ARM ASSY (L)

218 4-143-883-11 LOGO EMBLEM (A)

219 X-2514-448-2 ST STROBOSCOPE LOCK ASSY

CN901 1-822-402-11 SHOE CONNECTOR

MIC901 1-542-757-71 MICROPHONE UNIT

PL901 1-455-061-11 SOLENOID, PLUNGER

#8 3-078-890-01 SCREW, TAPPING

#12 3-080-204-21 SCREW, TAPPING, P2

#91 2-695-434-11 SCREW (T1.7), HEAD PAN TAPPING

#172 2-178-410-01 TITE (UB TITE) 1.4

#172

PL901

#8

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

218

219

#8

2-7

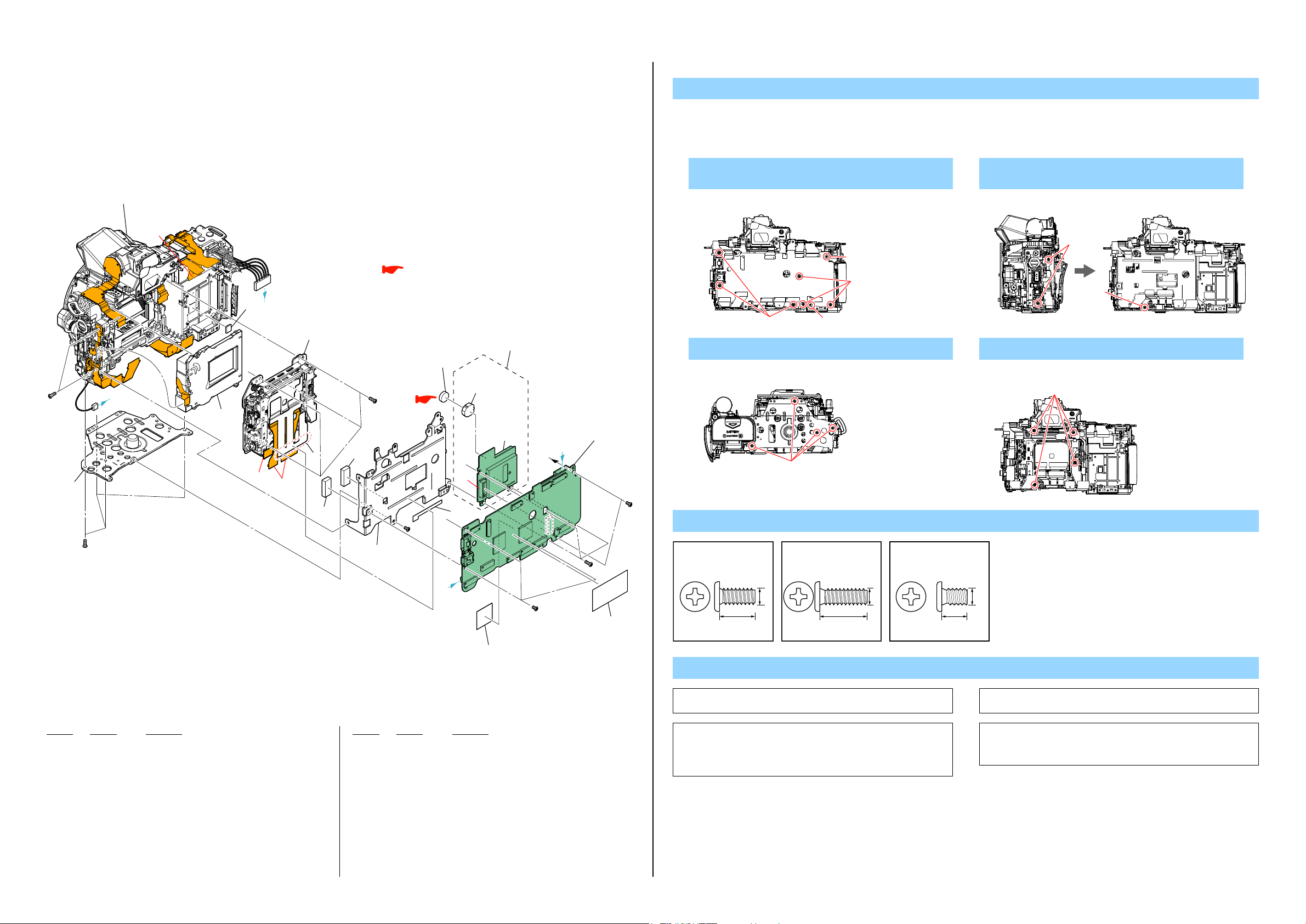

2-1-6. MAIN BOARD SECTION

ns:notsupplied

DISASSEMBLY

1. Remove to numerical order (8 to qs) in the left figure.

2. The meaning of the sign in left figure is as follows. Be careful when it removes.

u-X: Flexible Board, Flat Cable, Harness

#12

0 251

Remote Holder Section

(See Page 2-11)

u-8

A

#12

qs 253

(Note1)

C

252

B

qa�Imager Section

u-8

u-8

(See page 2-9)

9

254

#12

254

9 255

: BT900 (LITHIUM BATTERY)

Board on the mount position.

(See page Level3 6-50)

BT900

(CAUTION)

(Note3)

BH4501

(Note3)

257 8

ns

u-8

256

#109

B

C

AM-025

8�258

(Note2)

#12

#8

8 #8 X 2 → #109 X 3 → #12 X 3 →

MM-084 Board (8)

Back View

#8

#12

#109 #8

0 #12 X 4 qa #12 X 4

Bottom View

#12

Screw

#8: M1.7 X 3.5 (Tapping)

(Silver)

3-078-890-01

#12: M1.7 X 5.0 (Tapping)

(Black)

3-080-204-21

#109: M1.7 X 3.0

(Black)

2-515-483-21

9 #12 X 2 → #109 X 1 →

EM GF Tape (A) (9)

Right View

#12

#109

Back View

#12

Back View

A

Ref. No. Part No. Description Ref. No. Part No. Description

251 4-256-511-01 BD BOTTOM FRAME

* 252 4-159-021-01 EM MEDIA EMI SHEET

253 1-487-960-11 SHUTTER UNIT (AFE-3032) (Note1)

* 254 4-256-516-01 CUSHION, BD LIGHT INTERCEPTION

* 255 4-256-512-01 BD MAIN FRAME

256 4-192-226-01 EM GF TAPE (A)

257 A-1792-100-A MM-084 BOARD, COMPLETE

258 A-1797-666-A AM-025 BOARD, COMPLETE (SERVICE)

(DSLR-A560/A560L/A560Y) (Note2)

258 A-1797-667-A AM-025 BOARD, COMPLETE (SERVICE)

(DSLR-A580/A580L/A580Y/A580J) (Note2)

259 4-264-622-01 EM AM PCB SPACER

260 4-256-513-01 EM AM PCB SHIELD SHEET

0 BH4501 1-756-615-61 HOLDER, BATTERY (Note3)

0 BT900 1-756-135-31 BATTERY LITHIUM SECONDARY (CAUTION) (Note3)

#8 3-078-890-01 SCREW, TAPPING

#12 3-080-204-21 SCREW, TAPPING, P2

#109 2-515-483-21 SCREW (M1.7), NEW TRU-STAR, P2

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

260

#109

259

2-8

1.7

3.5

1.7

5.0

Note

Note1: Refer to “Assembly-5: Shutter Unit (AFE-3032)” when you

Note3: Replacethebatteryholder(BH4501)togetherwhenreplacing

(thebatteryholderremovedoncecannotbeusedagain.)

When mounting these parts, mount new battery holder first

assemble.

thelithiumbattery(BT900)ontheMM-084Board.

andattachnewlithiumbatterynext.

1.7

3.0

Note2: Referto “Assembly-11:Note on attachment of the SMR-001

andtheSLK-006FlexibleBoard”whenyouassemble.

Caution:

Dangerofexplosionoccursifbatteryisincorrectlyreplaced.Replaceonly

withthesameorequivalenttype. Disposeofusedbatteriesaccording

totheinstructions.

2-1-7. IMAGER SECTION

Peel off the

ns:notsupplied

Anti Shake Unit Section

(See page 2-10)

(including HOL-007 flexible board)

301 (including CP001 (DSLR-A560/A560L/A560Y) /

IC4501 (DSLR-A580/A580L/A580Y/A580J) (CMOS imager) and

IS-073 (DSLR-A580/A580L/A580Y/A580J) /

IS-077 (DSLR-A560/A560L/A560Y) complete board)

(Note1, 2, 3, 4)

Screw

#64: M1.7 X 5.0 (Tapping)

(Silver)

2-666-551-21

5.0

1.7

302

303

(Note1, 2, 3)

304 (Note1, 2)

DSLR-A560/A560L/

A560Y

305 (Note1)

306 (Note1)

ns

307

(Note2)

DSLR-A580/A580L/

A580Y/A580J

310

Note4:

Precautions for Replacement of Imager

• Iftheimagerhasbeenreplaced,carryoutalltheadjustmentsforthe

camerasection.

• Astheimagermaybedamagedbystaticelectricityfromitsstructure,

handleitcarefullylikefortheMOSIC.

Inaddition,ensurethatthereceiverisnotcoveredwithdustsnor

exposedtostronglight.

Ref. No. Part No. Description Ref. No. Part No. Description

301 A-1773-801-A IM IMAGER UNIT 14M (DSLR-A560/A560L/A560Y)

(including CP001 (CMOS imager) and IS-077 complete board) (Note1, 3, 4)

301 A-1799-352-A IM IMAGER UNIT 16M (866) T

(DSLR-A580/A580L/A580Y/A580J)

(including IC4501 (CMOS imager) and IS-073 complete board) (Note 2, 3, 4)

302 4-194-226-01 IM PLATE, LPF RETAINER

303 1-856-102-11 OPTICAL FILTER BLOCK (OFB-01-09)

(DSLR-A560/A560L/A560Y) (Note1, 3)

303 1-856-138-11 OPTICALFILTER BLOCK (OFB-01-13)

(DSLR-A580/A580L/A580Y/A580J) (Note2, 3)

306 4-194-127-01 IM TAPE, SPACER FIXED (S)

307 4-256-336-11 IM SHEET 4, SPACER

308 4-194-225-01 IM TAPE FPC GUIDE

* 309 4-194-227-01 IM PLATE GUIDE IMAGER FPC

310 1-880-878-11 ISP-001 FLEXIBLE BOARD

311 1-880-877-11 ISL-001 FLEXIBLE BOARD

312 4-194-224-01 IM SHEET GRAPHITE

308

312

309

311

#64

(DSLR-A560/A560L/A560Y) (Note1)

(DSLR-A580/A580L/A580Y/A580J) (Note2)

#64

Note

Note1: Refertothe following statementswhenreplacingthe Optical

*

*

FilterBlock.(DSLR-A560/A560L/A560Y)

MethodofRemoval

(1)Pourresolvent(alcoholorcleaningagent)betweenthe

imagerandtheIMSpacerSheet.

WaitforthattheadhesivepoweroftheIMSpacerFixed

Tapeweakens.

(2)RemovetheIMSpacerSheetfromtheimager.

Pour resolvent (alcohol or cleaning agent)

between the imager and the IM Spacer Sheet.

MethodofAttachment

(1)AttachtheIMFlareCutterandtheOpticalFilterBlockby

aligningthemwiththeoutershapeoftheIMSpacerSheet

evenly.

Thetwo-layersideoftheOpticalFilterBlockisonthe

imagerside.

(2)AttachtheIMSpacerFixedTapebyaligningitwiththe

outershapeoftheIMSpacerSheetevenly.

Peel off the

released paper.

IM Spacer

Fixed Tape

IM Spacer Sheet

IM Flare Cutter

The two-layer

side is on the

imager side.

Mount

Imager

Side

Side

Optical Filter Block

Peel off the

released paper.

Peel off the

released paper.

(3)SettheOpticalFilterBlockinitsattachmentjig

(J-6082-737-A),withtheattachedIMSpacerFixedTape

facingupward.

(4)Presstheimagerdownintothejigasshownbelowto

attachittotheOpticalFilterBlock.

Imager

Peel off the released paper.

Note2: Refertothe following statementswhenreplacingthe Optical

FilterBlock.(DSLR-A580/A580L/A580Y/A580J)

*

MethodofRemoval

(1)Pourresolvent(alcoholorcleaningagent)betweenthe

imagerandtheSpacerIMSheet4.

WaitforthattheadhesivepoweroftheSpacerIM

Sheet4weakens.

(2)RemovetheSpacerIMSheet4fromtheimager.

Pour resolvent (alcohol or cleaning agent)

between the imager and the Spacer IM Sheet 4.

*

MethodofAttachment

(1)AttachtheIMFlareCutterandtheOpticalFilterBlockby

aligningthemwiththeoutershapeoftheSpacerIM

Sheet4evenly.

Thetwo-layersideoftheOpticalFilterBlockisonthe

imagerside.

released paper.

Peel off the

The two-layer

side is on the

imager side.

Mount

Side

released paper.

Imager

Side

Optical Filter Block

Spacer IM Sheet 4

IM Flare Cutter

(2)SettheOpticalFilterBlockinitsattachmentjig

(J-6082-737-A),withtheattachedSpacerIMSheet4

facingupward.

(3)Presstheimagerdownintothejigasshownbelowto

attachittotheOpticalFilterBlock.

Imager

Peel off the released paper.

J-6082-737-A

304 4-193-875-01 CUTTER, IM FLARE (S) (Note1, 2)

305 4-185-993-01 IM SHEET, SPACER

(DSLR-A560/A560L/A560Y) (Note1)

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

#64 2-666-551-21 SCREW, TAPPING, P2

2-9

J-6082-737-A

Note3: Referto“3-2.CLEANINGPROCEDUREOFOLPF”onpage

3-7formethodofcleaningtheOLPF.

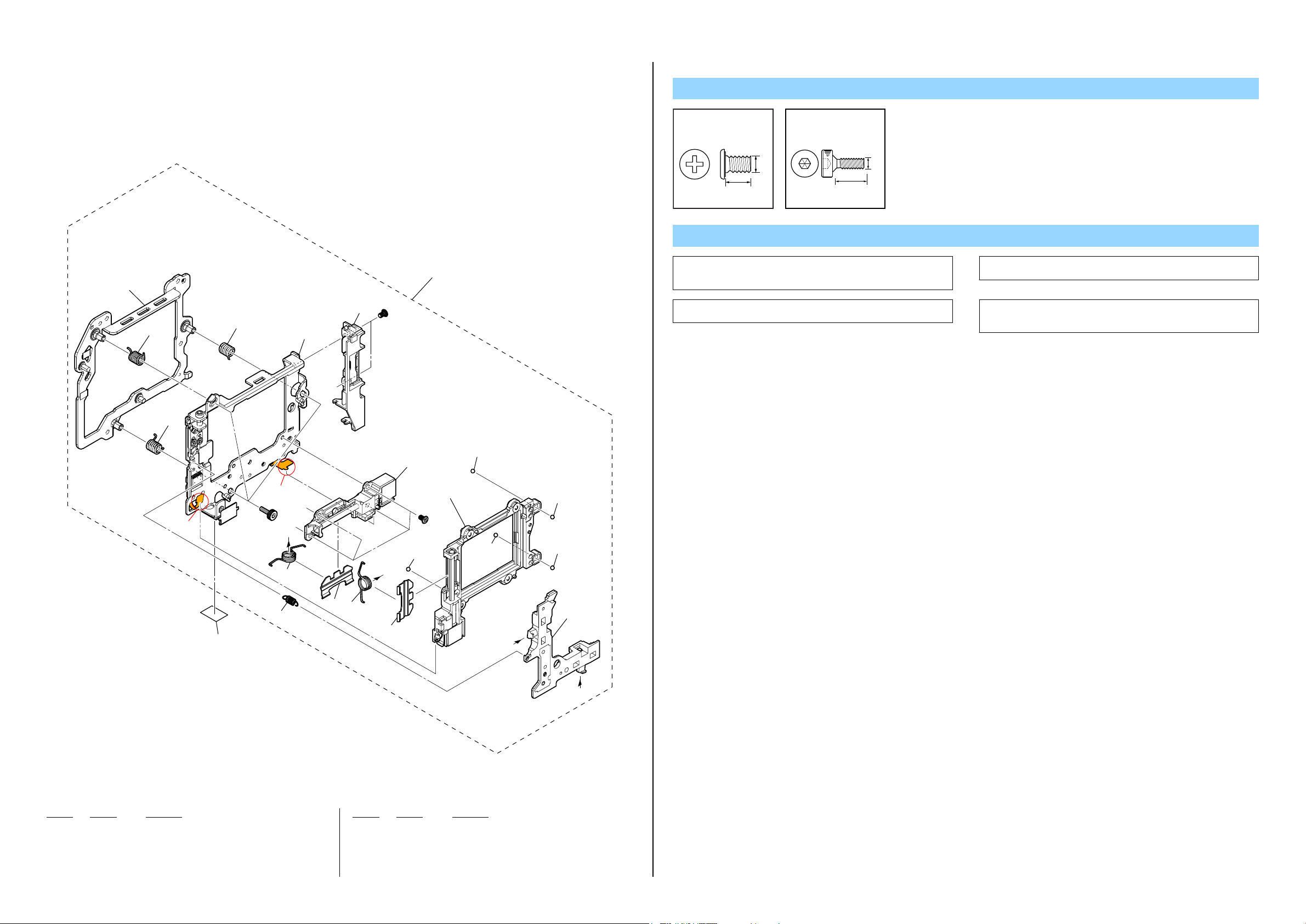

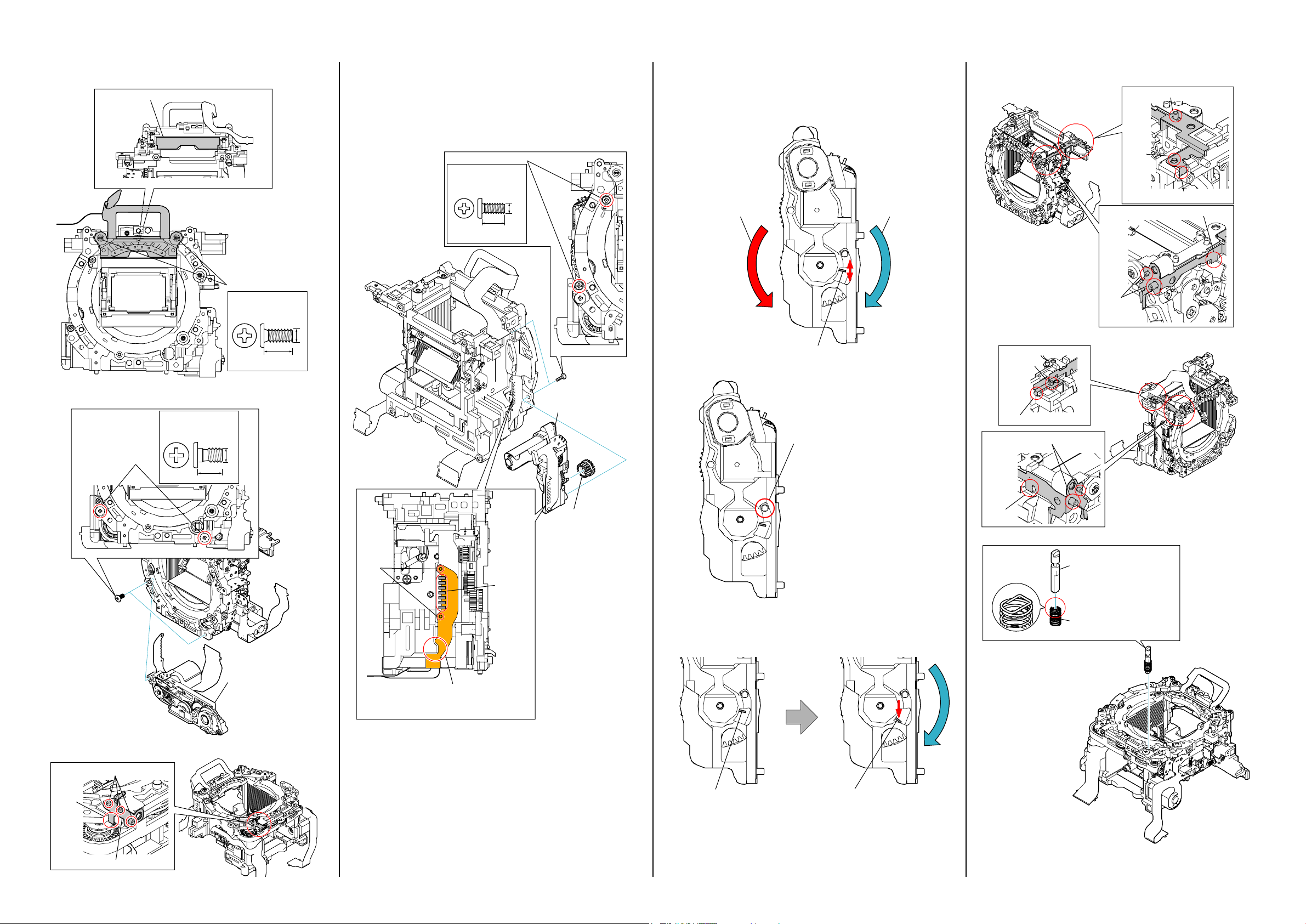

2-1-8. ANTI SHAKE UNIT SECTION

ns:notsupplied

Screw

#14: M1.7 X 2.5

(Silver)

2-599-475-11

#87: M1.6 X 5.3

(Black)

2-689-328-01

ns

352

352

352

ns

ns

#14

353 (Note4)

351

(Note1, 2)

354

1.7

2.5

1.6

5.3

Note

Note1: Referto“1-3.METHODFORCHECKINGTHEASSLIDER

UNIT(863)” on page 1-1 when checking the AS Slider Unit

Note3: Referto“1-5. METHODFORREPLACINGTHEAS SLIDER

(863).

BASSY”onpage1-2whenreplacingtheASSliderBAssy.

Note2: Referto“1-4.METHODFORADJUSTINGTHETEBURE

REVISE”onpage1-2whenadjustingtheTebureRevise.

Note4: Referto“1-6.METHODFORREPLACINGTHEASHOLDER

ACTUATORASSY” on p age 1-3 whe n r eplac in g theAS

HolderActuatorAssy.

Solder

356

Solder

#87

ns

ns

A

ns

ns

B

ns

354

#14

355

(Note3)

354

354

354

ns

B

A

Ref. No. Part No. Description Ref. No. Part No. Description

351 A-1782-917-A SLIDER UNIT (863 SERVICE), AS (Note1, 2)

352 4-110-892-01 SPRING, ADJUSTMENT AO

353 X-2548-677-1 AS HOLDER ACTUATOR ASSY (Note4)

354 2-695-356-11 BALL, BEARING

355 X-2548-676-1 AS SLIDER B ASSY (Note3)

* 356 4-256-515-01 HALL FPC PROTECTION SHEET

#14 2-599-475-11 SCREW (M1.7)

#87 2-689-328-01 SCREW, CCD BLAST ADJUSTMENT

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

2-10

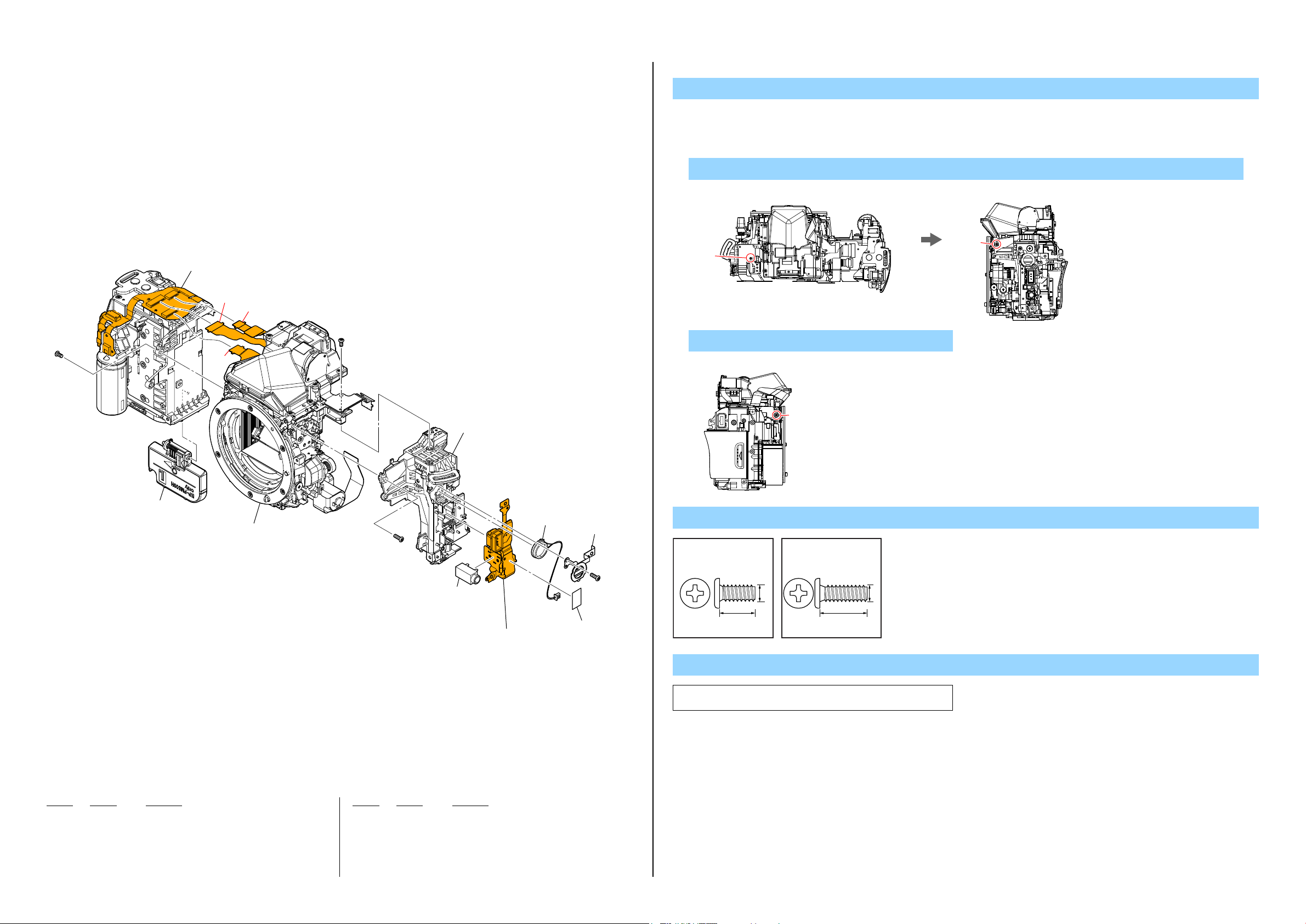

2-1-9. REMOTE HOLDER SECTION

DISASSEMBLY

1. Remove to numerical order (qd to qf) in the left figure.

2. The meaning of the sign in left figure is as follows. Be careful when it removes.

u-X: Flexible Board, Flat Cable, Harness

qd #8 X 1 → #12 X 1

Top View Right View

#12

qf Battery Holder Section

(See page 2-12)

u-14

u-14

u-14

401

AF Module Section

(See page 2-13)

#8

#12

qd�402

SP901 (Note)

404

#8

qf #12 X 1

Left View

Screw

#8: M1.7 X 3.5 (Tapping)

(Silver)

3-078-890-01

#12

#12: M1.7 X 5.0 (Tapping)

(Black)

3-080-204-21

#12

J9101

Ref. No. Part No. Description Ref. No. Part No. Description

401 X-2515-694-1 BD BATTERY CASE LID ASSY

402 X-2549-445-1 BD RT HOLDER ASSY

403 A-1797-668-A SMR-001 FLEXIBLE BOARD, COMPLETE (SERVICE)

(including J901 (Remote Holder)) (Note)

404 X-2549-875-1 BD SPEAKER SHEET METAL ASSY

405 3-076-631-01 CV PRV FLEXIBLE FIXED TAPE

J9101 1-691-737-42 JACK (SMALL TYPE)

SP901 1-858-462-11 LOUDSPEAKER (1.0CM) (Note)

#8 3-078-890-01 SCREW, TAPPING

#12 3-080-204-21 SCREW, TAPPING, P2

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

#12

403

(including J901 (Remote Holder))

(Note)

405

2-11

1.7

3.5

1.7

5.0

Note

Note: Referto“Assembly-4:SRM-001FlexibleBoard,Loudspeaker”

whenyouassemble.

2-1-10. BATTERY HOLDER SECTION

ns:notsupplied

Screw

#8: M1.7 X 3.5 (Tapping)

(Silver)

3-078-890-01

#91: M1.7 X 3.0 (Tapping)

(Silver)

2-695-434-11

457

462

461

458

(Note)

461

#8

#8

459

463

460

#91

#8

464

Claw

J902

(including battery terminal)

#8

465

Claw

ns

1.7

3.5

1.7

3.5

Note

Note: Refer to “Assembly-3: CV MCVedia Lid Spring” when you

assemble.

456

#8

452

455

454

#91

ns

451

453

C901

Ref. No. Part No. Description Ref. No. Part No. Description

451 4-154-720-01 BD CAPACITOR FIXED TAPE

452 A-1735-725-A ST-218 BOARD, COMPLETE

453 X-2549-448-1 BD BATTERY HOLDER ASSY

454 3-282-888-01 BD BATTERY LOCK CLAW

455 4-156-770-01 BD BT LOCK CLAW TENSION SP

461 4-154-702-01 BD GYRO CUSHION

462 1-489-243-11 GYJ-003 FLEXIBLE BOARD

* 463 4-154-700-01 BD EYELET (G)

* 464 4-154-701-01 BD GYRO BASE

465 X-2514-444-1 CV MEDIA BASE ASSY

456 1-880-444-11 STG-001 FLEXIBLE BOARD

457 4-154-727-21 CV MEDIA LID

* 458 4-154-730-01 CV MEDIA LID SPRING (Note)

* 459 4-154-729-01 CV MEDIA LID PLATE SPRING

* 460 4-154-728-01 CV MEDIA LID SHAFT

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

0* C901 1-114-603-11 ELECT 250uF 99% 330V

0 J902 1-822-838-11 DC JACK (including battery terminal)

#8 3-078-890-01 SCREW, TAPPING

#91 2-695-434-11 SCREW (T1.7), HEAD PAN TAPPING

2-12

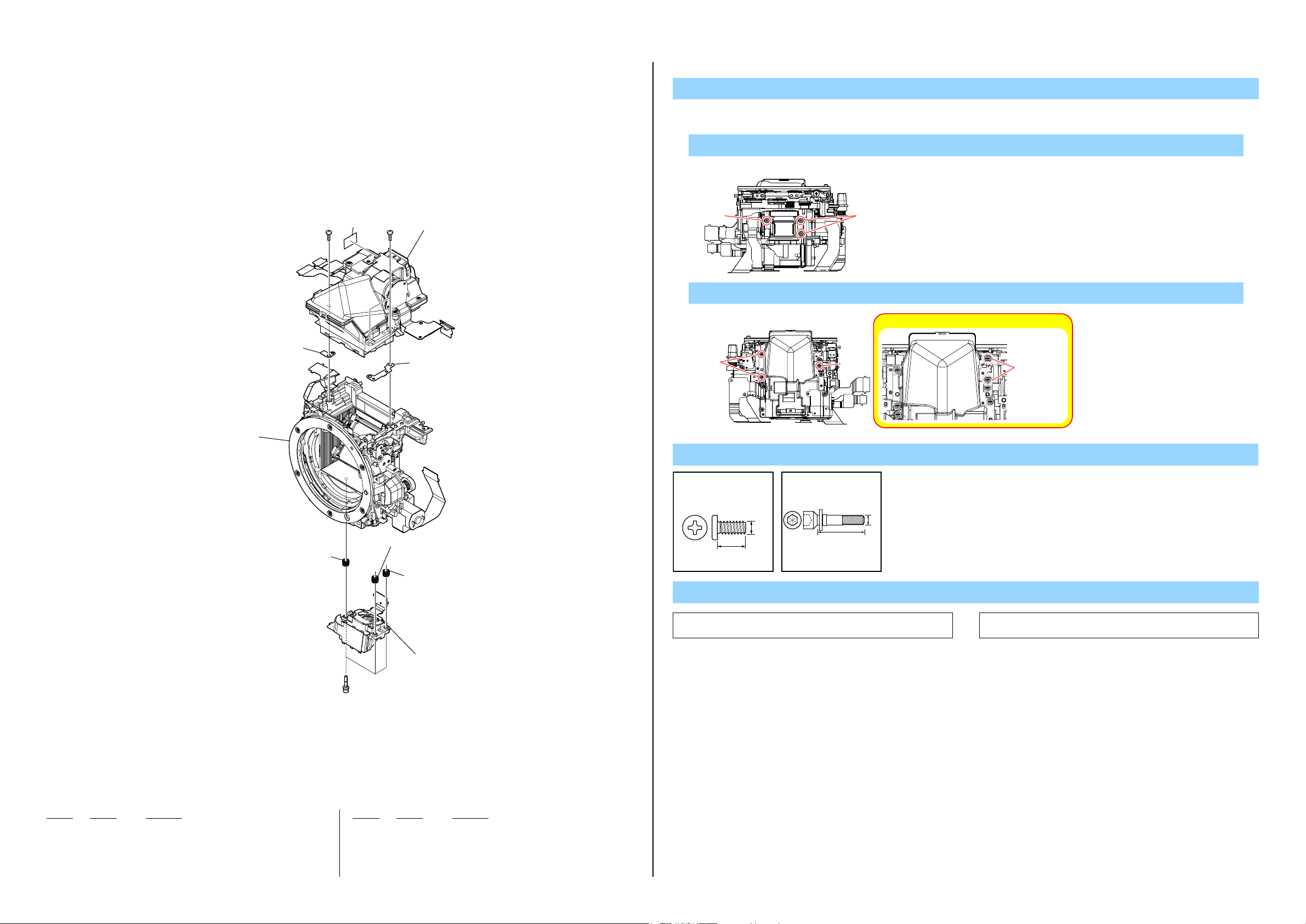

2-1-11. AF MODULE SECTION

DISASSEMBLY

1. Remove to numerical order (qg to qj) in the left figure.

qg #207 X 3 → S Adjustment SP (qg) X 3

Bottom View

qj Mirror Box Section (Sub Unit-1)

(See page 2-15)

503

qh-1

505

#64 #64

502

qg

qh�Mirror Box Section (Penta Unit)

(See page 2-14)

504

qh-2

502

qg

502

qg

#207

#207

qh #64 X 3 → VB Spacer (L) (qh-1) → VB Spacer (R) (qh-2)

#64

Top View

#64

Caution: Never touch two screws.

Screw

#64: M1.7 X 5.0 (Tapping)

(Silver)

2-666-551-21

5.0

1.7

#207: M1.6 X 8.0

(Silver)

4-191-605-01

1.6

8.0

Note

Don't touch

qg 501

(including AF-132 flexible board)

(Note1, 2)

#207

Ref. No. Part No. Description Ref. No. Part No. Description

501 A-1786-064-A ALX-8650 (including AF-132 flexible board) (Note1, 2)

502 2-693-420-01 SP, S ADJUSTMENT

503 4-141-111-31 VB SPACER (L)

504 4-141-110-31 VB SPACER (R)

* 505 4-154-698-01 EM ST SHIELD SHEET

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

#64 2-666-551-21 SCREW, TAPPING, P2

#207 4-191-605-01 S ADJUSTMENT SCREW

2-13

Note1: Refer to “Assembly-2: ALX-8650 (AF Module)” when you

assemble.

Note2: Refe r to “Assem bly-1 0: SAd justmen t Screw” wh en you

assemble.

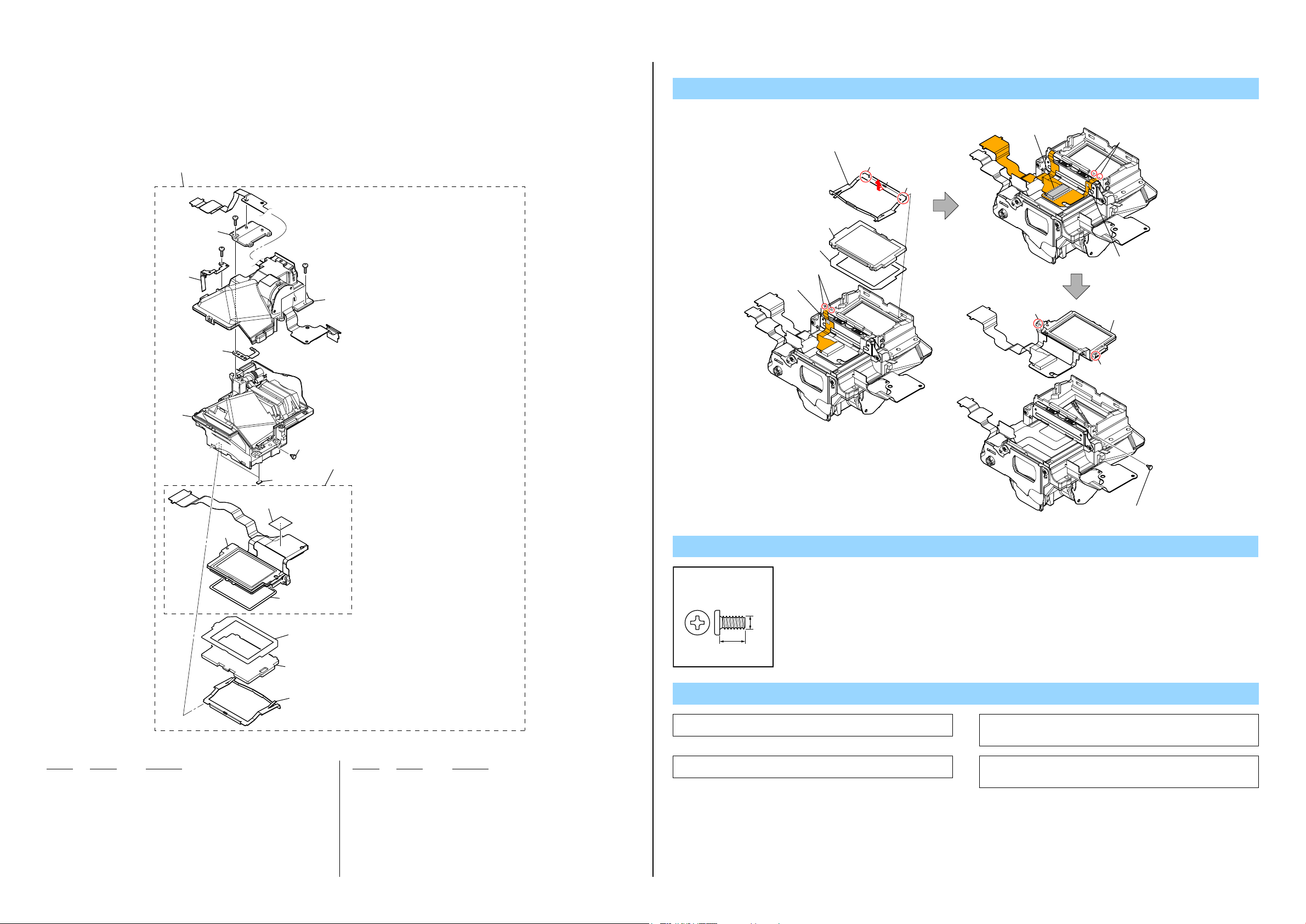

2-1-12. MIRROR BOX SECTION (PENTA UNIT)

ns:notsupplied

551

(including AE-036 flexible board, LCD903 (finder LCD),

IFL-004 flexible board and VTN-003 flexible board) (Note3)

DISASSEMBLY

VM OSD Unit Removal

1 Remove two claws pushing part A

below, and remove the VM FS Retainer

in the direction of arrow.

Claw

A

Claw

6 Adhesive Tape

8 Two Claws

ns

ns

ns

#76

ns

#76

ns

#76

ns

554

552

(including LCD902 (SI LCD), SIL-002 flexible board

and SI-067 flexible board)

553

555 (CAUTION)

(Size: 8.5mm X 12.2mm)

4 Adhesive Tape

Screw

2 Focus Plate

3 VB Spacer

5 Two Claws

0 Pin

7 Adhesive Tape

qs VM OSD Unit

qa Pin

9 OSD Holder VM Pin (L)

556

557 - 560

(Note2)

561

(Note1)

562

Ref. No. Part No. Description Ref. No. Part No. Description

551 A-1788-809-A VM PENTA UNIT 865S (including AE-036 flexible board,

LCD903 (finder LCD), IFL-004 flexible board and VTN-003 flexible board) (Note3)

552 4-152-739-01 VM PIN (L), OSD HOLDER

553 4-144-439-01 MB MAIN MIRROR CUSHION

554 A-1788-810-A VM OSD UNT 865S

(including LCD902 (SI LCD), SIL-002 flexible board and SI-067 flexible board)

555 CAUTION TAPE, VM SIL FPC DOUBLE STICK

556 4-152-743-01 VM OSD HOLDER CUSHION

557 4-152-746-01 VM SPACER, VB (T= 0.20 mm) (Note2)

558 4-152-746-11 VM SPACER, VB (T= 0.15 mm) (Note2)

559 4-152-746-21 VM SPACER, VB (T= 0.10 mm) (Note2)

560 4-152-746-31 VM SPACER, VB (T= 0.05 mm) (Note2)

561 A-1743-821-A VO FOCUSING SCREEN (SERVICE) (Note1)

562 4-152-745-01 VM FS RETAINER

#76 2-666-551-11 SCREW, TAPPING, P2

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

2-14

#76: M1.7 X 4.0 (Tapping)

(Silver)

2-666-551-11

1.7

4.0

Note

Note1: Refertopage1-1“1-1.METHODOFREPLACINGTHEFOCUS

Note3: Refertopage3-8“3-3.CLEANINGPROCEDUREOFVIEW-

PLATE”whenthefocusplateisreplaced.

FINDER”formethodofcleaningtheviewfinder.

Note2: Theseare spacers useto adjust thickness when Viewfinder

BackAdjustmentisdone.

AdjustingItem:“ViewfinderBackAdj.”

Caution:

Forthepartof555,cutSHEET,ADHESIVE(2-649-300-01)intothe

desiredlengthanduseit.

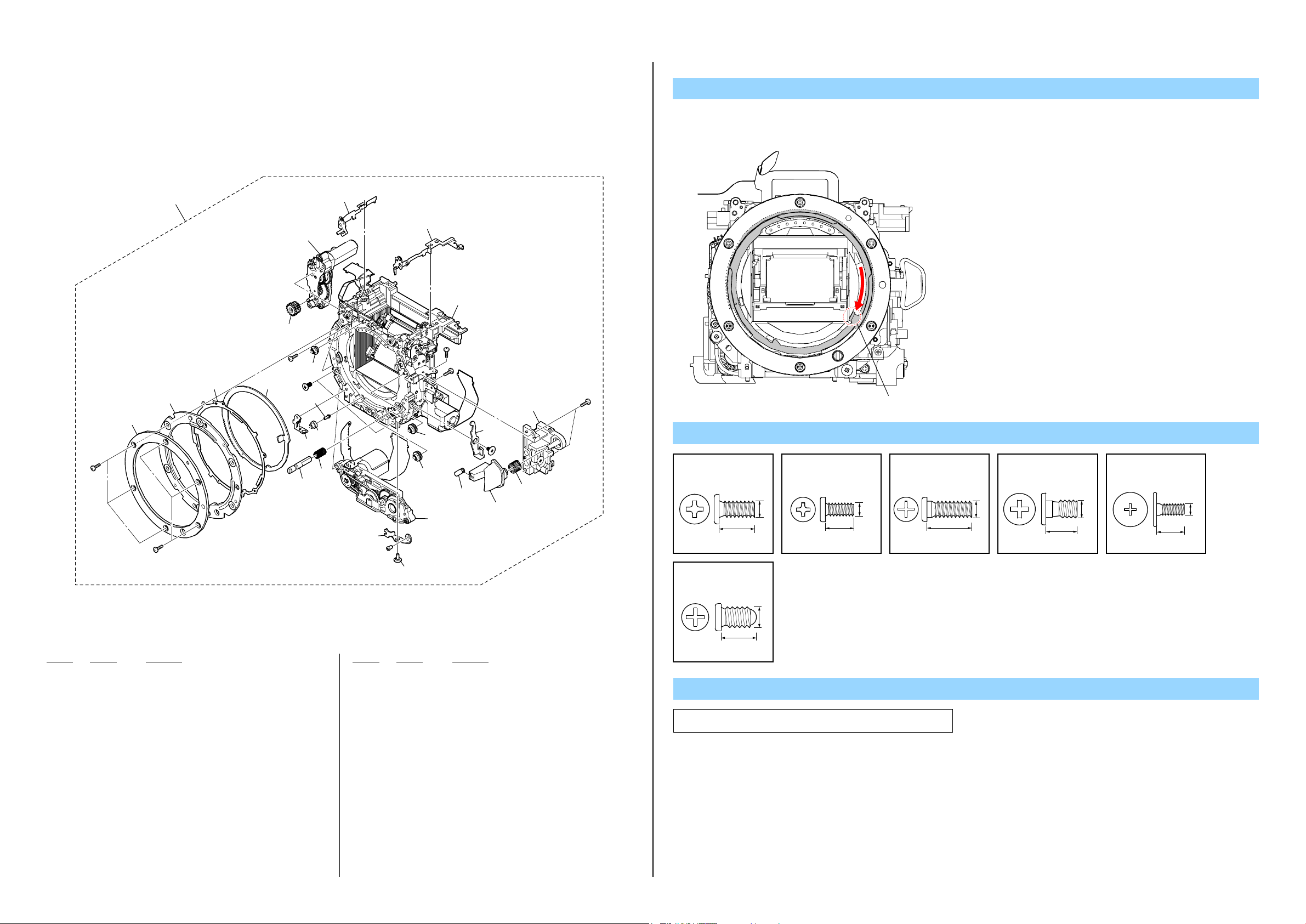

2-1-13. MIRROR BOX SECTION (SUB UNIT-1)

DISASSEMBLY

Iris Ring Removal

Rotate the Iris Ring clockwise, and remove it at the stop position (iris-in end).

At this time, do not rotate the Iris Joint Gear of the Aperture Unit.

#163

602

601 (Note)

603

#163

613

(including M902 (aperture motor)

and AP-033 flexible board)

612

#64

611

#164

604

605

610

609

608

607

606

614

623

#166

615

Mirror Box Section (Sub Unit-2)

(See page 2-16)

#23

#23

621

621

619

622

(including M901 (AF motor)

and AFP-005 flexible board)

624

620

618

#165

616

617

#23

Screw

#23: M1.7 X 4.0 (Tapping)

(Black)

3-080-204-11

4.0

#166: M1.7 X 3.0 (Tapping)

(Silver)

3-271-395-11

#64: M1.7 X 5.0 (Tapping)

(Silver)

2-666-551-21

1.7

5.0

Iris Ring Lever

#163: M2.0 X 5.5 (Tapping)

1.7

(Silver)

2-695-575-11

5.5

2.0

#164: M2.0 X 3.9

(Black)

3-268-954-11

3.9

#165: M1.7 X 3.0 (Tapping)

2.0

(Silver)

2-695-434-31

3.0

1.7

Ref. No. Part No. Description Ref. No. Part No. Description

601 A-1788-092-A MB MIRROR BOX SUB UNIT (Note)

602 2-689-021-01 MB H MOUNT

603 4-141-109-01 MB MOUNT SPACER

604 2-689-198-01 MB RING SP

605 4-141-393-01 AP IRIS RING

606 4-141-108-01 AF COUPLER

* 607 4-141-103-01 AF COUPLER TENSION SP

* 608 4-141-104-01 EM A MOUNT LUG PLATE (LOWER)

609 3-277-916-01 AP RING ROLLER C

610 3-268-951-01 SHAFT, RING ROLLER (C) (SV)

611 2-689-314-01 ROLLER B (SV), RING

612 2-689-306-01 GEAR, IRIS JOINT

613 A-1709-450-A AP APERTURE UNIT

(including M902 (aperture motor) and AP-033 flexible board)

* 614 4-141-102-02 EM A MOUNT LUG PLATE (UL)

* 615 4-141-101-02 EM A MOUNT LUG PLATE (UR)

616 A-1709-451-A MB LENS LOCK UNIT

* 617 4-141-090-01 MB LENS LOCK SP

* 618 4-141-091-01 MB LENS LOCK BUTTON

* 619 4-141-092-01 MB LENS LOCK PIN

620 4-141-105-01 MB COUPLER JOINT LEVER

621 2-689-313-01 ROLLER A (SV), RING

622 A-1709-449-A AF DRIVING UNIT

(including M901 (AF motor) and AFP-005 flexible board)

623 4-141-106-01 MB COUPLER LEVER

* 624 2-689-289-11 SHAFT, COUPLER LEVER

#23 3-080-204-11 SCREW, TAPPING, P2

#64 2-666-551-21 SCREW, TAPPING, P2

#163 2-695-575-11 SCREW (T2), +P1 PAN TAPPNG

#164 3-268-954-11 SCREW, AF BASE PLATE STOPPER

#165 2-695-434-31 SCREW (T1.7), HEAD PAN TAPPING

#166 3-271-395-11 SCREW (M1.7), LEVER ADJUSTMENT

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

1.7

3.0

Note

Note: Referto“Assembly-1:MirrorBoxSubUnit”whenyou

assemble.

2-15

2-1-14. MIRROR BOX SECTION (SUB UNIT-2)

ns:notsupplied

Screw

#23: M1.7 X 4.0 (Tapping)

(Black)

3-080-204-11

#93: M1.7 X 3.5 (Tapping)

(Silver)

3-254-082-01

654

(including BL-034 flexible board)

#23

653

655

656

ns

657

658

661

659

660

ns

#23

ns

#93

662

663

1.7

4.0

1.7

3.5

Note

Note: Referto“Assembly-6:SLK-006FlexibleBoard”whenyou

assemble.

652

651

Ref. No. Part No. Description

651 3-279-657-11 RETAINER, MAIN MIRROR

652 4-141-080-01 MB MAIN MIRROR

653 4-207-870-01 MB AF MASK PLATE

654 A-1734-156-A MB BL CONTACT HOLDER UNIT857

(including BL-034 flexible board)

655 3-268-935-01 SP, SUB MIRROR FUNCTION

* 656 3-279-649-11 SHEET, BL DUST PROTECT

657 X-2348-731-1 MB MIRROR CHARGE LEVER ASSY

658 3-268-931-01 SP, SHUTTER CHARGE LEVER

659 4-207-867-01 MB SHUTTER CHARGE LEVER

660 3-268-937-01 RETAINER, ADJUSTMENT PLATE

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

665

(including M903

(charge motor))

#23

ns

ns

664

(including SLK-006 flexible board)

(Note)

Ref. No. Part No. Description

661 4-207-868-01 MB MIRROR CHARGE CAM GEAR

662 3-268-929-01 DRIVING (SP), MIRROR (SV)

663 3-268-930-01 RETAINER, MIRROR DRIVING (SP)

664 X-2514-252-1 MB CHARGE BASE PLATE B ASSY

(including SLK-006 flexible board) (Note)

665 A-1734-155-A MB CHARGE BASE PLATE A UNIT

(including M903 (charge motor))

#23 3-080-204-11 SCREW, TAPPING, P2

#93 3-254-082-01 SCREW

#93

#93

2-16

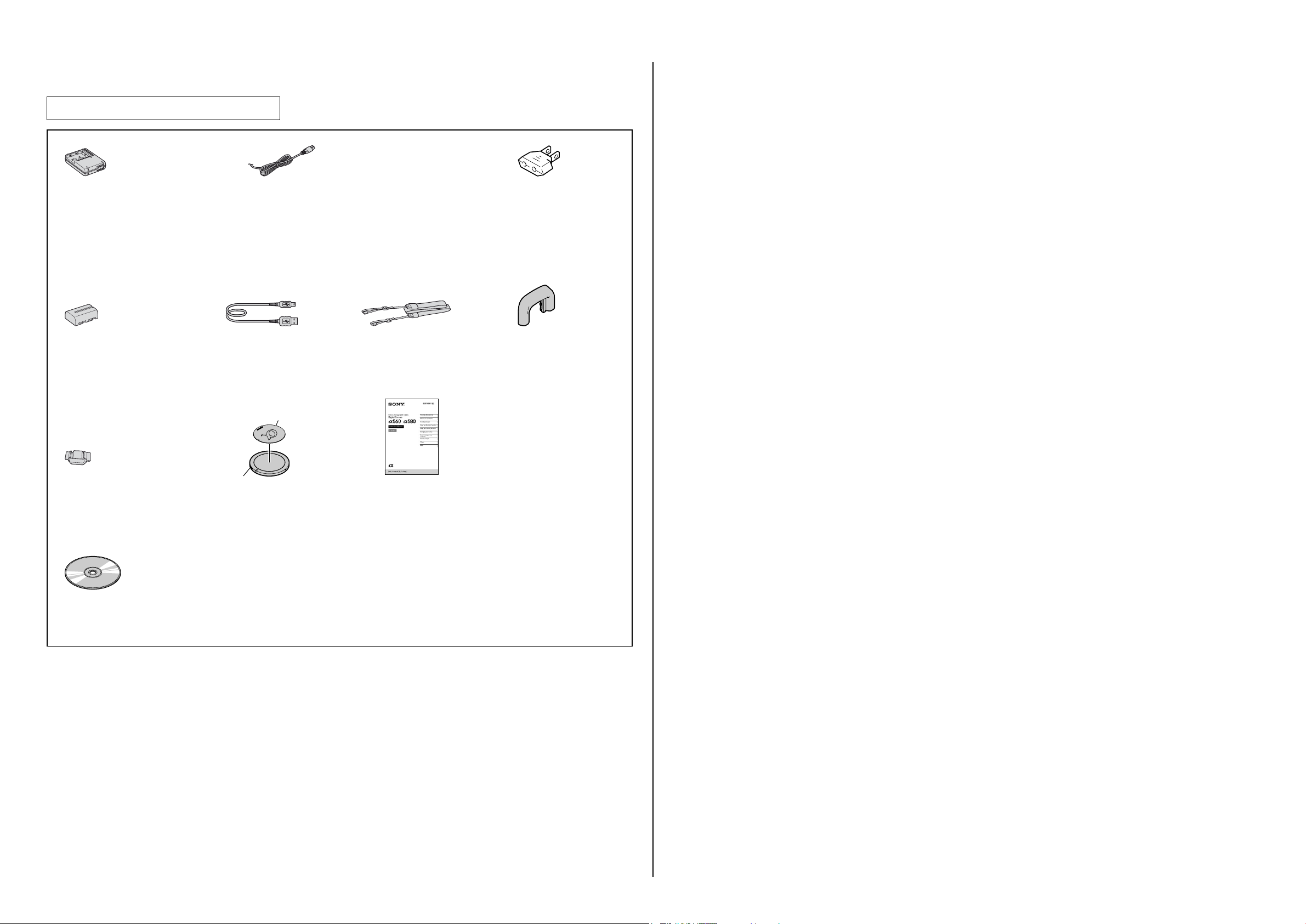

Checking supplied accessories.

Note: Thisitemissuppliedwiththeunitasan

accessory,butisnotpreparedasaservicepart.

Battery charger

(BC-VM10)

0 1-479-742-41 (EXCEPT US)

0 1-479-742-51 (US)

Rechargeable battery pack

(NP-FM500H)

(Note)

Eyepiece cover

3-273-458-01

CD-ROM

- Application Software for α camera

4-195-615-02

Power cord (mains lead)

0 1-790-107-42 (US)

0 1-832-121-51 (CH)

0 1-837-421-11 (UK, E (Saudi, Hong Kong))

0 1-837-427-11 (AEP, E (EXCEPT Saudi, Hong Kong))

0 1-837-428-11 (KR)

0 1-837-429-11 (AUS)

USB cable

1-829-868-31

Body Cap Seal

2-894-387-01

Body Cap

3-282-743-01

Shoulder strap

4-145-436-01

Instruction Manual

• (Only for destination Japanese model)

英語,韓国語,中国語のみ部品供給可能です。

4-207-863-11 (ENGLISH)

∗ 4-207-863-21 (FRENCH, ITALIAN)

∗ 4-207-863-31 (SPANISH, PORTUGUESE)

∗ 4-207-863-41 (GERMAN, DUTCH)

∗ 4-207-863-51 (TRADITIONAL CHINESE,

∗ 4-207-863-61 (RUSSIAN)

∗ 4-207-863-71 (ARABIC, PERSIAN)

4-207-863-81 (KOREAN)

4-207-863-91 (SIMPLIFIED CHINESE) (CH)

∗ 4-209-041-11 (POLISH)

Conversion (2P) Adaptor

0 1-569-008-12

Eyecup

X-2514-442-1

SIMPLIFIED CHINESE) (E)

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

2-17E

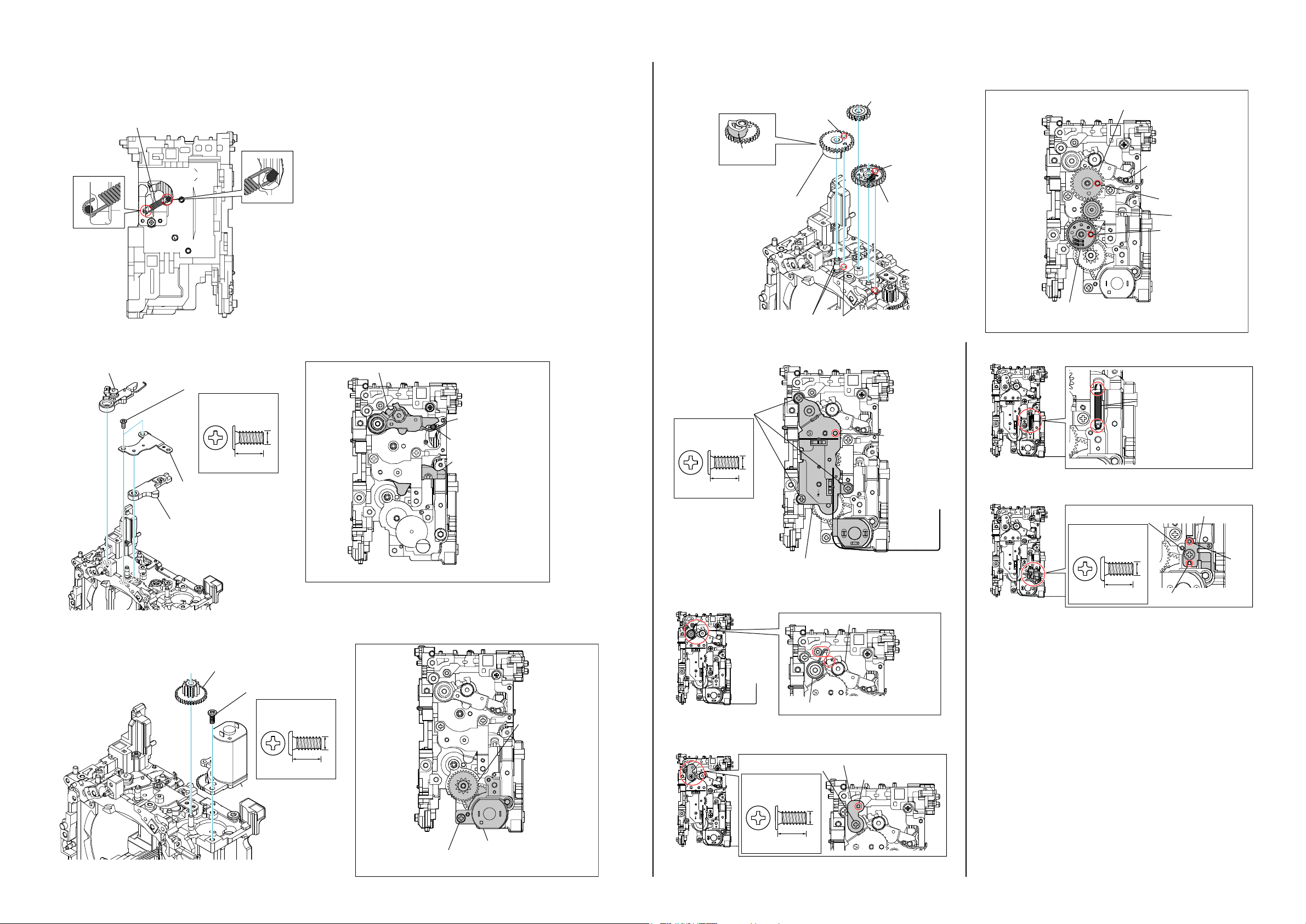

3-1. ASSEMBLY

1-3. Charge Base Plate A Unit, Deceleration Gear 2

Assembly-1: Mirror Box Sub Unit

1-1. Sub Mirror Function Spring

Sub Mirror Function Spring

∗ Note the direction.

3. ASSEMBLY

1-4. Shutter Cam Gear Assy, Idle Gear, Mirror Charge Cam Gear

Hole

2 Idle Gear

- Gears Position -

Mirror Charge Cam Gear

- Left View -

1-2. Mirror Charge Lever Assy, Shutter Charge Lever

1 Mirror Charge Lever Assy

4 Screw

#93: M1.7 X 3.5 (Tapping)

(Silver)

3-254-082-01

3.5

3 Charge Base Plate C Assy

2 Shutter Charge Lever

G G-85

3 Mirror Charge Cam Gear

Hole

1 Shutter Cam Gear Assy

Main Mirror Holder Down

Hole

Idle Gear

Hole

Shutter Cam Gear Assy

G G-85

1-5. Charge Base Plate B Assy

Hole

- Right View -

1-8. Shutter Charge Lever Spring

Mirror Charge Lever Assy

Shutter Charge Lever Spring

∗ Note the direction.

(Silver)

3-254-082-01

3.5

Screw

Hole

1.7

- Right View -

Spring

1.7

Main Mirror Holder Boss

#93: M1.7 X 3.5 (Tapping)

Shutter Charge Lever

1-9. Adjustment Plate Retainer

Adjustment Plate Retainer

4.0

Screw

1.7

Boss

Boss

- Right View -

1-6. Mirror Driving Spring

Charge Base Plate B Assy

- Right View -

- Right View -

#23: M1.7 X 4.0 (Tapping)

(Black)

3-080-204-11

Mirror Charge Lever Assy

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

3 Deceleration Gear 2

2 Screw

#23: M1.7 X 4.0 (Tapping)

(Black)

3-080-204-11

1 Charge Base Plate A Unit

Deceleration Gear 2

1.7

4.0

- Right View -

1-7. Mirror Driving (SP) Retainer

#93: M1.7 X 3.5 (Tapping)

Mirror Driving Spring

Screw

(Silver)

3-254-082-01

1.7

3.5

Mirror Driving (SP) Retainer

Boss

Charge Base Plate A Unit

Screw (#23)

- Right View -

- Right View -

3-1

1-10. BL Contact Holder Unit, BL Dust Protect Sheet

BL Dust Protect Sheet

- Back View -

Screw

#23: M1.7 X 4.0 (Tapping)

(Black)

3-080-204-11

1-13. Iris Joint Gear, Aperture Unit

∗ The Aperture Unit is supplied by being set in the charge position

(initial position), but if this position is disordered when the Aperture

Unit is removed, or if the charge position is to be set again, perform

as follows.

∗ Refer to "1-14. The Aperture Unit Charge Position Setting" for

the confirm method at the charge position.

3 Screw

#64: M1.7 X 5.0 (Tapping)

(Silver)

2-666-551-21

1.7

5.0

1-15. The Aperture Unit Free Position Setting

∗ Set the Aperture Unit to a free position once, if the gear was rotated

accidentally and the charge position is disordered, or if the charge

position was shifted during disassembly.

Gear rotating

direction to set

the charge position

Gear rotating

direction to make

the unit free

1-16. A Mount Lug Plate (UR)

Boss

Boss

Claw

Claw

Boss

- Front View -

1-11. AF Driving Unit

#164: M2.0 X 3.9

Screw

- Front View -

(Black)

3-268-954-11

1.7

4.0

- Front View -

In a free state, the edge of this spring

will move up and down about 1 mm if

the gear is moved a little.

1-17. A Mount Lug Plate (UL)

Boss

2 Aperture Unit

Claw

In a free state, a hole in the gear almost

coincides with a hole in the Aperture Unit.

2.0

3.9

1 Iris Joint Gear

Claw

Boss

1-18. AF Coupler, AF Coupler Tension Spring

Boss

AF Coupler

Soldering

Note: The spring is deformed and cannot

be used if the gear is rotated too

AF Coupler Tension Spring

∗ Note the direction.

much from a free state.

AF Driving Unit

1-12. A Mount Lug Plate (Lower)

Boss

Claw

A Mount Lug Plate (Lower)

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

AF Driving Unit Flexible

Board Arrangement

- Left View -

1-14. The Aperture Unit Charge Position Setting

1. Check that the Aperture Unit is in a free state.

2. After confirming that the Aperture Unit is in a free state, rotate the

gear by 3 turns.

3. After rotating the gear by 3 turns, set the Aperture Unit where the

holes in the gear and the Aperture Unit coincide. This position is the

charge position.

∗ Refer to "1-15. The Aperture Unit Free Position Setting" for

the setting and the confirm method at the free position.

3-2

First, check the

spring edge position.

If the edge of spring is located downward,

rotate the gear in the arrow direction to

search a free position.

∗ In a free position, the edge of spring is

located upward.

ALX-8650 Flexible Board

1-19. Coupler Lever

Claw

1-21. Ring Roller (A), Iris Ring

1. With the Aperture Unit set in the charge position (see "1-14.

The Aperture Unit Charge Position Setting" ), install it on

the front frame set.

∗ The Aperture Unit has been set in the charge position, if it is not

removed.

However, the iris ring must be in the removed state (where the Iris

Joint Gear is not rotated).

2. Install the Iris Ring with it's a punch mark aligned with a line that

connects the Iris Joint Gear shaft and the optical axis center.

Optical Axis Center

Ring Roller (A)

Ring Roller (A)

Iris Ring

1-24. Ring (SP), Mount Spacer, H Mount

Ring (SP)

Mount Spacer

Assembly-2: ALX-8650 (AF Module)

Rib

G G-85

Coupler Lever Shaft

1-20. Lens Lock Unit

#23: M1.7 X 4.0 (Tapping)

(Black)

3-080-204-11

Screw

4.0

Lens Lock Unit

- Right View -

Lever Adjustment Screw

#166: M1.7 X 3.0 (Tapping)

Claw

1.7

- Top View -

Soldering

(Silver)

3-271-395-11

3.0

Screw

#23: M1.7 X 4.0 (Tapping)

(Black)

3-080-204-11

Claw

Coupler Lever

1.7

4.0

- Back View -

H Mount

6

2

Assembly-3: CV Media Lid Spring

1

CV Media Lid Spring

Iris Joint Gear Shaft

1-22. Ring Roller (B), Ring Roller (C), Ring Roller (C) Shaft

Ring Roller (B)

Ring Roller (C)

1.7

Ring Roller (C) Shaft

Ring Roller (C)

G G-85

Ring Roller (C) Shaft

Ring Roller (C)

Iris Ring

Ring Roller (C) Shaft

1-23. Lens Lock Button, Lens Lock

Punch Mark

Ring Roller (B)

Iris Ring

- Front View -

Pin, Lens Lock Spring

Lens Lock Pin

- Front View -

4

3

∗ Tighten six screws in order of the number.

#163: M2.0 X 5.5 (Tapping)

(Silver)

2-695-575-11

2.0

5.5

1-25. Coupler Joint Lever

5

Rib

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

Lens Lock Spring

Lens Lock Button

3-3

Coupler Joint Lever

Screw

#165: M1.7 X 3.0 (Tapping)

(Silver)

2-695-434-31

3.0

1.7

Assembly-4: SMR-001 Flexible Board, Loudspeaker

Claw

Boss

Boss

SMR-001 Flexible Board

Assembly-5: Shutter Unit (AFE-3032)

Mirror

DC Power Supply

(2V, 1A)

Assembly-6: SLK-006 Flexible Board

Claw

7-2. ST Strobe Guide Arm Assy (L/R)

ST Strobe Guide Arm Assy (R)

Open

Match shape.

Boss

Loudspeaker

Rib

Supply the power (2V, 1A) to the charge motor to rotate

it forward so as to move up the mirror completely.

Boss

Boss

Shutter Unit (AFE-3032)

Push the surplus part of the flexible board in.

Rib

Assembly-7: Top Cover Block

7-1. ST Strobe Base Cover Assy

ST Strobe Base Cover Assy

Do not bend the spring.

Shaft

CV Top Cover Assy

Install ST Strobe Guide Arm Assy (L) similarly.

Screw

#91: M1.7 X 3.0 (Tapping)

(Silver)

2-695-434-

1.7

3.5

7-3. ST Strobe Hinge Collar

Shaft

Rotate it by 180°.

Screw

Do not open the space.

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

ST Strobe Hinge Collar

Rib

3-4

7-4. Microphone Assy.

Microphone Assy

7-7. Control Switch Block (TK86500)

Confirm the position of each part.

CV Top Cover Assy Side

Power Knob

Control Switch Block Side

7-8. Control Switch Block (TK86500) Flexible Board

Boss

Claw

7-10. Microphone Unit Harness

Boss

7-5. Shoe Connector.

BD Eye Piece Frame

Shoe Connector

#12: M1.7 X 5.0 (Tapping)

(Black)

3-080-204-21

Power Knob

LV Knob

“LIVE VIEW”

Side

Mode Dial

Mode Dial

45°

Power Lever

LV Knob

Make "M" the horizontal.

Hook

45°

Slide Lever

Boss

7-9. Flash Unit (FL85700)

Valley fold

HookRib

Claw

7-11. Flash Unit (FL85700) Harness / Shoe Connector Flexible Board

Rib

Valley fold

Rib

Shoe Connector Flexible Board

7-12. Pop Up Spring

Rib

Pop Up Spring

Valley fold

BD Eye Piece

Dust Cushion (865)

7-6. Plunger Solenoid

Solder

Screw

#172: M1.4 X 4.0 (Tapping)

(Black)

2-178-410-01

4.0

Screw

ST Stroboscope Lock Assy

1.4

Control Switch Block (TK86500)

5.0

Plunger Solenoid

Boss

1.7

Screw (#8)

Screw (#8)

#8: M1.7 X 3.5 (Tapping)

(Silver)

3-078-890-01

3.5

Screw (#8)

#12: M1.7 X 5.0 (Tapping)

1.7

Boss

Screw (#12)

(Black)

3-080-204-21

5.0

Screw (#8)

Screw (#8)

1.7

Rib

White

Pink

Black

Claw

Boss

Adhesive Tape

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

3-5

7-13. ST Strobe Cover

ST Strobe Cover

7-14. Connector Housing 2P

Connector Housing 2P

(Red)

Ditch

Connector Housing 2P

(White)

Assembly-10: S Adjustment Screw

S Adjustment Screw

Pink

White

Black

Ditch

Claw

Claw

Claw

Assembly-8: Top Cover Block Assy

LV Knob

Confirm the position of the

LIVE VIEW/OVF switch.

B B-50

S Adjustment Screw

Assembly-11: Note on attachment of the SMR-001 and

the SLK-006 Flexible Board

When attach the SME-001 Flexible Board and the SLK-006 Flexible

Board to the AM-025 Board, attach the SMR-001 Flexible Board firstly

to make the SLK-006 Flexible Board outside of it.

AM-025 Board

1 SMR-001 Flexible Board

2 SLK-006 Flexible Board

Screw

#12: M1.7 X 5.0 (Tapping)

(Black)

3-080-204-21

1.7

5.0

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

Assembly-9: Flash Unit (FL85700) Harness

Rib

Assembly-12: Assemble the CV FRONT COVER ASSY

When assembling the CV Front Cover Assy, check if

the Focus Mode Switch of both the CV Front Cover Assy and

the MB AF MF Change Lever are in AF position.

CV Front Cover Assy

Focus Mode Switch

MB AF MF Change Lever

3-6

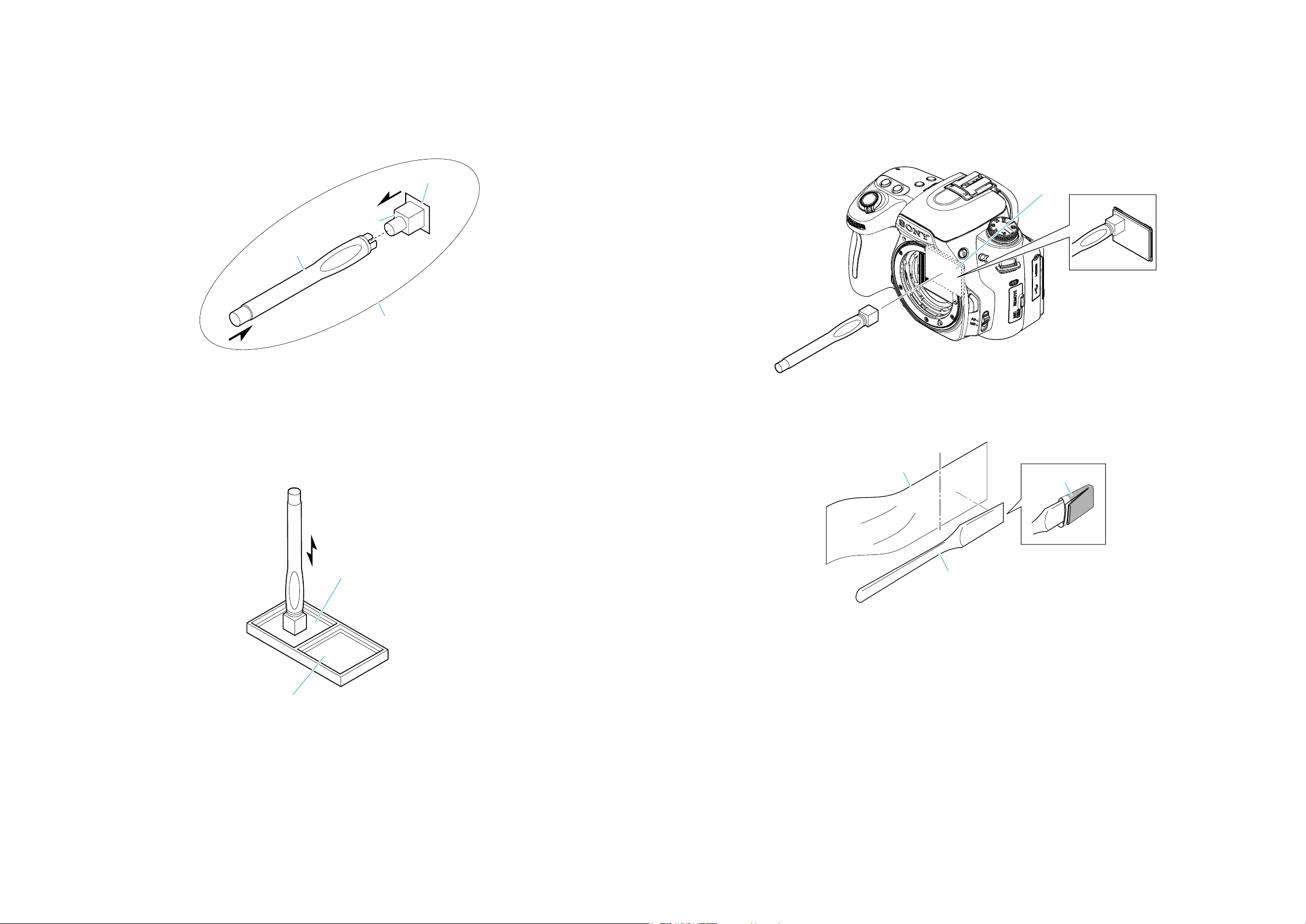

3-2. CLEANING PROCEDURE OF OLPF

<Preparation for Remedy>

If you use the new Jig (J-6082-663-A) below, make sure to clean the CCD Cleaning Jig (Tip) below before using, please.

Note: Protection sheet is for preventing the scratch of a surface on the Jig (Tip).

The protection sheet may be come off the Jig when you take the Jig from a bag, but it is no problem.

Protection Sheet

CCD Cleaning Jig (Tip)

CCD Cleaning Jig

CCD Cleaning Jig (New)

(J-6082-663-A)

<Cleaning Procedure for Tip of CCD Cleaning Jig>

1. Put the two cleaning cloths on a tray like below.

1 Souse the one cleaning cloth in ethyl alcohol.

2 Put the other cleaning cloth on a tray as it is dry.

2. Dab the tip of CCD cleaning jig at the cleaning cloth of 1 5 or 6 times.

* Do not slide the tip from right to left or up and down while dabbing.

3. Dab the tip of CCD cleaning jig at the cleaning cloth of 2 5 or 6 times.

* Do not slide from right to left or up and down while dabbing.

4. Wait until the tip will be dried completely.

<Cleaning Procedure for the OLPF>

1. Clean up the tip of CCD cleaning jig.

2. Set a camera to a cleaning mode.

3. Dab the tip of CCD cleaning jig at the OLPF, and pull up straight.

* Do not slide from right to left or up and down while dabbing.

4. Repeat “3” several times to clean up.

5. According to service manual, check if there is dirt on the CCD.

OLPF

<CAUTION>

If you cannot remove dirt with remedy above, cleaning by the following jig are used.

Soak a small amount of EE3310 (Liquid cleaner) after wrapping the cleaning cloth (J-6082-636-A) around the cleaning jig (J-6082-635-A).

Cut

Cleaning Cloth

(J-6082-636-A)

EE3310

2 The dry cleaning cloth.

DSLR-A560/A560L/A560Y/A580/A580L/A580Y/A580J_L2

1 Souse the cleaning

cloth in ethyl alcohol.

Cleaning Jig

(J-6082-635-A)

3-7

Loading...

Loading...