Sony CDPXE-330 Service manual

http://cxema.ru

CDP-XE330

SERVICE MANUAL

AEP Model

UK Model

Model Name Using Similar Mechanism CDP-XE220/XE320

CD Mechanism Type CDM14FL-5BD29C

Base Unit Name BU-5BD29C

Optical Pick-up Name KSS-213BA/F-NP

SPECIFICATIONS

Compact Disc Player

Laser Semiconductor laser (λ = 780 nm)

Emission duration: continuous

Laser output Max 44.6 µW*

* This output is the value measured at a distance of

200 mm from the objective lens surface on the

Optical Pick-up block with 7 mm aperture.

Frequency response 2 Hz to 20 kHz ± 0.5 dB

Signal-to-noise ratio More than 100 dB

Dynamic range More than 92 dB

Harmonic distortion Less than 0.005%

Channel separation More than 95 dB

Output

Jack Maximum Load

type output impedance

level

LINE OUT Phono 2 V Over 10 kΩ

jacks (at 50 kΩ)

DIGITAL OUT Optical –18 dBm Wave length:

(OPTICAL) output 660 nm

connector

General

Power requirements 220 V – 230 V AC, 50/60 Hz

Power consumption 10W

Dimensions (approx.) 430 × 110 × 290 mm

(w/h/d) (17 × 4

Mass (approx.) 3.1 kg (6 lbs 14 oz)

Supplied accessories

Audio cord (2 phono plugs–2 phono plugs) (1)

Remote commander (remote) (1)

R6 (size AA) batteries (2)

Design and specifications are subject to change without notice.

3

/8 × 11 1/2 in.) incl. projecting parts

MICROFILM

COMPACT DISC PLAYER

http://cxema.ru

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

TABLE OF CONTENTS

1. SERVICING NOTE .......................................................... 3

2. GENERAL .......................................................................... 4

3. DISASSEMBLY

3-1. Front Panel ············································································ 5

3-2. Base Unit (BU-5BD29C) ······················································ 5

4. TEST MODE ....................................................................... 6

5. ELECTRICAL BLOCK CHECKING .......................... 8

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

6. DIAGRAMS

6-1. Circuit Boards Location ...................................................... 10

6-2. Printed Wiring Board – BD Section –................................. 11

6-3. Schematic Diagram – BD Section – ................................... 13

6-4. Printed Wiring Board – Main Section –.............................. 15

6-5. Schematic Diagram – Main Section – ................................ 17

6-6. Printed Wiring Board – Display Section –.......................... 19

6-7. Schematic Diagram – Display Section – ............................ 21

6-8. IC Pin Functions ................................................................. 23

6-9. IC Block Diagrams ............................................................. 29

7. EXPLODED VIEWS

7-1. Main Section ....................................................................... 32

7-2. CD Mechanism Section (CDM14FL-5BD29C) ................. 33

7-3. Base Unit Section (BU-5BD29C) ....................................... 34

8. ELECTRICAL PARTS LIST ........................................ 35

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

— 2 —

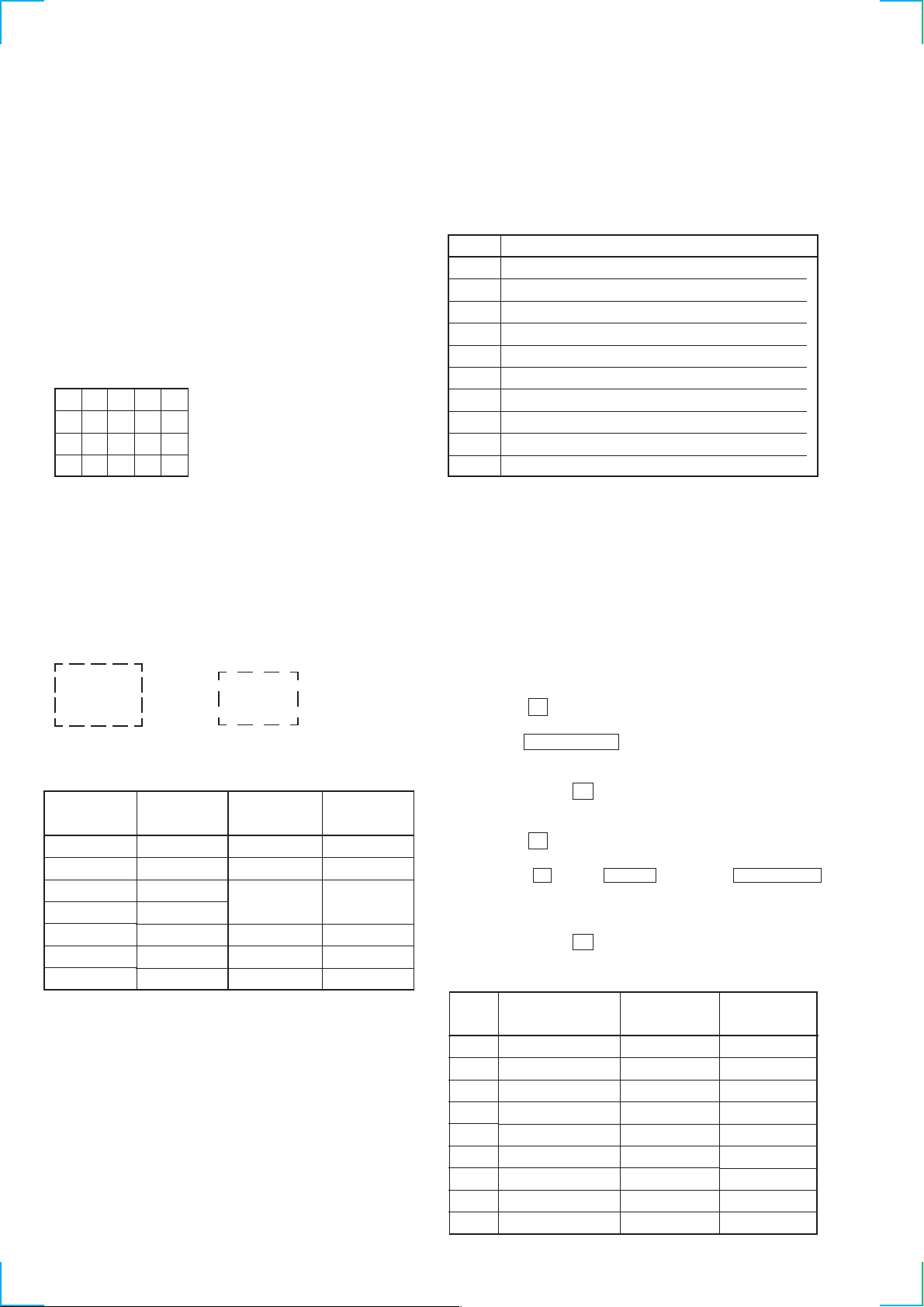

MODEL IDENTIFICATION

— BACK PANEL —

Parts No.

PARTS No. MODEL

4-214-171-0

4-214-171-1

AEP, North European, CIS

UK

http://cxema.ru

SECTION 1

SERVICING NOTE

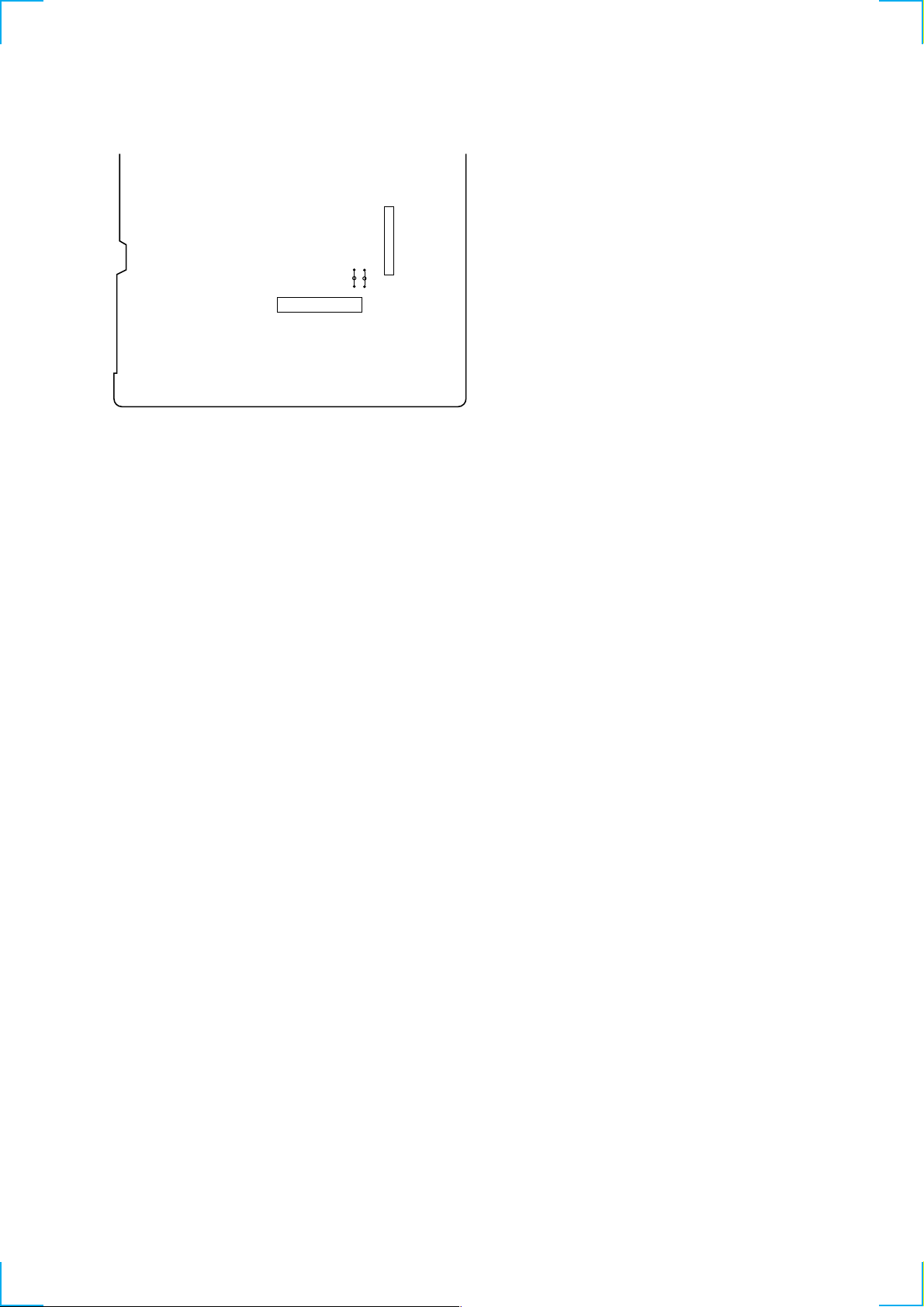

HOW TO OPEN THE DISC TRAY WHEN POWER SWITCH

TURNS OFF

Insert a tapering driver into the aperture of the unit bottom, and turn

in the direction of arrow.

*

To close the disc table, turn the driver in the reverse direction.

Pull out disc table.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer

electrostatic breakdown because of the potential difference

generated by the charged electrostatic load, etc. on clothing and

the human body.

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveform is output two times.

— 3 —

http://cxema.ru

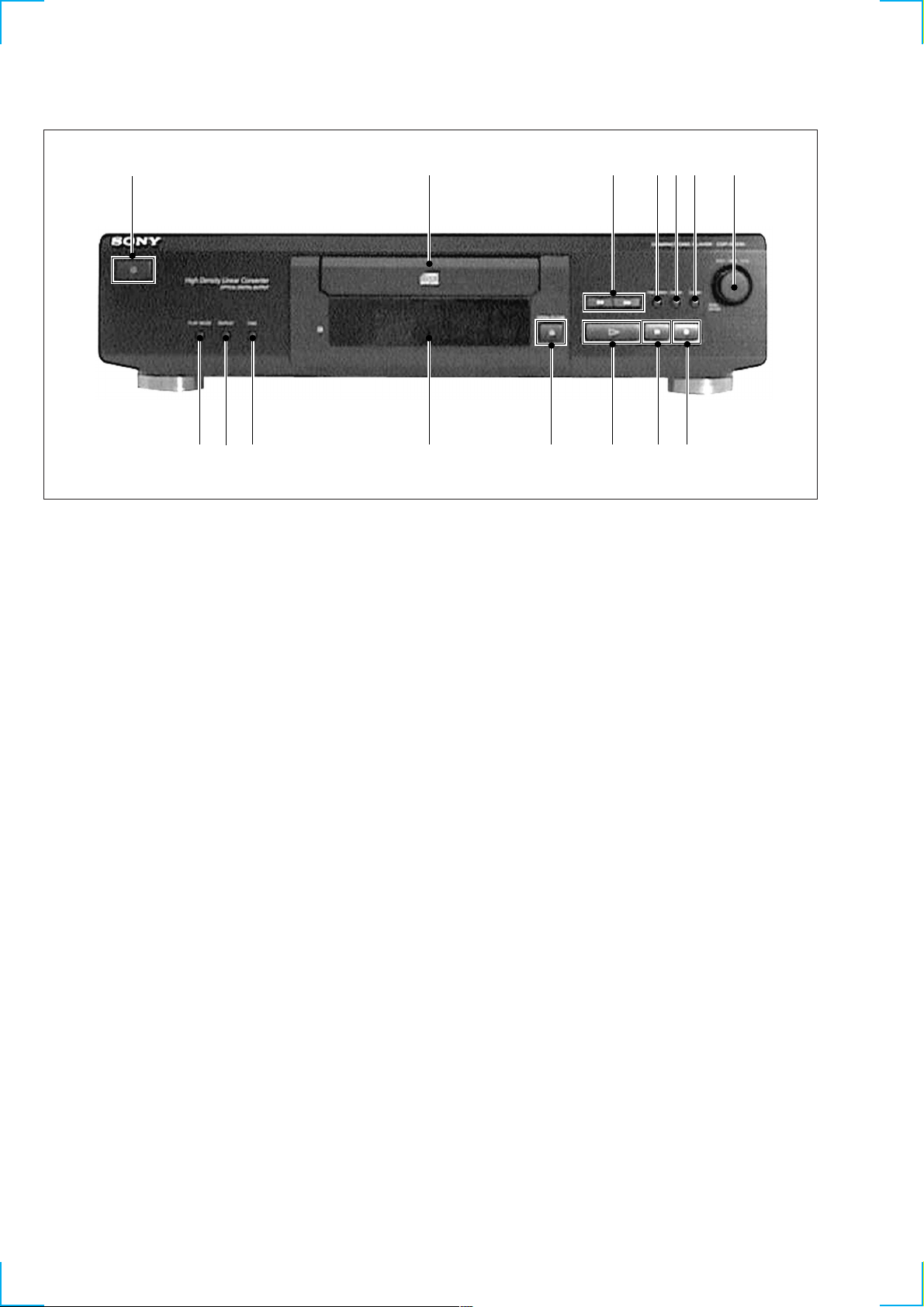

Front Panel

SECTION 2

GENERAL

1

2

LOCATION OF PARTS AND CONTROLS

1 U switch

2 DISC tray

3 PEAK SEARCH button

4 CHECK button

5 CLEAR button

6 0,) button

7 ≠, AMS * ± knob

(PUSH ENTER button)

8 p (stop) button

9 P (pause) button

0 · (play) button

!¡ § OPEN CLOSE button

!™ Display window

!£ TIME button

!¢ REPEAT button

!∞ PLAY MODE button

* AMS is the abbre viation for Automatic Music Sensor.

63457

890!¡!™!£!¢!∞

— 4 —

http://cxema.ru

SECTION 3

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

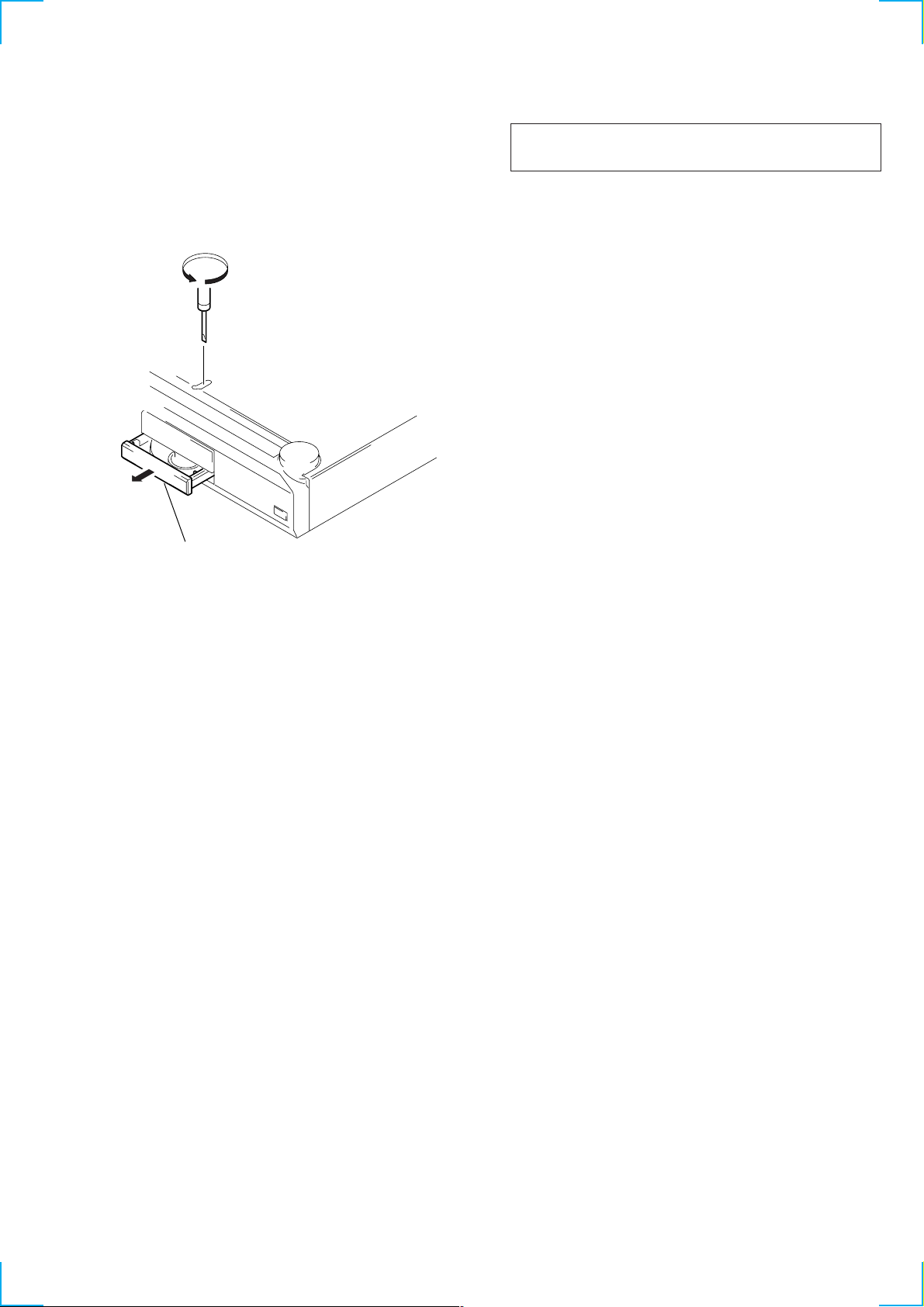

3-1. FRONT PANEL

• In order to remove the front panel block when the power supply

does not turn on, rotate the cam with tapering driver as the figure

shows, and the loading part will be moved.

Then pull out the loading part by your hand to remove the loading

panel as the figure shows. After that take out the front panel block.

Tapering driver

Loading panel

Loading part

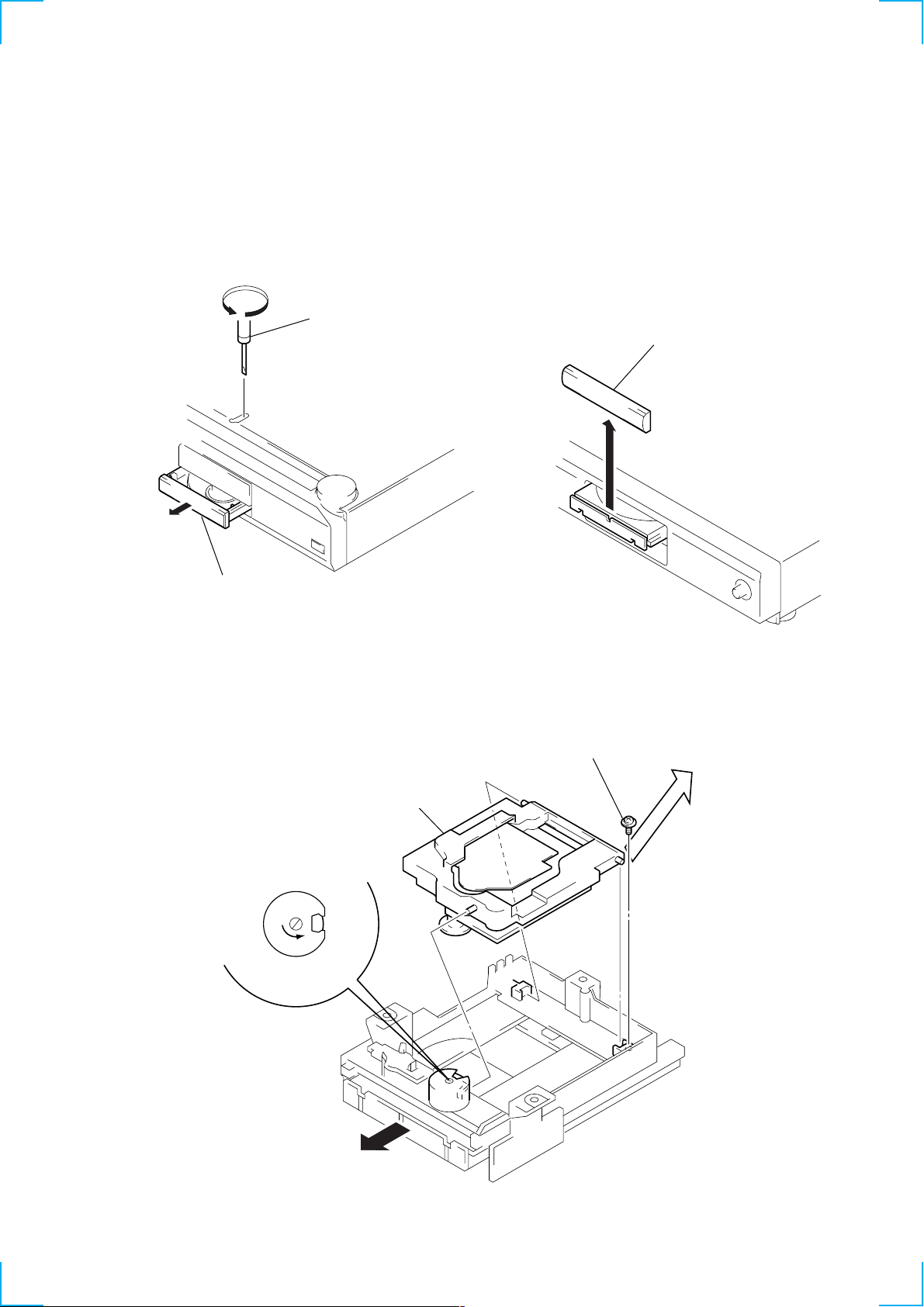

3-2. BASE UNIT (BU-5BD29C)

1

Turn the cam to the direction of

arrow (counter clock wise) by

tapering driver.

BU-5BD29C

3

Yoke bracket

4

Remove the Base unit

(BU-5BD29C) to the direction

of arrow.

2

Take off the disc table.

— 5 —

http://cxema.ru

SECTION 4

TEST MODE

4-1. AF MODE

The following checks can be performed in the AF mode, which is

set by connecting the TP2 (JW40 : AF ADJ) terminal on MAIN board

to the Ground and turning on the power.

• FL tube check

After all segments light up, when the · button is pressed

continuously, the follo wing will be displayed . (Partial lighting 1)

8 8 8

When the p button is pressed continuously , the following will be

displayed. (partial lighting 2)

24

6810

12 14

16 18 20

When the OPEN/CLOSE § button is pressed continuously, all

will light up again.

• Key check

All buttons have corresponding button numbers. When a button

is pressed, the counter will count up and display the button’s

number. Ho we ver, the counter will only count to “13”. It will not

count for buttons already pressed once, but will display the button’ s

number.

(Partial lighting 1)

(Partial lighting 2)

4-2. ADJ MODE

The following operations are performed in the ADJ mode, which

is set by connecting the TP3 (JW41 : ADJ) terminal to the Ground

and turning on the power.

FUNCTIONS OF NUMBER BUTTONS

(With the general remote commander)

Button

1

2

3

4

5

6

7

8

9

10

Focus bias adjustment plus (Not used in servicing)

EF-BALANCE adjustment plus (Not used in servicing)

Tracking servo off

Tracking gain adjusting plus (Not used in servicing)

Laser power control off (Not used in servicing)

Focus bias adjustment minus (Not used in servicing)

EF-BALANCE adjustment minus (Not used in servicing)

Tracking servo on

Tracking gain adjustment minus ((Not used in servicing)

Laser power control on (Not used in servicing)

Function

4-3. Aging Mode

This unit is equipped with an aging mode to check operations of the

mechanism deck.

• When faults occur:

Aging stops, and the state when aging stopped is displayed on the

fluorescent display tube.

• When no fault has occurred:

Aging is continued repeatedly.

888888

Â

Display of counting

Button

P

ENTER (AMS)

0

)

TIME

REPEAT

PLAY MODE

Button No.

Displayed

Display of button number

02

04

05

06

07

08

09

When the AMS knob is rotated to the right, the music calendar

changes from 1 n – – n 20 n 1.

When rotated to the left, it changes from 20 n 1 n 20 – –

• Remote commander check

When the · button of the remote commander is pressed, the

“·” lights up. All go off when the other buttons are pressed.

Â

Button

PEAK SERCH

CHECK

CLEAR

OPEN/

CLOSE §

PLAY ·

STOP p

Button No.

Displayed

10

11

12

All lit

Partial lighting 1

Partial lighting 2

Aging method 1

(When using the aging mode remote controller (J-2501-123-A)):

1. Press the U button and turn ON the power.

2. Set the disc on the tray.

3. Press the AGING START button of the aging remote controller .

4. Aging starts and the message shown in Fig. 1 is displayed on

the fluorescent display tube.

5. To end, press the U button.

Aging method 2 (When no aging mode remote controller):

1. Press the U button and turn ON the power.

2. Set the disc on the tray.

3. Press the ∏ button, CHECK button, and PLAY MODE

button together in this order.

4. Aging starts and the message shown in Fig. 1 is displayed on

the fluorescent display tube.

5. To end, press the U button.

Fig. 1 Message in Aging Mode

Code

No.

0

Load in

1

Access to TOC

2

Access to last track

3

Playback of last track

(3 seconds)

4

Access to first track

5

Playback of first track

(3 seconds)

6

Load out

State

Display when

normal

A0

A1

A2

Counter display

A4

Counter display

A6

Display when

abnormal

E0

E1

E2

E3

E4

E5

E6

— 6 —

http://cxema.ru

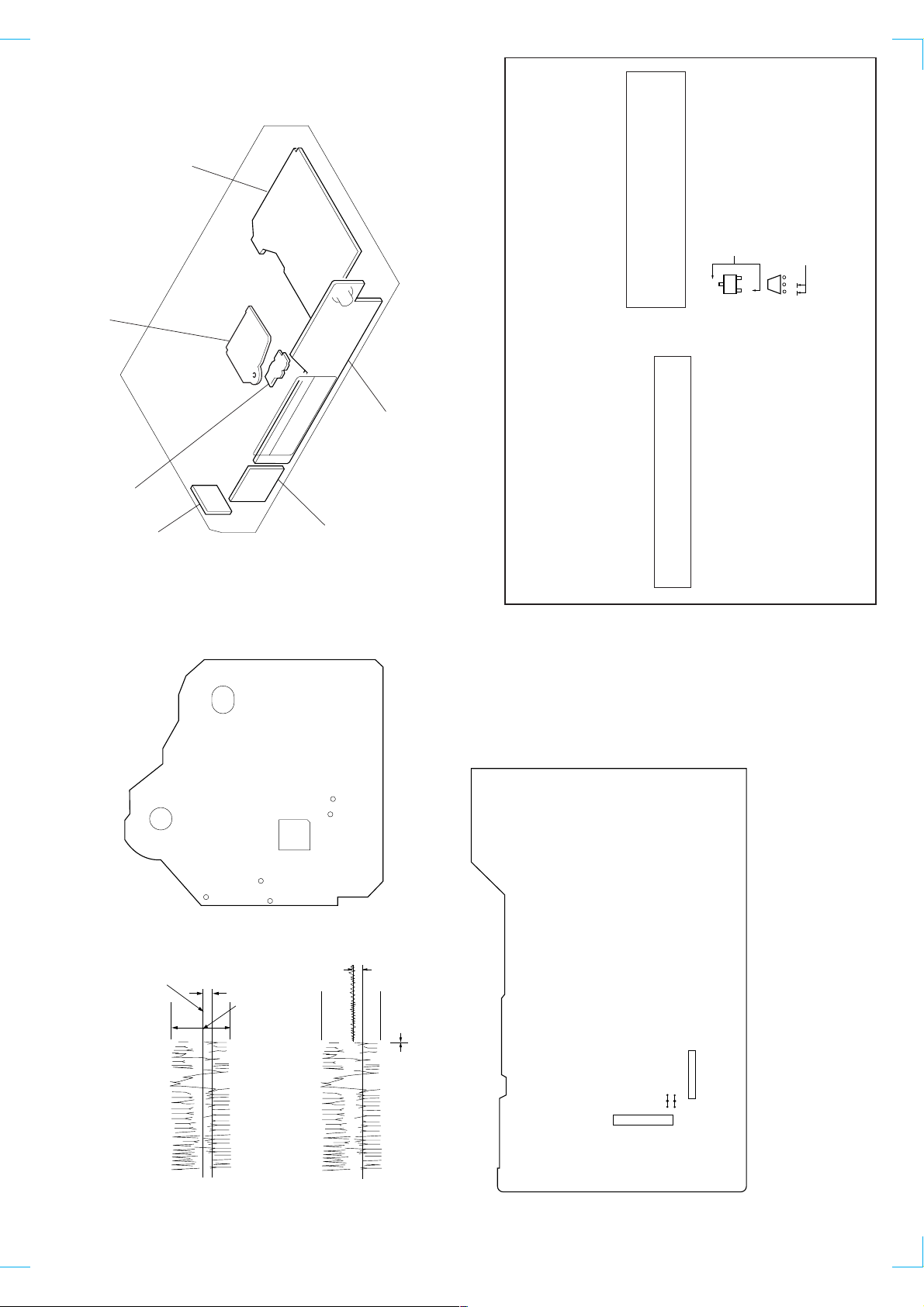

[ MAIN BOARD ] — Component Side —

TP3

(JW41: ADJ)

CN402

IC401

TP2

(JW40: AF ADJ)

— 7 —

http://cxema.ru

SECTION 5

oscilloscope

BD board

TP (TEO)

TP (VC)

oscilloscope

BD board

TP (TEO)

TP (VC)

ELECTRICAL BLOCK CHECKING

Note:

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

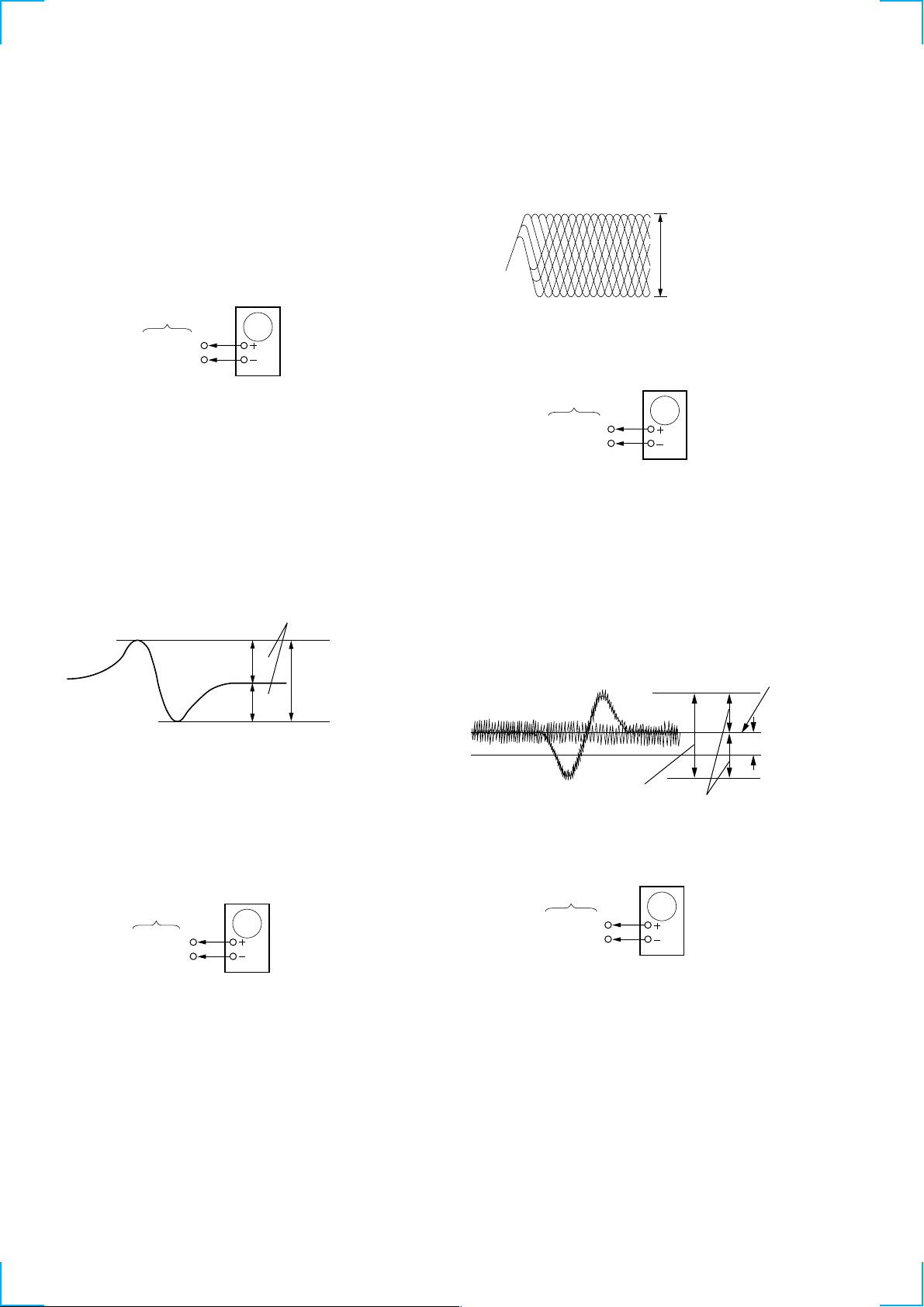

S Curve Check

oscilloscope

BD board

TP (FEO)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (FEO) on BD board.

2. Connect between test point TP (FOK) and ground by lead wire.

3. Turn Power switch on.

4. Put disc (YEDS-18) in and turn Power switch on again and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

5. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within 3±1

Vp-p.

S-curve waveform

symmetry

Note:

A clear RF signal waveform means that the shape “◊” can be clearly

distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

level : 1.3 ± 0.3 Vp-p

E-F Balance (1 Track Jump) Check

(Without remote commander)

Procedure :

1. Connect oscilloscpe to test point TP (TEO) on BD board.

2. Turn Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Press the “P (Pause)” button. (Becomes the 1 track jump mode)

5. Check the level B of the oscilliscope's waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 7%

A

Within 3

B

±

1 Vp-p

6. After check, remove the lead wire connected in step 2.

Note :

• Try to measure several times to make sure than the ratio of A : B

or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

BD board

TP (RF)

TP (VC)

oscilloscope

Procedure :

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turn Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

1 track jump waveform

Center of the waveform

B

0V

level : 500

±

100 mVp-p

symmetry

A (DC voltage)

E-F Balance Check (With remote commander)

Procedure :

1. Connect the test point TP3 (ADJ) on MAIN board to the ground

with a lead wire on main board.

2. Connect oscilloscpe to test point TP (TEO) on BD board.

3. Turn the Power switch on to set the ADJ mode.

4. Put disc (YEDS-18) in to play the number five track.

5. Press the “3” button. (The tracking servo is turned OFF.)

— 8 —

http://cxema.ru

MAIN board

SECTION 6

DIAGRAMS

6-1. CIRCUIT BOARDS LOCATION

BD board

LOADING board

POWER SW board

KEY board

DISPLAY board

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed

in each block.)

: Through hole.

®

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

• b : Pattern from the side which enables seeing.

For printed wiring boards.

For schematic diagrams.

(The other layers' patterns are not indicated.)

Note:

• X : parts extracted from the component side.

•

W or less unless otherwise

4

/

1

specified.

50 WV or less are not indicated except for electrolytics

and tantalums.

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

• All resistors are in Ω and

(Side A) parts face are indicated.

: internal component.

with mark ! are critical for safety.

¢

•

Replace only with part number specified.

Note: The components identified by mark ! or dotted line

• C : panel designation.

These are omitted

C

Q

• Indication of transistor

under no-signal (detuned) conditions.

no mark : STOP

• U : B+ Line.

• V : B– Line.

• Voltages and waveforms are dc with respect to ground

EB

: Impossible to measure

∗

( ) : PLAY

EB

C

Voltage variations may be noted due to normal produc-

tion tolerances.

• Voltages are taken with a V OM (Input impedance 10 MΩ).

These are omitted

Voltage variations may be noted due to normal produc-

tion tolerances.

• Waveforms are taken with a oscilloscope.

J : CD

• Circled numbers refer to waveforms.

• Signal path.

– 10 –

c : digital out

Adjustment Location :

[ BD BOARD ] — Side A —

Center of the waveform

(DC voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 7%

Traverse waveform

6. Check the level B of the oscilliscope's waveform and the A

(VC)

)

A (DC voltage

B

0V

(FOK)

(RF)

100 mVp-p

±

level : 500

Confirm the C (DC voltage) is almost equal to the A (DC

voltage) is step 6.

7. Press the “8” button. (The tracking servo is turned ON.)

IC101

(FEO)

(TEO)

– 9 –

C (DC

voltage)

Tracking servo

ON

IC401

Tracking servo

OFF

CN402

Traverse waveform

0V

8. Disconnect the lead wire of TP3 (ADJ) connected in step 1.

[ MAIN BOARD ] — Component Side —

TP2 (JW40: AF ADJ)

TP3 (JW41: ADJ)

Loading...

Loading...