CDP-XA30ES

SERVICE MANUAL

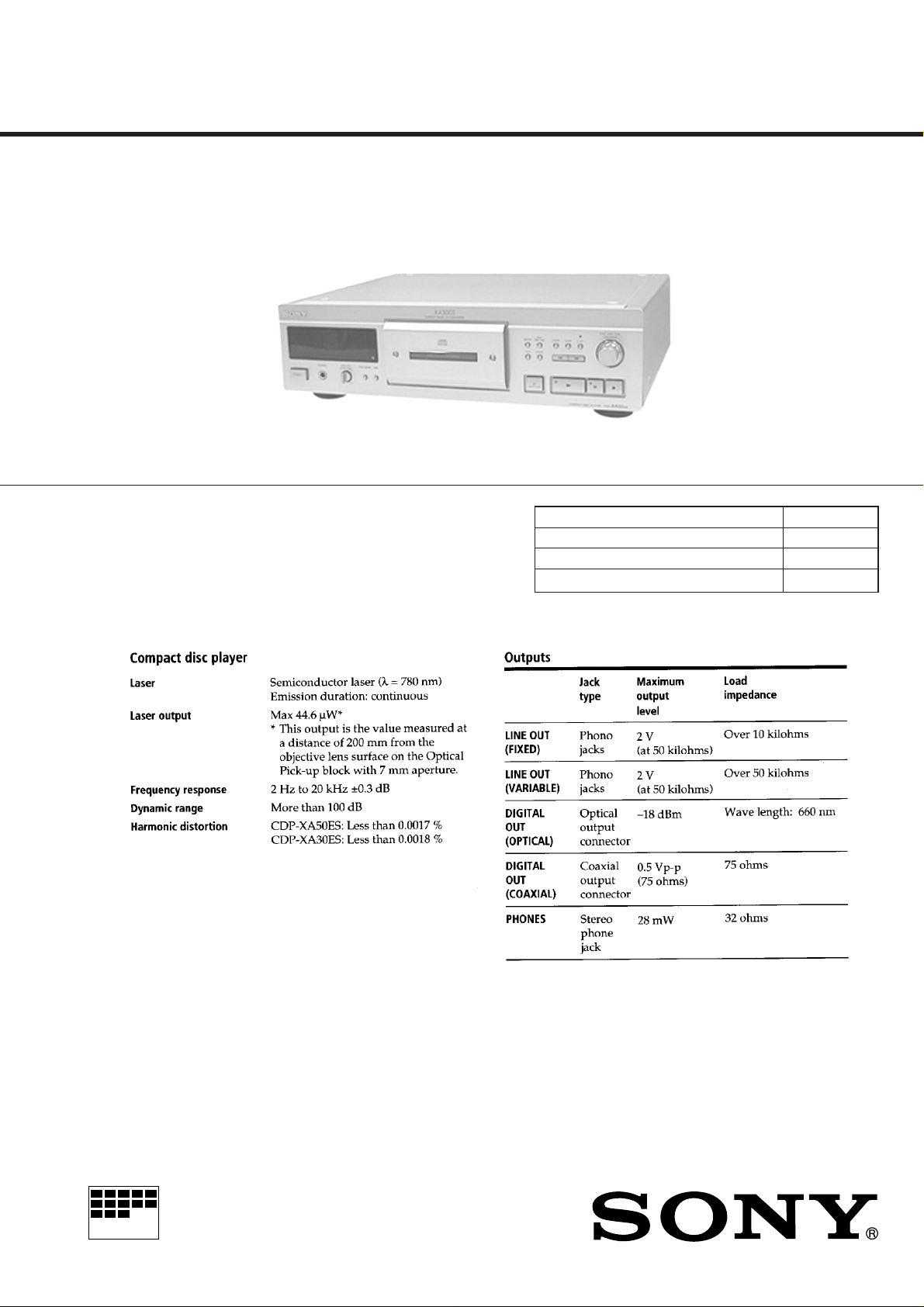

Photo : Gold

SPECIFICATIONS

AEP Model

E Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type

Base Unit Type BU-14A

Optical Pick-up Type KSS-213B

CDM36A-14A

MICROFILM

– Continued on next page –

COMPACT DISC PLAYER

MODEL IDENTIFICATION

– BACK PANEL –

TABLE OF CONTENTS

1. SERVICING NOTES

1-1. How to Open the Disc Tray When Power Switch

Turns Off.......................................................................... 3

1-2. Preparation for Adjustment and Measurement ................ 3

2. GENERAL ................................................................... 4

3. DISASSEMBLY.......................................................... 15

4. TEST MODE

4-1. AF Mode.......................................................................... 19

4-2. ADJ Mode ....................................................................... 20

5. ELECTRICAL ADJUSTMENTS .......................... 21

6. DIAGRAMS

6-1. IC PIN FUNCTION DISCRIPTION............................... 23

6-2. Block Diagram................................................................. 35

6-3. Printed Wiring Boards –BD Section –............................. 38

6-4. Schematic Diagram — BD Section — ............................ 41

6-5. Schematic Diagram — MAIN Section — ....................... 46

6-6. Printed Wiring Boards — MAIN Section —................... 51

6-7. Schematic Diagram — PANEL Section — ..................... 55

6-8. Printed Wiring Boards — PANEL Section —................. 59

7. EXPLODED VIEWS ................................................. 61

4-986-682-

AEP MODEL : 1 π (CED)

Singapore Model : 2

π

(SP)

8. ELECTRICAL PARTS LIST .................................. 66

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objecti ve lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of

procedures other than those specified herein may

result in hazardous radiation exposure.

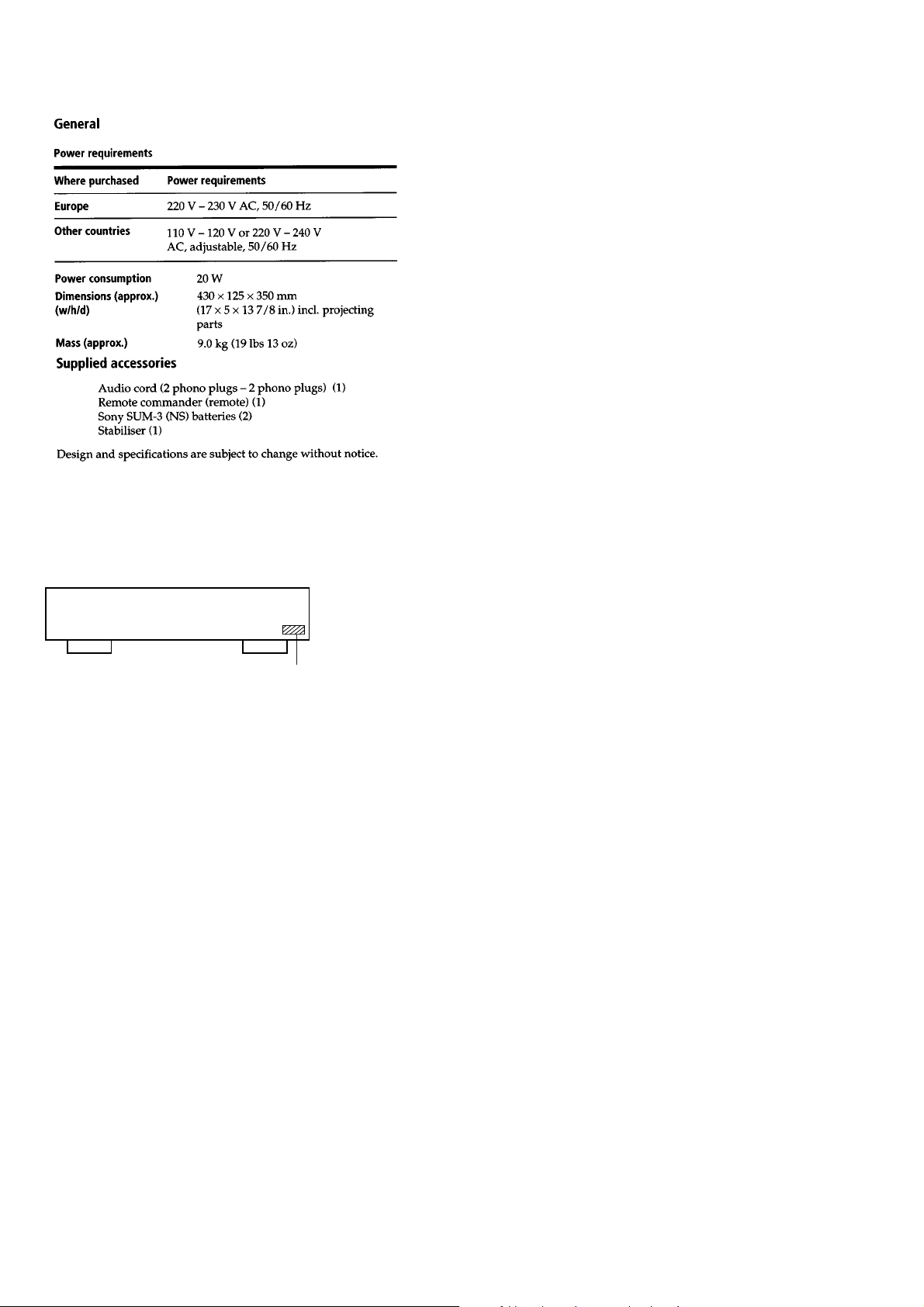

1-1. H OW T O OPEN THE DISC TRAY WHEN

POWER SWITCH TURNS OFF

1 Insert a tapering driver into the aperture of the unit bottom,

and move the limiter (LEVER) to direction of the arrow A.

2 Pull the tray to direction fo the arrow B.

tray

B

Limiter (LEVER)

A

tapering driber

*

To close the disc tray, move the driver in

the reverse direction (to IN direction).

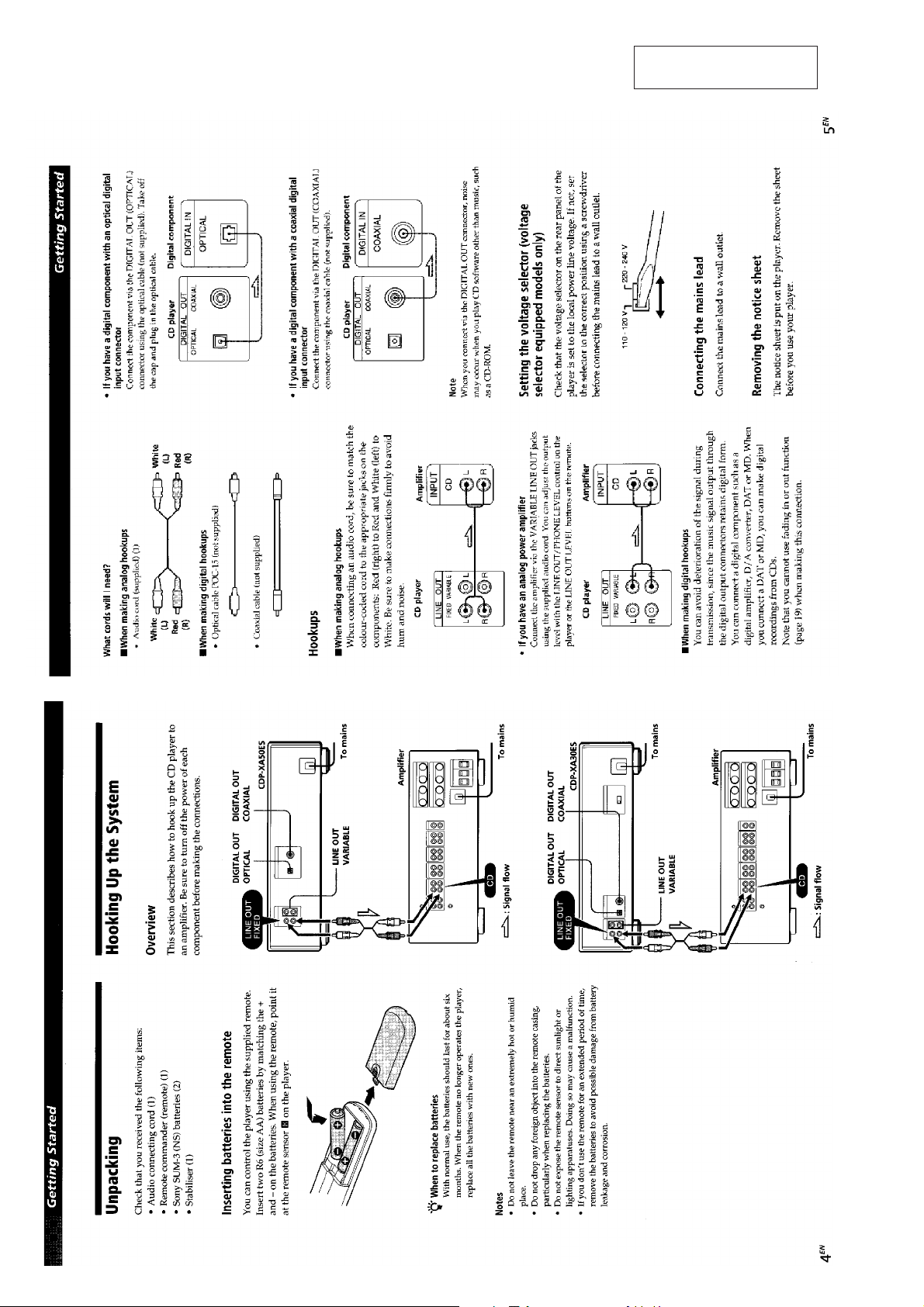

1-2. PREPARATION FOR ADJUSTMENT AND

MEASUREMENT

Perform connecting the IC361 pin 2 of BD board to the line of

+5V because this unit does not work without the stabilizer structurally.

Connecting Location:

[BD BOARD] (SIDE B)

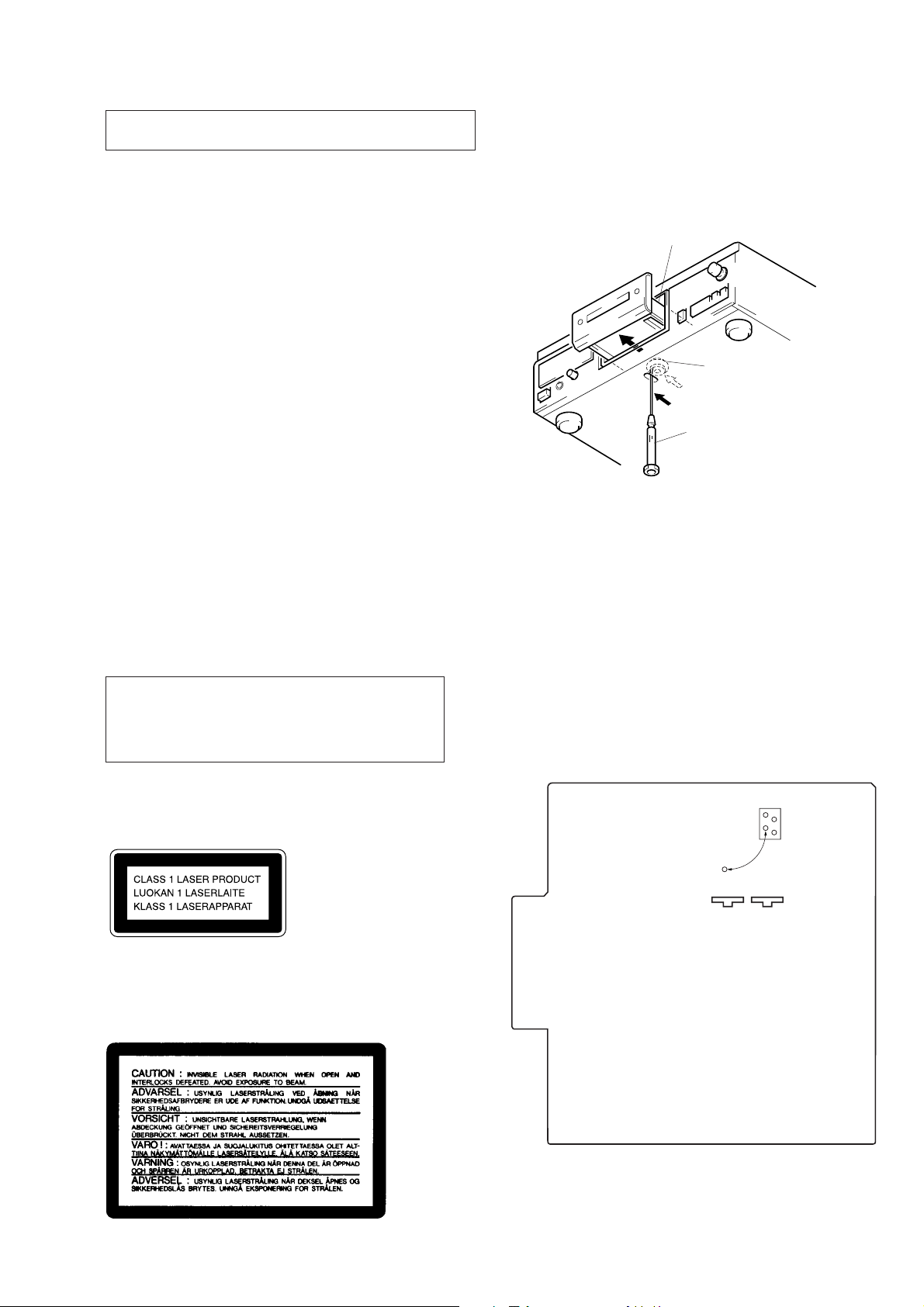

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

Q301

+5V

IC361

2

1

Q302

– 3 –

SECTION 2

GENERAL

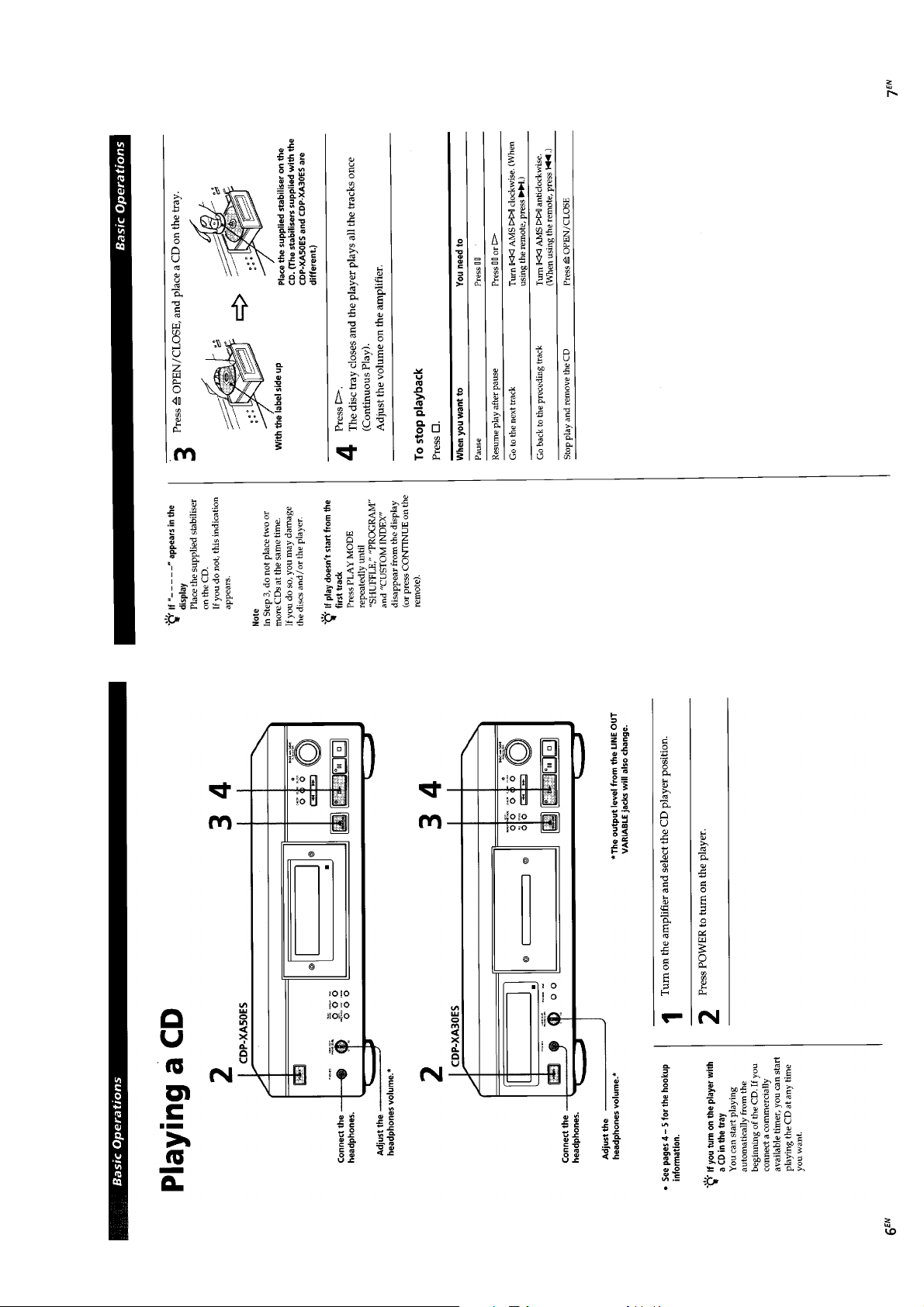

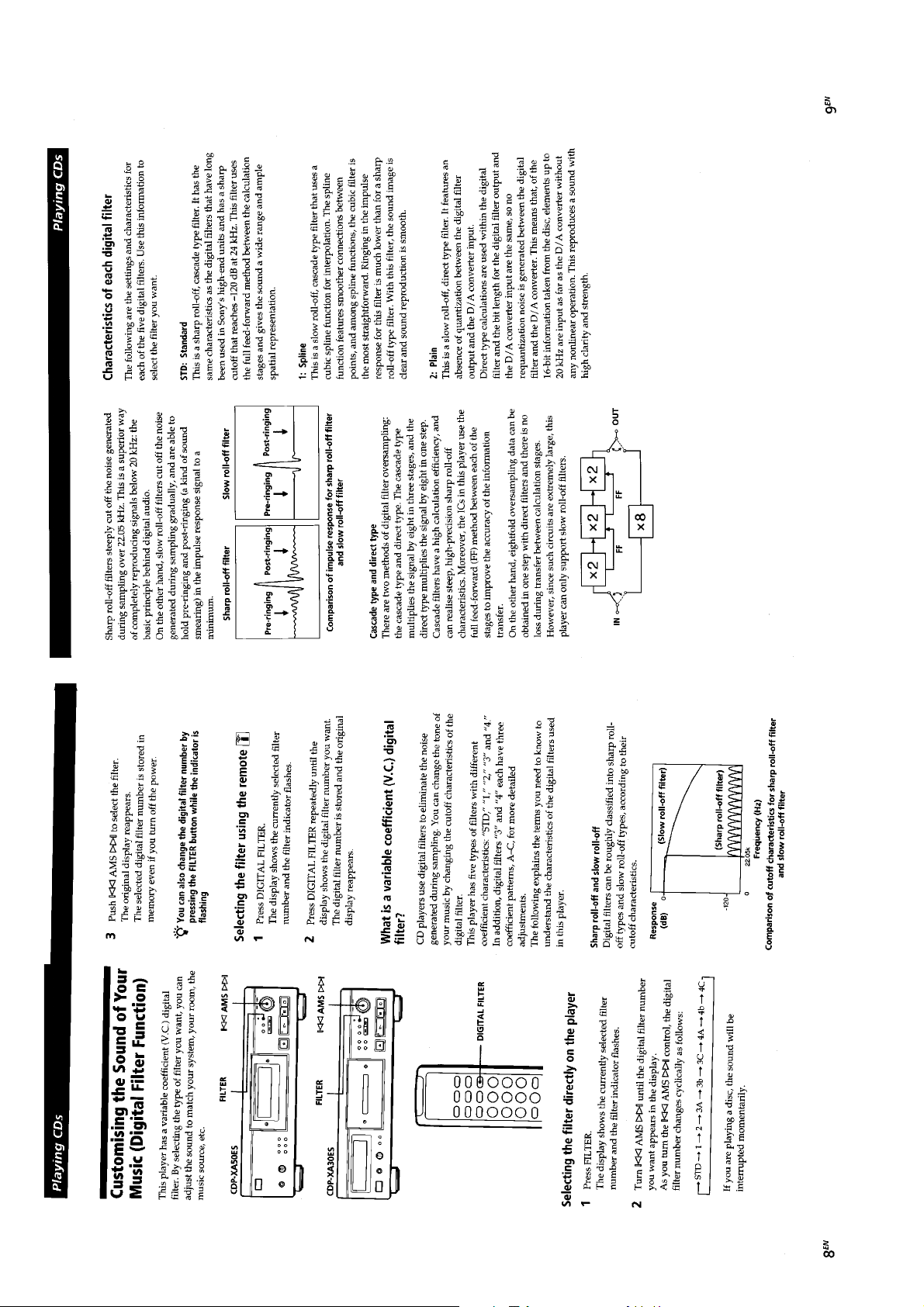

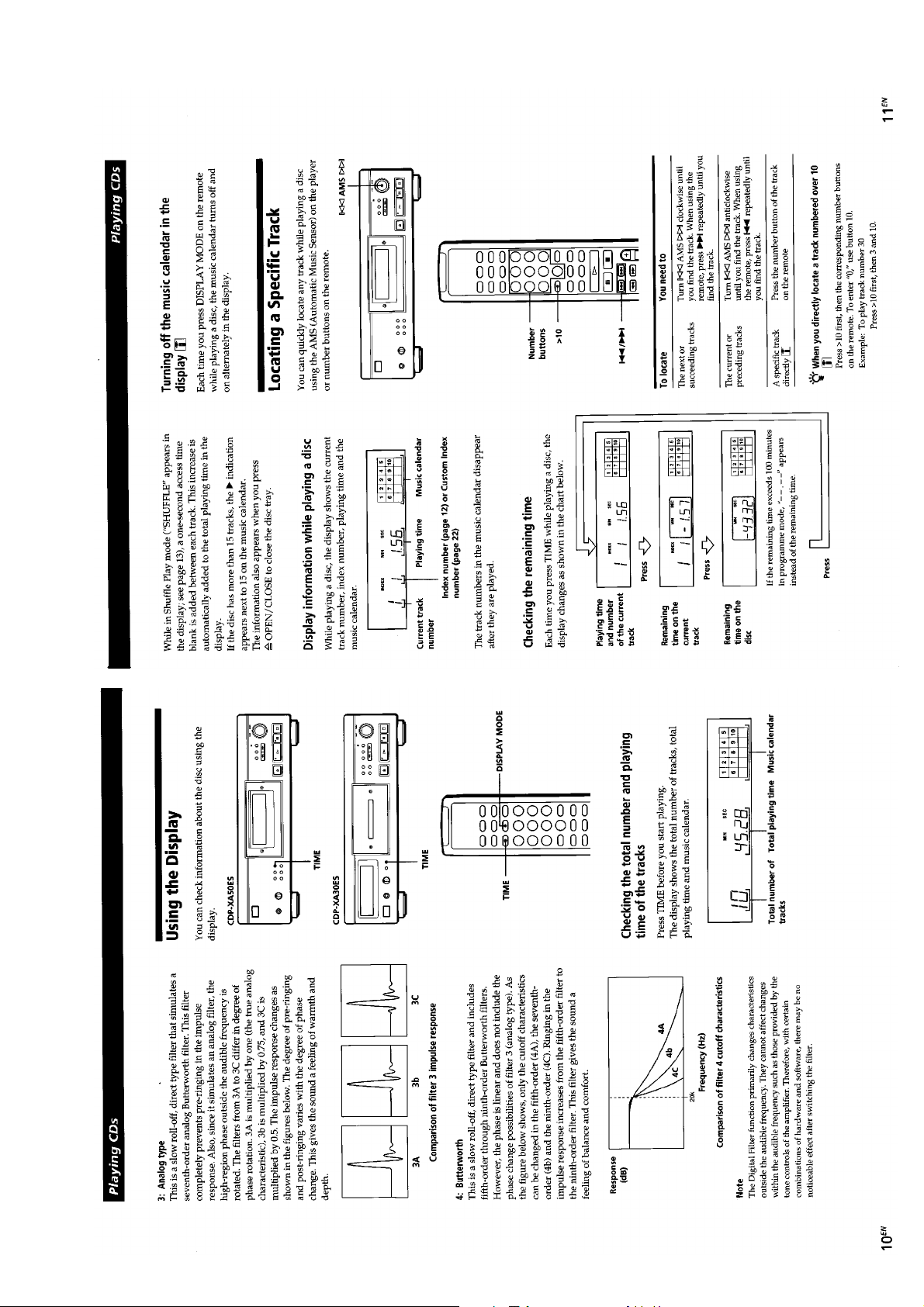

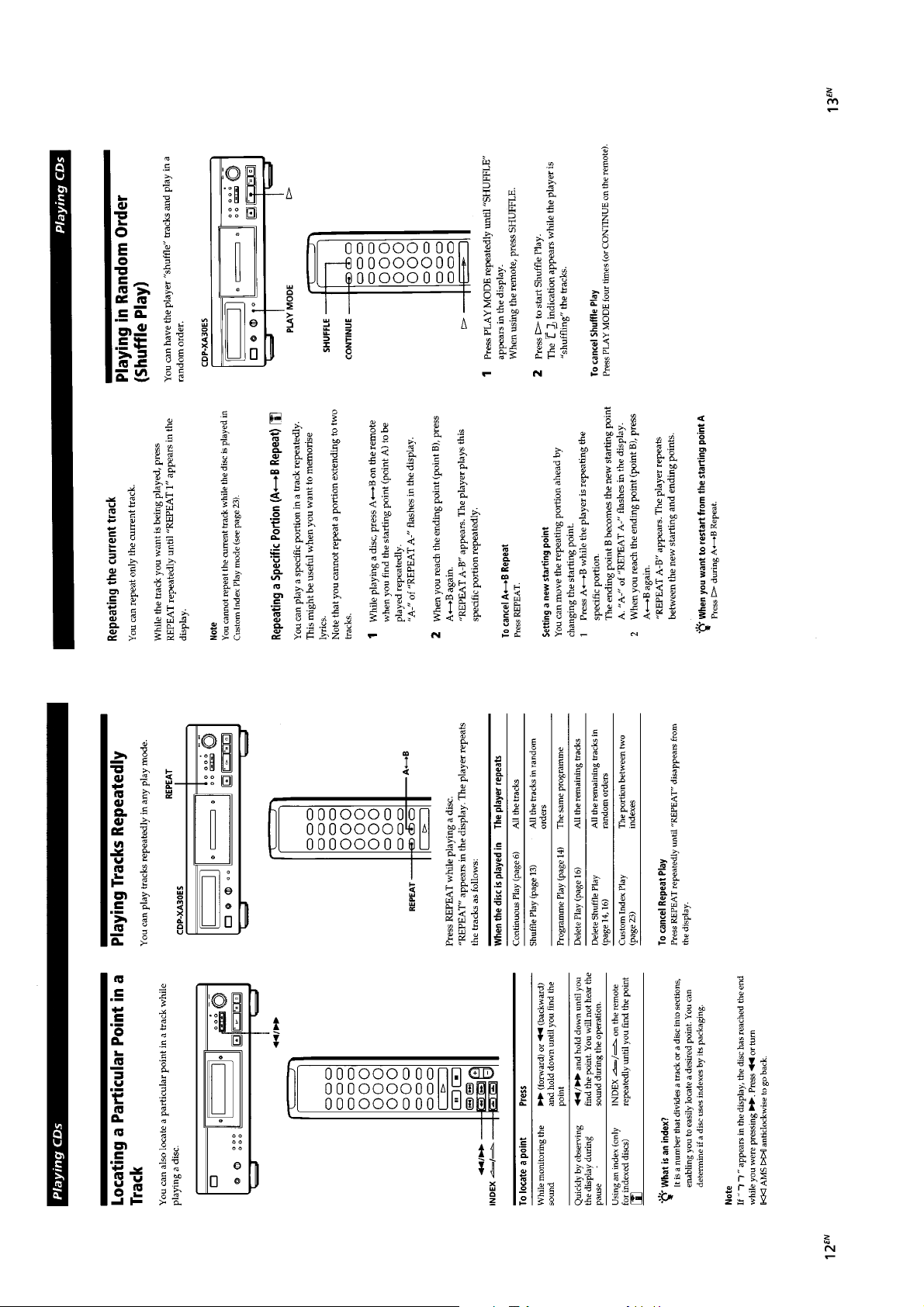

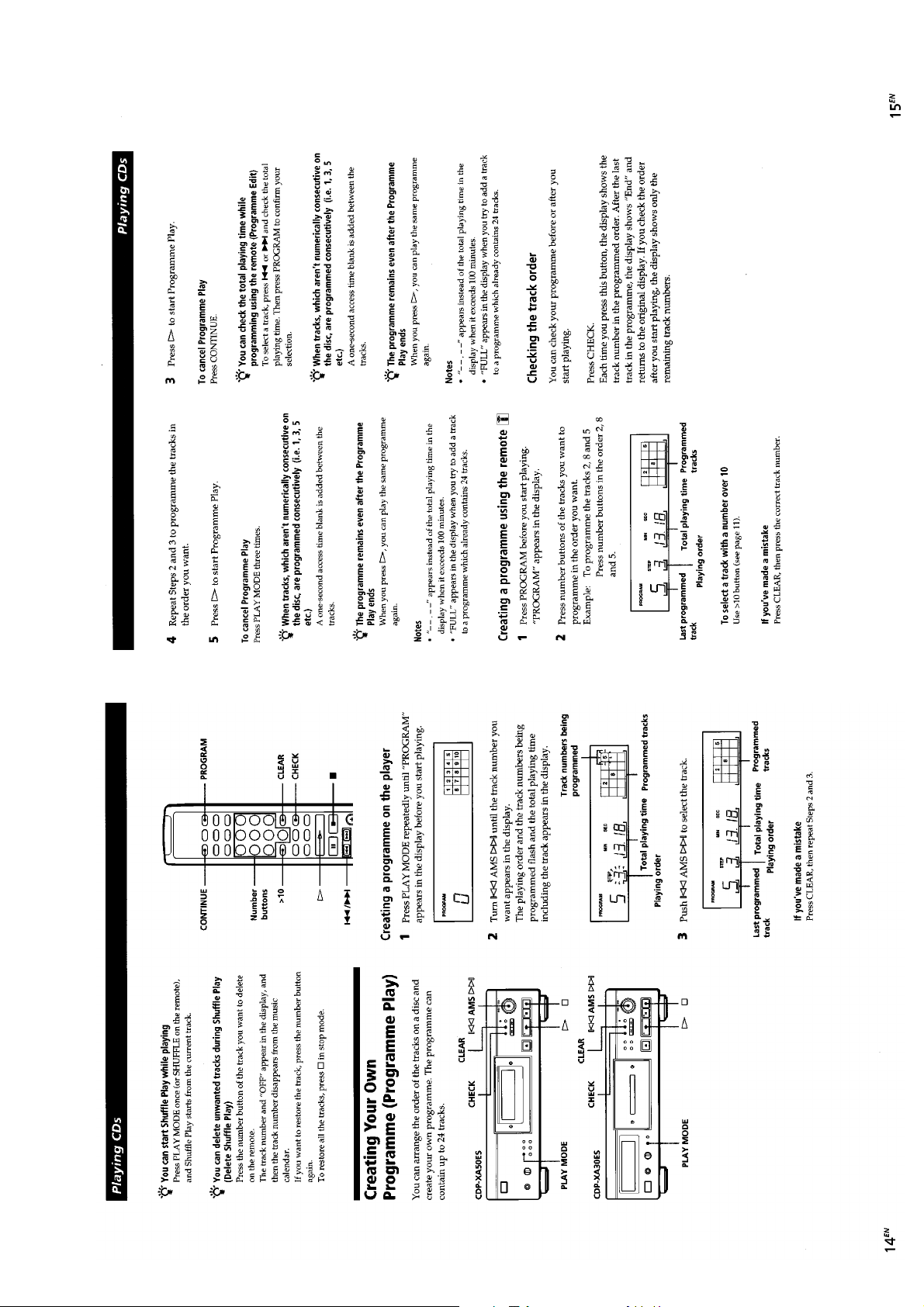

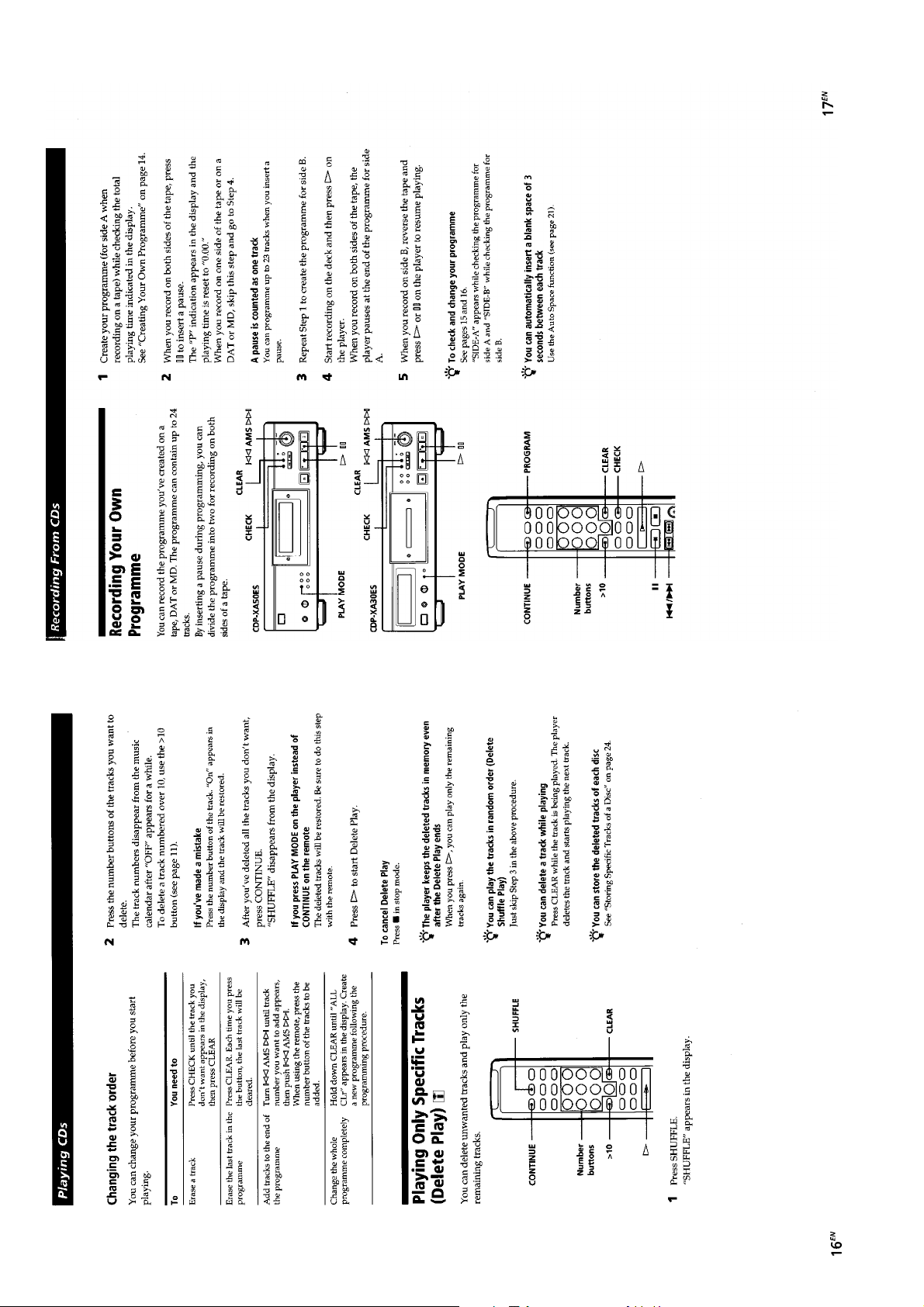

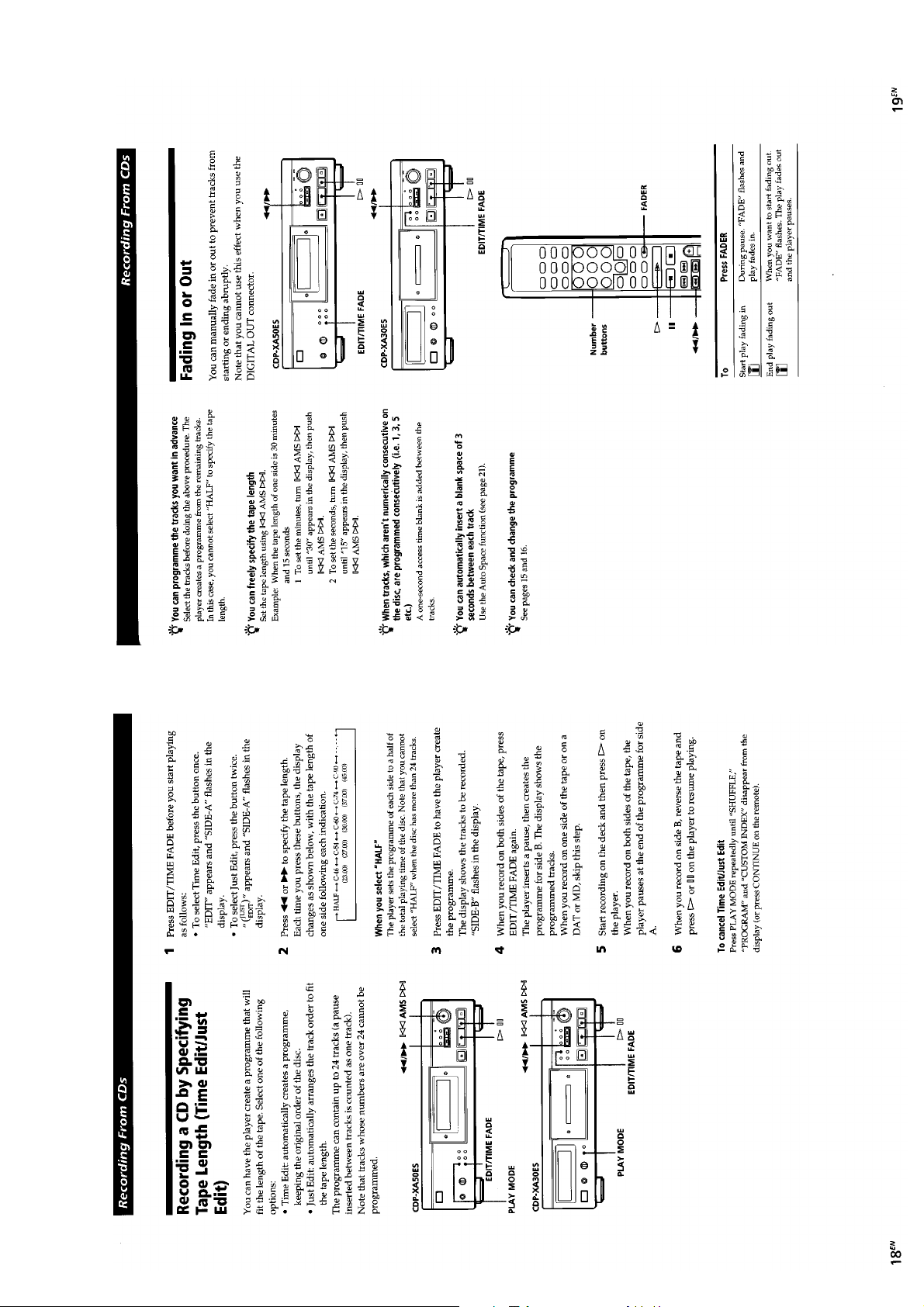

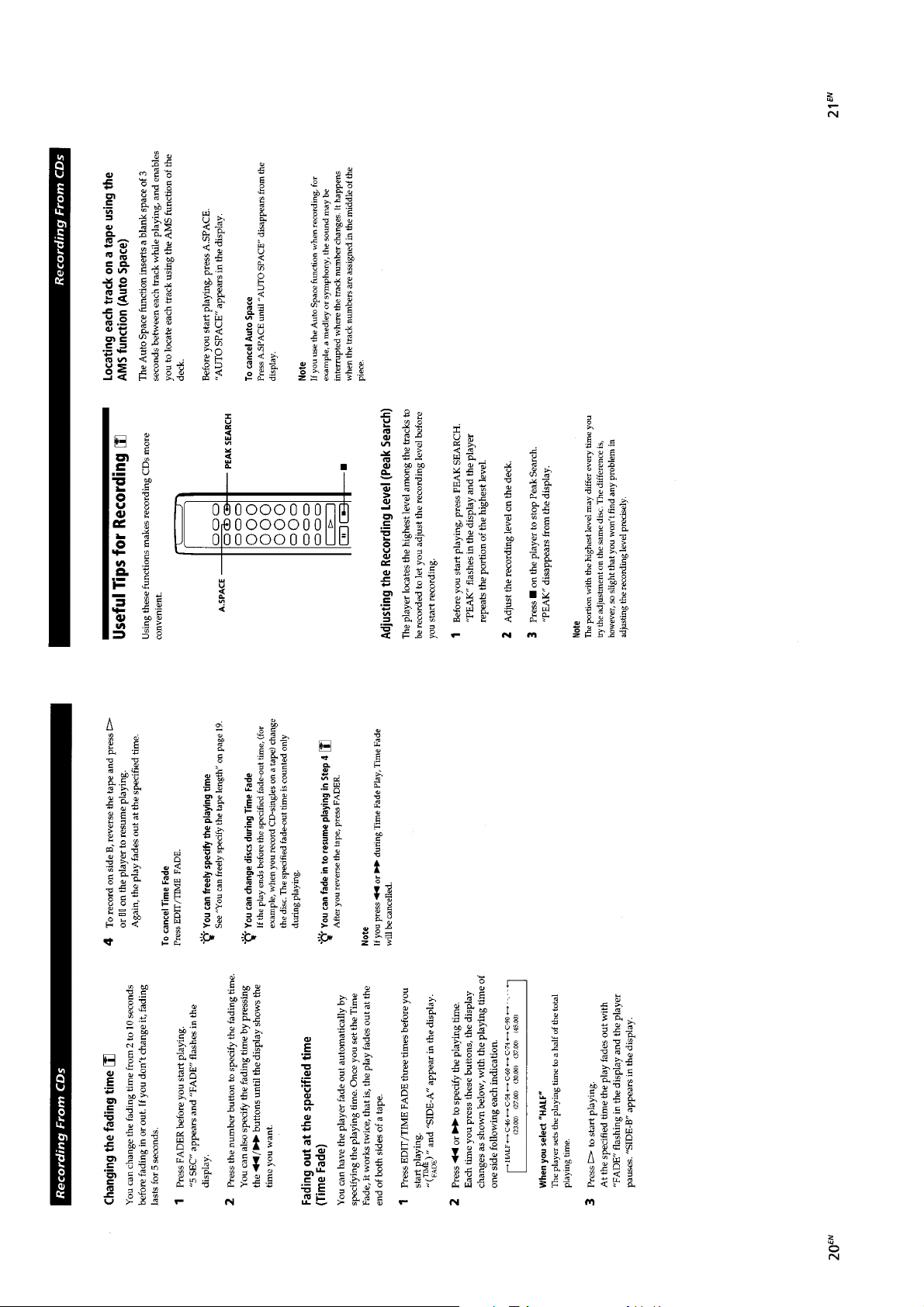

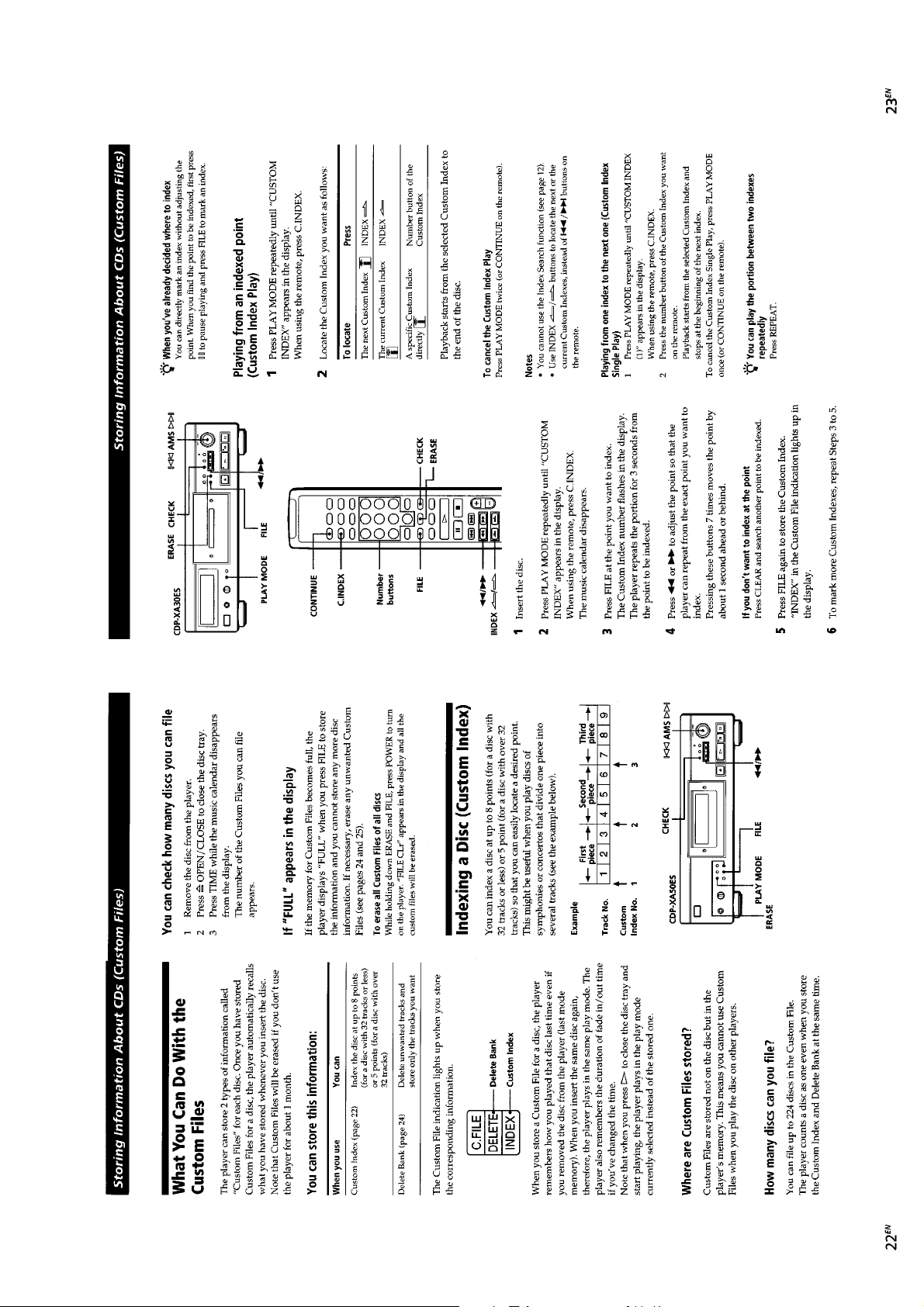

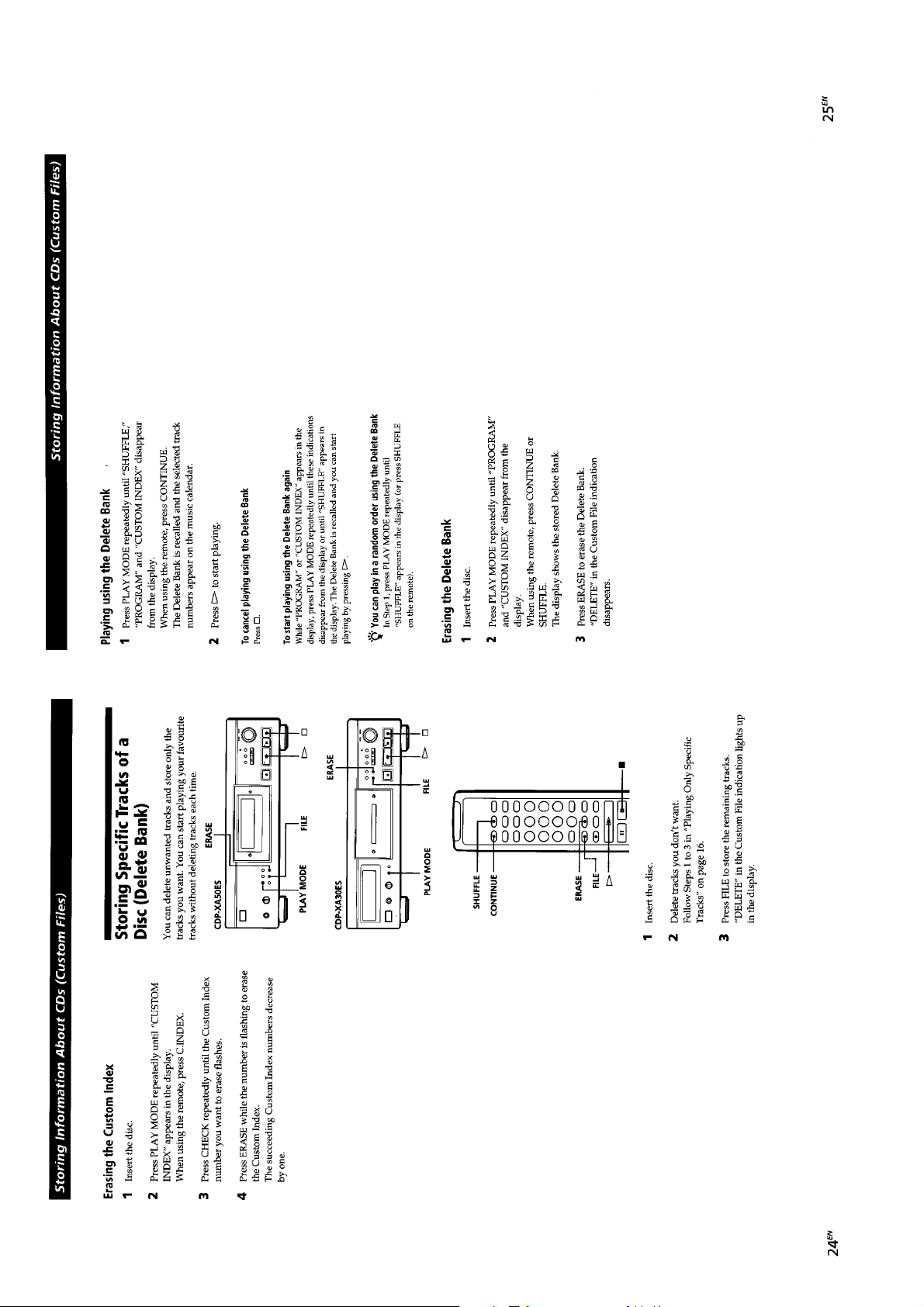

This section is extracted

from instruction manual.

– 4 –

– 5 –

– 6 –

– 7 –

– 8 –

– 9 –

– 10 –

– 11 –

– 12 –

– 13 –

– 14 –

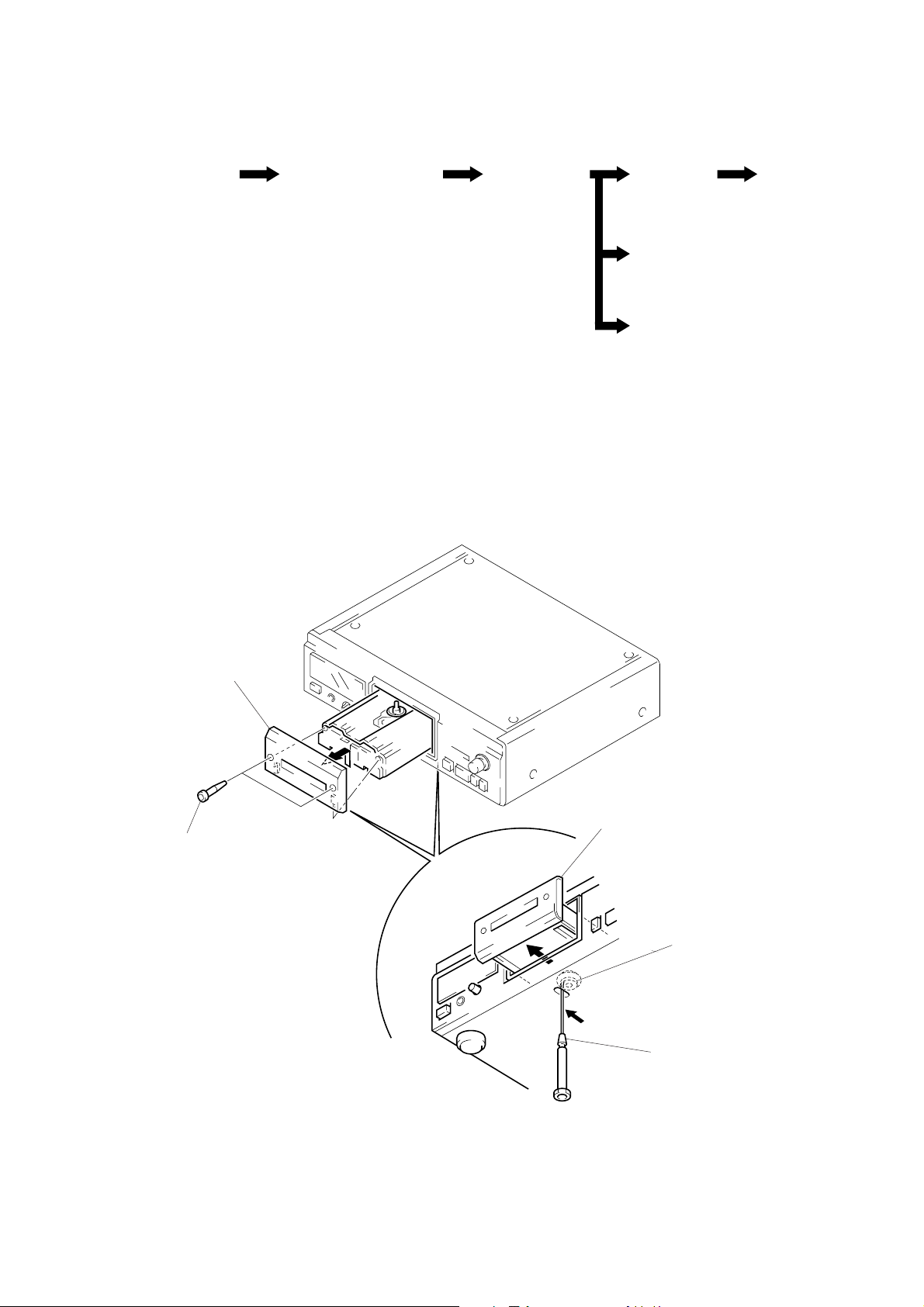

• This set can be disassembled in the order shown below.

SECTION 3

DISASSEMBLY

LOADING PANEL

SECTION

(Page 15)

Note: Follow the disassembly procedure in the numerical order given.

CASE,

FRONT PANEL SECTION

(Page 16)

LOADING PANEL SECTION

MECHANISM

DECK SECTION

(Page 16)

BASE UNIT

(Page 17)

LOADING MOTOR

(Page 18)

POWER BOARD, MAIN BOARD

(Page 18)

OPTICAL PICK-UP

(Page 17)

4

loading panel section

3

two hexagon hole bolts

(LID)

B

2

Pull the loading panel to

direction of the arrow

A

1

B

.

limiter (LEVER)

Insert a tapering driver,

and move the limiter (LEVER)

to direction of the arrow

A

.

– 15 –

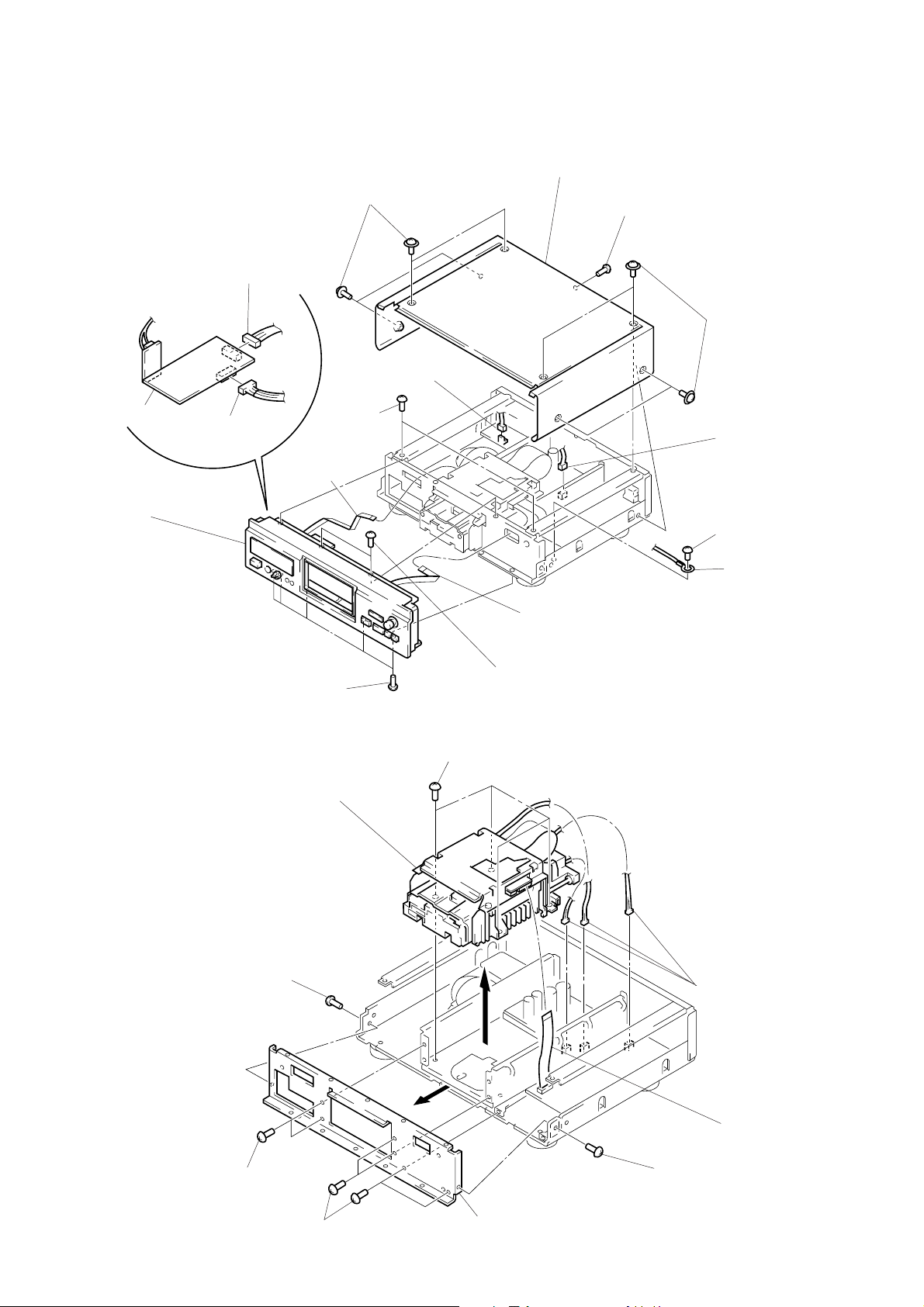

CASE, FRONT PANEL SECTION

7

connector

(CN407)

1

four screws

(CASE 3 TP2)

9

connector

(CN992)

3

case

2

screw

(BVTT3

×

6)

1

four screws

(CASE 3 TP2)

!∞

front panel

HP board

8

connector

(CN402)

MECHANISM DECK SECTION

0

5

flat wire (10 core)

(CN106)

!£

five screws

(BV3

×

8)

6

mechanism deck

(CDM36A-14A)

two screws

(BVTT3

×

6)

5

four screws

(BVTT3

!¢

×

6)

6

flat wire (9 core)

(CN107)

two screws

(BVTT3

×

6)

4

connector

(CN206)

!¡

screw

(BVTT3

!™

lug

×

6)

3

screw

(BVTT3

3

two screws

(BVTT3

×

6)

×

6)

3

four screws

(BVTT3

×

6)

4

– 16 –

sub panel

3

1

three connectors

(CN201, 205, 251)

2

flat wire (16 core)

(CN101)

screw

(BVTT3

×

6)

BASE UNIT

9

3

screw

(BVTP3

×

8)

!º

lug

!¡

base unit

(BU-14A)

5

cover (F) (DRAWER)

panel (DRAWER)

6

two screws

(BVTP3

8

flat wire (30 core)

(CN108)

×

8)

2

two screws

(BVTP3

7

panel (R) (DRAWER)

×

8)

2

two screws

(BVTP3

×

8)

4

two screws

(BVTP3

OPTICAL PICK-UP

9

Removal the optical pick-up

to direction of the arrow

×

8)

2

two precision screws

(P17

×

2.5)

5

screw

(BVTP3

A

1

pull the tray

×

8)

.

6

A

leaf spring (OP)

7

claw

8

sled shaft

1

flat wire (16 core)

3

two screws

(BVTP 2.6

4

BD TRANSLA TION

board

×

8)

– 17 –

LOADING MOTOR

1

Pull the tray.

2

connector

(CN103)

4

screw

(BVTP 3

×

8)

7

Removal the two

solders of loading motor.

8

5

6

LOADING MOTOR board

loading motor

two claws

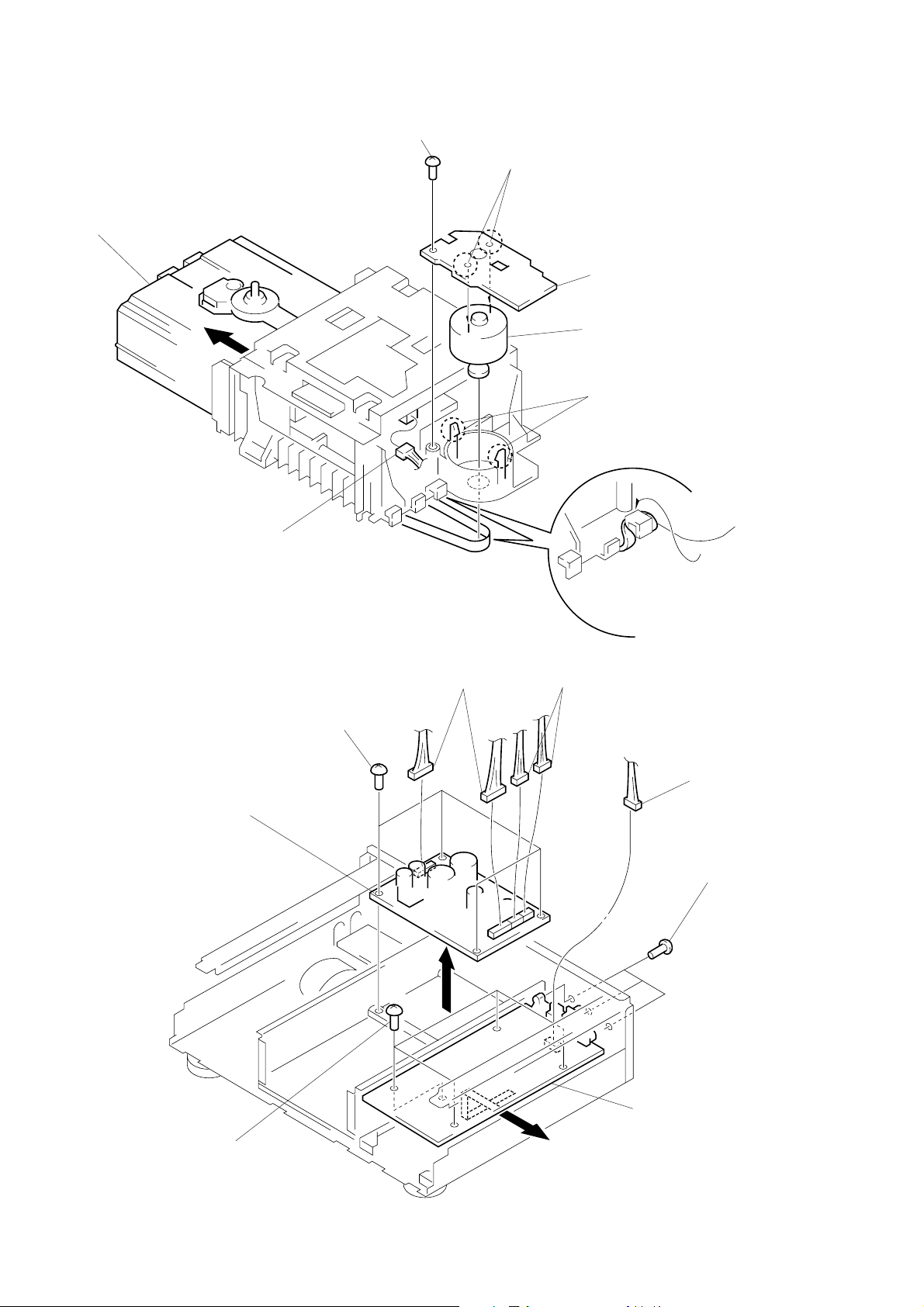

POWER BOARD, MAIN BOARD

4

POWER board

3

four screws

(BVTT3

3

Hang the belt

1

two connectors

(CN207, 309)

×

6)

2

two connectors

(CN203, 204)

5

connector

(CN302)

6

three screws

(BV/RING)

7

four screws

(BVTT3

8

Removal the MAIN board

A

×

6)

to direction of the arrow

A

.

– 18 –

SECTION 4

TEST MODE

4-1. AF MODE

Connect the TP19 (AFADJ) on the BD board to the ground and

turn on the power supply.

The AF mode is then activated and the following check can be

made.

4-1-1. Fluorescent Indicator Tube Check

After confirming display of all on, keep pressing the following

button, and the following display is attained.

p (STOP) button

(Display: 01)

” (PLAY) button

(Display: 02)

P (PAUSE) button

(Display: 03)

) button

SHUFFLE

0 button

PROGRAM

REPEAT

AUTO SPACE

STEP

INDEX

A-

EDIT

–

1

B

PEAK

(Display: 04)

(JUST)

(Display: 05)

Keep pressing the §OPEN/CLOSE button, and all on display is

attained again.

4-1-2. Key Check

All buttons are assigned with numbers respectively , and when each

button is pressed, it is counted and its number is displayed. Up to

“16” can be counted.

A button pressed once is not further counted but the number is

displayed. (Table 4-1)

(

count display

button number

display

(

Table 4-1.

Button Display Button Display

ERASE 00 P 03

EDIT/

TIME FADE

12 ) 04

FILE 13 0 05

FILTER 20 CHECK 06

ENTER 23 CLEAR 07

6 all light

OPEN/CLOSE up

P MODE 09

p 01 REPEAT 10

( 02 TIME 11

4-1-3. Remote Commander Check

Press the ( button on remote commander, and “ ˚ ” ( on the

set turn on. Nothing will be displayed if pressing another button.

CHECK button

CLEAR button

135

79

11 13 15

(Display: 06)

24

6810

12 14 ”

(Display: 07)

– 19 –

4-2. ADJ MODE

Connect the TP18 (ADJ) on the BD board to the ground and turn

on the power supply. The ADJ mode is then activated and the

following operation is executed.

• There is no problem even if Guarded Frame Sync is low value

continuously during playing.

• Do not perform high speed search during an access.The gain of

focus servo and spindle servo does not lower during playing.

• Manual operation and measurement of the servo system are possible. (For detailed operating method, see Table 4-2. in ADJ

Mode.)

Connecting Location:

[BD BOARD] (SIDE B)

CN107

TP19

(AFDJ)

TP18

(ADJ)

2

IC361

1

4-2-1. Button Operation Table in ADJ Mode

After all music numbers are displayed, press the TIME button,

and the jitter display mode is then set. The button functions are as

listed below.

Button Functions (Operate with remote commander.)

Table 4-2.

Button No. Test Mode

3 Tracking servo off

8 Tracking servo on

11 S-curve measuring mode

12 All servo off

13 Top turnblack display

14 Botton turnblack display

15 Center display

16 Optimum point display

17 Optimum jitter display

18 TE traverse display

19 VC, FE and RF display

20

Autogain display

(Focus, tracking and sled)

* For button numbers 3, 8, 11, and 12, use them only when an

oscilloscope is connected.

IC102

CN101

IC104

4-3. CLV-S MODE

The spindle servo can be operated for play in the CLV-S mode by

connecting TP18 (ADJ) and after turning on the power supply.

4-4. RELEASE THE TEST MODE

Disconnect the lead wire of test point connected in first step.

– 20 –

SECTION 5

ELECTRICAL ADJUSTMENTS

Notes:

1. CD block basically constructed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (Part No.: 3-702-101-01) unless otherwise

indicated.

3. Use the oscilloscope with more than 10 MΩ impedance.

4. Clean an object lens by an applicator with neutral detergent

when the signal level is low than specified value with the following checks.

S-Curve Check

Connection:

BD board

TP2 (FE)

TP (VC)

Procedure:

1. Connect the oscilloscope to TP2 (FE) and TP (VC) on BD

board.

2. Connect the TP3 (FEI: IC101 pin @ª) and TP (VC) with lead

wire.

3. Turned power switch on.

4. Put disc (YEDS-18) in and turned power switch on again and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

5. Confirm that the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak level within

3.0 ± 1.0 Vp-p.

S-curve waveform

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure that the ratio

of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

Connection:

BD board

TP1 (RF)

TP (VC)

Procedure:

1. Connect the oscilloscope to TP1 (RF) and TP (VC) on BD

board.

2. Turned power switch on. (stop mode)

3. Put disc (YEDS-18) in and press the ( button.

4. Confirm that the oscilloscope waveform is clear and check RF

signal level is correct or not.

Note: Clear RF signal waveform means that the shape “≈” can

be clearly distinguished at the center of the waveform.

oscilloscope

+

–

symmetry

A

B

oscilloscope

(AC range)

+

–

within 3.0 ± 1.0 Vp-p

RF signal waveform

When observing the eye pattern, set the oscilloscope for A C range

and raise vertical sensitivity.

E-F Balance (Traverse) Check

Connection:

BD board

TP4 (TE)

TP (VC)

Procedure:

1. Connect the TP18 (ADJ) to ground and TP5 (TEI: IC101 pin

@¶) to TP (VC)with lead wire.

2. Connect the oscilloscope to TP4 (TE) and TP (VC) on BD

board.

3. Turned power switch on.

4. Put disc (YEDS-18) in and press the ( button.

5. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to A Vdc, and check this level.

Traverse waveform

×

100 is ± 20 % or less.

A/B

oscilloscope

(DC range)

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

(with the 10: 1 probe

in use)

level: 1.2 Vp-p

+

–

A

B

level: 1.3 ± 0.7 Vp-p

+0.25

–0.20

Symmetry

6. After check, remove the lead wire connected in step 1.

RF PLL Free-run Frequency Check

Connection:

BD board

TP13 (XPLCK)

Procedure:

1. Connect the frequency counter to TP13 (XPLCK).

2. Turned power switch on.

3. Put disc (YEDS-18) in and press the ( button.

4. Confirm that the reading on frequency counter is 4.3218 MHz.

frequency counter

+

–

Connecting Location:

[BD BOARD] (SIDE B)

TP13

(XPLCK)

CN107

CN101

TP1

(RF)

TP5

(TEI)

TP (VC)

TP3 (FEI)

TP2 (FE)

TP4

(TE)

TP18

(ADJ)

IC361

IC102

IC104

– 21 –

– 22 –

SECTION 6

DIAGRAMS

6-1. IC PIN FUNCTION DISCRIPTION

BD BOARD IC101 CXD2545Q

(DIGITAL SIGNAL PROCESSOR, FOCUS/TRACKING/SLED SERVO, EFM COMPARATOR)

Pin No. Pin Name I/ O Function

1 SRON O Sled servo drive PWM signal output terminal Not used (open)

2 SRDR O Sled servo drive PWM signal (–) output to the BA6297AFP (IC102)

3 SFON O Sled servo drive PWM signal output terminal Not used (open)

4 TFDR O Tracking servo drive PWM signal (–) output to the BA6297AFP (IC102)

5 TRON O Tracking servo drive PWM signal output terminal Not used (open)

6 TRDR O Tracking servo drive PWM signal (+) output to the BA6297AFP (IC102)

7 TFON O Tracking servo drive PWM signal output terminal Not used (open)

8 FFDR O Focus servo drive PWM signal (+) output to the BA6297AFP (IC102)

9 FRON O Focus servo drive PWM signal output terminal Not used (open)

10 FRDR O Focus servo drive PWM signal (–) output to the BA6297AFP (IC102)

11 FFON O Focus servo drive PWM signal output terminal Not used (open)

12 VCOO O Oscillator circuit output terminal for analog PLL of the playback EFM Not used (open)

13 VCOI I Oscillator circuit input terminal for analog PLL of the playback EFM Not used (fixed at “L”)

14 TEST I Input terminal for the test (fixed at “L”)

15 DVSS — Ground terminal (digital system)

16 TES2 I Input terminal for the test (fixed at “L”)

17 TES3 I Input terminal for the test (fixed at “L”)

18 PDO O Charge-pump output terminal for analog PLL of the playback EFM Not used (open)

19 VPCO O PLL charge-pump output terminal for the variable pitch Not used (open)

20 VCKI I Clock signal input from external VCO for the variable pitch Not used (fixed at “L”)

21 AVD2 — Power supply terminal (+5V) (analog system)

22 IGEN I Power supply terminal (+5V) (for operational amplifier)

23 AVS2 — Ground terminal (analog system)

24 ADII I Input terminal for the A/D converter Not used (open)

25 ADIO O Output terminal of the operational amplifier Not used (open)

26 RFDC I RF signal (DC level) input terminal for the digital servo process

27 TE I Tracking error signal input from the RF amplifier in optical pick-up

28 SE I Sled error signal input from the RF amplifier in optical pick-up

29 FE I Focus error signal input from the RF amplifier in optical pick-up

30 VC I Middle point voltage (+2.5V) input from the RF amplifier in optical pick-up

31 FILO O Filter output terminal for master clock of the playback master PLL

32 FILI I Filter input terminal for master clock of the playback master PLL

33 PCO O Phase comparison output terminal for master clock of the playback EFM master PLL

34 CLTV I Internal VCO control voltage input of the playback master PLL

35 AVS1 — Ground terminal (analog system)

36 RFAC I RF signal (AC level) input terminal for the EFM demodulator

37 BIAS I Constant current input terminal of the playback EFM asymmetry circuit

38 ASYI I Playback EFM asymmetry comparator voltage input terminal

39 ASYO O

40 AVD1 — Power supply terminal (+5V) (analog system)

41 DVDD — Power supply terminal (+5V) (digital system)

42 ASYE I Playback EFM asymmetry circuit on/off selection input terminal (fixed at “H”)

43 PSSL I Audio data output mode selection input terminal (fixed at “L”)

Playback EFM full-swing output terminal

Pin No. Pin Name I/ O Function

44 WDCK O Word clock signal (88.2 kHz) output terminal Not used (open)

45 LRCK O L/R sampling clock signal (44.1 kHz) output to the CXD8595Q (IC301)

46 DATA O

47 BCLK O

48 64 DATA O

4 9 64 BCLK O

5 0 64 LRCK O

51 GTOP O

52 XUGF O

53 XPLCK O

54 GFS O

55 RFCK O

56 C2PO O

57 XRAOF O

58 MNT3 O

59 MNT2 O

60 MNT1 O

61 MNT0 O

62 XTAI I System clock input terminal (16 MHz)

63 XTAO O System clock output terminal (16 MHz) Not used (open)

64 XTSL I System clock selection input terminal (fixed at “L”)

65 DVSS — Ground terminal (digital system)

66 FSTI I 2/3 divider input terminal of pins ^™ (XATI) and ^£ (XTAO)

67 FSTO O 2/3 divider output terminal of pins ^™ (XATI) and ^£ (XTAO)

68 C4M O 4.2336 MHz clock signal output terminal Not used (open)

69 C16M O 16.9344 MHz clock signal output terminal Not used (open)

70 MD2 I Digital out on/off control signal input from the system controller (IC351)

71 DOUT O Digital signal (for coaxial out and optical out) output terminal

72 EMPH O Emphasis control signal output terminal Not used (open)

73 WFCK O Write frame clock signal output terminal Not used (open)

74 SCOR O Sub-code sync (S0+S1) detection signal output to the system controller (IC351)

DA16 output when PSSL=“H”, 48-bit slot serial data output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Serial data output to the CXD8595Q (IC301)

DA15 output when PSSL=“H”, 48-bit slot bit clock signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Bit clock signal (2.8224 MHz) output to the CXD8595Q (IC301)

DA14 output when PSSL=“H”, 64-bit slot serial data output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA13 output when PSSL=“H”, 64-bit slot bit clock signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA12 output when PSSL=“H”, 64-bit slot L/R sampling clock signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA11 output when PSSL=“H”, GTOP signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA10 output when PSSL=“H”, XUGF signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA09 output when PSSL=“H”, XPLCK signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA08 output when PSSL=“H”, GFS (guard frame sync) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA07 output when PSSL=“H”, RFCK (read frame clock) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA06 output when PSSL=“H”, C2PO signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA05 output when PSSL=“H”, XRAOF (RAM over flow) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA04 output when PSSL=“H”, MNT3 (monitor 3) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA03 output when PSSL=“H”, MNT2 (monitor 2) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA02 output when PSSL=“H”, MNT1 (monitor 1) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA01 output when PSSL=“H”, MNT0 (monitor 0) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

– 23 –

– 24 –

Pin No. Pin Name I/O Function

75 SBSO O Sub-code P-W serial data output terminal Not used (open)

95

96

97

98

76 EXCK I Sub-code P-W serial data reading clock signal input terminal Not used (fixed at “L”)

77 SUBQ O Sub-code Q data signal output to the system controller (IC351)

78 SQCK I Sub-code Q data reading clock signal input from the system controller (IC351)

79 MUTE I Mute signal input from the system controller (IC351)

80 SENS O Internal status (SENSE) signal output to the system controller (IC351)

81 XRST I

82 DIRC I 1-track jump mode input terminal Not used (fixed at “H”)

83 SCLK I Sense serial data reading clock signal input from the system controller (IC201)

84 DFSW I Defect on/off select signal input terminal Not used (fixed at “L”)

85 ATSK I Input terminal for the anti-shock Not used (fixed at “L”)

86 DATA I Serial data input from the system controller (IC351)

87 XLAT I Serial data latch pulse signal input from the system controller (IC351)

88 CLOK I Serial data transfer clock signal input from the system controller (IC351)

89 COUT O Track number count signal output terminal Not used (open)

90 DVDD — Power supply terminal (+5V) (digital system)

91 MIRR O Mirror detection signal output terminal Not used (open)

92 DFCT O Defect signal output terminal Not used (open)

93 FOK O Focus OK signal output terminal Not used (open)

94 FSW O Selection signal output terminal of the output filter for spindle motor Not used (open)

MON O Spindle motor on/off control signal output terminal Not used (open)

99 SSTP I

100 SFDR O Sled servo drive PWM signal (+) output to the BA6297AFP (IC102)

MDP O Spindle servo control signal output terminal

MDS O Spindle servo control signal output terminal Not used (open)

LOCK O

System reset signal input from the reset signal generator (IC206) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

GFS is sampled by 460 Hz “H” output when GFS is “H” Not used (open)

Detection input from the sled limit-in detect switch (SW102)

The optical pick-up is inner position when “H”

– 25 –

• BD BOARD IC351 CXP84124-068Q (SYSTEM CONTROL)

Pin No. Pin Name I/O Function

1A3O

2A4O

3A5O

4A6O

5A7O

6A8O

7A9O

8 A10 O

9 A11 O

10 A12 O

11

12

13 NC O Not used (open)

14 LED-PLAY O

15 LED-PAUSE O

16 LED-FILTER O FILTER LED (D873) drive signal output terminal “H”: LED on

17 SPDL-MUTE O Mute signal output to the spindle motor driver (IC102, 104)

18 SHIFT-ON/OFF O

19 VOL UP O Volume up control signal output to the volume control motor driver (IC354)

20 VOL DOWN O Volume down control signal output to the volume control motor driver (IC354)

21

22

23

24

WE O Write enable signal output to the static RAM (IC352)

NC O Not used (open)

BLANK O Blank signal output to the fluorescent indicator tube driver (IC801 to IC803)

FL D0 O Serial data output to the fluorescent indicator tube driver (IC803)

FL D1 O Serial data output to the fluorescent indicator tube driver (IC802)

FL D2 O Serial data output to the fluorescent indicator tube driver (IC801)

Address signal output to the static RAM (IC352)

( LED (D871) drive signal output terminal “H”: LED on

P LED (D872) drive signal output terminal “H”: LED on

Reset signal output to the CXD2562Q-CS (IC302) “L”: reset

25

26

27 SENSER SW O

28 SENSER I Detect signal input from the stabilizer detect sensor (IC361) “H”: on

29

30

31

32

33

34

35

36

37

38 ADJ/AFADJ I Setting terminal for the test mode “L” active

39

40

41 K2 I

FL CLK O Serial data transfer clock signal output to the fluorescent indicator tube driver (IC801 to IC803)

FL WR O Read/write select signal output to the fluorescent indicator tube driver (IC801 to IC803)

On/off control signal output to the stabilizer detect sensor (IC361) “H”: on

LIMIT OUT I

RESET I

XTALI I Main system clock input terminal (4 MHz)

XTALO O Main system clock output terminal (4 MHz)

VSS — Ground terminal

TX O Sub system clock output terminal Not used (open)

TEX I Sub system clock input terminal Not used (fixed at “L”)

AVSS — Ground terminal (for A/D converter)

AVREF I Reference voltage input terminal (+5V)

K0 I Key input terminal (A/D input) (fixed at “H”)

K1 I

Detection input from the sled limit-out detect switch

The optical pick-up is outer position when “L” Not used (fixed at “L”)

System reset signal input from the reset signal generator (IC206) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

Key input terminal (A/D input)

P MODE, TIME keys (S819S820) input

Key input terminal (A/D input)

ERASE, CHECK, CLEAR, FILTER, 0, ) , keys (S801 to S806) input

– 26 –

Pin No. Pin Name I/O Function

42 K3 I

n

Key input terminal (A/D input) EDIT/TIME FADE, REPEAT, FILE,

§ OPEN/CLOSE, (, P, p keys (S811 to S817) input

43 K4 I

44 K5 I

45 IN/OUT SW I Detection input from the loading in/out detect switch (S281, S282) (A/D input)

46 SCLK O Sense serial data reading clock signal output to the CXD2545Q (IC101)

47 PRGL O Serial data latch pulse signal output to the CXD8595Q (IC301)

48 CLK O Serial data transfer clock signal output to the CXD2545Q (IC101) and CXD8595Q (IC301)

49 SENSE I Internal status (SENSE) signal input from the CXD2545Q (IC101)

50 DATA O Serial data output to the CXD2545Q (IC101) and CXD8595Q (IC301)

51 SQCK O Sub-code Q data reading clock signal output to the CXD2545Q (IC101)

52 SUBQ I Sub-code Q data signal input from the CXD2545Q (IC101)

53 TEST O Output terminal for the test Not used (open)

54 SEL1 I Destination setting terminal (fixed at “L”)

55 SEL0 I Destination setting terminal (fixed at “L”)

56 RMIN I Remote control signal input from the remote control receiver (IC804)

57 TIMER I Timer control input terminal Not used (fixed at “H”)

58 TEST O Output terminal for the test Not used (open)

59 TEST O Output terminal for the test Not used (open)

60 SCOR I Sub-code sync (S0+S1) detection signal input from the CXD2545Q (IC101)

61 AMUTE O Muting control signal output to the analog mute driver and mute relay driver

62 LDON O Laser diode on/off selection signal output to the RF amplifier in optical pick-up

63 XLT O Serial data latch pulse signal output to the CXD2545Q (IC101)

64 LOAD OUT O Loading motor (M2) drive signal output to the NJM4558 (IC182) *1

65 LOAD IN O Loading motor (M2) drive signal output to the NJM4558 (IC182) *1

66 DOUT O Digital out on/off control signal output to the CXD2545Q (IC101) Not used (Open)

67 DMUTE O Muting control signal output to the CXD2545Q (IC101) and CXD8595Q (IC301)

68 D0 I/O

69 D1 I/O

70 D2 I/O

71 D3 I/O

72 VDD — Power supply terminal (+5V)

73 NC I Not used (fixed at “H”)

74 D4 I/O

75 D5 I/O

76 D6 I/O

77 D7 I/O

78 A0 O

79 A1 O Address signal output to the static RAM (IC352)

80 A2 O

Rotary encoder input terminal (A/D input) AMS ± key (RV801) input

Rotary encoder input terminal (A/D input) AMS ≠ key (RV801) input

Two-way data bus with the static RAM (IC352)

Two-way data bus with the static RAM (IC352)

*1 Loading motor (M2) control

Operatio

Terminal

LOAD OUT (pin ^¢)

LOAD IN (pin ^∞)

OFF OUT I N BRAKE

“L” “H” “L” “H”

“L” “L” “H” “H”

– 27 –

Main Ports

d

n

d

SPDL-MUTE (pin !¶)

From the viewpoint of performance of the set, the disc must

not move nor sway when the disc table opens. These

problems however occur in the actual case due to the offset

voltage generated and the voltage generated because of the

positional relation between the BSL coil and Hall element.

The spindle motor driver (IC102, IC104) is therefore mute

while the tray is open. Pin !¶ provides the timing for this.

H

SP MUTE

SENSER SW (pin @¶)

As IC361 IS471F operate in pulse as shown i n the figure, the

sound quality may be affected if operated constantly. As the

purpose of IC361 is to detect if the presence of the stabilizer,

it should be operated only when the tray is drawn in. IC361

operates as it is “H” only at this time. Normally it is “L”.

Eep

Ee

Eed

L

(MUTE ON)

OPEN

Reverses after a

certain period of time.

CLOSE SPINDLE

Reverses after a

certain period of time.

Time while the

disc can be see

(Estimate).

PLAY

KICK

The spindle

motor driver is

muted during

this time.

BLANK (pin @¡)

This port is required because the display tube in this set static

lights up and a dedicated screwdriver is required. It is

basically a RESET pin. But as problems will occur if u se

also a s RESET, timings are specially provided using t he

micro-processor.

0

GLout pin

output waveform

Eepis the luminance of the signal light tuned with the low

*

Time

level timing of the GLout pin output.

Eedis the luminance of the D.C. light. Th e light source is

the infrated-emitting diode (λp=940 nm).

SENSER (pin @•)

The results of the detection of IC361 IS471F is output to this

pin. It becomes “ L ” when there is no stabilizer (when light

reaches). The next process of imposing the next focus is not

performed. (Effective only when pin @¶ is “H”.)

Therefore, it must be noted that if PLAY is performed when th

servo board a t the top of the CDM is not assembled properly,

the detection circuit operates and this pin does not operate.

It is does not operate, refer to 1. SERVICING NOTES ” Preparations for Adjustment and Measurement” on page 3.

– 28 –

• IC Block Diagrams

– BD Section –

IC103 CXA1821M

VEE

1

LD

VCC

PD

2

A

3

B

4

C

5

D

6

7

F

8

E

9

10

EI

VEE

+

–

VC

RF SUMMING AMP

+

–

+

–

VREF

VEE

–

+

VC

VEE

VC

VC

+

–

APC LD AMP

–

+

FOCUS ERROR AMP

VC

VC

VCC

VEE

RF EQ AMP

VC

TRACKING ERROR AMP

–

+

VC BUFFER

+

–

VCC

–

+

20

VCC

LD ON

19

LC/PD

18

RFE

17

RFO

16

15

FE

FE BIAS

14

TE

13

VC

VC

12

EO

11

IC181 TA7256P

+

–

2 345 6 7 8 9 10

1

VEE

–IN1

+IN1

+IN2

OUT1

SENSE1

–IN2

+

–

VCC

OUT2

SENSE2

– 29 –

– MAIN Section –

IC206 M51957AL

–

+

1.25V

1 2

VDD

3

IN

GND

IC301 CXD8595Q

NRGCLR

51 50 49 48 47 46 45 44

IF SELD

52

IF SELC

53

54

NC

55

SBCKI

SDATAR

SDATAL

DFDTOL

DFBCKO

DFDTEN

TEST1

TEST2

VSS

4BIT DATA

56

BITSTREAM

57

58

NC

59

60

61

62

63

64

4

DL

SYSM

LATCH

ATT

IIR

OVERFLOW DETECTOR

5

OUT

SHIFT

MODE

FIR 4

FIR 2FIR 1 FIR 3

P/S CONVERT

D/F-CLK GEN.

ATT

INIT

LRCKI

DATAI

BCKI

VSS

VSS

NC

INVO2

INVO1

INVI

NC

128FSO

CKVDD

DINIT

42

43

TIMING

CIRCUIT

S / P

ATT

IIR

FIR 4

FIR 2FIR 1 FIR 3

OVERFLOW DETECTOR

&

40 39 38 37 36 35 34 33

41

ATT

x 0.75

ATT

x 0.75

POLALITY

OR

L . I . P.

DITHER

L . I . P.

"0" DETECT

CIRCUIT

CLOCK

GENERATOR

MUTE

3rd order

NOISE

SHAPER

3rd order

NOISE

SHAPER

32

31

30

29

28

27

26

25

24

23

22

21

20

INAF

OVFLAG

MUTER

MUTEL

MTPOL

DRPOL

MODE

NC

DFDTOR

DFLRCKO

TEST4

TEST3

VSS

1 2

PLMG2

VDD

3

NSDOL4

DATA SELECT

4

5

NSDOL3

NSDOL2

6

NSDOL1

2

8

7

NC

NC

9 10

VDD

VDD

12 13

11

NC

64FSI

DATA SELECT

NSDOR1

14

NSDOR2

15 16 17

NSDOR3

NSDOR4

MCKIN

18 19

VDD

PLMG1

– 30 –

IC302 CXD2562Q

DPO/BCKO

DM2/SDRO

DM1/SDLO

DLO

51 50 49 48 47

DRO

LRCKO

INAF

DINIT

43444546

128FS

DVSSL

DVSSR

512FSO

BCKI

DLI

DRI

LRCKI

MUTEL

MUTER

33343536373839404142

INIT

DATAOUT

52

ON/OFF

TEST1

53

54

TEST2

55

TEST3

DVDDL

56

VSUB (D) L

VSUB (CHIP) L

VDD2

VDD

L1 (–)

VSS

L1 (+)

VSS2

57

58

59

60

61

62

63

64

IC354 BA6208

INTERPOLATER

INTERPOLATER

THIRD ORDER

NOISE SHAPER

THIRD ORDER

NOISE SHAPER

2 345 6 7 8 9

1

VSS

VSS2

L2 (+)

L2 (–)

VDD

VDD2

CLOCK

GENERATOR

XVDD

VSUB (A) L

TIMING CIRCUIT

10

11

XIN

XOUT

PLM

PLM

XVSS

XVSS

VDD2

VSUB (A) R

VDD

R2 (–)

S/P

VSS

1918171615141312

R2 (+)

VSS2

32

SYNC

31

COEF

SPLM

30

18/20

29

DVDDR

28

27

VSUB (D) R

VSUB (CHIP) R

26

VDD2

25

VDD

24

R1 (–)

23

VSS

22

R1 (+)

21

VSS2

20

GND

MOTOR

DRIVE

MOTOR

DRIVE

REG

Vcc

SWITCH

SWITCH

1 2 3 4 5 6 7

NC

INPUT 1

NC

INPUT 2

OUTPUT 2

8

OUTPUT1

9

NC

– 31 –

IC501, 601 CXA8042AS

1

I01+

2

I02–

3

NC

4

I01–

5

I02+

6

NC

7

VCC2

8

C2

C1

9

10

VCC1

VREF

VCNT

GND1

RIREF

REFERENCE

11

12

13

14

VOLTAGE

CIRCUIT

– PANEL Section –

IC801, 802, 803 LC7570E

SWITCHING

CIRCUIT

CONSTANT

CURRENT

CIRCUIT

CONTROL

CIRCUIT

28

IN2–

27

IN2+

26

NC

25

IN1+

IN1–

24

NC

23

C4

22

C3

21

GND2

20

VEE2

19

18

VEE1

17

C6

C5

16

15

CIREF

BLK

VSS

SIN

S33

S32

S31

S30

S29

S28

S27

S26

NC

VDA

DATACLWR

464748 45 44 43 42 41 40 39 38 37

1

NC

2

3

4

5

6

7

8

9

10

11

12

13

14

NC

S25

SHIFT REGISTER

A/D CONVERTER

LATCH, FL DRIVER

15

16

S24

VFLS0S1S2S3NCS4

17 181920 21 22 23

S22

S21NCS20

S23

S19

S18

S17

36

S5

35

S6

34

S7

33

S8

32

S9

31

S10

30

S11

29

S12

28

S13

27

S14

26

S15

25

S16

24

NC

– 32 –

• Wave forms

– MAIN BOARD –

1 IC302 !º (XIN)

45.455 MHz

– BD BOARD –

2 IC351 #™ (XOUT)

4.00 MHz

2.02 Vp-p

5.92 Vp-p

6 IC101 $∞ (LRCK)

44.053 kHz

7 IC101 #§ (RFAC)

200 mV/DIV, 500 nS/DIV

6.32 Vp-p

+0.25

1.25 Vp-p

–0.20

3 IC101 %£ (XPLCK)

4.310 MHz

4 IC101 %∞ (RFCK)

7.353 kHz

6.8 Vp-p

5.84 Vp-p

8 IC101 @ª (FE)

0.1 Vp-p

9 IC101 @¶ (TE)

8.4 Vp-p

5 IC101 $¶ (BCLK)

2.1186 MHz

!º IC101 (§ (MDP)

3.6Vp-p

6.24 Vp-p

131.58 kHz

– 33 –

• Circuit Boards Location

BD board

VOL SEL board

POWER board

DISPLAY board

POWER SW board

HP board

BD TRANSLA TION board

PANEL board

LOADING MOTOR board

LOADING SW board

MAIN board

BSL board

– 34 –

SECTION 7

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE)

↑

Cabinet's Color

(1) CASE, LOADING PANEL SECTION

10

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference num-

ber in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of the

electrical parts list.

8

9

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

11

not supplied

10

#1

12

not

supplied

#1

8

front panel

8

10

7

5

#1

#1

6

4

not supplied

3

not supplied

1

2

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1 3-703-685-21 SCREW (+BV 3X8)

2 4-970-998-21 BOLT (LID), HEXAGON HOLE (GOLD)

2 4-970-998-31 BOLT (LID), HEXAGON HOLE (BLACK)

3 4-987-965-01 EMBLEM (FIXED PICKUP) (GOLD)

3 4-987-965-11 EMBLEM (FIXED PICKUP) (BLACK)

4 4-986-744-01 PANEL, LOADING (GOLD)

4 4-986-744-11 PANEL, LOADING (BLACK)

5 4-986-745-01 BASE, LOADING PANEL (GOLD)

5 4-986-745-11 BASE, LOADING PANEL (BLACK)

6 1-777-844-11 WIRE (FLAT TYPE) (9 CORE)

7 1-777-845-11 WIRE (FLAT TYPE) (10 CORE)

8 4-959-077-01 DAMPER

* 9 4-615-354-01 SPACER

10 3-363-099-01 SCREW (CASE 3 TP2) (BLACK)

10 3-363-099-11 SCREW (CASE 3 TP2) (GOLD)

11 4-969-469-01 CASE (BLACK)

11 4-969-469-31 CASE (GOLD)

* 12 4-962-329-01 DAMPER

– 61 –

(2) FRONT PANEL SECTION

59

62

59

53

52

#2

54

57

55

56

58

supplied with

J401

not supplied

74

73

59

60

59

64

supplied with

VR405

65

66

61

68

67

70

59

63

59

69

supplied with RV801

71

72

51

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 4-987-121-01 KNOB (AMS) (GOLD)

51 4-987-121-11 KNOB (AMS) (BLACK)

52 4-950-189-01 KNOB (A) (VOL) (BLACK)

52 4-950-189-41 KNOB (A) (VOL) (GOLD)

53 4-942-568-01 EMBLEM (NO.5), SONY (BLACK)

53 4-942-568-31 EMBLEM (NO.5), SONY (GOLD)

54 4-986-664-01 PANEL, FRONT (GOLD)

54 4-986-664-11 PANEL, FRONT (BLACK)

55 4-986-670-01 PLATE, INDICATION

56 4-986-666-01 BASE (L), PANEL (GOLD)

56 4-986-666-11 BASE (L), PANEL (BLACK)

57 4-923-520-51 KNOB, POWER (POWER) (BLACK)

57 4-923-520-61 KNOB, POWER (POWER) (GOLD)

* 58 1-663-575-12 POWER SW BOARD

59 4-951-620-01 SCREW (2.6X8), +BVTP

* 60 A-4699-566-A HP BOARD, COMPLETE (BLACK)

* 60 A-4699-710-A HP BOARD, COMPLETE (GOLD)

61 4-986-669-01 FILTER

* 62 A-4699-353-A DISPLAY BOARD, COMPLETE

63 4-986-668-01 BRACKET (PACKING)

#2

64 4-986-667-01 PACKING

65 4-986-687-01 BUTTON (P.MODE) (GOLD)

65 4-986-687-11 BUTTON (P.MODE) (BLACK)

66 4-986-671-01 BUTTON (2) (GOLD)

66 4-986-671-11 BUTTON (2) (BLACK)

67 4-986-672-01 BUTTON (3) (GOLD)

67 4-986-672-11 BUTTON (3) (BLACK)

68 4-986-673-01 BUTTON (FF) (0. )) (GOLD)

68 4-986-673-11 BUTTON (FF) (0. )) (BLACK)

* 69 A-4699-354-A PANEL BOARD, COMPLETE

* 70 3-362-478-01 HOLDER (T), LED

71 X-4945-276-1 BUTTON (PLAY) ASSY

(§ OPEN/CLOSE. (. P. p) (BLACK)

71 X-4948-030-1 BUTTON (PLAY) ASSY

(§ OPEN/CLOSE. (. P. p) (GOLD)

72 4-986-665-01 BASE (R), PANEL (GOLD)

72 4-986-665-11 BASE (R), PANEL (BLACK)

73 4-971-776-01 INDICATOR

74 4-949-302-21 WASHER

– 62 –

(3) CHASSIS SECTION

mechanism deck

(CDM36A-14A)

104

not

supplied

114

T1

107

#1

not

supplied

not

supplied

#1

#1

not

supplied

not

supplied

#1

106

105

107

not supplied

#1

not supplied

#1

#1

not supplied

108

#1

not supplied

109

CNP1

#1

110

#1

111

#1

#1

#1

not supplied

not supplied

112

103

not supplied

#1

#1

113

103

#6

#1

#4

102

101

102

The components identified by mark

! or dotted line with mark ! are

101

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

101 4-970-124-01 CUSHION (F50180S)

102 4-970-123-01 FOOT (F50180S)

103 4-984-485-01 CUSHION (FOOT)

* 104 1-663-576-13 VOL SEL BOARD

105 1-777-873-11 WIRE (FLAT TYPE) (16 CORE)

* 110 3-703-244-00 BUSHING (2104), CORD

111 3-704-515-21 SCREW (BV/RING)

* 112 4-986-682-11 PANEL, BACK (AEP)

* 112 4-986-682-22 PANEL, BACK (Singapore)

113 3-831-441-XX CUSHION, SPEAKER

critical for safety.

Replace only with part number

specified.

* 106 A-4699-712-A POWER BOARD, COMPLETE

107 4-985-057-01 WASHER

* 108 A-4699-567-A MAIN BOARD, COMPLETE

* 109 4-923-873-01 BRACKET, CORD STOPPER

114 1-543-653-11 CORE ASSY, BEAD (DIVISION TYPE)

! CNP1 1-558-568-21 CORD, POWER

! T1 1-431-214-11 TRANSFORMER, POWER (Singapore)

! T1 1-431-215-11 TRANSFORMER, POWER (AEP)

– 63 –

(4) MECHANISM DECK SECTION-1

(CDM36A-14A)

156

155

#2

#2

#2

not supplied

#2

not supplied

#2

#2

BU-14A

152

#2

#5

153

154

153

not supplied

158

not supplied

#2

159

161

160

#3

164

165

166

not supplied

168

162

163

167

#2

M2

not supplied

not supplied

151

Ref. No. Part No. Description Remark

* 151 4-977-889-01 PLATE (BU), GROUND

152 4-989-303-01 SPRING (BU-LF), COMPRESSION

153 4-988-104-01 SPRING (BU), COMPRESSION

* 154 4-986-917-01 COVER (F) (DRAWER)

155 4-986-916-01 PANEL (DRAWER)

* 156 4-986-918-01 COVER (R) (DRAWER)

* 157 4-977-888-01 SHAFT

* 158 4-977-892-01 BEARING

* 159 4-977-891-01 PLATE, GROUND

160 X-4924-457-1 ROLLER ASSY

161 4-934-376-01 SHAFT (ROLLER)

162 1-777-843-11 WIRE (FLAT TYPE) (30 CORE)

172

#2

171

169

157

170

Ref. No. Part No. Description Remark

* 163 A-4699-708-A BD BOARD, COMPLETE

164 4-977-897-01 GEAR

165 4-977-898-01 LEVER (SWING)

166 4-977-896-01 PULLEY

* 167 1-663-579-11 LOADING MOTOR BOARD

* 168 1-663-581-11 LOADING SW BOARD

169 4-968-905-01 BELT (CDM)

170 4-986-919-01 LIMITTER (LEVER)

171 4-988-103-01 SLIDER (SWING)

172 4-988-107-01 CUSHION (LD)

M2 A-4660-970-A MOTOR ASSY (LOADING)

– 64 –

(5) MECHANISM DECK SECTION-2

(BU-14A)

214

215

210

209

211

208

#6

not

supplied

#6

207

212

204

#7

213

205

220

207

218

216

217

211

219

221

203

M1

223

202

Ref. No. Part No. Description Remark

201 4-951-620-01 SCREW (2.6X8), +BVTP

* 202 1-663-580-11 BD TRANSLATION BOARD

203 A-4672-247-A BASE (OUTSERT) ASSY

204 4-977-921-01 GEAR (B), FLAT

* 205 4-977-918-01 BASE (OUTSERT)

206 4-977-920-01 GEAR (C), FLAT

207 4-917-562-11 INSULATOR

* 208 4-977-924-01 SPRING (OP), LEAF

209 1-775-991-11 WIRE (FLAT TYPE) (16 CORE)

! 210 8-848-379-31 OPTICAL PICK-UP KSS-213B/S-N

206

not supplied

201

201

Ref. No. Part No. Description Remark

213 4-977-925-01 SPRING (SLIDE BASE), COMPRESSION

214 4-968-871-01 WASHER (SPINDLE)

215 4-968-867-01 CAP, CENTERING

216 4-968-869-01 SPRING (CENTERING), COMPRESSION

217 A-4660-814-A PULLEY ASSY, DISK

218 4-971-266-01 SCREW (M2.6X4)

219 X-4947-796-1 BASE ASSY, SLIDE

220 X-4947-797-1 ROTOR ASSY

221 1-777-842-11 WIRE (FLAT TYPE) (10 CORE)

222 A-4699-360-A BSL BOARD, COMPLETE

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

222

211 4-977-923-01 SHAFT, SLED

212 4-977-926-01 RACK, SLIDE

223 X-4947-838-1 STABILIZER ASSY

M1 X-4947-303-1 MOTOR ASSY (SLED)

– 65 –

BD

SECTION 8

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used on

the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark

* A-4699-708-A BD BOARD, COMPLETE

*******************

< CAPACITOR >

C93 1-124-997-11 ELECT 470uF 20% 10V

C94 1-124-997-11 ELECT 470uF 20% 10V

C101 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C102 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C103 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C104 1-163-145-00 CERAMIC CHIP 0.0015uF 5% 50V

C105 1-135-155-21 TANTALUM CHIP 4.7uF 10% 16V

C108 1-163-035-00 CERAMIC CHIP 0.047uF 50V

C109 1-163-145-00 CERAMIC CHIP 0.0015uF 5% 50V

C110 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board.

Ref. No. Part No. Description Remark

C163 1-164-492-11 CERAMIC CHIP 0.15uF 10% 16V

C171 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C172 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C173 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C175 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C261 1-126-177-11 ELECT 100uF 20% 10V

C325 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C351 1-125-622-11 CAPACITOR 0.1F 5.5V

C352 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C360 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C370 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C371 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C372 1-126-177-11 ELECT 100uF 20% 10V

C111 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C112 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C113 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C114 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C115 1-124-673-11 ELECT 100uF 20% 10V

C116 1-124-673-11 ELECT 100uF 20% 10V

C117 1-126-209-11 ELECT 100uF 20% 4V

C118 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C119 1-163-231-11 CERAMIC CHIP 15PF 5% 50V

C122 1-164-336-11 CERAMIC CHIP 0.33uF 25V

C123 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C124 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C125 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C126 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C127 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C128 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C131 1-164-346-11 CERAMIC CHIP 1uF 16V

C132 1-164-346-11 CERAMIC CHIP 1uF 16V

C140 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C141 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C151 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C152 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C153 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C154 1-164-336-11 CERAMIC CHIP 0.33uF 25V

C155 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C156 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C157 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C158 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C161 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C162 1-163-038-00 CERAMIC CHIP 0.1uF 25V

< CONNECTOR >

CN101 1-691-894-21 SOCKET, CONNECTOR 16P

* CN102 1-563-017-11 CONNECTOR, FPC 30P

* CN103 1-568-941-11 PIN, CONNECTOR 3P

* CN104 1-564-518-11 PLUG, CONNECTOR 3P

* CN105 1-564-518-11 PLUG, CONNECTOR 3P

CN106 1-568-853-11 SOCKET, CONNECTOR 10P

* CN107 1-568-852-11 SOCKET, CONNECTOR 9P

CN113 1-506-481-11 PIN, CONNECTOR 2P

< DIODE >

D101 8-719-016-74 DIODE 1SS352

D351 8-719-016-74 DIODE 1SS352

D361 8-719-938-07 DIODE GL480

< IC >

IC101 8-752-369-78 IC CXD2545Q

IC102 8-759-071-79 IC BA6297AFP

IC103 8-752-072-45 IC CXA1821M-T6

IC104 8-759-071-79 IC BA6297AFP

IC351 8-752-884-95 IC CXP84124-068Q

IC352 8-759-289-94 IC LH5160TF

IC361 8-749-010-61 IC IS471F

< COIL >

L101 1-414-234-11 INDUCTOR, FERRITE BEAD

– 66 –

BD

Ref. No. Part No. Description Remark

< TRANSISTOR >

Q101 8-729-010-08 TRANSISTOR MSB710-R

Q102 8-729-010-08 TRANSISTOR MSB710-R

Q103 8-729-424-18 TRANSISTOR UN2113-TX

Q104 8-729-421-19 TRANSISTOR UN2213

Q105 8-729-424-18 TRANSISTOR UN2113-TX

Q106 8-729-421-19 TRANSISTOR UN2213

Q301 8-729-424-08 TRANSISTOR UN2111

Q302 8-729-421-22 TRANSISTOR UN2211

< RESISTOR >

R101 1-216-077-00 METAL CHIP 15K 5% 1/10W

R102 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R103 1-216-077-00 METAL CHIP 15K 5% 1/10W

R104 1-216-085-00 METAL CHIP 33K 5% 1/10W

R105 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R106 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R107 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R108 1-216-073-00 METAL CHIP 10K 5% 1/10W

R109 1-216-121-00 METAL GLAZE 1M 5% 1/10W

R110 1-216-025-00 METAL GLAZE 100 5% 1/10W

R111 1-216-693-11 METAL CHIP 56K 0.5% 1/10W

R112 1-216-049-00 METAL GLAZE 1K 5% 1/10W

R113 1-216-073-00 METAL CHIP 10K 5% 1/10W

R114 1-216-073-00 METAL CHIP 10K 5% 1/10W

R115 1-216-677-11 METAL CHIP 12K 0.5% 1/10W

R116 1-216-695-11 METAL CHIP 68K 0.5% 1/10W

R117 1-216-073-00 METAL CHIP 10K 5% 1/10W

R118 1-216-073-00 METAL CHIP 10K 5% 1/10W

R119 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R120 1-216-105-00 METAL GLAZE 220K 5% 1/10W

R121 1-216-073-00 METAL CHIP 10K 5% 1/10W

R122 1-216-073-00 METAL CHIP 10K 5% 1/10W

R123 1-216-073-00 METAL CHIP 10K 5% 1/10W

R124 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R125 1-216-049-00 METAL GLAZE 1K 5% 1/10W

R126 1-216-049-00 METAL GLAZE 1K 5% 1/10W

R127 1-216-049-00 METAL GLAZE 1K 5% 1/10W

R131 1-216-037-00 METAL CHIP 330 5% 1/10W

R132 1-216-695-11 METAL CHIP 68K 0.5% 1/10W

R133 1-216-049-00 METAL GLAZE 1K 5% 1/10W

R134 1-216-049-00 METAL GLAZE 1K 5% 1/10W

R135 1-216-295-00 CONDUCTOR, CHIP (2012)

R136 1-216-295-00 CONDUCTOR, CHIP (2012)

R137 1-216-295-00 CONDUCTOR, CHIP (2012)

R138 1-216-295-00 CONDUCTOR, CHIP (2012)

R141 1-216-089-00 METAL GLAZE 47K 5% 1/10W

R142 1-216-081-00 METAL CHIP 22K 5% 1/10W

R143 1-216-103-00 METAL CHIP 180K 5% 1/10W

R144 1-216-103-00 METAL CHIP 180K 5% 1/10W

R145 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R146 1-216-073-00 METAL CHIP 10K 5% 1/10W

R147 1-216-081-00 METAL CHIP 22K 5% 1/10W

R148 1-216-001-00 METAL CHIP 10 5% 1/10W

R149 1-216-003-11 METAL GLAZE 12 5% 1/10W

R150 1-216-659-11 METAL CHIP 2.2K 0.5% 1/10W

Ref. No. Part No. Description Remark

R153 1-216-073-00 METAL CHIP 10K 5% 1/10W

R154 1-216-073-00 METAL CHIP 10K 5% 1/10W

R155 1-216-073-00 METAL CHIP 10K 5% 1/10W

R156 1-216-073-00 METAL CHIP 10K 5% 1/10W

R157 1-216-025-00 METAL GLAZE 100 5% 1/10W

R161 1-216-308-00 METAL CHIP 4.7 5% 1/10W

R167 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R168 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R169 1-216-105-00 METAL GLAZE 220K 5% 1/10W

R171 1-216-073-00 METAL CHIP 10K 5% 1/10W

R172 1-216-073-00 METAL CHIP 10K 5% 1/10W

R173 1-216-073-00 METAL CHIP 10K 5% 1/10W

R174 1-216-073-00 METAL CHIP 10K 5% 1/10W

R175 1-216-073-00 METAL CHIP 10K 5% 1/10W

R176 1-216-073-00 METAL CHIP 10K 5% 1/10W

R177 1-216-025-00 METAL GLAZE 100 5% 1/10W

R179 1-216-308-00 METAL CHIP 4.7 5% 1/10W

R180 1-216-659-11 METAL CHIP 2.2K 0.5% 1/10W

R181 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R182 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R183 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R184 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R186 1-216-105-00 METAL GLAZE 220K 5% 1/10W

R187 1-216-659-11 METAL CHIP 2.2K 0.5% 1/10W

R188 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R189 1-216-659-11 METAL CHIP 2.2K 0.5% 1/10W

R190 1-216-105-00 METAL GLAZE 220K 5% 1/10W

R191 1-216-695-11 METAL CHIP 68K 0.5% 1/10W

R192 1-216-001-00 METAL CHIP 10 5% 1/10W

R193 1-216-001-00 METAL CHIP 10 5% 1/10W

R195 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R196 1-216-073-00 METAL CHIP 10K 5% 1/10W

R197 1-216-073-00 METAL CHIP 10K 5% 1/10W

R301 1-216-623-11 METAL CHIP 68 0.5% 1/10W

R312 1-216-073-00 METAL CHIP 10K 5% 1/10W

R351 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R352 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R353 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R354 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R355 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R356 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R357 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R358 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R359 1-216-089-00 METAL GLAZE 47K 5% 1/10W

R360 1-216-647-11 METAL CHIP 680 0.5% 1/10W

R361 1-216-615-11 METAL CHIP 33 0.5% 1/10W

R362 1-216-295-00 CONDUCTOR, CHIP (2012)

R364 1-216-017-00 METAL GLAZE 47 5% 1/10W

R365 1-216-017-00 METAL GLAZE 47 5% 1/10W

R366 1-216-073-00 METAL CHIP 10K 5% 1/10W

R367 1-216-017-00 METAL GLAZE 47 5% 1/10W

R371 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R372 1-216-073-00 METAL CHIP 10K 5% 1/10W

< SWITCH >

S153 1-762-930-11 SWITCH, LEVER (LOAD OUT)

R151 1-216-073-00 METAL CHIP 10K 5% 1/10W

R152 1-216-073-00 METAL CHIP 10K 5% 1/10W

– 67 –

BD BD TRANSLATION BSL DISPLAY HP

Ref. No. Part No. Description Remark

< VIBRATOR >

X351 1-577-358-21 VIBRATOR, CERAMIC (4MHz)

************************************************************

* 1-663-580-11 BD TRANSLATION BOARD

*********************

< CONNECTOR >

* CN108 1-568-933-11 SOCKET, CONNECTOR 30P

CN109 1-774-380-11 CONNECTOR, FFC/FPC 16P

CN110 1-580-864-11 SOCKET, CONNECTOR (SMT) 10P

< SWITCH >

SW102 1-571-958-11 SWITCH, PUSH (1 KEY) (LIMIT SW)

************************************************************

A-4699-360-A BSL BOARD, COMPLETE

********************

1-580-881-11 SOCKET, CONNECTOR (SMT) 10P

< DIODE >

H11 8-719-987-62 DIODE LT140SAZ

H12 8-719-987-62 DIODE LT140SAZ

< RESISTOR >

R01 1-216-295-00 CONDUCTOR, CHIP (2012)

R02 1-216-295-00 CONDUCTOR, CHIP (2012)

R11 1-216-049-00 METAL GLAZE 1K 5% 1/10W

R12 1-216-049-00 METAL GLAZE 1K 5% 1/10W

************************************************************

Ref. No. Part No. Description Remark

< TRANSISTOR >

Q804 8-729-424-18 TRANSISTOR UN2113-TX

Q805 8-729-421-19 TRANSISTOR UN2213

< RESISTOR >

R817 1-216-045-00 METAL CHIP 680 5% 1/10W

R827 1-216-029-00 METAL CHIP 150 5% 1/10W

R828 1-216-089-00 METAL GLAZE 47K 5% 1/10W

R829 1-216-097-00 METAL GLAZE 100K 5% 1/10W

< SWITCH >

S819 1-554-303-21 SWITCH, TACTILE (P MODE)

S820 1-554-303-21 SWITCH, TACTILE (TIME)

************************************************************

* A-4699-566-A HP BOARD, COMPLETE (BLACK)

* A-4699-710-A HP BOARD, COMPLETE (GOLD)

**************************

< CAPACITOR >

C365 1-126-012-11 ELECT 470uF 20% 16V

C366 1-126-012-11 ELECT 470uF 20% 16V

C405 1-164-159-11 CERAMIC 0.1uF 50V

C550 1-162-294-31 CERAMIC 0.001uF 10% 50V

C650 1-162-294-31 CERAMIC 0.001uF 10% 50V

< CONNECTOR >

CN402 1-564-523-11 PLUG, CONNECTOR 8P

CN407 1-564-524-11 PLUG, CONNECTOR 9P

< IC >

* A-4699-353-A DISPLAY BOARD, COMPLETE

************************

* 4-969-510-01 HOLDER (FL)

< CAPACITOR >

C801 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C802 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C803 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C804 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C805 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C806 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C807 1-163-031-11 CERAMIC CHIP 0.01uF 50V

< CONNECTOR >

CN810 1-568-853-11 SOCKET, CONNECTOR 10P

< FLUORECENT INDICATOR >

FLD801 1-517-357-11 INDICATOR TUBE, FLUORESCENT

< IC >

IC801 8-759-324-36 IC LC7570E

IC802 8-759-324-36 IC LC7570E

IC803 8-759-324-36 IC LC7570E

IC804 8-759-373-48 IC NJL53H400

IC354 8-759-962-08 IC BA6208

IC356 8-759-981-85 IC RC4556D

< JACK >

J401 1-750-162-61 JACK (LARGE TYPE) (PHONES) (BLACK)

J401 1-779-219-11 JACK (LARGE TYPE) (PHONES) (GOLD)

< COIL >

L310 1-412-473-21 INDUCTOR 0uH

L311 1-412-473-21 INDUCTOR 0uH

L503 1-412-473-21 INDUCTOR 0uH

L603 1-412-473-21 INDUCTOR 0uH

< TRANSISTOR >

Q504 8-729-141-30 TRANSISTOR 2SC3623A-LK

Q604 8-729-141-30 TRANSISTOR 2SC3623A-LK

< RESISTOR >

R369 1-247-807-31 CARBON 100 5% 1/4W

R370 1-247-807-31 CARBON 100 5% 1/4W

R532 1-249-441-11 CARBON 100K 5% 1/4W

R533 1-247-890-11 CARBON 300K 5% 1/4W

R534 1-249-441-11 CARBON 100K 5% 1/4W

R535 1-247-890-11 CARBON 300K 5% 1/4W

R536 1-249-402-11 CARBON 56 5% 1/4W

R537 1-249-425-11 CARBON 4.7K 5% 1/4W

R632 1-249-441-11 CARBON 100K 5% 1/4W

R633 1-247-890-11 CARBON 300K 5% 1/4W

– 68 –

MAINLOADING SWLOADING MOTORHP

Ref. No. Part No. Description Remark

R634 1-249-441-11 CARBON 100K 5% 1/4W

R635 1-247-890-11 CARBON 300K 5% 1/4W

R636 1-249-402-11 CARBON 56 5% 1/4W

R637 1-249-425-11 CARBON 4.7K 5% 1/4W

< VARIABLE RESISTOR >

VR405 1-223-747-11 RES, VAR, CARBON 10K/10K

(LINE OUT PHONE LEVEL)

************************************************************

* 1-663-579-11 LOADING MOTOR BOARD

*********************

< CAPACITOR >

C181 1-126-023-11 ELECT 100uF 20% 25V

C182 1-126-023-11 ELECT 100uF 20% 25V

C183 1-164-699-11 CERAMIC CHIP 0.0033uF 5% 50V

C184 1-126-059-11 ELECT 10uF 20% 50V

C185 1-163-038-00 CERAMIC CHIP 0.1uF 25V

< IC >

IC181 8-759-202-01 IC TA7256P

IC182 8-759-100-96 IC uPC4558G2

< RESISTOR >

Ref. No. Part No. Description Remark

C266 1-136-850-11 FILM 0.1uF 5% 63V

C271 1-124-994-11 ELECT 100uF 20% 10V

C272 1-164-159-11 CERAMIC 0.1uF 50V

C274 1-164-159-11 CERAMIC 0.1uF 50V

C301 1-164-159-11 CERAMIC 0.1uF 50V

C306 1-162-208-31 CERAMIC 24PF 5% 50V

C307 1-164-159-11 CERAMIC 0.1uF 50V

C310 1-164-159-11 CERAMIC 0.1uF 50V

C320 1-128-200-11 ELECT 47uF 20% 63V

C321 1-128-202-11 ELECT 220uF 20% 63V

C322 1-117-775-11 FILM 0.1uF 10% 250V

C323 1-102-947-00 CERAMIC 10PF 5% 50V

C324 1-102-947-00 CERAMIC 10PF 5% 50V

C358 1-164-159-11 CERAMIC 0.1uF 50V

C359 1-126-012-11 ELECT 470uF 20% 16V

C360 1-124-686-71 ELECT 220uF 20% 16V

C362 1-117-914-51 ELECT 330uF 20% 25V

C363 1-117-914-51 ELECT 330uF 20% 25V

C364 1-124-686-71 ELECT 220uF 20% 16V

C370 1-164-159-11 CERAMIC 0.1uF 50V

C371 1-164-159-11 CERAMIC 0.1uF 50V

C501 1-136-850-11 FILM 0.1uF 5% 63V

C502 1-126-023-11 ELECT 100uF 20% 25V

C503 1-136-850-11 FILM 0.1uF 5% 63V

R001 1-216-073-00 METAL CHIP 10K 5% 1/10W

R002 1-216-073-00 METAL CHIP 10K 5% 1/10W

R003 1-216-073-00 METAL CHIP 10K 5% 1/10W

R004 1-216-073-00 METAL CHIP 10K 5% 1/10W

R005 1-216-051-00 METAL CHIP 1.2K 5% 1/10W

R006 1-216-047-00 METAL GLAZE 820 5% 1/10W

R007 1-216-025-00 METAL GLAZE 100 5% 1/10W

R008 1-216-045-00 METAL CHIP 680 5% 1/10W

¡ R009 1-249-474-11 CARBON 1 5% 1/2W F

R010 1-216-001-00 METAL CHIP 10 5% 1/10W

************************************************************

* 1-663-581-11 LOADING SW BOARD

*****************

< SWITCH >

S152 1-762-424-11 SWITCH, MICRO (LOADING SW)

************************************************************

* A-4699-567-A MAIN BOARD, COMPLETE

*********************

< CAPACITOR >

C259 1-161-494-00 CERAMIC 0.022uF 25V

C260 1-162-215-31 CERAMIC 47PF 5% 50V

C261 1-136-850-11 FILM 0.1uF 5% 63V

C262 1-136-850-11 FILM 0.1uF 5% 63V

C263 1-136-850-11 FILM 0.1uF 5% 63V

C264 1-136-850-11 FILM 0.1uF 5% 63V

C504 1-128-198-11 ELECT 22uF 20% 50V

C505 1-136-850-11 FILM 0.1uF 5% 63V

C510 1-128-200-11 ELECT 47uF 20% 63V

C512 1-130-892-00 FILM 0.015uF 5% 63V

C516 1-136-850-11 FILM 0.1uF 5% 63V

C517 1-136-850-11 FILM 0.1uF 5% 63V

C518 1-128-200-11 ELECT 47uF 20% 63V

C519 1-128-198-51 ELECT 22uF 20% 63V

C520 1-128-200-11 ELECT 47uF 20% 63V

C521 1-130-973-00 FILM 0.022uF 5% 100V

C522 1-130-955-00 FILM 0.01uF 5% 100V

C523 1-130-955-00 FILM 0.01uF 5% 100V

C524 1-130-339-11 FILM 0.0056uF 5% 100V

C525 1-130-339-11 FILM 0.0056uF 5% 100V

C526 1-136-814-11 FILM 0.001uF 5% 100V

C527 1-136-814-11 FILM 0.001uF 5% 100V

C530 1-136-817-11 FILM 0.0033uF 2% 100V

C531 1-136-813-11 FILM 680PF 5% 100V

C532 1-128-201-11 ELECT 100uF 20% 50V

C533 1-137-506-11 FILM 0.47uF 10% 63V

C535 1-136-802-11 FILM 0.015uF 5% 100V

C536 1-128-198-51 ELECT 22uF 20% 63V

C537 1-128-201-11 ELECT 100uF 20% 50V

C601 1-136-850-11 FILM 0.1uF 5% 63V

C602 1-126-023-11 ELECT 100uF 20% 25V

C603 1-136-850-11 FILM 0.1uF 5% 63V

C604 1-128-198-11 ELECT 22uF 20% 50V

C605 1-136-850-11 FILM 0.1uF 5% 63V

C610 1-128-200-11 ELECT 47uF 20% 63V

– 69 –

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

MAIN

Ref. No. Part No. Description Remark

C612 1-136-802-11 FILM 0.015uF 5% 100V

C615 1-130-973-00 FILM 0.022uF 5% 100V

C616 1-136-850-11 FILM 0.1uF 5% 63V

C617 1-136-850-11 FILM 0.1uF 5% 63V

C618 1-136-850-11 FILM 0.1uF 5% 63V

C619 1-128-198-11 ELECT 22uF 20% 50V

C620 1-128-198-11 ELECT 22uF 20% 50V

C621 1-130-973-00 FILM 0.022uF 5% 100V

C622 1-130-955-00 FILM 0.01uF 5% 100V

C623 1-130-955-00 FILM 0.01uF 5% 100V

C624 1-130-339-11 FILM 0.0056uF 5% 100V

C625 1-130-339-11 FILM 0.0056uF 5% 100V

C626 1-136-814-11 FILM 0.001uF 5% 100V

C627 1-136-814-11 FILM 0.001uF 5% 100V

C630 1-136-817-11 FILM 0.0033uF 2% 100V

C631 1-136-813-11 FILM 680PF 5% 100V

C632 1-128-201-11 ELECT 100uF 20% 50V

C633 1-137-506-11 FILM 0.47uF 10% 63V

C635 1-136-802-11 FILM 0.015uF 5% 100V

C636 1-128-198-51 ELECT 22uF 20% 63V

C637 1-128-201-11 ELECT 100uF 20% 50V

< CONNECTOR >

CN201 1-564-506-11 PLUG, CONNECTOR 3P

* CN301 1-568-835-11 SOCKET, CONNECTOR 16P

CN302 1-564-511-11 PLUG, CONNECTOR 8P

* CN303 1-564-509-11 PLUG, CONNECTOR 6P

CN304 1-564-509-11 PLUG, CONNECTOR 6P

CN305 1-564-506-11 PLUG, CONNECTOR 3P

< DIODE >

D220 8-719-210-21 DIODE 11EQS04

D221 8-719-210-21 DIODE 11EQS04

D261 8-719-987-31 DIODE 1N4148M

D262 8-719-987-31 DIODE 1N4148M

D263 8-719-987-31 DIODE 1N4148M

D264 8-719-987-31 DIODE 1N4148M

D301 8-719-987-63 DIODE 1N4148M

D302 8-719-109-98 DIODE RD6.8ES-B3

D303 8-719-987-63 DIODE 1N4148M

< IC >

IC208 8-749-921-12 IC GP1F32T (DIGITAL OUT OPTICAL)

IC211 8-759-604-86 IC M5F7807L

IC212 8-759-604-90 IC M5F7907L

IC213 8-759-231-53 IC TA7805S

IC251 8-759-242-70 IC TC7WU04F

IC301 8-759-462-70 IC CXD8679Q

IC302 8-759-454-42 IC CXD2562Q-CS

IC303 8-759-180-84 IC TC7W74F

IC501 8-759-371-51 IC CXA8042AS

IC502 8-759-443-33 IC OPA2132PA

Ref. No. Part No. Description Remark

IC503 8-759-259-12 IC OPA2604AP

IC601 8-759-371-51 IC CXA8042AS

IC602 8-759-443-33 IC OPA2132PA

IC603 8-759-259-12 IC OPA2604AP

< JACK >

J301 1-569-443-21 JACK, PIN 4P (LINE OUT)

J351 1-770-905-21 JACK, PIN 1P (DIGITAL OUT COAXIAL)

< COIL >

L251 1-410-322-11 INDUCTOR 3.3uH

L252 1-410-322-11 INDUCTOR 3.3uH

L302 1-410-503-11 INDUCTOR 3.3uH

L303 1-410-322-11 INDUCTOR 3.3uH

L304 1-410-970-11 INDUCTOR 6.8uH

L504 1-412-473-21 INDUCTOR 0uH

L505 1-412-473-21 INDUCTOR 0uH

L604 1-412-473-21 INDUCTOR 0uH

L605 1-412-473-21 INDUCTOR 0uH

< FILTER >

LPF201 1-424-153-11 FILTER, NOISE

LPF202 1-424-153-11 FILTER, NOISE

LPF301 1-424-153-11 FILTER, NOISE

< TRANSISTOR >

Q301 8-729-900-65 TRANSISTOR DTA144ES

< RESISTOR >

R254 1-249-393-11 CARBON 10 5% 1/4W

R255 1-249-417-11 CARBON 1K 5% 1/4W

R256 1-249-401-11 CARBON 47 5% 1/4W

R257 1-249-393-11 CARBON 10 5% 1/4W

R258 1-249-417-11 CARBON 1K 5% 1/4W

R259 1-249-417-11 CARBON 1K 5% 1/4W

R260 1-249-417-11 CARBON 1K 5% 1/4W

R262 1-249-401-11 CARBON 47 5% 1/4W

R263 1-249-393-11 CARBON 10 5% 1/4W

R301 1-249-437-11 CARBON 47K 5% 1/4W

R302 1-249-417-11 CARBON 1K 5% 1/4W

R303 1-249-417-11 CARBON 1K 5% 1/4W

R306 1-249-409-11 CARBON 220 5% 1/4W

R307 1-249-417-11 CARBON 1K 5% 1/4W

R310 1-249-441-11 CARBON 100K 5% 1/4W

R311 1-249-417-11 CARBON 1K 5% 1/4W

R312 1-249-417-11 CARBON 1K 5% 1/4W

R313 1-249-411-11 CARBON 330 5% 1/4W

R314 1-249-417-11 CARBON 1K 5% 1/4W

R315 1-249-411-11 CARBON 330 5% 1/4W

R316 1-249-441-11 CARBON 100K 5% 1/4W

R317 1-249-409-11 CARBON 220 5% 1/4W

R321 1-249-429-11 CARBON 10K 5% 1/4W

¡ R351 1-217-997-11 FUSIBLE 10 5% 1/2W F

– 70 –

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

MAIN PANEL

Ref. No. Part No. Description Remark

R501 1-259-380-11 CARBON 10 5% 1/6W

R502 1-259-380-11 CARBON 10 5% 1/6W

R503 1-259-380-11 CARBON 10 5% 1/6W

R504 1-259-380-11 CARBON 10 5% 1/6W

R505 1-249-455-11 CARBON 4.7 5% 1/4W

R506 1-249-520-11 CARBON 47 5% 1/4W

R508 1-249-911-11 CARBON 330 1% 1/4W

R509 1-249-911-11 CARBON 330 1% 1/4W

R510 1-249-887-11 CARBON 33 1% 1/4W

R511 1-249-887-11 CARBON 33 1% 1/4W

R512 1-249-931-11 CARBON 2.2K 1% 1/4W

R513 1-249-931-11 CARBON 2.2K 1% 1/4W

R514 1-249-933-11 CARBON 2.7K 1% 1/4W

R515 1-249-933-11 CARBON 2.7K 1% 1/4W

R516 1-249-553-11 CARBON 1.1K 5% 1/4W

R517 1-249-560-00 CARBON 2.2K 5% 1/4W

R519 1-249-528-00 CARBON 100 5% 1/4W

R520 1-249-606-11 CARBON 180K 5% 1/4W

R523 1-247-891-00 CARBON 330K 5% 1/4W

R539 1-259-416-11 CARBON 330 5% 1/6W

R540 1-259-416-11 CARBON 330 5% 1/6W

R541 1-259-416-11 CARBON 330 5% 1/6W

R542 1-259-416-11 CARBON 330 5% 1/6W

R543 1-249-504-11 CARBON 10 5% 1/4W

R550 1-249-917-11 CARBON 560 1% 1/4W

R551 1-249-560-00 CARBON 2.2K 5% 1/4W

R601 1-259-380-11 CARBON 10 5% 1/6W

R602 1-259-380-11 CARBON 10 5% 1/6W

R603 1-259-380-11 CARBON 10 5% 1/6W

R604 1-259-380-11 CARBON 10 5% 1/6W

R605 1-249-455-11 CARBON 4.7 5% 1/4W

R606 1-249-520-11 CARBON 47 5% 1/4W

R608 1-249-911-11 CARBON 330 1% 1/4W

R609 1-249-911-11 CARBON 330 1% 1/4W

R610 1-249-887-11 CARBON 33 1% 1/4W

R611 1-249-887-11 CARBON 33 1% 1/4W

R612 1-249-931-11 CARBON 2.2K 1% 1/4W

R613 1-249-931-11 CARBON 2.2K 1% 1/4W

R614 1-249-933-11 CARBON 2.7K 1% 1/4W

R615 1-249-933-11 CARBON 2.7K 1% 1/4W

R616 1-249-553-11 CARBON 1.1K 5% 1/4W

R617 1-249-560-00 CARBON 2.2K 5% 1/4W

R619 1-249-528-00 CARBON 100 5% 1/4W

R620 1-249-606-11 CARBON 180K 5% 1/4W

R623 1-247-891-00 CARBON 330K 5% 1/4W

R639 1-259-416-11 CARBON 330 5% 1/6W

Ref. No. Part No. Description Remark

< TRANSFORMER >

T201 1-409-594-11 COIL (WITH CORE)

< VIBRATOR >

X321 1-579-161-11 VIBRATOR, CRYSTAL (45MHz)

************************************************************

* A-4699-354-A PANEL BOARD, COMPLETE

**********************

< CONNECTOR >

* CN817 1-568-852-11 SOCKET, CONNECTOR 9P

< DIODE >

D801 8-719-303-02 DIODE SEL2510C-D (()

D802 8-719-301-52 DIODE SEL2810A-C (P)

D803 8-719-046-41 DIODE SEL5521C-TP15 (FILTER)

< TRANSISTOR >

Q801 8-729-900-80 TRANSISTOR DTC114ES

Q802 8-729-900-80 TRANSISTOR DTC114ES

Q803 8-729-900-80 TRANSISTOR DTC114ES

< RESISTOR >

R801 1-249-415-11 CARBON 680 5% 1/4W

R802 1-249-417-11 CARBON 1K 5% 1/4W

R803 1-249-419-11 CARBON 1.5K 5% 1/4W

R804 1-249-421-11 CARBON 2.2K 5% 1/4W

R805 1-247-843-11 CARBON 3.3K 5% 1/4W

R806 1-249-427-11 CARBON 6.8K 5% 1/4W

R811 1-249-415-11 CARBON 680 5% 1/4W

R812 1-249-417-11 CARBON 1K 5% 1/4W

R813 1-249-419-11 CARBON 1.5K 5% 1/4W

R814 1-249-421-11 CARBON 2.2K 5% 1/4W

R815 1-247-843-11 CARBON 3.3K 5% 1/4W

R816 1-249-427-11 CARBON 6.8K 5% 1/4W

R821 1-249-410-11 CARBON 270 5% 1/4W

R822 1-249-406-11 CARBON 120 5% 1/4W

R823 1-249-410-11 CARBON 270 5% 1/4W

R831 1-249-429-11 CARBON 10K 5% 1/4W

R832 1-249-429-11 CARBON 10K 5% 1/4W

< VARIABLE RESISTOR >

RV801 1-475-006-11 ENCODER, ROTARY

(AMS/≠± PUSH ENTER)

R640 1-259-416-11 CARBON 330 5% 1/6W

R641 1-259-416-11 CARBON 330 5% 1/6W

R642 1-259-416-11 CARBON 330 5% 1/6W

R643 1-249-504-11 CARBON 10 5% 1/4W

R650 1-249-917-11 CARBON 560 1% 1/4W

R651 1-249-560-00 CARBON 2.2K 5% 1/4W

< RELAY >

RY301 1-515-804-11 RELAY

< SWITCH >

S801 1-554-303-21 SWITCH, TACTILE (ERASE)

S802 1-554-303-21 SWITCH, TACTILE (CHECK)

S803 1-554-303-21 SWITCH, TACTILE (CLEAR)

S804 1-554-303-21 SWITCH, TACTILE (FILTER)

S805 1-554-303-21 SWITCH, TACTILE (0)

S806 1-554-303-21 SWITCH, TACTILE ())

S811 1-554-303-21 SWITCH, TACTILE (EDIT/TIME FADE)

S812 1-554-303-21 SWITCH, TACTILE (REPEAT)

S813 1-554-303-21 SWITCH, TACTILE (FILE)

S814 1-554-303-21 SWITCH, TACTILE (§ OPEN/CLOSE)

– 71 –

PANEL

POWER POWER SW

Ref. No. Part No. Description Remark

S815 1-554-303-21 SWITCH, TACTILE (()

S816 1-554-303-21 SWITCH, TACTILE (P)

S817 1-554-303-21 SWITCH, TACTILE (p)

************************************************************

* A-4699-712-A POWER BOARD, COMPLETE

***********************

* 4-962-201-01 PLATE (HP), GROUND

7-685-871-01 SCREW +BVTT 3X6 (S)

< CAPACITOR >

C201 1-110-578-11 ELECT 3300uF 20% 25V

C202 1-110-578-11 ELECT 3300uF 20% 25V

C203 1-128-091-11 ELECT 1000uF 20% 50V

C204 1-128-091-11 ELECT 1000uF 20% 50V

C207 1-124-556-11 ELECT 2200uF 20% 16V

C209 1-124-563-11 ELECT 2200uF 20% 25V

C210 1-162-294-31 CERAMIC 0.001uF 10% 50V

C211 1-126-162-11 ELECT 3.3uF 20% 50V

C213 1-162-294-31 CERAMIC 0.001uF 10% 50V

C215 1-126-059-11 ELECT 10uF 20% 50V

C216 1-126-017-11 ELECT 6800uF 20% 16V

C217 1-126-017-11 ELECT 6800uF 20% 16V

C218 1-124-556-11 ELECT 2200uF 20% 16V

C219 1-124-556-11 ELECT 2200uF 20% 16V

C220 1-164-159-11 CERAMIC 0.1uF 50V

Ref. No. Part No. Description Remark

D212 8-719-210-21 DIODE 11EQS04

D213 8-719-987-63 DIODE 1N4148M

D214 8-719-987-63 DIODE 1N4148M