Page 1

MODIFICATION

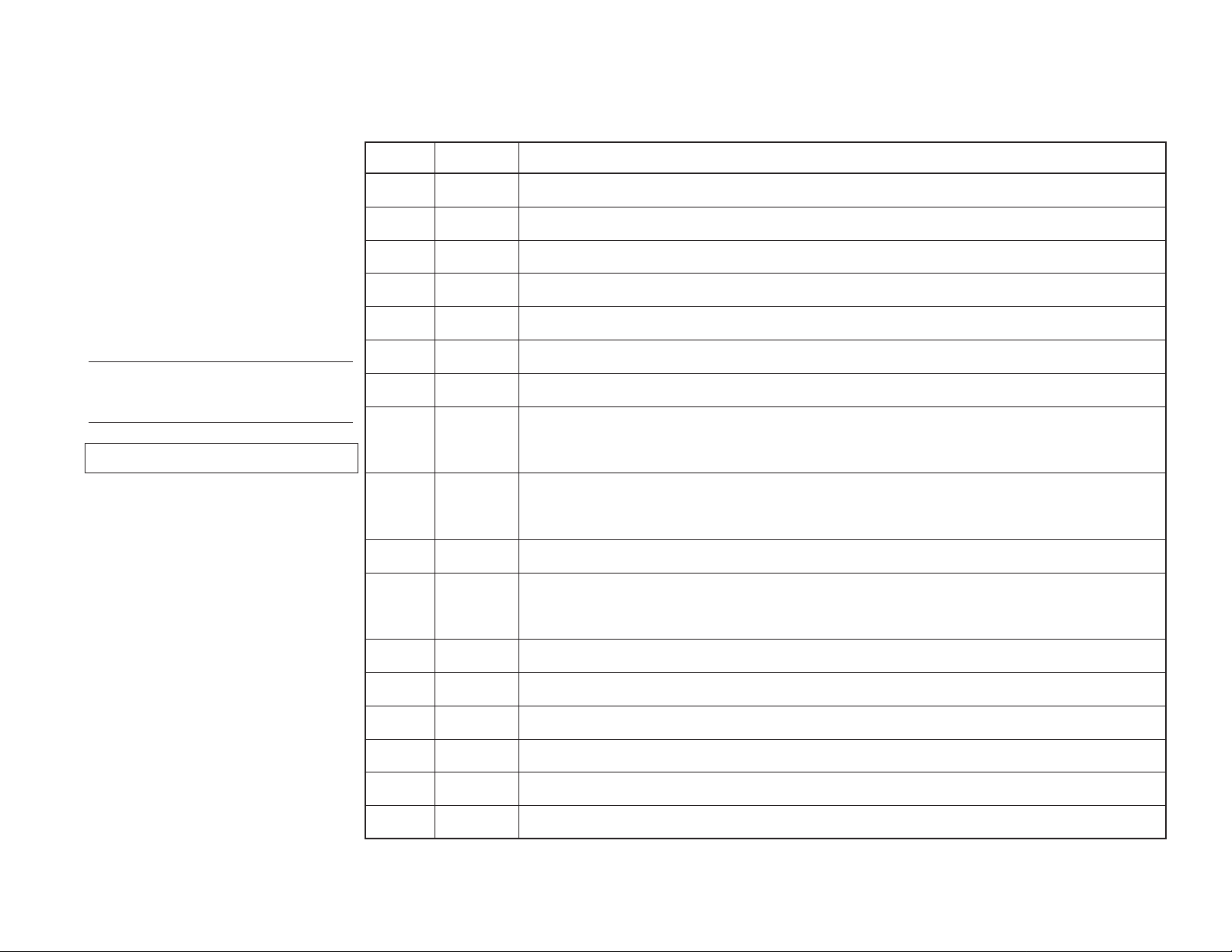

# No. DATA CONTENTS

#1 2000.2 Adds omitted parts numbers. (P.7-2, 7-3, 7-4, 7-5, 7-6, 7-7, 7-8)

HISTORY

MODEL NAME :

CPD-E100/E100E/E100P

SERVICE MANUAL

PARTS No. : 9-978-659-04

* Blue characters are linking.

#2 2000.2 Alteration of parts supply, as the service division had changed. (P.6-1)

#3 2000.3 Parts number clerical error correction of MANUAL, INSTRUCTION (AEP). (P.6-2)

#4 2000.3 Decide on part nunmber (IC901 on D board). (P.7-5)

#5 2000.3 Parts number clerical error correction (C625 on D board). (P.7-4)

#6 2000.5 Add omitted part (LABEL, INFORMATION). (P.6-1)

#7 2000.11 Parts number clerical error correction (Q517 on D board). (P.7-6)

#8 2000.11 Because of sets for NH was added, two parts were added to the Exploded Views.

(P.6-1, 6-2)

#9 2000.12 Correction and modification due to addition of model name. (CPD-E100P)

(P.6-1, 6-2)

#10 2001.6 Addition of Schematic Diagram of D Board for CPD-E100P. (P.5-17)

#11 2001.6 Format of electrical parts list was renewed. New correction is included as well as

previous correction.

Page 2

CPD-E100/E100E/E100P

* Recommended horizontal and vertical timing condition

• Horizontal sync width should be more than 1.0 µsec.

• Horizontal blanking width should be more than 3.6

µsec.

• Vertical blanking width should be more than 500 µsec.

Design and specifications are subject to change without

notice.

SERVICE MANUAL

CPD-E100

US Model

Canadian Model

EQ Model

S.Hemisphere Model

N.Hemisphere Model

Chassis No. SCC-L27J-A

CPD-E100E

AEP Model

Chassis No. SCC-L27L-A

CPD-E100P

AEP Model

Chassis No. SCC-L27G-A

CRT 0.24 mm aperture grille pitch

(center)

15 inches measured diagonally

90-degree deflection

Viewable image size Approx. 285 × 214 mm (w/h)

Resolution

Maximum Horizontal: 1280 dots

Recommended Horizontal: 800 dots

Standard image area Approx. 270 × 202 mm (w/h)

Deflection frequency* Horizontal: 30 to 70 kHz

AC input voltage/current 100 to 240 V, 50 – 60 Hz, 1.2 –

Power consumption Max. 95 W

Dimensions

Mass Approx. 14 kg (30 lb 14 oz)

Plug and Play DDC1/DDC2B

Supplied accessories Power cord (1)

1

/4 × 8 1/2 inches)

(11

14.0" viewing image

Vertical: 1024 lines

Vertical: 600 lines

3

/4 × 8 inches)

(10

Vertical: 48 to 120 Hz

0.6 A

Approx. 356 × 378 × 388 mm

(14 1/8 × 15 × 15 3/8

(w/h/d)

inches)

Windows Monitor Information

Disk (1)

Warranty card (1)

Notes on cleaning the screen’s

surface (1)

This instruction manual (1)

SPECIFICATIONS

X11R

CHASSIS

TRINITRON® COLOR COMPUTER DISPLAY

Page 3

CPD-E100/E100E/E100P

DIAGNOSIS

Failure Power LED

HV or +B Failure or H Stop Blink Amber (On 0.5 sec, Off 0.5 sec)

V Stop Blink Amber (On 1.5 sec, Off 0.5 sec)

ABL Failure Blink Amber (On 0.5 sec, Off 1.5 sec)

Aging/Self-Test Blink Amber (On 0.5 sec, Off 0.5 sec) .... Blink Green (On 0.5 sec, Off 0.5 sec)

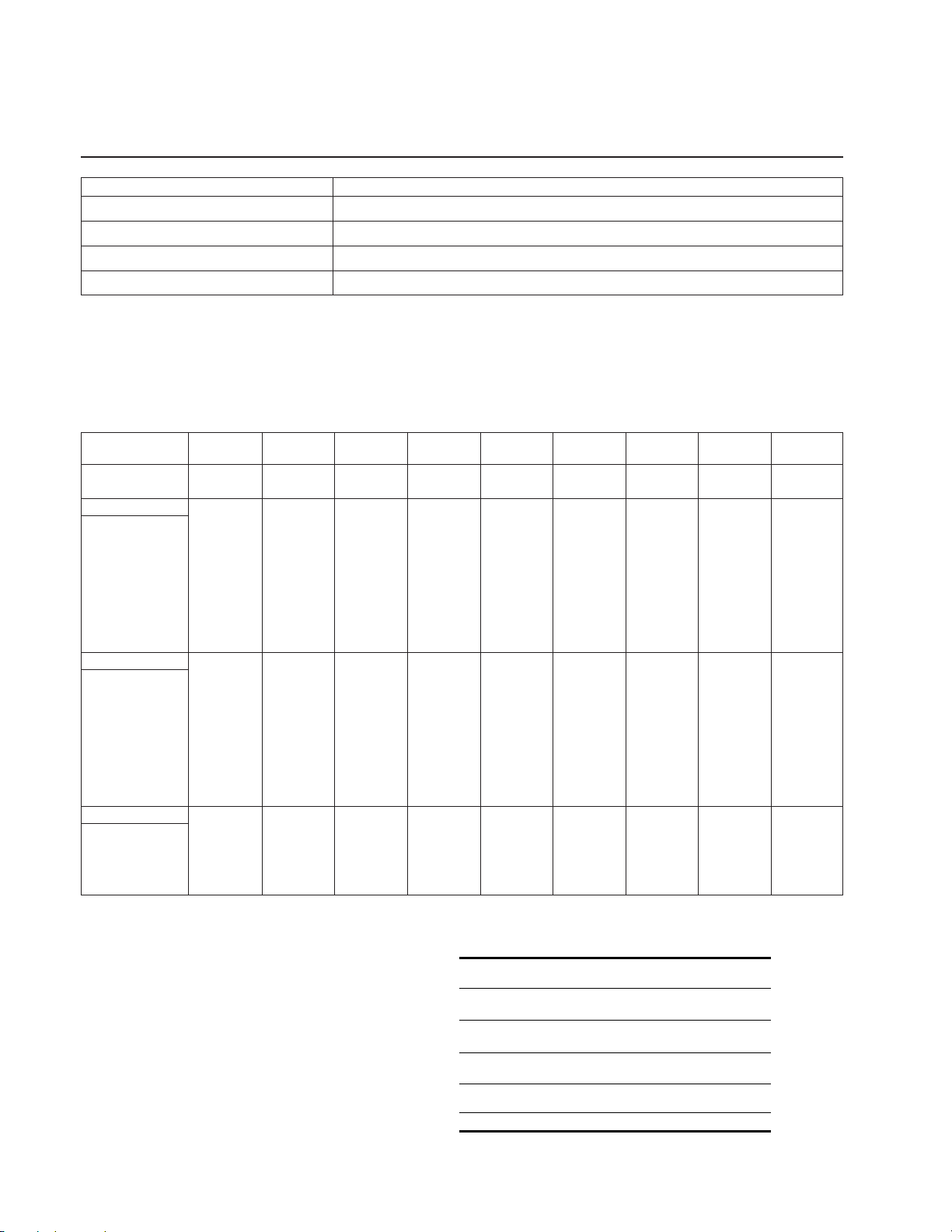

TIMING SPECIFICATION

PRIMARY MODE

MODE AT PRODUCTION

RESOLUTION 640 X 480 640 X 480 720 X 400 800 X 600 800 X 600 832 X 624 1024 X 768 1024 X 768 1280 X 1024

CLOCK 25.175 MHz 36.000 MHz 28.322 MHz 49.500 MHz 56.250 MHz 57.283 MHz 78.750 MHz 94.500 MHz 108.000 MHz

— HORIZONTAL —

H-FREQ 31.469 kHz 43.269 kHz 31.469 kHz 46.875 kHz 53.674 kHz 49.725 kHz 60.024 kHz 68.677 kHz 63.981 kHz

H. TOTAL 31.778 23.111 31.777 21.333 18.631 20.111 16.660 14.561 15.630

H. BLK 6.356 5.333 6.355 5.172 4.409 5.586 3.657 3.725 3.778

H. FP 0.636 1.556 0.636 0.323 0.569 0.559 0.203 0.508 0.444

H. SYNC 3.813 1.556 3.813 1.616 1.138 1.117 1.219 1.016 1.037

H. BP 1.907 2.222 1.907 3.232 2.702 3.910 2.235 2.201 2.296

H. ACTIV 25.422 17.778 25.422 16.162 14.222 14.524 13.003 10.836 11.852

— VERTICAL —

V. FREQ(HZ) 59.940 Hz 85.008 Hz 70.087 Hz 75.000 Hz 85.061 Hz 74.550 Hz 75.030 Hz 84.997 Hz 60.020 Hz

V. TOTAL 525 509 449 625 631 667 800 808 1066

V. BLK 45 29 49 25 31 43 32 40 42

V. FP 10112111111

V. SYNC 2 3 2 333333

V. BP 33 25 35 21 27 39 28 36 38

V. ACTIV 480 480 400 600 600 624 768 768 1024

— SYNC —

INT(G) NO NO NO NO NO NO NO NO NO

EXT(H/V)/POLARITY YES -/- YES -/- YES -/+ YES +/+ YES +/+ YES -/- YES +/+ YES +/+ YES +/+

EXT(CS)/POLARITY NO NO NO NO NO NO NO NO NO

INT/NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT

MODE 1 MODE 2 MODE 3 MODE 4 MODE 5 MODE 6 MODE 7 MODE 8 MODE 9

usec usec usec usec usec usec usec usec usec

lines lines lines lines lines lines lines lines lines

99.7.2 VER.

Power saving function

This monitor meets the power-saving guidelines set by

E

NERGY STAR, and NUTEK. If the monitor is

VESA,

connected to a computer or video graphics board that is

DPMS (Display Power Management Signaling) compliant,

the monitor will automatically reduce power consumption

in three stages as shown right.

* “Sleep” and “deep sleep” are power saving modes defined by the

Environmental Protection Agency.

**When your computer enters the “active off” mode, the input

signal is cut and NO INPUT SIGNAL appears on the screen.

After 20 seconds, the monitor enters the power saving mode.

Power mode Power

normal

consumption

≤ 95 W green

1 (power) indicator

operation

1 standby ≤ 15 W green and orange

alternate

2 supend

(sleep)*

3 active off**

≤ 15 W

≤ 5 W

green and orange

alternate

orange

(deep sleep)*

power off* 0 W off

– 2 –

Page 4

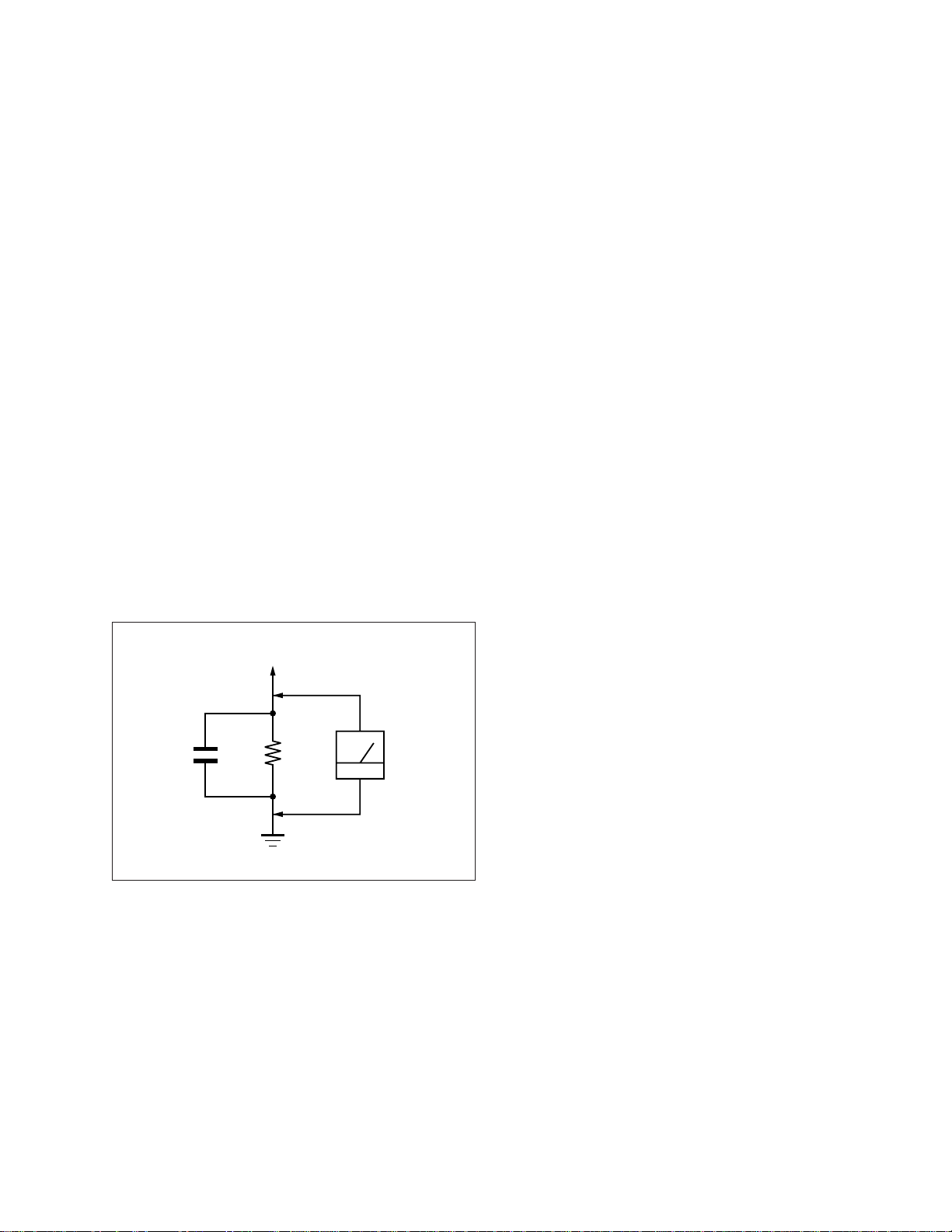

SAFETY CHECK-OUT

r

CPD-E100/E100E/E100P

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps,

and mounting hardware have been replaced. Be absolutely

certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer and

recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend

the replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specified values.

Make sure your instruments are accurate; be suspicious of

your HV meter if sets always have low HV.

8. Check the antenna terminals, metal trim, “metallized”

knobs, screws, and all other exposed metal parts for AC

Leakage. Check leakage as described below.

To Exposed Metal

Parts on Set

0.15 µF

1.5 k

Ω

AC

Voltmete

(0.75 V)

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having a return to chassis, must not exceed 0.5 mA (500

microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to

use these instruments.

2. A battery-operated AC milliammeter. The Data Precision

245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are

examples of a passive VOMs that are suitable. Nearly all

battery operated digital multimeters that have a 2 V AC

range are suitable. (See Fig. A)

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN

WHICH THE DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

¡ ON THE SCHEMATIC DIAGRAMS, EXPLODED

VIEWS AND IN THE PARTS LIST ARE CRITICAL FOR

SAFE OPERATION. REPLACE THESE COMPONENTS

WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE CRITICAL FOR SAFE OPERATION

ARE IDENTIFIED IN THIS MANUAL. FOLLOW THESE

PROCEDURES WHENEVER CRITICAL COMPONENTS

ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

AVERTISSEMENT!!

NE JAMAIS METTRE SOUS TENSION QUAND LA

BOBINE DE DEMAGNETISATION EST ENLEVÉE.

ATTENTION AUX COMPOSANTS RELATIFS À LA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE TRAME ET

UNE MARQUE

¡ SONT CRITIQUES POUR LA SÉCURITÉ.

NE LES REMPLACER QUE PAR UNE PIÈCE PORTANT LE

NUMÉRO SPECIFIÉ. LES RÉGLAGES DE CIRCUIT DONT

L’IMPORTANCE EST CRITIQUE POUR LA SÉCURITÉ DU

FONCTIONNEMENT SONT IDENTIFIÉS DANS LE

PRÉSENT MANUEL. SUIVRE CES PROCÉDURES LORS

DE CHAQUE REMPLACEMENT DE COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS FONCTIONNEMENT

EST SUSPECTÉ.

– 3 –

Page 5

CPD-E100/E100E/E100P

TABLE OF CONTENTS

Section Title Page

1. GENERAL .................................................................. 1-1

2. DISASSEMBLY

2-1. Cabinet Removal ................................................. 2-1

2-2. A and D Boards Removal ................................... 2-1

2-3. H Board Removal ................................................. 2-1

2-4. Picture Tube Removal .......................................... 2-2

2-5. Harnes Location ................................................... 2-3

3. SAFETY RELATED ADJUSTMENT............. 3-1

4. ADJUSTMENTS ...................................................... 4-1

5. DIAGRAMS

5-1. Block Diagrams ................................................... 5-1

5-2. Circuit Boards Location ...................................... 5-5

5-3. Schematic Diagrams and Printed Wiring Boards ...... 5-6

(1) Schematic Diagram of A Board ........................... 5-7

(2) Schematic Diagram of D Board .......................... 5-11

(3) Schematic Diagram of H Board .......................... 5-21

5-4. Semiconductors ................................................... 5-23

6. EXPLODED VIEWS

6-1. Chassis ................................................................. 6-1

6-2. Packing Materials ................................................ 6-2

7. ELECTRICAL PARTS LIST ............................ 7-1

– 4 –

Page 6

SECTION 1

The operating instructions mentioned here are partial abstracts

from the Operating Instruction Manual. The page numbers of

the Operating Instruction Manual remein as in the manual.

4

Precautions

Warning on power connections

• Use the supplied power cord. If you use a different power cord,

be sure that it is compatible with your local power supply.

For the customers in the U.S.A.

If you do not use the appropriate cord, this monitor will not

conform to mandatory FCC standards.

• Before disconnecting the power cord, wait at least 30 seconds

after turning off the power to allow the static electricity on the

screen’s surface to discharge.

• After the power is turned on, the screen is demagnetized

(degaussed) for about 5 seconds. This generates a strong

magnetic field around the screen which may affect data stored

on magnetic tapes and disks placed near the monitor. Be sure to

keep magnetic recording equipment, tapes, and disks away

from the monitor.

Installation

Do not install the monitor in the following places:

• on surfaces (rugs, blankets, etc.) or near materials (curtains,

draperies, etc.) that may block the ventilation holes

• near heat sources such as radiators or air ducts, or in a place

subject to direct sunlight

• in a place subject to severe temperature changes

• in a place subject to mechanical vibration or shock

• on an unstable surface

• near equipment which generates magnetism, such as a

transformer or high voltage power lines

• near or on an electrically charged metal surface

Maintenance

• Clean the screen with a soft cloth. If you use a glass cleaning

liquid, do not use any type of cleaner containing an anti-static

solution or similar additive as this may scratch the screen’s

coating.

• Do not rub, touch, or tap the surface of the screen with sharp or

abrasive items such as a ballpoint pen or screwdriver. This type

of contact may result in a scratched picture tube.

• Clean the cabinet, panel and controls with a soft cloth lightly

moistened with a mild detergent solution. Do not use any type

of abrasive pad, scouring powder or solvent, such as alcohol or

benzene.

Transportation

When you transport this monitor for repair or shipment, use the

original carton and packing materials.

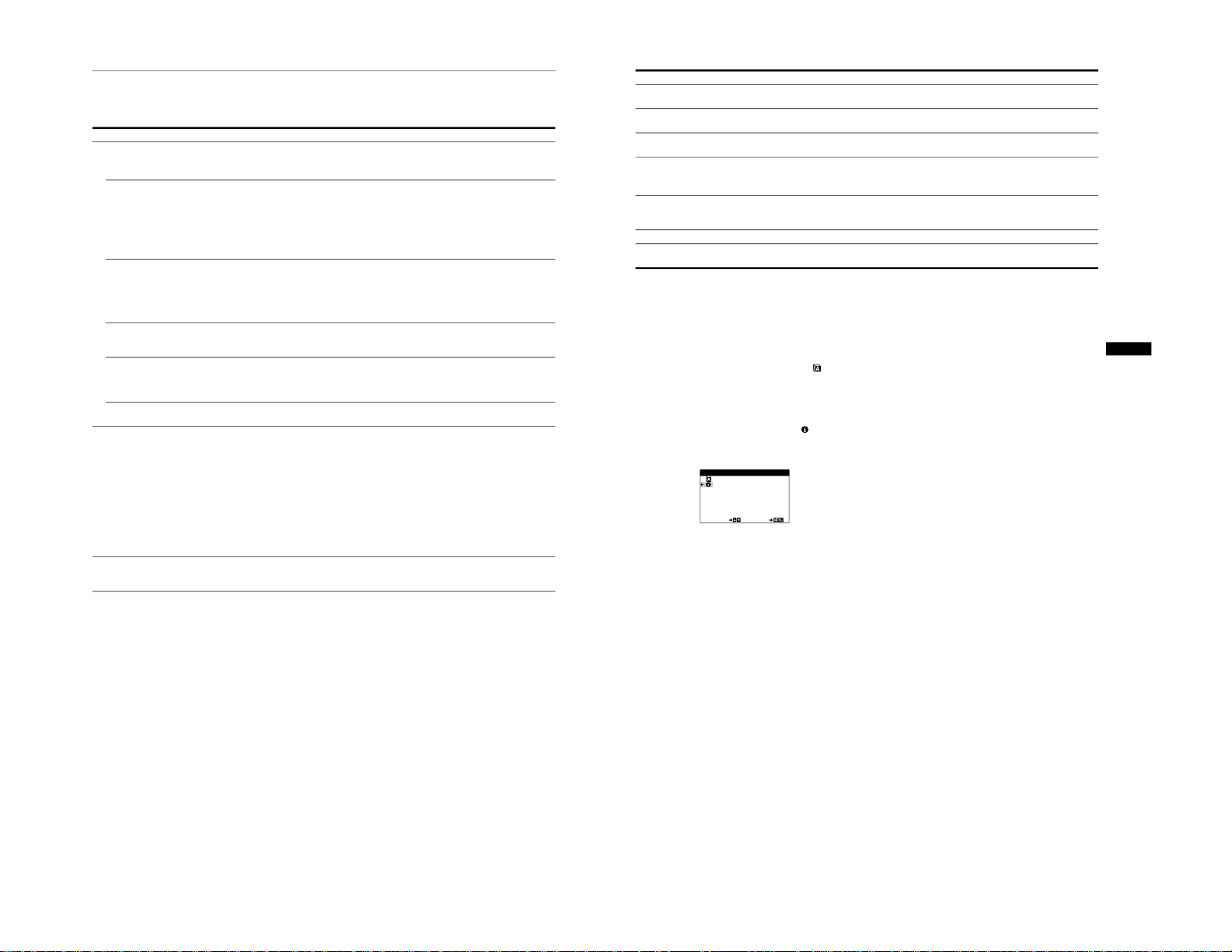

Use of the tilt-swivel

This monitor can be adjusted within the angles shown below. To

find the center of the monitor’s turning radius, align the center of

the monitor’s screen with the centering dots on the stand.

Hold the monitor at the bottom with both hands when you turn it

horizontally or vertically. Be careful not to pinch your fingers at

the back of the monitor when you tilt the monitor up vertically.

The equipment should be installed near an easily accessible

outlet.

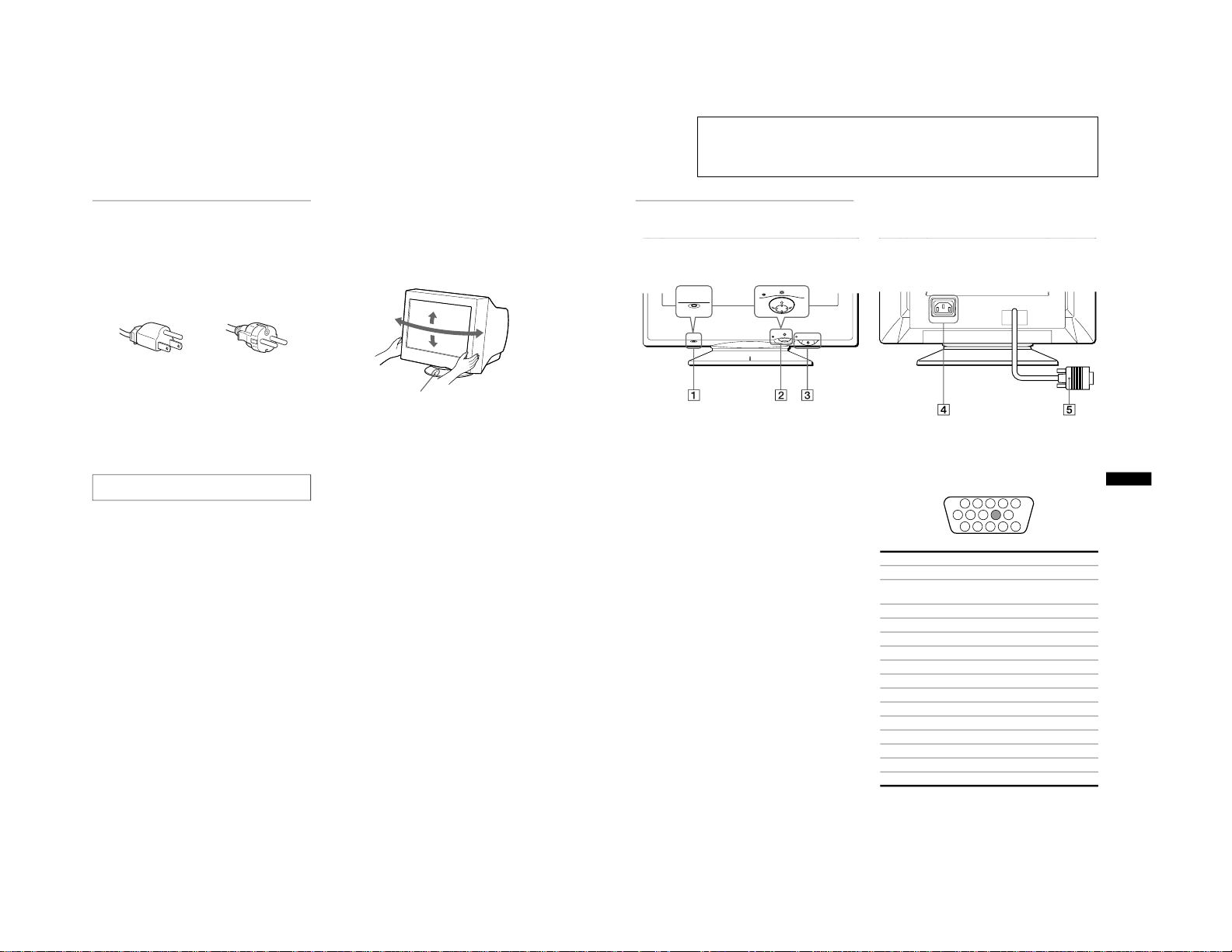

Example of plug types

for 100 to 120 V AC

for 200 to 240 V AC

90˚

5˚

90˚

15˚

Centering dots

5

US

Identifying parts and controls

See the pages in parentheses for further details.

1 RESET button (page 12)

This button resets the adjustments to the factory settings.

2 Control button (page 9)

The control button is used to display the menu and make

adjustments to the monitor, including brightness and contrast

adjustments.

3 1 (power) switch and indicator (pages 7, 13, 16)

This button turns the monitor on and off. The power indicator

lights up in green when the monitor is turned on, and either

flashes in green and orange, or lights up in orange when the

monitor is in power saving mode.

4 AC IN connector (page 6)

This connector provides AC power to the monitor.

5 Video input connector (HD15) (page 6)

This connector inputs RGB video signals (0.700 Vp-p,

positive) and sync signals.

* DDC (Display Data Channel) is a standard of VESA.

AC IN

MENU

RESET

MENU

RESET

RearFront

Pin No. Signal

1 Red

2 Green

(Sync on Green)

3 Blue

4 ID (Ground)

5 DDC Ground*

6 Red Ground

7 Green Ground

8 Blue Ground

9–

10 Ground

11 ID (Ground)

12 Bi-Directional Data (SDA)*

13 H. Sync

14 V. Sync

15 Data Clock (SCL)*

1 2

3 4

5

876

11 12 13 14

15

10

9

GENERAL

1-1

Page 7

6

Setup

Before using your monitor, check that the following accessories

are included in your carton:

• Power cord (1)

• Windows Monitor Information Disk (1)

• Warranty card (1)

• Notes on cleaning the screen’s surface (1)

• This instruction manual (1)

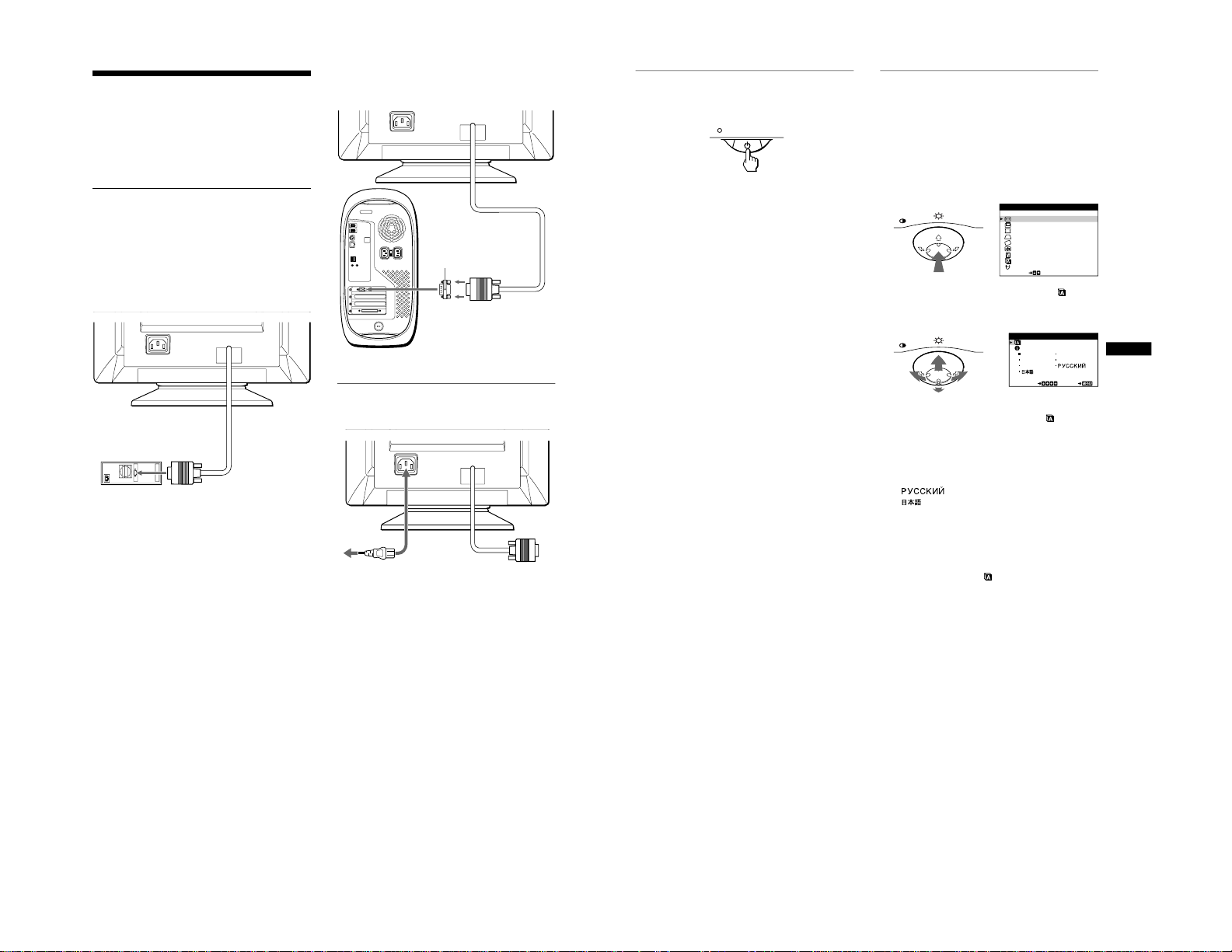

Step 1:Connect your monitor to

your computer

Turn off the monitor and computer before connecting.

Note

Do not touch the pins of the video cable connector as this might bend the

pins.

x Connecting to an IBM PC/AT or compatible

computer

x Connecting to a Macintosh or compatible

computer

Step 2:Connect the power cord

With the monitor and computer switched off, first connect the

power cord to the monitor, then connect it to a power outlet.

AC IN

IBM PC/AT or

compatible computer

to video output

AC IN

You will need a Macintosh adapter (not supplied).

Macintosh adapter (not supplied)

to video output

Macintosh or

compatible computer

AC IN

to AC IN

to a power outlet

power cord (supplied)

7

US

Step 3:Turn on the monitor and

computer

First turn on the monitor, then turn on the computer.

The installation of your monitor is complete.

If necessary, use the monitor’s controls to adjust the picture.

If no picture appears on your screen

• Check that the monitor is correctly connected to the computer.

• If NO INPUT SIGNAL appears on the screen, confirm that

your computer’s graphic board is completely seated in the

correct bus slot.

• If you are replacing an old monitor with this model and OUT

OF SCAN RANGE appears on the screen, reconnect the old

monitor. Then adjust the computer’s graphic board so that the

horizontal frequency is between 30 – 70 kHz, and the vertical

frequency is between 48 – 120 Hz.

For more information about the on-screen messages, see “Trouble

symptoms and remedies” on page 14.

For customers using Windows 95/98

To maximize the potential of your monitor, install the new model

information file from the supplied Windows Monitor Information Disk

onto your PC.

This monitor complies with the “VESA DDC” Plug & Play standard. If

your PC/graphics board complies with DDC, select “Plug & Play Monitor

(VESA DDC)” or this monitor’s model name as the monitor type in the

“Control Panel” of Windows 95/98. If your PC/graphics board has

difficulty communicating with this monitor, load the Windows Monitor

Information Disk and select this monitor’s model name as the monitor

type.

For customers using Windows NT4.0

Monitor setup in Windows NT4.0 is different from Windows 95/98 and

does not involve the selection of monitor type. Refer to the Windows

NT4.0 instruction manual for further details on adjusting the resolution,

refresh rate, and number of colors.

Adjusting the monitor’s resolution and color number

Adjust the monitor’s resolution and color number by referring to your

computer’s instruction manual. The color number may vary according to

your computer or video board. The color palette setting and the actual

number of colors are as follows:

• High Color (16 bit) t 65,536 colors

• True Color (24 bit) t about 16.77 million colors

In true color mode (24 bit), speed may be slower.

Selecting the on-screen menu

language (LANGUAGE/

INFORMATION)

English, French, German, Italian, Spanish, Russian and Japanese

versions of the on-screen menus are available. The default setting

is English.

1

Press the center of the control button.

See page 9 for more information on using the control button.

2

Move the control button m/M to highlight

LANGUAGE/INFORMATION and press the center of

the control button again.

3

Move the control button m/M to select

(LANGUAGE) and move </, to select a language.

• ENGLISH

• FRANÇAIS: French

• DEUTSCH: German

• ITALIANO: Italian

• ESPAÑOL: Spanish

• : Russian

• : Japanese

To close the menu

Press the center of the control button once to return to the main MENU,

and press again selecting EXIT to return to normal viewing. If no buttons

are pressed, the menu closes automatically after about 30 seconds.

To reset to English

Press the RESET button while the (LANGUAGE) menu is displayed

on the screen.

MENU

EX I T

H- S I ZE / CENTER

V-SIZE/CENTER

PIN/PIN BALANCE

KEY / KEY BALANCE

ROTATION

ZOOM

COLOR

SELECT

LA NGU AGE / I NFORMAT NOI

DEGAUSS / CANCEL MO ERI

MENU

MENU

ENGL I SH FRANÇA I S

DEUTSCH ITA L I ANO

ESPAÑOL

SELECT EXI T

LANGUAGE / I NFORMAT I ON

1-2

Page 8

8

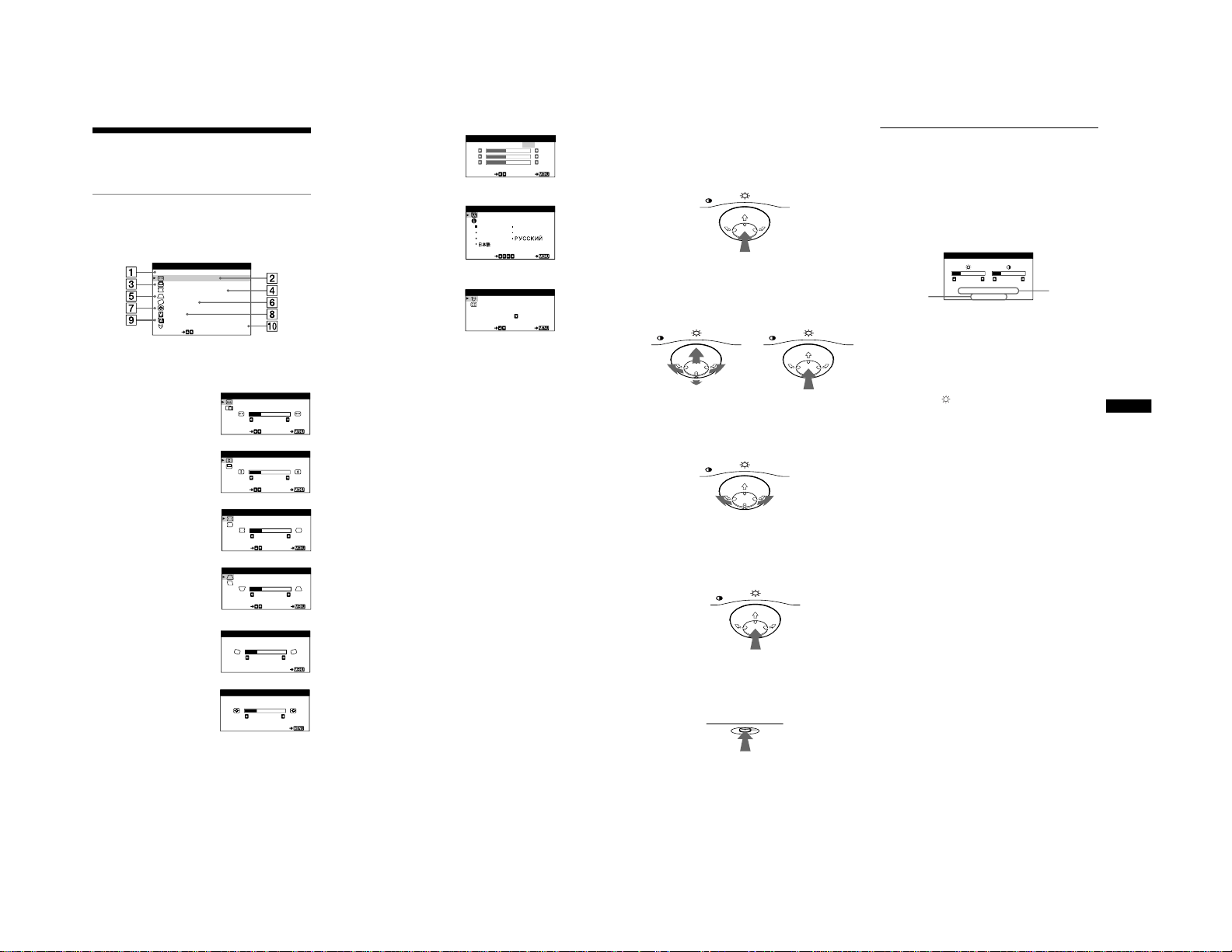

Customizing Your Monitor

You can make numerous adjustments to your monitor using the

on-screen menu.

Navigating the menu

Press the center of the control button to display the main MENU

on your screen. See page 9 for more information on using the

control button.

Use the control button to select one of the following menus.

1 EXIT

Select EXIT to close the menu.

2 H-SIZE/CENTER (page 10)

Select the H-SIZE/CENTER

menu to adjust the picture’s

horizontal size and centering.

3 V-SIZE/CENTER (page 10)

Select the V-SIZE/CENTER

menu to adjust the picture’s

vertical size and centering.

4 PIN/PIN BALANCE (page 10)

Select the PIN/PIN BALANCE

menu to adjust the curvature

picture’s sides.

5 KEY/KEY BALANCE

(page 10)

Select the KEY/KEY BALANCE

menu to adjust the angle of the

picture’s sides.

6 ROTATION (page 11)

Select the ROTATION menu to

adjust the picture’s rotation.

7 ZOOM (page 11)

Select the ZOOM menu to enlarge

or reduce the picture.

EX I T

H- S I ZE / CENTER

V-SIZE/CENTER

PIN/PIN BALANCE

KEY / KEY BALANCE

ROTATION

ZOOM

COLOR

SELECT

LA NGU AGE / I NFORMAT NOI

DEGAUSS / CANCEL MO ERI

MENU

H-SIZE

26

SELECT EXI T

H- SI ZE / CENTER

V-SIZE

26

SELECT EXI T

V-SIZE/CENTER

PIN

26

SELECT EXI T

PIN/PIN BALANCE

KEY

26

SELECT EXI T

KEY / KEY BALANCE

ROTATION

26

EXI T

ROTATION

ZOOM

26

EXI T

ZOOM

8 COLOR (page 11)

Select the COLOR menu to adjust

the picture’s color temperature.

You can use this to match the

monitor’s colors to a printed

picture’s colors.

9 LANGUAGE/INFORMATION

(page 7, 15)

Select the LANGUAGE/

INFORMATION menu to choose

the on-screen menu’s language

and display this monitor’s

information box.

q; DEGAUSS/CANCEL MOIRE

(page 12)

Select the DEGAUSS/CANCEL

MOIRE menu to degauss the

screen and adjust the moire

cancellation level.

KKK

R50

G50

B50

SELECT EXI T

COLOR

5000 6500 9300

USER

ENGL I SH FRANÇA I S

DEUTSCH ITA L I ANO

ESPAÑOL

SELECT EXI T

LANGUAGE / I NFORMAT I ON

DEGAUSS

ON

SELECT EXI T

DEGAUSS/CANCEL MOI RE

9

US

x Using the control button

1 Display the main MENU.

Press the center of the control button to display the main

MENU on your screen.

2 Select the menu you want to adjust.

Highlight the desired menu by moving the control button

towards the rear to go up (M), towards the front to go down

(m), and left (<) or right (,) to move sideways.

3 Adjust the menu.

Move the control button left (<) or right (,) to make the

adjustment.

4 Close the menu.

Press the center of the control button once to return to the

main MENU, and press again selecting EXIT to return to

normal viewing. If no buttons are pressed, the menu closes

automatically after about 30 seconds.

x Resetting the adjustments

Press the RESET button. See page 12 for more information on

resetting the adjustments.

Adjusting the brightness and

contrast

Brightness and contrast adjustments are made using a separate

BRIGHTNESS/CONTRAST menu.

These settings are stored in memory for all input signals.

1 Move the control button in any direction.

The BRIGHTNESS/CONTRAST menu appears on the

screen.

The horizontal and vertical frequencies of the current input

signal are displayed in the BRIGHTNESS/CONTRAST

menu. If the signal matches one of this monitor’s factory

preset modes, the resolution is also displayed.

2 Move the control button m/M to adjust the

brightness ( ), and </, to adjust the contrast

(6).

The menu automatically disappears after about 3 seconds.

MENU

MENU

MENU

REAR

FRONT

MENU

MENU

RESET

26 26

68.7kHz/85.0Hz

1024X768

BRI GHTNESS/ CONTRAST

the resolution

of the current

input signal

the horizontal

and vertical

frequencies

of the current

input signal

1-3

Page 9

10

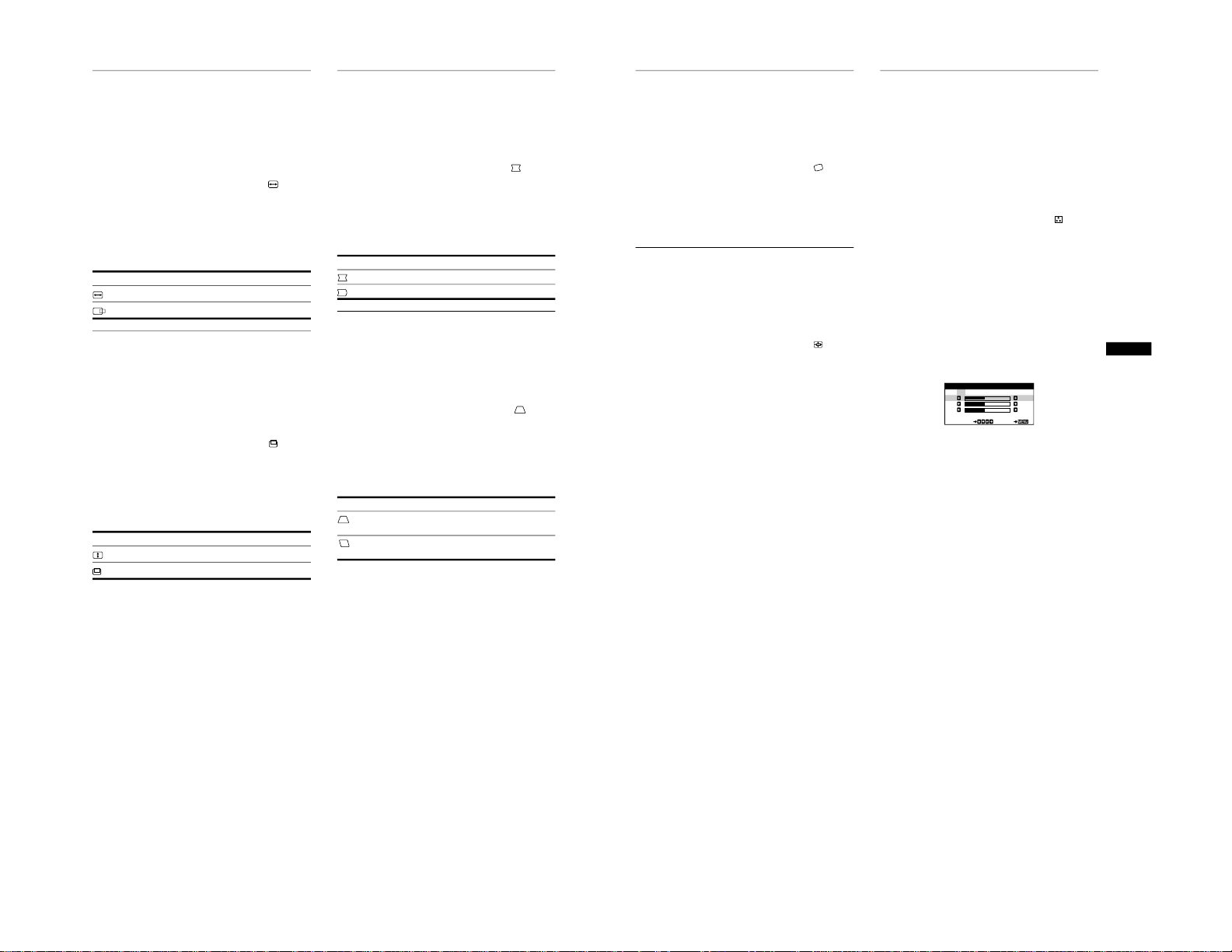

Adjusting the horizontal size or

centering of the picture (H-SIZE/

CENTER)

These settings are stored in memory for the current input signal.

1 Press the center of the control button.

The main MENU appears on the screen.

2 Move the control button m/M to highlight H-SIZE/

CENTER and press the center of the control button

again.

The H-SIZE/CENTER menu appears on the screen.

3 First move the control button m/M to select the

desired adjustment item. Then move the control

button </, to make the adjustment.

Adjusting the vertical size or

centering of the picture (V-SIZE/

CENTER)

These settings are stored in memory for the current input signal.

1 Press the center of the control button.

The main MENU appears on the screen.

2 Move the control button m/M to highlight V-SIZE/

CENTER and press the center of the control button

again.

The V-SIZE/CENTER menu appears on the screen.

3 First move the control button m/M to select the

desired adjustment item. Then move the control

button </, to make the adjustment.

Adjusting the curvature of the

picture’s sides (PIN/PIN BALANCE)

These settings are stored in memory for the current input signal.

1 Press the center of the control button.

The main MENU appears on the screen.

2 Move the control button m/M to highlight PIN/PIN

BALANCE and press the center of the control

button again.

The PIN/PIN BALANCE menu appears on the screen.

3 First move the control button m/M to select the

desired adjustment item. Then move the control

button </, to make the adjustment.

Adjusting the angle of the picture’s

sides (KEY/KEY BALANCE)

These settings are stored in memory for the current input signal.

1 Press the center of the control button.

The main MENU appears on the screen.

2 Move the control button m/M to highlight KEY/

KEY BALANCE and press the center of the control

button again.

The KEY/KEY BALANCE menu appears on the screen.

3 First move the control button m/M to select the

desired adjustment item. Then move the control

button </, to make the adjustment.

Select To

H-SIZE

adjust the horizontal size

H-CENTER

adjust the horizontal centering

Select To

V-SIZE

adjust the vertical size

V-CENTER

adjust the vertical centering

Select To

PIN

expand or contract the picture sides

PIN BALANCE

shift the picture sides to the left or right

Select To

KEY

adjust the picture width at the top of

the screen

KEY BALANCE

shift the picture to the left or right at

the top of the screen

11

US

Adjusting the picture’s rotation

(ROTATION)

This setting is stored in memory for all input signals.

1 Press the center of the control button.

The main MENU appears on the screen.

2 Move the control button m/M to highlight

ROTATION and press the center of the control

button again.

The ROTATION menu appears on the screen.

3 Move the control button </, to rotate the picture.

Enlarging or reducing the picture

(ZOOM)

This setting is stored in memory for the current input signal.

1

Press the center of the control button.

The main MENU appears on the screen.

2

Move the control m/M button to highlight ZOOM

and press the center of the control button again.

The ZOOM menu appears on the screen.

3

Move the control button </, to enlarge or reduce

the picture.

Note

Adjustment stops when either the horizontal or vertical size reaches its

maximum or minimum value.

Adjusting the color of the picture

(COLOR)

The COLOR settings allow you to adjust the picture’s color

temperature by changing the color level of the white color field.

Colors appear reddish if the temperature is low, and bluish if the

temperature is high. This adjustment is useful for matching the

monitor’s colors to a printed picture’s colors.

This setting is stored in memory for all input signals.

1

Press the center of the control button.

The main MENU appears on the screen.

2

Move the control button m/M to highlight COLOR

and press the center of the control button again.

The COLOR menu appears on the screen.

3

Move the control button </, to select a color

temperature.

The preset color temperatures are 5000K, 6500K, and 9300K.

Since the default setting is 9300K, the whites will change

from a bluish hue to a reddish hue as the temperature is

lowered to 6500K and 5000K.

4

If necessary, fine tune the color temperature.

First move the control button </, to select USER. Then

move the control button m/M to select R (red), G (green), or

B (blue) and move </, to make the adjustment.

If you fine tune the color temperature, the new color settings

are stored in memory and recalled whenever you select

USER.

KKK

R50

G50

B50

SELECT EXI T

COLOR

5000 6500 9300

USER

1-4

Page 10

12

Additional settings (DEGAUSS/

CANCEL MOIRE)

You can manually degauss (demagnetize) the monitor, and adjust

the moire cancellation level.

1

Press the center of the control button.

The main MENU appears on the screen.

2

Move the control button m/M to highlight

DEGAUSS/CANCEL MOIRE and press the center of

the control button again.

The DEGAUSS/CANCEL MOIRE menu appears on the

screen.

3

Move the control button m/M to select the desired

adjustment item.

Adjust the selected item according to the following

instructions.

Degaussing the screen

The monitor is automatically demagnetized (degaussed) when the

power is turned on.

To manually degauss the monitor, first move the

control button m/M to select (DEGAUSS). Then move

the control button ,.

The screen is degaussed for about 5 seconds. If a second degauss

cycle is needed, allow a minimum interval of 20 minutes for the

best result.

Adjusting the moire*

If elliptical or wavy patterns appear on the screen, adjust the

moire cancellation level.

To adjust the amount of moire cancellation, first move

the control button m/M to select (CANCEL MOIRE).

Then move the control button </, until the moire

effect is at a minimum.

* Moire is a type of natural interference which produces soft, wavy lines

on your screen. It may appear due to interference between the pattern

of the picture on the screen and the phosphor pitch pattern of the

monitor.

Resetting the adjustments

This monitor has the following three reset methods. Use the

RESET button to reset the adjustments.

Resetting a single adjustment item

Use the control button to select the adjustment item you want to

reset, and press the RESET button.

Resetting all of the adjustment data for the

current input signal

Press the RESET button when no menu is displayed on the screen.

Note that the following items are not reset by this method:

• on-screen menu language (page 7)

• picture’s rotation (page 11)

Resetting all of the adjustment data for all input

signals

Press and hold the RESET button for more than two seconds.

Note that the following item is not reset by this method:

• color menu user settings (page 11)

Example of moire

RESET

13

US

Technical Features

Preset and user modes

When the monitor receives an input signal, it automatically

matches the signal to one of the factory preset modes stored in the

monitor’s memory to provide a high quality picture at the center of

the screen.

(See Appendix for a list of the factory preset modes.)

For input signals that do not match one of the factory preset modes,

the digital Multiscan technology of this monitor ensures that a

clear picture appears on the screen for any timing in the monitor’s

frequency range (horizontal: 30 – 70 kHz, vertical: 48 – 120 Hz).

If the picture is adjusted, the adjustment data is stored as a user

mode and automatically recalled whenever the same input signal

is received.

Note for Windows users

For Windows users, check your video board manual or the utility

program which comes with your graphic board and select the

highest available refresh rate to maximize monitor performance.

Power saving function

This monitor meets the power-saving guidelines set by VESA,

ENERGY STAR, and NUTEK. If the monitor is connected to a

computer or video graphics board that is DPMS (Display Power

Management Signaling) compliant, the monitor will automatically

reduce power consumption in three stages as shown below

.

* “Sleep” and “deep sleep” are power saving modes defined by the

Environmental Protection Agency.

** When your computer enters the “active off” mode, the input signal is

cut and NO INPUT SIGNAL appears on the screen. After 20 seconds,

the monitor enters the power saving mode.

Troubleshooting

Before contacting technical support, refer to this section.

If thin line appears on your screen

(damper wire)

The line you are experiencing on your screen is normal for the

Trinitron monitor and is not a malfunction. This is shadow from

the damper wire used to stabilize the aperture grill and is most

noticeable when the screen’s background is lightly (usually

white). The aperture grille is the essential element that makes a

Trinitron picture tube unique by allowing more light to reach the

screen, resulting in a brighter, more detailed picture.

On-screen messages

If there is something wrong with the input signal, one of the

following messages appears on the screen. To solve the problem,

see “Trouble symptoms and remedies” on page 14.

The input signal condition

OUT OF SCAN RANGE

indicates that the input signal is not supported by the monitor’s

specifications.

NO INPUT SIGNAL

indicates that no signal is being input to the monitor.

Power mode Power consumption 1 (power)

indicator

normal

operation

≤ 95 W green

1 standby ≤ 15 W green and orange

alternate

2 suspend

(sleep)*

≤ 15 W green and orange

alternate

3 active off**

(deep sleep)*

≤ 5 W orange

power off 0 W off

Damper wire

INFORMATION

OUT OF SCAN RANGE

Input signal

condition

1-5

Page 11

14

Trouble symptoms and remedies

If the problem is caused by the connected computer or other equipment, please refer to the connected equipment’s instruction manual.

Use the self-diagnosis function (page 16) if the following recommendations do not resolve the problem.

Symptom Check these items

No picture

If the 1 (power) indicator is not lit • Check that the power cord is properly connected.

• Check that the 1 (power) switch is in the “on” position.

If the NO INPUT SIGNAL message

appears on the screen, or if the 1

(power) indicator is either orange or

alternating between green and

orange

• Check that the video signal cable is properly connected and all plugs are firmly seated in

their sockets (page 6).

• Check that the HD15 video input connector’s pins are not bent or pushed in.

xProblems caused by the connected computer or other equipment

• The computer is in power saving mode. Try pressing any key on the computer keyboard.

• Check that the computer’s power is “on.”

• Check that the graphic board is completely seated in the proper bus slot.

If the OUT OF SCAN RANGE

message appears on the screen

xProblems caused by the connected computer or other equipment

• Check that the video frequency range is within that specified for the monitor. If you

replaced an old monitor with this monitor, reconnect the old monitor and adjust the

frequency range to the following.

Horizontal: 30 – 70 kHz

Vertical: 48 – 120 Hz

If no message is displayed and the 1

(power) indicator is green or flashing

orange

• Use the Self-diagnosis function (page 16).

If using Windows 95/98 • If you replaced an old monitor with this monitor, reconnect the old monitor and do the

following. Install the Windows Monitor Information Disk (page 7) and select this monitor

(“CPD-E100”) from among the Sony monitors in the Windows 95/98 monitor selection

screen.

If using a Macintosh system • Check that the Macintosh adapter (not supplied) and the video signal cable are properly

connected (page 6).

Picture flickers, bounces,

oscillates, or is scrambled

• Isolate and eliminate any potential sources of electric or magnetic fields such as other

monitors, laser printers, electric fans, fluorescent lighting, or televisions.

• Move the monitor away from power lines or place a magnetic shield near the monitor.

• Try plugging the monitor into a different AC outlet, preferably on a different circuit.

• Try turning the monitor 90° to the left or right.

xProblems caused by the connected computer or other equipment

• Check your graphics board manual for the proper monitor setting.

• Confirm that the graphics mode (VESA, Macintosh 16" Color, etc.) and the frequency of

the input signal are supported by this monitor (Appendix). Even if the frequency is within

the proper range, some video boards may have a sync pulse that is too narrow for the

monitor to sync correctly.

• Adjust the computer’s refresh rate (vertical frequency) to obtain the best possible picture.

Picture is fuzzy • Adjust the brightness and contrast (page 9).

• Degauss the monitor* (page 12).

• Select CANCEL MOIRE and adjust the moire cancellation effect (page 12).

15

US

* If a second degauss cycle is needed, allow a minimum interval of 20 minutes for the best result. A humming noise may be heard, but this is not a

malfunction.

Displaying this monitor’s name, serial number,

and date of manufacture (INFORMATION)

1

Press the center of the control button.

The main MENU appears on the screen.

2 Move the control button m/M to highlight

LANGUAGE/INFORMATION and press the center of

the control button again.

The LANGUAGE/INFORMATION menu appears on the

screen.

3 Move the control button m/M to select

(INFORMATION).

This monitor’s information box appears on the screen.

If the problem persists, call your authorized Sony dealer and give

the following information.

• Model name: CPD-E100

• Serial number

• Name and specifications of your computer and graphics board.

Picture is ghosting • Eliminate the use of video cable extensions and/or video switch boxes.

• Check that all plugs are firmly seated in their sockets.

Picture is not centered or sized

properly

• Adjust the size or centering (page 10). Note that some video modes do not fill the screen

to the edges.

Edges of the image are curved • Select PIN/PIN BALANCE, KEY/KEYBALANCE, or ROTATION, and adjust the

picture’s shape and rotation (page 10, 11).

Wavy or elliptical pattern (moire)

is visible

• Select CANCEL MOIRE and adjust the moire cancellation effect (page 12).

xProblems caused by the connected computer or other equipment

• Change your desktop pattern.

Color is not uniform • Degauss the monitor* (page 12). If you place equipment that generates a magnetic field,

such as a speaker, near the monitor, or if you change the direction the monitor faces, color

may lose uniformity.

White does not look white • Adjust the color temperature (page 11).

A hum is heard right after the

power is turned on

• This is the sound of the auto-degauss cycle. When the power is turned on, the monitor is

automatically degaussed for five seconds.

Symptom Check these items

MODEL : CPD- E1 0 0

SERIAL :12345678

MANUFACTURED: 19 9 9- 52

SELECT EXI T

LANGUAGE / I NFORMAT I ON

Example

1-6

Page 12

16

Self-diagnosis function

This monitor is equipped with a self-diagnosis function. If there is

a problem with your monitor or computer, the screen will go blank

and the 1 (power) indicator will either light up green or flash

orange. If the 1 (power) indicator is lit in orange, the computer is

in power saving mode. Try pressing any key on the keyboard.

If the 1 (power) indicator is green

1

Disconnect the video input cable or turn off the

connected computer.

2 Press the 1 (power) button twice to turn the monitor

off and then on.

3 Move the control button , for 2 seconds before the

monitor enters power saving mode.

If all four color bars appear (white, red, green, blue), the monitor

is working properly. Reconnect the video input cable and check

the condition of your computer.

If the color bars do not appear, there is a potential monitor failure.

Inform your authorized Sony dealer of the monitor’s condition.

If the 1 (power) indicator is flashing orange

Press the 1 (power) button twice to turn the monitor off

and then on.

If the 1 (power) indicator lights up green, the monitor is working

properly.

If the 1 (power) indicator is still flashing, there is a potential

monitor failure. Count the number of seconds between orange

flashes of the 1 (power) indicator and inform your authorized

Sony dealer of the monitor’s condition. Be sure to note the model

name and serial number of your monitor. Also note the make and

model of your computer and video board.

MENU

RESET

1 (power) indicator

MENU

1-7

Page 13

CPD-E100/E100E/E100P

SECTION 2

DISASSEMBLY

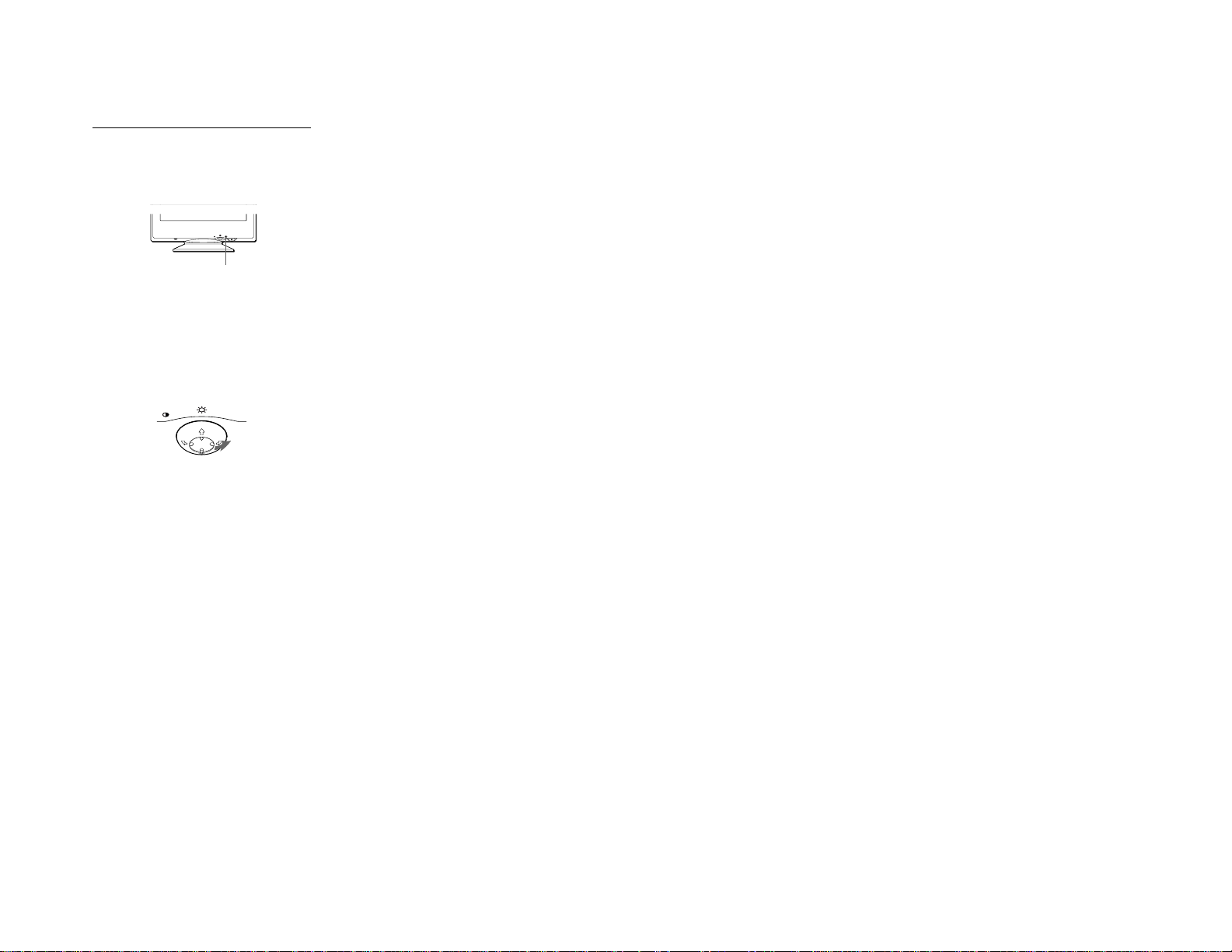

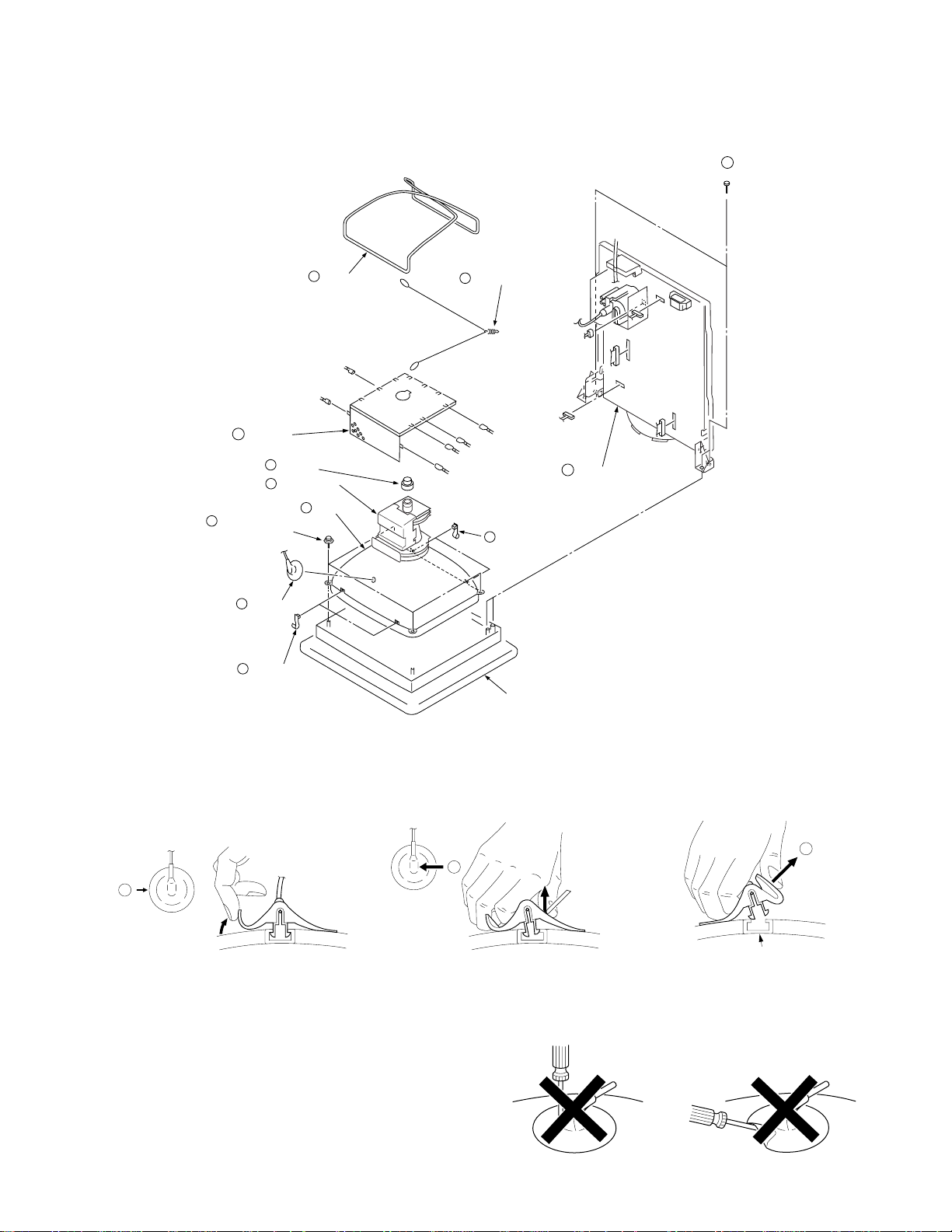

2-1. CABINET REMOVAL

2

Two claws

3

Cabinet

1

Two screws

(+BVTP 4 x 16)

2-3. H BOARD REMOVAL

Claw

3

2

H board

4

P701

H bracket

Screw

1

(+BVTP 3 x 12)

2-2. A AND D BOARDS REMOVAL

7

Claw

8

Two claws

7

Claw

GND

CN906

GND

GND

GND

6

Two screws

(+BVTP 3 x 12)

CN505

CN501

1

A board

CN502

GND

GND

GND

2

Screw

(+BVTT 4 x 8)

3

Cable stopper

4

Two screws

(+BVTP 3 x 12)

5

Cable bracket

2-1

CN603

9

D board

Page 14

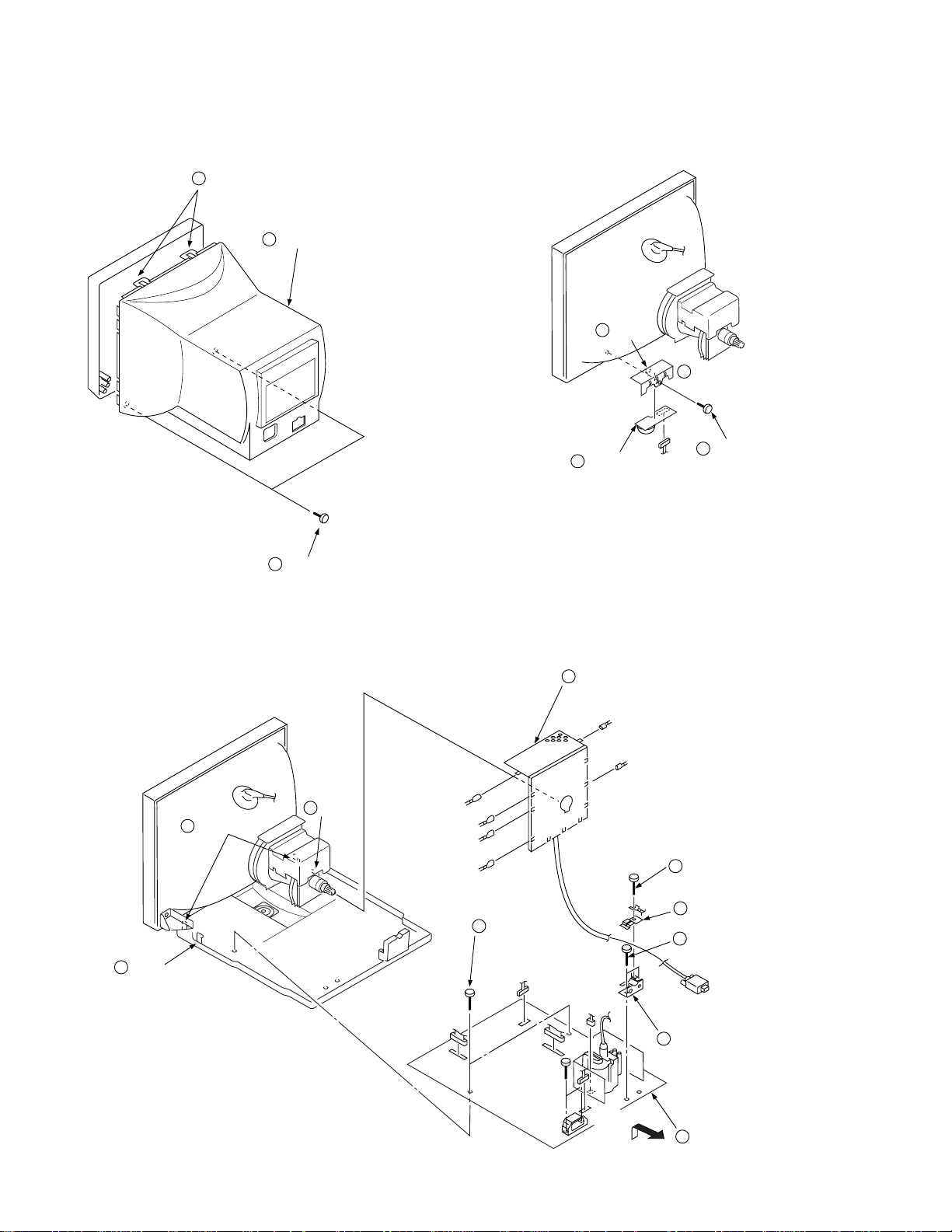

2-4. PICTURE TUBE REMOVAL

9

Demagnetic coil

Two tension springs

10

CPD-E100/E100E/E100P

3

Four screws

(+BVTP 4 x 16)

CN603

CN501

CN906

2

A board

8

Four screws

(Tapping screw 5)

1

Anode cap

11

Two degaussing

coil holders

GND

5

Neck assy

6

Deflection yoke

7

Picture tube

GND

GND

GND

GND

12

GND

Two

degaussing

coil holders

Cushion

CN505

CN502

4

Bottom cover

(D board)

• REMOVAL OF ANODE-CAP

NOTE: Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield or carbon painted on the CRT,

after removing the anode.

• REMOVING PROCEDURES

b

a

1 Turn up one side of the rubber cap in

the direction indicated by the arrow a.

2 Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow b.

• HOW TO HANDLE AN ANODE-CAP

1

Don’t scratch the surface of anode-caps with shartp shaped material!

2 Don’t press the rubber hardly not to damege inside of anode-caps!

A material fitting called as shatter-hook terminal is built in the

rubber.

3 Don’t turn the foot of rubber over hardly!

The shatter-hook terminal will stick out or damage the rubber.

c

Anode Button

3 When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling up it in

the direction of the arrow c.

2-2

Page 15

CPD-E100/E100E/E100P

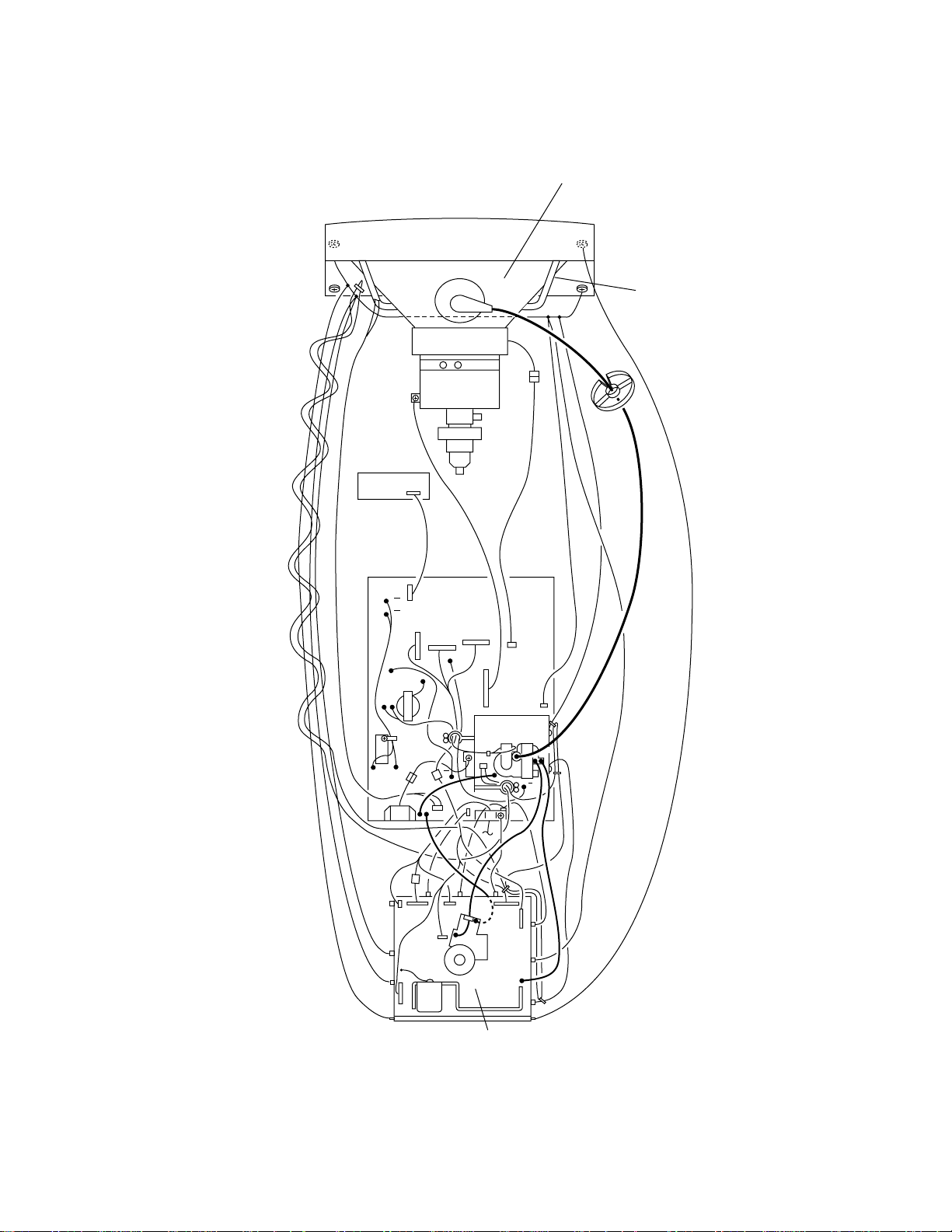

2-5. HARNESS LOCATION

Picture tube

Demagnetic coil

P701

H board

CN906

B1

B2

G

K

HEAT SINK

B2

B1

CN310

CN311

CN504

CN901

F

G

CN603

CN301 CN302

CN306

I

CN507

CN902

CN501

CN502

D board

CN505

CN506

FBT

I

CN304

CN303

CN309

CN305

A board

2-3

Page 16

SECTION 3

SAFETY RELATED ADJUSTMENT

CPD-E100/E100E/E100P

When replacing or repairing the shown below table, the

following operational checks must be performed as a

safety precaution against X-rays emissions from the unit.

Part Replaced ([)

RV501HV ADJ

Part Replaced (])

HV Regulator

Circuit Check

HV Hold-down

Circuit Check

Beam Current

Protector Circuit

Check

Confirm one minute later turning on the power.

*

D board IC502, IC503, Q511,

D510, C535, R515,

R554, R559, R560,

R596, RV501,

T501 (FBT)

D board IC501, R598, R599,

T501 (FBT)

D board T501 (FBT)

• HV Protector Circuit Check

Confirm that the voltage between cathode of D521 on D

board and GND is more than 28.5 V DC and Using external DC Power Supply, apply the voltage shown below

between cathode of D521 and GND, and confirm that

the HV HOLD DOWN circuite works. (TV Raster disappears)

Standard voltage : Less than 34 V DC

Check Condition

• Input voltage : 100 – 120 V AC

• Input signal : White Cross hatch at Max fH

• Beam control : CONT : 255, BRT : 80

• Beam Current Protector Check

Connect a variable resistor (250 kΩ or more) and an ammeter in series between FBT pin 1 on D board and

GND. Decrease gradually the resistance of the variable

resistor from maximum to minimum, and confirm that

the Beam Current Protector Circuite works (TV Raster

disappears). The current must be within the range shown

below.

• Standard current : Less than 1.50 mA

Check Condition

• Input voltage : 100 – 120 V AC

• Input signal : White Cross hatch at Max fH

• Beam control : CONT : 255, BRT : 80

• B+ Voltage Check

Standard voltage : 152 ± 5.0 V DC

Check Condition

• Input voltage : 100 – 120 V AC

Note : Use NF power supply or make sure that

distortion factor is 3% or less.

• Input signal : White Cross hatch at 64.0 kHz

• Beam control : CONT : 255, BRT : 80

3-1

Page 17

CPD-E100/E100E/E100P

SECTION 4

ADJUSTMENTS

Connect the communication cable of the computer to the connector located on the D board on the monitor. Run the service software

and then follow the instruction.

2

I

C Interface Card

2

C Interface Cable

I

HD15 Connector Adapter

Computer

as a Jig

• Landing Fine Adjustment

1. Put the set inside the Helmholtz coil.

2. Set TLH plate to zero position.

3. Input the single green signal.

4. Demagnetize the CRT surface with the hand degausser , and

perform auto degaussing.

5. Attach the wobbling coil to the designated part of the CRT

neck.

6. Attach the sensor of the landing adjustment unit on the CRT

surface.

Purity magnet position

7. Adjust the DY position and purity, and the DY tilt.

8. Fasten DY with screw.

+2

Note: Torque 20

kgcm

-1

9. Adjust top and bottom pins by pitching DY up and down

with two wedges.

Also leave the yaw of DY to physical center position with

Another two wedes.

Video Cable

L/D control specification

± 5 ± 7 ± 5

± 5 ± 7 ± 5

± 5 ± 7 ± 5

(µm)

10. If the corner landing is out of specification, put a disk magnet for the landing correction.

11. Perform auto degauss in case disk magnets are used.

12. Remove the sensor and wobbling coil.

13. Fix purity magnet on DY with UL black tape.

a

cd

b

“a” and “b” must be equal, and

“c” and “d” must be equal.

<How to drive in wedges>

4-1

Page 18

CPD-E100/E100E/E100P

A

270 mm

B

MODE All mode

202 mm

a 1.5 mm

b 1.5 mm

a

B

A

b

• Convergence Rough Adjustment

1. Enter the crosshatch signal.

2. Recheck focus and readjust when focus was worse.

3. Adjust roughly H. STAT and V. STAT convergence by 4

pole magnet.

4. Adjust roughly HMC and VMC by 6 pole magnet.

• Convergence Adjustment

1. Adjust H and V Stat by 4 pole magnet.

2. Adjust 6 pole magnet perform HMC and VMC.

3. Adjust 4 pole magnet close both Stat of R.G.B just overlap

each other Horizontal and Vertical.

4. Adjust TLH for side MC by TLH magnet when R or B is in

the opposite direction.

5. Adjust XCV to correct Vertical cross MC.

6. Adjust TLV to corect Vertical tilt MC.

7. Adjust YCH to correct top and bottom Horizontal cross MC.

8. Using permalloys to correct MC of the cornters.

9. Check convergence for whole screen. If necessary, perform

step from 3-7 and correct with permalloys.

10. Paint lock 4 pole magnet, 6 poles magnets, XBV reactor

XCV corrector and TLH corrector handle.

6Pole Mg

Purity Mg.

DY

CRT

YCH

XCV

TLV

• Convergence Specification

B

A

MODE All mode

0.30 mm

A

0.35 mm

B

• White Balance Adjustment Specification

(1) 9300K (2) 6500K

x = 0.283 ± 0.01 x = 0.313 ± 0.01

y = 0.298 ± 0.01 y = 0.329 ± 0.01

(2) 5000K

x = 0.346 ± 0.01

y = 0.359 ± 0.01

• Vertical and Horizontal Position and Size

Specification

TLH

4Pole Mg

XCV YCH

B

• Focus adjustment

Adjust the focus volume H and V for the optimum focus.

Focus 1

R

R

B

B

R

RB

TLHTLV

RR

BB

(V)

FBT

A board

4-2

Focus (H)

Page 19

CPD-E100/E100E/E100P

MEMO

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4-3

Page 20

5-1. BLOCK DIAGRAMS

SIGNAL-IN

D-SUB15

PIG-TAIL

15

10

414

9

313

8

212

7

1511

6

TO

D BOARD

CN902

TO

D BOARD

CN901

1-4

A

B

CN301

R GND

RED

G GND

GREEN

B GND

BLUE

GND

VD

HD

CN302

+5V

DDC SCL

DDC SDA

CPU GND

CN304

VS OUT

HS OUT

V BLK

GND

BP CLP

C SYNC

G1

ABL

CN306

+5V

DDC SCL

DDC SDA

CPU GND

SECTION 5

DIAGRAMS

1

2

3

4

5

6

7

8

9

1

2

3

4

1

2

3

4

5

6

7

8

1

2

3

4

A

(VIDEO)

V BLK

Q004

SONG BUFF

CLAMP AMP

Q001,002

IC004

EEP ROM

V CLK

7

6

SCL

SDA

5

Q008

IC001 PRE AMP,OSD MIX

11

R IN R OUTR IN

6

G IN

2

B IN

7

SOGI

19

CLAMP

15

ABL IN

SOG OUT

18

BLK

27

R OUT

G OUT

B OUT

DA4

DA3

DA2

DA1

OSDR

OSDG

OSDB

OSD BLK IN

SCL

SDA

29

32

35

23

24

25

26

BRIGHT

CONT

Q007

4

9

13

1

20

21

IC002

RGB OUT

8

9

G OUTG IN

11

13

15

17

12

B OUTB IN

IC005

RGB CUT OFF CONT

VOC1

VI1

1

(B)

VI2

2

(G)

VI3

3

(R)

5

6

IC003 OSD

R

G

B

BLK

SCK

SIN

(B)

VOC2

(G)

VOC3

(R)

VERT

5

3

1

9

8

7

V SYNC

19

H

18

CS

4

BUFF

Q005

H SYNC

BUFF

Q003

R.G.B

HI

CN305

+146VS1

BRI

2

+75VS

3

4

GND

5

H1

6

H2

7

+5V

8

GND

9

+12VS

10

GND

CRT

G2

G1

TO

HV

D BOARD

FBT

CN309

D

G2

FV

TO

D BOARD

FBT

TO

D BOARD

FBT

TO

D BOARD

CN504

TO

D BOARD

CN901

5-!¡

TO

D BOARD

CN906

C

E

CN303

CS

GND

12C SDA

12C SCL

GND

HR TRC

VR TRC

P701

+5V

MENU

GND

RIGHT(+)

LEFT(-)

ORG LED

GRN LED

1

2

3

4

5

6

7

1

2

3

4

5

6

7

H

(CONTROL)

LED701

POWER

5-1 5-2

B-SS3501<J>-B/D-24

SW701

B-SS3501<J>-B/D-24

Page 21

D516

T503

TO

A BOARD

CN306

TO

A BOARD

CN303

TO

A BOARD

CN304

TO

H BOARD

P701

SW

Q535

IC 501

DEFLECTION

CONTROLLER

V SYNC

14

H SYNC

15 8

CLBL

16

17

H UNLOCK

SCL

18

SDA

19

H DRV

V OUT2

D517

54

RESET

SCL/D

34

SDA/D

35

PC/DET

33

CS

22

32

H/RTN

26

V SYNC/O

SOG

28

30

H SYNC/I

20

V SYNC/I

TEST

38

SDA

37

36

SCL

7

ABL

17

MENU

18

RIGHT(+)

23

LEFT(-)

24

ORG LED

53

GRN LED

52

DEGAUSSING

13

IC901 CPU

H SYNC/O

OSC/I

H-DRV

H/CENTER

CS0,CS1,CS2

PMGO

PMGI

27

D903

46BLANK/O

39

SCL

SDA

44OSC//O

X901

24MHz

45

19UFB

6H-SIZE

8

4

49

50

51

48

CS3

+12V

12MUTE

1TILT

15

14

D509

SW

Q534

BOP CONT

Q512,513

+5V

RESET

Q901,Q902

CN901

1

+5V

SCL/D

B

C

A

E

SDA/D

PC/DET

CS

GND

SDA

SCL

GND

H/R

V/R

CN902

V/IN

H/IN

V BLK

GND(G1)

BP CLP

SOG

GND

ABL

CN906

+5V

MENU

GND

RIGHT(+)

LEFT(-)

ORG LED

GRN LED

2

3

4

5

6

7

8

9

10

11

SOG BUFF

Q907

H SYNC AMP

Q908

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

ABL CONT

SCL

SDA

S901

MENU

V BLK

Q401

Q533

IC902

EEP ROM

ABL CONT

Q528,Q529

BP CLP CONT

Q526

7TEST

5SDA

6SCL

BRIGHT

Q531,532

T502

SC CONTROL

Q505-509,524

2

-V IN1

+V IN1

3

7

OUT2

HDT

1

OUT 1

IC503 HV REGULATION

6

-V IN2

5

+V IN2

H DRIVE

Q520,521

IC401

V OUT

5OUT

13V OUT1

12

1HFLB

11EW DRV

5B IN

6B DRV

3BOP

32FOCUS

2XRAY

+V IN

7

1

+15V

-V IN

B DRIVE

Q515,516

3

2

+VIN 1

-V IN 1

3FLYBACK

IC504

TILT AMP

OUT 1

H DRIVE

OUT

Q502

H DRIVE

Q523,527

SWITCHING

Q501

IC502 HV REGULATION

57

+V IN2

OUT2

TILT DRIVE

1

Q5E2,5E3

H CENT

DF AMP

1

Q519

Q530

HV REG

OUT 1

OUT

Q511

+V IN1

H OUT

Q503

D515

3

H CENT

DRIVE

Q517,518

GENERATOR

Q504

EHT

Q514

L505

HLC

CN501

H DY(+)

1

H DY(+)

2

H DY(-)

3

H DY(-)

4

V DY(-)

5

V DY(+)

6

T501 FBT

RV501

ADJ

HV

HV

TO CRT ANODE CAP

G2

TO NECK BOARD

CN309

FV1

TO CRT

FV2

TO CRT

CN505

TILT

TILT

10

L570

9

D511

L503

D521

T504

DFT

2

5

3

2

D512

4

5

6

11

7

HV

G2

12

11

14

13

1

ABL

TILT(ROTATION)

COIL

H.DY

V.DY

SW

Q616

+15V SW

CONT

IC603

D618

Q610

+15V SW

Q609

S601

IC606

D601

AC RECT

D626 D604

(P GND)

IC608

A

R

K

A

R

K

Q611

Q601

SW

SW

D609

D610

IC601

PWM CONTROL

V REF

8

1

COMP

2FB

Vcc

?

I SENSE

SWITCHING

OUT

6

Q602

FB603

3

TH602

LF601

LFT

RY601

RELAY DRIVE

TH601

Q615

CN601

AC IN

CN603

DGC

DGC2

NC 2

DGC1

F601

1

3

T603 PIT

89

6

4

1

2

3

IC602

VOLTAGE

FEEDBACK

10

12

13

14

15

17

D613

D615

D616

D617

D622

KA

VOLTAGE

FEEDBACK

R

5-3

+6.3V SW

CONT

Q608

+6.3V SW

Q607

I

IC605

+5V REG

+160V

+80V/H-D

IC607

+12V REG

I

+15V

-15V

+6.3V

O

O

+5V

POWER SUPPLY,DEFLECTION,

CPU

D

B-SS3501<J>-B/D-24

1

2

3

4

5

6

7

8

9

10

CN504

+160V

BRI

+80V/VIDEO

GND

+6.3V

GND

+5V

GND

+12V

GND

TO

A BOARD

D

CN305

5-4

Page 22

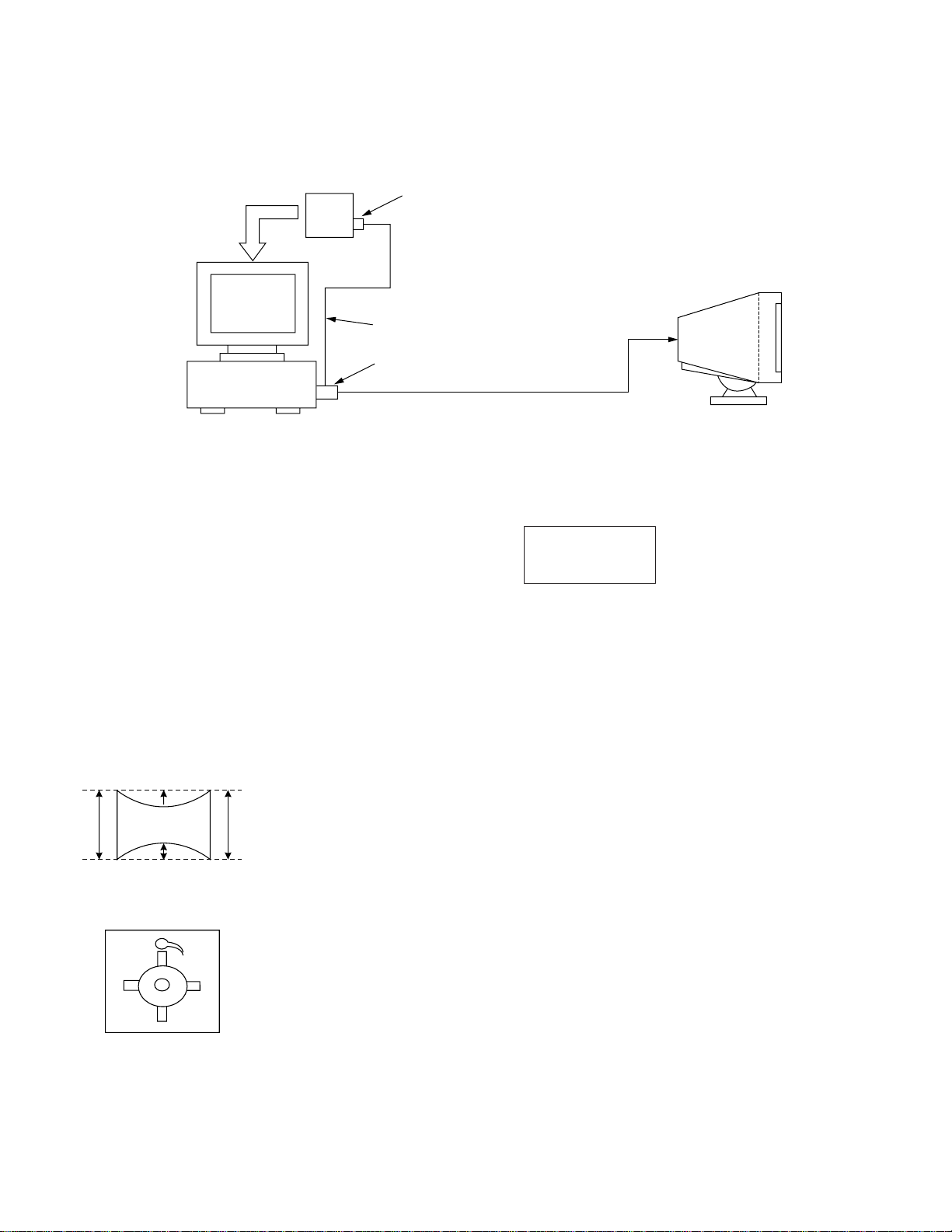

5-2. CIRCUIT BOARDS LOCATION

H

D

5-3. SCHEMATIC DIAGRAMS AND PRINTED

WIRING BOARDS

Note:

• All capacitors are in µF unless otherwise noted. (pF: µµF)

Capacitors without voltage indication are all 50 V.

• Indication of resistance, which does not have one for rating

electrical power, is as follows.

Pitch: 5 mm

Rating electrical power 1/4 W (CHIP : 1/10 W)

A

• All resistors are in ohms.

f : nonflammable resistor.

•

• F : fusible resistor.

¢ : internal component.

•

p : panel designation, and adjustment for repair.

•

• All variable and adjustable resistors have characteristic curve B,

unless otherwise noted.

e : earth-ground.

•

• E : earth-chassis.

• All voltages are in V.

• Readings are taken with a 10 MΩ digital multimeter.

• Readings are taken with a color-bar signal input.

• Voltage variations may be noted due to normal production

tolerances.

•

• Circled numbers are waveform references.

•

• S : B – bus.

• The components identified by

• When replacing components identified by

• When replacing the part in below table, be sure to perform the

: Can not be measured.

*

s : B + bus.

have been carefully factory-selected for each set in order to

satisfy regulations regarding X-ray radiation.

Should replacement be required, replace only with the value

originally used.

necessary adjustments indicated. (See page 3-1)

related adjustment.

[ in this basic schematic diagram

], make the

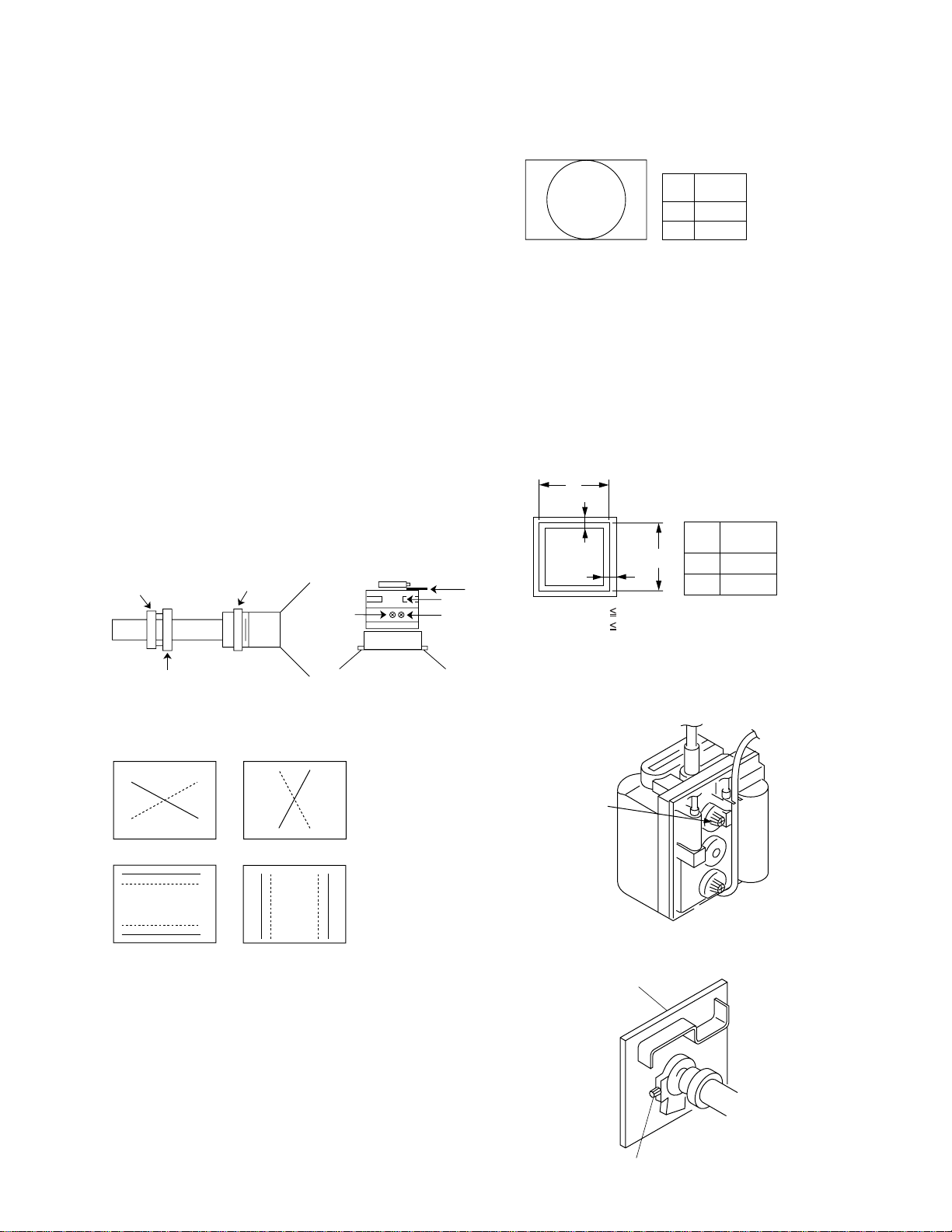

• Divided circuit diagram

One sheet of D board circuit diagram is divided into three

sheets, each having the code D-a to D-c . For example, the

destination ab1 on the D-a sheet is connected to ab1 on the

D-b sheet.

1

a

b

Ref. No.

Circuit diagram division code

HV Regulator

Circuit Check

HV Hold-down

Circuit Check

Beam Current

Protector Circuit

Check

Part Replaced ([)

RV501HV ADJ

Part Replaced (])

D board IC502, IC503, Q511,

D510, C535, R515,

R554, R559, R560,

R596, RV501,

T501 (FBT)

D board IC501, R598, R599,

T501 (FBT)

D board T501 (FBT)

Note: The components identified by shading and mark

! are critical for safety. Replace only with part

number specified.

Note: Les composants identifiés par un tramé et une

marque ! sont critiques pour la sécurité. Ne les

remplacer que par une pièce portant le numéro

spécifié.

5-5

5-6

Page 23

(1) Schematic Diagram of A Board

A

B

C

D

E

F

G

H

1

5

15

10

4

14

9

3

13

8

2

12

7

1

11

6

SIGNAL IN

HD15

PIG-TAIL

TO D BOARD

CN901

5 - 11 PIN

TO D BOARD

CN902

TO D BOARD

CN504

2

CN310

TAB PIN

GND

CN301

9P

RGND

RED

GGND

GREEN

BGND

BLUE

GND

VD

HD

CN303

7P

CS

GND

12CSDA

12CSCL

GND

HRTRC

VRTRC

CN304

8P

VSOUT

HSOUT

VBLK

GND

BPCLP

CSYNC

G1

ABL

CN311

GND

CN305

10P

+146VS

BRI

+75VS

GND

H1

H2

+5V

GND

+12VS

GND

VCC

R VOUT3

7

IC004

24C21/P

EEPROM

1234

/TEST

NC

/WP

VSS

GND2

41.9

C015

0.1

100V

VCC

VCLK

SCL

SDA

10

G VOUT2

GND11B VOUT1

23456

52.3

8 9

4.2

4.1

2.0

5 6 7 8

C045

1000P

2KV

C040 C041

220p

220p

50V

50V

11

C308

0.1

100V

+6.3V

C013

0.1

50V

R042

1k

1/2W

D017

SG001 FB007

BYV26C

1.2KV 2.3UH

C014

1000p 2kV

+78V

R114

12k

FB104

C108

0.1

100V

+78V

R214

12k

FB204

C208

0.1

100V

+78V

R314

12k

FB304

D008

1N4148

FB009

2.3UH

FB010

2.3UH

D009

1SS119

HG

H

FB203

43

1/2W

10

11

12

FB103

43

1/2W

FB303

43

1/2W

J001

CRT_SOKET

RGB

G2

G1

L102

0.47µH

D103

1N4148

L202

0.47µH

D203

1N4148

L302

0.47µH

D303

1N4148

D010

1N4148

D011

1N4148

V901

PICTURE

TUBE

HV

TO

D BOARD FBT

R034

51k

1/2W

+78V

D104

BAV20

B+

+78V

D204

C206

0.1

BAV20

100V

B+

R211

1M

D205

BAV20

+78V

D304

C306

0.1

BAV20

100V

B+

R311

1M

D305

1N4148

(VIDEO)

A

12

C106

0.1 100V

R111

1M

R112

D105

220

1/2W

BAV20

SG101

200V

R212

220

1/2W

SG201

200V

R312

100

1/2W

SG301

200V

FB008R036 R035

2.3UH47 47

D013

1N4148

C038 C037

0.1

50V

B-SS3501<J>-A..-24

13

CN307

TAB PIN

GND

CN309

TO D BOARD

G2

CN502

CN306

4P

1

+5V

DDCSCL

DDCSDA

CPUGND

CN302

4P

CPUGND

DDCSDA

DDCSCL

+5V

TO D BOARD

CN901

1 - 4 PIN

2

3

4

4

3

2

1

0.1

50V

14

43

+12V

D301D302

1SS1191SS119

D201D202

1SS1191SS119

D101D102

1%

0.2

Q002

2N3904

CLAMP AMP

R046

C102

10 50V

C202

10 50V

C302

10 50V

C001

50V

1k

10

R049

10k

1.5

Q008

2N3904

SONG BUFF

R050

4.7k

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

FB101

FB201

FB301

FB011

2.3UH

JW

JW

JW

FB012

2.3UH

R002

100

C301 C201 C101

33p 33p 33p

VSYNC

C022

R007

560p

100

50V

-0.2

R008

2.2k

2N3904

CLAMP AMP

D002

1N4148

C025

0.1

50V

R301 R201 R101

751%751%75

+5V

R011

330

R009

1k

R010

100

1.1

0.8

Q001

+5V

4.4

R052

R048

0.1

1k

R020

2k

+5V

R026

510

4.4

H SYNC BUFF

B+

+78V

+6.3V

+5V

+12V

+12VF

15k

3.9

D014

RLZ3.6A

R021C042

10k180p

50V

C026

2200p

50V

R029 C029

1.5k 1000p

50V

Q003

2N3904

0

R053

5.5k

+5V

R019

100

R018

100

D018

1N4148

R022

2.2k

5.0

Q005

RN1203

V SYNC

BUFF

+5V

Q007

2SA733

BRIGHT

CONTROL

R015

240

1/4W

+5V

R025

240

R024 C028

1k 0.1

JW006

2µH

1

2

3

4

5

6

7

8

9

10

FB002

2.3UH

FB003

2UH

FB004

2.3UH

FB005

2.3UH

C017 C018 C021

0.1

0.1

0.1

50V

100V

50V

D004

1N4148

D005

0.2

1N4148

0.8

Q004

2N3904

V BLK

50V

R027

0

1k

D003

R028

5.1V

1k

D016

PG104R

L002

JW

C019C020

100

47

10V

16V

C016

33

200V

+5V

1.0

R051

1.5k

+5V

R014 R013

4.7k 4.7k

1SS1191SS119

+12V

+12V

+5V +12V

R016

3k

C003

100

10V

R012

1k

R017

100

C002

220

16V

C203

0.1

50V

C103

0.1

50V

C004

0.22

16V

C044

0.1

100V

C303

0.1

50V

C034

0.1

50V

+5V

R039

2.4k

C033

4700p 50V

C032

1 50V

+5V

100

10V

R060

1M

PRE AMP/OSD MIX

0.1

123456789101112131415161718

2.6

0.1

2.9

3.1

0.1

2.6

0.1

4.4

0.6

C024C023

0.1

50V

1.3

12345678910

5.0

5.0

5.0

5.0

IC001

M52743BSP

VCC2

OSD BLKIN

5

BOUT

BIN

6

EXTFB

VCCB

OSDB

GNDA

4

GOUT

GNDB

3

EXTFB

GIN

MBRI

SOGI

2

ROUT

VCCG

EXTFB

OSDG

BLK

GNDG

1

DA1

RIN

DA2

VCCR

DA3

OSDR

DA4

GNDR

GND5

ABLIN

SDA

NC

SCL

VCC

CLAMP

SOG OUT

IC003

M35045-160SP

OSD

VDD2

CPOUT

VIR

VERT

AC

HOR

CS

P5/B

P4

SCK

P3/G

SIN

TCK

P2

VDD1

P1/R

P0/BK0

P6

P7

VSS

2.0

19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

5.0

3.8

11 12 13 14 15 16 17 18 19 20

+12VF

L001

2.9

4.4

1.1

2.1

4.7

0.6

2.1

1.5

2.9

2.9

5.0

5.0

0.2

100µH

R004

100

C043

4.7

35V

N.P

C005 C006

+12VF

R006

R005

C008

16V

10k

0.1

50V

47

0.1

50V

R304

100

R303

1k

R204

100

R203

1k

R104

100

1k

R103

1k

1/4W

C304 C204 C104

0.1

0.1

50V

50V

RGB OUT

L301

0.1µH

L201

0.1µH

L101

0.1µH

IC005

TDA6103Q

RGB CUT-OFF

CONTROL

R108

15k

R208

15k

0.1

50V

R308

15k

R309

6.8k

IC002

LM2409T

FB006

2.3UH

C010

0.1

50V

R109

6.8k

R209

6.8k

+5V

C030 C031

100

0.1

10V

50V

R313

0

33

R213

0

33

R113

0

33

0

R030

10k

98765

B VIN1

VBB

G VIN2

+12VF

2.9

2.0

2.1

C009

47

16V

VI1

VI2

VI3

GND

VIP

VCC

2.7

C311

100p

R107

150k

R207

150k

1/4W

R307

150k

1/4W

C111

100p

3.1

C207

4.7

50V

VSYNC

C211

100p

VOC3

75.0

71.5

R032

5.1k

1/4W

50V

1 2 3 4 5 6 7 8 9

2.6

3.0

VOC2

R037C039

4.7k0.1

R VIN3

FB001

+78V

C012

0.1

100V

VOC1

C107

76.0

100V

R031

15k

+5V

GND

7891011

51.6

C011

10

100V

+78V

0.1

+12VF

D012

1N4148

4.5

I

• A BOARD WAVEFORMS

1

0.7 Vp-p (H)

2

H

H

3.7 Vp-p (H)

3

1.0 Vp-p (H)

4

4.6 Vp-p (H)

5

0.7 Vp-p (H)

6

7

8

9

H

3.6 Vp-p (H)

52.0 Vp-p (H)

64.0 Vp-p (H)

52.0 Vp-p (H)

0

52.0 Vp-p (H)

!¡

64.0 Vp-p (H)

Schematic diagram

5-7

ll

board

l

A

ll

5-8

!™

52.0 Vp-p (H)

Page 24

(a)

VIDEO

— A BOARD (Conductor Side) —

1

2 3

• A BOARD

SEMICONDUCTOR

LOCATION

IC

Conductor

()

IC001 B–1 B–3

IC002 A–1 A–3

IC003 B–3 B–1

IC004 B–1 B–3

IC005 A–3 A–1

Component

()

Side

Side

— A BOARD (Component Side) —

1

2 3

TRANSISTOR

A

Conductor

()

Q001 C–3 C–1

Q002 B–3 B–1

Q003 B–3 B–1

Q004 C–3 C–1

Q005 B–3 B–1

Q007 B–1 B–3

Q008 B–1 B–3

Component

()

Side

Side

A

DIODE

Conductor

()

D002 C–3

D003 B–3

D004 B–3

D005 C–3

D008 C–2

B

C

D009 B–2

D010 C–2

D011 B–2

D012 B–1

D013 C–1

D014 B–1

D016 A–1 A–3

D017 B–3 B–1

D018 A–1

D101 B–1 B–3

D102 B–1 B–3

D103 A–2

D104 A–2 A–2

D105 A–2 A–2

D201 B–1 B–3

D202 B–1 B–3

D203 A–2

D204 A–2 A–1

D205 A–3 A–1

D301 B–1 B–2

D302 B–2 B–2

D303 A–2

D304 A–2

D305 A–3

Component

()

Side