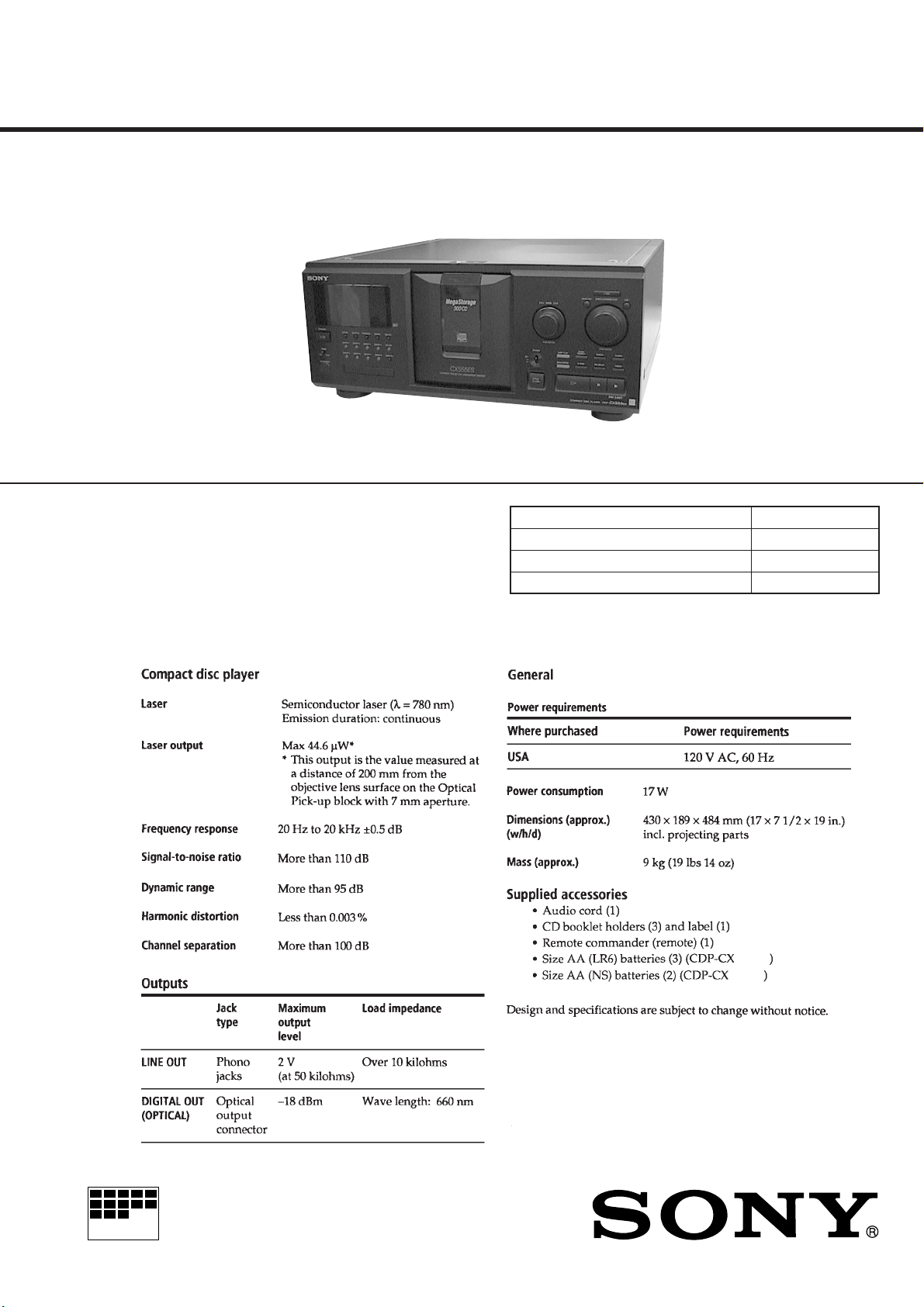

Sony CDPCX-333-ES, CDPCX-555-ES Service manual

CDP-CX333ES/CX555ES

SERVICE MANUAL

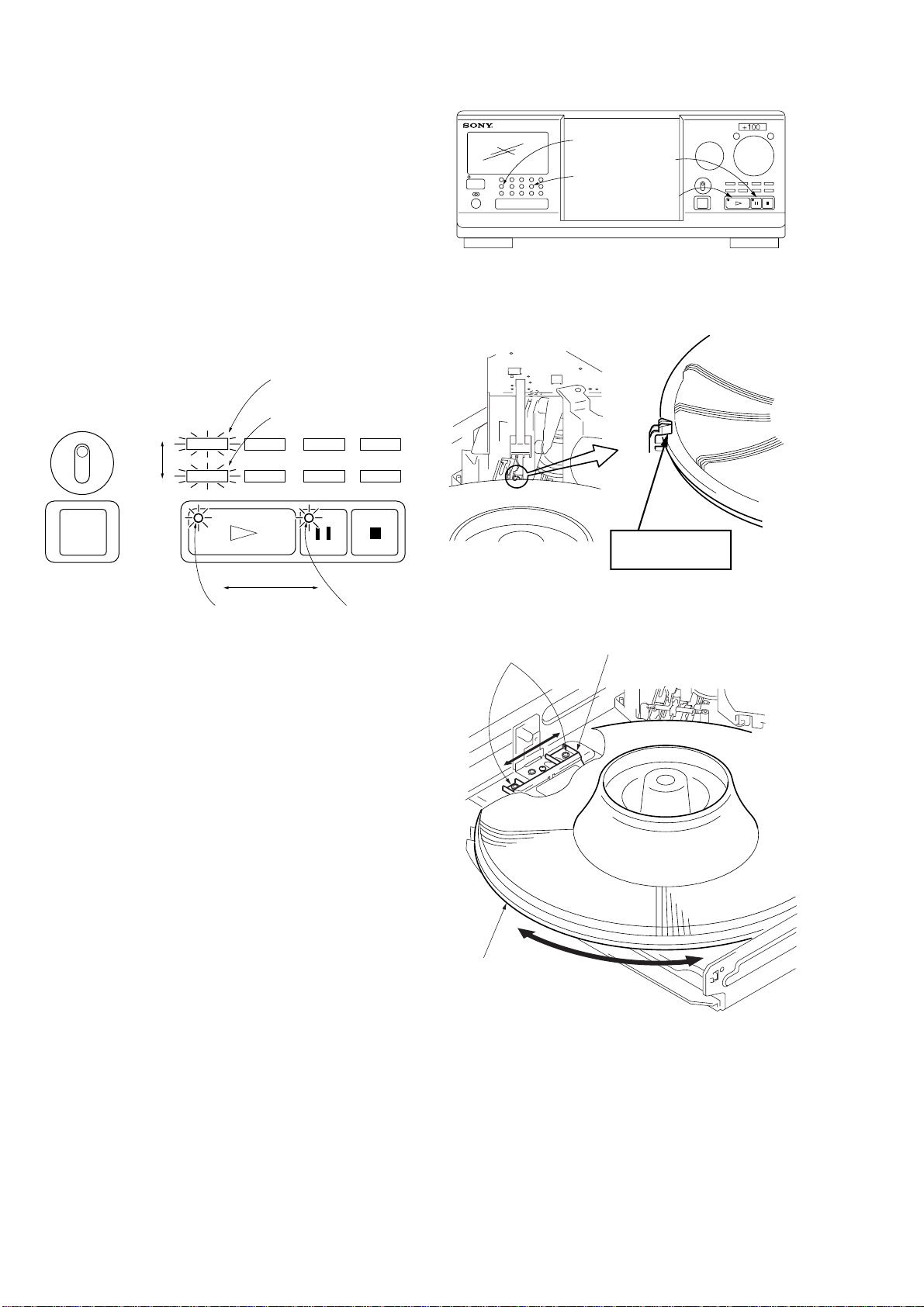

Photo: CX555ES

US Model

Canadian Model

Model Name Using Similar Mechanism CDP-CX300

CD Mechanism Type CDM54-KIBD35B

Base Unit Type KSM-213BFN/C2NP

Optical Pick-up Type KSS-213B/C2N

SPECIFICATIONS

555ES

333ES

MICROFILM

COMPACT DISC PLAYER

SECTION 1

SERVICING NOTES

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 2

2. GENERAL ................................................................... 8

3. DISASSEMBLY ......................................................... 9

4. SERVICE MODE...................................................... 12

5. TEST MODE.............................................................. 16

6. MECHANICAL ADJUSTMENTS....................... 17

7. ELECTRICAL ADJUSTMENT............................ 19

8. DIAGRAMS

8-1. Block Diagram – BD Section – ..................................... 21

8-2. Block Diagram – MAIN Section – ................................ 22

8-3. Note for Printed Wiring Boards

and Schematic Diagrams ................................................ 23

8-4. Printed Wiring Board – BD Board – ............................. 24

8-5. Schematic Diagram – BD Board – ................................ 25

8-6. Printed Wiring Board – MAIN Board – ........................ 26

8-7. Schematic Diagram – MAIN Board (1/3) – .................. 28

8-8. Schematic Diagram – MAIN Board (2/3) – .................. 29

8-9. Schematic Diagram – MAIN Board (3/3) – .................. 30

8-10. Printed Wiring Board – JACK Board –......................... 31

8-11. Schematic Diagram – JACK Board – ............................ 31

8-12. Printed Wiring Board – DISPLAY Board – .................. 32

8-13. Schematic Diagram – DISPLAY Board – ..................... 33

8-14. Printed Wiring Board – JOG Board – ........................... 34

8-15. Schematic Diagram – JOG Board – .............................. 35

8-16. Printed Wiring Boards – D.SENSOR (IN)/

D.SENSOR (OUT)/SENSOR (T) Boards – ................... 36

8-17. Schematic Diagram – D.SENSOR (IN)/

D.SENSOR (OUT)/SENSOR (T) Boards – ................... 37

8-18. Printed Wiring Boards – D.MOTOR/D.SWITCH/

KEY/LED/L.T.MOTOR/L.SWITCH (A)/

L.SWITCH (B) Boards – ................................................ 38

8-19. Schematic Diagram – D.MOTOR/D.SWITCH/

KEY/LED/L.T.MOTOR/L.SWITCH (A)/

L.SWITCH (B) Boards – ................................................ 39

8-20. Printed Wiring Board – POWER Board –..................... 40

8-21. Schematic Diagram – POWER Board –........................ 41

8-22. IC Pin Function Description ........................................... 49

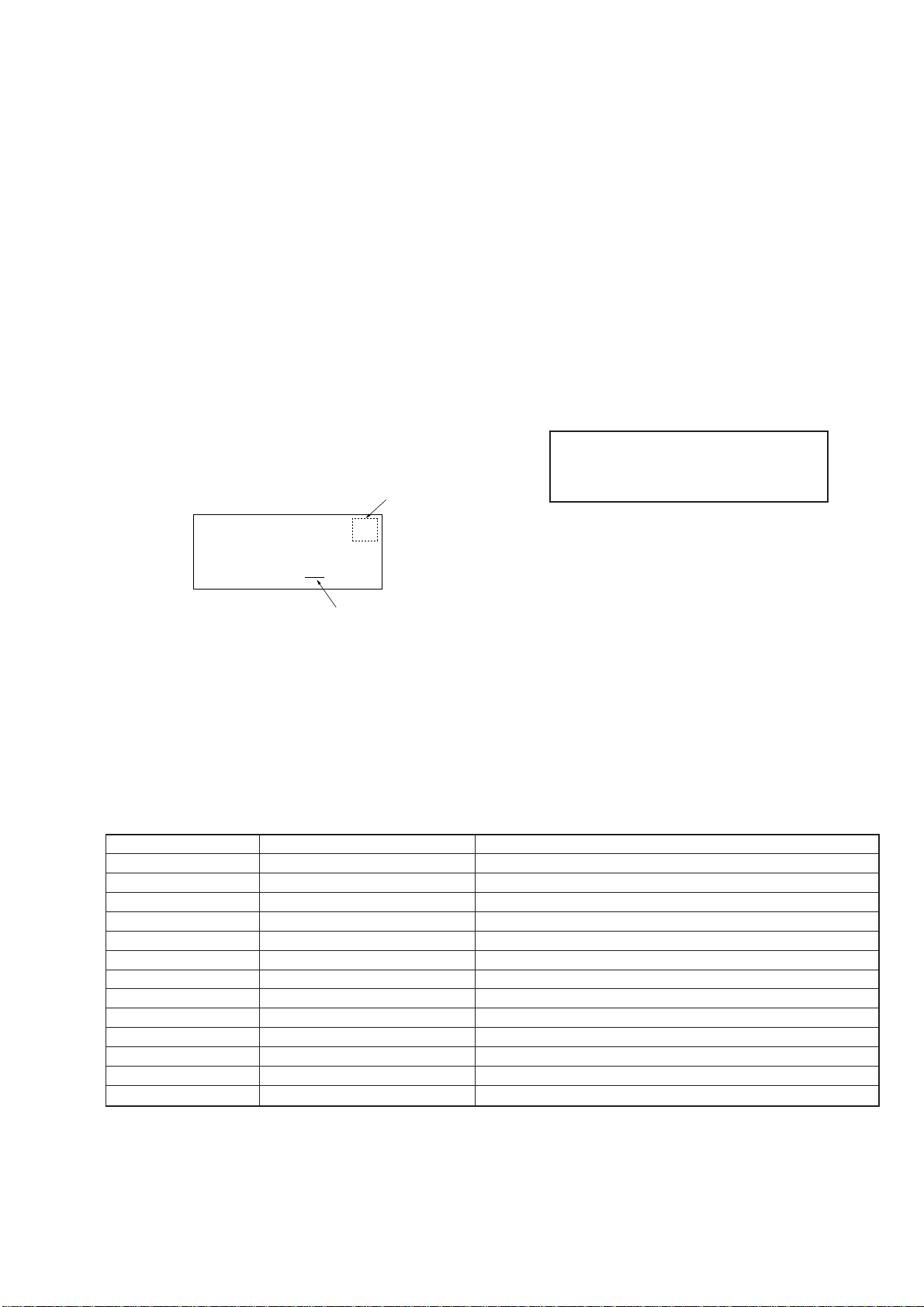

MODEL IDENTIFICATION

— BACK PANEL —

PA R T N o . MODEL

4-217-909-0

4-217-909-1

4-217-909-2

4-217-909-3

CX333ES: US model

CX333ES: Canadian model

CX555ES: US model

CX555ES: Canadian model

PART No.

9. EXPLODED VIEWS ................................................ 54

10. ELECTRICAL PARTS LIST ............................... 61

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

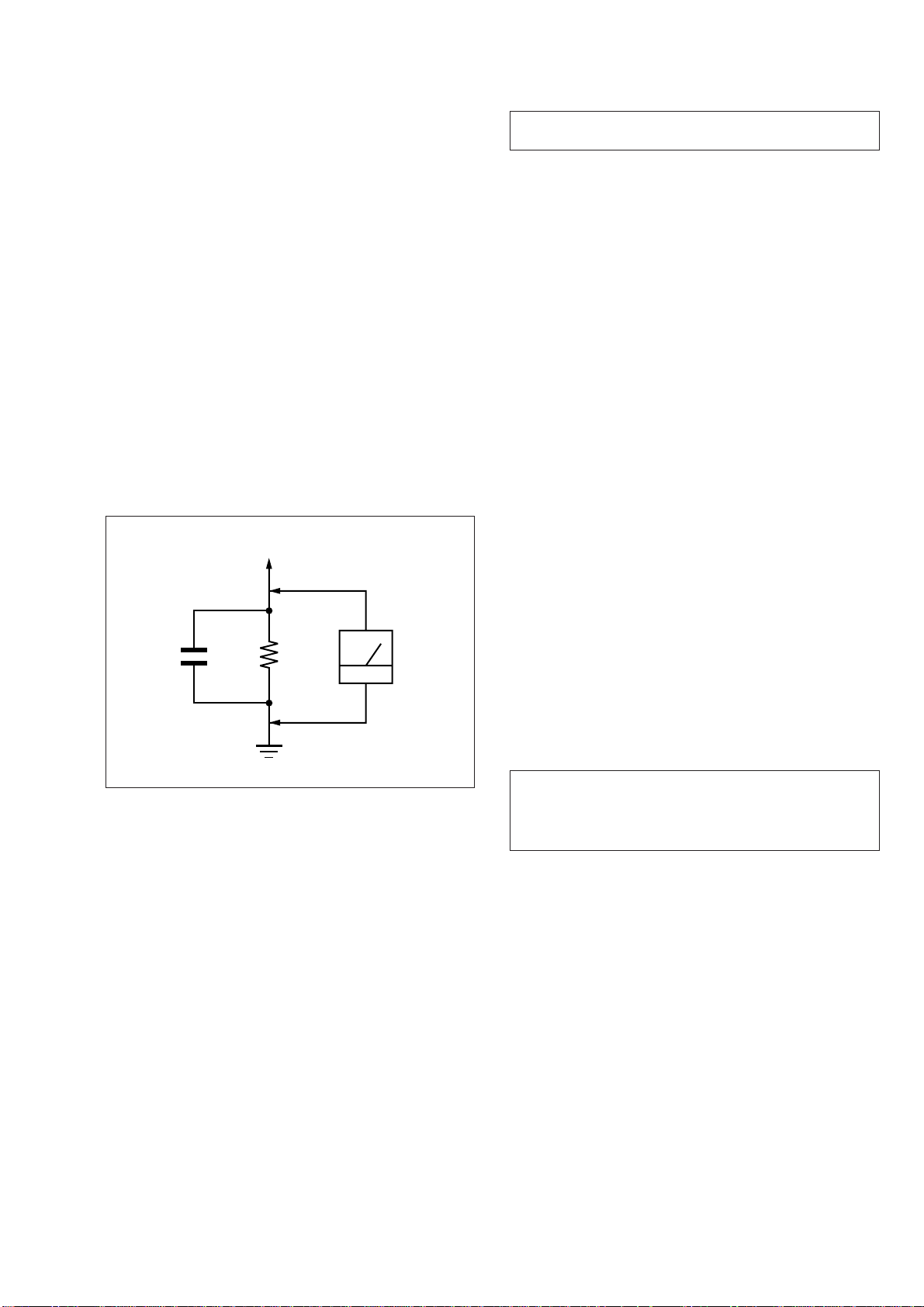

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

AC

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

Ω

Earth Ground

voltmeter

(0.75 V)

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

3

CD-TEXT TEST DISC

This unit is able to display the TEXT data (character information) written in the CD on its fluorescent indicator tube.

The CD-TEXT TEST DISC (TGCS-313:J-2501-126-A) is used for checking the display.

To check, perform the following procedure.

Checking Method:

1. Turn ON the power, set the disc on the disc table with the side labeled as “test disc” as the right side, close the front cover, and chuck

the disc.

2. The following will be displayed on the fluorescent indicator tube. (The display switches each time the [TIME/TEXT] button is pressed.)

Display: CD TEXT TEST DISC (Album Title)

3. Press the [] button and play back the disc.

4. The following will be displayed on the fluorescent indicator tube. (If nothing is displayed, press the [TIME/TEXT] button.)

5. Rotate [AMS] knob to switch the track. The text data of each track will be displayed.

For details of the displayed contents for each track, refer to “Table 1: CD-TEXT TEST DISC Text Data Contents” and “Table 2: CDTEXT TEST DISC Recorded Contents and Display”.

Restrictions in CD-TEXT Display

In this unit, some special characters will not be displayed properly. These will be displayed as a space or a character resembling it. For

details, refer to “Table 2: CD-TEXT DISC Recorded Contents and Display”.

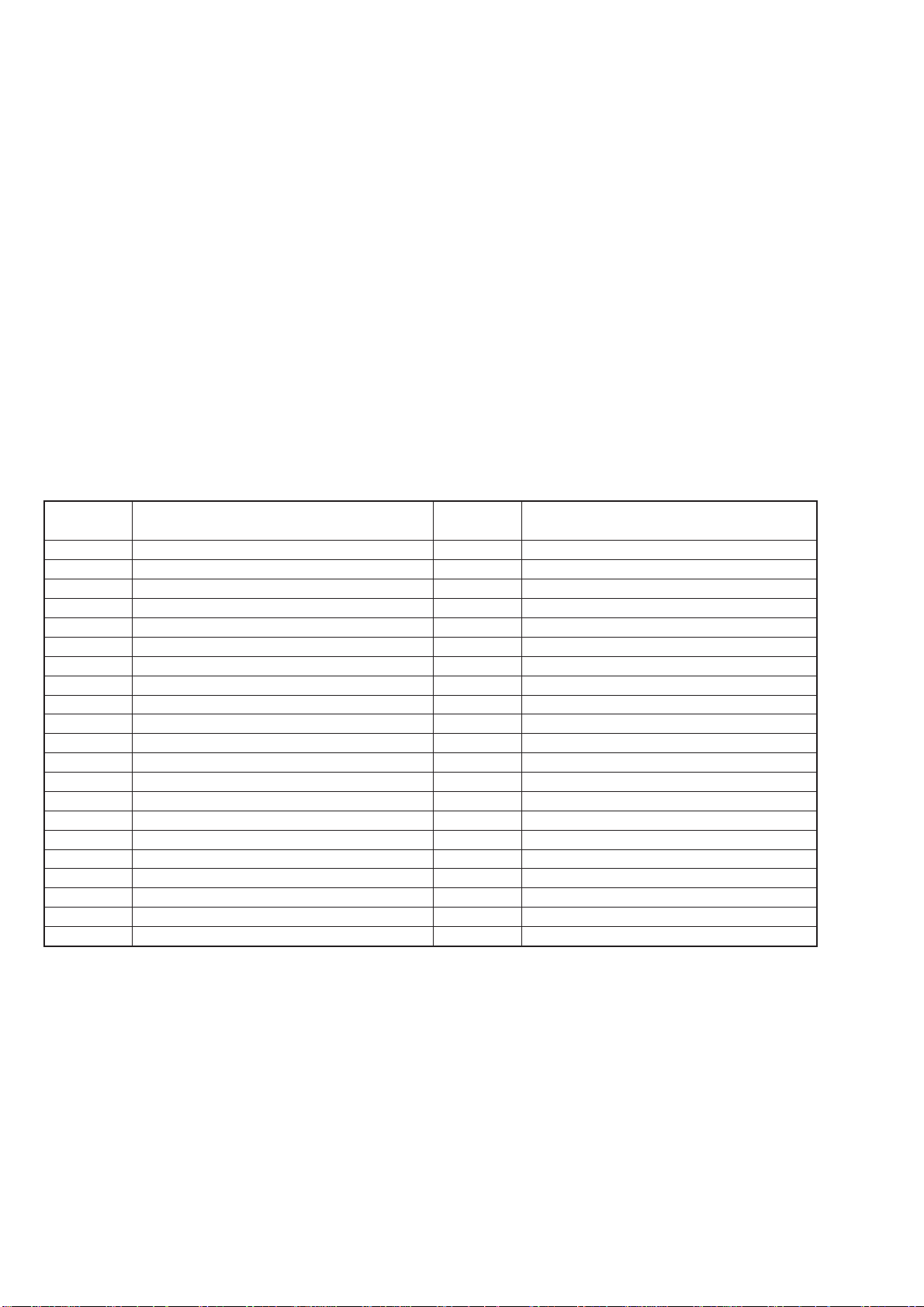

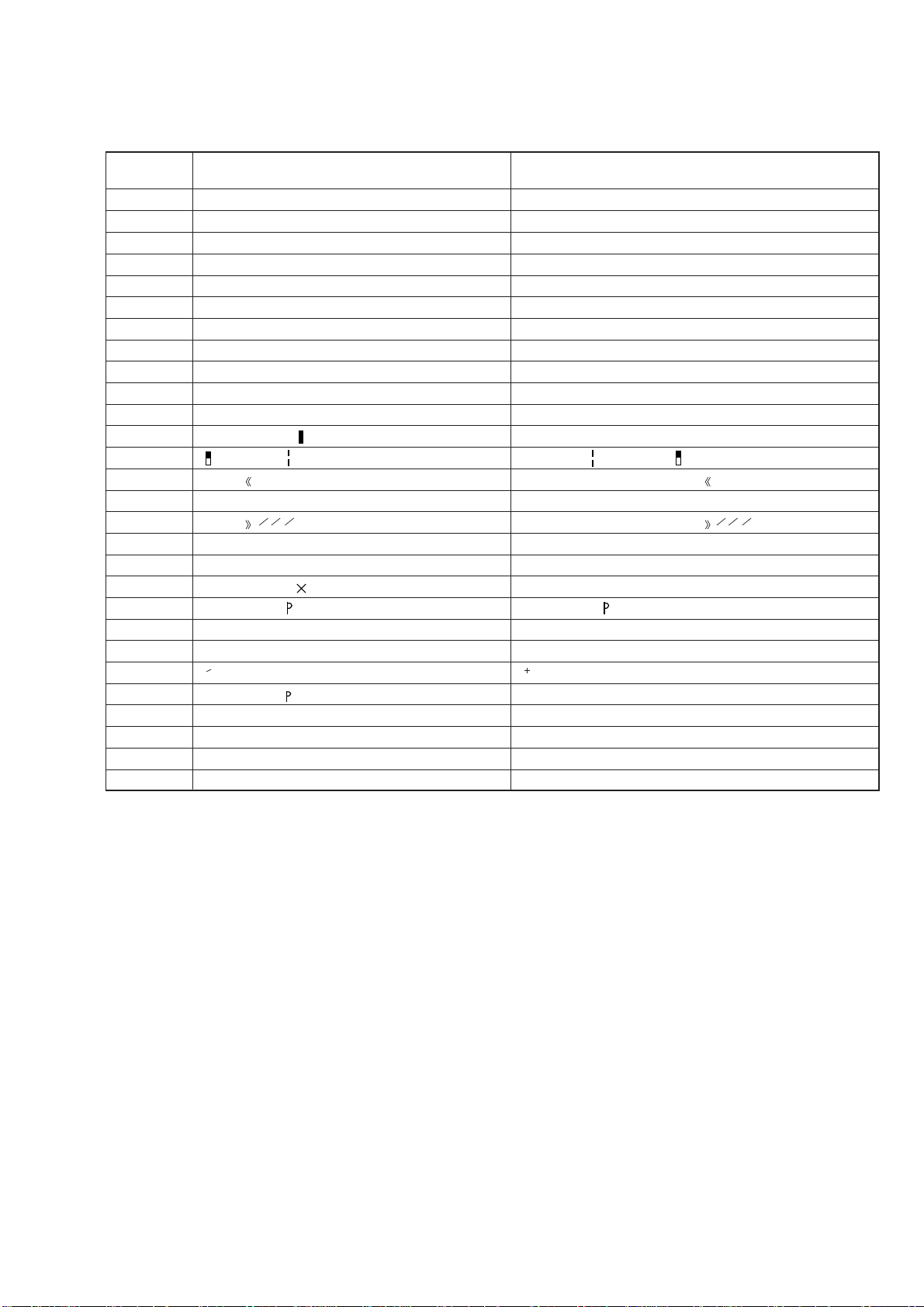

Table 1: CD-TEXT TEST DISC Text Data Contents (TRACKS No. 1 to 41:Normal Characters)

·

Display: 1 kHz/0 dB/ L&R

≠ ±

TRACK

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Note: The contents of Track No. 1 to 41 are the same as those of the current TEST DISC-their titles are displayed.

1 kHz/0 dB/L&R

20 Hz/0 dB/L&R

40 Hz/0 dB/L&R

100 Hz/0 dB/L&R

200 Hz/0 dB/L&R

500 Hz/0 dB/L&R

1 kHz/0 dB/L&R

5 kHz/0 dB/L&R

7 kHz/0 dB/L&R

10 kHz/0 dB/L&R

16 kHz/0 dB/L&R

18 kHz/0 dB/L&R

20 kHz/0 dB/L&R

1 kHz/0 dB/L&R

1 kHz/-1 dB/L&R

1 kHz/-3 dB/L&R

1 kHz/-6 dB/L&R

1 kHz/-10 dB/L&R

1 kHz/-20 dB/L&R

1 kHz/-60 dB/L&R

1 kHz/-80 dB/L&R

Displayed Contents

TRACK

No.

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Displayed Contents

1 kHz/-90 dB/L&R

Infinity Zero w/o emphasis//L&R

Infinity Zero with emphasis//L&R

400 Hz+7 kHz(4:1)/0 dB/L&R

400 Hz+7 kHz(4:1)/-10 dB/L&R

19 kHz+20 kHz(1:1)/0 dB/L&R

19 kHz+20 kHz(1:1)/-10 dB/L&R

100 Hz/0 dB/L*

1 kHz/0 dB/L*

10 kHz/0 dB/L*

20 kHz/0 dB/L*

100 Hz/0 dB/R*

1 kHz/0 dB/R*

10 kHz/0 dB/R*

20 kHz/0 dB/R*

100 Hz Squer Wave//L&R

1 kHz Squer Wave//L&R

1 kHz w/emphasis/-0.37 dB/L&R

5 kHz w/emphasis/-4.53 dB/L&R

16 kHz w/emphasis/-9.04 dB/L&R

4

Table 2: CD-TEXT TEST DISC Recorded Contents and Display

(In this unit, some special characters cannot be displayed. This is no a fault.)

TRACK

No.

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

to

99

Recorded Contents

! ” # $ % & ´ (21h to 27h) 1kHz 0dB L&R

( )*+ , – . / (28h to 2Fh)

01234567 (30h to 37h)

8 9 : ; < = > ? (38h to 3Fh)

@A B C D E F G (40h to 47h)

H I J K L M N O (48h to 4Fh)

P Q R S T U V W (50h to 57h)

X Y Z [ ¥ ] ^ _ (58h to 5Fh)

a b c d e f g (60h to 67h)

′

h i j k l m n o (68h to 6Fh)

p q r s t u v w (70h to 77h)

x y z { I } ~ (78h to 7Fh)

i ¢ £ ¤ ¥ § (A0h to A7h) 8859-1

¬

≥ C ª

23

•±

†1º ¿ (B8h to BFh)

–

PR

′µ ¶ • (B0h to B7h)

113

424

(A8h to AFh)

АБВГДЕЖЗ (C0h to C7h)

И Й К Л М Н О П (C8h to CFh)

DСТУФХЦ (D0h to D7h)

ШЩЪЫЬY Я (D8h to DFh)

à á â ã ä å æ ç (E0h to E7h)

è é ê ë ì í î ï (E8h to FFh)

∂ стуфхц÷ (F0h to F7h)

шщъыьy я (F8h to FFh)

No.66

No.67

to

No.99

Displayed Contents

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

X Y Z [ \ ] ^ _ (58····

N All the same

N All the same

N All the same

x y z { I } ~ (78····

i ¢ £ ¤ ¥ § (A0···· is not displayed

≥ (A8···· C ª ¬ PR–are not displayed

′ µ • (B0····

† ¿ (B8····1º are not displayed

•±23

113

424

¶ are not displayed

N All the same

N All the same

N All the same

Φ Ù Ú Û Ü Y ß (D8····

N All the same

N All the same

oстуфхц÷ (F0····

N All the same

N All the same

N All the same

to

N All the same

5

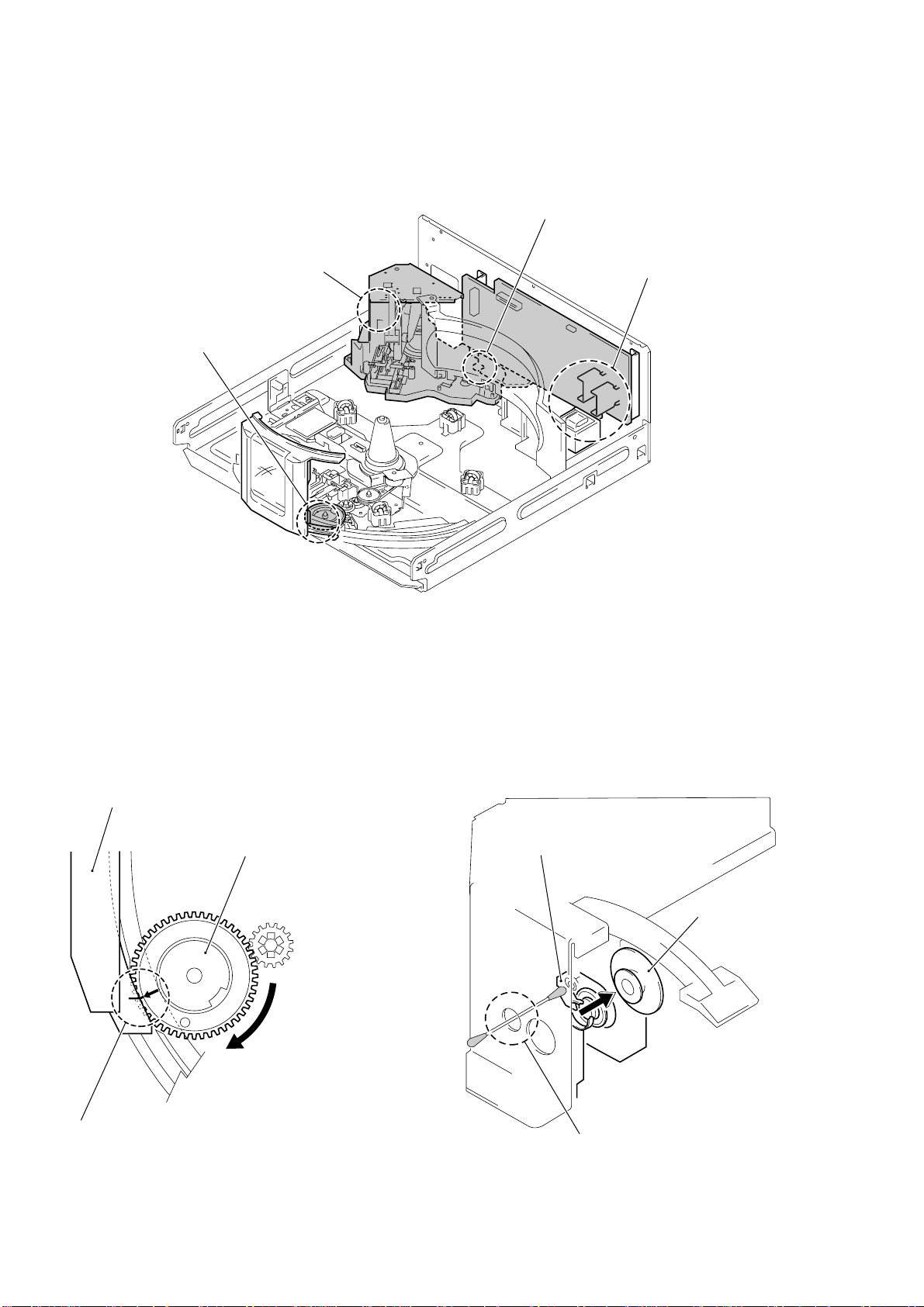

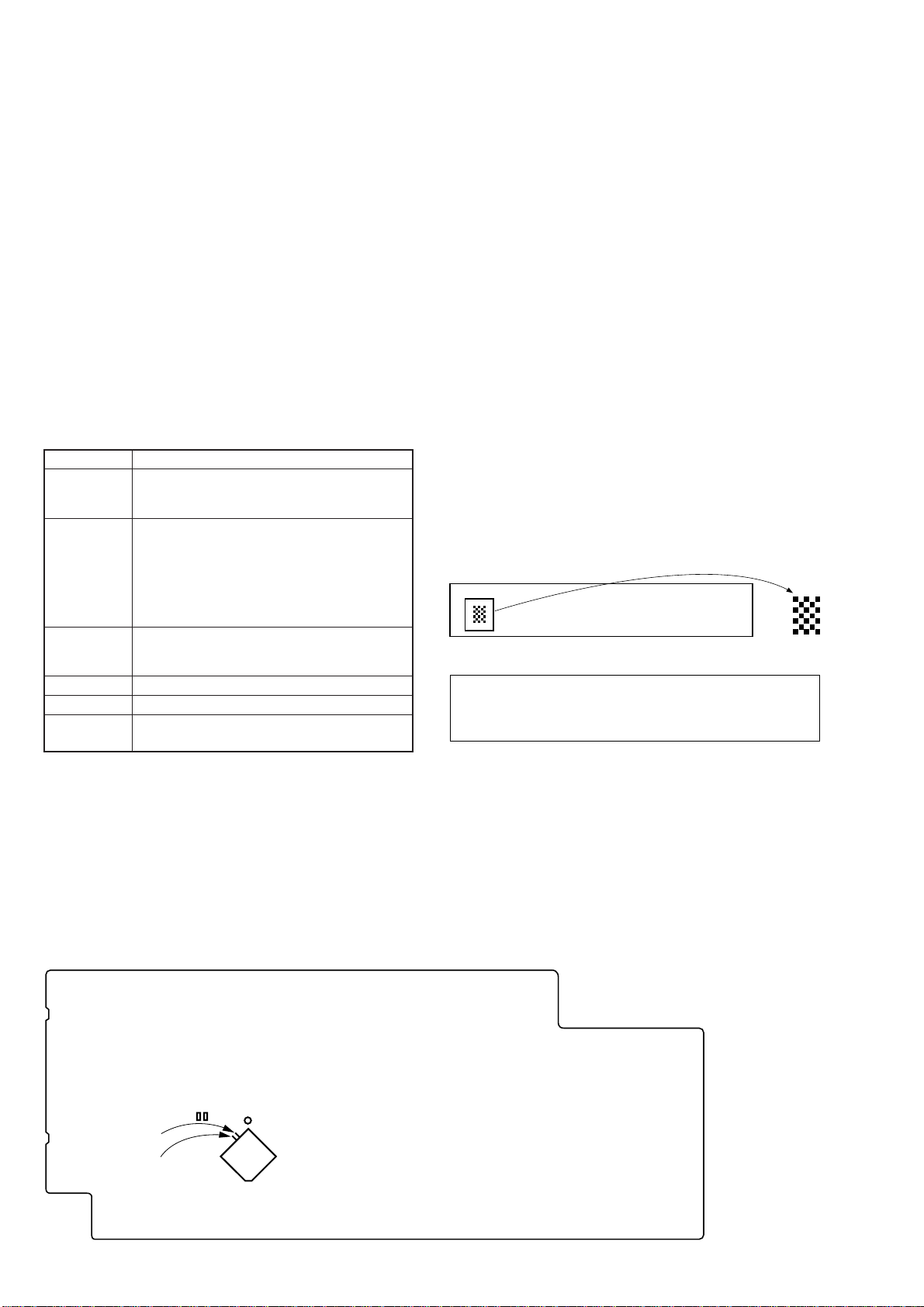

PRECAUTIONS AT SERVICING

y

Handling of wires

(loading motor). (Fig. 3)

Cleaning of optical

pick-up. (Fig. 2)

Alignment of door

drive gear phase.

(Fig. 1)

Destruction of IC due

to shortcircuit. (Fig. 4)

ALIGNMENT OF DOOR DRIVE GEAR

PHASE WITH DOOR (CD) (Fig. 1)

door (CD)

door drive gear

Align a slit of door (CD) with a marking on

the bottom land of gear tooth when the gear

is rotated fully in arrow direction, as shown.

CLEANING OF OPTICAL PICK-UP (Fig. 2)

optical pick-up

magnet assembl

Remove the magnet assembly, and

clean the lens of optical pick-up

through this hole.

6

HANDLING OF WIRES (LOADING MOTOR) (Fig. 3)

When assembling this set after

service, let the wires connected

from loading motor to MAIN board

through a notch of JACK board

and clamp with a lead pin so that

they are not caught in by the gear

(table).

loading motor

MAIN board

lead pin

JACK board

gear (table)

DESTRUCTION OF IC DUE TO SHORTCIRCUIT (Fig. 4)

In removing or mounting the back panel or MAIN board with

the power supplied, an accidental shortcircuit of heatsink to

the power transformer could destroy the IC on heatsink.

heatsink

Power

transformer

Be careful of shortcircuit here.

7

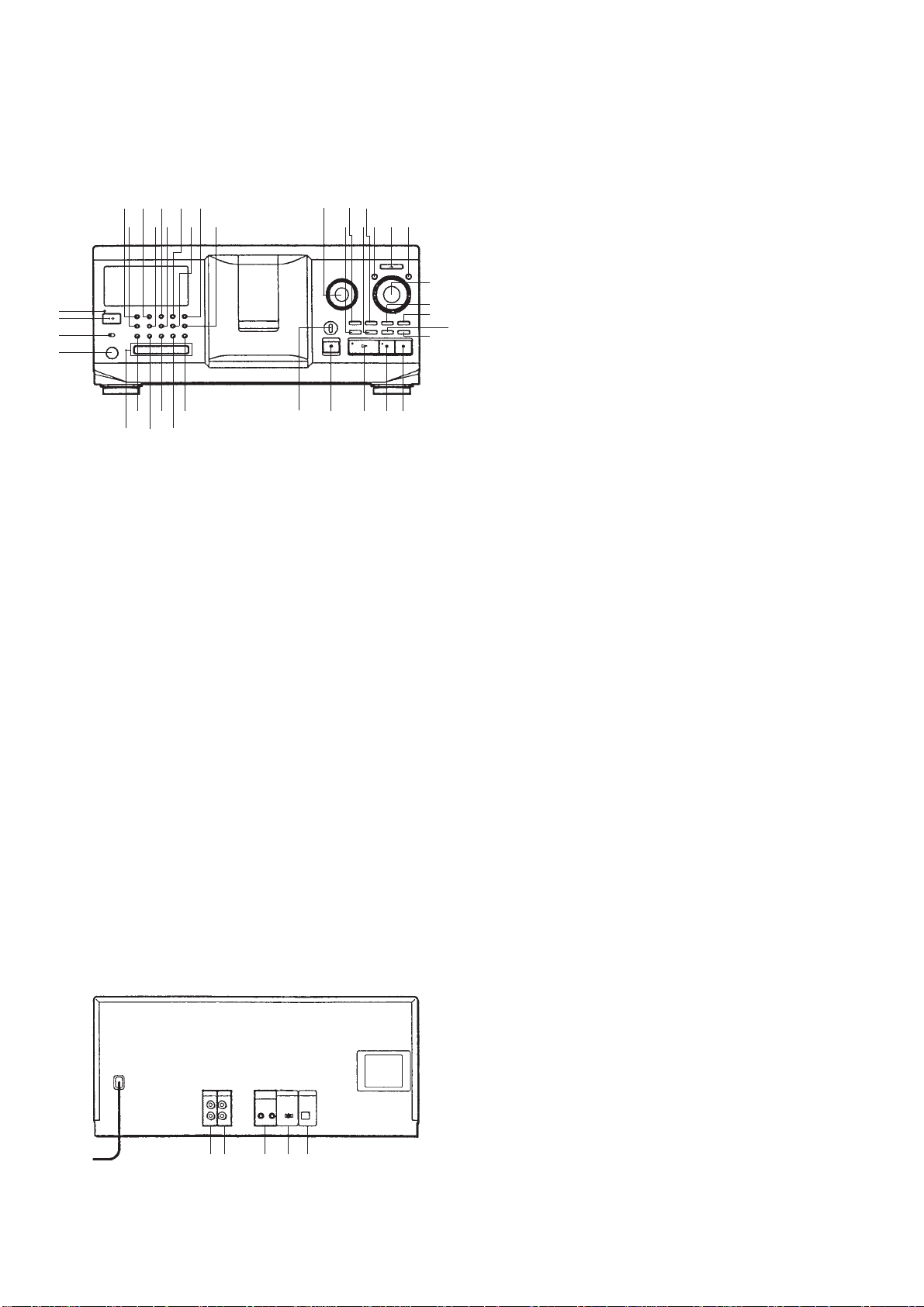

SECTION 2

GENERAL

• LOCATION OF CONTROLS

– Front Panel –

9!¡

57

68

1

2

3

4

@•@ª#º#¡#™

0

!£

!™ !¢

#£

#¢

!∞!§!¶

#∞

!•

!ª

#§

@º

@¡

#¶#•

@™

@£

@¢

@∞

@¶

1 STANDBY indicator

2 1/u button

3 TIMER switch

4 KEYBOARD jack

5 CONTINUE button

6 GROUP1 button and indicator

7 SHUFFLE button

8 GROUP2 button and indicator

9 PROGRAM button

0 GROUP3 button and indicator

@§

!¡ REPEAT button

!™ GROUP4 button and indicator

!£ TIME/TEXT button

!¢ HIT LIST button and indicator

!∞ ≠AMS±, PUSH ENTER knob and button

!§ MEGA CONTROL button and indicator

!¶ EASY PLAY button and indicator

!• X-FADE button

!ª MEMO SEARCH button

@º MENU/NO button

@¡ +100 button

@™ YES button

@£ DISC/CHARACTER, PUSH ENTER knob and button

@¢ CHECK button

@∞ CLEAR button

@§ NO DELAY button

@¶ FADER button

@• IR Repeater window (CX555ES)

@ª GROUP5 button and indicator

#º GROUP6 button and indicator

#¡ GROUP7 button and indicator

#™ GROUP8 button and indicator

#£ GROUP FILE button

#¢ FILTER switch

#∞ § OPEN/CLOSE button

#§ · button and indicator

#¶ P button and indicator

#• p button

– Rear Panel –

8

12

3

4

1 2ND CD IN jack

2 LINE OUT jack

3 CONTROL A1II jack

4 COMMAND MODE CD switch

5 DIGITAL OUT OPTICAL output terminal

5

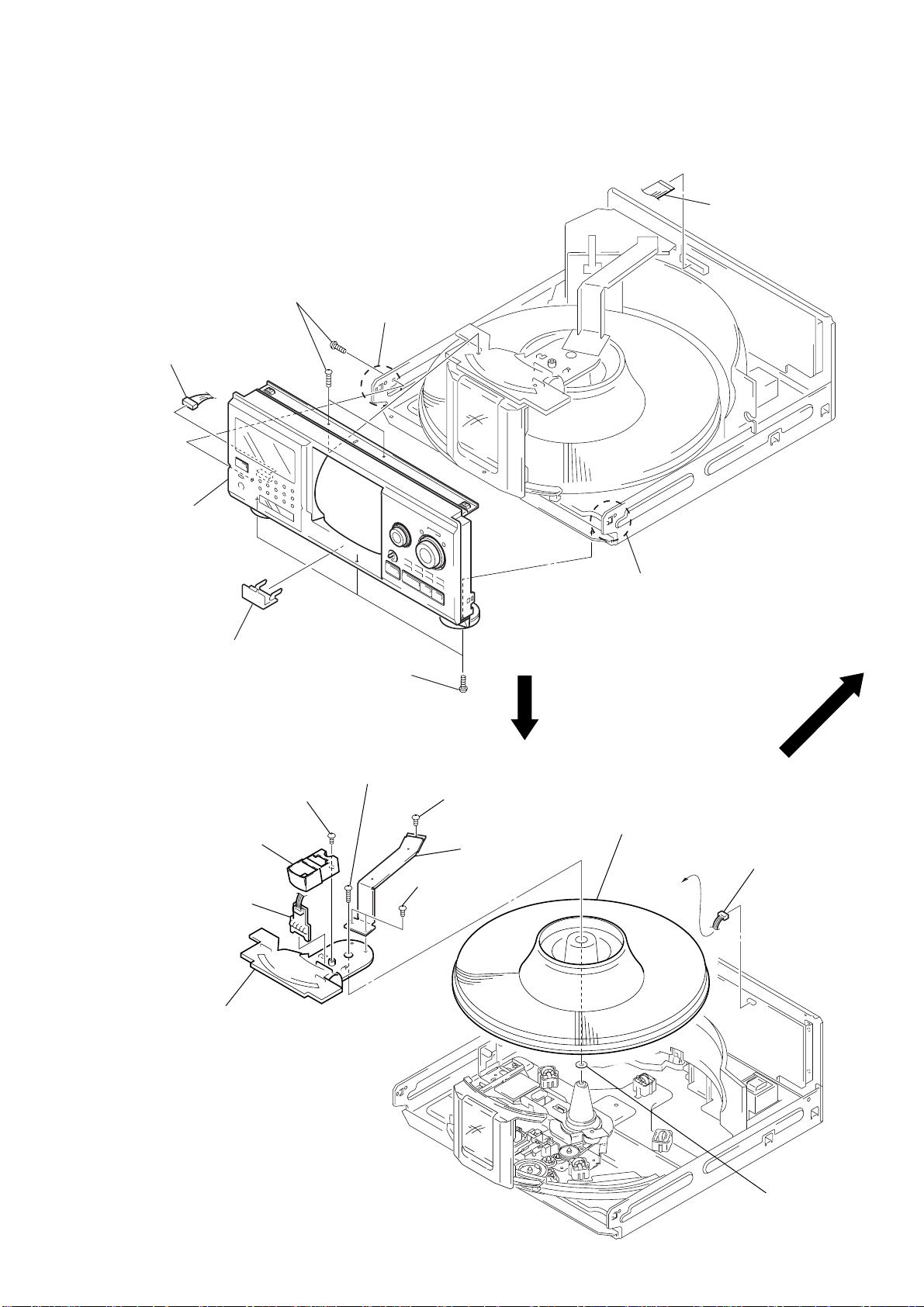

SECTION 3

r

r

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

FRONT PANEL ASSEMBLY

3

three screws

(BVTP3

×

8)

4

claw

2

connector

(CNP203)

1

flat wire

(CN502)

5

front panel

assembly

6

cover

(chassis)

TABLE (300) ASSEMBLY

4

screw

(BVTP3

5

window

6

LED board

×

8)

3

three screws

(BVTP3

7

screw

(BVTP3

4

claw

×

8)

×

16)

2

screw

×

8)

bracket (F.W)

×

8)

9

table (300)

assembly

LED board

1

connecto

(CN504)

2

two screws

(BVTP3

(BVTP3

3

8

guide (door.T)

!º

washe

9

BASE (DOOR, GEAR) ASSEMBLY AND COVER (P. T.)

r

4

Remove the

door assembly

B

9

bracket

(guide.B)

2

two screws

(BVTP3

3

in arrow B

direction.

7

three screws

(BVTP3

×

8)

cover

(front)

×

8)

6

base (door.gear)

assembly

1

connector

(CN509)

!º

two screws

(BVTP3

!¡

×

8)

cove

(P.T)

POP-UP ASSEMBLY

A

5

five screws

(BVTP3

A

×

8)

1

step screw

8

four screws

(BVTP3

3

pop-up assembly

×

8)

10

2

screw

(PTPWH3

×

6)

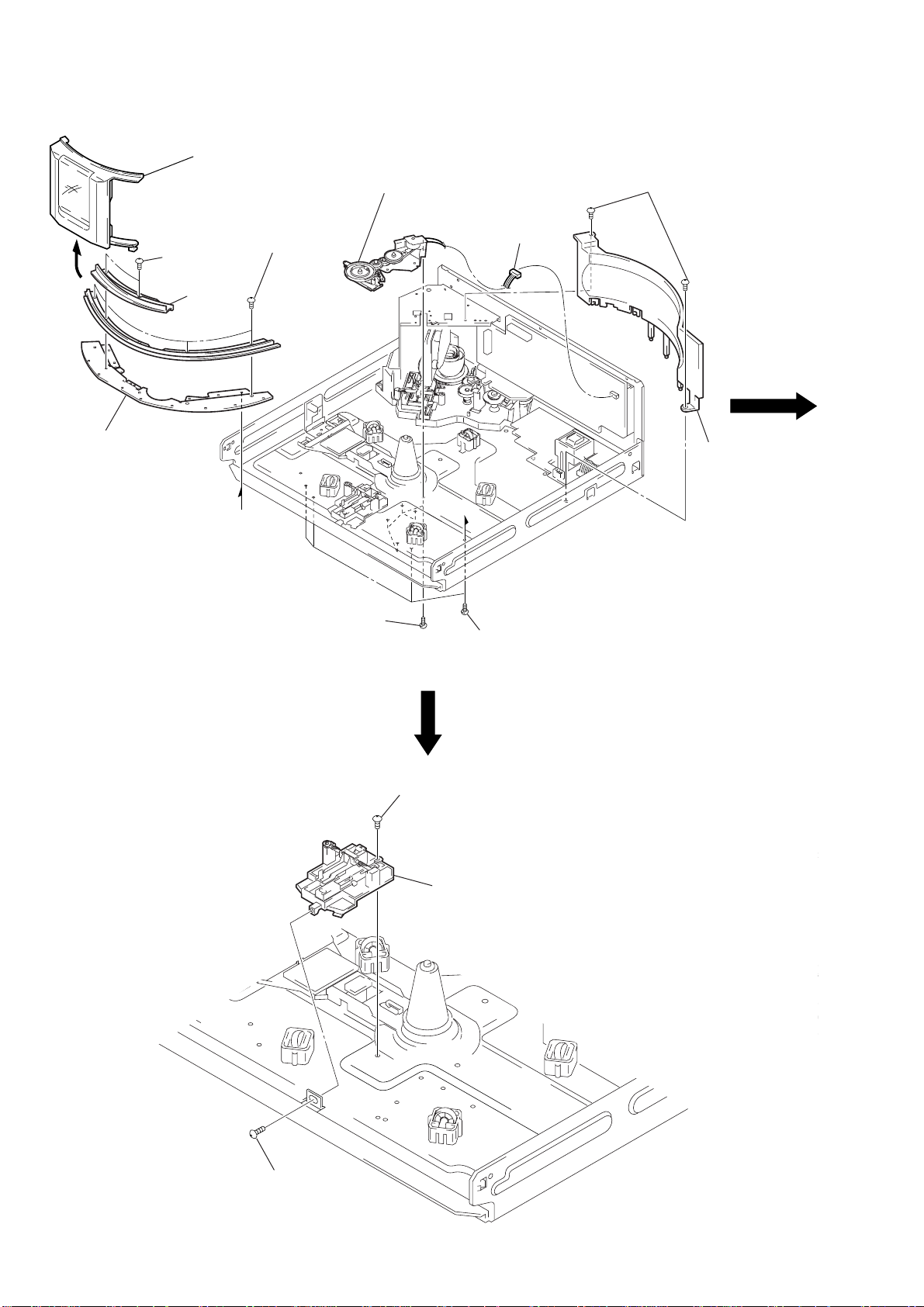

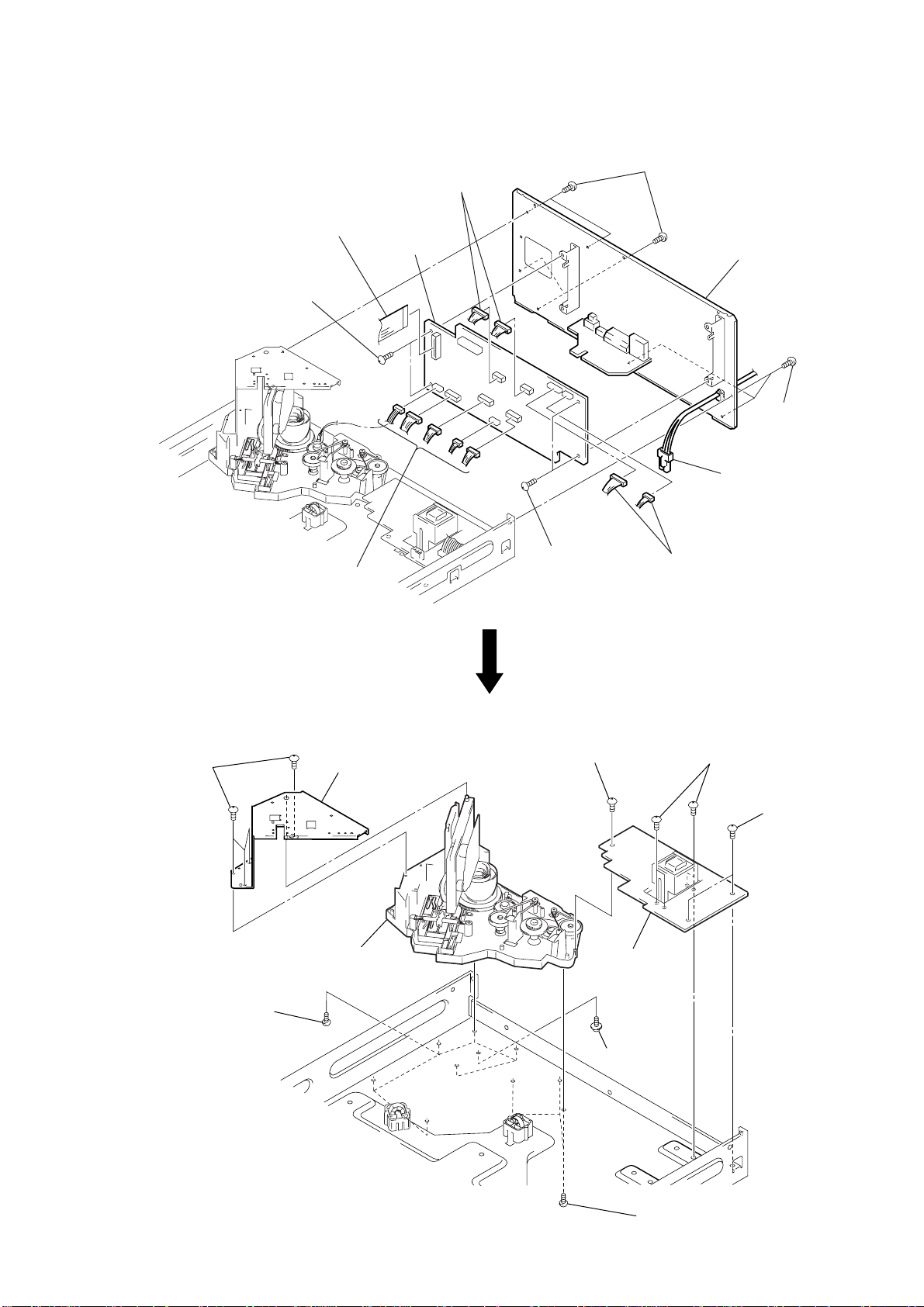

MAIN BOARD AND BACK PANEL SECTION

2

two connectors

(CN503, 507)

1

flat wire

(CN501)

4

MAIN board

3

two screws

(BVTP3

×

8)

2

five connectors

CN505, 508, 510,

()

511, 902

3

two screws

(BVTP3

6

four screws

(3

×

8)

7

back panel

section

6

three screws

(3

×

8)

5

connector

(CN991)

2

×

8)

two connectors

(CN901, 903)

POWER BOARD AND CDM ASSEMBLY

4

four screws

(BVTP3

×

8)

6

six screws

(BVTP3

5

bracket

(top)

8

CDM assembly

×

8)

1

two screws

(BVTP3

×

8)

3

POWER board

7

screw

(PSW3

2

four screws

(PTTWH3

×

8)

×

6)

1

two screws

(BVTP3

×

8)

6

three screws

(BVTP3

×

8)

11

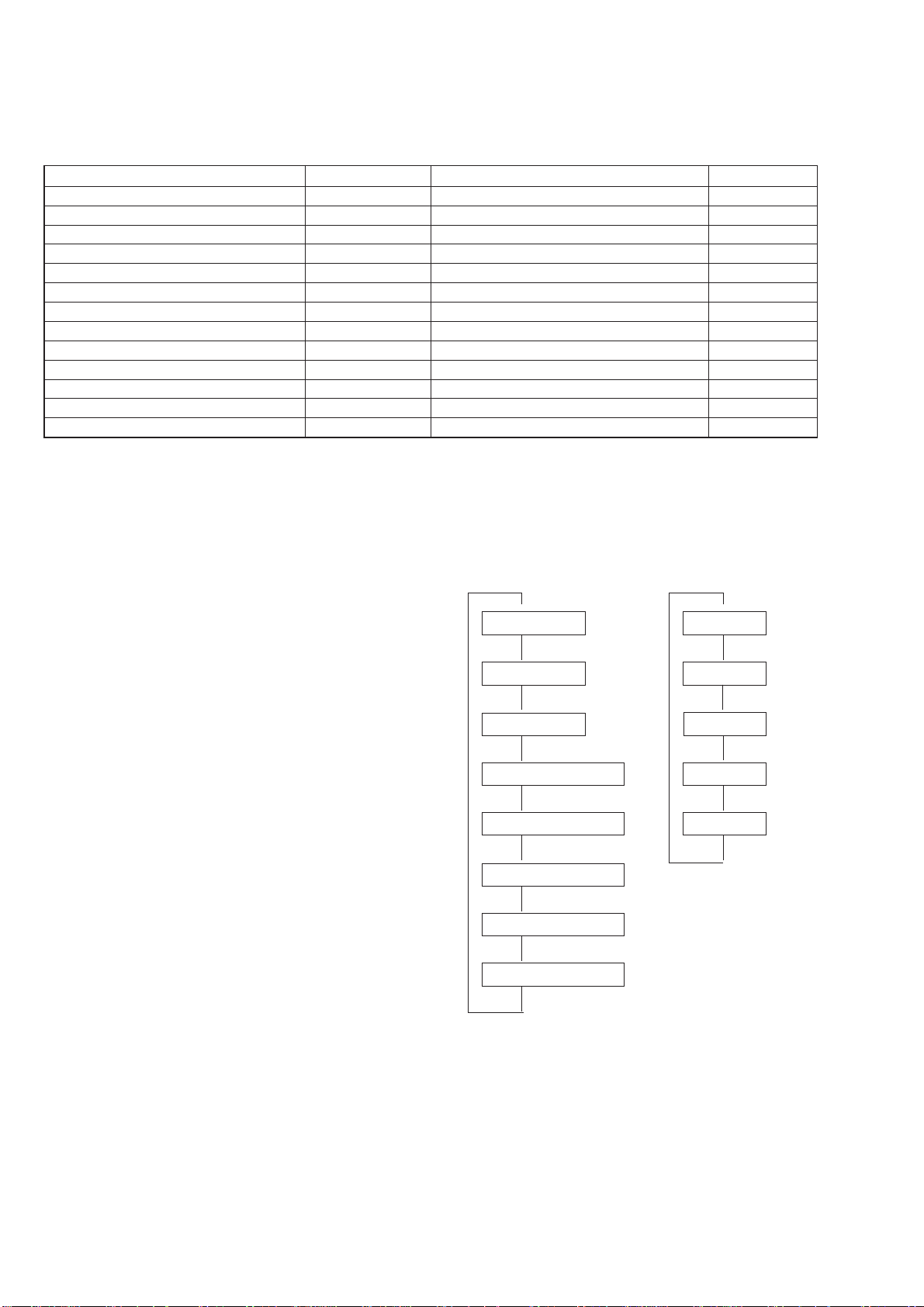

SPECIAL FUNCTION

This unit is provided with several service modes.

Details are shown in the following table.

SECTION 4

SERVICE MODE

Mode name

ALL ERASE

AGING MODE

LOARDING AGING MODE

T ABLE AGING MODE

DOOR POP UP AGING MODE

TABLE LOTATION MODE

TITLE MEMO SHIFT MODE

MODEL NAME DISPLAY

MICROPROCESSOR VERSION DISPLAY

ALL LIT MODE

MECHANISM ADJUSTMENT MODE

SHIPMENT MODE

TITLE MEMO RECORDING CHECK MODE

Note 1

Do not execute unless with a proper reason, otherwise the memory of the title memo recorded by the customer will be erased.

The title memo recording check mode is not required for servicing. Do not execute.

Power supply state

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

Button operation

[CLEAR] + []

[GROUP1] + [OPEN/CLOSE] + [+100]

[GROUP2] + [OPEN/CLOSE] + [+100]

[GROUP3] + [OPEN/CLOSE] + [+100]

[GROUP4] + [OPEN/CLOSE] + [+100]

[GROUP5] + [OPEN/CLOSE] + [+100]

[GROUP7] + [OPEN/CLOSE] + [+100]

[GROUP1] + [] + [+100]

[GROUP2] + [] + [+100]

[GROUP3] + [] + [+100]

[GROUP4] + [] + [+100]

[GROUP5] + [] + [+100]

[GROUP6]

1/u

§

§

§

§

§

§

·

·

·

·

·

+ [] + [+100]

·

ALL ERASE

This mode is used for clearing information such as the title memo.

Do not execute if information such as the title memo is not to be

erased.

Procedure:

While pressing the [CLEAR] button with the power OFF, press

the 1/u button and turn on the power.

[]

The fluorescent indicator tube displays “ALL ERASE” and all

memories will be cleared.

AGING MODE

• Mode which repeatedly changes and plays back discs automatically in the unit.

• It will repeat aging as long as no errors occur.

• If an error occurs during aging, it will stop all servos, motors,

etc. instantaneously, display the error number, and stop operations. However, the stopping conditions differ according to

whether the unit is equipped with the “self-protection function

during errors” described later.

The function serves to maintain the state of the unit when errors

occur.

Sequence of Aging Mode

$

1. Disc change

$

2. Load in

$

3. TOC read

$

4. Access of last track

$

5. 3 second playback

$

6. Access of first track

Order of Disc Change

Remarks

Note 1

Used in adjustment

Note 1

Note 1

$

1. No. 60

$

2. No. 240

$

3. No. 180

$

4. No. 300

$

5. No. 120

$

12

$

7. 3 second playback

$

8. Load out

$

Special Aging Mode Functions

e

The aging mode is provided with the following convenient functions

• Disc setting mode (*1)

• Selection of presence of protection function during error (*2)

• Count function of aging cycle (*3)

*1 Disc setting mode:

5 discs are set before setting the aging mode. This mode makes

the setting of these discs more easy.

*2 Self protection function during errors:

Function which voluntarily corrects errors which occur during normal operations by retries.

If this function is not provided, all operations will be stopped

without retiring. It is suitable for checking errors with low reproducibility .

If this function is provided, and errors can be corrected by

retries, aging will be continued without stopping.

*3 Aging cycle count function:

Functions which displays the number of agings carried out on

the Fluorescent indicator tube in numbers. One aging cycle

consists of five discs.

number of disc tabl

1DISC

CD1

120

Aging Procedure

1. Turn ON the power of the unit. Press the [OPEN/CLOSE]

§

and open the front cover.

2. Change the [COMMANDMODE] switch (S901) on set to [CD1].

3. Press the [AGINGSTART] button of the remote commander

for aging mode (J-2501-123-A).

4. When the disc set mode is set, the [] and [] LEDs blink.

·

P

5. Rotate the [DISC/CHARACTER] dial. The slits (No. 60, 120,

180, 240, 300) for setting the discs will come forward. Insert

the discs into these slits. Do not set the discs in other slits.

6. Set whether the self-protection function during errors is

equipped with the unit. Press the [REPEAT] button. If “RE-

PEA T” is displayed on the fluorescent indicator tube, it means

the function is provided. If “REPEAT” is not displayed, it

means the function is not provided.

Error Display

Disc number

when aging

180

120 E01 #

Disc number

with error

Error code

Aging cycle

number

AGED 10

7. Press the · button.

8. The · LED blinks, the aging mode is set, and aging is

started.

number of agings

9. If errors occur during aging, the error number will be displayed

on the fluorescent indicator tube. (Refer to the following table

for the details of the errors.)

10. Aging will be repeated as long as no errors occur.

11. After each aging cycle, the number displayed on the fluorescent indicator tube will increase.

12. To release this mode, press the 1/

Note: As an alternative to steps 2 and 3, press the [GROUP1] button,

[OPEN/CLOSE] button, and [+100] button at the same time.

§

Error code

Code number

Err 01

Err 02

Err 03

Err 04

Err 05

Err 06

Err *1

Err *2

Err *3

Err *4

Err *5

Err *6

Err *7

DISC sensor check 1

DISC sensor check 2

Table operation check 1

Table operation check 2

Loading operation check 1

Loading operation check 2

BU related check 1

BU related check 2

BU related check 3

BU related check 4

BU related check 5

BU related check 6

BU related check 7

Name

No disc in the specified slit

Disc in other slits

Table motor current over

No table sensor input

Load in timeover

Load out timeover

Access timeover

High speed search NG

Q data read error

BU operation (from focus search to until signal can be read) timeover

GFS monitor error

Focus cannot be imposed by focus search

Auto focus bias adjustment cannot be performed

The * numbers mean the following according to the state of the unit during aging

2 : From chucking to end of TOC read

3 : From end of TOC read to end of last track playback

4 : From end of last track playback to end of first track playback

[]

[]

Contents

[]

u button.

13

LOADING AGING MODE

• This mode is used for repeating loading operations continuously.

• Aging will be performed continuously unless an error occurs.

• When an error occurs, the error code will be displayed on the

fluorescent indicator tube.

Procedure:

1. Set a disc in the DISC 1 slit.

2. With the power ON, while pressing the [GROUP2] button

§

and [OPEN/CLOSE] button, press the [+100] button.

3. When the mode is set, both the [] and [] indicators will

·

P

start to blink.

4. When the [] button is pressed, only the [] indicator will

·

·

blink and aging starts.

1/

5. To release the mode, press the [] button.

u

The error codes displayed during operations and when errors occur are the same as the “AGING MODE” described earlier.

TABLE AGING MODE

• This mode is used for rotating the table randomly.

• Aging will be performed continuously unless an error occurs.

• When an error occurs, the error code will be displayed on the

fluorescent indicator tube.

Procedure:

1. Set discs in slits 1, 2, 99, 100, and 200.

2. With the power ON, while pressing the [GROUP3] button

§

and [OPEN/CLOSE] button, press the [+100] button.

3. When the mode is set, both the [] and [] indicators will

·

P

start to blink.

4. When the [] button is pressed, only the [] indicator will

·

·

blink and aging starts.

1/

u

5. To release the mode, press the

[] button.

During aging, operations will be carried out sequentially in the

order of No. 1, No. 2, No. 100, No. 99, and No. 200 slits.

The error codes displayed during operations and when errors occur are the same as the “AGING MODE” described earlier.

DOOR POP UP AGING MODE

• This mode is used for performing aging of the CD pop up part

and door open/close.

It is used for checking if operations are performed normally.

Procedure:

1. To select a slot to be aged, press the [OPEN/CLOSE] button

§

and rotate the [DISC/CHARACTER] knob with the front door

opened to select a number.

2. With the power ON, while pressing the [GROUP4] button

§

and [OPEN/CLOSE] button, press the [+100] button.

3. When the [] button is pressed, aging starts, and door open/

·

close and up/down operations of the pop up part are performed

continuously.

4. To release the mode, press the [] button.

u

1/

The number of times aging is performed will be displayed on the

fluorescent indicator tube during operations.

TABLE ROTATION MODE

• This mode is used for electrical adjustments. Refer to the section on Electrical Adjustments.

TITLE MEMO SHIFT MODE

• This mode is used for writing title memo information recorded

in this unit in a different unit.

Use it for transferring disc memo contents written by the customer to the new units when replacing the unit, etc.

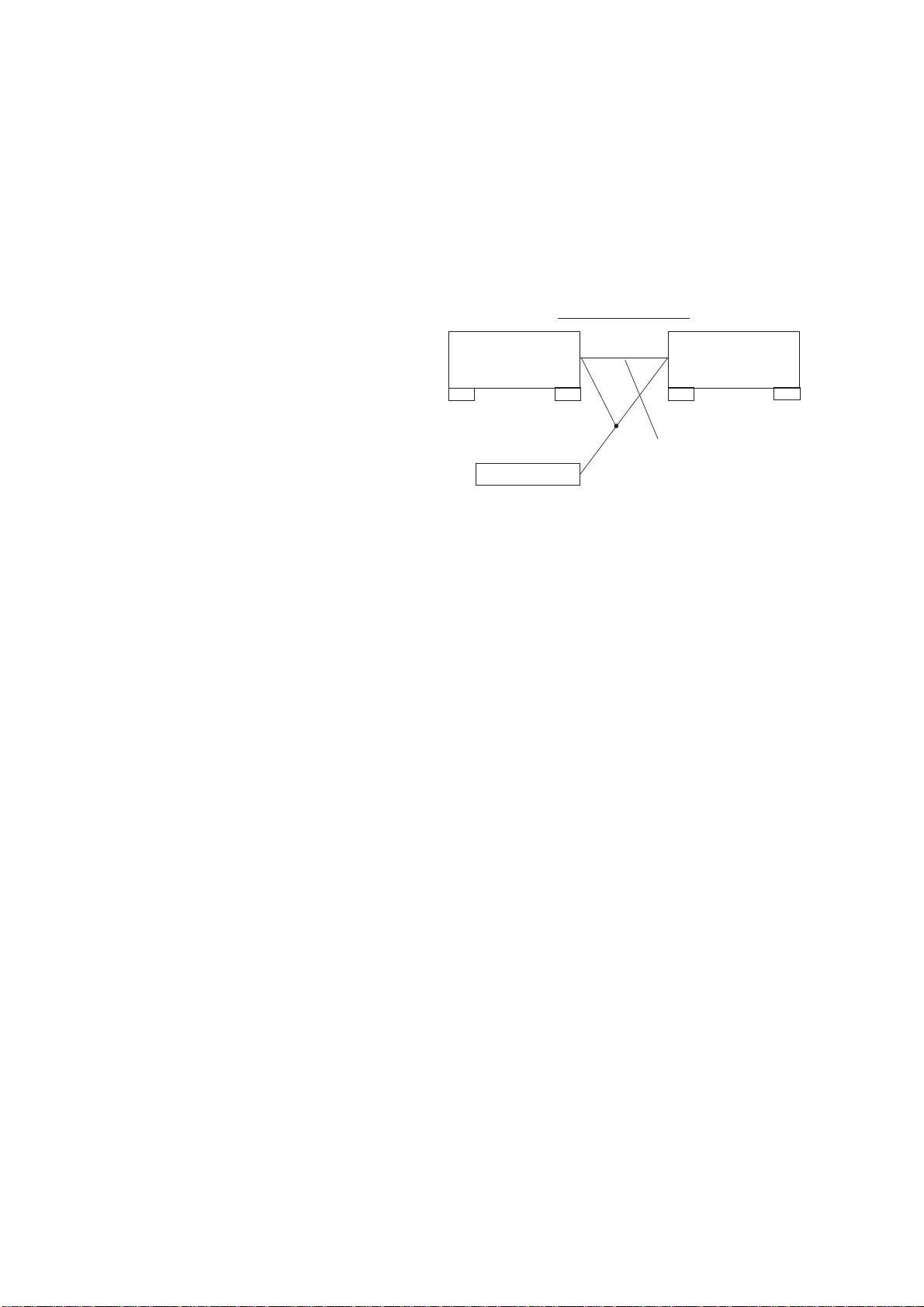

Connection:

Flow of data

This unit

(Copy source)

COMMAND MODE: CD3 COMMAND MODE: CD1

CONTROL A1 II

$

$

CONTROL A1 II connection cord

provided

$

Another unit

$

(Copy destination)

Procedure:

1. Connect two units using the [CONTROLA1II] connection cord

shown in the figure.

2. Set the [COMMANDMODE] switch of the copy source unit

to [CD3] and the [COMMANDMODE] switch of the copy des-

tination unit to [CD1].

3. With the power on, while pressing the [GROUP7] button and

§

[OPEN/CLOSE] button of the copy destination unit, press

[+100] button.

the

4. When the data has been transferred, the fluorescent indicator

tube displays “complete” for about 1 second.

MODEL NAME DISPLAY

• Model names can be displayed on the fluorescent indicator tube

for checking the microprocessor model setting, etc.

Procedure:

With the power ON, while pressing the [GROUP1] and []

·

buttons, press the [+100] button.

The model name is displayed on the fluorescent indicator tube.

MICROPROCESSOR VERSION DISPLAY

• The microprocessor version can be displayed on the fluorescent

indicator tube.

Procedure:

With the power ON, while pressing the [GROUP2] and []

·

buttons, press the [+100] button.

The microprocessor version is displayed on the fluorescent indicator tube.

ALL LIT MODE

• This mode is used for lighting the whole fluorescent indicator

tubes and LEDs.

Procedure:

With the power ON, while pressing the [GROUP3] and []

·

buttons, press the [+100] button.

Both the fluorescent indicator tubes and LEDs will light up completely.

To release this mode, press the [] mode.

u

1/

14

MECHANISM ADJUSTMENT MODE

• This mode is used for mechanism adjustments. Refer to the section on Mechanism Adjustments.

SHIPMENT MODE

• This mode is used for setting the unit to the shipment state.

Do not execute it without a proper reason as it erases the memory

of the title memo recorded by the customer.

Procedure:

[COMMANDMODE] switch to [CD1] and the [TIMER]

Set the

switch to [OFF]. Next, with the power ON, while pressing the

[GROUP5] button and [] button, press the [+100] button. If

the switch state is normal, the model name will be displayed on

the fluorescent indicator tube and the unit will set into the shipment mode.

If the various switches are not set to their designated positions,

error codes will be displayed on the fluorescent indicator tube.

TITLE MEMO RECORDING CHECK MODE

This mode is not required for servicing. Do not execute without a

proper reason.

If executed, the memory of the title memo recorded by the customer will be erased.

·

15

SECTION 5

TEST MODE

5-1. ADJ MODE

1. Turn ON the power of the unit, set disc to disc table, and perform chucking.

2. Remove the power cord from the outlet.

3. To set ADJ mode, connect the ^¡ pin of IC501 (ADJ) of the

MAIN board to ground, and connect the power cord to the

outlet.

In this mode, table rotation and loading operations are not performed because it is taken that the disc has already been chucked.

Note: The same operations are also performed in the following when the

^¡ pin of IC501 (ADJ) is connected to ground after turning on the

power.

• Direct search (movement of sledding motor) is not performed

during accessing

• Ignored even when GFS becomes L

• Ignored even when the Q data cannot be read

• Focus gain does not decrease

ADJ Mode Special Functions Table

Button

CONTINUE

SHUFFLE

PROGRAM

GROUP 3 (3)

GROUP 8 (8)

CHECK

Servo average display

Displays VC, FE, RF, TE and traverse in hexadecimal numbers

Focus bias display

Each time this is pressed, the focus bias is

switched between 1 and 2

(1)

Bias actually set Optimum bias Minimum jitter

(2)

U:Upper aliasing bias L:Lower aliasing bias

Auto gain display

Displays focus, tracking, sledding in

hexadecimal numbers

Turns off the tracking and sledding servo

Turns on the tracking and sledding servo

S-curve observation mode.

(Release this mode when the 1/u button is pressed.)

Function

[]

5-2. KEY AND DISPLAY CHECK MODE

To set this mode, connect the ^º pin of IC501 (AFADJ) on the

MAIN board to ground, and connect the power cord to the outlet.

Note: When this mode is executed, all title memos recorded will be erased.

• When this button is pressed, “line # No. #” will be displayed. However,

these will not be displayed for the following special buttons. However,

these will not be displayed for the following special buttons.

[]

p (stop) button : FL segment check

(Refer to FL Tube Check Patterns)

[]

P (pause) button: FL grid check

(Refer to FL Tube Check Patterns)

[]

The P LED also lights up simultaneously.

[]

· (play) button : All FL segment and grid will light up.

[]

· LED also lights up simultaneously.

TIMER switch : When the switch position is[PLAY], the

[STANDBY] LED lights up. It goes OFF

when set to[OFF].

Each time this button is pressed, the value of the “Go+ ## keys”

increases. Buttons pressed once will not be counted when pressed

again.

FL Tube Check Patterns

Segment check

Magnified

Grid check

A B C D E F G

• Checking Location

– MAIN BOARD (Conductor Side) –

R516

^º

pin (ADJ)

^¡

pin (AFADJ)

R517

75

76

GND

51

IC501

100 1

50

• When the jog dial is rotated to the right, the GROUP LEDs light

up in the order of 1n2..8nHIT LISTnEASY PLA YnMEGA

CONTROLn1.

• When the jog dial is rotated to the left, the GROUP LEDs light

up in the order of 8n 7..1n MEGA CONTROLn EASY

PLAYnHIT LISTn8.

• Abbreviation

FL: Fluorescent Indicator Tube

26

25

16

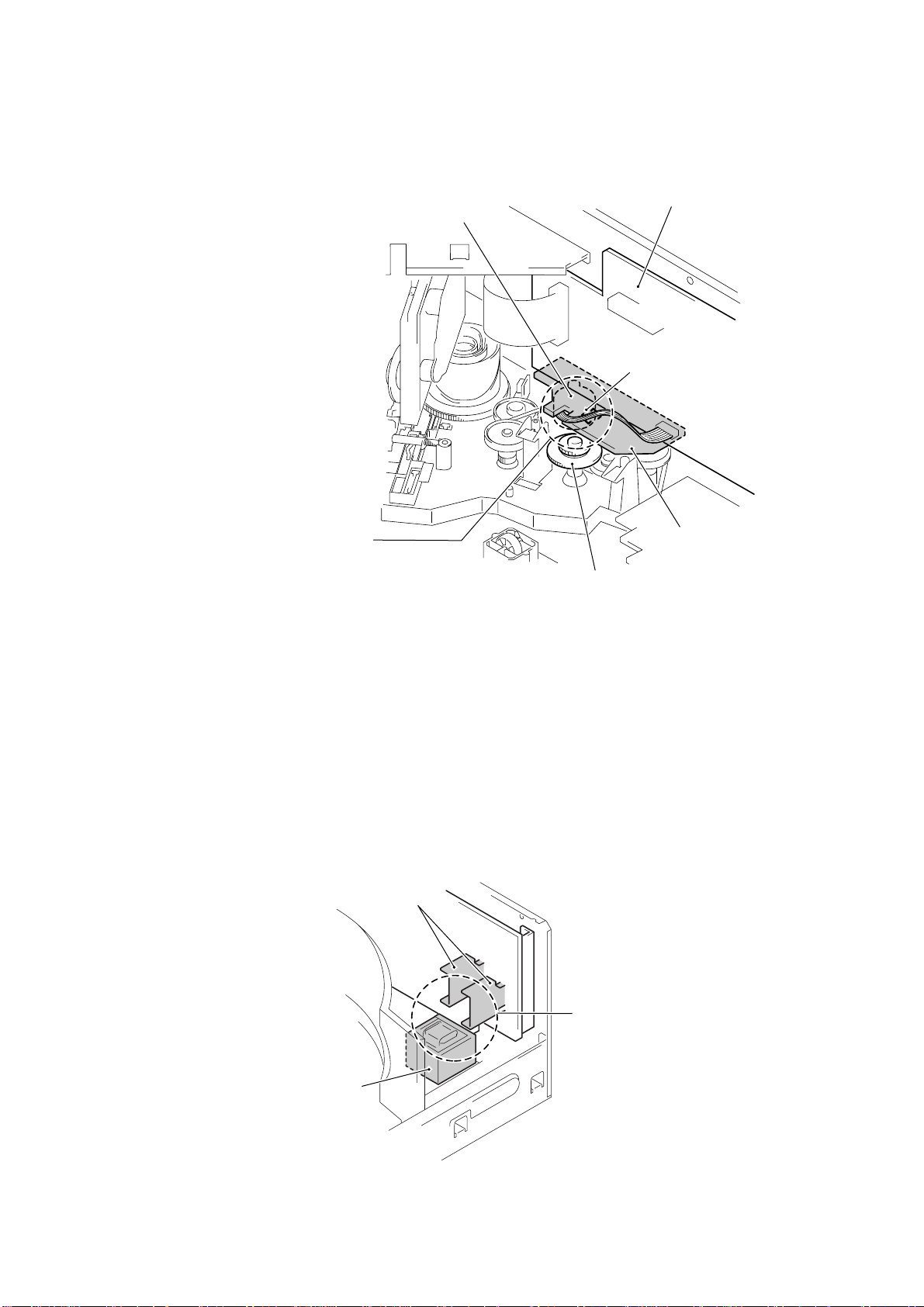

SECTION 6

GROUP 1

GROUP 2

GROUP 4

Lever (pop up)

Fix to the center so that the

lever (POP UP) does not

touch the slit.

Cover (chassis)

At this position,this

part will be locked.

MECHANICAL ADJUSTMENTS

POP UP MECHANISM ADJUSTMENT

1. With the power ON, while pressing the [GROUP4] and []

buttons, press the [+100] button to enter the mechanism adjustment mode.

2. Press the [GROUP1] button to operate the loading mechanism, and continue pressing until the disc table locks. (Fig-1)

3. Press the [GROUP2] button to raise the pop up part.

4. Remove the cover (chassis), loosen the adjusting screw, move

the screwdriver left and right until the lever (POP UP) does

not touch the slit wall, and secure the screw. (Fig-2)

The following buttons have special functions in this mode.

[GROUP1] button: Loading mechanism IN operation

[GROUP5] button: Loading mechanism OUT operation

[GROUP2] button: Pop up part UP operation

[GROUP6] button: Pop up part DOWN operation

·

Fig-1

Fig-2

17

SENSOR ADJUSTMENT

1. With the power ON, while pressing the [GROUP4] and []

·

buttons, press the [+100] button to enter the mechanism adjustment mode.

2. Press the [GROUP1] button to operate the loading mechanism, and continue pressing until the disc table locks. (Fig-3)

3. Loosen the fixing screw, mo v e the holder (TABLE SENSOR)

slightly, and when the LED (green) of the [] button switches

to the LED (orange) of the [] button (or vice versa), secure

P

·

the holder (TABLE SENSOR). (Fig-4)

4. Moving the disc table right and left with a hand after the screw

is fixed, the table will move by the play of a disc table. If the

LEDs light up alternately, the adjustment will be performed

correctly. (Fig-4)

Linked with P indicator

GROUP 1

PAUSE button

GROUP 4

PLAY button

PLAY indicator

Linked with

·

indicator

PAUSE indicator

Fixed screws

At this position,this

part will be locked.

Fig-3

Holder (table sensor)

18

Table assembly

Swing

Fig-4

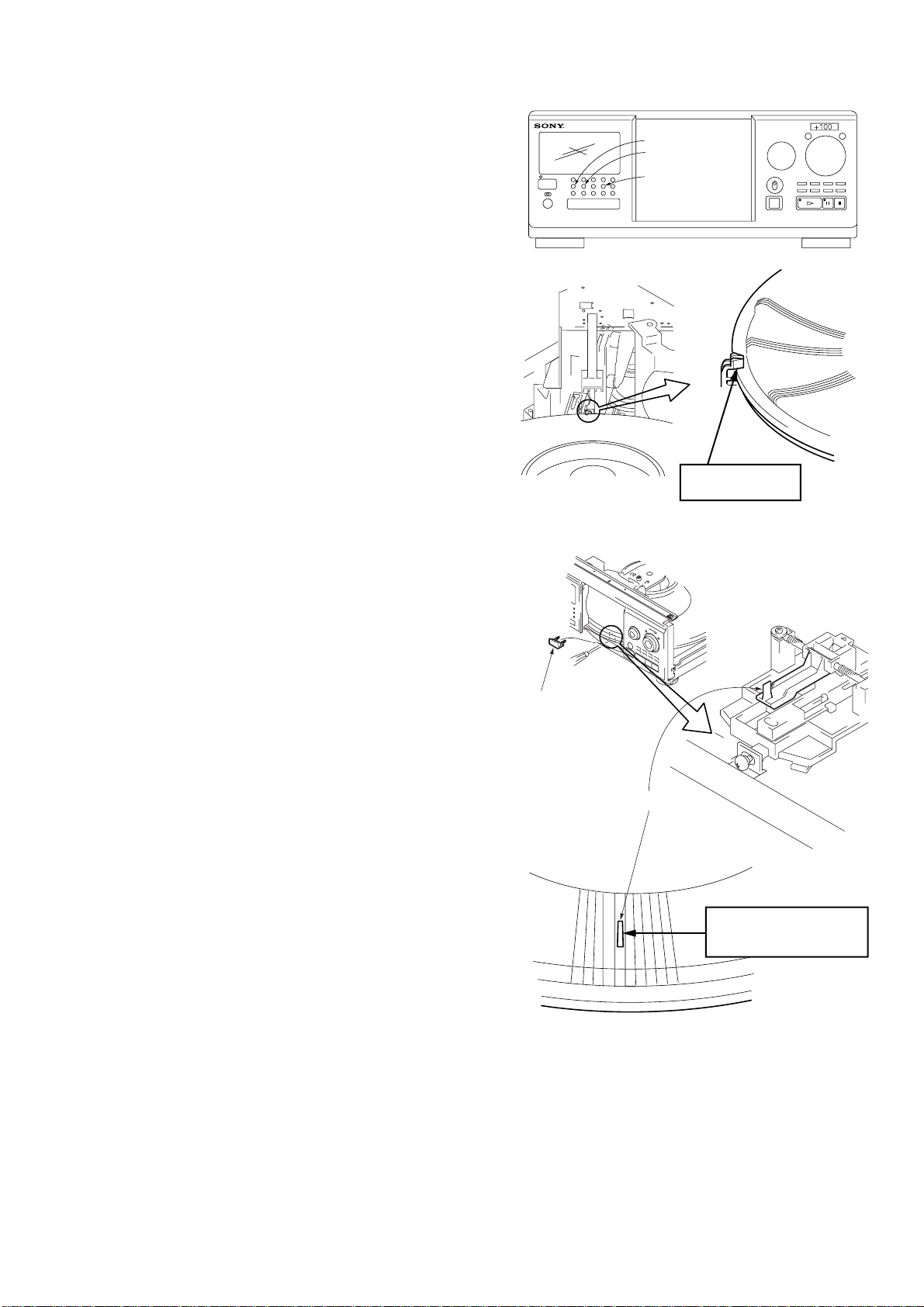

SECTION 7

e

e

V

oscilloscope

BD board

TP (TE)

TP (VC)

ELECTRICAL ADJUSTMENT

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10 MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the following checks.

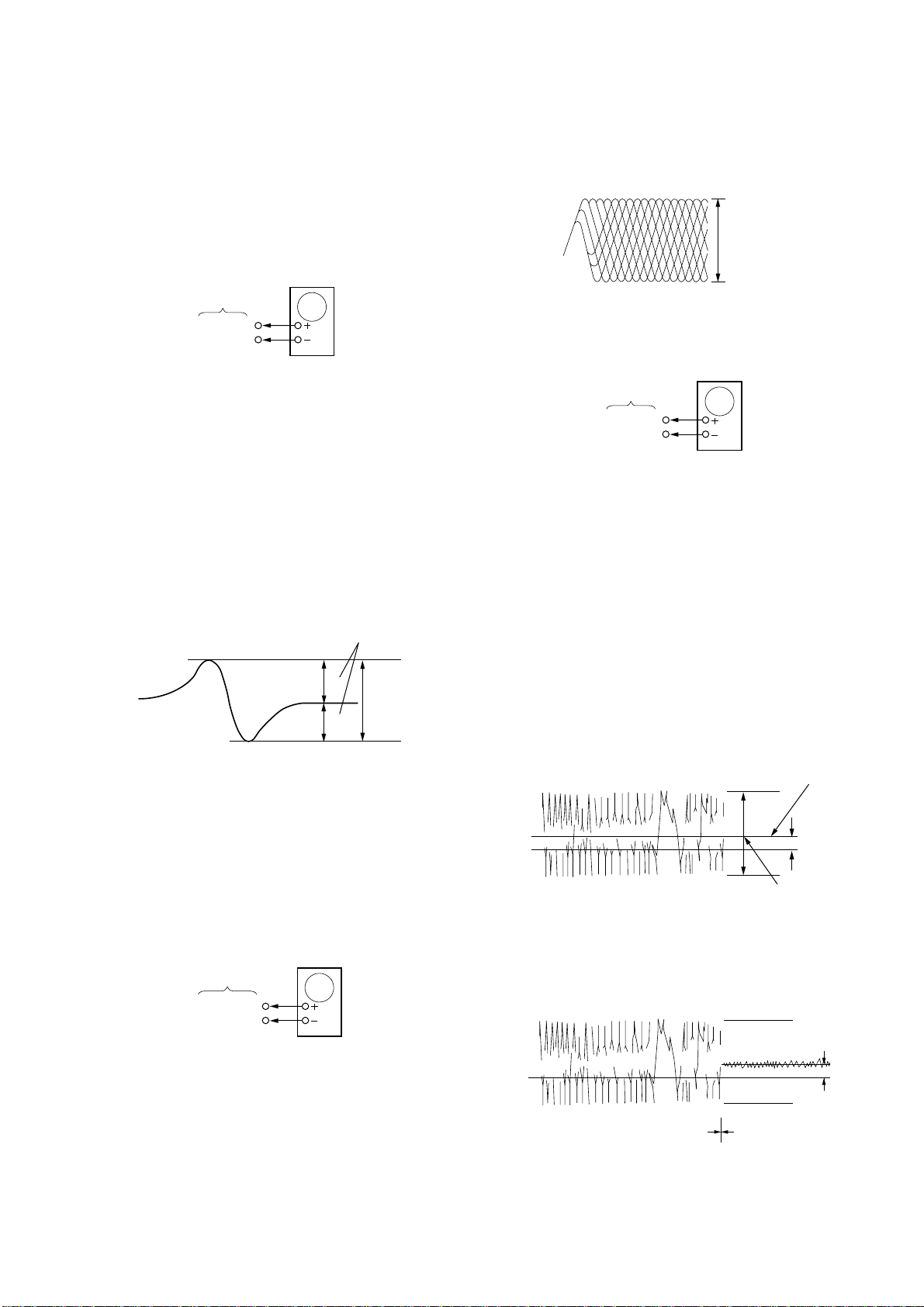

S-Curve Check

oscilloscop

BD board

TP (FE1)

TP (VC)

Procedure :

1. Chuck the disc (YEDS-18) beforehand, and remove the power

cord from the outlet.

2. Connect oscilloscope to test point TP (FE1) on BD board.

3. Connect ^¡ pin of IC501 (ADJ) on MAIN board to ground

with lead wire.

4. The ADJ mode is set when the power cord is inserted into the

outlet and power is supplied.

5. The fifth track is played automatically.

6. Press the [CHECK] button.

7. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within

3±1 Vp-p.

S-curve waveform

symmetry

A

Within 3 ± 1 Vp-p

B

8. Pressing the 1/u button stops the output of the waveform

[]

(s curve).

9. After check, disconnect the lead wire connected in step 3.

Note : • Try to measure several times to make sure than the ratio of A :

B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the brightness

to obtain best waveform.

Note: A clear RF signal waveform means that the shape “≈” can be clearly

distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV: 200 m

TIME/DIV: 500 ns

level: 1.2 Vp-p

+0.25

–0.20

Adjustment Location: BD board

E-F Balance Check

Procedure :

1. Chuck the disc (YEDS-18) beforehand, and disconnect the

power cord from the outlet.

2. Connect oscilloscpe to test point TP (TE) on BD board.

3. Connect ^¡ pin of IC501 (ADJ) on MAIN board to ground

with lead wire.

4. The ADJ mode is set when the power cord is inserted into the

outlet and power is supplied.

5. The fifth track is played automatically.

6. Press the [GROUP3] button. (The tracking servo and the sledding servo are turned OFF.)

7. Check the level B of the oscilliscopes waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 22%

Traverse waveform

Center of the waveform

B

0V

A (DC voltage)

Adjustment Location: BD board

RF Level Check

oscilloscop

BD board

TP (RFO)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (RFO) on BD board.

2. Turn Power ON.

3. Put disc (YEDS-18) in to play the number five track.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

±

level : 1.3

0.6 mVp-p

8. Press the [GROUP8] button. (The tracking servo and sledding servo are turned ON.) Confirm the C (DC voltage) is almost equal to the A (DC voltage) is step 7.

Traverse waveform

0V

Tracking servo

Sledding servo

OFF

Tracking servo

Sledding servo

ON

C (DC

voltage)

9. Disconnect the lead wire connected in step 3.

Adjustment Location: MAIN board

19

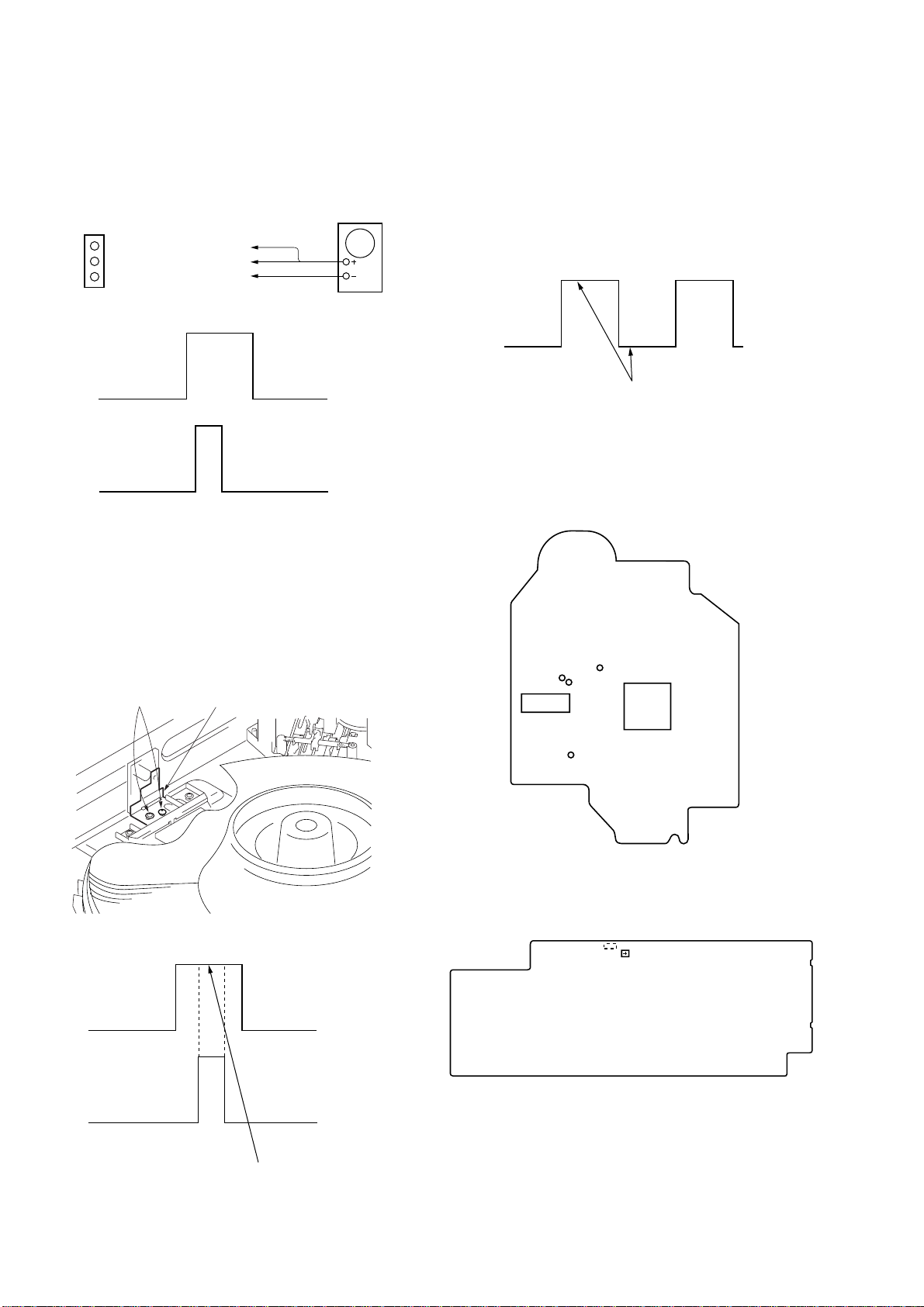

Disc In Detect Sensor Adjustment

D.S

Adjust so that these widths

become the same.

Be sure to perform this adjustment after sensor adjustment in

MECHANICAL ADJUSTMENT .

Connection:

MAIN board

CN506

T.P

GND

D.S

T.P: Pin

D.S: Pin

GND: Pin

1

3

2

oscilloscope

W aveform:

D.S

5. Rotate the [DISC/CHARACTER] knob in the counterclockwise direction and the disc table starts to rotate in the same

direction. Check that the waveform at this time is the same as

that in step 4. If larger by a considerable extent, rotate the

[DISC/CHARACTER] knob in the clockwise direction and the

disc table starts to rotate in the same direction. Repeat from

step 4.

6. Rotate RV501 of the MAIN board and adjust so that the H and

L portions of the D.S waveform become the same.

Adjustment Location: MAIN board

P.T

1. Connect the oscilloscope to Pins 1, 2, and 3 of CN506 of

the MAIN board.

2. Check that no discs are loaded in the unit.

3. With the power ON, while pressing the [GROUP5] and

§

[OPEN/CLOSE] buttons, press the [+100] button. The disc

table starts to rotate in the clockwise direction.

4. Loosen the fixing screw , move the mounting board (SENSOR),

and secure the mounting board (SENSOR) at the point the H

portion of the P.T waveform comes the center of the H portion

of the D.S waveform.

Fixing screw Mounting board (SENSOR)

• Adjustment Location

– BD BOARD (Conductor Side) –

TP

TP

(VC)

(RFO)

TP

(TE)

IC101

TP

(FE1)

IC103

– MAIN BOARD (Component Side) –

CN506

3

1

RV501

20

D.S

P.T

Should be at the center

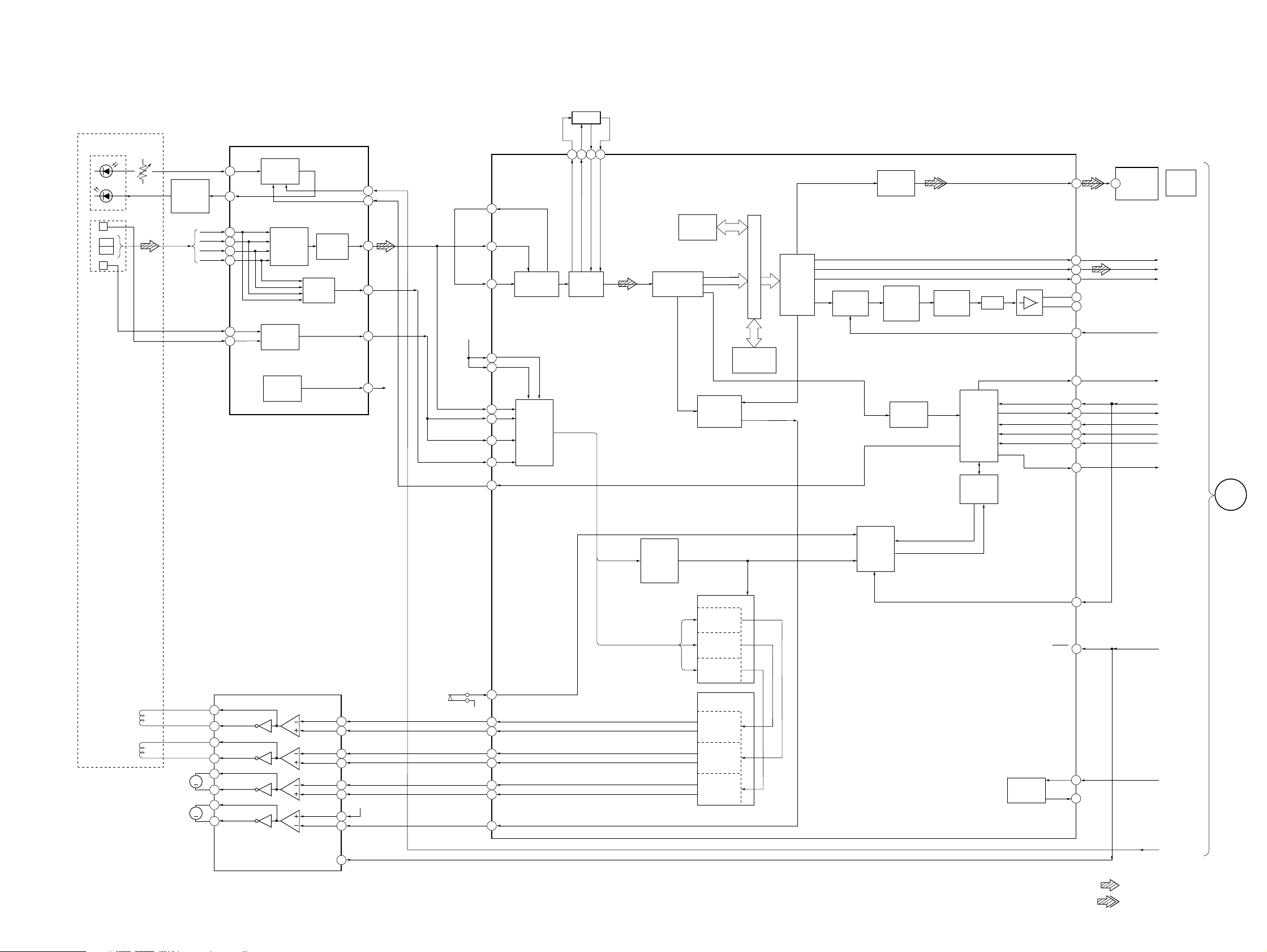

8-1. BLOCK DIAGMRAM – BD Section –

CDP-CX333ES/CX555ES

SECTION 8

DIAGRAMS

OPTICAL PICK-UP

(KSS-213B/C2N)

LASER

DIODE

PD

LD

DETECTOR

E

PD1

PD2

F

LD

POWER

AUTOMATIC

POWER

CONTROL

Q101

APC LD

AMP

SUMMING

AMP

TRACKING

ERROR

AMP

VC

BUFFER

IC103

RF

RF AMP,FOCUS/TRACKING ERROR AMP

PD

4

LD

3

A

5

B

6

C

7

D

8

F

10

E

11

FOCUS

ERROR

AMP

RF EQ

AMP

HOLDSW

LDON

RFO

FILTER

INTERNAL BUS

ERROR

CORRECTOR

IC101

D/A

INTERFACE

SERIAL

IN

INTERFACE

SERVO

INTERFACE

DIGITAL

OUT

OVER

SAMPLING

DIGITAL

FILTER

SUBCODE

PROCESSOR

3rd ORDER

NOISE

SHAPER

PWM

CPU

INTERFACE

SERVO

AUTO

SEQUENCER

DOUT

LRCK

PCMD

BCK

LOUT1

LOUT2

SYSM

SCOR

SQCK

SQSO

DATA

CLOK

SENS

60 3

61

62

63

72

75

20

XLAT

IC901

OPTICAL

TRANSCEIVER

4

2

1

5

6

7

8

DIGITAL

OPTICAL

LRCK

ADATA

BCLK

AMUTE

SCOR

SQCK

SUBQ

DATA

XLT

CLOK

SENS

OUT

A

MAIN

SECTION

(Page 22)

5654 53 55

FILI

PCO

FILO

CLTV

21

22

16

FE

14

TE

13

VC

12

VC

ASYO

48

RFAC

51

ASYI

ASYMMETRY

49

CORRECTION

VC

VC

38

CE

42

RFDC

43

TE

41

40

39

14

SE

FE

XLON

A/D

CONVERTER

DIGITAL

PLL

DIGITAL SIGNAL PROCESSOR,DIGITAL SERVO PROCESSOR,DIGITAL FILTER,D/A CONVERTER

16K

RAM

EFM

DEMODULATOR

DIGITAL

CLV

MIRR

DFCT

FOK

DETECTOR

SCLK

XRST

XTAI

XTAO

9

3

66

67

XRST

16.9MHz

AGC

SERVO DSP

FOCUS

SERVO

TRACKING

SERVO

FOCUS/TRACKING COIL DRIVE,

CH1 OUT F

TRACKING

COIL

FOCUS

COIL

M102

(SLED)

M101

(SPINDLE)

05

1

CH1 OUT R

2

CH3 OUT F

16

CH3 OUT R

17

CH2 OUT F

13

M

CH2 OUT R

12

CH4 OUT F

27

M

CH4 OUT R

26

IC102

SPINDLE/SLED MOTOR DRIVE

CH1 R IN

CH1 F IN

CH3 R IN

CH3 F IN

CH2 R IN

CH2 F IN

VB IN

VS IN

MUTE

4

5

19

20

10

9

VC

23

24

15

S101

(LIMIT IN)

D+5V

SSTP

27

TFDR

30

TRDR

31

FFDR

32

FRDR

33

SRDR

29

SFDR

28

MDP

26

SLED

SERVO

PWM

GENERATOR

TRACKING

PWM

GENERATOR

FOCUS

PWM

GENERATOR

SLED

PWM

GENERATOR

TIMING

LOGIC

• SIGNAL PATH

: CD PLAY(ANALOG OUT)

: CD PLAY(DIGITAL OUT)

2121

Loading...

Loading...