SURVEYING INSTRUMENTS

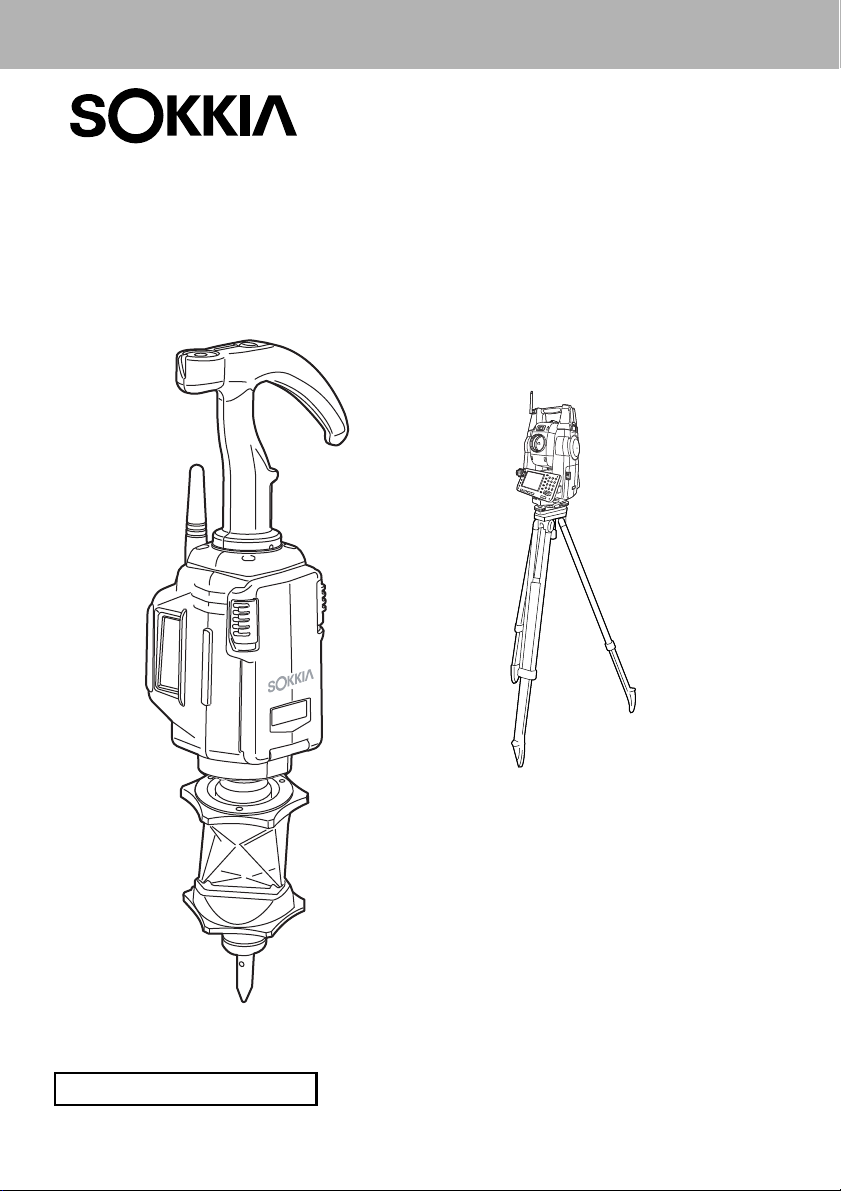

On-demand Remote Control System

RC-PR4

Class 1 Laser Product

SYSTEM MANUAL

:This is the mark of the Japan Surveying

Li-ion

S Li-ion

Instruments Manufacturers Association.

SURVEYING INSTRUMENTS

On-demand Remote Control System

RC-PR4

Class 1 Laser Product

• Thank you for selecting the On-demand Remote Control System RC-PR4.

• Please read this operator's manual carefully before using this product.

• Verify that all equipment is included.

C“10.1 Standard Equipment”

• The specifications and general appearance of the instrument are subject to change without prior

notice and without obligation by Sokkia Topcon Co., Ltd. and may differ from those appearing in

this manual.

• The content of this manual is subject to change without notice.

• Some of the diagrams shown in this manual may be simplified for easier understanding.

SYSTEM MANUAL

HOW TO READ THIS MANUAL

Symbols

The following conventions are used in this manual.

G : Indicates precautions and important items which should be read before

operations.

C : Indicates a cross-reference to refer to for additional information.

$ : Indicates supplementary explanation.

& : Indicates an explanation for a particular term or operation.

[DIST] etc. : Indicates softkeys on the total station display.

{ESC} etc. : Indicates operation keys on the total station.

I POWER etc. : Indicates RC-Controller LEDs.

Notes regarding manual style

• Except where stated, "SRX" or "Series SRX" means SRX1X/SRX2X/SRX3X/SRX5X, "NET" means

NET05AX and NET1AX, "total station" means SRX/NET in this manual.

• Screens and illustrations used in this manual are of SRX (with RC-TS3 handle).

• The On-demand Remote Control System adds remote control functions to the total station. Please

read this manual in conjunction with the operator’s manual for your instrument.

• The content of this system manual is mainly concerned with explaining the operation of the RCController. For precautions and operating method, please read the operator’s manual for your total

station or data collector.

• Bluetooth

• All other company and product names featured in this manual are trademarks or registered

trademarks of each respective organization.

®

is a registered trademark of Bluetooth SIG, Inc.

ii

CONTENTS

1. PRECAUTIONS FOR SAFE OPERATION ................ 1

2. PRECAUTIONS .......................................................... 3

3. LASER SAFETY INFORMATION ............................... 6

4. ON-DEMAND REMOTE CONTROL FUNCTIONS .... 7

4.1 Turning Operation Flow ..................................................... 8

4.2 Measurement Flow ............................................................ 9

5. SYSTEM CONFIGURATION .................................... 12

5.1 Parts of the RC-Controller ............................................... 12

5.2 System Configuration of the SRX/NET ........................... 14

5.3 System Configuration of the RC-Controller ..................... 15

6. SETTINGS FOR THE SRX/NET .............................. 20

6.1 Settings for Bluetooth Communication ............................ 20

6.2 Settings for Auto Pointing and Auto Tracking ................. 22

6.3 Performing Turning from the SRX/NET ........................... 24

6.4 Turning Error ................................................................... 26

7. BASIC OPERATION ................................................. 27

7.1 Using the Battery ............................................................. 27

7.2 Configuring Bluetooth Connections to the SRX/NET ....... 28

7.3 Button Operations ........................................................... 29

7.4 Communication Status .................................................... 31

7.5 Calibrating the Electronic Compass ................................ 32

8. ERROR INDICATIONS ........................................... 35

9. TROUBLESHOOTING ............................................. 36

10.

STANDARD EQUIPMENT AND OPTIONAL ACCESSORIES

10.1 Standard Equipment ....................................................... 38

10.2 Optional Accessories ...................................................... 38

10.3 Power Supply System ..................................................... 40

38

iii

CONTENTS

11. SPECIFICATIONS ....................................................41

12. EXPLANATION ........................................................ 44

12.1 High Accuracy with the 360° Prism.................................. 44

13. REGULATIONS ........................................................ 45

iv

1. PRECAUTIONS FOR SAFE OPERATION

For the safe use of the product and prevention of injury to operators and other persons as well as

prevention of property damage, items which should be observed are indicated by an exclamation point

within a triangle used with WARNING and CAUTION statements in this system manual.

The definitions of the indications are listed below. Be sure you understand them before reading the

main text.

Definition of Indication

C

C

General

C

D

G

E

WARNING

CAUTION

This symbol indicates items for which caution (hazard warnings

inclusive) is urged. Specific details are printed in or near the symbol.

J

This symbol indicates items which are prohibited.

Specific details are printed in or near the symbol.

D

This symbol indicates items which must always be performed.

Specific details are printed in or near the symbol.

I

Warning

Do not use the unit in areas exposed to high amounts of dust or ash, in areas where

there is inadequate ventilation, or near combustible materials. An explosion could occur.

Do not perform disassembly or rebuilding. Fire, electric shock, burns, or hazardous

radiation exposure could result.

When securing the instrument in the carrying case make sure that all catches, including

the side catches, are closed. Failure to do so could result in the instrument falling out

while being carried, causing injury.

Ignoring this indication and making an operation error could possibly

result in death or serious injury to the operator.

Ignoring this indication and making an operation error could possibly

result in personal injury or property damage.

Caution

C

When mounting the instrument on the pole, tighten the pole-securing knob securely.

Failure to tighten the knob properly could result in the instrument falling off the pole,

E

causing injury.

Do not carry the pole with the tip pointed at other persons. A person could be injured if

D

struck by the shoe.

Keep hands and feet away from the tip of the pole when fixing the pole in the ground. A

E

hand or foot stab wound could result.

1

1. PRECAUTIONS FOR SAFE OPERATION

Do not use the carrying case as a footstool. The case is slippery and unstable so a

D

person could slip and fall off it.

Power Supply

Warning

C

Do not short circuit. Heat or ignition could result.

D

Do not place articles such as clothing on the battery charger while charging batteries.

D

Sparks could be induced, leading to fire.

Do not use batteries other than those designated. An explosion could occur, or abnormal

D

heat generated, leading to fire.

Use only the specified battery charger to recharge batteries. Other chargers may be of

E

different voltage rating or polarity, causing sparking which could lead to fire or burns.

Do not use the battery for any other purpose. Fire or burns caused by ignition could

D

result.

Do not heat or throw batteries into fire. An explosion could occur, resulting in injury.

H

To prevent shorting of the battery in storage, apply insulating tape or equivalent to the

E

terminals. Otherwise shorting could occur resulting in fire or burns.

Do not use batteries or the battery charger if wet. Resultant shorting could lead to fire or

D

burns.

Caution

C

Do not touch liquid leaking from batteries. Harmful chemicals could cause burns or

F

blisters.

Bluetooth wireless technology

Warning

C

Do not use within the vicinity of hospitals. Malfunction of medical equipment could

D

result.

Use the instrument at a distance of at least 22 cm from anyone with a cardiac

pacemaker. Otherwise, the pacemaker may be adversely affected by the

E

electromagnetic waves produced and cease to operate as normal.

Do not use onboard aircraft. The aircraft instrumentation may malfunction as a result.

D

Do not use within the vicinity of automatic doors, fire alarms and other devices with

automatic controls as the electromagnetic waves produced may adversely affect

D

operation resulting in an accident.

2

2. PRECAUTIONS

Precautions

• Protect instruments from heavy shocks or vibration.

• Never touch the RC-Controller laser projection port or the total station beam detector. The ability of

the system to perform Turning may be adversely affected.

• Turn the power OFF before removing the battery from the RC-Controller.

• Remove the battery when the RC-Controller is not used for long periods.

• Do not allow sand to come into contact with the battery cover catches or the 360° Sliding Prism

ATP1S release button. Otherwise sand particles could jam the motion of the catches/button. In the

event that sand has jammed the catches/button, hold the unit so that the catches/button are facing

downward and operate the catches/button several times until the sand has fallen out.

Maintenance

• Wipe the RC-Controller laser projection port and total station beam detector with the wiping cloth

(total station accessory).

• To clean the RC-Controller, lightly moisten a soft cloth in a mild detergent solution. Wring out excess

water until the cloth is slightly damp, then carefully wipe the surface of the unit. Do not use any

alkaline cleaning solutions, alcohol, or any other organic solvents on the instrument.

• Wipe the slide pole for the ATP1S with tissue paper or a cloth when prism movement along the pole

ceases to be smooth. Do not use lubricants.

• Store the instrument in a dry room where the temperature remains fairly constant.

• Check the RC-Controller for proper adjustment periodically to maintain the instrument accuracy.

Precautions concerning water and dust resistance

The RC-Controller conforms to IP55 specifications for waterproofing and dust resistance when the

battery cover is closed and connector caps are attached correctly.

• Make sure that moisture or dust particles do not come in contact with the terminals.

Operating the instrument with moisture or dust on the terminals may cause damage to the

instrument.

• Make sure that the inside of the carrying case and the instrument are dry before closing the case. If

moisture is trapped inside the case, it may cause the instrument to rust.

Charging the battery

• The battery (BDC46C) was not charged at the factory. Charge the battery fully before using.

3

2. PRECAUTIONS

Precautions concerning Bluetooth wireless technology

• Use of this technology must be authorized according to telecommunications regulations of the

country where the instrument is being used. Contact your local dealer in advance.

C "13. REGULATIONS"

• Sokkia Topcon Co., Ltd. is not liable for the content of any transmission nor any content related

thereto. When communicating important data, run tests beforehand to ascertain that communication

is operating normally.

• Do not divulge the content of any transmission to any third party.

Radio interference when using Bluetooth technology

Bluetooth communication with the RC-Controller uses the 2.4 GHz frequency band. This is the same

band used by the devices described below.

•Industrial, scientific, and medical (ISM) equipment such as microwaves and pacemakers

• portable premises radio equipment (license required) used in factory production lines etc.

• portable specified low-power radio equipment (license-exempt)

•IEEE802.11b/IEEE802.11g standard wireless LAN devices

The above devices use the same frequency band as Bluetooth communications. As a result, using the

RC-Controller within proximity to the above devices may result in interference causing communication

failure or reduction of transmission speed.

Although a radio station license is not required for this instrument, bear in mind the following points

when using Bluetooth technology for communication.

● Regarding portable premises radio equipment and portable specified low-power radio

equipment:

• Before starting transmission, check that operation will not take place within the vicinity of portable

premises radio equipment or specified low-power radio equipment.

• In the case that the instrument causes radio interference with portable premises radio equipment,

terminate the connection immediately.

• In the case that the instrument causes radio interference with portable specified low-power radio

equipment, move away from said equipment and try again. If the problem persists contact your local

dealer.

● When using the RC-Controller in proximity to IEEE802.11b or IEEE802.11g standard wireless

LAN devices, turn off all devices not being used.

• Interference may result, causing transmission speed to slow or even disrupting the connection

completely. Turn off all devices not being used.

● Do not use the RC-Controller in proximity to microwaves.

• Microwave ovens can cause significant interference resulting in communication failure. Perform

communication at a distance of 3m or more from microwave ovens.

● Refrain from using the RC-Controller in proximity to televisions and radios.

• Televisions and radios use a different frequency band to Bluetooth communications.

However, even if the RC-Controller is used within proximity to the above equipment with no adverse

effects with regard to Bluetooth communication, moving a Bluetooth-compatible device (including

4

2. PRECAUTIONS

the RC-Controller) closer to said equipment may result in electronic noise in sound or images,

adversely affecting the performance of televisions and radios.

Precautions regarding transmission

● For best results

• When using in conjunction with a total station, perform communication within a line-of-sight distance

of approximately 300m. The usable range becomes shorter when obstacles block the line of sight,

or devices other than total stations, such as PDAs or computers, are used. Wood, glass and plastic

will not impede communication but the usable range becomes shorter. Moreover, wood, glass and

plastic containing metal frames, plates, foil and other heat shielding elements as well as coatings

containing metallic powders may adversely affect Bluetooth communication and concrete,

reinforced concrete, and metal will render it impossible.

• Use a vinyl or plastic cover to protect the instrument from rain and moisture. Metallic materials

should not be used.

• The direction of the Bluetooth antenna can have adverse effects upon usable range. For best

results make sure that the antennas of both the RC-Controller and the companion device are

pointing towards one another.

● Reduced range due to atmospheric conditions

The radio waves used by the RC-Controller may be absorbed or scattered by rain, fog, and moisture

from the human body with the limit of usable range becoming lower as a result. Similarly, usable range

may also shorten when performing communication in wooded areas. Moreover, as wireless devices

lose signal strength when close to the ground, perform communication at as high a position as

possible.

G

• Sokkia Topcon Co., Ltd. cannot guarantee that all Bluetooth devices are compatible with the Ondemand Remote Control System.

Exceptions from responsibility

• The user of this product is expected to follow all operating instructions and make periodic checks

(hardware only) of the product’s performance.

• The manufacturer, or its representatives, assumes no responsibility for results of faulty or intentional

usage or misuse including any direct, indirect, consequential damage, or loss of profits.

• The manufacturer, or its representatives, assumes no responsibility for consequential damage, or

loss of profits due to any natural disaster, (earthquake, storms, floods etc.), fire, accident, or an act

of a third party and/or usage under unusual conditions.

• The manufacturer, or its representatives, assumes no responsibility for any damage (change of

data, loss of data, loss of profits, an interruption of business etc.) caused by use of the product or

an unusable product.

• The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of

profits caused by usage different to that explained in the operator’s manual.

• The manufacturer, or its representatives, assumes no responsibility for damage caused by incorrect

operation, or action resulting from connecting to other products.

5

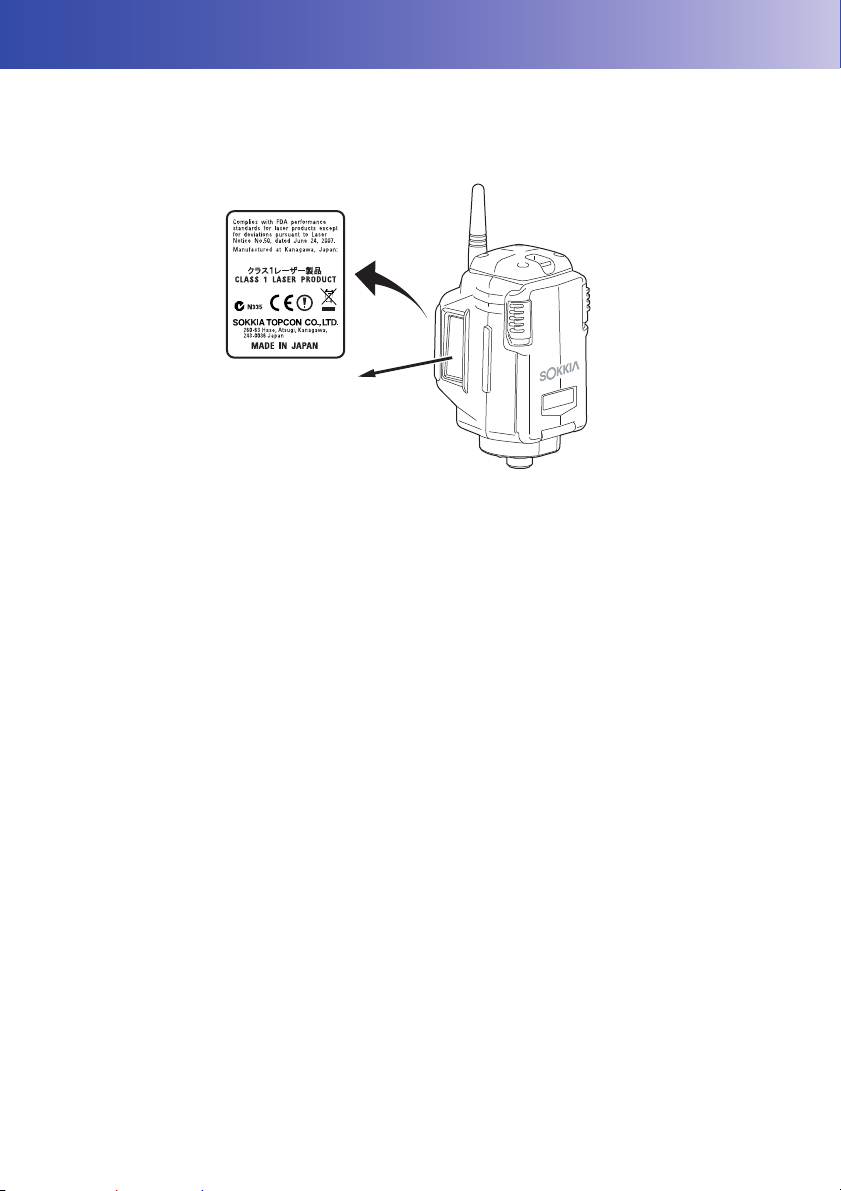

3. LASER SAFETY INFORMATION

Laser beam is emitted

from here

RC-Controller is classified as a Class 1 Laser Product according to IEC Standard Publication 608251 Ed. 2.0: 2007 and United States Government Code of Federal Regulation FDA CDRH 21CFR

Part1040.10 and 1040.11 (Complies with FDA performance standards for laser products except for

deviations pursuant to Laser Notice No.50, dated June 24, 2007.)

CWarning

• Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

• Never point the laser beam at another person. If the laser beam strikes skin or an eye, it could cause

serious injury.

• If an eye injury is caused by exposure to the laser beam, seek immediate medical attention from a

licensed ophthalmologist.

CCaution

• Perform checks at start of work and periodic checks and adjustments with the laser beam emitted

under normal conditions.

• When the instrument is not being used, turn OFF the power.

• When disposing of the instrument, destroy the battery connector so that the laser beam cannot be

emitted.

• Operate the instrument with due caution to avoid injuries that may be caused by the laser beam

unintentionally striking a person in the eye. Avoid setting the instrument at heights at which the path

of the laser beam may strike pedestrians or drivers at head height.

• Never point the laser beam at mirrors, windows or surfaces that are highly reflective. The reflected

laser beam could cause serious injury.

6

4. ON-DEMAND REMOTE CONTROL FUNCTIONS

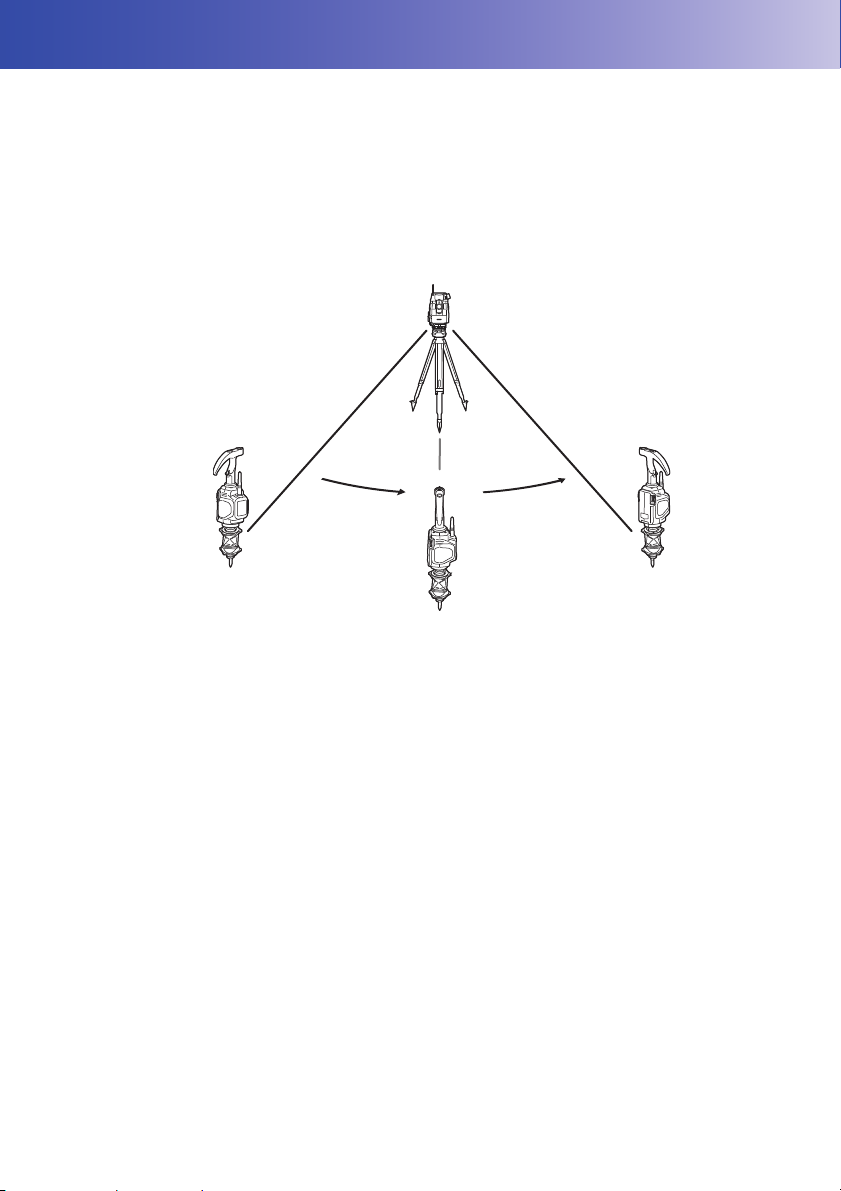

The On-demand Remote Control System works as follows. A laser is emitted from the laser projection

port on the RC-Controller. The total station rotates until its beam detector receives this beam. In this

way the total station is able to detect the position of the RC-Controller. This operation is called

"Turning".

With the On-demand Remote Control System it is possible for a single operator to perform

measurements, unaided, at multiple measurement points.

The RC-Controller incorporates a Bluetooth unit which allows simultaneous communication with both

the total station and a data collector.

&Electronic compass

The RC-Controller is equipped with an electronic compass. Using the Earth’s magnetism, this

compass can detect the RC-Controller’s horizontal angle from magnetic north.

The current angle is compared with that for the previous measurement to estimate the direction

in which the RC-Controller moved following the previous measurement. By then taking into

account the aspect of the telescope the RC-Controller can instruct the total station regarding the

quickest rotation direction to the prism.

The onboard electronic compass was calibrated before being shipped from the factory. A

function within the compass will automatically perform any necessary calibration in response to

changes in the magnetic field.

&Auto Pointing and Auto Tracking

When Auto Pointing is performed, the total station analyses the image of the prism in the field of

view and moves the telescope to sight the center of this prism. When used in conjunction with

the Auto Tracking function, the SRX/NET will then "track" the prism as it is moved to the next

measurement point. When the prism has been "lost" due to an obstacle in the line-of-sight or

operation has been interrupted, the On-demand Remote Control System allows you to quickly

resume operation where you left off.

7

4. ON-DEMAND REMOTE CONTROL FUNCTIONS

4.1 Turning Operation Flow

To perform Turning, follow the procedure below.

CFor measurement procedure, see "4.2 Measurement Flow"

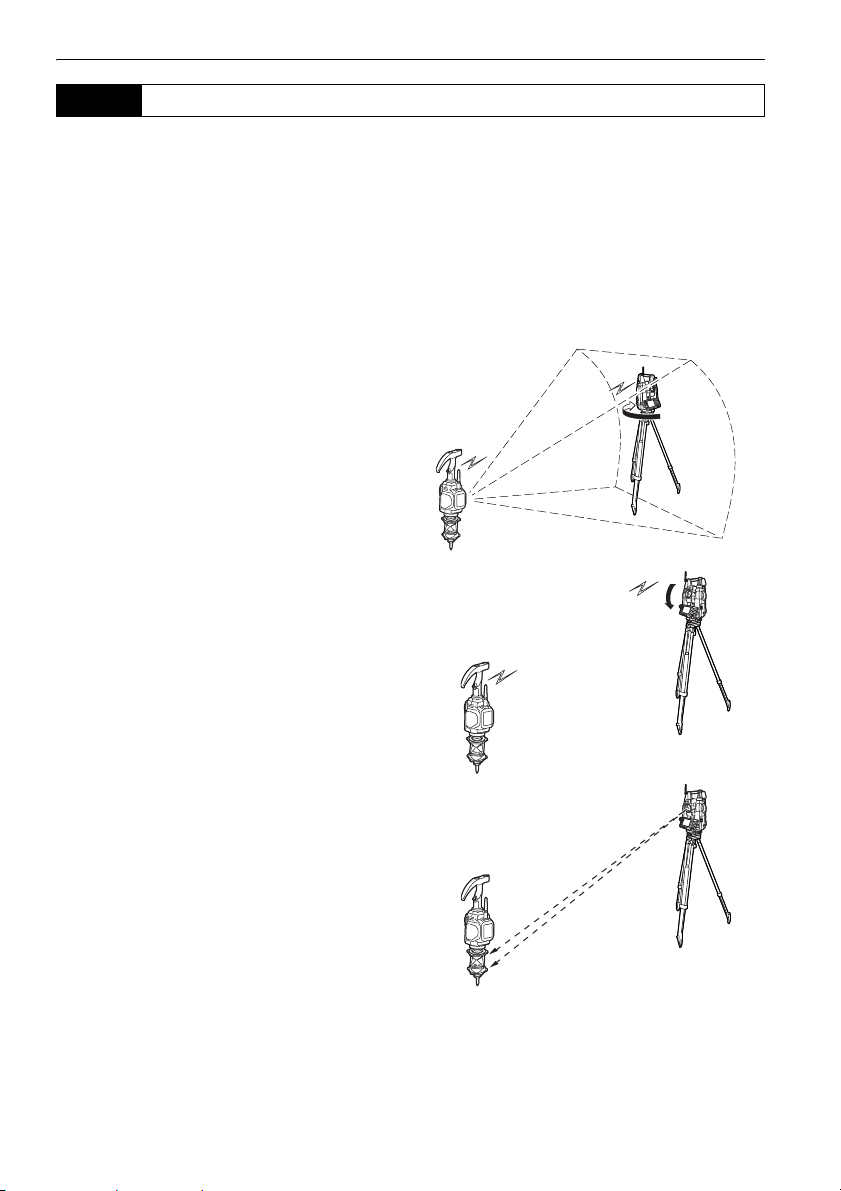

1. Point the RC-Controller laser projection port

and prism in the direction of the total station

and instruct the instrument to start Turning. A

laser beam is emitted from the projection port.

At the same time, the Bluetooth unit (COM 1)

relays the instruction to begin Turning.

2. The total station begins to rotate horizontally,

searching for the emitted laser beam. If it is

not detected by the end of the second rotation,

an error occurs.

3. Once the position of the horizontal direction

has been determined, the total station

telescope then begins to rotate along the

vertical axis searching for the position of the

prism.

4. Once the position of the vertical direction has

been determined an audio sounds and the

total station automatically sights the prism in

the field of view.

5. The SRX/NET tracks a sighted prism as it is

moved to the next measurement point when

Auto Tracking is set.

8

4. ON-DEMAND REMOTE CONTROL FUNCTIONS

Beam

detector

G

• The time limit for Turning is 60 seconds from the start of Turning operation. If the operation exceeds

this time limit, an error occurs.

$

• When Auto Tracking has been selected, the SRX/NET will start tracking a moving prism once

Turning to that prism has been completed.

4.2 Measurement Flow

This section explains the measurement procedure for a single operator working from the RCController. An operator working alone will need a data collector (available as an optional accessory).

G

• When reflected laser signal is strong (object with high reflection factor):

If there is an object with a high reflection factor, such as a window or standing water, in the vicinity

of the total station/prism, the laser beam may be reflected and Turning operation performed pointing

at the object instead of the RC-Controller. In this case the accuracy of measurement results may be

adversely affected.

• Fix the pole vertically over the measurement point.

$

• For communication settings for data collectors etc., see the operator’s manual for your respective

device.

XPROCEDURE

1. Connect the instruments.

C "5. SYSTEM CONFIGURATION"

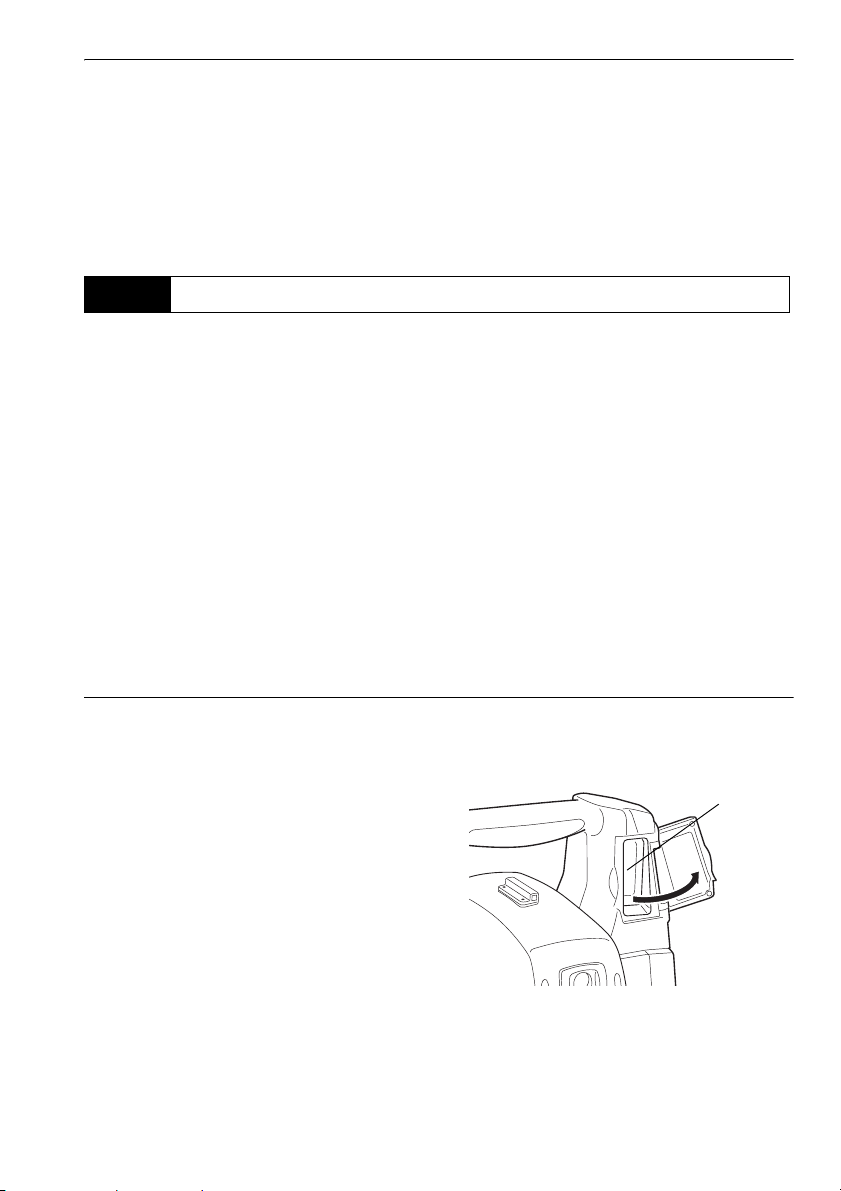

2. Switch ON the power to the total station. Open

the beam detector cover.

3. Set measurement settings for the total station

and select prism type.

C"6.2 Settings for Auto Pointing and Auto

Tracking"

Prism selection: Operator’s Manual "30.3

EDM Settings"

9

4. ON-DEMAND REMOTE CONTROL FUNCTIONS

4. Check that SRX/NET Bluetooth settings are

made and the instrument is ready for

communcation.

C"6.1 Settings for Bluetooth

Communication"

After completing the total station preparations

above, the next step is to prepare the RCController.

5. Press the POWER button to switch ON

the RC-Controller. ● POWER is Lit.

6. Fix the pole vertically over the measurement

point and point the laser projection port of the

RC-Controller roughly in the direction of the

total station.

If the distance between the total station and the

RC-Controller is over 100m (normal

atmospheric conditions)/150m (good

atmospheric conditions), set to Far Mode by

pressing the FAR button

( ● FAR is Lit).

CFor atmospheric conditions, see

"7.3.2 Setting Distance Mode"

7. When the total station is instructed (using a

data collector) to perform distance

measurement, Turning operation is carried

out. Measurement starts when this Turning

operation is complete.

$

• When returned laser signal is weak (object with low reflection factor):

Even if the laser beam received by the total station has been reflected off an unrelated object, or

sunlight has entered the beam detector, the total station still attempts to complete the stages of

Turning operation as far as Auto Pointing. When the total station judges that the laser beam has not

travelled directly from the RC-Controller to the beam detector, this position reading taken in error is

nullified and the total station automatically continues Turning operation at the next position.

However, the time limit for Turning is 60 seconds from the start of Turning operation and if the

operation exceeds this time limit, an error occurs.

• Using the SRX guide light when performing Turning operation allows the operator to confirm

whether or not the SRX has correctly located the RC-Controller laser beam. When a work site

contains highly reflective surfaces it is recommended that measurement is performed using the

guidelight. If the SRX has completed Turning operation pointing at the RC-Controller, both the red

and green guide lights are visible from the position of the RC-Controller.

C For the total station guide light, see the Series SRX Operator’s Manual

• With data collectors it is possible to specify the rotation direction for Turning operation before

performing distance measurement.

C For operation procedure, see the operator's manual for your data collector.

10

4. ON-DEMAND REMOTE CONTROL FUNCTIONS

40m

20m

180m 250m 300m

Height difference

Measurement

range

Slope distance

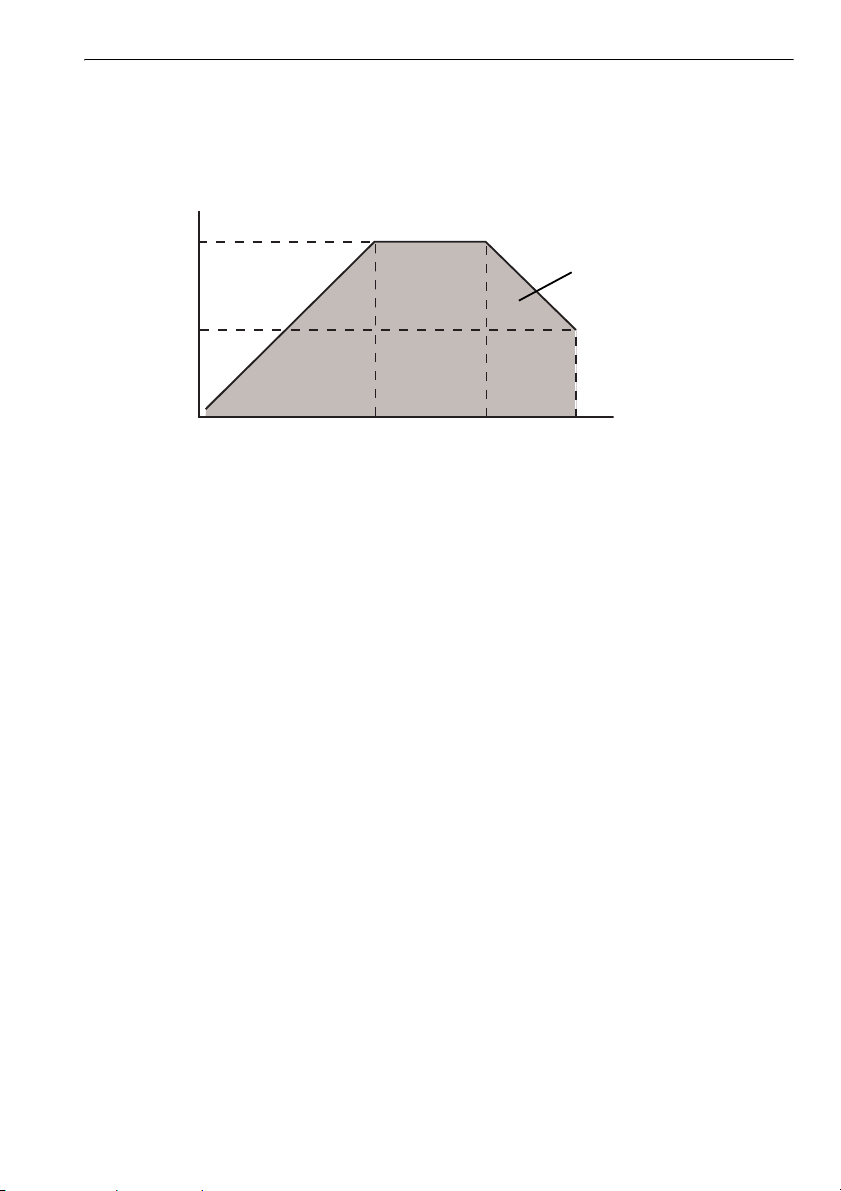

& Height difference and slope distance

The maximum measuring range depends on the height difference between the total station and

the RC-Controller.

The shaded area in the graph below represents the measurement range when set to Far Mode.

11

5. SYSTEM CONFIGURATION

Control panel

Laser projection

Battery cover

Laser projection

Control panel

side

port

Bluetooth

antenna

Blind cap

port side

FAR bu tt on

SEARCH button

POWER button

● COM1

● COM2

Control panel

● POWER

● SEARCH

● FAR

5.1 Parts of the RC-Controller

● RC-Controller (RC-PR4)

$

• COM1 is for communication with the total station. COM2 is for communication with the data

collector.

12

5. SYSTEM CONFIGURATION

Circular level

Circular level

Stra p

adjusting screws

RC-Handle (RC-PRH4)

●

The RC-Handle incorporates a circular level.

& Adjusting the circular level

First attach the RC-Handle and 360° Prism ATP1 to the RC-PR4, and then attach the RC-PR4

to the instrument height adapter (AP41) etc. Holding the RC-Handle, keep the instrument level.

Check the position of the bubble of the circular level. If the bubble is not off-center, no adjustment

is necessary. If the bubble is off-center, perform the following adjustment. First confirm the offcenter direction. Use the adjusting pin to loosen the circular level adjustment screw on the side

opposite to the direction the bubble is displaced to move the bubble to the center. Adjust the

adjusting screws until the tightening tension of the three screws is the same to align the bubble

in the middle of the circle.

13

5. SYSTEM CONFIGURATION

5.2 System Configuration of the SRX/NET

Only instruments incorporating a handle equipped with a beam detector (RC-TS3 or RC-TS3A) can

be used with the On-demand Remote Control System.

Always open the beam detector cover when using the On-demand Remote Control System.

G

• The beam detector cover can be damaged if forced open beyond a certain angle. Always close the

beam detector cover before moving the instrument.

14

RC-Handle for RC-PR4

Adapter

Pin pole for

Pin

Pin pole point

AP66

SB184

360° Prism

360° Sliding Prism

RC-PRH4

h1

ATP 1

PP2

ATP 1S

Pin pole point

AP66

5 cm

5 cm

5 cm

h2

Pin Pole

example

pole

ATP1S

Pin

pole

Pin

pole

Protector

RP3

Protector

RP3

5. SYSTEM CONFIGURATION

5.3 System Configuration of the RC-Controller

For use with other prism types, contact your local dealer.

Pin Pole Type

●

15

5. SYSTEM CONFIGURATION

The pole reading shows

Protector

360° Prism

RC-Controller

attachment

One-touch

AP67/67A

SB179BSB179A

Telescopic Pole

5/8 inch

Setting screw

(W5/8-11) pole

SB188

h3

Telescopic Pole AP67

example

RC-PR4

RP3

ATP 1

the height from the bottom

of the pole shoe to the

center of the 360° Prism

(ATP1) when using the

configuration shown at

right.

● Range Pole Type

● Height to center of prism

The height to the center of the prism differs as shown below depending on the selection of prism/pole

combination. Read the following in conjunction with the above diagrams.

Pin Pole Type

h1: Height from the tip of the prism foot to the center of prism is 10 cm when mounting the 360°

Prism ATP1 on the adapter SB184 and stainless steel prism foot AP66.

h2: Height from the tip of the prism foot to the center of prism is 10 cm when mounting the 360°

Sliding Prism ATP1S on the pin pole for ATP1S PP2 and the prism is at the lowest position on

the pole. Graduations on the pin pole for ATP1S PP2 are at 5cm intervals. Aligning the top of

the sliding prism with one of the graduations then sliding up or down to the next graduation

will result in a vertical movement of 5 cm. Maximum range of the sliding pole is 40 cm.

G

•Do not subject the prism to strong shock when set at the highest position on the pin

pole. Otherwise, the prism may slip downwards.

Range Pole Type

h3: Height from the base of the one-touch attachment to the center of prism is as follows when

mounting the 360° Prism ATP1 on the Range Pole.

AP67/67A with SB179A: 87 mm

5/8 inch Setting screw pole with SB179A and SB188: 130 mm

5/8 inch Setting screw pole with SB179B: 74 mm

16

5. SYSTEM CONFIGURATION

Locknut

2. Rotate the One-touch attachment clockwise

until the locknut meets the top of the pole.

Locating plate

4. Rotate the locknut towards the pole until

secured in place.

Attaching/Releasing the One-touch attachment

●

Slide the lock release button to the right then press to release the One-touch attachment.

Attaching the One-touch attachment (SB179A) to the range pole (AP67/67A)

●

Attach to the pole using the following procedure.

1. Rotate the locknut counterclockwise until it

reaches the upper limit.

3. Adjust until the locating plate is on the left

(with the graduations facing forward).

17

5. SYSTEM CONFIGURATION

● Adjusting position of 360° Prism (ATP1S) on pin pole (PP2)

Pressing the release button allows the prism to

slide up and down the pin pole. Release the

release button to secure the prism at the desired

position.

G

• A strong shock, such as dropping the prism,

when the prism is mounted on the pin pole or

when used as a stand-alone prism may cause

the release button to lock. In this event, turn the

prism upside down so the the release button is

facing downwards and lightly tap the prism or pin

pole on a hard surface such as concrete.

18

Connecting the 360° Prism to the RC-Controller

60

30

30

Adjusting screw (1)

Adjusting screw (2)

Moved to either left or

right position

Direction in which 360° Prism is attached

●

Attach the 360° Prism to the RC-Controller so that the center of

the RC-Controller and the sighting direction of the prism are

aligned and the laser projection port is pointing in the same

direction as the prism sighting direction.

Check the stickers to make sure the prism is the right way up.

CPrism sighting direction "12.1 High Accuracy with the 360°

Prism"

Adjust as follows when the center of the RC-Controller and the

sighting direction of the prism are not aligned. Detach the

Protector RP3 and loosen adjusting screw (1) with the

hexagonal wrench. Re-position the prism, then fix in place. If

the RC-Controller and sighting direction are still not aligned,

detach the 360° Prism and adjust adjusting screw (2). First

move adjusting screw (2) fully to the left or right position and

secure in place, then attempt re-alignment again using

adjusting screw (1). If the desired result is still not obtained try

moving adjusting screw (2) to the opposite position, then

attempt re-alignment with adjusting screw (1) again.

5. SYSTEM CONFIGURATION

19

6. SETTINGS FOR THE SRX/NET

The following settings are necessary in order to use the SRX/NET as part of the On-demand Remote

Control System.

C For other functions and operations, see the operator's manual for your total station.

For further details regarding Bluetooth communications, see "2. PRECAUTIONS Precautions

concerning Bluetooth wireless technology"

6.1 Settings for Bluetooth Communication

G

• RC Handle with Bluetooth (RC-TS3) is necessary for Bluetooth communication.

• Bluetooth communication causes SRX/NET battery power to be depleted at a rate higher than that

for normal operation.

When communicating between the total station and RC-Controller using Bluetooth wireless

technology, the modem for the total station will be set as the "Master" device and the SRX/NET will be

set as the "Slave" device.

1. Select "Comms" in SETTINGS mode. Set

"Comms mode" in the Comms setup tab to

"Bluetooth".

Check that the status panel icon has changed to

.

G

• Changing communication settings during

Bluetooth communication will cancel the

connection.

• The status bar icon cannot be tapped in

<Communication Setup>.

20

2. Select "Slave" as the SRX/NET mode and press

[OK]. Selection can also be made by tapping the

icon in the status panel until a menu

appears.

$

• When communicating between a data collector

and the RC-Controller using Bluetooth wireless

technology, set modem for the data collector as

the "Slave" device. Set the data collector as the

"Master" device.

C "7.4 Communication Status & Bluetooth

connections"

3. The display returns to Meas mode and SRX/NET

enters "Waiting" mode. The RC-Controller

searches for the total station wireless device and

initiates a connection.

C"7.2 Configuring Bluetooth Connections to

the SRX/NET"

4. When a connection has been successfully

established is displayed in the status bar.

• ● COM1 on the RC-Controller control panel is lit.

6. SETTINGS FOR THE SRX/NET

$

•Press [Info] in the Bluetooth tab to display the Bluetooth device address.

21

6. SETTINGS FOR THE SRX/NET

6.2 Settings for Auto Pointing and Auto Tracking

G

• Auto Pointing model does not support Auto Tracking.

XPROCEDURE

1. Select "Motor" in <Configuration>.

Set Auto Pointing/Auto Tracking functions in

the Configuration tab.

For Auto Pointing only set "A.T. Setting" to

"Search". For Auto Tracking, set "A.T. Setting" to

"Track" and "Accu. search" to "Fine".

Set "Srch method" to "R.C.".

Settings and Options

(1) Accu. search &

Fine/Rapid

(2) A.T. Setting

Auto Pointing model: None/Search

Auto Tracking model: None/Search/Track

(3) Srch method &

G.S./R.C.

& Accu. search

Set to "Fine" for greater accuracy during Auto Pointing. Make sure that the prism is securely

mounted on a tripod etc.

Set to "Rapid" when supporting the pole by hand.

When "Fine" is set the SRX/NET checks that the prism position is stable, then searches for the

prism direction. Once the SRX/NET confirms that the prism is sighted at the approximate center

of the field-of-view, Auto Pointing is complete. Although this setting provides greater accuracy,

when supporting the pole by hand, hand movements will result in Auto Pointing taking too long

to complete and a "Time out" error will occur.

When "Rapid" is set however, Auto Pointing can be performed even with slight instability of

prism position or minor shifts of target position in the field-of-view. The SRX/NET will use the

data obtained to determine the direction of the target.

Auto Pointing performed using the "Rapid" setting can be completed in a much quicker time than

the "Fine" setting.

"Fine" is recommended when a high level of measurement accuracy is needed. Sighting

accuracy for Auto Pointing will be the "Fine" setting. The range for the offset between the target

22

6. SETTINGS FOR THE SRX/NET

and reticle after Auto Pointing completed changes as shown below depending on the Accu.

search. setting.

"Fine": ± 5" (approx.)

"Rapid": ± 30" to ± 10’ (depending on distance)

2. Set "Srch. method" to "R.C." in order to start

Turning operation in response to a Turning

command issued from the RC-Controller.

Set to "G.S." to search for the target in the area

specified in the Search area tab.

3. When necessary, set the JOG dial turning speed

for vertical and horizontal rotation of the

telescope. The "Shift" point signifies the dial

turning speed at which telescope rotation

switches from the Lo speed setting to the Hi

speed setting.The higher the "Shift" point setting,

the faster the jog dial turning speed needed to

activate the "Hi" speed setting.

Settings and Options

(1) Lo

1 to 4 (steps. 4 is fastest)

(2) Hi

1 to 7 (steps. 7 is fastest)

(3) Shift point

1 to 6 (steps)

Press [INIT] to return JOG Setting tab settings

only to their factory settings.

4. Press [OK].

23

6. SETTINGS FOR THE SRX/NET

[ ← RC] [RC → ]

6.3 Performing Turning from the SRX/NET

It is possible to allocate SRX/NET softkeys for both designating the Turning direction, and issuing the

instruction to start Turning.

C For allocating softkey functions, see the Series SRX or NET05AX/NET1AX Operator’s Manual

● SRX softkey operation

• [RC]: SRX/NET begins Turning directly in the direction of the RC-Controller.

• [ ← RC] : SRX/NET begins Turning in a counterclockwise (left) direction (from the point of

view of the operation panel).

• [RC → ]: SRX/NET begins Turning in a clockwise (right) direction (from the point of view of

• [RC Cont]: Nullifies the current measurement position and continues Turning operation.

the operation panel).

The functions of the following softkeys change according to the settings made in "A. T. Setting" and

"Srch method" in <Motor configuration>.

When "Search" is set

"Motor"

S oftke y

[SRCH] Performs Auto Pointing

[DIST] Performs Turning

[RC] Rotates directly in the direction of the RC-Controller then performs Auto Pointing

[<-RC] Rotates in a counterclockwise direction (from the point of view of the RC-

[RC->] Rotates in a clockwise direction (from the point of view of the RC-Controller) then

[RC Cont] Nullifies the current measurement position then continues Turning operation

When "Search" set in "A.T. Setting"

setting

"Srch method" is R.C.

operation then angle/

distance measurement

Controller) then performs Auto Pointing

performs Auto Pointing

"Srch method" is G.S.

(Global Search)

Performs Auto Pointing

then angle/distance

measurement

When "None" set in

"A.T. Setting"

Performs angle and

distance measurement

24

6. SETTINGS FOR THE SRX/NET

[AT On]

(Auto

Tracking

model only)

● When "Track" is set (Auto Tracking model only)

"Motor"

Softkey

[SRCH] Performs Auto Pointing then Auto Tracking Performs Auto Pointing

[DIST] Performs Turning

[RC] Rotates directly in the direction of the RC-Controller

[<-RC] Rotates in a counterclockwise direction (from the

[RC->] Rotates in a clockwise direction (from the point of

[RC Cont] Nullifies the current measurement position then

[AT On] Performs Turning

Performs Turning

operation then Auto

Tracking

When "Track" set in "A.T. Setting"

setting

"Srch method" is R.C.

operation then distance

measurement/Auto

Tracking

then performs Auto Pointing

point of view of the RC-Controller) then performs

Auto Pointing/Auto Tracking

view of the RC-Controller) then performs Auto

Pointing/Auto Tracking

continues Turning operation/Auto Tracking

operation then Auto

Tracking

Performs Auto Pointing

then Auto Tracking

"Srch method" is G.S.

(Global Search)

Performs Auto Pointing

then distance

measurement/Auto

Tracking

Performs Auto Pointing

then Auto Tracking

Performs Auto Tracking

*1

When "None" set in

"A.T. Setting"

Performs angle and

distance measurement

Rotates in the direction

specified by the RCController then performs

Auto Pointing

Rotates in a

counterclockwise

direction (from the point

of view of the RCController) then performs

Auto Pointing

Rotates in a clockwise

direction (from the point

of view of the RCController) then performs

Auto Pointing

Nullifies the current

measurement position

then continues Turning

operation

Performs Auto Tracking

*1

*1: Pressing [AT On] when A.T. Setting is set to "None" will result in one of the following operations

being performed.

When "R.C." selected: Performs Turning operation then Auto Tracking

When "G.S." selected: Performs Auto Pointing then Auto Tracking

25

6. SETTINGS FOR THE SRX/NET

Auto Tracking

Obstacle

Target

"Prism wait" selected

Target found

"Search"

"Prism wait"

Sighting terminates

Target

Target found

not found

selected

not found

Auto Tracking continues in predicted

direction (1 to 5 sec.)

"Target lost"

Global Search

(Auto Tracking idle)

Target found

Target

not found

6.4 Turning Error

When Turning fails to detect the prism, an error occurs

When the laser beam from the RC-Controller is reflected off an unrelated object the SRX/NET

completes Turning operation pointing at the object instead of the RC-Controller. When this happens,

press [RC Cont] to nullify the current measurement position and continue Turning operation.

& Lost Prism

In the event that an obstacle prevents the SRX/NET sighting the target during Auto Tracking,

the instrument will predict the direction in which the target will travel and continue Auto Tracking

based on this prediction for the time period set in "Forecast time". If the SRX/NET re-acquires

the target in this predicted direction, Auto Tracking continues without change. If the target is not

re-acquired however, the target is considered "lost" ("Target lost" status) and the SRX/NET

enters either "Prism wait" or "Search" mode. When "Prism wait" has been selected in "Target

lost" and the target enters the field of view or a Turning command is received from the RCController within 60 seconds, the SRX/NET will search for the target, then resume Auto

Tracking. If the target is not re-acquired within 60 seconds, sighting terminates.

Start Auto Tracking procedure again from step 1.

C For error messages, see the Series SRX or NET05AX/NET1AX Operator's Manual

26

7. BASIC OPERATION

Battery

Battery

cover

This section explains basic operation of the RC-Controller.

7.1 Using the Battery

Mount the charged battery (BDC46C). When the remaining battery power becomes low, the ●

POWER Flashes.

C Types of power source: "10.3 Power Supply System"

G

• Remove the battery when the instrument is not being used.

• Before removing the battery, turn off the power to the instrument. If the battery is removed while

the power is switched on, a warm boot occurs.

• When installing/removing the battery, make sure that moisture or dust particles do not come in

contact with the inside of the instrument.

XPROCEDURE Mounting the battery

1. Slide down the catches on the battery cover to

open.

2. Insert the battery in the direction of the arrow

printed on the side and press down.

3. Close the battery cover. A click is heard when

the cover is secure.

XPROCEDURE Removing the battery

1. Slide down the catches on the battery cover to

open.

2. Push the battery up to release.

3. Close the battery cover. A click is heard when

the cover is secure. Make sure that both

catches on the battery cover have returned to

their original positions.

27

7. BASIC OPERATION

7.2 Configuring Bluetooth Connections to the SRX/NET

The RC-Controller should be set to "Master" when pairing the total station with the RC-Controller for

Bluetooth wireless communication for the first time. The RC-Controller searches for the total station

wireless device and initiates a connection.

1. Turn on the total station and set

communication settings.

C "6.1 Settings for Bluetooth

Communication"

2. Turn on the RC-Controller while pressing the

SEARCH button . ● FAR flashes and the

RC-Controller searches for the total station

wireless device. When the search is complete

an audio tone sounds to indicate the number

of devices found. Proceed to step 3.

If the total station wireless device is not

found an audio tone sounds continuously

and the RC-Controller powers off

automatically. Check communication

settings and conditions.

C "2. PRECAUTIONS Precautions

concerning Bluetooth wireless

technology

"

3. ● COM1 and ● FAR are lit when the audio

tone stops. When

status bar of the total station companion

device, press

the pairing. The RC-Controller

automatically powers off.

is displayed on the

the FAR button to confirm

28

7. BASIC OPERATION

When

the total station companion device, the RCController is currently paired to different

device. Press

switch the pairing from the current device to

the next locally available device.

displayed after a brief period, press

button to confirm the pairing. If however,

FAR button

changes. If the

pressed as many times as there are locally

available devices and the status bar icon still

does not change, an audio tone sounds

continuously and the RC-Controller

automatically powers off.

The wireless device for the total station was

not found. Check communcation settings

and conditions.

is displayed on the status bar of

the SEARCH button to

If is

the FAR

continues to be displayed, press

until the status bar icon

SEARCH button is

the

C "2. PRECAUTIONS Precautions

concerning Bluetooth wireless technology

6.1 Settings for Bluetooth Communication"

"

",

7.3 Button Operations

The RC-Controller is operated using the buttons on the control panel.

7.3.1 Power ON/OFF

Press the POWER button to switch ON the RC-Controller. ● POWER is Lit.

Press and hold the POWER button to switch OFF the RC-Controller. An audio tone sounds twice

and ● POWER Flashes before an audio tone sounds and the RC-Controller switches OFF.

29

7. BASIC OPERATION

7.3.2 Setting Distance Mode

The FAR button is used to set the Distance Mode depending on the distance between the total

station and the RC-Controller.

Pressing the FAR button switches the ● FAR from Lit to Off and vice versa.

Lit: Far Mode

Off: Standard Mode

Set to Far Mode when the distance between the total station and the RC-Controller is over 100m

(normal atmospheric conditions)/150m (good atmospheric conditions).

& Atmospheric conditions

• Normal: slight haze, visibility about 20 km, sunny periods, weak scintillation.

• Good: no haze, visibility about 40 km, overcast, no scintillation.

G

• Set to Standard Mode ( ● FAR is Off) when the total station and RC-Controller are close.

• Using Far Mode ( ● FA R is Lit) when the total station and RC-Controller are close could result in the

emitted laser beam being reflected off nearby objects. If this happens the total station will complete

Turning pointing to the object instead of the RC-Controller.

• Set to Far Mode ( ● FAR is Lit) even when the distance between the total station and the RC-

Controller is 100m or less if the height difference is large.

• Far Mode depletes battery power at a greater rate than Standard Mode.

The FAR button cannot be pressed while the total station is Turning.

7.3.3 Starting Turning Operation

Press the SEARCH button to start Turning operation.

• ● SEARCH Flashes when the total station is currently performing Turning operation.

• When Turning operation is complete, an audio tone sounds and ● SEARCH remains Lit for approx.

2 seconds.

• Press the SEARCH button during operation to stop Turning.

• If the total station fails to detect the prism, a long audio tone sounds and ● SEARCH Flashes

quickly for approx. 2 seconds to indicate that an error has occurred.

• When the laser beam from the RC-Controller is reflected off a unrelated object the total station

completes Turning operation pointing at this object instead of the RC-Controller. When this happens,

press and hold the SEARCH button to nullify the current measurement position and continue

Turning operation.

30

7. BASIC OPERATION

COM2

Handle: RC-TS3

Slave

COM1

Master

Slave

Master

7.4 Communication Status

The Bluetooth wireless modem incorporated in the RC-Controller allows simultaneous communication

between the RC-Controller and both the total station and data collector. COM1 is designed for longrange (line-of-sight distance up to 300m) communication with the total station. COM2 is for

communication with data collectors. COM2 usable range varies depending on the usable range of the

companion device.

& Bluetooth connections

Communication between a pair of Bluetooth devices requires one device to be set as the "Master"

and the other as the "Slave". To initiate connections from the SRX/NET side, set the SRX/NET as

the "Master" device. To initiate connections from the paired device side, set the SRX/NET as the

"Slave" device. The factory setting for the SRX/NET is "Slave".

Bluetooth connections are as follows:

COM1: Total station (Slave) - RC-Controller (Master)

COM2: Data collector (Master) - RC-Controller (Slave)

Port

COM1

(total station)

COM2

(data collector)

Control panel status

Lit Flashing

Comm OK

Comm OK

Searching for total

Data collector is

searching for RC-

station

Controller

31

7. BASIC OPERATION

7.5 Calibrating the Electronic Compass

The onboard electronic compass was calibrated before being shipped from the factory. A function

within the compass will automatically perform any necessary calibration in response to changes in the

magnetic field. Although this function by itself is sufficient in normal situations, when the RC-Controller

becomes highly magnetized, manual calibration is necessary.

G

• When the power is ON, automatic calibration is performed to adjust for changes in temperature and

magnetic field. When transporting the RC-Controller, with the power still ON, using modes of

transport such as cars or trains which contain a large amount of magnetic substance (iron, magnets

etc.), this function will calibrate for the magnetic field of said car or train. As a result, the direction in

which the RC-Controller instructs a rotation in subsequent surveying tasks may not be correct.

Always turn the power OFF when transporting.

• Manually calibrate the compass in the event that the RC-Controller has been transported with the

power still ON and the resulting calibration inaccuracy persists.

• The ideal location for performing manual calibration would be an open area clear of any objects.

Failing that, make sure that the surrounding area (i.e. several meters around the instrument

including ground level) is clear of metallic objects (desks, steel frames, etc.) or devices containing

magnets.

• Hold the RC-Controller on the pole at a height of at least 1m.

• Avoid physical contact with metallic objects (cellular phones, tape measures, etc.) or magnetic

objects (such as magnetic necklaces) while performing manual calibration.

XPROCEDURE Checking whether manual calibration is necessary

1. Press the POWER button to switch ON

the RC-Controller. ● POWER is Lit.

If ● FAR and ● SEARCH flash and a rapid

error tone sounds repeatedly, relocate to a

position several meters away from metallic

objects (desks, steel frames, etc.) or devices

containing magnets before trying again.

If the audio tone continues to sound even after

changing location, manual calibration is

necessary.

2. When calibration is necessary, switch OFF

and proceed to "PROCEDURE Manually

calibrating the compass".

32

XPROCEDURE Manually calibrating the compass

1m or above

1. Press the POWER button while pressing

the FAR button with the power switched

OFF. An audio tone sounds and the RC-

Controller is switched ON in calibration mode.

● FAR and ● SEARCH are Lit.

2. Hold the RC-Controller vertical and press the

SEARCH button .

● FAR flashes red and calibration starts.

3. Without moving the position of the RC-

Controller, rotate it 1.5 to 2 times in a

horizontal direction.

G

Rotate 1.5 to 2 times in approximately 10

seconds.

7. BASIC OPERATION

4. After rotating, continue to hold the RC-

Controller vertical and press the SEARCH

button .

● SEARCH turns Off.

5. Hold the RC-Controller horizontal and press

the SEARCH button .

● FAR Flashes.

33

7. BASIC OPERATION

1m or above

6. Without moving the position of the RCController, rotate it 1.5 to 2 times in a

horizontal direction.

7. After rotating, continue to hold the RCController horizontal and press the SEARCH

button .

8. ● FAR turns Off.

9. Push and hold the POWER button on the

RC-Controller to switch OFF. ●POWER turns

Off and calibration is complete.

34

8. ERROR INDICATIONS

When an error occurs, the nature of the error is indicated by the condition of the LEDs on the RCController.

LED Condition Error

● POWER Flashing

3 long audio tones and the

● POWER Flashes then

power is cut off

Audio tone continues to

sound and the ● POWER

Flashes quickly/audio tone

sounds continuously for

approx. 10 seconds

● FAR /all LEDs Flashing

quickly

A long audio tone sounds

and ● SEARCH Flashes

quickly for approx. 2

seconds

3 audio tones and the

● FAR/ ● SEARCH Flash

Remaining battery power is low.

Replace the batteries.

C "7.1 Using the Battery"

No battery power remaining.

Replace the batteries.

C "7.1 Using the Battery"

The remaing battery power of the total

station is low or the total station has switched

OFF.

Check the power to the total station.

C Operator’s manual for your total station

Hardware error.

Switch the power to the RC-Controller OFF

and ON again. If the error reoccurs after

restart, contact your local dealer.

Turning failure

C "9. TROUBLESHOOTING"

There are magnetic/metallic objects in the

vicinity. Retry at a distance greater than sev-

eral meters from such objects. If the audio

tone continues to sound even after changing

location, manual calibration is necessary.

C "7.5 Calibrating the Electronic Compass"

35

9. TROUBLESHOOTING

● Pressing the POWER button does not switch ON the power.

→ Check that the battery has been inserted.

Replace the battery.

C "7.1 Using the Battery"

● The total station does not perform Turning operation even when distance measurement is executed.

→ The Turning operation setting of the total station is deactivated.

Set the "Srch method" setting for the SRX/NET to "R.C.".

C "6.2 Settings for Auto Pointing and Auto Tracking"

→ A connection has not been established with the total station.

Check the pairing settings and communication conditions for the total station and RC-Controllers

being used.

C "6.1 Settings for Bluetooth Communication", "7.2 Configuring Bluetooth Connections to the

SRX/NET"

● Turning operation failure

→ The beam detector cover is closed.

Close the beam detector cover.

→ Both the laser projection port and the prism are not pointing in the direction of the total station.

Point the laser projection port and the prism towards the total station.

→ The total station cannot receive the beam emitted from the RC-Controller as the amount of light is

too low.

Check that the Distance Mode setting is correct.

C "7.3.2 Setting Distance Mode"

→ Turning operation has located the horizontal position but cannot find the vertical position.

Turning operation for the vertical position cannot be performed while the pole is tilted at an angle.

Check that the pole is fixed in the correct position, vertically over the measurement point.

→ Check that there are no obstacles between the beam detector of the total station and the laser

projection port of the RC-Controller/prism.

→ Flat white surfaces in close proximity to the optical path between the total station beam detector

and RC-Controller laser projection port may reflect the emitted laser beam and

cause Turning operation failure. Have someone stand in front of such objects or otherwise cover,

such as with a dark-colored cloth.

→ There is dust or dirt on the beam detector/laser projection port.

Dust off minute particles with the lens brush before carefully wiping with the cleaning cloth.

● Total station finishes Turning operation pointing in the wrong direction.

→ The total station receives the emitted laser beam after it has been reflected off a highly-reflective

surface in the vicinity of the RC-Controller.

Continue Turning operation.

C "4.2 Measurement Flow"

C "6.3 Performing Turning from the SRX/NET"

36

9. TROUBLESHOOTING

The signal for the data collector/RC-Controller equipped with Bluetooth wireless tech-

●

nology is weak.

→ The wireless modem signal is poor because the data collector/RC-Controller is placed in a low

position, close to ground level.

Place the modem in as high a position as possible.

37

10. STANDARD EQUIPMENT AND OPTIONAL ACCESSORIES

1 RC-PR4 main unit . . . . . . . . . . . . . . . . 1

2 Battery (BDC46C) . . . . . . . . . . . . . . . . 2

3 Carrying case (SC228) . . . . . . . . . . . . 1

4 On-demand Remote Control System . 1

5 Manual . . . . . . . . . . . . . . . . . . . . . . . . 1

1 360° Prism (ATP1) . . . . . . . . . . . . . . . 1

2 Protective cover . . . . . . . . . . . . . . . . . 1

3 Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

G

• Place the instrument in its case in accordance with the layout plan on the inside of the carrying case.

• Place the data collector in its dedicated protective case before inserting into the carrying case.

10.1 Standard Equipment

Please verify that all equipment is included.

10.2 Optional Accessories

For use with other prism types, contact your local dealer.

360° Prism (ATP1)

38

● Protective cover

Inner: light grey (cleaning

cloth section)

1 360° Sliding Prism (ATP1S). . . . . . . . . . . . . . 1

2 Pin Pole for ATP1S (PP2) . . . . . . . . . . . . . . 1

3 Protective cover. . . . . . . . . . . . . . . . . . . . . . . 1

The 360° Sliding Prism can be packed away in the

carrying case (SC228). Packing is secured inside

the carrying case to protect the contents. Remove

this packing and place the prism at the bottom of

the case.

G

• Be careful when removing the packing.

Otherwise, the fastening may break.

1 RC-Handle (RC-PRH4). . . . . . . . . . . . 1

2 Strap . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Attach the protective cover when the

prism is not being used to protect the

prism surface from dirt and damage.

$

• The inner (light grey) section can be

used as a cleaning cloth to wipe the

surface of the prism.

360° Sliding Prism (ATP1S)

10. STANDARD EQUIPMENT AND OPTIONAL ACCESSORIES

RC-Handle (RC-PRH4)

39

10. STANDARD EQUIPMENT AND OPTIONAL ACCESSORIES

Battery

BDC46C* CDC68

EDC113A/113B/113C

(100 V AC)

Charger

٨Battery

Protector (RP3)

10.3 Power Supply System

Operate your RC-PR4 with the following combinations of power equipment.

G

• Never use any combination other than those indicated below. If you do, the instrument could be

damaged.

Those indicated by * are standard accessories. Others are optional accessories (sold separately)

The power cable shown here is EDC113A

40

11. SPECIFICATIONS

Whole System Specifications

Range: (Slope distance between instrument and measuring point)

(normal atmospheric conditions

Standard Mode: 2

Far Mode: 2*2 to 250m*4 /300m

Operating time*5: About 15 sec.*1/18 sec.*6 Up to finishing distance measurement

Operating range of function for automatically determining rotation direction:

Data collector: SOKKIA total station/3-D station-compatible product

Control panel (keyboard) 3 Keys

Indicator 5 LED

Audio tone Yes

Operating temperature -20 to 50°C

Storage temperature range -30 to 70°C

Water resistance IP55 (IEC 60529:2001)

Size 69 (L) X 80.5 (W) X 131 (H) mm (excluding antenna)

Weight About 420 g (with BDC46C)

*1: Normal: Slight haze, visibility about 20 km, sunny periods, weak scintillation.

*2: Possible to use 1.8m (horizontal distance), height of instrument point and measurement point

is almost the same, instrument height is 1.5m, and prism height is 0.10m.

*3: About 20m height difference between instrument and RC-Controller laser projection port.

*4: About 40m height difference between instrument and RC-Controller laser projection port.

*5: Time taken between the start of the search and the obtaining of distance measurement results

after the completion of Auto Pointing. Normal atmospheric conditions, instrument Turning

horizontally 90°, 100m distance between instrument and measuring point.

Depends on the conditions and wireless modem used.

*6: At a distance of less than 5m, pole leaning slightly.

*7: For details, contact your local dealer.

*2

to 100m

(Rapid (single))

Magnetic inclination is 80° or less and horizontal component is

more than 10µT

*3

*3

*7

*1

)

*7

RC-Controller (RC-PR4)

Laser Projection Port

Signal source Laser diode (IEC60825-1 Ed. 2.0: 2007/FDA CDRH 21 CFR Part

1040.10 and 1040.11 (Complies with FDA performance standards for

laser products except for deviations pursuant to Laser Notice No.50,

dated July 26, 2001.))

Wavelength: 785nm

Beam projection area

Horizontal direction: -10 to 10°

Angle of elevation: More than 40°

Angle of depression: More than 30°

Rotation direction detector

Direction detector magnetic compass sensor (geomagnetic measurement method)

With automatic/manual calibration function

Measurement resolution ±1°

41

11. SPECIFICATIONS

Wireless communication

Transmission method: FHSS

Modulation: GFSK, π/4DQPSK, 8DPSK

Frequency band: 2.402 to 2.480GHz

Bluetooth profile SPP, DUN

Power class Class 1

Usable range 200m (No obstacles, few vehicles or sources of radio emissions/

interference in the near vicinity of the instrument, no rain)

300m (No obstacles, few vehicles or sources of radio emissions/

interference in the vicinity of the instrument, no rain)

Usable range of the data collector varies depending on the usable

Authentication Yes/No (selectable)

Antenna External antenna

range of the companion device.

Power Supply (BDC46C)

Battery

Type: Rechargeable Li-ion battery BDC46C

Working duration

Standard Mode: 40 hours

Far Mode: 35 hours

Charging time at 25 °C: about 2.5 hours (using CDC68)

*8: Repeat Turning with the instrument turned 90° and distance measurement performed in Rapid

measurement (single) every 1 minute.

*8

(25°C)

RC-Handle (RC-PRH4)

Sensitivity of levels 35’/2mm

Size (when attached to RC-PR4)

80.5 (W) X 126.5 (D) X 242 (H) mm

Weight (when attached to RC-PR4, with BDC46C)

About 510g

360° Prism (ATP1)

Measuring range (Using SRX/NET, angles of elevation and inclination both less than

15°)

EDM 1.3 to 1000m

Auto Tracking 2 to 500m

Auto Pointing 2 to 600m

Prism constant 7mm

3D positioning accuracy (standard deviation)

3mm (Angles of elevation and inclination both less than 20°)

Prism height 37mm (from mounting face (flange face) when attached to RC-PR4)

Operating temperature -20 to 50°C

Storage temperature range -30 to 70°C

Size 70 (W) X 104 (H) mm (with cap)

Weight 265g (with cap)

*9

*9

*9

42

11. SPECIFICATIONS

*9: No haze, visibility over 20 km, slightly overcast (less than 30000 lx), no scintillation.

360° Sliding Prism (ATP1S)

Measuring range (Using SRX/NET, angles of elevation and inclination both less than

15°)

EDM 1.3 to 1000m

Auto Tracking 2 to 400m

2 to 500m

Auto Pointing 2 to 500m

2 to 600m

Prism constant 7mm

3D positioning accuracy (standard deviation)

3mm (Angles of elevation and inclination both less than 20°)

Prism height 50mm (When attached to Pin Pole for ATP1S PP2, from bottom of pin

pole)

100mm (When attached to Pin Pole for ATP1S PP2 and prism foot

AP66, from tip of prism foot)

Prism slide range 50mm to 350mm (When attached to Pin Pole for ATP1S PP2,

graduations at 50mm intervals)

Operating temperature -20 to 50°C

Storage temperature range -25 to 70°C

Size

360° Sliding Prism ATP1S

65 (W) X 77.5 (H) mm

Pin Pole for ATP1S PP2 Ø6mm X 432mm (including connecting screw section and pole ends)

Weight

360° Sliding Prism ATP1S

160g

Pin Pole for ATP1S PP2 110g

ATP1S, PP2 and AP66 290g

*1

*1

*10

*1

*10

*10: Good: No haze, visibility about 40 km, overcast, no scintillation.

43

12. EXPLANATION

: Hexagonal points

Prism sighting direction

12.1 High Accuracy with the 360° Prism

Sighting can be more accurately performed by facing the 360° Prism toward the total station.

When using the ATP1, the 360° Prism should be set up so that a pair of diametrically-opposed

hexagonal points on its rubber flanges are aligned with the sighting direction of the total station (see

the diagram below).

When using the ATP1S, the 360° Prism should be set up so that a pair of diametrically-opposed marks

on top of the prism are aligned with the sighting direction of the total station.

44

13. REGULATIONS

Users must ensure that their instrument is compliant with the relevant regulations and legal restrictions

in place in the country of use.

For users in the US

WARNING: Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful inter-ference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

This transmitter must not be co-located or operated in conjunction with any other antenna or

transmitter.

This equipment complies with FCC radiation exposure limits set forth for uncontrolled equipment and

meets the FCC radio frequency (RF) Exposure Guidelines in Supplement C to OET65. This equipment

should be installed and operated with at least 20cm and more between the radiator and person’s body

(excluding extremeties: hands, wrists, feet and ankles).

For users in Canada

This Class A digital apparatus meets all requirements of Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la Class A respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

This class A digital apparatus complies with Canadian ICES-003.

Cet appareil numerique de la classe A est conforme a la norme NMB-003 du Canada.

Operation is subject to the following two conditions: (1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause undesired

operation of this device.

This equipment complies with IC radiation exposure limits set forth for uncontrolled equipment and

meets RSS-102 of the IC radio frequency (RF) Exposure rules. This equipment should be installed

and operated with at least 20cm and more between the radiator and person’s body (excluding

extremeties: hands, wrists, feet and ankles).

45

13. REGULATIONS

For users in the European Economic Area (EEA)

For a copy of the CE Conformity Declaration for this instrument, contact your local dealer.

RC-PR4 with WT11

46

13. REGULATIONS

For users in Mexico

Este equipo opera a titulo secundario, consecuentemente, debe aceptar interferencias perjudiciales

incluyendo equipos de la misma clase y puede no causar interferencias a sistemas operando a titulo

primario.

COFETEL + RCPSOWT08-0101

47

13. REGULATIONS

06223/POSTEL/2008

2311

For users in Indonesia

For users in Taiwan

For users in the United Arab Emirates

48

Approved by TRA

Button Operations

Operation Button Operation Indication

POWER ON

POWER OFF

Far Mode

Standard Mode

Start Turning

Turning in

operation

Turning complete

Cancel Turning

Continue Turning

Press once

Press and hold

When ● FAR is Off,

press once

When ● FAR is Lit,

press once

Press once

Press once

while Turning in

operation

Press and hold

● POWER is Lit

● POWER Flashes then turns

Off

● FAR is Lit

● FAR is Off

● SEARCH Flashes

● SEARCH is Lit for 2

seconds

● SEARCH is Off

● SEARCH Flashes

5th ed. 07-1202 ©2008 SOKKIA TOPCON CO., LTD.

Loading...

Loading...