Page 1

Serial Number 000001 and after

OPERATORS

MANUAL

Partnumber 511147-000-EN

1

November 2012

Page 2

Page 3

Page 4

EC

DECLARATION

OF

CONFORMITY

FOR MACHINERY

MACHINERY:

Powered Aerial Platform known as:

Type: SPM20

E. C. Type Examination Certificate No:

Note: Modification of the specified unit renders this declaration invalid

Page 5

OPERATION

WARNING

All personnel shall carefully read, understand and follow all safety rules and operating instructions before operating

Electrocution Hazard Tip Over Hazard Collision Hazard Fall Hazard

THIS MACHINE

INSULATED!

IS NOT

or performing maintenance on any Snorkel aerial work platform.

Safety Rules

NEVER

drive the machine while elevated

unless the machine is on a firm,

elevate the platform or

level surface.

NEVER

overhead obstructions or other

position the platform

without first checking for

hazards.

MANUAL

NEVER

platform guardrails or midrail.

climb, stand, or sit on

USE OF

used for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings, cranes, roof

structures, buildings etc.). All other uses of the aerial work platform are prohibited!

THIS

electrical equipment!

Exceeding the specified permissible maximum load is prohibited! See “Special Limitations” on page 4 for details.

The use and operation of the aerial work platform as a lifting tool or a crane (lifting of loads from below upwards or from up high on

down) is prohibited!

NEVER

DISTRIBUTE

NEVER

debris; and avoiding them.

OPERATE

NEVER

IN CASE OF

IF

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete structures,

etc., is prohibited!

Dismantling the swing gate or other railing components is prohibited! Always make certain that the swing gate is closed and

securely locked!

It is prohibited to keep the swing gate in an open position (held open with tie-straps) when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited!

NEVER

INSPECT

damaged cables or hoses before using.

VERIFY

NEVER

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its

working range.

NEVER

Modifications to the aerial work platform are prohibited or permissible only at the approval by Snorkel

AFTER

The driving of MEWPs on the public highways is subject to regulations made under the Road Traffic Acts.

THE

AERIAL WORK

AERIAL WORK

exceed the manual force allowed for this machine. See “Special Limitations” on page 4 for details.

all platform loads evenly on the platform.

operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or

machine only on surfaces capable of supporting wheel loads.

operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 4 for details.

EMERGENCY

ALARM

SOUNDS

perform service on machine while platform is elevated without blocking elevating assembly.

the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and

that all labels are in place and legible before using.

use a machine that is damaged, not functioning properly, or has damaged or missing labels.

charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas.

USE, secure the work platform from unauthorized use by turning both keyswitches off and removing key.

PLATFORM

while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level surface.

PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material

IS NOT

push EMERGENCY STOP switch to deactivate all powered functions.

INSULATED!

For this reason it is imperative to keep a safe distance from live parts of

Page 6

2

FOREWORD

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees

with the precautions and operating procedures essential for the safe and proper machine operation

for its intended purpose.

Due to continuous product improvements, the manufacturer reserves the right to make

specification changes without prior notification. Contact the manufacturer for updated

information.

Other Publications Available:

Illustrated Parts Manual…………………………………………………. ……………………

Page 7

3

SAFETY

ALERT

SYMBOLS

This is the Safety Alert Symbol. It is used to alert you to the potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

AND

SAFETY SIGNAL

WORDS

DANGER

INDICA TES

SERIOUS INJURY

IN

AN

IMMINENTLY HAZARDOUS SITUATION. IFNOT AVOIDED,

OR DEATH.

WILL RESULT

WARNING

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT AVOIDED, COULD

RESULT INSERIOUS INJURY

OR DEATH.

CAUTION

INDICA TES

MINOR

A

POTENTIALITY HAZARDOUS SITUATION.IFNOT AVOIDED, MAY RESULT

OR

MODERA TE INJURY.

IT MAY ALSO ALERT AGAINST

UNSAFE

PRACTICES.

IN

INDICA TES PROCEDURES ESSENTIAL

IMPORT

FOR SAFE OPERATION.

ANT

WARNING

THIS

THE MANUFACTURER OR IT’S LOCAL AUTHORIZED REPRESENTATIVE FOR

INFORMATION

ISSUED

THE MANUFACTURER SENDS SAFETY RELATED BULLETINS TO THE OWNER OF

RECORD OFTHIS MACHINE. CONT ACT

CURRENT OWNER RECORDS

THE

IT’S

OR DEATH OF

PERSONAL PROPERTY

PRODUCT

FOR

MANUFACTURER

PRODUCTS

MUST COMPLY WITH ALL SAFETY RELATED BULLETINS. CONTACT

REGARDING

THIS

PRODUCT.

HAVE BEEN

PERSONNEL

SAFETY-RELATED

IMPORT

THE

ARE

UPDATED

IMPORT

MUST BE

OR THE PRODUCT.

NOTIFIED IMMEDIATELY

INVOLVED

OR WHEN SUBSTANTIAL DAMAGE HAS

BULLETINS WHICH MAY HAVE BEEN

ANT

MANUFACTURER

AND ACCURATE.

ANT

IN AN

ACCIDENT INVOLVING

IN ALL

TO

ENSURE

INSTANCES

BODILY INJURY

OCCURRED

THAT THE

WHERE

TO

Page 8

4

SUBJECT-SECTION,

TABLE OF

PARAGRAPH PAGE NO.

CONTENTS

FOREWORD ................................................................................................................2

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS ....................................3

SECTION

1 -

SAFETY

PRECAUTIONS

1. 1 GENERAL ...........................................................................................................7

1. 2 PRE-OPERATION. .............................................................................................. 7

Operator Training And Knowledge ......................................................................7

Workplace Inspection ..........................................................................................8

Machine Inspection ............................................................................................. 8

1. 3 OPERATION .......................................................................................................8

General ...............................................................................................................8

Trip and Fall Hazard ............................................................................................9

Electrocution Hazard ...........................................................................................9

Safety Rules for Electrical Cont rol System ...................................................... 10

Tipping Hazard .................................................................................................. 11

Crushing And Collision Hazard ......................................................................... 11

1. 4 TOWING, LIFTING, AND HAULING .................................................................12

1. 5 Plates and Warning Labels ...............................................................................12

Nameplate and CE mark ...................................................................................12

Warning labels ..................................................................................................13

SECTION

2 -

PREPARATION

AND INSPECTION

2.1 PERSONNEL TRAINING .............................. ....................................................18

Operator Training .............................................................................................. 18

Training Supervision .........................................................................................18

Operator Responsibility .....................................................................................18

2.2 PREPARATION, INSPECTION, AND MAINTENANCE ....................................18

2.3 PRE-START INSPECTION ...............................................................................19

2.4 DAILY WALK-AROUND INSPECTION ............... ..............................................20

2.5 FUNCTION CHECK ..........................................................................................21

SECTION

3 -

MACHINE CONTROLS, INDICATORS

AND OPERATION

3.1 GENERAL ............................................................................................... ......... .24

3.2 MACHINE DESCRIPTION ................................................................................24

3.3 MACHINE OPERATION ...................................................................................24

Getting Started ..................................................................................................24

3.4 BATTERY CHARGING ........................................................................ .............24

Battery Low Voltage Warning Indicators ...........................................................25

To Charge Batteries ..........................................................................................26

Battery Charging Status Indicators ...................................................................26

Page 9

5

3.5 GROUND CONTROL STATION – OPERATION ............................................... 26

Main Power Key Switch .......... .................... ..... ..........................................26

Emergency Stop/Shut Down Button .................................................................27

Platform Up ............................................................................. ..........................27

Platform Down .................................................................................................. 27

Manual Descent Control Valve ..........................................................................27

3.6 PLATFORM CONTROL CONSOLE OPERATION ............................................ 28

At Ground Control Station .................................................................................28

Emergency Stop/Shut-Down Button ................................................................29

Driving Machine ................................................................................................ 29

Elevating/Lowering the Platform .......................................................................30

3.7 PARKING MACHINE .........................................................................................31

3.8 PLATFORM CONFIGURATIONS .....................................................................31

3.9 FALL PROTECTION – LANYARD ATTACHMENT............................................. 32

3.10 QUICK-CHANGE PLATFORM MOUNTING ...................................................... 33

Platform Removal ............................................................................................. 33

Platform Installation ..........................................................................................33

3.11 TRANSPORTING, LIFTING PROCEDURES ................................................... 34

General .............................................................................................................34

Truck Transport ............................................................................ ..................... 34

Fork Lift Truck Transport ...................................................................................35

SECTION

4 -

EMERGENCY

PROCEDURES

4.1 GENERAL INFORMATION ...............................................................................36

4.2 EMERGENCY OPERATION .............................................................................36

Operator Unable to Control Ma chine ...............................................................36

Platform caught Overhead ................................................................................36

4.3 INCIDENT NOTIFICATION ...............................................................................36

Page 10

6

SECTION

5 -

GENERAL SPECIFICATIONS

AND

OPERATOR

MAINTENANCE

5.1 INTRODUCTION .............................................................................................. 37

5.2 GENERAL SPECIFICATIONS ..........................................................................37

Machine Specifications .....................................................................................37

Machine Dimension ..........................................................................................38

Machine Operating Area ...................................................................................39

Electrical Specifications ....................................................................................39

Platform Data .................................................. ..................................................40

Machine Component Weights ...........................................................................40

Serial Number Locations ...................................................................................40

5.3 OPERATOR MAINTENANCE ...........................................................................40

Lubrication ........................................................................................................40

Hydraulic Diagram ............................................................ ................................ 41

SECTION

6 -

INSPECTION

AND

REPAIR

LOG

LIST OF

FIGURES

2-1. Daily Walk-Around Inspection for SPM20 Machines ..................................................21

3-1. Battery Charger Location ........................................................................................... 25

NO. TITLE PAGE

FIGURES

NO.

3-2. Ground Control Station. (Machine Rear View) ..........................................................28

3-3. Platform Control Console. ......................................................................................... 28

3-4. Forklift Truck Lifting Pockets and Machine Tie Down Bar Locations ..........................35

LIST OF TABLES

TABLE NO. TITLE PAGE

NO.

1-1 Minimum Safe Approach Distance (M.S.A.D.). .........................................................10

2-1 Inspection and Maintenance Table .............................................................................19

3-1 Machine Operating Specifications ..............................................................................23

5-1 Lubrication Specifications .......................................................................................... 42

5-2 Lubrication Intervals for Various Components ............................................................42

6-1 Inspection and Repair Log ......................................................................................... 44

Page 11

7

1.1 GENERAL

SECTION

1.

SAFETY

PRECAUTIONS

This section outlines the necessary precautions for proper and safe machine usage and maintenance.

For proper machine use, it is mandatory that a daily routine be established based on the

content of this manual. A maintenance program, using the information provided in this manual

and the Service and Maintenance Manual, must also be established by a qualified person and

must be followed to ensure that the machine is safe to operate.

The owner/user/operator/lessor/lessee of the machine should not accept operating responsibility until this

manual has been read, training is accomplished, and operation of the machine has been

completed under the supervision of an experienced and qualified operator.

If there are any questions with regard to safety, training, inspection, maintenance, application,

and operation, please contact the manufacturer.

FAILURE

TO

COMPLY WITH

COULD RESULT

WARNING

THE

SAFETY PRECAUTIONS LISTED

IN

MACHINE DAMAGE, PROPERTY DAMAGE, PERSONAL INJURY

IN

THIS

MANUAL

OR

DEATH.

1.2

PRE-OPERA

Operator Training And Knowledge

• Read and understand this manual before operating the machine.

TION

• Do not operate this machine until complete training is performed by authorized persons.

• Only authorized and qualified personnel can operate the machine.

• Read, understand, and obey all DANGERS, WARNINGS, CAUTIONS, and operating

instructions on the machine and in this manual.

• Use the machine in a manner, which is within the scope of its intended application set by

the manufacturer.

• All operating personnel must be familiar with the emergency controls and emergency

operation of the machine as specified in this manual.

Page 12

8

• Read, understand, and obey all applicable employers, local, and governmental regulations

as they pertain to operation of the machine.

Workplace Inspection

• The operator is to take safety measures to avoid all hazards in the work area prior to

machine operation.

• Do not operate or raise the platform while on trucks, trailers, railway cars, floating vessels,

scaffolds or other equipment unless approved in writing by the manufacturer.

• This machine can be operated in temperatures of –20 c to 40 c . Consult the manufacturer

for operation outside this range.

Machine Inspection

• Before machine operation, perform inspections and functional checks. Refer to Section 2

of this manual for detailed instructions.

• Do not operate this machine until it has been serviced and maintained according to

requirements specified in the Service and Maintenance Manual.

• Ensure all safety devices are operating properly. Modification of these devices is a safety

violation.

MODIFICATION OR ALTERATION

ONLY

WITH PRIOR WRITTEN PERMISSION FROM

WARNING

OF AN AERIAL WORK

PLATFORM

THE MANUFACTURER

SHALL BE MADE

• Do not operate any machine on which the safety or instruction placards or decals are

missing or illegible.

• Avoid any build up of debris on platform floor. Keep mud, oil, grease, and other slippery

substances from footwear and platform floor.

1.3 OPERATION

General

• Do not use the machine for any purpose other than positioning personnel, their tools and

• Never operate a machine that is not working properly. If a malfunction occurs, shut down

• Never slam a control switch or lever through neutral to an opposite direction. Always

• Do not allow personnel to tamper with or operate the machine from the ground with

• Do not carry materials directly on platform railing unless approved by the manufacturer.

equipment, or for hand stock picking.

the machine.

return switch to neutral and stop before moving the switch to the next function. Operate

controls with slow and even pressure.

personnel in the platform, except in an emergency.

• Always ensure that power tools are properly stowed and never left hanging by their cord

from the platform work area.

• Fully lower mast assembly and shut off all power before leaving machine.

Page 13

9

• When performing welding operations at elevation, precautions must be taken to protect all

machine components from contact with weld splatter or molten metal.

• Battery fluid is highly corrosive. Avoid contact with skin and clothing at all times.

• Charge batteries on in a well ventilated area.

Trip and Fall Hazard

• The manufacturer recommends that the operator in the platform wear a full body harness with a

lanyard attached to an authorized lanyard anchorage point. For further information

regarding fall protection requirements on the products, contact the manufacturer.

• Before operating the machine, make sure all railing and gates are fastened in their proper

position.

• Keep both feet firmly positioned on the platform floor at all times. Never use ladders,

boxes, steps, planks, or similar items on platform to provide additional reach.

• Never use the mast assembly to enter or leave the platform.

• Use extreme caution when entering or leaving platform. Ensure that the mast assembly is

fully lowered. Face the machine when entering or leaving the platform. Always maintain

“three point contact” with the machine, using two hands and one foot or two feet and one

hand at all times during entry and exit.

• Platform-to-structure transfers at elevated positions are discouraged. Where transfer is

necessary, enter/exit through the gate only with the platform within 1 foot (0.3m) of a safe

and secure structure. 100% tie-off is also required in this situation utilizing two lanyards.

One lanyard must be attached to the platform with the second lanyard attached to the structure.

The lanyard connected to the platform must not be disconnected until such time the

transfer to the structure is safe and complete.

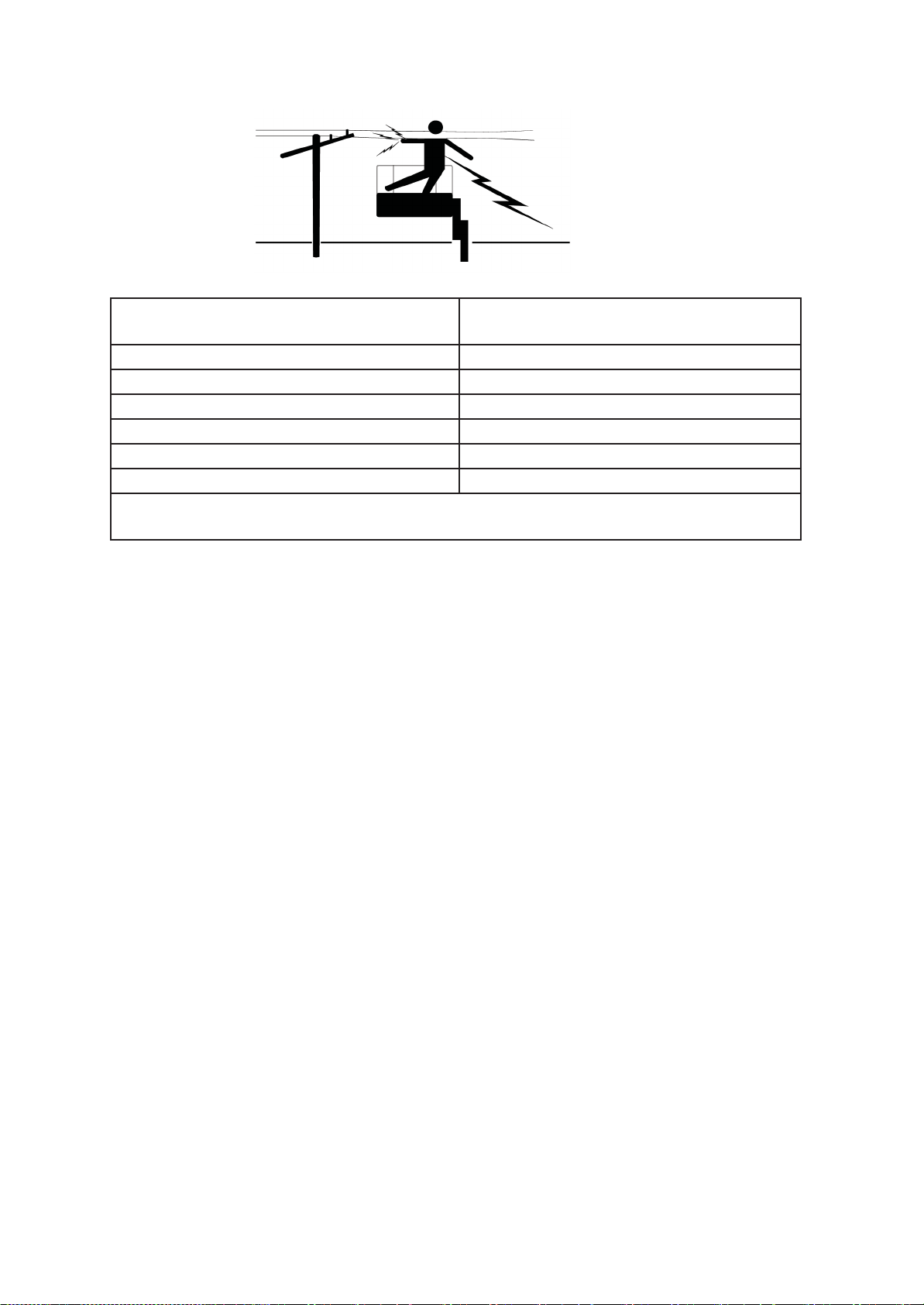

Electrocution Hazard

Page 14

10

VOLTAGE

RANGE

(PHASE

TO PHASE)

MINIMUM

SAFE APPROACH

DISTANCE-Feet

(m)

0-50KV 10(3)

Over 50KV to 200KV

15(5)

Over 200KV to 350KV

20(6)

Over 350KV to 350KV

25(8)

Over 500KV to 750KV

35(11)

Over 750KV to 1000KV

45(14)

NOTE: This Minimum Safe Approach Distance shall apply except where employer, local,

or governmental regulations are more stringent.

Table

1-1.

Minimum

Safe

Approach Distance (M.S.A.D.)

Maintain a clearance of at least 10 ft (3m) between any part of the machine and its

occupants, their tools, and their equipment from any electrical line or apparatus carrying

up to 50,000 volts. One foot (0.3m) additional clearance is required for every additional

30,000 volts or less.

The minimum safe approach distance may be reduced if insulating barriers are installed to prevent

contact, and if the barriers are rated for the voltage of the line being guarded. These barriers

shall not be part of (or attached to) the machine. The minimum safe approach distance shall be

reduced to a distance within the designed working dimensions of the insulating barrier. This

determination shall be made by a qualified person in accordance with

employer, local, or governmental requirements for work practices near energized equipment.

Safety Rules for Electrical Control System

• Only personnel who are properly trained and have adequate knowledge and skill should

undertake all electrical/electronic troubleshooting and repair.

• Do not alter or bypass protective interlocks.

• Before starting, read and observe all warning labels.

• When trouble shooting make sure the power source has been disconnected and main

switch has been locked.

• Take extra precautions in damp areas to protect you from accidental grounding.

• Before applying power to any equipment it must be established, without a doubt, that all

persons are clear.

• Do not open the electrical control panel unless it is necessary to check the electrical

equipment.

• Do not alter the electrical circuits unless authorized to do so by the manufacturer.

• When replacing electrical components, make sure they conform to the manufacturer’s

specifications, including proper color coding.

• Do not wear metal frame glasses, metallic necklaces or chains while working on any

electrical equipment. Also do not wear any ring, watch or bracelet while operating

electrical equipment.

Page 15

11

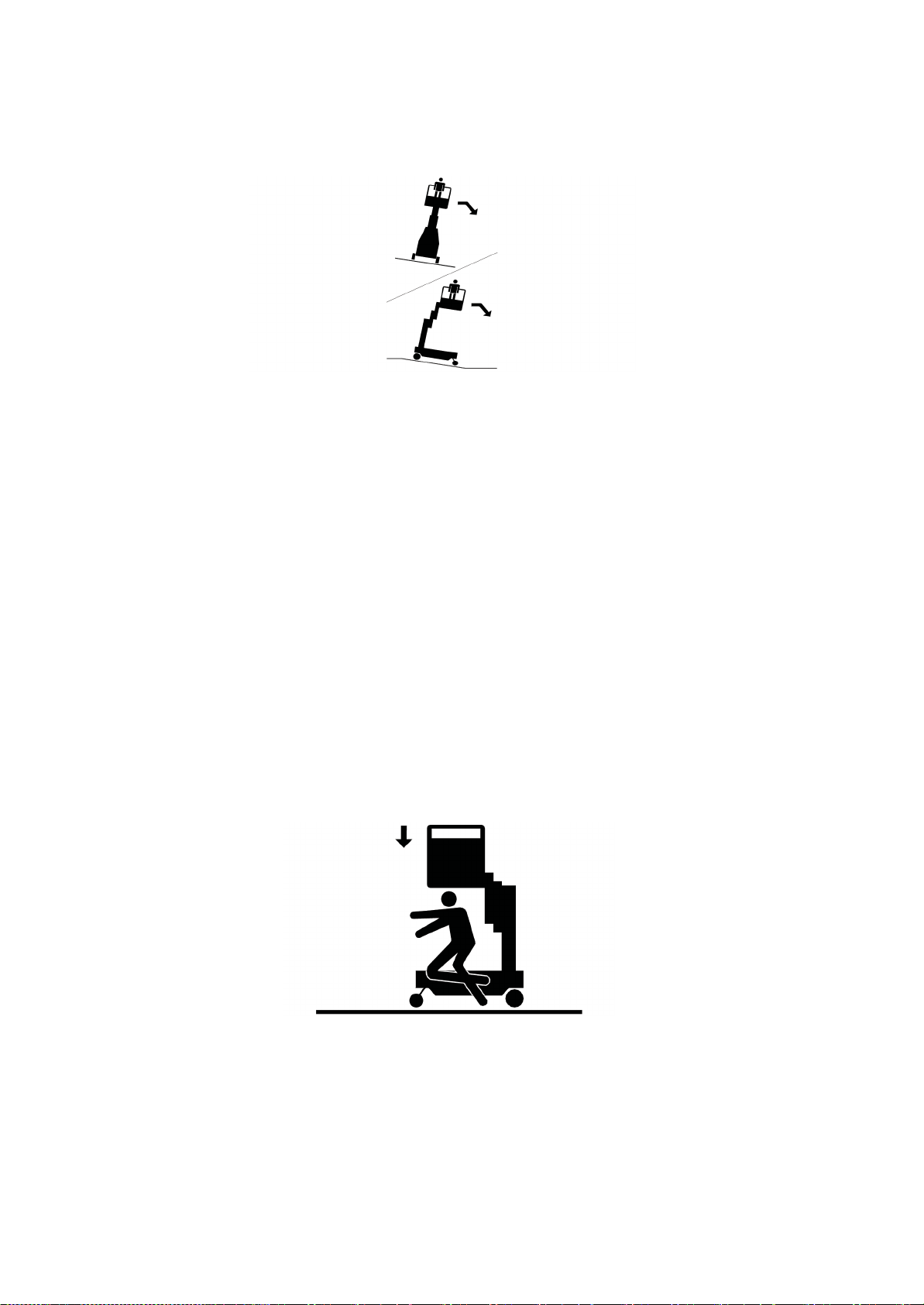

Tipping Hazard

• The user should be familiar with the surface before driving. Do not exceed the allowable

side slope and grade while driving.

• Do not elevate platform or drive with platform elevated while on a slope, or on an uneven

or soft surface.

• Before driving on floors, bridges, trucks, and other surfaces, check allowable capacity of

the surfaces.

• Never exceed the maximum platform capacity. Distribute loads evenly on platform floor.

• Keep the chassis of the machine a minimum of 2 ft. (0.6m) from holes, bumps, drop-offs,

obstructions, debris, concealed holes, and other potential hazards at the ground level.

• Never attempt to use the machine as a crane. Do not tie-off machine to any adjacent

structure.

• Do not increase the platform size with unauthorized deck extensions or attachments,

increasing the area exposed to wind will decrease stability.

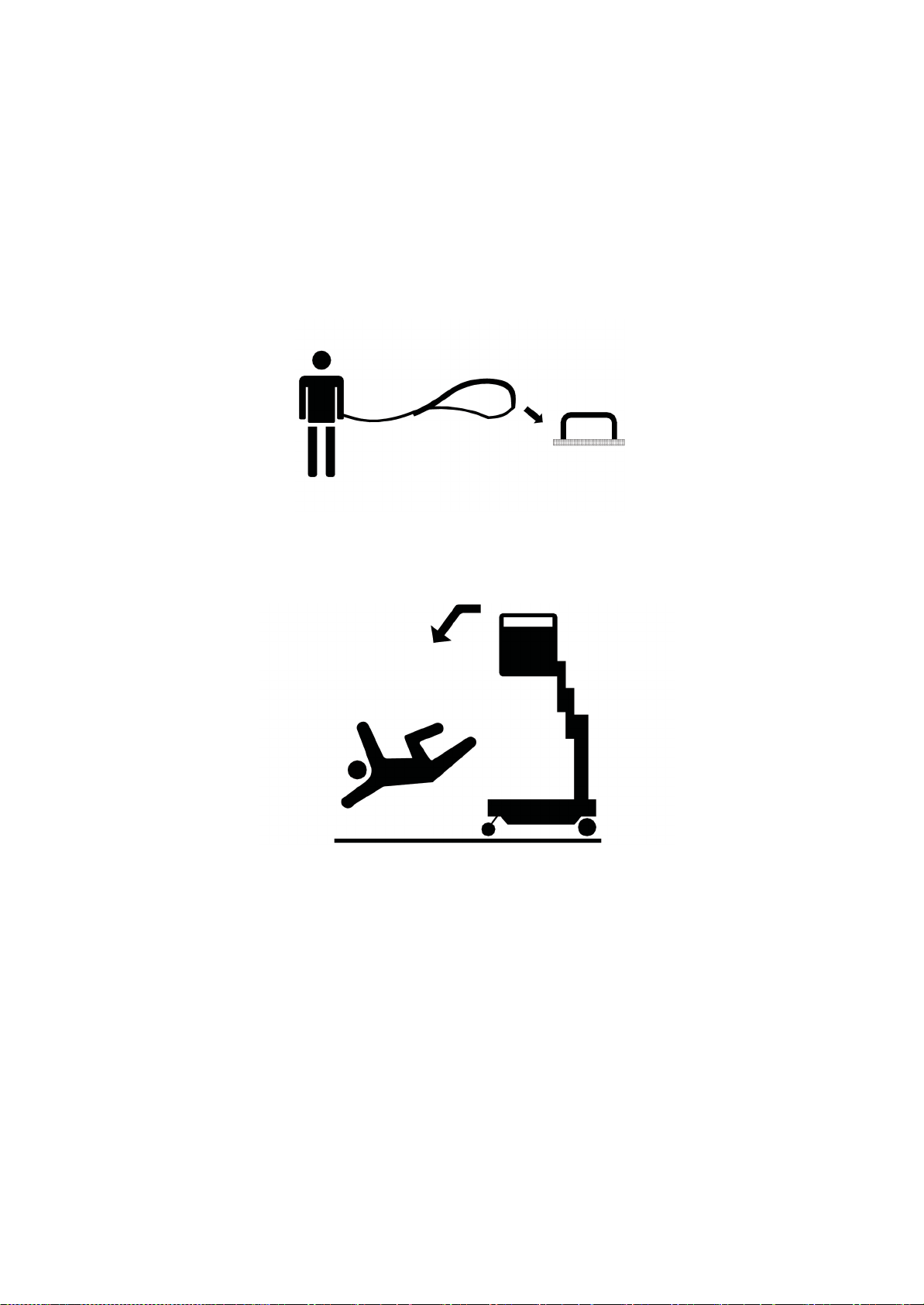

• If mast assembly or platform is caught so that one or more wheels are off the ground,

the operator must be removed before attempting to free the machine. Use cranes, forklift

trucks, or other appropriate equipment to stabilize machine and remove personnel.

Crushing And Collision Hazard

• Personal protection equipment must be worn by all operating and ground personnel.

• Check work area clearances above, on sides, and bottom of platform while driving and

lifting or lowering platform

• During operation, keep all body parts inside platform railing.

• Always post a lookout when driving in areas where vision is obstructed.

• Keep non-operating personnel at least 6 ft. (1.8m) away from machine during all driving

operations.

• Limit travel speed according to conditions of ground surface, congestion, visibility, slope,

location of personnel, and other factors causing hazards of collision or injury to personnel.

• Be aware of stopping distances in restricted or close quarters or when driving in reverse.

Page 16

12

• Do not drive at high speeds in restricted or close quarters or when driving in reverse.

• Exercise extreme caution at all times to prevent obstacles from striking or interfering with

operating controls and persons in the platform.

• Ensure that operators of other overhead and floor level machines are aware of the aerial

work platform’s presence. Disconnect power to overhead cranes.

• Warn personnel not to work, stand, or walk unde

floor as necessary.

1.4

TOWING, LIFTING,

• Never allow personnel in platform while towing, lifting, or hauling.

• This machine should not be towed, except in the event of emergency, malfunction, power

failure, or loading/unloading. Refer to the Emergency Procedures Section of this manual

for emergency towing procedures.

• Ensure platform is fully retracted and completely empty of tools prior to towi

hauling.

• Do not assist a stuck or disabled machine by pushing or pulling except by pulling at the

chassis tie-down bars.

• When lifting machine with a forklift, position forks only at designated areas of the machine.

Lift with a forklift of adequate capacity.

• Refer to the Machine Operation section of this manual for lifting information.

AND HAULING

r a raised platform. Position barricades on

ng, lifting or

1.5 Plates and Warning Labels

Upon unpacking, check the plates and warning labels. Do not operate the machine on which

the plates or labels are missing or illegible. Contact the dealer immediately.

The following plates are visible on the machine.

Nameplate and CE mark

Page 17

13

Warning labels

Page 18

14 15

Page 19

WARNING

Page 20

16 17

Page 21

Page 22

18

2.1

PERSONNEL

SECTION

TRAINING

2.

PREPARATION

AND INSPECTION

The aerial platform is a personnel-handling device; so it is necessary that it be operated and

maintained only by trained personnel.

Persons under the influence of drugs or alcohol or who are subject to seizures, dizziness or

loss of physical control must not operate this machine.

Operator Training

Operator training must cover:

1. Use and limitations of the controls in the platform and at the ground, emergency controls

and safety systems.

2. Control labels, instructions, and warnings on the machine.

3. Rules of the employer and government regulations.

4. Use of approved fall protection device.

5. Enough knowledge of the mechanical operation of the machine to recognize a

malfunction/

6. The safest means to operate the machine where overhead obstructions, other moving

equipment, and obstacles, depressions, holes, drop-offs are present.

7. Means to avoid the hazards of unprotected electrical conductors.

8. Specific job requirements or machine application.

Training Supervision

Training must be done under the supervision of a qualified person in an open area free of

obstructions until the trainee has developed the ability to safely control and operate the machine.

Operator Responsibility

The operator must be instructed that he/she has the responsibility and authority to shut down the

machine in case of a malfunction or other unsafe condition of either the machine or the job site.

NOTE: The Manufacturer or Distributor will provide qualified people for training assistance

with the first unit(s) delivered and from that time forward as requested by the user or

2.2

The following table covers the periodic machine inspections and maintenance recommended by the

manufacturer. consult local regulations for further requirements for aerial work platforms. The

frequency of inspections and maintenance must be increased as necessary when the

machine is used in a harsh or hostile environment, if the machine is used with increased

frequency, or if the machine is used in a severe manner.

THE

HAS

PRODUCT

his/her personnel.

PREPARATION, INSPECTION,

AND MAINTENANCE

IMPORT

ANT

MANUFACTURER RECOGNIZES A QUALIFIED MECHANIC

SUCCESSFULLY COMPLETED

THE

SERVICE TRAINING

MODEL.

AS A

PERSON

WHO

FOR THE SPECIFIC

Page 23

19

TYPE

FREQUENCY

PRIMERY

RESPONSIBILITY

SERVICE

QUALIFICATION

REFERENCE

Pre-Start

Inspection

Before using each day,

or whenever there’s an

Operator change.

User or Operator

Operator and Safety

Manual

Pre-Delivery

Inspection

(See Note)

Before each sale, lease,

or rental delivery.

Owner, Dealer, or

User

Qualified

Mechanic

Service and

Maintenance

Manual and applicable

Inspection form

Frequent

Inspection

In service for 3 months

or 150 hours, whichever

comes first; or; Out of

service for a period of

more than 3 months; or

Purchased used.

Owner, Dealer, or

User

Qualified

Mechanic

Service and

Maintenance

Manual and applicable

Inspection form

Annual

Machine

Inspection

Annually, no later than 13

months from the date of

prior inspection.

Owner, Dealer, or

User

Qualified

Mechanic

Service and

Maintenance

Manual and applicable

Inspection form

Preventative

Maintenance

At intervals as specified

in the Service and

Maintenance Manual.

Owner, Dealer, or

User

Qualified

Mechanic

Service and

Maintenance

Inspection form

NOTE: Inspection forms are available from the manufacture. Use the Service and Maintenance Manual to

perform inspections.

SUCCESSFULLY COMPLETED

Table

THE

SERVICE TRAINING

PRODUCT MODEL.

2-1.

Inspection and Maintenance Table

FOR THE

SPECIFIC

2.3

PRE-START

INSPECTION

The Pre-Start Inspection should include each of the following:

1. Cleanliness – Check all surfaces for leakage (oil, fuel, or battery fluid) or foreign objects.

Report any leakage to the proper maintenance personnel.

2. Decals and Placards – Check all for cleanliness and legibility. Make sure no decals or

placards are missing. Make sure all illegible decals and placards are cleaned or replaced.

3. Operators and Safety Manuals – Make sure a copy of the Operation and Safety Manual,

Safety Manual, and Manual of Responsibilities is enclosed.

4. Daily Walk - Around Inspection – (See Section 2.4)

5. Battery – Charge as required.

6. Hydraulic Oil – Check the hydraulic oil level.

NOTE: Check Service Manual for instructions and hydraulic oil specification before adding.

DO NOT OVERFILL.

Page 24

20

7. Function Check – Check all machine controls for operation. (See Section 2.5)

If optional equipment is installed on this machine refer to Section 3 for specific Pre-Start

Inspection and Operation instructions.

2.4 DAILY

WALK-AROUND INSPECTION

Begin the “Walk – Around Inspection” at item one (1) as noted on the diagram. Continue around

machine check each item in sequence for the conditions listed in the following checklist.

TO AVOID

AROUND

POSSIBLE

INJURY, BE SURE MACHINE

INSPECTION”.

WARNING

POWER

IS “OFF”

DURING “WALK-

DO NOT

DO

THIS

DAMAGE.

NOTE: On all components, make sure there are no loose or missing parts, that they are

1. Drive and Caster Wheels – Check for any debris stuck to or around wheels.

2. Base Frame – Check pot-hole-protection system components; check for loose wires or

3. Manual Descent Control Valve – See note above.

4. Motor/Pump/Reservoir Unit – No evidence of hydraulic leaks.

5. Batteries – Battery cables; no corrosion.

6. Platform Assembly and Gate – Quick-Change platform mounting and mounting screws;

7. Platform Control console – Platform control; placards secure and legible; emergency stop

OPERATE MACHINE UNTIL

NOT OVERLOOK VISUAL INSPECTION

AREA FOR OBJECTS OR

ALL

MALFUNCTIONS

IMPORT

ANT

OF THE BASE

DEBRIS, WHICH

HAVE BEEN CORRECTED.

FRAME UNDERSIDE.

COULD CAUSE

EXTENSIVE

securely fastened, and that no visible damage, leaks or excessive wear exists in

addition to any other criteria mentioned.

cables dangling below the base.

platform fasteners; platform railings; entry bar or gate in proper working order.

switch reset for operation; Control markings legible.

CHECK

MACHINE

8. Ground Control Station – Main Power Selector Switch operable; placards secure and

legible; emergency stop switch operates properly.

9. Mast Assembly – Mast sections; slide pads; mast chains; sequencing cables; platform

control and power cables (on side of mast); power cables properly tensioned and seated in

sheaves; cable sheaves rotating freely.

Page 25

21

Figure

2-1.

Daily Walk-Around Inspection for

SPM20

Machines.

1. Drive and Caster Wheels

2. Base Frame

3. Manual Descent Control Valve

2.5

FUNCTION

CHECK

Once the “Walk-Around” Inspection is complete, perform a function check of all systems in

an area free of overhead and ground level obstructions. Refer to Section 3 for more specific

operating instructions.

IF THE MACHINE DOES NOT OPERATE PROPERLY, TURN OFF THE MACHINE

IMMEDIATELY!

REPORT THE PROBLEM TO THE PROPER MAINTENANCE PERSONNEL. DO NOT

OPERATE

Perform a Function Check as

THE

MACHINE UNTIL

1. From the ground controls with no load in the platform:

a. Operate ground control functions, platform lift up and lift down.

4. Motor/Pump/Reservoir Unit

5. Batteries (Open Cover Doors)

6. Platform Assembly

WARNING

IT IS

DECLARED

follows:

SAFE FOR OPERATION.

7. Platform Control Console

8. Ground Control Console

9. Mast Assembly

Page 26

22

NOTE:

Ensure Pot-Hole-Protection device is fully engaged (both bars down) when the

platform is elevated.

b. Ensure that all machine functions are disabled when the Emergency Stop Button is

activated.

c. Check Manual Control valve is operating properly.

2. From the platform control console:

a. Ensure that the control console is properly mounted and secure.

b. Raise and lower platform 2 ft. to 3 ft. (.61m to .92m) several times. Check for smooth

elevation and lowering of platform.

c. Operate all functions and check all limit and cutout switches.

d. Ensure that all machine functions are disabled when the Emergency Stop Button is

activated.

3. With platform in the transport (stowed)

a. Drive the machine on a grade, not to exceed the rated grade ability, and stop to ensure

the brakes hold.

b. Check the 1.0 degree tilt sensor alarm to ensure proper ope

position:

ration.

Page 27

23

1

SECTION

3.

MACHINE CONTROLS, INDICATORS

AND

OPERATION

Table 3-1 Machine Operating Specifications

SPM20

Maximum Occupants:

Maximum Work Load (Capacity):

Maximum Travel Grade (Grade ability): 15-20%

Maximum Travel Grade (Side

Slope):(Platform STOWED ONLY)

Maximum Height (Platform Stowed)

Maximum Vertical Platform Height:

Maximum Wheel Load (Per Wheel):

Maximum Drive Speeds (Operator

Variable):

Max. Platform Speeds (w/Max. Load):

Platform Up:

Platform Down:

150kg

5°

2100mm

6m

360kg

0.6 - 8 km/h

27-36 sec.

30-35 sec.

Gross Machine Weight (Standard

Equipment/Platform Empty):

1050kg

Page 28

24

3.1 GENERAL

IMPORT

THE

MANUFACTURER

OPERATION.

THE

WITH GOOD SAFETY

This section provides the necessary information needed to understand control function and

HAS

USER

AND

PRACTICES.

DIRECT CONTROL OVER MACHINE APPLICATION

OPERATOR

ANT

ARE

RESPONSIBLE

AND

FOR CONFORMING

operation.

3.2

MACHINE

DESCRIPTION

The SPM20 Model Lifts are electric self-propelled machines with an aerial work platform

mounted to an elevating aluminum mast mechanism. The personnel lift’s intended purpose is

to personnel access to areas above ground level.

The primary control station is located in the platform. From the Platform Control Console the

operator can drive the machine and raise or lower the platform.

The controls of the programmable Ground Control Station are to be used during machine power-up,

machine maintenance or in case of emergency should the operator in the platform be unable

to lower the platform.

Vibrations emitted by these machines are not hazardous to an operator working in the

platform.

The continuous A-Weighted sound pressure level at the work platform is less than 70db (A).

3.3

MACHINE

OPERATION

Getting Started

The following control conditions must be met before the machine can be operated from either

the Ground or Platform Controls.

• The batteries contain enough voltage to operate the machine.

• The Main Power Selector Switch on the Ground Control Station must be set for either

Ground Control Mode or Platform Control Mode.

• Both Emergency Stop Switches, one on the Ground Control Station the other on the

Platform Control Console must be in the RESET position.

• If equipped, the On/Off Key Switch on the Platform Console must be set to the ON

position.

3.4

BATTERY

CHARGING

SPM20 machines are equipped with an AC voltage input/DC voltage output battery charger.

The charger automatically terminates charging when the batteries reach full capacity.

NOTE:

The machine’s platform drive function is disabled when the battery charger is plugged into an

AC receptacle.

Page 29

25

Figure

Battery Voltage and Charging Status Indicators

The Ground Control Station indicate battery voltage ,Battery state-of-charge: 10-bar, tri-color LED (5-bar

green 3-bar yellow 2-bar red)

.

3-1.

Battery Charger Location.

Battery Charger Front

Battery Indicators

Panel

Page 30

26

NOTE: (a) To maximize battery life, it is recommended that the factory supplied batteries

be charged continuously for a minimum of 4 hours or until 8 bars are lit on the

ground station LCD Display before operating the machine. When drained to

Warning Level 2 or 3, batteries must be charged until 8 bars are lit on the ground

station LCD display to clear the fault code.

To Charge Batteries

1. Park machine in a well ventilated area near an AC voltage electrical outlet.

2. Closed key switch.

NOTE:

The batteries on SPM20 machines require approximately five (5) hours to fully charge

when drained to LOW BATTERY VOLT AGE warning on the Ground Control Module LCD

display.

3. Plug a heavy duty AC extension cord into the Charger AC Input Receptacle on the

center rear cover of the machine.

Battery Charging Status Indicators

3.5

GROUND CONTROL

STATION-OPERATION

(See Figure 3-2.)

Main Power Key Switch

Set the Main Power Key Switch to on Station

POWER

OFF

POWER

ON

TURN CLOCKWISE TURN COUNTERCLOCKWISE

Key Switch Key Switch

Page 31

27

Emergency Stop/Shut Down

POWER

OFF

PUSH IN-To Engage

Emergency Stop

Button

POWER

ON

TURN CLOCKWISE and RELEASE-To Reset

Emergency Stop

Platform Up Platform Down

TURN UP Left Toggle Switch, TURN UP Left Toggle Switch,

And TURN UP Right Toggle Switch And TURN DOWN Right Toggle Switch

Toggle Switch Toggle Switch

Manual Descent Control Valve

DRAW-OUT TO LOWER Platform RELEASE TO –STOP Platform Descent

Page 32

28

Figure

3-2.

Ground Control Station. (Machine Rear View)

1. Emergency Stop 2. Hour Run/BCI Meter

3. Main Power Key Switch 4. Deadman Toggle Switch, on-(on)

5. Toggle Switch (on)-off-(on) 6. Charger A/C Input Receptacle

7. Manual Descent Control Valve

3.6

PLATFORM CONTROL CONSOLE OPERATION

Figure

3-3.

Platform Control Console

1. Emergency Stop 2. Horn Button

3. Joystick with Enable Button 4. Toggle switch SPDT on-on

Page 33

29

Emergency Stop/Shut-Down

Button

POWER-OFF

PUSH IN-To Engage TURN CLOCKWISE and RELEASE-To Reset

Emergency Stop Emergency Stop

Driving Machine

WHEN DRIVING WITH PLATFORM LOWERED,

A RAMP

(GRADE)

WARNING

OF

GREATER

THAN

TWENTY

POWER-ON

DO

NOT ATTEMPT

PER

CENT (20%),

TO

DRIVE

AS TIPPING

MACHINE

COULD

UP

OCCUR.

POINT

& GO®

The Joystick can be moved in any direction off center.

Drive Power is applied proportionally the further the Joystick is moved off center.

1. PRESS and RELEASE the Drive Function Button.

2. While the Drive Function is active. PRESS and HOLD the enable button on side the

joystick.

Page 34

30

3. Move the joystick the desired direction of travel. TO STOP the machine return the joystick

back to center.

Elevating/Lowering the Platform

WARNING

IF THE TILT ALARM HAS BEEN ACTIVATED, THE PLATFORM WILL NOT ELEVATE.

ALSO

THE DRIVE

LOWERED.

IF THE TILT

FUNCTION

ALARM

HAS BEEN ACTIVATED WHEN THE PLATFORM IS

WILL BE DISABLED UNTIL THE PLATFORM IS COMPLETELY

ELEVATED,

1. Drive the machine to the area where overhead work is to be performed and position the

machine into its approximate work position.

2. PRESS and RELEASE the Platform Function Button.

3. While the Platform Function is active. PRESS and HOLD the Enable Button on side the

Joystick.

4. Push the Joystick FORWARD from center TO ELEVATE the Platform.

TO STOP platform movement return the joystick back to center. Pull

the Joystick BACK from center TO LOWER the Platform.

5. If necessary, reposition (drive) lift using platform controller joystick to bring work object within

reach.

Page 35

31

Model

Max. Capacity

SPM20

150kg

1. Sliding Bar Entry Gate 3. Platform Control Console

2. Extension Slide/Lock Handle 4. Sliding Extendible Section

3.7

PARKING

MACHINE

1. Drive machine to a well-protected and well-ventilated area.

2. Ensure the platform is fully lowered, turn the main power key switch to the OFF

position (centered).

NOTE:

If required, charge batteries in preparation for next workday.

3.8

PLATFORM

CONFIGURATIONS

EXTENDIBLE PLATFORM (SLIDING

BAR

ENTRY

)

Page 36

32

3.9

FALL

THE

FULL BODY

ANCHORAGE

PROTECTION

– LANYARD ATTACHMENT

MANUFACTURER RECOMMENDS

HARNESS WITH

A LANYARD

POINT.

CAUTION

THE

OPERATOR

ATTACHED TO

IN THE

AN

PLATFORM WEAR

AUTHORIZED

The main lanyard attach point for all SPM20 machines is located on the lower right side of

the mast platform header, just behind the operators platform.

AFTER ENTERING

CLOSE

THE

PLATFORM ENTRY

CAUTION

THE

PLATFORM, BEFORE BEGINNING OPERATION

GATE (S).

ALWAYS

A

LANYARD

Page 37

33

3.10 QUICK-CHANGE PLATFORM

MOUNTING

SPM20 Model Lifts are equipped with quick-change platform mount, which allow quick

removal and installation of currently available quick-change platform.

NOTE: SPM20 Models require the installation of the Quick-Change mount kit to use Quick-

Chang Platforms.

1. Upper Platform Mount

2. Upper Mount Fasteners

3. Lower Platform Mount

4. Lower Mount Fasteners

Platform Removal

1. Remove the platform control console from the platform and lay aside.

2. Remove both upper and lower mount fasteners securing the platform support rails to the

mast mounting channels.

3. Swing and lift the platform out of the mounts and lay aside.

Platform Installation

1. Set platform in upper and lower mounts.

2. Install mount fasteners in upper and lower mounts.

3. Attach platform control console to platform rail.

WARNING

ENSURE

ALL

FASTENERS

ARE

INSTALLED

AND

SECURE PRIOR

TO OPERATION.

Page 38

34

3.11 TRANSPORTING, LIFTING

General

AND TIE

DOWN

PROCEDURES

All SPM20 Series Model Personnel Lifts may be transported to a work site using the following

methods:

• Driving the machine around on its base wheels if travel surface area permits.

• Loaded, IN AN UPRIGHT POSITION ONLY onto a heavy-duty vehicle with the payload

capacity capable of supporting the full weight of the machine (Check machine gross weigh

in the Operating Spec Chart at the beginning of this Section).

• Moved with a forklift truck using the forklift pockets in the base frame.

Truck Transport

DO NOT

OF

TRANSPORT

BATTERY

HYDRAULIC

THE

ACID

FROM

RESERVOIR.

CAUTION

MACHINE IN A HORIZONTAL POSITION

THE

BATTERIES

OR

HYDRAULIC

FLUID

DUE TO LEAKAGE

FROM

THE

The machine may be winched onto a tilted roll-back truck bed (see important note following),

which has been rolled back to ground level. Disengage the brakes and always winch (pull)

from the mast (rear) end of the machine.

IMPORT

DO

NOT ATTEMPT

TILTED

THE

THE

ROLL-BACK

SPM20 MACHINES POWER MODULE COULD SUSTAIN SERIOUS

UNIT

IS

PUSHED,

TO

DRIVE MACHINE ONTO,

TRUCK

OR

BED.

TOWED

AT

SPEEDS GREATER

ANT

OFF OF, OR

PUSH MACHINE ONTO

DAMAGE WHEN

THAN 2 MPH.

A

WHEN TOWING

RE-ENGAGE

AND

READY

OR

WINCHING,

THE BRAKES

ONCE MACHINE

FOR TIE DOWN.

THE

MACHINE’S

BRAKES

IS IN PLACE

MUST

BE DISENGAGED.

WITH TRUCK

BED LEVEL

Machine Tie-Down

With machine in position to be tied down and brakes engaged, use the following guidelines

for restraining the machine during transport.

IMPORT

USE OF

CAUSE

1. Secure machine with an adequate chain attached through the tie down loops located at

2. The chain should be securely tightened with a force of approximately 100 lb. applied two

EXCESSIVE FORCE WHEN SECURING MACHINE (DRIVE WHEEL

DAMAGE TO THE

MACHINES DRIVE WHEEL

the front and rear of machine. (See Figure 3-11.)

feet from the pivot handle.

ANT

LOAD), CAN

COMPONENTS.

Page 39

35

NOTE: Lifting devise must be capable of handling the gross weight of the machine, see the

Operating Specifications table at the beginning of this Section.

Fork-Lift Truck Transport

All SPM20 Model Lifts are equipped with wide forklift pockets running through the base frame.

(See Figure 3-11.) This allows the machine to be either transported around a work area

or lifted onto a higher level using a standard fork-lift truck.

NOTE: Fork-lift trucks must be capable of handling the gross weight of the machine, see the

Operating Specifications table at the beginning of this Section.

2

Figure

3-4.

Forklift Truck Lifting Pockets and Machine Tie Down Bar Locations.

2

3

1. Rear Tie-Down Loop 2. Fork Lift Pockets 3. Front Tie-Down Loop

Page 40

36

4.1

GENERAL

SECTION

INFORMATION

4.

EMERGENCY PROCEDURES

This section explains the steps to be taken in case of an emergency situation during

operation.

4.2

EMERGENCY

Operator Unable to Control Machine

OPERATION

IF THE PLATFORM OPERATOR IS PINNED, TRAPPED OR UNABLE TO OPERATE OR

CONTROL THE MACHINE:

1. Other personnel should operate the machine from ground controls only as

required.

2. Only qualified personnel in the platform may use the platform controls. DO NOT

CONTINUE OPERATION IF CONTROLS DO NOT FUNCTION PROPERLY.

3. Cranes, forklift trucks or other equipment can be used to remove the platform

occupant and stabilize motion of the machine.

Platform Caught Overhead

If the platform becomes jammed or snagged in overhead structures or equipment, rescue the

platform occupant prior to freeing the machine.

4.3

INCIDENT

NOTIFICATION

The manufacturer must be notified immediately of any incident involving an SPM20 product.

Even if no injury or property damage is evident, the factory should be contacted by telephone

and provided with all necessary details.

Failure to notify the manufacturer of an incident involving a product within 48 hours of such

an occurrence may void any warranty consideration on that particular machine.

IMPORT

FOLLOWING ANY ACCIDENT, THOROUGHLY INSPECT THE MACHINE AND TEST

ALL

FUNCTIONS

PLATFORM CONTROL

DO

NOT LIFT

REPAIRED,

IF

FIRST FROM THE GROUND CONTROL STATION, THEN FROM THE

CONSOLE.

ABOVE 10

REQUIRED,

FT. (3M) UNTIL YOU

AND

THAT

ALL

ANT

ARE

SURE THAT

CONTROLS

ALL

ARE

OPERATING

DAMAGE

CORRECTLY.

HAS BEEN

Page 41

37

SECTION

5.

GENERAL SPECIFICATIONS

AND OPERATOR

MAINTENANCE

5.1 INTRODUCTION

This section of the manual provides additional necessary information to the operator for

proper operation and maintenance of this machine.

The maintenance portion of this section is intended as information to assist the machine operator to

perform daily maintenance tasks only, and does not replace the more thorough Preventive

Maintenance and Inspection S

Other Publications Available Specific to this Machine:

Service and Maintenance Manual

Illustrated Parts Manual

5.2

GENERAL

Machine Specifications

SPECIFICATION

Gross Machine Weight (Platform

Empty):

Machine Height (Platform Stowed): 2100mm

Maximum Ground Bearing

Pressure: (per wheel)

Maximum Operating Incline:

Maximum Travel Grade (Grade

ability): (Platform STOWED ONLY)

Maximum Travel Grade (Side

Slope): (Platform STOWED ONLY)

Maximum Drive Speeds (Operator

Variable):

Maximum Base – Overall: (Width

Length)

Maximum Wind Speed:

Maximum Horizontal Manual Side

Force:

SPECIFICATIONS

chedule inc

x

luded in the Service and Maintenance Manual.

SPM20

1050kg

360kg

1.0

°

15-20%

5

°

1.1- 4.0 km/h

76cm x 136cm

0 km/h-Machine rated for indoor use only

200 N

Maximum Hydraulic System

Pressure: (Recommended initial

setting)

Hydraulic Reservoir Capacity:

12MPa

5L

Page 42

38

Machine Dimension

Model

SPM20

Max. platform

height

mm mm kg

6000

Max. working

height

7700 150

Rated load

The number of

persons allowed

on platform

Person(s)

Platform

size AxB

mm mm

1

695x800 1360x800x2096

Stored

dimension

LxWxH

Page 43

39

SPM 2 0 Machine Operating Area

SPECIFICATION

SPM20,

System Voltage:

24 Volts DC

Battery Specifications: Battery Type:

V

oltage:

Amp Hour (AH) Rating:

12 Volts DC

100 Amp Hr. @20Hr.

Battery Charger (DC Models) Input:

Output:

120/240 Volts AC-50/60 Hz –Voltage Selectable

24 volt, 20 Amp Output – with 2 Amp Finish

Electrical Specifications

Page 44

40

Platform Data

SPECIFICATION

Occupants: (Persons allowed in Platform)

Maximum Work Load Standard:

Platform Height – Mast Fully Extended

– (Ground to Platform Floor):

Platform Cycle Performance: Lift Up:

(in seconds, rated load ) Lift Down:

SPM20

1

150kg

6 m

27-36 sec.

30-35 sec.

Machine Component Weights

SPECIFICATION

Platform : Standard Platform:

(Quick-Change Platforms)

Battery: (per battery)

SPM20

32kg

20kg

Serial Number Locations

For machine identification, a serial number plate is affixed to the machine. The plate is

located on the back of the mast, just above the mast support bracket.

5.3

OPERATOR

MAINTENANCE

Lubrication

Hydraulic Oil (HO)

HYDRAULIC

OPERATING TEMPERATURE

+0° F to +180° F (-18° C -83°C )

+0° F to +210° F (-18° C -99°C ) 10W-20, 10W-30

+0° F to +210° F (-18°C - 99°C) 20W-20

SYSTEM

RANGE

SAE

VISCOSITY

GRADE

10W

Hydraulic oils must have anti-wear qualities, and sufficient chemical stability for mobile

hydraulic system service. The manufacturer recommends Mobil fluid 424 hydraulic oil, which

has an SAE viscosity of 10W-30 and a viscosity index of 152.

For cold weather applications, i.e. When temperatures remain consistently below +20 ° F (7 c ) T he manufacturer recommends using Mobil DTE 13 hydraulic oil.

Aside from The manufacturer’s recommendations, it is not ad

visable to mix oils of different

brands or types, as they may not contain the same required additives or be of comparable

viscosities. If use of hydraulic oil other than Mobil fluid 424 is desired, contact the

manufacturer for proper recommendations.

Page 45

41

Hydraulic Diagram (SPM20)

Page 46

42

ITEM

KEY

SPECIFICATIONS

MPG-

Multipurpose Grease having a minimum dripping point of 350 ° F. Excellent wat er resistance and

adhesive qualities, and being of extreme pressure type. (Timken OK 40 pounds minimum.)

EPGL-

Extreme Pressure Gear Lube (oil) meeting API service classification GL-5 or MIL -Spec MIL –L-

2105.

HO-

Hydraulic Oil. ISO-Vg grade 32, 46.

CL-

Chain Lube. Use a good quality chain lubricant

Table 5-1. – Lubrication Specifications

NOTE:

Refer to Lubrication Chart, Table 5-2 for specific lubrication locations on machine

Table

5-2.

Lubrication Intervals for Various Components

COMPONENT

Hydraulic oil

1

Fill the

NO/

Reservoir HO-Check Hyd.

(a)

TYPE

LUBE

POINTS

LUBE/METHOD

Oil

Level

HO-Change Hyd.

Oil

3

MONTHS 6 MONTHS 1 YEAR 2 YEARS

INTERVAL

Caster

2

Axles 2-

Grease

Fittings MPG-Pressure

Gun √

(b)

COMMENTS

Check fluid level

every day. (c)

√

Change

hydraulic oil

every 1 year.

Page 47

43

3

Swivel

Raceways

2-Front

Casters

MPG-Pressure

Gun

√

4

Mast Chains

2-Per Mast

Section

CL-Brush or

Spray

√

Inspect,

lubricate if

dry or rusting.

Key to Lubricants: MPG- Multipurpose Grease

HO- Hydraulic Oil – ISO-Vg grade 32, 46.

CL- Chain Lube. Use a good quality chain lubricant

Notes: (a) Be certain to lubricate like items on each side of the machine.

(b) Recommended lubricating intervals are based on normal use. If machine is subjected

to severe operating conditions, such as a high number of cycles, location, corrosive/dirty

environment, etc., user must adjust lubricating requirements accordingly.

(c) Prior to checking hydraulic oil level, operate machine through one complete cycle of lift

function (full up and down). Failure to do so will result in incorrect oil level reading on the hydraulic

reservoir.

Page 48

44

Date

Comments

SECTION

6.

INSPECTION

Machine Serial Number:

Table

6-1.

Inspection and Repair Log

AND

REPAIR LOG

Page 49

45

Date

Comments

Table

6-1.

Inspection and Repair Log

Page 50

46

BATTERY WARNING

Battery posts,

terminals and related accessories contain lead and

lead compounds, chemicals known to cause cancer

and reproductive harm.

Batteries also contain other harmful chemicals.

WASH

HANDS AFTER HANDLING!

Page 51

Page 52

Local Distributor / Lokaler Vertiebshändler / Distributeur local

El Distribuidor local / ll Distributore locale

EUROPE, MIDDLE EAST

AFRICA & ASIA

PHONE: +44 (0) 845 1550 058

FAX: +44 (0) 845 1557 756

NORTH & SOUTH AMERICA

PHONE: +1 785 989 3000

TOLL FREE: +1 800 225 0317

FAX: +1 785 989 3070

AUSTRALIA

PHONE: +611300 700 450

FAX: +61 2 9609 3057

NEW ZEALAND

PHONE: +64 6 3689 168

FAX: +64 6 3689 164

Loading...

Loading...