Page 1

Operator’s

Manual

Diesel Powered

P/N 11809A

September 2005 V2

Page 2

LIMITED WARRANTY

Snorkel warrants each new machine manufactured and sold by it to be free from defects in material and workmanship for a

period of one (1) year from date of delivery to a Customer or for one year after the machine has been placed in first service in a

Dealer rental fleet, whichever comes first. Any part or parts which, upon examination by the Snorkel Service Department, are

found to be defective, will be replaced or repaired, at the sole discretion of Snorkel, through its local Authorized Dealer at no

charge.

Snorkel further warrants the structural components; specifically, the mainframe chassis, turntable, booms and scissor arms,

of each new machine manufactured by it to be free from defects in material and workmanship for an additional period of four

(4) years. Any such part or parts which, upon examination by the Snorkel Service Department, are found to be defective will

be replaced or repaired by Snorkel through its local Authorized Dealer at no charge; however, any labor charges incurred as a

result of such replacement or repair will be the responsibility of the Customer or Dealer.

The Snorkel Service Department must be notified within forty-eight (48) hours of any possible warranty situation during the

applicable warranty period. Personnel performing warranty repair or replacement must obtain specific approval by Snorkel

Service Department prior to performing any warranty repair or replacement.

Customer and Dealer shall not be entitled to the benefits of this warranty and Snorkel shall have no obligations hereunder

unless the “Pre-Delivery and Inspection Report” has been properly completed and returned to the Snorkel Service

Department within ten (10) days after delivery of the Snorkel product to Customer or Dealer’s rental fleet. Snorkel must be

notified, in writing, within ten (10) days, of any machine sold to a Customer from a Dealer’s rental fleet during the warranty

period.

At the direction of the Snorkel Service Department, any component part(s) of Snorkel products to be replaced or repaired

under this warranty program must be returned freight prepaid to the Snorkel Service Department for inspection. All warranty

replacement parts will be shipped freight prepaid (standard ground) from the Snorkel Service Department or from Snorkel’s

Vendor to Dealer or Customer.

REPLACEMENT PARTS WARRANTY

Any replacement or service part made or sold by Snorkel is not subject to the preceding Limited Warranty beyond the

normal warranty period of the machine upon which the part was installed.

THIS WARRANTY EXCLUDES AND SNORKEL DOES NOT WARRANT:

1. Engines, motors, tires and batteries which are manufactured by suppliers to Snorkel, who furnish their own warranty.

Snorkel will, however, to the extent permitted, pass through any such warranty protection to the Customer or Dealer.

2. Any Snorkel product which has been modified or altered outside Snorkel’s factory without Snorkel’s written approval, if

such modification or alteration, in the sole judgment of Snorkel’s Engineering and/or Service Departments, adversely

affects the stability, reliability or service life of the Snorkel product or any component thereof.

3. Any Snorkel product which has been subject to misuse, improper maintenance or accident. “Misuse” includes but is

not limited to operation beyond the factory-rated load capacity and speeds. “Improper maintenance” includes but is not

limited to failure to follow the recommendations contained in the Snorkel Operation, Maintenance, Repair Parts

Manuals. Snorkel is not responsible for normal maintenance, service adjustments and replacements, including but not

limited to hydraulic fluid, filters and lubrication.

4. Normal wear of any Snorkel component part(s). Normal wear of component parts may vary with the type application or

type of environment in which the machine may be used; such as, but not limited to sandblasting applications.

5. Any Snorkel product that has come in direct contact with any chemical or abrasive material.

6. Incidental or consequential expenses, losses, or damages related to any part or equipment failure, including but not

limited to freight cost to transport the machine to a repair facility, downtime of the machine, lost time for workers, lost

orders, lost rental revenue, lost profits or increased cost.

This warranty is expressly in lieu of all other warranties, representations or liabilities of Snorkel, either expressed or implied,

unless otherwise amended in writing by Snorkel’s President, Vice President-Engineering, Vice President-Sales or Vice

President-Marketing.

SNORKEL MAKES NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION OF THIS LIMITED WARRANTY.

SNORKEL MAKES NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

AND DISCLAIMS ALL LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT

LIMITED TO INJURY TO PERSONS OR PROPERTY.

The Customer shall make all warranty claims through its local Authorized Dealer and should contact the Dealer from whom

the Snorkel product was purchased for warranty service. Or, if unable to contact the Dealer, contact the Snorkel Service

Department for further assistance.

Ef fec tive July 1995

© Snorkel – all rights reserved Printed in New Zealand

Page 3

■

DANGER

DANGER

Electrical Hazard Warning

Electrical Hazard

Electrical Hazard

SP ELEVATING WORK PLATFORMS

ARE NOT ELECTRICALLY INSULATED.

If the plat form, booms, or any other con duc tive part of an SP con tacts a high-voltage elec tri cal con duc tor,

the re sult can be SERIOUS INJURY or DEATH for per sons on or near the ma chine.

GO NO CLOSER THAN THE MINIMUM SAFE APPROACH DISTANCES

(M.S.A.D) - AS OUTLINED IN TABLE 1. AND FIGURE 1.,

ON THE NEXT PAGE.

Be sure to al low for sag and sway in the wires and the work plat form.

If an SP comes in contact with a live electrical conductor, the entire machine can be charged.

If that happens, you should remain on the machine and not contact any other structure or object within

reach. That includes the ground, adjacent buildings, poles, and any object not a part of the SP.

Such con tact could make your body a con duc tor to the other ob ject cre at ing an elec tri cal shock haz ard

re sult ing in SERIOUS INJURY or DEATH.

DO NOT attempt to enter or leave the SP until you are sure the electricity has been turned off.

If an SP is in contact with a live conductor, the platform operator MUST warn others on the ground in the

vicinity of the SP to STAY AWAY from the machine, since their bodies can also form a path for electricity to

ground thus creating an electrical shock hazard with possible ELECTROCUTION and DEATH.

DO NOT attempt to operate SP ground controls when the platform, scissors arm assembly, or any other

conducting part of the SP is in contact with electrical wires or if there is an immediate danger of such

contact.

Re gard all con duc tors as en er gized.

Personnel working on or near an SP must be continuously aware of electrical hazards, recognizing that

SERIOUS INJURY or DEATH can result if contact with an electrical wire does occur.

Operators must check local power regulations before using the SP unit near power

lines

SP20/SP22 – 11890A page - i

Page 4

Electrical Hazard

Denotes

prohibited

zone

■

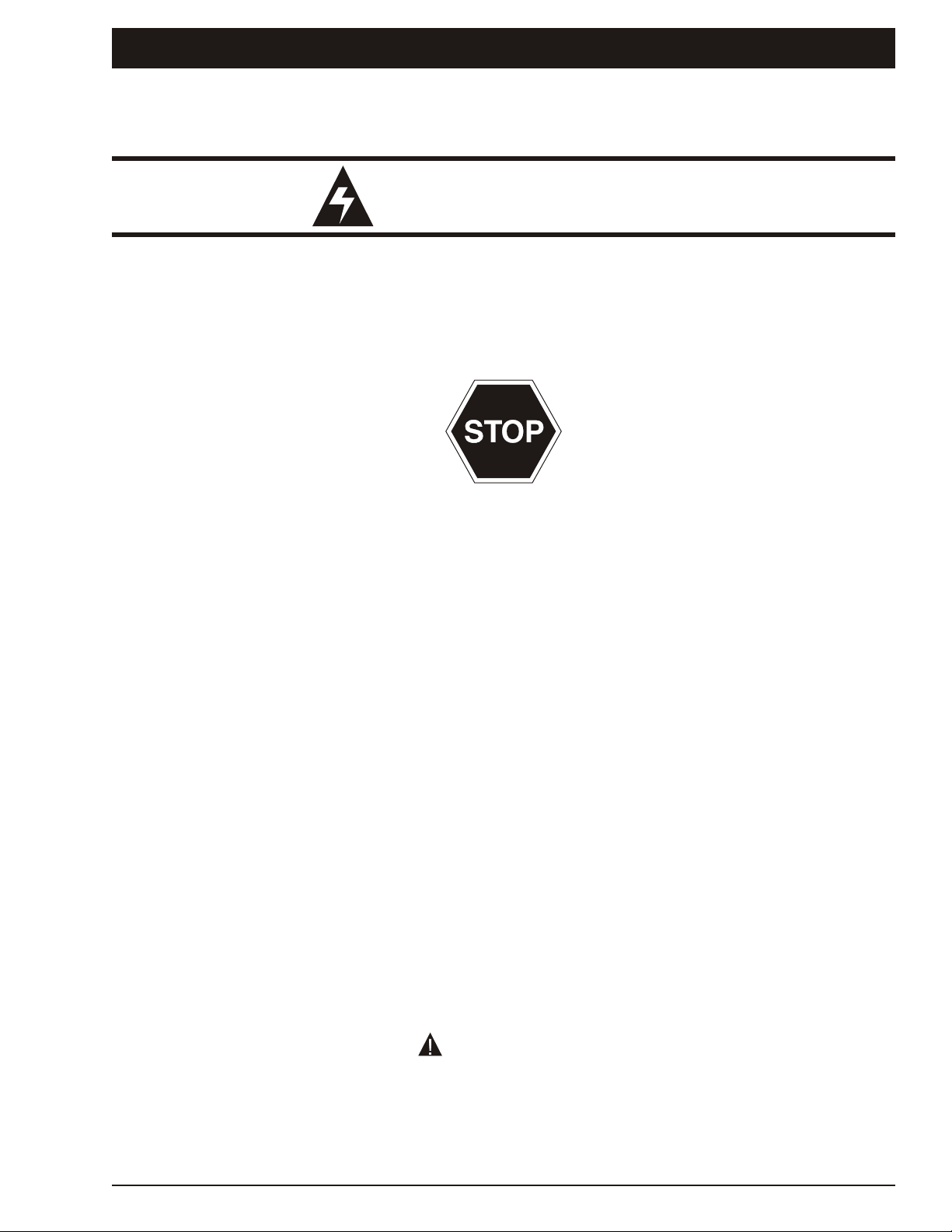

Minimum Safe Approach Distance

An SP is an all metal NOT ELECTRICALLY INSULATED, aerial work platform. DO NOT operate it near

ELECTRICAL conductors. Regard all conductors as being energized. Use the table and illustration below

to determine safe clearance from electrical conductors. (Table 1 and Figure 1, below, are from ANSI/SIA

A92.6–1990 Standard, reprinted with permission of Scaffold Industry Association.)

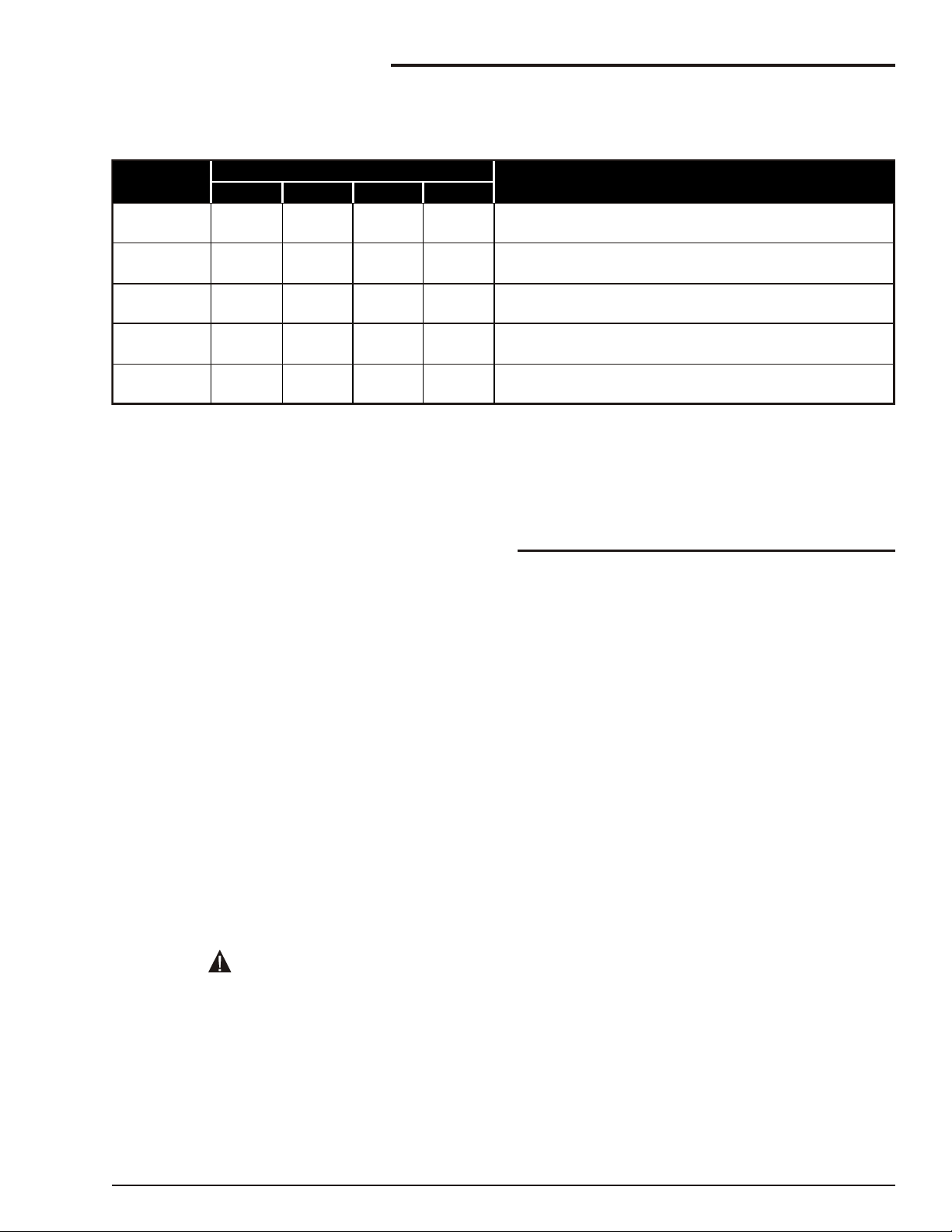

❑ Table 1 - (M.S.A.D.)

Minimum Safe Approach Distance

to energized (exposed or insulated power lines)

Voltage range Minimum safe approach distance

(phase to phase)

0 to 300V

over 300v to 50kv

over 50kv to 200kv

over 200kv to 350kv

over 350kv to 500kv

over 500kv to 750kv

over 750kv to 1000kv

(Feet) (Meters)

Avoid contact

10

15

20

25

35

45

3.05

4.60

6.10

7.62

10.67

13.72

❑ Figure 1 - (M.S.A.D.)

page - ii SP20/SP22 – 11890A

Page 5

Introduction

DANGER

CAUTION

DANGER

The aerial platform is a boom-supported elevating

work platform used to raise personnel, their tools,

and material to the workstation. The booms are

raised and lowered with hydraulic cylinders.

Hydraulic motors on each of the drive wheels

provide power to move the aerial platform.

The aerial platform has been manufactured to

conform to all applicable requirements of the

following organizations.

●

Occupational Safety and Health

Administration (OSHA)

●

American National Standards Institute (ANSI)

●

Canadian Standards Association (CSA)

●

Australian Standard Association (AS)

●

European Standard (EN)

This manual provides information for safe and

proper operation of the aerial platform. Read and

understand the information in this manual before

operating the aerial platform on the job.

Additional copies of this manual may be ordered

from Snorkel. Supply the model and manual part

number from the front cover to assure that the

correct manual will be supplied.

All information in this manual is based on the latest

product information at the time of publication.

Snorkel reserves the right to make product

changes at any time without obligation.

■

Safety Alerts

A safety alert symbol is used throughout this

manual to indicate danger and caution instructions.

Follow these instructions to reduce the likelihood of

personal injury and property damage. The terms

danger and caution indicate varying degrees of

personal injury or property damage that can result

if the instruction is not followed.

Indicates a situation which if not avoided

can result in death or serious injury.

Indicates a situation which if not avoided

can result in minor injury or property

damage.

Notes

Notes are used to provide special information or

helpful hints to assist in aerial platform operation, but

do not indicate a hazardous situation.

■

Options

This manual provides information about the

following options even though some machines

may not be equipped with them.

●

Diesel liquid cooled engine

●

Diesel air cooled engine

●

Spark arrestor muffler

●

Sound suppression kit

●

Driving lights

●

Platform work lights

●

Platform control box cover

●

Swinging platform gate

●

8¢ aluminum platform

●

Air line to platform

●

Hostile environment kit

●

Cold weather start-up kit

●

Hydraulic system warm-up kit

●

Vandalism protection kit

●

Tow kit

●

AC generator

●

CE certification

■

Operation

The aerial platform has built-in safety features and

has been factory tested for compliance with

Snorkel specifications and industry standards.

However, any personnel lifting aerial platform can

be potentially dangerous in the hands of untrained

or careless operators.

The potential for an accident increases when

the aerial platform is operated by personnel

who are not trained and authorized. Death or

serious injury can result from such

accidents. Read and understand the

information in this manual and on the

placards and decals on the machine before

operating the aerial platform on the job.

Training is essential and must be performed by a

qualified person. Become proficient in knowledge

and actual operation before using the aerial

platform on the job. You must be authorized to

operate the aerial platform.

The operator bears ultimate responsibility for

following all manufacturer’s instructions and

warnings, regulations and safety rules of their

employer and/or any state or federal law.

SP20/SP22 – 11890A page - iii

Page 6

Introduction

■

Maintenance

Every person who maintains, inspects, tests, or

repairs the aerial platform must be qualified to do

so. Following the daily prestart inspection in this

Operator’s Manual will help keep the aerial

platform in optimum working condition. Other

maintenance functions must be performed by

maintenance personnel who are qualified to work

on the aerial platform.

Do not modify this aerial platform without prior

written consent of the Snorkel Engineering

Department. Modification may void the warranty,

adversely affect stability, or affect the operational

characteristics of the aerial platform.

■

Manual of Responsibilities

All owners and users of the aerial platform must

read, understand, and comply with all applicable

regulations. Ultimate compliance to OSHA

regulations is the responsibility of the user and their

employer.

ANSI publications clearly identify the

responsibilities of all personnel who may be

involved with the aerial platform. A reprint of the

“Manual of Responsibilities for Dealers, Owners,

Users, Operators, Lessors and Lessees of

ANSI/SIA A92.5-1992 Boom-Supported Elevating

Work Platforms” is available from Snorkel dealers

or from the factory upon request.

Copies are also available from:

Scaffold Industry Association, Inc.

14039 Sherman Way

Van Nuys, CA 91405-2599

■

Additional Information

For additional information contact your local dealer

or Snorkel at:

Snorkel

P.O. Box 1041

Levin 5500

New Zealand

+64 6 3689168

page - iv SP20/SP22 – 11890A

Page 7

Table of Contents

Electrical Hazard

Electrical Hazard Warning .................-i

Minimum Safe Approach Distance ..........-ii

Table 1 - (M.S.A.D.) ...................-ii

Figure 1 - (M.S.A.D.) ...................-ii

Introduction

Safety Alerts ...........................-iii

Options ...............................-iii

Operation .............................-iii

Maintenance ...........................-iv

Manual of Responsibilities ................-iv

Additional Information ....................-iv

Chapter 1. Specifications

Component Identification.................1-1

Working Envelope—SP20................1-2

Working Envelope—SP22................1-3

General Specifications—SP20 ............1-4

General Specifications—SP22 ............1-5

Engine Specifications ...................1-6

Engine Oil Viscosity.....................1-6

Hydraulic Hose Age.....................1-6

Chapter 2. Safety

Electrocution Hazards ...................2-1

Minimum Safe Approach Distance .......2-1

Safety Overview .......................2-1

Use of the Aerial Work Platform .........2-1

Safe Operation ........................2-2

Pre-start Inspection...................2-2

Work Place Inspection and Practices .....2-2

Electrocution ........................2-3

Tipover and Falling Hazards............2-3

Crushing ...........................2-4

Special Limitations .....................2-4

Manual Force .......................2-4

General Safety Precautions ..............2-4

Personnel Precautions ................2-4

Operator General Precautions ..........2-4

Mounting and Dismounting Precautions ...2-4

Starting and Stopping Precautions .......2-4

Operating Precautions ................2-4

Operator Maintenance Precautions ......2-4

Electrical System ....................2-4

Hydraulic System ....................2-4

Fuel Handling Precautions .............2-5

Safety Decals and Placards ..............2-5

Beaufort Scale.........................2-5

Safety Placards and Decals Drawing 1......2-6

Safety Placards and Decals Drawing 2......2-7

Chapter 3. Safety Devices

Emergency Stop Controls ................3-1

At ground control box .................3-1

At platform control box ................3-1

Emergency Power System ...............3-1

Manual Lowering Knob ..................3-1

Platform Foot Switch ...................3-2

Guardrails ............................3-2

Lanyard Anchors .......................3-2

Horn.................................3-2

Tilt Alarm .............................3-2

All Motion Alarm .......................3-2

Flashing Light .........................3-2

Driving Lights..........................3-2

Platform Working Lights .................3-3

Chapter 4. Gauges and Displays

Hour Meter ...........................4-1

Engine Air Filter Gauge ..................4-1

Fuel .................................4-1

Engine Oil ............................4-1

Hydraulic Fluid Filter Gauge ..............4-2

Chapter 5. Shut-offs and Circuit Breakers

Automatic Shut-offs .....................5-1

Engine temperature (Cummins engine) ...5-1

Engine temperature (Deutz engine) ......5-1

Engine oil pressure ...................5-1

Dynamic brakes .....................5-1

Platform height vs. drive speed .........5-1

Axle lockout.........................5-1

Circuit Breakers........................5-1

Main circuit breakers..................5-1

RCD / ELCB ........................5-1

Chapter 6. Controls

Chassis Controls .......................6-1

Battery Disconnect Switch .............6-1

Ground Controls .......................6-1

Master Switch .......................6-1

Emergency Stop ....................6-1

Ground Operation ...................6-1

Emergency Power....................6-1

Platform Controls.......................6-2

Emergency Stop Button ...............6-2

Component Select Switches............6-2

Boom and Platform Joystick ............6-2

Drive and Steer Joystick ...............6-2

High Range Switch ...................6-3

Horn Button.........................6-3

Emergency Power Switch..............6-3

AC Generator (Optional) .................6-3

Platform Foot Switch ....................6-3

SP20/SP22 – 11890A

Page 8

Table of contents

Chapter 7. Pre-operational Inspection

Operator’s Manual......................7-2

Engine ...............................7-2

Oil Level ...........................7-2

Coolant ............................7-2

Fuel Tank ..........................7-3

Fuel Line ...........................7-3

Air Filter............................7-3

Electrical System.......................7-3

Battery Fluid Level ...................7-4

Battery Terminals ....................7-4

Cables and Wiring Harness ............7-4

Hydraulic System ......................7-4

Fluid Level..........................7-4

Fluid Filter ..........................7-4

Hoses, Tubes, and Fittings .............7-4

Tires and Wheels ......................7-5

Foam Filled .........................7-5

Ground Control Station ..................7-5

Operating Controls ...................7-5

Emergency Stop .....................7-5

Emergency Power....................7-5

Emergency Lowering .................7-6

Level Sensor ..........................7-6

Flashing Lights ........................7-6

Hostile Environment Kit ..................7-6

Structures ............................7-7

Weldments .........................7-7

Slide Pads..........................7-7

Fasteners ..........................7-7

Wire Ropes ........................7-7

Platform Control Station .................7-7

Guardrail System ....................7-8

Lanyard Anchors.....................7-8

Operating Controls ...................7-8

Emergency Stop .....................7-8

Emergency Power....................7-8

RCD / ELCB Outlet ...................7-8

Air Line ..............................7-9

All Motion Alarm .......................7-9

Driving and Work Lights .................7-9

Platform Control Cover ..................7-9

Placards and Decals ...................7-10

Decal inspection drawing 1............7-11

Decal inspection drawing 2............7-12

Electrical Power Outlet ..................8-3

Air Line ..............................8-3

Chapter 9. Emergency Operation

Emergency Power System ...............9-1

Ground Controls .....................9-1

Platform Controls ....................9-1

Emergency Lowering....................9-2

Towing...............................9-2

Chapter 10. Stowing and Transporting

Stowing .............................10-1

Transporting .........................10-1

Driving............................10-1

Winching ..........................10-2

Hoisting ...........................10-3

Securing for Transport ...............10-3

Chapter 11. Options

Optional Tow Kit ......................11-5

Chapter 12. Fire Fighting & Chemical Control

Hazardous Components ................12-7

Antifreeze (UN 1993) ................12-7

Battery, Lead/Acid (UN 2794)..........12-7

Diesel Fuel (NA 1993)................12-7

Foam In Tires ......................12-8

Gasoline (UN 1203) .................12-8

Hydraulic Oil (UN 1270) ..............12-9

Liquefied Petroleum Gas (UN 1075).....12-9

Motor Oil (UN 1270) .................12-9

Chapter 13. Troubleshooting

Troubleshooting Chart..................13-1

Appendix A. Glossary

Chapter 8. Operation

Preparing for Operation..................8-1

Ground Controls .......................8-1

Platform Controls.......................8-2

Boom Operation .....................8-2

Driving.............................8-2

Steering............................8-3

SP20/SP22 – 11890A

Page 9

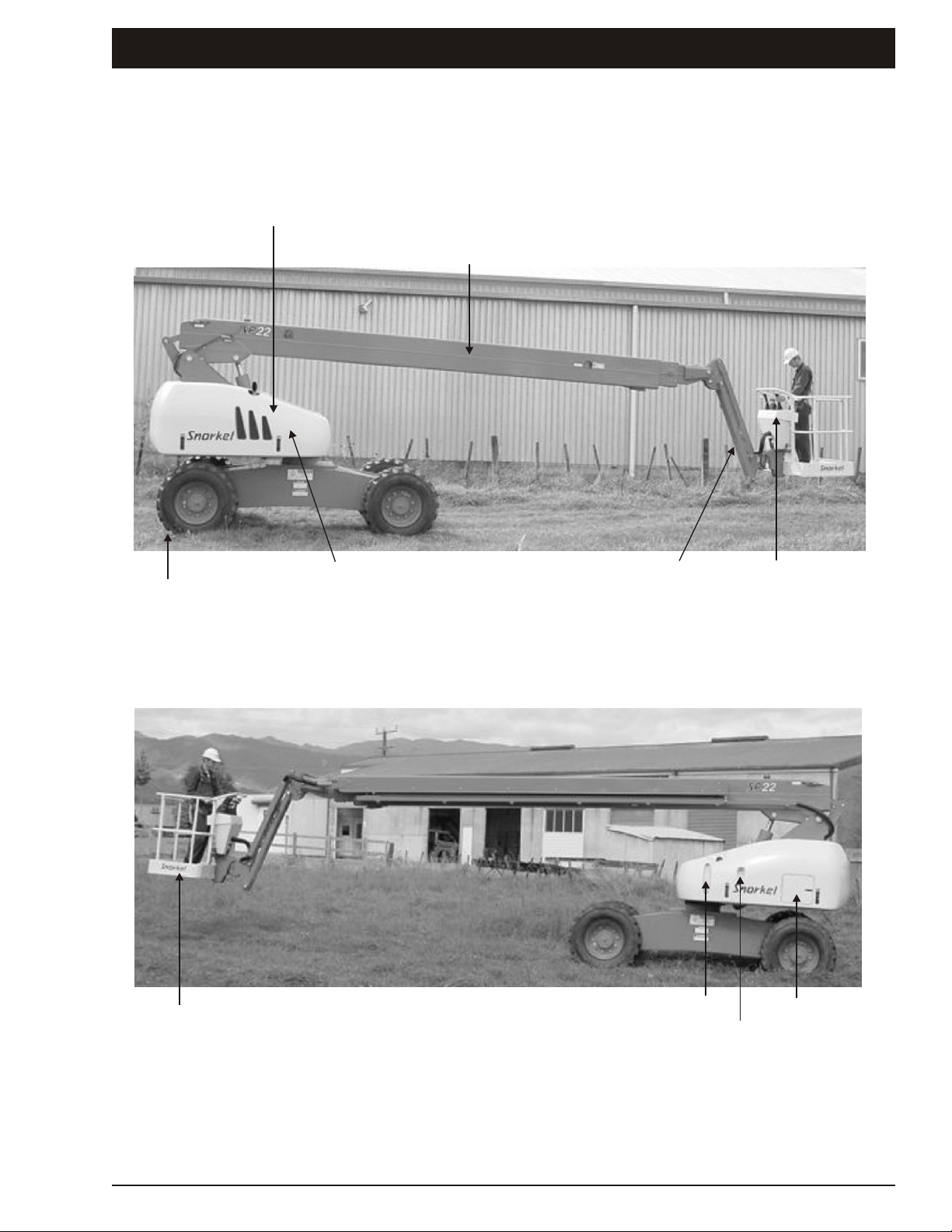

■

Hydraulic Oil Tank

Diesel Fuel Tank

Ground Controls

Main Boom

Engine Side Cover

Jib Boom

Serial Plate Under

Engine Cover

Steer Wheels

Platform

Platform Controls

Right Hand Side

Left Hand Side

Component Identification

Chapter 1. Specifications

SP20/SP22 – 11890A page 1 - 1

Page 10

Chapter 1. Specifications

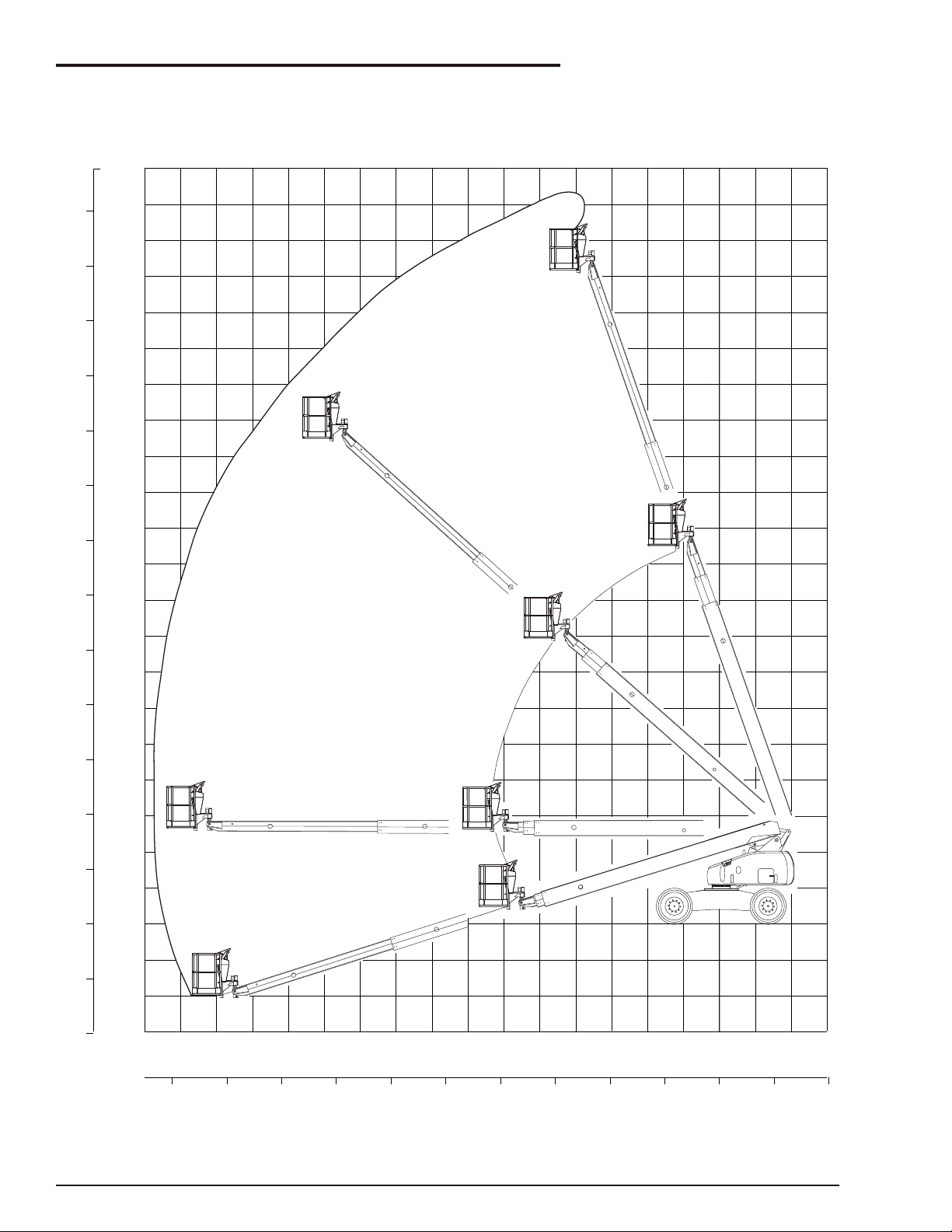

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 -1 -2 -3

50 45 40 35 30 25 20 15 10 5 0 -5 -10

METRES

FEET

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-5

-10

4

3

2

1

0

-1

-2

-3

METRES

FEET

21

68.8

■

Working Envelope—SP20

page 1 - 2 SP20/SP22 – 11890A

Page 11

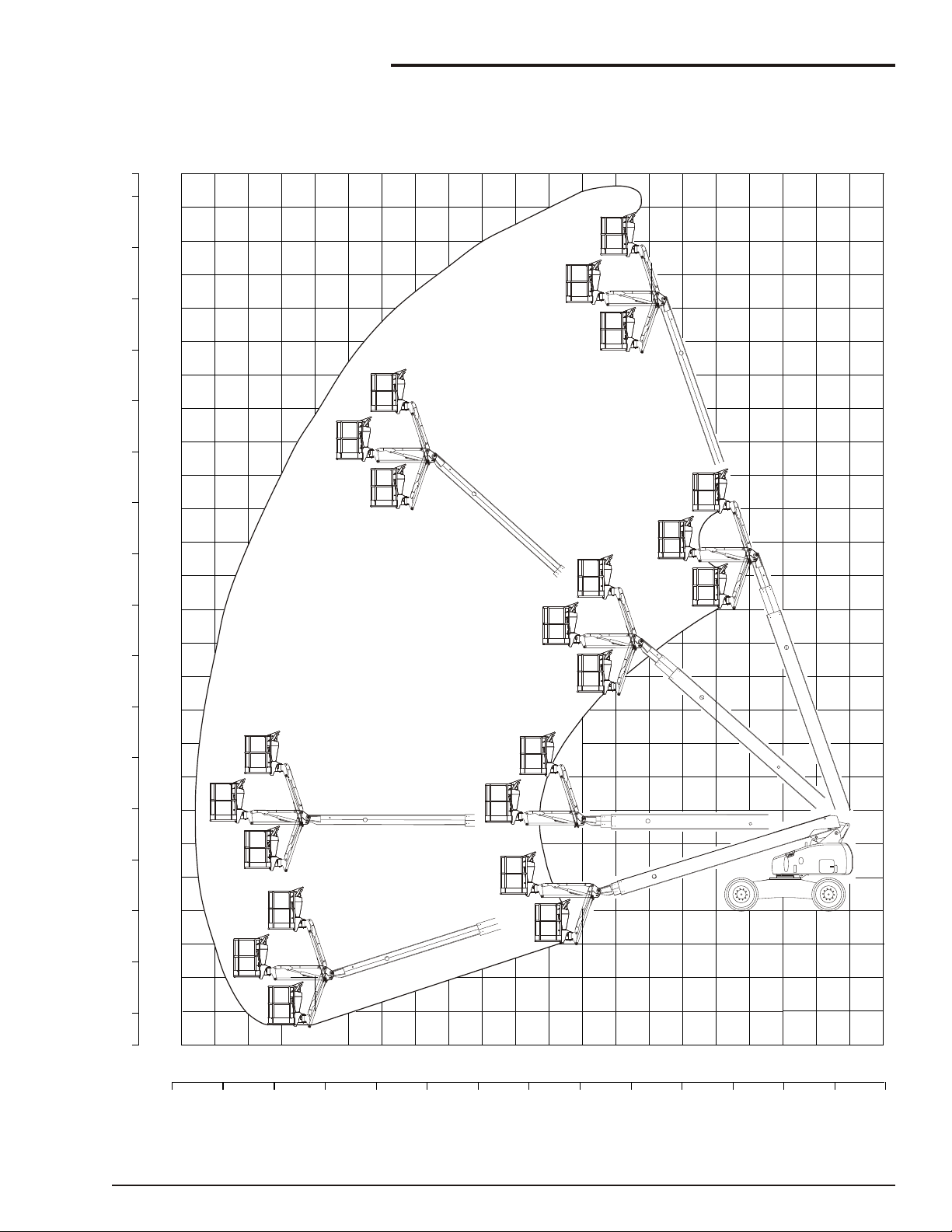

METRES

FEET

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 -1 -2 -31718

50 45 40 35 30 25 20 15 10 5 0 -5 -105560

METRES

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

-1

-2

-3

-4

20

21

22

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-5

-10

FEET

70

72

-13

■

Working Envelope—SP22

Chapter 1. Specifications

SP20/SP22 – 11890A page 1 - 3

Page 12

Chapter 1. Specifications

■

General Specifications—SP20

Working height ...................20.3m (66’)

Maximum single wheel load ....5780kg (12716 lb)

Maximum platform height ...........18.3m (60’)

Horizontal outreach ...............15.8m (50’)

Turntable rotation .............360° continuous

Main boom

Articulation ....................-16° to +72°

Platform

Dimensions

Standard .........760 x 1830mm (30” x 72”)

Optional .........30² x 96² (76 cm x 244 cm)

Guardrail height .............1100mm (43.3”)

Rated work load..............227 kg (500 lb)

Rotation............................180°

Maximum number of occupants .......2 people

Cycle times

Turntable rotation ...............115/120 sec

Main boom

Up ..........................45/50 sec

Down ........................45/50 sec

Extend .......................65/70 sec

Retract.......................55/65 sec

Platform rotation ..................16/20 sec

Drive system

Standard ....................4-wheel drive

Steering system

Standard ....................2-wheel steer

Weight ...................10250kg (22550 lb)

Ground bearing strength

Minimum...................441kPa (64 psi)

Electrical system

Voltage.....12 V DC negative chassis ground

Source .....1 - 12 V 15 plate 600 CCA battery

Fluid recommended ........... distilled water

Hydraulic system

Maximum pressure .........3250 psi (224 bar)

Reservoir capacity ......100 litres (26.3 US gal)

System capacity .......129 litres (33.9 US gal)

Maximum operating temperature ...93°C(200°F)

Hydraulic fluid recommended

Shell Tellus T37 ........................

Engine..........................Deutz F4L

Optional .....................Cummins 4B

Fuel tank capacity........100 litres (26.3 US gal)

Ambient air temperature operating range

Celsius .....................-18°C to 43°C

Fahrenheit....................0°F to 110°F

Maximum wind speed

12.5m/sec ................45 km/h (28 mph)

Tires, 14ply

Foam filled ..................15 x 19.5 HD

Gradeability ..........................40%

Drive speed

High .....................3.2 km/h (2 mph)

Low ...................0.87 km/h (0.5 mph)

Turning radius, inside

Inside .......................3.8m (12’ 2”)

Outside........................6.1m (20’)

Tailswing

Stowed......................225mm (8.8”)

Overside ...................850mm (33.5”)

Stowed height ................2790mm (9’ 2”)

Stowed width .................2380mm (7’ 9”)

Stowed length ...............8790mm (28’ 9”)

Wheelbase...................2600mm (8’ 6”)

Ground clearance ..............370mm (14.5”)

Axle oscillation .........................7.8

0

page 1 - 4 SP20/SP22 – 11890A

Page 13

■

General Specifications—SP22

Working height .................21.8m (71’ 6’)

Chapter 1. Specifications

Axle oscillation .........................7.8

0

Maximum platform height ...........19.8m (65’)

Horizontal outreach .............17.6m (55’ 9”)

Turntable rotation .............360° continuous

Main boom

Articulation ....................-16° to +72°

Jib boom articulation .......-72 to + 72 degrees

Platform

Dimensions

Standard .........760 x 1830mm (30” x 72”)

Optional .........30² x 96² (76 cm x 244 cm)

Guardrail height .............1100mm (43.3”)

Rated work load..............227 kg (500 lb)

Rotation............................180°

Maximum number of occupants .......2 people

Cycle times

Turntable rotation ...............115/120 sec

Main boom

Up ..........................45/50 sec

Down ........................45/50 sec

Extend .......................65/70 sec

Retract.......................55/65 sec

Platform rotation ..................20/25 sec

Drive system

Standard ....................4-wheel drive

Steering system

Standard ....................2-wheel steer

Maximum single wheel load ....5960kg (13112 lb)

Weight ...................10894kg (23966 lb)

Ground bearing strength

Minimum...................537kPa (78 psi)

Electrical system

Voltage.....12 V DC negative chassis ground

Source .....1 - 12 V 15 plate 600 CCA battery

Fluid recommended ........... distilled water

Hydraulic system

Maximum pressure .........3250 psi (224 bar)

Reservoir capacity ......100 litres (26.3 US gal)

System capacity .......129 litres (33.9 US gal)

Maximum operating temperature ...93°C(200°F)

Hydraulic fluid recommended

Shell Tellus T37 ........................

Engine..........................Deutz F4L

Optional .....................Cummins 4B

Fuel tank capacity........100 litres (26.3 US gal)

Ambient air temperature operating range

Celsius .....................-18°C to 43°C

Fahrenheit....................0°F to 110°F

Maximum wind speed

12.5m/sec .................45 km/h (28 mph)

Tires, 14ply

Foam filled ..................15 x 19.5 HD

Gradeability ..........................40%

Drive speed

High .....................3.2 km/h (2 mph)

Low ...................0.87 km/h (0.5 mph)

Turning radius, inside

Inside ........................3.8m (12’2”)

Outside ........................6.1m (20’)

Tailswing

Stowed......................225mm (8.8”)

Overside ...................850mm (33.5”)

Stowed height ................2790mm (9’ 2”)

Stowed width .................2380mm (7’ 9”)

Stowed length ..............8207mm (26’ 11”)

Wheelbase...................2600mm (8’ 6”)

Ground clearance ..............370mm (14.5”)

SP20/SP22 – 11890A page 1 - 5

Page 14

Chapter 1. Specifications

Cummins Diesel Engine

Deutz Diesel Engine

11 - 4Q 99

11- 4Q 99

Manufacturing Plant Number

Sample Hose Code

Year of Manufacture

Manufacturing Period (i.e. 4th Quarter)

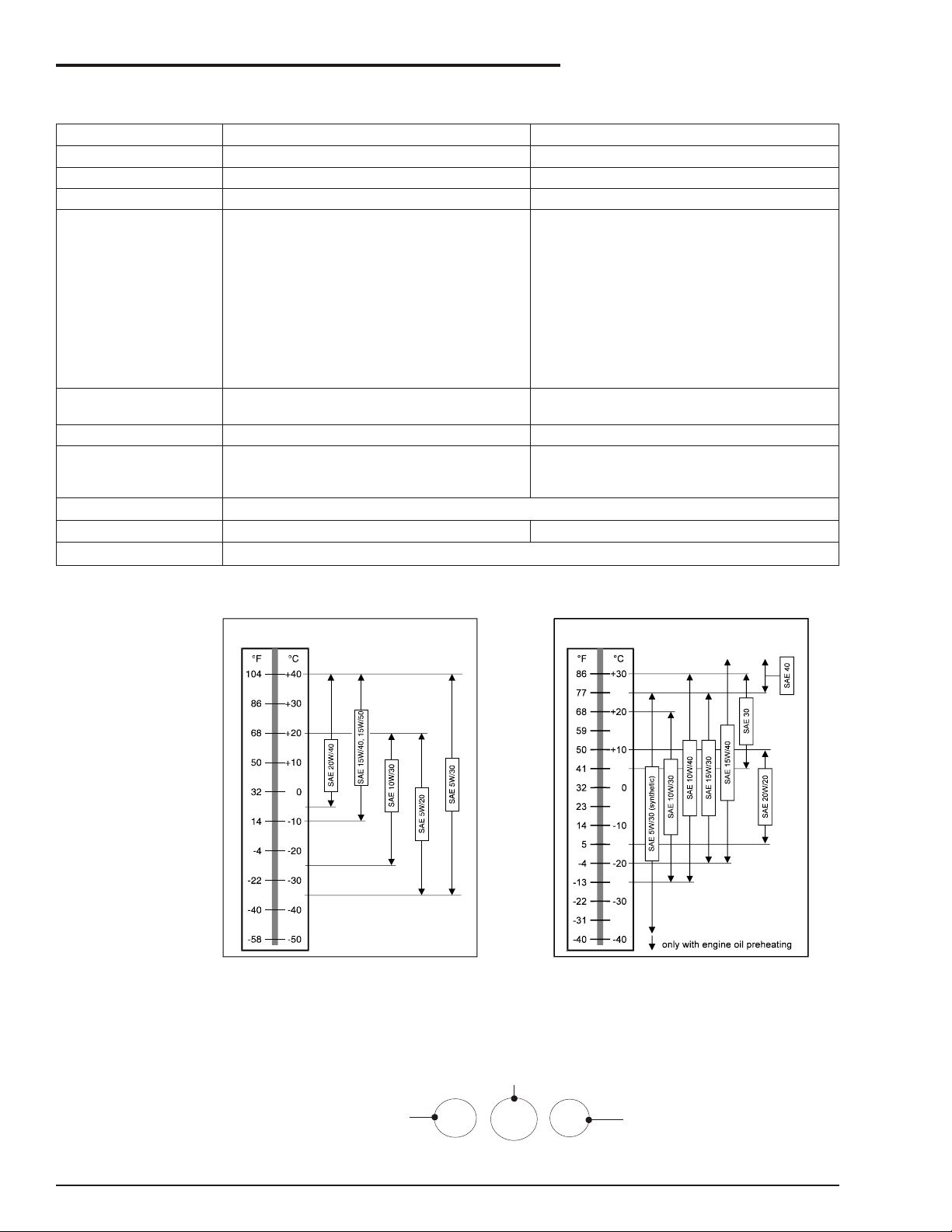

■

Engine Specifications

Engine Make Cummins Deutz

Model B3.3 F4L-1011

Horsepower 60 hp @ 2,500 rpm 53.5 hp @ 3000 rpm

Coolant Liquid (50% water 50% ethylene glycol) Air

Fuel

Type

Grade

Diesel

• ASTM No. 2 D

• Cetane # > 40

Diesel

• DIN 51 601

• BS 2869: A1 and A2

• For operating temperatures below 32°F (0°C)

use winterized No 2D.

Operating temperature 141°F to 211°F

Oil capacity 7l (7.3 US qt) 10l (10.5 US qt)

Oil grade API: CH-4

Oil viscosity

Oil filter capacity 0.5l (0.52 US qt) 0.5 l (0.52 US qt)

Running time

■

Engine Oil Viscosity

(60°C to 100°C)

See engine Oil Viscosity

One full tank of diesel will last for eight hours under normal working conditions

• ASTM D 975-81: 1-D

and 2-D

• W-F-800C: DF-A, DF-1

and DF-2.

172°F to 203°F

(78°C to 95°C)

API: CF-4

CG-4

CH-4

■

Hydraulic Hose Age

EN982 Clause 7.3.1 requires the manufacturing date of each hydraulic hose to be clearly visible on the

hose. Hoses used in production of this unit are manufactured by Parker and the manufacturing date is

present in a coded format. The key to decode the date format is as follows:

page 1 - 6 SP20/SP22 – 11890A

Page 15

Chapter 2. Safety

WARNING

Safety Rules

Electrocution Hazard

This machine is not insulated

DANGER

DANGER

All personnel shall carefully read, understand and follow all safety rules and operating instructions

before operating or performing maintenance on any Snorkel aerial work platform.

■

Electrocution Hazards

The ae rial plat form is made of metal com po nents

and is not in su lated. Re gard all con duc tors as en er gized. Do not op er ate out side dur ing a thun der storm. (See also Elec tri cal Haz ard sec tion at the

be gin ning of this man ual).

The aerial platform is not electrically

insulated. Death or serious injury can result

from contact with, or inadequate clearance

from, an energized conductor. Do not go

closer than the minimum safe approach

distance as defined by ANSI.

ANSI publications define minimum distances that

must be observed when working near bus bars and

energized power lines.

❑ Minimum Safe Approach Distance

Minimum safe approach distances to energized

power lines and their associated parts must be

observed while operating the aerial platform

■

Safety Overview

Knowledge of the information in this manual, and

proper training, provide a basis for safely operating

the aerial platform. Know the location of all controls

and how they operate to act quickly and

responsibly in an emergency.

Safety de vices re duce the like li hood of an ac ci dent. Never dis able, mod ify, or ig nore any safety

de vice. Safety alerts in this man ual in di cate sit u a tions where ac ci dents may oc cur.

If any mal func tion, haz ard or po ten tially un safe

con di tion re lat ing to ca pac ity, in tended use, or safe

op er a tion is sus pected, stop ae rial plat form op er a tion and seek as sis tance.

The op er a tor bears ul ti mate re spon si bil ity for fol low ing all man u fac turer’s in struc tions and warn ings, reg u la tions and safety rules of their em ployer

and/or any state or fed eral law.

❑ Use of the Aerial Work Platform

The SP20/SP22 aerial work platform is intended to

lift personnel and their tools, as well as the material

used for the job.

It is designed for repair and assembly jobs and

Op er a tors must check lo cal power

reg u la tions be fore us ing the SP unit near

power lines.

THIS AERIAL WORK PLATFORM IS NOT

INSULATED! For this reason it is imperative to

keep a safe distance from live parts of electrical

equipment. (See Electrical Hazard Section at the

beginning of this manual)

SP20/SP22 – 11890A page 2 - 1

assignments at overhead workplaces (ceilings,

cranes, roof structures, buildings etc.).

All other uses of the aerial work platform are

prohibited!

Exceeding the specified permissible maximum

load is pro hib ited! See Spec i fi ca tions Chap ter

page for de tails.

Page 16

Chapter 2. Safety

CAUTION

The use and operation of the aerial work platform

as a lifting tool or crane (lifting of loads from below

upwards or from a height to the ground) is

prohibited!

NEVER exceed the manual force allowed for this

machine. See Special Limitations on page of this

chapter for details.

DISTRIBUTE all platform loads evenly on the

platform.

NEVER operate the machine without first

surveying the work area for surface hazards such

as holes, drop-offs bumps, curbs, or debris, and

avoiding them.

OPERATE the machine only on surfaces capable

of supporting wheel loads.

NEVER operate the machine when wind speeds

exceed this machines rating. See Beaufort Scale

on page 5 of this chapter for details.

IN CASE OF EMERGENCY push the

EMERGENCY STOP to deactivate all powered

functions.

Climbing up the railing of the platform, standing on

or stepping from the platform onto buildings, steel

or prefab concrete structures, etc., is prohibited!

NEVER use a machine that is damaged, not

functioning properly, or has damaged or missing

labels.

NEVER charge batteries near sparks or open

flames. Charging batteries emit explosive

hydrogen gas.

Modifications to the aerial work platform are

prohibited or permissible only with the approval of

Snorkel.

AFTER USE, secure the SP20/SP22 from

unauthorized use by turning the key switches off

and removing the key.

■

Safe Operation

The following safety information is vitally important

for safe operation of the SP. Failure to follow these

instructions can result in personal injury or DEATH.

❑ Pre-start Inspection

At the start of each work shift, the SP shall be given

a visual inspection and function test. See the

Pre-operational Inspection chapter 7, in this

manual for a list of items to inspect and test.

IF AN ALARM SOUNDS while the platform is

elevated, STOP, and carefully lower the platform.

Move the machine to a firm, level surface.

Bypassing any safety equipment is prohibited

and presents a danger for the persons on the aerial

work platform and its working range.

Dismantling the entry gate or other railing

components is prohibited! Always make certain

that the entry gate is closed and securely locked!

It is prohibited to keep the entry gate in an open

position (held open with tie-straps) when the

platform is raised!

Extending the height or the range of the platform by

placing ladders, scaffolds, or similar devices on the

platform is prohibited!

NEVER perform service on the machine while the

platform is elevated without blocking the elevating

assembly.

INSPECT the machine thoroughly for cracked

welds, loose or missing hardware, hydraulic leaks,

loose wire connections, and damaged cables

before using.

VERIFY that all labels are in place and legible

before using the machine.

DO NOT op er ate the SP un less you are

trained and au tho rized, un der stand the

op er a tion char ac ter is tics of the SP, and

have in spected and tested all func tions to be

sure they are in proper work ing or der.

❑ Work Place Inspection and Practices

Do not use the SP as a ground for welding. Ground

to the work piece.

Before the SP is used, and during use, check the

area in which the SP is to be used for possible

hazards such as, but not limited to:

●

Drop-offs or holes.

●

Side slopes.

●

Bumps and floor obstructions.

●

Debris.

●

Overhead obstructions and electrical

conductors.

●

Hazardous locations.

●

Inadequate surface and support to withstand

all load forces imposed by the aerial platform

in all operating configurations.

●

Wind and weather conditions.

●

Presence of unauthorized persons.

page 2 - 2 SP20/SP22 – 11890A

Page 17

Chapter 2. Safety

DANGER

DANGER

●

Other possible unsafe conditions.

A recommended safety practice is to have

personnel that are trained in the operation of the

emergency controls working in the immediate area

of the SP to assist the platform operator in the

event of an emergency to:

●

Help in case of an emergency

●

Operate emergency controls as required

●

Watch for loss of control by platform operator

●

Warn the operator of any obstructions or

hazards that may not be obvious to them

●

Watch for soft terrain, sloping surfaces,

drop-offs, etc. where stability could be

jeopardized

●

Watch for bystanders and never allow

anyone to be under, or to reach through the

booms while operating the aerial platform

Pinch points may exist between moving

components. Death or serious injury can

result from becoming trapped between

components, buildings, structures or other

obstacles. Make sure there is sufficient

clearance around the machine before moving

the chassis, booms, or platform. Allow

sufficient room and time to stop movement to

avoid contact with structures or other

hazards.

When moving the platform, check the clearance

around the SP to avoid contact with structures or

other hazards. Always look in the direction of

motion.

Keep ground personnel from under the platform

when the platform is raised.

NOTE

When low er ing the plat form, pay spe cial

at ten tion to see that there are no peo ple near or

ap proach ing the ma chine. Should this be the

case, in ter rupt the low er ing pro cess

im me di ately. Con tinue low er ing the plat form

only when any peo ple who were too near the

ma chine are out of its op er at ing per im e ter.

Secure all accessories, containers, tools, and

other materials in the platform to prevent them from

accidentally falling or being kicked off the platform.

DO NOT engage in any form of horseplay or stunt

driving while operating the SP.

DO NOT permit riders on the machine anyplace

other than on the platform.

Remove all loose objects stored in or on the

machine, particularly in the platform. Remove all

objects which do not belong in or on the machine.

When other moving equipment is in the area, take

special precautions to comply with local

regulations regarding warnings.

Never steady the platform by positioning it against

another platform.

DO NOT op er ate an SP that is not func tion ing

prop erly, or has been dam aged, un til the ma chine

has been re paired by a qual i fied main te nance

per son.

DO NOT operate a SP that does not have all its

decals and placards attached and legible.

Drive the machine with care and at speeds

compatible with conditions. Use extra caution

when driving over rough ground, on slopes, and

when turning.

Know and understand the job site traffic-flow

patterns and obey the flag-men, road signs, and

signals.

Watch for bystanders and never allow anyone to be

under, or to reach through, the machine and its

equipment while operating.

Use the recommended transport device when

loading the machine.

❑ Electrocution

The SP is an all metal, NON-INSULATED, aerial

work platform. DO NOT operate it near

ELECTRICAL conductors. Regard all conductors

as being energized.

DO NOT operate outside during a thunderstorm.

❑ Tipover and Falling Hazards

DO NOT raise the platform if the SP is on soft

ground. Operate the platform only on a firm surface

capable of withstanding all load forces imposed by

the aerial platform in all operating conditions.

The ae rial plat form can tip over if it be comes

un sta ble. Death or se ri ous in jury can re sult

from a tip-over ac ci dent. Do not drive or

po si tion the ae rial plat form for el e vated use

near any drop-off, hole, slope, soft or un even

ground, or other tip-over haz ard.

Care shall be taken to prevent rope, electric cords,

and hoses, etc., from becoming entangled in the

aerial platform.

SP20/SP22 – 11890A page 2 - 3

Page 18

Chapter 2. Safety

DANGER

DANGER

DANGER

❑ Crushing

Always look in the direction of travel. Avoid

overhead obstructions.

Make sure the area below the platform is free of

personnel before lowering.

■

Special Limitations

❑ Manual Force

Manual force is the force applied by the occupants

to objects such as walls or other structures outside

the work area.

The maximum allowable manual force is limited to

200 N (45 lbs.) of force per occupant, with a

maximum of 400 N (90 lbs.) for two or more

occupants.

DO NOT ex ceed the max i mum amount of

man ual force for this ma chine.

■

General Safety Precautions

❑ Personnel Precautions

If you encounter any suspected malfunction of the

aerial platform, or any hazard or potentially unsafe

condition relating to capacity, intended use, or safe

operation, cease operation and seek assistance

from management.

❑ Operator General Precautions

Make sure that all protective guards, cowlings, and

doors are in place and secure.

Be sure the guardrail system, including the gate, is

in place and secure.

❑ Mounting and Dismounting Precautions

Use three points of support when getting on or off

the platform (two hands and one foot or a similar set

of points). Keep the platform clean.

DO NOT jump off the machine.

DO NOT dismount while the machine is in motion.

❑ Starting and Stopping Precautions

DO NOT start un til all per son nel are clearly away

from the ma chine.

Before leaving the operators station, place the

machine in the stowed position.

When leaving the machine parked or unattended,

remove the starter key from the Key switch and set

the Battery switch to off.

❑ Operating Precautions

When parts or components are replaced, they shall

be identical or equivalent to original Snorkel parts

or components.

❑ Operator Maintenance Precautions

❑ Electrical System

Charge batteries in a well-ventilated area free of

flame, sparks, or other hazards that might cause

fire or explosion.

Batteries give off hydrogen and oxygen that

can combine explosively. Death or serious

injury can result from a chemical explosion.

Do not smoke or permit open flames or

sparks when checking the batteries.

Battery acid can damage the skin and eyes.

Serious infection or reaction can result if

medical treatment is not given immediately.

Wear face and eye protection when working

near the batteries.

Batteries contain sulfuric acid that can damage

your eyes or skin on contact. Wear a face shield,

rubber gloves, and protective clothing when

working around batteries. If acid contacts your

eyes, flush immediately with clear water and get

medical attention. If acid contacts your skin, wash

off immediately with clear water.

❑ Hydraulic System

The hydraulic system contains hoses with

hydraulic fluid under pressure.

DO NOT use your hand to search for

hy drau lic oil leaks. High pres sure hy drau lic

oil can eas ily cut and pen e trate your skin a

very se ri ous in jury that re quires im me di ate

at ten tion by a med i cal spe cial ist trained in

that type of in jury. Use a piece of card board

or wood to search for hy drau lic oil leaks.

DO NOT attempt repairs unless you are trained.

Refer to manuals and experienced repair

personnel for help.

page 2 - 4 SP20/SP22 – 11890A

Page 19

Chapter 2. Safety

CAUTION

BEAUFORT

SCALE

WIND SPEED

GROUND CONDITIONS

m/s km/h ft/s mph

3 3.4~5.4 12.5~19.4 11.5~17.75 5~12.0 Papers and thin branches move, flags wave.

4 5.4~8.0 19.4~28.8 17.75~26.25 12.0~18 Dust is raised, paper whirls up, and small branches sway.

5 8.0~10.8 28.8~38.9 26.25~35.5 18~24.25 Shrubs with leaves start swaying. Wave crests are apparent in ponds

or swamps.

6 10.8~13.9 38.9~50.0 35.5~45.5 24.5~31 Tree branches move. Power lines whistle. It is difficult to open an umbrella.

7 13.9~17.2 50.0~61.9 45.5~56.5 31~38.5 Whole trees sway. It is difficult to walk against the wind.

■

Beaufort Scale

Never operate an SP20/SP22 when wind speeds exceed 45 km/h (28 mph) [Beaufort scale6]

❑ Fuel Handling Precautions

DO NOT smoke or permit open flames while fueling

or near fueling operations.

Never remove the fuel cap or refuel a gasoline

engine while the engine is running or hot. Never

allow fuel to spill on hot machine components.

Maintain control of the fuel filler nozzle when filling

the tank.

DO NOT fill the fuel tank to capacity. Allow room for

expansion.

Clean up spilled fuel immediately.

Tighten the fuel tank cap securely. If the fuel cap is

lost, replace it with an approved cap from Snorkel.

Use of a non-approved cap without proper venting

may result in pressurization of the tank.

Never use fuel for cleaning purposes.

For diesel engines, use the correct fuel grade for

the operating season.

■

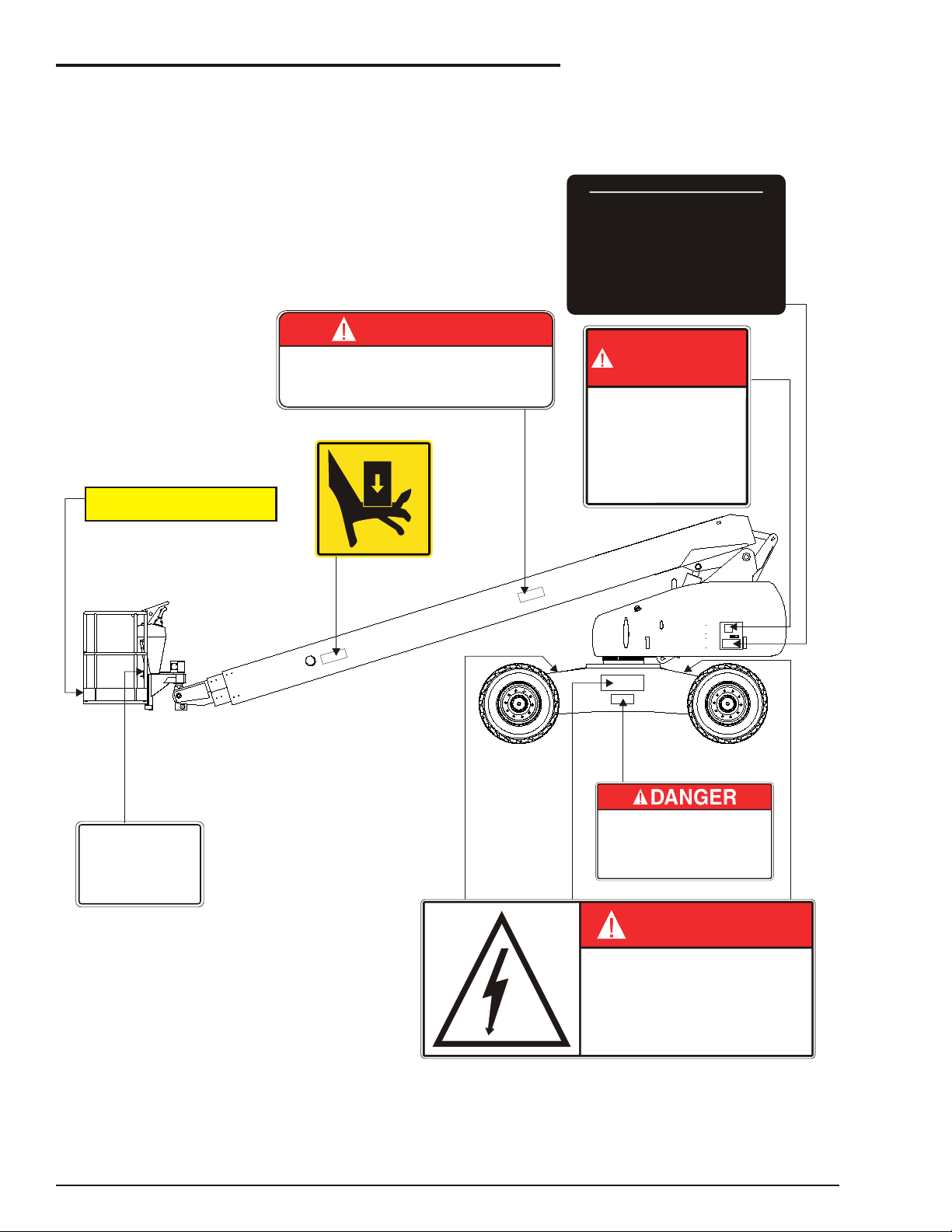

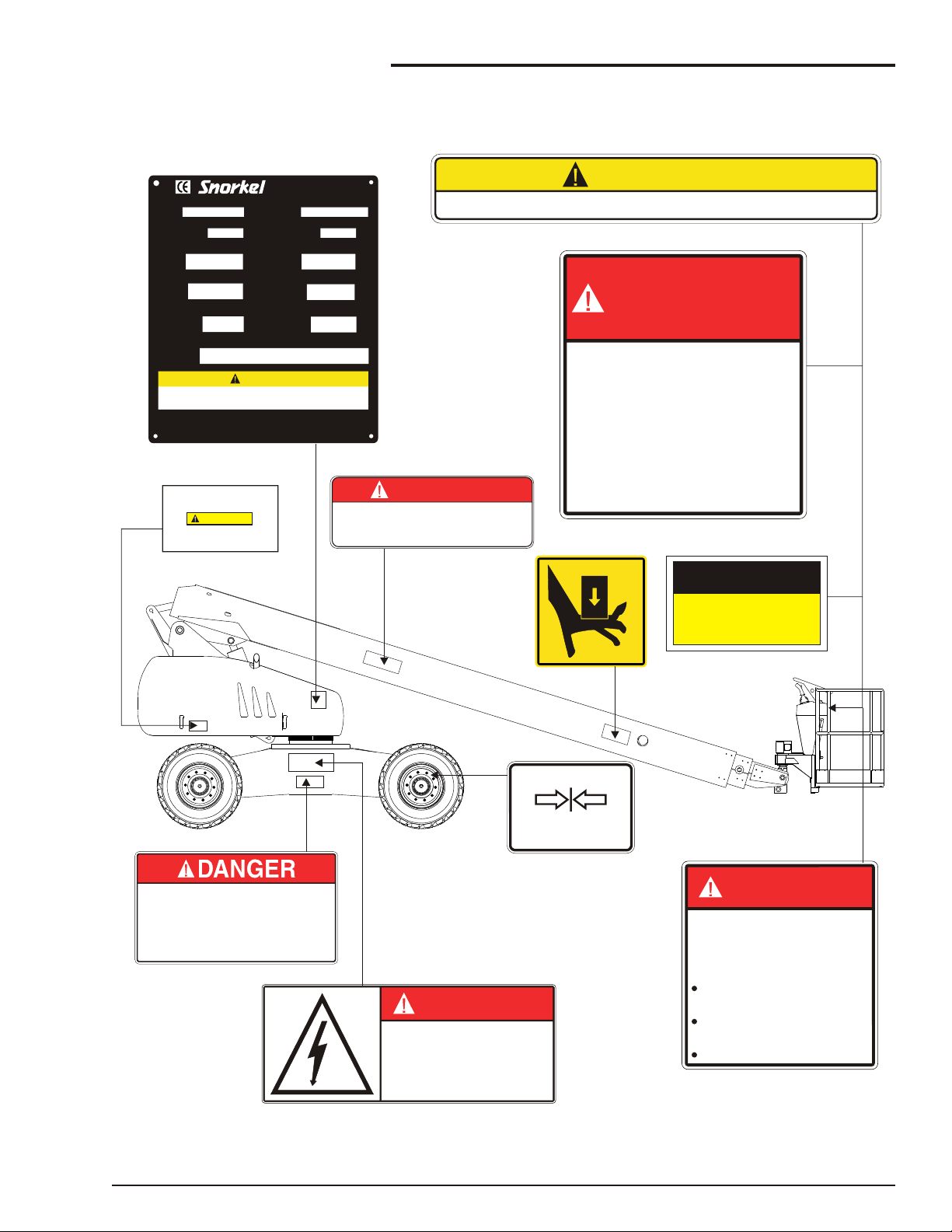

Safety Decals and Placards

There are several safety decals and placards on

the SP. Their locations and descriptions are shown

in this section. Take time to study them.

You MUST replace a decal or placard if it is

damaged, missing, or cannot be read. If it is on a

part that is replaced, make sure a new decal or

placard is installed on the replaced part. See your

Snorkel dealer for new decals and placards.

NOTE

Refer to Placards and Decals Inspection Chart and

Drawing in the Pre-operational Inspection and

Maintenance chapter , for part numbers, location,

and required quantities of all placards and decals..

Be sure that all the safety de cals and

plac ards on the SP are leg i ble. Clean or

re place them if you can not read the words or

see the pic tures. Clean with soap & wa ter

and a soft cloth. Do not use sol vents.

SP20/SP22 – 11890A page 2 - 5

Page 20

Chapter 2. Safety

This machine is equipped with foam filled or solid tires, wheel weight is

critical for stability.

To prevent machine tip over, replace tires with factory approved foam

filled or solid tires ONLY.

DO NOT attempt to inflate foam filled or solid tires.

0073298

MACHINE TIPOVER HAZARD

DEATH or serious injury can result if machine tips over.

0190989E

YOU MUST NOT OPERATE THIS DEVICE UNLESS:

AN UNTRAINED OPERATOR SUBJECTS HIMSELF AND OTHERS TO

DEATH OR SERIOUS INJURY.

0323897

1.

2.

YOU HAVE BEEN TRAINED IN THE SAFE OPERATION OF THIS

DEVICE AND HHHH

YOU KNOW AND FOLLOW THE SAFETY AND OPERATING

RECOMMENDATIONS CONTAINED IN THE MANUFACTURER'S

MANUALS, YOUR EMPLOYER'S WORK RULES, AND APPLICABLE GOVERNMENTAL REGULATIONS. HHHHHHHH

DANGER

300699

INSPECT AND/OR TEST THE FOLLOWING DAILY

OR AT THE BEGINNING OF EACH SHIFT

OPERATORS CHECKLIST

1. OPERATING AND EMERGENCY CONTROLS.

2. SAFETY DEVICES.

3. PERSONAL PROTECTIVE DEVICES.

4. HOSES, FITTINGS AND VALVES FOR LEAKS.

5. CABLES AND WI RING HARNESS.

6. LOOSE OR MISSING PARTS.

7. TIRES AND WHEELS.

8. PLACARDS, WARNINGS, CONTROL MARKINGS

AND OPERATING MANUAL(S).

9. GUARDRAIL SYSTEM.

10. OIL LEVELS.

11. BATTERY FLUI D LEVEL.

DANGER

DO NOT ALTER OR DISABLE

LIMIT SWITCHES, SAFETY

SWITCHES, OR INTERLOCKS.

451986

DANGER

ELECTROCUTION

HAZARD

KEEP CLEAR

Death or serious injury can result from touching

this machine if this machine is in contact with

electrical power lines or apparatus.

0323896

Attach lanyard

of fall restraint

to loop below

0150448

SWL

227

KG

0323896

300699

0150448

0190989E

0073298

2025-227

0323897

451986

■

Safety Placards and Decals Drawing 1

page 2 - 6 SP20/SP22 – 11890A

Page 21

■

DANGER

DO NOT ALTER OR DISABLE

LIMIT SWITCHES, SAFETY

SWITCHES, OR INTERLOCKS.

451986

0190989E

DANGER

ELECTROCUTION

HAZARD

KEEP CLEAR

Death or serious injury can result from touching

this machine if this machine is in contact with

electrical power lines or apparatus.

0323896

This machine is equipped with foam filled or solid tires, wheel weight is

critical for stability.

To prevent machine tip over, replace tires with factory approved foam

filled or solid tires ONLY.

DO NOT attempt to inflate foam filled or solid tires.

0073298

MACHINE TIPOVER HAZARD

DEATH or serious injury can result if machine tips over.

0072277

TORQUE

200-225 Ft. Lbs.

·

271-305 N m

DANGER

ELECTROCUTION

HAZARD

THIS MACHINE IS NOT

ELECTRICALLY INSULATED.

0323899

Death or serious injury can result from

contact or inadequate clearance to

electrical power lines and apparatus.

Maintain 10 feet minimum clearance

from electrical power lines and

apparatus.

Allow for sway, rock, and sag.

CAUTION

DO NOT USE BOOM TO LIFT OR PUSH MACHINE

0073668

YOU MUST NOT OPERATE THIS DEVICE UNLESS:

AN UNTRAINED OPERATOR SUBJECTS HIMSELF AND OTHERS TO

DEATH OR SERIOUS INJURY.

0323897

1.

2.

YOU HAVE BEEN TRAINED IN THE SAFE OPERATION OF THIS

DEVICE AND HHHH

YOU KNOW AND FOLLOW THE SAFETY AND OPERATING

RECOMMENDATIONS CONTAINED IN THE MANUFACTURER'S

MANUALS, YOUR EMPLOYER'S WORK RULES, AND APPLICABLE GOVERNMENTAL REGULATIONS. HHHHHHHH

DANGER

11868

0323896

0323899

0073298

11896

0072277

0190989E

99228

451986

0323897

0073668

SAFETY BELTS WITH

CAUTION

SHOULDER STRAPS OR

SAFETY HARNESS ARE

TO BE USED

SAFETY BELTS WITH

9928

ENGINE SWING TRAY LATCH

ENSURE TRAY IS PROPERLY LATCHED AND

SECURITY PIN IS IN PLACE BEFORE RUNNING

ENGINE.

ALWAYS ENSURE PIVOT LOCK IS ENGAGED

WHEN ENGINE TRAY IS IN OPEN POSITION

WARNING

11868

CAUTION

Do not remove any weight from this machine Any weight added must be

distributed equally on each axle. Proper stability and axle weights of

this machine are based on the platform size shown above.

SERIAL

NUMBER

MODEL

NUMBER

MAXIMUM

MACHINE

WEIGHT

lbs

kg

MAXIMUM

WHEEL

LOAD

lbs

kg

MONTH / YEAR

OF MANUFACTURE

SLOPE SENSOR

ALARM SETTING

deg

MAXIMUM

PLATFORM

HEIGHT

ft

m

MACHINERY DIRECTIVE 98/37/CEE

PLATFORM

CAPACITY

MAXIMUM

ALLOWABLE

MANUAL FORCE

(SIDE PULL)

lbs

N

MAXIMUM

ALLOWABLE

WIND SPEED

mi/h

m/s

OUTRIGGER

LOAD

ft

m

11896

36 Bruce Road

Levin 5500 - New Zealand

= 227 kg = 2 PERSONS + ADD. LOAD

Safety Placards and Decals Drawing 2

Chapter 2. Safety

SP20/SP22 – 11890A page 2 - 7

Page 22

Page 23

Chapter 3. Safety Devices

DANGER

This aerial platform is manufactured with safety

devices, placards, and decals to reduce the

likelihood of an accident. For the safety of all

personnel, do not disable, modify, or ignore any

safety device. Safety devices are included in the

Pre-operational Inspection.

The potential for an accident increases when

safety devices do not function properly.

Death or serious injury can result from such

accidents. Do not alter, disable, or override

any safety device.

If any safety devices are defective, remove the

aerial platform from service until qualified

maintenance personnel can make repairs.

■

Emergency Stop Controls

There is an emergency stop control at the lower

and upper controls.

❑ At ground control box

Press the large red EMERGENCY STOP (re fer to

Fig ure 3.1) but ton in and the en tire ma chine

stops, the en gine turns off, and noth ing moves.

This but ton must be out (on) to con trol the SP (pull

the button and it will pop out).

This button must be out (on) to control the SP from

the platform (pull the button and it will pop out).

Figure 3.2—Platform Controls

■

Emergency Power System

The emergency power system includes a back-up

pump, motor, and battery. Use this system to

operate the boom and turntable functions to lower

the platform if the main power system fails due to

engine or pump failure.

Operate the emergency power switch (refer to

Figure 3.1 and 3.2) to activate the emergency

power system.

Figure 3.1—Ground Controls

NOTE

The lower controls override the upper controls. If

the upper control emergency stop button is

engaged the lower controls can still be used to

operate the aerial platform.

❑ At platform control box

Press the large red EMERGENCY STOP (refer to

Figure 3.2) button in and the entire machine

stops, the engine turns off, and nothing moves.

The length of time the pump can be operated

depends on the capacity of the battery.

■

Manual Lowering Knob

The manual emergency lowering knob (refer to

Figure 3.3) may be used to lower the booms if the

engine will not start and the emergency power

system will not work. The knob is located on the

base control panel.

Figure 3.3—Emergency Lowering Knob

SP20/SP22 – 11890A page 3 - 1

Page 24

Chapter 3. Safety Devices

DANGER

NOTE

CEE COMPLIANCE

There is an additional emergency bleed down knob

located at the base of the main lift cylinder.

■

Platform Foot Switch

The platform foot switch (refer to Figure 3.4)

prevents boom and platform movement if a control

on the upper control panel is accidentally moved.

All personnel in the platform must connect their fall

restraint device to a lanyard anchor before raising

the platform. Do not use the aerial platform for

personal fall arrest anchorage.

■

Horn

The horn (refer to Figure 3.2) may be used to

warn personnel on the ground. The horn is

operational when the machine is set up for

operation from the upper controls.

■

Tilt Alarm

If the aerial platform chassis is out of level more

than five degrees when the main boom is raised or

extended, an alarm will sound.

The aerial platform can tip over if it becomes

unstable. Death or serious injury can result

from a tip-over accident. Do not drive or

position the aerial platform for elevated use

near any drop-off, hole, slope, soft or uneven

ground, or other tip-over hazard.

Figure 3.4—Platform

Step down on the platform foot switch to activate

the boom and platform controls.

■

Guardrails

The guardrail system includes a top rail, mid rail,

and toeboards around the sides of the platform

(refer to Figure 3.4).

A gravity gate or an optional swinging gate allows

for access to the platform (refer to Figure 3.4).

The swinging gate closes automatically after

entering or exiting the platform. The gate is part of

the guardrail system and must be securely

fastened after entering the platform.

■

Lanyard Anchors

Two lanyard anchors for fall restraint anchorage

are provided below the upper controls at the front of

the platform (refer to Figure 3.4).

NOTE

The lanyard anchors are not for lifting or tying the

machine down.

Completely lower and retract the main boom and

then drive to a level surface when the tilt alarm

sounds.

The tilt alarm is for added protection and does not

justify operating on anything other than firm, flat,

level surfaces.

■

All Motion Alarm

An all motion alarm is be provided on the machine.

When boom or drive control is moved out of neutral,

the alarm sounds to warn personnel in the work

area to stand clear.

■

Flashing Light

An amber flashing light is located on the top of the

boom. The flashing light warns personnel that the

aerial platform is in the area.

The light flashes at about one flash per second

when the engine is running.

■

Driving Lights

Optional headlights and blinking tail lights may be

installed on the machine. The headlights are 30

watts each and are located on the top of the front

cowling. The tail lights are 25 watts each and are

mounted on the sides of the rear cowling.

Driving lights help improve visibility while driving

the aerial platform and help others see it too.

Driving lights are not for driving on public

roadways.

page 3 - 2 SP20/SP22 – 11890A

Page 25

■

Platform Working Lights

Optional platform working lights may be located on

the top rail of the platform, one on each side of the

upper control panel.

Use the platform lights to improve visibility while

working aloft in dimly lit areas. Do not use the

platform work lights to drive on public roadways.

Chapter 3. Safety Devices

SP20/SP22 – 11890A page 3 - 3

Page 26

Page 27

Chapter 4. Gauges and Displays

The aerial platform is equipped with several

gauges to monitor the condition of the machine

before and during operation.

■

Hour Meter

The hour meter is located at the lower controls

(refer to Figure 4.1). It measures the accumulated

operating time.

■

Fuel

The fuel tank (refer to Figure 4.3). Is ‘see through’

and this allows the operator to quickly gauge the

amount of fuel.

Figure 4.3—Diesel Fuel Gauge

NOTE

Do not run a diesel fuel tank empty. Air in the fuel

line makes the engine hard to start.

Figure 4.1—Ground Controls

■

Engine Air Filter Gauge

The air filter gauge is located under the engine

cowling (refer to Figure 4.2). The gauge measures

the air pressure between the intake manifold and

the air filter. The yellow indicator disk raises toward

the red area of the sight glass as the filter clogs.

The indicator disk stays at its highest setting and

does not go to the bottom of the sight glass when

the engine is turned off. When the disk reaches the

red area, it’s time to change the air filter.

■

Engine Oil

The engine oil level is measured with a dipstick. Oil

sump and filter capacities in the engine

specification charts are approximate. The dipstick

is the only way to accurately determine the engine

oil level. The engine oil level should always be in

the cross-hatched area of the dipstick.

The dipstick on a Deutz engine is located behind

the door on the right side of the turntable (refer to

Figure 4.4).

Figure 4.2 Deutz Air Filter Gauge

The dipstick on a Cummins engine is located

behind the door on the right side of the turntable

(refer to Figure 4.5).

SP20/SP22 – 11890A page 4 - 1

Figure 4.4—Deutz Engine Dipstick

Page 28

Chapter 4. Gauges and Displays

Figure 4.5—Cummins Engine Dipstick

■

Hydraulic Fluid Filter Gauge

The fluid filter gauge (refer to Figure 4.6) is located

next to the filter under the cover on the left side of the

turntable. The gauge indicates the condition of the

filter. When the needle on the gauge is in the red

zone, it is time to change the filter.

Figure 4.6—Fluid Filter Gauge

page 4 - 2 SP20/SP22 – 11890A

Page 29

Chapter 5. Shut-offs and Circuit Breakers

■

Automatic Shut-offs

❑ Engine temperature (Cummins engine)

There is a temperature sensor in the engine. It

measures the temperature of the antifreeze-water

mixture as the mixture leaves the top of the radiator

and enters the top of the engine.

If the temperature reaches 2100F (990C) an alarm

sounds. If the temperature continues to rise, the

engine shuts off when the temperature reaches

2300F (1100C).

The engine will not restart until the temperature

drops below 2100F (990C).

❑ Engine temperature (Deutz engine)

The Deutz engine is oil cooled therefore it is the oil

temperature that is monitored.

Should the engine oil temperature exceed 1300 C

the engine will shut down automatically.

It will restart but will be shut down again unless the

oil temperature returns to normal.

❑ Engine oil pressure

There is an oil pressure sensor in the engine. It

measures the engine oil pressure at the oil filter.

If the pressure falls below a safe operating value

the engine shuts off.

The engine will restart with low pressure but it will

only run a few seconds before it automatically

shuts off again.

❑ Dynamic brakes

When you drive an SP down a slope, if the SP

begins to coast (outrun the drive motors) the

hydraulic system “senses” the coasting condition.

Figure 5.1—Axle Lockout Indicator Light

■

Circuit Breakers

❑ Main circuit breakers

There are three circuit breakers, on the SP. These

are located inside the lower control box (Refer to

Figure 5.2). Their purpose is to protect the

electrical circuits from electrical overloads. When a

circuit breaker trips (pops out) push it back in then

attempt to use the SP.

If the circuit breaker trips a second time, take the

SP out of service and refer the problem to a

qualified trained service technician for repair.

The hydraulic drive motors then become hydraulic

brakes and the SR is slowed. This action prevents

SP’s from speeding down grades.

❑ Platform height vs. drive speed

When the platform is raised above horizontal the

drive speed is limited to its slowest speed and the

engine revs are also automatically lowered.

❑ Axle lockout

The articulating axle will automatically “lock” when

the boom is extended beyond 50% and the column

is slewed out over the side of the base.There is a

warning light in the platform control box (Refer to

Figure 5.1) that indicates when the axle is in the

locked position.

SP20/SP22 – 11890A page 5 - 1

❑ RCD / ELCB

The RCD (Residual Current Device) is located at

the ground and will protect against short circuits to

earth (Refer to Figure 5.3). When there is a short

circuit the RCD will shut down the 230v AC power

to the platform outlet.

Figure 5.2—Circuit Breakers

Page 30

Chapter 5. Shut-offs and Circuit Breakers

To reset the outlet disconnect the power tool lead

from the platform box and reset the RCD at the

ground.

If the problem persists call a trained service

technician.

Figure 5.3—RCD / ELCB

page 5 - 2 SP20/SP22 – 11890A

Page 31

Chapter 6. Controls

CAUTION

Controls to position the platform are located on the

lower control panel on the turntable and on the

upper control panel in the platform. Drive controls

are located on the upper control panel only.

■

Chassis Controls

❑ Battery Disconnect Switch

The battery disconnect switch is located under the

cover on the right side of the turntable (refer to

Figure 5.1)

The battery disconnect removes electrical power

from all electrically controlled functions when in the

off position. Place the switch in the on position to

operate any electrically controlled function.

●

Hour meter

●

Manual control levers for all functions

Figure 5.2—Ground Controls

❑ Master Switch

The master switch works like an automobile

ignition switch. Hold it at start until the engine

starts, then release it to on. If the engine dies, the

key must be turned to off before it will go back to

start.

Figure 5.1—Battery Disconnect Switch

Only authorized personnel should operate

the aerial platform. Unqualified personnel

may cause injury to coworkers or property

damage. Lock the battery disconnect switch

in the off position before leaving the aerial

platform unattended.

Lock the battery disconnect switch in the off

position to prevent unauthorized use of the aerial

platform.

■

Ground Controls

The lower controls (refer to Figure 5.2) are located

on the right side of the turntable. Boom and

platform functions can be operated from the lower

controls. The following are located on the lower

control panel.

●

Master key switch

●

Emergency stop switch

●

Ground/platform select switch

●

Emergency power switch

❑ Emergency Stop

The emergency stop is a two-position, red button

on the front of the lower control panel. Push the

button in to disconnect power to all control circuits

at the lower controls.

❑ Ground Operation

Switch to ground operation to operate aerial

platform functions from the lower controls.

❑ Emergency Power

Press the emergency power switch to operate

aerial platform functions using the emergency

power system.

NOTE

The emergency power system is for lowering the

platform during an emergency and is not intended

for normal machine operation.

SP20/SP22 – 11890A page 6 - 1

Page 32

Chapter 6. Controls

NOTE

CEE COMPLIANCE

There are two changes to the Ground Control box

to ensure compliance with Machinery Directive

98/37/CEE

1. Key start switch is replaced with a 3 position

switch the same as the Platform control

station.

2. The Ground/Platform selector is changed to

a key type selector with the key removable in

each position.

■

Platform Controls

The upper controls (refer to Figure5.3 and 5.4) are

located on the control box at the platform. Boom,

platform, and drive functions can be operated from

the upper controls. The following controls are

located on the upper control panel.

●

Emergency stop button

●

Start switch

●

Boom and platform joysticks

●

Drive and steer joystick

●

High range switch

●

Horn button

●

Emergency power switch

●

High revs switch

●

Platform rotate switch SP22 only

Figure 5.4— Platform Controls, SP22

❑ Emergency Stop Button

The emergency stop is a two-position, red push

button on the top of the upper control panel. Push

the button in to disconnect power to all control

circuits at the upper controls. Pull the button out to

restore power.

NOTE

The lower controls override the upper controls. If

the upper control emergency stop button is

engaged the lower controls can still be used to

operate the aerial platform.

Push the emergency stop button in when the upper

controls are not in use to protect against

unintentional platform operation.

❑ Component Select Switches

The following aerial platform components may be

selected from the upper control panel.

●

Platform rotate - SP22 only (refer to item

Figure 5.4)

Operate the appropriate switch to select a function.

❑ Boom and Platform Joystick

The boom and platform joysticks (refer to Figure

5.3 and 5.4) controls movement of the selected

component.

Movement of the joystick in a given direction

produces a corresponding movement of the aerial

platform.

❑ Drive and Steer Joystick

Figure 5.3—Platform Controls, SP20

page 6 - 2 SP20/SP22 – 11890A

The drive and steer joystick (refer to Figures 5.3

and 5.4) controls drive forward and reverse, and

Page 33

steer right and left. The steering and drive functions

may be operated simultaneously.

Movement of the joystick in a given direction

produces a corresponding movement of the aerial

platform.

NOTE

The steering wheels are not self-centering. Set the

steering wheels straight ahead after completing a

turn.

❑ High Range Switch

The high range button is on the upper right side of

the upper control panel.

Normal operation of the drive wheels is with low

speed and high torque. Press the range button to

change the drive system to high speed and low

torque operation.

❑ Horn Button

The horn button is on the right side of the upper

control panel. Press the push-button switch to

sound the horn.

Chapter 6. Controls

Figure 5.5—Platform Foot Switch

❑ Emergency Power Switch

Operate the emergency power switch to access the

aerial platform functions using the emergency

power system.

NOTE

The emergency power system is for lowering the

platform during an emergency and is not intended

for normal machine operation.

■

AC Generator (Optional)

The control for the generator is located on the

upper control panel.

Place the switch in the generator position to

provide electrical power to the two electrical outlets

at the platform and to the outlet on the end of the

generator housing.

Machine functions will not operate while the switch

is in the generator position.

■

Platform Foot Switch

The upper controls are interlocked through the

platform foot switch (refer to Figure 5.5). Step down

on and hold the platform foot switch to activate the

drive and boom functions from the upper controls.

SP20/SP22 – 11890A page 6 - 3

Page 34

Page 35

Chapter 7. Pre-operational Inspection

DANGER

WARNING

Potential service and safety problems may be

detected by inspecting the aerial platform every

Set the Key Switch to OFF before you begin this

inspection.

day (or 8 hour shift).

This chapter includes a Pre-operational Inspection

table (refer to Figure 6.1) and information on

properly inspecting each item listed in the table.

The purpose of the Pre-operational Inspection is to

keep the SP in proper working condition and to

detect signs of malfunction at the earliest possible

time.

Perform the inspection at the beginning of each

shift before using the aerial platform on the job.

The inspection site must have a smooth and level

surface. Use the Pre-operational Inspection table

The potential for an accident increases when

operating an aerial platform that is damaged

or malfunctioning.

Death or se ri ous in jury can re sult from such

ac ci dents.

Do not op er ate the ae rial plat form if it is

dam aged or mal func tion ing.

Re pair all equip ment dam age or

mal func tions be fore plac ing the SP into

ser vice.

to ensure no areas are overlooked.

If pre-operational and periodic inspections are neglected, it will not be possible to detect problems in their early

stages or prevent consequent accidents.

Make it a habit to perform the recommended pre-operational and periodic inspections. If any abnormality is

found, take corrective action immediately.

Item Inspect for

Operator’s manual In manual holder

Engine

Oil level

Coolant

Fuel tank

Fuel line

Air filter

Charging system

Electrical system

Battery fluid level

Battery terminals

Cables and wiring harness

Hydraulic system

Fluid level

Fluid filter

Hoses, tubes, and fittings

Tires and wheels

Foam filled Good condition

Lower control station

Operating controls

Emergency stop

Emergency power

Emergency lowering Proper operation

Level sensor Sounds tilt alarm

Flashing light Proper operation

Hostile environment kit In place and proper operation

Sound suppression kit In place and proper operation

Between full and add marks

Liquid cooled engines-proper fluid level

Air cooled engines-air intake and fan free of

obstructions. Belt in good condition

Tank full, cap in place and tight

No leaks

Yellow disk in the green zone

Proper operation

Proper level

Clean, connectors tight

No wear or physical damage

Between full and add marks

Verify operation in the green or yellow zone

No leaks

Proper operation

Shuts off lower controls

Proper operation

SP20/SP22 – 11890A page 7 - 1

Page 36

Chapter 7. Pre-operational Inspection

CAUTION

Item Inspect for