Page 1

100028-020

100028-020-9804-.1-D

FOR MORE INFORMATION

USA Local Distributor:

TEL: (1) 209-891-5200

FAX: (1) 209-896-9012

PARTSFAX: (1) 209-896-9244

1775 Park St., Selma, CA 93662

http://www.upright.com

EUROPE

TEL: (353) 1-285-3333

FAX: (353) 1-284-0015

Pottery Road, Dun Laoire, Ireland

ÉTATS-UNIS Distributeur local :

TÉL. : (1) 209-891-5200

TÉLÉC. : (1) 209-896-9012

TÉLÉC. (PIÈCES) : (1) 209-896-9244

1775 Park St., Selma, CA 93662

http://www.upright.com

EUROPE

TÉL : (353) 1-285-3333

TÉLÉC. : (353) 1-284-0015

Pottery Road, Dun Laoire, Ireland

USA Inr Ortsveitrieb:

TEL: (1) 209-891-5200

FAX: (1) 209-896-9012

Fax für Ersatzteile: (1) 209-896-9244

1775 Park St., Selma, CA 93662

http://www.upright.com

EUROPA

TEL: (353) 1-285-3333

FAX: (353) 1-284-0015

Pottery Road, Dun Laoire, Ireland

USA Distribudor local:

TÉLÉFONO: (1) 209-891-5200

FACSÍMIL : (1) 209-896-9012

FACSÍMIL PARA REPUESTOS: (1) 209-896-9244

1775 Park St., Selma, CA 93662

http://www.upright.com

EUROPA

TÉLÉFONO: (353) 1-285-3333

FACSÍMIL : (353) 1-284-0015

Pottery Road, Dun Laoire, Ireland

1

Operator Manual

Guide de lopérateur

Betriebsanleitung

Manual del operador

WARNING

All personnel shall carefully read, understand and follow all safety rules, and

operating instructions before performing maintenance on or operating any

UpRight aerial work platform.

AVERTISSEMENT

Tout le personnel doit lire attentivement et respecter toutes les consignes de

sécurité avant dentretenir ou dutiliser une plate-forme élévatrice UpRight.

WARNUNG

Alle Bediener müssen die Sicherheitsregeln und Bedienungsanleitungen gründlich

durchlesen, verstehen und befolgen, bevor sie an irgendeiner UpRight-Hocharbeitsbühne

Wartungsarbeiten ausführen oder diese in Betrieb nehmen.

ADVERTENCIA

Todo el personal debe leer atentamente, entender y respetar todas las reglas de

seguridad, las instrucciones de operación antes de efectuar trabajos de

mantenimiento o manejar cualquier plataforma aérea de trabajo UpRight.

Refer to page 2 for the English language version of this Operator Manual.

Reportez-vous à la page 12 pour la version française de ce guide de lopérateur.

Bezüglich der deutschsprachigen Ausgabe dieser Betriebsanleitung siehe Seite 22.

Referirse a la página 32 para la versión en español de este manual del operador.

SB-60

SB-60

SERIAL NO. 1000 TO CURRENT

Page 2

2

English Language Section

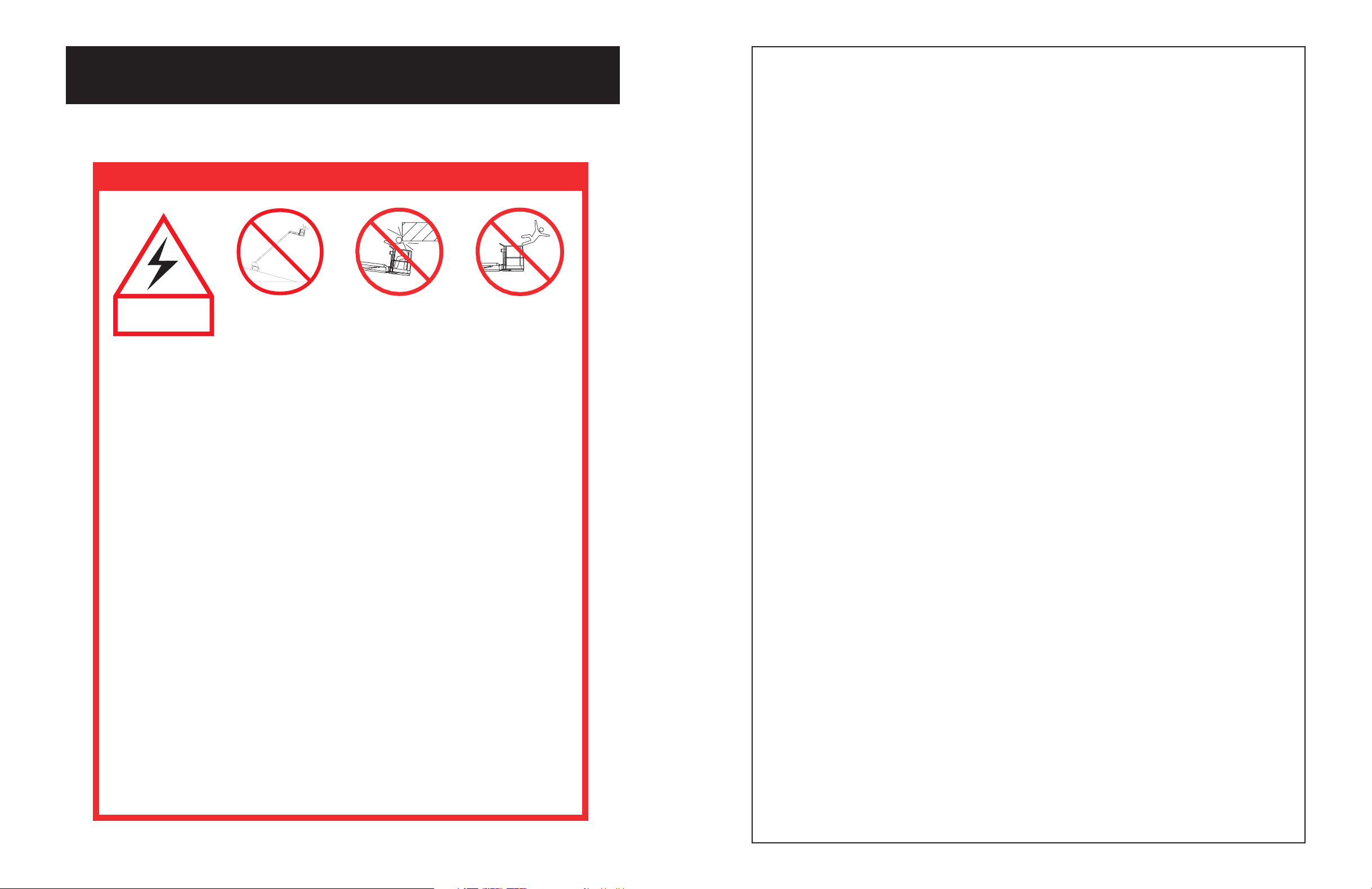

THIS MACHINE IS

NOT INSULATED.

NEVER operate

the boom or drive

with platform

elevated unless on

firm level surface.

NEVER position the

platform without first

checking for overhead obstructions or

other hazards.

NEVER climb, stand

or sit on platform

guardrails or midrail.

Electrocution Hazard Tip Over Hazard Collision Hazard Fall Hazard

ALL occupants must wear an approved fall restraint properly attached to designated platform

anchorage point. Attach only one fall restraint to each anchorage point.

NEVER exceed maximum platform load of 500 lbs. (225 kg) and two (2) occupants.

NEVER exceed 45 lbs. (200 N) of side force per occupant.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as

holes, drop-offs, bumps, curbs, or debris; and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed 28 mph (12.5 m/sec. = beaufort scale 6).

IN CASE OF EMERGENCY push emergency stop button to deactivate all powered functions.

ALWAYS close and secure sliding rail after entering platform.

NEVER exit or enter platform while elevated.

NEVER use ladders, scaffolding, or other items to gain height; work only from the platform floor.

NEVER climb down elevating assembly while platform is elevated.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks,

loose wire connections, and damaged cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing

labels.

IF ALARM SOUNDS while boom is elevated, STOP, carefully retract boom and lower platform

without rotating. Move machine to a firm, level surface.

NEVER attach overhanging loads or use boom as a crane.

NEVER alter operating or safety systems without manufacturers written consent.

NEVER charge battery near sparks or open flame. Charging batteries emit explosive hydrogen

gas.

NEVER replace any component or part with anything other than original UpRight replacement

parts without the manufacturer's written consent.

NEVER tow the machine. Transport by truck or trailer only.

AFTER USE, secure the work platform from unauthorized use by turning both keyswitches off

and removing all keys.

SAFETY RULES

47

NOTES:

Page 3

46

NOTES:

3

Introduction

This manual covers the operation of internal combustion

powered models of the SB-60 Boom. This manual must

be stored on the machine at all times.

Pre-Operation and Safety

Inspection

Carefully read, understand and follow all safety rules,

labels, and operating instructions, then perform the

following steps each day before use.

Perform a complete visual inspection of the entire unit

prior to operating. Check the following areas for

discrepancies:

1. Open panels and check hydraulic components /

hoses for damage or leaks. Check electrical

components / wiring for damage or loose connections.

2. Inspect chassis, axles, hubs, rims, and steering

linkage for damage, deformation, loose or missing

hardware, and cracked welds.

3. Check tires for damage, punctures, and inflation (if

equipped with air filled tires); tire pressure must be

5.5 bars (80 psi).

4. Check all hoses for leakage / hoses and cables for

wear.

5. Inspect elevating assembly for damage, deformation,

loose or missing hardware, and cracked welds.

6. Inspect platform and guardrails for damage,

deformation, loose or missing hardware, and cracked

welds. Insure that the sliding rail operates freely.

7. Check Hydraulic fluid level with platform fully lowered.

8. Check fluid level in batteries (see Battery

maintenance, page 9).

9. Check fuel level, add fuel if necessary (see Fueling,

page 9).

10. Check engine oil level.

11. Check air filter. Replace if necessary.

NEVER remove the cap from a hot radiator. Hot

coolant can cause severe burns

12. Ensure that radiator is cold, check coolant level. Add if

necessary. Check radiator and hoses for damage.

If you smell propane, close the supply valve on

the tank immediately until you have located and

corrected the leak.

SYSTEM FUNCTION INSPECTION

Note: Refer to figures 2 through 5 for chassis and

platform control locations.

1. Before performing the following tests, check area

around machine and overhead for obstructions, holes,

drop-offs, and debris.

2. Turn chassis key switch to chassis, and pull out

emergency stop switches at the chassis control panel

and at the platform control panel.

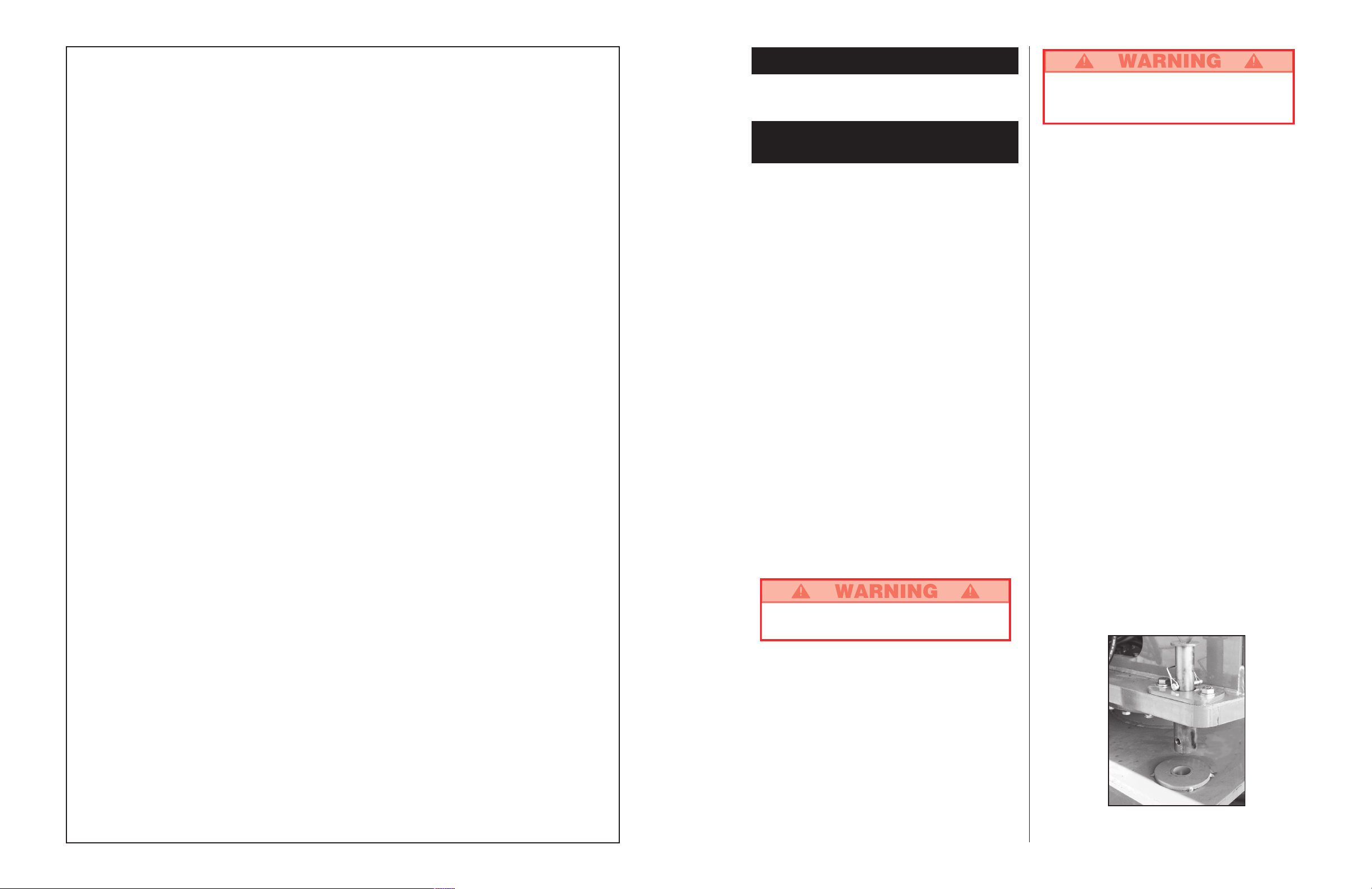

3. Retract locking bolt. See figure 1.

4.

Press the engine start button to crank the engine;

release when engine starts. If engine is cold: press

the glow plug button button and hold for six seconds

prior to starting diesel models.

5. Push in the chassis emergency stop button, engine

should stop. Repeat for platform emergency stop

button. Return both emergency stop buttons to the on

position, and start engine.

6. Operate each function switch to raise / lower, extend /

retract, rotate left / right, each section of the elevating

assembly and observe the operation of the machine.

All functions should operate through full cycle

smoothly.

7. Turn chassis key switch to platform.

8. Mount the platform, attach approved fall restraint to

designated platform anchorage point. (If required by

National Legislation) Attach only one fall restraint to

each point.

9. While engaging the hand interlock, move the drive

control handle forward and reverse. Observe that

proportional functions operate smoothly, and that

brakes apply quickly after control is released.

10. While engaging the hand interlock, operate steer

switch to left and right. Observe that steering wheels

turn properly.

Figure 1: Locking bolt

Page 4

4

DO NOT use a machine that is damaged or

malfunctioning. Tag and remove the unit from

service until it is repaired.

11. While depressing foot switch, operate boom controls.

Observe that boom operates smoothly, and that boom

raise and lower, turret rotation, and boom extension

and retraction operate proportionally in conjunction

with stroke of handle. Observe that platform maintains

level when boom is elevated.

12. With the boom elevated five degrees above horizon or

greater, operate drive control handle. Observe that

drive speed should be no faster than (1 foot [0.30 m]

per second). Lower upper boom to stowed position.

13. Press the service horn button. Observe that horn is

audible.

NOTE: Hand interlock controls drive / steer

functions only.

NOTE: Foot switch interlock controls boom functions

only.

Figure 3: Platform Controls

Figure 2: Platform Controls

32

33

Controls and Indicators

Figure 5: Platform Controls

4

7

Figure 4: Chassis Controls

1

2

8

9

10

11

12

13

14

15

5

6

3

18

19

20

21

24

23

2217

31

30

2827

26

25

1. Oil pressure gauge

2. Water temperature gauge

3. Hourmeter

4. Emergency stop

5. Key switch

6. Engine start

7. Glow plug (Diesel only)

8. Auxiliary power for emergency lowering only

9. Function enable

10. Boom control

11. Boom extension control

12. Turret control

13. Jib control

14. Cage rotation

15. Cage level control

16. Circuit breaker

16

29

17. Generator (optional)

18. Horn button

19. Emergency stop

20. Tilt warning indicator

21. Low oil pressure indicator

22. Torque/Speed selector

23. Fuel selector (Gasoline only)/

Glow plug (Diesel only)

24. Auxiliary power for emergency lowering only

25. Boom/Turret control

26. Boom extension control

27. Cage rotate control

28. Jib control

29. Cage level control

30. Drive control handle/interlock

31. Lights (optional)

32. Engine start switch

33. Foot interlock switch

45

Electrical Schematic; SB-60 DIESEL

Schéma de câblage; SB-60 DIESEL

Elektrischer Schaltplan; SB-60 (Diesel)

Esquema eléctrico; SB-60 DIESEL

Page 5

Electrical Schematic; SB-60 DUAL FUEL

Schéma de câblage; SB-60 À DEUX COMBUSTIBLES

Elektrischer Schaltplan SB-60 (Zweistoff)

Esquema eléctrico; SB-60 DOBLE DIESEL

44

5

Starting the engine

From the lower controls

1. Turn the chassis key switch to chassis position.

2. Press the start button to crank the engine. Release

when the engine starts.

3. Diesel Engines: When the engine is cold, press and

hold the glow plug button for six seconds prior to

starting.

From the platform controls

1. Turn the chassis key switch to platform controls.

2. Turn the platform rotary switch fully clockwise to crank

the engine. Release when engine starts.

3. Diesel Engines: When the engine is cold, press and

hold the glow plug button for six seconds prior to

starting.

Driving

With Boom Lowered

1.

Turn chassis key switch to platform, and pull out the

chassis emergency stop switch.

2. Mount the platform, close the sliding rail. Make sure

that the sliding rail is safely closed. Keeping the

sliding rail open with the platform elevated (e.g. tying

down the sliding rail) is prohibited!

3. Attach approved fall restraint to designated platform

anchorage point. Attach only one fall restraint to each

point. (If required by National Legislation)

4. Start engine.

5. Check that the area around and above the work

platform is clear of obstructions, holes, drop-offs,

persons in the route of travel, and the surface is

capable of supporting wheel loads.

6. Engage the interlock switch and move the drive

control handle forward to travel forward and rearward

to travel in the reverse direction.

Note: When the boom is rotated to the front of the

chassis (steering wheels aft) directions of travel and

steering will be reversed. Observe the color coded

arrows on the control panel near the drive control

handle, and on the chassis. They will indicate the

direction of travel when the drive control handle is

moved.

Operation

Before operating work platform insure that:

Pre-operation and safety inspection has been

completed, and any discrepancies have been

corrected.

System function inspection has been performed.

Operator has been thoroughly trained on the

operation of the machine.

Work area is clear of all obstructions, holes, drop-

offs, or persons in the route of travel.

Surface is capable of supporting wheel loads.

Refer to figures 2 through 5 for control locations.

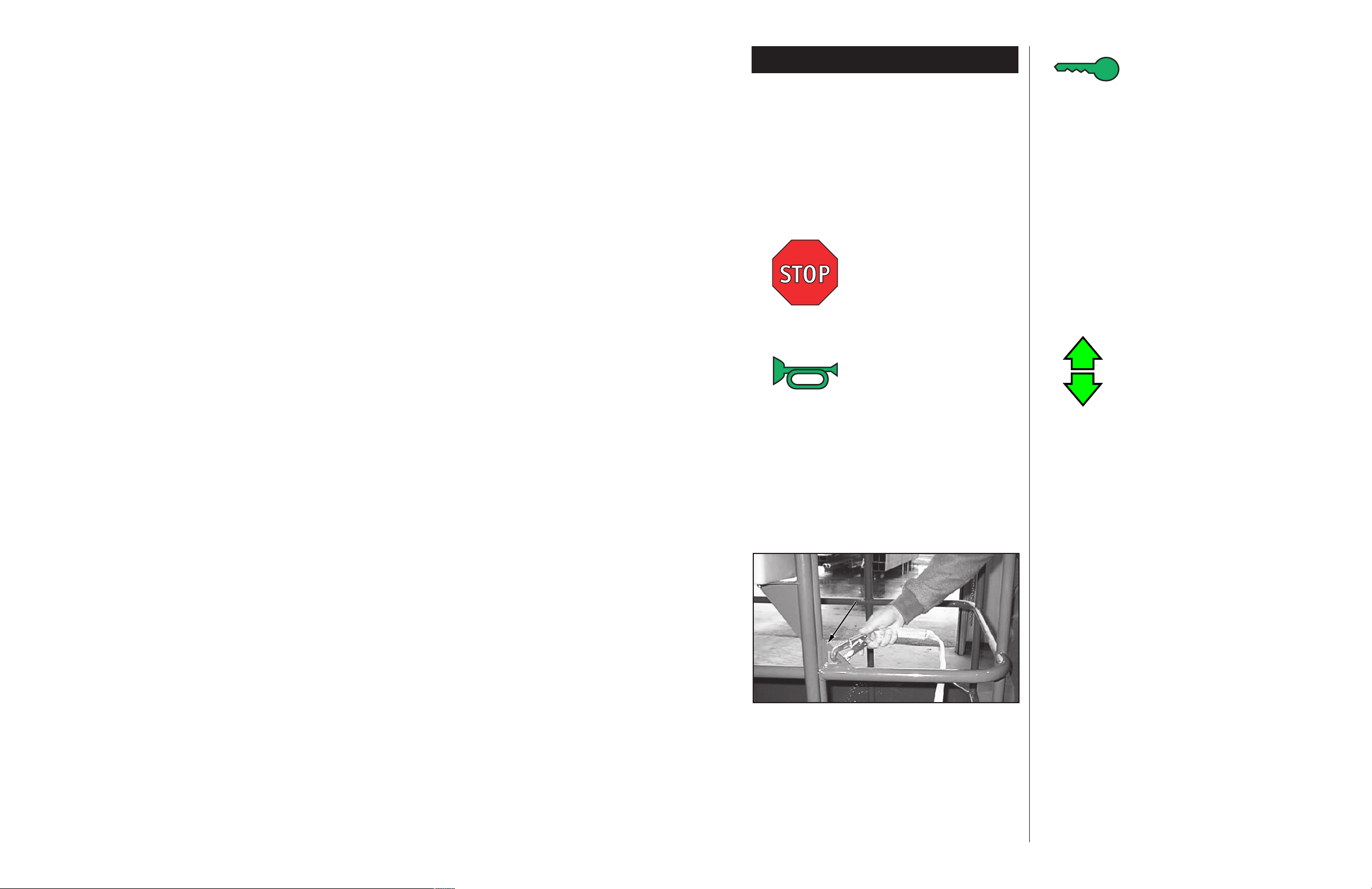

Emergency Stop

At any time during operation, press the emergency stop

button to stop all functions in an emergency.

Service Horn

At any time during operation, press the service horn

button to sound an audible warning if necessary.

Figure 6: Typical Fall Restraint Anchorage Point

NOTE: Always wear an approved fall restraint

properly attached to designated platform anchorage

point when driving or elevating the machine. (If

required by National Legislation) (see figure 6).

Attach only one fall restraint to each anchorage point.

Page 6

6

With Boom Elevated

Travel with boom elevated is restricted to firm level

surfaces only.

When driving elevated, the machine will travel at creep

speed (0.30 m [1 foot] per second).

Steering

1. While engaging the hand interlock, push the steering

switch (located on top of the control handle) to the left

to turn left, and right to turn right.

Note: Steering is not self centering. Wheels must be

returned to the straight ahead position by operating

the steering switch.

POSITIONING THE PLATFORM

Positioning the platform as close as possible to the work

area requires some planning. First, you must survey the

work site to find a suitable place to park the machine. This

must be a firm level area as close as possible to the work

area. Take into consideration all obstructions on the

ground and overhead and avoid them.

Always, before operating any function, check the area

around and overhead for any obstructions or electrical

conductors.

Multifunction Controls

The UpRight SB-60 employs the use of multifunction

controls. This means that any two functions can operate

at full speed simultaneously.

The turret may be rotated while driving if necessary to

make turns in tight areas. All other boom functions will not

operate while driving.

Lower Control Operation

Do not operate from lower controls if someone is in

platform, except in emergency situations.

All boom functions will operate at fixed speed.

1. Turn chassis keyswitch to chassis controls.

2. With engine running, operate boom control switches

to position the platform.

Leveling the Platform

DO NOT operate the machine if the platform does

not maintain level when elevated.

Note: Platform leveling can be performed only with

the boom stowed and should be done only to

calibrate the automatic leveling system.

While depressing the foot switch, move the platform

level control switch forward to swing the platform

upward, rearward to swing the platform downward.

Release the switch to stop leveling. Leveling can be

performed only when boom is stowed and retracted.

Rotating the Turret

While depressing the foot switch, move the boom

rotation joystick to the right to rotate right, left to rotate

left. Release the switch to stop rotation. The turret

rotation will function at a speed proportional to the

stroke of the joystick. Make sure the area around the

boom is clear of all obstructions before rotating the

turret.

Elevating the Boom

While depressing the foot switch, move the joystick

forward to elevate the boom, rearward to lower the boom.

Release the control lever to stop elevating / lowering. The

boom elevate will function at a speed proportional to the

stroke of the joystick.

Extending the Boom

While depressing the foot switch, move the boom

extension control joystick rearward to extend the

boom, forward to retract the boom. Release the

control lever to stop extending / retracting. The boom

extension will function at a speed, proportional to the

stroke of the joystick.

43

Hydraulic Schematic; SB-60

Schéma hydraulique; SB-60

Hydraulikschaltplan; SB-60

Esquema hidráulico; SB-60

Page 7

42

06-BSCITAMEHCSCILUARDYHTHGIRPU

000-720001.ONTRAP

HSILGNESIAÇNARFNAMREGHSINAPS

PMUDTNEMESREVÉDgnureeltnEAGRACSED

DEELBDEEPSWOLESSETIVESSAB,EGRUPgnutfültnegnaghceirKDADICOLEVAJABAAGRUP

SSAPYBNOITAVIRÉDssapyBNÓICAVIRED

RETLIFERTLIFretliFORTLIF

PMUPYRAILIXUAERIAILIXUAEPMOPepmupsfliHRAILIXUAABMOB

PMUPEPMOPepmuPABMOB

RENIARTSNOITCUSNOITARIPSA'DENIPÉRCbeisguasnANÓICARIPSAEDORTLIF

PMUPCITATSORDYHEUQITATSORDYHEPMOPepmupkcurdlÖACITÁTSORDIHABMOB

REETSNOITCERIDnekneLRIGIRID

TFILEGAVELnebeHNÓICAVELE

GNIWSNOITALLICSOneknewhcSOECNALAB

DNETXEEGNOLLARnerhafsuANÓISNETXE

LEVELUAEVINnereilleviNLEVIN

GNIWSNOITALLICSOneknewhcSOECNALAB

RETSAMERTÎAMlitnevtpuaHORTSEAM

EVALSEVALCSElitnevegloFOVALCSE

REWOPMOOBEHCÈLF,.MILAlitnevtfarkregelsuAAMULPALEDAÍGRENE

ROTATORMROFTALP-ETALP,NOITATORED.PSID

EMROF

gnuknewhcsnenhübstiebrAALEDNÓICATOR

AMROFATALP

EKARBNIERFesmerBONERF

KCOLELXAUEISSE'LEDEGALLIUORREVerrepsshcAEJELEDORUGES

GNILPUOCYRATOR.PSID,TNEMELPUOCCA

FITATOR

ßulhcsnaherDOVITATOROTNEIMALPOCA

RAERTFELEHCUAG,ERÈIRRAsknilnetnihODREIUQZIORESART

TNORFTFELEHCUAG,TNAVAsknilnrovODREIUQZIORETNALED

RAERTHGIRETIORD,ERÈIRRAsthcernetnihOHCEREDORESART

TNORFTHGIRETIORD,TNAVAsthcernrovOHCEREDORETNALED

REDIVIDWOLFECIRTUBIRTSIDENNAVrelietsgnumörtSOJULFEDROSIVID

ELXAGNITALICCOTNALLICSOUEISSEeshcalednePETNALICSOEJE

GNIREETSNOITCERIDgnukneLNÓICCERID

7

Elevating the Jib

While depressing the foot switch, move the jib

control switch forward to elevate the jib, rearward

to lower the jib. Release the control lever to stop

elevating / lowering.

Rotating the Platform

While depressing the foot switch, toggle the control

switch left to rotate left, right to rotate right. Release

the switch to stop rotation.

EMERGENCY OPERATION

In the event of a malfunction, the elevating assembly may

be lowered using the following procedure.

NEVER climb down the elevating assembly. If

controls do not respond, follow the emergency

lowering procedure.

Lowering Elevating Assembly

1. Engage the auxiliary power unit switch.

2. Operate any boom function in the normal manner.

Note: Auxiliary battery is capable of one emergency

lowering cycle before requiring recharge.

Battery is recharged while engine is in

operation.

EMERGENCY TOWING

DO NOT tow the machine faster than 5 km/h

(3 mph). Faster speeds will damage drive

components and void warranty.

There are no brakes when the center caps are

installed in the inverted position.

Perform the following only when the machine will not

operate under its own power and it is necessary to move

the machine or when winching onto a trailer for

transportation.

DO NOT use a machine that is damaged or

malfunctioning. Tag and remove the unit from

service until it is repaired.

1. Insure that the platform is fully lowered, and that

the turret is rotated so that the platform is to the

rear of the machine.

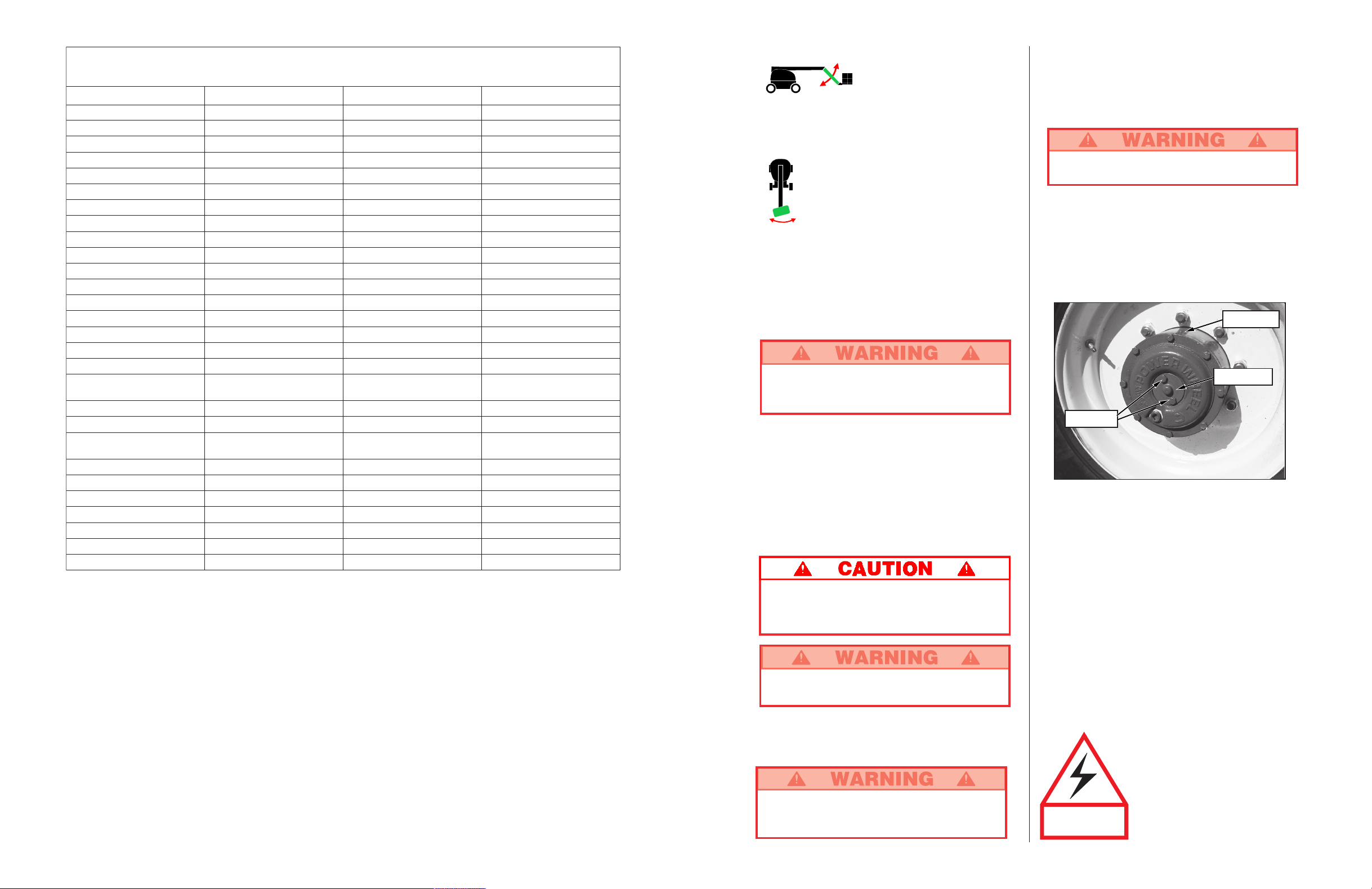

2. Refer to figure 7 and disengage all four drive hubs.

Remove two (2) cap screws and center cap.

Reinstall center cap in the opposite direction.

Chock wheels before disengaging hubs. Machine

may roll.

3. When ready to move the machine, remove the

chocks. Tow or winch into position and replace

chocks.

4. Attach adequate chain/cable of sufficient strength for

towing the machine to the front or rear tie down lugs.

5. Engage all four drive hubs by returning the center

caps to their original orientation.

Switching Fuels (Gas / Propane Only)

1. With the engine running, push the Fuel Selector

Switch to the center position.

2. After the engine has quit running, select the

appropriate fuel supply.

3. Restart the engine.

AFTER USE EACH DAY

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably under

cover, secure against vandals, children or

unauthorized operation.

3. Turn the key switch to OFF and remove the key to

prevent unauthorized operation.

Figure 7: Drive Hub (Operating position shown)

Drive Hub

Center Cap

Screws

THIS MACHINE IS

NOT INSULATED.

This machine is not insulated.

Follow your national safety

standards and maintain the

required safety distance when

working near energized equipment.

Page 8

8

BY CRANE

Stand clear of machine when lifting.

Check specifications on back page, insure that

crane and slings are of correct capacity to lift

weight of unit.

1. Insure that boom is fully lowered and retracted.

2. Attach straps to chassis lifting lugs only. Insure that

straps are adjusted properly to keep unit level when

lifting.

BY TRUCK OR TRAILER

1. Insure that boom is fully lowered and retracted.

2. Maneuver the machine onto bed of truck / trailer.

3. When winching, follow instructions for emergency

towing on page 7. Attach adequate winch cable of

sufficient strength to front tie down lugs.

Transportation

Do not winch machine faster than 5 km/h (3 mph.)

4. After winching, insure that all four drive hubs are

engaged by returning the center caps to their original

orientation.

5. Secure the machine to the transport vehicle using

chains / straps of adequate load capacity (refer to

specifications, back page) attached to chassis tie

down lugs (see figures 8 and 10).

6. Place wooden block (10cm x 10cm x 91cm)

(4" x 4" x 36") under platform support braces.

(Figure 9)

7. Attach ratchet strap under platform floor grating,

over support braces. (Figure 9) Do not over tighten.

Elevating boom functions while on transport

vehicle is prohibited except during loading and

unloading.

Figure 10: Rear chassis tie down lifting lugs.

Figure 9: Securing the machine for transportation.

Figure 8: Front chassis tie down lifting lugs.

Platform Tie Down Strap

Wooden Block

4" x 4" x 36"

Support Braces

Chassis Tie Down Lifting

Lugs

Chassis Tie Down

Lifting Lugs

41

Especificaciones**

* Especificaciones sujetas a modificación sin aviso previo.

Ver información completa sobre componentes y mantenimiento en el Manual de mantenimiento.

ÍTEM ESPECIFICACIÓN

Altura

Altura máxima de trabajo 20,3 m (66 pies)

Altura máxima de la plataforma 18,3 m (60 pies)

Pasa en la plataforma en altura 0,15 m (6 plg)

Altura en conducción 18,3 m (60 pies)

Alcance horizontal 16 m (52 pies 8 plg)

Rotación de la torre 360 grados continuous

Rotación de la plataforma 180 grados

Oscilación de la cola 1,35 m (53 plg)

Longitud del brazo 2,4 m (8 pies)

Arco del brazo 150 grados

Radio de giro interno 3,96 m (13 pies)

Radio de giro externo 6,76 m (22 pies 2 plg)

Velocidad de conducción (reducida) 6,4 km/h (4 mph)

Velocidad de conducción (elevada) 1,2 km/h (0,7 mph)

Gradabilidad 24grados / 45%

Nivel de ruido 80 dB

Presión del suelo 80 psi/presión de los neumáticos

rellenos con aire

Dimensiones (pluma recogida)

Tamaño de la plataforma 1,0 m x 1,83 m. opc 1,0 m x 2,44 m

(39 plg x 72 plg opc 39 plg x 96 plg)

Altura de la baranda 1,14 m (45 plg)

Tabla de pie 0,15 m (6 plg)

Cantidad máxima de ocupantes 2 más carga adicional

Peso/Gasolina 10 705 kg (23 600 lbs)

Peso/Diesel 10 750 kg (23 700 lbs)

Altura total (almacenado) 2,6 m (8 pies 6 plg)

Longitud total (almacenado) 9,07 m (29 pies 9 plg)

Ancho total 2,43 m (7 pies 11,75 plg)

Base de la rueda 2,59 m (8 pies 6 plg)

Banda de rodamiento de la rueda 1,5 m (59 plg)

Terreno libre 0,29 m (11,5 plg)

Fuente de energía / combustible GM 3,0 Liter

Fuente de energia / diesel Perkins 704-30

Voltaje del sistema 12 VDC

Presión hidráulica máxima 345 bars (5000 psi)

Controles Proporcional eléctrico

Neumáticos con rodadura número 14/80 psi

ÍTEM

ESPECIFICACIÓN

DIAGRAMA DE ALCANCE ENVOLVENTE

DIMENSIONES EN METROS

Page 9

40

Referencias de la Tabla de mantenimiento

de rutina

Intervalo

Diario = cada turno (todos los días) o cada ocho horas

30

D

= cada mes (30 días) o cada cincuenta horas

3

M

= cada 3 meses o cada 125 horas

6

M

= cada 6 meses o cada 250 horas

1

A

= cada año o cada 500 horas

2

A

= cada dos años o cada 1000 horas

S = Sí / aceptable

N = No / No aceptable

R = Reparada / Aceptable

Tabla de mantenimiento de rutina

MANTENIMIENTO DE RUTINA

Usar la tabla siguiente como guía para mantenimiento de

rutina. La inspección y el mantenimiento serán

realizados por personal entrenado y con experiencia

en mecánica y electricidad. Ver las instrucciones de

mantenimiento en el Manual de mantenimiento.

Fotocopiar esta página y usar la Tabla de mantenimiento

de rutina como hoja de control al inspeccionar una

máquina.

Informe de mantenimiento

Fecha:

Propietario:

Modelo No.: No. de serie:

Realizó mantenimiento:

Intervalo de mantenimiento:

COMPONENTE INSPECCIÓN O SERVICIOS INTERVALO S N R

Estructura Inspección de rajaduras estructurales Diario

elevadora Control de desgaste de pivotes 30D

Control de torsión correcta de tornillos

30

D

de retención de pasador de pivote

Control de deformación de partes Diario

Chasis Control de deformación o desgaste de las mangueras Diario

Controlar torsión correcta de montaje de componentes 6M

Revise el perno del apoyo de péndulo (par de torsión

123 Nm) (90 libras-pies)

6M

Control de soldaduras resquebrajadas Diario

Torre Control lubricación y desgaste de engranajes de anillos Diario

Revise el nivel del aceite 150H/3M

Lubricación de cojinetes de anillos (grasa MoS2) 150H/3M

Cubos de Control de fugas Diario

desplazamiento

Control de nivel de aceite 250H/6M

Cambio de aceite después de período de rotura 50H/30D

Cambio de aceite (aceite de engranajes SAE 90 wt.) 2000H/2A

Ajuste los elementos de montaje de las tasas a un

par de torsión de 123 Nm (90 libras-pie)

6M

Cilindros de Control de desgaste de varillas de cilindros 30D

elevación Control de torsión correcta de tornillos de

30

D

retención de pasadores de pivote

Control de fugas en sellos 30D

Inspección de desgaste de pivotes 30D

Control de torsión correcta de conectores 30D

Unidad Control y reparación de daño por colisión Diario

completa Control de torsión correcta de pasadores 3M

Control de corrosión, retirar y pintar 3M

Lubricación 30D

Etiquetas Control de estado, legibilidad o falta

Diario

de etiquetas, reemplazar

COMPONENTE INSPECCIÓN O SERVICIOS INTERVALO S N R

Aceite del Control de nivel y estado Diario

motor

Control de fugas Diario

Cambio de aceite y filtro (Combustible doble) 200HORAS

Cambio de aceite y filtro (Diesel) 500HORAS

Sistema de Control de nivel de combustible Diario

combustile

Control de fugas Diario

Reemplazo de filtro de combustible 6M

Verificar filtro de aire Diario

Baterías Contol de nivel de electrólitos Diario

Limpieza exterior 3M

Limpieza de terminales 3M

Refrigerante Control de nivel de refrigerante (con motor frío) Diario

del motor Reemplazo de refrigerante 2A

Aceite Control de nivel de aceite Diario

hidráulico Cambio de filtro 6M

(*vea nota) Drenaje y reemplazo con aceite compatible ISO 46 2A

Sistema Control de fugas Diario

hidráulico Control de conexiones de mangueras 30D

Control de desgaste exterior de mangueras 30D

Sistema Control de funcionamiento de anulador de

Diario

hidráulico de emergencia unidad de energía Diario

emergencia

Controlador Control de funcionamiento de todos los controles Diario

Cable de Verifique que la parte exterior del cable no se encuentre

control apretada, amarrada o gastada.

Diario

Piso y rieles Control de torsión correcta de pasadores Diario

de la Control de soldaduras resquebrajadas Diario

plataforma Control del estado de la plataforma Diario

Control de estado de puntos de anclaje Diario

Control de estado del manual del operador Diario

Neumáticos Control de daños Diario

Controlar la presión de aire (excepto rellenas con

gomaespuma) (5.5 bar [80 psi])

Diario

Control tuercas de anillos de amarre

(torsión 123 Nm [90 libras-pie])

30D

Bomba Limpieza 30D

hidráulica Control de fugas en superficies de unión 30D

Control de fugas en accesorios de mangueras Diario

Control de torsión correcta en tornillos de montaje 30D

Sistema de Control de funcionamiento de motor hidráulico Diario

conducción Control de fugas en mangueras, conectores

Diario

hidráulica y válvulas de bloqueo

Sistema de Control de par de torsión en conectores 6M

dirección Control de péridas en cilindro de dirección 30D

Control de zonas de desgaste en en enlace 30D

Control de retenes flojos o faltantes Diario

*Mobil DTE 15M, ISO grado 46, para un promedio de temperaturas de entre 4,4oC y

43,3

o

C (40oF y 110oF)

*Para climas más fríos:

Mobil DTE 13M, ISO grado 32, para un promedio de temperaturas de entre -12,2

o

C y

18,3

o

C (10oF y 65oF)

9

BATTERY MAINTENANCE

Hazard of explosive gas mixture. Keep sparks,

flame and smoking materials away from batteries.

Always wear safety glasses when working with

batteries.

Battery fluid is highly corrosive. Rinse away any

spilled fluid thoroughly with clean water.

Check battery fluid level daily, especially if work platform

is being used in a warm, dry climate.

If electrolyte level is lower than 10 mm (3/8 in.) above

plates add distilled water only. DO NOT use tap water it

will shorten battery life.

Keep terminals and top of battery clean.

TIRES

Tire selection can affect the stability of the machine. Use

only tires supplied by UpRight (15-19.5 NHS Tubeless 14

Ply Rating) unless approved by the manufacturer in

writing. If equipped with air filled tires, check tire air

pressure daily. 5.5 bars (80 psi).

FUELING

Gasoline

1. Open left turret cover, open fill pipe cap. (see

figure 11)

2. Fill to capacity with unleaded motor fuel only.

3. Fuel tank full capacity is 159 L (42 US gallons).

Diesel

1. Open left turret cover, open fill pipe cap. (see

figure 11)

2. Fill to capacity with diesel motor fuel only. Use

distillate fuel only, do not use residual or blend.

3. Fuel tank full capacity is 159 L (42 US gallons).

HYDRAULIC OIL

1. Open left turret cover and check oil level at sight

gauge with the boom stowed and retracted. Engine

running or stopped. (see figure 12)

2. If necessary, fill to capacity with clean ISO 46

compatible hydraulic oil. Refer to Routine Service

table on page 10.

3. Clean area around cap before opening.

4. Open filler / breather cap to add hydraulic oil.

5. Replace cap.

6. Properly dispose waste hydraulic oil.

LUBRICATION

Refer to service manual for lubrication chart and

guidelines.

Maintenance

Figure 11: Fuel tank

Fuel cap

Figure 12: Hydraulic Oil Tank

Hydraulic Oil Filler / Breather Cap

Hydraulic Oil Level Gauge

Page 10

10

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Elevating Inspect for structural cracks Daily

Assembly Check pivot points for wear 30D

Check pivot pin retaining bolts for proper torque 30D

Check members for deformation Daily

Chassis Check hoses for pinch or rubbing points Daily

Check component mounting for proper torque 6M

Check swing bearing bolt (torque

to 123 Nm [90 ft. lbs.])

6M

Check welds for cracks Daily

Turret Check ring gear for proper lubrication and wear Daily

Check planetary oil level 150H/3M

Lubricate ring gear (MoS

2

grease) 150H/3M

Torque Check for leaks Daily

Hubs Check oil level 250H/6M

Change oil after break-in period 50H/30D

Change oil (SAE 90 wt. gear oil) 2000H/2Y

Torque hub mounting hardware to

123 Nm [90 ft. lbs.]

6M

Lift Check the cylinder rods for wear 30D

Cylinders Check pivot pin retaining bolts for proper torque 30D

Check seals for leaks 30D

Inspect pivot points for wear 30D

Check fittings for proper torque 30D

Entire Check for and repair collision damage Daily

Unit Check fasteners for proper torque 3M

Check for corrosion, remove and repaint 3M

Lubricate 30D

Labels Check for peeling, missing, or unreadable

Daily

labels & replace

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Engine Oil Check level and condition Daily

Check for leaks Daily

Change oil & filter (Dual Fuel) 200HOURS

Change oil & filter (Diesel) 500HOURS

Engine Fuel Check fuel level Daily

System Check for leaks Daily

Replace fuel filter 6M

Check air cleaner Daily

Batteries Check electrolyte level Daily

Clean exterior 3M

Clean terminals 3M

Engine Check coolant level (with engine cold) Daily

Coolant Replace coolant 2Y

Hydraulic Check oil level Daily

Oil Change filter 6M

(*See note ) Drain and replace with ISO 46 compatible oil 2Y

Hydraulic Check for leaks Daily

System Check hose connections 30D

Check hoses for exterior wear 30D

Emergency Check operation of emergency override power unit Daily

Hydraulic

System

Controller Check operation of all controls Daily

Control Check the exterior of the cable

Daily

Cable for pinching, binding or wear

Platform Check fasteners for proper torque Daily

Floor and Check welds for cracks Daily

Rails Check condition of platform Daily

Check condition of anchorage points Daily

Check condition of operators manual Daily

Tires Check for damage Daily

Check air pressure (except foam filled)

(5.5 bar [80 psi])

Daily

Check lug nuts (torque to 123 Nm [90 ft. lbs.]) 30D

Hydraulic Wipe clean 30D

Pump Check for leaks at mating surfaces 30D

Check for hose fitting leaks Daily

Check mounting bolts for proper torque 30D

Hydraulic Check hydraulic drive motor operation Daily

Drive System Check hoses, fittings, and valve block for leaks Daily

Steering Check fittings for proper torque 6M

System Check steering cylinder for leaks 30D

Check linkage for wear areas 30D

Check for missing / loose retainers Daily

Interval

Daily=each shift (every day) or every eight hours

30

D

=every month (30 days) or every 50 hours

3

M

=every 3 months or 125 hours

6

M

=every 6 months or 250 hours

1

Y

=every year or 500 hours

2

Y

=every 2 years or 1000 hours

Y=Yes/Acceptable

N=No/Not Acceptable

R=Repaired/Acceptable

Routine Service Table

Service Report

Date: _________________

Owner: _________________

Model No: _____________ Serial No: _____________

Serviced By: _____________

Service Interval: __________

ROUTINE SERVICE

Use the following table as a guide for routine

maintenance. Inspection and maintenance shall be

performed by personnel who are trained and familiar

with mechanical and electrical procedures. Refer to

the Service Manual for complete service instructions.

Please copy this page and use the Routine Service Table

as a checklist when inspecting a machine for service.

Routine Service Table Key

*Mobil DTE 15M, ISO grade 46, for temperature range of 40oF up to

110

o

F.

*For colder climates:

Mobil DTE 13M, ISO grade 32, for temperature range of 10

o

F up to

65

o

F.

39

MANTENIMIENTO DE LA BATERÍA

Peligro de mezcla de gases explosiva. Mantener

la batería lejos de chispas, llama o humo.

Usar siempre anteojos de seguridad al trabajar

con baterías.

El fluido de la batería es muy corrosivo. Lavar

bien los derrames de fluido con agua limpia.

Controlar diariamente el nivel del fluido, especialmente si

se usa la plataforma en clima seco y cálido.

Si el nivel de electrolitos sobre las placas es inferior

a 10 mm (

3

/8 plg) sólo agregar agua destilada.

NO usar agua potable ya que acorta la vida de la batería.

Mantener limpias las terminales y la tapa de la batería.n.

NEUMÁTICOS

La elección de los neumáticos puede afectar la

estabilidad de la máquina. Sólo usar los neumáticos de

UpRight (15-19.5 NHS sin tubos, 14 espesor nominal),

salvo autorización escrita del fabricante. Si viene

equipada con neumáticos rellenos con aire, verifique la

presión de los neumáticos diariamente, 5,5 bars (80 psi).

COMBUSTIBLE

Gasolina

1. Abra la cubierta de la torre izquierda, abra la tapa del

caño de llenado (ver figura 11).

2. Llenar solamente con combustible para motores sin

plomo.

3. La capacidad total del tanque es de 159 lts.

(42 galones).

Diesel

1. Abra la cubierta de la torre izquierda, abra la tapa del

caño de llenado (ver figura 11).

2. Llenar solamente con combustible para motores

diesel. Solo usar combustible destilado, no usar

residual o mezcla.

3. La capacidad total del tanque es de 159 lts.

(42 galones).

ACEITE HIDRÁULICO

1. Abra la cubierta de la torre izquierda y revise el nivel

del aceite en el indicador con la pluma guardada y

contraída. El motor en marcha o detenido. (ver

figura 12)

2. Si es necesario, llenar con aceite hidráulico

compatible ISO 46. Vea el cuadro de Mantenimiento

de rutina en la página 40.

3. Limpiar el área de alrededor de la tapa antes de

abrirla.

4. Abrir la tapa de llenado y respiración y agregar aceite.

5. Tapar de nuevo.

6. Desechar el aceite hidráulico apropiadamente

LUBRICACIÓN

Ver cuadro de lubricación e instrucciones en el manual de

mantenimiento.

Mantenimiento

Figura 11: Tanque de combustible

Tapa de

combustible

Figura 12: Tanque de aceite hidráulico

Tapa de llenado / respirador

de aceite hidráulico

Indicador de nivel

del aceite hidráulico

Page 11

38

POR GRÚA

Pararse lejos de la máquina cuando ésta es

levantada.

Ver las especificaciones en la última página,

controlar que la grúa y las eslingas tengan la

capacidad adecuada para levantar el peso de la

unidad.

1. Verificar que la pluma esté totalmente baja y

replegada.

2. Sólo colocar correas en los anillos de amarre del

chasis. Las correas deben estar bien ajustadas para

mantener la unidad nivelada al levantarla.

POR CAMIÓN O TRÁILER

1. Verificar que la pluma esté totalmente baja y retraida.

2. Colocar la máquina en el piso del camión o tráiler.

3. Para levantar la unidad seguir las instrucciones para

remolque de emergencia en la página 37. Colocar el

cable del cabrestante adecuado de suficient fuerza en

los anillos de amarre delanteros.

No levantar la máquina a una velocidad superior

a 5 km/h (3 millas por hora).

4. Después de levantar, verificar que las cuatro tasas

estén colocadas volviendo las tapas centrales a su

orientación original.

5. Asegurar la máquina al vehículo de transporte

usando cadenas o correas de capacidad de peso

adecuadas en los anillos de amarre del chasis

(ver especificaciones en la última página) (ver

figuras 8 y 10).

6. Colocar un bloque de madera (10 cm x 10 cm x 91 cm)

(4 plg x 4 plg x 36 plg) debajo de las barras de apoyo

de la plataforma. (figura 9)

7. Colocar una correa de trinquete debajo del enrejado

del piso de la plataforma, sobre las barras de apoyo.

(figura 9). No ajustar en exceso.

La funciones de elevación de la pluma están

prohibidas mientras que se encuentra en el

vehículo de transporte, excepto durante la carga

y descarga.

Transporte

Figura 10: : Anillos de amarre traseros para elevación

del chasis

Figura 9: Asegurar la máquina para transporte

Figura 8: Anillos de amarre delanteros para elevación

del chasis

Correa de amarre

de la plataforma

Bloque de madera

10 cm x 10 cm x 91 cm

(4 plg x 4 plg x 36 plg )

Barra de apoyo

Anillas de amarre para

elevación del chasis

Anillas de amarre para

elevación del chasis

11

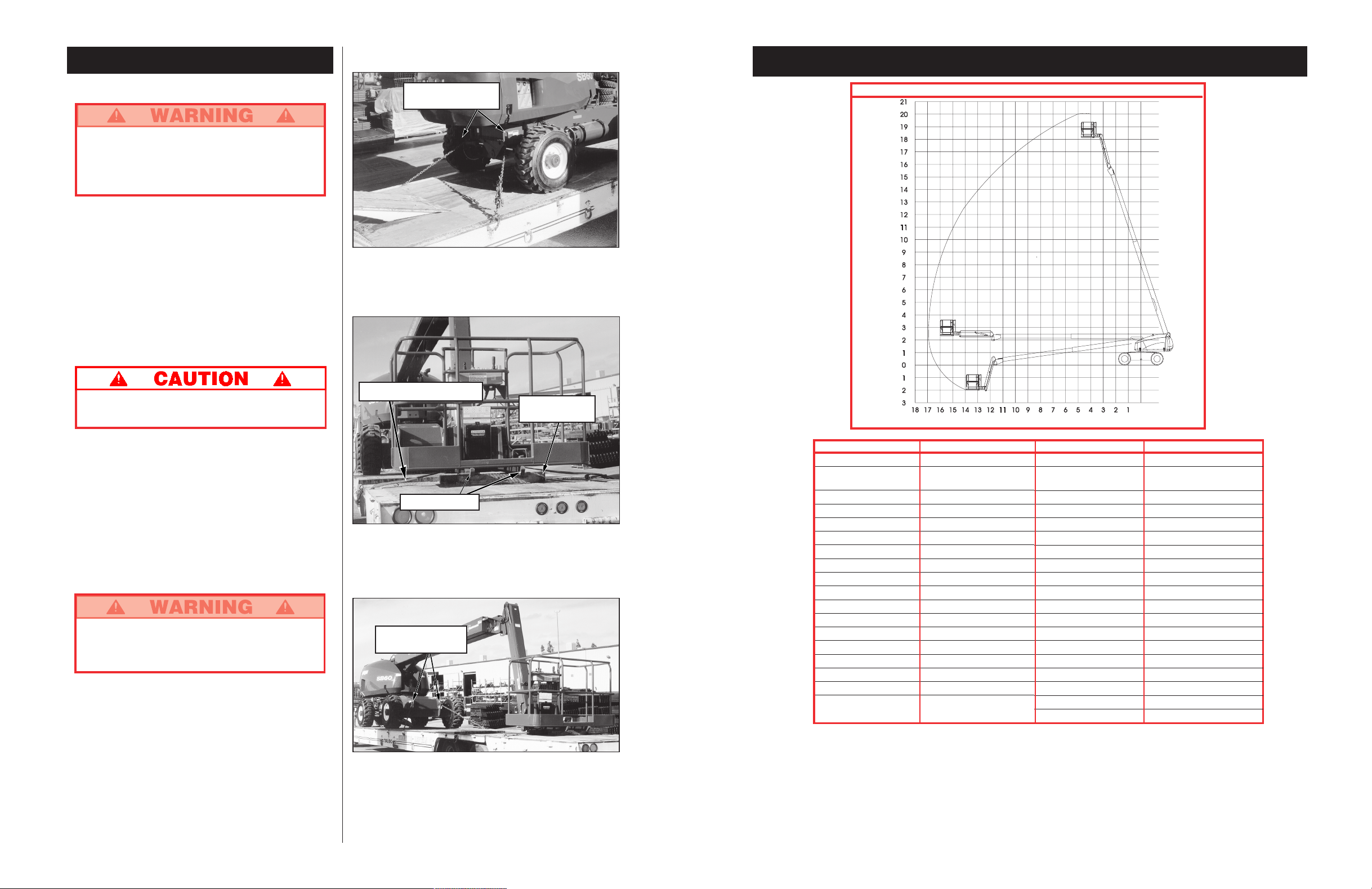

Specifications*

* Specifications subject to change without notice.

Refer to Service Manual for complete parts and service information.

ITEM SPECIFICATION

Height

Working height maximum 20.3 m (66 ft.)

Platform height maximum 18.3 m (60 ft.)

Platform step in height 0.15 m (6 in.)

Drivable height 18.3 m (60 ft.)

Horizontal outreach 16 m (52 ft. 8in.)

Turret rotation 360 deg. continuous

Platform rotation 180 deg.

Tail swing 1.35 m (53 in.)

Jib length 2.4 m (8 ft.)

Jib arc 150 deg.

Inside turning radius 3.96 m (13 ft)

Outside turning radius 6.76 m (22 ft. 2 in.)

Drive speed (lowered) 6.4 km/h (4 mph)

Drive speed (elevated) 1.2 km/h (.7 mph)

Gradability 24deg. / 45%

Noise Level 80 dB

Ground Pressure 80 psi/ Air filled tire pressure

Dimensions (boom stowed)

Platform Size 1.0 x 1.83m. opt 1.0 x 2.44 m

(39 in. x 72 in. opt 39 in. x 96 in.)

Guardrail height 1.14 m (45 in.)

Toeboards 0.15 m (6 in.)

Maximum no. of occupants 2 Plus additional load

Weight \ Gasoline 10,705 kg (23,600 lbs.)

Weight \ Diesel 10,750 kg (23,700 lbs.)

Overall height (Stowed) 2.6 m (8 ft. 6 in.)

Overall length (Stowed) 9.07 m (29 ft. 9 in.)

Overall width 2.43 m (7 ft. 11.75 in.)

Wheel base 2.59 m (8 ft. 6 in.)

Wheel track 1.5 m (59 in.)

Ground Clearance 0.29 m (111/2 in.)

Power source \ Gasoline GM 3.0 Liter

Power source \ Diesel Perkins 704-30

System voltage 12VDC

Maximum Hyd. Pressure 345 bar (5000 psi)

Controls Electric Proportional

Tires 14 ply lug tread/80 psi

ITEM SPECIFICATION

REACH ENVELOPE DIAGRAM

DIMENSIONS IN METERS

Page 12

12

CETTE MACHINE

NEST PAS ISOLÉE.

NE JAMAIS utiliser le

bras articulé à flèche

ni conduire plateforme élevée sans

que la machine ne

soit sur une surface

horizontale solide.

NE JAMAIS positionner

la plate-forme sans

sêtre dabord assuré

quil ny a pas

dobstacles ou autres

sources de danger aux

alentours.

NE JAMAIS monter,

sasseoir ou se tenir

debout sur les rampes

du garde-corps.

Danger délectrocution Danger de basculement Danger de collision Danger de chute

TOUS les occupants doivent porter un dispositif antichute dun modèle approuvé, correctement fixé au

point de fixation désigné à cet effet de la plate-forme. Ne fixer quun dispositif antichute par point de

fixation.

NE JAMAIS dépasser la charge maximale de la plate-forme, établie à 225 kg (500 lb) et à deux (2)

occupants.

NE JAMAIS dépasser une force latérale par occupant de 200 N (45 lb).

RÉPARTIR également toutes les charges sur la plate-forme.

NE JAMAIS utiliser la machine sans avoir dabord vérifié si la surface de la zone de travail ne présente

pas de dangers tels que des trous, des dénivellations, des bosses, des bordures ou des débris et sans

sêtre assuré quon peut les éviter.

NE faire fonctionner la machine QUE sur des surfaces pouvant supporter la charge des roues.

NE JAMAIS utiliser la plate-forme lorsque la vitesse du vent dépasse 12,5 m/s (28 mi/h) = échelle de

Beaufort 6.

EN CAS DURGENCE, appuyer sur le bouton darrêt durgence pour désactiver toutes les fonctions

alimentées.

TOUJOURS fermer au loquet le rail coulissant après être monté sur la plate-forme.

NE JAMAIS tenter de descendre de la plate-forme ni tenter dy monter lorsquelle est élevée.

NE JAMAIS dresser déchelle, déchafaudage ni dautres objets permettant de prendre de la hauteur ;

toujours travailler à partir du plancher de la plate-forme.

NE JAMAIS descendre par le dispositif délévation lorsque la plate-forme est élevée.

VÉRIFIER la machine à fond, avant de lutiliser, afin dy déceler toute soudure fissurée, toute pièce de

fixation ayant du jeu ou qui manquerait, toute fuite du circuit hydraulique, toute connexion lâche et tout

câble ou tuyau qui serait endommagé.

SASSURER que toutes les étiquettes sont en place et bien lisibles avant dutiliser la machine.

NE JAMAIS utiliser une machine qui est endommagée, qui ne fonctionne pas correctement, ou dont les

étiquettes sont endommagées ou manquantes.

SI LALARME RETENTIT alors que la flèche est élevée, ARRÊTER, rentrer la flèche avec précaution, et

abaisser la plate-forme sans faire pivoter la machine. Amener la machine jusque sur une surface horizontale solide.

NE JAMAIS fixer une charge qui déborde ni utiliser la flèche comme une grue.

NE JAMAIS modifier les dispositifs dexploitation ou de sécurité de la machine sans le consentement écrit

préalable du fabricant.

NE JAMAIS charger la batterie daccumulateurs près dune flamme ou dune source détincelles : les

batteries dégagent de lhydrogène gazeux explosif lorsquelles rechargent.

NE JAMAIS remplacer quelque élément ou quelque pièce que ce soit par autre chose quune pièce

dorigine UpRight sans le consentement écrit du fabricant.

NE JAMAIS remorquer la machine : ne la transporter quà bord dun camion ou dune remorque.

APRÈS AVOIR UTILISÉ la plate-forme élévatrice, tourner les deux clés de linterrupteur à la position

darrêt (« OFF »), puis les retirer afin de prévenir lutilisation de la plate-forme par toute personne non

autorisée.

CONSIGNES DE SÉCURITÉ

Section française

37

Rotación de la

plataforma

Mueva el interruptor de control hacia la izquierda para

girar hacia la izquierda, hacia la derecha para girar

hacia la derecha. Soltar el control para detener la

rotación.

OPERACIÓN DE EMERGENCIA

En el caso de un desperfecto, la estructura de elevación

puede bajarse manualmente con el siguiente

procedimiento.

NUNCA descender por la estructura de elevación.

Si los controles no responden, seguir el

procedimiento de bajada de emergencia

Cómo bajar la estructura de elevación

1. Coloque el interruptor de la unidad de energía

auxiliar.

2. Opere cualquier función de la pluma normalmente

Nota: La batería auxiliar soporta un ciclo de bajada de

emergencia antes de ser recargada. La batería

se recarga mientras el motor está en operación.

REMOLQUE DE EMERGENCIA

NO remolcar la máquina a una velocidad mayor a

5 km/h (3 millas por hora). Velocidades mayores

dañarán componentes de transmisión y anularán

la garantía.

Los frenos no funcionan cuando las tapas

centrales están instaladas en la posición

invertida.

Sólo realizar este procedimiento cuando la máquina no va

a funcionar por sí misma y es necesario moverla o

cargarla en un camión para transportarla.

NO utilizar una máquina dañada o defectuosa.

Identificar la unidad y no utilizarla hasta que sea

reparada.

1. Verificar que la plataforma esté totalmente baja y que

la torre esté rotada de manera que la plataforma esté

detrás de la máquina.

2. Ver figura 7 y desajustar los cuatro cubos. Quitar dos

tornillos y centrar la tapa. Reinstalar la tapa central en

dirección opuesta.

Fijar las ruedas mediante topes antes de desajustar

los cubos. La máquina puede rodar.

3. Antes de mover la máquina, quitar los topes. Ajustar

en la posición y reemplazar los topes.

4. Colocar en los anillos de amarre delanteros o

traseros una cadena o cable de adecuada resistencia

para remolcar la máquina.

5. Ajustar los cuatro cubos al volver a colocar las tapas

centrales de acuerdo la orientación original.

Cambio de combustibles

(Combustible/Propano solamente)

1. Con el motor andando, mueva el selector de com-

bustible a la posición central.

2. Cuando el motor se apague, elija el combustible

apropiado.

3. Arranque el motor.

Después de cada uso diario

1. Cerciórese que la plataforma esté totalmente abajo.

2. Estacione la máquina en piso horizontal, de

preferencia bajo techo, asegurada contra vándalos,

niños o usos no autorizados.

3. Apague el motor y saque la llave OFF para

prevenir usos no autorizados.

Figura 7: Cubo (posición de operación mostrada)

Tornillos

Cubo

Tapa Central

LA MÁQUINA NO

ESTÁ AISLADA

.

Esta máquina no está aislada.

Proceder según los estándares

de seguridad nacionales y

mantener la distancia prudencial

requerida al trabajar con equipo

energizado.

Page 13

36

Con la pluma levantada

El desplazamiento con la pluma levantada está

restringido a superficies llanas y firmes solamente.

Con la pluma levantada la máquina se moverá lentamente

(0,30 m [1 pie] por segundo).

Dirección

1. Al colocar el enganche manual, presionar el cambio

de dirección (ubicado arriba de la palanca de control)

a la izquierda para doblar a la izquierda y a la

derecha para doblar a la derecha.

Nota: La dirección no es autocentrante. Las ruedas

deben enderezarse nuevamente usando el cambio de

dirección.

UBICACIÓN DE LA PLATAFORMA

Ubicar la plataforma lo más cerca posible del área de

trabajo requiere preparación. Primero, hay que

inspeccionar la zona para encontrar un lugar adecuado

para estacionar la máquina. Debe ser una zona llana y

firme, lo más cerca posible del área de trabajo. Tener en

cuenta todos los obstáculos aéreos y en el terreno y

evitarlos.

Antes de utilizar cualquier función siempre verificar la

presencia de obstrucciones o conductores eléctricos en la

zona aledaña.

Controles multifunción

El equipo UpRight SB-60 tiene controles multifunción.

Esto significa que cualquiera de las dos funciones pueden

operar simultáneamente a velocidad completa.

Se puede rotar la torre durante la conducción si es

necesario girar en zonas angostas. Las demás funciones

de la pluma no funcionarán durante la conducción.

Operación de controles inferiores

No operar desde los controles inferiores si hay

alguien en la plataforma, excepto en situaciones de

emergencia.

Todas las funciones de la pluma actuarán a una velocidad

fija.

1. Girar el interruptor del chasis a controles del chasis

(chassis controls).

2. Con el motor en marcha, accionar los controles de la

pluma para ubicar la plataforma.

Nivelación de la

plataforma

NO usar la máquina si la plataforma no se

mantiene nivelada al elevarla.

Nota: La nivelación de la plataforma sólo se puede

efectuar con la pluma encigida y sólo debe hacerse

para calibrar el sistema de nivelación automático.

Al tiempo que se presiona el cambio de pie, mover

hacia adelante el control del nivel de la plataforma

para elevarla y hacia atrás para bajarla. Soltar el

control para dejar de nivelar. La nivelación se puede

realizar solamente cuando la pluma está guardada y

contraída.

Rotación de la torre

Al liberar el interruptor del pedal, empuje la palanca

de rotación de la pluma hacia la derecha para girar

hacia la derecha y hacia la izquierda para girar hacia

la izquierda. Libere el interruptor para detener la

rotación. La rotación de la torre funciona a una

velocidad proporcional al movimiento de la palanca.

Asegúrese de que no existan obstáculos alrededor de

la pluma antes de girar la torre.

Elevación de la pluma

Al liberar el interruptor del pedal, empuje la palanca

hacia adelante para elevar la pluma, hacia atrás para

bajar la pluma. Libere la palanca de control para

detener la elevación/descenso. La función de

elevación de la pluma opera a una velocidad

proporcional al movimiento de la palanca.

Extensión de la pluma

Al tiempo que se presiona el cambio de pie, empujar

hacia atrás la palanca de extensión de la pluma para

extenderla y hacia adelante para replegarla. Soltar la

palanca de control para dejar de extender o replegar.

La función de extensión de la pluma opera a una

velocidad proporcional al movimiento de la palanca.

Elevación del brazo

Al tiempo que se presiona el cambio de pie, empujar

la palanca de control del brazo hacia adelante para

elevarlo y hacia atrás para bajarlo. Soltar la palanca

para dejar de elevar o bajar.

13

Si une odeur de propane est perceptible, fermer

immédiatement le robinet du réservoir. Avant de

louvrir à nouveau, repérer la fuite et la réparer.

Introduction

Ce manuel couvre lutilisation des modèles de bras

articulé SB-60 à moteur à combustion interne. On veillera

à le garder sur la machine en tout temps.

Vérification préliminaire de

sécurité et dutilisation

Lire dabord attentivement toutes les règles de sécurité,

les étiquettes et le mode demploi, en sassurant de les

comprendre et de sy conformer. Chaque jour avant

dutiliser la machine, exécuter les tâches suivantes :

Effectuer une inspection visuelle complète de la

machine avant de lutiliser. Porter une attention

particulière aux points suivants :

1. Ouvrir les panneaux, et vérifier que les composants

des circuits hydrauliques/les tuyaux ne présentent

pas de fuites ni de dommages. Vérifier quaucun

composant/filage électrique ne présente de dommages ni de connexions ayant du jeu.

2. Vérifier à fond le châssis, les essieux, les moyeux,

les jantes et la timonerie de direction pour sassurer

quils ne présentent pas de dommages, de

déformations, de peinture gondolée, de pièces de

fixation ayant du jeu ou qui manquent, ni de

soudures fissurées.

3. Vérifier si les pneus sont endommagés, perforés ou

mal gonflés (si lengin est muni de véritables

pneumatiques); la pression de gonflage doit être de

5,5 bars (80 lb/po

2

).

4. Contrôler tous les tuyaux pour vérifier sils fuient/

contrôler les câbles et les tuyaux pour sassurer

quils ne sont pas usés.

5. Vérifier à fond le dispositif délévation pour sassurer

quil ne présente pas de dommages, de déformations, de pièces de fixation ayant du jeu ou qui

manquent, ni de soudures fissurées.

6. Vérifier à fond la plate-forme et les garde-corps pour

sassurer quils ne présentent pas de dommages, de

déformations, de pièces de fixation ayant du jeu ou

qui manquent, ni de soudures fissurées. Sassurer

que le rail coulissant fonctionne librement.

7. La plate-forme étant abaissée complètement,

vérifier le niveau dhuile hydraulique.

8. Vérifier le niveau délectrolyte de la batterie. (Voir

« Entretien de la batterie », à la page 19.)

9. Vérifier le niveau de carburant; faire lappoint si

nécessaire. (Voir « Faire le plein », à la page 19.)

10. Vérifier le niveau dhuile moteur.

11. Vérifier le filtre à air. Remplacer si nécessaire.

NE JAMAIS ôter le bouchon dun radiateur chaud.

Le liquide de refroidissement chaud peut causer

de graves brûlures.

12.

Sassurer que le radiateur est froid, et vérifier le

niveau de liquide de refroidissement. Faire lappoint si

nécessaire. Vérifier si le radiateur et les durites ne

sont pas endommagés.

ESSAI DE FONCTIONNEMENT

DES ÉLÉMENTS

Nota : Se reporter aux figures 2 à 5 pour obtenir les

emplacements du pupitre de commande sur le châssis et

sur la plate-forme.

1. Avant deffectuer les essais suivants, vérifier dabord

que laire qui entoure la machine ne présente pas de

dangers tels que des obstacles en surplomb, des trous,

des dénivellations et des débris.

2. Tourner linterrupteur à clé du boîtier de commande à la

position de châssis (« CHASSIS »), puis tirer les

interrupteurs darrêt durgence au tableau de commande monté sur le châssis ainsi quau tableau de

commande monté sur la plate-forme.

3. Retirer le boulon de blocage. Voir figure 1.

4. Enfoncer le bouton de démarrage du moteur pour

lancer le moteur; relâcher le bouton de démarrage

lorsque le moteur a démarré. Si le moteur est froid :

appuyer sur le bouton de préchauffage et le maintenir

enfoncé pendant six (6) secondes avant de démarrer,

dans le cas des modèles à moteur diesel.

5. Enfoncer le bouton darrêt durgence du châssis; le

moteur devrait sarrêter. Répéter lessai avec le bouton

darrêt durgence de la plate-forme. Ramener les deux

boutons darrêt durgence à la position « ON », puis

démarrer le moteur.

6.

Actionner chaque interrupteur de fonction pour élever/

abaisser, déployer/rentrer, faire pivoter à gauche/à droite,

chaque section du dispositif délévation, et observer le

fonctionnement de la machine. Toutes les fonctions

devraient effectuer le cycle complet en douceur.

7. Tourner linterrupteur à clé du châssis à la position de

plate-forme (« PLATFORM »).

8. Monter sur la plate-forme, et fixer le dispositif anti-chute

approuvé au point de fixation désigné de la plate-forme.

(Si exigé par la législation du pays.) Ne fixer quun seul

dispositif antichute par point de fixation.

9. Tout en engageant le dispositif denclenchement solidaire à main, déplacer le levier de direction en avant,

puis en arrière. Noter si les fonctions proportionnelles se

déroulent en douceur et si les freins sappliquent

rapidement une fois la commande relâchée.

10. Tout en engageant le dispositif denclenchement

solidaire à main, actionner le bouton de commande de

direction vers la gauche et vers la droite. Noter si les

roues directrices braquent correctement.

Figure 1 : Boulon de blocage

Page 14

14

11. Tout en enfonçant linterrupteur à pédale, faire

fonctionner les commandes du bras articulé à flèche.

Noter si le bras articulé à flèche fonctionne en

douceur et si les commandes délévation et

dabaissement du bras articulé à flèche, de rotation du

revolver et de rallonge/retrait de la flèche fonctionnent

de façon proportionnelle à la course du levier. Noter si

la plate-forme se maintient de niveau lorsque le bras

articulé à flèche est élevé.

12. Le bras articulé à flèche étant élevé de cinq (5)

degrés ou plus au-dessus de la ligne dhorizon,

manoeuvrer le levier de direction. Sassurer que la

vitesse davance nest pas supérieure à 0,30 m (1 pi)

à la seconde. Abaisser la flèche en position

escamotée.

13. Appuyer sur le bouton de la sirène dappel. Noter si le

timbre retentit.

NOTA : Le dispositif denclenchement solidaire à

main ne contrôle que les fonctions de

déplacement/direction

NOTA : Linterrupteur denclenchement solidaire à

pédale ne contrôle que les fonctions du bras

articulé à flèche.

NE PAS utiliser la machine si elle est endommagée

ou en mauvais état de fonctionnement. Apposer une

étiquette volante sur la machine et la retirer du

service jusquà ce quelle ait été réparée.

Figure 4 : Emplacement des commandes

sur le châssis

1. Manomètre à huile

2. Indicateur de température de liquide de refroidissement

3. Horomètre

4. Bouton darrêt durgence

5. Interrupteur à clé

6. Bouton de démarrage du moteur

7. Bougie de préchauffage (diesel seulement)

8. Alimentation auxiliaire pour abaissement

durgence seulement

9. Mise en service de fonction

10. Commande du bras articulé à flèche

11. Commande de la rallonge de flèche

12. Commande du revolver

13. Commande du bras en porte-à-faux

14. Rotation du garde-corps de la plate-forme

15. Commande du positionnement horizontal du garde-corps

16. Coupe-circuit

17. Génératrice (facultative)

18. Bouton davertisseur sonore

19. Bouton darrêt durgence

20. Témoin lumineux dinclinaison

21. Témoin lumineux de basse pression dhuile

22. Sélecteur de couple/vitesse

23. Sélecteur de combustible (essence seul.)/

bougie de préchauffage (diesel seul.)

24. Alimentation aux. pour abaissement durgence seul.

25. Commande du bras articulé à flèche/du revolver

26. Commande de la rotation de la flèche

27. Commande du niveau du garde-corps de la plate-forme

28. Commande du bras en porte-à-faux

29. Commande du niveau du garde-corps de la plate-forme

30. Levier de direction/denclenchement solidaire

31. Phares (facultatifs)

32. Interrupteur d'allumage du moteur

33. Interrupteur d'enclenchement solidaire à pédale

Commandes et indicateurs

4

7

1

2

8

9

10

11

12

13

14

15

5

6

3

16

Figure 3 : Emplacement des commandes

sur la plate-forme

Figure 2 : Emplacement des commandes

sur la plate-forme

32

33

Figure 5 : Emplacement des commandes

sur la plate-forme

18

19

20

21

24

23

2217

31

30

2827

26

25

29

35

Arranque

Desde los controles inferiores

1. Poner el interruptor de llave en la posición chasis.

2. Presionar el botón de arranque para encender el

motor. Soltar cuando arranca.

3. Motores diesel: cuando el motor está frío, presione y

mantenga presionado el botón de la bujía

incandescente durante 6 segundos antes del

arranque.

Desde los controles de la plataforma

1. Poner el interruptor de llave en la posición chasis.

2. Girar completamente el interruptor giratorio de la

plataforma en el sentido de las agujas del reloj para

arrancar el motor. Soltar cuando arranca.

3. Motores diesel: cuando el motor está frío, presione y

mantenga presionado el botón de la bujía

incandescente durante 6 segundos antes del

arranque.

Conducción

Con la pluma baja

1. Poner el interruptor del chasis en plataforma

(platform) y tire hacia afuera el interruptor de parada

de emergencia del chasis.

2. Montar la plataforma, cerrar el riel de deslizamiento.

Asegurarse de que el riel de deslizamiento esté

cerrado de modo seguro. ¡Está prohibido mantener el

riel de deslizamiento abierto con la plataforma

elevada! (ej: amarrar el riel de deslizamiento)

3. Colocar el sujetador aprobado en el punto de anclaje

indicado en la plataforma. Colocar un solo sujetador

en cada punto. (Si es requerido por la legislación

nacional)

4. Encender el motor.

5. Verificar que la zona y el espacio aéreo de la

plataforma de trabajo estén libres de obstrucciones,

hoyos, desniveles, personas en el recorrido y que la

superficie sea capaz de soportar la carga de las

ruedas.

6. Colocar el interruptor del enganche y mover la

palanca de conducción hacia adelante para avanzar y

hacia atrás para retroceder.

Nota: Cuando se rota la pluma hacia el frente del

chasis (ruedas de dirección hacia atrás) el sentido

del desplazamiento y la dirección se invertirán. Mirar

las flechas de colores en el panel de control cerca de

la palanca de conducción y en el chasis. Cuando se

mueva la palanca de conducción las flechas

indicarán el sentido de desplazamiento.

Operación

Antes de usar la plataforma de trabajo verificar lo

siguiente:

Que se ha completado la inspección pre-operatoria y

de seguridad y cualquier problema ha sido

corregido.

Se realizó la inspección de la función del sistema.

Que el operador ha sido entrenado en la operación

total de la máquina.

Que el área de trabajo está libre de obstrucciones,

hoyos, desniveles o personas en el recorrido de la

unidad.

Que la superficie puede soportar la carga de las

ruedas.

Ver la ubicación de los controles en figuras 2 a 5.

Parada de emergencia

En una emergencia, presionar el botón de parada de

emergencia para detener todas las funciones, cualquiera

sea el momento de la operación.

Bocina

Cualquiera sea el momento de la operación, si es

necesario dar una advertencia sonora, presionar el botón

de la bocina de servicio.

NOTA: Siempre usar un sujetador contra caídas

autorizado colocado en el punto de anclaje de la

plataforma al conducir o elevar la máquina. (Si es

requerido por la legislación nacional) (ver figura 6).

Colocar solo un sujetador en cada punto de anclaje.

Figura 6: Punto de anclaje típico del

sujetador contra caídas

Page 15

34

11. Al liberar el interruptor del pedal , opere los controles

de la pluma. Observe que la pluma opere suavemente

y que las funciones de elevación y descenso de la

pluma, la rotación de la torre y las funciones de

extensión y de contracción de la pluma operen

proporcionalmente en conjunto con el movimiento de

la palanca.

Observar que la plataforma se mantenga

nivelada al elevar la pluma.

12. Con la pluma elevada a cinco grados sobre el

horizonte o más, accionar la palanca de

conducción.La velocidad de conducción debe estar

limitada a una marcha lenta (0,30 m [1 pie] por

segundo). Descender la pluma superior a posición

encogida.

13.

Presionar el botón de la bocina; debe ser audible.

NOTA: El enganche manual controla las funciones de

desplazamiento/dirección solamente.

NOTA: El mecanismo de enganche del interruptor del

pedal controla las funciones de la pluma

solamente.

NO usar una máquina dañada o que no funcione

bien. Identificar la unidad y sacarla de servicio

hasta que sea reparada.

Figura 4: Controles del chasis

1. Indicador de presión de aceite

2. Indicador de temperatura del agua

3. Contador de horas

4. Parada de emergencia

5. Interruptor de llave

6. Arranque del motor

7. Bujía incandescente (diesel solamente)

8. Energía auxiliar para descenso de emergencia

solamente

9. Facilitador de función

10. Control de la pluma

11. Control de extensi/on de la pluma

12. Control de la torre

13. Control del brazo

14. Rotación de la jaula

15. Control del nivel de la jaula

16. Quebradora de circuito

17. Generador (opcional)

18. Botón de la bocina

19. Parada de emergencia

20. Indicador de advertencia de la función de inclinación

21. Indicador de bajo nivel de aceite

22. Selector de torsión/velocidad

23. Selector de combustible (Sólo gasolina)/

bujía incandescente (sólo Diesel)

24. Energía auxiliar para descenso de emergencia

solamente

25. Control de la torre/pluma

26. Control de extensi/on de la pluma

27. Control del rotación de la jaula

28. Control del brazo

29. Control del nivel de la jaula

30. Enganche/palanca de control de desplazamiento

31. Luces (opcional)

32. Interruptor de arranque del motor

33. Interruptor del mecanismo de enganche del pedal

Controles e indicadores

4

7

1

2

8

9

10

11

12

13

14

15

5

6

3

16

Figura 3: Controles de la plataforma

Figura 2: Controles de la plataforma

32

33

Figura 5: Controles de la plataforma

18

19

20

21

24

23

2217

31

30

2827

26

25

29

15

Démarrage du moteur

À partir du tableau de commande

monté sur le châssis

1. Tourner linterrupteur à clé à la position châssis

(« CHASSIS »).

2. Appuyer sur le bouton de démarrage pour lancer le

moteur. Relâcher le bouton lorsque le moteur démarre.

3.

Moteurs diesel : si le moteur est froid, appuyer sur le

bouton de préchauffage et le maintenir enfoncé

pendant six (6) secondes avant de démarrer.

À partir du tableau de commande

monté sur la plate-forme

1. Tourner linterrupteur à clé à la position plate-forme

(« PLATFORM »).

2. Tourner linterrupteur rotatif

de la plate-forme

complètement dans le sens horaire pour lancer le

moteur. Relâcher linterrupteur à clé lorsque le moteur

démarre.

3.

Moteurs diesel : si le moteur est froid, appuyer sur le

bouton de préchauffage et le maintenir enfoncé

pendant six (6) secondes avant de démarrer.

Conduite

Bras articulé à flèche baissé

1. Tourner linterrupteur à clé du tableau de commande

monté sur le châssis à la position plate-forme

(« PLATFORM »), tirer linterrupteur darrêt durgence

du châssis.

2. Monter sur la plate-forme et fermer le rail coulissant.

Sassurer que le rail coulissant est fermé de façon

sécuritaire. Il est défendu de garder le rail coulissant

en position ouverte (p. ex. en lattachant) lorsque la

plate-forme est levée!

3. Fixer le dispositif antichute approuvé au point de

fixation désigné de la plate-forme. Nattacher quun

seul dispositif antichute par point dattache. (Si exigé

par la législation du pays.)

4.

Démarrer le moteur.

5. Vérifier que laire de travail est exempte de tout

obstacle, de tout trou/dénivellation et de toute

personne qui se trouverait sur la voie de passage, et

que la surface peut supporter la charge des roues.

6. Engager linterrupteur denclenchement solidaire, et

amener le levier de direction en avant pour se diriger

en marche avant, ou vers larrière, pour se diriger en

marche arrière.

Nota : Lorsque le bras articulé à flèche a pivoté à

lavant du châssis (roues directrices à larrière), les

sens de marche se trouvent inversés par rapport à la

position du levier de direction. Noter les flèches à

code de couleur qui se trouvent sur le tableau de

commande, près du levier de direction, ainsi que sur

le châssis : elles indiquent le sens de la marche

commandé par le levier de direction.

Mode demploi

Avant dutiliser la plate-forme élévatrice, sassurer :

Que la vérification préliminaire de sécurité et

dutilisation a été effectuée, et que tout écart noté

est corrigé.

Que lessai de fonctionnement des éléments a bien

été réalisé.

Que lopérateur a reçu une formation pratique qui lui

a permis de bien connaître lutilisation de la

machine.

Que laire de travail est exempte de tout obstacle, de

tout trou/dénivellation et de toute personne qui se

trouverait sur la voie de passage.

Que la surface peut supporter la charge des roues.

Voir les emplacements des commandes aux figures 2 à 5.

Arrêt durgence

En tout temps pendant lutilisation, lorsquune situation

durgence se présente, appuyer sur le bouton darrêt

durgence pour arrêter toutes les fonctions.

Sirène dappel

En tout temps pendant lutilisation, appuyer sur le bouton

de sirène dappel pour faire retentir une alarme sonore, si

nécessaire.

NOTA: Toujours porter un dispositif antichute

approuvé, fixé correctement au point de fixation

désigné de la plate-forme, pendant la conduite ou

lélévation de la machine. (Si exigé par la législation

du pays.) (voir figure 6).

Ne fixer quun seul dispositif antichute par point de

fixation.

Figure 6 : Point de fixation type

pour dispositif antichute

Page 16

16

Bras articulé à flèche élevé

Les déplacements bras articulé à flèche élevé se

limitent exclusivement aux surfaces horizontales

solides.

En conduite bras articulé à flèche élevé, la machine

navance quen marche extra-lente (0,30 m [1 pi] à la

seconde).

Commande de direction

1. Tout en engageant le dispositif denclenchement

solidaire à main, déplacer le bouton de commande de

direction (qui se trouve sur le dessus du levier de

commande) vers la gauche pour virer à gauche, ou

vers la droite pour virer à droite.

Nota : La direction nest pas de type à centrage

automatique : pour ramener les roues tout droit,

actionner le bouton de commande de direction.

POSITIONNEMENT DE LA

PLATE-FORME

Une certaine planification préalable est nécessaire pour

positionner la plate-forme le plus près possible de laire

de travail. Il faut dabord étudier le chantier afin de

trouver un endroit convenable pour garer la machine; ce

doit être un lieu à surface horizontale solide, situé le

plus près possible de laire de travail. Tenir compte de

tous les obstacles qui peuvent se trouver au sol ou en

hauteur, et les éviter.

Avant de commander une fonction quelconque, toujours

vérifier pour sassurer quil ny a aucun obstacle ni

conducteur électrique autour et au-dessus de la

machine.

Commandes multifonctions

Le modèle UpRight SB-60 utilise des commandes

multifonctions.

Cela signifie que deux fonctions

quelconques peuvent être utilisées simultanément, à plein

régime.