Page 1

Operator Manual

Manuel de l’utilisateur

Betriebsanleitung

Manual del Operador

LX Series

LX Series

SERIAL NO. 1001 TO CURRENT

WARNING

All personnel shall carefully read, understand and follow all safety rules, and operating

instructions before performing maintenance on or operating any UpRight aerial work platform.

Refer to page 2 for the english language version of this Operator Manual.

AVERTISSEMENT

Tout le personnel doit lire attentivement et respecter toutes les consignes de

sécurité avant d’entretenir ou d’utiliser une plate-forme de travail aérien UpRight.

Réferez-vous à la page 11 pour la version en français de ce manuel de l’utilisateur.

WARNUNG

Alle Bediener müssen die Sicherheitsregelungen und die Betriebsanweisungen

gründlich durchlesen, verstehen und befolgen, bevor sie Wartungsarbeiten an

irgendeiner UpRight Scheren-Hubbühne vornehmen oder selbige benutzen.

Siehe Seite 21 zwecks der deutschsprachigen Ausgabe dieser Betriebsanleitung.

ADVERTENCIA

Todo el personal debe leer atentamente, entender y respetar todas las reglas de seguridad

y las instrucciones de operación antes de efectuar trabajos de mantenimiento o

manejar cualquier plataforma aérea de trabajo UpRight.

Referirse a la página 31 para la versión en español de este manual del operador.

1

Page 2

English Language Section

SAFETY RULES

NEVER

within ten feet of power lines.

THIS MACHINE IS NOT

INSULATED

NEVER

drop-offs, bumps and debris.

NEVER

torqued.

SECURE

KEEP

NEVER

NEVER

LOOK

DISTRIBUTE

NEVER

cover.)

NEVER

INSPECT

control cable, loose wire connections and wheel bolts.

NEVER

NEVER

NEVER

explosive hydrogen gas.

AFTER USE

key.

NEVER

without the manufacturer's consent.

operate the machine

.

operate the machine without first surveying the work area for surface hazards such as holes,

operate the machine if all guardrails are not properly in place and secured with all fasteners properly

and lock gate after mounting platform.

all body parts clear of outriggers when extending or retracting.

use ladders or scaffolding on the platform.

attach overhanging loads or increase platform size.

up, down and around for overhead obstructions and electrical conductors.

all loads evenly on the platform. See the back cover for maximum platform load.

use damaged equipment. (Contact UpRight for instructions. See toll-free phone number on back

change operating or safety systems.

the machine thoroughly for cracked welds, loose hardware, hydraulic leaks, damaged

climb down elevating assembly with the platform elevated.

perform service on machine while platform is elevated without blocking elevating assembly.

recharge battery near sparks or open flame; batteries that are being charged emit highly

secure the work platform against unauthorized use by turning key switch off and removing

replace any component or part with anything other than original UpRight replacement parts

NEVER

or drive the machine while

elevated unless the machine is

on firm level surface.

elevate the platform

NEVER

guardrail or midrail.

sit, stand or climb on

2

Page 3

Introduction

This manual covers all models of the LX Series

Work Platforms. This manual must be stored on

the machine at all times.

Note: When using LP gas, use clean, water free

liquid petroleum gas, preferably from a bulk

storage tank. Follow the instructions located on

the power module tray for filling the tank.

Pre-Operation and Safety

Inspection

Carefully read, understand and follow all safety

rules, labels, and operating instructions, then

perform the following steps each day before

use.

1. Open modules and inspect for damage, oil

leaks or missing parts.

2. Check the hydraulic oil level sight gauge on

the hydraulic tank with the platform fully

lowered. Add ISO #46 hydraulic oil if necessary.

3. Check that fluid level in the battery is correct

(See Battery Maintenance, Page 7).

4. Check the engine oil level and fuel level.

5. Check that all guardrails are in place, the slide

out deck extension is secured with the pin and

all fasteners are properly tightened.

6. Check tire pressure; 50 psi (3.4 bar).

7. Carefully inspect the entire work platform for

damage such as cracked welds or structural

members, loose or missing parts, oil leaks,

damaged cables or hoses, loose connections

and tire damage.

8. Move machine, if necessary, to unobstructed

area to allow for full elevation.

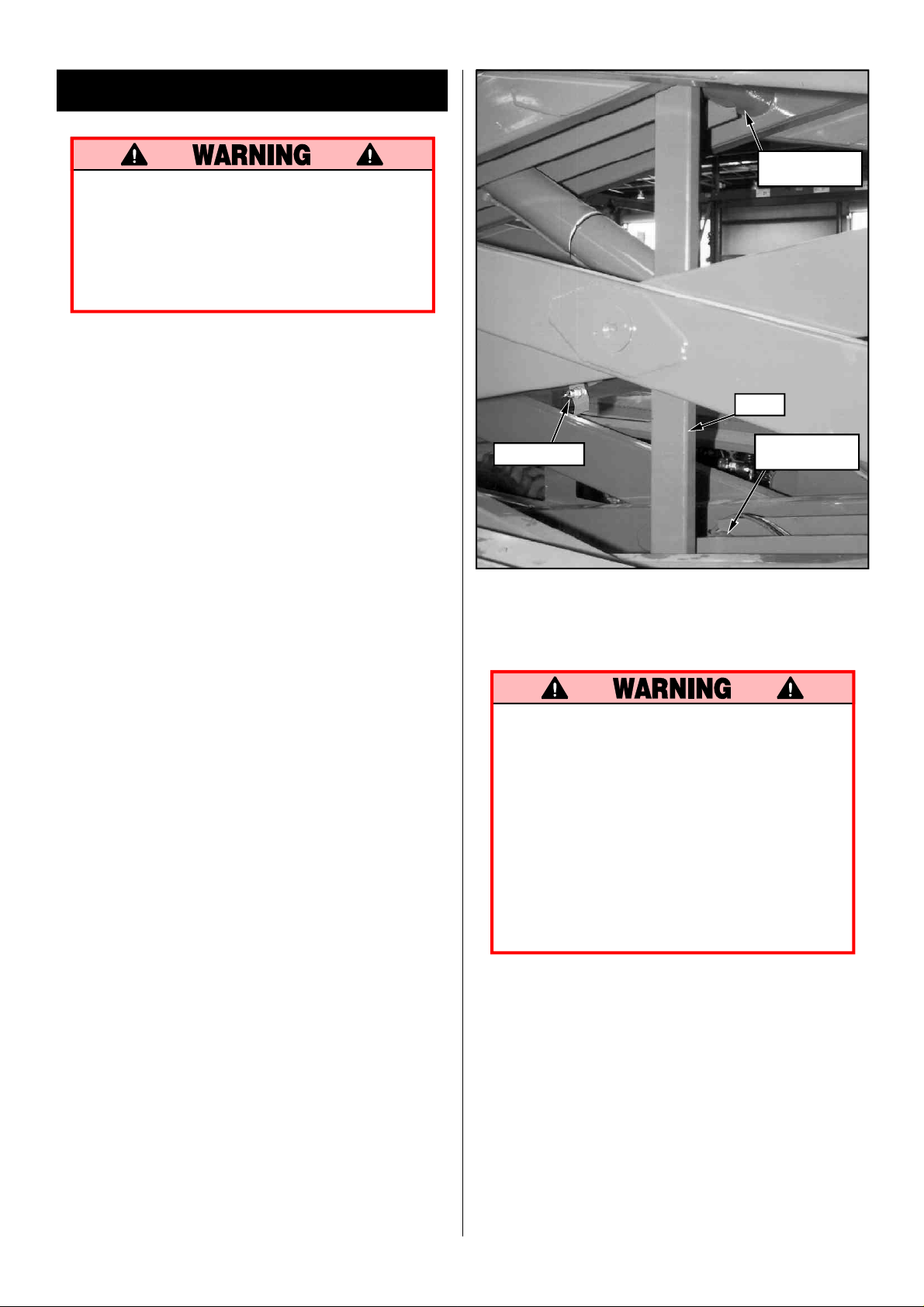

9. Place chassis and platform emergency stop

switches in the ON position (Figure 1 & 2) by

pulling the buttons out.

10.Verify platform/chassis switch is on PLAT-

FORM (Figure 1).

11.Dual Fuel Models: set dual fuel selector to

desired position. Set to the center position to

purge the system when switching fuels. If the

machine is to be operated on propane, open

the supply valve on the tank.

If you smell propane, close the supply

valve on the tank immediately until you

have located and corrected the leak.

12.While the engine is cool check the engine

coolant level.

DO NOT check coolant when engine or

radiator is hot, hot coolant can cause

severe burns.

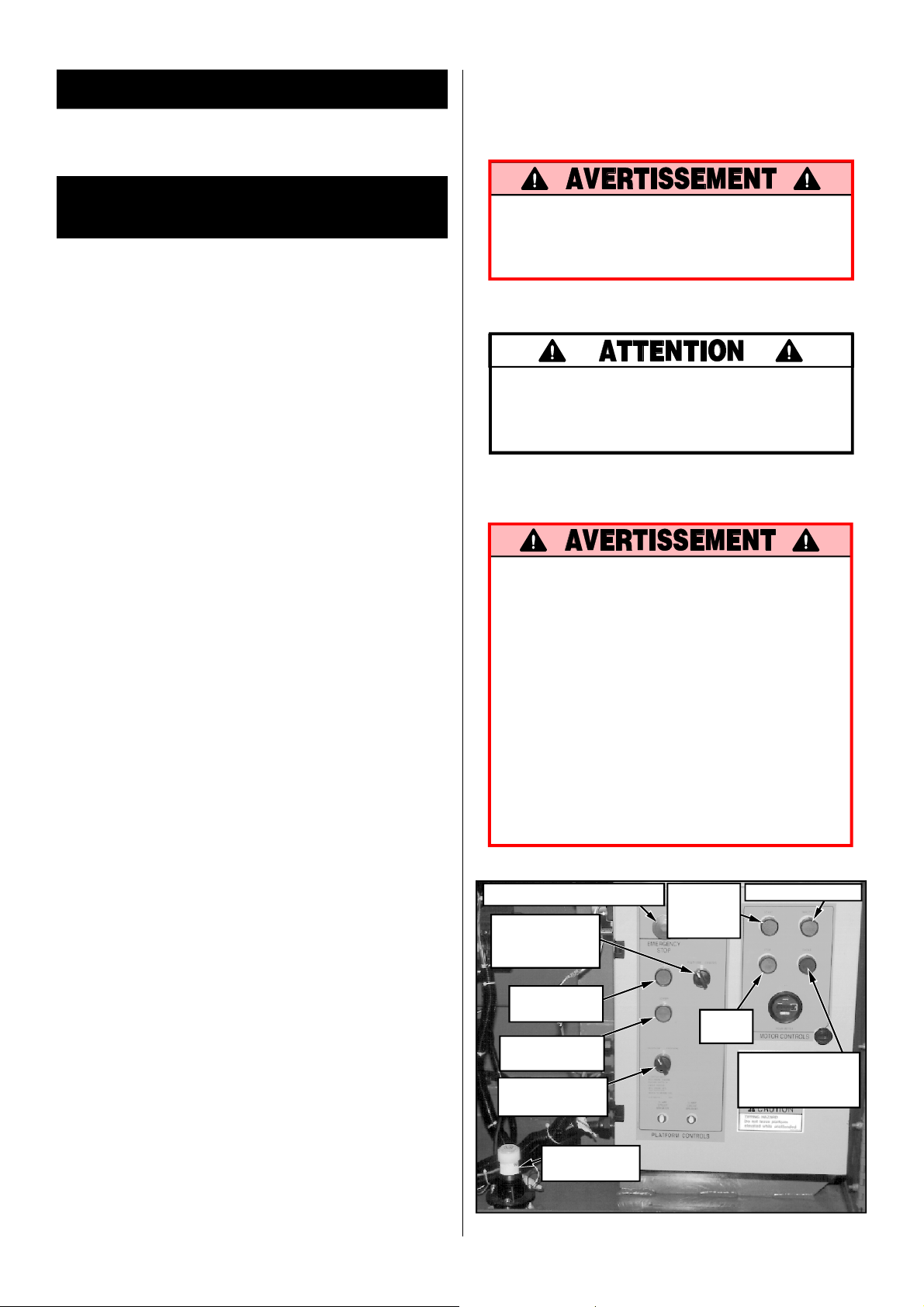

System Function Inspection

STAND CLEAR of the work platform

while performing the following checks.

Before operating the work platform survey

the work area for surface hazards such as

holes, drop-offs, bumps and debris.

Check in ALL directions, including above

the work platform, for obstructions and

electrical conductors.

Protect control console cable from possible

damage while performing checks.

Emergency Stop Switch

Platform/Chassis

Switch

Raise Button

Lower Button

Fuel Selector Switch

Start

Button

Stop

Button

Throttle

Button

Choke/Glow

Plug Button

Tilt Sensor

Figure 1: Chassis, Left Side

3

Page 4

1. Unhook controller from front guardrail. Firmly

grasp controller hanger in such a manner that

the interlock lever can be depressed, while

performing the following checks from the

ground.

2. Turn controller key switch clockwise to ON.

Turn fully clockwise to start engine, releasing

the key once the engine starts.

Note: If the engine is cold, on dual fuel models,

depress and hold the choke button in while

starting the engine. On diesel models, depress

and hold the glow plug button for 6 seconds to

engage the glow plugs.

3. Position drive/lift switch to DRIVE position.

4. With the speed range switch first in HIGH

TORQUE and then again in HIGH SPEED

depress the interlock lever and slowly push the

control lever to FORWARD then REVERSE

positions to check for speed and directional

control. The farther you push or pull the

control lever the faster the machine will travel.

5. Push steering switch RIGHT then LEFT to

check for steering control.

6. Depress the interlock switch on the control

handle and position each outrigger switch to

the EXTEND position to deploy all four outriggers. Check the drive enable indicator light, it

should be off.

7. Fully retract all outriggers and check the drive

enable indicator, it should be on.

8. Rehook controller on front guardrail.

9. Turn the platform/chassis switch to CHAS-

SIS .

10.Push the throttle button in. Push chassis raise

button to elevate platform while pushing the

Steering Switch

Outrigger

Switches

Interlock Lever

Control Lever

Speed Range

Switch

tilt sensor (Figure 1) off of level. The platform

should only partially elevate and the tilt alarm

should sound. If the platform continues to

elevate and/or there is no alarm STOP and

remove the machine from service until it is

repaired.

11.Release the tilt sensor and fully elevate platform.

12.Visually inspect the elevating assembly, lift

cylinder, cables and hoses for damage or

erratic operation. Check for missing or loose

parts.

13.Lower the platform partially by pushing in on

the chassis lower switch, and check operation

of the audible lowering alarm.

14.Open the chassis emergency lowering valve

(Figure 3) to check for proper operation by

pulling and holding the knob out. Once the

platform is fully lowered, close the valve by

releasing the knob.

15.Turn the platform/chassis switch to PLAT-

FORM.

16.Mount the platform making sure the gate is

latched.

17.Position drive/lift switch to LIFT.

18.Depress the interlock lever and slowly push

the control lever to RAISE to raise the platform, fully actuate the control lever to check

proportional lift speed. Elevate the platform to

12 feet (3.7 m).

19.Depress the interlock switch on the control

handle and position any outrigger switch to

the EXTEND position, outriggers should be

disabled. If an outrigger extends during this

test STOP. Lower the platform and remove

the machine from service until it is repaired.

20.Slowly pull control lever to DOWN position to

lower platform. Check that lowering alarm

sounds.

21.Turn controller key switch to OFF, push the

emergency stop button and dismount the

platform.

22.Close and secure module covers.

Emergency

Stop Switch

Choke / Glow Plug Button

Lift/Drive

Switch

Figure 2: Controller

Drive Enable

Indicator

Key Switch

4

Page 5

Operation

Before operating work platform, ensure that the

pre-operation and safety inspection has been

completed, any deficiencies have been corrected

and the operator has been thoroughly trained on

this machine.

Travel With Platform Lowered

1. Verify chassis emergency stop switch is in the

ON position (turn counterclockwise), the drive

enable indicator is on, and that the platform/

chassis switch is on PLATFORM.

Note: Steering is not self-centering. Wheels

must be returned to the straight ahead position

by operating the steering switch.

Leveling the Platform (Outrigger

equipped machines only)

Never attempt to use the outriggers on soft

ground. The surface beneath them must be

suitable to support the weight of the machine.

Note: If the drive enable indicator is off, verify

that the platform is fully lowered and (if so

equipped) the outriggers are all fully retracted.

2. After mounting platform, close and latch gate.

Check that guardrails are in position and properly assembled with fasteners properly torqued.

3. Check that route is clear of persons, obstructions, holes and drop-offs and is capable of

supporting the wheel loads.

4. Check clearances above, below and to the

sides of the platform.

5. Pull controller emergency stop button out to

ON position.

6. Turn controller key switch fully clockwise to start

engine, releasing the key once the engine starts.

Note: If the engine is cold, on dual fuel models,

depress and hold the choke button in while

starting the engine. On diesel models, depress

and hold the glow plug button for 6 seconds to

engage the glow plugs.

7. Set the drive/lift speed range switch to HIGH

TORQUE.

8. Grasp the control lever so the interlock lever is

depressed (releasing the interlock lever cuts

power to controller). Slowly push or pull the

control lever to FORWARD or REVERSE to

travel in the desired direction. The farther you

push or pull the control lever from center the

faster the machine will travel.

9. While moving, push the drive/lift speed range

switch to HIGH SPEED for travel on level

surfaces or to HIGH TORQUE for climbing

grades or traveling in confined areas.

1. Look around the machine, make sure that

there is nothing obstructing the outriggers, and

that the surface beneath them is suitable to

support the weight of the machine.

2. Depress the interlock lever on the control

handle and operate the outrigger switches to

extend each outrigger until it is making firm

contact with the ground.

3. While observing the bubble level on the front

guardrail (fig. 3), extend the outrigger opposite

the position of the bubble until the platform is

level. For example: if the bubble is to the front

and left in the orbit, extend the rear right

outrigger. Continue to adjust until the bubble is

centered in the small circle indicating that the

platform is level.

4. Outriggers must be in firm contact with the

supporting surface, observe each outrigger to

verify.

To retract the outriggers:

1. Fully lower the platform.

2. Position each outrigger switch to RETRACT.

Observe the outriggers to ensure that they are

fully retracted. The drive enable indicator

light will not come on until all four outriggers

are fully retracted.

Steering

1. Push the steering switch RIGHT or LEFT to

turn the wheels. Observe the tires while maneuvering to insure proper direction.

Figure 3: Platform Orbit Level

5

Page 6

Raising and Lowering the Platform

1. Position the drive/lift switch to LIFT. Position

the outrigger on/off switch to OFF.

2. While holding the control lever so the interlock

lever is depressed, push the control lever

slowly to UP to raise the platform. Pushing the

control lever farther increases the lift speed.

3. When the work task is completed, position the

drive/lift switch to LIFT and lower the platform by pulling back on the control lever until

the platform is fully lowered.

Travel with Work Platform Elevated

Travel with platform elevated ONLY on firm and

level surfaces with outriggers fully retracted.

Note: The work platform will travel at reduced

speed when in the elevated position, and then

only when the front axle is parallel with the

rear axle, and (if so equipped) all four

outriggers are fully retracted. Drive is disabled

above 8m (26ft).

1. Check that the route is clear of persons, obstructions, holes and drop-offs, is level and

capable of supporting the wheel loads.

2. Check clearances above, below and to the

sides of platform.

3. Position the drive/lift switch to the DRIVE

position.

4. Push the control lever to FORWARD or RE-

VERSE for the desired direction of travel.

If the machine quits driving and the tilt alarm

sounds, immediately lower the platform and

move the machine to a level location before reelevating the platform.

2. Once the platform is fully lowered, release the

knob to close the valve.

Switching Fuels (Dual Fuel Only)

1. With engine running turn the fuel selector

switch (Figure 1) to the center position.

2. After the engine has quit running select the

appropriate fuel supply.

3. Restart the engine.

After Use Each Day

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably

under cover, secure against vandals, children

or unauthorized operation.

3. Turn the key switch to OFF and remove the

key to prevent unauthorized operation.

Parking Brake Release (Figure 5)

Perform the following only when the machine

will not operate under its own power and it is

necessary to move the machine or when winching

onto a trailer to transport.

1. Close the needle valve by turning the knob

clockwise.

2. Pump the brake release pump until the parking brakes release and the wheels can be

turned.

3. The machine will now roll when pushed or

pulled.

4. Be sure to open the needle valve and verify

that the parking brakes have engaged before

the machine is operated.

Emergency Lowering

The emergency lowering valve is located at the

front of the machine at the base of the scissor

assembly, (Figure 4).

1. Open the emergency lowering valve by pulling

on the knob and holding it.

Figure 4: Emergency Lowering Valve Knob

Never operate work platform with the

parking brakes released. Serious injury or

damage could result.

Pump

Needle

Valve

Figure 5: Parking Brake Release Pump

6

Page 7

Fold Down Guardrails

This procedure is only for passing through doorways. Guardrails must be returned to proper

position before using the machine.

Fold Down Procedure (Figure 6)

4. Raise front guardrail, aligning holes and install

bolts, washers and nuts. Tighten securely.

5. Hang controller from front guardrail.

6. Before operating work platform check that all

fasteners are in place and properly torqued.

Note: When performing the following procedures retain all fasteners.

1. Place controller on platform.

2. Starting at the front of the platform, remove

nuts, bolts and washers from the top of the

front guardrail. Fold the front guardrail down

onto the platform.

3. Close and latch the gate.

4. Remove nuts, bolts and washers from the top

of the rear guardrail. Fold the rear guardrail

down onto the platform being careful to keep

gate latched at all times.

5. Remove nuts, bolts and washers from the top

of the side guardrails and from the slideout

deck midrail. Lift up and fold one side guardrail in so it rests on the deck. Repeat with other

side guardrails.

Erection Procedure

1. Raise side guardrails making sure each is

pushed down to secure the guardrail in the

vertical position.

2. Install bolts, washers and nuts between the

side guardrails, tighten securely.

3. Raise rear guardrail assembly, aligning holes

and install bolts, washers and nuts. Tighten

securely.

Before operating machine, guardrails must

be securely fastened in their proper position.

Transporting Work Platform

By Crane

1. Secure straps to chassis tie down/lifting lugs

only (Figure 7).

By Truck

1. Maneuver the work platform into transport

position and chock wheels.

2. Secure the work platform to the transport

vehicle with chains or straps of adequate load

capacity attached to the chassis tie down/lifting

lugs (Figure 7).

Overtightening of chains or straps through

tie down lugs may result in damage to

work platform.

Figure 6: Fold Down Guardrails

Figure 7: Transporting Work Platform

7

Page 8

Maintenance

Never perform service on the work platform in the elevating assembly area while

platform is elevated without first blocking

the elevating assembly.

DO NOT stand in elevating assembly area

while deploying or storing brace.

Blocking Elevating Assembly (Figure 8)

Installation

Upper Scissor

Center Pivot

1. Park the work platform on firm level ground.

2. Verify platform emergency stop switch is ON.

3. Turn platform/chassis switch to CHASSIS.

4. Start the engine using the chassis controls.

5. Push the throttle button in, the button will stay

in and the engine speed will increase. Using the

raise button, elevate platform until the scissors

brace can be rotated to the vertical position.

6. From the left side of the machine, disengage

the locking pin securing the brace. Rotate the

scissor brace counterclockwise until it is vertical

and between the two scissor center pivots.

7. Push lower button and gradually lower platform until brace is supporting the platform.

8. Disengage throttle by pushing throttle button

in again, the button will retract and the engine

will come to idle speed.

Removal

1. Using chassis controls, gradually raise platform

until the scissors brace clears the two scissor

center pivots.

2. Rotate scissors brace clockwise until the locking

pin engages.

3. Push lower button to completely lower platform.

4. Make sure the throttle button is disengaged and

platform/chassis switch is on PLATFORM.

Brace

Locking Pin

Figure 8: Blocking Elevating Assembly

Lower Scissor

Center Pivot

Battery Maintenance

Hazard of explosive gas mixture. Keep

sparks, flame and smoking materials away

from batteries.

Always wear safety glasses when working

with batteries.

Battery fluid is highly corrosive. Rinse

away any spilled fluid thoroughly with

clean water.

Always replace batteries with UpRight

batteries or manufacturer approved replacements weighing 62 lbs. each.

Check battery fluid level daily, especially if work

platform is being used in a warm, dry climate.

If electrolyte level is lower than 3/8 in. (10 mm)

above plates add distilled water only. DO NOT

use tap water with high mineral content it will

shorten battery life.

Keep terminals and tops of batteries clean.

Refer to the Service Manual to extend battery life

and for complete service instructions.

8

Page 9

Routine Service

Use the following table as a guide for routine

maintenance. Inspection and maintenance shall

be performed by personnel who are trained and

familiar with mechanical and electrical procedures. Refer to the Service Manual for complete

service instructions.

Please copy this page and use the Routine Service

Table as a checklist when inspecting a machine for

service.

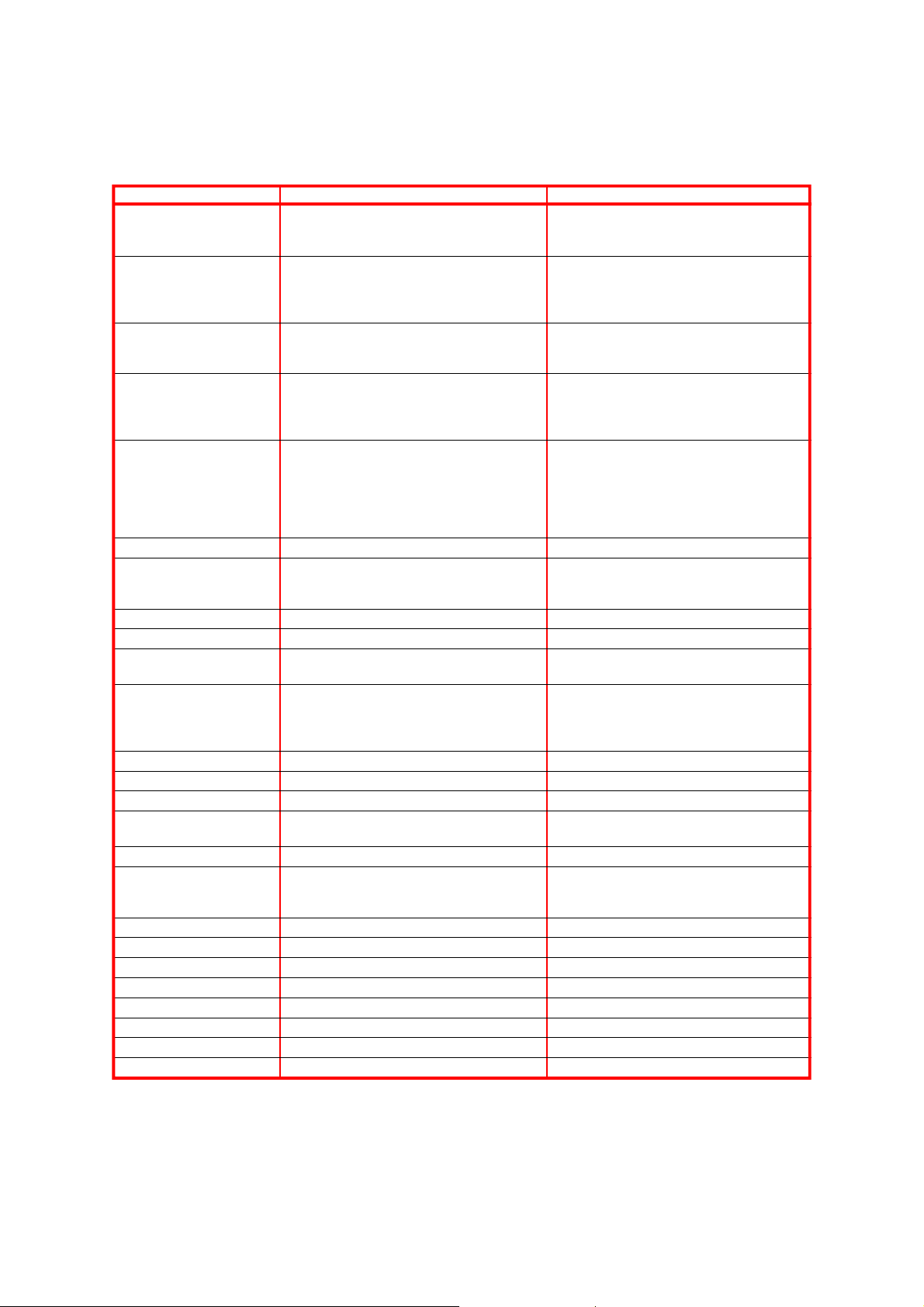

Routine Service Table

Routine Service Table Key

Interval

Daily=each shift (every day) or every eight hours

30d=every month (30 days) or every 50 hours

3m=every 3 months or 125 hours

6m=every 6 months or 250 hours

1y=every year or 500 hours

2y=every 2 years or 1000 hours

Y=Yes/Acceptable

N=No/Not Acceptable

R=Repaired/Acceptable

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Engine Oil Check level and condition Daily

Engine Fuel Check fuel level Daily

System Check for leaks Daily

Engine Check electrolyte level Daily

Battery Check specific gravity 30

System Clean exterior 6

Engine Check coolant level (with engine cold) Daily

Coolant Replace coolant 3

Hydraulic Check oil level Daily

Oil Change filter 6

Hydraulic Check for leaks Daily

System Check hose connections 30

Emergency Open the emergency lowering Daily

Hydraulic valve and check for

System serviceability

Controller Check switch operation Daily

Control Check the exterior of the cable Daily

Cable for pinching, binding or wear

Platform Check fasteners for proper torque Daily

Deck and Check welds for cracks Daily

Rails Check condition of deck Daily

Tires Check for damage Daily

Hydraulic Wipe clean 30

Pump Check for leaks at mating surfaces 30

Drive Motors

Steering Check hardware & fittings 6

System for proper torque

Check for leaks Daily

Change oil & filter (Dual Fuel) 30

Change oil & filter (Diesel) 100

Replace fuel filter 6

Check air cleaner Daily

Check battery cable condition Daily

Clean terminals 6

Drain and replace oil 2

Check hoses for exterior wear 30

Check air pressure (50psi) Daily

Check lug nuts (torque to 90 ft. lbs. [123 Nm]) 30

Check for hose fitting leaks Daily

Check mounting bolts for proper torque 30

Check for operation and leaks Daily

Oil all pivot points 30

Check steering cylinder for leaks & 30

mounting bolts for proper torque

D

HOURS

M

D

M

M

M

M

Y

D

D

D

D

D

D

M

D

D

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Elevating Inspect for structural cracks Daily

Assembly Check pivot points for wear 30

Check pivot pin mounting bolts 30

for proper torque

Check scissor arms for bending 6

Grease scissor pins 30

Chassis Check hoses for pinch or Daily

rubbing points

Check component mounting 6

for proper torque

Check welds for cracks Daily

Lift Check the cylinder rod for wear 30

Cylinder Check pivot pin mounting bolts 30

for proper torque

Check seals for leaks 30

Inspect pivot points for wear 30

Check fittings for proper torque 30

Axle Check the cylinder rod for wear 30

Cylinder Check mounting pin pivot bolts 30

for proper torque

Check seals for leaks 30

Inspect pivot points for wear 30

Check fittings for proper torque 30

Entire Check for and repair Daily

Unit collision damage

Check fasteners for proper torque 3

Check for corrosion-remove 6

and repaint

Lubricate 30

Labels Check for peeling, missing, or unreadable Daily

labels & replace

D

D

M

D

M

D

D

D

D

D

D

D

D

D

D

M

M

D

Service Report

Date: _______________

Owner: ___________________________________

Model No:_____________ Serial No: __________

Serviced By: _______________________________

Service Interval:____________________________

9

Page 10

Specifications*

ITEM

Platform Size (Inside Toeboards)

Standard

w/ Extension

Max. Platform Capacity

Standard

w/ Extension

on Extension

Max. No. of occupants

Standard

on Extension

Height

Working Height

Max. Platform Height

Min. Platform Height

Dimensions

Weight, Standard

w/ Extension

Overall Width

Overall Height

Overall Length, Standard

Driveable Height

Surface Speed

Platform Lowered

Platform Raised

System Voltage

Hydraulic Tank Capacity

Maximum Hydraulic System

Pressure

Hydraulic Fluid

Normal Use (>32 °F [0 °C])

Low Temp. Use

(-10 to 32 °F [-23 to 0 °C])

Lift System

Lift Speed

Platform Leveling

Power Source

Drive Control

Control System

Horizontal Drive

Tires

Parking Brakes

Turning Radius

Maximum Gradeability

Wheel Base

Guardrails

Toeboard

(inside)

143.38 in. x 70 in. [3.64 m x 1.78 m]

179.38 in. x 68 in. [4.56 m x 1.73 m]

2000 lbs. [907kg]

2000 lbs. [907 kg]

500 lbs. [227 kg]

8 people

2 people

37 ft. [11.28 m]

31 ft. [9.45 m]

56.25 in. [1.43 m]

2WD: 9,220 lbs. [4,182 kg] 4WD: 9,580 lbs. [4,345 kg]

2WD: 9,650 lbs. [4,377 kg] 4WD: 10,010 lbs. [4,540 kg]

90 in. [2.29 m]

99.75 in. [2.53 m]

160.5 in. [4.08 m]

31 ft. [9.45 m]

0 to 3.1 mph [0 to 5.0 km/h]

0 to 0.3 mph [0 to .48 km/h]

12 Volt DC

28.3 Gallons [107.13 l]

3000 psi [206.8 bar]

ISO #46

5W-20 Motor Oil

One Single Stage Lift Cylinder

Raise, 40 sec./Lower, 60 sec.

8.5o (12in. [.3m]) Side/Side, 6o (12in. [.3m]) Fore/Aft

Diesel or Gasoline 20 HP Kubota, 3 Cylinder,

Water Cooled Engine

Proportional

Joystick Controller with Interlock Lever and

Thumb Rocker Steering; Speed & Function

Selector Switches and Emergency Stop Button

2WD: 2 Wheel, Hyd. Motors 4WD: 4 Wheel, Hyd. Motors

10-16.5 NHS 8 Ply, 50psi [3.4 bar]

Two, Spring Applied, Hydraulic Release, Multiple Disc

48 in. [1.22 m]

2WD: 30% [16.7º] 4WD: 35% [19.3º]

115.75 in. [2.94 m]

43.5 in. [1.1 m] high, Fold Down with Gate

6 in. [152 mm] High

* Specifications subject to change without notice.

Refer to Service Manual for complete parts and service information.

LX31

143.38 in. x 70 in. [3.64 m x 1.78 m]

179.38 in. x 68 in. [4.56 m x 1.73 m]

1,500 lbs. [680kg]

1,500 lbs. [680kg]

500 lbs. [227 kg]

6 people

2 people

47 ft. [14.33 m]

40 ft. 6 in. [12.34 m]

65.25 in. [1.66 m]

2WD: 10,560 lbs. [4,790 kg] 4WD: 10,920 lbs. [4,953 kg]

2WD: 10,990 lbs. [4,985 kg] 4WD: 11,350 lbs. [5,148 kg]

90 in. [2.29 m]

108.75 in. [2.76 m]

160.5 in. [4.08 m]

40 ft. 6 in. [12.34 m]

0 to 3.1 mph [0 to 5.0 km/h]

0 to 0.3 mph [0 to .48 km/h]

12 Volt DC

28.3 Gallons [107.13 l]

3000 psi [206.8 bar]

ISO #46

5W-20 Motor Oil

One Single Stage Lift Cylinder

Raise, 45 sec./Lower, 65 sec.

8.5o (12in. [.3m]) Side/Side, 6o (12in. [.3m]) Fore/Aft

Diesel or Gasoline 20 HP Kubota, 3 Cylinder,

Water Cooled Engine

Proportional

Joystick Controller with Interlock Lever and

Thumb Rocker Steering; Speed & Function

Selector Switches and Emergency Stop Button

2WD: 2 Wheel, Hyd. Motors 4WD: 4 Wheel, Hyd. Motors

10-16.5 NHS 8 Ply, 50psi [3.4 bar]

Two, Spring Applied, Hydraulic Release, Multiple Disc

48 in. [1.22 m]

2WD: 30% [16.7º] 4WD: 35% [19.3º]

115.75 in. [2.94 m]

43.5 in. [1.1 m] high, Fold Down with Gate

6 in. [152 mm] High

LX41

10

Page 11

Version française

RÈGLES DE SÉCURITÉ

NE JAMAIS

moins de 3 mètres de lignes

d’énergie électrique.

MACHINE N’EST PAS ISOLÉE.

NE JAMAIS

dangers, tels que des trous, des dénivellations, des bosses et des débris.

NE JAMAIS

moyen de toutes les pièces de fixation serrées au bon couple.

REFERMER

NE PAS

NE JAMAIS

NE JAMAIS

REGARDER

ou autre obstacle aux alentours.

RÉPARTIR

voir la fiche technique à la page couverture arrière.

NE JAMAIS

composant le numéro sans frais inscrit à la page couverture arrière.)

NE JAMAIS

VÉRIFIER

commande sont en bon état, que toutes les pièces de fixation sont bien serrées, y compris les boulons de fixation des

roues, que le circuit hydraulique ne présente aucune fuite et que tous les fils électriques sont bien branchés.

NE JAMAI

NE JAMAIS

avoir d’abord bloqué ce dernier au moyen d’un étai.

NE JAMAIS

rechargement, les batteries dégagent de l’hydrogène gazeux hautement explosif.

APRÈS AVOIR UTILISÉ

la retirer afin de prévenir l’utilisation de la plate-forme par toute personne non autorisée.

NE JAMAIS

sans le consentement du fabricant.

utiliser la machine à

CETTE

utiliser la machine sans avoir d’abord vérifié si la surface de la zone de travail ne présente pas de

utiliser la machine sans que tous les garde-corps soient bien montés en place et fixés solidement au

et verrouiller le portillon après être monté sur la plate-forme.

s’approcher des stabilisateurs au moment d’élever ou d’abaisser la plate-forme.

dresser d’échelle ni d’échafaudage sur la plate-forme.

agrandir la surface de la plate-forme, ni y fixer une charge qui la déborde.

en haut, en bas et tout autour de la machine afin de s’assurer qu’il n’y a aucun conducteur électrique

également toutes les charges sur la plate-forme. Pour connaître la capacité maximale de cette dernière,

utiliser une machine endommagée. (Si la machine est endommagée, communiquer avec UpRight en

modifier les éléments assurant le fonctionnement de la machine, ni les dispositifs de sécurité.

la machine de fond en comble en s’assurant que toutes les soudures et tous les câbles électriques ou de

S descendre par le dispositif d’élévation lorsque la plate-forme est élevée.

effectuer des travaux d’entretien dans la zone du dispositif d’élévation d’une plate-forme élevée sans

recharger la batterie d’accumulateurs près d’une flamme ou d’une source d’étincelles : au moment du

la plate-forme élévatrice, tourner la clé de l’interrupteur à la position d’arrêt « OFF », puis

remplacer quelque élément ou quelque pièce que ce soit par autre chose qu’une pièce d’origine UpRight,

NE JAMAIS

que la machine ne soit sur une surface

horizontale solide et, lorsque la plateforme est élevée, NE déplacer la

machine QUE sur une telle surface.

élever la plate-forme sans

NE JAMAIS

se mettre debout sur les rampes du

garde-corps de la plate-forme.

s’asseoir, monter ou

11

Page 12

Introduction

Ce manuel se rapporte à tous les modèles de plateformes élévatrices de travail appartenant à la série LX.

On veillera à le garder sur la machine en tout temps.

Nota : En cas d’alimentation au gaz de pétrole

liquéfié (G.P.L.), utiliser un G.P.L. propre et sans eau

qui, préférablement, provient d’un grand réservoir.

Pour faire le plein, voir les consignes fournies sur le

support du bloc de puissance.

Vérification préliminaire de

sécurité

Lire d’abord attentivement toutes les règles de

sécurité, les étiquettes et le mode d’emploi, en

s’assurant de les comprendre et de s’y conformer.

Chaque jour avant d’utiliser la machine, exécuter les

tâches suivantes :

1. Ouvrir les modules, puis vérifier que les éléments

sont en bon état, qu’il n’y a aucune fuite d’huile et

qu’aucune pièce ne manque.

2. La plate-forme baissée, vérifier le niveau d’huile

hydraulique à l’aide de la jauge à fenêtre du

réservoir. Ajouter au besoin de l’huile ISO no 46.

3. Vérifier le niveau d’électrolyte de la batterie. (Voir

« Entretien de la batterie », à la page 17.)

4. Vérifier le niveau d’huile du moteur et le niveau de

carburant.

5. S’assurer que les garde-corps sont en place, la plateforme coulissante de rallonge est goupillée et les

pièces de fixation sont toutes bien serrées.

6. Vérifier si la pression des pneus est de 3,4 bars

(50 lb/po2).

7. Vérifier la plate-forme élévatrice de fond en comble

en s’assurant que les soudures et toutes les pièces

— comme les éléments porteurs, les câbles

électriques, les tuyaux flexibles et les pneus — sont

en bon état, que toutes les pièces sont fixées

solidement en place et qu’aucune d’elles ne

manque, qu’il n’y a aucune fuite d’huile et que tous

les fils électriques sont bien branchés.

8. Si besoin est, déplacer la machine à un endroit

dépourvu d’obstacles afin de pouvoir élever la

plate-forme à la hauteur maximale.

9. Aux tableaux de commandes du châssis et de la

plate-forme, tirer sur le bouton d’arrêt d’urgence

pour le régler à la position « ON » (figures 1 et 2).

10. Régler le sélecteur de châssis/plate-forme à la

position « PLATFORM » (figure 1).

11. Modèle à deux combustibles : régler le sélecteur de

combustible à la position désirée. Au moment de

changer de combustible, purger le circuit

d’alimentation en réglant le sélecteur à la position

centrale. Pour alimenter la machine au propane,

ouvrir le robinet d’alimentation du réservoir.

Si une odeur de propane est perceptible, fermer

immédiatement le robinet du réservoir. Avant

de l’ouvrir à nouveau, repérer la fuite et la

réparer.

12. Pendant que le moteur est froid, vérifier le niveau

du liquide de refroidissement.

NE PAS vérifier le niveau du liquide de

refroidissement lorsque le moteur ou le

radiateur sont chauds. Une fois chaud, ce

liquide peut causer de graves brûlures.

Essai de fonctionnement des

éléments

S’ÉLOIGNER de la plate-forme de travail au

moment d’effectuer les essais décrits ci-après.

Avant d’utiliser la plate-forme de travail,

vérifier si la surface de la zone de travail ne

présente pas de dangers à l’utilisateur, tels que

des trous, des dénivellations, des bosses et des

débris.

REGARDER en haut, en bas et tout autour de

la machine afin de s’assurer qu’il n’y a aucun

conducteur électrique ou autre obstacle aux

alentours.

En effectuant les essais, protéger le câble du

pupitre de commande contre tout dommage

éventuel.

Bouton d’arrêt d’urgence

Sélecteur de

châssis/plate-

forme

Bouton

d’élévation

Bouton

d’abaissement

Sélecteur de

combustible

Bouton

de

démarrage

Bouton

d’arrêt

Bouton des gaz

Bouton

d’étrangleur/de

préchauffage

12

Détecteur

d’inclinaison

Figure 1 : Châssis, côté gauche

Page 13

1. Décrocher le boîtier de commande du garde-corps

avant. Saisir fermement le crochet de suspension

du boîtier de commande, de façon à pouvoir

actionner le levier d’enclenchement solidaire au

moment d’effectuer les essais au sol décrits ci-après.

2. Régler l’interrupteur à clé du boîtier de commande

à la position « ON ». Pour ce faire, tourner la clé à

fond dans le sens des aiguilles d’une montre pour

lancer le moteur, et la relâcher dès que le moteur se

met en marche.

Nota : Marches à suivre lorsque le moteur est froid.

Dans le cas d’un modèle à deux combustibles, rentrer

le bouton d’étrangleur et le maintenir durant le

démarrage. Dans le cas d’un modèle diesel, rentrer le

bouton de préchauffage et le maintenir durant six

secondes pour enclencher les bougies de

préchauffage.

3. Régler le sélecteur de mode de fonctionnement à la

position de déplacement « DRIVE ».

4. Le sélecteur de plage de vitesses réglé d’abord à la

position de couple élevé « HIGH TORQUE », puis

à la position de grande vitesse « HIGH SPEED »,

vérifier les commandes de vitesse et de direction.

Pour ce faire, appuyer sur le levier d’enclenchement

solidaire et déplacer progressivement le levier de

commande à la position de marche avant

« FORWARD », puis à la position de marche arrière

« REVERSE ». La vitesse de déplacement de la

machine augmentera à mesure que le levier de

commande s’éloigne de la position neutre.

5. Vérifier la commande de direction en déplaçant le

bouton de commande de direction d’abord vers la

DROITE, puis vers la GAUCHE.

6. Appuyer sur le levier d’enclenchement solidaire du

levier de commande, puis régler chacun des

boutons de commande de stabilisateur à la position

de déploiement « EXTEND », afin de déployer tous

les quatre stabilisateurs. S’assurer que le témoin du

mode de déplacement s’éteint.

7. Rentrer à fond tous les stabilisateurs et s’assurer

que le témoin du mode de déplacement s’allume.

8. Raccrocher le boîtier de commande au garde-corps

avant.

9. Régler le sélecteur de châssis/plate-forme à la

position « CHASSIS ».

Bouton de commande

de direction

Bouton de

commande de

stabilisateur

Levier d'enclenchement

solidaire

Levier de

commande

Sélecteur de

plage de vitesses

Témoin du mode

de déplacement

10. Rentrer le bouton des gaz. Appuyer sur le bouton

d’élévation situé sur le tableau de commande du

châssis, puis déplacer le détecteur d’inclinaison

(figure 1) de sa position de nivelage en le poussant.

La plate-forme devrait arrêter avant d’atteindre sa

hauteur maximale, et l’alarme du détecteur

d’inclinaison devrait sonner. Si la plate-forme

continue à s’élever ou que l’alarme ne sonne pas,

ARRÊTER la machine et la faire réparer avant de

l’utiliser à nouveau.

11. Relâcher le détecteur d’inclinaison, et élever la

plate-forme à la hauteur maximale.

12. Vérifier le bon état et le bon fonctionnement des

éléments suivants : le dispositif d’élévation, le

vérin, les câbles et les tuyaux flexibles. S’assurer

que les pièces sont fixées solidement en place et

qu’aucune d’elles ne manque.

13. Abaisser partiellement la plate-forme au moyen du

bouton d’abaissement situé sur le tableau de

commande du châssis, puis vérifier le

fonctionnement de l’alarme sonore d’abaissement.

14. Au châssis, vérifier le bon fonctionnement de la

soupape d’abaissement de secours (figure 4). Pour

ce faire, l’ouvrir en tirant sur sa tirette de

commande et la maintenir dans la position ouverte.

Une fois la plate-forme abaissée à fond, fermer la

soupape en relâchant la tirette.

15. Régler le sélecteur de châssis/plate-forme à la

position « PLATFORM ».

16. Monter sur la plate-forme et fermer le portillon au

loquet.

17. Régler le sélecteur de mode de fonctionnement à la

position d’élévation « LIFT ».

18. Appuyer sur le levier d’enclenchement solidaire et

déplacer progressivement le levier de commande à

la position d’élévation « RAISE » pour élever la

plate-forme. Ce faisant, actionner le levier sur toute

sa course afin de vérifier la vitesse d’élévation

proportionnelle. Élever la plate-forme jusqu’à une

hauteur de 3,7 mètres (12 pi).

19. Appuyer sur le levier d’enclenchement solidaire du

levier de commande, puis régler un des boutons de

commande de stabilisateur à la position de sortie

« EXTEND » : aucun stabilisateur ne doit se

déployer. Si l’un des stabilisateurs se déploie,

INTERROMPRE l’essai et abaisser la plate-forme.

Faire réparer la machine avant de l’utiliser à

nouveau.

20. Déplacer progressivement le levier de commande à

la position d’abaissement « DOWN », pour abaisser

la plate-forme. S’assurer que l’alarme

d’abaissement sonne.

21. Tourner la clé du boîtier de commande à la position

« OFF », rentrer le bouton d’arrêt d’urgence et

descendre de la plate-forme.

22. Fermer les modules en s’assurant que les couvercles

sont fixés solidement en place.

Bouton d'arret

d'urgence

Bouton d'étrangleur/de préchauffage

Figure 2 : Boîtier de commande

Selecteur de

mode de

fonctionnement

Interrupteur

à clé

13

Page 14

Mode d’emploi

Avant d’utiliser la plate-forme élévatrice de travail,

effectuer la vérification préliminaire de sécurité et

réparer toute défectuosité relevée. S’assurer également

que l’opérateur a reçu une formation pratique qui lui a

permis de bien connaître l’utilisation de la machine.

GAUCHE, selon le cas. En manoeuvrant, observer

le mouvement des pneus afin d’assurer qu’ils

s’orientent dans la bonne direction.

Nota : La direction n’est pas de type à centrage

automatique. Pour ramener les roues à la position

droite, il faut donc actionner le bouton de commande

de direction.

Déplacement — plate-forme abaissée

1. Au tableau de commande du châssis, régler le

bouton d’arrêt d’urgence à la position « ON » en le

tournant dans le sens inverse des aiguilles d’une

montre. S’assurer que le témoin du mode de

déplacement s’allume, et régler le sélecteur de

châssis/plate-forme à la position « PLATFORM ».

Nota : Si le témoin du mode de déplacement ne

s’allume pas, s’assurer que la plate-forme est abaissée

à fond et que tous les stabilisateurs sont

complètement rentrés (dans le cas d’une machine qui

en est équipée).

2. Monter sur la plate-forme et fermer le portillon au

loquet. S’assurer que les garde-corps sont bien

montés en place et que leurs pièces de fixation sont

toutes bien serrées.

3. Vérifier la voie de passage en s’assurant qu’elle est

libre de personnes, d’obstacles, de trous et de

dénivellations, et qu’elle est capable de supporter

les charges des roues.

4. Vérifier l’espace disponible de chaque côté de la

plate-forme, y compris au-dessus et au-dessous de

celle-ci.

5. Tirer sur le bouton d’urgence d’arrêt pour le régler

à la position « ON ».

6. Au boîtier de commande, tourner la clé à fond dans

le sens des aiguilles d’une montre pour lancer le

moteur, et la relâcher dès que le moteur se met en

marche.

Nota : Marches à suivre lorsque le moteur est froid.

Dans le cas d’un modèle à deux combustibles, rentrer

le bouton d’étrangleur et le maintenir durant le

démarrage. Dans le cas d’un modèle diesel, rentrer le

bouton de préchauffage et le maintenir durant six

secondes pour enclencher les bougies de

préchauffage.

7. Régler le sélecteur de plage de vitesses à la position

de couple élevé « HIGH TORQUE ».

8. Saisir le levier de commande de façon à appuyer

sur le levier d’enclenchement solidaire. (Le fait de

relâcher ce dernier coupe l’alimentation du boîtier

de commande.) Déplacer progressivement le levier

de commande à la position de marche avant

« FORWARD » ou à celle de marche arrière

« REVERSE », selon le cas. La vitesse de

déplacement de la machine augmentera à mesure

que le levier de commande s’éloigne de la position

neutre.

9. Pendant que la machine se déplace, régler le

sélecteur de plage de vitesses à la position de

grande vitesse « HIGH SPEED » pour rouler sur

une surface horizontale, ou à la position de couple

élevé « HIGH TORQUE » pour monter une pente

ou rouler dans un espace restreint.

Nivelage de la plate-forme (machines

équipées de stabilisateurs seulement)

Ne jamais appuyer les stabilisateurs sur un sol

mou. Ces derniers doivent s’appuyer contre

une surface suffisamment solide pour soutenir

le poids de la machine.

1. Regarder autour de la machine pour s’assurer

qu’aucun obstacle ne gênera le déploiement des

stabilisateurs et vérifier si la surface d’appui est

suffisamment solide pour soutenir le poids de la

machine.

2. Appuyer sur le levier d’enclenchement solidaire du

levier de commande, puis régler les boutons de

commande de stabilisateur de façon à déployer tous

les stabilisateurs jusqu’à ce que chacun s’appuie

fermement contre le sol.

3. Tout en observant le niveau à bulle situé sur le

garde-corps avant (figure 3), déployer davantage le

stabilisateur situé du côté opposé à la position de la

bulle, jusqu’à ce que la plate-forme soit à

l’horizontale. Par exemple : si la bulle se trouve à

l’avant et vers la gauche du globe, déployer le

stabilisateur arrière droit. Continuer à effectuer de

tels réglages jusqu’à ce que la bulle soit bien centrée

dans le petit repère circulaire, ce qui indique que la

plate-forme est de niveau.

4. S’assurer que chaque stabilisateur s’appuie

fermement contre le sol.

Escamotage des stabilisateurs

1. Abaisser la plate-forme à fond.

2. Régler chacun des boutons de commande de

stabilisateur à la position d’escamotage

« RETRACT ». S’assurer que tous les stabilisateurs

sont complètement escamotés. Le témoin du mode

de déplacement ne s’allumera pas tant que tous les

quatre stabilisateurs ne sont pas complètement

escamotés.

Commande de direction

1. Pour orienter les roues, déplacer le bouton de

commande de direction vers la DROITE ou vers la

Figure 3 : Niveau globulaire de la plate-forme

14

Page 15

Élévation et abaissement de la

plate-forme

1. Régler le sélecteur de mode de fonctionnement à la

position d’élévation « LIFT ». Régler l’interrupteur

du circuit des stabilisateurs à « OFF ».

2. Saisir le levier de commande de façon à appuyer

sur le levier d’enclenchement solidaire, et le

déplacer progressivement à la position d’élévation

« UP » pour faire lever la plate-forme. Pour

augmenter la vitesse d’élévation, éloigner

davantage le levier de commande de la position

neutre.

3. Une fois le travail terminé, régler le sélecteur de

mode de fonctionnement à la position d’élévation

« LIFT » et abaisser la plate-forme en déplaçant le

levier de commande vers soi, jusqu’à ce que la

plate-forme s’abaisse à fond.

Déplacement — plate-forme élevée

Lorsque la plate-forme est élevée, NE déplacer la

machine QUE sur des surfaces horizontales solides et

que si les stabilisateurs sont rentrés à fond.

Nota : La plate-forme élevée, la machine se déplace à

vitesse réduite, et ce seulement à condition que les

essieux avant et arrière soient parallèles et que les

quatre stabilisateurs soient rentrés à fond (dans le cas

d’une machine qui en est équipée). Le mécanisme

assurant le déplacement de la machine ne fonctionne

pas lorsque la plate-forme est élevée à une hauteur

supérieure à huit mètres (26 pieds).

1. Vérifier la voie de passage en s’assurant qu’elle est

libre de personnes, d’obstacles, de trous et de

dénivellations, et qu’elle est capable de supporter

les charges des roues.

2. Vérifier l’espace disponible de chaque côté de la

plate-forme, y compris au-dessus et au-dessous de

celle-ci.

3. Régler le sélecteur de mode de fonctionnement à la

position de déplacement « DRIVE ».

4. Déplacer le levier de commande à la position de

marche avant « FORWARD » ou à celle de marche

arrière « REVERSE », selon le cas.

Si la machine arrête de rouler et que l’alarme du

détecteur d’inclinaison sonne, abaisser

immédiatement la plate-forme et déplacer la machine

sur une surface horizontale avant d’élever à nouveau

la plate-forme.

Abaissement d’urgence

La soupape d’abaissement de secours se trouve à

l’avant de la machine, à la base du support articulé de

la plate-forme (figure 4).

1. Ouvrir la soupape d’abaissement de secours en

tirant sur sa tirette et en maintenant celle-ci dans la

position sortie.

2. Une fois la plate-forme abaissée complètement,

relâcher la tirette pour fermer la soupape.

Changement de combustible (modèles

à deux combustibles seulement)

1. Le moteur en marche, régler le sélecteur de

combustible (figure 1) à la position centrale.

2. Une fois le moteur arrêté, sélectionner le

combustible désiré.

3. Remettre le moteur en marche.

Après utilisation, tous les jours

1. Abaisser à fond la plate-forme.

2. Stationner la machine sur une surface plane,

préférablement à l’abri des vandales, des enfants et

de toute personne qui pourrait éventuellement s’en

servir sans autorisation.

3. Tourner la clé de l’interrupteur à la position d’arrêt

« OFF », puis la retirer afin de prévenir l’utilisation

de la plate-forme par toute personne non autorisée.

Desserrage des freins de

stationnement (figure 5)

On ne doit exécuter cette marche à suivre que lorsqu’il

faut déplacer la machine et qu’elle ne réagit pas aux

commandes, ou pour la charger sur une remorque à

l’aide d’un treuil.

1. Fermer le robinet à pointeau en tournant sa poignée

dans le sens des aiguilles d’une montre.

2. Actionner la pompe de desserrage du frein, jusqu’à

ce que les freins de stationnement se desserrent et

que les roues puissent tourner.

3. La machine peut maintenant être déplacée en la

poussant ou en la tirant.

4. Avant d’utiliser à nouveau la machine, ouvrir le

robinet à pointeau et s’assurer que les freins de

stationnement sont bloqués.

Pompe

Robinet à

pointeau

Figure 4 : Tirette de la soupape d’abaissement de secours Figure 5 : Pompe de desserrage des freins

de stationnement

15

Page 16

Ne jamais utiliser la plate-forme à moins que

les freins de stationnement ne soient bloqués.

Sinon l’on risque de provoquer des dommages

ou des blessures graves.

Garde-corps rabattables

On ne doit exécuter cette marche à suivre que pour

faire passer la machine par une entrée de porte. Avant

d’utiliser à nouveau la machine, il faut remettre les

garde-corps dans leur position normale.

Mise à plat des garde-corps (figure 6)

Nota : Récupérer toutes les pièces de fixation afin de

pouvoir les utiliser à nouveau.

1. Placer le boîtier de commande sur la plate-forme.

2. Depuis l’avant de la plate-forme, déposer les

écrous, les boulons et les rondelles situés à

l’extrémité supérieure du garde-corps avant, puis

abaisser ce dernier sur la plate-forme.

3. Fermer le portillon au loquet.

4. Déposer les écrous, les boulons et les rondelles

situés à l’extrémité supérieure du garde-corps

arrière, puis abaisser ce dernier sur la plate-forme.

Veiller à ce que le portillon reste verrouillé.

5. Déposer les écrous, les boulons et les rondelles

situés à l’extrémité supérieure des garde-corps

latéraux, ainsi que ceux de la rampe intermédiaire

de la plate-forme coulissante de rallonge. Soulever

un des garde-corps et le replier sur la plate-forme.

Replier les autres de la même façon.

Redressement

1. Lever les garde-corps latéraux dans leur position

verticale et les fixer solidement en place en les

poussant à fond.

2. Poser les boulons, les rondelles et les écrous reliant

les garde-corps latéraux, et bien les serrer.

3. Lever le garde-corps arrière et aligner les trous de

fixation. Poser les boulons, les rondelles et les

écrous, puis bien les serrer.

4. Lever le garde-corps avant et aligner les trous de

fixation. Poser les boulons, les rondelles et les

écrous, puis bien les serrer.

5. Accrocher le boîtier de commande au garde-corps

avant.

6. Avant d’utiliser la plate-forme élévatrice, s’assurer

que toutes les pièces de fixation sont en place et

qu’elles sont bien serrées.

Avant d’utiliser à nouveau la machine,

s’assurer que les garde-corps sont bel et bien en

place et qu’ils sont fixés solidement.

Transport de la plate-forme

élévatrice

Déplacement par grue

1. Attacher les sangles au châssis, seulement aux

brides de levage/arrimage (figure 7).

Par camion

1. Mettre la plate-forme élévatrice en position de

transport en la manoeuvrant, puis caler les roues.

2. Arrimer la plate-forme élévatrice sur le véhicule de

transport au moyen de chaînes ou de sangles assez

fortes pour la retenir. Attacher ces dernières aux

brides de levage/arrimage du châssis (figure 7).

Le fait de trop serrer les chaînes ou les sangles

peut endommager la plate-forme élévatrice.

Figure 6 : Garde-corps rabattables

16

Vue de l’arrière

Brides de levage/arrimage

Figure 7 : Transport de la plate-forme élévatrice

Vue de l’avant

Page 17

Entretien

NE JAMAIS effectuer des travaux d’entretien

dans la zone du dispositif d’élévation d’une

plate-forme élevée sans avoir d’abord bloqué

ce dernier au moyen d’un étai.

NE PAS se tenir dans la zone du dispositif

d’élévation au moment de déployer ou de

ranger l’étai.

Étayage du dispositif d’élévation

(figure 8)

Axe d’articulation

central supérieur

du support

articulé

Déploiement de l'étai

1. Stationner la plate-forme élévatrice sur une surface

horizontale solide.

2. Régler le bouton d’arrêt d’urgence de la plate-forme

à la position « ON ».

3. Régler le sélecteur de châssis/plate-forme à la

position « CHASSIS ».

4. Mettre le moteur en marche à partir du tableau de

commandes du châssis.

5. Rentrer le bouton des gaz : celui-ci restera dans la

position rentrée et la vitesse de rotation du moteur

augmentera. Au moyen du bouton d’élévation,

élever suffisamment la plate-forme pour pouvoir

mettre l’étai du support articulé dans la position

verticale en le faisant pivoter.

6. Depuis le côté gauche de la machine, libérer la

goupille de blocage retenant l’étai. Faire pivoter

l’étai dans le sens inverse des aiguilles d’une

montre, jusqu’à ce qu’il se trouve dans la position

verticale, entre les deux axes de rotation centraux

du support articulé.

7. Appuyer sur le bouton d’abaissement et abaisser

progressivement la plate-forme, jusqu’à ce que le

poids de la plate-forme repose sur l’étai.

8. Réduire les gaz en appuyant de nouveau sur le

bouton des gaz : celui-ci sortira et le moteur se

mettra à tourner au ralenti.

Escamotage de l'étai

1. Au moyen des commandes du châssis, élever

progressivement la plate-forme, jusqu’à ce que l’étai

puisse passer entre les deux axes d’articulation

centraux du support articulé.

2. Faire pivoter l’étai dans le sens des aiguilles d’une

montre, jusqu’à ce que la goupille de blocage

s’engage dans le trou qui lui est destiné.

3. Appuyer sur le bouton d’abaissement pour abaisser

à fond la plate-forme.

4. S’assurer que le bouton des gaz est sorti, et régler le

sélecteur de châssis/plate-forme à la position

« PLATFORM ».

Étai

Goupille de

blocage

Figure 8 : Étayage du dispositif d’élévation

Axe d’articulation

central inférieur du

support articulé

Entretien de la batterie

Risque d’émanations gazeuses explosives.

Tenir la batterie à l’écart d’étincelles, de

flammes et de toute source de chaleur extrême.

Ne jamais manipuler la batterie sans porter de

lunettes de sécurité.

L’électrolyte est un liquide très corrosif.

Éliminer toute trace de liquide déversé de la

batterie en rinçant à grande eau claire.

Toujours remplacer la batterie par une batterie

UpRight ou de rechange homologuée par le

fabricant et pesant au moins 28 kg (62 lb).

Vérifier le niveau d’électrolyte tous les jours, surtout

lorsque le temps est sec et chaud.

Si l’électrolyte ne recouvre pas les plaques de batterie

d’au moins 10 mm (3/8 po), ajouter de l’eau distillée

seulement. NE PAS utiliser de l’eau de robinet à haute

teneur en minéraux, sinon la vie utile de la batterie sera

raccourcie.

Garder les bornes et le dessus de la batterie propres.

Le manuel d’entretien contient les marches à suivre

détaillées pour entretenir la batterie et lui assurer une

longue vie utile.

17

Page 18

Entretien courant

Le tableau ci-après sert de guide pour l’entretien

courant. Seules les personnes formées qui

connaissent les opérations mécaniques et électriques

doivent réaliser la vérification de contrôle et

l’entretien de la plate-forme élévatrice. Les consignes

d’entretien se trouvent dans le Manuel d’entretien.

Au moment de vérifier la machine, reproduire cette

page et utiliser le tableau qui s’y trouve comme liste de

vérification.

Tableau d’entretien courant

ÉLÉMENT VÉRIFICATION OU ENTRETIEN À EFFECTUER

Huile Vérifier le niveau et l’état Quot.

moteur Vérifier l’absence de fuites Quot.

Vidanger l’huile et changer de filtre 30j

(modèle à deux combustibles)

Vidanger l’huile et changer de filtre 100 hres

(modèle diesel)

Circuit Vérifier le niveau de carburant Quot.

carburant Vérifier l’absence de fuites Quot.

Remplacer le filtre à carburant 6m

Vérifier le filtre à air Quot.

Batterie Vérifier le niveau d’électrolyte Quot.

d'accuma- Vérifier le poids volumique 30j

lateurs Nettoyer l’extérieur 6m

Vérifier l’état du câble de batterie Quot.

Nettoyer les bornes 6m

Liquide Vérifier le niveau (le moteur froid) Quot.

de refroi- Remplacer le liquide de refroidissement 3m

dissement

Huile Vérifier le niveau Quot.

hydraulique Changer de filtre 6m

Remplacer l’huile hydraulique 2a

Circuit Vérifier l’absence de fuites Quot.

hydraulique Vérifier le raccordement des tuyaux flexibles 30j

Vérifier l’usure extérieure des tuyaux flexibles 30j

Circuit Ouvrir la soupape d’abaissement Quot.

hydraulique de secours et vérifier son bon

de secours fonctionnement

Boîtier de Vérifier le bon fonctionnement des boutons Quot.

commande de commande

Câble de Vérifier l’absence de toute trace de Quot.

commande pincement, de coincement ou d’usure

Plate-forme Vérifier le serrage des pièces de fixation Quot.

de travail et Vérifier le bon état des soudures Quot.

garde-corps Vérifier l’état de la plate-forme de travail Quot.

Pneus Vérifier le bon état Quot.

Vérifier la pression d’air (3,4 bars [50 lb/po2]) Quot.

Vérifier le serrage des écrous (123 N m [90 lbf-pi]) 30j

Pompe Bien essuyer 30j

hydraulique Vérifier l’absence de fuites aux surfaces de contact 30j

Vérifier l’absence de fuites aux raccordements Quot.

Vérifier le serrage des boulons de fixation 30j

Moteurs d'en- Vérifier le bon fonctionnement

traînement et l’absence de fuites Quot.

Commande Vérifier le serrage des pièces de fixation 6m

de direction et des raccords

Graisser tous les points d’articulation 30j

Vérifier le vérin de direction en s’assurant 30j

de l’absence de fuites et du bon serrage des

boulons de fixation

PÉRIODICITÉ

O N R

Légende du tableau

Périodicité

Quot. = chaque quart de travail (quotidiennement)

ou toutes les huit heures

30j = tous les mois (30 jours) ou toutes les

50 heures

3m = tous les 3 mois ou toutes les 125 heures

6m = tous les 6 mois ou toutes les 250 heures

1a = chaque année ou toutes les 500 heures

2a = tous les 2 ans ou toutes les 1 000 heures

O = oui/acceptable

N = non/inacceptable

R = réparé/acceptable

ÉLÉMENT VÉRIFICATION OU ENTRETIEN À EFFECTUER

Dispositif Vérifier l’absence de fissures Quot.

d’élévation Vérifier l’usure des pièces aux points 30j

d’articulation

Vérifier le serrage des boulons de fixation 30j

des axes d’articulation

Vérifier l’absence de toute torsion/tout 6m

gauchissement des bras du support articulé

Graisser les axes d’articulation 30j

Châssis Vérifier l’absence de toute trace de Quot.

pincement ou d’usure par frottement

Vérifier le serrage des pièces de fixation des 6m

éléments constitutifs

Vérifier le bon état des soudures Quot.

Vérin Vérifier l’usure de la tige de vérin 30j

d’élévation Vérifier le serrage des boulons de fixation des 30j

axes d’articulation

Vérifier l’absence de fuites aux joints 30j

Vérifier l’usure des pièces aux points 30j

d’articulation

Vérifier le serrage des raccordements 30j

Vérin Vérifier l’usure de la tige de vérin 30j

d’essieu Vérifier le serrage des boulons de fixation 30j

des axes d’articulation

Vérifier l’absence de fuites aux joints 30j

Vérifier l’usure des pièces aux points 30j

d’articulation

Vérifier le serrage des raccordements 30j

Ensemble Vérifier l’absence de tout signe d’endommage- Quot.

de la ment dû aux chocs; réparer au besoin

machine Vérifier le serrage des pièces de fixation 3m

Vérifier l’absence de toute trace de corrosion; 6m

décaper et peindre au besoin

Lubrifier 30j

Étiquettes Vérifier le bon état et la lisibilité des étiquettes Quot.

en s’assurant qu’aucune ne manque;

remplacer au besoin

PÉRIODICITÉ

Fiche d’entretien

Date :_________________

Propriétaire : __________________________________

No de modèle : _________ No de série : ___________

Nom du technicien :____________________________

Périodicité d’entretien : _________________________

O N R

18

Page 19

ÉLÉMENT

Dimensions de la plateforme

(intérieur de la plinthe

Normales

Avec plate-forme de rallonge

Capacité max. de la plate-forme

Normale

Avec plate-forme de rallonge

De la plate-forme de rallonge

Nombre max. de personnes

Normale

Sur la plate-forme de rallonge

Hauteur

Hauteur de travail

Hauteur max. de la plate-forme

Hauteur min. de la plate-forme

Dimensions

Poids normal

avec plate-forme de rallonge

Largeur hors tout

Hauteur hors tout

Longueur hors tout, normale

Hauteur max. au déplacement

Vitesse de déplacement

Plate-forme baissée

Plate-forme leveé

Tension du circuit électrique

Capacité du réservoir

hydraulique

Pression maximale du circuit

hydraulique

Liquide hydraulique

Utilisation, conditions

normales (>0 oC [32 oF])

Utilisation à basse température

(-23 à 0 oC [-10 à 32 oF])

Dispositif d’élévation

Vitesse d’élévation

Nivelage de la plate-forme

Moteur

Mécanisme d’entraînement

Système de commande

Traction

Pneus

Freins de stationnement

Rayon de virage

Pente gravissable max.

Empattement

Garde-corps

Plinthe

(intérieur)

)

Fiche technique*

LX31 LX41

3,64 m x 1,78 m (143,38 po x 70 po)

4,56 m x 1,73 m (179,38 po x 68 po)

907 kg (2 000 lb)

907 kg (2 000 lb)

227 kg (500 lb)

8 personnes

2 personnes

11,28 m (37 pi)

9,45 m (31 pi)

1,43 m (56,25 po)

Traction 2 roues : 4 182 kg (9 220 lb);

4 roues : 4 345 kg (9 580 lb)

Traction 2 roues : 4 377 kg (9 650 lb);

4 roues : 4 540 kg (10 010 lb)

2,29 m (90 po)

2,53 m (99,75 po)

4,08 m (160,5 po)

9,45 m (31 pi)

0 à 5,0 km/h (0 à 3,1 mi/h)

0 à 0,48 km/h (0 à 0,3 mi/h)

12 V c.c.

107,13 L (28,3 gal.)

206,8 bars (3 000 lb/po2)

ISO no 46

Huile moteur 5W-20

Un vérin d’élévation à un étage

Élévation : 40 s; abaissement : 60 s

Axe transversal : 8,5o (0,3 m [12 po]); axe

longitudinal : 6o (0,3 m [12 po])

Moteur Kubota diesel ou à essence de 20 ch à 3

cylindres, refroidi au liquide

Régulation proportionnelle

Manche à balai muni d’un levier

d’enclenchement solidaire et d’un bouton de

commande de direction à bascule au pouce;

sélecteurs de vitesse et de mode de

fonctionnement; bouton d’arrêt d’urgence

Traction 2 roues : moteurs hydrauliques aux 2 roues;

traction 4 roues : moteurs hydrauliques aux 4 roues

8 plis NHS 10-16,5; 3,4 bars (50 lb/po2)

Deux, à ressort, desserrage hydraulique, disques multiples

1,22 m (48 po)

Traction 2 roues : 30 % (16,7o); 4 roues : 35 % (19,3o)

2,94 m (115,75 po)

1,1 m (43,5 po) de hauteur; à rabattement; portillon

152 mm (6 po) de hauteur

3,64 m x 1,78 m (143,38 po x 70 po)

4,56 m x 1,73 m (179,38 po x 68 po)

680 kg (1 500 lb)

680 kg (1 500 lb)

227 kg (500 lb)

6 personnes

2 personnes

14,33 m (47 pi)

12,34 m (40 pi, 6 po)

1,66 m (65,25 po)

Traction 2 roues : 4 790 kg (10 560 lb);

4 roues : 4 953 kg (10 920 lb)

Traction 2 roues : 4 985 kg (10 990 lb);

4 roues : 5 148 kg (11 350 lb)

2,29 m (90 po)

2,76 m (108,75 po)

4,08 m (160,5 po)

12,34 m (40 pi, 6 po)

0 à 5,0 km/h (0 à 3,1 mi/h)

0 à 0,48 km/h (0 à 0,3 mi/h)

12 V c.c.

107,13 L (28,3 gal.)

206,8 bars (3 000 lb/po2)

ISO no 46

Huile moteur 5W-20

Un vérin d’élévation à un étage

Élévation : 45 s; abaissement : 65 s

Axe transversal : 8,5o (0,3 m [12 po]); axe

longitudinal : 6o (0,3 m [12 po])

Moteur Kubota diesel ou à essence de 20 ch à 3

cylindres, refroidi au liquide

Régulation proportionnelle

Manche à balai muni d’un levier

d’enclenchement solidaire et d’un bouton de

commande de direction à bascule au pouce;

sélecteurs de vitesse et de mode de

fonctionnement; bouton d’arrêt d’urgence

Traction 2 roues : moteurs hydrauliques aux 2 roues;

traction 4 roues : moteurs hydrauliques aux 4 roues

8 plis NHS 10-16,5; 3,4 bars (50 lb/po2)

Deux, à ressort, desserrage hydraulique, disques multiples

1,22 m (48 po)

Traction 2 roues : 30 % (16,7o); 4 roues : 35 % (19,3o)

2,94 m (115,75 po)

1,1 m (43,5 po) de hauteur; à rabattement; portillon

152 mm (6 po) de hauteur

* Ces caractéristiques peuvent être changées sans préavis.

La liste des pièces et les consignes d’entretien détaillée se trouvent dans le manuel d’entretien.

19

Page 20

Nota:

20

Page 21

Deutschsprachiger Teil

SICHERHEITSREGELN

BEDIENEN

innerhalb von 3 Meter einer

Stromlinie.

NICHT ISOLIERT.

BEDIENEN

Löcher, Bodensenkungen, Schlaglöcher oder Schutt.

BEDIENEN

gut angezogen sind.

SCHLIEßEN

HALTEN

VERWENDEN

BRINGEN

vergrößern.

SCHAUEN

VERTEILEN

Wagenbühnenbeladung.

VERWENDEN

gebührenfreie Telefonnummer auf der Rückseite.)

ÄNDERN

INSPIZIEREN

hydraulischen Lecks, beschädigten Kontrollen oder Stromkabeln, sowie losen Drahtverbindungen.

KLETTERN

FÜHREN

den Hebemechanismus zu blockieren.

LADEN

strömen hochexplosives Wasserstoffgas aus.

NACH VERWENDUNG

abschalten und den Schlüssel abziehen.

ERSETZEN

ohne vorher die Zustimmung des Herstellers erhalten zu haben.

Kalifornien Antrag 65 - Vorsicht

Benzin- und Dieselmotoren vertreiben Abgase und einige der Komponenten sind nach Ansicht des Staates Kalifornien

mögliche Verursacher von Krebs, Geburtsschäden und anderen Fortpflanzungsschäden.

Sie die Maschine

DIESE MASCHINE IST

Sie die Maschine

Sie die Maschine

und sichern Sie das Gitter nach dem Betreten der Wagenbühne.

Sie alle Körperteile vom Stützgeländer fern, wenn Sie die Hebebühne erweitern oder einziehen.

Sie

NIE

Sie

NIE

überhängende Ladungen an der Wagenbühne an, versuchen Sie

Sie nach oben, unten und rundherum nach Hindernissen und Oberleitungen.

Sie alle Ladungen gleichmäßig auf der Wagenbühne. Siehe Angaben auf der Rückseite bzgl. maximaler

Sie

NIE

Sie

NIE

die Bedienungs- oder Sicherheitssysteme.

Sie die Maschine gründlich nach gebrochenen Schweißnähten, losen oder fehlenden Systemteilen,

Sie

NIE

an der Hebebühne herunter, wenn die Wagenbühne erhöht ist.

Sie

NIE

irgendwelche Reparaturen an der Maschine durch, während die Wagenbühne erhöht ist, ohne vorher

Sie die Batterie

Sie

NIE

irgendwelche Komponenten oder Teile mit Ersatzteilen, die nicht original UpRight Teile sind,

NIE

NIE

NIE

Leitern oder Gerüste auf der Wagenbühne.

beschädigte Ausrüstung. (Beziehen Sie sich auf UpRight bzgl. Anweisungen. Benutzen Sie die

NIE

in der Nähe von Funken oder offener Flamme auf; Batterien, die aufgeladen werden,

sichern Sie die Arbeitsbühne gegen unbefugte Verwendung, indem Sie den Schlüsselschalter

ERHÖHEN

und

während sie sich in erhöhtem Zustand

befindet, es sei denn sie befindet sich

auf einem festen, ebenen Untergrund.

, ohne vorher den Arbeitsbereich bezüglich Gefahrenstellen zu überprüfen, wie z.B.

, wenn nicht alle Schutzgeländer richtig aufgerichtet und alle Befestigungsriegeln

Sie die Wagenbühne

FAHREN

Sie die Maschine

NIE

NIE

SITZEN

Sie

die Mittelgestänge der

Wagenbühne.

NIE

, stehen oder erklettern

NIE

das Schutzgeländer oder

, die Wagenbühne zu

21

Page 22

Einleitung

Diese Bedienungsanleitung betrifft alle Modelle der

Arbeitsbühnen der LX Serie. Diese Bedienungsanleitung

muß zu allen Zeiten mit der Maschine zusammen

aufbewahrt werden.

Anmerkung: Wenn Sie flüssiges Benzin verwenden,

benutzen Sie sauberes, wasserfreies flüssiges Benzin,

am besten von einem Großvorratstank. Befolgen Sie

die Anweisungen, die sich an der

Kraftstoffmodulablage zum Auffüllen des Tanks

befinden.

Vor-Inbetriebnahme und

Sicherheitsinspektion

Lesen, verstehen und befolgen Sie diese

Sicherheitsregeln, den Aufschriften und

Bedienungsanweisungen genau, und führen Sie dann

die folgenden Schritte täglich vor jedem Gebrauch aus.

1. Öffnen Sie die Module und prüfen Sie nach Schaden,

Öllecks oder fehlenden Teilen.

2. Überprüfen Sie den Hydraulikölstand am

Sichtmesser, der sich am Hydrauliktank befindet;

dazu muß die Wagenbühne ganz gesenkt sein. Füllen

Sie ISO #46 Hydrauliköl nach, wenn nötig.

3. Überprüfen Sie den Flüssigkeitsstand der Batterie

(Siehe Batteriewartung, Seite 26).

4. Überprüfen Sie den Stand von Motoröl und Benzin.

5. Prüfen Sie, ob alle Schutzgeländer richtig angebracht

sind, daß die Gleitdeckverlängerung mit dem Splint

und den Riegeln gesichert und gut festgezogen ist.

6. Prüfen Sie den Reifendruck; 3,4 bar (50 psi).

7. Überprüfen Sie die gesamte Arbeitsbühne genau auf

Schaden, wie z.B. gebrochene Schweißnähte oder

Strukturteile, lose oder fehlende Teile, Öllecks,

beschädigte Kabel oder Schläuche, sowie lose

Kontakte und Reifenschäden.

8. Bringen Sie die Maschine unter Umständen in einen

ungehinderten Bereich, um volle Aufrichtung

möglich zu machen.

9. Schalten Sie den Fahrwerk- und WagenbühneNotschalter auf ON (Ein) (Abb. 1 & 2), indem Sie die

Knöpfe herausziehen.

10. Versichern Sie sich, daß sich der Wagenbühne/

Fahrwerkschalter in der PLATFORM (Wagenbühne)

Position befindet (Abb.1).

11. Bei Doppelbenzin Modellen: schalten Sie die

Doppelbenzinwahl in die gewünschte Position.

Schalten Sie auf Mittelposition, um das System zu

reinigen, wenn Sie Benzin umschalten. Wenn die

Maschine mit Propangas betrieben wird, öffnen Sie

das Zulaufventil am Tank.

Wenn Sie Propangas riechen, schließen Sie das

Zulaufventil am Tank sofort, bis Sie das Leck

gefunden und repariert haben.

12. Während der Motor kalt ist, überprüfen Sie den

Kühlflüssigkeitsstand des Motors.

Prüfen Sie die Kühlflüssigkeit nicht, wenn der

Motor oder der Kühler heiß ist, heiße

Kühlflüssigkeit kann ernsthafte Verbrennungen

verursachen.

Inspektion der Systemfunktionen

HALTEN Sie sich von der Arbeitsbühne FERN,

während die folgenden Kontrollen

vorgenommen werden.

Bevor Sie die Arbeitsbühne in Betrieb nehmen,

untersuchen Sie den Arbeitsbereich bzgl.

Oberflächengefahren, wie z.B. Löcher,

Bodensenkungen, Schlaglöcher oder Schutt.

Überprüfen Sie in ALLEN Richtungen, auch

oberhalb der Arbeitsbühne, nach Hindernissen

und elektrischen Leitern.

Schützen Sie das Kabel des Kontrollpult vor

möglichem Schaden, während Sie die Kontrollen

vornehmen.

Notschalter

Wagenbühne /

Fahrwerk Schalter

Startknopf

Drosselknopf

Hebeknopf

Senkknopf

Benzinwahlschalter

22

Stopknopf

Choke-/

Vorglühknopf

Kippsensor

Abbildung 1: Fahrwerk, linke Seite

Page 23

1. Haken Sie den Controller vom vorderen Schutzgeländer

ab. Halten Sie den Controlleraufhänger so, daß der

Sperrhebel gedrückt werden kann, während die

folgenden Kontrollen vom Boden aus vorgenommen

werden.

2. Drehen Sie den Controller Schlüsselschalter im

Uhrzeigersinn auf ON (Ein). Drehen Sie ganz im

Uhrzeigersinn, um den Motor anzulassen, lassen Sie

den Schlüssel locker, sobald der Motor angesprungen

ist.

Anmerkung: Bei Doppelbenzin Modellen, wenn der

Motor kalt ist, drücken und halten Sie den ChokeKnopf innen, während Sie den Motor starten. Bei

Diesel Modellen, drücken und halten Sie den

Vorglühknopf 6 Sekunden lang, um die Glühkerzen zu

entzünden.

3. Schalten Sie den Fahr/ Hebeschalter auf die DRIVE

(Fahr) Position.

4. Drücken Sie den Sperrhebel, wobei der

Geschwindigkeitsschalter zuerst auf HIGH

TORQUE (Hohe Umdrehung) und dann auf HIGH

SPEED (Hohe Geschwindigkeit) gestellt wird.