Page 1

Operator Manual

AB62

SERIAL NO. 1266 to Current

WARNING

All personnel shall carefully read, understand and follow all safety rules,

operating instructions, and the Scaffold Industry Association’s

MANUAL OF RESPONSIBILITIES of ANSI A92.6-1999 before performing

maintenance on or operating any UpRight Aerial Work Platform.

P/N 104044-001

Page 2

AB62

Aerial Work Platform

Serial Numbers 1266 - Current

When contacting UpRight for service or parts information, be sure to include the MODEL and SERIAL NUMBERS

from the equipment nameplate. Should the nameplate be missing, the SERIAL NUMBER is also stamped on top of

the chassis above the front axle pivot.

UpRight, Inc.

801 South Pine Street

Madera, California 93637

TEL: 559-662-3900

FAX: 559-673-6184

PAR T S: 1- 88 8- UR -PAR TS

PARTS FAX: 1-800-669-9884

Call Toll Free in U.S.A.

1-800-926-LIFT

UpRight

Unit S1, Park West Industrial Park

Friel Avenue

Nangor Road

Dublin 12, Ireland

TEL: +353 1 620 9300

FAX: +353 1 620 9301

Page 3

PERATOR

O

M

ANUAL

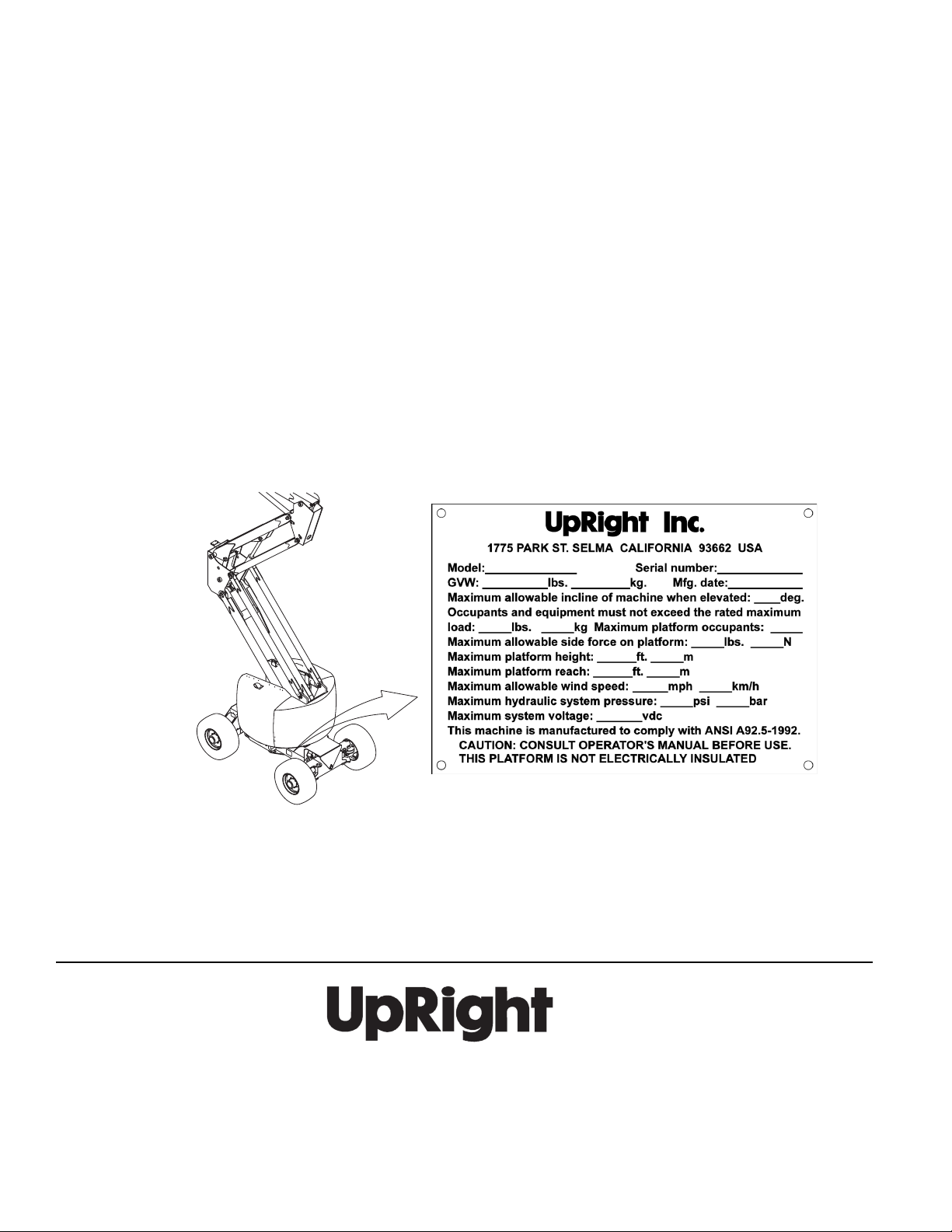

WARNING

All personnel shall carefully read, understand and follow all safety rules and operating instructions

Electrocution Hazard

Electrocution Hazard Tip Over Hazard

Electrocution HazardElectrocution Hazard

before operating or performing maintenance on any UpRight aerial work platform.

Safety Rules

Safety Rules

Safety RulesSafety Rules

Tip Over Hazard Collision Hazard

Tip Over HazardTip Over Hazard

Collision Hazard Fall Hazard

Collision HazardCollision Hazard

Fall Hazard

Fall HazardFall Hazard

NEVER operate the machine within ten

(10) feet of power lines.

THIS MACHINE IS NOT INSULATED.

•

ALL OCCUPANTS

one fall restraint to each anchorage point.

•

NEVER

•

NEVER

curbs, or debris.

•

ALWAYS

•

NEVER

•

NEVER

•

LOOK

•

DISTRIBUTE

•

NEVER

•

NEVER

•

INSPECT

hoses, loose wire connections, and wheel bolts.

•

NEVER

•

IF ALARM SOUNDS

surface.

•

IN CASE OF EMERGENCY

•

NEVER

•

NEVER

turer’s written consent.

•

VERIFY

•

NEVER

•

AFTER USE

exceed the maximum platform load. See “Specifications” on page 20.

operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps,

close and secure entrance after entering the platform.

use ladders or scaffolding on the platform.

attach overhanging loads or use the aerial work platform as a crane or lifting tool.

up, down and around for overhead obstructions and electrical conductors.

use damaged equipment. (Contact UpRight for instructions. See toll free phone number on inside back cover.)

change operating or safety systems.

the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, damaged cables or

climb down the elevating assembly when the platform is elevated.

recharge batteries near sparks or open flame; batteries that are being charged emit explosive hydrogen gas.

replace any component or part with anything other than original UpRight replacement parts without the manufac-

that all labels are in place and legible before using.

tow the machine. Transport by truck or trailer only.

must wear an approved fall restraint properly attached to a designated anchorage point. Attach only

all platform loads evenly on the platform.

while the platform is elevated, STOP, carefully lower the platform. Move the machine to a firm, level

, secure the work platform against unauthorized use by turning key switches off and removing all keys.

NEVER operate the boom or drive with

the platform elevated unless on firm,

push the Emergency Stop button to cut power to all machine functions.

level surface.

NEVER position the platform without

first checking for overhead obstructions

or other hazards.

NEVER climb, stand or sit on the

platform guardrails or midrail.

California Proposition 65 Warning

Gasoline and diesel engine exhaust and some of their constituents are known to the State of California to

cause cancer, birth defects, and other reproductive harm.

Battery Posts, terminals and related accessories contain lead compounds, chemicals known to the State of

California to cause cancer and reproductive harm. Wash hands after handling.

104044-001 AB62 Work Platform - Operator Manual Page 1

Page 4

C

ONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Special Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

All Models:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Platform Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Manual Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Beaufort Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lift Overload Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Pre-Operation Safety Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

System Function Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Controller Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Service Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Positioning the Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Multifunction Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lower Control Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Upper Control Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Leveling the Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Rotating the Turret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Elevating the Riser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Elevating the Upper Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Extending the Upper Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Elevating the Jib . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rotating the Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Switching Fuels (LPG Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Emergency Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

After Use Each Day. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

By Crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

By Truck or Trailer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Fueling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hydraulic Fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inspection and Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Daily Preventative Maintenance Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Safety Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Page 2 104044-001 AB62 Work Platform - Operator Manual

Page 5

I

NTRODUCTION

Introduction

G

ENERAL

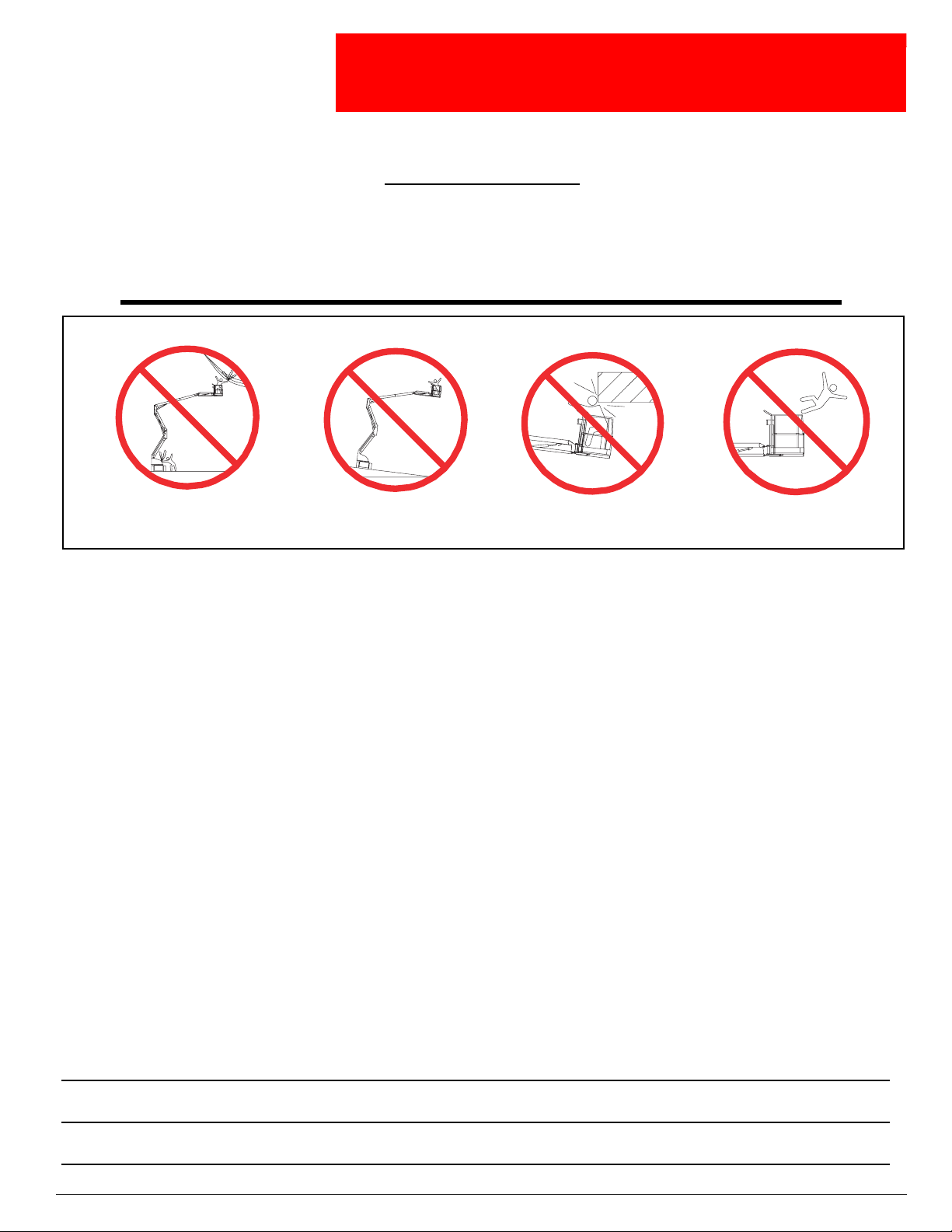

This manual covers the operation of the AB62 Articulated Boom.

machine at all times.

D

ESCRIPTION

1. Platform

• The platform has a non-slip aluminum floor, guardrails with

midrail, toeboards, and an

entrance gate at the rear of the

platform.

2. Platform Controls

• The Platform Controller is

located at the front of the platform cage. The foot switch must

be depressed to operate any

function from the platform.

3. Riser

• Used to raise the platform.

4. Boom

• Used to extend the platform.

5. Jib

• Used to level and rotate the

platform, and to raise or lower

the platform at the end of the

boom.

6. Power Module

• The Power Module contains the engine and the hydraulic pump.

7. Control Module

• The Control Module contains the fuel tank, hydraulic fluid tank and components, the hydraulic manifold,

the batteries, and the Chassis Controller.

8. Chassis Controls

9. Chassis

3

7

8

This manual must be stored on the

Figure 2:

AB62 Work Platform

4

5

2

6

1

9

!

WARNING

DO NOT use the work platform without guardrails properly assembled and in place.

104044-001 AB62 Work Platform - Operator Manual Page 3

!

Page 6

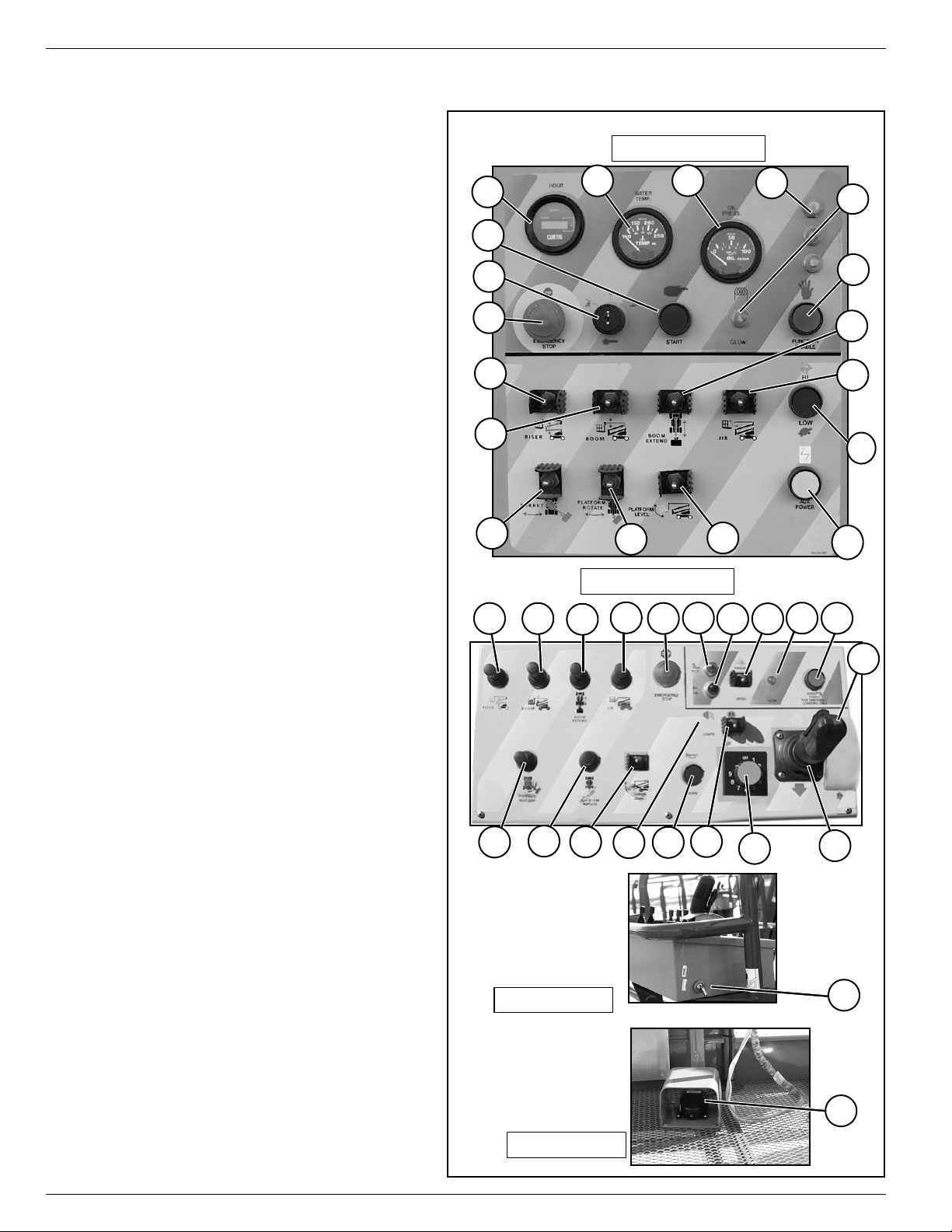

Controls and Indicators

C

ONTROLS

AND

I

NDICATORS

1. Hour Meter

2. Water Temp.

3. Oil Pressure

4. Breaker

5. Diesel - Glow Plug Light

Gasoline/LPG - Plugged

6. Function Enable

7. Engine Start

8. Key Switch

9. Emergency Stop

10. Riser

11. Boom Extend/Retract

12. Jib Raise/Lower

13. Boom Raise/Lower

14. Turret Rotate

15. Platform Rotate

16. Platform Level

17. Function Speed HI/LOW

18. Auxiliary Power

19. Riser

20. Boom Raise

21. Boom Extend

22. Jib Raise

23. Emergency Stop

24. YELLOW-Tilt

25. RED-Oil Pressure Warning

26. Torque / Speed

27. Diesel - Glow Plug Light

Gasoline/LPG - Fuel Selector Switch

28. Auxiliary Power

29. Turret Rotate

30. Cage Rotate

31. Cage Level

32. Auxiliary Light (option)

33. Horn

34. Generator (option)

35. Function Speed

36. Drive Control Handle

37. Steering Rocker Switch

38. Key Switch

39. Foot Switch

Diesel Model

1

7

8

9

10

13

14

29

20

30

Key Switch

19

2

15

Platform Controls

22

21

31

32

Figure 3:

Chassis Controls

3

16

24

23

33

25

34

Controls and Indicators

4

5

6

11

12

17

18

27

26

35

28

37

36

38

39

Foot Switch

Page 4 104044-001 AB62 Work Platform - Operator Manual

Page 7

P

a

b

RE

Pre-Operation Safety Inspection

-O

PERATION

V

ISUAL

NOTE:

Carefully read, understand and follow all safety rules, labels, and operating instructions; then perform the

following steps each day before use.

Perform a complete visual inspection of the entire unit prior to operating. Check the following areas for discrepancies:

1. Open the covers and check hydraulic components and hoses for damage or leaks.

2. Check electrical components and wiring for damage or loose connections.

3. Inspect the chassis, axles, hubs, and steering linkage for damage, deformation, buckled paint, loose or

missing hardware, and cracked welds.

4. Air-filled tires: check for damage, punctures, and inflation; tire pressure must be 5.5 bar (

5. Check all hoses and cables for wear.

6. Inspect the elevating assembly for damage, deformation, buckled paint, loose or missing hardware, and

cracked welds.

7. Inspect the platform and guardrails for damage, deformation, buckled paint, loose or missing hardware,

and cracked welds. Ensure that the gate operates freely and latches securely.

8. Check the hydraulic fluid level with the platform fully lowered.

9. Check the battery fluid level.

10. Check the fuel level; add fuel if necessary.

11.

Dual Fuel Models:

S

I

NSPECTION

AFETY

See “Switching Fuels (LPG Option)” on page 11.

I

NSPECTION

80 psi

).

NOTE:

When using propane, use clean, water free liquid petroleum gas, preferably from a bulk storage tank.

!

WARNING

If you smell propane, close the supply valve on the tanks immediately until you have located and

corrected the leak.

12. Ensure that the radiator is cold; check coolant level. Add if necessary.

!

WARNING

NEVER remove the cap from a hot radiator. Hot coolant can cause severe burns.

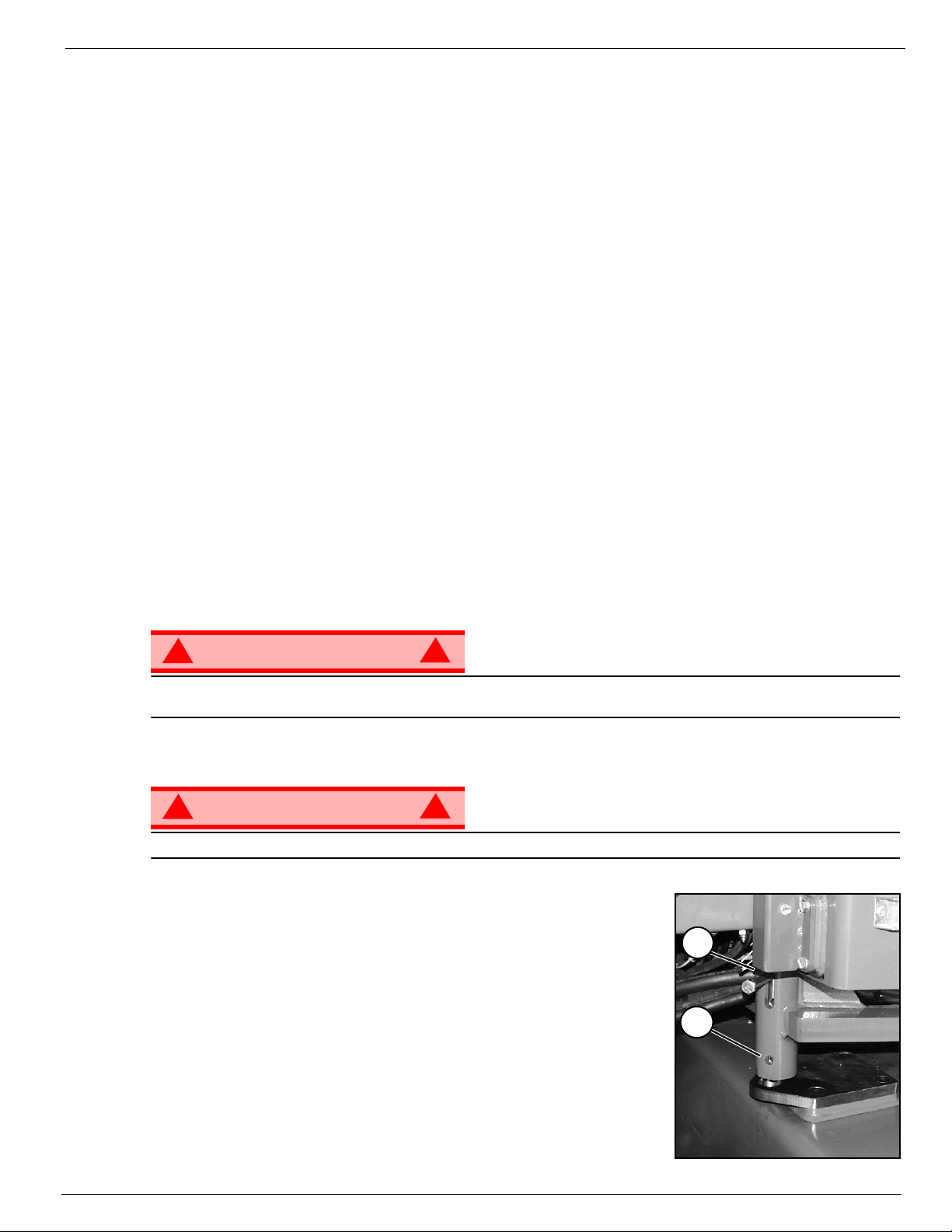

13. Retract the locking pins.

• The locking pins prevent turret rotation during transport and loading or

unloading from a truck or trailer. There are two pins; one on each side,

at the base of the turret, at the front of the machine.

a. Lift the locking pin with the pin stop rod.

b. insert the snap pin into the bottom hole.

!

!

Figure 4:

Locking Pin

NOTE:

Locking pins must be engaged for loading or unloading the machine onto a

truck or trailer, and during transport.

104044-001 AB62 Work Platform - Operator Manual Page 5

Page 8

Pre-Operation Safety Inspection

S

YSTEM

1. Move the machine to a firm level surface with room to fully elevate and extend the platform.

2. Before performing the following tests, check the area around the machine and overhead for obstructions, holes, drop-offs, and debris.

3. Ensure that the locking pins are retracted (refer to Figure 4 on page 5).

F

CAUTION

Attempting to rotate the turret with locking pins engaged may cause damage to the machine.

4. Turn the chassis key switch to the left (CHASSIS).

5. Pull out the Emergency Stop switches to the ON position at the chassis control panel and at the platform control panel.

6. Turn the key switch ON.

a. Gasoline/LPG:

b.

Diesel:

7. Push in the Chassis Emergency Stop button; the engine should stop. Return the Chassis Emergency

Stop button to the ON position, and start the engine.

8. Push in the Platform Emergency Stop button; the engine should stop. Return the Platform Emergency

Stop button to the ON position, and start the engine.

9. Make sure that the Function Speed Control (on the platform controls) is not at zero.

• Operate each function switch on the lower control panel to raise/lower, extend/retract, rotate left/right,

each section of the elevating assembly, and observe the operation of the machine.

• All functions should operate through full cycle smoothly.

10. Stop the engine.

11. Turn chassis key switch to the right (PLATFORM).

12. Mount the platform, lower the bar, and attach an approved fall restraint to the designated platform

anchorage point. Attach only one fall restraint to each point.

13. Start the engine.

14. Without depressing the foot switch, move the Drive Control handle; the machine should not function.

15. Depress the foot switch and move the Drive Control handle forward and reverse. Observe that the proportional functions operate smoothly, and that the brakes apply quickly after the control is released.

16. While depressing the foot switch, operate the steer switch to left and right. Observe that the steering

wheels turn properly.

17. While depressing the foot switch, turn the Function Speed Control knob to the desired setting, and

operate the boom controls.

• Observe that the boom operates smoothly, and that the upper boom, jib, turret rotation, platform level,

riser, and boom extend operate proportionally in conjunction with the Function Speed Control knob.

• Observe that the platform maintains level when the boom is elevated.

18. With the upper boom elevated 0,3 m (

speed is limited to creep (0,3 m [

19. With the upper boom extended 0,3 m (

speed is limited to creep (0,3 m [

20. Press the Service Horn button. Observe that the horn is audible.

UNCTION

Press the Engine Start button to crank the engine.

Wait for Glow Plug light to go off. When the Glow Plug light goes off, start engine.

I

NSPECTION

1 ft.

] per second). Lower the upper boom to the stowed position.

1 ft.

] per second). Retract the upper boom to the stowed position.

1 ft.

), operate the Drive Control handle. Observe that the drive

), operate the Drive Control handle. Observe that the drive

1 ft.

!

WARNING

DO NOT use a machine that is damaged or malfunctioning. Tag and remove the unit from service until

it is repaired.

Page 6 104044-001 AB62 Work Platform - Operator Manual

!

Page 9

O

PERATION

Operation

Before operating the work platform ensure that:

• Pre-operation and safety inspection has been completed, and any discrepancies have been corrected.

• The operator has been thoroughly trained on the operation of the machine.

• The work area is clear of all obstructions, holes, drop-offs, or persons in the route of travel.

• The surface is capable of supporting wheel loads.

Figure 5:

!

WARNING

Always wear an approved fall restraint properly

attached to the designated platform anchorage point

when driving or elevating the machine. Attach only

one fall restraint to each anchorage point.

C

ONTROLLER

Refer to Figure 3 on page 4 for control locations.

E

MERGENCY

At any time during operation, press the Emergency Stop button to stop all functions in an emergency.

F

UNCTIONS

S

TOP

!

Typical Fall Restraint Anchorage Point

S

ERVICE

At any time during operation, press the Service Horn button to sound an audible warning if necessary.

S

TARTING

F

ROM THE LOWER CONTROLS

1. Turn platform controls key to the ON position.

• Diesel: wait for the Glow Plug light to go off.

2. Turn the chassis controls key switch to the left (CHASSIS) position.

3. Press the Start button to crank the engine. Release when the engine starts.

F

ROM THE PLATFORM

1. Turn the chassis controls key switch to the right (PLATFORM) position.

2. Turn platform controls key to the ON position.

• Diesel: wait for the Glow Plug light to go off.

3. Turn the platform lever switch fully clockwise to crank the engine. Release when the engine starts.

THE

H

ORN

E

C

NGINE

ONTROLS

104044-001 AB62 Work Platform - Operator Manual Page 7

Page 10

Operation

D

RIVING

W

ITH BOOM LOWERED

1. Turn the chassis key switch to PLATFORM, and turn on (turn clockwise) the chassis Emergency Stop

switch.

2. Mount the platform, close and latch the gate.

3. Attach an approved fall restraint to the designated platform anchorage point. Attach only one fall

restraint to each point.

4. Start the engine.

5. Check that the area around and above the work platform is clear of obstructions, holes, drop-offs, persons in the route of travel, and that the surface is capable of supporting wheel loads.

6. Depress the foot switch and move the drive control handle forward to travel forward and reverse to travel

in the reverse direction.

NOTE:

When the boom is rotated to the front of the

chassis (steering wheels aft), directions of

travel and steering will be reversed. Observe

the color-coded arrows on the control panel

near the drive control handle and on the

chassis. They will indicate the direction of

travel when the drive control handle is moved.

Figure 6:

Direction Arrows on Chassis

W

ITH BOOM

Travel with the boom elevated is restricted to

firm, level surfaces only.

When driving with the boom elevated or

extended, the machine will travel at creep

speed (0,3 m [

E

LEVATED

] per second).

1 ft.

Page 8 104044-001 AB62 Work Platform - Operator Manual

Page 11

Operation

S

TEERING

1. Depress the foot switch.

2. Push the steering rocker switch to the left to turn left.

3. Push the steering rocker switch to the right to turn right.

NOTE:

Steering is not self-centering. Wheels must be returned to the straight ahead position by operating the steering

switch.

NOTE:

When the boom is rotated to the front of the chassis (steering wheels aft), directions of travel and steering will

be reversed. Observe the color-coded arrows on the control panel near the drive control handle and on the chassis.

They will indicate the direction of travel when the drive control handle is moved. Refer to Figure 6 on page 8.

P

OSITIONING

Positioning the platform as close as possible to the work area requires some planning. First, you must survey the work site to find a suitable place to park the machine. This must be a firm, level area as close as

possible to the work area. Take into consideration all obstructions on the ground and overhead, and avoid

them.

Once you have moved the machine to a firm, level surface as near as possible to the work area, follow the

instructions on the following pages to position the platform as close to the work area as possible.

Always, before operating any function, check the area around and overhead for any obstructions or electrical conductors.

THE

P

LATFORM

!

WARNING

NEVER exit the platform while the boom is elevated. Keep both feet on the platform floor at all times.

M

ULTIFUNCTION

The UpRight AB62 employs the use of multifunction controls. This means that the riser or boom extension

will function at full speed while simultaneously operating the upper boom, jib, turret, or rotating the platform.

!

WARNING

If the tilt alarm sounds, lower and retract the boom, then drive the machine to a firm, level surface

before elevating.

L

OWER

All boom functions will operate at the speed selected by the upper speed control functions.

NOTE:

The Platform Ignition switch must be turned ON in order to operate the lower controls.

1. Turn ON the platform ignition switch.

2. Turn the chassis key switch to the left (chassis).

3. With the engine running, operate the boom control switches to position the platform.

• If slower operation is desired, move the Function Speed (HI/LOW) switch to the low position (see

4. The Hi/Low switch will select between maximum speed and a lower fixed Function Speed, depending on

the position of the platform Function Speed control.

C

ONTROL

Figure 3 on page 4).

C

O

!

ONTROLS

!

PERATION

104044-001 AB62 Work Platform - Operator Manual Page 9

Page 12

Operation

U

PPER

1. Turn the chassis key switch to the left (Platform).

2. Turn ON the platform ignition switch.

C

L

EVELING

ONTROL

THE

O

PERATION

P

LATFORM

!

WARNING

DO NOT operate the machine if the platform does not maintain level when elevated.

NOTE:

Platform leveling should be done only to calibrate the automatic leveling system.

1. Set the Function Speed control dial to the desired setting. Rotate the dial clockwise to increase speed,

counterclockwise to decrease. If you are not sure what speed to use, start out slow; the speed can be

varied while operating the function.

2. While depressing the foot switch, push the Platform Level control switch forward to swing the platform

upward, rearward to swing the platform downward. Release the switch to stop leveling.

R

OTATING

1. Set the Function Speed control dial to the desired setting. Rotate the dial clockwise to increase speed,

counterclockwise to decrease. If you are not sure what speed to use, start out slow; the speed can be

varied while operating the function.

2. While depressing the footswitch, push the Turret Rotation control lever right to rotate counterclockwise;

left to rotate clockwise. Release the switch to stop rotation. Observe the area around the boom when

rotating the turret to avoid any obstructions.

THE

T

URRET

!

E

LEVATING

1. Set the Function Speed control dial to the desired setting. Rotate the dial clockwise to increase speed,

counterclockwise to decrease.

2. While depressing the foot switch, push the Riser control lever forward to elevate the riser, rearward to

lower the riser. Release the control lever to stop elevating/lowering.

E

LEVATING

1. Set the Function Speed control dial to the desired setting. Rotate the dial clockwise to increase speed,

counterclockwise to decrease. If you are not sure what speed to use, start out slow; the speed can be

varied while operating the function.

2. While depressing the foot switch, push the upper Boom control lever forward to elevate the upper boom,

rearward to lower the upper boom. Release the control lever to stop elevating/lowering.

Page 10 104044-001 AB62 Work Platform - Operator Manual

THE

THE

U

R

PPER

ISER

B

OOM

Page 13

Operation

E

XTENDING

1. Set the Function Speed control dial to the desired setting. Rotate the dial clockwise to increase speed,

counterclockwise to decrease. If you are not sure what speed to use, start out slow; the speed can be

varied while operating the function.

2. While depressing the foot switch, push the Boom Extend control lever rearward to extend the boom, forward to retract the boom. Release the control lever to stop extending/retracting.

E

LEVATING

1. Set the Function Speed control dial to the desired setting. Rotate the dial clockwise to increase speed,

counterclockwise to decrease. If you are not sure what speed to use, start out slow; the speed can be

varied while operating the function.

2. While depressing the foot switch, push the Jib control lever forward to elevate the jib, rearward to lower

the jib. Release the control lever to stop elevating/lowering.

THE

U

PPER

THE

J

IB

B

OOM

R

OTATING

1. While depressing the foot switch, push the Platform Rotate control lever right to go counterclockwise and

left to go clockwise. Release the lever to stop rotation.

S

WITCHING

1. With the engine running, turn the fuel selector switch to the opposite position.

• The engine should continue running on the selected fuel.

2. If the engine stalls, check the following:

• check the fuel supply in the selected tank.

• if LPG is selected, make sure that the valve is open on the tanks.

3. Restart the engine.

F

UELS

THE

P

LATFORM

(LPG O

PTION

)

104044-001 AB62 Work Platform - Operator Manual Page 11

Page 14

Emergency Operation

E

MERGENCY

In the event of a powered function failure, the elevating assembly may be lowered by using the Auxiliary

Power Unit. Hold in the Auxiliary Power button and operate the Lowering Controls as normal.

O

PERATION

A

FTER

T

OWING

!

WARNING

NEVER climb down the elevating assembly. If controls do not respond, ask someone on the ground to

lower the boom manually.

U

SE

E

ACH

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably under cover

3. Secure against vandals, children or unauthorized operation.

4. Turn the upper key switch to OFF.

5. Turn the lower key switch to the center position (OFF).

6. Remove all keys to prevent unauthorized operation.

Perform the following only when the machine will not operate under its own power and it is necessary to

move the machine or when winching onto a trailer for transportation

D

AY

CAUTION

DO NOT move the machine faster than 5 km/h

(

components and void warranty.

). Faster speeds will damage drive

3 mph

!

Figure 7:

Drive Hub

Disengaging Drive Hub

!

WARNING

Never disengage the hubs unless the wheels

are properly chocked and the machine is on a

level surface.

1. Chock the wheels.

2. Ensure that the platform is fully lowered, and

that the turret is rotated so that the platform is to the rear of the machine.

3. Attach a chain or cable of sufficient strength for towing the machine to the front or rear tie down lugs.

4. Refer to Figure 7 and disengage all four drive hubs. Remove the two screws and center cap. Re-install

the center cap in the opposite direction.

NOTE:

When hubs are disengaged, the brakes are ineffective. The machine will roll freely.

!

WARNING

Chock the wheels before disengaging the hubs. The machine may roll.

5. When ready to move the machine, remove the chocks. Tow or winch into position and replace the

chocks.

6. Engage all four drive hubs by returning the center caps to their original orientation.

!

Center Cap

!

Page 12 104044-001 AB62 Work Platform - Operator Manual

Page 15

T

RANSPORTATION

Transportation

BY C

1. Ensure that the boom is fully lowered and retracted.

2. Ensure that the locking pins are engaged (refer to Figure 4 on page 5).

3. Attach straps to the Chassis Lifting lugs only. Ensure that the straps are adjusted properly to keep the

BY T

1. Ensure that the boom is fully lowered and retracted.

2. Ensure that the locking pins are engaged (refer to Figure 4 on page 5).

D

RIVE ONTO TRANSPORT VEHICLE

1. Raise the jib before the machine starts up or down the ramp to avoid the platform contacting ground.

2. Maneuver the machine onto the bed of the truck/trailer.

W

1. When winching, follow instructions for “To w i n g ” on page 12. Attach the winch cable to the front tie down

RANE

unit level when lifting.

RUCK

INCH ONTO TRANSPORT VEHICLE

lugs.

OR

T

RAILER

CAUTION

Do not winch the machine faster than 5 km/h (

and void warranty.

2. After winching, ensure that the wheels are chocked.

S

ECURE TO TRANSPORT VEHICLE

1. Secure the machine to the transport

vehicle using chains or straps of adequate load capacity attached to chassis

tie down lugs (refer to “Specifications” on

page 20).

2. Place a wooden block, 20 cm x 10 cm x

75 cm (

platform support braces as shown.

3. Attach a ratchet strap under the platform

floor grating, and over the support

braces. Tighten securely; do not overtighten.

7.5 in. x 4 in. x 28 in.

), under the

3mph

). Faster speeds will damage drive components

Figure 8:

Wooden Block

20 cm x 10 cm x 75 cm

(8 in. x 4 in. x 28 in.)

Securing the Machine for Transportation

Chassis Tie Down

Lifting Lug (typ.)

!

WARNING

NEVER elevate the machine while on a truck or trailer.

104044-001 AB62 Work Platform - Operator Manual Page 13

!

Page 16

Daily Maintenance

Fuel Cap

Hydraulic Fluid Filler Cap

Level Gauge

D

AILY

M

F

UELING

G

ASOLINE

1. Open the left turret cover, then open the fill cap.

2. Fill to capacity with unleaded gasoline only.

3. Install the cap.

D

IESEL

1. Open the left turret cover, then open the fill cap.

2. Fill to capacity with diesel motor fuel only, grade #1-D or #2-D.

3. Install the cap.

AINTENANCE

Stop the engine and turn off the key switch before re-fueling.

• Fuel tank full capacity is 159 liters (

Use distillate fuel only; do not use residual or blend.

• Fuel tank full capacity is 159 liters

42 US gallons

(42 US gallons

).

).

Figure 9:

Fuel Tank

LPG (

1. Unfasten the coupler from the LPG valve on the tanks.

2. Remove the LPG tanks from the machine and fill according to ASME, NFPA and local standards.

IMPORTANT: When using propane, use clean, water free liquid petroleum gas, preferably from a bulk storage tank.

!

If you smell propane, close the supply valve on both tanks immediately until you have located and

corrected the leak.

H

YDRAULIC

1. Open the turret cover and check the fluid level at the sight

gauge with the boom stowed and retracted; engine running or

stopped.

NOTE:

Never add hydraulic fluid if the boom is elevated or extended.

2. If necessary, fill to capacity with clean ISO compatible hydraulic

fluid.

• Normal Temperature, above 0° C (

• Low Temperature, below 0° C (

• Extreme Temperature, below -17° C (

3. Clean the area around the cap before opening.

4. Open the filler/breather cap to add hydraulic fluid.

5. Install the cap.

OPTION

)

WARNING

F

LUID

!

)__ ISO #46.

32° F

) ____ ISO #32.

32° F

0° F

) ISO #15.

Figure 10:

Hydraulic Fluid Tank

Page 14 104044-001 AB62 Work Platform - Operator Manual

Page 17

B

ATTERY

M

AINTENANCE

Daily Maintenance

!

WARNING

Hazard of explosive gas mixture. Keep sparks, flame, and smoking material away from battery.

Always wear safety glasses when working with batteries.

Battery fluid is highly corrosive. Thoroughly rinse away any spilled fluid with clean water.

Always replace batteries with UpRight batteries or manufacturer approved replacements weighing >

kg (

62 lbs.

Check battery fluid level daily.

If the electrolyte level is lower than 10 mm (

water with high mineral content; it will shorten battery life.

The battery and cables should be inspected regularly for signs of cracks in the case, electrolyte leakage

and corrosion of the terminals. Inspect the cables for worn spots or breaks in the insulation and for broken

cable terminals.

Refer to the Service Manual to extend battery life and for complete service instructions.

T

IRES

Tire selection can affect the stability of the machine. Use only tires supplied by the manufacturer unless

approved by the UpRight in writing.

) each.

!

) above plates, add distilled water ONLY. Do not use tap

3/8 in.

28

Check air filled tire pressure daily. Inflate to 5,5 bar (

Optional poly-filled tires do not require air pressure.

80 psi

).

104044-001 AB62 Work Platform - Operator Manual Page 15

Page 18

Inspection and Maintenance schedule

I

NSPECTION

AND

The complete inspection consists of visual and operational checks, together with all necessary minor

adjustments to assure proper performance. Daily inspection will prevent abnormal wear and prolong the

life of all systems.

A thorough inspection and maintenance shall be performed by personnel who are trained and familiar with

mechanical and electrical procedures at regular intervals. Refer to the Service Manual for the Preventative Maintenance Check List.

Please photocopy the Daily Preventative Maintenance Check List and use the table as a checklist when

inspecting the machine for service.

M

AINTENANCE

SCHEDULE

Page 16 104044-001 AB62 Work Platform - Operator Manual

Page 19

D

M

T

K

P

M

R

AILY

P

REVENTATIVE

M

AINTENANCE

Inspection and Maintenance schedule

C

HECK

L

IST

AINTENANCE

ABLE

EY

Y = Yes/Acceptable

N = No/Not Acceptable

R = Repaired/Acceptable

COMPONENT INSPECTION OR SERVICES Y N R

Battery Check electrolyte level

Engine Oil and Filter

Engine Fuel System

Engine

Coolant

Hydraulic Fluid Check fluid level

Hydraulic System Check for leaks

Emergency Hydraulic

System

Controller Check operation of all controls

Control Cable

Platform Floor and

Rails

Check level and condition

Check for leaks

Check fuel level

Check for leaks

Check air cleaner

Check coolant level (with engine cold)

Operate the emergency lowering valve and

check for serviceability

Check the exterior of the cable for pinching,

binding or wear

Check fasteners for proper torque

Check welds for cracks

Check condition of platform

Check condition of anchorage points

Check condition of operator manual

REVENTATIVE

AINTENANCE

EPORT

Date: _______________________________________

Owner: _____________________________________

Model No: ___________________________________

Serial No: ___________________________________

Serviced By: _________________________________

COMPONENT INSPECTION OR SERVICES Y N R

Tires

Hydraulic Pump Check for hose fitting leaks

Hydraulic Drive

System

Torque Hubs Check for leaks

Steering System Check for missing/loose retainers

Elevating Assembly

Chassis

Tu rr et Check ring gear for proper lubrication and wear

Entire Unit Check for and repair collision damage

Labels

Check for damage

Check air pressure (5,5 bar

Check hydraulic drive motor operation

Check hoses,fittings, and valve block for leaks

Inspect for structural cracks

Check members for deformation

Check hoses for pinch or rubbing points

Check welds for cracks

Check for peeling, missing, or unreadable labels

& replace

[80 psi]

)

104044-001 AB62 Work Platform - Operator Manual Page 17

Page 20

Safety Labels

S

AFETY

1) 061205-002

5) 066552-000

L

ABELS

Proper label installation is required. All of these labels shall be present and in good condition before operating the work platform. Be sure to read, understand and follow these labels

BEFORE

operating the work

platform.

Figure 11:

21) 068639-000

33) 068633-000

23) 066554-000

Safety Labels

6) 005221-000

7) 066555-001

8) 066556-000

9) 066553-001

10) 060197-000

11) 027898-001

12) 064166-000

24) 068979-000

26) Diesel 104562-000

Gasoline 104562-001

29) Diesel 104330-000

Gasoline 104330-001

34) 068635-000

35) 068637-000

36) 068637-001

37) 066553-004

38) 066553-005

40) 062814-000

30) 066562-005

13) 010076-001

32) 068632-000

19) 062557-012

41) 100346-000

42) 064189-001

Page 18 104044-001 AB62 Work Platform - Operator Manual

Page 21

Safety Labels

19

Both

Sides

23

41

Both

Sides

11

12

10

23

29

Figure 12:

Safety Labels Locations

8

26

9

37

Both

Sides

38

Both

Sides

or

40

Both

Sides

24

Front

& Rear

30

Front

& Rear

35

42

Both

Sides

(Option)

38

Both

Sides

40

Both

Sides

23

32

36

32

7

5

6

34

13

33

9

8

37

21

1

35

24

Front

& Rear

30

Front

& Rear

32

36

104044-001 AB62 Work Platform - Operator Manual Page 19

Page 22

Specifications

S

PECIFICATIONS

Specifications are subject to change without notice. Hot weather or heavy use may affect performance.

ITEM

Specification Reach Envelope Diagram

Height

Working Height 20,7 m [

Max. Platform Height 18,9 m [

Platform step in Height 343 mm [

Up and Over Height 9,1m [

Drivable Height 18,9 m [

Horizontal Outreach

Turret Rotation

Platform Rotation

Tail Swing

Jib Length

Jib Arc

Inside Turning Radius

Outside Turning Radius

Drive Speed

(boom stowed and lowered)

Drive Speed (Elevated)

HIGH

LOW

0,96 km/h [

Maximum Gradeability

68 ft.

62 ft.

13.5 in.

30 ft.

62 ft.

10,7 m [

35 ft.

360° Continuous

180°

0

1,9 m [

6ft. 4 in.

140°

2,5 m [

8 ft.

5.5 m [

18 ft.

6,8 km/h [

2,6 km/h [

22° [

40%

4.25 mph

1.6 mph

0.6 mph

Dimensions (boom stowed)

Platform Size, Standard 1,8 m [

Platform Size, Optional 2,4 m [

Guardrails 1,4 m [

Toeboard 152 mm [

Platform Capacity (Maximum)

Occupants (Maximum)

Weight

Overall Height

Overall Length

Overall Width

Wheel Base

Ground Clearance

] 1 m x 1,8 m [

6 ft.

] 1 m x 2,4 m [

8 ft.

10,614 kg [

8,2 m or 7,2 m Minimum

[

27 ft. or 23 ft. 6 in. Minimum

CENTER

2,3 m [

AXLE

227 kg [

2,5 m [

2,3 m [

0,46 m [

0,32 m [

39 in. x 72 in.

39 in. x 96 in.

45 in.

6 in.

500 lbs.

2

23,400 lbs.

8 ft. 2 in.

7 ft. 7.5 in.

8 ft. 6 in.

12.5 in.

Power Source

Dual Fuel GM 3.0 L – 83 HP

Diesel Perkins 704-30 – 63 HP

System Voltage

Maximum Hydraulic Pressure

Controls

12 VDC

345 bar [

5000 PSI

Electric Proportional

Tires

Size 19 x 15 NHS - 14 PLY

Pressure 5,5 bar [

80 PSI

]

]

]

]

18 in.

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

Page 20 104044-001 AB62 Work Platform - Operator Manual

Page 23

Call Toll Free in U.S.A.

1-800-926-LIFT

Page 24

USA

TEL: (1) 800-926-5438 or (1) 559-662-3900

FAX: (1) 559-673-6184

Parts FAX: (1) 800-669-9884

801 South Pine Street

Madera, California 93637

http://www.upright.com

E

UROPE

TEL: +353 1 620 9300

FAX: +353 1 620 9301

Unit S1, Park West Industrial Park

Friel Avenue

Nangor Road

Dublin 12, Ireland

L

OCAL DISTRIBUTOR

:

P/N 104044-001

06-02

Loading...

Loading...