Singer 211G146, 211G157, 211G158, 211G351, 211G357 Service Manual

...

Form

30-289

G/1073-894

SINGER

Service

Manual

MACHINES

211G146,

211G151 AND 211G157,

158,

351,

357,

358,

451,

457,

651,

657,

658

*A

TrademarkofTHE

SINGER

COMPANY

THE

SINGER

COMPANY

Copyright

© 1965 by

The

Singer

Company

Copyright

under

International

Copyright

Union

All

Rights

Reserved

under

Inter-American

Copyright

Union

PrintedinWest

Germany

CONTENTS

DESCRIPTION

3

INSTALLATION

4

LUBRICATION

4-5

OPERATOR

INFORMATION

5-9

ADJUSTMENTS .9-16

INDEX

Arm

Shaft Connection Belt Replacement

.16

Bobbin Case Opener, Adjusting 14

Bobbin Case Opener, Timing 14

Bobb

in Case.

Removal

From Sewing

Hook

13

Bobbin

Removal

7

Bobbin Replacement 7

Bobbin

Thread

Tension

8

Bobbin

Winding

7

Description of Machines 3

Feed Dog Adjustment 15

Feed Eccentric Adjustment 15

Feed Reversing Mechanism (211G157) 11

Feed Reversing Mechanism

Adjustment (211G157/158)

Hook

Height 12

Hook

Lubrication

5

Hook

Position

RelativetoNeedle

12

Hook Removal 13, 14

HookTiming

13

Installation

4

Lubrication

4

Needles 5

Needle Bar Bushing (211G146) 10

Nedle Bar Height (211G146) 10

Needle Bar Height

(211G151

& 211G157) 10

Needle

Bar

Position

RelativetoPresser

Bar

10

Needle

Bar

Rock

Frame

Removal

16

Needle Setting 6

Needle

Thread

Tension

8

Pressure

on

Material

9

Speed 5

Stitch Length Regulation 9

Take-up Lever Removal 16

Thread

Controller

A, 9

Thread

Tensions

8

Threading Bobbin

Cose

8

Threading (Lower) 7

Threading (Upper) 6

DESCRIPTION

OF

MACHINES

The

Singer

211G146,

211G151

and

211G157

are

high

speed, single needle,

long

arm,

precision lockstitch

machines,

designed

for

top

performance

on a

variety

of medium to heavy weight fabrics.

GENERAL

FEATURES

Vertical

axis

hook

with

metered

lubrication.

Hook

can be removed without disturbing hook shaft.

Safety clutch, adjustable to sewing conditions, to

prevent hook damage during occasional strain.

Fully automatic lubrication to all moving ports

from two

reservoirs

enclosedinthe

machine.

Thread lubricator reservoir, inside face plate,

filled through oil hole without disturbing face plate.

Adjustable feed driving eccentric located on hook

driving

shaft, produces a

uniform

stitch

length

at

all

speeds.

Oil reservoir in hook saddle permits controlled

lubrication to bobbin

case,

bobbin

case

opener mech

anism

and

hook.

Arm

shaft,

hook

shaft,

and

belt

driven bed

shaft

are mounted in boll

bearings

at rear and in automat

ically lubricated plain bearings in front.

Plunger

for

changing

length

of stitch is on top

surfaceofbed.

Needle bar and needle bar driving mechanism are

lubricated automatically

from

oil reservoir in machine

arm.

Sleeve type take-up.

Thread take-up guard.

Belt

drive.

Knee

lifter.

Needle

bar

stroke:

1-5/16

inches.

Bed: 18-3/4 inches long, 7 inches wide.

Space at right of needle:

10-1/2

inches.

Federal Stitch Type 301.

SPECIAL

FEATURES

211G146

DROP

FEED

Primarily for shoes and a variety of leather products.

Boll bearing roller presser.

Clearance under roller presser:

1/4

inch.

Maximum

stitch length: 6 per inch.

211G151

COMPOUND

FEED

Ideal for stitching coots, overalls, rainwear, work-

clothes,

sports

outerwear and similar

items.

Combination of needle feed and drop feed prevents

slipping of upper and lower plies of material during

sewing, insuring uniform

stitching

and even

plies.

Clearance under presser foot:

1/4

inch. (3/8 inch

clearance

available

on order).

Maximum

stitch

length: 5 per inch.

211G157 COMPOUND

FEED/REVERSE

FEED

Similartomachine

211G151

with

addition

of

feed

re

versing mechanism controlled by hand or foot. Direc

tion of feed can be reversed at any time, and at any

speed.

Spring

biased

reverse

lever

resumes

forward

stitching position immediately, when hand or foot

pressureisreleased.

Clearance under

presser

foot:

1/4

inch.

(3/8

inch

clearance

available

on order).

Maximum

stitch length: 6 per inch.

The

211G158

machineisthe

same

as

the

211G157

machine,

the

only variation is

the

fact

that

a stitch length of

approx. 10 mm

canbeobtained

with this

machine,

depen

ding on

the

material

sewn.

The

maximum

speed

recommended

for this

machine

(211

G 158) is

1800

rpm.

The

211 G 351: 211 G

357;

211 G

358;

211 G

451;

211 G

457;

211 G 651; 211 G

657

and

211 G

658

machines

are

compound

feed

varieties within

the

machine

class

211

G.

Machine

Features

Max. St.

Length

5

SPI

= 5

mm

6

SPI=4.2

mm

2/2

SPI=10

mm

5

SPI

= 5

mm

6

SPI=4.2

mm

5

SPI

= 5

mm

6

SPI=4.2

mm

211G351

Large Vertical Axis Hook. All other features comply

with

211 G 151

machine.

211 G

357

Large Vertical Axis Hook. All other features comply

with

211G157

machine.

211G358

Large Vertical Axis Hook. All other features comply

with

211G158

machine.

211G451

Underbed

Thread

Trimmer

with

Thread

Wiper.

All

other

features

comply

with

211G151

machine.*

211G457

Underbed

Thread

Trimmer

with

Thread

Wiper.

All

other

features

comply with

211G157

machine.*

211G651

Large Vertical Axis Hook; Underbed Thread Trimmer with Wiper.

All

other

features

comply

with

211G151

machine.*

211G657

Large Vertical Axis Hook;

Underbed

Thread

Trimmer with Wiper.

All

other

features

comply

with

211G157

machine.*

211G658

Large Vertical Axis Hook; Underbed Thread Trimmer with Wiper.

All

other

features

comply with

211G158

machine.*

2/2

SPI=10

mm

For machines with UTT, Service Manual Form No.

30-349G

should be

used

as supplementary literature.

*

these

machinesare

not

equipped

with

the

automatic

needle

thread

lubrication.

The lubricating

pad

has

to be

soaked

manually if needle thread is to be lubricated.

Max.

Speed

2,700

RPM

2,700

RPM

1,800

RPM

4,000

RPM

4,000

RPM

2,700

RPM

2,700

RPM

1,800

RPM

STOP

DRAIN

STUD«

PIPE

'

JDI

€'

I I

Fig.

2. Installotion View

lifter

ROD

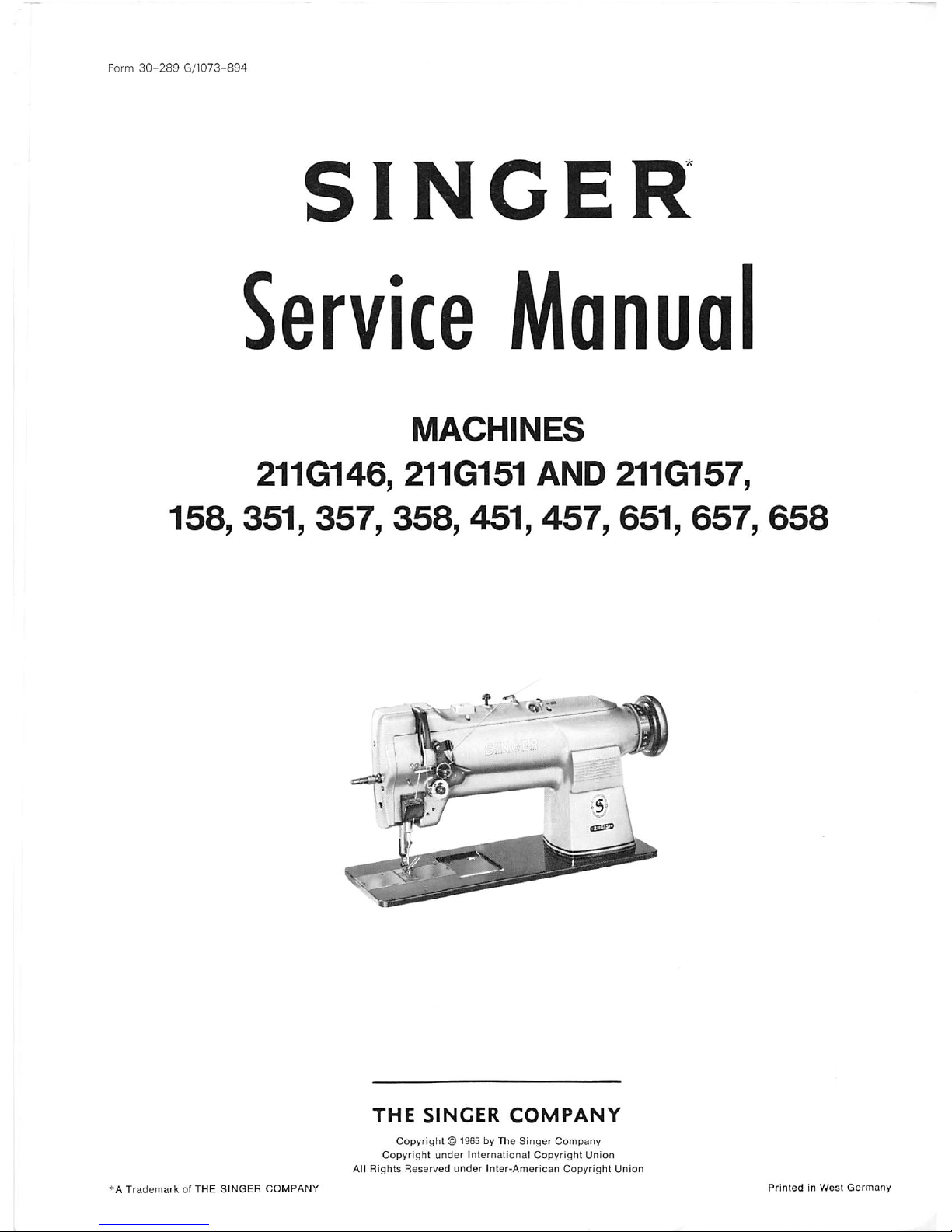

INSTALLATION

Fasten drip pan to table with its left end even

with

left

end

of

cut-out.

Fasten

knee

lifter

bracket

in location

shown

in Fig. 2 Assemble it so that lifter

rod does not strike drip pan. Screw slots in bracket

provide

necessary adjustment. Set stop-stud to stop

the action of knee lifter

as

soon

as

presser

foot is

raised enough to trip hand lever. Screw drain pipe

into drain hole in drippan and attach oil jar as shown.

LUBRICATION

•BEFORE

STARTING

MACHINE

FILL

TO

HIGH

MARK

HIGH

MARK

Fig.3.Arm

Reservoir

'CHECK

TWICE

DAILY

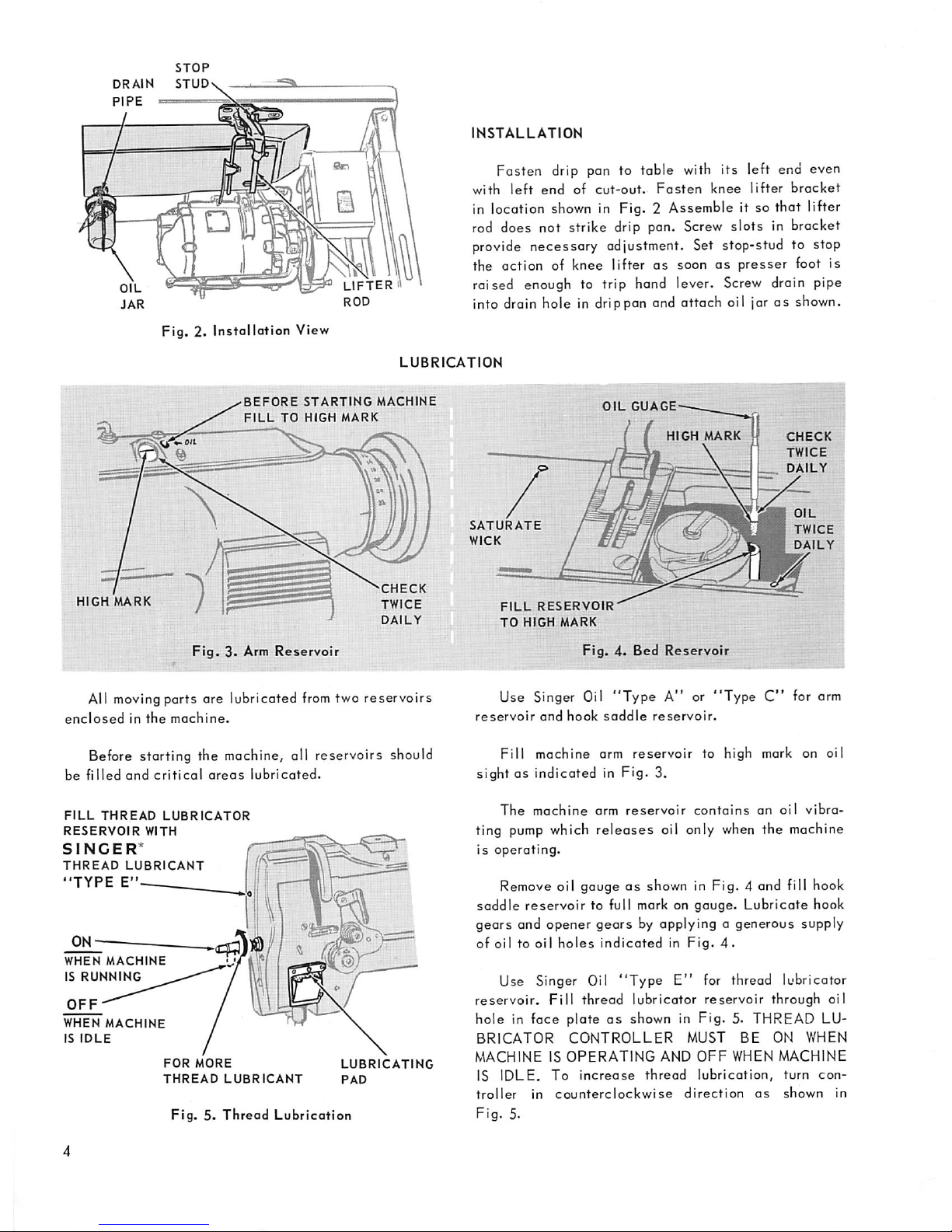

All moving parts are lubricated from two

reservoirs

enclosedinthe

machine.

Before storting the machine, oil reservoirs should

be

filled

and

criticol

oreos

lubricated.

FILL

THREAD

LUBRICATOR

RESERVOIR

WITH

SINGER*

THREAD

LUBRICANT

//)

"TYPE

E" I

WHEN

MACHINE

IS

RUNNING

OFF-^"""^'^

WHEN

MACHINE

IS

IDLE

Vii)

FOR

MORE

LUBRICATING

THREAD

LUBRICANT

PAD

Fig.5.Thread

Lubrication

OIL

GUAGE-

SATURATE

WICK

FILL

RESERVOIR'

TO

HIGH

MARK

HIGH

MARK H

Fig.4.Bed

Reservoir

CHECK

TWICE

DAILY

OIL

TWICE

DAILY

i?

.• E

Use Singer Oil

"Type

A" or

"Type

C"

for arm

reservoir

and

hook

saddle

reservoir.

Fill

machine arm

reservoir

to high mark on oil

sightOSindicated in Fig. 3.

The

machine

arm

reservoir

contains

on

oil

vibra

ting

pump

which

releases

oil only when the machine

is

operating.

Remove oil gaugeasshown in Fig. 4 and fill hook

saddle

reservoir to full mark on gouge. Lubricate hook

gears and opener gears by applying a generous supply

of

oiltooil

holes

indicated

in

Fig.

4.

Use Singer Oil

"Type

E"

for thread lubricator

reservoir.

Fill

thread lubricator reservoir through oil

hole in face plate

as

shown in Fig. 5. THREAD LU

BRICATOR

CONTROLLER

MUST

BE

ON WHEN

MACHINEISOPERATING

AND

OFF

WHEN

MACHINE

IS

IDLE.

To

increase

thread

lubrication,

turn

con

troller

in

counterclockwise

direction

as

shown

in

Fig.

5.

CONTROL

PI

VALVE

SET

SCREW

.j

•..|a

ep One)

Fig.

6« Hook

Lubrication

(Step One)

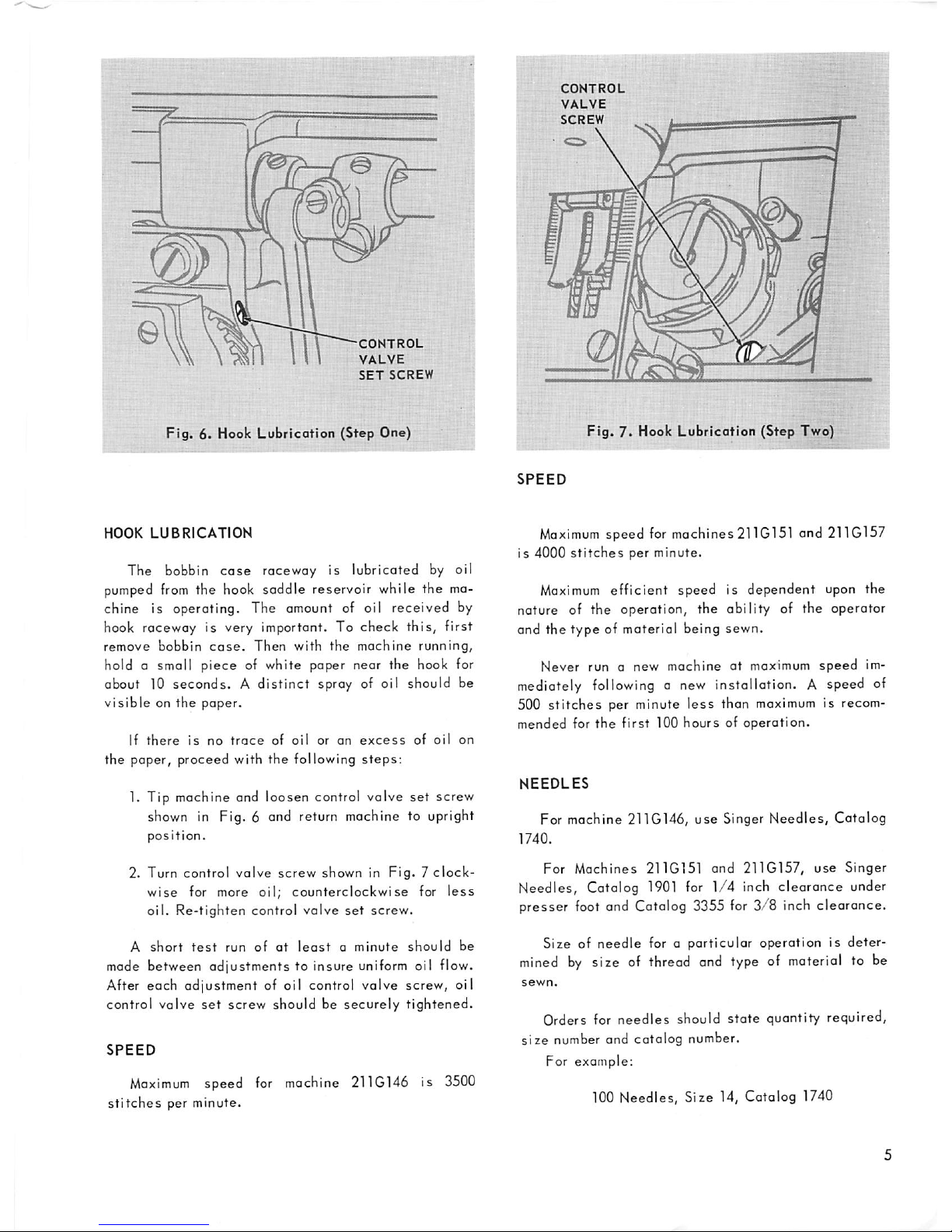

HOOK

LUBRICATION

The bobbin

case

raceway is lubricated by oil

pumped

from

the hook saddle reservoir while the

ma

chine is operating. The amount of oil received by

hook raceway is very important. To check this, first

remove

bobbin

case.

Then

with

the

machine

running,

hold a small

piece

of white paper near the hook for

about 10 seconds. A distinct spray of oil should be

visibleonthe

paper.

If

there

is

no

trace

of

oil

or on

excess

of

oil

on

the paper, proceed with the following

steps:

1. Tip machine and loosen control valve

set

screw

shown in Fig. 6 and return machine to upright

position.

2. Turn control

valve

screw

shown in

Fig.7clock

wise

for more oil;

counterclockwise

for

less

oil.

Re-tighten

control

valve

set

screw.

A

short

test

run

of

at

least

a

minute

should

be

mode between

adjustments

to insure uniform oil flow.

After each adjustment of oil control valve screw, oil

control valve

set

screw should be securely tightened.

SPEED

Maximum

speed for machine 211G146 is 3500

stitches

per minute.

CONTROL

VALVE

SCREW

Fig.

7* Hook Lubrication (Step Two)

SPEED

Maximum

speed for mochines

211G151

and

211G157

is 4000

stitches

per minute.

Maximum

efficient

speed is dependent upon the

nature of the operation, the ability of the operator

and the

type

of materiel being sewn.

Never run a new machine at maximum

speed

im

mediately

followinganew

installation. A speed of

500

stitches

per minute

less

than maximum is recom

mended for

the

first

100

hoursofoperation.

NEEDLES

For machine 211G146,

use

Singer

Needles,

Catalog

1740.

For

Machines

211G151

and

211G157,

use

Singer

Needles, Catalog

1901

for

1/4

inch clearance under

presser foot and Catalog 3355 for

3/8

inch clearance.

Size of needle for a particular operation is

deter

mined

by

size of thread and type of material to be

Orders for needles should state quantity required,

size

number and catalog number.

For example;

100 Needles, Size 14, Catalog 1740

MOVE

TO^

HIGHEST

POINT

LONG-^

GROOVE

TO

LEFT

LOOSEN

NEEDLE

CLAMPING

SCREW

INSERT

NEEDLES

AS

FAR

POSSIBLE

AND

TIGHTEN

SCREW

Fig. 8* Needle Setting

HOLD

THIS

END

TWIRL

OVER

TOWARD

YOU

Fig.9.Thread

Twist

Determination

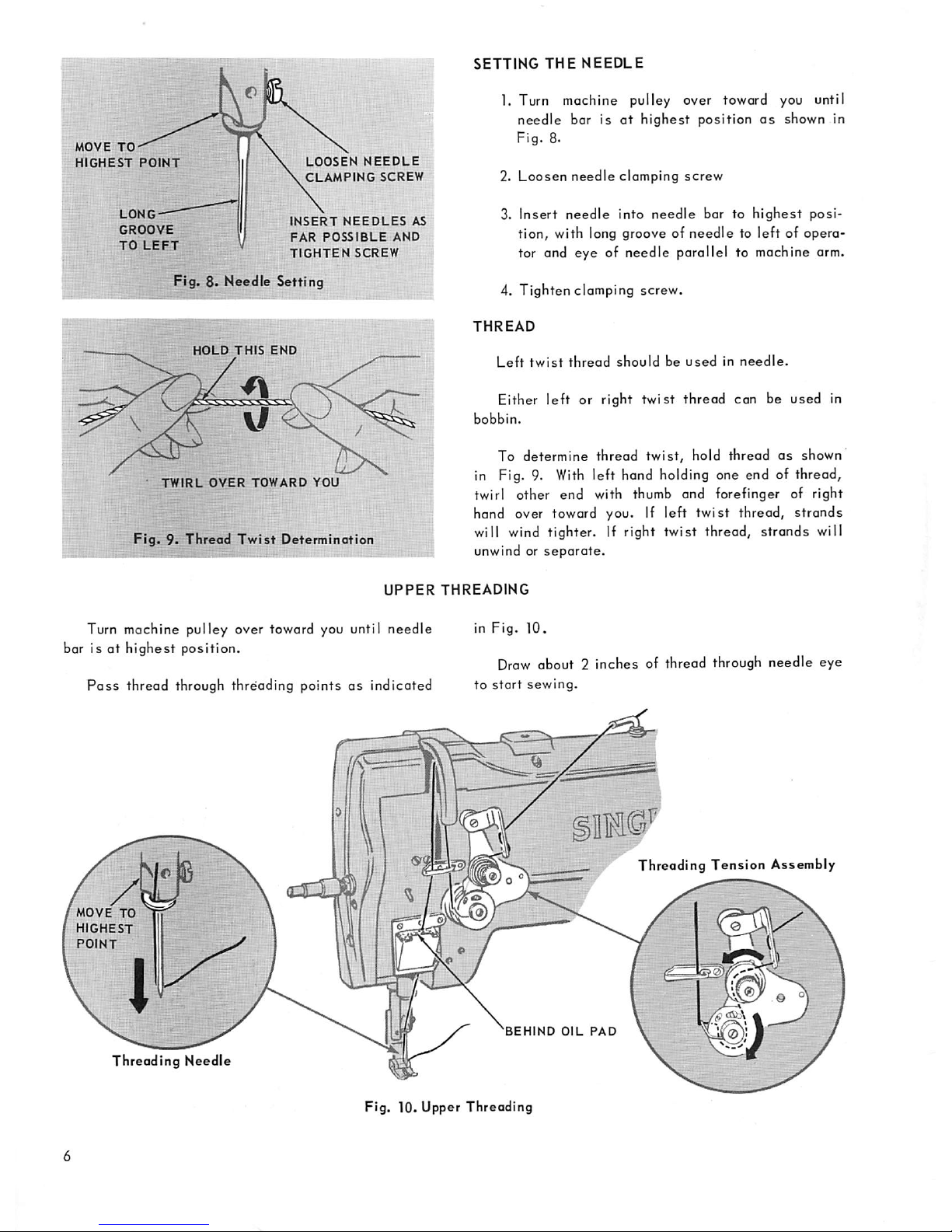

SETTING

THE

NEEDLE

1. Turn machine pulley over toward you until

needle

bar isathighest

position

as

shown in

Fig.

8.

2.

Loosen

needle

clamping

screw

3. Insert

needle

into

needle

bar to

highest

posi

tion, with long groove of

needletoleft

of opera

tor and eye of needle parallel to machine arm.

4. Tighten clamping screw.

THREAD

Left

twist

thread

should

be

usedinneedle.

Either

left

or right

twist

thread

can be used in

bobbin.

To determine thread

twist,

hold thread

as

shown

in Fig. 9.

With

left hand holding one end of thread,

twirl other end with thumb and forefinger of right

hand over toward you. If left

twist

thread,

strands

will wind tighter. If right twist thread, strands will

unwind or

separate.

UPPER

THREADING

Turn machine pulley over toward you until

needle

bar is ot

highest

position.

Pass

thread through threfading points as indicated

MOVE

TO

HIGHEST

POINT

Threading

Needle

in

Fig.

10.

Draw

about 2 inches of thread through needle eye

to

start

sewing.

Threading

Tension

Assembly

'BEHIND

OIL

PAD

Fig. 10. Upper

Threading

LOWER

THREADING

BOBBIN

REMOVAL

1. Open slide plate in bed of machine

2. Turn machine pulleyover toward you until needle

bar

reaches

highest

position.

3.

Raise

bobbin

latch

and

lift

out

bobbin

as

in

dicatedinFig.

11.

BOBBIN

WINDING

Attach bobbin winder to

table

with driving pulley

in front of

beltasshowninFig.

12.

Securely place bobbin on bobbin winder spindle.

Pass

thread through thread guide, then around and

between

tension

discs

as

shown.

Wind

thread

clock

wise

around

bobbin a few

times

as

indicated

in

Fig.

12.

Move

bobbin winder pulley over against machine

belt

and

start

machine.

The

amount

of

thread

to

be

wound

on

bobbin

is

regulatedbyscrew B, Fig.

12.

To

wind

more

thread

on bobbin, turn screw B inward. For

less

thread on

bobbin, turn screw B outward. This screw should be

regulated to stop bobbin winder spindle when thread

on

bobbinis1/16

inch

shortofbobbin

rim.

If thread winds unevenly on bobbin, loosen tension

bracket screw A, Fig. 12, and

move

bracket to right

or

lefttoobtain

even

winding.

Adjusting knurled nut C, Fig.

12,

regulates tension

of thread being

wound

on

bobbin.

For fine thread,

use

light

tension.

Bobbins

maybewound

while machine is stitching.

BOBBIN

REPLACEMENT

Place

bobbinoncenter

stud

with

thread

wound in

counterclockwise

direction

as shown in

Fig.

13. Draw

about

2 or 3

inchesofthread

from

bobbin.

Bpf''

LIFT

LATCH

LIFT

OUT

BOBBIN

Fig. 11. Bobbin Removal

Fig.

12. Bobbin Winding

PLACE

BOBBIN

ON

CENTER

STUD

CLOSE

LATCH

•

DIRECTION

OF

THREAD

AROUND

BOBBIN

Fig.

13. Bobbin Replacement

Loading...

Loading...