Page 1

MAMMOMAT Novation

Planning Guide

DR

SP

System

with DROC (Direct Ray Operation Console)

© Siemens AG 2003

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

English

Print No.: SPB7-250.891.01.04.02 Doc. Gen. Date: 08.05

Replaces: SPB7-250.891.01.03.02

Page 2

0 - 2 Revision

Chapter Page Revision

all all 01

all all 02

all all 03

all all 04

Document revision level

The document corresponds to the version/revision level effective at the time of system delivery.

Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified personnel

who are employed by Siemens or one of its affiliates or who are otherwise authorized by Siemens or

one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with or authorized by Siemens or one of its affiliates are directed to contact one of the local offices of Siemens or

one of its affiliates before attempting installation or service procedures.

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 2 of 4 Siemens AG

Page 3

Contents 0 - 3

Page

1 _______General Notes _________________________________________________ 1 - 1

General Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

MAMMOMAT Novation

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 5

Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

DICOM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 5

2 _______Room Planning ________________________________________________ 2 - 1

Room Planning Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Room Planning Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Stand Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Radiation Shield Dimensions (Option) . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Installing the Control Console on the Wall or on a Table . . . . . . . . . . . . . . . . 2 - 5

Acquisition Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

DR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

3 _______Preparation for Installation _______________________________________ 3 - 1

Stand Floor Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

(The floor plate is designed to also be the unit base) . . . . . . . . . . . . . . . . 3 - 1

Radiation Shield Floor Plate (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

On-site Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

On-site Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

4 _______System Connections ____________________________________________ 4 - 1

Remarks Regarding Laying of Cables. . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Fixpoint Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Fixpoint List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 3

List of Fixpoints Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

5 _______Technical Data _________________________________________________ 5 - 1

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Dimensions, Weight and Heat Dissipation . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Packaging and Transport Routes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Paint Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 2

6 _______Changes to Previous Version_____________________________________ 6 - 1

Siemens AG SPB7-250.891.01 Page 3 of 4 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

DR

Page 4

0 - 4 Contents

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 4 of 4 Siemens AG

Page 5

General Notes 1

1 - 1

General Notes 1

- With distribution of these revision level, all preceding planning guides (PGs), Speed Infos and drafts

lose their validity.

- All layouts issued by the Planning Departments must bear a note referring to the installation and

delivery conditions of Siemens Medical Engineering. The installation and delivery conditions must

be submitted with the layouts.

- Unless otherwise specified, all dimensions are indicated in "mm".

- The symbol indicates a change (see revision status).

- Orientation points

Points specific to system components to which reference is made when positioning system

components to each other or in the room.

The isocenter of a radiographic system is always illustrated as the orientation point.

- Fixpoints

Clearly marked points on system components, installation ceiling, walls or floor on which cable

outlets are located.

Illustration in the drawings: octagon with letter/number-combination.

The cable lengths specify the maximum fixpoint distances and thus the maximum distances

between the individual system components.

- Room height

The room height is the distance measured from the top surface of the floor to the bottom surface of

the ceiling structural elements (Unistrut rails) (bottom surface of drop ceiling).

- Room lighting

According to DIN 68 68-57 (international standard in preparation), the lighting in rooms in which

image playback devices (monitors) are used for diagnosis, the following requirements must be

met:

adjustable, no anti-glare screen, reproducible adjustment of the lighting (e.g. dimmer with

scale),

no glare or reflection from windows, lights and light boxes in the standard working position of

the monitors.

Hotline + 49 (9191) 18 - 8080

Siemens AG SPB7-250.891.01 Page 1 of 6 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

DR

Page 6

1 - 2 General Notes

Safety 1

- The provisions of the relevant fire safety regulations must be observed for the premises.

- The system has been developed according to EN 60601 - 1.

- Minimum dimensions (e.g. room heights, safety distances) indicated in the planning guides are

marked "min."

- Basic resistance to electromagnetic sources of interference.

Result of lightning discharges.

The protection targets of the different lightning protection areas up to the unit connection are also

specified in the IEC 1024, DIN 48810, VDE 0675 and in the DEMVT recommendations.

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 2 of 6 Siemens AG

Page 7

General Notes 1 - 3

System Overview 1

Siemens AG SPB7-250.891.01 Page 3 of 6 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

DR

Page 8

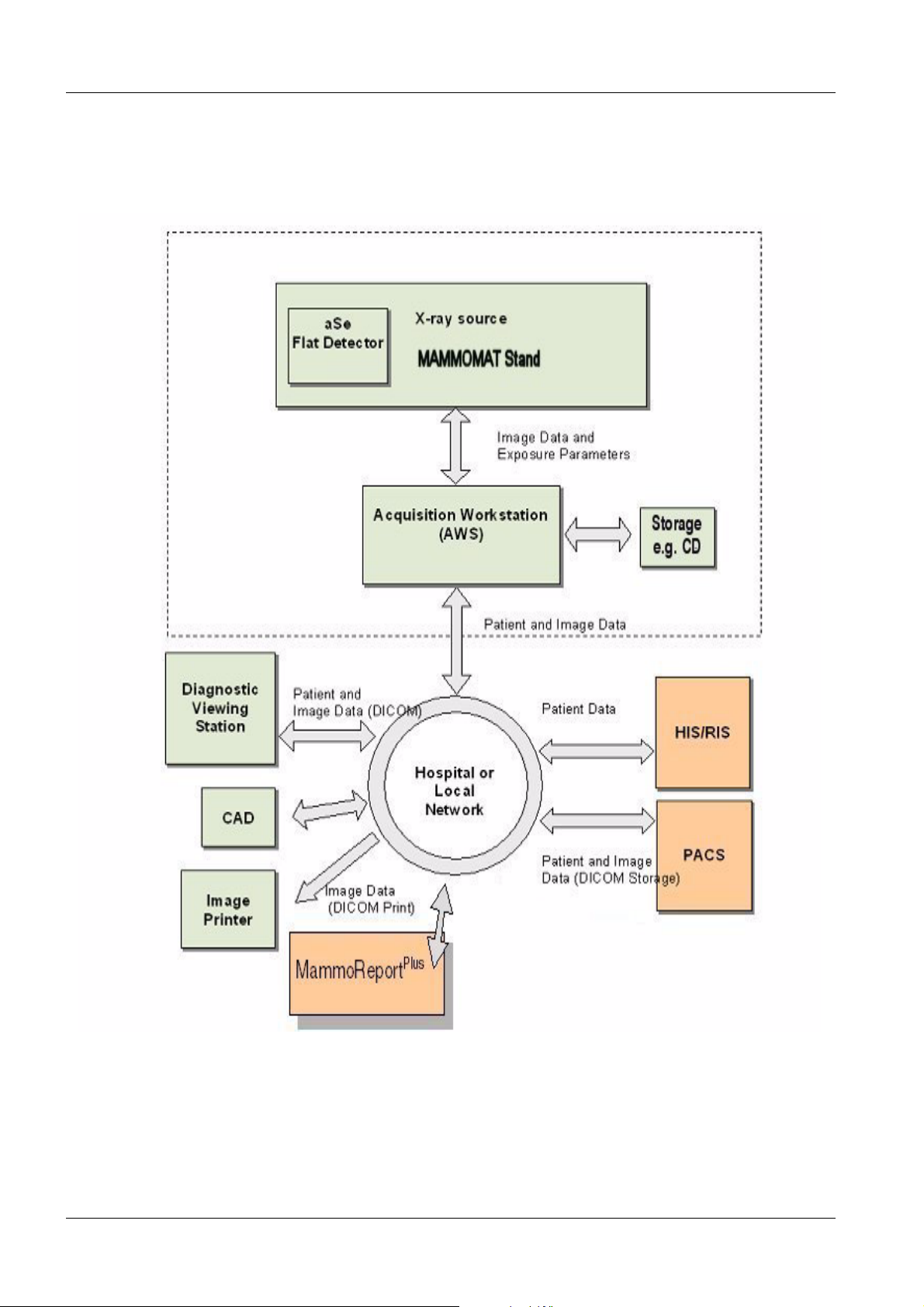

1 - 4 General Notes

MAMMOMAT Novation

DR

Overview of the MAMMOMAT system

1

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 4 of 6 Siemens AG

Page 9

General Notes 1 - 5

Network 1

The acquisition workstation supports the TCP/IP protocol. Due to the required data volumes, we recommend a network of 100 MB/s. Please note that all required network cables, as well as the required

power outlets must be available on site. If needed, an outside contractor must be obtained on site.

Software Installation 1

The acquisition workstation is shipped with the software already preinstalled.

DICOM 1

For detailed information on the DICOM, see PG TDIT-000.891.02...,

which can be found on the Intranet under: CS/ForService/Planning/General...

Siemens AG SPB7-250.891.01 Page 5 of 6 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

DR

Page 10

1 - 6 General Notes

This page intentionally left blank.

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 6 of 6 Siemens AG

Page 11

Room Planning 2

2 - 1

Room Planning Example 1 2

2 cable conduits (each 2 m) included

in the shipment for "on-the-floor"

laying of cables

For additional cable conduits, see

*2

Focus

*1 min. 150 mm if the unit is not secured to the

*3

*3 For safety reasons, the acquisition workstation must be set up outside the area,

per IEC 60601-1-1.

floor (in a special service situation, the generator must be swung out from behind at the stand;

for this, the stand must be moved 500 mm away

from the wall).

min. 500 mm if the unit is secured to the floor.

*2 If needed, additional cable conduits, Part No. 64

38 795 X041E, can be ordered for the connection between the stand and the radiation shield.

NOTE

Siemens AG SPB7-250.891.01 Page 1 of 6 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

The room planning example shows one possible arrangement of the units.

Other arrangements are possible, provided the necessary unit distances

based on the available cable lengths are maintained.

DR

Page 12

2 - 2 Room Planning

Room Planning Example 2 2

2 cable conduits (each 2 m) included

in the shipment for "on-the-floor"

laying of cables

For additional cable conduits, see

*2

Focus

*1 min. 150 mm if the unit is not secured to the

floor (in a special service situation, the generator must be swung out from behind at the stand;

for this, the stand must be moved 500 mm away

from the wall).

min. 500 mm if the unit is secured to the floor.

*2 If needed, additional cable conduits, Part No. 64

38 795 X041E, can be ordered for the connection between the stand and the radiation shield.

*3

*3 For safety reasons, the acquisition workstation must be set up outside the area,

per IEC 60601-1-1.

NOTE

The room planning example shows one possible arrangement of the units.

Other arrangements are possible, provided the necessary unit distances

based on the available cable lengths are maintained.

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 2 of 6 Siemens AG

Page 13

Room Planning 2 - 3

Stand Dimensions 2

Focus

Siemens AG SPB7-250.891.01 Page 3 of 6 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

DR

Page 14

2 - 4 Room Planning

Radiation Shield Dimensions (Option) 2

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 4 of 6 Siemens AG

Page 15

Room Planning 2 - 5

Installing the Control Console on the Wall or on a Table 2

If the system is not equipped with the optional radiation shield, install the control console on the wall or

on a table that is located behind one of the on-site radiation shields. The parts required for vertical or

horizontal installation of the control console on the wall are included in the shipment.

NOTE

Installing the Control Console on the Wall (two possibilities)

Screw anchors and screws are not included in the shipment. Please obtain

these locally and make sure that they are suitable for the particular type of wall

construction.

Cable conduit, on-site

Installation of the Control Console on a Table

Siemens AG SPB7-250.891.01 Page 5 of 6 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

DR

Page 16

2 - 6 Room Planning

Acquisition Workstation 2

Comprised of: 18" color display, PC, keyboard, mouse

Table (option)

1 : 20

The height of table for the acquisition workstation can be adjusted using a motor.

NOTE

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

If the table (option) for the acquisition workstation is not ordered, it must be

provided by the customer.

DR

SPB7-250.891.01 Page 6 of 6 Siemens AG

Page 17

Preparation for Installation 3

3 - 1

Stand Floor Plate 3

(The floor plate is designed to also be the unit base) 3

If due to local regulations (e.g. in earthquake regions) or due to the quality of the floor covering, floor

installation is required, the stand can be installed using heavy-duty expansion bolts or threaded rods

(with a counter-plate). Heavy-duty expansion bolts and threaded rods must be obtained locally.

Cable lead-in from the floor only if the on-the-floor cable conduits included in the

shipment cannot be used. For on-the-floor cable conduits, see Pages 2-1, 2-2

Slots for cable

lead-in

Cable lead-in from the floor left or

right. Obtain cable conduits on site.

1 : 10

View Z

See Page 3-2

*1 See *1 Pages 2-1, 2-2

The max. pull forces that occur per mounting point: 1.5 kN

Siemens AG SPB7-250.891.01 Page 1 of 4 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

DR

Page 18

3 - 2 Preparation for Installation

Radiation Shield Floor Plate (Option) 3

The radiation shield must always be installed on the floor in accordance with IEC 60601-2-32.

Z

Max. pull forces that occur per

mounting point: 1.5 kN

For mounting example, see below

1 : 10

Installation example

Z (1 : 2)

Leveling screw

Cover plate

Room for cable lead-in in floor

Floor plate

Caulk all around using

sanitary silicon

E.g. Hilti heavy duty anchor bolts

HSL M8/20

If safety screws are used, the

manufacturer’s specifications

and instructions must be

observed

With installation on the a solid

floor, cut out the floor covering.

Concrete quality for the solid

floor, min. C20/25

Leveling screw

1 : 2

Mounting materials must be

obtained locally.

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 2 of 4 Siemens AG

Page 19

Preparation for Installation 3 - 3

On-site Electrical Installation 3

Recommendation for an on-site power distributor per DIN VDE 0100-710 or national regulations

Must be constructed on site

Power cable for radiation

To external conductive parts

FI switch, 63 A/I

current and pulsed DC fault currents (recommendation:

Siemens FI 5SZ3 466 0KG05 all current sensitive or

ABB No. F 804 - 63 /0.03. Can be ordered from ABB

Stotz - contact Heidelberg, Tel. 06221 701-00). For other

power line voltages, an appropriate FI switch must be

obtained locally.

System power switch

N 30 mA, UN = 400/415 V ∼ for AC

∆

Emergency off switch with latch mechanism

SIEMENS

On/off switch with pilot lamp

Data corresponds to free lengths in m

This is a dedicated power cable. Thus the following may not be connected:

• Electrical systems

• Heating/air conditioning units

• Elevators

• General electrical equipment

Siemens AG SPB7-250.891.01 Page 3 of 4 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

DR

Page 20

3 - 4 Preparation for Installation

On-site Electrical Installation 3

Recommendation for an on-site power distributor per DIN VDE 0100-710 or national regulations

Must be constructed on site

2-phase

Power cable for radiation

SIEMENS

To external conductive parts

FI switch 63 A/I

pulsed DC fault currents (recommendation: Siemens FI

5SZ3 466 0KG05 all current sensitive or ABB No. F 804

- 63 /0.03. Can be ordered from ABB Stotz - contact

Heidelberg, Tel. 06221 701-00). For other line voltages,

an appropriate FI switch must be obtained locally.

System power switch

N 30 mA, UN = 400/415 V ∼ for AC and

∆

Emergency off switch with latch mechanism

SIEMENS

On/off switch with pilot lamp

Data corresponds to free lengths in m

This is a dedicated power cable. Thus the following may not be connected:

• Electrical systems

• Heating/air conditioning units

• Elevators

• General electrical equipment

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 4 of 4 Siemens AG

Page 21

System Connections 4

4 - 1

Remarks Regarding Laying of Cables 4

Recommendation for Laying Cables

Cable trough depth: 60 mm

if there are cross-overs, it may be necessary to provide greater depth.

Lay high voltage cables and power cables separately from signal cables and video cables (if possible,

provide shielding measures).

Absolutely observe:

Avoid creating cable coils, avoid cable cross-overs.

• Lay in separate conduits or closed cable troughs.

• If laying in open cable troughs, lay cables separately using metal separators or a similar device.

Metal separators

Cable trough

Siemens AG SPB7-250.891.01 Page 1 of 4 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

DR

Page 22

4 - 2 System Connections

Fixpoint Overview 4

*1 Mains power on/off switch is necessary in the installation room, to be able to switch off the entire

power to the system, for service and maintenance purposes.

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 2 of 4 Siemens AG

Page 23

System Connections 4 - 3

Fixpoint List 4

Wiring

Har-

ness

No.

1VKP1 ⎯⎯⎯⎯Power cable, on site

2 P1 P1a 500 1 1/4 Ø 30 10

3P1D3 45 3/4Ø 15 7.5

4D3

5 P1 Lamp ⎯ 1/2 Ø 10 ⎯

6P1

from

Fix-

point

to

Fixpoint

Clinic

network

Door

switch

Cable Chan-

nel Cross

Section in

2

mm

45 3/4 Ø 15 3.5

⎯ 1/2 Ø 10 ⎯

Con-

duit, dia.

in

inches

Minimum

Opening

in mm

Maximum

Fixpoint

Distance

in m

Remark

Control console cable,

shipped length: 11.5 m

Fiber optic cable,

shipped length: 10 m

Ethernet cable,

shipped length: 3.5 m

On-site cable,

3 x 1.5 mm, shielded

On-site cable,

3 x 1.5 mm, shielded

List of Fixpoints Used 4

Fixpoint Subsystem Remark

D3 Acquisition Workstation Floor fixpoint

P1 MAMMOMAT Novation

P1a Radiation shield Floor fixpoint

VK Power distributor box Wall fixpoint

DR

Floor fixpoint

Siemens AG SPB7-250.891.01 Page 3 of 4 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

DR

Page 24

4 - 4 System Connections

This page intentionally left blank.

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 4 of 4 Siemens AG

Page 25

Technical Data 5

5 - 1

Electrical Data 5

Power line connection 1~/2~208, 230, 240, 277 V, ±10%, 50/60 Hz

2~400 V, ±10%, 50/60 Hz

Input fusing: 25 A

Power cable Recommended cable cross section: 6 mm

2

Internal power line resistance, Ri

Fusing (internal) 30 A at 208, 230, 240, 277 and 400 V

I max. 40 A at 230 V, 35 A at 400 V (2-phase)

Power consumption Short-term power consumption,

approx. 10 kVA

Power factor (cos ϕ) 0.6 at 230 V

Connection value 4.6 kVA at 230 V

U

208

230

240

277

400

[V]

N

Long-term load,

approx. 0.8 kVA

Ri

max

0.45

0.50

0.60

0.65

0.85

[Ω]

Environmental Conditions 5

Adm. ambient temperature + 20

Operation Transport/Storage

MAMMOMAT

° ... + 30° C- 10° ... + 70° C+ 10° ... + 40° C

Transport/Storage

Detector in packaging

Adm. rel. humidity

(non condensing)

30% ... 70% 10% ... 95% 10% ... 80%

Dimensions, Weight and Heat Dissipation 5

Dimensions

(W x D x H)

[mm]

Stand with floor plate and generator ⎯ approx. 360 approx. 800

Control console 520 x 200 x 80 approx. 4 approx. 80

Radiation shield with floor plate ⎯ approx. 50 ⎯

Workstation 445 x 97 x 445 approx. 12 approx. 100

18" color display 464 x 240 x 430 approx. 10 approx. 75

Weight [kg] Heat Dissipation [W]

Siemens AG SPB7-250.891.01 Page 1 of 2 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

DR

Page 26

5 - 2 Technical Data

Packaging and Transport Routes 5

Largest crate Crate Dimensions

L x W x H [mm]

Stand 2100 x 800 x 1500 approx. 525

Radiation shield, Acquisition Workstation & accessories 2100 x 800 x 1200 app. 220-300 *1

Detector 900 x 800 x 600 approx. 40

*1 depending on the order

Weight [kg]

Paint Colors 5

Basic color Medical White A610

Combination color Neutral Gray C612

Medical Blue, Med C750

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 2 of 2 Siemens AG

Page 27

Changes to Previous Version 6

Chapter Page Change

0 - 6 Rev. level of the document increased from 03 to 04.

5 5-1 Environmental Conditions at operation updated.

6 6-1 Changes to Previous Version updated.

6 - 1

Siemens AG SPB7-250.891.01 Page 1 of 2 MAMMOMAT Novation

Medical Solutions Rev. 04 08.05 CS SD 21

DR

Page 28

6 - 2 Changes to Previous Version

This page intentionally left blank.

MAMMOMAT Novation

Rev. 04 08.05 CS SD 21 Medical Solutions

DR

SPB7-250.891.01 Page 2 of 2 Siemens AG

Loading...

Loading...