Page 1

MAMMOMAT 3000 Nova

Installation

Installation Instructions

AEC upgrade kit for Fuji CR

SP

© Siemens AG 2002

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

English

Print No.: SPB7-230.812.05.03.02 Doc . Gen. Date: 11.02

Replaces: SPB7-230.812.05.02.02 66 47 114

Page 2

0 - 2 Revision

Chapter Page Revision

All All 03

Document revision level

The document corresponds to the version/revision level effective at the time of system delivery. Revisions to hardcopy documentation are not automatically distribute d.

Please contact your local Siemens office to order current re vision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified personnel

who are employed by Siemens or one of its affiliates or who are otherwise authorized by Siemens or

one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with or authorized by Siemens or one of its affiliates are directed to contact one of the local offices of Siemens or

one of its affiliates before attempti ng installation or service procedures.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 2 of 4 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 3

Contents 0 - 3

Page

1 _______General_______________________________________________________ 1 - 1

2 _______Introduction ___________________________________________________2 - 1

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Important note. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Components included . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Tools, meters and appliances required . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Time required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

MAMMOMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Fuji equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

3 _______Unpacking and setup of the AEC kit for Fuji CR _____________________3 - 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Remaining work steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

4 _______Start-up of the Fuji FCR 5000MA __________________________________4 - 1

Starting up the image reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Erasing the IP cassette(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

5 _______Backup of Fuji CR Console ______________________________________5 - 1

Starting the Service Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Service Utility Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

User Utility Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

6 _______Setup of service PC_____________________________________________6 - 1

Verify Fuji CR Console’s IP configuration . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Verify Fuji FCR 5000MA IP configuration . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Setup of service PC IP address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Editing hosts file. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

AECImageExtract installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

Adding environmental variables . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 5

Start the AECImageExtract applicat ion . . . . . . . . . . . . . . . . . . . . . . .6 - 6

7 _______Setup of Fuji CR Console________________________________________7 - 1

Verify the service PC’s hostname . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Creating network nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Verify connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 6

Create AEC Calibration exposure menu. . . . . . . . . . . . . . . . . . . . . . . 7 - 6

Property setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 9

Siemens-Elema AB SPB7-230.812.05 Page 3 of 6 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 4

0 - 4 Contents

Page

8 ______ Examination ___________________ ___ ____________________________ _8 - 1

9 ______ Calibrating and adjusting the AEC_________________________________9 - 1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 2

Protective measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

Delay times between two exposures . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

Preparation of bac kup floppy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 4

Backup of existing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 4

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 6

Object table group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 6

General conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 6

Calibration conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 6

Reference IP cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 6

Mains voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 6

Sensitivity conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 6

Overview of work routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 7

DLF switch off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 8

Cassette loaded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 8

Increase grid speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 8

AEC Correction tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 9

Installation of AEC correction tables . . . . . . . . . . . . . . . . . . . . . . . . 9 - 9

Calibrate correction tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 11

Recalibration of an object table. . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 16

Sensitivity correction (fine setting) . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 17

Sensitivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 19

Testing the AEC-function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 20

AEC performance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 20

Image detector dose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 20

Reinstall/Install program parameters for OPDOSE. . . . . . . . . . . . . . . . . . .9 - 21

Factory settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 22

Final procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 23

10 _____ Restore configuration _______________________ ___________________10 - 1

Restore Service Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 - 1

Restore User Utility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 - 3

11 _____ Final work steps_______________________________________________11 - 1

12 _____ Start-up protocol _______________ ___ __ __________________________12 - 1

Backup of existing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 - 1

AEC performance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 - 2

Wing 1 M3000, Wing 2 M1000 . . . . . . . . . . . . . . . . . . . . . . . . . . .12 - 2

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 4 of 6 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 5

Contents 0 - 5

Page

Wing 2 M3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 3

Image detector dose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 4

OPDOSE settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 4

13 ______Troubleshooting Guide _________________________________________13 - 1

Ping Network fails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 1

Verify Connection fails. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 1

No images are transferred to the Fuji CR Console . . . . . . . . . . . . . . . . . . 13 - 1

The AEC Calibration exposure menu does not appear in the exposure menu . . . . 13 - 1

14 ______Changes to previous version ____________________________________ 14 - 1

Siemens-Elema AB SPB7-230.812.05 Page 5 of 6 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 6

0 - 6 Contents

This page intentionally left blank.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 6 of 6 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 7

General 1

These instructions describe how t o set u p a Fuji CR Console f or AEC Calibr ation and how

to perform the calibration.

1 - 1

Siemens-Elema AB SPB7-230.812.05 Page 1 of 2 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 8

1 - 2 General

This page intentionally left blank.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 2 of 2 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 9

Introduction 2

Safety information 2

When carrying out the work steps and test, the product-specific safety information contained in this document, as well as the general safety information must be observed.

Important note 2

The figures in this document are based on softwar e version A06 of the Fuji CR Console.

User interface of later software versions might look different.

Components included 2

The AEC upgrade kit for Fuji CR (Siemens material No. 66 33 502) includes:

Quantity Material No. Name

1 66 01 897 AEC M3000 DIGISCAN M

1 66 33 510 AECImageExtract

1 30 77 740 Ethernet switch*

2 - 1

3 66 01 582 Ethernet cable

1 66 30 961 This document

1 66 33 536 Label

1 65 91 577 Barcode label

6 60 01 486 Floppy disk

1 61 62 411 Plastic folder

* 100-240 V~, 50-60 Hz. Delivered with power cord for Europe.

Tools, meters and appliances required 2

• Standard installation tool kit.

• Service PC network board, 10/100 Mbit/s, TCP/IP compatible.

• Operating system Windows2000.

• Connecting cable (PC - Generator), material No. 99 00 440 RE999.

• AEC calibration plexi:

Three plates, 2 cm (material No. 65 61 232)

One plate 1 cm (material No. 65 61 224)

• Ionization chamber and electrometer calibrated at the mammography x-ray beam

energies thin enough to be placed in cassett e compartment (material No. 97 17 612 or

equivalent).

Time required 2

Approximately 8 hours for one Customer Support Engineer.

Siemens-Elema AB SPB7-230.812.05 Page 1 of 2 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 10

2 - 2 Introduction

Prerequisites 2

MAMMOMAT 2

1. The installation of the Siemens MAMMOMAT must be completed.

2. For MAMMOMAT 3000 Nov a with serial No. low er than 6850, upgrade with

extended radiation field kit No. 64 83 551.

3. For MAMMOMAT 3000 Nova with serial No. lower than 7000, upgrade with AEC

kit No. 65 52 819. If the AEC kit is inst alled directly before the prom kit No.

66 24 410, use proms from the prom kit if those are of higher version than the AEC

proms.

Prerequisites (installat ion kit no. 65 52 819):

Depending on the serial number and/or version of t he software of your

MAMMOMAT, complementary measures may have to be taken. These measures

are described below.

- For MAMMOMAT 3000 with serial number lower than 2056:

If not done previously; cha nge the polarity of the stereo le ver switch.

- For MAMMOMAT 3000 with serial number lower than 3242:

Make sure that the art icle no. of the PC board D702 is 64 21 288.

- For MAMMOMAT 3000 software version lower than v1.5:

Replace HSE detectors. The part no. of the HSE detect ors must be 38 47 626.

- For MAMMOMAT 3000 software version lower than v2.2:

Calibrate the swivel-arm rotati on.

NOTICE

The tables for Fuji CR HR-BD imaging plate in IP CASS-BD M will

be installed on D and will overwrite existing tables.

Make sure that the correction tables for the film/screen combination are installed on H.

If more than one film/screen combination has been installed, one

of them has to be removed.

Fuji equipment 2

Fuji FCR 5000 MA reader with Fuji CR Console with SW versio n A06 or higher.

The installation of the Fuji FCR 5000MA reader and the Fuji CR Console must be com-

pleted.

It is recommended that a Fuji service engineer is present during the installation.

Abbreviations 2

FCR = Fuji Computed Radiography

IVK = Installed Volume Component

IP = Imaging Plate

LAN = Local Area Network

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 2 of 2 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 11

Unpacking and setup of the AEC kit for Fuji CR 3

= Option

Unpacking 3

Unpack the accessories from the box.

Setup 3

• Disconnect the network cables from the Fuji equipment. The original network connection

shall be restored when the AEC calibratio n has been performed.

• Connect the MAMMOMAT, Fuji FCR 5000 MA reader, Fuji CR Console and service PC

to the switch with the enclosed network cabl es (Siemens material No. 99 00 440)

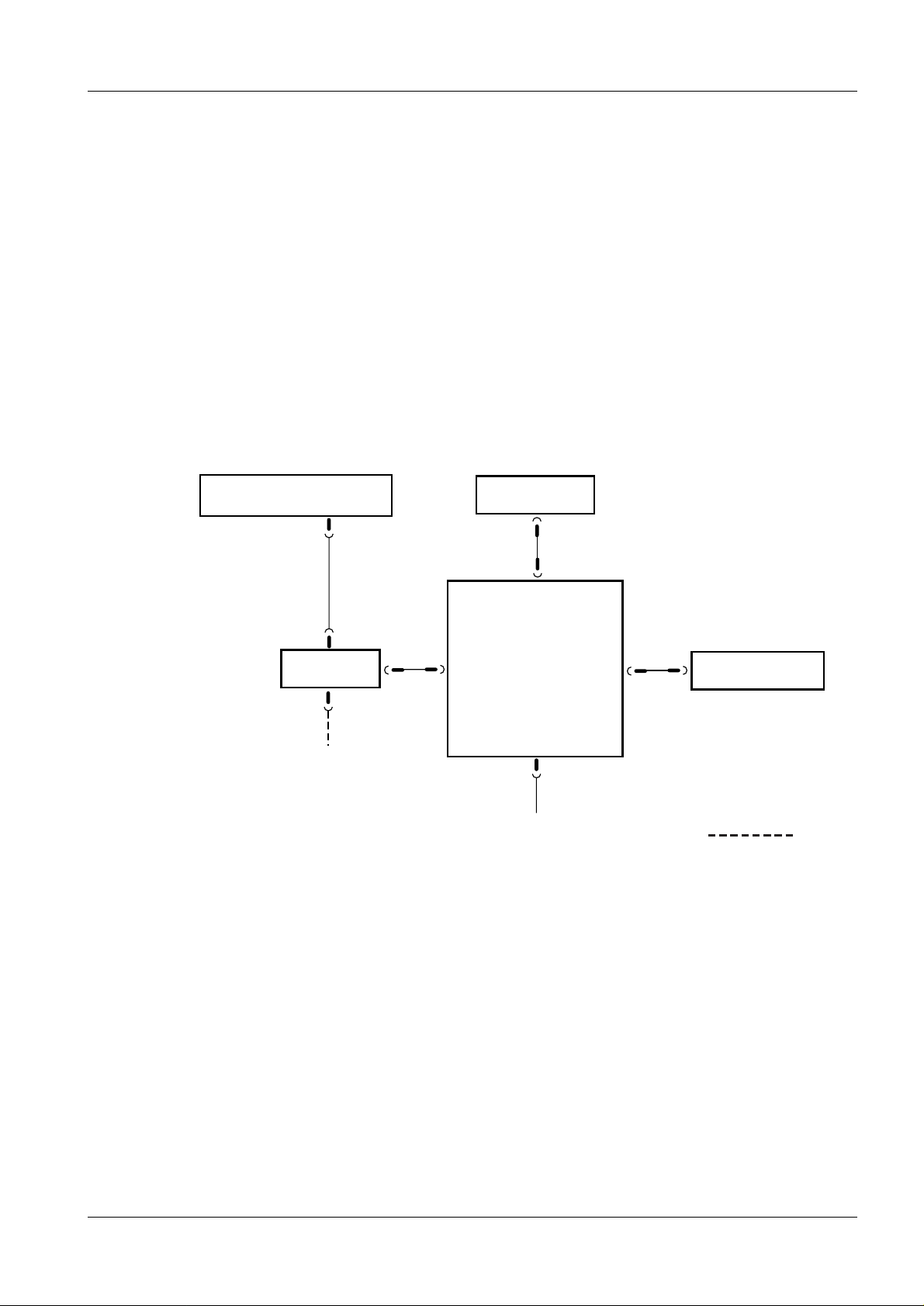

according to Fig. 1. Use the same network socket s on the Fuji equipment as before.

• Connect the switch to the incoming mains.

• Connect the service PC to the MAMMOMAT according to the MAMMOMAT’s Technical

Manual.

3 - 1

MAMMOMAT 3000 Nova

Service PC Switch

Incoming mains

Fig. 1 Configuration

Image reader

Fuji CR Console

Incoming mains

Remaining wor k st eps 3

Remove and dispose of all packaging materials from the components.

Siemens-Elema AB SPB7-230.812.05 Page 1 of 2 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 12

3 - 2 Unpacking and setup of the AEC kit for Fuji CR

This page intentionally left blank.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 2 of 2 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 13

Start-up of the Fuji FCR 5000MA 4

Starting up the image reader 4

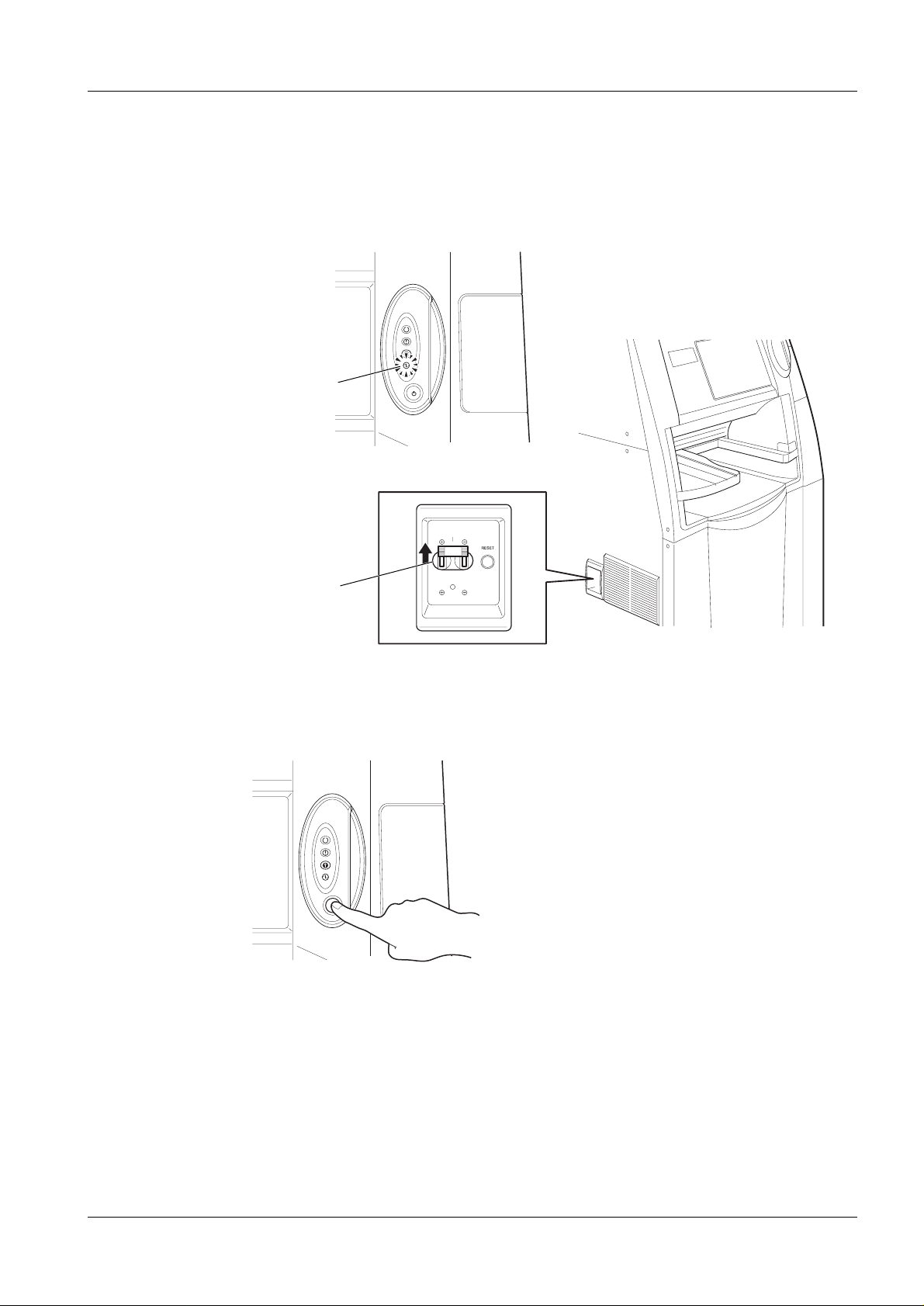

1. Make sure that the power lamp on the operat ion panel lights green.

If it is not lit, the image re ader’s circuit breaker has been turned OFF. Turn the

circuit breaker back ON by turning it to the “I” side.

Power lamp

FFDM00006

4 - 1

Circuit breaker

Fig. 1 Confirming that the power lamp has lit

2. Press the system power switch ON.

FFDM00008

Fig. 2 System power switch ON

FFDM00007

Siemens-Elema AB SPB7-230.812.05 Page 1 of 2 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 14

4 - 2 Start-up of the Fuji FCR 5000MA

1

Erasing the IP cassette(s) 4

When conducting exposure with an IP that has been over exposed, the IP cassette must

be subjected to secondary- and primary erasure processing.

1. Touch the processing mode switchover key and the pr ocessing selection screen

will be displayed.

READING

FFDM00012

Fig. 3 Processing mode switchover key

2. Touch the secondary erasure key to select secondary erasure.

SECONDARY ERASURE

PRIMARY ERASURE

SECONDARY ERASURE

READING

URGENT

Fig. 4 Secondary erasure key

2

FFDM00013

3. Secondary erasure processing has been sele cted for the cassette to be insert ed.

Insert the appropriate ca ssette in the cassette setting uni t. The IP inside the

cassette will be subjected to secondar y erasure processing.

4. Touch the primary erasure key to selec t primary erasure.

5. Primary erasure processing has been select ed for the cassette to be inserted.

Insert the appropriate ca ssette in the cassette setting uni t. The IP inside the

cassette will be subjected to pri mary erasure processing.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 2 of 2 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 15

Backup of Fuji CR Console 5

Make a backup of the Fuji CR Console’s original settings. The backup will be used to

restore the Fuji CR Console’s settings when the AEC calibration has been performed.

The following floppy disks are needed:

Service Utility backup floppy disks Two backup floppy disks to store Service Utility

data from before the installation, marked with “Service Utility Backup 1(2)” and “Service Utility

Backup 2(2)”.

User Utility backup floppy disks Two backup floppy disk to store User Utility from

before the installation, marked with “User Utility

Backup 1(2)” and “User Utili ty Backup 2(2) ”.

Starting the Service Ut il ity 5

The procedure for starting the Service Utility varies depending on whether the Fuji CR

Console power is ON or OFF.

When the power is OFF

Turn ON the PC power. Windows 2000 starts up. After about one minute the Fuji CR

Application starts. When the initial windo w opens , sequen tially c lic k its upper l eft and right

corners within a period of five seconds . The Service Utility starts and the IP Service Utility

window opens.

5 - 1

When the power is ON

Hold down the Shift key and choose Shut down on the menu. Keep the Shift key

pressed until the desktop screen appears. Fr om the menu, sequentially choose

Programs > Fuji Film > FCR. The Fuji CR Applic ation star ts in about one minute.

When the initial window opens, sequentially click its upper left and right corners within a

period of five seconds. The Service Utility starts and the IIP Service Utility window opens .

Service Utility Backup 5

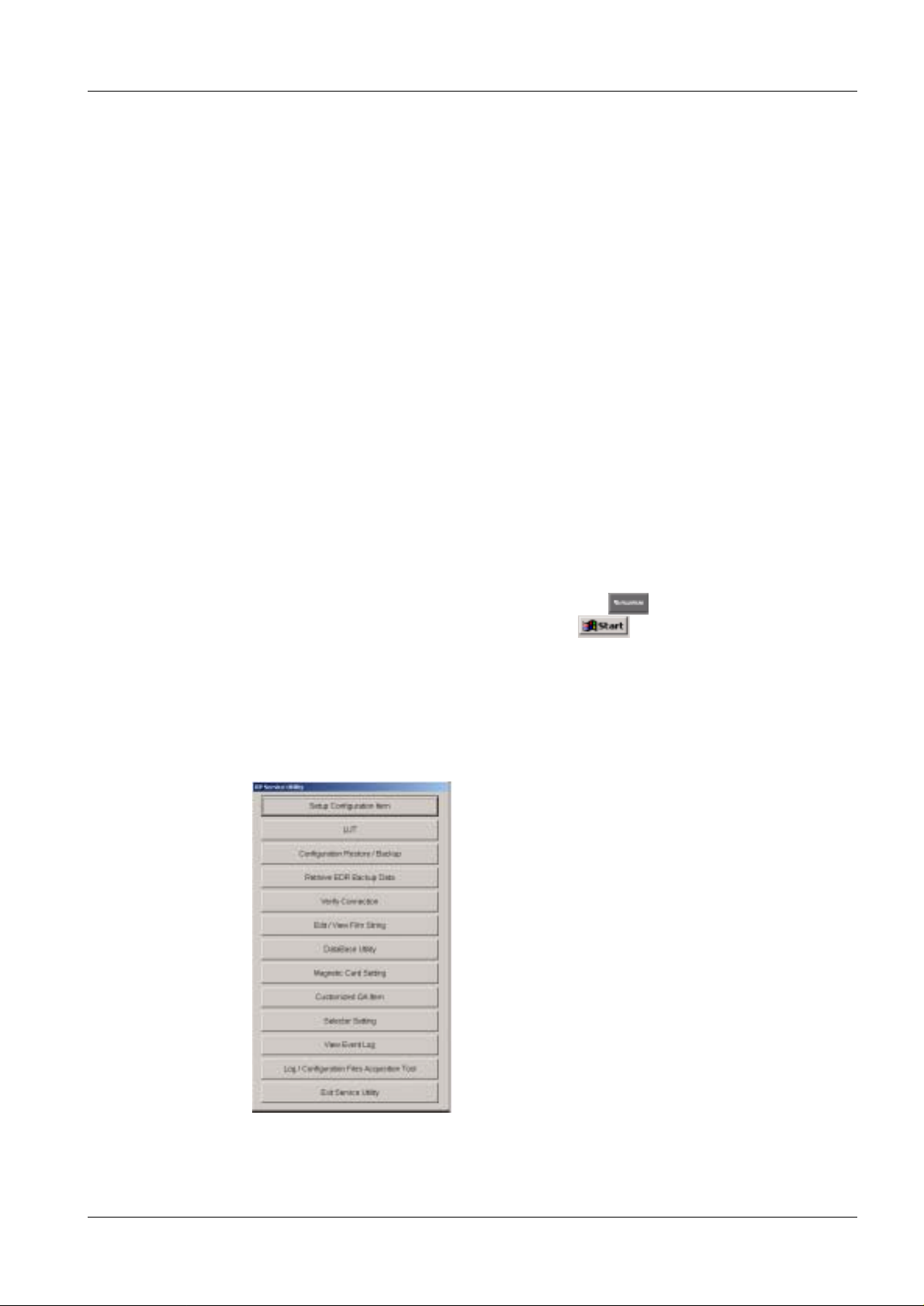

1. Press the Configuration Restore / Backup button acc ording to Fig. 1.

Fig. 1 IIP Service Utility

Siemens-Elema AB SPB7-230.812.05 Page 1 of 4 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 16

5 - 2 Backup of Fuji CR Console

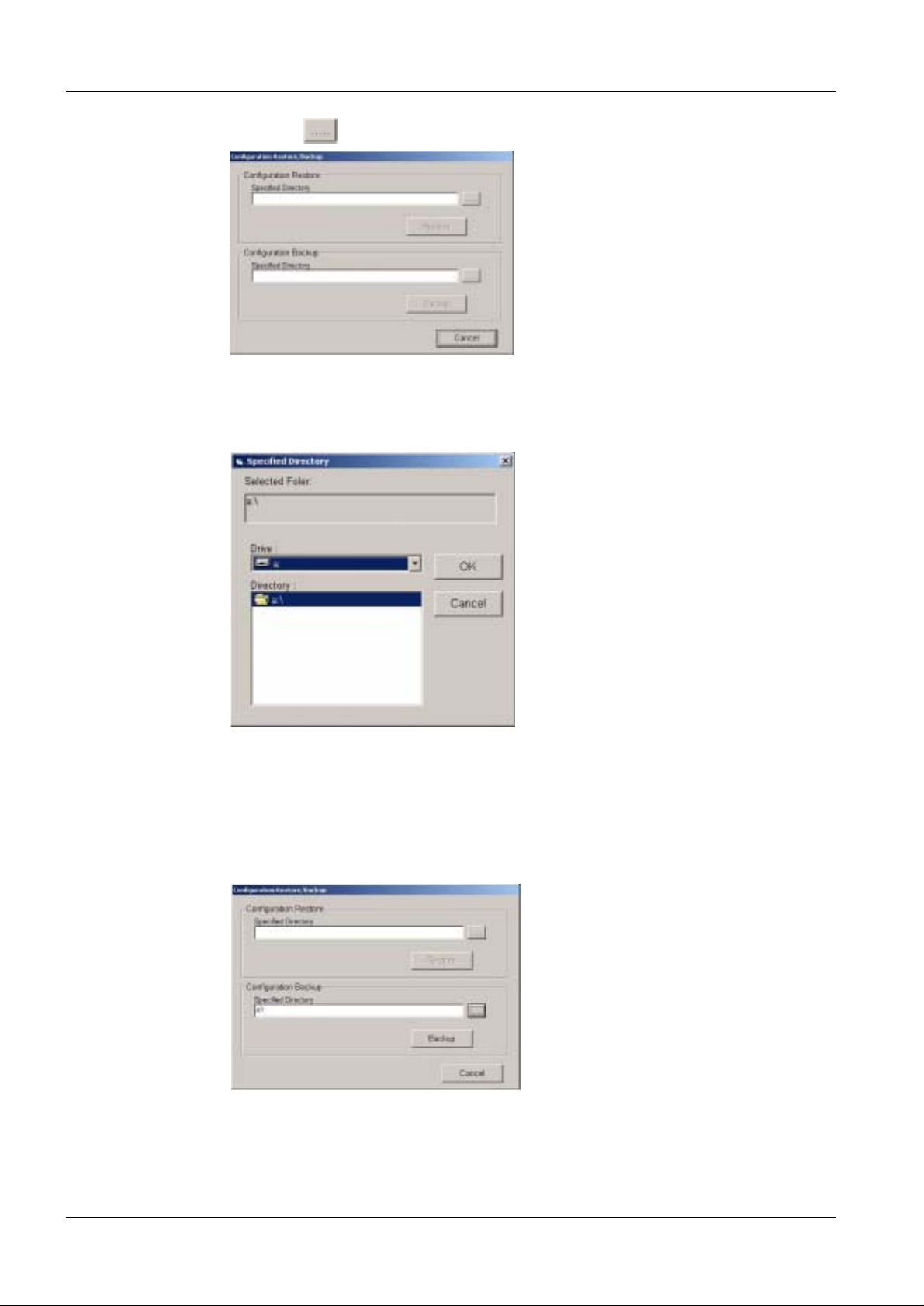

2. Press the button belonging to Configuration Bac kup according to Fig. 2.

Fig. 2 Configuration Restore / Backup

3. Insert the Service Utility Back up 1(2) floppy in drive A: Choose A: from Drive

combo box and press OK according to Fig . 3.

Fig. 3 Specified Directory

4. Press Backup button according to Fig. 4. Follow the instruct ion on the screen.

Even when the backup process ends, no message appears to indicate it. While

the process is being performed, th e mouse cursor is replaced by an hourglass

cursor. When the hourglass cursor chang es back to the mouse cursor, it means

that the process has ended.

Fig. 4 Configuration Restore / Backup

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 2 of 4 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 17

Backup of Fuji CR Console 5 - 3

5. Remove backup floppy.

6. When the process has ended, p ress Cancel button according to Fig . 4. Press Exit

Service Utility button according to Fig. 1.

7. From the menu, sequentially choose Programs > Fuji Film > FCR to start

the Fuji CR Application.

User Utility Backup 5

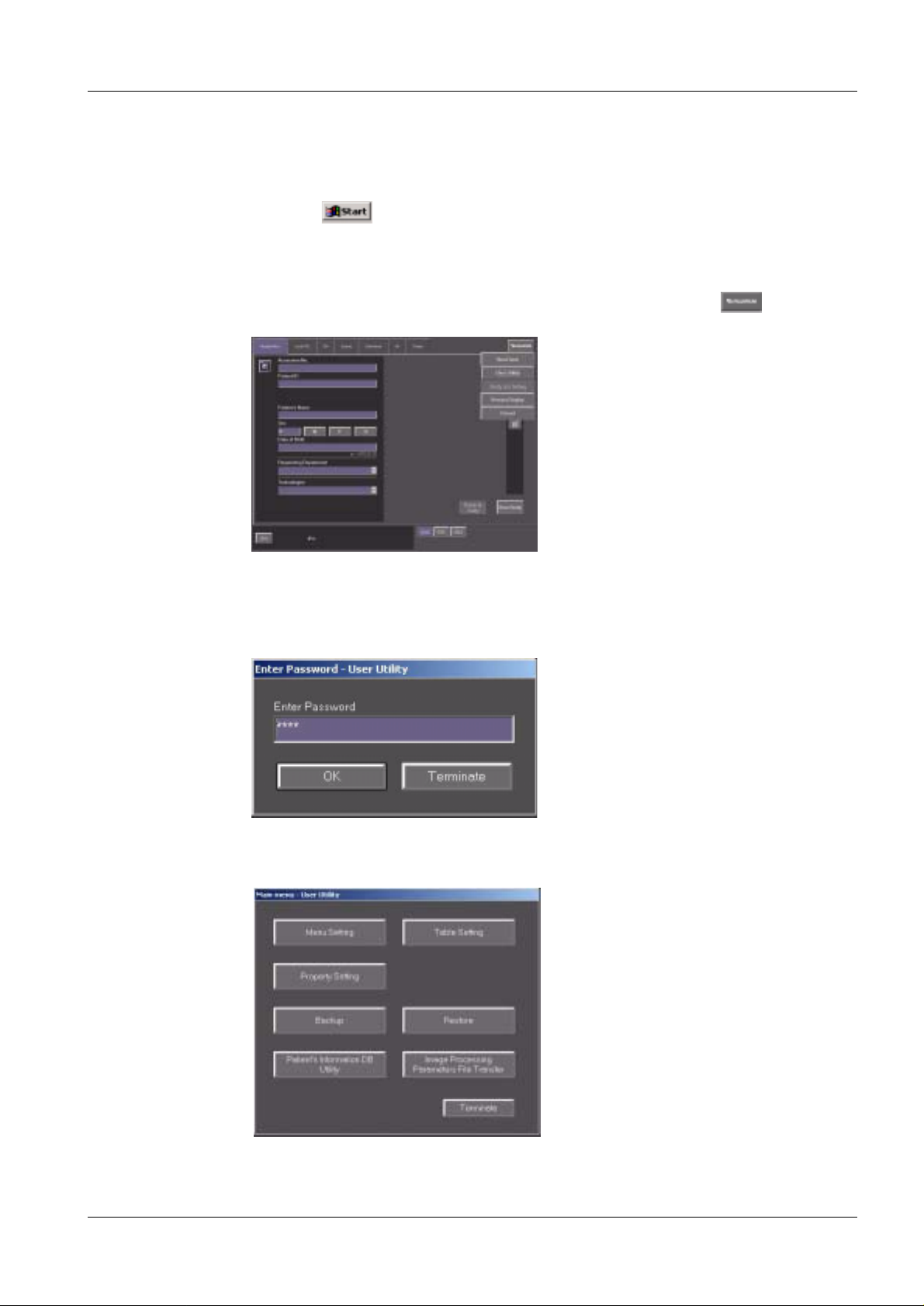

1. Enter the User Utility Main Menu b y choosing User Utility on the menu

according to Fig. 5.

Fig. 5 Enter User Utility

2. Press the OK button in the Enter Pass word – User Utility windo w , without

entering any pass word, according to Fig. 6.

Fig. 6 Enter Password – User Utility

3. Press Backup button according to Fig. 7.

Fig. 7 Main Menu - User Utility

Siemens-Elema AB SPB7-230.812.05 Page 3 of 4 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 18

5 - 4 Backup of Fuji CR Console

4. Insert the User Utility Back up 1(2) floppy in drive A: Mark all fo ur check boxes and

press Start button according to Fig. 8. Follow the instructi ons on the screen.

Fig. 8 Backup – User Utility

5. When the backup process is finished, pr ess the Terminate button according to

Fig. 8 and Terminate button according to Fig. 7.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 4 of 4 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 19

Setup of service PC 6

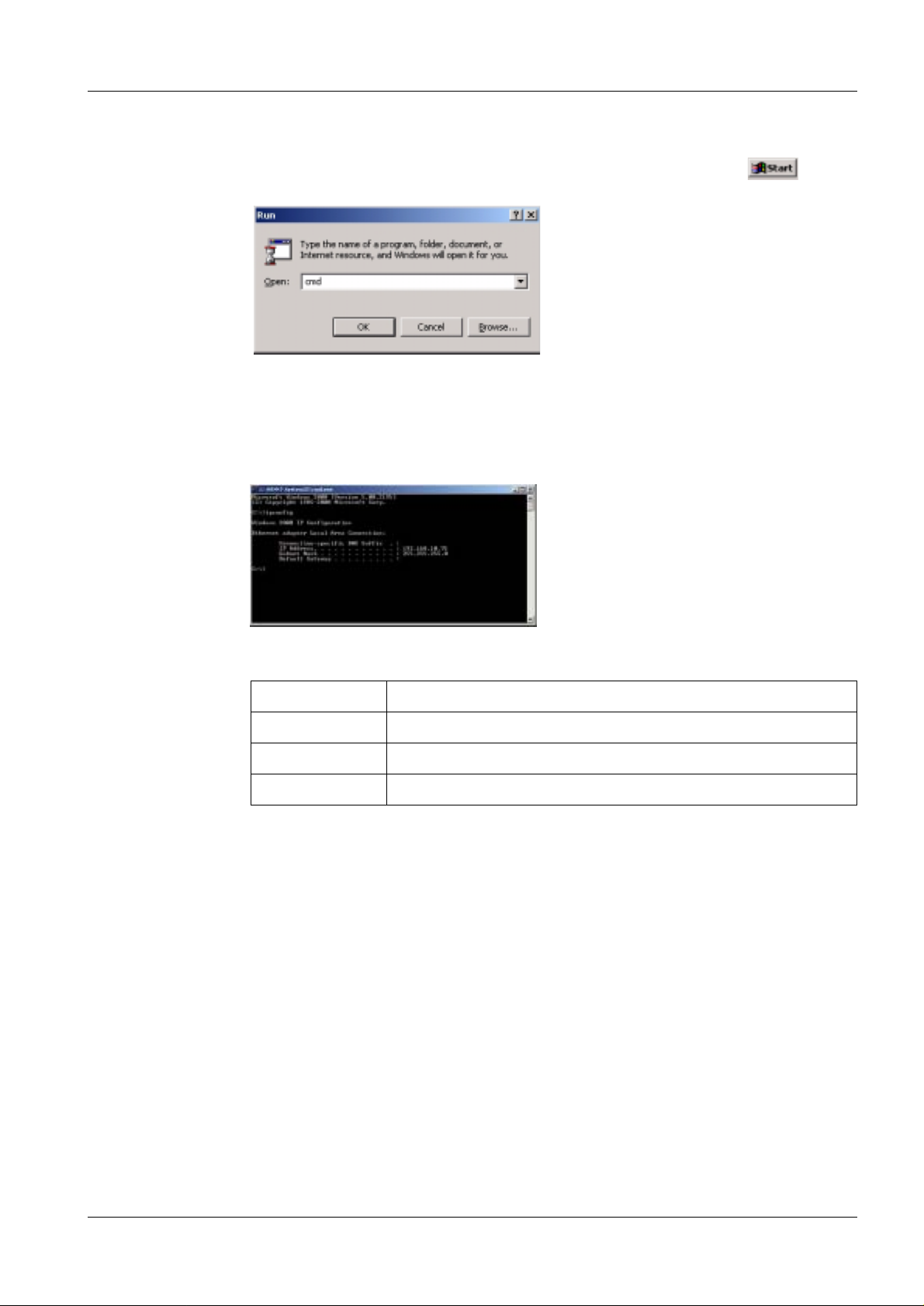

Verify Fuji CR Console’s IP configuration 6

1. Verify the Fuji CR Console IP address: From t he Fuji CR Console’s menu,

choose Run…. Type cmd and press OK according to Fig. 1.

Fig. 1 Run

2. In the DOS prompt, type ipconfig and press Enter. The CR Console’s IP address,

subnet mask and default gateway will show accordi ng to Fig. 2 Note the

information in the table belo w.

6 - 1

Fig. 2 IP Configuration

IP address

Subnet mask

Default gateway

Hostname

3. Close Command window.

Siemens-Elema AB SPB7-230.812.05 Page 1 of 6 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 20

6 - 2 Setup of service PC

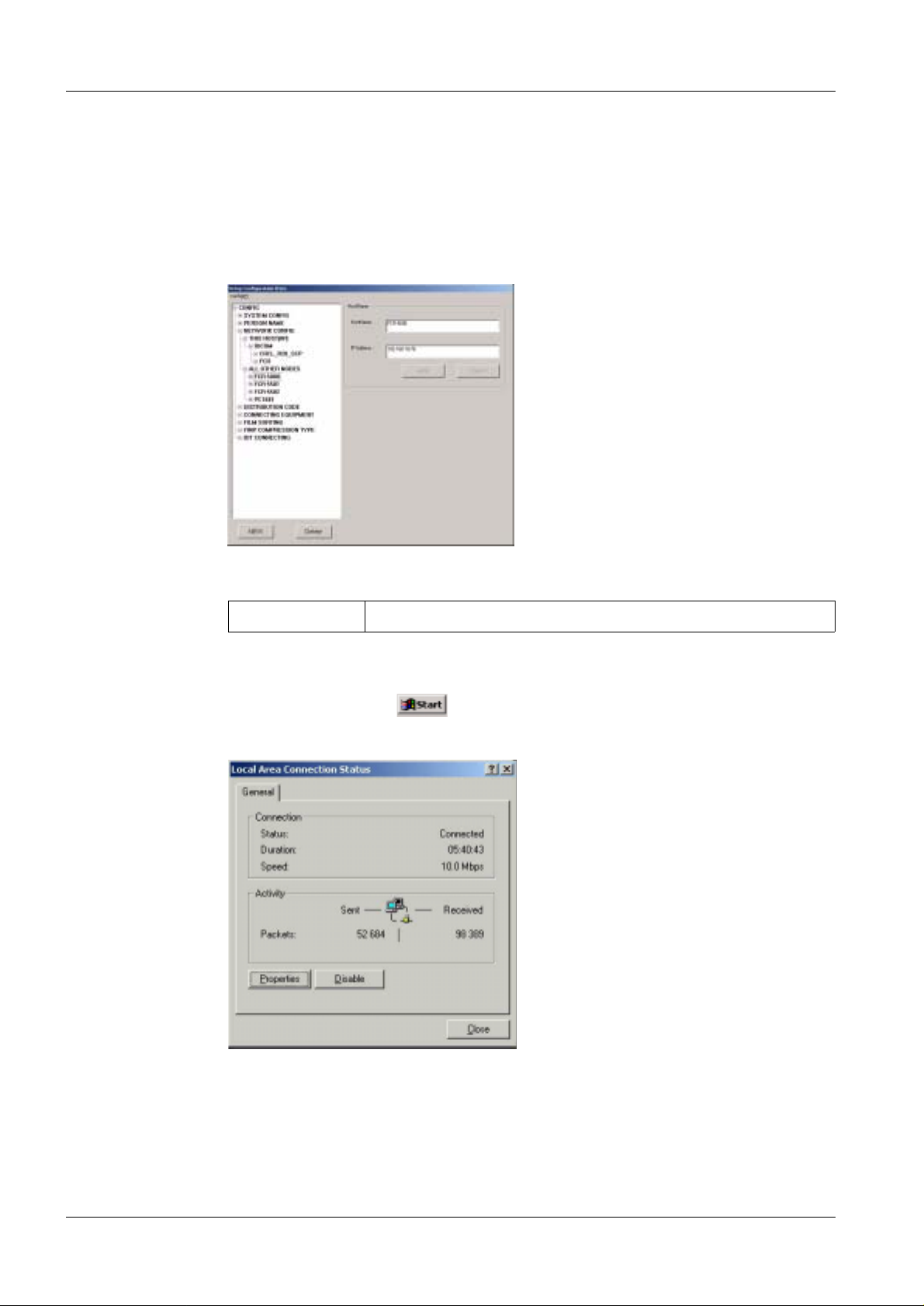

V erify Fuji FCR 5000MA IP configuration 6

1. Verify the Fuji FCR 5000MA IP address: Start t he Service Utility according to

"Starting the Service Utili ty" on Page 5 - 1. Press the Setup Configurati on Item

button according to Fig. 1, Page 5 - 1. Ma rk CONFIG > NETWORK CONFIG >

ALL OTHER NODES > FCR 5000 to view the Fuji reader IP address, according to

Fig. 3. Close the Service Utility by pr essing Config(F) > Close(C). Note the IP

address in the table below.

Fig. 3 Reader IP configuration

IP address

Setup of service PC IP address 6

1. From the service PC’s menu, choose Settings > Control Panel >

Network and Dial-up connections > Local Area Connection. Press Properties

button according to Fig. 4.

Fig. 4 Local Area Connection Status

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 2 of 6 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 21

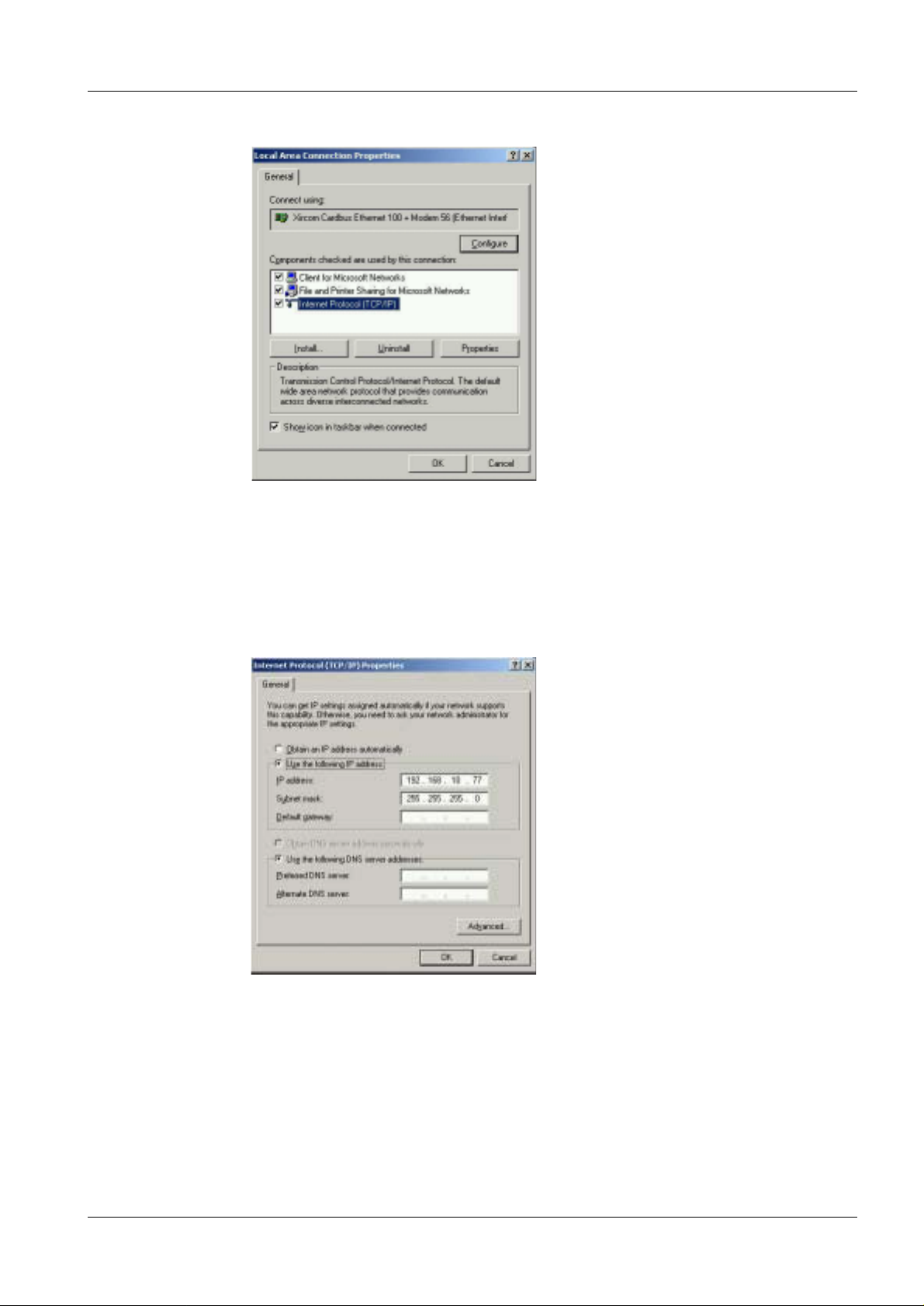

Setup of service PC 6 - 3

2. Mark TCP/IP and press the Properties button according to Fig. 5.

Fig. 5 Local Area Connection Properties

3. Change the service PC’s IP address in such a way t hat the three first groups are

identical to the CR Consoles (see step 2., Page 6 - 1) and the FCR 5000MA (see

step 1., Page 6 - 2), and the fourth gr oup is unique in the LAN. Change the service

PC’s Subnet Mask and Default Gateway to be ide ntical to the Fuji CR Console’s

and press OK button according to Fig. 6. Press OK but ton according to Fig. 5.

Press Close button according to Fig. 4.

Fig. 6 Internet Protocol (TCP/IP) Properties

Siemens-Elema AB SPB7-230.812.05 Page 3 of 6 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 22

6 - 4 Setup of service PC

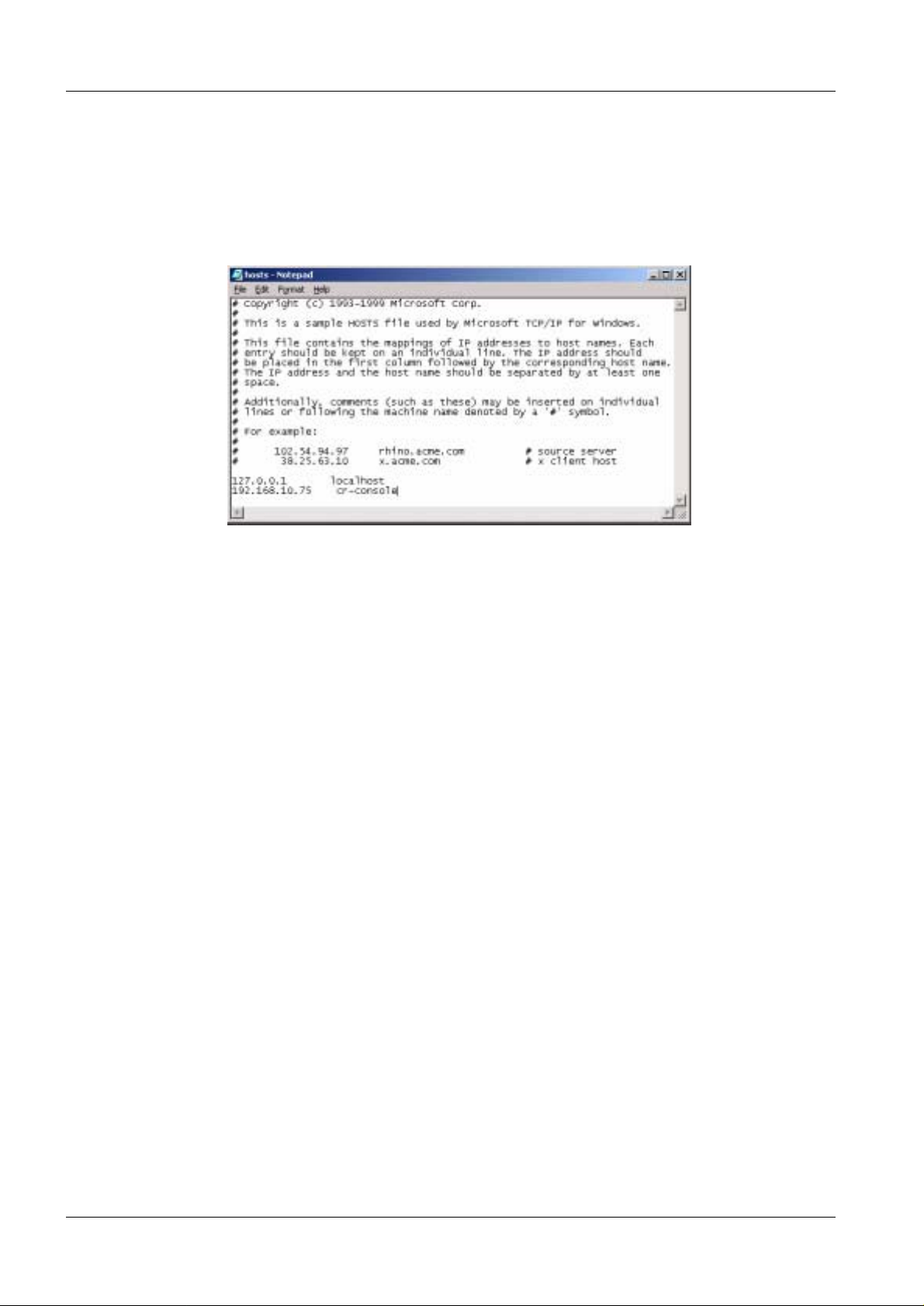

Editing hosts file 6

1. The IP address of the Fuji CR Console needs to be adde d to the service PC’s

Windows file hosts. This file can be found in the direc tory

C:\WinNT\system32\drivers\etc. Open the file with e.g. Notepad and add a line

with the Fuji Consoles IP address (s ee step 2., Page 6 - 1), and a name to identify

it, according to Fig. 7. Save the fi le and exit Notepad.

Fig. 7 Edit the Windows file hosts

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 4 of 6 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 23

Setup of service PC 6 - 5

AECImageExtract installation 6

1. Start service PC.

2. Log in (make sure you have administrator ri ghts).

3. Open Windows Explorer.

4. Insert the AECImageExtract floppy i n drive A:.

5. Run the self-extracting file, AECImageExtract.exe.

6. Unzip to folder C:\, press Unzip button and press Close button according to Fig. 8.

Fig. 8 UnZip Self-Extractor

7. Remove AECImageExtract floppy.

Adding environmental variables 6

1. From the menu, choose Settings > Control Panel > System >

Advanced. Press Environmental Variables button according to Fig. 9.

Fig. 9 System Properties

Siemens-Elema AB SPB7-230.812.05 Page 5 of 6 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 24

6 - 6 Setup of service PC

2. Add a new User Variables for Administrator by pres sing New… button

according to Fig. 10.

Fig. 10 Environmental Variables

3. Type MERGE _INI in the Variable Name field and

C:\AECImageExtract\Merge\Mergecom.ini in the Variable Value field and

press OK button according to Fig. 11. Press OK button according to Fig. 10 and

according to Fig. 9. Restart the ser vice PC.

Fig. 11 New User Variable

Start the AECImageExtract application 6

1. Start service PC.

2. Log in (make sure you have administr ator rights).

3. Open Windows Explorer.

4. Start the AECImageExtract applicati on on the service PC by running the batch file

go.bat that can be found under the director y C:\AECImageExtract.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 6 of 6 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 25

Setup of Fuji CR Co nsole 7

Verify the service PC’s hostname 7

1. From the service PC’s menu, choose Run…. Type cmd and press OK

button according to Fig. 1.

Fig. 1 Run cmd

2. In the DOS prompt, type “hostname” and press Enter. The service PC’ s

hostname will show according to Fig. 2. Close Command window. Note the

hostname in the table below.

7 - 1

Fig. 2 Hostname

Hostname

Siemens-Elema AB SPB7-230.812.05 Page 1 of 10 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 26

7 - 2 Setup of Fuji CR Console

Creating network nodes 7

1. Enter the Fuji CR Console’s IIP Servi ce Utility according to "Star ting the Service

Utility" on Page 5 - 1. Press the Setup Confi guration Item button according to

Fig. 3.

Fig. 3 Service Utility

2. Add a network node for the service PC by markin g CONFIG > NETWORK

CONFIG > ALL OTHER NODES and pressing the NEW button according to Fig.

4.

Fig. 4 Creating a new network node

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 2 of 10 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 27

Setup of Fuji CR Console 7 - 3

3. Type the service PC’s HostName (see step 2., Page 7 - 1) and IP address in

respectively field, mark DICOM check box and press OK button according to Fig.

5.

Fig. 5 Network node information

4. Type the service PC’s Application Entity Name; DICOM_HIC, which is preset by

the AECImageExtract application, type Port Number; 21760, also preset by

AECImageExtract, in respectively field, choose OD_FILE from the Attribute

combo box and press the New button according to Fig . 6.

Fig. 6 Creating Service Classes as SCP

5. Set Abstract Syntax combo box to CRImageStorage, set Role to SCP, s et

Transfer Syntax combo box to ImplicitVRLittleEndian, set Acceptable Density

to ST & HQ & SH, set Default Output Density to HQ / SH, set Image Processing

to NONE(N), clear the Multibyte check box and press the OK button according to

Fig. 7.

Fig. 7 CRImageStorage as SCP

Siemens-Elema AB SPB7-230.812.05 Page 3 of 10 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 28

7 - 4 Setup of Fuji CR Console

6. Press New button accordi ng to Fig. 6. Set Abstract Syntax combo box to

Verification, set Role to SCP, clear the MultiByte check box and press the OK

button according to Fig. 8. Press OK button according to Fig. 6.

Fig. 8 Verification as SCP

7. Mark the row in Network Config > This Host IIP > DICOM where the ser vice

classes has SCU roles, and press New button according to Fig. 9.

Fig. 9 Creating Service Classes as SCU

8. Set Abstract Syntax combo box to CRImageStorage, set Role to SCU, set

Transfer Syntax combo box to ImplicitVRLittleEndian, cl ear the Multibyte

check box and press the OK button according to Fig. 10.

Fig. 10 CRImageStorage as SCU

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 4 of 10 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 29

Setup of Fuji CR Console 7 - 5

9. Press the New button according to Fig. 9. Set Abstract Syntax combo box to

Verification, set Role to SCU, clear the Multibyte check box and press the OK

according to Fig. 11.

Fig. 11 Verification as SCU

10. Mark Connecting Equipment and press the New button according to Fig. 12.

Fig. 12 Connect new equipment

11. Choose, or write, OD_FILE in the Function combo box. Choose the service PC’s

AE Title in the first Equipment combo box, even th ough other equipment are

preset, and press OK button according to Fig. 13.

Fig. 13 C onnect ing service PC

12. Save Network configuration by pressing Config(F) > Save(V) in t he top left corner

according to Fig. 12. Exit the Servi ce Utility by pressing Config(F) > Close(C).

Siemens-Elema AB SPB7-230.812.05 Page 5 of 10 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 30

7 - 6 Setup of Fuji CR Console

V erify connection 7

1. Choose Verify Connection according to Fig. 3. Select service PC’s hostname in

the upper combo box and press Ping Network button.

2. Start AECImageExtract applicati on on service PC according to "Start the

AECImageExtract application" on Page 6 - 6.

3. Choose service PC AE Title in lower combo box and press Ver ify Connection

button. Press Close button accordi ng to Fig. 14.

Fig. 14 Verify Connection

4. Exit Service Utility by pressing Exit Serv ice Utility button according t o Fig. 3.

Create AEC Calibration exposure menu 7

1. Start the AECImageExtract applicati on on the service PC according to "Start the

AECImageExtract application" on Page 6 - 6.

2. From the menu on the Fuji CR Console, sequentially choose Programs >

Fuji Film > FCR. The Fuji CR Applicat ion starts in about one minute.

3. Choose User Utility on the menu accor ding to Fig. 15.

Fig. 15 Enter User Utility

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 6 of 10 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 31

Setup of Fuji CR Console 7 - 7

4. Press OK button in the Enter Password – User Utility window, without ent ering

any password, according to Fig. 16.

Fig. 16

5. Press Menu Setting button according to Fig. 17.

Fig. 17 User Utility Menu

6. Mark exposure menu Max 4.0 in the Exposure / Study Menu field, an d create a

new exposure menu by pressing New button according to Fig. 18.

Fig. 18 Menu Setting

Siemens-Elema AB SPB7-230.812.05 Page 7 of 10 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 32

7 - 8 Setup of Fuji CR Console

7. Name the new exposure menu AEC Calibration in the field ANK Exp osure Menu

Name. In Exposure Parameter 1 task card, set EDR Mode to Fix, change S

value to 121 and set Film Output Format to One Image ac cording to Fig. 19.

Fig. 19 Exposure Parameter 1

8. In Exposure Parameter 2 task card, set Film Reference Orientati on to Portrait,

Film Edge to Black and press OK button according t o Fig. 20.

Fig. 20 Exposure Parameter 2

9. Drag and drop the AEC Calibration Exposure Menu f rom the Exposure/Study

Menu field to one of the empty buttons in the TEST t ask card and press OK button

according to Fig. 21.

Fig. 21 Drag and Drop

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 8 of 10 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 33

Setup of Fuji CR Console 7 - 9

Property setting 7

1. The Property Settings has to be changed to pr event images to be sent to printers

and to other storages than the service PC.

2. Enter property setting by pressing t he Property Setting button according to Fi g.

17.

3. Set Setting of action to be taken… to Terminate Study after QA is completed.

(For Fuji CR Console software version A08: Set The method at the time pushed

“Study finish” button. (There is no unreg istration menu) to Finish exposure

& QA in the task card Study setting).

4. Set Auto-distribution Setting to Distributes automatically after QA

completion (in Fuji CR Console software vers ion A08 this is done in the task card

Distribution setting).

5. Set PRINT Attribute to (none) to prevent the AEC exposures to be printed (in Fuj i

CR Console software version A08 this is done in the task card Distribution

setting).

6. Set FILE Attribute to the service PC’s AE Title to enable automatic dist ribution of

images to the service PC (in Fuji CR Console sof tware version A08 this is done in

the task card Distribution se tting).

7. Press OK button according to Fig. 22. Exit the User Utilit y menu by pressing the

Terminate button according to Fi g. 17.

Fig. 22 Property Setting

Siemens-Elema AB SPB7-230.812.05 Page 9 of 10 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 34

7 - 10 Setup of Fuji CR Console

This page intentionally left blank.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 10 of 10 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 35

Examination 8

1. Input patient informati on (either Patient ID or Patient´s Name is necessary) and

press the Exposure Menu button accor ding to Fig. 1.

Fig. 1 Patient registration

2. During the whole AEC calibration, choose t he AEC Calibration exposure menu

from the TEST task card according to Fig. 2 and press OK button.

8 - 1

Fig. 2 AEC Calibration

3. Start the study by pressing the Start St udy button according to Fig. 3.

Fig. 3 Start Study

Siemens-Elema AB SPB7-230.812.05 Page 1 of 4 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 36

8 - 2 Examination

4. Insert the IP cassette in the object table according to Fig. 4.

FFDM00020

Fig. 4 Insertion of IP cassette

5. Make an exposure with the MAMMOMAT. Register the cassette ei ther by the

Barcode Scanner, or by pressing the IP# but ton according to Fig. 3, and then type

the 8 digit number from the cassette according to Fig. 5 and press Enter on the

keyboard.

Fig. 5 Cassette registration

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 2 of 4 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 37

Examination 8 - 3

6. Make sure that the cassette ready lamp light s green.

Cassette ready lamp li ghts

FFDM00025

Fig. 6 Inserting the cassette

7. With the IP cassette’s barcod e window facing up and in front, insert the IP

cassette slowly straight al ong the guide on the right.

CAUTION

Be sure to insert the cassette as illustrated, straight along the

guide on the right. Cassettes that have been set upside-down, in

the wrong direction or at a slant will result in abnormalities and

may damage the equipment.

Cassette guide

FFDM00026

Fig. 7 Insert straight slowly

Siemens-Elema AB SPB7-230.812.05 Page 3 of 4 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 38

8 - 4 Examination

8. After approximately 60 s when the cassette removal lamp is lighting, remove the

cassette slowly and straight. (The cassette can be used directly for a new

exposure.)

FFDM00028

Fig. 8 Removing the cassette

9. When the image has been sent from the reader and app ears on the Fuji CR

Console Screen, press the button once to return to the Registrati on task

card and to send the image to the service PC acc ording to Fig. 9.

Fig. 9 Image transfer

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 4 of 4 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 39

Calibrating and adjusting the AEC 9

General 9

These instructions describe installation of AEC floppy disk with material No. 66 01 897.

This floppy di sk makes AEC tables for Fuji CR HR-BD imaging plate in IP CASS-BD M

available.

The AEC is based on correcti on tables. The tables are optimized for the IP/cassette combinations in table 1.

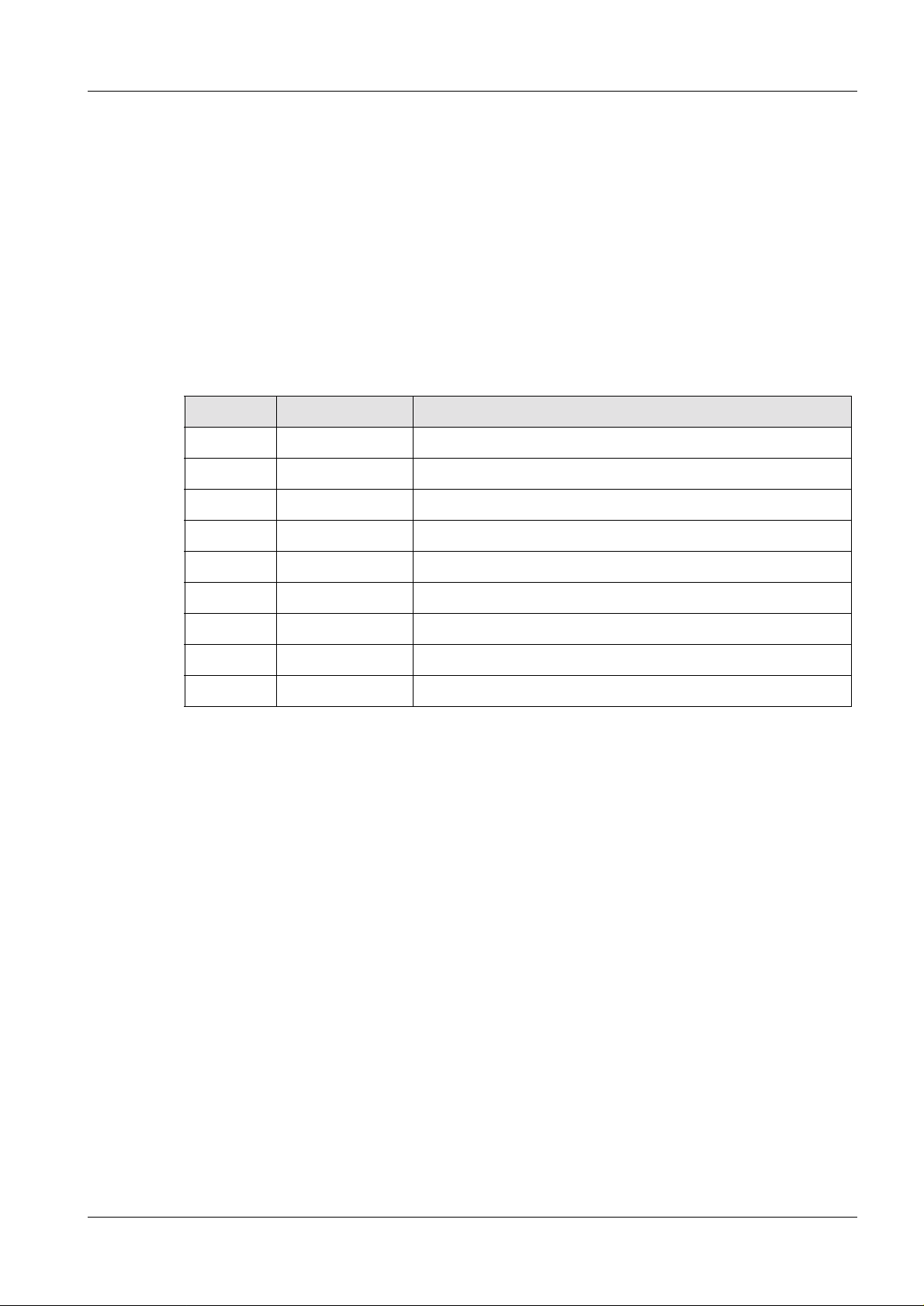

Table 1 Correction table identifications

Scanner IP Cassette Sensitivity Mo/Mo Mo/Rh W/Rh

9 - 1

Fuji

FCR5000MA

plus

Fuji

CR HR-BD

Fuji

IP CASS-BD M 0 1401 1402 1403

Siemens-Elema AB SPB7-230.812.05 Page 1 of 24 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 40

9 - 2 Calibrating and adjusting the AEC

m

A

p

Definitions 9

AD Value

D V alue

ax 1023

450

min 0

0.01 0.1 1 10

log Ex

Old backup floppy disk Backup floppy disk to store data from before the

installation. To be marked “Old backup” and with serial

No. of the MAMMOMAT system, date, and version of the

correction tables.

New backup floppy disk Backup floppy disk to store data during and after the

installation. To be marked “New backup ” and wit h serial

No. of the MAMMOMAT system, date, and version of the

correction tables.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 2 of 24 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 41

Calibrating and adjusting the AEC 9 - 3

Protective measures 9

It is very important that any interv ention in the equipment wil l start by disconnect ing it from

the power supply with the main circuit-breaker.

WARNING

WARNING

If the system is only switched off at the control panel or with

S2/D711, line vol ta ge will still be prese nt a t the generat or l ine connection, line filter Z1, Z2, transformer T1, transformer T10 and

PC board D711 (see MAMMOMAT 3000 Nova Wiring Diagram).

Life-threatening electric shock hazard exists.

Disconnect mains cable and com ply with the information on this

page.

After shut-down of the system, there may still be 380 V DC

present on the intermediate circuit.

Life-threatening electric shock hazard exists.

The voltage level will be indicated by LED V24 on PC board D710.

The voltage will dr op to less than 30 V withi n about 3 minutes, the

LED goes out at about 30 V.

Symbols 9

Checks and adjustments that m ust be perf ormed with radi ation ON are i dentif ie d

by the radiation w a rning symbol.

Delay times between two exposures 9

Delay times listed below must be followed in order to prevent the tube from overheating.

Exposure mAs value Delay time between two exposures (seconds)

max 100 min 15

max 200 min 30

max 300 min 45

max 400 min 60

max 500 min 75

Siemens-Elema AB SPB7-230.812.05 Page 3 of 24 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 42

9 - 4 Calibrating and adjusting the AEC

Preparation of backup floppy 9

1. Start service PC.

2. Log in (make sure you have administr ator rights).

3. Open Windows Explorer.

4. Create a new folder under C: and name it “AEC_inst”.

5. Insert the service program floppy i n drive A:.

6. Copy the files service.exe and m300.h60 fr om A: to C:\AEC_inst.

7. Insert the floppy AEC correction tabl es in drive A:.

8. Copy all files from A: to C:\AEC_inst.

9. Mark an empty backup floppy with new backup, seri al number of the

MAMMOMAT system, version of the correction tables , and date. Insert the floppy

in drive A.

10. Copy the content of C:\AEC_inst to A:.

Use this floppy for the rest of the i nstallation.

11. Press Start and select Programs > Accessories > Command Prompt.

12. In the DOS prompt, type:

“CD \” and press Enter,

“MKDIR mammomat” and press Enter,

“CD mammomat” and press Enter,

“A:” and press Enter.

13. If AEC correction tables have been install ed on the MAMMOMAT before, make a

backup of these tables, see "Backup of ex isting system" on Page 9 - 4.

14. Start the service program by running the service.exe file from A:.

Backup of existing system 9

1. Make sure that the service fl oppy is still in drive A:.

2. Start the service program by writi ng: Service, then press Enter.

3. - In the log in-menu, enter your name and pr ess Enter.

- Type the password for the service progra m and press Enter.

- In Program-mode set: normal.

4. Check that service program version 4. 3 or higher is used. The version is shown in

the top left corner of th e display.

5. In Mainmenu select Configuration > Power. Note the displayed power values in

the test protocol on Page 12 - 1.

6. Take the backup to hard disk: Backup > Copy insta llation area to disk > All.

7. Take out the floppy with the service pro gram and insert an empty floppy disk and

mark it with old backup, serial number of system, version of the cor rection tables,

and date. This floppy is defined as old backu p floppy.

8. In Mainmenu select Configuration > Save config file. Press F2 t o save.

9. In Mainmenu select Service > Copy error buffer to file.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 4 of 24 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 43

Calibrating and adjusting the AEC 9 - 5

10. If the MAMMOMAT is equipped with OPDOSE, press the left progr am button on

the panel. Note the displayed exposu re settings in the test protocol on Page 12 - 1.

Repeat for all four programs. Ente r menu Configuration > Miscellaneous >

Auto limits. Note the three values in test protocol on Page 12 - 1, in colu mn

“Breast thickness”.

11. Quit the service program by pres sing F10.

12. Type “C:” and press Enter.

13. Type “COPY *.TXT A:” and press Enter.

14. Check that the following backu p files are stored on the floppy disk ( by typing

“dir a:”, then pressing Enter):

- a_backup.txt for AEC parameters

- s_backup.txt for stand parameter s

- p_backup.txt for panel parameter s

- momo_h.txt for AEC correction tables

- morh_h.txt for AEC correction tabl es

- wrh_h.txt for AEC correction tabl es

- momo_d.txt for AEC correction tables

- morh_d.txt for AEC correction tabl es

- wrh_d.txt for AEC correction tabl es

- mammo.cfg for configuration parameters

- errorbuf.txt for err or log

15. Type “DEL *.TXT” and press Enter.

16. Remove the floppy disk and make it write pr otected.

17. Insert the new backup floppy in drive A:.

18. Start the service program by r unning the service.exe file from A:.

Siemens-Elema AB SPB7-230.812.05 Page 5 of 24 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 44

9 - 6 Calibrating and adjusting the AEC

Definitions 9

Object table group 9

An object table group contai ns all object tab les of the same type. There are four groups of

object tables - Grid, No grid, Magni fication and Stereo. For ex ample the obj ect tab le group

Grid, consists of Grid 18x24 and Grid 24x30.

NOTE

Stereo shall not be used together with Fuji CR.

General conditions 9

When performing the settings in this chapter, there are some general conditions valid for

all settings:

• The detector is to be in chest wall position.

MAM00616

• The AEC calibration plexi (material No. 65 61 224 and 65 61 232) must extend at least 10

mm beyond the chest wall edge of the table and be centere d. Place the AEC calibration

plexi in the same position for all exposures.

Calibration conditions 9

Compression plate must not be used during the calibration of corre ction tables. From the

point sensitivity correction (fine setting) a compression plate may be used.

Reference IP cassette 9

Every DIGISCAN M system should have a reference IP cassette. Use this reference IP

cassette where required and for the settings in this chapter. If there is no dedicated reference IP cassette, pick one IP cassette, mark it and use it for the settings in this chapter.

Mains voltage 9

Unless otherwise stated, the mains voltage and system must be ON and the service program running, before performing any setting in this chapter.

Sensitivity conditions 9

• One step (1/8 E.P.) corresponds to approximately 4 AD Values.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 6 of 24 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 45

Calibrating and adjusting the AEC 9 - 7

Overview of work routine 9

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

AEC

Miscellaneous

Filament

AEC

Reset installation parameters

Detector normalization

AEC Correction tables

Sensitivity correction

Copy H to D

Copy D to H

Sensitivity

MAM00611

1. "AEC Correction tables" on Page 9 - 9.

2. "Sensitivity correcti on (fine setting)" on Page 9 - 17.

3. "Sensitivity" on Page 9 - 19.

Siemens-Elema AB SPB7-230.812.05 Page 7 of 24 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 46

9 - 8 Calibrating and adjusting the AEC

DLF switch off 9

Deactivate the DLF switch. In Main menu select Configuration > Miscellaneous > DLF

switch. Press spa c e to se t switc h to O F F. Pre ss F2 to save.

Cassette loaded 9

In Mainmenu select Configuration > Miscellaneous > Cassette loaded check. Press

space to set switch to OFF. Press F2 to save.

Increase grid speed 9

Increase the grid speed. In Main menu select Configuration > Grid speed. Set the fo l-

lowing values. Press F2 to save.

Grid

Grid fast speed time 1500

Grid fast speed 90

Grid slow speed 30

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

ms (2.5 s max)

% of max

% of max

MAM00761

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 8 of 24 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 47

Calibrating and adjusting the AEC 9 - 9

AEC correction tab

AEC Correction tables 9

This section will guide you through the following steps:

• Installation of correction tables (F2).

• Calibration of correction tables (F3), inclu ding rough setting of sensitiv ity correction.

The AEC uses one correction table for each Anode/Filter/Speed combination. Each correction table has separ ate corrections for eac h object tabl e group (Magnifi cation, Grid and

No grid).

Installation of AEC correction tables 9

1. Start the AECImageExtract applicat ion on the service PC by running the batch fi le

go.bat that can be found under the direc tory C:\AECImageExtract.

2. In Mainmenu select Configuration > AEC > AEC correction tables.

Fig. 1

The dashes in the ID column show that no correct ion table is installed (

).

AEC correction tab

Existing tables in the AEC:

Anode/Filter Speed ID Calibrated

Mo/Mo H ---- --- --- --- --Mo/Mo D ---- --- --- --- --Mo/Rh H ---- --- --- --- --Mo/Rh D ---- --- --- --- --W/Rh H ---- --- --- --- --W/Rh D ---- --- --- --- ---

<ESC> to exit, <F2> to install new table, <F3> to calibrate existing

1 Help 2 Inst Cal3 45678910Quit

Fig. 1 AEC correction tables

NOTE

Install the correction tables on D only!

les

Mag Grid No grid Stereo

MAM00599

Siemens-Elema AB SPB7-230.812.05 Page 9 of 24 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

3. Make sure that the new backup floppy is in serted.

4. Decide for which combination you need to in stall correction table. (F or av ailable

identifications for correc tion tables see Tabl e 1, Page 9 - 1 or the new back up

floppy.)

Page 48

9 - 10 Calibrating and adjusting the AEC

5. Place the cursor by one of the desired Anod e/Filter/Speed combinations. Press

F2.

Install new table

New ID: 0000

<F2> to continue, <ESC> to exit

MAM00600

6. Type the ID number of the new correction table ( see Table 1, Page 9 - 1) in the

dialog which appears. Press F2 to ins tall the table. A message box will appear

before the correction file has been f ound.

Searching for correction file...

MAM00736

Installing correction table

ID: 1401 for Mo/Mo D

29% done

MAM00880

7. When the transaction of tables is finished, a dialog like Fig. 2, Pag e 9 - 12 will

appear. To complete the calibr ation, proceed from step 5 of that se ction.

NOTICE

In order to resume calibrati ng aft e r having quit the program:

Follow the instructions from step 1 under "Calibrate correction

tables" on Page 9 - 11.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 10 of 24 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 49

Calibrating and adjusting the AEC 9 - 11

AEC correction tab

Calibrate correction tables 9

NOTE

The new backup floppy must be inserted.

The Anode/Filter/Speed combinations should be cali brated one at a time.

1. In Mainmenu select Configuration > AEC > AEC correction tables.

AEC correction tab

Existing tables in the AEC:

Anode/Filter Speed ID Calibrated

Mo/Mo H ---- --- --- --- --Mo/Mo D 1401 No No No No

Mo/Rh H ---- --- --- --- --Mo/Rh D 1402 No No No No

W/Rh H ---- --- --- --- --W/Rh D 1403 No No No No

<ESC> to exit, <F2> to install new table, <F3> to calibrate existing

1 Help 2 Inst Cal3 45678910Quit

les

Mag Grid No grid Stereo

MAM00881

NOTICE

All object table groups and Anode / Filter combinations available

at the site must be calibrated prior to release for clinical use.

2. Place the marker by one of the desired Anode/Fil ter/Speed combinations. Press

F3 to transfer the table.

3. This message box is displayed while the serv ice program receives the correction

table.

Receiving correction table

for Mo/Mo D

63% done

MAM00882

Siemens-Elema AB SPB7-230.812.05 Page 11 of 24 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 50

9 - 12 Calibrating and adjusting the AEC

4. When the transfer is done, the dialog Calibr ation AEC correction table appears.

Calibration AEC correction table

Mo/Mo D, Table ID: 1401

Object table group

Magnification Not calibrated

Grid Not calibrated

No grid Not calibrated

Stereo Not calibrated

<ESC> to exit, <F2> to save, <F3> to calibrate, <F4> to clear calibration

1 Help 2 Save Cal3 45678910Quit

Fig. 2 Dialog Calibration AEC correction table shows which object tables, in the current Anode/Filter/Speed

combination, have been calibrated.

Clear

5. To calibrate the correction table for an object table group, place the cur sor in front

of the group. Press F3.

Please mount a

grid table

and press <ENTER> to continue

or <ESC> to cancel.

<ENTER> - ok / <ESC> - cancel

6. Follow the instructions in the message box above and press Enter.

Sensitivity correction

MAM00608

MAM00883

Used: 0

New: 0

<F2> save, <F3> exp support, <F4> continue, <ESC> exit

Fig. 3 Dialog Sensitivity correction

MAM00764

7. Before calibrating the in stalled correction tab les, it is necessary to make a rough

setting of the sensitivity c orrection for the chosen object tab le group .

8. Insert the referenc e IP cassette in the object table.

NOTE

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 12 of 24 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Make sure the new backup floppy is inserted.

Page 51

Calibrating and adjusting the AEC 9 - 13

NOTE

9. Press F3.

10. Follow the instruction s in the message box in the service program, press Enter

and perform an examination according to "Examination" on Page 8 - 1.

11. Register the AD Value (Average p ixel value for the area of interest ) that is

displayed in the AECImageExtract window at the service PC.

12. If the value differs f rom 450, switch to the service program, adj ust the values in

dialog AEC - Sensitivity correction (Fig. 3) according to the Rough ref erence value

displayed in the AECImageExtract window.

13. Save the new Sensitivity correct ion value with F2. Repeat the procedures

described from step 8 to step 13 until th e value is within 450+2.

If the value is satisfacto ry, proceed by pressing F4.

Do not use a compression plate.

Please put x cm of Plexi

on the object table.

Perform an exposure and

press <ENTER> when ready

or <ESC> to cancel.

<ENTER> - ok / <ESC> - cancel

MAM00728

NOTE

NOTE

One adjustment step of sensitivity correction (1/8 E.P .)

corresponds to approximately 4 AD Values, i.e.

450 x–

----------------- -y=

4

x = obtained AD Value

y = suggested adjustment for sensitivity correction

It is important to use 450 and the specified AEC calibration plexi

(material No. 65 61 224 and 65 61 232) during the procedures

under “Calibrate correction tables”, since measurements are

relative to factory results at 450.

The AD Value preferred by the customer can be adjusted later

either in Sensitivity correction or Sensitivity.

Siemens-Elema AB SPB7-230.812.05 Page 13 of 24 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 52

9 - 14 Calibrating and adjusting the AEC

14. Take another IP cassette than the ref erence IP cassette. Since it will not be

developed, the IP cassette can be used for all exposures during the followin g

calibration.

NOTE

Using secondary erasure, erase the used IP cassette after the

fourth exposure, otherwise the IP cassette cannot be utilized for

one day.

Calibration object table group

Mo/Mo D, Table ID: 1401, Object table group Grid

Exp. Plexi kV Dose rate Diff. from nominal

1 3 25 --------- ------2 3 28 --------- ------3 4 25 --------- ------4 4 32 --------- ------5 4 35 --------- ------6 6 25 --------- ------7 7 28 --------- ------8 7 32 --------- ------9 7 35 --------- -------

<ESC> to exit, <F2> to calibrate & save, <F3> to measure dose rate

1 Help 2 Save Exp support3 4 5 6 7 8 9 10 Quit

MAM00885

Fig. 4 Dialog Calibration object table group shows the dose rates for a number of exposures. The dashed

lines below Dose rate indicate that no exposures have been performed yet.

15. To proceed with the calibration, pl ace the cursor by one of the alternativ es. Press

F3.

Please put x cm of Plexi

on the object table.

Perform an exposure and

press <ENTER> when ready

or <ESC> to cancel.

<ENTER> - ok / <ESC> - cancel

16. Follow the instructions in the message box shown.

NOTE

Do not use 2 8 1 cm plexi plates instead of a 2 cm plate.

MAM00728

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 14 of 24 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 53

Calibrating and adjusting the AEC 9 - 15

17. When the exposure is done, the di alog Calibration exposure appea rs with values

for Dose rate and Diff. from nominal.

Calibration exposure

Mo/Mo D, Table ID: 1401, Object table group Grid

Exp. 5

Tension 25 kV

PMMA 4 cm

Dose rate 267.23

Diff. from nominal -21.47%

<ESC> to exit, <F2> to save, <F3> to perform exposure

1 Help 2 Save Exp support3

5678910

4

Quit

MAM00884

NOTE

If the Diff. from nominal exceeds &50% ensure that the exposure

really has taken place, the thickness of AEC calibration plexi

(material No. 65 61 224 and 65 61 232) is correct and properly

positioned and that the cassette (loaded with IP) is in serted and

repeat the last exposure. If the difference still exceeds +50%

accept the value and proce ed.

18. Save the values with F2.

19. Repeat steps 15 to 18 until all exposur es are done.

20. Perform a secondary- and a primary erasur e of the IP cassette according to

"Erasing the IP cassette(s)" on Page 4 - 2.

21. When all exposures for one object t able group are done, save the values with F2

in the dialog Calibr ation object table group.

22. The dialog Calibration AEC correct ion table appears. Select the next obje ct table

group and repeat steps 5 to 22.

23. When all desired object t able groups are calibrated, pre ss F2 to install the

calibrated correction table in the AEC.

Installing correction table

ID: 1401 for Mo/Mo D

29% done

MAM00880

24. The dialog AEC correction tabl es appears. Repeat from step 2 until all avail able

Anode/ Filter combinations are cali brated.

Siemens-Elema AB SPB7-230.812.05 Page 15 of 24 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 54

9 - 16 Calibrating and adjusting the AEC

Recalibration of an object table 9

An already calibrated object table group can be recalibrated.

NOTE

1. Repeat the procedure described in steps 1 to 4, Page 9 - 11.

2. To recalibrate a correction table for an object table group, place the cur sor in front

of the group. Press F4. This will res et the existing calibration of the chosen object

table group and replace it with the origi nal correction table stored on the fl oppy.

3. Press F2 to save.

4. Recalibrate the desired object tabl e group according to the normal procedure,

from step 2, Page 9 - 11.

Make sure the new backup floppy is inserted.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 16 of 24 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 55

Calibrating and adjusting the AEC 9 - 17

MAM00532

Sensitivity correction (fine setting) 9

NOTE

New backup floppy must be inserted. The specified AEC

calibration plexi (material No. 65 61 224 and 65 61 232) must be

used.

When all desired object table groups are calibrated, a fine setting of the sensitivity correction should be performed for all av ailable object tables.

AEC - Sensitivity correction

HD

Mo/Mo Mo/Rh W/Rh Mo/Mo Mo/Rh W/Rh

Grid 18x24 0 00 000

Grid 24x30 0 0 0 0 0 0

No grid 18x24 0 0 0 0 0 0

No grid 24x30 0 0 0 0 0 0

Magnification 1.5 0 0 0 0 0 0

Magnification 1.8 0 0 0 0 0 0

Stereo 0 0 0 0 0 0

valid entries from -120 to 120 in 1/8 E.P. (+/-15 E.P.)

<ESC> to exit, <TAB> move to next entry field, <F2> to save, <F3> exp support

1 Help 2 Save 3 45678910Quit

Fig. 5 Set the sensitivity correction for all desired object tables.

Exp support

1. In Mainmenu select Configuration > AEC > Sensit ivity correction.

2. Install an object table.

3. Insert the reference IP cass ette in the object table.

4. Perform an examination according to " Examination" on Page 8 - 1.

NOTE

From this point forward a compression plate may be used.

5. Register the AD Value (Average pixel val ue for the area of interest) t hat is

displayed in the AECImageExtract window at the service PC.

6. If the value differs from 400 (fact ory recommended value) or the customer

preferred value, switch to t he service program, adjust the valu es in dialog AEC -

Sensitivity correction (Fig. 3) according to the Fine reference value displayed in

the AECImageExtract window.

7. The AD value should be as close to 400 (or by customer pre ferred) as possible.

One adjustment step of sensiti vity correction (1/8 E.P.) corresponds to

approximately 4 AD Values. If the value i s more than 4 AD Values from the

preferred value, switch t o the service program and adjust the va lues in dialog AEC

Siemens-Elema AB SPB7-230.812.05 Page 17 of 24 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 56

9 - 18 Calibrating and adjusting the AEC

- Sensitivity correc tion (Fig. 5). Save with F2. Repeat the pr ocedure described in

steps 3 to 5.

NOTE

One adjustment step of sensiti vity correction (1/8 E.P.)

corresponds to approximately 4 AD Values, i.e.

400(or customer preferred) x–

--------------------------------------------------------------------------y=

4

x = obtained AD Value

y = suggested adjustment for sensitivity correction

8. Repeat this procedure for the other obj ect tables if applicable.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 18 of 24 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 57

Calibrating and adjusting the AEC 9 - 19

M

Sensitivity 9

Adjustment of AD Value for the whole AEC is performed under Mainmenu > Configuration > AEC > Sensitivity.

AEC - Sensitivity

HD

Sensitivity 0 0

valid entries from -64 to 64 in 1/8 E.P. (+/-8 E.P.)

<ESC> to exit, <TAB> move to next entry field

NOTE

Save

The AD Value preferred by the customer can be set with this

1 Help 2 3 5 678910Quit

function. The customer’s own phantom(s) can also be used.

AM00654

Siemens-Elema AB SPB7-230.812.05 Page 19 of 24 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 58

9 - 20 Calibrating and adjusting the AEC

Testing the AEC-function 9

AEC performance test 9

Testing of the AEC-function is to be performed according to the test protocol on

Page 12 - 2, and for the object tables in question. (Should error codes Er013 or Er450

appear; change to AEC

calibration plexi (material No. 65 61 224 and 65 61 232) which is 1 cm thinner.)

NOTE

Tolerance only valid for IP/cassette combinations list ed in

Table 1 under "General" on Page 9 - 1.

Image detector dose 9

1. Position 3-5 cm plexi on the grid object table. Be careful to position th e plexi so

that it is overlapping the chest wall edge with approximately 1 cm, in order for the

AEC to operate in a correct way.

2. Insert the reference IP cas ette in the grid object table.

3. Make an AEC exposure with 28 kV and Mo/Mo. Select the AEC D button to use

the AEC mode.

4. Record the indicated mAs value in the test pr otocol.

5. Remove the reference IP cassette.

6. Position the ionization chamber ins ide the cassette compartment above the AEC

detector.

7. Manually select (on the control panel of MAMMOMAT 3000 Nova) the mAs value

that is closest to the measured AEC mAs value and use i t during the following

measurements (with AEC mode disabled).

8. Make an exposure with 28 kV and Mo/Mo.

9. Read the dose from the ionization chamber and reco rd the value in the test

protocol. The image detector dose shall not exceed 100 mGy (10mr ad), the

recommended dose is 70 mGy.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 20 of 24 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 59

Calibrating and adjusting the AEC 9 - 21

Reinstall/Inst a ll program para meters for OPDOSE 9

NOTE

If OPDOSE shall be used for the IP cassettes, the following steps

must be done.

1. If the system is ON and the service progr am is running, go to step 4, else go to

step 2.

2. System ON.

3. Start up the service program.

4. In Mainmenu select Configuration > Miscellaneous > Panel progra mming.

The panel program switch must be ON. Save with F2.

5. In Mainmenu select Configuration > Miscellaneous > Auto limits. Make sure

the values are Program 1 30 mm, Program 2 45 mm and Program 3 60 mm or

the values desired by the customer. Chang e if needed and then save with F2.

6. Set kV (1/Fig. 6), density (2/ Fig. 6), H/D (3/Fig. 6) and anode/fi lter combination

(4/Fig. 6), for one of the progr ams according to the test valu es previously noted in

the protocol, except density co rrection which should be set to 0.

7. Save the program parameters if needed by press ing the store button (6/Fig. 6)

and then the program button (5/Fig. 6) . Keep both buttons pressed until t he

program button stops flashing (ap proximately 5 s). Repeat the procedure in st ep 5

to 6 for the remaining programs.

Fig. 6

WARNING

W

Mo

kV

1

2

AECmAs

3

Mo

Rh Rh

Mo

Program

4

5

Auto

Lim.

MAM00018

6

Siemens-Elema AB SPB7-230.812.05 Page 21 of 24 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 60

9 - 22 Calibrating and adjusting the AEC

Factory settings 9

Changes can be made with the service program (Configuration, Miscellaneous, Auto limits).

Thickness

≥ 61 mm 26 W / Rh

46 - 60 mm 27 Mo / Rh

31 - 45 mm 27 Mo / Mo

0 - 30 mm 26 Mo / Mo

Fig. 7 Installations with filter disc Mo 0.030 / Rh 0.025 / Rh 0.050

Thickness

≥ 61 mm 28 Mo / Rh

46 - 60 mm 27 Mo / Rh

31 - 45 mm 27 Mo / Mo

0 - 30 mm 26 Mo / Mo

Fig. 8 Installations with filter disc Mo 0.030 / Rh 0.025

kV Anode/filter

kV Anode/filter

combination

combination

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 22 of 24 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 61

Calibrating and adjusting the AEC 9 - 23

Testing OPDOSE

1. Mount an 18x24 cm compression plate to the MAMMOMAT 3000.

2. Select a thickness of AEC calibration plexi (material No. 65 61 224 and 65 61

232), that is within the thicknes s interval of the program to be test ed. The

thickness intervals can be found in Mai nmenu > Configuration > Misce llaneous

> Auto limits. For more information about Auto limits, s ee Chapter

“Miscellaneous -> Auto limits” in t he service manual “Service Program” for

MAMMOMAT 3000.

3. Select AUTO on control panel.

4. Place the AEC calibration plexi on the object table in question and compress to 6

kg or more.

5. Check that the correct program is bl inking on the control panel. Sel ect the

program by pressing the corresponding pr ogram button on the control panel.

6. Perform an examination according to " Examination" on Page 8 - 1, use the

BREAST, L (DSR) exposure menu from the BREAST task card.

7. Register the AD Value (Average pixel val ue for the area of interest) t hat is

displayed in the AECImageExtract window at the service PC.

8. The AD Value shall be as close to 400 as possible (or the density preferred by

customer). If necessary adjust density correction on control panel. Save by

pressing the store button and then the program button. Keep both butt ons pressed

until the program button stops flash ing.

9. Repeat the procedure described in steps 2 to 8 f or the other used programs.

10. Note the OPDOSE settings in the attached test protocol.

Final procedures 9

1. If the service program is running, go to step 7., else go to step 2..

2. Start service PC.

3. Log in (make sure you have administrator ri ghts).

4. Press Start and select Programs > Accessories > Command Prompt.

5. Type “CD mammomat” and press Enter. Make sure that the new bac kup floppy is

inserted. Type “A:” and press Enter .

6. Start the service program by writ ing: Service, then press Enter.

7. Activate the DLF switch. In Main menu select Configuration > Miscellaneous >

DLF switch, press space to set switch to ON. Press F2 to save.

8. In Mainmenu select Configuration > Miscellaneous > Cassette loaded check .

Set to ON.

Siemens-Elema AB SPB7-230.812.05 Page 23 of 24 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 62

9 - 24 Calibrating and adjusting the AEC

9. Reduce the grid speed. In Main menu select Configurat ion > Grid speed. Set

the following values. Press F2 t o save.

Grid

Grid fast speed time 500

Grid fast speed 80

Grid slow speed 20

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 4 5 6 7 8 9 10 Quit

ms (2.5 s max)

% of max

% of max

10. In Main menu select Service > Copy error buffer to file.

11. Take the backup to hard disk: Backup > Copy insta llation area to disk > All.

12. Make sure the new backup floppy is insert ed, marked with serial number of

system and version of the correction t ables (can be found on the AEC floppy disk

with material No. 66 01 897).

13. In Mainmenu select Configuration > Save config file. Press F2 to save.

14. In Mainmenu select Service > Dele te error buffer. Press y to delete.

15. Quit the service program by pres sing F10.

16. Type “C:” and press Enter.

17. Type “COPY *.TXT A:” and press Enter.

18. Check that the following backup fil es are stored on the floppy disk (by typi ng

“dir a:”, then pressing Enter):

MAM00762

- a_backup.txt for AEC parameter s

- s_backup.txt for stand parameter s

- p_backup.txt for panel par ameters

- momo_h.txt for AEC correction tables

- morh_h.txt for AEC correction tabl es

- wrh_h.txt for AEC correction tabl es

- momo_d.txt for AEC correction tables

- morh_d.txt for AEC correction tabl es

- wrh_d.txt for AEC correction tabl es

- mammo.cfg for configuration parameter s

- errorbuf.txt for err or log

19. Type “DEL *.TXT”.

20. Type “CD..”.

21. Type “RMDIR mammomat”.

22. Mains voltage and system OFF.

NOTE

Keep all floppy disks in the plastic folder (material No. 61 62 411),

which is incl uded in the upgrade kit, with other documentati on for

the MAMMOMAT in question.

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 24 of 24 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 63

Restore configuration 10

Restore Service Utility 10

1. Start the Service Utility accor ding to "Starting the Servic e Utility" on Page 5 - 1.

2. Press the Configuration Restore /Backup button ac cording to Fig. 1.

10 - 1

Fig. 1 IIP Service Utility

3. Press the button belonging to Configuration Restore according to Fig. 2.

Fig. 2 Configuration Restore / Backup

Siemens-Elema AB SPB7-230.812.05 Page 1 of 4 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 64

10 - 2 Restore configuration

4. Insert the Service Utility Back up 1(2) floppy in drive A: Choose A: from Drive

combo box and press OK button accord ing to Fig. 3.

Fig. 3 Specified Directory

5. Press Restore button according to Fig. 4. Follow the instruct ions on the screen.

6. When the restore process is finis hed for disk 1(2) insert the Servic e Utility Backup

2(2) floppy in drive A: and press the Restore but ton according to Fig. 4.

7. When the restore process is finis hed for disk 2(2), press Cancel b utton according

to Fig. 4 and press Exit Service Utilit y button according to Fig. 1.

Fig. 4 Restore Service Utility

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 2 of 4 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 65

Restore configuration 10 - 3

Restore User Utility 10

1. From the menu, sequentially choose Programs > Fuji Film > FCR to start

the Fuji CR Application. Enter the User Utility according to Fig. 5.

Fig. 5 Enter User Utility

2. Press OK button in the Enter Password – User Utility window, without ent ering

any password, according to Fig. 6.

Fig. 6 Enter Passwor d – User Utility

3. Press Restore button accordi ng to Fig. 7.

Fig. 7 Main Menu - User Utility

Siemens-Elema AB SPB7-230.812.05 Page 3 of 4 MAMMOMAT 3000 Nova

Solna, Sweden Rev. 03 11.02 SPS-UD Installation

Page 66

10 - 4 Restore configuration

4. Insert the User Utility Backup 1(2) floppy in drive A:. Mark al l four check boxes and

press Start button according to Fig. 8. Follow the instructi ons on the screen.

When the restore process is finis hed, press the Terminate button according to

Fig. 8, Page 5 - 4 and Terminate button according t o Fig. 7.

Fig. 8 Restore – User Utility

MAMMOMAT 3000 Nova SPB7-230.812.05 Page 4 of 4 Siemens-Elema AB

Installation Rev. 03 11.02 SPS-UD Solna, Sweden

Page 67

Final work steps 11

ls

• Remove the service PC.

• Restore the network connection.

• Attach the enclosed labels on the MAMMOMAT label plate according to Fig. 1.

s

Stand

Item.

(1P) Model No.

(S) Serial No.

X-ray Equipment

Classified by

Underwriters Laboratories Inc.

with Respect to Electrical Fire Shock

and Mechanical Hazards Drty.

245 B

R

LR56549C

110V, 208V, 230V

240V, 277V, 400V

1 - 2 phase 50/60 Hz

Momentary 10 kVA

Long-time 0.8 kVA

This Mammomat 3000 X041E has been upgraded with

Automatic Exposure Control to work within

Mammomat 3000 system specifications together with

Fujifilm FCR 5000MA. All rights to this upgrade

are reserved for Siemens Medical Solutions.

Unauthourized use or copying prohibited.

Siemens-Elema AB * Made in Sweden

MODEL NO.:

SERIAL/LOT No.:

Made in Sweden

R

CERTIFIED TO THE REQUIREMENTS

OF THE CANADIAN ELECTRICAL

CODE. CSA HAS NOT INVESTIGATED

OTHER PHYSIOLOGICAL EFFECTS.

CERTIFIÉ SELÓN LES EXIGENCES DU

CÓDE CANADIEN DE L'ÉLECTRICITE.

L'ACNOR N'A PAS E'TUDIÉ LES AUTRES

EFFETS PHYSIOLOGIQUES POSSIBLES.

s

MADE IN SWEDEN

IVK

s

Stand

Item.

(1P) Model No.

IVK

(S) Serial No.

Made in Sweden

X-ray Equipment

Classified by

Underwriters Laboratories Inc. ®

with Respect to Electrical Fire Shock

and Mechanical Hazards Drty.

245 B

CERTIFIED TO THE REQUIREMENTS

OF THE CANADIAN ELECTRICAL

CODE. CSA HAS NOT INVESTIGATED

OTHER PHYSIOLOGICAL EFFECTS.

®

LR56549C

CERTIFIÉ SELÓN LES EXIGENCES DU

CÓDE CANADIEN DE L'ÉLECTRICITE.

L'ACNOR N'A PAS E'TUDIÉ LES AUTRES

EFFETS PHYSIOLOGIQUES POSSIBLES.

110V, 208V, 230V

240V, 277V, 400V

1 - 2 phase 50/60 Hz

Momentary 10 kVA

Long-time 0.8 kVA

s

This Mammomat 3000 X041E has been upgraded with

Automatic Exposure Control to work within

Mammomat 3000 system specifications together with

Fujifilm FCR 5000MA. All rights to this upgrade

are reserved for Siemens Medical Solutions.

Unauthourized use or copying prohibited.

Siemens-Elema AB * Made in Sweden

MODEL NO.:

SERIAL/LOT No.:

MADE IN SWEDEN