Page 1

Friedrich

MAMMOMAT 1000/3000 Nova

SP

Maintenance Instructions

System

MAMMOMAT 1000/3000 Nova

The protocol SPB7-230.105.02.05.02 is required for

these instructions

Print No.:

Replaces: SPB7-230.101.02.04.02

SPB7-230.101.02.05.02

06134709

© Siemens AG

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

English

Doc. Gen. Date: 02.06

2002

Page 2

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise

authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated

with or authorized by Siemens or one of its affiliates are directed to contact one of the

local offices of Siemens or one of its affiliates before attempting installation or service procedures.

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 2 of 34

Medical Solutions

Page 3

Table of Contents 3

0 Table of Contents

1 _______ General information______________________________________________ 5

Training. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Required documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Required tools, measurement and auxiliary devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Required lubricants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Text emphasis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety information and preventive measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Explanation of abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 _______ System _______________________________________________________ 13

Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 _______ Column stand __________________________________________________ 17

Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 _______ Compression and system movements _____________________________ 20

Testing the "Compression" function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Testing the "Decompression" function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Applying oil and grease. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Compression thickness display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Checking miscellaneous system movements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Checking miscellaneous system movements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 _______ Test exposures ________________________________________________ 25

Evaluating test values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Testing the dose rate control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Testing the radiation field/light field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Testing image quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Evaluating the films . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6 _______ Miscellaneous _________________________________________________ 31

Blocking exposure release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Final tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 3 of 34

Page 4

4 Table of Contents

7 _______ Changes since the previous version _______________________________ 34

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 4 of 34

Medical Solutions

Page 5

General information 5

1-

1 General information

1.1 Training

• Self-instruction packet or training workshop and at least 1 installation

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 5 of 34

Page 6

6 General information

1.2 Required documents

• Planning Guide SPB7-230.021...

• MAMMOMAT 1000/3000 Nova Wiring Diagrams SPB7-230.051...

• Installation and Start-Up Instructions SPB7-230.033...

• Service Program SPB7-230.114...

• Maintenance Protocol SPB7-230.105...

• Instructions for Use SPB7-230.201...

• Supplement to the Instructions for Use (Stereo) SPB7-230.203...

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 6 of 34

Medical Solutions

Page 7

General information 7

1.3 Required tools, measurement and auxiliary devices

NOTE

All tools, measurement and auxiliary devices, with the exception of

those marked with "*", are listed in the STC (Service Tools Catalog)

along with their specifications.

• Oscilloscope

• Digital multimeter

• mAs meter

• Service PC with connection cable

• SIB phantom or Normi 7 or 4-cm Plexi or customer phantom*

• Sensitometer/densitometer

• Film pack 24 x 30 or larger

• Cleaning agents* specified in the operating instructions

• Protective conductor meter

• Spring scale 0-20 kp (1 kp increments) with cord*

• Water level

• Spray enamel* according to the PG (to touch up chipped paint)

• Standard installation tools*

• Electric screwdriver* with sockets (recommended)

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 7 of 34

Page 8

8 General information

1.4 Required lubricants

• All purpose grease PD2

• Viscogen oil

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 8 of 34

Medical Solutions

Page 9

General information 9

1.5 Text emphasis

DANGER

WARNING

CAUTION

NOTICE

DANGER indicates that there is an immediate danger of death or

serious physical injury.

¹ n.a.

WARNING indicates that there is a risk of possible death or serious

physical injury.

¹ n.a.

CAUTION used with the safety alert symbol indicates that there is

a risk of slight or moderate physical injury and/or damage to property.

¹ n.a.

NOTICE used without the safety alert symbol indicates that

non-compliance may cause a situation leading to an undesirable

result or state other than death, physical injury or damage to property.

¹ n.a.

NOTE

NOTE contains information provided with special emphasis to facilitate proper use of the equipment or proper execution of a procedure, i.e. hints, tips.

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 9 of 34

Page 10

10 General information

1.6 Safety information and preventive measures

NOTE

• When completing repair work and tests, please note:

- the product-specific safety information in the document,

- the safety information in TD00-000.860.01... ,

• When the system is switched off via the operating panel or

S2/D711, line voltage is still present at the line voltage connection for the generator, at line voltage filter Z1, at transformer T1,

at transformer T10, and on board D711 (refer to circuit diagram).

• After switching off the system, approximately 380 V DC may be

present in the intermediate circuit as indicated by the V24 LED

on board D710. Within 3 minutes, the voltage will drop to less

than 30 V, and the LED will go out.

• Tests or adjustments that must be made with the radiation

switched on are identified by the radiation warning symbol.

During these types of adjustments, radiation protective clothing must be worn.

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 10 of 34

Medical Solutions

Page 11

General information 11

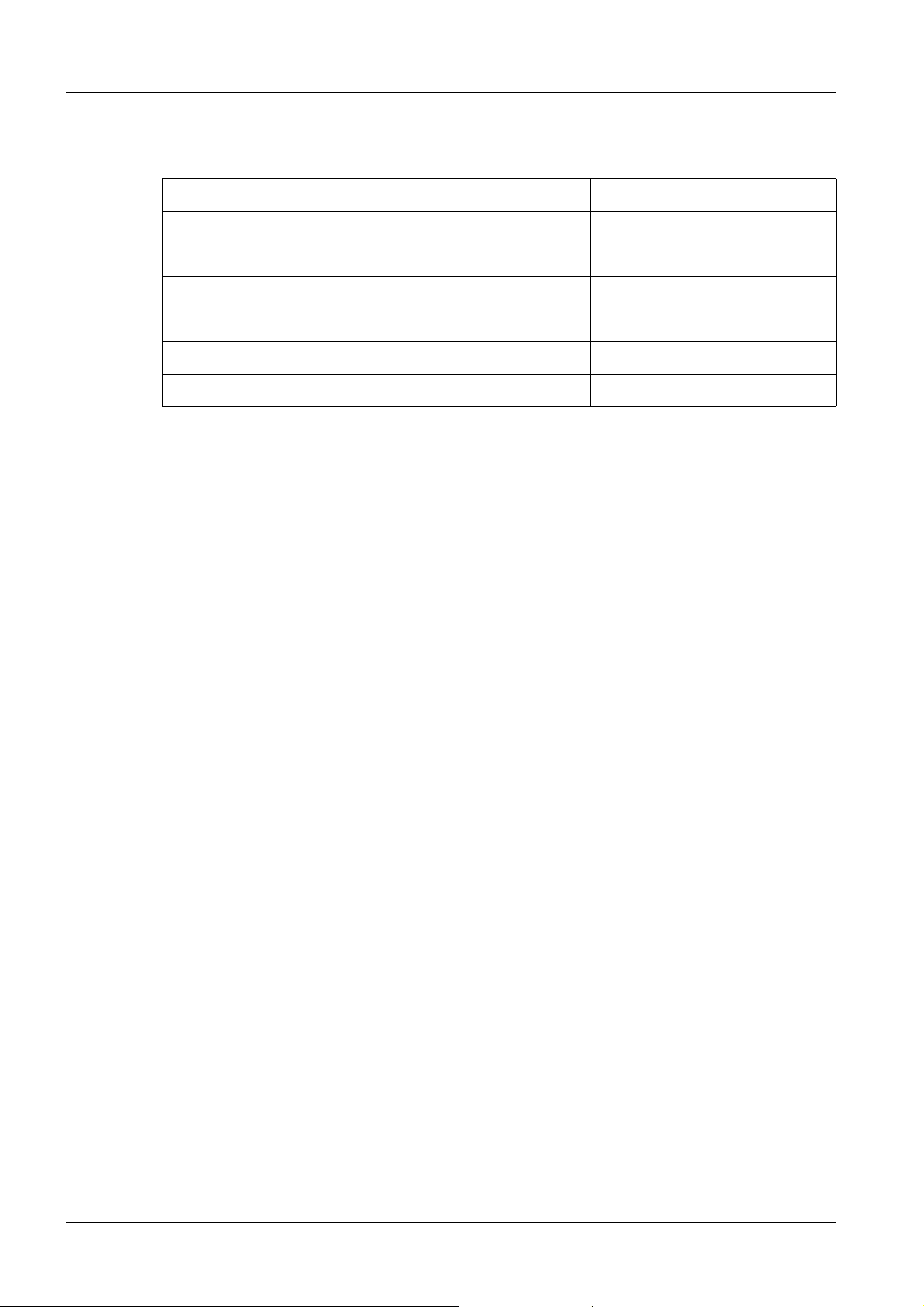

1.7 Explanation of abbreviations

Abbrev. Explanation

SI Safety Inspection

SIE Safety Inspection, Electrical

SIM Safety Inspection, Mechanical

PM Preventive Maintenance

PMP Preventive Maintenance, Periodic

PMA Preventive Maintenance, Adjustments

PMF Preventive Maintenance, Function Check, Operating Value Check

Q System Quality, Image Quality

QIQ Image Quality

QSQ System Quality Check

SW Software Maintenance

CSE Customer Support Engineer

CS No.: Customer-specific number

IVK Installed Volume Component

WE Maintenance Unit

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 11 of 34

Page 12

12 General information

1.8 Symbols

Checks and adjustments that must be performed with the radiation ON are identified by

the

X radiation warning symbol.

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 12 of 34

Medical Solutions

Page 13

System 13

2-

2 System

2.1 Checks

Fig. 1: MAMMOMAT checks

PMP Radiation protection

• Check the radiation protection shield for possible damage (1/Fig.1/p.13).

• Information regarding the lead equivalent value must be legible.

SIM Swivel arm/PPS tube attachment

• Check the swivel arm/PPS tube attachment by pulling on both support rails

(a minimum play of approximately ± 2° is correct). (2/Fig.1/p.13).

SIM Basic table

• Check the mounting of the basic table as well as the locking mechanism for the expo-

sure system (3/Fig.1/p.13).

SIM Flying wing (MAMMOMAT 3000 Nova only)

• Check the "Flying Wing" locking mechanism (wing basic table). Swivel "wing 1"

("wing 1" is the table with the stereo connector) toward "wing 2" and back

(6/Fig.1/p.13).

SIM Level

• Verify that the system is level with respect to the floor. Check the level screws

(4/Fig.1/p.13) with a water level and, if available, the floor mounting (optional).

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 13 of 34

Page 14

14 System

PMP Face shield and compression plate

• Check the face shield and compression plate for correct seating and for damage

(5/Fig.1/p.13).

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 14 of 34

Medical Solutions

Page 15

System 15

2.2 Preparations

Fig. 2: X-ray tube covers

Fig. 3: Covers

SIE Cables

Fig. 4: Generator front covers

• System OFF

• Check the condition of the cables and the corrugated tubing (3/Fig.2/p.15) while re-

moving the following covers:

- X-ray tube covers (left, right, and front) (1, 2/Fig. 2 / p. 15)

- All covers of the stand (3, 6/Fig. 3 / p. 15)

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 15 of 34

Page 16

16 System

NOTE

The edges of the metal curtain are very sharp and can cause severe injury. Attach the protective strips.

- Generator front cover (3/Fig.4/p.15).

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 16 of 34

Medical Solutions

Page 17

Column stand 17

3-

3 Column stand

3.1 Checks

SIM Steel ropes

• Do the steel ropes (balancing and flap), the drive belt, the suspension, or the pulleys

have any damage (e.g. fraying or splitting) or show signs of wear?

PMA Oil and grease

• If they are OK, lightly oil the wire cable, grease the rails, and then remove the protective

strips.

SIE Limit switches

• System ON. Move the lifting carriage up and down several times, the lifting carriage

should be in an upright (0°) position.

NOTE

It is normal to hear some noise from the rotation of the radiation

filter in the collimator when switching the system ON.

• Do the limit switches stop carriage travel at the top and at the bottom?

• Activate safety switch S882. System movements must be blocked.

PMF Vertical travel

• Is the vertical travel smooth and noiseless?

• Switch OFF the system and attach the protective strips once again.

SIM Safety catch and rotation safety catch

• Do the safety catch (1/Fig.1/p.17) and rotation safety catch (2/Fig.1/p.17) have any

visible damage? Are the springs in good condition?

Fig. 1: Safety catch

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 17 of 34

Page 18

18 Column stand

SIM Ball bearings

• Depending on the serial no. of the MAMMOMAT, the lifting carriage is equipped with ei-

ther ten or twelve ball bearings (refer to (Fig.2/p.18)). The two ball bearings that are

missing in MAMMOMATs with ten bearings are only indicated in the figure. Check that

all ball bearings are in place and that they show no sign of damage.

Fig. 2: Lifting carriage

Pos. 1 Not on all MAMMOMATs

SIM Mounting for the X-ray tube

Fig. 3: X-ray tube

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 18 of 34

Medical Solutions

Page 19

Column stand 19

• Check the mounting for the X-ray tube unit (1/Fig.3/p.18).

PMA Grease the grid spindle

Fig. 4: Grid spindle

• Remove the cover plate from the object table and lightly grease the grid spindle

(1/Fig.4/p.19). Reattach the cover plate.

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 19 of 34

Page 20

20 Compression and system movements

4-

4 Compression and system movements

4.1 Testing the "Compression" function

Fig. 1: Compression

• Attach the spring scale as shown in (1/Fig.1/p.20) and be careful not to damage the

compression plate during the following tests: Tolerance: ±1 kp.

4.1.1 Switching off

• System ON

PMF Presetting

• Select any value (e.g. 6 kp) on the potentiometer (2/Fig.1/p.20) and compress. Does

the compression unit switch off at this setting?

SIE Max. value switch off

• Select the maximum value (20 kp) with the potentiometer (2/Fig.1/p.20). (20 kp).

Does the unit switch off when it reaches the maximum value?

• Correct display (7/Fig.1/p.13).

PMF OPCOMP

• Position your forearm between the object table and the compression plate and check

the OPCOMP function.

¹ Typically, the cutoff value is between 6 and 10 kp at the factory setting.

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 20 of 34

Medical Solutions

Page 21

Compression and system movements 21

4.2 Testing the "Decompression" function

Fig. 2: Compression unit with covers Fig. 3: Compression unit without covers

• Attach the spring scale as shown in (1/Fig.2/p.21).

Tolerance: ±1 kp.

4.2.1 Switching off

SIE Safety switch

• Does decompression switch off at a counter pressure of approximately 5 kp?

¹ Because of the measurement location, this value corresponds to a value of

approximately 3 kp at the compression plate.

4.2.2 Travel

PMF Compression travel

• Move the compression plate up and down. Is the movement smooth and noiseless

through the entire range?

4.2.3 Applying oil and grease

PMA Apply oil and grease to the compression unit

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 21 of 34

Page 22

22 Compression and system movements

• System OFF

Remove the upper and lower covers (snap closures, (2/Fig.2/p.21) and pot knob

(3/Fig.2/p.21).

• After removing the "small" Allen screws (two above and two below), the right cover

(4/Fig.2/p.21) of the compression unit can be removed.

• Grease the rails (2/Fig.3/p.21) lightly and check the belt (1/Fig.3/p.21) and string

(3/Fig.3/p.21) for damage/wear as well as for tension.

• Reinstall the covers on the compression unit.

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 22 of 34

Medical Solutions

Page 23

Compression and system movements 23

4.3 Compression thickness display

PMF Thickness indicator

• System ON. Move the compression plate to its full height and measure the height.

¹ The value displayed (7/Fig.1/p.13) must agree with the value measured.

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 23 of 34

Page 24

24 Compression and system movements

4.4 Checking miscellaneous system movements

4.4.1 Checking miscellaneous system movements

SIE Switch off

• Check whether the motorized rotation movements shut off when a preset angle is

reached. The angle (e.g. 90°) is preset with the potentiometer, (3/Fig.1/p.13).

• Check the automatic switch-off function when passing the 0° position as well.

PMF Rotation movements

• Is the rotation movement smooth and noiseless through the entire range?

• Is the display correct (7/Fig.1/p.13)?

SIM Blocking rotation and vertical travel

• Rotation and vertical travel must be blocked at a compression force of > 3 kp.

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 24 of 34

Medical Solutions

Page 25

Test exposures 25

5-

5 Test exposures

• System OFF

• Connect the following measurement devices:

- Service PC to D702.X990

- Oscilloscope to MP kVactual.X711 (1V 5kV) and mAactual.X707,

OVA.X708 (1V 40mA)

- mAs meter to D710 (remove X3 - X4 jumpers)

- Multimeter at MP.BIAS on D706 (measurement range 200V=)

• System ON

X

• Test the kV/mA control loop according to the Installation & Start-Up Instructions, chap-

ter "Checks with high voltage".

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 25 of 34

Page 26

26 Test exposures

5.1 Evaluating test values

PMF Anode acceleration

• Listen to the sound generated by the accelerating anode. Is the sound normal?

PMF kV and mA

• Do the measured kV and mA values agree with the values selected?

PMF mAs selection

• Do the measured mAs values agree with the values selected?

PMF mAs value displayed

• Does the measured mAs value agree with the displayed mAs value (for AEC)?

PMF Grid voltage

• Attach the magnification table. Measure the grid voltage (small focus) on tube test point

G against test point H

col?

• Test both focal spots (if available).

PMF Signal lamp

. Does the measured value agree with the value in the test proto-

3

• Does the radiation-ON indicator light up?

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 26 of 34

Medical Solutions

Page 27

Test exposures 27

5.2 Testing the dose rate control

X • Cover the measurement field (e.g.with a lead apron) and release an exposure.

PMF Dose rate control

• Does the dose rate control circuit switch OFF the exposure after approximately 100

ms? (The value is 50 ms for MAMMOMAT 1000/3000 Nova with serial no. 7000 and

higher or MAMMOMAT 1000/3000 with a serial number lower than 7000 but upgraded

with the "AEC upgrade kit", i.e. having

- generator and stand with firmware version 4.0 or higher, and

- service software version 4.1 or higher.)

• Check both wings (MAMMOMAT 3000 Nova only).

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 27 of 34

Page 28

28 Test exposures

5.3 Testing the radiation field/light field

X • Proceed with the test according to the Installation & Start-Up Instructions, chapter

"Checking the radiation field limitation".

PMF Format collimation

• Is the format collimation correct? (18 x 24, 24 x 30, small focus)

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 28 of 34

Medical Solutions

Page 29

Test exposures 29

5.4 Testing image quality

• Attach the most frequently used exposure system (e.g. grid table 18 x 24).

• Load the "test cassette" with film and insert it.

• Position the SIB phantom over the 2-cm Plexiglas or other IQ phantom (e.g. Normi 7).

• Select the most frequently used kV value, AEC and automatic decompression.

X

PMF Automatic decompression

• Compress slightly and release an exposure.

• Does decompression occur immediately following the end of the exposure?

• In addition, expose a sensitometer strip and develop the exposure.

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 29 of 34

Page 30

30 Test exposures

5.5 Evaluating the films

QIQ Phantom exposures

• Compare the phantom exposures to those on hand and/or archive them for the next

maintenance as starting values.

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 30 of 34

Medical Solutions

Page 31

Miscellaneous 31

6-

6 Miscellaneous

6.1 Blocking exposure release

PMF Blocking

Exposure release must be blocked under the following conditions

(indicated on the control console):

- No cassette is inserted.

- Cassette was not changed after the last exposure.

- Table is not attached or not locked in place.

- Wing 1 or wing 2 is not locked in place. (Mammomat 3000 Nova only).

- For stereo only: no external collimator for beam limitation in the collimator.

(Mammomat 3000 Nova only).

- The two exposure release switches were not pressed simultaneously.

- No external collimator for 18 x 24 or magnification. (Mammomat 1000 only).

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 31 of 34

Page 32

32 Miscellaneous

6.2 Checks

SIE Emergency STOP

• Press Emergency STOP, see chapter "Compression and system movements"

(4/Fig.1/p.20).

- Are the compression, rotation and vertical travel of the lifting carriage blocked?

• Release the Emergency STOP.

PMF Indicators

• Check the LEDs on the operating console by starting the panel test via the service PC.

PMP Error memory

• Read out the error memory and the exposure counter with the service PC.

PMP Record the error memory.

PMP Delete the error memory.

• Enter the data from the exposure counter and the error memory in the protocol and de-

lete the error memory only.

PMF Auxiliary voltages

• Use the voltmeter to measure the auxiliary voltages according to circuit diagram

X041E, sheet 2-12/13 (test points on D801, D802 and D704).

• System OFF

PMF Cassette locking

• Check that the cassettes being used lock in properly to the object tables.

PMF OPDOSE

• Check the selection of various anode/filter combinations and OPDOSE according to the

Installation Start-Up Instructions, chapter "Start-up and functional test of the IONTOMAT" or "Calibrating and adjusting the AEC".

PMF Stereo unit (Mammomat 3000 Nova only)

• If attached, check the stereotactic biopsy option according to the supplement to the In-

structions for Use.

PMA UIs and SPEED info

• Check whether all relevant UIs and SPEED info has been completed.

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 32 of 34

Medical Solutions

Page 33

Miscellaneous 33

6.3 Final tests

• Remove the measurement devices.

PMF Operating problems

• Were there any operating problems during the checks?

PMP Covers

• Remove the protective strips and attach all removed covers. Check that all covers are

completely and firmly attached, including the cable duct.

SIE Protective conductor test

• Perform the protective conductor test according to ARTD-002.731.17....

PMP Cleaning/damaged paint

• Clean the unit using the materials recommended in the Instructions for Use and repair

any damaged paint.

• System ON.

QSQ Final test exposure

• Take one final test exposure.

Siemens AG SPB7-230.101.02.05.02 MAMMOMAT 1000/3000 Nova

Medical Solutions

02.06 CS PS SP

Page 33 of 34

Page 34

34 Changes since the previous version

7-

7 Changes since the previous version

Document was converted to DMS.

MAMMOMAT 1000/3000 Nova SPB7-230.101.02.05.02 Siemens AG

02.06 CS PS SP

Page 34 of 34

Medical Solutions

Loading...

Loading...