Page 1

MAMMOMAT 1000/3000

Service Instructions

New AEC

SP

© Siemens AG 2000

The reproduction, tr ansmis sion or

use ofthi s document or itscontents

is not permitted witho ut express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Register 5 English

Print No.: SPB7-230.898.01.01.02 Doc. Gen. Date: 04.00

Replaces: n.a.

Page 2

0 - 2 Revision

Chapter Page Revision

1all01

2all01

3all01

4all01

5all01

6all01

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 2 of 4 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 3

Contents 0 - 3

Page

1 _______Functional description __________________________________________1 - 1

Overview ........................................1-1

MainfunctionoftheMAMMOMAT............................1-1

Tube.........................................1-1

Filter.........................................1-2

ObjectTable.....................................1-2

FilmandScreen...................................1-3

Detector.......................................1-3

MeasuredSignal...................................1-3

Gain.........................................1-3

DoseMeasuring...................................1-3

DoseRateMeasuring................................1-4

TimeDependency..................................1-4

TwoWings......................................1-4

UserChoices ....................................1-4

Exposurecontrol ....................................1-4

ControlofOneExposure ..............................1-5

InitialDose......................................1-5

DoseCorrection...................................1-5

EntireSetofControlParameters..........................1-7

CorrectionTables..................................1-7

SensitivityCorrection................................1-8

Sensitivity......................................1-8

2 _______Error messages ________________________________________________2 - 1

3 _______Parts replacement ______________________________________________3 - 1

ActionlistforMAMMOMAT1000/3000withnewAEC.................3-1

4 _______Description of LED’s and measuring points_________________________ 4 - 1

MeasuringpointsonAECboardD701.........................4-1

SwitchesonAECboardD701..............................4-1

JumpersonAECboardD701..............................4-1

LEDsonAECboardD701 ...............................4-2

5 _______Tests_________________________________________________________5 - 1

Check the AEC according to "Installation and start-up instructions"

forMAMMOMAT1000/3000............................5-1

Siemens AG Register 5 SPB7-230.898.01 Page 3 of 4 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

Page 4

0 - 4 Contents

Page

6 ______ Problems during Installation/ Service ______________________________6 - 1

AECCorrectiontables.................................6-1

Measured dose rate exceeds +

Errorduringbackupfromdisc/floppy .........................6-2

Errorduringresetofinstallationparameters......................6-3

Errorsduringoffsetcompensationtest.........................6-4

DetectorNormalization.................................6-6

Normalizationfactoroutofrange..........................6-6

Miscellaneous .....................................6-7

CommunicationErrorswithServicePC ......................6-7

30%........................6-1

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 4 of 4 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 5

F

Functional description 1

Overview 1

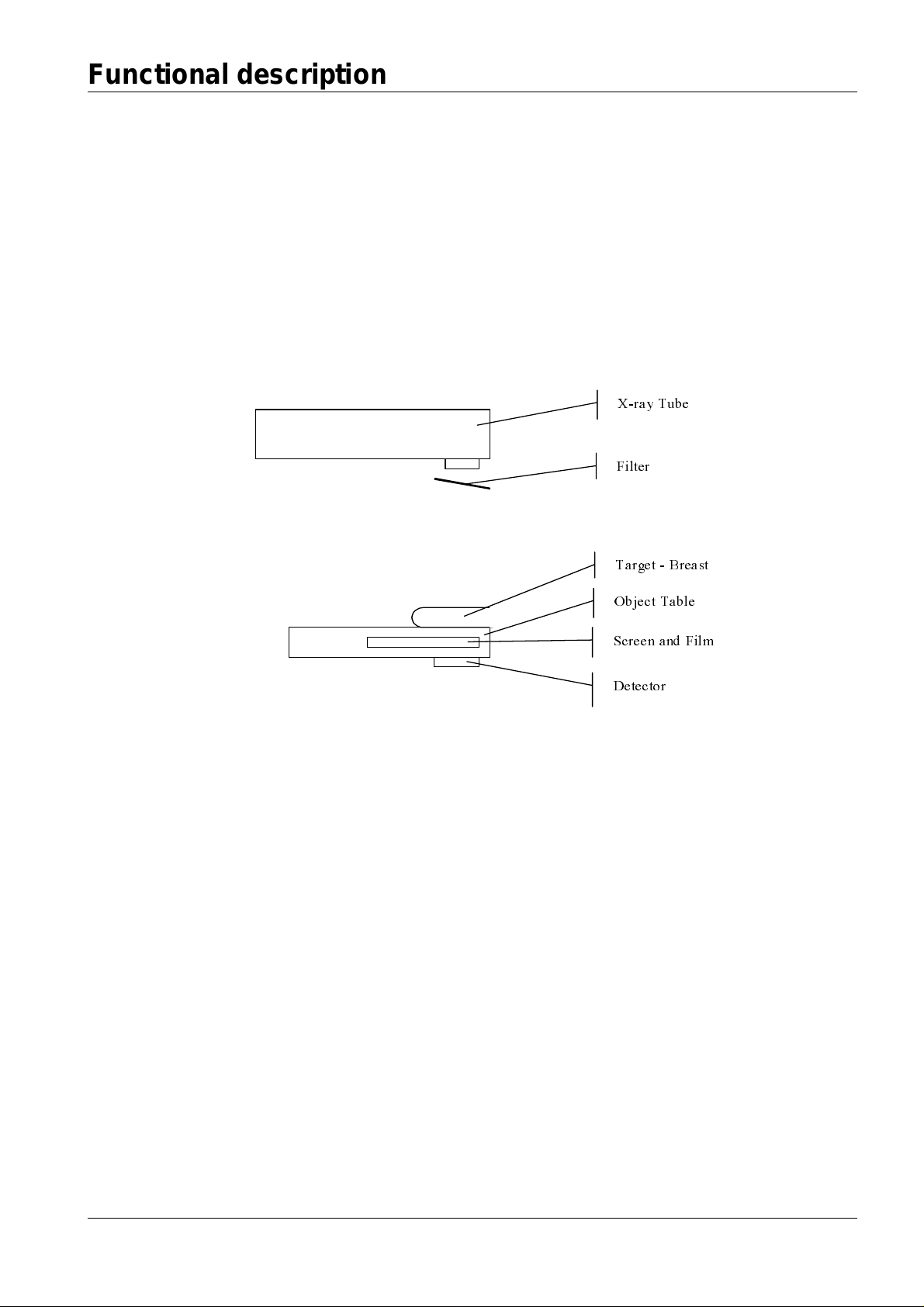

This document describes the control model of the AEC unit for M1000/3000. A view of the

function of the Mammomat is given together with a summary of possible exposure settings, their effects and characteristics of Mammomat performance. The function of dose

control is described together with an explanation of measurements done during the exposure, on which it is based.

Main function of the MAMMOMAT 1

Picture below gives a schematic view of the exposure system.

X-ray Tube

ilter

1-1

Target - Breast

Obj ect Tab le

Screen and F ilm

Detector

Schematic view of the Mammomat

The generator supplies a voltage across the x-ray tube. The resulting radiation is filtered

before it reaches the target. Then it passes through an object table and reaches the fluorescent screen, which emits visible light giving the desired picture on the film. The part of

the radiation, which is not attenuated in the screen, reaches finally the detector and

results in a signal measured by the AEC unit. The main purpose of the AEC unit is to stop

the exposure so that the resulting picture is given the desired average optical density

based on current exposure settings and the measured signal from the detector.

Tube 1

When a voltage is applied acrossthe x-ray tube, the electrons, hitting the anode, initiate

radiation. The tube contains two different anode materials - molybdenum and tungsten giving different kind of x-ray spectra. There are actually two different anodes for each

mentioned material, used to give large and small focus for the x-ray beam. Small focus is

usedtogether with magnifying objecttables. Large focus is used for all other object tables.

Siemens AG Register 5 SPB7-230.898.01 Page 1 of 8 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

Page 6

1 - 2 Functional description

Theoperator isallowedto choosea desiredtubevoltagefrom a rangebetween23 and35

kV with 1 kV resolution. The voltage influences the energy spectrum and gives the operator a control of how hard x-rays are used during the exposure. The current through the

tube, which is directly proportional to the overall intensity of the beam, is a function of the

chosen voltage, the maximum power setting and the maximum current limit.

Neither the energy spectrum of the beam nor it's intensity are constantduring the exposure, due to raising and falling times for the voltage and the tube current. The voltage has

typical raising timesof app. 50 ms and the tube current 5 ms.

Filter 1

Different filtering is used to give the beam desired energy spectrum. For the molybdenum

anode, two filter selections are possible: molybdenum and rhodium. For the tungsten

anode, only rhodium is used as the filter material. This gives three possible anode/filter

combinations - Mo/Mo, Mo/Rh and W/Rh - resulting in three main kinds of x-ray beam.

Within each, a fine adjustment of the energy spectrum, i.e. the hardness of the beam, is

possible by adjusting the voltage.

Object Table 1

There are totally 7 different kinds of object tables that can be used described in the table

below.

Name Type Used beam focus Size Magnification

Grid 18 x 24 Grid Large 18 x 24 cm Grid 24 x 30 Grid Large 24 x 30 cm NoGrid 18 x 24 Grid-less Large 18 x 24 cm NoGrid 24 x 30 Grid-less Large 24 x 30 cm Mag 1.5 Magnification Small - 1.5

Mag 1.8 Magnification Small - 1.8

Biopsy

table

According to their x-ray characteristics and use, the object tables are ordered into four

groups: grid, grid-less, magnification and biopsy:

Gridtablesareusedtotakeordinarypicturesandareequippedwithamovinggridthat

reduces the amountof secondaryradiation, i.e.scatteredradiationfrom thetarget

object.

The grid-less tables are not equipped with a grid.

The Magnification tables have enlarged distance between the object and the film, giving

togetherwithsmallfocusof theradiation thedesiredmagnificationin thepicture.

Grid-less with

biopsyunit

Large

--

The biopsy table, also called stereotactictable, isvery similar to the grid-less tables.

Itis equippedwitha biopsyunit thattogether withstereotacticsisusedto identify the

3D-position of the biopsy target within the breast and perform the biopsy. The pictures

are smaller and can be taken from a direction not perpendicular tothe object table.

Angles of+

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 2 of 8 Siemens AG

10° are used.

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 7

Functional description 1 - 3

Film and Screen 1

A considerable part of the radiation, which passes the target and possibly the grid of the

object table, is attenuated in the fluorescent screen. The energy is than emitted as visible

light and gives the desired picture on the film. The film is also sensitive to the x-rays, however the x-rays do not contribute to the picture significantly, compared to the visible light

emitted by the screen.

Detector 1

After passing the filter, the breast, the object table with screen and film, the radiation

finally reaches the detector. It is a semiconductor device that acts as a current source

supporting a current proportional to the overall intensity of the attenuated radiation. The

attenuation of the detector varies of course with the energy of the radiation, which makes

the generated current dependent on the energy spectrum of the beam. The generated

current is amplified and converted to a voltage level, which is the signal received from the

detector by the AEC unit.

Measured Signal 1

The signal from the detector is amplified on the AEC board and than converted to pulses

with a frequency proportional to the voltage level of the signal. The AEC unit contains a

PLD (Programmable Logic Device), programmed to register the detector signal by counting the pulses that the signal is conver ted to.

Gain 1

Before every exposure, there is a possibility to alter the gain applied to the detector signal

by the AEC board. Higher gain gives stronger signal to the V/F-converter, i.e. more pulses

and better precision in the counters of the PLD. There is however an upper bound for the

voltage level of the amplified signal - the V/F-converter functions for signals up to 10 V

and all voltages above this limit does not contribute to larger frequency of out-coming

pulses.

Dose Measuring 1

ThedoseismeasuredbycountingthepulsesfromtheV/F-converterduringatimeof

interest. This dose measure is not comparable to any conventional dose units because it

gives varying responses depending strongly on the energy spectrum of the radiation registered by the detector. However, for the same anode, filter, tube voltage, object table,

screen and object, this dose measure is directly proportional to the dose received by the

screen.

A logarithmic scale for the dose is also used. It is based on the usual definition of relative

exposure and the unit exposure points (EP).

Dose

ΕΦ

DoseDoseEP

01

log10 log log10

1

Dose

0

The used logarithmic scale is however absolute in the sense that 0 EP is defined to be

equal to 100 counts:

Dose

EP

10

Dose

counts

Siemens AG Register 5 SPB7-230.898.01 Page 3 of 8 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

10100

i.e.

Dose

EP

log10

Dose

100

counts

Page 8

1 - 4 Functional description

Dose Rate Measuring 1

In order to measure the dose rate, the pulses are counted during a period of time and the

resultingdoseisthendividedbythelengthofthetimeperiod.Theresultingdoserateis

an average over the chosen time interval.

Time Dependency 1

Due to the raising and falling times of the tube voltage and current, the detector signal is

also time dependent and has typical raising times of 50 ms.

Two Wings 1

The Mammomat can have one or two wings using separatedetectors.

User Choices 1

The following table summarises possible user choices affecting the exposure:

User choice Range Change consequence

Anode/ filter Mo/Mo, Mo/Rh, W/Rh Rough change of spectral properties of the

beam, possibly affecting power settings and

automatic choice of tube current.

Tube voltage 23 - 35 kV Fine change of spectral propertiesof the

beam, possibly affecting power settings and

automatic choice of tube current.

Speed H or D Choice between two sets of parameters for

two different film/ screen-combinations.

Density correction -24/8 to + 24/8 EP Relative adjustment of exposurelength,

0 = nominal AEC exposure.

Object table One of 7 See section Object Table

Wing 1 or 2 Different detectors in both wings.

Exposure control 1

Thecontrolmodelforthe AEC-unitis typically subdividedinto twoparts.Firstpart handles

the control of a single exposure with one set of exposure settings such as kV, anode/filter

etc. It is based on the knowledge of these parameters before the start and measurements

done during the exposure. Second part puts the control model for one exposure into a

systematic approach to all possible exposure settings for the Mammomat. It explains how

the entire set of control parameters for the AEC-unit is build up in order to cover all possible combinations of kV, object tables, anode/filter choices and up to 2 film/screen combinations.

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 4 of 8 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 9

Functional description 1 - 5

Ε

Φ

Control of One Exposure 1

Before start of exposure, the AEC-unit is only aware of exposure settings chosen by the

operator and has no knowledge of thickness or density of the actual breast. This implies a

two step approach to control of the entire exposure. First step is done before the exposure

start and contains calculation of an initial dose that will be executed before the AEC will

decide what to do next. During the execution of the initial dose, the unit measures the

dose rate and uses it to calculate a correction dose that has to be executed before the

exposure stops. When the AEC-unit has registered a total dose being equal to the sum of

the initial dose and the correction dose, it will stop the exposure.

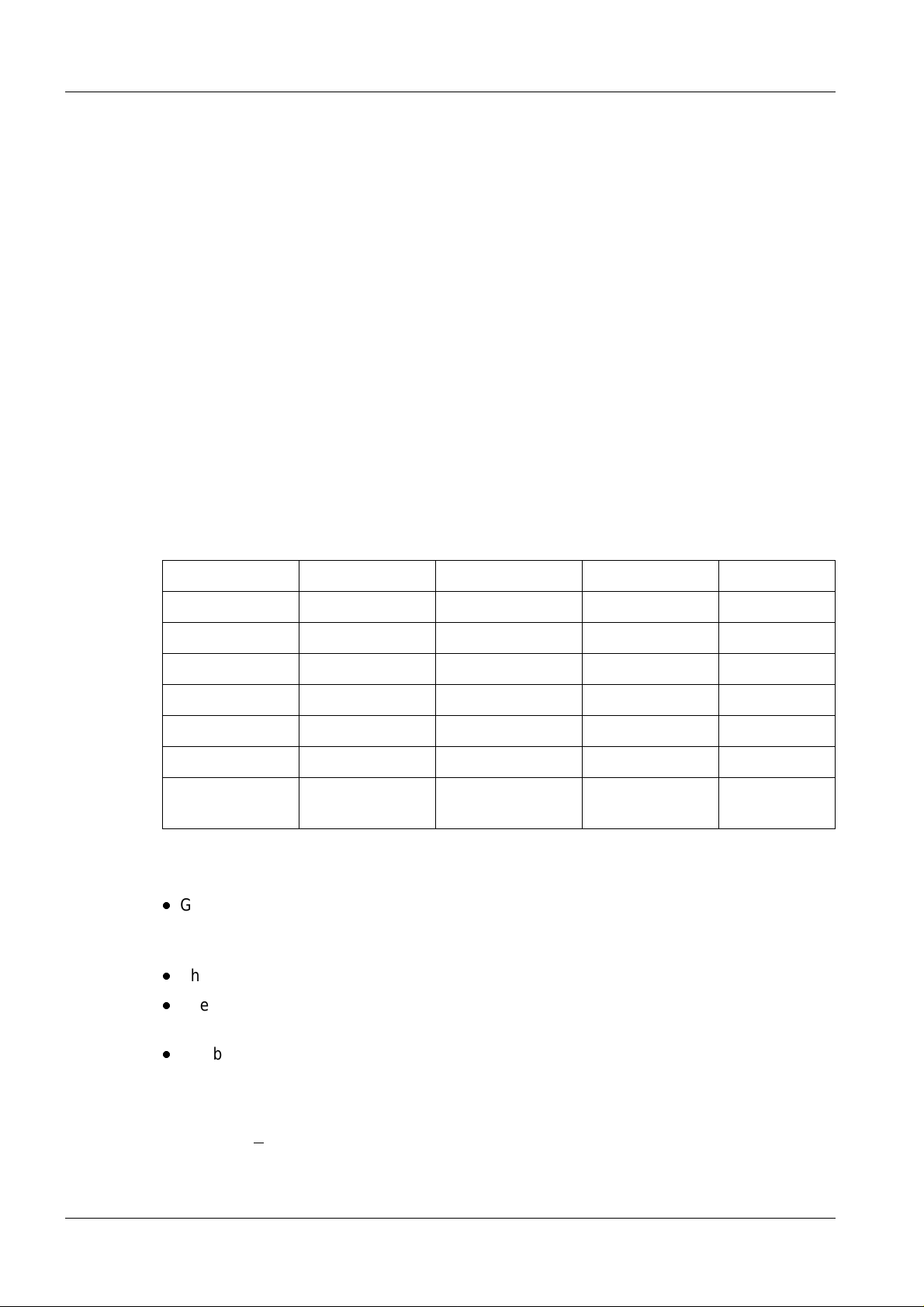

Initial Dose 1

The initial d ose is chosen in EP. It co nsists of an estimated dose, a sensitivity, a sensitivity

correction and a density correction:

DcScSDoseDose

ΗΗΗΖ

EPEPEPEPestimatedEPinitial

,,,,,

where:

Dose

estimated,EP

- the estimated dose, a value specifically chosen for the used film/screen

combination, anode/filter combination, object table group and tube voltage.

- the sensitivity, a value controlling an overall level of target optical density for all

S,

EP

AEC-exposures.

SC,

- the sensitivity correction, chosen as a part of the calibration of specific equipment

EP

(Mammomat, object tables).

DC,

- the density correction, a value that is chosen by the operator for each exposure.

EP

The estimated dose is usually chosen, so it will give an OD = 1,5 for a 5 mm thick PMMAphantom.

Dose Correction 1

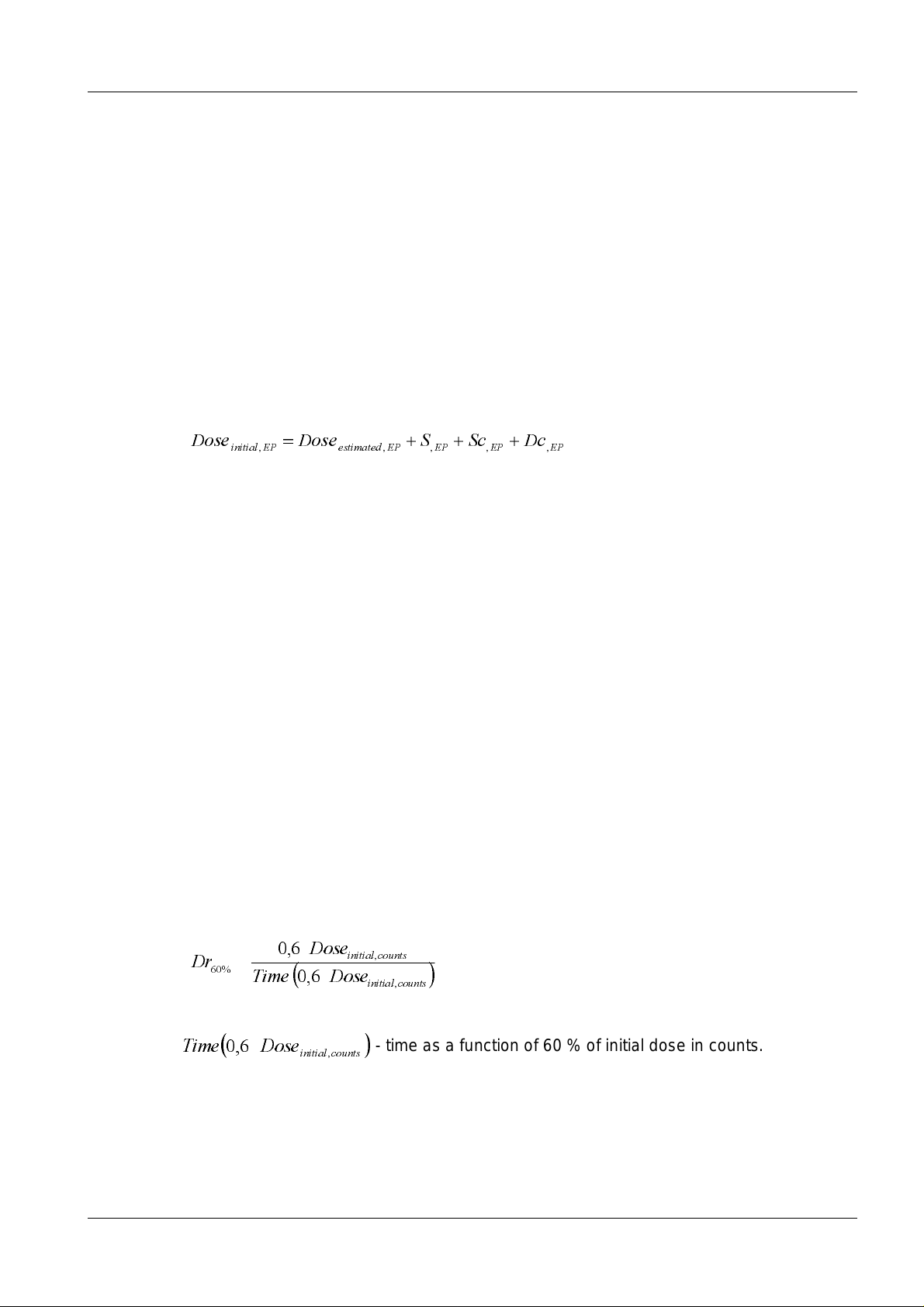

In order to measure the dose rate with the detector, the following procedure is used. The

initial dose is subdivided into a 60%-part and a 40%-part. Both parts are handled in the

AEC-unit by two separate counters, implemented in the PLD. At the exposure start, the

60% counter starts counting down at the rate of pulses from the V/F-converter that handles the amplifiedsignal from the detector. During counting down the 60% of the initial

dose, time is measuredby a time monitor. Whenthe 60% counterhas reached 0, the time

is read and used together with the actual value of 60 % of the initial dose as an average

dose rate:

Dose

Dr

6,0

%60

ΕΦ

DoseTime

6,0

countsinitial

,

countsinitial

,

where

DoseTime,6,0

Siemens AG Register 5 SPB7-230.898.01 Page 5 of 8 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

- time as a function of 60 % of initial dose in counts.

countsinitial

Page 10

1 - 6 Functional description

D

D

D

D

D

D

At the same time, the 40% counter is enabled and continues monitoring of the dose.

During execution of the remaining part of the initial dose, a calculation of the correction

dose has to be done. The measured dose rate is compared with a decreasing sequence

of dose rates, forming a so-called correction table. The index of each dose rate is a correctiondosein1/16EPneededforatargetgivingsuchadoserate,inordertogivethe

desired OD on the film. When the first dose rate, being equal to or lower than the measured, is found in the sequence, the corresponding index is used as the correction dose.

This givesthe total dose of:

ΕΦ

ΗΖ

In order to receive the dose correction in counts, which is needed for initialising the third

and last dose counter in the PLD of the AEC unit, the following formula is used:

DoseDoseDose

ϑΖ

where the total dose and the initial dose are translatedfrom EP to counts.

When the 40 % counter reaches 0, the correction counter initialised with the correction

dose is enabled. When the correction dose is executed as well, the AEC-unit stops the

exposure. The entire picture of dose calculation and execution is given in the figure below.

DoseDcScSDose

ΖΗΗΗ

EPinitialEPEPEPEPestimated

,,,,,

DrDoseDoseDose

EPcorrEPinitialEPtotal

countsinitialcountstotalcountscorr

,,,

%60,,,

Exposure start

Counter 60% = 0

Read time and

calculate correction

Dose

,

EP

Dose

Dose

Check correction table to get

Ζ

,

counts

countsinitial

,

Dose

6,0

DoseTime

ΕΦ

6,0

ΕΦ

DrDose

EPcorr

10

10100

,

countsinitial

Counter 40%

Counter 60%

Counter Corr

,

countsinitial

Ζ

4,0

6,0

%60,

Dr

Counter 40% = 0

correction loaded

Counter Corr = 0

Exposure finnished

%60

ose

Dose

counts

ose

10100

Dose

,

EP

10

ose

ϑΖ

countinitialcountstotalcountscorr

,,,

ose

ose

ose

ΗΖ

EPcorrEPinitialEPtotal

,,,

Dose calculation and execution in the AEC-unit

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 6 of 8 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 11

Functional description 1 - 7

Entire Set of Control Parameters 1

The entire set of control parameters consists of three differently used parts. First part contains parameters that are chosen specifically for a film/screen-combination at laboratory

by series of tests. These are called correction tables. Second part is sensitivity correction,

used to calibrate a specific Mammomat. Third part is sensitivity, used to adjust the target

OD for a specific Mammomat and one film/screen-combination (i.e. one speed) to the

level requested by the customer.

Correction Tables 1

Correction tables contains gain values, estimated doses and correction values. These are

structured in the following way:

Gain

(one value)

Set for 23 kV

Set for grid tables

Set fo r Mo/Mo

Set for one film/screen

Estimated dose

(one value)

4 sets

Correction sequence of dose rates

(a minimum of 80 values)

…

13 sets

…

Set fo r Mo/Rh Set for W/Rh

Set for stereo table

Set for 35 kVSet for 24 kV

kV-set: one gain value, one estimated dose and a minimumof 80 dose rates forming the

correction sequence, define the set of parameters used for specific tube voltage, object

table group, anode/filter and speed.

Table-group-set: 13 kV-sets defining the set of parameters for all tube voltages, one

object table group, anode/filter and speed.

Anode/Filter-set: 4 table-group-sets defining the set of parameters for all voltages, all

object table groups, one anode/filter and speed.

Film/screen-set: 3Anode/Filter-sets defining the set of parametersfor all user choices

withinone speedi.e.one film/screen-combination.

Because the Mammomat gives the user a possibility to choose between two different

speeds, it can be equipped withtwo film/screen sets of parameters - one for each speed,

HandD.

Siemens AG Register 5 SPB7-230.898.01 Page 7 of 8 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

Page 12

1 - 8 Functional description

Sensitivity Correction 1

The sensitivity correction is possible to choose differently for all 7 object tables, 3 anode/

filter- combinations and 2 speeds. This makes totally 42 possible values, adjustable in

1/8 EP-steps.

Sensitivity 1

One sensitivity setting is allowed for each speed, H and D, wh ich gives totally 2 sensitivities, adjustable in 1/8 EP-steps.

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 8 of 8 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 13

Error messages 2

ERROR messages of the new AEC Er 4xx are described in the document

"service program" from SW 4.0.

2-1

NOTICE

NOTICE

The error messages Er 419 - Er 422 are internal errors.

They do not interfer with an exposure and are not shown on the

control panel.

Please report this errors immediately in accordance with the

established processes.

Siemens AG Register 5 SPB7-230.898.01 Page 1 of 2 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

Page 14

2 - 2 Error messages

This page intentionally left blank.

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 2 of 2 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 15

Parts replacement 3

Action list for MAMMOMA T 1000/ 3000 with new AEC 3

Change of Consequence

3-1

Power

Filter

Tube

Inverter

Detector

D701

AE C T est according to

"Installation and startup

instructions for MAMMOMAT

1000/3000"

Install o ld backup of A EC and

correction tables

En tire calibration

of AEC

AEC Test

Not

ok

Detector

n o r ma lization

D702

D705

Object table

Adjust kV Filamen t adaption

S ens it iv it y corr ection

adjustm ent

Siemens AG Register 5 SPB7-230.898.01 Page 1 of 2 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

Page 16

3 - 2 Parts replacement

This page intentionally left blank.

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 2 of 2 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 17

Description of LED’s and measuring points 4

Measuring points on AEC board D701 4

TX Communication from D701

RX Bus communication

KVA_EXP_DONE Indicates end of normal exposure

KVA_ABORT_EXP Indicates exposure aborted by CPU on D701

0VD 0VA VCC 5 V

D15V 15 V for logic

P15V + 15 V

N15V -15 V

VOSCTL 1 Signal for control of offset compensation

SEL_RDL Detector signal

4-1

A3_RDL Amplified detector signal

A4_RDL Amplified detector signal compensated for offset

AD_RDL V/F converter output signal

FRDL V/F converter output pulses

OFS_RDL Offset compensation signal

X1 For factory test only

X2 For factory test only

Switches on AEC board D701 4

S1 For factory test only, set to zero

Jumpers on AEC board D701 4

X114 1-2Normal/2-3Nodosemonitoring

J1 Forces offset compensation mode

J2 Forces measuring mode

J3 Generates an offset test signal

Siemens AG Register 5 SPB7-230.898.01 Page 1 of 4 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

Page 18

4 - 2 Description of LED’s and measuring points

LEDs on AEC board D701 4

Processor

(status)

Gain PLD

(detected

error)

PLD

(configuration

status)

Processor LEDs ()

x x x x

x x x

x x

( EPROM Check finished)

x

x x

x x

x x

CPU not Running

RAM Check

EPROM Check

Flash check

Ready

RAM Error EPROM Error

Gain LEDs ()

0

2

=1

1

2

2

2

3

2

4

2

5

2

6

2

7

2

=2

=4

=8

=16

=32

=64

=128

NOTICE

x

x

x x

x

x x

x x

x x x

The gain displayed corresponses to the total gain, which is a

function of the correction table gain (SW controlled) and the D7 01

gain (HW controlled).

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 2 of 4 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 19

Description of LED’s and measuring points 4 - 3

PLD LED ()

If PLD is correctly configured and running, the LED is toggled with period of 1 sec.

PLD LEDs ()

If an error is detectedby the PLD an 8-bit code is displayed on the4 LED’s in a sequence

as follows:

1. Initially the 4 LSB (least significantbits) of the error code are displayed during

1second.

2. Thenthe 4 MSB(mostsignificantbits)of theerrorcode aredisplayed during

1second.

To indicate that the entire error code has been displayed, each of the four LED’sare

turnedon one at time.

The sequence described above will be repeated until reset of the PLD.

An error code detected by the PLD can also be found with the Service PC program by

entering the menu <Normal mode> <AEC data>.

Siemens AG Register 5 SPB7-230.898.01 Page 3 of 4 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

Page 20

4 - 4 Description of LED’s and measuring points

This page intentionally left blank.

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 4 of 4 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 21

Tests 5

Check the AEC according to "Installation and start-up instructions" for MAMMOMAT 1000/ 3000 5

If AEC tests fails, check that:

correct plexi has been used and positioning of plexi is correct and that used kV-setting is

correct.

usedfilm/screencombination iscorrect(reference cassetteshallbe used).

correction for variations in film developing process has been correctly performed.

5-1

Siemens AG Register 5 SPB7-230.898.01 Page 1 of 2 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

Page 22

5-2 Tests

This page intentionally left blank.

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 2 of 2 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 23

Problems during Installation/ Service 6

AEC Correction tables 6

Measured d ose rate exceeds + 30% 6

Perform

calibr a t ion of

AE C correction

table s

Me asured dose

rate exceeds +

30%

6-1

Not

OK

Not

OK

Not

OK

Ch eck size and

positioning of

used plexi

OK

Check that correct

film/s c r een is used

OK

C heck supply

voltage to the unit

Accept, but note

the e xposure s

where the

measured dose

rate exceeds!

Siemens AG Register 5 SPB7-230.898.01 Page 1 of 8 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

Page 24

6 - 2 Problems during Installation/ Service

Error during backup from disc/ floppy 6

Perform Backup

from

se rvic e p rog ra m

E rror d urin g

Backup

Rep eat

3times

Not

OK

Not

OK

Not

OK

Check backup files

on disc/ floppy

OK

Che ck co nnection

with Service PC

OK

Perform backup

Not OK a fter 3 times

Fata l e rro r

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 2 of 8 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 25

Problems during Installation/ Service 6 - 3

Error during reset of installation parameters 6

Perform R eset

inst a l la t io n

pa ra m e te rs fro m

se rvic e p rog ra m

E rro r o c cu re d

Not

OK

Re peat

3times

Not

OK

Che ck co nnection

with Service PC

OK

Perform reset

Not OK a fter 3 times

Chan ge D7 01

Siemens AG Register 5 SPB7-230.898.01 Page 3 of 8 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

Page 26

6 - 4 Problems during Installation/ Service

Errors during offset compensation test 6

Perform Offset

co mpe n s a tion te s t w ith

service program

Measured dose

rate out of range

No

Detector blocked

from radiation

Yes

Disconnect detector

cables X10 & X11

Press F3

Measured dose

rateoutofrange?

Yes

Change D701

Connect X 10 & X 11

Press F3

No

Measured dose

rate out of range ?

Yes

fro m 6-5 to 6-5

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 4 of 8 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

F at al erro r

No

OK

Page 27

Problems during Installation/ Service 6 - 5

from 6-4to 6-4

Connect X 10

Press F3

No

Connect X 11

Press F3

Measured dose

rate out of range ?

Change detector

wing 2

Outofrange?

Yes

Change detector

wing 1

Siemens AG Register 5 SPB7-230.898.01 Page 5 of 8 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

Page 28

6 - 6 Problems during Installation/ Service

Detector Normalization 6

Normalization factor out of range 6

Perform

exposures for

nor ma liza t ion with

service program

N or ma liza t io n

factor out of range

after pressing

<F2> ?

Not

OK

Not

OK

Not

OK

Check size and

position of u se d P lex i

OK

Check that correct

table is use d and no

cassette is inserted

OK

Check connection of

detector

OK

Change detector

Fa ta l e rro r

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 6 of 8 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Page 29

Problems during Installation/ Service 6 - 7

Miscellaneous 6

Communication Errors with Service PC 6

Check if the PC is equipped with an IRtransmitter and disable it.

Siemens AG Register 5 SPB7-230.898.01 Page 7 of 8 MAMMOMAT 1000/3000

Medical Engineering Rev. 01 04.00 TD SD 24

Page 30

6 - 8 Problems during Installation/ Service

This page intentionally left blank.

MAMMOMAT 1000/3000 Register 5 SPB7-230.898.01 Page 8 of 8 Siemens AG

Rev. 01 04.00 TD SD 24 Medical Engineering

Loading...

Loading...