Page 1

MAMMOMAT 1000/3000

Installation

Installation and Start-Up Instructions

© Siemens AB 1999

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Register 3 English

Print No.: SPB7-230.033.07.03.02 Doc . Gen. Date: 11.99

Replaces: SPB7-230.033.07.02.02

65 27 464

Page 2

0 - 2 Revision

Chapter Page Revision

17 All 03

Mammomat 1000/3000 Register 3 SPB7-230.033.07 Page 2 of 2 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 3

Contents 0 - 1

Page

1 _______Prerequisites __________________________________________________1 - 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

MAMMOMAT 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

MAMMOMAT 3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Meters and appliances, tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Meters and appliances required. . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

Tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Important notes on start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Checking and recording for the area of applicati on of the X-ray decree (§16 Germany)1 - 4

Checking and recording for the DHHS area of applicati on . . . . . . . . . . . . . . . 1 - 5

Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Note on delivery state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

2 _______Protective measures ____________________________________________ 2 -1

Protective measures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -1

3 _______Preparatory work_______________________________________________3 - 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Unpacking the stand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Removing the transport safeguards. . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Removing the swivel-arm system transport sa feguard . . . . . . . . . . . . . . . 3 - 3

Transport safeguard for the lifting carriage . . . . . . . . . . . . . . . . . . . . . 3 - 3

Transport safeguard for the rotary motion. . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Protective strips for the metal curtain . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 5

Unpacking the generator and mounting the radiation shield (optional) . . . . . . . . .3 - 6

4 _______Installing the generator and the stand _____________________________4 - 1

Arranging the components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Notes on installations with separate generat or and separate control console. . . . 4 - 1

Free-standing radiation shield (option) . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Removing the generator cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 2

Installing the cable ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Installations with separate control console . . . . . . . . . . . . . . . . . . . . . 4 - 3

Laying the cable harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Installations with separate control console . . . . . . . . . . . . . . . . . . . . . 4 - 5

Aligning the stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

5 _______Cable connections______________________________________________5 - 1

EMC measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

EMC measures at the cable entry. . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

Siemens-Elema AB Register 03 SPB7-230.033.07 Page 1 of 4 MAMMOMAT 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-up

Page 4

0 - 2 Contents

Page

Fitting the hose clamps and ferrite sleeves

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Note on separate control console and separate generator. . . . . . . . . . . . . 5 - 2

EMC measures on the bottom plate . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Fitting the cables X1, X8 and X9 onto the bottom plate . . . . . . . . . . . . . . 5 - 3

Connecting the stand cable-ha rness . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

High-voltage connectors, alternative types . . . . . . . . . . . . . . . . . . . . . 5 - 4

Connecting the high-voltage connector . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

Connecting the cable harness to the generat or . . . . . . . . . . . . . . . . . . . . 5 - 6

Unit control cable X1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Filament cable X8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Power supply cable X14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

IONTOMAT signal cable X10 and X11 . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Rotating anode cable X9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7

Installations with separate control console and separate generator

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 8

Main voltage connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 10

Connecting the incoming mains to the stand (400 V, 2-pha se). . . . . . . . . . . . .5 - 11

400 V 2-phase connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 11

Connecting the mains supply to the generator (400 V, 2-phase). . . . . . . . . . . .5 - 12

Measures for changing from 2-phase to 1-phase con nection . . . . . . . . . . .5 - 13

6 ______ Mains connection and power supply_______________________________6 - 1

Checks before powering up the generator . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Measuring the line resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Checking the line voltage in the generator . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Checking the supply voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

7 ______ Attaching the swivel-arm covers __________________________________7 - 1

Attaching the swivel-arm covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Arranging the swivel-arm system. . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Connecting the cables to control-button boards and patient handles . . . . . . . 7 - 1

Attaching the side covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Attaching the front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

8 ______ Checking the microprocessors ___________________________________8 - 1

Microprocessors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

9 ______ Checks without high voltage _____________________________________9 - 1

Checks without high voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

10 _____ Checks with high voltage _______________________________________10 - 1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 - 1

Checking X-ray tube high voltage, tube currrent and mAs values . . . . . . . . . . .10 - 2

MAMMOMAT 1000/3000 Register 03 SPB7-230.033.07 Page 2 of 4 Siemens-Elema AB

Installation and Start-up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 5

Contents 0 - 3

Page

Tube current reduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Oscilloscope diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 3

11 ______Start-up and functional test of the IONTOMAT______________________11 - 1

Checking and programming with the service PC . . . . . . . . . . . . . . . . . . . 11 - 1

Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 1

Sensitivity correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 2

Correction curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 2

Other film/screen combinations . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 3

Correction curve diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 4

Checking the film density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 8

Checking the automatic transparency adaption. . . . . . . . . . . . . . . . . . . . 11 - 9

Checking the automatic transparency adaption and OPDOSE (MAMMOMAT 3000 only) 11

- 10

Checking cut-off dose and re solution (§16 Germany). . . . . . . . . . . . . . . . .11 - 11

Output values of constancy testing (§16 Ge rmany). . . . . . . . . . . . . . . . . .11 - 12

12 ______Further programming __________________________________________12 - 1

Setting the real time clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 1

Prerequisite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 1

Setting the time in the Mammomat . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 1

Setting the tube-current reduction. . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 1

Reducing the generator power . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 2

Main menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 2

13 ______Checking the swivel-arm system_________________________________13 - 1

Rotary motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 1

Vertical adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 2

Emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 3

14 ______Field light ____________________________________________________14 - 1

Checking and adjusting the field light time . . . . . . . . . . . . . . . . . . . . . . 14 - 1

Checking the field light time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 - 1

Adjusting the field light time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 - 2

15 ______Checking the compression device and OPCOMP ___________________15 - 1

Checking the compression device. . . . . . . . . . . . . . . . . . . . . . . . . . . 15 - 1

Decompression button (only with separate control console) . . . . . . . . . . . 15 - 2

Checking the OPCOMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 - 3

Adapting OPCOMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 - 3

16 ______Checking the exposure blocking_________________________________16 - 1

Checking the exposure blocking . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 - 1

Siemens-Elema AB Register 03 SPB7-230.033.07 Page 3 of 4 MAMMOMAT 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-up

Page 6

0 - 4 Contents

Page

17 _____ Checking the radiation field limitation_____________________________17 - 1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 - 1

Measuring procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 - 2

Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 - 3

Alignment radiation field/light field . . . . . . . . . . . . . . . . . . . . . . . . .17 - 3

Radiation field limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 - 3

18 _____ Final procedures _____________ __ ___ __ __________________________18 - 1

Service PC and measuring instruments . . . . . . . . . . . . . . . . . . . . . . . .18 - 1

Recording the programmed values . . . . . . . . . . . . . . . . . . . . . . . . .18 - 1

Reading the exposure counter and deleting the error memory. . . . . . . . . . .18 - 1

Saving the configuration file . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 1

Removing the measuring instruments . . . . . . . . . . . . . . . . . . . . . . . . .18 - 2

Checking the protective grounding res istance . . . . . . . . . . . . . . . . . . . . .18 - 2

Mounting the cable duct covers . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 2

Mounting the stand covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 2

Mammomat stand with separate rear side covers. . . . . . . . . . . . . . . . . .18 - 3

Mammomat stand with single rear cover.. . . . . . . . . . . . . . . . . . . . . .18 - 4

Fitting the Mammomat cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 5

Fitting the cable outlet cover . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 5

Mounting the front cover onto the generator . . . . . . . . . . . . . . . . . . . . . .18 - 6

Final protective grounding resistance test . . . . . . . . . . . . . . . . . . . . . . .18 - 6

Face shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 7

Warni ng label on control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 8

Affixing the ide n tification labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 9

Returning the LINA card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 9

19 _____ Bolting the stand/generator to the floor ___________________________19 - 1

Stativ and generator with integrated radiation shield and control panel . . . . . . . .19 - 1

Installation with separate generator . . . . . . . . . . . . . . . . . . . . . . . .19 - 2

Free-standing radiation shield (option) . . . . . . . . . . . . . . . . . . . . . . .19 - 3

20 _____ Appendix ______________ ___ ________________________________ ___20 - 1

Working with the service PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 - 1

Description of the syntax used in these instructions . . . . . . . . . . . . . . . .20 - 1

Connecting the service PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 - 2

Starting up and using the service PC. . . . . . . . . . . . . . . . . . . . . . . .20 - 2

Measuring protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 - 3

MAMMOMAT 1000/3000 Register 03 SPB7-230.033.07 Page 4 of 4 Siemens-Elema AB

Installation and Start-up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 7

Prerequisites 1

General 1

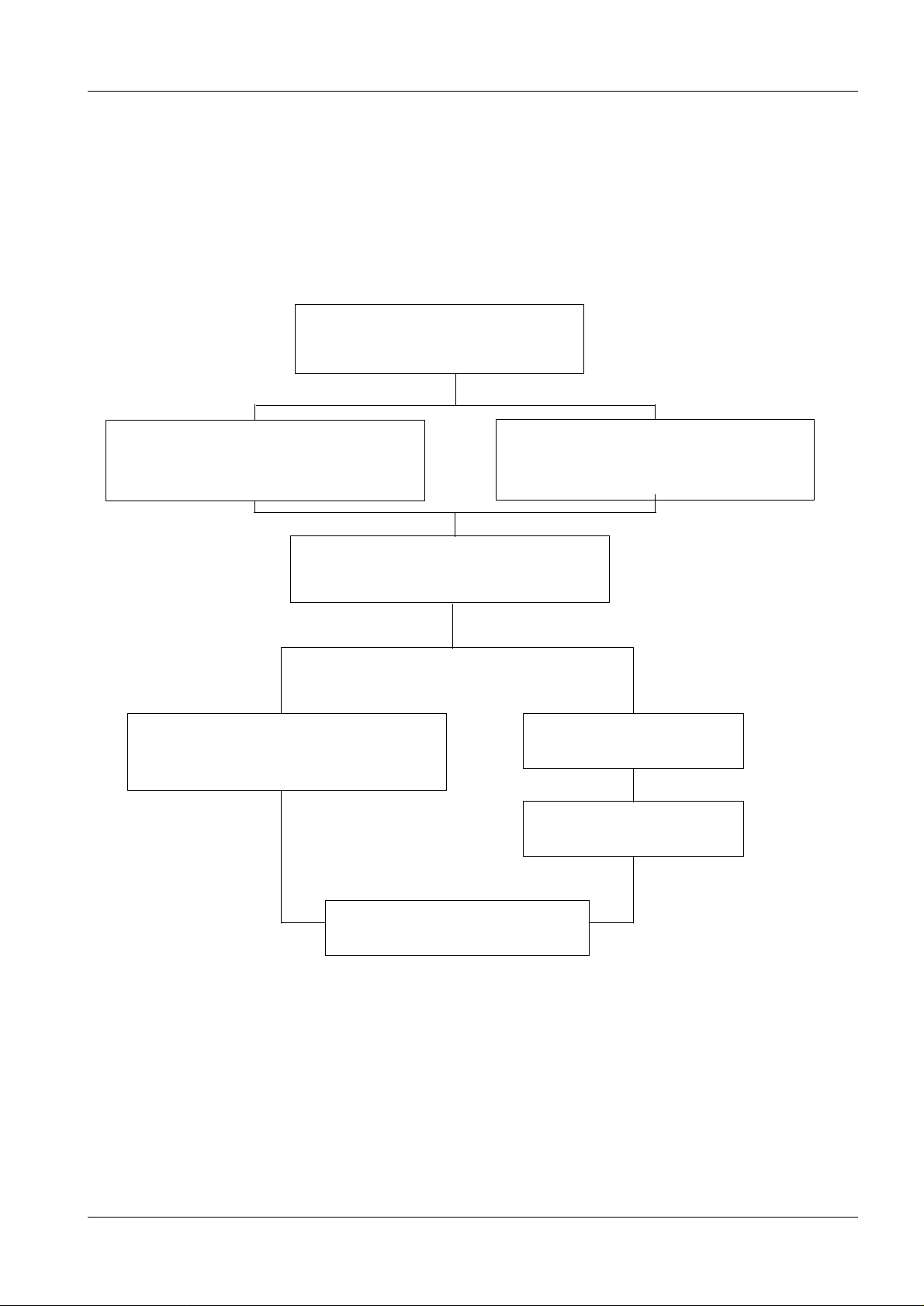

The configuration of the Mammomat installation is dependent on the customer’s choice.

Up to twelve various combinations are possible as shown below:

MAMMOMAT 1000 1

Mammomat 1000 - Basic unit

1 - 1

Molybdenum anode X-ray tube

assembly with filter Mo 0.03

Fixed object-table arm

("Wing 2" no counterweight)

Generator with integrated

control panel and radiation shield

Molybdenum anode X-ray tube

assembly with filter disc

Mo 0.03/Rh 0.025

Separate generator

Separate control console

Free-standing radiation shield

Fig. 1

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 1 of 6 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 8

1 - 2 Prerequisites

NOTICE

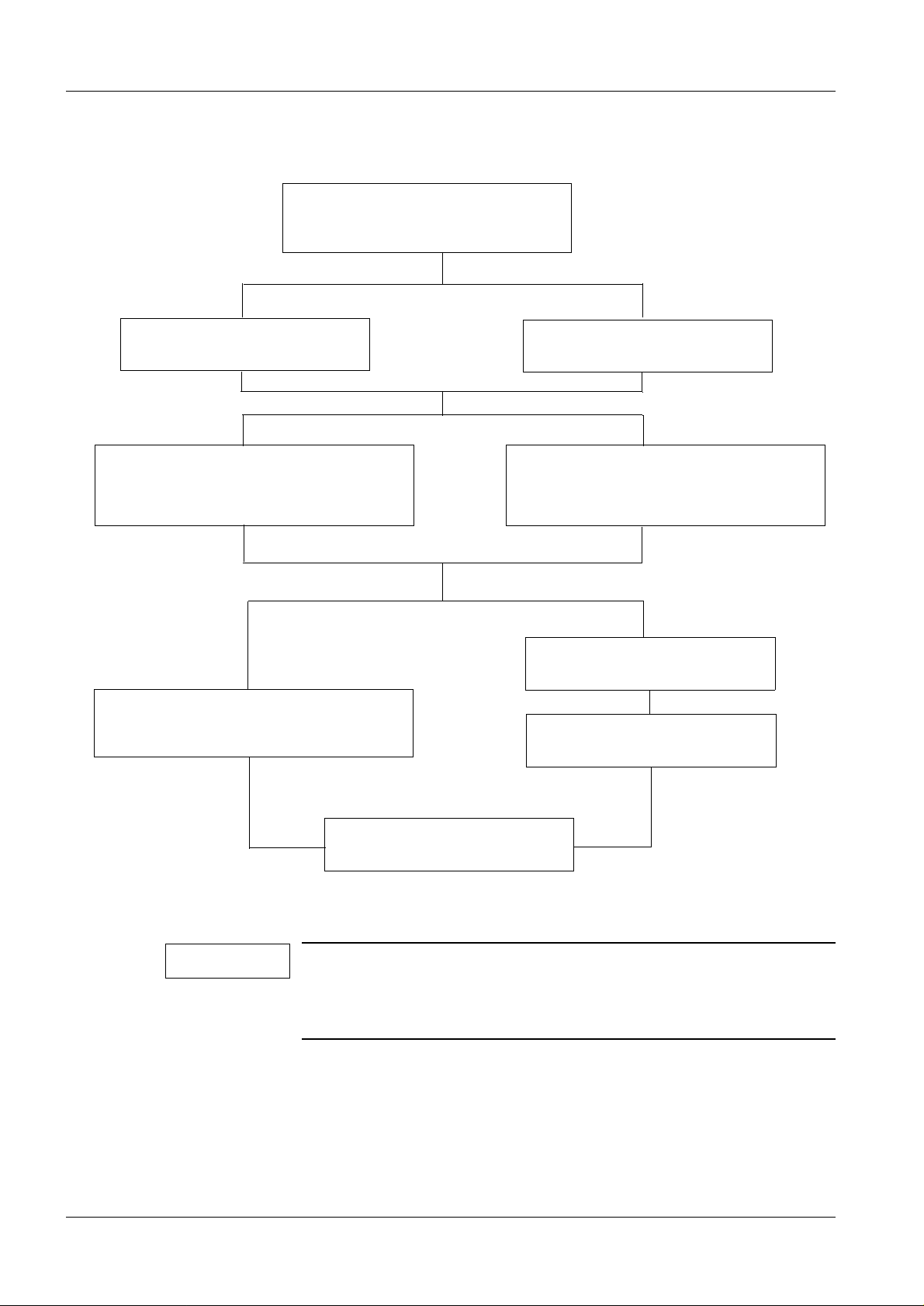

MAMMOMAT 3000 1

Mammomat 3000 - Basic unit

Pivoting object-table arm

("Wing 1"+ "Wing 2")

Molybdenum/tungsten anode X-ray

tube assembly with filter disc

Mo 0.03/Rh 0.025/Rh 0.050

Generator with integrated

control panel and radiation shield

Fixed object-table arm

("Wing 1" + counterweight)

Molybdenum anode X-ray tube

assembly with filter disc

Mo 0.03/Rh 0.025

Separate generator

Separate control console

Free-standing radiation shield

Fig. 2

A P40 MoW tube will be delivered irrespective of whether the customer has chosen the molybdenum/tungsten anode X-ray tube or

the molybdenum anode X-ray tube. In the last case, the tungsten

anode is deselected by the software.

Unless otherwise stated, these instructions describe the stand with pivoted object-table

arm and generator with integrated radiation shield and control panel.

Depending on the installation configurat ion, some points may be omitted.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 2 of 6 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 9

Prerequisites 1 - 3

NOTICE

WARNING

NOTICE

Meters and appliances, tools 1

Meters and appliances required 1

Calibrated instruments are required.

• Power Line Impedance Meter 84 28 104 RE999.

• Protective ground-wire tester 44 15 899 RV090.

• Oscilloscope, e.g TEKTRONIX 314.

• Digital multimeter incl. mAs meter.

• Densitometer e.g PDA 81.

• Service PC (e.g Siemens-Nixdorf PCD 3NSX/20 or similar) with connecting cable (PC-

Generator), part no. 99 00 440 RE999.

• Normi 7 test body (provided by the customer) or SIB phantom Type 42 001 (PTW or

INAK).

• Centering cross, part no. 96 60 051 RE 999.

• Plexiglass plates, three plates measuring150 mm x 20 mm x 20 mm and one plate

measuring 150 mm x 150 mm x 10 mm, part no. 85 49 438 and 97 88 423 respectively.

For safety reasons, the existing protective ground conductor in

the power cord must under no circumstances be disconnected

when operating the oscilloscope. For those measurements, in

which any resulting ground loop may falsify the measuring result,

use the differential amplifier (difference measurement).

Tools required 1

• Standard installation tool kit.

• Torque wrench for bolting the stand/generator to the f loor (optional).

• Electrical screwdriver with adjustable torque is r ecommended.

Checks and/or adjustments, which must be made with X-ray

radiation switched on, are marked with the warning symbol:

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 3 of 6 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 10

1 - 4 Prerequisites

NOTICE

Important notes on start-up 1

The MAMMOMAT is adjusted, programmed and tested in the factory, leaving only the

adaption to the on-site mains voltage and the functi onal tests to be performed.

When the measurements to be made (kV, mAs, etc.) are within th e tolerances stated in

these instructions, this confirms that the settings made in the factory have not changed

and the equipment is fully serviceable.

The measured values marked with

entered in the "start-up" column in the test certificate provided.

The service PC is required only for programming according to:

? in Chapter 10 "Checks with high voltage" shall be

• Chapter 10 "Checks with high voltage"

• Chapter 11 "Start-up and functional test of the IONTOMAT"

Programming the "Correction curve"

Setting the "sensitivity" (film density)

Setting the "sensitivity correction" (adaption to different exposure techniques)

• Chapter 12 "Further programming"

• Chapter 18 "Final procedures"

Description of the Service-PC syntax is found in Chapter 20 "Appen dix".

If the generator is switched off with the Service PC connected,

wait approximately 5 s before switching it on again.

Checking and recording for the area of application of the X-ray

decree (§16 Germany)

1

In the area of application of the X-ray decree, an acceptance test certificate is supplied,

with most of the data filled in by the factory.

Only:

• the cut-off dose

• the resolution of the film/screen systems used

• the output values of the constancy test

must be determined by the owner of the equipment and recorded in the acceptance test

certificate. Furthermor e, the front page of the acceptance test certificate must also be

completed with the operator´s data.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 4 of 6 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 11

Prerequisites 1 - 5

Checking and recording for the DHHS area of application 1

In the area of application of the DHHS regulations, maintenance measurements must be

made according to the "DHHS Maintenance Instructio ns" SPB7-230.662.03.01.02 and the

"DHHS Supplements to the instructions for use" SPB7-230.661.02.01.02.

Sections 1

• Required labels.

• Radiation ON indicators.

• Manual termination of exposure.

• Checking the maximum adjustable mAs.

• Filters in beam limiting device (BLD).

• Reproducibility.

• kVp-accuracy.

• mAs-accuracy.

• Automatic exposure control (AEC).

• Coincidence of radiation field/image receptor.

• Alignment of light field/X-ray field.

• Illuminance of light localizer (light field).

• Shut-down of motor-driven compression movement.

The result must be recorded in "DHHS Measurement certificates"

SPB7-230.663.03.01.02.

Some of the values to be determined can be taken from the acceptance test certificate.

The radiation-field limitat ion is set at the factor y and recorded i n the acceptance t est certi f-

icate.

If the measurements to be made concerning the radiation-fi eld li mitati on are withi n the tol-

erances stated in these instructions, this confirms that the settings made at the factory

have not changed.

Note on delivery state 1

The MAMMOMAT has been tested and adjusted at the factory, and should therefore be

ready for operation after completion of the i nstallation.

The equipment is set to 400 V, 2-pase, on delivery.

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 5 of 6 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 12

1 - 6 Prerequisites

This page intentionally left blank.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 6 of 6 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 13

Protective measures 2

WARNING

WARNING

CAUTION

e

WARNING

Protective measures 2

It is very important that any interventi on in the equipment will start with disconnecting it

from the power supply with the main circuit-breaker. Before removing or inse rting any of

the printed circuit board, swit ch of the equipment. To prevent accidental triggering of high

voltage and radiation, set the switch S2 (SS) on p.c. board D702 to "OFF" (lower posit ion,

no triggering of the SS relay).

If the system is only switched off at the control panel or with

S2/D711, line voltage will still be present at the generator line

connection, line filter Z1, Z2, transformer T1, transformer T10 and

p.c. board D711 (see wiring diagram).

After shut-down of the system, there may still be 380 V DC

present on the intermediate circuit. This will be indicated by LED

V24 on p.c. board D710. The voltage will drop to less than 30 V

within about 3 minutes, the LED goes out at about 30 V.

2 - 1

The p.c. boards contain electrostatic highly sensitive components

requiring particular care in their handling (ground before making

contact and place only on a conductive surface).

The edges of the metal curtain of the stand are very sharp and

may cause severe injury. Apply the protective strips as mentioned

in section Protective Measures after removing the covers fr om th

the stand. Remove the protective strips only when the covers are

to be mounted or when vertical adjustment of the swivel-arm

system is necessary.

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 1 of 2 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 14

2 - 2 Protective measures

This page intentionally left blank.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 2 of 2 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 15

Preparatory work 3

WARNING

General 3

Scope of delivery 3

The MAMMOMAT is normally packed in o ne crate and one ca rdboard bo x ( the number of

packages is dependent on the customer’s choice, however):

Crate (length 2140 mm, width 800 mm, height 1375 mm)

The crate contains:

• Compression plate

• Stand with X-ray tube assembly and base plate

• Object table 18 cm x 24 cm (Bucky)

• External diaphragm

• Cover panels

• Installation material

• Optional: Stanchions for the lead-glass pane (radiati on shield)

3 - 1

• Cable ducts

• Technical documents

Cardboard box (lenght 1210 mm, width 820 mm, height 700 mm)

The cardboard box contains:

• Generator with integrated control panel, high-v oltage generator and base plate.

• Optional: Lead-glass pane

• Optional: Separate control console

Further accessories are packed in a separate cardboard box.

Unpacking 3

As a general rule, the directional marks on the crates should be observed during transport, storage and unpacking.

The stand crate is bolted together, while the cardboard box is secured with plastic straps.

Wear safety footwear!

Siemens-Elema AB Register 03 SP B7-230.033.07 Page 1 of 8 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 16

3 - 2 Preparatory work

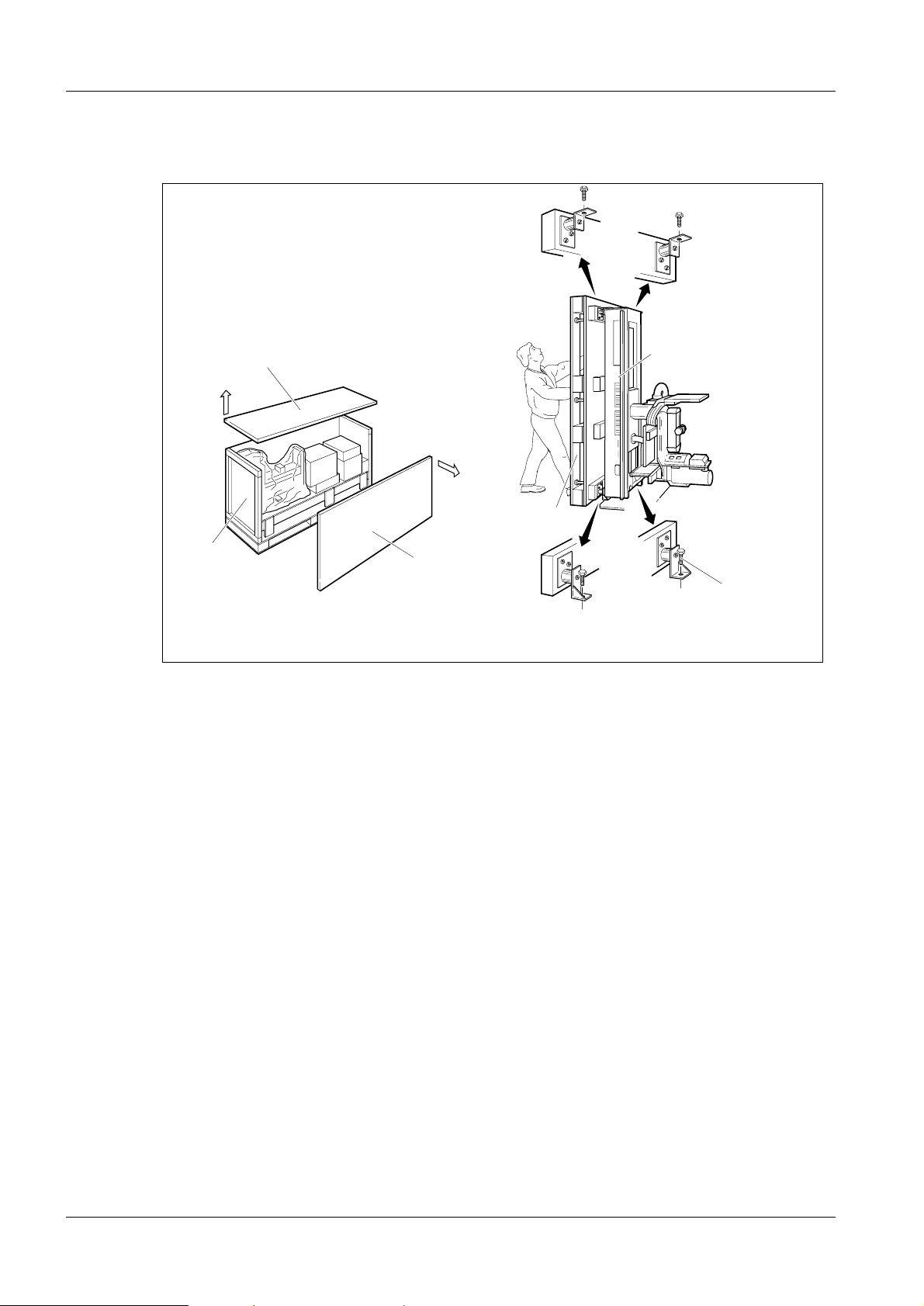

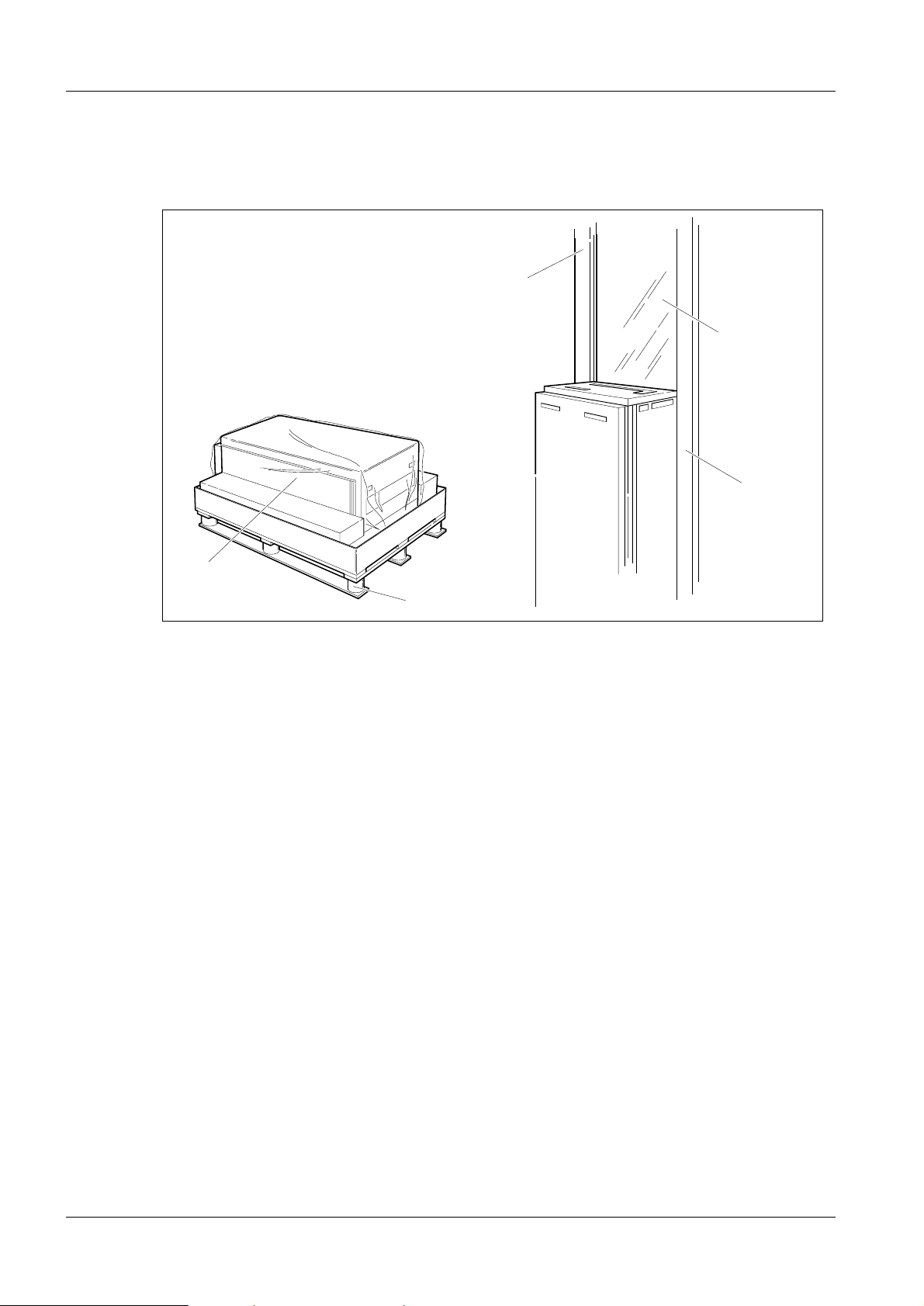

Unpacking the stand 3

1

3

Fig. 1 Unpacking the stand

1

2

5

2

4

6

Unpacking

1. Open the stand crate by removing the top (1) and then the side wall (2).

2. Take out all enclosed packages (accessor ies, installation material, cover panels

etc.) from the crat e.

MAM00167

3. Remove the wooden supports.

4. Remove the remaining walls (3 ).

5. Move the stand and pallet to the site of erection.

6. Upend the stand (4), with pallet (5) (two persons are required).

7. Loosen the four bolts (6) and remove the pa llet (5).

Mammomat 1000/3000 Register 03 SP B7-230.033.07 Page 2 of 8 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 17

Preparatory work 3 - 3

NOTICE

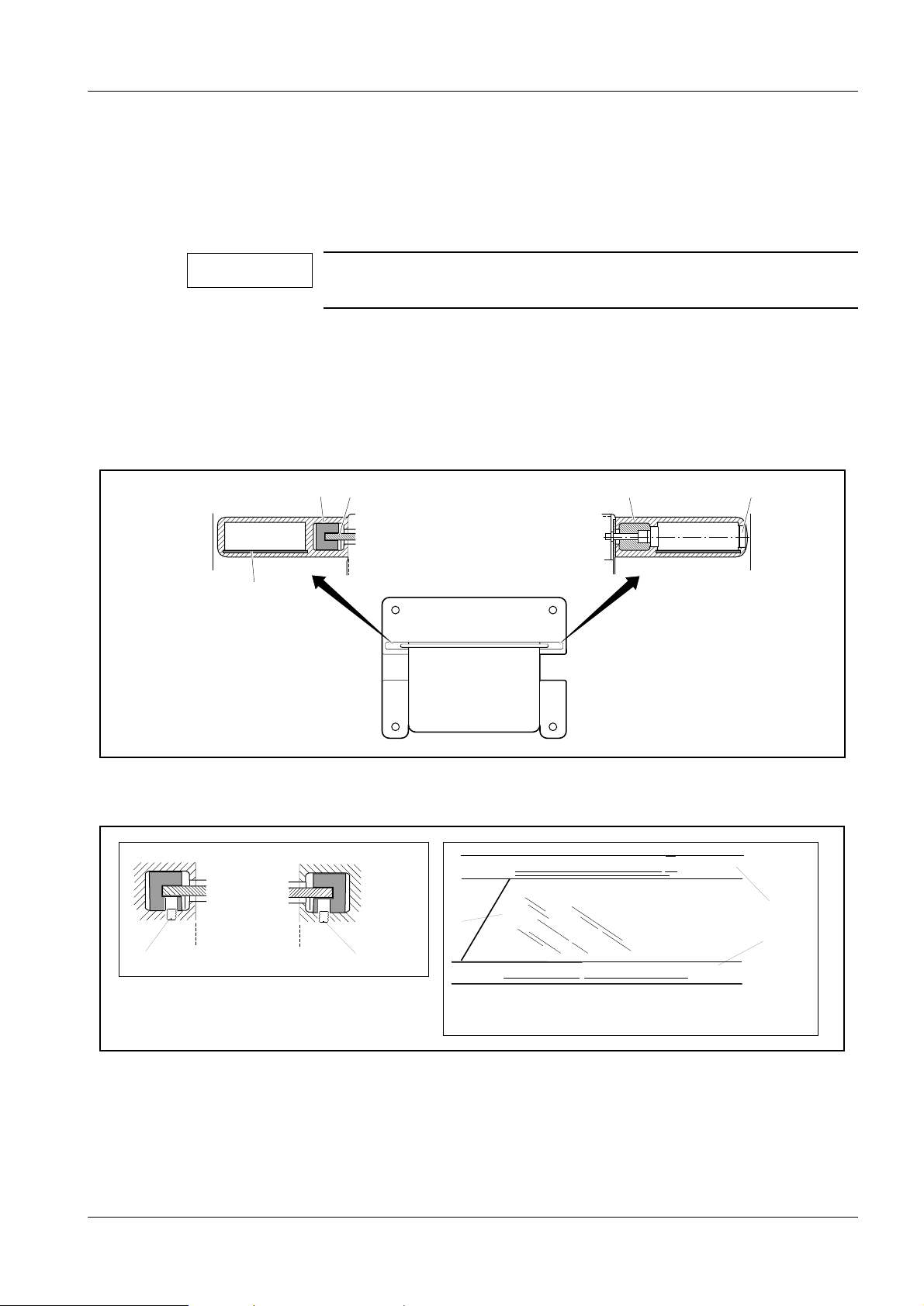

Removing the transport safeguards 3

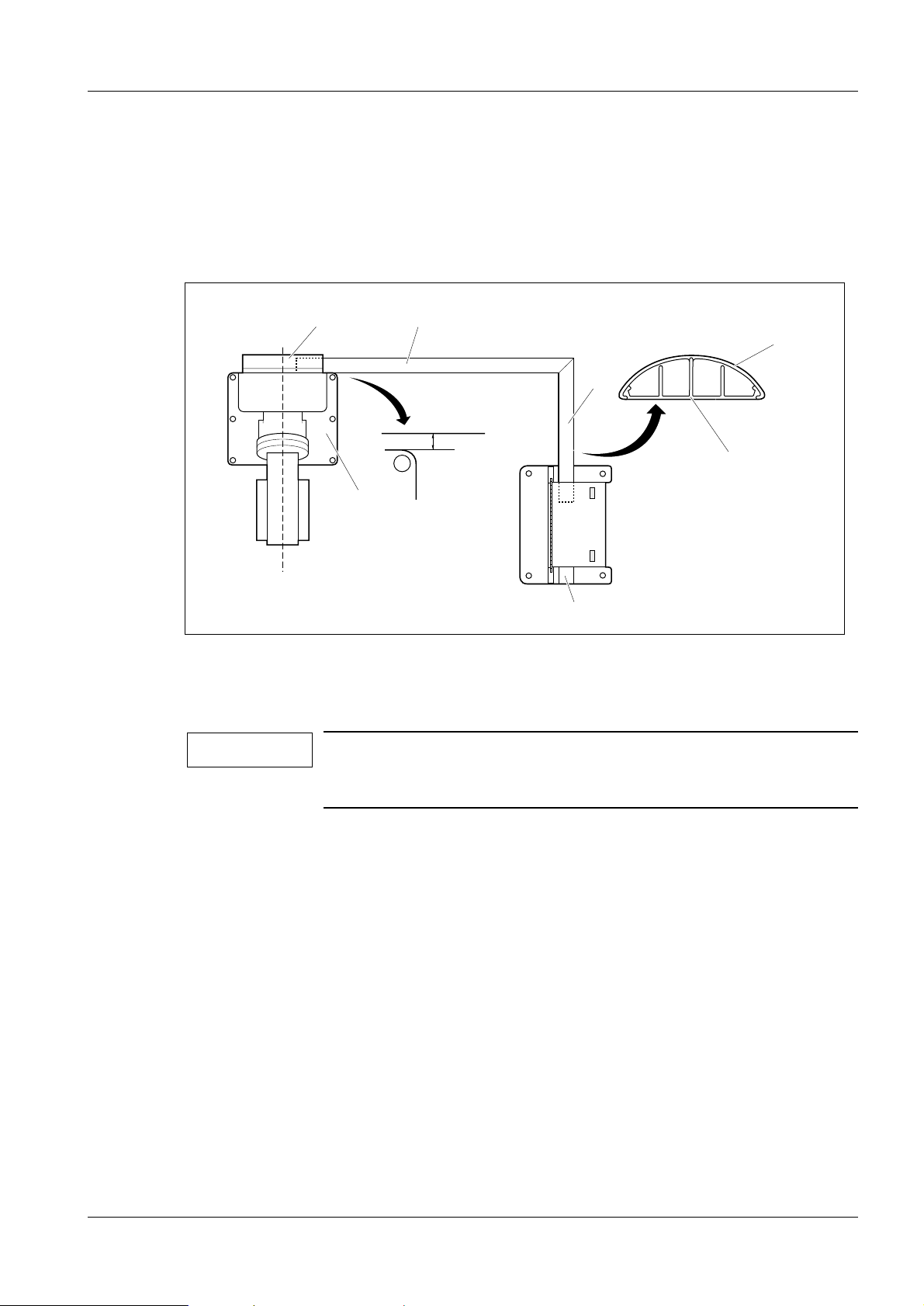

Removing the swivel-arm system transport safeguard 3

1

2

3

MAM00081

Fig. 2 Swivel-arm system transport safeguard

1. Loosen the transport safeguard nuts ( 1/Fig. 2) and remove the tube head scr ews

(2/Fig. 2).

2. Push the red transport safeguard (3/Fi g. 2) inwards, away from the tube head.

Removal of the swivel-arm system transport safeguard is done

after the equipment has been powered up, see further section

"Attaching the swivel-arm covers" on page 7 - 1.

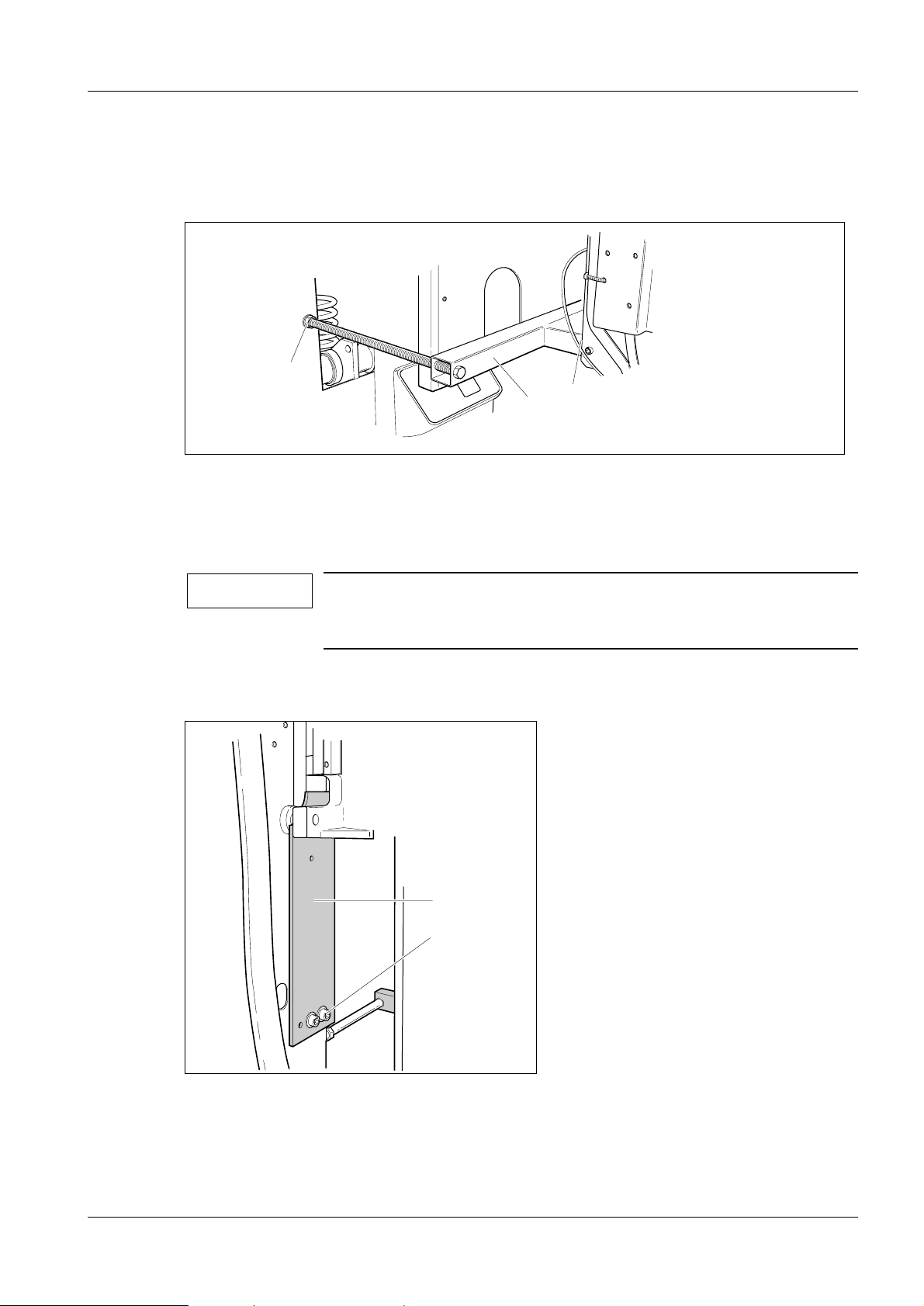

Transport safeguard for the lifting carriage 3

2

1

MAM00082

Fig. 3 Transport safeguard for the lifting carriage

1. Loosen the two screws (1/Fig. 3) and remove the red transport safeguard (2/ Fi g.

3). Reinsert screws (1/Fig. 3), they might be needed for service purposes.

Siemens-Elema AB Register 03 SP B7-230.033.07 Page 3 of 8 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 18

3 - 4 Preparatory work

NOTICE

MAM00312

The lifting carriage transport safeguard shall be kept for service

purposes (Fig. 5).

2. Cut and remove the cable tie securing the balancing spring during transport.

Transport safeguard for the rotary motion 3

1

MAM00083

Fig. 4 Transport safeguard for the rotary motion

1. Remove the transport safeguard screw (1/F ig. 4) with spacer to enable rotary

motion.

The screw and the spacer should be kept for the mounti ng of the lifting carriage

transport safeguard.

2. Mount the red lifting carriage t ransport safeguard with screw and spacer

(1/Fig. 4) on the left hand side of the stand, see Fig. 5. Insert the screw through the

slot from the inside of the sta nd, see Fig. 6

MAM00314

MAM00313

Fig. 5 Transport safeguard mounted on the stand Fig. 6 Screw and spacer inserted from the inside of the

stand

3. Tighten the screw. Make sure that the transport safeguard is parallell to the

stand.

Mammomat 1000/3000 Register 03 SP B7-230.033.07 Page 4 of 8 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 19

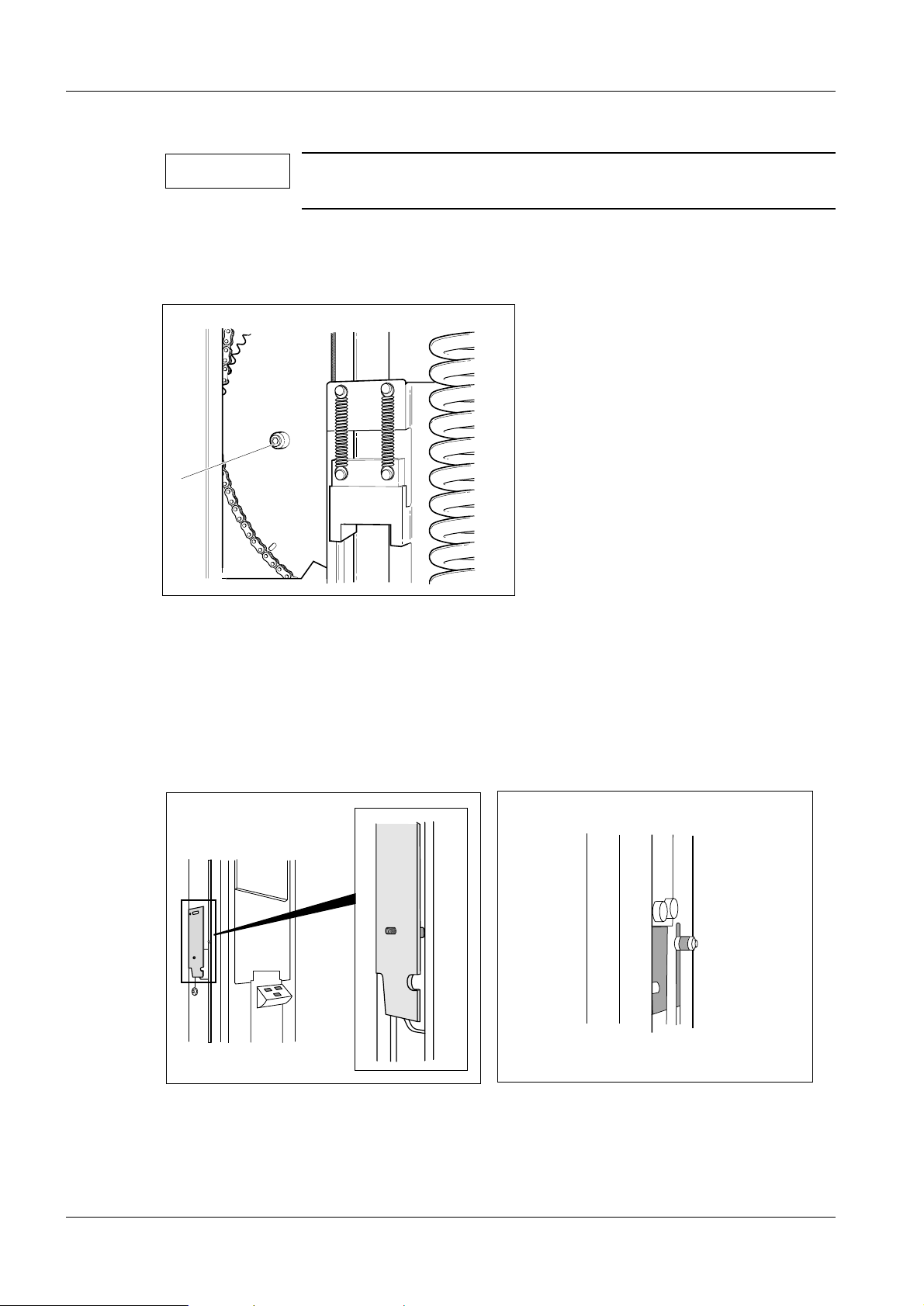

Preparatory work 3 - 5

CAUTION

Protective strips for the metal curtain 3

1

2

MAM00084

Fig. 7 Protective strips for the metal curtain

The edges of the metal curtain are very sharp and are therefore provided with protective

strips (1) on delivery. These strips must always be ap plied onto the edges of the metal

curtain during service and maintenance work.

The protective strips must be removed from the metal curtain

before any vertical adjustment of the swivel-arm system is

performed.

Holders (2) for storing the protective strips when n o t in use, are provided on both si des of

the curtain, see Fig. 7.

Siemens-Elema AB Register 03 SP B7-230.033.07 Page 5 of 8 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 20

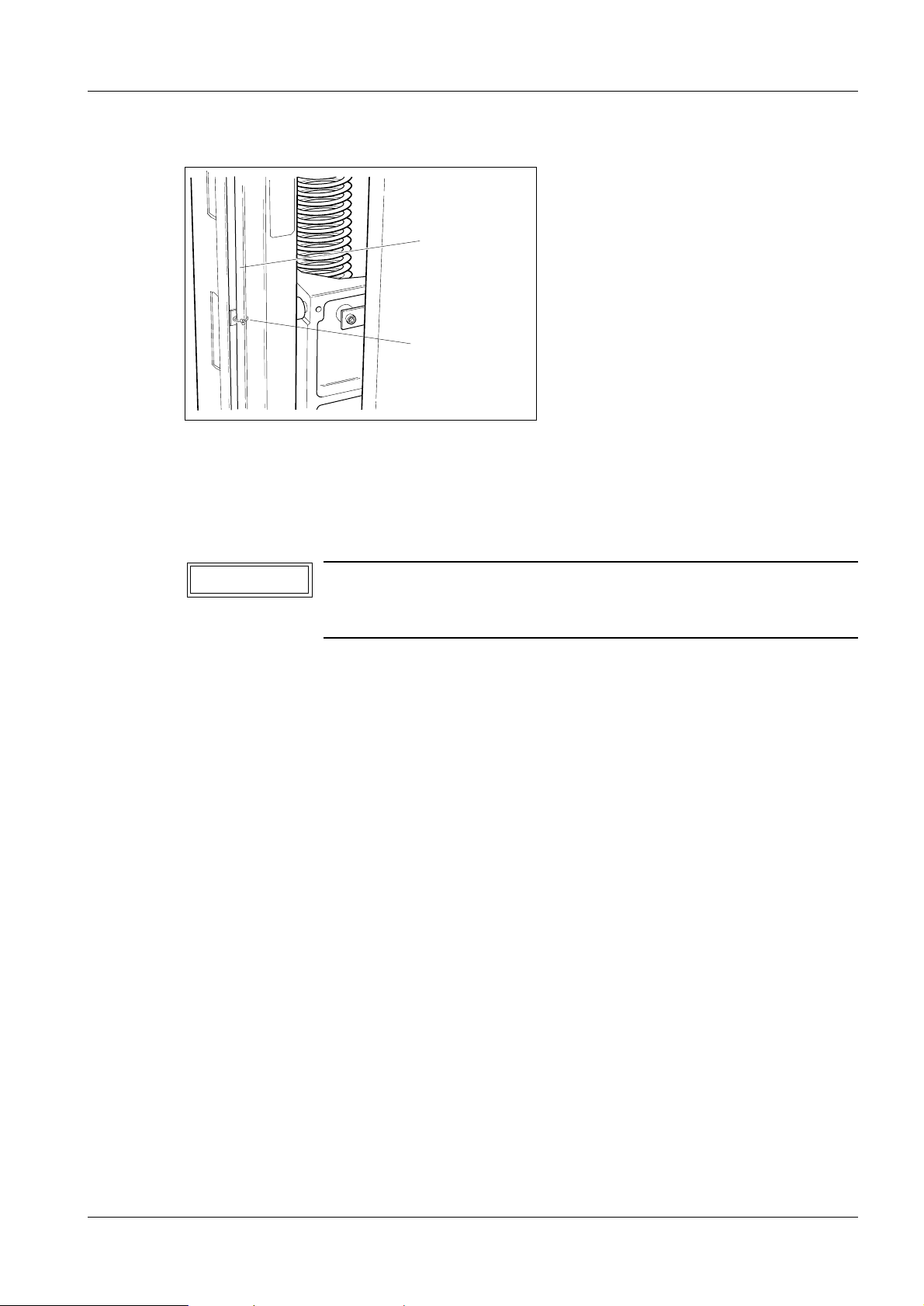

3 - 6 Preparatory work

Unpacking the generator and mounting the radiation shield

(optional)

1

3

3

4

3

2

MAM00085

Fig. 8 Unpacking the generator

1. Open the cardboard box by cutting the plas tic straps.

2. Lift out the lead-glass and put it away in a safe place.

3. Remove the protective cover from the generat or.

4. Upend the generator (1/Fig. 8) and lift i t off the pallet (2/Fig. 8) ( two persons are

required).

Mammomat 1000/3000 Register 03 SP B7-230.033.07 Page 6 of 8 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 21

Preparatory work 3 - 7

NOTICE

➪ Optional:

5. Insert sheet-metal strip (5/Fi g. 9) (additional radiation prot ection) into both

stanchions.

6. Fit the lead-glass (4/Fig. 9) into both vibration absorbing stri p (6/Fig. 9) and fix it

softly by screws (1/Fig. 10).

The screws must be mounted before the lead-glass is inserted in

the stanchions.

7. Fit the lead-glass (2/Fig. 10) into the groove of one of the stanchions (3 /Fig. 10)

and keep it in position while mounting t he other stanchion (3 /Fig. 10).

8. Mount the stanchions and lead-glass unit wi th 6 screws onto the generator (3, 4 /

Fig. 8) (two persons are required ).

9. Cover the holes with plastic caps (7/F ig. 9).

6

5

Fig. 9 Mounting the radiation shield

3

74

MAM00086

3

2

1

1

MAM00630

3

MAM00633

Fig. 10

Siemens-Elema AB Register 03 SP B7-230.033.07 Page 7 of 8 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 22

3 - 8 Preparatory work

This page intentionally left blank.

Mammomat 1000/3000 Register 03 SP B7-230.033.07 Page 8 of 8 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 23

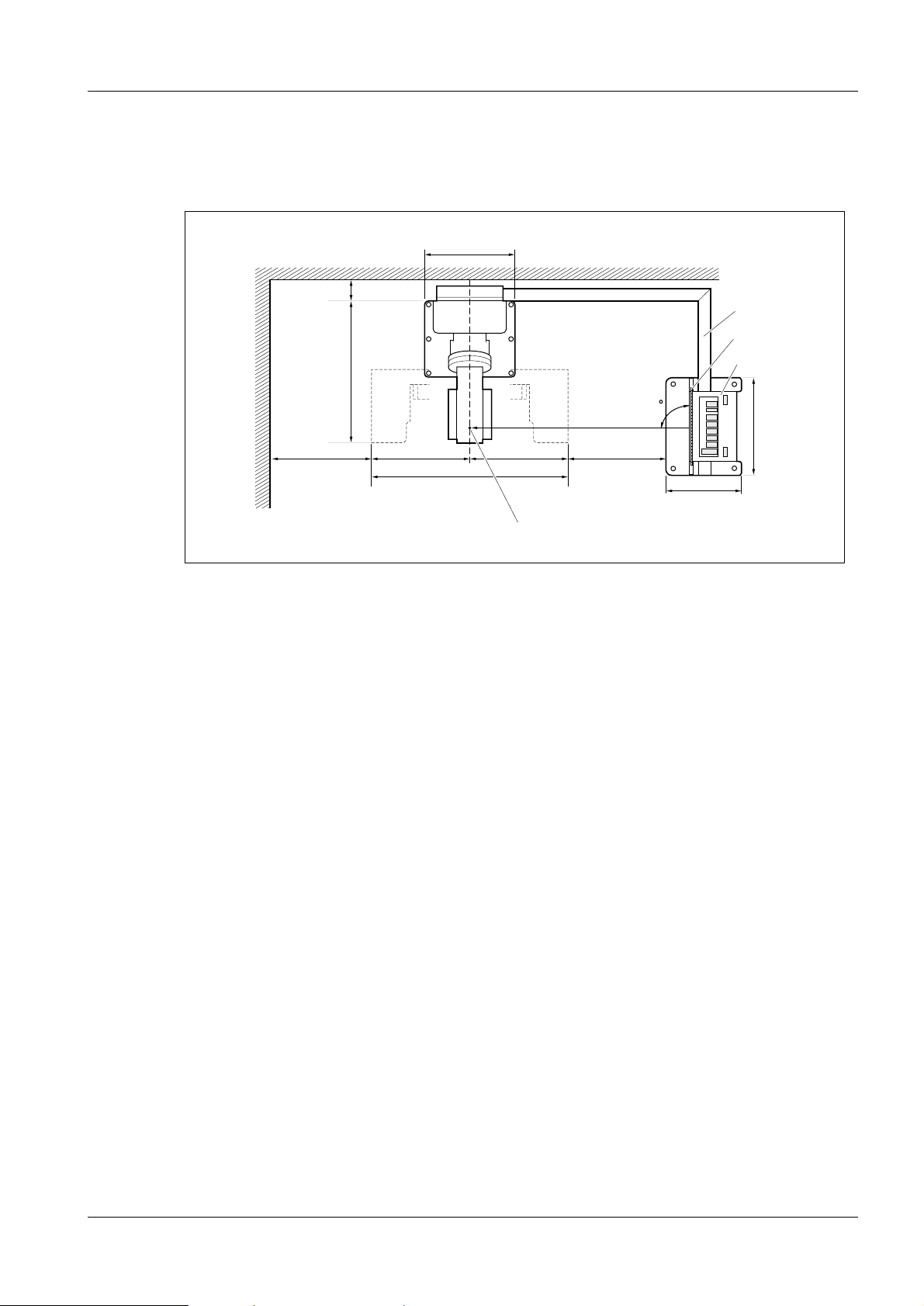

Installing the generator and the stand 4

Arranging the components 4

Position the stand and the generator in accor dance with inst alla ti on plan and Fi g. 1 below.

640

4 - 1

700

Fig. 1 Installation, top view

180

1091

700 700

1400

4

90

700

540

1

2

3

708

MAM00503

Cable duct (1) and generator (3) with radiation shield (2) can be instal led opt ionall y to the

left or to the right of the the stand. The cables can also be laid under floor. Maximum cable

length between stand and generator is approximately 3.5 m.

Radiation shield (2) at right angles to the swivel-arm system and centered to the focus

mark (4) on the tube-head cover according to Fig. 1.

Recommended minimum distance to wall and generator base plate respectively is

700 mm (shorter distances may be used at the customer´s desire, if in compliance with

local regulations).

For the installation of the cable duct, a minimum distance of 180 mm between wall and

stands is required.

Notes on installations with separate gene rator and separate cont rol console

- The separate genera tor can be installed in any suitable place. The maximum dist ance

of 3.5 m (maximum cable length) to the stand must be maintained, however. If

separately installed, the genera tor must be bolted to the floor alternati vely be attached

to the wall by means of wall brackets, see furt her Chapter 19 "Bolting the stand/

generator to the floor".

- The separate cont rol console can be installed in a suit able place (wall-mounted or

mounted on a table, for example in an adjacen t room with radiation-proof window), or

be mounted onto the free-standing radiation shield (option). The connect ion cable to

the generator measures 10 m.

4

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 1 of 6 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 24

4 - 2 Installing the generator and the stand

NOTICE

Free-standing radiation shield (option) 4

For the installation of the free-standi ng radi ation shield, please refer to separate instructions enclosed with the radiation shiel d.

Removing the generator cover 4

1. Pry loose the plastic strip (1) and remove the sixteen screws (2), eight on eac h

side.

Pay special attention to the contact washers (there are four contact washers on either side). They are needed again when reassembling the front cover to establish protective ground

connection and to fulfil EMC (Electro Magnetic Compatibility)

requirements.

2. Remove the front cover (3) from the gener ator.

3

Fig. 2 Removing the generator cover

2

MAM00091

1

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 2 of 6 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 25

Installing the generator and the stand 4 - 3

NOTICE

Installing the cable ducts 4

1. Position the cable ducts (1) to the stand and t he generator respectively.

2. Leave sufficient space, approx 10 mm between the cable ducts (1) and the base

plate of the stand (3) to allow for t he mounting of the cable outlet cover (4).

3. Check that the cable duct (1) is sligh tly overlapped by the cable outlet cover (4) .

4

3

Fig. 3 Installing the cable ducts (top view)

1

1

10 mm

6

7

1. Mark the outlines of the cable duct s (1) on the floor.

2. Cut the bottom of the cable ducts (6) and the cable duct cover (5) to proper lengt h.

Fig. 3 shows a right-angled installation of the cable ducts. If the

generator is to be inst alled at an other angl e to the s tand, you just

have to cut the cable ducts correspondingly.

5

MAM00089

3. Fasten the bottom plate of the cable ducts ( 6) to the floor according to marki ng,

using double-sided adhesive tape.

4. At the generator, cover the cable entry not used with the enclosed cover plate ( 7).

Installations with separate control console 4

For the connection cable separate control console – gener ator, additional cable duct s are

required, unless the cables are to be laid underfloor.

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 3 of 6 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 26

4 - 4 Installing the generator and the stand

NOTICE

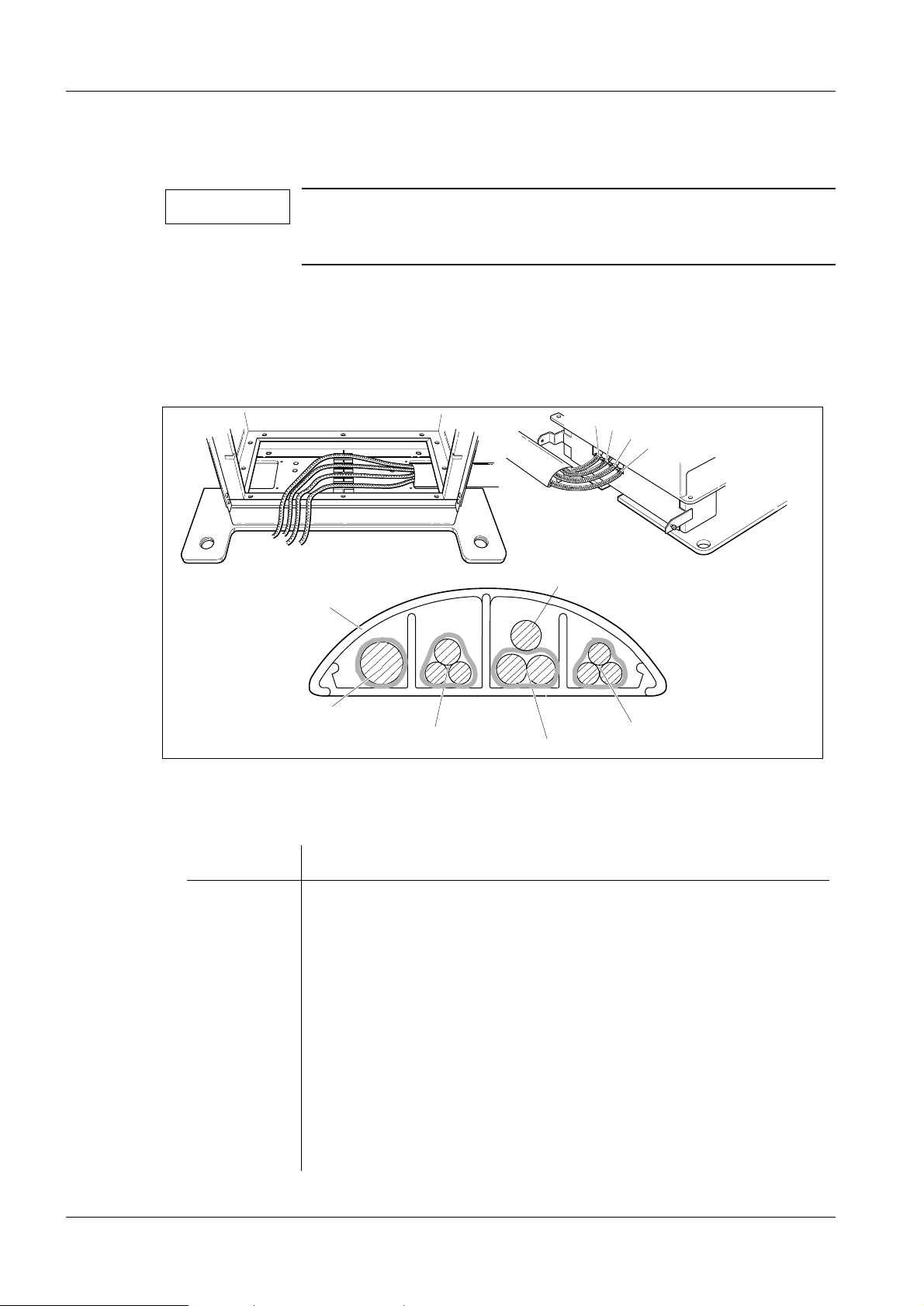

Laying the cable harness 4

Remove the transport safeguards which consist of cable ties

(four around the cable harness and one at the end of each

shielded cable).

1. Separate the cable harness.

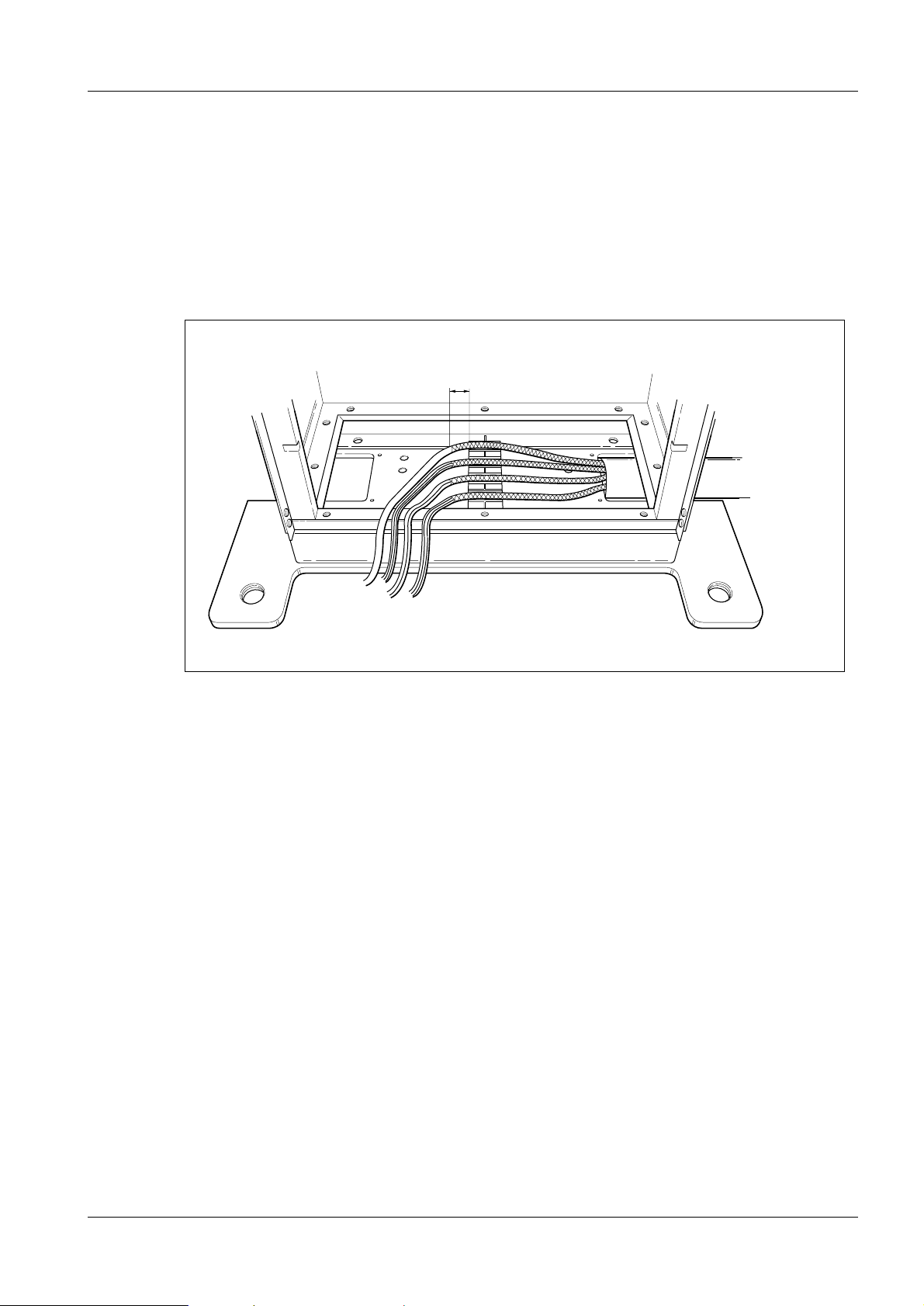

2. Lay the stand cable harness in the cable duct, as shown in Fig. 4, all the way to the

generator.

3. Fit the cable duct covers (6) onto the c able ducts.

1

2

3

4

6

1

2

Fig. 4 Laying the cable harness

The cable harness consists of four shiel ded cables, see Fig. 4.

Pos in Fig. 4 Description

1 High voltage cable H1

2 IONTOMAT signal cables X10 and X11

Unit control cable X1

Power supply cable X14

MAM00092

5

MAM00215

4

3

3 Anode rotation cable X9

Filament cable X8

4 Mains supply cables L1, L2

Protective ground

5 Decompression-button cable (only with separate control consol e)

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 4 of 6 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 27

Installing the generator and the stand 4 - 5

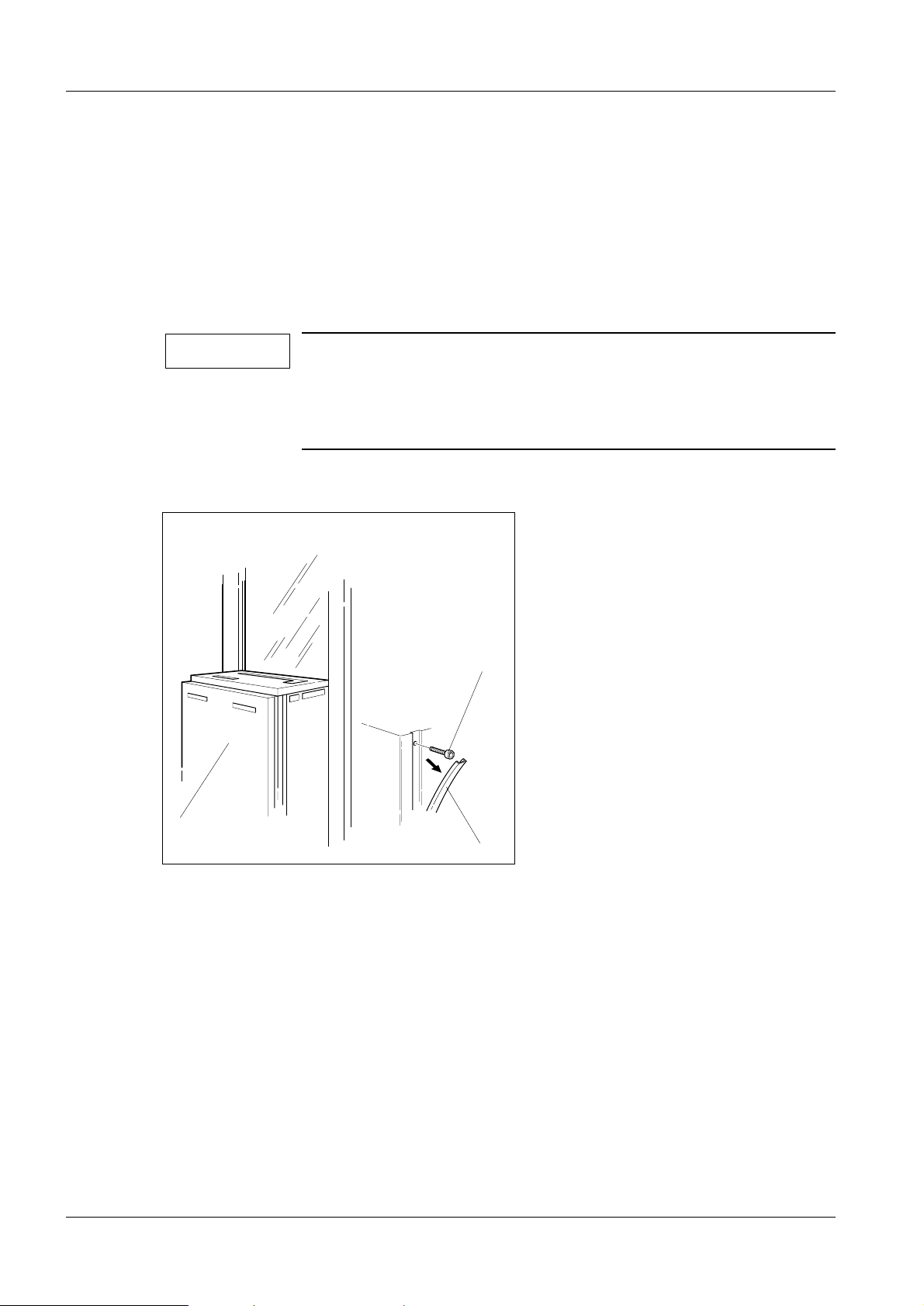

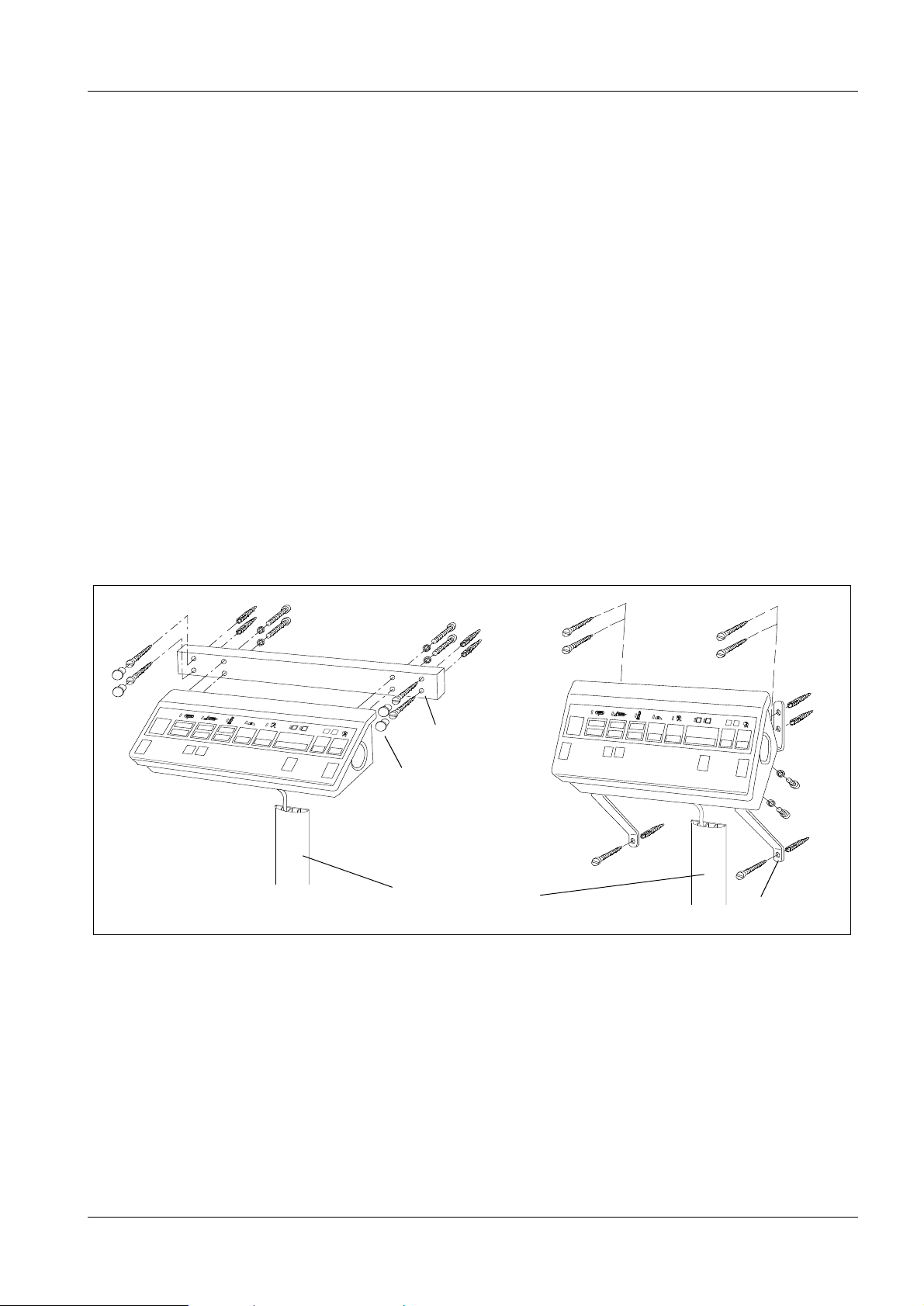

Installations with separate control console 4

Lay the connecting cable from the control console in additional cable ducts, alternatively

underfloor, to the free cable entry of the generator, see further section Chapter 5 "Cable

connections" on page 5 - 8.

The separate control consol e can be wal l-mounted – hor izont ally o r v ertic ally as shown in

Fig. 5 below – or be mounted on a table, either in the examination room or in an adjacent

room with radiation-proof window. It is important that the control console be placed so that

the operator has good view of the patient from the control console.

Ensure that the control console is attached to the wall with a dequate safety mar gins. Dowels and screws are not supplied. Please obtai n th ese lo cally and ensure that they are sui table for the material used in the wall. The separate control console has a weight of 4 kg.

There are two cable outlets on the separate control console; one at the back and one on

the underside. On delivery, the cable is led through the outl e t at the back of the control

console. For wall-mounted contro l console, the cable shall be led t hrough the outl et on the

underside.

If the control console is to be mounted on a table, the minimum/maximum length of the

screws penetrating into the control console must be observed, see Fig. 7 below.

The control console can als o be mounted o n t he free- standin g ra diat ion shi eld ( opt ion) as

shown in Fig. 6 below, see separate instructions enclosed with the radiation shield.

MAM00168

Horizontal mounting

Fig. 5 Wall-mounted control console

6.5 mm

∅

Plastic cap

Wall-mounted cable duct

is recommended

Vertical mounting

6.5 mm

∅

MAM00169

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 5 of 6 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 28

4 - 6 Installing the generator and the stand

NOTICE

NOTICE

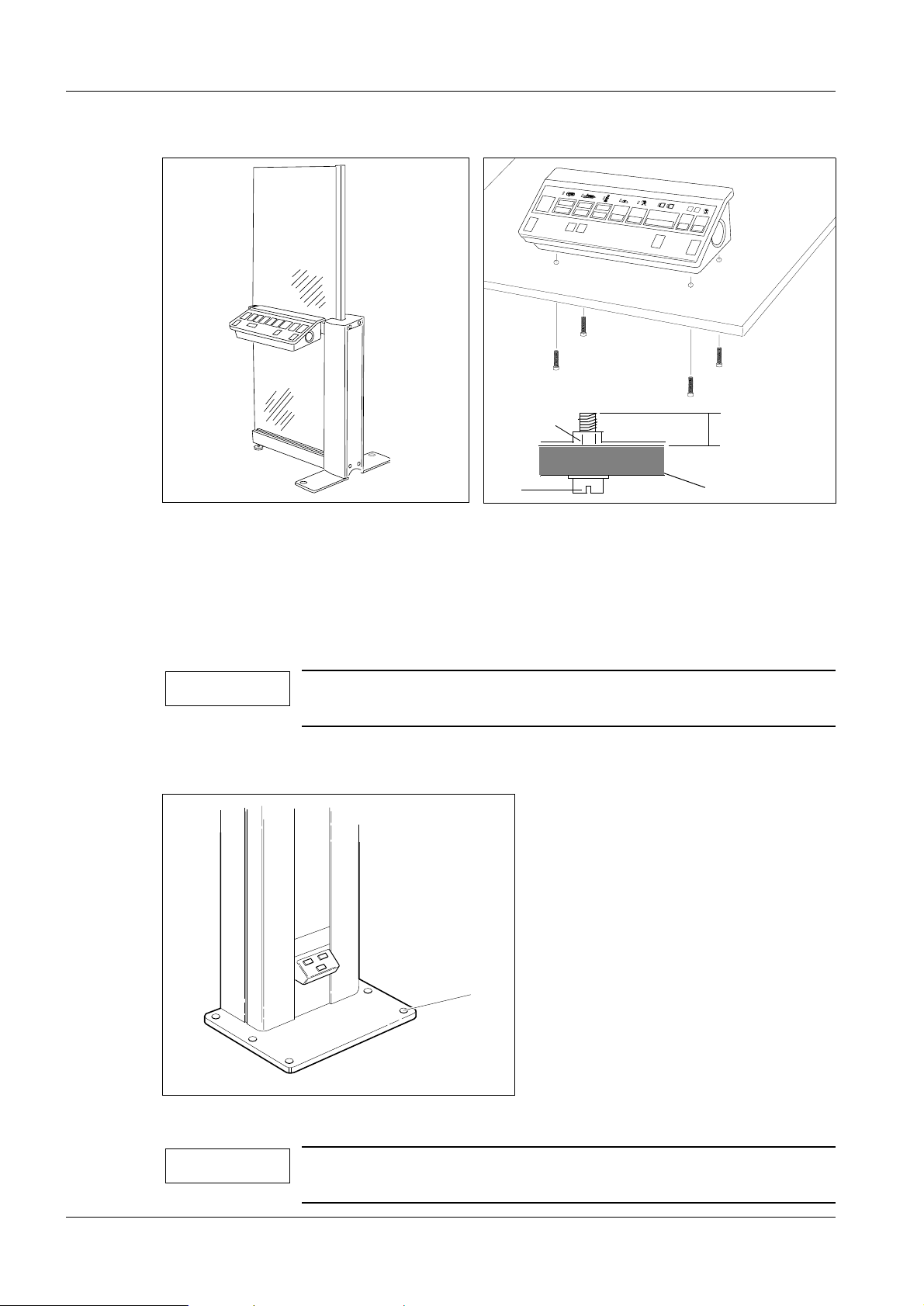

MAM00171

<

min. 10 mm –

max. 30 mm

<

Table top

MAM00170

Fig. 6 Control console on free-standing radiation shield

(option)

Welded nut

M6

Fig. 7 Control console mounted on table

Aligning the stand 4

1. Align the stand vertically by means of the l evelling screws (1/Fig. 8) .

For adjustment of the levelling scr ews, use a ratchet spanner 1/2" with ex tension

(without socket).

It is important that all six screws bear against the floor to ensure

optimum stability of the stand.

2. Cover the levelling screws with the c over discs supplied.

1

MAM00090

Fig. 8 Levelling screws

If bolting to the floor is required, please refer to Chapter 19 "Bolting the stand/generator to the floor" on page 19 - 1.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 6 of 6 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 29

Cable connection s 5

EMC measures 5

The following measures are required to ensur e electr omagnetic compat ib ili ty of the equipment.

EMC measures at the cable entry 5

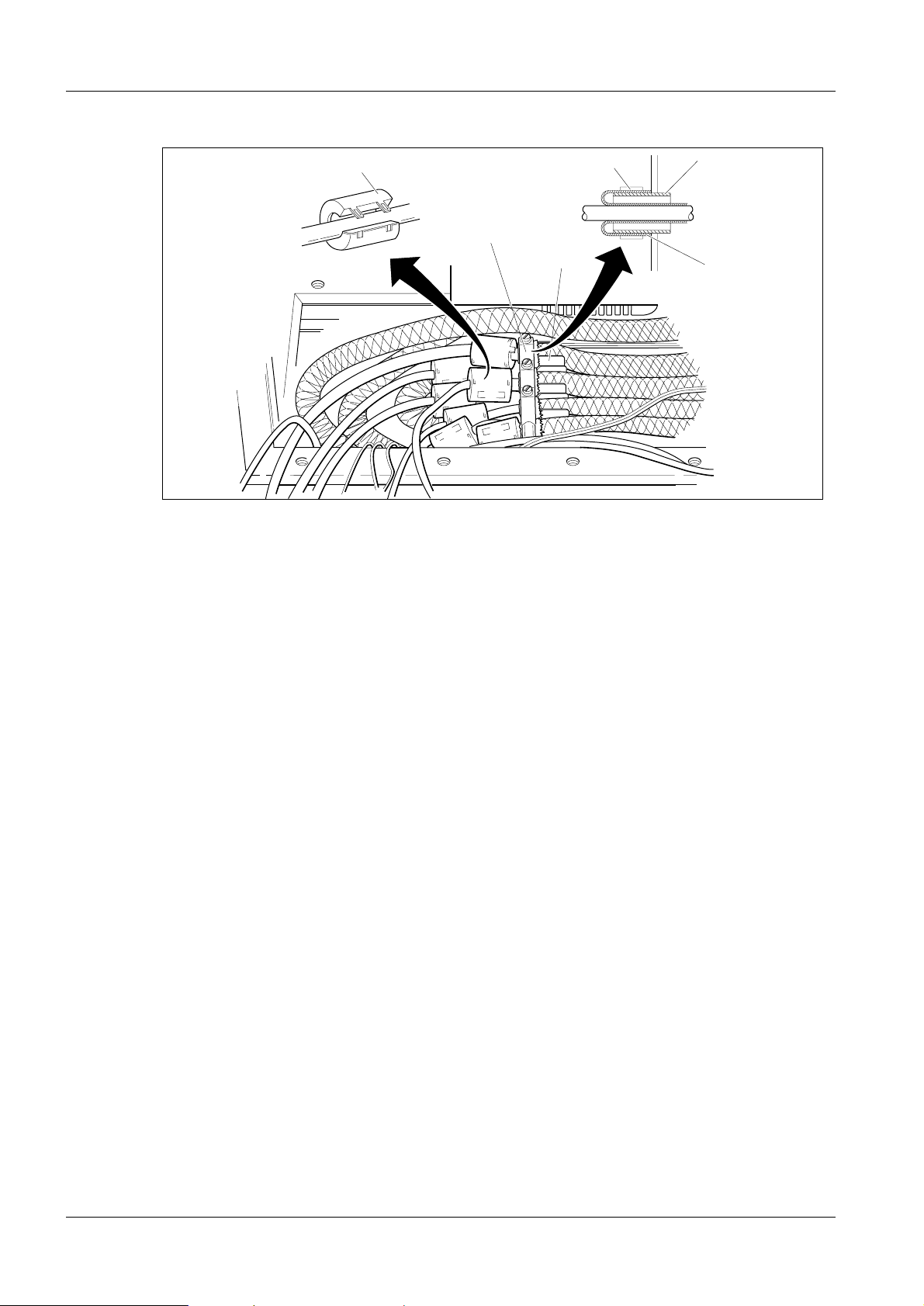

Fitting the hose clamps and ferrite sleeves

3cm

5 - 1

5

Fig. 1 Cables from the stand

1. Lay the cable harness from the stand to the generator and leave approximately

3 cm of the shielding at the U-bracket, see Fig. 1.

Stow away excessive cable lengths as shown in Fig. 2.

MAM00100

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 1 of 14 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 30

5 - 2 Cable connections

4

Fig. 2 Ferrite sleeves and hose clamp

3

3

2

2

1

2. Provide each incoming cable with a ferrite sleeve (4), except for mains s upply

cables L1 and L2 and the ground wire, which shall be laid t ogether in one and the

same ferrite sleeve. Ferrite sl eeves are included in the delivery.

MAM00098

3. Provide each cable with a hose clamp (3). Hose clamps are included in the

delivery.

4. Fold the shield braid (1) backwards over the U-bracket (2) on each cable and

secure with the hose clamp (3).

Note on separate control console and separate generator 5

If the installation includes a separate control console and separat e generator , please refer

to page 5 - 8 for information on ho w to inst all the addi tional connecti on cable bet ween the

control console and the generator.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 2 of 14 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 31

Cable connections 5 - 3

NOTICE

NOTICE

EMC measures on the bottom plate 5

Fitting the cables X1, X8 and X9 onto the bottom plate 5

3

Fig. 3 Bottom plate

4

2

1

1. Fit the bottom plate at the botto m of the generator stand as shown in Fig. 3.

2. Carefully cut away the insulation on c ables X1, X8 and X9 to lay bare the shield

braid (1).

3. Select proper clamps (2) with regar d to the thickness of the cables. Cable clamps

in different sizes are provided on t he bottom plate.

4. Fit the clamp (2) over the shiel d braid and screw tight to ensure satisf actory

contact between shield braid and cl amp.

5. Fasten the bottom plate with four sc rews (3) and contact washers (4).

Cable X9 shall also be clamped to the side wall of the cabinet, if

not already done, see Fig. 7 in this chapter.

MAM00099

Do not remove insulation and do not ground the shields of the

IONTOMAT signal cables to X10 and X11.

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 3 of 14 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 32

5 - 4 Cable connections

NOTICE

Connecting the stand cable-harness 5

High-voltage connectors, alternative types 5

3

1

2

MAM00161

Type A

Fig. 4 High-voltage connector, alternative types

Type B

The high-voltage connector (1) is factory-adjusted for correct fit.

Mount the angular cable-sleeve halves and sleeve nut (Type B

only). The high-voltage connector shall be inserted wit h silicone

oil, silicone-rubber ring (2) and sili cone-r ubber disc (3) . Lubrica te

the silicone-rubber disc and the pins with silicon oil bef ore

mounting the disc. Make sure that there aren’t any air bubbles

between the disc and the connector.

3

1

2

MAM00093

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 4 of 14 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 33

Cable connections 5 - 5

Connecting the high-voltage connector 5

3

2

1

Type A Type B

Fig. 5 Connecting the high-voltage connector, alternative types

4

MAM00162

1

2

tillf00162

Type A

1. Plug in the high-voltage connector (1) at H1.

2. Tighten the sleeve nut (2) by hand.

3. Tighten the stop screws on the sleeve nut.

4. Position the high-voltage cable (3 ) to the right in the generator an d fasten with

cable ties (4).

3

4

MAM00243

Type B

1. Plug in the high-voltage connector (1) at H1.

2. Tighten the sleeve nut (2) by hand.

3. Position the high-voltage cable (3 ) to the right in the generator an d fasten with

cable ties (4).

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 5 of 14 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 34

5 - 6 Cable connections

NOTICE

NOTICE

Connecting the cable harness to the generator 5

Required EMC measures are described on page 5 - 1 in this chapter.

2

1

6

5

Fig. 6 Cable harness at the generator

F10 F20

F1

F2

F3

F4

F5

3

4

7

MAM00165

MAM00165

Unit control cable X1 5

1. Connect the unit control cable X1 to D700 X1 (1).

Filament cable X8 5

1. Connect the filament cable X8 to D700 X8 (2).

Power supply cable X14 5

1. Connect the power supply cable X14 to D711 X14 ( 3).

2. Strain-relieve it on the side wi th a cable tie (4).

IONTOMAT signal cable X10 and X11 5

The Iontomat signal cable consists of two cables laid together as

one cable with two connectors labeled X10 and X11 at the end of

the cable.

1. Connect the IONTOMAT signal cable connectors, X10 and X11, to D700 X10 ( 5)

and X11 (6).

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 6 of 14 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 35

Cable connections 5 - 7

CAUTION

Rotating anode cable X9 5

2

4

3

1

MAM00163

Fig. 7 Connecting X9 to the generator

1. Connect the rotating anode cable X9 to D711 X9 (1 ).

2. Connect the two blue free wires from connector D711 X9 (1) to capacitor C51 (2).

3. Clamp the cable to the chassis with a cable cl amp (3).

When fitting the cable clamp, ensure satisfactory contact

between shield braid (4) and chassis.

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 7 of 14 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 36

5 - 8 Cable connections

NOTICE

MAM001 2

Installations with separate control console and separate generator

MAM00166

Connection cable from separate control console

5

Fig. 8 Connection cable from separate control console

Shielding the cable from the separate control console as

described below is an absolute demand to comply with the EMC

regulations.

1. Lay the connection cable from the separate control consol e in additional cable

ducts, alternatively under floor, to t he f ree cabl e entry of the gener ato r, see Fig. 8.

2. Lay the connection cable in a free U-bracke t. Fold the shield braid over the

U-bracket and secure with a hose clamp as shown i n Fig. 9.

MAM00173

Fig. 9 Shielding the control console cable

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 8 of 14 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

MAM00172

Page 37

Cable connections 5 - 9

F

3. Shield the control console cabl e to the bottom plate of the generator as shown i n

Fig. 10.

4. Provide the cables with ferrite sleev es. Cables X5 and X32 can be laid together in

one ferrite sleeve, X30 and the decompres sion-button cable in another sleeve

(two extra ferrite sleeves are i ncluded in the delivery). Plug together the decompression button cables. Shiel d the decompression button cable to t he bottom plate

, see Fig. 10. Lay the decompressio n button cable in the cable duct, alter -natively

underfloor, to the stand, see Fig. 4 i n Chapter 4 "Installing the generator and the

stand".

X5, X32

Ground wire

Fig. 10 Cables from separate control console

X30

Decompression

button cable

5. Connect X5 and X32 to the corresponding sockets on cir cuit board D700, X30 to

connector T3/X30 at the side of t he circuit board chassis. Connect the ground wire

to the protective ground termin al below fuse F10, see Fig. 11.

3

F4

F5

MAM00174

Protective

F10 F20

X32 X5 T3/X30

Fig. 11 Connecting the cables from the separate control console

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 9 of 14 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

ground

MAM00164

Page 38

5 - 10 Cable connections

NOTICE

6. Shield the decompression button cable to the stand chassis as shown in Fig. 12.

Connect to terminals 2 and 3 in terminal block X803 on the inside of the stand

chassis, see Fig. 12.

Fig. 12 Connecting the decompression button cable at the stand

1

Z801

2

1

23

X880

4

X885

MAM00175

Main voltage connection 5

The equipment has been set to 400 V, 2-phase, in the factory (see test certificate).

Adjustment to the line frequency is not needed. If the mains volt age is not 400 V, 2-p hase

at the installation site, a reconnection of the mains is necessary.

Should a reconnection for the mains voltage be necessary, this must be done at transformer T10 as well as p.c. board D711 (insertion or removal of fuses and labeling is specified in the wiring diagram, see Line Input page 5-3).

Change the rated voltage labels to the correct voltage (there are two labels on the generator and one on the stand). Labels are included in the install ation material.

For more details about changing mains, insertion or removal of

jumpers, fuses, labeling etc, see Wiring Diagram.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 10 of 14 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 39

Cable connections 5 - 11

Connecting the incoming mains to the stand (400 V, 2-phase) 5

400 V 2-phase connection 5

N

L1

L2

L3

1

2

1

1

4

3

1

Fig. 13 Incoming mains cable

1. Connect the incoming mains cable (1) to X899 (2) in the stand as shown in Fig. 13

and Fig. 14.

2. Fit plastic tubes (4) on the plates.

3. Strain-relieve (3) the i ncoming mains cable.

TWO-PHASE

GENERATOR STAND

F10

F20

X881

Incoming mains

208, 230, 240, 277 or 400 VAC

P.ENL1L2L3

X899

MAM00097

MAM00095

Fig. 14 Incoming mains, 2-phase

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 11 of 14 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 40

5 - 12 Cable connections

Connecting the mains supply to the generator (400 V, 2-phase) 5

F1

Fig. 15 Mains supply to the generator

F10 F20

F2

F3

F4

F5

2

1

3

MAM00176

1. Check that there is no wire jumper at F2 0 (1) and no brass plug at F5 (2).

Fuses must be inserted into fuse holde rs F20 and F5.

2. Connect the mains supply cables between stan d and generator to fuses F10 and

F20 on the generator.

Wire marked L1 to F10 and L2/N to F20.

3. Connect the protective ground wire fr om the stand to the generator (3).

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 12 of 14 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 41

Cable connections 5 - 13

CAUTION

NOTICE

Measures for changing from 2-phase to 1-phase connection 5

SINGLE PHASE

GENERATOR STAND

F10

X881

Fig. 16 Incoming mains, 1-phase

Incoming mains

110, 208, 230, 240 or 277 VAC

P.ENL1L2L3

X899

MAM00096

1. Move wire marked N/L2 from X899 L2 to X899 N (stand).

2. Connect incoming phase of the power supply to L1 and the neutral conductor of

the power supply (0 V) to N and fuse F20.

3. Strain-relieve the incoming main s cable as shown in Fig. 13.

4. Short circuit F20 (1) and F5 (2) in Fi g. 15 with the jumper and brass plug included

in the service bag.

For single-phase mains connection, make sure that the neutral

conductor of the power supply (0V) is connected to terminal N

and fuse F20.

Connections on transformer T10 must be adapted to the actual

mains voltage, see Wiring Diagram for details.

5. Connect the mains supply cable between s tand and generator to fuses F10 and

F20 on the generator. Wire marked L1 to F10 and L2/N t o F20.

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 13 of 14 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 42

5 - 14 Cable connections

This page intentionally left blank.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 14 of 14 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 43

Mains connection and power supply 6

Checks before powering up the generator 6

On P.C. board D702:

1. Set switch S1(UZW) to "OFF" (lower positi on).

2. Set switch S2 (SS) to "OFF" (lower position)

.

6 - 1

ZBL

AR

KVE

BRAKE

STATUS

UZW

SS

TEST

V6

V7

V1

V2

V3

V4

V5

VH

NSE1

NSE2

DS

SS

BS

GND

X990

X967

X980

X981

X982

X983

X984

X985

S1

S2

S3

J39

X962

X964

X960

R13

R11

R43

J50

X965

X961

X963

IHREG

MAREG

X966

X968

X969

X702

MAM00106

Fig. 1 P.C. board D702

Measuring the line resistance 6

See Fig. 2.

1. Remove fuses F10 (1) and F20 (2) or, when sin gle-phase supply, fuse F10 (1).

2. Connect line resistance meter to fu se holders F10 and F20.

3. Mains supply "ON".

4. Carry out measurement.

5. Mains supply "OFF".

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 1 of 4 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 44

6 - 2 Mains connection and power supply

To achieve the full output, the resistance measured must not exceed the following values:

• 0.25 c at 110 V (1-phase)

• 0.45 c at 208 V

• 0.50 c at 230 V

• 0.60 c at 240 V

• 0.65 c at 277 V

• 0.85 c at 400 V (2-phase)

If the above values are exceeded, reduce the generator power in accordance to Chapter

13 "Checking the swivel-arm system" in this manual.

Checking the line voltage in the generator 6

1. If not already done, remove fuses F10 (1) and F20 (2) or, when single-phase

supply, fuse F10 (1).

4

5

6

1

2

3

Fig. 2 Line voltage in the generator

2. Mains supply "ON".

3. Measure the voltage at fuse holders F10 ( 1) and F20 (2).

4. Check that the mains voltage agrees with the v oltage plugged on transformer T10

(3) and P.C. board D711 (4), located above line f ilter Z1 (5).

5. Mains supply "OFF".

MAM00177

6. Reinsert fuses F10 (1) and F20 (2).

7. Mains supply "ON" (Do not switch the system on yet).

8. Measure the voltage at transformer T1 (6) terminals 1 and 3, transformer T1 is

located under the line filter Z1 (5). There must be 195 V- 253 V between the

terminals.

9. Measure the voltage at the output of lin e filter Z1 it must lie within 195 V- 264 V.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 2 of 4 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 45

Mains connection and power supply 6 - 3

Checking the supply voltages 6

The correct supply voltages +5 V, +15 V and +24 V have already been tested in the factory. Only a visual check of the function is therefor e needed.

1. System "ON".

2. Check that the following orange dio des are "ON" on p.c. board D704:

V39 (+15 V)

V38 (-15 V)

V41 (+5 V)

V40 (+24 V)

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 3 of 4 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 46

6 - 4 Mains connection and power supply

This page intentionally left blank.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 4 of 4 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 47

Attaching the swivel-arm covers 7

Attaching the swivel-arm covers 7

Arranging the swivel-arm system 7

1. Remove the cable tie securing the balanc ing spring at the back of the stand.

2. Install object table, no compressi on force (swivel-arm system still ups ide down).

3. Remove the protective strips from the meta l curtain.

4. Run the lifting carriage upwards.

5. Put back the protective strips onto t he metal curtain.

6. Rotate the swivel-arm system to 0 degre es by pressing one of the switches for

clockwise rotation on the supporti ng arm.

7. System and mains "OFF".

8. Remove the swivel-arm system transpo rt safeguard, see Chapter 3 "Preparato ry

work".

Connecting the cables to control-button boards and patient handles 7

7 - 1

MAMMOMAT 1000/3000

4

2

2

Fig. 1 Connecting the cables

Before installing the side covers, the cables are to be connected.

MAMMOMAT 1000/3000

1. Connect cables X807 (1) to control-butt on circuit boards D807 (2).

2. Connect ground wires (3) to patient handles (4).

1

1

4

3

3

MAM00108

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 1 of 2 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 48

7 - 2 Attaching the swivel-arm covers

NOTICE

CAUTION

CAUTION

Attaching the side covers 7

Screws in different sizes are inc luded in the delivery.

5

4

Fig. 2 Covers and sign

2

1

1. Mount the side covers (1) with six screws (2) on each side.

Do not forget to fit the sign (3) when mounting the side covers.

Use the two longer screws.

3

MAM00178

Attaching the front cover 7

Because of the risk of damages, the following work must be carried out with caution. If the covers are exposed to internal stress

due to poor fit, cracks might arise.

1. The side covers must be flush at the front. If necessary, loosen the screws and

adjust the side covers.

2. Carefully fit the front cover (4) so that both openings engage with the lugs of the

side covers.

3. Carefully swing the front cover upwards and l et it snap in position over the side

covers.

The front cover must not press against the collimator (risk of

damage).

4. Fasten the front cover to the side covers with two short screws (5).

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 2 of 2 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 49

Checking the microprocessors 8

Microprocessors 8

The following LED displays on the processor P.C. boards indicate whether the relevant

microprocessors are operating correctly.

1. Mains and system "ON".

The following conditions must be indi cated after not more than 15 s.

8 - 1

Microprocessors for:

Master: P.c. board D702

IONTOMAT PM: P.c. board D701

P.C. board D711:

• V9 "ON" (line voltage on).

• V13 "OFF" (system stand-by).

• V11 "ON" (system on).

• V16 "ON" (intermediate circuit - filament).

LED displays

Must be off.

Flashing rapidly.

Must be off.

Must be flashing

(2-3 Hz).

MAM00110

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 1 of 2 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 50

8 - 2 Checking the microprocessors

This page intentionally left blank.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 2 of 2 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 51

Checks without high voltage 9

NOTICE

Checks without high voltage 9

1. System "OFF".

2. On P.C. board D702 set switch S1 (UZW) to "ON" (upper p osition) and switch S2

(SS) to "OFF" (lower position).

3. System "ON".

4. Insert a cassette.

The cassette must be removed and reinserted after each

exposure to allow for the next exposure release. This is to avoid

double exposures.

5. Press the exposure buttons on the control panel . The rotating anode shal l start up.

At the end of the limit time, the rot ating anode is braked.

6. Release the exposure buttons.

7. System "OFF".

9 - 1

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 1 of 2 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 52

9 - 2 Checks without high voltage

This page intentionally left blank.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 2 of 2 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 53

Checks with high voltage 10

WARNING

NOTICE

Preparation 10

This section describes how to check:

• Radiographic voltage.

• Tube current.

• mAs values.

Radiation

Check that the high-voltage plug is plugged into H1 and properly

secured.

10 - 1

kV>17

V39

kV>50

V41

IHIST

UZIST

KVIST

0VA

KVE

KVA

ZBL

0VD

V40

X706

X707

X705

X704

X713

X710

X712

X711

X708

X714

X715

X716

X717

X709

R136

X703

WR_AUS

MASOLL

MAIST

IHSOLL

ISCHWING

KVSOLL

BRAKE

Fig. 1 P.C. board D705

1. Set switch S2 (SS) to "ON" (upper position) on P.C. board D702.

2. Remove the jumper and connect the mAs meter to mAs measuri ng sockets X3

and X4 on P.C. board D710.

MAM00111

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 1 of 6 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 54

10 - 2 Checks with high voltage

NOTICE

NOTICE

NOTICE

3. Connect oscilloscope to P.C. board D705 as follows:

• Channel 1 to measuring point "KVIST(actual value)" (1 V= 5 kV).

• Channel 2 to measuring point "MAIST(actual value)" (1 V= 40 mA).

• Trigger at measuring point "KVE" (start with high volt age "ON"), rising edge.

• Twist the measuring leads and connect their grounding br aids to measuring

point "0 VA".

4. Connect service PC to circuit board D702 using th e connection cable.

Switch S3 on circuit board D702 must be set to upper position.

5. Start service program, see Chapter 20 "Append ix".

6. Check the anode menu for correct selecti on (tungsten anode enabled or disabled,

depending on which type of X-ray tube the customer has choosen). See Service

Program Instructions RX B7-230.114.0 1. ... .

It is possible to select tungsten anode, even if the customer does

not have this option. However, the 50 µm Rh filter will then be

missing.

Checking X-ray tube high voltage, tube currrent and mAs values10

1. System "ON".

2. Set the "cassette loaded" switch to " OFF" with the service PC program:

Configuration - Miscellaneous - Cassette loaded check.

3. Trigger test exposures with the following exposure values and check the kV

values and tube current characterist ic on the oscilloscope (see oscill ograms).

The accuracy of the kV is &5% plus &1.5 kV during the first 5 ms of the exposure.

For mA values < 50 mA, the accuracy of the kV is &5% plus &2 kV during the first

5ms.

The tube current must rise quickly to t he set value at the beginning of the exposure and run linearly during th e exposure, however, not when TCR is running.

The accuracy of the mAs product must be &10%.

4. Replace the jumper previously removed.

Tube current reduction 10

In MAMMOMAT, the tube current reduction is factory-set to "ON"

(see Chapter 12 "Further programming" and test certificate). In

this way, the tube current is reduced to approximately 50 mA at

the start of the exposure during the time programmed in Chapter

12 "Further programming". The tube current reduction is eff ective

only in IONTOMAT mode with Bucky.

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 2 of 6 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 55

Checks with high voltage 10 - 3

NOTICE

NOTE

Oscilloscope diagrams 10

• MAMMOMAT in mAs mode, see Fig. 2 - Fig. 9.

• MAMMOMAT with tube current reduction switched on, Iontomat mode with Bucky, see

Fig. 10 - Fig. 11.

• MAMMOMAT in Iontomat mode with tube current reduction switched off, see

Fig. 12 - Fig. 13.

Checks indicated by

filter disc Mo 0.03 / Rh 0.025 (molybdenum rotating anode).

Tube P40 MoW, MAMMOMAT 3000

* tungsten anode 0.3

30 kV 20 mAs (P = 4.7 kW)

* shall be disregarded in installations with

Tube P40 MoW, MAMMOMAT 1000/3000

molybdenum anode 0.3

30 kV 20 mAs (P = 3.75 kW)

?

MAM00179

Fig. 2 Fig. 3

30 kV 1 V/T (1 T <=> 5 kV) 30 kV 1 V/T (1 T <=> 5 kV)

?

MAM00112

158 mA 1 V/T (1 T <=> 40 mA) 125 mA 1 V/T (1 T <=> 40 mA)

127 ms 20 ms/T 160 ms 20 ms/T

Record the measured kV and mAs value in the measuring protocol, page 20 - 3.

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 3 of 6 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 56

10 - 4 Checks with high voltage

Tube P40 MoW, MAMMOMAT 3000

* tungsten anode 0.3

35 kV 100 mAs (P = 4.7 kW)

MAM00180

Fig. 4 Fig. 5

Tube P40 MoW, MAMMOMAT 1000/3000

molybdenum anode 0.3

35 kV 100 mAs(P = 3.75 kW)

35 kV 1 V/T (1 T <=> 5 kV) 35 kV 1 V/T (1 T <=> 5 kV)

134 mA 1 V/T (1 T <=> 40 mA) 107 mA 1 V/T (1 T <=> 40 mA)

0.75 s 0.2 s/T 0.93 s 0.2 s/T

MAM00113

25 kV 100 mAs (P = 4.7 kW)

MAM00181

Fig. 6 Fig. 7

25 kV 100 mAs(P = 3.75 kW)

25 kV 1 V/T (1 T <=>5 kV) 25 kV 1 V/T (1 T <=> 5 kV)

188 mA 2 V/T (1 T <=> 80 mA) 150 mA 2 V/T (1 T <=> 80 mA)

0.53 s 0.1 s/T 0.67 s 0.1 s/T

MAM00114

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 4 of 6 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 57

Checks with high voltage 10 - 5

NOTICE

NOTICE

Tube P40 MoW, MAMMOMAT 3000

* tungsten anode 0.15

30 kV 10 mAs (P = 0.85 kW)

Tube P40 MoW, MAMMOMAT 1000/3000

molybdenum anode 0.15

30 kV 10 mAs (P = 0.70 kW)

?

MAM00182

Fig. 8 Fig. 9

30 kV 1 V/T (1 T <=> 5 kV) 30 kV 1 V/T (1 T <=> 5 kV)

28 mA 0.5 V/T (1 T = 20 mA) 23 mA 0.5 V/T (1 T <=> 20 mA)

360 ms 50 ms/T 430 ms 100 ms/T

>>

?

MAM00115

Small focus is selected by attaching a magnification table.

Record the measured kV and mAs value in the measuring protocol, page 20 - 3.

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 5 of 6 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 58

10 - 6 Checks with high voltage

MAM00317

30 kV

Iontomat

(P = 4.7 kW)

40 mm plexiglass

Tube P40 MoW, MAMMOMAT 3000

* tungsten anode 0.3

30 kV

Iontomat w. grid

(P = 4.7 kW)

40 mm plexiglass

MAM00316

Fig. 10 Fig. 11

30 kV 1 V/T (1 T <=> 5 kV) 30 kV 1 V/T (1 T <=> 5 kV)

158 mA 1 V/T (1 T = 40 mA) 125 mA 1 V/T (1 T <=> 40 mA)

Tube P40 MoW, MAMMOMAT 1000/3000

molybdenum anode 0.3

30 kV

Iontomat w. grid

40 mm plexiglass

*) 100 ms /t *) 100 ms /T

(P = 3.75 kW)

MAM00315

Fig. 12 Fig. 13

30 kV 1 V/T (1 T <=> 5 kV) 30 kV 1 V/T (1 T <=> 5 kV)

158 mA 1 V/T (1 T <=> 40 mA) 125 mA 1 V/T (1 T <=> 40 A)

*) 100 ms /T) *) 100 ms /T

*) total exposure time dependent on programmed sensitivity

30 kV

Iontomat

40 mm plexiglass

(P = 3.75 kW)

MAM00318

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 6 of 6 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 59

Start-up and functional test of the IONTOMAT 11

NOTICE

NOTICE

Checking and programming with the service PC 11

Use the service PC to check and program the IONTOMAT.

Operation of the service PC is described in Chapter 20 "Appendix".

The tables in this kit are optimized for the foll o wing four film/screen combinations.

Table 1

11 - 1

Film

Kodak Min-RE

Fuji UM-MA HC

Agfa Mamoray MR6

Dupont Microvision C

Screen

Kodak Min-R

Fuji HR Mammo Fine

Agfa MR Detail S

Dupont Quantavision ME

Cassette

Kodak Min-R2

Fuji EC-MA

Agfa MR Detail S

Dupont Quantavision

Sensitivity

11

9.5

7

12

Correction

curve

A

B

C

D

Program the IONTOMAT values as follows:

If it is a M 3000 stand equipped with one "wing" only and counterweight, the programming for "wing 2" shall be omitted. If it is a

M 1000 stand, the programming is done for "base plate".

Sensitivity 11

Start with the sensitivi ty li sted i n the tabl e f or the film/ scr een combinat ion used by the customer. Program this values for "wing 1" and "wing 2" under H. If the customer uses one

more film/screen combination, program this value for "wing 1" and "wing 2" under D, otherwise program the same values as under H.

If the film/screen combination used by the customer is not listed in table 1, star t

with sensitivity 11.

MAM00185

Be sure to use the same type of cassette, screen and film in each

object table as the customer uses.

IONTOMAT PM - Sensitivity

Wing 1

Wing 2

Valid entries from 0 to 31 in 1/2 E.P.

Input of decimal point not required!

Help 2 Save 3 45678910Quit

1

Fig. 1

HD

11.0

11.0 11.0

11.0

Values from 0 to 31 can be entered.

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 1 of 12 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

MAM00186

Page 60

11 - 2 Start-up and functional test of the IONTOMAT

Sensitivity correction 11

IONTOMAT PM - Sens. correction

Without grid

Wing 1

.0

Wing 2

.0

With grid

Magnification

Valid entries from -8 to 8 in 1/2 E.P.

For pos entries 1 st digit is < space >, for neg entries type < - >.

Input of decimal point not required!

1 Help 2 Save 3 45678910Quit

Fig. 2

.0

.0

.0

.0

MAM00187

Indicates the sensitivi ty correction f or dif ferent types of object tab les. The positio n "without

grid" applies to Stereotactic Biopsy Attachment as well.

Factory set to "0", "0", "0".

Different film-density corrections can be programmed for the different tables with the

"Sens-cor" module.

Correction curve 11

Program "Correction curve" according to table 1 abo ve (see al so M3000 Servi ce Instructions).

If the customer uses another combination or a mixture of those listed in table 1,

please refer to page 11 - 3.

IONTOMAT PM - Correction curve

Curve number

Speed H

Speed D

1 Help 2 Save 3 45678910Quit

Fig. 3

_A

A

Values shown as delivered.

MAM00188

Mammomat 1000/3000 Register 3 SP B7-230.033.07 Page 2 of 12 Siemens-Elema AB

Installation and Start-Up Rev. 03 11.99 SPS-UD Solna, Sweden

Page 61

Start-up and functional test of the IONTOMAT 11 - 3

NOTICE

Other film/screen combinations 11

In case the customer uses another film/screen combination t han those the correction

curves are optimized for, see table 1 of correction curves on page 11 - 1, proceed as follows:

1. Begin with curve C, speed H, and make test exposures usi ng a grid table at 25 kV

(Mo/Mo), 2 and 6 cm plexi (5 cm if limit (ER550) or ER 013 occurs, due to

insufficient dose rat e). If the image from 6 cm plexi (O.D.-6 cm) is lighter than one

from 2 cm plexi (O.D.-2 cm), choose correction curve A or B (A makes images

from thick objects darker than B does, i .e. A corrects more than B). On the other

hand, if O.D.-6 cm is darker than O.D.-2 cm, choose curve D. Repeat the test with

the chosen curve. The difference betwee n O.D.-6 cm and O.D.-2 cm (

should be less than 0.30 O.D.

2. Now test 27 kV, 2 and 6 cm. Try even 30 and 35 kV if these kV´s are of interest for

the customer. If this

another curve (choose between A, B, C and D) at 27 kV. Choose the best one and

repeat the test at 25 kV. Continue in this manner until the res ult is as good as

possible for the kV´s of interest for the customer. Diagrams 1, 3, 5 and 7 on the

following pages can be of help. Note th at the steeper the curve is, the more the

thicker objects are corrected (t hey will be darker).

∆ Ο.D.

is ≤ 0.30 O.D., go to 3. If not, it is necessar y to test

∆ Ο.D.)

3. Check also the correction with 2 cm plexi between the diffe rent kV values of

interest. If this

not be possible to reach the specified O. D. corrections, choose then the best

compromise for the customer´s needs.

4. Do the same tests with magnification table, but use 2 and 5 cm plexi instead. The

permissible

satisfactory, try another curve wit h speed button D. Choose between correction

curves A, B, C and D. Diagrams 2, 4, 6, and 8 on the foll owing pages can be of

help. Normally, the magnification tables and the conta ct exposures tables function

properly with the same curve family, which means t hat the other speed button can

be used for another film/screen combinat ion.

5. Test the chosen curve/curves with t he other anode/filter combinations as well .

∆ Ο.D.

∆ Ο.D.

The film density levels may vary from cassette to cassette.

Therefore, be sure to use one and the same cassette for all test

exposures.

is ≤ 0.30 O.D., an acceptable curve has been chosen. It may

for magnification table s is ≤ 0.40 O.D. If the result is not

Siemens-Elema AB Register 3 SP B7-230.033.07 Page 3 of 12 Mammomat 1000/3000

Solna, Sweden Rev. 03 11.99 SPS-UD Installation and Start-Up

Page 62

11 - 4 Start-up and functional test of the IONTOMAT

Correction curve diagrams 11

The following diagrams approximately show the families of correction curves. The axes

"Quotient" and "Transparency correction" are the values shown in "Normal mode, Iontomat data" with the service program.

25 kV Mo/Mo Grid

25

dark

20

A

15

O.D.

10

5

light

0

70

Diagram 1

25

dark

20

15

71

thin object

72 73 74 75 76 77

quotient

25 kV Mo/Mo Mag

78 79

thick object

B

C

D

80

MAM00189

A

B

O.D.

light

10

5

0

65

thin object

70 75

quotient

thick object

C

D

MAM00190

Diagram 2