Siemens Mammomat 300 Wiring Diagram

MAMMOMAT 300

Wiring Diagram

RX B7-120.051.01.08.02 English

Replaces:RX B7-120.051.01.07.02 12.95

Weitergabe sowie Vevielfältigung dieser Unterlage, Ververtung und Mitteilung

ihres inhalts nicht gestattet, soweit nicht ausdrûcklich zugestanden. Zuwiderhandlungen verpflichten zu Schadenersatz. Alle Rechte fûr den Fall der Patenterteilung oder GM-Eintragung vorbehalten.

Proprietry data, company confidential. All rights reserved.

Confié a titre de secret d’enterprise. Tous droits réservés.

Confiado como secrato industrial. Nos reservamos todos los derechos.

63 85 772

X041E

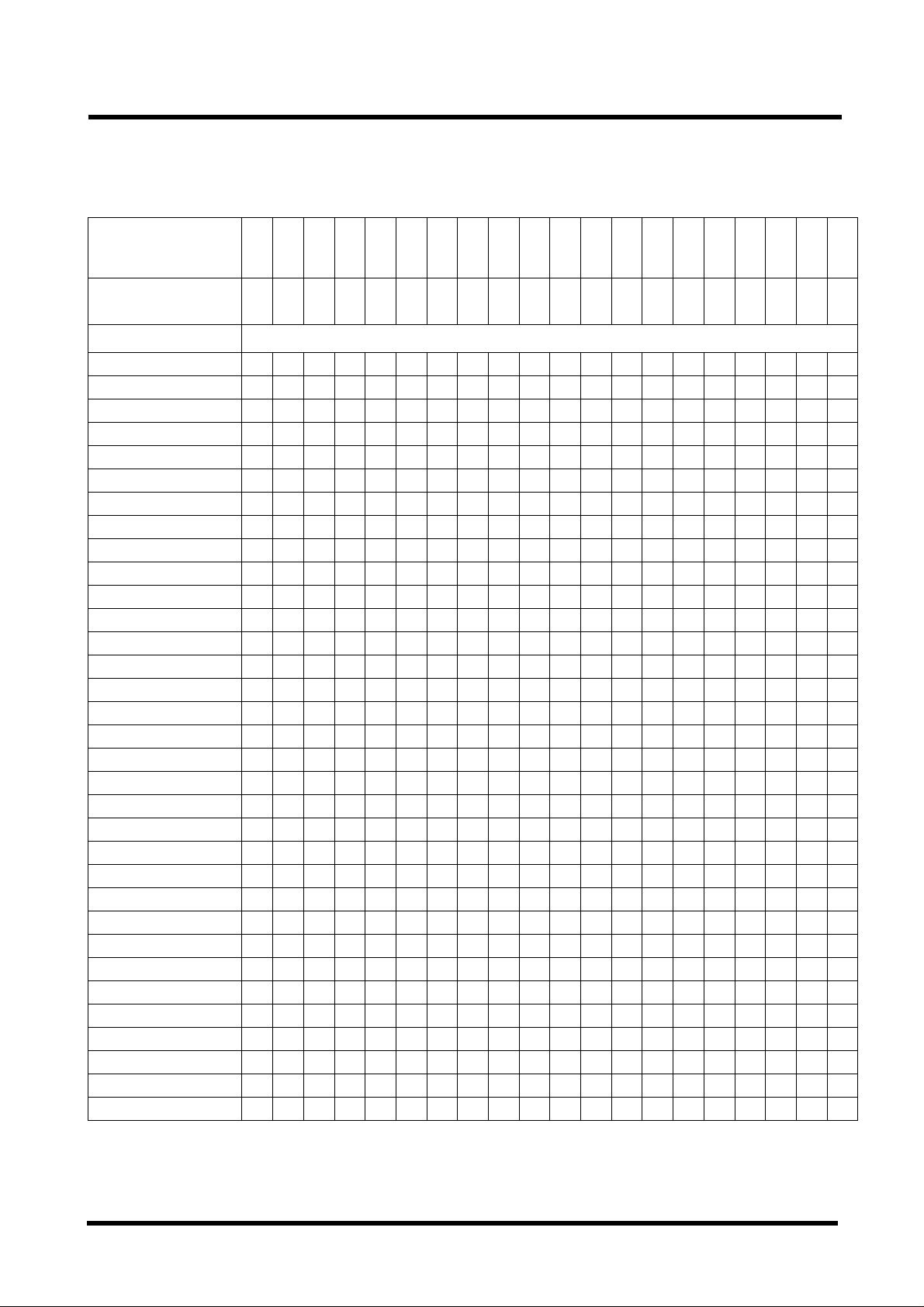

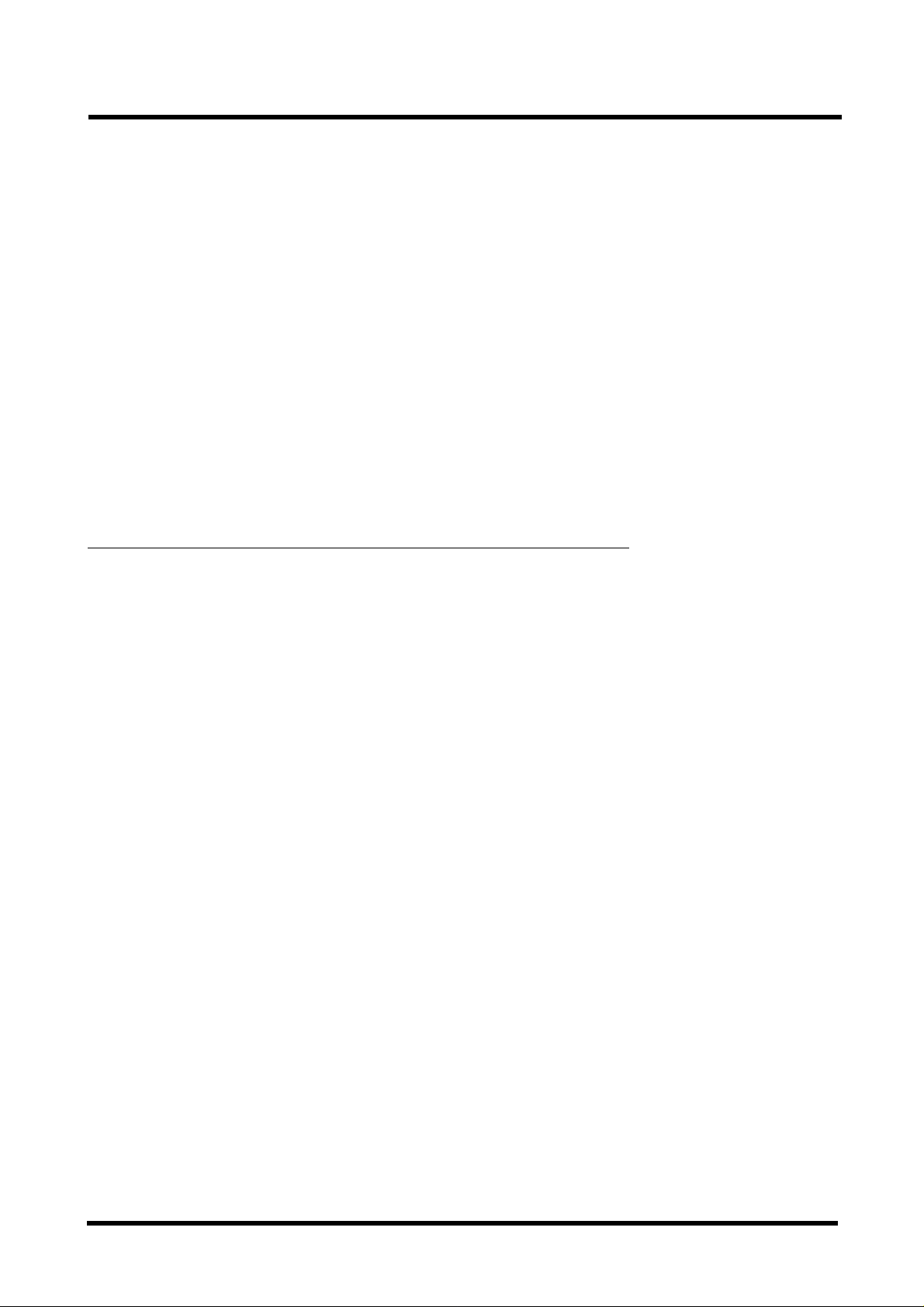

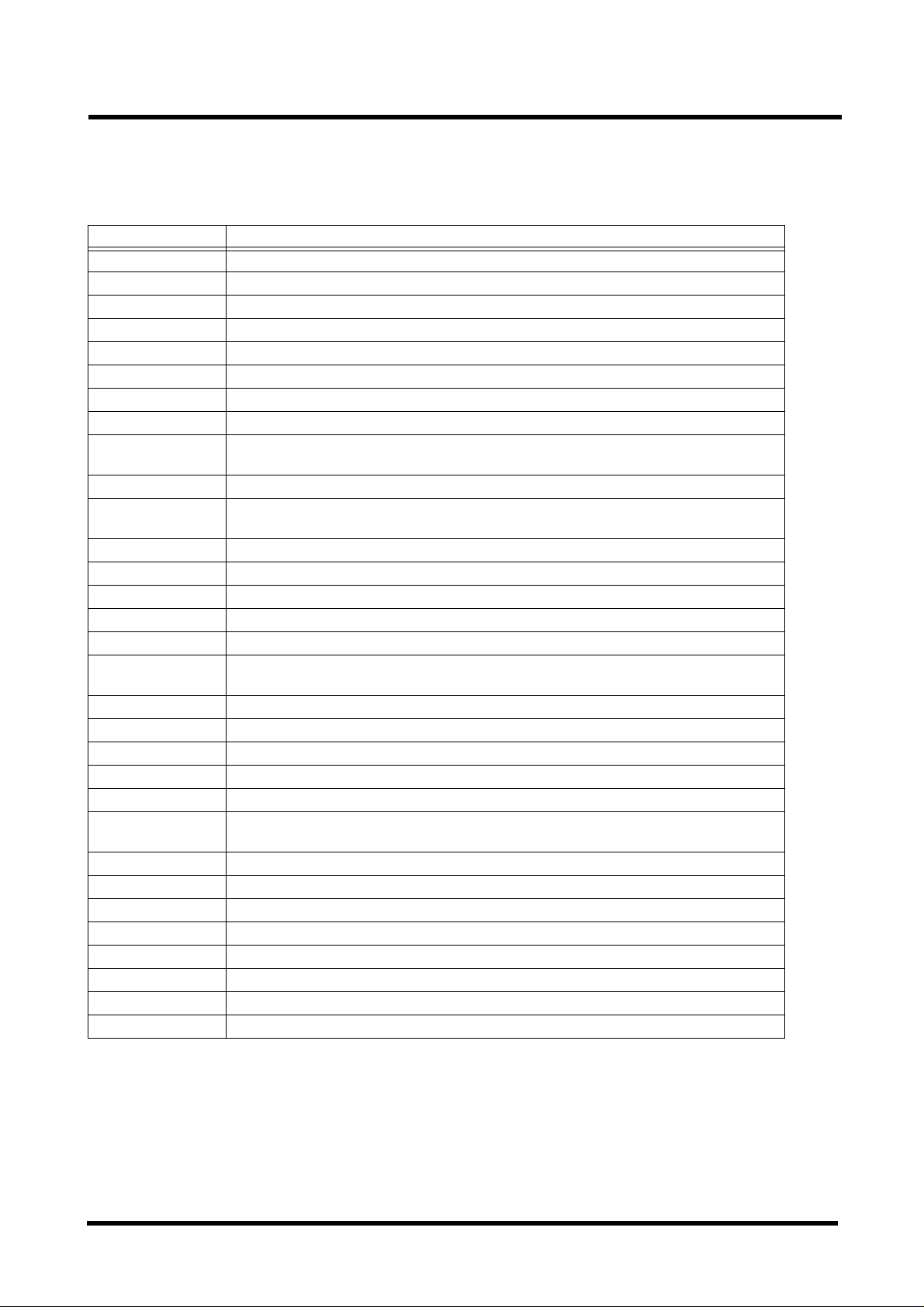

REVISION STATUS

From serial No.

Revision no. of

document

Page Revision no. of page

0-1 0111111

0-2 0111111

1-1 0111111

1-2 0000000

2-1 0122333

2-2 0111222

2-3 0122222

2-4 0122222

2-5 0111121

2-6 0122222

2-7 0111112

2-8 0122222

2-9 0122222

2-10 0000000

1006

1021

1056

1096

1221

1426

4001

012345678910111213141516171819

3-1 0122222

3-2 0123333

3-3 0122333

3-4 0122333

3-5 0111111

3-6 0122333

3-7 0122333

3-8 0122222

3-9 0122222

3-10 0122222

3-11 0122223

3-12 0111111

3-13 0122333

3-14 0111111

3-15 0112222

3-16 0000000

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.06 12.95 63 85 772

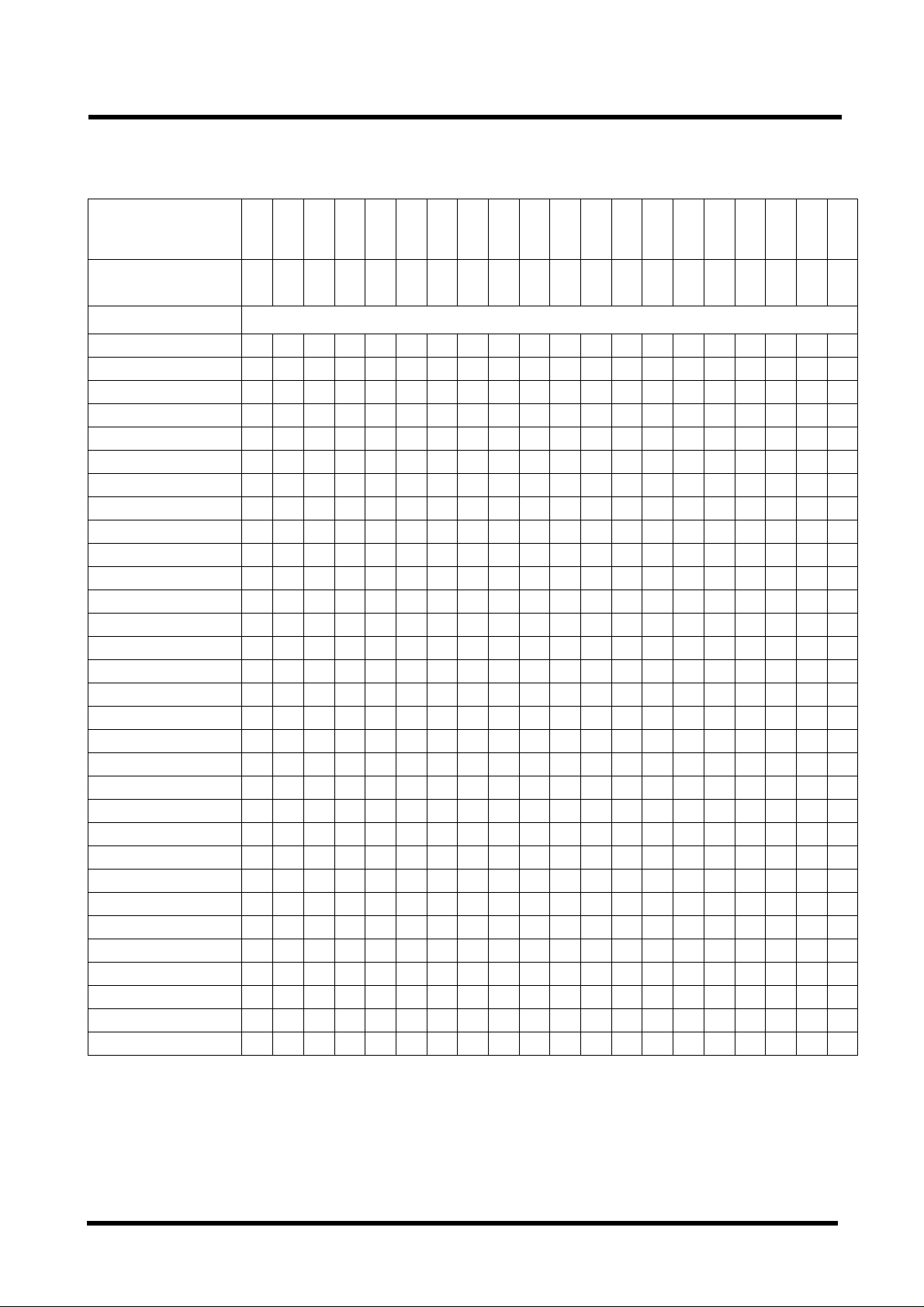

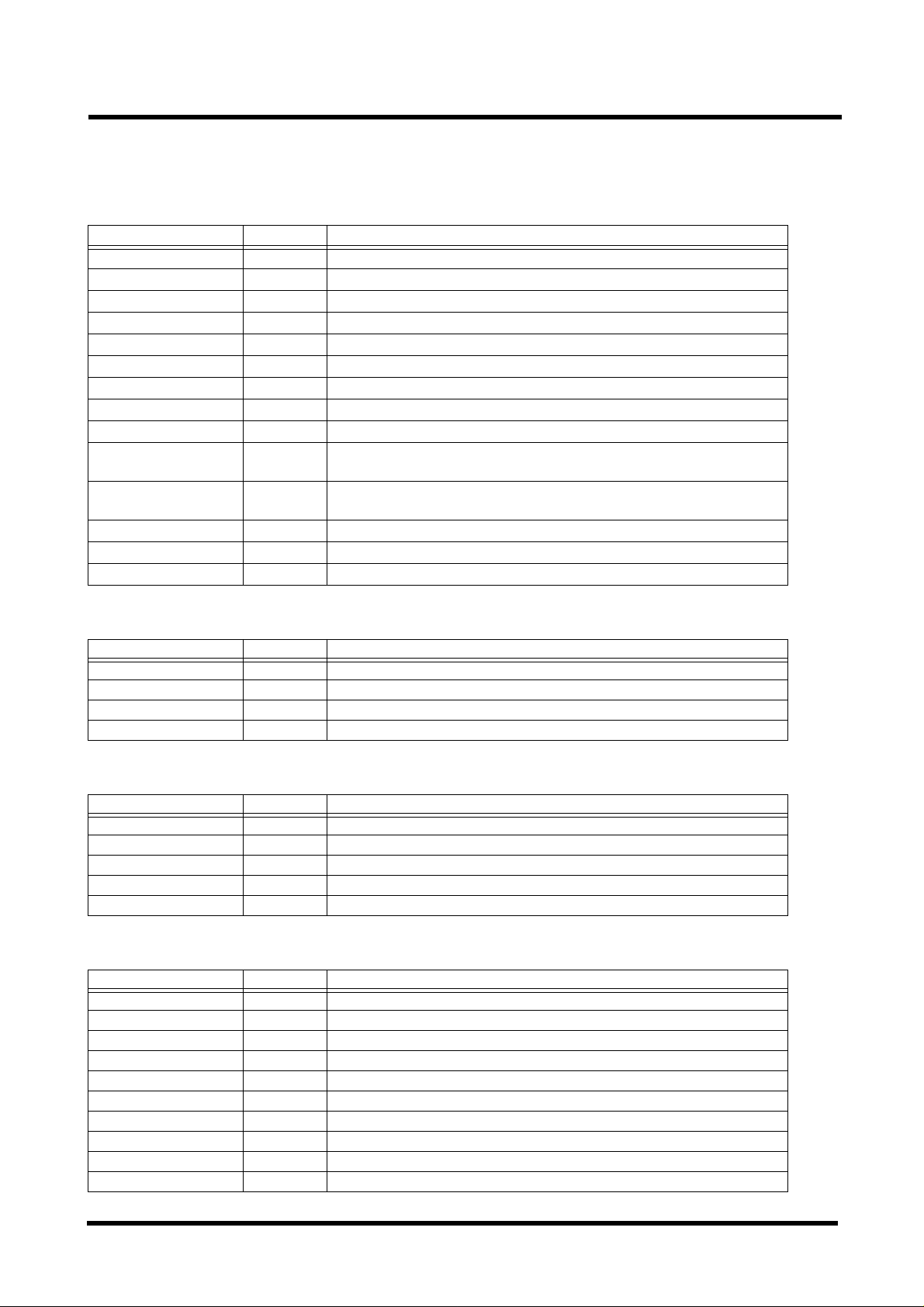

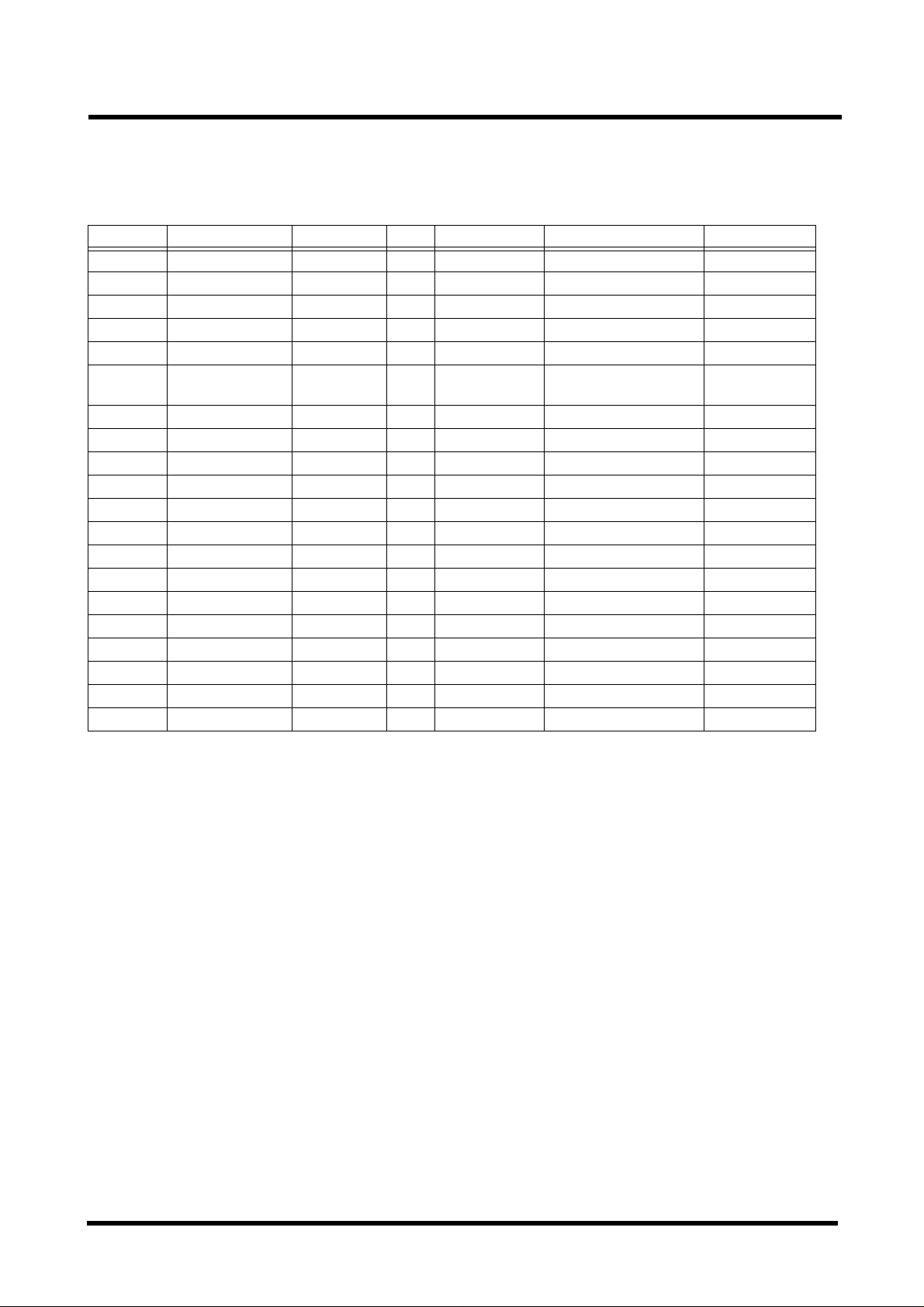

REVISION STATUS

X041E

From serial No.

Revision no. of

document

Page Revision no. of page

4-1 0122222

4-2 0122223

4-3 0111111

4-4 0122223

4-5 0122233

4-6 0111111

4-7 0122222

4-8 0122222

4-9 0111111

4-10 0122222

4-11 0122222

4-12 0122222

4-13 0122222

4-14 0111111

1006

1021

1056

1096

1221

1426

4001

012345678910111213141516171819

5-1 0122223

5-2 0122222

5-3 0122223

5-4 0122222

5-5 0122222

5-6 0122223

5-7 0122222

5-8 0122223

5-9 0122222

5-10 0123333

6-1 0111111

6-2 0122222

7-1 0123455

7-2 0123455

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.06 12.95 63 85 772

X041E 0-1

TABLE OF CONTENTS

1 System Overview..................................................1-1

2 Stand Overvie w................. ... .. ................. .. ... ......... 2-1

Placement of PC-boards and Components, Stand ...........................2-1

List of Boards and Fuses, Stand.......................................................2-2

List of Switches and Components, Stand..........................................2-3

List of Signals and Testpoints, Stand ................................................2-4

List of Voltages and Testpoints, Stand ..............................................2-8

3 Stand Functional Diagrams...................................3-1

Block Diagram Cable Connections....................................................3-1

Grounding Connections ....................................................................3-2

Mains Connection, Power Supply CPU.............................................3-3

Power Supply Motor Control .............................................................3-4

Display ..............................................................................................3-5

CPU Board Internal, Generator Interface..........................................3-6

Tube, Temperature Monitoring..........................................................3-7

Lift and Rotation Motor Drive.............................................................3-8

Lift and Rotation Switches.................................................................3-9

Compression Measurement Signals ...............................................3-10

Compression Motor Drive................................................................3-11

Tube Angle Measurement, Pot. Return...........................................3-12

Collimator........................................................................................3-13

Object Table ....................................................... ....... ...... ................3-14

Automatic Exposure Control (AEC).................................................3-15

4 Generator Overview..............................................4-1

Mains Voltage Connection ................................................................4-1

List of PC-Boards and Components, Generator................................4-2

List of Fuses, Generator....................................................................4-3

Placement of PC-Boards and Components, Generator....................4-4

Control Panel Functions....................................................................4-5

List of Switches and Components, Generator...................................4-6

List of Signals and Testpoints, Generator..........................................4-8

Signal Diagram ...............................................................................4-14

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.01 12.95 63 85 772

0-2 X041E

TABLE OF CONTENTS

5 Generator Functional Diagrams............................5-1

Block Diagram. ...... ...... .............................................. ...... ....... ........... 5-1

Ground, 0V and Protection Ground Distribution................................5-2

Line Input ..........................................................................................5-3

Back Plane D700 ..............................................................................5-4

Principle Diagram, Master.................................................................5-5

Principle Diagram, Tube Filament.....................................................5-6

Principle Diagram, Inverter Control and KV Regulation....................5-7

Principle Diagram, Inverter................................................................5-8

Principle Diagram, Control Panel......................................................5-9

Principle Diagram, Iontomat............................................................5-10

6 Generator PC Board Overview.............................6-1

7 Compatibility List................................................... 7-1

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.01 12.95 63 85 772

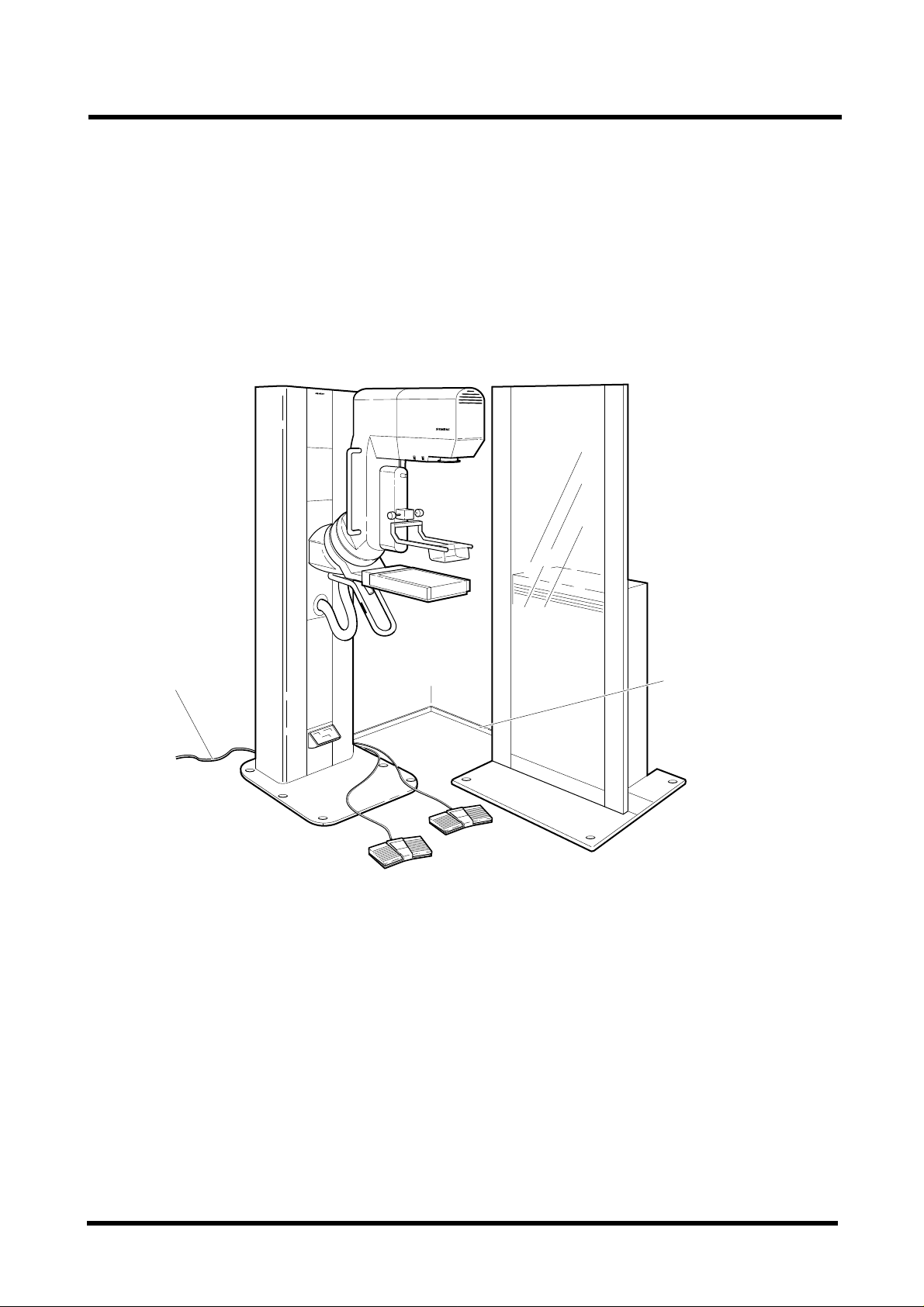

X041E 1-1

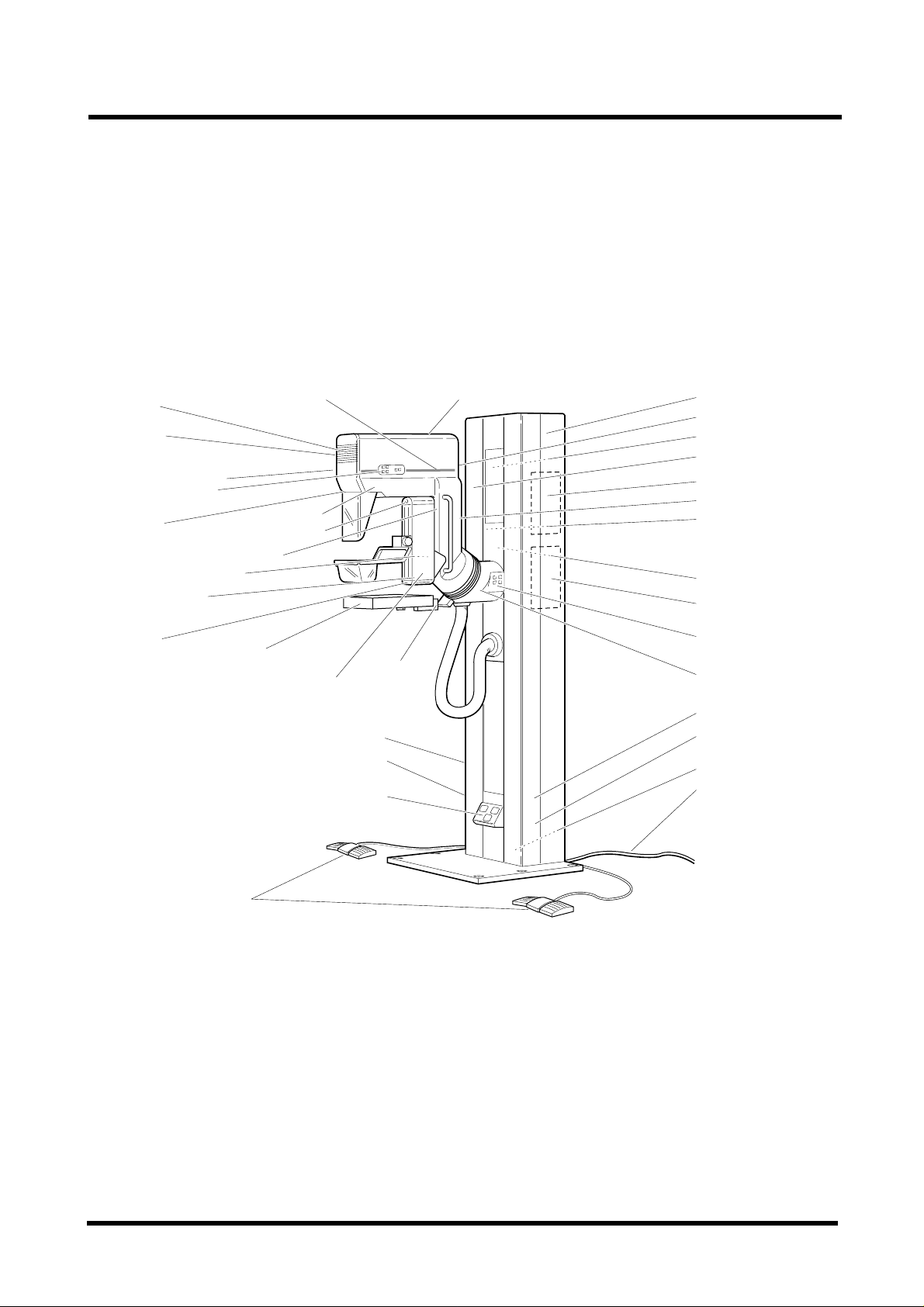

SYSTEM OVERVIEW

Cable ductCable duct

STAND GENERATOR

9555 0001

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.01 12.95 63 85 772

1-2 X041E

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.00 12.95 63 85 772

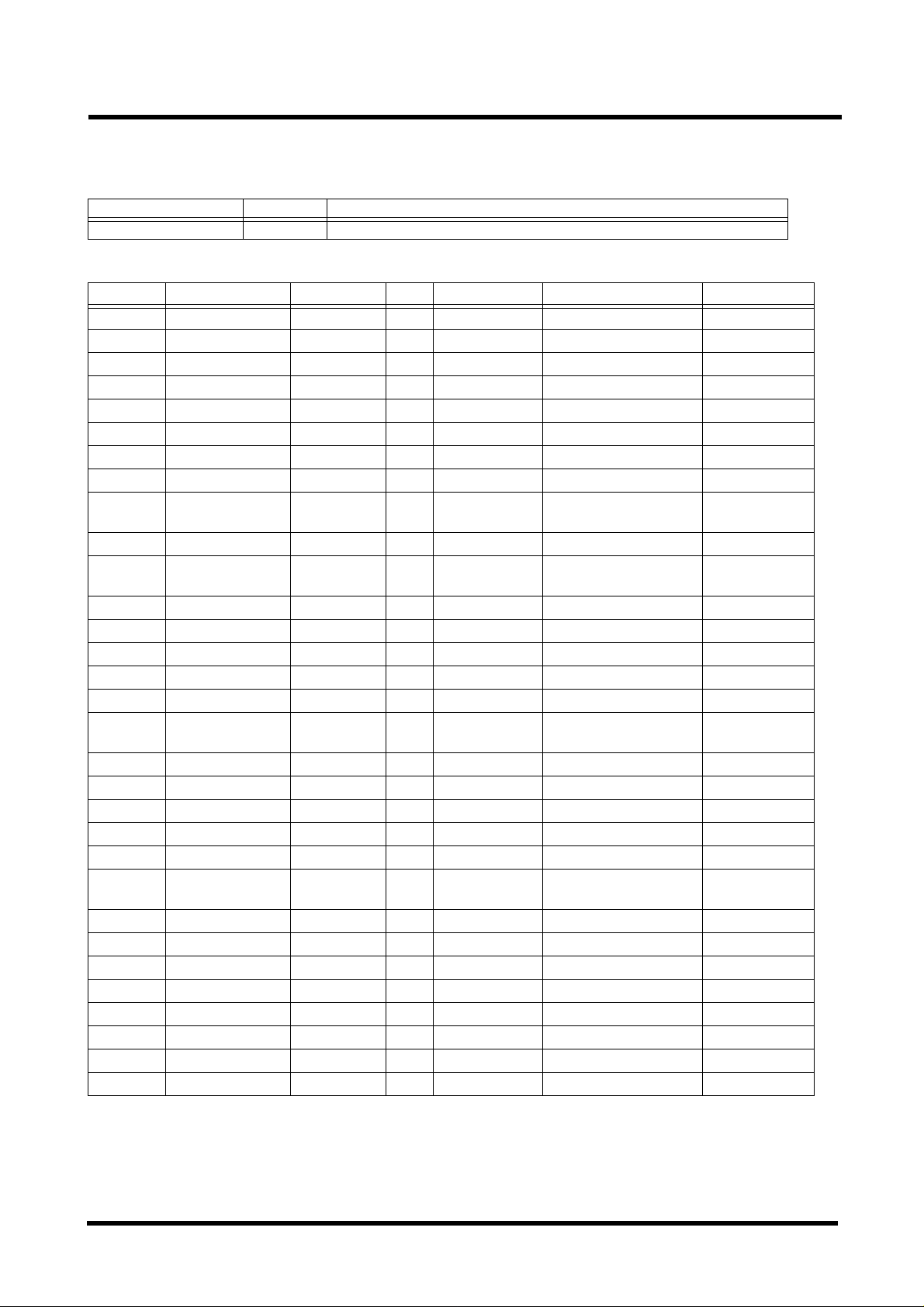

X041E 2-1

PLACEMENT OF PC-BOARDS AND COMPONENTS, STAND

Tube

K7-K9

D807 Rigth side

D807 Left side

Lamp

M2 (Compression)

Strain gauge

D804

R861

X874

Object table

S1

S2

M

S897

R863

S883

S884

D803

S892

X892

M6 (Fan)D805

M1 (Lift)

R871

S882

S881

D801

S880

D806

With

Photo transistor

M3 (Rotation)

D802

D808 Right side

D808 Left side

D803

X880

X899

T801

Incoming mains

Fooy pedals

9555500

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.03 12.95 63 85 772

2-2 X041E

LIST OF BOARDS AND FUSES, STAND

PCB OVERVIEW

D801 CPU BOARD

D802 MOTOR CONTROL BOARD

D803 DISPLAY BOARD

D804 FORCE AMPLIFIER BOARD

D805 WING BOARD

D806 ANGLE DETECTOR BOARD

D807 BOARD FOR LIFT, ROTATION AND LAMP SWITCHES

D808 BOARD FOR LIFT AND ROTATION SWITCHES

FUSES OVERVIEW

PCB FUSE FUSED VOLTAGE

D801 F1 2 AT +5V, +5V_REF, +5V_DSP, +7V

D801 F2 1 AT +5V_DUEP

D802 F1 5 AT +5V, +5V_M, +14V, D805/+5V

D802 F2 3.15 AT +24VF, +15V

D802 F3 6.3 AT +24V

D802 F4 4 AT 16VAC (LAMP)

D802

Chassis-mounted

fuses

NOTE! See spare parts list for replacement fuses.

F5 1 AT

F801 2 AT

F802 1 AT 11 V_DP

F803 5 AT 14 VAC

F804 5 AT 16 VAC

F805 6.3 AT 24 VAC

24VACF (FAN)

11 VAC

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.02 12.95 63 85 772

X041E 2-3

LIST OF SWITCHES AND COMPONENTS, STAND

SWITCHES

Switch Page Description

S2/Object table 3-14/2A Cassette inserted switch.

S1/D801 3-6/1D Reset switch for stand CPU.

S1/Object table 3-14/2A Grid out switch located in the object table.

S1-S6/D807 3-8/2A Control switches for lamp, lift- and rotation movement. Left and right side.

S1-S4/D808 3-8/4B Control switches for lift- and rotation movement. Left and right side.

S861 3-11/2G Compression limit switch, compression unit.

S862 3-11/2G Decompression limit switch, compression unit.

S880 3-4/2B Emergency stop, switches off 24VAC and 14VAC, machine blocked.

S881 3-8/2G Lift up limit switch, rotating unit.

S882 3-4/2A Limit switch, distance tube head - floor <50 mm, switches off 24VAC,

machine blocked.

S883 3-8/4B Collision protection switch, risk for collision when tubehead is less than

120 mm from the floor.

S884 3-8/2G Down limit switch, rotating unit.

S892 3-14/2C Object table locked in position.

S897 3-13/2D Diaphragm switch.

POTENTIOMETERS

Potentiometer Page Description

R803 3-12/2A Tube angle, 2k.

R861 3-10/3E Preset force, 10k.

R863 3-10/3E Thickness, 2k.

R871 3-12/2A Preset angle, 10k.

MOTORS

Motor Page Description

M1 3-8/2G Lift motor.

M2 3-11/2G Compression motor.

M3 3-8/3G Rotation motor.

M6 3-7/4E Fan, tube cooling.

M 3-14/2A Grid motor

MISCELLANEOUS

Misc. Page Description

T801 3-3/2C Mains transformer.

LAMP 3-13/3G Object illumination.

R801 3-13/5F Lamp resistor.

R807 3-8/2G Lift motor varistor.

COMP. UNIT 3-10/2C Compression unit.

CABLE DUCT 3-2/3A Generator to stand cable protection

GROUND RAIL 3-2/1E System grounding terminal

K7 3-7/4E Fan thermostat

K8 3-7/4E Tube temperature above normal

K9 3-7/4E Tube temperature too high

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.03 12.95 63 85 772

2-4 X041E

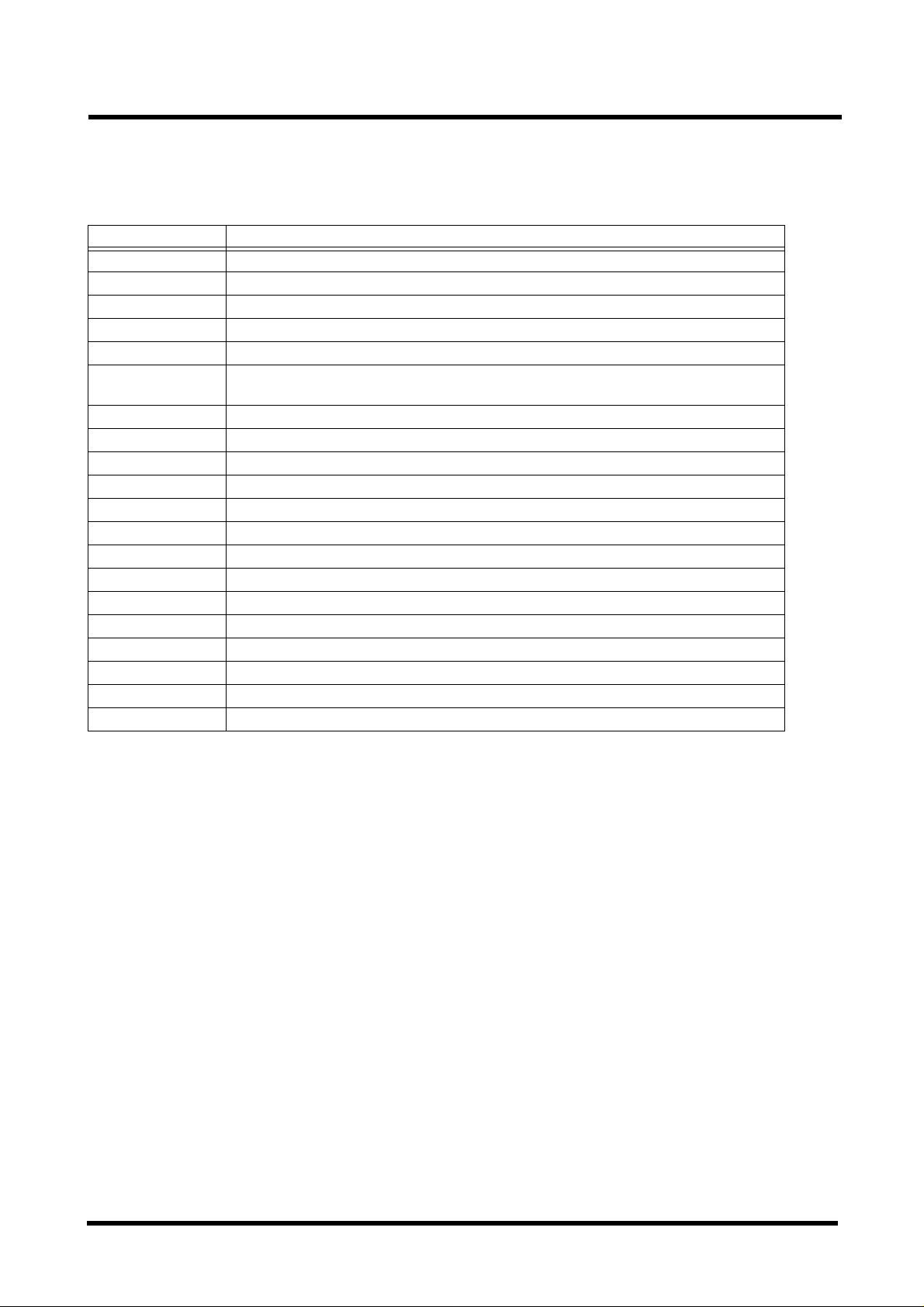

LIST OF SIGNALS AND TESTPOINTS, STAND

Misc. Page Description

L801 - L809 3-8, 3-11 UHF chokes (EMC)

Page Signal Name Origin Via Destination Testpoint LED

3-14/2E AEC_POS D805 D801

3-6/2B AR D801 GENERATOR D801 AR

3-10/3B BR_OPEN D804 D804.X843 pin 8 V2

3-10/3B BR_RET D804 D804.X843 Pin 7

3-14/1A CASS_LOADED OBJ. TABLE D805 D801

3-11/1B

3-10/2F COMP_FORCE D804 D801 D804.X843 pin 5

3-11/1E COMP D802 D805 COMP. UNIT

3-11/3E COMP_OK D802 D801 D802 V2

3-11/1E COMP_PROT D802 D801 D802

3-11/1B

3-11/2D C_PWM D802 D802

3-11/4F COMPRESS PEDAL D805 D801, D802

3-11/1E DECOMP D802 D805 COMP. UNIT

3-11/4F DECOMPRESS PEDAL D801

3-8/2C

3-8/4F DRIVE_OK D802 D801 D802 V12

3-8/1E DRIVE_PROT D802 D801 D802

3-14/3B GRID_MOTOR_N D802 D805 OBJ. TABLE

3-14/2A GRID_OUT OBJ. TABLE D805 D801 D801 GRID_O

3-14/2G

3-10/3D I1_OUT D804 D804.X843 pin 6

3-6/2B

3-13/3G LAMP D807 D805 D801

3-13/4D

3-9/3A LIFT_DOWN D807, D808 D805 D801, D802

3-9/3A LIFT_UP D807, D808 D805 D801, D802

3-8/2E L_PWM D802 D802

3-6/3B MPS D801 GENERATOR D801

3-7/4C OKT1_ TUBE/K8 GENERATOR

3-7/4C OKT2_ TUBE/K9 GENERATOR

COMP_DIR D801 D802 D802 COMP_D

*

COMP_SPEED D801 D802 D801, D802

*

DIR D801 D802 D802

*

GRID_SPEED D801 D802 D801 GRID_SP

*

KVA D801 D700

*

LAMP_CTRL D801 D802

*

(GENERATOR)

COMP_SP

D801

COMP_ERR

DRIVE_ERR

“*SIGNAL” = “SIGNAL” active low

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.02 12.95 63 85 772

X041E 2-5

LIST OF SIGNALS AND TESTPOINTS, STAND

Signal Name Description

AEC_POS AEC-detector in position near breast. Not used in M300.

AR Signal given to generator as exposure request. If grid used, grid has started.

BR_OPEN Bridge open, strain gauge for compression force not working correctly.

BR_RET Compression force strain guage return line (appr. 0V)

CASS_LOADED Cassette inserted in object table.

COMP_DIR Controls compression motor to compress (moving down)

*

COMP_FORCE Analog signal indicating compression force.

COMP Power output via compression limit switch to compression motor.

COMP_OK Compression motor working correctly, no over current.

COMP_PROT Compression relay K1 is working correctly, checked 1s after pedal release.

COMP_SPEED Pulse Width Modulated signal to control speed of compression motor.

*

C_PWM Pulse Width Modulated power output to compression motor.

COMPRESS Operator control signal to move compression plate down.

DECOMP Power output via decompression limit switch to compression motor.

DECOMPRESS Operator control signal to move compression plate up.

DIR Selecting direction of rotation or lift motor.

*

DRIVE_OK Rotation and lift motor are working correctly, no over current.

DRIVE_PROT DMG relay K3 is working correctly, checked 3s after rot/lift botton is released.

GRID_MOTOR_N Grid motor return line.

GRID_OUT Active when the grid is not in stand by position.

GRID_SPEED Pulse Width Modulated signal control speed of grid motor.

*

I1_OUT Output signal from compression force preamplifier.

KVA Signal to terminate exposure.

*

LAMP Operator control signal to the field lamp.

LAMP_CTRL Signal to switch object illumination on.

*

LIFT_DOWN Operator control signal to move compre ssion plate down.

LIFT_UP Operator control signal to m ove compress ion plate up.

L_PWM Pulse Width Modulated power output to rotation or lift motor.

MPS Multi processor serial communication for information exchange Master - Slaves.

OKT1_ Signal from temperature switch K8 on the tube.

OKT2_ Signal from the over pressure switch K9 on the tube.

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.01 12.95 63 85 772

2-6 X041E

LIST OF SIGNALS AND TESTPOINTS, STAND

Page Signal Name Origin Via Destination T es tpoin t LED

3-12/2D POT_RETURN POT D801

3-10/2E PRES_FORCE R861 D801

3-12/1A PRESET_ANGLE R871 D805 D801

3-11/2D PU D802 D802

3-6/1E

3-6/1E

3-6/1E RESET_SW D801

3-9/3A ROT_CW D807, D808 D 80 5 D802

3-9/3A ROT_CCW D807, D808 D805 D802

3-12/4A ROT_POS D806 D801

3-6/3D RXD GEN. D801 D801

3-8/3C

3-8/2C

3-13/4A STEREO_COLL S897 D801

3-14/1B TABLE_ C ONF IG OBJ.TABLE D805 D801

3-10/3E THICKNESS R863 D801

3-12/2A TUBE_ANGLE R803 D 801

3-6/4D TXD D801 GENERATOR D801 TXD

3-6/3B VH GEN. D801

3-10/3C ZERO D804 D804.X843 pin 4

RESET D801

*

RESET_HW D801

*

SEL_ROT D801 D802 D802 SEL_ROT

*

SPEED D801 D802 D801, D802 SPEED

*

“*SIGNAL” = “SIGNAL” active low

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.02 12.95 63 85 772

X041E 2-7

LIST OF SIGNALS AND TESTPOINTS, STAND

Signal Name Description

POT_RETURN Return line potentiometers connected to 0VA via a resistor.

PRES_FORCE Analog signal as preset value for maximum compression force.

PRESET_ANGLE Analog signal as preset value for requested rotation angle.

PU Pull up signal for error comparators = +15V, +5V, +24V voltages OK.

RESET Reset signal to the CPU.

*

RESET_HW Reset signal from the CPU to the reset circuit, used for slave restart and CPU watchdog

*

RESET-SW Signal from the reset switch to the CPU via the reset circuit.

*

ROT_CW Operator control signal to rotate the x-ray system clockwise.

ROT_CCW Operator control signal to rotate the x-ray system counter clockwise.

ROT_POS Low level signal pulse indicating +10 or -10 degrees of rotation.

RXD Input for receiving data via MPS.

SEL_ROT Low level signal selects the rotation drive to be controlled.

*

SPEED Pulse Width Modulated signal to control speed of rotation or lift motor.

*

STEREO_COLL Diaphragm switch, diaphragm in place. For 18 x 24 or spot diaphragm.

TABLECONFIG Inputs from object table, see configuration table.

THICKNESS Analog signal indicating the compression thickness.

TUBE ANGLE Analog signal indicating the rotation angle.

TXD Output for sending data via MPS.

VH The stand is informed that the generator has completed its preparation.

ZERO Used for adjusting offset of the compression force amplifiers.

reset.

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.01 12.95 63 85 772

2-8 X041E

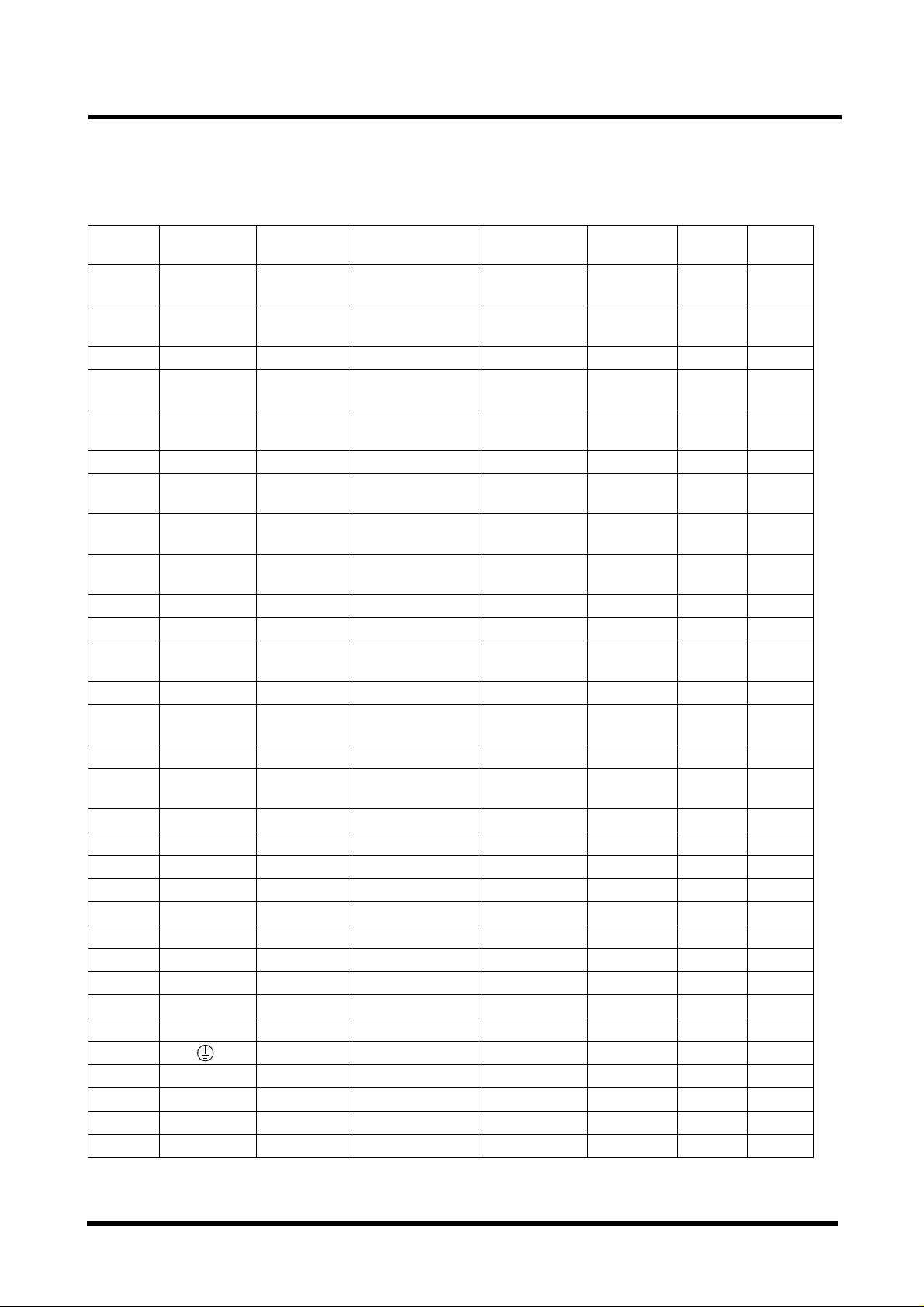

LIST OF VOLTAGES AND TESTPOINTS, STAND

Page Voltage Origin Supplied

from

3-3/4E +5V D80 1 11V Digital IC,

3-3/4E

3-10/3B

3-3/3E +5V_DSP D801 11V D803, Display 5V_DSP V6 D801/F1

3-3/2E

3-10/3B

3-3/3E +5V_DP D801 11V_DP Generator

3-3/3D 0VD GND D801/X811 Digital IC 0VD1, 0VD2

3-3/3D

3-10/3B

3-6/5D 0V_DP D700/GND Generator inter-

3-3/2C 11V T801 230VAC +5V, +5V_DSP,

3-6/5B 11V_DP T801 230VAC +5VDP D801/F2

3-4/3D +5V D802 14VAC Digital IC 5V V7 D802/F1

3-4/4E +5V_M D802 +5V D801-D802

3-4/3D +14V D802 14VAC +5V, D805/+5V 14V D802/F1

3-4/2D +15V D802 +24V Transistor

3-4/2C +24V D802 24VAC +15V, +24VF D802/F3

3-4/2D +24VF D802 +24V Switches,

3-4/3A 14VAC T801 230VAC +14V D802/F1

3-13/5E 16VAC T801 230VAC LAMP D802/F4

3-4/2A 24VAC T801 230VAC D802/F3

3-4/2E 24VACF D802 24VAC Fan D802/F5

3-4/3B 0V GND D802/X821 Ground 0V, OV1

3-4/2F +5V D805 D802/+14V Digital IC 5V V17 D802/F1

3-4/2G +5V_R D805 +5V User switches D802/F1

3-4/3D +14V D802 +24V Switches,relays D802/24VF D802/F2

3-4/2D +24VF D802 +24V Switches,relays D802/24VF D802/F2

3-3/2B 230VAC Generator D701/X14 Stand X881/2,3

3-3/1C P.E. Stand X899 Inc. mains voltage Whole system X899/PE

3-3/1C N Stand X 899 Inc. mains voltage Whole system X899/N

3-3/1C L1 Stand X899 Inc. mains voltage Whole system X899/L1

3-3/1C L2 Stand X899 Inc. mains voltage Whole system X899/L2

3-3/1C L3 Stand X899 X899/L3

+5V_REF D801 +5V Pots.

+7V D801 11V Analog IC,

0VA 0VD D801 Analog IC

Supply for Testpoint LED Fuse

5V V7 D801/F1

+5V_REF

D804

D804

interface

D804

face ground

+7V

upto interface

drivers

relays

5V_REF

X843 pin 2

7V

X843 pin1

5V_DP V8 D801/F2

0V A1, 0VA 2

X843 pin 3

0V_DP

15V V49 D802/F2

24VF D802/F2

V5 D801/F1

V7 D802/F1

D801/F1

D801/F1

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.02 12.95 63 85 772

X041E 2-9

LIST OF VOLTAGES AND TESTPOINTS, STAND

Voltage Description ( typical value)

+5V Regulated DC voltage, 4.75V < +5V < 5.25V

+5V_REF Regulated DC voltage, +5V -5% < +5V_REF < +5V

+5V_DSP Regulated DC voltage, 4.75V < +5V_DSP < 5.25V

+7V Regulated DC voltage, 6.60V<+7V<7.25V

+5V_DP Regulated DC voltage, 4.75V < +5V_DP < 5.25V

0VD Digital ground

0VA Analog ground

0V_DP Generator interface ground. Floating, grounded by generator.

11V AC supply voltage, 11VAC

11V_DP AC supply voltage, 11VAC

1)

1)

+5V Regulated DC voltage, 4.75V < +5V < 5.25V

+5V_M Regulated DC voltage, 4.75V < +5V_M < 5.25V

+14V Unregulated DC voltage, 18V

1)

+15V Regulated DC voltage, 14.25V < +15V < 15.75V

+24V Unregulated DC voltage, 32V

+24VF Unregulated DC voltage, 32V

14VAC AC supply voltage, 14 VAC

16VAC AC supply voltage, 16 VAC

24VAC AC supply voltage, 24VAC

1)

1)

1)

1)

1)

24VACF AC supply voltage for the fan

0V Circuit ground

+5V Regulated DC voltage, 4.75V < +5V < 5.25V

+5V_R Regulated DC voltage, 4.40V < +5V_R < 5.25V

+14V Unregulated DC voltage, 18V

+24VF Unregulated DC voltage, 32V

1)

1)

230VAC Stand mains voltage input, 195VAC < 230VAC < 253VAC

P.E. Protective earth terminal, incoming mains

N Neutral line terminal, incoming mains

L1 Line 1 terminal, incoming mains vo ltage

L2 Line 2 terminal, incoming mains vo ltage

L3 Not used

1)

STANDBY TYPICAL VALUE, 230VAC INPUT

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.03 12.95 63 85 772

2-10 X041E

Siemens-Elema SRX-U RX B7-120.051.01.0 8.02 MAMMOMAT 300

Solna, Sweden REV.00 12.95 63 85 772

X041E 3-1

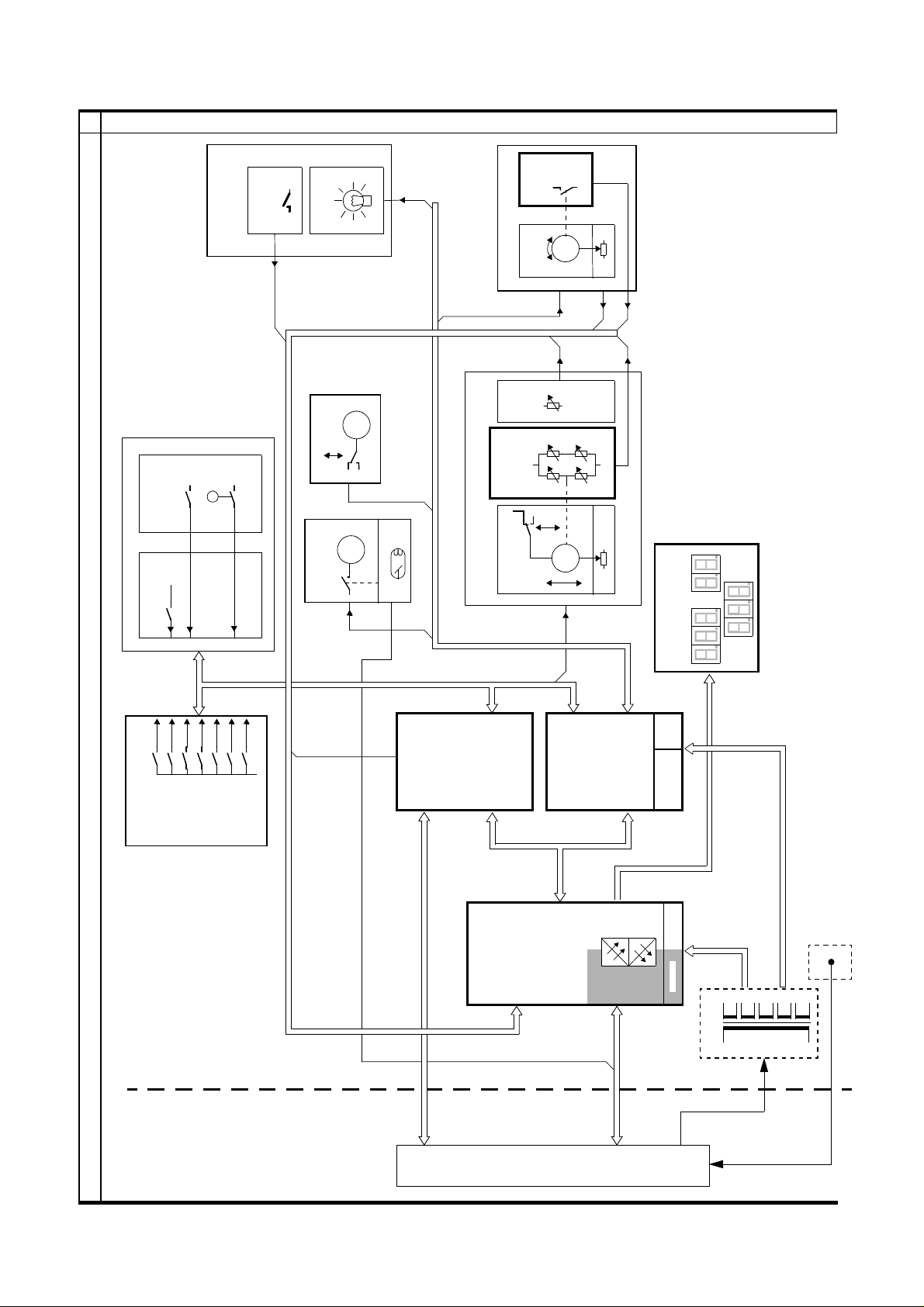

BLOCK DIAGRAM CABLE CONNECTIONS

123

4

5

OBJECT TABLE

TABLE BASE OBJECT TABLE

LAMP

X894

COLLIMA TOR

X894

D806

ANGLE

DETECTOR

ROTATION

ROTATION

X888

X874

PRESET

FORCE

X841 X861

M

D804

COMPRESSION

CASS IN PLACE

M

GRID OUT

GRID

X887

M

FAN LIFT

T. IN POS

TUBE TEMP

X895

X895

COMPRESSION

FORCE

F

MM

COMPRESSION

USER INTERFACE

STAND

X826-X829

COMP

DECOMP

X892

X844-X849

X880

ROT CW

ROT CCW

LIFT UP

LIFT DOWN

D803

DISPLAY

X801

X851

X889

X865

X869

X871

X863

X865

X868

+24V

D805

WING BOARD

X855

X856

X858

LAMP

X870

X860

D801

80C535

CPU BOARD

X824

D802

X812

X813

X814

X813

X814

X823

X824

X821

16V AC

+24V +15V

+7V +5V

+5V_DP

+14V +5V

INCOMING MAINS

110, 208, 230, 240, 277 OR 400V

X811

X886

X886

SINGLE OR TWO PHASE

X899

MOTOR CONTROL

X822

X823

X816

T801

230V FROM GENERATOR

X886

ABCDEFG

GENERATOR

Siemens-Elema

SRX-U RX B7-120.051.01.08.02

Solna, Sweden

REV.

02

X10

.

GEN

X11

X1 X815

MAMMOMAT 300

12.95

63 85 772

3-2 X041E

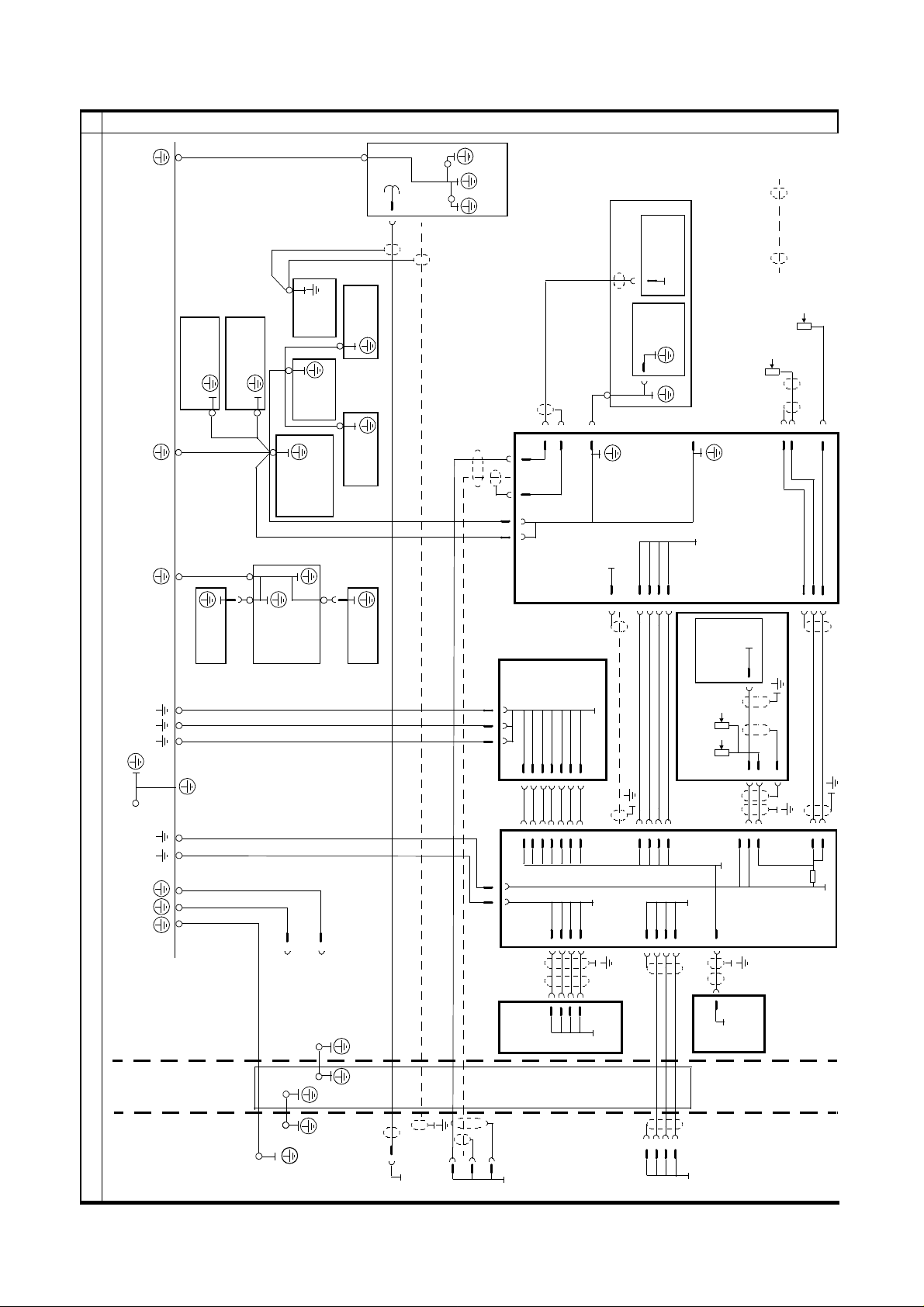

GROUNDING CONNECTIONS

123

FRONT

COVER

TUBE

REAR

H3

X896

COVER

X897

HOUSING

4

5

STAND

BELLOWS RING

GROUND RAIL

CURTAIN

BELLOWS RING

UPPER

LIFT

CARRIAGE

TUBE

TUBE

COMPRESSION

UNIT

PLATE

CHASSIS

PATIENT

HANDLE

PATIENT

HANDLE

LOWER

X884

DETECTOR

4

0V_RDL

FILAMENT

ROTATION

OBJEKT

BOARD

9

WING 2

X892

16

X869

14

BOARD

X871

SHLD_1

252729

12

X855

0V

30

X856

COMPRESSION

6

5

58

2

X821

4

X870 6

X860

D805

WING

D802

MOTOR

BOARD

1234568

X822

NOTE

DOTTED CONNECTIONS INDICATE

SHEILDED CABLES WITHOUT

0V CONNECTION

10k

R871

PRESET_ANGLE

R803

2k

TUBE_ANGLE

X86856

X863

X855

1

SHLD

4

5

3

POT_RET

X859

0V

0V A

2

X841

D804

COMPRESSION

FORCE

THICK-

NESS

2k

R863

726

10k

X874

UNIT

PRES_FORCE

R861

INCOMING MAINS

X899

P.E.

1

2

33

34

X813

1

137

8

X815

141615

X814

0V

0V_DUEP

36

X813

9

17

20

0V A

X880

1234568

X812

4

3

X811

1

4

X881

D801

CPU

X816

151617

0V D

18

STAND

4

X861

D806

0V

ANGLE

DETECTOR

151617

18

X801

D803

FOR FOOTPEDALS

CABLE

CABLE

DUCT

DISPLAY

0V D

ABCDEFG

GENERATOR

Siemens-Elema

Solna, Sweden

X9

X8

X11

A

J

P

H

0V_RDL

SRX-U RX B7-120.051.01.08.02

REV.

03

12.95

X1

136

11

GND

MAMMOMAT 300

63 85 772

Loading...

Loading...