Siemens Mammomat 300 Service manual

SIEMENS

MAMMOMAT

A

Service

Instructions

300

SP

Register

RX

Replaces:

5

B7-120.061.01.05.02

RX

B7-120.061.01.04.02

Weitergabe

Mitteilung

standen.

Rechte

sowie

Vervielfaltigung

ihres

Inhalis

Zuwiderhandlungen

fůr

den

Fall

der

nicht

dieser

gestattet,

verpflichten

Patenterteilung

Unterlage,

soweit

nicht

zu

Schadenersatz.

oder

GM-Eintragung

Verwertung

ausdrůcklich

Alle

vorbehalten.

und

zuge-

Proprietry

Confié a titre

Confiado

data,

de

como

company

secret

secreto

confidential.

d'enterprise.

industrial.

Nos

All

rights

Tous

droits

reservamos

reserved.

réservés.

todos

los

english

10.96

derechos.

64

27

806

Service

Instructions

0-1

Table

1

of

contents,

Prerequisites

Required

Recuired

Required

Protective

Location

Safety

2

Preparations

Stand

Swivel-arm

Transport

Generator

3

Subassemblies

Compression

Collimator

Printed

Motors

Miscellaneous

Revision

documents

measuring

tools

measures

of

components

system

safeguard

unit

unit

circuit

boards

status

instruments

appliances

and

Page

1-1

1-1

1-1

1-1

1-1

1-1

1-2

2-1

2-1

2-2

2-4

2-5

3-1

3-1

3-3

3-5

3-6

3-9

Rev.

03

02

01

4

Adjustment

5

Exchange

6

Replacing

7

Checks

and

Configuration

Service

Save/show

Normal

Stand

Saving

Removal

Installation

Type

labeling,

and

IONTOMAT

Power

Control

configuration

mode

configuration/test

of

Firmware

existing

the

X-ray

Adjustments

PM

Pack

Deck

Service

data,

Exchange

tube

Return

of

PC

Programs

file

assembly

LINA

card

of

the

Generator

4-1

4-1

4-18

4-21

4-23

4-28

5-1

5-1

6-1

6-1

6-2

6-3

7-1

7-1

7-16

7-22

04

01

01

03

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

04

10.96

MAMMOMAT

300

0-2

Service

Instructions

8

9

Checks

Lifting

Radiation

Error

List

and

Adjustments

carriage

field

Messages

of

error

(vertical

messages

of

the

movement)

Stand

Table

of

contents,

Revision

Page

8-1

8-1

8-3

9-1

9-1

status

Rev.

01

03

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

04

10.96

MAMMOMAT

300

Prerequisites

1-1

Required

-

-

-

Required

-

-

-

-

-

-

-

documents

Wiring

Installation

Function

measuring

Densitometer - Sensitometer

Oscilloscope,

Digital

Service

Service

Plexiglass

(three

and

part

Digital

Fluke

diagram

and

description

multimeter

PC

with

cable

plates

plates

one

plate

no.

85

49

voltmeter

type

87,

MAMMOMAT

setting

instructions

instruments

e.g.

TEKTRONIX

incl.

mAs-

connecting

measuring

measuring

438

and

97

(Fluke

part

no.

type

97

150

150

88

03

300

|

and

appliances

314

meter

cable

mm x 150

mm x 150

423

respectively)

8060A,

976

part

Y4290)

RX

B7-120.051.01...

RX

B7-120.033.01...

RX

B7-120.041.01...

63

82

746

mm x 20

mm x 10

no.

97

mm

mm,

02

101

(X041E)

Y4290,

or

Reguired

-

Common

-

Scale 0 -

-

Electrical

Protective

Checks

the

radiation

Location

See

wiring

tools

tool

25

screwdriver

measures

which

of

must

warning

components

diagram

kit

kg

(in

be

symbol

X041E

steps

of

with

0.1

bit

performed

ve

for

MAMMOMAT

kg)

set

(recommended)

under

.

X-ray

300.

radiation

are

marked

with

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

03

11.95

MAMMOMAT

300

1-2

Safety

Warning!

When

in

washers

eliminate

reassembling

the

original

must

interferences.

any

assembly.

be

functional

part

of

Screws

to

establish

the

equipment,

must

be

all

contact

securely

protective

tightened

ground

Prerequisites

washers

and

connections

must

the

be

contact

and

used

to

as

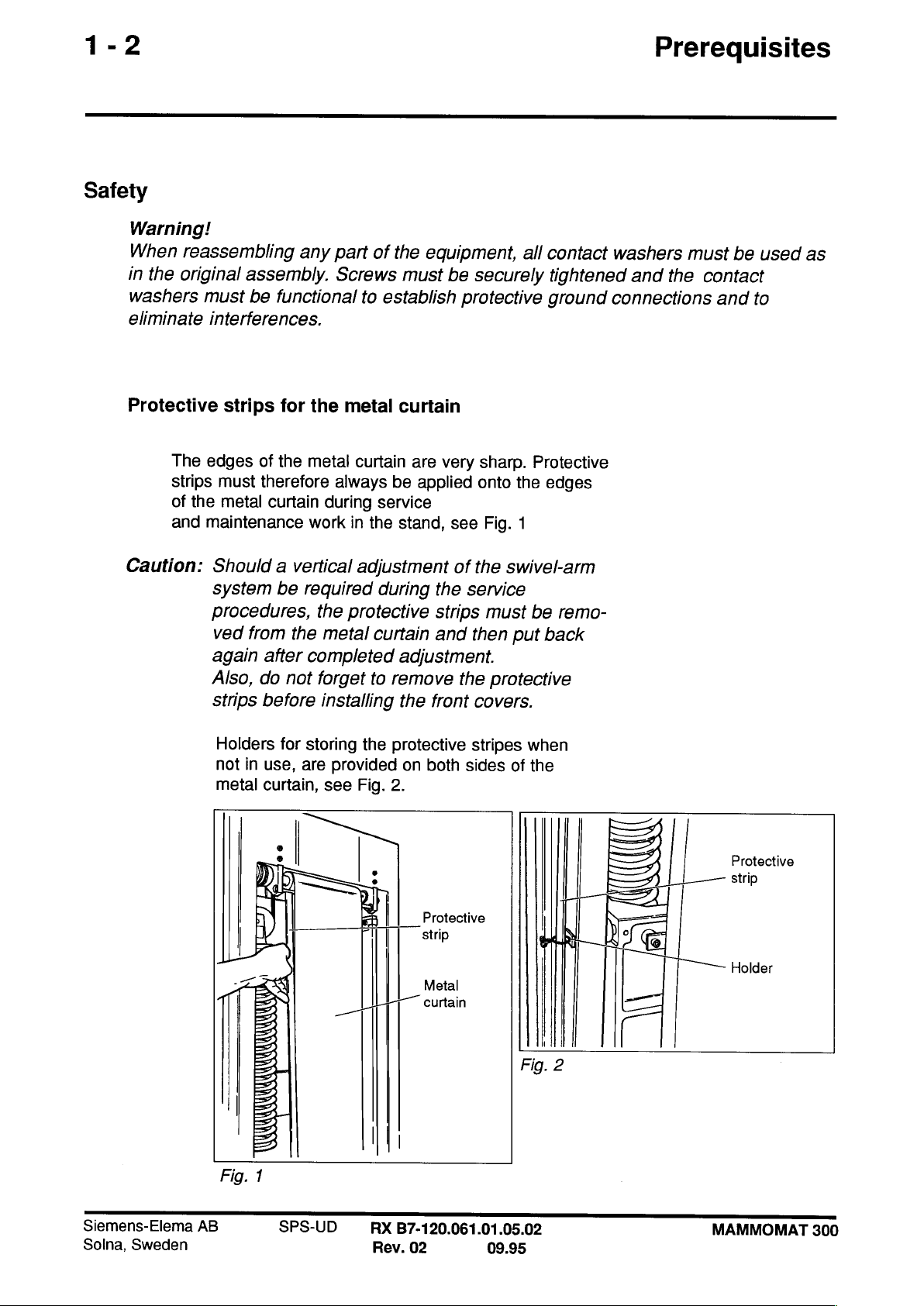

Protective

The

strips

of

the

and

Caution:

strips

edges

must

metal

maintenance

Should a vertical

system

procedures,

ved

again

Also,

strips

Holders

not

metal

for

of

the

therefore

curtain

be

from

the

after

do

not

before

for

in

use,

curtain,

the

metal

metal

always

during

work

required

the

protective

metal

completed

forget

installing

storing

are

provided

see

curtain

curtain

in

adjustment

the

Fig.

are

be

applied

service

the

stand,

during

curtain

to

and

adjustment.

remove

the

front

protective

on

both

2.

very

sharp.

onto

see

Fig.

of

the

the

service

strips

must

then

the

covers.

stripes

sides

Protective

the

edges

1

swivel-arm

be

remo-

put

back

protective

when

of

the

Siemens-Elema

Solna,

Sweden

一

725

TI

=

E

ES

=

=

=

ES

ES

I

ES

ESA

=

ビジ

Fig.

1

AB

:

:

—

Hd

В

Ns

一

一

|

117-5

|

SPS-UD

RX

Rev.

Protective

Metal

curtain

|

B7-120.061.01.05.02

02

09.95

LI

q

AE

TT

Fig.

2

|

Protective

strip

Holder

MAMMOMAT

300

Preparations

2-1

Stand,

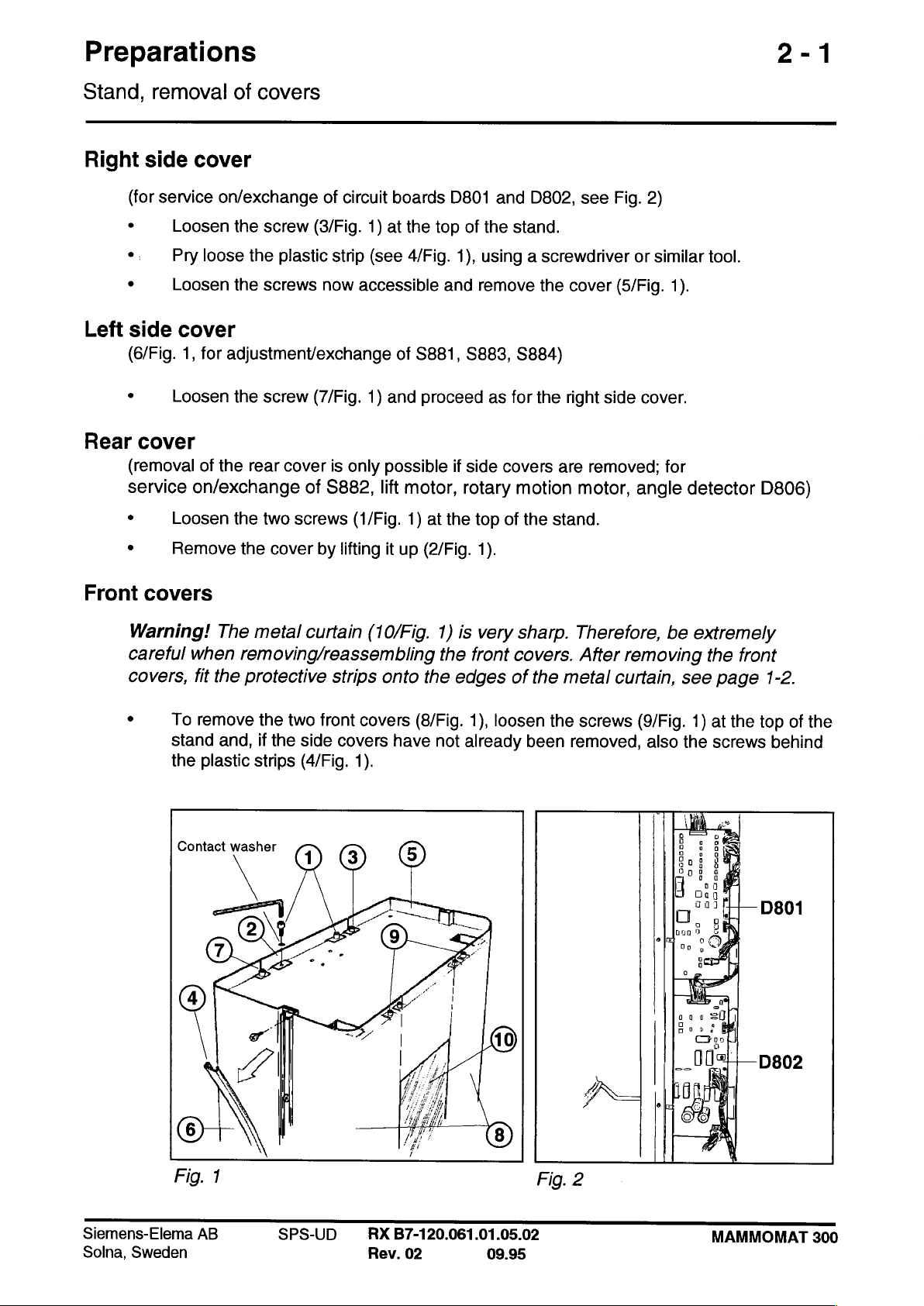

Right

(for

*

e.

*

Left

side

(6/Fig.

*

Rear

(removal

service

‧

removal

side

service

Loosen

Pry

Loosen

cover

1,

Loosen

COVer

Loosen

of

covers

cover

on/exchange

the

screw

loose

the

the

screws

for

adjustment/exchange

the

screw

of

the

rear

on/exchange

the

two

(3/Fig.

plastic

(7/Fig.

cover

of

screws

of

circuit

1)

strip

(see

now

accessible

1)

is

only

$882,

(1/Fig.

boards

at

the

top

4/Fig.

of

S881,

and

proceed

possible

lift

motor,

1)

at

D801

and

D802,

of

the

stand.

1),

using a screwdriver

and

remove

$883,

as

if

side

rotary

the top

the

S884)

forthe

covers

motion

of

the

stand.

see

cover

right

are

removed;

motor,

Fig.

or

(5/Fig.

side

cover.

angle

2)

similar

1).

for

detector

tool.

D806)

*

Front

*

Remove

covers

Warning!

careful

covers,

when

fit

To

remove

stand

the

the

cover

The

metal

removing/reassembling

the

protective

the

and,

if

the

plastic

strips

by

curtain

strips

two

front

side

(4/Fig.

lifting

covers

1).

it

up

(2/Fig.

(10/Fig.

onto

covers

(8/Fig.

have

1) is

the

the

not

1).

very

front

edges

1),

loosen

already

sharp.

covers.

of

the

metal

the

been

Therefore,

After

removing

curtain,

screws

removed,

(9/Fig.

also

be

extremely

the

see

1)

at

the

screws

|

A,

E

Bo

8

Bo:

a.

front

page

the top

1-2.

of

behind

D801

the

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

02

P

Fig.

2

09.95

—

D802

MAMMOMAT

300

2-2

Preparation

Swivel-arm

(for

service

。

Loosen

.

Loosen

remove.

ο

Before

Fig.

covers

on/exchange

the

the

removing

4.

two

six

of

screws

screws

the

cover

X-ray

(2/Fig.

tube,

(1/Fig.

3) of

half,

+

Identification

Swivel-arm

collimator,

3)

and

remove

the

cover

disconnect

circuit

the

half

you

plug

X807

system,

board

front

cover.

want

and

X807

removal

D805/D807)

to

the

ground

Patient

of

handle

covers

wire,

Ground

see

wire

Face

Fig.

3

shield

.

To

it

off

remove

the

holder

the

face

(3/Fig.3).

shield,

just

bend

Fig.

the

two

4

sides

slightly

outwards

Patient

handle

and

Ground

pull

wire

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

02

09.95

MAMMOMAT

300

Preparation

2-3

Swivel-

Support-arm

。

arm

To

screws

cover

system,

cover

adjust

or

(2/Fig.

(1/Fig.

removal

exchange

5),

unplug

5)

of

covers

the

rotation

X808

potentiometer

and

remove

the

R803,

right

loosen

part

of

the

six

the

support-arm

Fig.

5

Base-plate

(for

service

.

Loosen

device.

9

Loosen

the

.

Loosen

double

cover

on/exchange

the

two

the

four

base

plate.

the

ten

detector

of

screws

screws

screws

is

now

HSE

double

(1/Fig.

(2

(4/Fig.

accessible.

6) to

and

6)

3/Fig.6)

and

Fig.

6

detector)

remove

remove

to

remove

the

cover

the

the

base-plate

over

the

table-locking

table-locking

cover.

device

The

from

HSE

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

01

04.94

MAMMOMAT

300

2-4

Preparation

Bucky-table

(for

service

*

Loosen

at

cover

the

front

on

the

the

grid

four

(2/Fig.

device)

long

screws

7).

Remove

Bucky-table

on the top

cover.

The

side

grid

cover,

(1/Fig.

7)

device

transport

and

the

four

is

now

accessible.

safeguard

short

screws

Transport

(for

service

*

Note:

safeguard

on/exchange

Lower

(1/Fig.8).

the

carriage

Fit

the

safeguard.

shaft

and

of

of

lift

the

motor,

lock

the

bearing

driving

carriage

(2/Fig.

belt)

8)

Fig.

by

means

into

the

8

of

the

recess

transport

of

the

transport

safeguard

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

01

04.94

MAMMOMAT

300

Preparation

2-5

Generator,

Front

cover

(for

.

.

Note:

service

Pry

a

Loosen

the

removal

on/exchange

loose

screwdriver

front

Pay

washers

reassembling

the

the

sixteen

cover

special

of

plastic

covers

of

or

similar

screws

(2/Fig.

attention

on

either

the

generator

strips

tool.

9).

side).

front

(1/Fig.

now

to

cover,

components)

9)

on

accessible

the

contact

These

washers

to

both

sides,

(eight

washers

are

establish

using

on

either

(there

needed

protective

are

side)

four

again

ground

and

remove

contact

when

connection.

Fig.

9

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

01

04.94

MAMMOMAT

300

2-6

This

page

intentionally

left

Preparation

Generator

blank.

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

01

Rev.

04.94

MAMMOMAT

300

Subassemblies

3-1

Compression

Removal

Remove

Disconnect

Disconnect

Disconnect

Loosen

unit

the

the

swivel-arm

plugs

plug

ground

three

X872

X874

wires

fixing

covers,

and

X873

located

(1/Fig.

screws

see

page 2 -

(1

and

behind

2).

(2/Fig.

2/Fig.

the

compression

2)

and

2.

1)

on

remove

circuit

compression

board

unit.

D805.

unit.

Fig.

1

Exchanging

Remove

is

accessible

Disengage

Exchange

the

force-presetting

the

potentiometer

after

the

the

snap

lock

potentiometer.

knob

front

cap

(4/Fig.

Fig.

2

potentiometer

(3/Fig.

on

1)

the

and

1).

The

knob

remove

has

R861

knob

been

the

upper

is

held

pried

by

a

loose.

cover.

screw,

which

Siemens-Elema

Solna,

Sweden

Recalibrate

AB

potentiometer

SPS-UD

RX

Rev.

check

B7-120.061.01.05.02

01

and

preset

04.94

force

acc.

to

4

-

30,

4

-

31.

MAMMOMAT

300

3-2

Subassemblies

Exchanging

Note:

.

.

.

*

*

.

.

9

Note

Program

Compress

decompress!

Adjust

Reprogram

Decompress

(the

Place a 3

Adjust

the

MIN

(S862) - MAX

Before

position

the

S861

compression

S862

exchanging

to

value

Force = 200 N to

for

to

240 N with the

If

so

that

Force = 200 N to

to

the

kg

weight

so

that

the

ensure

necessary,

plate

as

correct

Force = 200

3FF

it

just

opens

top,

run

must

in

the

compression

it

opens

(S861)

above-mentioned

positioning

N,

see

and

motor

back

to O N

at

its

original

the

compression

not

touch

(2 - 5

force-limit

page 4 -

place

and a normal

240 N (230 - 250

kg).

the

and

value.

the

plate.

switches,

of

the

30.

scale

repeat.

plate

object

Compression

switch

mark

new

switch(es)

on the

compression

downwards

table).

object

N).

their

original

as

table.

plate.

approx.

possible.

Do

not

50

mm

unit

.

Recheck

Exchanging

9

.

Remove

install

Note:

the

calibration

the

compression

the

compression

the

new

Before

to

tightening

the

object

of O N

compression

the

table

as

Compression

and

unit

unit

as

described

unit.

fixing

follows:

screws,

plate

200 N with

on

the

compression

the

service

page 3 -

PC

1.

(see

unit

must

page 4 -

be

oriented

30).

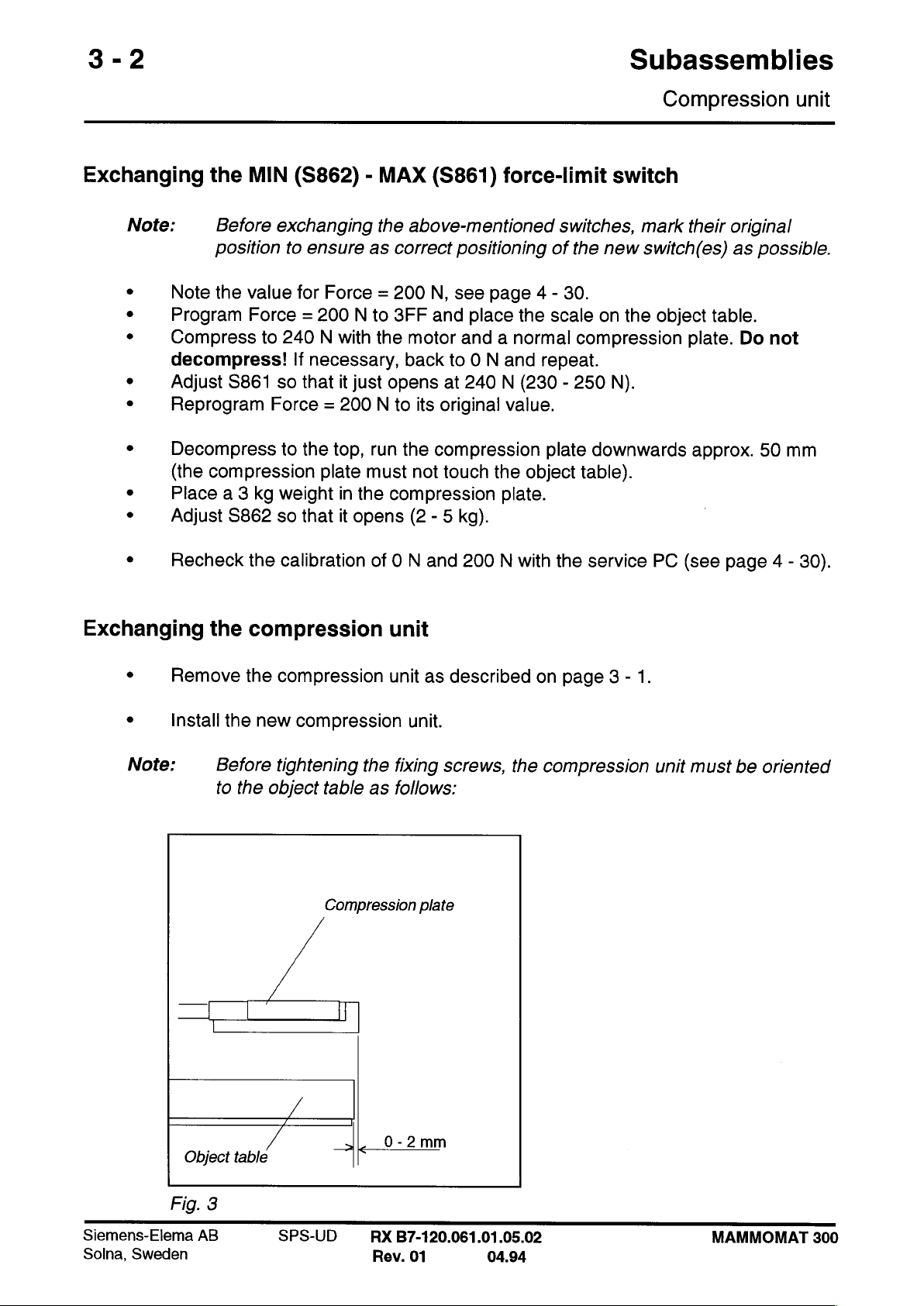

Fig.

Siemens-Elema

Solna,

Sweden

Object

table

3

AB

SPS-UD

0-2mm

TTT

RX

B7-120.061.01.05.02

Rev.

01

04.94

MAMMOMAT

300

Subassemblies

3-3

Compression

2.

.

Tighten

*

Calibrate

See

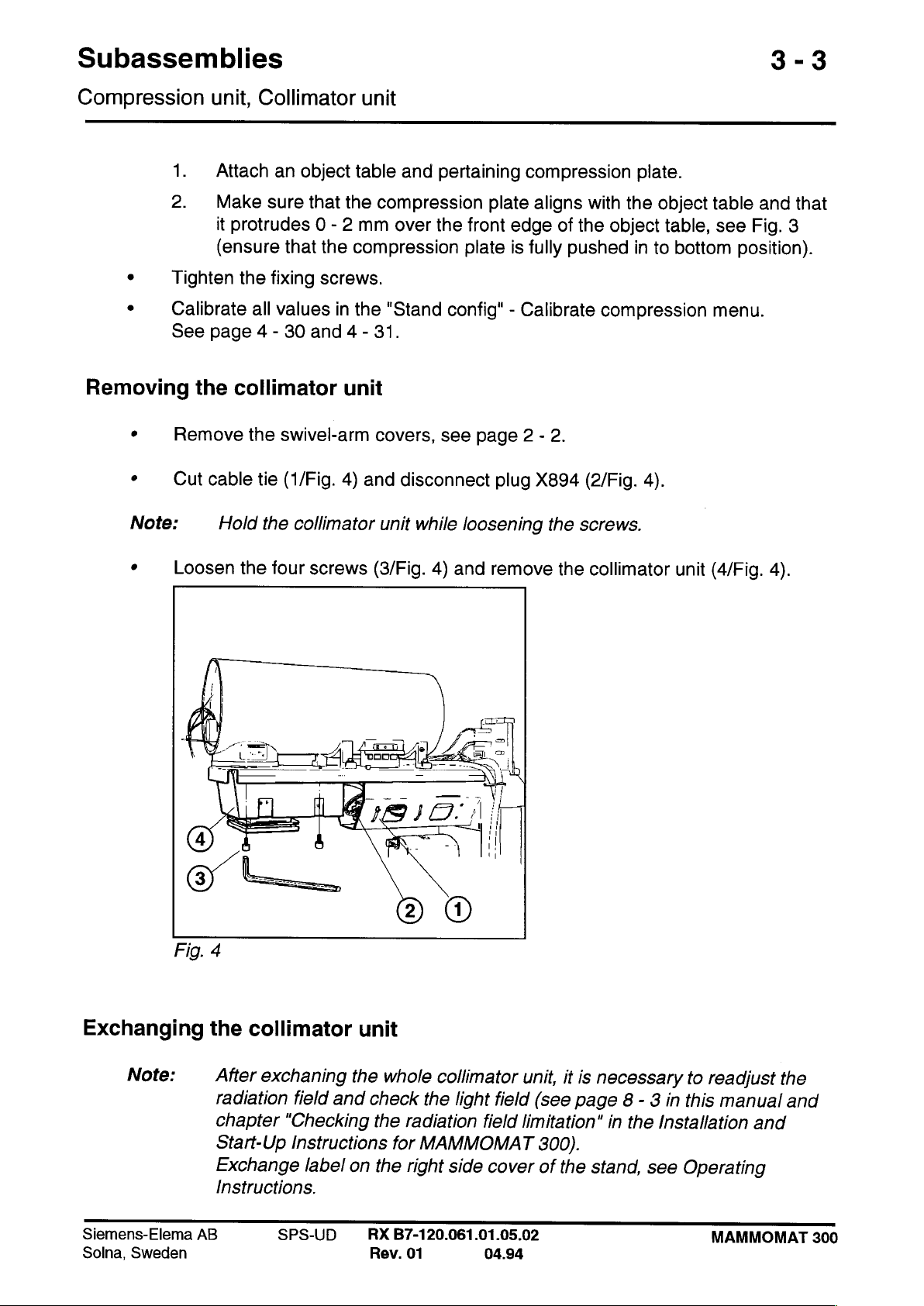

Removing

°

Remove

.

Cut

Note:

unit,

page 4 -

the

cable

Collimator

Attach

Make

it

(ensure

an

object

sure

protrudes 0 - 2 mm

that

the

fixing

all

values

30

collimator

the

swivel-arm

tie

(1/Fig.

Hold

the

collimator

unit

table

that

the

the

compression

screws.

in

the

and 4 -

unit

4)

and

and

pertaining

compression

over

the

front

plate

"Stand

31.

covers,

disconnect

unit

config" - Calibrate

see

while

loosening

compression

plate

aligns

edge

is

fully

page 2 -

plug

X894

of

pushed

2.

the

plate.

with the

the

object

in

to

compression

(2/Fig.

screws.

4).

object

table,

bottom

table

and

see

Fig.

position).

menu.

that

3

.

Loosen

Fig.

the

4

four

screws

(3/Fig.

4)

and

remove

the

collimator

unit

(4/Fig.

4).

Exchanging

Note:

Siemens-Elema

Solna,

Sweden

the

collimator

After

exchaning

radiation

chapter

Start-Up

Exchange

Instructions.

AB

field

"Checking

Instructions

SPS-UD

and

label

unit

the

whole

check

the

on

RX

Rev.

the

the

radiation

MAMMOMAT

for

right

B7-120.061.01.05.02

01

collimator

light

side

unit,

field

field

limitation"

300).

cover

04.94

it

(see

of

the

is

necessary

page

8

in

the

stand,

to

readjust

-

3

in

this

manual

Installation

see

Operating

MAMMOMAT

the

and

and

300

3-4

Subassemblies

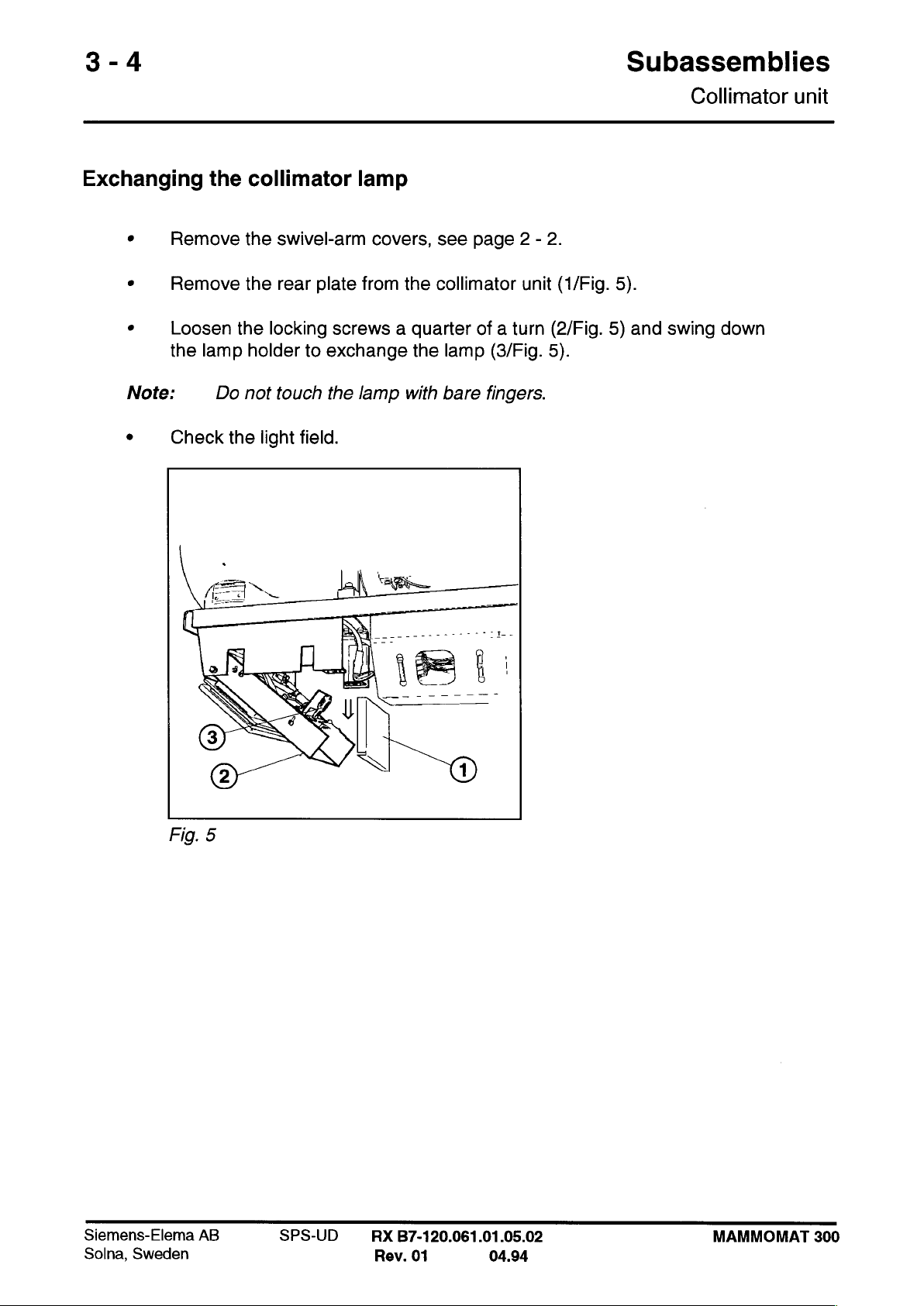

Exchanging

°

Remove

.

Remove

.

Loosen

the

Note:

*

Check

the

collimator

the

the

the

lamp

holder

Do

not

the

light

swivel-arm

rear

plate

locking

touch

screws a quarter

to

exchange

the

field.

lamp

covers,

from

the

lamp

with

see

page 2 -

collimator

of a turn

the

lamp

bare

2.

unit

(2/Fig.

(3/Fig.

fingers.

5).

(1/Fig.

5).

5)

and

Collimator

swing

down

unit

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

01

04.94

MAMMOMAT

300

Subassemblies

3-5

Printed

Exchanging

circuit

If

°

Remove

°

Remove

°

Disconnect

°

Remove

.

Remove

.

Exchange

possible,

boards

CPU

right

the

firmware

the

board

read

out

side

screw

all

plugs

seven

board,

D801

programmed

cover

profile

19

reinstall

and

on

CPU

(2/Fig.

nuts

holding

(1/Fig.

firmware

right

board

6).

values

front

6)

D801.

the

board.

and

or

save

configuration

cover,

reconfigurate

see

page 2 -

(see

file.

1.

from 4 -

28).

Exchanging

.

Remove

°

Remove

.

Disconnect

.

Remove

°

Exchange

Siemens-Elema

Solna,

Sweden

Fig.

6

motor-control

right

the

screw

all

the

six

board.

AB

SPS-UD

board

side

cover

profile

plugs

nuts

on

holding

D802

and

right

front

(1/Fig.

motor-control

RX

B7-120.061.01.05.02

Rev.

the

01

6)

board.

cover,

board

04.94

see

D802.

page 2 -

1.

MAMMOMAT

300

Subassemblies

Exchanging

Remove

Display

Disconnect

display

the

including

including

two

plug

2

|

board

screws

circuit

X801

and

ZZ = LA

‘Zn

D803

at

the

board

exchange

|

mm

bottom

swings

(1/Fig.

out.

complete

7).

unit.

Printed

circuit

boards

Fig.

Exchanging

Disengage

compression

Disconnect

Adjust

Attach a normal

Decompress

Connect

Adjust

with

Move

Compress

Adjust

\/

7

compression-force

the

snap

unit.

plugs

potentiometers

to

the

digital

R9

(offset)

respect

the

to 0 VA.)

voltmeter

to

200

R8

(gain)

lock

on the

compression

the

top,

multimeter

for 0 +30 mV.

lead

N.

for

3.5 V +0.1

board

and

board

R8

and

run

from

|

D804

remove

and

R9

as

plate.

the

compression

to

X843,

(Note

pin 5 to

V.

the

bottom

exchange

follows:

pin

that

comp_force

pin 3 (0

5(+)

cover

board

plate

VA).

(2/Fig.

downwards

(comp_force),

(1/Fig.

cannot

8)

8).

and

from

approx.

pin

be

set

the

50

mm.

4(-)

to 0 V

(0).

Siemens-Elema

Solna,

Sweden

Calibrate O N

AB

and

200 N with

SPS-UD

the

service

RX

B7-120.061.01.05.02

Rev.

01

04.94

PC

(see

page 4 -

30).

MAMMOMAT

300

Subassemblies

3-7

Printed

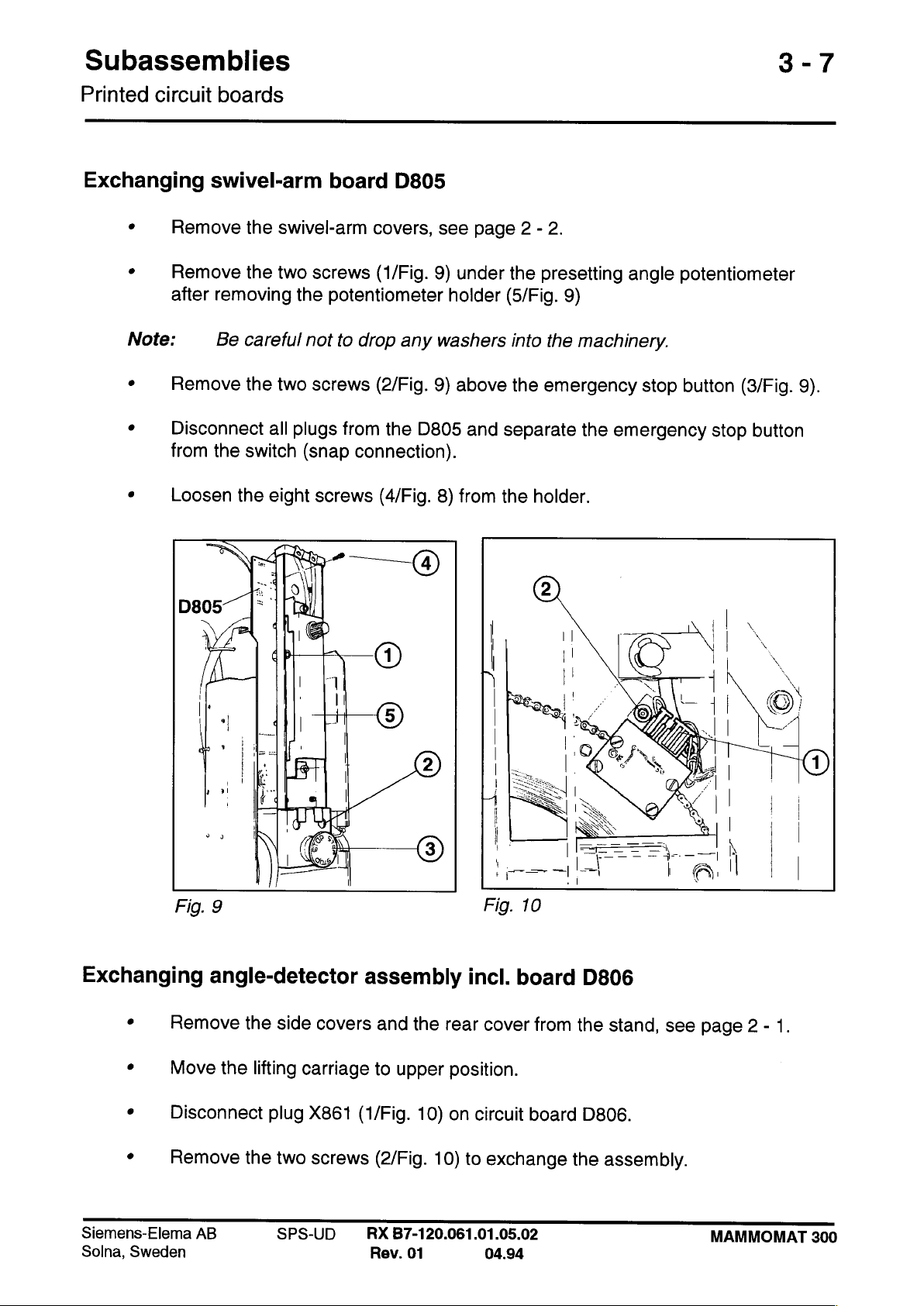

Exchanging

circuit

.

.

Note:

°

.

.

Remove

Remove

after

Remove

Disconnect

from

Loosen

boards

swivel-arm

the

swivel-arm

the

two

removing

Be

careful

the

the

switch

the

the

not

two

all

plugs

(snap

eight

board

screws

potentiometer

to

screws

from

screws

D805

covers,

(1/Fig.

drop

any

(2/Fig.

the

connection).

(4/Fig.

see

9)

holder

washers

9)

D805

8)

page 2 -

under

above

and

separate

from

the

2.

the

presetting

(5/Fig.

into

the

9)

the

emergency

holder.

angle

machinery.

stop

the

emergency

potentiometer

button

(3/Fig.

stop

button

9).

Fig.

Exchanging

.

Remove

Move

.

Disconnect

.

.

Remove

Siemens-Elema

Solna,

Sweden

9

angle-detector

the

AB

the

side

covers

lifting

the

carriage

plug

two

SPS-UD

X861

screws

assembly

and

the

rear

10)

10)

01

position.

on

to

upper

(1/Fig.

(2/Fig.

RX

B7-120.061.01.05.02

Rev.

incl.

to

board

cover

circuit

board

exchange

04.94

from

D806

the

stand,

D806.

the

assembiy.

see

page

2

MAMMOMAT

-

1.

300

Subassemblies

Motors

Exchanging

Remove

Lock

Open

Loosen

Note:

the

the

the

Tighten

CE

ts

lifting

side

covers

lifting

the

carriage

driving

three

the

carriage

and

rear

by

means

belt

(1/Fig.

screws

belt

(1/Fig.

carefully

==)

motor

cover

of

13).

11)

after

from

the

stand,

the

transport

to

remove

exchanging

see

safeguard,

the

motor

the

motor.

page 2 -

see

(1/Fig.

1.

page 2 -

12).

4.

Exchanging

ο

Remove

see

Note:

ο

Loosen

(2/Fig.

remove

“n

Fig.

11

the

rotary

page 2 -

Hold

mounting

it

in

cable

the

13),

the

motion

all

covers

1.

the

chain

the

upper

position,

tie.

three

disconnect

motor.

я

=

už

=0

:=0

n

motor

from

while

motor

screws

the

dis-

and

using

plug

7

/

7

stand,

fix

a

and

A

ο

Siemens-Elema

Solna,

Sweden

Exchange

the

chain

AB

motor

carefully.

SPS-UD

and

tighten

RX

B7-120.061.01.05.02

Rev.

01

Fig.

13

MAMMOMAT

04.94

300

Subassemblies

Miscellaneous

3-9

Detector

.

Remove

.

Disconnect

*

Exchange

Note:

.

Recalibrate

Replacing

.

Remove

9

Due

device.

the

exchange

the

Special

cassette

the

to

different

To

grid

device.

table

base-plate

plug.

the

HSE

double

attention

sensitivity,

switch

carbon-fibre

wiring

do

that,

loosen

For

readjustment,

detector.

should

see

page 4 -2.

S2

plate

in

the

the

cover,

be

paid

cover,

tables,

four

it

screws

mark

see

to

see

might

page 2 -

the

detector

page 2 -

be

necessary

(3/Fig.

the

original

3.

insulation.

3.

7,

page 2 -

position

to

remove

of

4)

and

the

the

remove

grid

grid

device.

.

*

24

cm x 30

Loosen

attention

18

Loosen

sided

Replace

six

to

cm x 24

four

tape

switch.

cm

object

nuts

from

the

grounding

cm

object

screws

is

used

below

(two

for

table:

and

spring).

table:

on

either

fixing

the

withdraw

side)

plastic

plates).

bottom

and

withdraw

plate

bottom

to

the

left

(pay

plate

special

(double-

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

01

04,94

MAMMOMAT

300

3-10

Subassemblies

Miscellaneous

Replacing

.

Remove

page 3 -

.

Find

.

Replace

the

the

rotary

rotary

8.

chain

chain

motion

motion

connecting

and

chain

motor,

tighten

see

link

and

open

carefully.

chain.

Fig.

Replacing

*

Remove

.

Lock

.

Open

*

Replace

14

the

the

belt

lifting

right

lifting

belt

carriage

side

carriage,

(1/Fig.

and

cover

12)

tighten

and

using

driving

rear

cover,

the

it

carefully.

belt

see

transport

safe

page 2 -

guard,

1.

see

page 2 -

4.

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

01

04.94

MAMMOMAT

300

Adjustment

and

Service

PC

Programs

4-1

Stand

μα.

type,

1

exposure

—

|

Quit

Help

Main

Configuration

Service

SAve

SHow

Normal

Stand

Stand

Stand

config

config

config

test

2

menu

file

file

mode

type

Stand

Save

system

type

3

|

=

M300

5.

ーー

„Stand

Configuration

type

Exposure

IONTOMAT

Tube

type

Learn

Power

Clock

Miscellaneous

filament

device

6

system

7

PM

8

——

9

10

Quit

Indicates

>

ロー

type

of

generator

—

Main

Configuration

Service

sAve

SHow

Normal

Stand

Stand

Quit

Exposure

menu

—

config

config

config

test

file

mode

system(s)

Channel

and

file

control

”上

Exposure

A

panel.

上

Correct

一

[一

Stand

Exposure

IONTOMAT

Tube

Learn

Power

Clock

Miscellaneous

system

_

попе

designation

Configuration 一 一

type

type

filament

device

is

M300.

=

system

PM

1

Help

Indicates

Channel A is

Channel B is

Siemens-Elema

Solna,

which

Sweden

2

channel

not

used

set

to

AB

Channel

Save

is

with

24 x 30

SPS-UD

B

3

activated

M300

by

and

the

firmware

24 x 30

5.6

in

the

IONTOMAT.

shall

therefore

("none"

RX

B7-120.061.01.05.02

Rev.

02

always

or

"18 x 24"

07.94

7

be

set

is

not

8

to

none.

allowed

9

with

channel B ).

MAMMOMAT

10

Quit

300

4-2

Adjustment

and

Service

PC

Programs

—

Configuration

Quit

Main

Service

SAve

SHow

Normal

Stand

Stand

config

config

config

test

mode

menu

file

file

О

Configuration

Stand

Exposure

IONTOMATPM

Tube

Learn

Power

Clock

Miscellaneous

type

system

type.

filament

device

||

IONTOMAT

—

一

>

г

ЮМТОМАТ

Sens.

Corr.

PM,

Sensitivity

РМ

corr

curve

>

IONTOMAT

1

Help 2 Save

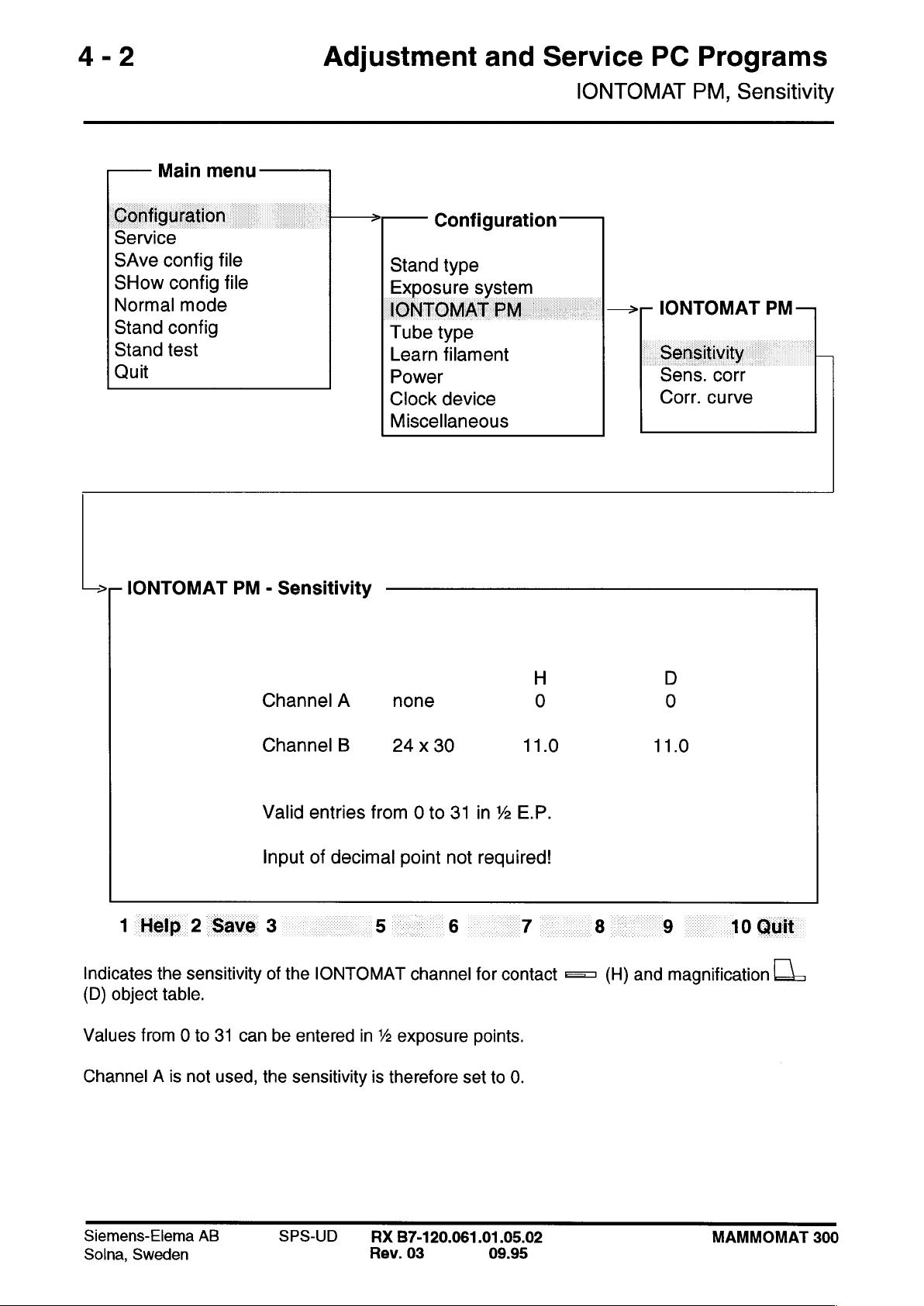

Indicates

(D)

object

the

sensitivity

table.

PM - Sensitivity

Channel

Channel

Valid

Input

3

of

the

A

B

entries

of

decimal

5

IONTOMAT

from 0 to

none

24 x 30

point

channel

31

in % E.P.

not

required!

6

for

H

0

11.0

7

contact

==

8

(H)

D

0

11.0

o

and

magnification し し

10Quit

Values

Channel A is

Siemens-Elema

Solna,

from O to

Sweden

not

AB

31

can

used,

be

entered

the

sensitivity

SPS-UD

in Y exposure

is

therefore

RX

B7-120.061.01.05.02

Rev.

03

set

points.

to

0.

09.95

MAMMOMAT

300

Adjustment

and

Service

PC

Programs

4-3

IONTOMAT

r—

|

Configuration

Main

Service

SAve

SHow

Normal

Stand

Stand

config

config

config

test

Ouit

mode

PM,

Sensitivity

menu

file

file

correction

——

Stand

Exposure

|

Tube

Learn

Power

Clock

Miscellaneous

Configuration

type

system

ОМТОМАТРМ

type

filament

device

——

F-

|

IONTOMAT

Sensitivity

Sens.

corr

Corr.

curve

PM

>r-

IONTOMAT

1

Help 2 save

Indicates

The

position

Without

With

Magnification

the

sensitivity

"without

PM - Sens.

grid

grid

Valid

For

pos

Input

entries

of

3

correction

grid"

applies

correction

from

entries

decimal

1st digit

5

for

different

to

tables

-8

to 8 in % E.P.

is < space

point

not

required!

6

types

with

as

well

of

object

as

24 x 30

:.0

>,

7

tables.

without

0

0

for

8

neg

grid.

entries

9

type < -

10

>.

Quit

Factory-set

Siemens-Elema

Solna,

to

Sweden

"0",

AB

"0", "0".

SPS-UD

RX

B7-120.061.01.05.02

Rev.

03

09.95

MAMMOMAT

300

4-4

Adjustment

and

Service

PC

Programs

———

Configuration

Stand

Ouit

Main

Service

SAve

SHow

Normal

Stand

config

config

config

test

menu

mode

file

file

m

Configuration

Stand

type

Learn

Power

Clock

Miscellaneous

filament

device

IONTOMAT

—

PM,

Correction

IONTOMAT

Sensitivity

Sens.

Corr.

corr

curve

curve

PM

|

>

IONTOMAT

1

Help

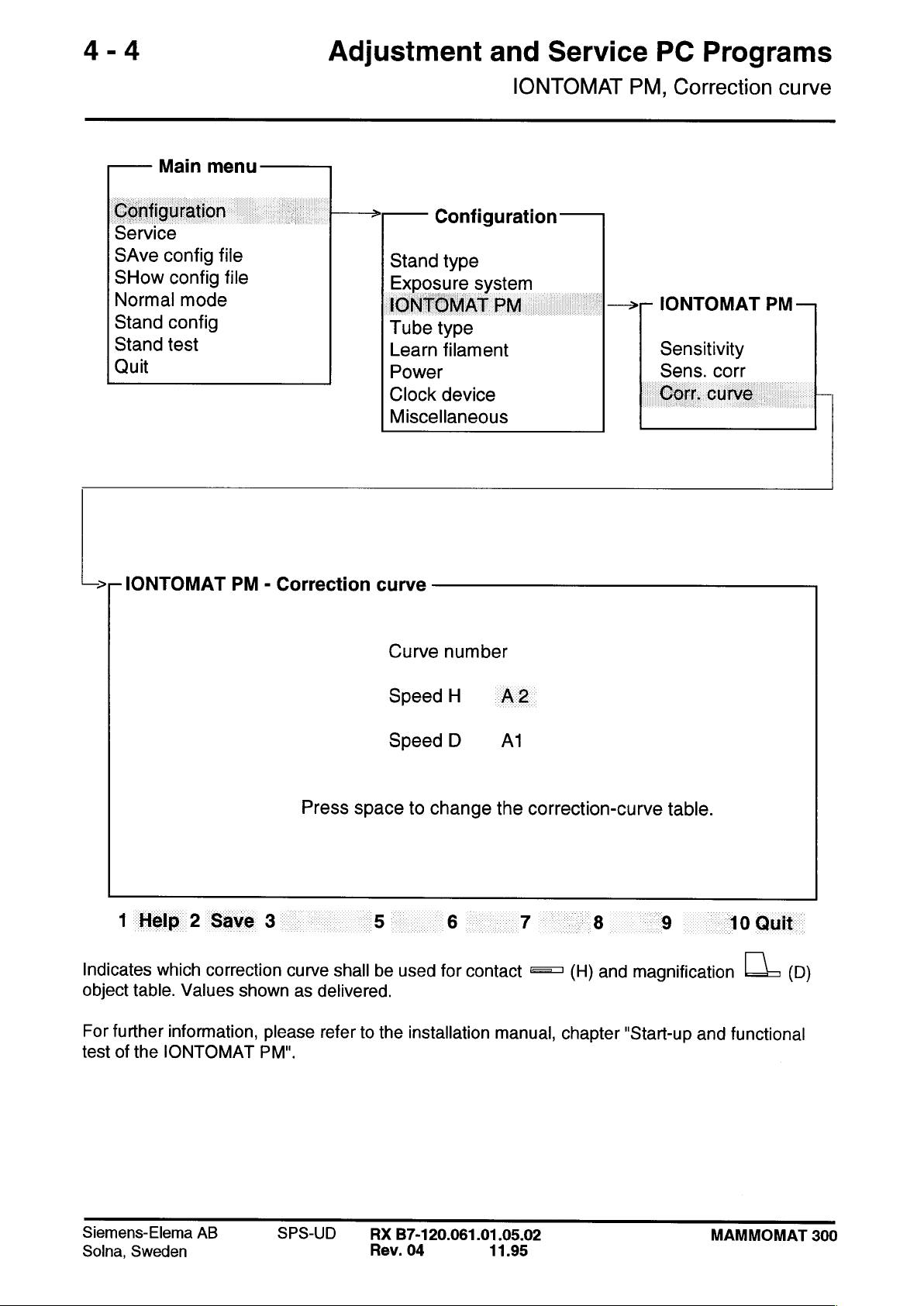

Indicates

object

For

test

table.

further

the

of

PM - Correction

2

Save

which

correction

Values

information,

IONTOMAT

shown

Press

3

curve

as

please

PM".

curve

Curve

Speed

Speed

space

5

shall

be

used

delivered.

refer

to

the

number

H

D

to

change

6

for

installation

A2

Al

the

7

contact

manual,

correction-curve

6

==

(H)

and

chapter

table.

9

magnification

"Start-up

του

LL

and

functional

(D)

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

04

11.95

MAMMOMAT

300

Adjustment

and

Service

PC

Programs

4-5

Tube

type

г

—

Мат

Configuration

Service

>

Quit

-—

Tube

SAve

SHow

Normal

Stand

Stand

config

config

mode

config

test

type

menu

file

file

_

——

Configuration

Stand

Exposure

Learn

Power

Clock

Miscellaneous

type

filament

device

system

1

Indicates

For

M300,

Help

the

type

P49

2

of

Mo @3

Save

X-ray

tube

shall

Tube

3

be

type

“5

used

in

entered.

the

system.

P49

6

Mo

@3

7

8

9

10Quit

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

02

07.94

MAMMOMAT

300

4-6

Adjustment

and

Service

PC

Programs

-——

Main

menu

[Configuration

Servic

SAve

SHow

Normal

Stand

Stand

Quit

config

file

config

mode

config

test

file

上

一 >

|

Learn

Configuration

Stand

Exposure

IONTOMAT

Tube

type

system

PM

type

filament

Power

Clock

Miscellaneous

device

Learn

——

|-

filament,

Learn

Large

Small

large

menu

focus

focus

focus

——

ト

>-

Learn

1

Help 2 Save

Indicates

made

also

are

filament

the

adapted

in

this

large

3

filament

menu.

focus

Actual

Filament

tube

5

current

is

P49

Mo

current @ 25

.6

for

large

focus.

@3

kV

7.

Adaption

6937

mA

8

exposures

9

for

the

filament

10

Quit

current

Pressing

Alt-F6

If

the

Siemens-Elema

Solna,

F2

starts

tube

has

Sweden

sets

the

the

exposure.

been

AB

exposure parameters

Repeat

replaced,

SPS-UD

this

program

RX

Rev.

procedure

the

B7-120.061.01.05.02

on

the

control

until

filament-current

02

panel,

the

07.94

and

subsequently

tube-current

value

stated

deviation

in

the

test

pressing

is

within

certificate.

MAMMOMAT

+5%.

300

Adjustment

and

Service

PC

Programs

4-7

Learn

filament,

-——

Main

menu

[Configuration

Service

SAve

SHow

Normal

Stand

Stand

Quit

config

config

mode

config

test

small

file

file

focus

Configuration

Stand

Exposure

IONTOMAT

Tube

Learn

Power

Clock

Miscellaneous

type

system

type

filament

device

PM

——

©

|>-

Learn

|

menu

>

Learn

1

Help 2 Save 3 |.

Indicates

are

also

made

filament

the

adapted

in

this

small

filament

menu.

focus

Actual

Filament

tube

5

current

is

P49

current @ 25

6

for

small

focus.

Mo

@3

kV

7

Adaption

7518

mA

8

exposures

9

for

the

filament

10

Quit

current

Pressing

Alt-F6

If

the

Siemens-Elema

Solna,

F2

starts the

tube

has

Sweden

sets

the

exposure.

been

AB

exposure

Repeat

replaced,

SPS-UD

parameters

this

procedure

program

the

RX

B7-120.061.01.05.02

Rev.

on

the

contro!

until

filament-current

02

panel,

the

07.94

and

subsequently

tube-current

value

stated

deviation

in

the

test

pressing

is

within

certificate.

MAMMOMAT

+5%.

300

4-8

Adjustment

and

Service

PC

Programs

Power

—

Configuration

>|-

Main

Service

SAve

SHow

Normal

Stand

Stand

Quit

config

config

mode

config

test

Power

menu

file

file

—

Configuration

Stand

Exposure

type

system

IONTOMAT

Tube

Learn

Power

Clock

Miscellaneous

type

filament

device

PM

=>...

—

=

EE

1

Help 2 Save

Indicates

The

values

the

maximum

programmed

Small

3

power

must

Large

Input

5

for

large

not

exceed

Power

focus

focus

of

decimal

and

6

small

the

point

focus

values

70

not

required!

7

respectively.

stated

3.75

above.

kW

KW

8

9

10

Quit

Siemens-Elema

Solna,

Sweden

AB

SPS-UD

RX

B7-120.061.01.05.02

Rev.

02

07.94

MAMMOMAT

300

Loading...

Loading...