Page 1

MAMMOMAT 1000/3000

Service

Service Program

SP

© Siemens AG 1999

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Register 5 English

Print No.: SPB7-230.114.02.01.02 Doc . Gen. Date: 03.99

Replaces: n.a.

65 19 792

Page 2

0 - 2 Revision

Chapter Revision

All 01

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 2 of 4 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 3

Contents 0 - 1

Page

This document is valid from serial No. 6500 and from FW-version 3.0.

1 _______Working with the service PC _____________________________________1 - 1

Description of the syntax used in these instructions . . . . . . . . . . . . . . . . . . 1 - 1

Connecting the service PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

2 _______Adjustment and service PC programs _____________________________2 - 1

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 37

Normal mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 47

Te st DUEP communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 55

Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 56

3 _______Error messages________________________________________________3 - 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

Error messages of the master Er 0XX. . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Error messages of the control deck Er 3XX. . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Error messages of the IONTOMAT PM Er 5XX . . . . . . . . . . . . . . . . . . . . .3 - 8

Error messages of the power pack Er 6XX . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Error messages of the stand Er 8XX . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 15

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 1 of 2 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 4

0 - 2 Contents

Page

This page intentionally left blank.

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 2 of 2 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 5

Working with the service PC 1

Description of the syntax used in these instructions 1

< ..... > The indication of which function keys to press is given between

these characters, for example <ENTER>, <ESC> etc.

CAPITALS Capital letters indicate data which must be entered unchanged,

for example the name of a register, files etc.

1 - 1

Italics

[ ..... ] Square brackets enclose additions to commands which may be

Bold Data relating to formats, user entries etc., which is important for

xx yy zz Data can be entered in place of

{...} Curved brackets indicate that out of several terms listed one be-

NOTICE

* * * * * When the password is entered, only these characters are shown.

Menu Selection: When several menus, programs, fi les etc. are presented f or selec-

Italics represent data in whi ch a value should be ent ered, e. g. for

user name, the name of the technician should be entered.

optionally entered.

the following entry, is shown in bold as it appears on the monitor

screen.

This character indicates that at this point the space key must be

pressed.

"x, y, z"

(e.g. day´s date).

low the other, one must be selected.

Important remarks are indicated with this box.

tion, they are shown in a box (program window).

Selection is made with the <↓> and <↑> keys.

The module selected is highligthed in the display.

<ENTER> Every entry must be confirmed with the <ENTER> key.

<ESC> ESC allows paging back through the program.

<xx> + <y> Some functions are selected by pressing two keys

simultaneously. Procedure: Press, for example, the <Shift> key

and keep it depressed, press the <*> key and then release both

keys.

<F1> Key <F1> calls up a selective help text.

<F10> Key <F10> exits the program.

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 1 of 6 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 6

1 - 2 Working with the service PC

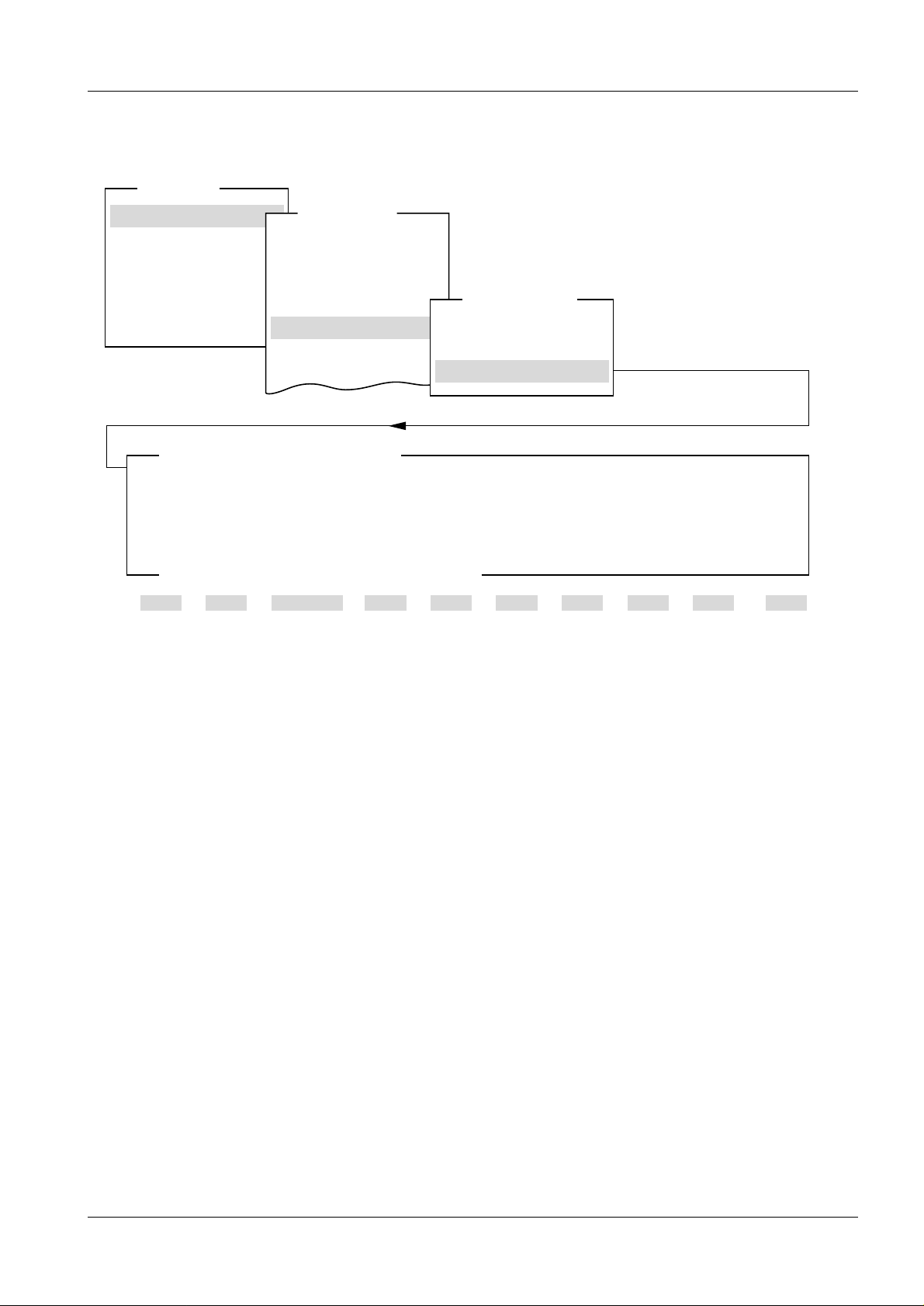

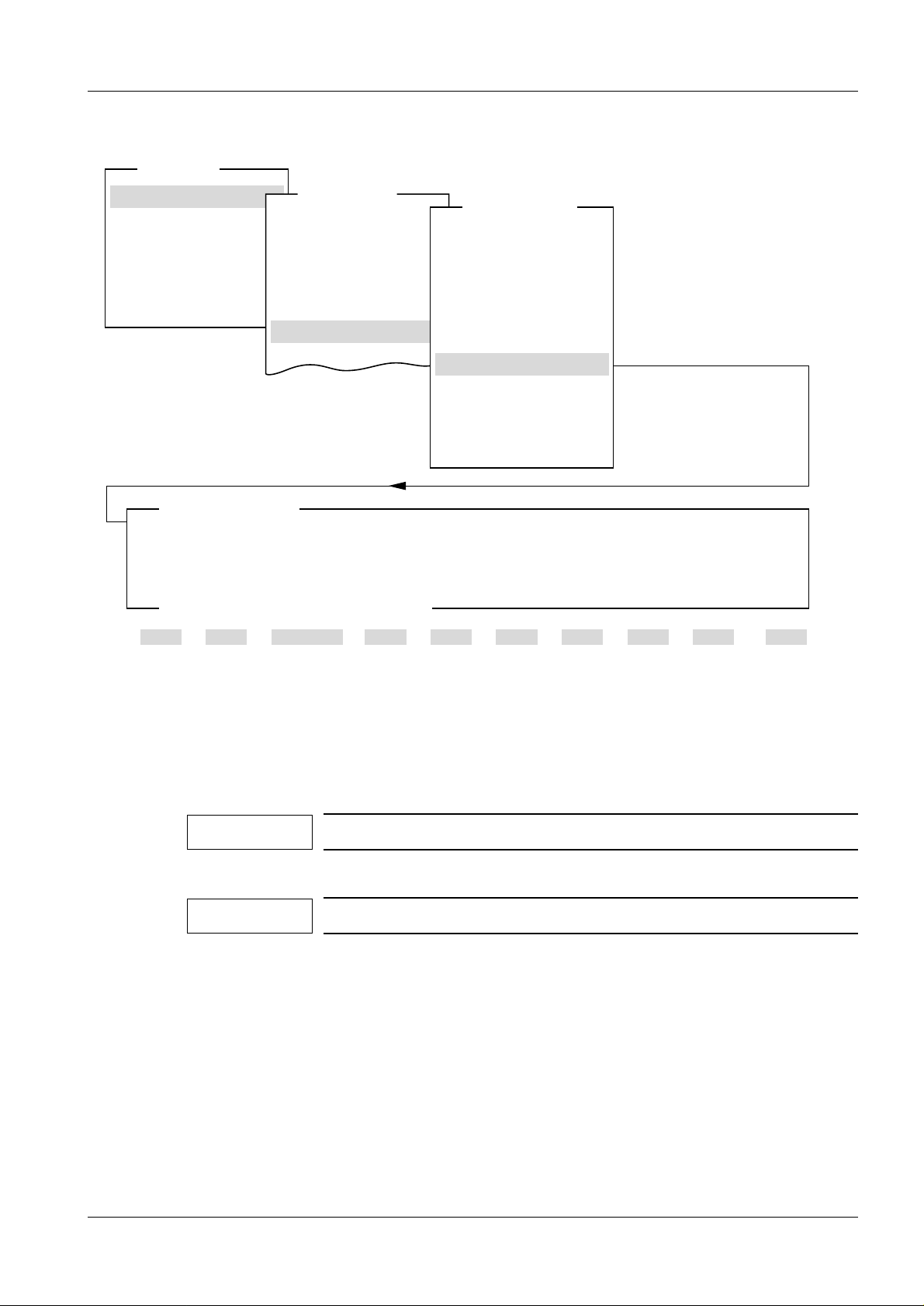

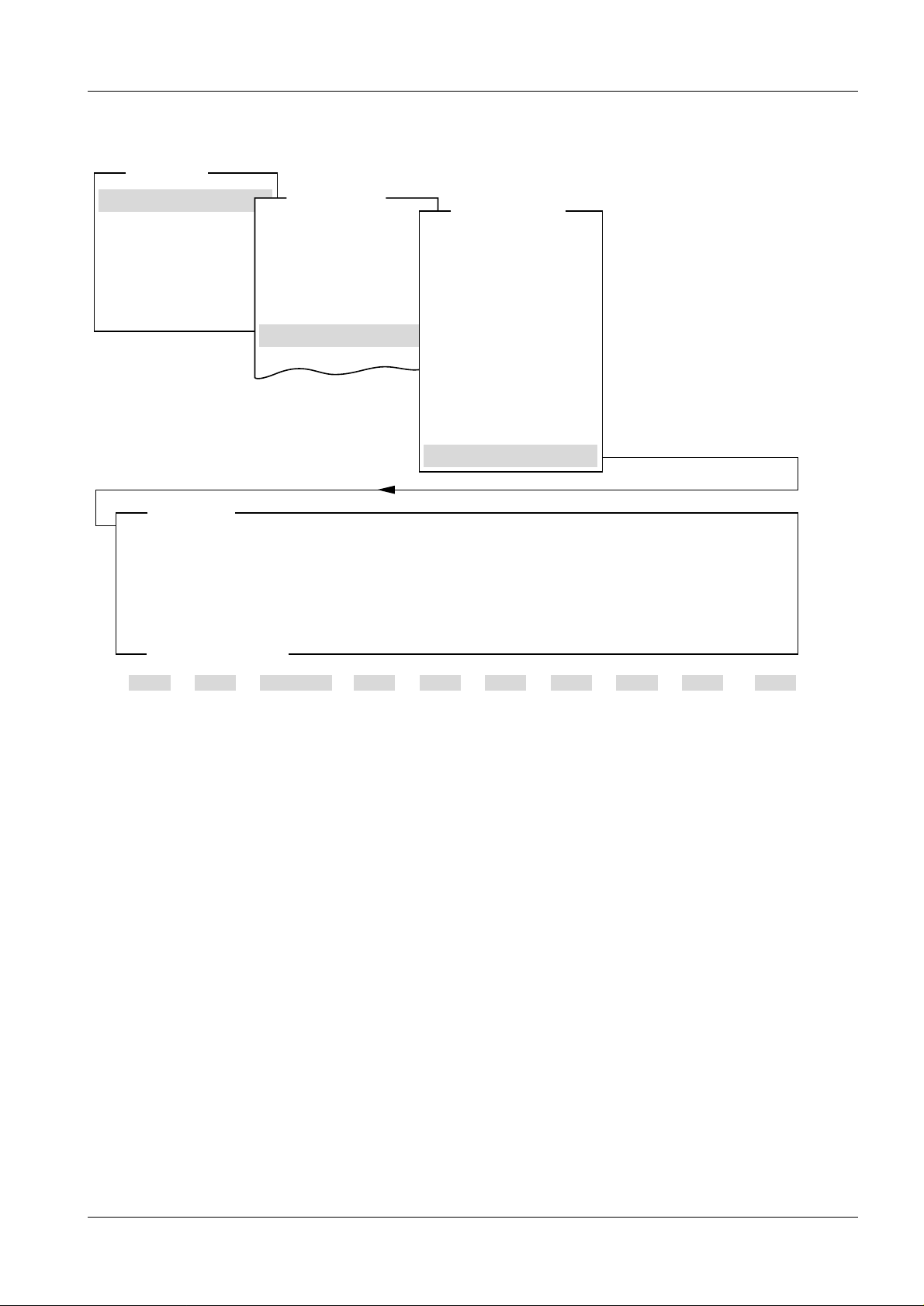

XXX - - XXX - XXX - - XXX

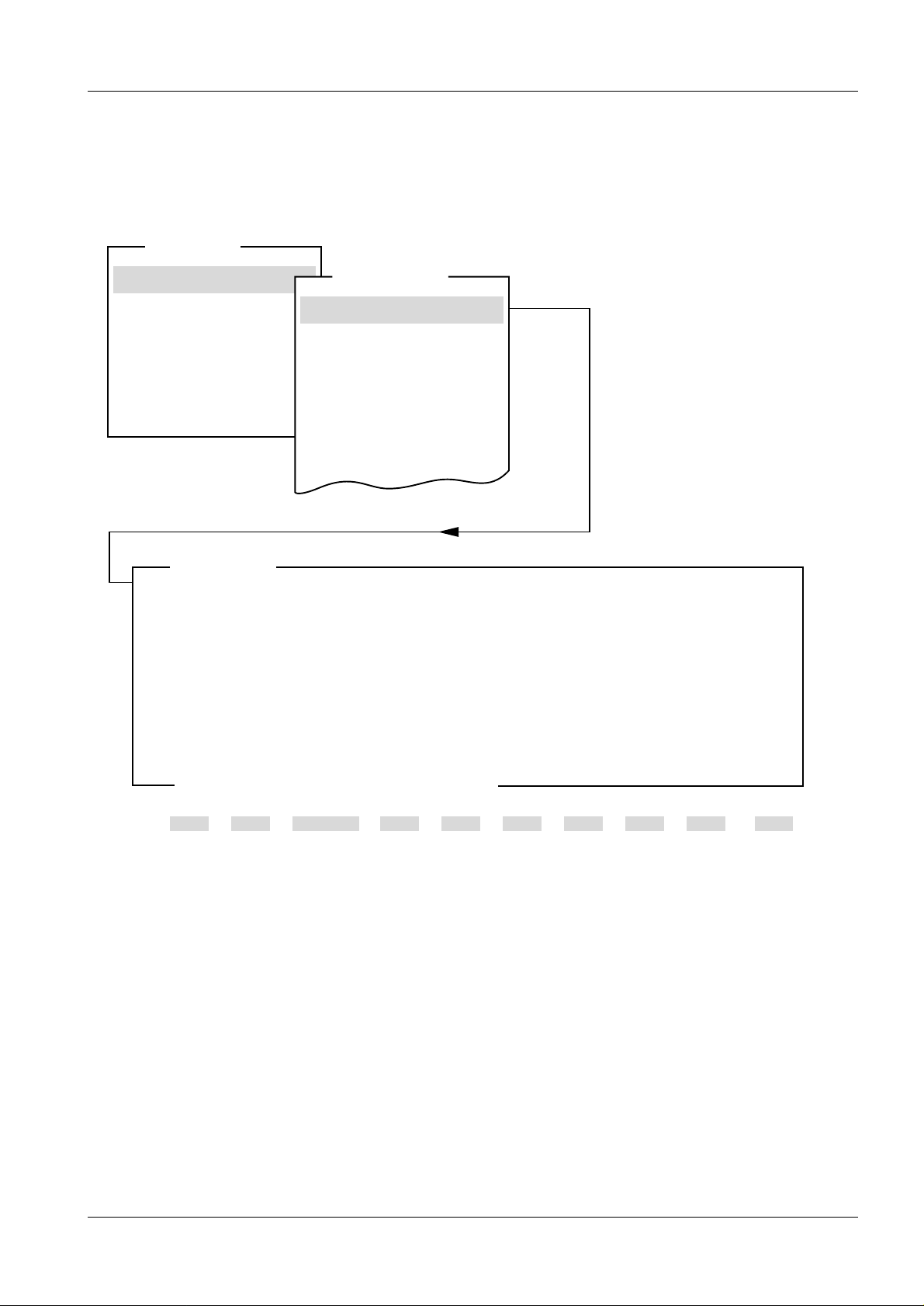

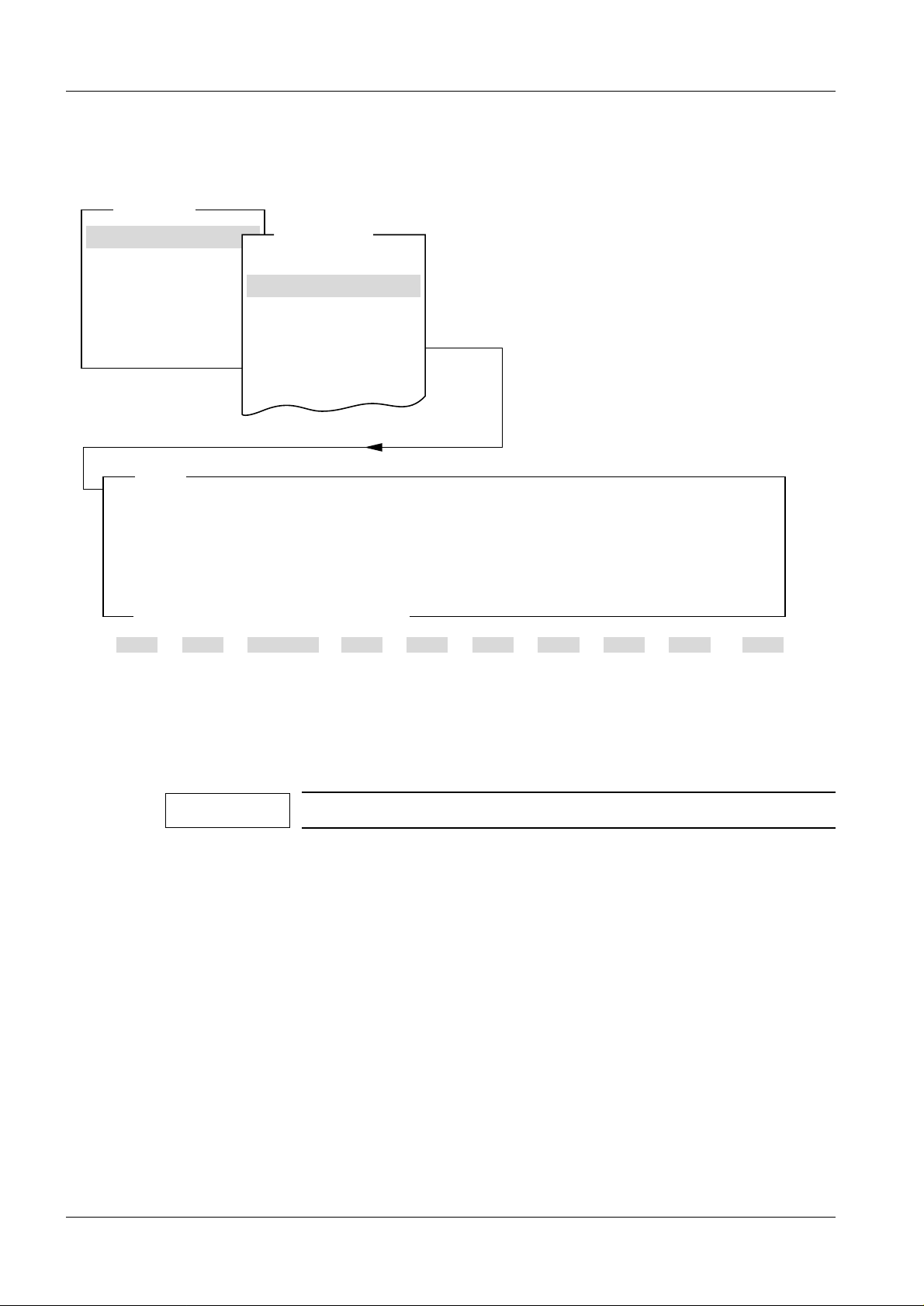

By this means, the way is shown how to call up a particular subroutine (display windows).

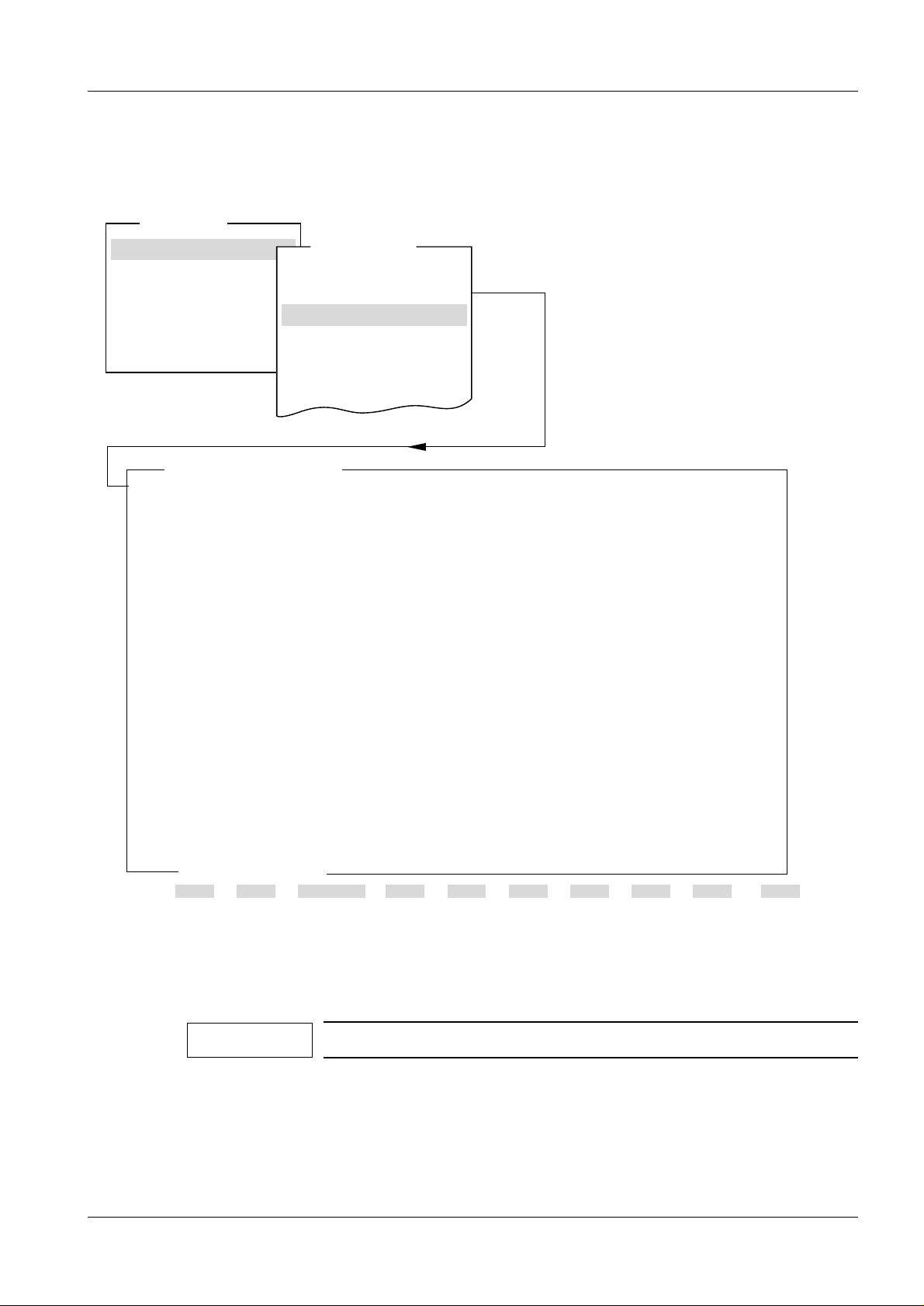

For example:

Main menu –

Configuration –

Iontomat –

Corr . curve –

Connecting the service PC

The service PC must be connected with connecti ng cable part no. 99 00 440 RE999 to p.c.

board in the generator (do not i nsert the diskette in the drive yet). Use port COM 1 on the

service PC.

Starting up and using the service PC

1. Switch on generator and service PC.

After initialization, the s ervice PC shows: C:\>

2. Now insert the discette with th e service program.

3. Select the appropriate drive and then press <ENTER>. The screen shows:

A:\> or B:\>

{A:}

{B:}

4. Start the service program by typing ’SERVICE’, then press <ENTER>.

The program asks for the use’sr name:

Type the name of the technician, for examp le NN, and then press <ENTER>.

5. The program asks for the password:

Type the password (********) and then pr ess <ENTER>.

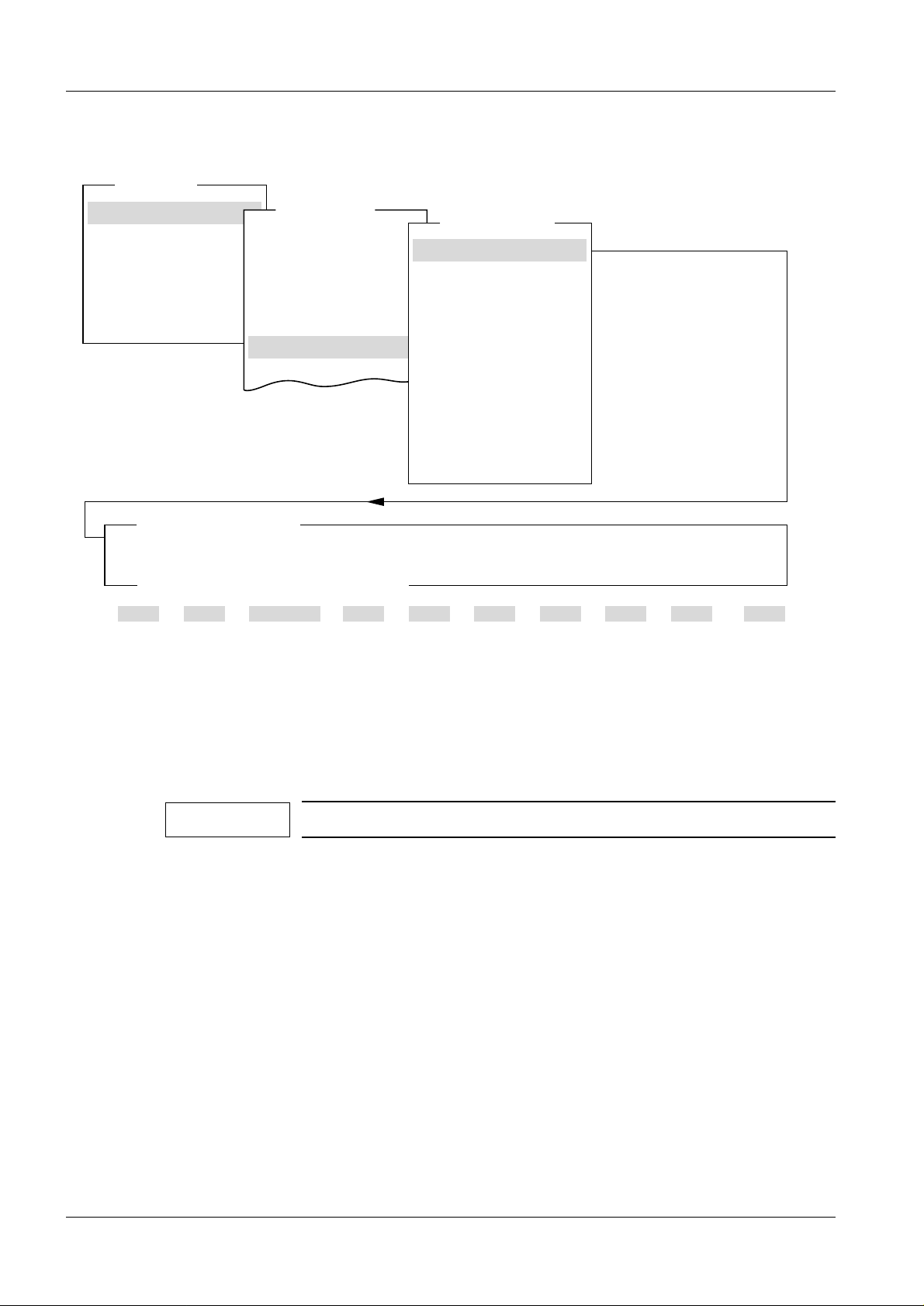

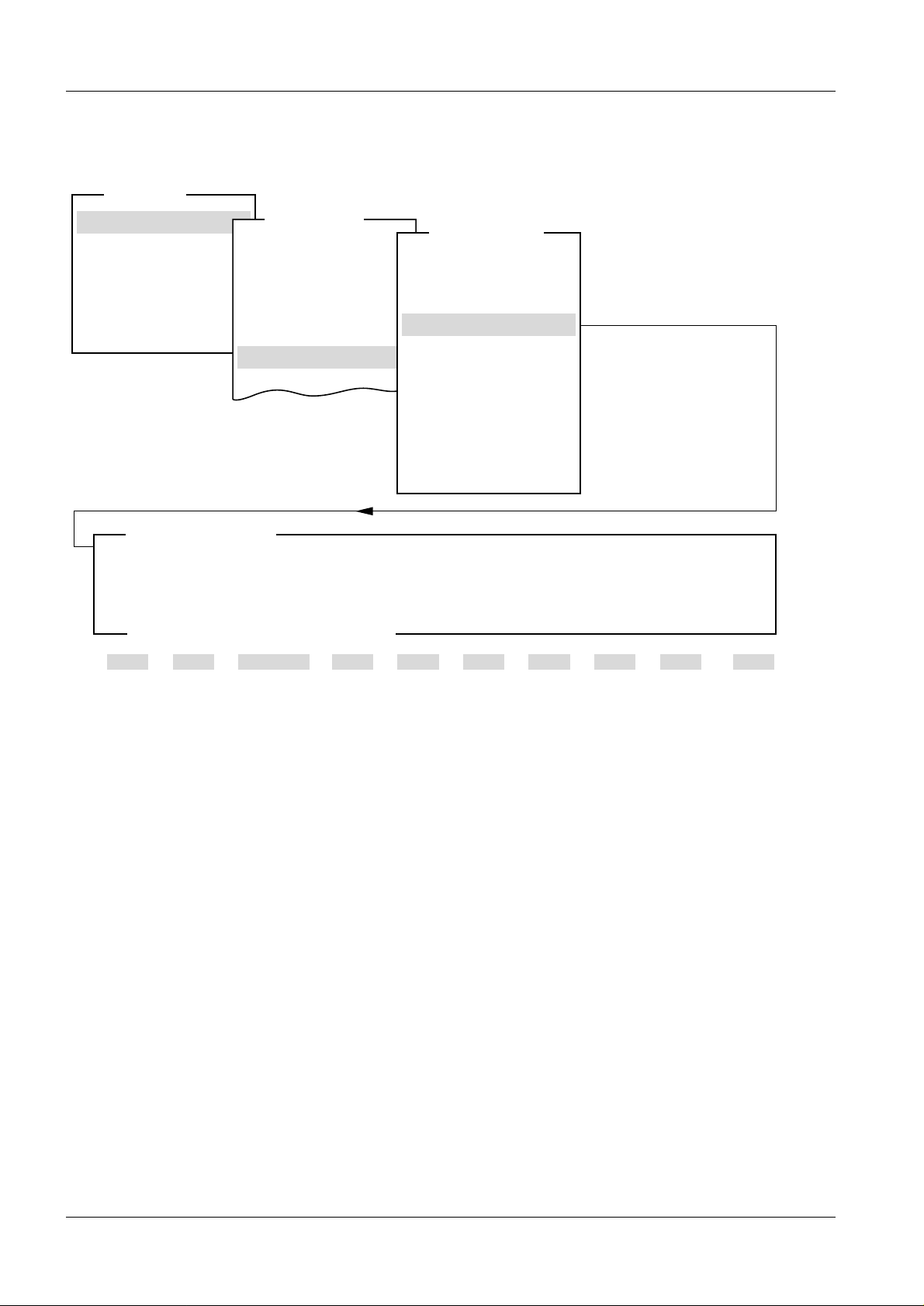

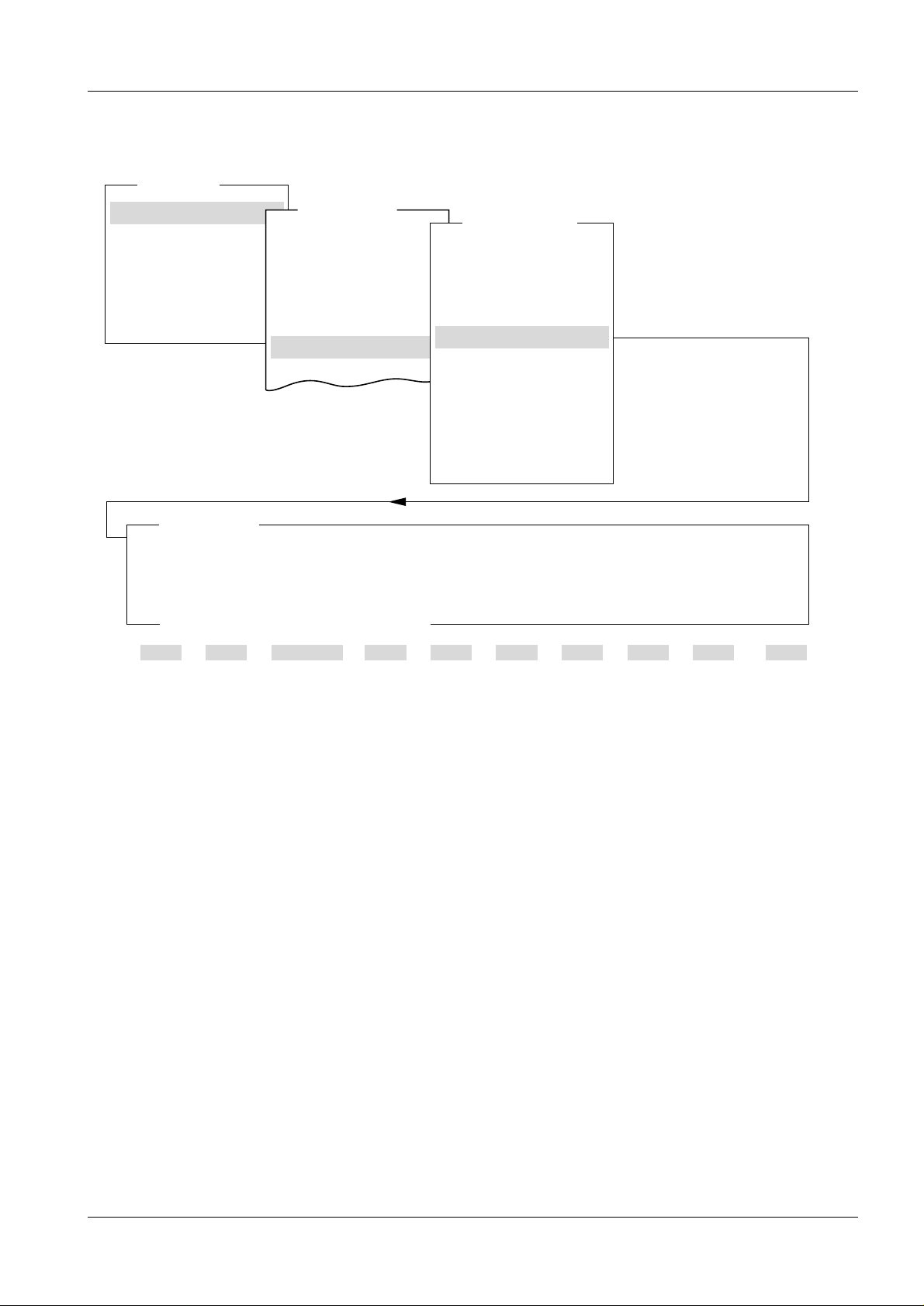

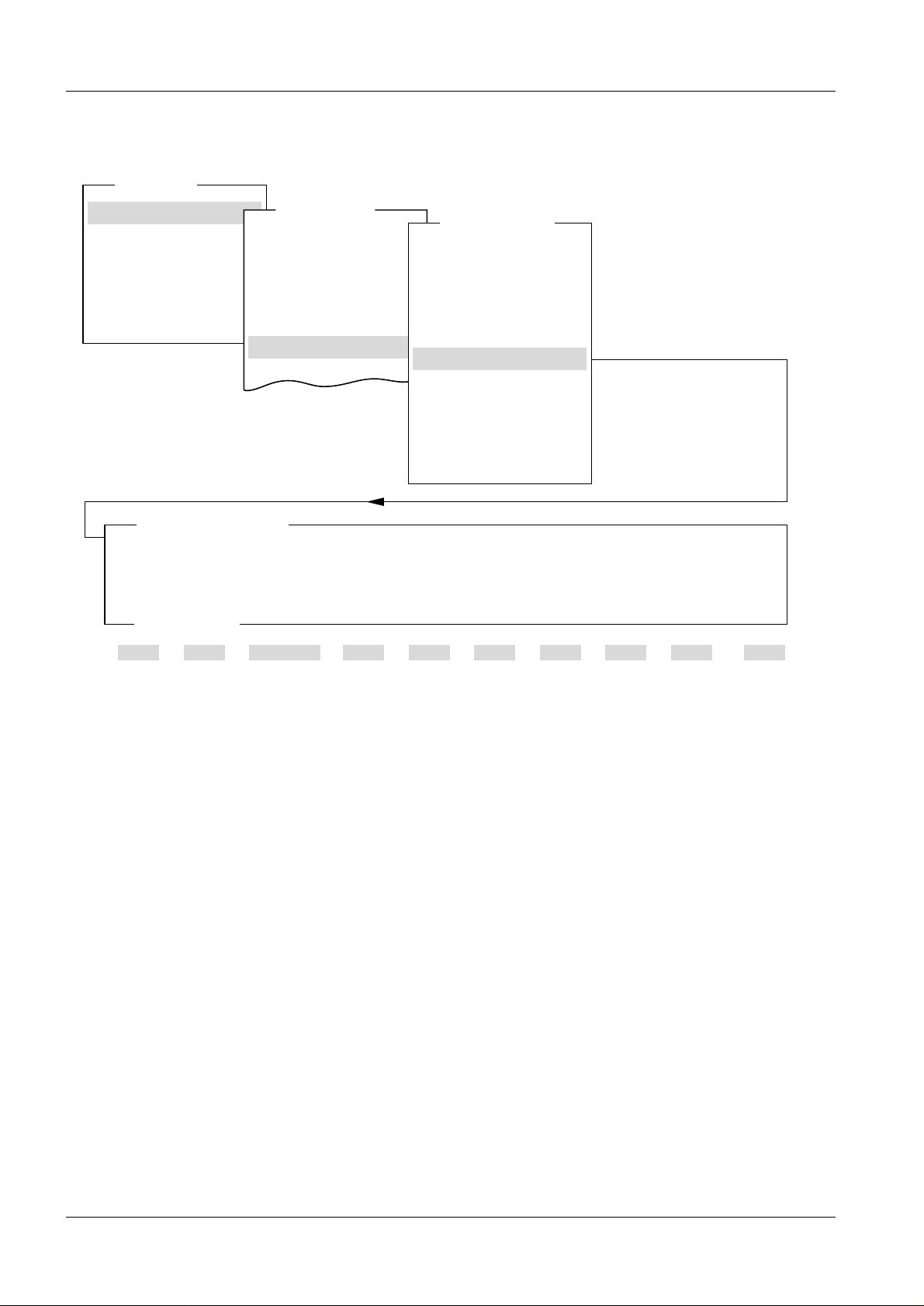

6. The display window shows:

If

Mode: Normal

Mode: Stand-alone

if

press <ENTER>.

The display window shows:

7. Select the program part to be used with keys < ↑> and/or <↓>, then press

<ENTER>.

The program part selected is shown with a b ackground:

If necessary, additional sub routines can be similarly selected here.

8. Make the necessary entries in the appr opriate part of the program. Save the

entered data with <F2>. Page back in the pro gram with <ESC>. The appropriate

instructions are shown on the monit or.

End the procedure with the service PC with <F10>.

is the correct choice then press < ENTER> or

PRGRAM-MODE; Mode: Normal

is wanted press the <SPACE> key once and then

Main menu

Your name, please

Password, please

Configuration

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 2 of 2 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 7

Adjustment and Service PC Programs 2

2 - 1

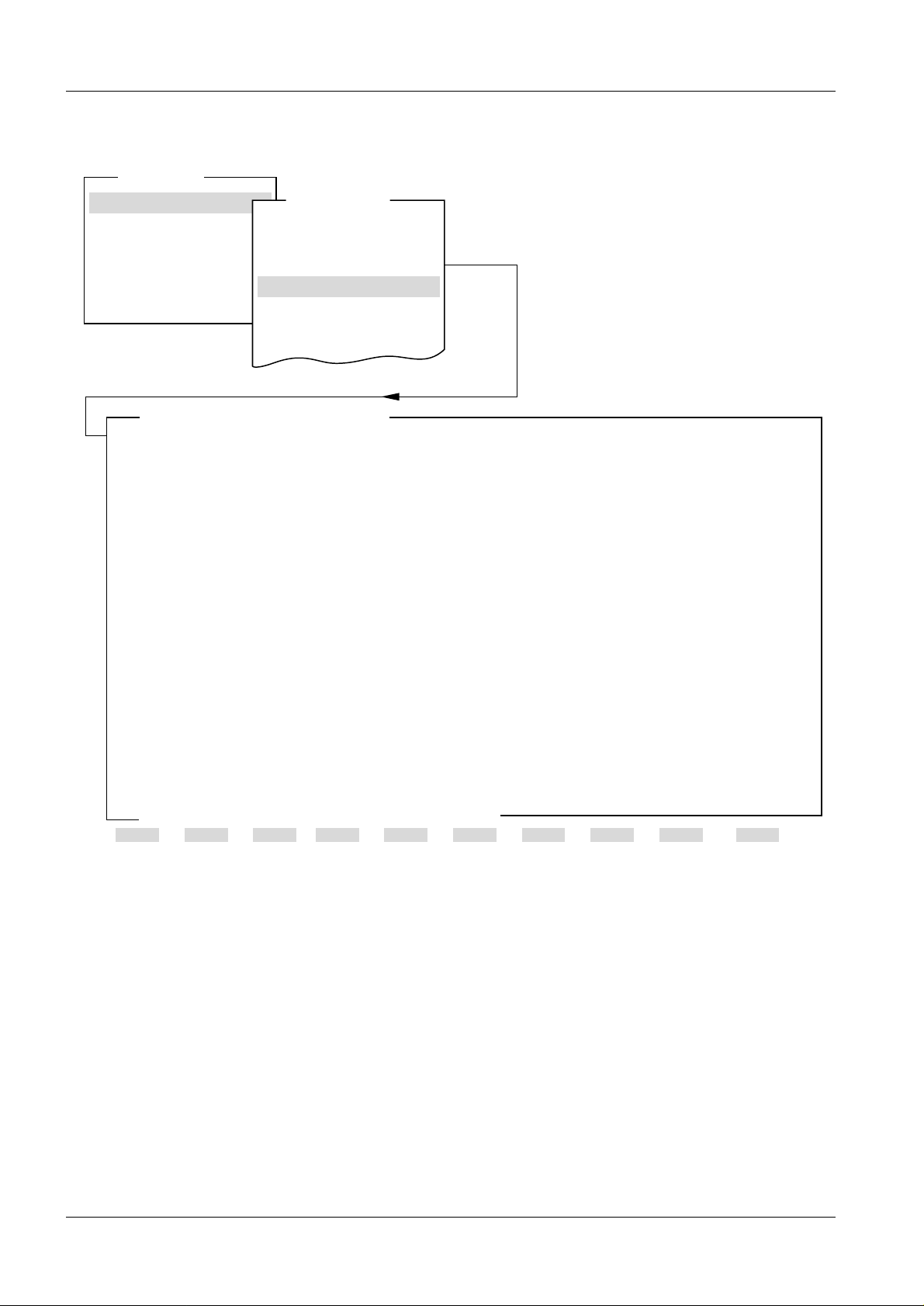

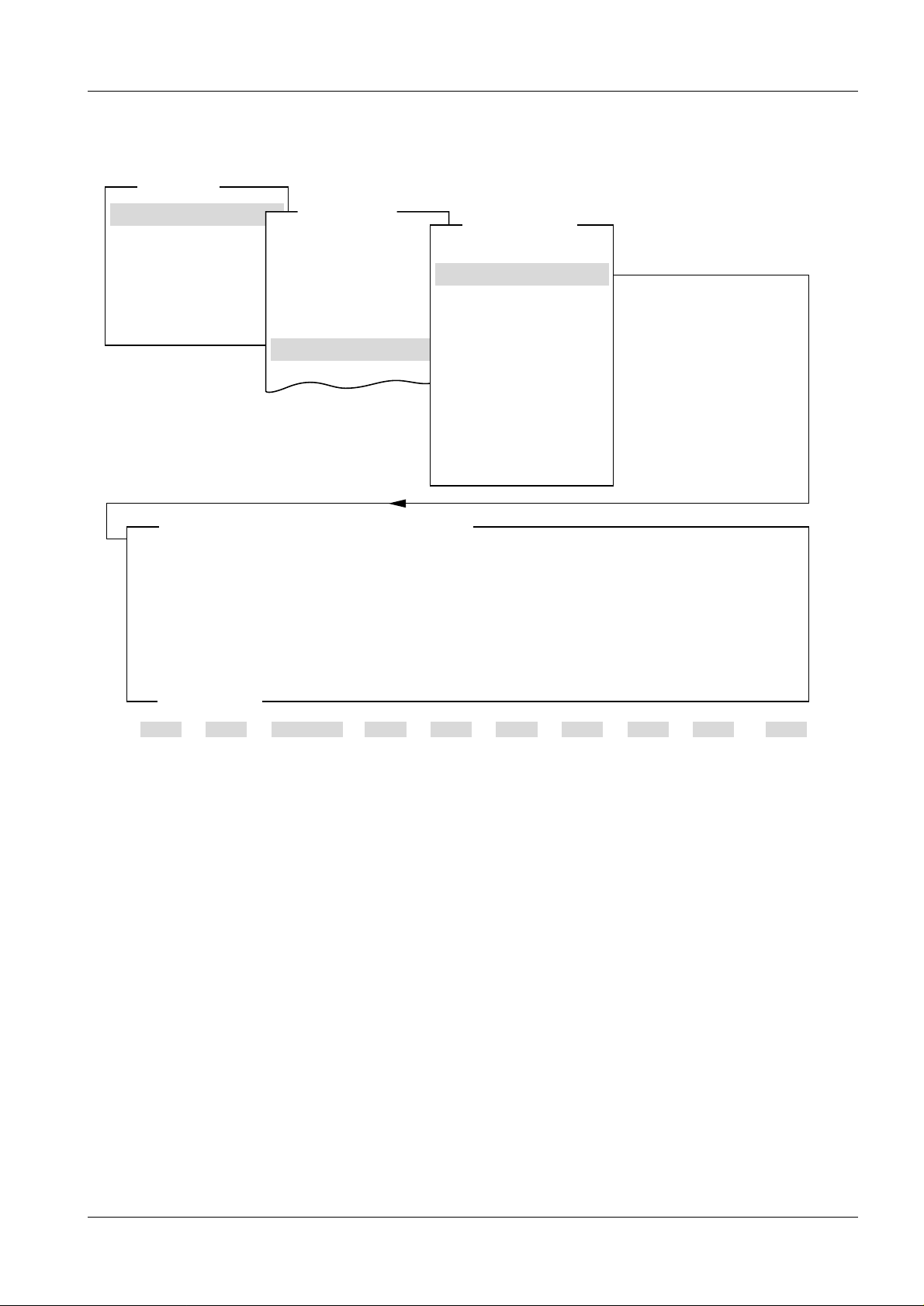

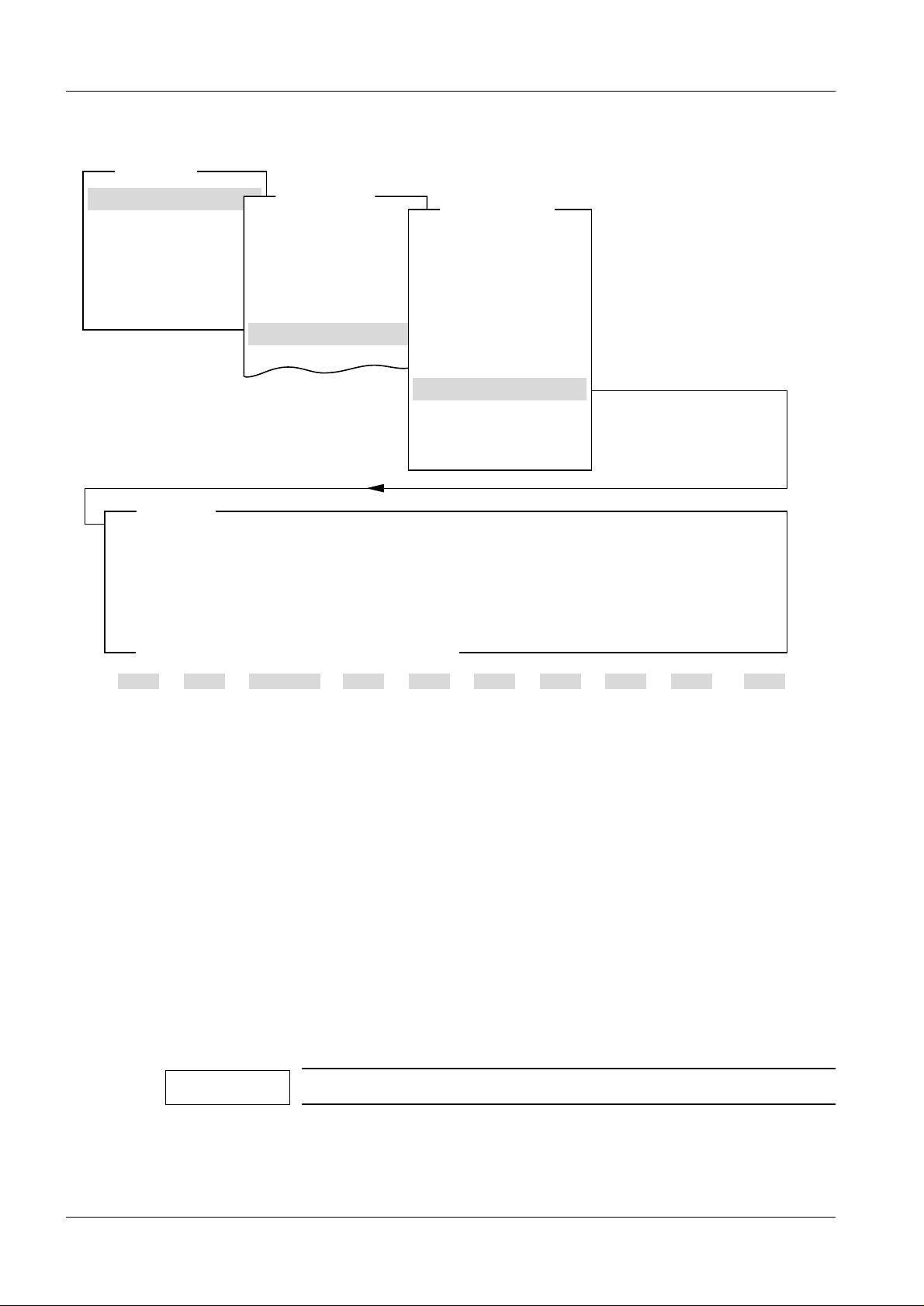

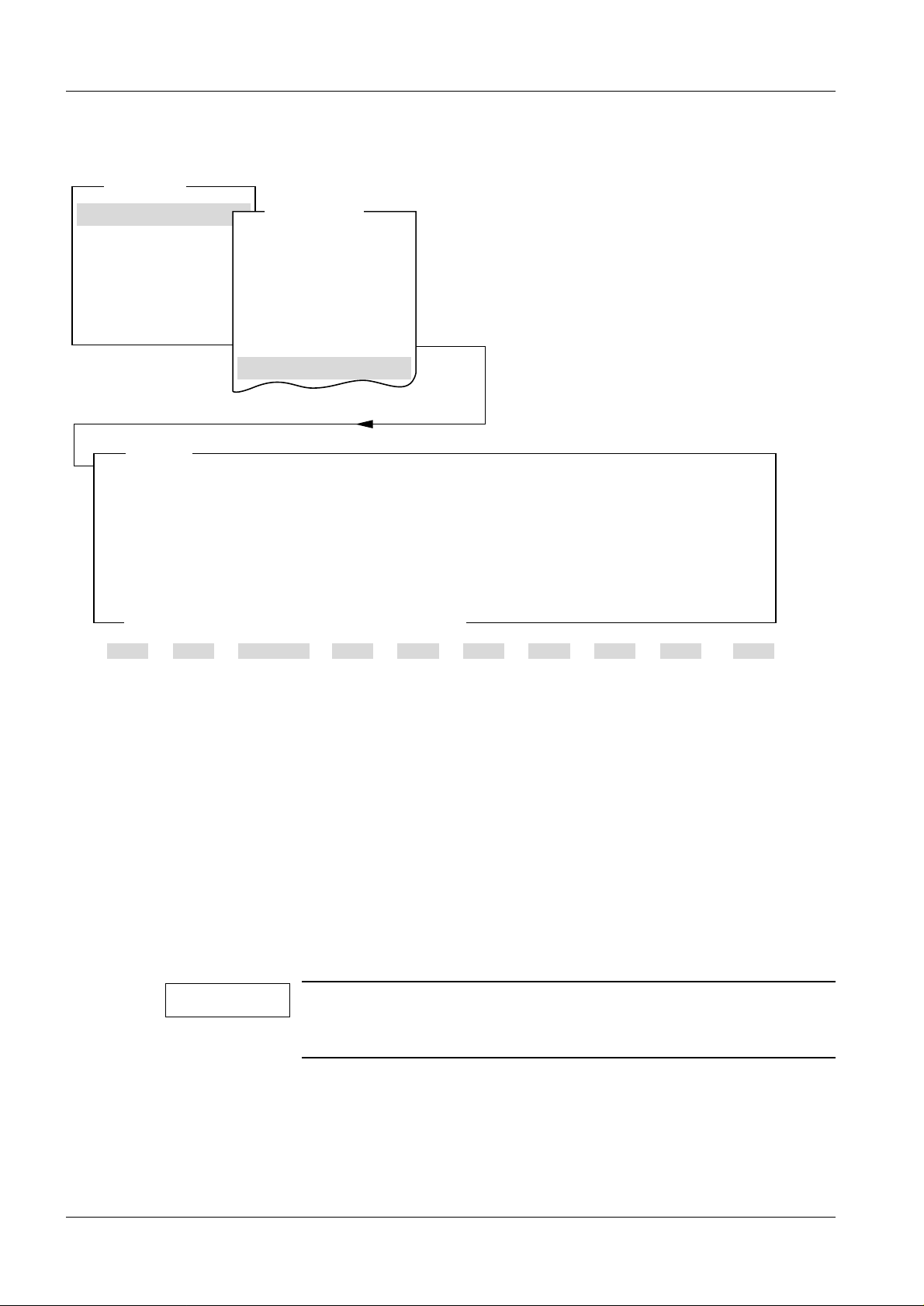

Configuration 3

System type 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

System type

NOTE: If changing system type, always check the power setting

and, when changing from M1000 to M3000, also the anode selection.

Collimator choice is valid only for M1000.

Changes in the ’System type’ and ’Collimator’ above become active

after next power up of the system.

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

System type

Collimator

M3000

Automatic

<ESC> to exit, <space> to toggle entry

1 Help 2 Save 3 45678910Quit

Fig. 1

System type indicates type of stand, generator and control panel. Collimator indicates

type of collimator in the stand. Collimator choice (Automatic or Maual) valid only for

MAMMOMAT 1000.

When MAMMOMAT 1000 is selected, the tungsten anode is automatically deselected,

and furthermore, the

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 1 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Anode

menu cannot be selected.

MAM00449

Page 8

2 - 2 Adjustment and Service PC Programs

NOTICE

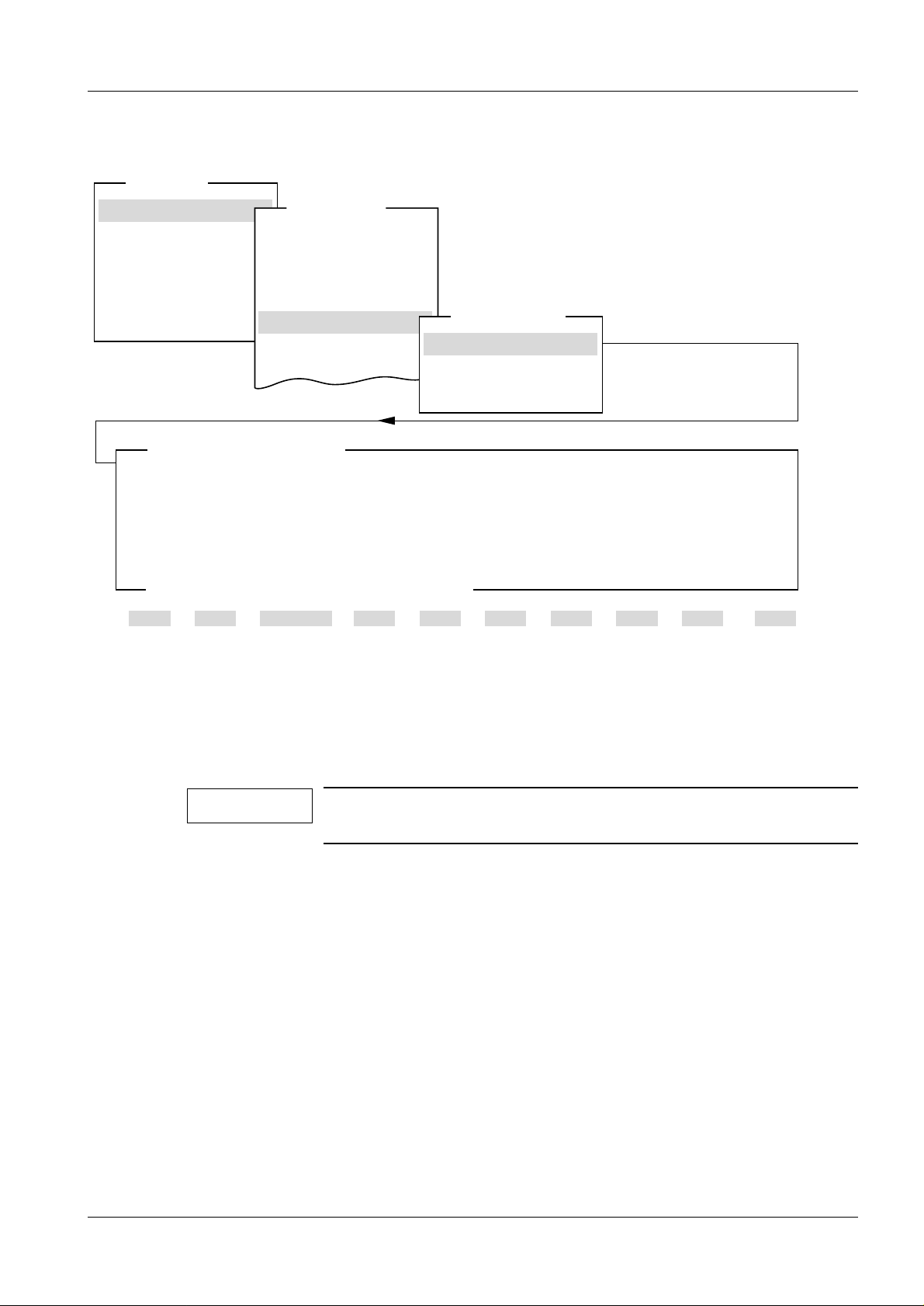

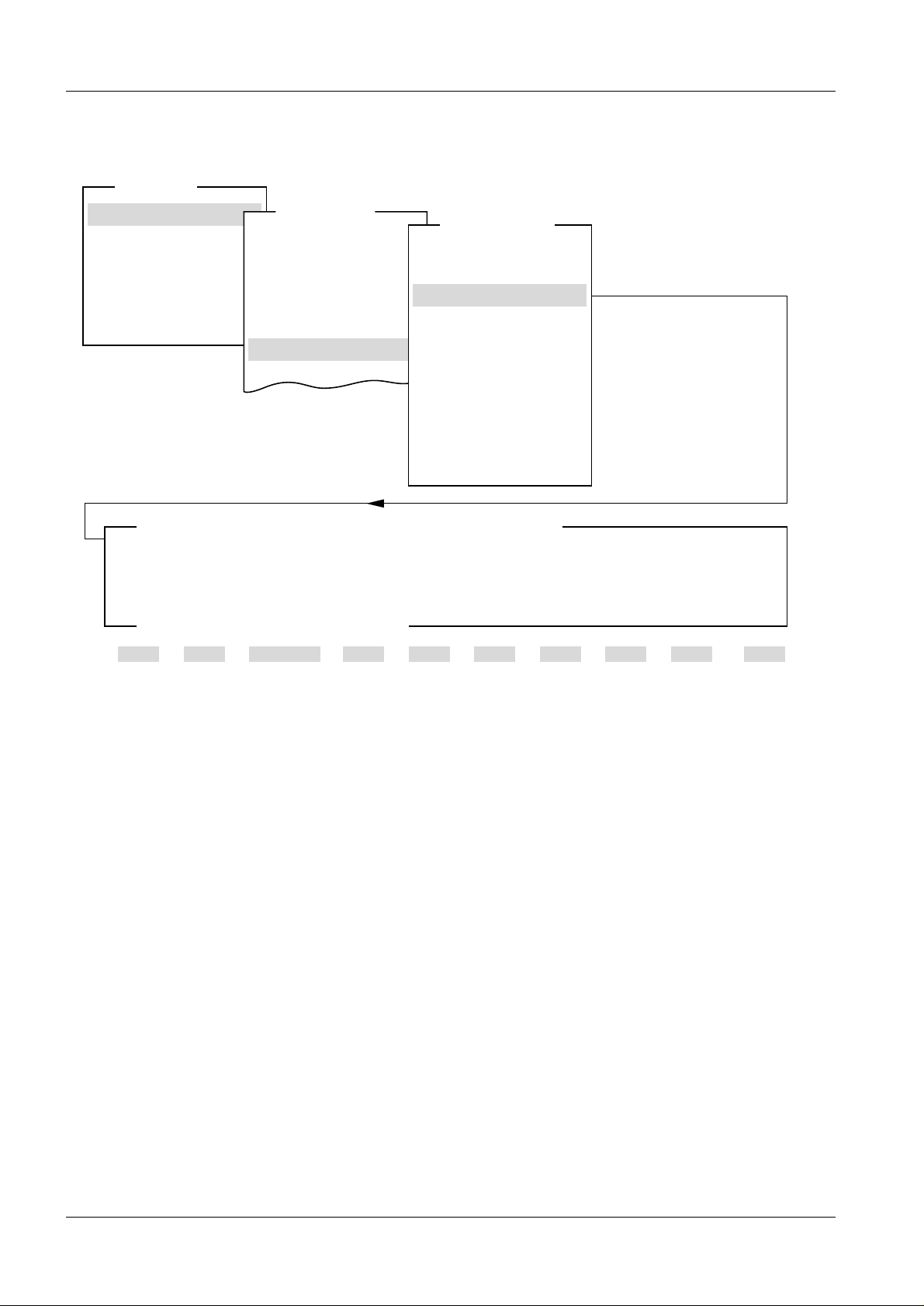

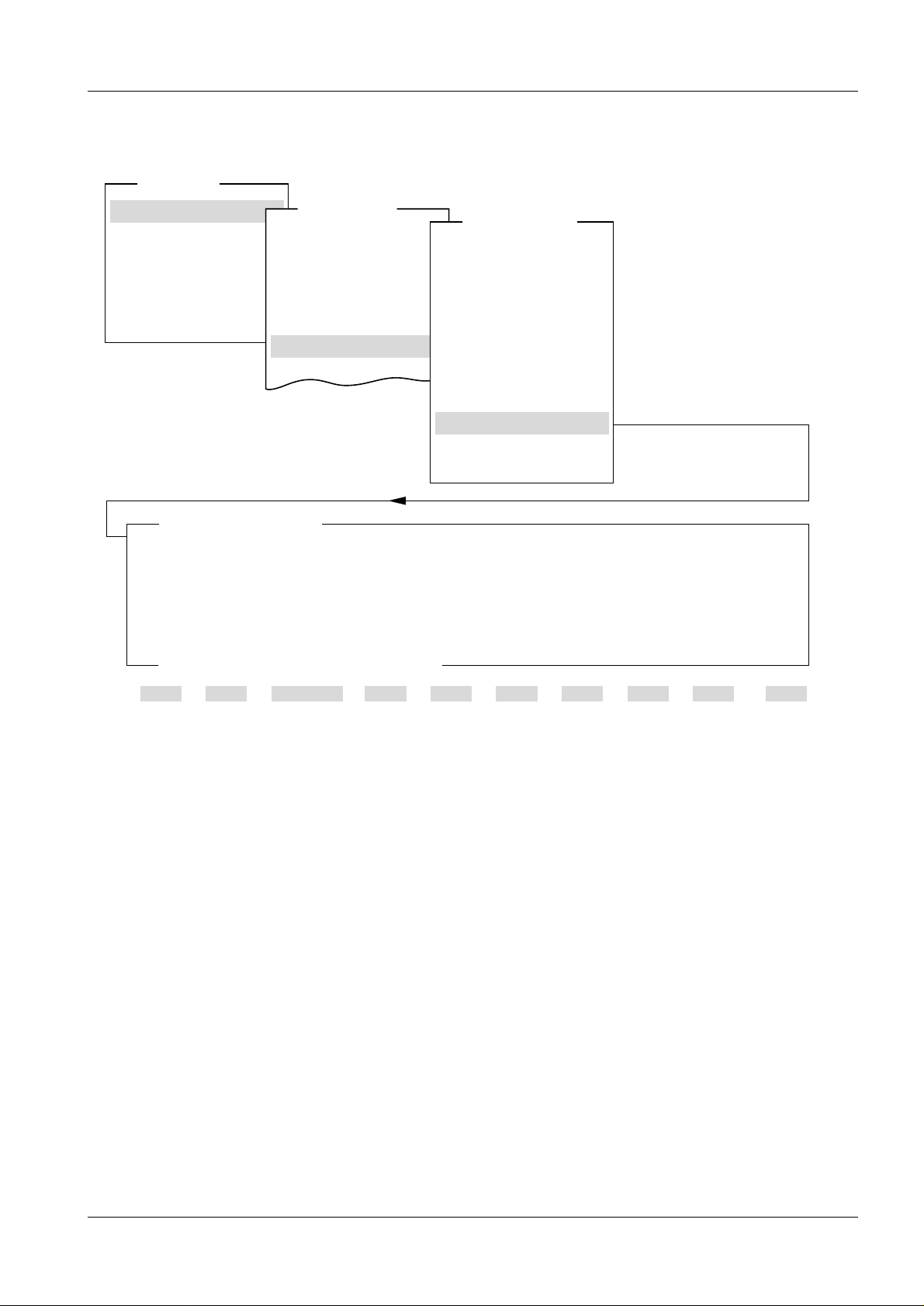

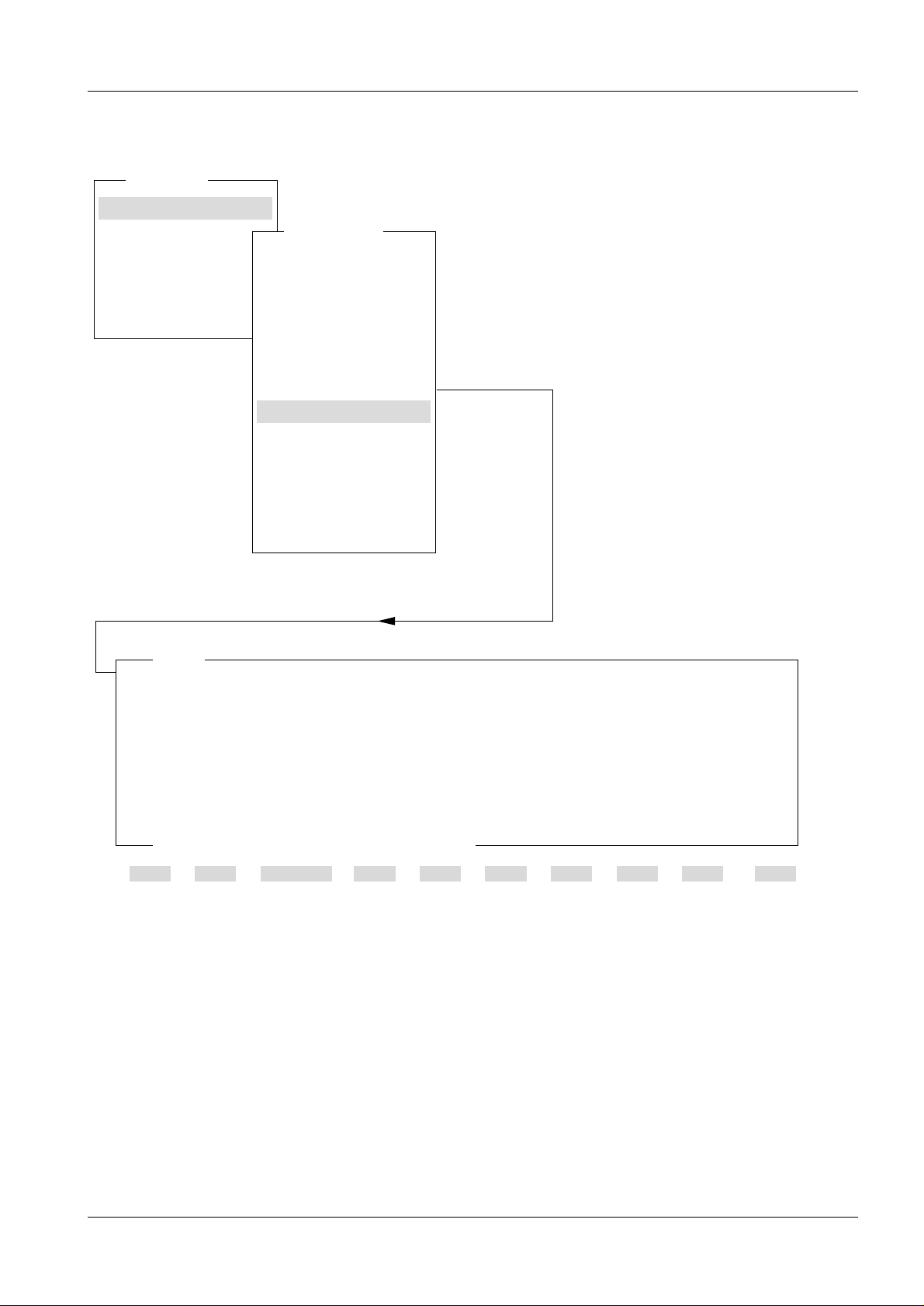

Anode 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Anode

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Tungsten anode

NOTE: When changing the anode selection, always check the power setting.

<ESC> to exit, <space to toggle entry>

1 Help 2 Save 3 45678910Quit

Fig. 2

Enable

Activation and deactivation of the tungsten anode. When deactivated, it will not be

possible to select W/Rh alternative on the control panel.

This menu is not selectable when t he s ystem type i s set t o M1000.

MAM00454

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 2 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 9

Adjustment and Service PC Programs 2 - 3

NOTICE

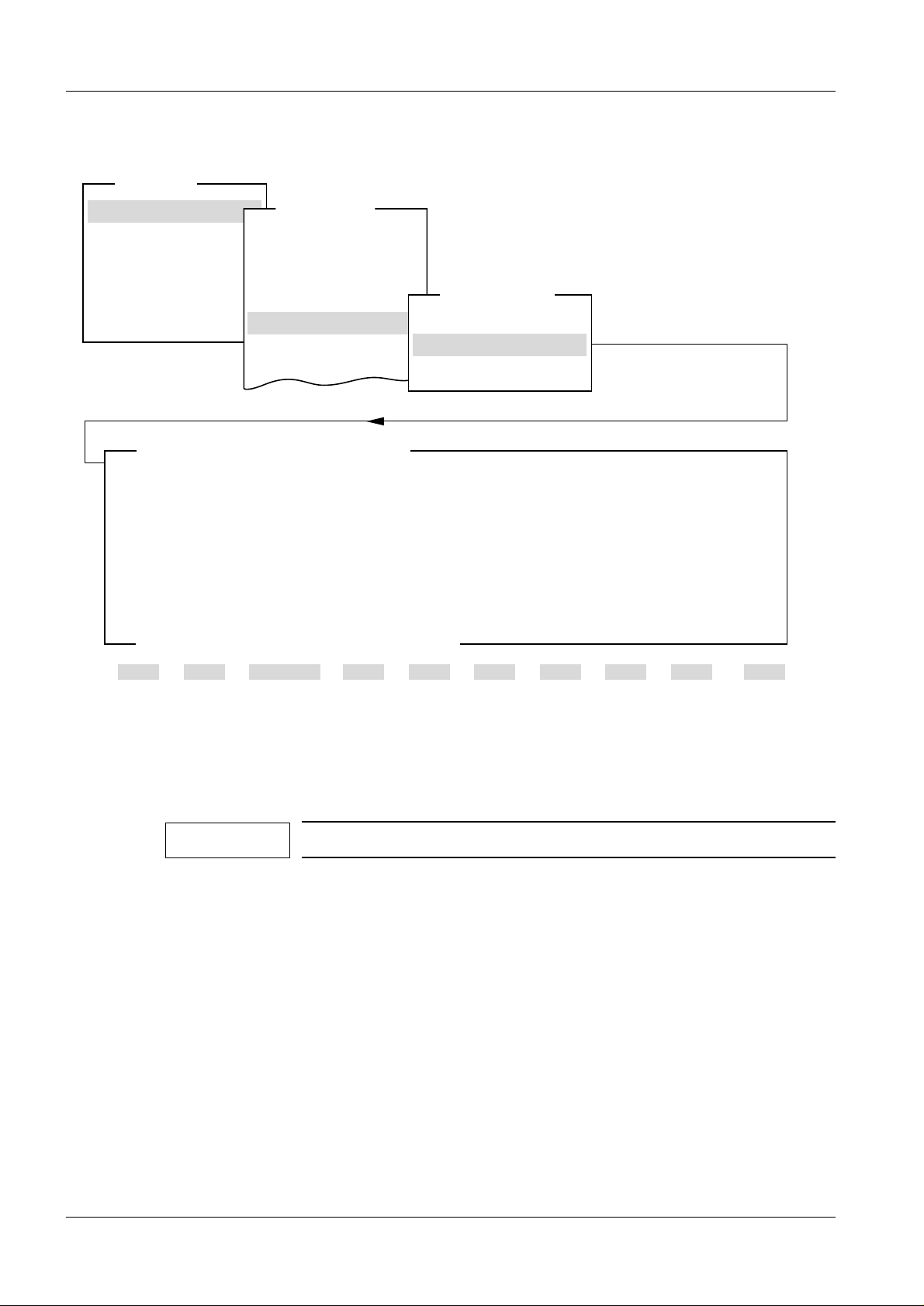

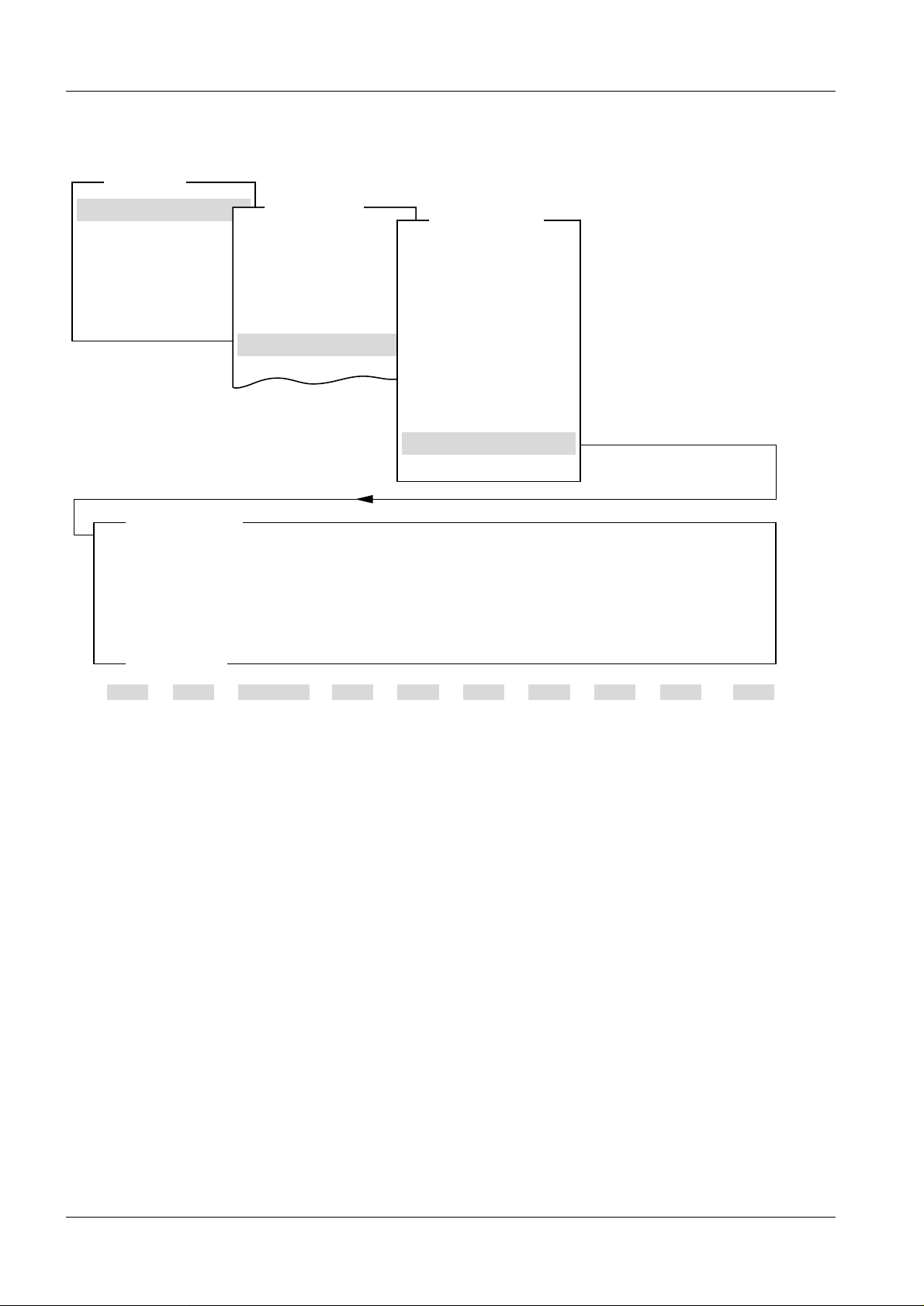

Show configuration file 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Show file mammo.cfg

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Fig. 3

System M3000

Power

Molly large focus 3.75 kW Tungsten large focus 4.70 kW

Molly small focus 0.70 kW Tungsten small focus 0.85 kW

Filament current

Molly large focus 6500 mA Tungsten large focus 6500 mA

Molly small focus 6500 mA Tungsten small focus 6500 mA

Tube current reduction ON

Power supply OFF

Sensitivity Wing 1

H 11.0

D 11.0

Correction curve A

Sensitivity correction

no grid

grid

magnification

Optimized compression

OPCOMP 18*24 and 24*30 ON

OPCOMP mag 15 and 18 OFF

Auto limits P1 30mm P2 45mm P3 60mm

Any key to continue

1 Help 2 3 45678910Quit

Tungsten Anode

H AD

ENABLED

Reduction time: 100 ms

Wing 2

11.0

11.0

Wing 1

0

0

0 0

Wing 2

0

0

Collimator AUTOMATIC

This menu displays the system configuration as stored in the “mammo.cfg” file.

MAM00450

All data are examples and may vary for the unit in question.

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 3 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 10

2 - 4 Adjustment and Service PC Programs

Save configuration file 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Save configuration -> mammo.cfg

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

System M3000 Tungsten Anode

Power

Molly large focus 3.75 kW Tungsten large focus 4.70 kW

Molly small focus 0.70 kW Tungsten small focus 0.85 kW

Filament current

Molly large focus 6500 mA Tungsten large focus 6500 mA

Molly small focus 6500 mA Tungsten small focus 6500 mA

Tube current reduction ON

Power supply OFF

Sensitivity Wing 1

H 11.0

D 11.0

Correction curve A

Sensitivity correction

no grid

grid

magnification

Optimized compression

OPCOMP 18*24 and 24*30 ON

OPCOMP mag 15 and 18 OFF

Auto limits P1 30mm P2 45mm P3 60mm

<ESC> to exit, <F2> save list in file mammo.cfg

1 Help 2 Save 3 45678910Quit

Fig. 4

H AD

ENABLED

Reduction time: 100 ms

Wing 1

0

0

00

Collimator AUTOMATIC

Wing 2

11.0

11.0

Wing 2

0

0

MAM00451

This menu is used for storing information about the system confi guration in the

“mammo.cfg” file.

The file will be stor ed on the hard disk of the service PC at current directory, if the service

PC program is running from this.

If the service PC program is running from a floppy disk, the file wil l be stored on this.

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 4 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 11

Adjustment and Service PC Programs 2 - 5

NOTICE

IONTOMAT PM, sensitivity 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

IONTOMAT PM - Sensitivity

Wing 1 11.0

Wing 2 11.0 11.0

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

IONTOMAT PM

Sensitivity

Sensitivity correction

Correction curve

HD

11.0

Valid entries from 0 to 31 in 1/2 E.P.

Input of decimal point not required!

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

Fig. 5

Indicates the sensiti vity of the IONTOMAT channel for high speed (H) and high resolution

screen (D) respectively.

Values from 0 to 31 can be entered in 1/2 exposure points.

If only one type of film-screen-combination is used, set both val ues (for H and D) to the same level.

Also see “Installation and Start-Up Inst ructions”.

MAM00455

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 5 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 12

2 - 6 Adjustment and Service PC Programs

NOTICE

IONTOMAT PM, sensitivity correction 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

IONTOMAT PM - Sensitivity correction

Without grid 0

With grid 0

Magnification 0

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

IONTOMAT PM

Sensitivity

Sensitivity correction

Correction curve

Wing 1 Wing 2

0

0

0

Valid entries from -8 to 8 in 1/2 E.P.

For pos entries 1st digit is <space> for neg entries type <->.

Input of decimal point not required!

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

Fig. 6

Indicates the sensitivity correction for different types of object tables.

All data are examples and may vary for the unit in question.

MAM00456

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 6 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 13

Adjustment and Service PC Programs 2 - 7

IONTOMAT PM, correction curve 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

IONTOMAT PM - Correction curve

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Curve number

Speed H A

Speed D A

IONTOMAT PM

Sensitivity

Sensitivity correction

Correction curve

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

Fig. 7

Indicates which correction curve shall be used for high speed (H) and high resolution (D)

screen respectively.

For further information, please refer to the installation manual, chapter “Start-up and functional test of the IONTOMAT PM”.

MAM00457

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 7 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 14

2 - 8 Adjustment and Service PC Programs

NOTICE

Miscellaneous, DLF switch 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Dynamic learn filament

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Miscellaneous

DLF switch

Reduction of power

Tube mA reduction

Printer

Power supply

Potentiometer check

Panel programming

Auto limits

Cassette loaded check

Illumination time

Version info

Switch is ON

<ESC> to exit, <space> to toggle entry

1 Help 2 Save 3 45678910Quit

Fig. 8

Activation and deactivation of the filament current adapti on. When activated, the adapti on

takes place after a total of ten exposures has been made wit h the actual focus, i f the deviation of the average value from the nominal value is within -15% to + 5%.

Without any exceptional reason, the DLF-switch shall be “ON”.

MAM00458

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 8 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 15

Adjustment and Service PC Programs 2 - 9

Miscellaneous, reduction of power 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Reduction of power depending on line quality

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Miscellaneous

DLF switch

Reduction of power

Tube mA reduction

Printer

Power supply

Potentiometer check

Panel programming

Auto limits

Cassette loaded check

Illumination time

Version info

Tube is P40MoW

Select nominal line voltage

240 V <-- with cursor keys and <Enter>

Type in line impedance

Power is 4.70 kW TUNGSTEN

3.75 kW MOLLY

<ESC> to exit

1 Help 2 Save 3 45678910Quit

Fig. 9

Calculates the maximum power allowed with regard to nominal voltage and line impedance.

Select the line voltage a nd type in t he line impeda nce you have meas ured. The proce ssor

will calculate the power and wi ll indicat e whe n the power must be redu ced be cause of the

line impedance.

Finally press <F2> to save.

MAM00459

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 9 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 16

2 - 10 Adjustment and Service PC Programs

Miscellaneous, tube current reduction 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Tube current reduction (TCR) at short exposure time (100ms)

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Miscellaneous

DLF switch

Reduction of power

Tube mA reduction

Printer

Power supply

Potentiometer check

Panel programming

Auto limits

Cassette loaded check

Illumination time

Version info

TCR switch is ON

Exposure time with 50 mA tube current is 100 ms

<ESC> to exit, <space> to toggle entry

1 Help 2 Save 3 45678910Quit

Fig. 10

Activation and deactivation of TCR.

When this function is activated, the tube current is reduced to 50 mA, in IONTOMAT

mode, at the start of exposure.

The time for the reduction is always 100 ms.

MAM00460

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 10 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 17

Adjustment and Service PC Programs 2 - 11

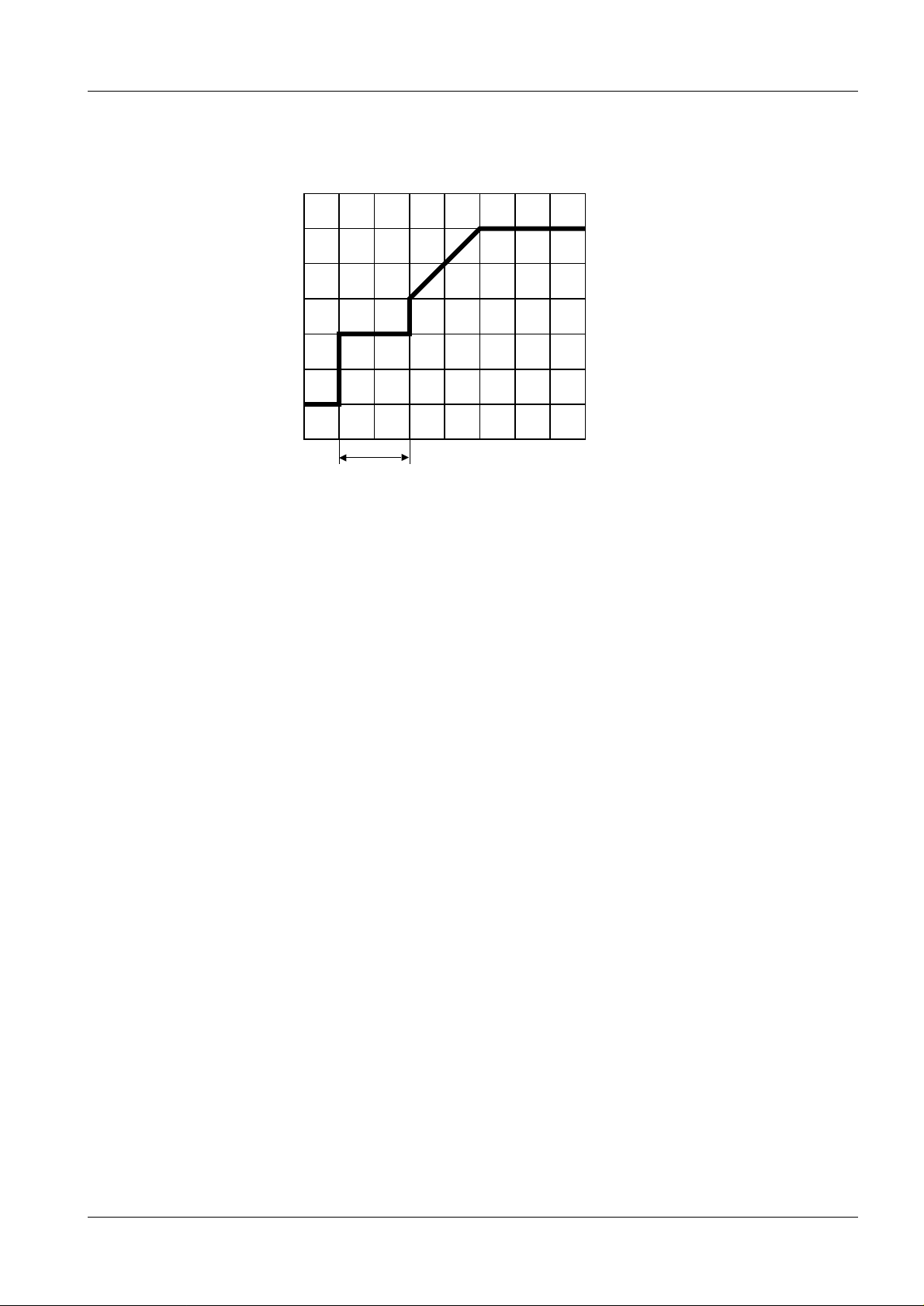

If TCR switch is “ON”, the tube current will look like this: 3

50 mA

approx.

100 ms

MAM00461

Fig. 11

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 11 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 18

2 - 12 Adjustment and Service PC Programs

Miscellaneous, printer 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Miscellaneous

DLF switch

Reduction of power

Tube mA reduction

Printer

Power supply

Potentiometer check

Panel programming

Auto limits

Cassette loaded check

Illumination time

Version info

Printer type selection

Actual setting

<ESC> to exit, <space> to toggle entry

1 Help 2 Save 3 45678910Quit

Fig. 12

No print

Select no print, RS 232C or PC print.

RS 232C is used when the printer is connected directly to the generator.

PC print is used when the printer is connected to the system via a PC connected to the

generator.

MAM00462

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 12 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 19

Adjustment and Service PC Programs 2 - 13

Miscellaneous, power supply 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Power supply

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Miscellaneous

DLF switch

Reduction of power

Tube mA reduction

Printer

Power supply

Potentiometer check

Panel programming

Auto limits

Cassette loaded check

Illumination time

Version info

Switch is

<ESC> to exit, <space> to toggle entry

1 Help 2 Save 3 45678910Quit

Fig. 13

OFF

Indicates whether the Mammomat is powered by an external power supply (e.g. Power

Aid) or not.

MAM00463

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 13 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 20

2 - 14 Adjustment and Service PC Programs

Miscellaneous, potentiometer check 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Potentiometer check

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Miscellaneous

DLF switch

Reduction of power

Tube mA reduction

Printer

Power supply

Potentiometer check

Panel programming

Auto limits

Cassette loaded check

Illumination time

Version info

A/D value

<ESC> to exit

1 Help 2 Save 3 45678910Quit

Fig. 14

032A

Sampled calibration value for the return current through the four potentiometers “preset

force”, “preset angle”, “thickness” and “angle”. This retur n current is continuously monitored by the system. Should the return current deviate too much from the calibration

value, this is probably due to a faulty potentiometer or due to a contact failure with one of

the potentiometers, which results in error code 825 or 826.

MAM00464

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 14 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 21

Adjustment and Service PC Programs 2 - 15

NOTICE

NOTICE

Miscellaneous, panel programming 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Panel programming

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Miscellaneous

DLF switch

Reduction of power

Tube mA reduction

Printer

Power supply

Potentiometer check

Panel programming

Auto limits

Cassette loaded check

Illumination time

Version info

Switch is

<ESC> to exit, <space> to toggle entry

1 Help 2 Save 3 45678910Quit

Fig. 15

ON

Activation and deactivation of the Memory button on the control panel, making it possible

to change the program settings for the four programs.

With the switch “OFF”, any change of data is blocked.

Should be switched “OFF” only if customer demands.

This menu is not selectable when the sys tem t ype is set to M1000.

MAM00465

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 15 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 22

2 - 16 Adjustment and Service PC Programs

NOTICE

Miscellaneous, auto limits 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Auto limits

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Auto limits

Program 1

Program 2 45 mm

Program 3 60 mm

Miscellaneous

DLF switch

Reduction of power

Tube mA reduction

Printer

Power supply

Potentiometer check

Panel programming

Auto limits

Cassette loaded check

Illumination time

Version info

30 mm

Valid entries from 0 to 180 mm

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

Fig. 16

Set the upper thickness limits for the programs 1-3.

Program 1 has a lower limit of 0 and Program 4 has a higher limit of 180 mm.

Supposing the above used values are stored in auto mode:

• The program key P1 is automatically selected with a compression thickness between 0

and 30 mm.

• The program key P2 is automatically selected with a compression thickness between 31

and 45 mm.

• The program key P3 is automatically selected with a compression thickness between 46

and 60 mm.

• The program key P4 is automatically selected with a compression thickness more than

60 mm.

MAM00466

This menu is not selectable when t he s ystem type i s set t o M1000.

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 16 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 23

Adjustment and Service PC Programs 2 - 17

Miscellaneous, cassette loaded check 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Cassette loaded check

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Miscellaneous

DLF switch

Reduction of power

Tube mA reduction

Printer

Power supply

Potentiometer check

Panel programming

Auto limits

Cassette loaded check

Illumination time

Version info

Switch is

<ESC> to exit, <SPACE> to toggle entry

1 Help 2 Save 3 45678910Quit

Fig. 17

ON

Activate or deactivate the check that a cassette is loaded/reloaded.

With this function activa ted, the casset te symbol on the contr ol panel will light up when the

inserted cassette has been exposed or if no cassette is insert ed a t all. Exposure release

is in this case blocked. The film cassette must be exchanged after each exposure.

During service it might be helpful to set the switch to “OFF”. When finishing service, do not

forget to set it back to the original setting.

MAM00467

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 17 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 24

2 - 18 Adjustment and Service PC Programs

Miscellaneous, illumination time 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Illumination time

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Miscellaneous

DLF switch

Reduction of power

Tube mA reduction

Printer

Power supply

Potentiometer check

Panel programming

Auto limits

Cassette loaded check

Illumination time

Version info

Illumination time

<ESC> to exit

1 Help 2 Save 3 45678910Quit

Fig. 18

20 s

Duration of switched-on field light (collimator lamp). 1-99 s.

Duration should be set according to customer’s wishes.

MAM00468

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 18 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 25

Adjustment and Service PC Programs 2 - 19

Miscellaneous, version info 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Version info

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Miscellaneous

DLF switch

Reduction of power

Tube mA reduction

Printer

Power supply

Potentiometer check

Panel programming

Auto limits

Cassette loaded check

Illumination time

Version info

MASTER PANEL STAND

Version:

Date: 94-02-15 93-11-23 94-03-05

Any key to continue

1 Help 2 3 45678910Quit

Fig. 19

2.1 1.2 1.4

Shows software versions and dates for the three computers in the system.

MAM00469

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 19 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 26

2 - 20 Adjustment and Service PC Programs

NOTICE

Filament 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Filament

Filament current @ 25 kV

Large focus molly 6900

Large focus tungsten 6500

Small focus molly 7500

Small focus tungsten 6500

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

<ESC> to exit, <TAB> to move to next entry field

1 Help 2 Save 3 45678910Quit

Fig. 20

Learn

Indicates the adapted filament current of both anode materials for large and small focus.

Adaption exposures for the filament current are also made in this menu.

Pressing F3 sets the exposure parameters on the control panel, and subsequently press-

ing Alt-F6 starts the exposure. Repeat this procedure until the tube-current deviation is

within ±5%.

If the tube has been replaced, program the filament current value 200 mA lower than the

value stated in the test certificat e as a preadjust ment. (e.g. If tube value is 6900, pr ogram

6700.)

If a new filament current ha s been entered you must sav e the new value (press F2) before

the learn filament is performed.

The Dynamic-Learn-Filament may change this adjustment. But

the DLF will only learn when the exposure time is longer than 60

ms.

MAM00470

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 20 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 27

Adjustment and Service PC Programs 2 - 21

Power 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Power

Clock

Compression

Lift

Rotation

Grid speed

Beam limiting device

Power

Power

Large focus molly 3.75 kW

Large focus tungsten 4.70 kW

Small focus molly .70 kW

Small focus tungsten .85 kW

Input of decimal point not required!

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

Fig. 21

Indicates the maximum power for large and small focus of both anode materials.

The values programmed must not exceed the values stated above.

These maximum values are only possible when the line impedance is not too high.

MAM00471

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 21 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 28

2 - 22 Adjustment and Service PC Programs

Clock 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Power

Clock

Compression

Lift

Rotation

Grid speed

Beam limiting device

Clock

PC date = 25.05.94

PC time = 13:31.08

Mammo date = 18.11.93

Mammo time = 14:19.11

Oscillator off

Press <F2> to set mammo clock to PC clock

and to switch oscillator on.

<ESC> to exit

1 Help 2 Set 3 45678910Quit

Fig. 22

Off

Indicates date and time.

Date and time should be correct because they are used when storing an error message

and marking films.

MAM00472

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 22 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 29

Adjustment and Service PC Programs 2 - 23

Compression, configuration 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Power

Clock

Compression

Lift

Rotation

Grid speed

Beam limiting device

Compression

Configuration

Calibration

Optimized compression

Compression configuration

Slow compression

Compression speed

Decompression speed

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

Fig. 23

3 kp/s

40 mm/s

60 mm/s

Slow compression 3

When compression force exceeds 1 kg (10N) , the f orce i ncrease p er s econd i s regul ated.

The value indicates the reference value for the regulation.

Compression speed 3

Speed of compression plate in mm/s during compression.

Admissible values: 1 - 80. A higher value will not generate any error, nor wil l it cause any

speed increase.

Decompression speed 3

MAM00473

Speed of compression plate in mm/s during decompression. Same values as above.

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 23 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 30

2 - 24 Adjustment and Service PC Programs

Compression, calibration 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Power

Clock

Compression

Lift

Rotation

Grid speed

Beam limiting device

Compression

Configuration

Calibration

Optimized compression

Compression calibration

Force = 0 N

Force = 200 N

Preset force = 0 N

Preset force = 200 N

Thickness bottom

Thickness bottom

Thickness top

Thickness top 180 mm

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

Fig. 24

Calibrate

006D

02A4

00

FF

01AC

0 mm

039B

Force = 0 N 3

Sampled calibration value for the forc e sensor at a compression f orce of 0 N after running

the compression plate downwards. Stop before reaching the object table.

Force = 200 N 3

Sampled calibration value for the force sensor at a compression force of 200 N. Put the

scale on the object table and compress to 200 N by motor only. If 200 N is exceeded,

restart from 0 N!

MAM00474

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 24 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 31

Adjustment and Service PC Programs 2 - 25

Preset force = 0 N 3

Sampled calibration value with the preset force potentiometer set to minimum (turned

counter clockwise to end position).

Preset force = 200 N 3

Sampled calibration value with the preset force potentiometer set to maximum (turned

clockwise to end position).

Thickness bottom (HEX) 3

Sampled calibration value for the thickness sensor, when the compression plate is in bottom position.

Thickness bottom (mm) 3

Measured distance between compression plate and object table, when the compression

plate is in bottom position. If the compression pla te reaches the object table (normal

case), type in 0.

Thickness top (HEX) 3

Sampled calibration value for the thickness sensor, when the compression plate is in

uppermost position.

Thickness top (mm) 3

Measured distance between compression plate and object table, when the compression

plate is in uppermost position. Measure with a rule r.

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 25 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 32

2 - 26 Adjustment and Service PC Programs

NOTICE

Compression, optimized 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Power

Clock

Compression

Lift

Rotation

Grid speed

Beam limiting device

Compression

Configuration

Calibration

Optimized compression

Best compression table

OPCOMP code 18 x 24 and 24 x 30

OPCOMP code mag 15 and 18

Tautness factor 18x24

Tautness factor 24x30

Tautness factor mag 15

Tautness factor mag 18

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

Fig. 25

5137

1234

70

70

70

70

Loop count compare

Sample time diff

Flex factor 18x24

Flex factor 24x30

Flex factor mag 15

Flex factor mag 18 74

72

98

74

4

4

OPCOMP code 18x24 and 24x30 3

Enable or disable OPCOMP. A correct input code will enable OPCOMP.

OPCOMP is aviable as an option for M1000.

Adapting OPCOMP 3

MAM00475

If the factory-set OPCOMP is not to the customer’s satisfaction, an adjustment can be

done with the tautness fact ors in the “ Best compre ssion table ”. A lower taut ness valu e will

increase the compression force and vice versa.

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 26 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 33

Adjustment and Service PC Programs 2 - 27

NOTICE

Increase/decrease the tautness fact or by e.g. 10 the first time. Let the customer use this

setting for at least two weeks, before further changes are made.

OPCOMP has been thoroughly tested by Siemens. If any factors

are changed, OPCOMP will no longer be an optimization of com-

pression force and image quality according to Siemens’ clinical

test.

Tautness factor 18x24 3

This factor determines how hard a breast is pressed. Lower tau tness factor gives more

pressure to the breast.

Tautness factor 24x30 3

This factor determines how hard a breast is pressed. Lower tau tness factor gives more

pressure to the breast.

Tautness factor mag 15 (not used) 3

This factor determines how hard a breast is pressed when a magnification table 1.5 is

attached. Lower tautness factor gives more pressure to the breast.

Tautness factor mag 18 (not used) 3

This factor determines how hard a breast is pressed when a magnification table 1.8 is

attached. Lower tautness factor gives more pressure to the breast.

Loop count compare 3

Number of times that OPCOMP condition should be fulfilled to stop compression.

Sample time diff 3

Table index difference (time) between sample s of thi ckness, used to determine if

OPCOMP condition is fulfilled.

Flex factor 18x24 3

A value of the mechanical system’s flexibility. The value is usually factory defined.

Flex factor 24x30 3

A value of the mechanical system’s flexibility. The value is usually factory defined.

Flex factor mag 15 (not used) 3

A value of the mechanical system’ s flexibility for magnifi cation table 1.5. The value is usually factory defined.

Flex factor mag 18 (not used) 3

A value of the mechanical system’ s flexibility for magnifi cation table 1.8. The value is usually factory defined.

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 27 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 34

2 - 28 Adjustment and Service PC Programs

Lift 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Power

Clock

Compression

Lift

Rotation

Grid speed

Beam limiting device

Lift

Upward acceleration 1

Downward acceleration 1

Upward brake 10

Downward brake 10

Upward start 5

Downward start 5

Upward stop 40

Downward stop 40

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

Fig. 26

Up acceleration 3

To attai n desired acceleration of the lift movement, the pulse width of the motor- control

signal is ramped up. The digit is a measure of the acceleration rate ate the start of the lift

movement in upward direction. It indicates the increase of the duty cycle on the signal for

each change event, which occurs every 10 ms.

Admissible values: 1 - 99. The higher the value the faster the acceleration.

MAM00477

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 28 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 35

Adjustment and Service PC Programs 2 - 29

Down acc 3

Same as above, but for downward lift movement.

Admissible values: 1 - 99

Up brake 3

To attain desired deacceleration of the lift movement, the pulse width of the motor-control

signal is ramped down. The digit is a measure of at which deaccel erati on rate the upward

lift movement shall stop. It indicates the decr ease of the duty cycle on the signal for each

change event, which occurs every 10 ms.

Admissible values: 1 - 99. The higher the value the faster it slows the motor down.

Down brake 3

Same as above, but for downward lift movement.

Admissible values: 1 - 99

Up start 3

To enable instantaneous start of the upward movement, the motor-control signal starts

with a predetermined pulse width. The digit is a measure of the size o f the pulse width (in

percentage of the supply voltage). Increase val ue, if movement does not start instantaneously, decrease value if movement starts too abruptly.

Admissible values: 1 - 99

Down start 3

Same as above, but for downward movement.

Admissible values: 1 - 99

Up stop 3

At upward movement, the parameter indicates at which duty cycle the ramping of the

pulse width is interrupted and the pulse wid th set to zero.

Admissible values: 1 - 99

Down stop 3

Same as above, but for downward movement.

Admissible values: 1 - 99

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 29 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 36

2 - 30 Adjustment and Service PC Programs

Rotation, configuration 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Power

Clock

Compression

Lift

Rotation

Grid speed

Beam limiting device

Rotation

Configuration

Calibration

Rotation configuration

Brake distance 6

<ESC> to exit

1 Help 2 Save 3 45678910Quit

Fig. 27

The brake distance of the tube, i.e. how many degrees before wanted stop angle that

rotation is being slowed down.

MAM00478

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 30 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 37

Adjustment and Service PC Programs 2 - 31

NOTICE

Rotation, calibration (When the system type is set to M1000.) 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Power

Clock

Compression

Lift

Rotation

Grid speed

Beam limiting device

Rotation

Configuration

Calibration

Fig. 28

Rotation calibration

Angle 030A+135

Angle 02A8+90

Angle 0 01E4

Angle 007D-165

Angle 009D-150

Angle 00BE-135

Angle 00DF-120

Angle 00FF-105

Angle 0141-75

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 5 678910Quit

Calibrate Calculate

Angle 0120-90

Angle 005C-180

Angle 0161-60

Angle 0182-45

Angle 01A3-30

Angle 01C3-15

Angle 0205+15

Angle 0225+30

Preset Angle 0 00

Preset Angle 90 FF

Angle 0246+45

Angle 0267+60

Angle 0287+75

Angle 02C9+105

Angle 02E9+120

F1 Displays a help text.

F2 Saves the values from the entry fields in the stand electronics.

F3 Measures the value for the highlighted entry field.

F4 Enters the measured value in the entry field. (after F3 or F5)

F5 Calculates theoretical values for all 15° steps (except for -90°, 0° and +90°)

from -165° to +120° based on the values in the -180°, -90°, 0°, +90° and +135°

MAM00452

entry fields.

F4 must be pressed after F5 and prior to F2 in order to save the

calculated values.

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 31 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 38

2 - 32 Adjustment and Service PC Programs

NOTICE

Preset Angle 0° 3

Highlight the entry field, set the preset angl e po tentiometer to minimum (fully counterclockwise) and calibrate with F3, F4. Save with F2.

Preset Angle 90° 3

Highlight the entry field, set the preset angle potentiometer to maximum (fully clockwise)

and calibrate with F3, F4. Save with F2.

Preparation for angle calibration 3

Prior to calibrating the angles, high light +135° and enter 03FF, highlight +90° and enter

0300, highlight 0° and enter 0200, highlight -90° and enter 0100, hig hlight -18 0° and enter

0000, press F5 followed by F4. Save with F2.

Angle +135°, +90°, 0 °, -90°, -180° 3

Highlight +135°. Run the rotation motor to +135 ° (near the CW stop). Calibrate the value

with F3 followed by F4. Highli ght +90°. Run t he rotati on motor to + 90°. Calibrate the val ue

with F3 followed by F4. Repeat this for 0°, -90° and -180°.

Remaining angles 3

Press F5 followed by F4 to calculate values for the remaining angles. Save with F2.

The angles must be reprogrammed if the tube angle pot. R803, or

the CPU D801 is changed.

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 32 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 39

Adjustment and Service PC Programs 2 - 33

NOTICE

Rotation, calibration (When the system type is set to M3000.) 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Power

Clock

Compression

Lift

Rotation

Grid speed

Beam limiting device

Rotation

Configuration

Calibration

Rotation calibration

Angle 030A+135

Angle 005C-180

Angle 007D-165

Angle 009D-150

Angle 00BE-135

Angle 00DF-120

Angle 00FF-105

Angle 0120-90

Angle 0141-75

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 5 678910Quit

Fig. 29

Calibrate Calculate

Preset angle 000

Preset angle FF90

Angle 0161-60

Angle 0182-45

Angle 01A3-30

Angle 01C3-15

Angle 01E40

Angle 0205+15

Angle 0225+30

Angle 0246+45

Angle 0267+60

Angle 0287+75

Angle 02A8+90

Angle 02C9+105

Angle 02E9+120

F1 Displays a help text.

F2 Saves the values from the entry fields in the stand electronics.

F3 Measures the value for the highlighted entry field.

F4 Enters the measured value in the entry field. (after F3 or F5)

F5 Calculates theoretical values for all 15° steps from -165° to +120° based on the

values in the -180° and +135°entry fields.

MAM00070

F4 must be pressed after F5 and prior to F2 in order to save the

calculated values.

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 33 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 40

2 - 34 Adjustment and Service PC Programs

NOTICE

Preset Angle 0° 3

Highlight the entry field, set the preset angl e po tentiometer to minimum (fully counterclockwise) and calibrate with F3, F4. Save with F2.

Preset Angle 90° 3

Highlight the entry field, set the preset angle potentiometer to maximum (fully clockwise)

and calibrate with F3, F4. Save with F2.

Preparation for angle calibration 3

Prior to calibrating the angles, high light +135° and enter 03FF, highlight -180° and enter

0000, press F5 followed by F4. Save with F2.

Angle +135° 3

Highlight +135°. Run the rotation motor to approx. +135° (near the CW stop) and move

the stereo lever full y to stereo position. If necessary, r otate the head slightl y with the motor

until the lever can be fully engagded. Rotate the head upwards (towards 0°) to the stereo

stop and back to the centre position until it st ops. Calibrate the value with F3 followed by

F4.

Angle -180° 3

Highlight -180°. Run the rotation motor to approx. -180° (near the CCW stop) and move

the stereo lever fully to stereo posi tion . If necessary, rotate the head slightly until the lever

can be fully engagded. Rot ate the head upwar ds (to wards 0°) t o t he ster eo stop and back

to the centre position until it stops. Calibrate the value with F3 followed by F4.

Angle -165° to +120° 3

Press F5 followed by F4 to recalculate approximate values for the angles prior to calibration of the remaining angles. Save with F2.

Higlight -165

stereo position. If necessary, rotate the head slightly until the leve r can be fully engaged.

Rotate the head upwards (towards 0

until it stops. Calibrate the value with F3 fol lowed by F4.

Move the stereo lever back to normal mode and run the rotation motor to the next position, -150

the table in the same manner. It is sufficient to calibrate each value with F3, F4 and save

all the values afterwards with F2.

Check 0° and all 15° st eps from 0° to +90° for proper stereo l ever operation by setting the

preset angle control to 15, 30°, etc and run the rotation motor to both plus and minus

angles. 0° is checked by allowing the head to stop when going from positiv angle values to

negativ angle values and vice.versa. Recalibrate any angle which needs improvement by

highlighting it and calibrating as above. Remember to save (F2) after performing a recalibration.

°. Run the rotation motor to approx. -165° and move the stereo lever fully to

°) to the stereo stop and back to the centre position

°. Highlight -150° and calibrate as above. Calibrate all the remaining values in

The angles must be reprogrammed if the tube angle pot. R803, or

the CPU D801 is changed.

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 34 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 41

Adjustment and Service PC Programs 2 - 35

Grid speed 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Power

Clock

Compression

Lift

Rotation

Grid speed

Beam limiting device

Grid

Grid fast speed time 500

Grid fast speed 80

Grid slow speed 20

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Save 3 45678910Quit

Fig. 30

ms (2.5 s max)

% of max

% of max

Grid fast speed time 3

The time during which the grid is moving at high speed after start of radiation.

Admissible values: 10 - 2500 ms

Grid fast speed 3

Indicates the high-speed reciprocation of the grid applied after start, i.e. during exposure.

The speed is indicated as a percentage of the maximum pulse width of the grid motorcontrol signal.

Admissible values: 1 - 99. The higher the value the faster the motor.

Grid slow speed 3

MAM00479

Indicates the low speed of the gr id after trans ition from high s peed. The speed is indicat ed

as a percentage of the m aximum pulse width of the grid motor-control signal.

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 35 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 42

2 - 36 Adjustment and Service PC Programs

NOTICE

Beam limit 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Configuration

System type

Anode

Show configuration file

Save configuration file

Iontomat

Miscellaneous

Filament

Power

Clock

Compression

Lift

Rotation

Grid speed

Beam limiting device

Beam limiting device

Small molly, mm from edge 17 Steps from flank

Large molly, mm from edge 17 Steps from flank

Small tungsten, mm from edge 17 Steps from flank

Large tungsten, mm from edge 17 Steps from flank

<ESC> to exit, <TAB> move to next entry field

1 Help 2 Calibrate 45678910Quit

Fig. 31

77

31

78

31

mm from edge (focus) 3

Number of mm:s from film edge to radiation field after a calibration exposure. Set to 17

when doing a calibration exposure.

steps from flank 3

A calculated value, not editabl e, t hat shows how far fr om the mi ddle of the moving ar ea of

the beam limiting device that the beam limiting device will be moved.

Beam Limiting Device

The

mator is set to Manual in configuration System type.

menu is not selectable when the colli-

MAM00480

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 36 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 43

Adjustment and Service PC Programs 2 - 37

Service 3

View error buffer 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Service

View error buffer

Copy error buffer to file

Delete error buffer

Display error message

Show exposure counter

Reset exposure counter

Panel test

Stand test

0 - Er 608

1 - Er 826

1 Help 2 3 45678910Quit

Fig. 32

With this selection of the “View erro r buffer” menu, the error buffer in the panel is read in

and displayed on the screen. Using the arrow keys, you can now scroll through the entire

error buffer. If you want more detailed information about the indicated error, just press

<ENTER>. The error shown at the head of the list is the most recently occurred error. A

maximum of 40 errors can be stored.

MAM00481

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 37 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 44

2 - 38 Adjustment and Service PC Programs

Copy error buffer to file 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Service

View error buffer

Copy error buffer to file

Delete error buffer

Display error message

Show exposure counter

Reset exposure counter

Panel test

Stand test

Saving error buffer to file

Please wait!

MAM00482

Fig. 33

Choosing this menu item will read the error buf fer and save to the file C:errorbuf.txt.

When using the error buffer the first time the fi le error buf .txt i s automati cally created. Thi s

file will be stored on hard disk. If you want to have on the fl oppy belonging to the parti cular

unit, transfer file to floppy.

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 38 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 45

Adjustment and Service PC Programs 2 - 39

Delete error buffer 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Delete error buffer

Service

View error buffer

Copy error buffer to file

Delete error buffer

Display error message

Show exposure counter

Reset exposure counter

Panel test

Stand test

Fig. 34

Delete the whole error buffer

Are you sure (y, n) ???

<ESC> to exit, <y> to delete

1 Help 2 3 45678910Quit

Selecting the “Delete error buffer” menu and pressing the “Y” key empties the error buffer

in the panel. If you then try to call up “View error buffer again, the service program will

respond by displaying the message “Error buffer empty”.

It is recommended to empty the error buffer only on finishing a service call successfully!

MAM00483

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 39 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 46

2 - 40 Adjustment and Service PC Programs

Display error message 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Display error message

Service

View error buffer

Copy error buffer to file

Delete error buffer

Display error message

Show exposure counter

Reset exposure counter

Panel test

Stand test

Fig. 35

Error number:

<ESC> to exit

1 Help 2 3 45678910Quit

A text explaining the error will be shown after input of an error number and <RETURN>.

MAM00484

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 40 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 47

Adjustment and Service PC Programs 2 - 41

Show exposure counter 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Show exposure counter

Service

View error buffer

Copy error buffer to file

Delete error buffer

Display error message

Show exposure counter

Reset exposure counter

Panel test

Stand test

Fig. 36

Actual exposure count is 317

Any key to continue

1 Help 2 3 45678910Quit

By selecting the “Show exposure counter” menu, the exposure counter value in the panel

is read in and displayed on the screen.

It is indicating the number of exposures taken with the attached X-ray tube.

MAM00485

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 41 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 48

2 - 42 Adjustment and Service PC Programs

NOTICE

Reset exposure counter 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Reset exposure counter

Service

View error buffer

Copy error buffer to file

Delete error buffer

Display error message

Show exposure counter

Reset exposure counter

Panel test

Stand test

Fig. 37

Reset exposure counter to zero

Are you sure (y,n) ???

<ESC> to exit, <y> to reset

1 Help 2 3 45678910Quit

Selecting the “Reset exposure counter” menu and pressing the “Y” key resets the exposure counter value in the panel to zero.

Only to be done after tube exchange.

MAM00486

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 42 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 49

Adjustment and Service PC Programs 2 - 43

Panel test 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Panel test

Service

View error buffer

Copy error buffer to file

Delete error buffer

Display error message

Show exposure counter

Reset exposure counter

Panel test

Stand test

Fig. 38

Panel

How often?

<ESC> to exit, <TAB> move to next entry field

1 Help 2 45678910Quit

Start test

Selftest

Just once

When pressing F2 Start test, the panel selftest will start.

MAM00487

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 43 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 50

2 - 44 Adjustment and Service PC Programs

Stand test, A/D-converter 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Stand test : A/D converter

<ESC> to exit, <TAB> move to next entry field, <SPACE> to toggle entry

Service

View error buffer

Copy error buffer to file

Delete error buffer

Display error message

Show exposure counter

Reset exposure counter

Panel test

Stand test

A/D channel

How often?

Force

Just once

Stand test

A/D-converter

Grid

Filter

Collimator

Beam limiting device

Switches

Fig. 39

1 Help 2 45678910Quit

Start test

A/D converter test 3

This menu displays two fields for selection of test data. Desired fields is selcted with the

TAB key.

In the first field you can choose which analog input (to the CPU in the st and) shall be read

off.

The possible inputs are: Force, Angle, Thickness, Preset force, Preset angle, Grid motor

V and Poti check.

In the second field you can choose whether the reading shall be carried out just once or

continously (until interruption).

In both fields you can scroll through the different alternatives by pressing the spacer.

Press F2 or the return key to read off desired alternative.

MAM00488

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 44 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 51

Adjustment and Service PC Programs 2 - 45

NOTICE

Stand test, grid 3

Selection of this menu immediately starts the grid test. If a grid movement error is

detected, an error message is displayed, as usual, on the control panel.

Stand test, filter 3

Selection of this menu immediately starts the fi lter test. If a filter movement error is

detected, an error message is displayed, as usual, on the control panel.

Stand test, collimator 3

Selection of this menu immediately starts the collimator test. If a collimator movement

error is detected, an error message is displayed, as usual, on the control panel.

Stand test, beam limiting device 3

Selection of this menu immediately starts the beam limiting device test. If a beam limiting

device movement error is detected, an error message is displayed, as usual, on the control panel.

Stand test filter , stand test col limator and stand t est beam limiting

device is not selectable when the collimator is set to Manual.

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 45 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 52

2 - 46 Adjustment and Service PC Programs

Stand test, switches 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Stand test : Switches

How often? Just once

<ESC> to exit, <SPACE> to toggle entry

Service

View error buffer

Copy error buffer to file

Delete error buffer

Display error message

Show exposure counter

Reset exposure counter

Panel test

Stand test

Stand test

A/D-converter

Grid

Filter

Collimator

Beam limiting device

Switches

Fig. 40

1 Help 2 45678910Quit

Start test

Switches 3

This menu displays one field for selection of test data. You can choose whether the position reading of the switches shall be carried out just once or continuously (until interruption). Press the spacer to choose between these two different alternatives. Press F2 or

the return key to read off desired alte rnative.

MAM00489

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 46 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 53

Adjustment and Service PC Programs 2 - 47

NOTICE

Normal mode

Generator data 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Normal mode

Generator data

Stand data

IONTOMAT data

DLF data

Actual values

Fig. 41

Generator data

Nominal high voltage

Nominal tube current 150.0 mA

Nominal standby filament current 3500 mA

Nominal exposure filament current 7032 mA

Counter pulses for boost of rotation anode 275

<ESC> to exit, <ENTER> to refresh data

1 Help 2 3 45678910Quit

25 kV

None of the menus under “Normal mode” are editable.

Nominal high voltage 3

Shows the kV set.

Nominal tube current 3

MAM00490

Shows the nominal value of the tube current.

Stand-by filament current 3

Shows the nominal value of the stand-by filament curr ent.

Exposure filament current 3

Shows the nominal value of the filament preparation.

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 47 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 54

2 - 48 Adjustment and Service PC Programs

Counter pulses for boost of rot. anode 3

Shows the number of inverter pulses used for the anode accelera tion.

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 48 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 55

Adjustment and Service PC Programs 2 - 49

Stand data 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Stand data

Normal mode

Generator data

Stand data

IONTOMAT data

DLF data

Actual values

Fig. 42

Compression thickness

Compression force 10 N

Filter combination 1 (Mo/Mo)

<ESC> to exit, <ENTER> to refresh data

1 Help 2 3 45678910Quit

34 mm

Compression thickness 3

Shows the thickness at last compression.

Compression force 3

Shows the force at last compression.

Filter combination 3

Shows the choosen anode/filter combination on the control panel.

MAM00491

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 49 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 56

2 - 50 Adjustment and Service PC Programs

IONTOMAT data 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

IONTOMAT data

Normal mode

Generator data

Stand data

IONTOMAT data

DLF data

Actual values

Fig. 43

Sense correction

Channel B

Quotient (TRA/RDL) 64 / 255

Transparency correction 3 / 8

Dose counter (RDL)

Transparency counter (TRA) 1469

Maximum current time product 600 mAs

Maximum exposure time 2000 ms

<ESC> to exit, <ENTER> to refresh data

1 Help 2 3 45678910Quit

1.0 E.P.

4322

Sense correction 3

Shows the sum of the density correction programmed via the “Sens. corr” menu and the

density correction set on the control deck.

Channel 3

Indicates which IONTOMAT channel is used.

MAM00492

Quotient (TRA/RDL) 3

Indicates the ratio between the dose pulses for the upper and lower detector .

Transparency correction 3

Dependent on the film - screen combination and the object, a density cor rection takes

place automatically. The digit indicates the size of the correction.

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 50 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 57

Adjustment and Service PC Programs 2 - 51

Dose counter (RDL) 3

Number of pulses from upper detector.

Transparency counter (TRA) 3

Number of pulses from lower detector.

Maximum current/time product 3

Shows the maximum mAs value allowed for selected operating mode.

Maximum exposure time 3

Shows the maximum exposure time allowed for selected operating mode.

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 51 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 58

2 - 52 Adjustment and Service PC Programs

DLF data 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

DLF data

Normal mode

Generator data

Stand data

IONTOMAT data

DLF data

Actual values

Fig. 44

Large focus molly

+0 % -22 % -2 %<- +0 % -1 % +0 % +0 % +0 % +0 % +0 %

avg = - 2 %

Large focus tungsten

+0 %<- +0 % +0 % +0 % +0 % +0 % +0 % +0 % +0 % +0 %

avg = + 0 %

Small focus molly

+0 %<- +0 % +0 % +0 % +0 % +0 % +0 % +0 % +0 % +0 %

avg = + 0 %

Small focus tungsten

+0 %<- +0 % +0 % +0 % +0 % +0 % +0 % +0 % +0 % +0 %

avg = + 0 %

<ESC> to exit, <ENTER> to refresh data

1 Help 2 3 45678910Quit

This menu shows the percentage deviation between actual and desired tube current as

well as the average deviation for the last ten exposures.

The arrow indicates the latest exposure.

MAM00493

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 52 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 59

Adjustment and Service PC Programs 2 - 53

Actual values 3

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Actual values

Normal mode

Generator data

Stand data

IONTOMAT data

DLF data

Actual values

Fig. 45

Actual high voltage 25.1 kV

Actual tube current 150.6 mA

Actual standby filament current 3470 mA

Actual intermediate circuit voltage 311 V

Actual current time product 24.8 mAs

Actual exposure time 170 ms

<ESC> to exit, <ENTER> to refresh data

1 Help 2 3 45678910Quit

Actual high voltage 3

Shows the actual kV at the start of the exposure.

Actual tube current 3

Shows the actual tube current at the start of the exposure.

Actual filament current 3

Shows the actual stand-by filament current.

MAM00494

Actual intermediate circuit voltage 3

Shows the intermediate circuit voltage applied at the start-up of the unit.

Actual current/time product 3

Shows the mAs value for the latest exposure.

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 53 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 60

2 - 54 Adjustment and Service PC Programs

Actual exposure time 3

Shows the exposure time for the latest exposure. The time may be 400-500 ms longer

than the maximum exposure time in the IONTOMAT data menu, depending on tube current reduction and how the filament current is adapted.

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 54 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 61

Adjustment and Service PC Programs 2 - 55

Test DUEP Communication

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Communication test

Switch is OFF

<ESC> to exit, <SPACE> to toggle entry

Fig. 46

1 Help 2 3 45678910Quit

Save

The Test DUEP Communication menu alternative is used to trace internal messages

between generator, panel iontomat and stand. This can be helpful when having problems

to report to software responsible.

Press F2 to switch test on. Received messages are shown.

Press F2 to switch test off.

Press F2 to show messages or space+F2 to hide them.

Press space+F2 to store messages to the file C:messages.txt or F2 not to store them.

MAM00495

Siemens-Elema AB Register 5 SPB7-230.114.02 Page 55 of 56 Mammomat 1000/3000

Solna, Sweden Rev. 01 03.99 SPS-UD Service Program

Page 62

2 - 56 Adjustment and Service PC Programs

Backup

Main menu

Configuration

Service

Normal mode

Test DUEP Communic.

Backup

Quit

Fig. 47

Backup

Copy installation area to disk

Copy installation area to floppy

Copy disk to installation area

Copy floppy to installation area

Submenu

Iontomat

Stand

Panel

All

MAM00496

Quit

Copy installation area to disk/floppy 3

Will copy installation parameters for the item(s) chosen in the submenu to file(s) on hard

disk/floppy (C:/A:).

The files will be named:

• i_backup.txt for iontomat parameters

• p_backup.txt for panel parameters

• s_backup.txt for stand parameters

Copy disk/floppy to installation area 3

Will copy installation parameters for the item(s) chosen in the submenu(s) from file(s) on

hard disk/floppy (C:/A:).

Exit the Service Program.

F10 can also be used.

Mammomat 1000/3000 Register 5 SPB7-230.114.02 Page 56 of 56 Siemens-Elema AB

Service Program Rev. 01 03.99 SPS-UD Solna, Sweden

Page 63

Error messages 4

NOTICE

General 4

• These messages only contain notes on error correction, no instruct ions for trouble-

shooting.

The service PC used must meet the following requirement:

• RAM minimum 4 MByte

• TYP minimum 386SX/25MHz

• HD minimum 2.5 MByte free memory

A short description is delivered with the service PC-SW.