Page 1

MAMMOMAT 1000/3000

Wiring Diagrams

© Siemens AB 1999

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders w ill be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Register 6 English

Print No.: SPB7-230.051.05.02.02 Doc. Gen. Date: 10.99

Replaces: SPB7-230.051.05.01.02 65 27 25 8

Page 2

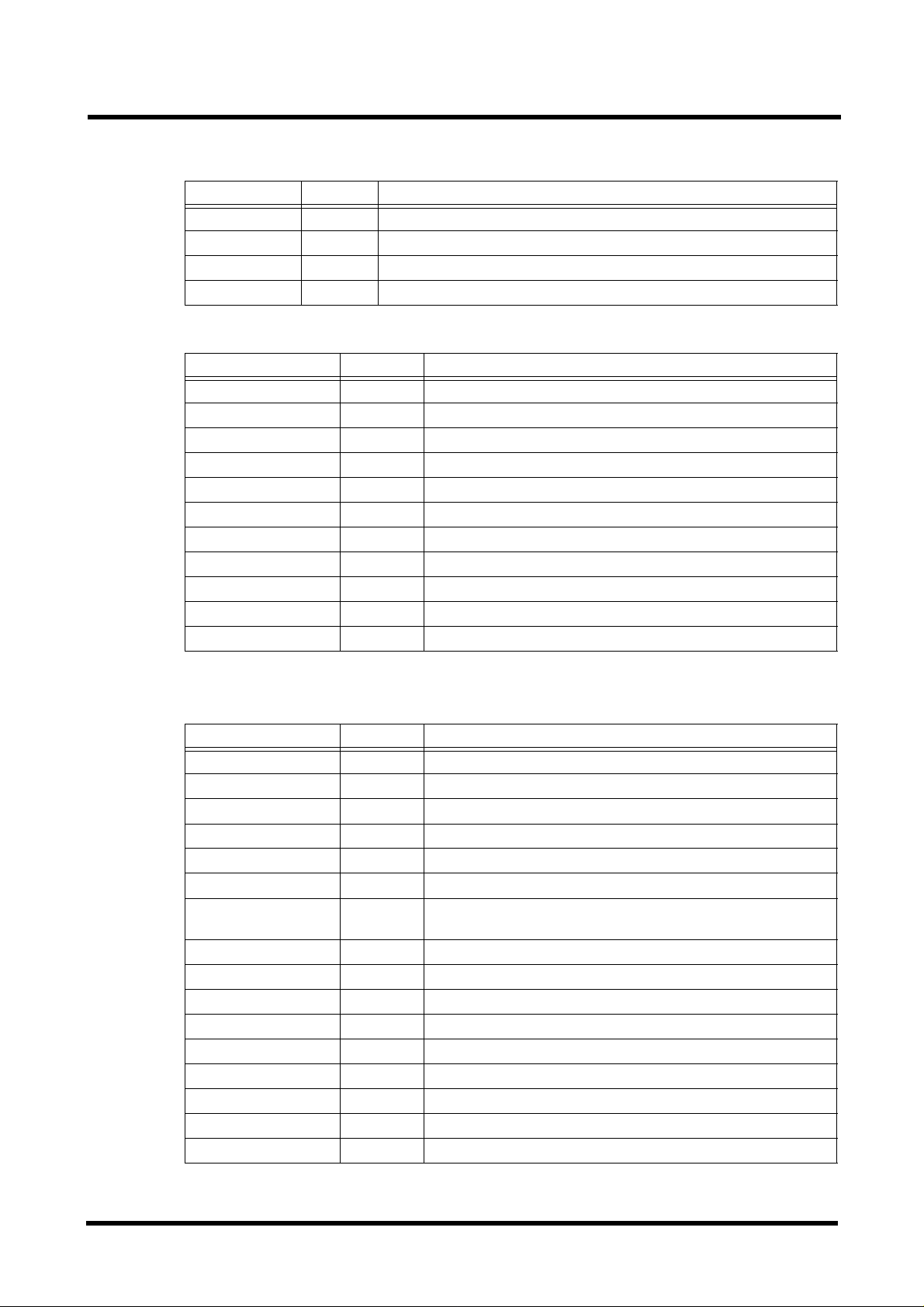

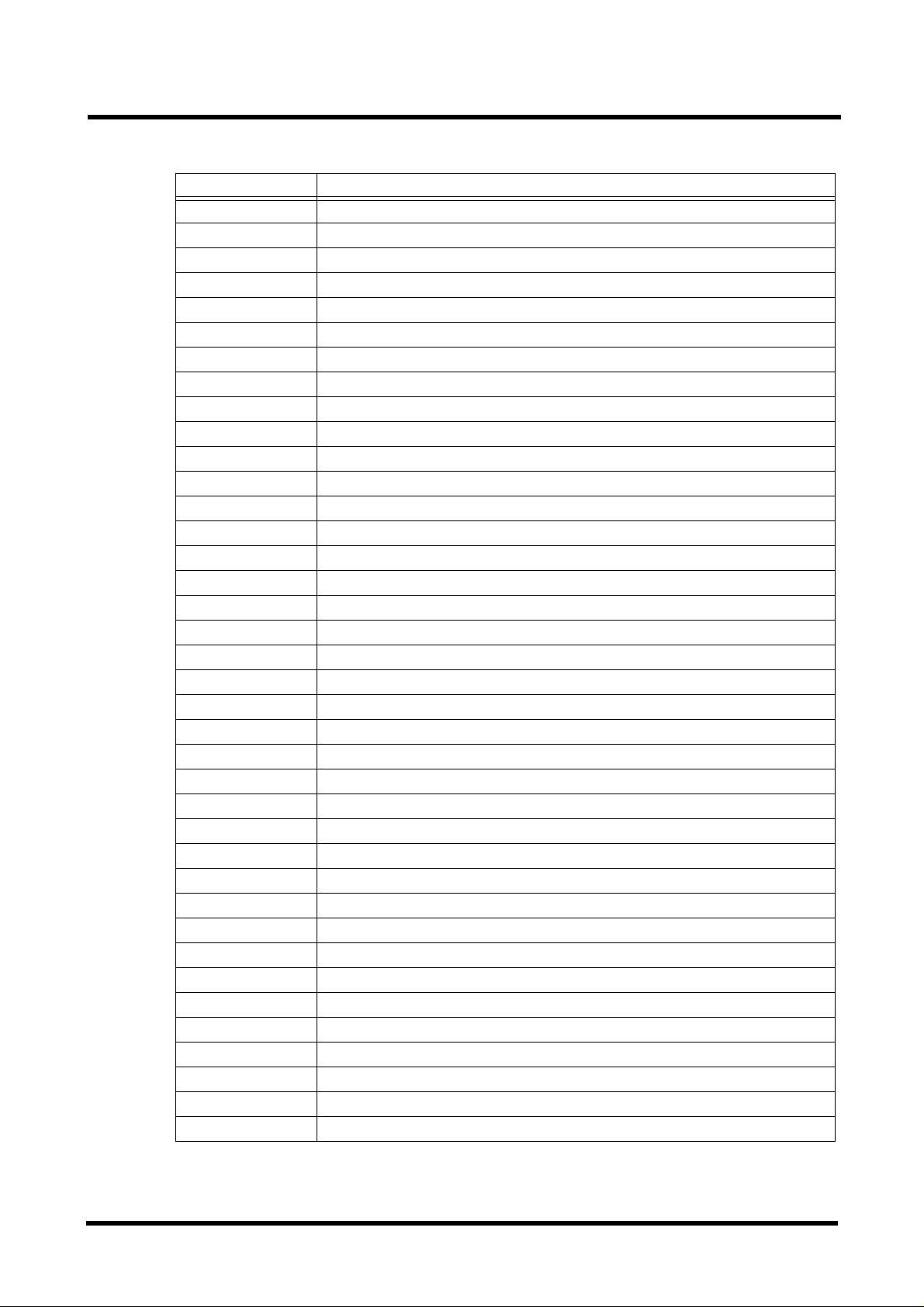

0 - 2 Revision

Chapter Page Revision

1202

2 2, 4-9, 11-12 02

3 1-2, 11 02

5202

MAMMOMAT 1000/3000 Register 6 Drucknr_kurz_V Page 2 of 4 Siemens-Elema AB

Manual_V Rev . _V 10.99 SPS-UD Solna, Sweden

Page 3

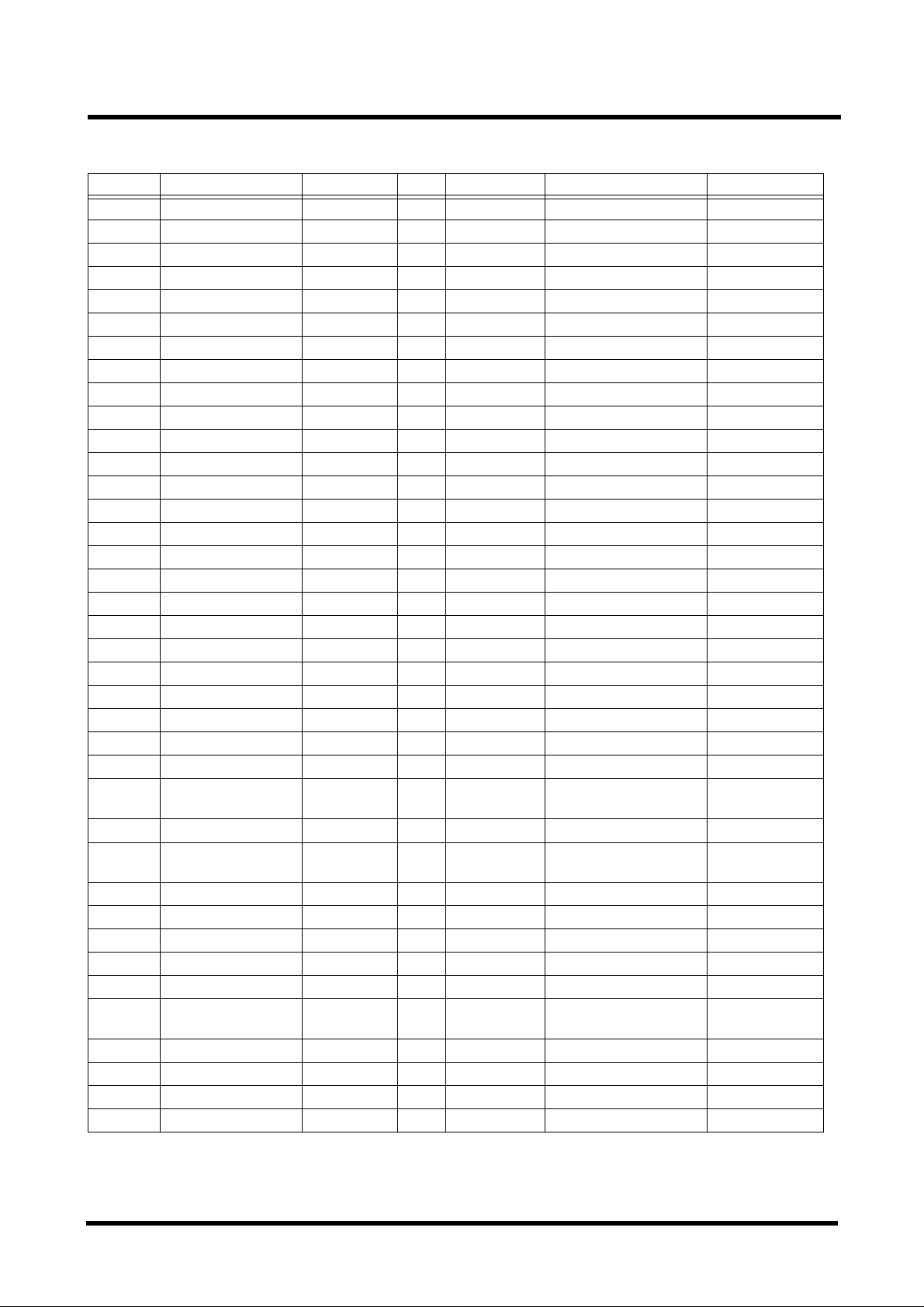

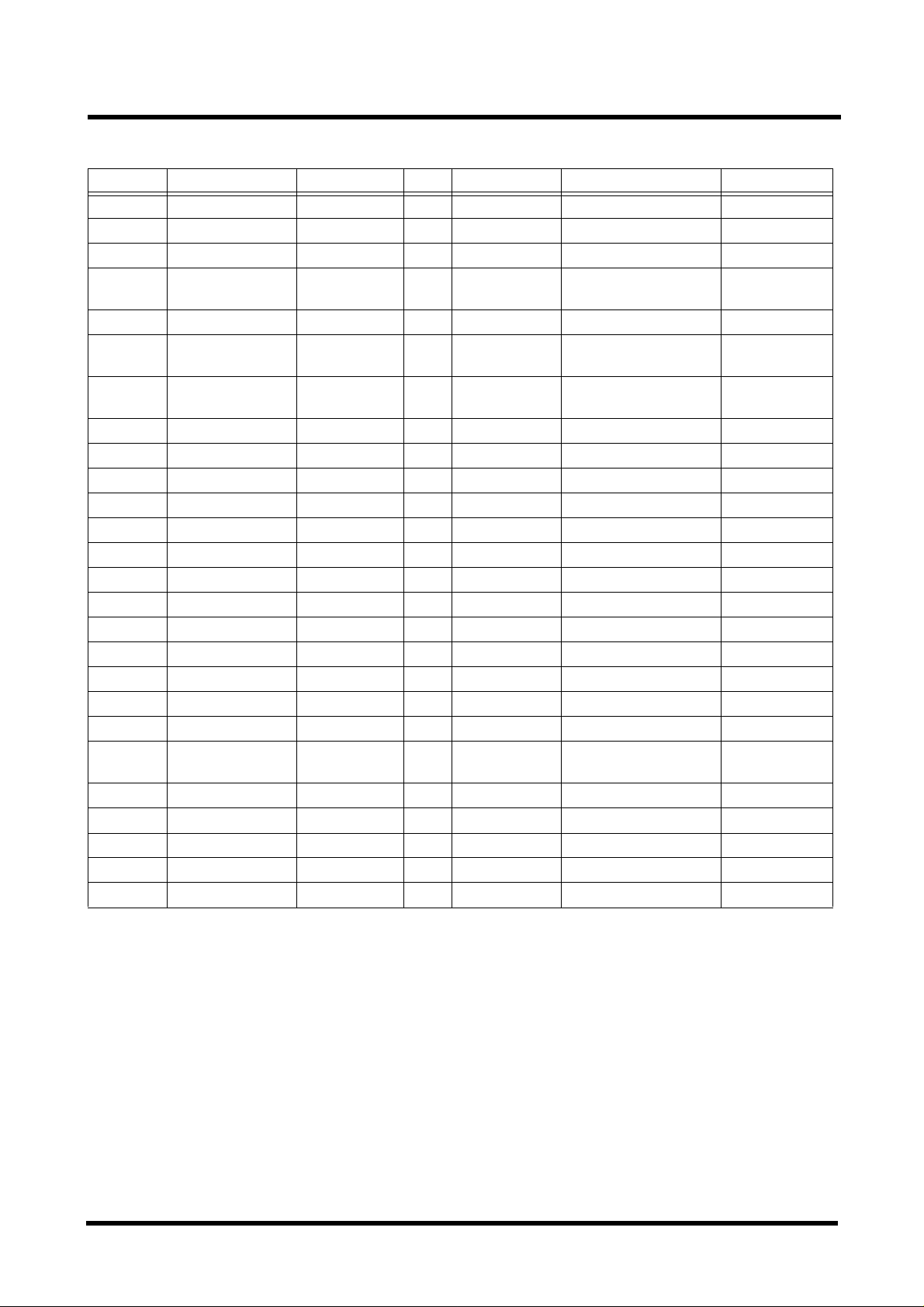

Contents 0 - 3

Page

This document is valid from serial No. 6500

1 _______System Overview ______________________________________________1 - 1

System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

MAMMOMAT 1000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

MAMMOMAT 1000 WITH REMOTE CONTROL. . . . . . . . . . . . . . . . . 1 - 2

MAMMOMAT 3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

2 _______Stand Overview _______________________________________________ 2 - 1

Placement of PC-boards and Components, Stand . . . . . . . . . . . . . . . . . .2 - 1

MAMMOMAT 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

MAMMOMAT 3000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

List of Boards and Fuses, Stand . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 4

PCB Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 4

Fuses Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 4

List of Switches and Components, Stand . . . . . . . . . . . . . . . . . . . . . . .2 - 5

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Potentiometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

List of Signals and Test Points, Stand . . . . . . . . . . . . . . . . . . . . . . . . .2 - 8

List of Voltages and Test Points, Stand . . . . . . . . . . . . . . . . . . . . . . . 2 - 12

3 _______Stand Functional Diagrams ______________________________________3 - 1

Block Diagram Cable Connections. . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

Grounding Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

Mains Connection, Power Supply CPU . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Grounding Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Power Supply Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 4

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 5

CPU Board Internal, Generator Interface . . . . . . . . . . . . . . . . . . . . . . .3 - 6

Tube, Temperature Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 7

Lift and Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Lift and Rotation Motor Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 9

Lift and Rotation Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Lift and Rotation Switches, M1000 with Remote Control . . . . . . . . . . . . . . 3 - 11

Compression Measurement Signals . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

Compression Motor Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 13

Tube Angle Measurement, Pot. Return,Tilt Signal . . . . . . . . . . . . . . . . . 3 - 14

Collimator 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 15

Collimator 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 16

Siemens-Elema AB Register 6 SP B7-230.051.05 Page 3 of 4 Mammomat 1000/3000

Solna, Sweden Rev. 02 10.99 SPS-UD Wiring Diagrams

Page 4

0 - 4 Contents

Page

Object Table 1 + 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 17

Automatic Exposure Control (AEC) . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 18

4 ______ Generator Overview ____________________________________________4 - 1

Mains Voltage Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

List of PC-boards and Components, Generator . . . . . . . . . . . . . . . . . . . 4 - 2

Subassembly and PC board overview/Baugruppen un d Platinenübersicht . . . . 4 - 2

Control Panel Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

List of Switches and Components, Generator . . . . . . . . . . . . . . . . . . . . 4 - 4

Control Panel Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

List of Switches and Components, Generator . . . . . . . . . . . . . . . . . . . . 4 - 6

Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Potentiometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Compon ent Overview (Generator)/ Bauteileübersicht (Generator) . . . . . . . . 4 - 7

List of Signals and Test Points, Generator . . . . . . . . . . . . . . . . . . . . . . 4 - 8

Signal Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 14

5 ______ General Functional Diagrams_____________________________________5 - 1

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Ground, 0V and Protec t ion Ground Dis t ribution. . . . . . . . . . . . . . . . . . 5 - 2

Line Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Back Plan e D 700 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Principle D iagram, Mas t er . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

Principle D iagram, Tube Filament . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Principle D iagram, Foc us Selection Bo ard . . . . . . . . . . . . . . . . . . . . 5 - 7

Principle D iagram, Inve rt er Control an d k V R egulation . . . . . . . . . . . . . . 5 - 8

Principle D iagram, Inve rt er . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 9

Principle D iagram, Cont rol Panel . . . . . . . . . . . . . . . . . . . . . . . .5 - 10

Principle D iagram, Iont om at . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 11

6 ______ Generator PC Board Overview____________________________________6 - 1

Contact Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Mammomat 1000/3000 Register 6 SP B7-230.051.05 Page 4 of 4 Siemens-Elema AB

Wiring Diagrams Rev . 02 10.99 SPS-UD Solna, Sweden

Page 5

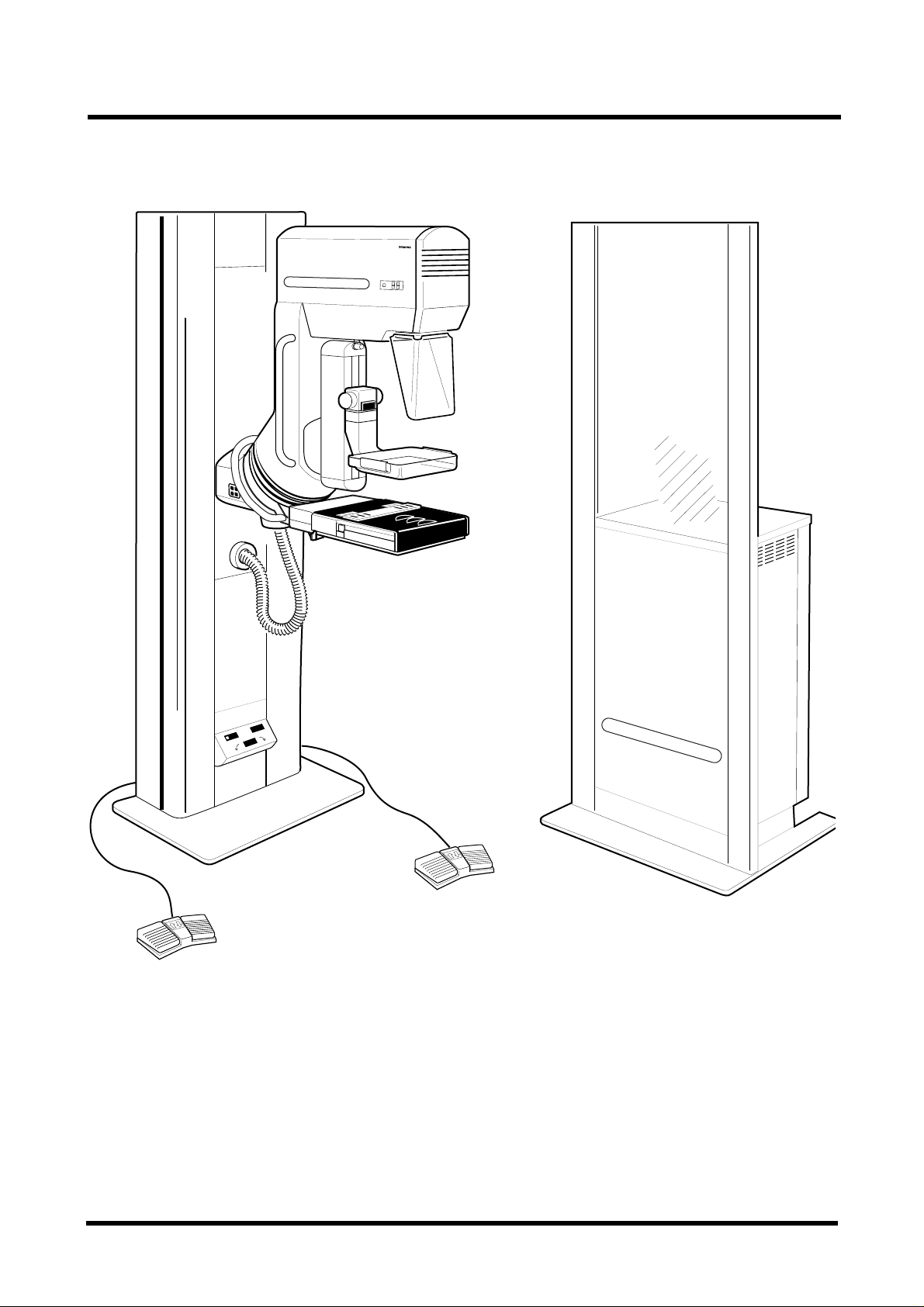

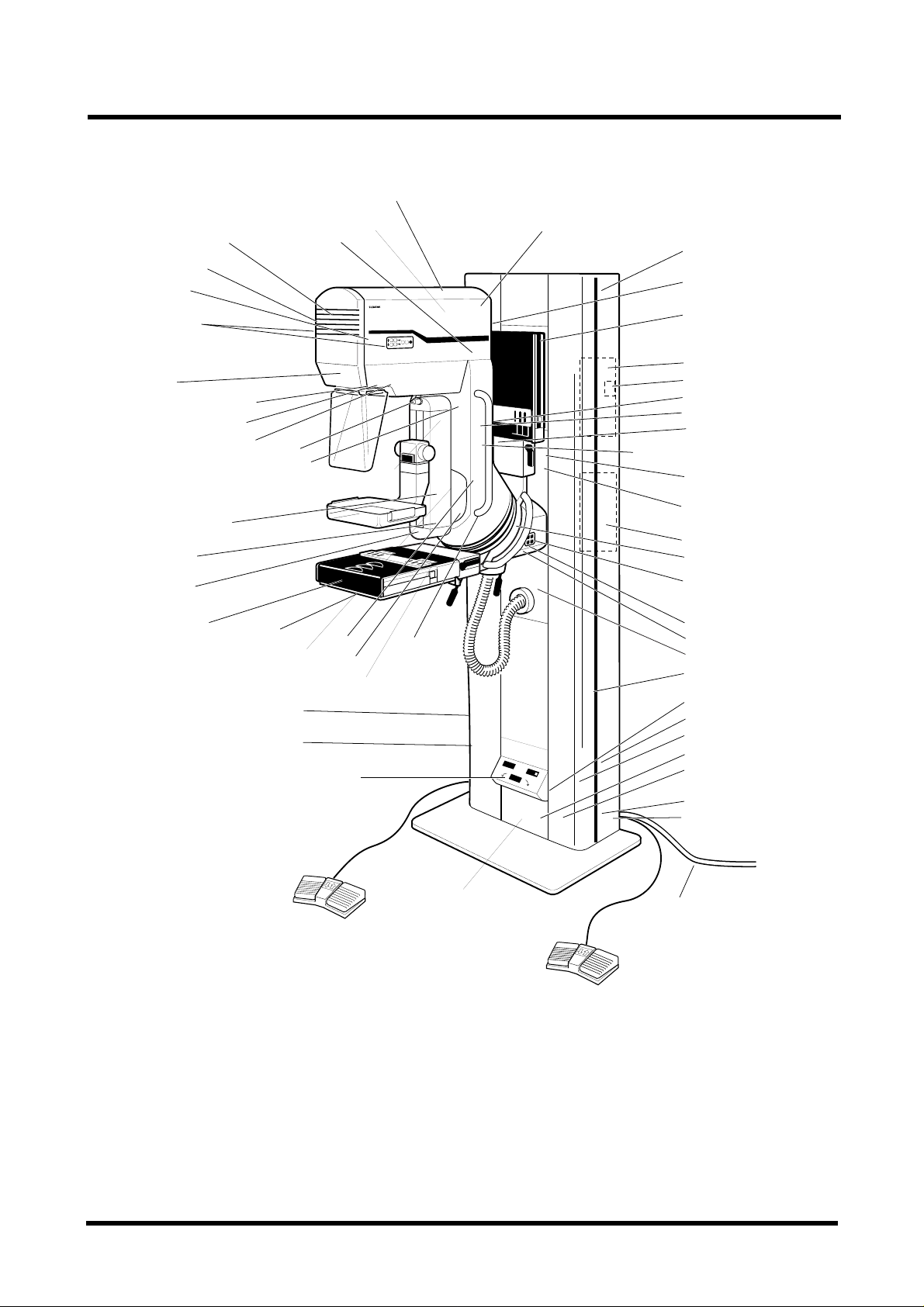

X041E 1-1

SYSTEM OVERVIEW

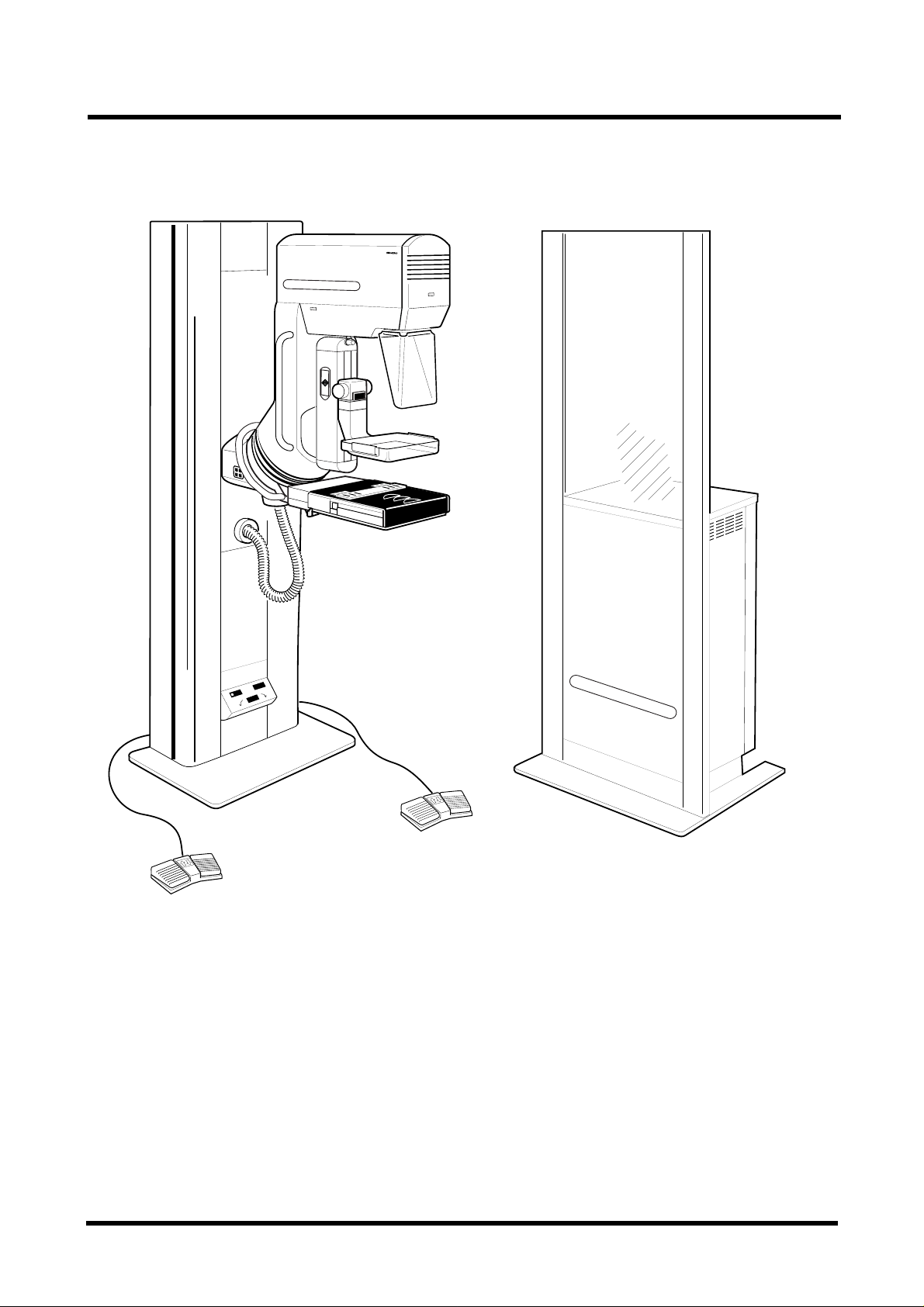

MAMMOMAT 1000 0

MAMMOMAT 1000

Fig. 1 Mammomat1000 with generator with integrated control panel a nd radiation shield.

MAMMOMAT

Siemens Elema AB Register 6 SP B7-230.051.05 Page 1 of 4 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 6

1-2 X041E

SYSTEM OVERVIEW 1

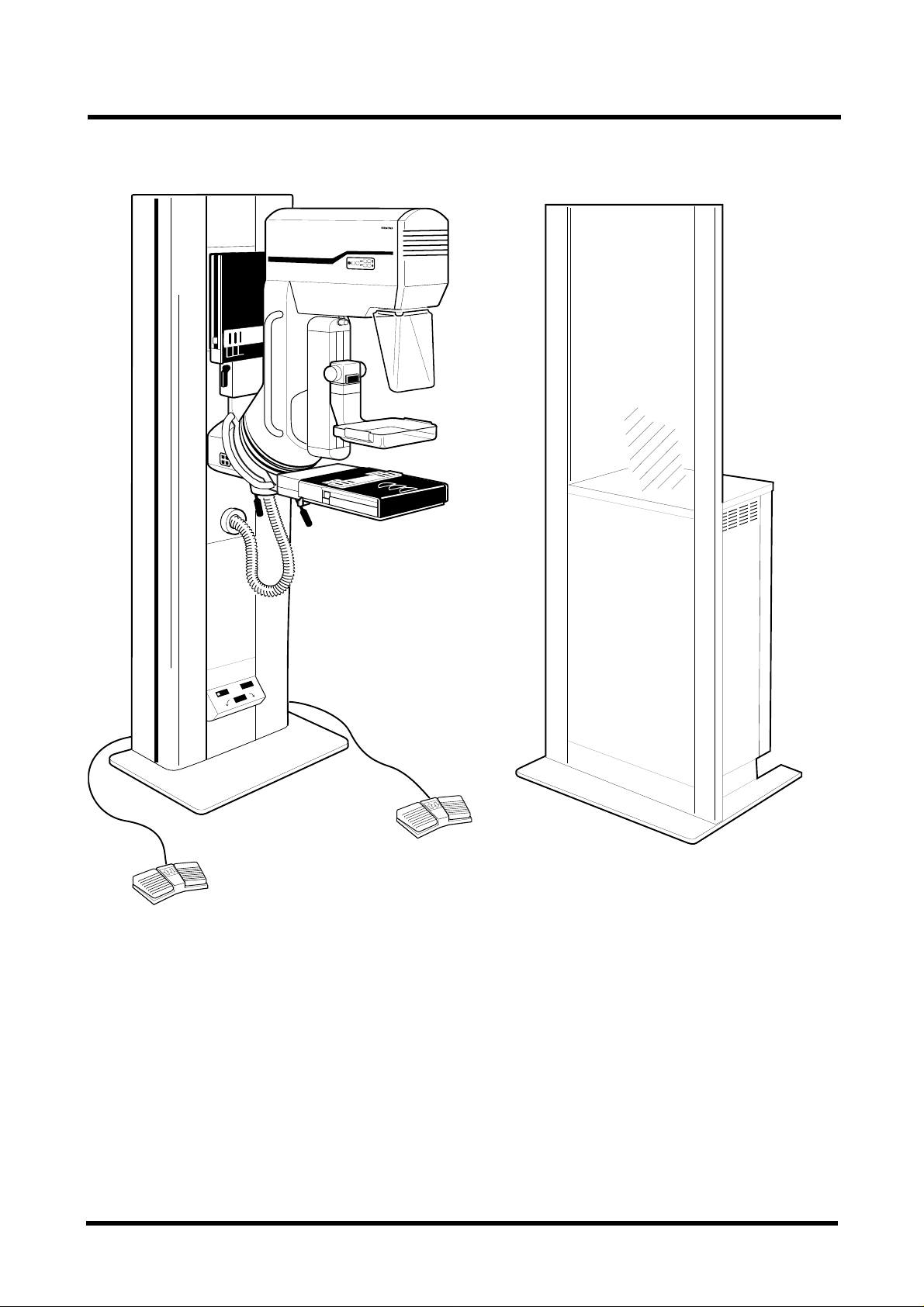

MAMMOMAT 1000 WITH REMOTE CONTROL 0

MAMMOMAT 1000

MAMMOMAT 1000

MAMMOMAT

MAMMOMAT

Fig. 2 Mammomat 1000 gene rat or with integrated control panel and ra diation shield .

MAM00638

MAM00638

Siemens Elema AB Register 6 SP B7-230.051.05 Page 2 of 4 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 7

X041E 1-3

SYSTEM OVERVIEW 1

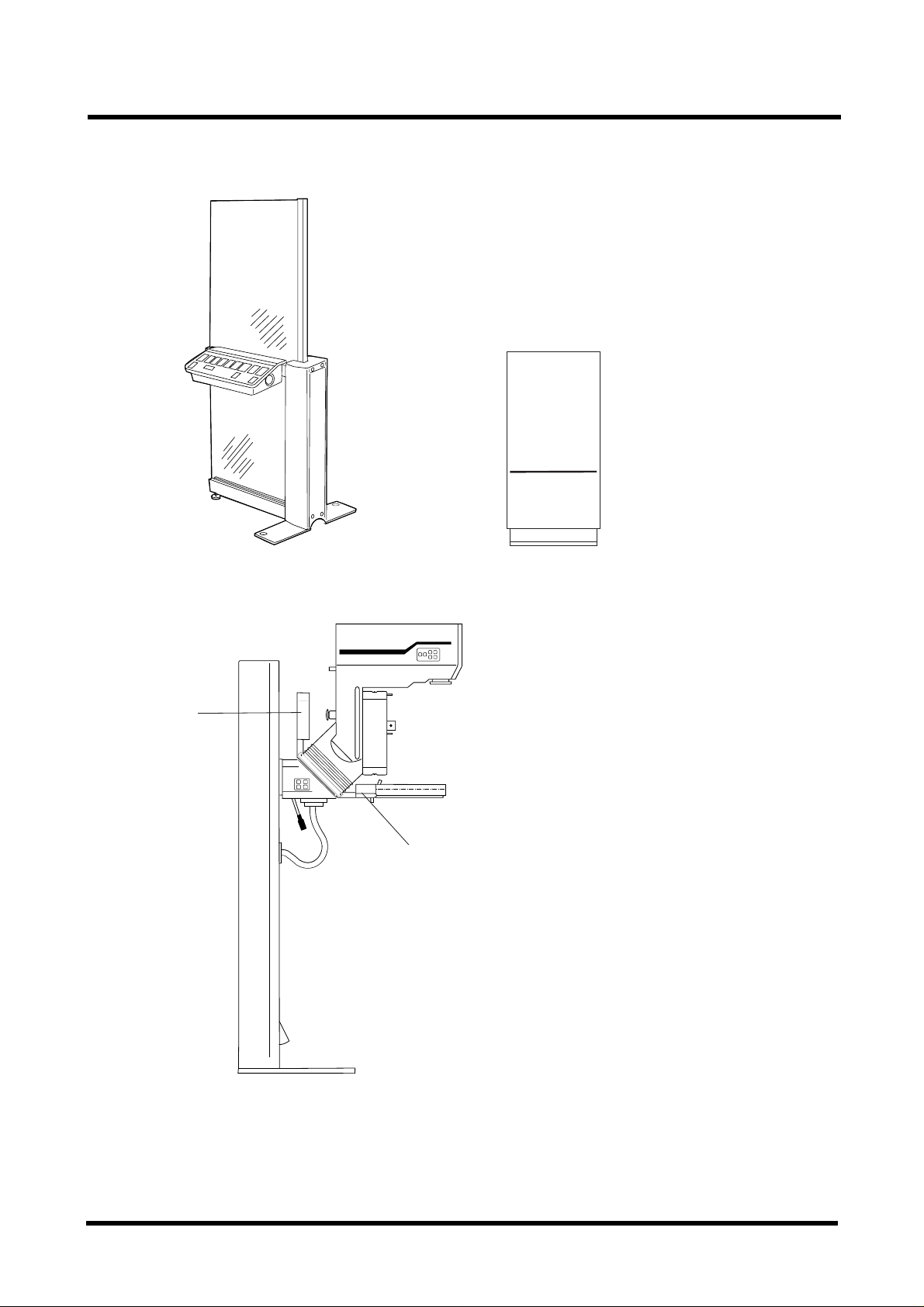

MAMMOMAT 3000 0

Fig. 3

MAMMOMAT 3000 in stallation with pivoted obje c t- ta ble arm and generator with integrated control panel and radiation shield.

Alternat iv ely, the contro l panel and the radiation shi eld can be sepa rat ed from the generator, see overle af .

Siemens Elema AB Register 6 SP B7-230.051.05 Page 3 of 4 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

MAM00421

Page 8

1-4 X041E

MAM00423

SYSTEM OVERVIEW 1

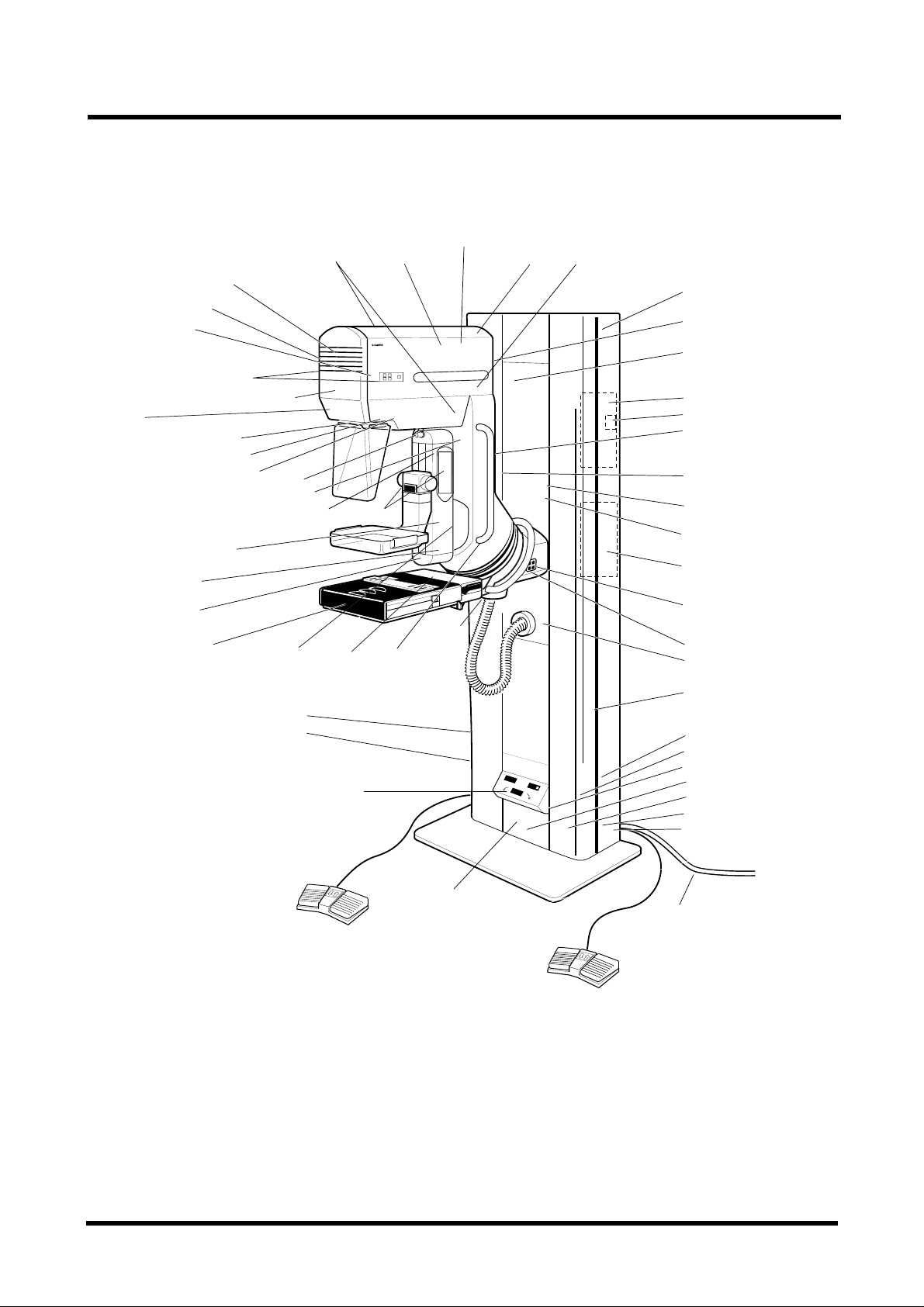

MAMMOMAT 1000/3000

SIEMENS

MAMMOMAT 3000

Counterweight

Fig. 4 Free-standing radiation shield with separate

contro le console

SIEMENS

·

Fixed object-table arm

MAM00424

Fig. 5 Separate generator

MAMMOMAT 3000

MAM00427

Fig. 6 Stand with fixed object-table arm

Pivoted object-table arm (“f ly ing wing”) replac ed by fixed objec t -t able arm and cou nt erweight.

Siemens Elema AB Register 6 SP B7-230.051.05 Page 4 of 4 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 9

X041E 2-1

PLACEMENT OF PC-BOARDS AND COMPONENTS, STAND

MAMMOMAT 1000 0

K7-K9

S867*

m5*

D807 Right side

D807 Left side

S865*

S866*

m4*

m7*

* not fitted with one

filter collimator

** not used with one

filter collimator

*** not used

Lamp, X894

M2 (Compression)

Strain gauge

D804

Object table

S1

S2

M

Tube

S897

S868*

m8*

D813****

R861

X874

S861

S862

S883

S884

D813****

R863

S892

X892

D803

X801

X877

X878**

D811****

X858***

X870

M6

MAMMOMAT 1000

D813****

Z801

D812****

D805

M1 (Lift), X887, R807

R871

S882

D801

D809

S880

S881

S869

M3 (Rotation)

X888

D802

D808 Right side

D808 Left side

R803

X898, R806

R805

X881

X885

X880, X803

T802

T801

X899

F801-805

MAM00637

Incoming mains

**** option, remote control

Fig. 7

Siemens Elema AB Register 6 SP B7-230.051.05 Page 1 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 10

2-2 X041E

PLACEMENT OF PC-BOARDS AND COMPONENTS, STAND

MAMMOMAT 3000 0

M6

K7-K9

S867, M5

D807 Right side

D807 Left side

S865

S866

Lamp, X894

M4

M7

Tube

S897

S868

m8

R861

X874

D805

X877

X878

R863

D810

M1 (Lift), X887, R807

R871

S882

D801

D809

S880

S896

S881

S892

X892

S869

M2 (Compression)

Strain gauge

D804

Object table

S1

S2

M

S890

S884

S861

S862

S883

S896

S895

S891

X891

D803

X801

X858

X870

Z801

M3 (Rotation)

X888

D802

S894

D808 Right side

D808 Left side

R803

S860

X898, R806

R805

X880, X803

X881

X885

T802

T801

X899

F801-805

MAM00426

Incoming mains

Fig. 8 Stand with pivoted object-table arm

Siemens Elema AB Register 6 SP B7-230.051.05 Page 2 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 11

X041E 2-3

PLACEMENT OF PC-BOARDS AND COMPONENTS, STAND

SIEMENS

·

Counterweight

Fixed object-table arm

MAM00427

Fig. 9 Stand with fixed object-table arm

Pivoted object-table aram (“flying w ing”) replaced by fixed objec t -t able arm and c ounterweigh t

Siemens Elema AB Register 6 SP B7-230.051.05 Page 3 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 12

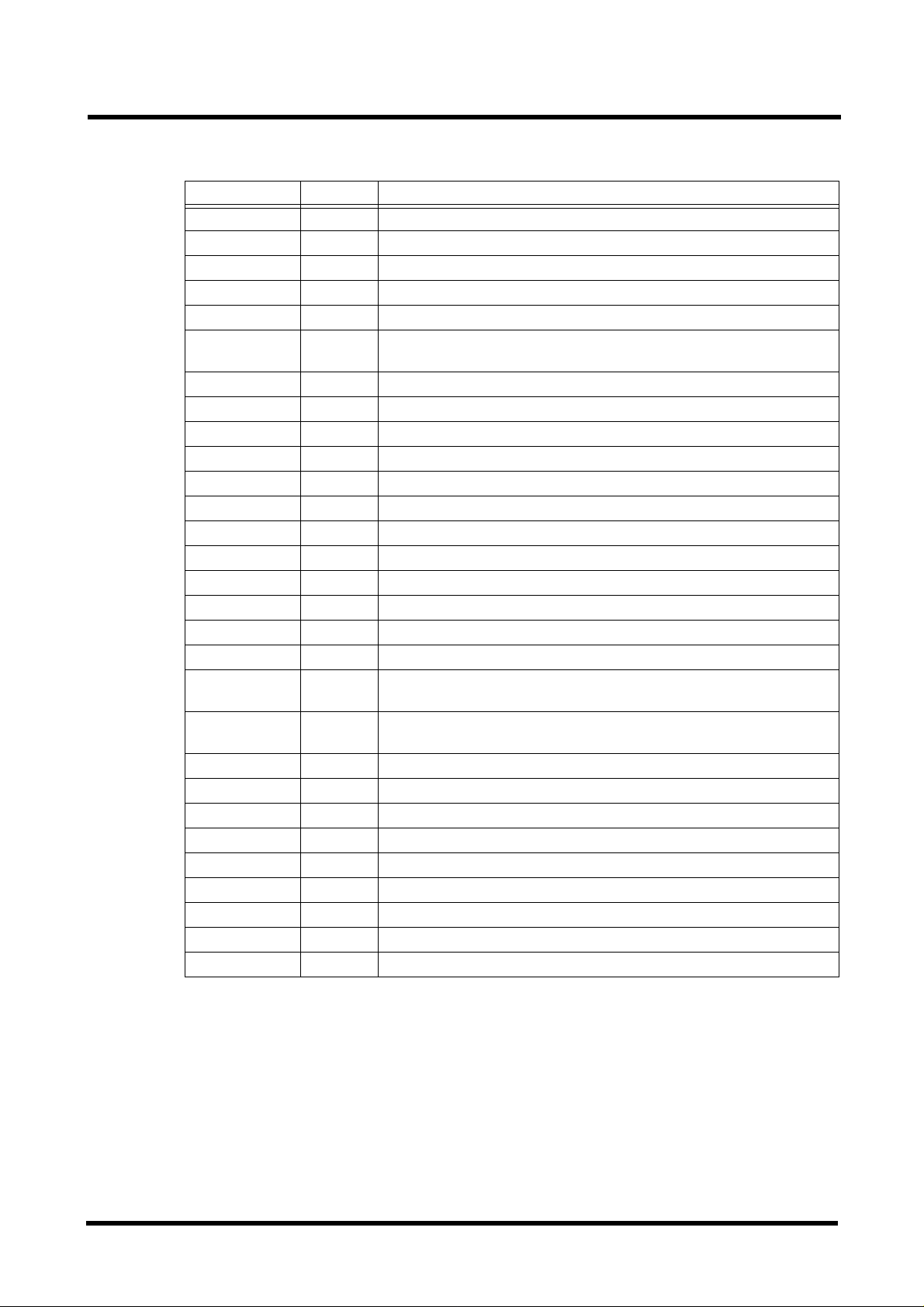

2-4 X041E

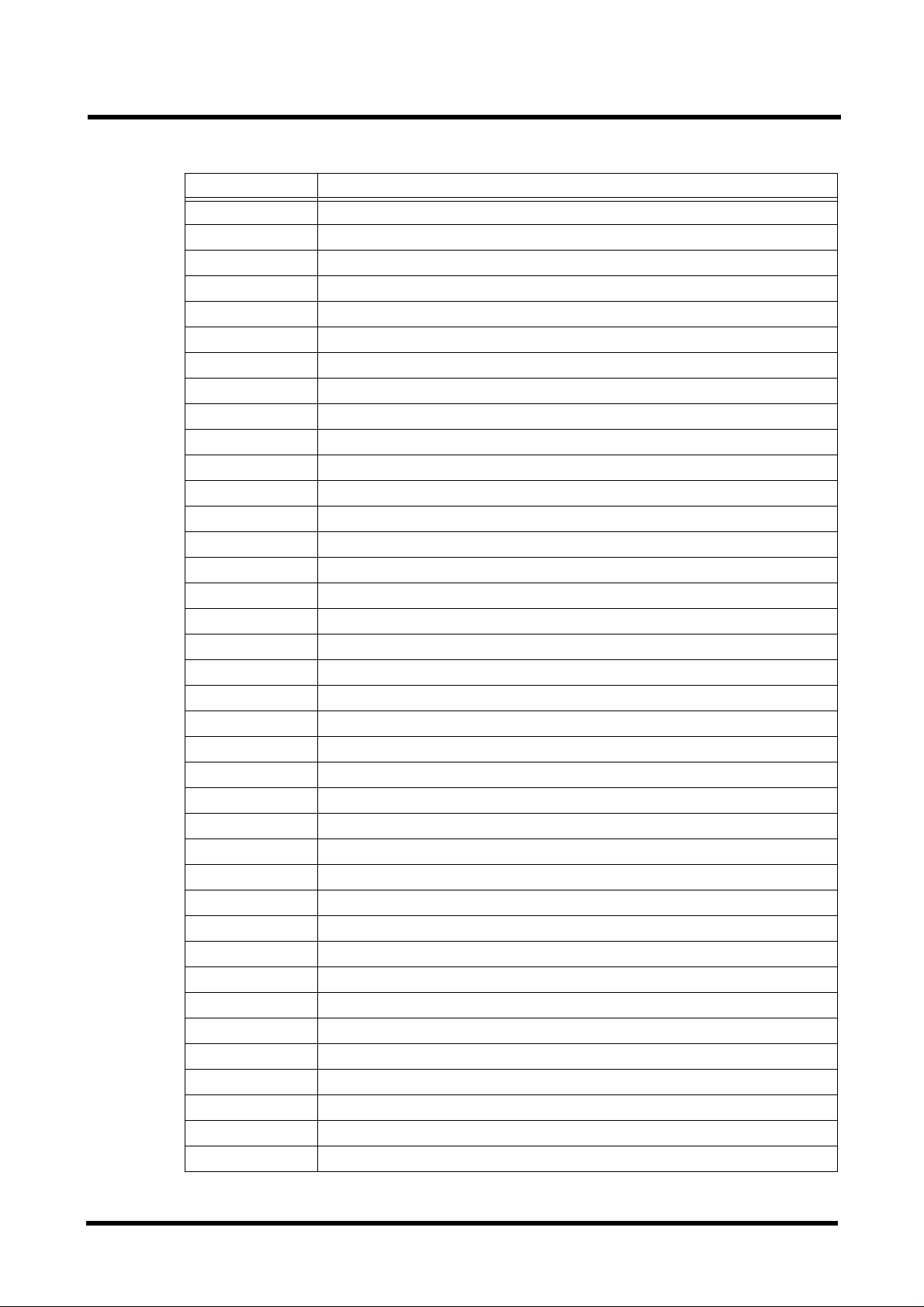

LIST OF BOARDS AND FUSES, STAND

PCB Overview 0

D801 CPU BOARD

D802 MOT OR CONTROL BOARD

D803 DISPLAY BOARD

D804 FORCE AMPLIFIER BOARD

D805 WING BOARD

D807 BOARD FOR LIFT, ROTATION AND LAMP SWITCHES (NOT FIT-

TED IN M1000)

D808 BOARD FOR LIFT AND ROTA TION SWITCHES

D809 THICKNESS ADAPTER BOARD

D810 TILT SWITCH BOARD (Not fit ted i n M1000)

Option, remote control (MAMMOMAT 1000 only) 0

D81 1 REMOTE CONTROL TRANSMITTER (2 INCLUDED)

D812 REMOTE CONTROL RECEIVER (1 INCLUDED)

D833 REMOTE CONTROL DETECTOR (4 INCLUDED)

Fuses Overview 0

PCB FUSE FUSED VOLTAGE

D801 F1 2 AT +5V, +5V_REF, +5V_DSP, +7V

D801 F2 1 AT +5V_MPS

D802 F1 5 AT +5V, +5V_M, +14V, D805/+5V

D802 F2 3.15 AT +24VF, +15V

D802 F3 6.3 AT +24V

D802 F5 5AT 17VAC (LAMP)

D802

Chassis-mounted

fuses

F4 1 AT 24VACF (FAN)

F801 2 AT 11 VAC

F802 1 AT 11 V_M P S

F803 5 AT 14 VAC

F804 5 AT 17 VAC

F805 6.3 AT 24 VAC

NOTE! See spare parts list for replacement fuses.

Siemens Elema AB Register 6 SP B7-230.051.05 Page 4 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 13

X041E 2-5

LIST OF SWITCHES AND COMPONENTS, STAND

Switches 0

Switch Page Description

S1/D 801 3-6/1D Reset switch fo r st a n d C P U .

S1/Object table 3-16/2A Grid out switch located in the object tabl e.

S1-1-4/D802 3-9/3D Current li m it switches: 1=+3%, 2=+6 %, 3=+12% , 4=+24%.

S1-5/D802 3-9/3D Tacho On/Off switch for rotation motor drive.

S1-S6/D807* 3-10/2A Control switches for lamp, lift- and r otation movement. Left and right side.

S1-S6/D811**** Control swithces and transmitter fo r la mp , lift- and rotation move ment.

Left and right side. 2 provided.

S1-S4/D808 3-10/4B Control switches for lift- and rotat ion movement. Left and right side.

S2/Object table 3-16/2A Cassette inserted switch.

S860* 3-16/3C Stereo lever switch

S861 3-12/2G Compression limit switch, compression unit.

S862 3-12/2G Decompression limit switch, compression unit.

S865** 3-15/2E 18 x 24 Collimator optoswitch

S866** 3-15/3E 24 x 30 Collimator optoswitch**.

S867** 3-15/4E Filter position, optoswitch**.

S868** 3-15/5E Focus position optoswitch**.

S869 3-8/3G Tacho opt oswitch

S880 3-4/2B Emergency stop, switches off 24VAC and 14VAC, machine blocked.

S881 3-9/2G Lift up limit switch, rotating unit.

S882 3-4/2A Limit switch, dista nce tube head - floor <50 mm, switch es off 24VAC,

machine blocked.

S883 3-8/4B Collision protection switch, risk of collision when tubehead is less than

120 mm from the floor.

S884 3-9/2G Lift down limit switch, rotating unit.

S890* 3-16/3C AEC in position switch (Wing 1)

S891* 3-16/3C Object table locked in position (Wing1)*.

S892 3-16/2C Object table locked in posi tion (Wing 2)***.

S894* 3-16/3C Select wing 1 switch*, ***.

S895* 3-16/3C Select wing 2 switch*, ***.

S896* 3-13/5B Tilt opto-switch. 0° or ±10

S897 3-15/2G Diaphr agm swit ch.

S3 3-12/5F Decompression button (only with separate control console)

*.

**.

*.

0

used with stereo option*.

.

* Not fitted in M1000

** Not fitted in M1000 with one filter

*** Not fitted in M3000 one wing

**** M1000 option, remote control

Siemens Elema AB Register 6 SP B7-230.051.05 Page 5 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 14

2-6 X041E

LIST OF SWITCHES AND COMPONENTS, STAND

Potentiometers 0

Potentiometer Page Description

R803 3-13/2A Tube angle, 2k.

R861 3-11/3E Preset force, 10k.

R863 3-11/3E Thickness, 2k.

R871 3-13/2A Preset angle, 10k.

Motors 0

Motor Page Description

M 3-16/2A Grid motor, pl aced in object table with gri d.

M1 3-9/2G Lift motor.

M2 3-12/2G Compression motor.

M3 3-9/ 3G Ro tation motor.

M4* 3-15/3D Collimator stepping motor

M5* 3-15/4D Filter st epping motor

M6 3-7/4E Fan, tube cooling.

M7* 3-14/4G Mirror magnet

M8* 3-15/5D Focus stepping motor

M9 3-9/ 5G Ro tat ion brake.

M10 3-9/5G Rotation brake.

*.

*.

*.

*.

* Not fitted in M1000 with one fil ter

Miscellaneo us 0

Misc. Page Description

COMP. UNIT 3-11, 3-12 Compression unit.

CABLE DUCT 3-2/3A Generator to stand cable protecti on.

GROUND RAIL 3-2/1E System grounding terminal.

K7 3-7/4E Fan thermost at.

K8 3-7/4E Tube overtemperature t herm ostat.

K9 3-7/4E Tube housing overpressure switch.

L804 - L809 3-9/SG

3-12/2G

LAMP 3-14/5G F iel d light lamp.

R805 3-9/5G Brake resistor, 6.2Ω.

R806 3-9/5G Brake varistor

R807 3-9/2G Lift motor varistor.

R860 3-11/2A Strain gauge (R=300-400 Ω)

T801 3-3/2C Mains transformer.

T802 3-3/3C Insolation transformer

Z801 3-3/4C Stereo mains filter, stand

C801 - C803 3-12/5G EMC capacitors

VHF choke (EMC)

Siemens Elema AB Register 6 SP B7-230.051.05 Page 6 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 15

X041E 2-7

LIST OF SIGNALS AND TEST POINTS, STAND

This page int entionally le ft blank.

Siemens Elema AB Register 6 SP B7-230.051.05 Page 7 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 16

2-8 X041E

LIST OF SIGNALS AND TEST POI NTS,STAND

Page Signal Name Origin Via Destination Testpoint LED

3-9/1C ACT_SPEED TACHO D802 ACT_SPEED

3-16/3C AEC_POS S890 D801 D801

3-10/2A ANGLE_MEM A.M. -pot D807 D801

3-6/2B AR VH D801 GENERATOR D801 AR

3-11/3B BR_OPEN D804 D804.X843 pin 8 V2

3-11/3B BR_RET D804 D804.X843 Pin 7

3-9/4B

3-9/4E

3-9/4E

3-15/3C C_LA D805 M4

3-15/3C C_LB D805 M4

3-9/4E C_LIM D802 V11

3-15/3C

3-15/3C

3-15/3C

3-15/3C

3-12/2D C_PWM D802 M2 D802

3-16/1A CASS_LOADED OBJ. TABLE D805 D801

3-16/2C

3-16/2C

3-16/3E COLL_POS_18X24 18x24 switch D805 D801 COLL_P1

3-16/4E COLL_POS_24X30 24x30 switch D805 D801 COLL_P2

3-12/1E COMP_LIMIT D802 D805 COMP. UNIT

3-12/1B

3-11/2F COMP_FORCE D804 D801 D804.X843 pin 5

3-12/3E COMP_OK D802 D801 D802 V2

3-12/1E COMP_PROT D802 D801 D802

3-12/1B

3-12/4F COMPRESS PEDAL D805 D801, D802

3-9/2D D_PWM D802 D802

3-12/1E DECOMP_ LIMIT D802 D805 COMP. UNIT

3-12/4F DECOMPRESS PEDAL / ** D801

3-9/3B

3-9/4F DRIVE_OK D802 D801 D802

3-9/1E DRIVE_PROT D802 D801 D802

3-15/3D FI_LA D805 M5

3-15/3D FI_LB D805 M5

3-15/3D

“*SIGNAL” = “SIGNAL” active low

**plus decomp ression button on sepa rate control console.

BRAKE D801 D802

*

BRAKE_RET D802 M9, M10 D802

*

BRAKE_RELAY D802 not used

*

C_PA1 D805 M4

*

C_PA2 D805 M4

*

C_PB1 D805 M4

*

C_PB2 D805 M4

*

COLL_DIR D801 D805 D805 COLL_D

*

COLL_STEP D801 D805 D801, D805 COLL_ST

*

COMP_DIR D801 D802 D802 COMP_D

*

COMP_SPEED D801 D802 D801, D802

*

DIR D801 D802 D802

*

FI_PA1 D805 M5

*

COMP_SP

COMP_ERR

V24DRIVE_ERR

Siemens Elema AB Register 6 SP B7-230.051.05 Page 8 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 17

X041E 2-9

LIST OF SIGNALS AND TEST POINTS, STAND

Signal Name Description

ACT_SPEED Test point for frequency to volt age converted tacho signal .

AEC_POS AEC-detector in position near breast.

ANGLE_MEM Operator control signal for preset stop angle.

AR Signal given to generator as exposure request. If grid used, grid has started.

BR_OPEN Bridge open, compression force stra in gauge not working correctly .

BR_RET Compression force strain guage retur n li ne (appr . 0V)

*BRAKE Control signal to brake reversing relay.

*BRAKE_RET Output to the brakes for max or min braking when active.

BRAKE RELAY Output to brake reversing relay, max brake if *BRAKE_RET active.

*

C_LA Output li ne A. Col li m ator stepping motor M4

C_LB Output li ne B. Col li m ator stepping motor M4

C_LIM Rotation and fast-acting current limit

C_PA1 Output Phase A1. Collimator stepping motor M4

*

C_PA2 Output Phase A2. Collimator stepping motor M4

*

C_PB1 Output Phase B1. Collimator stepping motor M4

*

C_PB2 Output Phase B2. Collimator stepping motor M4

*

C_PWM Pulse Width Modulated power output to compression motor.

CASS_LOADED Cassette inserte d in obj ect table.

COLL_DIR Directi on Control signal . For the fi lter stepping motor.

*

COLL_STEP Step control signal for the collimator ste pp in g m o to r.

*

COLL_POS_18X24 Signal from the 18 x 24 colli m ator optoswitch

COLL_POS_24X30 Signal from the 24 x 30 colli m ator optoswitch

COMP Power output via compression limit switch to compression motor.

COMP_DIR Controls compression motor to compress (mo ving down)

*

COMP_FORCE Analog signal indicating compression force.

COMP_OK Compression motor working correctly, no over current.

COMP_PROT Compression relay K4 is working correctly, checked 1s after pedal release.

COMP_SPEED Pulse Width Modulated signal to control speed of compression motor (20kHz) .

*

COMPRESS Operator control signal to move compression plate down.

D_PWM Pulse Width Modulated power output to r otation or lift motor.

DECOMP Power output via decompression limit switch to compression motor.

DECOMPRESS Operator control signal to move compression plate up.

DIR Selecting direct ion of rotation or lift motor.

*

DRIVE_OK Rotation and lift motor are working corr ectly, no over current, approx. 1.5 s delay.

DRIVE_PROT DMG relay K6 is working correctl y, checked 3s after rot/l if t button is released.

FI_LA Output line A. Filter stepping motor M5

FI_LB Output line B. Filter stepping motor M5

FI_P A1 Output phase A1. Filter steppi ng mo tor M5

*

Siemens Elema AB Register 6 SP B7-230.051.05 Page 9 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 18

2-10 X041E

LIST OF SIGNALS AND TEST POINTS, STAND

Page Signal Name Origin Via Destination Testpoint LED

3-15/4C

3-15/4C

3-15/4C

3-15/2C

3-15/2B FILTER_POS Filter switch D805 D801 FILT_P

3-15/2C

3-15/5C FO_LA D805 M8

3-15/5C FO_LB D805 M8

3-15/5C

3-15/5C

3-15/5C

3-15/5C

3-15/1C

3-15/1B FOCUS_POS Focus switch D805 D801 FOCUS_P

3-15/1C

3-16/3B GRID_MOTOR_N D802 D805 OBJ. TABLE D802 GRID_M

3-16/2A GRID_OUT OBJ. TABLE D805 D801 D801 GRID_O

3-16/2G

3-1 1/3D I1_OUT D804 D804.X843 pin 6

3-6/2B

3-14/5G LAMP D807, D812** D805 D801

3-14/4C

3-14/5F LAMP_V D802 LAMP D802 LAMP

3-8/3D LED D802 TACHO switch

3-15/2E LED_1 D805 18 x 24 switch

3-15/3E LED_2 D805 24 x 30 switch

3-15/4E LED_3 D805 Filter switch

3-15/5E LED_4 D805 Focus switch

3-10/2A LIFT_DOWN D807, D808, D812** D805 D801, D802

3-10/2A LIFT_UP D807, D808, D812** D805 D801, D802

3-14/4F

3-6/3B MPS D801 GENERATOR D801

3-7/4C OKT1_ TUBE/K8 GENERATOR

3-7/4C OKT2_ TUBE/K9 GENERATOR

3-9/2C PGM_SPEED D802 PGM_SPEED

3-13/2D POT_RETURN POT D801

3-11/2E PRES_FORCE R861 D801

3-13/1A PRESET_ANGLE R871 D805 D801

FI_PA2 D805 M5

*

FI_PB1 D805 M5

*

FI_PB2 D805 M5

*

FILTER_DIR D801 D805 D805 FILT_D

*

FILTER_STEP D801 D805 D805 FILT_ST

*

FO_PA1 D805 M8

*

FO_PA2 D805 M8

*

FO_PB1 D805 M8

*

FO_PB2 D805 M8

*

FOCUS_DIR D801 D805 D805 FOCUS_D

*

FOCUS_STEP D801 D805 D805 FOCUS_DT

*

GRID_SPEED D801 D802 D801 GRID_SP

*

KVA D801,D701

*

LAMP_CTRL D801 D802

*

MIRROR_MAGNET D802 M7 D802 MIRROR

*

D702, D705

D700 (GENERATOR) D801 (D705, X715)

“*SIGNAL” = “SIGNAL” acti ve low * * M1 000 option, remote contr ol, D807 not fitted

Siemens Elema AB Register 6 SP B7-230.051.05 Page 10 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 19

X041E 2-11

LIST OF SIGNALS AND TEST POINTS, STAND

Signal Name Description

FI_PA2 Output phase A2. Filter steppi ng m otor M5

*

FI_PB1 Output phase B1. Filter stepping m otor M5

*

FI_PB2 Output phase B2. Filter stepping m otor M5

*

FILTER_DIR Control signal . For the filter stepping motor.

*

FILTER_POS Signal from the filter pos collimator optoswitch

FILTER_STEP Step control. For the filter stepping motor.

*

FO_LA Output line A. Focus ste pping motor M8

FO_LB Output line B. Focus ste pping motor M8

FO_PA1 Output Phase A1. Focus stepping motor M8

*

FO_PA2 Output Phase A2. Focus stepping motor M8

*

FO_PB1 Output Phase B1. Focus stepping motor M8

*

FO_PB2 Output Phase B2. Focus stepping motor M8

*

FOCUS_DIR Control sign al f or the focus stepping motor.

*

FOCUS_POS Signal from the focus pos collimator optoswitc h.

FOCUS_STEP Step contr ol si gnal for the focus step ping motor .

*

GRID_MOTOR_N Grid motor return line.

GRID_OUT Active when the grid is not in end position.

GRID_SPEED Pulse Width Modulated si gnal control speed of grid motor.

*

I1_OUT Output signal from compress ion force preamplifier.

KVA Signal to terminate exposure. WIRED-OR line, see generator.

*

LAMP Operator control signal for the field light lamp.

LAMP_CTRL Signal to switch on the field light lamp.

*

LAMP_V Output to the field light lamp.

LED Output to the LED in the tacho opto switch in the rotation motor.

LED_1 Output to the LED in the 18 x 24 collimator opto switch.

LED_2 Output to the LED in the 24 x 30 collimator opto switch.

LED_3 Output to the LED in the filter collimator opto swi tch.

LED_4 Output to the LED in the focus collimator opto switch.

LIFT_DOWN Operator control signal to move compression plate down.

LIFT_UP Operator control signal to move compression plate up.

MIRROR_MAGNET Output to mirror magnet. Enabled via *LAMP_CTRL.

*

MPS Multi processor ser ial communication for information exchange Master - Slaves.

OKT1_ Signal from temperat ure switch K8 on the tube.

OKT2_ Signal from the over pr essure switch K9 on the tube.

PGM_SPEED T est point for duty cycle to vol tage converted programmed speed signal.

POT_RETURN Return line for potentiometers connected to 0VA via a 20Ω resistor.

PRES_FORCE Analog signal as preset value for maximum compression force.

PRESET_ANGLE Analog signal as preset value for requested rotation angle.

Siemens Elema AB Register 6 SP B7-230.051.05 Page 1 1 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 20

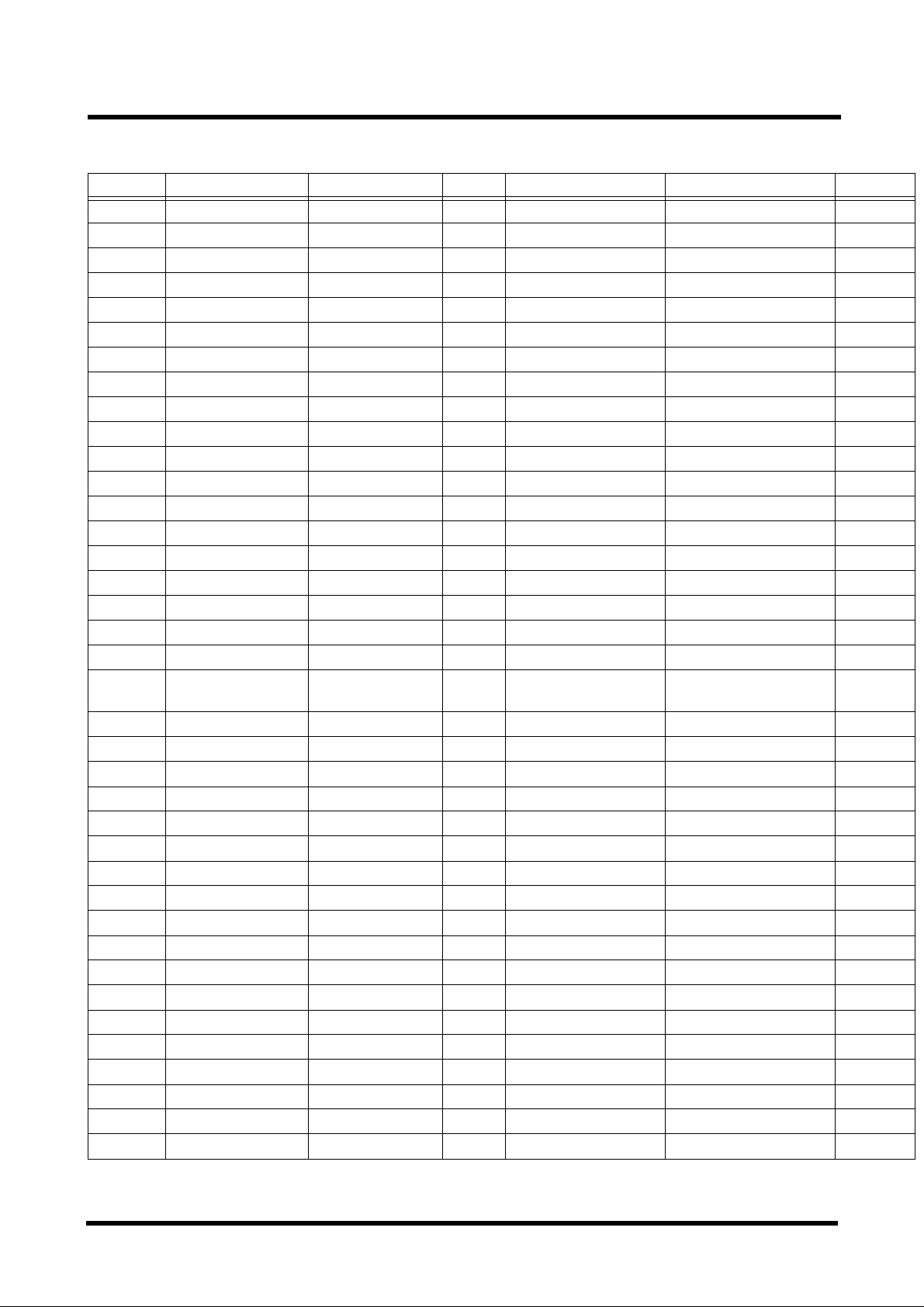

2-12 X041E

LIST OF VOLTAGES AND TEST POINTS , STAND

Page Signal Name Origin Via Destinati on Testpoint LED

3-12/2D PU D802 PU

3-9/4B

3-6/1E

3-6/1E

3-6/1E RESET_SW D801

3-10/3A ROT_CW D807, D808,

3-10/3A ROT_CCW D807, D808,

3-13/4A ROT_POS** D806** D801

3-6/3D RXD GEN. D801 D801

3-9/3B

3-16/3C SELECT_WING1 S891 D801

3-16/4C SELECT_WING2 S892 D801

3-9/2B

3-15/2C

3-15/1B STEREO_COLL S897 D801

3-16 STEREO_LEVER S860 D805 D801

3-14/1B TABLE_CONFIG OBJ.TABLE D805 D801

3-8/3G TACHO Tacho switch D802 D802 TACHO

3-11/3E THICKNESS R863 D801

3-11/5E THICKNESS_B THICKNESS D809

3-11/5F THICKNESS_STE-

3-13/5B TILT S896/D810 D80 5 D801 D810 V8

3-13/2A TUBE_ANGLE R803 D801

3-6/4D TXD D801 GENERATOR D801 TXD

3-6/3B VH GEN. D801

3-11/3C ZERO D804 D804.X843 pin 4

RELEASE D801 D802 D802

*

RESET D801

*

RESET_HW D801

*

D805 D801, D802

D812***

D805 D801, D802

D812***

SEL_ROT D801 D802 D802 SEL_ROT

*

SPEED D801 D802 D801, D802 SPEED

*

STEP_ENABLE D801 D805 D805 STEP_EN

*

D809 X885

REO

“*SIGNAL” = “SIGNAL” active low.

** Not used with software v2.1 or higher.

*** M1000 option, remote control, D807 not fitted

Siemens Elema AB Register 6 SP B7-230.051.05 Page 12 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 21

X041E 2-13

LIST OF VOLTAGES AND TEST POINTS, STAND

Signal Name Description

PU Pull up signal for er ror comparators = +15V, +5V, +24V voltages OK.

RELEASE Control signal to release the brakes from min or max to permanent magnet braking.

*

RESET Reset signal to the CPU.

RESET_HW Reset signal from the CPU to the reset cicuit, caused by slave restart and CPU watchdog

reset.

RESET_SW Signal from the reset switch to the CPU via the reset circuit.

ROT_CW Operator control signal to rot ate the x-ray system clockwise.

ROT_CCW Operator control signal to rotate t he x-ray system cou nter clockwise.

ROT_POS Low level signal pulse indicating +10 or -10 degrees of rotati on.

RXD Input for receiving data via MPS.

SEL_ROT Low level signal selects the rotation drive to be controlled.

*

SELECT_WING1 Signal from select wing 1 switch. Wing 1 selected.

SELECT_WING2 Signal from select wing 2 switch. Wing 2 selected.

SPEED Pulse Width Modulated signal to control speed of rotation or l ift motor (20 kHz).

*

STEP_ENABLE Control signal to ena ble all stepping motors.

*

STEREO_COLL External diaphragm switch, diaphragm in place. For stereo or spot diaphragm, 18 x 24

collimator in M1000 with one filter.

STEREO_LEVER Signal from stereo lever switch, indicating lever not in stereo position.

TABL E_CO NFIG 4 inputs from object table, see table configuration .

TACHO Signal from rotation motor tachometer.

THICKNESS Analog signal indicating the compression thickness.

THICKNESS_B Buffer ed output to the thicknes s adapter board D809 (Stereo opt ion)

THICKNESS_STE-REO Isolated anal og signal indicating compression thickness for stereo evaluation unit.

TILT Indicates that the stereo angl e is 0° or ±10°. Visible through vent opening behind tube.

TUBE ANGLE Analog signal indicating the rot ation angle.

TXD Output for sending data via MPS.

VH The stand is informed that the generator has completed its preparation.

ZERO Used for adjusting offset of the compression force amplifiers.

Siemens Elema AB Register 6 SP B7-230.051.05 Page 13 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 22

2-14 X041E

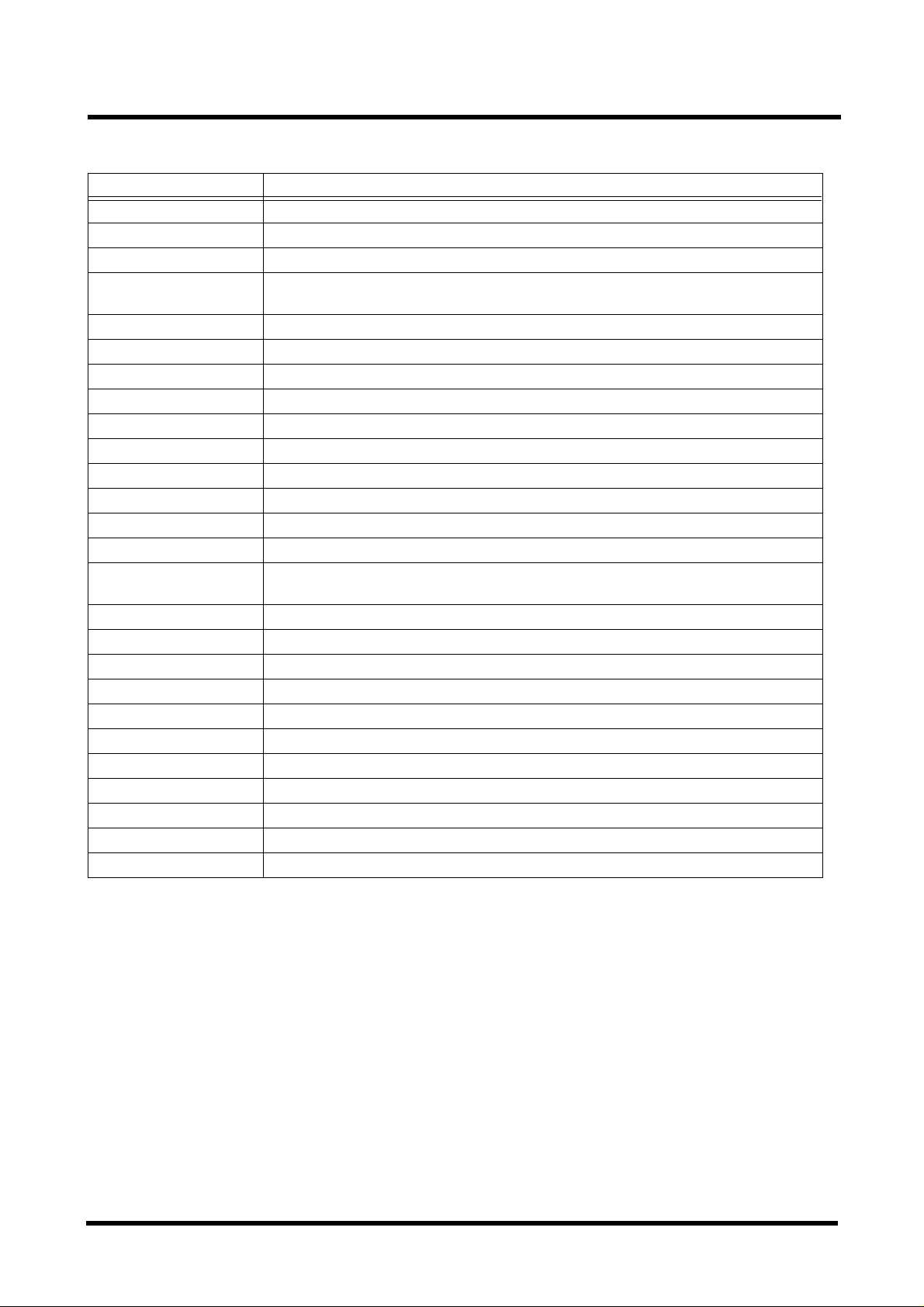

LIST OF VOLTAGES AND TEST POINTS , STAND

Page Voltage Origin Supplied from Supply for T est LED Fuse

3-3/4E +5V D801 11V Di gital IC,

+5V_REF

3-3/4E

3-1 1/3B

3-3/3E +5V_DSP D801 11V D803, Display 5V_DSP V6 D801/F1 F801

3-3/2E

3-10/3B

3-3/3E +5V_MPS D801 11V_MPS Generato r

3-3/3D 0VD GND D801/X811 Digital IC 0VD1,OVD2

3-3/3D

3-10/3B

3-6/5D 0V_MPS D700/GND Generator inter-

3-3/2C 11V T801 230VAC +5V, +5V_DSP,

3-6/5B 1 1V_MPS T801 230V AC +5V_MPS D801/F2 F802

3-4/3D +5V D802 14VAC Digital IC 5V V57 D802/F1 F803

3-4/4E +5V_M D802 +5V D801-D802

3-2/5C 0V_W D801 D805/X856 Optointerface

3-2/4C 0V_M D801 D80 2/X822 Optoi nterface

3-4/3D +14V D802 14VAC +5V, D805 14V D802/F1 F803

3-4/2D +15V D802 +24VF Transistor

3-4/2C +24V D802 24VAC +15V D802/F3 F805

3-4/2D +24VF D802 +24V Switches,

3-4/3A 14VAC T801 230V AC +14V D802/F1 F803

3-14/5B 17VAC T801 230VAC LAMP 17VACF D802/F5 F804

3-14/4E 17VACF D802 17VAC LAMP 17VAC_RET D802/F5 F80 4

3-14/4D 0V_L D802 D802 Lamp control

3-14/5D -V_L D802 17VACF Lamp control

3-4/2A 24VAC T801 230V AC D802/F3 F805

3-4/2E 24VACF D802 24VAC Fan D802/F4

3-4/3B 0V GND D802/X821 Ground 0V, 0V1

3-4/2F +5V D805 D802/+14V Di gital IC 5V V17 D802/F1 F803

3-4/2G +5V_R D805 +5V User switches D802/F1 F803

+5V_REF D801 +5V Pots.

D804

+7V D801 11V Analog IC,

D804

interface

0V A 0VD D801 Analog IC

D804

face ground

+7V

opto interface

drivers M1,M3

relays, etc

5V V7 D801/F1 F801

5V_REF

X843 pin 2

7V

X843 pin1

5V_MPS V26 D801/F2 F802

0V A1

X843 pin 3

D801 MPS

15V V16 D802/F2

24VF D802/F2

V5 D801/F1 F801

V57 D802/F1 F803

D801/F1 F801

D801/F1 F801

Siemens Elema AB Register 6 SP B7-230.051.05 Page 14 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 23

X041E 2-15

LIST OF VOLTAGES AND TEST POINTS, STAND

Voltage Description ( typical value)

+5V Regulated DC voltage, 4.75V < +5V < 5.25V

+5V_REF DC voltage, +5V -5% < +5V_REF < +5V

+5V_DSP Regulated DC voltage, 4.75V < +5V_DSP < 5.25V

+7V Regulated DC voltage, 6.60V<+7V<7.25V

+5V_MPS Regulated DC voltage, 4.75V < +5V_MPS < 5.25V

0VD Digital ground

0VA Analog ground

0V_MPS Generator interface ground. Floating, grounded by generator.

1 1V AC supply voltage, 11VAC

1 1V_M P S AC supply voltag e, 11VAC

+5V Regulated DC voltage, 4.75V < +5V < 5.25V

+5V_M Regulated DC voltage, 4.75V < +5V_M < 5.25V for optointerface D801-D805

0V_W Digital ground optointerface D801 - D805

0V_M Digital ground optointerface D801 - D802

+14V Unregulated DC voltage, 18V

+15V Regulated DC voltage, 14.25 V < +15V < 15.75V

+24V Unregulated DC voltage, 32V

+24VF Unregulated DC volta ge, 32V

14V AC AC supply voltage, 14 VAC

17VAC AC supply voltage, 17 VAC

17VACF AC supply for lamp

0V_L Floating ground for LAMP voltage regulation

-V_L Unregulated supply voltage for lamp control circuit

24VAC AC supply voltage, 24VAC

24VACF AC supply voltage for the fan 1)

0V Circuit ground

+5V Regulated DC voltage, 4.75V < +5V < 5.25V

+5V_R Regulated DC voltage, 4.40V < +5V_R < 5.2 5V

1) 2)

1) 2)

1)

1)

1)

1) 2)

1) 2)

1)2)

1)2)

1)2)

1) 2)

2)

Siemens Elema AB Register 6 SP B7-230.051.05 Page 15 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 24

2-16 X041E

LIST OF VOLTAGES AND TEST POINTS , STAND

Page Voltage Origin Supplied

from

3-3/2B 230VAC Generator D711/X14 Stand X881/2,3

3-3/1C P.E. Stand X899 Inc. ma ins voltage Whole syst em X899/PE

3-3/1C N Stand X899 Inc. mains voltage Whole system X899/N

3-3/1C L1 Stand X899 Inc. mains voltage Whole syst em X899/L1

3-3/1C L2 Stand X899 Inc. mains voltage Whole syst em X899/L2

3-3/1C L3 Stand X899 Not used X899/L3

1)

ST ANDBY TYPICAL VALUE, 230VAC INPUT

2)

Floating voltage. Measure with digital multimeter or differential amplifier.

Vol tage Description ( typical value)

230V AC Stand mains volta ge input, 207VAC < 230VAC < 253VAC

P.E. Protective earth terminal, incoming mains

N Neutral line terminal, incoming mains

L1 Line 1 terminal, incoming mains voltage

L2 Line 2 terminal, incoming mains voltage

L3 Not used

Supply for Test LED Fuse

Siemens Elema AB Register 6 SP B7-230.051.05 Page 16 of 16 Mammomat 1000/3000

Solna, Sweden Rev . 02 10.99 SPS-UD Wiring Diagrams

Page 25

X041E 3-1

BLOCK DIAGRAM CABLE CONNECTIONS

123

FILTER

FOCUS

M8

COLLIMATOR

X879

X890

OBJECT TABLE 2

OBJECT TABLE 1

T. IN POS

TABLE BASE 1 OBJECT TABLE 1

MIRROR

18X24

24X30

M7

M4

SPOT

STEREO

LAMP

X854

X852

X877

X853

X894

PRESET

M5

X866

X867

X878

M1

M

CASS IN PLACE

GRID OUT

GRID

X887

D804

COMPRESSION

M6

FAN LIFT

SET WING 1

AEC IN_POS

STEREO

TUBE TEMP, PR ESS URE

X895

X895

COMPRESSION

4

5

D810

D806*

ANGLE

DETECTOR

TILT

STEREO LE VER

TACHO

BRAKE

ROTATION

ROTATI O N

X868

X888

X874

FORCE

COMPRESSION

FORCE

X868

X841 X861

M9, M10

X824

X823

X826

* D806 no t used with s oftware v2.1 or higher.

**REMOTE CONTROL OPTION

F

M2 M3

D803

X891

X892

X883

X884

X3**

X808

X807

USER INTERFACE

COMP

DECOMP

ROT CW

ROT CCW

LIFT UP

X893

X823

X824

X851

X857

X859

X865

X869

X871

X864*

X856

X863

X868

+5V_R

D805

WING BOARD

X858

LIFT DOWN

LAMP

ANGLE MEM

X870

X889

X855

X856

X860

X824

+5V +/4V

D802

MOTOR CONTROL

X825

X822

X823

X824

DISPLAY

X801

X821

17V AC

+24V +15V

+14V +5V

X1**

X809

X812

X813

X814

230 VAC

Tostereo

D809

Z801

80C535

T802

X802

STAND

X885

Stereo ( option)

D801

CPU BOARD

X813

X814

X816

INCOMING MAINS

110, 208, 230, 240, 277 OR 400V

X811

+7V +5V

X886

+5V_MP

X886

SINGLE OR TWO PHASE

X899

T801

230V FROM GENERATOR

X886

ABCDEFG

GENERATOR

X10

X11

.

GEN

X1 X815

Siemens-Elema AB SP B7-230.051.05 Page 1 of 18 Mammoma t 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 26

3-2

GROUNDING CONNECTION S

X041E

123

FRONT

COVER

REAR

H3

X896

FILAMENT

PATIENT

HANDLE

TUBE

PLATE

TUBE

CHASSIS

PATIENT

HANDLE

COMPRESSION

UNIT

COVER

X897

ROTATION

X870

GROUND RAIL

CURTAIN

UPPER

LIFT

CARRIAGE

LOWER

STAND

0V

INCOMING MAINS

X899

NOT FIT TED

X81

D810

IN M1000

P.E.

0V

X81

D812

M1000 OPTION

4

X880

TUBE

4

6

4

X858

58

2

X821

4

3

X811

HOUSING

6

X871

87

X860

D805

X866

D802

MOTOR

BOARD

1234568

X822

1234568

X812

D801

CPU

FERRIT SL EE VE

WING

6

X816

X859

BOARD

X823

151617

0V

D804

X813

X885

PRES_FORCE

252423

COMPRESSION

THICK-

R863

R861

0V_W

36

FORCE

2k

10k

X814

X841

NESS

X874

5

22

0V A

2

726

141615

NOTE

DOTTED CONNECTIONS INDICATE

SHIELDED CABLES WITHOUT

0V CONNECTION

10k

R871

PRESET_ANGLE

R803

2k

TUBE_ANGLE

X86856

X863

1

SHLD

345

X855

POT_RET

9

17

20

0V_A

13

4

4

DETECTOR

X884

X892

WING 2

WING 1

0V

5

8

18

4X883

FERRIT SLEEVE

0V_RDL

X2

X893

25

24

23

22

Stereo

1

X856

X813

X815

252729

1

2

137

option

30

COMPRESSION

UNIT

33

34

0V_MPS

8

X1

X891

SHLD_1

12

X855

0V

0V_M

0V D

3

STAND

4

151617

18

X801

D803

FOR FOOT SWITCHES

CABLE

CABLE

DUCT

DISPLAY

0V D

X861

D806*

X809

D809

0V

ANGLE

0V_A

7

X809

DETECTOR

13

X885

ABCDEFG

L1

L2

GENERATOR

X14

X9

X8

X11

468

P

X10

468

0V_RDL

Siemens-Elema AB SP B7-230.051.05 Page 2 of 18 Mammoma t 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

X1

136

11

GND

with software

v2.1 or hi gh er

* D806 not us ed

0V

13

X893

Page 27

X041E 3-3

MAINS CONNECTION, POWER SUPPLY CPU

123

X811

F1

2AT

0VD2

D801

7V

0VA

V5

7V

0VA1

0VA1

7V

V5

0VD

+5V_DSP

V6

0VD2

5V_DSP

0VD1

5V_REF

5V_REF

5V

5V_DSP

V6

+5V

+5V_REF

6.8

5V

4

F2

1AT

5V_MPS

V26

0V_MPS

V7

0VD2

0VD

V7

0VD1

5

GENERATOR STAND

~

0VA

F1

2AT

0VD

=

D801

6

9

X811

3

X886

F801

GROUND RAIL

3

X886A

RD

2 AT

48

4

11V

GN

11V_MPS

T801

YE

1

P.E. N L1 L2 L3

X899

INCOMING MAINS

208,230,240,277, OR 400 V

TWO PHASE

P.E.

X886A

1

X886

2

2

X881

YE

2

2

3

3

230V AC

Z3

F10

F20

3

SURGE-

ARRESTER

V

V

T10

X14

VARIST OR

D711

1

7

GND

1

X880-4

Z801

(SEE PAGE 3-6)

X802

1

T802

3

X802

42 2

NL2

SINGLE PHASE

INCOMING MAINS

110,208,2 30,240 OR 277V

P.E. L1 L3

X899

GROUND RAIL

P.E.

1

X881

F10

GENERATOR STAND

ABCDEFG

Siemens-Elema AB SP B7-230.051.05 Page 3 of 18 Mammoma t 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 28

3-4

POWER SUPPLY MOTOR CONTROL

X041E

123

X866

X864

X865

0V 5V

V35

+5V_R

F

V

4

2

+

D805

4

X860

R

F

F

F

V

C

C

F

4

A

A

V

2

V

V

4

+

4

4

2

2

2

+

9

X824

14

12

18

X823

+5V

0V

50

V35

5V

0V

+14V

5V

UREG

V

0

6

5

T

L

O

V

_

R

F

F

O

V

V

T

4

4

O

2

2

M

+

+

11

17

7

X822

D805

X824

X822

D802

V

V

4

0

1

+

8

9

X823

X823

V16

15V

M

_

V

5

+

X82210X824

24VF

0V

0V

V

5

+

11

X871

X860

X821

5AT

1AT

6.3AT

3.15AT

5AT

14VACR

5

X873

X859

F1 F2 F3 F4 F5

4

X872

X868

X869

X855

X856

X857

X823

V57

5V

14V

0V1

V

1

5

V

1

V

0

+

0

2

0

8

D

ABCDEFG

6

1

V

V

5

1

F

V

4

2

V

V

4

0

2

+

T

4

A

F

1

T

A

3

3

F

.

6

1

2

6

8

X

6

3

8

1

8

X

5

0

8

F

A

6

3

8

1

8

X

Y

G

1

0

8

T

1

Y

C

N

E

0

8

G

8

S

R

P

E

O

M

T

E

S

2

8

8

S

T

A

C

3

.

A

6

6

4

8

V

1

8

4

X

2

A

6

4

8

1

8

T

X

V

=

~

1

2

8

X

E

Y

6

8

1

8

X

G

V

E

5

R

1

U

T

A

2

5

F

1

.

3

V

0

2

5

8

)

3

-

3

E

E

G

Y

A

P

2

E

E

S

(

V

V

4

5

1

V

0

V

0

V

0

=

~

R

C

T

1

A

A

F

5

V

4

1

1

2

8

X

6

8

8

X

A

6

8

8

X

3

4

0

9

1

3

T

0

A

8

5

F

0

9

1

C

A

V

K

H

4

B

W

1

7

5

V

V

V

5

+

0

8

8

S

0

G

E

V

5

R

U

)

3

1

-

3

E

G

A

C

P

A

E

V

E

7

S

1

(

Siemens-Elema AB SP B7-230.051.05 Page 4 of 18 Mammoma t 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 29

X041E 3-5

DISPLAY

123

OK

OPCOM

x8

0123456

BIN/OCT

124

x8

ENC11D

ADDRESS

0VD

D803

D0D1D2D3D4D5D6

34567

X801

DATA

0V

D7

8

9

10

151617

+5V_DSP

STROBEA3A2

2

1

19

18

20

141112

4

THICKNESS

7

&

0VD

A1

13

X801

FORCE

D803

5

OK

ANGLE

OPCOM

DATA

34567

X816

D0D1D2D3D4

D801

ABCDEFG

POWER SUPPLY

8

9

10

D6D7D5

DATA

151617

0VD1

0V

2

1

19

18

20

+5V_DSP

ADDRESSSTROBE

141112

5V_DSP

13

A3A2A1

ADDRESS

X816

CPU

V6

0VD1

5V_DSP

D801

Siemens-Elema AB SP B7-230.051.05 Page 5 of 18 Mammoma t 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 30

3-6

CPU BOARD INTERNAL, GENERATOR INTERF ACE

X041E

123

X813

X812

AR

KVA

COLL_ST

GRID_SP

COMP_SP

SPEED

FILT_P

ROT_POS

FOCUS_P

D801 TESTPOINTS AND LED’s

RESET

*

<4.6V

COMP

RESE T SW

*

+5V

S1

RESET_HW

*

STATUSLED’s

J1

X816

PROM

0VD2

COLL_P2

COLL_P1

V1

V2

X112MHz

V1V2V3

V3

GRID_0

V4

V4

X814

J1

CPU

TXD

RXD

0VA1

7V

V5

X811

F1

5V_REF

5V_DSP

0VD1

5V

V7

V6

I9

DATA AND ADDRE SS

PROM RAM EEPROM

128k x 8 32k x 8 8k x 8

CPU

80C535

4

F2

X815

V26

5V_MPS

MPS

0V_MPS

S1

RESET SWITCH

5

STATUS LED’s DURING STARTUP:

PROM/RAM TEST V1, V4 LIT.

V2, V3 LIT IF PROM CHECKSUM ERROR.

V3, V4 LIT IF RAM ERROR.

ALL TESTS PASSED, V1-V4 ARE DARK.

RESET

0VD

D801

GENERATOR STAND

ABCDEFG

0V_MPS

KVA

*

RESET

*

D700

BACKPLANE

AR

*

6

X815

KVA

*

12

X1

4

137

5

AR

VH

5

6

314

RXD

0VA

0VD

0VD1

+5V_MPS

0V_MPS

0V_MPS

8

0V_MPS

11

GND

TXD

MPS

2

MPS

2

COMMUNICATION

+5V_MPS

0V_MPS

5V_MPS

V26

=

~

GENERATOR INTERFACE

F2

1AT

1

2

X811

FLOATING, GROUNDED BY GENERATOR

56

1AT

F802

X886

BUBN

11V_MPS

56

X886A

T801

Siemens-Elema AB SP B7-230.051.05 Page 6 of 18 Mammoma t 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 31

X041E 3-7

TUBE, TEMPERATURE MONITORING

123

IOII

K7

K9

TUBE

K8

FAN

FRONT VI EW

TO H1

H11

h2W

h1W

TUBE

h2M

K8 K9 K7

h1MH3G

W

M

TUBE

0

X897

I

II

2

1

0

h3

h1M

X896

1

0

TOP VIEW

h2M

START FAN

START WARNING BLINK

ON PANEL

INHIBIT EXPOSURE

K7K8K9

K9

P

G

h1W

h2W

4

3

4

2

G

1

X815

6

X895/H11.X1

D802

4

X824

1

X895/H11.X1

2

K7

K8

ϑ

ϑ

FAN

1

5

X821

F3 F4

M6

X815

D801

5

2

3

18

X824

9

+24V

0V

8

X9

H1

HIGH VOLTAGE

GENERAT OR

12

GENERATOR STAND

C51

ABCDEFG

F4

1AT

0V_MPS

ROTATION

1

0

FILAMENT

1

2

3

0

2

4

D801

D802

OKT2_TUBE_

OKT1_TUBE_

9X13

3

2

5

6

4

9X95

1

1

X8

SM_FOC2

LG_FOC1

0V_FIL

SM_FOC1

K5

K4

LG_FOC2

BIAS

8

GND

+15V_EXT

7

10 +15V_EXT

~

F3

6.3AT

6

1

X821

S880

EMERGENCY

STOP

S882

14

13

X886

F805

6.3AT

24VAC

24VAC RN

13

14

X886A

VT

GR

T801

Siemens-Elema AB SP B7-230.051.05 Page 7 of 18 Mammoma t 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 32

3-8

LIFT AND ROTATION

X041E

123

RDBKWHBUGN

BRAKE_RET

LAMP

X825 X822

D802

TACHO

PGM_SPEED

ACT_SPEED

V24

DRIVE_ERR

S1

*DIR

*SPEED

D802

*SEL_ROT

LIFT MOTOR

X822

DRIVE_PROT

DRIVE_PROT

1

X887

21

ACT_SPEED

TACHO

X825

K2 K3

X823

D_PWM

0V

M1

L806

GN

M

R807

S881

UP LIMIT

4

X823

13

D_PWM

PGM_SPEED

*SPEED

4

X822

17

*DIR

0V1

RD

S884

L807

10

TACHO S869

X887

DOWN LIMIT

7

5

4

S1

3

2

1

*SEL_ROT

11

X888 L808

2

3

+3%+6%+12%+24% SERVO

0V

0V1

RD

M

1

ROTATION

MOTOR

M3

6

17

15

24VF

+24VF

BRAKE_RET

+5V

CURRENT LIMIT

(FACTORY ADJUSTED)

0V

0V

BK

L809

2

RDBKWHBUGN

1

X826

x825

1

LED

R805

X898

5

BU

2

R806

M9

RD

1

M10

4

BRAKE

TACHO

*BRAKE_RETURN

3

2

5

4

GND

2

3

5

0V

+5V

0V

DRIVE_OK

X824

X824

8

26 22

25

X822 16 13

1

2

5

10

*SPEED

*DIR

*SEL_ROT

X812

17

141411

S883

COLLISION

0VD1

D801

21

ABCDEFG

DRIVE_PROT

X812

0VD

(TABLE IN

PLACE)

X813

TABLE_CONFIG

CPU

(X4)

X814

SEE PAGE 3-14

*SPEED

20 KHz

COLLISION

258311322

X813

TUBE_ANGLE

COMP_FORCE

PWM

ANGLE_MEM

LAMP

X812

DRIVE_OK

LIFT_UP

LIFT_DOW

252613

ROT_CCW

ROT_CW

16

M1/M3

+24VF

X812

D801

ROT_CCW

ROT_CW

X813

LAMP

*SPEED

ANGLE_MEM

3-10

SEE PAGE

LIFT_DOWN

LIFT_UP

0VD1

Siemens-Elema AB SP B7-230.051.05 Page 8 of 18 Mammoma t 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 33

X041E 3-9

LIFT AND ROTATION MOTOR DRIVE

123

RD

ROTATION

+5V

COMPYX X>Y

4

3

2

1

S1

TACHO

BK

M

L809

2

MOTOR

M3

V24

DRIVE ERROR

(OVERCURRENT)

D

+5V

CURRENT LIMIT

+3% +6% +12% +24%

0V

> C1

22

DRIVE_OK

+5V

0V

R

0V

+5V

M1

M

R807

+24VF

+24VF

PWM

K6

RD

S884

10

+24VF

L807

K3

+24VF

K7

X887

DOWN LIMIT

7

D_PWM

0V

2

3

+24VF

K2

&

(OVER-

CURRENT)

L808

1

X888

6

PU

0V

L806

GN

LIFT MOTOR

1

X887

S881

UP LIMIT

4

21

X823

X822

13

+24V

C_LIM

0V

17

V11

0V

+24VF

4

*BRAKE_RETURN

X824

15

BRAKE_RET

0V

0V

8

*BRAKE_RELAY

+24VF

+5V

R805

+24VF

+24VF

5

BU

2

X898

0V

0V

R806

M9

RD

1

M10

BRAKE

0V

0V

PGM_

SPEED

0V

CPU

DRIVE_PROT

SEE PAGE

3-8

D802

ACT_SPEED

TACHO

4

X825

0VD1

F/V

0VD

TACHO

MUX

*SPEED

X822

X812

*SPEED

5

0V

17

17

S1

SERVO

*BRAKE

*DIR

*RELEASE

18

14

14

15 15

18

X824

1

2

LIFT_UP

LIFT_DOWN

5

10

ROT_CCW

ROT_CW

*SEL_ROT

11

11

DRIVE_OK

25

X822 161326

CPU

ABCDEFG

CPU

20 KHz

PWM

D801

Siemens-Elema AB SP B7-230.051.05 Page 9 of 18 Mammoma t 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

SEE PAGE

3-8

Page 34

3-10

LIFT AND ROTATION SWITCHES

X041E

123

S6

X807

S6S5

S3

S4S1

D808

S2

S3

S4S1

S2

X808

D807

TO D801, D802, S883

SEE PAGE 3-8

LIFT_DOWN

LIFT_UP

+24VF

X856

16

15

13

14

ROT_CW

12

22

10

(NOT USED)

S3 S4 S5

S2

LIFT_B

S1

LIFT_A

POSITION

FUNCTI ON AL TABLE FOR

ROT_CCW

ANGLE_MEM

20

LEFT S.B. L_DOWN L_UP RO T_CW ROT _CCW ANGLE_M EM LAMP

S1-S6 ON D807, D808

LAMP

7

36

34

D805

RIGHT S.B. L_UP L_DOWN ROT_CW ROT_CCW ANGLE_MEM LAMP

4

X865

0V

X851

X889

5

X856

+5V_R

LIFT_DOWN

D805

LIFT_UP

1234567

X851

1234567

X807

ROT_CW

ROT_CCW

+24VF

+5V_R

LIFT_DOWN

LIFT_UP

ROT_CW

LIFT_DOWN

+5V_R

LIFT_UP

ROT_CW

ROT_CCW

LAMP

LAMP

SPARE

ANGLE_MEM

8

1234567

X865

SPARE

ANGLE_MEM

8

123

X889

135

X808

+5V_R

LIFT_A

S1S2S3

ROT_CCW

4

567

7

9

LIFT_B

ROT_CW

ROT_CCW

S4

111315

SPARE 1

SPARE 2

8

SPARE 3

D808

264

X808

8

1234567

X807

8

1

X808

357

8

101214

9

111315

16

+5V_R

LIFT_A

LIFT_B

ROT_CCW

ROT_CW

S1S2S3S4S5

ABCDEFG

D807

LEFT

SIDE

BOARD

LIFT_A

LIFT_B

S1S2S3

648

ROT_CW

ANGLE_MEM

LAMP

SPARE

S6

+5V_R

ROT_CW

LIFT_A

LIFT_B

S1S2S3S4S5

ROT_CCW

ANGLE_MEM

LAMP

SPARE

S6

D807

RIGHT

SIDE

BOARD

+5V_R

D808

2

X808

ROT_CCW

S4

101214

SPARE 2

SPARE 3

RIGHT SIDE BOARD LEFT SIDE BOARD

16

SPARE 1

Siemens-Elema AB SP B7-230.051.05 Page 10 of 18 Mammomat 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 35

X041E 3-11

LIFT AND ROTATION SWITCHES,

123

S3

S4S1

S2

X808

D808

TO D801, D802, S883

SEE PAGE 3-8

LIFT_DOWN

LIFT_UP

+24VF

X856

16

15

X851

1234567

SOLDERED

+5V_R

13

8

+24VF

12

10

14

M1000 WITH REMOTE CONTROL

4

X864

X865

S3 S4

S2

LIFT_B

S1

LIFT_A

POSITION

LEFT S.B. L_DOWN L_UP RO T_CW ROT _CCW

FUNCTIONAL TABL E FO R

S1-S4 ON D808

LAMP

ROT_CCW

ROT_CW

ANGLE_MEM

7

20

22

34

RIGHT S.B. L_UP L_DOWN ROT_CW ROT_CCW

36

0V 5V

R50

0OHM

X851

X889

D805

5

X860

7

9

X856

X3

X81

X2B X2A

31

5

0

SW1

D813

+5V

+5V_R

LIFT_UP

LIFT_DOWN

ROT_CW

D805

1234567

X864

8

X3

+5V

5V

ROT_CCW

7

6

5

D812

+5V

8

7 65

432

9

10

X2B

ABCDEFG

1

X1C

X1D

D813

4

I

D813

OR D)

(A,B,C

X1

1,

2,3

I

LAMP

SPARE

ANGLE_MEM

8

0V

X860

LIFT_DOWN

+5V_R

LIFT_UP

ROT_CW

ROT_CCW

LAMP

SPARE

ANGLE_MEM

8

7

6

5

4

3

2

1

X865

+5V_R

123

X889

135

X808

LIFT_DOWN

LIFT_UP

ROT_CW

ROT_CCW

4

7

567

9

8

111315

OR4

LED

1

3

2

4

9

10

X2A

X1B

D813

3

I

X81

0V

5

SW1

ADR

+5V

0

0V

7

8

54321

6

345

6

1

2

X1A

0

0V

+5V

1

I

D813

2

I

D811

+

D811

JP1

S6

S4

_

+

ADR

6

0

S5

S2

S1

D808

+5V_R

264

X808

1

X808

+5V_R

LIFT_A

LIFT_B

S1S2S3

357

LIFT_A

LIFT_B

S1S2S3

ROT_CW

8

ROT_CW

ROT_CCW

SPARE 1

S4

101214

9

111315

SPARE 1

ROT_CCW

S4

SPARE 2

SPARE 3

0

ADR

5

16

D811

_

+

SPARE 2

SPARE 3

RIGHT SIDE BOARD LEFT SIDE BOARD

D808

ROT_CW

LAMP

ROT_CCW

LIFT_DOWN

X808

2

648

101214

16

LIFT_UP

Siemens-Elema AB SP B7-230.051.05 Page 11 of 18 Mammomat 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 36

3-12

COMPRESSION MEASUREMENT SIGNALS

123

X041E

4

5

20

POT_RETURN

11

X814

1-20

X801

7

1

X809X809

X885X893

+5V

5

D809

2

1

THICKNESS_STEREO

6

+

+

THICKNESS_B

1

1

POT_RETURN

0VA

+7V

13

SEE PAGE 3-13

12

13

7

8

-

-

4

see page 3-16

13

THICKNESS

0V

7

CMR SHIELD

3

OK

FORCE

OPCOM

D803

1-20

X816

CPU

1

1

0VD

+5V_REF

+7V

0VA

A/D

1

D801

3

8

10

16

X814

COMP_FORCE

6

781

X874

4

6

4

3

PRES_FORCE

+5V_REF

10k

15

5

2

2k

THICKNESS

R863

POT_RETURN

R861

213

X841

+7V

0VA

+5V_REF

COMPRESSION UNIT

D804

X842

ABCDEFG

R860

4

11_OUT

COMP_FORC

X816

GAIN

20k

0VA

V2

(BR OPEN)

OFFSET

20k

0VA +5V_REF

+5V_REF

1

4

2

3

R

+5V_REF

R

F

RR

+5V_REF

0.1V

0VA

STRAIN GAUGE

ZERO

4

0VA

BR_OPEN

0VA

+7V

+5V_REF

BR_RET

X843 27138 56

D801

X842

GAIN OFFSET

BR_OPEN

BR_RET

I1_OUT

COMP_FORCE

D804

X843

ZERO

0VA

5V_REF

+7V

X841

TEST CONNECTOR

V2

X814

0VA1

5V_REF

7V

X809

D809

Siemens-Elema AB SP B7-230.051.05 Page 12 of 18 Mammomat 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 37

X041E 3-13

COMPRESSION MOTOR DRIVE

123

S861

S862

COMP_LIMIT

COMPRESSION UNIT

4

1

3

2

X872

D805

1

3

X860

COMP_LIMIT

23

X822

COMP_PROT

+14V

X82312

0V

DECOMP_LIMIT

K4

M2

COMP

MOTOR

GN

DECOMP_LIMIT

L804

X873

+14V

6

9

+14V

BK

M

L805

RD

BK

NOT USED

1

3

2

1

2

4

12

+24VF

2

X876

+24VF

+24VF

0V

5

7

8

3-2

SEE PAGE

8

+5V

0V

PU

3

1

X875

+24VF

X856 31 32

33

X856

COMPRESS

3

24

X822

X824

0V

V2

COMP ERROR

(OVER CURRENT )

COMP_OK

+24VF

0V

1

X880

BK

COMPRESSION PEDALS

X823 14

4

C802

C803

3

2

BK

4

WH

WH

RD

RD

2

1

X803

COMP.

5

C801

4

3

DECOMPRESSION BUTTON (ONLY

+24 VF

ON SEPARATE CONTROL CONSOLE)

S3

+14V

D802

COMP_PROT

(LOW = COMPRESS)

COMP_D

X822

X812

CPU

D801

ABCDEFG

23

X812

X814

SEE PAGE 3-1 1

+24VF

K5

1

9

COMP_

DIR

*

9

864

THICKNESS

COMP_FORCE

+5V

PU (SEE PAGE 3- 8)

0V

0V1

C_PWM

+15V

0V

+5V

0V

0V

COMP

Y

COMP

X X>YYX X>Y

DC1R

+5V

0V

0V

COMP_OK

DECOMPRESS

COMPRESS

D805

X872

X868

X855

X873

X869

X871

X859

X856

X857

X860

&

(OVERCURR ENT)

COMP_SP

20

COMP_

SPEED

*

20

0VD

0VD1

COMP_SP

PWM

20KHz

COMPRESS

29

X813

PRES_FORCE

0VD

0VD2

1 23

X880

TABLE_CONFIG

DECOMPRES S

COMP_OK

TABLE IN PLACE

27

24

X812

X813

(SEE PAGE 3-14)

(x4)

X812

D801 D802

X824

X822

V16

COMP_ D

COMP_ SPPUCOMP_ PROT

+15V

4

0V

10

0VD2

COMP_SP

X823

C_PW M

X814

0V1

Siemens-Elema AB SP B7-230.051.05 Page 13 of 18 Mammomat 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 38

3-14

TUBE ANGLE MEASUREMENT, POT. RETURN, TILT SIGNAL

123

4

X041E

5

THICK NE SS

FORCE

D803

D801

X813

OK

ANGLE

OPCOM

1-20

X801

1-20

X816

CPU

5V_REF

+5V_REF

X814

1

5

1

1

18

D801 TESTPOINTS AND LED’s

X863

D805

A/D

0VD

0VA

0VA 0VA

+5V_REF

20

0VA

POT_RETURN

2

9

15

17

3

1

6

3

8

X

X816

PROM

ROT_POS

TILT

8

X809

D809

ROT_POS

1

X855 X868

0V_M

M

_

V

5

+

X813 35 36

X814

CPU

0VA1

7V

V5

X860

X856

31

X811

F1

D810

S1

RESET SWITCH

X80

LED

X81X82X83

software v2.1 or higher

* D806 not used with

** Not fitted in M1000

TILT

17

X856

0VD1

5V_REF

0VD2

5V

5V_DSP

V7

V6

X861 X862

D806

+24VF

D805

6

2

10

X855

+5V_REF

PRESET_ANGLE

D805

321

ABCDEFG

X863

R871

10k

(SEE PAGE 2-3)

4

5

POT_RETURN

PRESET ANGLE

1

3

3

5

1

X874

POT_RETURN

TUBE_ANGLE

675

8

X868

R803

2k

TUBE ANGLE

COMPRESSION

2POT_RETURN

THICKNESS

PRES_FORCE

2k

R863

10k

R861

+/- 10°

UNIT

M3

X861

D806*

1

X862

ROT_POS

1

3

2

4

0V

YE

RD

9

X868

X83

+24VF

0V_M

D810**

2

1

X80

RDBKWHBNBU

4

X860

X81

X82

TILT

V8

+5V

6

5

4

3

YE

S896**

0°, ±10°

Siemens-Elema AB SP B7-230.051.05 Page 14 of 18 Mammomat 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

2

Page 39

X041E 3-15

COLLIMATOR 1

123

LAMP

MIRROR

X822

X813

X812

COLL_ST

FILT_P

FOCUS_P

X823

COLL_P2

COLL_P1

D801 D802

FOCUS_ST

FOCUS_D

FILT_ST

FILT_D

COLL_ST

COLL_D

D805

STEP_ENV

X851

* NOT FITTED IN M1000 WITH ONE FILTER

X821

17VACF

F5

17VAC_RET

5V/DIV

X856

X860

50ms/DIV

COLLIMATOR

0V

MIRROR

X878

X823

+24VF

4

*

M7

MIRROR

MAGNET

1

12

2

X824

6

MIRROR

0V

V52

0V

17VACF

0V

0V_L

R131

SET LAMP_V

5

LAMPL1

1

1

X894

16

X823

LAMP

LAMP_V

Phase

angle

control

angle

RMS

U

+

RMS

/DC

–

2

3

18

17VAC_RET

-V_L

0V_L

0V_L

-V_L

F5

1234568

D802

X822

7

X856

+5V_R

LAMP

15

24VF

X812

0V

12

X822

12

X812

0V_M

LAMP_CTRL

*

D805

7

1

X851

7

1

X865

4

X860

CPU

5AT

7

X821

9

12

11

X886

5AT

F804

12

11

X886A

17VAC

OG

YE

T801

1

1

7

X807

LAMP

7

X807

LAMP

D801

LAMP

13

X813

29

ABCDEFG

S6

D807

LEFT SIDE BOARD

Siemens-Elema AB SP B7-230.051.05 Page 15 of 18 Mammomat 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

S6

D807

LAMP ON

RIGHT SIDE BOARD

COMPRESS

SEE PAGE 3-11

Page 40

3-16

COLLIMATOR 2

123

X877X877

21

X041E

4

5

8

X855716

12

13

EXTERNAL

S897

COLLIMATOR

+24VF

+5V

16 X856

+5V

COLL_POS_18X24

+5V

0V

0V

+5V

+5V

COLL_POS_24X30

+5V

0V

0V

+5V

FILTER_POS

+5V

+5V

0V

0V

+5V

FOCUS_POS

+5V

+5V

0V

0V

D805

123

4

5

OGYEBN BK

C_PA2

6

COLLPOS_24X30

0V

M4*

GN

C_LB

C_PB1

C_PB2

X866

FILTER

8

7

X867

+14V

123

4

LED_30V+5V

FILT_POS

RDBKWHBUGN

*

FILTER S867

M5*

YE

BK OGBN

RDYEOGBKBN

65412

FI_LA

FI_PB2

FI_PA2

FI_PA1

5

6

0V

123

X890

LED_40V+5V

RDBKWHBUGN

4

5

6

FOCUS_POS

0V

*

FOCUS S868

M8*

BN BK YE

OG

FOCUS

RDYEBKBNOG

GN

X879854217

873

FI_LB

FI_PB1

FO_LA

+14V

FO_PA1

FO_PA2

GN

3

6

FO_LB

FO_PB1

FO_PB2

0V

123

4

5

X852

LED_10V+5V

RDBKWHBUGN

* NOT FITTED IN M1000 WITH ONE FILTER

17

FILTER STEP*FILTER DIR*STEP_ENABLE

*

18

28

2220X813

FOCUS STEP

FOCUS DIR

*

*

18 X 24 S865*

21

30

COLL STEP

COLL DIR

*

*

6

X853

COLLPOS_18X24

0V

LED_20V+5V

RDBKWHBUGN

24 X 30 S866*

COLLIMATOR

RDYEOGBKBN

54123

6

X854

C_LA

+14V

C_PA1

0V

CPU

(TABLE IN

PLACE)

STERE O COLL

D801

15

X813

ABCDEFG

TABLE_CONFIG

COLL_ST

+14V

FOCUS_P

(X4)

STEP

DRIVE

FILT_P

COLL_P2

COLL_P1

5

24

26

12

SEE PAGE 3-1 6

D805

MOTOR

COLL_D COLL_ST

21

23

X856

+14V

STEP

DRIVE

MOTOR

STEP_EN

FILT_D

FILT_ST

28

19

26

+14V

0V

0V

STEP

DRIVE

MOTOR

FOCUS_STFOCUS_D

24

35

Siemens-Elema AB SP B7-230.051.05 Page 16 of 18 Mammomat 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 41

X041E 3-17

OBJECT TABLE 1 + 2

123

19

X812

0VD

0VD2

GRID_SP

20KHz

PWM

GRID_O

D801

1

2

7109144

X813

CONNECTOR X892 WITH CABLING, S892, S894 AND S895 ARE OMITTED.

X868-2 IS JUMPERED TO X868-10.

* ONE TABLE OPTION (FIXED OBJECT-TABLE ARM): OBJECT TABLE 2,

S860, S894, S895 ARE OMITTED. X868-1, X868-3 ARE JUMPERED TO X868-10.

** M1000 OBJECT TABLE 1, CONNECTOR X891 WITH CABLING, S890, S891,

TABLE_CONFIG_0

TABLE_CONFIG_1

TABLE_CONFIG_2

TABLE_CONFIG_3

1

X8564235

3

16

CASS_LOADED

GRID_OUT

AEC_POS

8

6

252729

0V_W

11

23

33

34

SELECT_WING_1

STEREO_LEVER

9

30

0V

18

4

12

X824

GRID_M

GRID_SPEED

*

GRID_MOTOR_N

+24VF

+24VF

+24VF

K8

GRID_SP

5

-1.25

U

0V

0VA

0V UREG

0V

0V

0V

0V

1

I

0V

0V

D802

19

X822

X872

X868

8

7

X860

X869

X876

X875

X873

X871

X859

1

D805

12345

X869

X892 *

+24VF

ABCDEFG

1

2

123

TABLE

CONFIG

S2

CASS

LOADED

8

11

10

S892 *

7

8

5

3

4

0

(SEE

BELOW)

S1

GRID_OUT

M

OBJEC T TABLE 2 *

X855

X856

X857

D805

X860

1

AEC_POS

+24VF

STEREO_LEVER

7

1

12345

X871

X857

12345

X891**

6

9

123

+24VF

GRID_MOTOR_N

TABLE

CONFIG

(SEE

BELOW)

S2

CASS

LOADED

8

6

10711

X859

**

S890

GRID_OUT

CASS_LOADED

8

6

0

S1

GRID_OUT

**

S891

7

9

GRID_MOTOR_N

M

1

**

10

1

X868

S860

1

25

X893

MOTOR AND GRIDOUT SWITCH

OMITTED IF NO GRID

OBJECT TABLE 1**

0V

K1

SELECT_WING_2

SELECT_WING_1

3

**

S895*

SEE PAGE

3-11

OBJECT TABLE

GRID_MOTOR_N

2

*

11

**

X856

S894

STEREO

(OPTION)

1

X885

3

9

7

1

CONNECTOR

REAR VIEW

TABLE CONFIGURATION

D802

25

D801

TABLE TYPE

3210

NC NC NC NC NO TABLE LOCKED IN PLACE

TABLE_CONFIG

X824

X822

GRID_SP

GRID_M

0V

X813

X812

GRID_SP

NC NC NC 24V 18X24 W I TH GRID

NC NC 24V NC 24X30 W I TH GRID

NC NC 24V 24V 18X24 WITHO UT GR I D

NC 24V NC NC 24X30 WITHOUT GRID

NC 24V NC 24V MAGNIFICAT ION 1. 5

GRID_0

0VD2

(18x24)

NOT USED__

X__

X__

X__

NC 24V 24V NC STEREOTAXI MOUNTED

NC 24V 24V 24V MAGNIFI CATION 1.8

24V__

Siemens-Elema AB SP B7-230.051.05 Page 17 of 18 Mammomat 1000/3000

Solna Sweden Rev . 02 10.99 SPS-UD Wiring Diagram

Page 42

3-18

AUTOMATIC EXPOSURE CONTROL (AEC)

123

TRA2

RDL2

N15V_ION

P15V_ION

TRA1

RDL1

0V_RDL

0V_TRA

TRA1

RDL1

X041E

4

RDL2

N15V_ION

P15V_ION

0V_TRA

0V_RDL

5

TRA2

A23

A245

X701

B23

B24

A25

B25

C24

C23

D700 D701

7

8